Page 1

CNC SYSTEM

OSP-P300S

MACT

URN

250/350 80/120-TOOL MAGAZINE SPECIFICATION

INSTRUCTION MANUAL

(1st Edition)

Pub No. 6226-E (LE61-621-R1) Feb. 2013

Page 2

6226-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 OVERVIEW..............................................................................................1

SECTION 2 MACHINE SPECIFICATIONS..................................................................2

1. Machine Overview ................................................................................................................... 2

1-1. Magazine .......................................................................................................................... 2

1-2. Tool Number..................................................................................................................... 2

2. ATC Operation Overview......................................................................................................... 3

3. ATC Operation Sequence........................................................................................................5

SECTION 3 ATC LOGIC TABLES ...............................................................................8

SECTION 4 DATA SETTING .....................................................................................29

1. ATC Function Display Screen................................................................................................ 29

2. Data Setting Screen............................................................................................................... 31

2-1. Magazine Information List .............................................................................................. 32

2-2. List of not Mounted Tools ............................................................................................... 33

2-3. List of Lack Tools............................................................................................................ 34

2-4. Registering and Attaching a Tool ................................................................................... 34

2-5. Main Magazine Tool Specification.................................................................................. 34

SECTION 5 MANUAL OPERATION ..........................................................................35

1. Manual Magazine Operation.................................................................................................. 35

1-1. Overview......................................................................................................................... 35

1-2. Mechanical Lock.............................................................................................................35

2. Interlock Function for Magazine Door Open/Close Operation ............................................... 36

3. Manual ATC Operation ..........................................................................................................37

SECTION 6 ATC PROGRAM COMMANDS ..............................................................39

1. ATC Commands .................................................................................................................... 40

2. Description of Machining Program......................................................................................... 42

2-1. OSP without Tool Life Management Specification ......................................................... 42

2-2. OSP with Tool Life Management Specification .............................................................. 45

3. ATC Commands and ATC Operation .................................................................................... 48

SECTION 7 PARAMETERS.......................................................................................49

1. ATC Parameter...................................................................................................................... 49

2. Machine System Parameter .................................................................................................. 49

2-1. System Check Mode (Machine System Parameter)....................................................... 49

2-2. ATC (Machine System Parameter)................................................................................. 50

Page 3

6226-E P-(ii)

TABLE OF CONTENTS

SECTION 8 OTHERS ................................................................................................51

1. System Variables................................................................................................................... 51

2. ATC Macro Command ........................................................................................................... 51

2-1. Shutter Operation ...........................................................................................................51

2-2. Flowchart ........................................................................................................................ 52

SECTION 9 ALARM AND ERROR ............................................................................56

Page 4

6226-E P-1

SECTION 1 OVERVIEW

SECTION 1 OVERVIEW

The 80/120-tool magazine specification consists of two types of magazine, main magazine (rotating

magazine) and sub magazine (fixed magazine).

The main magazine is mounted on the saddle, allowing tool change operation at any position on the Z-axis to

reduce tool change time.

Although the main magazine can store only up to 41 tools, tool storage capacity is expanded to 80 or 120

tools by installing the sub magazine. Tools are exchanged between the main magazine and the sub magazine

to handle wide variety of workpiece kinds.

This Operation Manual deals with the 80/120-tool magazine specification of MacTurn. For general information

of the ATC of MacTurn, refer to the following manual.

OSP-P300S MACTURN/MULTUS Series Operation Manual

Page 5

SECTION 2 MACHINE SPECIFICATIONS

SECTION 2 MACHINE SPECIFICATIONS

1. Machine Overview

1-1. Magazine

Two types of magazine capacity are available, 80 tools and 120 tools.

1-2. Tool Number

There are two kinds of command modes for tool preparation commands: TL and TD, which can be

selected in the parameter settings.

The TL command mode is a tool preparation command that has been used with OSP-P200 and

former OSP versions; the TD command mode is a mode used in the tool information management

function that has been added to OSP-P300S. This is the mode that enables tools to be offset by

specifying the posture number which has been registered in the TOOL DATA SETTING screen in

advance.

6226-E P-2

[TD command mode]

Tool numbers between No.1 and No.9999 can be used.

[TL command mode]

Tool numbers between No.1 and No.96 can be used. Or tool numbers between No.1 and No.200

can be used when the number of tool management groups is 200 sets. The same numbers can be

used for the tool offset numbers.

For the details of TL and TD command modes, refer to the operation manual of OSP-P300S

MACTURN/MULTUS series.

Page 6

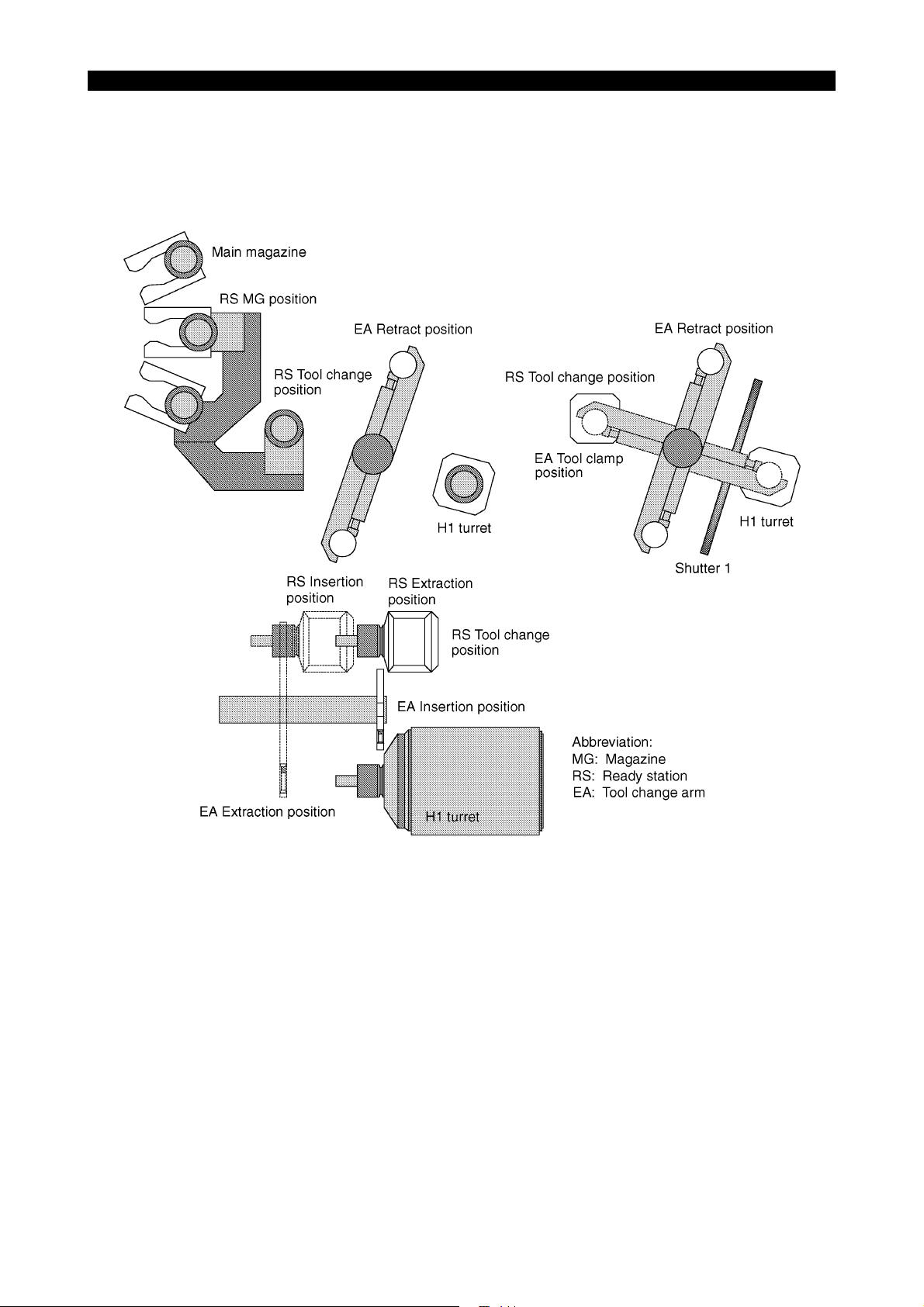

2. ATC Operation Overview

The illustration below shows the mechanism of the ATC.

(1) ATC

6226-E P-3

SECTION 2 MACHINE SPECIFICATIONS

LE61621R0100400030001

Page 7

SECTION 2 MACHINE SPECIFICATIONS

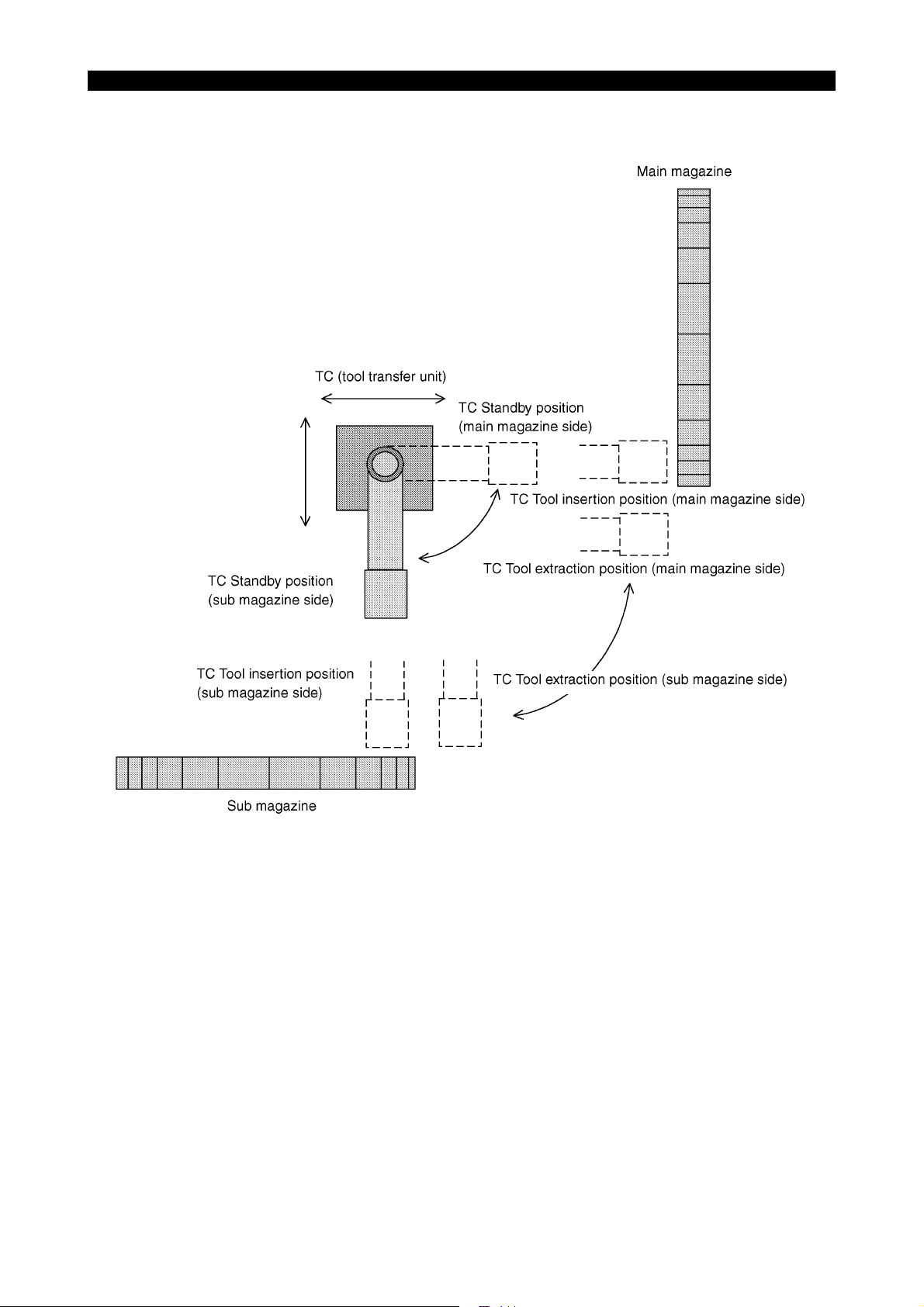

(2) TC (Tool Transfer Unit)

The illustration below shows the top view of the TC (tool transfer unit) and how it operates.

6226-E P-4

LE61621R0100400030002

Page 8

3. ATC Operation Sequence

ATC operation sequence of the 80/120-tool magazine specification is as indicated below.

(Tool change for tools in the main magazine)

* Same ATC operation sequence as 44/30-tool specification magazine

S1 Next tool write/Main MG Search/Sub MG Search

S2 Dummy sequence

S3 Main MG Indexing next tool

S4 RS Insertion

S5 RS Tool change position

S6 RS Extraction/Shutter 2 close

S7 Waiting for completion of machining

S8 Main MG Starting indexing of tool storing pot (Turret)

S9 Shutter open

S10 EA Tool change

S11 Shutter close

6226-E P-5

SECTION 2 MACHINE SPECIFICATIONS

S12 Main MG Tool storing pot indexed (RS)

S13 RS Insertion/Shutter 2 open

S14 RS MG position

S15 RS Extraction

Abbreviation:

MG : Magazine

RS : Ready station

EA : Tool change arm

Page 9

SECTION 2 MACHINE SPECIFICATIONS

(Tool change for sub magazine tools)

S22 Sub MG Indexing the next tool/Main MG TC Indexing the empty pot

S23 TC Tool insertion position (Sub MG side)

S24 TC Tool extraction position (Sub MG side)

S25 Waiting for completion of machining

S26 Main MG TC Empty pot indexing confirmation

S27 TC Turn to the main MG side

S28 Dummy sequence

S29 TC Tool insertion position (Main MG side)

S30 TC Standby position (Main MG side)

S31 TC Turn to the sub MG side/Main MG Indexing the tool mounting pot

S32 RS Insertion

S33 RS Tool change position

S34 RS Extraction/Shutter 2 close

S35 Dummy sequence

S36 Shutter open/Main indexing

S37 EA Tool change

S38 Shutter close

6226-E P-6

S39 Main MG Tool mounting pot indexed

S40 RS Insertion/Shutter 2 open

S41 RS MG position

S42 RS Extraction

S43 Main MG TC Indexing the tool mounting pot/Sub MG Indexing the empty pot/TC Turn to

main MG side

S44 TC Tool insertion position (Main MG side)

S45 TC Tool extraction position (Main MG side)

S46 Sub MG Empty pot indexing confirmation

S47 TC Turn to sub MG side

S48 Dummy sequence

S49 TC Tool insertion position (Sub MG side)

S50 TC Standby position (Sub MG side)

Abbreviation:

MG : Magazine

TC : Tool transfer unit (transfers a tool between sub magazine and main magazine)

RS : Ready station

EA : Tool change arm

Page 10

6226-E P-7

SECTION 2 MACHINE SPECIFICATIONS

(Tool movements)

S61 Main MG Empty pot search

S62 Main MG Indexing the return tool to TC position/Sub MG Indexing the empty pot/TC Turn

to main MG side

S63 TC Tool insertion position (Main MG side)

S64 TC tool extraction position (Main MG side)

S65 Sub MG Confirming indexing of the empty pot

S66 TC Turn to the sub MG side

S67 Dummy sequence

S68 TC Tool insertion position (Sub MG side)

S69 TC Standby position (Sub MG side)

S70 Sub MG Indexing the next tool/Main MG TC Indexing the empty pot

S71 TC Tool insertion position (Sub MG side)

S72 TC Tool extraction position (Sub MG side)

S73 Main MG TC Confirming indexing of the empty pot

S74 TC Turn to the main MG side

S75 Dummy sequence

S76 TC tool insertion position (Main MG side)

S77 TC Standby position (Main MG side)

S78 TC Turn to the sub MG side

S81 Dummy sequence

S82 Main MG TC Indexing the next tool/Sub MG Indexing the empty pot/TC Turn to the main

MG side

S83 TC Tool insertion position (Main MG side)

S84 TC Tool extraction position (Main MG side)

S85 Sub MG Confirming the indexing of the empty pot

S86 TC Turn to the sub MG side

S87 Dummy sequence

S88 TC Tool insertion position (Sub MG side)

S89 TC Standby position (Sub MG side)

Abbreviation:

MG : Magazine

TC : Tool transfer unit (transfers a tool between sub magazine and main magazine)

RS : Ready station

EA : Tool change arm

Page 11

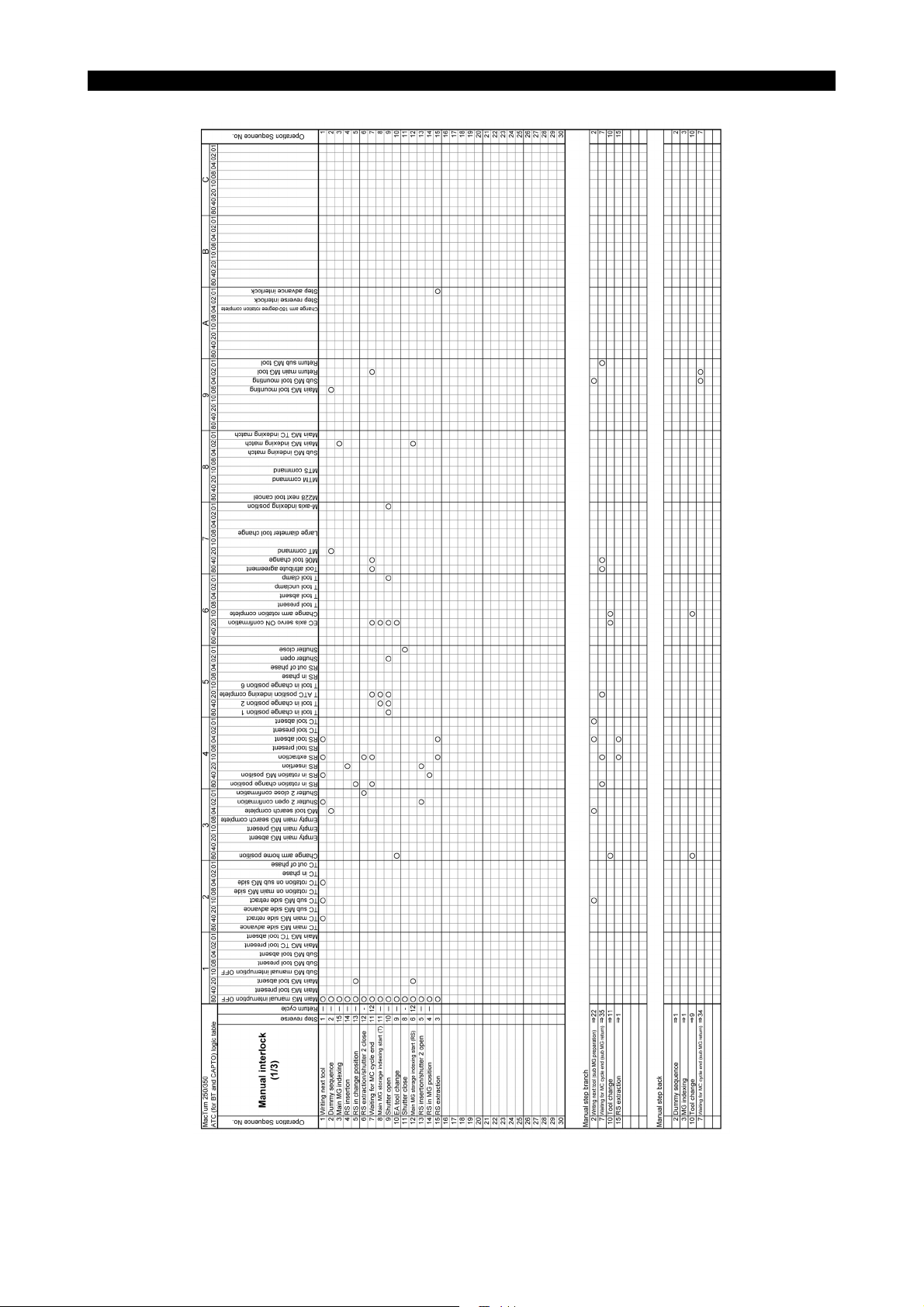

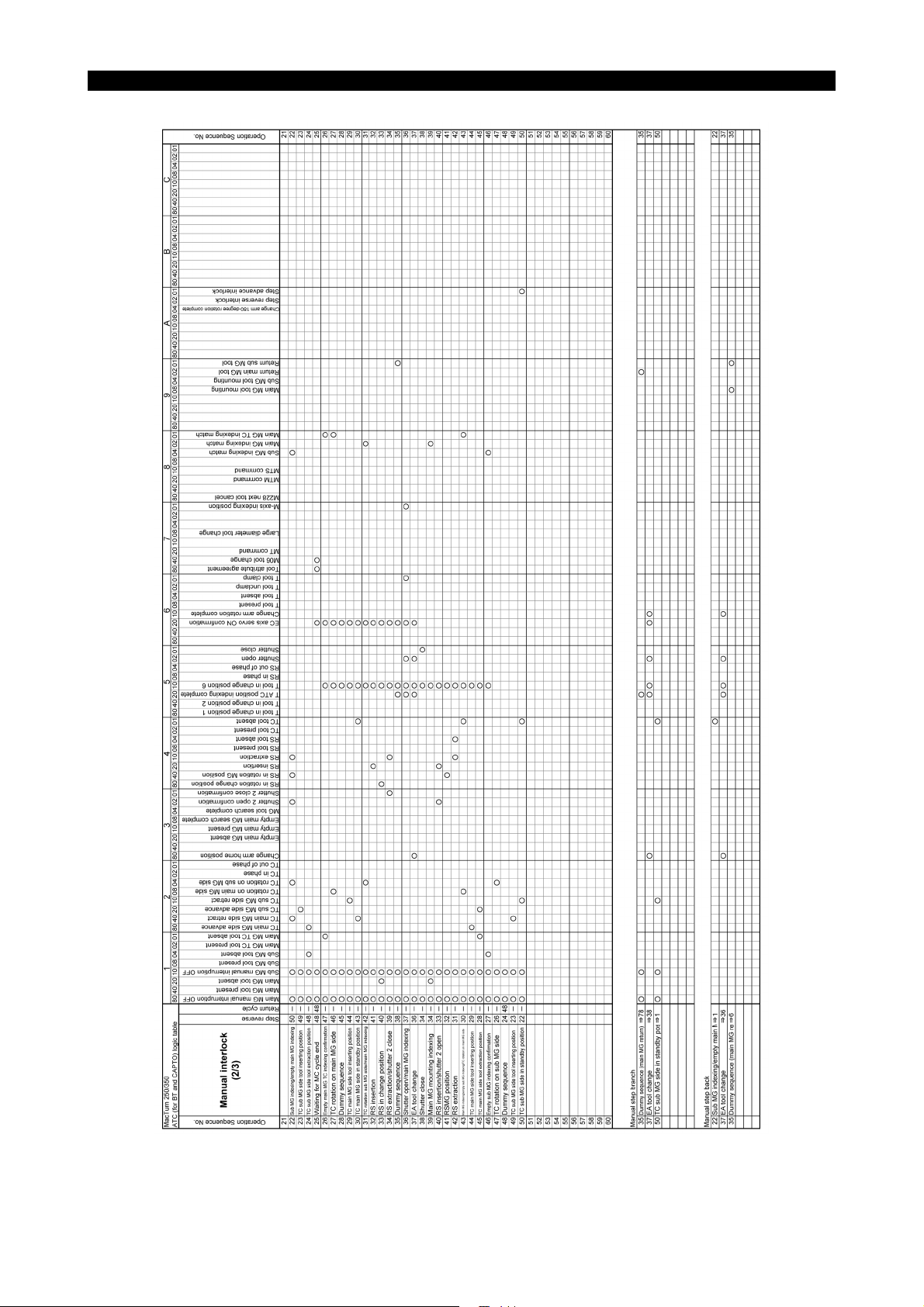

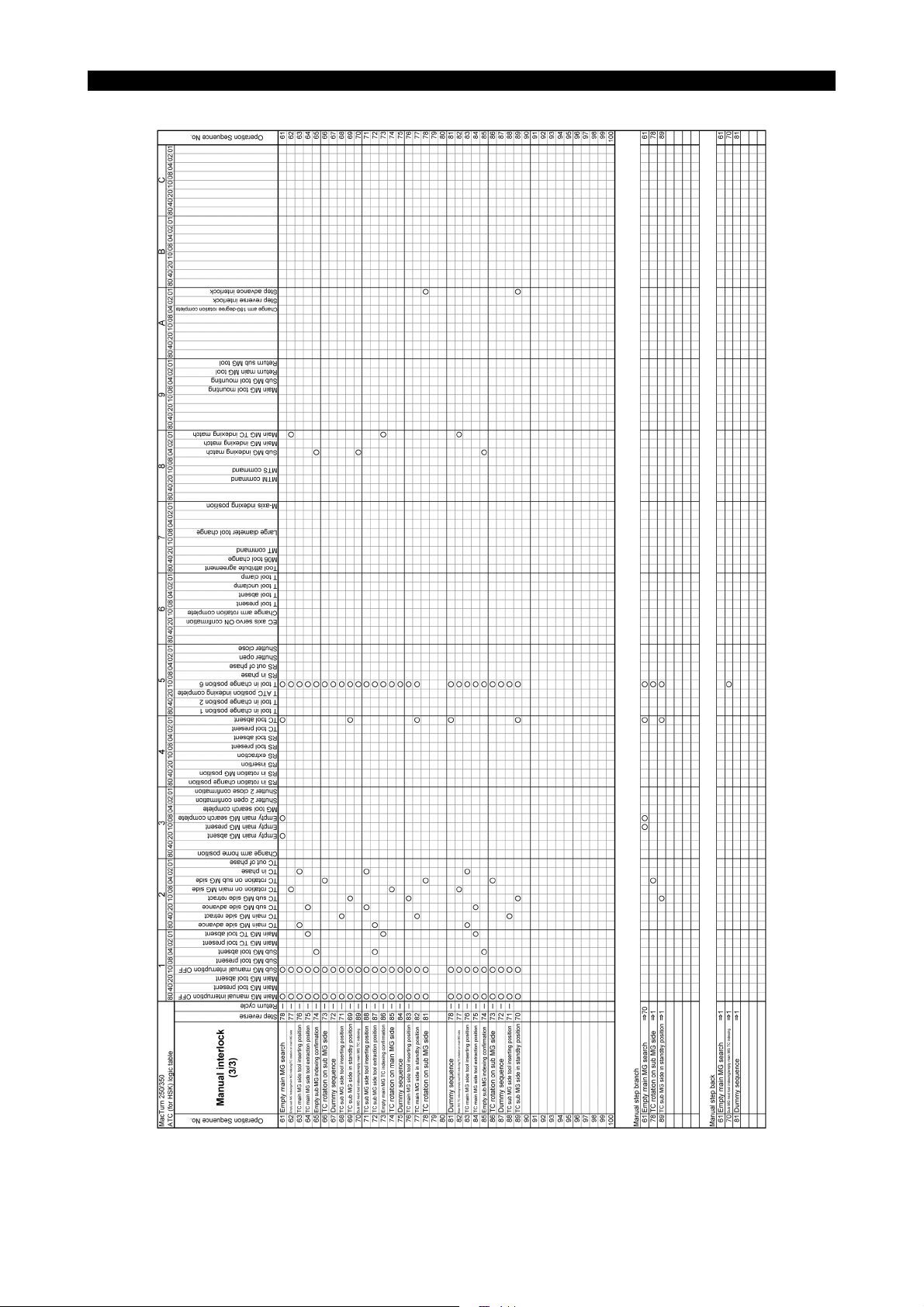

6226-E P-8

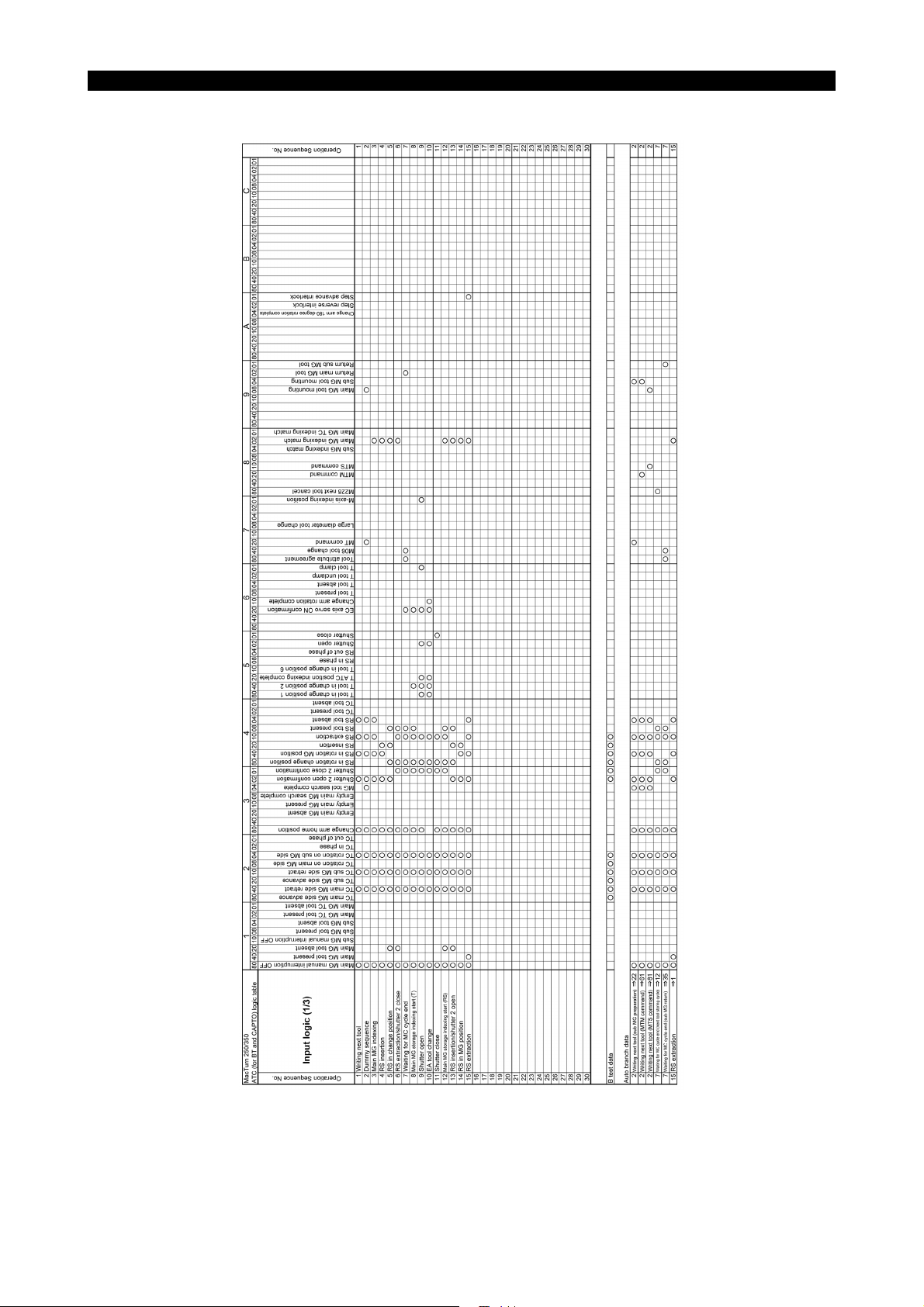

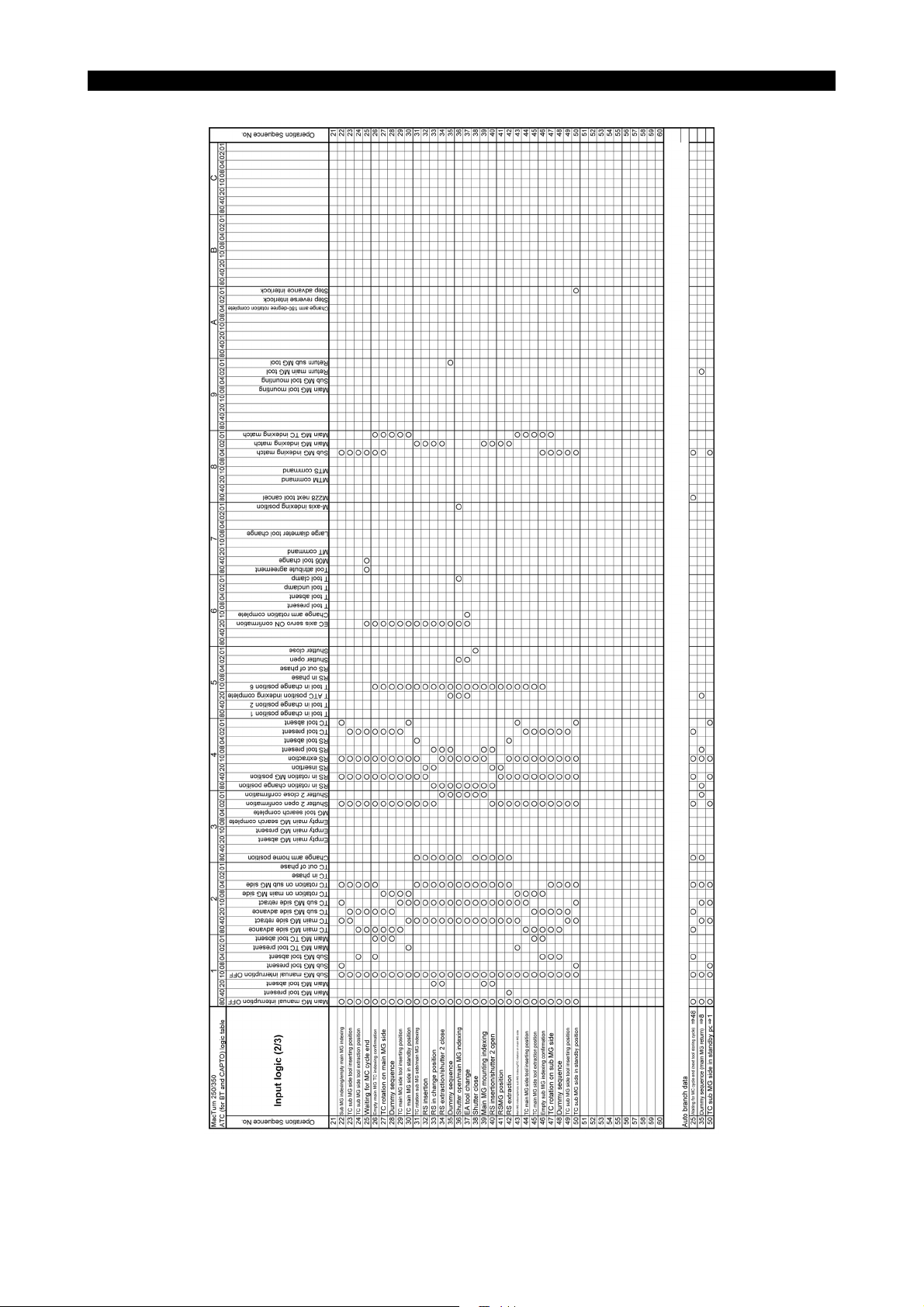

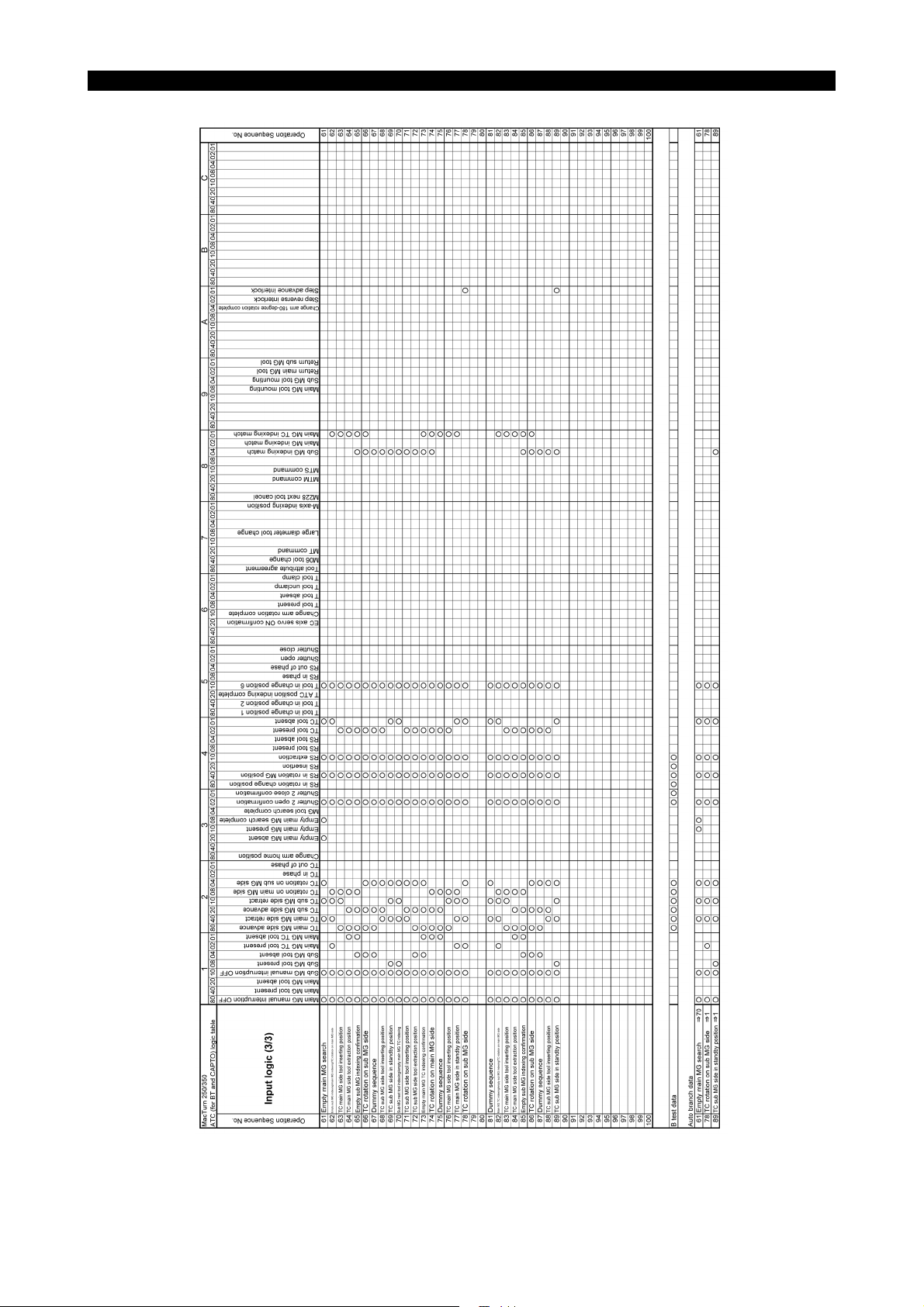

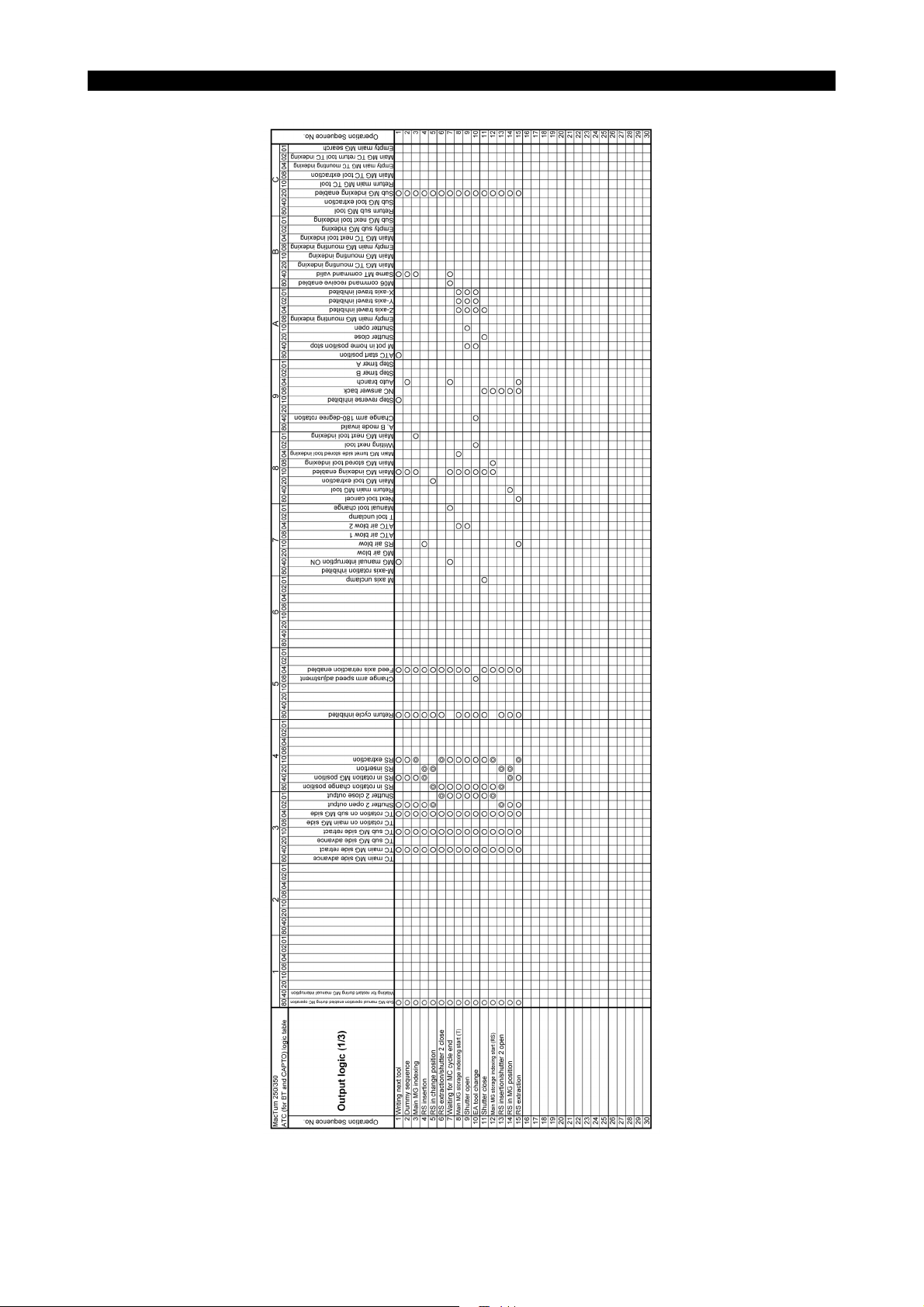

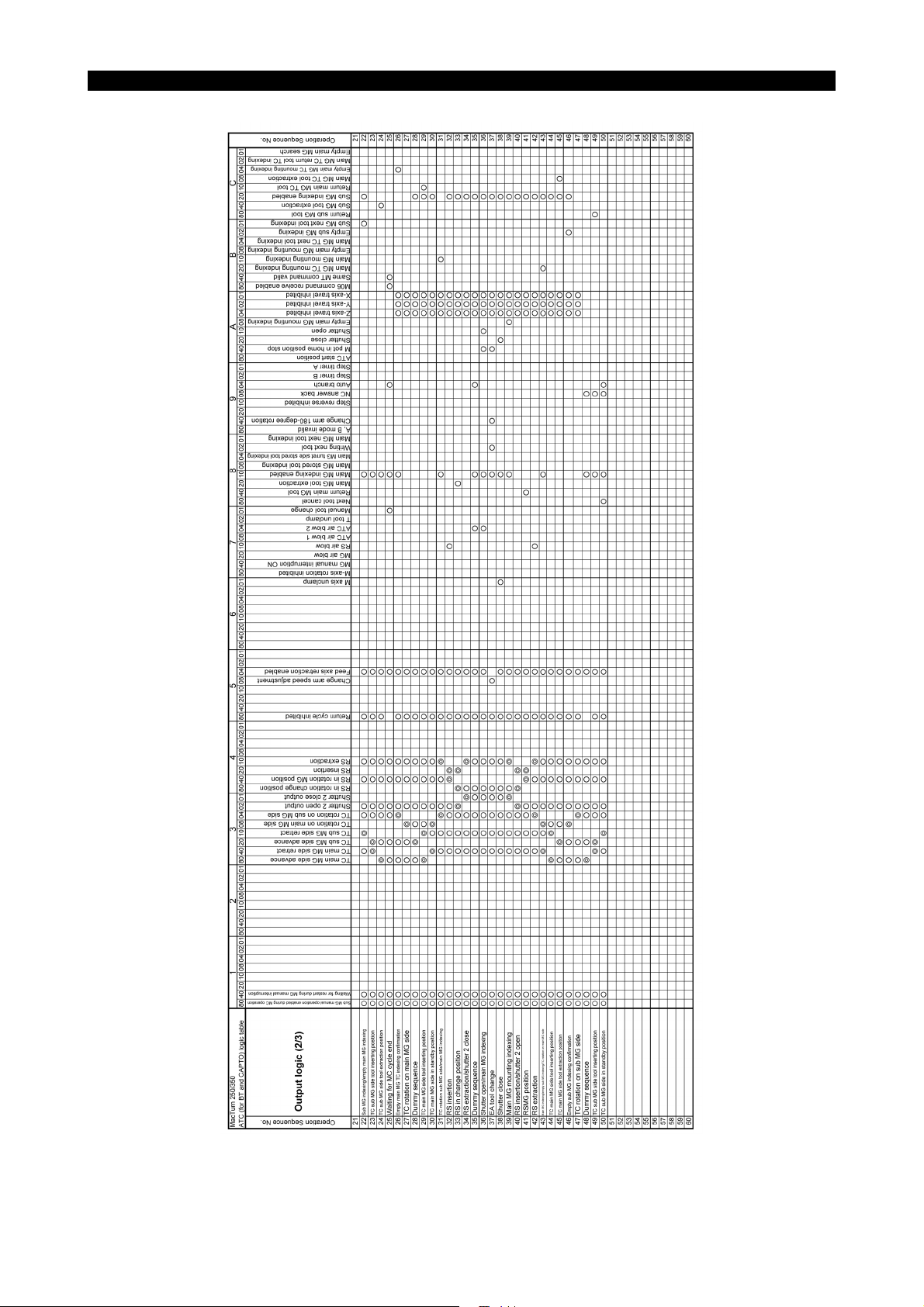

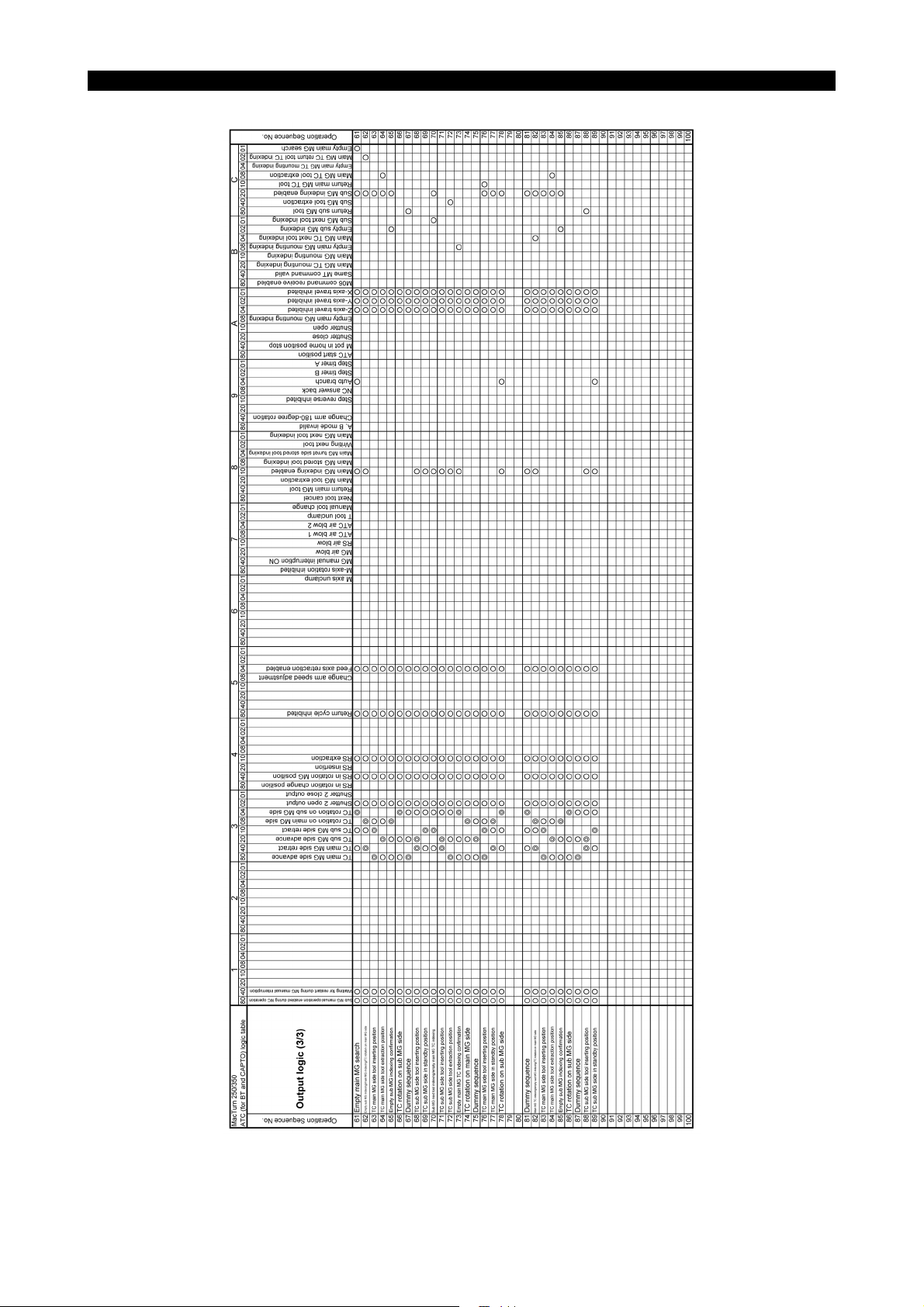

SECTION 3 ATC LOGIC TABLES

SECTION 3 ATC LOGIC TABLES

The logic tables are prepared for the respective kinds of tools. Refer to the logic table that meets the tool kind

of the tool to be used. Note that the cam axis logic table is used in common to the different kinds of tools.

For the method to read the logic tables, refer to the following manual.

OSP-P300S MACTURN/MULTUS Series Operation Manual

Page 12

(1) BT, CAPTO Specification

6226-E P-9

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010001

Page 13

6226-E P-10

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010002

Page 14

6226-E P-11

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010003

Page 15

6226-E P-12

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010004

Page 16

6226-E P-13

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010005

Page 17

6226-E P-14

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010006

Page 18

6226-E P-15

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010007

Page 19

6226-E P-16

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010008

Page 20

6226-E P-17

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010009

Page 21

(2) HSK Specification

6226-E P-18

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010010

Page 22

6226-E P-19

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010011

Page 23

6226-E P-20

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010012

Page 24

6226-E P-21

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010013

Page 25

6226-E P-22

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010014

Page 26

6226-E P-23

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010015

Page 27

6226-E P-24

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010016

Page 28

6226-E P-25

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010017

Page 29

6226-E P-26

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010018

Page 30

6226-E P-27

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010019

Page 31

6226-E P-28

SECTION 3 ATC LOGIC TABLES

LE61621R0100500010020

Page 32

SECTION 4 DATA SETTING

SECTION 4 DATA SETTING

This section explains how to set the tool data on the TOOL DATA SETTING screen.

1. ATC Function Display Screen

When the "machine operation" button on the machine operation panel is pressed, the optional icon

buttons are displayed on the right side of the screen.

The ATC function screen is displayed by touching the ATC icon.

(On the 1st page)

6226-E P-29

The selected magazine is displayed.

LE61621R0100600020001

The list in the pot/tool correspondence table switches between "1ST MG (main magazine)" and

"2ND MG (sub magazine)" by pressing the [F1] (MENU) key.

By operating the function keys, "1 cycle start" and "1 step advance/reverse" can be performed with

the ATC.

Page 33

(On the 2nd page)

6226-E P-30

SECTION 4 DATA SETTING

LE61621R0100600020002

This is the screen to check the conditions of each machine part.

By activating the ATC individual operation on the ATC system check mode screen of the machine

system parameter, machine operation can be executed individually.

The ATC individual operation is the function which is to be used when ATC operation becomes

disabled.

Therefore, interlocks to prevent interference become disabled during ATC individual operation.

When performing individual operations, take sufficient care for interference with each machine part

and carefully carry out the operation.

For ATC individual operations, refer to the MULTUS/MACTURN operation manual.

Page 34

2. Data Setting Screen

The TOOL DATA SETTING screen is displayed by pressing the tool data setting mode key.

By selecting the MAGAZINE INFO. sheet, the magazine conditions are displayed.

6226-E P-31

SECTION 4 DATA SETTING

LE61621R0100600030001

Page 35

2-1. Magazine Information List

The list of turret, ready station, return station, and tools mounted in the magazine is displayed on the

left side of the MAGAZINE INFO. sheet screen.

The tools mounted in the main magazine and the sub magazine are displayed in one table.

Tools are displayed as "1- (pot no,)" when mounted in the main magazine and as "2- (pot no.)" when

in the sub magazine.

When a tool is mounted by manual operation, the tool can only be mounted in the turret or in the sub

magazine; there is no operation to attach or remove a tool into or from the main magazine.

With the tool to be returned to the main magazine, "@" appears in the KIND column with turret,

ready station, and return station.

6226-E P-32

SECTION 4 DATA SETTING

The tool indicated with "@" is a

tool to be returned to the main

magazine.

LE61621R0100600040001

Page 36

2-2. List of not Mounted Tools

By pressing the function key [F2] (UNMNT-TL DISPLAY), the list of the tools which are not mounted

in any of turret, ready station, return station and magazine is displayed.

Select the tool to be mounted from the list by touching the screen.

Then press either [F1] (TURRET ATTACH) or [F2] (MAGAZINE ATTACH) to mount the tool.

(1) [F1] (TURRET ATTACH)

If the tool has been mounted in the turret already, execute tool removal.

At the time when attaching a tool in the turret, a pop-up window to specify the return magazine

appears. Select either the main magazine or the sub magazine.

6226-E P-33

SECTION 4 DATA SETTING

1ST MG -> The main magazine installed to the saddle

2ND MG -> The sub magazine installed next to the machine

LE61621R0100600050001

(2) [F2] (MAGAZINE ATTACH)

When a tool is mounted by manual operation, the tool can only be mounted in the sub

magazine; there is no operation to attach a tool into the main magazine. When attaching a tool

to the magazine, specify the pot number of the sub magazine.

Page 37

2-3. List of Lack Tools

If the tool used in the part program which is currently selected has not been mounted in any of turret,

ready station, return station and magazine, the list of the tools is displayed.

Tools in the list can be attached to the turret or to the magazine by the same operation as the not

mounted tools.

2-4. Registering and Attaching a Tool

When the function key [F1] (TOOL REG&ATT.) is pressed on the MAGAZINE INFO. sheet screen,

the TOOL REG_ATTACH sheet is displayed as shown below.

When "register" is pressed after the tool basic information and the tool model data are set, a pop-up

window to specify the return magazine appears. Select either the main magazine or the sub

magazine.

6226-E P-34

SECTION 4 DATA SETTING

1ST MG -> The main magazine installed to the saddle

2ND MG -> The sub magazine installed next to the machine

2-5. Main Magazine Tool Specification

To cancel "main magazine tool" specification, perform either of the following two methods.

(1) Specify the M code command "M652" in the MDI mode. The "main magazine tool" specifications

can be cancelled in a batch.

(2) When the tool life management function is provided, the "main magazine tool" specification is

also cancelled by canceling the specification of the selected tool with the tool index in the tool group.

LE61621R0100600070001

Page 38

SECTION 5 MANUAL OPERATION

1. Manual Magazine Operation

1-1. Overview

When mounting a tool to the magazine or replacing a tool in the magazine with another tool, it is

necessary to index the magazine to the tool change position manually. To enable this, call the

manual magazine operation mode. Usually, manual operation of the magazine is carried out for the

sub magazine (fixed magazine). To call the manual sub magazine operation mode, the machine

may not be stopped but it requires the ATC to be in the stopped state.

For details of manual operation of the magazine, refer to the following manual.

OSP-P300S MACTURN/MULTUS Series Operation Manual

[Supplement]

To select the main magazine/sub magazine, set “ON/OFF” for the corresponding machine system

parameter of “SYSTEM CHECK MODE”.

Manual main magazine operation is required in maintenance work, etc.

6226-E P-35

SECTION 5 MANUAL OPERATION

1-2. Mechanical Lock

With the MacTurn 250/350, mechanical lock device is used for the magazine door.

When the mechanical lock device is mounted, the condition below must be satisfied to turn off the

manual interruption mode.

- The magazine door must be closed to turn off the sub magazine manual interruption mode.

Pressing the [INT] key on the magazine operation panel cannot turn off the magazine manual

interruption mode in the state the “magazine manual interruption mode is ON” and the “magazine

door not closed”.

Page 39

6226-E P-36

SECTION 5 MANUAL OPERATION

2. Interlock Function for Magazine Door Open/Close Operation

The magazine door (magazine door of sub magazine) is of one door type with the mechanical lock

device mounted to it. Since the sub magazine is the fixed type magazine, ATC operation must be

stopped to open the magazine door.

The magazine door is locked when the magazine and the ATC are in any of the following states.

• During ATC operation

• During sub magazine rotation

• Sub magazine manual interruption mode OFF

Note that the magazine door is not locked in the following cases even if any of the conditions above

is satisfied.

• Machine lock state

• Magazine door close input signal OFF

• Alarm message “Please open magazine door” displayed on the screen

Page 40

3. Manual ATC Operation

This subsection explains how to perform ATC manual operation in the TOOL DATA SETTING

screen mode.

Select the MAGAZINE INFO. sheet or the TOOL DATA (ALL) sheet and press [F6] (MANUAL TOOL

CHG). Then the ATC manual operation screen appears.

6226-E P-37

SECTION 5 MANUAL OPERATION

Operable functions

LE61621R0100700040001

Procedure :

1 Select the target tool in the magazine tool list by touching the screen.

2 Select the motion to be operated and press the function keys between F1 and F4.

The functions that are operable are indicated with a green triangle mark at the left upper corner

of each function key.

[F1] (TOOL CHANGE)

This key is enabled when a tool in the magazine tool list in the MAGAZINE INFO. sheet is

selected.

This key is enabled when a tool in the tool list in the TURRET INFO. sheet is mounted in the

magazine.

[F2] (TOOL INDEX)

When the cursor is located at the current tool number in the TOOL DATA (ALL) sheet, the turret

and the M-spindle are indexed according to the posture number.

[F3] (TOOL RETURN)

This key is enabled when a tool is mounted in the turret.

Page 41

6226-E P-38

SECTION 5 MANUAL OPERATION

[F4] (NEXT TL RETURN)

This key is enabled when a tool exists in the ready station or the return station.

Interlock conditions

When all the following conditions are met, manual tool change operation can be enabled.

• In the ATC manual operation mode

• The turret is located at the X-axis positive variable limit.

• The upper turret (G13) is selected.

• Not during ATC sequence. → The ATC sequence No. is "1" and the ATC is on standby for the

MT command.

• Manual interruption OFF with the magazine operation panel

• The front door open/close confirmation limit SW has been checked at power ON.

• The front door has been closed.

• Not during manual tool attach/removal mode

Page 42

6226-E P-39

SECTION 6 ATC PROGRAM COMMANDS

SECTION 6 ATC PROGRAM COMMANDS

The commands explained below are used for controlling ATC operation for the 80/120-tool magazine

specification. The program is basically described in the sequence indicated below.

(1) Canceling the designation of “MAIN-MG TOOL”

Since the tools to be designated for “MAIN-MG TOOL” change for each main program, the command for

canceling “MAIN-MG TOOL” designation collectively for all tools is specified before starting the first

machining, in the start section of a machining program.

(2) Specifying the MTM command for all tools necessary for machining at the beginning of a machining

program

The tools designated with the MTM command (tool transfer from the sub magazine to the main

magazine) are moved from the sub magazine to the main magazine. If there is not sufficient number of

pots in the main magazine to store all tools to be used in machining, the MTM command prepares an

empty pot where the MTM designated tool is stored.

When preparing an empty pot, the tool for which “MAIN-MG TOOL” designation is canceled although it is

presently mounted in the main magazine is returned to the sub magazine.

Conversely, the tool moved from the sub magazine to the main magazine according to the execution of

the MTM command is designated as the “MAIN-MG TOOL”.

(3) Perform the tool change command by specifying an MT command, M06 command (M321/M421

commands practically), or TD command.

Page 43

1. ATC Commands

(1) MT = {{{{01: Next tool preparation command

The specified tool {{{{ is prepared for tool change operation.

With a multi-tool magazine, the specified tool is prepared on the tool transfer unit from the sub

magazine or on the ready station from the main magazine.

In either case, if the specified tool is not mounted in the magazines, alarm C "ATC Next tool

preparation disable" occurs and ATC operation is not executed.

If the MT command is executed with an ATC operation sequence number other than 1, 7 and

25, an alarm occurs.

(2) TC = 1 ...Turret indexing command to ATC position

The turret of the number (with H1 turret, fixed to "1") specified with TC is indexed to the ATC

position.

(3) M06: Tool change command

This command mounts the tool which is prepared on the tool transfer unit or on the ready

station to the turret, and returns the tool in the turret to the sub magazine or to the main

magazine.

If the M06 command is executed with an ATC operation sequence number other than 7 and 25,

an alarm occurs.

6226-E P-40

SECTION 6 ATC PROGRAM COMMANDS

(4) M321/M421: Tool change command macro

With the M321 (M421) command, the tool change position (home position) varies depending on

whether the current tool is specified as the main magazine tool or as the sub magazine tool at

the time of specification.

[When specified as a main magazine tool]

The tool moves to the tool change position HP (home position) no. 1 to execute tool change

between the main magazine and the turret.

Since the main magazine is installed on the saddle, it moves along with the ZA-axis. Thus the

tool change position is not identified with the ZA-axis.

Therefore, set the XA/YA-axis position for tool change position HP1.

[When specified as a sub magazine tool]

The tool moves to the tool change position HP (home position) no.6 to execute tool change

between the sub magazine and the turret.

The sub magazine is provided because the number of pots is not sufficient only with the main

magazine installed on the saddle, which helps not to limit the machining workpiece kinds.

Since the tool on the sub magazine is changed from the main magazine after transferred to the

main magazine by the tool transfer unit, the tool change position is identified with the ZA-axis.

Therefore, set the XA/YA/ZA-axis position for tool change position HP6.

<M421/M321 selection>

M421 and M321 can be selected by selecting the parameter.

Optional parameter Others No42 M code macro command type selection Enabled/Disabled

(Optional parameter bit No11 bit2)

Enabled → M321

Disabled → M421

Page 44

6226-E P-41

SECTION 6 ATC PROGRAM COMMANDS

(5) TD= @@{{{{ M423 (or M323) ... Tool change and indexing command (Enabled only with

the TD mode)

The tool is changed to the tool of the specified number. The turret is indexed to the specified

command.

@@: Posture number

{{{{: Tool number

The TD command and the M423 (or M323) command must be specified in the same block.

They cannot be specified in the same block as other commands.

Example of NG) G00 X1000 Z1000 TD=010001 M323

<M423/M323 selection>

M423 and M323 can be selected by selecting the parameter.

Optional parameter Others No42 M code macro command type selection Enabled/Disabled

(Optional parameter bit No11 bit2)

Enabled → M323

Disabled → M423

(6) M228 ...Tool return command

The tool prepared as the next tool is returned to the magazine.

(7) MTM = {{{{: Tool transfer command from the sub magazine to the main magazine

The command moves the specified tool {{{{ from the sub magazine to the main magazine.

When tool transfer operations from the sub magazine to the main magazine are all completed,

the command returns the block answer.

If the specified tool is not mounted in either the main or sub magazines, alarm C "ATC Next tool

preparation disable" occurs and ATC operation is not executed.

If the MTM command is executed with an ATC operation sequence number other than 1, an

alarm occurs.

(8) MTS = {{{{: Tool transfer command from the main magazine to the sub magazine

The command moves the specified tool {{{{ from the main magazine to the sub magazine.

When tool transfer operations from the main magazine to the sub magazine are all completed,

the command returns the block answer.

If the specified tool is not mounted in either the main or sub magazines, alarm C "ATC Next tool

preparation disable" occurs and ATC operation is not executed.

If the MTS command is executed with an ATC operation sequence number other than 1, an

alarm occurs.

(9) MGS = ##: Sub magazine indexing command

The command indexes magazine pot ## of the specified sub magazine to the ATC position.

When sub magazine indexing operation is completed, the command returns the block answer.

If the MGS command is executed with an ATC operation sequence number other than 1, an

alarm occurs.

(10) MG = $$: Main magazine indexing command

The command indexes magazine pot number $$ of the specified main magazine to the ATC

position.

Page 45

SECTION 6 ATC PROGRAM COMMANDS

2. Description of Machining Program

How the ATC operation commands are described in a machining program is explained below using

examples. Also refer to the following.

2-1. OSP without Tool Life Management Specification

(Example 1) When the TD command mode is used

It is necessary to register the posture number used for cutting with each tool in

advance on the TOOL DATA SETTING screen.

Moves the turret to the turret index position.

Jumps to NST1 unless work counter is "1".

Executed in the

first time of

machining

Cancels "MAIN-MG TOOL" designation collectively.

Positioning to the ATC home position.

Designates tool No. 0003 as the MAIN-MG TOOL.

6226-E P-42

Machining 1 (Tool No. 0004)

Machining 2 (Tool No.0003)

Machining 3 (Tool No.0011)

Designates tool No. 0004 as the MAIN-MG TOOL.

Designates tool No. 0011 as the MAIN-MG TOOL.

After changed to tool No. 0004, indexed to posture No.1.

Next tool preparation command (tool No. 0004)

Cutting is started.

Moves the turret to the turret indexable position.

After changed to tool No. 0003, indexed to posture No.1.

Next tool preparation command (tool No. 0011)

Cutting is started.

Moves the turret to the turret indexable position.

After changed to tool No. 0011, indexed to posture No.1.

Cutting is started.

LE61621R0100800040001

Page 46

SECTION 6 ATC PROGRAM COMMANDS

(Example 2) When no ATC macro (M321) is used with the TL command mode

Moves the turret to the turret index position.

Jumps to NST1 unless work counter is "1".

Cancels "MAIN-MG TOOL" designation collectively.

Executed in the

first time of

machining

Positioning to the ATC home position.

Designates tool No. 0003 as the MAIN-MG TOOL.

Designates tool No. 0004 as the MAIN-MG TOOL.

Designates tool No. 0011 as the MAIN-MG TOOL.

Next tool preparation command (04: tool No.)

Turret indexing and positioning to the tool change position.

Tool change command (tool No.4 is mounted in the turret)

6226-E P-43

Machining 1 (Tool No. 0004)

Machining 2 (Tool No. 0003)

Next tool preparation command (03: tool No.)

Positioning to the return position.

Indexing the turret to the cutting position.

Cutting is started.

Moves the turret to the turret indexable position.

Turret indexing and positioning to the tool change position.

Tool change command (tool No.3 is mounted in the turret)

Next tool preparation command (11: tool No.)

Positioning to the return position.

Moves the turret to the turret index position.

Indexing the turret to the cutting position.

Cutting is started.

Moves the turret to the turret indexable position.

Turret indexing and positioning to the tool change position.

Tool change command (tool No.11 is mounted in the turret)

Positioning to the return position.

Machining 3 (Tool No. 0011)

Moves the turret to the turret index position.

Cutting is started.

LE61621R0100800040002

Page 47

SECTION 6 ATC PROGRAM COMMANDS

(Example 3) When an ATC macro (M321) is used with the TL command mode

Moves the turret to the turret index position.

Jumps to NST1 unless work counter is "1".

Cancels "MAIN-MG TOOL" designation collectively.

Executed in the

first time of

machining

Positioning to the ATC home position.

Designates tool No. 0003 as the MAIN-MG TOOL.

Designates tool No. 0004 as the MAIN-MG TOOL.

Designates tool No. 0011 as the MAIN-MG TOOL.

Next tool preparation command (04: tool No.)

ATC macro command (tool No.4 is mounted in the turret)

Next tool preparation command (03: tool No.)

Moves the turret to the turret index position.

6226-E P-44

Machining 1 (Tool No. 0004)

Machining 2 (Tool No. 0003)

Machining 3 (Tool No. 0011)

Indexing the turret to the cutting position.

Cutting is started.

Moves the turret to the turret indexable position.

ATC macro command (tool No.3 is mounted in the turret)

Next tool preparation command (11: tool No.)

Moves the turret to the turret index position.

Indexing the turret to the cutting position.

Cutting is started.

Moves the turret to the turret indexable position.

ATC macro command (tool No.11 is mounted in the turret)

Moves the turret to the turret index position.

Cutting is started.

LE61621R0100800040003

Page 48

SECTION 6 ATC PROGRAM COMMANDS

2-2. OSP with Tool Life Management Specification

(Example 1) When the TD command mode is used

It is necessary to register the posture number used for cutting with each tool in advance on

the TOOL DATA SETTING screen.

Moves the turret to the turret index position.

Jumps to NA1 unless work counter is "1".

Jumps to NA2 if tool index takes place.

Executed in

the first time

of machining

Executed in the

first time of

machining and

at tool indexing

Jumps to NST1.

Cancels "MAIN-MG TOOL" designation collectively.

Positioning to the ATC home position.

Designates the selected tool in tool group No. 3 as the MAIN-MG TOOL.

Designates the selected tool in tool group No. 4 as the MAIN-MG TOOL.

Designates the selected tool in tool group No. 11 as the MAIN-MG TOOL.

6226-E P-45

After changed to the selected tool in tool group No. 4, indexed to posture No.1.

Next tool preparation command (group No.3)

Cutting is started

Machining 1 (Tool group No. 0004)

Moves the turret to the turret indexable position.

After changed to the selected tool in tool group No. 3, indexed to posture No.1.

Next tool preparation (tool No. 0011)

Cutting is started

Machining 2 (Tool group No. 0003)

Moves the turret to the turret indexable position.

After changed to the selected tool in tool group No. 11, indexed to posture No.1.

Cutting is started

Machining 3 (Tool group No. 0011)

LE61621R0100800050001

Page 49

SECTION 6 ATC PROGRAM COMMANDS

(Example 2) When no ATC macro (M321) is used with the TL command mode

Moves the turret to the turret index position.

Jumps to NA1 unless work counter is "1".

Jumps to NA2 if tool index takes place.

Executed in

the first time

of machining

Executed in the

first time of

machining and

at tool indexing

Jumps to NST1.

Cancels "MAIN-MG TOOL" designation collectively.

Positioning to the ATC home position.

Designates the selected tool in tool group No. 3 as the MAIN-MG TOOL.

Designates the selected tool in tool group No. 4 as the MAIN-MG TOOL.

Designates the selected tool in tool group No. 11 as the MAIN-MG TOOL.

Tool preparation command

Positioning to the tool change position.

Tool change command (the tool in tool group No.4 is mounted in the turret)

Next tool preparation command (group No.3)

Positioning to the return position.

Moves the turret to the turret index position.

Indexing the turret to the cutting position.

Cutting is started

6226-E P-46

Machining 1 (Tool group No. 0004)

Moves the turret to the turret indexable position.

Positioning to the tool change position.

Tool change command (the tool in tool group No.3 is mounted in the turret)

Next tool preparation command (group No.11)

Positioning to the return position.

Moves the turret to the turret index position.

Indexing the turret to the cutting position.

Cutting is started

Machining 2 (Tool group No. 0003)

Moves the turret to the turret indexable position.

Positioning to the tool change position.

Tool change command (the tool in tool group No.11 is mounted in the turret)

Positioning to the return position.

Cutting is started

Indexing the turret to the cutting position.

Machining 3 (Tool group No. 0011)

LE61621R0100800050002

Page 50

SECTION 6 ATC PROGRAM COMMANDS

(Example 3) When an ATC macro (M321) is used with the TL command mode

Moves the turret to the turret index position.

Jumps to NA1 unless work counter is "1".

Jumps to NA2 if tool index takes place.

Executed in

the first time

of machining

Executed in the

first time of

machining and

at tool indexing

Jumps to NST1

Cancels "MAIN-MG TOOL" designation collectively.

Positioning to the ATC home position.

Designates the selected tool in tool group No. 3 as the MAIN-MG TOOL.

Designates the selected tool in tool group No. 4 as the MAIN-MG TOOL.

Designates the selected tool in tool group No. 11 as the MAIN-MG TOOL.

Next tool preparation command (group No.4)

ATC macro command (the tool in tool group No.4 is mounted in the turret)

Next tool preparation command (group No.3)

Moves the turret to the turret index position.

Indexing the turret to the cutting position.

Cutting is started

Machining 1 (Tool group No. 0004)

Moves the turret to the turret indexable position.

ATC macro command (the tool in tool group No.3 is mounted in the turret)

Next tool preparation command (group No.11)

Moves the turret to the turret index position.

Indexing the turret to the cutting position.

Cutting is started

Machining 2 (Tool group No. 0003)

Moves the turret to the turret indexable position.

ATC macro command (the tool in tool group No.11 is mounted in the turret)

Indexing the turret to the cutting position.

Cutting is started

Machining 3 (Tool group No. 0011)

6226-E P-47

LE61621R0100800050003

Page 51

SECTION 6 ATC PROGRAM COMMANDS

3. ATC Commands and ATC Operation

How the ATC sequence is performed in response to the ATC command is described below. The

arrows indicate movements of a tool.

6226-E P-48

Mounted in the

main magazine

and returned to

the main

magazine

Mounted in the

sub magazine

and returned to

the sub magazine

Mounted in the

main magazine

and returned to

the sub magazine

Mounted in the

sub magazine

and returned to

the main

magazine

Sub

magazine

MT command

TD command

MT command

TD command

Transfer unit

TC

M06 command

M06 command

Main

magazine

MT command

TD command

MT command

TD command

Ready-

station

M06 command

M06 command

Turret

Moves from

sub magazine to

MTM command

main magazine

Moves from

main magazine

MTS command

to sub magazine

LE61621R0100800060001

Whether the tool is returned to the main magazine or the sub magazine is automatically determined

according to magazine specification at tool registration.

Page 52

SECTION 7 PARAMETERS

SECTION 7 PARAMETERS

1. ATC Parameter

The “ATC PARAMETER” screen called in the parameter setting mode has the pages for setting the

main magazine axis data and the sub magazine axis data, respectively.

- ZERO OFFSET : Setting unit: 0.001°, Initial value: 0.000

- BACKLASH : Setting unit: 0.001°, Initial value: 0.000

- DROOP : Setting unit: 0.001°, Initial value: 0.000

2. Machine System Parameter

2-1. System Check Mode (Machine System Parameter)

• GB (7) axis P. H. mode

Enables pulse handle feed operation for the GB axis (sub magazine axis).

6226-E P-49

• GB axis rapid feed PB

Enables axis feed operation using the feed buttons on the operation panel for the GB axis (sub

magazine axis).

• MG panel main MG control

Selects the main magazine for the control target of the magazine operation panel. Unless this

parameter is set, control target of the magazine operation panel is the sub magazine.

Page 53

2-2. ATC (Machine System Parameter)

• Sub MG tool mount MAX

Setting range: 0 - 3

Sets the number of “pots for sub magazine tools” to be secured in the main magazine.

Pots for sub magazine tools : Pots used for mounting the tools to be transferred from the sub

magazine to the main magazine before they are mounted to

the turret.

[Supplement]

When transferring a right-large diameter/heavy tool, a left-large diameter/heavy tool or a superlarge diameter/heavy tool from the main magazine to the turret or from the main magazine to the

sub magazine, or when transferring a tool from the “pot for sub magazine tool” to the turret,

designation of return pot (reserve pot designation) is not made in the main magazine for the

transferred tool.

• Main MG TC offset position

Setting range: 0 - Max. number of main magazine pots

Sets the offset data to determine the tool change position of the main magazine where tool

change is executed between the main magazine and the tool transfer unit (TC) in reference to

the tool change position where tool change is executed between the main magazine and the

ready station.

Count the number of pots, from the pot at the tool change position taken as the reference (main

magazine/ready station) to the one at the tool change position to be set (main magazine/tool

transfer unit), in the direction the pot number decreases and set it as the offset data.

6226-E P-50

SECTION 7 PARAMETERS

• Offset of Sub MG manual tool change position

Setting range: 0 - Max. number of sub magazine pots

Sets the offset data of to determine the position of the pot indexed to the magazine door in

reference to the tool change position where tool change is executed between the sub magazine

and the tool transfer unit.

Count the number of pots, from the pot at the tool change position taken as the reference to the

one indexed at the magazine door, in the direction the pot number decreases and set it as the

offset data.

• GB axis override

Setting range: 0 - 100

Sets the override value for the GB-axis (sub magazine axis) feed operation.

If “0” is set, the GB-axis operates without override.

Page 54

SECTION 8 OTHERS

1. System Variables

(1) VGINB: Tool index flag

This system variable is used for the tool life management specification. If tool index occurs in

the registered tool groups when the TLID command is executed, “1” is set for this system

variable. When tool index occurs in none of the tool groups, “0” is set.

(2) VTMMG: “MAIN-MG TOOL” designation

This system variable is used for reading if “MAIN-MG TOOL” designation is made or not for the

tool presently mounted in the turret. “1” is set if “MAIN-MG TOOL” designation is made and “0”

is set if “MAIN-MG TOOL” designation is not made. Positioning target position is judged

according to the setting of this system parameter when the ATC macro command M321/M421

is executed.

HP = 1 : Tool change between the main magazine and the turret

(“MAIN-MG TOOL” designation is made)

HP = 6 : Tool change between the sub magazine and the turret

(“MAIN-MG TOOL” designation is not made)

6226-E P-51

SECTION 8 OTHERS

2. ATC Macro Command

For the execution of ATC, the next tool preparation command (MT) and the tool change/return

command (M321, M421) are used even for the 80/120-tool magazine specification. At the execution

of the M321/M421 command, the system judges whether or not the present tool is the “MAIN-MG

TOOL” designated tool to determine the tool change operation pattern.

• If “MAIN-MG TOOL” designation is made, positioning is made to tool change HP = 1.

Tool change cycle is executed from this HP.

→ Tool change between the main magazine and the turret

• If “MAIN-MG TOOL” designation is not made, positioning is made to tool change HP = 6.

Tool change cycle is executed this HP.

→ Tool change between the sub magazine and the turret

2-1. Shutter Operation

The shutter opens simultaneously with the start of positioning to the tool change position (HP = 1) to

reduce tool change cycle time when tool change is made between the main magazine and the

turret.

When tool change is executed between the sub magazine and the turret, if the shutter opens

simultaneously with the start of positioning to the tool change position (HP = 6), the shutter remains

open for a long time since the time from the completion of positioning to the start of tool change arm

operation takes a long time. This causes coolant and chip to enter the ATC mechanism while the

shutter is open.

To avoid this, the shutter opens immediately before the start of tool change arm operation (ATC

operation sequence S8, S35) when tool change is executed between the sub magazine and the

turret.

Page 55

2-2. Flowchart

The following flowchart shows the processing sequence of the M321 (M421) command.

6226-E P-52

SECTION 8 OTHERS

LE61621R0101000040001

Page 56

6226-E P-53

SECTION 8 OTHERS

LE61621R0101000040002

Page 57

6226-E P-54

SECTION 8 OTHERS

LE61621R0101000040003

Page 58

6226-E P-55

SECTION 8 OTHERS

LE61621R0101000040004

Page 59

6226-E P-56

SECTION 9 ALARM AND ERROR

SECTION 9 ALARM AND ERROR

The alarms related to the operation of the 80/120-tool magazine specification are indicated below.

If an alarm occurred, also refer to the “Alarm & Error List” and the “OSP-P300S MACTURN/MULTUS Series

Operation Manual”.

Alarm A

8537 Magazine door Interlock

Any of the following operations is attempted while the magazine door is open.

Spindle rotation, axis movement, turret indexing, M-tool spindle rotation, sub-spindle rotation.

Or an attempt is made to open the magazine door in any of the above indicated state.

[Code]

1-> Spindle rotation

2-> M-tool spindle rotation

3-> Axis movement

4-> Turret indexing

6-> Sub-spindle or pick-off spindle rotation

7-> ATC operation

8556 No mount magazine

Alarm B

2613 Mistake in MTM command

The tool number command used with the MTM command is wrong.

The tool number specified with the MTM command is the one for the tool not mounted in the turret or

the tool mounted in a wrong turret pot.

2614 Mistake in MTS command

The tool number command used with the MTS command is wrong.

The tool number specified with the MTS command is the one for the tool not mounted in the turret or the

tool mounted in a wrong turret pot.

2615 Mistake in MGS command

The tool number command used with the MGS command is wrong.

2719 Invalid ATC command

Two or more M06 or M228 or MT or MG or MTM or MTS or MGS commands were specified at the

same time.

M06: Tool change command

M228: ATC next tool return command

MT: Next tool ready command

MG: Magazine index command

MTM: Tool transfer command from sub magazine to main magazine

MTS: Tool transfer command from main magazine to sub magazine

MGS: Sub magazine index

Page 60

SECTION 9 ALARM AND ERROR

Alarm D

4730 Magazine door open

The magazine door is open.

4741 Magazine operation panel manual interrupt

Magazine operation is manual interruption mode.

[Code]

None -> Manual interruption mode of main magazine.

1 -> Manual interruption mode of sub magazine.

(Error message)

9468 No open pot

When a tool with large diameter at the left or at the right or with super large diameter is supplied into the

magazine, a tool is mounted in the adjacent pot.

9469 Unable to clear tool No.

6226-E P-57

A tool is attempted to be removed from the main magazine by operation not from the screen (tool

setting API).

9476 Tool mount impossible

A tool is attempted to be supplied to the main magazine on the magazine supply pop-up window.

9493 Main-MG non open pot

The empty pot that is specified with "1st MG" and set with "size" on the return magazine selection popup window does not exist in the main magazine.

9494 Sub-MG non open pot

The empty pot that is specified with "2nd MG" and set with "size" on the return magazine selection popup window does not exist in the sub magazine.

Page 61

LIST OF PUBLICATIONS

Publication No. Date Edition

6226-E February 2013 1st

This manual may be at variance with the actual product due to specification or

design changes.

Please also note that specifications are subject to change without notice.

If you require clarification or further explanation of any point in this manual, please

contact your OKUMA representative.

Loading...

Loading...