Page 1

C. ADJUSTMENT METHOD

C-2020ZOOM

C. ADJUSTMENT METHOD

[1] TABLE FOR SERVICING TOOLS .......................................................................... C-2

[2] EQUIPMENT ........................................................................................................... C-2

[3] ADJUSTMENT ITEMS AND ORDER ..................................................................... C-2

[4] SETUP ....................................................................................................................C-2

[5] CONNECTING THE CAMERA TO THE COMPUTER ............................................C-3

[6] ADJUSTMENT ........................................................................................................C-4

1. IC501 OSCILLATION FREQUENCY ADJUSTMENT ....................................... C-4

2. 5.1 V (A) VOLTAGE ADJUSTMENT.................................................................. C-4

3. 13.0 V (D) VOLTAGE ADJUSTMENT ............................................................... C-4

4. 7.0 V (L) VOLTAGE ADJUSTMENT .................................................................. C-4

5. AWB ADJUSTMENT .........................................................................................C-4

6. COLOR MATRIX ADJUSTMENT ......................................................................C-5

7. LENS ADJUSTMENT .......................................................................................C-5

8. CCD DEFECT DETECT ADJUSTMENT ...........................................................C-5

9. LCD PANEL ADJUSTMENT............................................................................. C-5

9-1. LCD H AFC ADJUSTMENT .......................................................................C-5

9-2.LCD GAIN ADJUSTMENT ...........................................................................C-6

9-3. LCD RGB OFFSET ADJUSTMENT ...........................................................C-6

9-4. LCD RED BRIGHTNESS ADJUSTMENT ................................................C-6

9-5. LCD BLUE BRIGHTNESS ADJUSTMENT ...............................................C-6

9-6. LCD TINT ADJUSTMENT (FOR PAL) ....................................................... C-7

[7] ADJUSTMENT VALUE ........................................................................................... C-7

SIEMENS STAR CHART ................................................................................................C-8

CHECKING OF LENS UNIT ...........................................................................................C-9

SERVER_DIS

C-1

Ver.1/Rev.7

Page 2

C. ADJUSTMENT METHOD C-2020ZOOM

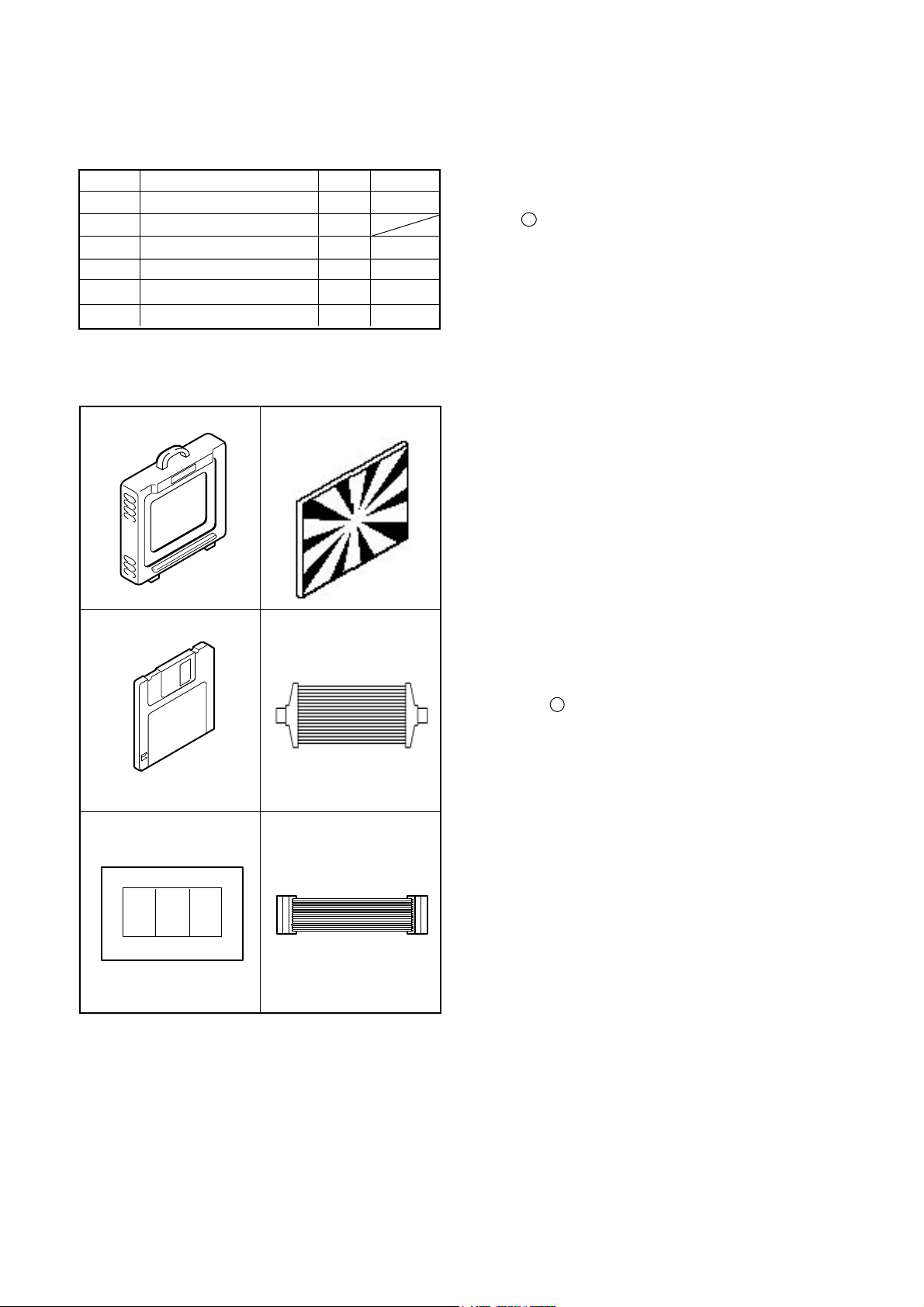

[1] Table for Servicing Tools

Ref. No.

J-1

Color viewer 5,100 K

Siemens star chart

J-2

J-3

Calibration software

J-4

Extension cord VJ8-0162

Extension cord VJ8-0165

J-5

J-6

Chart for color adjustment

Note: J-1 color viewer is 100 - 110 VAC only.

Name

Qt’y

1

1

1

1

1

1

J-1 J-2

J-3

J-4

Part code

VJ8-0007

VJ8-0159

VJ8-0155

[2] Equipment

1. Oscilloscope

2. Digital voltmeter

3. AC adaptor

4. IBM R -compatible PC

5. DC regulated power supply

[3] Adjustment Items and Order

1. IC501 Oscillation Frequency Adjustment

2. 5.1 V (A) Voltage Adjustment

3. 13.0 V (L) Voltage Adjustment

4. 7.0 V (L) Voltage Adjustment

5. AWB Adjustment

6. Color Matrix Adjustment

7. Lens Adjustment

8. CCD Defect Detect Adjustment

9. LCD Panel Adjustment

9-1. LCD H AFC Adjustment

9-2. LCD Gain Adjustment

9-3. LCD RGB Offset Adjustment

9-4. LCD Red Brightness Adjustment

9-5. LCD Blue Brightness Adjustment

9-6. LCD Tint Adjustment (for PAL)

Note:

1. If the lens, CCD, board and changing the part in item 5-8

replace, it is necessary to adjust again. Item 5-8 adjust

ments should be carried out in sequence.

J-6

J-5

[4] Setup

1. System requirements

Windows R 95 or 98

IBM R -compatible PC with 486 or higher processor

CD-ROM drive

3.5-inch high-density diskette drive

Serial port with standard RS-232C interface

8 MB RAM

Hard disk drive with at least 15 MB available

VGA or SVGA monitor with at least 256-color display

2. Installing calibration software

1. Insert the calibration software installation diskette into your

diskette drive.

2. Open Explorer.

3. Copy the DSC Cal folder on the floppy disk in the FD drive

to a folder on the hard disk.

SERVER_DIS

C-2

Ver.1

Page 3

C. ADJUSTMENT METHODC-2020ZOOM

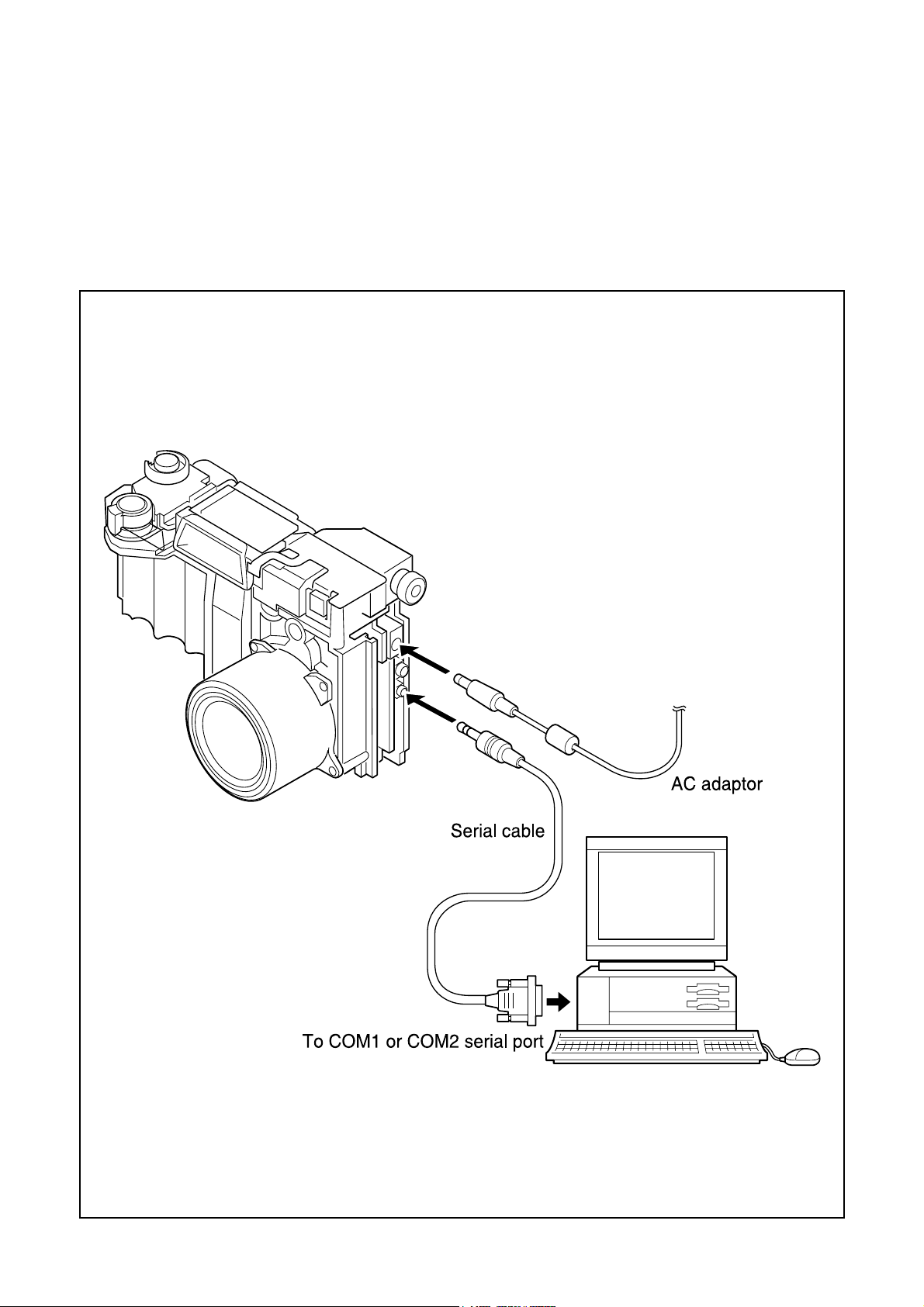

[5] Connecting the camera to the computer

1. Turn off both camera and computer.

2. Locate the port cover on the side of the camera. Press on the arrows and slide the cover down to open it.

3. Line up the arrow on the cable connector with the notch on the camera's serial port. Insert the connector.

4. Locate a serial port on the back of your computer. You may have two serial ports labeled COM1 and COM2, or the ports

may be labeled with icons. If you have two serial ports available, use port 1 to connect your camera.

5. Line up the serial connector on the cable with one of the serial ports on your computer, and insert the connector.

Ver. 1

C-3 SERVER_DIS

Page 4

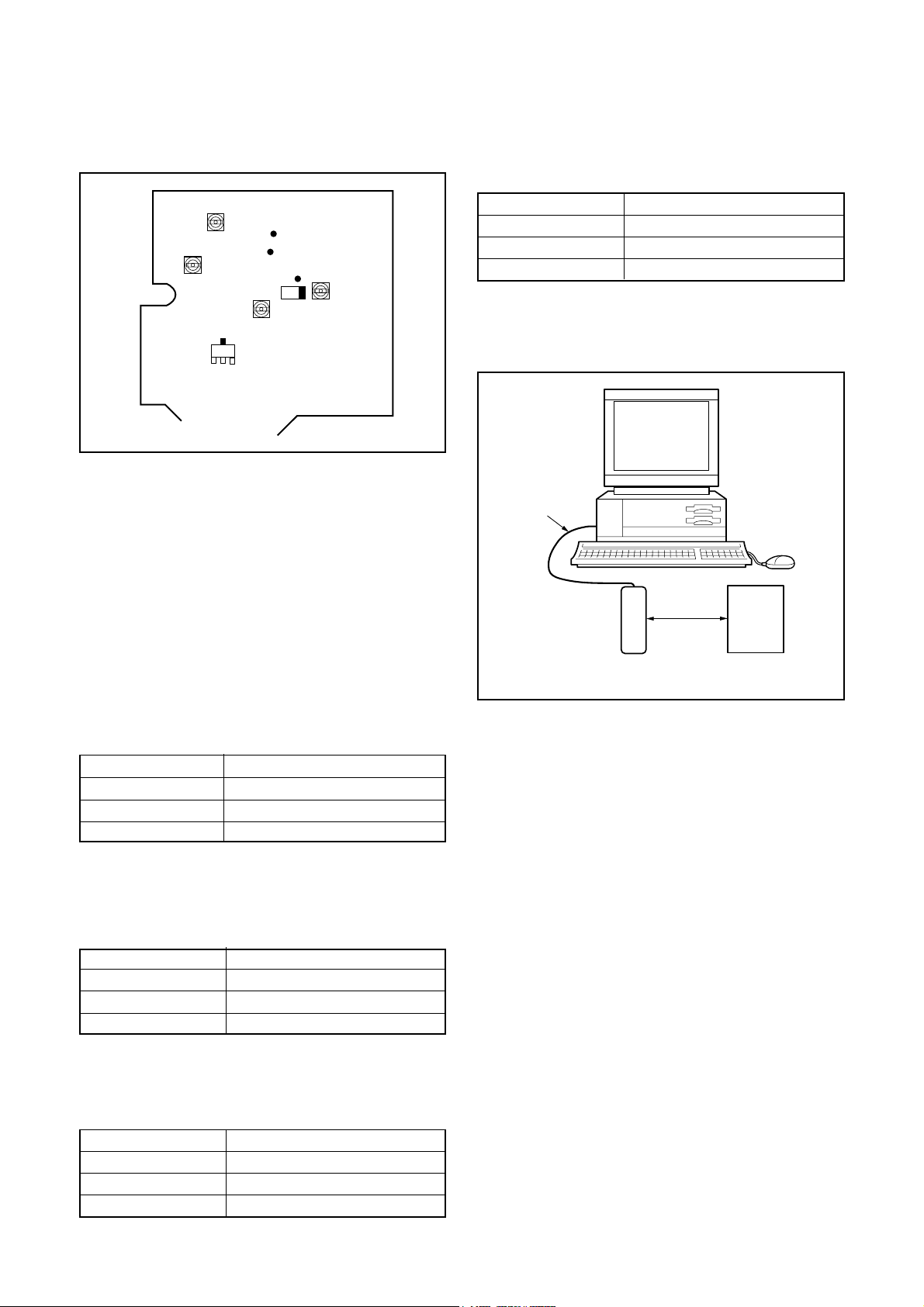

[6] Adjust Specifications

[ST1 board (Side B)]

C. ADJUSTMENT METHOD C-2020ZOOM

Adjustment method:

1.Adjust with VR504 to 13.00 ± 0.05 V.

4. 7.0 V (L) Voltage Adjustment

VR502

VR501

CL522

CL524

CL566

VR505

L5012

VR504

Q5001

Collector

Note:

1. Voltage adjustment is necessary to repair in the ST1 board

and replace the parts.

2. Carry out adjustment with disconnect wires for storbe.

Preparation:

1. Short the both edge of S3004 in the SY1 board.

2. Connect the SY1 board (CN301) and the CA2 board

(CN106) with extension cord. (VJ8-0165)

3. Connect the ST1 board (CN501) and the CA2 board (CN104)

with extension cord. (VJ8-0162)

4. Connect LCD panel.

5. Insert the card.

6. Turn on the power switch, and then set the camera mode.

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

L5012 or CL566

Digital voltmeter

VR505

7.00 ± 0.05 V

Adjustment method:

1. Adjust with VR505 to 7.00 ± 0.05 V.

5. AWB Adjustment

Serial cable

Camera

0 - 18 cm

Color viewer (5,100K)

All white pattern

1. IC501 Oscillation Frequency Adjustment

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

Adjustment method:

1. Adjust with VR501 to 200 ± 1 kHz.

Q5001 Collector

Frequency counter

VR501

200 ± 1 kHz

2. 5.1 V (A) Voltage Adjustment

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

Adjustment method:

1. Adjust with VR502 to 5.10 ± 0.05 V.

CL524

Digital voltmeter

VR502

5.10 ± 0.05 V

3. 13.0 V (L) Voltage Adjustment

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

CL522

Digital voltmeter

VR504

13.00 ± 0.05 V

SERVER_DIS

Preparation:

POWER switch: ON

Adjusting method:

1. When setting the camera in place, set it to an angle so that

nothing appears in any part of the color viewer except the

white section. (Do not enter any light.)

2. Double-click on the DscCalV122.

3. Click the “AWB”, and click the “Yes”.

4. AWB adjustment value will appear on the screen.

5. Click the OK.

C-4

Ver.1

Page 5

C. ADJUSTMENT METHODC-2020ZOOM

6. Color Matrix Adjustment

Serial cable

Camera

Preparation:

POWER switch: ON

Adjustment method:

1. Set the color adjustment chart to the color viewer.

(Do not enter any light.)

2. Set the color adjustment chart so that it becomes center of

the screen.

3. Double-click on the DscCalV122.

4. Click the “ UV Matrix “, and Click the “ Yes “.

5. Adjustment values will appear on the screen.

6. Click the OK.

15 cm ± 1 cm

All white pattern color

viewer (5,100K) and

color matrix adjustment chart

Adjustment method:

1. Set the siemens star chart 150 cm ± 3 cm so that it becomes center of the screen.

2. Double-click on the DscCalV122.

3. Click the “ Focus “, and Click the “ Yes “.

4. Flange-back adjustment value will appear on the screen.

If an error is made in adjustment, the following value will

result.

0: Incorrect adjustment precision (large difference when

adjusting and checking)

5. Click the OK.

8. CCD Defect Detect Adjustment

Preparation:

POWER switch: ON

Adjustment method:

1. Double-click on the DscCalV122.

2. Click the “ CCD Defect Detection “, and click the “ Yes “.

3. After the adjustment is completed, adjustment value will

appear.

9. LCD Panel Adjustment

[CA2 board (Side B)]

CL413

CL414

CL415

7. Lens Adjustment

Serial cable

Camera

Preparation:

POWER switch: ON

Adjustment condition:

Siemens star chart (A3)

Fluorescent light illumination with no flicker (incandescent light

cannot be used.)

Illumination above the subject should be 400 lux ± 10%.

150 cm ± 3 cm

Siemens

star chart

9-1. LCD H AFC Adjustment

Preparation:

POWER switch: ON

Adjusting method:

1. Double-click on the DscCalV122.

2. Select 0 on the LCD “ H AFC “.

3. While watching the LCD monitor, adjust “ H AFC “ so that

the edge of the LCD adjustment frame are the same distance from the left and right edge of the LCD screen. (A = B)

LCD

LCD screen

A

FPC

adjustment

B

frame

Ver. 1

C-5 SERVER_DIS

Page 6

C. ADJUSTMENT METHOD C-2020ZOOM

9-2. LCD Gain Adjustment

Adjusting method:

1. Adjust LCD “ Gain “ so that the amplitude of the CL415

waveform is 1.0 Vp-p ± 0.1 V.

1.0V

±0.1Vp-p

VG

Waveform (CL415)

CL415 waveform

9-3. LCD RGB Offset Adjustment

Adjusting method:

1. Adjust LCD “ RGB Offset “ so that the amplitude of the

CL415 waveform is 5.1 Vp-p ± 0.1 V.

Note:

9-2. LCD Gain adjustment should always be carried out first.

5.1V

±0.1Vp-p

CL415 waveform

9-4. LCD Red Brightness Adjustment

Adjusting method:

1. Adjust LCD “ R Bright “ so that the amplitude of the CL414

waveform is VG± 0.1 V with respect to the CL415 (VG)

waveform.

Note:

9-2. LCD Gain adjustment and 9-3. LCD RGB Offset adjustment should always be carried out first.

VG±

0.1Vp-p

Waveform (CL414)

9-5. LCD Blue Brightness Adjustment

Adjusting method:

1. Adjust LCD “ B Bright “ so that the amplitude of the CL413

waveform is ± 0.1 V with respect to the CL415 (VG) waveform.

Note:

9-2. LCD Gain adjustment and 9-3. LCD RGB Offset adjustment have done.

VG

Waveform (CL415)

SERVER_DIS

C-6

VG±

0.1Vp-p

Waveform (CL413)

Ver.1

Page 7

C. ADJUSTMENT METHODC-2020ZOOM

9-6. LCD Tint Adjustment (for PAL)

Adjusting method:

1. Adjust “ Tint “ so that the amplitude of CL414 waveform is

minimum.

Note:

9-6. LCD TINT adjustment should always be carried out last.

a

a

a

[7] Adjustment Values

Explanation of adjustment values

Adjustment values are values which have been estimated

statistically from the distribution of adjustment values obtained from similar machine models and prototypes. Accordingly these values should be used as a guide only.

Because these values are guides, equipment which is in

good working order may still produce values which are outside the adjustment value ranges, so that the equipment

should be operated in order to determine whether it is in

fact operational or defective.

Range of adjustment values

(1) AWB adjustment ranges

R: 150-400

G: 128 (fixed value)

B: 150-400

Note : If adjustment value “a0” is following value,

it means adjustment NG.

a0 = 65535 65535 65535....

(2) Color matrix adjustment ranges

Adjustment values are normal except following cases.

a

a) It does not detect any signal from CCD. In this case,

adjustment values are all “1”.

UVMAT0: 1

UVMAT1: 1

UVMAT2: 1

UVMAT3: 1

b) Abnormal adjustment values judged by UMAT3 value.

UVMAT3: 0 (Normal)

UVMAT3: 2 (Aperture error)

UVMAT3: 3 (Shutter speed error)

UVMAT3: 4 (Zoom sensor (PR) error)

(3) Frange-back adjustment ranges

Adjustment value : Within 6 and 122

Note : Adjustment value is “ 0 “ means NG.

Ver. 1

C-7 SERVER_DIS

Page 8

C. ADJUSTMENT METHOD

C-2020ZOOM

C-8 Ver. 1

Page 9

C-2020ZOOM C.ADJUSTMENT METHOD

CHECKING OF LENS UNIT

1. Check Item

1)Backlash Pulse of LD

2)LD ERROR Pulse

3)Basklash Pulse of ZOOM

4)ZOOM ERROR Pulse

2. Tools

1

2

3

4

5

Part No.

KC0331

KC0334

KC0338

FPC-Adaptor

FPC-Adaptor

Description

Lens Checker LCK1

Connector Cable P5

Clip Connector 17

12-PINS for K-FPC

14-PINS for S-FPC

Q’ty

1

1

2

1

1

3. Checking Prosedure

Fi x 2 FPC-Adaptors (12 and 14 PINS) to ClipConnector

17.

Connect Connector Cable P5, Clip Connector 17

and Lens Checker LCK-1

1) AUTO

I. Tum on Lens Checker LCK-1

080-10

FPC-Adaptor 12

PINS for K-FPC

FPC-Adaptor 14

PINS for S-FPC

The last 2 digits are mean-

ing the number of Pin.

Ex.) 080-12 :12PINS

Lens Checker LCK-1

Connector Cable P5

Initial Setting

II. Set AUTO / MANU SW at AUTO

III.Set Dial SW at 3

IV. Set CW / CCW SW at CW

LCK-1 Ver.1 0 Auto

PUSH START SW

(0 : Number of Dial SW 0-5)

V. Connect the both FPCs (K-FPC and S-FPC) to

Clip Connectors. Hold a lens unit by hand, and keep

it horizontally.

VI. Push START SW. (More than 0.2 sec.)

LCK-1 Ver.1 0 Auto

ZOOM RESET

Clip Connector 17

C-9Ver. 1/Rev.7

Page 10

C.ADJUSTMENT METHOD

C-2020ZOOM

When an error occurs, an error is indicated, and it stops.

LCK-1 Ver.1 0 Auto

LD RESET

LCK-1 Ver.1 0 Auto

LD BACKLASH CHK

LB*

* is BACKLASH PULSE of LD

LCK-1 Ver.1 0 Auto

LD D CHK

LB1 D *

* is LD ERROR PULSE

LCK-1 Ver.1 0 Auto

ZOOM BACKLASH CHK

LB1 D1 ZB *

* is BACKLASH PLUSE of ZOOM

In case of GOOD

LCK-1 Ver.1 0 Auto

PUSH START SW

LB1 D1 ZB1 D12

GOOD

In case of NG :

LCK-1 Ver.1 0 Auto

PUSH START SW

LB D6

NO GOOD ZM D Err

ERROR is indicated

(The indication which isn’t being explained is the condition

of PR and PI.)

When CW/CCW SW is set at CCW, the automatic check of

the motor chosen with a LD/ZOOM SW is done.

2) Manual

I. Set AUTO/MANU SW at MANU

LCK-1 Ver.1 0 Manu

LD CW

LCK-1 Ver.1 0 Auto

ZOOM D CHK

LB1 D1 ZB1 D * *

* * is ZOOM ERROR PULSE (ZOOM AREA : SET-UP AREA)

The contents chosen with the LD/ZOOM SW and the CW/

CCW SW indicated in LCD.

II. Push START SW (More than 0.2 sec.)

LCK- Ver.1 0 Manu

LD CW

MOVE

When a motor works, “MOVE” is indicated in LCD.

C-10 Ver. 1/Rev.7

Page 11

C-2020ZOOM C.ADJUSTMENT METHOD

LD Motor

When PI signal 500 pulses (500pps) are changed,LD motor

stops

CW : Turn Out CCW : Tum In

ZOOM Motor

When PI signal 2200 pulses (300pps) are changed, ZOOM

motor stops

CW : W to T CCW : T to W

4. Others

Turn off LCK-1 promptly if something is wrong.

5, ERROR Indication

PI, PR Err : PI or PR Pulse does not change.

LD BK Err : LD BACKLASH PULSE is out of standard.

LD D Err : LD Pulse Error

ZD BK Err : ZOOM BACKLASH PULSE is out of

standard

ZD D Err : ZOOM Pulse Error

C-11Ver. 1/Rev.7

Loading...

Loading...