Page 1

BELT SANDER PBSD 600 A1

BELT SANDER

Translation of the original instructions

BANDSCHLEIFER

Bedienungsanleitung

IAN 364419_2010

ΤΑΙΝΙΟΛΕΙΑΝΤΉΡΑΣ

Μετάφραση των αυθεντικών οδηγιών λειτουργίας

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of

the device.

Πριν ξεκινήσετε την ανάγνωση, ανοίξτε τη σελίδα με τις εικόνες και εξοικειωθείτε με όλες τις λειτουργίες

της συσκευής.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE / NI/CY Translation of t he original instructions Page 1

GR / CY Μετάφραση των αυθεντικών οδηγιών λειτουργίας Σελίδα 13

DE / AT / CH Originalbetriebsanleitung Seite 25

Page 3

A

Page 4

Contents

Introduction ............................................................ 2

Intended use ........................................................................2

Depicted components .................................................................2

Package contents ....................................................................2

Technical data ......................................................................2

General Power Tool Safety Warnings ...................................... 3

1. Work area safety ..................................................................3

2. Electrical safety ...................................................................3

3. Personal safety ....................................................................4

4. Power tool use and care ............................................................4

5. Service ..........................................................................5

Appliance-specific safety instructions for grinders ...........................................5

Operation ............................................................. 5

Tensioning/replacing the abrasive belt ...................................................5

Adjusting the additional handle .........................................................6

Flipping up the front cover .............................................................6

Attaching/removing a dust extraction unit .................................................6

Working procedures ..................................................................7

Use ................................................................... 7

Switching on and off .................................................................7

Emptying the dust collector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Selecting speed and abrasive belt .......................................................8

Stationary work .....................................................................8

Tips and tricks .......................................................................9

Maintenance and cleaning ................................................ 9

Disposal ............................................................... 9

Kompernass Handels GmbH warranty .................................... 10

Service ............................................................... 11

Importer .............................................................11

Translation of the original Conformity Declaration ........................... 12

PBSD 600 A1

GB│IE│NI│CY

│

1 ■

Page 5

BELT SANDER PBSD 600 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen a high-quality product. The

operating instructions are part of this product. They

contain important information about safety, usage

and disposal. Before using the product, please familiarise yourself with all operating and safety instructions. Use the product only as described and for the

range of applications specified. Please also pass

these operating instructions on to any future owner.

Intended use

The belt grinder is designed for the dry surface

sanding of wood, plastic, metal and plaster and

painted surfaces (depending on the type of sandpaper used). The appliance may only be used for

dry sanding. Please note that you need to use

appropriate abrasive belts with different grains for

working different materials, and that you may need

to adapt the speed to suit the material. The appliance is not intended for commercial use. Any other

use of or modification to the appliance is deemed

to be improper and carries the risk of serious

personal injury. The manufacturer accepts no

responsibility for damage(s) attributable to misuse.

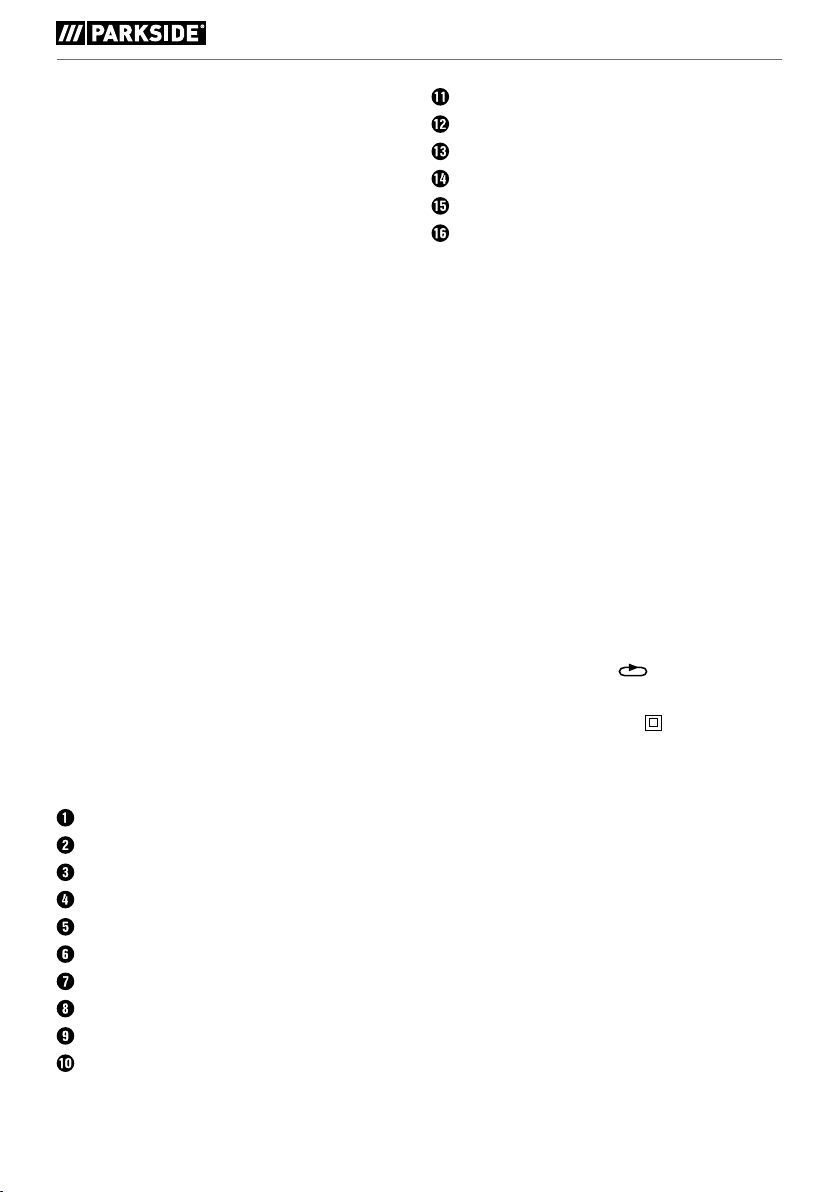

Depicted components

ON/OFF switch

Additional handle (rubberised grip)

Front cover

Clamping lever for abrasive belt

Belt speed adjusting wheel

Handle (rubberised grip)

Screw for adjusting the handle

Recesses for screw clamps

Connection for dust collector

Locking button for ON/OFF switch

Dust collector

Adjustment screw for belt tracking

Abrasive belt

Screw clamp

Reducer

Dust extraction adapter

Package contents

1 belt sander PBSD 600 A1

1 abrasive belt for wood (grain 80)

1 dust collector

1 dust extraction adapter and reducer

(for external dust extraction)

2 screw clamps

1 set of operating instructions

Technical data

Rated voltage 230 V ∼, 50 Hz

(AC)

Rated power consumption 600 W

Idling belt speed 170–250 m/min

Rated idling speed

Abrasive belt 75 x 457 mm

Protection class II /

Noise emission value

Noise measurement value determined in accordance with EN 62841. The A-rated noise level of

the power tool is typically as follows:

Sound pressure level L

Uncertainty K

Sound power level L

Uncertainty K

Wear hearing protection!

Total vibration value

Total vibration value (vector total of three directions) determined in accordance with EN 62841:

Grinding with the grinding disc a

Uncertainty K = 1.5 m/s

n0 360–560 rpm

(double insulation)

= 91 dB (A)

pA

= 3 dB

pA

= 102 dB (A)

WA

= 3 dB

WA

= 4.2 m/s

h

2

2

■ 2 │ GB

│IE│NI│

CY

PBSD 600 A1

Page 6

NOTE

► The vibration emission values and the noise

emission values given in these instructions

have been measured in accordance with a

standardised test procedure and can be used

for comparison of the power tool with

another tool.

► The specified total vibration values and the

noise emission values can also be used to

make a provisional load estimate.

WARNING!

► Depending on the manner in which the

power tool is being used, and in particular

the kind of workpiece that is being worked,

the vibration and noise emission values can

deviate from the values given in these instructions during actual use of the power tool.

► Try to keep the load as low as possible.

Measures to reduce the vibration load are,

e.g. wearing gloves and limiting the working

time. Wherein all states of operation must be

included (e.g. times when the power tool is

switched off and times where the power tool

is switched on but running without load).

General Power Tool

Safety Warnings

WARNING!

► Read all safety warnings, instructions,

illustrations and specifications provided

with this power tool. Failure to follow all

instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

The term „power tool“ in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1. Work area safety

a) Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

PBSD 600 A1

GB│IE│NI│CY

│

3 ■

Page 7

3. Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection.

as a dust mask, non-slip safety shoes, hard hat or

hearing protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your finger on the switch or energising

power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away

from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use

of dust collection can reduce dust-related

hazards.

h) Do not let familiarity gained from frequent

use of tools allow you to become complacent

and ignore tool safety principles. A careless

action can cause severe injury within a fraction

of a second.

Protective equipment such

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source

and/or remove the battery pack, if detachable, from the power tool before making any

adjustments, changing accessories, or storing

power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation. If

damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for

safe handling and control of the tool in unexpected situations.

■ 4 │ GB

│IE│NI│

CY

PBSD 600 A1

Page 8

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

Appliance-specific safety instructions

for grinders

■ Hold the appliance by the insulated handles

as the abrasive belt can come into contact

with its own power cable. Damage to a live

wire may make exposed metal parts of the

power tool live and could give the operator an

electric shock.

WARNING!

■ Dusts from materials such as leaded paint,

some types of wood and metal can be

harmful to your health.

■ Contact with or inhalation of these dusts can

represent a health hazard for the person

operating the appliance and other people in

the vicinity.

■ Wear safety goggles and a protective dust

mask!

Operation

Tensioning/replacing the abrasive

belt

WARNING! RISK OF INJURY!

■ Always remove the power plug from the wall

socket before carrying out any work on the

belt grinder.

1. Loosen the clamping device for the abrasive

belt by swivelling the clamping lever

way out. The abrasive belt can now be

removed.

2. Now fit a new abrasive belt

belt to work on a different material or to use

adifferent grain size.

IMPORTANT: The direction of the arrows on

the inside of the abrasive belt and on the

appliance housing must match.

3. Push the clamping lever

position.

Manually adjusting the abrasive belt

If the belt tracking is not centred when you switch

on the appliance, you may need to manually

adjust it.

♦ To do this, turn the adjusting screw

front roller until the abrasive belt is running

centred.

IMPORTANT: It is important to ensure that

the abrasive belt does not rub against the

housing. Check the belt tracking regularly and

adjust it with the adjusting screw if required .

back into its initial

all the

or swap the

on the

PBSD 600 A1

GB│IE│NI│CY

│

5 ■

Page 9

Adjusting the additional handle

You can position the additional handle in

several different positions.

♦ To reposition the additional handle

screw .

♦ Move the additional handle

position.

♦ Retighten the screw

.

undo the

to the required

Flipping up the front cover

You can flip up the front cover to grind in hardto-reach areas (see illustration).

WARNING!

► The front cover

upwards if the additional handle is also

positioned upwards (see section "Adjusting

the additional handle").

♦ Flip up the front cover

can only be flipped

.

Attaching/removing a dust

extraction unit

WARNING! RISK OF EXPLOSION!

■ If there is an explosive dust/air mixture, you

must use a specially designed extraction

appliance. RISK OF FIRE DUE TO FLYING

SPARKS! Do not use dust extraction systems

(dust collector

grinding metals.

■ Materials containing asbestos must not be

processed. Asbestos is a known carcinogen.

WARNING! RISK OF FIRE!

■ When working with power tools which have

a dust collector or can be connected to a

vacuum cleaner via a vacuum cleaner adapter,

there is a risk of fire! In unfavourable conditions, e.g. when sparks are flying while

sanding metal or metal residues in wood,

wood dust in the dust collector (or the bag of

the vacuum cleaner) can spontaneously

ignite. This is a particular risk if the wood dust

is mixed with paint residues or other chemicals and the workpiece has become hot after

being worked for a long time. Therefore, do

not allow the workpiece to overheat and

always empty the dust box or the dust bag

ofthe vacuum cleaner before taking a break

from work.

■ Ensure that your workplace is adequately

ventilated.

■ Observe the regulations applicable in your

country regarding the materials to be

worked.

or vacuum cleaner) when

■ 6 │ GB

│IE│NI│

CY

■

Wear a dust mask.

PBSD 600 A1

Page 10

Fitting the dust collector

♦ Push the dust collector onto the dust collector

connection from above.

Dismantling/removing the dust collector

♦ Pull the dust collector

Connecting a dust extraction adapter and

reducer for an external extraction appliance

♦ Push the dust extraction adapter

connection .

♦ Push the reducer

adapter into the adapter fitting .

♦ Push the hose from a suitable dust extraction

appliance (e.g. a workshop vacuum cleaner)

onto the reducer

extraction.

Removing the dust extraction adapter and

reducer for an external extraction appliance

♦ Pull off the hose of the dust extraction

appliance.

♦ Remove the reducer

extraction.

♦ Pull the dust extraction adapter

offthe connection .

off upwards.

onto the

for the dust extraction

for external vacuum

for external dust

upwards

Working procedures

A light grinding pressure is sufficient

■ Apply minimal pressure when grinding. The belt

grinder's own weight is sufficient for a good

grinding result. In addition, working this way

helps to reduce the wear on the abrasive belt

and the surface of the workpiece will become

more smooth.

Removal and surface

■ The material removal rate and surface quality

are determined by the belt speed and grain

strength of the abrasive belt

section "Selecting speed and abrasive belt").

(see also the

Grinding

■ Place the appliance on the workpiece when

switched on and work at a moderate feed rate.

Guide the grinder in parallel and overlapping

sanding motions over the workpiece. To avoid

unpleasant transverse grinding marks, always

sand in the direction of the grain.

After completing the task, lift the appliance from

the workpiece and then switch it off.

NOTE

► Always hold the appliance firmly with two

hands while working.

Use

Switching on and off

While operating the belt grinder, you can choose

between instantaneous and continuous operation.

Switching to instantaneous operation

♦ Press the ON/OFF switch

Switching off instantaneous operation

♦ Release the ON/OFF switch

Switching to continuous operation

♦ Press the ON/OFF switch

and then press the lock button .

Switching off continuous operation

♦ Press the ON/OFF switch

release it.

Emptying the dust collector

The dust collector should be emptied after every

10 minutes of operation at least.

♦ Pull the dust collector

"Attaching/removing a dust extraction unit")

♦ Shake the dust collector

binto empty it.

♦ Fit the dust collector

appliance.

.

.

, keep it pressed in

and then

off (see section

over a rubbish

back onto the

PBSD 600 A1

GB│IE│NI│CY

│

7 ■

Page 11

Selecting speed and abrasive belt

You can use the belt speed adjusting wheel to

adjust the speed, even while the appliance is

running. The optimum belt speed is dependent on

the workpiece or material being processed. We

recommend carrying out a practice run to determine the correct speed. In the table below, you will

find some recommended values which will help you

determine which belt and speed to use for which

job.

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) 240

Speed preselection high (5–6)

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) 180

Speed preselection high (5–6)

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) 150

Speed preselection high (5–6)

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) ––

Speed preselection high (5–6)

Softwood

60

Hardwood

60

Chipboard

60

Removing

paint/varnish

60

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) 320

Speed preselection low (1–2)

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) 120

Speed preselection medium/high (3–4)

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) 240

Speed preselection low/medium (2–3)

Material/

working area

Rough sanding

(grain size)

Finishing (grain size) 150

Speed preselection medium/high (3–4)

Rubbing down

paintwork/varnish

150

Removing

rust from steel

40

Plastics

120

Non-ferrous metals

(e.g. aluminium)

80

Stationary work

♦ Turn the additional handle to the horizontal

position.

♦ Turn the power tool as shown in the illustration

and place it on a stable worktop.

♦ Fit the two screw clamps

provided and clamp the power tool tightly.

in the recesses

■ 8 │ GB

│IE│NI│

CY

PBSD 600 A1

Page 12

Tips and tricks

■ Never use the same abrasive belt to work

wood and metal.

■ Worn or cracked abrasive belts can damage

the workpiece. Therefore, be sure to replace

worn abrasive belts before starting work.

■ Always hang up the abrasive belts to store

them, as kinks etc. can make them unusable.

Maintenance and cleaning

WARNING! RISK OF INJURY! Switch

off the appliance and pull out the

power plug before starting any

work on the appliance.

The belt grinder is maintenance-free.

■ Always clean the appliance directly after

finishing work.

■ Use a dry cloth to clean the housing. Under no

circumstances should you use fuel, detergents,

solvents or abrasive cleaners.

Emptying/cleaning the dust collector

♦ Pull the dust collector off the appliance.

♦ Empty the dust collector

knocking out the contents and then push the

dust collector back onto the appliance.

♦ Ensure ventilation openings are always free.

♦ Remove any adhering grinding dust with a

brush.

completely by

Disposal

The packaging is made from environmentally friendly material and can be

disposed of at your local recycling

plant.

Do not dispose of power tools

in your normal domestic waste!

European Directive 2012/19/EU

requires that worn-out power tools be

collected separately and recycled in an environmentally compatible manner.

Your local community or municipal authorities

can provide information on how to dispose of the

appliance.

Dispose of the packaging in an

environmentally friendly manner.

Note the labelling on the packaging

and separate the packaging material

components for disposal if necessary. The packaging material is labelled with abbreviations (a)

and numbers (b) with the following meanings:

1–7: plastics, 20–22: paper and cardboard,

80–98: composites.

Your local community or municipal

authorities can provide information

on how to dispose of the worn-out

product.

PBSD 600 A1

GB│IE│NI│CY

│

9 ■

Page 13

Kompernass Handels GmbH

warranty

Dear Customer,

This appliance has a 3-year warranty valid from

the date of purchase. If this product has any faults,

you, the buyer, have certain statutory rights. Your

statutory rights are not restricted in any way by the

warranty described below.

Warranty conditions

The warranty period starts on the date of purchase.

Please keep your receipt in a safe place. This will

be required as proof of purchase.

If any material or manufacturing fault occurs within

three years of the date of purchase of the product,

we will either repair or replace the product for you

or refund the purchase price (at our discretion).

This warranty service requires that you present the

defective appliance and the proof of purchase

(receipt) within the three-year warranty period,

along with a brief written description of the fault

and of when it occurred.

If the defect is covered by the warranty, your

product will either be repaired or replaced by us.

The repair or replacement of a product does not

signify the beginning of a new warranty period.

Warranty period and statutory claims for

defects

The warranty period is not prolonged by repairs

effected under the warranty. This also applies to

replaced and repaired components. Any damage

and defects present at the time of purchase must

be reported immediately after unpacking. Repairs

carried out after expiry of the warranty period shall

be subject to a fee.

Scope of the warranty

This appliance has been manufactured in accordance with strict quality guidelines and inspected

meticulously prior to delivery.

The warranty covers material faults or production

faults. The warranty does not extend to product

parts subject to normal wear and tear or to fragile

parts which could be considered as consumable

parts such as switches or parts made of glass.

The warranty does not apply if the product has

been damaged, improperly used or improperly

maintained. The directions in the operating instructions for the product regarding proper use of

the product are to be strictly followed. Uses and

actions that are discouraged in the operating

instructions or which are warned against must be

avoided.

This product is intended solely for private use and

not for commercial purposes. The warranty shall

be deemed void in cases of misuse or improper

handling, use of force and modifications / repairs

which have not been carried out by one of our

authorised Service centres.

The warranty period does not apply to

■ Normal reduction of the battery capacity

overtime

■ Commercial use of the product

■ Damage to or alteration of the product by the

customer

■ Non-compliance with safety and maintenance

instructions, operating errors

■ Damage caused by natural hazards

■ 10 │ GB

│IE│NI│

CY

PBSD 600 A1

Page 14

Warranty claim procedure

To ensure quick processing of your case, please

observe the following instructions:

■ Please have the till receipt and the item number

(e.g.IAN12345) available as proof of purchase.

■ You will find the item number on the type plate

on the product, an engraving on the product,

on the front page of the operating instructions

(below left) or on the sticker on the rear or

bottom of the product.

■ If functional or other defects occur, please

contact the service department listed either by

telephone or by e-mail.

■ You can return a defective product to us free

of charge to the service address that will be

provided to you. Ensure that you enclose the

proof of purchase (till receipt) and information

about what the defect is and when it occurred.

You can download these instructions

along with many other manuals,

product videos and installation

software at www.lidl-service.com.

This QR code will take you directly to the Lidl

service page (www.lidl-service.com) where you

can open your operating instructions by entering

the item number (IAN) 364419_2010.

WARNING!

■ Have the power tool repaired by the

service centre or a qualified electrician and

only using genuine replacement parts. This

will ensure that the safety of the appliance is

maintained.

■ Always ensure that the power plug or the

mains cable is replaced only by the manufacturer of the appliance or by an approved

customer service provider. This will ensure

that the safety of the appliance is maintained.

NOTE

► Replacement parts not listed (such as carbon

brushes, switches, dust collector) can be

ordered via our service hotline.

Service

Service Great Britain

Tel.: 0800 404 7657

E-Mail: kompernass@lidl.co.uk

Service Ireland

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: kompernass@lidl.ie

CY

Service Cyprus

Tel.: 8009 4409

E-Mail: kompernass@lidl.com.cy

IAN 364419_2010

Importer

Please note that the following address is not the

service address. Please use the service address

provided in the operating instructions.

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

44867 BOCHUM

GERMANY

www.kompernass.com

PBSD 600 A1

GB│IE│NI│CY

│

11 ■

Page 15

Translation of the original Conformity Declaration

We, KOMPERNASS HANDELS GMBH, documents officer: Mr. Semi Uguzlu, BURGSTR. 21,

44867 BOCHUM, GERMANY, hereby declare that this product complies with the following

standards, normative documents and EC directives:

Machinery Directive

(2006/42/EC)

EMC (Electromagnetic Compatibility)

(2014/30/EU)

RoHS Directive

(2011/65/EU)*

* The manufacturer bears the full responsibility for compliance with this conformity declaration. The object of the

declaration described above complies with the requirements of the Directive 2011/65/EU of the European Parliament

and Council of 8 June 2011 on the limitations of use of certain dangerous substances in electrical and electronic

appliances.

Applied harmonised standards

EN 62841-1:2015

EN 62841-2-4:2014

EN 55014-1:2017

EN 55014-2:2015

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 50581:2012

Type designation of machine: Belt sander PBSD 600 A1

Year of manufacture: 12–2020

Serial number: IAN 364419_2010

Bochum, 15/01/2021

Semi Uguzlu

- Quality Manager We reserve the right to make technical changes in the context of further product development.

■ 12 │ GB

│IE│NI│

CY

PBSD 600 A1

Page 16

Περιεχόμενα

Εισαγωγή ............................................................. 14

Προβλεπόμενη χρήση ...............................................................14

Απεικονιζόμενα στοιχεία .............................................................14

Παραδοτέος εξοπλισμός .............................................................14

Τεχνικά χαρακτηριστικά ..............................................................14

Γενικές υποδείξεις ασφαλείας για ηλεκτρικά εργαλεία ......................... 15

1. Ασφάλεια στο χώρο εργασίας .......................................................15

2. Ηλεκτρική ασφάλεια ...............................................................15

3. Ασφάλεια ατόμων ................................................................16

4. Χρήση και χειρισμός του ηλεκτρικού εργαλείου .........................................16

5. Σέρβις .........................................................................17

Συγκεκριμένες υποδείξεις ασφαλείας για λειαντήρες .......................................17

Θέση σε λειτουργία ..................................................... 17

Σύσφιξη/Αλλαγή λειαντικού ιμάντα .....................................................17

Ρύθμιση πρόσθετης χειρολαβής .......................................................18

Ανασήκωμα μπροστινού καλύμματος ...................................................18

Τοποθέτηση/Απομάκρυνση διάταξης αναρρόφησης σκόνης ................................18

Υποδείξεις εργασίας ................................................................19

Χειρισμός ............................................................. 19

Ενεργοποίηση και απενεργοποίηση .....................................................19

Εκκένωση κουτιού σκόνης ............................................................19

Επιλογή αριθμού στροφών και λειαντικού ιμάντα ..........................................20

Σταθερή εργασία ...................................................................21

Συμβουλές ........................................................................21

Συντήρηση και καθαρισμός ..............................................21

Απόρριψη ............................................................21

Εγγύηση της Kompernass Handels GmbH ..................................22

Σέρβις. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Εισαγωγέας ........................................................... 23

Μετάφραση της Πρωτότυπης Δήλωση συμμόρφωσης ......................... 24

PBSD 600 A1

GR│CY

│

13 ■

Page 17

ΤΑΙΝΙΟΛΕΙΑΝΤΉΡΑΣ

PBSD 600 A1

Εισαγωγή

Συγχαρητήρια για την αγορά της νέας σας συσκευής. Το προϊόν που αποκτήσατε είναι ένα προϊόν υψηλής ποιότητας. Οι οδηγίες χρήσης αποτελούν τμήμα αυτού του προϊόντος. Περιλαμβάνουν

σημαντικές υποδείξεις για την ασφάλεια, τη χρήση

και την απόρριψη. Πριν από τη χρήση του προϊόντος, εξοικειωθείτε με όλες τις υποδείξεις χειρισμού

και ασφάλειας του προϊόντος. Χρησιμοποιείτε το

προϊόν μόνο όπως περιγράφεται και για τους αναφερόμενους τομείς χρήσης. Παραδώστε όλα τα

έγγραφα σε περίπτωση παράδοσης του προϊόντος

σε τρίτους.

Προβλεπόμενη χρήση

Ο ταινιολειαντήρας, ανάλογα με το γυαλόχαρτο,

έχει κατασκευαστεί για στεγνή λείανση επιφανειών

ξύλου, πλαστικού, μετάλλου και στόκου, καθώς και

βαμμένων επιφανειών. Η συσκευή επιτρέπεται να

χρησιμοποιείται μόνο για στεγνή λείανση. Για την

επεξεργασία των διαφορετικών υλικών θα πρέπει

να χρησιμοποιούνται αντίστοιχα γυαλόχαρτα με

διαφορετική κόκκωση και, επίσης, να προσαρμόζεται

και ο αριθμός στροφών στο υλικό. Η συσκευή δεν

προορίζεται για επαγγελματική χρήση. Κάθε άλλη

χρήση ή μετατροπή της μηχανής ισχύει ως μη σύμφωνη με τους κανονισμούς και κρύβει σημαντικούς

κινδύνους ατυχημάτων. Για βλάβες από χρήση μη

σύμφωνη με τους κανονισμούς, ο κατασκευαστής

δεν αναλαμβάνει καμία ευθύνη.

Απεικονιζόμενα στοιχεία

Διακόπτης ON/OFF

Πρόσθετη χειρολαβή (λαστιχένια επιφάνεια

λαβής)

Μπροστινό κάλυμμα

Μοχλός τάνυσης για τον λειαντικό ιμάντα

Τροχίσκος ρύθμισης ταχύτητας ιμάντα

Χειρολαβή (λαστιχένια επιφάνεια λαβής)

Βίδα ρύθμισης χειρολαβής

Εσοχές για τη μέγγενη

Σύνδεση κουτιού σκόνης

Πλήκτρο ασφάλισης διακόπτη ON/OFF

Κουτί σκόνης

Βίδα ρύθμισης για τη διαδρομή του ιμάντα

Λειαντικός ιμάντας

Μέγγενη

Εξάρτημα συστολής

Αντάπτορας αναρρόφησης

Παραδοτέος εξοπλισμός

1 Ταινιολειαντήρας PBSD 600 A1

1 Λειαντικός ιμάντας για ξύλο (κόκκωση 80)

1 Κουτί σκόνης

1 Αντάπτορας αναρρόφησης και εξάρτημα συστο-

λής (για εξωτερική αναρρόφηση της σκόνης)

2 Μέγγενες

1 Οδηγίες χρήσης

Τεχνικά χαρακτηριστικά

Τάση μέτρησης 230 V ∼, 50 Hz

(εναλλασσόμενο ρεύμα)

Κατανάλωση μέτρησης 600 W

Ταχύτητα ταινίας στο

ρελαντί 170–250 m/min

Αριθμός στροφών ρελαντί

μέτρησης

n0 360–560 min

Λειαντικός ιμάντας 75 x 457 mm

Κατηγορία προστασίας II /

(διπλή μόνωση)

Τιμή εκπομπής θορύβου

Η τιμή μέτρησης θορύβου υπολογίστηκε σύμφωνα

με το πρότυπο EN 62841. Η Α-σταθμισμένη στάθμη θορύβου του ηλεκτρικού εργαλείου παρουσιάζει συνήθως τα ακόλουθα στοιχεία:

Στάθμη ηχητικής πίεσης L

Αβεβαιότητα K

Στάθμη ηχητικής ισχύος L

Αβεβαιότητα K

= 91 dB (A)

pA

= 3 dB

pA

= 102 dB (A)

WA

= 3 dB

WA

Φοράτε προστασία για την ακοή!

Συνολική τιμή κραδασμών

Οι ολικές τιμές κραδασμών (διανυσματικό

άθροισμα τριών κατευθύνσεων) υπολογίστηκαν

σύμφωνα με το πρότυπο EN 62841:

Λείανση με δίσκο λείανσης a

= 4,2 m/s

h

Συντελεστής αβεβαιότητας K = 1,5 m/s

-1

2

2

■ 14 │ GR

│

CY

PBSD 600 A1

Page 18

ΥΠΟΔΕΙΞΗ

► Οι αναφερόμενες συνολικές τιμές κραδασμών

και οι αναφερόμενες τιμές εκπομπής θορύβου έχουν μετρηθεί σύμφωνα με μία πρότυπη

διαδικασία ελέγχου και μπορούν να χρησιμοποιηθούν για τη σύγκριση ενός ηλεκτρικού

εργαλείου με ένα άλλο.

► Οι αναφερόμενες τιμές εκπομπής κραδασμών

και οι αναφερόμενες τιμές εκπομπής θορύβου

μπορούν, επίσης, να χρησιμοποιηθούν για

μια αρχική εκτίμηση του φορτίου.

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

► Οι εκπομπές κραδασμών και θορύβου μπορεί,

κατά τη διάρκεια της πραγματικής χρήσης

του ηλεκτρικού εργαλείου, να αποκλίνουν

από τις αναφερόμενες τιμές, ανάλογα με το

είδος και τον τρόπο που χρησιμοποιείται το

ηλεκτρικό εργαλείο, κυρίως ανάλογα με το

είδος του τεμαχίου επεξεργασίας.

► Προσπαθείτε να διατηρείτε την επιβάρυνση

σε όσο το δυνατόν χαμηλότερα επίπεδα.

Παραδειγματικά μέτρα μείωσης της επιβάρυνσης λόγω δονήσεων είναι η χρήση γαντιών

κατά τη χρήση του εργαλείου και ο περιορισμός του χρόνου εργασίας. Εδώ πρέπει να

συνυπολογίζονται όλα τα μέρη του κύκλου

εργασίας (παραδείγματος χάριν, χρόνοι,

κατά τους οποίους το ηλεκτρικό εργαλείο

είναι απενεργοποιημένο, και χρόνοι, κατά

τους οποίους είναι μεν ενεργοποιημένο, αλλά

λειτουργεί χωρίς φορτίο).

Γενικές υποδείξεις

ασφαλείας για ηλεκτρικά

εργαλεία

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

► Διαβάστε όλες τις υποδείξεις ασφαλείας,

τις οδηγίες, τις εικόνες και τα τεχνικά

χαρακτηριστικά που συνοδεύουν αυτό το

ηλεκτρικό εργαλείο. Παραλείψεις κατά την

τήρηση των παρακάτω οδηγιών μπορούν να

προκαλέσουν ηλεκτροπληξία, πυρκαγιά

και/ή σοβαρούς τραυματισμούς.

Φυλάξτε όλες τις υποδείξεις ασφαλείας και τις

οδηγίες, για να μπορείτε να ανατρέξετε σε αυτές

μελλοντικά.

Ο χρησιμοποιούμενος σε αυτές τις υποδείξεις

ασφαλείας όρος «Ηλεκτρικό εργαλείο» αναφέρεται

σε ηλεκτρικά εργαλεία (με καλώδιο ρεύματος) που

λειτουργούν με ρεύμα και σε ηλεκτρικά εργαλεία

(χωρίς καλώδιο ρεύματος) που λειτουργούν μέσω

συσσωρευτή.

1. Ασφάλεια στο χώρο εργασίας

α) Διατηρείτε το χώρο εργασίας σας καθαρό και

φροντίζετε για επαρκή φωτισμό. Η ακαταστα-

σία και οι μη φωτισμένοι χώροι εργασίας

μπορούν να οδηγήσουν σε ατυχήματα.

β) Μην εργάζεστε με το ηλεκτρικό εργαλείο σε

εκρήξιμα περιβάλλοντα με εύφλεκτα υγρά,

αέρια ή σκόνη. Τα ηλεκτρικά εργαλεία δημιουρ-

γούν σπινθήρες, οι οποίοι μπορούν να προκαλέσουν ανάφλεξη στη σκόνη ή στους ατμούς.

γ) Κρατάτε τα παιδιά και άλλα άτομα μακριά

κατά τη χρήση του ηλεκτρικού εργαλείου. Σε

περίπτωση διάσπασης της προσοχής, μπορεί

να χάσετε τον έλεγχο του ηλεκτρικού εργαλείου.

2. Ήλεκτρική ασφάλεια

α) Το βύσμα σύνδεσης του ηλεκτρικού εργαλείου

πρέπει να ταιριάζει στην πρίζα. Το βύσμα δεν

επιτρέπεται να τροποποιηθεί με κανέναν

τρόπο.

Μην χρησιμοποιείτε βύσματα προσαρμογέων

μαζί με γειωμένα ηλεκτρικά εργαλεία.

Τα βύσματα που δεν έχουν τροποποιηθεί και οι

κατάλληλες πρίζες μειώνουν τον κίνδυνο ηλεκτροπληξίας.

β) Αποφεύγετε τη σωματική επαφή με γειωμένες

επιφάνειες, όπως σωλήνες, θερμαντικά σώματα, εστίες και ψυγεία. Υπάρχει αυξημένος

κίνδυνος λόγω ηλεκτροπληξίας όταν το σώμα

σας είναι γειωμένο.

γ) Κρατάτε τα ηλεκτρικά εργαλεία μακριά από τη

βροχή ή την υγρασία. Η διείσδυση νερού σε

ένα ηλεκτρικό εργαλείο αυξάνει τον κίνδυνο

ηλεκτροπληξίας.

PBSD 600 A1

GR│CY

│

15 ■

Page 19

δ) Μη χρησιμοποιείτε το καλώδιο σύνδεσης

άσκοπα, π.χ. για να μεταφέρετε το ηλεκτρικό

εργαλείο, να το κρεμάσετε ή για να αποσυνδέσετε το βύσμα από την πρίζα. Κρατάτε το

καλώδιο σύνδεσης μακριά από υψηλές θερμοκρασίες, λάδια, αιχμηρές άκρες ή κινούμενα

μέρη. Τα φθαρμένα ή μπερδεμένα καλώδια σύν-

δεσης αυξάνουν τον κίνδυνο ηλεκτροπληξίας.

ε) Όταν εργάζεστε με ένα ηλεκτρικό εργαλείο σε

εξωτερικό χώρο, χρησιμοποιείτε αποκλειστικά

εγκεκριμένα για εξωτερικούς χώρους καλώδια

προέκτασης. Η χρήση κατάλληλου για εξωτερικό

χώρο καλωδίου προέκτασης μειώνει τον κίνδυνο

ηλεκτροπληξίας.

στ) Εάν δεν μπορεί να αποφευχθεί η λειτουργία

του ηλεκτρικού εργαλείου σε υγρό περιβάλλον, χρησιμοποιείτε διακόπτη ασφαλείας.

Η χρήση διακόπτη ασφαλείας μειώνει τον

κίνδυνο ηλεκτροπληξίας.

3. Ασφάλεια ατόμων

α) Να είστε προσεκτικοί, προσέχετε τι κάνετε και

χρησιμοποιείτε τη λογική όταν εργάζεστε με

ένα ηλεκτρικό εργαλείο. Μη χρησιμοποιείτε

ηλεκτρικά εργαλεία εάν είστε κουρασμένοι ή

υπό την επήρεια ναρκωτικών, αλκοόλ ή φαρμάκων. Ένα μόνο λεπτό απροσεξίας κατά τη

χρήση του ηλεκτρικού εργαλείου αρκεί για να

οδηγήσει σε σοβαρούς τραυματισμούς.

β) Φ

οράτε ατομικό προστατευτικό εξοπλισμό και

πάντα γυαλιά προστασίας. Όταν φοράτε ατομι

κό προστατευτικό εξοπλισμό, όπως μάσκα για

τη σκόνη, αντιολισθητικά υποδήματα ασφαλείας,

κράνος ή προστασία για την ακοή, ανάλογα με

το είδος και τη χρήση του ηλεκτρικού εργαλείου,

μειώνεται ο κίνδυνος τραυματισμών.

γ) Αποφεύγετε τυχόν ακούσια έναρξη λειτουργί-

ας. Βεβαιώνεστε ότι το ηλεκτρικό εργαλείο έχει

απενεργοποιηθεί, προτού το συνδέσετε στην

τροφοδοσία ρεύματος και/ή το συσσωρευτή,

το σηκώσετε ή το μεταφέρετε. Όταν μεταφέρετε

το ηλεκτρικό εργαλείο και έχετε το δάχτυλο στο

διακόπτη ή συνδέετε το ηλεκτρικό εργαλείο

ενεργοποιημένο στην παροχή ρεύματος, μπορεί

να προκληθούν ατυχήματα.

δ) Απομακρύνετε εργαλεία ρύθμισης ή μηχανικά

κλειδιά, πριν ενεργοποιήσετε το ηλεκτρικό

εργαλείο. Ένα εργαλείο ή κλειδί, το οποίο βρί-

σκεται σε ένα περιστρεφόμενο τμήμα του ηλεκτρικού εργαλείου, μπορεί να οδηγήσει σε

τραυματισμούς.

ε) Αποφεύγετε λάθος στάση του σώματος.

Φροντίζετε για μια ασφαλή στάση και διατηρείτε πάντα την ισορροπία. Έτσι, μπορείτε να

ελέγχετε το ηλεκτρικό εργαλείο καλύτερα σε μη

αναμενόμενες καταστάσεις.

στ) Φοράτε κατάλληλο ρουχισμό. Μη φοράτε

μακριά ρούχα ή κοσμήματα. Κρατάτε τα μαλλιά και τα ρούχα μακριά από κινούμενα τμήματα. Τα χαλαρά ρούχα, τα κοσμήματα ή τα

μακριά μαλλιά μπορούν να πιαστούν από κινούμενα τμήματα.

ζ) Εάν μπορούν να συναρμολογηθούν διατάξεις

απορρόφησης και συλλογής σκόνης, αυτές

θα πρέπει να συνδέονται και να χρησιμοποιούνται σωστά. Η χρήση μιας διάταξης αναρ-

ρόφησης σκόνης μπορεί να μειώσει τους κινδύνους από τη σκόνη.

η) Μη νιώθετε τόσο σίγουροι για τον εαυτό σας

και μην αγνοείτε τους κανόνες ασφαλείας για

ηλεκτρικά εργαλεία, ακόμη και εάν έχετε εξοικειωθεί με το ηλεκτρικό εργαλείο λόγω συχνής χρήσης. Απρόσεκτες ενέργειες μπορούν

να οδηγήσουν μέσα σε κλάσματα του δευτερολέπτου σε σοβαρούς τραυματισμούς.

-

4. Χρήση και χειρισμός του

ηλεκτρικού εργαλείου

α) Μην καταπονείτε το ηλεκτρικό εργαλείο. Χρη-

σιμοποιείτε για την εργασία σας το αντίστοιχο

ηλεκτρικό εργαλείο. Με το κατάλληλο ηλεκτρικό

εργαλείο εργάζεστε καλύτερα και ασφαλέστερα

στο δοθέν πεδίο απόδοσης.

β) Μη χρησιμοποιείτε ηλεκτρικά εργαλεία, των

οποίων ο διακόπτης έχει υποστεί βλάβη. Ένα

ηλεκτρικό εργαλείο, το οποίο δεν μπορεί πλέον

να ενεργοποιηθεί ή απενεργοποιηθεί, είναι

επικίνδυνο και πρέπει να επισκευαστεί.

γ) Αποσυνδέετε το βύσμα από την πρίζα και/ή

απομακρύνετε τον αποσπώμενο συσσωρευτή,

πριν διεξάγετε ρυθμίσεις στη συσκευή, πριν

αλλάξετε μέρη εργαλείων χρήσης ή πριν απο-

■ 16 │ GR

│

CY

PBSD 600 A1

Page 20

θηκεύσετε το ηλεκτρικό εργαλείο. Αυτό το

μέτρο ασφαλείας εμποδίζει τη μη ηθελημένη

εκκίνηση του ηλεκτρικού εργαλείου.

δ) Φυλάτε τα μη χρησιμοποιημένα ηλεκτρικά

εργαλεία σε σημεία μη προσβάσιμα για τα

παιδιά. Μην επιτρέπετε να χρησιμοποιούν το

ηλεκτρικό εργαλείο άτομα, τα οποία δεν

έχουν εξοικειωθεί μαζί του ή δεν έχουν διαβάσει αυτές τις οδηγίες. Τα ηλεκτρικά εργαλεία

είναι επικίνδυνα όταν χρησιμοποιούνται από

άπειρα άτομα.

ε) Φροντίζετε τα ηλεκτρικά εργαλεία και τα ερ-

γαλεία χρήσης με προσοχή. Ελέγχετε εάν τα

κινούμενα μέρη λειτουργούν σωστά και δεν

κολλάνε, εάν κάποια μέρη έχουν σπάσει ή

παρουσιάζουν τέτοια βλάβη, ώστε να επηρεάζεται η λειτουργία του ηλεκτρικού εργαλείου.

Τα εξαρτήματα με βλάβη πρέπει να επισκευάζονται πριν από τη χρήση του ηλεκτρικού

εργαλείου. Πολλά από τα ατυχήματα οφείλονται

στην κακή συντήρηση των ηλεκτρικών εργαλείων.

στ) Διατηρείτε τα εργαλεία κοπής αιχμηρά και

καθαρά. Τα προσεκτικά φροντισμένα εργαλεία

κοπής με αιχμηρές ακμές κοπής κολλάνε λιγότερο και είναι ευκολότερα στο χειρισμό.

ζ) Χρησιμοποιείτε το ηλεκτρικό εργαλείο, τα

εργαλεία χρήσης, κλπ., σύμφωνα με αυτές τις

οδηγίες. Λαμβάνετε υπόψη τις συνθήκες

εργασίας και την προς διεξαγωγή ενέργεια. Η

χρήση ηλεκτρικών εργαλείων για διαφορετικές

από τις προβλεπόμενες χρήσεις μπορεί να οδηγήσει σε επικίνδυνες καταστάσεις.

η) Οι χειρολαβές και οι επιφάνειες αυτών πρέπει

να είναι στεγνές, καθαρές, χωρίς λάδια και

γράσα. Οι ολισθηρές λαβές και επιφάνειες δεν

επιτρέπουν τον ασφαλή χειρισμό και έλεγχο

του ηλεκτρικού εργαλείου σε απρόβλεπτες

καταστάσεις.

5. Σέρβις

α) Το ηλεκτρικό εργαλείο σας πρέπει να επισκευ-

άζεται αποκλειστικά από εξειδικευμένο ειδικό

προσωπικό και μόνο με γνήσια ανταλλακτικά.

Κατά αυτόν τον τρόπο, διατηρείται η ασφάλεια

του ηλεκτρικού εργαλείου.

Συγκεκριμένες υποδείξεις ασφαλείας

για λειαντήρες

■ Πιάνετε τη συσκευή από τις μονωμένες επιφά-

νειες των λαβών, διότι ο λειαντικός ιμάντας

μπορεί να προσεγγίσει το ίδιο το καλώδιο

δικτύου. Ζημιά σε ένα ρευματοφόρο αγωγό

μπορεί να θέσει υπό τάση μεταλλικά τμήματα

της συσκευής με συνέπεια να προκληθεί ηλεκτροπληξία.

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

■ Σκόνες από υλικά, όπως μπογιά που περιέχει

μόλυβδο, ορισμένα είδη ξύλου και μέταλλο,

μπορεί να είναι επιβλαβή για την υγεία.

■ Η επαφή ή η εισπνοή αυτών των σκονών μπο-

ρεί να αποτελέσει κίνδυνο για το χειριστή ή

για άτομα, τα οποία βρίσκονται κοντά.

■ Φοράτε γυαλιά προστασίας και μάσκα προ-

στασίας από τη σκόνη!

Θέση σε λειτουργία

Σύσφιξη/Αλλαγή λειαντικού ιμάντα

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

ΚΙΝΔΥΝΟΣ ΤΡΑΥΜΑΤΙΣΜΟΥ!

■ Αποσυνδέετε πάντα το βύσμα από την πρίζα,

προτού διεξάγετε εργασίες στον ταινιολειαντήρα.

1. Λασκάρετε τη διάταξη σύσφιξης για τον λειαντικό ιμάντα περιστρέφοντας εντελώς προς τα

έξω το μοχλό τάνυσης

ντας μπορεί να αφαιρεθεί.

2. Τοποθετήστε τώρα ένα νέο λειαντικό ιμάντα

ή αντικαταστήστε τον, για επεξεργασία διαφορετικού υλικού ή για να αλλάξετε το πάχος

κόκκωσης.

ΣΗΜΑΝΤΙΚO: Η κατεύθυνση των βελών στην

εσωτερική πλευρά του λειαντικού ιμάντα και

στο περίβλημα της συσκευής πρέπει να συμφωνούν.

3. Πιέστε πάλι το μοχλό τάνυσης

θέση.

. Ο λειαντικός ιμά-

στην αρχική

PBSD 600 A1

GR│CY

│

17 ■

Page 21

Χειροκίνητη ρύθμιση λειαντικού ιμάντα

Εάν, μετά την ενεργοποίηση, δεν κεντραριστεί η

διαδρομή ιμάντα, πρέπει να την επαναρυθμίσετε

ενδεχ. χειροκίνητα.

♦ Για το σκοπό αυτό, περιστρέψτε τη βίδα ρύθμι-

σης

στον μπροστινό κύλινδρο, έως ότου ο

λειαντικός ιμάντας να κινείται κεντραρισμένα.

ΣΗΜΑΝΤΙΚO: Προσέξτε απαραίτητα ώστε ο

λειαντικός ιμάντας να μην ακουμπάει στο

περίβλημα. Ελέγχετε τακτικά τη διαδρομή του

ιμάντα και ρυθμίζετέ την εκ νέου, εφόσον απαιτείται, με τη βίδα ρύθμισης .

Ρύθμιση πρόσθετης χειρολαβής

Μπορείτε να ρυθμίσετε την πρόσθετη χειρολαβή

σε περισσότερες θέσεις.

♦ Για την μετατόπιση της πρόσθετης χειρολαβής

λασκάρετε τη βίδα

♦ Ρυθμίστε την πρόσθετη χειρολαβή

επιθυμητή θέση.

♦ Σφίξτε πάλι καλά τη βίδα

.

στην

.

Ανασήκωμα μπροστινού καλύμματος

Μπορείτε να ανασηκώσετε το μπροστινό

κάλυμμα

σημεία (βλ. Εικόνα).

♦ Γυρίστε το μπροστινό κάλυμμα

για τη λείανση σε δύσκολα προσβάσιμα

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

► Το μπροστινό κάλυμμα

κωθεί, μόνο εάν η επιπρόσθετη χειρολαβή

έχει επίσης ανασηκωθεί (

μιση πρόσθετης χειρολαβής»

επάνω.

μπορεί να αναση-

βλ. Κεφάλαιο «Ρύθ-

).

προς τα

Τοποθέτηση/Απομάκρυνση διάταξης

αναρρόφησης σκόνης

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

ΚΙΝΔΥΝΟΣ ΕΚΡΉΞΉΣ!

■ Σε περίπτωση εκρηκτικής σκόνης/μίγματος

αέρα, πρέπει να χρησιμοποιείτε μια αντίστοιχη κατάλληλη διάταξη αναρρόφησης.

ΚΙΝΔΥΝΟΣ ΠΥΡΚΑΓΙΑΣ ΛΟΓΩ ΣΠΙΝΘΗΡΙΣΜΩΝ! Κατά τη λείανση μετάλλων, μη χρησιμοποιείτε διάταξη αναρρόφησης σκόνης

(κουτί σκόνης

σκούπα).

■ Δεν επιτρέπεται να γίνεται επεξεργασία υλικών,

τα οποία περιέχουν αμίαντο. Ο αμίαντος θεωρείται καρκινογόνος.

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

ΚΙΝΔΥΝΟΣ ΠΥΡΚΑΓΙΑΣ!

■ Κατά την εργασία με ηλεκτρικές συσκευές

που διαθέτουν ένα κουτί συλλογής σκόνης

ή≈που συνδέονται μέσω μιας διάταξης αναρρόφησης σκόνης με την ηλεκτρική αναρροφητική σκούπα, υπάρχει κίνδυνος πυρκαγιάς!

Υπό δυσμενείς συνθήκες, όπως π.χ. σε σπινθηρισμούς, κατά τη λείανση μετάλλου ή μεταλλικών υπολειμμάτων σε ξύλο, ενδέχεται η

σκόνη ξύλου να αυτοαναφλεχθεί στο κουτί

συλλογής σκόνης (ή στο σάκο σκόνης της

αναρροφητικής διάταξης). Αυτό μπορεί κυρίως να συμβεί εάν η σκόνη ξύλου έχει αναμειχθεί με υπολείμματα μπογιάς ή άλλες χημικές

ουσίες και το αντικείμενο λείανσης έχει υπερθερμανθεί λόγω μακράς επεξεργασίας. Για

το λόγο αυτό, αποφεύγετε απαραίτητα υπερθέρμανση του αντικειμένου λείανσης και της

συσκευής και αδειάζετε πάντα, πριν από τα

διαλείμματα κατά την εργασία, το κουτί συλλογής σκόνης ή το σάκο σκόνης της αναρροφητικής διάταξης.

■ Φροντίζετε για καλό αερισμό του χώρου

εργασίας.

■ Τηρείτε τις ισχύουσες στη χώρα σας προδια-

γραφές για τα προς επεξεργασία υλικά.

■

Φοράτε μάσκα προστασίας

από τη σκόνη.

ή ηλεκτρική αναρροφητική

■ 18 │ GR

│

CY

PBSD 600 A1

Page 22

Τοποθέτηση κουτιού σκόνης

♦ Ωθήστε το κουτί σκόνης από επάνω στη

σύνδεση για το κουτί σκόνης.

Αποσυναρμολόγηση/Απομάκρυνση κουτιού

σκόνης

♦ Αφαιρέστε το κουτί σκόνης

Σύνδεση αντάπτορα αναρρόφησης και

εξαρτήματος συστολής για εξωτερική διάταξη

αναρρόφησης σκόνης

♦ Ωθήστε τον αντάπτορα αναρρόφησης

σύνδεση .

♦ Ωθήστε το εξάρτημα συστολής

εξωτερική διάταξη αναρρόφησης σκόνης στον

ανάπτορα αναρρόφησης

♦ Ωθήστε τον εύκαμπτο σωλήνα μιας αντίστοιχης

διάταξης αναρρόφησης σκόνης (π.χ. μιας

αναρροφητικής σκούπας συνεργείου) στο

εξάρτημα συστολής

φησης σκόνης.

Απομάκρυνση αντάπτορα αναρρόφησης και

εξαρτήματος συστολής για εξωτερική διάταξη

αναρρόφησης σκόνης

♦ Αφαιρέστε τον εύκαμπτο σωλήνα της διάταξης

αναρρόφησης σκόνης.

♦ Αφαιρέστε το εξάρτημα συστολής

εξωτερική διάταξη αναρρόφησης.

♦ Αφαιρέστε τον

από τη σύνδεση προς τα επάνω.

αντάπτορα αναρρόφησης

προς τα επάνω.

στη

για την

.

της διάταξης αναρρό-

για την

Υποδείξεις εργασίας

Ελάχιστη πίεση λείανσης αρκεί

■ Να εργάζεστε με ελάχιστη πίεση λείανσης. Το

ίδιο βάρος του ταινιολειαντήρα αρκεί για καλές

αποδόσεις λείανσης. Επιπλέον, με αυτόν τον

τρόπο εργασίας προστατεύετε από φθορές τον

λειαντικό ιμάντα

ου επεξεργασίας γίνεται πιο λεία.

Απόξεση και επιφάνεια

■ Η απόδοση απόξεσης και το φινίρισμα επιφά-

νειας καθορίζονται από την ταχύτητα και το

πάχος κόκκωσης του λειαντικού ιμάντα

(βλ. επίσης το απόσπασμα «Επιλογή αριθμού

στροφών και λειαντικού ιμάντα»).

και η επιφάνεια του τεμαχί-

Διαδικασία λείανσης

■ Τοποθετήστε τη συσκευή ενεργοποιημένη επάνω

στο τεμάχιο επεξεργασίας και εργαστείτε με μετρημένη πρόωση. Διεξάγετε τη διαδικασία λείανσης παράλληλα και επικαλυπτικά προς τις διαδρομές επαφής. Προς αποφυγή

προβληματικών, εγκάρσιων ιχνών λείανσης, λειαίνετε μόνο προς την κατεύθυνση των ινών.

Μετά την επεξεργασία, σηκώστε πρώτα τη συσκευή από το τεμάχιο επεξεργασίας και μετά

απενεργοποιήστε τη.

ΥΠΟΔΕΙΞΗ

► Κατά την εργασία, κρατάτε πάντα τη συσκευή

σφιχτά και με τα δύο χέρια.

Χειρισμός

Ενεργοποίηση και απενεργοποίηση

Κατά τη λειτουργία του ταινιολειαντήρα, μπορείτε

να επιλέξετε μεταξύ στιγμιαίας και συνεχούς λειτουργίας.

Ενεργοποίηση στιγμιαίας λειτουργίας

♦ Πιέστε το διακόπτη ON/OFF

Απενεργοποίηση στιγμιαίας λειτουργίας

♦ Αφήστε ελεύθερο το διακόπτη ON/OFF

Ενεργοποίηση συνεχούς λειτουργίας

♦ Πιέστε το διακόπτη ON/OFF

πατημένο και πιέστε το πλήκτρο ασφάλισης

Απενεργοποίηση συνεχούς λειτουργίας

♦ Πιέστε το διακόπτη ON/OFF

τον ελεύθερο.

Εκκένωση κουτιού σκόνης

Το κουτί σκόνης πρέπει να αδειάζει κατά τη

διάρκεια της λειτουργίας κάθε 10 λεπτά.

♦ Αφαιρέστε το κουτί σκόνης

«Τοποθέτηση/Απομάκρυνση διάταξης αναρρόφησης σκόνης»

♦ Ανακινήστε το κουτί σκόνης

κάδο απορριμμάτων για να το αδειάσετε.

♦ Τοποθετήστε πάλι το κουτί σκόνης

συσκευή.

)

.

.

κρατήστε τον

,

και αφήστε

(

βλ. Κεφάλαιο

πάνω από έναν

στη

.

PBSD 600 A1

GR│CY

│

19 ■

Page 23

Επιλογή αριθμού στροφών και

λειαντικού ιμάντα

Με τον τροχίσκο ρύθμισης ταχύτητας ιμάντα

μπορείτε να επιλέξετε τον αριθμό στροφών και με

τη συσκευή σε λειτουργία. Η βέλτιστη ταχύτητα

ιμάντα εξαρτάται από το τεμάχιο επεξεργασίας ή

το υλικό που θα επεξεργαστείτε. Καθορίζετε πάντα

οι ίδιοι τον εκάστοτε καλύτερο αριθμό στροφών με

μια δοκιμή στην πράξη. Στον ακόλουθο πίνακα

μπορείτε να βρείτε μη δεσμευτικές τιμές που διευκολύνουν τον υπολογισμό σας.

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 60

Φινίρισμα (κόκκωση) 240

Προεπιλογή αριθμού

στροφών

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 60

Φινίρισμα (κόκκωση) 180

Προεπιλογή αριθμού

στροφών

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 60

Φινίρισμα (κόκκωση) 150

Προεπιλογή αριθμού

στροφών

Μαλακό ξύλο

υψηλός (5 – 6)

Σκληρό ξύλο

υψηλός (5 – 6)

Μοριοσανίδες

υψηλός (5 – 6)

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 60

Φινίρισμα (κόκκωση) ––

Προεπιλογή αριθμού

στροφών

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 150

Φινίρισμα (κόκκωση) 320

Προεπιλογή αριθμού

στροφών

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 40

Φινίρισμα (κόκκωση) 120

Προεπιλογή αριθμού

στροφών

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 120

Φινίρισμα (κόκκωση) 240

Προεπιλογή αριθμού

στροφών

Υλικό/

Τομέας εργασίας

Προλείανση (κόκκωση) 80

Φινίρισμα (κόκκωση) 150

Προεπιλογή αριθμού

στροφών

Απομάκρυνση

χρωμάτων/βερνικιών

υψηλός (5 – 6)

Τρίψιμο βερνικιών

χαμηλός (1–2)

Αφαίρεση σκουριάς

σε χάλυβα

μέτριος/υψηλός

(3 – 4)

Πλαστικά

χαμηλός/μέτριος

(2 – 3)

Μη σιδηρούχα μέταλλα (π.χ. αλουμίνιο)

μέτριος/υψηλός

(3 – 4)

■ 20 │ GR

│

CY

PBSD 600 A1

Page 24

Σταθερή εργασία

♦ Θέστε την πρόσθετη χειρολαβή στην

οριζόντια θέση.

♦ Περιστρέψτε το ηλεκτρικό εργαλείο, όπως

φαίνεται στην Εικ. Α, και τοποθετήστε το επάνω

σε μια σταθερή πλάκα εργασίας.

♦ Τοποθετήστε δύο μέγγενες

μενες εσοχές και σφίξτε καλά το ηλεκτρικό

εργαλείο.

στις προβλεπό-

Συμβουλές

■ Ποτέ μην επεξεργάζεστε με τον ίδιο λειαντικό

ιμάντα ξύλο και μέταλλο.

■ Φθαρμένοι ή σκισμένοι λειαντικοί ιμάντες

μπορεί να προκαλέσουν ζημιά στο τεμάχιο

επεξεργασίας. Για το λόγο αυτό, αλλάζετε

έγκαιρα τους λειαντικούς ιμάντες.

■ Φυλάτε τους λειαντικούς ιμάντες μόνο κρεμα-

σμένους, διότι μπορεί να αχρηστευθούν από

τσακίσματα, κλπ.

Συντήρηση και καθαρισμός

ΠΡΟΕΙΔΟΠΟΙΗΣΗ! ΚΙΝΔΥΝΟΣ

ΤΡΑΥΜΑΤΙΣΜΟΥ! Πριν από όλες τις

εργασίες, απενεργοποιείτε τη συσκευή

και τραβάτε το βύσμα από την πρίζα.

Ο ταινιολειαντήρας δεν απαιτεί συντήρηση.

■ Καθαρίζετε τη συσκευή αμέσως μετά την

ολοκλήρωση της εργασίας.

■ Για τον καθαρισμό της συσκευής, χρησιμο-

ποιείτε ένα στεγνό πανί και σε καμία περίπτωση

βενζίνη, διαλυτικά μέσα ή καθαριστικά που

καταστρέφουν το πλαστικό.

Εκκένωση/Καθαρισμός κουτιού σκόνης

♦ Αφαιρέστε το κουτί σκόνης από τη συσκευή.

♦ Αδειάστε το κουτί σκόνης

το και τοποθετήστε πάλι το κουτί σκόνης

συσκευή.

♦ Διατηρείτε πάντα ελεύθερα τα ανοίγματα

αερισμού.

♦ Απομακρύνετε τη σκόνη τροχίσματος που

προσκολλάται με ένα πινέλο.

εντελώς χτυπώντας

Απόρριψη

Η συσκευασία αποτελείται από φιλικά

προς το περιβάλλον υλικά, τα οποία

μπορείτε να απορρίψετε μέσω των

τοπικών σημείων ανακύκλωσης.

Μην πετάτε τα ηλεκτρικά εργαλεία

στα οικιακά απορρίμματα!

Σύμφωνα με την ευρωπαϊκή οδηγία

2012/19/ΕU, τα χρησιμοποιημένα

ηλεκτρικά εργαλεία πρέπει να συλλέγονται χωριστά

και να επαναχρησιμοποιούνται με φιλικό προς το

περιβάλλον τρόπο.

Ενημερωθείτε για τις δυνατότητες απόρριψης της

χρησιμοποιημένης συσκευής από την αρμόδια

υπηρεσία της κοινότητας ή της πόλης σας.

Απορρίπτετε τη συσκευασία με τρόπο

φιλικό προς το περιβάλλον. Λαμβάνετε

υπόψη τη σήμανση στα διάφορα υλι-

κά συσκευασίας και, εφόσον απαιτείται, ξεχωρίζετέ τα. Τα υλικά συσκευασίας φέρουν

σήμανση με συντομογραφίες (a) και ψηφία (b) με

την εξής σημασία: 1–7: Πλαστικά, 20–22: Χαρτί

και χαρτόνι, 80–98: Συνθετικά υλικά.

Για τις δυνατότητες απόρριψης του προ-

ϊόντος μετά το τέλος του κύκλου ζωής

του, απευθυνθείτε στην αρμόδια υπη-

ρεσία της κοινότητας ή της πόλης σας.

στη

PBSD 600 A1

GR│CY

│

21 ■

Page 25

Εγγύηση της

Kompernass Handels GmbH

Αξιότιμη πελάτισσα, αξιότιμε πελάτη,

Η παρούσα συσκευή διαθέτει 3 χρόνια εγγύηση

από την ημερομηνία αγοράς. Στην περίπτωση

ελλείψεων στο προϊόν έχετε νομικά δικαιώματα

έναντι του πωλητή του προϊόντος. Αυτά τα νομικά

δικαιώματα δεν περιορίζονται μέσω της κατωτέρω

αναφερόμενης εγγύησης.

Προϋποθέσεις εγγύησης

Η περίοδος εγγύησης ξεκινά την ημερομηνία αγοράς. Φυλάσσετε την απόδειξη αγοράς. Απαιτείται

ως αποδεικτικό αγοράς.

Εάν, εντός τριών ετών από την ημερομηνία αγοράς,

παρατηρηθεί κάποιο σφάλμα υλικού ή κατασκευής

στο προϊόν, θα επισκευάσουμε ή θα αντικαταστήσουμε (κατόπιν κρίσης μας) το προϊόν δωρεάν ή

θα σας επιστραφεί το ποσό αγοράς. Η παρούσα

εγγύηση προϋποθέτει ότι η ελαττωματική συσκευή

και η απόδειξη αγοράς θα υποβληθούν μαζί με

μια σύντομη περιγραφή αναφορικά με το πού

βρίσκεται η έλλειψη και πότε παρατηρήθηκε, εντός

της περιόδου των τριών ετών.

Εάν το ελάττωμα καλύπτεται από την εγγύησή μας,

θα λάβετε το επισκευασμένο ή ένα νέο προϊόν.

Περίοδος εγγύησης και νομικές απαιτήσεις

λόγω ελλείψεων

Ο χρόνος εγγύησης δεν παρατείνεται μέσω της παροχής εγγύησης. Αυτό ισχύει και για εξαρτήματα,

τα οποία έχουν αντικατασταθεί και επισκευαστεί.

Ενδεχόμενες ήδη υπάρχουσες ζημιές και ελλείψεις

κατά την αγορά πρέπει να γνωστοποιούνται αμέσως μετά την αποσυσκευασία. Μετά τη λήξη του

χρόνου εγγύησης, τυχόν εμφανιζόμενες επισκευές

χρεώνονται.

Εύρος εγγύησης

Η συσκευή κατασκευάστηκε σύμφωνα με αυστηρές

οδηγίες ποιότητας και ελέγχθηκε προσεκτικά πριν

από την αποστολή.

Η εγγύηση ισχύει για σφάλματα υλικού ή κατασκευής. Η παρούσα εγγύηση δεν καλύπτει

εξαρτήματα του προϊόντος που υπόκεινται σε

φυσιολογική φθορά και, ως εκ τούτου, θεωρούνται

αναλώσιμα εξαρτήματα ή ζημιές σε εύθραυστα

εξαρτήματα, π.χ. διακόπτες ή γυάλινα εξαρτήματα.

Η παρούσα εγγύηση ακυρώνεται εάν προκληθεί

ζημιά στο προϊόν, εάν δεν γίνεται σωστή χρήση ή

συντήρηση. Για μια σωστή χρήση του προϊόντος

πρέπει να τηρούνται επακριβώς οι αναφερόμενες

υποδείξεις στις οδηγίες χειρισμού. Σκοποί χρήσης

και χειρισμοί που δεν συνιστώνται ή για τους οποίους υπάρχει προειδοποίηση πρέπει απαραίτητα να

αποφεύγονται.

Το προϊόν προορίζεται μόνο για ιδιωτική και όχι

για επαγγελματική χρήση. Σε περίπτωση κακής μεταχείρισης και ακατάλληλης χρήσης, χρήσης βίας

και παρεμβάσεων, οι οποίες δεν διεξήχθησαν από

το εξουσιοδοτημένο μας τμήμα σέρβις, η εγγύηση

παύει να ισχύει.

Η εγγύηση δεν ισχύει στις παρακάτω περιπτώσεις

■ σε φυσιολογική εξασθένηση της χωρητικότητας

συσσωρευτή

■ σε περίπτωση επαγγελματικής χρήσης του

προϊόντος

■ σε περίπτωση ζημιάς ή τροποποίησης του

προϊόντος από τον πελάτη

■ σε περίπτωση μη τήρησης των προδιαγραφών

ασφάλειας και συντήρησης, καθώς και σφαλμάτων χειρισμού

■ σε περίπτωση ζημιών λόγω φυσικών φαινομένων

■ 22 │ GR

│

CY

PBSD 600 A1

Page 26

Διαδικασία σε περίπτωση εγγύησης

Για την εξασφάλιση γρήγορης επεξεργασίας του

ζητήματός σας, τηρείτε τις ακόλουθες υποδείξεις:

■ Για όλες τις ερωτήσεις έχετε έτοιμη την από-

δειξη αγοράς και τον κωδικό προϊόντος

(π.χ.ΙΑΝ12345) ως απόδειξη για την αγορά.

■ Για τον κωδικό προϊόντος, ανατρέξτε στην πινα-

κίδα τύπου στο προϊόν, σε μια ετικέτα στο προϊόν, στο εξώφυλλο των οδηγιών χρήσης (κάτω

αριστερά) ή σε ένα αυτοκόλλητο στην πίσω ή

κάτω πλευρά του προϊόντος.

■ Εάν προκύψουν σφάλματα λειτουργίας ή

άλλες ελλείψεις, επικοινωνήστε κατ’ αρχήν

με το ακόλουθο αναφερόμενο τμήμα σέρβις

τηλεφωνικά ή μεE-Mail.

■ Ένα προϊόν που θεωρείται ελαττωματικό μπο-

ρείτε να το αποστείλετε ατελώς στην αναφερόμενη διεύθυνση του σέρβις επισυνάπτοντας

την απόδειξη αγοράς (απόδειξη ταμείου) και

αναφέροντας που βρίσκεται η έλλειψη και πότε

εμφανίστηκε.

Στην ιστοσελίδα

www.lidl-service.com μπορείτε να

πραγματοποιήσετε λήψη των παρόντων ή άλλων οδηγιών χρήσης,

βίντεο προϊόντων και λογισμικού.

Με αυτόν τον κωδικό QR μεταβαίνετε απευθείας

στη σελίδα εξυπηρέτησης Lidl

(www.lidl-service.com) και εισαγάγοντας τον κωδικό προϊόντος (IAN) 364419_2010 μπορείτε να

ανοίξετε τις αντίστοιχες οδηγίες χρήσης.

ΥΠΟΔΕΙΞΗ

► Μπορείτε να παραγγείλετε τα μη αναφερό-

μενα ανταλλακτικά (π.χ. ψήκτρες άνθρακα,

διακόπτες, κουτί σκόνης) μέσω του τηλεφωνικού μας κέντρου.

Σέρβις

Σέρβις Ελλάδα

Tel.: 801 5000 019 (0,03 EUR/Min.)

E-Mail: kompernass@lidl.gr

CY

Σέρβις Κύπρος

Tel.: 8009 4409

E-Mail: kompernass@lidl.com.cy

IAN 364419_2010

Εισαγωγέας

Η ακόλουθη διεύθυνση δεν είναι διεύθυνση

σέρβις. Επικοινωνήστε, κατ’ αρχήν, με την

αναφερόμενη υπηρεσία σέρβις.

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

44867 BOCHUM

ΓΕΡΜΑΝΙΑ

www.kompernass.com

ΠΡΟΕΙΔΟΠΟΙΉΣΉ!

■ Αναθέτετε την επισκευή των συσκευών σας

στην υπηρεσία σέρβις ή σε εξειδικευμένο

ηλεκτρολόγο και μόνο με γνήσια ανταλλακτικά. Έτσι διατηρείται η ασφάλεια της

συσκευής.

■ Η αλλαγή του βύσματος ή του καλωδίου

δικτύου πρέπει να διεξάγεται πάντα από

τον κατασκευαστή της συσκευής ή από το

τμήμα εξυπηρέτησης πελατών του. Έτσι

διατηρείται η ασφάλεια της συσκευής.

PBSD 600 A1

GR│CY

│

23 ■

Page 27

Μετάφραση της Πρωτότυπης Δήλωση συμμόρφωσης

Εμείς, η KOMPERNASS HANDELS GMBH, Υπεύθυνος τεκμηριώσεων: Semi Uguzlu, BURGSTR. 21,

44867 BOCHUM, Γερμανία, δηλώνουμε δια της παρούσης ότι το παρόν προϊόν πληροί τα ακόλουθα

πρότυπα, τα κανονιστικά έγγραφα και τις οδηγίες της ΕΚ:

Οδηγία περί μηχανών

(2006/42/ΕC)

Ηλεκτρομαγνητική συμβατότητα

(2014/30/ΕU)

Οδηγία RoHS (Σχετικά με τον περιορισμό χρήσης συγκεκριμένων

επικίνδυνων ουσιών στον ηλεκτρικό και ηλεκτρονικό εξοπλισμό)

(2011/65/ΕU)*

* Ο κατασκευαστής φέρει αποκλειστική ευθύνη για τη σύνταξη αυτής της δήλωσης συμμόρφωσης. Το ανωτέρω

περιγραφόμενο αντικείμενο της δήλωσης πληροί τις προδιαγραφές της οδηγίας 2011/65/ΕU του Ευρωπαϊκού

Κοινοβουλίου και του Συμβουλίου της 8ης Ιουνίου 2011 σχετικά με τον περιορισμό της χρήσης συγκεκριμένων

επικίνδυνων υλικών σε ηλεκτρικές και ηλεκτρονικές συσκευές.

Εφαρμοσμένα εναρμονισμένα πρότυπα

EN 62841-1:2015

EN 62841-2-4:2014

EN 55014-1:2017

EN 55014-2:2015

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 50581:2012

Ονομασία τύπου του μηχανήματος: Ταινιολειαντήρας PBSD 600 A1

Έτος κατασκευής: 12–2020

Σειριακός αριθμός: IAN 364419_2010

Bochum, 15.01.2021

Semi Uguzlu

- Διευθυντής ποιότητας Με την επιφύλαξη τεχνικών αλλαγών υπό την έννοια της συνεχούς ανάπτυξης.

■ 24 │ GR

│

CY

PBSD 600 A1

Page 28

Inhaltsverzeichnis

Einleitung ............................................................. 26

Bestimmungsgemäßer Gebrauch .......................................................26

Abgebildete Komponenten ...........................................................26

Lieferumfang .......................................................................26

Technische Daten ...................................................................26

Allgemeine Sicherheitshinweise für Elektrowerkzeuge ....................... 27

1. Arbeitsplatzsicherheit ..............................................................27

2. Elektrische Sicherheit ..............................................................27

3. Sicherheit von Personen ............................................................28

4. Verwendung und Behandlung des Elektrowerkzeugs .....................................28

5. Service .........................................................................29

Gerätespezifische Sicherheits hinweise für Schleifer .........................................29

Inbetriebnahme .......................................................29

Schleifband einspannen/wechseln .....................................................29

Zusatzhandgriff einstellen .............................................................30

Frontabdeckung hochklappen .........................................................30

Staubabsaugung anbringen/ entfernen ..................................................30

Arbeitshinweise. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Bedienung ............................................................31

Ein- und ausschalten .................................................................31

Staubbox entleeren .................................................................31

Drehzahl und Schleifband wählen ......................................................32

Stationäres Arbeiten .................................................................32

Tipps und Tricks ....................................................................32

Wartung und Reinigung .................................................33

Entsorgung ...........................................................33

Garantie der Kompernaß Handels GmbH ..................................34

Service ............................................................... 35

Importeur ............................................................35

Original-Konformitätserklärung ..........................................36

PBSD 600 A1

DE│AT│CH

│

25 ■

Page 29

BANDSCHLEIFER PBSD 600 A1

Einleitung

Wir beglückwünschen Sie zum Kauf Ihres neuen

Gerätes. Sie haben sich damit für ein hochwertiges

Produkt entschieden. Die Bedienungsanleitung ist

Teil dieses Produkts. Sie enthält wichtige Hinweise

für Sicherheit, Gebrauch und Entsorgung. Machen

Sie sich vor der Benutzung des Produkts mit allen

Bedien- und Sicherheitshinweisen vertraut. Benutzen Sie das Produkt nur wie beschrieben und für

die angegebenen Einsatzbereiche. Händigen Sie

alle Unterlagen bei Weitergabe des Produkts an

Dritte mit aus.

Bestimmungsgemäßer Gebrauch

Der Bandschleifer ist - je nach Schleifpapier - für

trockenes Flächenschleifen von Holz, Kunststoff,

Metall und Spachtelmasse sowie lackierten Oberflächen ausgelegt. Das Gerät darf nur für Trockenschliff verwendet werden. Beachten Sie bitte, dass

Sie zur Bearbeitung der verschiedenen Materialien

entsprechende Schleifblätter mit unterschiedlicher

Körnung einsetzen und die Drehzahl ebenfalls dem

Material anpassen. Das Gerät ist nicht für den

gewerblichen Einsatz bestimmt. Jede andere Verwendung oder Veränderung der Maschine gilt als

nicht bestimmungsgemäß und birgt erhebliche

Unfallgefahren. Für aus bestimmungswidriger Verwendung entstandene Schäden übernimmt der

Hersteller keine Haftung.

Abgebildete Komponenten

EIN-/AUS-Schalter

Zusatzhandgriff (Gummierte Grifffläche)

Frontabdeckung

Spannhebel für Schleifband

Stellrad Bandgeschwindigkeit

Handgriff (Gummierte Grifffläche)

Schraube für Handgriffverstellung

Aussparungen für Schraubzwinge

Anschluss für Staubbox

Feststelltaste für EIN-/AUS-Schalter

Staubbox

Justierschraube für Bandlauf

Schleifband

Schraubzwinge

Reduzierstück

Absaugadapter

Lieferumfang

1 Bandschleifer PBSD 600 A1

1 Schleifband für Holz (Körnung 80)

1 Staubbox

1 Absaugadapter und Reduzierstück

(zur externen Staubabsaugung)

2 Schraubzwingen

1 Bedienungsanleitung

Technische Daten

Bemessungsspannung 230 V ∼, 50 Hz

(Wechselstrom)

Bemessungsaufnahme 600 W

Leerlauf-

Bandgeschwindigkeit 170–250 m/min

Bemessungs-

Leerlaufdrehzahl

Schleifband 75 x 457 mm

Schutzklasse II /

Geräuschemissionswert

Messwert für Geräusch ermittelt entsprechend

EN62841. Der A-bewertete Geräuschpegel des

Elektrowerkzeugs beträgt typischerweise:

Schalldruckpegel L

Unsicherheit K

Schallleistungspegel L

Unsicherheit K

Gehörschutz tragen!

Schwingungsgesamtwert

Schwingungsgesamtwerte (Vektorsumme dreier

Richtungen) ermittelt entsprechend EN 62841:

Schleifen mit Schleifteller a

Unsicherheit K = 1,5 m/s

n0 360–560 min

(Doppelisolierung)

= 91 dB (A)

pA

= 3 dB

pA

= 102 dB (A)

WA

= 3 dB

WA

= 4,2 m/s

h

-1

2

2

■ 26 │ DE

│AT│

CH

PBSD 600 A1

Page 30

HINWEIS

► Die angegebenen Schwingungsgesamtwerte

und die angegebenen Geräuschemissionswerte sind nach einem genormten Prüfverfahren gemessen worden und können zum

Vergleich eines Elektrowerkzeugs mit einem

anderen verwendet werden.

► Die angegebenen Schwingungsgesamtwerte

und die angegebenen Geräuschemissionswerte können auch zu einer vorläufigen Einschätzung der Belastung verwendet werden.

WARNUNG!

► Die Schwingungs- und Geräuschemissionen

können während der tatsächlichen Benutzung

des Elektrowerkzeugs von den Angabewerten

abweichen, abhängig von der Art und Weise,

in der das Elektrowerkzeug verwendet wird,

insbesondere, welche Art von Werkstück bearbeitet wird.

► Versuchen Sie, die Belastung so gering wie

möglich zu halten. Beispielhafte Maßnahmen

zur Verringerung der Vibrationsbelastung

sind das Tragen von Handschuhen beim Gebrauch des Werkzeugs und die Begrenzung

der Arbeitszeit. Dabei sind alle Anteile des

Betriebszyklus zu berücksichtigen (beispielsweise Zeiten, in denen das Elektrowerkzeug

abgeschaltet ist, und solche, in denen es

zwar eingeschaltet ist, aber ohne Belastung

läuft).

Allgemeine

Sicherheitshinweise für

Elektrowerkzeuge

WARNUNG!

► Lesen Sie alle Sicherheitshinweise, Anwei-

sungen, Bebilderungen und technischen

Daten, mit denen dieses Elektrowerkzeug

versehen ist. Versäumnisse bei der Einhaltung

der nachfolgenden Anweisungen können

elektrischen Schlag, Brand und/oder schwere

Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

Der in den Sicherheitshinweisen verwendete Begriff

„Elektrowerkzeug“ bezieht sich auf netzbetriebene

Elektrowerkzeuge (mit Netzleitung) und auf akkubetriebene Elektrowerkzeuge (ohne Netzleitung).

1. Arbeitsplatzsicherheit

a) Halten Sie Ihren Arbeitsbereich sauber und

gut beleuchtet. Unordnung und unbeleuchtete

Arbeitsbereiche können zu Unfällen führen.

b) Arbeiten Sie mit dem Elektrowerkzeug nicht

in explosionsgefährdeter Umgebung, in der

sich brennbare Flüssigkeiten, Gase oder

Stäube befinden. Elektrowerkzeuge erzeugen

Funken, die den Staub oder die Dämpfe entzünden können.

c) Halten Sie Kinder und andere Personen

während der Benutzung des Elektrowerkzeugs fern. Bei Ablenkung können Sie die

Kontrolle über das Elektrowerkzeug verlieren.

PBSD 600 A1

2. Elektrische Sicherheit

a) Der Anschlussstecker des Elektrowerkzeugs

muss in die Steckdose passen. Der Stecker

darf in keiner Weise verändert werden.

Verwenden Sie keine Adapterstecker gemeinsam mit schutzgeerdeten Elektrowerkzeugen.

Unveränderte Stecker und passende Steckdosen verringern das Risiko eines elektrischen

Schlages.

DE│AT│CH

│

27 ■

Page 31

b) Vermeiden Sie Körperkontakt mit geerdeten

Oberflächen wie von Rohren, Heizungen,

Herden und Kühlschränken. Es besteht ein er-

höhtes Risiko durch elektrischen Schlag, wenn

Ihr Körper geerdet ist.

c) Halten Sie Elektrowerkzeuge von Regen oder

Nässe fern. Das Eindringen von Wasser in ein

Elektrowerkzeug erhöht das Risiko eines elektrischen Schlages.

d) Zweckentfremden Sie die Anschlussleitung

nicht, um das Elektrowerkzeug zu tragen,

aufzuhängen oder um den Stecker aus der

Steckdose zu ziehen. Halten Sie die Anschlussleitung fern von Hitze, Öl, scharfen Kanten

oder sich bewegenden Teilen. Beschädigte

oder verwickelte Anschlussleitungen erhöhen das

Risiko eines elektrischen Schlages.