panasonic PV-M1327, PV-M1347, PV-M1357W, VV1307, VV1317W Service Manual

...

ORDER NO. MKS9701M321

B3, B6

Combination-VCR

P

P

P

Q

Q

P

P

Q

Q

PV-M1327 PV-M1347 PV-M1357W VV1307 VV1317W PV-M2037 PV-M2047 VV2007 VV2017W

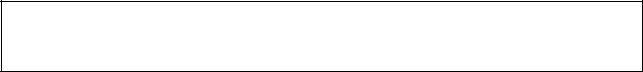

SPECIFICATIONS

ITEM |

SPECIFICATION |

1 2 3 4 5 6 |

ITEM |

SPECIFICATION |

1 2 3 4 5 6 |

|||||||

|

Head: 2 rotary heads helical scanning system |

- |

- |

|

Tape |

SP: 1-5/16 i.p.s (33.35 mm/sec), LP: 21/32 i.p.s (16.67 mm/sec), |

|

|

|

|||

|

4 rotary heads helical scanning system |

- - |

- - |

|

SLP: 7/16 i.p.s (11.12 mm/sec) |

|

|

|

||||

Video |

Input Level: VIDEO IN Jack (Phono type) 1.0 Vp-p 75Ω unbalanced |

|

|

VCR |

Speed |

Record/Playback Time: 8 Hrs with 160 min. type tape used in SLP mode |

|

|

|

|||

|

|

|

FF/REW Time: Less than 3 min. (120 min. type tape) |

|

|

|

||||||

|

Signal-to-Noise Ratio: SP: |

more than 43 dB |

|

|

|

Tape |

Tape width 1/2" (12.7 mm) high density tape |

|

|

|

||

|

LP/SLP: more than 41 dB |

|

|

|

|

|

|

|||||

|

|

|

|

Format |

|

|

|

|

||||

|

Horizontal Resolution: Color/Monochrome: more than 230 lines |

|

|

|

|

|

|

|

||||

|

|

|

FM Radio |

Band |

87.5 ~ 108.1 MHz |

- - |

|

- |

||||

|

Head: Normal Mono: 1 stationary head |

|

|

|

|

|||||||

|

|

|

|

|

Renge |

|

|

|

|

|||

|

Input Level: AUDIO IN Jack (Phono type) -10 dBv 50kΩ unbalanced |

|

|

|

|

|

|

|

||||

|

|

|

DISPLAY |

Picture |

13 inch measured diagonal 90° deflection |

|

|

- - - |

||||

|

Frequency Response: Normal Mono: |

SP: |

100 Hz ~ 8 kHz |

|

|

Tube |

20 inch measured diagonal 90° deflection |

- - - |

|

|||

|

|

|

LP: |

100 Hz ~ 6 kHz |

|

|

|

Power |

Source: 120V AC ± 10%, 60 Hz ± 0.5% |

|

|

|

VCR Audio |

|

|

SLP: |

100 Hz ~ 5 kHz |

|

|

|

Consumption: Approx. 69 watts (power on), Approx. 6 watts (power off) |

|

|

- - - |

|

|

Signal-to-Noise Ratio: Normal Mono: |

SP: |

more than 42 dB |

|

|

|

Television |

Approx. 110 watts (power on), Approx. 6 watts (power off) - - - |

|

|||

|

|

|

LP/SLP: more than 40 dB |

|

|

|

EIA Standard (525 lines, 60 fields) NTSC Color Signal |

|

|

|

||

|

Wow and Flutter: Normal Mono: SP |

Less than 0.2% WRMS |

|

|

|

System |

|

|

|

|

||

|

|

|

|

Operating |

41°F(5°C) ~ 104°F(40°C) (Temperature) |

|

|

|

||||

|

|

LP: |

Less than 0.3% WRMS |

|

|

|

|

|

|

|||

|

|

SLP: |

Less than 0.4% WRMS |

|

|

GENERAL |

Condition |

10% ~ 75% (Humidity) |

|

|

|

|

|

Broadcast Channels: |

VHF 2 ~ 13, UHF 14 ~ 69 |

|

|

|

|

15-3/16"(386mm) (W) X 15-7/8"(402.5mm) (H) X 16-11/16"(424mm) (D) |

- |

|

- - - |

||

|

|

|

|

Dimension |

15-3/16"(386mm) (W) X 15-3/16"(385mm) (H) X 16-11/16"(424mm) (D) |

- |

- - - - |

|||||

|

CATV Channels: |

Midband A through I (14 ~ 22) |

|

|

|

|||||||

|

|

Superband J through W (23 ~ 36) |

|

|

|

|

20-3/10"(515mm) (W) X 19-4/5"(503mm) (H) X 19-1/10"(484mm) (D) |

- - - |

- |

|||

|

|

|

|

|

|

20-3/10"(515mm) (W) X 19-4/5"(505mm) (H) X 19-1/10"(484mm) (D) |

- - - - - |

|||||

Tuner |

|

Hyperband AA ~ EEE (37 ~ 64) |

|

|

|

|

||||||

|

|

|

|

|

27.4 lbs. (12.4 kg) |

- |

|

- - - |

||||

|

|

Lowband A-5 ~ A-1 (95 ~ 99) |

|

|

|

|

|

|||||

|

|

|

|

|

|

26.0 lbs. (11.8 kg) |

- |

- - - - |

||||

|

|

Special CATV channel 5A (01) |

|

|

|

Weight |

||||||

|

|

|

|

|

49.95 lbs. (22.67 kg) |

- - - |

- - |

|||||

|

|

Ultraband 65 ~ 94, 100 ~ 125 |

|

|

|

|||||||

|

|

|

|

|

|

50.12 lbs. (22.75 kg) |

- - - - - |

|||||

|

|

|

|

|

|

|

|

|

50.67 lbs. (23 kg) |

- - - - - |

||

1. PV-M1327 |

|

|

|

|

|

|

|

Weight and dimensions shown are approximate. |

||||

2. VV1307/VV1317W |

|

|

|

|

|

|

|

Specifications are subject to change without notice. |

||||

3.PV-M1347/PV-M1357W

4.PV-M2037

5.VV2007/VV2017W

6.PV-M2047

|

|

|

©1996 Matsushita-Kotobuki Electronics Industries LTD. |

|

|

|

|

|

|

|

|

|

|

|

All rights reserved. Unauthorized copying and distribution |

|

R |

® |

is a violation of law. |

|

|

|

|

! WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

Use Marks shown in the chart below to distinguish the different models included in this Service Manual.

MODEL |

MARK |

MODEL |

MARK |

|

|

|

|

PV-M1327 |

A |

PV-M2037 |

F |

|

|

|

|

VV1307 |

B |

VV2007 |

G |

|

|

|

|

VV1317W |

C |

VV2017W |

H |

|

|

|

|

PV-M1347 |

D |

PV-M2047 |

I |

|

|

|

|

PV-M1357W |

E |

NOT USED |

Z |

|

|

|

|

TABLE OF CONTENTS

SAFETY PRECAUTIONS ................................................ |

1-1 |

X-RADIATION .................................................................. |

1-1 |

PREVENTION OF ESD TO ES DEVICES ....................... |

1-2 |

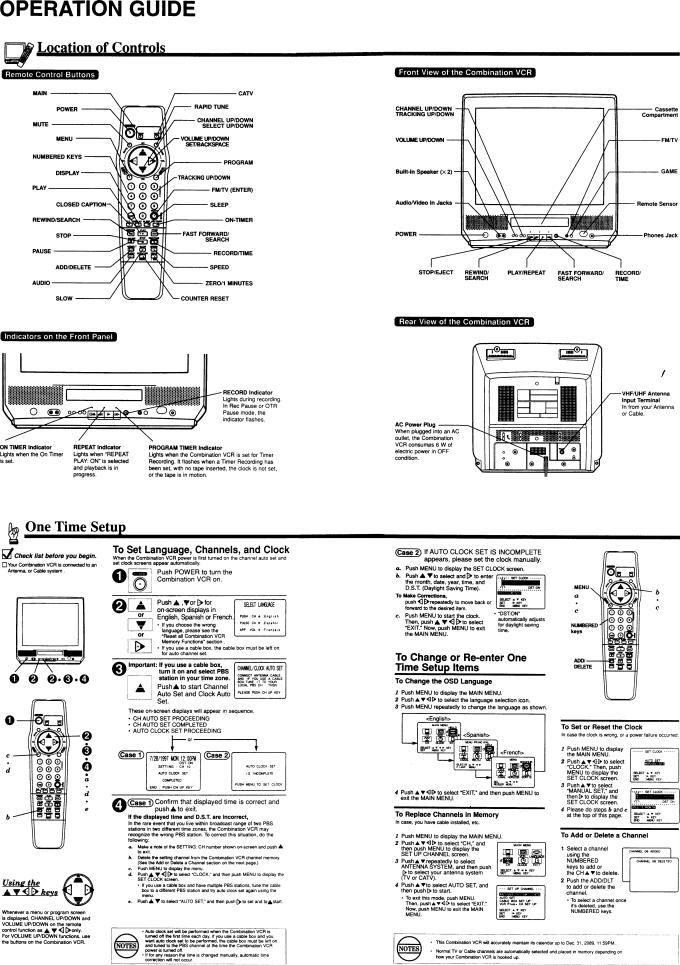

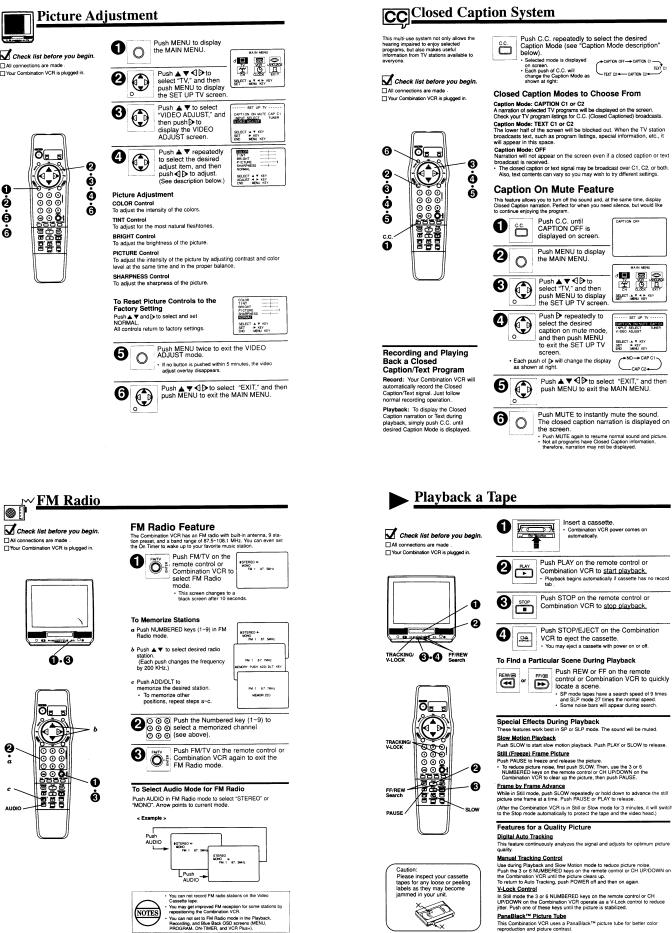

OPERATION GUIDE ....................................................... |

1-3 |

SERVICE NOTES ............................................................ |

1-7 |

IC, Transistor and Chip Part Information .................... |

1-16 |

DISASSEMBLY/ASSEMBLY PROCEDURES |

|

Disassembly/Assembly |

|

Procedures of Cabinet Parts ..................................... |

2-1 |

Disassembly/Assembly |

|

Procedures of Mechanism ........................................ |

2-7 |

Disassembly/Assembly |

|

Procedures of Cassette Up Ass'y ............................ |

2-16 |

ADJUSTMENT PROCEDURES |

|

Service Fixtures and Tools ......................................... |

2-18 |

Mechanical Adjustment .............................................. |

2-19 |

Electrical Adjustment .................................................. |

2-26 |

Test Points and Control Location ............................... |

2-34 |

SCHEMATIC DIAGRAMS |

|

Schematic Diagram |

|

and Circuit Board Layout Notes ................................ |

3-1 |

Junction Schematic Diagram ........................................ |

3-2 |

Stereo Amp Schematic Diagram .................................. |

3-4 |

Main I (Power Supply/System Control |

|

/Servo/Operation) Schematic Diagram ..................... |

3-7 |

Main II (Signal Process/OSD |

|

/Audio/Audio Amp) Schematic Diagram .................. |

3-11 |

Main III (TV Y/C Process) Schematic Diagram .......... |

3-15 |

Main IV (Power Supply) Schematic Diagram ............. |

3-19 |

TV Stereo Schematic Diagram ................................... |

3-19 |

TV Main Schematic Diagram ...................................... |

3-23 |

CRT Schematic Diagram ............................................ |

3-25 |

UHF/VHF Tuner/TV Demodulator |

|

Schematic Diagram ................................................. |

3-27 |

Head Amp Schematic Diagram .................................. |

3-31 |

Interconnection Schematic Diagram ........................... |

3-37 |

CIRCUIT BOARD LAYOUT |

|

Head Amp C.B.A. ......................................................... |

4-1 |

TV Stereo C.B.A. .......................................................... |

4-2 |

Stereo Amp C.B.A. ....................................................... |

4-2 |

Junction C.B.A. ............................................................. |

4-3 |

Main (Power Supply/Signal Process/OSD |

|

/Audio/Audio Amp/TV Y/C Process |

|

/System Control/Servo/Operation) C.B.A. ................. |

4-4 |

TV Main C.B.A. ........................................................... |

4-12 |

CRT C.B.A. ................................................................. |

4-14 |

Signal Waveform ........................................................ |

4-15 |

BLOCK DIAGRAMS |

|

Power Supply Block Diagram ....................................... |

5-1 |

Video Signal Path Block Diagram ................................. |

5-2 |

Audio Signal Path Block Diagram ................................. |

5-3 |

TV Stereo/Stereo Amp Block Diagram ......................... |

5-5 |

System Control Block Diagram ..................................... |

5-7 |

Servo Block Diagram .................................................... |

5-8 |

TV Y/C Process/OSD/CCV |

|

/TV Main Block Diagram ......................................... |

5-10 |

Troubleshooting Hints ................................................. |

5-13 |

EXPLODED VIEWS |

|

1. Mechanism (Top) Section ......................................... |

6-1 |

2. Mechanism (Bottom) Section ................................... |

6-2 |

3. Cassette Up Compartment Section .......................... |

6-3 |

4. Chassis Frame Section (1) ....................................... |

6-4 |

5. Chassis Frame Section (2) ....................................... |

6-5 |

6. Packing Parts |

|

and Accessories Section ........................................... |

6-6 |

REPLACEMENT PARTS LISTS |

|

Before Replacing Parts, Read the Following ................ |

7-1 |

Mechanical Replacement Parts List ............................. |

7-2 |

Electrical Replacement Parts List ................................. |

7-4 |

SAFETY PRECAUTIONS

GENERAL GUIDELINES

1.IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout, Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer's specified parts to prevent X-RADIATION, shock, fire, or other hazards. Do not modify the original design without permission of manufacturer.

in the Schematic Diagrams, Circuit Board Layout, Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer's specified parts to prevent X-RADIATION, shock, fire, or other hazards. Do not modify the original design without permission of manufacturer.

2.An Isolation Transformer should always be used during the servicing of Combination VCR whose chassis is not isolated from the AC power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It will also protect Combination VCR from being damaged by accidental shorting that may occur during servicing.

3.When servicing, observe the original lead dress, especially the lead dress in the high voltage circuits. If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4.After servicing, see to it that all the protective devices such as insulation barriers, insulation papers, shield, and isolation R-C combinations are properly installed.

5.Before turning the receiver on, measure the resistance between B+ line and chassis ground. Connect (-) side of an ohmmeter to the B+ lines, and (+) side to chassis ground. Each line should have more resistance than specified, as follows :

B+ Line 130V 27V 17V

6.When the TV set is not used for a long period of time, unplug the power cord from the AC outlet.

7.Potentials, as high as 25.0KV (Model: A, B, C, D, E) or 30.0KV (Model: F, I) or 29.0KV (Model: G, H) are present when this TV set is in operation. Operation of the TV set without the rear cover involves the danger of a shock hazard from the TV set power supply. Servicing should not be attempted by anyone who is not thoroughly familiar with the precautions necessary when working on high voltage equipment. Always discharge the anode of the picture tube to the CRT ground of receiver before handling the tube.

8.After servicing make the following leakage current checks to prevent the customer from being exposed to shock hazards.

LEAKAGE CURRENT COLD CHECK

1.Unplug the AC cord and connect a jumper between the two prongs on the plug.

2.For physically operated power switches, turn power on. Otherwise skip step 2.

3.Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on the receiver, such as screwheads, connectors, etc. When the exposed metallic part has a return path to the chassis, the reading should be between 1 M ohm and 12 M ohms. When the exposed metal does not have a return path to the chassis, the reading must be infinity.

LEAKAGE CURRENT HOT CHECK

1.Plug the AC cord directly into the AC outlet.

Do not use a isolation transformer for this check.

2.Connect a 1.5K ohms, 10 watts resistor, in parallel with a 0.15 micro farad capacitor, between each exposed metallic part on the set and a good earth ground , as shown in Figure 1.

3.Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4.Check each exposed metallic part, and measure the voltage at each point.

5.Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6.The potential at any point should not exceed 0.75 volt RMS. A leakage current tester (Simpson Model 229 equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 milliampere. In case a measurement is outside of the limits specified, there is a possibility of shock hazard, and the receiver should be repaired and rechecked before it is returned to the customer.

Hot-Check Circuit

AC VOLTMETER

0.15µF

TO APPLIANCES

EXPOSED

EARTH GROUND METAL PARTS

EARTH GROUND METAL PARTS

1500Ω. 10W

Figure 1

X-RADIATION

WARNING :

1.The potential source of X-Radiation in TV sets is the High Voltage section and the picture tube.

2.When using a picture tube test fixture for service, ensure that the fixture is capable of handling 25.0KV (Model: A, B, C, D, E) or 30.0KV (Model: F, I) or 29.0KV (Model: G, H) without causing X-Radiation.

NOTE :

It is important to use an accurate periodically calibrated high voltage meter.

1.Reduce the brightness to minimum.

2.Set the SERVICE switch to SERVICE .

3.Measure the High Voltage. The meter reading should indicate 23.5 +/- 1.5KV (Model: A, B, C, D, E) or 28.5 +/- 1.5KV (Model: F, I) or 27.5 +/- 1.5KV (Model: G, H).

If the meter indication is out of tolerance, immediate service and correction is required to prevent the possibility of premature component failure.

4.To prevent an X-Radiation possibly, it is essential to use the specified picture tube.

1-1

HORIZONTAL OSCILLATOR DISABLE CIRCUIT TEST

SERVICE WARNING :

The test must be made as a final check before set is returned to the customer.

1.With the rear cover removed, supply about a 120V AC power source to the set, turn on the set.

2.Set the customer controls to normal operating positions.

3.Short between TP891 and TP892 on the Main circuit board with a jumper wire. Confirm that the picture goes out of horizontal sync.

4.If this does not occur, the horizontal oscillator disable circuit is not operating. Follow the Repair Procedures of horizontal oscillator disable circuit before the set is returned to customer.

REPAIR PROCEDURES OF HORIZONTAL OSCILLATOR DISABLE CIRCUIT

1.Connect a DC voltmeter between capacitor C513 (+) on the Main circuit board and chassis ground.

2.If approximately +21.9V is not present at that point when 120V AC is applied, find the cause. Check R503, R5505, C5507, C513 and D503.

3.Carefully check above specified parts and related circuits and parts. When the circuit is repaired, try the horizontal oscillator disable circuit test again.

CIRCUIT EXPLANATION

HORIZONTAL OSCILLATOR DISABLE CIRCUIT

The positive DC voltage, supplied from the D503 cathode for monitoring high voltage, is applied to the IC5301 Pin11 through R503 and R5504. Under normal conditions, the voltage at IC5301 Pin 11 is less than approx 3V. If the high voltage at Flyback Tr Pin 6 exceeds the specified voltage, the positive DC voltage which is supplied from the D503 cathode also increases. The increased voltage is applied to IC5301 Pin11 through R503 and R5504. Due to the increased voltage at IC5301 Pin11, the horizontal oscillator frequency increases, the picture goes out of horizontal sync, the beam current decreases and the picture becomes dark in order to keep X- radiation under specification.

D503 |

R503 |

R5504 |

IC5301 |

|

11 |

||||

To Pin 6 |

|

|

||

of Flyback |

|

|

|

|

Transformer |

+ |

|

+ |

|

C513 |

|

|||

- |

R5505 - C5507 |

|||

Figure 2

PREVENTION OF ELECTROSTATIC DISCHARGE (ESD) TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors are semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge (ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your body touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7.Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material to the chassis or circuit assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

"NOTE to CATV system installer :

This reminder is provided to call the CATV system installer's attention to Article 820-40 of the NEC that provides guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding system of the building, as close to the point of cable entry as practical."

1-2

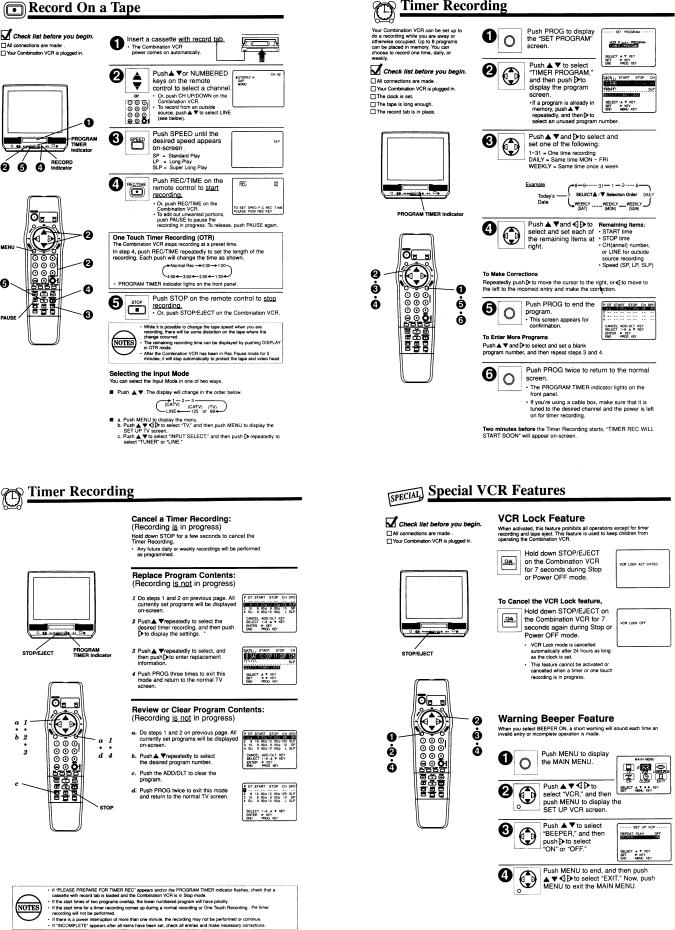

1-3

1-4

1-5

1-6

SERVICE NOTES

Simplified Fault Finding Data

Simplified Self-Diagnostic System facilitates finding the cause of the fault. 4 digit fault code will be displayed on TV screen. The Simplified Fault finding data is stored in the Memory IC (IC6004). This data is cleared after it is displayed and then, the POWER button is pressed back on.

1.With power turned off, press FF and REW buttons on unit together for over 3 seconds.

Power is OFF. + REW

FF

FF

Press (Over 3 seconds)

Fig. 1-1

2.TV power goes on and the unit goes into service mode. Fault code indication (4 digit number) will be displayed.

Code Digit Position |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

SERVICE MODE |

|

|||||||||

|

|

|

|

|

|

||||||||||

• Cassette Down SW. |

2 1 9 2 |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

and S-Tab SW. Data |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Fault Code |

|

|||||||||

|

|

|

|

|

|

|

|

||||||||

• Take Up Photo and |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

Supply Photo Sensor Data |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||

• Present mechanism position code |

|

|

|

TV Screen |

|

||||||||||

|

|

|

|

||||||||||||

• Lock code |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

Fig. 1-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Explanation of Codes |

|

Code No. |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S-Tab SW. Data |

|

|

|

|

|

|

|

|

|

|

|

||||

• S-Tab SW. is off. |

|

|

|

|

|

|

1 |

|

|

|

|

||||

• S-Tab SW. is on. |

|

|

|

|

|

|

2 |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Take Up and Supply Photo Sensor Data |

|

|

|

|

|

||||||||||

• No light detected at either sensor. |

|

|

|

1 |

|

|

|||||||||

• Take Up Photo Sensor detected at |

|

|

|

2 |

|

|

|||||||||

beginning of tape. |

|

|

|

|

|

|

|

|

|

|

|

||||

• Supply Photo Sensor detected at end |

|

|

|

3 |

|

|

|||||||||

of tape. |

|

|

|

|

|

|

|

|

|

|

|

||||

• Light detected at both sensors. |

|

|

|

|

|

|

|

|

4 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Present Mechanism Position Code |

|

|

|

|

1 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

Mechanism Position is indicated. |

|

|

|

|

3 |

|

|||||||||

|

|

|

|

4 |

|

||||||||||

(Refer to Fig. 1-4.) |

|

|

|

|

|

|

|

|

|

5 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

|

Lock Code |

|

|

|

|

|

|

|

|

|

|

|

||||

• VCR is not in shut-off condition. |

|

|

|

|

|

0 |

|||||||||

• Reel lock. |

|

|

|

|

|

|

|

|

|

|

1 |

||||

• Cylinder lock. |

|

|

|

|

|

|

|

|

|

|

2 |

||||

• Exceeds loading/unloading time. |

|

|

|

|

|

3 |

|||||||||

(Mechanism Lock) |

|

|

|

|

|

|

|

|

|

|

|

||||

• Exceeds Cassette loading/unloading time. |

|

|

|

|

|

||||||||||

(Cassette Lock) |

|

|

|

|

|

|

|

|

|

|

|

||||

Tape Unloading (direction) |

|

|

|

|

|

|

|

|

|

1 |

4 |

||||

Tape Loading (direction) |

|

|

|

|

|

|

|

|

|

2 |

4 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 1-3

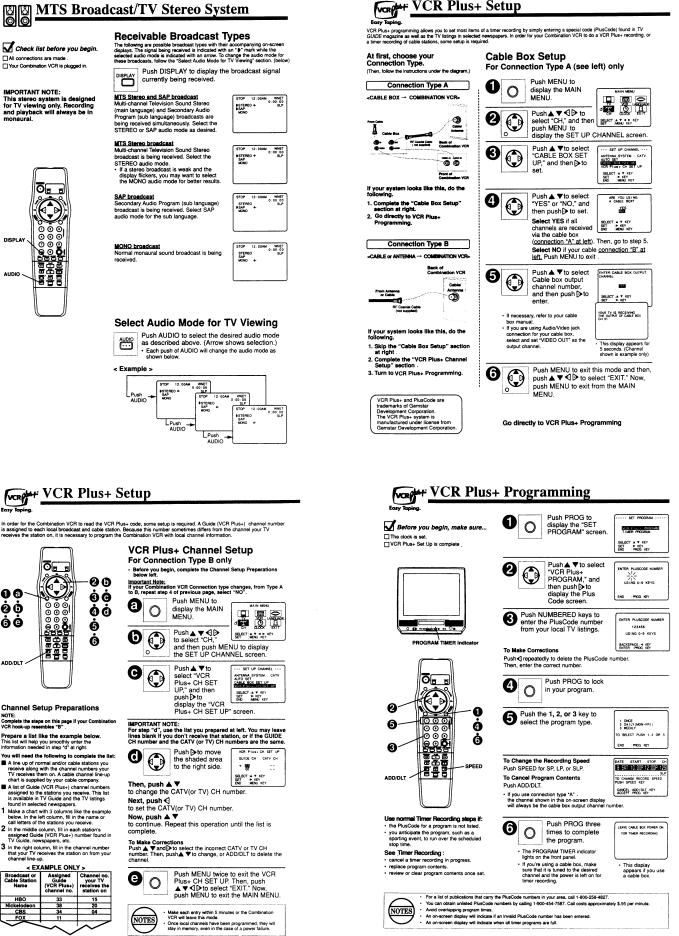

Mode

Select SW.

|

|

|

|

LOAD |

|

UNLOAD |

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

REV |

|

|

|

STOP |

|

|

|

|

|

|

|

7 |

6 |

|

|

||

PLAY/CUE |

|

|

|

5 |

|

|

||||

/SLOW/STILL |

|

8 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

|

9 |

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

BRAKE |

B |

|

|

|

|

|

|

4 |

|

|

|

|

C |

|

|

|

|

|

|

|

|

FF/REW |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EJECT |

|

2 |

|

|

|

|

CASSETTE |

|

|

|

|

|

C B |

A |

|

|

DOWN |

|

||

|

|

|

|

|

|

|

|

|||

Mechanism |

EJECT |

CASSETTE |

STOP/ |

REV |

|

PLAY/CUE/ |

BRAKE |

FF/REW |

||

position |

|

DOWN |

|

STBY |

|

|

SLOW/STILL |

|

|

|

|

|

|

|

|

|

|

||||

position code |

1 |

2 |

3 |

4 |

5 |

6 7 |

8 |

9 |

A B C |

D |

Fig. 1-4

Note:

When 1 to 4 listed in Lock code occurs, the VCR stops and all VCR function buttons except for power become non-operational.

3.Press any operation button except for POWER on either the unit, or the remote to detect that a key has been pressed.

The 1st digit changes to "0" only when key is detected.

SERVICE MODE 2 1 9 2

Any operation button

Press |

SERVICE MODE |

|

0 1 9 2 |

||

|

||

Changes to "0" |

|

|

|

Fig. 1-5 |

1-7

Service Position

The Basic Service Position does not require the use of Extension Cables. However, for more extensive servicing, Extension Cables should be used.

1. Basic Service Position

Service Position |

Purpose |

|

|

Service Position (1) |

Mechanism check |

|

Mechanical adjustment |

|

Electrical adjustment |

|

|

Service Position (2) |

Main C.B.A. check |

|

TV Main C.B.A. check |

|

|

CAUTION:

HOT CIRCUIT (Primary circuit) exists on the Main C.B.A. and TV Main C.B.A.

Use extreme care to prevent accidental shock when servicing.

Note:

When disassembling/assembling, refer to "Disassembly/ Assembly Procedures of Cabinet" section.

Service Position (1)

1.Remove Rear Cover, VCR Unit, (Stereo Amp C.B.A.: Model I), and Top Shield Plate Ass'y.

2.Then, place VCR Unit as shown.

TV

TV Main

C.B.A.

Main

C.B.A.

VCR Unit

Mechanism Chassis

and Cassette Up Ass'y

It is not necessary to connect Degaussing Coil Connector

CAUTION:

HOT CIRCUIT

DO NOT touch Power curcuit during service.

Fig. 2-1

Service Position (2)

1.Remove Rear Cover, VCR Unit, (Stereo Amp C.B.A.: Model I), and Top Shield Plate Ass'y.

2.Place VCR Unit as shown.

In order to stabilize VCR Unit, place it on a slanted support, such as a loose-leaf binder etc.

Insulated material

TV

TV Main C.B.A.

VCR Unit

Main C.B.A.

|

It is not necessary to |

|

open |

connect Degaussing |

|

Coil Connector |

||

|

Stereo Amp C.B.A. |

|

|

(Model: I) |

|

|

CAUTION: |

|

Mechanism |

HOT CIRCUIT |

|

DO NOT touch Power |

||

Chassis and |

||

Cassette Up |

curcuit during service. |

|

Ass'y |

|

|

|

Fig. 2-2 |

1-8

2. Service Position with Extension Cable Kit

In Service Position with Extension Cable Kit, mechanism check from the Bottom Side of Mechanism Chassis and Capstan Stator Unit (Capstan Motor Drive, Loading Motor Drive Circuit) check with power on condition can be performed.

Service Position

Mode Select SW. on Main C.B.A.

Rotate

TV

It is not necessary to connect |

CAUTION: |

|

HOT CIRCUIT |

||

Degaussing Coil Connector |

SERVICE

Alignment

Projection

DO NOT touch Power curcuit during service.

TV Main C.B.A. tape

tape

P3003

Frame

Main C.B.A.

P4001

|

P6002 |

|

Mode Select |

|

P6201 |

|

|

|

SW. Connector |

masking tape |

|

(Foil Side) |

|

|

|

|

|

|

|

Safety Tab SW. |

Keep away these cables from TV Main C.B.A. as possible.

tape |

Extension |

|

|

||

|

Cable -1 |

|

|

Mechanism |

|

|

Chassis and |

|

|

Cassette Up Ass'y |

|

P3501 |

Full Erase Head |

|

Extension Cable -2 |

||

Connector |

||

|

||

Mode Select SW. Ass'y |

|

Fig. 3-1

CAUTION:

HOT CIRCUIT (Primary circuit) exists on the Main C.B.A. and TV Main C.B.A. Use extreme care to prevent accidental shock when servicing.

Note:

When disassembling/assembling, refer to "Disassembly/Assembly Procedures of Cabinet" section.

1-9

Extension Cable Kit (VUZS0002)

Mode Select SW. Ass'y |

Extension Cable -1 |

(VUVS0001) |

(VUVS0002) |

3 clip-on |

|

wires |

|

8 pin |

|

|

14 pin |

|

2 pin |

Extension Cable -2 |

Extension Cable -2 |

(VUVS0005) for 2 Head Model |

(VUVS0004) for 4 Head Model |

Mode Select SW. |

|

|

|

on Mode Select |

Head Amp C.B.A. |

|

|

SW. Ass'y |

|

||

EJECT |

|

P3501 |

Shaft of Main |

Position |

|

P2552 |

|

|

Cam Gear |

||

Alignment |

|

||

|

|

||

Projection |

|

P2531 |

|

Rotate |

|

|

|

SERVICE |

|

|

See 3 Clip-on |

|

|

Wires connection |

|

|

|

|

|

12 pin |

15 pin |

Extension Cable -2 (VUVS0003) for Hi-Fi Model

20 pin

Fig. 3-2

Note:

3 types of Extension Cable -2 are included in this kit. Since there is a difference in the number of P3501 Head Amp C.B.A. pins between 2 Head, 4 Head, and Hi-Fi models, be sure to use the proper cable.

How to place the unit into Service Position with Extension Cables

1.Remove Rear Cover, VCR Unit, (Stereo Amp C.B.A.: Model I), Top Shield Plate Ass'y, Mechanism Chassis, and Cassette Up Ass'y.

2.Connect the Extension Cables as follows:

Extension Cable -1: Full Erase Head Connector on the Mechanism Chassis Unit ~ P4001 on the Main C.B.A.

Extension Cable -1: Full Erase Head Connector on the Mechanism Chassis Unit ~ P4001 on the Main C.B.A.

Note: No change in performance if pins are reversed.

Extension Cable -2: P3501 on the Head Amp C.B.A. ~ P3003 on the Main C.B.A.

Extension Cable -2: P3501 on the Head Amp C.B.A. ~ P3003 on the Main C.B.A.

Mode Select SW. Ass'y: a) 3 Clip-on Wires ~ Mode Select SW. Connector on the Main C.B.A.

Mode Select SW. Ass'y: a) 3 Clip-on Wires ~ Mode Select SW. Connector on the Main C.B.A.

|

1 Pin (Not Used) |

Red Wire |

~ 2 pin |

Orange Wire |

~ 3 pin |

Yellow Wire |

~ 4 pin |

b)8 Pin Connector ~ P6002 on the Main C.B.A.

c)14 Pin Connector ~ P6201 on the Main C.B.A.

d)Set Mode Select SW. on the Mode Select SW. Ass'y to EJECT position and install onto Mechanism Chassis.

1-10

Full Erase

Head Connector

Extension Cable -1

Extension Cable -2

Mode Select SW. Ass'y

3 Clip-on Wires connection

Orange |

Mode Select SW. |

|

|

Yellow |

Red |

|

Not Used |

4 3 2 1

IC6001 |

Main C.B.A. |

(Component Side) |

(Foil Side)

Fig. 3-3

3.Place the VCR Unit as shown in Fig. 3-1.

4.Secure the Extension Cables with tape as shown

in Fig. 3-1. When recording, cover the Safety Tab SW. with masking tape to turn this SW. on.

Note:

To avoid damaging the connectors on Main C.B.A., it is necessary to secure connectors with tape as shown in Fig. 3-1.

5.Set Mode Select SW. on the Main C.B.A. to Service Position.

6.Plug the AC plug into an AC outlet.

7.Insert a cassette.

The power comes on, the tape is fully loaded, and the unit goes into the STOP Mode.

8.Place a jumper between TP6001 and GND to place the unit in Service Mode.

9.Check and/or repair the unit.

10.Press the STOP/EJECT button to eject the cassette.

Note:

When inserting a cassette again, remove the jumper between TP6001 and GND and insert the cassette. Then, reconnect the jumper.

11.After servicing, remove the jumper between TP6001 and GND to release the unit from Service Mode.

Note:

When disassembling/assembling, refer to "Disassembly/ Assembly Procedures of Cabinet" section.

How to Remove a jammed Tape

Manual Method

When a tape jam is encountered, check the tape loading condition and use the following procedure to remove a tape jam.

Yes |

Pinch Roller is up |

No |

|

against Capstan Rotor |

|

|

Unit shaft |

|

|

|

|

|

|

|

Main Cam Gear can be rotated

Yes No

Method 2 Method 1 |

Method 3 |

Fig. 4-1

Method -1:

1.While releasing 2 Locking Tabs (A) of Opener Piece, pull the Opener Piece up as far as you can.

2.Move the pin of Pinch Arm Unit out of the groove of the Main Cam Gear so that the Pinch Roller is separated from the shaft of the Capstan Rotor Unit.

Rear Side View

Pinch Arm

Unit

Opener

Piece

Main Cam Gear

|

Shaft of Capstan |

|

Rotor Unit |

|

Locking |

|

Tabs (A) |

|

Pull Up |

Opener Piece |

Pinch |

|

|

|

Roller |

Pin of Pinch Arm Unit |

Pinch |

|

Arm Unit |

Groove

Main Cam Gear

Fig. 4-2

3.Remove the tape from the tape path.

4.Rewind the tape into the cassette by rotating the Center Clutch Unit counterclockwise.

5.Unhook Spring (A) of the Drive Rack Unit.

6.Remove Screw (A).

7.Lift the Drive Rack Unit up so that the slot clears the guide tab. While pulling the Drive Rack Unit out far enough so that it clears the Drive Rack Arm,.slide the Drive Rack Unit as indicated by the arrow to remove the cassette tape from the

Cassette Up Ass'y.

9. Check the cause of mechanical trouble and repair.

Screw (A) |

Drive Rack Arm |

|

Drive Rack

Unit slide

Spring (A) Slot

pull Guide

Main Cam Gear

Fig. 4-3

Method -2:

1.Rotate Main Cam Gear clockwise with needlenose pliers, etc. so that the Pinch Roller is separated from the shaft of the Capstan Rotor Unit.

2.Perform Step 3 through Step 8 of Method -1.

Method -3:

1. Perform Step 3 through Step 8 of Method -1.

Note:

After repairing mechanical trouble, make sure that all gear alignments are correct, especially the Wiper Arm Unit and Drive Rack Unit of Cassette Up Ass'y.

1-11

Electrical Method

Electrical method can only be performed when the mechanism is moved by rotating the Main Cam Gear.

CAUTION:

If loading dose not start in approx. 2 seconds after DC Power Supply is applied, DO NOT continue to apply DC Power Supply. Instead, perform "Manual Method."

Method -1:

1.Remove the solder as shown and apply +10.0 VDC Power Supply (DC + to Portion "a," DC - to Portion "c").

2.When the Loading Posts reach the fully unloaded position, remove the Power Supply.

Motor P.C.B of |

P2551 |

Unsolder |

Motor Block Ass'y |

|

|

|

|

|

|

- |

|

+ "c" |

|

"b" |

"a"

"a" "b"

P2552

Rear Side View

Chassis |

DC Power Supply |

|

(+10VDC) |

Fig. 5-1

Note:

Be careful not to let the DC Power Supply Unit GND contact the chassis GND. This may damage the Loading Motor Drive IC (IC 2501).

Be sure to apply DC + to Portion "a" of Motor P.C.B.

If DC + is applied to Portion "b", the Loading Motor Drive IC (IC2501) may be damaged.

4. Rewind the tape into the cassette by turning the Center Clutch Unit counterclockwise.

5. Eject the cassette by applying +10.0VDC Power Supply again.

6. After completing the removal procedure, solder Portion "a" and Portion "b."

Method -2:

1.Locate the Jumper (J6004) on the System Control Section of the Main C.B.A. and cut it near the center.

Main C.B.A.

- |

+ |

|

J6004 |

|

J6005 |

Fig. 5-2

2.Apply +10.0VDC Power Supply to the jumpers. When the Loading Posts reach the fully unloaded position, remove the Power Supply.

Note:

Be careful not to let the DC Power Supply Unit GND contact the chassis GND. This may damage the Loading Motor Drive IC (IC 2501).

Be sure to apply DC + to Portion "a" of J6004.

If DC + is applied to Portion "b" of J6004, the Loading Motor Drive IC (IC2501) may be damaged.

TV Main C.B.A.

Main C.B.A.

b

- + a

a

J6005

J6004

J6004

DC Power Supply |

Motor P.C.B. |

(+10.0VDC) |

Fig. 5-3

4.Rewind the tape into the cassette by turning the Center Clutch Unit counterclockwise.

5.Eject the cassette by applying +10.0VDC Power Supply again.

6.After completing the removal procedure, resolder Jumper (J6004).

1-12

Wire and Lead position Diagram

After servicing, make sure that all wires and leads are placed in their original position. It is important for the best operation of the unit.

(Model : A, B, C, D, E) |

(Model : F, G, H) |

||

|

Anode Cap |

|

Anode Cap |

|

45° |

|

45° |

|

Degaussing Coil |

|

Degaussing Coil |

|

Deflection Yoke |

|

Deflection Yoke |

|

Grounding Wire |

|

Grounding Wire |

Speaker-R |

|

Speaker-R |

|

White |

- |

White |

- |

Red |

+ |

Red |

+ |

|

|

||

|

Clamper |

|

Clamper |

P1002 |

|

P1002 |

|

VCR Main |

|

VCR Main |

|

C.B.A. |

|

C.B.A. |

|

P4591 |

Clamper |

|

P4591 |

Clamper |

|

|

|

PK1 |

|

||||

PK3 |

Deflection |

PK3 |

Deflection |

PK1 |

||

PK2 |

||||||

Frame |

Yoke |

Frame |

Yoke |

PK2 |

||

Connector |

|

Connector |

|

|||

|

|

|

|

Flyback |

|

Flyback |

|

Transformer |

|

Transformer |

|

Clamper |

Clamper |

Clamper |

|

TV Main |

TV Main |

||

|

|||

C.B.A. |

|

C.B.A. |

|

|

Degaussing Coil Connector |

|

Clamper

Clamper

Clamper

CRT C.B.A.

CRT C.B.A.

Anode Cap

Anode Cap

P354

45°

Degaussing Coil

Clamper

Degaussing Coil Connector

Clamper |

CRT C.B.A. |

P354 |

(Model : I)

Speaker -R

White

Red

P1002

VCR Main

C.B.A.

P4592

Frame

TV Main

C.B.A.

Note:

No lead wires or flat cables should touch any heating parts or the Heat Sink Plate of IC451, IC801, or Q551.

Deflection Yoke |

(Model: G, H) |

(Model: F) |

Grounding Wire |

|

|

|

|

|

|

Speaker -L |

- |

|

|

- |

White |

+ |

|

|

+ |

Red |

|

|

|

|

|

|

Clamper |

|

|

|

|

Stereo Amp C.B.A. |

|

|

|

P4601 |

|

P4602 |

|

|

|

|

|

|

|

|

P4605 |

P4604 |

TV Stereo C.B.A. |

|

|

|

|

||

|

|

|

P4301 |

|

|

|

|

Clamper |

|

PK3 |

Deflection |

PK1 |

|

|

|

Yoke |

PK2 |

|

|

|

Connector |

|

|

|

|

|

Flyback |

|

|

|

|

Transformer |

|

|

|

|

Clamper |

Clamper |

|

|

|

|

|

|

|

|

|

Degaussing Coil Connector |

|

|

|

|

Clamper |

|

Clamper |

|

|

|

|

|

|

|

CRT C.B.A. |

|

|

|

|

P354 |

|

Fig. 6

1-13

Cylinder Rotation in STOP mode

The cylinder will continue to rotate for approximately 5 minutes after the STOP button is pressed in Play mode etc. Eject the tape in order to stop the cylinder.

Black Screws on the Chassis

Black Screws are used on the Mechanism Chassis to identify screws that require adjustment.

Variable Voltage Isolation Transformer

An Isolation Transformer should always be used during the servicing of Combination VCR whose chassis is not isolated from the AC power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It will also protect Combination VCR from being damaged by accidental shorting that may occur during servicing.

Also, when troubleshooting the above type of Power Supply Circuit, a variable isolation transformer is required in order to increase the input voltage slowly.

Special Note

All integrated circuits and many other semiconductor devices are electrostatically sensitive and therefore require the special handling techniques described under the "ELECTROSTATICALLY SENSITIVE (ES) DEVICES" section of this service manual.

Replacement Procedure for Leadless (Chip) Components

The following procedures are recommended for the replacement of the leadless components used in this unit.

1.Preparation for replacement

a.Soldering Iron

Use a pencil-type soldering iron that uses less than 30 watts.

b.Solder

Eutectic Solder (Tin 63%, Lead 37%) is recommended.

c.Soldering time

Do not apply heat for more than 4 seconds.

d.Preheating

Leadless capacitor must be preheated before installation. – (266°F ~ 302°F)

(130°C ~150°C) for about two minutes.

Note:

a.Leadless components must not be reused after removal.

b.Excessive mechanical stress and rubbing of the component electrode must be avoided.

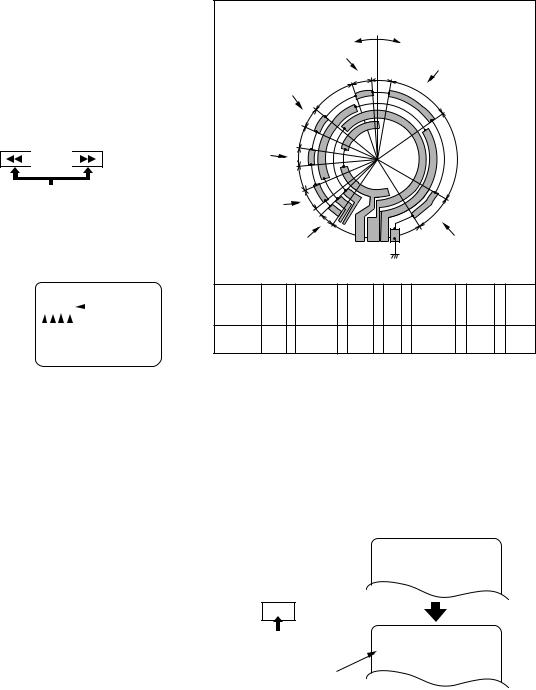

2.Removing the leadless component

Grasp the leadless component body with tweezers and alternately apply heat to both electrodes. When the solder on both electrodes is melted, remove the leadless component with a twisting motion.

Note:

a.Do not attempt to lift the component off the board until the component is completely disconnected from the board by a twisting action.

b.Be careful not to break the copper foil on the printed circuit board.

Tweezers

Chip

Soldering Iron

Fig. 7-1

3.Installing the leadless component

a. Presolder the contact points on the circuit board.

Presolder

Soldering Iron

Fig. 7-2

b.Press the part downward with tweezers and solder both electrodes as shown below.

Tweezers

Soldering Iron

Solder

Fig. 7-3

Note:

Do not glue the replacement leadless component to the circuit board.

1-14

Hot Circuit

Primary circuit exists on the Main C.B.A. and TV Main C.B.A. This circuit is identified as "HOT" on the C.B.A. and in the Service Manual. Use extreme care to prevent accidental shock when servicing.

Service Mode

In order to inhibit detection of the Supply & Takeup Photo Transistors, Reel Sensor, and Cylinder Lock, place a jumper between TP6001 and GND.

In this mode, Mechanism movement can be confirmed. When removing Cassette Up Ass'y or loading mecanism manually, it can be confirmed without a cassette.

To release from this mode, remove the jumper between TP6001 and GND.

Defeating the Auto Tracking

To defeat the Auto Tracking Function, place the instrument in the STOP mode and place a jumper between TP6003 and TP6009 on the Main C.B.A. The tracking will be placed in the neutral position.

How to set Tracking to the Neutral Position

Ejecting the cassette tape and then, reinserting it will reset the tracking to the Neutral position.

How to reset all Combination VCR Memory functions

To reset (clear) the select language, channel auto set and set clock functions to their initial power on condition (power on, no cassette inserted), hold down the PLAY and REWIND buttons on the unit together for more than 5 seconds.

Power will shut off.

Method for Manual Loading / Unloading of Mechanism

Turn the Main Cam Gear counterclockwise (for loading) or clockwise (for unloading) using needlenose pliers etc.

Needlenose Pliers

Main Cam Gear

Load

Unload/Eject

Fig. 8-1

When loading without a cassette, press Portion "a" on both sides of the Holder Unit of Cassette Up Ass'y so that the Lever clears Tab and Hole.

Lever |

Top Plate |

|

Lever |

Tab |

Hole |

Hole |

Tab |

|

|

Slide

Holder Unit |

Portion "a" |

Fig. 8-2

Model No. Identification Mark

Use Marks shown in the chart below to distinguish the different models included in this Service Manual.

MODEL |

MARK |

|

|

PV-M1327 |

A |

VV1307 |

B |

VV1317W |

C |

PV-M1347 |

D |

PV-M1357W |

E |

PV-M2037 |

F |

VV2007 |

G |

VV2017W |

H |

PV-M2047 |

I |

Not Used |

Z |

|

|

Note:

Refer to Item 5 of Schematic Diagrams and Circuit Board Layout Notes, for mark "Z."

1-15

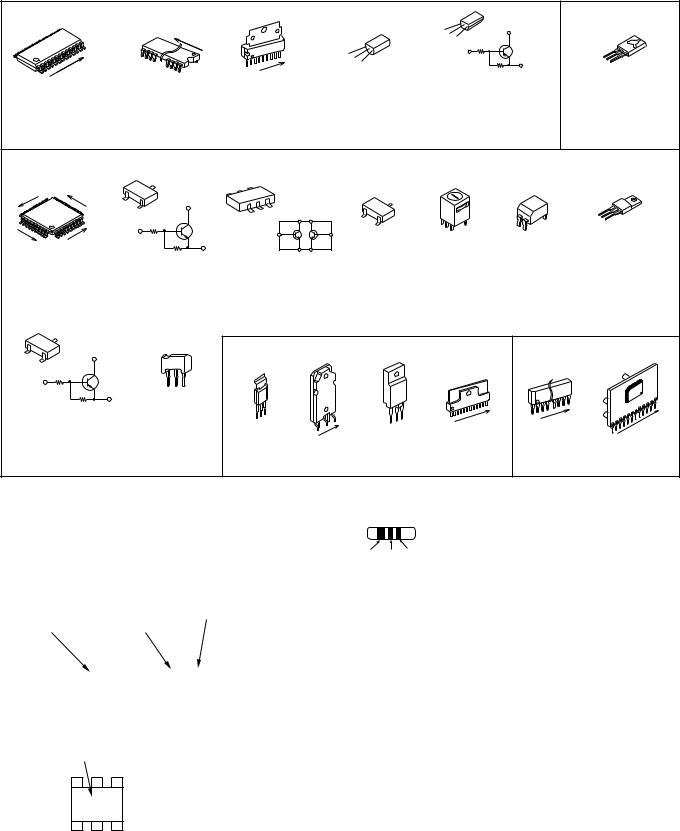

IC, TRANSISTOR AND CHIP PART INFORMATION

GENERAL C.B.A./ASS'Y PARTS |

|

|

|

|

|

|

|

|

|

|

|

CRT C.B.A. |

||||

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

C B |

R1 |

|

|

|

|

|

|

|

1 |

|

|

|

|

E |

|

|

B |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

ECB |

|||||

|

|

|

|

|

|

1 |

|

|

C B |

|

|

|

|

E |

||

1 |

|

|

|

|

|

|

|

|

|

|

|

R2 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UPC4570C, |

|

|

LC8643125957, |

|

|

AN5265, |

2SC945A, 2SA733, |

|

DTA143ES |

|

|

2SC3063 |

||||

MN3885S, |

|

|

TC4053BP, |

|

|

AN3809K |

2SC1473 |

|

|

(R1=47K, R2=OPEN), |

|

|

||||

AN3361SB, |

|

|

24LC01B/PS1 |

|

|

|

|

|

|

|

|

DTA144ES |

|

|

|

|

AN3371SB |

|

|

|

|

|

|

|

|

|

|

|

(R1=47K, R2=47K) |

|

|

||

VCR MAIN C.B.A. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

C1 |

B2 |

E2 |

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

||

|

|

B |

C |

|

|

|

B1 C2 |

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

E1 |

C1 C2 |

B |

|

|

|

|

3 |

B |

CE |

|

|

|

|

R1 |

|

|

|

|

|

|

1 |

4 |

|

|

|||

|

|

|

|

|

|

|

|

E |

|

|

|

|||||

1 |

|

|

B |

|

|

|

B1 |

B2 |

|

|

1 2 |

|

|

|||

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E1 E2 |

|

|

|

|

|

|

|

|

|

|

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

AN5367FB, |

|

UN2213(R1=47K, R2=47K), |

|

|

|

IMX1 |

|

2SD601, 2SD601A, |

T4101, |

|

ON3131-R.KT |

2SD2375, 2SC3852, |

||||

AN3475FBP, |

|

UN2212(R1=22K, R2=22K), |

|

|

|

|

|

2SB709 |

|

VLTS0304 |

|

2SC4533LP.KT, |

||||

MN675058A5P2 |

|

UN2215 |

|

|

|

|

|

|

|

|

|

|

|

2SC5130LF608 |

||

|

|

(R1=10K, R2=OPEN) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

C |

|

|

|

|

TV MAIN C.B.A. |

|

|

|

|

|

TV STEREO C.B.A. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

E C B |

|

|

|

|

|

|

|

|

|

|

|

|

|

R2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BCE |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

B |

C E |

|

1 |

|

1 |

|

|

||

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

1 |

|

UN2112(R1=22K, R2=22K), |

2SD1458, 2SD636, |

|

|

|

|

|

|

|

|

|

|

|

||||

|

2SC2653H |

STR30130 |

2SD1555LBMTV, |

|

LA7837 |

AN7420 |

|

VCRS0214 |

||||||||

UN2115 |

|

|

2SB641, 2SD2259 |

|

|

|

||||||||||

(R1=10K, R2=OPEN) |

|

|

|

|

|

|

|

2SD2499LBMA |

|

|

|

|

|

|

||

HOW TO READ THE IDENTIFICATION MARK OF CHIP COMPONENTS.

MARKING |

PART NO. |

MARKING |

PART NO. |

A |

2SB709 |

6B |

UN2112 |

N9 |

MA372J |

8C |

UN2213 |

X1 |

IMX1 |

|

|

MARKING |

|

|

|

|

hfe classification |

|||||||||

MARKING |

||||||||||||||

|

|

|

C |

|

|

|

|

C |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8C |

|

|

A Q |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HOW TO READ THE VALUES OF THE CYLINDRICAL TYPE CHIP COMPONENTS.

The widest color band must be read first for

value.

1st 2nd 3rd

(a) RESISTOR

There are two types (ERD10LLJ... and ERD10TLJ...) of chip parts.

1)ERD10LLJ : Refer to above type.

2)ERD10TLJ : The narrow color band must be read

first for value.

If this part is included in the parts list, be sure that the color band is read properly when servicing.

B E B E

UN2213 2SB709

MARKING

C1 B2 E2

X1

E1 B1 C2

(b) CAPACITOR

Because of the width of the color bands, the reading direction cannot be specified. However, the color band can be read on either side. Be sure to confirm the value using the schematic diagram.

CAUTION :

Once chip parts are removed, they must not be reused. Always use a new part when installing a chip part.

IMX1

1-16

DISASSEMBLY/ASSEMBLY PROCEDURES

DISASSEMBLY/ASSEMBLY PROCEDURES OF CABINET

Disassembly Flowchart

Perform all disassembly procedures in the order described in the "Disassembly Flowchart" shown below. When reassembling, use the reverse procedure.

CAUTION:

Disconnect AC plug before disassembly.

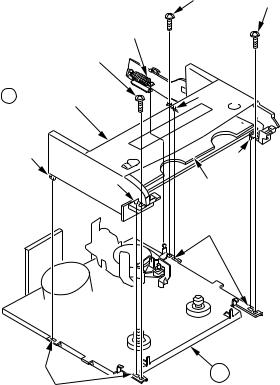

(Model: A, D, E)

1 Swivel Unit

2 Rear Cover

3 VCR Unit

4 |

CRT Unit |

(Model: I) |

|

5Stereo Amp C.B.A.

6Top Shield Plate Ass'y

7 TV Main C.B.A.

8 |

VCR Chassis Unit |

|

|

9 |

Main C.B.A. |

10 |

Cassette Up Ass'y |

|

11 |

Mechanism Chassis |

|

Fig. D1

Swivel Unit (Model: A, D, E)

Disassembly Procedure

1.While pushing one of the Locking Tabs (A) outward, pull that portion of the Swivel Unit free from the unit.

2.Repeat step 1 for other Locking Tabs (A) to remove the Swivel Unit.

Bottom View

Locking Tabs (A) |

1 Swivel Unit |

|

Locking Tabs (A)

Fig. D2

2-1

Rear Cover

Disassembly Procedure

Remove 7 Screws (A). Then, pull the Rear Cover away.

(Model: A, B, C, D, E) |

|

|

Rear View |

Screws (A) |

2 Rear Cover |

|

|

|

Screws (A) |

|

|

Fig. D3-1 |

|

(Model: F, G, H, I) |

|

|

Rear View |

Screws (A) |

2 Rear Cover |

|

|

Screws (A)

Fig. D3-2

VCR Unit

Disassembly Procedure

1.Discharge the Anode to the CRT Ground. Then, remove the Anode Cap.

2.Disconnect the Connector P354 from the CRT C.B.A.

3.Carefully pull out the CRT C.B.A. from the CRT Unit.

4.Disconnect the Deflection Yoke Connector and the Degaussing Coil Connector from the Main C.B.A.

5.(Model : A, B, C, D, E, F, G, H )

Disconnect the Connector P4591 on the Main C.B.A. and remove the leads from the clampers.

(Model : I )

Disconnect 2 Connectors P4604 and P4605 on the Stereo Amp C.B.A. and remove the leads from the clampers.

TV |

Anode Cap |

CRT C.B.A. |

|

|

|

|

|

CRT Unit |

P354

P4605

(Model : I)  Stereo Amp

Stereo Amp

C.B.A.

(Model : I)

Clampers

Clamper

Main

C.B.A.

P4591 |

|

|

Degaussing |

|

(Model : A, B, |

P4604 |

|

||

|

Coil Connector |

|||

C, D, E, F, G, H) |

(Model : I) |

|||

|

||||

|

Deflection |

|

3 VCR Unit |

|

|

Yoke |

|

|

|

|

Connector |

TV Main C.B.A. |

||

Fig. D4-1

6.(Model: A, B, C, D, E)

Slightly lift up the rear side of the VCR Unit to release Tabs

(Model: F, G, H, I)

Slightly lift up the rear side of the VCR Unit to release Tabs

(B)and (C).

7.Slide the VCR Unit out as far as it will go.

Then, lift up the VCR Unit to release 3 Guide Tabs (A) and remove the VCR Unit all the way out from the TV cavity.

2-2

Holes (A)

VCR Unit |

|

VCR Unit |

Guide Tabs (A) |

|

Tabs (B)

Tabs (C)

Bottom view of VCR Unit

Fig. D4-2

Reassembly Notes

1.Installation of VCR Unit

1)When installing the VCR Unit, swing the Cassette DoorLid all the way open until the Cassette Door tab clears the Opener Lever.

2)Make sure that all guide tabs are aligned properly. Then, press the VCR unit in.

Cassette Door-Lid

Press

View "A"

CAUTION

VCR Unit

View "A" |

Cassette Door-Lid |

|

Cassette Door Tab

Opener Lever

Fig. D4-3

CRT Unit

Disassembly Procedure

Remove 4 Screws with Washers (A). Then, pull out the CRT Unit.

Note:

Place the Unit face down on a soft cloth before removing the

CRT Unit.

TV

4 CRT Unit

Screws with |

Screws with |

Washers (A) |

Washers (A) |

Fig. D5

Stereo Amp C.B.A. (Model: I)

Disassembly Procedure

1.Disconnect 2 Connectors P4592 on the Main C.B.A. and P4301 on the TV Stereo C.B.A.

2.Release 3 Clampers (A) on the TV Stereo C.B.A. Then, remove the Stereo Amp C.B.A.

5 Stereo Amp C.B.A. |

|

Clampers (A) |

TV Stereo C.B.A. |

|

|

|

P4301 |

Main C.B.A. |

Top Shield |

|

Plate Ass'y |

P4592

Fig. D6

2-3

Top Shield Plate Ass'y

Disassembly Procedure

1.Release the 2 Clampers (B) on the Top Shield Plate Ass'y and remove the leads from the clampers.

2.Remove 3 Screws (B). Then, remove the Top Shield Plate Ass'y.

Clampers (B) Screws (B)

6 Top Shield

Plate Ass'y

Clamper

Clamper

Fig. D7-1

Reassembly Notes

1.When installing the Top Shield Plate Ass'y, make sure the 2 Clampers (B) on the Cassette Up Ass'y are turned in the direction shown.

If not, the Top Shield Plate Ass'y cannot be installed.

Clampers (B)

Cassette Up Ass'y

Fig. D7-2

TV Main C.B.A.

Disassembly Procedure

1.Disconnect Connector P1002 on the Main C.B.A.

2.Disconnect 3 Connectors PK1, PK2, and PK3 on the TV Main C.B.A.

Note :

When disconnecting or connecting 3 Connectors PK1, PK2, and PK3, take extreme care not to break them.

3.Remove the TV Main C.B.A. by releasing 2 Locking Tabs (B) and A/C Cord from the frame.

PK2

PK1

7 TV Main C.B.A.

PK3

Main C.B.A.

A/C Cord

P1002

Locking Tabs (B)

Fig. D8

2-4

VCR Chassis Unit

Disassembly Procedure

1.Slide the Holder Unit (refer to "Method for Manual Loading/ Unloading of Mechanism" in Service Notes) to remove 2 Screws (C).

2.(Model: A, B, C, D, E)

Remove 3 Screws (D) and Screw (E). (Model: F, G, H, I)

Remove 2 Screws (D) and Screw (E).

3.Remove 2 Screws with Washers (B).

|

Screw (D) |

|

|

(Model: A, B, C, D, E) |

|

Screw with |

Screw (D) |

|

Washer (B) |

Screws (C) |

|

|

Screw (E) |

|

Screw (D) |

|

|

|

|

Screw with |

|

"A" |

Washer (B) |

8 VCR Chassis

Unit

Holder

Unit

Locking

Frame |

Tab (C) |

|

Fig. D9

4.While pushing Locking Tab (C) outward, lift the right side of the Cassette Up Ass'y (Portion "A"). Then, lift the VCR Chassis Unit out of the Frame.

Note:

Work carefully so as not to break tab.

Main C.B.A.

Disassembly Procedure

1.Disconnect 4 Connectors of P2531, P2552, P3501 and P4001.

2.Carefully lift the Mechanism Chassis Unit straight out from the Main C.B.A.

Note:

Work carefully so as not to break Sensor LED, when lifting

the Mechanism Chassis Unit.

Mechanism |

P2531 |

Hole |

|

Chassis Unit |

|

|

P3501 |

P2552 |

Full Erase Head |

Mode Select |

9 Main C.B.A. |

SW. |

|

|

P4001 |

Sensor LED

Fig. D10-1

Reassembly Notes

1.Make sure that the Mode Select SW. on the Main C.B.A. is in EJECT position before installing the Mechanism Chassis Unit onto the Main C.B.A. If not, rotate the Mode Select SW. until the alignment projection is in the EJECT Position.

Mode Select SW. |

EJECT Position |

|

|

|

|

Rotate

Alignment

Projection

SERVICE

Fig. D10-2

2.Be sure to install the Mechanism Chassis Unit straight onto the Main C.B.A. so that the Sensor LED clears the hole in the Mechanism Chassis Unit.

3.Be sure that 4 Connectors (P2531, P2552, P3501, and

P4001) are aligned and seated securely.

2-5

Cassette Up Ass'y

Disassembly Procedure

1.Slide the Holder Unit (refer to "Method for Manual Loading/ Unloading of Mechanism" in Service Notes) to remove 2 Screws (F).

2.Remove Screw (G).

3.Unhook Spring (A).

4.Slide the Cassette Up Ass'y towards the front to release Tab (C). Then, lift it up and remove.

|

Screw (G) |

|

Screw (F) |

Spring (A) |

|

Screw (F) |

|

10 Cassette Up |

Pin |

Ass'y |

|

Tab (C) |

Pin |

|

|

Pin |

Holder |

|

Unit |

|

Guide |

|

Holes |

|

11 Mechanism |

Guide Holes |

Chassis |

|

|

|

Fig. D11 |

Reassembly Notes

1.Installation of Cassette Up Ass'y

1)Confirm that the 3 pins and Tab (C) under the Cassette Up Ass'y are in each of the 4 Guide Holes on the Mechanism Chassis when installing the Cassette Up Ass'y. Then, slide the Cassette Up Ass'y towards the back.

2)Tighten 2 Screws (F) and Screw (G).

Be careful not to tighten them too much, or the Cassette Up Ass'y may be bent outward.

2-6

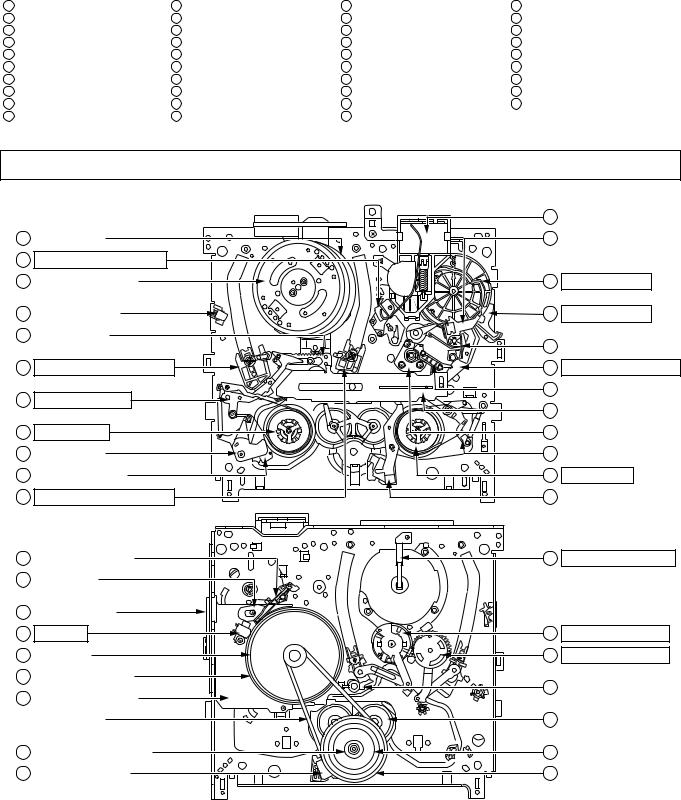

DISASSEMBLY/ASSEMBLY

PROCEDURES OF MECHANISM

Disassembly Method

This chart indicates Step/Location No. of Parts to be serviced and prior steps to gain access items to be serviced when disassembling. When reassembling, perform the step(s) in the reverse order.

Step |

Part |

Prior Step(s) |

Step |

Part |

Prior Step(s) |

Step |

Part |

|

Prior Step(s) |

Step |

Part |

Prior Step(s) |

/Loc. |

/Loc. |

/Loc. |

|

/Loc. |

||||||||

No. |

|

|

No. |

|

|

No. |

|

|

|

No. |

|

|

1 |

Cylinder Unit |

------------ |

11 |

Main Lever Drive Arm |

3, 4, 5, 7, 8, 9 |

21 |

Loading Post Base-S Unit |

16 |

31 |

S Loading Arm Unit |

30 |

|

2 |

Upper Cylinder Unit |

------------ |

12 |

T Brake Unit |

9 |

22 |

Loading Post Base-T Unit |

9, 20 |

32 |

Center Clutch Unit |

------------ |

|

3 |

Opener Piece |

------------ |

13 |

Changing Lever A |

9 |

23 |

Capstan Rotor Unit |

------------ |

33 |

Changing Gear Spring |

32 |

|

4 |

Pinch Arm Unit |

3 |

14 |

T Reel Table |

9, 12, 13 |

24 |

Capstan Holder Unit |

23 |

34 |

Changing Gear |

32, 33 |

|

5 |

Motor Block Ass'y |

------------ |

15 |

Full Erase Head |

------------ |

25 |

SS Brake Arm Unit |

------------ |

35 |

Changing Lever-B |

32, 33, 34 |

|

6 |

Audio Control Head Unit |

5 |

16 |

Tension Arm Unit |

------------ |

26 |

Junction C.B.A. |

|

------------ |

36 |

Idler Arm Unit |

32, 33, 34 |

7 |

Main Cam Gear |

3, 4, 5 |

17 |

S Spring Arm |

------------ |

27 |

Capstan Stator Unit |

23, 25, 26 |

37 |

Loading Rack |

9, 30 |

|

8 |

Drive Rack Arm |

3, 4, 5, 7 |

18 |

S Reel Table |

16, 17 |

28 |

Sub Rotor |

|

23, 25, 26, 27 |

38 |

Grounding Plate Unit |

------------ |

9 |

Main Lever |

------------ |

19 |

S Brake Arm Unit |

9, 16, 17, 18 |

29 |

PCB Holder |

|

23, 25, 26, 27 |

39 |

FG Head |

------------ |

10 |

P5 Arm Unit |

9 |

20 |

Main Lever Guide |

9 |

30 |

T Loading Arm Unit |

------------ |

|

|

|

|

Step/Loc. No.: Order of steps in procedure. |

Part : Part to be removed or installed. |

Prior Step(s) : Steps to be completed prior to the current step. |

||||||||||

Note: When the mechanical parts surrounded by rectangle are removed or replaced, be sure to perform necessary adjustment or alignment procedures according to the mechanical adjustment procedures section and disassembly/assembly procedures of mechanism section.

Perform all disassembly and alignments procedures in EJECT Position. |

|

|

||

TOP VIEW |

5 |

Motor Block Ass'y |

||

1 |

Cylinder Unit |

4 |

Pinch Arm Unit |

|

6 Audio Control Head Unit |

|

|

||

2 |

Upper Cylinder Unit |

7 |

Main Cam Gear |

|

15 |

Full Erase Head |

8 |

Drive Rack Arm |

|

37 |

Loading Rack |

3 |

Opener Piece |

|

|

|

|||

21 |

Loading Post Base-S Unit |

11 |

Main Lever Drive Arm |

|

16 |

Tension Arm Unit |

10 |

P5 Arm Unit |

|

9 |

Main Lever |

|||

|

|

|||

18 |

S Reel Table |

24 |

Capstan Holder Unit |

|

17 |

S Spring Arm |

12 T Brake Unit |

||

19 |

S Brake Arm Unit |

14 |

T Reel Table |

|

22 |

Loading Post Base-T Unit |

13 Changing Lever A |

||

BOTTOM VIEW |

|

|

||

25 |

SS Brake Arm Unit |

38 |

Grounding Plate Unit |

|

29 |

PCB Holder |

|

|

|

26 |

Junction C.B.A. |

|

|

|

39 |

FG Head |

30 |

T Loading Arm Unit |

|

28 |

Sub Rotor |

31 |

S Loading Arm Unit |

|

23 |

Capstan Rotor Unit |

20 |

Main Lever Guide |

|

27 |

Capstan Stator Unit |

|||

|

|

|||

|

Capstan Belt |

36 |

Idler Arm Unit |

|

33 |

Changing Gear Spring |

34 |

Changing Gear |

|

35 |

Changing Lever-B |

32 |

Center Clutch Unit |

|

Fig. J1

2-7

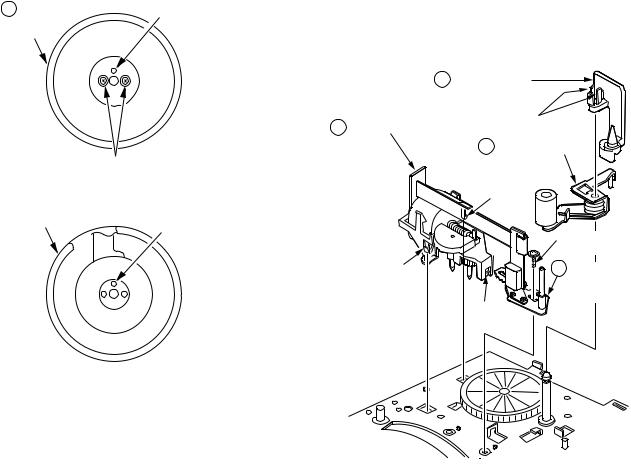

Cylinder Unit

Disassembly Procedure

1.Remove 3 Screws (A) and 2 Screws with Washers (A). Then, lift the Cylinder Unit and the Head Amp C.B.A. out from the mechanism.