Page 1

Programme’s After Market Services

Tesla For Windows

WinTesla User Guide

Page 2

WinTesla User Guide

PAMS

NHD–4

Technical Documentation

CONTENTS –

Page No

Tesla for Windows Operating System 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing WinTesla On Your Hard Disk 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using The Windows Interface 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common User Interface 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Connections 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Wintesla 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Independence 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Login ID Setup 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Login Screen 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The WinTesla Screen 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Product Menu 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Configure Menu 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Fault Log Application. 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HD881 Module 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the HD881 Service Module 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Servicing Equipment 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer Setups 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning Steps of Radio Unit 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accuracy of the Equipment During Measurement 27. . . . . . . . . . . . . . . . . .

General 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Voltage Adjustment 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charge Voltage Adjustment 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Temperature Adjustment 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AMPS Tuning 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Bias Current Tuning 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC Tuning 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deaf Channel Frequency Tuning 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Output Power 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Modulation Index Calibration 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RSSI 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Original 11/97

Page 3

PAMS

WinTesla User Guide

Technical Documentation

RX Audio Gain 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA Tuning 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Offset Tuning – (RX/TX) 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Offset Tuning – (RX) 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rx Slope 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rx Slope Rx 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rx Gain Switch Calibration 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA TX Bias Tuning 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Align TX Gain Limiting Tuning 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aux. AGC Tuning 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGC Tuning 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T esting 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADC Readings 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Division Modulator (PDM) Control 51. . . . . . . . . . . . . . . . . . . . . . . . . .

NHD–4

AMPS / BaseBand Test Screen 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AMPS Testing 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC Tuning Functionality Test 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC – Deaf Channel Tuning Functionality Test 54. . . . . . . . . . . . . . . . . . . .

AMPS TX Power Level Tuning Functionality Test 55. . . . . . . . . . . . . . . . . .

AMPS TX Bias Tuning Functionality Test 56. . . . . . . . . . . . . . . . . . . . . . . . .

RSSI Tuning Functionality Test 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

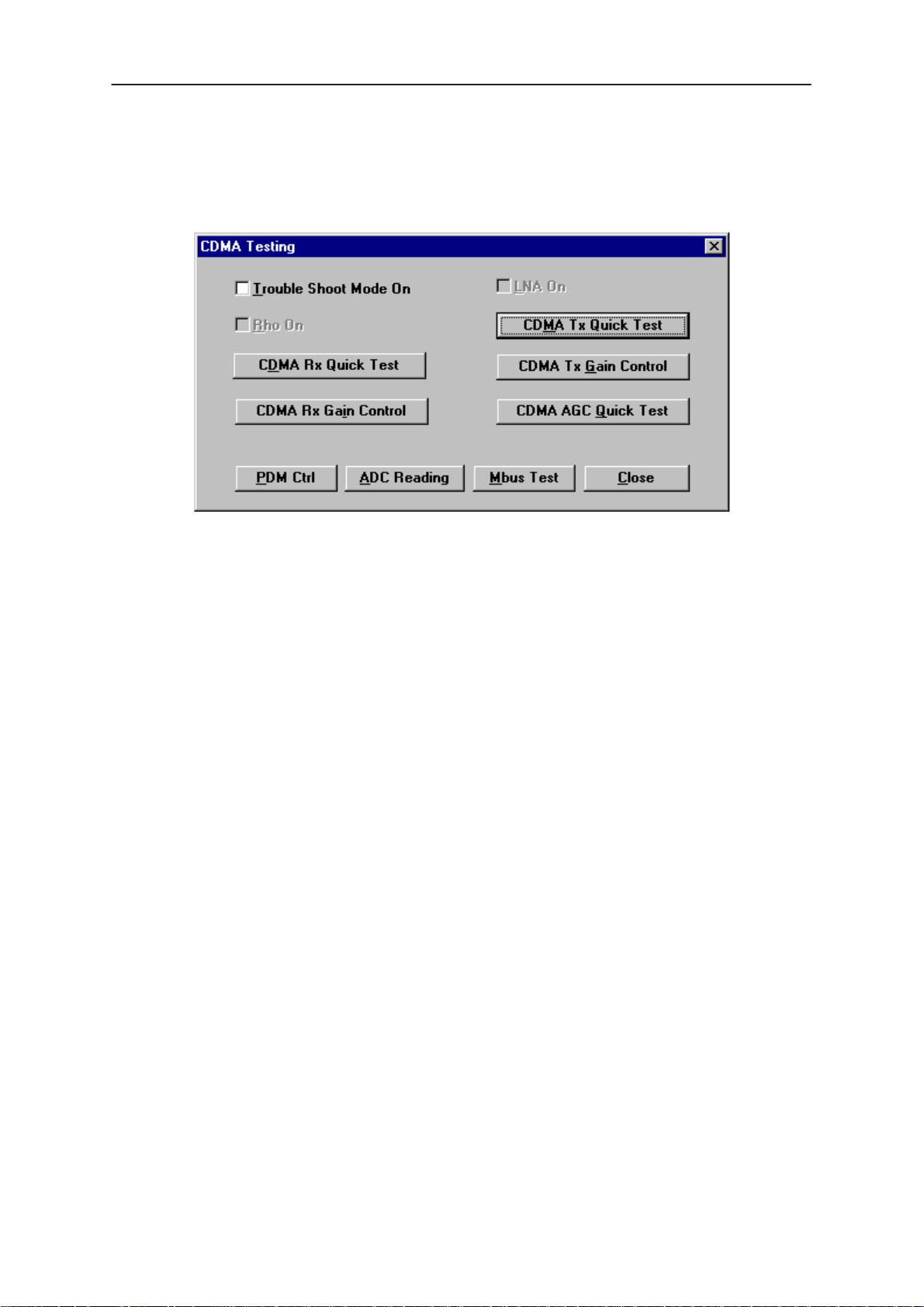

CDMA Testing 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA TX Bias Tuing Functionality Test 58. . . . . . . . . . . . . . . . . . . . . . . . . .

TX Gain Limiting Tuning Functionality Test 59. . . . . . . . . . . . . . . . . . . . . . . .

Aux. AGC Tuning Functionality Test 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LNA Gain Calibration Functionality Test 61. . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA TX Spurious Check 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LNA Gain Calibration 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Menu 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flashing 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dialog Options 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialize EEPROM 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer Menu 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NAM Programming 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Code Memory (SCM) 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SID Programming 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calling Cards 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Authentication Key (A–Key) Programming 72. . . . . . . . . . . . . . . . . . . . . . . .

Original 11/97

Page 3

Page 4

WinTesla User Guide

PAMS

NHD–4

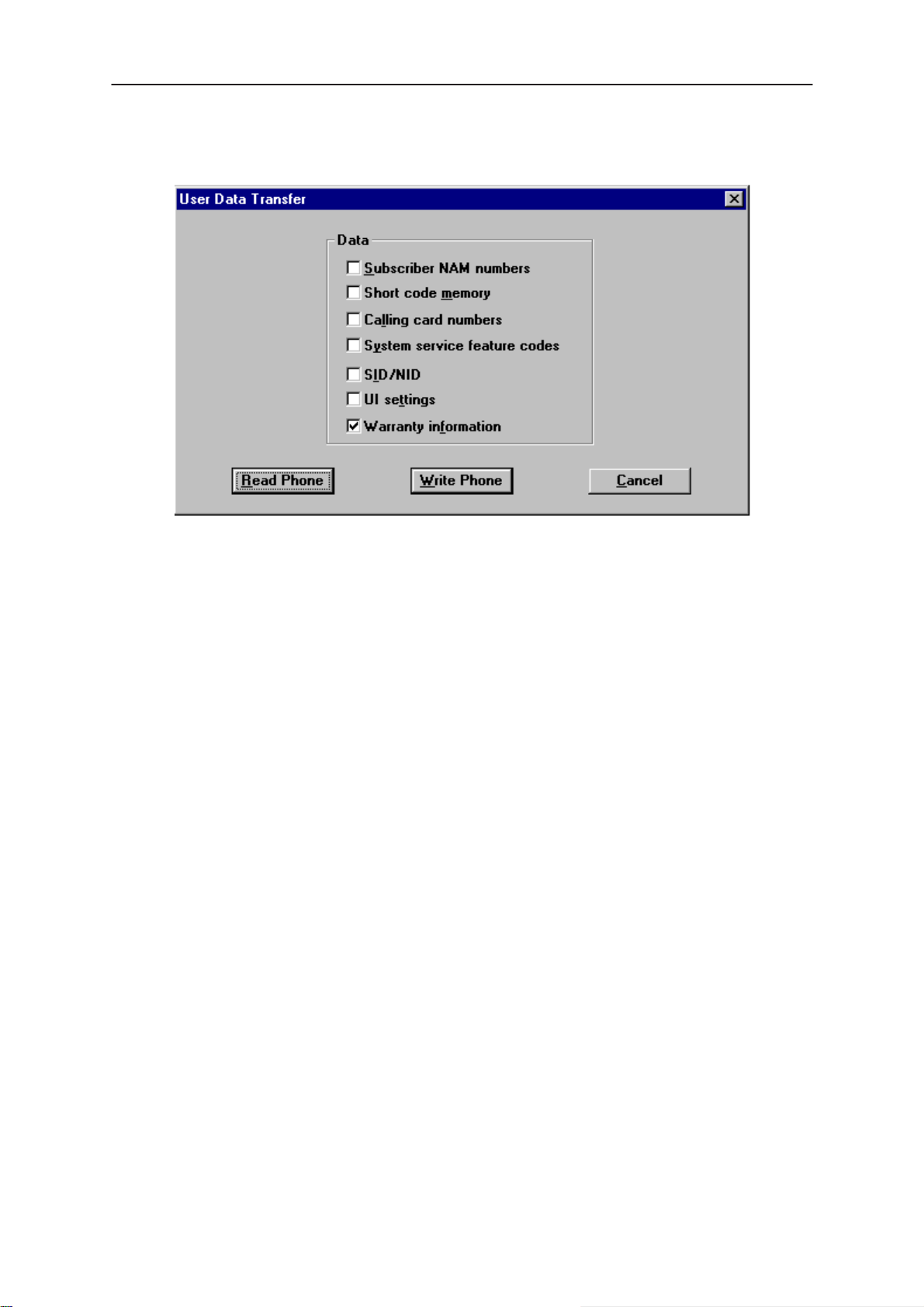

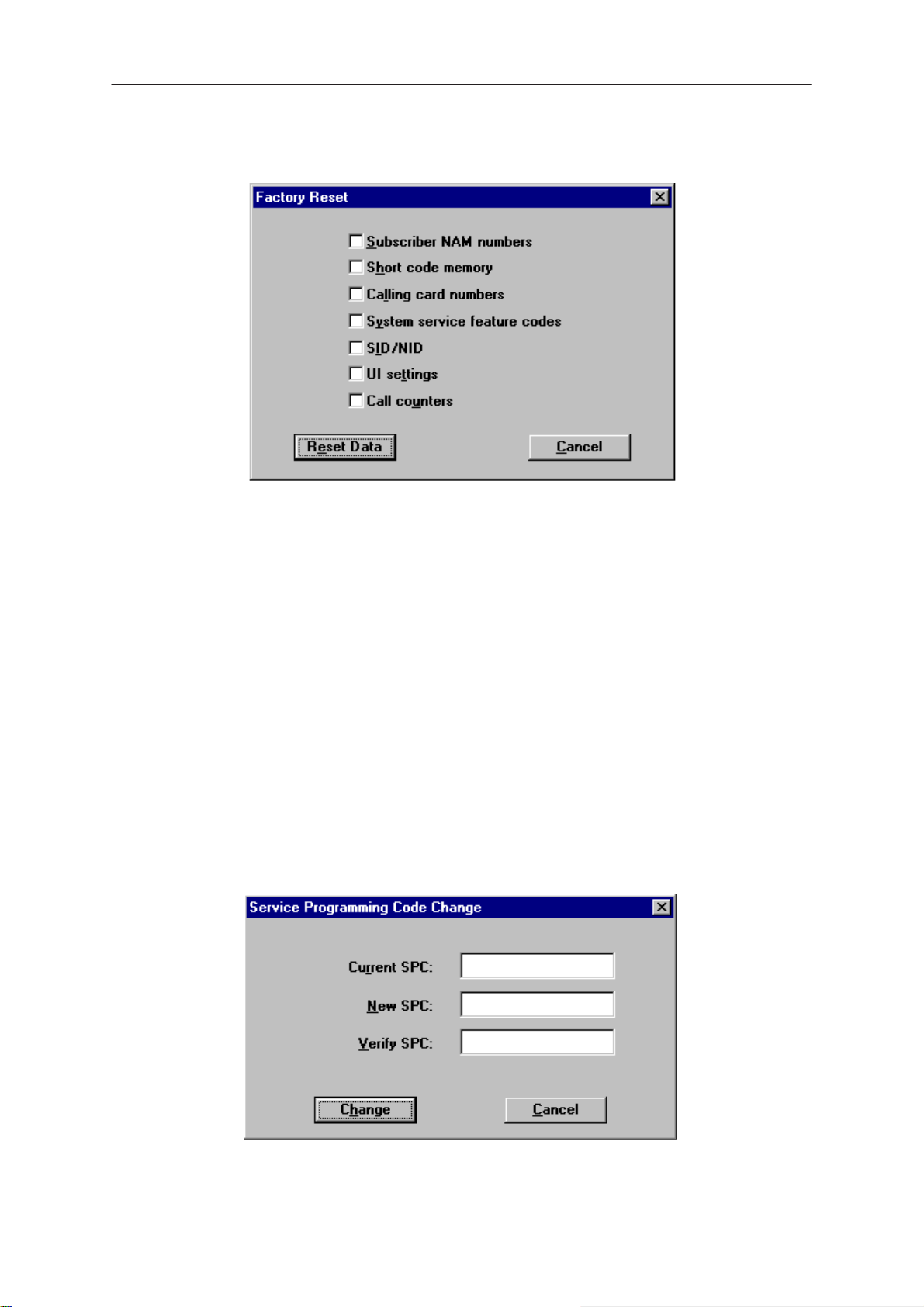

User Data Transfer 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Factory Values 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPC code change 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

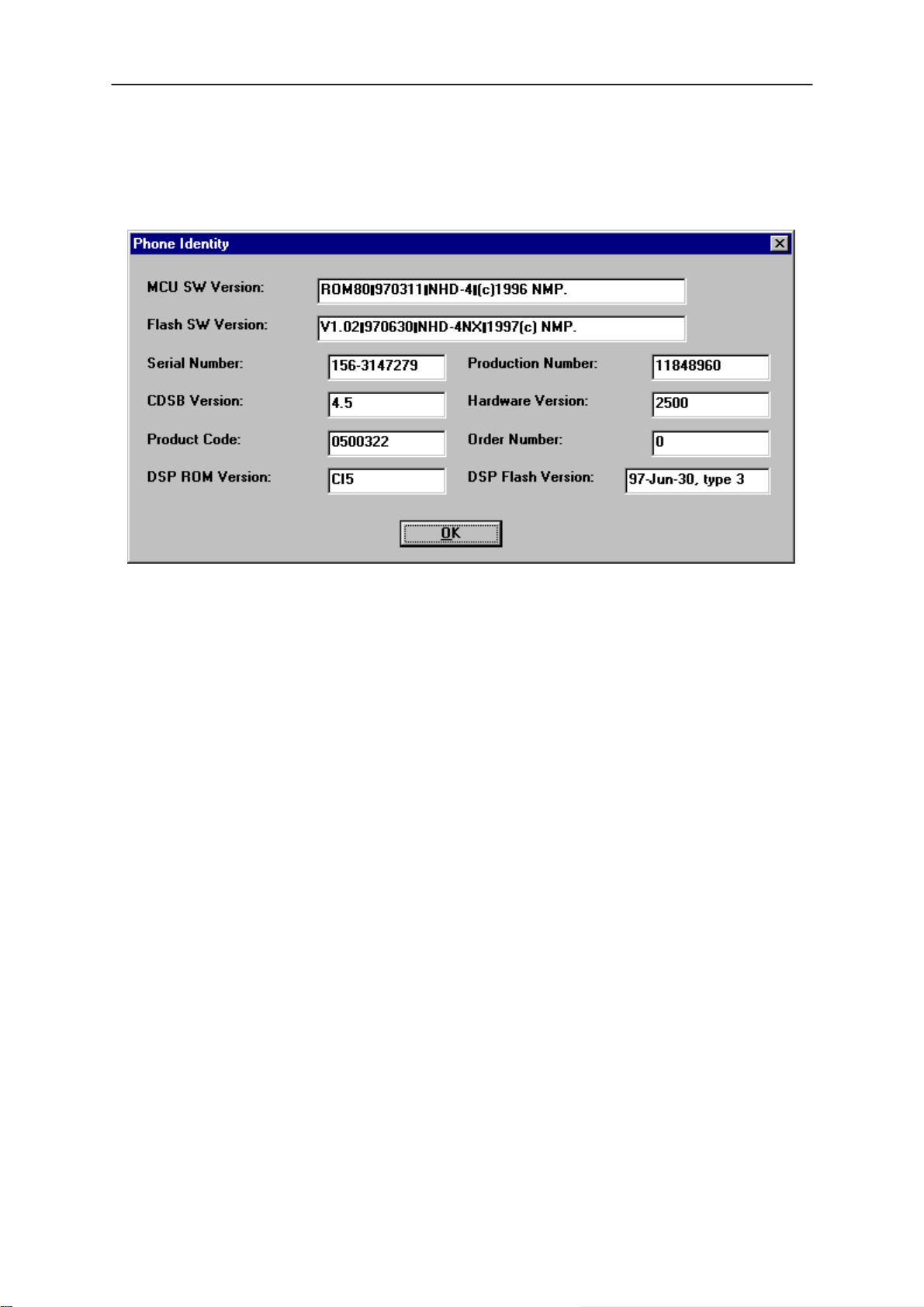

View Menu 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Identity 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Parameters 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Problems 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up the computer Hardware 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Errors 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Support 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Documentation

List of Figures–

Figure 1. Dongle Insertion 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

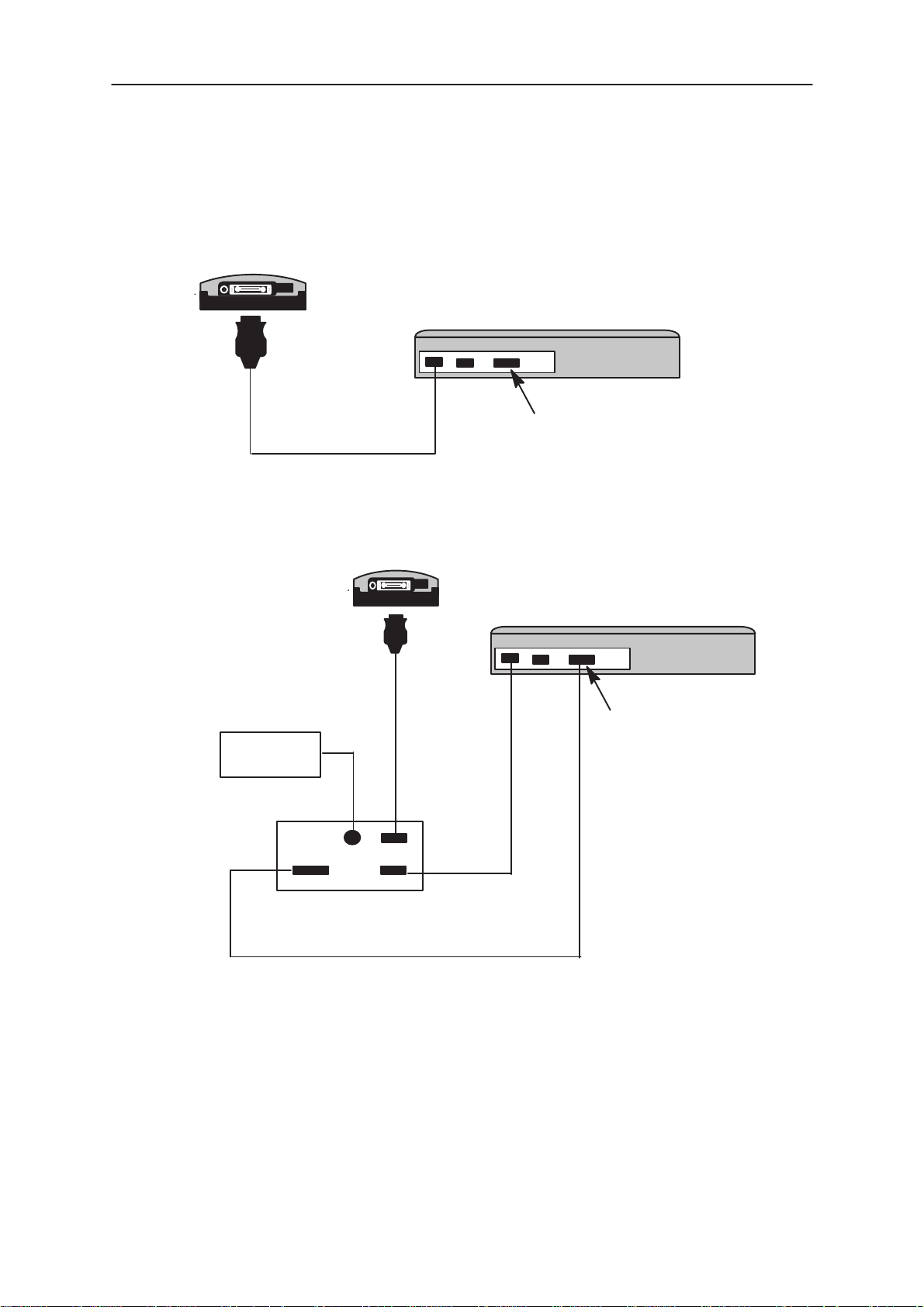

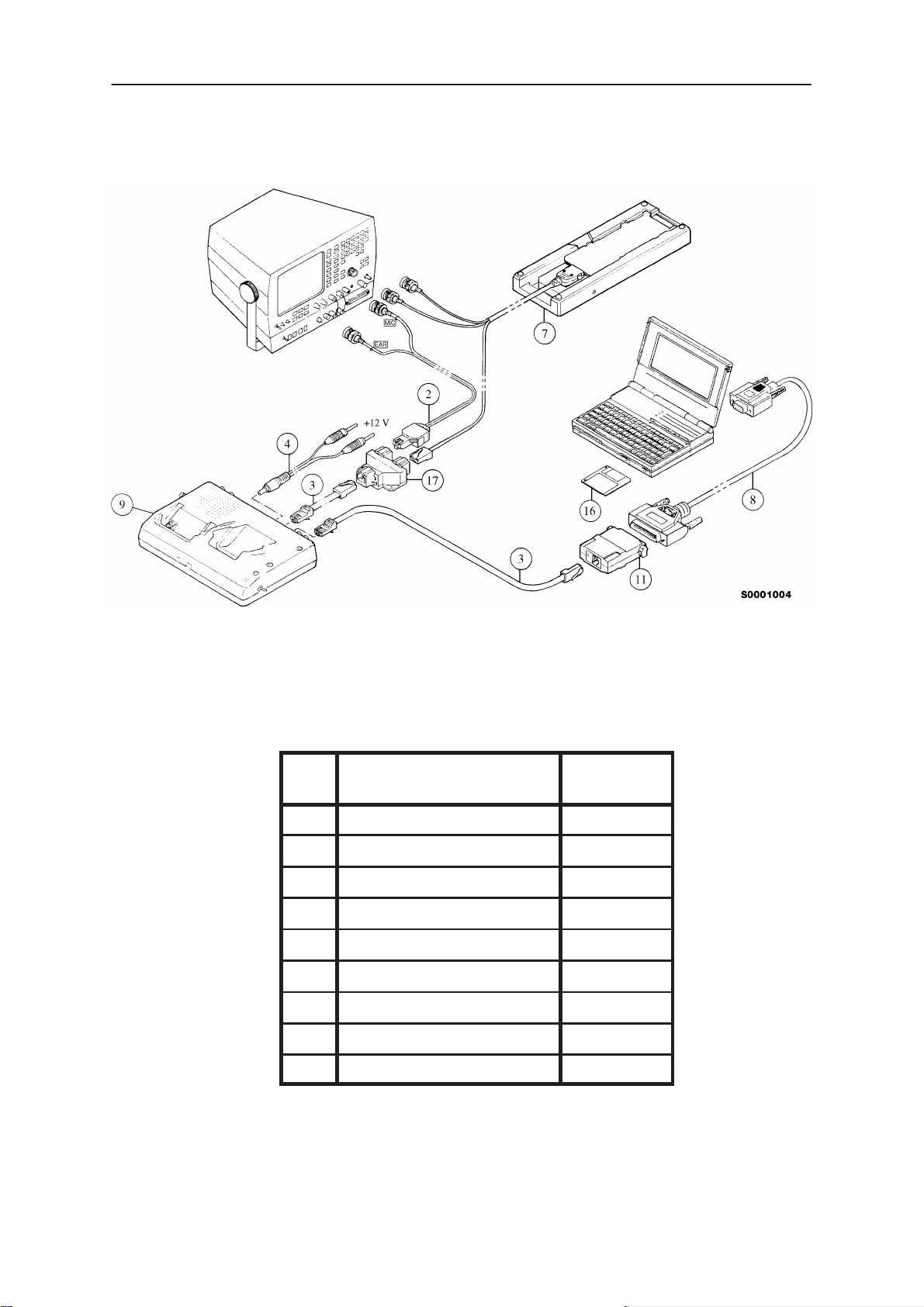

Figure 2. Servicing setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3. Flash setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

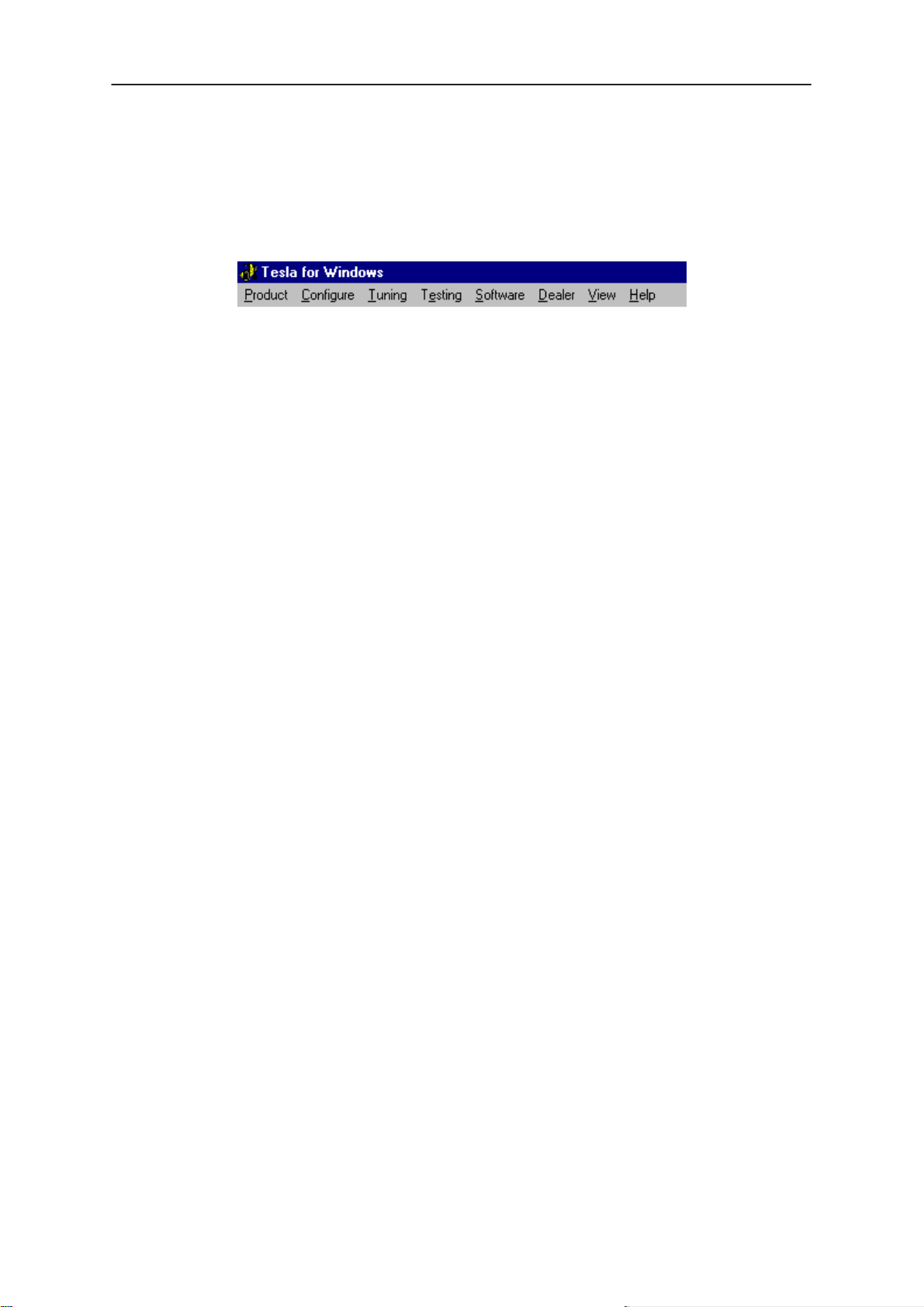

Figure 4. WinTesla with loaded interfaces 8. . . . . . . . . . . . . . . . . . . . . . . . . .

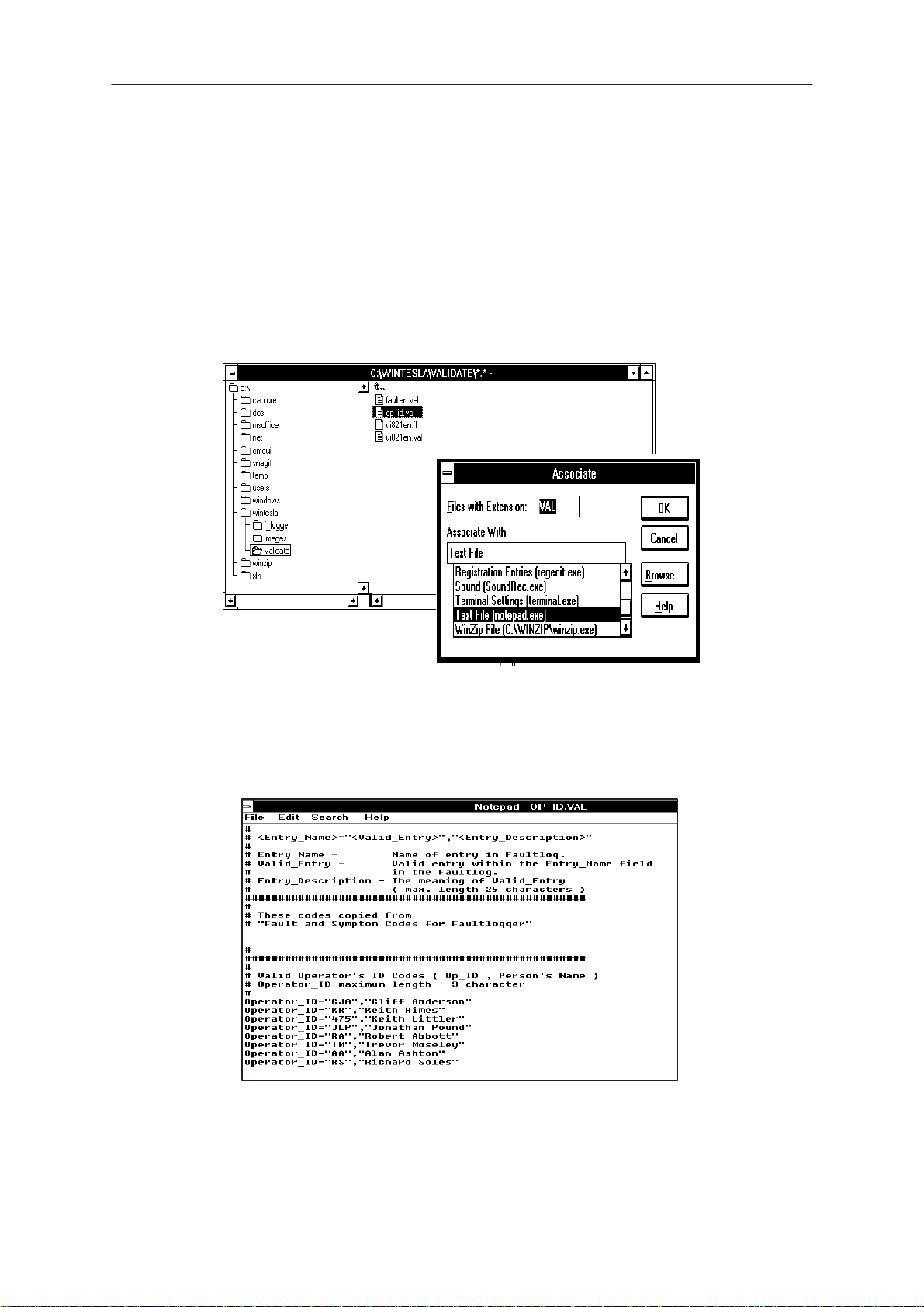

Figure 5. Accessing Op_ID. val file 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6. Editing Op_ID.val file 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

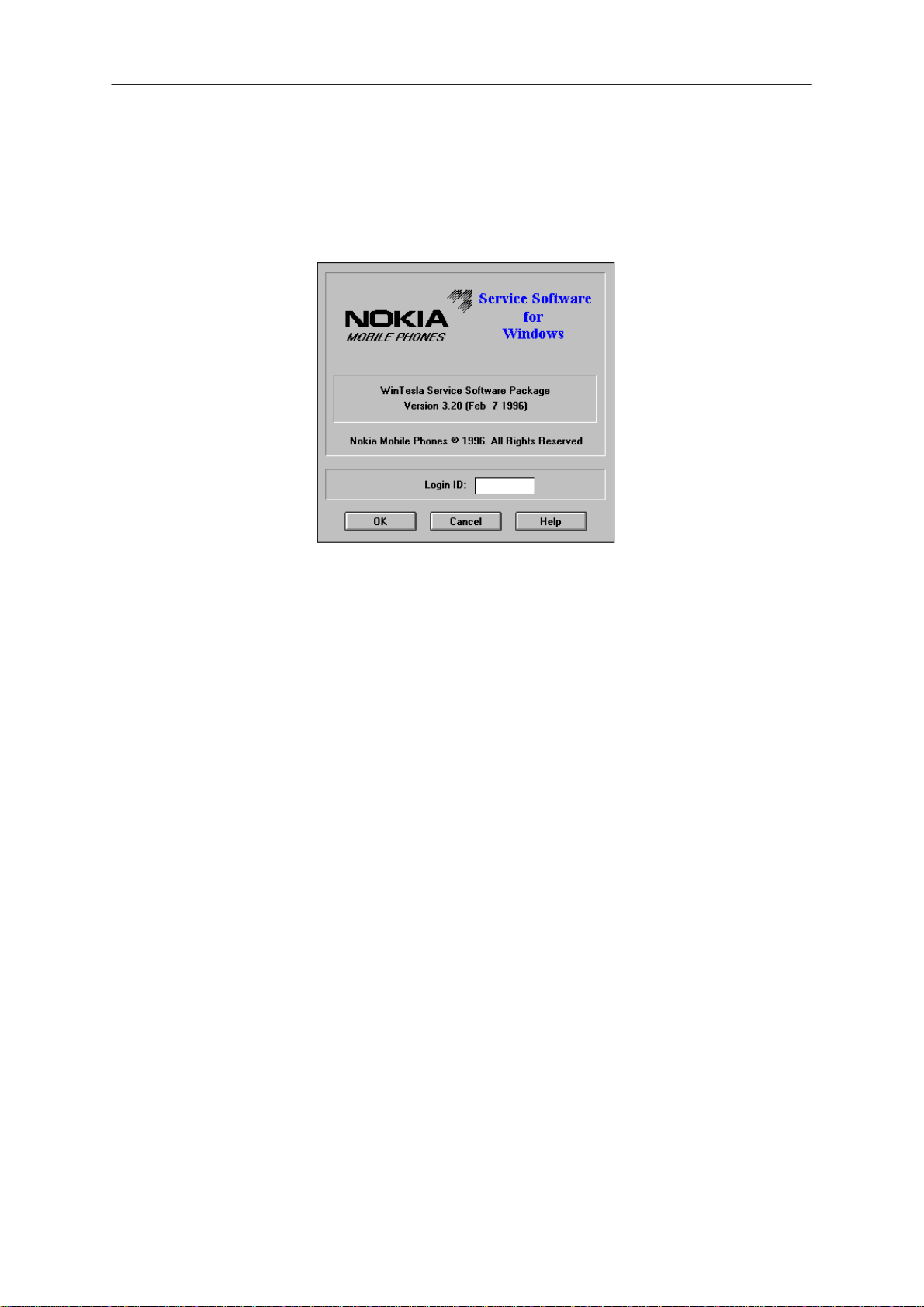

Figure 7. Login Screen 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8. FaultLog – configuration 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9. Editing fault, symptoms, modules files 19. . . . . . . . . . . . . . . . . . . . .

Figure 10. FaultLog – macro setup 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11. Testing/Tuning with covers off 24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 12. Testing/Tuning with covers on 25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 13. CDMA TX Output power 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 14. Auxiliary AGC Operation 1 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 15. Auxiliary AGC Operation 2 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 16. TX Slope 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Original 11/97

Page 5

PAMS

WinTesla User Guide

Technical Documentation

Tesla for Windows Operating System

The name TESLA, when used by Nokia, is an acronym for TEst and

Service Locals Application. Tesla for WIndows (i.e. WinTesla) is a

software package designed to operate in the Microsoft Windows

environment. The software package is made of two modules, the

Wintesla core module and a service software module. The Wintesla

module is similar to an operating system for various service modules. In

this way many Nokia products can be serviced using one common

software package, running different service modules (in this case, for the

Nokia 2180).

Note: The Wintesla core module MUST be installed for ”any” service module to run.

Installing WinTesla On Your Hard Disk

The WinTesla core software is delivered on a 3.5” diskette and is

protected with a protection “key” (PKD–1), which must be attached to the

parallel port LPT 1 when the WinTesla service software is being used.

NHD–4

To install the WinTesla core software package, proceed as follows:

Note: For instructions on installing the HD881 service module (see Installing the

HD881 Service Module)

Insert the WinTesla Application diskette into drive A: of your PC.

From DOS ( NOT running windows ) type

A: INSTALL <Enter>

From Windows File Manager double click the mouse on

a:\install.exe

Follow the instructions given and use the

Repeat this procedure for the required module installation using the

upgrade

Note: For interim WinTesla releases use the upgrade option.

Your Windows desktop will now have a “Service Software” group and a

“Service Software” icon within that group.

To start the program, double click on the “Service Software” icon .

option instead of

(Windows will boot up automatically)

Or

new

option when requested.

new

.

Using The Windows Interface

If not familiar with the windows type interface, consult the

Windows User Guide

Original 11/97

for further information.

Microsoft

Page 5

Page 6

WinTesla User Guide

PAMS

NHD–4

Common User Interface

Due to the modular design of WinTesla, various generations of Nokia

products can be serviced, while sharing a similar user interface. The

common user interface is explained in the first part of this document and

is followed by the specific module information.

The software can be used to control the phone by entering commands via

the keyboard of a PC/AT – running MS Windows 3.1 or 3.11.

Note: Windows 95 and Windows NT are not supported.

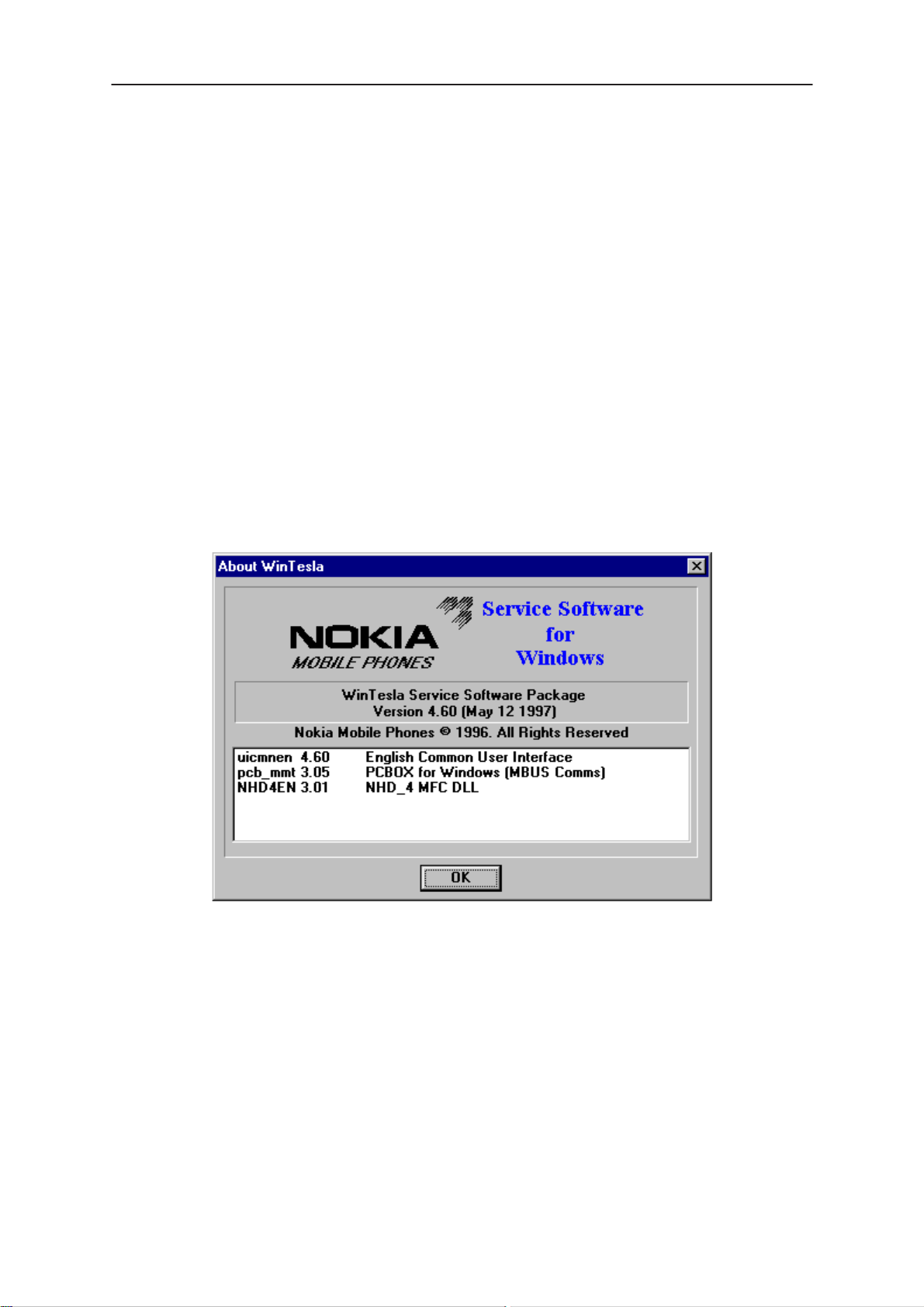

This document refers to WinTesla Version 4.60 or greater.

Equipment Required

Computer : IBM 486 PC/AT or compatible with at least

one, unused serial port, COM1 or COM2 one parallel port

(LPT1), 5 Meg. hard disk space required, 16 Meg of RAM

: Any supported by MS Windows version 3.1 or 3.11

Technical Documentation

Operating System : DOS 5.0 or later running MS Windows

3.1 or 3.11

WinTesla Application Software (product code 0774046)

Software Protection Key PKD–1 (product code – 0750018)

Mechanical Connections

The software controls the phone via a separate adapter (DAU–2)

connected to the serial port of the PC and to the phone’s bottom

connector using the Nokia proprietary communication method called

M2BUS.

Attach the protection key PKD–1 to parallel port one (25–pin female

D–connector) of the PC. When connecting the PKD–1 to the parallel port

be sure that you insert the PC end of the PKD–1 to the PC (male side).

Page 6

Figure 1.Dongle Insertion

Original 11/97

Page 7

PAMS

WinTesla User Guide

Technical Documentation

The PKD–1 should not affect devices working with it. If some errors do

occur try printing without the PKD–1 connected. If printing is now OK

please contact your supplier who will endeavor to replace your PKD–1.

DAU–2

NHD–4

COM1 COM2 LPT–1

PC

PKD–1

Figure 2. Servicing setup

Power

Supply

Power

FPS–3C

COM1 COM2 LPT–1

PC

DAU–2

PKD–1 (connect to dongle)

Phone

SerialParallel

Figure 3. Flash setup

Original 11/97

Page 7

Page 8

WinTesla User Guide

PAMS

NHD–4

Using Wintesla

Phone Independence

The WinTesla application, “WinTesla.exe”, is phone independent. It relies

on separate, phone specific, “modules” to provide communication, menus

and test algorithms.

Technical Documentation

Figure 4. WinTesla with loaded interfaces

For each phone type – or product family – a phone interface module and

menu module are required. The modularity of WinTesla allows support for

other languages, so one phone type may have one phone interface

module and several menu modules, all in different languages.

WinTesla allows you to select the language you wish to use (if available),

and will automatically load the correct phone interface module for the

connected phone. When a different phone type is connected, WinTesla

will load the new phone interface and associated menus.

Page 8

Original 11/97

Page 9

PAMS

WinTesla User Guide

Technical Documentation

Login ID Setup

Once the software has been installed you need to set up your own Login

ID (max. 3 characters). Start Windows file manager and locate the

validate\op_id.val

NO TAG.

Double clicking on the ‘

message, in order to avoid this use the File |Associate command in file

manager and link the file to the notebook application as shown below.

(located in the Wintesla subdir) file as shown in

Op_ID.val’

file (a text file) gives a windows error

NHD–4

Figure 5. Accessing Op_ID. val file

Now by double clicking on the ‘

Op_ID.val

’, notebook opens and your own

ID can be entered and saved accordingly. Enter or edit any operator

definitions following the existing format in this file.

Enter your id here

Figure 6. Editing Op_ID.val file

Original 11/97

Page 9

Page 10

WinTesla User Guide

PAMS

NHD–4

The Login Screen

When WinTesla first starts, the Login screen below will appear. Type in

your 3 character ID and press <Enter> or click on the OK button.

Technical Documentation

Figure 7. Login Screen

If WinTesla can not find the file,

then the OK button will be ‘greyed’.

If CANCEL is clicked then the Fault Logging feature of WinTesla will be

deactivated.

op_id.val

, which contains the Login IDs,

Page 10

Original 11/97

Page 11

PAMS

WinTesla User Guide

Technical Documentation

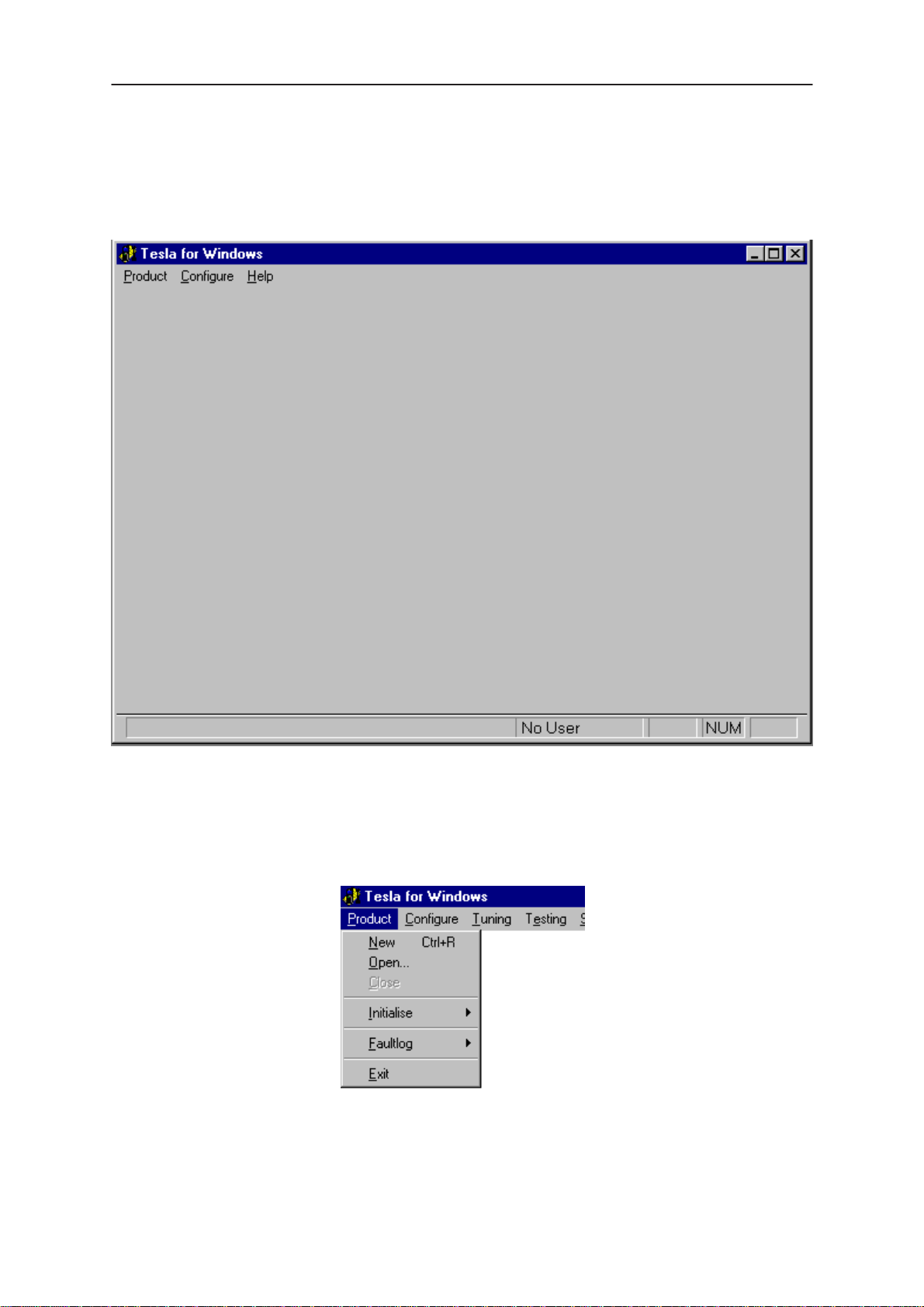

The WinTesla Screen

The main WinTesla screen – if no phone is attached – is displayed with 3

menu items at the top of the screen and a status bar at the bottom.

NHD–4

The information on the left of the status bar will be used to provide

information when WinTesla is performing tasks: such as reading data from

the phone. The status bar also includes the name of the current user.

The Product Menu

Original 11/97

Page 11

Page 12

WinTesla User Guide

PAMS

NHD–4

New (Ctrl+R)

The ‘New’ function (which can also be activated by pressing Ctrl+R ) is

used to scan for a phone when either the automatic rescan option is off or

the automatic rescan timer has not expired ( see

for automatic rescan ).

If the phone type is unrecognized or unsupported by the current WinTesla

system then a warning message will be displayed.

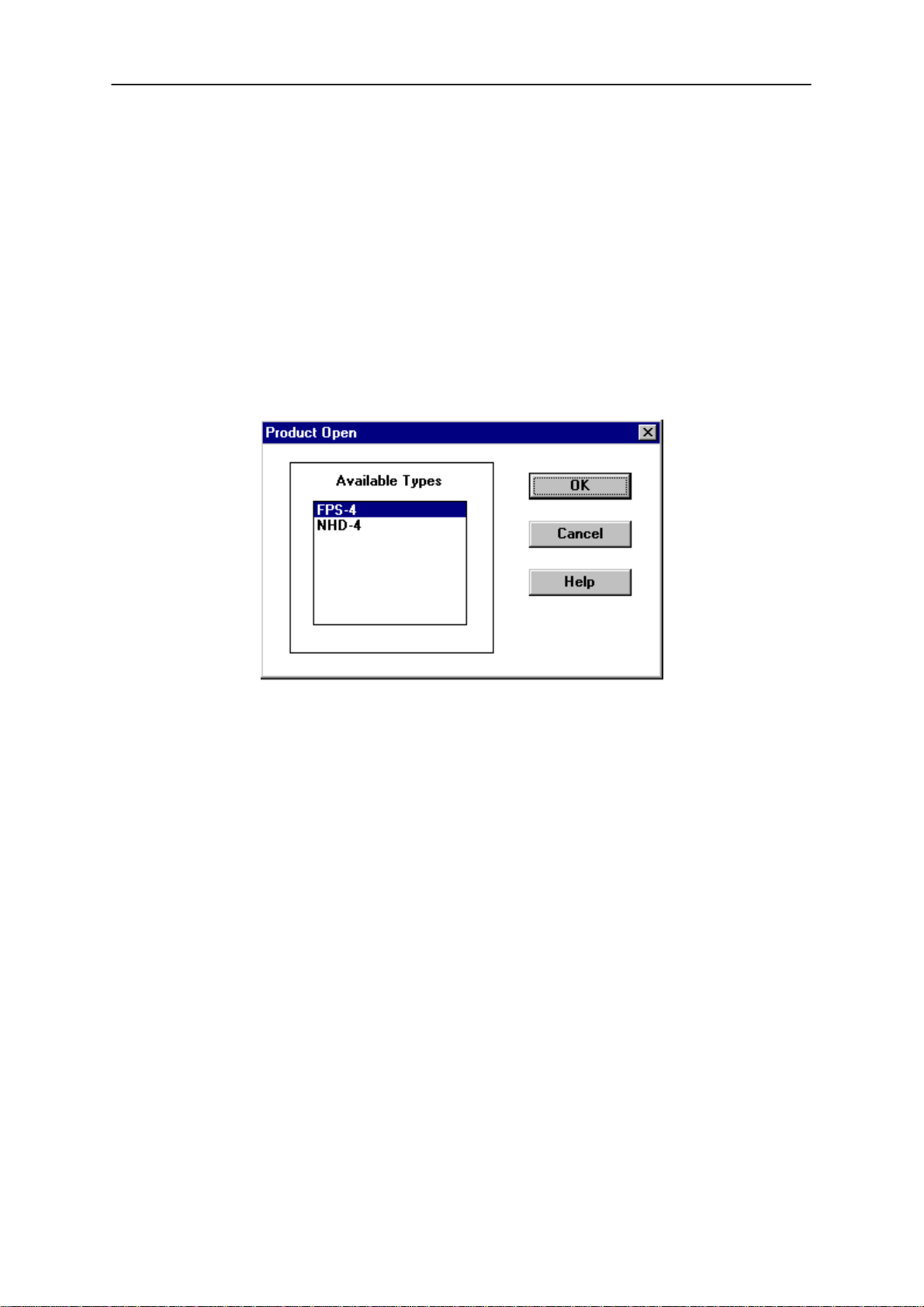

Open

The ‘Open’ function allows you to ‘force load’ a phone interface, even if

there is no phone connected to the system.

Technical Documentation

Configure|Options section

Close

A dialog box will appear and list the supported phone types (see figure

above). To select a particular phone type to load; highlight the phone type

name and click on OK.

Clicking on CANCEL will stop the request and no new phone type will be

loaded.

Loading a phone interface will disable the automatic rescan function ( see

Configure|Options section for automatic rescan).

This function will close the currently loaded phone type interface that had

been loaded using the

Product|Open function. You can not ‘Close’ a loaded

phone type interface if it was loaded by a rescan.

Page 12

Original 11/97

Page 13

PAMS

WinTesla User Guide

Technical Documentation

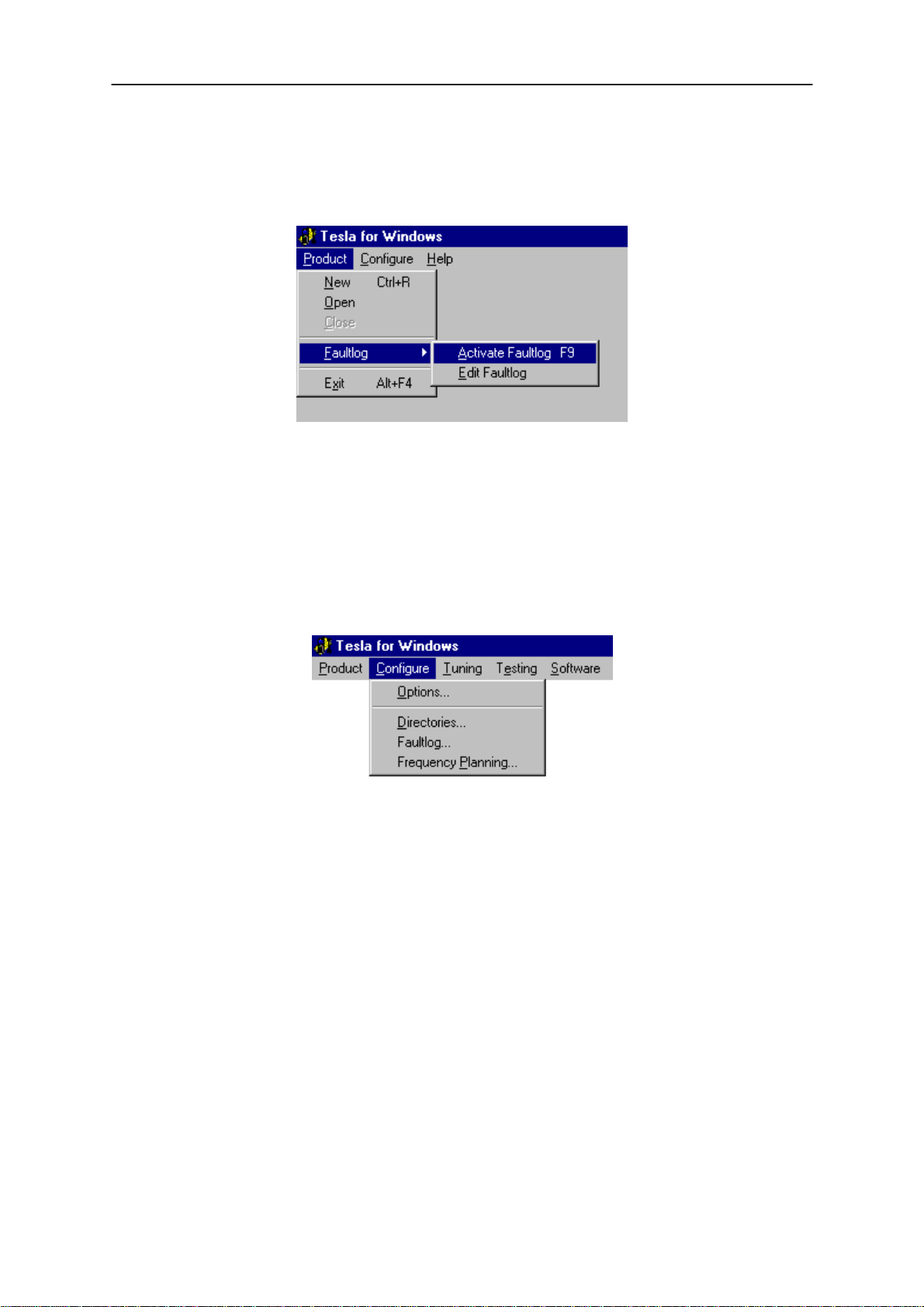

FaultLog

The ‘FaultLog’ option has a sub–menu (below). These functions are

described in the ‘FaultLog Application’ section.

If the FaultLog function has been disabled – either because the Login ID

was not correct or disabled through the

these menus will be ‘greyed’ and made un–selectable.

Exit (Alt+F4)

NHD–4

Configure|FaultLog function – then

Selecting this option will shut–down the WinTesla program.

The Configure Menu

The configuration menu allows you to setup such things as directory

paths, user interface language and FaultLog options.

Original 11/97

Page 13

Page 14

WinTesla User Guide

PAMS

NHD–4

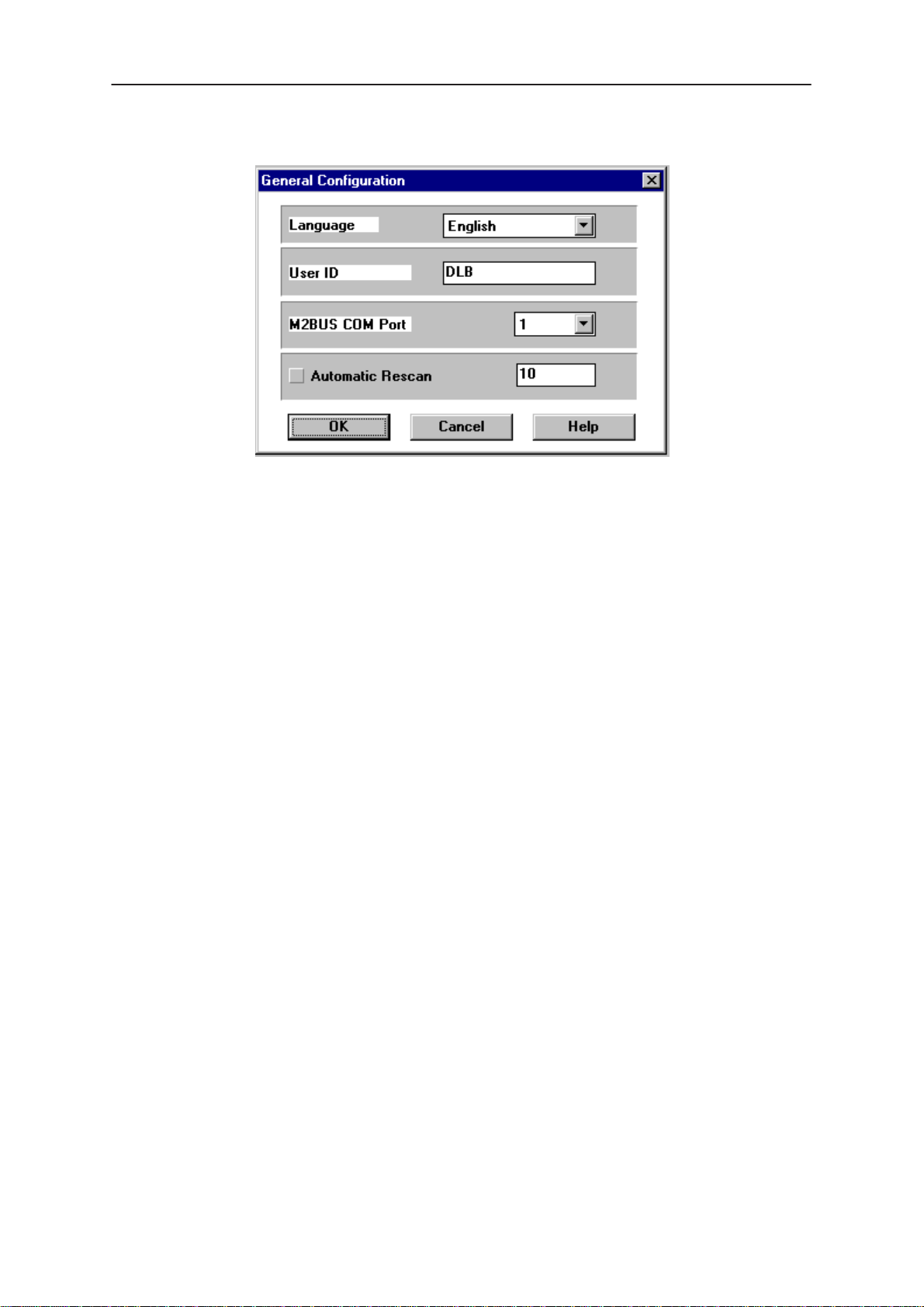

Options

Language

Technical Documentation

This option allows you to change the language used in the WinTesla

application.

Current Password / New Password / Retype Password

Currently not available

User ID

Allows the user ID to be entered if the users name is setup in the

opt_id.val (validation) file.

M2BUS COM Port

This option allows you to select which communications port the phone is

to be connected. The change will take place immediately after pressing

OK.

Automatic Rescan

Automatic rescan is a mechanism to automatically check for a new phone;

the time between re–scans is user configurable. When a phone is

scanned and recognized, the corresponding phone interface and menu

are loaded, extending the main menu at the top of the screen and

displaying the phone type and description at the bottom of the screen.

Product|New (or Ctrl+R ) function can be used to rescan the phone

The

in–between automatic rescans or when automatic rescan has been

disabled. The automatic re–scan mechanism is disabled when the

Product|Open function is used to load a phone interface.

Page 14

A tick in the check–box indicates that the automatic rescan option has

been enabled. Clicking on the check–box (making the check–box blank)

will disable the automatic re–scan option. The time between re–scans (in

seconds) is entered into the edit box.

Pressing the OK button will save any changes made. Pressing CANCEL

will discard any changes you may have made.

Original 11/97

Page 15

PAMS

WinTesla User Guide

Technical Documentation

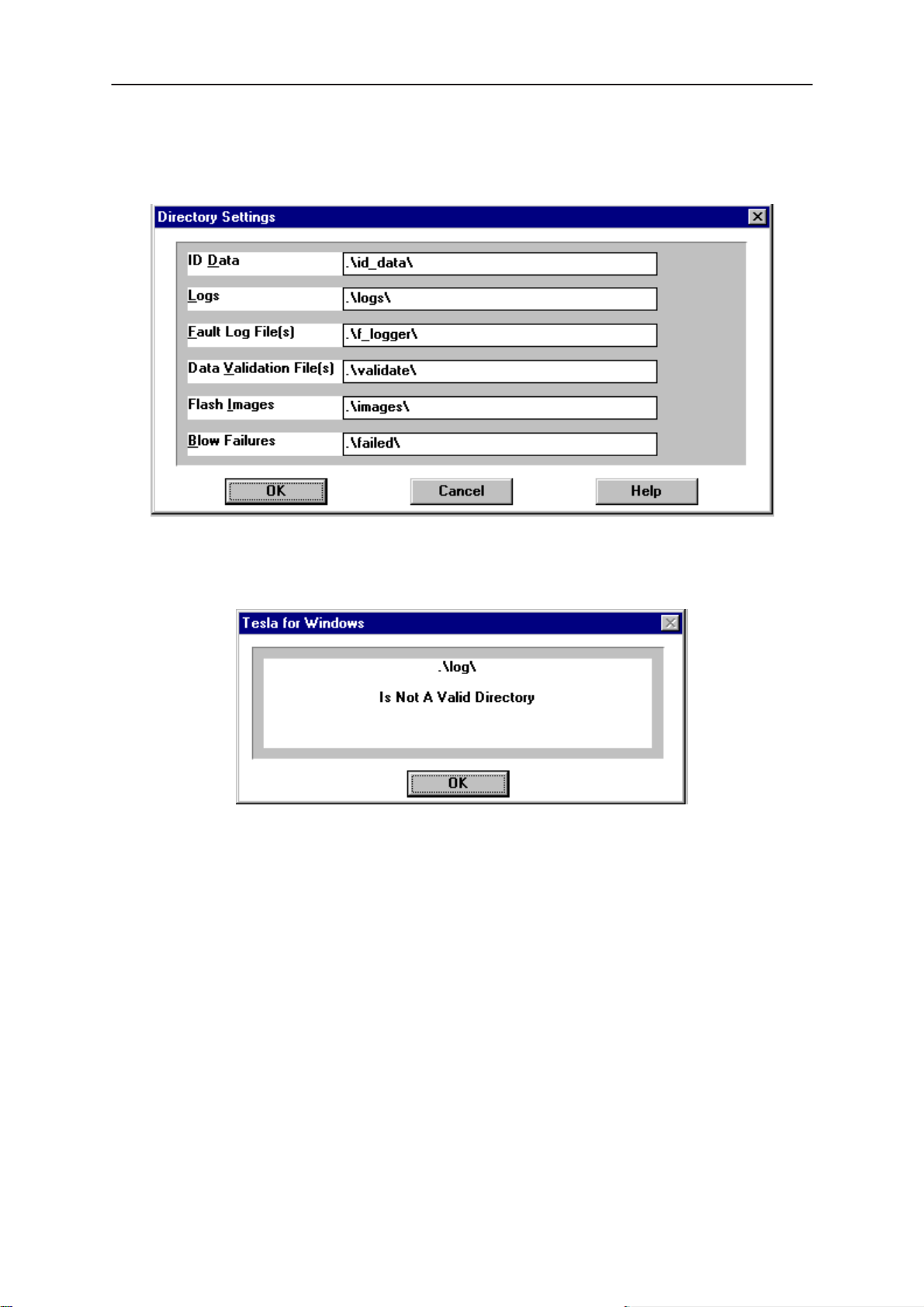

Directories

This function allows you to organize your data into different directories.

The directories must already exist. If an invalid directory is entered then

an error message will be displayed (below).

NHD–4

The use of a backslash (‘\’) at the end of the directory name is optional.

Clicking on the OK button will save your changes.

Original 11/97

Page 15

Page 16

WinTesla User Guide

PAMS

NHD–4

Fault Log Configuration

Fault Log is a feature that allows the PC to create a record of each phone

that is serviced for historical tracking. This function allows you to configure

the FaultLog mechanism. Clicking OK after making selections, saves all

changes made.

Technical Documentation

Figure 8. FaultLog – configuration

Fault Log

This option allows you to enable or disable the FaultLog mechanism.

Choosing to disable the FaultLog mechanism results in the

|FaultLog options being ‘greyed’ and the F9 button being disabled.

Allow Manual Entry

This option allows you to disable manual entry of data that was

unavailable from the phone.

Automatic Fault Log Prompting

Enabling this option results in a prompt being displayed if the phone has

changed.

Station Identity

Enter the unique identity of your ‘workstation’; this ID is used to write

FaultLog files.

Country Of Repair

Enter the country of repair.

Product

Warranty Period ( months )

Each product code has an associated warranty period. This option allows

you to change those warranty periods. If no phone is connected then all

product codes supported will be displayed. However, if a phone is

connected then only the product codes associated with that phone type

are displayed.

Page 16

Original 11/97

Page 17

PAMS

WinTesla User Guide

Technical Documentation

Note: Changing the Warranty Period in the Fault Log data file has no affect on the

products warranty terms as stated from the manufacturer.

Maximum Time To Repair ( minutes )

Enter the maximum time allowed to repair a phone.

1. Fault Log Application.

The aim of the Fault Log application is to provide NMP After Sales

Companies worldwide a standard method for the collection of Fault and

Repair Data from their service process’s. This information can also be

used by NMP R&D and Manufacturing organizations as well.

The Fault Log application can be regarded as a data entry sub–routine

run from the WinTesla Service Software package at the end of a repair.

This allows for quick and uniform recording of the service performed on

the product.

Each product repaired, will generate one unique record in a FaultLog file

consisting of up to 37 data fields containing information about the product

and how it was repaired. This information is read automatically where

possible, from the products own internal EEPROM and then entered

manually by the Service Technician to form a complete service record.

NHD–4

For more advanced implementations, the repair records are copied and

collected by the electronic mail system installed in the Service Center and

are sent electronically to a Central Service Database located in Finland.

Completing a FaultLog Record

Once WinTesla has been configured correctly it operates in the following

manner:–

Wintesla automatically reads the product details from the

products EEPROM and writes them as a record to a

pre–determined file.

Proceed with the repair task, utilising a combination of

software driven tuning and hardware modifications.

On completion of the repair task you have a choice:

A.)With the product still connected to the PC, manually display

the repair data entry screen by selecting Function Button F9.

B.) Alternatively, the product can be disconnected and the next

product for repair connected in its place.

So long as Automatic Prompting is enabled then the previous products

repair data entry screen will be displayed.

– Enter the repair work performed on the product in the repair

data screen.

Original 11/97

– Check the automatic data for this product, read earlier, to

ensure its accuracy.

– When satisfied with the data, save the entry. This process

adds a complete record containing the product details and

the repair details to the FaultLog output file.

Page 17

Page 18

WinTesla User Guide

PAMS

NHD–4

Technical Documentation

The output file can then be manipulated by a number of different systems,

as required, as a detailed record of the product fault.

To attempt to record all of this information 37 data fields are defined for

each FaultLog record. These can be split as follows:–

– Product definition information fields

– Repair / fault information fields.

Most products have their information stored in EEPROM, WinTesla

automatically reads this information from the EEPROM and writes it to the

FaultLog record. This part of the record is shown below.

Operator

Phone

Fault

Fields that are ‘greyed out’ etc. are data that has been automatically

retrieved from the phone’s EEPROM. All other fields are entered

manually; fields are summarized below.

Automatic: Station, Country

Manual :

Automatic: Product code, Production SN, Order No., Hardware

ID, Software version, Mfr. SN/ESN/IMEI, Mfr. Date,

Manual:

Automatic: none

Manual

The current FaultLog application allows for the entering of three priority

levels of fault / repair information seen as

faults.

Time to repair, Job ID, Operator ID

Issue date

Warranty

Module, Fault, Symptom, Circuit ref., Part Number

Primary, Secondary

and

Tertiary

Page 18

Original 11/97

Page 19

PAMS

WinTesla User Guide

Technical Documentation

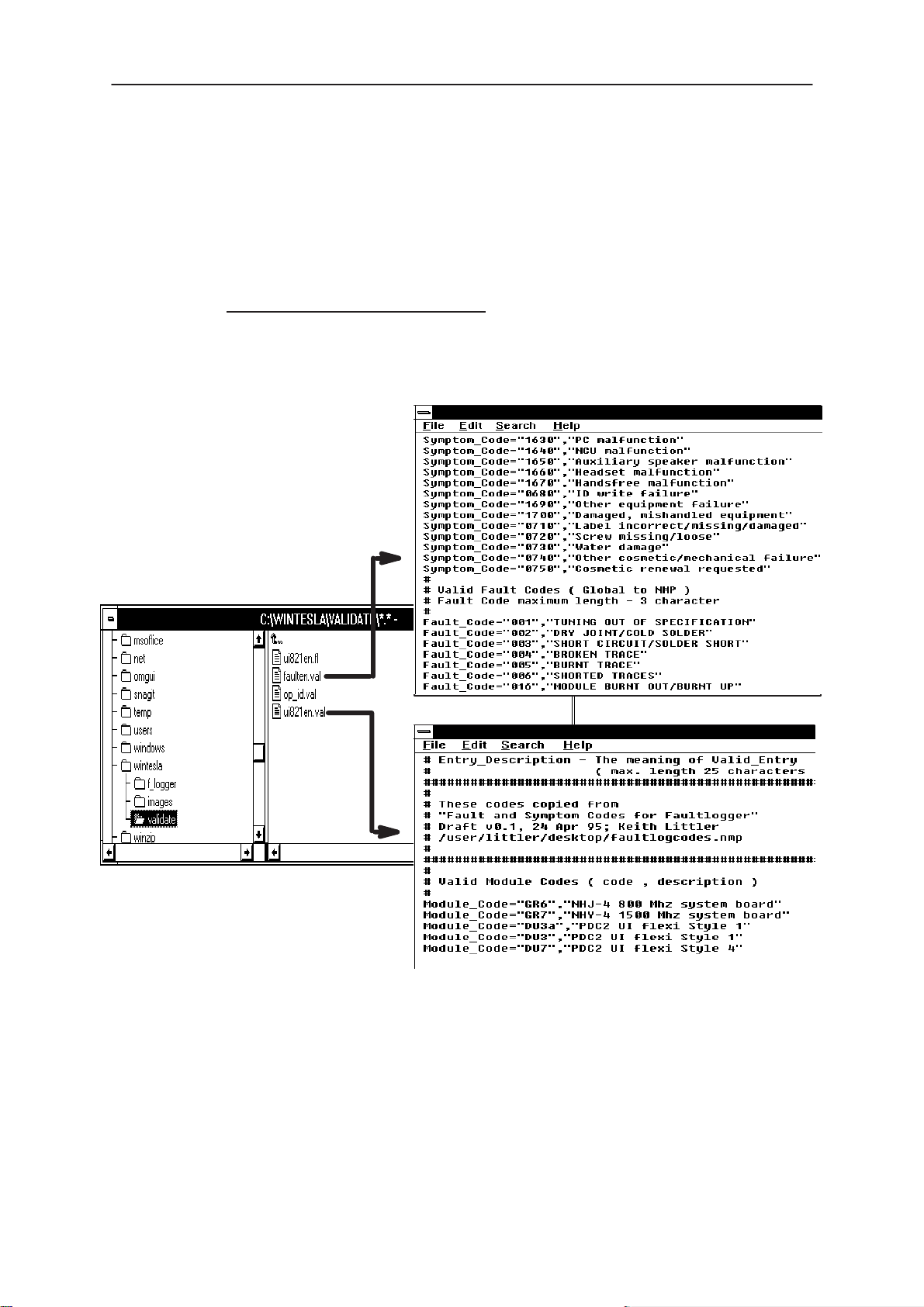

Module, Fault

The

arrows alongside each respective field.

A comprehensive list of faults and symptoms as well as all current

modules are already listed within the software. These three fields can be

updated by accessing and editing the following files ias described in each

file.

Field DOS File

–

–

and

Symptom

Modules

nhd4en.val–

Faults, Symptoms

NHD–4

fields have variables selected by the

faulten.val

Notepad – FAULTEN.VAL

Other Parts Replaced

Automatic none

Manual all fields

Enter other parts that have been replaced i.e. for wear and tear purposes

etc..

Notepad – UI821EN.VAL

Figure 9. Editing fault, symptoms, modules files

Original 11/97

Page 19

Page 20

WinTesla User Guide

PAMS

NHD–4

This Entry

Automatic ; Entry Indicator, Date, Time

Manual ;

Cost

Automatic ; Total

Manual ;

This facility is for the use of third party repairers only

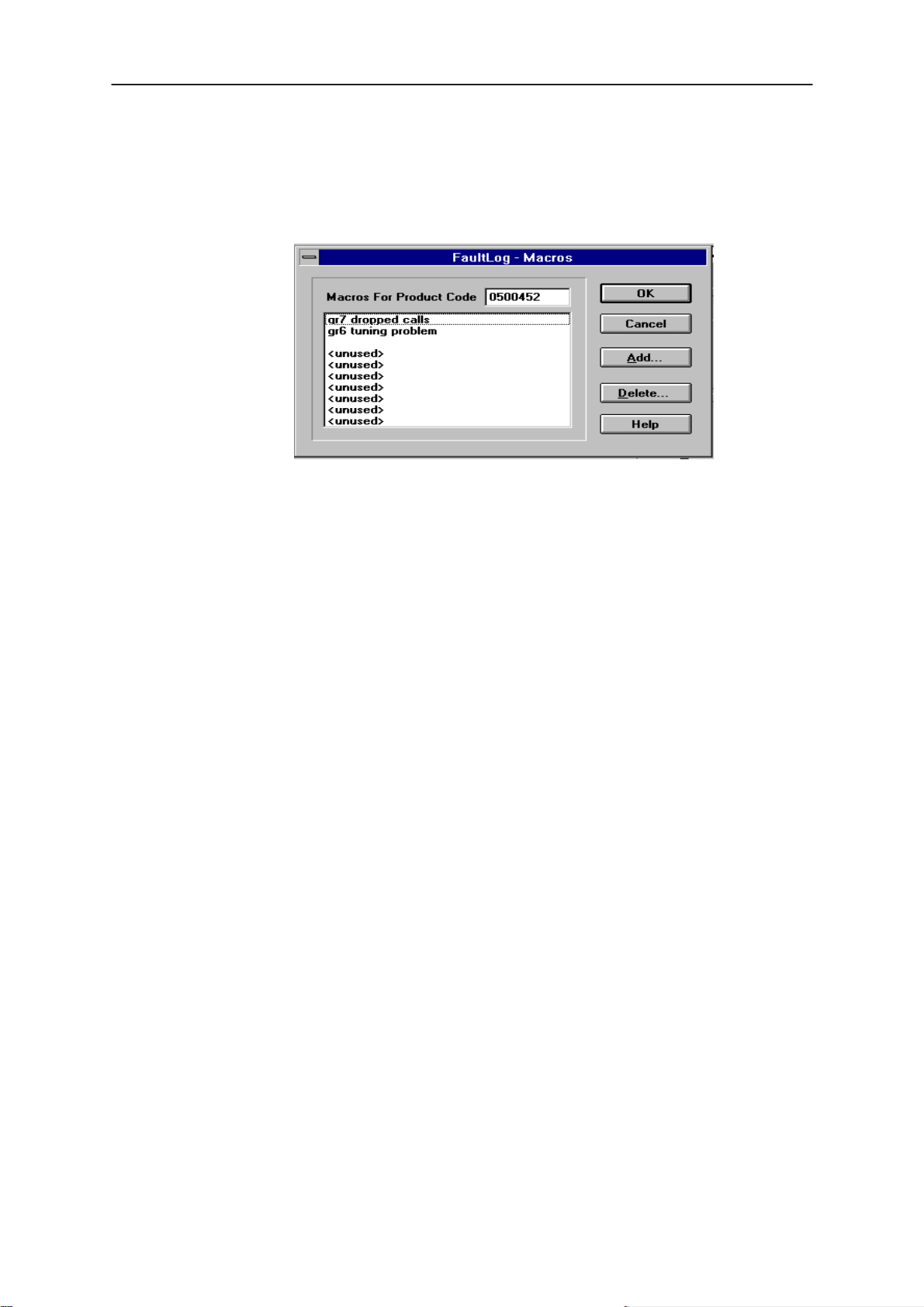

FaultLog Macros

The Macro sub–menu can be accessed by selecting the

the FaultLog main screen.

Macro’s in FaultLog are a set of standard repair actions defined and

stored in order to represent frequently repeated repairs. These Macro’s

are related to the Product Code of the product, so whatever product is

connected, FaultLog will display the Macro list for that particular Product

Code.

Technical Documentation

Comment

Parts, Labour

macros button on

A Macro’s standard repair information can also be pasted into the

FaultLog record for that product.

Macro’s are saved initially under a name you can define yourself from the

main FaultLog screen. All the information contained in the manually

entered fields i.e. Module, Fault, Symptom, Circuit Ref and Part Number is

recorded and saved under this name.

Page 20

Original 11/97

Page 21

PAMS

WinTesla User Guide

Technical Documentation

Setting up a macro

1. After completing a manual entry as normal but before saving the

record, select the

definition screen.

2. Place the cursor over the next available Macro entry then select

Add

NHD–4

Macros button. This will bring you into the Macro

Figure 10. FaultLog – macro setup

Help

3. Give the Macro record a meaningful name and press OK. You

have now saved the repair data into a Macro for future use.

4. Use the

Delete function to remove unwanted macros

Now, when a similar problem is seen with another unit you can recall this

saved repair information into the units FaultLog record. If needed, the

FaultLog record can be edited after being recalled to customize the repair

before saving the FaultLog record.

There are a maximum of 10 Macro’s definable for each Product Code. If

an eleventh is required, it will be necessary to overwrite one of the

previous Macro’s.

The Macro definition file is called

macro.fl

and will be found in the path

specified for the data validation files. If this path is a networked path all

operators connected to the network will be permitted to share a common

Macro list helping with reporting uniformity.

An extensive help facility is available by clicking any screen or toolbar help

button and features convenient hypertext linking for easy navigation.

Original 11/97

Page 21

Page 22

WinTesla User Guide

PAMS

NHD–4

HD881 Module

Information in this section is specific to the HD881 module and assumes

that the setup procedures in the common interface section have been

carried out.

Installing the HD881 Service Module

The HD881 Service module software is delivered on a 3.5” diskette and

must be run under the Wintesla core software package.

To install the HD881 Service Module software, proceed as follows:

Insert the HD881 Service Module diskette into drive A: of your PC.

From Windows File Manager select the file a:\install.exe and

press OK.

Follow the on screen instructions and select the

prompted to do so.

Caution: The service module requires the Wintesla core software

application to be installed first for this module to function.

Technical Documentation

new

install option when

Note: Be sure to install the Service Module in the same directory as the Wintesla

core software application.

Required Servicing Equipment

The following is a list of equipment that is needed in order to service the

HD881 family of products along with their respective product codes.

HD881 Software Service Module (0774062)

Dongle ‘blackbox’ adapter DBA–1 (0630044)

M2BUS adapter DAU–2 (0750006)

RS–232 adapter, 9–to–25 pins (4626170)

RS–232 cable (0730090)

Centronics cable (0730029)

Service cable SCS –1 (0770010)

Service cable SCS–10 (0775059)

Audio cable ADS–1 (0730011)

Modular cable XCM–1 (4626131)

Flash Programmer Set FPS–3C (0271330)

Page 22

Power connector PCS–1 (0730012)

Modular T Connector cable (4626134)

Dummy Battery BTS–4 (0770009)

Covers off Jig JBS–8 (0770014)

Service box JBS–7 (0770015)

Original 11/97

Page 23

PAMS

WinTesla User Guide

Technical Documentation

Equipment Setup

Caution: Make sure that you have switched off the PC and the printer

before making connections !

Caution: Do not connect the PKD–1 key to the serial port. You may

damage your PKD–1 !

Attach the protection key PKD–1 to parallel port one (25–pin female

D–connector) of the PC. When connecting the PKD–1 to the parallel port

be sure that you insert the PC end of the PKD–1 to the PC (male side). If

you use a printer on parallel port one, place the PKD–1 between the PC

and your printer cable.

Next connect the M2BUS adapter to the serial port (RS–232) of the

computer. In case you are using a 9–pin serial port (normal with an AT

set) use the mating adapter supplied with the M2BUS adapter.

Attach one end of the XCM–1 modular cable to the DAU–2 PC/M2BUS

adapter and the other end to the JBS–7 service box. Use suitable adapter,

SCS–1 service cable when the covers of the phone are in place, JBS–8

test frame with the phone covers off, and attach it to the phone. Then

connect it to the service box.

NHD–4

Original 11/97

Page 23

Page 24

WinTesla User Guide

PAMS

NHD–4

Dealer Setups

Technical Documentation

Figure 11. Testing/Tuning with covers off

Item Description Product

Code

2 ADS–1 0730011

3 XCM–1 4626170

4 PCS–1 0730012

7 JBS–8 0770014

8 RS232 Adapter 4626170

9 JBS–7 0770015

11 DAU–2 0750006

16 Software diskette 0774062

17 Modular T connector 4626134

Page 24

Original 11/97

Page 25

PAMS

WinTesla User Guide

Technical Documentation

NHD–4

Figure 12. Testing/Tuning with covers on

Item Description Product

Code

2 ADS–1 0730011

3 XCM–1 4626170

4 PCS–1 0730012

5 SCS–1 0770010

6 BTS–4 0770009

8 RS232 Adapter 4626170

9 JBS–7 0770015

11 DAU–2 0750006

16 SWSA881 0774062

17 Modular T connector 4626134

Original 11/97

Page 25

Page 26

WinTesla User Guide

PAMS

NHD–4

Main Menu

The main menu bar below appears when HD881 initializes, adding the

following new categories,

Product

Product

The following items are added to this menu when HD881 is recognized:

Initialize

Allows the phone to be set up in either

Normal Mode

and

Configure

Technical Documentation

Tuning,Testing, Software, Dealer

have also changed.

Normal, Local or Minimum

and

Help.

mode.

When selecting

base station and a message displays this. This is ”normal” operation

mode of the phone.

Local Mode

When

operation and set to a special mode allowing Tuning and Testing to be

done.

Minimum Mode

When

MCU will communicate with the PC using the Service Software. This

mode is used for Flash software changes.

Local

Minimum

Configure

Channel Settings

This configures the channel number, for a product type, to be

High

in order to allow losses to be configured for manual testing.

Norma

mode is selected the phone is suspended from normal

mode is selected the phone is deactivated and only the

l mode, the phone tries to synchronize into the

Low, Mid,

Page 26

Original 11/97

Page 27

PAMS

WinTesla User Guide

Technical Documentation

Tuning Steps of Radio Unit

The Service software program places the phone into the Locals mode, in

which the phone can be outwardly controlled via the M2BUS interface.

The tuning values of the phone reside on the EEPROM. Before tuning,

these values are read by the Service software and the user can change

these values with tuning functions.

Note: During tuning, keep the following in mind:

– Take care not to damage sensitive measuring instruments with exces-

sive RF power.

– Carry out all tuning steps in the shortest possible time to avoid exces-

sive heating of RF units.

– Perform all tuning steps in the order presented.

– Never try to mask a fault by tuning it out!

NHD–4

Accuracy of the Equipment During Measurement

– Power supply 1; nominal voltage 12 ±0.5 V current cap. min. 1.5 A for

service box (JBS–7).

– Power supply 2 ;nominal voltage 6.0 ±0.1 V, current cap. min. 1.5 A.

– Modulation analyzer power level resolution 0.1 dB, accuracy ±0.5 dB.

Frequency counter accuracy 0.1 ppm 〈±80 Hz).

– RF generator; frequency res. 10 Hz amplitude res. 0.1 dB frequency

stab. ±0.25 ppm.

– Spectrum analyzer; dynamic range 70 dB, accuracy ±1 dB (For power

level measurement accuracy ±0.5 dB).

Original 11/97

Page 27

Page 28

WinTesla User Guide

PAMS

NHD–4

General

Caution: The phone can not be Tuned properly if connected to the

FPS–3C Flash Programming Box. Please use only one of the setup

configurations listed in the “Dealer Setups” section of the NHD–4NX

Service Manual.

Battery Voltage Adjustment

A reference value for the battery is calibrated by using an accurate 6.0 V

supply.

Calibration of the A/D converter channels:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ” Tuning – Battery voltage”.

– The Program reads the 6 Volts applied and displays the corresponding

A/D reading fed to the phone via the VBATT line.

Technical Documentation

– Store this new value to the phone by pressing ”Tune”. Then Exit

Charge Voltage Adjustment

A reference value for charge voltage is set by using an accurate 6.0 V

supply.

Calibration of the charge voltage:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6 V to VCHARGE line.

– Select ”Tuning – Charge voltage ”.

– The Program reads 6 V, A/D reading fed to phone VCHARGE line.

– Store this new value to the phone by pressing ”Tune”. Then Exit

RF Temperature Adjustment

This adjustment should be made with the phone at room temperature. It

is important that all RF transmitter tunings be done as quickly as possible.

This is to ensure that this reference temperature adjustment is within limits

required for temperature compensation.

Page 28

Calibration of the RF Temperature:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6 V to VCHARGE line.

– Select ”Tuning – RF Temperature ”.

– Press ”Tune”. The Program reads the internal thermistor value and

stores this value to the phone.

Original 11/97

Page 29

PAMS

WinTesla User Guide

Technical Documentation

AMPS Tuning

Analog Bias Current Tuning

The purpose of this tuning is to optimize transmitter‘s efficiency.

Bias tuning is needed if:

– PLL circuit (N500) is replaced

– Any of the power amplifiers V110, V111, V112, V113 or the duplex filter

is replaced

– Any of power amplifier resistors are replaced

This affects only power consumption and thus gain and linearity of power

amplifier.

Description of Tuning

This tuning sets the bias current to the CLY–10 (V113) final PA gain stage

for AMPS mode operation at output power level 7. The TXB PDM is used

to set this bias. The bias is set to provide 100 mA of current to the

CLY–10 in this state. This 100 mA current is the amount of current draw

above the quiescent state of the phone in AMPS mode, as described in

the AMPS Mode Quiescent Current section 3.1. Note that the CLY–10 will

draw additional current at higher output AMPS power levels. This is due

to self biasing by the drive signal.

NHD–4

Analog bias current tuning steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Start the service software and go to ”Main” menu.

– Select ” Tuning – Analog Bias Tuning ”

– Measure step1 current consumption from power supply current display

and input it to Service software prompt. Then press OK.

– Adjust first analog mode bias current to the target value displayed in

tuning dialog by using Arrow keys or PgUp/PgDn keys.

Original 11/97

Page 29

Page 30

WinTesla User Guide

PAMS

NHD–4

AFC Tuning

This tuning is done to calibrate the VCTCXO oscillator frequency.

This tuning is needed if the VCTCXO (G300), any component of AFC–line

or the CDRFI (N700) is changed.

Description of Tuning

This procedure tunes the VCTCXO to 15.36 MHz. The unmodulated

AMPS transmitter carrier on channel 384 is used to perform this test. The

output carrier is monitored with a spectrum analyzer with a 10 kHz span.

The VCTCXO is tuned by adjusting the AFC PDM until the carrier is on

frequency at 836.52 MHz within 200 Hz. For standard AFC operation the

RX_SLOPE PDM is high, at approximately 3.15 V.

AFC calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

Technical Documentation

– Apply +6.0 V to dummy battery.

– Select ” Tuning – AFC ”

– Connect the modulation (or spectrum) analyzer to antenna connector

and measure transmitter frequency. Adjust frequency to 836.52 MHz +

– 200Hz with arrow or PgUp/PgDn –keys.

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Page 30

Original 11/97

Page 31

PAMS

WinTesla User Guide

Technical Documentation

Deaf Channel Frequency Tuning

This tuning is done to calibrate the VCTCXO oscillator frequency to adjust

for “deaf” or “blocked” AMPS channels.

This tuning is needed if the VCTCXO (G300), any component of AFC–line

or the CDRFI (N700) is changed.

Description of Tuning

This is a secondary tuning done on the VCTCXO for a special case

involving AMPS channels 184, 440 and 696, known as the Deaf channels.

This tuning is performed exactly as it was in the AFC Tuning above, but

now channel 440 is used rather than channel 384. In this case the

RX_SLOPE PDM is low at approximately 0.0 V. Again the AFC PDM is

adjusted to tune the transmit carrier to within 200 Hz of the center

frequency, this time 838.20 MHz. Consult the HD881 Synthesizer

Functional Description for more information on the Deaf Channel

functionality of the synthesizer.

NHD–4

AFC calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ” Tuning – Deaf Channel Frequency”

– Connect the modulation (or spectrum) analyzer to antenna connector

and measure transmitter frequency. Adjust frequency to 838.20 MHz +

– 200Hz with arrow or PgUp/PgDn –keys.

– Press <save & exit> to store value to EEPROM or <Close> to exit

without saving.

Original 11/97

Page 31

Page 32

WinTesla User Guide

PAMS

NHD–4

TX Output Power

This adjustment loads the power levels of the phone transmitter into

EEPROM. When doing this, a power meter must be used.

This tuning is needed if CDRFI (N700), duplex filter, power RF transistors

or power control parts are replaced

Description of Tuning

This tuning sets the AMPS transmitter power levels 2–7 to the required

power output. To perform this tuning the phone is placed in AMPS Mode

and the carrier is turned on. AMPS TX power control on the 2180 is done

by adjusting the TXI_REF PDM.

Power levels programming:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

Technical Documentation

– Select ” Tuning – TX power level”

– Connect power meter to antenna via the phone’s bottom connector.

– Adjust the tuning value with the arrow keys (fine tuning) or with PgUp

and PgDn–keys (coarse tuning) until the desired output power is

reached. Tuning starts from the highest power level.

Note: There is a little cable loss between the antenna connector and the RF power

meter. The total attenuation of 1 meter long RG–58 cable and the service box is about

0.7 dB. Please take this into account.

Power

level

Target Power level

values (milliWatts)

Example value

A/D converter

2 26.8 dB (479 mW) 143

3 22.8 dB (239.9 mW) 0

4 18.8 dB (95.5 mW) –40

5 14.8 dB (38.0 mW) –89

6 10.8 dB (15.1 mW) –129

7 6.8 dB (6.03 mW) –161

– Use the <TAB> key to move to tune the next power level.

Page 32

– Press <Save & exit> to store calculated values to the phone and exit

or <Close> to exit without storing.

Original 11/97

Page 33

PAMS

WinTesla User Guide

Technical Documentation

TX Modulation Index Calibration

This tuning is done to adjust the FM Modulators and the gain of TX–audio

path.

This tuning is needed if Codec (N600), or components D1, N500 or D704

is changed.

Description of Tuning

This tuning adjusts the level of FM modulation on the AMPS transmitter.

To do this, the Signaling Tone (ST) is turned on and the modulation level

on the transmit signal is monitored. The TX_MOD level in the DSP is

adjusted in software. This value controls the level of the audio frequency

tone leaving the CDRFI pin 25 on route to the VHF synthesizer for

modulation. At the CDRFI, pin 25 this line is called DAFOUT. Into the

VHF synthesizer it named ANATX. For the ST tone the TX_MOD level is

adjusted until the FM modulation is 8 kHz +/– 0.2 kHz

FM Modulation adjustment:

NHD–4

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ” Tuning – TX Modulation Index”

– Connect modulation analyzer to antenna connector. Use 20 kHz low

pass filter.

– Use PgUp/PgDn keys to adjust to 8.0 kHz +/– 100 Hz. (ST signal is

switched ON)

– Press <Save & Exit> to store values to the phone and exit or <Cancel>

to exit without saving.

Original 11/97

Page 33

Page 34

WinTesla User Guide

PAMS

NHD–4

RSSI

This step consist of tuning the analog mode reference value for the

receiver signal strength meter.

This tuning is needed if FM detector (D1); any parts of RX–chain; duplex

filter or saw filter has been changed

Note: Take into account any cable loss.

Description of Tuning

This tuning records the RSSI values for low and high power received

signals. This is done by feeding a –95 dBm signal into the AMPS receiver

at channel 384 with modulation of 8 kHz FM, 1 kHz audio. The RSSI

voltage generated by the AMPS receiver IC (D1) routes to the MCU, pin

58. The MCU reads the RSSI value resulting from its onboard A/D

converter. For the –65 dBm input signal this digital value is stored in

EEPROM as RSSI_HI. This process is repeated for a –65 dBm

modulated input signal, and the stored value is termed RSSI_LO. The

RSSI values read by the MCU are 10 bit numbers.

Technical Documentation

Analog RSSI level tuning steps:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect signal generator to antenna connector at 881.52 MHz (chan-

nel 384) using modulating frequency 1.0 kHz with a deviation of 8.0

kHz and level of –95 dBm.

– Select ” Tuning – RSSI”.

– The program reads the reference value stored on phone together with

the reference value read from A/D converter.

– A/D converter value should be between 0 – 255.

– Press <Tune> to store values to the phone and exit or <Cancel> to exit

without storing.

– Connect signal generator to antenna connector at 881.52 MHz (chan-

nel 384) using modulating frequency 1.0 kHz with a deviation of 8.0

kHz and level of –65 dBm.

– A/D converter value should be between 0 – 255.

Page 34

– Press <Tune> to store values to the phone and exit or <Cancel> to exit

without storing.

Original 11/97

Page 35

PAMS

WinTesla User Guide

Technical Documentation

RX Audio Gain

The purpose of this tuning operation is to calibrate the gain of audio path.

This tuning is needed if FM detector (D1) including surrounding

components of FM detector or Audio Codec (N600) is changed

Description of Tuning

This tuning adjusts ratio of output audio gain vs. the level of received FM

frequency deviation. A –80 dBm signal with 2.9 kHz FM, 1 kHz audio is

fed into the phone on channel 384 (881.52 MHz). The received,

demodulated output audio level is read from the ear piece at the output of

the bottom connector. The rxgaina value sets the amount of audio gain.

This value is tuned until the output audio level at the ear piece is 78 mVac

, +/– 2 mV.

Demodulation adjustment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

NHD–4

– Apply +6.0 V to dummy battery.

– Select ” Tuning – RX Audio Gain”

– Apply modulated test signal (ch. 384, RX frequency 881.52 MHz, mod-

ulation 1 kHz with 2.9 kHz deviation and RF level –80 dBm) to antenna

connector.

– Adjust tuning value with arrow keys (fine tuning) or with PgUp and

PgDn–keys (coarse tuning) until measured EAR level is 79 mVrms +/–

1mV.

– Press <Save & Exit> to store values to the phone and exit or <Cancel>

to exit without storing.

Original 11/97

Page 35

Page 36

WinTesla User Guide

PAMS

NHD–4

CDMA Tuning

RX Offset Tuning – (RX/TX)

The purpose of this tuning operation is to calibrate the mid point of the

CDMA Receiver’s dynamic range.

This tuning is needed if the duplexor, CDGACR (N1) or BBFIL (N2) is

changed.

Definition of Tuning

The purpose of this tuning is to center the dynamic range of the RxDac to

correspond to the midpoint of the dynamic range of the CDMA receiver. A

–65 dBm 881.62 MHz signal is fed into the phone. –65 dBm is the

midpoint of the –25 to –105 dynamic range of the CDMA receiver. The

RX_OFFSET PDM is adjusted until the RxDac is at its midpoint of

approximately 200H. The RX/TX designation on the name of this tuning

implies that both the receiver and transmitter are functioning when this

tuning occurs. A separate tuning must occur when the transmitter is not

on, hence the reason for the RX_OFFSET (RX) tuning.

Technical Documentation

TX Offset calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect the modulation (or spectrum) analyzer to antenna connector.

– Select ” Tuning – Rx Gain Offset”

– Adjust the Rx Offset Value with arrow or PgUp/PgDn –keys until the

current RxDAC register value is with the target limits.

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Page 36

Original 11/97

Page 37

PAMS

WinTesla User Guide

Technical Documentation

RX Offset Tuning – (RX)

The purpose of this tuning operation is to calibrate the center the dynamic

range of the RxDAC to correspond to the midpoint of the dynamic range of

the CDMA receiver.

This tuning is needed if the duplexor, CDGACR (N1) or BBFIL (N2) is

changed.

Definition of Tuning

The purpose of this tuning is to center the dynamic range of the RxDAC to

correspond to the midpoint of the dynamic range of the CDMA receiver. A

–65 dBm 881.62 MHz signal is fed into the phone. –65 dBm is the

midpoint of the –25 to –105 dynamic range of the CDMA receiver. The

RX_OFFSET PDM is adjusted until the RxDAC is at its midpoint of

approximately 200H. The RX designation on the name of this tuning

implies that the CDMA receiver is functioning when this tuning occurs, but

not the transmitter. A separate tuning must occur when the transmitter is

on as well, hence the reason for the RX_OFFSET (RX/TX) tuning found

above.

NHD–4

TX Offset calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect the modulation (or spectrum) analyzer to antenna connector.

– Select ” Tuning – Rx Gain Offset Rx”

– Adjust the Rx Offset Rx Value with arrow or PgUp/PgDn –keys until the

current RxDAC register value is with the target limits.

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Original 11/97

Page 37

Page 38

WinTesla User Guide

PAMS

NHD–4

Rx Slope

The purpose of this tuning operation is to calibrate the linear relationship,

or slope, between a change in the received power by the CDMA receiver.

This tuning is needed if the duplexor, CDGACR (N1), CDSB (D704),

CDRFI (N700) or BBFIL (N2) is changed.

Definition of Tuning

This tuning determines the linear relationship, or slope, between a change

in the received power by the CDMA receiver. To do this a CW signal is fed

into the CDMA receiver. The initial CW signal power is stored as BPOW1.

Next, the CW signal power is incremented until the RxCtr changes by 256

steps. The CW signal power required to do this is recorded as BPOW2.

The difference between BPOW1 and BPOW2 should be approximately 32

dB. From this data the RX Slope is determined. It is then manipulated

mathematically so that the RX Slope equals “1”. When it does, a one bit

change in the RxCtr will result in a 1/8 dB change in receiver gain. The

RX/TX designator on the name of this tuning implies that the transmitter is

on when this tuning is performed. A separate tuning must occur when the

transmitter is not on, hence the reason for the RX_Slope (RX) tuning.

Technical Documentation

Rx Slope calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ” Tuning – Rx Slope”

– Set up the signal generator as requested and press the step 1 key.

– Change signal generator set up as requested and press the step 2

key.

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Page 38

Original 11/97

Page 39

PAMS

WinTesla User Guide

Technical Documentation

Rx Slope Rx

The purpose of this tuning operation is to calibrate the linear relationship,

or slope, between a change in the received power by the CDMA receiver.

This tuning is needed if the duplexor, CDGACR (N1), CDSB (D704),

CDRFI (N700) or BBFIL (N2) is changed.

Definition of Tuning

This tuning determines the linear relationship, or slope, between a change

in the received power by the CDMA receiver and a change in the RxCtr

register value in the CDSB ASIC. To do this a CW signal is fed into the

CDMA receiver. The initial CW signal power is stored as BPOW1. Next,

the CW signal power is incremented until the RxCtr changes by 256 steps.

The CW signal power required to do this is recorded as BPOW2. The

difference between BPOW1 and BPOW2 should be approximately 32 dB.

From this data the RX Slope is determined. It is then manipulated

mathematically so that the RX Slope equals “1”. When it does, a one bit

change in the RxCtr will result in a 1/8 dB change in receiver gain. The

RX/TX designator on the name of this tuning implies that the transmitter is

on when this tuning is performed.

NHD–4

Rx Slope Rx calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ” Tuning – Rx Slope Rx”

– Set up the signal generator as requested and press the step 1 key.

– Change signal generator set up as requested and press the step 2

key.

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Original 11/97

Page 39

Page 40

WinTesla User Guide

PAMS

NHD–4

Rx Gain Switch Calibration

The purpose of this tuning operation is to calibrate the gain differential of

the receiver system with the LNA on and off.

This tuning is needed if the LNA (V12), N701 or N702 is changed

Definition of Tuning

This operation determines the gain differential of the receiver system with

the LNA on and off. The CDMA receiver system is then calibrated

accordingly. To do this a constant level CW tone is fed into the CDMA

receiver. The LNA is turned on and the received signal strength to the

CDSB ASIC (D704) is read and stored. This is the also known as the

RxCtr value. With the same input signal the LNA is then turned off and

the RxCtr is read again. The dB power difference between the two RxCtr

values is equivalent to the gain that the LNA provides.

Rx Gain Switch calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

Technical Documentation

– Apply +6.0 V to dummy battery.

– Select ” Tuning – Rx Gain Switch Calibration”

– Set the signal generator as requested and press the tune Key.

– Press <save & exit> to store value to EEPROM or <close> to exit with-

out saving.

Page 40

Original 11/97

Page 41

PAMS

WinTesla User Guide

Technical Documentation

CDMA TX Bias Tuning

The purpose of this tuning operation is to calibrate the Power Amplifiers

bias current limit.

This tuning is needed if the Power Amplifier (V113) or any transistor in the

TX chain (V110 – V112) is changed.

Definition of Tuning

This tuning sets the bias current limits on the CLY–10 (V113) final PA gain

stage. Bias current on the CLY–10 is dynamic in CDMA operation. The

TXB PDM is used to set this bias. Low power is defined as less than or

equal to +10 dBm of output CDMA TX bandpower. For the low power

case the bias is set to provide 100 mA of current to the CLY–10. Max

Power is defined as greater than or equal to +23 dBm of output CDMA TX

bandpower. For the Max Power case the bias is set to provide 250 mA of

current to the CLY–10. Between Low and Max Power the bias current

ramps up linearly from 100 to 250 mA. These currents described are the

amount of current draw above the quiescent state of the phone in CDMA

mode. The figure below better describes the TXB Slope.

NHD–4

CLY–10 Bias Current vs. CDMA TX Output Power

250mA

CLY–10 Bias

Current

TXB Slope

100 mA

+10 dBm 23 dBm

Figure 13. CDMA TX Output power

Note: This Tuning may need to be repeated several times to ensure proper

calibration. It is recommended that each step be reverified since this tuning step will

affect battery performance.

Original 11/97

Page 41

Page 42

WinTesla User Guide

PAMS

NHD–4

Technical Documentation

TX Offset calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect the Current meter in line with the power supply to the phone.

– Connect the modulation (or spectrum) analyzer to antenna connector

and measure transmitter power.

– Select ” Tuning – Digital Bias”

– Enter the current draw measured from the current meter into the dia-

log prompt and press <OK>.

– Use the Up, Dn Keys to adjust the “Present Bias Value” until the Cur-

rent draw is within 5 mA of the “Target Bias Current”.

– Enter the actual current measurement into the “Actual Current” box.

– Press TAB to highlight the “Present Output Power” box.

– Use the Up, Dn Keys to adjust the “Present Output Power” value until

a the measured Transmitter output is within the “Target Output Power”

range.

– Enter the actual power measured into the “Actual Power” box.

– Press <save> to store value to EEPROM or <close> to exit without

saving.

– Repeat the above process for Step 2 using the associated Target val-

ues.

Page 42

Original 11/97

Page 43

PAMS

WinTesla User Guide

Technical Documentation

Align TX Gain Limiting Tuning

The purpose of this tuning operation is to calibrate the Maximum Power

output in CDMA mode.

This tuning is needed if the Power Amplifier (V113) or surrounding

components of is changed .

Definition of Tuning

This tuning sets the upper limit on the output power of the CDMA TX. To

do so, the CDMA TX is initially railed high, providing the maximum output

power that the phone’s software will allow it to produce. This output

power is then reduced until it is approximately 24.5 dBm. This is

accomplished by decreasing the value of the TXI_REF PDM. The value

of TXI_REF PDM determines the TX limit by comparing itself to the TXI

voltage generated by the detector. It is important to keep in mind that this

24 dBm value refers to power within the 1.23 MHz CDMA channel band.

Thus it is a bandpower measurement, not a peak power measurement.

NHD–4

TX Offset calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect the modulation (or spectrum) analyzer to antenna connector

and measure transmitter frequency. Adjust frequency to 838.20 MHz +

– 200Hz with arrow or PgUp/PgDn –keys.

– Select ” Tuning – TX Maximum Gain”

– Adjust tuning value with arrow keys (fine tuning) or with PgUp and

PgDn–keys (coarse tuning) until measured Power level is within the

Target value.

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Original 11/97

Page 43

Page 44

WinTesla User Guide

PAMS

NHD–4

Aux. AGC Tuning

The purpose of this tuning operation is to calibrate the Automatic Gain

Control circuit in CDMA mode.

This tuning is needed if CDCONT (N201), N1, N2, N100 or N700 is

changed.

Aux. AGC is an auxiliary transmitter gain control feature implemented to

improve the signal to noise ratio of the CDMA TX output. The figures

below will assist in the explanation of the Aux. AGC functionality.

The gain of the CDMA transmitter is controlled by two devices, the

CDAGCT IC (N100) and the AT–109 variable attenuator (V106). CDMA

TX output power is controlled by the CDAGCT IC across the dynamic

range of –50 dBm to 15 dBm. The 15 dBm output point is referred to as

the Switch Point. Above the Switch Point (15 dBm), the AT–109 variable

attenuator controls the output power level. This secondary gain control

mechanism is referred to as Auxiliary AGC (Aux. AGC). A more thorough

description of Auxiliary AGC is found in the Transmitter Troubleshooting

Manual and Functional Description.

Technical Documentation

Below the Switch Point (less than 15 dBm CDMA TX power) the

attenuation of the AT–109 is set to its maximum level of tuned attenuation.

Above the Switch Point this attenuation is decreased, thus increasing the

overall gain of the CDMA TX chain. The Aux. AGC circuit is tuned to

provide a 10 dB dynamic range of attenuation. Without this 10 dB of

attenuation in place the output power increases 10 dB above the switch

point to approximately 25 dBm. In practice the 25 dBm may not be

reached due to the TX Gain Limiting feature. Figure 5.4.1 below depicts

this functionality.

The amount of attenuation provided by the AT–109 (V106) is controlled by

the voltage VC. VC is a function of the AGC_REF PDM. For minimum

attenuation the AUX. AGC PDM voltage is typically 0.75 V, resulting in

3.25 V for VC. For maximum attenuation the AUX. AGC PDM voltage is

typically 10.0 mV, resulting in 1.50 V for VC. The Auxiliary AGC can be

manually adjusted using the AGC_REF PDM controls found in the Service

Software.

Page 44

Original 11/97

Page 45

PAMS

WinTesla User Guide

Technical Documentation

Auxiliary AGC Operation

AT–109 Attenuation vs. Output Power

Aux. AGC Slope

Aux. AGC Offset

10 kB Dynamic Range

15 dBm

25 dBm

Output Power

NHD–4

Figure 14. Auxiliary AGC Operation 1

There are three steps in the Aux. AGC tuning to determine the 10 dB

dynamic range of attenuation used on the AT–109, as well as the

maximum and minimum attenuation points. The Figure below will assist in

the description of these three tuning steps.

Auxiliary AGC Operation

AT–109 Attenuation vs. Output Power

Aux. AGC Slope

Aux. AGC Offset

10 kB Dynamic Range

Original 11/97

15 dBm

Output Power

Figure 15. Auxiliary AGC Operation 2

25 dBm

Page 45

Page 46

WinTesla User Guide

PAMS

NHD–4

Band Power 1 Tuning (BPOW1)

Description of Tuning

For this step the AT–109 is set to minimum attenuation and the

TX_OFFSET PDM is adjusted until the CDMA TX output bandpower is 16

dBm +/– 1.0 dB. This bandpower level is position BPOW1 on Figure 2.2

above.

TX Offset calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect the modulation (or spectrum) analyzer to antenna connector.

– Select ” Tuning – Auxiliary AGC”

– Use the Up, Dn, PgUp or PgDn keys to adjust the BPOW1 power level

to the target range.

Technical Documentation

– Enter the actual measured TX Power into the dialog box and press

<Enter>.

Band Power 1 – 2 Tuning (BPOW1 – BPOW2)

Description of Tuning

For this step the AGC_REF PDM is adjusted to provide 5 dB of

attenuation from the AT–109. The CDMA TX output bandpower will then

be approximately 11 dBm, 5 dB off from the initial 16 dBm set in the

BPOW1 step. This bandpower position is referred to as BPOW2. This 5

dB is necessary to move the AT–109 dynamic range off the curved portion

of the attenuation response as seen between points BPOW1 and BPOW2.

– Use the Up, Dn, PgUp or PgDn keys to adjust the BPOW2 power level

to the target range.

– Enter the actual measured TX Power into the dialog box and press

<Enter>.

Page 46

Original 11/97

Page 47

PAMS

WinTesla User Guide

Technical Documentation

Band Power 2 –3 Tuning (BPOW2 – BPOW3)

Description of Tuning

For this step the AGC_REF PDM is adjusted to provide an additional 10

dB of attenuation from the AT–109. The CDMA TX output bandpower will

then be approximately 1.0 dBm, 10 dB off from the 11 dBm set in the

previous tuning step. This bandpower position is referred to as BPOW3.

This 10 dB attenuation is the dynamic range that the AT–109 will operate

from.

– Use the Up, Dn, PgUp or PgDn keys to adjust the BPOW3 power level

to the target range.

– Enter the actual measured TX Power into the dialog box and press

<Enter>.

– Press <continue> for the next screen or <cancel> to exit without sav-

ing.

Band Power 3 Tuning (BPOW3)

NHD–4

Description of Tuning

This tuning step simply reports the BPOW3 bandpower position tuned in

during the previous step. This is the level of attenuation that the AT–109

will maintain when the phone transmitting below the Switch Point (15

dBm) while in CDMA operation power

– Use the Up, Dn, PgUp or PgDn keys to adjust a reference power level

into the target range and press <continue>.

TX Offset Tuning

Definition of Tuning

This tuning adjusts the mid–point of the TxDac register to correspond to

–8 dBm of TX output power, the mid–point of the TX output dynamic

range.

– Use the Up, Dn, PgUp or PgDn keys to adjust BPOW1 power level into

the target range and press <Enter>.

Original 11/97

Page 47

Page 48

WinTesla User Guide

PAMS

NHD–4

TX Slope Tuning

Definition of Tuning

This tuning determines the linear relationship, or slope, between a change

in the output bandpower of the CDMA TX and a change in the TxDac. To

do this the CDMA transmitter is turned on and set to an output bandpower

corresponding to a TxDac value referred to as TxDac1. The resultant

bandpower is read and stored as BPOW1. Next, the TxDac is

decremented by a fixed amount that should result in approximately 32 dB

less output bandpower than the initial state. This TxDac value is called

TxDac2. Again the output bandpower is read, and stored as BPOW2.

From this data the TX Slope is determined. It is then manipulated

mathematically so that the TX slope equals “1”. When it does, a one bit

change in the TxDac will result in a 1/8 dB change in output power. The

following graph should help describe the TX Slope concept.

Technical Documentation

T X Slope

TxDac1

TX Slope

TxDac2

BPOW2

TX Output Power (dBm)

Figure 16. TX Slope

– Manually enter the new TX Power measurement into the BPOW2 loca-

tion. This value will be approximately minus 32 dB (–32 dB).

32 dB

~

BPOW1

Page 48

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Original 11/97

Page 49

PAMS

WinTesla User Guide

Technical Documentation

AGC Tuning

The purpose of this tuning operation is to determines the difference

between the received CDMA signal power and the transmit CDMA signal

power of the phone when it is in the Open–Loop AGC mode.

This tuning is needed if any component in the receiver or transmitter chain

is replaced.

Description of Tuning

This tuning determines the difference between the received CDMA signal

power and the transmit CDMA signal power of the phone when it is in the

Open–Loop AGC mode. This delta value is better known as CloopRef.

To do this a –73 dBm CW tone is fed into the CDMA receiver and the

CloopRef value is adjusted in software until the CDMA transmitter output

bandpower measures 0.0 dBm.

AGC calibration steps & equipment:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

NHD–4

– Apply +6.0 V to dummy battery.

– Select ” Tuning – AGC”

– This tuning is done in duplex mode. Therefore the need to inject a Re-

ceive signal, while measuring a transmitt signal is required.

– Inject a signal at the antenna port as described by the tuning screen.

– Adjust the output power to obtain the specified target level.

– Press <save & exit> to store value to EEPROM or <cancel> to exit

without saving.

Original 11/97

Page 49

Page 50

WinTesla User Guide

PAMS

NHD–4

Testing

Self Tests

This option runs the phone’s self test sequences and reports any

processor visible faults. The self tests provide an effective initial test for a

faulty phone.

ADC Readings

Technical Documentation

This option allows the phone’s ADC readings to be displayed. The

readings are updated every few seconds. There may be some delay

before the mouse or keyboard responds while running this test.

Page 50

Original 11/97

Page 51

PAMS

WinTesla User Guide

Technical Documentation

Pulse Division Modulator (PDM) Control

This test screen is to allow control of each PDM separately. The tests in

this section will use the PDM controls from this screen during their

execution.

PDM Register Control

NHD–4

KEYS:

– <Set Default> – Sets all PDMs to there default values.

– <Set Maximum> – Sets all PDMs to there Maximum values.

– <Set Minimum> – Sets all PDMs to there Minimum values.

Original 11/97

Page 51

Page 52

WinTesla User Guide

PAMS

NHD–4

AMPS / BaseBand Test Screen

This screen is used when testing and troubleshooting the phone in AMPS

mode. Below is an example screen.

Technical Documentation

Keys:

High – Sets the AMPS channel to the Highest Frequency according to the

Frequency planning set in the “configure” menu.

Mid – Sets the AMPS channel to the Middle Frequency according to the

Frequency planning set in the “configure” menu.

Low – Sets the AMPS channel to the Lowest Frequency according to the

Frequency planning set in the “configure” menu.

Up – Increments the channel selection by one.

Dn – Decrements the channel selection by one.

PDM Ctrl – Opens the PDM Control Screen.

ADC Reading – Opens the ADC reading screen.

Quick RX Test – Opens the Quick Receiver test screen.

Mbus Test – Tests the communication between the phone and the

computer.

Close – Exits the current screen.

Page 52

Original 11/97

Page 53

PAMS

WinTesla User Guide

Technical Documentation

RF Controls:

Power Level – Turns the transmitter on/off and sets power levels.

Channel – Changes the AMPS channel of the phone.

RF Modulation Off – Turns on/off RF modulation to the antenna port.

Compander On– Turns on/off the Compressor and Expander.

Views: