Page 1

CNC SYSTEM

OSP-E100

OSP-E10

MacMan

INSTRUCTION MANUAL

(6th Edition)

Pub No. 4345-E-R5 (SE34-008-R6) May 2002

Page 2

SAFETY PRECAUTIONS

4345-E P-(i)

SAFETY PRECAUTIONS

The NC unit that features the IGF function is equipped with a variety of safety devices to protect personnel and the machine from hazards arising as a result of unforeseen accidents while operating

the machine.

However, incorrect use of the function can lead to serious accidents and injuries. In order to prevent

such accidents, read this manual and related manuals carefully so that you can use the IGF function

correctly.

The points presented below are those that require particular attention when using the IGF function.

Be sure to read this information and follow the instructions in it. The cautions below and the warning

signs attached to the machine cover only those hazards which we can predict. Be aware that they

do not cover all possible hazards.

1. Precautions on Reading This Manual

This manual only provides information relating to the IGF function: in addition to this manual, manuals relating to the operation of the machine and NC unit, the parameters, alarms/errors, maintenance, etc., are also provided.

Read these manuals before actually using the IGF function or running an NC program created using

the IGF function.

2. Precautions on Use

Eeospkkpl001

Eeospkkpl002

2-1. Starting up the IGF Function

For details about turning on the power and selecting the operation mode before starting up the IGF

function, refer to the manuals relating to operation of the machine and NC unit. Strictly observe the

cautions given in these manuals.

2-2. Operations while Using the IGF Function

If any alarm or error occurs while using the IGF function, determine its exact nature and take corrective action by referring to this manual and the manuals relating to alarms and errors.

Eeospkkpl003

Eeospkkpl004

Page 3

SAFETY PRECAUTIONS

2-3. Running NC Programs Created Using the IGF Function

4345-E P-(ii)

(1) Use the simulation function of the IGF function to check the operation before running an NC

program created using the IGF function to perform actual machining.

(2) Never run a program created using the IGF function to perform actual machining without check-

ing its operation. Run the program with no workpiece and make sure that there is no interference, then cut a workpiece in the single block mode. If no problems are discovered, automatic

operation may be started.

(3) Confirm safety before performing operations involving spindle rotation or axis motion.

(4) Never touch the moving parts of the machine, chips, or the workpiece during machine opera-

tion.

(5) Check the tool offset values.

(6) Check the zero offset values.

(7) Make sure that all override settings on the machine operation panel are set to 100%. Or, if nec-

essary, use a lower override.

(8) If using a machine with a cover, always close the cover before starting operation. Do not oper-

ate the machine with any safety cover removed.

(9) Check carefully that the spindle speed, feedrates, infeeds, etc. specified in created programs

are within the permissible ranges for the tools, chuck, fixture, etc., used during operation.

3. On Finishing Work

(1) On finishing work, clean the vicinity of the machine.

(2) Return all devices to their predetermined retraction positions.

Eeospkkpl005

Eeospkkpl006

(3) Always turn off the power to the machine before leaving it.

(4) Always quit the IGF function before turning off the power.

(5) To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the

main power disconnect switch.

4. When Performing Maintenance Inspections/When Trouble Occurs

(1) To execute an emergency stop, press the emergency stop button on the operation panel.

(2) Consult the person responsible for maintenance to determine what corrective measures need

to be taken.

(3) Before contacting the service center after an alarm or error has occurred, write down all the rel-

evant alarm and error messages displayed.

(4) Carefully read this manual and the manuals relating to alarms and errors, machine and NC unit

operation, and parameters, etc., before taking corrective action during a maintenance inspection or in response to trouble. Strictly observe the cautions given in these manuals.

Eeospkkpl007

Page 4

5. Symbols Used in Manual

4345-E P-(iii)

SAFETY PRECAUTIONS

The following warning indications are used in this manual to draw attention to information of particular importance. Read the instructions marked with these symbols carefully and follow them.

Eeospkkpl008

DANGER

Indicates an imminent hazard which, if not avoided, will result in death or serious injury.

WARNING

Indicates hazards which, if not avoided, could result in death or serious injury.

CAUTION

Indicates hazards which, if not avoided, could result in minor injuries or damage to devices or

equipment.

NOTICE

Indicates precautions relating to operation or use.

Page 5

INTRODUCTION

4345-E P-(i)

INTRODUCTION

Thank you very much for purchasing our numerical control unit.

Before using this NC unit (hereafter simply called NC), thoroughly read this manual in order to

ensure correct use.

This manual explains how to use and maintain the NC so that it will deliver its full performance and

maintain accuracy over a long term.

You must pay particular attention to the cautions given in this manual, read them carefully, and

make sure you fully understand them before operating the NC.

Display Screens

The NC display screens vary with the selected NC specifications.

The screens shown in this manual, therefore, may not exactly the

same with those displayed on your NC.

Eeospkkan001

Page 6

4345-E P-(i)

TABLE CONTENTS

TABLE CONTENTS

SECTION 1 MacMan......................................................................................................1

1. MacMan Provides the Live Productions Status Information ......................................................... 1

2. MacMan Slashes Down Time ....................................................................................................... 3

3. Screen Transition Diagram ........................................................................................................... 3

SECTION 2 MacMan MAIN SCREEN............................................................................4

1. Machining Status .......................................................................................................................... 5

2. Recent Machining Report ............................................................................................................. 6

3. Adjusting the Number of Work Count ........................................................................................... 7

4. Changing the Reason of Not-operating Status ............................................................................. 7

SECTION 3 REPORT INFORMATION DISPLAY........................................................11

SECTION 4 MACHINING REPORT DISPLAY.............................................................14

1. Daily Machining Report (Today) ................................................................................................. 14

2. Daily Machining Report (Pre Day) ..............................................................................................16

3. Period Machining Report ............................................................................................................ 17

4. Output to Floppy Disk ................................................................................................................. 18

SECTION 5 OPERATING REPORT ............................................................................19

1. Daily Operating Report (Today).................................................................................................. 19

2. Daily Operating Report (Pre Day)............................................................................................... 20

3. Period Operating Report ............................................................................................................ 21

SECTION 6 OPERATING HISTORY ...........................................................................23

1. Daily Operating History (Today) ................................................................................................. 23

2. Daily Operating History (Pre Day) .............................................................................................. 25

SECTION 7 TROUBLESHOOTING INFORMATION...................................................26

SECTION 8 ALARM HISTORY ....................................................................................27

1. Displaying the Alarm History....................................................................................................... 27

2. Changing Logged Alarm Levels..................................................................................................28

SECTION 9 OPERATION HISTORY ...........................................................................30

1. Operate Panel............................................................................................................................. 30

SECTION 10 PARAMETER SETTING .........................................................................33

1. REPORT DATA .......................................................................................................................... 34

Page 7

4345-E P-(ii)

TABLE CONTENTS

2. OUTPUT DATA .......................................................................................................................... 36

3. Initialization ................................................................................................................................. 39

Page 8

SECTION 1 MacMan

4345-E P-1

SECTION 1 MacMan

The MacMan has been developed by focusing on the following problems among a variety of problems to be solved:

• What should we do to improve operation efficiency of the machine tools and other production

equipment?

• What should we do to shorten lead time to output products?

Higher operation efficiency and shorter lead time are both the key themes to be achieved to successfully shift the production style to small lot production with a large number of workpiece kinds

and then to variable lot size production.

The MacMan will provide you the information necessary for finding solutions to these themes.

Eeospkku1001

1. MacMan Provides the Live Productions Status Information

If you want to run the production equipment more efficiently, the first step you must take is to "find"

the actual operating efficiency. Here, the term "find" does not mean "seeing", but it includes the processing to "digitize" the information. Similarly, to shorten the lead time, you must "find" the status

how the production progresses. To "find" the actual status is the first step to improvements.

The MacMan collects and outputs the continuously changing actual status of production.

• It outputs the actual status to the NC screen. Improvements at the production field by an opera-

tor is possible by viewing the actual status.

• It outputs the actual status to the MS-DOS format floppy disk. Production field management by

using a personal computer is possible.

Eeospkku1002

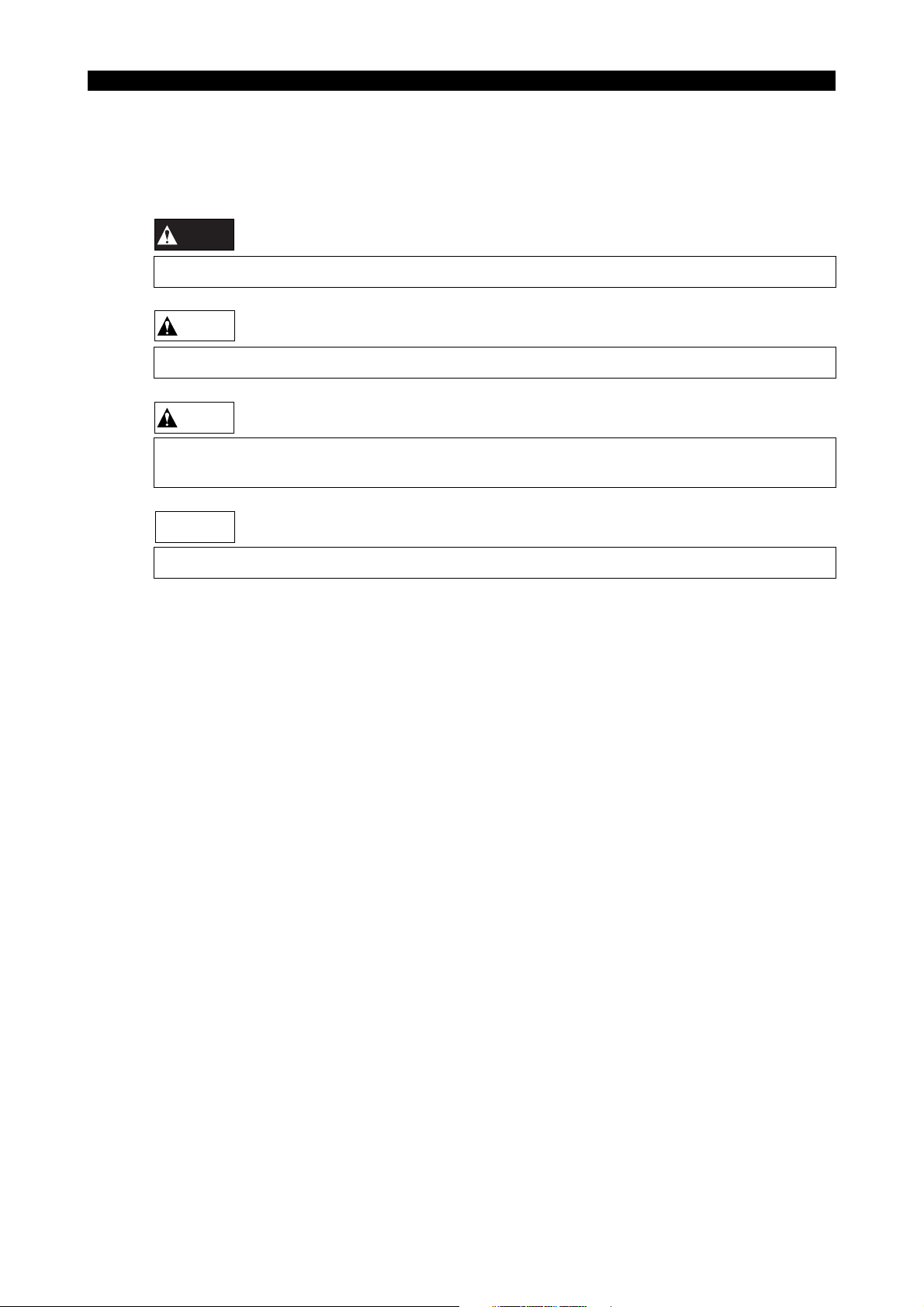

(1) Machining Report

Job progress status is displayed for each of the selected main programs.

EIOSPKKU1003R01

Page 9

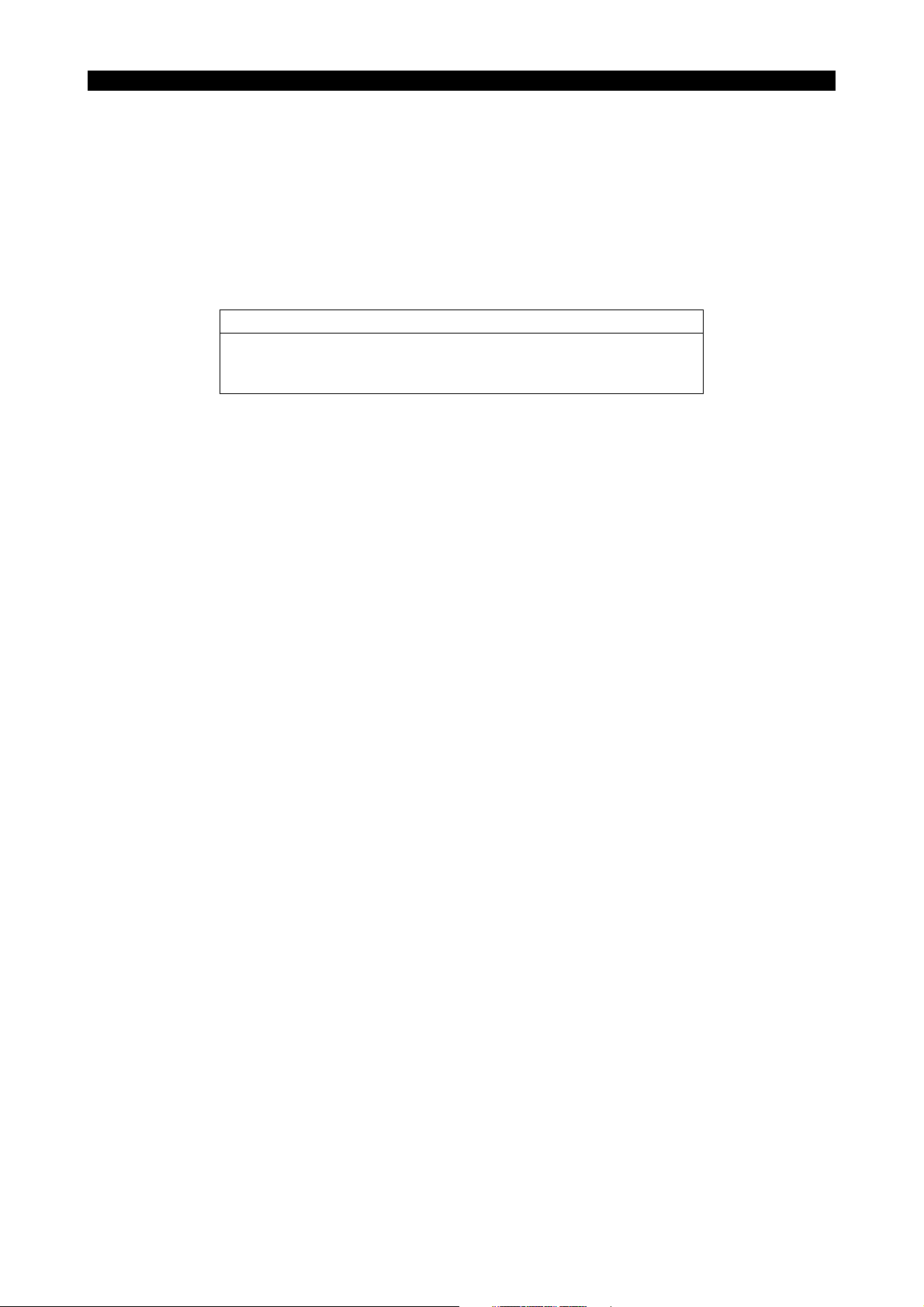

(2) Operating Report

Operating status is displayed in bar graph.

4345-E P-2

SECTION 1 MacMan

(3) Operating History

Operating status is displayed in time chart.

EIOSPKKU1001R01

EIOSPKKU1002R01

Page 10

2. MacMan Slashes Down Time

4345-E P-3

SECTION 1 MacMan

Precise understanding of the situation of a trouble is the key to pin-pointed troubleshooting and

quick recovery of the machine operation.

Using the MacMan, you can get the information necessary for troubleshooting to be output onto MSDOS formatted floppy disk.

• If you output the information to the floppy disk, the information can be analyzed by using a per-

sonal computer by either yourself or Okuma service technician.

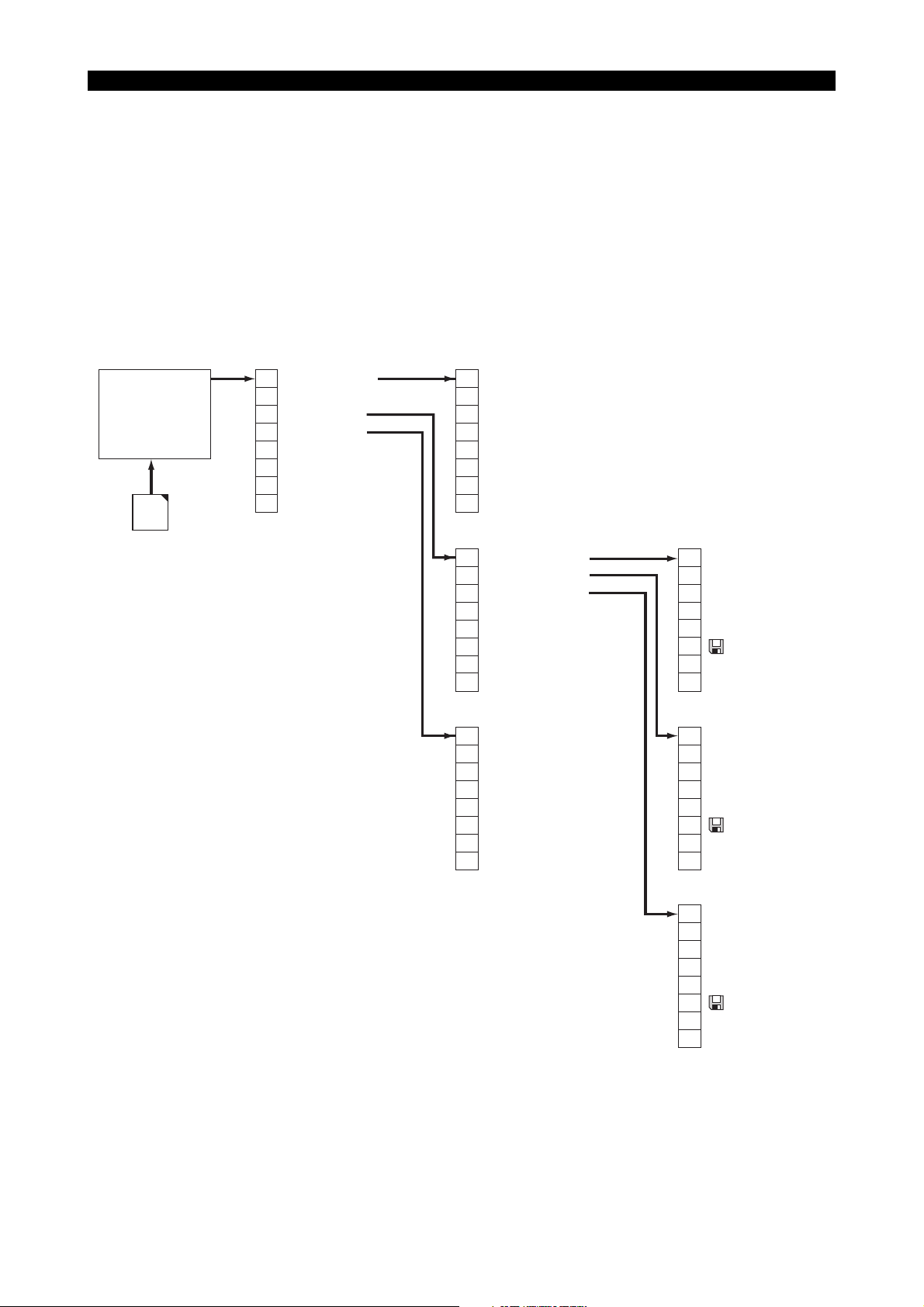

3. Screen Transition Diagram

[Selecting the reason for not-operating]

F1

Which Non op.

MaMan

MAIN

Mac

Man

(*1)

This function is displayed for network function

(IT plaza set,DNC-T etc.) specification only.

F2

F3

Report Info.

F4

Trouble Info.

F5

F6

Network (*1)

F7

F8

Refresh

[Report menu]

F1

IN-PRO SETUP

F2

NO OPERATOR

F3

PART WAITING

F4

MAINTENANCE

F5

OTHER

F6

F7

Quit

F8

F1

Machine Report

F2

Operate Report

F3

Operate History

F4

F5

F6

F7

Quit -> Return to the previous screen

F8

Eeospkku1003

Eeospkku1004

[Machining report]

F1

Daily (Today)

F2

Daily (Pre day)

F3

Period

F4

F5

F6

File

F7

Quit -> Return to the previous screen

F8

Refresh

[Trouble information menu]

F1

NC status at alaem

F2

Current NC status

F3

Alarm History

F4

Operation History

F5

Variable History

F6

System configuration

F7

Quit -> Return to the previous screen

F8

[Operation report]

F1

Daily (Today)

F2

Daily (Pre day)

F3

Period

F4

F5

F6

File

F7

Quit -> Return to the previous screen

F8

Refresh

[Operating History]

F1

Daily (Today)

F2

Daily (Pre day)

F3

F4

F5

F6

File

F7

Quit -> Return to the previous screen

F8

Refresh

EIOSPKKU1004R01

Page 11

SECTION 2 MacMan MAIN SCREEN

SECTION 2 MacMan MAIN SCREEN

4345-E P-4

Eeospkku2001

EIOSPKKU2001R01

Page 12

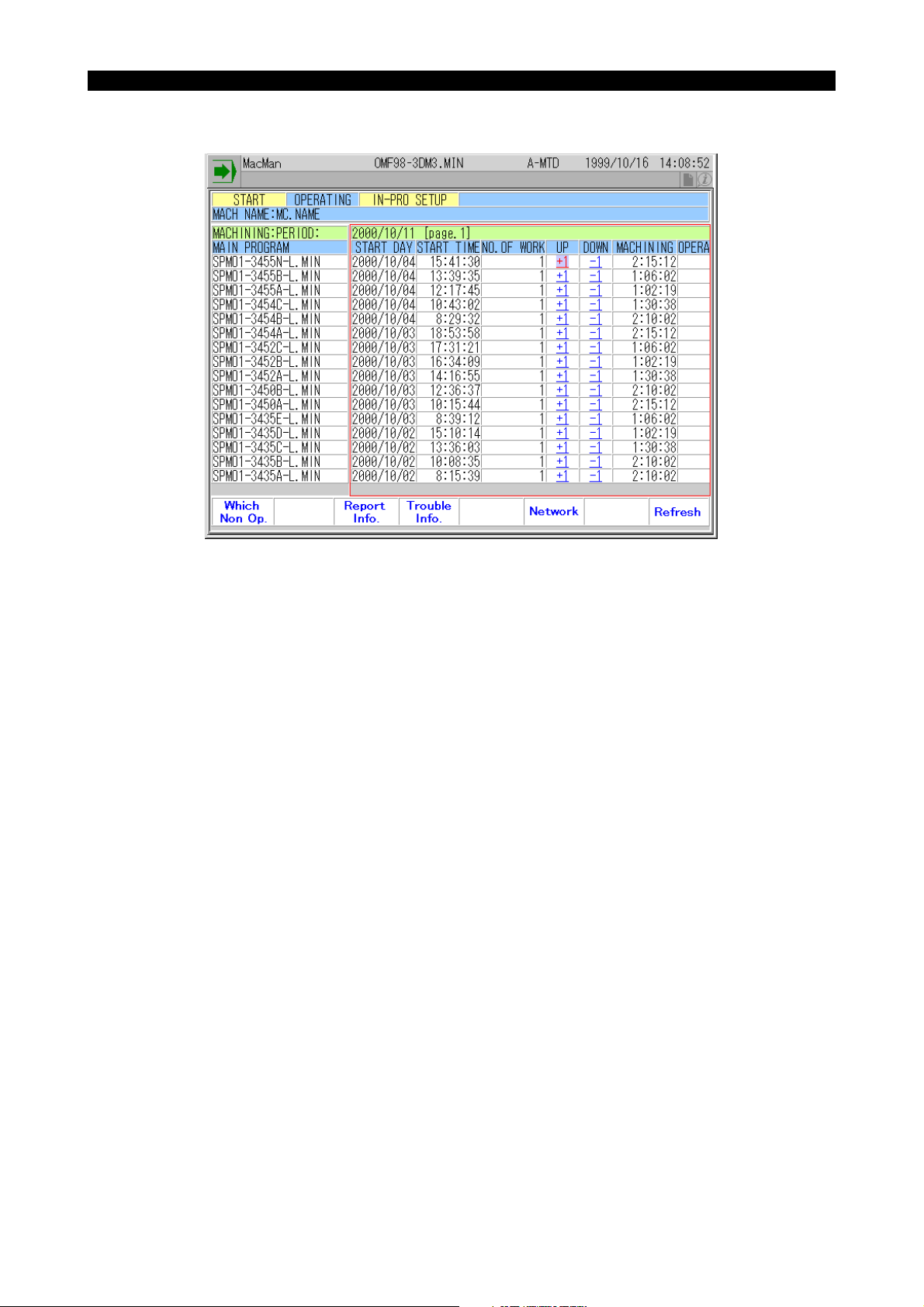

1. Machining Status

4345-E P-5

SECTION 2 MacMan MAIN SCREEN

(1) On the screen, whether or not a program has been selected is indicated by "START" and

Eeospkku2002

whether or not a program is being executed is indicated by "OPERATING".

The area indicating the status explained above is common to all display screens.

A main program has not been selected (NOT START status).

A main program is not being executed (NOT OPERATING status).

The reason for "not-operating status" is in-process setup.

To be set by selecting "REPORT/PRINTER" on the PREFERENCE SETTING screen.

The default machine name is "MC.NAME".

Date and time (today, current time)

Selecting a program

A main program has been selected (START status).

A main program is not being executed (NOT OPERATING status).

The reason for "not-operating status" is in-process setup.

Reason for "not-operating" is displayed here:

IN-PRO SETUP, NO OPERATOR, PART WAITING, MAINTENANCE, or OTHER

Executing the program

The main program has been selected (START status).

The main program is being executed (OPERATING status).

After the completion of the main program execution,

the machine enters the NOT OPERATING status due to in-process setup.

EIOSPKKU2002R01

Page 13

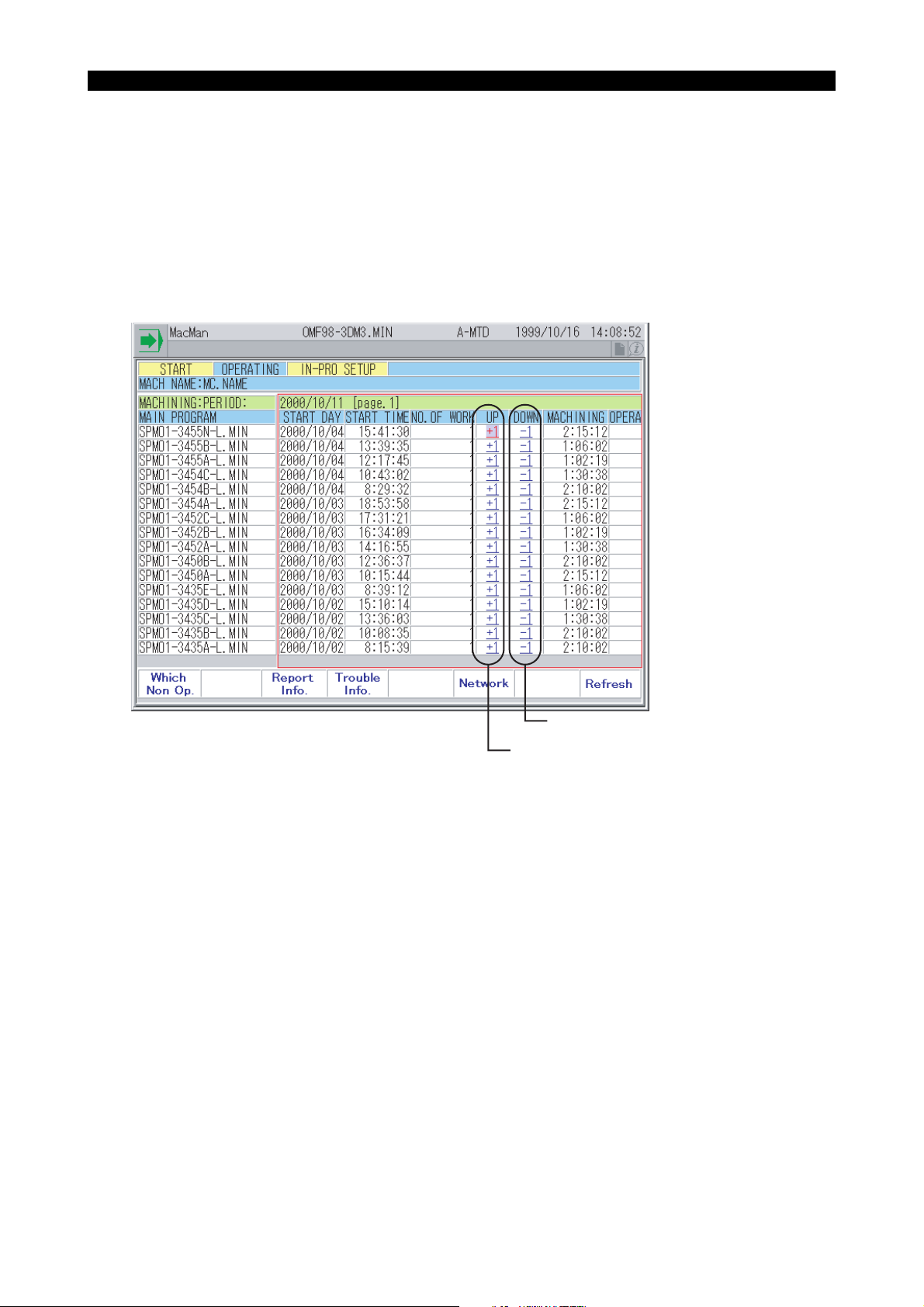

2. Recent Machining Report

4345-E P-6

SECTION 2 MacMan MAIN SCREEN

(1) Recent machining report is displayed.(up to 16 main programs)

Machining report for the program currently selected

• MAIN PROGRAM

The file name of the main program having been selected

• START DAY

Date of the main program selection [year/month/day]

• START TIME

Time of the main program selection [hour:minute:second]

• NO. OF WORK

The number of times the M02 or M30 command has been executed

Execution of the M02 or M30 command in the machine lock mode operation and dry run

mode operation (NC lathe) is not counted.

• OPERATING %

Percentage of machine operating time in reference to power ON time [%]

(Operating % = Machine operating time (OPERATING) / Power ON time (RUNNING) X 100)

Eeospkku2003

EIOSPKKU2003R01

• RUNNING

Length of time for which power supply to the NC has been ON [hours:minutes:seconds]

(Length of time for which main program has been selected)

• OPERATING

Length of time for which a main program has been executed [hours:minutes:seconds]

• CUTTING

Length of time for which an axis has been moved at a cutting feedrate [hours:minutes:seconds]

Length of time an axis has been moved at a cutting feedrate in the machine lock mode or dry

run mode (NC lathe) is not counted.

• CYCLE TIME

Length of time for which power has been ON for producing one piece of workpiece

[hours:minutes:seconds/pc.]

(Cycle time = Power on time (RUNNING) / No. of workpieces (NO. OF WORK))

• MACHINING

Length of operating time used for producing one piece of workpiece [hours:minutes:seconds/pc.]

(Machining time = Operating time (RUNNING) / No. of workpieces (NO. OF WORK))

(2) The items of report are scrolled right or left by pressing the "right" or "left" cursor key (1 item/

cursor key operation). Note that the MAIN PROGRAM is not shifted.

Page 14

4345-E P-7

SECTION 2 MacMan MAIN SCREEN

3.

Adjusting the Number of Work Count

You can correct the report data if the number of machined parts recorded in the machining report

differs from the number of actually machined parts.

When including the test-cut parts in the total number, for instance, you can increase (+1) the number

of parts. Conversely, when defective workpieces are found, you can decrease (-1) the number.

To correct the number, use the arrow keys and move the cursor to the [+1] or [-1] button for the

report data that you want to increase or decrease. Then, press the WRITE key.

If this page does not include the data that you want to correct, select a required report from the

report information screen.

Eeospkku2004

Decreases the number of parts by one.

Increases the number of parts by one.

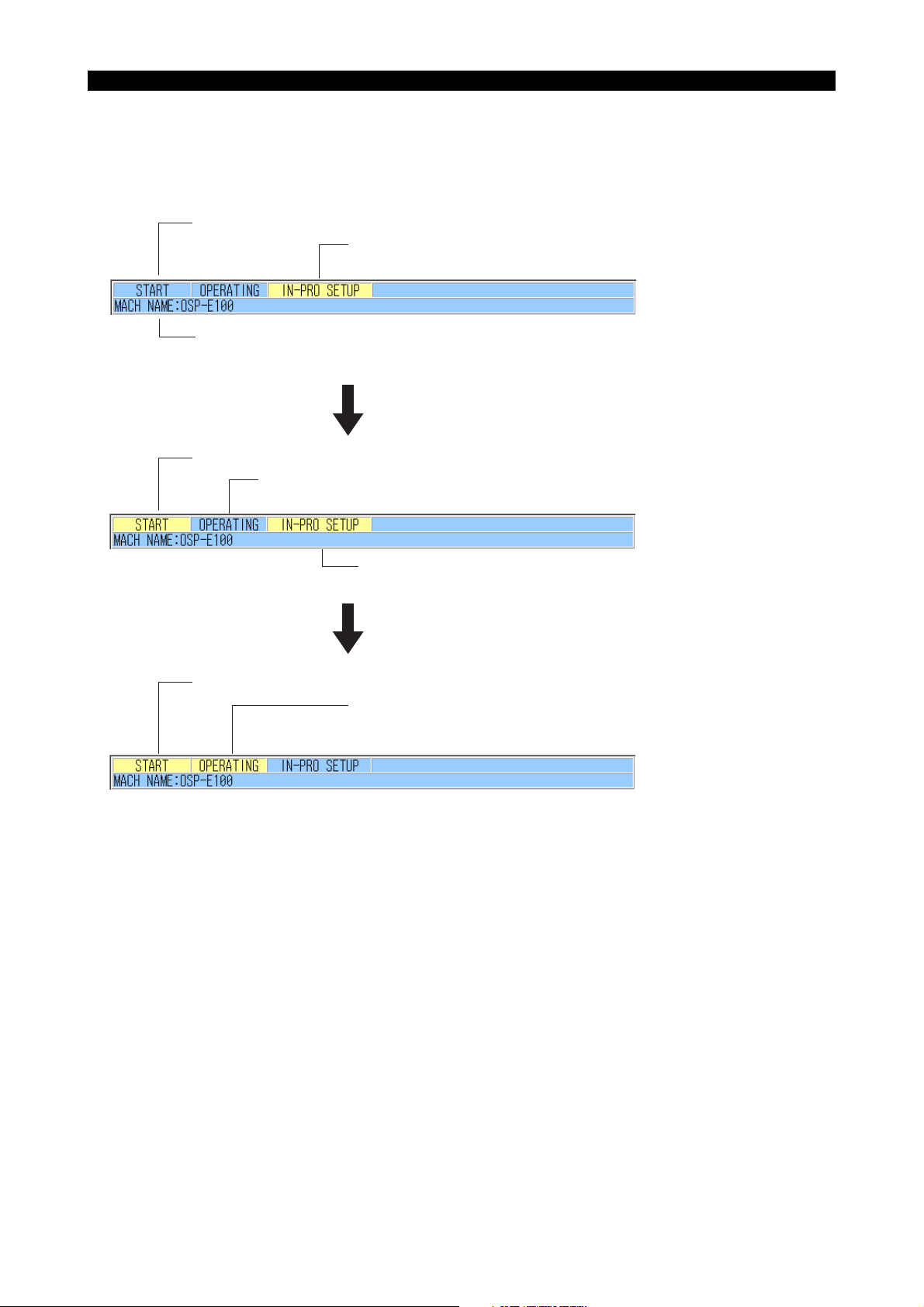

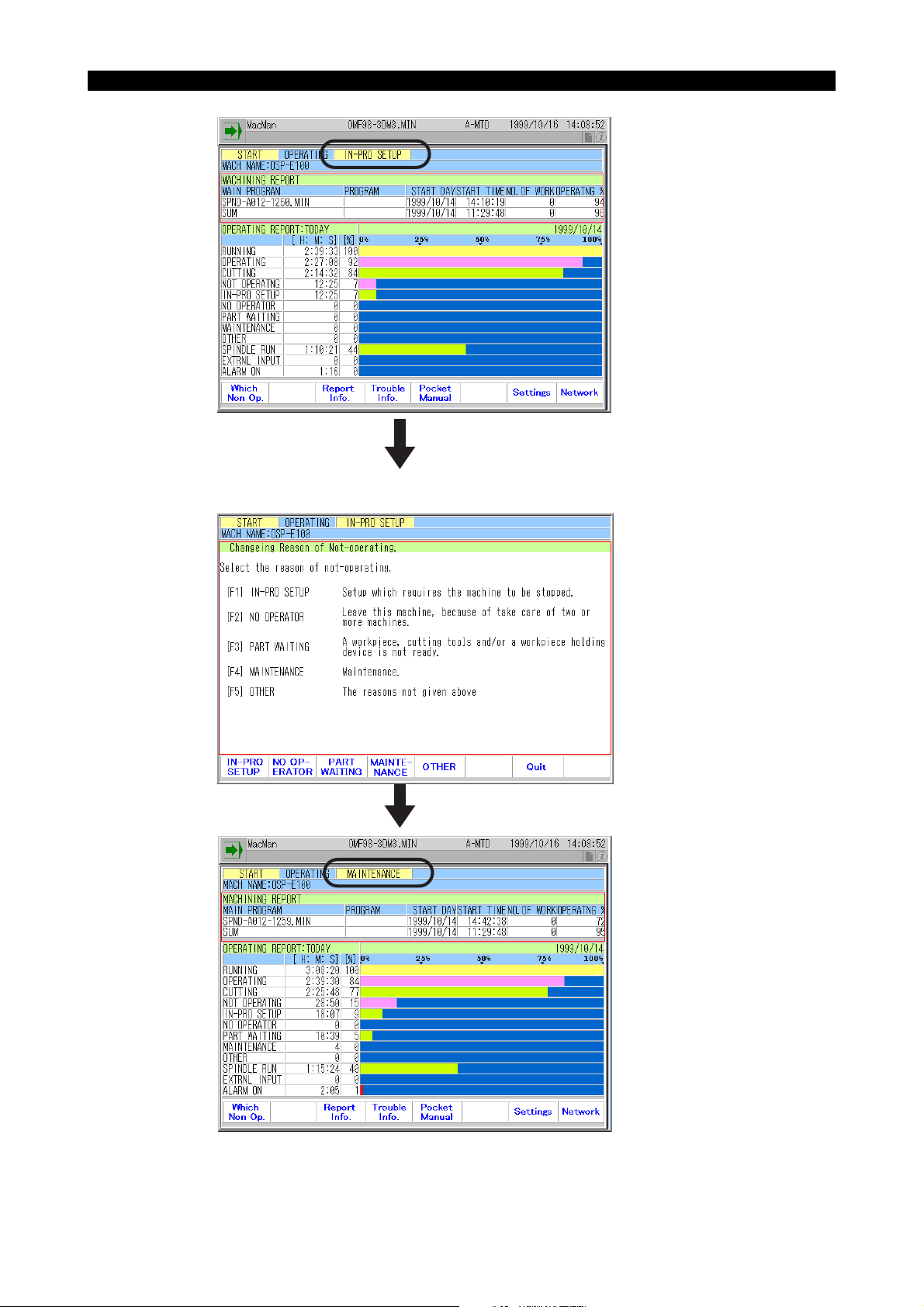

4. Changing the Reason of Not-operating Status

The current reason is in-process setup. Now, you are starting maintenance and the reason must be

changed to maintenance accordingly.

EIOSPKKU2004R01

Eeospkku2005

Page 15

SECTION 2 MacMan MAIN SCREEN

Press the function key [F1] (Which Non Op.).

4345-E P-8

Press the function key [F4] (Maintenance).

EIOSPKKU2005R01

Page 16

4345-E P-9

SECTION 2 MacMan MAIN SCREEN

(1) Reasons for Not-operating Status

The MacMan provides five categories for the reasons for not-operating status.

• IN-PRO SETUP

Select this reason when you perform setup change by stopping the machine.

(Setup change performed without stopping the machine is called post-process setup.)

• NO OPERATOR

One operator usually takes care of tow or more machines. Select this reason when you must

go to another machine.

• PART WAITING

If a workpiece, cutting tool(s), and/or a workpiece holding device is not ready or is not supplied to the machine on time, the machine will not be able to operate until all of them are

supplied to it.

Select this reason if the machine has to be stopped in such status.

• MAINTENANCE

Select this reason if the machine has to be stopped due to maintenance.

• OTHER

Select this reason if the machine has to be stopped due to the reasons not given above.

(2) Changing the Reason Manually

If you want to change the reason for not-operating status, press function key [F1] (WHICH NON

OP) and input the code number heading the reason to be selected. For example, change the

reason to "MAINTENANCE" before you begin maintenance.

• After pressing function key [F1] (WHICH NON OP), if you do not want to change the reason,

simply press the [WRITE] key without keying in a code number.

• It is possible to change the reason for not-operating status while the machine is operating. If

you have to leave the machine while it is operating to take care of other machine, you can

change the reason to "NO OPERATOR" before you leave the machine.

(3) Changing the Reason Automatically

The MacMan can determine the reason for not-operating status automatically. If you select "INPROCESS SETUP" for the reason, you are not requested to change the reason while the

machine is operating continuously.

• Ordinary not-operating status, due to such as changing workpieces and removing chips, is

classified into "IN-PROCESS SETUP".

• Assume that you leave the machine, without changing the reason:

While you are not attending the machine, that situation is recognized by the NC from the fact

that none of keys on the NC operation panel has not been pressed for a period longer than

the parameter-set time. Upon recognition of this, the NC automatically changes to reason

from "IN-PROCESS SETUP" to "NO OPERATOR".

• If you come back to the machine for which the reason for not-operating has been changed to

"NO OPERATOR":

The NC recognizes that you have returned to the machine from the fact that a key on the NC

operation panel has been pressed. Then, the NC automatically switches the reason back to

"IN-PROCESS SETUP".

Page 17

4345-E P-10

SECTION 2 MacMan MAIN SCREEN

• If the reason for not-operating status is "PART WAITING", "MAINTENANCE", or "OTHER",

the automatic change function is not valid. If the machine has to be stopped, due to any of

these reasons, change the reason manually. When the machine restarts, change the reason for not-operating status manually again.

The initial parameters are so set that the NC does not automatically change the reason for

not-operating status. To make the NC change the reason automatically, select MacMan

PARAMETER in the parameter setting mode and set the required data at the following

parameters:

• USE NOT OPERATING ITEM FOR AUTO DECISION (0=NO,1=YES)

0 (No)

• TIME ALLOWED BEFORE DETERMINING NO OPERATOR PRESENT (hh:mm:ss)

00:20:00 (20 minutes)

Page 18

SECTION 3 REPORT INFORMATION DISPLAY

SECTION 3 REPORT INFORMATION DISPLAY

Eeospkku3001

4345-E P-11

EIOSPKKU3001R01

Press function key [F1], [F2], or [F3], and the corresponding machining or operation report screen is

displayed.

Machining Report

The report shows the progress of each of the selected main programs.

Program progress report:

• MAIN PROGRAM

The file name of the main program having been selected.

• START DAY

Date of the main program selection [year/month/day]

• START TIME

Time of the main program selection [hour:minute:second]

• NO. OF WORK

The number of times the M02 or M30 command has been executed

Execution of the M02 or M30 command in the machine lock mode operation and dry run mode

operation (NC lathe) is not counted.

• OPERATING %

Percentage of machine operating time in reference to power ON time [%]

(Operating % = Machine operating time (OPERATING) / Power ON time (RUNNING))

• RUNNING

Length of time for which power supply to the NC has been ON [hours:minutes:seconds]

(Length of time for which main program has been selected)

• OPERATING

Length of time for which a main program has been executed [hours:minutes:seconds]

Length of time the main program has been executed in the machine lock mode or dry run mode

(NC lathe) is not counted.

Page 19

4345-E P-12

SECTION 3 REPORT INFORMATION DISPLAY

• CUTTING

Length of time for which an axis has been moved at a cutting feedrate [hours:minutes:seconds]

Length of time an axis has been moves at a cutting feedrate in the machine lock mode or dry

run mode (NC lathe) is not counted.

• CYCLE TIME

Length of time for which power has been ON for producing one piece of workpiece [hours:minutes:seconds/pc.]

(Cycle time = Power on time (RUNNING) / No. of workpieces (NO. OF WORK))

• MACHINING

Length of operating time used for producing one piece of workpiece [hours:minutes:seconds/

pc.]

(Machining time = Operating time (RUNNING) / No. of workpieces (NO. OF WORK))

Operating Report

The report shows the operating status of the machine.

Machine operating report:

• RUNNING

Length of time for which power supply to the NC has been ON [hours:minutes:seconds]

(Power ON (RUNNING) = OPERATING + NOT OPERATNG)

• OPERATING

Length of time for which a main program has been executed

Length of time the main program has been executed in the machine lock mode or dry run mode

(NC lathe) is not counted.

(OPERATING = CUTTING + Not cutting)

• CUTTING

Length of time for which an axis has been moved at a cutting feedrate [hours:minutes:seconds]

Length of time an axis has been moved at a cutting feedrate in the machine lock mode or dry

run mode (NC lathe) is not counted.

• NOT OPERATNG

Length of time for which a main program has not been executed

(NOT OPERATING = IN-PRO SETUP + NO OPERATOR + PART WAITING + MAINTENANCE

+ OTHER)

• IN-PRO SETUP

Constituent of not-operating time: machine has not been operating due to in-process setup.

• NO OPERATOR

Constituent of not-operating time: machine has not been operating due to no operator attendance.

• PART WAITING

Constituent of not-operating time: machine has not been operating due to waiting for workpiece

to be machined.

• MAINTENANCE

Constituent of not-operating time: machine has not been operating due to machine maintenance.

• OTHER

Constituent of not-operating time: machine has not been operating due to reasons not classified

into the items indicated above.

• SPINDLE RUN

Length of time for which the spindle has been rotating

Length of time the spindle has been rotating in the machine lock mode is not counted.

Page 20

4345-E P-13

SECTION 3 REPORT INFORMATION DISPLAY

• EXTERNAL INPUT

Length of time for which an external input signal has been ON

• ALARM ON

Length of time for which the NC has been in an alarm state (alarm A, alarm B, alarm C)

Operating History

The operating history shows the operating status (ON/OFF) of the machine using the time chart in

intervals of 10 minutes.

Machine history:

• RUNNING

Length of time for which power supply to the NC has been ON

• OPERATING

Length of time for which a main program has been executed

Length of time the main program has been executed in the machine lock mode or dry run mode

(NC lathe) is not counted.

• CUTTING

Length of time for which an axis has been moved at a cutting feedrate

Length of time an axis has been moved at a cutting feedrate in the machine lock mode or dry

run mode (NC lathe) is not counted.

• NOT OPERATNG

Length of time for which a main program has not been executed

• IN-PRO SETUP

Constituent of not-operating time: machine has not been operating due to in-process setup.

• NO OPERATOR

Constituent of not-operating time: machine has not been operating due to no operator attendance.

• PART WAITING

Constituent of not-operating time: machine has not been operating due to waiting for workpiece

to be machined.

• MAINTENANCE

Constituent of not-operating time: machine has not been operating due to machine maintenance.

• OTHER

Constituent of not-operating time: machine has not been operating due to reasons not classified

into the items indicated above.

• SPINDLE RUN

Length of time for which the spindle has been rotating

Length of time the spindle has been rotating in the machine lock mode is not counted.

• EXTERNAL INPUT

Length of time for which an external input signal has been ON

• ALARM ON

Length of time for which the NC has been in an alarm state (alarm A, alarm B, alarm C)

(1) You can output the report information to the floppy disk.

• Simply press the function key [F6] ( File), and the operation report presently displayed on

the screen is output to the floppy disk. The default device and file names can be set at the

MacMan parameters displayed in the parameter setting mode. These parameters are factory-set so that the date is entered in the file name.

Page 21

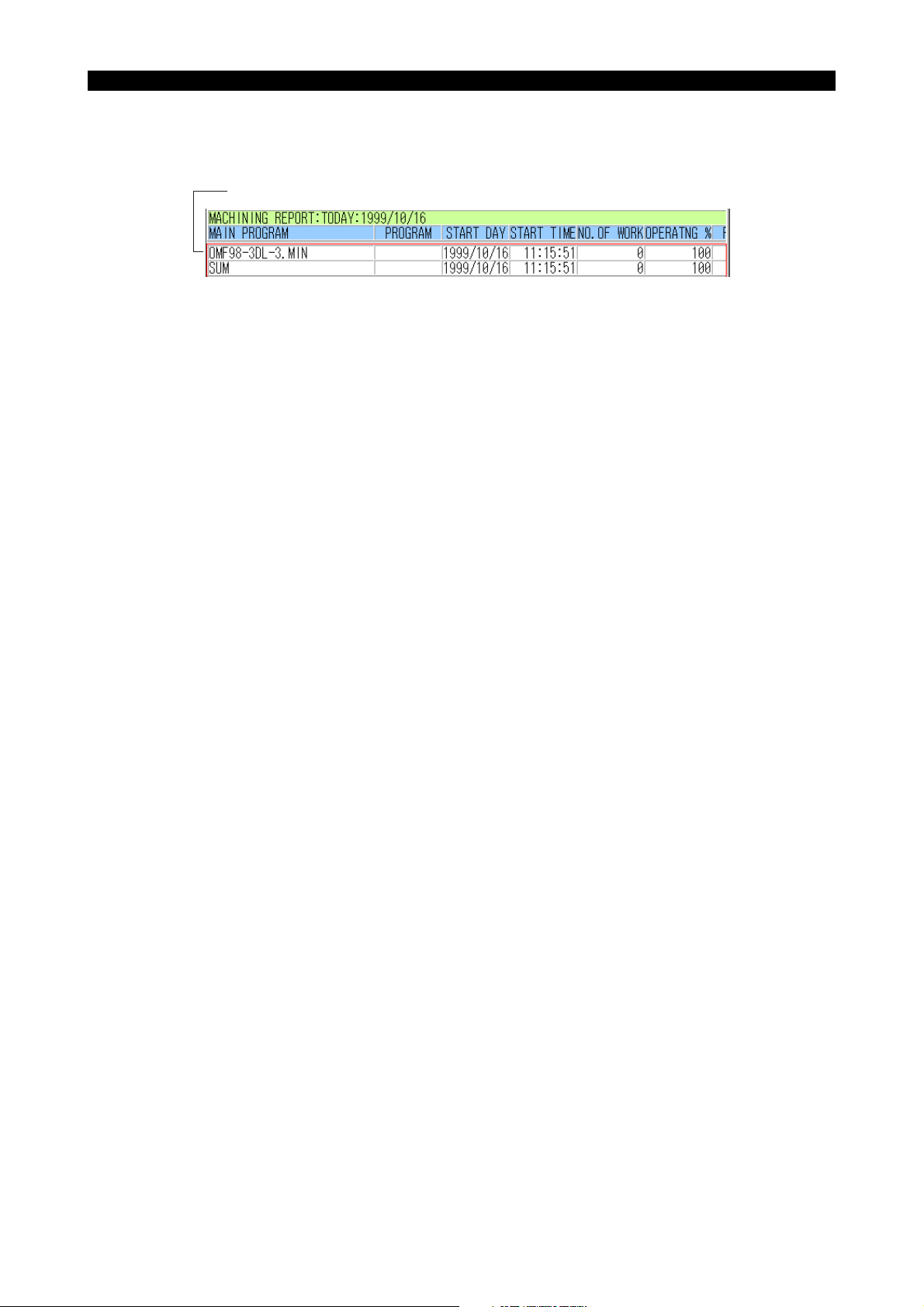

SECTION 4 MACHINING REPORT DISPLAY

SECTION 4 MACHINING REPORT DISPLAY

1. Daily Machining Report (Today)

4345-E P-14

Eeospkku4001

EIOSPKKU4001R01

(1) The machining result of the main programs selected today is displayed for each main program

in the order the main programs selected later (START TIME).

• The first line in the first page shows the machining result of the main program presently

selected.

• When the screen is changed to the MACHINING REPORT screen, the DAILY MACHINING

REPORT (TODAY) screen is displayed.

Date (today)

EIOSPKKU4002R01

Page 22

4345-E P-15

SECTION 4 MACHINING REPORT DISPLAY

(2) The machining report consists of a main program file name and nine items showing the

progress of the main program. Since one line in the display screen in able to show a main program file name and four items, use the "left" and "right" cursor keys to scroll the screen to display the other items. Note that the main program file name stays displayed at the same column

even when the display of the items is scrolled.

"Left" cursor key

"Right" cursor key

EIOSPKKU4003R01

(3) One page of the machining report display page shows the information on 16 main programs. If

you have selected more than 16 main programs for a day, press the page key to display the

other pages.

EIOSPKKU4004R01

Page 23

SECTION 4 MACHINING REPORT DISPLAY

2. Daily Machining Report (Pre Day)

4345-E P-16

Eeospkku4002

EIOSPKKU4005R01

(1) The machining results of the main programs selected in the previous day are displayed in the

order of selection, with the latest one being the top (START TIME).

• The term previous day does not always mean "yesterday". It indicates the last day the NC

was operated. If the NC had been stopped for two days, the previous day refers to the day

three days before today.

• The functions of the cursor keys and the page keys are the same as those used in the

MACHINING REPORT (TODAY) screen.

Date (previous day)

EIOSPKKU4006R01

Page 24

3. Period Machining Report

4345-E P-17

SECTION 4 MACHINING REPORT DISPLAY

Eeospkku4003

EIOSPKKU4007R01

(1) The machining result of the main programs having been selected up to today is displayed for

each main program in the order the main programs selected later (START TIME).

• The first line in the first page shows the machining result of the main program presently

selected.

• One page of the report display shows the machining report of up to 16 main programs. In

this report.

• If the total number of the selected main programs exceeds 13, the report is given on the fol-

lowing pages which are accessible by pressing a cursor key or a page key. The functions of

the cursor keys and the page keys are the same as those used in the MACHINING

REPORT (TODAY) screen.

(2) The period machining report function is able to store the machining result information for up to

91 main programs, including the main program selected presently.

• If the memory has already stored the machining result information for 91 main programs,

selection of a new main program will cause the machining result information of the oldest

main program among the stored 91 main programs to be deleted. The machining report of

the newly selected main program is created instead.

• The machining report (today) is created by extracting the machining report of the main pro-

grams for which the START DAY is today from the period machining report.

• The machining report (pre day) is created by extracting the machining report of the main pro-

grams for which the START DAY is previous day from the period machining report.

Page 25

4. Output to Floppy Disk

4345-E P-18

SECTION 4 MACHINING REPORT DISPLAY

You can save the machining report displayed on the screen by outputting it to floppy disk.

(1) Insert an MS-DOS format floppy disk to the floppy disk drive. The machining report displayed

on the screen is output to the floppy disk.

(2) The machining report displayed on the screen can be output to the floppy disk by simply press-

ing function key [F6] ( File). The device name and the file name are set at the MacMan

parameters displayed in the parameter setting mode.

• Device name

The machining report is output to the device set at DEFAULT DEVICE. The initial setting for

DEFAULT DEVICE NAME is "FD0". Therefore, to output the machining report to a floppy

disk set in the FD0, you do not have to set the output device name.

• Output file name

The machining report to be output to the floppy disk is assigned the file name which is set at

DEFAULT FILE of the MacMan parameter displayed in the parameter setting mode. The initial setting for DEFAULT FILE NAME is:

Daily machining report file DW*Y*M*D. TXT

Period machining report file. TW*Y*M*D. TXT

Eeospkku4004

EIOSPKKU4008R01

If today is April 12, 1999 and the previous day is April 07, 1999, the actual file names to be

assigned are:

Daily machining report (today) DW990412. TXT

Daily machining report (pre day) DW990407.TXT

Period machining report TW990412.TXT

(3) If you output the machining report to the floppy disk (MS-DOS format), it is output in the text file.

Refer to Section 19. "OUTPUT FILES".

• If the report information is output in the text file, it can be displayed or analyzed using word

processor software.

Page 26

SECTION 5 OPERATING REPORT

1. Daily Operating Report (Today)

4345-E P-19

SECTION 5 OPERATING REPORT

Eeospkku5001

(1) Today's machine operating report is displayed.

When the screen is changed to the daily operating report screen, the DAILY OPERATING

REPORT (TODAY) screen is displayed.

Date (today)

Bar graph showing the rate of time to the NC running time

Rate of time to the NC running time [%]

Time [hours:minutes:seconds]

EIOSPKKU5001R01

EIOSPKKU5002R01

Page 27

2. Daily Operating Report (Pre Day)

4345-E P-20

SECTION 5 OPERATING REPORT

Eeospkku5002

EIOSPKKU5003R01

(1) The machine operating report of the previous day is displayed.

The term previous day does not always indicate yesterday. If the NC is turned on after it has

been stopped for two days, the previous day means the day two days before yesterday.

Date (previous day)

Bar graph indicating the ratio

Ratio to RUNNING TIME [%]

Time [hours:minutes:seconds]

EIOSPKKU5004R01

Page 28

3. Period Operating Report

4345-E P-21

SECTION 5 OPERATING REPORT

Eeospkku5003

EIOSPKKU5005R01

(1) The total operating time for the period up to today is displayed.

Start day of data accumulation

Bar graph showing the rate of time to the NC running time

Rate of time to the NC running time [%]

Time [hours:minutes:seconds]

EIOSPKKU5006R01

Page 29

4345-E P-22

SECTION 5 OPERATING REPORT

(2) Operating Time in the Period Operating Report

The operating time of each item displayed on the operating report is the accumulated time from

the day the operating report was cleared last. When the NC is turned on in the same day set as

the clear date, the period operating report is cleared and the operating time is accumulated

from "0".

• The period operating report clear day is set at a MacMan Parameter displayed in the param-

eter setting mode.

• The period operating report is cleared at the first power on operation to the NC on the same

day as set for the OPERATING REPORT CLEAR DAY. The report is not cleared in the succeeding power on operation.

• Make sure that no holiday is set as the OPERATING REPORT CLEAR DAY. The operating

report is not cleared only when the NC is turned on in the preset report clear date.

Example: setting the period operating report clear day

• To use the period operating report as the weekly report, set the date of Monday of the next

week (Tuesday, if Monday is holiday) for PERIOD OPERATING REPORT CLEAR DAY.

• To use the period operating report as the monthly report, set the first day of the next month (the

second day if the first day is holiday) for PERIOD OPERATING REPORT CLEAR DAY.

• To collect the result of improvements in operation, set the next day on the day when improve-

ment preparation has been finished.

Page 30

SECTION 6 OPERATING HISTORY

1. Daily Operating History (Today)

4345-E P-23

SECTION 6 OPERATING HISTORY

Eeospkku6001

(1) The machine operating status for one day (today) is displayed in time chart.

The operating status of the machine (ON/OFF) is checked in every 10 minutes and the results

of the check are displayed on the screen in time chart.

11:00

Date of report (today)

NC was ON, but Main program was not executed.

Reason: In-process setup

11:30

12:00

EIOSPKKU6001R01

EIOSPKKU6002R01

Page 31

4345-E P-24

SECTION 6 OPERATING HISTORY

(2) A screen shows the operating history for five hours. To display the history before or after the

displayed time zone, locate the cursor on [<<] [<] [>] [>>] using the cursor keys with left and

right arrows, and press WRITE.

Goes back

by 4 hours

Goes back by

1 hour

Advance by

1 hour

Advance by

4 hours

EIOSPKKU6003R01

Page 32

2. Daily Operating History (Pre Day)

4345-E P-25

SECTION 6 OPERATING HISTORY

Eeospkku6002

(1) The machine operating status for one day (previous day) is displayed in time chart.

The operating status of the machine (ON/OFF) is checked in every 10 minutes and the results

of the check are displayed on the screen in time chart.

• The term previous day does not always indicate yesterday. If the NC is turned on after it has

been stopped for two days, the previous day means the day three days before yesterday.

• The operating history for 5 hours is displayed on the screen. The display can be scrolled to

view the history of other operating hours by using the "right" and "left" cursor keys.

You can scroll the screen in the same manner as explained in 10-1. "Daily Operating History

(Today)".

15:00

Date of report (previous day)

15:30

16:00

EIOSPKKU6004R01

NC was ON, but Main program was not executed.

Reason: In-process setup

EIOSPKKU6005R01

Page 33

SECTION 7 TROUBLESHOOTING INFORMATION

SECTION 7 TROUBLESHOOTING INFORMATION

Eeospkku7002

4345-E P-26

EIOSPKKU7001R01

(1) On the TROUBLESHOOTING INFORMATION screen, press function keys [F1] to [F6] accord-

ing to the function you want to call. The information which will help you check and troubleshoot

the problem is displayed.

• To check the alarm occurrence time and nature of alarm:

ALARM HISTORY

• To check the alarm occurrence time and type of operation involved:

OPERATE HISTORY

a. [F3] (ALARM HISTORY)

The alarm history is displayed on the screen. At each occurrence of an alarm, the data

which identify the alarm are logged - date, time, alarm number, alarm code, and alarm

character string.

It is possible to output the alarm history to the floppy disk.

b. [F4] (OPERATE HISTORY)

The screen shows two kinds of operation histories. The operation history can be also output to the floppy disk.

OPERATING PANEL : NC operation panel keys that have been pressed

I/O SIGNALS : ON/OFF status of the I/O signals

(2) You can output the trouble information to the floppy disk.

• Simply press function key [F6] ( File), and the trouble information isoutput to the floppy

disk. The information presently displayed is output. The device name and the file name are

set on the PARAMETER SETTING screen. With the setting made at the shipping, date is

entered to the file name.

Page 34

SECTION 8 ALARM HISTORY

4345-E P-27

SECTION 8 ALARM HISTORY

Eeospkkua001

1. Displaying the Alarm History

You can back track the occurrence of alarms.

(1) At each occurrence of an alarm, the data which identify the alarm are logged and displayed on

the screen. The information which identifies individual alarms consists of the date, time, alarm

number, alarm code, and alarm character string.

(2) On the ALARM HISTORY screen, up to 16 sets of alarm information are displayed. To view

other alarms which are not displayed on the screen, press function key [F5] (Page ↓).

EIOSPKKUA001R01

Eeospkkua002

Page 35

2. Changing Logged Alarm Levels

4345-E P-28

SECTION 8 ALARM HISTORY

The alarm levels logged in the alarm history can be changed.

The factory-set alarm levels to be logged in the alarm history are alarms A, B, C, and D.

Eeospkkua004

Lathes

Change the alarm levels on the OPTIONAL PARAMETER (OTHER FUNCTION) screen displayed

in the parameter setting mode.

Select the alarm level from:

Alarm A, B, C, D

Alarm A, B, C

Alarm A, B

Alarm A

EIOSPKKUA003R01

Page 36

4345-E P-29

SECTION 8 ALARM HISTORY

Machining Centers

Change the alarm levels on the NC OPTIONAL PARAMETER (DISPLAY RELATION PARAMETER) screen displayed in the parameter setting mode.

Select the alarm level from:

Alarm A, B, C, D

Alarm A, B, C

Alarm A, B

Alarm A

EIOSPKKUA004R01

Page 37

SECTION 9 OPERATION HISTORY

1. Operate Panel

4345-E P-30

SECTION 9 OPERATION HISTORY

Eeospkkub003

EIOSPKKUB003R01

(1) The following operations are records as the operation panel history with the date and time.

1) Key input

2) Operation on the screen components

3) Function key input

4) MDI input

5) Occurrence of error

6) Mode change

7) Depression of help key

8) Execution of one-touch window close

9) Others, including changes between turret A and turret B

<<Limitations>>

The panel operations, however, are not recorded on the following screens:

1) One-Touch IGF-XM screen

2) OSP browser screen (for MacMan or Pocket Manual)

(2) History of a key input is displayed as follows:

> "Key name"

The illustration below shows an example displayed when depression of the cursor key [↓] has

been recorded.

EIOSPKKUB005R01

Page 38

4345-E P-31

SECTION 9 OPERATION HISTORY

Table 1 shows the keys and the corresponding character strings displayed as a record.

(3) The MacMan System also records the operations on the screen components such as input in

the TextBox, changing ON/OFF status in the CheckBox, changing number in the SelectionBox

or ListBox. These records are displayed as follows:

"Screen component name": "Operation"

If, for example, you turned on a CheckBox, the operation record is displayed as illustrated

below.

EIOSPKKUB007R01

In the above illustration, (Table (1, 1)) at the end is the internal data of the system and not

related with your operation.

(4) Depression of a function key is displayed as follows:

"Function key number" ["Function key label"]

When a window is open, the MacMan System shows all the screen components in the window

to which the cursor can be moved. When no window is open, it shows the state of cursorlocated screen components.

<Example 1> Main program selection screen (lathe)

EIOSPKKUB009R01

If the function key [F7] (OK) is pressed on the above example screen, the following record is

displayed.

EIOSPKKUB010R01

Page 39

4345-E P-32

SECTION 9 OPERATION HISTORY

(5) Record of manual data input is displayed as follows:

MDI Input: "Input character string"

(6) If an error occurs, the error number and the error character-string are displayed as an error

record.

The illustration below shows an example of record displayed when Error "337 floppy ready"

occurred.

EIOSPKKUB012R01

(7) Record of mode change is displayed as follows:

Mode Change: "Mode name"

(8) When a help screen is opened by depression of the help key, the following record is displayed:

Help

When the help screen is closed by re-depression of the help key, the record is displayed as follows:

Mode Change: "Mode name"

(9) When a window is closed using the one-touch window close function (pressing the same mode

key as the currently selected one when the window is open), the record is displayed as follows:

One-touch Window Close: "Mode name"

(10) When a turret is changed on the lathe by depression of turret A key or turret B key, the record is

displayed as follows:

A-Turret

B-Turret

(when turret A is selected)

(when turret B is selected)

Page 40

SECTION 10 PARAMETER SETTING

SECTION 10 PARAMETER SETTING

4345-E P-33

Eeospkkue001

EIOSPKKUE001R01

(1) Press a proper function key to access the required function. The function keys are summarized

below.

a) REPORT DATA

Used to set the machine names and the parameters needed for collecting the operating

data.

b) OUTPUT DATA

Used to set the default device name and the default file name of the various operation data

files and various trouble information files.

c) INIT

Used to initialize (or clear) the history data of report information or trouble information.

Page 41

1. REPORT DATA

4345-E P-34

SECTION 10 PARAMETER SETTING

Eeospkkue002

MACHINE NAME

• Explanation

The machine name set here is displayed on all screens of the cell operation management function. The machine name is described in the file when outputting the report or troubleshooting

information to a floppy disk. When outputting the report or troubleshooting information to a

printer, the machine name is printed at the head of the print-out.

• Setting

Within eight alphanumeric characters

EIOSPKKUE002R01

Page 42

4345-E P-35

SECTION 10 PARAMETER SETTING

OPERATING REPORT CLEAR DAY

• Explanation

If the date of today agrees with the date set for "OPERATING REPORT CLEAR DATE", the

period operating report in the memory is cleared when the NC is turned on.

• Setting

Ten characters (fixed)

If the number of digits of a number used to express the month or day is not two, prefix "0" to the

number.

Examples: 1999/07/30 Acceptable

1999/7/30 Not acceptable

USE NOT OPERATING ITEM FOR AUTO DECISION

TIME ALLOWED BEFORE DETERMINING NO OPERATOR PRESENT

• Explanation

If you set [YES] for "USE NOT OPERATING ITEM FOR AUTO DECISION", the reasons for notoperating status are automatically determined as follows:

• If a key on the NC operation panel has not been pressed for the period set for "TIME

ALLOWED BEFORE DETERMINING NO OPERATOR PRESENT", the reason for not-operating status is changed to "NO OPERATOR". Note that this automatic change is made only

when the current reason is "IN-PRO SETUP".

• If a key on the NC operation panel is pressed, the reason for not-operating is automatically

changed to "IN-PRO SETUP". Note that this automatic change is made only when the current reason is "NO OPERATOR".

• Setting

Eight characters (fixed)

If the number of digits of a number used to express the time is not two, prefix "0" to the number.

Examples: 08:59:00 Acceptable

8:59:00 Not acceptable

Page 43

2. OUTPUT DATA

4345-E P-36

SECTION 10 PARAMETER SETTING

Page 1

(1) DEFAULT DEVICE NAME

• Explanation

The default name of the device where the file is output if no device name is specified for file output operation is set.

Note that the setting simply specifies the device name and the status of the floppy disk drive is

not checked. This means the floppy disk drive may not be installed even if the setting is made.

• Setting

FD0: to FD9:

Eeospkkue007

EIOSPKKUE003R01

(2) DAILY MACHINING REPORT FILE: DEFAULT FILE NAME

(3) DAILY OPERATING REPORT FILE: DEFAULT FILE NAME

(4) DAILY OPERATING HISTORY FILE: DEFAULT FILE NAME

Page 2

(5) PERIOD MACHINING REPORT FILE: DEFAULT FILE NAME

(6) PERIOD OPERATING FILE: DEFAULT FILE NAME

EIOSPKKUE004R01

Page 44

4345-E P-37

SECTION 10 PARAMETER SETTING

Page 3

(7) ALARM HISTORY FILE: DEFAULT FILE NAME

(8) OPERATION PANEL HISTORY FILE: DEFAULT FILE NAME

• Explanation

The default names of the files used to output the report or troubleshooting information to the

floppy disk. Since the report and troubleshooting information are output to the MS-DOS format

floppy disk, the default file names to be set must conform to the rule of MS-DOS.

EIOSPKKUE005R01

• Setting

For a name, within 65 characters of alphanumerics which are preceded and followed by the

back slash code () can be input. Set a file name following the path name. Note that the directory

name and path name must conform to the MS-DOS rule.

\ABCDEFGH.TXT

Path name File name

\PART13.DIR\WORK954.DIR\RP.TXT

Path name File name

EIOSPKKUE008R01

Page 45

4345-E P-38

SECTION 10 PARAMETER SETTING

If you specify a specific character (Y, M, D, h, m, s) following an asterisk (*), it is replaced with a

two-digit number.

*Y : Year (Example: 1999, July 30 -> 99)

*M : Month (Example: 1999, July 30 -> 07)

*D : Date (Example: 1999, July 30 -> 30)

*h : Hour (Example: 8:34:52 -> 08)

*m : Minute (Example: 8:34:52 -> 34)

*s : Second (Example: 8:34:52 -> 52)

Year/month/day : Today if DAILY REPORT (TODAY) or PERIOD REPORT is

output.

Previous day if DAILY REPORT (PRE DAY) is output.

Hour/minute/second : The time at which the file is output.

Example 1: To output DAILY OPERATING REPORT (TODAY) in July 30th of 1999

DW*Y*M*D.TXT’DW990730.TXT

Example 2: To output DAILY OPERATING REPORT (PRE DAY) in July 30th of 1999 (date

of previous day: July 29th)

DW*Y*M*D.TXT’ DW990729.TXT

Example 3: To output the ALARM HISTORY at 13:30:48 in July 30th of 1999

AL*h*m*s.D*D ’ AL133048.D30

Page 46

3. Initialization

4345-E P-39

SECTION 10 PARAMETER SETTING

Eeospkkue008

EIOSPKKUE009R01

ALL INFO CLEAR

Turning on this check box clears all the report information and trouble information in G buffer.

OPERATING REPORT (TODAY, PRE.DAY, PERIOD)

Turning on this check box clears the today, pre day, and period machining report in G buffer.

MACHINING REPORT (TODAY, PRE.DAY, PERIOD)

Turning on this check box clears the today, pre day, and period machining report in G buffer.

OPERATING HISTORY (TODAY, PRE. DAY)

Turning on this check box clears the today and pre-day machining history in G buffer.

OPERATION HISTORY (OPERATING PANEL, I/O SIGNALS)

Turning on this check box clears the operation panel and the I/O signal operation history in G buffer.

Page 47

LIST OF PUBLICATIONS

Publication No. Date Edition

4345-E January 2000 1st

4345-E-R1 August 2000 2nd

4345-E-R2 Octobrt 2000 3rd

4345-E-R3 May 2001 4th

4345-E-R4 November 2001 5th

4345-E-R5 May 2002 6th

This manual may be at variance with the actual product due to specification or

design changes.

Please also note that pecifications are subject to change without notice.

If you requireclarification or further explanation of any point in this manual, please

contact your OKUMA representative.

Loading...

Loading...