PAINT SPRAY SYSTEM PFS 280 A1

PAINT SPRAY SYSTEM

Operation and Safety Notes

Translation of original operation manual

FARbSPRühSYSTEM

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

ΣΥΣΤΗΜΑ ΒΑΦΗΣ ΨΕΚΑΣΜΟΥ

Υποδείξεις χειρισμού και ασφαλείας

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

6

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τη σελίδα με τις εικόνες και εξοικειωθείτε με όλες τις λειτουργίες της

συσκευής.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / CY Operation and Safety Notes Page 5

GR / CY Υποδείξεις χειρισμού και ασφαλείας Σελίδα 15

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 25

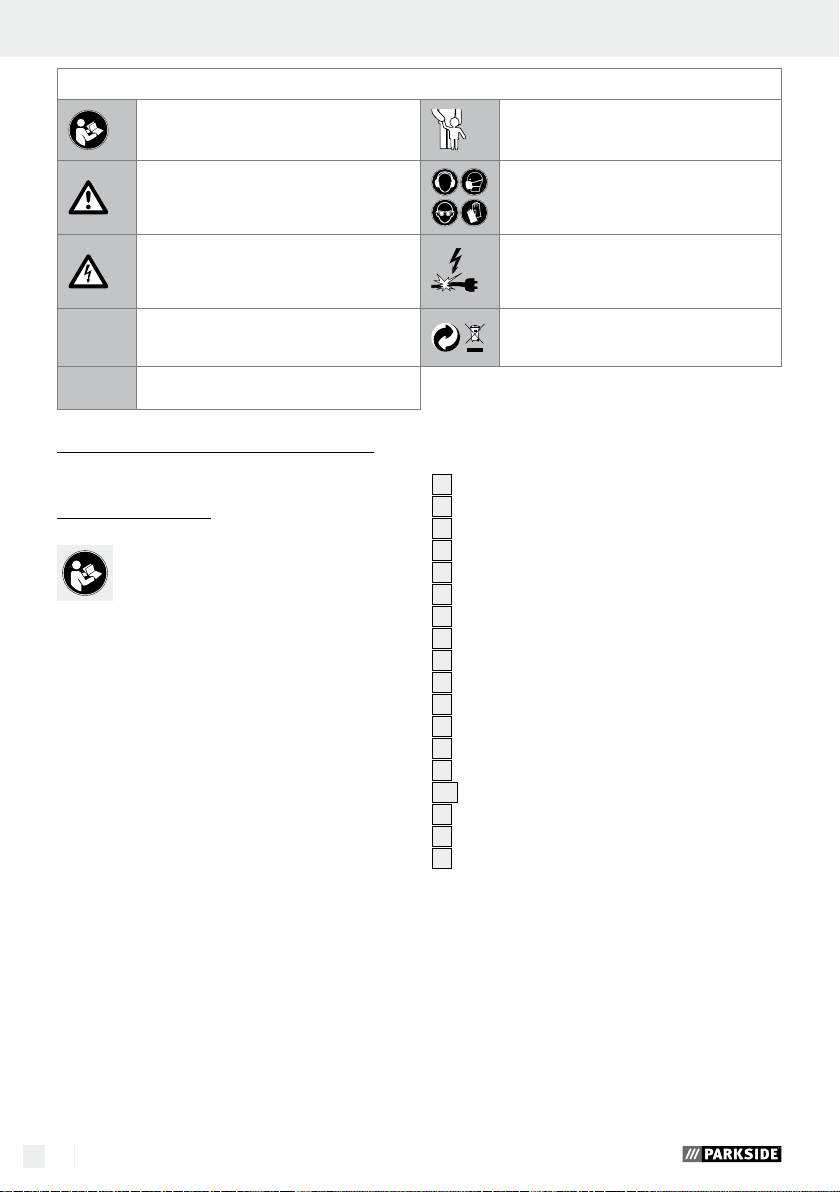

9

2

1

8

7

A

13

10

3

4

14 a

14

12

6

5

1615

17

B

11

14 a

13

8

DC

Table of contents

Introduction

Proper use ........................................................................................................................ Page 6

Features and equipment ................................................................................................. Page 6

Included items ................................................................................................................. Page 6

Technical data ................................................................................................................. Page 7

General safety advice for electrical power tools

1. Workplace safety ....................................................................................................... Page 7

2.

Electrical safety ........................................................................................................... Page 7

3. Personal safety ............................................................................................................ Page 8

4.

Careful handling and use of electrical power tools ................................................. Page 8

Safety instructions for fine spray systems ....................................................................... Page 8

Before use

Connecting the air hose .................................................................................................. Page 9

Preparing the spraying surface ...................................................................................... Page 9

Diluting the spray material .............................................................................................. Page 9

Placing sprayed material into the paint cup .................................................................. Page 10

Bringing into use

Switching on .................................................................................................................... Page 10

Switching off .................................................................................................................... Page 10

Advice on use .................................................................................................................. Page 10

Selecting / replacing the nozzle ..................................................................................... Page 10

Adjusting the spray pattern ............................................................................................ Page 10

Care and cleaning ................................................................................................ Page 11

Servicing ...................................................................................................................... Page 11

Warranty ..................................................................................................................... Page 11

Disposal ........................................................................................................................ Page 12

Declaration of Conformity / Manufacturer.................................... Page 13

5 GB/IE/CY

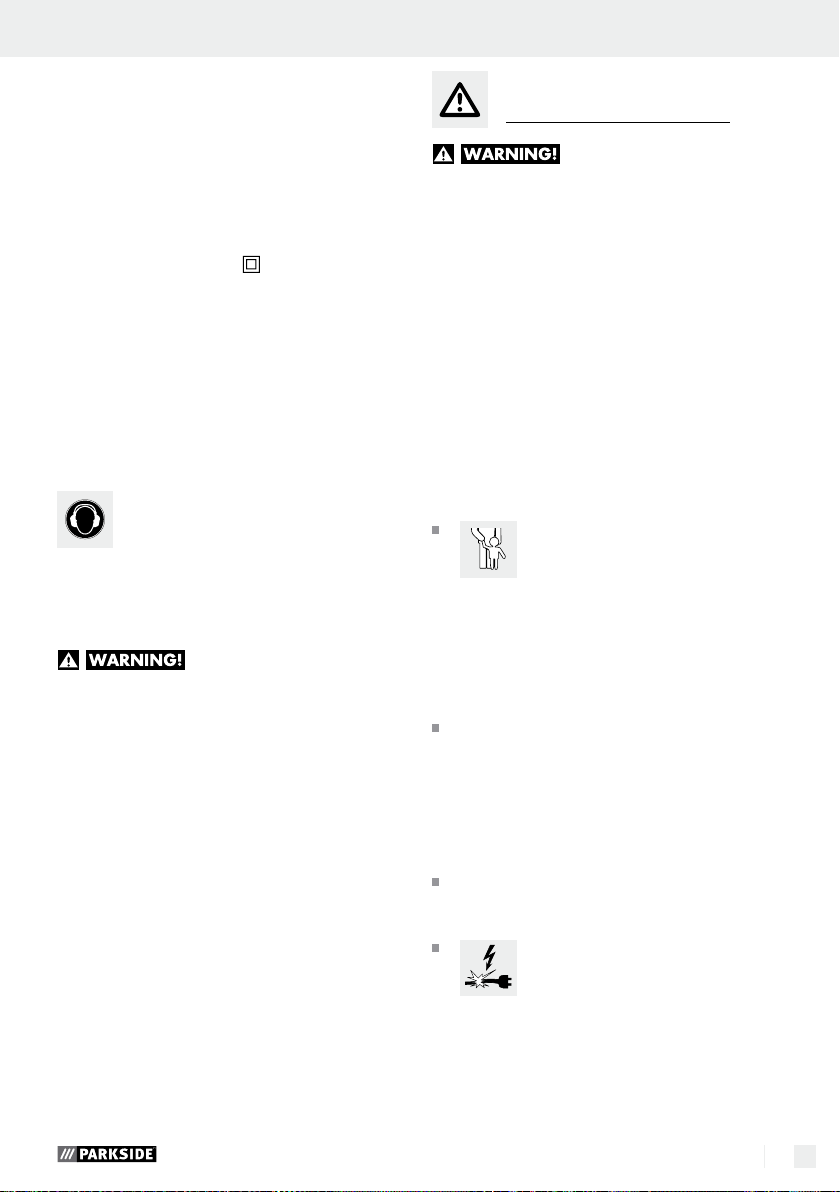

The following pictograms are used in these operating instructions / on the device:

Read instruction manual!

Observe caution and safety notes!

Caution – electric shock!

Danger to life!

V

W

Volt (AC)

~

Watts (effective power)

Paint spray system PFS 280 A1

Q

Introduction

Please make sure you familiarise your-

self fully with the way the device works

before you use it for the first time and

that you understand how to handle electrical power tools correctly. To help you do this please read

the accompanying operating instructions. Keep

these instructions in a safe place. If you pass the

device on to anyone else, please ensure that you

also pass on all the documentation.

Q

Proper use

The paint spray system is intended only for spraying

solvent- or water-based paints, glazes, primers, clear

varnishes, car paints, stains, wood preservatives,

insecticides and fungicides for plants, oils and disinfectants. This electrical power tool is not suitable

for use with dispersion or latex paints, lyes, acidic

coatings, sprayed materials containing suspended

grains or other solids, and sprayed materials formulated to inhibit splashing or dripping. Any other use

or modification shall be deemed to be improper use

and could give rise to considerable risk of accident.

We will not accept liability for loss or damage arising from improper use. The device is not intended

for commercial use.

6 GB/IE/CY

Keep children away from electrical

power tools!

Wear hearing protection, dust

protection mask, protective glasses and

protective gloves.

Risk of loss of life by electric shock

from damaged mains lead or mains

plug!

Dispose packaging and appliance in

an environmentally-friendly way!

Q

Features and equipment

Hose release button

1

Hose connection socket (gun)

2

Spray control thumbwheel

3

Trigger

4

Handle

5

Paint cup

6

Suction tube

7

Nozzle(s)

8

Union nut

9

ON / OFF switch

10

Motor

11

Hose connection socket (motor)

12

Air intake cover

13

Carrying strap with carabiner

14

Attachment eye

14 a

Air hose

15

Measuring cup

16

Protective cap

17

Q

Included items

1 Paint spray system PFS 280 A1

1 Carrying strap

2 Nozzles (1x round jet, 1x wide jet)

1 Air hose

2 Protective caps

1 Measuring cup

1 Operating instructions

Introduction / General safety advice for electrical power toolsIntroduction

Q

Technical data

Rated voltage: 230 V∼ 50 Hz

Rated power: 280 W

Spraying capacity: 130 g / min

Paint cup volume: Approx. 600 ml

Air hose: 2 m

Mains lead: 5 m

Protection class: II /

IP rating: IP23

General safety advice for

electrical power tools

Read all the safety advice

and instructions! Failure to observe the safety

advice and instructions may result in electric shock,

fire and / or serious injury.

Keep all the safety advice and instructions

in a safe place for future reference!

Noise and vibration data:

Measured values for noise are determined in accordance with EN 50144-2-7:2000. The A-weighted

noise level of the electrical power tool are typically:

Sound pressure level: 78.3 dB(A)

Sound power level: 91.3 dB(A)

Uncertainty K: 3 dB

Wear ear protection!

Evaluated acceleration, typical:

Hand / arm vibration = 0.532 m / s

Uncertainty K = 1.5 m / s

instructions has been measured in accordance with

a standardised measurement procedure specified in

EN 50144-2-7:2000 and can be used to compare

devices. Different uses of the device give rise to different vibration levels and in many cases they may

exceed the values given in these instructions. It is

easy to underestimate the vibration load if the electrical power tool is used regularly in particular circumstances.

Note: If you wish to make an accurate assessment

of the vibration loads experienced during a particular

period of working, you should also take into account

the intervening periods of time when the device is

switched off or is running but is not actually in use.

This can result in a much lower vibration load over

the whole of the period of working.

2

The vibration level given in these

2

The term “electrical tool” used in the safety advice

refers to electrical tools powered by mains electricity (by means of a mains lead) and electrical tools

powered by rechargeable batteries (without a

mains lead).

1. Workplace safety

Keep children and other

people away while you are

operating the electrical tool.

Distractions can cause you to lose control of

the device.

2. Electrical safety

The mains plug on the device must match

the mains socket. The plug must not

be modified in any way. Do not use

an adapter plug with devices fitted

with a protective earth. Unmodified

plugs and matching sockets reduce the risk of

electric shock.

Keep the device away from rain or

moisture. Water entering an electrical device

increases the risk of electric shock.

Do not use the mains lead for

any purpose for which it was

not intended, e.g. to carry the

device, to hang up the device or to pull

the mains plug out of the mains socket.

Keep the mains lead away from heat,

oil, sharp edges or moving parts of the

device. Damaged or tangled mains leads

increase the risk of electric shock.

7 GB/IE/CY

When working outdoors with an

electrical power tool always use extension cables that are also approved

for use outdoors. The use of an extension

cable suitable for outdoor use reduces the risk

of electric shock.

Use a residual current device (RCD)

for protection if operating the electrical power tool in a moist environment

is unavoidable. The use of an RCD reduces

the risk of electric shock.

3. Personal safety

Wear personal protective

equipment and always wear

safety glasses. The wearing of

personal protective equipment such as dust

masks, non-slip safety shoes, safety helmets or

ear protectors, appropriate to the type of electrical power tool used and work undertaken,

reduces the risk of injury.

4.

Careful handling and use

of electrical power tools

Do not use an electrical power tool if

its switch is defective. An electrical power

tool that can no longer be switched on and off

is dangerous and must be repaired.

When not in use always ensure that

electrical power tools are kept out of

reach of children. Do not let anyone use

the device if he or she is not familiar

with it or has not read the instructions

and advice. Electrical power tools are danger-

ous when they are used by inexperienced peo

Use the electrical power tool, accesso-

ries, inserted tools etc. in accordance

with these instructions and advice, and

the stipulations drawn up for this particular type of device. In doing this, take

into account the working conditions

and the task in hand. The use of electrical

power tools for purposes other than those intended can lead to dangerous situations.

8 GB/IE/CY

Safety instructions for

fine spray systems

Keep your work area clean, well lit

and free of paint or solvent containers,

rags and other combustible materials.

Potential danger of spontaneous combustion. Keep fully functioning fire extinguish-

ers / extin-guishing equipment available at all times.

Ensure good ventilation in the spray-

ing area and sufficient quantities of

fresh air through-out the room. Evapo-

rating flammable solvents create an explosive

environment.

The spray gun must never be used for

spraying inflammable substances.

Spray guns must never be cleaned

using inflammable solvents.

Do not spray or clean with materials

with a flashpoint below 21°C. Use

materials on the basis of water, lowvolatile hydrocarbons or similar materials. Highly volatile evaporating solvents

create an explosive environment.

Do not spray in the area of ignition

sources such as static electricity sparks,

open flames, pilot lights, hot objects,

motors, cigarettes and sparks from inserting and disconnecting power cords

or the operation of switches. Such

of sparks can lead to ignition of the surrounding area.

Do not spray any materials for which

it is not known whether they pose a

danger. Unknown materials can create dan-

gerous conditions.

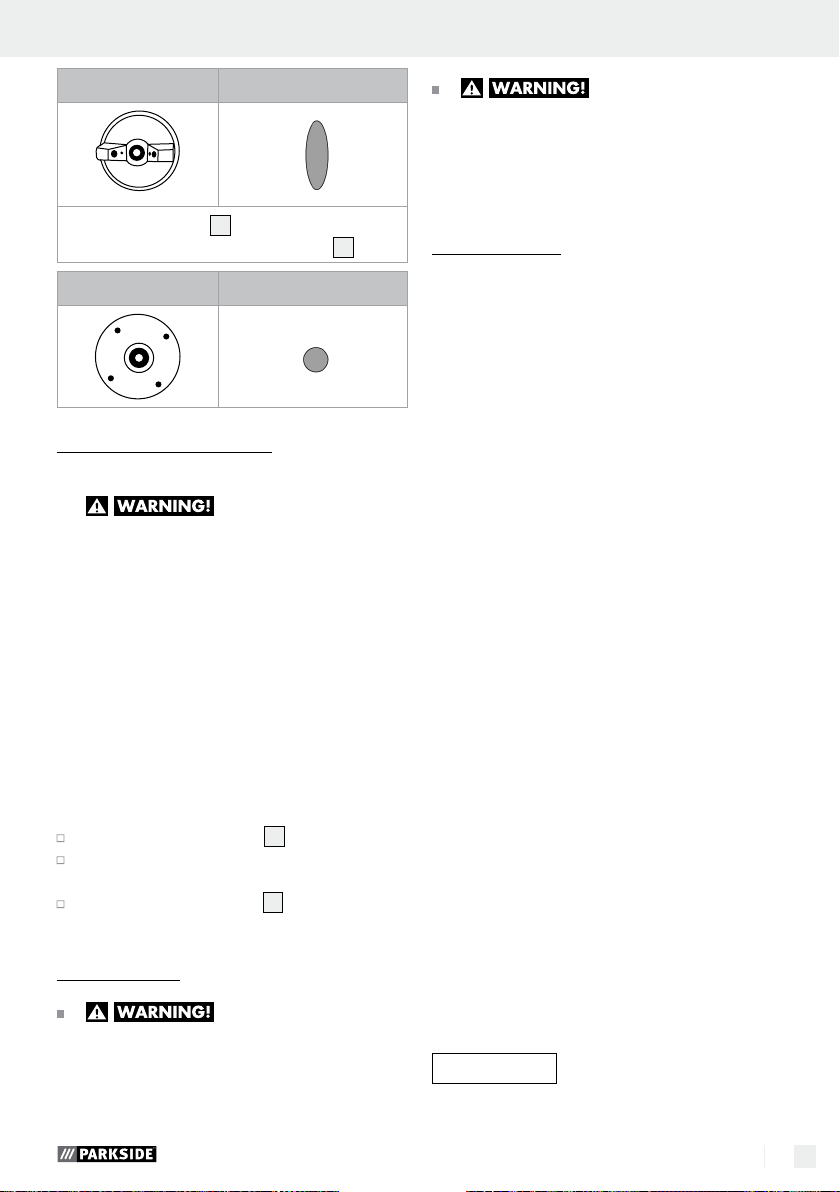

Wear additional personal

protective equipment such as

ple.

and protective masks or respirators

when spraying or handling chemicals.

The wearing of protective equipment in such conditions reduces exposure to harmful substances.

Do not spray on yourself, other people

or animals. Keep hands and other body

parts away from the spray jet. If the

spray penetrates the skin, seek medical help immediately. The material being

appropriate protective gloves

sources

General safety advice for electrical power tools / Before useGeneral safety advice for electrical power tools

sprayed can even penetrate the skin through a

glove and be injected into your body.

Do not treat an injection as a simple cut.

A high pressure jet may inject toxins

into the body and cause serious inju

ries.

If the spray is injected into the skin, seek medical

help immediately.

Pay attention to any possible dangers

of the material being sprayed. Note

the markings on the container or the

manufacturer’s information relating

to the material being sprayed, including the instruction to use personal

protective equipment. The manufacturer’s

in-structions must be followed to reduce the risk

of fire, as well as injuries caused by toxins, carcinogens, etc.

Never spray without the nozzle head

in place. The use of a special nozzle insert

with the appropriate nozzle head reduces the

probability of a high-pressure jet penetrating

the skin and injecting toxins into the body.

Take care when cleaning or replacing

the nozzle inserts. If the nozzle insert

becomes blocked during spraying,

follow the manufacturer’s instructions

and switch of the device and release

the pressure before you remove the

nozzle for cleaning. Liquids under high

pressure can penetrate the skin and inject the

body with poison, which can lead to serious injuries.

K

eep the mains lead plug and the spr

ay

gun trigger free of paint and other liquids. Never hold the lead to help keep

it connected. If the connection comes apart

it could result in an electric shock.

Children or persons who lack the knowledge or

experience to use the device or whose physical,

sensory or intellectual capacities are limited

must never be allowed to use the device without

supervision or instruction by a person responsible for their safety. Children must never be

allowed to play with the device.

Q

Before use

Pull the mains plug out of the

mains socket before you carry out any task on the

electrical power tool.

Q

Connecting the air hose

Remove the protective caps 17 and insert the

air hose

on the spray gun. Rotate the air hose

hose lock button

into the hose connection socket 2

15

until the

15

fits into place and engages.

1

Insert the other end of the air hose 15 into the

hose connection socket

on the motor.

12

Note: After use protect the hose ends with the

protective caps

Q

Preparing the spraying surface

.

17

Mask off the surroundings of the spraying sur-

face thoroughly over a wide area. Otherwise

all non-covered areas or surfaces may become

soiled.

Make sure that the spraying surface is clean,

dry and free of grease.

Roughen smooth surfaces and then remove the

sanding dust.

Q

Diluting the spray material

Note: Before diluting, check that the sprayed ma-

terial and the thinner are compatible. Consult the

sprayed medium manufacturer’s documentation for

information about suitable thinners (water, solvents).

If the wrong thinner is used, it can lead to lumps

forming, which may clog up the spray gun.

Proceed as follows for a sprayed material

that the manufacturer says must be thinned:

Take a measuring cup 16 with millilitre graduations.

Pour the required amount of sprayed material

into the paint cup

.

6

Thin the sprayed material by 10 % with the

thinner in accordance with the manufacturer’s

instructions.

9 GB/IE/CY

Thoroughly stir the sprayed material again.

Before you start spraying, always carry out a

trial spray on the test surface (see “Spraying”).

Q

Placing sprayed material

into the paint cup

Unscrew the paint cup 6 from the spray gun.

When spraying objects generally below the

gun, position the suction tube towards the front

of the gun, i.e. nearer the nozzle

head work, position the suction tube towards

the back of the gun, i.e. nearer the handle

Pour the sprayed material into the paint cup 6

and screw the paint cup

6

spray gun.

Q

Bringing into use

. For over-

8

tightly on to the

over the surface to be sprayed. Instead, start

and stop the spraying process approximately

10 cm outside the surface to be sprayed.

First spray the corners using short bursts of spray.

Then continue with spraying process in

accordance with Fig. D

– keep the spray gun parallel to the surface

– keep the spray gun upright laterally (don’t

wobble from side to side)

– move the spray gun at a constant speed

– apply the sprayed medium as thinly as possible

– the layer(s) of sprayed medium need(s) to be

allowed to dry for some time before you ap-

.

5

ply the next coat at right angles to the paths

of the previous coat (Fig. C). The coated sur-

face will have an even appearance if the

strips of sprayed material overlap by 4–5 cm.

Do not allow the paint cup 6 to empty com-

pletely while spraying – drops may form!

You can also sling the motor 11 over your shoul-

der. Always hook the carabiners attached to the

carrying strap

to the attachment eyes

14

If necessary, adjust the length of the carrying

strap to suit your requirements.

Ensure that the motor 11 cannot suck in any of

the sprayed material during operation. Position

it at an adequate distance away, on a clean,

dust-free surface.

Q

Switching on

Insert the mains plug into the mains socket.

Press the ON / OFF switch 10 on the motor.

Q

Switching off

Press the ON / OFF switch 10 on the motor.

Pull the mains lead out of the mains socket.

Q

Advice on use

Spray as shown in Fig. D.

Do not switch the device on or off while it is

10 GB/IE/CY

14 a

Q

Selecting / replacing the nozzle

.

Loosen the union nut 9.

Insert the desired nozzle 8.

Tighten the union nut 9 again.

Q

Adjusting the spray pattern

Turn the spray control thumbwheel 3 into the

desired position:

(–) = minimum spray rate

(+) = maximum spray rate

Note: We recommend that you start with the

minimum spray rate.

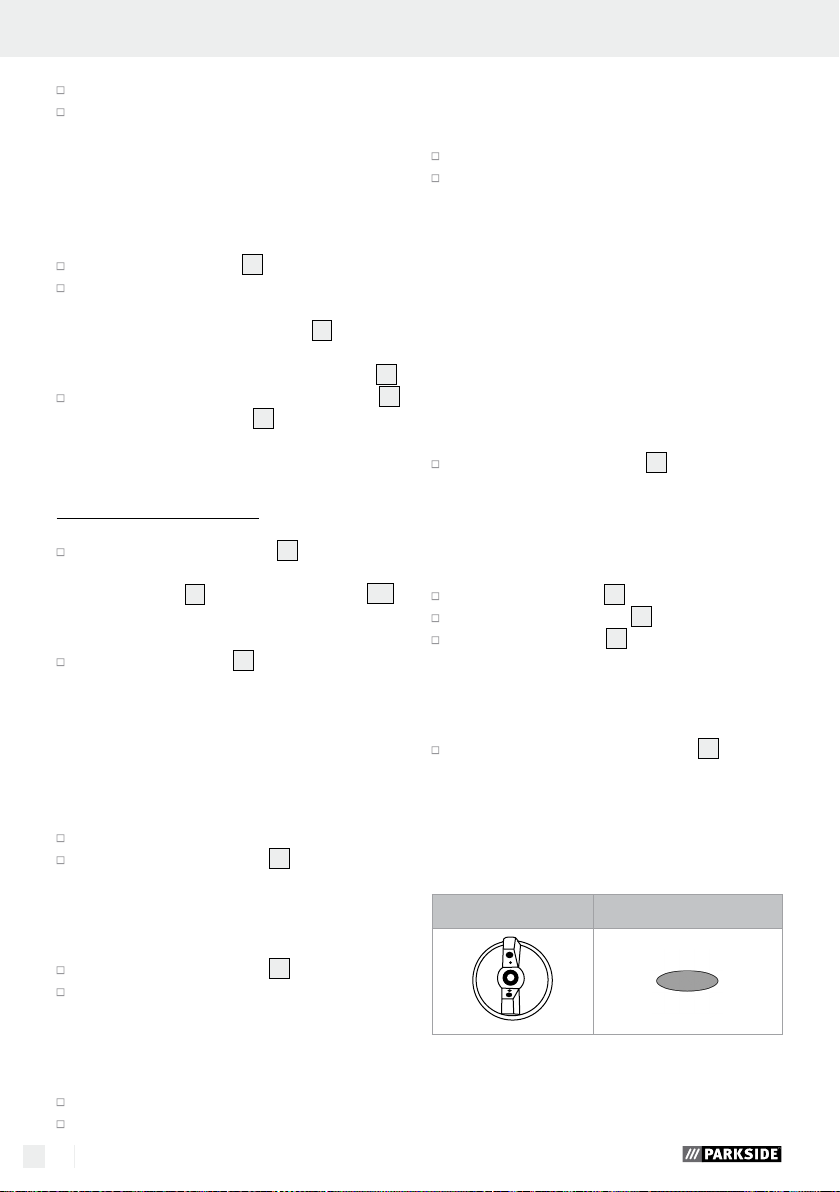

Wide jet nozzle

Jet

Bringing into use / Care and cleaning / Servicing / WarrantyBefore use / Bringing into use

Wide jet nozzle

Loosen the union nut 9. Turn the nozzle into the

desired position and tighten the union nut 9 again.

Round jet nozzle

Q

Care and cleaning

General advice:

1.

fore you carry out any tasks on the spray gun.

Do the same when you take a break from

spraying.

2. After each use, spray thinners (in the open air

only – danger of explosion!) or water

through the device as appropriate.

3. Never use inflammable solvents to clean the

device.

4. Use a dry cloth to clean the housing. Never

use petrol, solvents or cleaning agents that

might attack plastic.

Cleaning the air filter:

Clean the air filter if it is dirty.

Open the air intake cover 13.

Take out the air filter and knock it to remove

the dirt.

Close the air intake cover 13.

Pull out the mains plug be-

Jet

Jet

If the plug or mains

lead needs to be replaced, always

have the replacement carried out by

the manufacturer or his service centre.

T

his will ensure that the device remains safe to u

Q

Warranty

The warranty for this appliance is for 3 years

from the date of purchase. The appliance

has been manufactured with care and meticulously examined before delivery. Please

retain your receipt as proof of purchase. In

the event of a warranty claim, please make

contact by telephone with our Service Department. Only in this way can a post-free

despatch for your goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile compon

e.g. buttons or batteries. This product is for private

use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering not carried out by our authorized service branch.

Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

se.

ents,

Q

Servicing

Have your device re-

paired only by qualified specialist

personnel using original manufacturer

parts. This will ensure that the device remains

safe to use.

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP/Min.)

e-mail: kompernass@lidl.co.uk

IAN 56847

11 GB/IE/CY

Loading...

Loading...