Parkside PESG 120 B2 Assembly Manual

ARC WELDER PESG 120 B2

ELEKTRO-SCHWEISSGERÄT

Montage-, Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

ARC WELDER

Assembly, operating and safety instructions

Translation of the original instructions

IAN 273439

ΣΥΣΚΕΥΗ ΗΛΕΚΤΡΟΣΥΓΚΟΛΗΣΗΣ

Οδηγίες συναρμολόγησης, χειρισμού και ασφάλειας

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

273439_Elektro-Schweissgeraet_PESG 120 B2_cover_GB_IE_CY.indd 3 18.01.16 16:33

GB / IE / CY Assembly, operating and safety instructions Page 5

GR / CY Οδηγίες συναρμολόγησης, χειρισμού και ασφάλειας Σελίδα 15

DE / AT / CH Montage-, Bedienungs- und Sicherheitshinweise Seite 27

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τις δυο σελίδες με τις εικόνες και εξοικειωθείτε με όλες τις

λειτουργίες της συσκευής.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

273439_Elektro-Schweissgeraet_PESG 120 B2_cover_GB_IE_CY.indd 4 18.01.16 16:33

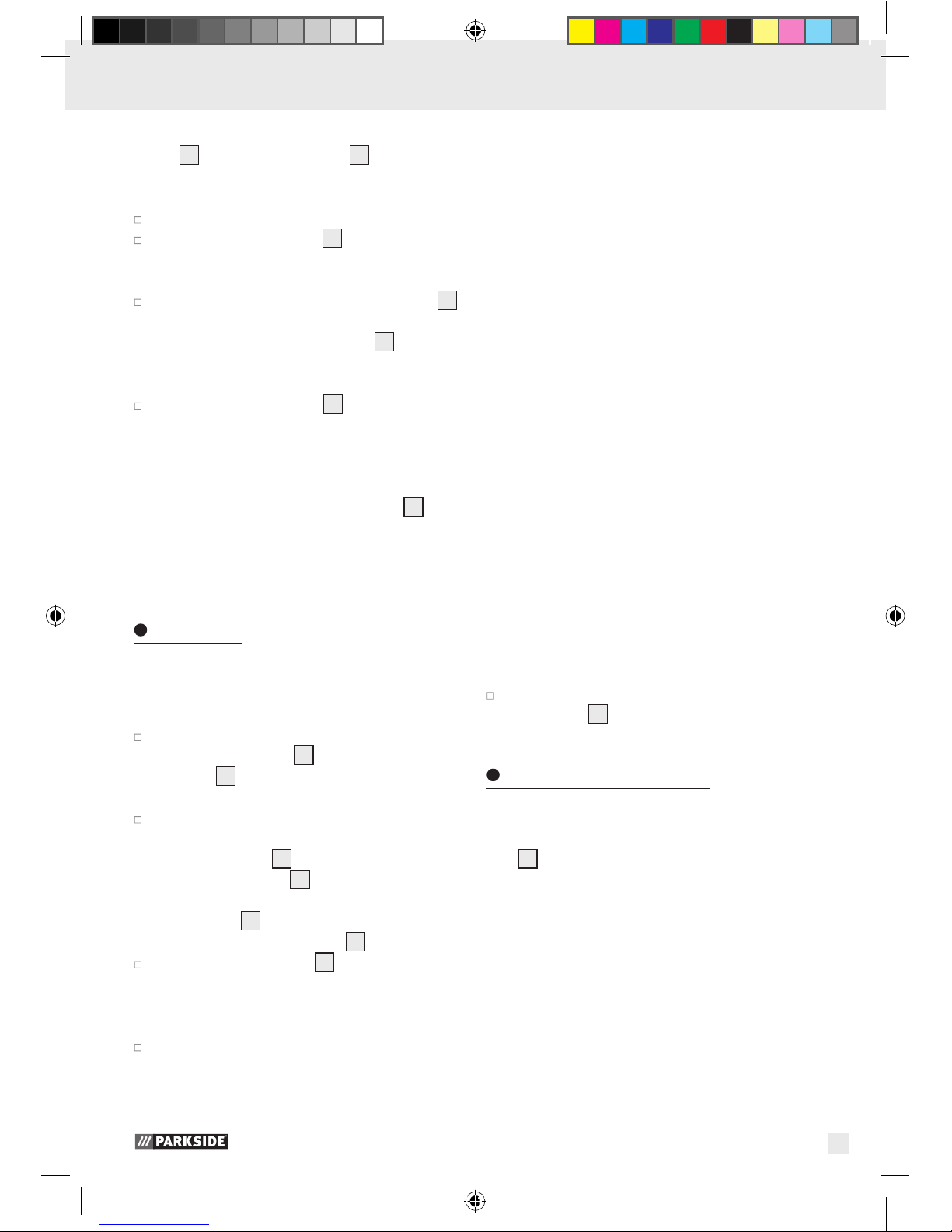

B

8

7

10

A

7 8

10

9

6

3

2

4

7

8

5

1

273439_Elektro-Schweissgeraet_PESG 120 B2_cover_GB_IE_CY.indd 5 18.01.16 16:33

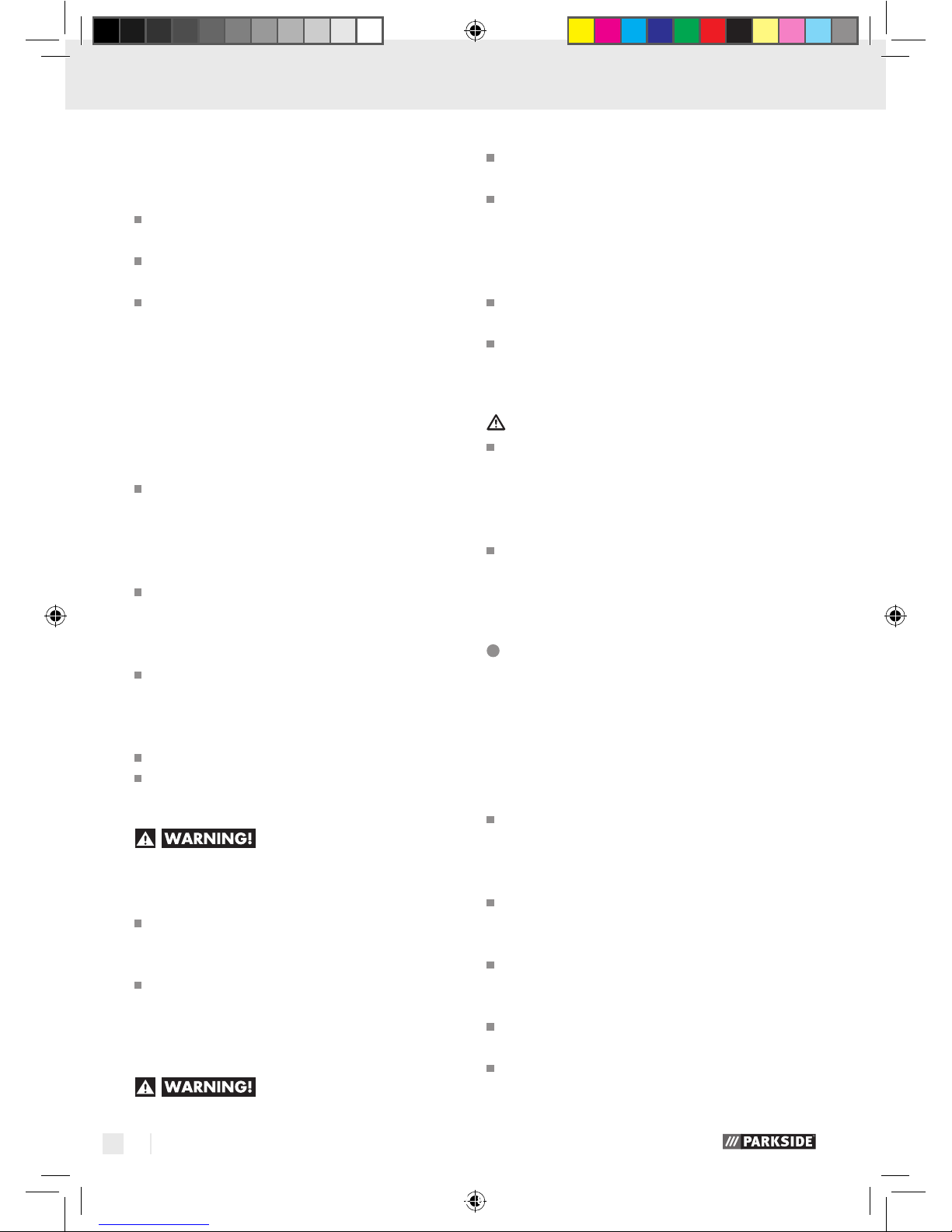

Wiring diagram

Schaltplan

273439_Elektro-Schweissgeraet_PESG 120 B2_cover_GB_IE_CY.indd 8 18.01.16 16:33

5 GB/IE/CY

List of pictograms used ........................................................................................................ Page 6

Introduction

Intended use ........................................................................................................................................ Page 7

Parts description .................................................................................................................................. Page 7

Technical Data ....................................................................................................................................Page 7

Scope of delivery ................................................................................................................................ Page 7

Safety information .................................................................................................................. Page 7

Safety hazards during arc welding ...................................................................................................Page 8

Safety notices specific to the welding shield ..................................................................................... Page 10

Tight and moist spaces .......................................................................................................................Page 10

Protective clothing ............................................................................................................................... Page 10

Protecting against rays and burns ...................................................................................................... Page 10

Assembling the welding shield ..................................................................................... Page 10

Preparing to weld .................................................................................................................... Page 10

Welding ............................................................................................................................................Page 11

Overheat protection ..............................................................................................................Page 11

Maintenance ................................................................................................................................. Page 12

Environmental instructions and disposal information ..............................Page 12

Information about warranty and service processing ............................... Page 12

Warranty terms

Extent of warranty ............................................................................................................................... Page 12

Processing of warranty claims ............................................................................................................ Page 13

Service ...............................................................................................................................................Page 13

EU Conformity Declaration ............................................................................................... Page 13

Table of contents

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 5 18.01.16 16:37

6 GB/IE/CY

List of pictograms used

Attention, potential dangers!

Alternating current symbol and

with covered rod electrodes

Welding sparks can cause an

Arc rays can damage the eyes

value in continuous mode

value in intermittent mode Σ

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 6 18.01.16 16:37

7 GB/IE/CY

Introduction / Safety information

Arc welder PESG 120 B2

Introduction

Congratulations! You have

chosen a high-quality device

from our company. Familiarise

yourself with the product before using it for the first

time. In addition, please carefully refer to the operating instructions and the safety advice below. Initial

operation of this tool must be performed by trained

personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Intended use

This electric welding equipment is suitable for

manual arc welding using the appropriate coated

electrodes. Improper product handling can be dangerous to persons, animals and objects. Only use

the welding shield with welding glass and protective glass overlay marked accordingly, and only for

welding. The welding shield is not suitable for laser

welding! Only use the product as described and

for the indicated purpose. Keep these instructions in

a safe place. When passing this product on to others,

please also include all the documents. Any use other

than the intended is prohibited and potentially dangerous. Damages resulting from noncompliance or

misuse are not covered by the warranty and are not

included in the manufacturer‘s liability. This device

has been designed for household use and may not

be used for commercial or industrial purposes.

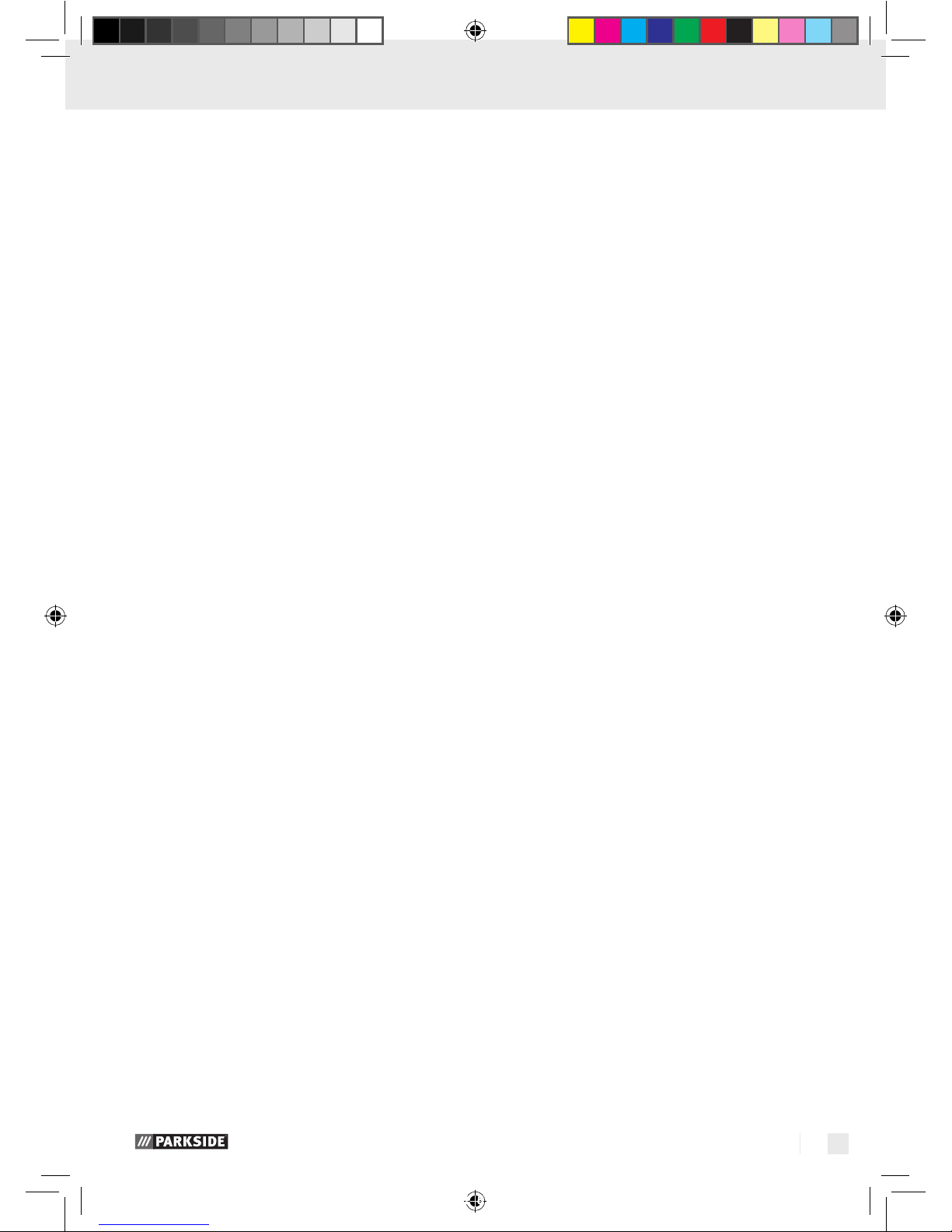

Parts description

Electric Welding Equipment

1

Handle

2

ON / OFF switch

3

Hand wheel

4

Earth terminal

5

Electrode holder

6

Overheating control lamp

Welding shield

7

Welding shield

8

Handle

9

Brush

10

Protective glass

Technical Data

Mains connection: 230 V∼ 50 Hz

Max. welding current

and the respective

conventional load voltage: 75 A /

21 V-100 A / 22 V

Rated value

of the mains current: U

1

: 230 V

Highest rated value

of the mains current: I

1max

: 22.5 A

Maximum effective

input current: I

1eff

: 7 A

Rated value of the

no-load voltage: U

0

: 48 V

Protection type: IP21S

Scope of delivery

1 Arc welder

1 Welding shield

2 Welding cables

1 Combination wire brush with chipping hammer

1 Instructions for assembly and use

Safety information

Please carefully read the instructions for use and follow the specified notices. Familiarise yourself with the

equipment, its proper use and the safety notices using

these instructions for use. The nameplate contains all

the

technical data for this welding equipment, please ob

-

tain information on the technical facts of this equipment.

This device may be used by children age 16

years and up, as well as by persons with reduced

physical, sensory or mental capacities or lacking

experience and / or knowledge, so long as they

are supervised or instructed in the safe use of

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 7 18.01.16 16:37

8 GB/IE/CY

Safety information

the device and understand the associated risks.

Do not allow children to play with the device.

Cleaning and user maintenance should not be

performed by children without supervision.

Only have repairs and / or maintenance per-

formed by electrically skilled persons.

Only use the welding cables included (PESG

120 B2 H01N2-D1x10 mm²).

During use the equipment should not be located

directly against a wall, be covered, or be jammed

between other equipment to ensure ample air

can be taken in through the ventilation louvres.

Verify the equipment is correctly connected to

the mains voltage. Avoid any tensile load on the

mains. Unplug the mains plug from the socket

before transferring the equipment to a different

location.

Always switch the equipment off with the ON /

OFF switch when not in use. Set the electrode

holder down on an insulated pad and allow to

cool for 15 minutes before removing the electrodes from the holder.

Pay attention to the condition of the welding

cables, the electrode holders and the earth terminals. Worn insulation and conducting parts can

produce hazards and reduce the welding quality.

Arc welding produces sparks, melted metal

parts and smoke. Therefore note: Remove any

flammable substances and / or materials from

the work area and its immediate surroundings.

Ensure the work area is ventilated.

Do not weld atop containers, receptacles or

pipes, which do or did contain flammable

liquids or gasses.

Avoid any direct contact with

the welding circuit. The no-load voltage between

the electrode holder and earth terminal can be

dangerous, there is a risk of electric shock.

Do not store or use the equipment in a moist or

wet environment or in the rain. The Protection

Provision IP21S applies in this respect.

Protect the eyes with the appropriate safety glass

(DIN Grad 9-10) to be installed in the included

welding shield. Use gloves and dry protective

clothing free from oil and grease to protect the

skin from ultraviolet rays and the arc.

Do not use the welding power

source to thaw pipes.

Remember:

The arc ray can damage the eyes and cause

burns to the skin.

Arc welding produces sparks and drops of

molten metal, the welded work piece begins to

glow and remains very hot for a relatively long

time. Therefore do not touch the work piece with

bare hands.

Arc welding releases noxious fumes. Be careful

not to inhale these as best possible.

Protect yourself from the dangerous effects of the

arc and keep persons not involved in the work

at least 2 m away from the arc.

Attention!

Depending on mains conditions at the connec-

tion point, operating the welding equipment may

interfere with the voltage supply for other loads.

When in doubt, please contact your power

supply company.

Operating the welding equipment may interfere

with the functionality of other devices, e.g.

hearing aids, pacemakers, etc.

Safety hazards

during arc welding

Arc welding produces a variety of safety hazards.

It is therefore particularly important for the welder

to observe the following rules to avoid putting himself and others in danger and to prevent damage

to persons and the equipment

Only have work to the mains voltage end, e.g.

to cables, plugs, outlets, etc. performed by a

electrically skilled person in accordance with

national and local regulations.

In the event of an accident, immediately dis-

connect the welding equipment from the mains

voltage.

If electrical contact voltage occurs, immediately

switch the equipment off and have it inspected

by an electrically skilled person.

Always ensure good electrical contacts on the

welding current end.

Always wear insulating gloves on both hands

whilst welding. These will protect from electric

shock (no-load voltage of the welding current),

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 8 18.01.16 16:37

9 GB/IE/CY

Safety information

from hazardous rays (heat and UV rays) and

glowing metal and weld splashes.

Wear solid, insulating shoes. The shoes should

also insulate when exposed to moisture. Low

shoes are not suitable, as glowing metal drops

falling could cause burns.

Wear suitable protective clothing, no synthetic

garments.

Do not look into the arc with unprotected eyes,

only use a welding shield with approved pro-

tective glass per DIN. In addition to light- and

heat rays which could result in blinding or burns,

the arc also emits UV rays. Without adequate

protection, this invisible ultraviolet radiation

causes very painful conjunctivitis which is only

noticed a few hours later. UV rays further cause

burns similar to a sunburn in unprotected areas

of the body.

Persons near the arc or assistants must also be

informed of the risks and outfitted with the nec-

essary protection. If necessary, set up protective

panels.

Ensure an adequate supply of fresh air whilst

welding, particularly in small spaces, as it pro-

duces smoke and harmful gasses.

Do not weld containers in which gasses, fuels,

mineral oils, etc. were stored - even if emptied

a long time ago - as residue poses an explosion

hazard.

Special regulations apply in rooms posing fire-

and explosion hazards.

Welded joints exposed to great strain and

needing to meet certain safety requirements

must be made by specially trained and certi-

fied welders. Examples are pressure vessels,

running rails, tow couplings, etc.

ATTENTION! Always connect the earth termi-

nal as close as possible to the point of weld to

provide the shortest possible path for the weld-

ing current from the electrode to the earth ter-

minal. Never connect the earth terminal to the

housing of the welding equipment!

Never connect the earth terminal to earthed

parts far away from the work piece, e.g. a

water pipe in another corner of the room. This

could otherwise damage the protective bond-

ing system of the room you are welding.

Do not use the welding equipment in the rain.

Do not use the welding equipment in a moist

environment.

Only place the welding equipment in a level

location.

The output is rated at an ambient temperature

of 20 °C. The welding time may be reduced in

higher temperatures.

Danger of electric shock:

Electric shock from a welding electrode

can be fatal. Do not weld in rain or snow.

Wear dry insulating gloves. Do not touch

the electrode with bare hands. Do not wear wet or

damaged gloves. Protect yourself from electric shock

by insulating from the work piece. Do not open the

equipment housing.

Danger due to welding smoke:

Inhaling welding smoke can jeopardize your health.

Keep your head out of the smoke. Use facilities in

open areas. Use ventilation to remove smoke.

Danger due to welding sparks:

Welding sparks can cause an explosion or fire.

Keep flammables away from the welding area. Do

not weld next to flammables. Welding sparks can

cause a fire. Keep a fire extinguisher nearby and

an observer ready to use it. Do not weld on top of

drums or any closed containers.

Danger due to arc rays:

Arc rays can damage the eyes and injure the skin.

Wear a hat and safety goggles. Wear hearing protection and a closed, high shirt collar. Wear welding

helmets and proper filter sizes. Wear full personal

protection.

Danger due to electromagnetic fields:

Welding current produces electromagnetic fields.

Do not use along with medical implants. Never wrap

the welding cables around the body. Consolidate

welding cables.

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 9 18.01.16 16:37

10 GB/IE/CY

Safety information / Assembling the welding shield / Preparing to weld

Safety notices specific to the

welding shield

Using a hot light source (e.g. lighter) always

check the welding shield is working properly

before starting to weld.

Welding splashes can damage the glass shield.

Replace damaged or scratched glass shields

immediately.

Promptly replace damaged or heavily soiled /

splashed components.

The equipment may only be operated by per-

sons who have turned 16.

Familiarise yourself with the safety instructions

for welding. Also refer to the safety instructions

of your welding equipment.

Always use the welding shield when welding.

Failure to use the shield may result in serious in-

juries to the retina.

Always wear protective clothing when welding.

Never use the welding shield without protective

glass, as the optics can otherwise be damaged.

Replace the protective glass early to ensure g

ood

visibility and fatigue-proof working.

Tight and moist spaces

When working in tight, moist or hot spaces, use

insulating pads and intermediate layers in ad-

dition to gauntlet gloves made from leather or

other insulating materials to insulate the body

from earth.

When using welding equipment in electrically

dangerous conditions, e.g. in tight spaces from

conductive walls (kettles, pipes, etc.), in wet

spaces (soaking of work clothes), the output

voltages of the welding equipment may not be

higher than 48 Volts (rms value) in open loop.

Based on the output voltage this welding equip-

ment may be used in these conditions.

Protective clothing

Whilst working the welder must be protected

against rays and burns all over the body with

the appropriate clothing and face protection.

Remember the following steps:

- Put on protective clothing before welding.

- Put on gloves.

- Open windows or vent to ensure air supply.

- Wear safety goggles and a mask.

Wear gauntlet gloves made from suitable ma-

terial (leather) on both hands. These must be

in good condition.

Wear suitable aprons to protect the clothing

from sparks and burns. When required based

on the working method, e.g. welding overhead,

wear a protective suit and, if necessary, a head

guard.

Protecting against

rays and burns

Mark the work area with a sign “Danger! Do

not look into flames!“ to indicate the risk to the

eyes. If possible, shield the work areas to protect

persons nearby. Keep unauthorised persons

away from the welding area.

Walls in the direct vicinity of fixed work areas

should be neither light coloured nor glossy.

Protect windows against rays passing through

or reflecting at a minimum to head height, e.g.

with suitable paint.

Assembling the welding shield

Attach the handle 8 to the welding shield 7

as shown in Fig. B.

Install the protective glass 10 to the welding

shield

7

as shown in Fig. B.

Then fold the three sides of the welding shield.

The two sides each connect to the top with two

press studs.

Preparing to weld

Note: When activating the power verify the current

indicator moves and the lead screw is not jammed.

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 10 18.01.16 16:37

11 GB/IE/CY

Preparing to weld / Welding / Overheat protection

Note: If the tensioning force of the electrode

holder

5

and the earth terminal 4 subsides,

replace immediately.

Connect the electric cables.

Set the ON / OFF switch 2 to the “ON“ posi-

tion. The current indicator will light up when

operation starts.

To end operation, set the ON / OFF switch 2

to the auf “OFF“ position.

Note: The yellow indicator light

6

lighting

up indicates overheating. The electric circuit will

automatically be broken. Operation will end.

Attach the earth terminal 4 directly to the

work piece or to the pad on which the work

piece is placed.

Note: Ensure direct contact to the work piece.

Thus avoid painted surfaces and / or insulation.

Note: Always use the welding shield

7

whilst

welding. It protects the eyes from the light beam

emitted by the arc, yet allows for a clear view

of the work piece.

Welding

After making all the electrical connections for the

power supply and for the welding circuit, proceed

as follows:

Insert the uncoated end of the electrode into

the electrode holder

5

and connect the earth

terminal

4

to the work piece. Be sure the

electrical contact is good.

The device features a latch for setting the plate

thickness. Switch on the device by setting the

ON / OFF switch

2

to the “ON“ position. Then

use the hand wheel

3

to select the electrode

thickness: For 1.6 or 2.0 mm electrodes set the

hand wheel

3

to position 1.6 / 2.0. For 2 mm

electrodes set the hand wheel

3

to position 2.5.

Hold the welding shield 7 in front of your face

and guide the tip of the electrode over the work

piece as if trying to light a match. This is the best

method for sparking the arc.

Use a test piece to check if you selected the

correct electrode and current.

ATTENTION!

Do not dab the work piece with the electrode. It

could become damaged and make it more difficult to

spark the arc. Once the arc is sparked, try to maintain a distance to the work piece appropriate for the

selected electrode diameter. Keep the distance as

consistent as possible whilst welding. The electrode

grade in the work flow direction should be 20–30

degrees.

ATTENTION!

Always use forceps to dispose of used electrodes or

move hot work pieces. Please remember to always

place the electrode holder onto an insulating pad

after welding.

Only remove slag once the seam has cooled. If

continuing to weld on an interrupted weld seam,

first remove the slag at the start of weld.

ATTENTION!

Welding produces heat. The welding equipment

must therefore be operated in open loop after use

for at least half an hour. Or alternatively allow the

equipment to cool off for one hour. Only pack up

and store the equipment once the equipment temperature has normalised.

Switch the equipment off by setting the ON /

OFF switch

2

to the “OFF“ position.

Overheat protection

The welding equipment features overheat protection.

If the overheat protection is triggered, the control

light

6

will light up. Allow the welding equipment

to cool down for a while.

PESG 120 B2 (with AC 230 V 50 Hz power plug):

The supply line fuses to the mains sockets must meet

the requirements (VDE 0100). Earthed wall sockets

must be protected with max. 16 A (model and technical data: NDM1-63, AC 230 / 400 V C16.

IEC 60898.time lag. Manufacturer: Nader) (fuses

or line circuit breaker). Higher fuse ratings can result

in burnt wires or fire damage to the building.

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 11 18.01.16 16:37

12 GB/IE/CY

… / Maintenance / Environmental instructions … / Information about … / Warranty terms

Attention: The equipment must be connected to

a mains source with the fuse rating specified above.

If the electrode holder and earth terminal is short

circuited, the fuse can be triggered in 16–20 secon

ds.

Classification per EMV standard: Class A per IEC

60974-10

Warning: Equipment categorised Class A are

intended for industrial use. When used in other

areas, electromagnetic tolerance may not be warranted or failures may occur.

Maintenance

Regularly clean dust and dirt off the equipment.

Clean the equipment with a fine brush or a dry

cloth.

Environmental instructions

and disposal information

Don‘t waste,

recycle!

Device, accessories and packaging

should be recycled in an environmentally friendly manner.

Do not dispose of the power welding equipment with

your household waste, or throw into fire or water. If

possible, non-operational equipment should be recycled. Contact your local retailer for information.

Information about warranty

and service processing

Creative Marketing Consulting GmbH

warranty

Dear customer, the warranty for this device is

3 years from the date of purchase. In the event of

product defects, you have legal rights against the

retailer of this product. Your statutory rights are not

limited in any way by our warranty detailed below.

Warranty terms

The warranty period begins on the date of purchase.

Please retain the original receipt safely. This document is required as your proof of purchase.

Should this device show any fault in materials or

manufacture within three years from date of purchase, it will be repaired or replaced - at our choice

- by us free of charge. This warranty is conditional

on the defective device and the receipt of purchase

(store receipt) being presented within the three year

warranty period, and that there is a brief written

description of the nature of the defect and of the

date it arose.

If the defect is covered by our warranty, we will

return the repaired equipment or replacement thereof.

A repair or exchange of the equipment does not

extend a new warranty period.

Extent of warranty

The appliance has been manufactured to strict

quality guidelines and meticulously examined

before delivery.

The warranty applies to faults in material or manufacture. This warranty does not apply to product

parts subject to normal wear and tear and which

can therefore be considered as wear items, or to

damage to fragile parts, e.g. switches, storage

batteries or glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All

instructions provided in the operating instructions

must be followed strictly to constitute proper use of

the product. Purposes and practices which the operating instructions warn of or advise against must

be avoided without fail.

This product is intended for private, non-commercial

use only. Any incorrect or improper use of the device,

use of force and changes not performed by our authorized service branch will void the warranty.

273439_Elektro-Schweissgeraet_PESG 120 B2_content_GB_IE_CY.indd 12 18.01.16 16:37

Loading...

Loading...