Omron E5ZN-DRT Operation Manual

Cat. No. H119-E1-01

E5ZN-DRT

DeviceNet Communications Unit

for E5ZN Temperature Controllers

OPERATION MANUAL

E5ZN-DRT

DeviceNet Communications Unit

for E5ZN Temperature Controllers

Operation Manual

Produced October 2002

iv

Notice:

r

f

OMRON products are manufactured for use accordin g to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to ind icate and classify pr ecautions in this manual . Always heed

the information provided with them . Failure to heed precautions can result in in jur y to people or damage to property.

!DANGER Indicates an immine ntly hazardous situation whi ch, if not avoided, will result in death or

serious inj ury.

!WARNING Indicates a potentially hazardous situatio n which, if not avoided, could resu lt in death or

serious inj ury.

!Caution Indicates a potentially hazardous si tuation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displ ays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PV” is used in this manual to indic ate the process value of the E5ZN Temperature

Controller.

The abbreviation “PLC” means P rogrammable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the le ft column of the manual to help you locate different types of

information.

OMRON, 2002

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in an y fo rm, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to th e use of the in fo rmation c ontain ed he rein. M oreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of pa rticular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

vi

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

6 EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features and System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3 Connecting Temperature Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-4 Initial Temperature Controller Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SECTION 2

Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-1 Setup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Startup Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SECTION 3

Parts, Installation, and Wiring . . . . . . . . . . . . . . . . . . . . . . . 21

3-1 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3-2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-3 Wiring the Terminal Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-4 DeviceNet Communications Cables Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 4

Remote I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . 35

4-1 Allocation Method Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4-2 Simple I/O Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4-3 Allocating I/O from the Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-4 Allocating Data in the Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4-5 Ladder Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

SECTION 5

Operations from the Configurator . . . . . . . . . . . . . . . . . . . . 69

5-1 List of Operations from the Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5-2 Operations from the Edit Device Parameters Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5-3 Maintenance Mode Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5-4 DeviceNet Communications Unit Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

vii

TABLE OF CONTENTS

SECTION 6

Explicit Message Communications . . . . . . . . . . . . . . . . . . . . 89

6-1 Overview of Explicit Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6-2 Sending CompoWay/F Commands to a Temperature Controller . . . . . . . . . . . . . . . . . . . . . 93

6-3 Examples Using CompoWay/F Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6-4 Example of Sending Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6-5 Sending Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

SECTION 7

Communications Performance . . . . . . . . . . . . . . . . . . . . . . . 109

7-1 Remote I/O Communications Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7-2 Message Communications Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

SECTION 8

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . 121

8-1 Indicators and Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8-2 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Appendices

A Connecting to a Master from Another Company . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

B List of Connectable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

viii

About this Manual:

This manual descri bes the installation and operation of the E5ZN -DRT DeviceNet Communications

Unit for E5ZN Temperature Controllers and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to insta ll or operate the E5ZN- DRT DeviceNet Communications Unit. Be s ure to read the

precautions provided in the following section.

Precautions provides general precautions for using the E5ZN -DRT DeviceNet Communicatio ns Unit,

Programmable Controller, and related devices.

Section 1 introduces the features and system configuration of the E5ZN-DRT DeviceNet Communications Unit, the types of E5ZN Temperature Controller that can be used, and other basic information.

Section 2 outlines the basic operating procedures of the E5ZN-DRT DeviceNet Communications Unit.

Section 3 descr ibes the method s used to instal l and wire the E5ZN -DRT DeviceNet Communications

Unit and the E5ZN Temperature Controll er. The settings of DeviceNet Communications Unit switches

are also described.

Section 4 describes the input (IN) area s and output (OUT) ar e as tha t E 5ZN- DRT DeviceNet Communications Unit s can use for remote I/O communica tion s. The methods to allocate data for master c ommunications are also described.

Section 5 describes the DeviceNet Configurator operations that can be used for the E5ZN-DRT

DeviceNet Communications Unit except for allocation proce dures, which ar e descr i bed in SECTION 4

Remote I/O Communications.

Section 6 describes how to send explicit messages to the E5ZN-DRT DeviceNet Communications

Unit, including how to send CompoWay/F commands using explicit messages. CompoWay/F commands are supported by the E5ZN Temperature Controller.

Section 7 provides information on the time required for a complete communic ations cyc le, for an output response to be made to an input, to start the system, and to send messages.

Section 8 descr ibes error processing, per iodic maintenance operations, and tr oubleshooting procedures needed to keep the DeviceNet Network ope rating properly. Details on resetting replaced Units

are also provided. Read through the error processing procedures in both this manual and the operation

manual for the DeviceNet master being used before operation so that operating errors can be identified

and corrected more quickly.

The Appendices provide the hand ling m ethods for EDS setting files requir ed for multivender environments, the device profile of the E5ZN-DRT DeviceNet Communications Unit, and information on

related products.

!WARNING Failure to read and under stand the information provided in th is manual m ay result in p er-

sonal injury or death, damage to th e product, or product failure. Please rea d ea ch section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

x

PRECAUTIONS

This section provides general precautions for using the E5ZN-DRT DeviceNet Communications Unit, Programmable

Controller, and related devices.

The information contained in this section is important for the safe and reliable application of the DeviceNet

Communications Unit. You must read this section and understand the information contained before attempting to

set up or operate a DeviceNet Communications Unit and PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

6 EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

xi

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA equipment

• Personnel in charge of designing FA systems

• Personnel in charge of installing and connecting FA equipment

• Personnel in charge of managing FA systems and facilities

2 General Precautions

The user must operate t he product according to t he performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the produ ct to nuclear control s ystems, railroad systems,

aviation systems, vehicles, combustion systems, medic al equipmen t, amusement machines, safety equipment, and oth er systems, machines, and equi pment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performan ce charact er is ti cs of the pr od uc t are

sufficient for the systems, machi nes, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for installing and operating OMRON

DeviceNet Communications Units. Be s ure to read this manual b efore operation and keep this manual close at hand for reference during operation.

!WARNING It is extremely impor tant that a PLC and al l PLC Units b e used for the spec i-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC system to the above mentioned applications.

3 Safety Precautions

!WARNING Provide emergency sto p circuits, external inter lock circuits, limit circuits, an d

other safety circuits in addition to any provided within the PLC to ensure

safety in the event of errors resulting from product failure or externa l causes.

This measures must als o be provided as external m easures, not only in the

PLC. Incorrect operation can result in serious accidents.

!Caution Always connect terminal screws and cable connector screws to the spe cified

torque. Loose screws can result in fires or faulty operation.

Communications cable connector screws: 0.25 and 0.3 N·m

Terminal screws: 0.40 to 0.56 N·m.

!Caution Confirm safety at the destination node before transferring a program to

another node or changing c ontents of the I/O memory ar ea. Doing either of

these without confirming safety may result in injury.

xii

!Caution Execute online edit only after confirming that no adverse effects will be

caused by extending the cycle time. Other wise, the input signals may not be

readable.

Operating Environment Precautions 4

!Caution Never touch any of the terminals while power is being supplied. Doing so may

result in serious electrical shock or electrocution.

!Caution Never attempt to disassemble any Units while power is being suppli ed. Doin g

so may result in serious electrical shock or electrocution.

!Caution Do not allow any pieces of metal or conductive materials to ent er the Unit.

They can cause electric shock, fire, or Unit failure.

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight

• Locations subject to severe changes in temperature, condensation, or

icing

• Locations subject to dust or corrosive gases (particularly sulfurized or

ammonia gas)

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient co untermeasures when in stalling systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

!Caution Do not operation the control syste m in locations subject to temperatures or

humidity outside the range specified in the specifications.

!Caution The operating environment of the P LC Syste m can h ave a large effect on the

longevity and reliability of the sy stem. Improper operating environme nts can

lead to malfunction, failure, and other unforeseeable problems with the PLC

System. Be sure that the op erating environmen t is within the sp ecified c onditions at installation and remai ns within the specifi ed conditions dur ing the life

of the system.

5 Application Precautions

Observe the following precautions when using the DeviceNet Communications Unit or the PLC.

!Caution Do not exceed the communications distances given in the specifications.

!Caution Do not lay communications cables near or parallel to high-voltage lines or

power supply lines.

!Caution Use the specified communications cables.

xiii

EC Directives 6

!Caution Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

!Caution Do not drop the Unit or expose it to excessive shock or vibration. Unit failure

or malfunction may result.

!Caution Always use the power supply voltages specified in the op eration manuals. An

incorrect voltage may result in malfunction or burning.

!Caution Connect terminals with the correct polarity and lay communications and

power supply lines c orrectly. System failure can result if thes e are not performed correctly.

!Caution Do not connect or disconnect any connectors while the power supply is turned

ON. System failure or malfunction may occur.

!Caution Double-check all wiring and switch settings before turning O N the power sup-

ply. Incorrect wiring may result in burning.

!Caution Take appropriate measures to ensure that the specifie d power with the rated

voltage and frequency is suppli ed. B e particular ly ca reful in pl aces whe re th e

power su pply is un stab l e . An in corr ect po we r sup ply m a y r esult in m alfun cti on.

!Caution Do not use organic solvents to clean the Unit.

!Caution Do not replace the Unit while the power supply is turned ON.

6 EC Directives

6-1 Concepts

•EMC Directives

• Low Voltage Directive

EMC Directives

OMRON devices that comply with EC Directives also conform to the r elated

EMC standards so tha t they can be more easil y built in to ot her devices or the

overall machine. The actual products have been checked for conformity to

EMC standards. Whether the products conform to the standards in the system

used by the customer, however, must be checked by the customer.

EMC-related perfor ma nce o f th e O M RON devices that c omp ly wi th EC Di re ctives will vary depending on the configuration, wi ring, an d other conditio ns of

the equipment or control panel on which the OMRON devices are installed .

The customer must, therefore, perform the fi nal c heck to confir m th at devices

and the overall machine conform to EMC standards.

xiv

EC Directives 6

6-2 Conformance to EC Directives

The E5ZN-DRT DeviceNet Communications Unit complies with EC Directives.

To ensure that the machi ne or device in wh ich the U nit is us ed comp lies wit h

EC Directives, the Unit must be installed as follows:

1,2,3... 1. The Unit must be installed within a control panel.

2. You must use rei nforced insulation or double insulation for the DC power

supplies used for the communications power supply , internal power supply,

and I/O power supplies.

3. Units complying with EC Directives also conform to the Common Emission

Standard (EN50081-2). Radiated emission characteristics (10-m regulations) may vary dependin g o n the configuration of the co ntrol pa nel u sed ,

other devices connected to the control panel, wiring, and other conditions.

You must therefore confirm that the overall machine or equipment complies

with EC Directives.

The following example shows one means of reducing noise.

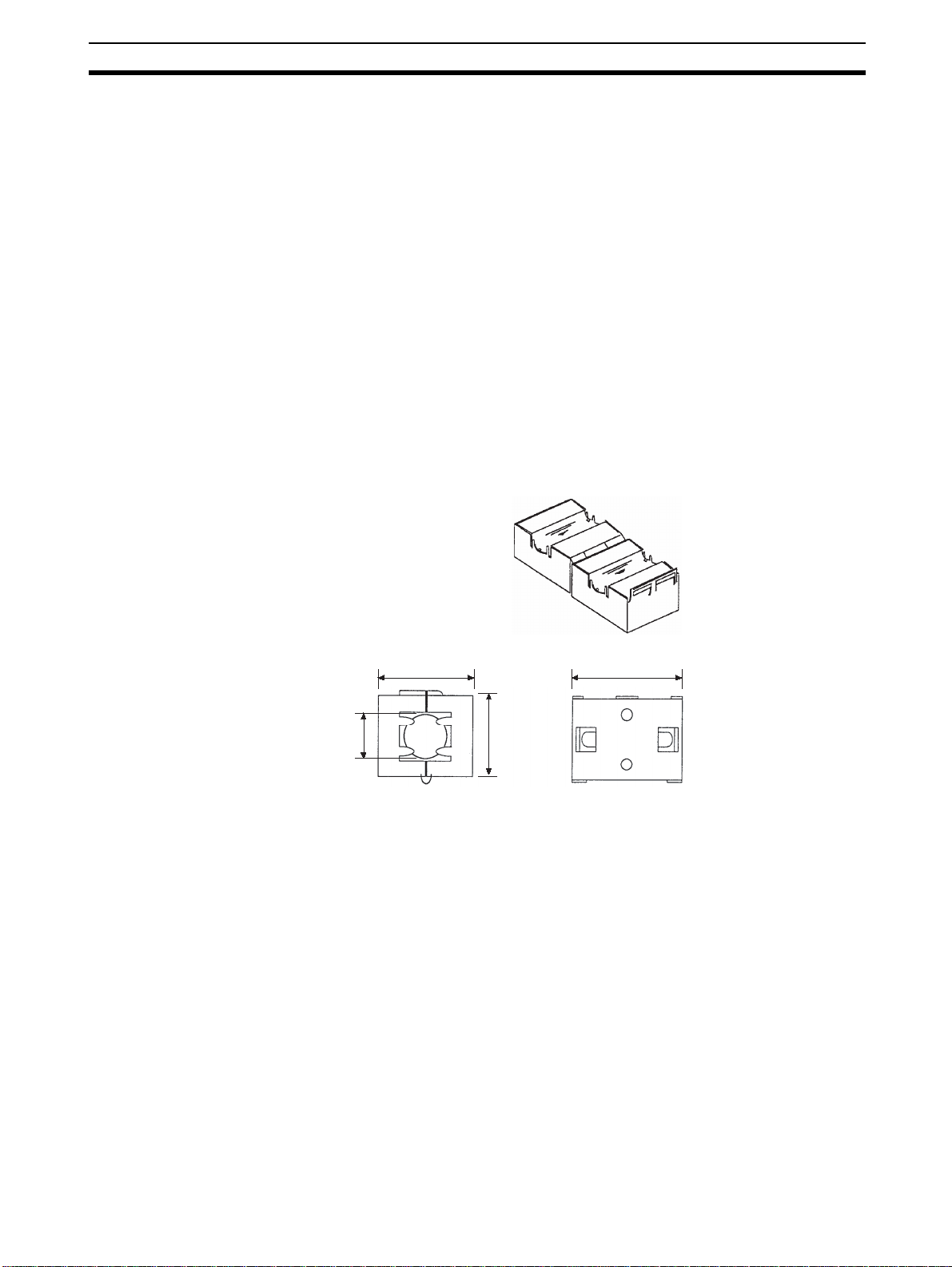

1,2,3... 1. Noise from the communications cable can be reduced by installing a ferrite

core on the communications cable within 10 cm of the DeviceNet Unit.

30 mm

13 mm 29 mm

Ferrite Core (Data Line Filter): 0443-164151 (manufactured by Fair-Rite Products Co., Ltd.)

Impedance specifications

25 MHz: 105

100 MHz: 190 Ω

30 mm

13 mm

29 mm

33 mm

2. Wire the control panel with as thick and short electric lines as possible and

ground to 100

3. Keep DeviceNet communications cables as shor t as pos sible and ground

to 100

Ω

Ω min.

Ω min.

33 mm

xv

EC Directives 6

xvi

SECTION 1

Overview

This section introduces the features and system configuration of the E5ZN-DRT DeviceNet Communications Unit, the

types of E5ZN Temperature Controller that can be used, and other basic information.

1-1 Features and System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Overview of Unit Communications Functions. . . . . . . . . . . . . . . . . 4

1-1-3 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-2-1 DeviceNet Communications Specifications . . . . . . . . . . . . . . . . . . . 9

1-2-2 Function and Performance Specifications . . . . . . . . . . . . . . . . . . . . 10

1-2-3 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3 Connecting Temperature Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-3-1 Temperature Controller ID and Number of Connectable Units . . . . 11

1-3-2 Temperature Controller Communications . . . . . . . . . . . . . . . . . . . . 12

1-3-3 Temperature Controller Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-3-4 Temperature Controller Power Supply. . . . . . . . . . . . . . . . . . . . . . . 12

1-3-5 Temperature Controller Registration . . . . . . . . . . . . . . . . . . . . . . . . 13

1-4 Initial Temperature Controller Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1

Features and System Configuration Section 1-1

1-1 Features and System Configuration

1-1-1 Features

The DeviceNet Communications Unit enables a DeviceNet master to communicate with multiple E5 ZN Temperature Controllers throu gh the DeviceNet to

monitor their process values, write parameters, and control operation.

Using DeviceNet Functions

Simultaneously Managing

Multiple Temperature

Controllers from the

Master

Remote I/O

Communications

Explicit Message

Communications

Up to 16 Temperature Controllers can be connected to a single DeviceNet

Communications Unit. The DeviceNet Communications Unit is connected to

the master as a DeviceNet slave. Up to 63 slaves can be connected to a single master, so multiple DeviceNet Communic ations Units and othe r types of

slaves can be managed as part of the same system.

The master and DeviceNet Communications Units can share I/O by using

remote I/O communications. Data in the E5 ZN Temperature Contr ollers, such

as process values (PVs) a nd set poi nts (S Ps), c an be al loca ted for communications with the master to enable sending and receiving the allocated data via

remote I/O communications, without requiring special programming.

• Remote I/O Communications without a Configurator

Using the DeviceNet Communicatio ns Un it, bas ic Temperature Controller

data can be allocate d for communications with the master, such as process values (PVs) and set poin ts (SPs), without re quiring a Confi gurator.

This is called “si mple I/O allocation.” Simple I/O allocation c an be easily

set from the DIP switch on the rear of the DeviceNet Communications

Unit.

• User-set Data Allocations with a Configurator

The specific data req uired for communications with the mas ter can also

be allocated by using I/O allocations from the Configurator.

By executing commands from th e PLC, various o perat io ns can be performed,

including reading/writing specific parameters, such as reading process values

or writing set po ints, and performing operations using o peration commands.

CompoWay/F communications commands can also be executed using explicit

message communications.

Setting, Monitoring, and

Operating the

Temperature Controller

from the Configurator

Automatically Detects

Baud Rate

2

The Configurator can be used to create the device parameters for the

DeviceNet Communications Unit , including settings for the DeviceNet Communications Unit and setti ng for the Temperature Controllers. The Config urator can then be used t o download the parameters tog ether to the DeviceNet

Communications Unit and Temperature Controllers. (See note.)

The Configurator can also be used to monitor Temperature Controller process

values, and execute operation commands for the Temperature Controllers.

The Configurator can be used to copy parameters between Temperature Controller channels, allowing the initial parameters of Temperature Controllers

requiring the same or similar parameters to be easily set.

Previously, the baud rate had to be set for each slave, but the DeviceNet Communications Unit automatically detects and matches the baud rate of the master, so this setting is not required. (If the ma ster's baud rate is changed, turn

OFF the communications power supply to the DeviceNet Communications

Unit and then turn it ON again.)

Features and System Configuration Section 1-1

Wide Range of

Copy Function (Uploading

or Downloading

Temperature Controller

Parameters)

Monitoring Network P ower

Voltage

Monitoring the Unit

Conduction Time

Unit Comments Any name can be set for a DeviceNet Communications Unit and recorded in

Setting Temperature

Controller Comments

Maintenance Functions

Parameters for all Temperature Controllers connec ted to the DeviceNet Communications Unit can be upl oaded or downloaded togeth er. (The parameters

that have been read are stored in the DeviceNet Communications Unit.) When

Temperature Controllers are replaced, the new Controllers can be easily reset

onsite without using a Configurator.

The DeviceNet network communications power voltage values (present value,

peak value, and bottom value) can be stored in the DeviceNet Communications Unit, and the rec orded voltages can be read fro m the Configurator. By

setting the voltage monitor value in the DeviceNet Communications Unit, notification will be sent to the master if the voltage level drops below the monitor

value.

The conduction time of th e DeviceNet Communications Unit ’s internal circuit

power supply can be r ecorded. The recorded conductio n time can be read

from the Configurator or us ing explicit messages. By sett ing a monitor value

for the conduction time in the DeviceNet Communications Unit, notification will

be sent to the master when the total time exceeds the monitor value.

the Unit. Specifying names enables the user to easily differentiate the applications of the DeviceNet Communications Units when setting and monitoring

them from the Configurator.

A name can be set for each Temperature Controll er cha nne l c onne ct ed to th e

DeviceNet Communications Unit and rec orded in th e DeviceNet Communic ations Unit. Specifying na mes enables the u ser to easily differentiate the function of each channel when setting and monitoring them from the Configurator.

Monitoring

Communications Error

History

Monitoring Temperature

Controller P ower Status

Monitor Temperature

Controller Conduction

Time and RUN Time

Easy Expansion

Connecting Existing

Terminal Units

Internal Circuit Power

Supply for Slaves Not

Required

The error status for the last four communications errors (the causes and communications power voltage when the communicatio ns error occurred) can be

recorded in the D eviceNet Communications Unit. The recorded communications error history can be read from the Configurator.

The power supply to the Temperature Contr ollers can monitored to confirm

that power is ON and send notification of the status to the master. (The power

status can be checked for Temperature Controllers connected to the

DeviceNet Communications Unit only.) The power status of the Temperature

Controllers can be read from the Configurator or using explicit messages.

The conduction time of the Temperature Controller’s internal circuit power

supply or the RUN time of the Temperature Controller can be totaled and

recorded. (Select whet her to total the co nducti on tim e or RUN time by setting

the monitor mode.) The recorded total tim e can be read using the Config urator or explicit messages. By setting a monitor value in the DeviceNet Communications Unit, notification will be sent to the master if the Unit conduction time

exceeds the monitor value.

DeviceNet Communications Units can be connected to the Terminal Units

used for previous (non-DeviceNet) E5ZN Temperature Controllers, so existing

Temperature Controllers can easily be connected to DeviceNet.

The internal circui t power of the DeviceNet Communications Unit is supplie d

from the DeviceNet communications power supply. Therefore, power supply

wiring is not req uir ed for the DeviceNet Co mmunications Unit. (The Temperature Controller power supply must be supplied separately.)

3

Features and System Configuration Section 1-1

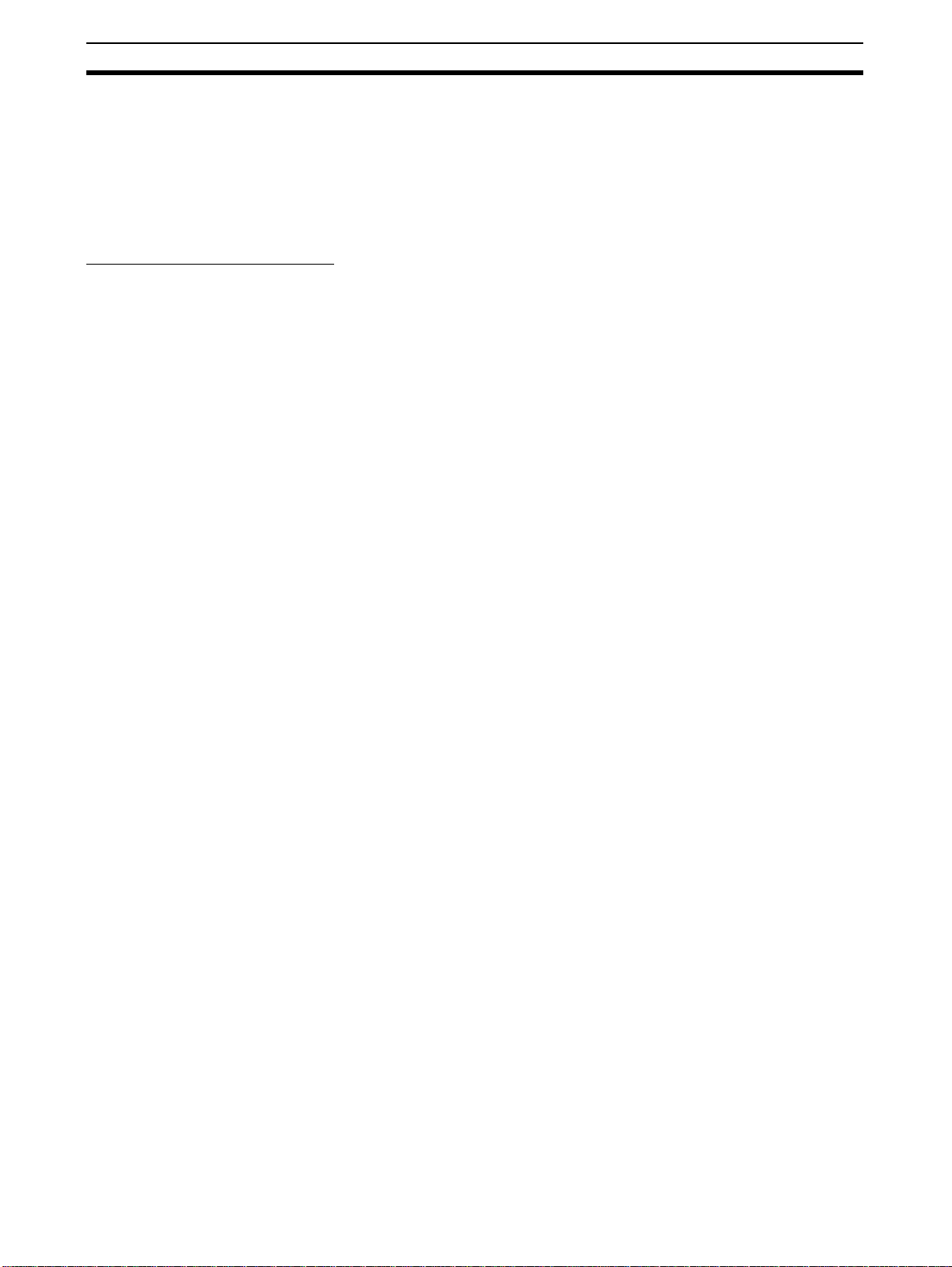

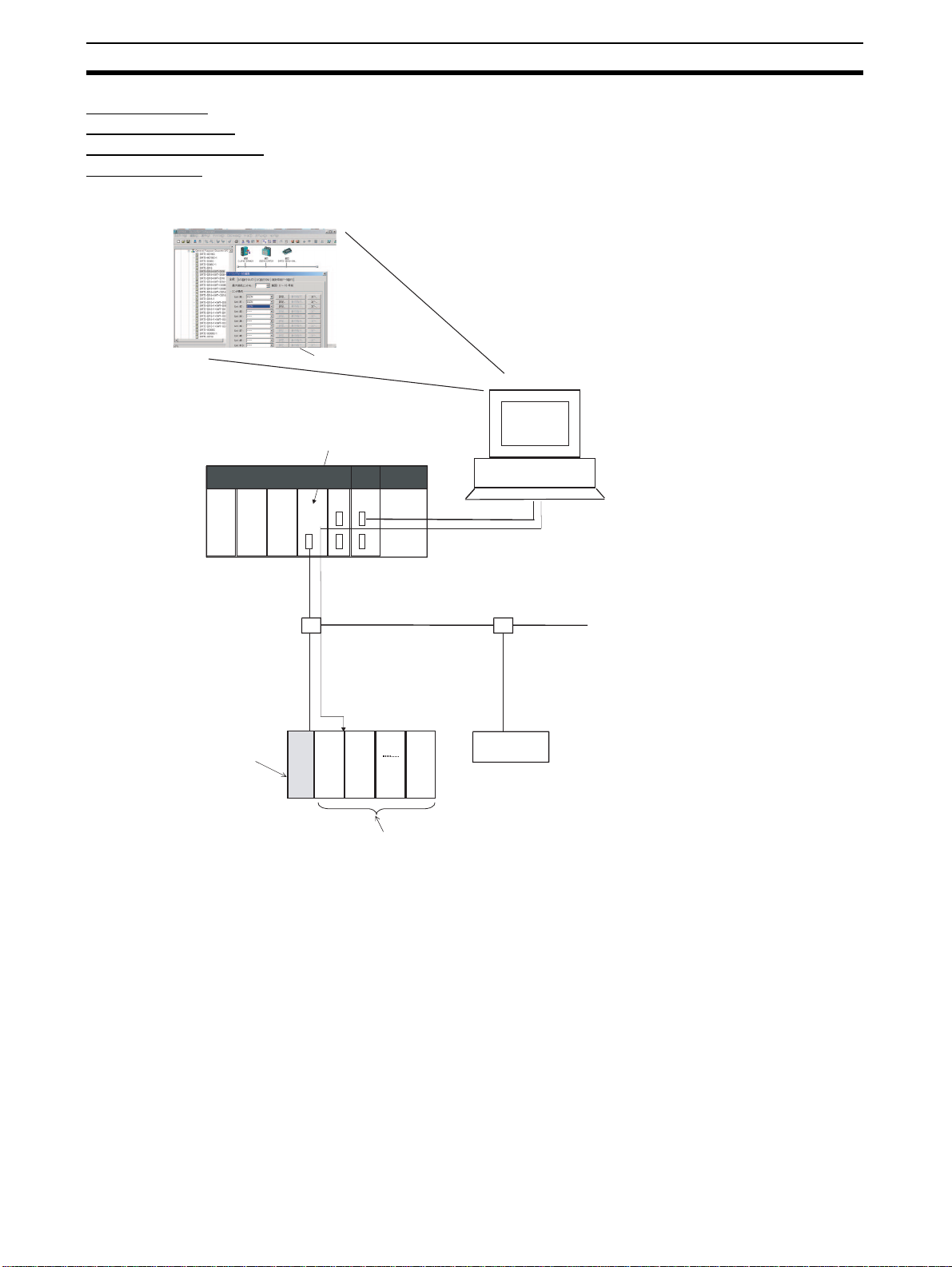

1-1-2 Overview of Unit Communications Functions

Remote I/O

Communications

DeviceNet Communications Unit data is shared with the master’s IN Area and

OUT Area through DeviceNet. Up to 100 words (200 bytes) each can be used

as the IN Area and OUT Area for the DeviceNet Communications Unit. (Th e

first two words (four bytes) of the OUT Area are always allocated as Outpu t

Enable Bits).

The IN Area is a llocated for data such as the co mmunicatio ns status and the

process values of the Temperature Control ler channels and th e OUT Area is

allocated for the set points of the channels and other data.

When using a CS/CJ-series DeviceNet Unit as the master, the IN Area can be

divided into two areas. One is normally used for input data (such as Temperature Controller p rocess values), a nd the ot her can be used for rea ding st atus

(such as Temperature Controller s tatus). Even when the IN Area is divided

into two areas, however, the total number of words that can be used for the IN

Area is still 100 words (200 bytes).

DeviceNet Unit

Remote I/O communications

output area

Input Area

CPU Unit

Unit 0, Ch 1 SP

Unit 0, Ch 2 SP

Unit 1, Ch 1 SP

Unit 15, Ch 2 PV

Unit 0, Ch 1 PV

Unit 0, Ch 2 PV

Unit 1, Ch 1 PV

PLC

Remote I/O

communications

E5ZN-DRT

DeviceNet Communications Unit

Unit 0 Unit 1

Unit 15, Ch 2 PV

DeviceNet

Unit

15

E5ZN Temperature Controllers

4

Features and System Configuration Section 1-1

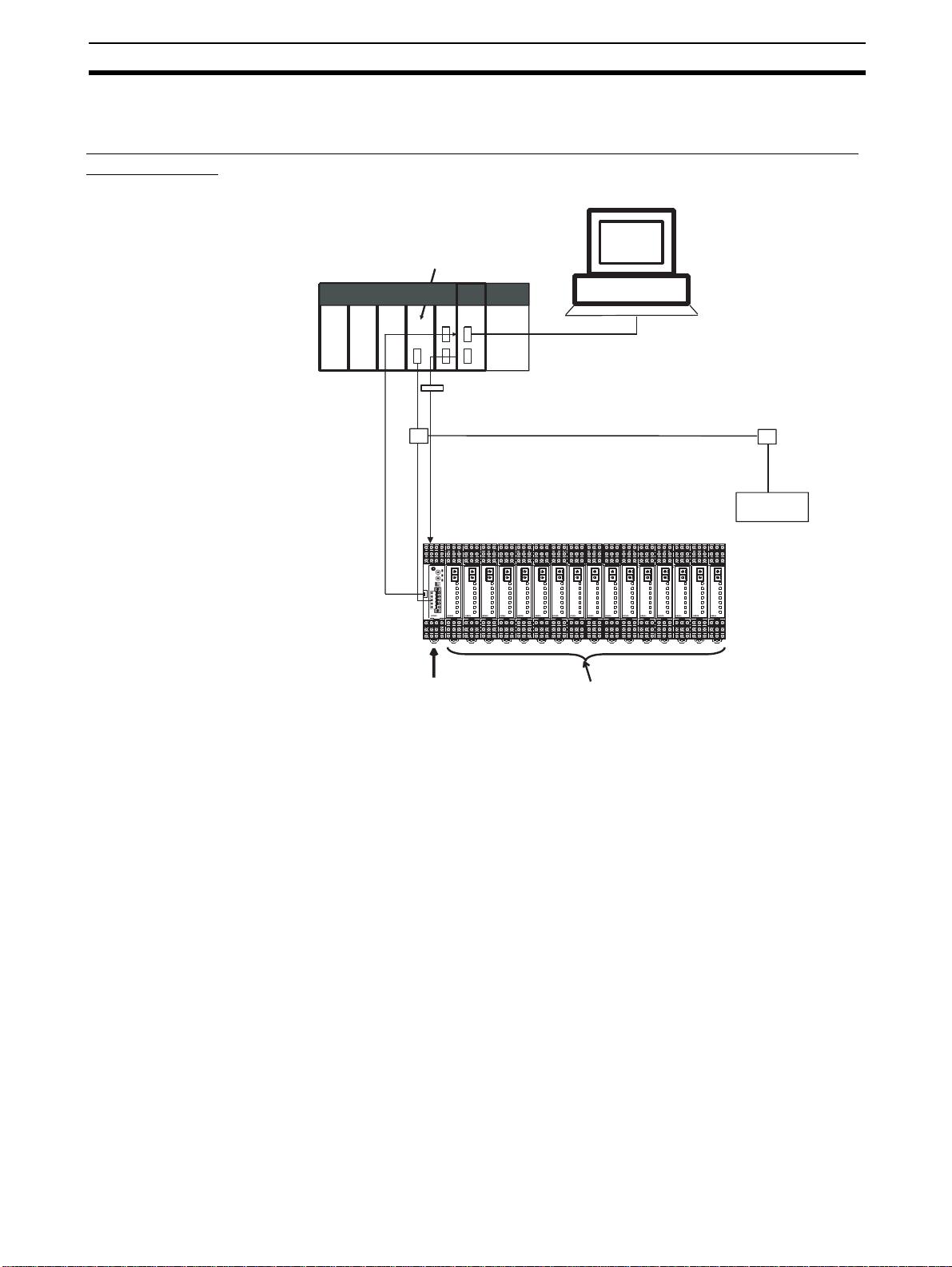

p

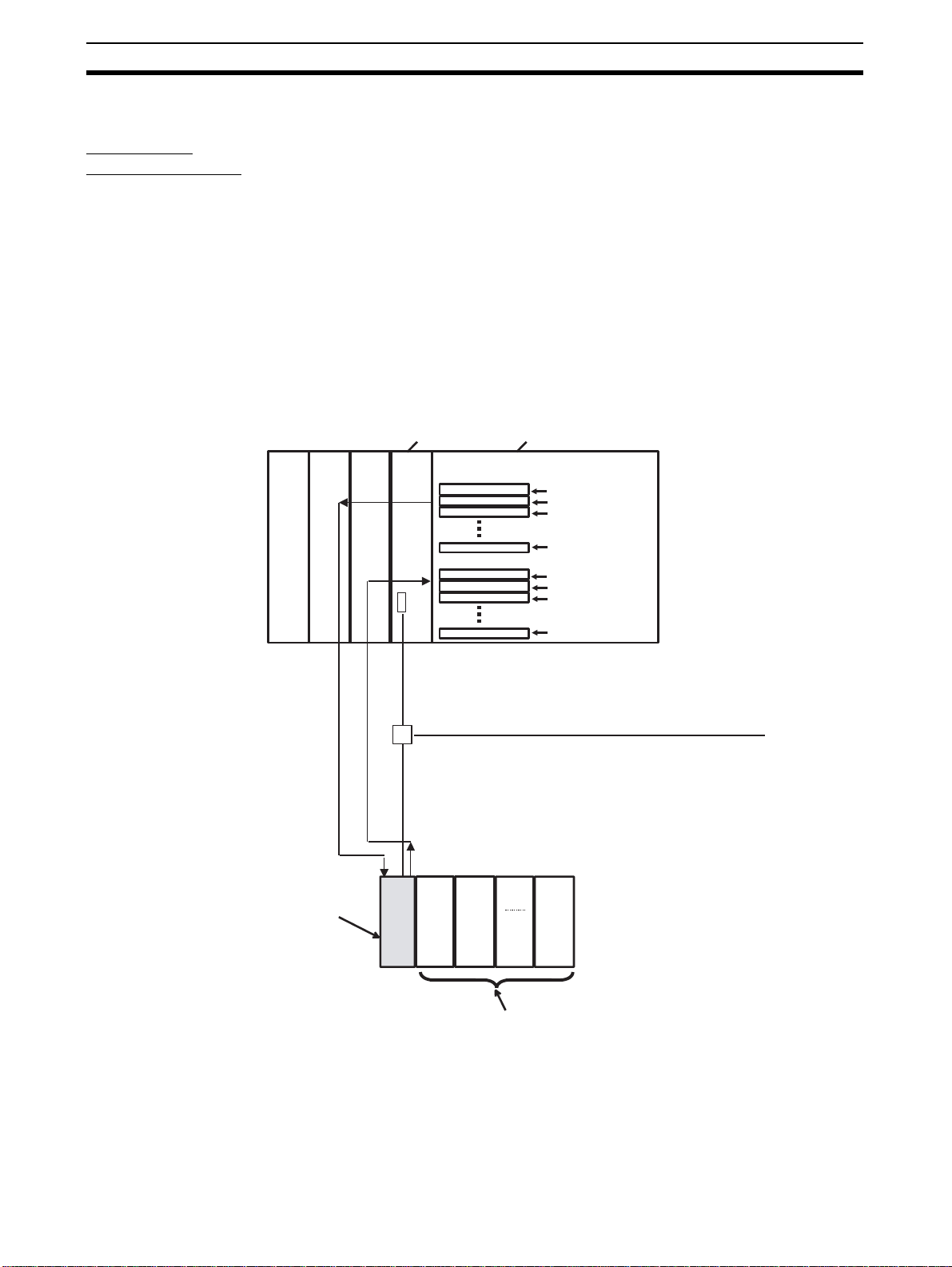

Explicit Message

Communications

Explicit message commands can be sent from the m aster to the DeviceNet

Communications Unit to read or wr ite the parameters of the con nected Temperature Controllers. CompoWay/F communications commands that were

previously used for Temperature Controll ers c an also be sent (in explicit me ssage format).

The DeviceNet Communications Unit’s own parameters can also be read or

written.

DeviceNet Unit CPU Unit

PLC

Ladder program

CMND or other

communications

instruction

Explicit message communications

DeviceNet

E5ZN-DRT

DeviceNet Communications Unit

Unit 0 Unit 1

E5ZN Tem

Unit

15

erature Controllers

5

Features and System Configuration Section 1-1

Transferring,

Monitoring, and

Operating from the

Configurator

Any of the Temperature Controller parameter s can be read or wr itten from a

personal computer usin g the Confi gurator ( Ver. 2.31 or later), and then saved

as a file.

The setup parameters for each Temperature C ontroller channel can be copied, allowing the same or si milar s ettings to be eas ily se t for multiple Temperature Controllers.

DeviceNet Configurator

E5ZN Temperature Controller

CS/CJ-series DeviceNet Unit

PLC

Serial connection

Setting, monitoring, and executing operation commands for the

Temperature Controllers using the Configurator.

• Setting Temperature Controller settings and downloading them.

• Monitoring Temperature Controller process values and target values.

• Executing Temperature Controller operation commands.

DeviceNet

E5ZN-DRT

DeviceNet Communications Unit

Unit 0Unit

1

Unit

15

E5ZN Temperature Controllers

DeviceNet Slave

6

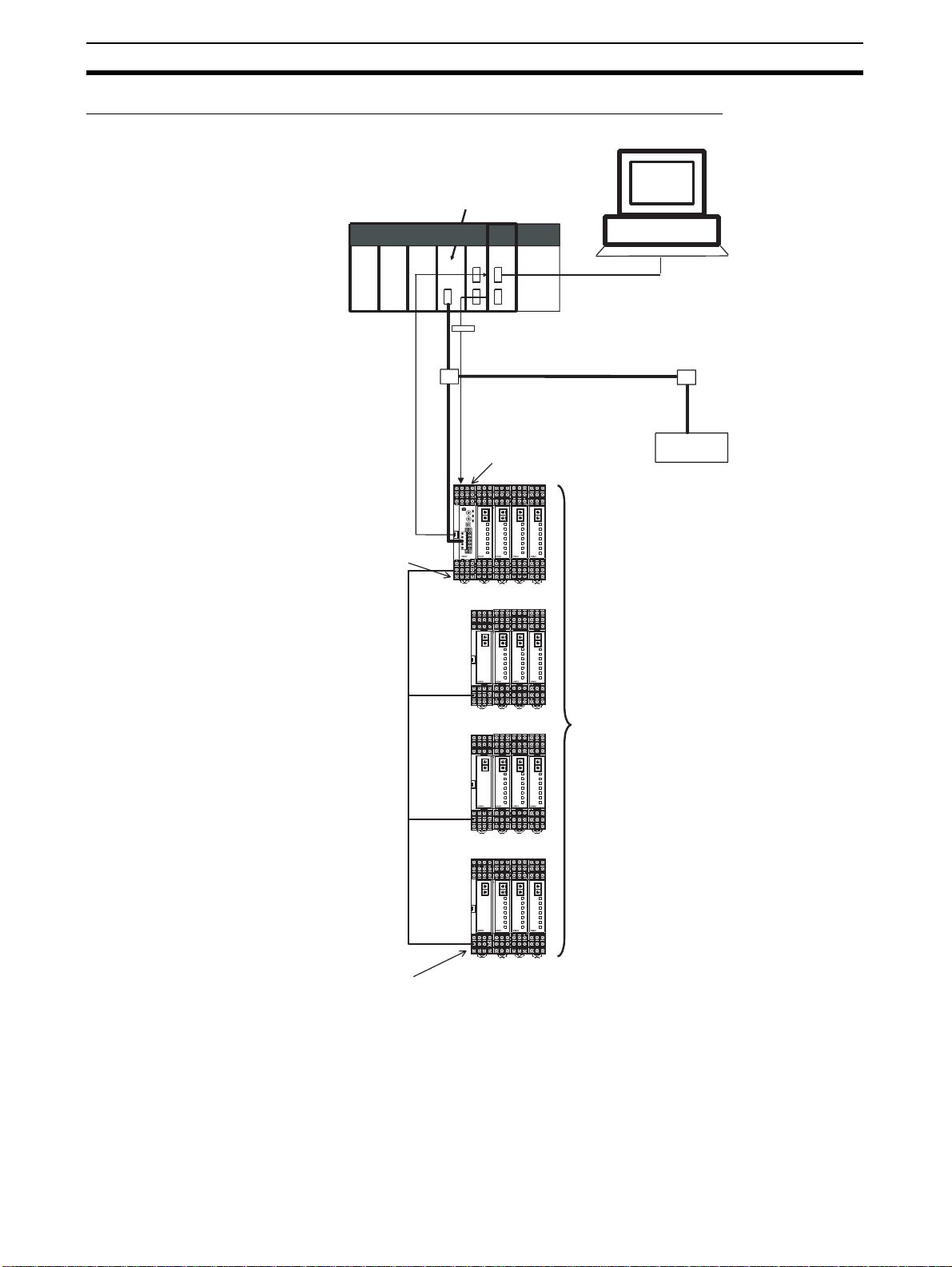

Features and System Configuration Section 1-1

1-1-3 System Configuration

The DeviceNet Communications Unit and Temperature Controllers are configured as

a single block.

DeviceNet Configurator

CS/CJ-series DeviceNet Unit

PLC

Serial connection

(setting, monitoring, and operating)

Explicit messages

DeviceNet

DeviceNet slave

UNIT

UNIT

UNIT

UNIT

UNIT

UNIT

UNIT

UNIT

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

E5ZN-DRT

DeviceNet Communications Unit

UNIT

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN Temperature Controllers

(up to 16 Controllers)

UNIT

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

Connect the master to the DeviceNet Communicati ons Unit, and connect the

DeviceNet Communications Unit to the Temp erature Controllers through the

Terminal Units.

The DeviceNet Communications Unit and Temperature Controllers can be

connected without using RS-485 communications cable.

The DeviceNet Communications Unit shares I/O with the master as a

DeviceNet slave, and can send data to and receive data from the master

using explicit messages.

Up to 63 slaves can be connecte d to a single master. Up to 16 Temperature

Controllers can be connected to a single DeviceNet Communications Unit.

Note Always connect the DeviceNet Communications Unit to the E5ZN-SCT24S

Terminal Unit on the left end of the block.

7

Features and System Configuration Section 1-1

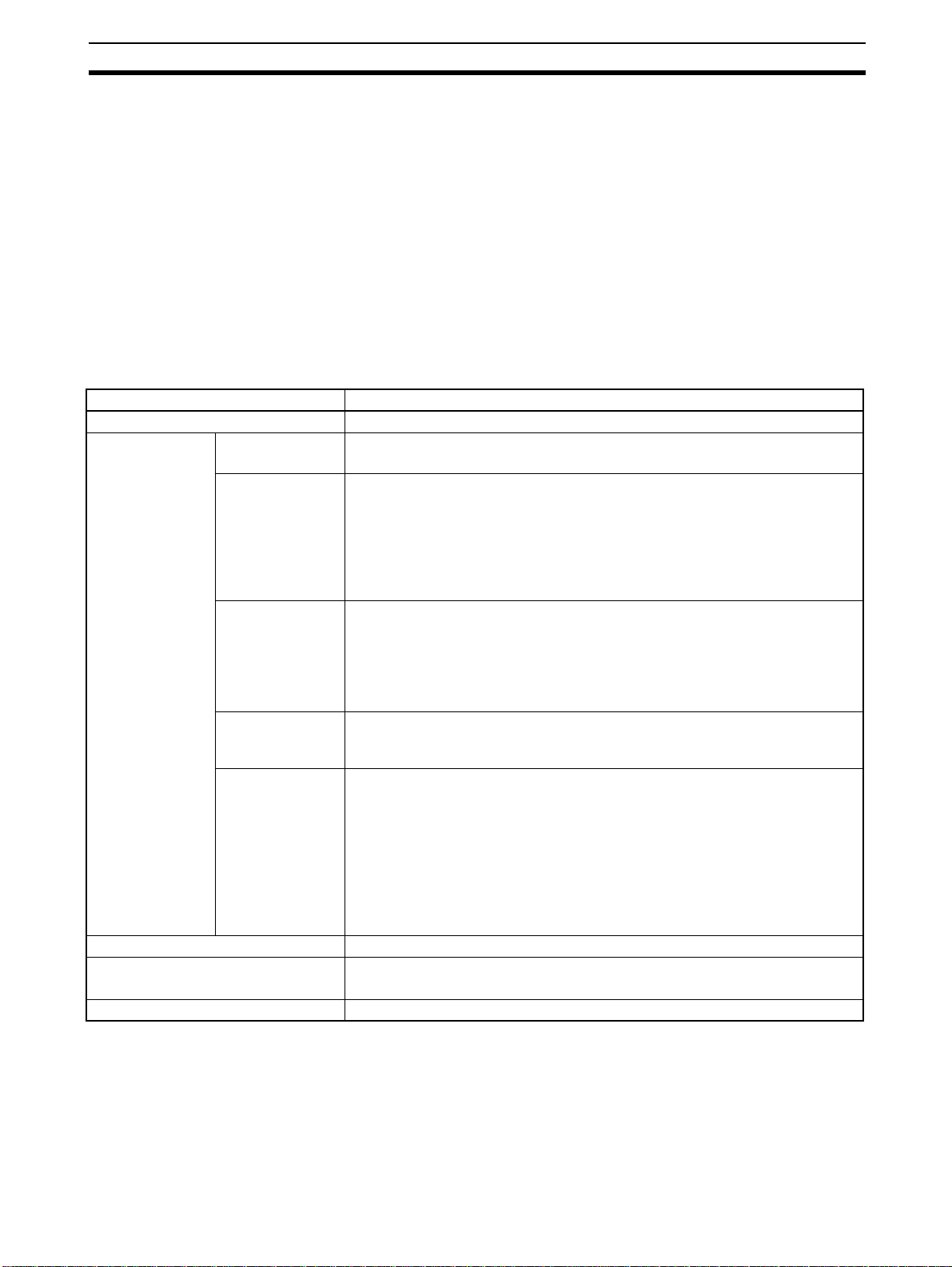

Multiblock Configuration Using

Terminating resistance of 100 to 125 Ω

(1/2 W) connected to both ends of the

RS-485 transmission path

RS-485 Communications Connections

DeviceNet Configurator

CS/CJ-series DeviceNet Unit

PLC

Serial connection

(setting, monitoring, and operating)

Explicit messages

DeviceNet

E5ZN-DRT

DeviceNet Communications Unit

DeviceNet slave

UNIT

UNIT

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

RS-485 communications cable

(length: 500 m max.)

Terminating resistance of 100 to 125 Ω

(1/2 W) connected to both ends of the

RS-485 transmission path

Connect the master and DeviceNet Communic ations Unit, and then u se RS485 communications to connect the Temperature Controllers divided into multiple blocks. Connect the DeviceNet Communications Unit to any one of the

blocks. Connect each block with the Terminal Unit on the end.

The total cable length for RS-485 communication s can be up to 500 m, so

Temperature Controllers locate d a t a di s tanc e ca n be ope rated usin g a s i ngl e

DeviceNet Communications Unit.

UNIT

UNIT

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

E5ZN Temperature Controllers

(up to 16 Controllers)

UNIT

UNIT

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

UNIT

UNIT

UNIT

BPS

BPS

BPS

POWER

POWER

POWER

ERROR

ERROR

ERROR

SD/RD

SD/RD

SD/RD

OUT1

OUT1

OUT1

OUT2

OUT2

OUT2

SUB1

SUB1

SUB1

SUB2

SUB2

SUB2

E5ZN

E5ZN

E5ZN

E5ZN

8

Specifications Section 1-2

Up to 63 slaves can be connecte d to a single master. Up to 16 Temperature

Controllers total for all blocks can be connected to a sing le DeviceNet Communications Unit.

Terminating resistance of 100 to 125

Ω (1/2 W) must be connec ted to both

ends of the RS-485 communications transmission path. For details on RS-485

communications with Temperature Controllers, refer to the E5ZN Temperature

Controller Operation Manual (H113).

Note Connect the DeviceNet Communica tions Unit to th e E5ZN-SCT24S Terminal

Unit on the left end of any one of the blocks.

1-2 Specifications

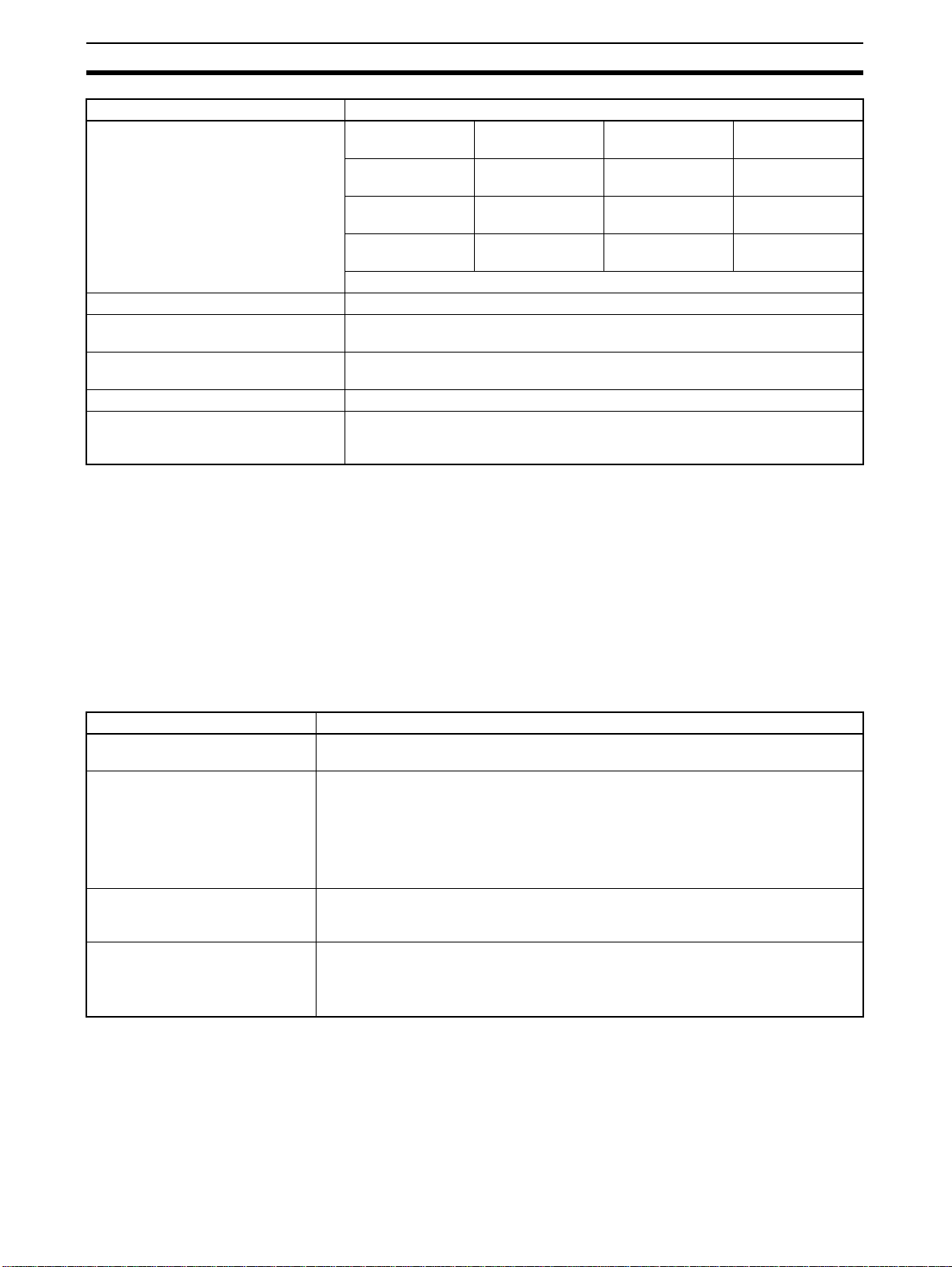

1-2-1 DeviceNet Communications Specifications

Item Specifications

Communicati ons protocol Conforms to DeviceNet

Communications

functions

Connection format Combination of multidrop and T-branch connections (for trunk and drop lines)

Baud rate DeviceNet: 500, 250, or 125 kbps, or automatic detection of master baud rate

Communications media Special 5-wire cable (2 signal lines, 2 power lines, and 1 shield line)

Remote I/O communications

Simple I/O allocation

I/O allocations

from the Configurator

Message communications

Setting, monitoring

and controlling

operations from

the Configurator

• Master-slave connections (polling, bit-strobe, COS, or cyclic)

• Conform to DeviceNet specifications.

• Allocates I/O data using switch settings only, without a Configurator.

• I/O is allocated for Temperature Controller status es , process v alues , se t points ,

alarm output status, and other basic data only.

• One block for IN area, up to 46 words (words are allocated through the maximum number of units connected)

• One block f o r O UT are a, u p to 38 w o rds (words are allocated through t he m ax imum number of units connected)

• Can be used to allocate any I/O data from the Configurator.

• Can be used to allocate any data, such as parameters specific to the

DeviceNe t Comm unicati ons U nit and th e Temperature Controller va riabl e area.

• Up to 2 blocks for the IN area, up to a total of 100 words. (See note 1.)

• One block for OUT area 1 block, up to 100 words (first two words are always

allocated to Output Enable Bits). (See note 2.)

• Explicit message communications

• CompoWay/F communications commands can be sent (commands are sent in

explicit message format).

Supported by DeviceNet Configurator (using the Edit Parameters and Device

Monitor functions of the DeviceNet Communications Unit and Temperature Controllers).

• Used to set and monitor the DeviceNet Communications Unit.

• Used to register connection configurations, make initial settings (see note 3),

change settings, and monitor the Temperature Controllers.

• Use to allocates data for master communications.

• Used to allocates word in the IN and OUT Areas for specific data.

• Used to sends operation commands to the Temperature Controllers.

RS-485: 38.4 kbps

9

Specifications Section 1-2

Item Specifications

Communications distance Baud rate Network length Drop line length Total drop line

500 kbps 100 m max.

250 kbps 250 m max.

125 kbps 500 m max.

The values in parentheses apply when Thin Cables are used.

Communications power supply 11 to 25 VDC

Maximum numb er of nodes tha t can be

connected

Maximum number of slaves that can be

connected

Error control CRC error detection

Power supply Power supplied from DeviceNet communications connector (DeviceNet commu-

64 (includes Configurator when used.)

63

nications power supply and DeviceNet Communications Unit internal circuit

power supply)

(100 m max.)

(100 m max.)

(100 m max.)

6 m max. 39 m max.

6 m max. 78 m max.

6 m max. 156 m max.

Note 1. When a CS/CJ-series DeviceNet Unit is used as the ma ster, two blocks

can be used for the IN Area (the connect ions can also be set). When a

CVM1, CV-series, or C200HX/HG/HE DeviceNet Master Unit is used, th e

IN Area must be in 1 block, and up to 100 words (200 bytes) are allocated.

(Only polling connections can be used.)

2. When a CVM1, CV-series, or C200HX/HG/HE DeviceNet Mast er Unit is

used, up to 32 words can be allocated in the master for a single node.

3. The set points, alarm setting values, PID constants, and other Temperature Controller parameters can be set together.

length

1-2-2 Function and Performance Specifications

Item Specifications

Maximum number of Temperature

Controllers that can be connected

Applicable Temperature Controllers

Pow e r supply Pow er suppli ed from Terminal Unit terminal block (terminals 19 and 20) (Com mun ica-

Copying The parameters of the connected T emperature Controllers can be uploaded or down-

16

• E5ZN-2QNH03TC-FLK

• E5ZN-2QPH03TC-FLK

• E5ZN-2TNH03TC-FLK

• E5ZN-2TPH03TC-FLK

• E5ZN-2CNF03TC-FLK

• E5ZN-2CPF03TC-FLK

tions power supply between DeviceNet Communications Unit and Temperature Controller, and internal circuit power supply of Temperature Controller)

loaded as a batch, merely by manipulating the DIP switch on the front panel of the

DeviceNet Communications Unit.

The uploaded parameters are stored in the DeviceNet Communications Unit.

• E5ZN-2QNH03P-FLK

• E5ZN-2QPH03P-FLK

• E5ZN-2TNH03P-FLK

• E5ZN-2TPH03P-FLK

• E5ZN-2CNF03P-FLK

• E5ZN-2CPF03P-FLK

10

Connecting Temperature Controllers Section 1-3

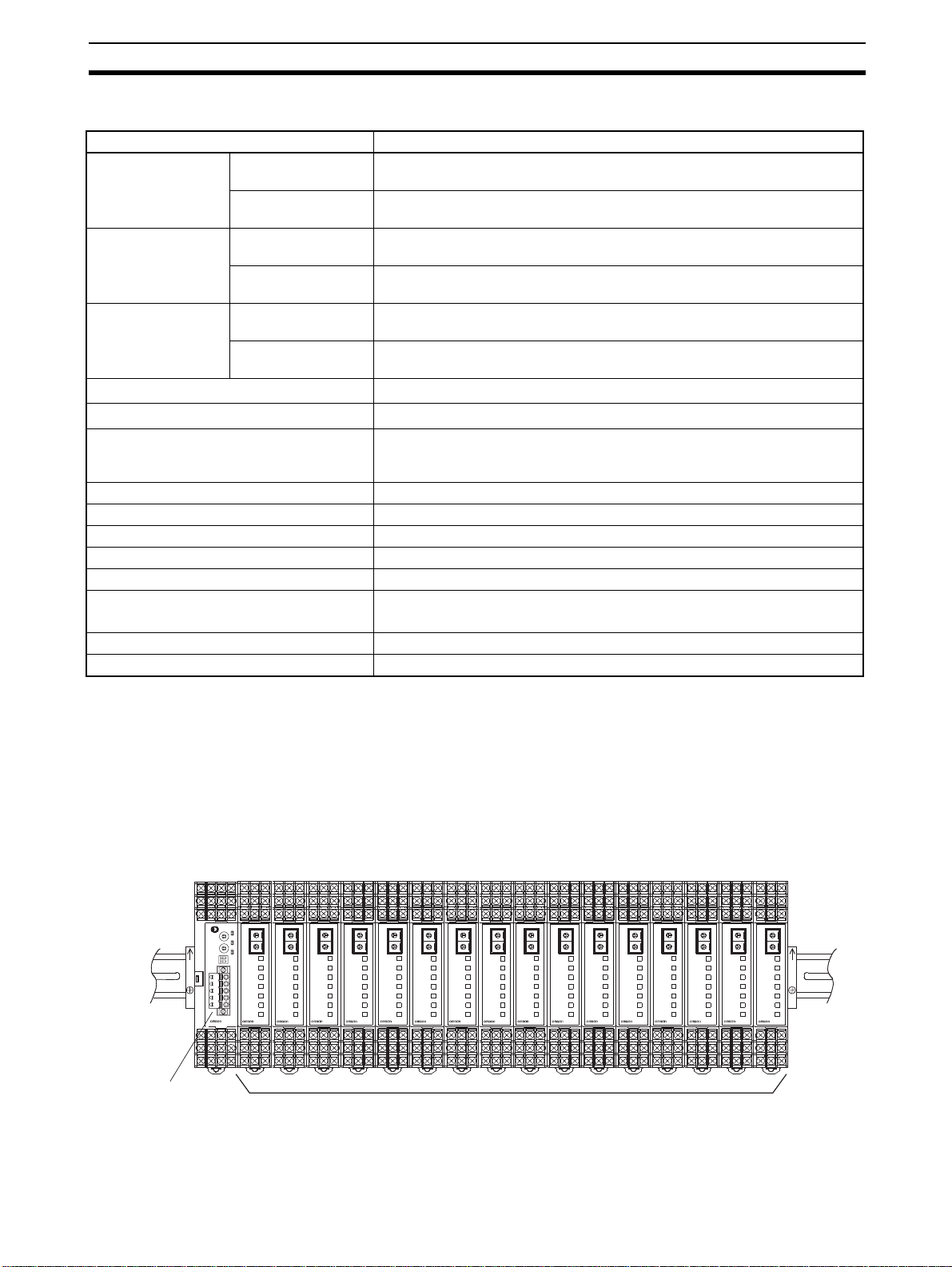

1-2-3 General Specifications

Item Specifications

Supply voltage DeviceNet power

supply

External input powe r

supply

Allowab le voltage

range

DeviceNet power

supply

External input powe r

supply

Current consumption DeviceNet power

supply

External input powe r

supply

Vibration resistanc e

Shock resistance

Dielectric strength 500 VAC 50 or 60 Hz 1min between DIN Track and entire terminal block

Insulatio n resistance 20 MΩ min. (at 100 VDC)

Ambient temperature −10 to 55°C (with no condensation or icing)

Ambient humidity 25% to 85%

Storage temperature −25 to 65°C (with no condensation or icing)

Enclosure rating IP00

Dimensions 30 × 130 × 89.6 mm (W × D × H)

Memory protection EEPROM, 100,000 write operations (backup data)

Weight 100 g max. (not including Terminal Unit)

24 VDC (internal circuit)

24 VDC (for RS-485 communications circuit/ Temperature Controllers)

11 to 25 VDC

20.4 to 26.4 VDC

45 mA max. (24 VDC: Current co nsumption of DeviceNet Communications

Unit)

20 mA max. (24 VDC) (See note.)

2

10 to 55 Hz, 10m/s

2

150m/s

max. 3 times each in 3 axes, 6 directions

for 2 hours each in X, Y, and Z directions

(DeviceNet connector) or between DIN Track and all terminals (terminal

sockets)

(When connected to an E5ZN-SCT24S Terminal Unit.)

Note Current supplied to the Temperature Controllers is not included.

1-3 Connecting Temperature Controllers

1-3-1 Temperature Controller ID and Number of Connectable Units

The Temperature Controllers a re connected alongside the DeviceNet Communications Unit and the block is linked through the Terminal Units connected

to the back of the Temperature Controllers, as shown in the following diagram.

Up

DeviceNet

Communications Unit

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT1

OUT2

OUT2

SUB1

SUB1

SUB2

SUB2

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT1

OUT2

OUT2

SUB1

SUB1

SUB2

SUB2

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

E5ZN

E5ZN

UNIT

BPS

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

UNIT

UNIT

BPS

BPS

POWER

POWER

ERROR

ERROR

SD/RD

SD/RD

OUT1

OUT1

OUT2

OUT2

SUB1

SUB1

SUB2

SUB2

E5ZN

E5ZN

E5ZN Temperature Controllers

The DeviceNet Communications Unit differentiates each of the connected

Temperature Controllers accordi ng to uni t number s (0 to F) . The Temperature

Up

E5ZN

11

Connecting Temperature Controllers Section 1-3

Controllers can be connected in any order. The unit number of each T emperature Controller is s et using the upper rotar y switch on the front panel o f the

Temperature Controller. Always set a unique unit numb er for each Temperature Controller.

Up to 16 Temperature Controllers can be connected to a single DeviceNet

Communications Unit. RS-48 5 connections also support up to 16 Temperature Controllers.

The E5ZN-SDL Setting Display Unit for E5ZN Temperature Controllers can be

connected at the same time.

Note There is no priori ty between operation commands and s ettings for DeviceNet

communications from the ma ster or Configurator, and operation commands

and settings from the S etting Display Unit. Do not change the same dat a or

send different operation commands more than one source at the same time.

1-3-2 Temperature Controller Communications

The DeviceNet Communications Unit and Temperature Controllers communicate at a baud rate of 38,400 bps. Set the baud rate using the lower rotar y

switch on the front panel of the Temperature Controllers to 3 (= 38,400 bps).

Communications are performed using a transmission format of 7-bit data, 2

stop bits, and 2 parity bits. These are the default settings. If the default values

have been changed, use the E5ZN-SDL Setting Display Unit to return the

Temperature Controller settings to 7-bit data, 2 stop bits, 2 parity bits.

1-3-3 Temperature Controller Models

The DeviceNet Communications Unit can be conn ected to th e following Temperature Controllers.

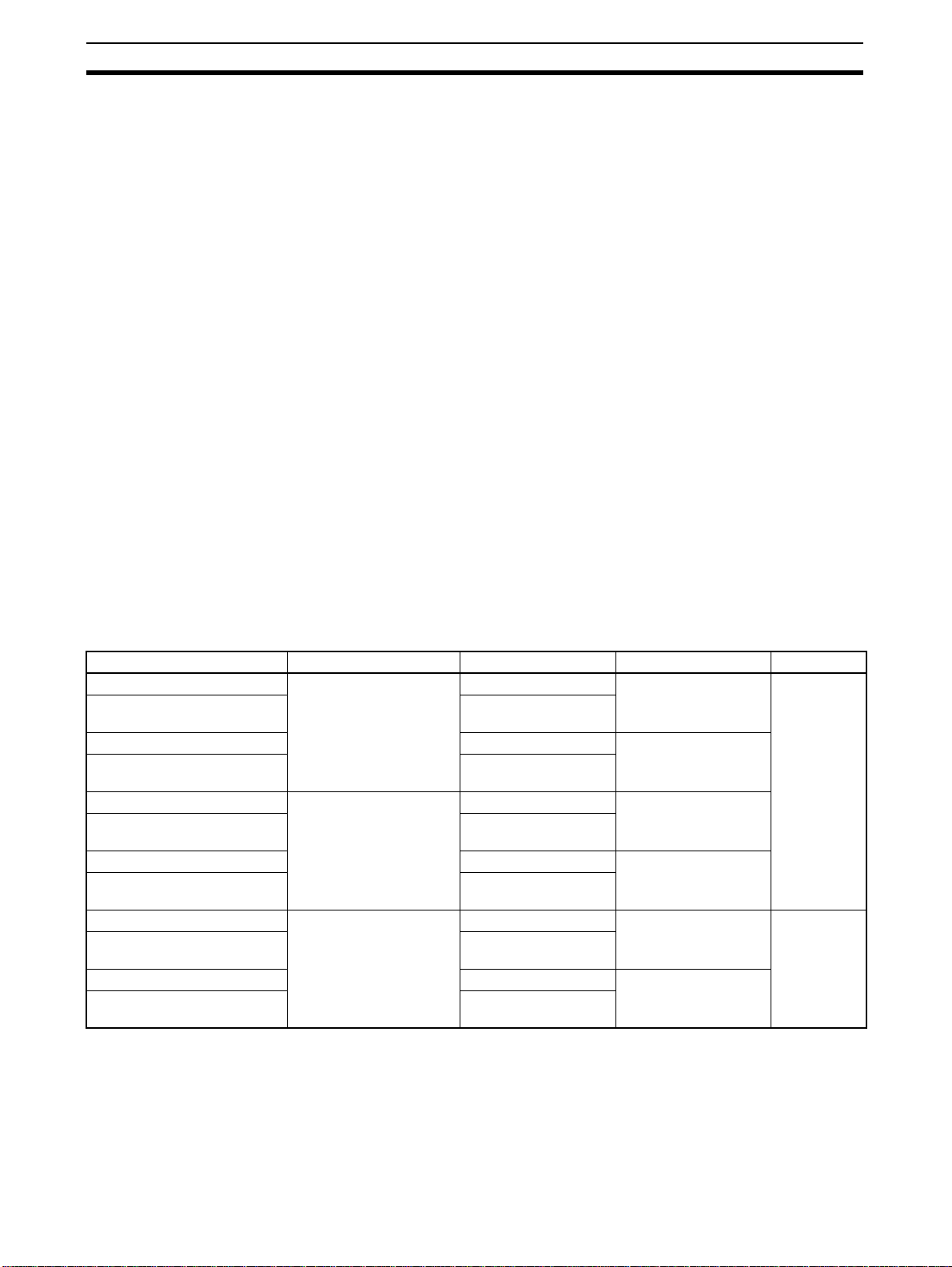

Model Control output Input type Auxiliary output HB

E5ZN-2QNH03TC-FLK Voltage output (pulse outE5ZN-2QNH03P-FLK Platinum-resistance

E5ZN-2QPH03TC-FLK Thermoc ouple Sour cing (PNP)

E5ZN-2QPH03P-FLK Platinum-resistance

E5ZN-2TNH03TC-FLK Transistor output (pulse

E5ZN-2TNH03P-FLK Platinum-resistance

E5ZN-2TPH03TC-FLK Thermocouple Sourcing (PNP)

E5ZN-2TPH03P-FLK Platinum-resistance

E5ZN-2CNF03TC-FLK Analog output (current

E5ZN-2CNF03P-FLK Platinum-resistance

E5ZN-2CPF03TC-FLK Thermocouple Sourcing (PNP)

E5ZN-2CPF03P-FLK Platinum-resistance

put)

output)

output)

Thermocouple Sinking (NPN) Yes

thermometer

thermometer

Thermocouple Sinking (NPN)

thermometer

thermometer

Thermocouple Sinking (NPN) None

thermometer

thermometer

1-3-4 Temperature Controller Power Supply

Power is supplied to the Temperature Controllers through terminals 19 and 20

of the E5ZN-SCT24S Terminal Units.

12

Initial Temperature Controller Settings Section 1-4

1-3-5 Temperature Controller Registration

The unit numbers of the c onnected Temperature Controllers must be regi stered in the configuration in the DeviceNet Communications Unit. The

DeviceNet Communications Unit autom ati ca ll y veri fie s t hat t he r eg ist ered uni t

numbers match the numbers of the Controllers currently able to communicate.

If the unit numbers do not match in the verification proc ess, the Temperature

Controllers will be determined to have an error, causing the following status.

• The TS indicator will flash red.

• The Communicating Flag will turn OFF and the Communications Error

Flag will turn ON for each Temperature Controll er that is not commun icating but is registered as being c onnected to the DeviceNet Communications Unit.

The following two methods can be used to regis ter the conne ction config uration of the Temperature Controller.

1,2,3... 1. Registering with the Configurator or explicit messages (Turn OFF pin 1 on

the DIP switch on the rear of the DeviceNet Communic ations Unit to enable this method)

2. Registe ring w it h th e r ot a ry switches on th e r ear of the De vi ce Net C o mm u nications Unit (Turn ON pin 1 on the DIP switch on re ar of the DeviceNet

Communications Unit to enable this method.)

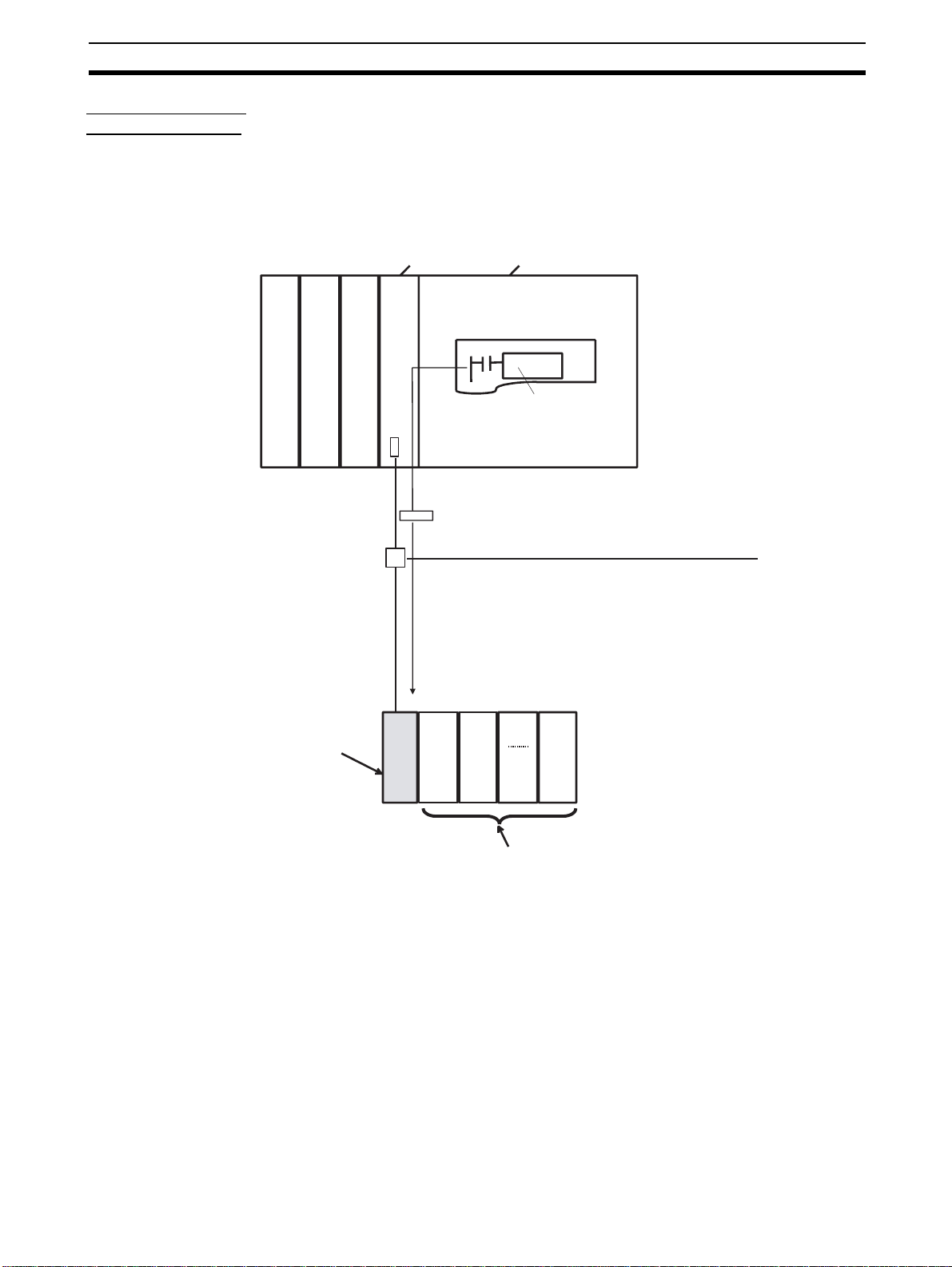

1-4 Initial Temperature Controller Settings

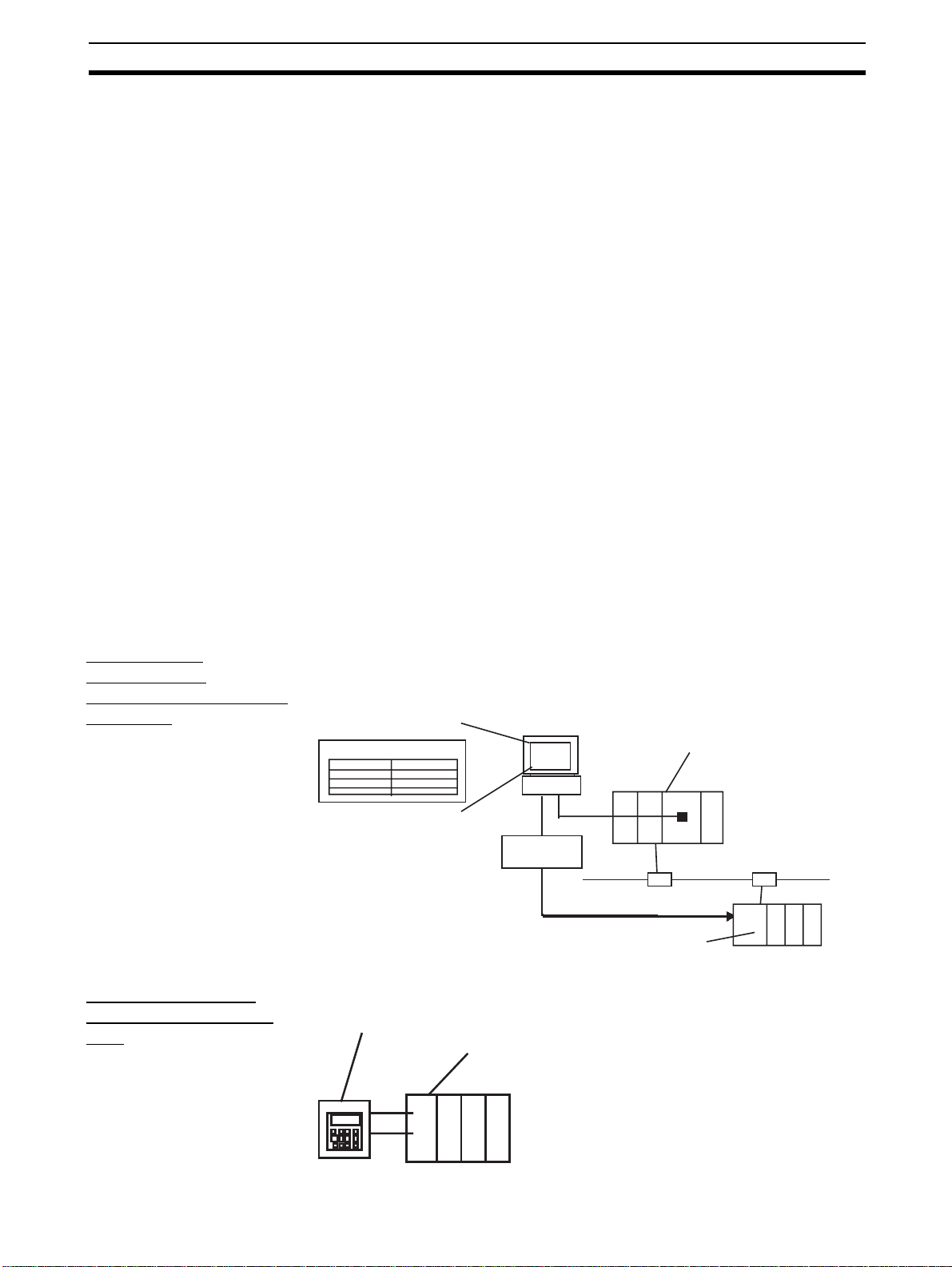

The following four methods are provided for setting the E5ZN Temperature

Controllers.

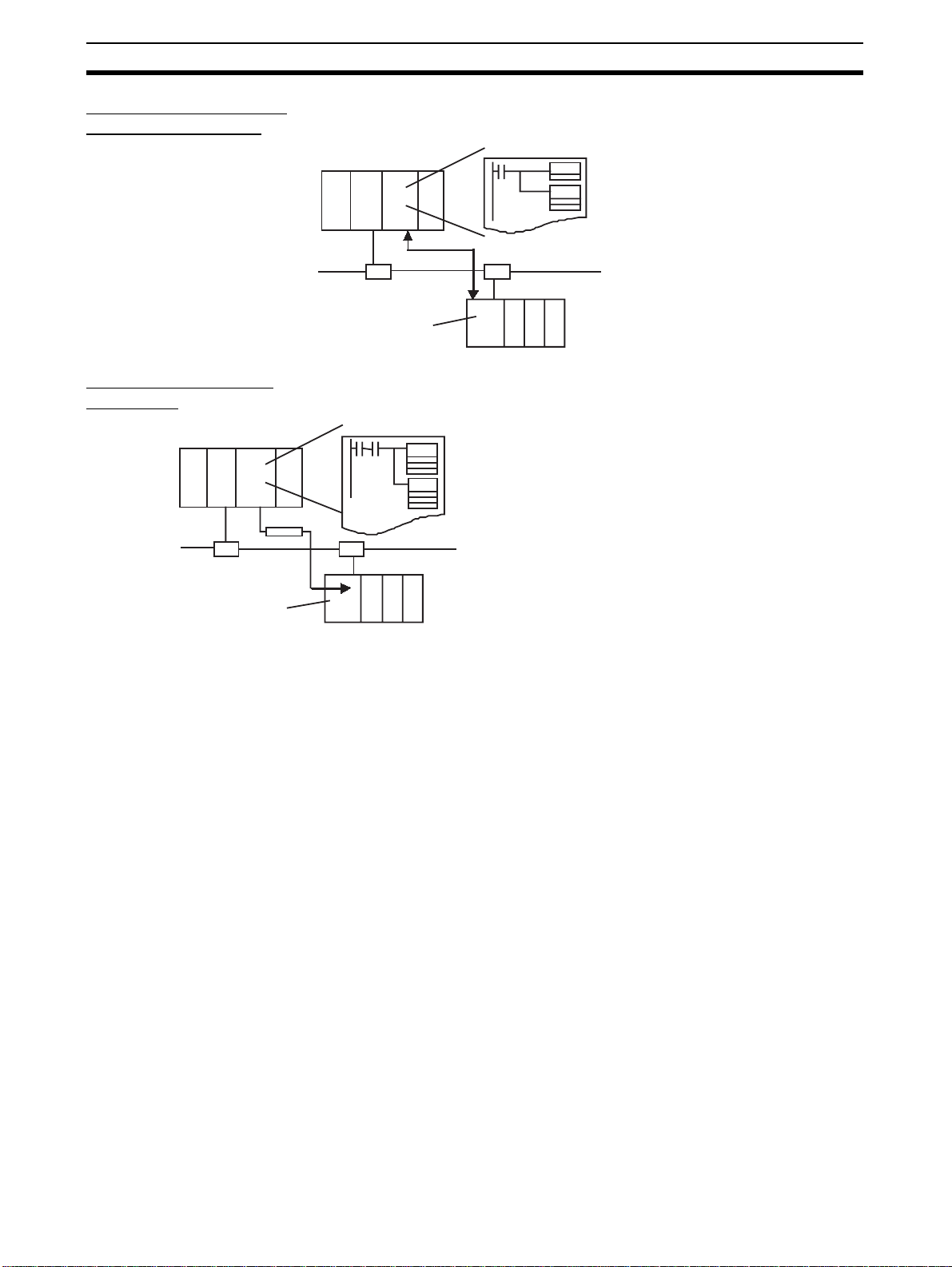

Transferring

T emperature

Controller P arameters

Together

Setting with E5ZNSDL Setting Display

Unit

Set each of the Temperature Controller parameters in the E dit Device Parameters Window from the DeviceNet Configurator, and then transfer them

together via the DeviceNet network.

Edit device parameters

Edit Unit parameters

Proportional band

Target value

Configurator

Temperature

Controller

parameters

DeviceNet

Communications Unit

Set the parameters from the E5ZN-SDL Setting Display Unit.

E5ZN-SDL Setting Display Unit

Terminal Unit connected to DeviceNet

Communications Unit

CS/CJ-series DeviceNet Unit

PLC

DeviceNet

+

−

13

Initial Temperature Controller Settings Section 1-4

Setting with Remote I/

O Communications

Setting with Explicit

Messages

PLC

Set the parameters from the P LC w ith the ma ste r using remote I/O communications.

PLC

DeviceNet

Communications Unit

SET

(1) Execute a command to shift to setting area 1.

MO V

(2) Set the parameters in variable area C3.

Set the initial settings from the PLC with the ma ster by sending an explicit

message.

(1) Send a command to shift to setting area 1.

CMND

CMND

(Operation command 30 05, command code 07)

(2) Set the parameters in variable area C3.

(VARIABLE AREA WRITE 01 02, variable type C3).

DeviceNet

Communications Unit

14

SECTION 2

Operating Procedures

This section outlines the basic operating procedures of the E5ZN-DRT DeviceNet Communications Unit.

2-1 Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-2 Startup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2-1 Simple I/O Allocation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2-2 I/O Allocation Using the Configurator. . . . . . . . . . . . . . . . . . . . . . . 18

15

Loading...

Loading...