Parkside PDMFW 15 A1 Translation Of The Original Instructions

AIR MULTI TOOL PDMFW 15 A1

AIR MULTI TOOL

Translation of the original instructions

DRUCKLUFT-MULTIFUNKTIONSWERKZEUG

Originalbetriebsanleitung

TRYKLUFT-MULTIVÆRKTØJ

Oversættelse af den originale driftsvejledning

IAN 292170

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE/NI Translation of the original instructions Page 1

DK Oversættelse af den originale driftsvejledning Side 15

DE / AT / CH Originalbetriebsanleitung Seite 29

Z52 C3

Z32 D4

Z85 D4

HCS

HCS

Contents

Introduction ......................................................2

Intended use ................................................................ 2

Features ................................................................... 2

Package contents ............................................................ 3

Technical data .............................................................. 3

General safety instructions for compressed air tools ....................3

Hazards caused by flying parts ................................................. 4

Hazards caused by entanglement ............................................... 4

Hazards during operation ..................................................... 4

Hazards caused by repetitive movements ......................................... 5

Hazards caused by accessories ................................................. 5

Hazards in the workplace ..................................................... 5

Hazards caused by dust and vapours ............................................ 6

Hazards caused by noise ...................................................... 6

Hazards caused by vibrations .................................................. 7

Additional safety instructions ................................................... 7

Additional safety notices ...................................................... 8

Before use .......................................................8

Fitting the connector nipple .................................................... 8

Lubrication ................................................................. 8

Topping up the oil ........................................................... 9

Connecting to a compressed air source ........................................... 9

Before use .......................................................9

Selecting a tool ............................................................. 9

Changing tools ............................................................. 10

Fitting the sanding sheet onto the sanding plate ...................................10

Switching on and off ........................................................11

Maintenance and cleaning .........................................11

Troubleshooting .................................................11

Disposal ........................................................12

Kompernass Handels GmbH warranty ..............................12

Service .........................................................13

Importer .......................................................13

Translation of the original Conformity Declaration .....................13

PDMFW 15 A1

GB│IE│NI

│

1 ■

AIR MULTI TOOL PDMFW 15 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please

familiarise yourself with all operating and safety

instructions. Use the product only as described and

for the range of applications specified. Please also

pass these operating instructions on to any future

owner.

Intended use

The appliance is intended for sawing, cutting and

grinding. The following materials are preferable

for processing: wood, plastic, drywall elements,

light and non-ferrous metals, fasteners (e.g. nails,

screws) and wall tiles.

It is particularly suitable for near-edge and flush

work.

The tool may only be operated with a compressed

air supply. The maximum permissible operating

pressure specified on the tool must not be exceeded.

This tool must not be operated with explosive,

flammable or health-damaging gases.

Do not use as a lever, crusher or striking tool.

Any other usage or modification of the appliance

is deemed to be improper and carries a significant

risk of accidents. The manufacturer accepts no responsibility for damage(s) resulting from improper

usage. This tool is intended for domestic use only.

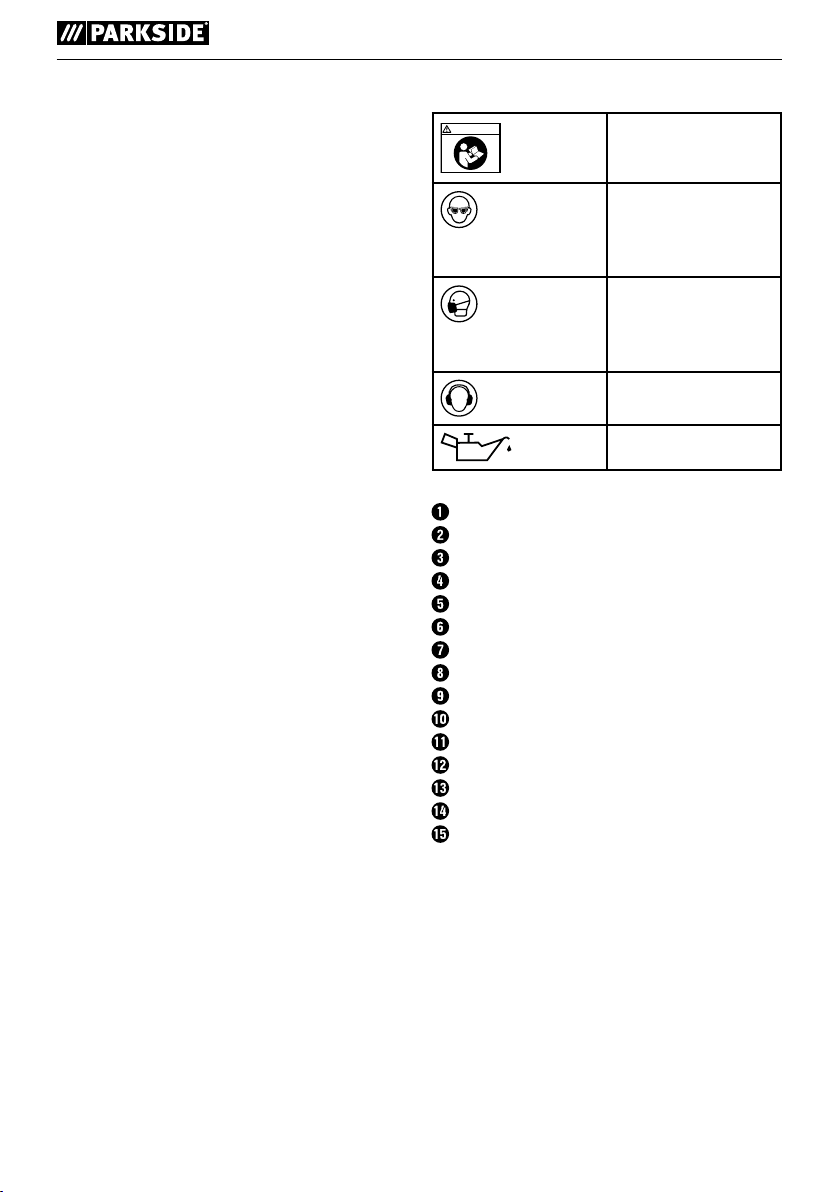

Symbols on the compressed air tool:

WARNING!

Read the operating

instructions before use.

Always wear eye protection when using or

maintaining the compressed air polisher.

Always wear a dust

mask in situations in

which dust is being

generated.

Always wear hearing

protection.

Oil daily

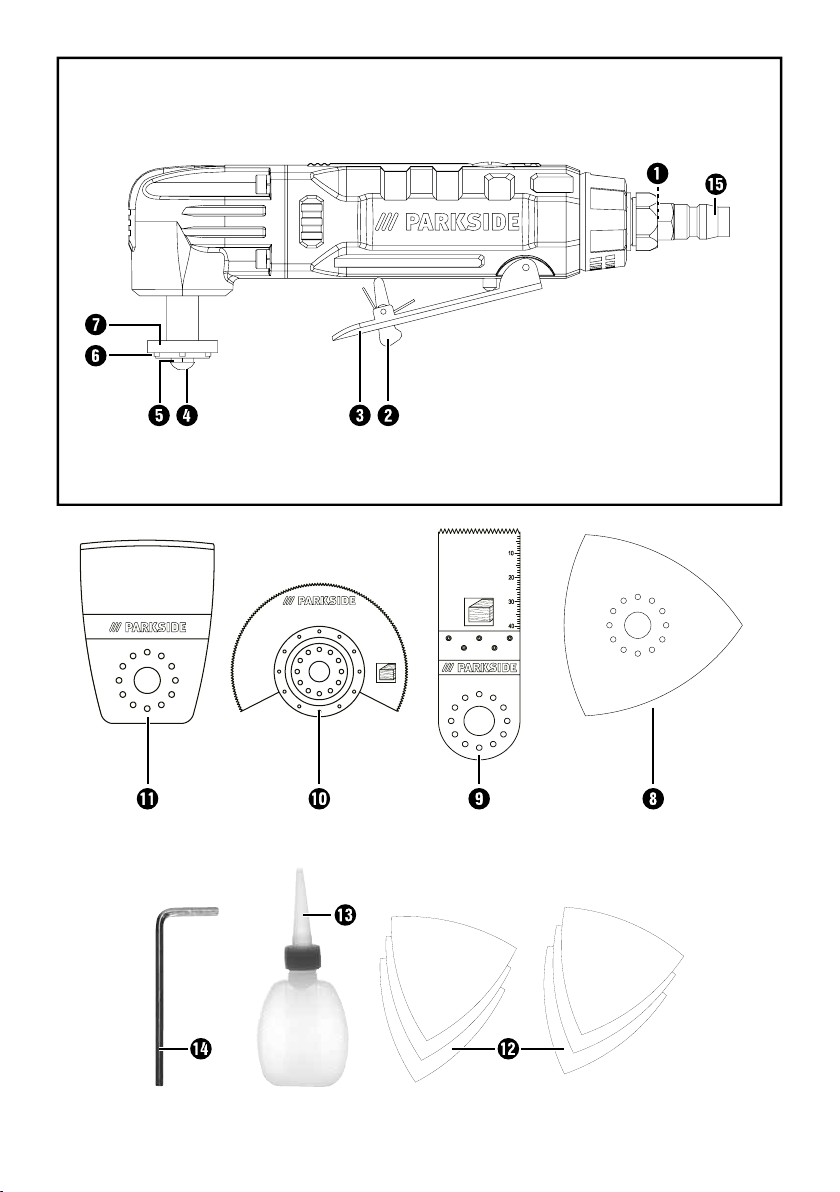

Features

Air inlet

Trigger lock

Trigger

Hex screw

Spring washer

Plain washer

Tool holder

Sanding plate

Plunge saw blade

Segment saw blade

Scraper

Sanding sheets

Oil bottle

Hex key

Connector nipple

■ 2 │ GB

│IE│

NI

PDMFW 15 A1

Package contents

1 air multi tool PDMFW 15 A1

1 plunge saw blade (32 mm) Z32 D4

1 sanding plate

1 segment saw blade Z85 D4

1 scraper Z52 C3

6 sanding sheets for sanding wood

(80/120/240)

1 connector nipple 6.35 mm (1/4")

1 oil bottle

1 hex key

1 carrying case

1 set of operating instructions

Technical data

Rated air pressure: max. 6.3 bar

Maximum frequency: n

Noise emission values:

Noise measurement determined in accordance

with ISO15744:

Sound pressure level: L

Uncertainty: K

Sound power level: L

Uncertainty: K

Wear hearing protection!

Vibration emission value:

Vibration values determined in accordance with

ISO 28927-8 and EN 12096:

a

= 9.73 m/s

h

2

Uncertainty K = 1.42 m/s

18000 rpm

0

= 90 dB (A)

pA

= 3 dB

pA

= 101 dB (A)

WA

= 3 dB

WA

2

WARNING!

► The noise emission levels specified in these in-

structions have been measured in accordance

with the standardised measuring procedure

specified in ISO 15744 and can be used to

make equipment comparisons. The noise emission values vary in accordance with the use

of the compressed air tool and may be higher

than the values specified in these instructions

in some cases. It is easy to underestimate the

noise emission load if the compressed air tool

is used regularly in a certain manner.

NOTE

► For an accurate estimate of the noise emis-

sion load during a certain working period,

the times during which the appliance is

switched off or is running but not actually

being used must also be taken into consideration. This can significantly reduce the noise

emission load over the total working period.

WARNING!

General safety instructions for compressed

air tools

WARNING!

► Read all safety warnings and all instruc-

tions. Failure to follow the warnings and

instructions may result in electric shock, fire

and/or serious injury.

NOTE

► The terms "compressed air tool" or "tool" used

in the following text refer to the compressed air

tools specified in these operating instructions.

PDMFW 15 A1

GB│IE│NI

│

3 ■

Save all warnings and instructions for future

reference.

■ The user must evaluate the specific risks that

may arise due to different kinds of use.

■ Please ensure that you have read and understood

the safety instructions before fitting, operating,

repairing, servicing or replacing any accessories

and before working near the compressed air

tool. Failure to do this can result in serious

bodily injury.

■ The compressed air tool should only be set up,

adjusted or used by adequately qualified and

trained operators.

■ The compressed air tool may not be modified.

Modifications can reduce the effectiveness of

the safety measures and increase the risks for

the operator.

■ Never use damaged compressed air tools.

Maintain compressed air tools with care. Check

regularly whether moving parts function correctly

and do not jam; check whether any parts are

broken or damaged to an extent that the compressed air tool will no longer operate correctly.

Check signs and labels for completeness and

readability. If damaged, have parts repaired or

replaced before using the compressed air tool.

Many accidents are caused by poorly maintained compressed air tools.

Hazards caused by flying parts

■ If a workpiece or accessory of the compressed

air tool breaks, parts can be flung out at high

speeds.

■ Always wear impact-resistant safety goggles

during operation, when replacing accessory

parts or during repair or maintenance of the

compressed air tool. The level of the required

protection must be evaluated separately for

each individual task.

■ You must ensure that the workpiece has been

securely fixed in place.

■ Ensure that sparks and fragments created during

work do not constitute any hazard.

■ Separate the compressed air tool from the com-

pressed air supply before replacing the attachment or accessories or before you adjust the

settings, service or clean the tool.

■ Ensure that no dangers are created for other

persons either.

Hazards caused by entanglement

■ Be careful to avoid entanglement!

Suffocation, scalping and/or cut wounds can

occur if loose clothing, jewellery, necklaces, hair

or gloves are not kept away from the machine

and its accessories.

Hazards during operation

■ When using the compressed air tool, the opera-

tor's hands can be subject to hazards such as

cuts, grazing and heat. Wear suitable gloves to

protect your hands.

■ The operator and maintenance personnel must

be physically capable of handling the size,

weight and power of the compressed air tool.

■ Hold the compressed air tool correctly: be

ready to counteract any normal or sudden

movements – keep both hands ready.

■ Keep proper footing and balance at all times.

■ Prevent unintentional starting. If the air supply is

interrupted, switch off the compressed air tool

using the On/Off switch.

■ Use only the lubricants recommended by the

manufacturer.

■ 4 │ GB

│IE│

NI

PDMFW 15 A1

■ Use personal protective equipment. Always

wear eye protection. Wearing personal protective equipment such as protective gloves,

non-slip safety shoes or hearing protection,

depending on the type and use of the power

tool reduces the risk of personal injuries and it

is recommended.

■ Wear a safety helmet for overhead work.

■ Do not try to brake the saw blades by applying

lateral counterpressure.

■ Torn or deformed saw blades may not be used.

■ Ensure that the saw blades are fitted properly.

■ Sparks must be diverted safely.

■ Ensure that no hazard is caused by sparks cre-

ated during use. Explosive or flammable dusts

can be generated when processing certain

materials. There is a risk of explosion or fire.

Hazards caused by repetitive movements

■ Users of the compressed air tool may experience

unpleasant sensations in their hands, arms,

shoulders, neck area or other body parts.

■ Assume a comfortable position when working

with the compressed air tool, pay attention to

safe footing and avoid unfavourable positions

or such that make it difficult to keep your balance. During work over longer periods, the

operator should change posture regularly to

avoid discomfort and fatigue.

■ If the operator notices symptoms such as persis-

tent discomfort, throbbing, pain, tingling, burning

or stiffness, these warning indications should not

be ignored. The operator should consult a qualified medical doctor.

Hazards caused by accessories

■ Separate the compressed air tool from the com-

pressed air supply before replacing the attachment or accessory.

■ Only use accessories that are intended for this

appliance and comply with the requirements

and specifications listed in these operating

instructions.

■ Avoid direct contact with the accessory tool

during and after use because it may be hot or

have sharp edges.

Observe the following guidelines:

■ Only use tools that are specifically made for

use with this appliance.

■ Do not use cutting discs or any other cutting

tools (other than the saw blades supplied) with

this appliance.

■ Ensure that the maximum operating speed of

the tool is higher than that of the machine.

■ Self-adhesive grinding discs must be applied

concentrically on the mounting plate.

Hazards in the workplace

■ Slipping, tripping up and falling are the main

causes of injuries in the workplace. Watch out

for surfaces that may have become slippery

from the use of the compressed air tool and

tripping hazards caused by the air hose.

■ Proceed with caution in new surroundings.

Hidden hazards caused by power or other

supply lines may be present.

■ This compressed air tool is not suitable for use

in explosive atmospheres and is not insulated

against contact with power sources.

■ Make sure (e.g. by using a metal detector) that

there are no hidden power, water or gas lines

in the location where you are working.

PDMFW 15 A1

GB│IE│NI

│

5 ■

Hazards caused by dust and vapours

■ The dusts and vapours produced by using the

machines can be hazardous to health (e.g.

cause cancer, birth defects, asthma and/or dermatitis); it is essential to carry out a risk assessment in respect of these risks and to implement

corresponding regulatory mechanisms.

■ The risk assessment should include the dust

caused by using the machine and any existing

dust that may be raised at the same time.

■ The compressed air tool is to be operated and

maintained in accordance with the recommendations contained in this manual to keep the

release of dust and vapours to a minimum.

■ The exhaust air should be extracted so that the

minimum amount of dust is raised in an already

dusty environment.

■ If dusts or vapours are created, the main priority

must be to control these where they are released.

■ All components of the compressed air tool or

accessories intended for collecting, extracting

or suppressing airborne dust or vapours or

should be used and serviced properly in accordance with the manufacturer’s instructions.

■ Consumables/tools should be selected, main-

tained and replaced in accordance with the

recommendations in this guide in order to avoid

unnecessary intensification of dust or vapour

production.

■ Use a dust mask as per the instructions provided

by your employer or as required by health and

safety regulations.

■ Working with certain materials can lead to

emissions of dust and vapours that are potentially explosive.

Hazards caused by noise

■ Excessive noise levels in conjunction with insuffi-

cient hearing protection may lead to permanent

hearing damage, loss of hearing and other

problems, such as tinnitus (ringing, buzzing,

whistling or humming in your ears).

■ It is essential to carry out a risk assessment with

regard to these hazards and implement suitable

control mechanisms.

■ Suitable control mechanisms include measures

such as the use of insulating materials to avoid

ringing noises from occurring on the workpieces.

■ Use hearing protection as required by work and

health safety regulations.

■ The compressed air tool is to be operated and

maintained in accordance with the recommendations contained in these instructions in order

to reduce any unnecessary increase of the noise

levels.

■ Consumables and the tool should be selected,

maintained and replaced in accordance with

the recommendations in these instructions in

order to avoid any unnecessary increase of the

noise levels.

■ The integrated silencer may not be removed

and must be in good working order.

■ 6 │ GB

│IE│

NI

PDMFW 15 A1

Hazards caused by vibrations

■ Vibrations can damage the nerves and cause

malfunctions to the blood circulation in the

hands and arms.

■ Wear warm clothing when working in a cold

environment and keep your hands warm and

dry.

■ If you notice that the skin of your fingers or

hands is becoming numb, tingles, hurts or shows

white discolouration, stop working with the

compressed air tool and consult a doctor.

■ The compressed air tool is to be operated and

maintained in accordance with the recommendations contained in this manual to reduce any

unnecessary increase in the vibrations.

■ Consumables and the tool should be selected,

maintained and replaced in accordance with

the recommendations in this guide in order to

avoid unnecessary increase of oscillations.

■ To support the weight of the compressed air

tool, use a stand, clamp or a balancing unit

wherever possible.

■ Hold the compressed air tool securely but not

too firmly while maintaining the necessary

hand-reaction force, as the vibration risk generally increases the harder the machine is held.

■ An inadequately mounted or damaged acces-

sory tool can lead to excessive vibrations.

Additional safety instructions

■ Compressed air can cause serious injury.

■ When the compressed air tool is not in use, the

air supply must always be shut off and the air

hose depressurised. The compressed air tool

must be disconnected from the compressed air

supply before replacing accessories or when

conducting repair work.

■ Never aim the airflow at yourself or anyone

else.

■ Thrashing hoses can cause serious injury. There-

fore, always check whether the hoses and their

fixings are undamaged and have not come

loose.

■ If universal rotary joints (claw couplings) are

used, locking pins must be inserted and Whipcheck hose restraints must be used to provide

protection in the case of a failure of the connection between the hose and the compressed

air tool.

■ Ensure that the maximum permissible pressure

on the compressed air tool is not exceeded.

■ Never carry compressed air tools by the hose.

■ If you are operating the compressed air tool

with a tool holder, ensure that it is securely

fastened. Loss of control can lead to injuries.

PDMFW 15 A1

GB│IE│NI

│

7 ■

Additional safety notices

■ If applicable, observe special work safety or

accident prevention regulations for the handling

of compressors and compressed air tools.

■ Ensure that the maximum permissible working

pressure specified in the Technical Data is not

exceeded.

■ Do not overload this tool – use this tool only

within the capacity range specified in the

Technical Data.

■ Use safe lubricants. Ensure sufficient ventila-

tion at the place of work. In case of increased

discharge:

check the compressed air tool and have it repaired if necessary.

■ Do not use this tool if you are distracted. Be

alert, watch what you are doing and use common sense when operating a compressed air

tool. Do not use tools when you feel tired or are

under influence of drugs, alcohol, or medication. A moment of inattention when operating

the tool can result in serious personal injuries.

■ Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

■ Keep compressed air tools out of reach of

children.

■ Do not store outdoors or in damp environments

without protection.

■ Protect the compressed air tool, in particular

the compressed air connection and operating

elements against dust and dirt.

Before use

NOTE

► The compressed air tool may only be oper-

ated using cleaned, oil-atomised compressed

air and the maximum operating pressure of

6.3 bar must not be exceeded on the appliance. The compressor must be fitted with a

pressure reducer to regulate the working

pressure.

Fitting the connector nipple

♦ Screw the connector nipple into the air

inlet .

Lubrication

NOTE

► Regular lubrication is particularly important

to avoid friction and corrosion damage.

We recommend using a suitable special oil

for compressed air tools (e.g. Liqui Moly

compressor oil).

– Lubrication with mist oiler

A mist oiler (not supplied) continuously

and optimally lubricates the appliance

as a preparation stage after the pressure

reducer. A mist oiler gives off fine drops

of oil into the air flow and thus guarantees regular lubrication.

– Manual lubrication

If you do not have a mist oiler, lubricate

the tool before every use or longer work

sessions. Add 3–4 drops of pneumatic

oil into the connector nipple

.

■ 8 │ GB

│IE│

NI

PDMFW 15 A1

Topping up the oil

To ensure that the tool remains operational for a

long time, the tool must have sufficient pneumatic oil.

The following options are available:

♦ Attach a maintenance unit with an oiler to the

compressor.

♦ Install an add-on oiler in the compressed air line

or the compressed air tool.

♦ Add 3–5 drops of pneumatic oil into the con-

nector nipple

every 15 minutes of operation.

Connecting to a compressed air

source

NOTE

► Before connecting the compressed air source,

– the correct working pressure (6,3 bar)

must be fully reached, and

– make sure that the trigger is in the upper

position.

► Use only connection hoses with an internal

diameter of at least 9 mm.

► Use only filtered, lubricated and regulated

compressed air.

♦ Screw the connector nipple

. Tighten the connection with a pair of pliers.

♦ Attach the tool to a compressor by connecting

the connector nipple

the compressed air source.

into the air inlet

with the supply hose of

Before use

Selecting a tool

NOTE

► The easy-change tool holder fitting is suitable

for standard accessories.

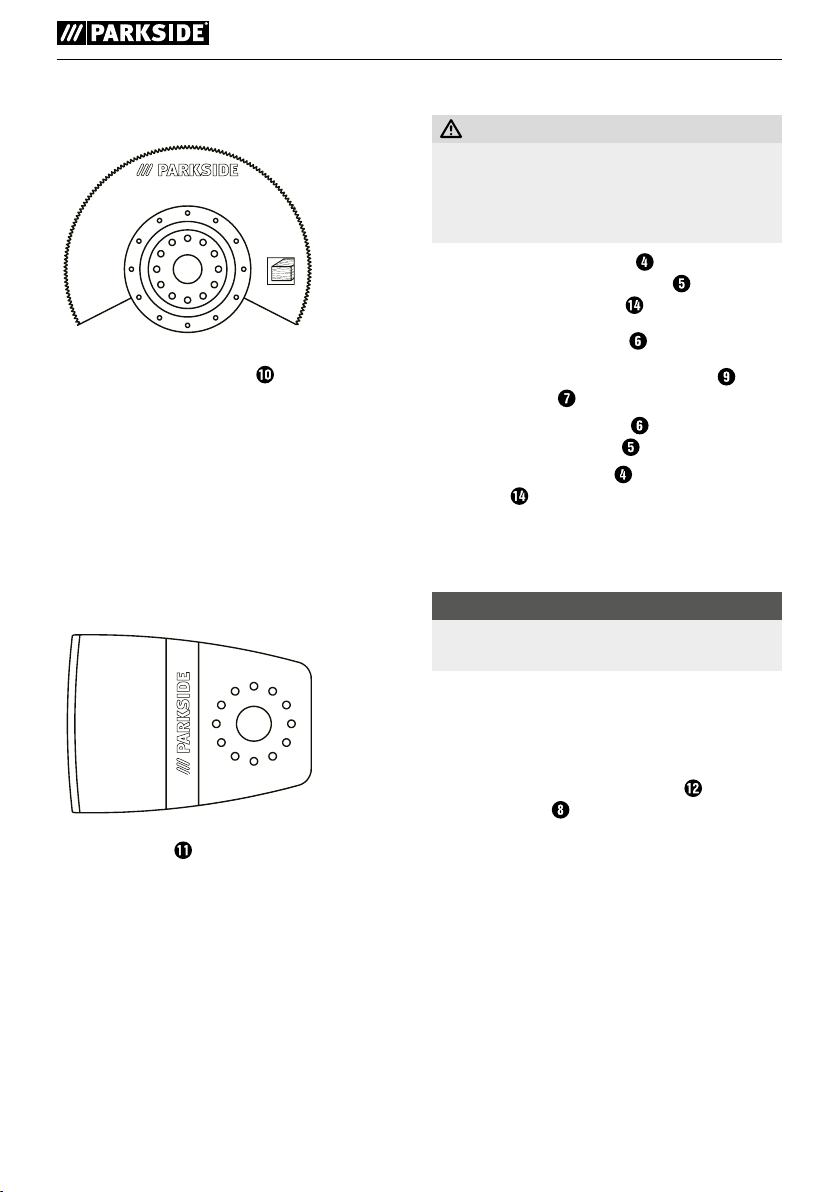

Application:

cutting and shortening pipes and sheets.

HCS

Z32 D4

Plunge saw blade (32 mm) Z32 D4

Materials:

wood, plastic, gypsum (plaster) and other soft

materials

Application:

– separation and plunge saw cuts

– sawing close to edges, even in hard-to-reach

areas

Example: sawing recesses in lightweight walls.

CAUTION!

► Ensure that the compressed air hose is

firmly attached. A loose hose can thrash

about uncontrollably causing grave danger.

Likewise, ensure the firm seat of the two screw

connections between the coupling piece and

the appliance.

♦

The compressed air source must be equipped

with a pressure reducer so that you can regulate the air pressure.

PDMFW 15 A1

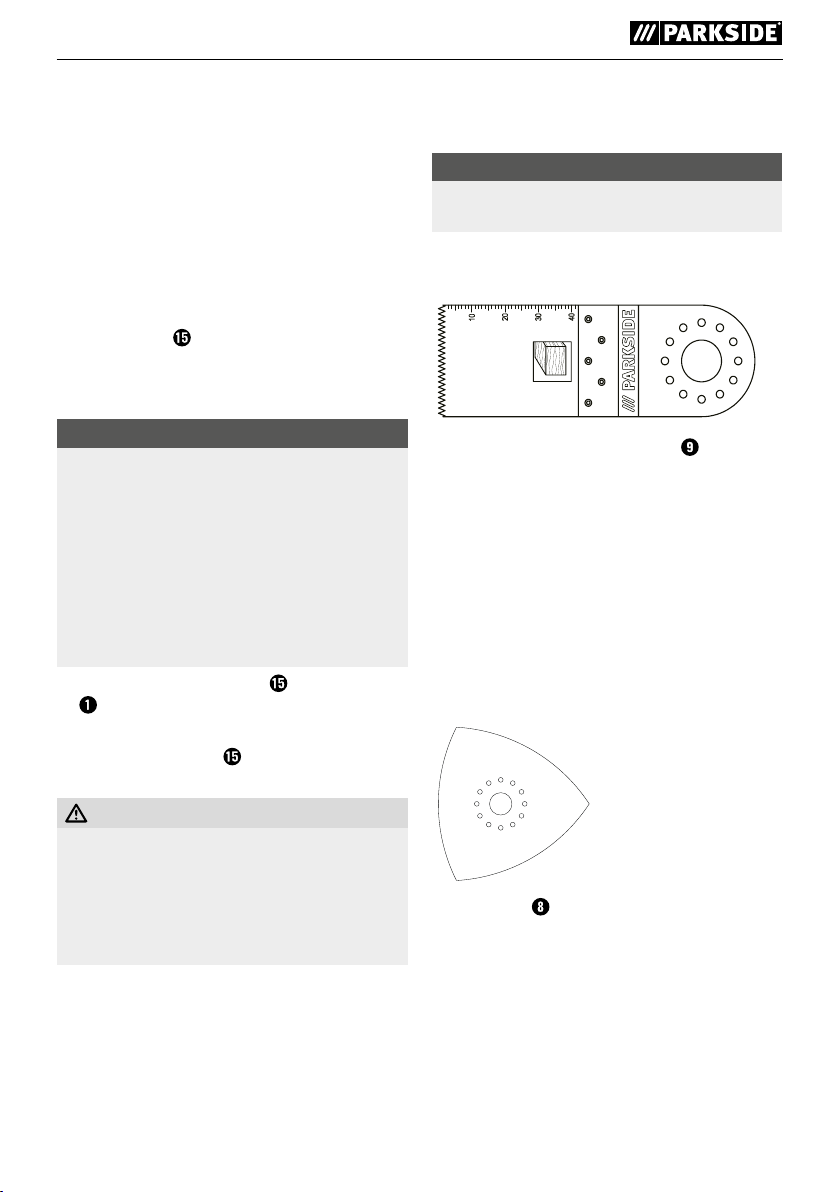

Sanding plate

Materials:

lumber, metal (sanding sheets included in the

delivery), paints*, stone*

*depending on the sanding sheet

GB│IE│NI

│

9 ■

Application:

sanding up to edges and hard-to-reach areas.

Z85 D4

HCS

Segment saw blade Z85 D4

Material:

wood

Application:

– separation and plunge saw cuts

– sawing close to edges, even in hard-to-reach

areas

Example: working parquet and other flooring

materials, also with plunge cuts.

Changing tools

WARNING! RISK OF INJURY!

■ Always detach the tube from the compressor

before changing accessories.

■ Ensure that the appliance is no longer in

operation.

■ First, loosen the hex screw

together with the spring washer . To do this,

use the supplied hex key .

■ Remove the plain washer

■ Fit the tool (e.g. the plunge saw blade

the tool holder .

■ Replace the plain washer

place the spring washer on top of it.

■ Screw in the hex screw

hex key .

■ Check that the tool is fitted firmly. Incorrectly

or insecurely fitted tools can come loose during

use and cause you an injury.

NOTE

► You can fit the tools in any snap position on

the tool holder.

and remove it

.

onto the tool and

using the supplied

) onto

Z52 C3

Scraper Z52 C3

Materials:

mortar/concrete residues, tile/carpet glue, paint/

silicone residues

Application:

– removal of material residues, such as tile

adhesive, when replacing damaged tiles.

■ 10 │ GB

│IE│

NI

Fitting the sanding sheet onto the

sanding plate

Attachment:

♦ You can attach the sanding sheet

to the

sanding plate using the Velcro.

PDMFW 15 A1

NOTE

► Before fitting a new sanding sheet

any dust and dirt from the sanding plate .

► Ensure that the dust extraction holes of the

sanding plate and sanding sheet are flush.

Removal:

♦ Simply pull the sanding sheet off the sander

plate

.

, remove

Switching on and off

Switching on:

♦ First, press the trigger lock

then the trigger to switch the tool on.

Switching off:

♦ Release the trigger

♦ When you have finished working, disconnect

the tool from the compressed air source.

forwards and

.

Maintenance and cleaning

WARNING! RISK OF INJURY! Discon-

nect the tool from the compressed air

supply.

CAUTION!

► Before maintenance, clean off any hazardous

substances that may have accumulated on

the tool (due to working processes). Avoid

all skin contact with these substances. If the

skin comes into contact with hazardous dusts,

this can lead to severe dermatitis. If dust is

produced or swirled up during maintenance,

it can be inhaled.

NOTE

► To ensure correct functioning and a long

service life for the tool, pay attention to the

following points:

■ Sufficient and continuous oil lubrication is highly

important for optimum functioning.

■ If the tool is exhibiting excessive vibration levels,

the cause of the vibrations must be identified

and repaired.

■ Use only the genuine replacement parts recom-

mended by the manufacturer, otherwise you

could put users at risk. In doubt, contact the

Service Centre.

■ Clean the tool with a soft, dry cloth only.

■ Never use sharp or abrasive cleaning agents

under any circumstances.

Troubleshooting

Fault Possible

cause

Speed too

slow, air

escapes from

the outlet.

Tool does

not move;

compressed

air escapes

completely

through the

outlet.

Motor parts

jamming due

to dirt.

Pressure

supply too

low.

Motor is

jammed due

to material

build-up.

Remedy

Check the

pressure

supply filter

for contamination.

Check the

pressure

supply filter

for contamination.

Lubricate the

tool as described in the

instructions.

If necessary,

repeat the

steps outlined

above.

Lubricate the

tool as described in the

instructions.

PDMFW 15 A1

GB│IE│NI

│

11 ■

Loading...

Loading...