Parkside PBK 4 A1 Translation Of The Original Instructions

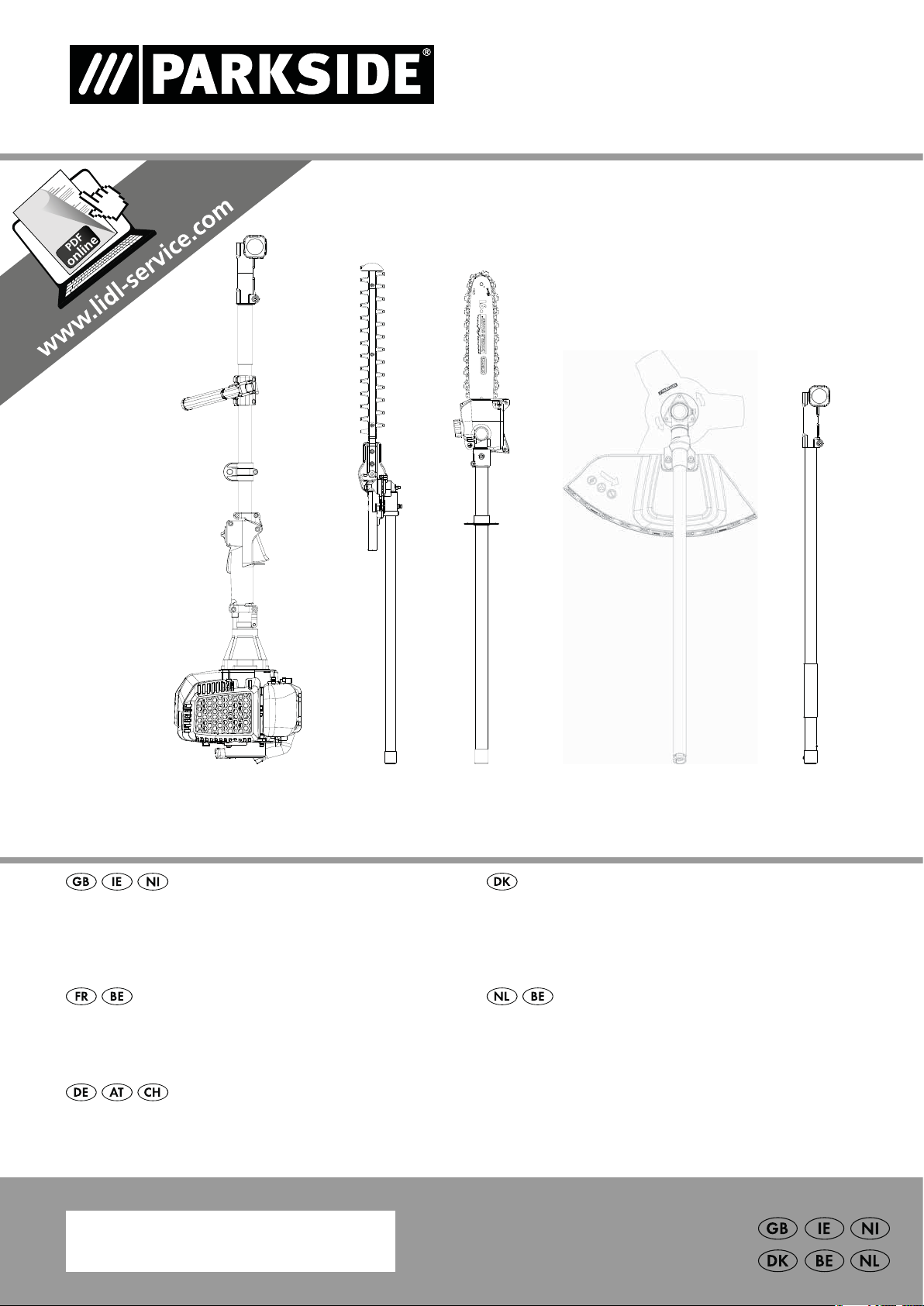

4-IN-1 PETROL MULTI-TOOL PBK 4 A1

4-IN-1 PETROL MULTI-TOOL

Translation of the original instructions

Read carefully before using machine!

BENZINDREVET MULTIHAVEMASKINE

4-I-1

Oversættelse af den originale driftsvejledning

Læs venligst omhyggeligt, før du bruger maskinen!

OUTIL MODULABLE À ESSENCE 4 EN 1

Traduction du mode d’emploi d’origine

Lire consciencieusement avant d’utiliser a machine!

BENZIN-KOMBIGERÄT 4 IN 1

Originalbetriebsanleitung

Vor dem Gebrauch der Maschine sorgfältig lesen!

IAN 311700

BENZINE-COMBIAPPARAAT 4-IN-1

Vertaling van de originele gebruiksaanwijzing

Aandachtig lezen voordat u het apparaat gebruikt!

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Før du læser, vend begge sidene med billeder frem og bliv bekendt med alle apparatets funktioner.

Avant de lire le mode d’emploi, ouvrez les deux pages contenant les illustrations et familiarisez-vous ensuite

avec toutes les fonctions de l’appareil.

Vouw vóór het lezen de beide pagina‘s met de afbeeldingen open en maak u vertrouwd met alle functies

van het apparaat.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB / IE / NI Translation of the original instructions Page 1

DK Oversættelse af den originale driftsvejledning Side 19

FR / BE Traduction du mode d’emploi d’origine Page 37

NL / BE Vertaling van de originele gebruiksaanwijzing Pagina 55

DE / AT / CH Originalbetriebsanleitung Seite 73

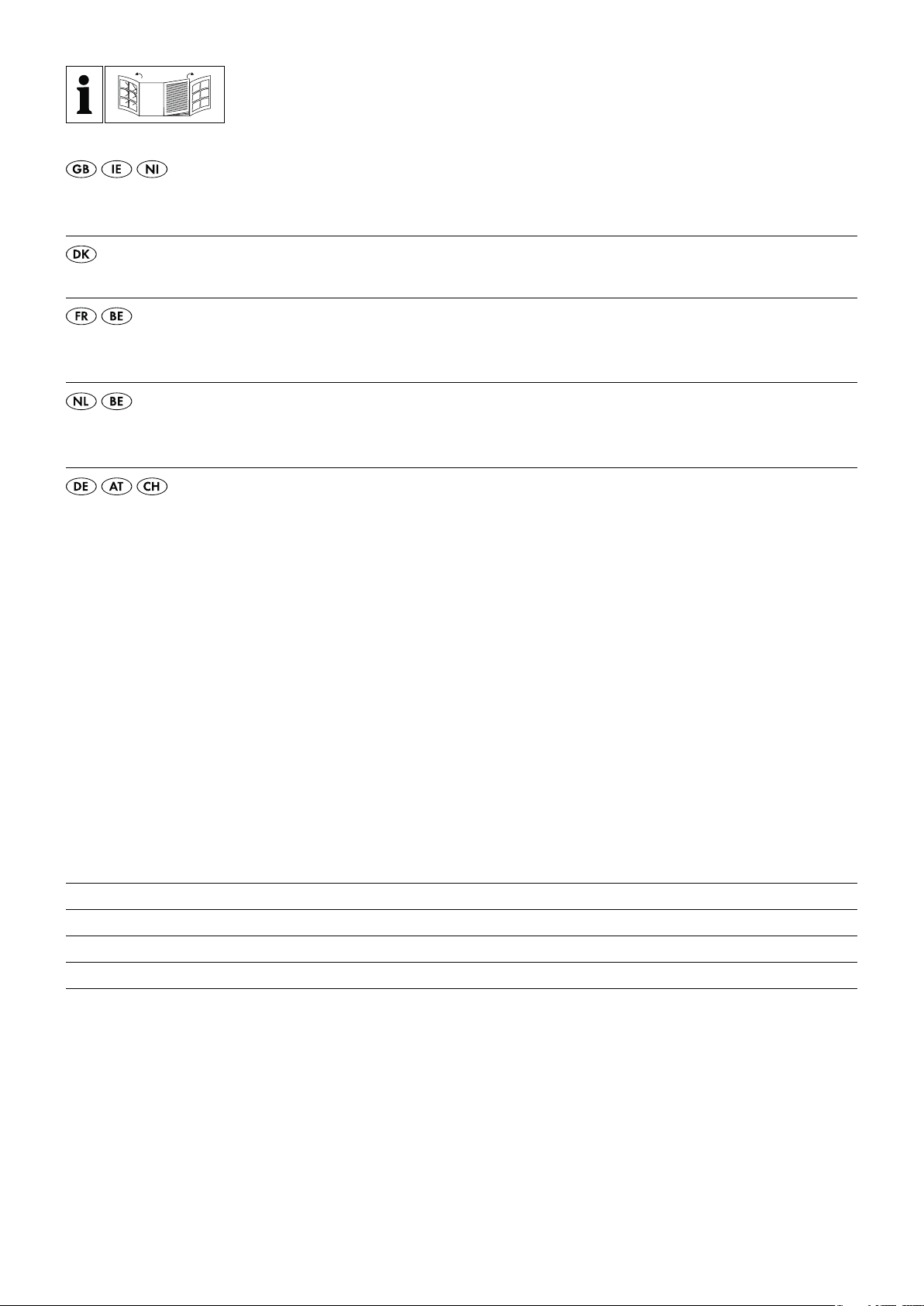

5a

5b

5c

1a 1b 1c

1d 1e

1f

2a

2b 2c

3d3a 3b 3c

3e

3f

3g

3h

3i

5c

y

6a 6b

4

5a

H1

H2

5d 5e 5f

6c 6d 6e

5b

y

A

Contents

Introduction .................................2

Intended use ........................................2

Features............................................2

Package contents.....................................3

Technical data.......................................3

Explanation of the symbols used ........................4

Safety instructions............................6

Operational safety instructions for hedge trimmers ...........6

Supplementary safety instructions for hedge trimmers.........7

Operational safety instructions for pole pruners .............7

Precautions against kickback............................8

Operational safety instructions for strimmers................8

Operational safety instructions for cutting blades ............9

Safety devices/equipment .............................9

Before use .................................10

Attaching the round handle............................10

Assembling the quick release mechanism . . . . . . . . . . . . . . . . . 10

Fixing/attaching the carrying harness....................10

Assembling the hedge trimmer .........................10

Removing the hedge trimmer...........................10

Swivelling the hedge trimmer...........................10

Mounting the saw chain and blade .....................10

Removing the saw chain ..............................10

Tightening and checking the saw chain ..................11

Lubricating the chain .................................11

Sharpening the saw chain.............................11

Attaching the extension attachment......................11

Fitting/removing the protective guard ....................11

Installing/replacing the cutting blade ....................11

Installing/replacing the strimmer ........................12

Putting on the carrying harness .........................12

Setting the cutting height ..............................12

Fuel and oil ........................................12

Transport ..................................14

Cleaning ...................................14

Maintenance ...............................14

Storage and transportation ...................15

Troubleshooting.............................16

Engine unit.........................................16

Pole pruner ........................................16

Hedge trimmer......................................16

Maintenance intervals .......................16

Pole pruner ........................................16

Hedge trimmer......................................16

Ordering spare parts ........................16

Disposal ...................................17

Kompernass Handels GmbH warranty..........17

Service ....................................18

Importer...................................18

Translation of the original Conformity Declaration 18

Use .......................................12

Starting when the engine is cold ........................12

Starting when the engine is hot .........................12

Working with the hedge trimmer........................13

Cutting techniques ...................................13

Working with the pole pruner ..........................13

Sawing techniques ..................................13

Working safely .....................................14

PBK 4 A1

GB│IE│NI │

1 ■

4-IN-1 PETROL MULTI-TOOL PBK 4 A1

Introduction

Congratulations on the purchase of your new appliance. You have chosen

a high-quality product. The operating instructions are a part of this product.

They contain important information about safety, usage and disposal.

Before using the product, please familiarise yourself with all operating and

safety instructions. Use the product only as described and for the range of

applications specified. Please also pass these operating instructions on to

any future owner.

Intended use

Long-handled hedge trimmer

This appliance is intended for the cutting and trimming of hedges, bushes

and flowering shrubs in the home environment. This is a hand-held appliance

with an integrated engine unit with linear reciprocating cutting blades.

WARNING!

► Hedge trimmers are not suitable for use by children.

Pole pruner

This appliance is intended for trimming branches in trees.

3-section cutting blade/strimmer

Use with the 3-section cutting blade: for cutting high grass, undergrowth

and light scrub.

Use with strimmer: for cutting grass and small weeds.

Extension attachment

CAUTION!

■ Do not use the extension attachment/boom in combination with

the 3-section cutting blade/strimmer attachment!

Any other use that is not expressly permitted in these operating instructions

may damage the appliance and represents a serious risk for the user.

Please make sure that you pay attention to the restrictions in the safety

instructions. Comply with all national regulations which may restrict the

use of the machine. Any other uses of or modification to the appliance is

deemed to be improper and carries the risk of serious personal injury.

Not intended for commercial use.

PROHIBITED APPLICATIONS!

Due to the physical risk posed to the user, the appliance may not be used

to perform the following activities: cleaning footpaths and as a shredder

for shredding tree and hedge sections. Furthermore, the appliance may not

be used to level ground elevations such as molehills. For safety reasons,

the appliance may not be used as a drive unit for any other devices. The

user, not the manufacturer, is liable for any resulting damage or injuries of

any kind.

Features

Engine unit PBK 4 A1-1

Safety lock-out

On/Off switch

Carrying lug

4 x mounting bolts

Round handle

5a

Rubber ring

5b

Pin

Barrier bar

Screw grip

Boom

Throttle control

Spark plug connector

Choke lever

Starter pull cord

Fuel tank

Filler cap

Fuel pump (primer)

Air filter housing cover

Hedge trimmer attachment PBK 4 A1-3

Handle

Lock/release

Gear housing

Cutter bar

Base plate (hedge trimmer)

Control lever

Front boom (hedge trimmer)

Locking pin

Drive shaft

Pole pruner attachment PBK 4 A1-4

Front boom (pole pruner)

Safety ring

Oil filler cap

Oil tank

Blade

Saw chain

Bench grinder support

Stop

Locking pin

Drive shaft

Nut

Thread

Sprocket cover

Blade guide

Blade hole

Guide rail

Oil dispenser

Chain sprocket

Oil adjusting screw

Chain tensioner pin

Chain tensioner screw

■ 2 │ GB│IE│NI

PBK 4 A1

Strimmer/cutting blade attachment PBK 4 A1-2

2 x bolts (with snap ring, washer)

Blade guard

3-section cutting blade

Strimmer with cutting filament

Front boom (strimmer/3-section cutting blade)

Locking pin

Drive shaft

Extension attachment

Boom

Screw grip

Locking pin

Drive shaft

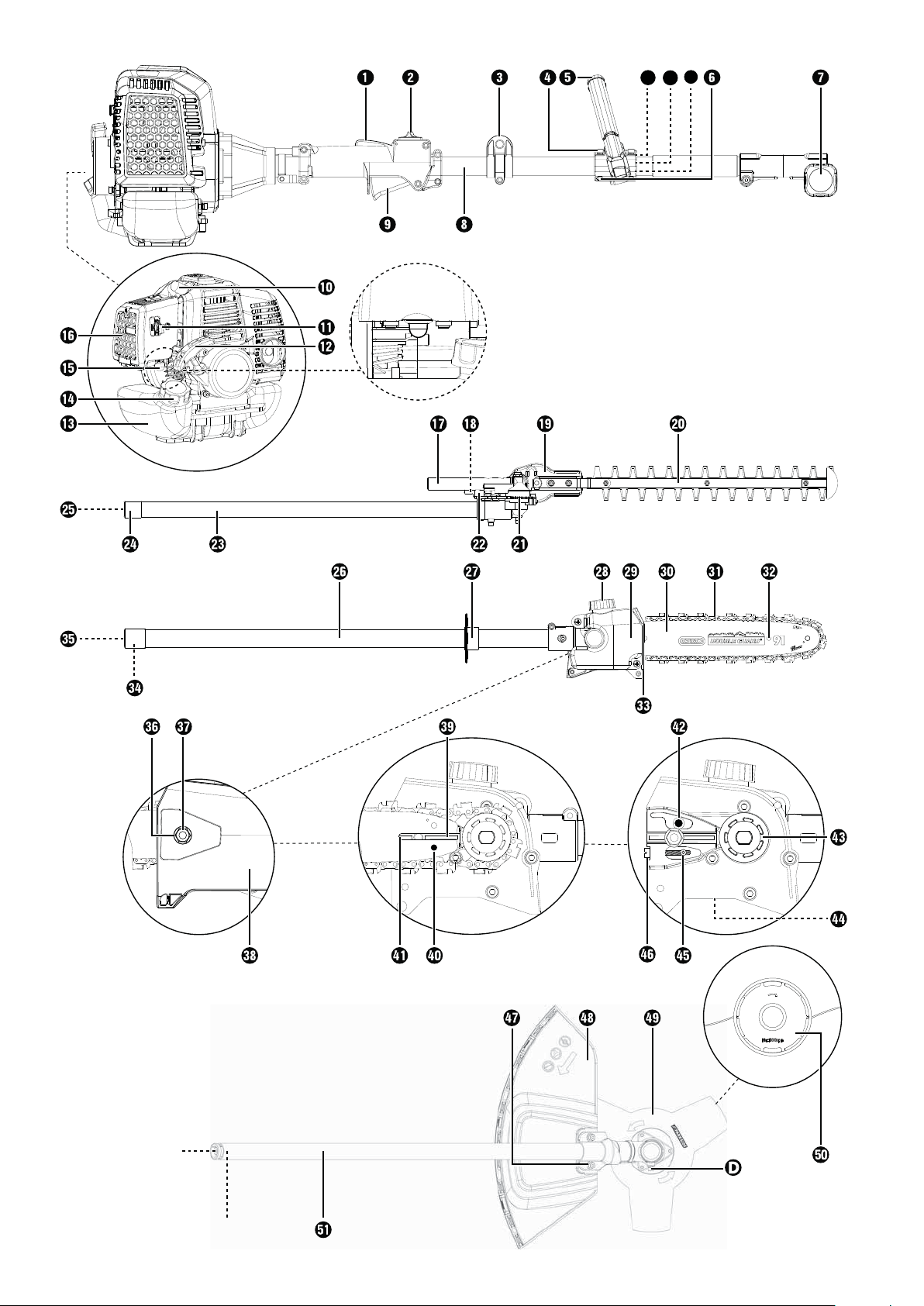

Accessories

Carrying strap

Protective cover for blade

Chain guard

Organic chain oil

Oil/petrol mixing canister

Safety goggles

Hex key 4 mm

Hex key 5 mm

Open-ended spanner SW 8/10

Spark plug wrench/flat-blade screwdriver

Tool bag

Nut M19 x 1.0 (left-hand thread)

Pressure plate cover

Pressure plate

Drive plate

Cutting filament

Funnel

Package contents

1 engine unit

1 hedge trimmer attachment PBK 4 A1-3 (hereinafter hedge trimmer)

1 pole pruner attachment PBK 4 A1-4 (hereinafter pole pruner)

1 strimmer/cutting blade attachment PBK 4 A1-2

1 extension attachment

1 handle with barrier bar

1 strimmer with cutting filament

1 cutting filament (filament Ø: 2.4 mm/filament length: 6 m)

1 3-section cutting blade

1 Carrying harness

1 chain guard

1 blade guard

1 oil/petrol mixing canister

1 100 ml organic chain oil

1 tool bag

1 4 mm hex key

1 5 mm hex key

1 spark plug wrench/flat-blade screwdriver

1 SW 8/10 open-ended spanner

1 pair of safety goggles

1 funnel

1 operating instructions

Technical data

Engine unit: PBK 4 A1-1

Engine type: 2-stroke engine, air-cooled, chrome cylinder

Engine output (max.): 1.35 kW/1.85 hp

Cylinder capacity: 42.7 cm³

-1

3

(rpm)

-1

(rpm)

-1

(rpm)

-1

(rpm)

-1

(rpm)

-1

(rpm)m

-1

(rpm)

-1

(rpm)

3

Engine idle speed: 3000 min

Max. engine speed

with 3-section cutting blade: 9200 min

with strimmer: 8700 min

with chainsaw: 9200 min

with hedge trimmer: 9200 min

Max. cutting speed

with 3-section cutting blade: 6900 min

with strimmer: 6525 min

with chainsaw: 20 m/s

with hedge trimmer: 1550 min

Ignition: electronic

Drive: centrifugal clutch

Weight:

(empty tank): approx. 5.6 kg

Fuel tank capacity: 1200 cm

Spark plug: CDK L8RTC

Fuel consumption at

max. engine performance: 0.6 kg/h

Specific

fuel consumption

at max. engine performance: 431 g/kWh

Hedge trimmer: PBK 4 A1-3

Cut length: 425 mm

Tooth spacing: 24 mm

Weight

(ready for use): approx. 2.24 kg

Pole pruner attachment: PBK 4 A1-4

Weight (ready for use): approx. 1.6 kg

Oil tank, recommended fill level: 140 cm

Cut length: approx. 260 mm

Blade: Oregon type 100SDEA318

Saw chain: Oregon 91P040X

Strimmer/cutting blade

attachment: PBK 4 A1-2

Strimmer with cutting filament (IAN 311700):

Filament cutting circle Ø: 430 mm

Filament length: 6.0 m

Filament Ø: 2.4 mm

3-section cutting blade (IAN 311700):

Cutting blade cutting

diameter Ø: 255 mm

PBK 4 A1

GB│IE│NI │

3 ■

Noise and vibration information:

Noise measurement value determined in accordance with ISO 22868,

EN 10517. The A-rated noise level of the power tool is typically as follows:

Hedge trimmer:

Sound pressure level L

Uncertainty K

WA

Sound power level L

Guaranteed sound power level L

Uncertainty K

WA

: 98.79 dB(A)

pA

: 2.5 dB

: 109.53 dB(A)

WA

: 114 dB(A)

WA

: 2.5 dB

Pole pruner:

Sound pressure level L

Uncertainty K

WA

: 97.06 dB(A)

pA

: 2.5 dB

Sound power level: 110.87 dB(A)

Uncertainty K

: 2.5 dB

WA

3-section cutting blade:

Sound pressure level L

Uncertainty K

PA

Sound power level L

Uncertainty K

WA

: 97.64 dB(A)

pA

: 2.5 dB

: 111.27 dB(A)

WA

: 2.5 dB

Strimmer:

Sound pressure level L

Uncertainty K

PA

Sound power level L

Uncertainty K

WA

: 99.08 dB(A)

pA

: 2.5 dB

: 111.10 dB(A)

WA

: 2.5 dB

Wear ear protectors to prevent hearing damage!

Vibration values (vector total of three directions) determined in accordance with EN 11806-1, EN ISO 10517, EN ISO 11680-1:

Hedge trimmer:

Vibration on the front handle: vibration emission value

= 4.182 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

Vibration on the rear handle: vibration emission value

= 9.695 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

Pole pruner:

Vibration on the front handle: vibration emission value

= 3.855 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

Vibration on the rear handle: vibration emission value

= 7.590 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

Strimmer:

Vibration on the front handle: vibration emission value

= 4.864 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

Vibration on the rear handle: vibration emission value

= 9.750 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

3-section cutting blade:

Vibration on the front handle: vibration emission value

= 4.622 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

Vibration on the rear handle: vibration emission value

= 7.708 m/s2

a

h,D

Uncertainty K = 1.5 m/s

2

NOTE

►

The vibration level specified in these instructions has been measured

in accordance with the standardised measuring procedure specified

in EN ISO 11806-1, EN ISO 10517, EN ISO 11680-1 and can be

used to make equipment comparisons. The specified vibration emission value can also be used to make an initial exposure estimate.

WARNING!

► The vibration level varies in accordance with use and may be higher

than the value specified in these instructions in some cases. There is a

risk of underestimation of the vibration load if the appliance is used

regularly in this manner. To estimate the vibration load during a specific working period accurately, periods during which the appliance

is switched off (or running, but not being used) must also be taken

into account. This can significantly reduce the vibration load over the

total working period.

WARNING!

■ You can reduce the vibration risk, for example, the risk of Raynaud's

phenomenon, by taking regular breaks during which you rub your

hands together.

Explanation of the symbols used

Warning! Read the operating instructions before use!

Wear protective gloves!

Wear safety shoes!

Wear ear protection!

Wear a hard hat!

Wear protective goggles!

Important, hot parts. Keep a safe distance away!

1

I

o

ON

1. Switch on the appliance

2

FULL

2. Fill fuel pump (primer)

3

PULL

3. Pull the choke lever

4

PULL

4. Pull the starter pull cord

CHOKE

Pull the choke lever

■ 4 │ GB│IE│NI

PBK 4 A1

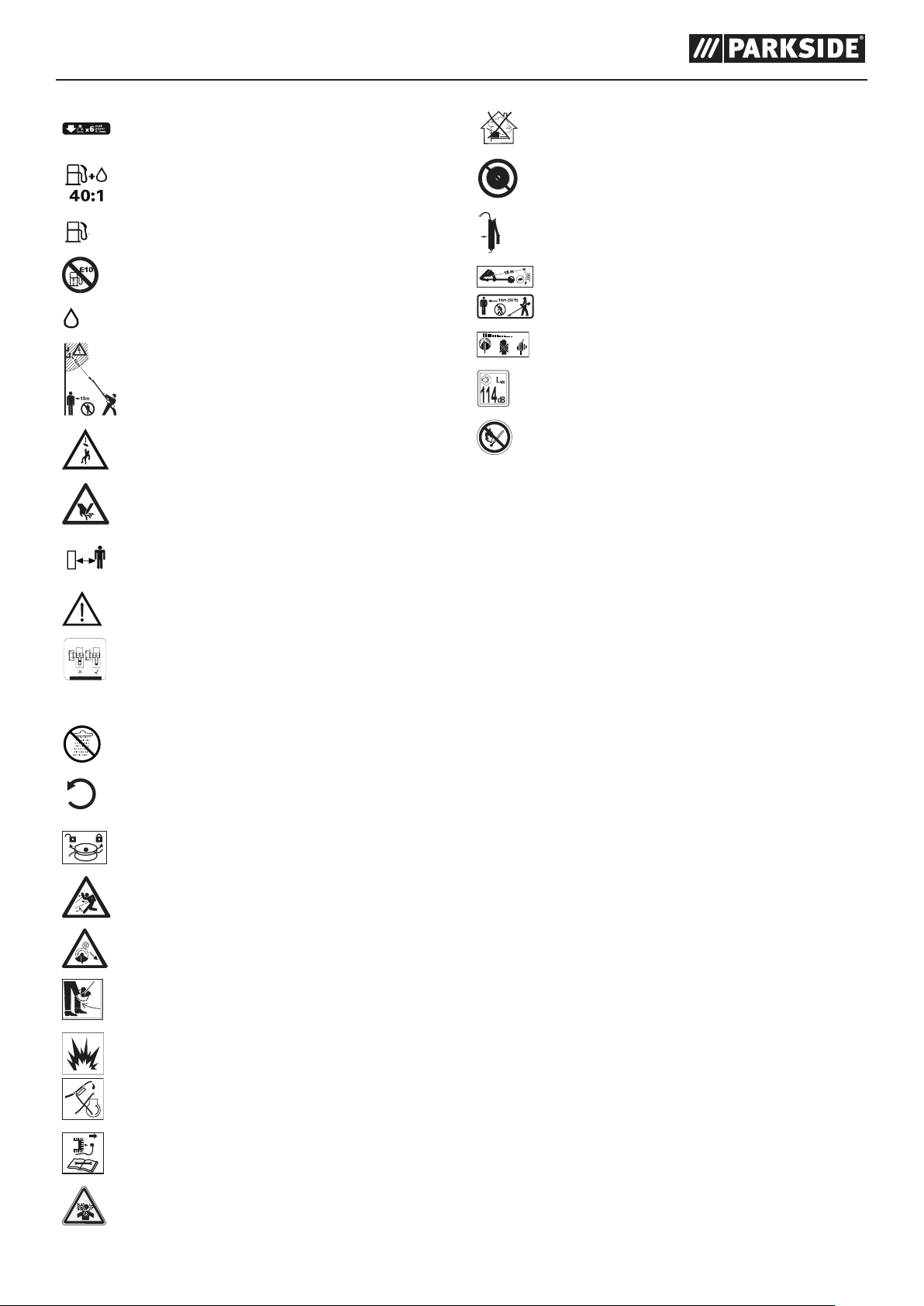

Press the fuel pump (primer) 6x

Mixing ratio: 40 parts petrol to 1 part oil

Caution! Poisonous CO vapours (carbon monoxide vapours)!

Do not use the appliance in confined spaces!

Warning! Do not use circular saw blades for the cutting

blade function.

Petrol: ROZ 95/ROZ 98

No E10 refuel

2-stroke-motor oil: ISO-L-EGD/JASO FD

Risk of fatal electrical shock! Keep at least 10m away from

overhead power lines!

Attention! Falling objects.

Especially when cutting above head height.

Attention! Risk of injury due to running blades!

Keep a safe distance away!

General warning!

1. Push the pin on the front boom into the groove on the

engine unit boom as far as the stop.

2. Once it is correctly inserted, the red line must match up

with the one on the engine unit boom.

20 h

Add a little grease after every 20 hours of operation

(gear grease)

A distance of 15 metres must be maintained between the

machine and third parties!

The cutting tool continues running after it is turned off

(cutting blade/cutting filament)!

Sound power level LWA data in dB.

Fire, naked flames and smoking are prohibited!

min

max. 9000

Protect the appliance from rain and moisture!

-1

Max. 9000 min

-1

(rpm)

Attention! Left-hand thread.

Beware of flung objects!

Beware of kickback!

Caution! Risk of injury from rotating cutting blade!

Keep hands and feet away!

Attention – petrol is highly flammable!

Explosion hazard! Do not spill fuel!

Turn the appliance off and disconnect the spark plug before

performing any maintenance work!

Attention! Risk of suffocation!

PBK 4 A1

GB│IE│NI │

5 ■

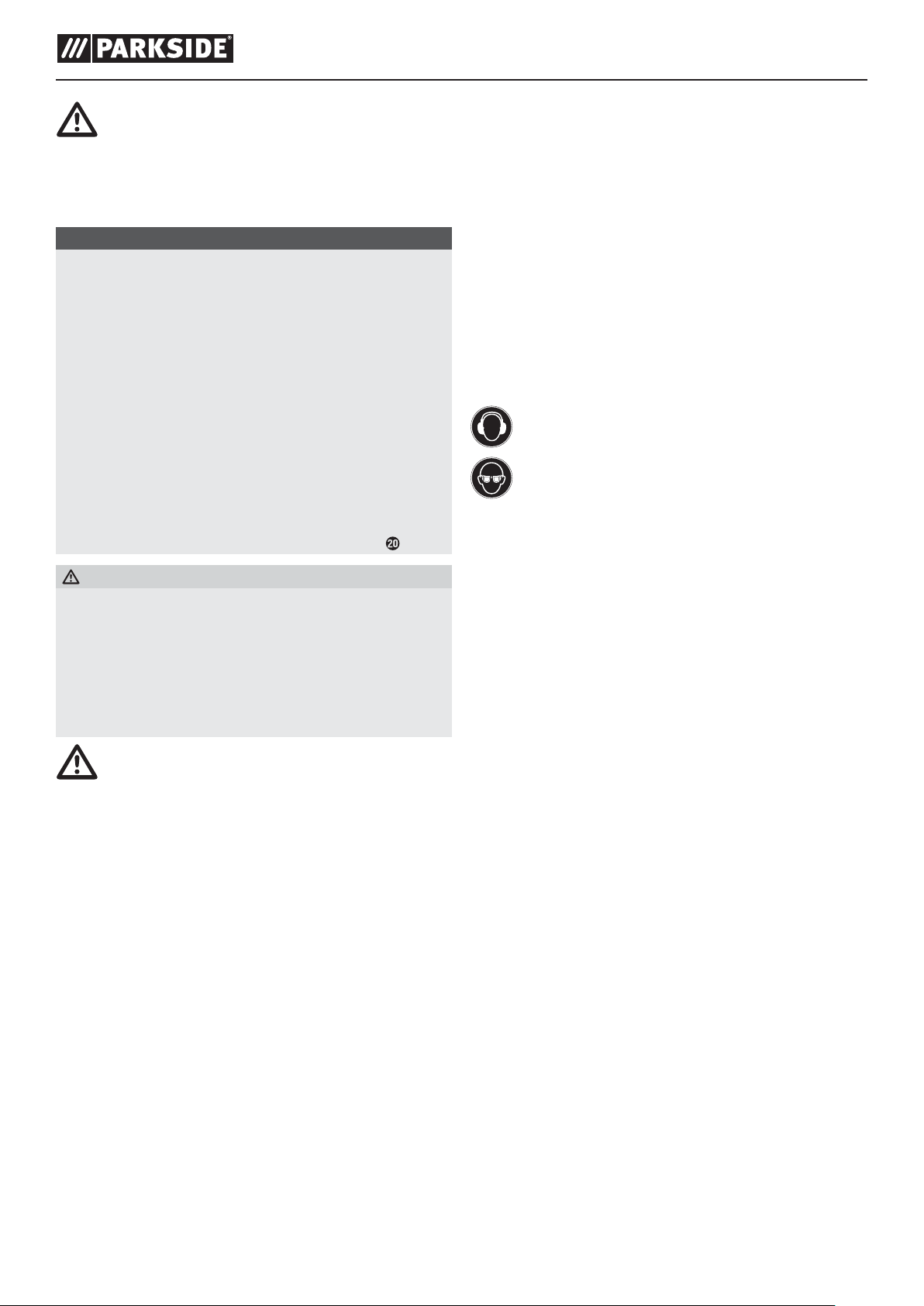

Safety instructions

IMPORTANT! READ CAREFULLY BEFORE USE!

KEEP FOR YOUR RECORDS.

Operational safety instructions for hedge trimmers

NOTE

The hedge trimmer is supplied completely assembled.

►

► Instructions and pictorial representations regarding the settings and

use of the hedge trimmer and/or its controls, maintenance, lubrication

by the user can be found in these instructions and on the fold-out

page.

► Notes on the working position (see fold-out page).

► Notes on the operating controls (see fold-out page).

► Notes on the safe handling of fuel (see section "Preparation", point f).

► Notes on the recommended replacement or repair of parts or the

Customer Service and specification of spare parts to be used,

inasmuch as these affect the health and safety of the user, can be

found in these instructions.

► The explanation of all graphical symbols, information, features and

technical data as well as the procedure in the event of accidents and

faults can be found in these instructions.

► Blocked tool: Remove any blockages from the cutter bar .

– Do not smoke.

– Refuel outside only.

– Never store the hedge trimmer or the fuel tank in a room where there is

an open flame, for example in a hot water boiler.

– If the petrol has overflowed, do not attempt to start the engine. Remove

the machine from the fuel-contaminated area before restarting.

– Always replace the filler cap after refuelling and close it securely.

– If the tank is empty, this should be done in the open.

g) If the cutting unit comes in contact with a foreign object or if the oper-

ating noise increases or the hedge trimmer starts to vibrate abnormally,

stop the engine and allow the hedge trimmer to come to a standstill.

Pull the spark plug connector off the spark plug and take the following

action:

– check for damage;

– check for loose parts and secure all the loose parts;

– replace damaged parts with equivalent parts or have them repaired.

Wear ear protection!

Wear protective goggles!

WARNING!

■ Children may never use the hedge trimmer.

■ Stay alert, watch what you are doing and use common sense

when operating the appliance. Do not use the appliance while you

are ill, tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating the appliance may result in

serious personal injury.

■ Avoid improper use. Use the machine only as described under

"Intended use".

Familiarise yourself with the operating instructions before you

operate the appliance.

Preparation

a) THE HEDGE TRIMMER CAN CAUSE SERIOUS INJURIES! Read the

instructions on correct handling, preparation, maintenance, starting and

stopping the hedge trimmer very carefully. Familiarise yourself with all

manual controls and the proper use of the hedge trimmer.

b) Children may never use the hedge trimmer.

c) Beware of overhead power lines.

d) Do not use the hedge trimmer while anyone, especially children, is in

the vicinity.

e) Wear appropriate clothing! Do not wear loose clothing or jewellery

which could get caught in moving parts. We recommend wearing

heavy-duty gloves, non-slip footwear and goggles.

f) Handle fuel carefully. It is highly flammable and the vapours are

explosive. The following points should be followed:

– Use only specially-designed containers.

– Never open the tank filler cap or top up the petrol tank while the motor

is running or hot. Allow the motor and the exhaust components to cool

down before refuelling.

■ Familiarise yourself with the operation of the hedge trimmer so that you

know how to stop immediately in an emergency.

Operation

a) The engine is to be immobilised before:

– cleaning or removal of a blockage;

– inspection, maintenance or work on the hedge trimmer;

– setting the working position of the cutting unit;

– if the hedge trimmer is to be left unattended.

b) Always make sure that the hedge trimmer is in the proper working position

before the engine is started.

c) During operation of the hedge trimmer, always ensure that you have firm

footing, especially when using a ladder.

d) Do not use the hedge trimmer if it has a defective or badly worn cutting

unit.

e) To minimise the risk of fire, ensure that the engine and the silencer are

free of residues, leaves or leaked lubricant.

f) Ensure that all supplied handles and safety guards are mounted when

operating the hedge trimmer. Never attempt to operate an incompletely

assembled hedge trimmer or a hedge trimmer with non-approved modi-

fications.

g) Always use both hands if the hedge trimmer is equipped with two handles.

h) Always familiarise yourself with your environment and be aware of

potential dangers that you may not be able to hear because of the

noise of the hedge trimmer.

■ 6 │ GB│IE│NI

PBK 4 A1

Maintenance and storage

a) If the hedge trimmer is shut down for maintenance, inspection or storage,

switch off the engine, pull the spark plug connector off the spark plug

and ensure that all rotating parts have come to a standstill. Allow the

machine to cool down before carrying out an inspection, settings, etc.

b) Store the hedge trimmer where the petrol vapours cannot come into

contact with flames or sparks. Always allow the hedge trimmer to cool

down before storage.

c) When transporting or storing the hedge trimmer, cover the cutting unit

with the protective cover for the cutting unit.

Supplementary safety instructions for hedge

trimmers

Environmental safety

■ Only operate the hedge trimmer in daylight or good artificial light.

■ While trimming, ensure that you do not come into contact with objects

such as fence wire or plant supports. They could cause damage to the

cutter bar . Inspect the hedge to be cut carefully and remove any

wires or other foreign bodies.

■ Be aware of your environment and all possible hazards that you may

be unable to hear while cutting the hedge.

DANGER!

► In the event of imminent danger or an emergency, switch off the

engine immediately.

Electrical safety

■ Hold the power tool only by the insulated grips as the cutting blades

could come into contact with hidden power lines. Contact between

the blades and a live wire may make exposed metal parts of the power

tool live and could give the operator an electric shock.

Personal safety

■ During operation, no other person or animal may be within a radius

of 15 metres. The operator is responsible for third parties within the

working area.

■ During operation, ensure that you have proper footing and balance at

all times, especially when used on steps or ladders.

■ Never touch the cutter bar of the hedge trimmer.

■ Keep your hands away from the cutting blades. Do not attempt to

clear clippings or hold onto the material to be cut while the blades

are still in motion. Remove any jammed clippings only when the

appliance has been switched off. A moment of inattention while

operating the hedge trimmer may result in serious personal injury.

■ Wait until the tool has come to a standstill before putting it down.

Use and handling

CAUTION!

► Between tasks or after completion of a task, do not set the cutter bar

down on its tip as this could cause damage to the cutter bar

■ Before use, always check that the blades, the blade screws and other

parts of the cutting tool are not worn or damaged. Never work with a

damaged or heavily worn blade.

■ After making settings to the working angle, check whether both setting

levers are clicked firmly into place. If one of the setting levers remains

open, the second could be unintentionally be released by a branch

and the cutter bar could swing down.

■ Never use the hedge trimmer with defective or missing safety devices.

■ Never grasp the hedge trimmer by the safety guards.

.

■ Carry the hedge trimmer by the front handle when switched off,

with the cutter bar facing away from your body. When transporting

or storing the trimmer, always put on the protective cover. Careful

handling of the appliance reduces the likelihood of accidental contact

with the moving blades.

■ Store the hedge trimmer in a dry, high or closed space out of the reach

of children.

■ Do not attempt to repair the equipment unless you have received the

necessary training.

■ For safety's sake, change worn or damaged parts.

DANGER!

► In the event of imminent danger or an emergency, switch off the

engine immediately.

Operational safety instructions for pole pruners

CAUTION! RISK OF INJURY!

► To prevent injuries, never touch the appliance above the safety ring

while it is running!

Preparation

■ Always wear a hard hat, ear protection and safety gloves. Also wear

safety goggles to prevent splashes of oil or sawdust from getting into

your eyes. Wear a dust mask to protect yourself from dust.

■ Wear sturdy, non-slip boots.

■ Do not use the appliance in the rain.

■ Before use, check the appliance's safety condition, especially the blade

and the saw chain.

■ Do not use the appliance near power lines. Maintain a minimum dis-

tance of 10 m to above-ground power lines.

Electrical safety

■ Do not use the appliance in a potentially explosive environment con-

taining flammable liquids, gases or dusts. The sparks generated by the

machine could ignite the vapours or gases.

■ Appliances with defective switches must be repaired immediately to

avoid damage or injuries.

Personal safety

■ Never use the appliance while standing on a ladder.

■ Do not lean too far forward while using the appliance. Ensure you are

standing firmly and keep your balance at all times. Use the supplied

carrying harness to spread the weight evenly on the body.

■ To avoid injuries due to falling branches, do not stand under the

branches that you want to cut off. Be aware of branches that may

spring back and cause injuries. Work at an angle of approximately

60°.

■ Be aware that an appliance kickback can occur.

■ Keep an eye not only on the branches being cut, but also on falling

material, to avoid tripping.

■ Cover the guide rail and the chain with the cover during transport and

storage.

■ Avoid unintentional starting of the appliance.

■ Store the appliance outside the reach of children. Only those who are

fully acquainted with the operating instructions and the appliance itself

may operate the appliance.

PBK 4 A1

GB│IE│NI │

7 ■

Use and handling

■ Never start the appliance before the blade, saw chain and sprocket

covers have been fitted correctly.

■ Do not cut any wood that is lying on the ground and do not attempt to

saw roots that are protruding from the soil. Avoid immersing the saw

chain in the soil at all costs, as this could blunt the saw chain.

■ If the appliance accidentally comes into contact with a solid object, turn

off the engine immediately and inspect the appliance for damage.

■ After 30 minutes of work, take a break of at least one hour.

■ If the pole pruner is shut down for maintenance, inspection or storage,

switch off the engine, pull the spark plug connector off the spark plug

and ensure that all rotating parts have come to a standstill. Allow the

machine to cool down before carrying out an inspection, settings, etc.

■ Service the appliance carefully. Check for misalignment or binding

of moving parts, breakage of parts and any other damage that may

impair the tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly-maintained tools.

■ Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

■ Have the appliance checked by qualified specialists. Use only the re-

placement parts recommended by the manufacturer.

■ Any such reaction can lead to you losing control over the saw and

possibly injuring yourself. Do not rely solely on the chainsaw's built-in

safety devices. As the user of a chainsaw, you can take a number of

measures to avoid accidents and injury. A kickback is caused by incorrect use or misuse. It can be avoided by taking proper precautions, as

described below:

■ Hold the saw firmly with both hands, with your thumb and fingers

around the handles of the chainsaw. Position your body and arms

so you can withstand kickback forces. If suitable measures are taken,

the operator can control the recoil forces. Never let go of the chainsaw.

■ Avoid any abnormal posture and do not saw over shoulder height.

This will prevent inadvertent contact with the tip of the rail and allows

a better control of the chainsaw in unexpected situations.

■ Always use the replacement rails and saw chains specified by the

manufacturer. Incorrect replacement rails and saw chains can lead to

a tearing of the saw chain and/or kickback.

■ Follow the manufacturer's instructions for sharpening and mainten-

ance of the saw chain. Setting the depth limiter too low can increase

the risk of kickback.

■ Do not saw with the tip of the blade. This can lead to a kickback.

■ Ensure that there aren’t any objects on the ground that you can trip

over.

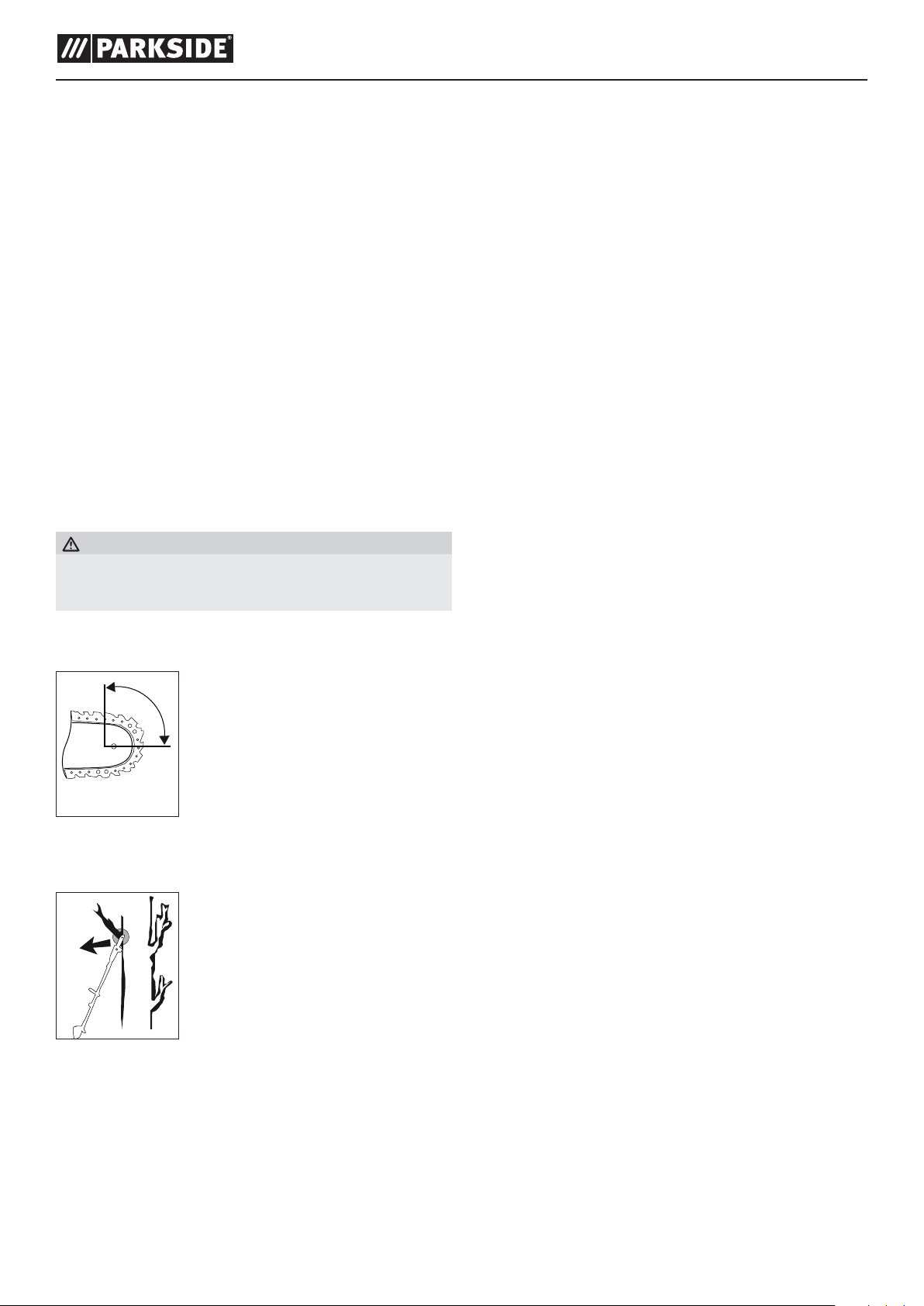

Precautions against kickback

CAUTION KICKBACK!

► Be aware of the danger of kickback when working with the appli-

ance. There is a risk of personal injury. You can avoid kickbacks by

being careful and using the correct sawing technique.

■ Contact with the tip of the rail may in some cases lead to an unexpected

rearwards reaction resulting in the guide rail flying upwards towards

the operator (see fig. A).

Bild 1

Fig. A

■ Kickbacks can occur if the tip of the guide rail touches an object or if

the wood bends and the saw chain gets caught in the cut (see fig. B).

Operational safety instructions for strimmers

Preparation

■ Wear close-fitting clothes that offer good protection, such as long

trousers, sturdy work shoes, heavy-duty protective gloves, a hard hat,

a protective mask for your face or safety goggles to protect your eyes

and good ear plugs or some other hearing protection against noise.

■ Always use the enclosed shoulder strap.

■ Always ensure that the handles are dry and clean and that no petrol

mixture is present.

■ Before working, check the area for objects such as pieces of metal,

bottles, stones, etc, that could get thrown up and cause injuries to the

user.

■ Before starting the engine, make sure that the strimmer is not in contact

with any obstacles.

■ Do not use the appliance until you have familiarised yourself with its

use.

Electrical safety

■ Never use the appliance near highly flammable liquids or gases, either

in closed rooms or in the open. This may result in explosions and/or

fire.

■ Do not work with a damaged or incomplete appliance or an appliance

that has been modified without the consent of the manufacturer. Never

use the unit with defective protective equipment. Do not use the appliance if it has a defective on/off switch. If the appliance has been

dropped, check for significant damage or defects.

Fig. B

■ If the saw chain jams in the upper edge of the guide rail, the rail can

kick back violently towards the operator.

■ 8 │ GB│IE│NI

Personal safety

■ This appliance may only be operated, adjusted and maintained by

appropriately trained individuals and adults.

■ If you are not familiar with the appliance, practice handling the appli-

ance while the engine is off.

■ Do not touch the exhaust.

■ Do not operate the appliance under the influence of alcohol or drugs.

■ Always hold the appliance with both hands. Your thumbs and fingers

should encircle the handles.

PBK 4 A1

■ Work posture: Do not operate the appliance in an uncomfortable pos-

ition, when you are unbalanced, with arms fully stretched or with only

one hand.

■ Always ensure that you have a solid and firm stance.

■ Do not use the appliance if bystanders or animals are in the direct vicin-

ity. Maintain a minimum distance of 15 metres between the operator

and other people or animals when trimming. Maintain a minimum distance of 30 metres between the operator and other people or animals

when mowing down to the ground.

■ When mowing on a slope, always stand at a lower level than the cutting

tool. Never cut or trim on an icy, slippery hill or slope.

■ Any modifications to the product may risk personal safety and void the

manufacturer's warranty.

■ Children should be supervised to ensure that they do not play with the

appliance.

■ Do not use the appliance if it is damaged or if there are visible defects.

Use and handling

■ Use the appliance only for its intended purpose: cutting grass, mowing,

pruning branches, cutting and trimming hedges and bushes.

■ Do not use the appliance for extended periods; take regular breaks.

■ Ensure that screws and connecting elements are firmly tightened. Never

operate the appliance if it is not correctly adjusted, incomplete or if it is

not properly assembled.

■ Open the fuel tank slowly in order to allow any pressure which may

have built up in the tank to dissipate. To prevent the risk of fire, move at

least 3 metres away from the refuelling area before starting the appliance.

■ Guide the strimmer to the desired height. Avoid contact with small

objects (e.g. stones) when using the strimmer.

■ Always hold the strimmer on the ground when the appliance is in oper-

ation.

■ Do not use the appliance unless the appropriate protective guard has

been installed and is in good condition.

■ Do not use any other cutting tools. For your safety, only use the ac-

cessories and additional devices that are indicated in the operating

instructions. The use of parts other than those recommended in the

operating instructions, or other accessories, can put you at risk of injury.

■ Always trim and cut using the high speed range. Do not let the engine

run at a low speed when starting to mow or trim.

■ When starting and operating the appliance, ensure that it does not

come into contact with the ground, stones, wire or other foreign material. Switch off the appliance before you put it down.

■ Switch off the appliance before you put it away.

■ Always turn the engine off before working on the cutting tool.

Operational safety instructions for cutting blades

Preparation

■ The cutting blade flings objects and soil with great force. These can

blind or cause other injuries. Wear eye, face and leg protection.

Always remove objects from the work area before using the cutting blade.

■ The cutting blade continues running after the throttle lever has been

released. A running-down cutting blade can inflict cuts to yourself or

other people standing nearby. Turn the engine off and make sure that

the cutting blade has come to a complete stop before performing any

work on the cutting blade.

Personal safety

■ The appliance can blind and cause injuries to bystanders. Maintain a

minimum distance of 15 metres in all directions between the appliance

and other people or animals.

Use and handling

■ Do not use the appliance if any of the cutting blade accessories have

not been properly installed.

■ The cutting blade can kick back from objects with force. This can cause

injuries to your arms and legs. If the appliance comes into contact with

a foreign body, immediately shut down the engine and wait until the

cutting blade has come to a complete stop. Check the cutting blade for

damage. Always replace the cutting blade if it is bent or cracked.

Safety devices/equipment

The relevant plastic protective guard for the cutting blade or filament

operation must be installed when working with the appliance in order to

prevent objects from being flung away.

WARNING!

■ Never mow/trim while other individuals, especially children or

animals, are in the vicinity.

■ Maintain a safety distance of 15 m. Turn off the appliance immedi-

ately if this distance is not maintained.

CAUTION! RISK OF POISONING!

■ Exhaust gases, fuels and lubricants are toxic. Exhaust gases must

never be inhaled.

WARNING!

■ Petrol is highly flammable. Store petrol only in the containers

provided.

■ Refuel only outdoors and do not smoke.

■ The filler cap must not be opened and refuelling must not take place

while the engine is running or when the appliance is hot.

■ Do not attempt to start the engine if the petrol has overflowed. In-

stead, remove the appliance from the area polluted by petrol. Do not

attempt to restart the appliance until the petrol fumes have dissipated.

■ For safety reasons, the petrol tank and filler cap must be replaced if

they are damaged.

Limit the noise generation and vibrations to a minimum!

■ Only use appliances that are in good condition.

■ Maintain and clean the appliance on a regular basis.

■ Adapt your working method to the appliance.

■ Do not force the power tool.

■ Have the appliance inspected if necessary.

■ Switch the appliance off when not in use.

■ Wear protective gloves.

PBK 4 A1

GB│IE│NI │

9 ■

Before use

CAUTION!

■ Always wear non-slip footwear and appropriate safety clothing

such as protective gloves, a hard hat, a protective mask and safety

goggles as well as hearing protection.

■ Check the area in which the appliance is to be used and remove any

objects that may be caught and slung away.

■ Before use and after dropping or other impacts, always visually in-

spect the appliance to check whether the cutting tool, mounting bolts

and the entire cutting unit are damaged. Worn or damaged cutting

tools and mounting bolts must be replaced.

■ Always carry out a visual inspection before use to check whether the

cutting tools are worn or damaged. To prevent imbalance, worn or

damaged cutting tools and mounting bolts should be replaced only

as complete sets.

Attaching the round handle

♦ Start by fitting the rubber ring 5a on the boom .

♦ Attach the barrier bar onto the rubber ring 5a from below, as

shown in the diagram.

♦ The pin 5b of the barrier bar must be pushed into one of the two

holes on the boom

♦ Push the round handle onto the rubber ring 5a provided on the

boom

♦ Insert the 4 mounting bolts from above through the round handle

♦ Tighten the screws .

.

and fix them onto the barrier bar with the 4 nuts.

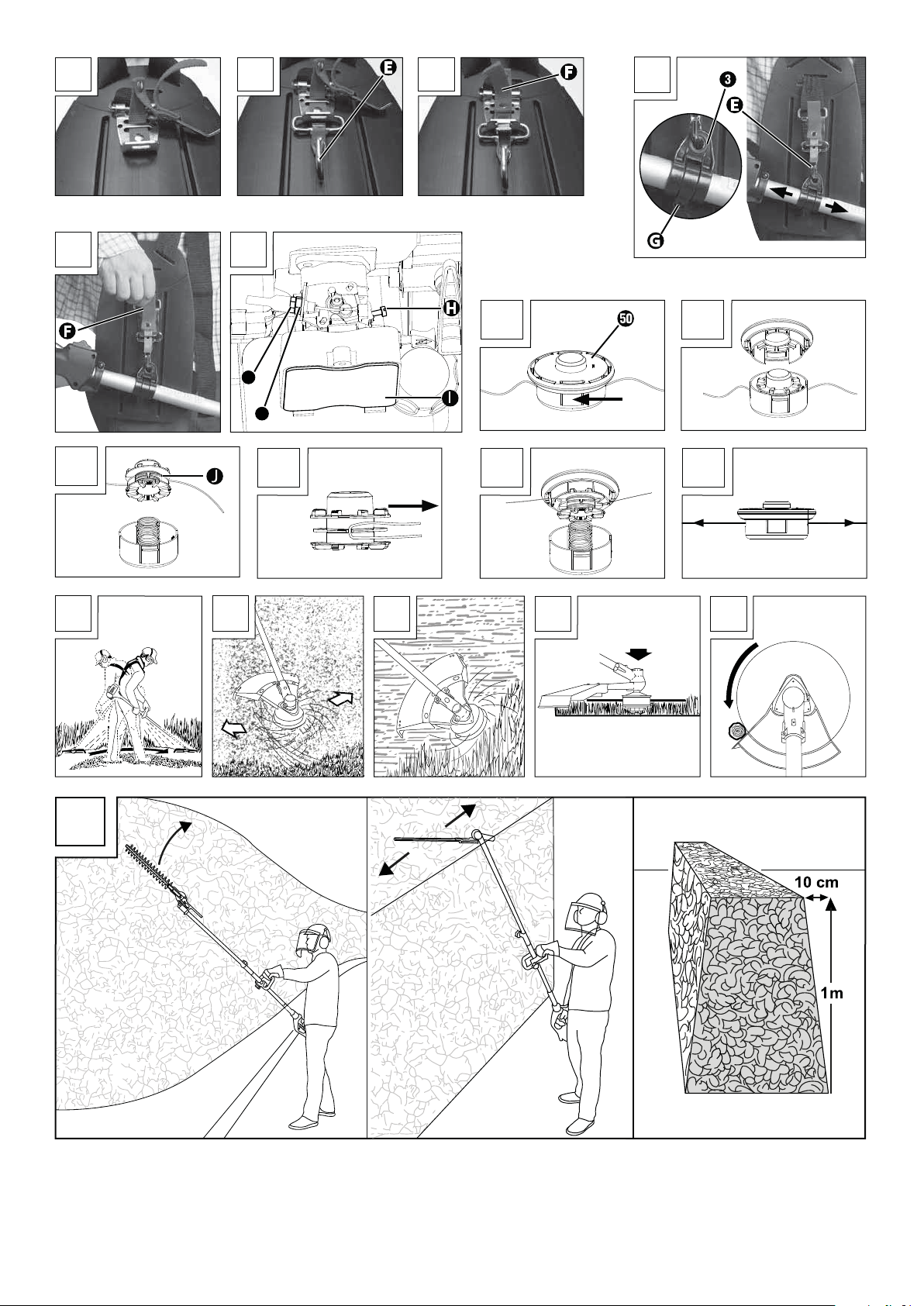

Assembling the quick release mechanism

♦ Hook in the carabiner and secure it with the red strap on the quick

release mechanism (see figures). Pull on the red strap if you have to

put down the appliance quickly.

Fixing/attaching the carrying harness

♦ Hook the carrying harness into the carrying lug .

♦ Adjust the length of the carrying harness to your size so that the

carrying lug

to lock into place.

is at hip height when the strap is hooked in place.

Assembling the hedge trimmer

♦ Start by undoing the screw grip on the boom of the engine unit.

♦ Push the pin on the front boom of the

hedge trimmer into the groove on the engine

unit boom

correctly inserted, the red line must match

up with the one on the engine unit boom.

♦ Tighten the screw grip .

NOTE

Assembly of the pole pruner/strimmer/3-section cutting blade/exten-

►

sion attachment is carried out in the same order.

as far as the stop. Once it is

Removing the hedge trimmer

♦ Undo the screw grip and pull the front boom of the hedge trimmer

out of the engine unit boom

NOTE

Removal of the pole pruner/strimmer/3-section cutting blade/extension

►

attachment is carried out in the same order.

.

Swivelling the hedge trimmer

♦ Release the lock/release .

♦ Press the control lever and swivel the hedge trimmer into the desired

position.

♦ Allow the control lever to click into the recess in the base plate

(hedge trimmer)

.

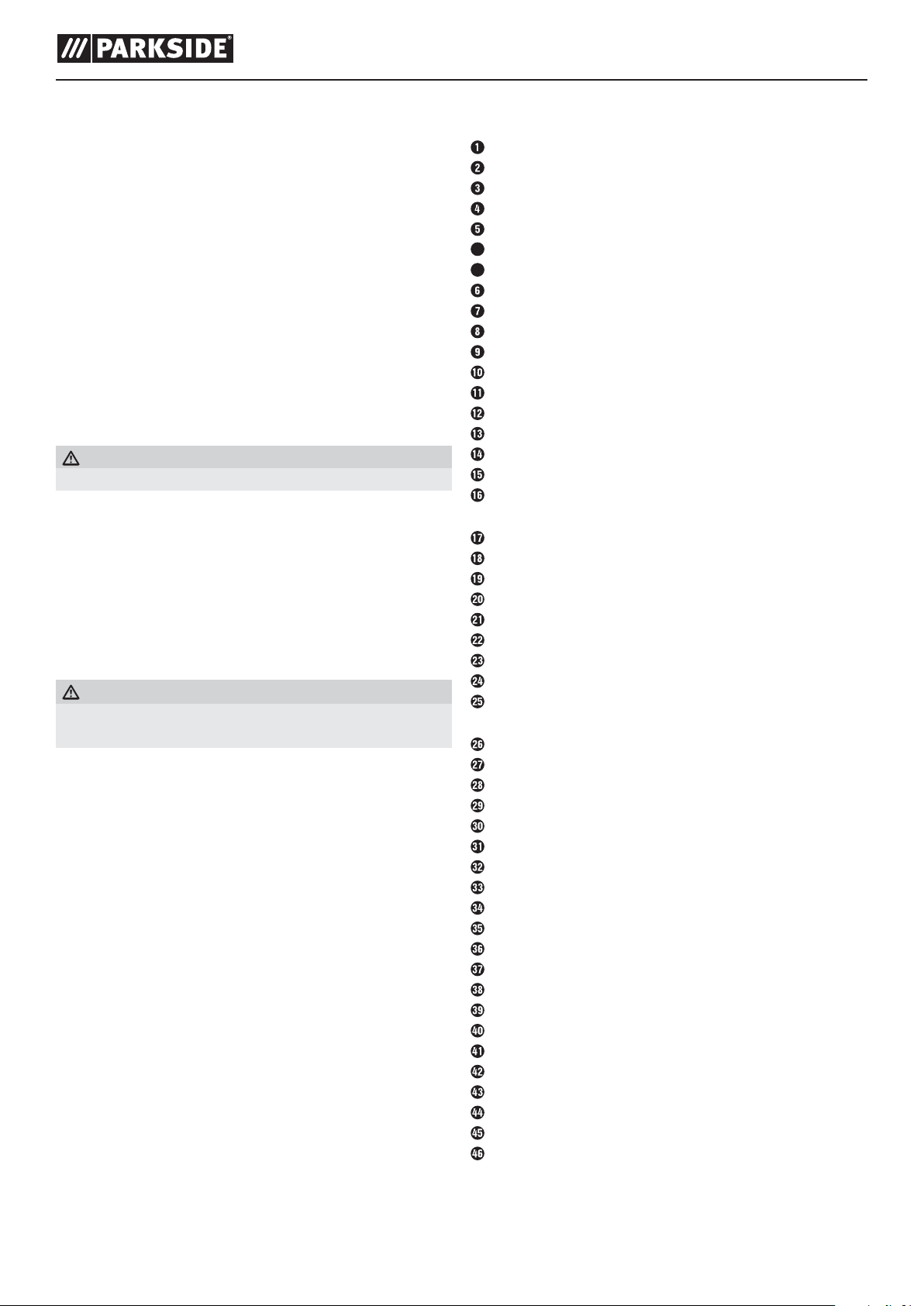

Mounting the saw chain and blade

WARNING!

► Wear protective gloves! There is a danger of injury from the sharp

cutting teeth!

NOTE

► Pay close attention to the running direction of the saw chain on

the blade

► Depending on wear, the blade can be turned.

♦ Undo the nut using the open-ended spanner .

♦ Remove the sprocket cover .

♦ Lay the saw chain over the blade starting at the tip.

♦ Now fit the blade and saw chain .

♦ Lay the guide rail over the blade guide , while inserting the chain

tensioner pin

chain

♦ Now you can tighten the saw chain

checking the saw chain").

♦ Replace the sprocket cover and tighten the nut gently.

and at the base plate (hedge trimmer) .

in the blade hole . At the same time, lay the saw

over the chain sprocket .

(see section "Tightening and

Removing the saw chain

♦ You may have to loosen the saw chain to remove the blade

and the saw chain

chain"). Follow these instructions in reverse order.

(see section "Tightening and checking the saw

■ 10 │ GB│IE│NI

PBK 4 A1

Tightening and checking the saw chain

Fitting/removing the protective guard

WARNING!

► Wear protective gloves! There is a danger of injury from the sharp

cutting teeth!

♦ Turn the chain-tensioner screw in a clockwise direction using the

flat-blade screwdriver

♦ The saw chain must lie against the underside of the blade. Check

whether the saw chain

NOTE

►

A new saw chain stretches and must be tightened more frequently.

to increase the tension.

can be drawn over the blade

by hand.

Lubricating the chain

♦ Remove the oil filler cap .

♦ Fill the oil tank with approx. 100ml of organic chain oil .

♦ The chain lubrication can be increased or decreased using the oil

adjusting screw

♦ Press and then turn the oil adjusting screw clockwise to decrease

the chain lubrication.

♦ Press and then turn the oil adjusting screw anticlockwise to increase

the chain lubrication.

WARNING!

► Never work without lubricating the chain first!

If the saw chain runs dry, the cutting equipment may become irreparably damaged within a short time. Always check chain lubrication

and oil level in the tank before starting work.

NOTE

Use only saw chain oil. Preferably biodegradable. Do not use waste

►

oil, motor oil, etc.

► While working, check whether the chain lubrication is working

correctly.

.

Sharpening the saw chain

NOTE

►

A bench grinder can be attached to the bench grinder support for

a secure grip during grinding.

► You will find detailed information on sharpening in a sharpening set,

e.g. from Oregon.

► Alternatively, you can use an electrical saw chain sharpening device

and follow the manufacturer's instructions.

► If you have any doubts about carrying out the work, the saw chain

should be replaced.

Attaching the extension attachment

CAUTION!

■ Do not use the extension attachment/boom in combination with

the 3-section cutting blade/strimmer attachment!

WARNING!

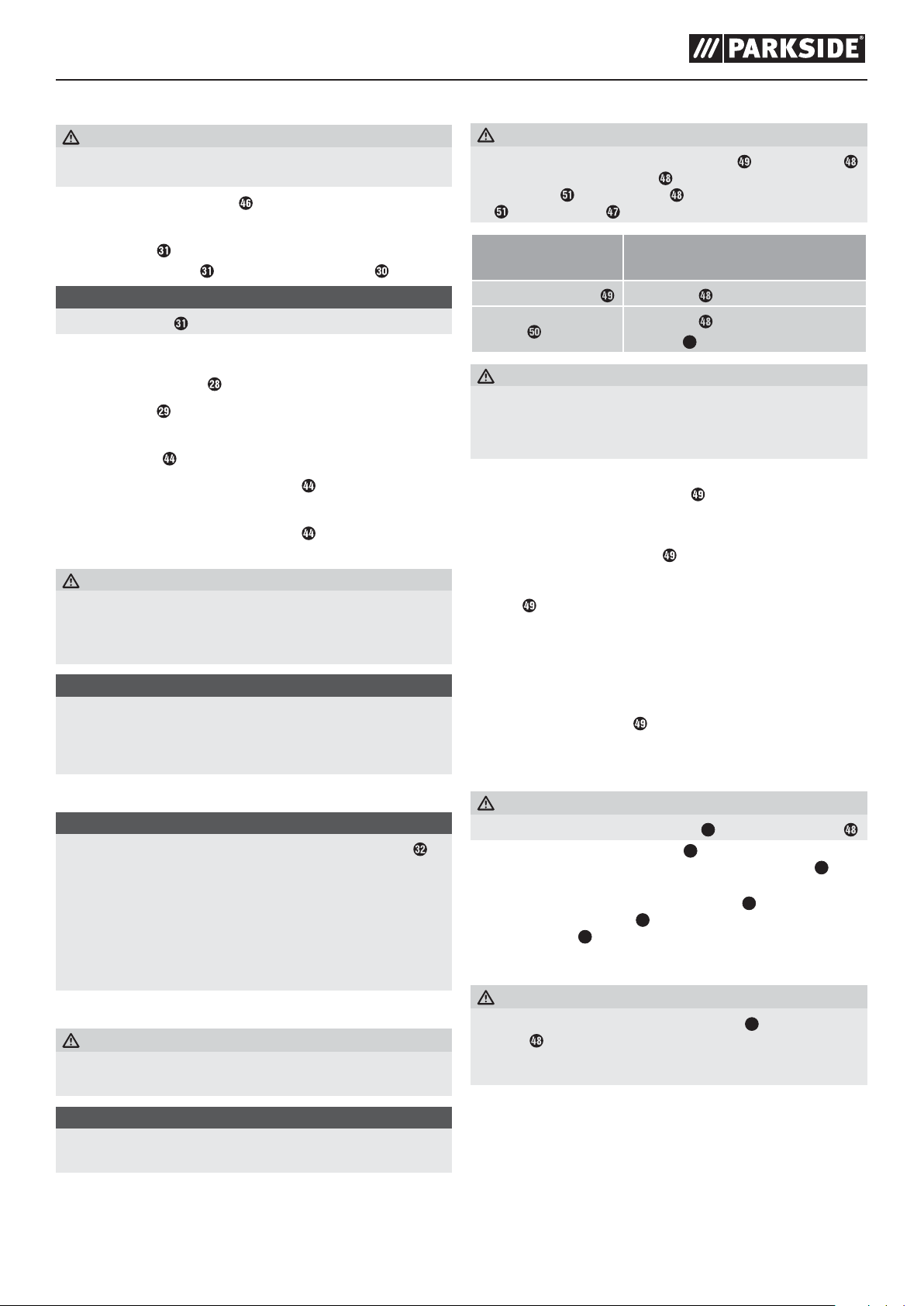

■ When working with the 3-section cutting blade , the blade guard

must be fitted. The blade guard is positioned under the metal panel

of the boom . The blade guard is now attached to the front boom

with the 2 screws . To do this, use the supplied hex key .

Cutting equipment

3-section cutting blade Blade guard

Strimmer

WARNING!

► Do not use any other cutting equipment apart from that which is

supplied with the product. The use of any other cutting equipment

or protective equipment is deemed to be improper and carries a

significant risk of accidents.

Protective equipment

Blade guard + cutting filament protective guard

C

Installing/replacing the cutting blade

■ Fit/remove the 3-section cutting blade as shown in figures 1a–1f.

■ Find the hole in the drive plate , align it with the opposite hole and

block it with the supplied hex key

■ Place the 3-section cutting blade on the drive plate (see fig. 1b).

The inscription must be visible from above when holding the tool in the

working position (see fold-out page). Both sides of the 3-section cutting

blade

■ Fit the pressure plate over the thread over the splined shaft (see fig.

1c).

■ Fit the pressure plate cover (see fig. 1d).

■ Tighten the nut with the spark plug spanner anticlockwise ACH-

TUNG! Left-hand thread! (see fig. 1f).

■ The 3-section cutting blade is fitted with a plastic cover on delivery.

This must be removed before use and refitted during periods when not

in use.

■ The plastic cover can now be removed.

■ Fit the cutting filament protective guard C on the protective guard .

■ The cutting filament protective guard C must be fitted when working

with the cutting filament. The cutting filament protective guard

(pre-fitted on delivery) is fitted as shown in figure 2a.

■ Ensure that the cutting filament protective guard C is correctly clicked

into place. There is a blade A on the inside of the cutting filament

protective guard C. This is covered with a safety cover (see fig. 2a.).

■ Remove the safety cover before starting work and replace it after finish-

ing work.

■ To remove the cutting filament protective guard C from the protective

can be used.

CAUTION! SHARP EDGES, WEAR PROTECTIVE GLOVES

CAUTION! SHARP EDGES, WEAR PROTECTIVE GLOVES

guard , take a tool, such as a screwdriver, to carefully remove the

three mounting pins.

ATTENTION! RISK OF INJURY!

.

C

NOTE

► Use the extension attachment/boom for working at greater

heights.

♦ Fit the extension attachment/boom between the engine unit and

the hedge trimmer/pole pruner. The assembly is carried out in the

same manner as for the attachments described previously.

PBK 4 A1

GB│IE│NI │

11 ■

Installing/replacing the strimmer

■ Install/replace the strimmer as displayed in figure 2c.

■ Find the hole in the drive plate , align it with the opposite hole and

block it with the supplied hex key .

■ Screw the strimmer onto the thread in an anticlockwise direction.

ATTENTION! Left-hand thread!

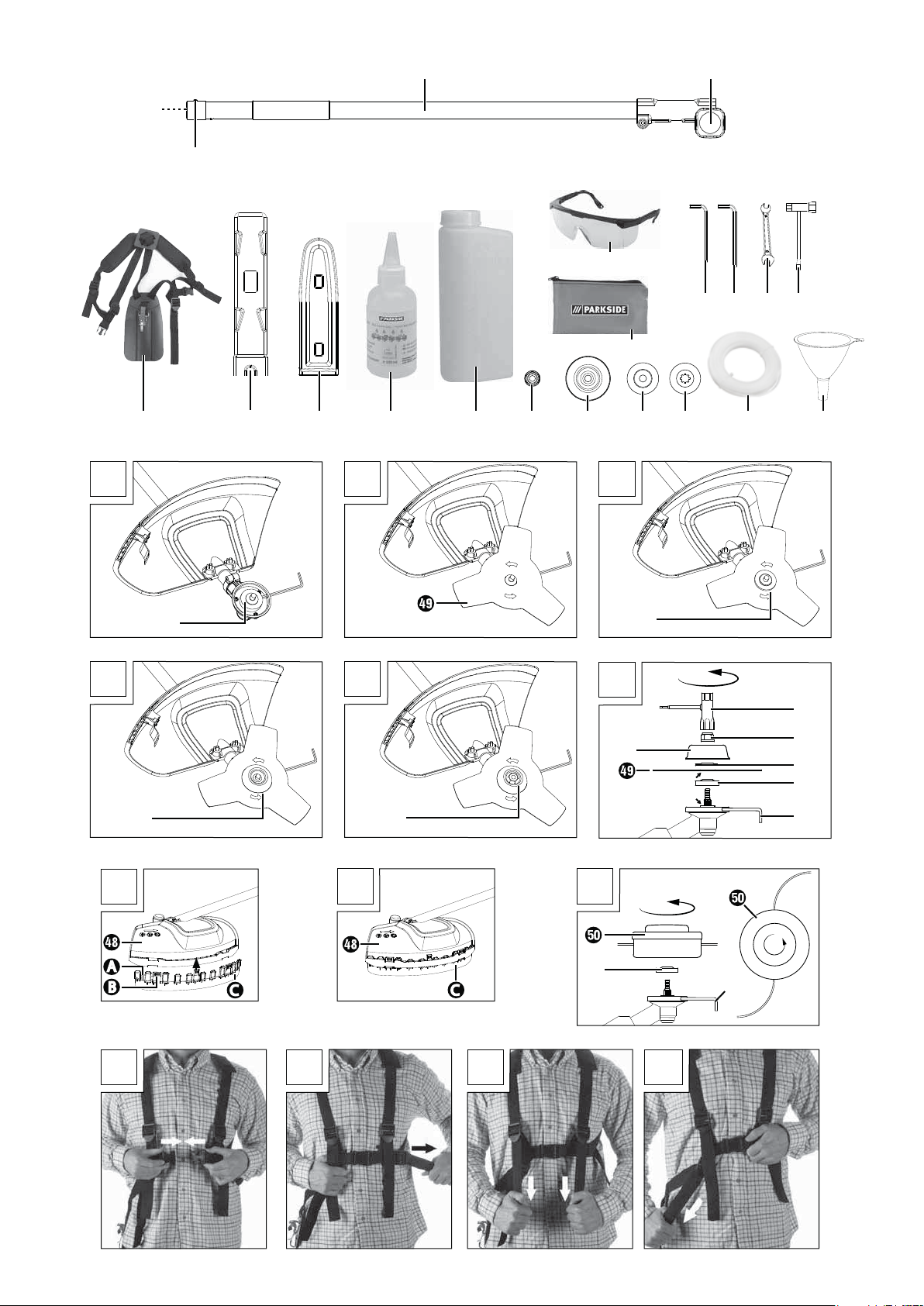

Putting on the carrying harness

NOTE

The following adjustments can be made to make sure that you can

■

work without becoming fatigued. The settings may vary depending

on your body size.

■ Before starting work, adjust the carrying harness to suit your body

size.

■ Balance the appliance with the fitted cutting tool so that the cutting

tool swings just over the ground without the need to move the appliance with your hands.

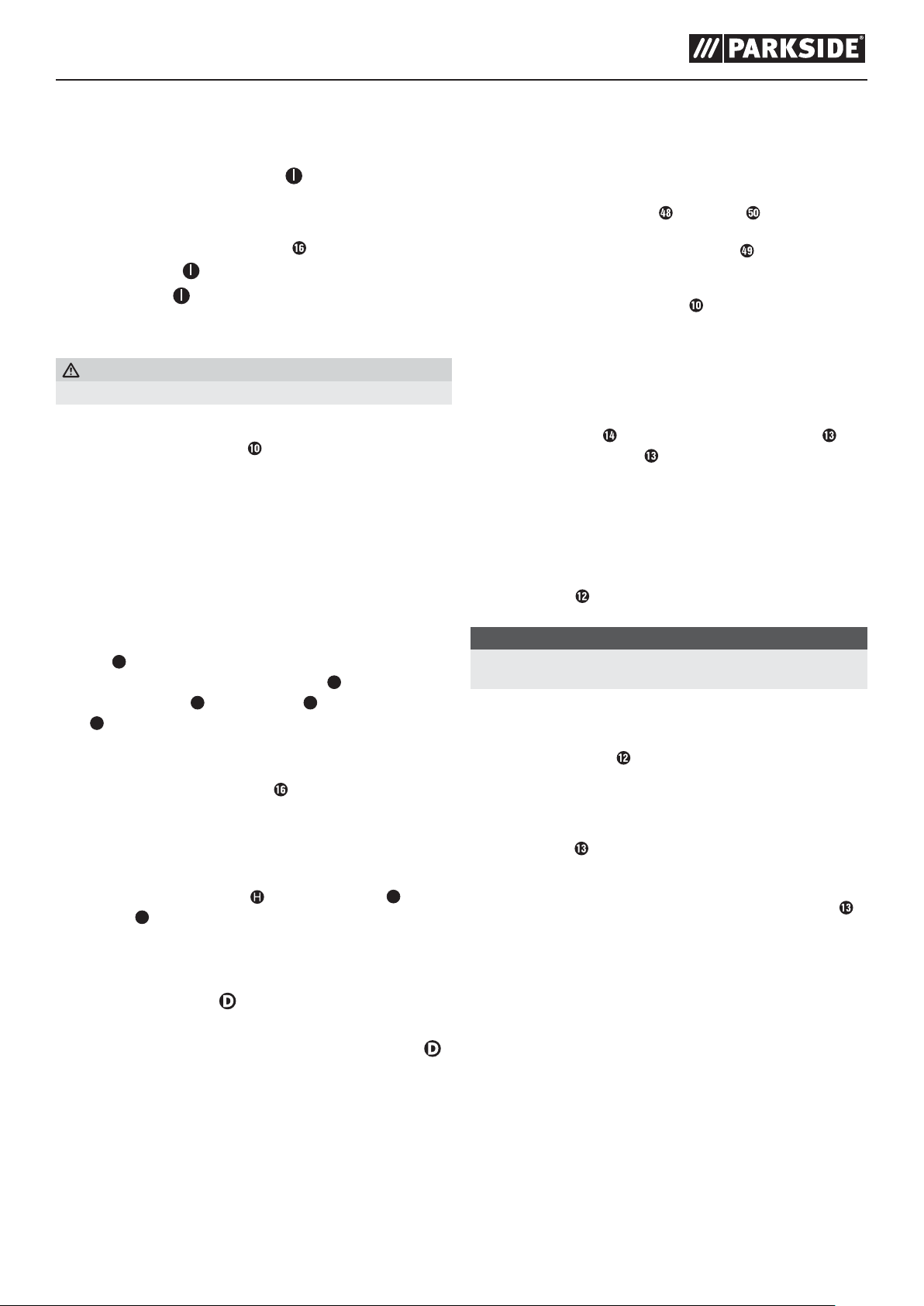

1.) Put on the carrying harness

into place (see fig. 3a).

2.) As shown in figure 3b, pull on the belt

harness

3.) To tighten the two shoulder straps, pull on the two shoulder straps as

shown in figure 3c.

4.) To ensure to the correct position of the appliance on the carrying harness,

pull the belt as shown in figure 3d.

5.) Hook in the carabiner

strap

6.) Now take the appliance and hang it so that the carrying lug

into the carabiner

also be moved by loosening the screw

optimum orientation of the appliance.

centrally on your body and adjust the upper body size.

on the quick release mechanism.

, as shown in figure 3h. The carrying lug can

and close the clasps so that they click

, to position the carrying

(see figs. 3e–3g) and secure it with the red

clicks

and sliding it to achieve the

Setting the cutting height

■ Put on the carrying harness and hook in the appliance (see section

"Putting on the carrying harness").

■ Use the various belt straps on the carrying harness to adjust the

optimum working and cutting position (see section "Putting on the

carrying harness").

■ Perform a few circular movements without starting the engine in order to

find the ideal shoulder strap length (see fig. 6a).

■ The carrying harness is equipped with a quick release mechanism.

Pull on the red strap if you have to release the appliance quickly

(see fig. 3i).

CAUTION!

■ Always use the carrying harness when working with the device.

Put on the carrying harness as soon as you have started the

engine and it is ticking over. Turn off the engine before removing the

carrying harness

.

Fuel and oil

■ Only use a mixture of unleaded petrol (at least ROZ 95) and special

2-stroke engine oil (JASO FD/ISO-L-EGD). Mix the fuel mixture in accordance with the fuel mix table.

■ Add the respective correct amounts of unleaded petrol and 2-stroke oil

to the supplied oil/petrol mixing canister (see “Fuel mix table”).

Then shake the canister well.

Fuel mix table

Mixing process: 40 parts petrol to 1 part oil

Petrol 2-stroke oil

0.5 litres 12.5 ml

Use

CAUTION!

■ Please pay attention to the statutory provisions in the relevant noise

protection regulations.

Before starting the appliance, always check that:

■ The fuel system is not leaking.

■ The protective equipment and cutting equipment is complete and in

perfect working order.

■ All screw connections are firmly tightened.

■ All moving parts can move smoothly and freely.

Starting when the engine is cold

CAUTION!

■ Never allow the starter pull cord to whip back. This could cause

damage.

1.) Fill the fuel tank

“Fuel and oil”).

2.) Push the fuel pump (primer)

3.) Switch the On/Off switch

4.) Pull the choke lever

5.) Hold the appliance firmly and pull out the starter pull cord

point of first resistance. Now pull hard on the starter pull cord

The appliance starts.

6.) If the engine does not start, repeat step 5.

7.) As soon as the engine is running, press first the safety lock-out

then the throttle

If the engine does not start after several attempts, read the “Troubleshooting

guide” section.

CAUTION!

■ Always pull the starter pull cord straight out. Hold the handle of

the starter pull cord

Do not allow the starter pull cord

NOTE

At very high ambient temperatures, it is possible that even a cold

■

engine has to be started without using the choke!

Starting when the engine is hot

(The appliance has been turned off for less than 15–

20 minutes)

1.) Switch the On/Off switch

2.) The choke lever

3.) Hold the appliance firmly and pull out the starter pull cord

point of first resistance. Now pull hard on the starter pull cord

appliance should start after 1–2 pulls. If the appliance still hasn’t started

after 6 pulls, repeat steps 1–7 under “Starting when the engine is cold”.

with the help of the funnel (see also the section

6 times.

to “I”.

into the position “ ”.

to the

.

and

to activate the automatic choke.

firmly when the starter pull cord

does not need to be pulled out to start a warm motor.

to whip back.

to “I”.

retracts.

to the

. The

■ 12 │ GB│IE│NI

PBK 4 A1

Turning the engine off

Emergency stop sequence

If the appliance needs to be stopped immediately, turn the On/Off switch

to "0".

Normal sequence

■ Release the throttle lever and wait until the engine has slowed down

to its idling speed. Then move the On/Off switch to "0".

CAUTION!

■ The 3-section cutting blade must be stationary when the engine is

idling. If the 3-section cutting blade is turning, adjust the carburettor!

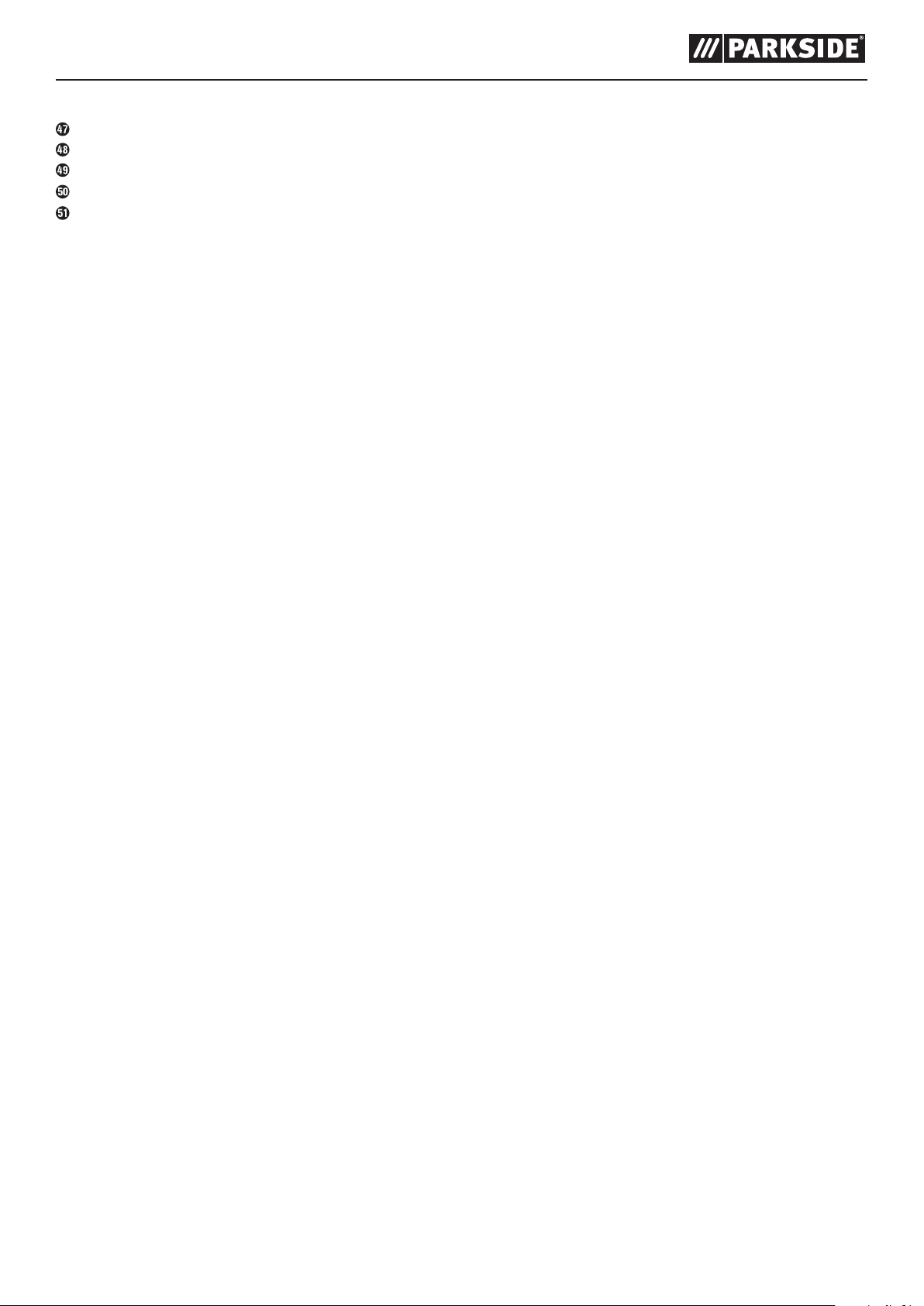

Working procedures

Before using the appliance, practice all working techniques (see figs. 6a–6c)

with the engine stopped.

Extending the cutting filament

To extend the cutting filament, run the engine at full speed and tap the

strimmer on the floor. The filament extends automatically. The knife A

C

on the cutting filament protective guard

length (see fig. 6d).

CAUTION!

Grass/weed residues can get caught under the protective guard

■ Remove the remains using a scraper or similar item when the engine

is switched off.

Various cutting methods

Trimming/mowing (3-section cutting blade or strimmer)

■ Swing the appliance in a scything motion (see fig. 6a).

■ Hold the cutting tool parallel to the ground and set the desired cutting

height.

Low trimming (with strimmer)

■ Hold the appliance with a slight incline to the ground (see fig. 6b).

Always cut away from your body. Never pull the appliance towards

you.

cuts the thread to the permissible

.

Prevent kickback

When working with the 3-section cutting blade there is a risk of kickback if

the blade strikes against solid obstacles (tree trunks, branches, tree stumps,

rocks or similar). This will result in the cutting tool being catapulted back

against the direction of rotation. This can lead to the loss of control of the

appliance. Do not use the cutting blade near fences, metal posts, boundary

stones or foundations. To cut low-density shrubs, position the appliance as

shown in fig. 6e to avoid kickbacks.

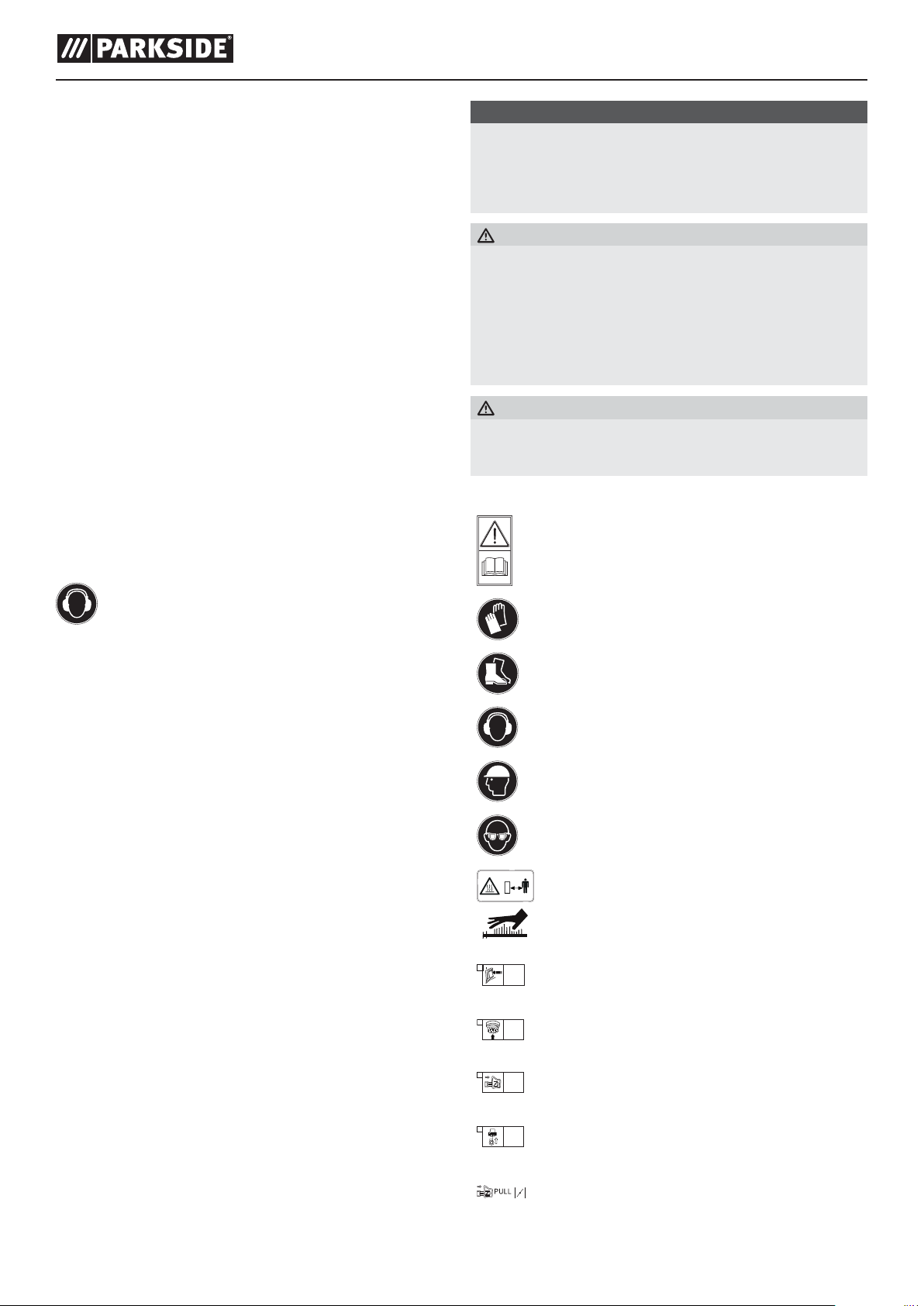

Working with the hedge trimmer

Cutting techniques

■ The double-sided cutter bar allows cutting in both directions or by using

swinging movements from one side to the other.

■ For a vertical cut, move the hedge trimmer evenly forwards or up and

down in an arc.

■ For a horizontal cut, move the hedge trimmer in a scything motion

along the edge of the hedge so that cut branches fall to the ground.

■ See fold-out page (figure A).

NOTE

Remove thicker branches with a branch cutter.

►

Working with the pole pruner

Sawing techniques

WARNING!

► Always pay attention to the falling clippings.

► Be aware of the danger of branches swinging back.

NOTE

►

Place the stop on the branch. This will help you work more safely

and quietly.

► Now you can begin sawing.

Sawing off small branches

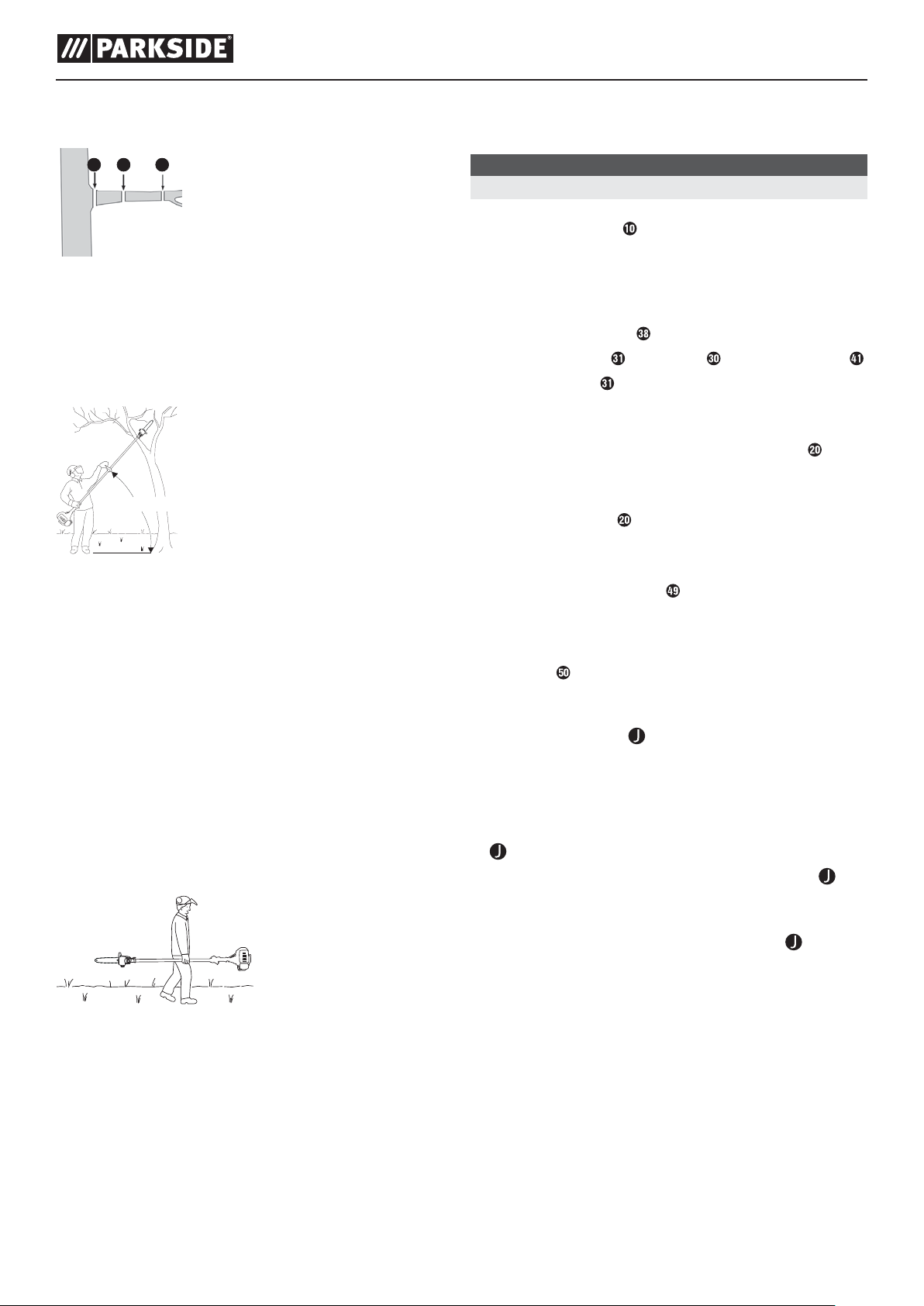

♦ Saw small branches (Ø 0–8 cm) from the top down (see figure).

Short mowing (with strimmer)

■ Short mowing removes all the vegetation right down to the ground.

Angle the strimmer 30° to the right. Set the handle to the desired

position (see fig. 6c).

Cutting against trees/fences/foundations (with strimmer)

NOTE

The filament will wear or fray quickly if it comes into contact with

■

trees, rocks, walls or foundations. The filament will break off if it

strikes fence mesh.

CAUTION!

■ Do not use the appliance to remove any objects from footpaths, etc.!

The appliance is powerful and can fling small stones or other objects

15 metres or more and may cause injuries or damage to cars,

houses and windows.

Seizing

Immediately turn off the engine if the cutting tool becomes blocked.

Remove all grass and scrub from the appliance before restarting the appliance.

Wear protective goggles!

Sawing off larger branches

♦ When sawing larger branches (Ø 8–25 cm), first make a relief cut A

(see figure). A relief cut also prevents peeling of the bark on the main

trunk.

♦ Saw from the top B to the bottom A.

B

A

2

1

PBK 4 A1

GB│IE│NI │

13 ■

Saw in sections

Trim long or thick branches before you make the final cut (see figure).

C A B

cb a

Working safely

■ Keep the appliance, the cutting mechanism and the chain guard in

good condition to prevent injury.

■ If the appliance has been dropped, check for significant damage or

defects.

■ Observe the specified working angle max. 60°±10° to ensure safe

working (see figure).

max. 60°±10°

■ Do not use the appliance while standing on a ladder or with unsteady

footing.

■ Do not be tempted into making a poorly considered cut.

You could endanger yourself and others.

■ Children should be supervised to ensure that they do not play with the

appliance.

■ Change your working position regularly. Using the appliance for a long

time can lead to vibration-related circulation disorders of the hands.

You can extend the usage duration by using appropriate gloves or by

taking regular breaks. Note that any personal predisposition to poor

blood circulation, low external temperatures or large gripping forces

can reduce the usage period.

Transport

■ Use the protective cases / for transporting the appliance.

■ To prevent injuries, ensure that the appliance cannot switch on during

transport (see figure).

Cleaning

Cleaning the engine unit

NOTE

Clean the appliance thoroughly after every use.

■

■ Always switch off the appliance before cleaning and then disconnect

the spark plug connector

■ Clean the appliance regularly with a damp cloth and a mild detergent.

Make sure that no water can penetrate into the interior of the appliance.

Cleaning the pole pruner

■ The pole pruner must be cleaned of sawdust at regular intervals.

♦ Remove the sprocket cover .

♦ Remove the saw chain from the blade and clean the guide rail .

♦ Keep the saw chain sharp and check the tension; check the oil level

and the oil supply.

Cleaning the hedge trimmer

♦ Check the hedge trimmer for loose screws on the cutter bar and

tighten these if necessary.

♦ Remove stuck cuttings.

♦ Maintain the cutter bar using an oil spray or an oil can.

Cleaning the strimmer/cutting blade attachment

♦ Remove stuck cuttings.

♦ Keep the 3-section cutting blade sharp to facilitate your work.

.

Maintenance

Replacing the strimmer/cutting filament

1.) The strimmer

replacing the strimmer". Press the marking (see fig. 5a) and remove the

cover (see fig. 5b).

2.) Remove the spool bobbin

3.) Remove any remaining cutting filament.

4.) Double the new cutting filament and hook the loop that you have made

into the recess on the spool bobbin (see fig. 5d).

5.) Wind the filament tightly in an anticlockwise direction. The spool bobbin

separates the two halves of the cutting filament (see fig. 5d).

6.) Now take the cover in your hand and place the spool bobbin

Make sure that the filament holder of the spool bobbin lines up with the

filament guide on the cover.

7.) Now release the cutting filament from the spool bobbin

it through the metal eyes in the cover.

8.) Put the two halves of the housing back together so that they click into

place.

9.) Cut any excess filament back to about 13 cm. This reduces the load on

the engine when starting and warming up.

10.) Refit the strimmer (see section "Installing/replacing the strimmer").

must be removed as described in the section "Installing/

from the strimmer housing (see fig. 5c).

in it.

and guide

■ 14 │ GB│IE│NI

PBK 4 A1

Air filter maintenance

Contaminated air filters reduce the engine performance due to low air

supply to the carburettor.

Regular inspection is essential. The air filter

every 25 hours of operation and cleaned if necessary.

The air filter must be checked more frequently if the air is dusty.

1.) Remove the cover of the air filter housing

2.) Remove the air filter

3.) Clean the air filter

air).

4.) Assembly is done in the reverse order.

CAUTION!

■ Never clean the air filter with petrol or flammable solvents.

Spark plug maintenance

1.) Pull off the spark plug connector

2.) Remove the spark plug using the enclosed spark plug spanner

3.) Assembly is done in the reverse order.

Electrode gap = 0.6 mm (distance between the electrodes between which

the ignition spark is generated). Check the spark plug for contamination

after the first 10 hours of operation and clean it with a copper wire brush

if required.

Afterwards, service the spark plug after every 50 hours of operation.

Grinding the protective guard blade

A

The blade

be the case, undo the 2 screws that hold the blade

filament protective guard

blade

of the cutting edge.

Adjusting the carburettor

Remove the cover of the air filter housing

Adjusting the throttle cable

If the appliance no longer reaches maximum speed after a while and all

other causes as described in the "Troubleshooting" section have been ruled

out, this may mean that the throttle cable needs to be adjusted. To adjust

the throttle cable, screw in the screw

as the lock nut

Lubricating the gears

■ Add liquid gear grease after every 20 hours of operation (approx.

10 g) to lubricate the angle gear.

♦ To do this, undo the screw (see fold-out page) to press the gear

grease into the gear housing.

(see fig. 2a) can become blunt over time. If you find this to

A

with a sharpening stone and make sure you maintain the angle

H2

correctly (see Fig. 4).

.

by tapping or blowing it out (with compressed

C

. Clamp the blade A in a vice. Grind the

must be inspected after

.

.

A

onto the cutting

.

or the adjusting screw

H1

as well

.

Storage and transportation

■ Store the appliance in a safe location.

■ Store the appliance and accessories in a safe location which is pro-

tected against naked flames and sources of heat/sparks, such as gaspowered water heaters, dryers, oil stoves or mobile heaters, etc.

■ Ensure that the protective guard , the strimmer and the engine are

free of cutting residue when storing.

■ The plastic cover for the 3-section cutting blade must be refitted for

transport and storage.

■ Always turn the appliance off before performing any maintenance work

and remove the spark plug connector .

Storing the appliance

The appliance must be prepared for storage if it is to be stored for longer

than 30 days. Otherwise the residual fuel in the carburettor will evaporate

and leave a gooey sediment. This may make starting the appliance more

difficult and result in expensive repair work.

1.) Remove the filler cap

Carefully empty the fuel tank

2.) To remove all fuel from the carburettor, start the engine and leave it to

run until it stops.

3.) Allow the engine to cool for about 10 minutes.

4.) Remove the spark plug (see section "Spark plug maintenance").

5.) Add 1 teaspoon of 2-stroke oil to the combustion chamber. Pull the

starter pull cord

Replace the spark plug.

NOTE

Store the appliance in a dry place and away from possible ignition

■

sources.

Start-up after storage

1.) Remove the spark plug (see section "Spark plug maintenance").

2.) Pull the starter pull cord

from the combustion chamber.

3.) Clean the spark plug and observe the correct electrode gap on the

spark plug.

4.) Fill the fuel tank

Transport

■ If you are planning to transport the appliance, empty the fuel tank

as explained in the section "Storage".

to relieve any pressure in the fuel tank .

.

several times to wet all mechanical parts with oil.

quickly in order to remove any excess oil

. See the section "Fuel and oil".

♦ After filling the gearbox, close the lubrication hole with the screw .

PBK 4 A1

GB│IE│NI │

15 ■

Troubleshooting

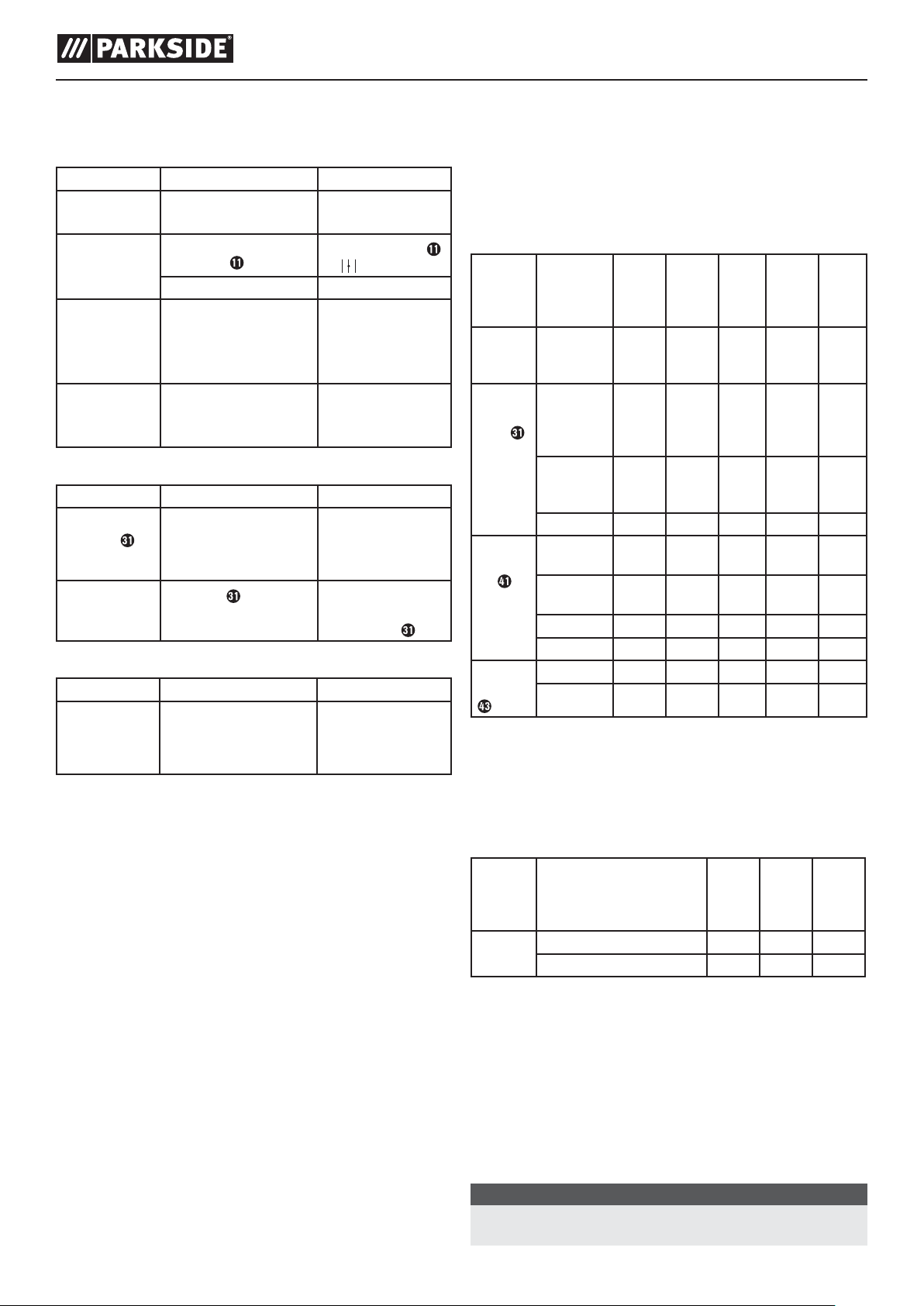

Maintenance intervals

Engine unit

Problem Possible cause Troubleshooting

The engine does

not start.

The engine starts

but does not run

at full power.

The engine does

not run smoothly.

Soot deposits or

wetness on the

spark plug.

Incorrect start-up process. Follow the instructions

regarding starting.

Incorrect adjustment of the

choke lever

Contaminated air filter. Clean air filter.

Incorrect spark plug gap. Clean the spark plug

Incorrect carburettor

adjustment.

.

Set the choke lever

".

to "

and adjust the spark

plug gap or replace

the spark plug.

Clean spark plug or

replace it with a new

spark plug.

Pole pruner

Problem Possible cause Troubleshooting

Motor is running,

saw chain

does not move.

No progress.

Hedge trimmer attachment

or pole pruner attachment

is not connected properly

to the engine unit.

Saw chain

heating or is sagging.

dry/over-

Check assembly.

Top up the oil or regrind, replace or tighten

the saw chain

Hedge trimmer

Problem Possible cause Troubleshooting

Motor is running,

blades do not

move.

Hedge trimmer attachment

or pole pruner attachment

is not connected properly

to the engine unit.

Check assembly.

.

Pole pruner

The figures given here are based on normal operating conditions. In the

event of more difficult conditions, such as strong dust generation and

longer daily operating hours, the given intervals are to be reduced correspondingly.

Appliance part

Lubricating the

chain

Check

saw

chain

Check

guide

rail

Check

sprocket

Action Before

starting

work

Check

and pay

attention to

the sharpness

Check

chain

tension

sharpen X

(wear,

damage)

clean and

turn

deburr X

replace X X

replace

Weekly In the

event

of

faults

X

X

X

X

XX

X

In the

event

of damage

Hedge trimmer

The figures given here are based on normal operating conditions. In the

event of more difficult conditions, such as strong dust generation and longer

daily operating hours, the given intervals are to be reduced correspondingly.

As required

X

■ 16 │ GB│IE│NI

Appliance part

Cutting

blade

Action Before

starting

work

Visual inspection X

Cleaning X X

After

completion

of work

As required

Ordering spare parts

Ordering spare parts

The following information should be provided when ordering spare parts:

■ Type of appliance

■ Item number of the appliance

■ Device ID number

Current prices and information are available at

www.kompernass.com

NOTE

Replacement parts which are not listed (e.g. strimmer, cutting filament)

■

can be ordered via our service hotline.

PBK 4 A1

Disposal

The packaging is made from environmentally friendly material

and can be disposed of at your local recycling plant. The appliance and its accessories are made from various materials, such

as metal and plastic.

Your local community or municipal authorities can provide information on

how to dispose of the appliance.

Dispose of the packaging in an environmentally friendly

manner.

Note the labelling on the packaging and separate the

packaging material components for disposal if necessary. The

packaging material is labelled with abbreviations (a) and

numbers (b) with the following meanings:

1–7: Plastics,

20–22: Paper and cardboard,

80–98: Composites

Your local community or municipal authorities can provide

information on how to dispose of the worn-out product.

Environmental protection

■ Carefully empty the petrol and oil tank and dispose of your appliance

at a recycling plant. The plastic and metal parts used can be separated

and recycled.

■ Dispose of waste oil and petrol at a waste collection centre and do not

dump these into the sewerage or drainage system.

■ Dispose of contaminated maintenance material and working materials

at a collection point provided for this purpose.

Kompernass Handels GmbH warranty

Dear Customer,

This appliance has a 3-year warranty valid from the date of purchase. If

this product has any faults, you, the buyer, have certain statutory rights.

Your statutory rights are not restricted in any way by the warranty described below.

Warranty conditions

The validity period of the warranty starts from the date of purchase. Please

keep your original receipt in a safe place. This document will be required

as proof of purchase.

If any material or production fault occurs within three years of the date of

purchase of the product, we will either repair or replace the product for

you at our discretion. This warranty service is dependent on you presenting

the defective appliance and the proof of purchase (receipt) and a short

written description of the fault and its time of occurrence.

If the defect is covered by the warranty, your product will either be repaired

or replaced by us. The repair or replacement of a product does not signify

the beginning of a new warranty period.

Warranty period and statutory claims for defects

The warranty period is not prolonged by repairs effected under the

warranty. This also applies to replaced and repaired components. Any

damage and defects present at the time of purchase must be reported immediately after unpacking. Repairs carried out after expiry of the warranty

period shall be subject to a fee.

Scope of the warranty

This appliance has been manufactured in accordance with strict quality

guidelines and inspected meticulously prior to delivery.

The warranty covers material faults or production faults. The warranty does

not extend to product parts subject to normal wear and tear or fragile parts

such as switches, batteries, baking moulds or parts made of glass.

The warranty does not apply if the product has been damaged, improperly

used or improperly maintained. The directions in the operating instructions

for the product regarding proper use of the product are to be strictly followed. Uses and actions that are discouraged in the operating instructions

or which are warned against must be avoided.

This product is intended solely for private use and not for commercial

purposes. The warranty shall be deemed void in cases of misuse or improper

handling, use of force and modifications/repairs which have not been

carried out by one of our authorised Service centres.

Warranty claim procedure

To ensure quick processing of your case, please observe the following

instructions:

■ Please have the till receipt and the item number (e.g. IAN 12345)

available as proof of purchase.

■ You will find the item number on the type plate, an engraving on the

front page of the instructions (bottom left), or as a sticker on the rear or

bottom of the appliance.

■ If functional or other defects occur, please contact the service depart-

ment listed either by telephone or by e-mail.

■ You can return a defective product to us free of charge to the service

address that will be provided to you. Ensure that you enclose the proof

of purchase (till receipt) and information about what the defect is and

when it occurred.

You can download these instructions along with many other

manuals, product videos and software on www.lidl-service.com.

PBK 4 A1

GB│IE│NI │

17 ■

Service

WARNING!

■ Have your appliance repaired by qualified specialists only. Always

use genuine spare parts. This will ensure that the safety of the appliance is maintained.

Service Great Britain

Tel.: 0800 404 7657

E-Mail: kompernass@lidl.co.uk

Service Ireland

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: kompernass@lidl.ie

IAN 311700

Importer

Please note that the following address is not the service address. Please

use the service address provided in the operating instructions.

KOMPERNASS HANDELS GMBH

BURGSTRASSE 21

DE - 44867 BOCHUM

GERMANY

www.kompernass.com

Translation of the original Conformity

Declaration

We, KOMPERNASS HANDELS GMBH, document officer: Mr. Semi Uguzlu,

BURGSTR. 21, DE - 44867 BOCHUM, GERMANY, hereby declare that

this appliance complies with the following standards, normative documents

and EC directives:

Machinery directive

(2006/42/EC)

Electromagnetic compatibility

(2014/30/EU)

Outdoor directive

(2005/88/EC)

(2000 / 14 / EC)

Emissions directive

(2012/46/EU)

2016/1628/EU (amended by the latest 2017/656/EU)

Applied harmonised standards:

EN ISO 11806-1: 2011

EN ISO 10517: 2009+A1

EN ISO 11680-1: 2011

EN ISO 14982:2009

Type/appliance designation:

4-in-1 Petrol Multi-Tool PBK 4 A1

Year of manufacture: 10 - 2018

Serial number: IAN 311700

Bochum, 26/10/2018

Semi Uguzlu

- Quality Manager -

We reserve the right to technical changes in the context of further product

development.

■ 18 │ GB│IE│NI