Parkside PDRS 27 A1 Translation Of The Original Instructions

AIR RATCHET SET PDRS 27 A1

AIR RATCHET SET

Translation of the original instructions

CLÉ À CLIQUET PNEUMATIQUE ET

ACCESSOIRES

Traduction des instructions d’origine

DRUCKLUFT-RATSCHENSET

Originalbetriebsanleitung

TRYKLUFT-SKRALDENØGLE

Oversættelse af den originale driftsvejledning

PERSLUCHT-RATELSET

Vertaling van de originele gebruiksaanwijzing

IAN 292168

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Avant de lire le mode d'emploi, ouvrez la page contenant les illustrations et familiarisez-vous ensuite avec

toutes les fonctions de l'appareil.

Vouw vóór het lezen de pagina met de afbeeldingen open en maak u vertrouwd met alle functies van het

apparaat.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE/NI Translation of the original instructions Page 1

DK Oversættelse af den originale driftsvejledning Side 17

FR / BE Traduction des instructions d’origine Page 33

NL / BE Vertaling van de originele gebruiksaanwijzing Pagina 49

DE / AT / CH Originalbetriebsanleitung Seite 65

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Features ................................................................... 2

Package contents ............................................................ 3

Technical data .............................................................. 3

General safety instructions for compressed air tools ....................4

Hazards caused by flying parts ................................................. 7

Hazards caused by entanglement ............................................... 7

Hazards during operation ..................................................... 7

Hazards caused by repetitive movements ......................................... 8

Hazards caused by accessories ................................................. 8

Hazards in the workplace ..................................................... 9

Hazards caused by dust and vapours ............................................ 9

Hazards caused by noise ...................................................... 9

Hazards caused by vibrations .................................................10

Additional safety instructions for pneumatic machines ............................... 10

Additional safety notices .....................................................11

Before use ......................................................11

Fitting the connector nipple ...................................................11

Lubrication ................................................................11

Refilling oil ................................................................ 12

Connecting to a compressed air source .......................................... 12

Operation ......................................................12

Compressed air ratchet ...................................................... 12

Switching on and off ........................................................12

Maintenance and cleaning .........................................13

Troubleshooting .................................................13

Disposal ........................................................13

Kompernass Handels GmbH warranty ..............................14

Service .........................................................15

Importer .......................................................15

Translation of the original Conformity Declaration .....................15

PDRS 27 A1

GB│IE│NI

│

1 ■

AIR RATCHET SET PDRS 27 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please

familiarise yourself with all operating and safety

instructions. Use the product only as described and

for the range of applications specified. Please also

pass these operating instructions on to any future

owner.

Intended use

The ratchet attachment is suitable for fastening and

loosening screw connections in the automotive (tyre

fitting, etc.) and agricultural fields. Note the necessary torques when tightening screws and nuts.

The tool may only be operated with a compressed

air supply. The maximum permissible operating

pressure specified on the tool must not be exceeded.

This tool must not be operated with gases that are

explosive, flammable or hazardous to health.

Do not use as a lever, crusher or striking tool.

Any other usage or modification of the tool is

deemed to be improper and carries a significant

risk of accidents. The manufacturer accepts no responsibility for damage(s) resulting from improper

usage. This tool is intended for domestic use only.

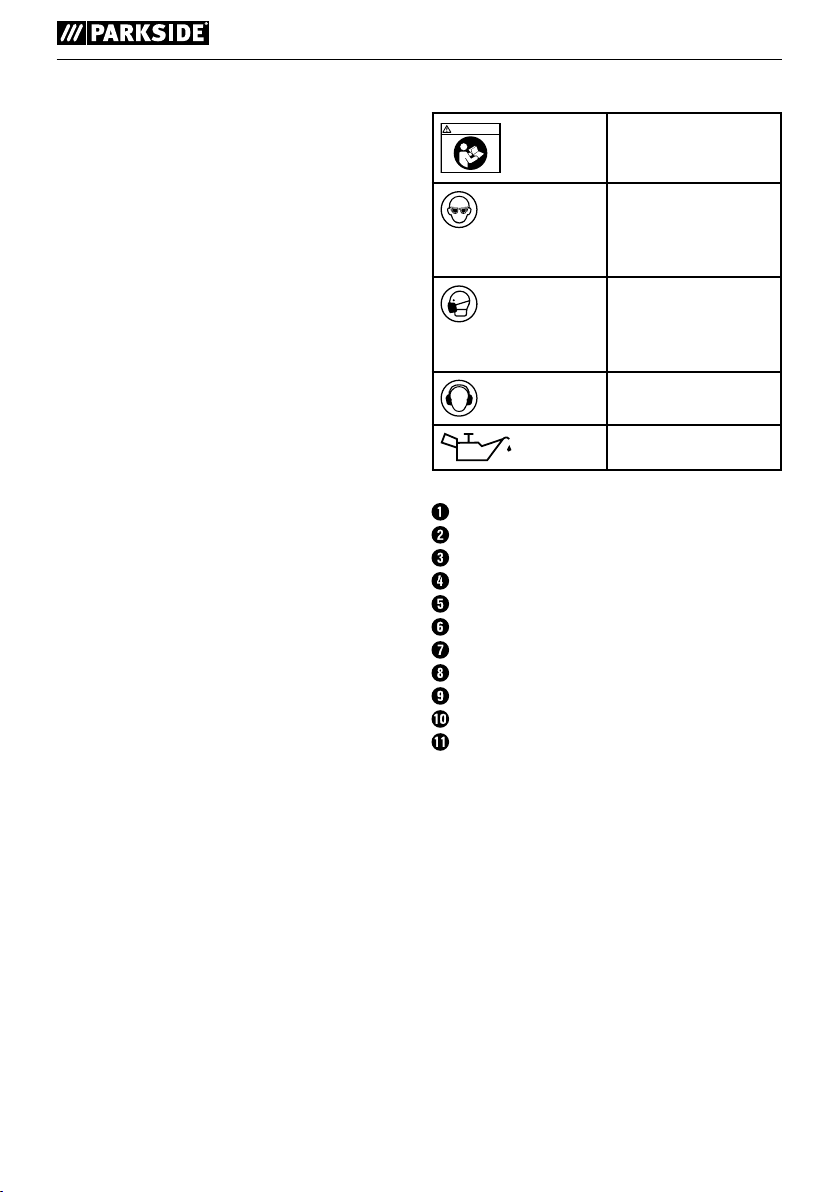

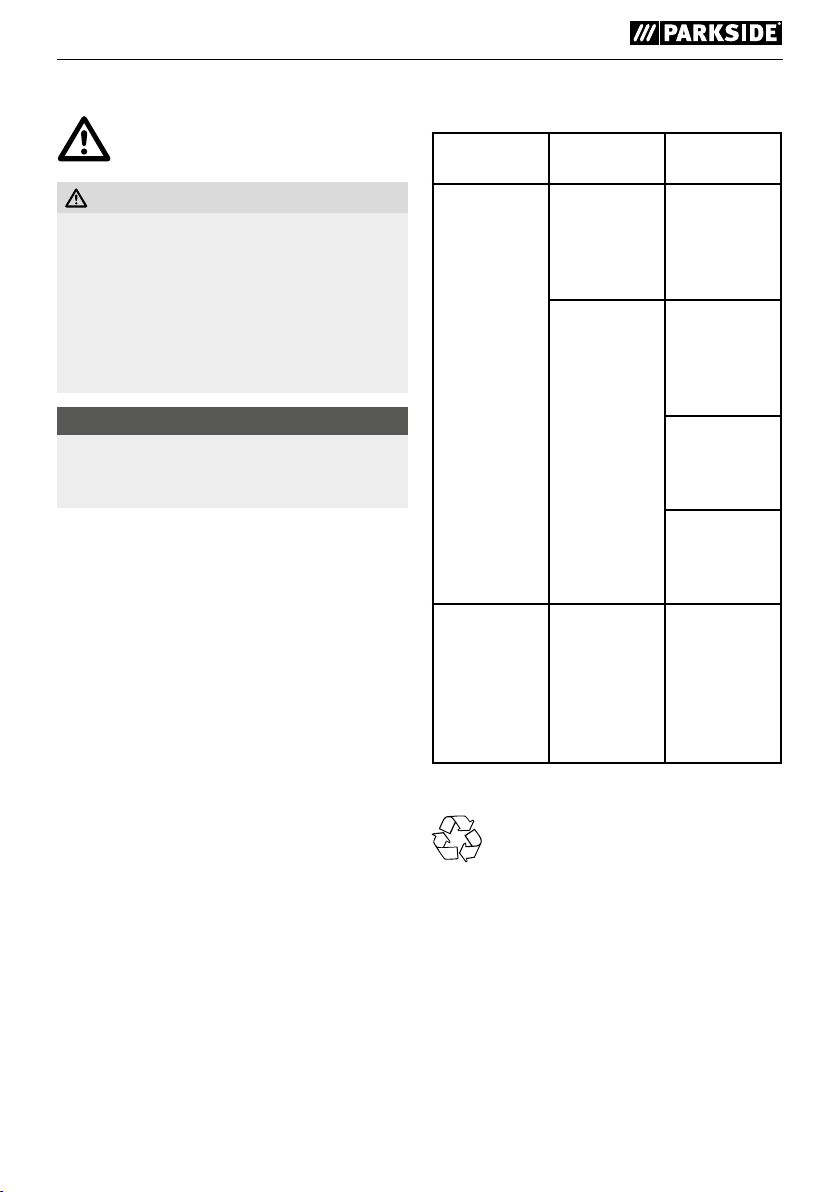

Symbols on the compressed air tool:

WARNING!

Read the operating

instructions before use.

Always wear eye

protection when using

or maintaining the

compressed air tool.

Always wear a dust

mask in situations in

which dust is being

generated.

Always wear hearing

protection.

Oil daily

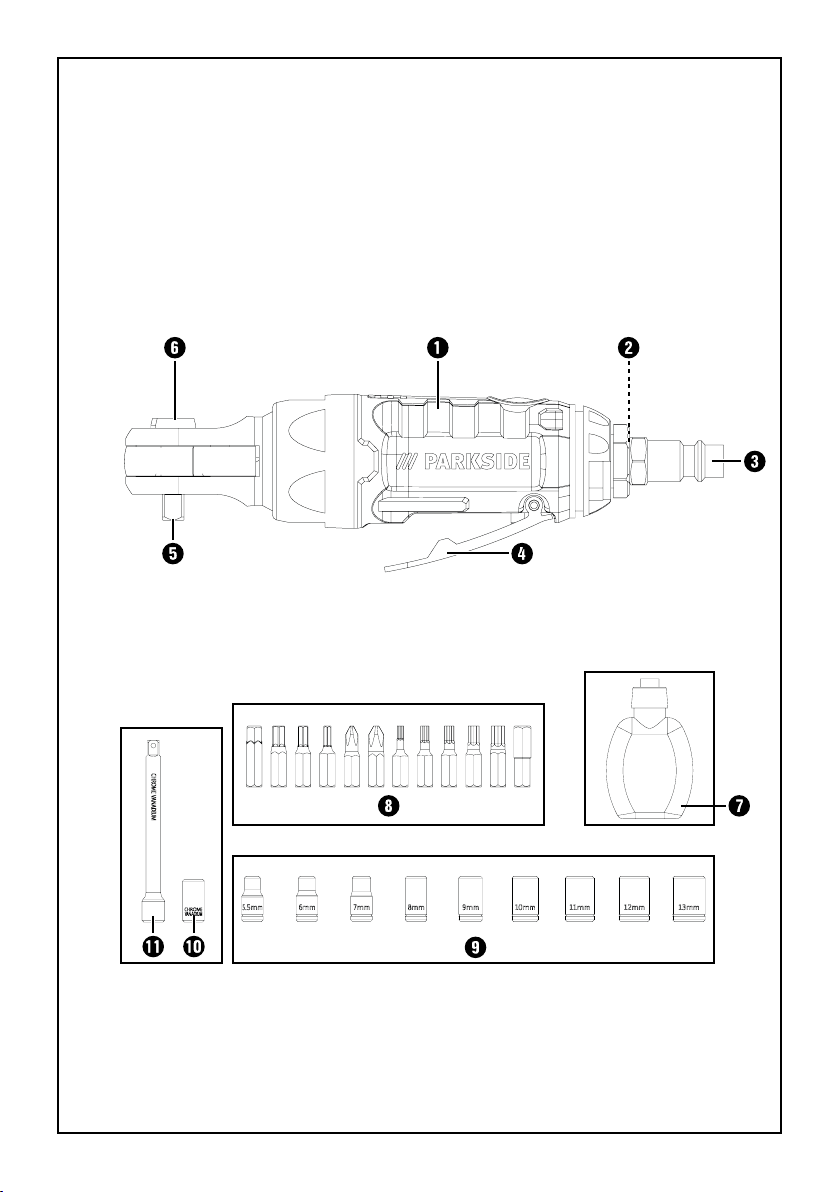

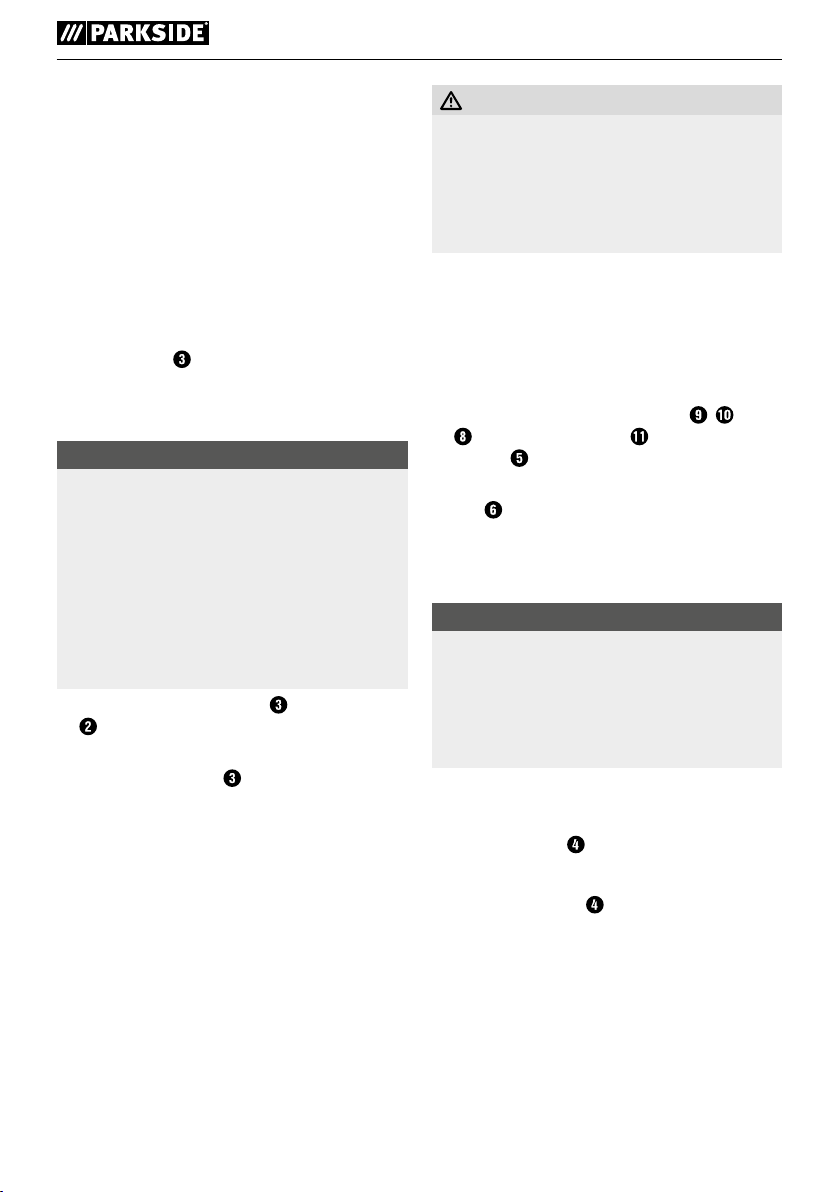

Features

Compressed air ratchet

Air inlet

Connector nipple

Trigger

Square retainer

Turn bolt

Oil bottle

Screwdriver bits

Sockets

Adapter

Extension piece

■ 2 │ GB

│IE│

NI

PDRS 27 A1

Package contents

1 Compressed air ratchet

9 sockets (5.5mm/6/7/8/9/10/11/12/13)

12 screwdriver bits

25mm (1x PH1/1x PH2/HEX 3/4/5/6/

7T10/T15/T20/T25/T30)

1 extension piece 100mm

1 adapter 1/4" square to 1/4" hexagonal

1 oil bottle

1 connector nipple 6.35mm (1/4")

1 carrying case

1 set of operating instructions

Technical data

Rated air pressure: max. 6.3 bar

Air consumption: 72 l/min

Max. rotation speed: max. 250 rpm

Max. torque: 40 Nm

Change of rotation: clockwise and anticlockwise

Tool fitting: 1/4"

Noise emission values:

Noise measurement determined in accordance

with ISO15744:

Sound pressure level: L

Uncertainty: K

Sound power level: L

Uncertainty: K

Wear hearing protection!

= 91.8 dB (A)

pA

= 3 dB

pA

= 102.8 dB (A)

WA

= 3 dB

WA

WARNING!

► The noise emission levels specified in these

instructions have been measured in accordance with the standardised measuring

procedure specified in ISO 15744 and can

be used to make equipment comparisons.

The noise emission values vary in accordance

with the use of the compressed air tool and

may be higher than the values specified in

these instructions in some cases. It is easy to

underestimate the noise emission load if the

compressed air tool is used regularly in a

certain manner.

NOTE

► For an accurate estimate of the noise emis-

sion load during a certain working period,

the times during which the appliance is

switched off or is running but not actually

being used must also be taken into consideration. This can significantly reduce the noise

emission load over the total working period.

Vibration emission value:

Total vibration value calculated according to

ISO 28927-7:

Compressed air ratchet:

a

= 2.88 m/s

h

Uncertainty K = 0.81 m/s

2

2

PDRS 27 A1

GB│IE│NI

│

3 ■

WARNING!

General safety instructions for compressed air

tools

WARNING!

► Read all safety warnings and all instruc-

tions. Failure to follow the warnings and

instructions may result in electric shock, fire

and/or serious injury.

NOTE

► The terms "compressed air tool" or "tool" used

in the following text refer to the compressed

air tools specified in these operating instructions.

Save all warnings and instructions for future

reference.

■ The user must evaluate the specific risks that

may arise due to different kinds of use.

■ Please ensure that you have read and understood

the safety instructions before fitting, operating,

repairing, servicing or replacing any accessories

and before working near the compressed air tool.

Failure to do this can result in serious bodily injury.

■ The compressed air tool should only be set up,

adjusted or used by adequately qualified and

trained operators.

■ The compressed air tool may not be modified.

Modifications can reduce the effectiveness of

the safety measures and increase the risks for

the operator.

■ Never use damaged compressed air tools.

Maintain compressed air tools with care. Check

regularly whether moving parts function correctly

and do not jam; check whether any parts are

broken or damaged to an extent that the compressed air tool will no longer operate correctly.

Check signs and labels for completeness and

readability. If damaged, have parts repaired or

replaced before using the compressed air tool.

Many accidents are caused by poorly maintained compressed air tools.

■ This tool is not intended for use by persons (in-

cluding children) with limited physical, physiological or intellectual abilities or lack of experience

and/or knowledge, unless they are supervised

by a person who is responsible for their safety,

or receive instructions from this person on how

to use the device.

■ Do not allow children to play with the tool.

WARNING – RISK OF INJURY!

► Disconnect the compressed air supply before

carrying out maintenance work.

■ RISK OF EXPLOSION! Never use gasoline

or other flammable liquids to clean the compressed air tool! Sparks can ignite vapours

remaining in the compressed air tool and lead

to an explosion of the compressed air tool. Do

not operate the compressed air tool in explosive

atmospheres or environments with flammable

liquids, gases or dust. Do not work with any

materials that are or could become inflammable

or explosive.

■ Use the tool only in the fields of application for

which it was designed!

■ Do not force the tool.

■ Never use hydrogen, oxygen, carbon dioxide

or other gas in bottles as sources of energy for

this tool, as this can lead to an explosion and

consequently serious injuries.

■ Maintain and clean the tool on a regular basis

as specified (see Section "Maintenance and

cleaning").

■ Check the tool for any possible defects before

use. Ensure that the tool is in good working

condition before every use.

■ 4 │ GB

│IE│

NI

PDRS 27 A1

■ Remain alert at all times! Unexpected move-

ments of the tool can cause dangers.

■ Do not overreach. Keep proper footing and bal-

ance at all times. This provides for better control

over the compressed air tool in unexpected

situations.

■ Do not use the tool if its switch is defective. Any

tool that cannot be switched on or off is dangerous and must be repaired.

■ Keep compressed air tools that are not being

used out of the reach of children. Do not allow

persons unfamiliar with the power tool or these

instructions to operate the power tool. Compressed air tools are dangerous in the hands of

inexperienced users.

■ Treat the tool with care. Check whether moving

parts function correctly and do not jam; check

whether any parts are broken or damaged to

an extent that the power tool will no longer

operate correctly. If damaged, have the tool repaired before use. Many accidents are caused

by poorly maintained tools.

■ Switch off the appliance when not in use.

■ Use personal protective equipment. Always

wear eye protection. Wearing protective equipment such as a dust mask, non-slip safety shoes,

a helmet or hearing protection depending on

the type and use of the compressed air tool

reduces the risk of personal injuries.

■ Check all connections and supply lines. All

maintenance units, couplings and hoses must

correspond to the appliance parameters in

terms of pressure and air flow. If the pressure is

too low, the function of the tool will be compromised and if the pressure is too high, this can

cause property damage and personal injury.

■ Protect the hoses against kinking, constriction,

solvents and sharp edges. Keep hoses away

from heat, oil and rotating parts.

■ Ensure that the hose clamps are always tight-

ened firmly. Loose or damaged hose clamps

can allow air to escape in an uncontrolled

manner.

■ Replace a damaged hose immediately. A defec-

tive supply line can cause a compressed air

hose to thrash about and cause personal injury.

■ If the power cable of this tool is damaged, it

must be replaced by the manufacturer or its customer service or by a similarly qualified person

in order to avoid hazards.

■ Do not use the tool if you are tired or under the

influence of drugs, alcohol or medication.

A moment of inattention when operating the

tool can result in serious personal injury.

■ Do not breathe in the exhaust air directly. Avoid

getting exhaust air in your eyes. The exhaust air

from the compressed air tool can contain water,

oil, metal particles or dirt from the compressor.

This can cause damage to health.

WARNING!

► BE CAREFUL WHEN PUTTING DOWN THE

TOOL! Always put the tool down in such a

way that it does not lie on the trigger. Under

certain circumstances, this might cause an

accidental activation of the tool, which in turn

might lead to hazards.

■ Only suitable accessories may be used. You

can purchase these from the manufacturer.

Accessories other than original equipment can

cause hazards.

■ Use only filtered and regulated compressed air.

Dust, caustic fumes and/or moisture can damage the motor of a compressed air tool.

PDRS 27 A1

GB│IE│NI

│

5 ■

■ The hose must be designed for min. 6.3 bar

or 125 psi, at least for 150% of the maximum

pressure generated in the system.

■ The tool and the supply hose must be fitted with

a hose coupling that allows the pressure of

the coupling hose to be dispersed completely

during disconnection.

■ DANGER! Avoid contact with an energised line!

This tool is not insulated against electric shock.

WARNING – RISK OF INJURY!

► Under certain circumstances, high working

pressures can cause kickback to occur. This

can cause hazards due to the continuous

loading.

■ If you are inexperienced with the appliance,

seek training in how to use it safely.

WARNING – RISK OF INJURY!

► RISK OF PUNCTURE WOUNDS! Do not

treat an injection wound as a simple cut.

A high-pressure jet can inject toxins into the

body and cause serious injuries. In the event

of an injection into the skin, seek medical

assistance immediately.

■ The compressed air tool must not be modified in

any way without the manufacturer's approval.

■ Use the compressed air tool only with the speci-

fied pressure (6.3 bar).

■ The compressed air tool must always be discon-

nected from the air supply after use and for as

long as it is not in use.

■ The compressed air tool must not be used if it is

not airtight or if it requires repair.

■ Never connect the compressed air tool with a

compressed air hose that exceeds a pressure

of 6.3 bar.

■ Keep work area clean and well lit. Cluttered or

dark areas invite accidents. This enables better

control of the tool in unexpected situations.

WARNING!

► Have your power tool serviced by qualified

trained personnel using only original spare

parts. This ensures that the safety of the tool

is maintained.

■ Keep children and other persons away from the

tool during operation. Distractions can cause

you to lose control.

■ Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

■ Put the trigger and the tool away in the case of

an unexpected stoppage of the compressor.

■ Wherever possible, use a condensate separator

or drain the condensate (water) from the hoses

and tubing regularly before and during the use

of the compressed air tools.

■ NOTICE! An undersized compressed air system

will reduce the efficiency of your tool.

■ Please ensure that you have read and under-

stood the safety instructions regarding multiple

hazards before installation, operation, repair,

service and replacement of any accessories

and before work near the automatic screwdriver. Otherwise, there is a risk of serious physical

injuries.

■ The automatic screwdriver should only be fitted,

adjusted or used by qualified and trained

operators.

■ 6 │ GB

│IE│

NI

PDRS 27 A1

■ The automatic screwdriver may not be modified.

Modifications can reduce the effectiveness of

the safety measures and increase the risks for

the operator.

■ Do not lose the safety instructions – hand them

to the operator.

■ Never use a damaged machine on screwed joints.

■ The machines must be serviced regularly to

check whether the rated values and markings

required in the present part of ISO 11148 are

appended legibly on the machine. The employee/operator must contact the manufacturer

to obtain replacement stickers for labelling if this

is necessary.

Hazards caused by flying parts

■ If a workpiece or one of the accessory parts or

even the machine tool itself breaks, parts can

be thrown off at high speeds.

■ Always wear impact-resistant safety goggles

during operation, when replacing accessory

parts or during repair or maintenance work.

The level of the required protection must be

evaluated separately for each individual task.

■ You must ensure that the workpiece has been

securely fixed in place.

■ Check regularly that the rotation speed of

the compressed air tool is not higher than the

specified rotation speed appended on the

compressed air tool. These rotation speed tests

must be conducted without any accessory tools

attached.

■ Ensure that sparks and fragments created during

work do not present any hazards.

■ Separate the compressed air tool from the com-

pressed air supply before replacing the attachment or accessories or before you adjust the

settings, service or clean the tool.

■ Ensure that no dangers are created for other

persons either.

Hazards caused by entanglement

■ Hazards caused by entanglement can result

in suffocation, scalping and/or cut wounds if

loose clothing, personal jewellery, necklaces,

hair or gloves are not kept away from the

machine and its accessories.

■ Gloves can get caught in the rotating drive,

which can lead to injuries or fractures of the

fingers.

■ Rubber or metal-reinforced gloves can become

entangled easily in rotating drive fittings and

extensions.

■ Never wear loose-fitting gloves or gloves with

cut-off or worn-out glove fingers.

■ Never hold onto the drive, the fitting or the drive

extension.

■ Keep your hands away from the rotating drive.

■ Dress properly. Do not wear loose clothing or

jewellery. Keep hair, clothing and gloves away

from the compressed air tool and moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts. There is a risk of personal injury.

Hazards during operation

■ When using the machine, the operator's hands

may be exposed to risks such as crushing,

striking, cutting, abrasion and heat. Wear

suitable gloves to protect your hands.

■ The operator and maintenance personnel must

be physically capable of handling the size,

weight and power of the machine.

■ Hold the machine correctly: be ready to coun-

teract any normal or sudden movements – keep

both hands ready.

■ Ensure that your body is balanced and that you

have stable footing.

■ Keep proper footing and balance at all times.

■ Prevent unintentional starting. If the air supply is

interrupted, switch off the compressed air tool

using the On/Off switch.

PDRS 27 A1

GB│IE│NI

│

7 ■

■ When aids are needed to absorb the reaction

torque, we recommend using a suspension unit

wherever possible. If this is not possible, side

handles for machines with a straight grip and

machines with pistol grip are recommended.

We recommend always using aids to absorb

the torque if it is higher than 4 Nm on machines

with straight grips, and higher than 10 Nm on

machines with a pistol grip, and higher than

60 Nm on offset screwdrivers.

■ Release the start/stop control in case of a

disruption to the electricity supply.

■ Use only the lubricants recommended by the

manufacturer.

■ Fingers might be crushed in nut wrenches with

an open pan head.

■ Keep your hands away from the rotating collet

chuck and the rotating drill.

■ Do not use the tool in confined spaces and en-

sure that your hands are not crushed between

the machine and the work piece, especially

when removing screws.

Hazards caused by repetitive movements

■ Users of an automatic screwdriver may experi-

ence unpleasant sensations in their hands, arms,

shoulders, neck area or other body parts while

working with the tools.

■ Assume a comfortable position when working

with this machine, pay attention to safe footing

and avoid unfavourable positions or such that

make it difficult to keep your balance. During

work over longer periods, the operator should

change posture to avoid discomfort and fatigue.

■ If the operator notices symptoms such as persis-

tent discomfort, throbbing, pain, tingling, burning or stiffness, these warning indications should

not be ignored. The operator should consult a

qualified medical doctor.

Hazards caused by accessories

■ Disconnect the machine from the energy supply

before changing the machine tool or accessory.

■ Do not touch fittings or accessories during the strik-

ing process because this can increase the risk of

cuts, burns or injuries caused by vibrations.

■ Use only accessories and supplies of the sizes

and types recommended by the manufacturer

of machines for screw connections; do not use

any other types or sizes of accessories or consumable materials.

■ Use only impact fittings that are in good working

order because any defects in the handles and

accessories can cause these to break and be

ejected when used with impact wrenches.

■ 8 │ GB

│IE│

NI

PDRS 27 A1

Hazards in the workplace

■ Slipping, tripping up and falling are the main

causes of injuries in the workplace. Pay attention to surfaces that may have become slippery

from the use of the machine and also be aware

of tripping hazards caused by air or hydraulic

hoses.

■ Proceed with caution in unknown surroundings.

Hidden hazards caused by power or other

supply lines may be present.

■ This compressed air tool is not suitable for use

in explosive atmospheres and is not insulated

against contact with power sources.

■ Ensure that there are no electric cables, gas

pipes, etc. that might result in a hazard if damaged by using the machine.

Hazards caused by dust and vapours

■ The dusts and vapours produced by using auto-

matic screwdrivers can be hazardous to health

(e.g. cause cancer, birth defects, asthma and/

or dermatitis); it is essential to carry out a risk

assessment in respect of these risks and to implement corresponding regulatory mechanisms.

■ The risk assessment should include the dust

caused by using the machine and any existing

dust that may be raised at the same time.

■ The exhaust air should be extracted so that the

minimum amount of dust is raised in an already

dusty environment.

■ If dusts or vapours are created, the main priority

must be to control these at the site of their

release.

■ All machine components or accessories in-

tended for collecting, extracting or suppressing

airborne dust or vapours or should be used and

serviced properly in accordance with the manufacturer’s instructions.

■ Use a dust mask as per the instructions provided

by your employer or as required by health and

safety regulations.

Hazards caused by noise

■ Excessive noise levels in conjunction with insuffi-

cient hearing protection may lead to permanent

hearing damage, loss of hearing and other

problems, such as tinnitus (ringing, buzzing,

whistling or humming in your ears). It is essential

to carry out a risk assessment with regard to

these hazards and implement suitable control

mechanisms.

■ Suitable control mechanisms include measures

such as the use of insulating materials to avoid

ringing noises from occurring on the workpieces.

■ Use hearing protection according to the instruc-

tions provided by your employer and as required by work and health safety regulations.

■ The automatic screwdriver is to be operated

and maintained in accordance with the recommendations contained in this manual in order to

reduce any unnecessary increase of the noise

levels.

■ If the automatic screwdriver is equipped with

a sound absorber, it must always be available

and in good working order when using the

automatic screwdriver.

■ Consumables and the machine tool should

be selected, maintained and replaced in accordance with the recommendations in these

instructions in order to avoid any unnecessary

increase of the noise levels.

PDRS 27 A1

GB│IE│NI

│

9 ■

■ The compressed air tool is to be operated and

maintained in accordance with the recommendations contained in these instructions in order

to reduce any unnecessary increase of the noise

levels.

■ The integrated sound absorber may not be

removed and must be in good working order.

Hazards caused by vibrations

■ Vibrations can damage the nerves and cause

malfunctions to the blood circulation in the

hands and arms.

■ Keep your hands away from the fittings of the

nut wrenches.

■ Wear warm clothing when working in a cold

environment and keep your hands warm and

dry.

■ If you notice that the skin of your fingers or

hands is becoming numb, tingles, hurts or shows

white discolouration, stop working with the

machine and consult a doctor.

■ The automatic screwdriver must to be operated

and maintained in accordance with the recommendations contained in this manual to reduce

any unnecessary increase of the vibrations.

■ Do not use any worn-out or poorly matching

fittings and extensions, as there is a high probability that this will lead to a significant increase

in the vibrations.

■ Consumables and the machine tool should be

selected, maintained and replaced in accordance with the recommendations in this guide in

order to avoid unnecessary increase of oscillations.

■ If possible, sleeve fittings should be used.

■ To support the weight of the machine, use a

stand, clamp or a balancing unit wherever

possible.

■ Hold the machine securely but not too firmly

while maintaining the necessary hand-reaction

force, as the vibration risk generally increases

the harder the machine is held.

■ An inadequately mounted or damaged acces-

sory tool can lead to excessive vibrations.

Additional safety instructions for

pneumatic machines

■ Compressed air can cause serious injuries:

– When the machine is not in use, the air

supply must always be shut off and the air

hose depressurised. The machine must be

disconnected from the compressed air supply before replacing accessories or when

conducting repair work.

– Never aim the airflow at yourself or anyone

else.

■ Thrashing hoses can cause serious injury. There-

fore, always check whether the hoses and their

fixings are undamaged and have not come

loose.

■ Cold air must be directed away from the hands.

■ Do not use any quick-lock couplings on the tool

inlet for impact and impulse drills. For hose connections with a thread, always only use those

made of tempered steel (or a material with

comparable impact resistance).

■ If universal rotary joints (claw couplings) are

used, locking pins must be inserted and Whipcheck hose restraints must be used to provide

protection in the case of a failure of the connection between the hose and the machine.

■ Ensure that the maximum permissible pressure

on the machine is not exceeded.

■ 10 │ GB

│IE│

NI

PDRS 27 A1

■ For torque-controlled machines with continuous

rotation, the air pressure has effects on performance that are relevant in terms of safety.

Requirements for the length and diameter of the

hose must therefore be defined.

■ Never carry pneumatic machines by the hose.

Additional safety notices

■ If applicable, observe special work safety or

accident prevention regulations for the handling

of compressors and compressed air tools.

■ Ensure that the maximum permissible working

pressure specified in the Technical Data is not

exceeded.

■ Do not overload this tool – use this tool only

within the capacity range specified in the

Technical Data.

■ Use safe lubricants. Ensure sufficient ventila-

tion at the place of work. In case of increased

discharge:

check the compressed air tool and have it repaired if necessary.

■ Do not use this tool if you are distracted. Be

alert, watch what you are doing and use common sense when operating a compressed air

tool. Do not use tools when you feel tired or are

under influence of drugs, alcohol, or medication. A moment of inattention when operating

the tool can result in serious personal injuries.

■ Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

■ Keep compressed air tools out of reach of

children.

■ Do not store outdoors or in damp environments

without protection.

■ Protect the compressed air tool, in particular

the compressed air connection and operating

elements against dust and dirt.

Before use

NOTE

► The compressed air tool may only be oper-

ated using cleaned, oil-atomised compressed

air and the maximum operating pressure of

6.3 bar must not be exceeded on the appliance. The compressor must be fitted with

a pressure reducer to regulate the working

pressure.

Fitting the connector nipple

♦ Screw the connector nipple into the air

inlet .

Lubrication

NOTE

► Regular lubrication is particularly important

to avoid friction and corrosion damage.

We recommend using a suitable special oil

for compressed air tools (e.g. Liqui Moly

compressor oil).

– Lubrication with mist oiler

A mist oiler (not supplied) continuously

and optimally lubricates the appliance

as a preparation stage after the pressure

reducer. A mist oiler gives off fine drops

of oil into the air flow and thus guarantees

regular lubrication.

– Manual lubrication

If you do not have a mist oiler, lubricate

the tool before every use or longer work

sessions. Add 3–4 drops of pneumatic

oil into the connector nipple

.

PDRS 27 A1

GB│IE│NI

│

11 ■

Refilling oil

To ensure that the tool remains operational for

a long time, the tool must have a sufficient fill of

pneumatic oil.

You have the following options:

♦ Attach a maintenance unit with an oiler to the

compressor.

♦ Install an add-on oiler in the compressed air

line or the compressed air tool.

♦ Add 3–5 drops of pneumatic oil into the con-

nector nipple

every 15 minutes of operation.

Connecting to a compressed air

source

NOTE

► Before connecting the compressed air source,

– the correct working pressure (6.3 bar)

must be fully reached, and

– make sure that the trigger is in the upper

position.

► Use only connection hoses with an internal

diameter of at least 9 mm.

► Use only filtered, lubricated and regulated

compressed air.

♦ Screw the connector nipple

. Tighten the connection with a pair of pliers.

♦ Attach the tool to a compressor by connecting

the connector nipple

of the compressed air source.

into the air inlet

with the supply hose

CAUTION!

► Ensure that the compressed air hose is

firmly attached. A loose hose can thrash

about uncontrollably causing grave danger.

Likewise, ensure the firm seat of the two screw

connections between the coupling piece and

the appliance.

♦ The compressed air source must be equipped

with a pressure reducer so that you can regulate the air pressure.

Operation

Compressed air ratchet

♦ Fit the required plug-in attachment , +

or the extension piece onto the square

retainer .

♦ Set the correct rotational direction on the turn

bolt

:

R = anticlockwise

F = clockwise

♦ Fit the plug-in attachment onto the screw head.

NOTE

► The connection with the compressed air

source is made using a flexible compressed

air hose with a quick coupler.

You will reach the best performance of your

ratchet wrench with a compressed air hose

LW 10 mm.

Switching on and off

Switching on:

♦ Press the trigger

Switching off:

♦ Release the trigger

♦ When you have finished working, disconnect

the tool from the compressed air source.

to turn the appliance on.

.

■ 12 │ GB

│IE│

NI

PDRS 27 A1

Maintenance and cleaning

WARNING! RISK OF INJURY! Discon-

nect the tool from the compressed air

supply.

CAUTION!

► Before maintenance, clean off any hazardous

substances that may have accumulated on

the tool (due to working processes). Avoid

all skin contact with these substances. If the

skin comes into contact with hazardous dusts,

this can lead to severe dermatitis. If dust is

produced or swirled up during maintenance,

it can be inhaled.

NOTE

To ensure correct functioning and a long service

life for the tool, pay attention to the following

points:

■ Sufficient and continuous oil lubrication is highly

important for optimum functioning.

■ Check the speed and vibration levels after each

use.

■ Check the idle speed regularly and after any

maintenance is performed:

use a rev counter and perform the measurement without any clamped tools. At a residual

pressure of 6.3 bar, the idle speed may not be

exceeded under any circumstances.

■ If the tool is exhibiting excessive vibration levels,

the cause of the vibrations must be identified

and repaired.

■ Use only the genuine replacement parts recom-

mended by the manufacturer, otherwise you

could put users at risk. In doubt, contact the

Service Centre.

■ Clean the tool with a soft, dry cloth only.

■ Never use sharp or abrasive cleaning agents

under any circumstances.

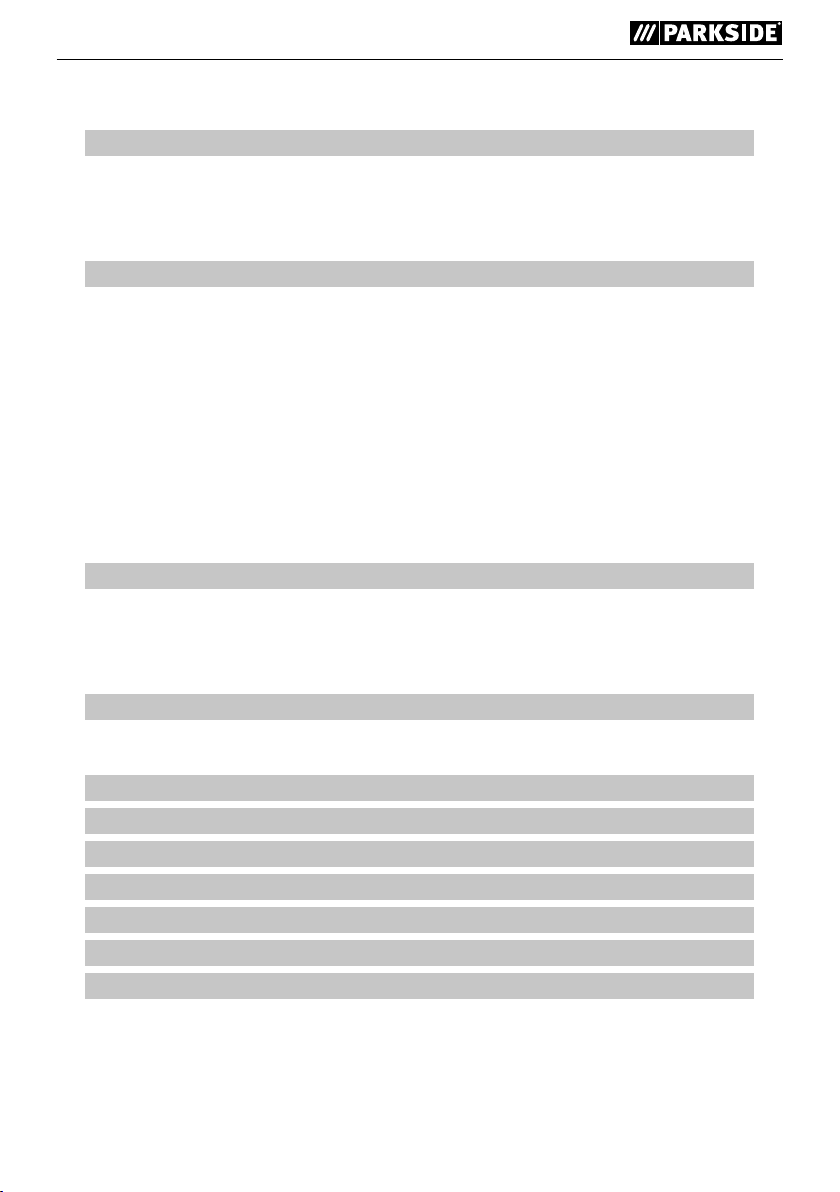

Troubleshooting

Fault Possible

cause

Speed too

slow, air

escapes from

the outlet.

Tool does

not move;

compressed

air escapes

completely

through the

outlet.

Motor parts

jamming due

to dirt.

Pressure

supply too

low.

Motor is

jammed due

to material

build-up.

Remedy

Check the

pressure

supply filter

for contamination.

Check the

pressure

supply filter

for contamination.

Lubricate the

tool as described in the

instructions.

If necessary,

repeat the

steps outlined

above.

Lubricate the

tool as described in the

instructions.

Disposal

The packaging consists of environmentally

friendly material. It can be disposed of at

any local recycling container.

Do not dispose of the appliance in the normal

domestic waste!

Your local community or municipal authorities can

provide information on how to dispose of the wornout appliance.

PDRS 27 A1

GB│IE│NI

│

13 ■

Kompernass Handels GmbH

warranty

Dear Customer,

This appliance has a 3-year warranty valid from

the date of purchase. If this product has any faults,

you, the buyer, have certain statutory rights. Your

statutory rights are not restricted in any way by the

warranty described below.

Warranty conditions

The validity period of the warranty starts from the

date of purchase. Please keep your original receipt

in a safe place. This document will be required as

proof of purchase.

If any material or production fault occurs within

three years of the date of purchase of the product,

we will either repair or replace the product for you

at our discretion. This warranty service is dependent on you presenting the defective appliance and

the proof of purchase (receipt) and a short written

description of the fault and its time of occurrence.

If the defect is covered by the warranty, your product

will either be repaired or replaced by us. The repair

or replacement of a product does not signify the

beginning of a new warranty period.

Warranty period and statutory claims for

defects

The warranty period is not prolonged by repairs

effected under the warranty. This also applies to

replaced and repaired components. Any damage

and defects present at the time of purchase must

be reported immediately after unpacking. Repairs

carried out after expiry of the warranty period shall

be subject to a fee.

Scope of the warranty

This appliance has been manufactured in accordance

with strict quality guidelines and inspected meticulously prior to delivery.

The warranty covers material faults or production

faults. The warranty does not extend to product parts

subject to normal wear and tear or fragile parts such

as switches, batteries, baking moulds or parts made

of glass.

The warranty does not apply if the product has been

damaged, improperly used or improperly maintained.

The directions in the operating instructions for the

product regarding proper use of the product are

to be strictly followed. Uses and actions that are

discouraged in the operating instructions or which

are warned against must be avoided.

This product is intended solely for private use and

not for commercial purposes. The warranty shall be

deemed void in cases of misuse or improper handling,

use of force and modifications/repairs which have

not been carried out by one of our authorised

Service centres.

Warranty claim procedure

To ensure quick processing of your case, please

observe the following instructions:

■ Please have the till receipt and the item number

(e.g. IAN 12345) available as proof of purchase.

■ You will find the item number on the type plate,

an engraving on the front page of the instructions

(bottom left), or as a sticker on the rear or bottom of the appliance.

■ If functional or other defects occur, please

contact the service department listed either by

telephone or by e-mail.

■ You can return a defective product to us free of

charge to the service address that will be provided

to you. Ensure that you enclose the proof of

purchase (till receipt) and information about

what the defect is and when it occurred.

■ 14 │ GB

│IE│

NI

You can download these instructions

along with many other manuals,

product videos and software on

www.lidl-service.com.

PDRS 27 A1

Service

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/Min.)

E-Mail: kompernass@lidl.co.uk

Service Ireland

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: kompernass@lidl.ie

IAN 292168

Importer

Please note that the following address is not the

service address. Please use the service address

provided in the operating instructions.

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

DE - 44867 BOCHUM

GERMANY

www.kompernass.com

Translation of the original

Conformity Declaration

We, KOMPERNASS HANDELS GMBH, document officer: Mr Semi Uguzlu, BURGSTR. 21,

DE - 44867 BOCHUM, GERMANY, hereby declare

that this product complies with the following standards, normative documents and EC directives:

Machinery Directive

(2006/42/EC)

Applied harmonised standards:

EN ISO 11148-6:2012

Type designation of machine:

AIR RATCHET SET PDRS 27 A1

Year of manufacture: 10 - 2017

Serial number: IAN 292168

Bochum, 17/10/2017

Semi Uguzlu

- Quality Manager -

PDRS 27 A1

We reserve the right to make technical changes in

the context of further product development.

GB│IE│NI

│

15 ■

■ 16 │ GB

│IE│

NI

PDRS 27 A1

Indholdsfortegnelse

Indledning ......................................................18

Anvendelsesområde ......................................................... 18

Udstyr .................................................................... 18

Pakkens indhold ............................................................19

Tekniske data ..............................................................19

Generelle sikkerheds anvisninger for trykluftprodukter ................20

Farer på grund af udslyngede dele .............................................23

Farer på grund af fastgribning/opvikling ......................................... 23

Farer under drift ............................................................23

Farer på grund af gentagne bevægelser .........................................24

Farer på grund af tilbehørsdele ................................................24

Farer på arbejdspladsen ..................................................... 25

Farer på grund af støv og dampe .............................................. 25

Farer på grund af støj ........................................................ 25

Farer på grund af vibrationer .................................................. 26

Yderligere sikkerhedsanvisninger for trykluftmaskiner ...............................26

Yderligere sikkerhedsanvisninger ...............................................27

Før ibrugtagning .................................................27

Montering af tilslutningsnippel ................................................. 27

Smøring .................................................................. 27

Påfyldning af olie ...........................................................28

Tilslutning til trykluftkilde ...................................................... 28

Ibrugtagning ....................................................28

Trykluftskralde ..............................................................28

Tænd/sluk ................................................................28

Vedligeholdelse og rengøring ......................................29

Afhjælpning af fejl ...............................................29

Bortskaffelse ....................................................29

Garanti for Kompernass Handels GmbH .............................30

Service .........................................................31

Importør .......................................................31

Oversættelse af den originale overensstemmelseserklæring ............31

PDRS 27 A1

DK

│

17 ■

TRYKLUFT-SKRALDENØGLE

PDRS 27 A1

Indledning

Tillykke med købet af dit nye produkt. Du har valgt

et produkt af høj kvalitet. Betjeningsvejledningen

er en del af dette produkt. Den indeholder vigtige

informationer om sikkerhed, anvendelse og bortskaffelse. Du bør sætte dig ind i alle produktets

betjenings- og sikkerhedsanvisninger før brug. Brug

kun produktet som beskrevet og kun til de angivne

anvendelsesområder. Lad alle dokumenter til produktet følge med, hvis du giver produktet videre til

andre.

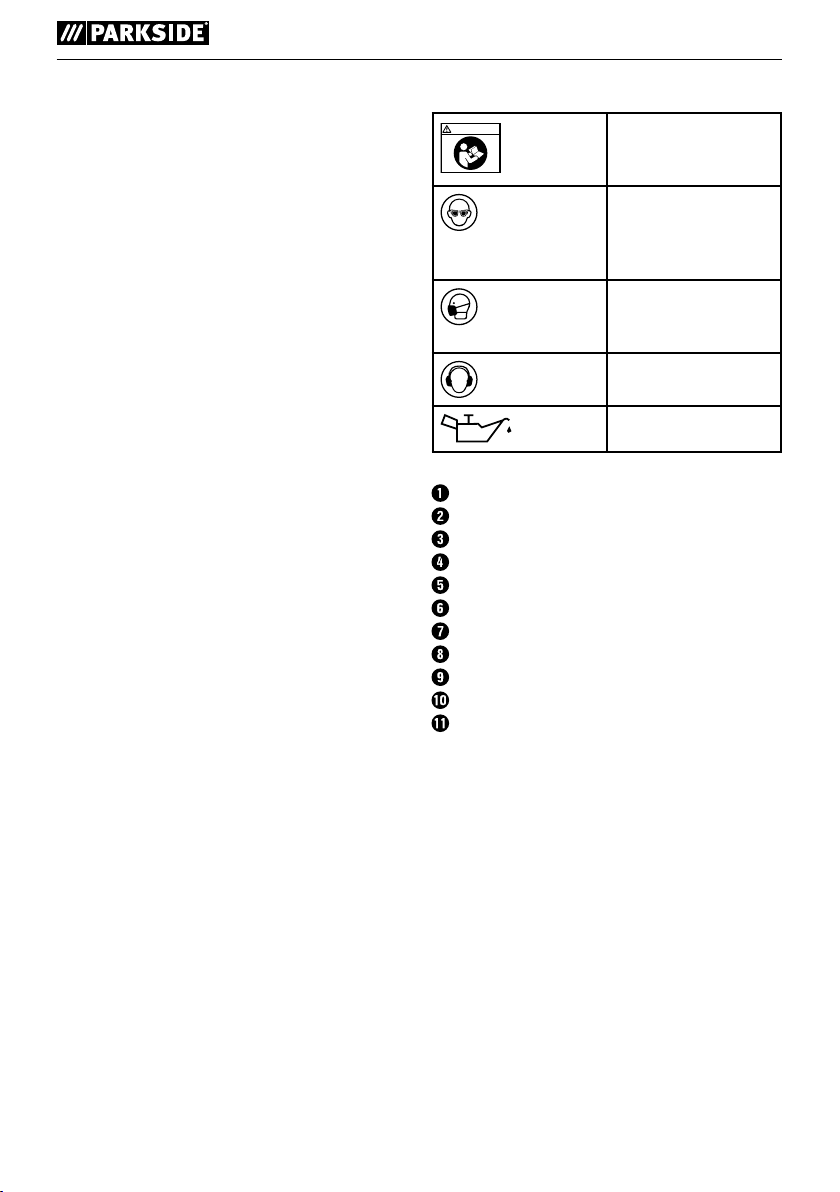

Symboler på trykluftværktøjet:

WARNING!

Før ibrugtagning skal

betjeningsvejledningen

læses.

Brug altid øjenbeskyttelse ved anvendelse

eller vedligeholdelse

af trykluftprodukt.

Brug altid åndedrætsværn ved støvudvikling.

Bær altid høreværn.

Anvendelsesområde

Skraldeopsatsen er velegnet til tilspænding og

løsning af skruesamlinger på autoværksteder

(dækmontage mv.) samt i landbrugssektoren. Ved

tilspænding af skruer og møtrikker skal man overholde de nødvendige tilspændingsmomenter.

Dette produkt må kun drives med en trykluftforsyning.

Det maksimalt tilladte driftstryk, som er angivet på

produktet, må aldrig overskrides.

Dette produkt må ikke drives med eksplosive,

brændbare eller sundhedsskadelige gasarter.

Det må ikke anvendes som løftestang, brækjern

eller slagværktøj.

Enhver anden anvendelse eller ændring af produktet

anses for at være uden for anvendelsesområdet og

indebærer betydelige farer for uheld. Vi påtager

os intet ansvar for skader, der opstår som følge

af anvendelse uden for anvendelsesområdet.

Produktet er kun beregnet til privat anvendelse.

Smør dagligt med olie

Udstyr

Trykluftskralde

Luftindløb

Tilslutningsnippel

Aftrækkerarm

Firkantet holder

Omskifterbolt

Olieflaske

Skruebits

Topnøgler

Adapter

Forlængerstykke

■ 18 │ DK

PDRS 27 A1

Pakkens indhold

1 trykluftskralde

9 topnøgler (5,5mm/6/7/8/9/10/11/12/13)

12 skruebits

25 mm (1x PH1 / 1x PH2 / HEX 3/4/5/6/

7 T10/T15/T20/T25/T30)

1 forlængerstykke 100 mm

1 adapter 1/4” firkant til 1/4" sekskant

1 olieflaske

1 tilslutningsnippel 6,35 mm (1/4")

1 kuffert

1 betjeningsvejledning

Tekniske data

Dimensioneret lufttryk: maks. 6,3 bar

Luftforbrug: 72 l/min

Maks. omdrejningstal: maks. 250 min

Maks. drejningsmoment: 40 Nm

Ændring af rotations-

retning: højre- og venstrerotation

Holder: 1/4"

Støjemissionsværdier:

Måleværdi for støj beregnet i henhold til ISO

15744:

Lydtrykniveau: L

Usikkerhed: K

Lydeffektniveau: L

Usikkerhed: K

= 91,8 dB (A)

PA

= 3 dB

pA

= 102,8 dB (A)

WA

= 3 dB

WA

Bær høreværn!

-1

ADVARSEL!

► Støjemissionsværdierne, som er angivet i

disse anvisninger, er målt med en målemetode, der er standardiseret efter ISO 15744,

og som kan anvendes til sammenligning af

maskiner. Støjemissionsværdierne ændrer sig

afhængigt af trykluftværktøjets anvendelse og

kan i mange tilfælde ligge over de angivne

værdier i disse anvisninger. Støjemissionsbelastningen kan undervurderes, hvis trykluftværktøjet anvendes jævnligt på denne måde.

BEMÆRK

► For at opnå en nøjagtig vurdering af støjemis-

sionsbelastningen i et bestemt arbejdstidsrum er man også nødt til at medregne de

tidspunkter, hvor produktet er slukket, eller

ganske vist er tændt, men ikke anvendes.

Dette kan reducere støjemissionsbelastningen

over hele tidsrummet betydeligt.

Vibrationsemissionsværdi:

Samlet vibrationsværdi beregnet efter ISO 28927-7:

Trykluftskralde:

a

= 2,88 m/s

h

Usikkerhed K = 0,81 m/s

2

2

PDRS 27 A1

DK

│

19 ■

WARNING!

Generelle sikkerhedsanvisninger for trykluftprodukter

ADVARSEL!

► Læs alle sikkerhedsanvisninger og -instruk-

tioner. Hvis de angivne sikkerhedsanvisninger

og -instruktioner ikke overholdes, kan det

medføre elektrisk stød, brand og/eller alvorlige kvæstelser.

BEMÆRK

► Begrebet "trykluftprodukt" eller "produkt", som

anvendes i den efterfølgende tekst, henviser

til de trykluftprodukter, som er omtalt i denne

betjeningsvejledning.

Opbevar sikkerhedsanvisningerne og

-instruktionerne til senere brug.

■ Det påhviler brugeren at vurdere de specifikke

risici, som kan opstå i forbindelse med enhver

anvendelse.

■ Sikkerhedsanvisningerne skal være læst og for-

stået før enhver justering, betjening, reparation,

vedligeholdelse og udskiftning af tilbehørsdele

samt før arbejde i nærheden af trykluftværktøjet. Hvis det ikke er tilfældet, kan det føre til

alvorlige personskader.

■ Trykluftværktøjet må udelukkende justeres, ind-

stilles eller anvendes af kvalificerede og uddannede operatører.

■ Trykluftværktøjet må ikke ændres. Modifikationer

kan reducere sikkerhedsanordningernes effektivitet og forøge risikoen for operatøren.

■ Brug aldrig beskadigede trykluftværktøjer. Vedli-

gehold trykluftværktøjet omhyggeligt. Kontrollér

jævnligt om bevægelige dele fungerer, som de

skal, og ikke sætter sig fast, om dele er defekte

eller så beskadigede, at trykluftværktøjets funktion er påvirket. Kontrollér skilte og påtryk for

fuldstændighed og læselighed. Få beskadigede

dele repareret eller udskiftet, inden du bruger

produktet. Mange uheld skyldes dårligt vedligeholdt trykluftværktøj.

■ Dette apparat må ikke benyttes af personer

(inklusive børn) med begrænsede fysiske, sensoriske eller psykiske evner eller med manglende

erfaringer og/eller manglende viden, medmindre en ansvarlig person holder opsyn med dem

og giver dem anvisninger til, hvordan apparatet

skal benyttes.

■ Sørg for, at børn ikke leger med produktet.

ADVARSEL! FARE FOR PERSON-

SKADER!

► Afbryd trykluftforsyningen før vedligeholdel-

sesarbejder.

■ EKSPLOSIONSFARE! Brug aldrig benzin el-

ler andre brændbare væsker til rengøring af

trykluftproduktet! Dampe, som bliver tilbage i

trykluftproduktet, kan antændes af gnister og

medføre, at trykluftproduktet eksploderer.

Arbejd aldrig med produktet i eksplosionsfarlige

omgivelser, hvor der befinder sig brændbare

væsker, gasser eller støv. Arbejd ikke med materialer, som er eller kan være let antændelige

eller eksplosive.

■ Brug kun produktet til de anvendelsesformål,

det er tiltænkt!

■ Overbelast ikke produktet.

■ Brug aldrig brintoxid, ilt, kuldioxid eller anden

gas i flasker som energikilde til dette værktøj, da

det kan føre til eksplosion og dermed alvorlige

personskader.

■ Vedligehold og rengør produktet regelmæssigt

som foreskrevet (se kapitlet "Vedligeholdelse

og rengøring").

■ Kontrollér produktet for eventuelle skader

før ibrugtagning. Sørg for, at produktet er i

upåklagelig tilstand før enhver anvendelse.

■ 20 │ DK

PDRS 27 A1

■ Vær altid opmærksom! Uventede bevægelser af

produktet kan føre til risici.

■ Undgå akavede kropsstillinger. Sørg for, at du

står sikkert, og hold altid balancen. Derved kan

du bedre kontrollere trykluftproduktet i uventede

situationer.

■ Brug aldrig et produkt, hvor kontakten er defekt.

Et produkt, som ikke længere kan tændes og

slukkes, er farligt og skal repareres.

■ Ubenyttede trykluftprodukter skal opbevares

utilgængeligt for børn. Personer, som ikke

kender produktet, eller som ikke har læst disse

anvisninger, må ikke bruge produktet. Trykluftprodukter er farlige, hvis de anvendes af uerfarne personer.

■ Vedligehold produktet omhyggeligt. Kontrollér

om bevægelige dele fungerer, som de skal, og

ikke sætter sig fast, om dele er defekte eller så

beskadigede, at produktet ikke kan fungere længere. Få beskadigede dele repareret, inden du

bruger produktet. Mange uheld skyldes dårligt

vedligeholdte produkter.

■ Sluk for produktet, når det ikke længere skal

bruges.

■ Brug personligt beskyttelsesudstyr, og bær altid

beskyttelsesbriller. Når du bruger personligt beskyttelsesudstyr som f.eks. støvmaske, skridsikre

sikkerhedssko, beskyttelseshandsker, sikkerhedshjelm og høreværn afhængigt af trykluftværktøjets type og anvendelse, reduceres risikoen for

kvæstelser.

■ Kontrollér tilslutninger og forsyningsledninger.

Alle vedligeholdelsesenheder, koblinger og

slanger skal være dimensioneret efter kompressorens mærkedata for tryk og luftmængde. Hvis

trykket er for lavt, påvirkes produktets funktion,

og hvis det er for højt, kan det føre til materielle

skader og personskader.

■ Beskyt slangerne mod knæk, forsnævringer,

opløsningsmidler og skarpe kanter. Hold slangerne på afstand af varme, olie og roterende

dele.

■ Sørg for, at slangebåndene altid er spændt fast.

Slangebånd, der ikke er spændt fast eller er defekte, kan forårsage ukontrolleret udslip af luft.

■ Udskift omgående beskadigede slanger. Defekte

forsyningsledninger kan føre til tilbagesvirpende

trykluftslanger og forårsage skader.

■ Hvis dette produkts tilslutningsledning beska-

diges, skal den udskiftes af producenten eller

dennes kundeservice eller af en person med

tilsvarende kvalifikationer, så farlige situationer

undgås.

■ Brug ikke produktet, hvis du er træt eller påvirket

af narkotika, alkohol eller medicin. Et øjebliks

uopmærksomhed kan medføre alvorlige kvæstelser ved brug af produktet.

■ Indånd ikke udstødningsluften direkte. Undgå at

få udstødningsluft i øjnene. Udstødningsluften

fra trykluftproduktet kan indeholde vand, olie,

metalpartikler eller urenheder fra kompressoren.

Dette kan være sundhedsskadeligt.

ADVARSEL!

► VÆR FORSIGTIG, NÅR DU LÆGGER PRO-

DUKTET VÆK! Læg altid produktet fra dig på

en sådan måde, at det ikke hviler på udløserknappen. Under visse omstændigheder kan

det føre til uønsket aktivering af produktet,

hvilket kan udgøre en risiko.

■ Der må kun anvendes egnet tilbehør. Dette kan

købes hos producenten. Alt andet end originalt

tilbehør kan resultere i farer.

■ Anvend kun filtreret og reguleret trykluft. Støv,

ætsende dampe og/eller fugtighed kan beskadige motoren på et trykluftværktøj.

PDRS 27 A1

DK

│

21 ■

■ Slangen skal være dimensioneret til min. 6,3 bar

eller 125 psi, dog mindst 150 % af anlæggets

genererede maksimaltryk.

■ Værktøjet og forsyningsslangen skal altid være

forsynet med en slangekobling, så trykket er

fjernet helt, når koblingsslangen tages af.

■ FARE! Undgå kontakt med en spændingsføren-

de ledning. Dette produkt er ikke isoleret mod

elektrisk stød.

ADVARSEL! FARE FOR PERSON-

SKADER!

► Ved højt arbejdstryk kan der forekomme

tilbageslag, som i nogle situationer kan være

farlige eller føre til vedvarende belastning.

■ Hvis du er uerfaren i brugen af produktet, bør

du sørge for oplæring, så du kan bruge det

uden risiko.

ADVARSEL! FARE FOR PERSON-

SKADER!

► FARE VED STIKSÅR! Betragt ikke en indsprøjt-

ning som et simpelt snitsår. En højtryksstråle

kan indsprøjte giftstoffer i kroppen og føre til

alvorlige personskader. I tilfælde af indsprøjtning under huden skal du omgående søge

lægehjælp.

■ Trykluftproduktet må ikke ændres på nogen

måde uden samtykke fra producenten.

■ Trykluftproduktet må kun anvendes med det

foreskrevne tryk (6,3 bar).

■ Trykluftproduktet skal efter anvendelsen, og når

det ikke anvendes, altid være koblet fra luftforsyningen.

■ Hvis trykluftproduktet ikke er lufttæt, eller det

skal repareres, må det ikke anvendes.

■ Forbind aldrig trykluftproduktet med en trykluft-

slange, hvis tryk overstiger 6,3 bar.

■ Hold arbejdspladsen ren og godt oplyst. Rod

og dårligt oplyste arbejdspladser kan medføre

uheld. Derved kan du bedre kontrollere produktet, især i uventede situationer.

ADVARSEL!

► Lad kun en kvalificeret reparatør reparere dit

produkt og kun med originale reservedele.

Derved garanteres det, at produktets sikkerhed bevares.

■ Hold børn og andre personer på afstand, når

produktet anvendes. Hvis du bliver distraheret,

kan du miste kontrollen over værktøjet.

■ Bær velegnet påklædning. Bær ikke løstsid-

dende tøj eller smykker. Hold hår, tøj og handsker på afstand af dele, der bevæger sig. Løst

tøj, smykker eller hår kan gribe fat i dele, der

bevæger sig.

■ Læg udløser og produkt fra dig i tilfælde af et

uventet svigt i kompressoren.

■ Anvend så vidt muligt en kondensatudskiller,

eller tøm jævnligt slanger og rørledninger for

kondensat (vand) før og under brugen af trykluftproduktet.

■ OBS! Et underdimensioneret trykluftsystem kan

forringe produktets effektivitet.

■ Af hensyn til en række risici skal sikkerhedsanvis-

ningerne være læst og forstået før enhver montering, betjening, reparation, vedligeholdelse og

udskiftning af tilbehørsdele samt før arbejde i

nærheden af skruemaskinen. I modsat fald kan

det føre til alvorlige personskader.

■ Skruemaskinen må udelukkende justeres, indstil-

les eller anvendes af kvalificerede og uddannede operatører.

■ 22 │ DK

PDRS 27 A1

■ Skruemaskinen må ikke ændres. Modifikationer

kan reducere sikkerhedsanordningernes effektivitet og forøge risikoen for operatøren.

■ Sikkerhedsanvisningerne må ikke blive væk –

giv dem til operatøren.

■ Brug aldrig en beskadiget skruemaskine.

■ Maskinen skal jævnligt vedligeholdes for at

kontrollere, at de nominelle værdier og mærkninger, som kræves i den relevante del af ISO

11148, er tydeligt læselige på maskinen. Den

ansatte/brugeren skal kontakte producenten for

at få nye mærkater til mærkning, hvis dette er

nødvendigt.

Farer på grund af udslyngede dele

■ Ved brud på arbejdsemnet, en af tilbehørsde-

lene eller sågar selve maskinværktøjet kan der

slynges dele ud ved høj hastighed.

■ Ved betjening, ved udskiftning af tilbehørsdele

samt ved reparations- og vedligeholdelsesarbejder skal der altid benyttes slagfast øjenbeskyttelse. Graden af nødvendig beskyttelse skal

vurderes specifikt i hvert enkelt tilfælde.

■ Det skal sikres, at arbejdsemnet er fastgjort

sikkert.

■ Det skal jævnligt kontrolleres, at trykluftpro-

duktets omdrejningstal ikke er højere end den

hastighed, som er angivet på produktet. Denne

hastighedskontrol skal ske uden monteret indsatsværktøj.

■ Sørg for at de gnister og brudstykker, der opstår

under arbejdet, ikke udgør en risiko.

■ Frakobl trykluftproduktet fra trykluftforsyningen,

før du udskifter indsatsværktøj eller tilbehørsdele eller foretager justering, vedligeholdelse

eller rengøring.

■ Sørg for, at der ikke kan opstå farer for andre

personer.

Farer på grund af fastgribning/

opvikling

■ Farer pga. fastgribning/opvikling kan føre til

kvælning, skalpering og/eller snitsår, hvis løstsiddende tøj, personlige smykker, halskæder,

hår eller handsker ikke holdes på afstand af

maskinen og dens tilbehørsdele.

■ Handsker kan blive indfanget af det roterende

produkt, hvilket kan føre til kvæstelser eller brud

på fingre.

■ Gummierede eller metalforstærkede handsker

kan nemt blive fastgrebet/opviklet af roterende

drivfatninger og -forlængere.

■ Bær derfor ikke løstsiddende handsker eller

handsker med opslidsede eller slidte handskefingre.

■ Hold aldrig fast i drevet, fatningen eller drivfor-

længeren.

■ Hold hænderne væk fra det roterende drev.

■ Bær velegnet påklædning. Bær ikke løstsidden-

de tøj eller smykker. Hold hår, tøj og handsker

på afstand af trykluftværktøjet og bevægelige

dele. Løst tøj, smykker eller hår kan gribe fat i

dele, der bevæger sig. Der er fare for personskader.

Farer under drift

■ Ved anvendelse af maskinen kan operatørens

hænder blive udsat for risici som f.eks. kvæstelser, slag, snitsår, hudafskrabninger eller

brandsår. Bær derfor velegnede handsker til

beskyttelse af hænderne.

■ Operatøren og vedligeholdelsespersonalet skal

fysisk være i stand til at håndtere maskinens

størrelse, vægt og effekt.

■ Hold maskinen korrekt: Vær parat til at modvirke

almindelige eller pludselige bevægelser – hold

begge hænder klar.

■ Sørg for, at kroppen er i god balance, og at du

har et godt fodfæste.

■ Sørg for, at du står sikkert, og hold altid balancen.

PDRS 27 A1

DK

│

23 ■

Loading...

Loading...