Page 1

Programmes After Market Services

WinTesla Users Guide

NHP–4

Issue 1 04/99

Page 2

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

Contents

Tesla for Windows Operating System 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing WinTesla On Your Hard Disk 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using The Windows Interface 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common User Interface 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Connections 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Wintesla 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Independence 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Login ID Setup 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Login Screen 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The WinTesla Screen 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Product Menu 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No

The Configure Menu 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Log Application. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HD891 Module 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the HD891 Service Module 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Servicing Equipment 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer Setups 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning Steps of Radio Unit 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accuracy of the Equipment During Measurement 26. . . . . . . . . . . . . . . . . .

Baseband Alignment and Flash Station Tests 26. . . . . . . . . . . . . . . . . . . . . . . .

Flash Programming 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Factory Value Set 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Voltage Tuning 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charger Voltage Tuning 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Temperature Tuning 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Tuning and Testing 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA Bias Quiescent Current Test 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC Tuning 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX AGC Tuning and Dynamic Range Check 30. . . . . . . . . . . . . . . . . . . . . .

TX Gain Check 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX IF AGC Tuning and Dynamic Range Check 31. . . . . . . . . . . . . . . . . . . .

Page 2

Issue 1 04/99

Page 3

PAMS

WinTesla Users Guide

Technical Documentation

TX Limiting, TX Emissions, and Frequency Compensation 32. . . . . . . . . .

Open–Loop AGC Alignment 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADC Readings 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Division Modulator (PDM) Control 35. . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA Testing 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA RX Quick Test 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA RX Gain Control 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Phone 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Limiting 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA TX Gain Control 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDMA AGC Quick Test 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Menu 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flashing 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NHP–4

Dialog Options 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialize EEPROM 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer Menu 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NAM Programming 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Code Memory (SCM) 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SID Programming 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calling Cards 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Authentication Key (A–Key) Programming 46. . . . . . . . . . . . . . . . . . . . . . . .

User Data Transfer 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Factory Values 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPC code change 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View Menu 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Identity 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Parameters 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Problems 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up the computer Hardware 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Errors 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Support 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Issue 1 04/99

Page 3

Page 4

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

List of Figures

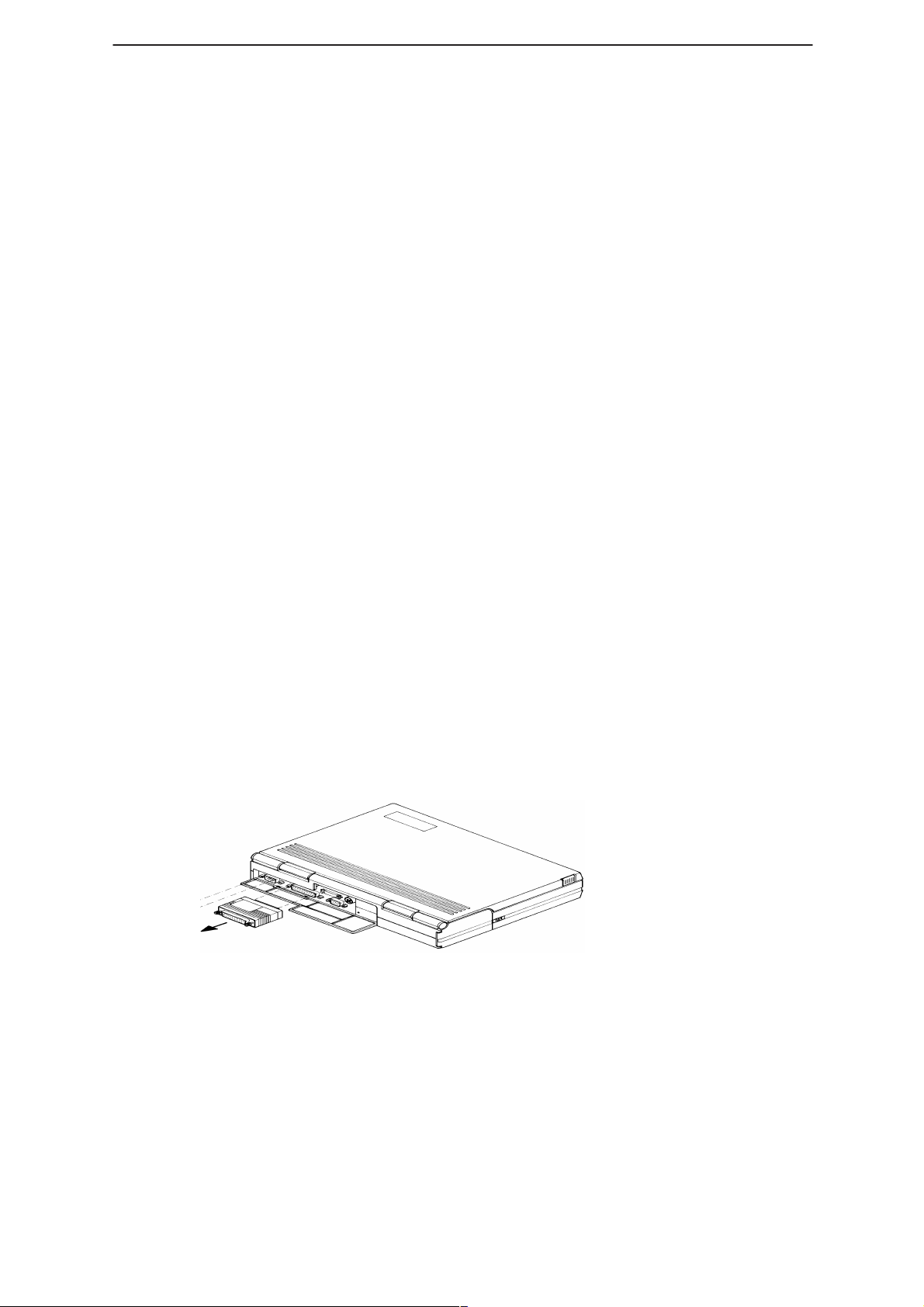

Figure 1. Dongle Insertion 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

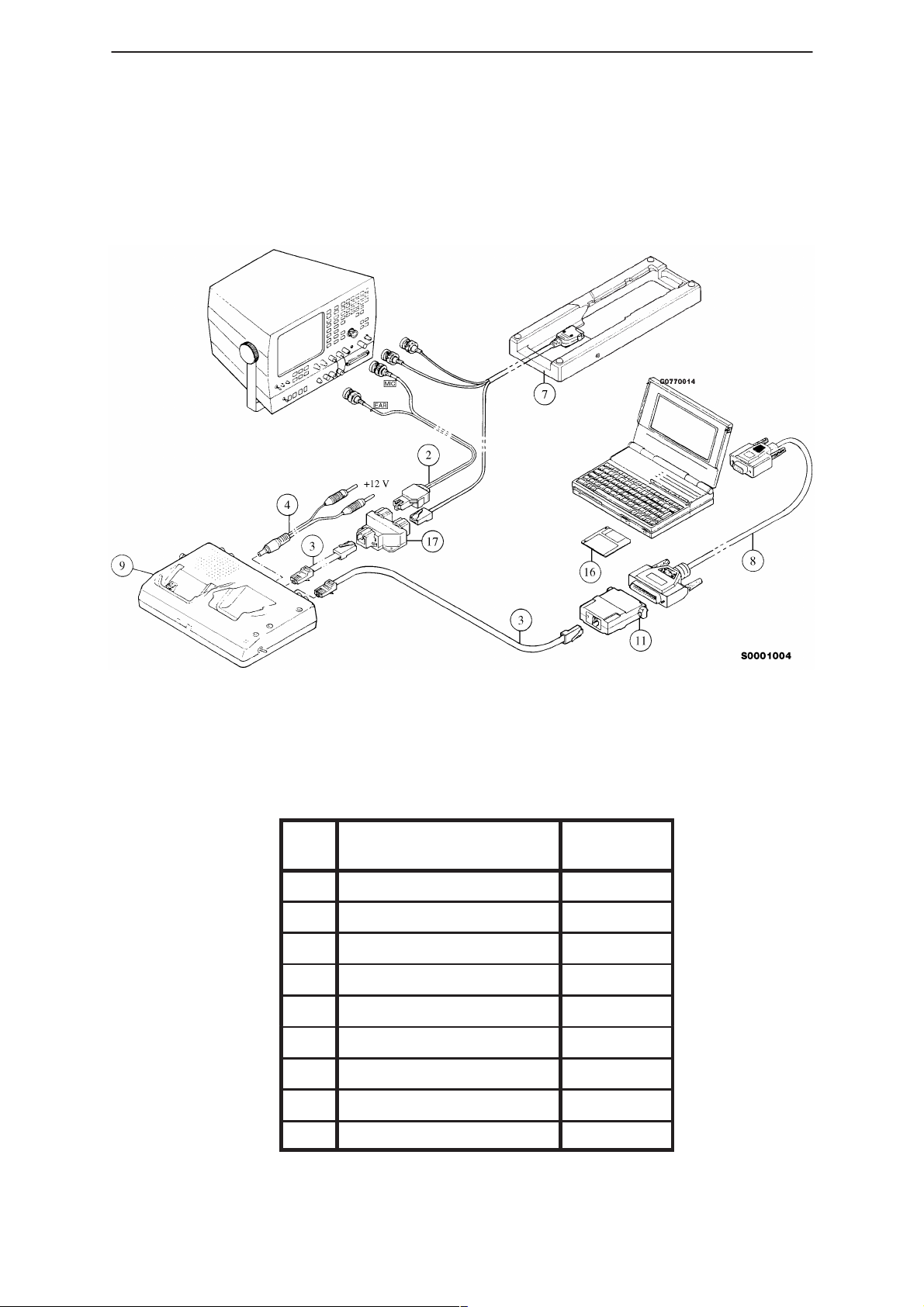

Figure 2. Servicing setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

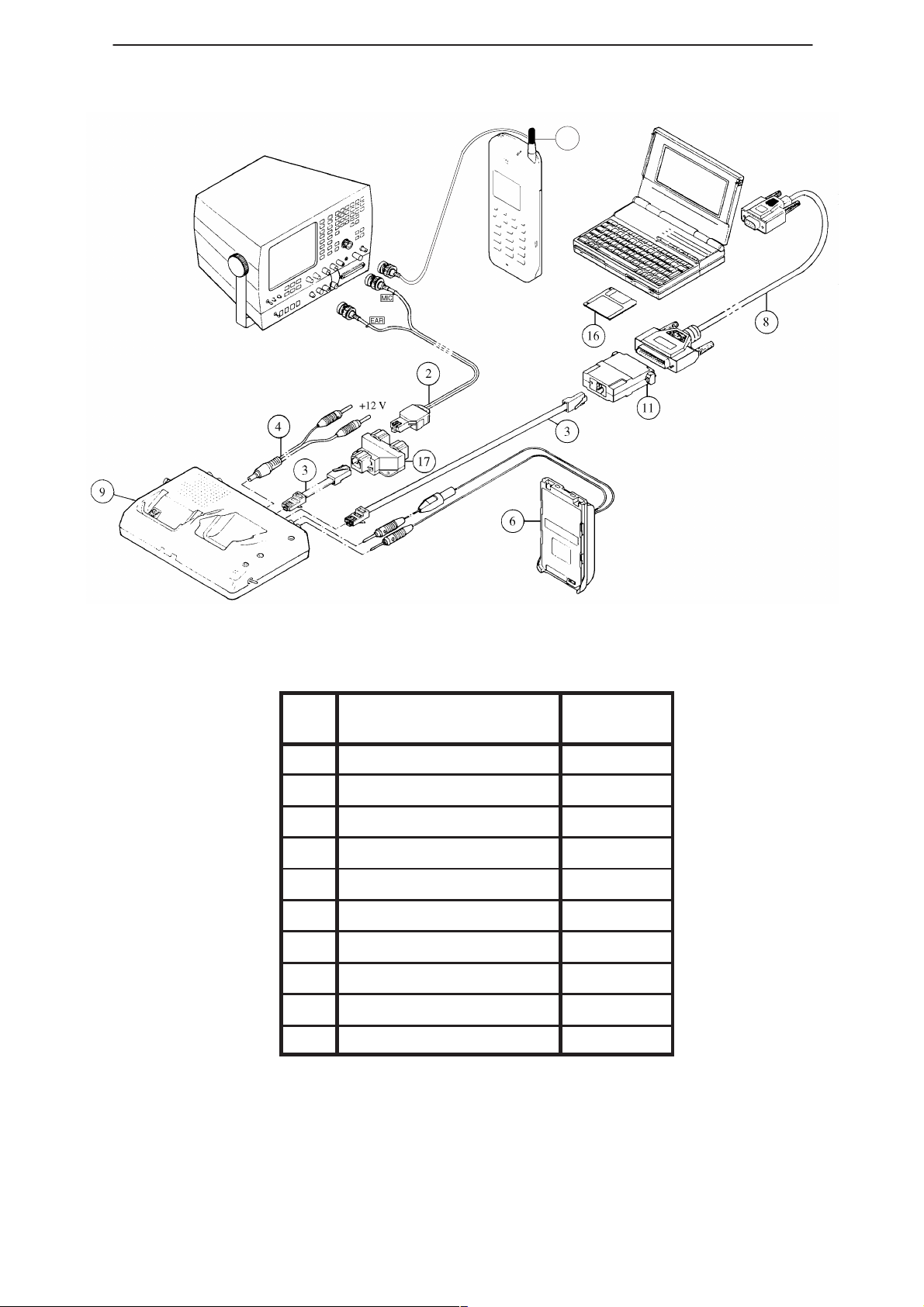

Figure 3. Flash setup 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

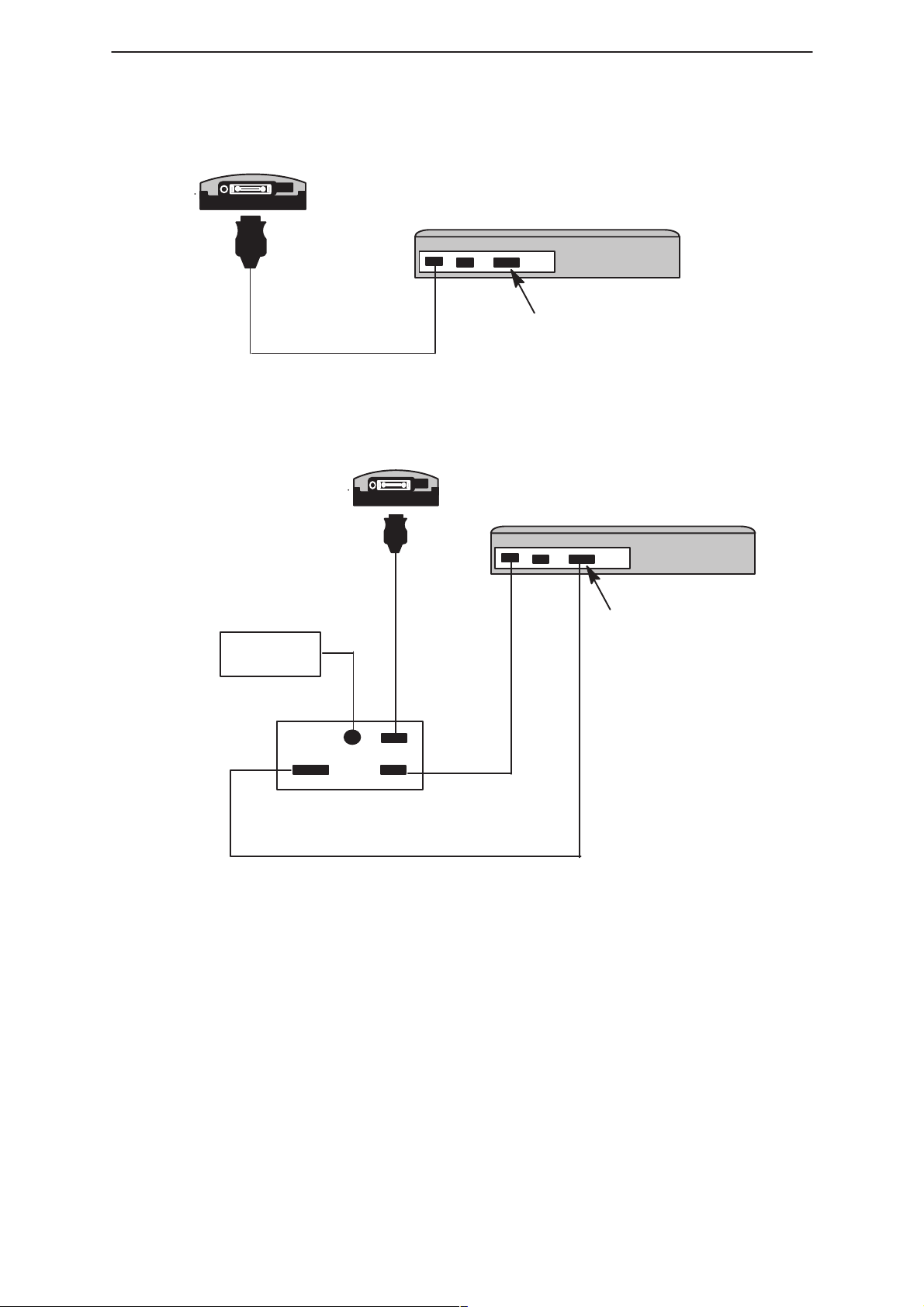

Figure 4. WinTesla with loaded interfaces 8. . . . . . . . . . . . . . . . . . . . . . . . . .

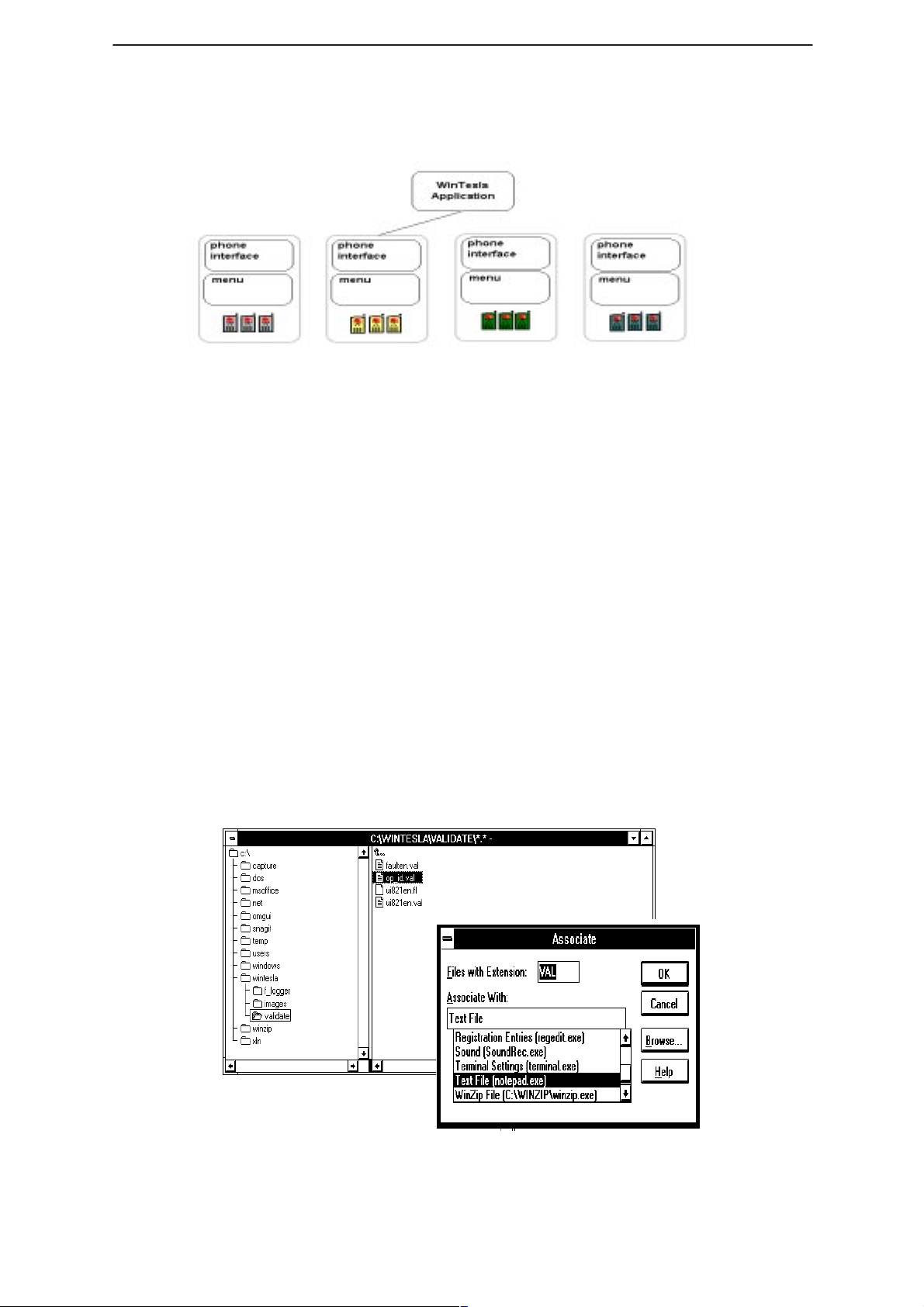

Figure 5. Accessing Op_ID. val file 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

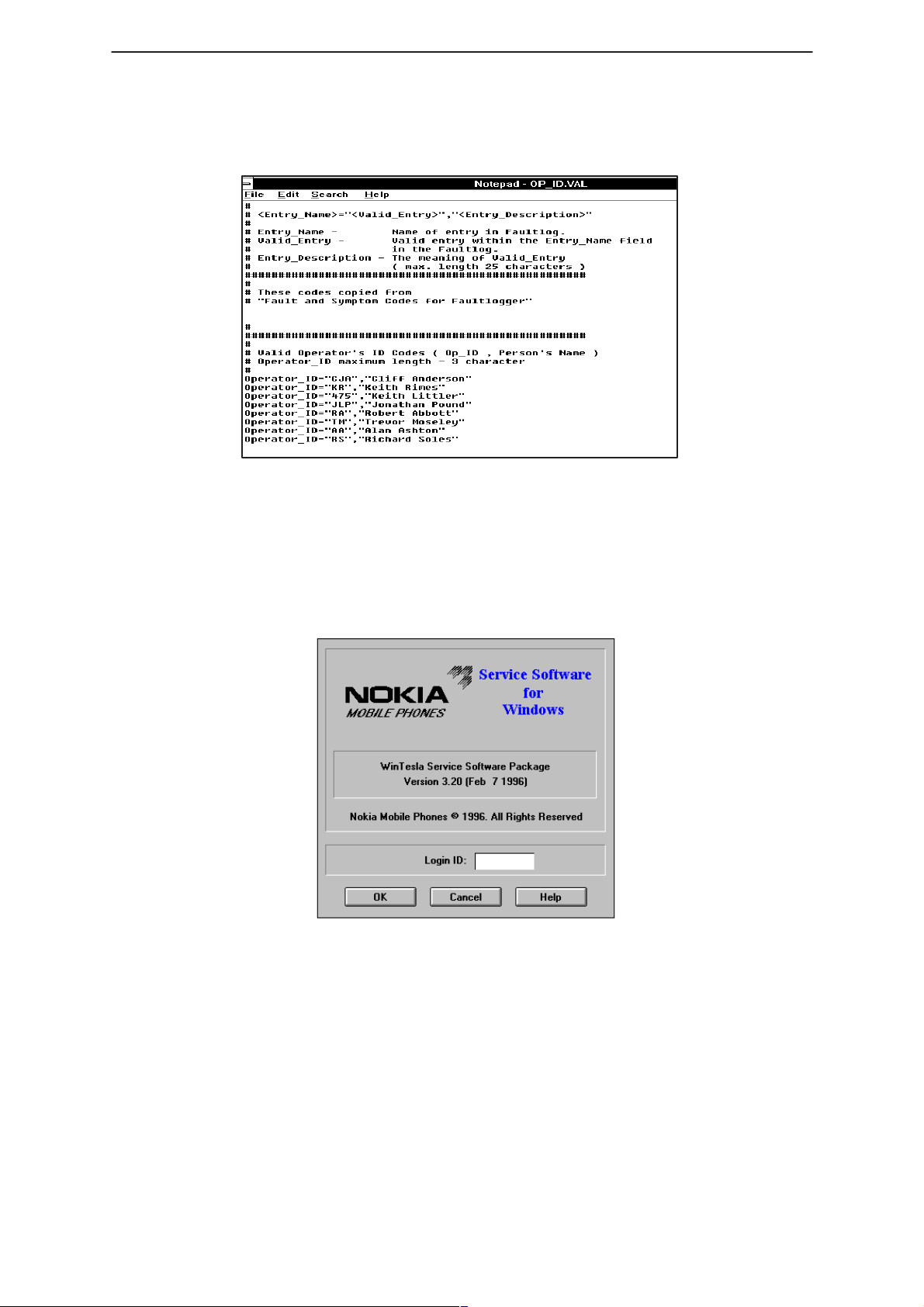

Figure 6. Editing Op_ID.val file 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7. Login Screen 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8. FaultLog – configuration 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9. Editing fault, symptoms, modules files 18. . . . . . . . . . . . . . . . . . . . .

Figure 10. FaultLog – macro setup 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11. Testing/Tuning with covers off 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 12. Testing/Tuning with covers on 24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No

Page 4

Issue 1 04/99

Page 5

PAMS

WinTesla Users Guide

Technical Documentation

Tesla for Windows Operating System

The name TESLA, when used by Nokia, is an acronym for TEst and

Service Locals Application. Tesla for WIndows (i.e. WinTesla) is a

software package designed to operate in the Microsoft Windows

environment. The software package is made of two modules, the

Wintesla core module and a service software module. The Wintesla

module is similar to an operating system for various service modules. In

this way many Nokia products can be serviced using one common

software package, running different service modules (in this case, for the

Nokia 2170).

Note: The Wintesla core module MUST be installed for ”any” service module to run.

Installing WinTesla On Your Hard Disk

The WinTesla core software is delivered on a 3.5” diskette and is

protected with a protection key (PKD–1, commonly referred as the

”dongle”) which must be attached to the parallel port LPT 1 when the

WinTesla service software is being used.

NHP–4

To install the WinTesla core software package, proceed as follows:

NOTE: For instructions on installing the HD891 service module (see Installing the

HD891 Service Module)

Insert the WinTesla Application diskette into drive A: of your PC.

From DOS ( NOT running windows ) type

A: INSTALL <Enter>

From Windows File Manager double click the mouse on

a:\install.exe

Follow the instructions given and use the

Repeat this procedure for the required module installation using the

upgrade

NOTE: For interim WinTesla releases use the upgrade option.

Your Windows desktop will now have a “Service Software” group and a

“Service Software” icon within that group.

To start the program, double click on the “Service Software” icon .

option instead of

(Windows will boot up automatically)

Or

new

.

Using The Windows Interface

new

option when requested.

If not familiar with the windows type interface, consult the

Windows User Guide

for further information.

Common User Interface

Due to the modular design of WinTesla, various generations of Nokia

products can be serviced, while sharing a similar user interface. The

common user interface is explained in the first part of this document and

is followed by the specific module information.

The software can be used to control the phone by entering commands via

the keyboard of a PC/AT – running MS Windows 3.1 or 3.11.

Issue 1 04/99

Microsoft

Page 5

Page 6

WinTesla Users Guide

PAMS

NHP–4

NOTE:

This document refers to WinTesla Version 4.60 or greater.

Windows 95 and Windows NT are not supported.

Equipment Required

Computer : IBM 486 PC/AT or compatible with at least

one, unused serial port, COM1 or COM2 one parallel port

(LPT1), 5 Meg. hard disk space required.

: Any supported by MS Windows version 3.1 or 3.11

Operating System : DOS 5.0 or later running MS Windows

3.1 or 3.11

WinTesla Application Software (product code

0774046)

Software Protection Key PKD–1 (product code –

0750018)

Technical Documentation

Mechanical Connections

The software controls the phone via a separate adapter (DAU–2)

connected to the serial port of the PC and to the phone’s bottom

connector using the Nokia proprietary communication method called

M2BUS.

Attach the protection key PKD–1 (dongle) to parallel port one (25–pin

female D–connector) of the PC. When connecting the PKD–1 to the

parallel port be sure that you insert the PC end of the PKD–1 to the PC

(male side).

Figure 1. Dongle Insertion

The PKD–1 should not affect devices working with it. If some errors do

occur try printing without the PKD–1 connected. If printing is now OK

please contact your supplier who will endeavor to replace your PKD–1.

Page 6

Issue 1 04/99

Page 7

PAMS

WinTesla Users Guide

Technical Documentation

DAU–2

NHP–4

COM1 COM2 LPT–1

PC

PKD–1

Figure 2. Servicing setup

Power

Supply

Power

FPS–3C

Using Wintesla

Phone Independence

COM1 COM2 LPT–1

PC

DAU–2

PKD–1 (connect to dongle)

Phone

SerialParallel

Figure 3. Flash setup

The WinTesla application, “WinTesla.exe”, is phone independent. It relies

on separate, phone specific, “modules” to provide communication, menus

and test algorithms.

Issue 1 04/99

Page 7

Page 8

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

Figure 4. WinTesla with loaded interfaces

For each phone type – or product family – a phone interface module and

menu module are required. The modularity of WinTesla allows support

for other languages, so one phone type may have one phone interface

module and several menu modules, all in different languages.

WinTesla allows you to select the language you wish to use (if available),

and will automatically load the correct phone interface module for the

connected phone. When a different phone type is connected, WinTesla

will load the new phone interface and associated menus.

Login ID Setup

Once the software has been installed you need to set up your own Login

ID (max. 3 characters). Start Windows file manager and locate the

validate\op_id.val

Figure 5.

Double clicking on the ‘

message, in order to avoid this use the

manager and link the file to the Notepad application as shown below.

(located in the Wintesla subdir) file as shown in

Op_ID.val’

file (a text file) gives a windows error

File |Associate command in file

Page 8

Figure 5. Accessing Op_ID. val file

Now by double clicking on the ‘

Op_ID.val

’, Notepad opens and your own

Issue 1 04/99

Page 9

PAMS

WinTesla Users Guide

Technical Documentation

ID can be entered and saved accordingly. Enter or edit any operator

definitions following the existing format in this file.

Enter your id here

NHP–4

Figure 6. Editing Op_ID.val file

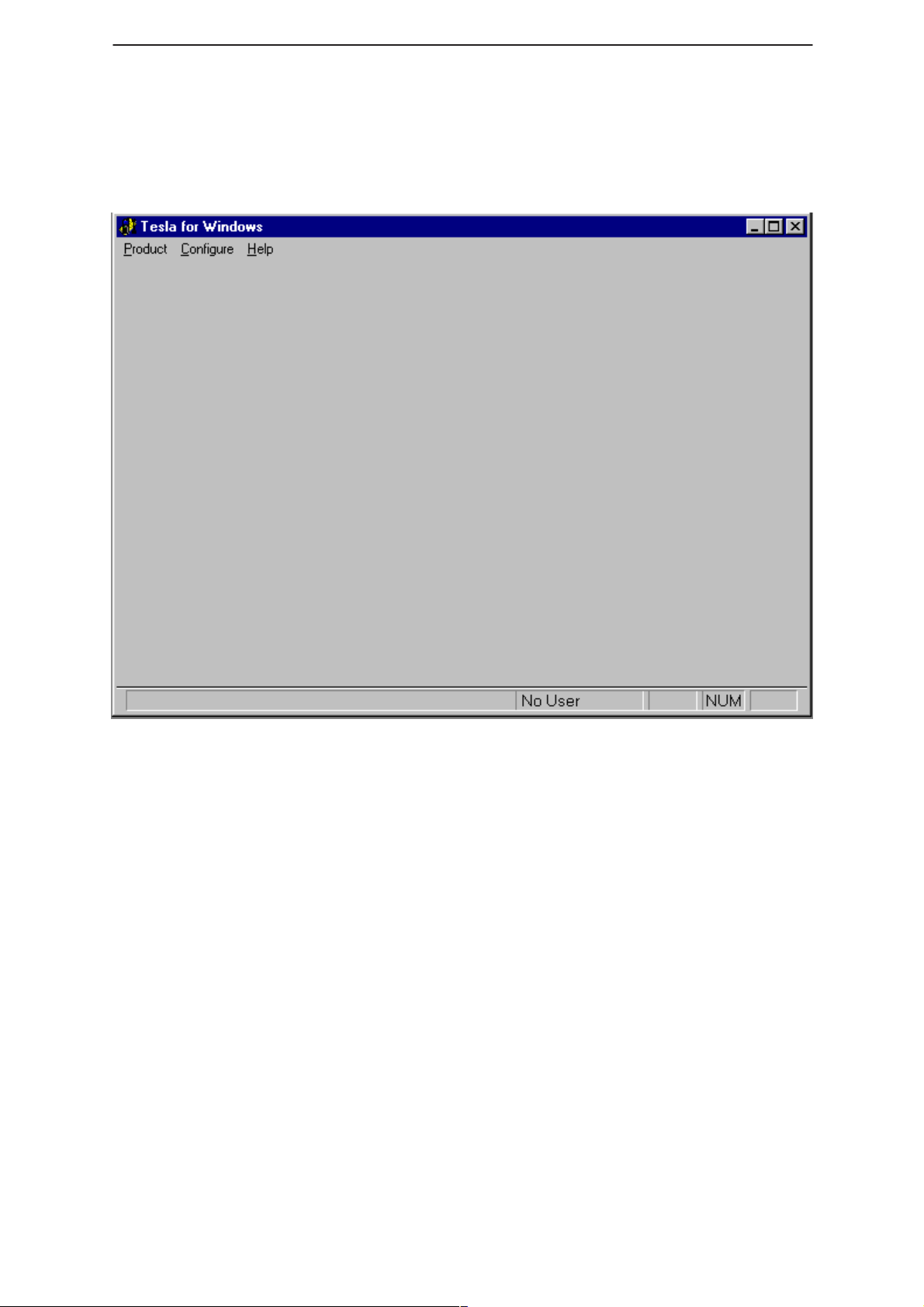

The Login Screen

When WinTesla first starts, the Login screen below will appear. Type in

your 3 character ID and press <Enter> or click on the ”OK” button.

If WinTesla can not find the file,

then the ”OK” button will be ‘greyed’.

Figure 7. Login Screen

op_id.val

, which contains the Login IDs,

If ”Cancel” is clicked then the Fault Logging feature of WinTesla will be

deactivated.

Issue 1 04/99

Page 9

Page 10

WinTesla Users Guide

PAMS

NHP–4

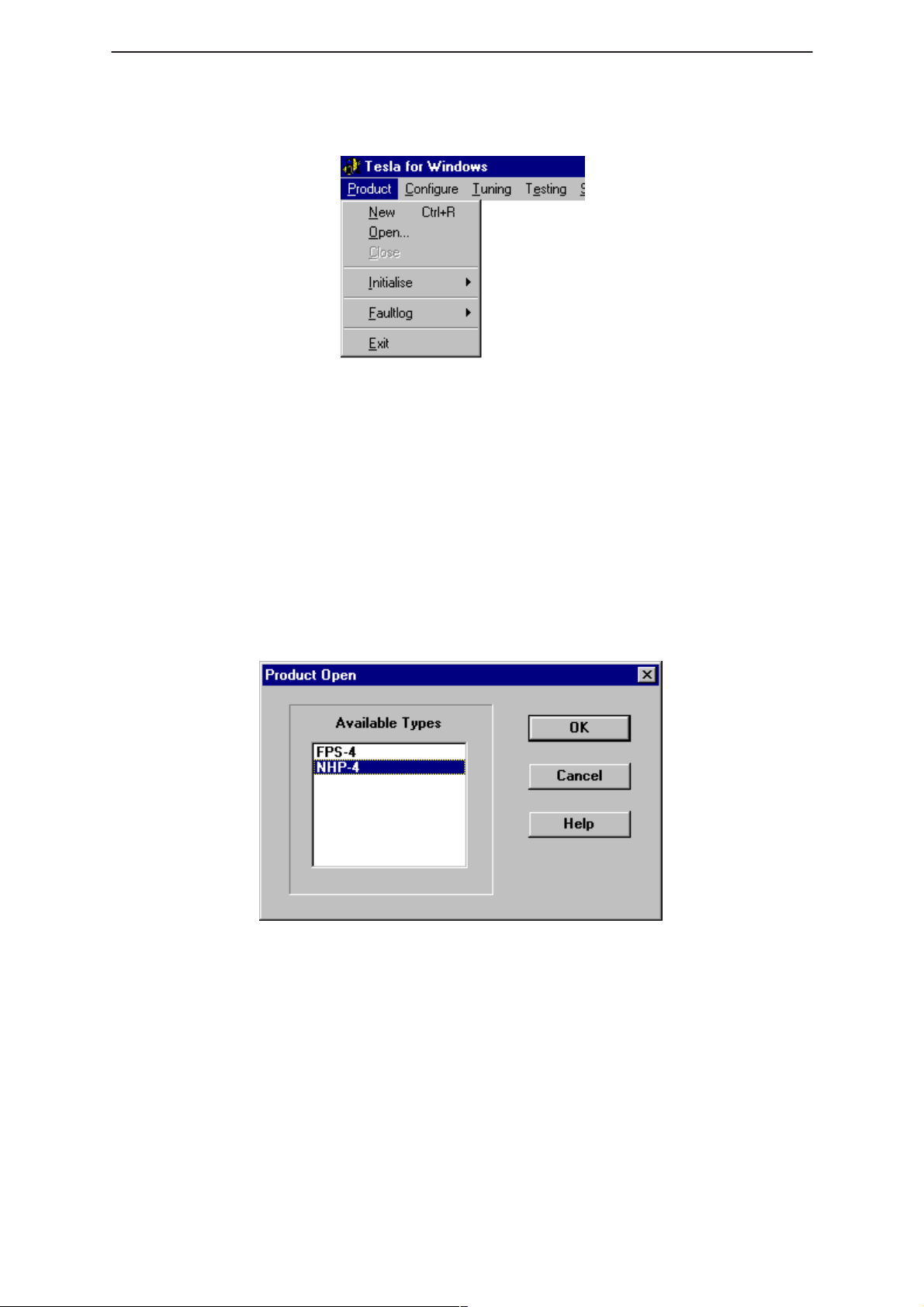

The WinTesla Screen

The main WinTesla screen – if no phone is attached – is displayed with 3

menu items at the top of the screen and a status bar at the bottom.

Technical Documentation

The information on the left of the status bar will be used to provide

information when WinTesla is performing tasks: such as reading data

from the phone. The status bar also includes the name of the current

user.

Page 10

Issue 1 04/99

Page 11

PAMS

WinTesla Users Guide

Technical Documentation

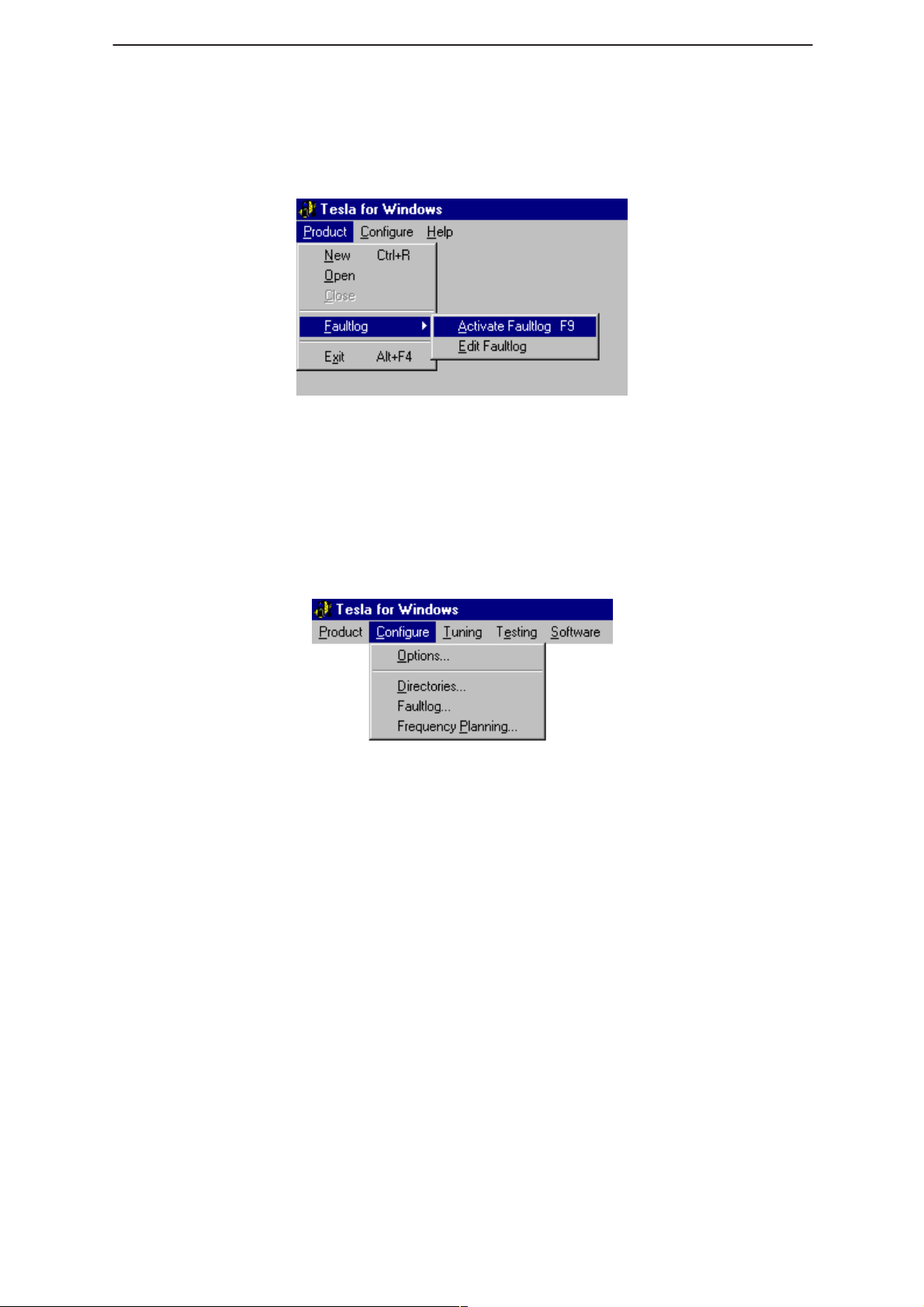

The Product Menu

New (Ctrl+R)

The ”New” function (which can also be activated by pressing <Ctrl+R>)

is used to scan for a phone when either the automatic rescan option is off

or the automatic rescan timer has not expired ( see

section for automatic rescan ).

NHP–4

Configure|Options

Open

If the phone type is unrecognized or unsupported by the current WinTesla

system then a warning message will be displayed.

The ”Open” function allows you to ”force load” a phone interface, even if

there is no phone connected to the system.

A dialog box will appear and list the supported phone types (see figure

above). To select a particular phone type to load; highlight the phone

type name and click on ”OK”.

Clicking on ”Cancel” will stop the request and no new phone type will

be loaded.

Loading a phone interface will disable the automatic rescan function (see

Configure|Options section for automatic rescan).

Close

This function will close the currently loaded phone type interface that had

been loaded using the

phone type interface if it was loaded by a rescan.

Issue 1 04/99

Product|Open function. You can not close a loaded

Page 11

Page 12

WinTesla Users Guide

PAMS

NHP–4

FaultLog

The FaultLog option has a sub–menu (below). These functions are

described in the ”FaultLog Application” section.

If the FaultLog function has been disabled – either because the Login ID

was not correct or disabled through the Configure|FaultLog function – then

these menus will be ”greyed” and made un–selectable.

Exit (Alt+F4)

Technical Documentation

Selecting this option will shut–down the WinTesla program.

The Configure Menu

The configuration menu allows you to setup such things as directory

paths, user interface language and FaultLog options.

Page 12

Issue 1 04/99

Page 13

PAMS

WinTesla Users Guide

Technical Documentation

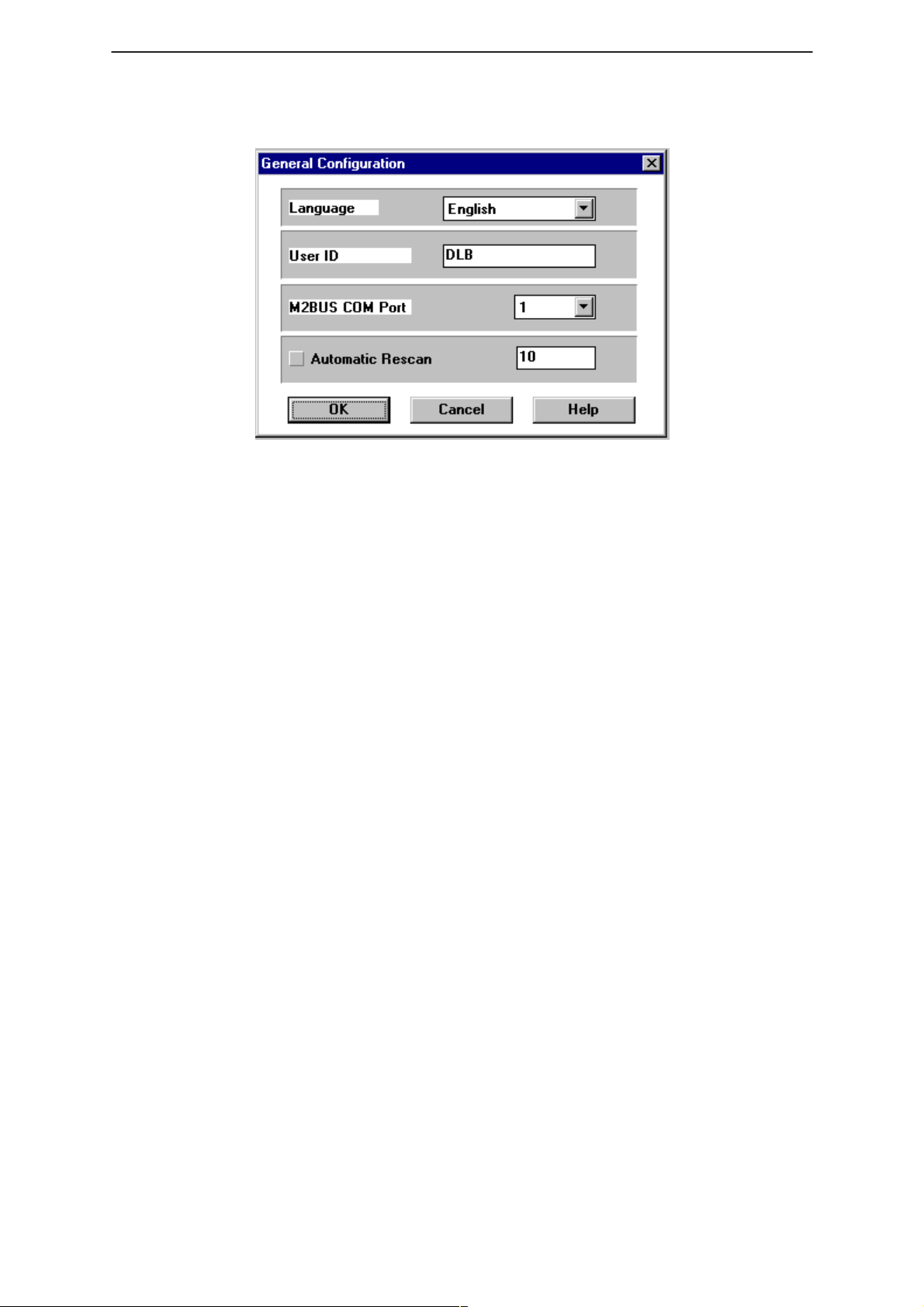

Options

Language

This option allows you to change the language used in the WinTesla

application.

NHP–4

Current Password / New Password / Retype Password

Currently not available

User ID

Allows the user ID to be entered if the users name is setup in the

opt_id.val (validation) file.

M2BUS COM Port

This option allows you to select which communications port the phone is

to be connected. The change will take place immediately after clicking

”OK”.

Automatic Rescan

Automatic rescan is a mechanism to automatically check for a new

phone; the time between rescans is user configurable. When a phone is

scanned and recognized, the corresponding phone interface and menu

are loaded, extending the main menu at the top of the screen and

displaying the phone type and description at the bottom of the screen.

Product|New (or Ctrl+R ) function can be used to rescan the phone

The

in–between automatic rescans or when automatic rescan has been

disabled. The automatic rescan mechanism is disabled when the

Product|Open function is used to load a phone interface.

A tick in the check–box indicates that the automatic rescan option has

been enabled. Clicking on the check–box (making the check–box blank)

will disable the automatic rescan option. The time between rescans (in

seconds) is entered into the edit box.

Clicking the ”OK” button will save any changes made. Clicking

”Cancel” will discard any changes you may have made.

Issue 1 04/99

Page 13

Page 14

WinTesla Users Guide

PAMS

NHP–4

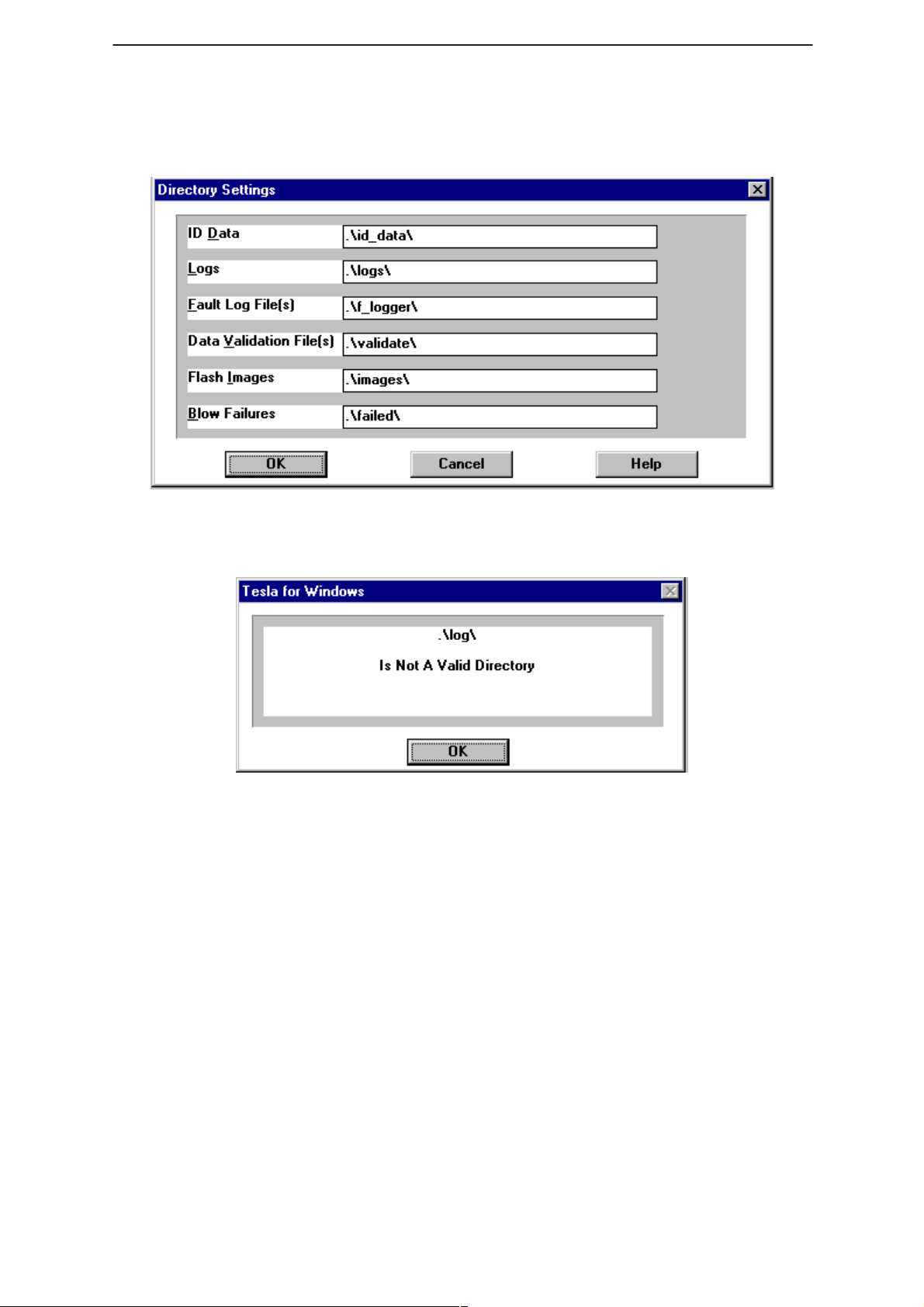

Directories

Technical Documentation

This function allows you to organize your data into different directories.

The directories must already exist. If an invalid directory is entered then

an error message will be displayed (below).

The use of a backslash (”\”) at the end of the directory name is optional.

Clicking on the ”OK” button will save your changes.

Page 14

Issue 1 04/99

Page 15

PAMS

WinTesla Users Guide

Technical Documentation

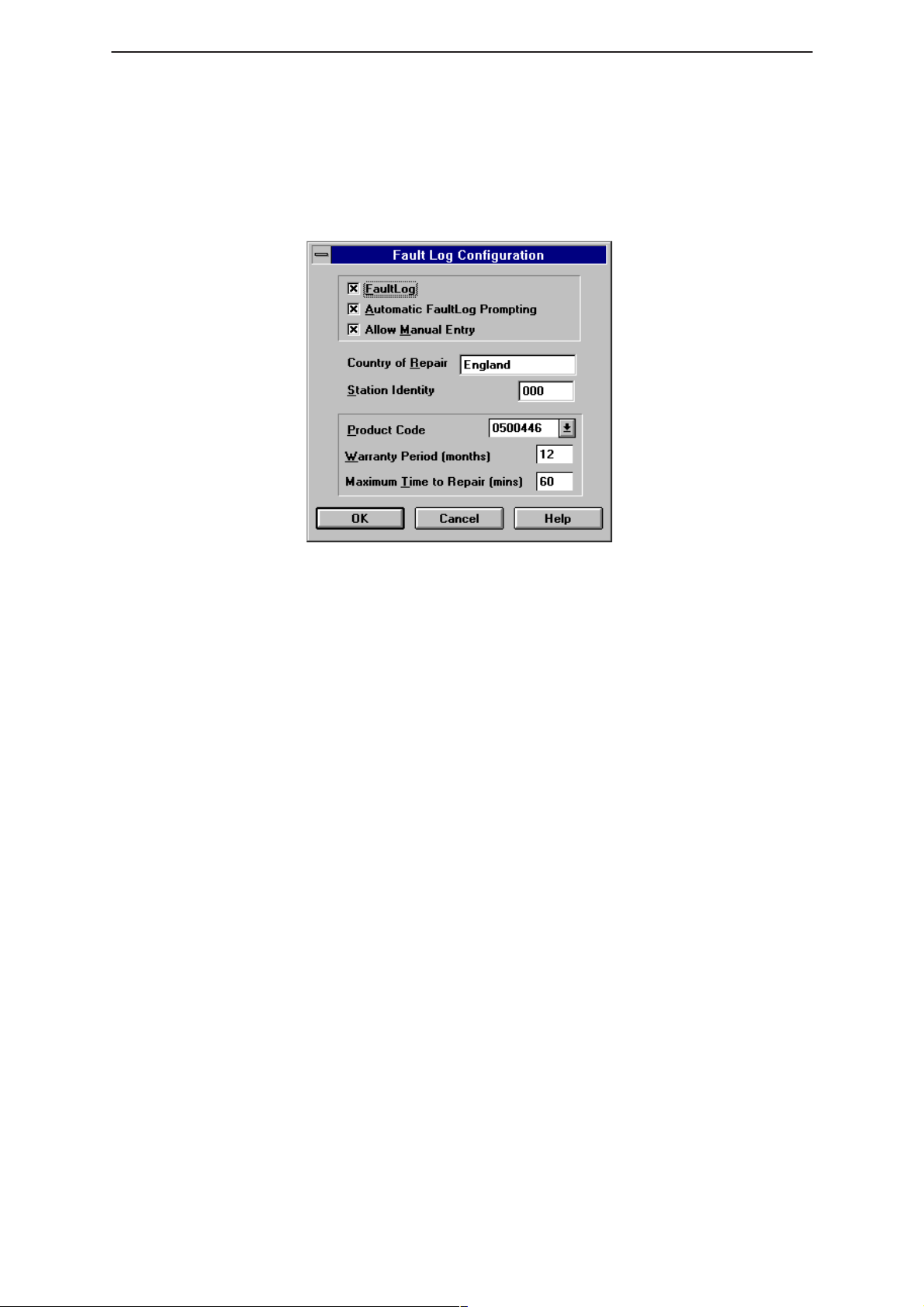

Fault Log Configuration

Fault Log is a feature that allows the PC to create a record of each phone

that is serviced for historical tracking. This function allows you to

configure the FaultLog mechanism. Clicking ”OK” after making

selections, saves all changes made.

NHP–4

Figure 8. FaultLog – configuration

Fault Log

This option allows you to enable or disable the FaultLog mechanism.

Choosing to disable the FaultLog mechanism results in the

|FaultLog options being ”greyed” and the F9 button being disabled.

Product

Allow Manual Entry

This option allows you to disable manual entry of data that was

unavailable from the phone.

Automatic Fault Log Prompting

Enabling this option results in a prompt being displayed if the phone has

changed.

Station Identity

Enter the unique identity of your ”workstation”; this ID is used to write

FaultLog files.

Country Of Repair

Enter the country of repair.

Warranty Period ( months )

Each product code has an associated warranty period. This option allows

you to change those warranty periods. If no phone is connected then all

product codes supported will be displayed. However, if a phone is

connected then only the product codes associated with that phone type

are displayed.

Note: Changing the Warranty Period in the Fault Log data file has no affect on the

products warranty terms as stated from the manufacturer.

Maximum Time To Repair ( minutes )

Enter the maximum time allowed to repair a phone.

Issue 1 04/99

Page 15

Page 16

WinTesla Users Guide

PAMS

NHP–4

Fault Log Application.

The aim of the Fault Log application is to provide NMP After Sales

Companies worldwide a standard method for the collection of Fault and

Repair Data from their service process’s. This information can also be

used by NMP R&D and Manufacturing organizations as well.

The Fault Log application can be regarded as a data entry sub–routine

run from the WinTesla Service Software package at the end of a repair.

This allows for quick and uniform recording of the service performed on

the product.

Each product repaired, will generate one unique record in a FaultLog file

consisting of up to 37 data fields containing information about the product

and how it was repaired. This information is read automatically where

possible, from the products own internal EEPROM and then entered

manually by the Service Technician to form a complete service record.

For more advanced implementations, the repair records are copied and

collected by the electronic mail system installed in the Service Center and

are sent electronically to a Central Service Database located in

Finland.Completing a FaultLog Record

Technical Documentation

Once WinTesla has been configured correctly it operates in the following

manner:–

Wintesla automatically reads the product details from the

products EEPROM and writes them as a record to a

pre–determined file.

Proceed with the repair task, utilising a combination of

software driven tuning and hardware modifications.

On completion of the repair task you have a choice:

A.)With the product still connected to the PC, manually display

the repair data entry screen by selecting Function Button F9.

Page 16

Issue 1 04/99

Page 17

PAMS

WinTesla Users Guide

Technical Documentation

B.) Alternatively, the product can be disconnected and the next

product for repair connected in its place.

So long as Automatic Prompting is enabled then the previous products

repair data entry screen will be displayed.

– Enter the repair work performed on the product in the repair

– Check the automatic data for this product, read earlier, to

– When satisfied with the data, save the entry. This process

The output file can then be manipulated by a number of different systems,

as required, as a detailed record of the product fault.

To attempt to record all of this information 37 data fields are defined for

each FaultLog record. These can be split as follows:–

– Product definition information fields

Most products have their information stored in EEPROM, WinTesla

automatically reads this information from the EEPROM and writes it to the

FaultLog record. This part of the record is shown below.

NHP–4

data screen.

ensure its accuracy.

adds a complete record containing the product details and

the repair details to the FaultLog output file.

Fields that are ”greyed out” etc. are data that has been automatically

retrieved from the phone’s EEPROM. All other fields are entered

manually; fields are summarized below.

Operator

Automatic: Station, Country

Manual :

Phone

Automatic: Product code, Production SN, Order No., Hardware

ID, Software version, Mfr. SN/ESN/IMEI, Mfr. Date,

Manual:

Issue 1 04/99

Time to repair, Job ID, Operator ID

Issue date

Warranty

Page 17

Page 18

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

Fault

Automatic: none

Manual

Module, Fault, Symptom, Circuit ref., Part Number

The current FaultLog application allows for the entering of three priority

levels of fault / repair information seen as

Tertiary

The

faults.

Module, Fault

and

Symptom

fields have variables selected by the

Primary, Secondary

and

arrows alongside each respective field.

A comprehensive list of faults and symptoms as well as all current

modules are already listed within the software. These three fields can be

updated by accessing and editing the following files in a similar manner

as described on page 8

Field DOS File

–

Modules

–

Faults, Symptoms

nhd4en.val–

faulten.val

Notepad – FAULTEN.VAL

Notepad – UI821EN.VAL

Page 18

Figure 9. Editing fault, symptoms, modules files

Issue 1 04/99

Page 19

PAMS

WinTesla Users Guide

Technical Documentation

Other Parts Replaced

Automatic none

Manual all fields

Enter other parts that have been replaced i.e. for wear and tear purposes

etc..

This Entry

Automatic ; Entry Indicator, Date, Time

Manual ;

Cost

Automatic ; Total

Manual ;

This facility is for the use of third party repairers only

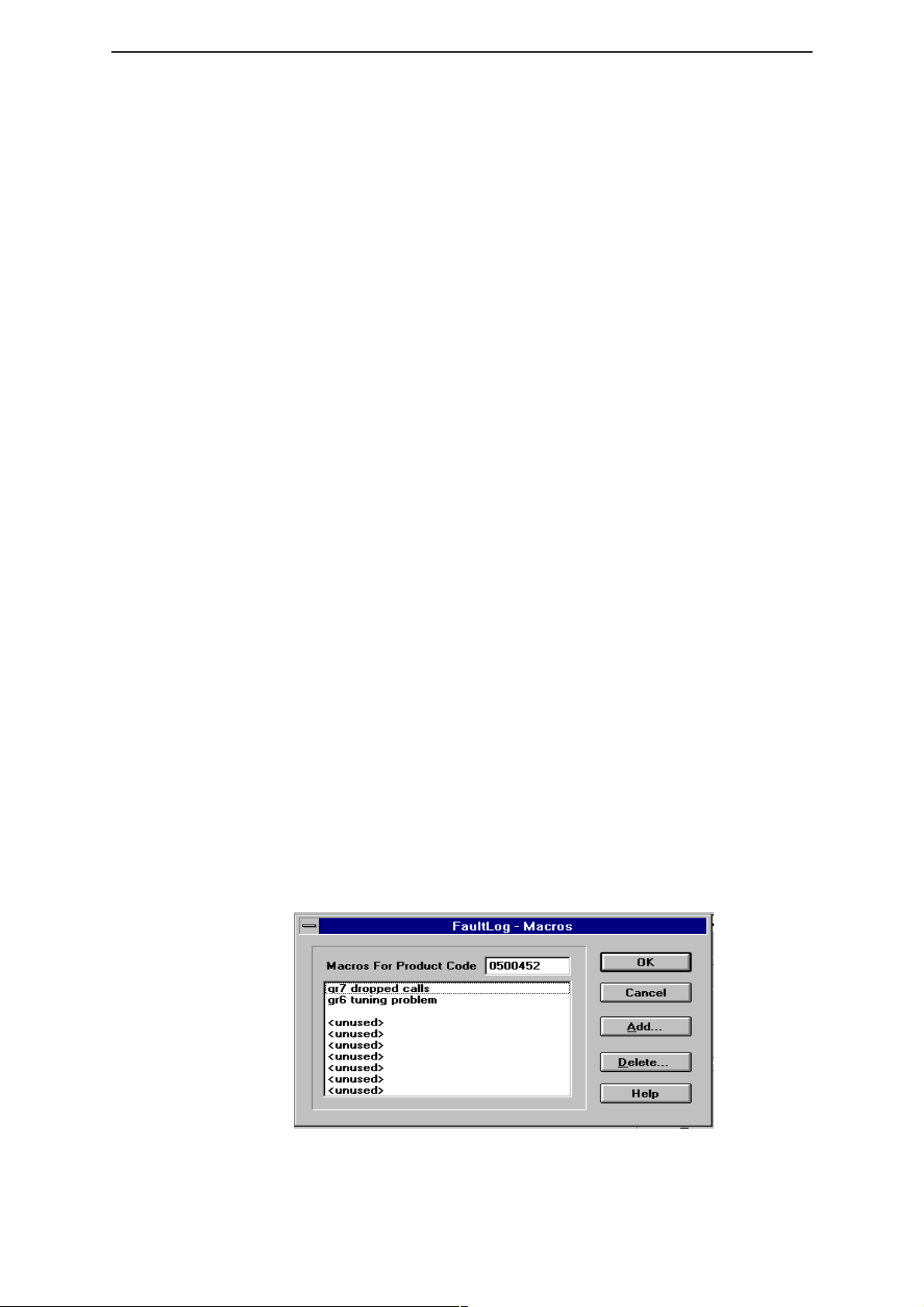

FaultLog Macros

The Macro sub–menu can be accessed by selecting the ”Macros”

button on the FaultLog main screen.

NHP–4

Comment

Parts, Labour

Macros in FaultLog are a set of standard repair actions defined and

stored in order to represent frequently repeated repairs. These Macro’s

are related to the Product Code of the product, so whatever product is

connected, FaultLog will display the Macro list for that particular Product

Code.

A Macro’s standard repair information can also be pasted into the

FaultLog record for that product.

Macro’s are saved initially under a name you can define yourself from the

main FaultLog screen. All the information contained in the manually

entered fields i.e. Module, Fault, Symptom, Circuit Ref and Part Number

is recorded and saved under this name.

Setting up a macro

After completing a manual entry as normal but before saving the

record, select the ”Macros” button. This will bring you into the

Macro definition screen.

Issue 1 04/99

Figure 10. FaultLog – macro setup

Page 19

Page 20

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

Place the cursor over the next available Macro entry then select

”Add”.

Give the Macro record a meaningful name and click on ”OK”. You

have now saved the repair data into a Macro for future use.

Use the ”Delete” function to remove unwanted macros.

Now, when a similar problem is seen with another unit you can recall this

saved repair information into the units FaultLog record. If needed, the

FaultLog record can be edited after being recalled to customize the repair

before saving the FaultLog record.

There are a maximum of 10 Macro’s definable for each Product Code. If

an eleventh is required, it will be necessary to overwrite one of the

previous Macro’s.

The Macro definition file is called

specified for the data validation files. If this path is a networked path all

operators connected to the network will be permitted to share a common

Macro list helping with reporting uniformity.

macro.fl

and will be found in the path

Help

An extensive help facility is available by clicking any screen or toolbar

help button and features convenient hypertext linking for easy navigation.

HD891 Module

Information in this section is specific to the HD891 module and assumes

that the setup procedures in the common interface section have been

carried out.

Installing the HD891 Service Module

The HD891 Service module software is delivered on a 3.5” diskette and

must be run under the Wintesla core software package.

To install the HD891 Service Module software, proceed as follows:

Insert the HD891 Service Module diskette into drive A: of your PC.

From Windows File Manager select the file a:\install.exe and click

”OK”.

Page 20

new

Follow the on screen instructions and select the

prompted to do so.

WARNING: The service module requires the Wintesla core software application to be

installed first for this module to function.

NOTE: Be sure to install the Service Module in the same directory as the Wintesla

core software application.

install option when

Issue 1 04/99

Page 21

PAMS

WinTesla Users Guide

Technical Documentation

Required Servicing Equipment

The following is a list of equipment that is needed in order to service the

HD891 family of products.

HD891 Software Service Module (product code: 0774062)

Dongle ‘blackbox’ adapter DBA–1 (product code: 0630044)

M2BUS adapter DAU–2 (product code: 0750006)

RS–232 adapter, 9–to–25 pins (product code: 4626170)

RS–232 cable (product code: 0730090)

Centronics cable (product code: 0730029)

Service cable SCS –1 (product code: 0770010)

Service cable SCS–10 (product code: 0775059)

Audio cable ADS–1 (product code: 0730011)

Modular cable XCM–1 (product code: 4626131)

Flash Programmer Set FPS–3C (product code: 0770110)

NHP–4

Power connector PCS–1 (product code: 0730012)

Modular T Connector cable (product code: 4626134)

Dummy Battery BTS–4 (product code: 0770009)

Covers off Jig JBS–16 (product code: 0775039)

Service box JBS–7 (product code: 0770015)

Issue 1 04/99

Page 21

Page 22

WinTesla Users Guide

PAMS

NHP–4

Equipment Setup

Caution: Make sure that you have switched off the PC and the printer before making

connections !

Caution: Do not connect the PKD–1 key to the serial port. Y ou may damage your

PKD–1 !

Attach the protection key PKD–1 to parallel port one (25–pin female

D–connector) of the PC. When connecting the PKD–1 to the parallel port

be sure that you insert the PC end of the PKD–1 to the PC (male side). If

you use a printer on parallel port one, place the PKD–1 between the PC

and your printer cable.

Next connect the M2BUS adapter to the serial port (RS–232) of the

computer. In case you are using a 9–pin serial port (normal with an AT

set) use the mating adapter supplied with the M2BUS adapter.

Attach one end of the XCM–1 modular cable to the DAU–2 PC/M2BUS

adapter and the other end to the JBS–7 service box. Use suitable

adapter, SCS–1 service cable when the covers of the phone are in place,

JBS–8 test frame with the phone covers off, and attach it to the phone.

Then connect it to the service box.

Technical Documentation

Page 22

Issue 1 04/99

Page 23

PAMS

WinTesla Users Guide

Technical Documentation

Dealer Setups

NHP–4

Figure 11. Testing/Tuning with covers off

Item Description Product

Code

2 ADS–1 0730011

3 XCM–1 4626170

4 PCS–1 0730012

7 JBS–16 0775039

8 RS232 Adapter 4626170

9 JBS–7 0770015

11 DAU–2 0750006

16 Software diskette 0774062

17 Modular T connector 4626134

Issue 1 04/99

Page 23

Page 24

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

5

Figure 12. Testing/Tuning with covers on

Item Description Product

Code

2 ADS–1 0730011

3 XCM–1 4626170

4 PCS–1 0730012

5 TDA–1 0750086

6 BTS–4 0770009

8 RS232 Adapter 4626170

9 JBS–7 0770015

11 DAU–2 0750006

16 Software Diskette 0774062

17 Modular T connector 4626134

Page 24

Issue 1 04/99

Page 25

PAMS

WinTesla Users Guide

Technical Documentation

Main Menu

The main menu bar below appears when HD891 initializes, adding the

following new categories,

and

Product

Configure

Product

The following items are added to this menu when HD891 is recognized:

Initialise

Allows the phone to be set up in either

Normal Mode

When selecting

station and a displays this message. This is ”normal” operation mode of

the phone.

Norma

NHP–4

Tuning,Testing, Software, Dealer

have also changed.

Normal, Local or Minimum

l mode, the phone tries to synchronize to the base

and

Help.

mode.

Minimum Mode

When

MCU will communicate with the PC using the Service Software. This

mode is used for Flash software changes.

Local Mode

When

operation and set to a special mode allowing Tuning and Testing to be

done.

Minimum

Local

Configure

Frequency Planning

This configures the channel number, for a product type, to be

High

in order to allow losses to be configured for manual testing.

mode is selected, the phone is deactivated and only the

mode is selected, the phone is suspended from normal

Low, Mid,

Issue 1 04/99

Page 25

Page 26

WinTesla Users Guide

PAMS

NHP–4

Tuning Steps of Radio Unit

The Service software program places the phone in the Local mode,

during which the phone can be externally controlled via the M2BUS

interface.

The tuning values of the phone reside in the EEPROM. Before tuning

these values are read by the Service software and the user can change

these values with tuning functions.

During tuning, keep the following in mind:

– Take care not to damage sensitive measuring instruments with

excessive RF power.

– Carry out all tuning steps in the shortest possible time to avoid

excessive heating of RF units.

– Perform all tuning steps in the order presented.

– Limit the power supply to a maximum current of 1.3 amps to prevent

excessive damage to the phone in the event of shorted components.

Technical Documentation

– Never try to mask a fault by ”tuning it out.”

Accuracy of the Equipment During Measurement

– Power supply 1; nominal voltage 12 ±0.5 V current cap. min. 1.5 A for

service box (JBS–7).

– Power supply 2 ;nominal voltage 6.0 ±0.1 V, current cap. min. 1.5 A.

– Modulation analyzer power level resolution 0.1 dB, accuracy ±0.5 dB.

Frequency counter accuracy 0.1 ppm 〈±80 Hz).

– RF generator; frequency res. 10 Hz amplitude res. 0.1 dB frequency

stab. ±0.25 ppm.

– Spectrum analyzer; dynamic range 70 dB, accuracy ±1 dB (For power

level measurement accuracy ±0.5 dB).

Baseband Alignment and Flash Station Tests

Flash Programming

This procedure programs the phone software into the flash memory.

Page 26

Flash Programming procedure:

– Connect the phone to the FPS–3C Flash Programming Box.

– Select ”Software –> Flash”.

– Select the flash file for the desired software version.

– Click ”OK”.

– Check the following boxes: ”Set the Phone to Minimum Mode”

and ”Initialize EEPROM after Flash”.

Issue 1 04/99

Page 27

PAMS

WinTesla Users Guide

Technical Documentation

– If the phone had been successfully aligned before and the RF tuning

parameters are to be retained, check the ”Keep RF Parameters”

box.

– If the user data (i.e., phone number, service settings, etc.) are to be

retained, check the ”Keep User Data” box.

– If the selected software had been previously downloaded to the flash

box, click the ”Skip Download to Flash Box” box. This feature

is particularly useful when doing multiple flash downloads with the

same software.

– Click on ”OK” to download the new software.

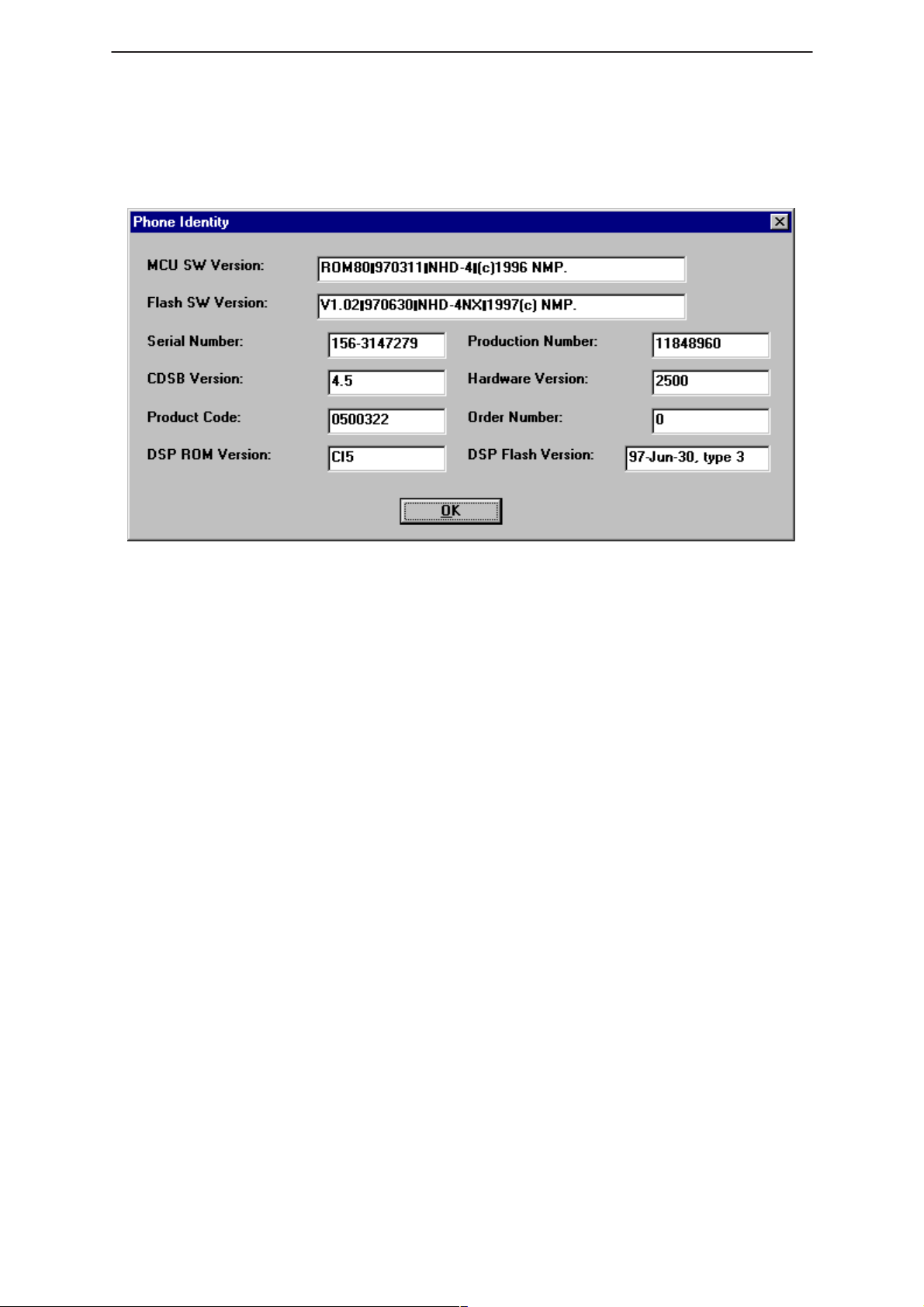

Flash Download Verification procedure:

– From the main menu of the Service Software, select ”View –>

Phone Identity”.

– If the window that pops up displays the software version that had been

selected for download, then the phone was successfully flashed.

Factory Value Set

NHP–4

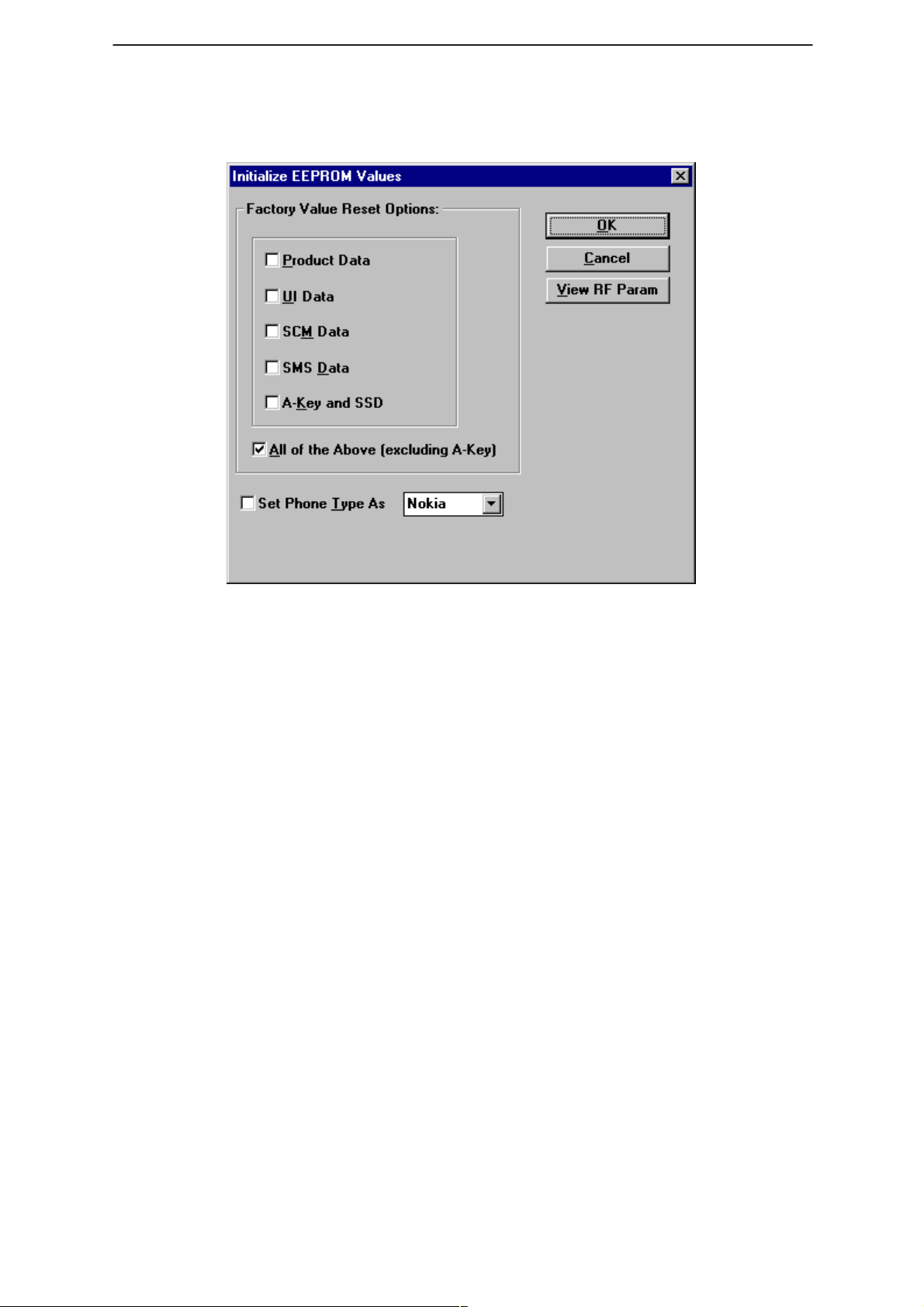

This procedure initializes the EEPROM with default values.

Factory Value Set procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ”Software –> Initialize EEPROM”.

– Select the phone type that the phone is to be set as, i.e., Sprint or

Nokia.

– Click on the box(es) for the EEPROM parameters that are to be

initialized.

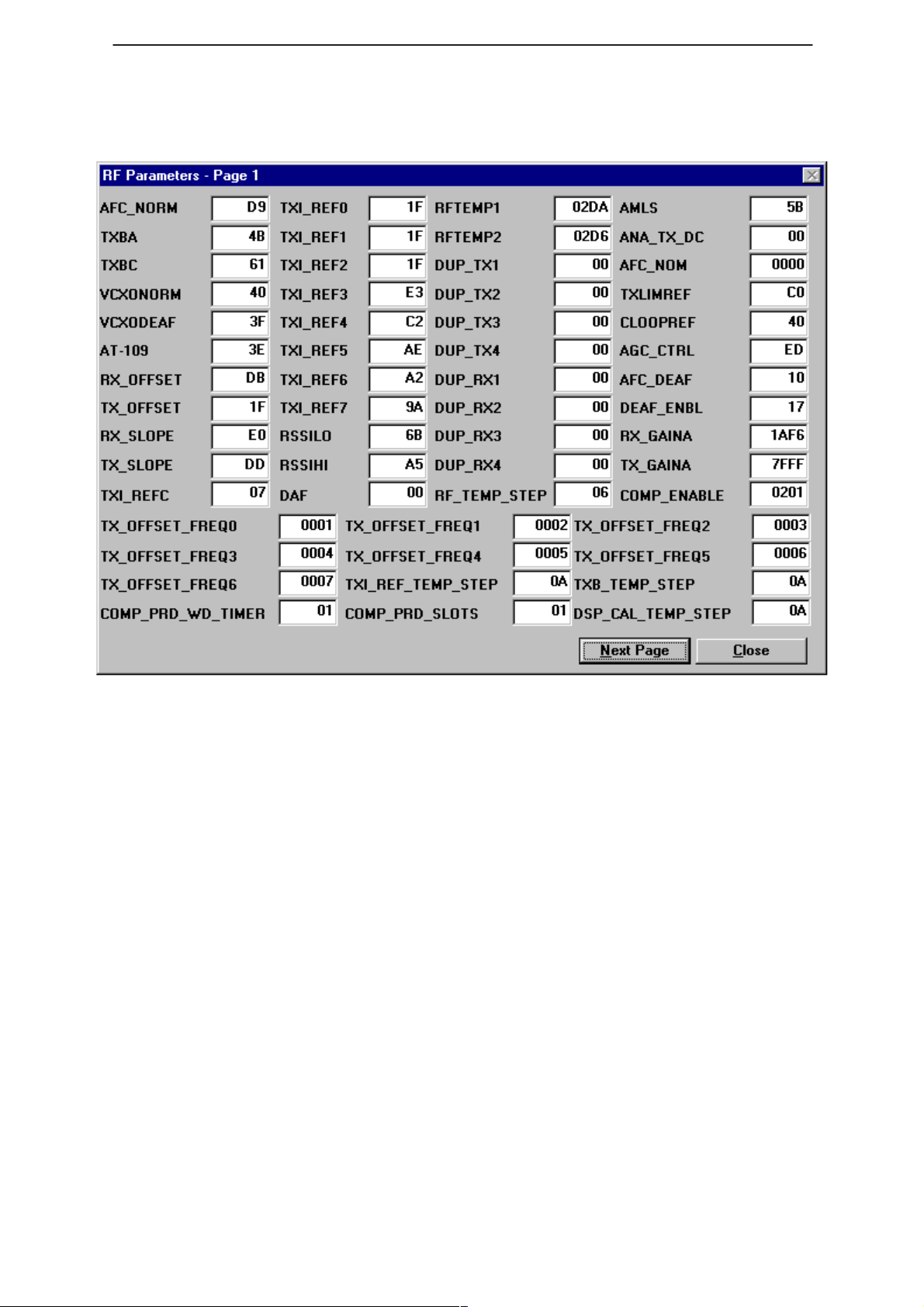

– Note that there is a ”View RF Param” button. This feature enables

the user to view the RF tuning parameters stored in the EEPROM.

The user may wish to use this feature to verify that the stored RF

parameters are no longer needed as initializing the EEPROM will

erase all previous values.

– Click ”OK” to initialize the EEPROM.

Battery Voltage Tuning

This procedure reads the analog–to–digital conversion value of the

BATT_ADC voltage when set to +6.0 V for a reference parameter. The

readings are performed ten times and an average result is calculated

which is then stored into the EEPROM.

Battery Voltage Tuning procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

Issue 1 04/99

with the dummy battery BTS–4.

Page 27

Page 28

WinTesla Users Guide

PAMS

NHP–4

– Apply +6.0 V to dummy battery.

– Select ”Tuning –> Battery Voltage”.

– Store the new values to the phone by clicking on ”Tune”.

Charger Voltage Tuning

Similar to Battery Voltage Tuning, this procedure reads the

analog–to–digital conversion value of the CHAR_ADC voltage when set

to +6.0 V for a reference parameter. The readings are performed ten

times and an average result is calculated which is then stored into the

EEPROM.

Charger Voltage Tuning procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ”Tuning –> Battery Voltage”.

Technical Documentation

– Store the new values to the phone by clicking on ”Tune”.

RF Temperature Tuning

This procedure reads the analog–to–digital conversion value of the

ambient temperature and stores it as two values, RFTEMP1 and

RFTEMP2, as a temperature reference for the phone. This adjustment

should be made with the phone at room temperature, +25C. It is

important that all RF transmitter tunings be done as quickly as possible.

This is to ensure that this reference temperature adjustment is within

limits required for temperature compensation.

RF Temperature tuning:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Select ”Tuning –> RF Temp”.

– The Program reads the ADC values of the ambient temperature for

the EEPROM parameters, RFTEMP1 and RFTEMP2.

– Store the new values to the phone by clicking on ”Tune”.

Page 28

Issue 1 04/99

Page 29

PAMS

WinTesla Users Guide

Technical Documentation

RF Tuning and Testing

WARNING: The phone can not be Tuned properly if connected to the FPS–3C Flash

Programming Box. Please use only one of the setup configurations listed in the “Dealer

Setups” section of the NHD–4NX Service Manual.

CDMA Bias Quiescent Current Test

CAUTION: During procedures that require the phone to transmit high power, ensure that

the power supply limits the current to a maximim of 1.3 amps. This is to prevent further

damage to the phone in the event there are any shorted components within the transmit

circuitry.

This test checks if there is excessive current drain while transmitting.

This procedure reads the current consumption of the phone while

transmitting with minimum gain.

CDMA Bias Quiescent Current test procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

NHP–4

– Connect a spectrum analyzer to the antenna connector.

– Select ”Testing –> CDMA Tests”.

– Check the ”Troubleshooting Mode On” box and allow the phone

– Check the ”Rho On” box to turn on the transmitter.

– Select ”CDMA TX Gain Control”.

– A warning message window will appear reminding the user to limit the

– A TX Gain Control slider with a range from 0 to 1023 will appear. The

– Check that the phone current is within specified limits.

– Click on ”Close” when done.

AFC Tuning

This procedure tunes the VCTCXO frequency to 15.36 MHz. An

unmodulated transmitter carrier on channel 650 is used to perform this

test. The VCTCXO is tuned by adjusting the AFC PDM until the carrier is

on frequency at 1882.50 MHz within +/–100 Hz and then storing the PDM

value into the EEPROM.

to enter Suspend CDMA mode.

power supply to 1.3 amps. Click ”OK” to continue.

slider represents the TX IF AGC DAC value with the value of 0 being

maximum gain and 1023 being minimum gain. Set the TX Gain

Control to minimum gain.

AFC Tuning procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

– Apply +6.0 V to dummy battery.

– Connect a spectrum analyzer to the antenna connector.

Issue 1 04/99

with the dummy battery BTS–4.

Page 29

Page 30

WinTesla Users Guide

PAMS

NHP–4

– Select ”Tuning –> AFC”.

– Follow the set–up instructions displayed and click on ”Continue”.

– Adjust the carrier frequency to 1882.50 MHz +/– 100 Hz with the

PgUp/PgDn keys for coase adjustments and the Up/Dn arrow keys for

fine adjustments.

– Click on ”Save & Exit” to store the PDM value to the EEPROM.

RX AGC Tuning and Dynamic Range Check

This procedure aligns the RX AGC circuitry. The RX AGC is aligned by

injecting a carrier signal at an offset of 540 kHz from the assigned

channel frequency (i.e., Ch 650 = 1962.5 MHz, injected signal = 1963.04

MHz.) The gain of the RX AGC circuitry (IF AGC IC, N9) is then adjusted

to obtain a fixed output level for the receiver I and Q output signals. The

amount of adjustment to obtain this fixed level corresponds to the RX

CTR value. By using the RX CTR value, an AGC tuning value is then

derived. The entire procedure is performed ten times corresponding to

ten different power levels of the injected carrier signal, ranging from –105

dBm to –25 dBm.

Technical Documentation

RX AGC Tuning and Dynamic Range Check procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect a signal generator to the antenna connector.

– Select ”Tuning –> RX AGC/Dynamic Range”.

– Follow the set–up instructions displayed.

– Click on ”Next” to read the AGC tuning value for the first RX signal

level.

– Repeat the procedures and continue until all ten power levels have

been measured.

– Click on ”Save & Exit” to store the AGC tuning values to the

EEPROM.

Page 30

Issue 1 04/99

Page 31

PAMS

WinTesla Users Guide

Technical Documentation

TX Gain Check

CAUTION: During procedures that require the phone to transmit high power, ensure that

the power supply limits the current to a maximim of 1.3 amps. This is to prevent further

damage to the phone in the event there are any shorted components within the transmit

circuitry.

This test checks the dynamic range of the TX attenuator to ensure that

there is enough gain in the TX chain. During normal operation the TX RF

ATT (N300) control signal is fixed and not adjusted. However, during this

procedure the phone will transmit with maximum gain from the TX IF AGC

IC (N308) and with maximum attenuation from the TX RF ATT (N300) at

channel 1175 to duplicate a worst case scenario for TX power output.

TX Gain Check procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect a spectrum analyzer, power meter, or CDMA Test Box to the

antenna connector.

NHP–4

– Select ”Tuning –> TX Gain Check”.

– Follow the set–up instructions displayed.

– Enter the measured power into the TX Power window.

– Click on ”Exit”.

TX IF AGC Tuning and Dynamic Range Check

CAUTION: During procedures that require the phone to transmit high power, ensure that

the power supply limits the current to a maximim of 1.3 amps. This is to prevent further

damage to the phone in the event there are any shorted components within the transmit

circuitry.

Since the gain of the TX PA (N304) and the amount of attenuation at TX

RF ATT (N300) are fixed, only the TX AGC circuitry needs to be

calibrated. For every TX CTR value used, a certain amount of TX gain is

expected form the TX AGC circuitry. This procedure transmits the phone

according to a predetermined TX CTR value and compares the measured

result to a typical expected value. The difference is then used to

calculate the tuning value. The procedure is done seventeen times for

different TX CTR values that correspond to a transmit range of from

approximately –69 dBm to +28 dBm to ensure linearity across the

dynamic range of the TX AGC circuitry.

TX AGC Tuning and Dynamic Range Check procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

– Apply +6.0 V to dummy battery.

– Connect a spectrum analyzer, power meter, or CDMA Test Box to the

Issue 1 04/99

with the dummy battery BTS–4.

antenna connector.

Page 31

Page 32

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

– Select ”Tuning –> TX IF AGC Tuning/Dynamic Range Check”.

– A warning message window will appear reminding the user to limit the

power supply to 1.3 amps. Click ”OK” to continue.

– Follow the set–up instructions displayed.

– Measure the transmit power for the first TX Counter value and enter it

in the corresponding window.

– Click on ”Next” to continue to the next TX Counter value.

– Repeat the measurement steps and continue until the transmit power

for all TX Counter values have been measured and entered.

– Click on ”Save & Exit” to store the tuning values to the EEPROM.

TX Limiting, TX Emissions, and Frequency Compensation

CAUTION: During procedures that require the phone to transmit power, ensure that the

power supply limits the current to a maximim of 1.3 amps. This is to prevent further

damage to the phone in the event there are any shorted components within the transmit

circuitry.

This procedure sets the limit for maximum TX output power. The TX limit

is set to ensure that the phone does not transmit excessive power which

may interfere with the CDMA network. Also, the TX limit ensures that the

phone meets SAR requirements and prevents excessive current

consumption thereby prolonging battery life. During this procedure the

TX limiting PDM (TXI REFC) is adjusted while the phone is transmitting to

obtain an output level of approximately 22.8 dBm. The current is also

measured to check that it is within specified limits.

After the TX limiting PDM value is determined, a TX emissions test is

done by measuring the difference (dBc) between the carrier and the ACP

(adjacent channel power), +/–1.265 MHz offset from the carrier.

Finally, the phone transmits on five other channels using the TX limiting

value just obtained. At each channel the output power is measured and

an algorithm determines the frequency compensation PDM values for a

flat frequency response across the TX bandwidth for TX limiting.

TX Limiting, TX Emissions, and Frequency Compensation procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect a spectrum analyzer and/or a CDMA Test Box (with a built–in

spectrum analyzer if used alone) to the antenna connector.

– Select ”Tuning –> TX Limiting Level”.

– Follow the set–up instructions displayed.

– Adjust the TX limit until approximately 22.8 dBm is obtained by using

the PgUp/PgDn keys for coarse adjustments and the Up/Dn arrow

keys for fine adjustments.

– Enter the measured TX power in the TX Output window.

– Enter the measured current consumption in the Phone current window.

Page 32

Issue 1 04/99

Page 33

PAMS

WinTesla Users Guide

Technical Documentation

– Click on ”Next” and follow the set–up instructions for TX Emissions

measurement.

– Measure the dBc of the ACP. Enter the absolute value of the dBc in

the TX Emissions window (i.e., enter 32 if the measure value was

–32dBc).

– Then enter the measured TX power in the window corresponding to

the first channel (1851.25 MHZ).

– Click on ”Next” and enter the measured transmit power for the next

frequency.

– Repeat the above step and continue until all other frequencies have

been measured.

– Click on ”Save & Exit” to store the TX limiting PDM and frequency

compensation values into the EEPROM.

Open–Loop AGC Alignment

This procedure ensures that the phone satisfies the CDMA system

requirement for open loop gain. The requirement is such that the power

level of the forward link plus the reverse link power must equal to –76

dBm. In other words, RX power + TX power = –76 dBm.

NHP–4

For example: If RX signal level = –90 dBm

Then TX signal level = +14 dBm

–90 dBm + 14 dBm = –76 dBm

A parameter called CLoopRef is used to offset the received signal so that

the TX output power level meets the open loop gain requirement. During

this procedure a RX signal at – 65 dBm is injected into phone and the

phone’s transmitted power is measured to determine the CLoopRef value.

This process is performed over seven different channels to ensure a flat

frequency response.

CLoopRef Alignment procedure:

– Using the JBS–7 service jig, replace the standard battery of the phone

with the dummy battery BTS–4.

– Apply +6.0 V to dummy battery.

– Connect a signal generator and a spectrum analyzer/power meter or a

CDMA Test Box to the antenna connector.

– Select ”Tuning –> Open–Loop AGC”.

– Follow the set–up instructions displayed.

– Measure the TX power for the first channel and enter it in the TX

– Click on ”Next” to measure the next channel.

– Repeat the measurement step above and continue until all channels

– Click on ”Save & Exit” to store the CLoopRef value to the

Issue 1 04/99

power window.

have been measured.

EEPROM.

Page 33

Page 34

WinTesla Users Guide

PAMS

NHP–4

Testing

Self Tests

This option runs the phone’s self test sequences and reports any

processor visible faults. The self tests provide an effective initial test for a

faulty phone.

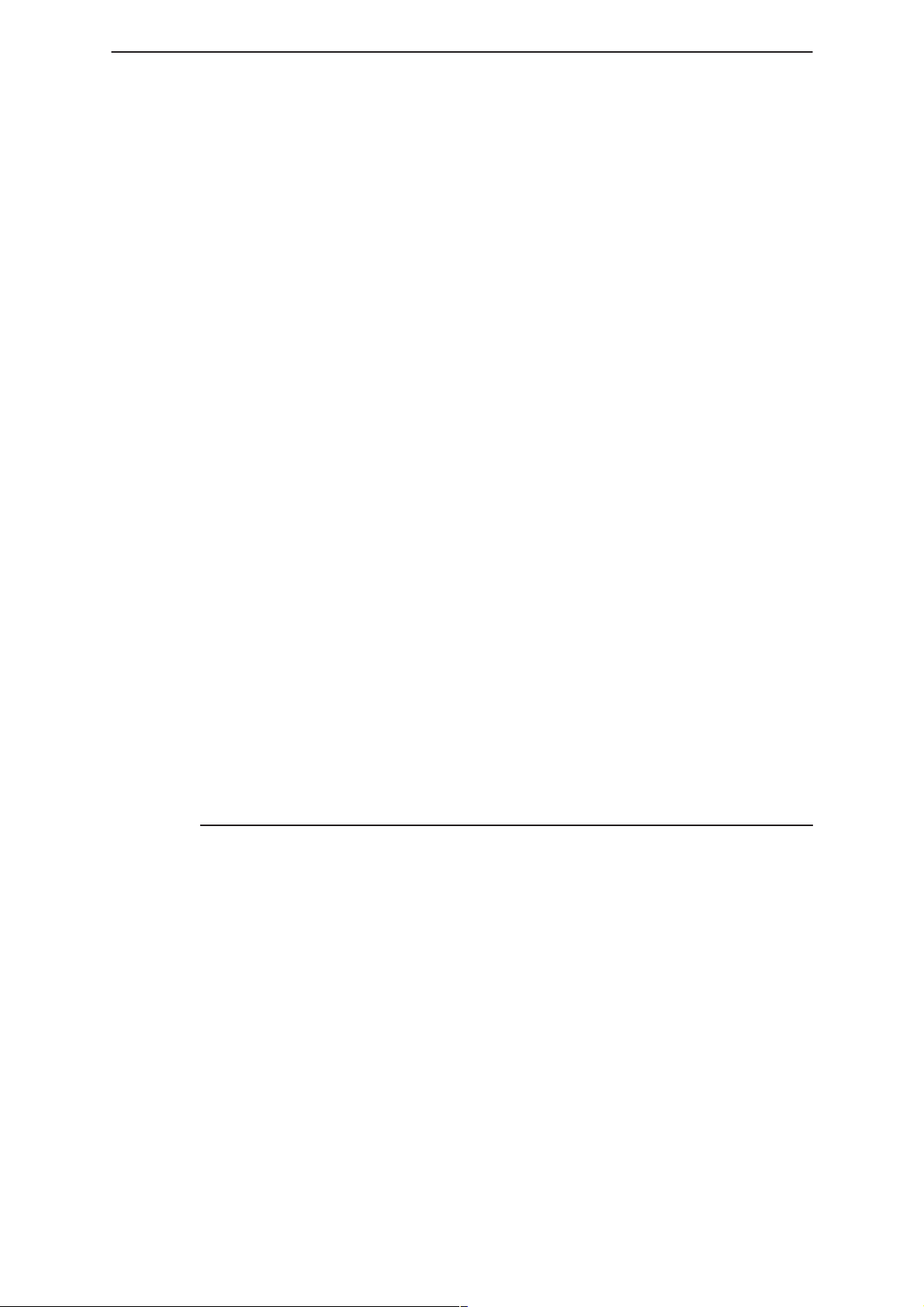

ADC Readings

Technical Documentation

This option allows the phone’s ADC readings to be displayed. The

readings are updated every few seconds. There may be some delay

before the mouse or keyboard responds while running this test.

Page 34

Issue 1 04/99

Page 35

PAMS

WinTesla Users Guide

Technical Documentation

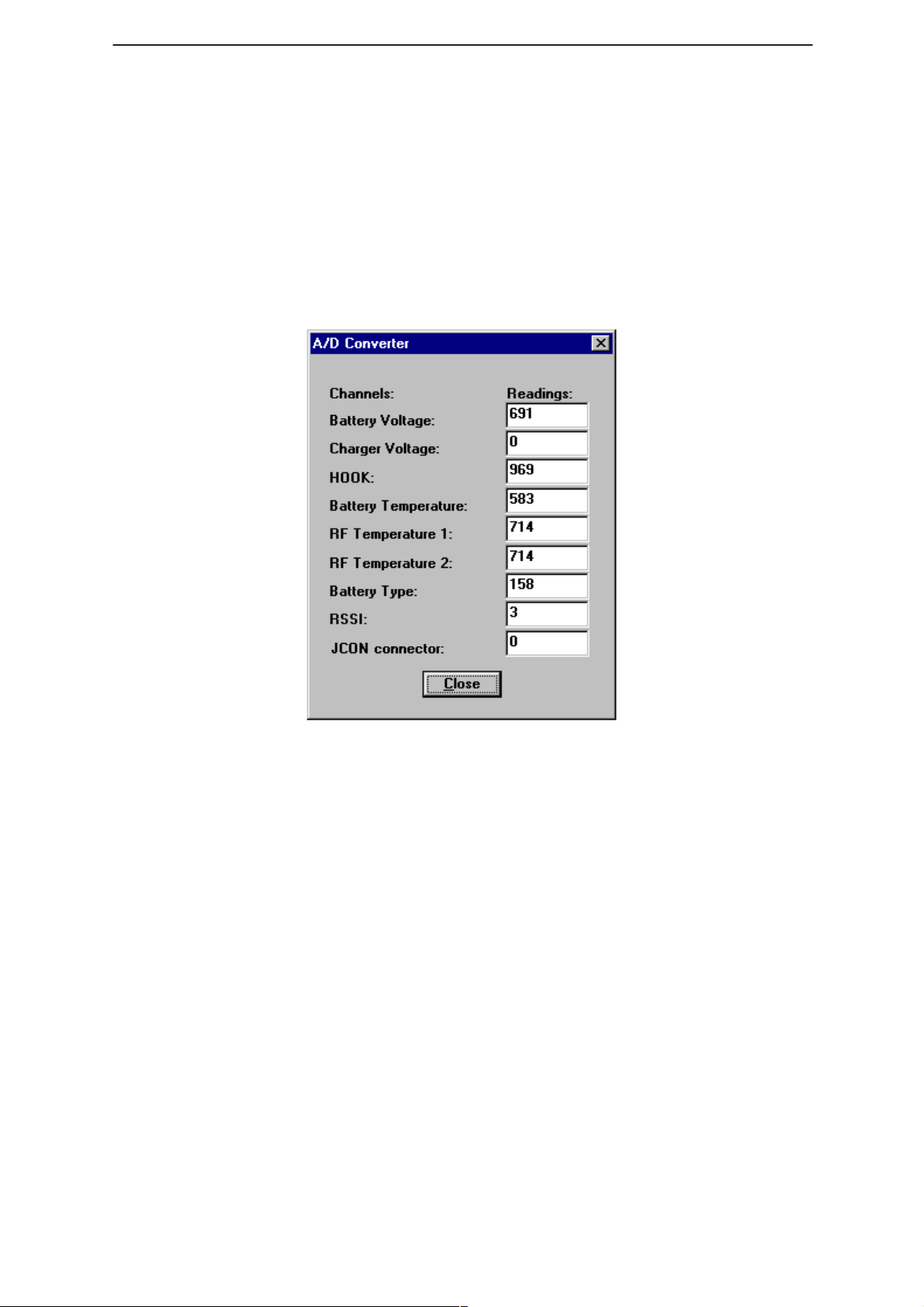

Pulse Division Modulator (PDM) Control

This test screen is to allow control of each PDM separately. The tests in

this section will use the PDM controls from this screen during their

execution.

PDM Register Control

NHP–4

KEYS:

– <Set Default> – Sets all PDMs to there default values.

– <Set Maximum> – Sets all PDMs to there Maximum values.

– <Set Minimum> – Sets all PDMs to there Minimum values.

Issue 1 04/99

Page 35

Page 36

WinTesla Users Guide

PAMS

NHP–4

CDMA Testing

This screen is used when testing and troubleshooting the phone in CDMA

mode. Below is an example screen.

Technical Documentation

Keys:

PDM Ctrl – Opens the PDM Control Screen.

ADC Reading – Opens the ADC reading screen.

Quick RX Test – Opens the Quick Receiver test screen.

Mbus Test – Tests the communication between the phone and the

computer.

Close – Exits the current screen.

RHO on:

RHO on – turns the CDMA transmitter on/off.

Troubleshooting mode on:

Troubleshooting Mode on – will set the phone into CDMA mode for

technical troubleshooting. This mode is the Local mode for CDMA.

CDMA RX Quick Test

This function provides a simple, yet effective method of verifying the

receiver operation. This test sets the phone to channel 650. The user is

then directed to input an RX signal at –65 dBm into the phone and

measure the RX counter value. The test then guides the user to vary the

RX input signal to –85 dBm and –105 dBm and measure the respective

RX counter values. By observing the difference in measured RX counter

values vs the input signals, the functionality of the receiver can be

observed.

Page 36

Issue 1 04/99

Page 37

PAMS

WinTesla Users Guide

Technical Documentation

CDMA RX Gain Control

This function enables the user to manually control the amount of gain in

the receiver. Upon selecting this function, the user is presented with a

slider control with a range from 0 to 1023. The value of the slider

represents the RX DAC value used to control the gain of the RX IF AGC

IC (N9) with the value of 0 being maximum gain and 1023 being minimum

gain.

Reset Phone

This function simply resets the phone to normal operating mode.

TX Limiting

This function allows the user to manually control the TX limiting PDM (TXI

REFC) resulting in changing the set point of the TX limit for the phone.

By controlling the PDM, the user can test the TX lImiting operation and

the related TX circuitry. This function also enables the user to test the

frequency compensation performance of the phone by presenting a

frequency sweep from channel 25 to 1175 at the TX limit. The user

selects the step gain of the frequency sweep, i.e., step up every 50

channels, and the amount of time (in miliseconds) the phone will transmit

at each channel.

NHP–4

CDMA TX Gain Control

This function enables the user to manually control the amount of gain in

the transmitter. Upon selecting this function, the user is presented with a

slider control with a range from 0 to 1023. The value of the slider

represents the TX DAC value used to control the gain of the TX IF AGC

IC (N308) with the value of 0 being maximum gain and 1023 being

minimum gain.

CDMA AGC Quick Test

This function allows the user to test both the RX and TX AGC

performance of the phone. The test sets the phone to channel 650 and

the phone transmits it output power in accordance with the receive signal

strength. The user is first directed to input an RX signal at –65 dBm

where the test records the RX and TX counter values for that signal level.

The user is then directed to change the RX siganl level to –85 dBm which

should change the RX and TX counter values accordanly. By measuring

the difference between the counter values for each receive signal level,

the user can quickly determine if the AGC circuitries are functional.

Issue 1 04/99

Page 37

Page 38

WinTesla Users Guide

PAMS

NHP–4

Software Menu

The Software menu provides the following options:

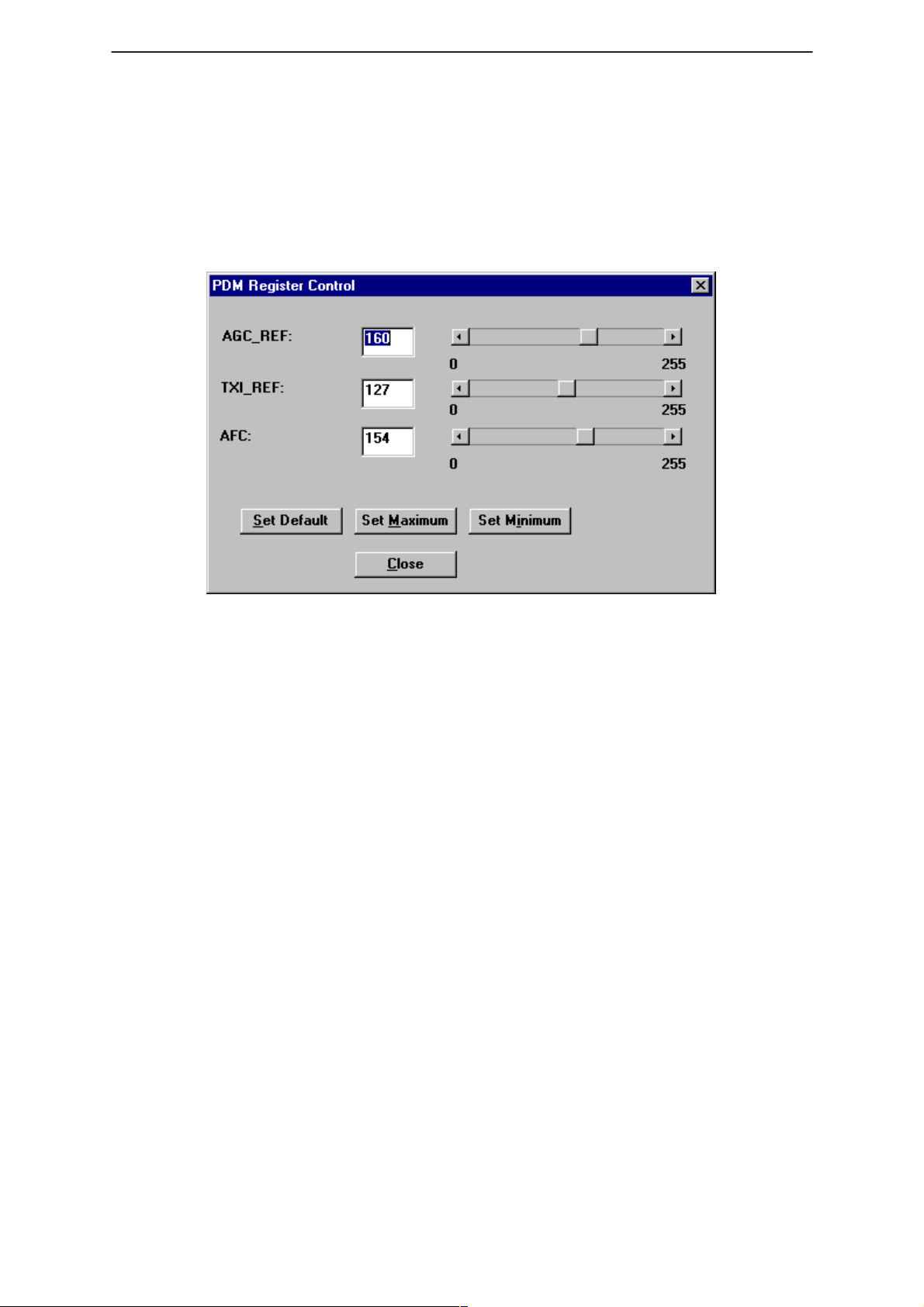

Flashing

Technical Documentation

This option allows you Reflash a phone with a new version of flash

software, enabling new features to be added and bugs to be removed.

This Reflash option relies on the phone being in full working order and

containing the correct HWID and Product Code.

NOTE: To successfully update the flash code, the Nokia FPS–3C MUST be

WARNING:The computer that is connected to the FPS–3C Flash box MUST have it’s

Reflashing summary:

– Ensure the computers parallel port is configured properly.

– Select ”Software –> Flash”.

– Select the correct flash file to be flashed to the phone.

– Set Flash options in dialog box.

– Click on the ”Flash” button.

Dialog Options

Each of the options available are described below. It is suggested that

only experienced operators change these settings from there default

values.

connected to the PC that is running the WinTesla software. (see mechanical

connections in the service manual for details)

parallel port configuration set to standard AT type. Otherwise downloading

the flash image to the “black box” will fail.

Page 38

File size selection

Changes the size parameters for the flash file. Default value is 8 Meg bits.

Check box – set phone to minimum mode

Automatically sets the phone to minimum mode. If not set, the operator

must “force” the phone to this mode using hardware.

Issue 1 04/99

Page 39

PAMS

WinTesla Users Guide

Technical Documentation

Check box – Keep RF parameters

This option will save the RF parameters before flashing the phone. Once

flash updating is complete, these parameters will be stored back to the

phone.

Check box – Keep User Data

This option will save user data before flashing the phone. Once flash

updating is complete, the user data will be saved back into the phone.

USER DATA SAVED:

– Short Code Memory

– NAM programming information

– Calling Card Numbers

– SID Lists

– System Feature codes

– UI Settings

NHP–4

– Warranty Information

Check box – Initialize EEPROM after Flash

This option will prompt for initialization of the EEPROM after flash

updating is complete. It is recommended that the EEPROM be

“Initialized“ after flash updating the phone. (

more details on this function

Check box – Skip download to Flash box

The flash update is done using a two step process. the flash image is

downloaded to the flash box in the first step. This takes about 30 to 45

seconds. Then the image is updated on the phone during the second

step.

This option is useful if you are updating several phones with the same

flash image. After completing the first phone update, checking this option

will skip the first step of downloading the flash image to the box again. It

is not necessary to download the image again because the box will

contain the last image loaded unless a loss of power occurs.

)

see Initialize EEPROM for

Issue 1 04/99

Page 39

Page 40

WinTesla Users Guide

PAMS

NHP–4

Initialize EEPROM

Technical Documentation

This option will re–initialize the phone’s EEPROM settings.

CAUTION: All the phone’s calibrated (tuned) data will be erased by this option and the

phone MUST now be recalibrated.

Product Data

This option will reset the Product data.

UI Data

This option will reset the user interface data.

SCM Data

This option will reset the short code memory data.

SMS Data

This option will reset the short messaging services data.

All of the above

This option will reset all of the above.

View RF Parameters

Opens the RF parameters dialog for viewing this data.

Page 40

Issue 1 04/99

Page 41

PAMS

WinTesla Users Guide

Technical Documentation

Dealer Menu

NAM Programming

NHP–4

This option allows you to program the NAM information, wake up

message, Emergency numbers, Lock code and security code of the

phone.

Keys:

NAM Selection

Selects NAM contents to be displayed.

Load File

Prompts user to select a file containing NAM information.

Save File

Allows user to save screen contents to a file.

Read Phone

Reads phone contents to screen.

Write Phone

Writes contents of screen to phone.

Issue 1 04/99

Page 41

Page 42

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

Default NAM Parameter Settings

These settings apply to both NAM 1 and NAM 2 unless stated otherwise. Values are shown in

decimal format.

Parameter Default Setting Valid Values

Own Number (Phone No. associated

with NAM, more specifically known as

the MIN)

Home SID List 1 – 32767 for each SID.

Access Overload Class last number of MIN 0 – 15

NAM Status Enabled/Disabled

Group ID 10 0 – 15

Access Method 1 0,1

Local Use Mark 1 0,1

Country Code 0 0 – 999

Network Code 0 0 – 99

000 000 XXXX (where XXXX

is the last 4 digits of ESN)

10 digits;

Up to 4 unique SIDs

Directory Number (Phone No. associated with NAM, more specifically known

as the MDN)

Emergency Numbers 911, *911, empty.

Lock Code 1234

Security Code 12345

000 000 XXXX (where XXXX

is the last 4 digits of ESN)

10 digits;

Page 42

Issue 1 04/99

Page 43

PAMS

WinTesla Users Guide

Technical Documentation

Short Code Memory (SCM)

NHP–4

This option allows the user to change the phone directory numbers (also

known as short code memory).

Keys:

Close

Closes Short Code memory screen.

Load File

Prompts user to select a file containing Short Code Memory information.

Save File

Allows user to save screen contents to a file.

Read Phone

Reads phone contents to screen.

Write Phone

Writes contents of screen to phone.

Edit

Edits the highlighted entry.

Delete

Deletes the highlighted entry.

Issue 1 04/99

Page 43

Page 44

WinTesla Users Guide

PAMS

NHP–4

SID Programming

This option allows you to edit the SID list. Highlight an entry using the

<TAB> key and press enter to edit.

Technical Documentation

Keys:

Load File

Prompts user to select a file containing SID information.

Save File

Allows user to save screen contents to a file.

Read Phone

Reads phone contents to screen.

Write Phone

Writes contents of screen to phone.

Page 44

Issue 1 04/99

Page 45

PAMS

WinTesla Users Guide

Technical Documentation

Calling Cards

NHP–4

This option allows the user to program the calling card information into

the phone.

Card Name

Allows user to change the name of the calling card display in the phones

menu.

Access Method

Allows user to select the appropriate method for connecting with the

service providers network according to the calling card requirements.

Please contact your service provider for details or the calling card

instructions. Changing this setting causes the phone to execute the

sequence of events according to option choosen.

– Access/Phone/Card – sends the service providers Access

number, then the Phone number being dialed by user, then

Calling Card

– Access/Card/Phone – sends the service providers Access

number, then Calling Card number, then the Phone number

being dialed by user.

– Prefix/Phone/Card – sends the service providers Prefix

number (typically a zero), then the Phone number being

dialed by user, then Calling Card

number.

number

Access Number

The number used to access the service provders network. Typically a toll

free number.

Card Number

Also known as “card ID”, this number is the actual calling card number

issued by the service provider.

Issue 1 04/99

Page 45

Page 46

WinTesla Users Guide

PAMS

NHP–4

Prefix

This number is sent to gain system access. Typically a zero.

International Prefix

Currently not used.

National Prefix

Currently not used.

Authentication Key (A–Key) Programming

Technical Documentation

This option allows you to program the Authentication key of the phone.

The A–key can

phone over writing the previous value.

To program the A–key a valid A–key plus a valid checksum must be

entered as one complete number.

Example:

Keys:

Write Selected

Writes the highlighted selection to the selected NAM in the phone if

A–Key is valid. Otherwise an error message is displayed.

Write All

Writes both A–Key numbers to the corresponding NAM of the phone if the

A–Key is valid. Otherwise an error message is displayed.

never

– Valid A–Key number= 6 to 20 digits (e.g. XXXXXXXXXX)

– Valid checksum = 6 digits (e.g. YYYYYY)

– A–Key Entry would be XXXXXXXXXXYYYYYY

be read from the phone, only programmed to the

Page 46

Issue 1 04/99

Page 47

PAMS

WinTesla Users Guide

Technical Documentation

User Data Transfer

This option allows you to transfer the selected user data from one phone

to another.

NHP–4

NOTE: The Warranty Information can not be unchecked and will always be

transferred. The information can on;y be transferred to a phone once. After that an error

dialog is displayed.

If a phone should need to be replaced at the point of return, this option

will read the selected information from the defective phone, allow the user

to change to a new (replacement) phone, and write the users data into

the replacement unit.

Steps involved

– With phone powered on, Connect defective unit and click on

”Read Phone”.

– Disconnect defective unit.

– Connect replacements unit and power on.

– Click on ”Write Phone”.

Issue 1 04/99

Page 47

Page 48

WinTesla Users Guide

PAMS

NHP–4

Set Factory Values

This option allows you to reset a phone’s settings to their initial (factory)

default values. The phone is also re–product profiled based on the

product code.

Technical Documentation

The following list is a subset of data which can be reset to factory

defaults:

– NAM information

– Clear Short Code Memory

– Calling Card information

– System Feature Codes

– System ID lists

– User Menu Settings

– Call Counters (except Life time counter)

NOTE: This option will NOT erase any calibrated values within the phone.

SPC code change

Page 48

This option allows you to change the Subscriber Programming Code

(SPC) if the original code is known.

Issue 1 04/99

Page 49

PAMS

WinTesla Users Guide

Technical Documentation

View Menu

Phone Identity

NHP–4

This option displays the following phone identity fields:

– ROM version

– Flash version

– Production Serial Number (PSN),

– Order Number,

– Product Code,

– Hardware ID.

Issue 1 04/99

Page 49

Page 50

WinTesla Users Guide

PAMS

NHP–4

RF Parameters

Technical Documentation

This dialog shows the RF parameters of the phone. Looking at these

parameters can help the technician in making decisions about the status

of the phone.

Page 50

Issue 1 04/99

Page 51

PAMS

WinTesla Users Guide

Technical Documentation

Help

Index

A comprehensive list of all WinTesla features, hypertext linked.

General Help (F1)

This option contains two options:

– Help on using WinTesla

– Help on using Help

Using Help

This option provides you with information on using the online help

function.

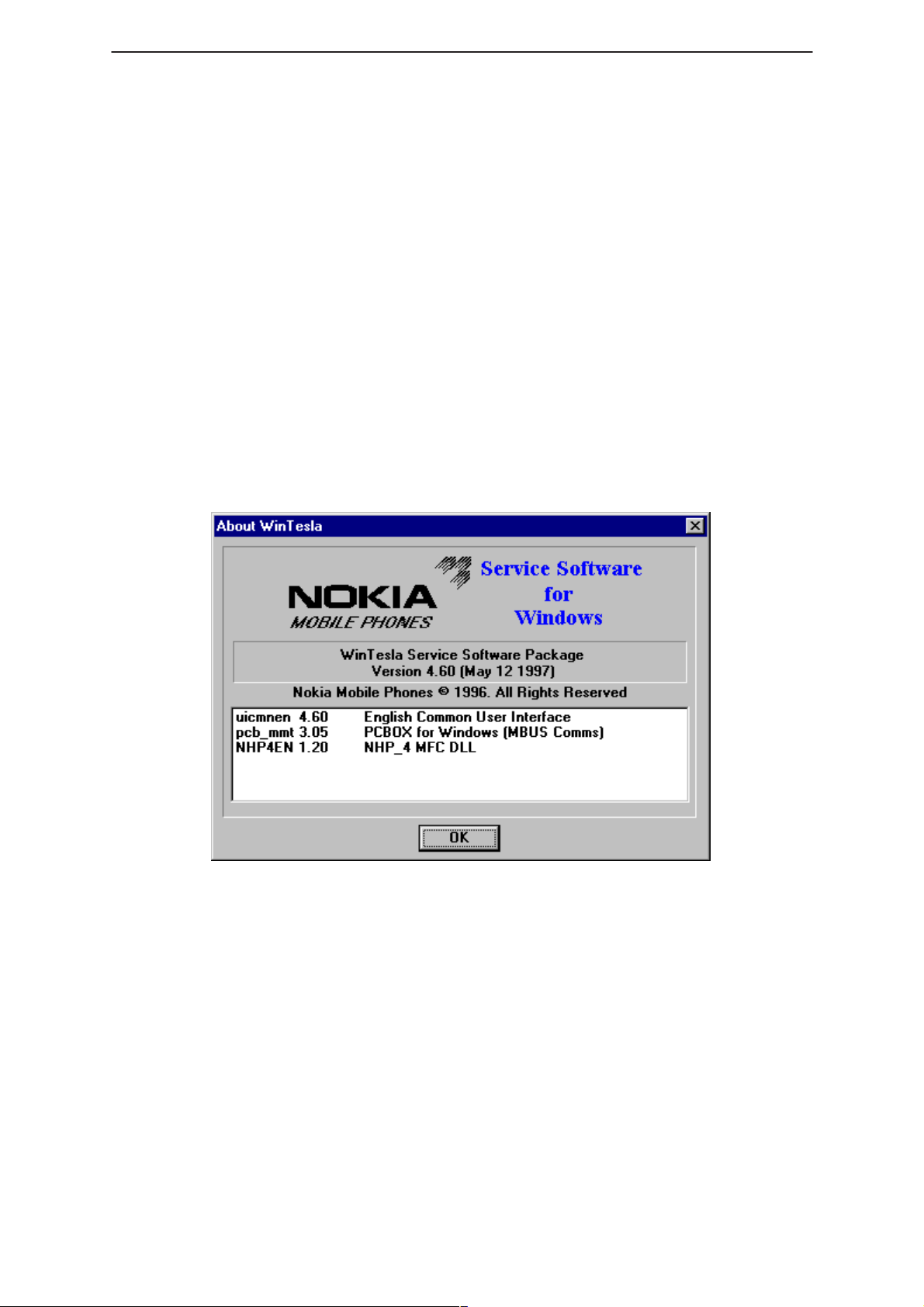

About WinTesla

Displays information on the the version that is running.

NHP–4

Issue 1 04/99

Page 51

Page 52

WinTesla Users Guide

PAMS

NHP–4

Common Problems

This section is a reference of known commo problems that may be

encountered when working with the Wintesla software package.

Setting up the computer Hardware

In order to avoid some common hardware problem, please ensure the

computer hardware is set up as follows.

COM Port Set up

COM port address (COM1 or COM2) should be set as the default values

for these ports. Special port address or IRQ settings may encounter

problems. to test this case set up a COM port as the default values and

try running the Wintesla application again.

Printer port set up

The printer port is used to attach the PKD–1 software Protection Key.

This device should work properly with most printer port settings.

However, if a problem is encountered, change the computer printer port

(LPT–1) setting to “Standard AT type”. This is NOT a Bi–directional

setting.

Technical Documentation

NOTE: When using an FPS–3C flash programming set, the printer port MUST be set

as “Standard AT Type”. The Flash box (FPS–3C) must have power connected.

Common Errors

Error – Functionality DLL not found

This error will be encountered if a phone is connected to WIntesla and it

is not recognized.

Solution

Install the Service Module for the phone type connected to Wintesla.

Contact your local Nokia vendor for information on how to obtain this

Service Module.

Error – PKD–1 not found

PKD–1 is the software Protection Key Device that is required for the

Wintesla application to run. This error will be encountered if the PKD–1

device is not installed on your printer port (LPT–1).

Solution

Attach the PKD–1 to the printer port (LPT–1) of the PC running Wintesla.

Page 52

Error – System hangs or Locks up

Wintesla may hang or Lock up if it is being run on Windows 95 or NT.

Solution

Run the Wintesla application on Windows 3.1 or 3.11. The Wintesla

application is NOT designed to run under Windows 95 or NT. If you are

using Windows 3.1 or 3.11 and are still experiencing problems please call

your local Authorized Service & Support location.

Issue 1 04/99

Page 53

PAMS

WinTesla Users Guide

Technical Documentation

Error – Reset FPS–3 box

This error only occurs when reflashing a phone with new software.

Solution

Remove power from the FPS–3C box for approximately 5 seconds. Then

reconnect power.

Error – Phone will not Tune properly

The phone can not be properly Tuned while connected to the FPS–3C

flash box. The voltage coming from the box will cause errors in the tuning

parameters.

Solution

Disconnect the FPS–3C box from the phone while Tuning. Only use one

of the set up configurations listed in the Dealer Setups section of the

NHD–4NX Service Manual.

Service and Support

NHP–4

Please contact your local Service location for more information and

support .

Or try our web site (http://www.Nokia.com)

Issue 1 04/99

Page 53

Page 54

WinTesla Users Guide

PAMS

NHP–4

Technical Documentation

[This page intentionally left blank]

Page 54

Issue 1 04/99

Loading...

Loading...