Page 1

Programmes After Market Services (PAMS)

Technical Documentation

NHB–3 Series Transceiver

NHB–3 Series Transceiver

Chapter 5

UIF MODULE GU8

Page 2

PAMS

Technical Documentation

CHAPTER 5 – UIF MODULE DU8

CONTENTS

Page No

Introduction 5–3

Technical Outline 5–3

Mechanics 5–3

Electronics 5–4

List of Submodules and Mechanical Parts 5–5

Technical Specifications 5–5

Maximum Ratings 5–5

DC Characteristics 5–5

Control Signals 5–6

AC Characteristics 5–6

External Signals and Connections 5–7

Mechanical Characteristics 5–9

Functional Description 5–9

Circuit Description 5–9

DU8C Circuit Description 5–9

Keyboard scanning and display driver control 5–9

Keyboard and display illumination 5–9

Audio Circuitry 5–10

LCD Module Interface 5–10

SIM interface 5–11

Power Distribution Diagram 5–11

Assembly 5–12

Construction 5–12

Assembly Description 5–12

Flexi Diagram 5–14

Assembly Parts of UIF Module DU8 5–14

Testing 5–14

Recommended Test Equipment 5–14

Test Procedure 5–14

Circuit Diagram of DU8 5–15

Layout and Foil Diagram 5–16

NHB–3

UIF Module DU8

Original 26/97

Page 5–2

Page 3

PAMS

Technical Documentation

Introduction

NOTE! UIM (User Identity Module) = SIM (Subscriber Identity Module)

DU8C UI–module ismade for HD851 project. It is used also in HD851EFR product. UI–module is based on GSM/PCN UI–module DU8. Two capacitors pads

added for 18pF capacitors (2320041) from microphone pins to ground. Reason

why capacitors are added is noise to microphone audio in certain situations.

Also some changes are done for reability and productivity reasons. DU8C UI–

module is for NOKIA1 design. Final product use only one 18pF capacitor between microphone pins.

Technical Outline

Mechanics

The module is made from a single flexible printed circuit board – loaded with all

the parts for the User Interface Module. A flexible circuit was used for a number of reasons:

NHB–3

UIF Module DU8

– The material is only 0.3 mm thick – so the phone’s height buildup can be

kept to a minimum.

– The Volume keys, SIM interface and microphone wiring can be folded to fit

in the phone during assembly – since the circuit is flexible.

– Connection from the UIF to the main circuit board can be made with a fold-

ing termination.

The major mechanical parts on the UIF assembly include the following:

– Display Module:– LCD, Heat seal, LCD driver TAB circuit and Light guide.

– Main Keydome assembly: Adhesive film holding 20 metal dome clickers

– Volume & Power Keydome assemblies: Adhesive film (2 films for Style 1)

holding 3 (2 + 1 for Style 1) domes for Vol Up, Vol Down & Power Key.

– Acoustic Components: microphone, speaker, buzzer.

Original 26/97

Page 5–3

Page 4

PAMS

Technical Documentation

NHB–3

UIF Module DU8

Electronics

1

30

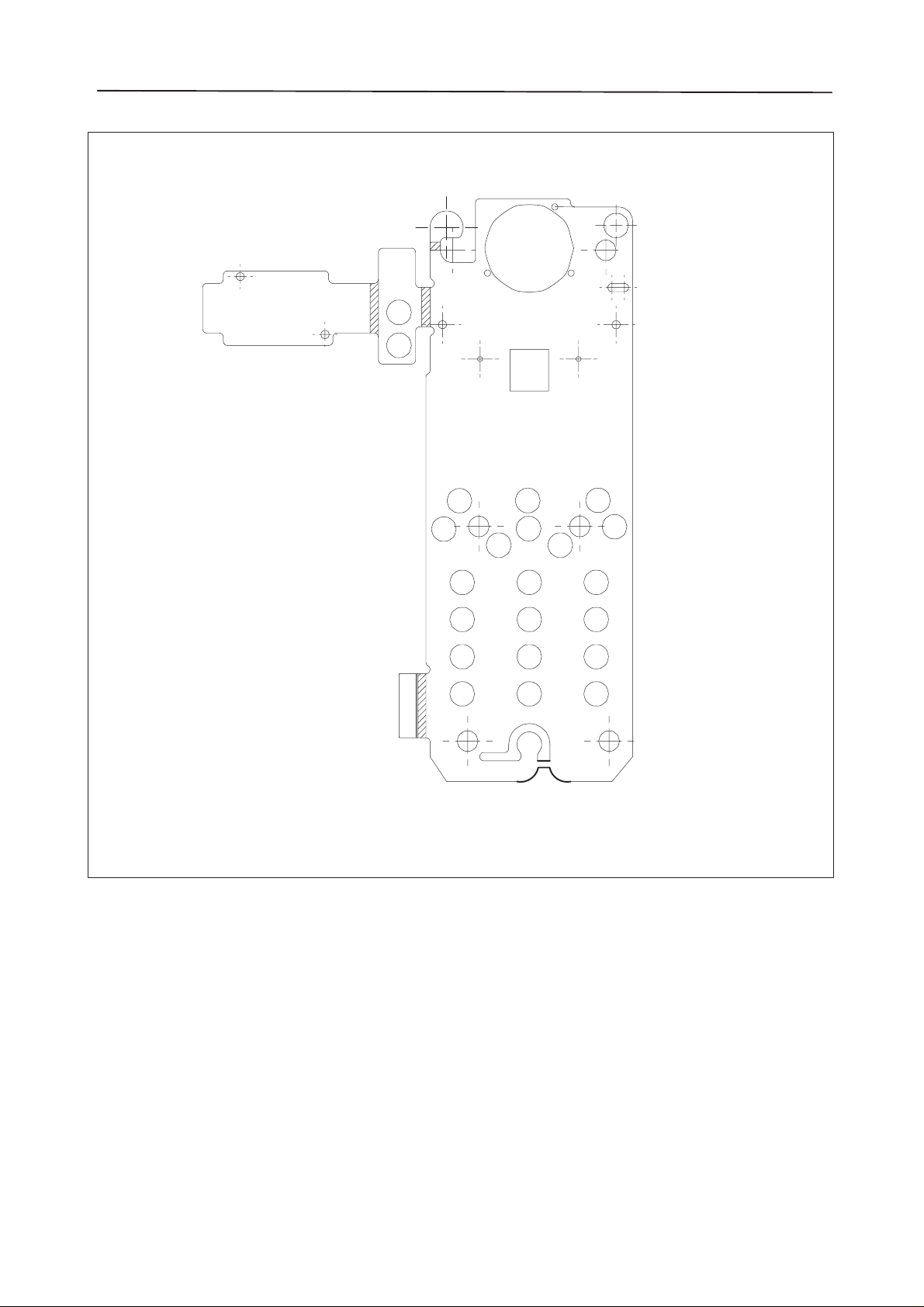

DU8C Style Flexi

Figure 1. Flexi Outline

The following sections of circuitry are on the flexi:

– Microphone Circuit

– Speaker Circuit

– LCD Display Module

– LCD voltage divider & temperature compensation circuit

– Keyboard & Display lighting circuits

– Keyboard switch matrix

– SIM Card Reader

Original 26/97

Page 5–4

Page 5

PAMS

Technical Documentation

UIF Module DU8

NHB–3

List of Submodules and Mechanical Parts

Module Submodule / Part Material code Notes

DU8C Euro/USA Display Module 4850038 Common part

DU8C Earphone Gasket 9450133 Common part

DU8C Lightguide Assembly 9460074 Common part

DU8C Mic Rubber 9460075 Common part

DU8C Reflector 9480061 Common part

DU8C Speaker Pad 9480062 Common part

DU8C Buzzer Gasket 9480078 Common part

DU8C Keydome Film Assembly 9795002 Main keyboard

DU8C Keydome Film Assembly 9795004 Power key (up right corner)

DU8C Keydome Film Assembly 9795006 Volume keys (side)

NOTE! All parts are common with DU8.

Technical Specifications

Maximum Ratings

DC Characteristics

Table 1. Supply Voltages and Power Consumption

Pin / Conn. Line Symbol Minimum Typical /

Nominal

1 / X4 VL1

24 / X4 VA1

3, 30 / X4 VBATT

4.5 4.65 4.8 V

1.5 mA LCD material B

0.8 mA LCD material D

4.5 4.65 4.8 V

250 uA mic enabled

25 mA max volume level to

5.3 6.0 9.0 V

85 mA 115 mA Buzzer with max vol-

40 mA Display illumination

Maximum Unit / Notes

(without temperature

compensation)

earphone

ume

Original 26/97

40 mA Keyboard illumina-

tion

Page 5–5

Page 6

PAMS

C

Technical Documentation

Control Signals

NHB–3

UIF Module DU8

Table 2. Control Signals

Pin / Conn. Line Symbol Minimum Typical /

Nominal

12 / X4 MIC_ENA

Mic_Enable

4 / X4 BACKLIGHT

Key and LCD light

17 / X4 CALL_LED

all indicator

25 / X4 SIMCLK 3.25 /1.625 MHz

26 / X4 SIMRESET

27 / X4 VSIM 4.5 4.65 5.5 V

28 / X4 SIMDATA

– 0 3 Volts Mic Enabled

VA1–0.4 VA1 VA1+3 Volts Mic Disabled

VA1–1.0 – VA1 V olts Lights On

0 – 2.0 Volts Lights Off

VA1–1.0 – VA1 V olts LED On

0 – 0.4 Volts LED Off

–0.3 0.6 V Low level

4.0 5.0 V High level

3.8 4.65 V High level

Maximum Unit / Notes

0.4 V Low level

AC Characteristics

Table 3. Audio Specifications

HPMIC 1 kHz rms NOTES

MRP pressure 2.8 dBPa 5 cm from MIC

MIC pressure –2.2 dBPa about 5 dB attenuation

MIC output 4.9 mV mic sensitivity –64 dB

0 dB = 1V/uBar 1uBar=0.1Pa

Codec gain 35 dB / 275 mV Codec maximum gain

Level – 8.5 dBmO 0 dBmO = 739 mV

HPEAR 1 kHz rms

Level – 6 dBmO / 245 mV 0 dBmO = 490 mV

Codec gain –3 dB 9 dB fixed gain – 12 dB atten.

Codec output 175 mV max. volume 435 mV (+12 dB)

Earpiece pressure 9 dBPa

Original 26/97

Page 5–6

Page 7

PAMS

Technical Documentation

Table 4. Other AC Specifications

BUZZER 2.7kHz Minimum Typical/Nominal Maximum NOTES

Buzzer 90 dB (S.P.L.) Level measured

UIF Module DU8

30 cm from

the buzzer with

pulse ratio 50/50

NHB–3

External Signals and Connections

Table 5. To Radio Module

Signal Name Pin / Conn. Notes

VL1 1 Logic supply voltage 4.65V

GND 2 Ground

VBATT 3, 30 Battery voltage

BACKLIGHT 4 Backlights on/off

UIF(0:6) 5 – 11 Lines for keyboard read and LCD–controller control

MIC_ENA 12 Microphone bias enable

COL(0:3) 13 – 16 Lines for keyboard write

CALL_LED 17 Call led enable

MICP 18 Microphone (positive node)

MICN 19 Microphone (negative node)

EARP 20 Earpiece (negative node)

EARN 21 Earpiece (positive node)

BUZZER 22 PWM signal buzzer control

XPWRON 23 Power key (active low)

VA1 24 Analog supply voltage 4.65V

SIMCLK 25 3.25 MHz Clock for SIM data

SIMRESET 26 Reset for SIM

VSIM 27 SIM voltage supply

SIMDATA 28 Serial data for SIM

AGND 29 Analog ground for the microphone

Original 26/97

Page 5–7

Page 8

PAMS

Technical Documentation

1

.

.

.

.

30

Figure 2. UIF Connections:

Order of Pin Numbering

Table 6. To LCD Module

Pin Signal Name Notes

1 GND Ground

NHB–3

UIF Module DU8

2,3 OSC1, OSC2 Oscillation terminals

4–8 V1–V5 LCD driving power source

9 V5OUT Negative voltage converter output

10–11 C1, C2 4.7 uF capacitor to generate negative volt-

age for the input voltage VCI

12 VCI Power source for voltage converter

13 VCC Power source

14 RS Register selection

15 R/W Read/write

16 EN Enable for read/write signal

17–20 D(0–3) Lower bits of 8 bit data bus, not used

21–24 D(4–7) 3–state 4 bit data bus

D7 also used for busy flag reading

Table 7. List of Connectors

Connector Name Code Notes Specifications / Ratings

X1 Display Module Connection.

X4 UIF Connector – FCB edge connector as de-

– FCB footprint for Display Mod-

ule

scribed above.

Refer to mentor footprint / Display Module Prodoc for pinout

30 connections at 0.5 mm

pitch

Original 26/97

Page 5–8

Page 9

PAMS

Technical Documentation

Mechanical Characteristics

Table 8. Mechanical Characteristics

NHB–3

UIF Module DU8

Module

Name

Bare Flexi circuit

DU8C

module

Dimensions (mm)

(W x H x D)

50 x 141 x 0.3mm except

in areas with partial thinning or thickening. (refer

to mechanical drawings for

more detail.

<3.6 deep at LCD

<4.2 deep at earpiece

<6.3 deep at buzzer

Functional Description

Circuit Description

DU8C Circuit Description

The module is connected with 30 pin flex connector to the system board, 24 pin

connector to the LCD module and 6 pin connector to the SIM card.

The module includes following main blocks:

Weight

(g)

5

22

– keyboard

– SIM interface

– illumination

– audio block

– LCD Module interface

Keyboard scanning and display driver control

COL(0–3) are used as column lines in keyboard. UIF(0–5) are used as row

lines. They are also multiplexed with display driver control signals.

When a key is pressed the ASIC gets an interrupt from a row and the MCU

starts scanning. One column at a time is written to low and rows are used to

read which key it was. The power off detection is multiplexed with one row;

when all keys on the row seems to be pressed the ASIC knows that power key

is pressed. The power key is also connected to PSL+ to switch the power on.

Row lines and UIF6 are used for display driver control. UIF(0–3) are used as 4

bit parallel data bus for the driver. UIF4 is used as read/write strobe, UIF5 to

select data or instruction register and UIF6 as enable strobe.

Keyboard and display illumination

The keyboard illumination is achieved by using two transistors wired as simple

constant current sinks. Each transistor supplies eight leds. The bases of the

Original 26/97

Page 5–9

Page 10

PAMS

Technical Documentation

transistors are all wired together and supplied by emitter follower V40. The led

current is fixed by the values of R44 and R45 and the ratio of R51 to R52. The

current is about 5 mA/ each LED. Note that on DU9 flexis, the 17

from an additional transistor.

The display illumination operates in a similar way to the keyboard drivers, two

transistors are used to drive eight leds. The current in this case is defined by

the value of R46, R47 and the ratio of R51 to R52. It is about 10 mA / each

LED.

The Call LED is fed from a simple emitter follower.

Audio Circuitry

The earpiece is routed directly via series resistors to connector X4. The earpiece is dynamic type. The impedance is 32 ohm and sensitivity 118 dB / 1 V.

Microphone is of the electret type and needs a voltage supply for operation.

When MIC_ENA is low bias voltage is connected to the microphone via transistor V8. V2 is wired as a switch for VA1, controlled by the microphone enable

line [MICENA]. VA1 is an analogue rail supplied by the PSL+ chip on the system board. It is 4.65V in magnitude. The sensitivity of the microphone is –62

dB (0 dB = 1V/ubar). C26 and C27 in the MIC nodes act as high pass filter with

pulldown resistors on the baseband side.–3dB point is about 100Hz.

NHB–3

UIF Module DU8

th

led is driven

The buzzer is dynamic one and the impedance is 25 ohm. Buzzer is driven

from a two transistor switch which acts as a buffer for a CMOS output signal

applied at BUZZER. The ringing volume is controlled by pulse width modulation.The diode V37 prevents damage to the transistor when switched off, absorbing the stored energy in the buzzer inductance and suppressing large positive going spikes on the transistor collectors.

Small value capacitors are fitted at critical points in the circuit to avoid problems

with RF interference. One is placed directly across the microphone (C15). V9

has a cap to ground from each of its three terminals (C14, C17 and C21).

There is also capasitors in earphone nodes.

LCD Module Interface

The LCD module includes the LCD and the display driver. The driver TAB is

connected with heat seal connection to the LCD. The LCD is FSTN type. The

duty ratio is 1/32 and the bias ratio 1/6.7. Viewing direction is 6 o‘clock.

The display driver is NJU6406–02 from JRC. It has internal clock oscillator and

negative voltage generator. It has 9600 bit character generator ROM and 64 * 8

bits character generator RAM. The dispaly module is connected to the UIF

module with 24 pin soldered connection.

The display module contains an oscillator to generate a negative voltage required for operation. The oscillator frequency is fixed on the UIF module by the

resistance from pins 2 to 3 of X1, with the values of R6 and R16 shown, the frequency is within 180 kHz to 370 kHz. The negative going pulses appear at pin 9

of X1 where they are smoothed by C1 to give a voltage which is nominally

equal but opposite to VL1.

Original 26/97

Page 5–10

Page 11

PAMS

Technical Documentation

For correct operation of the display, dc voltages between –VL1 and VL1 need

to be generated and fed back to the driver chip, at pins 4 to 8 inclusive (of X1).

The exact voltages depend on the relative values of the resistors R21, R37,

R38, R39, R40 and R33.

The display driver is connected to the radio module with a 4 bit data bus. Data

transfer is controlled with the following signals: R/W selects read or write operation (”0” = write, ”1” = read), Enable activates read/write operations and RS selects the register (”0” : instruction register (writing) or busy flag (reading), ”1” :

data register).

SIM interface

The SIM interface is the electrical interface between the smart card used in the

GSM and PCN applications and the MCU via the ASIC. Four signals are used

between the SIM card and the ASIC: SIMDATA, SIMCLK, SIMRESET and

VSIM. Serial data is transferred between the card and the ASIC, the clock frequency is 3.25 MHz. When there is no data transfer between the SIM card and

the HP the clock can be reduced to 1.625 MHz. Some cards allow to stop the

clock in that mode. The ASIC also generates the reset for the card and the supply voltage VSIM.

NHB–3

UIF Module DU8

Power Distribution Diagram

VA1

VL1

VSIM

VBATT

Call

LED

GND

AGND

KEY/

LCD

Lights

Figure 3. Power Distribution

Assembly

Buzzer

SIM card

reader

LCD

Keyboard

scan

Audio

Construction

The assembly drawings show the physical positioning of all the components on

the flexis.

Original 26/97

Page 5–11

Page 12

PAMS

Technical Documentation

The preassembled parts are the Display Module (LCD + TAB + Heatseal), KeyDome assemblies (Adhesive Film + Domes) and Lightguide/Reflector assembly

The basic assembly process is as follows:

– All SMD components placed & soldered.

– KeyDome assemblies fitted by hand (alignment jig recommended) (3 as-

semblies in DU8)

– Buzzer soldered manually

– Microphone soldered manually

– Speaker wires soldered manually

– Speaker attached to flexi with speaker pad

– Speaker gasket attached to top of speaker (self–adhesive)

– Display Module soldered to flexi (alignment pins required)

– Light guide/reflector assembly stuck onto the flexi over the TAB package

– LCD folded on to the top of the light guide and stuck down

– Functional tests performed.

Limited Bending Capability:

tion of three layers of polyimide and two layers of copper tracks. The polyimide

has almost unlimited bending capability – but the copper tracks cannot be bent

to tight radii very often. At all times before the flexi circuit is installed into a

phone, bending of the circuit should be avoided if possible. If the flexi circuit

has already been installed into the phone, then care should be taken not to

continuously fold the flexi circuit out flat and then back to its resting position too

often.

NHB–3

UIF Module DU8

The flexible circuits are constructed from a lamina-

Table 9. References to Other Construction Documents

Document Code Sheets Notes

Flexi outline 2D22779 1 Mechanical Outline Drawing

Assembly Description

Table 10. References to Other Assembly Documents

Document Drawing n:o Sheets Notes

Flexi assembly for DU8C 2C23369 1 Common with DU8 Assembly Drawing

Original 26/97

Page 5–12

Page 13

PAMS

Technical Documentation

Flexi Assembly for UIF Module DU8

NHB–3

UIF Module DU8

Original 26/97

Page 5–13

Page 14

PAMS

Technical Documentation

UIF Module DU8

Assembly Parts of UIF Module DU8

ITEM Q’TY CODE DESCRIPTION VALUE, TYPE

1 1 9855011 F.P.C. . . . . . . . . . . .

2 1 4850038 Display Module . . . . . . . . . . . .

3 1 9460074 Lightguide. . . . . . . . . . . .

4 1 9480061 Reflect. . . . . . . . . . . .

5 1 9795002 Keydome Film. . . . . . . . . . . .

6 1 9795006 Keydome Side. . . . . . . . . . . .

7 1 9480078 Buzzer Gasket. . . . . . . . . . . .

8 1 514H001 Earpiece. . . . . . . . . . . .

9 1 9450133 Speaker Gasket. . . . . . . . . . . .

10 1 9480062 Speaker Pad. . . . . . . . . . .

11 1 9460075 Microphone Rubber. . . . . . . . . . .

12 1 514H002 Microphone. . . . . . . . . . .

13 1 514H003 Buzzer. . . . . . . . . . .

14 1 9795004 Keydome Pwr. . . . . . . . . . .

NHB–3

T esting

Recommended Test Equipment

Radio Modules db1 and db6.

Test Procedure

1 Connect the UIF module to the radio module and place a SIM card to

the card reader of the flex.

2 Connect a battery to the battery connector.

3 Switch the power on and check that all the segments of the LCD are

displayed.

4 Verify that all keyboard and LCD backlight leds are illuminated.

5 Verify that the SIM card is accepted.

6 Press all keys and verify that all keypresses can be detected.

7 Verify that the earpiece is generating a tone during a keypress.

8 Make a call to the tranceiver.

9 Verify that the ringing tones are coming from the buzzer.

Original 26/97

10 Verify that the call led is illuminated.

11 Answer the call.

12 Verify that the microphone is working.

Page 5–14

Loading...

Loading...