Panasonic TX-L32EM5E Schematic

ORDER No. PCZ1208127CE

Service Manual

LCD Television

TX-L32EM5E

KM19E Chassis

Specifications

Power Source: 220-240V AC, 50 / 60Hz

Rated Power Consumption: 66W

Stand-by Power Consumption: 0.30W

Aerial Impedance: 75 unbalanced, Coaxial Type

Receiving System:

DVB-T Digital terrestrial services (

DVB-C Digital cable services (

PAL I/H, B/G,

SECAM B/G, L/L’

VHF E2-E12 VHF H1-H2 ( ITALY )

VHF A-H ( ITALY ) UHF E21-E69

CATV (S01-S05) CATV S1-S10(M1-M10)

CATV S11-S20 (U1-U10) CATV S21-S41 (HYPERBAND)

PAL D/K,

SECAM D/K

VHF R1-R2 VHF R3-R5

VHF R6-R12 UHF E21-E69

PAL 525/60 (AV only)

M.NTSC (AV only)

NTSC (AV only)

Aerial Input: VHF / UHF

Operating Conditions: Temperature: 0°C 35°C

Humidity: 20% 80% RH (non condensing)

MPEG2 and MPEG4-AVC(H.264))

MPEG2 and MPEG4-AVC(H.264))

© Panasonic Corporation 2012.

Unauthorized copying

distribution is a violation of law.

and

Terminals:

2

AV1 IN Video (21 pin) 1.0V p-p 75

Audio (21 pin) 500mV rms 10k

RGB (21 pin) 0.7V p-p 75

AV1 OUT Video (21 pin) 1.0V p-p 75

Audio (21 pin) 500mV rms 1k

AV2 IN Video (RCAx1) 1V p-p 75

(COMPONENT/VIDEO) Audio (RCAx2) 500mV rms 10k

Video (RCAx3) Y:1V p-p 75 (including synchronization)

Pb, Pr: ±0.35V p-p 75

HDMI 1 / 2 Type A Connector

HDMI2: Audio Return Channel

CARD SLOT Common Interface slot (complies with CI Plus) 1

DIGITAL AUDIO OUT PCM / Dolby Digital/ Fibre optic

USB USB2.0 DC 5 V, Max. 500mA

LCD screen: L5EDDYY00413

1920 x 1080 , 16:9

Visible Diagonal 800mm

Audio Output: 10W (2x5W)

Headphones: 3.5mm (M3) stereo mini jack 1

Accessories supplied : Remote Control

2 x R6 (UM3) Batteries

Dimensions:

Width: Height: Depth:

Including TV stand 764mm 518mm 196mm

TV set only 764mm 473mm 60mm

Mass:

Including TV stand 9 0 kg

TV set only 8.0 kg

Design and Specifications are subject to change without notice. Mass and dimensions shown are approximate.

This equipment complies with the EMC standards listed below:

EN55013, EN61000-3-2, EN61000-3-3, EN55020

Warning

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potencial dangers in attempting to service a product. Products

powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the

product or products deal within this service information by anyone else could result in serious injury or death.

CONTENTS

3

SAFETY PRECAUTIONS .......................................................................... 4

GENERAL GUIDE LINES..................................................................... 4

TOUCH – CURRENT CHECK.............................................................. 4

PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES .......................... 5

ABOUT LEAD FREE SOLDER (PBF)........................................................ 6

SUGGESTED PB FREE SOLDER....................................................... 6

APPLICABLE SIGNALS............................................................................. 7

SERVICE HINTS ....................................................................................... 8

CHASSIS BOARD LAYOUT ...................................................................... 9

LOCATION OF LEAD WIRING…………………………………………….9

TECHNICAL DESCRIPTION, MODEL AND KYES...................................10

SETTING INSPECTION........................................................................... 11

SELF-CHECK .......................................................................................... 12

POWER LED BLINKING TIMING CHART ............................................... 13

SERVICE MODE FUNCTION .................................................................. 14

SERVICE ................................................................................................ 15

ADJUSTMENT METHOD ........................................................................ 16

WIRING DIAGRAM.................................................................................. 17

BLOCK DIAGRAMS................................................................................. 18

PARTS LOCATION.................................................................................. 20

REPLACEMENT PARTS LIST................................................................. 22

SCHEMATIC DIAGRAMS........................................................................ 29

A-BOARD (1 OF 14) SCHEMATIC DIAGRAM ................................... 30

P-BOARD (1 OF 2) SCHEMATIC DIAGRAM...................................... 44

K-BOARD SCHEMATIC DIAGRAM ................................................... 46

CONDUCTOR VIEWS ............................................................................. 47

Safety Precautions

4

General Guide Lines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated

or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following touch current checks to prevent the customer from being exposed to shock hazards.

4. Always ensure cover label TKP0E16001 is correctly replaced before returning to customer (see Fig.1).

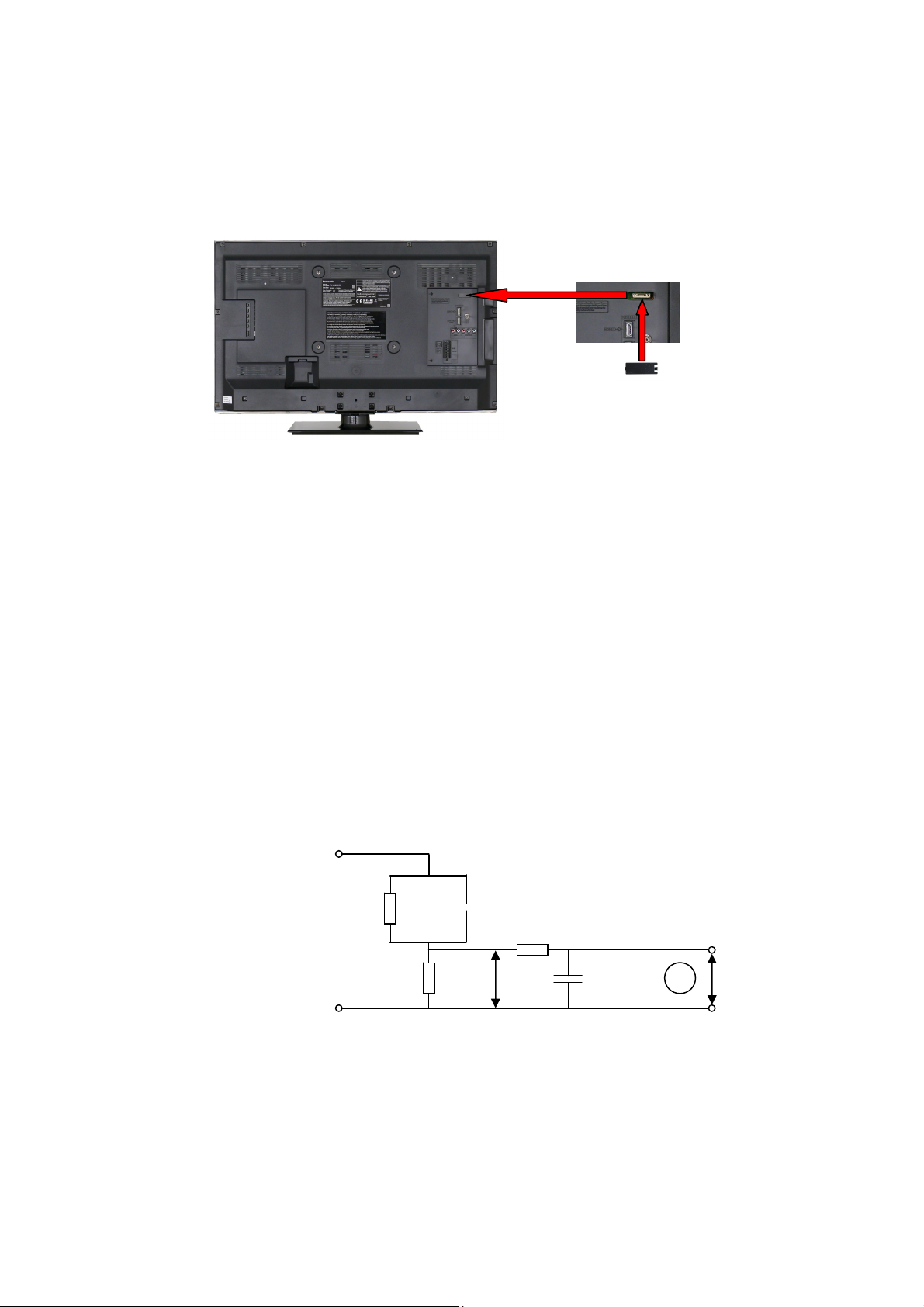

Fig. 1

Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth

ground such as a water pipe, as shown in Fig. 2.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and me asure the voltage at each point.

5. Reserve the AC plug in the AC outlet and re peat each of the above measure.

6. The potential at any point (TOUCH CURRENT) expressed as voltage U1 and U2, does not exceed the following values:

For a. c.: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For d. c.: U1 = 1.0 V,

Note:

The limit value of U2 = 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and

2.0 mA d. c.

The limit value U1 = 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100

kHz.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the customer.

COLD

WATER PIPE

(EARTH GROUND)

TO

APPLIANCES

EXPOSED

METAL PARTS

Resistance values in ohms ()

V: Voltmetr or oscilloscope

(r.m.s. or peak reading)

NOTE – Appropriate measures should be taken to obtain the correct value in case of non-sinusoidal waveforms

Measuring network for TOUCH CURRENTS

C

=1500

R

S

R0=500

Input resistance: 1M

Input capacitance:200pF

Frequency range: 15Hz to 1MHz and d.c.respectively

Fig. 2

=0.22F

S

U

10k

(V)

1

0.022F

V

U2 (V)

Prevention of Electrostatic Discharge (ESD) to Electrostatically

5

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistors and semiconductor "chip" components. The following techniques should be used to help reduce the incidence of

component damage caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD

wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD

protected)" can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity

(ESD) sufficient to damage an ES device).

There are special components used in this equipment which are important for safety.

These parts are marked by in schematic diagrams, exploded views and replacement parts list. It is essential that

these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire, or other hazards. Do

not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

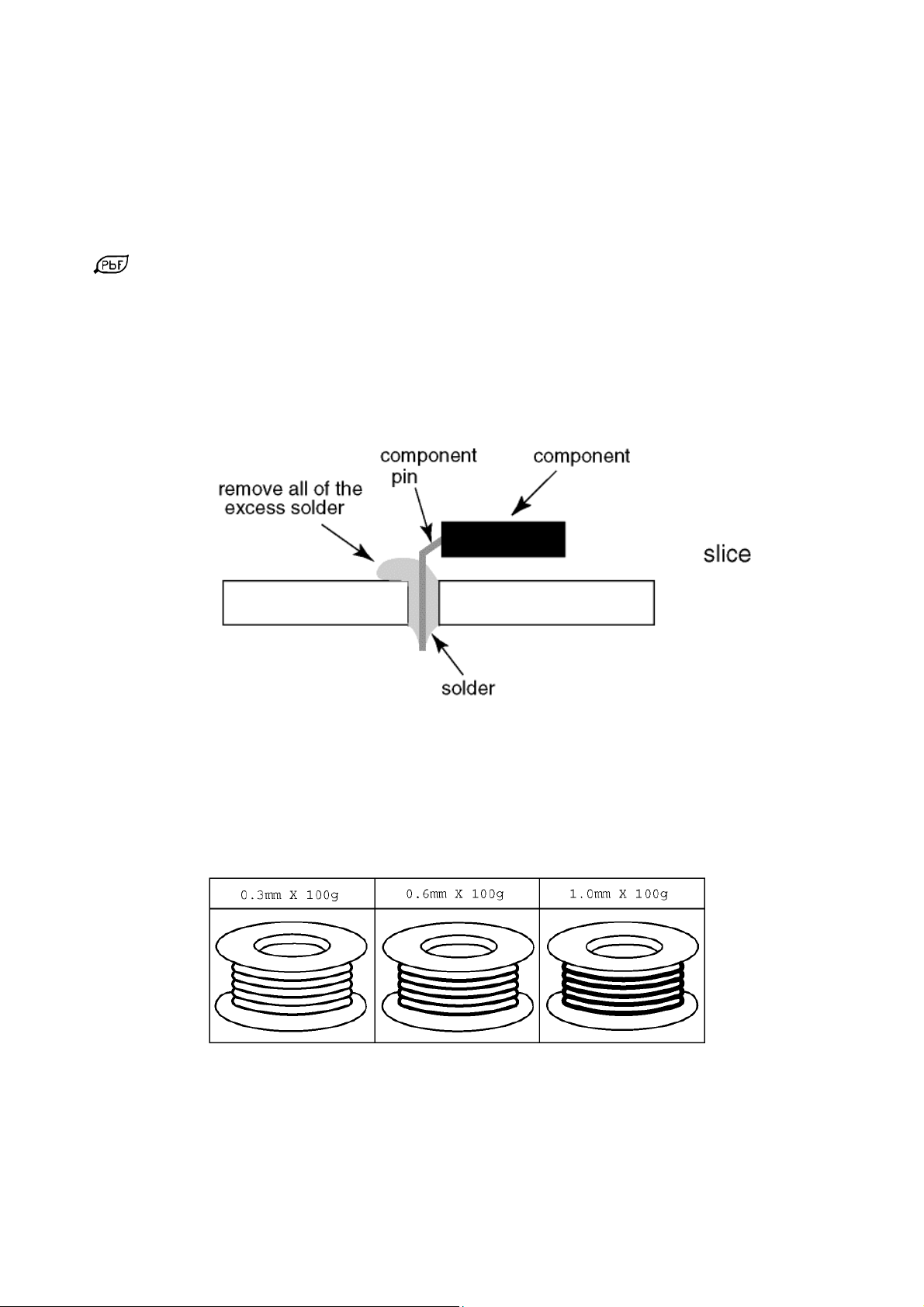

About lead free solder (PbF)

6

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work,

we’d suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

stamped on the back of PCB.

Caution

Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C)

higher. Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before

applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

After applying PbF solder to double layered boards, please check the component side for excess solder which may

flow onto the opposite side. (see Fig.3)

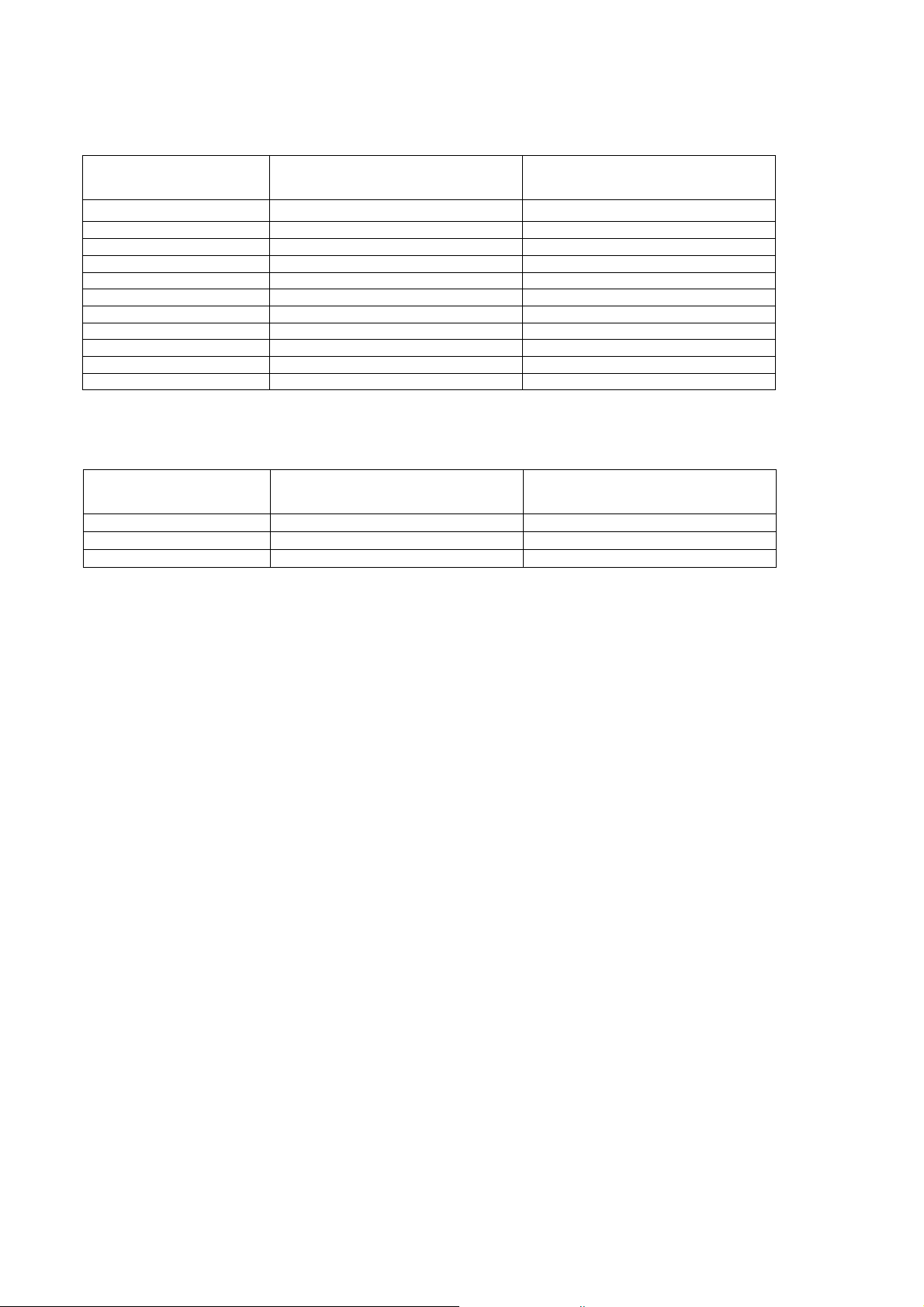

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used. (see Fig.4)

Fig.3

Fig.4

Applicable Signals

7

Component (Y, Pb, Pr), HDMI

Applicable input signal for PC is basically compatible to HDMI standard timing.

Signal name COMPONENT HDMI

525 (480) / 60i * *

525 (480) / 60p * *

625 (576) / 50i * *

625 (576) / 50p * *

750 (720) / 60p * *

750 (720) / 50p * *

1,125 (1,080) / 60i * *

1,125 (1,080) / 50i * *

1,125 (1,080) / 60p *

1,125 (1,080) / 50p *

1,125 (1,080) / 24p *

PC (from HDMI terminal)

Signal name Horizontal frequency (kHz) Vertical frequency (Hz)

640 480 @60 Hz

1,280 720 @60Hz

1,920 1,080 @60Hz

Note:

Signals other than above may not be displayed properly.

The above signals are reformatted for optimal viewing on your display.

PC signal is magnified or compressed for display, so that it may not be possible to show fine detail

with sufficient clarity.

31.47 60.00

45.00 60.00

67.50 60.00

Service Hints

8

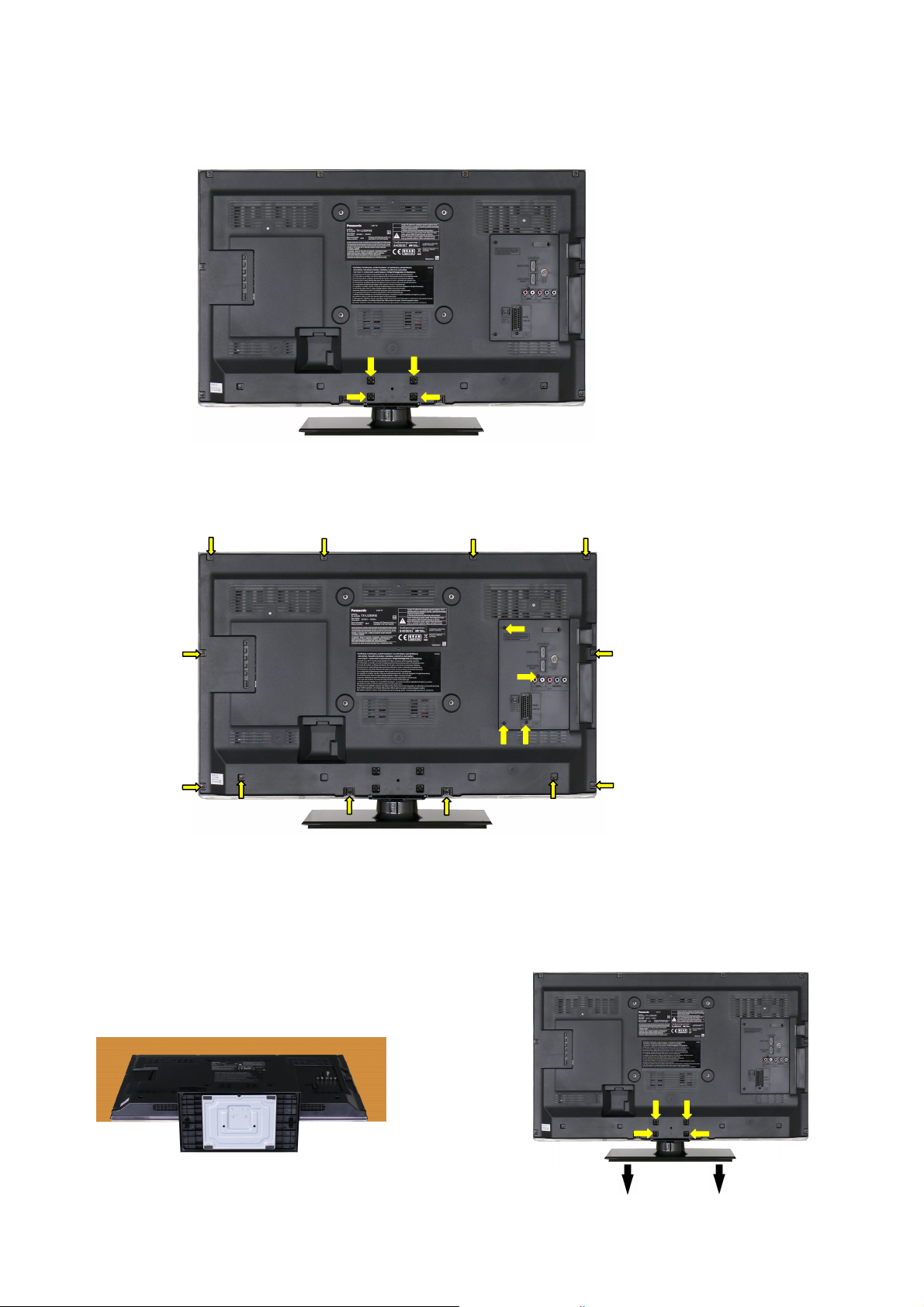

How to remove the backcover

Remove the 4 fixing screws (see Fig.5)

(4)

(4)

SCREWS

(4) XYN4+F12FJK /4pcs/

Remove the 16 fixing screws and the backcover. (see Fig.6)

(1)

(1)

(4)

Fig.5

(1)

(4)

(1)

(1)

Fig.6

(1)

(2)

(2)

(2)

(2)

(1)(1)

(1)

SCREWS

(1) THTD030J /12pcs

(2) XTV3+12JFJK /4pcs

(1)

(1)

(1)

How to remove the pedestal assembly.

Lay the main unit face down. (see Fig.7)

Remove the 4 fixing screws and the pedestal assembly. (see Fig.8)

Fig.7

(4)

(4)

(4)

Fig.8

(4)

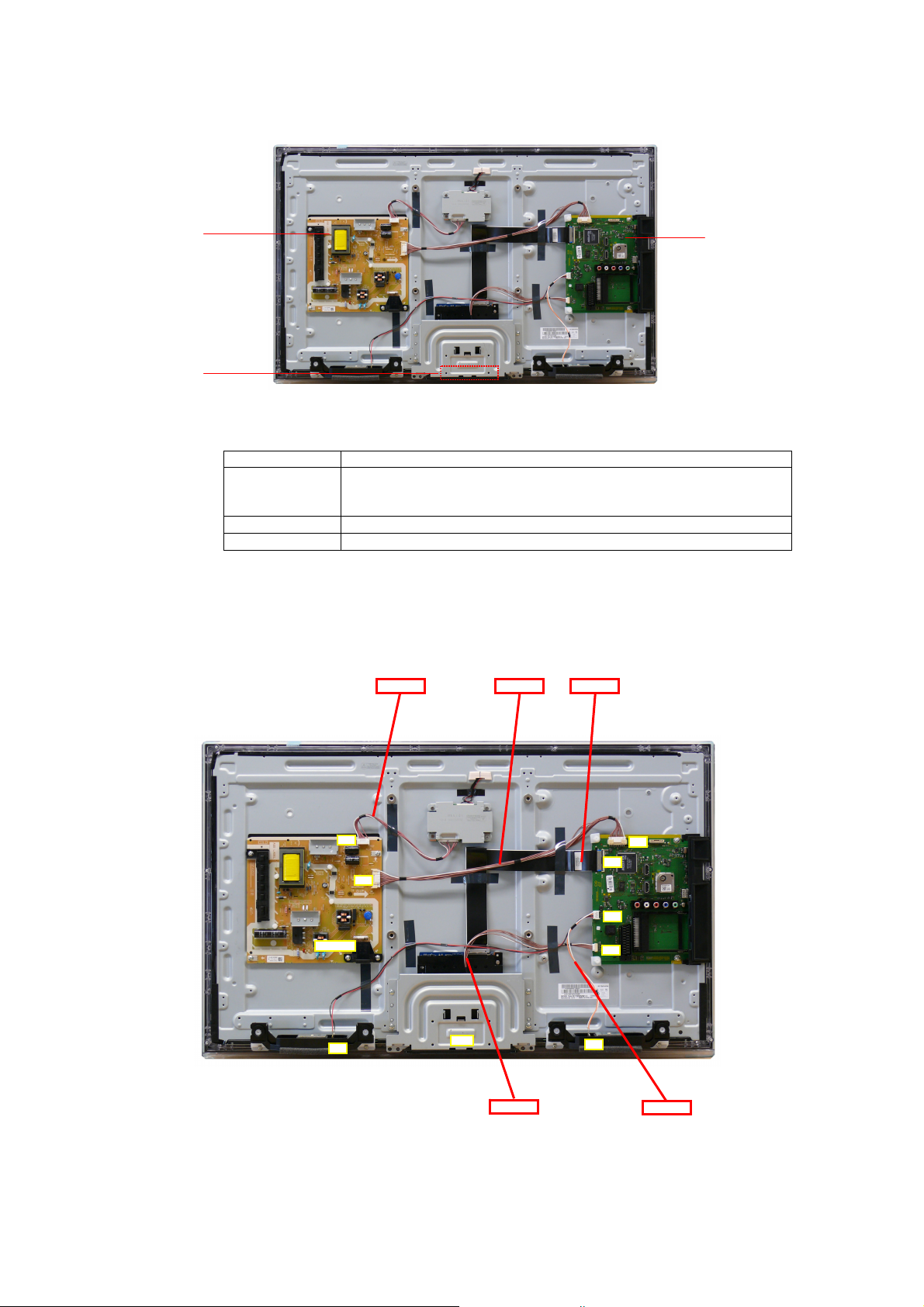

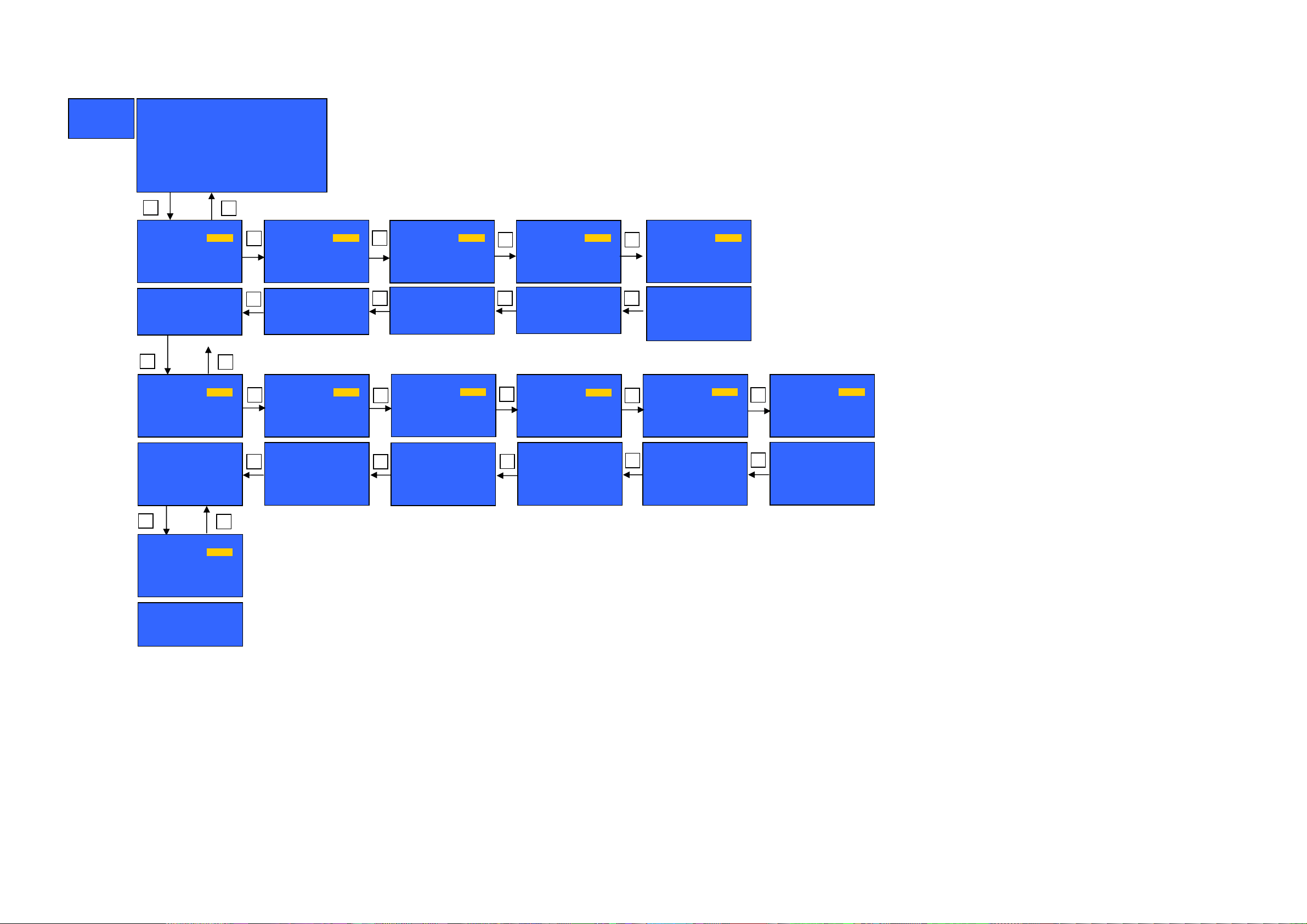

Chassis Board Layout

A

A

A10A

9

P-BOARD

K-BOARD

Board Name Function

AV Terminal, HDMI, Digital Audio Out,TV tuner, CI slot,

A-Board

P-Board Power Supply, Main Input, Key button, LED Driver

K-Board Remote Receiver, R/G LED, C.A.T.S.

MicroProcessor IC8001, Speaker Out, EEPROM,

Flash Memory, DDR SDRAM, USB

Location of Lead Wiring

To find the Part Number of required wire in Replacement Parts List click on the wire name in red box.

LD-P3

A09-P2

A16-CN

A-BOARD

P3

P2

09

16

JK7101

12

SP

K10

SP

A10-K10

A12-SP

Technical Description

10

Model and Keys:

All KEYS are not generated for all models.

The necessary KEYS are only generated and stored depend on the feature of models.

Model No.

TX-L32EM5E Yes Yes

CI PLUS HDCP

Keys

Setting Inspection

11

Voltage Confirmation

A board

Description Test point Voltage

SUB 1.8 V TP8700 1.74V - 1.9V

SUB1.2V TP8000 1.14V – 1.26V

SUB3.3V TP8701 3.19V - 3.46V

SUB5V TP8702 4.9V – 5.1V

STB5V TP5400 4.9V - 5.1V

PNL12V TP8307 11.5V – 12.5V

P board

Description Test point *Voltage( STEP1 ) **Voltage ( STEP2 )

24V TP7509 <1V 24V±1.2V

16.4V TP7508 <1V 16.4V±0.8V

5.3VS TP7507 5.3V±0.1V 5.3V±0.1V

STEP1 : Connect AC 230V to JK7101

STEP2 : Connect DC 2,5V to TV_SUB_ON P2 connector - pin 6 (TP7506) from voltage divider.

Self Check

V

12

Self-check is used to automatically check the bus lines and hexadecimal code of the TV set. To enter Self-Check mode, keep

pressing the down (-/v) button on the TV set and press the

the TV set at the power button.

TX-L32EM5E

32HD

TUN O.K.

MEM O.K.

ID O.K

Panasonic 2012 LCD

Self Check Complete

SOFT

EEP 1.00.000a

Model id 09222100000004

Display Ref. No. Description P.C.B.

TUN TU4802 TUNER A-Board

MEM IC8007 EEPROM A-Board

ID IC8001 MICRO PROCESSOR A-Board

MENU button on the remote control. To exit Self Check, switch off

er.2010

If the CCU ports have been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.".

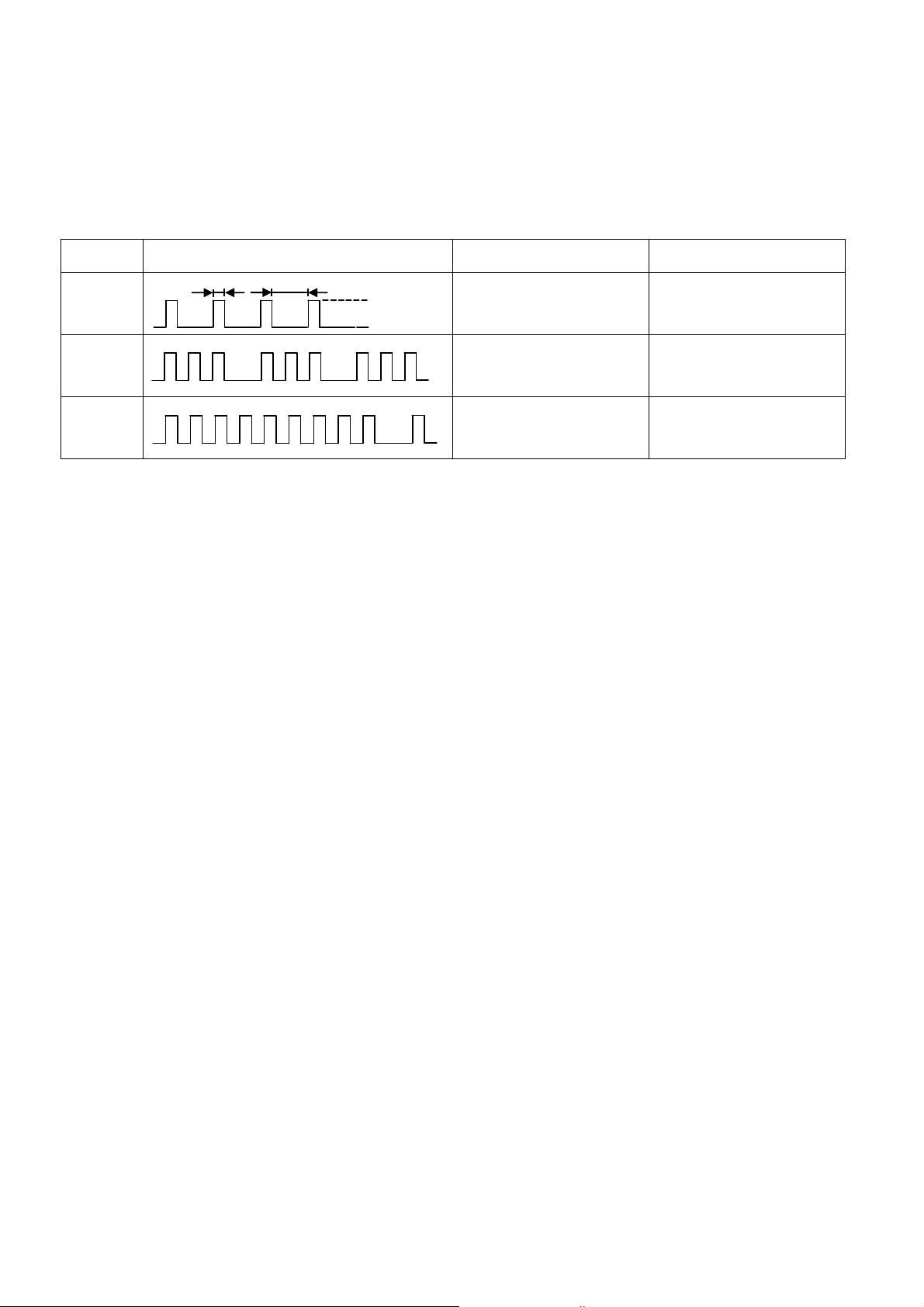

Power LED blinking timing chart

13

1. Subject

Information of LED Flashing timing chart.

2. Contents

When abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by number of blinking of the Power LED on the front panel of the unit.

Blinking

times

Once

1 BL_SOS

3 POWER SOS

Blinking timing Contents Check point

4 sec

Light

No Light

A BOARD

A BOARD

P BOARD

9 SOUND_SOS

A BOARD

Service Mode Function

14

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be

adjusted by remote control in Service Menu

How to enter SERVICE

While pressing (-/v) button on TV unit, press on the remote

control for 3 times within 2 seconds.

Note:

To exit from Service mode, press the exit button on remote control.

0

Service

A

A

V

15

SERVICE

ADJUST

WB-ADJ

OPTION

SOFT V2.010 MODEL ID 09222100000004

EEP 01.00.000a INV Cnt 0

TIME 0:0 COUNT 0

PCTCP 00.00.00.00.00

1 2

ADJUST DYNAMIC

H-POS

1,2:MAIN SELECT

3,4:SUB SELECT

9:PICTURE MENU SELECT

VOL :ADJUST

OK :WRITE

0

ADJUST DYNAMIC

H-AMP

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9:PICTURE MENU SELECT

VOL :ADJUST

OK :WRITE

1 2

WB-ADJ DYNAMIC

R-GAIN

BEFORE FF

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

7:COLOR TEMP SELECT

9:PICTURE MENU SELECT

0:WB METHOD SELECT

VOL :ADJUST

OK :WRITE/WB DIFF ADJ

FF

WB-ADJ DYNAMIC

G-GAIN

3

BEFORE C7

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4

7:COLOR TEMP SELECT

9:PICTURE MENU SELECT

0:WB METHOD SELECT

VOL :ADJUST

OK :WRITE/WB DIFF ADJ

1 2

OPTION DYNAMIC

BootLoader

upgrade

1,2:MAIN SELECT

VOL:ADJUST

OK:WRITE

No

C7

Key Command

Press the 3/4 button to change the adjustment values or function.

Press the 1/2 button to step up/down through the functions and adjustments

Press the numerical button VOLUME (+/-) to change of each option item.

Press the OK button after each adjustment has been made to store the required values.

0

1,2:MAIN SELECT

4

3,4:SUB SELECT

9:PICTURE MENU SELECT

VOL :ADJUST

OK :WRITE

WB-ADJ DYNAMIC

B-GAIN

3

BEFORE F8

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4

7:COLOR TEMP SELECT

9:PICTURE MENU SELECT

0:WB METHOD SELECT

VOL :ADJUST

OK :WRITE/WB DIFF ADJ

0

F8

DJUST DYNAMIC

V-POS

3

ADJUST DYNAMIC

V-AMP

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9:PICTURE MENU SELECT

VOL :ADJUST

OK :WRITE

WB-ADJ DYNAMIC

R-CENT

3

BEFORE 94

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4

7:COLOR TEMP SELECT

9:PICTURE MENU SELECT

0:WB METHOD SELECT

VOL :ADJUST

OK :WRITE/WB DIFF ADJ

0

94

DJUST DYNAMIC

VCOM

3

BEFORE 197

1,2:MAIN SELECT

4

3,4:SUB SELECT

5 :FLICKER PATTERN

9 :PICTURE MENU SELECT

OK :WRITE

OL :ADJUST

WB-ADJ DYNAMIC

G-CENT

3

BEFORE 80

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4

7:COLOR TEMP SELECT

9:PICTURE MENU SELECT

0:WB METHOD SELECT

VOL :ADJUST

OK :WRITE/WB DIFF ADJ

197

80

WB-ADJ DYNAMIC

B-CENT

3

BEFORE 9B

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4

7:COLOR TEMP SELECT

9:PICTURE MENU SELECT

0:WB METHOD SELECT

VOL :ADJUST

OK :WRITE/WB DIFF ADJ

9B

Adjustment Method

16

White Balance Adjustment

Instrument Name Connect to Remarks

1. Remote controller

2. LCD WB meter (Minolta CS-1000A e qu ivalent)

3. Comunication jig

4. Computer for external control

Procedure Remarks

White Balance adjustment

1. Procedure basically performs checking using the production software and

make automatic adjustment using external computer.

2. It adjusts in the mode of : Colour balance Cool

Viewing Mode Dynamic

WHITE Normal

x: 0.270 ± 0.010

y: 0.276 ± 0.010

GRAY Normal

x: 0.270 ± 0.010

y: 0.278 ± 0.010

Correlation can be also taken by

CA-210 or equivalent

Let the panel standfor more than 3

hours at more than 20 °C.

Basically perform adjustment in the

ambient environment of room

temperature more than 20 °C.

The aging time is more than 20 min

at above room temperature.

100% WHITE

50% GRAY

Loading...

Loading...