Page 1

IAN 43098

AIR NEEDLE SCALER PDNE 4000 A1

AIR NEEDLE SCALER

Operation and Safety Notes

Translation of original operation manual

PNEU JEHLOVÝ ODREZOVAČ

Pokyny pro obsluhu a bezpečnostní pokyny

Překlad originálního provozního návodu

DRUCKLUFT-NADELENTROSTER

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 2 04.06.14 13:18

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Před čtením si otevřete stranu s obrázky a potom se seznamte se všemi funkcemi přístroje.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB Operation and Safety Notes Page 5

CZ Pokyny pro obsluhu a bezpečnostní pokyny Strana 15

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 25

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 3 04.06.14 13:18

Page 3

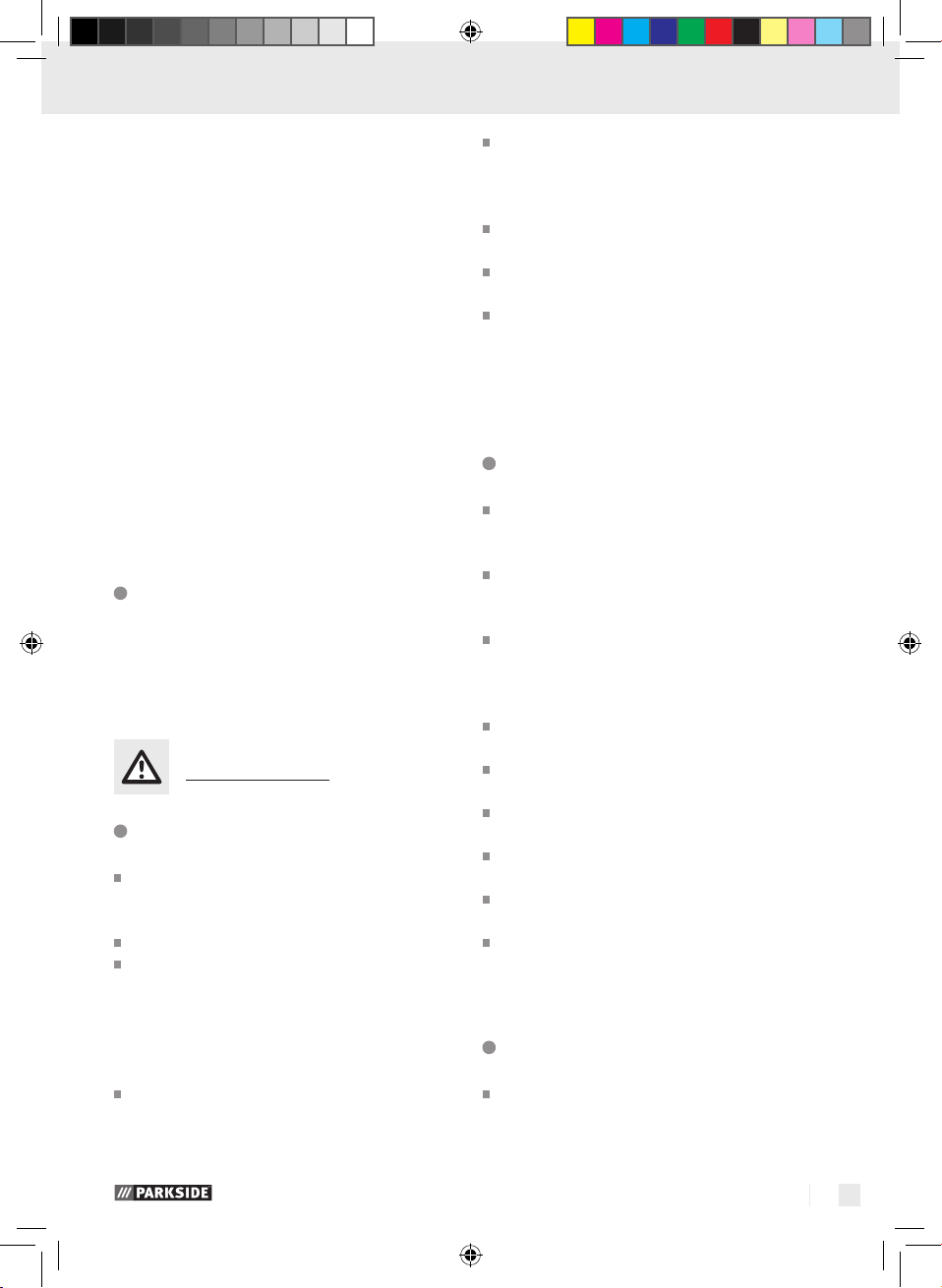

1 2

A B

C D

6

3

45

E F

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 4 04.06.14 13:18

G

Page 4

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_cover_CZ.indd 5 04.06.14 13:18

Page 5

Table of contents

Introduction

Intended use ........................................................................................................................................ Page 6

Features ...............................................................................................................................................Page 6

Technical Data ....................................................................................................................................Page 6

Scope of delivery ................................................................................................................................ Page 7

Safety notices

General safety rules ............................................................................................................................ Page 7

Risks due to projected parts ...............................................................................................................Page 7

Operating hazards .............................................................................................................................Page 7

Hazards due to repetitive motions ..................................................................................................... Page 8

Risks associated with accessories ......................................................................................................Page 8

Hazards in the work environment ...................................................................................................... Page 8

Hazards due to dust and vapours ..................................................................................................... Page 8

Noise hazards ..................................................................................................................................... Page 9

Hazard due to vibration ..................................................................................................................... Page 9

Additional safety instructions for pneumatic machinery ...................................................................Page 9

Before use ....................................................................................................................................... Page 10

Start-up .............................................................................................................................................Page 10

After initial use ...........................................................................................................................Page 10

Changing spare parts ...........................................................................................................Page 10

Maintenance ................................................................................................................................. Page 10

Cleaning and Care ................................................................................................................... Page 11

Information about warranty and service processing

Warranty terms ...................................................................................................................................Page 11

Extent of warranty ............................................................................................................................... Page 11

Processing of warranty claims ............................................................................................................ Page 12

Environmental instructions and disposal information .............................. Page 12

Declaration of Conformity ................................................................................................ Page 12

5 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 5 04.06.14 13:17

Page 6

Introduction

The following pictograms are used in these instructions for use / on the equipment:

Please read the operating instructions!

Note

Oil daily

Air needle scaler PDNE 4000 A1

Introduction

Congratulations!

You have chosen high-quality device

by our company. Familiarise yourself

with the product before using it for the first time. In

addition, please carefully refer to the operating instructions and the safety advice below. Initial operation of

this tool must be performed by trained personnel.

KEEP OUT OF THE REACH OF CHILDREN!

Observe the warning and safety

instructions!

Wear ear protection, dust mask, safety glasses and protective gloves.

Dispose of packaging and device in

an environmentally-friendly way!

Features

Check that all the items are present and

that the device is in perfect condition immediately after unpacking. Do not use

device if it is defective.

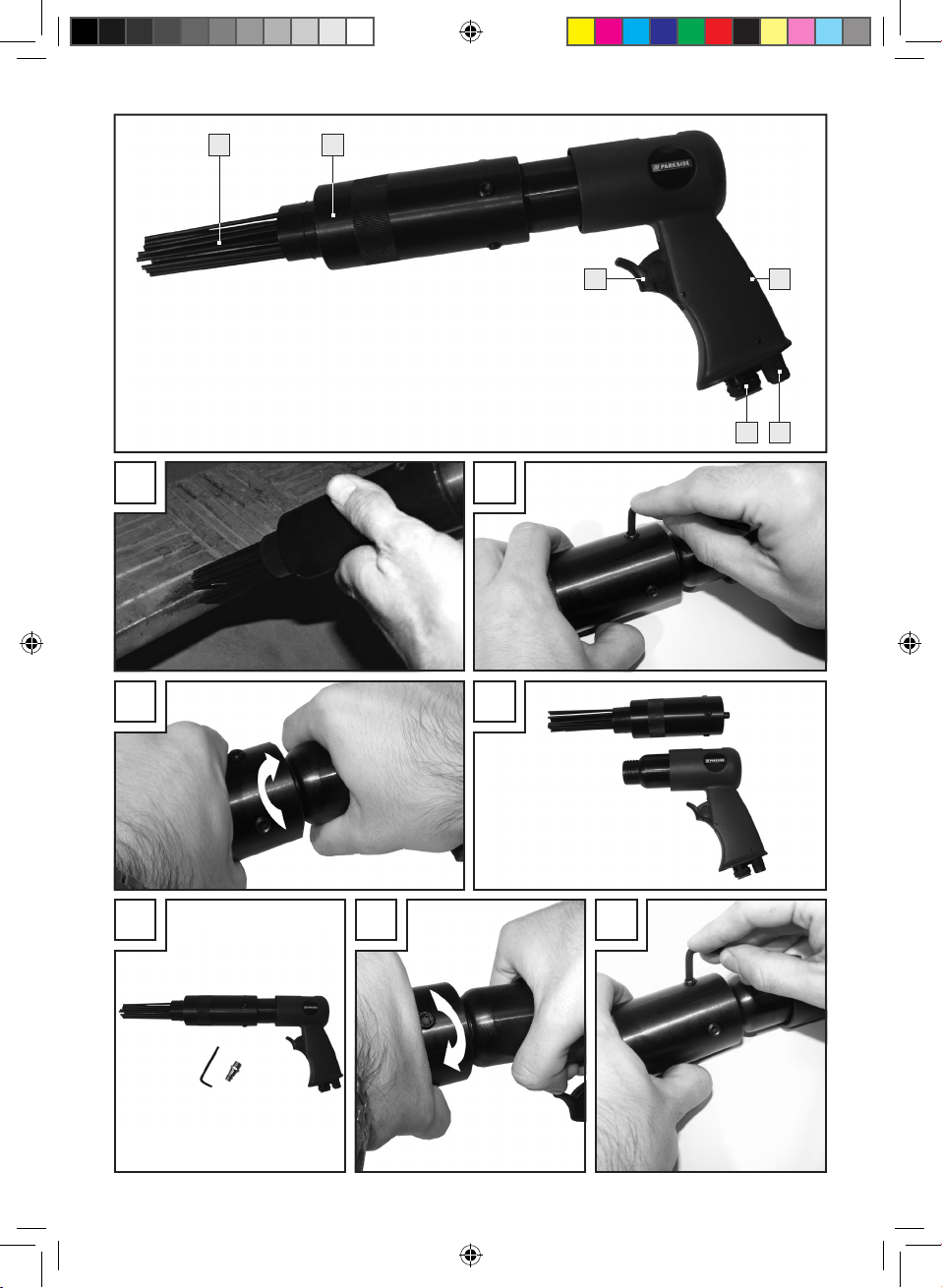

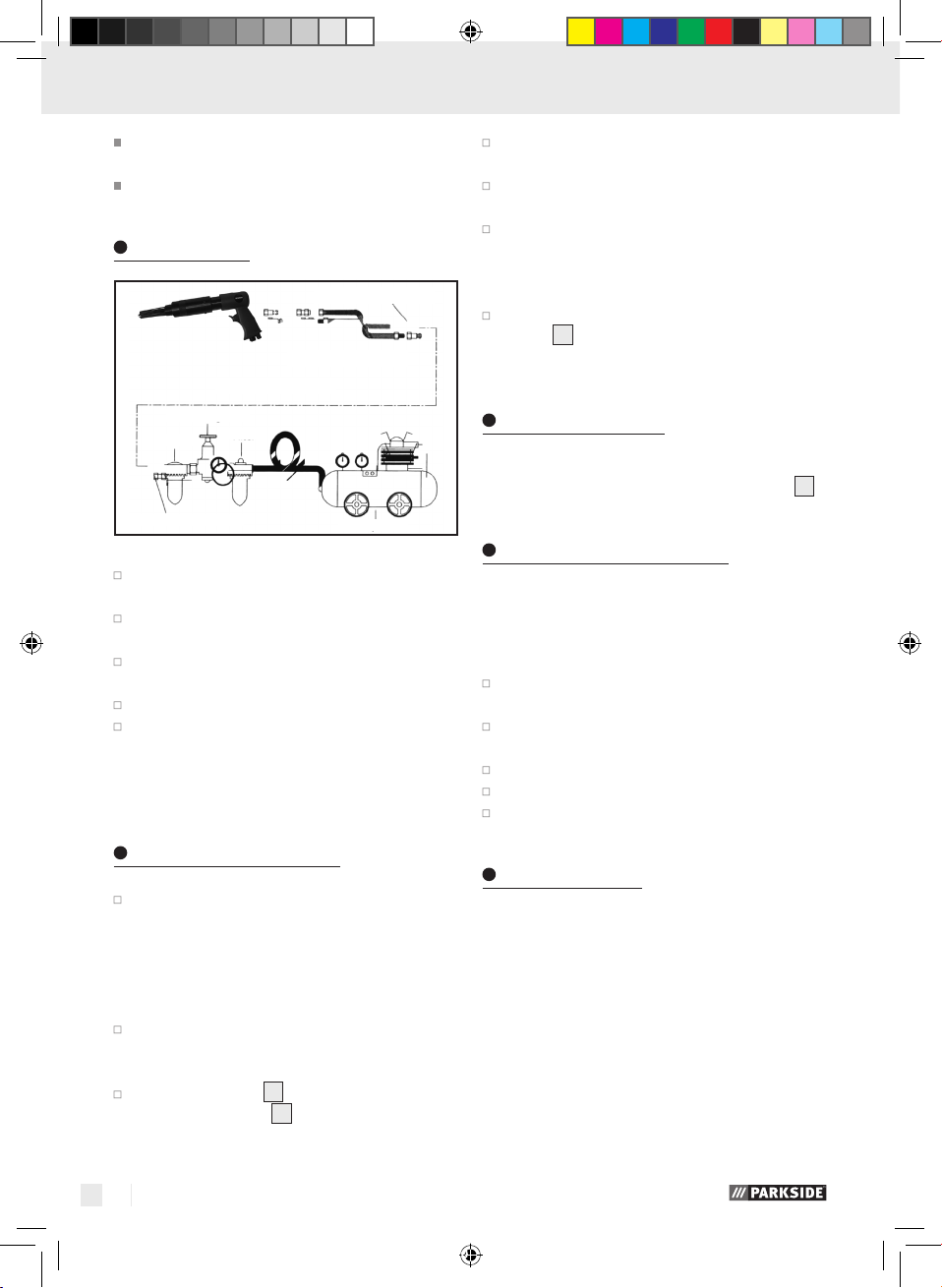

1

Needles

2

Needle guide

3

Handle

4

Air adjusting screw

5

¼“ Compressed air connection

6

Trigger

the

Technical Data

Intended use

Operating pressure: 6.3 bar

The needle scaler is solely for removing rust and

coatings (paint, lacquer, etc.) from solid metal parts,

and for shaping jobs. Only use the product as described and for the indicated purpose. Keep these

instructions in a safe place. When passing this product on to others, please also include all the document

Any use other than the intended is prohibited and

potentially dangerous. Damages resulting from

noncompliance or misuse are not covered by the

warranty and are not included in the manufacturer‘s

l

iability. This device has been designed for househol

use and may not be used for commercial or industrial purposes.

Compressed air connection: ¼“ (0.63 cm)

Percussion rate: 4000 rpm

Sound pressure level: 100.2 dB(A)

(EN ISO 15744)

Weight: 1900 g

s.

Noise- and vibration information: Measured values determined in accordance with ISO

15744.

Noise level L

Sound power level L

d

L

pC, peak

Uncertainty K

: 100.2 dB(A)

pA

= 117.4 dB(A)

= 3 dB

: 111.2 dB(A)

WA

These values are characteristic values referenced to

the device and do not reflect noise development at

6 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 6 04.06.14 13:17

Page 7

Introduction / Safety notices

the work location. Noise development at the work

location depends e.g. on the work environment, the

work piece, the work piece support and the number

of fastener driving processes.

In accordance with conditions at the work location,

individual noise reduction measures may need to

be carried out, such as placing the work piece on

a noise-suppressing surface, clamping or covering

to prevent work piece vibration and adjusting to the

minimum pressure required by the work process. In

certain cases, wearing personal hearing protection

is require.

Wear hearing protection!

Total vibration values in accordance with

ISO 28927-10, EN 12096:

Vibration emission value a

Uncertainty K = 1.5 m / s

Scope of delivery

= 69.83 m / s

h

2

2

1 Needle scaler (head preinstalled)

1 Threaded plug nipple

1 Allen key

1 Instructions for use

Safety notices

General safety rules

To connect the device to the air hose, never

point the front end (needle head) of the tool at

yourself or others.

Never point the tool at yourself or others.

In the cases of multiple hazards the safety in-

structions must be read and understood before

attaching, operating, repairing and exchanging

accessories and before working near the

non-rotating, percussive machine. Otherwise

severe bodily injuries may result.

The non-rotating, percussive machine should

only be set up, adjusted and used by qualified

and trained users.

Never modify the non-rotating, percussive

machine. Modifications may reduce the effectiveness of safety measures and increase operator risks.

Do not lose the safety instructions – hand them

to the operator.

Never use a damaged non-rotating, percussive

machine.

Regularly maintain machines to verify all re-

quired rated values and markings required by

ISO 11148 are legible on the machine. If necessary, the employee/user must contact the manufacturer for replacement labels for markings.

Risks due to projected parts

Disconnect the non-rotating, percussive ma-

chine from the power supply before replacing

the inserted tool or accessories.

If the work piece, one of the accessories, or the

tool itself breaks, parts may be projected at a

great speed.

Always wear eye protection when operating

the non-rotating, percussive machine. The level

of required protection required should be assessed individually for each application.

When working overhead, a safety helmet must

be worn.

In this case, the risk to other people must also

be assessed.

It must be ensured that the work-piece is prop-

erly secured.

Only operate the machine with the machine tool

secured in the machine with a suitable retainer.

To prevent injuries, any worn, broken or bent

parts of the retainer must be replaced.

Before switching on the machine, the machine

tool must be firmly applied to the surface you

will be working on.

Operating hazards

During uses, the operator‘s hands may be ex-

posed to hazards such as impact, cuts, abrasion

and heat. Wear suitable gloves to protect hands.

7 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 7 04.06.14 13:17

Page 8

Safety notices

The operator and maintenance personnel must

be physically capable of managing the size,

weight and power of the machine.

Hold the machine correctly: be prepared to

counteract typical or sudden movements – keep

both hands ready.

Be sure your body is well balanced and maintain

a solid stance.

In the event of power failure release the start-

or stop control.

Only use lubricants recommended by the manu-

facturer.

Avoid direct contact with the machine tool dur-

ing and after use, as it may be hot.

Notice indicating safety goggles

are required, and safety gloves and

protective clothing are recommended.

Hazards due to

repetitive motions

When using a non-rotating, percussive machine

the operator may experience discomfort in

hands,

arms, shoulders, neck or other body parts whilst

performing work-related tasks.

Maintain a comfortable position whilst working

with the non-rotating, percussive machine, be

mindful of a secure grip and avoid unfavourable

positions or those making it difficult to maintain

your balance. The operator should change his

posture during extended periods of use, which

may help to prevent discomfort and fatigue.

If the operator experiences symptoms such as

persistently feeling unwell, discomfort, palpitations, pain, tingling, numbness, a burning sensation or stiffness, these warning signs should not

be ignored. The user should consult a qualified

healthcare professional.

Risks associated with

accessories

Disconnect non-rotating, percussive machine

from the power supply before attaching or

changing tools or accessories.

Only use accessories and consumables of the

size and type recommended by the manufacturer of the non-rotating, percussive machine;

do not use other accessory or consumables

types or sizes.

Avoid direct contact with the machine tool dur-

ing and after use, as it may become very hot

or sharp-edged.

Hazards in the work

environment

Slipping, tripping and falling are the main causes

of injuries at the workplace. Keep in mind that

surfaces may have become slippery during

machine use, and remember tripping hazards

caused by the air- or hydraulic hose.

Proceed with caution in unfamiliar surroundings.

There may be hidden dangers due to electrical

cables or other supply lines.

The non-rotating, percussive machine is not in-

tended for use in explosive atmospheres and

not isolated against contact with electric power

sources.

Verify that there are no electrical lines, gas lines,

etc. that may result in a hazard in the event of

them becoming damaged during machine use.

Hazards due to dust

and vapours

Dusts and vapours generated by the use of

non-rotating, percussive machines may result in

damage to health (e.g. cancer, birth defects,

asthma and / or dermatitis); it is imperative to

perform a risk assessment for these hazards and

implement the respective regulatory mechanisms.

The risk assessment should include dust gener-

ated by machine use and the dust already

present in the area, which is possibly being

blown around.

The non-rotating, percussive machine must be

operated and maintained according to the recommendations in these instructions to minimise

the release of dust and vapours.

8 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 8 04.06.14 13:17

Page 9

Safety notices

Exhaust air must be discharged in such a way

that the amount of dust being blown about in a

dusty environment is minimised.

If dust or vapours are generated, the principal

task must be to control them in the area where

they are released.

All machine mounting parts or accessories in-

tended to collect, extract or eliminate airborne

dust or vapours should be used and maintained

according to manufacturer instructions.

Select, maintain and replace consumables and

machine tools as recommended in these instructions to prevent an unnecessary increase in the

production of dust or vapours.

Use respiratory protection equipment as required

by labour- and health protection regulations.

Noise hazards

With inadequate ear protection the impact of

high noise levels may result in permanent hearing damage, hearing loss and other problems,

e.g. tinnitus (ringing, whistling or buzzing in the

ear). It is imperative to perform a risk assessment

for these hazards and implement the respective

regulatory mechanisms.

Suitable regulatory mechanisms to minimise the

risk include measures such as using insulation

to prevent pinging sounds on work pieces.

Use ear protection as required by

labour- and health regulations.

The non-rotating, percussive machine must be

operated and maintained in accordance with

the recommendations within these instructions

to prevent an unnecessary increase in the noise

levels.

Select, maintain and replace consumables and

machine tools as recommended in these instructions to prevent an unnecessary increase in the

noise level.

I

f the non-rotating, percussive machine is eq

uipped

with a silencer, always ensure it is available and

in good working order when using this machine.

Hazard due to vibration

Exposure to vibration may cause damage to

the nerves and disturb blood circulation in hands

and arms.

Wear warm clothing and keep your hands warm

and dry when working in cold environments.

If you notice the skin on your fingers or your

hand becoming numb, tingling, hurting or becoming white, stop working with the machine

and consult a physician.

The non-rotating, percussive machine must be

operated and maintained in accordance with the

recommendations within these instructions to prevent an unnecessary increase in the vibration.

Do not hold the machine tool with your free

hand, as this will result in an increase in the

impact of vibration.

Hold the machine firmly, but not too tightly, main-

taining the necessary hand reaction forces, as

the vibration hazard typically increases when

firming the grip.

Hold attached handles at the centre and avoid

sliding the handles all the way in.

Additional safety instructions

for pneumatic machinery

Compressed air can result in serious injuries.

If the machine is not in use, always cut off the

air supply, depressurize the air hose and disconnect the machine from before replacing accessories or when performing repairs.

Never direc the air flow at yourself or others.

Hoses flapping about can result in serious inju-

ries. Therefore always inspect hoses and their

fasteners for damage and a secure fit.

Direct cold air away from hands.

Do not use quick-disconnect couplers at the tool

intake. Only use connectors made from hardened steel (or material with comparable impact

resistance) on threaded hose connections.

When using universal swivel couplings, always

use locking pins and use whip-check hose safety

cables for protection in the event the connection

between the hose and the machine or in between

hoses fails.

9 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 9 04.06.14 13:17

Page 10

… / Cleaning and Care / Information about warranty and service processing

… / Before use / Start-up / After initial use / Changing spare parts / Maintenance

Ensure not to exceed the maximum pressure

specified on the machine.

Never carry pneumatic tools by the hose.

Before use

Quick-release socket

Compressed air hose

Quick-release socket

Pressure regulator

Oils

Quick-opening sleeve

ATTENTION! Never start up the air tool with-

out oiling it.

Verify the compressor is positioned on solid

ground.

Check if all hose connections are connected

and secured correctly.

Connect the tool with the air hose.

If no function is detected after switching on de-

spite reaching the maximum pressure, switch the

device back off. Immediately contact the service hotline.

Filter

Compressor

Use the needle scaler to remove rust, paint,

lacquier and similar items.

Never use excess force to push the equipment

onto the tool, as this may cause damage.

Applying the equipment at a slight angle and

sliding it across the surface to be cleaned with

a little pressure across the area to be cleaned

for optimal results.

Regulate the air pressure using the air adjusting

4

screw

(next to the air inlet at the bottom of

the device) for optimal results.

After initial use

Once the task has been finished the equipment must

be disconnect from the compressed air supply

5

.

Changing spare parts

The head of the needle scaler must be replaced if

it shows damage or is severely worn. Proceed as

follows:

Using the included hexagon socket screw, loosen

the 4 screws for the head (see Fig. B).

Unscrew the old head using minimal force (see

Fig. C).

Properly dispose of the old head.

Screw in the new head hand tight (see Fig. F).

tighten the 4 screws on the head (see Fig. G).

Start-up (see Fig. A)

Maintenance

Screw a threaded plug fitting ¼“ (6.35 mm)

into the air tool.

Note: We recommend using Teflon tape to

achieve maximum leak-tightness. Otherwise the

equipment may potentially be unable to produce

its full capacity.

To connect the device to the air hose, never point

the front end (needle head) of the tool at yourself or others.

Pulling the trigger 6 will start the device.

Release the trigger

10 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 10 04.06.14 13:17

6

to stop the device.

Following the maintenance information specified

here will ensure a long service life for the product

and trouble-free operation. Your needle scaler

working properly for a long time requires regular

lubrication.

You may choose from the following

options:

With an oil-fog lubricator

A complete maintenance unit includes an oil-fog

lubricator and is attached to the compressor.

Page 11

… / Cleaning and Care / Information about warranty and service processing

Via in-line oiler

Install an in-line oiler directly adjacent to the tool

(approx. 50 cm clearance) to adequately supply

the tool with oil.

Manually

Add 3–5 drops of speciality tool oil to the compr

air connection before every use. If the compressed

air tool is not being used for several days, add 5–10

drops of oil to the compressed air connection before

switching it on.

Always store your compressed air tools in dry

rooms.

With frequent use and high contamination, main-

tenance should be performed every 30 min. The

equipment should always be lubricated in the

process

Verify the speed and the noise level after every

use.

Regularly check the speed.

ATTENTION! Clean the appliance before main-

tenance from all dangerous substances which

(due to work processes) may have accumulated

on the appliance. Avoid all skin contact with

these substances.

REMARK! The skin coming into contact with

dangerous dust may result in severe dermatitis.

If dust is produced or dispersed during the maintenance work, it can be inhaled.

essed

Cleaning and Care

Never clean with liquids such as petrol, solvents

or water.

Do not allow liquids to enter the tool.

Only clean the tool with a dry cloth.

Information about warranty

and service processing

Creative Marketing Consulting

GmbH warranty

Dear customer,

the warranty for this device is 3 years from the date

of purchase. In the event of product defects, you

have legal rights against the retailer of this product.

Your statutory rights are not limited in any way by

our warranty detailed below.

Warranty terms

The warranty period begins on the date of purchase.

P

lease retain the original receipt safely. This docume

is required as your proof of purchase.

Should this device show any fault in materials or

manufacture within three years from date of purchase,

it will be repaired or replaced - at our choice - by

us free of charge. This warranty is conditional on the

defective device and the receipt of purchase being

presented within the three year warranty period,

and that there is a brief written description of the

nature of the defect and of the date it arose.

If the defect is covered by our warranty, we will return the repaired device or replacement thereof. A

repair or exchange of the device does not extend

a new warranty period.

Extent of warranty

The appliance has been manufactured to strict quality guidelines and meticulously examined before

delivery.

The warranty applies to faults in material or manufacture. This warranty does not apply to product

parts subject to normal wear and tear and which

can therefore be considered as wear items, or to

damage to fragile parts, e.g. switches, storage batteries or glass parts.

This warranty becomes void if the device has been

damaged or improperly used or maintained. All instructions provided in the instructions for use must

be followed strictly to constitute proper use of the

product. Purposes and practices which the operating instructions warn of or advise against must be

avoided without fail.

This product is intended for private, non-commercial

use only. Any incorrect or improper use of the device,

nt

11 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 11 04.06.14 13:17

Page 12

… / Environmental instructions and disposal information / Declaration of Conformity

use of force and changes not performed by our authorized service branch will void the warranty.

Processing of warranty claims

Please follow the instructions below to ensure quick

processing of your claim:

When inquiring about your product please have

your receipt and product number (e.g. IAN) ready

as your proof of purchase.

The product number can be found on the type plate,

an engraving, the cover page of your instructions

(bottom left) or the decal at the back or bottom.

In the event of malfunctions or other defects, please

first contact the service department below by phone

or e-mail.

A product recorded as defective, along with the

proof of purchase (sales receipt) and a description

of the defect and when it occurred, can then be returned free of charge to you to the service address

provided.

Notice:

Visit www.lidl-service.com to download

this and many other manuals, product

videos and software.

How to contact us:

GB

Name: C. M. C. GmbH

Website: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

Phone: 0-808-189-0652

(standard German landline

rates apply)

Registered office: Germany

IAN 43098

Please note that the following address is not a service address.

Please first contact the service point named above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

Environmental instructions

and disposal information

Don‘t waste, recycle!

Device, accessories and packaging

should be recycled in an environmentally friendly manner.

Do not dispose of the air tool with your household

waste, or throw into fire or water. If possible,

non-operational equipment should be recycled.

Contact your local retailer for information.

Declaration of Conformity

We,

C. M. C. GmbH

Responsible for documentation: Markus Zimmer

Katharina-Loth-Str. 15

66386 St. Ingbert

Germany

declare in our sole responsibility that the product

Air needle scaler

Serial number: 1714

Year of manufacture: 2014/35

IAN: 43098

Model: PARKSIDE AIR NEEDLE SCALER

PDNE 4000 A1

meets the basic safety requirements of European

Directives

Machinery Directive

EC Directive 2006 / 42 /EC

12 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 12 04.06.14 13:17

Page 13

and its amendments.

The conformity assessment is based on the following

harmonised standards:

EN ISO 11148-4:2012

St. Ingbert, 30.06.2014

Karl Peter Uhle

- Managing Director -

Declaration of Conformity

13 GB

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 13 04.06.14 13:17

Page 14

14

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 14 04.06.14 13:17

Page 15

Seznam obsahu

Úvod

Použití ke stanovenému účelu..........................................................................................................Strana 16

Vybavení ...........................................................................................................................................Strana 16

Technické údaje ............................................................................................................................... Strana 16

Obsah dodávky ............................................................................................................................... Strana 17

Bezpečnostní pokyny

Všeobecná bezpečnostní pravidla..................................................................................................Strana 17

Ohrožení vymrštěnými díly .............................................................................................................. Strana 17

Ohrožení za provozu ...................................................................................................................... Strana 17

Ohrožení opakovanými pohyby ..................................................................................................... Strana 18

Ohrožení příslušenstvím ................................................................................................................... Strana 18

Ohrožení na pracovišti .................................................................................................................... Strana 18

Ohrožení prachem a výpary ...........................................................................................................Strana 18

Ohrožení hlukem ..............................................................................................................................Strana 19

Ohrožení vibracemi ......................................................................................................................... Strana 19

Přídavné bezpečnostní pokyny pro pneumatické výrobky ............................................................Strana 19

Před uvedením do provozu..........................................................................................Strana 20

Uvedení do provozu ...........................................................................................................Strana 20

Po použití ..................................................................................................................................... Strana 20

Výměna náhradních dílů ................................................................................................Strana 20

Údržba ............................................................................................................................................Strana 20

Čistění a ošetřování ............................................................................................................. Strana 21

Pokyny k záruce a provádění servisu

Záruční podmínky ............................................................................................................................ Strana 21

Rozsah záruky .................................................................................................................................. Strana 21

Postup v případě uplatňování záruky ............................................................................................. Strana 22

Ekologické pokyny a informace pro odstranění do odpadu .......... Strana 22

Prohlášení o konformitě .................................................................................................Strana 22

15 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 15 04.06.14 13:17

Page 16

Úvod

V tomto návodu k obsluze / na zařízení jsou použity následující piktogramy:

Přečtěte si návod kobsluze!

Upozornění

Denně mazat

Pneu jehlový odrezovač

PDNE 4000 A1

Úvod

Srdečně blahopřejeme!

Rozhodli jste se pro kvalitní výrobek

naší firmy. Před prvním uvedením do

provozu se seznamte s výrobkem. Ktomu si pozorně

přečtěte následující návod kobsluze a bezpečnostní

pokyny. Tento výrobek mohou do provozu uvádět

pouze zaškolené osoby.

VÝROBEK SE NESMÍ DOSTAT DO

RUKOU DĚTÍ!

Dbejte na výstrahy a řiďte se

bezpečnostními pokyny!

Noste ochranu sluchu, protiprachovou

masku, ochranné brýle a ochranné

rukavice.

Obal i výrobek odstraňujte do odpadu

ekologicky!

Vybavení

Bezprostředně po vybalení vždy zkontrolujte úplnost obsahu dodávky a stav

výrobku. Vadný výrobek nepoužívejte.

1

Jehly

2

Vodič jehly

3

Rukojeť

4

Šroub regulace vzduchu

5

¼" přípojka na stlačený vzduch

6

Spoušť

Technické údaje

Pracovní tlak: 6,3 bar

Použití ke stanovenému účelu

Přípojka stlačeného

vzduchu: ¼" (0,63 cm)

Jehlový odrezovač slouží výhradně k odstraňování rzi

a nánosů (barva, lak a mnohé další) na pevných

kovových součástech. Je však vhodný i pro modelovací práce. Používejte výrobek jen podle popisu a jen

Počet úderů: 4000 min

Hladina

akustického tlaku: 100,2 dB(A) (EN ISO 15744)

Váha: 1900 g

-1

v udaných oblastech. Tento návod si dobře uschovejte. Při předávání výrobku třetí osobě předávejte

současně i všechny jeho podklady. Jakékoliv použití,

které se liší od použití ke stanovenému účelu, je zakázané a hrozí potenciálním nebezpečím. Na škody

způsobené nerespektováním pokynů nebo chybným

použitím se nevztahuje záruka ani za ně výrobce

neručí. Výrobek je koncipovaný pro privátní, domácí

Informace o hluku a vibracích:

Naměřené hodnoty byly zjištěny podle norem

ISO 15744.

Hladina akustického tlaku L

Hladina akustického výkonu L

L

= 117,4 dB(A)

pC, peak

Nepřesnost K

= 3 dB

: 100,2 dB(A)

pA

: 111,2 dB(A)

WA

použití a nesmí být využíván komerčně ani průmyslově.

16 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 16 04.06.14 13:17

Page 17

Úvod / Bezpečnostní pokyny

Tyto hodnoty jsou charakteristické hodnoty přístroje

a nevyjadřují vývoj hluku na místě použití. Vývoj

hluku na místě použití závisí např. na pracovním

prostředí, obrobku, podložce obrobku, počtu sponkování.

Podle poměrů na pracovišti a provedení obrobku se

příp. musí přijmout individuální opatření pro snížení

hluku, jako např. pokládání obrobků na podložky

tlumící hluk, zabránění vibraci obrobků upnutím

nebo přikrytím, nastavení minimálního potřebného

tlaku pro příslušnou pracovní operaci. Ve zvláštních

případech je nutné nošení osobní ochrany sluchu.

Noste ochranu sluchu!

Celkové hodnoty vibrací podle normy

ISO 28927-10, EN 12096:

Hodnota emise vibrací a

Nepřesnost K = 1,5 m / s

Obsah dodávky

= 69,83 m / s

h

2

2

1 jehlový odrezovač (hlava je předem

namontována)

1 závitová nástrčná spojka

1 šestihranný klíč

1 návod kobsluze

Bezpečnostní pokyny

Všeobecná bezpečnostní

pravidla

Chcete-li zařízení připojit k přívodní vzduchové

hadici, není dovoleno obrátit přední konec

(jehlovou hlavu) nástroje proti sobě nebo jiným

osobám.

Nikdy nemiřte zařízením na sebe ani na jiné

osoby.

Vzhledem k možnému, několikanásobnému ohro-

žení je nutné si přečíst bezpečnostní upozornění

obzvlášť před provozem, instalací, opravami,

údržbou a výměnou příslušenství, stejně jako

před prací v blízkosti příklepového zařízení. V

opačném případě může dojít k těžkým zraněním.

Příklepové zařízení smí instalovat, používat a

seřizovat jen kvalifikovaná a zaškolená osoba.

Příklepové zařízení není dovoleno upravovat.

Změny mohou snížit účinnost bezpečnostních

opatření a zvýšit rizika pro obsluhu.

Bezpečnostní upozornění a pokyny se nesmí

ztratit – vždy je předávejte obsluze.

Nikdy nepoužívejte poškozené příklepové

zařízení.

U zařízení je zapotřebí provádět pravidelnou

údržbu, aby byla zajištěna kontrola požadovaných jmenovitých hodnot příslušné součásti

podle normy ISO 11148 a jejich čitelnost na

zařízení. Pokud je to potřebné musí zaměstnanec nebo obsluha kontaktovat výrobce k zaslání

potřebných, náhradních etiket.

Ohrožení vymrštěnými díly

Před výměnou nástroje nebo dílů příslušenství

nejdříve stroj odpojte od přívodu energie.

Při zlomení obrobku, dílu příslušenství nebo

dokonce nástroje mohou být díly materiálu vymrštěné velkou rychlostí.

Při provozu příklepového zařízení je nutné vždy

nosit ochranu zraku odolnou proti nárazu. Při

každém druhu použití je třeba zhodnotit jaká

ochrana je potřebná.

Při pracích nad hlavou se musí nosit ochranná

přilba.

V tomto případě je třeba posoudit i rizika pro

ostatní osoby.

Vždy se musí zajistit bezpečné upevnění obrobku.

Zařízení provozujte pouze tehdy, je-li nástroj v

zařízení upevněn pomocí vhodné aretace.

V rámci prevence zranění je nutné vyměnit

všechny zlomené, opotřebené či zdeformované

součásti aretace.

Před zapnutím zařízení je nutné nástroj pevně

přiložit na opracovávanou plochu.

Ohrožení za provozu

Při použití zařízení jsou ohroženy ruce obsluhy

např. příklepy, řezem, oděrem a vysokou teplotou. Noste vhodné rukavice.

17 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 17 04.06.14 13:17

Page 18

Bezpečnostní pokyny

Uživatel přístroje a personál údržby musí být

fyzicky schopni ovládat velikost, hmotnost a

výkon zařízení.

Držte zařízení správně: Buďte připraveni rea-

govat na normální nebo náhlé pohyby zařízení

– používejte obě ruce.

Dbejte na rovnováhu těla a bezpečný postoj.

V případě přerušení přívodu stlačeného vzduchu

uvolněte spouštěč.

Používejte jen maziva doporučená výrobcem.

Během a po použití nástroje se vyhýbejte pří-

mému kontaktu s nástrojem, protože může být

horký.

Poznámka: Je nutné nosit ochranné

brýle. Doporučeny jsou i ochranné

rukavice a ochranný oděv.

Ohrožení opakovanými

pohyby

Při použití příklepového zařízení může dojít u

obsluhy při používání k nepříjemnému zatížení

rukou, paží, ramen oblasti krku i jiných částí těla.

Při práci s příklepovým zařízením zaujměte vždy

pohodlný postoj a dbejte na bezpečnou polohu

– vyhýbejte se nevhodným polohám nebo ta-

kovým polohám, ve kterých můžete jen těžko

udržet rovnováhu. Obsluha by měla během

dlouhotrvající práce častěji změnit držení těla,

toto pomáhá proti únavě.

V případě symptomů (např. trvalá nevolnost,

potíže, tepání, bolest, brnění, necitlivost, pálení

nebo strnutí) by obsluha neměla tyto varovné

příznaky ignorovat. Obsluha by měla nepro-

dleně konzultovat odborného lékaře.

Ohrožení příslušenstvím

Před upevněním či výměnou nástroje nebo příslu-

šenství odpojte příklepové zařízení od napájení.

Používejte výhradně příslušenství a spotřební

materiál doporučených velikostí a typů od vý-

robce příklepového zařízení. Nepoužívejte jiné

typy ani velikosti příslušenství nebo spotřebního

materiálu.

Vyhýbejte se během nebo po použití nástroje

přímému kontaktu s nástrojem, protože může

být horký nebo na něm mohou být ostré hrany.

Ohrožení na pracovišti

Uklouznutí, zakopnutí a upadnutí jsou hlavní

příčiny zranění na pracovišti. Dávejte pozor na

povrchy, které mohou být po použití přístroje

kluzké, stejně tak jako na vzduchové a hydraulické hadice, o které můžete zakopnout.

Dávejte pozor v neznámém prostředí. Mohou

existovat skrytá nebezpečí, jako jsou elektrické

kabely a jiná vedení.

Příklepové zařízení není určeno k používání ve

výbušné atmosféře a není izolováno proti kontaktu se zdroji elektrického proudu.

Ujistěte se, zda nejsou v blízkosti elektrická ve-

dení nebo plynové rozvody, které by mohly být

při poškození nebezpečné.

Ohrožení prachem a výpary

Prach a výpary vzniklé při použití příklepových

zařízení mohou způsobit újmy na zdraví (např.

rakovinu, vrozené vady, astma nebo dermatitis),

a je proto nevyhnutelné provést zhodnocení rizika a zavést odpovídající regulační mechanizmy.

Při posuzování rizika je třeba brát na zřetel pra

ch

vznikající použitím výrobku spolu s prachem,

který se zvíří.

Příklepové zařízení je nutné používat a prová-

dět na něm údržbu podle doporučení v tomto

návodu, aby se omezilo zvíření prachu a rozšiřování výparů na minimum.

Odvětrávání je třeba zařídit tak, aby se zvíření

v prostoru s rozptýleným prachem redukovalo

na minimum.

Při vzniku prachu nebo výparů je hlavním úko-

lem kontrola jejich uvolňování na místě vzniku.

Všechny díly příslušenství a vestavěné pomůcky

sloužící pro zachycení, odsátí nebo potlačení

zvířeného prachu a výparů se musí správně

používat a udržovat podle pokynů výrobce.

Spotřební materiály a nástroje je nutné vybírat,

udržovat a vyměňovat dle doporučení v tomto

18 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 18 04.06.14 13:17

Page 19

Bezpečnostní pokyny

návodu, aby se zamezilo zbytečnému šíření

prachu a výparů.

Používejte pomůcky k ochraně dýchacích cest

dle pracovních a zdravotních předpisů.

Ohrožení hlukem

Působení vysoké hladiny hluku může vést, při

nedostatečné ochraně sluchu, k jeho trvalému

poškození, ztrátě sluchu nebo jiným problémům,

jako je např. tinnitus (zvonění, šumění, pískání

nebo hučení v uších). Je nezbytné provést zhodnocení rizika vzhledem k tomuto ohrožení a zavést vhodné regulační mechanizmy.

K vhodným opatřením omezujícím rizika patří

použití tlumících látek pro eliminování rezonancí

a hluku vznikajících na obrobku.

Používejte ochranu sluchu podle

pracovních a zdravotních předpisů.

Příklepové zařízení je nutné provozovat a udr-

žovat podle doporučení v tomto návodu, aby se

vyloučilo zbytečné zvýšení hluku.

Spotřební materiály a nástroje je nutné vybírat,

udržovat a vyměňovat podle doporučení v tomto

návodu, aby se zamezilo zbytečnému zvyšování hluku.

Je-li příklepové zařízení vybaveno tlumičem hluku,

je třeba vždy zajistit, aby byl tlumič příklepového

zařízení na místě, použitelný a v dobrém stavu.

Ohrožení vibracemi

Působením vibrací může dojít k poškození nervů

a narušení krevního oběhu v rukou a pažích.

V chladném prostředí noste teplé oblečení a

udržujte ruce v teple a suchu.

Jestliže zjistíte, že je pokožka na prstech nebo

rukou necitlivá, brní, bolí nebo je nápadně bílá,

přerušte práci s příklepovým zařízením a konzultujte lékaře.

Příklepové zařízení je nutné provozovat a udr-

žovat podle doporučení v tomto návodu, aby

se vyloučilo zbytečné zesílení vibrací.

Nástroj nedržte volnou rukou, protože takový

postup vede k zesílení účinku vibrací.

Nedržte zařízení příliš pevně, ale bezpečně

proti reakčním silám, protože příliš pevné svírání rukojetí obecně zvyšuje riziko negativního

působení vibrací.

Udržujte zavěšené rukojeti uprostřed a nepo-

souvejte je až k dorazům.

Přídavné bezpečnostní pokyny

pro pneumatické výrobky

Stlačený vzduch může způsobit závažná zranění.

Při delším nepoužívání, před výměnou příslušen-

ství nebo opravou je třeba vždy uzavřít přívod

vzduchu, vypustit z hadic tlak a odpojit výrobek

od přívodu vzduchu.

Nemiřte proudem vzduchu na sebe ani na jiné

osoby.

Zmítající se hadice mohou způsobit závažná

zranění. Kontrolujte, jestli nejsou hadice a jejich

připevňovací elementy poškozené nebo povolené.

Studený vzduch je nutné odvádět od rukou.

Nepoužívejte rychlospojky na přívodu nástroje.

Používejte hadicové spojky se závitem a jen z

tvrzené oceli (nebo z materiálu se srovnatelnými

vlastnostmi).

V případě použití univerzálních otočných spojek,

je nutno použít zajištění kolíky a jištění hadice

Whipcheck kvůli ochraně při selhání spojení

hadice s výrobkem nebo mezi jednotlivými díly

hadice.

Zajistěte, aby nebyl překročený maximální tlak

vyznačený na výrobku.

Nenoste brusku za hadici.

19 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 19 04.06.14 13:17

Page 20

Před … / Uvedení do provozu / Po použití / Výměna náhradních dílů / Údržba

Před uvedením do provozu

Rychle uzavírající zástrčka

Vzduchová tlaková hadice

Rychle uzavírající zástrčka

Tlakový regulátor

Maznice

Rychle uzavírající objímka

Filtr

Kompresor

POZOR! Pneumatický nástroj nikdy neuvádějte

do provozu bez fungujícího mazání olejem!

Zkontrolujte, zda kompresor stojí pevně na zemi.

Zkontrolujte, zda jsou všechna hadicová připo-

jení správně připojena a upevněna.

Připojte nástroj k hadici se stlačeným vzduchem.

Jestliže po zapnutí nástroj nefunguje ani po do-

sažení maximálního tlaku, zařízení opět vypněte.

Neprodleně kontaktujte servisní linku hotline.

Uvedení do provozu (viz obr. A)

poněkud pod tlakem posouvat přes plochu určenou k očištění.

Pro optimální výsledky regulujte tlak vzduchu

šroubem

4

(vedle vstupu vzduchu na spodní

straně přístroje).

Po použití

Po provedené práci musí být přístroj odpojen od připojení stlačeného vzduchu

5

.

Výměna náhradních dílů

Je-li na hlavě jehlového odrezovače patrné poškození nebo je hlava příliš opotřebovaná, je nutné ji

vyměnit. Postupujte při tom takto:

Pomocí dodávaných klíčů na šrouby s vnitřním

šestihranem uvolněte 4 šrouby na hlavě (viz

obr. B).

Pod mírnou silou odšroubujte opotřebovanou

hlavu (viz obr. C).

Opotřebovanou hlavu zlikvidujte podle předpisů.

Novou hlavu utáhněte rukou (viz obr. F).

Dotáhněte 4 šrouby na hlavě (viz obr. G).

Našroubujte závitovou násuvku ¼“ (6,35 mm)

do pneumatického přístroje.

Údržba

Poznámka: Chcete-li dosáhnout maximální

těsnosti, doporučujeme použít teflonovou pásku.

Jinak nebude zařízení za daných podmínek

schopno dosáhnout plného výkonu.

Chcete-li zařízení připojit k přívodní vzduchové

hadici, není dovoleno obrátit přední konec (jeh-

Dodržování zde uvedených pokynů k údržbě zaručí

dlouhou životnost a bezporuchový provoz tohoto

výrobku. Předpokladem pro dlouhotrvající, bezvadnou funkci jehlového odrezovače je jeho pravidelné

mazání.

lovou hlavu) nástroje proti sobě nebo jiným

osobám.

Máte k dispozici následující možnosti:

Nastartujte přístroj stlačením spouštěcí páčky

6

. Pro zastavení přístroje uvolněte páčku 6.

Pomocí jehlového odrezovače odstraňujte rez,

barvu, lak a podobné látky.

Mazání pomocí olejové mlhy

Kompletní údržbová jednotka obsahuje rozprašovač

oleje a je namontován na kompresoru.

Zařízeni nikdy netlačte k obrobku přílišnou silou,

protože byste mohli obrobek poškodit.

Optimálních výsledků dosáhnete tehdy, nasa-

díte-li zařízení zlehka šikmo a pomalu jej budete

Pomocí maznice rozvodu

V bezprostřední blízkosti nástroje (cca 50 cm) je

namontována maznice rozvodu, která zásobuje

zařízení dostatečným množstvím oleje.

20 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 20 04.06.14 13:17

Page 21

Údržba / Čistění a ošetřování / Pokyny k záruce a provádění servisu

Ruční mazání

Před každým uvedením pneumatického přístroje do

provozu nakapejte 3–5 kapek speciálního oleje do

přípojky stlačeného vzduchu. Jestliže byl přístroj delší

dobu mimo provoz musíte před použitím přidat 5 až

10 kapek oleje.

Přístroj skladujte v suché místnosti.

Při dlouhotrvajícím používání a při vyšším zne-

čištění je nutné každých 30 minut provést údržbu.

Při tom je nutné zařízení také vždy namazat.

Po každém použití zkontrolujte otáčky a počet

kmitů.

Pravidelně kontrolujte otáčky.

POZOR! Před údržbou vyčistěte přístroj od

nebezpečných látek, které se v něm usadily během provozu. Vyhýbejte se kontaktu pokožky

s podobnými látkami.

POZNÁMKA! Dostane-li se pokožka do styku

s nebezpečnými prachem, může dojít k těžké

dermatitidě. Během údržby vznikající nebo zvířený prach se může vdechnout.

Čistění a ošetřování

Na čištění nikdy nepoužívejte kapaliny jako

benzín, ředidla nebo vodu.

Do vnitřku přístroje se nesmí dostat žádné

kapaliny.

Čistěte výrobek pouze suchým hadrem.

Pokyny k záruce

a provádění servisu

Záruka od Creative Marketing

Consulting GmbH

Záruční podmínky

Záruční lhůta začíná běžet od data zakoupení.

Uschovejte si dobře originál pokladní stvrzenky. Tuto

s

tvrzenku budete potřebovat jako doklad o zakoupení.

Pokud se do tří let od data zakoupení tohoto výrobku

vyskytne vada materiálu nebo výrobní vada, výrobek Vám – dle našeho rozhodnutí – bezplatně opravíme nebo vyměníme. Předpokladem pro poskytnutí

záruky je, že předložíte vadný výrobek a doklad o

zakoupení (pokladní stvrzenku) během tříleté lhůty

a stručně popíšete, v čem závada spočívá a kdy se

objevila.

Pokud vada spadá do naší záruky, obdržíte od nás

opravený nebo nový výrobek. Opravou ani výměnou

výrobku nezačíná nová záruční lhůta.

Rozsah záruky

Výrobek byl vyroben snejvyšší pečlivostí podle

přísných kvalitativních směrnic a před odesláním

prošel výstupní kontrolou.

Záruka platí na vady materiálu a výrobní vady. Tato

záruka se nevztahuje na části výrobku, které jsou

vystaveny běžnému opotřebení a které lze proto

chápat jako rychle opotřebitelné součásti, nevztahuje se na poškození rozbitných částí, např. spínačů,

baterií nebo takových, které jsou zhotoveny ze skla.

Tato záruka zaniká, jestliže se výrobek poškodí,

neodborně použil nebo neobdržel pravidelnou

údržbu. Pro odborné používání výrobku se musí

přesně dodržovat všechny pokyny uvedené v návodu k obsluze. Je bezpodmínečně nutné vyhnout

se účelům použití a jednáním, od kterých se v návodu k obsluze odrazuje nebo před kterými návod

k obsluze varuje.

Vážená zákaznice, vážený zákazníku,

na tento výrobek dostáváte 3 roky záruku ode dne

zakoupení. V případě závad máte možnost uplatnění

zákonných práv vůči prodejci. Vaše práva ze zákona

nejsou omezena naší níže uvedenou zárukou.

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 21 04.06.14 13:17

Výrobek je určen pouze pro soukromé, nikoliv

komerční použití. Vpřípadě nesprávného a neodborného zacházení, použití násilí a zásahů, které

nebyly provedeny našimi autorizovanými servisními

provozovnami, záruční nároky zanikají.

21 CZ

Page 22

… / Ekologické pokyny a informace pro odstranění … / Prohlášení o konformitě

Postup v případě

uplatňování záruky

Pro zajištění rychlého zpracování Vašeho případu

se řiďte následujícími pokyny:

Pro všechny Vaše požadavky si připravte pokladní

stvrzenku a číslo výrobku (např. IAN) jako doklad

o zakoupení.

Číslo výrobku naleznete na typovém štítku, rytině,

na titulním listě návodu (vlevo dole) nebo na nálepce

na zadní nebo spodní straně.

Pokud se vyskytnou funkční vady, kontaktujte nejprve

telefonicky nebo e-mailem níže uvedený servis.

Výrobek s registrovanou závadou pak můžete, spolu

s pokladní stvrzenkou, popisem závady a údajem

kdy se vyskytla nezplatně zaslat na adresu servisu,

kterou vám sdělilo servisní oddělení.

Upozornění:

Na www.lidl-service.com si můžete

stáhnout tento a ostatní manuály, videa

výrobku a software.

Takto nás můžete kontaktovat:

CZ

Název: C.M.C. Creative Marketing &

Consulting GmbH Service CZ

Internetová adresa:

E-mail: info@bohemian-dragomans.com

Telefon: +49 (0) 6894 9989752

Sídlo: Německo

www.cmc-creative.de

(běžný tarif německé pevné sítě)

IAN 43098

Ekologické pokyny a

informace pro odstranění

do odpadu

Recyklace surovin místo

odhození do odpadu!

Výrobek, příslušenství a obal mají

být recyklovány.

Neodhazujte pneumatické výrobky do domácího

odpadu, do ohně nebo do vody. Pokud je to možné,

měly by být vadné nebo nepotřebné výrobky recyklovány. Požádejte o pomoc Vašeho místního prodejce.

Prohlášení o konformitě

My, firma

C. M. C. GmbH

Za dokumentaci zodpovědný pracovník:

Markus Zimmer

Katharina-Loth-Str. 15

66386 St. Ingbert

Německo

prohlašujeme na vlastní zodpovědnost, že výrobek

Pneu jehlový odrezovač

Sériové číslo: 1714

Rok výroby: 2014 / 35

IAN: 43098

Model: PARKSIDE PNEU JEHLOVÝ

ODREZOVAČ PDNE 4000 A1

Vezměte laskavě na vědomí, že následující adresa

není adresa servisu.

Nejprve kontaktujte výše uvedené servisní

středisko.

Adresa:

C. M. C. GmbH

Katharina-Loth-Str. 15

66386 St. Ingbert

Německo

22 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 22 04.06.14 13:17

odpovídá podstatným ochranným požadavkům,

které jsou stanoveny v evropské směrnici

Směrnice pro stroje

Směrnice EG 2006 / 42 / EG

a v jejích změnách.

K posouzení shody byly použité následující harmonizující normy:

Page 23

EN ISO 11148-4:2012

St. Ingbert, 30.06.2014

Karl Peter Uhle

- Obchodní vedoucí -

Prohlášení o konformitě

23 CZ

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 23 04.06.14 13:17

Page 24

24

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 24 04.06.14 13:17

Page 25

Inhaltsverzeichnis

Einleitung

Bestimmungsgemäße Verwendung .................................................................................................... Seite 26

Ausstattung .......................................................................................................................................... Seite 26

Technische Daten ................................................................................................................................ Seite 26

Lieferumfang ........................................................................................................................................ Seite 27

Sicherheitshinweise

Allgemeine Sicherheitsregeln ............................................................................................................. Seite 27

Gefährdungen durch herausgeschleuderte Teile .............................................................................. Seite 27

Gefährdungen im Betrieb ................................................................................................................... Seite 28

Gefährdungen durch wiederholte Bewegungen ..............................................................................Seite 28

Gefährdungen durch Zubehörteile .................................................................................................... Seite 28

Gefährdungen am Arbeitsplatz .........................................................................................................Seite 28

Gefährdungen durch Staub und Dämpfe .......................................................................................... Seite 29

Gefährdungen durch Lärm ................................................................................................................. Seite 29

Gefährdungen durch Schwingungen.................................................................................................Seite 29

Zusätzliche Sicherheitsan weisungen für pneumatische Maschinen .................................................Seite 30

Vor der Inbetriebnahme ....................................................................................................Seite 30

Inbetriebnahme ......................................................................................................................... Seite 31

Nach der Inbetriebnahme ................................................................................................Seite 31

Ersatzteile austauschen ....................................................................................................... Seite 31

Wartung ........................................................................................................................................... Seite 31

Reinigung und Pflege ............................................................................................................ Seite 32

Hinweise zu Garantie und Serviceabwicklung

Garantiebedingungen ........................................................................................................................Seite 32

Garantieumfang .................................................................................................................................. Seite 32

Abwicklung im Garantiefall ................................................................................................................ Seite 32

Umwelthinweise und Entsorgungsangaben ..................................................... Seite 33

EG-Konformitätserklärung ............................................................................................... Seite 33

25 DE/AT/CH

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 25 04.06.14 13:17

Page 26

Einleitung

Einleitung

In dieser Bedienungsanleitung / am Gerät werden folgende Piktogramme verwendet:

Bedienungsanleitung lesen!

Hinweis

Täglich ölen

Druckluft-Nadelentroster

PDNE 4000 A1

Einleitung

Herzlichen Glückwunsch!

Sie haben sich für ein hochwertiges

Produkt aus unserem Haus entschie

Machen Sie sich vor der ersten Inbetriebnahme mit

dem Produkt vertraut. Lesen Sie hierzu aufmerksam

die nachfolgende Bedienungsanleitung und die

Sicherheitshinweise. Die Inbetriebnahme dieses Produktes darf nur durch unterwiesene Personen erfol

NICHT IN DIE HÄNDE VON KINDERN

KOMMEN LASSEN!

den.

gen.

Warn- und Sicherheitshinweise

beachten!

Tragen Sie einen Gehörschutz, eine

Atem- / Staubschutzmaske, eine

Schutzbrille und Schutzhandschuhe.

Entsorgen Sie Verpackung und

Gerät umweltgerecht!

für den Hausgebrauch konzipiert und darf nicht

kommerziell oder industriell genutzt werden.

Ausstattung

Überprüfen Sie unmittelbar nach dem

Auspacken immer den Lieferumfang auf

Vollständigkeit sowie den einwandfreien

Zustand des Gerätes. Benutzen Sie das Gerät nicht,

wenn dieses defekt ist.

1

Nadeln

2

Nadelführung

3

Handgriff

4

Luftregulierschraube

5

¼“ Druckluftanschluss

6

Abzugshebel

Bestimmungsgemäße

Verwendung

Der Nadelentroster dient ausschließlich zum Entfern

von Rost und Beschichtungen (Farben, Lacke, uvm.)

an soliden Metallteilen, aber auch für Modellierarbeiten. Benutzen Sie das Produkt nur wie beschrieb

und für die angegebenen Einsatzbereiche. Bewahr

Technische Daten

en

Arbeitsdruck: 6,3 bar

Druckluftanschluss: ¼“ (0,63 cm)

Schlagzahl: 4000 min

en

Schalldruckpegel: 100,2 dB(A) (EN ISO 15744)

Gewicht: 1900 g

en

-1

Sie diese Anleitung gut auf. Händigen Sie alle Unterlagen bei Weitergabe des Produkts an Dritte

ebenfalls mit aus. Jegliche Anwendung, die von der

bestimmungsgemäßen Verwendung abweicht, ist

untersagt und potentiell gefährlich. Schäden durch

Nichtbeachtung oder Fehlanwendung werden nicht

von der Garantie abgedeckt und fallen nicht in den

Geräusch- und Vibrationsinformationen:

Messwerte ermittelt entsprechend ISO 15744.

Schalldruckpegel L

Schallleistungspegel L

L

= 117,4 dB(A)

pC, peak

: 100,2 dB(A)

pA

: 111,2 dB(A)

WA

Unsicherheit K = 3 dB

Haftungsbereich des Herstellers. Das Gerät wurde

26 DE/AT/CH

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 26 04.06.14 13:17

Page 27

Einleitung / Sicherheitshinweise

Diese Werte sind gerätebezogene Kennwerte und

geben nicht die Geräuschentwicklung am Verwendungsort wieder. Die Geräuschentwicklung am

Verwendungsort hängt z.B. ab von der Arbeitsumgebung, dem Werkstück, der Werkstückauflage,

der Zahl der Eintreibvorgänge.

Entsprechend den Arbeitsplatzverhältnissen und

der Werkstückgestaltung sind ggf. individuelle Geräuschminderungsmaßnahmen durchzuführen, wie

z.B. Auflegen der Werkstücke auf schalldämpfende

Unterlagen, Verhinderung von Vibration der Werkstücke durch Einspannen oder Zudecken, Einstellen

des für den Arbeitsvorgang erforderlichen gerings

ten

Druckes. In besonderen Fällen ist das Tragen von

persönlichem Gehörschutz erforderlich.

Gehörschutz tragen!

Schwingungsgesamtwerte nach

ISO 28927-10, EN 12096:

Schwingungsemissionswert a

Unsicherheit K = 1,5 m / s

Lieferumfang

2

= 69,83 m / s

h

2

1 Nadelentroster (Kopf bereits vormontiert)

1 Gewindestecknippel

1 Innensechskantschlüssel

1 Bedienungsanleitung

Sicherheitshinweise

Allgemeine Sicherheitsregeln

Wenn Sie das Gerät mit dem Luftzufuhrschlauch

verbinden möchten, dürfen Sie das vordere

(Nadelkopf) des Werkzeugs niemals gegen sich

selbst oder gegen andere Personen richten.

Richten Sie das Gerät nie auf sich selbst oder

gegen andere Personen.

Zu mehrfachen Gefährdungen müssen die Sicher-

heitshinweise vor dem Einbau, dem Betrieb, der

Reparatur, der Wartung und dem Austausch von

Zubehörteilen sowie vor der Arbeit in der Nähe

der nicht drehenden, schlagenden Maschine

Ende

gelesen und verstanden werden. Andernfalls

kann

dies zu schweren körperlichen Verletzungen

führen.

Die nicht drehende, schlagende Maschine sollte

ausschließlich von qualifizierten und geschulten

Bedienern eingerichtet, eingestellt oder verwendet werden.

Die nicht drehende, schlagende Maschine darf

nicht verändert werden. Veränderungen können

die Wirksamkeit der Sicherheitsmaßnahmen verringern und die Risiken für den Bediener erhöhen.

Die Sicherheitsanweisungen dürfen nicht verlore

gehen – geben Sie sie der Bedienperson.

Verwenden Sie niemals eine beschädigte nicht

drehende, schlagende Maschine.

Die Maschinen sind regelmäßig zu warten, um

zu überprüfen, dass die vom vorliegenden Teil

von ISO 11148 erforderten Bemessungswerte

und Kennzeichnungen lesbar auf der Maschine

gekennzeichnet sind. Der Angestellte / Benutzer

muss den Hersteller kontaktieren, um Ersatzetiketten zur Kennzeichnung zu erhalten, wenn

dies

notwendig ist.

Gefährdungen durch

herausgeschleuderte Teile

Trennen Sie die nicht drehende, schlagende

Maschine von der Energierversorgung, bevor

Sie das Maschinenwerkzeug oder Zubehörteile

austauschen.

Bei einem Bruch des Werkstücks oder eines der

Zubehörteile oder gar des Maschinenwerkzeugs

selbst können Teile mit hoher Geschwindigkeit

herausgeschleudert werden.

Beim Betrieb der nicht drehenden, schlagenden

Maschine ist immer ein schlagfester Augenschutz

zu tragen. Der Grad des erforderlichen Schut

sollte für jeden einzelnen Einsatz gesondert bewertet werden.

Bei Arbeiten über Kopf ist ein Schutzhelm zu tragen.

In diesem Fall sollten auch die Risiken für andere

Personen bewertet werden.

Es ist sicherzustellen, dass das Werkstück sicher

befestigt ist.

zes

n

27 DE/AT/CH

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 27 04.06.14 13:17

Page 28

Sicherheitshinweise

Betreiben Sie die Maschine nur dann, wenn das

Maschinenwerkzeug mit Hilfe einer geeigneten

Arretierung in der Maschine gehalten wird.

Um Verletzungen zu vermeiden, müssen alle Ver-

schleißerscheinungen zeigenden, gebrochenen

oder verbogenen Teile der Arretierung ausgetauscht werden.

Bevor die Maschine eingeschaltet wird, ist das

Maschinenwerkzeug fest auf der zu bearbeitenden Oberfläche aufzusetzen.

Gefährdungen im Betrieb

Beim Einsatz der Maschine können die Hände

der Bediener Gefährdungen wie z. B. Schlägen,

Schnitten, Abschürfungen und Wärme ausgesetzt sein. Tragen Sie geeignete Handschuhe

zum Schutz der Hände.

D

ie Bediener und das Wartungspersonal müsse

physisch in der Lage sein, die Größe, das Gewicht

und die Leistung der Maschine zu handhaben.

H

alten Sie die Maschine richtig: Seien Sie bere

den üblichen oder plötzlichen Bewegungen entgegenzuwirken – halten Sie beide Hände bereit.

Achten Sie darauf, dass Ihr Körper im Gleichge-

wicht ist und dass Sie einen sicheren Stand haben.

Geben Sie die Befehlseinrichtung zum In-Gang-

oder Stillsetzen im Fall einer Unterbrechung der

Energieversorgung frei.

Verwenden Sie nur die vom Hersteller empfoh-

lenen Schmiermittel.

Vermeiden Sie direkten Kontakt mit dem Maschi-

nenwerkzeug während und nach der Benutzung

weil es heiß sein kann.

Hinweis, dass eine Schutzbrille ge-

tragen werden muss und dass das

Tragen von Schutzhandschuhen und

Schutzkleidung empfohlen wird.

Armen, Schultern, im Halsbereich oder an anderen Körperteilen erfahren.

Nehmen Sie für die Arbeit mit der nicht drehen-

den, schlagenden Maschine eine bequeme

Stellung ein, achten Sie auf sicheren Halt und

vermeiden Sie ungünstige Positionen oder solche,

bei denen es schwierig ist, das Gleichgewicht

halten. Der Bediener sollte während lang dauernder Arbeiten die Körperhaltung verändern, was

helfen kann, Unannehmlichkeiten und Ermüdung

zu vermeiden.

Falls der Bediener Symptome wie z. B. andauern-

des Unwohlsein, Beschwerden, Pochen, Schmerz

Kribbeln, Taubheit, Brennen oder Steifheit an

wahrnimmt, sollten diese warnenden Anzeichen

nicht ignoriert werden. Der Bediener sollte einen

qualifizierten Mediziner konsultieren.

n

Gefährdungen durch

Zubehörteile

it,

Trennen Sie die nicht drehende, schlagende

Maschine von der Energieversorgung, bevor das

Maschinenwerkzeug oder Zubehörteil befestigt

oder gewechselt wird.

Verwenden Sie ausschließlich Zubehörteile und

Verbrauchsmaterialien der vom Hersteller der

schlagenden, nicht drehenden Maschinen empfohlenen Größen und Typen; verwenden Sie

keine anderen Typen oder Größen der Zubehörteile und Verbrauchsmaterialien.

Vermeiden Sie den direkten Kontakt mit dem

Maschinenwerkzeug während und nach der

,

Benutzung, weil es heiß oder scharfkantig sein

kann.

Gefährdungen am Arbeitsplatz

zu

,

sich

Ausrutschen, Stolpern und Stürzen sind Haupt-

Gefährdungen durch

wiederholte Bewegungen

gründe für Verletzungen am Arbeitsplatz. Acht

Sie auf Oberflächen, die durch den Gebrauch d

en

er

Maschine rutschig geworden sein können, und

Bei der Verwendung einer nicht drehenden,

schlagenden Maschine kann der Bediener bei

der Ausführung arbeitsbezogener Tätigkeiten

unangenehme Empfindungen in den Händen,

28 DE/AT/CH

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 28 04.06.14 13:17

auf durch den Luft- oder den Hydraulikschlauch

bedingte Stolpergefahren.

Gehen Sie in unbekannten Umgebungen mit

V

orsicht vor. Es können versteckte Gefährdunge

n

Page 29

Sicherheitshinweise

durch Stromkabel oder sonstige Versorgungsleitungen gegeben sein.

Die nicht drehende, schlagende Maschine ist

nicht zum Einsatz in explosionsfähigen Atmosphären bestimmt und nicht gegen den Kontakt

mit elektrischen Stromquellen isoliert.

Stellen Sie sicher, dass keine elektrischen Leitun-

gen, Gasrohrleitungen usw. vorhanden sind, die

i

m Fall der Beschädigung durch die Verwendun

der Maschine zu einer Gefährdung führen

könnten.

Gefährdungen durch

Staub und Dämpfe

Die beim Einsatz der nicht drehenden, schlagen-

den Maschinen entstehenden Stäube und Dämpfe

können gesundheitliche Schäden (wie z. B. Krebs

Geburtsfehler, Asthma und / oder Dermatitis)

verursachen; es ist unerlässlich, eine Risikobewertung in Bezug auf diese Gefährdungen

durchzuführen und entsprechende Regelungsmechanismen umzusetzen.

In die Risikobewertung sollten die bei der Ver-

wendung der Maschine entstehenden Stäube

und die dabei möglicherweise aufwirbelnden

vorhandenen Stäube einbezogen werden.

Die nicht drehende, schlagende Maschine ist

nach den in dieser Anleitung enthaltenen Empfehlungen zu betreiben und zu warten, um die

Freisetzung von Staub und Dämpfen auf ein

Mindestmaß zu reduzieren.

Die Abluft ist so abzuführen, dass die Aufwirbe-

lung von Staub in einer staubgefüllten Umgebung

auf ein Mindestmaß reduziert wird.

Falls Staub oder Dämpfe entstehen, muss die

Hauptaufgabe sein, diese am Ort ihrer Freisetzung zu kontrollieren.

Alle zum Auffangen, Absaugen oder zur Unter-

drückung von Flugstaub oder Dämpfen vorgesehenen Einbau- oder Zubehörteile der Maschine

sollten den Anweisungen des Herstellers entsprechend richtig eingesetzt und gewartet werden.

Die Verbrauchsmaterialien und das Maschinen-

werkzeug sind den Empfehlungen dieser Anleitung

entsprechend auszuwählen, zu warten und zu

ersetzen, um eine unnötige Intensivierung der

Staub- oder Dampfentwicklung zu vermeiden.

Verwenden Sie Atemschutzausrüstungen wie

nach den Arbeits- und Gesundheitsschutzvorschriften gefordert.

Gefährdungen durch Lärm

g

Die Einwirkung hoher Lärmpegel kann bei unge-

nügendem Gehörschutz zu dauerhaften Gehörschäden und anderen Problemen, wie z. B. Tinnitus

(Klingeln, Sausen, Pfeifen oder Summen im Ohr),

führen. Es ist unerlässlich, eine Risikobewertung

in Bezug auf diese Gefährdungen durchzufüh

und entsprechende Regelungsmechanismen

umzusetzen.

Zu den für die Risikominderung geeigneten

Regelungsmechanismen gehören Maßnahmen

,

wie die Verwendung von Dämmstoffen, um an

den Werkstücken auftretende Klingelgeräusche

zu vermeiden.

Verwenden Sie Gehörschutzausrüs-

tungen wie nach den Arbeits- und Gesundheitsschutzvorschriften gefordert.

Die nicht drehende, schlagende Maschine ist

nach den in dieser Anleitung enthaltenen Empfehlungen zu betreiben und zu warten, um eine

unnötige Erhöhung der Lärmpegel zu vermeiden.

Die Verbrauchsmaterialien und das Maschinen-

werkzeug sind den Empfehlungen dieser Anleitung entsprechend auszuwählen, zu warten und

zu ersetzen, um eine unnötige Erhöhung des

Lärmpegels zu vermeiden.

V

erfügt die nicht drehende, schlagende Masch

über einen Schalldämpfer, ist stets sicherzustellen,

dass dieser beim Betrieb der nicht drehenden,

schlagenden Maschine vor Ort ist und sich in

einem guten Arbeitszustand befindet.

Gefährdungen durch

Schwingungen

Die Einwirkung von Schwingungen kann Schä-

digungen an den Nerven und Störungen der

Blutzirkulation in Händen und Armen verursachen

ren

ine

.

29 DE/AT/CH

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 29 04.06.14 13:17

Page 30

Sicherheitshinweise / Vor der Inbetriebnahme

Inbetriebnahme / Nach der Inbetriebnahme / Ersatzteile austauschen / Wartung

Tragen Sie bei Arbeiten in kalter Umgebung

warme Kleidung und halten Sie Ihre Hände

warm und trocken.

Falls Sie feststellen, dass die Haut an Ihren Fin-

gern oder Händen taub wird, kribbelt, schmerzt

oder sich weiß verfärbt, stellen Sie die Arbeit

mit der nicht drehenden, schlagenden Maschine

ein und konsultieren Sie einen Arzt.

Die nicht drehende, schlagende Maschine ist

nach den in dieser Anleitung enthaltenen Empfehlungen zu betreiben und zu warten, um eine

unnötige Verstärkung der Schwingungen zu

vermeiden.

Halten Sie das Maschinenwerkzeug nicht mit

der freien Hand, denn dies hat eine Verstärkung

der Schwingungseinwirkung zur Folge.

Halten Sie die Maschine mit nicht allzu festem,

aber sicherem Griff unter Einhaltung der erforderlichen Hand-Reaktionskräfte, denn das Schwingungsrisiko wird in der Regel mit zunehmender

Griffkraft größer.

Halten Sie eingehängte Handgriffe mittig und

vermeiden Sie, die Handgriffe bis an die Anschläge zu schieben.

Zusätzliche Sicherheitsan-

weisungen für pneumatische

Maschinen

Verwenden Sie keine Schnellverschlusskupplun-

gen am Werkzeugeinlass. Verwenden Sie für

Schlauchanschlüsse mit Gewinde nur solche aus

gehärtetem Stahl (oder einem Werkstoff von

vergleichbarer Stoßfestigkeit).

Falls Universal-Drehkupplungen (Klauenkupplun-

gen) verwendet werden, müssen Arretierstifte

eingesetzt werden und verwenden Sie Whipcheck-

Schlauchsicherungen, um Schutz für den

Fall eines Versagens der Verbindung des

Schlauchs mit der Maschine oder von Schläuchen untereinander zu bieten.

Sorgen Sie dafür, dass der auf der Maschine an-

gegebene Höchstdruck nicht überschritten wird.

Tr

agen Sie mit Luft arbeitende Maschinen niem

am Schlauch.

als

Vor der Inbetriebnahme

Druckluft kann ernsthafte Verletzungen verur-

sachen.

Wenn die Maschine nicht in Gebrauch ist, vor

dem Austausch von Zubehörteilen oder bei der

Ausführung von Reparaturarbeiten ist stets die

Luftzufuhr abzusperren, der Luftschlauch drucklos

zu machen und die Maschine von der Druckluftzufuhr zu trennen.

Richten Sie den Luftstrom niemals auf sich selbst

oder gegen andere Personen.

Umherschlagende Schläuche können ernsthafte

Verletzungen verursachen. Überprüfen Sie da

immer, ob die Schläuche und ihre Befestigungsmittel unbeschädigt sind und sich nicht gelöst

haben.

Kalte Luft ist von den Händen fortzuleiten.

30 DE/AT/CH

43098_par_Druckluft-Nadelentroster PDNE 4000 A1_content_CZ.indd 30 04.06.14 13:17

her

ACHTUNG! Niemals das Druckluftwerkzeug

ohne Ölung in Betrieb nehmen!

Prüfen Sie, ob der Kompressor fest auf dem

Boden steht.

Prüfen Sie, ob alle Schlauchanschlüsse richtig

angeschlossen und fixiert sind.

Verbinden Sie das Werkzeug mit dem Druckluftschlauch.

Falls nach dem Einschalten, trotz erreichtem

Maximaldruck, keine Funktion zu erkennen ist,

schalten Sie das Gerät wieder ab. Kontaktieren

Sie umgehend die Service-Hotline.

Page 31

Inbetriebnahme / Nach der Inbetriebnahme / Ersatzteile austauschen / Wartung

Inbetriebnahme (s. Abb. A)

Schrauben Sie ein Gewindestecknippel ¼“

(6,35 mm) in das Druckluftgerät.

Hinweis: Um maximale Dichtheit zu erreichen,

wird die Verwendung von Teflonband empfohlen. Ansonsten wird das Gerät unter Umständen

nicht in der Lage sein, seine volle Leistungsfähigkeit zu entfalten.

Wenn Sie das Gerät mit dem Luftzufuhrschlauch

verbinden möchten, dürfen Sie das vordere Ende

(Nadelkopf) des Werkzeugs niemals gegen sich

selbst oder gegen andere Personen richten.

Durch betätigen des Abzugshebels 6 starten