Page 1

Programme’s After Market Services

NHD–4 Series Transceivers

Disassembly &

Troubleshooting

Original 11/97

Page 2

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

CONTENTS

Disassembly Instructions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Troubleshooting 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

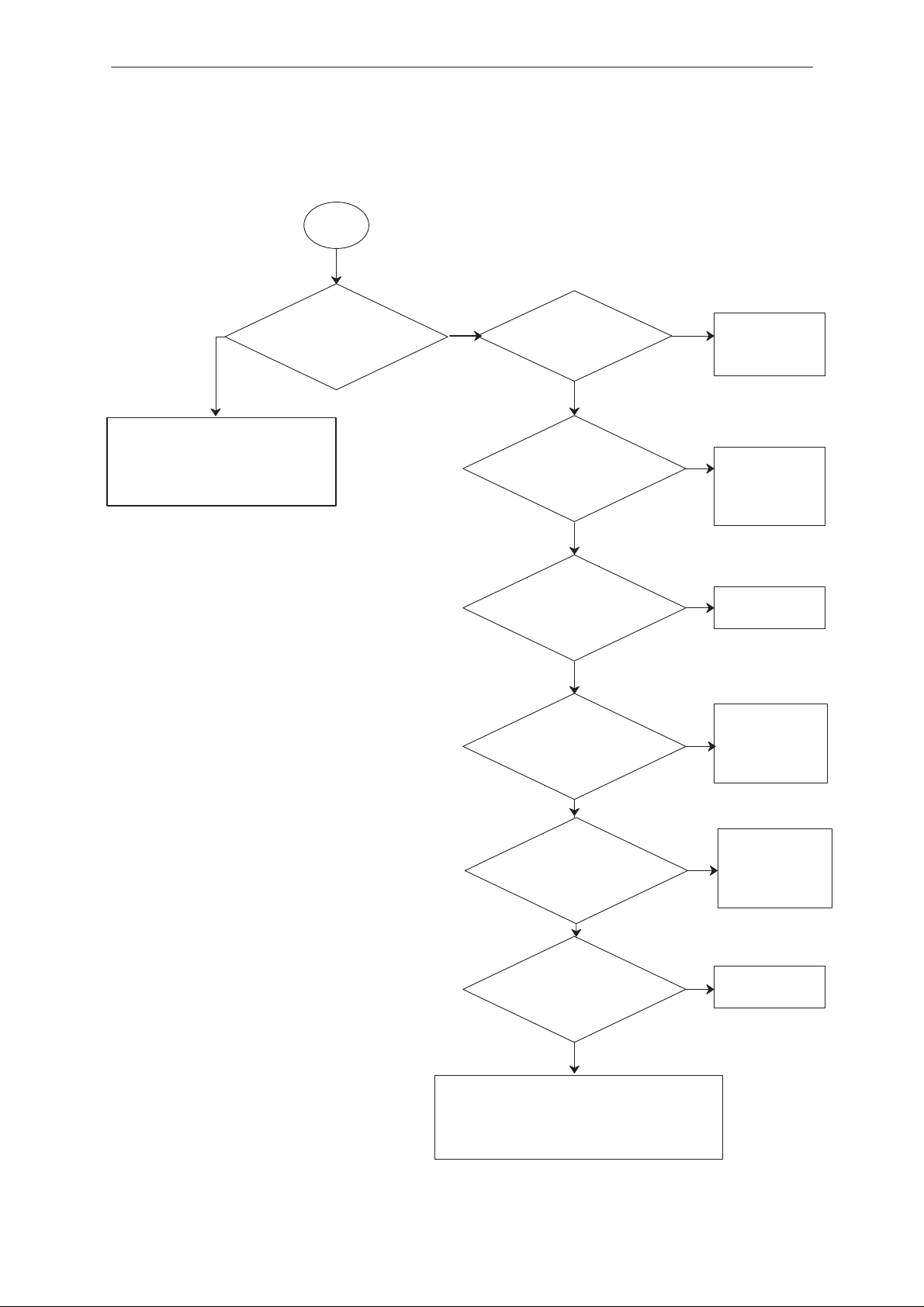

Troubleshooting Diagram; Flash Programming OK, part 1 10. . . . . . . . . .

Troubleshooting Diagram; Flash Programming OK, part 2 11. . . . . . . . . .

Troubleshooting Diagram; Flash Programming OK, part 3 12. . . . . . . . . .

Troubleshooting Diagram; Flash Programming OK, part 4 13. . . . . . . . . .

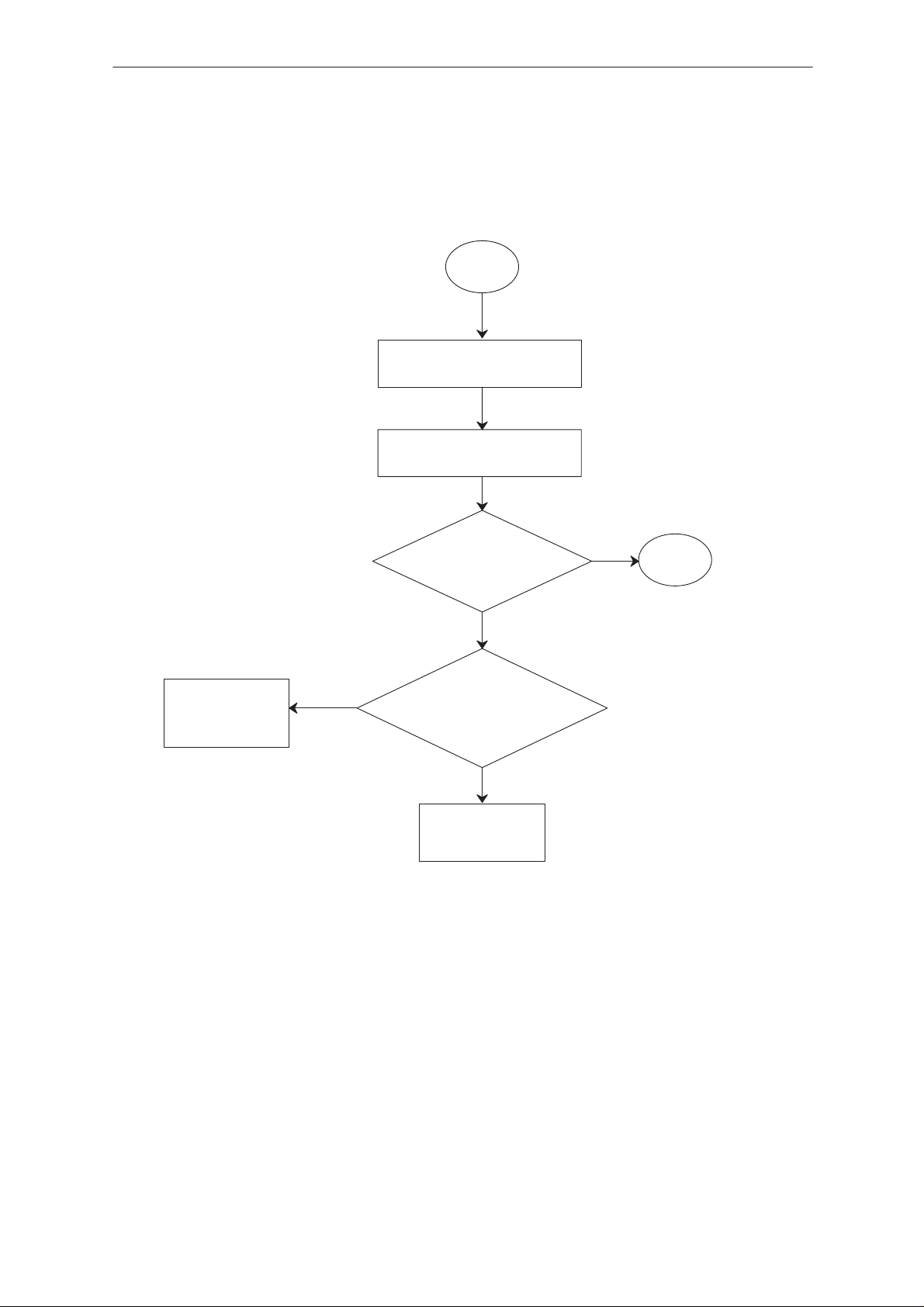

Troubleshooting Diagram; PWR Button Fault 14. . . . . . . . . . . . . . . . . . . . .

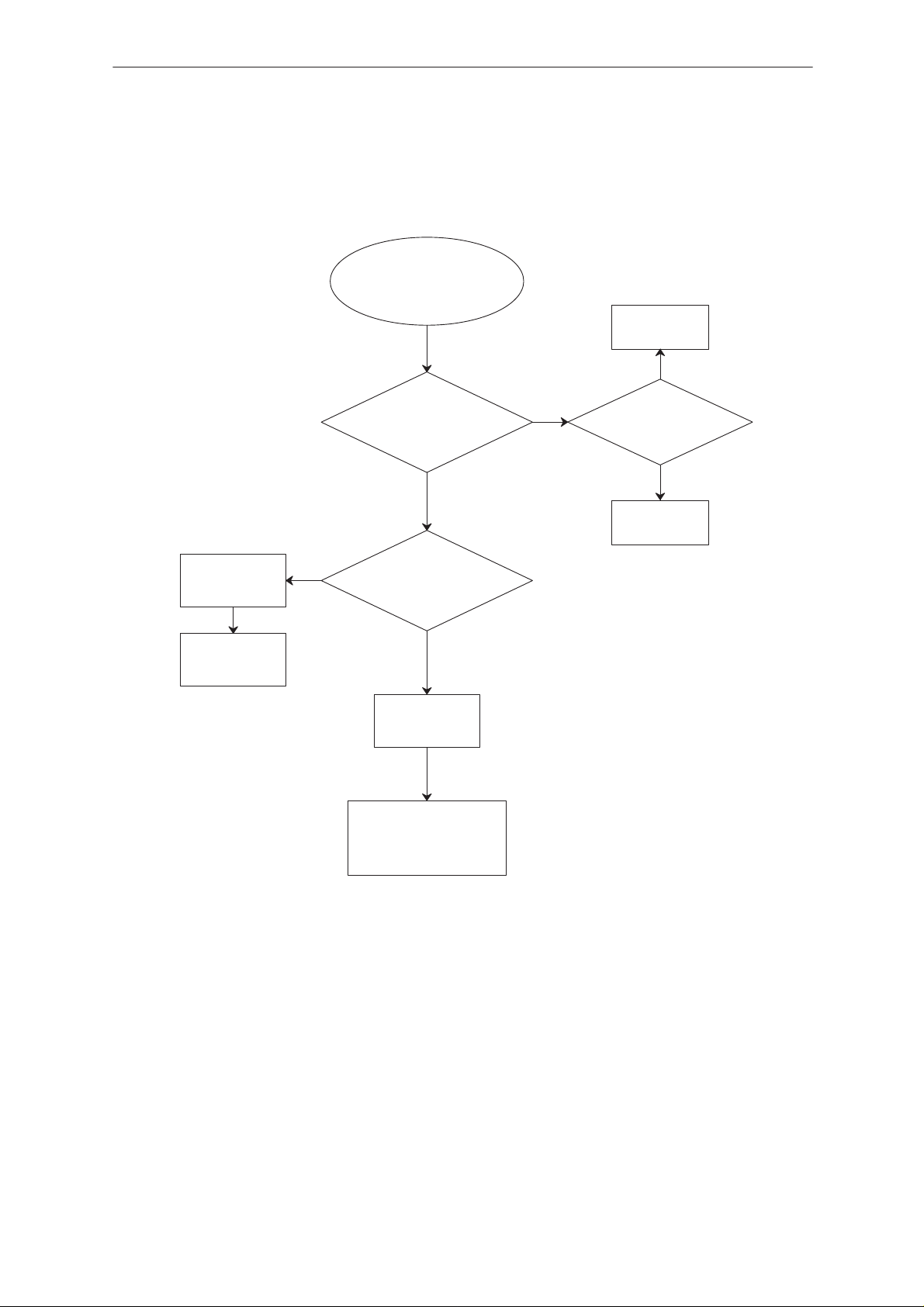

Troubleshooting Diagram; Audio Fault 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up Sequence Diagram 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repairing Instructions for Flash Faulty Units 17. . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Diagram; Power Up and MCU Self tests Malfunctions 18

Power Up Malfunction 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

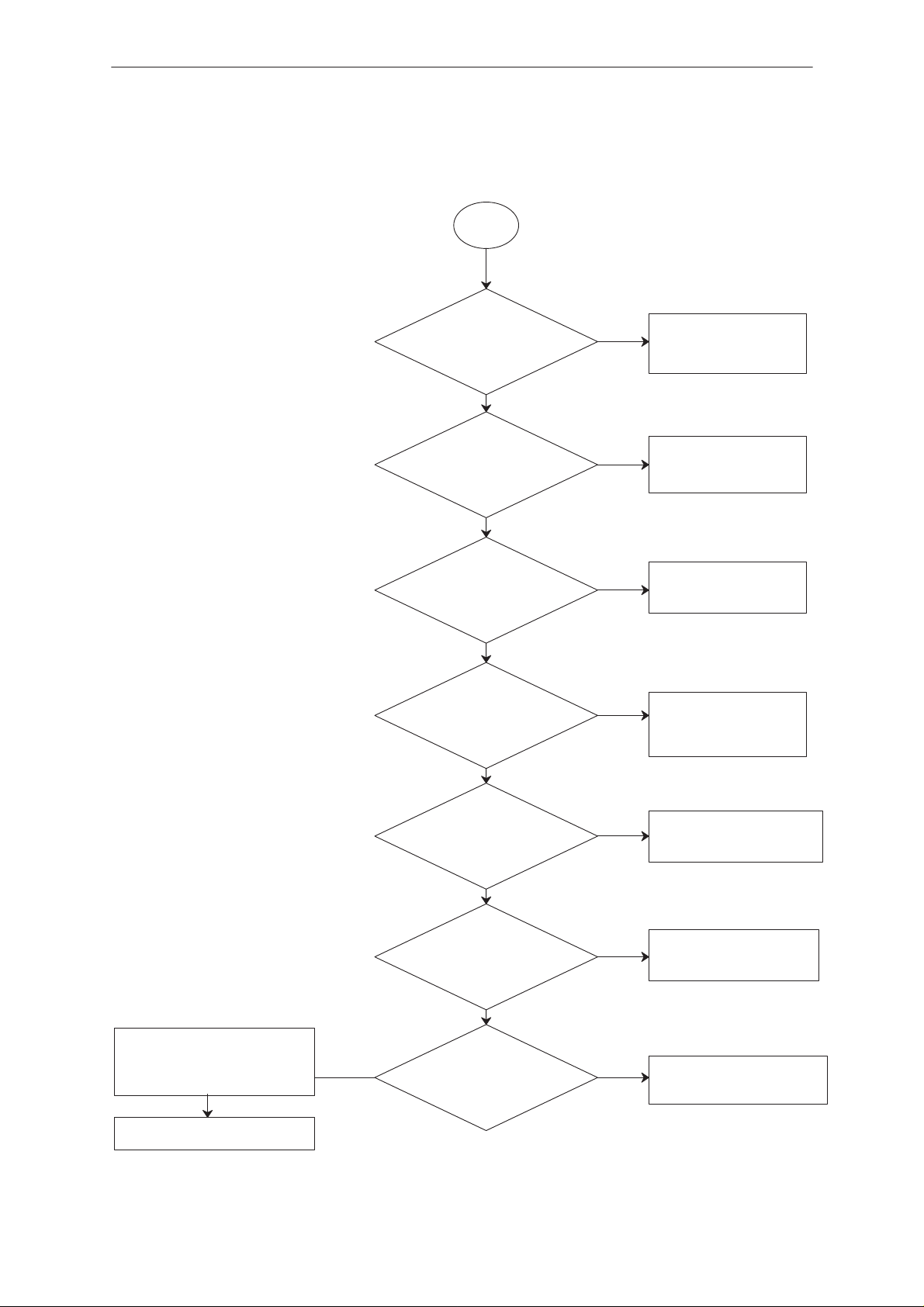

Troubleshooting Diagram; Power Up Malfunction 24. . . . . . . . . . . . . . . . . .

Important Information 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Troubleshooting 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Software Quick Checks 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Output Power Control 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detector DC Voltage Check – AMPS 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Node Voltage Checks 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Node Power Levels 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Gains and Losses 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing CDMA TX Gain Limiting 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Dynamic TXB 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing CDAGCT IC (N100) Gain Control 32. . . . . . . . . . . . . . . . . . . . . . . . .

Testing Auxiliary AGC 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Spurious Emissions of the CDMA TX Output 33. . . . . . . . . . . .

Hints and Suggestions 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AMPS Receiver Troubleshooting 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Introduction 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tests and Quick Checks 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Up the AMPS Receiver Test 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RSSI Check 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Voltage Checks 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart of AMPS RX DC Node Voltages 38. . . . . . . . . . . . . . . . . . . . . . . . . . .

Demodulation Test 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Original 11/97

Page 3

PAMS

NHD–4

Technical Documentation

RF Node Power Checks – AMPS Mode 38. . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA Receiver Troubleshooting 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA RX Quick Test with Service Software 40. . . . . . . . . . . . . . . . . . . . . .

Set Up CDMA RX Test 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Gain Control Test 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Voltage Checks 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart of CDMA RX DC Node Voltages 43. . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Demodulation Check 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Node Powers – CDMA RX Mode 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hints and Suggestions 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synthesizer Troubleshooting 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Check with Service Software – Transmitter Approach 46. . . . . . . .

DC Voltage Checks – AMPS Troubleshooting Mode 47. . . . . . . . . . . . . . .

Disassembly & Troubleshooting

Chart of Synth DC Node Voltages – AMPS Troubleshooting Mode 49. . .

RF Node Power Levels 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hints and Suggestions 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Original 11/97

Page 3

Page 4

NHD–4

PAMS

Disassembly & Troubleshooting

[This page intentionally left blank]

Technical Documentation

Page 4

Original 11/97

Page 5

PAMS

NHD–4

Technical Documentation

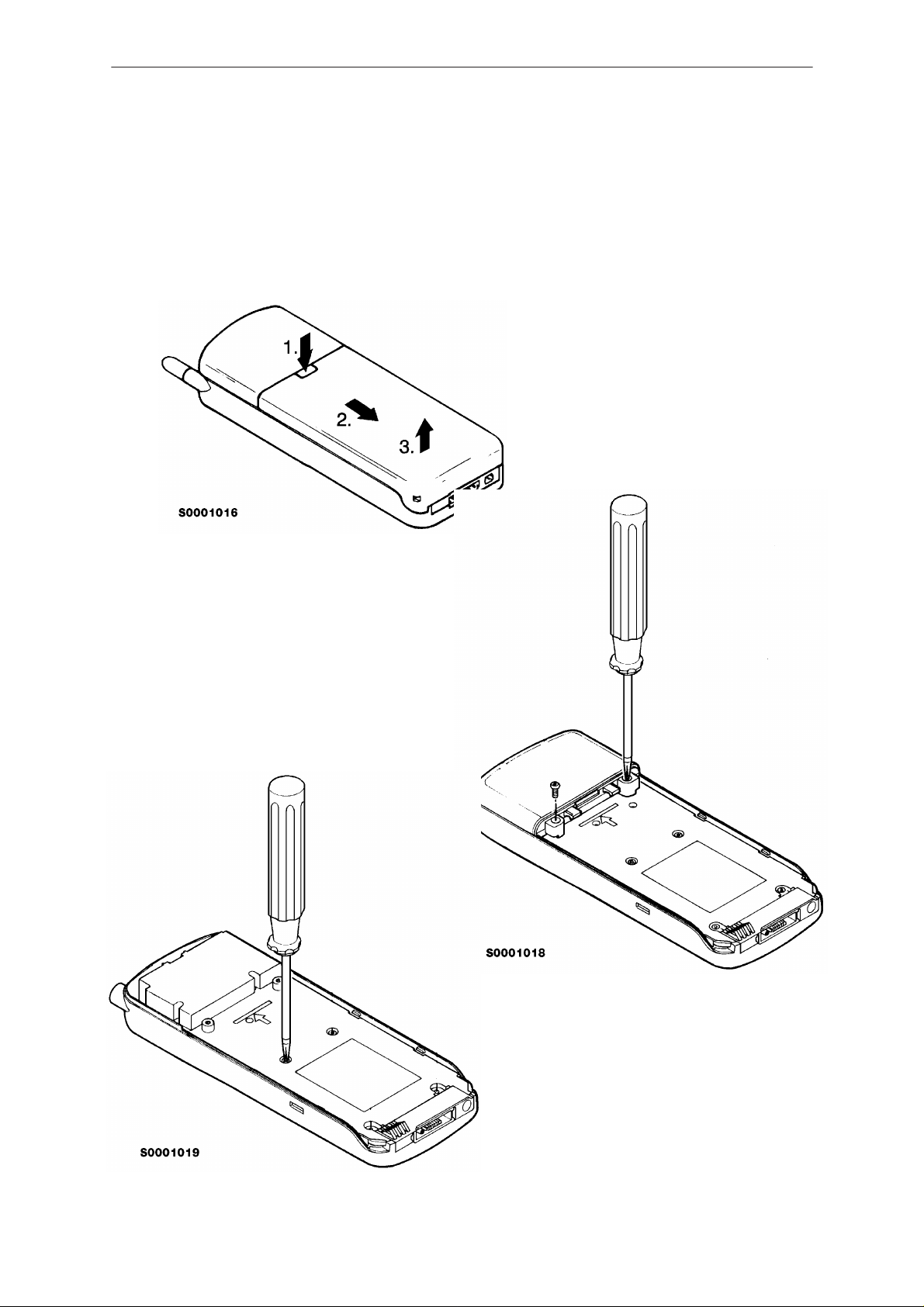

Disassembly Instructions

Remove the battery.

Disassembly & Troubleshooting

Now remove two back

cover screws and re-

move the back cover

by lifting it away.

2

1

4

3

6

Then remove six

chassis screws.

Original 11/97

5

Page 5

Page 6

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

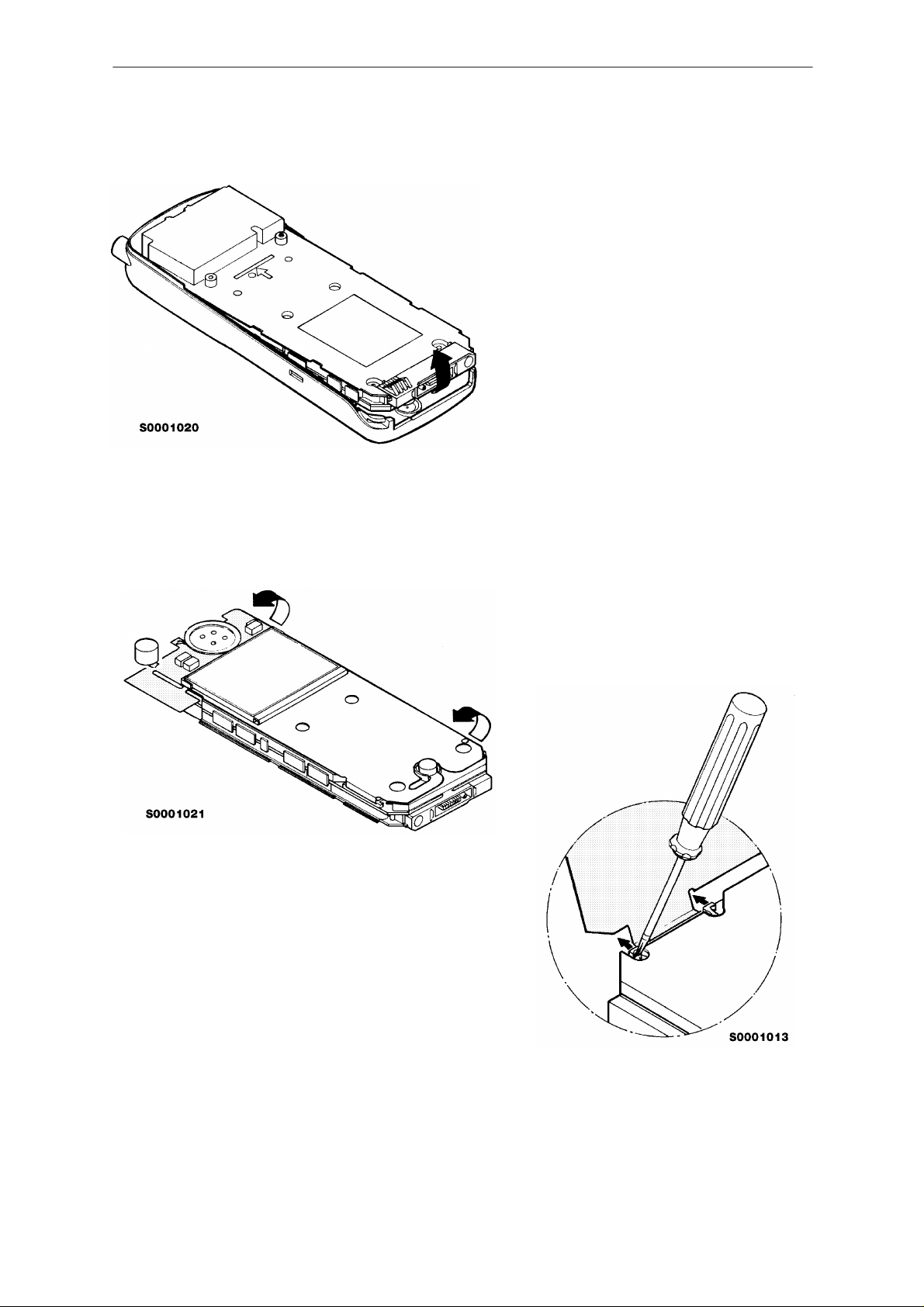

Remove the chassis by lifting.

Turn around the chassis and open

the display module a little.

Open the display module connector

by pressing both sides of connector

and slide off the display module

cable.

Page 6

Original 11/97

Page 7

PAMS

NHD–4

Technical Documentation

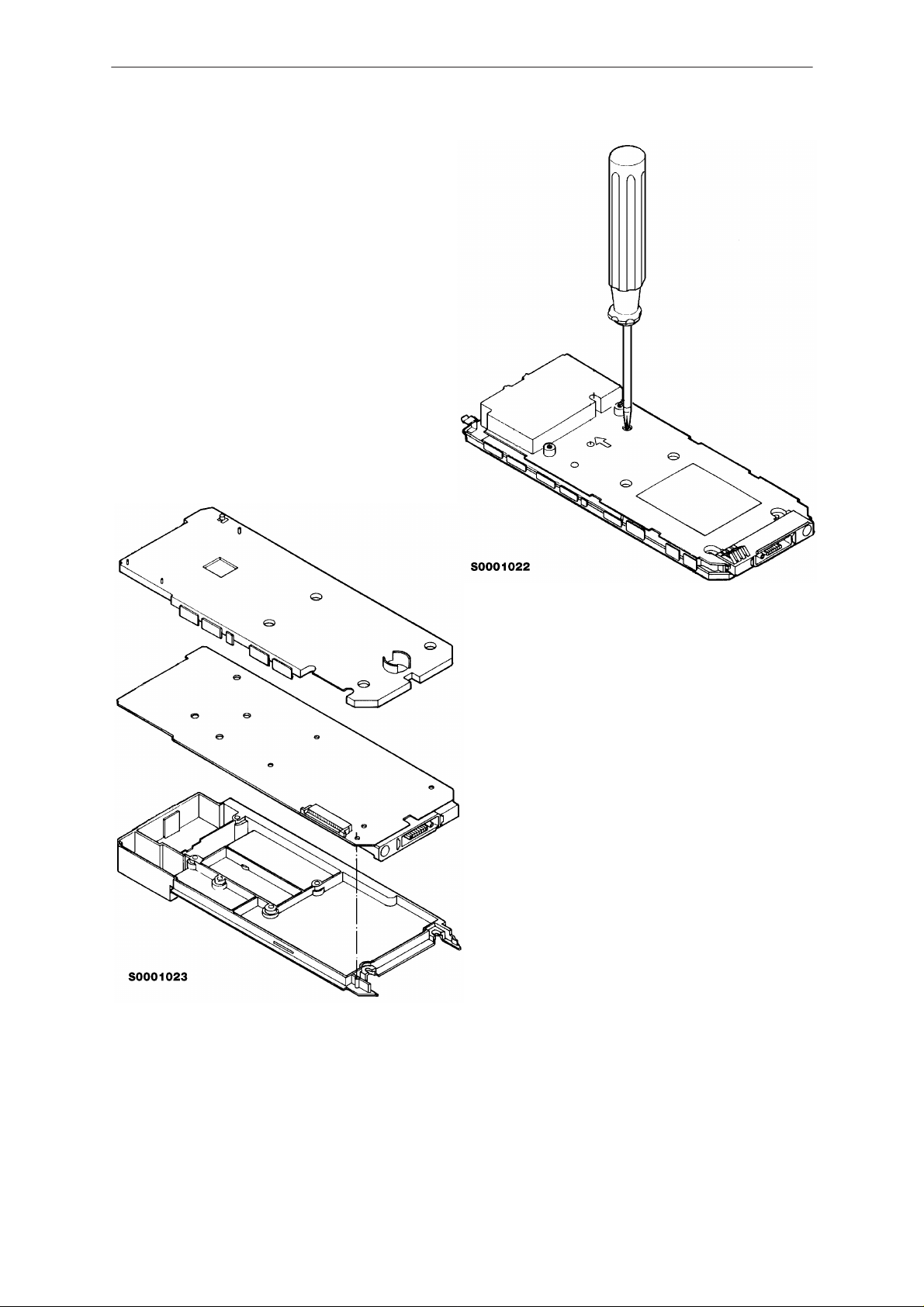

Turn chassis again and remove

four chassis screws.

Disassembly & Troubleshooting

1

4

3

2

Remove the plastic shield and

throw it away (it is disposable).

Now you can separate the system module from the bottom

shield by lifting it away.

Original 11/97

Page 7

Page 8

NHD–4

PAMS

Disassembly & Troubleshooting

Baseband Troubleshooting

Overview

Baseband oriented failures are usually found out during Flash updating of

the phone, the phone should be started to minimum mode and current

consumption measured. If current consumption is within acceptable limits

and MBUS registration is OK, flash is programmed. If flash programming

fails, service software can be used to activate MCU self tests. During the

MCU self tests all the major components of the baseband are tested.

Every test returns number of the test and result ( OK / failed ).

If phone can be flashed and all self tests performed, the baseband is

mainly OK.

In case of current consumption/MBUS registration failure, the phone must

be taken to more specific measurements of voltages, clocking signals and

states of reset signals.

Technical Documentation

The flow diagrams give the overview of the blocks. The purpose is to

proceed through the flow diagram so that, if answer is YES for the asked

question, go straight to the next level, but if answer is NO, take the

sub–branch.

Required servicing equipment:

Service software

Power supply (1.0 A)

Digital multimeter

Oscilloscope

Modular cable

RS232/MBUS adapter

Soldering iron and related tools.

Current consumption failures in flash station

Current consumption can fail in three ways. Typical to all these failures is

that phone can not be programmed or tested via MBUS. The most

common failure is that phone takes normal current during startup and

after a few seconds all circuits are powered down. The reason for this

could be in power, clock or reset distribution of the phone. In cases where

phone does not take current at all or phone takes all available current the

reason could be defective PSL_+3V(N500) or bad soldering (short or

open) around PSL_+3V(N500).

Page 8

Original 11/97

Page 9

PAMS

NHD–4

Technical Documentation

Phone takes all available current

If phone takes all available current, the problem can be caused by bad

solder joints in PSL_+3V(N500), components around it and bottom

connector(X701).

Phone does not take current at all

If phone does not take current at all, check the following things:

– solder joints in PSL_+3V(N500)

– VBATT voltage should be available in pins 5 and 20 of PSL_+3V(N500),

if connections of PSL_+3V(N500) are OK and VBATT in pins 5 and 20 are

OK, change PSL_+3V(N500).

Current consumption OK during power–up, then fail

If the phone starts almost normally, but after few seconds all circuits are

powered down, the power–down, could be caused by lack of watchdog

signal from MCU(D706) to PSL_+3V(N500) . There are three major things

to be checked in this type of situation. First, check power distribution to all

baseband–main components. Then check that clocks are delivered to

CDRFI(N700), ASIC(D704), DSP(D705) and MCU(D706). If everything is

OK, check RESET status of circuitry mentioned above.

Disassembly & Troubleshooting

Checking the baseband power distribution

Before voltage measurements, power–down of PSL_+3V(N500) must be

prevented. This is done by shorting the watch–dog timing capacitor C507

with a wire soldered from one end of the capacitor to the other.

1.Check PSL_+3V(N500) output voltages pins 4, 21,16, 2, 24 and 1.

Expected value is around 3.15V. Also, check voltage in pin 12 (DETIN) to

be between 1.46V and 1.72V.

2.Check MCU(D706) supply voltage VL1(3.15V) on pins 5 and 42. Check

VREF (3.15V) voltage on MCU(D706) pin 60. Check voltages of

MCU(D706) related memory components: FLASH(D709) pins 30, 31 and

11; RAM(D700) pin 28; and EEPROM(D703) pin 7.

3.Check ASIC(D704) supply voltage VL1(3.15V) on pins 13, 22, 27, 44,

60, 65, 74, 88,103, 109, 117, 132, 146, 151, 161, and 176.

4.Check DSP(D705) supply voltage VL2(3.15V) on pins 8, 11, 36, 39, 49,

64, 76, 87 and 90. VL2(3.15V) is also fed to DSP RAM (D707) to pin 11

and 33.

5.Check CDRFI(N700) supply voltage VL3(3.15V) on pins 32, 33, 60, 62,

2, 6, 8 and 19.

6.Check supply voltages of audio CODEC(N600). VA2(3.15V) is fed to

pins 2 and 3. VL1(3.15V) is connected to pin 15.

Original 11/97

Page 9

Page 10

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

Troubleshooting Diagram; Flash Programming, part 1

FLASH programming OK

MBUS

registration

OK?

NO

YES

Does LCD

display turns

ON?

YES

NO

Check D706 pins 3,80

ASIC pins 130,86

3

Short circuits in data

data lines. data line

disconnected, VREF

disconnected

Check that pin 4 of D500

NO

is 4.75V. Also check the

control line, it should be

high (3V on Pin 1 of

Check X701

C507 OK?

YES

Power

stays on?

NO

NO

NO

N500 pin 8/XRESET

VBATT

N500 pin 5,20

?

YES

3V after power ON?

YES

display turns

YES

MBUS line X701

pin 5, Is 4.75V after

YES

Does LCD

ON?

pwr ON?

NO

D500).

R500, R503

OK?

YES

Change N500

YES

Power supp. to the logic

circuits +3V after power

ON?

NO

Change N500

D706 pin 67

+3V after power ON?

NO

YES

2

YES

Change D706

Check V703,

R728, R726,

R727, if OK

change D706

Page 10

Original 11/97

Page 11

PAMS

NHD–4

Technical Documentation

Disassembly & Troubleshooting

Troubleshooting Diagram; Flash Programming, part 2

2

NO

Check D704 and D706 for

short/open pins, if pins look

OK change D704 if problem

continues change D706

D706 pin 10

XSYS_RESET +3V after

power on?

YES

15.36MHz at

D706 pin 69

?

YES

D706 pin8/MD2

and pin9/STBY are

+3V ?

YES

NO

NO

Check clock

signal in N700

and D704

Check these

two pins for

shorts and

opens

D706 pin 43/

XPWROFF has 0V to +3V

pulses after power

ON ?

YES

D706 pin 77

/IRQ0 +3V after

power on?

YES

D706 pin 11

/NMI 0V after

power on?

YES

D706 pin 4

/XMCU_WR +3V

after pwr on?

NO

Change D706

Check D704 and

NO

D706 for shorts

and opens. If OK

change D706

Check D704 and

NO

D706 for shorts

and opens. If OK

change D706

NO

Check D706

Original 11/97

YES

Check all soldered joints

The data and address signals must have

a clear difference between low (0 V)

and high (+3V)

Page 11

Page 12

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

Troubleshooting Diagram; Flash Programming, part 3

3

MBUS registration OK?

YES

Does LCD display turns ON ?

YES

Check D706

and D703

interface

NO

D703 initialization

(Factory Values Set) OK?

NO

D703

pin 18,19/D0,D1

+3V to 0V during r/w

operations ?

YES

Change D703

YES

4

Page 12

Original 11/97

Page 13

PAMS

NHD–4

Technical Documentation

Disassembly & Troubleshooting

Troubleshooting Diagram; Flash Programming, part 4

4

D709

/pin 23, 39 +12V while

programming?

YES

D706

/pin 64/HOOK_RXD2

pulses during prog?

YES

NO

NO

Check X701/pin14

L700,C729,R748

R741

Check X701 pin 6

R736,R739,R764

C723

X701 pin 7

/PHFS_TXD2 pulses

during programming?

YES

D709

pin 10/RP +3V after

power ON ?

YES

D709

pin 22/CE pulses

from +3V to 0V after

power ON?

YES

D709

pin 24/OE pulses

from +3V to 0V after

power ON ?

NO

NO

NO

NO

Check D706 pin 63

R725,R735,C721

Check VCO_EN line

at the D709 pin 10 for

shorts and opens

Check XFLASH_CS

line at theD704 pin 107

Check XMCU_RD line

at the D706 pin 3

Check D709 address and

data lines for shortcircuits

or unconnected pins

OK

Change D709

Original 11/97

YES

D709

pin 9/WE pulses

from +3V to 0V after

power ON ?

NO

Check XMCU_WR line

at the D706 pin 4

Page 13

Page 14

NHD–4

PAMS

Disassembly & Troubleshooting

Troubleshooting Diagram; PWR Button Fault

Nothing happens when

PWR button is pressed

N500

pin 10 +3V when

VBATT is connected?

YES

NO

Technical Documentation

Check

X701

NO

N500 pins 5,20

VBATT voltage?

YES

Change

N500

Check

UI–conn. X700

Change

UI

NO

pin 10 goes low when

N500

PWR button is

pressed?

YES

R500,R503

C507 OK

Check component

around N500, if OK

change N500

Page 14

Original 11/97

Page 15

PAMS

NHD–4

Technical Documentation

Troubleshooting Diagram; Audio Fault

Audio fault

Microphone or earphone

signal missing

N600 pin 19/CODEC_FS from D704

Microphone and

earphone signal

missing?

NO

YES

N600 pin 20/CODEC_MCLK from D704

D705 pins 29,37/CODEC_FS from D704

D705 pins 27,33/CODEC_MCLK from D704

Disassembly & Troubleshooting

Microphone signal

missing?

NO

Earphone signal

missing?

YES

YES

N600 pin 25,24/MICP,MICN

N600 pin 17/PCMOUT

N600 pin 21/MICENX

corresponding pins of UI–connector

N600 pin 7,8/EARP,EARN

N600 pin 10/PCMIN

corresponding pins of UI–connector

Original 11/97

Page 15

Page 16

NHD–4

PAMS

Disassembly & Troubleshooting

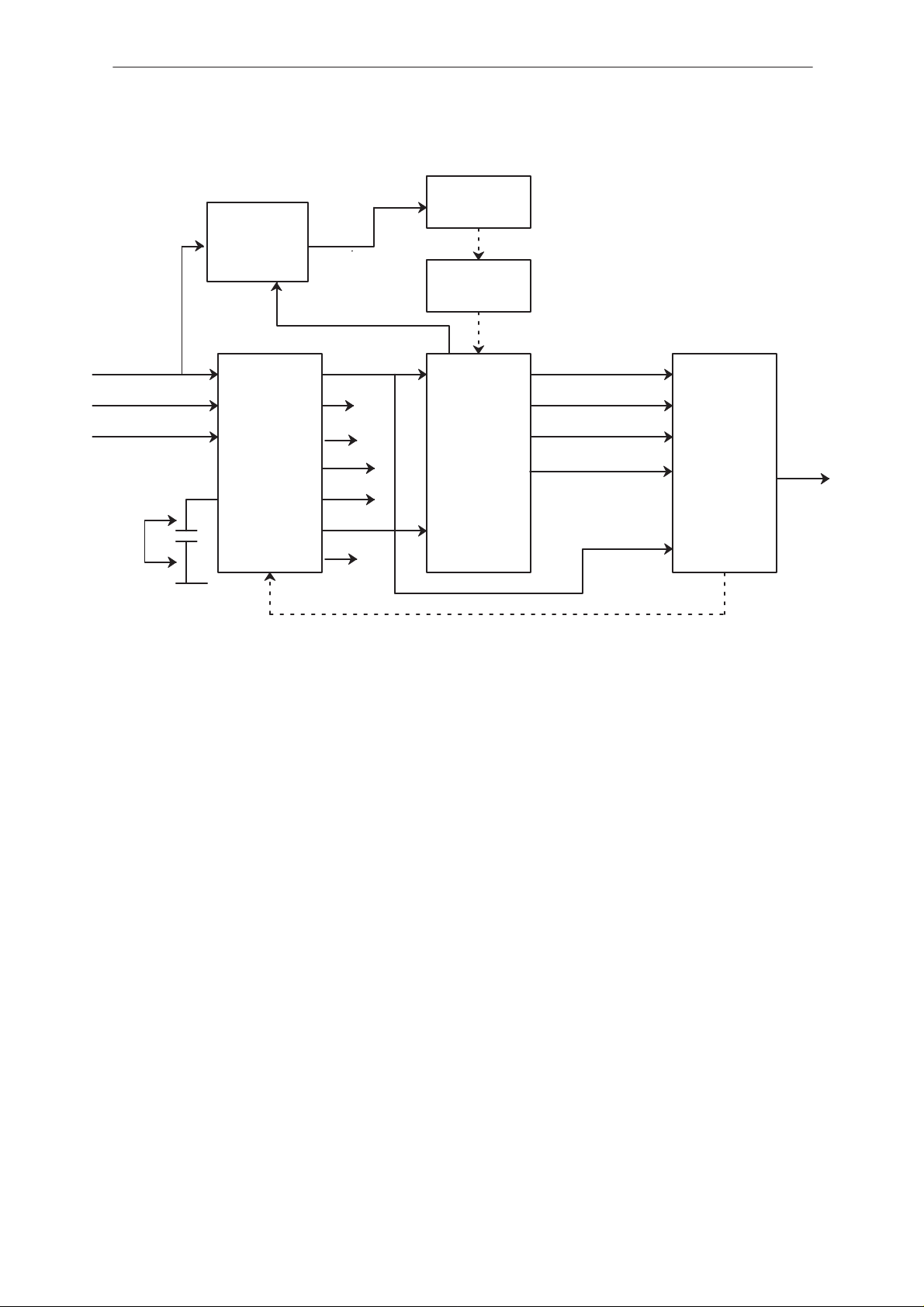

Power Up Sequence Diagram

VBAT 5.3....8V

CHRGDET

DETIN

ON

CDCONT

N201

5, 20

11

12

14

XPWROFF

C507

23

N500

9

13

VRXS 4.5V

VCO_EN

VL1 MCU_CLK (15.36MHz)

4

VL2

21

VL3

16

VA1

2

VA2

24

XRESET

82

VREF

1

VCTCXO

G300

CLK 15.36MHz

1

CDRFI N700

63

CLK 15.36MHz

128

147

104

168

ASIC MCUPSL

121

98

D704

Technical Documentation

Square circuitry

XSYS_RESET (3.15V)

MCU_INT0 (3.15V)

MCU_NMI (0V)

ON=3.15V

69

10

77

11

5,42

D706

43

66

TXD

PSL_+3V(N500)

Output voltages must stay high at least 7seconds when power is switched

on.

If no; check C507.

If it is OK; replace PSL_+3V(N500).

If the XRESET line doesn’t rise check DETIN. The voltage value at this

pin should be between 1.46V and 1.72V.

ASIC(D704)

When XRESET and CLK are supplied to the ASIC(D704) but MCUCLK or

XSYS_RESET to the MCU(D706) are not supplied; replace ASIC(D704).

MCU(D706)

If MCU_CLK and XSYS_RESET are supplied from ASIC(D704) but TXD

line (MBUS) doesn’t rise and solder joints of the MCU(D706) are good,

check that MCU_INT0 is high (3.15V) and MCU_NMI is low (0V), if that is

the case then replace MCU(D706).

XPWROFF 7s

Page 16

If TXD pin 66 of the MCU(D706) goes high but doesn’t stay there at least

7seconds.

The power of the phone can be kept ON by:

– Connecting PSL +(N500) pin 14 to the ground.

Now it is possible to use service software for troubleshooting.

Original 11/97

Page 17

PAMS

NHD–4

Technical Documentation

Disassembly & Troubleshooting

Repairing Instructions for Flash Faulty Units

1. When the phone doesn’t start (power off after 7seconds and probably no MBUS

connection) check following things:

VBATT is connected to the PSL_+3V(N500)

XRESET rises to 3.15V

VL1 is 3.15V

32KHz clock is running.

VRXS(4.5V) is connected to the VCTCXO and the crystal frequency is

15.36 MHz

XSYS_RESET signal rises to 3.15V

MCU_CLK signal is 15.36 MHz

MCU_NMI line stays low(0V)

MCU_IRQ0 line stays high(3.15V)

If all these happens, the MCU(D706) will supply power OFF pulses to the

PSL_+3V(N500) and the power will stay on.

In faulty conditions, most likely MCU_IRQ0 stays low(0V), which means

that interrupt is generated all the time.

In this case check data and address lines of ASIC(D704), MCU(D706)

and memory circuits for short circuits or unconnected pins.

2. When FLASH programming is not succeed, check following things:

System connector(X701) pins 6, 7, 14 are soldered and there are no short

circuits.

Flash programming voltage (VF=12V) is connected to the FLASH(D709)

pins 23 and 39.

The data and address lines of the FLASH(D709) are soldered.

EEPROM(D703) should be OK because of the initialization (program pa-

rameters are loaded always when program is loading the first time).

Calibrate Battery Voltage (VBATDET)= 6.0V

a) Check R505, R504

b) Check PSL_+3V(N500) pin 23

c) Check MCU(D706) pin 52

Calibrate Charge Voltage (VC)= 6.0V

a) Check R502, R501, R508

b) Check MCU(D706) pin 53

Original 11/97

Page 17

Page 18

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

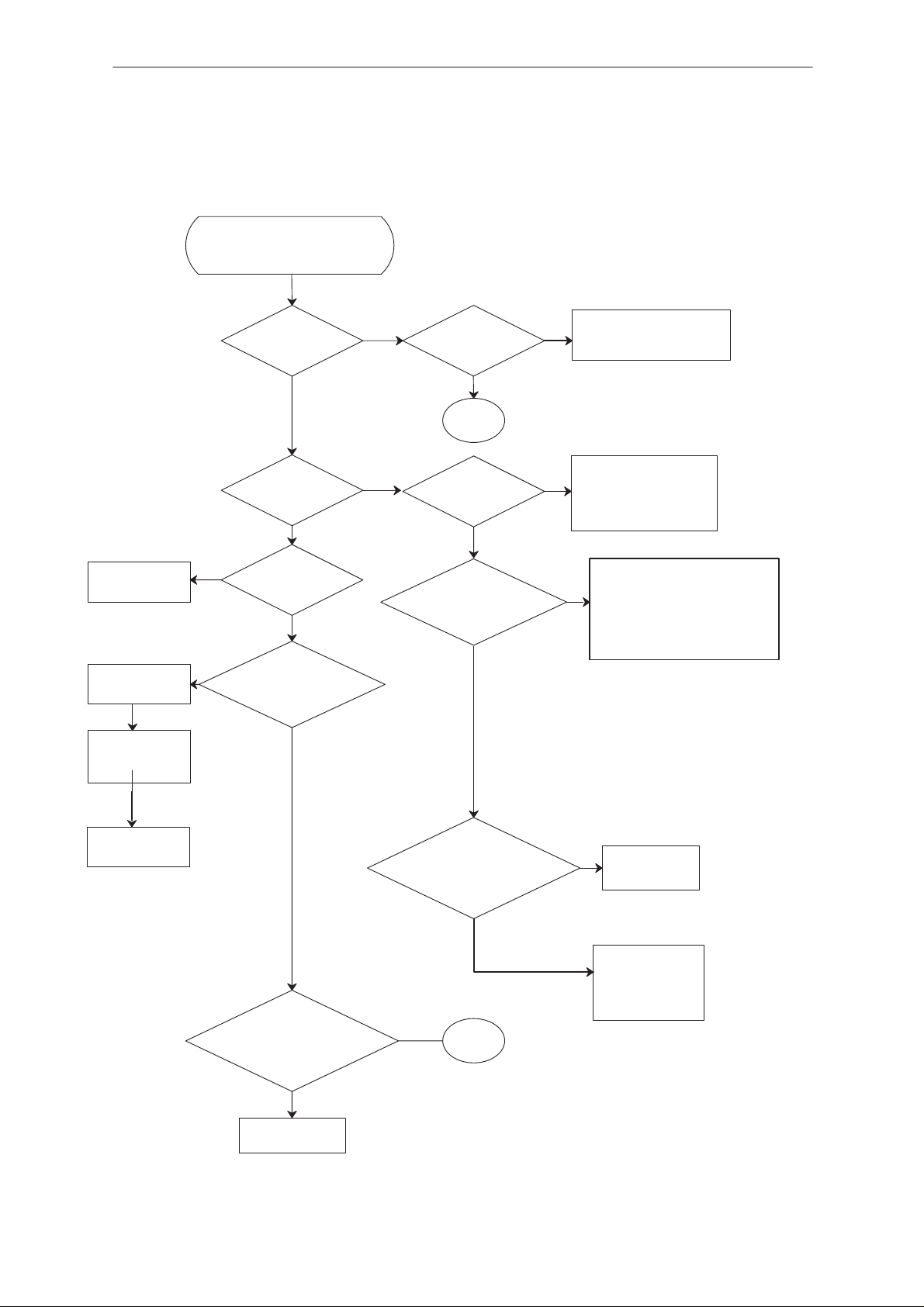

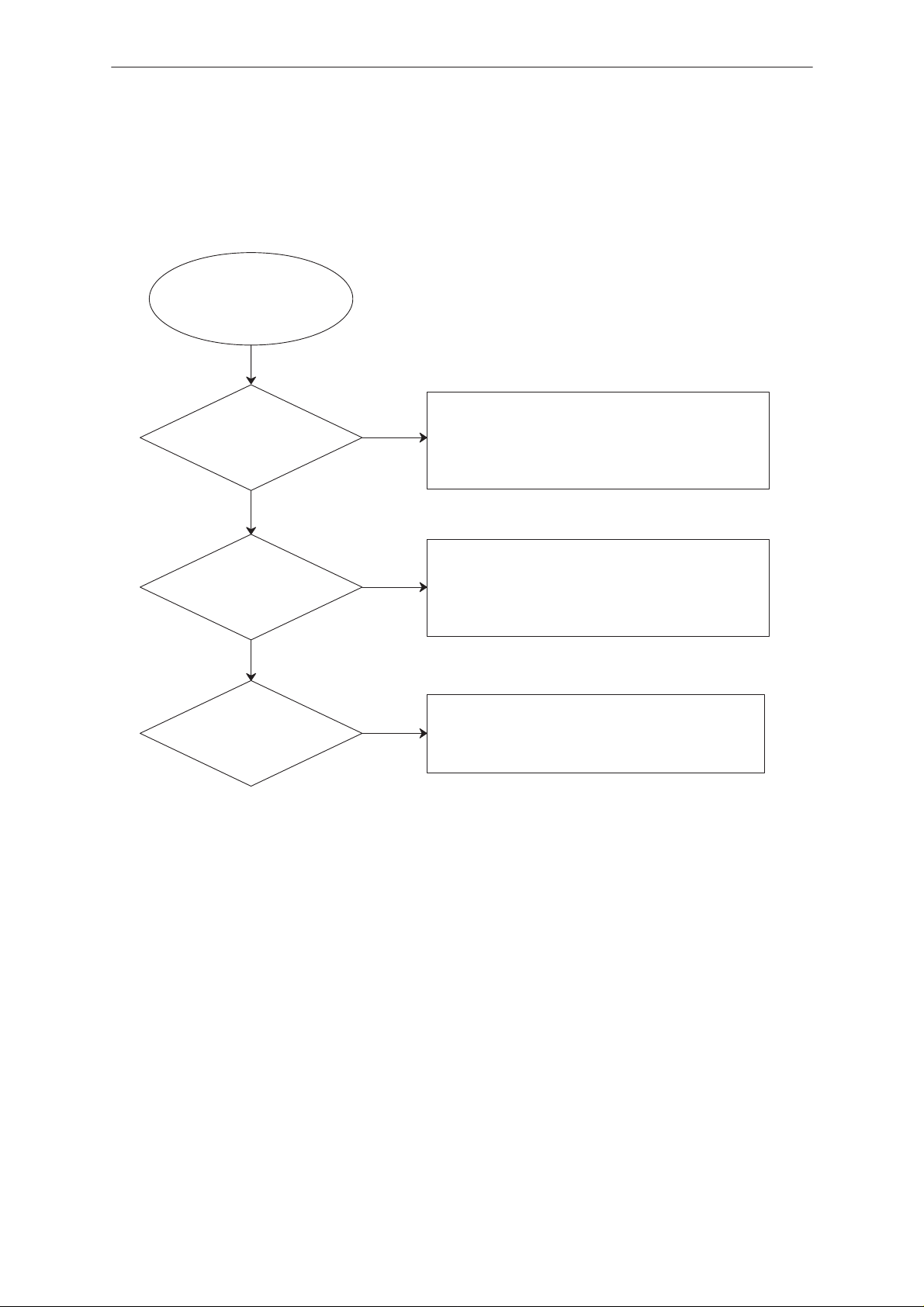

Troubleshooting Diagram; Power Up and MCU Self tests

Malfunctions

RADIO UNIT CHECK

Press power on

Current

consumption

OK?

YES

Run self tests

OK?

NO

NO

See Power Up

Malfunction

See Self Tests

Malfunction

YES

Call process

Audio check

OK

Page 18

Original 11/97

Page 19

PAMS

NHD–4

Technical Documentation

Power Up Malfunction

Basically there are two different problems that could occur while powering

up the phone. First, the current consumption is almost zero all the time.

Probably the fault is at the power circuit PSL_+3V(N500). Check all

PSL_+3V(N500) connections including VBATT line.

Second, the phone’s current consumption is normal for 7seconds and

goes to zero after that time. The reason for this is the watchdog.

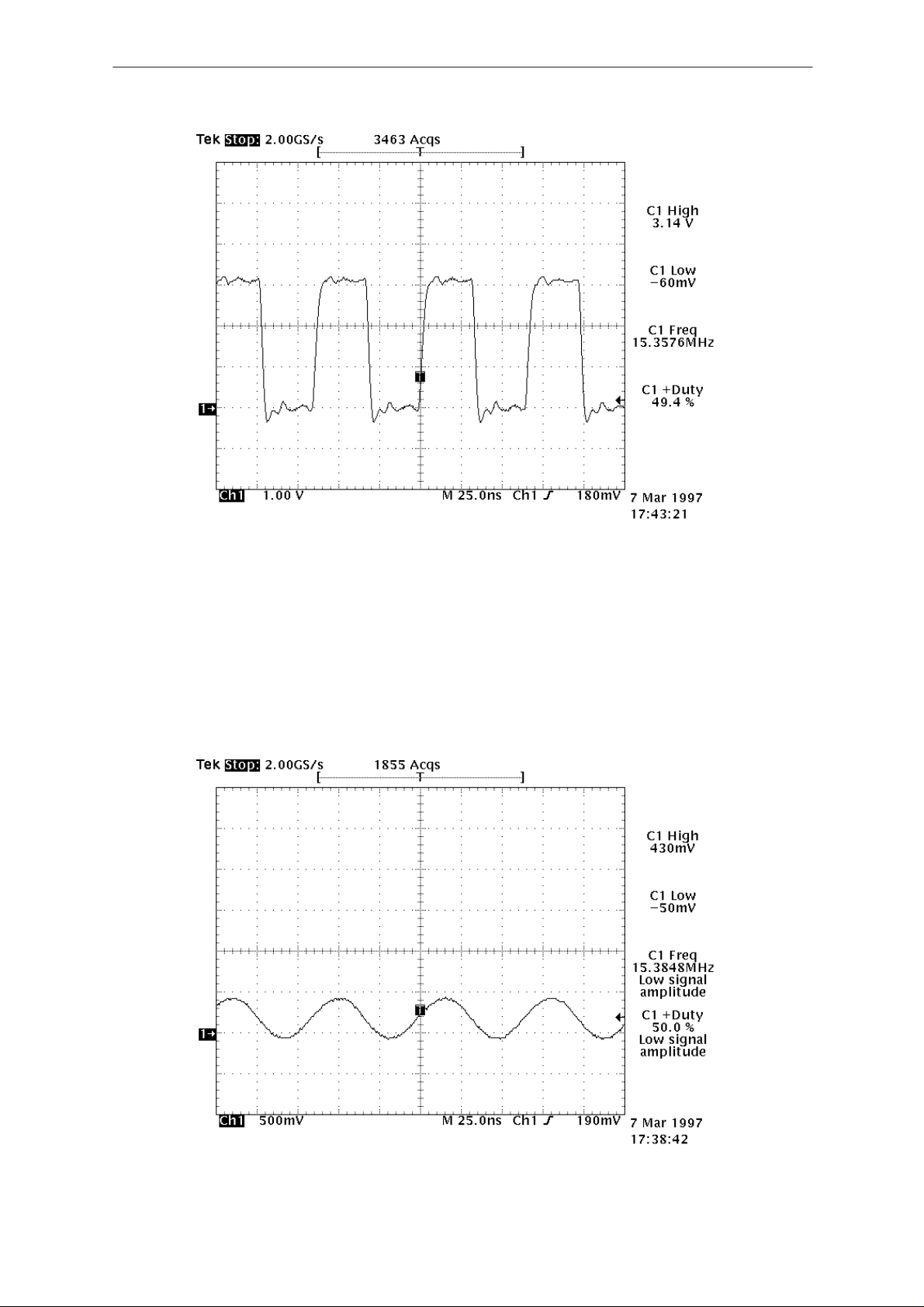

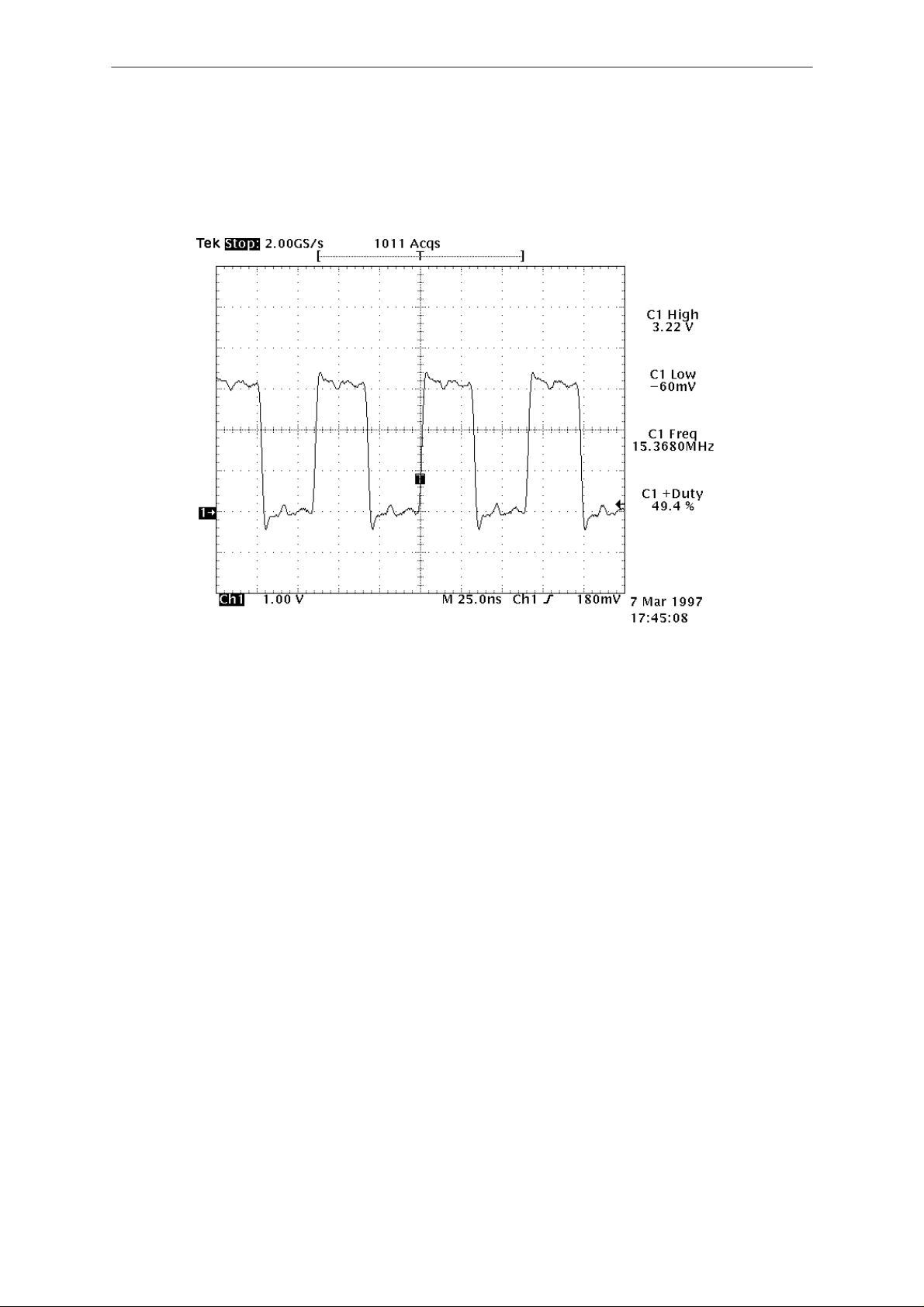

1.0 Is MCU’s clock running?

Check with oscilloscope if there is a clock signal at MCU(D706) pin 69. It

should be a square wave signal, 50% duty cycle, 3Vpp and 15.36MHz.

See Figure 1. Is the clock running?

YES! Go to 2.0 / NO! Go to 1.1

Disassembly & Troubleshooting

Figure 1

Original 11/97

1.1 Is VCTCXO running?

– Measure CDRFI(N700) pin 1. See Figure 2. Is there a

15.36MHz sine wave signal?

– YES! Go to 1.2 / NO! Go to 1.11

Page 19

Page 20

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

Figure 2

1.11 Check VCO_EN is high (3.15V) CDCONT(N201) pin 23.

1.12 Check VCTCXO(G300) waveform at CDCONT(N201) pin

35 looks like Figure 3. Also check that VRXS line is 4.5Vdc at

CDCONT(N201) pin 13. If all these conditions are meet check

solder joints for shorts and opens, if they are OK replace

CDCONT(N201).

Page 20

Figure 3

Original 11/97

Page 21

PAMS

NHD–4

Technical Documentation

1.2 Check CDRFI(N700) pin 63. See Figure 4. Is there a

15.36MHz clock signal present?

– YES! Go to 1.22 / NO! GO to 1.21

Disassembly & Troubleshooting

Figure 4

1.21 Check this signal solder joints, if OK replace

CDRFI(N600).

1.22 Check connections between ASIC(D704) and MCU

(D706), especially ASIC(D704) pin 104 and MCU(D706) pin

69. If no clock is present and connection looks OK replace

ASIC(D704).

2.0 Are MCU’s supply voltages OK?

Measure MCU(D706) supply voltages from pins 5 and 42 (nominal 3.15V

±0.15 Vdc). Are supply voltages right?

V

dc

YES! Go to 3.0 / NO! Go to 2.1

2.1 Check PSL_+3V(N500) VL1(3.15V) pin 4

3.0 Is XSYS_RESET signal OK?

Check XSYS_RESET at MCU(D706) pin 10. While a high (about 3.15

V

) is ok, GO to 4.0. If zero then MCU(D706) is in reset, GO to 3.1.

dc

Original 11/97

3.1 Is XPWR_RESET signal from PSL_+3V(N500) OK?

– Check XPWR_RESET line from PSL_+3V(N500) pin 8. If it

is high GO to 3.12, if zero GO to 3.11.

Page 21

Page 22

NHD–4

PAMS

Disassembly & Troubleshooting

3.11 Check PSL_+3V pin 12. Voltage should be between 1.46V

and 1.72V. if not check R500, R503 and VBATT voltage(5.3...8

V

)

NOTICE! Measure pin 10 from the PSL_+3V(N500) with

dc

oscilloscope. That is watchdog signal coming from

MCU(D706). There should be rising edges time to time.

these are OK and still XPWR_RESET is low replace the

PSL_+3V(N500).

3.12 Check reset line for shorts and open between MCU(D706)

and ASIC(D704), and between PSL_+3V(500) and

ASIC(D704). If OK replace ASIC(D704).

4.0 Is 32KHz clock running?

Check with oscilloscope if there is a 32.768KHz clock signal at

ASIC(D704) pin 87. It should look like Figure 5.

YES! Go to 5.0 / NO! Go to 4.1

Technical Documentation

If all

Page 22

Figure 5

4.1 Check solder joints in ASIC(D704) pins 36, 37, 46, 125.

Also check B700, C744, C745, R837, R757, If they are OK replace B700. If problem persists replace ASIC(D704).

5.0 Check all supply voltages!

Measure all power supply voltage lines VL1(3.15V), VL2(3.15V),

VL3(3.15V), VA2(3.15V) and VREF(3.15V).

Are voltages right? YES! Go to 6.0. / NO! Read ahead!

If any voltage is not the right one, check corresponding transistor. VL1

(V500), VL2(V502) and VL3(V501).

Check also all major circuits supply voltages MCU(D706), ASIC(D704),

PSL_+3V(N500), DSP(D705), CDRFI(N700) and CODEC(N600).

Original 11/97

Page 23

PAMS

NHD–4

Technical Documentation

6.0 FLASH–line OK? Power up function OK!

YES! Power up function OK! / NO! Do flashing again.

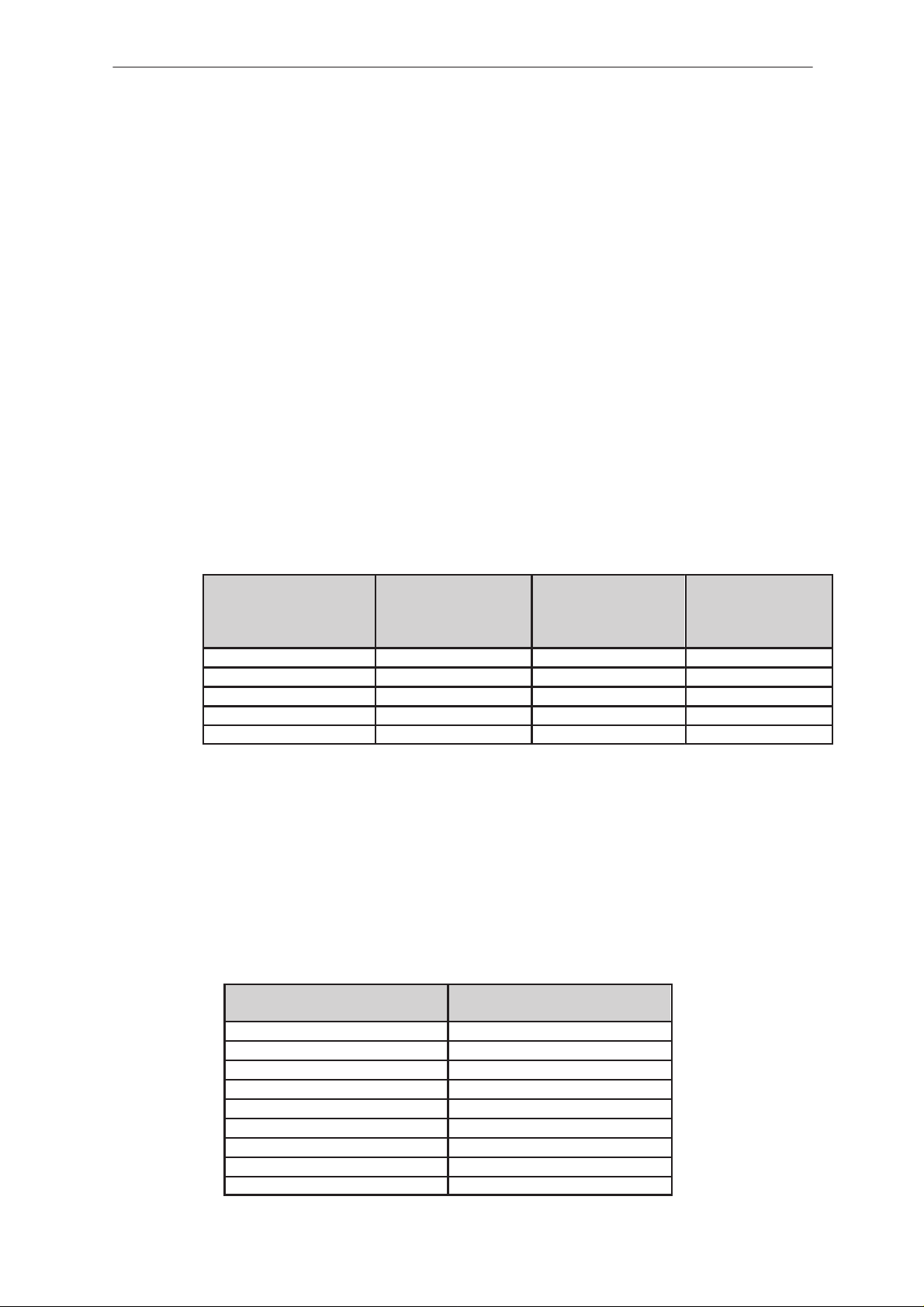

This table might help to locate power pins on main circuits.

Circuit Number Pins Supply voltage signal

MCU D706 5,42 VL1

ASIC D704 13,22,27,44,60,65,74,88,103 VL1

D704 109,117,132,146,151,161,176 VL1

DSP D705 8,11,36,39,49,64,76,87,90 VL2

CDRFI N700 32,33,60,62,2,6,8,19 VL3

CODEC N600 2,3 VA2

N600 15 VL1

FLASH D709 30,31,11 VL1

RAM D700 28 VL1

EEPROM D703 7 VL1

Disassembly & Troubleshooting

Original 11/97

Page 23

Page 24

NHD–4

PAMS

Disassembly & Troubleshooting

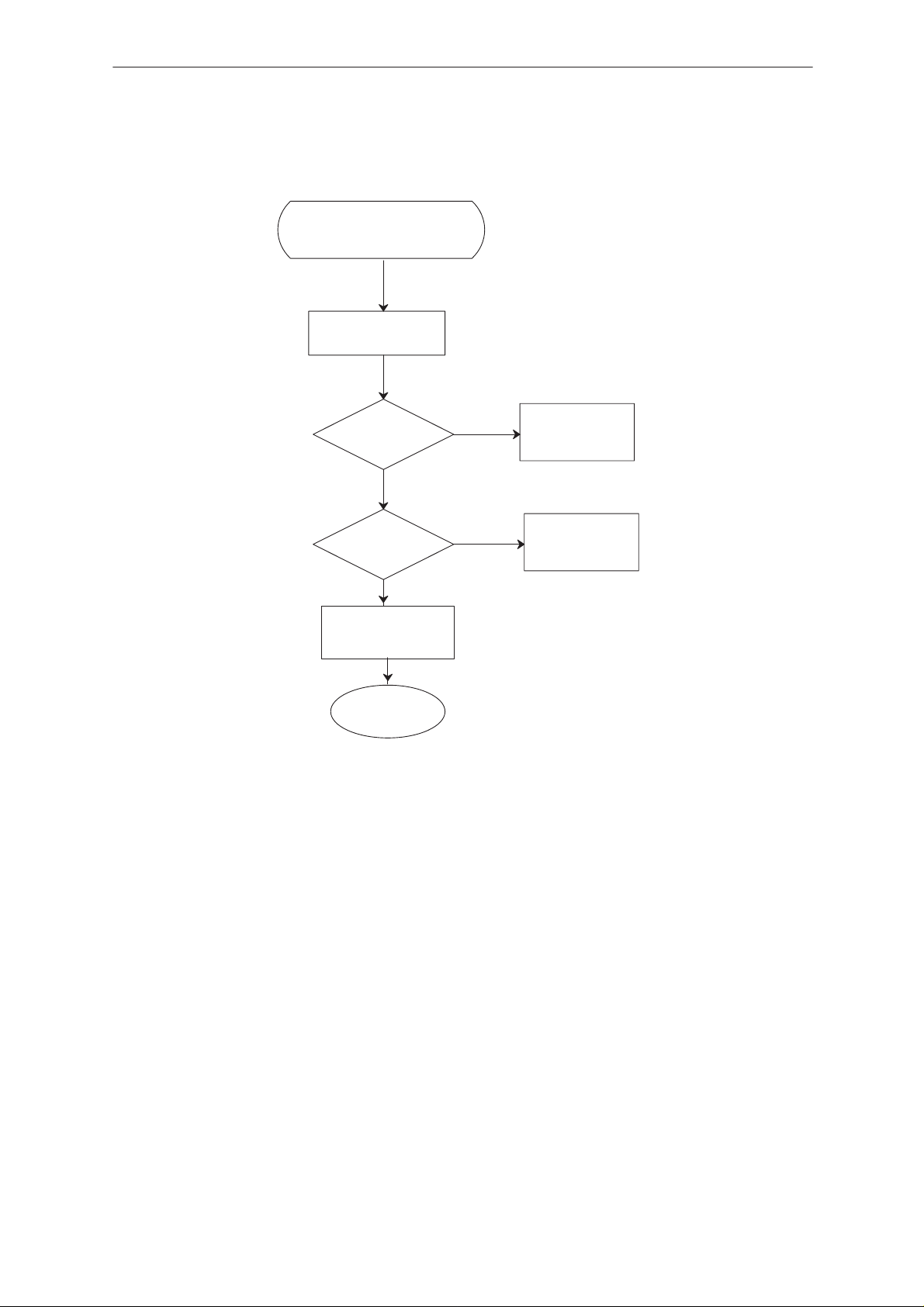

Troubleshooting Diagram; Power Up Malfunction

Start

1.11 Check

VCO_EN is 3V

1.12 Check

Vctcxo sine wave

and VRXS is

4.5V, if OK

replace CDCONT

(N201)

Check solder

joints, if OK

replace

CDRFI

(N700)

NO

1.1 VCTCXO

running OK?

YES

NO

1.2 Clock signal

at CDRFI (N700)

pin 63 ?

YES

1.22 Check connections

between D706 and D704

especially clock signals.

If they are OK replace

D704

NO

1. MCU

clock running

OK?

YES

2. MCU’s

supply voltages

OK?

YES

3. MCU

reset signal OK?

YES

NO

NO

Technical Documentation

2.1 Check PSL+(N500)

VL1–line at pin 4

3.1 Is N500

XPWR_RESET signal

OK?

YES

3.12 Check connections

between D706, D704 and

N500. If OK replace D704

NO

3.11 Check

PSL+(N500)

pins 10

and 12

if OK replace

PSL+(N500)

Page 24

Check

corresponding

component

Power up

OK!

YES

NO

4. Is 32KHz

clock running

OK ?

YES

5. All supply

voltages OK?

YES

6. FLASH line

OK?

NO

NO

4.1 Check D704 pins 36,

37,46,125. Also check

B700, C744, C745, R837.,

R757. If they are OK

replace B700. If problem

persists replace D704

Do flashing again

Original 11/97

Page 25

PAMS

NHD–4

Technical Documentation

Important Information

This section contains information that might be helpful while

troubleshooting an HD881 phone. However it is not needed to

troubleshoot power up problems.

9.8304MHz clock

This clock is ”ON” when the phone is set to CDMA non–slotted mode and

it is ”OFF” when the phone is set to AMPS mode. It is generated inside the

CDCONT(N201) from the 15.36MHz. The waveform signal coming out

from the CDCONT(N201) pin 40 should look like Figure 6.

Disassembly & Troubleshooting

Figure 6

Then this signal is fed to the CDRFI(N700) squaring circuit on pin 3 to get

the final 9.8304MHz clock signal that will go to the ASIC(D704). This clock

should look like Figure 7.

Original 11/97

Page 25

Page 26

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

Figure 7

Page 26

Original 11/97

Page 27

PAMS

Á

Á

NHD–4

Technical Documentation

Transmitter Troubleshooting

Introduction

Troubleshooting the NHD–4 transmitter is very straight forward.

Operation of the transmitter circuit changes little from AMPS to CDMA

mode, only the nature of the signal transmitted is distinctly different. A

substantial amount of information regarding the health of the transmitter

can be determined with just a simple DMM. The detector voltage will

provide you a sound estimate of the output power. Collector and base

voltages will inform you if biasing is correct on the gain stages (drain and

gate for CLY–10 V113). And the various control signal had their DC

voltage characteristics detailed in the Functional Description. An RF

probe can also be used to quickly determine if a gain stage or filter is

functioning properly.

Below are a number of techniques to test the transmitter, beginning with a

means to simply turn it on. Service Software features that provide manual

transmitter controls are detailed. Node voltages RF power levels and a

chart of gains and losses are provided. Means to test the various TX

control features are explained.

Disassembly & Troubleshooting

Service Software Quick Checks

The Service Software has a number of features that allow you to quickly

test out the functionality of the transmitter in both the CDMA and AMPS

modes. The following two quick checks simply turns the transmitter on in

either of these modes.

AMPS TX Quick Checks with Service Software

From the Service Software select the AMPS Quick Checks option from the

Testing menu. A window will appear. Within this window are numerous

AMPS related controls for the phone, including a means to turn on the

AMPS transmitter. This is done by simply selecting the AMPS power level

0–2 through 7. Measure the output power using a spectrum analyzer,

power meter or RF communications test set.

AMPS TX

Power Level

БББББ

0–2

3

4

5

6

7

AMPS TX

Output Power

ÁÁÁÁ

(dBm)

27.0

23.0

18.0

14.0

10.0

8.0

Original 11/97

Page 27

Page 28

NHD–4

Á

Á

PAMS

Disassembly & Troubleshooting

CDMA TX Quick Checks with Service Software

The Service Software contains a Quick Check for the CDMA TX. From

the Test menu choose the CDMA Quick Test selection. A sub menu will

appear. Select the CDMA TX Quick Check. A window will appear

instructing you to feed the transmitter output into either a spectrum

analyzer or CDMA test box. Selecting the “TEST” soft button will turn on

the CDMA transmitter to its maximum power, approximately 24 dBm. If

not, then there is either some gain missing or a failure to provide the

appropriate input signal.

It should be noted that in CDMA operation, proper output power

measurements require that the bandwidth be taken into strict

consideration. CDMA output power readings must be performed across a

1.23 MHz band. A spectrum analyzer used for such measurements must

have the functionality to read band power. Otherwise, a CDMA signal

simply appears as an amplified noise floor, 1.23 MHz wide. For maximum

CDMA TX output power, the peak of this noise–like signal will be

approximately 10 dBm. CDMA test boxes have this capability built in.

Technical Documentation

Manual Output Power Control

The following two tests provide means to manually control the output

power of the NHD–4 transmitter in either the AMPS or CDMA modes.

AMPS TX Gain Control – Manual Control

The AMPS transmitter gain is controlled from the TXI_REF PDM. This

PDM has a manual control within the AMPS Quick Checks window of the

Service Software Test menu. With the phone in AMPS Troubleshooting

Mode the transmitter output power can be manipulated with this PDM

control. The table below details approximate PDM values, in decimal,

necessary to achieve corresponding power levels. These values will vary

from phone to phone.

AMPS TX

Output Power

БББББ

(dBm)

30

27

24

21

18

15

12

9

6

TXI_REF PDM

decimal value

ÁÁÁÁ

00

238

208

176

166

160

155

152

151

Page 28

Original 11/97

Page 29

PAMS

Á

Á

Á

Á

Á

Á

NHD–4

Technical Documentation

CDMA TX Gain Control – Manual Controls

As the name suggests, the CDMA TX Manual Gain Control mechanism of

the Service Software provides a means to manually manipulate the output

power of the CDMA transmitter. This test is convenient for testing the two

gain control functions of the CDMA transmitter, the CDAGCT IC and

Auxiliary AGC.

You can find this control within the CDMA Quick Checks selection of the

Tests menu of the Service Software. The output power is controlled by

adjusting the slide bar up and down, or manually entering numeric values

within the text edit box. Use a spectrum analyzer with a 2 MHz span to

view the transmitter output.

This test is adjusting the CloopRef register value, a value that determines

the difference between the received power into the mobile and the

transmit power out of the mobile. Artificially adjusting it, as this test does,

results in a change in the transmit power level. For this test maximum

CDMA output power, about 24 dBm, is achieved with a decimal value of

approximately 105. Minimum CDMA output power is achieved with a

decimal entry of about 25. At this level the CDMA signal will be as low as

the noise floor.

Disassembly & Troubleshooting

Detector DC Voltage Check – AMPS

Measuring the detector voltage, TXI, is great way to test transmitter output

power without actually reading the RF output power. Probing the detector

with a DMM at N202 pin 1 will provide a DC voltage that directly

corresponds to the amount of RF power sampled by the detector (V114).

This is a good means to assist in isolating transmitter faults. Whether or

not the detector voltages are valid will inform you if power losses are

occurring before or after the final PA stage (CLY–10, V113).

The following table shows typical detector output voltages for each AMPS

output power level.

AMPS

Power Level

БББББ

БББББ

0–2

3

4

5

6

7

AMPS Output Pow-

er

ББББББ

( dBm )

ББББББ

27

23

18

14

10

8

Detector Voltage

TXI

БББББ

at N202 pin 1

(V)

БББББ

0.87

1.35

1.80

1.99

2.13

2.17

Original 11/97

Page 29

Page 30

NHD–4

PAMS

Disassembly & Troubleshooting

DC Node Voltage Checks

Typical nodal voltages are listed below. The phone must be at AMPS

output power level 2 or maximum CDMA output power when measuring

node voltages. These two states can be achieved by using the AMPS or

CDMA Troubleshooting Modes.

NODE

VTXS – DC supply at C144

VTXT – DC supply at R120

V114 – Detector output ( TXI ) at N202 pin 1

V114 – Detector supply at R127 ( VTXS )

V113 – CLY–10 PA supply at C160 ( VRFT )

V113 – CLY–10 PA gate at R138 ( VGG )

V112 – 3rd Gain stage collector at C157

V112 – 3rd Gain stage base at C164

V112 – 3rd Gain stage supply at R117

V110 – 2nd Gain stage collector at C154

V110 – 2nd Gain stage base at R129

V111 – 1st & 2nd Gain stages supply at C108

V111 – 1st Gain stage collector at C146

V111 – 1st Gain stage base at R128

V106 – AT–109 atten. – supply at C129 ( VTXS )

V106 – AT–109 atten. – control at C109 ( VC )

N100 – Bias to the CDAGCT IC at C133

RFE2 at V107 emitter

VRFT– Battery voltage at C142

VNEG – Gate Volt. Delay at R111

TX_PUNC – Puncture Control at V102

TX_IREF – Control current reference at C115

TX_ICT – Control current at C100

Technical Documentation

CDMA

VDC

4.40

5.30

1.20

4.40

6.20

–2.70

6.00

0.70

6.3

2.68

0.72

4.70

3.85

0.75

4.40

3.50

3.90

0.00

6.80 *

–4.12

3.12

3.60

3.60

AMPS

VDC

4.40

5.30

1.10

4.40

6.20

–2.30

6.00

0.70

6.20

2.67

0.72

4.70

3.83

0.75

4.40

4.35

3.90

3.10

6.80 *

–4.05

3.12

3.50

3.50

Note This is the Battery voltage. It directly reflects the power supply voltage to the

phone. It will only be 6.8 V when the DC supply to the phone is 6.8 V.

Note: The position of the probe’s GND pin is critical to obtain correct readings. The GND

pin MUST be touching the GND plane immediately next to the point being measured!!

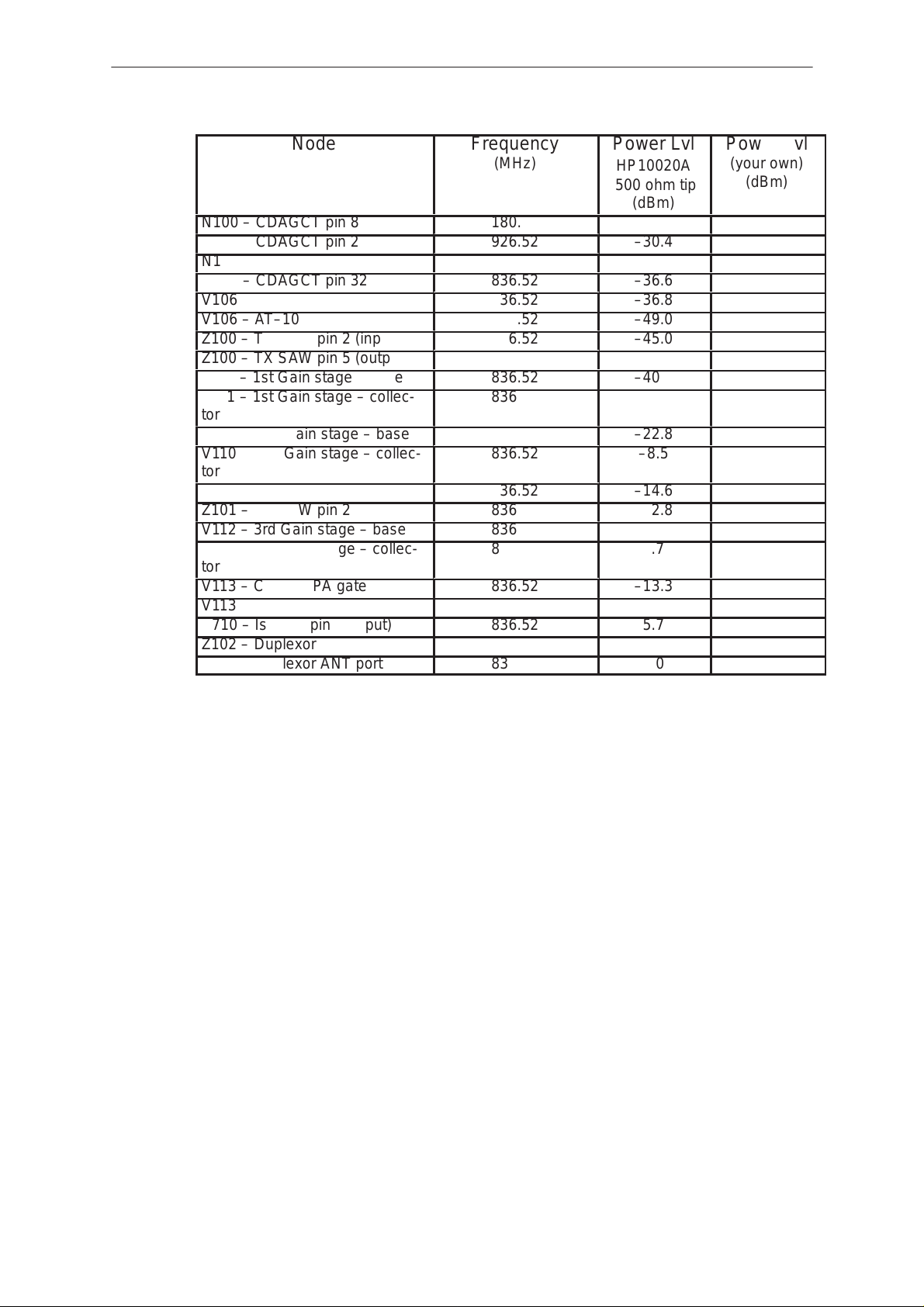

RF Node Power Levels

A high impedance passive RF probe may be used with a spectrum

analyzer to obtain the RF node power levels along the transmitter chain.

The author recommends a passive probe with a 500 ohm tip. The

following levels are based on a transmitter output at AMPS power level 7.

Maintain a 1.0 MHz span on the spectrum analyzer. A CDMA test box

with spectrum analyzer capabilities will do.

The RF power levels published below were found with a passive probe

with the 500 ohm tip. The blank column is reserved for values the user

will obtain with their own probe.

Page 30

Original 11/97

Page 31

PAMS

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

NHD–4

Technical Documentation

Node

БББББББББ

БББББББББ

БББББББББ

N100 – CDAGCT pin 8

N100 – CDAGCT pin 2

N100 – CDAGCT pin 31

N100 – CDAGCT pin 32

V106 – AT–109 pin 3 (input)

V106 – AT–109 pin 7 (output)

Z100 – TX SAW pin 2 (input)

Z100 – TX SAW pin 5 (output)

V111 – 1st Gain stage – base

V111 – 1st Gain stage – collector

V110 – 2nd Gain stage – base

V110 – 2nd Gain stage – collec-

БББББББББ

tor

Z101 – TX SAW pin 5

Z101 – TX SAW pin 2

V112 – 3rd Gain stage – base

V112 – 3rd Gain stage – collec-

БББББББББ

tor

V113 – CLY–10 PA gate

V113 – CLY–10 PA drain

V710 – Isolator pin 2 (input)

Z102 – Duplexor TX port

Z102 – Duplexor ANT port

Disassembly & Troubleshooting

Frequency

ББББББ

(MHz)

ББББББ

ББББББ

180.00

926.52

836.52

836.52

836.52

836.52

836.52

836.52

836.52

836.52

836.52

836.52

ББББББ

836.52

836.52

836.52

836.52

ББББББ

836.52

836.52

836.52

836.52

836.52

Power Lvl

ÁÁÁ

HP10020A

500 ohm tip

ÁÁÁ

(dBm)

ÁÁÁ

–22.5

–30.4

–35.0

–36.6

–36.8

–49.0

–45.0

–45.0

–40.0

–28.0

–22.8

–8.5

ÁÁÁ

–14.6

–12.8

–26.5

1.7

ÁÁÁ

–13.3

6.7

5.7

6.0

6.0

Power Lvl

ÁÁÁÁ

(your own)

(dBm)

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

Original 11/97

Page 31

Page 32

NHD–4

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

PAMS

Disassembly & Troubleshooting

Testing CDMA TX Gain Limiting

To test the CDMA TX Gain Limiting control perform the following steps:

1. Place the phone in the CDMA Troubleshooting Mode.

2. With an oscilloscope probe the LIM_ADJ line at C807.

3. Adjust the gain of the CDMA transmitter using the CDMA TX manual

gain control mechanism found in the Service Software.

4. The LIM_ADJ line will remain at about 3.2 VDC until the TX output

power reaches its limit, approximately 24 dBm. At this point the LIM_ADJ

line will toggle continuously, appearing as a square wave 3.2 Vpp with an

approximate frequency of 400 Hz.

Testing Dynamic TXB

To test the Dynamic TXB functionality, perform the following steps:

1. Place the phone in the CDMA Troubleshooting Mode.

2. Use the Service Software CDMA TX manual gain controls to achieve

10 dBm CDMA TX output power.

Technical Documentation

3 .Read the total current draw of the phone. It should be approximately

530 mA.

4. Increase the CDMA TX output power to 23 dBm. The current draw

should rise to approximately 690 mA.

Note the difference is about 150 mA, which is the difference between the two current

biasing levels.

CDMA TX

БББББББ

БББББББ

Current Draw

ÁÁÁ

10 dBm

(mA)

ÁÁÁ

530

ÁÁÁÁ

ÁÁÁÁ

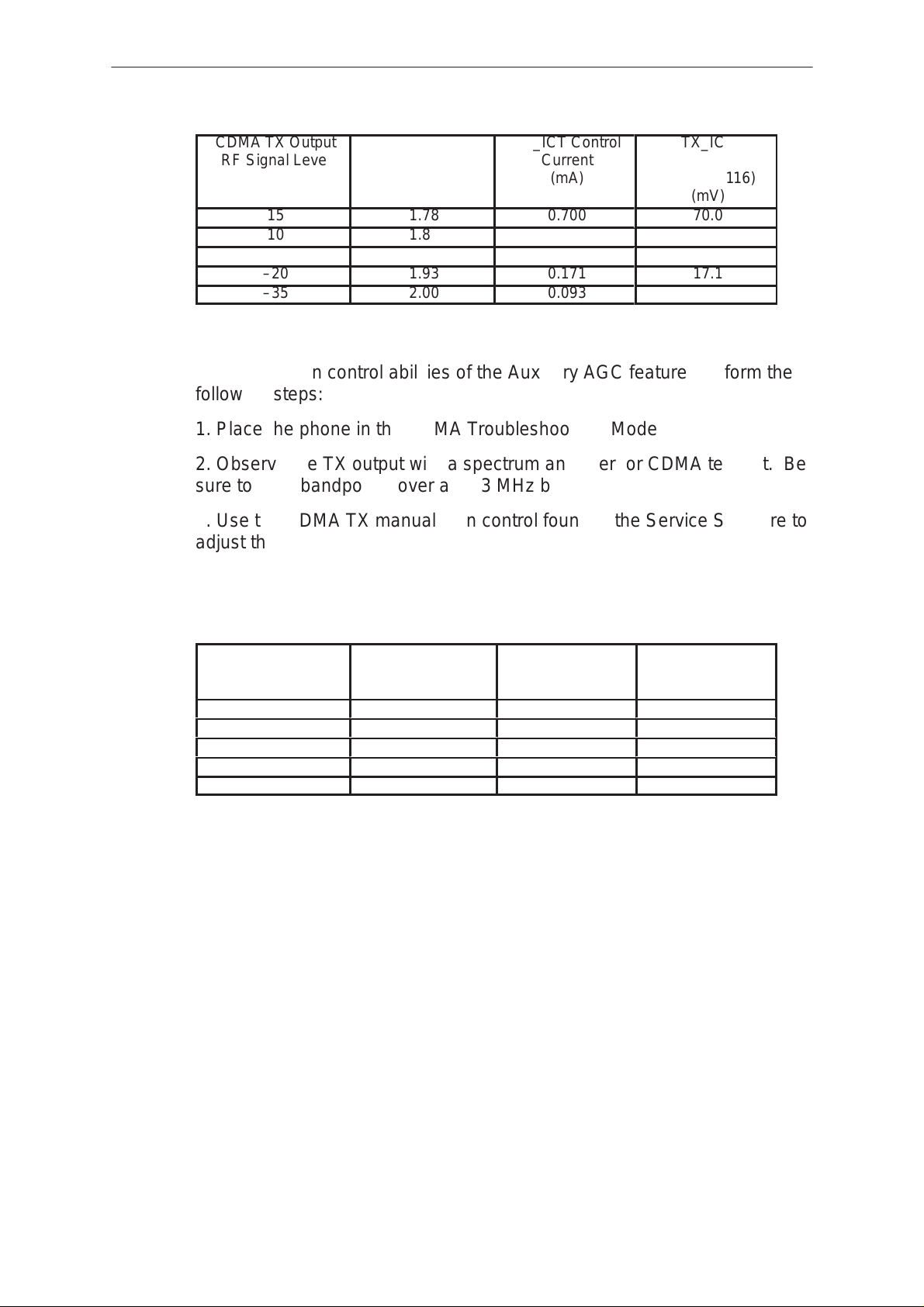

Testing CDAGCT IC (N100) Gain Control

To test the gain control abilities of the CDAGCT IC (N100) do the

following:

1. Place the phone in the CDMA Troubleshooting Mode

2. Observe the TX output with a spectrum analyzer or CDMA test set. Be

sure to read bandpower over a 1.23 MHz band.

CDMA TX

23 dBm

(mA)

690

AMPS Power

ÁÁÁÁ

Level 7

(mA)

ÁÁÁÁ

400

AMPS Power

ÁÁÁÁ

Level 2

(mA)

ÁÁÁÁ

610

Page 32

3. Use the CDMA TX manual gain control found in the Service Software

to adjust the output power from its minimum (noise floor) to 15 dBm.

4. Observe the TX_Gain voltage at C213 and the TX_ICT current as a

voltage drop across R116. The table below details approximate values

that should be read.

Original 11/97

Page 33

PAMS

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

NHD–4

Technical Documentation

CDMA TX Output

RF Signal Level

БББББ

(dBm)

БББББ

15

10

–5

–20

–35

Testing Auxiliary AGC

To test the gain control abilities of the Auxiliary AGC feature, perform the

following steps:

1. Place the phone in the CDMA Troubleshooting Mode

2. Observe the TX output with a spectrum analyzer or CDMA test set. Be

sure to read bandpower over a 1.23 MHz band.

3. Use the CDMA TX manual gain control found in the Service Software to

adjust the output power of the phone from 15 dBm to 23 dBm.

TX_GAIN Voltage

at C213

БББББ

БББББ

(V)

1.78

1.80

1.87

1.93

2.00

Disassembly & Troubleshooting

TX_ICT Control

Current

БББББ

БББББ

(mA)

0.700

0.560

0.298

0.171

0.093

TX_ICT

(as voltage drop

БББББ

across R116)

БББББ

(mV)

70.0

56.0

29.8

17.1

9.3

4. Observe the VC voltage at C109 and the AGC_REF PDM voltage at

C716. The table below details approximate values that should be read.

CDMA TX

БББББ

Output Power

БББББ

(dBm)

23

21

19

17

15

Hints and Suggestions

The 3rd stage (V112) is sensitive to shorts of the DC bias line.

Accidentally shorting the collector to ground always blows the 5.6 ohm

bias resistor (R117) but doesn’t harm the transistor.

AGC_REF PDM

БББББ

(decimal value)

БББББ

0

34

60

79

85

AGC_REF PDM

БББББ

voltage at C716

БББББ

(V)

0.798

0.583

0.456

0.367

0.333

БББББ

БББББ

VC

at C109

(V)

3.28

2.81

2.53

2.33

2.26

Original 11/97

Page 33

Page 34

NHD–4

PAMS

Disassembly & Troubleshooting

AMPS Receiver Troubleshooting

Introduction

Troubleshooting the NHD–4 AMPS receiver isn’t unlike troubleshooting

the AMPS receiver on any other Nokia phone. In fact, NHD–4 uses the

same FM receiver IC as many other Nokia phones. So long as the

NHD–4 phone is in an AMPS RX mode, this receiver will be on. The

following tests detail ways to make the AMPS receiver operational and

test its functionality.

Tests and Quick Checks

The Service Software software package contains a quick test for the

AMPS receiver. When selected, the software prompts you to send a

modulated carrier into the phone at a –65 dBm signal level. Hitting the

”Test” soft key prompts the software to read the RSSI voltage level that

the CDRFI IC has A/D converted into a digital signature. If the digital

value falls within the range which a –65 dBm signal should, it is a good

bet that the AMPS receiver is working properly. There is still a chance

that the demodulated baseband ANARX signal (the audio) is corrupt, but

you do know the rest of the AMPS receiver is functional.

Technical Documentation

If the RSSI values are less

RX sensitivity problem. Most likely a component or solder joint along the

AMPS RX receiver path has failed. The possibility exists that the error is

in the baseband A/D conversion. To ensure that the error is in the RF it is

recommended that the remaining tests below be performed until the error

is uncovered.

If the RSSI values are greater

energy above the stated input level is entering the RX path. Check the

level of the signal generator used for the test. It may be sourcing more

RF power than was requested by the test. Ensure that cable losses have

been properly accounted for.

than the ranges stated, than there is an AMPS

than the ranges stated than additional RF

Setting Up the AMPS Receiver Test

To troubleshoot the AMPS receiver first remove the shields. Apply power

and service cables to the phone and turn it on. Initiate the AMPS

Troubleshooting Mode from Service Software. Then feed a –65 dBm

881.52 MHz signal modulated with 8 kHz FM and 1 kHz audio into the RF

port of the phone via the bottom connector. A stand alone RF signal

generator should do the trick, or a CDMA test box with this functionality.

Do not forget to account for the signal loss between the signal generator

and the phone.

Page 34

Original 11/97

Page 35

PAMS

NHD–4

Technical Documentation

RSSI Check

The voltage on the ungrounded end of C13 directly represents the RSSI of

the phone. Checking this voltage will provide another quick indication of

the health of the AMPS RX module. With the –65 dBm modulated signal

mentioned above this voltage should be approximately 2.00 V.

The possibility exists that the AMPS RX is working fine with a –65 dBm

input, but has lost sensitivity and fails at lower input powers. You may

wish to perform this test at higher or lower input signal levels. The

following table details the RSSI voltage vs. input signal levels. Keep in

mind that there will be variations in the voltage levels from phone to

phone, but these are good approximations.

–45

–50

–55

–60

–65

–70

–75

–80

–85

–90

–95

–100

–105

Disassembly & Troubleshooting

2.32

2.31

2.26

2.16

2.00

1.89

1.78

1.65

1.54

1.41

1.26

1.17

1.07

If the RSSI DC voltages are significantly less than the ranges stated then

there is an AMPS RX sensitivity problem. A total AMPS RX failure would

yield about 1.00 V for this test for most input RF power levels. Most likely

a component or solder joint along the AMPS RX receiver path has failed.

Continue the DC Voltage Quick Checks to help determine if any of the

devices aren’t biased correctly.

If the RSSI values are significantly greater than the ranges stated then

additional RF energy above the stated input level is entering the RX path.

Check the level of the signal generator used for the test and ensure that

cable losses have been properly accounted for. Also check for any

undesired oscillations.

Original 11/97

Page 35

Page 36

NHD–4

PAMS

Disassembly & Troubleshooting

DC Voltage Checks

Check the following DC voltages with the –65 dBm modulated signal still

fed into the phone and the Service Software AMPS Troubleshooting Mode

initiated.

•The bias voltage on the AMPS RX IC (D1), pin 4 should be

approximately 4.40 V.

If not, first ensure that the phone is in the AMPS Troubleshooting Mode. Check the

VRXA supply voltage at C219, or CDCONT (N201), pin 42. If fault is found with this

DC supply then refer to the AGC Troubleshooting Manual to determine if there is a

problem with the CDCONT voltage regulators.

•Check the 1st IF gain stage V9:–

The voltage on the collector, pin 1 should be approximately 3.30 V.

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Inspect V9, R30

and R31. Ensure that VRXAM is approximately 4.15 V at R31

Technical Documentation

The voltage on the base, pin 3 should be approximately .97 V.

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Inspect V9, V4,

L13, L11, R4, R5, R13, R14, and R15. Ensure VRXM is at about 4.15 V at R13, and

VRXAM is about 4.15 V.

The voltage on the emitter, pins 2 and 4 should be approximately 0.25 V.

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Inspect V9,

L14, R25, and R28.

•Check the LNA, V12:–

The voltage on the collector should be approximately 3.70 V.

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Ensure VRXM

is at about 4.15 V at R833. Inspect V11, V12, L20, R33, R34, R38, and R833.

The voltage on the base should be .82 V.

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Ensure VRXM

is at about 4.15 V at R833. Inspect V11, V12, L21, L22, R33, R35, and R833.

•Check the control voltages on the RF Gain Switches N701 and N702.

Pin 1 on both should be approximately 3.80 V.

Page 36

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Ensure VRXM

is at about 4.15 V at R832. Inspect N701, N702, V1, V708, R775, R777, R779,

R781, R783, R803, R830, R831, and R832.

•Check the SWAGC line at R830. It should be logic level low,

approximately .0 V.

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Ensure VRXM

is at about 4.15 V at R832. Inspect V708, R765 and R830. Ohm out line from R765

to the ASIC N704 pin 94.

Original 11/97

Page 37

PAMS

Á

Á

NHD–4

Technical Documentation

•Check the RX_CAL line at R783, It should be logic level high, near 2.75 V.

If not, confirm that the phone is in the AMPS Troubleshooting Mode. Ensure VRXM

is at about 4.15 V at R832. Inspect V1, V708, R6, R765, R783, and R785. Ohm out

the RX_CAL line from pin 114 of the ASIC N704 to R785.

Chart of AMPS RX DC Node Voltages

The following chart summarizes the node voltages of the AMPS RX when

the phone is in the AMPS RX/TX Mode with a 881.52 MHz signal input of

–65 dBm, modulated with 8 kHz FM, 1 kHz audio.

ББББББББББББ

D1 – AMPS RX IC, pin 4

V9 – collector of 1st IF amp, pin 1

V9 – base of 1st IF amp, pin 3

V9 – emitter of 1st IF amp, pins 2, 4

V12 – collector of LNA

V12 – base of LNA

RF Gain Switches N701 and N702, pin 1

RF Gain Switches N701 and N702, pin 8

SWAGC line at R830

RX_CAL line at R783

Node

Disassembly & Troubleshooting

БББББББ

Voltage

(V)

4.40

3.30

0.97

1.12

3.70

0.82

3.80

0.00

0.00

2.75

Demodulation Test

If you have an oscilloscope available you may use it to do a visual check

on the demodulated 1 kHz tone on the ANARX+DA line. Again feed in the

modulated –75 dBm, 881.52 MHz, 8 kHz FM, 1 kHz audio RF signal into

the receiver and initiate the AMPS Troubleshooting Mode from Service

Software. Use a standard scope probe at C1 to look at the 1 kHz tone. It

should appear as a clean sine wave of approximately 380mVpp. Step

down the input RF power. At about –90 dBm the sine wave will begin to

become a bit fuzzy. At –105 dBm the waveform will be fuzzy, but still

distinguishable.

If not, confirm that the phone is in the AMPS Troubleshooting Mode.

Ensure the RF signal is modulated correctly and of the requested signal

level. Inspect R2, C1 and C10.

RF Node Power Checks – AMPS Mode

A high impedance passive RF probe may be used with a spectrum

analyzer to obtain the RF nodal power levels along the receiver chain.

The following levels assume a –65 dBm, 881.52 MHz, unmodulated tone

input into the receiver. Maintain a 1.0 MHz span on the spectrum

analyzer. A CDMA test box with spectrum analyzer capabilities will do.

The RF power levels published below were found a passive probe with the

500 ohm tip. The blank column is reserved for values the user will obtain

with their own probe.

Original 11/97

Page 37

Page 38

NHD–4

Á

Á

Á

Á

Á

Á

Á

Á

Á

ББББББ

Á

Á

Á

Á

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

ББББББ

PAMS

Disassembly & Troubleshooting

Node

БББББББББ

БББББББББ

БББББББББ

44.545 MHz osc. at D1, pin 2

AMPS RX IC D1 pin 16

SAW Z3 pin 3

SAW Z3 pin 6

Diode V10 pin 3/L15/R29/R30

1st IF Amp V9 collector, pin 1

1st IF Amp V9 base, pin 3

Mixer T1 pin 4 – IF

Mixer T1 pin 8 – LO

Mixer T1 pin 5 – RF

RF Switch N701 pin 7 – output

RF Switch N701 pin 5 – input

LNA V12 collector

LNA V 12 base

RF Switch N702 pin 7 – output

RF Switch N702 pin 5 – input

Duplexor Z102, RX In pin

Duplexor Z102, ANT pin

Coax W400 Antenna input

Coax W400 Connector input

Frequency

ÁÁÁÁ

(MHz)

ÁÁÁÁ

ÁÁÁÁ

44.545

45

45

45

45

45

45

45

926.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

Technical Documentation

Power Lvl

БББББ

HP10020A

500 ohm tip

БББББ

(dBm)

БББББ

–10

–62

–61.5

–57.5

–90

–90

–105

–80

–19

–75

–75.5

–75.5

–68

–90

–85.5

–85.5

–92

–89

–87

–88

Power Lvl

ÁÁÁÁ

(your own)

(dBm)

ÁÁÁÁ

ÁÁÁÁ

Page 38

Original 11/97

Page 39

PAMS

NHD–4

Technical Documentation

CDMA Receiver Troubleshooting

Introduction

Troubleshooting the CDMA receiver of the phone is unique, but not

complicated. The following tests detail numerous ways that the CDMA

receiver functionality can be verified, all using standard test equipment.

No special CDMA signal generators or measurement equipment are

necessary to verify the CDMA receiver.

CDMA RX Quick Test with Service Software

The Service Software software package contains a quick test for the

CDMA receiver. When selected, the software prompts you to send a CW

carrier into the phone at a –65, –85, and –105 dBm signal levels, one after

the other. Hitting the ”Test” soft key prompts the software to read the

received signal level that the phone perceives digitally. A numeric value

called the RxDAC (RX D/A converter) is generated within the CDMA ASIC

to represent the signal level received. If this number falls within the range

of values listed in the Service Software window coinciding with the

respective input signal level, the CDMA RX is operating properly. For

example, for a –65 dBm input signal should provide an RxDAC value

between 480 and 520.

Disassembly & Troubleshooting

Note: The results of this test will only fall into the ranges stated when the RX_OFFSET

is properly tuned. With this parameter improperly tuned the resultant values will be

slightly different, but still near the stated ranges, provided that the CDMA RX module is

functional.

Set Up CDMA RX Test

To troubleshoot the CDMA receiver first remove the shields. Apply power

and service cables to the phone and turn it on. Initiate the CDMA RX

Troubleshooting Mode from Service Software. Then feed a –65 dBm

881.62 MHz unmodulated CW carrier into the phone via the RF connector

at the bottom of the phone. An unmodulated –65 dBm carrier at channel

387 will also work. A stand alone RF signal generator should do the trick,

as will a CDMA test box with this functionality. Do not forget to account for

the signal loss between the signal generator and the phone.

RX Gain Control Test

A great test to check the health of the CDMA receiver is to monitor the

gain control current to the CDAGCR IC. As the CDMA signal strength

received by the phone drops, this current increases. Naturally it is difficult

and time consuming to break the circuit and position an ammeter in the

phone to read this current. A quick way to do so is to simply read the

voltage drop across resistor R16. Position one test lead of a volt meter on

either side of this resistor and vary the RF input power at 881.62 MHz,

unmodulated CW.

The voltage drop across this resistor should resemble the values in the

table that follows. Be sure to also check the voltage drop across R17, the

RX_IREF signal. This drop should be approximately 360 mV.

Original 11/97

Page 39

Page 40

NHD–4

Á

Á

Á

Á

PAMS

Disassembly & Troubleshooting

RF Input Power

БББББББ

881.62 MHz CW

БББББББ

(dBm)

–45

–50

–55

–60

–65

–70

–75

–80

–85

–90

–95

–100

–105

DC Voltage Checks

Check the following DC voltages with the –65 dBm 881.62 MHz CW signal

still fed into the phone and the Service Software CDMA Troubleshooting

Mode initiated.

Voltage Drop

БББББББ

Across R16

(RX_ICT)

БББББББ

(mV)

11

14

17

21

25

30

37

45

56

68

83

99

113

Technical Documentation

•The bias voltage on the BFILCT2 IC (N2), pin 4 should be approx 3.10 V.

If not, first ensure that the phone is in the CDMA Troubleshooting Mode. Check the

VBBFIL supply voltage at the collector of V203, or CDCONT (N201), pin 15, or C223.

It should be approximately 3.15 V.

•The bias voltage on the BFILCT2 IC (N2), pin 8 should be approx 3.05 V

If not, first ensure that the phone is in the CDMA Troubleshooting Mode. Check the

VRXD_R supply voltage at pin 4 of V206, or CDCONT (N201), pin 15, or C223. It

should be approximately 4.50 V.

•The bias voltage on the CDAGCR IC (N1), pin 13 should be approx 4.40 V.

If not, first ensure that the phone is in the CDMA Troubleshooting Mode. Check the

VRXD_R supply voltage at pin 4 of V206, or CDCONT (N201), pin 15, or C223. It

should be approximately 4.50 V.

•Measure the voltage drop across R17 at the RX_IREF line, (one probe on

either side of this resistor). The voltage drop should be approx 330 mV.

If not, first ensure that the phone is in the CDMA Troubleshooting Mode. Ensure that

the –75 dBm 881. 62 MHz CW signal is fed into the receiver. Perform the DC Voltage checks on that module to determine if there is a problem with the AGC circuitry.

Page 40

Original 11/97

Page 41

PAMS

NHD–4

Technical Documentation

•Check the voltage drop across R16 at the RX_ICT line, placing one probe

on either side of this resistor. The voltage drop should be approx 37 mV.

If not, first ensure that the phone is in the CDMA Troubleshooting Mode. Ensure that

the –75 dBm 881. 62 MHz CW signal is fed into the receiver. If fault is found then

continue with the remaining receiver DC Voltage checks. After doing so there is still

no problem, refer to the AGC Troubleshooting Manual. Perform the DC Voltage

checks on that module to determine if there is a problem with the AGC circuitry.

•Check the CDMA IF LNA V7 and V8

The voltage on the collector of V7, pin 1 should be approximately 1.38 V.

The voltage on the base of V7, pin 3 should be approximately 1.33 V.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Inspect V8, V7,

L5, R19, R20. Ensure that VRXDM is approximately 4.50 V at R21.

The voltage on the emitter of V7, pin 2 should be approximately .60 V.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Inspect V7, and

L6.

Disassembly & Troubleshooting

•Check the 1st IF gain stage V9

The voltage on the collector, pin 1 should be approximately 3.50 V.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Inspect V10,

V9, R22, R23, Z3. Ensure that VRXDM is approximately 4.50 V at R23

The voltage on the base, pin 3 should be approximately 1.85 V.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Inspect V9, V4,

L13, L11, R4, R5, R13, R14, R15, and R24. Ensure VRXDM is about 4.50 V at R21.

See that VRXM is at about 4.40 V at R13, and VRXAM is about 1.15 V at R14

The voltage on the emitter, pins 2 and 4 should be approximately 1.12 V.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Inspect V9,

L14, R25, and R28.

•Check the LNA, V12

The voltage on the collector should be approximately 3.90 V

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Ensure VRXM

is at about 4.40 V at R833. Inspect V11, V12, L20, R33, R34, R38, and R833.

The voltage on the base should be 1.0 V

•Check the control voltages on the RF Gain Switches N701 and N702.

Pin 1 on both should be approximately 3.80 V.

Original 11/97

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Ensure VRXM

is at about 4.40 V at R833. Inspect V11, V12, L21, L22, R33, R35, and R833.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Ensure VRXM

is at about 4.40 V at R832. Inspect N701, N702, V1, V708, R775, R777, R779,

R781, R783, R803, R830, R831, and R832.

Page 41

Page 42

NHD–4

PAMS

Disassembly & Troubleshooting

•Check the SWAGC line at R830, should be logic level low, approx .0 V.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Ensure VRXM

is at about 4.40 V at R832. Inspect V708, R765 and R830. Ohm out line from R765

to the ASIC N704 pin 94.

•Check the RX_CAL line at R783. It should be logic level high, near 2.75 V.

If not, confirm that the phone is in the CDMA Troubleshooting Mode. Ensure VRXM

is at about 4.40 V at R832. Inspect V1, V708, R6, R765, R783, and R785. Ohm out

the RX_CAL line from pin 114 of the ASIC N704 to R785.

Chart of CDMA RX DC Node Voltages

The following chart summarizes the node voltages of the CDMA RX when

the phone is in the CDMA RX/TX Mode with a 881.62 MHz signal input of

–65 dBm, CW.

Node

BFILCT2 IC (N2), pin 4

BFILCT2 IC (N2), pin 8

CDAGCR IC (N1), pin 13

R17 – voltage drop across this resistor

R16 – voltage drop across this resistor

V7 – collector of CDMA IF LNA, pin 1

V7 – base of CDMA IF LNA, pin 3

V7 – emitter of CDMA IF LNA, pins 2, 4

V9 – collector of 1st IF amp, pin 1

V9 – base of 1st IF amp, pin 3

V9 – emitter of 1st IF amp, pins 2, 4

V12 – collector of LNA

V12 – base of LNA

RF Gain Switches N701 and N702. Pin 1

RF Gain Switches N701 and N702. Pin 8

SWAGC line at R830

RX_CAL line at R783

Technical Documentation

Voltage

(V)

3.10

3.05

4.40

0.33

0.037

1.33

1.38

0.60

3.50

1.85

1.12

3.90

1.00

3.80

0.00

0.00

2.75

Baseband Demodulation Check

If you have an oscilloscope available you may use it to do a visual check

on the demodulated baseband CDMA I or Q signal . With the phone

tuned to channel 384, feed a –75 dBm, 881.62 MHz unmodulated CW RF

signal into the receiver. Initiate the CDMA Troubleshooting Mode from

Service Software. Use a standard scope probe at C58, the RX_I signal.

It should appear as a fuzzy sine wave of approximately 190 mVpp. This

frequency will be approximately 100 kHz.

Page 42

Original 11/97

Page 43

PAMS

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

NHD–4

Technical Documentation

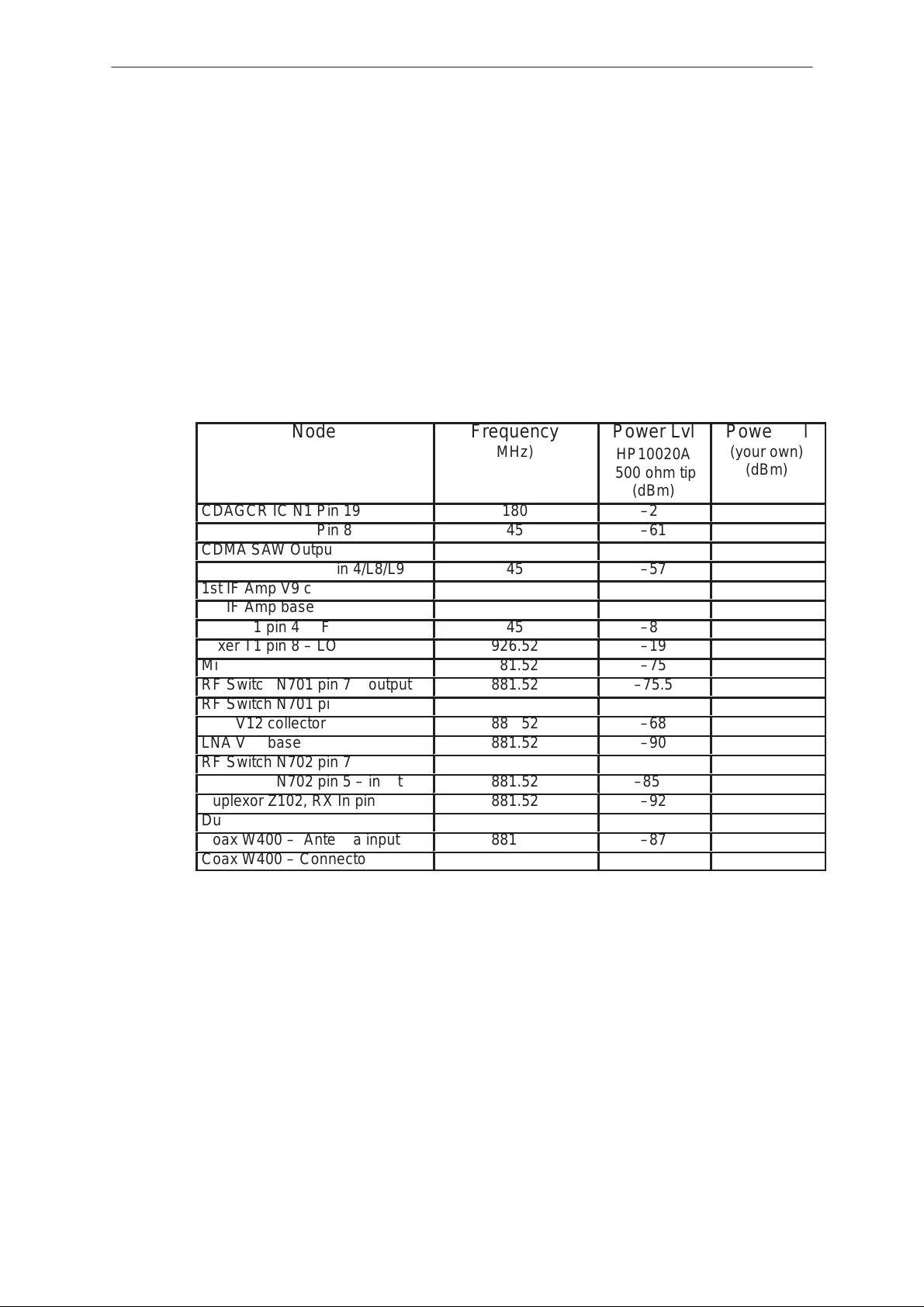

RF Node Powers – CDMA RX Mode

A high impedance passive RF probe may be used with a spectrum

analyzer to obtain the RF nodal power levels along the receiver chain.

The following levels assume the above probe and a –65 dBm, 881.52

MHz, unmodulated tone input into the receiver. Maintain a 1.0 MHz span

on the spectrum analyzer. A CDMA test box with spectrum analyzer

capabilities will do.

The RF power levels published below were found with a passive probe

with the 500 ohm tip. The blank column is reserved for values the user

will obtain with their own probe.

БББББББББ

БББББББББ

БББББББББ

CDAGCR IC N1 Pin 19

CDAGCR IC N1 Pin 8

CDMA SAW Output L6/L7/C63

Diode Switch V10 pin 4/L8/L9

1st IF Amp V9 collector, pin 1

1st IF Amp base, pin 3

Mixer T1 pin 4 – IF

Mixer T1 pin 8 – LO

Mixer T1 pin 5 – RF

RF Switch N701 pin 7 – output

RF Switch N701 pin 5 – input

LNA V12 collector

LNA V12 base

RF Switch N702 pin 7 – output

RF Switch N702 pin 5 – input

Duplexor Z102, RX In pin

Duplexor Z102, ANT pin

Coax W400 – Antenna input

Coax W400 – Connector input

Node

ББББББ

ББББББ

ББББББ

Frequency

MHz)

180

45

45

45

45

45

45

926.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

881.52

Disassembly & Troubleshooting

Power Lvl

ÁÁÁ

HP10020A

ÁÁÁ

500 ohm tip

(dBm)

ÁÁÁ

–24

–61

–88

–57

–57

–80

–80

–19

–75

–75.5

–75.5

–68

–90

–85.5

–85.5

–92

–89

–87

–88

Power Lvl

ÁÁÁÁ

(your own)

(dBm)

ÁÁÁÁ

ÁÁÁÁ

Original 11/97

Page 43

Page 44

NHD–4

PAMS

Disassembly & Troubleshooting

Hints and Suggestions

AMPS

•It is important to NOT adjust the tunable inductor L17. Doing so will

NOT assist in troubleshooting a faulty receiver, it will only make

things worse. This device is tuned by its manufacturer to the proper

inductance.

•While in AMPS Troubleshooting Mode, probe the 455 kHz ceramic filter

Z4. A noise pedastle approximatly 20 kHz wide will be visible about 10

dBm above the noise floor.

CDMA

•To determine in the CDAGCR IC (N1) quadrature demodulator is

functioning, connect both the RX_I and RX_Q to CH1 and CH2 of

oscilloscope. Put the scope in X–Y mode. A Lissajous pattern of a circle

should be displayed. Changing the received signal power should not

cause the size of the circle to change.

Technical Documentation

Page 44

Original 11/97

Page 45

PAMS

NHD–4

Technical Documentation

Disassembly & Troubleshooting

Synthesizer Troubleshooting

Introduction

Troubleshooting the synthesizer is difficult because the oscillations that it

produces cannot be measured at the output of the phone. The RF signals

it generates are routed to various portions of the phone. Assuming the

receiver and transmitter are functional, indirect means of determining the

health of the synthesizer can be used. Both the transmitter and receiver

depend on the synthesizers to operate. If one of the two synthesizers is

not working it is most certain that a problem will show up in either the

transmitter, receiver, or both. The Service Software RF quick checks are

great tools for initial testing. Beyond that there are a few quick DC

voltages that can be used to quickly assess the health of the phone. If all

else fails, RF node power levels can be read.

Quick Check with Service Software – Transmitter Approach

The fastest way to determine if both synthesizers are working is to turn on

the AMPS transmitter. This can be done from Service Software from the

AMPS/Baseband test menu. The unmodulated transmit signal can then

be viewed with a spectrum analyzer or CDMA test box. This test requires

that the AMPS transmitter be functional. If the transmitter is faulty the

receiver may also be used as a means to test the synthesizer.

To set up this test, connect the RF output of the phone to a spectrum

analyzer or CDMA test box using the bottom connector. If the CDMA test

box is used it is best to make use of the spectrum analyzer function if the

box used has one. If not, the AMPS TX test functions will work. Configure

the analyzer as such:

Center Frequency: 836.52 MHz (Channel 384)

Span: 20 MHz

Ref Level: 30 dBm

Turn on the AMPS transmitter from Service Software, setting the power

level to the lowest setting, level 7. Tune to channel 384. Initiating the

AMPS Troubleshooting mode also turns on the AMPS transmitter to

channel 384. Look at the AMPS transmit signal on the spectrum analyzer.

• If the signal is a strong (greater than –10 dBm) CW carrier locked to

836.52 MHz then both synthesizers are working properly. Change the

span of the analyzer to 100 kHz and ensure that the carrier is on

frequency to within 100 Hz.

• If a signal comes up but is slightly off frequency then the reference clock,

the VCTCXO (G300) is mistuned. Proceed to the section titled Testing

and Troubleshooting for Frequency Error.

Original 11/97

Page 45

Page 46

NHD–4

PAMS

Disassembly & Troubleshooting

Technical Documentation

• If the signal comes up, but is very much off frequency (more than a few

kHz) or is drifting around then the one or both of the PLLs is not locked.

Proceed to the section titled Testing and Troubleshooting for Synthesizer

Lock Error.

• If no signal is seen then it is possible that the transmitter is not working.

If the noise floor rose when you initiated the test, then it is likely that the

transmitter is working, but it has no signal to amplify. This would indicated

a faulty synthesizer. To rule out synthesizer error, proceed to the next

Service Software synthesizer test, the Receiver Approach. Performing the

DC Voltage Checks would also be advised.

Quick Check with Service Software – Receiver Approach

Another way to determine if both synthesizers are working is to test the

AMPS and CDMA receiver with a signal fed in. This can be done from

Service Software. Perform the CDMA RX RF Quick Test followed by the

AMPS RX RF Quick Test. These tests are found in the Service Software

Test menu.

• If the phone passes the CDMA RX RF Quick Test then both synthesizers

are working

• If the phone fails the CDMA RX RF Quick Test, but passes the AMPS RX

RF Quick Test, then the 180 MHz VHF synthesizer has failed, assuming

both the AMPS and CDMA receivers work. Proceed to the DC Voltage

Checks, VHF Synthesizer portion

• If the phone fails both RX RF Quick Tests then proceed to the DC

Voltage checks section.

DC Voltage Checks – AMPS Troubleshooting Mode

Put the phone into AMPS Troubleshooting Mode. This will turn both of the

synthesizers on. The following details the node voltages for the VCTCXO,

PLL IC, VHF and UHF portions of the synthesizer. Note that these node

voltages will change slightly when the phone is operating in CDMA mode.

VCTCXO (G300)

• Check the bias on pin 4. It should be near 3.60 V.

Page 46

If not, check R325, C303, and C334. Check VRXS at C207 near the CDCONT IC.

It should be approximately 4.40 V

Original 11/97

Page 47

PAMS

NHD–4

Technical Documentation

• Check the tune voltage on pin 1. It should be between 1.50 and 2.50 V.

If not, check R302, R301, and C302. Check the RX_SLOPE and AFC PDM lines.

Manually adjust them with the PDM controls within Service Software. Read the

RX_SLOPE PDM voltage at R700 and read the AFC PDM voltage at R701. While

tuned to channel 384 the RX_SLOPE PDM should be about 3.00 V. For channel 440

it should be 0.0 V. The AFC PDM will vary between 0.0 V and 3.00 V, generally near

the midrange of 1.50 V.

PLL IC (N301)

• Check the biasing on the PLL IC (N301). Pins 4 and 5 should have

approximately 3.15 V on them. Pin 18 should have about 4.40 V. Check

pin 19, AON, it should have about 2.80 V.

If not, check VRXS at C207 near the CDCONT IC. It should be approximately 4.40

V. Check the pin 14, Iset, for 1.25 V. Check VRX90 at C205 or R310. It should also

be approximately 4.40 V. Check R331, R307, R308, R310, R311, R807, R810 and

C337.

VHF Synthesizer

Disassembly & Troubleshooting

• Check the tune voltage at the cathode of V301. It should be stable at a

single voltage between 1.50 and 3.5 V.

If not, check to see that the 180 MHz oscillation is feeding back into the PLL IC at pin

15. Continue with the following two checks. Ensure that the varactor diode, V301 is

in the circuit correctly.

• Check the biasing of the buffer amp, V303.

The collector should be biased with 4.30 V.

The base should be biased with 3.30 V.

The emitter should be biased with 2.60 V.

If not, check VRX90 at R806 or at C205 near the CDCONT IC. It should be approximately 4.40 V. Inspect L303, R316, R318, R322, R323, R324, and R806. Also in-

spect C319, C321, C322, C323, C324, C328, C329, C330, C332, C333, and C340.

• Check the biasing on the oscillator transistor, V302.

The collector should be biased with 2.60 V.

The base should be biased with 2.30 V.