Page 1

MODELO :

SC-TM22

SB-TM22

$03/,),&$'25 6$70

3RWHQFLDGHVDOLGD :3032

&RQVXPRGHSRWHQFLD :

$OLPHQWDFLyQ 9FD+]

6HQVLELOLGDG$8; P9

5DQJRGHVLQWRQtD$0 N+]SDVRGHN+]

5DQJRGHVLQWRQtD)0 0+]SDVRGH.+]

'LPHQVLRQHVE[K[O PP[PP[PP

3HVR .JDSUR[

%DIOHV 6%70

,PSHGDQFLDGHHQWUDGD 7

%RFLQD7ZHHWHU FP

%RFLQD:RRIHU FP

'LPHQVLRQHVE[K[O

3HVR .JDSUR[

SA-TM22

0+]SDVRGH.+]

PP[PP[PP

SB-TM22

3RWHQFLDGHVDOLGDDPSOLILFDGRU

6&70

:5&0SRUFDQDO:N+]'$7

Page 2

1 Safety Precaution

1.1 Insulation Resistance Test

(This “Safety Precaution” is applied only in U.S.A.)

Before servicing, unplug the power cord to prevent an electric

shock.

When replacing parts, use only manufacturer’s recommended

components for safety.

Check the condition of the power cord. Replace if wear or

damage is evident.

After servicing, be sure to restore the lead dress, insulation

barriers, insulation papers, shields, etc.

Before returning the serviced equipment to the customer, be

sure to make the following insulation resistance test to

prevent the customer from being exposed to a shock

hazard.

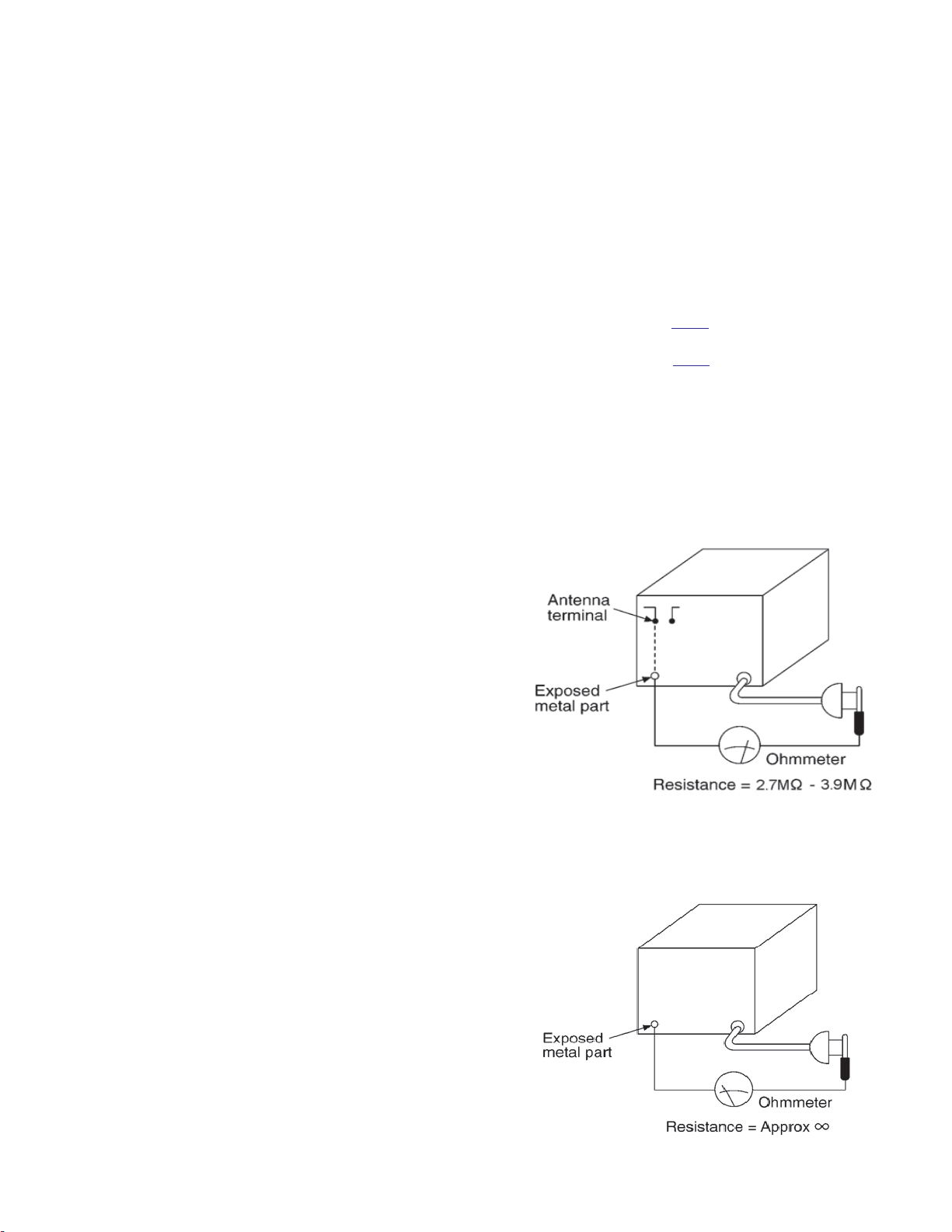

Unplug the power cord and short the two prongs of the plug

with a jumper wire.

Turn on the power switch.

Measure the resistance value with ohmmeter between the jumper

AC plug and each exposed metal cabinet part, such as

screwheads, antenna, control shafts, handle brackets, etc.Measure

the resistance value with ohmmeter between the jumper AC

plugand each exposed metal cabinet part, such as screwheads,

antenna, control shafts, handle brackets, etc.

Equipment with antenna terminals should read between 2.7M and

3.9M to all exposed parts*. ( Fig.1 )

Equipment without antenna terminals should read approximately

infinity to all exposed parts. ( Fig.2 )

*Note : Some exposed parts may be isolated from the chassisby

design. These will read infinity.

If the measurement is outside the specified limits, there is a

possibility of a shock hazard. The equipment should be

repaired and re-checked before it is returned to the

customer.

Fig.1

Fig.2

Page 3

2 Before Repair and

4 Prevention of Electr o

Adjustment

Disconnect AC power, discharge Power Supply Capacitors C520

and C540 through a 10˜, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver

blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a

variac, to avoid overcurrent.

Current consumption at AC 120V, 60 Hz in NO SIGNAL mode

(volume min at CD mode) should be ~600mA.

3 Protection Cir cuitry

The protection circuitry may have operated if either of the

following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for

example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the

indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

Turn off the power.

Static Discharge (ESD) to

Electrostatically Sensitive

(ES) Devices

Some semiconductor (solid state) devices can be damaged easily

by electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistorsand

semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

Immediately before handling any semiconductor component

or semiconductor-equiped assembly, drain off any ESD

on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging ESD wrist strap, whichshould be removed

for potential shock reasons prior to applying power to the

unit under test.

After removing an electrical assembly equiped with ES

devices, place the assembly on a conductive surface such

as aluminium foil, to prevent electrostatic charge build up

or exposure of the assembly.

Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

Use only an anti-static solder remover device. Some solder

removal devices not classified as “anti-static (ESD

protected)” can generate electrical charge to damage ES

devices.

Determine the cause of the problem and correct it.

Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate

unless the power is first turned off and then on again.

Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

Do not remove a replacement ES device from its protective

package until immediately before you are ready to install

it. (Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam,

aluminium foil orcomparable conductive material).

Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to

the chassis or circuit assembly into which the device will be

installed.

Page 4

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions. Minimize body motions

when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together of your

clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient todamage an

ES device).

5 Handling the Lead-free

Solder

5.1 About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF

stamp on the P.C.B.

Caution:

• Pb free solder has a higher melting point than standard

solder; Typically the melting point is 50 - 70°F (30 - 40°C) higher.

Please use a high temperature soldering iron. In case of soldering

iron with temperature control,please set it to 700 ± 20°F (370 ±

10°C).

• Pb free solder will tend to splash when heated too high

(about 1100°F/600°C).

• When soldering or unsoldering, please completely

remove all of the solder on the pins or solder area, and be sure to

heat the soldering points with the Pb free solder until it melts

enough.

6 Handling Precautions For

Traverse Deck

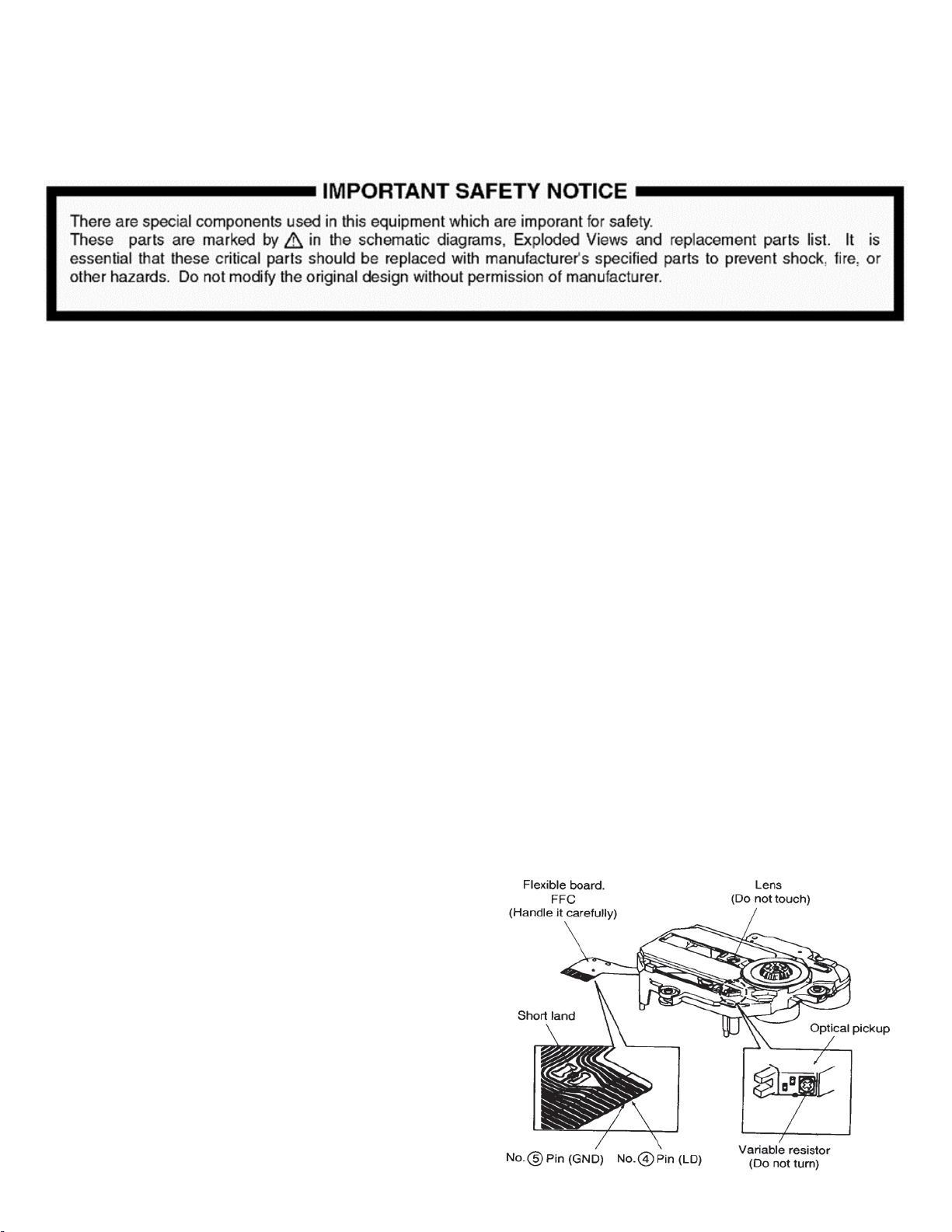

The laser diode in the traverse deck (optical pickup) may break

down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the

traverse deck (optical pickup).

• Handling of traverse deck (optical pickup)

Do not subject the traverse deck (optical pickup) to static

electricity as it is extremely sensitive to electrical shock.

The short land between the No.4(LD) and No.5(GND) pins on

the flexible board (FFC) is shorted with a solder build-up

to prevent damage to the laser diode.To connect to the PC

board, be sure to open by removing the solder build-up,

and finishthe workquickly.

Take care not to apply excessive stress to the flexible board

(FFC).

Do not turn the variable resistor (laser power adjustment). It

has already been adjusted.

Fig 6.1

Page 5

Grounding for electrostatic breakdown prevention

Human body grounding

7 Precaution of Laser

Use the anti-static wrist strap to discharge the static

electricity from your body.

Work table grounding

Put a conductive material (sheet) or steel sheet on the

area where the traverse deck (optical pickup) is placed,

and ground the sheet.

Caution :

The static electricity of your clothes will not be grounded through

the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when Replacing the Traverse Deck :

The traverse deck has a short point shorted with solder to protect

the laser diode against electroststics breakdown. Be sure to

remove the solder from the short point before making

connections.

Fig 6.2

Diode

CAUTION:

This unit utilizes a class 1 laser.

Invisible laser radiation is emitted from the optical pickup lens.

Wavelength: 780nm.

When the unit is turned on:

Do not look directly into the pick up lens.

Do not use optical instruments to look at the pick up lens.

Do not adjust the preset variable resistor on the pickup lens.

Do not disassemble the optical pick up unit.

If the optical pick up is replaced, use the manufacturer’s

specified replacement pick up only.

Use of control or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF

PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY

RESULT IN HAZARDOUSRADIATION EXPOSURE.

Use of caution label

Page 6

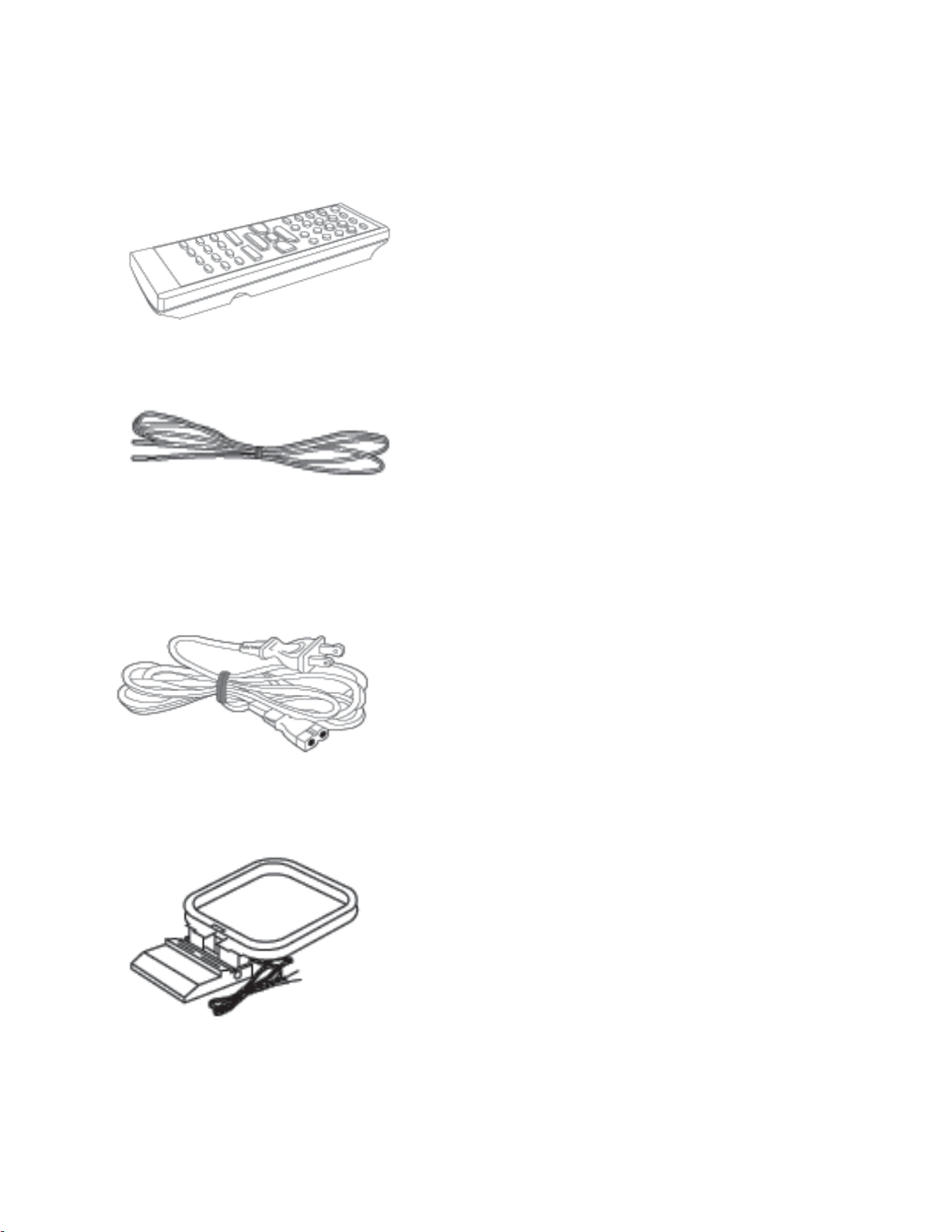

8 Accessories

Remote Control Transmitter

( EUR7710020)

FM Indoor Antenna

(N1EAYY000004)

9 Operacion procedures

( see next page )

AC Power Supply Cord

( SJA168-1A )

AM Loop Antenna

( N1DADYY00002 )

Page 7

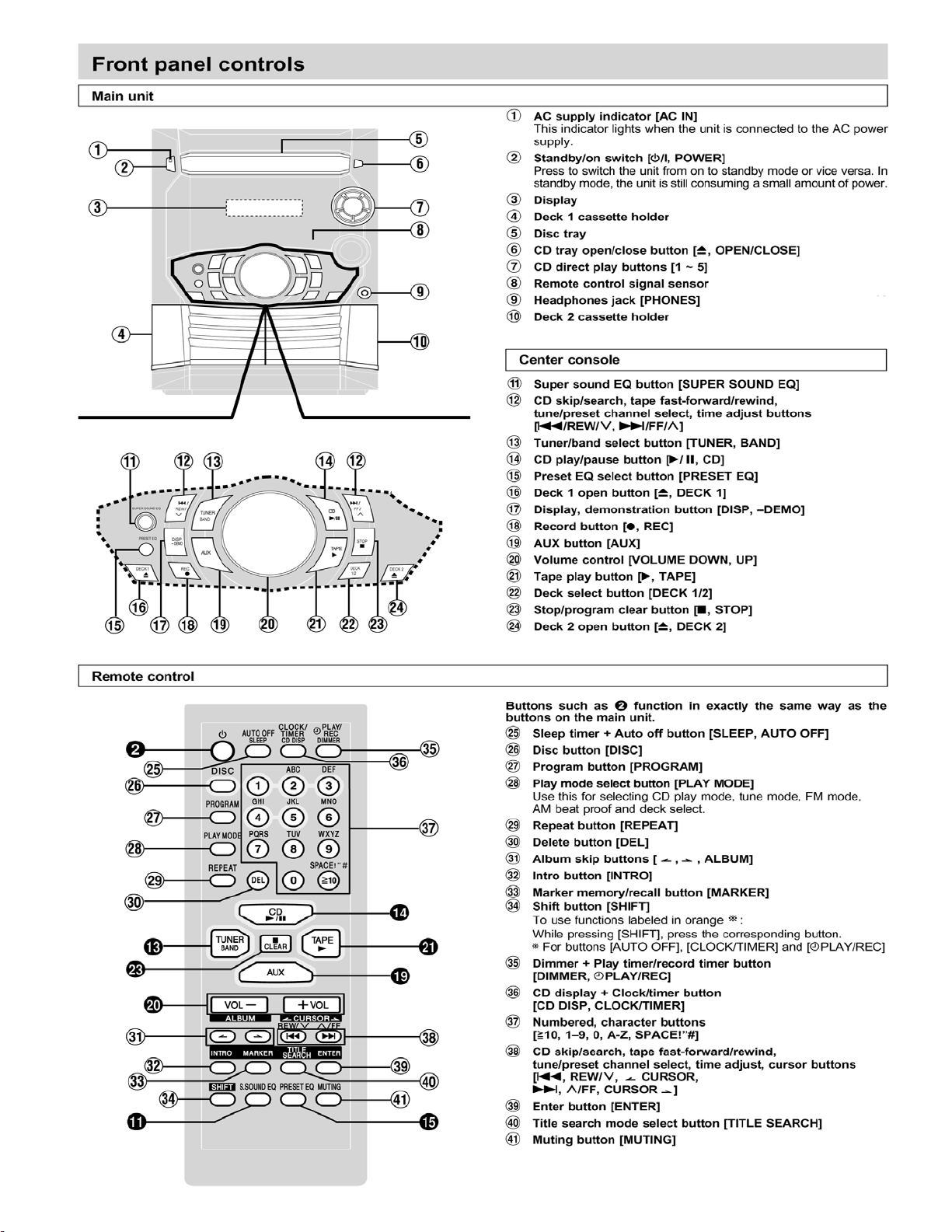

Page 8

10 Disassembly and

10.2 Disassembly of Top Cabinet

Assembly of Main

Component

10.1 Disassembly flow chart

The following chart is the procedure for disassembling the casing

and inside parts for internal inspection when carrying out the

servicing.

To assemble the unit, reverse the steps shown in the chart as

below.

and Rear Panel

Step 1 Remove 3 screws on each side and 5 screws at rear panel.

Step 2 Lift up both sides of top cabinet, push the cabinet ass’y

toward the rear and remove it.

Disassembly of Rear Panel

Step 3 Remove 6 screws.

Step 4 Draw rear panel backward to remove it.

Page 9

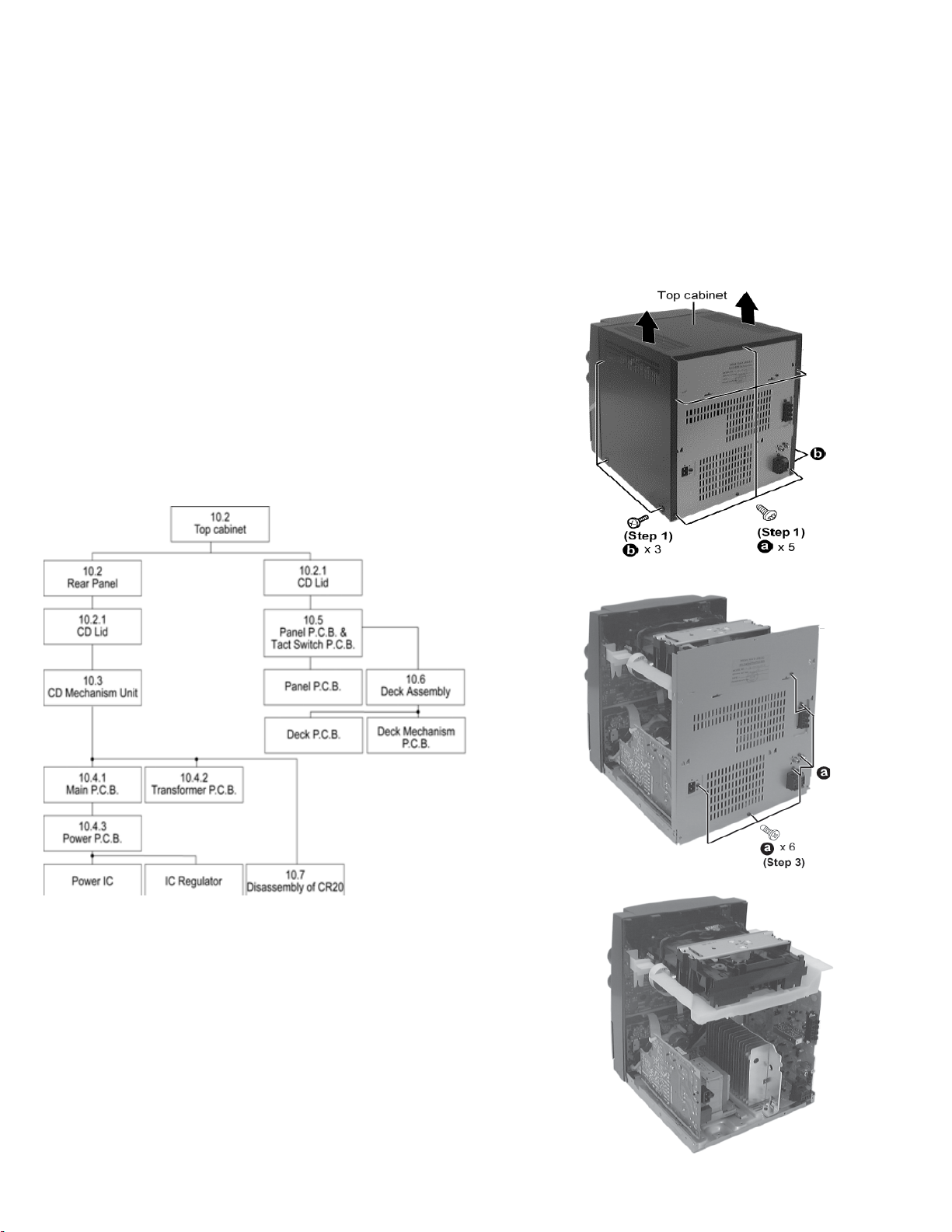

10.2.1 Disassembly for CD Lid

(The CD changer unit can be removed after the CD Lid is

removed)

• Follow the (Step 1) - (Step 5) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

When opening the disc tray automatically (Using Power Supply)

Step 1 Connect the AC power cord.

Step 2 Press the POWER button to power up the main unit.

Step 5 Press the OPEN/CLOSE button, the disc tray will close.

[Open the disc tray manually (Using service tools)]

Step 3 Press the OPEN/CLOSE button, the disc tray will open

automatically.

Step 1 Insert the gear tool into the hole on the underside of CD

chassis and then rotate in the direction of arrow. The disc tray will

be open.

Step 4 Release the 2 claws, and then remove the CD Lid.

Page 10

Step 2 Release the 2 claws, and then remove the CD lid cover.

10.3 Disassembly of CD Mechanism

Unit

• Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

Step 1 Detach the FFC boards (CN309 & CN310).

Step 3 Repeat Step 2 but rotate the gear tools in anti-clockwise

direction.

Step 2 Release the claws of both ends, and then lift up the CD

Mechanism Unit.

Step 4 The disc tray will be close.

Page 11

Step 3 Remove 4 screws.

Step 4 Remove the CD chassis.

Step 5 Lay the CD mechanism unit as shown.

• Note:

For disassembly of CD mechanism unit, please refer to

Section 10.7 of this manual.

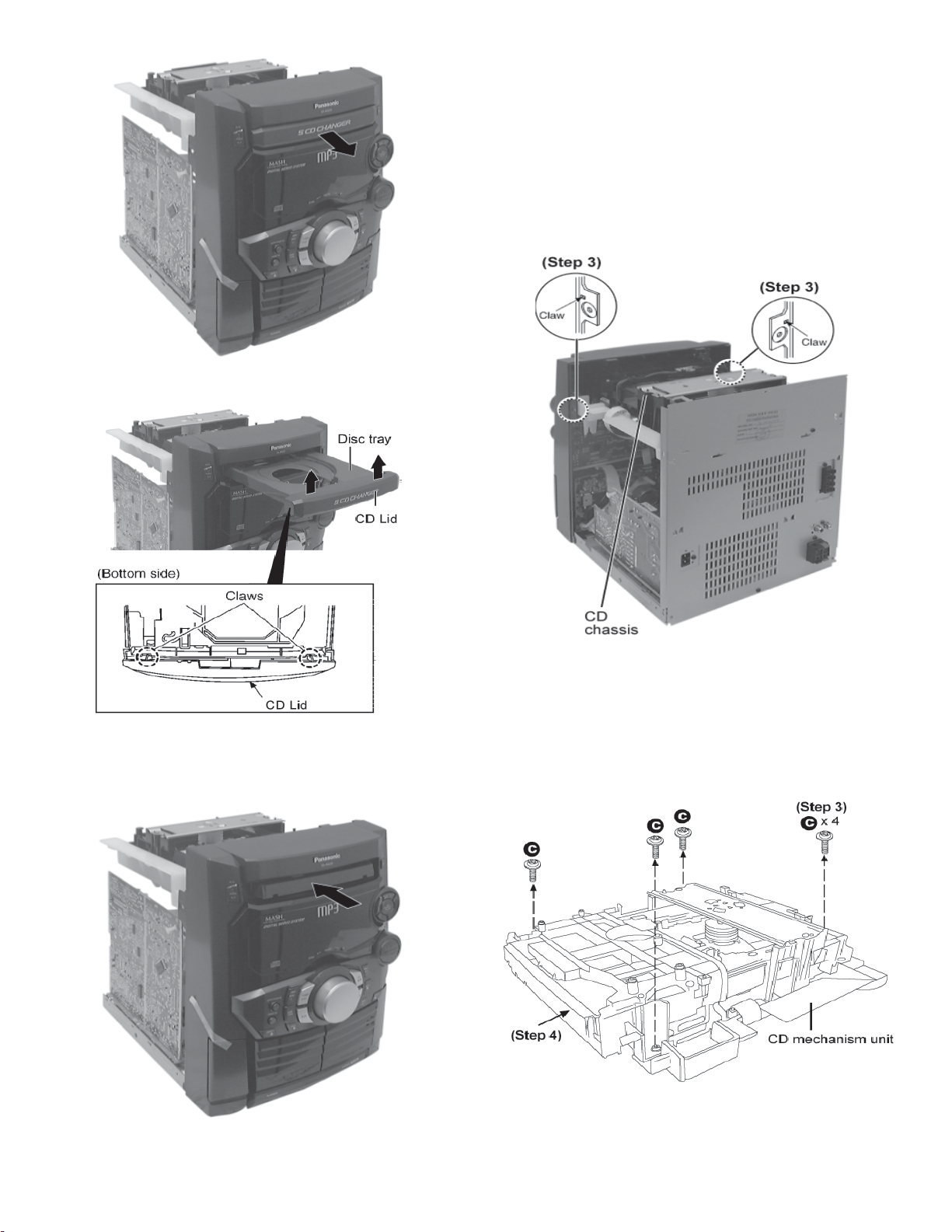

Step 2 Lift up Main P.C.B. by disconnect CN500 & CN501 as

arrow shown above.

10.4 Disassembly Main P.C.B.,

Transformer P.C.B.& Power P.C.B.

10.4.1 Disassembly for the Main

P.C.B.

• Follow the (Step 1) - (Step 4) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of the CD Mechanism Unit

Step 1 Disconnect FFC boards at CN303, CN302 & CN304 .

10.4.2 Disassembly of the

Transformer P.C.B.

• Follow the (Step 1) - (Step 4) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of the CD Mechanism Unit

Step 1 Remove 3 screws.

Step 2 Disconnect connector CN950.

Page 12

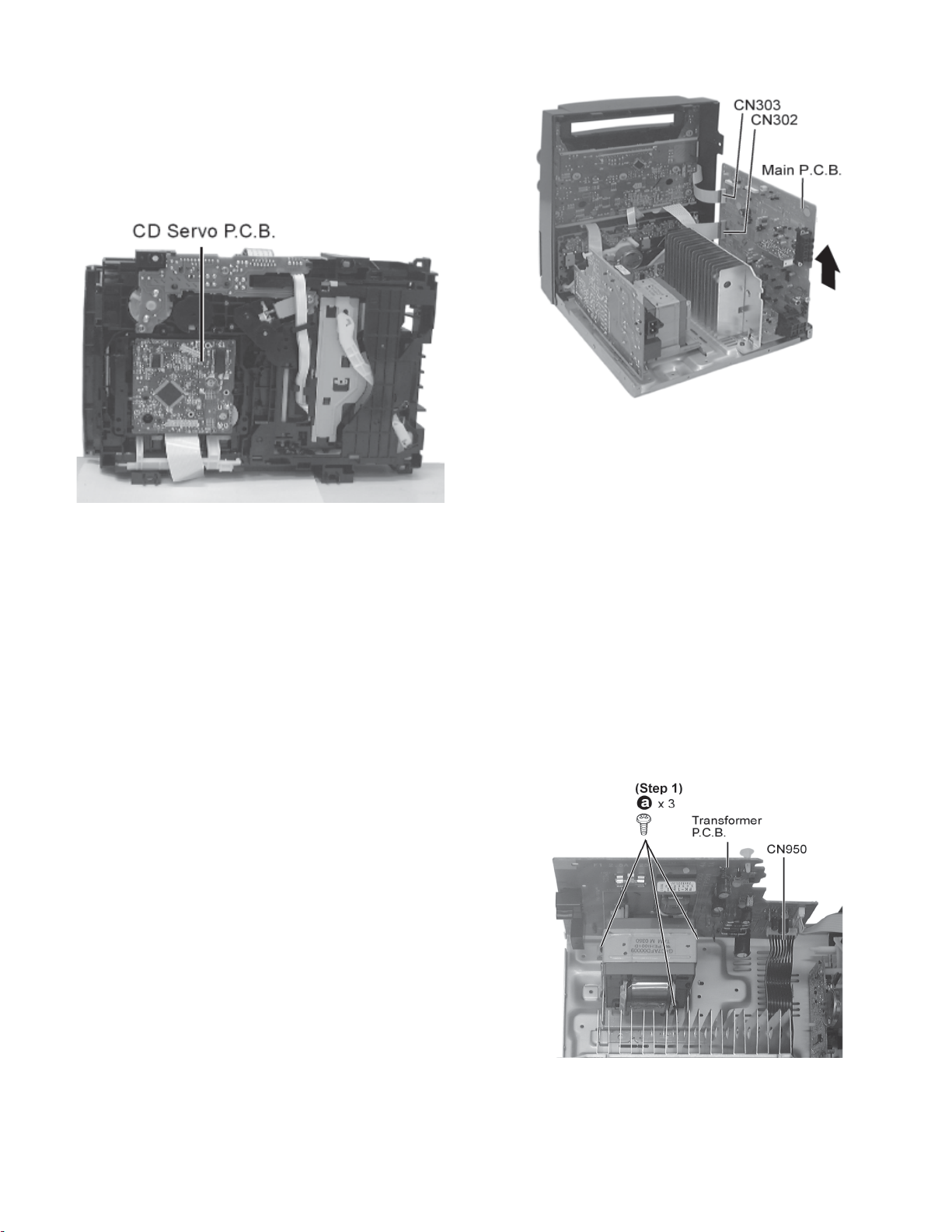

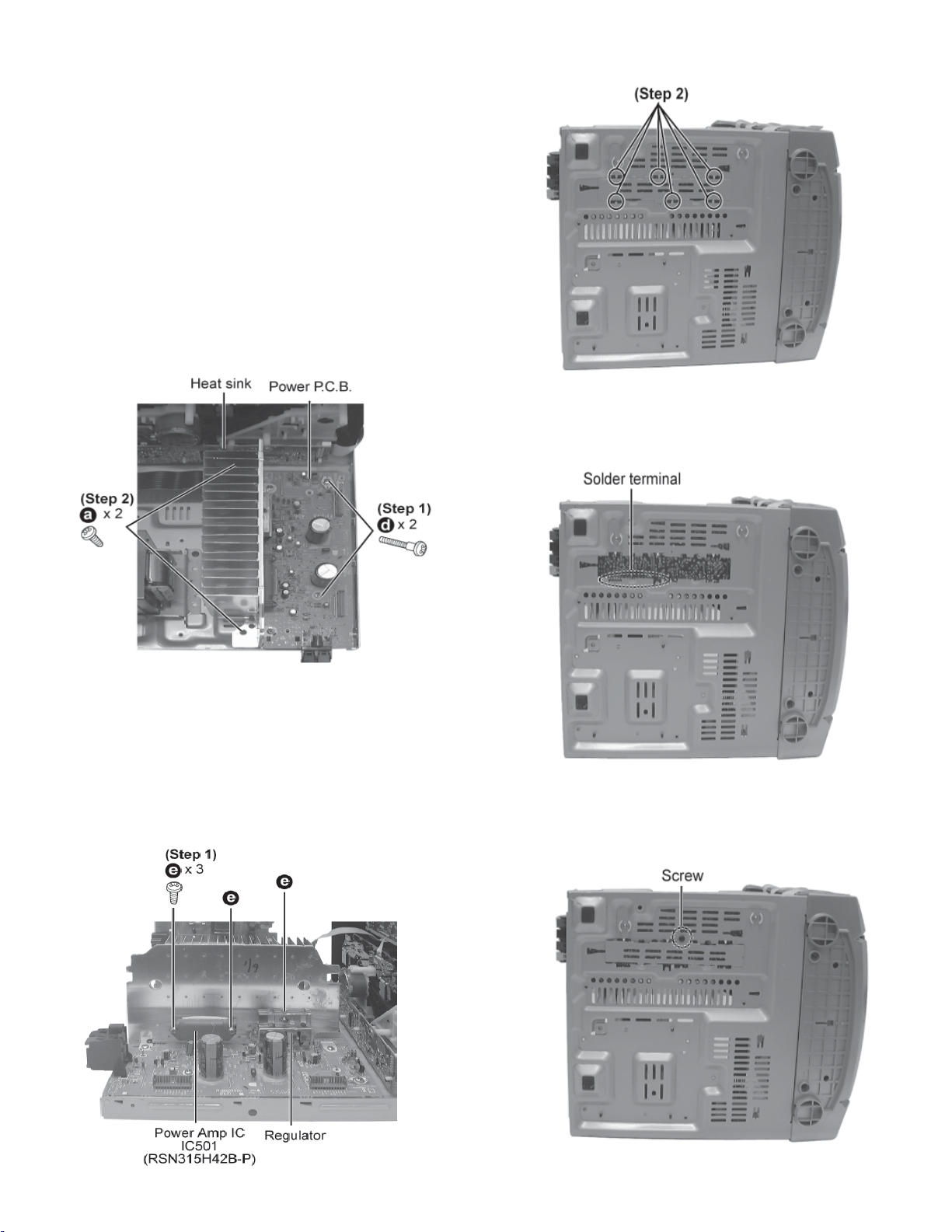

10.4.3 Disassembly of the Power

P.C.B.

• Follow the (Step 1) - (Step 4) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of the CD Mechanism Unit

• Follow the (Step 1) - (Step 2) of Item 10.4.1 Disassembly for the Main P.C.B.

Step 1 Remove 2 screws.

Step 2 Remove the 2 screws fixed at heat sink.

Step 2 Break the joint with a metal cutter as shown below.

Step 3 Unsolder the terminals of Power Amp IC, transistor and

replace the components.

NOTE:

Insulate Power P.C.B. with insulation material to avoid short

circuit.

• Replacement of Power Amplifier IC & Voltage Regulator

Step 1 Remove 2 screws (For Power Amp IC) and 1 screw (For

Voltage Regulator) .

Step 4 Fix back the cutted portion with a screw as shown.

Page 13

10.5 Disassembly of Panel P.C.B.&

Tact Switch P.C.B.

• Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 5) of Item 10.3 - Disassembly

of the CD Mechanism Unit

• Disassembly of Panel P.C.B.

Step 1 Lay the unit as shown below.

• Step 6 Pull out the volume knob.

Step 7 Pull Panel P.C.B. forward.

10.6 Disassembly of Deck

Step 2 Remove 2 screws, release 2 claws, and then draw the front

panel ass’y forward.

Mechanism Unit& Deck P.C.B.

• Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of the CD Mechanism Unit

Step 1 Detach FFC board. (CN971)

Step 2 Disconnect FFC flat cable from the connector (CN1001).

Step 3 Remove the 5 screws.

Step 3 Remove the 8 screws.

Step 4 Disconnect FFC board (CN302).

• Disassambly of Tact Switch P.C.B.

Step 5 Disconnect connector CN900.

Page 14

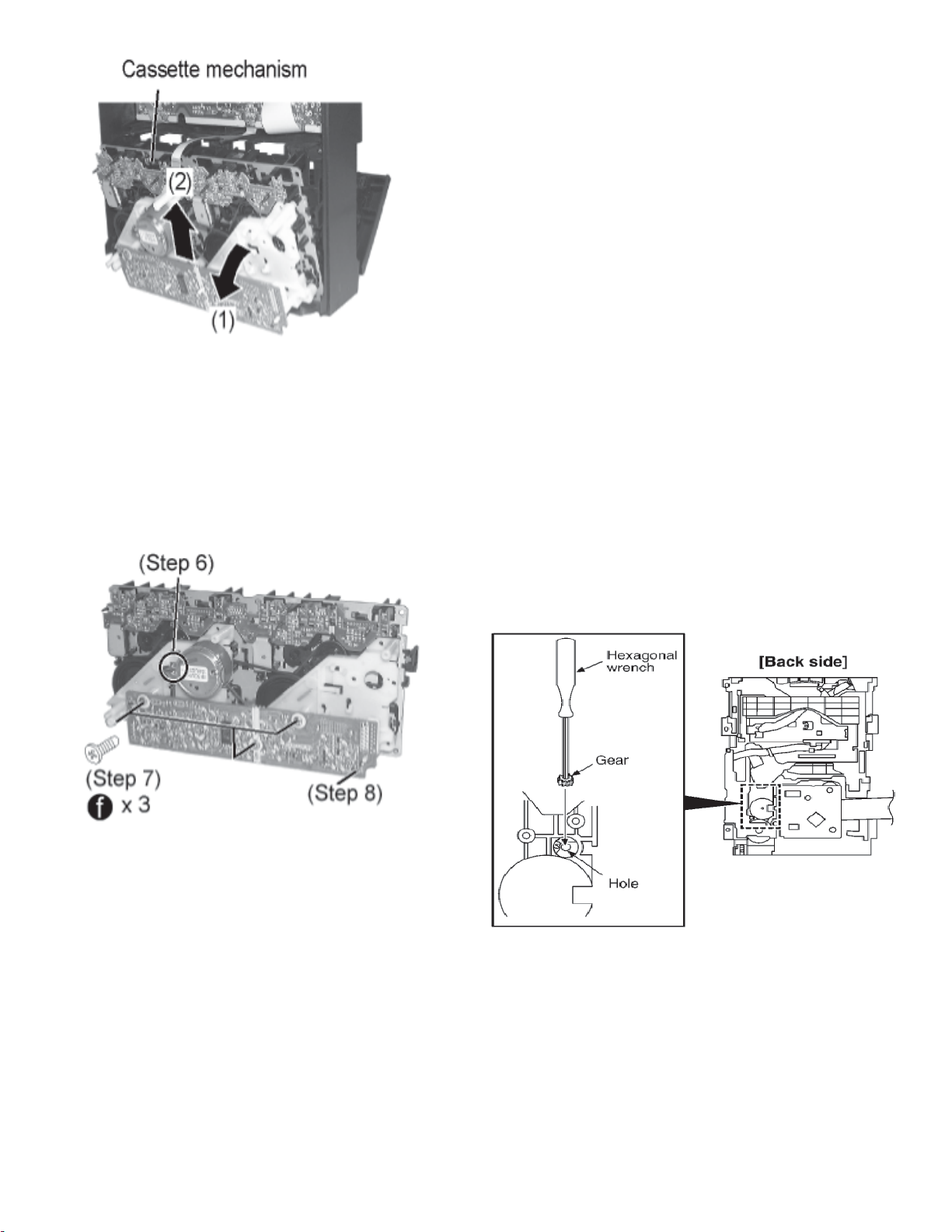

Step 4 Push the lever upward, and then open the cassette lid ass’y

(For DECK1 and DECK2).

Step 5 Tilt the cassette mechanism unit in the direction of arrow

(1), and then remove it in the direction of arrow (2).

10.7 CD Mechanism Main

Component Replacement

Procedures

• Follow the (Step 1) - (Step 4) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 5) of Item 10.3 - Disassembly

of the CD Mechanism Unit

10.7.1 Replacement of the Traverse

Deck

For replacement of Deck P.C.B.

Step 1 Remove the CD changer unit.

Step 6 Unsolder the motor terminals.

Step 7 Remove 3 screws.

Step 8 Remove Deck P.C.B.

Page 15

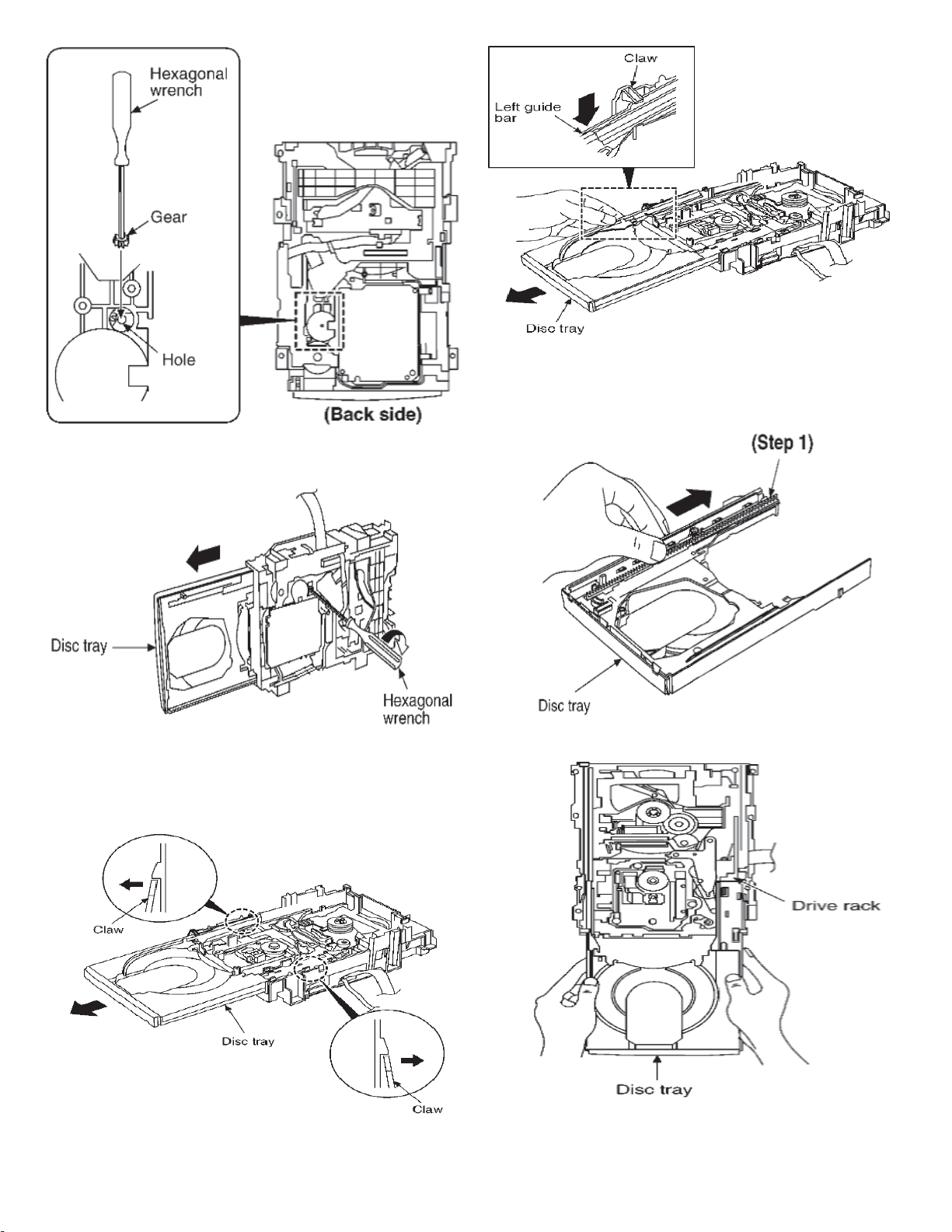

Step 2 Insert the gear with hexagonal wrench into the hole.

Step 7 Remove the traverse deck ass’y from the timing lever.

Caution:

Step 3 Rotate the hexagonal wrench in the direction of arrow

(clockwise), and then open the disc tray fully.

Step 4 With pressing the claw (A), rotate the hexagonal wrench

clockwise. (The slide plate R moves for a little amount.)

Step 5 Pressing the claw (B) in the direction of arrow (1), the

connection lever moves in the direction of arrow (2).

When removing or inserting the traverse deck avoid touching the

OPU lens and pressing onto the turntable

Step 8 Remove 3 screws.

Step 9 Unsolder the motor terminals (4 points).

Step 6 Lift up the traverse deck ass’y.

Step 10 Remove the FFC board from the connector, and then

remove the CD Servo P.C.B.

Page 16

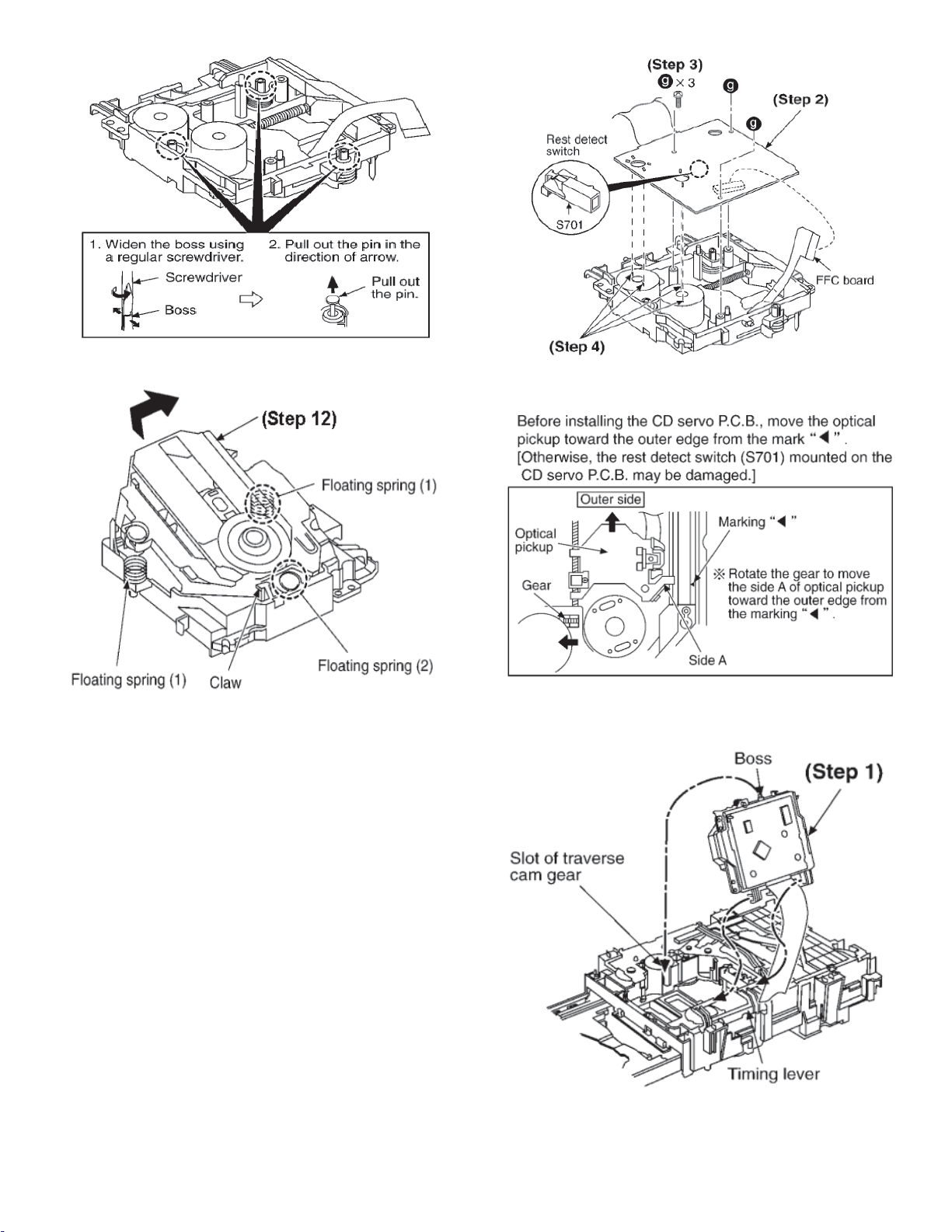

Step 11 Remove the pin.

Note for installation of the CD servo P.C.B.

Step 12 Release the claw, and then remove the traverse deck ass’y.

Note:

Be careful not to lose the 3 floating spring because those will also

be removed on removal of the traverse deck ass’y.

• Installation of the CD Servo P.C.B. after replacement

Step 1 Connect the FFC board.

Step 2 Install the CD servo P.C.B. in the traverse deck ass’y.

Step 3 Remove 3 screws.

Step 4 Solder.

Installation for traverse deck ass’y

Step 1 Install the traverse deck ass’y to the timing lever.

Step 2 Align the boss of traverse deck ass’y with the slot of

traverse cam gear.

Page 17

Step 3 Force the claw of timing lever.

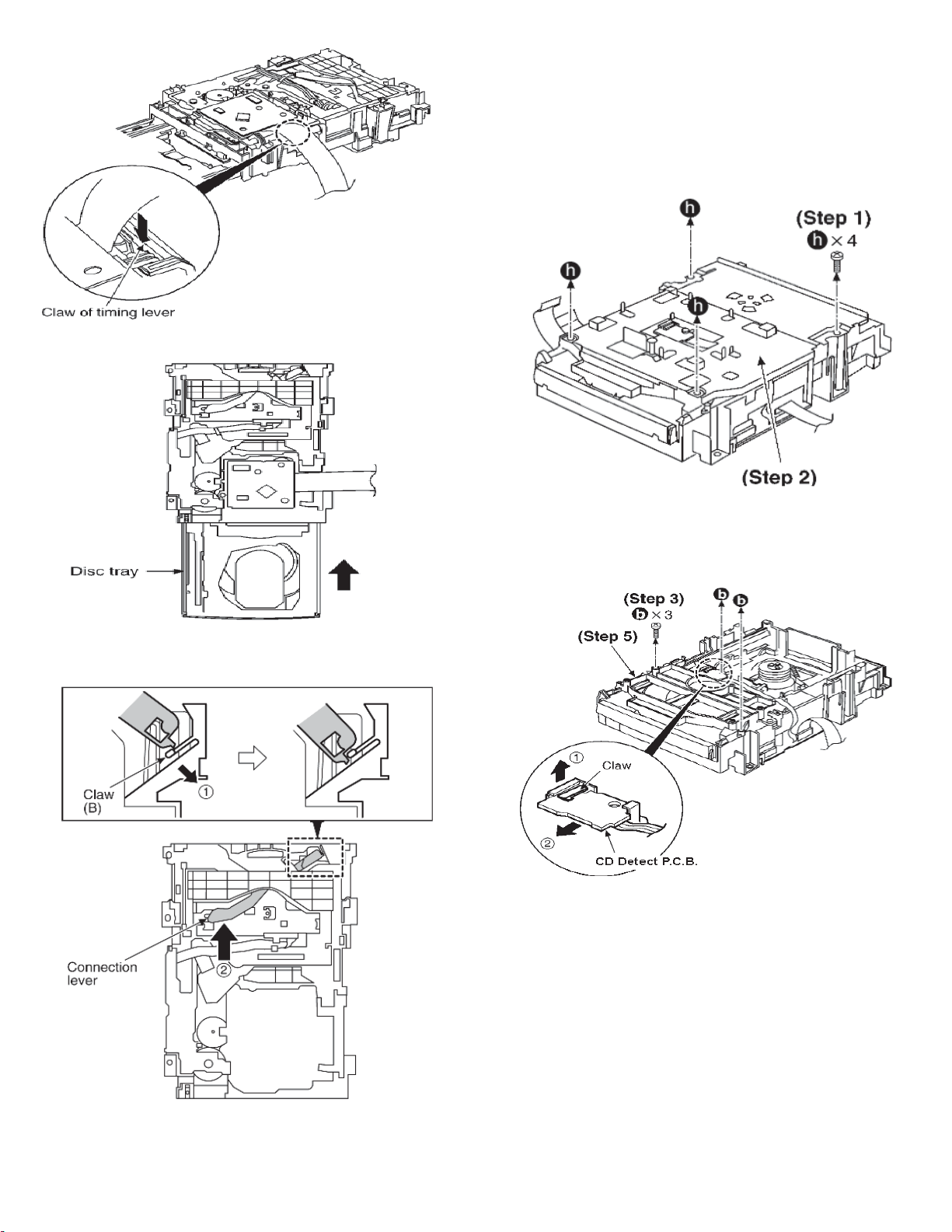

10.7.2 Replacement for the Disc

Tray

Step 1 Remove 4 screws

Step 2 Remove the upper plate.

Step 4 Force the disc tray fully.

Step 3 Remove 3 screws.

Step 4 With lifting the claw in the direction of (1), draw the CD

Detect P.C.B. in the direction of arrow (2).

Step 5 Remove the mechanism cover.

Step 5 With pressing the claw (B) in the direction of arrow (1),

force the connection lever in the direction of arrow (2).

Page 18

Step 6 Insert the gear with hexagonal wrench into the hole

Step 7 Rotate the hexagonal wrench in the direction of arrow, and

then open the disc tray fully.

Step 9 With forcing the left guide bar manually because the left

guide bar interfers with claw, draw the disc tray.

[Installation of the disc tray after replacement]

Step 1 Slide the drive rack fully in the direction of arrow.

Step 8 Release the both claws, and then draw the disc tray.

Step 2 Holding the drive rack not to move, install the disc tray.

Step 3 Align the drive rack with the drive gear.

Page 19

NOTE:

Force the right guide bar of tray base manually not to move

upwards.

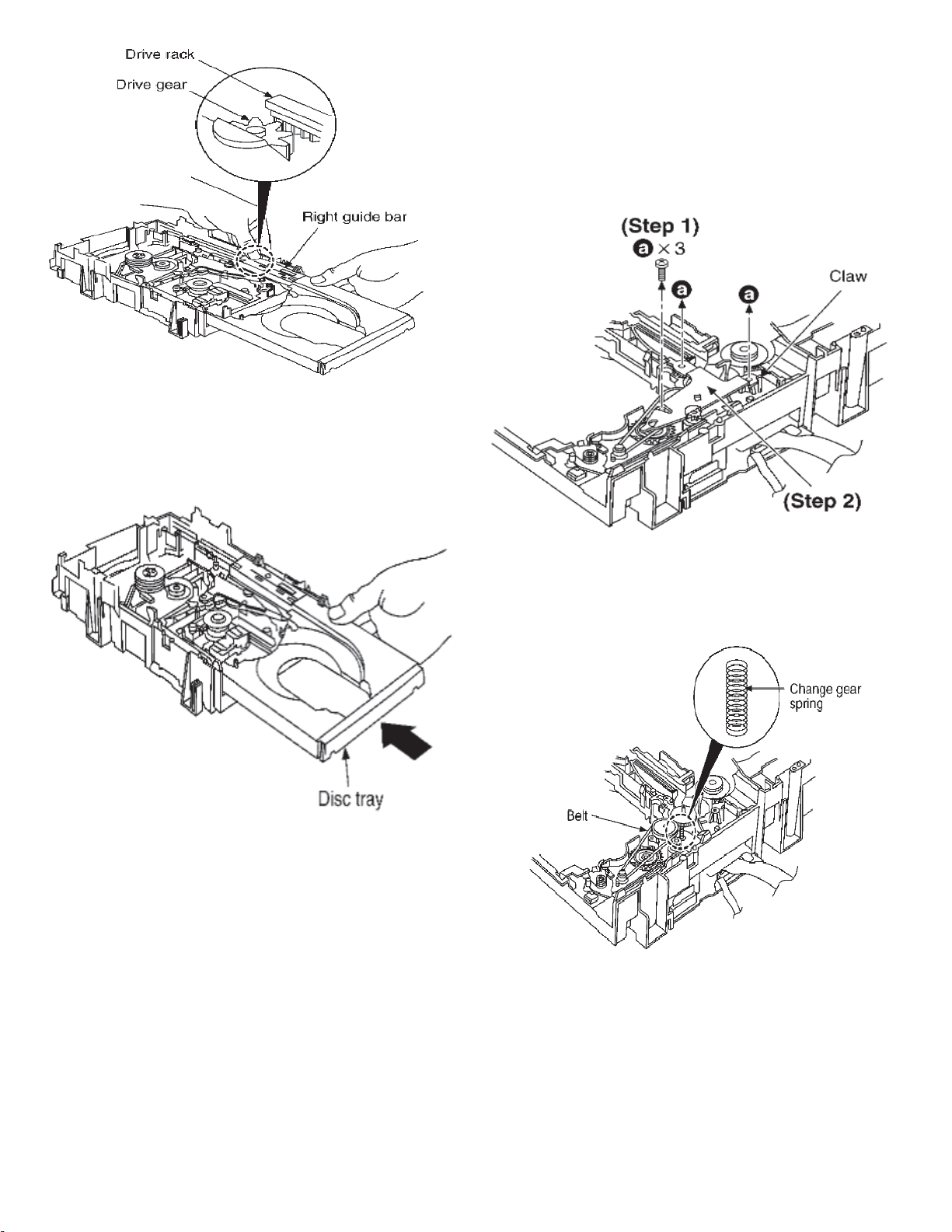

10.7.3 Disassembly and reassembly

for mechanism base drive unit

Step 1 Remove 3 screws.

Step 4 Holding the disc tray manually, push the disc tray in the

direction of the arrow.

Step 2 Release the claw, and then remove the gear holder.

Step 3 Remove the belt and change gear spring.

NOTE:

Take care not to lose the change gear spring.

Step 4 Remove the pulley gear, change gear and UP/DOWN gear.

Page 20

Step 5 Release the 2 claws, and then remove the bottom SW

P.C.B..

Step 9 Pressing the claw (B) in the direction of arrow (1), force

the connection lever in the direction of arrow (2).

Step 6 Install the tray lock spring to hook temporary.

Step 7 Release the claw, and then remove the tray lock.

Step 8 Release the claw, and then remove the rear lock.

Step 10 Move the slide plate 1 to the end of stock side.

Page 21

Step 11 Lift up the left end of spindle base unit in the direction of

arrow (1), and then remove the unit in the direction of arrow (2).

Step 13 Remove the traverse relay gear, traverse cam gear and

drive gear.

Step 12 Remove slide plate 1 and slide plate 2.

[Dissassembly/reassembly for the spindle base unit]

Step 1 Draw the 5 disc spacers.

Page 22

Step 2 Pushing the claw, slide the support plate in the direction of

arrow, and then remove it.

Step 4 Release the 2 claws, and then draw the relay gear B.

Step 5 Release the 2 claws as shown below.

NOTE:

Step 3 Rotate the disc lever in the direction of arrow (1), draw the

disc lever.

NOTE:

Take care not to lose the disc lever spring.

Hold the loading stopper ass’y manually bacause it is flipped by

spring.

Step 6 Remove the cushion spring.

Step 7 Remove the loading stopper ass’y in the direction of arrow.

Page 23

Step 8 Release the 2 claws, and then remove the relay gear A.

Step 9 Release the 2 claws, and then remove the spindle shaft.

Step 12 Squeeze the shaft of lower hook, and then draw it.

Step 10 Remove the lower spindle spring with tweezers.

Step 11 Force the lower hook with thin tip of minus screwdriver.

Step 13 Rotate the lower spindle in the direction of arrow until

the lower spindle interferes with stopper.

Step 14 Insert the thin tip of minus screwdriver between the lower

spindle and UP/DOWN base, and then slacken the lower spindle

to release the stopper. Then, rotate the lower spindle and remove

it.

Page 24

Step 15 Rotate the UP/DOWN base at a 90° angle. Then, spread

the hold bars of loading stopper and remove the UP/DOWN base.

[Installation for loading stopper ass’y]

Step 1 Align the claw of loading stoppers ass’y with the slot of

spindle base. (Caution should be exercised when alignment of

claw due to the size of claws.)

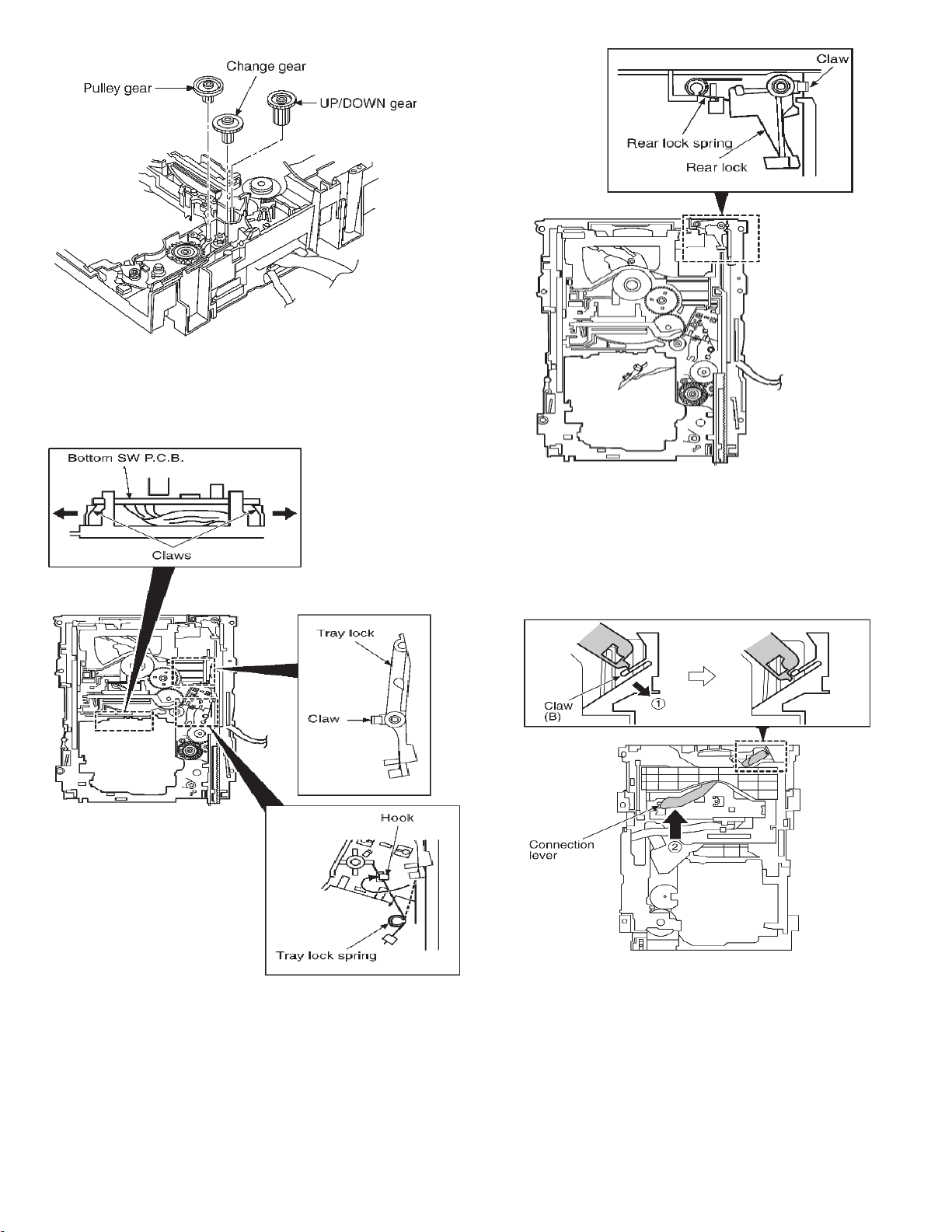

[Reassembly for mechanism base drive unit]

Step 1 Install the traverse cam gear.

Step 2 Rotate the traverse cam gear to the direction of arrow.

Step 2 Lower the loading stopper ass’y, and then align the lower

spindle with the trapezoid tooth of relay gear A.

Step 3 Force the loading stopper ass’y, latch the claw firmly.

Step 3 Install the drive gear and traverse relay gear.

Page 25

Step 7 Move the slide plate 1 to forward fully.

Step 4 Install the slide plate 2 to the mechanism base, and then

match to the connection lever.

Step 5 Install the slide plate 1 to the mechanism base, and then

match to the connection leve and align the trapezoid tooth of

traverse relay gear with the slide plate 1.

Step 8 Install the rear lock. (The claw should be latched.)

Step 9 Install the Spindle Position P.C.B.. (The claw should be

latched.)

Step 10 Install the tray lock. (The claw should be latched.)

Step 6 Install the spindle base unit. (First, slide plate 1.)

Step 11 Remove the tray lock spring from hook,and then latch to

the tray lock.

Step 12 Install the UP/DOWN gear, change gear, change gear

spring, pulley gear and belt in the order of (1) - (5).

Page 26

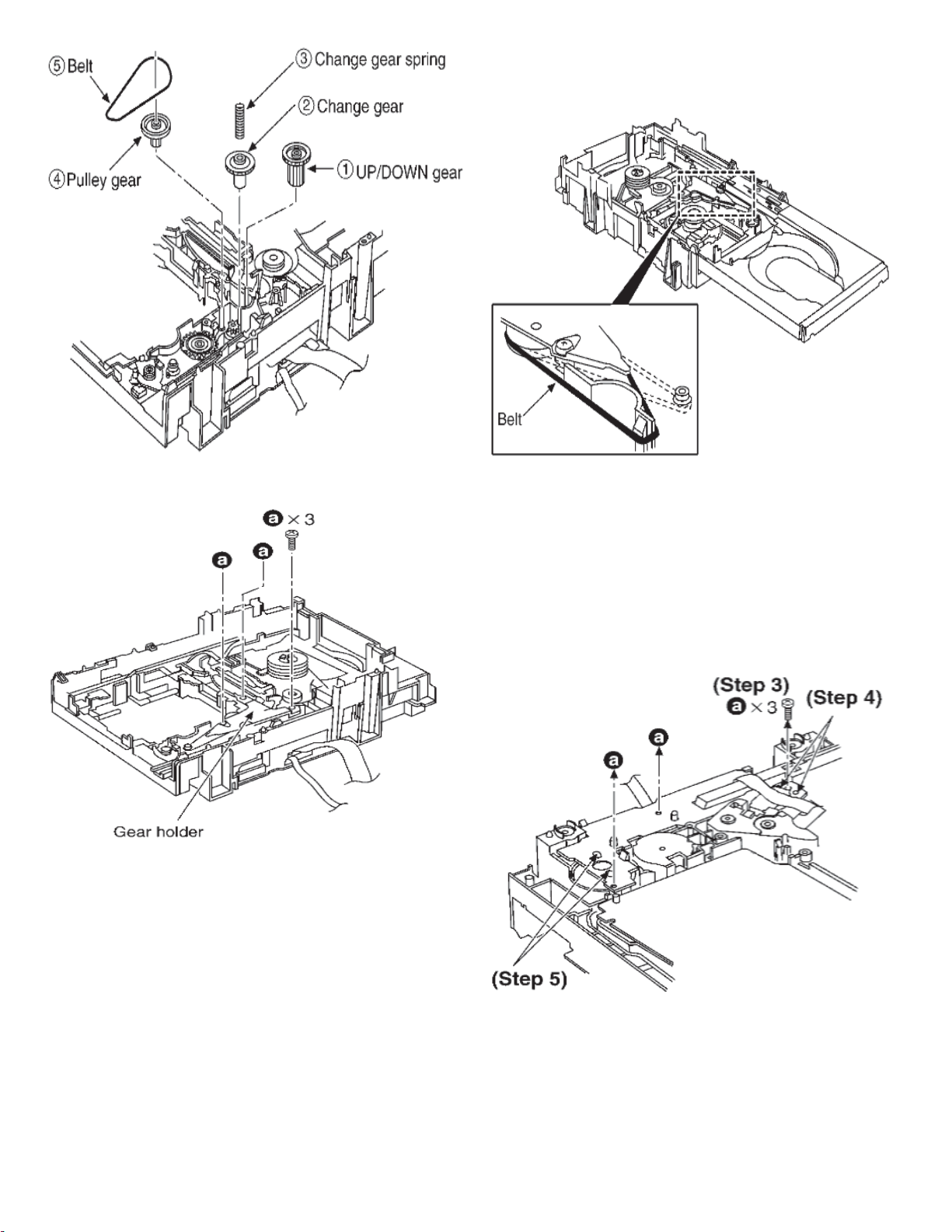

10.7.4 Replacement for the motor

ass’y

Step 13 Install the gear holder, and then tighten the screw (a).

Step 14 Install the tray base, traverse ass’y, mechanism cover and

upper plate.

Step 1 Install the belt temporarily.

NOTE:

Take care not apply the grease to the belt.

Step 2 Upset the CD loading unit.

Step 3 Remove 3 screws.

[Operation check after servicing]

Check the proper operation of following items with gear and

hexagonal screwdriver.

Open/close of tray base.

Moving the tray base to the stock side.

UP/DOWN operation of spindle base unit.

UP/DOWN operation of traverse ass’y.

Step 4 Unsolder the plunger terminals (2 points).

Step 5 Unsolder the motor terminals (2 points).

Page 27

Step 6 Release the 2 claws (A), and then remove the Motor P.C.B.

10.8 Replacement for the pinch

roller ass’y and head block

• Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of the CD Mechanism Unit

• Follow the (Step 1) of Item 10.4 - Disassembly the Main

P.C.B. & Transformer P.C.B.

• Follow the (Step 1) - (Step 2) of Item 10.5 - Disassembly

of the Panel P.C.B. & Tact Switch P.C.B.

• Follow the (Step 1) - (Step 5) of Item 10.6 - Disassembly

for the Deck Mechanism Unit & Deck P.C.B.

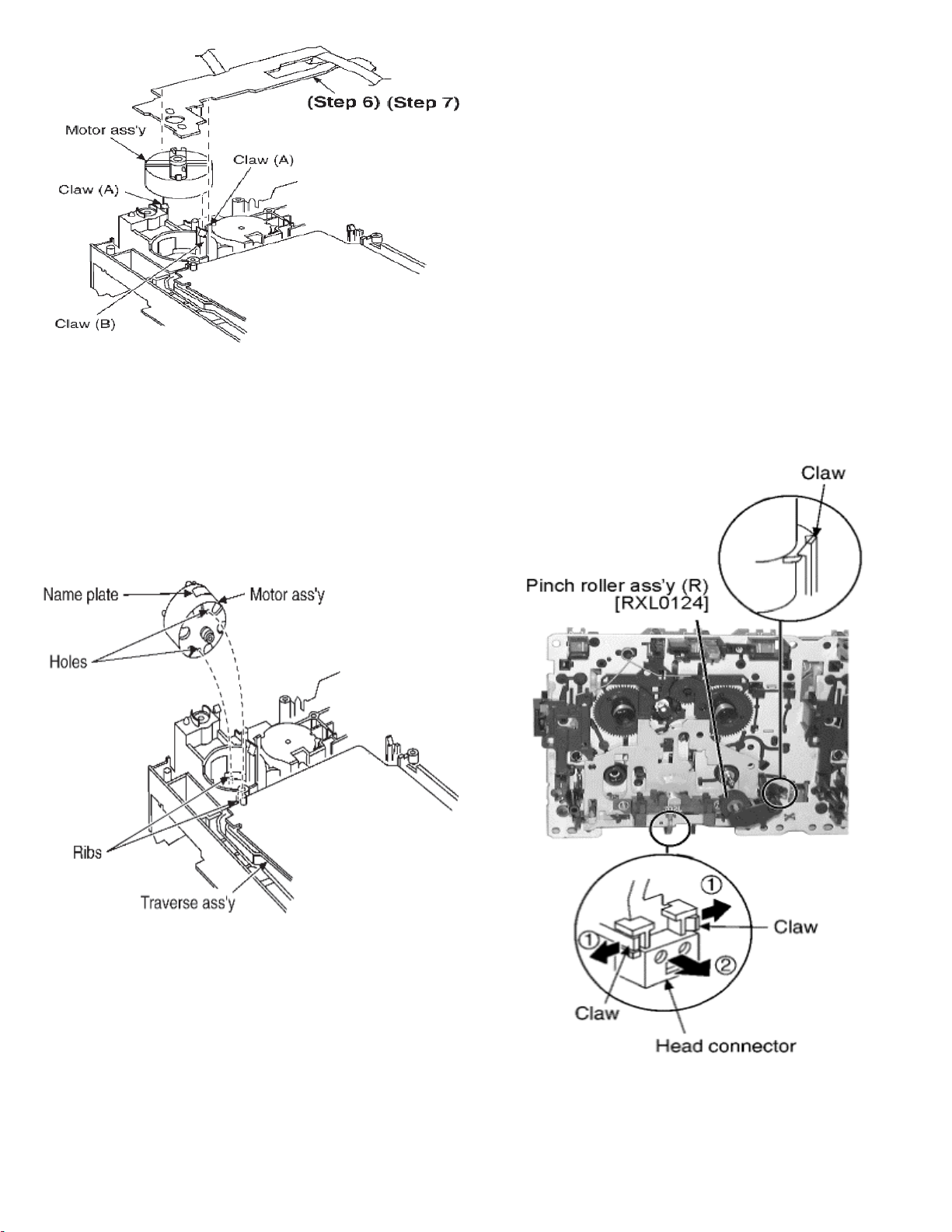

Step 7 Release the claw (B), and then remove the motor ass’y.

[Notice for motor ass’y installation]

Locate the name plate of motor to the traverse ass’y.

Align the hole of motor with the ribs.

* The mechanism as shown below is for DECK1. For the one of

DECK 2, perform the same procedures.

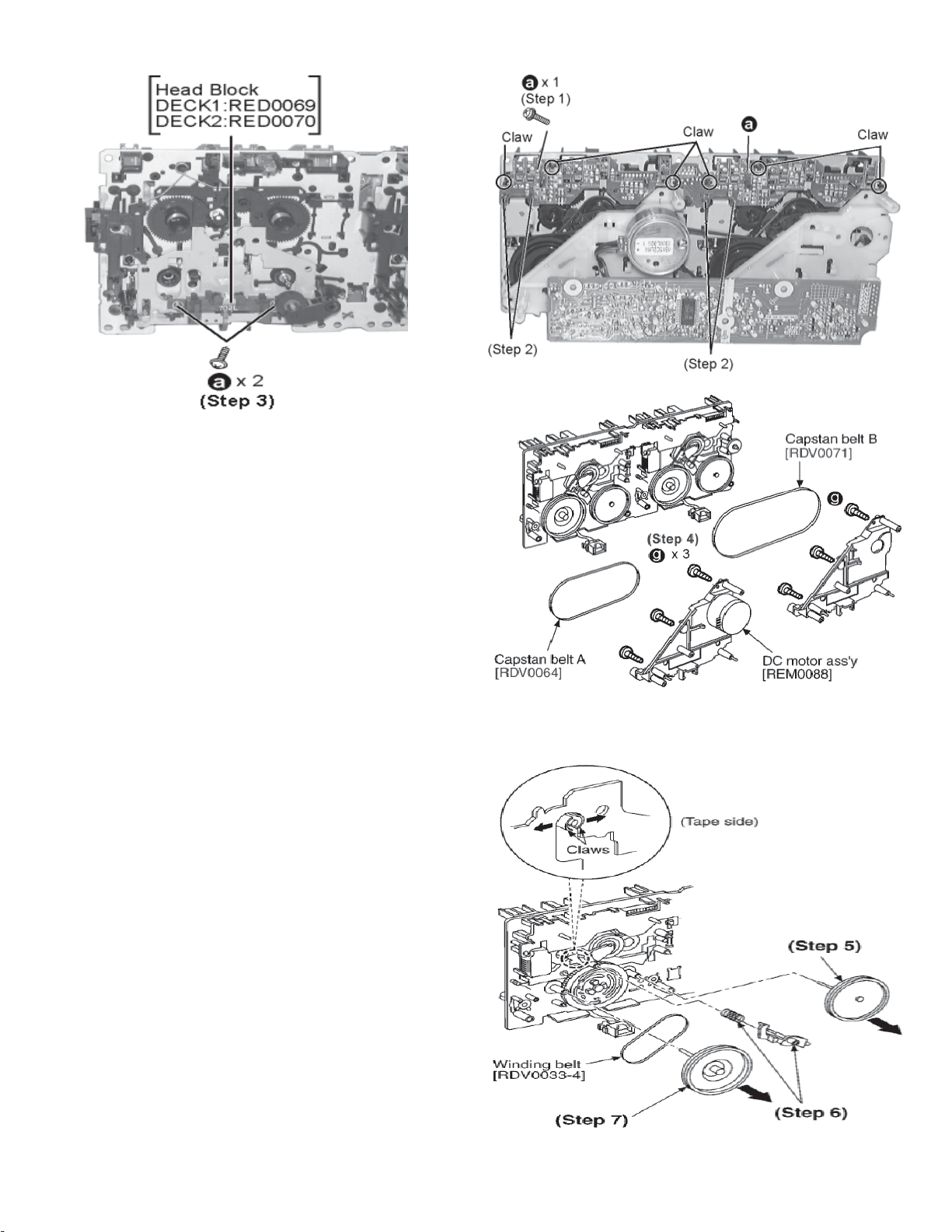

Step 1 Release the 2 claws, and then remove the pinch roller (R),

(F).

Step 2 Release ther 2 claws, and then remove the head connector.

Page 28

Step 3 Remove 2 screws.

10.9 Replacement for the

Deck motor ass’y, capstan

belt A, capstan belt B and

winding belt

• Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

• Follow the (Step 1) - (Step 5) of Item 10.2.1 Disassembly for CD Lid

• Follow the (Step 1) - (Step 2) of Item 10.3 - Disassembly

of the CD Mechanism Unit

• Follow the (Step 1) of Item 10.4 - Disassembly the Main

P.C.B. & Transformer P.C.B.

• Follow the (Step 1) - (Step 2) of Item 10.5 - Disassembly

of the Panel P.C.B. & Tact Switch P.C.B.

• Follow the (Step 1) - (Step 5) of Item 10.6 - Disassembly

for the Deck Mechanism P.C.B.

Step 1 Release the 2 claws, and then remove the head connector.

Step 4 Remove 3 screws.

Step 2 De-solder plunger point.

Step 3 Remove the Deck Mechanism P.C.B.

Page 29

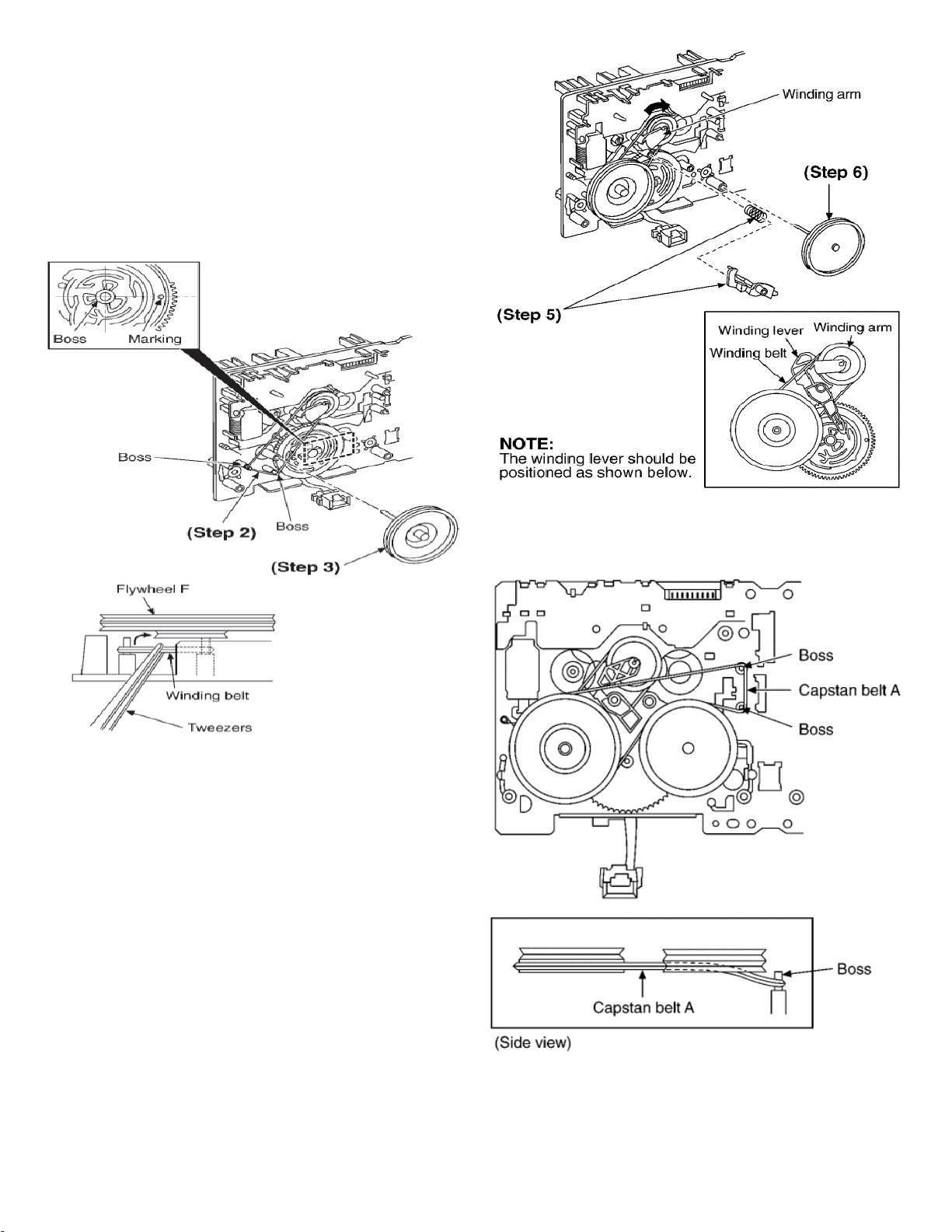

Step 5 Remove the flywheel R.

Step 6 Release the claw of tape side, and then remove the winding

lever and spring.

Step 7 Remove the flywheel F.

[Installation of the belt]

Step 1 The boss and marking should be positioned horizontally.

Step 2 Put the winding belt on the pulley temporarily.

Step 3 Install the flywheel F.

Step 4 Put the winding belt on the flywheel F.

Step 5 Install the winding lever and spring while pressing the

winding arm in the direction of arrow.

Step 7 Put the capstan belt A temporarily as shown below.

Step 6 Install the flywheel R.

Step 8 Put the capstan belt B on the motor ass’y pulley.

Step 9 Install the sub chassis to the mechanism, and then tighten

screws.

Page 30

Step 10 Remove 3 screws.

Step 11 Put the capstan belt B as shown below.

Step 12 Put the capstan belt A on the motor ass’y pulley.

Page 31

10.10 Replacement for the cassette

lid ass’y

• Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

Step 1 Push the lever upward, open the cassette lid ass’y. (For

DECK1 and DECK2)

10.11 Counter - measure for tape

trouble

• Follow the (Step 1) - (Step 2) of Item 10.2 - Disassembly

of Top Cabinet and Rear Panel

Step 1 If a cassette tape cannot be removed from the deck since

the tape is caught by the capstan or pinch roller during playback

or recording, rotate the flywheel F in the direction of the arrow to

remove the tape.

Step 2 Lift up the cassette lid ass’y in the direction of arrow. (For

DECK1 and DECK2).

Step 3 Remove the cassette lid ass’y. (For DECK1 and DECK2).

Step 2 Push the lever upward and open the cassette lid ass’y. Take

the cassette tape off.

Page 32

11.3 Checking the Panel, Tact

11 Service Position

11.1 Checking Procedur e

Note:

For the disassembling procedure, see Section 10.

11.2 Checking the Main P.C.B.,

Power P.C.B. and Transformer

P.C.B.

Disassembly of Top Cabinet and Rear Panel.

Disassembly of CD Lid.

Disassembly CD Mechanism Unit.

Connect FFC board (CN309 & CN310) from CD Mechanism

Unit.

Switch, Deck& Deck Mechanism

P.C.B.

Remove Top Cabinet and Rear Panel.

Remove CD Lid.

Remove CD Mechanism Unit.

Remove volume knob at front panel.

Remove Panel P.C.B. & Tact Switch P.C.B.

Remove Deck Mechanism Unit.

Use the extension cable (REEX0310 - 10 Pins) to reconnect

(CP600) Panel P.C.B. and (CN971) Deck Mechanism

P.C.B.

Page 33

12.1 Abnormality detection for Deck Mechanism bloc

k

No. Abnormal Items Error Display Method of Detection

1 MODE SW

abnormal

2 REC INH SW

abnormal

3 HALF SW

abnormal

4 Reel pulse

abnormal

H01 Normal operation during mecha transition, MODE SW abnormal is memorized. The content of abnormality can be confirmed in the

abnormal detection mode explained in the later section.

H02 The contect of abnormality can be confirmed in the abnormal detection mode explained in the later section.

H03 The contect of abnormality can be confirmed in the abnormal detection mode explained in the later section.

F01 The contect of abnormality can be confirmed in the abnormal detection mode explained in the later section.

12.2 Abnormality detection for CD/Changer block

No. Abnormal Items Error Display Method of Detection

1 REST SW

abnormal

2 Transmission

error between CD

servo LSI and

micon

3 CLAMP SW

abnormal

4 BOTTOM SW

abnormal

5 POSITION SW

abnormal

6 SW1 abnormal F28 Refer to CR20 control specification section 5-2 [ERROR CODE] table M-02 ~ M-08 error is detected.

F15 Under normal operation (Self-Diagnostic Mode inclusive), this error occurs when the REST SW ON is not detected within the

specified time and shall be memorized.

F26 Under normal operation (Self-Diagnostic Mode inclusive), this error occurs when the selection is set to CD and SENSE=’H’ is

detected and SENSE=’L’ is notdetected within a fail safe time (20ms) after system command transmission was sent.

F16 Refer to CR20 control specification section 5-2 [ERROR CODE] table M-0A error is detected.

F17 Refer to CR20 control specification section 5-2 [ERROR CODE] table M-09 error is detected.

F27 Refer tp CR20 control specification section 5-2 [ERROR CODE] table M-05 ~ M-08 error is detected.

7 SW2 abnormal F29 Refer to CR20 control specification section 5-2 [ERROR CODE] table M-02 ~ M-08 error is detected.

8 OPEN SW

abnormal

H15 Refer to CR20 control specification section 5-2 [ERROR CODE] table M-01 error is detected.

12.3 Power supply related error detection

No. Abnormal Items Error Display Method of Detection

1 POWER AMP

output abnormal

F61

During normal operation, if DCDET becomes ‘L’, normal POWER OFF process shall not be executed, PCNT shall be switched to ‘L’

immediately. GOODBYE shall not be displayed andthe error display F61 will be displayed instead.

2 seconds after the F61 display, ECONO shall be set to ‘L’ and FL display shall be turned off.

The error content shall be memorized when the abnormality occurs and can bedisplayed in the C-mecha self-diagnostic mode

described later.

Page 34

13 Self-Diagnostic Function

13.1 Self-diagnostic display

13.3 Cassette Mechanism Test (For

error code H01, H02, H03, F01,

F02)

This unit is equipped with a self-diagnostic display function

which, if a problem occurs, will display an error code

corresponding to the problem.

Use this function when performing maintenance on the unit.

13.2 How to enter the SelfDiagnostic Function

TOP PREVIOUS NEXT

Press “TAPE, DECK 1/2” to select Deck 2.

Load a cassette tape with the erasure prevention tab, remove

from left side only and close the cassette holder.

Press “FAST FORWARD MEMORY” (Tape will be stop after

2 seconds)

Load a cassette tape with the erasure prevention tab, remove

from right side only and close the cassette holder.

Press “REVERSE FM MODE/BP” (Tape will be stop after 2

seconds)

Load a pre-recorded tape with both side record tabs intact and

close the cassette holder.

Press “PLAY/TUNE/TIME ADJ UP” (After TPS function,

tape will stop automatically)

Press “REC/STOP” (Tape will not move)

Press “STOP/TUNE MODE” to indicate Error code.

• If several problem exist, error code will change each time

when “ /STOP” is pressed.

(e.g. H01 ! H03 ! F01 .....etc.)

Press “TAPE, DECK 1/2” to select Deck 1.

Repeat step 2 to 9 to test Deck 1. (Tape Deck 1 will not check

H02 because of no recording function)

Page 35

13.4 CD Mechanism Test (F15, F26,

F16, F17, F27, F28, F29, H15)

Press “CD”.

Press “OPEN/CLOSE (1)” and place a CD.

Press “OPEN/CLOSE (1)” to close the tray.

Press “OPEN/CLOSE (5)” and wait until the tray is open.

Press “OPEN/CLOSE (1)” and remove the CD.

Press “OPEN/CLOSE (1)” to close the tray.

Press “/STOP” to indicate Error Code.

• If several problem exist, error code will change each time

when “/STOP” is pressed. (e.g. F15 ! F26 ! F16 ....etc).

13.5 To clear all Error code

14 CD Test Mode Function

This CD test mode is provided to check CD unit without

connecting to changer loading mechanism. This mode shall

operate CD PLAY with CD unit being connected only and CD

Automatic Alignment result is shown on FL display.

14.1 How to set CD test mode

Press “STOP/TUNE MODE” button for 5 seconds.

FL indicator shows “CLEAR” for 1 second and change to

“T”.

13.6 How to get out from SelfDiagnostic function

Press “Power” button OFF.

13.7 Power Amplifier Failure (F61)

When power amplifier fail, F61 will indicate automatically.

Page 36

14.2 CD Automatically Adjustment

15 Measurements and

result indication

Under CD test mode, pressing the numeric key ‘0’ on the remote

controller will display the auto adjustment result. FLOCK,

TLOCK and CLVS status shall be shown as below:

During the above display, executing CD PLAY will display auto

adjustment result for CD PLAY mode.

Adjustments

15.1 Cassette Deck Section

• Measurement Condition

• Make sure head, capstan and press roller are clean.

• Judgeable room temperature 20 ± 5 °C (68 ± 9°F)

• Measuring instrument

• EVM (DC Electronic voltmeter)

• Digital frequency counter

• T est Tape

• Tape speed gain adjustment (3 kHz, -10 dB); QZZCWAT

15.1.1 Tape Speed Adjustment

(Deck 1/2)

Set the tape edit button to “NORMAL” position.

Insert the test tape (QZZCWAT) to DECK 2 and playback

(FWD side) the middle portion of it.

Adjust Motor VR (DECK 2) for the output value shown

below.

Adjustment target: 2940 ~ 3060 Hz (NORMAL speed)

After alignment, assure that the output frequency of the

DECK 1 FWD are within ±60 Hz of the value of the

output frequency of DECK 2 FWD.

Fig.1

Page 37

15.1.2 Bias and Erase Voltage

15.1.3 Bias Frequency Adjustment

Check

Set the unit “AUX” position.

Insert the Normal blank tape (QZZCRA) into DECK 2 and

the unit to “REC” mode (use “• REC/STOP” key).

Measure and make sure that the output is within the standard

value.

Bias voltage for Deck 2 14±4mV (Normal)

Erase voltage for Deck 2 80mV (Normal)

Fig.2

(Deck 1/2)

Set the unit to “AUX” position.

Insert the Normal blank tape (QZZCRA) into DECK 2 and

set the unit to “REC” mode (• use “REC/STOP” key).

Adjust L1002 so that the output frequency is within the

standard value.

Standard Value: 97 ±8 kHz

Fig.4

Fig.3

15.2 Tuner Section

15.2.1 AM-IF Alignment

Connect the instrument as shown in Fig.5.

Set the unit to AM mode.

Apply signal as shown in Fig. 5 from AM-SG.

Adjust Z102 so that the output frequency is maximized in

Fig. 6.

Fig.5

Page 38

Connect the instrument as shown in Fig. 7.

15.3 Alignment Points15.2.2 AM RF Adjustment

Set the unit to AM mode.

Set AM-SG to 520kHz.

Receive 520kHz in the unit.

Adjust Z101 (OSC) so that the EVM-AC is maximized.

Set AM-SG to 600Hz.

Receive 600Hz in the unit.

Adjust Z101 (ANT) so that the EVM-SG is maximized.

Set AM-SG to 520kHz.

Receive 520kHz in the unit.

Adjust Z101 (OSC) so that the EVM-DC value is with

1.1±0.5V.

Fig.7

15.3.1 Cassette Deck Section

15.3.2 Adjustment Point

Page 39

FM ANT

AM ANT

Z120

Q1

Q3

Q2

MIXER

OSC

Q4

BUFFER

1

RF AMP

5

CF201

7

Q101

IF AMP

CF202

FM

AM

ANT

COIL

Z101

AM

OSC

COIL

B

346

B

(FM)

8

RCH

PHASE

DET

VCO

FF FF

DECODER

STEREO

SWITCH

1316 15 14

PILOT

CANCEL

PILOT

FF

DET

24 23 22

ALC

AM

OSC

BUFFER

LEVEL

DET

FM

IF

12 3

S-CURVE

FM

DET

REG

21 20 19 18

AM

AM

RM AMP

MIX

AGC

AM

IF

AM/FM

IF

BUFFER

456

COMP

TUNING

DRIVE

SD

DET

7

17

AM

ST

REG

9810 11 12

B

IC101

LA1833NMNTLM

FM/AM IF AMP,

DET/AM OSC,

MIX/FM MPX

Z102

AM

IFT

X102

DO/ST

SD

16

17

18

11

15

B

B

PHASE DETECTOR

CHARGE PUMP

DETECTOR

POWER ON

RESET

Q106

TUNER

15V

SUPPLY

SWITCH

B

(FM)

UNLOCK

UNIVERSAL

COUNTER

19

REFERENCE

DIVIDER

SWALLOW COUNTER

1/6,1/17,4 BITS

12 BITS PROGRAMMABLE

DIVIDER

SHIFT REGISTER LATCH

10

7

1

2

6

8

9

IC102

LC72131MDTRM

PLL FREQUENCY SYNTHESIZER

C2B

I/F

X103

1

20

14

12

13

B

5

DO

CE

2

3

DI

4

CL

ST/DO

PLLDA

PLLCLK

CE

A

TO CD DRIVE BLOCK

Page 40

GRID11

GRID1

4,5,7,8,10,11,13,14,16,17,19,20,

22,23,25,26,28,31,33,35,37,40

FL DISPLAY

FL600

SEG1

SEG16

3,6,9,12,15,18,21,24,27,

29,30,32,34,36,38,39

FROM POWER

TRANSFORMER

PLLDA

STAT

ST/DO

PLLCLK

BLKCK

CD_RST

SD

MLD

MDATA

MCLK

CE

21~24,27~33

GRID1

GRID11

XTB

XT

47

46

IC603

C0JBAE000192

XOR GATE

43

4

1

SCK

CSB

SI

RSTB

41

42

44

IC602

C0HBB0000040

FL DRIVER

IC1

C0GAM0000005

MOTOR DRIVE

5

IN1

6

IN2

REG

3~12,15~20

SEG1

SEG16

OUT1

OUT2

8

VS

B

2

10

M

D1

RM1

Q1

POWER

SUPPLY

CONTROL

B

SW5

LOAD

D2

PUSH

PUSH

OPEN

SW4

CD

B

SW2

SW1

SW3

86

90

CHG_AD1

87

CHG_SW1

CHG_SW2

89

CHG_AD2

Q302

SWITCH

79

80

81

25

MLD

MDATA

MCLK

PLLCE

Q303

SWITCH

22

VCC

VREF

4

GND

7

1

B

Q324

CD

MOTOR

B

SUPPLY

SWITCH

Q323

PLUNGER

MOTOR

SUPPLY

CONTROL

SWITCH

71

FL_RESET

73

72

FL_CS

FL_DOUT

85

84

CHG_CW

CHG_CCW

C2CBJF000017

IC305

88

CHG_PLR

MICROPROCESSOR

83

CHG_HLF

74

23

19

77

SD

BLKCK

CD_RST

PLLCK

24

21

78

ST/DO

STATUS

PLLDA

FL_CLK

S701

REST SW

82

/RESTSW

V_JOG_A

67

VR600

JOG VOL

68

V_JOG_B

MBP2

7

Q313, Q314

SWITCH

X_IN

MBP1

15

6

X_OUT

13

X303

Page 41

(DECK 1)

P.B. HEAD LCH

(DECK 2)

R/P HEAD LCH

4

2

IC1004

C1AA00000612

R/P SELECT

Q1017

MOTOR

SWITCH

M

M1002

(DECK 2)

ERASE HEAD

3

5

(BEAT PROOF/

Q325

REC:

ON/OFF

CONTROL

B

SWITCHING

RECH)

Q1001,Q1003

IC1001

AN7348S-E1

P.B EQ/REC AMP/

ALC/TPS AMP

24(23)

1(2)

22(3)

21(4)

17(8)

6

19

15

12

L1002

Q322

SUPPLY

CONTROL

SWITCH

+

-

LOGIC L/H

ALC

NOR/CrO &

HI/LO LOGIC

LOGIC

REC/PB

9

B

RIPPLE

REJECTION

11

BIAS OSC

CONTROL

Q1004,Q1005,

Q1007

SWITCH

Q319

Q1014(Q1015)

20(5)

18(7)

10

16

14

13

Q320,Q321

REC:ON/OFF

CONTROL/

SWITCH

BP

Q1012

(Q1013)

MUTING

B

Q1016

DECK

MUTING

SWITCH

Q318

DECK

MUTING

CONTROL

SWITCH

BUFFER

AMP

Q1020

(Q1021)

MUTING

SWITCH

(MODE)

S951

53

52

MODE_1

IC951

CNB13030R2AU

PHOTO

INTERRUPTER

(HALF)

S952

HALF_1

Q326

SWITCH

B

Q612

SWITCH

PHOTO:ON/OFF

Q616

SWITCH

PHOTO:ON/OFF

55

PHOTO_1

Q615, Q619

PLUNGER

SUPPLY SWITCH/

PLUNGER:ON/OFF

SWITCH

56

PLG1

Q617, Q618

PLUNGER

SUPPLY SWITCH/

PLUNGER:ON/OFF

XC_IN

10

X301

D951

SWITCH

D971

57

PLG2

XC_OUT

11

Q610

SWITCH

PHOTO:ON/OFF

Q611

SWITCH

PHOTO:ON/OFF

54

PHOTO_2

C2CBJF000017

/CD

75

Q310

CD ON/OFF

SUPPLY

SWITCH

B

58

66

MTR

MICROPROCESSOR

IC305

D307

BP1

Q308, Q309

CURRENT

CONTROL/

VOLTAGE

STABILISER

CD 3.3V

60

59

REC

65

DMT

DECK1_H

B

B

IC971

CNB13030R2AU

PHOTO

INTERRUPTER

(MODE)

91

DECK2

Q328

SWITCH

B

(F.REC INH)

S975

S971

B

Q327

SWITCH

Z971

(HALF)

S972

INTERFACE

B

Page 42

AUX

JK300

CD SIGNAL

4(39)

5(38)

9(34)

8(35)

6(37)

3(40)

IN B1(2)

IN C1(2)

A_VOLIN1(2)

REC1(2)

IN D1(2)

IN A1(2)

IC300

C1BB00000747

AUDIO SOUND

PROCESSOR

CLOCK

DATA

22

21

OUT1(2)

19(24)

MUTE_H

Q407

(Q207)

MUTING

SWITCH

Q301

MUTING

CONTROL

SWITCH

IC301

C0AABB000117

HEADPHONE AMP

3(5)

Q401(Q201)

AUDIO

AMP

AGC

SWITCH

B

1(7)

Q402

(Q202)

MUTING

SWITCH

Q403(Q203)

HEADPHONE

MUTING

SWITCH

B

HP_L(R)

Q409

SWITCH

1(2)

LM_L(R)

D404

C2CBJF000017

26

27

ASP_DAT

MICROPROCESSOR

IC305

ASP_CLK

39

MUTE_H

40

MUTE_A

B

D312

B

12

/RESET/EFP_RESET

CONTROL

B

D306

B

B

Q315

POWER

RESET

SWITCH

D303

D304,D305

D302

KEY SW

47

DCDET

92~94

KEY1

KEY3

SYNC

PCONT/EFP_/CE

20

46

Q312

PCONT

SWITCH

Q316,

SSEQ_LED

76

Q614

D929

B

LED

DRIVE

RMT

18

Z600

Q317

POWER

SUPPLY

SWITCH

B

REMOTE SENSOR

Page 43

10(14)

11(13)

-IN L(R)

+IN L(R)

IC501

RSN35H2A-P

POWER HIC

OUT L(R)

+VCC

-VCC

4(1)

2

3

LCH

+

JK952

-

FULL RANGE

FAN

DC_DET

FAN

HP _SW

MUTE_H

SYNC

D513

7

12

9

MUTE C

IN GND

GND

HEADPHONE

SYNCHRONISING

Q512,Q513

DC DETECT

Q514

MUTING

SWITCH

Q952

SWITCH

FILTER

FILTER

SWITCH

AC DET

LATCH

-VCCM

Q501

10V VOLTAGE

REGULATOR

6

5

FILTER

8

B

Q502,Q505

VOLTAGE SUPPLY/

CURRENT CONTROL

SWITCH

JK601

HEADPHONE

RCH

Q950

SYSTEM 6V

VOLTAGE

B

REGULATOR

D961~D964

DC_DET

HP_SW

SYNC

SIGNAL LINES

MAIN SIGNAL LINE

FM OSC SIGNAL LINE

FM SIGNAL LINE

( )

Indicates the Pin No. of Right Channel.

Q503

15V VOLTAGE

B

REGULATOR

Q504,Q506,Q507Q508

5V VOLTAGE

B

REGULATOR

CURRENT STABILISER/

LIMIT SWITCH/

10V VOLTAGE REGULATOR

B

CD SIGNAL LINE

AM OSC SIGNAL LINE

AUX SIGNAL LINE

D954~D957

Q951

VOLTAGE

REGULATOR

(-VP)

FP533

FP950

D959

TO

FL DISPLAY

AM SIGNAL LINE

FM & AM SIGNALS LINE

CD-DA SIGNAL LINE

D950~D953

FP951

T950

POWER TRANSFORMER

Q953

POWER

SWITCH

CONTROL

PLAYBACK SIGNAL LINE

RECORDING SIGNAL LINE

RL950

T951

B

SUB

TRANSFORMER

JK950

F1

AC INLET

E500

NOTE : Signal lines are applicable to the Left Channel only.

Page 44

FM ANT

AM ANT

Z120

Q1

Q3

Q2

MIXER

OSC

Q4

BUFFER

1

RF AMP

5

CF201

7

Q101

IF AMP

CF202

FM

AM

ANT

COIL

Z101

AM

OSC

COIL

B

346

B

(FM)

8

RCH

PHASE

DET

VCO

FF FF

DECODER

STEREO

SWITCH

1316 15 14

PILOT

CANCEL

PILOT

FF

DET

24 23 22

ALC

AM

OSC

BUFFER

LEVEL

DET

FM

IF

12 3

S-CURVE

FM

DET

REG

21 20 19 18

AM

AM

RM AMP

MIX

AGC

AM

IF

AM/FM

IF

BUFFER

456

COMP

TUNING

DRIVE

SD

DET

7

17

AM

ST

REG

9810 11 12

B

IC101

LA1833NMNTLM

FM/AM IF AMP,

DET/AM OSC,

MIX/FM MPX

Z102

AM

IFT

X102

DO/ST

SD

16

17

18

11

15

B

B

PHASE DETECTOR

CHARGE PUMP

DETECTOR

POWER ON

RESET

Q106

TUNER

15V

SUPPLY

SWITCH

B

(FM)

UNLOCK

UNIVERSAL

COUNTER

19

REFERENCE

DIVIDER

SWALLOW COUNTER

1/6,1/17,4 BITS

12 BITS PROGRAMMABLE

DIVIDER

SHIFT REGISTER LATCH

10

7

1

2

6

9

IC102

LC72131MDTRM

PLL FREQUENCY SYNTHESIZER

C2B

I/F

8

X103

1

20

14

12

13

B

5

DO

CE

2

3

DI

4

CL

ST/DO

PLLDA

PLLCLK

CE

A

TO CD DRIVE BLOCK

Page 45

GRID11

GRID1

4,5,7,8,10,11,13,14,16,17,19,20,

22,23,25,26,28,31,33,35,37,40

FL DISPLAY

FL600

SEG1

SEG16

3,6,9,12,15,18,21,24,27,

29,30,32,34,36,38,39

FROM POWER

TRANSFORMER

PLLDA

STAT

ST/DO

PLLCLK

BLKCK

CD_RST

SD

MLD

MDATA

MCLK

CE

21~24,27~33

GRID1

GRID11

XTB

XT

47

46

IC603

C0JBAE000192

XOR GATE

43

4

1

SCK

CSB

SI

RSTB

41

42

44

IC602

C0HBB0000040

FL DRIVER

IC1

C0GAM0000005

MOTOR DRIVE

5

IN1

6

IN2

REG

3~12,15~20

SEG1

SEG16

OUT1

OUT2

8

VS

B

2

10

M

D1

RM1

Q1

POWER

SUPPLY

CONTROL

B

SW5

LOAD

D2

PUSH

PUSH

OPEN

SW4

CD

B

SW2

SW1

SW3

86

90

CHG_AD1

87

CHG_SW1

CHG_SW2

89

CHG_AD2

Q302

SWITCH

79

80

81

25

MLD

MDATA

MCLK

PLLCE

Q303

SWITCH

22

VCC

VREF

4

GND

7

1

B

Q324

CD

MOTOR

B

SUPPLY

SWITCH

Q323

PLUNGER

MOTOR

SUPPLY

CONTROL

SWITCH

71

FL_RESET

73

72

FL_CS

FL_DOUT

85

84

CHG_CW

CHG_CCW

C2CBJF000017

IC305

88

CHG_PLR

MICROPROCESSOR

83

CHG_HLF

74

23

19

77

SD

BLKCK

CD_RST

PLLCK

24

21

78

ST/DO

STATUS

PLLDA

FL_CLK

S701

REST SW

82

/RESTSW

V_JOG_A

67

VR600

JOG VOL

68

V_JOG_B

MBP2

7

Q313, Q314

SWITCH

X_IN

MBP1

15

6

X_OUT

13

X303

Page 46

(DECK 1)

P.B. HEAD LCH

(DECK 2)

R/P HEAD LCH

4

2

IC1004

C1AA00000612

R/P SELECT

Q1017

MOTOR

SWITCH

M

M1002

(DECK 2)

ERASE HEAD

3

5

(BEAT PROOF/

Q325

REC:

ON/OFF

CONTROL

B

SWITCHING

RECH)

Q1001,Q1003

IC1001

AN7348S-E1

P.B EQ/REC AMP/

ALC/TPS AMP

24(23)

1(2)

22(3)

21(4)

17(8)

6

19

15

12

L1002

Q322

SUPPLY

CONTROL

SWITCH

+

-

LOGIC L/H

ALC

NOR/CrO &

HI/LO LOGIC

LOGIC

REC/PB

9

B

RIPPLE

REJECTION

11

BIAS OSC

CONTROL

Q1004,Q1005,

Q1007

SWITCH

Q319

Q1014(Q1015)

20(5)

18(7)

10

16

14

13

Q320,Q321

REC:ON/OFF

CONTROL/

SWITCH

BP

Q1012

(Q1013)

MUTING

B

Q1016

DECK

MUTING

SWITCH

Q318

DECK

MUTING

CONTROL

SWITCH

BUFFER

AMP

Q1020

(Q1021)

MUTING

SWITCH

(MODE)

S951

53

52

MODE_1

IC951

CNB13030R2AU

PHOTO

INTERRUPTER

(HALF)

S952

HALF_1

Q326

SWITCH

B

Q612

SWITCH

PHOTO:ON/OFF

Q616

SWITCH

PHOTO:ON/OFF

55

PHOTO_1

Q615, Q619

PLUNGER

SUPPLY SWITCH/

PLUNGER:ON/OFF

SWITCH

56

PLG1

Q617, Q618

PLUNGER

SUPPLY SWITCH/

PLUNGER:ON/OFF

XC_IN

10

X301

D951

SWITCH

D971

57

PLG2

XC_OUT

11

Q610

SWITCH

PHOTO:ON/OFF

Q611

SWITCH

PHOTO:ON/OFF

54

PHOTO_2

C2CBJF000017

/CD

75

Q310

CD ON/OFF

SUPPLY

SWITCH

B

58

MTR

MICROPROCESSOR

IC305

D307

66

BP1

Q308, Q309

CURRENT

CONTROL/

VOLTAGE

STABILISER

CD 3.3V

60

59

REC

65

DMT

DECK1_H

B

B

IC971

CNB13030R2AU

PHOTO

INTERRUPTER

(MODE)

91

DECK2

Q328

SWITCH

B

(F.REC INH)

S975

S971

B

Q327

SWITCH

Z971

(HALF)

S972

INTERFACE

B

Page 47

AUX

JK300

CD SIGNAL

4(39)

5(38)

9(34)

8(35)

6(37)

3(40)

IN B1(2)

IN C1(2)

A_VOLIN1(2)

REC1(2)

IN D1(2)

IN A1(2)

IC300

C1BB00000747

AUDIO SOUND

PROCESSOR

CLOCK

DATA

22

21

OUT1(2)

19(24)

MUTE_H

Q407

(Q207)

MUTING

SWITCH

Q301

MUTING

CONTROL

SWITCH

IC301

C0AABB000117

HEADPHONE AMP

3(5)

Q401(Q201)

AUDIO

AMP

AGC

SWITCH

B

1(7)

Q402

(Q202)

MUTING

SWITCH

Q403(Q203)

HEADPHONE

MUTING

SWITCH

B

HP_L(R)

Q409

SWITCH

1(2)

LM_L(R)

D404

C2CBJF000017

26

27

ASP_DAT

MICROPROCESSOR

IC305

ASP_CLK

39

MUTE_H

40

MUTE_A

B

D312

B

12

/RESET/EFP_RESET

CONTROL

B

D306

B

B

Q315

POWER

RESET

SWITCH

D303

D304,D305

D302

KEY SW

47

DCDET

92~94

KEY1

KEY3

SYNC

PCONT/EFP_/CE

20

46

Q312

PCONT

SWITCH

Q316,

SSEQ_LED

76

Q614

D929

B

LED

DRIVE

RMT

18

Z600

Q317

POWER

SUPPLY

SWITCH

B

REMOTE SENSOR

Page 48

10(14)

11(13)

-IN L(R)

+IN L(R)

IC501

RSN35H2A-P

POWER HIC

OUT L(R)

+VCC

-VCC

4(1)

2

3

LCH

+

JK952

-

FULL RANGE

FAN

DC_DET

FAN

HP _SW

MUTE_H

SYNC

D513

7

12

9

MUTE C

IN GND

GND

HEADPHONE

SYNCHRONISING

Q512,Q513

DC DETECT

Q514

MUTING

SWITCH

Q952

SWITCH

FILTER

FILTER

SWITCH

AC DET

LATCH

-VCCM

Q501

10V VOLTAGE

REGULATOR

6

5

FILTER

8

B

Q502,Q505

VOLTAGE SUPPLY/

CURRENT CONTROL

SWITCH

JK601

HEADPHONE

RCH

Q950

SYSTEM 6V

VOLTAGE

B

REGULATOR

D961~D964

DC_DET

HP_SW

SYNC

SIGNAL LINES

MAIN SIGNAL LINE

FM OSC SIGNAL LINE

FM SIGNAL LINE

( )

Indicates the Pin No. of Right Channel.

Q503

15V VOLTAGE

B

REGULATOR

Q504,Q506,Q507Q508

5V VOLTAGE

B

REGULATOR

CURRENT STABILISER/

LIMIT SWITCH/

10V VOLTAGE REGULATOR

B

CD SIGNAL LINE

AM OSC SIGNAL LINE

AUX SIGNAL LINE

D954~D957

Q951

VOLTAGE

REGULATOR

(-VP)

FP533

FP950

D959

TO

FL DISPLAY

AM SIGNAL LINE

FM & AM SIGNALS LINE

CD-DA SIGNAL LINE

D950~D953

FP951

T950

POWER TRANSFORMER

Q953

POWER

SWITCH

CONTROL

PLAYBACK SIGNAL LINE

RECORDING SIGNAL LINE

RL950

T951

B

SUB

TRANSFORMER

JK950

F1

AC INLET

E500

NOTE : Signal lines are applicable to the Left Channel only.

Page 49

17 Schematic Diagram

• S701

: Rest switch

(All schematic diagrams may be modified at any time with

the development of the new technology)

Note:

• SW1

: Push switch

• SW2

: Push switch

• SW3

: Open switch

• SW4

: CD switch

• SW5

: Load switch

• S601

: Open/ Close switch

• S602

: CD 1 switch

• S603

: CD 2 switch

• S604

: CD 3 switch

• S605

: CD 4 switch

• S606

: CD 5 switch

• S612

: Power switch

• S613

: SSEQ switch

• S614

: Preset switch

• S615

• S901

: Rew switch

• S902

: Tuner switch

• S903

: CD switch

• S904

: FF switch

• S905

: Stop switch

• S906

: Deck 2 open switch

• S907

: T ape switch

• S908

: AUX switch

• S909

: Deck 1 open switch

• S910

: Display switch

• S951

: Mode switch

• S952

: Half switch

• S971

: Mode switch

• S972

: Half switch

• S975

: Recinh_F switch

• VR600

: VR Volume Jog

: Record switch

• S616

: Deck 1/2 switch

Page 50

• The voltage value and waveforms are the reference

voltage of this unit measured by DC electronic voltmeter (high

impedance) and oscilloscope on the basis of chassis. Accordingly,

there may arise some error in voltage values and

waveformsdependingupon the internal impedance of the tester or

the measuring unit.

No mark : Playback << >> : Rec < > : FM

(( )) : CD

• Importance safety notice :

Components identified by

mark

have special characteristics important for safety.

Furthermore, special parts which have purposes of fireretardant (resistors), high-quality sound (capacitors),

low-noise (resistors), etc. are used. Whenreplacingany of

components, be sure to use only manufacturer´s specified

parts shown in the parts list.

Caution !

IC, LSI and VLSI are sensitive to static electricity.

Secondary trouble can be prevented by taking care during repair.

• Cover the parts boxes made of plastics with aluminium

foil.

• Put a conductive mat on the work table.

• Ground the soldering iron.

• Do not touch the pins of IC, LSI or VLSI with fingers

directly.

Page 51

SCHEMATIC DIAGRAM - 1

OPTICAL

PICKUP CIRCUIT

: +B SIGNAL LINE

CD SERVO CIRCUIT

: CD-DA SIGNAL LINE

C3 0.22

VR1

R701

Q701

R750

5.6

4.7

C701

6.3V33

C714

6.3V100

1234

LPD

A

1

1

VCC

2

2

F

3

3

E

4

4

12

E

11

VREF

10

A

9

NC

8

LPD

7

GND

GND

VCC

LDG

1

C2 0.22

2

F

C1

3

B

LD

0.47

4

5

6

5

6

7

8

9

10

11

12

13

14

15

16

CN701

10

11

12

13

14

15

16

5

6

7

8

9

LD

LD GND

GND

B

GND

A

VREF

LPD

GND

T-

T+

F-

F+

C751

0.1

C713

C750

0.1

0.1

C770

0.1

LD

VCC

3132

C712

0.1

R738

6.8K

C711

0.1

R737

6.8K

Q701

B1ADCF000001

LASER POWER DRIVE

29

52662572482392210211120121913 14

EQSW

RFOUT

AN22004A-NF

F

DCB

RF VOLT

C702 0.47

C705 0.1

RFIN

CAGC

IC701

SERVO AMP

E

TBAL

27282930

41

30

R742 10K R743 4.7K

C707 0.039

CEA

ARF

FBAL

GCTL

39

R708 0

C747

470P

R744

34

39K

R706

(ENV) 3TOUT

FEOUT

1K

C703 6.3V100

C706 10

DCDET

FEN

C710

470P

R702

4.7K

R704

R707 0

R729 1.5K

C704 0.1K

C716 680P

BDO

OFTCONT

TEN

TEOUT

R705

39K

3900P

32

1K

C749

OFTR

VREF

42

15 16

/RFDET

EQ8ST

18 17

C742

0.047

40

LDON

GND

33

R728 18K

C735

0.1

C734

10V220

R727

1.5K

21

NC

VCC

22

VREF

23

IN4

24 25 26

IN3

RSTIN

NC

D3+

171615

D4-

NC

D4+

PGND2

GND

PVCC2

14

D3-

R749

18K

IC703

R736

D1+

D1-

NC

920101911181213

8

35

M702

SP MOTOR

38

M701

TRV MOTOR

IN1NCPC2NCIN2

7

NC

R735

100

/RST

12

3456

C738

0.047

R725

R723

560

5.6K

D2+

D2-

C737 0.1

36

M

C736 0.1

37

M

GND

PGND1

PVCC1

10

C715

0.22

C752

0.01

R731

22K

R739

C739

1K

0.01

IC703

AN8739SBTE2

FOCUS COIL/

TRACKING COIL/

TRAVERSE MOTOR/

SPINDLE MOTOR DRIVE

R715

2.7K

Page 52

SCHEMATIC DIAGRAM - 2

: +B SIGNAL LINE : CD SIGNAL LINE

CD SERVO CIRCUIT

: CD-DA SIGNAL LINE

R711

82K

C729 0.1

C717

0.1

R709

100K

C757

6.3V100

C758

0.1

C755

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

0.1

1000P

IREF

ARF

LDON

BDO

NRFDET

OFT

RFENV

TE

FE

FBAL

TBAL

IOVDD1

FOM

FOP

TRM

TRP

TRVM(PC)

TRVP

SPOUT

DVDD2

R721

100

C744

C741

20

C718

0.015

0.082

R712

820

41

43

444546

42

DSLF

ADPVCC

(DRF)RFSW

A2

A3

DVSS2

18

19

17

A3A2A1A0A9A4A5A6A7A8CASD3D2

48

49

50

47

PLLF

OUTL

AVSS1

AVSS2

PLLFO

AVDD2

IC702

MN6627934CH

SERVO PROCESSOR

DIGITAL SIGNAL PROCESSOR/

DIGITAL FILTER/

D/A CONVERTER

A5A4A9

A0

A1

16

11

14

1213

15

51

OUTR

10

C740

0.1

52

AVDD1

A8A7A6

53

DVSS3

(NCAS1)

A10

8

9

A10

C730

0.1

54

DVDD3

TMOD2

D3

NCAS0

7

6.3V220

25

R761 10K

56

55

EXT2

FLAG

NRAS

D2

6

5

R717

1K

R718

1K

C731

R762 10K

R763 10K

59

57

58

EXT0

EXT1

D1

NEW

4

2

3

RASWED1

C723

6.3V220

C724

0.1

60

TX

IOVDD2

DRVDD

D0

1

D0

1000P

1000P

MCLK

MDATA

MLD

BLKCK

PWMSEL

SMCK

SBCK

STAT

NRST

SPPOL

PMCK

DQSY

TXTD

TXTCK

NTEST

OUT X2

IN X1

DVSS1

DVDD1

MON

C725

C726

24

22

C727

50V1

C728

50V1

23

C753

470P

R760

12

11 10 9

61

62

63

64

65

66

67

R753 10

68

69

70

71

72

73

74

75

76

77

78

79

80

100

8

7

C722

12P

R720

1M

X701

RSXB16M9J02T

R714

C721

220

12P

C780

0.1

16

LCH OUT

19

A.GND

18

RCH OUT

17

+3.3V

16

D.GND

15

LD SW

14

TX

13

+7.5V

P.GND

MCLK

MDATA

MLD

NC

BLKCK

NC

NC

STAT

/RST

REST SW

13

12

11

10

9

8

7

6

5

4

3

2

1

CN702

TO

MAIN

CIRCUIT

(CN310) ON

TIC

SCHEMA

DIAGRAM-5

C743

0.1

C733

0.1

D2

D3

242526

D3

D2

VSS

VCC

1234

/CAS

WE

D1

D0

D1

D0

A9

CAS

21

2223

20

A9

NC

/OE

IC704

C3ABMB000027

16M DRAM

NC

NC

RAS

6197

5

RAS

WE

A8

A7

18

A8

A7

A0

A10

81791610

A10

A0

A1

A6

A6

A1

A5

A5

A2

111412

A2

A4

15

A4

VSS

A3

VCC

13

C781

0.1

A3

C748

0.1

C746

0.1

C782

0.1

REST SW

15

S701

1

Page 53

FM EXT

ANT

75 OHM

GND

AM LOOP ANT

AM EXT

ANT

JK101

SCHEMATIC DIAGRAM - 3

TUNER/MAIN CIRCUIT

TUNER PACK CIRCUIT

5.6P 2SK544

1

1

2

2

3

3

4

4

5

R110

AM ANT COIL

2

1

Z101

RLA2Z007-T

1K

2.7K

100K

C107

0.047

1000P

100K

220

4.7P

2.2P

3

AM OSC COIL

8

7

9

C108

R112

100K

8P

100K

: +B SIGNAL LINE

: FM/AM SIGNAL LINE

2.2P

2SC2786M

1.2U

18P

3.3P

680K

180P

390

560K

2SC1675l1l2

2.2P

2SC2787FL1TA

C136

4

5

6

1000P

R119

3.3K

1000P

680K

390

390

R118

3.3K

0.47U

5.6P

C114

50V3.3

7

6

8

: FM SIGNAL LINE

: FM OSC SIGNAL LINE

CF201

RLFFETWND01M

1

3

2

C101

0.01

R120

47K

C109

1000P

2324

AFC

OSC

OSC OUT

C104

1000P

R105

470

C102

16V10

C119

680P

2122

AM RF IN

R103

AGC

270

C103

0.01

R106

470K

C115

50V4.7

AM OUT

IC101

C116

0.033

DET OUT

R107

330

RLFFETWND01M

R101

0

Q101

R121

22K

R143

22K

150P

C131

: AM SIGNAL LINE

: AM OSC SIGNAL LINE

R104

1K

CF202

1

3

2

Q101

2SC2058SPTA

FM IF AMP

C120

16V10

C138

0.01

C139

50V4.7

0.01

C118

68K

4.7K

R123

R102

C137

3300P

16101511141213

RCH

MPX IN

PILOT IN

PILOT OUT

Q106

Q106

B1GCCFJJ0015

TUNER 15V

SUPPLY SWITCH

R146

100K

R142

6.8K

R141

6.8K

R145

100K

6800P

C143

C144

6800P

C117

0.01

LCH

C142

50V1

C141

50V1

D101

B0BC5R000009

R114

5.6K

C110

0.01

R152

0

LA1833NMNTLM

FM/AM IF AMP

DET/AM OSC MIX/

C130

6.3V100

C133

C112

27P

0.01

X103

RSXC7M20S05T

C134

27P

R138

3.3K

R130

10K

IC101

FM MPX

R113

10K

C132

C111

1000P

50V4.7

R115

560

R116

1K

17181920

AIN

VSS

XOUT

AOUT

LC72131MDTRM

PLL FREQUENCY SYNTHESIZER

CL

DI

CE

XIN

1234

R136 1K

R137 1K

PLLDA

CE

R111

390

C125

16V22

C113

1000P

82

R151

PD

VDD

FMIN

AMIN

IC102

LW

DO

51661571481391210

R135 1K

R134 470

DO/ST

PLLCLK

SDC

AM

R117

47K

MONO

STRQ

C127

16V22

G2BAE0000003

R129

27K

11

IFIN

FM

2

1

Z102

C124

100P

FM IF IN

1234

C126

1

3

5

R128

82

REG

AM MIX OUT

C106

0.01

4

6

SD

GND

AM IF IN

5206197188179

C147

1000P

C148

0.01

R126

C129

6.3V100

SD

1K

ST

DO/ST

R125

FM DET

470

C149

0.1

R124

X102

STRQ

VCC

33

R127

RLFDFT22DD

R132

10K

FM/AM

470

C122

R122

MONO

50V1

2.7K

C121

50V0.47

R133

1K

R144

120

R131

120

C123

50V1

TGND

DO/ST

+7.5V

RCH

LCH

PLLDA

DO/ST

PLLCLK

15V

SD

CE

TO

MAIN

CIRCUIT

(2A) ON

SCHEMATIC

DIAGRAM-8

1A

TO

MAIN

CIRCUIT

(2B) ON

SCHEMATIC

DIAGRAM-8

1B

Page 54

TO

DECK

CIRCUIT

(CN1001) ON

SCHEMATIC

DIAGRAM-14

AUX

TO

CD LOADING

CIRCUIT

(CN1) ON

SCHEMATIC

DIAGRAM-11

SCHEMATIC DIAGRAM - 4

: +B SIGNAL LINE

: -B SIGNAL LINE

MAIN CIRCUIT

CR02

1

MOTOR

2

BP1

3

DECK1_H

4

DMT

5

MOGND

6

MOT+B

7

REC_H

8

+15V

9

RECINR

10

RECINL

11

AFGND

12

PBR

13

PBL

14

CN304

C442

C410

0.22

RCH

LCH

JK300

CN309

CHG_CW

14

CHG_HALF

13

CD8V

12

CHG_CCW

11

CLAMP

10

OPEN

9

CD_SW1

8

PGND

7

CD_SW2

6

DGND

5

5V

4

POSITION

3

BOTTOMSW

2

PLUNGER

1

0.22

L305

J0JBC0000019

B0ACCK000005

Q308

D307

D308

D307-D308

B0ACCK000005

R329

330

R201

10K

C201

680

C401

680

R401

10K

R344 22K

R345 12K

C326

0.47

R348 220

R346 22K

R347 12K

D324

Q324

KTA12710YTA

CD MOTOR SUPPLY SWITCH

C321

0.01

Q309

C320

R328

10V22

2.2K

Q324

R324

R325

10K

R327

1K

12

C202

100P

C402

100P

R326

100

R340

10K

R350

10K

R323

15

Q310

: PLAYBACK SIGNAL LINE

: RECORD SIGNAL LINE

MOT10V

REC

+15V

REC_R

C443

R395

47K

0.1

REC_L

PBR

AUXR

AUXL

VREF+

R343

10K

CHG_CW

CHG_HLF

CD8V

CHG_CCW

CHG_AD1

CHG_AD2

CHG_SW1

CHG_SW2

SW5V

R202

3.3K

R402

3.3K

R396

47K

C306

50V1

Q323

CHG_PLR

R349

1K

MOT10V

Q323

B1GBCFJJ0039

PLUNGER MOTOR

SUPPLY CONTROL SWITCH

CD3.3V

D309

B0EAKM000117

CD8V

PBL

HI_L

HI_R

VREF+

EE_CS

EE_CLK

R803

22K

/CD

R802

22K

/DMT

DECK1_H

R444

1.2K

R244

1.2K

C364

330P

SW5V

/BP1

: AUX SIGNAL LINE

: MAIN SIGNAL LINE

MTR

C434

50V1

C234

50V1

C363

0.022

4321

C366

330P

R806

4.7K

EE_DAT

Q308

KTA12710YTA

CURRENT CONTROL

SWITCH

TO

PANEL CIRCUIT

(CP601) ON

SCHEMATIC DIAGRAM-10

8

7654321

KEY3KEY3

KEY1KEY1

KEY2KEY2

D_GND

R440

R240

SSEQ_LED

SSEQ_LED

0

0

C432

IC304

8765

KTC3199GRTA

VOLTAGE STABILISER

9

10

SW5V

FL_CLKFL_CLK

FL_DOUTFL_DOUT

SW5V

0

C232

0

BR93LC46FE2

E-EPROM

(NOT SUPPLIED)

Q309

CD3.3V

DGND

FL_CS

FL_RST

EXP_DAT

EXP_DAT

FL_RST

FL_CS

R245

220

IC304

Q310

B1GCCFGA0005

CD ON/OFF

SUPPLY SWITCH

17

161514131211

LED9V

EXP_CLK

LED9V

EXP_CLK

R445

CN303

220

Page 55

SCHEMATIC DIAGRAM - 5

R206

R204

33

33

R205

R207

33

33

C203

1000P

LHPF

Q202, Q402

B1ABEB000001

MUTING SWITCH

RHPF

C309

R309

10V10

27K

-9.0V

LDL

CD3.3V

CDR

CD7.5V

MCLK

MDATA

MLD

CBLKCK

CCDSTAT

CD_RST

R450 4.7K

RESTSW

MAIN CIRCUIT

Q203, Q403

B1ABEB000001

HEADPHONE MUTING

SWITCH

R203

HP_R

1

R208

3.3K

Q203 Q403

R209

560

C429

50V1

R435

1.5K

R235

1.5K

C229

50V1

R310

56K

Q301

B1GDCFJJ0023

AUDIO MUTING

CONTROL SWITCH

G0C101JA0030

L303

C398 1000P

R382 10K

R380 10K

R369 10K

R368 10K

1K

R366

: +B SIGNAL LINE

: -B SIGNAL LINE

R403

1

HP_L

R404

R409

560

R405

33

R408

3.3K

Q402

Q202

R228

R818

2.2K

Q301

1K

1K

R365

R364

Q207, Q407

B1ABEB000001

MUTING SWITCH

R406

33

33

R407

33

C403

1000P

R428

2.2K

2.2K

MUTE_A

R812 4.7K

1K

R363

R234

100K

16V10

R434

100K

C227

16V10

IC301

C0AABB000117

HEADPHONE AMP

Q201

B1ABCF000131

AGC CONTROL

R813 4.7K

R814 4.7K

10V100

1K

1K

R361

R362

: CD SIGNAL LINE

R432

2.2K

C427

C440

1000P

C240

0.01

C444

470P

C391

24531

PLG1/PLG1

PLG2

P_GND

PHOTO1

PHOTO2

/PHOTO2

/PHOTO1

/PLG2

D401

MA2J72800L

R431

C428

100K

16V10

R433

4.7K

-IN1

C425

100P

+IN1

R426

3.3K

GNDOUT1

R427

56K

C426

47P

1234

IC301

VCC

OUT2

-IN2 +IN2

5678

R227

56K

C225

C226

100P

47P