Page 1

Nokia Customer Care

SERVICE

MANUAL

[NMP Part No. 9239059]

RH-66 Mobile Terminal

2115i/2116/2116i

Issue 1

COMPANY CONFIDENTIAL

Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 2

Nokia Customer Care

Amendment Record Sheet

Revision Date Author Comments

001 03/2005 N. Cheshier Issue 1

Issue 1 03/2005 COMPANY CONFIDENTIAL 2

Copyright © 2005 Nokia. All Rights Reserved.

Page 3

Nokia Customer Care

Copyright© 2005 Nokia. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents in

this document in any form without the prior written permission of Nokia is

prohibited.

Nokia, Nokia Connecting People, X and Y are trademarks or registered

trademarks of Nokia Corporation. Other product and company names

mentioned herein may be trademarks or tradenames of their respective

owners.

Nokia operates a policy of continuous development. Nokia reserves the right to

make changes and improvements to any of the products described in this

document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or

income or any special, incidental, consequential or indirect damages

howsoever caused.

The contents of this document are provided "as is". Except as required by

applicable law, no warranties of any kind, either express or implied, including,

but not limited to, the implied warranties of merchantability and fitness for a

particular purpose, are made in relation to the accuracy, reliability or contents

of this document. Nokia reserves the right to revise this document or withdraw

it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personnel

only.

Issue 1 03/2005 COMPANY CONFIDENTIAL 3

Copyright © 2005 Nokia. All Rights Reserved.

Page 4

Please refer to the product’s user guide for instructions relating

to operation, care and maintenance including important safety

information. Note also the following:

Warnings:

1. IF THE DEVICE CAN BE INSTALLED IN A VEHICLE, CARE

MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED

WITH ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND

ANTI-SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT

CONDITIONS, EMITTED RF ENERGY CAN AFFECT THEIR

OPERATION. IF NECESSARY, CONSULT THE VEHICLE

DEALER/MANUFACTURER TO DETERMINE THE IMMUNITY

OF VEHICLE ELECTRONIC SYSTEMS TO RF ENERGY.

Nokia Customer Care

Warnings and Cautions

2. THE PRODUCT MUST NOT BE OPERA TED IN AREAS LIKEL Y

TO CONT AIN POTENTIALL Y EXPLOSIVE A TMOSPHERES EG

PETROL STATIONS (SERVICE STATIONS), BLASTING

AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT,

INCLUDING CELLULAR TELEPHONES, MAY INTERFERE

WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR

THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU

HA VE ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT

MAY ALSO BE SUBJECT TO INTERFERENCE.

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and

that an anti-static wrist strap is worn.

3. Ensure solder, wire, or foreign matter does not enter the mobile

terminal as damage may result.

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are correctly re-fitted after servicing and alignment. Ensure all cables

and wires are repositioned correctly.

Issue 1 03/2005 COMPANY CONFIDENTIAL 4

Copyright © 2005 Nokia. All Rights Reserved.

Page 5

Nokia Customer Care

For Your Safety

QUALIFIED SERVICE

Only qualified personnel may install or repair mobile terminal equipment.

ACCESSORIES AND BATTERIES

Use only approved accessories and batteries. Do not connect incompatible

products.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read its user’s guide for detailed safety

instructions. Do not connect incompatible products.

ESD Protection

Nokia requires that product service points have sufficient

ESD protection (against static electricity) when servicing

products.

Any product of which the covers are removed must be handled with ESD protection. The SIM card can be replaced

without ESD protection if the product is otherwise ready for

use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD.

Resistors, too, can be damaged by static electricity discharge.

All ESD sensitive parts must be packed in metallized protective bags during shipping and handling outside any ESD

Protected Area (EPA).

Every repair action involving opening the product or handling the product components must be done under ESD

protection.

ESD protected spare part packages MUST NOT be

opened/closed out of an ESD Protected Area.

For more information and local requirements about ESD

protection and ESD Protected Area, contact your local

Nokia After Market Services representative.

Issue 1 03/2005 COMPANY CONFIDENTIAL 5

Copyright © 2005 Nokia. All Rights Reserved.

Page 6

Nokia Customer Care

Battery Information

Note that a new battery's full performance is achieved only after two or three

complete charge and discharge cycles.

The battery can be charged and discharged hundreds of times but it will

eventually wear out. When the operating time (talk-time and standby time) is

noticeably shorter than normal, it is time to buy a new battery.

Use only batteries approved by the mobile terminal manufacturer and recharge

the battery only with the chargers approved by the manufacturer. Unplug the

charger when not in use. Do not leave the battery connected to a charger for

longer than a week, since overcharging may shorten its lifetime. If left unused

a fully charged battery will discharge itself over time.

Temperature extremes can affect the ability of your battery to charge.

For good operation times with Ni-Cd/NiMh batteries, discharge the battery

from time to time by leaving the product switched on until it turns itself off (or

by using the battery discharge facility of any approved accessory available for

the product). Do not attempt to discharge the battery by any other means.

Use the battery only for its intended purpose.

Never use any charger or battery which is damaged.

Do not short-circuit the battery. Accidental short-circuiting can occur when a

metallic object (coin, clip or pen) causes direct connection of the + and terminals of the battery (metal strips on the battery) for example when you

carry a spare battery in your pocket or purse. Short- circuiting the terminals

may damage the battery or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer or

winter conditions, will reduce the capacity and lifetime of the battery. Always

try to keep the battery between 15°C and 25°C (59°F and 77°F). A mobile

terminal with a hot or cold battery may temporarily not work, even when the

battery is fully charged. Batteries' performance is particularly limited in

temperatures well below freezing.

Do not dispose of batteries in a fire.

Dispose of batteries according to local regulations (e.g. recycling). Do not

dispose as household waste.

Issue 1 03/2005 COMPANY CONFIDENTIAL 6

Copyright © 2005 Nokia. All Rights Reserved.

Page 7

Nokia Customer Care

Care and Maintenance

The mobile terminal is a product of superior design and craftsmanship and

should be treated with care. The suggestions below will help you to fulfill any

warranty obligations and to enjoy this product for many years.

Keep the mobile terminal and all its parts and accessories out of the reach of

small children.

Keep the mobile terminal dry. Precipitation, humidity and all types of liquids or

moisture can contain minerals that will corrode electronic circuits.

Do not use or store the mobile terminal in dusty, dirty areas. Its moving parts

can be damaged.

Do not store the mobile terminal in hot areas. High temperatures can shorten

the life of electronic devices, damage batteries, and warp or melt certain

plastics.

Do not store the mobile terminal in cold areas. When it warms up (to its

normal temperature), moisture can form inside, which may damage electronic

circuit boards.

Do not drop, knock or shake the mobile terminal. Rough handling can break

internal circuit boards.

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean

the mobile terminal.

Do not paint the mobile terminal. Paint can clog the moving parts and prevent

proper operation.

Use only the supplied or an approved replacement antenna. Unauthorized

antennas, modifications or attachments could damage the mobile terminal and

may violate regulations governing radio devices.

All of the above suggestions apply equally to the product, battery, charger or

any accessory.

Issue 1 03/2005 COMPANY CONFIDENTIAL 7

Copyright © 2005 Nokia. All Rights Reserved.

Page 8

Nokia Customer Care

Company Policy

Our policy is of continuous development; details of all technical modifications

will be included with service bulletins.

While every endeavour has been made to ensure the accuracy of this

document, some errors may exist. If any errors are found by the reader, NOKIA

MOBILE PHONES Business Group should be notified in writing.

Please state:

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

Please send to:

NOKIA CORPORATION

Nokia Mobile Phones Business Group

Nokia Customer Care

PO Box 86

FIN-24101 SALO

Finland

Issue 1 03/2005 COMPANY CONFIDENTIAL 8

Copyright © 2005 Nokia. All Rights Reserved.

Page 9

Nokia Customer Care

Table of Contents

1 - General Information

2 - Parts Lists and Exploded View

3 - Service Software Instructions

4 - Service Tools

5 - Disassembly/Assembly

6 - Antenna Description and Troubleshooting

7 - Baseband Description and Troubleshooting

8 - RF Description and Troubleshooting

9 - Schematics

Issue 1 03/2005 COMPANY CONFIDENTIAL 9

Copyright © 2005 Nokia. All Rights Reserved.

Page 10

Nokia Customer Care

This page intentionally left blank.

10 COMPANY CONFIDENTIAL Issue 1 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 11

Nokia Customer Care

2115i/2116/2116i (RH-66)

Mobile Terminals

General Information

Issue 1 03/2005 Company Confidential ©2005 Nokia Corporation

Page 12

2115i/2116/2116i (RH-66)

General Information

Contents Page

Introduction ..................................................................................................................................................... 3

Sales Package ...............................................................................................................................................4

Supported Accessories ...............................................................................................................................4

Page 2 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 13

2115i/2116/2116i (RH-66)

Nokia Customer Care General Information

Introduction

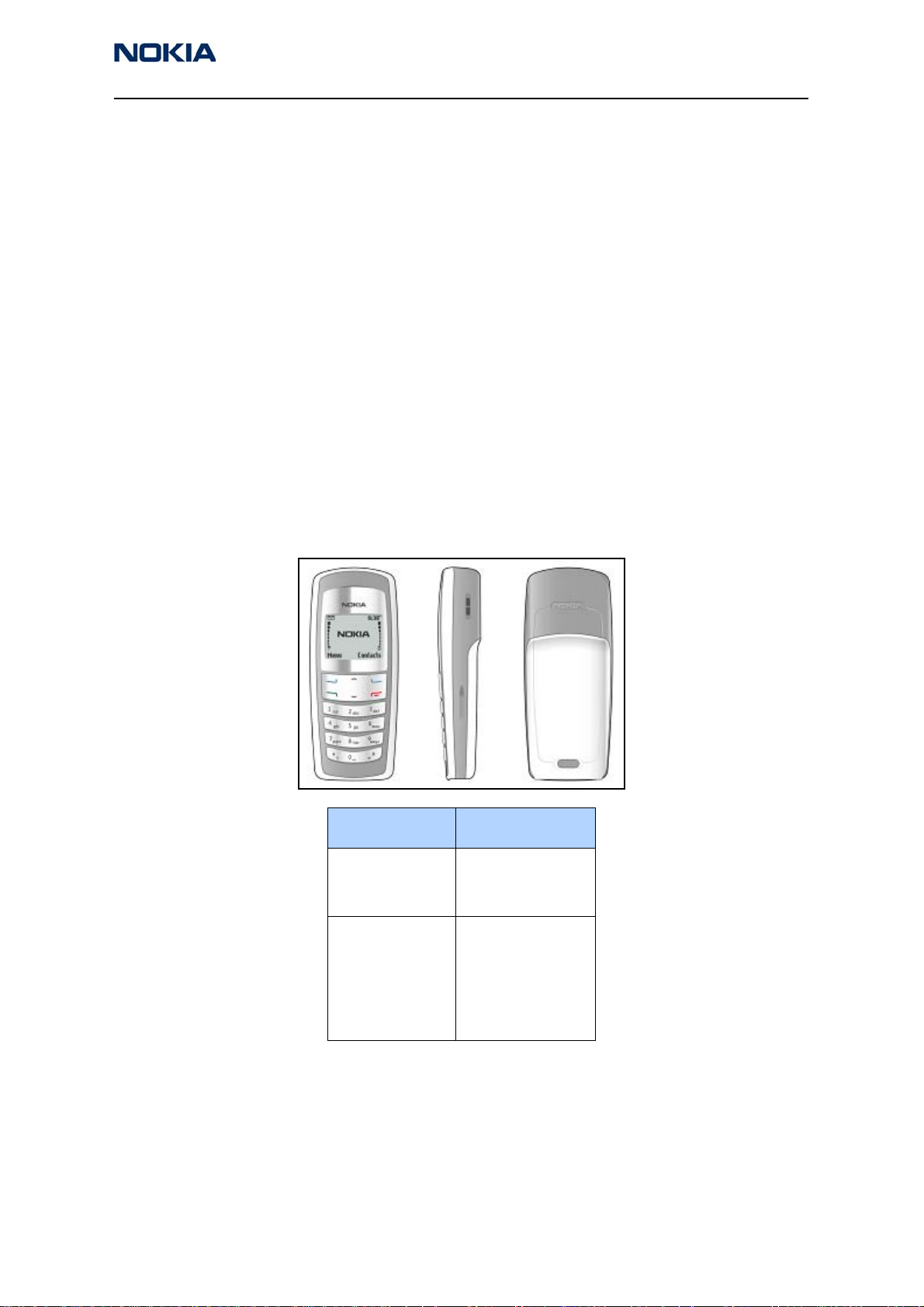

The Nokia 2115i/2116/2116i mobile terminal offers a CDMA trimode (800/1900MHz plus

AMPS) engine and includes the following features:

• Integrated, 2-way, hands-free speaker

• Flashlight

• Removable User Information Module (RUIM)

• 96 x 68 black and white display

• Internal vibra

• GPS for E-911 services (2115i and 2116i only)

• MIDI ring tone download and Qualcomm Code Excited Linear Prediction (QCELP)

decoding

• Changeable A-covers

• Openwave 4.1 browser

• Predictive text

Parameter Value and Unit

BL-6C

Talk time

Standby time

Dimensions:

Volume

Length

Width

Thickness

Weight

Up to 4.00 hours

Up to 212.00 hours

69 cc

102.4 mm

42.2 mm

21.5 mm

85 grams

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 3

Page 14

2115i/2116/2116i (RH-66)

General Information

Sales Package

Name Type

Transceiver RH-66

Supported Accessories

Type Name

AC-1 Travel Charger

ACP-7 AC Travel Charger

ACP-12 Rapid Performance Charger

AD-5B Wireless Audio Adapter

BHF-3 Hands-free Headrest

CA-42 Data Cable

CK-7W Advanced Car Kit

CK-10 Basic Car Kit (no bluetooth)

DCV-14 Desk Stand

Battery BL-6C

(1070 mAh Li-Ion)

Charger ACP-7

BL-6C

HDB-4 Boom Headset

HDW-3 Wireless Headset

HF-2 Activity Hands Free

HF-3 Easy-to-use Hands Free

HS-3 Fashion Stereo Headset

HS-4W Wireless Boom Headset

HS-5 Headset

HS-10 Retractable Headset

HS-11W Basic Wireless Headset

LCH-12 Cigarette Lighter Charger

LPS-4 Inductive Loopset

MBC-15S Mobile Holder

Page 4 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 15

Nokia Customer Care

2115i/2116/2116i (RH-66)

Mobile Terminals

Parts Lists and Exploded View

Issue 1 03/2005 Company Confidential ©2005 Nokia Corporation

Page 16

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Contents Page

Exploded View ................................................................................................................................................. 3

Assembly Parts List .....................................................................................................................................3

2115i/2116i Parts List — Version 002 ...................................................................................................... 5

2116 Parts List — Version 001................................................................................................................. 19

Page 2 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 17

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

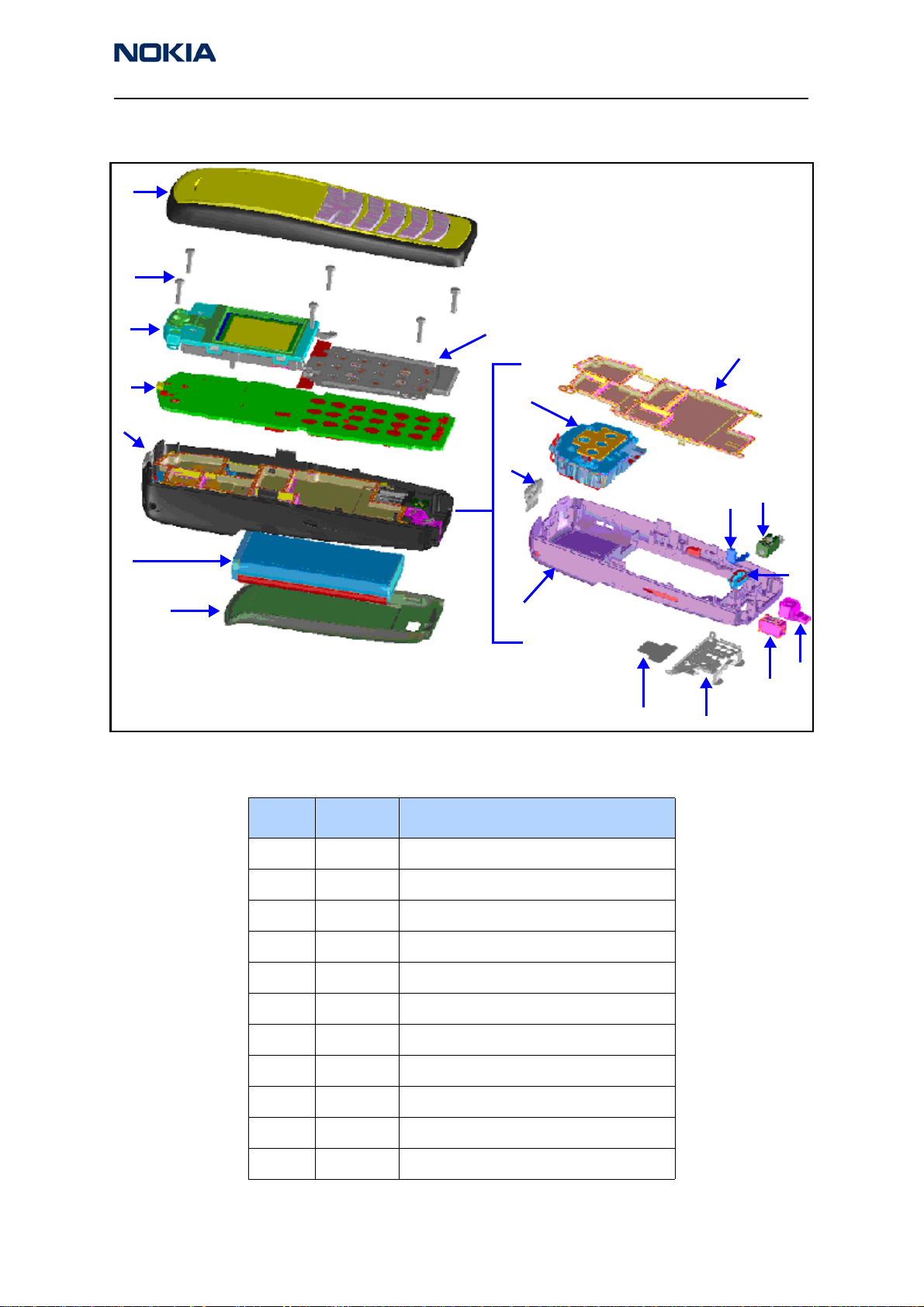

Exploded View

1

2

3

5

6

4

7

Assembly Parts List

8

6a

6b

6c

6f

6e

6g

6d

6h

6i

6k

6j

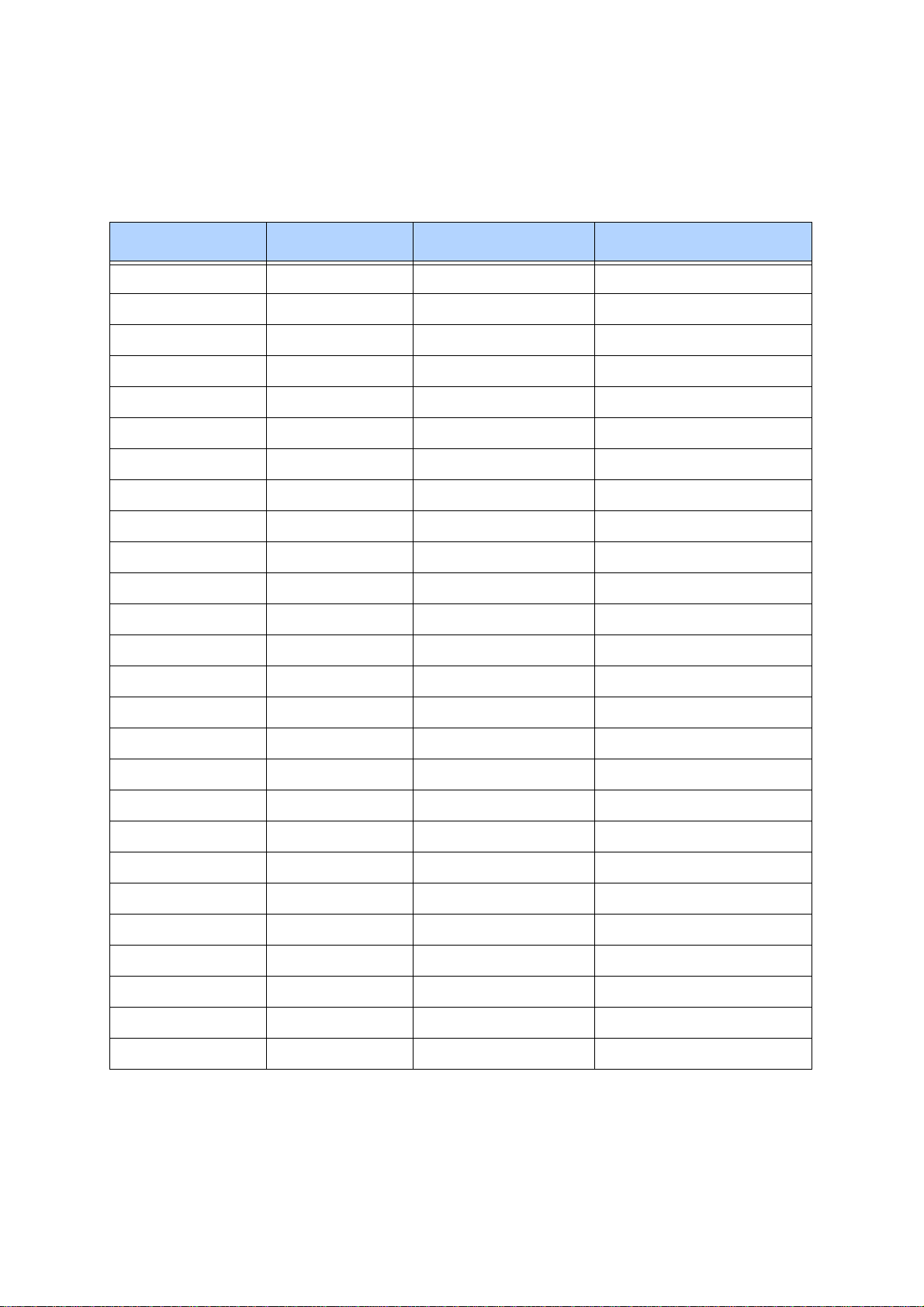

Item Qty Description

1 1 A-cover assembly

26 Screws

3 1 UI display assembly

4 1 Domesheet assembly

51 PWB

6 1 B-cover assembly

6a 1 PWB shield

6b 1 Antenna assembly

6c 1 Power button

6d 1 B-cover

6e 1 Release spring

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 3

Page 18

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Qty Description

6f 1 Vibra

6g 1 Release button

6h 1 Microphone

6i 1 DC jack

6j 1 SIM flap

6k 1 RUIM label

71 Battery

8 1 C-cover

Page 4 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 19

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

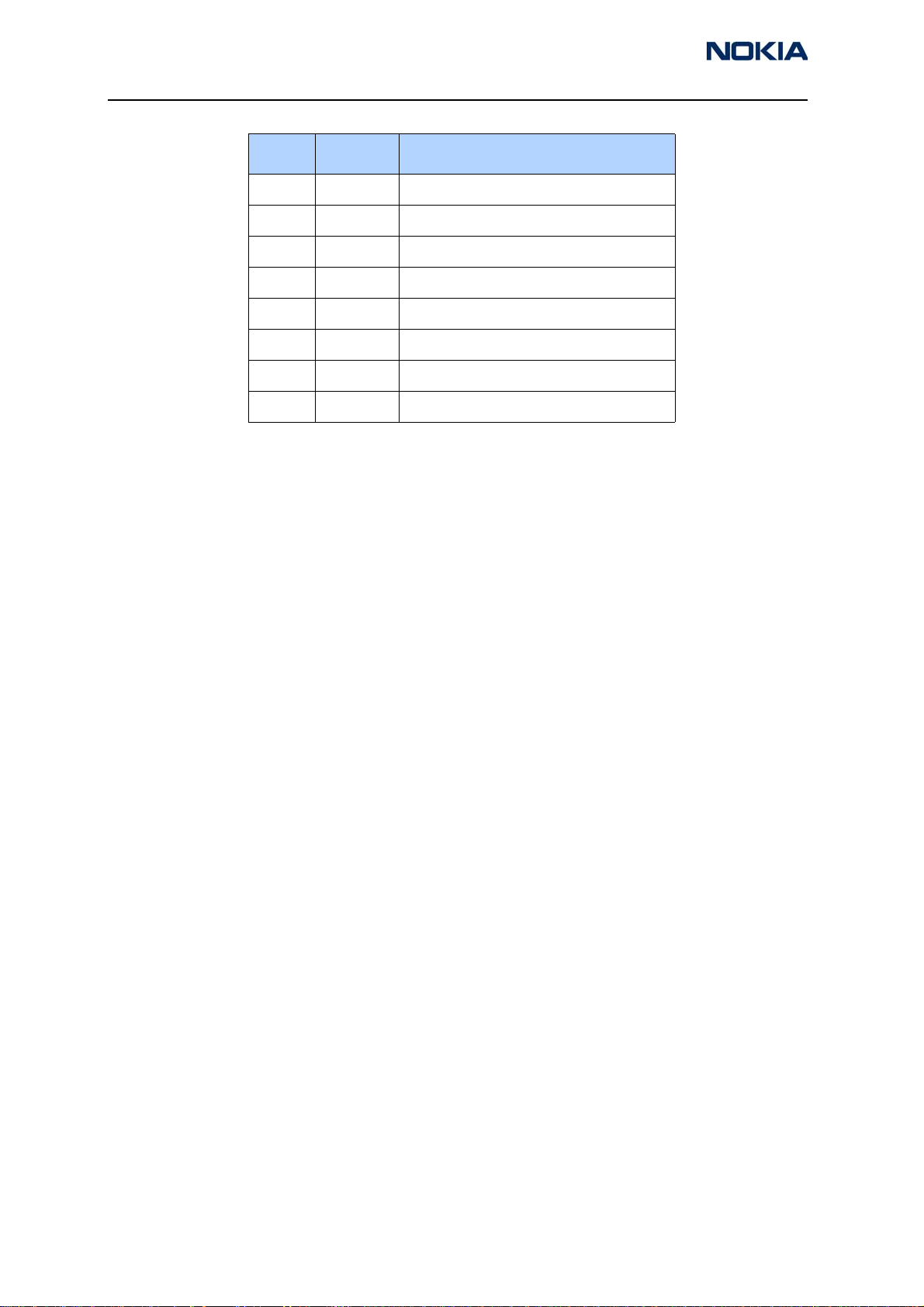

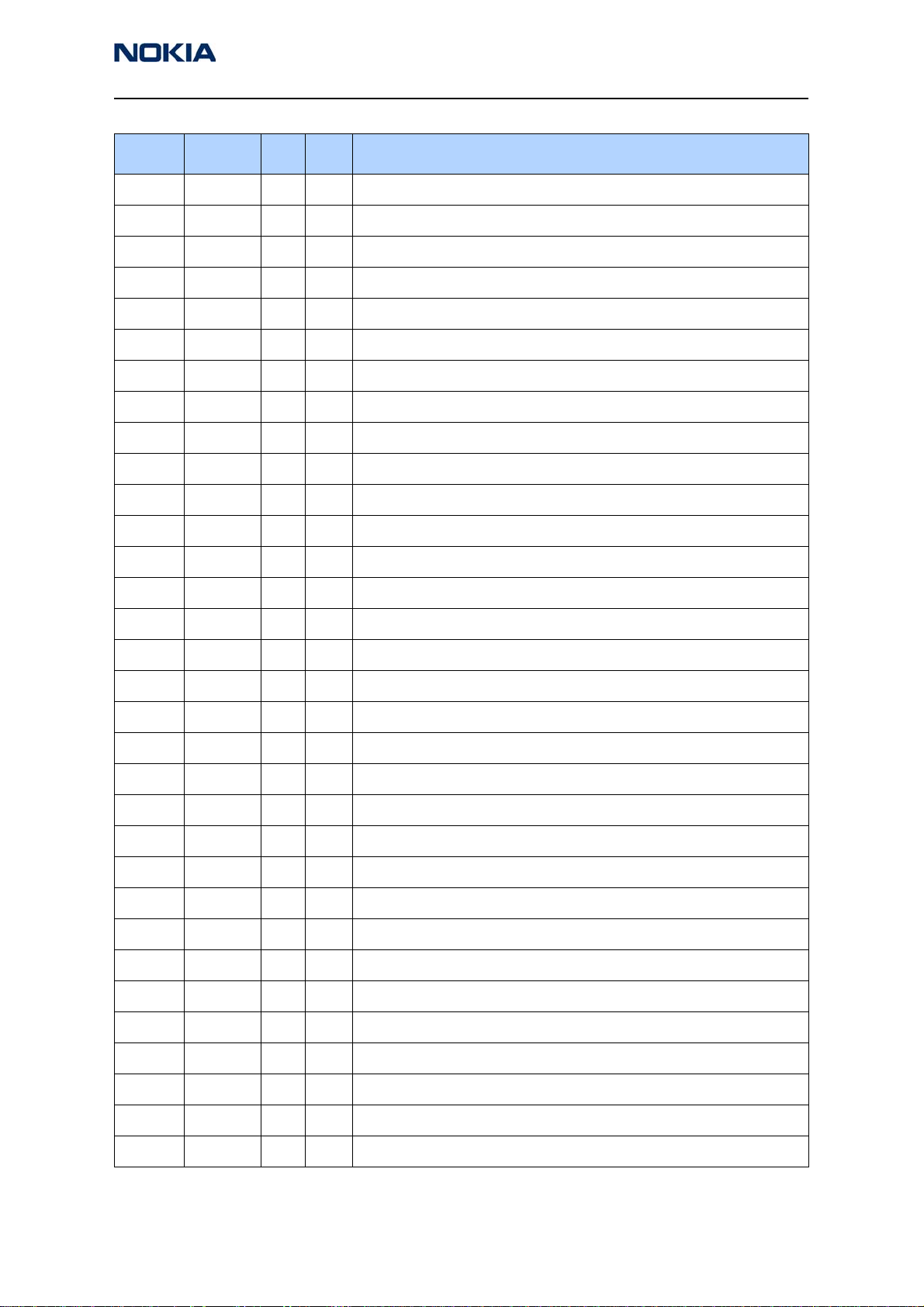

2115i/2116i Parts List — Version 002

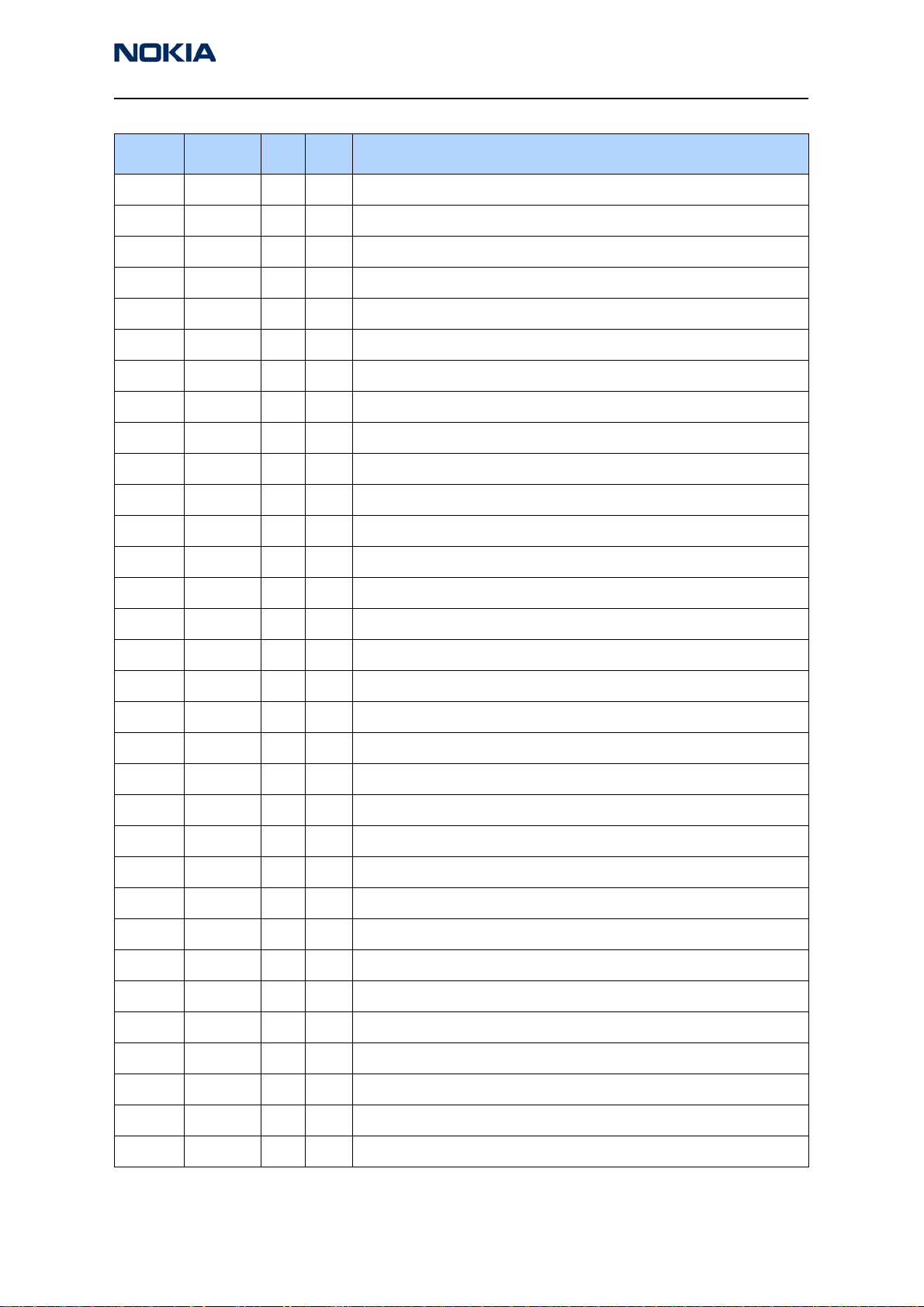

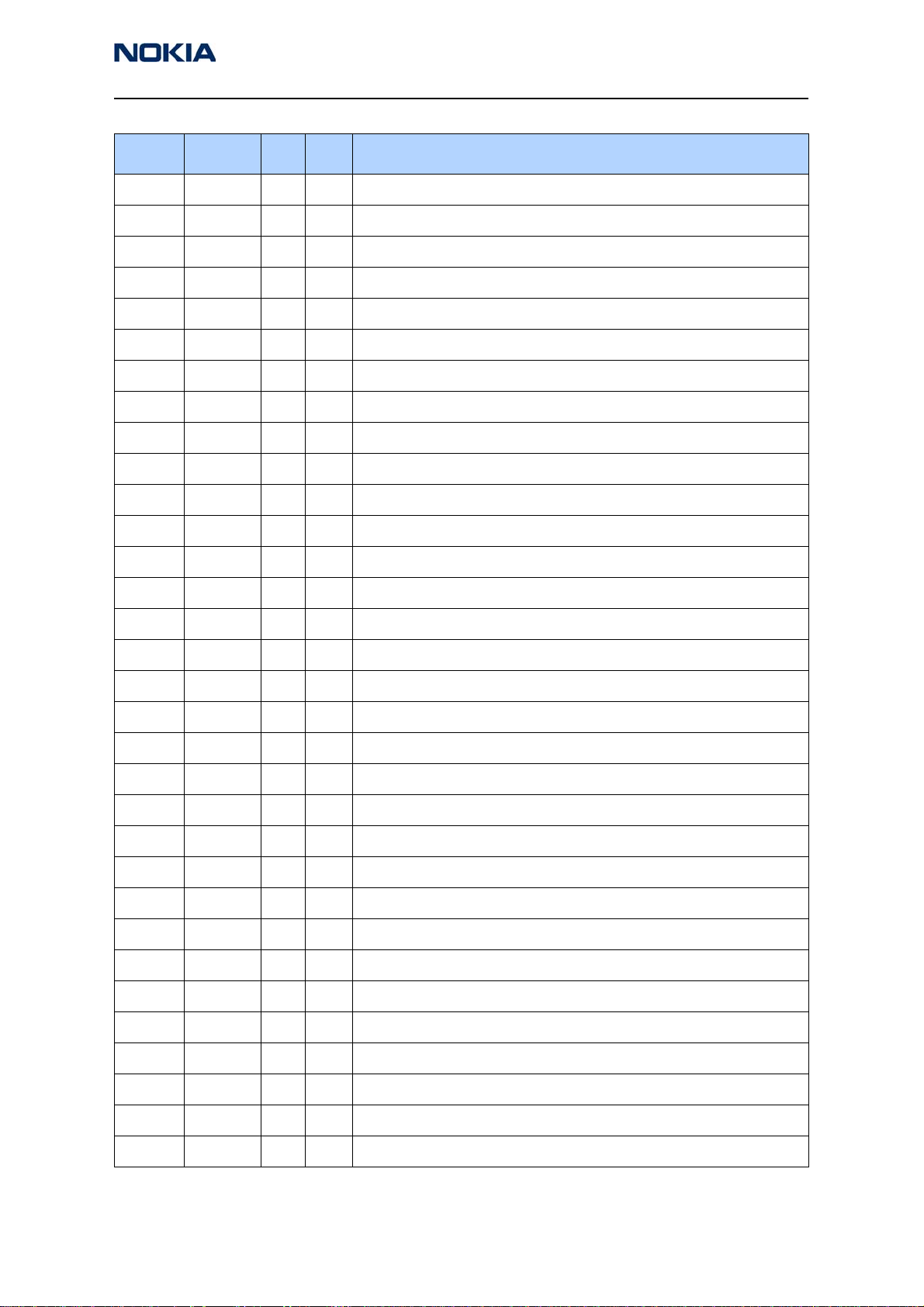

Item Side X Y Description

B2200 Bottom P 2 CRYSTAL 32.768KHZ+-20PPM 12.5PF

C2000 Bottom P 4 CHIPCAP X7R 10N K 50V 0603

C2001 Bottom F 8 CHIPCAP NP0 47P J 50V 0402

C2002 Bottom G 8 CHIPCAP X5R 10U M 6V3 0805

C2003 Bottom F 7 CHIPCAP NP0 47P J 50V 0402

C2004 Top T 5 CHIPCAP X7R 1N0 J 50V 0402

C2006 Bottom L 7 CHIPCAP X5R 1U K 6V3 0603

C2007 Bottom L 7 CHIPCAP X5R 1U K 6V3 0603

C2008 Bottom L 8 CHIPCAP X7R 10N K 16V 0402

C2009 Bottom R 7 CHIPCAP NP0 22P J 50V 0402

C2010 Bottom R 7 CHIPCAP NP0 22P J 50V 0402

C2011 Bottom Q 3 CHIPCAP NP0 22P J 50V 0402

C2012 Top T 6 CHIPCAP X7R 3N3 J 50V 0402

C2013 Top T 6 CHIPCAP X7R 3N3 J 50V 0402

C2014 Top T 7 CHIPCAP X7R 3N3 J 50V 0402

C2015 Top T 7 CHIPCAP X7R 3N3 J 50V 0402

C2100 Bottom O 4 CHIPCAP NP0 39P J 50V 0402

C2101 Bottom O 3 CHIPCAP NP0 39P J 50V 0402

C2102 Bottom P 4 CHIP ARRAY X5R 2X100N Y 10V 0405

C2104 Bottom R 4 CHIPCAP NP0 47P J 50V 0402

C2105 Bottom Q 3 CHIPCAP X5R 100N M 16V 0402

C2106 Bottom O 3 CHIPCAP NP0 39P J 50V 0402

C2107 Bottom O 3 CHIPCAP NP0 39P J 50V 0402

C2108 Bottom P 3 CHIP ARRAY X5R 2X100N Y 10V 0405

C2109 Top T 7 CHIPCAP NP0 47P J 50V 0402

C2110 Top T 7 CHIPCAP X5R 100N M 16V 0402

C2111 Bottom Q 3 CHIPCAP X7R 2N2 J 50V 0402

C2112 Bottom Q 3 CHIPCAP X7R 22N K 16V 0402

C2113 Bottom Q 3 CHIPCAP X7R 22N K 16V 0402

C2114 Bottom P 2 CHIPCAP X5R 1U K 6V3 0603

C2116 Bottom P 3 CHIPCAP X5R 100N M 16V 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 5

Page 20

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

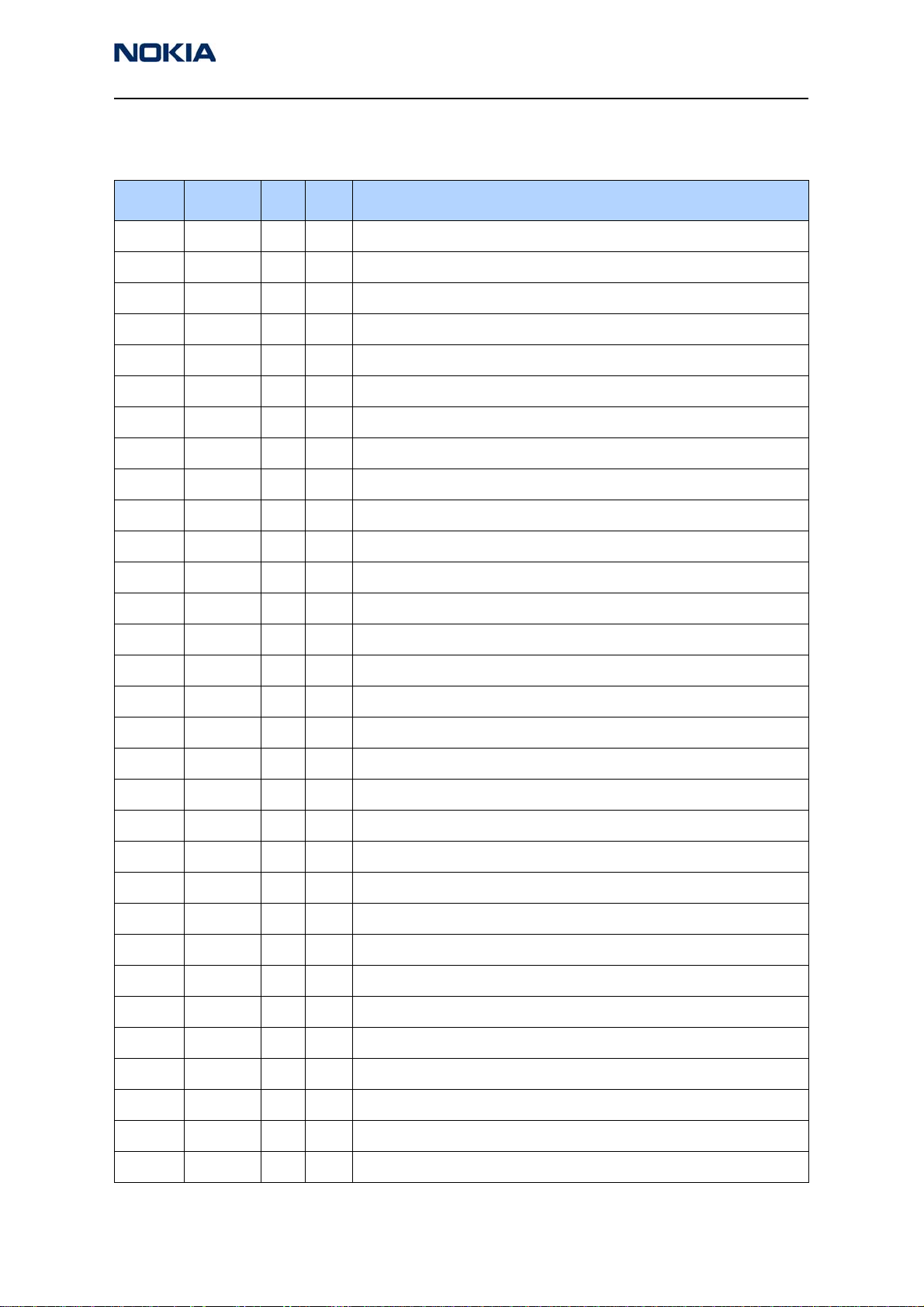

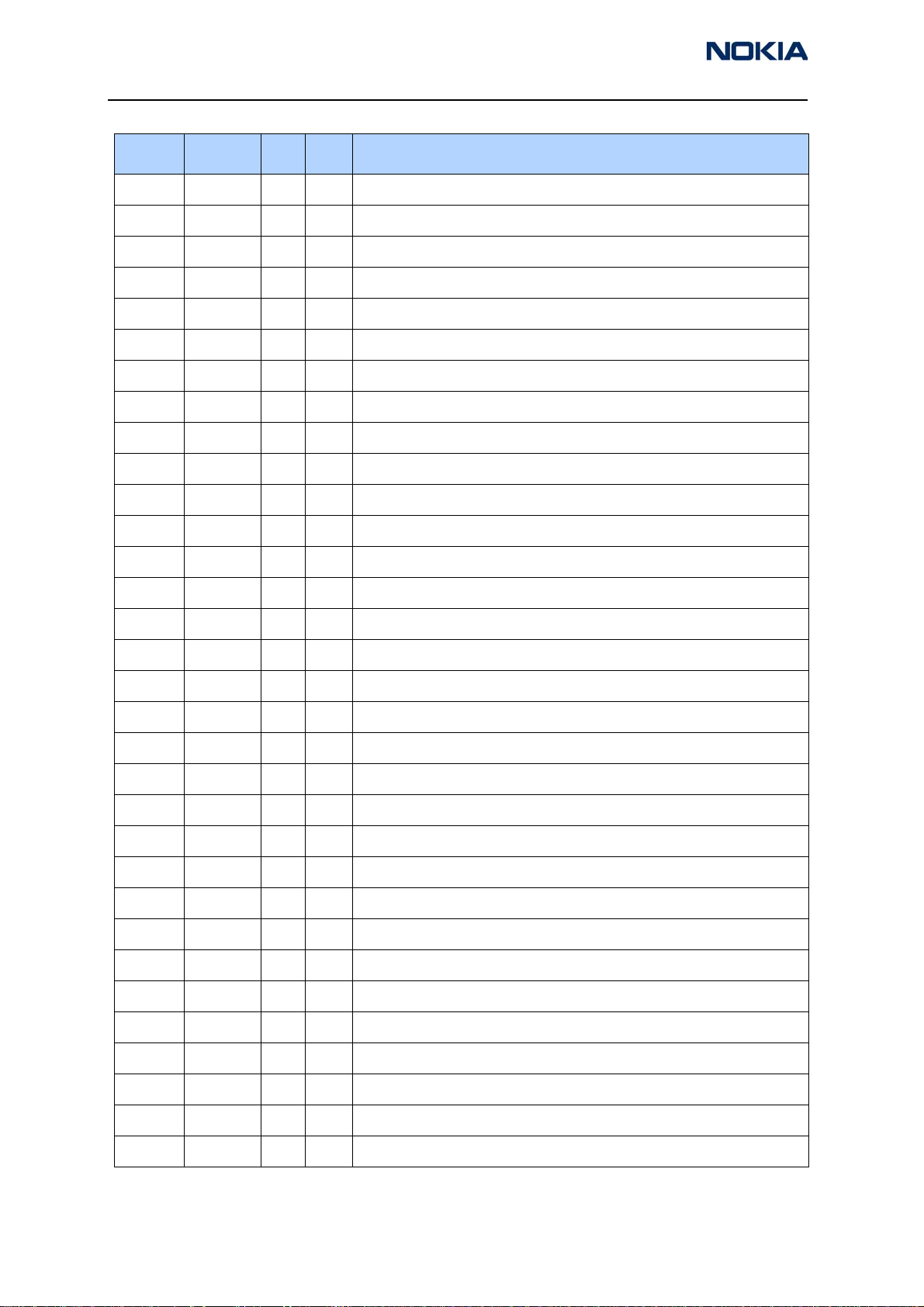

Item Side X Y Description

C2117 Bottom Q 2 CHIPCAP X5R 1U K 6V3 0603

C2118 Bottom P 3 CHIPCAP NP0 22P J 50V 0402

C2200 Bottom M 2 CHIPCAP X5R 1U K 6V3 0603

C2201 Bottom L 2 CHIPCAP X7R 10N K 16V 0402

C2202 Bottom N 2 CHIPCAP X5R 1U K 6V3 0603

C2203 Bottom N 2 CHIPCAP X5R 1U K 6V3 0603

C2204 Bottom O 4 CHIPCAP X5R 1U K 6V3 0603

C2205 Bottom L 2 CHIPCAP X5R 100N M 16V 0402

C2206 Bottom P 2 CHIPCAP NP0 18P J 50V 0402

C2207 Bottom P 2 CHIPCAP NP0 18P J 50V 0402

C2208 Bottom O 3 CHIPCAP X5R 1U K 6V3 0603

C2209 Bottom O 2 CHIPCAP X5R 1U K 6V3 0603

C2210 Bottom O 2 CHIPCAP X5R 1U K 6V3 0603

C2211 Bottom P 3 CHIPCAP X5R 1U K 6V3 0603

C2212 Bottom O 4 CHIPCAP X5R 1U K 6V3 0603

C2213 Bottom O 5 CHIPCAP X5R 1U K 6V3 0603

C2214 Bottom O 4 CHIPCAP X5R 1U K 6V3 0603

C2215 Bottom L 2 CHIPCAP X5R 10U M 6V3 0805

C2216 Bottom P 4 CHIPCAP X5R 100N M 16V 0402

C2217 Bottom P 5 CHIPCAP X5R 100N M 16V 0402

C2218 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2219 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2220 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2221 Bottom L 4 CHIPCAP X5R 100N M 16V 0402

C2222 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2223 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2224 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2225 Bottom M 2 CHIPCAP X5R 220N K 6.3V 0402

C2226 Bottom L 2 CHIPCAP X5R 1U K 6V3 0603

C2227 Bottom P 4 CHIPCAP X7R 10N K 16V 0402

C2228 Bottom P 4 CHIPCAP X7R 10N K 16V 0402

C2229 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

Page 6 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 21

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

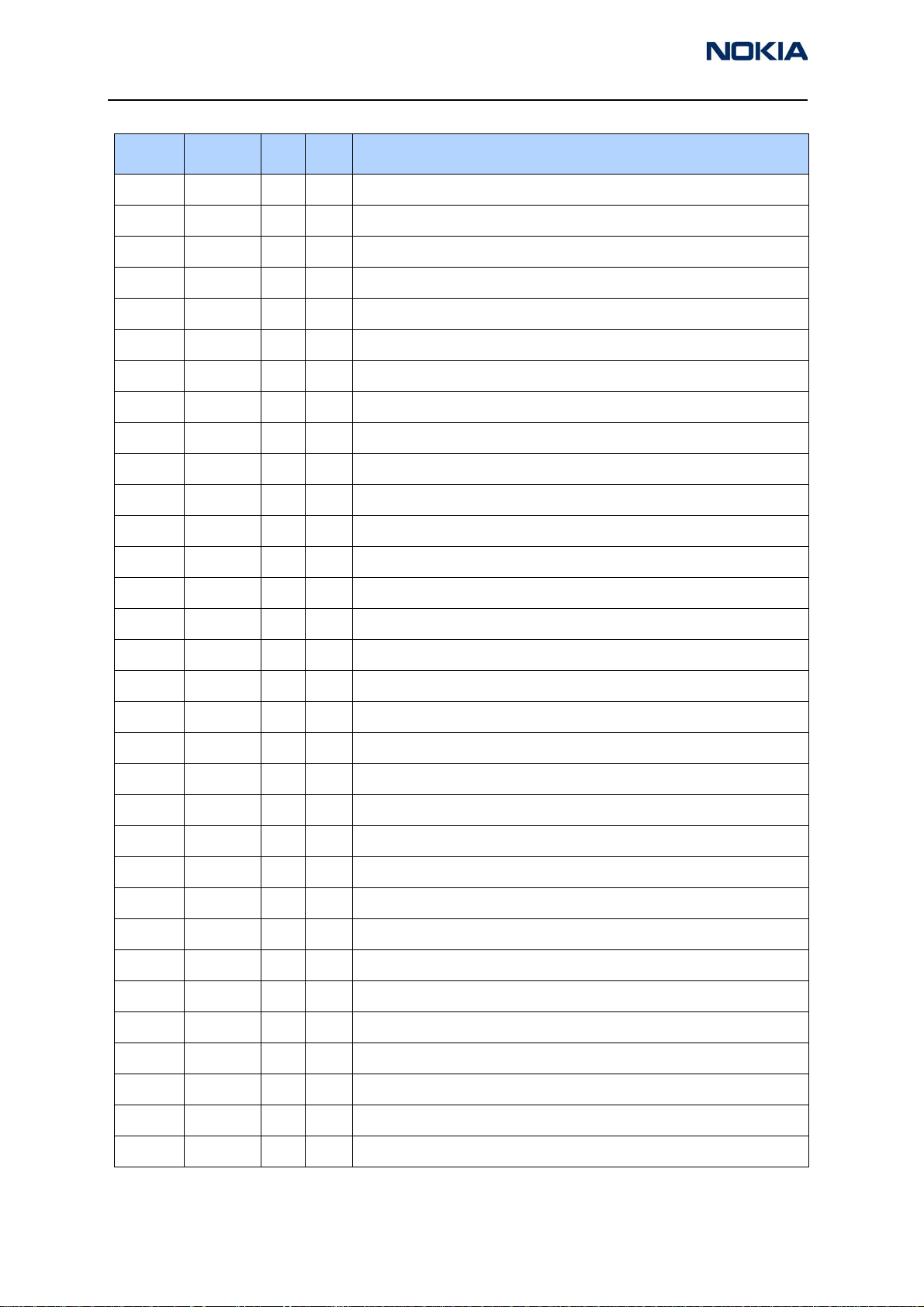

Item Side X Y Description

C2230 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2231 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2232 Bottom L 2 CHIPCAP X5R 1U K 6V3 0603

C2233 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2234 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2235 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2236 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2237 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2300 Bottom M 8 CHIPCAP X5R 10U M 6V3 0805

C2301 Bottom L 8 CHIPCAP X5R 100N M 16V 0402

C2302 Bottom L 8 CHIPCAP X5R 10U M 6V3 0805

C2400 Top C 6 CHIPCAP X5R 100N M 16V 0402

C2401 Top C 6 CHIPCAP X5R 100N M 16V 0402

C2403 Top A 6 CHIPCAP NP0 47P J 50V 0402

C2404 Bottom N 8 CHIPCAP X5R 1U0 M 25V 1206

C2405 Bottom L 7 CHIPCAP X5R 100N M 16V 0402

C2406 Bottom B 5 CHIPCAP NP0 22P J 50V 0402

C2407 Bottom M 8 CHIPCAP X5R 1U K 6V3 0603

C2700 Bottom R 8 CHIPCAP X5R 100N M 16V 0402

C2880 Bottom P 5 CHIPCAP X5R 100N M 16V 0402

C2881 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2882 Bottom M 7 CHIPCAP X5R 100N M 16V 0402

C2883 Bottom O 7 CHIPCAP X5R 100N M 16V 0402

C2884 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2885 Bottom N 7 CHIPCAP X5R 100N M 16V 0402

C2900 Bottom O 7 CHIPCAP X7R 10N K 16V 0402

C2901 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C2902 Bottom O 7 CHIPCAP X7R 10N J 16V 0402

C2903 Bottom N 8 CHIPCAP X7R 1N0 K 50V 0402

C2904 Bottom O 8 CHIPCAP X7R 33N K 10V 0402

C2905 Bottom O 8 CHIPCAP X7R 10N J 16V 0402

C2906 Bottom O 8 CHIPCAP X7R 1N0 K 50V 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 7

Page 22

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

C2907 Bottom O 8 CHIPCAP X7R 33N K 10V 0402

C3000 Bottom L 5 CHIPCAP X7R 10N K 16V 0402

C3001 Bottom L 5 CHIPCAP X5R 100N M 16V 0402

C3002 Bottom M 5 CHIPCAP X7R 10N K 16V 0402

C6200 Bottom K 4 CHIPCAP X5R 100N M 16V 0402

C6201 Bottom K 4 CHIPCAP X5R 100N M 16V 0402

C6202 Bottom I 4 CHIPCAP X5R 100N M 16V 0402

C6203 Bottom I 4 CHIPCAP X5R 100N M 16V 0402

C6204 Bottom I 4 CHIPCAP X5R 100N M 16V 0402

C6205 Bottom K 4 CHIPCAP X5R 100N M 16V 0402

C6206 Bottom K 5 CHIPCAP X5R 100N M 16V 0402

C6207 Bottom L 7 CHIPCAP X5R 2U2 K 6V3 0603

C6208 Bottom K 8 CHIPCAP X7R 10N J 16V 0402

C6209 Bottom K 7 CHIPCAP X5R 2U2 K 6V3 0603

C6250 Bottom E 3 CHIPCAP X5R 100N M 16V 0402

C6251 Bottom E 3 CHIPCAP NP0 27P J 50V 0402

C6252 Bottom E 4 CHIPCAP X5R 1U K 6V3 0402

C6253 Bottom J 2 CHIPCAP X7R 10N K 16V 0402

C6254 Bottom F 4 CHIPCAP NP0 47P J 50V 0402

C6255 Bottom J 2 CHIPCAP NP0 10P J 50V 0402

C6256 Bottom F 3 CHIPCAP NP0 6P8 C 50V 0402

C6257 Bottom E 4 CHIPCAP NP0 10P J 50V 0402

C6258 Bottom I 3 CHIPCAP NP0 2P7 C 50V 0402

C6259 Bottom I 3 CHIPCAP NP0 15P J 50V 0402

C6260 Bottom D 2 CHIPCAP NP0 2P2 C 50V 0402

C6261 Bottom I 2 CHIPCAP X7R 10N J 16V 0402

C6262 Bottom J 2 CHIPCAP X7R 10N J 16V 0402

C6263 Bottom I 3 CHIPCAP X7R 10N J 16V 0402

C6264 Bottom J 2 CHIPCAP NP0 22P J 50V 0402

C6265 Bottom J 2 CHIPCAP NP0 22P J 50V 0402

C6266 Bottom I 3 CHIPCAP NP0 22P J 50V 0402

C6267 Bottom I 3 CHIPCAP X5R 100N M 16V 0402

Page 8 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 23

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

C6268 Bottom K 2 CHIPCAP NP0 22P J 50V 0402

C6269 Bottom K 3 CHIPCAP X5R 100N M 16V 0402

C7000 Bottom I 8 CHIPCAP X7R 10N J 16V 0402

C7001 Bottom J 7 CHIPCAP X5R 100N M 16V 0402

C7002 Bottom I 8 CHIPCAP X7R 10N J 16V 0402

C7003 Bottom I 7 CHIPCAP NP0 10P J 50V 0402

C7004 Bottom I 7 CHIPCAP NP0 1P2 C 50V 0402

C7005 Bottom I 7 CHIPCAP NP0 1P2 C 50V 0402

C7006 Bottom J 8 CHIPCAP NP0 3P3 C 50V 0402

C7007 Bottom J 8 CHIPCAP NP0 220P J 25V 0402

C7008 Bottom I 7 CHIPCAP X7R 10N J 16V 0402

C7009 Bottom I 7 CHIPCAP NP0 47P J 50V 0402

C7010 Bottom I 8 CHIPCAP NP0 10P J 50V 0402

C7012 Bottom I 8 CHIPCAP NP0 0P5 C 50V 0402

C7013 Bottom I 7 CHIPCAP NP0 0P5 C 50V 0402

C7014 Bottom J 8 CHIPCAP NP0 100P J 50V 0402

C7015 Bottom K 8 CHIPCAP NP0 2N2 J 16V 0603

C7016 Bottom J 8 CHIPCAP NP0 100P J 50V 0402

C7018 Bottom I 8 CHIPCAP X7R 10N J 16V 0402

C7019 Bottom I 8 CHIPCAP NP0 18P J 50V 0402

C7020 Bottom J 8 CHIPCAP X5R 1U K 6V3 0402

C7021 Bottom J 8 CHIPCAP NP0 18P J 50V 0402

C7022 Bottom K 8 CHIPCAP X7R 10N J 16V 0402

C7023 Bottom J 7 CHIPCAP NP0 33P J 50V 0402

C7024 Bottom J 7 CHIPCAP NP0 18P J 50V 0402

C7025 Bottom J 7 CHIPCAP NP0 33P J 50V 0402

C7027 Bottom I 8 CHIPCAP NP0 3P3 C 50V 0402

C7028 Bottom I 8 CHIPCAP NP0 3P3 C 50V 0402

C7029 Bottom J 8 CHIPCAP NP0 8P2 C 50V 0402

C7030 Bottom J 7 CHIPCAP NP0 8P2 C 50V 0402

C7100 Bottom H 6 CHIPCAP X7R 10N J 16V 0402

C7101 Bottom H 6 CHIPCAP X5R 330N K 10V 0603

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 9

Page 24

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

C7102 Bottom H 6 CHIPCAP X7R 33N K 10V 0402

C7103 Bottom G 6 CHIPCAP NP0 33P J 50V 0402

C7104 Bottom G 6 CHIPCAP X7R 1N0 J 50V 0402

C7105 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7106 Bottom H 5 CHIPCAP X7R 10N K 16V 0402

C7107 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7108 Bottom G 5 CHIPCAP X7R 10N K 16V 0402

C7109 Bottom G 5 CHIPCAP X7R 10N K 16V 0402

C7110 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7111 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7112 Bottom F 5 CHIPCAP X7R 10N K 16V 0402

C7113 Bottom G 5 CHIPCAP X7R 10N K 16V 0402

C7160 Bottom C 5 CHIPCAP NP0 56P J 50V 0402

C7161 Bottom C 6 CHIPCAP NP0 2P2 C 50V 0402

C7162 Bottom C 4 CHIPCAP X5R 100N M 16V 0402

C7163 Bottom C 4 CHIPCAP NP0 10P J 50V 0402

C7164 Bottom C 4 CHIPCAP NP0 0P5 C 50V 0402

C7165 Bottom C 4 CHIPCAP NP0 1P5 C 50V 0402

C7166 Bottom D 6 CHIPCAP NP0 100P J 50V 0402

C7168 Bottom D 5 CHIPCAP NP0 5P6 C 50V 0402

C7169 Bottom F 5 CHIPCAP NP0 6P8 C 50V 0402

C7170 Bottom D 5 CHIPCAP X7R 1N0 J 50V 0402

C7171 Bottom E 5 CHIPCAP NP0 10P J 50V 0402

C7172 Bottom D 6 CHIPCAP NP0 3P9 C 50V 0402

C7173 Bottom D 5 CHIPCAP NP0 4P7 C 50V 0402

C7174 Bottom F 5 CHIPCAP NP0 6P8 C 50V 0402

C7175 Bottom C 3 CHIPCAP NP0 100P J 50V 0402

C7176 Bottom D 4 CHIPCAP X7R 3N3 J 50V 0402

C7177 Bottom D 4 CHIPCAP X7R 3N3 J 50V 0402

C7178 Bottom E 5 CHIPCAP X5R 100N M 16V 0402

C7179 Bottom D 4 CHIPCAP NP0 22P J 50V 0402

C7180 Bottom E 4 CHIPCAP NP0 2P2 C 50V 0402

Page 10 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 25

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

C7181 Bottom C 3 CHIPCAP NP0 100P J 50V 0402

C7182 Bottom G 4 CHIPCAP NP0 8P2 C 50V 0402

C7183 Bottom E 5 CHIPCAP NP0 100P J 50V 0402

C7184 Bottom C 5 CHIPCAP X7R 47N K 10V 0402

C7185 Bottom D 4 CHIPCAP NP0 12P J 50V 0402

C7186 Bottom C 4 CHIPCAP NP0 100P J 50V 0402

C7188 Bottom G 4 CHIPCAP NP0 8P2 C 50V 0402

C7200 Bottom L 4 CHIPCAP X5R 1U K 6V3 0402

C7203 Bottom L 4 CHIPCAP X7R 10N J 16V 0402

C7204 Bottom L 5 CHIPCAP X7R 1N0 J 50V 0402

C7206 Bottom L 5 CHIPCAP NP0 470P J 6V3 0402

C7207 Bottom L 4 CHIPCAP X7R 1N0 J 50V 0402

C7209 Bottom I 8 CHIPCAP NP0 470P J 6V3 0402

C7210 Bottom I 6 CHIPCAP NP0 470P J 6V3 0402

C7211 Bottom J 6 CHIPCAP X7R 470P J 50V 0402

C7212 Bottom I 5 CHIPCAP X7R 10N J 16V 0402

C7213 Bottom J 5 CHIPCAP X5R 100N M 16V 0402

C7214 Bottom J 6 CHIPCAP NP0 47P J 50V 0402

C7215 Bottom G 2 CHIPCAP X5R 1U K 6V3 0402

C7216 Bottom G 2 CHIPCAP X7R 10N J 16V 0402

C7218 Bottom J 6 CHIPCAP X7R 3N3 J 50V 0402

C7219 Bottom I 6 CHIPCAP X7R 1N0 J 50V 0402

C7220 Bottom I 5 CHIPCAP X7R 1N0 J 50V 0402

C7221 Bottom I 6 CHIPCAP X7R 33N K 10V 0402

C7222 Bottom I 6 CHIPCAP X7R 6N8 K 25V 0402

C7223 Bottom G 3 CHIPCAP NP0 1P8 C 50V 0402

C7224 Bottom H 4 CHIPCAP X5R 100N M 16V 0402

C7225 Bottom K 6 CHIPCAP X7R 10N J 16V 0402

C7226 Bottom K 5 CHIPCAP X5R 100N M 16V 0402

C7304 Bottom E 7 CHIPCAP X7R 1N0 J 50V 0402

C7306 Bottom E 8 CHIPCAP X7R 10N J 16V 0402

C7307 Bottom D 7 CHIPCAP NP0 15P J 50V 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 11

Page 26

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

C7308 Bottom E 9 CHIPCAP NP0 2P7 C 50V 0402

C7309 Bottom E 9 CHIPCAP X7R 1N0 J 50V 0402

C7310 Bottom E 7 CHIPCAP X5R 10U M 6V3 0805

C7311 Bottom C 8 CHIPCAP X7R 10N J 16V 0402

C7312 Bottom C 8 CHIPCAP X7R 3N3 J 50V 0402

C7313 Bottom C 8 CHIPCAP X7R 3N3 J 50V 0402

C7314 Bottom D 7 CHIPCAP NP0 47P J 50V 0402

C7315 Bottom D 6 CHIPCAP NP0 2P7 C 50V 0402

C7316 Bottom K 8 CHIPCAP X7R 1N0 J 50V 0402

C7317 Bottom E 7 CHIPCAP X7R 1N0 J 50V 0402

C7318 Bottom E 6 CHIPCAP NP0 100P J 50V 0402

C7319 Bottom D 6 CHIPCAP X7R 1N0 J 50V 0402

C7320 Bottom D 7 CHIPCAP X7R 1N0 J 50V 0402

C7321 Bottom E 7 CHIPCAP NP0 3P3 C 50V 0402

C7322 Bottom D 8 CHIPCAP NP0 2P2 C 50V 0402

D2200 Bottom N 4 UEMC 4.4 LF W/DOG ENA VCORE1V5

D2400 Bottom P 4 DIX2 BAV70W CC 70V .5A 4NS SOT323

D2401 Top Q 4 LED LW L283 WHITE 0603

D2402 Top Q 6 LED LW L283 WHITE 0603

D2403 Top N 4 LED LW L283 WHITE 0603

D2404 Top N 6 LED LW L283 WHITE 0603

D2405 Top A 5 LED CL430S-WF WHITE >500MCDD?20MA

D2800 Bottom N 6 UPP8M v4.2/v4.3/4.31 C027 12x12 UBGA144

D3000 Bottom L 6 FLASH 4MX16 1V8/1V8 VFBGA44 PBFREE

D6200 Bottom J 4 TWL5001 GPS BB ASIC V2.0 UBGA143

F2000 Top T 4 SM FUSE F 1.5A 32V ROHS-FREE 0603

G7200 Bottom L 5 VCTCXO 19.2MHZ +-2PPM 2.78V 2.2MA

G7201 Bottom H 3 UHF VCO 986-1034MHz/2040-2140MHz

L2000 Top T 4 FERR.BEAD 0R03 42R/100MHZ 3A 0805

L2001 Top T 6 FERRITE BEAD 600R 300MA 0.6R 0402

L2002 Top T 6 FERRITE BEAD 600R 300MA 0.6R 0402

L2003 Top T 6 CHIP BEAD ARRAY 2X1000R 0405

Page 12 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 27

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

L2004 Top T 7 CHIP BEAD ARRAY 2X1000R 0405

L2100 Bottom B 3 FERR.BEAD 240R/100M 0.4A 0R3 0402

L2101 Bottom B 3 FERR.BEAD 240R/100M 0.4A 0R3 0402

L2300 Bottom L 8 FERR.BEAD 0R03 42R/100MHZ 3A 0805

L2301 Bottom M 8 CHOKE 10UH M 0.49A 3.0X2.8X1.2MM

L2400 Bottom M 7 FERR.BEAD 0R03 42R/100MHZ 3A 0805

L2401 Bottom N 8 CHOKE 22U M 1R4 0.33A 3.3X3.3X1.5

L6250 Bottom E 4 CHIP COIL 15N J Q30/800MHZ 0402

L6251 Bottom F 3 CHIP COIL 3N9 +-0N3 Q28/800M 0402

L6252 Bottom I 3 CHIP COIL 8N2 J Q28/800MHZ 0402

L6253 Bottom D 2 CHIP COIL 15N J Q30/800MHZ 0402

L7000 Bottom I 7 CHIP COIL 27N J Q27/800MHZ 0402

L7001 Bottom I 7 CHIP COIL 33N J Q23/800MHZ 0402

L7002 Bottom I 7 CHIP COIL 27N J Q27/800MHZ 0402

L7003 Bottom I 8 CHIP COIL 6N8 J Q27/800MHZ 0402

L7004 Bottom I 7 CHIP COIL 12N J Q31/800MHZ 0402

L7005 Bottom I 8 CHIP COIL 6N8 J Q27/800MHZ 0402

L7101 Bottom G 6 CHIP COIL 33NH J Q12/100MHZ 0603

L7160 Bottom C 5 CHIP COIL 15N J Q30/800MHZ 0402

L7161 Bottom C 4 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7162 Bottom C 5 CHIP COIL 6N2 J Q20/250MHZ 0402

L7163 Bottom C 5 CHIP COIL 19N J Q25/250MHZ 0402

L7164 Bottom D 5 CHIP COIL 220N J Q8/50MHZ 0603

L7165 Bottom F 5 CHIP COIL 120N J Q16/100MHZ 0603

L7166 Bottom D 3 CHIP COIL 12N J Q31/800MHZ 0402

L7167 Bottom D 5 CHIP COIL 180N J Q13/100MHZ 0603

L7168 Bottom F 5 CHIP COIL 220N J Q8/50MHZ 0603

L7169 Bottom F 6 CHIP COIL 120N J Q16/100MHZ 0603

L7170 Bottom D 5 CHIP COIL 82N +-0N3 Q17/300M 0402

L7171 Bottom D 4 CHIP COIL 18N J Q29/800MHZ 0402

L7172 Bottom D 5 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7173 Bottom D 5 CHIP COIL 82N +-0N3 Q17/300M 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 13

Page 28

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

L7174 Bottom E 5 CHIP COIL 120N J Q16/100MHZ 0603

L7175 Bottom D 5 CHIP COIL 15N J Q30/800MHZ 0402

L7176 Bottom G 4 CHIP COIL 120N J Q16/100MHZ 0603

L7177 Bottom G 4 CHIP COIL 120N J Q16/100MHZ 0603

L7178 Bottom F 6 CHIP COIL 220N J Q8/50MHZ 0603

L7179 Bottom G 4 CHIP COIL 100N J Q12/100MHZ 0603

L7200 Bottom G 3 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7302 Bottom C 7 DIR.COUPLER 1850-1910MHZ 1.6X0.8

L7304 Bottom C 6 CHIP COIL 10N J Q30/800MHZ 0402

L7305 Bottom E 7 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7306 Bottom C 7 DIR.COUPLER 824-849MHZ 1.6X0.8MM

L7308 Bottom D 8 CHIP COIL 3N9 +-0N3 Q28/800M 0402

L7310 Bottom K 8 CHIP COIL 27N J Q27/800MHZ 0402

N2000 Bottom L 8 VREG LP3985ITLX-2.8 NOPB USMD5

N2100 Bottom P 3 AF AMP 0.4W LM4890/NCP2890 PBFREE

N2300 Bottom M 8 DC/DC CONV LM2708H-1.35V/1.05V

N2400 Bottom N 8 DC/DC CONV TK65600 USMD8

N6200 Bottom L 8 VREG LP3985ITLX-2.8 NOPB USMD5

N6250 Bottom K 3 TCXO 16.368MHZ+-1.5PPM 2.8V GPS

N6251 Bottom J 3 GPS RX TRF5101 PG2.1 PBGA-49

N7000 Bottom J 8 JUPITER D4 PMB3365G VQFN-40

N7100 Bottom H 5 BATMAN RF RX ASIC STB7102FTR

N7160 Bottom D 5 LNA/MIXER/DOWNCNTR ALFRED VQFN-24

N7200 Bottom J 6 1XPLL/SYNTH 2.5GHZ(LMX2310U)MLF20

N7300 Bottom C 8 ASIP STPAC01F2 CDMA PWR DET BGA-8

N7301 Bottom E 7 PW AMP RF3449 CDMA800 LFM

N7302 Bottom E 8 PW AMP RF3448 CDMA1900

R2000 Bottom O 8 NTC RES 0W1 47K J B 4050+-3% 0402

R2001 Bottom L 8 CHIPRES 0W06 100K J 0402

R2002 Bottom Q 3 CHIPRES 0W06 100K J 0402

R2003 Bottom Q 3 RES NETWORK 0W06 2X47R J 0404

R2004 Bottom R 7 RES NETWORK 0W06 2X47R J 0404

Page 14 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 29

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

R2006 Bottom R 7 RES NETWORK 0W06 2X47R J 0404

R2007 Bottom R 8 CHIPRES 0W06 220K J 0402

R2008 Top T 6 VARISTOR ARRAY 2XVWM16V VC50 0405

R2009 Top T 8 VARISTOR ARRAY 2XVWM16V VC50 0405

R2100 Bottom B 5 RES NETWORK 0W06 2X5R6 J 0404

R2101 Bottom O 4 RES NETWORK 0W06 2X1K0 J 0404

R2102 Bottom P 4 CHIPRES 0W06 47K J 0402

R2103 Bottom Q 4 RES NETWORK 0W06 2X1K0 J 0404

R2104 Bottom R 3 RES NETWORK 0W06 2X1K0 J 0404

R2105 Bottom B 5 VARISTOR ARRAY 2XVWM16V VC50 0405

R2106 Bottom O 3 RES NETWORK 0W06 2X1K0 J 0404

R2107 Bottom P 3 CHIPRES 0W06 47K J 0402

R2108 Top T 7 RES NETWORK 0W06 2X1K0 J 0404

R2109 Top T 7 RES NETWORK 0W06 2X1K0 J 0404

R2110 Top T 8 RES NETWORK 0W06 2X5R6 J 0404

R2111 Bottom Q 3 CHIPRES 0W06 470R J 0402

R2112 Bottom Q 3 CHIPRES 0W06 5K6 J 0402

R2113 Bottom Q 3 CHIPRES 0W06 180K F 200PPM 0402

R2200 Bottom M 2 CHIPRES 0W25 0R22 J 0805

R2201 Bottom P 5 RES NETWORK 0W03 4X100K J 0804

R2202 Bottom P 4 RES NETWORK 0W06 2X4K7 J 0404

R2205 Bottom R 7 CHIPRES 0W06 10K J 0402

R2403 Bottom Q 4 CHIPRES 0W06 33R J 0402

R2404 Bottom Q 4 CHIPRES 0W06 68R J 0402

R2405 Bottom Q 4 CHIPRES 0W06 68R J 0402

R2407 Bottom Q 4 CHIPRES 0W06 150R J 0603

R2408 Bottom Q 4 CHIPRES 0W06 150R J 0603

R2409 Bottom A 5 CHIPRES 0W06 4K7 J 0402

R2410 Bottom Q 4 CHIPRES 0W06 3K3 J 0402

R2411 Bottom N 8 CHIPRES 0W06 22K F 200PPM 0402

R2412 Bottom N 8 CHIPRES 0W06 1K3 F 250PPM 0402

R2700 Bottom R 7 ASIP SIM INTERFACE ** PB-FREE **

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 15

Page 30

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

R2900 Bottom O 7 CHIPRES 0W06 4K7 J 0402

R2901 Bottom O 7 CHIPRES 0W06 1K0 J 0402

R2902 Bottom O 7 CHIPRES 0W06 4K7 J 0402

R2903 Bottom O 8 CHIPRES 0W06 1K0 J 0402

R2904 Bottom O 8 CHIPRES 0W06 4K7 J 0402

R3000 Bottom M 5 CHIPRES 0W06 4K7 J 0402

R6202 Bottom I 4 CHIPRES 0W06 100K J 0402

R6203 Bottom L 8 CHIPRES JUMPER 0R0 0402

R6204 Bottom I 4 CHIPRES 0W06 100K J 0402

R6250 Bottom E 3 CHIPRES 0W06 120R J 0402

R6251 Bottom E 3 CHIPRES 0W06 22K J 0402

R6252 Bottom E 4 CHIPRES 0W06 10R J 0402

R6253 Bottom F 3 CHIPRES 0W06 150R J 0402

R7000 Bottom I 8 CHIPRES JUMPER 0R0 0402

R7001 Bottom J 8 CHIPRES 0W06 10K J 0402

R7002 Bottom J 8 CHIPRES 0W06 27K J 0402

R7003 Bottom I 7 CHIPRES 0W06 12K J 0402

R7004 Bottom K 7 CHIPRES JUMPER 0R0 0402

R7005 Bottom J 7 CHIPRES JUMPER 0R0 0402

R7006 Bottom K 7 CHIPRES JUMPER 0R0 0402

R7007 Bottom J 7 CHIPRES JUMPER 0R0 0402

R7008 Bottom H 8 CHIPRES JUMPER 0R0 0402

R7009 Bottom K 7 CHIPRES 0W06 150R J 0402

R7010 Bottom K 7 CHIPRES 0W06 100R J 0402

R7011 Bottom K 7 CHIPRES 0W06 33K J 0402

R7012 Bottom J 7 CHIPRES 0W06 2K2 J 0402

R7013 Bottom J 7 CHIPRES 0W06 39K J 0402

R7100 Bottom G 6 CHIPRES 0W06 1K0 J 0402

R7101 Bottom H 5 CHIPRES 0W06 470R J 0402

R7102 Bottom G 6 CHIPRES 0W06 4K7 J 0402

R7103 Bottom H 4 CHIPRES 0W06 8K2 J 0402

R7104 Bottom H 5 CHIPRES 0W06 27K J 0402

Page 16 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 31

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

R7160 Bottom C 4 CHIPRES 0W06 4R3 J 0402

R7161 Bottom C 3 CHIPRES 0W06 47K J 0402

R7162 Bottom D 4 CHIPRES 0W06 82R J 0402

R7163 Bottom C 3 CHIPRES 0W06 47K J 0402

R7164 Bottom D 4 CHIPRES 0W06 4R3 J 0402

R7165 Bottom C 4 CHIPRES 0W06 47K J 0402

R7200 Bottom L 4 CHIPRES 0W06 10R J 0402

R7204 Bottom L 5 CHIPRES 0W06 1K0 J 0402

R7205 Bottom L 4 CHIPRES 0W06 10K J 0402

R7208 Bottom J 5 CHIPRES 0W06 10R J 0402

R7209 Bottom G 2 CHIPRES JUMPER 0R0 0402

R7210 Bottom G 3 CHIPRES 0W06 150R J 0402

R7211 Bottom I 6 CHIPRES 0W06 10K J 0402

R7212 Bottom I 5 CHIPRES 0W06 10K J 0402

R7213 Bottom J 6 CHIPRES 0W06 3K9 J 0402

R7215 Bottom H 4 CHIPRES 0W06 2K2 J 0402

R7216 Bottom K 6 CHIPRES 0W06 10R J 0402

R7300 Bottom E 8 CHIPRES JUMPER 0R0 0402

R7301 Bottom C 7 CHIPRES 0W06 56R J 0402

R7302 Bottom C 7 CHIPRES JUMPER 0R0 0402

R7304 Bottom H 8 CHIPRES 0W06 100R J 0402

R7305 Bottom I 8 CHIPRES 0W06 100R J 0402

R7307 Bottom C 6 CHIPRES 0W06 56R J 0402

R7308 Bottom E 7 CHIPRES JUMPER 0R0 0402

R7309 Bottom F 8 NTC RES 0W1 47K J B 4050+-3% 0402

R7330 Bottom E 4 CHIPRES JUMPER 0R0 0402

S2418 Bottom A 5 SM TACT SW SIDE TRAVEL 0.2 MM

V2000 Top T 5 TVS DI 1PMT16AT3 16V 175W PWRMITE

V2400 Bottom R 5 TRX2 UMT1/PUMT1 P40V100MA SOT363

V2401 Bottom Q 5 TRX2 UMT1/PUMT1 P40V100MA SOT363

V2402 Bottom Q 5 TRX2 UMT1/PUMT1 P40V100MA SOT363

V2403 Bottom P 4 TR DTC143ZE N RBE4K7/47K 0A1 SC75

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 17

Page 32

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

V2404 Bottom R 4 TR DTC143ZE N RBE4K7/47K 0A1 SC75

V2900 Bottom O 8 TRX2+RX2 UMH3N N50V0.1A4K7 SOT363

V6250 Bottom F 3 TR BFP620 LNA 65GHZ NF.7DB SOT343

V7100 Bottom G 5 CAP.DI BBY57-02W 1/4 16/4P SOD523

X2000 Bottom G 7 SM BATTERY CONN 3POL SPR 12V 2A

X2001 Bottom T 6 SM SYSTEM CONNECTOR 14POL

X2400 Top B 7 SM CONN 2X5F P0.5 PWB/PWB

X2700 Bottom Q 7 SM SIM CONNECTOR 6POL P2.54

X6250 Bottom F 2 SM COAX CONN+SW F 50R 250V 6GHZ

X7300 Top B 4 SM COAX CONN+SW F 50R 250V 6GHZ

X8000 Top A 9 MODULE ID COMPONENT 2.8X1.8X0.3

Z2005 Top T 6 ASIP 4XESD *** PB-FREE *** BGA5

Z2400 Bottom R 6 ASIP KEYBOARD INTERFACE *PB-FREE*

Z6250 Bottom D 4 CER FILT 1575.42+-4MHZ 3.5X3.5X2

Z6251 Bottom I 2 SAW FILT 1575+-2MHZ/2DB 2.6X2.1X1

Z7000 Bottom H 7 SAW FILT 836.5+-12.5MHZ 2X1.6

Z7001 Bottom H 7 SAW FILT 1880+-30MHZ/3.5DB 2X1.6

Z7160 Bottom C 6 SAW FILT 881.5+-12.5MHZ/2.5 2X1.6

Z7161 Bottom D 4 SAW FILT 1960+-30MHZ/3.2DB 2X1.6

Z7162 Bottom E 5 XTAL FILT 128.1MHZ/4DB 3X3X1

Z7163 Bottom F 4 SAW FILT 128.1MHZ 7X5X1.48

Z7300 Bottom B 6 DIPL 824-894/1850-1990MHZ 2X1.25

Z7301 Bottom D 8 DUPL 1850-1910MHz 5X5

Z7302 Bottom D 7 DUPL 824-849/869-894MHZ 3.8X3.8X1.5

Page 18 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 33

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

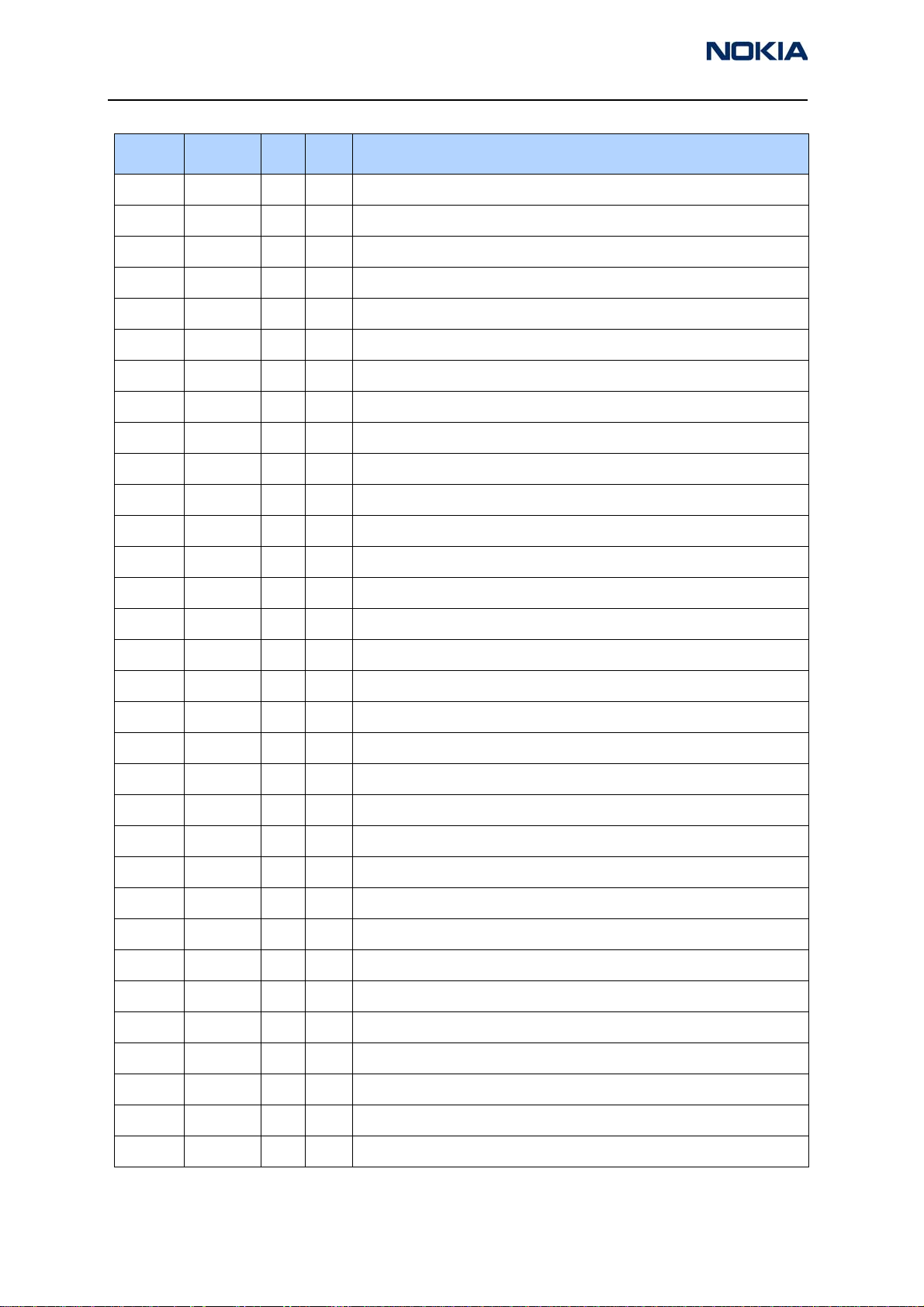

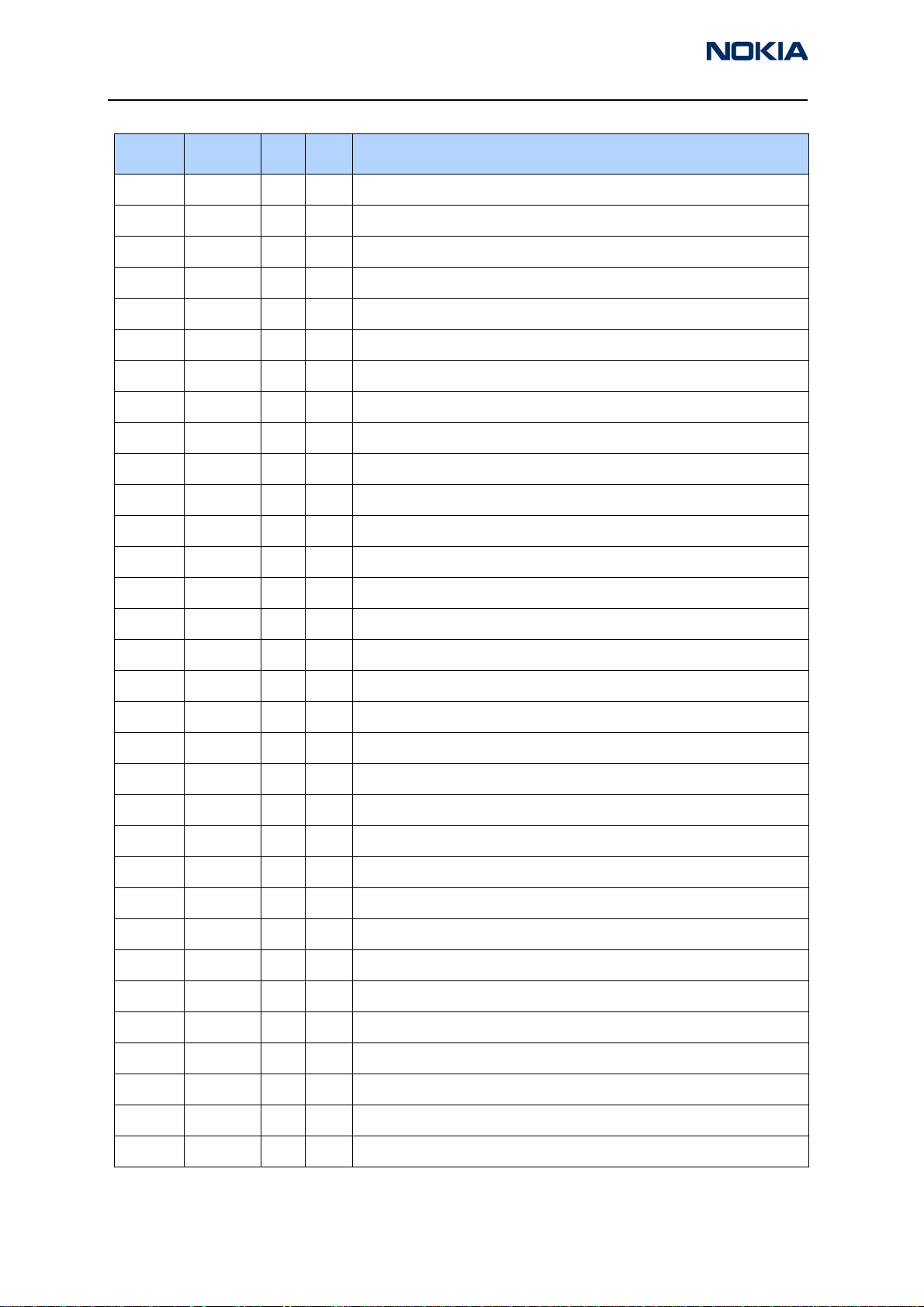

2116 Parts List — Version 001

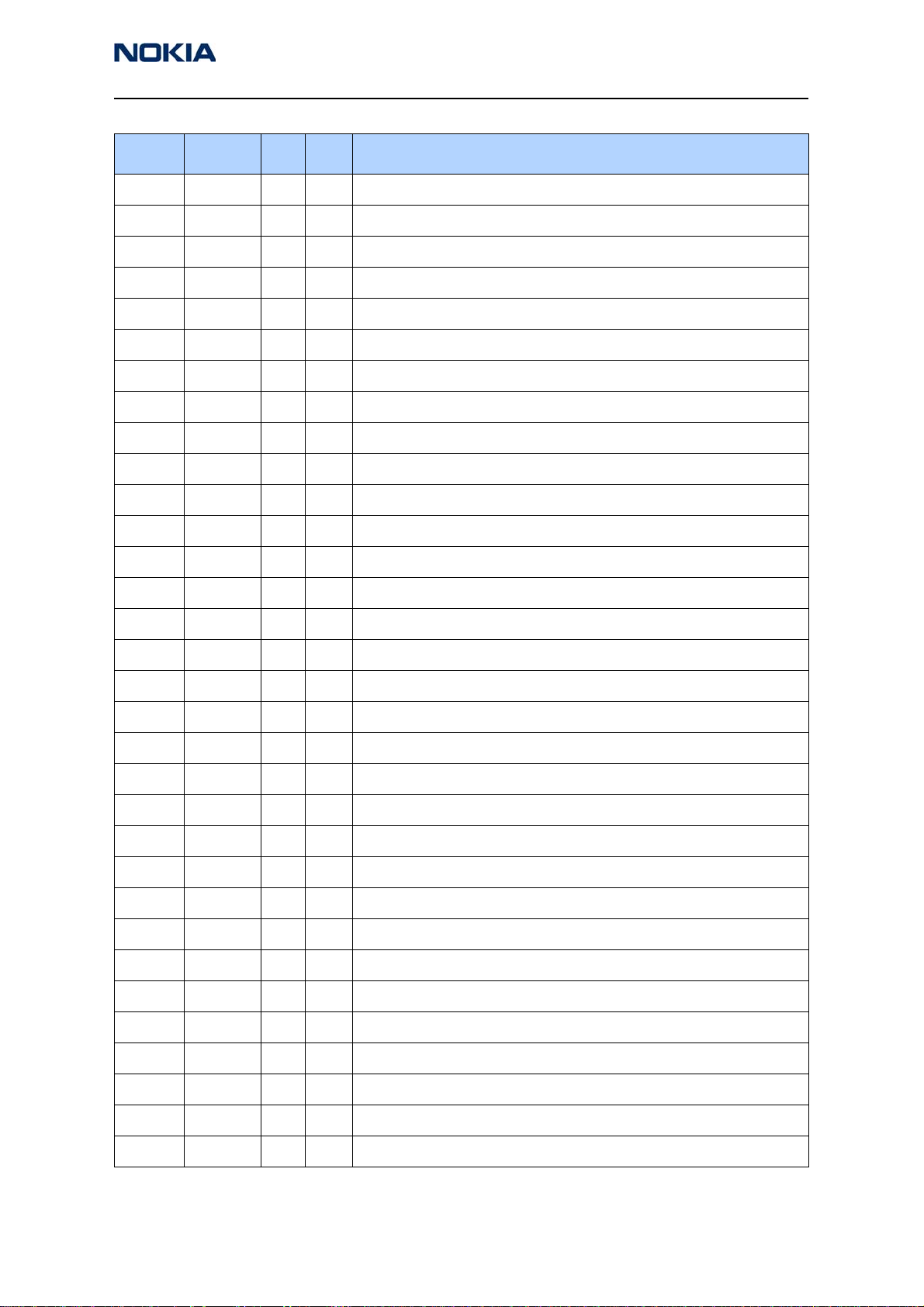

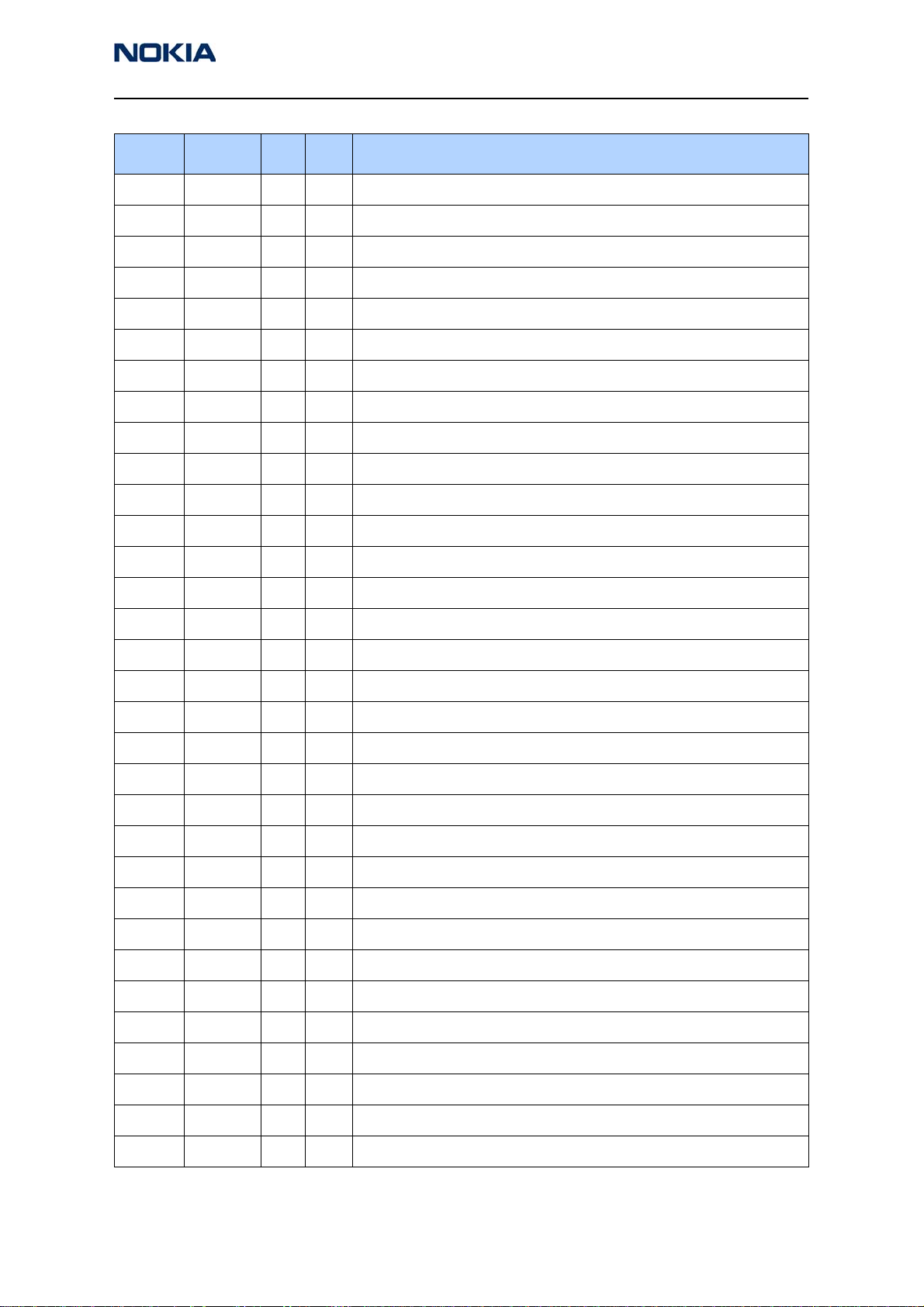

Item Side X Y Description

B2200 Bottom P 2 CRYSTAL 32.768KHZ+-20PPM 12.5PF

C2000 Bottom P 4 CHIPCAP X7R 10N K 50V 0603

C2001 Bottom F 8 CHIPCAP NP0 47P J 50V 0402

C2002 Bottom G 8 CHIPCAP X5R 10U M 6V3 0805

C2003 Bottom F 7 CHIPCAP NP0 47P J 50V 0402

C2004 Top T 5 CHIPCAP X7R 1N0 J 50V 0402

C2006 Bottom L 7 CHIPCAP X5R 1U K 6V3 0603

C2007 Bottom L 7 CHIPCAP X5R 1U K 6V3 0603

C2008 Bottom L 8 CHIPCAP X7R 10N K 16V 0402

C2009 Bottom R 7 CHIPCAP NP0 22P J 50V 0402

C2010 Bottom R 7 CHIPCAP NP0 22P J 50V 0402

C2011 Bottom Q 3 CHIPCAP NP0 22P J 50V 0402

C2012 Top T 6 CHIPCAP X7R 3N3 J 50V 0402

C2013 Top T 6 CHIPCAP X7R 3N3 J 50V 0402

C2014 Top T 7 CHIPCAP X7R 3N3 J 50V 0402

C2015 Top T 7 CHIPCAP X7R 3N3 J 50V 0402

C2100 Bottom O 4 CHIPCAP NP0 39P J 50V 0402

C2101 Bottom O 3 CHIPCAP NP0 39P J 50V 0402

C2102 Bottom P 4 CHIP ARRAY X5R 2X100N Y 10V 0405

C2104 Bottom R 4 CHIPCAP NP0 47P J 50V 0402

C2105 Bottom Q 3 CHIPCAP X5R 100N M 16V 0402

C2106 Bottom O 3 CHIPCAP NP0 39P J 50V 0402

C2107 Bottom O 3 CHIPCAP NP0 39P J 50V 0402

C2108 Bottom P 3 CHIP ARRAY X5R 2X100N Y 10V 0405

C2109 Top T 7 CHIPCAP NP0 47P J 50V 0402

C2110 Top T 7 CHIPCAP X5R 100N M 16V 0402

C2111 Bottom Q 3 CHIPCAP X7R 2N2 J 50V 0402

C2112 Bottom Q 3 CHIPCAP X7R 22N K 16V 0402

C2113 Bottom Q 3 CHIPCAP X7R 22N K 16V 0402

C2114 Bottom P 2 CHIPCAP X5R 1U K 6V3 0603

C2116 Bottom P 3 CHIPCAP X5R 100N M 16V 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 19

Page 34

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

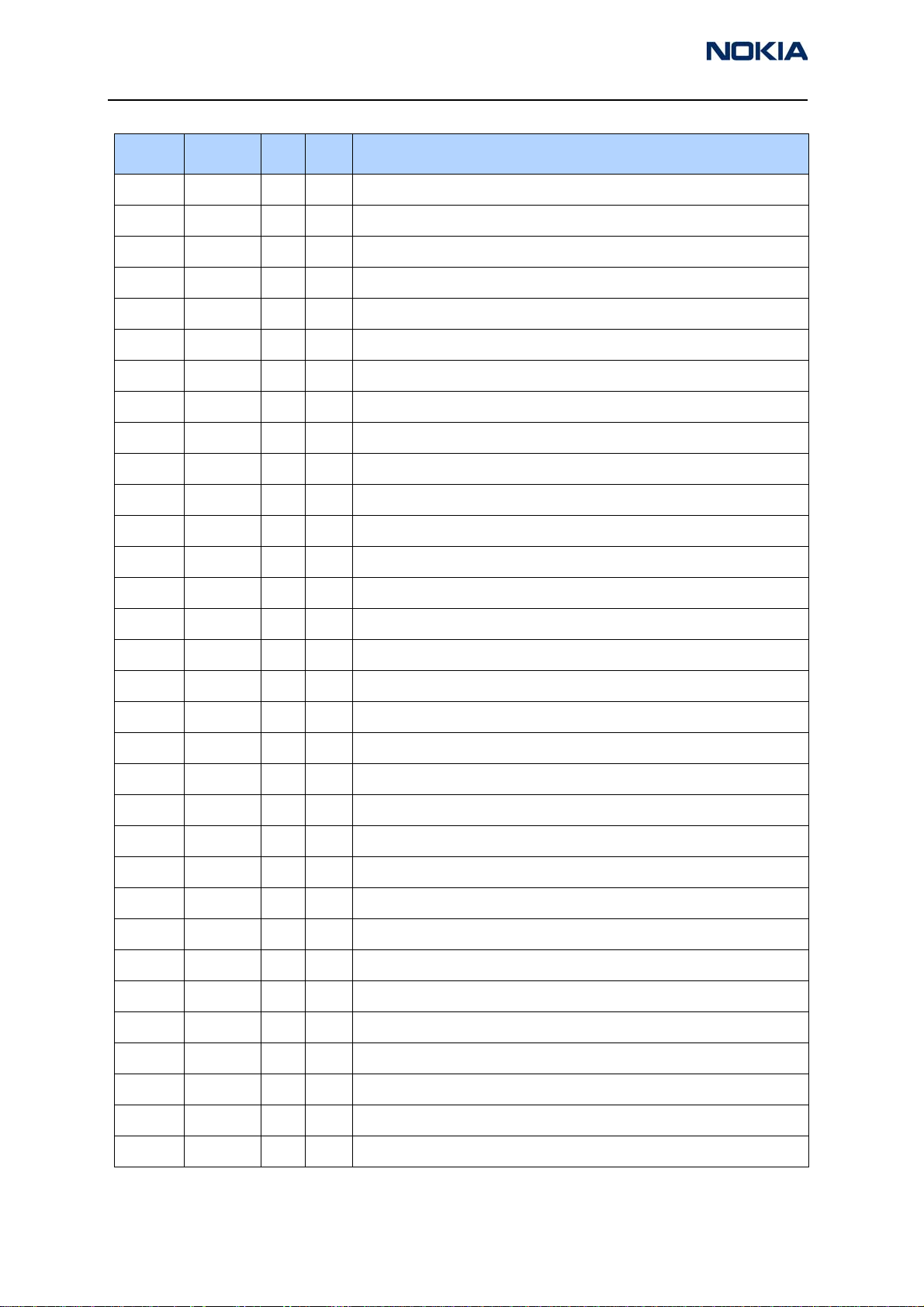

Item Side X Y Description

C2117 Bottom Q 2 CHIPCAP X5R 1U K 6V3 0603

C2118 Bottom P 3 CHIPCAP NP0 22P J 50V 0402

C2200 Bottom M 2 CHIPCAP X5R 1U K 6V3 0603

C2201 Bottom L 2 CHIPCAP X7R 10N K 16V 0402

C2202 Bottom N 2 CHIPCAP X5R 1U K 6V3 0603

C2203 Bottom N 2 CHIPCAP X5R 1U K 6V3 0603

C2204 Bottom O 4 CHIPCAP X5R 1U K 6V3 0603

C2205 Bottom L 2 CHIPCAP X5R 100N M 16V 0402

C2206 Bottom P 2 CHIPCAP NP0 18P J 50V 0402

C2207 Bottom P 2 CHIPCAP NP0 18P J 50V 0402

C2208 Bottom O 3 CHIPCAP X5R 1U K 6V3 0603

C2209 Bottom O 2 CHIPCAP X5R 1U K 6V3 0603

C2210 Bottom O 2 CHIPCAP X5R 1U K 6V3 0603

C2211 Bottom P 3 CHIPCAP X5R 1U K 6V3 0603

C2212 Bottom O 4 CHIPCAP X5R 1U K 6V3 0603

C2213 Bottom O 5 CHIPCAP X5R 1U K 6V3 0603

C2214 Bottom O 4 CHIPCAP X5R 1U K 6V3 0603

C2215 Bottom L 2 CHIPCAP X5R 10U M 6V3 0805

C2216 Bottom P 4 CHIPCAP X5R 100N M 16V 0402

C2217 Bottom P 5 CHIPCAP X5R 100N M 16V 0402

C2218 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2219 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2220 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2221 Bottom L 4 CHIPCAP X5R 100N M 16V 0402

C2222 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2223 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2224 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2225 Bottom M 2 CHIPCAP X5R 220N K 6.3V 0402

C2226 Bottom L 2 CHIPCAP X5R 1U K 6V3 0603

C2227 Bottom P 4 CHIPCAP X7R 10N K 16V 0402

C2228 Bottom P 4 CHIPCAP X7R 10N K 16V 0402

C2229 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

Page 20 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 35

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

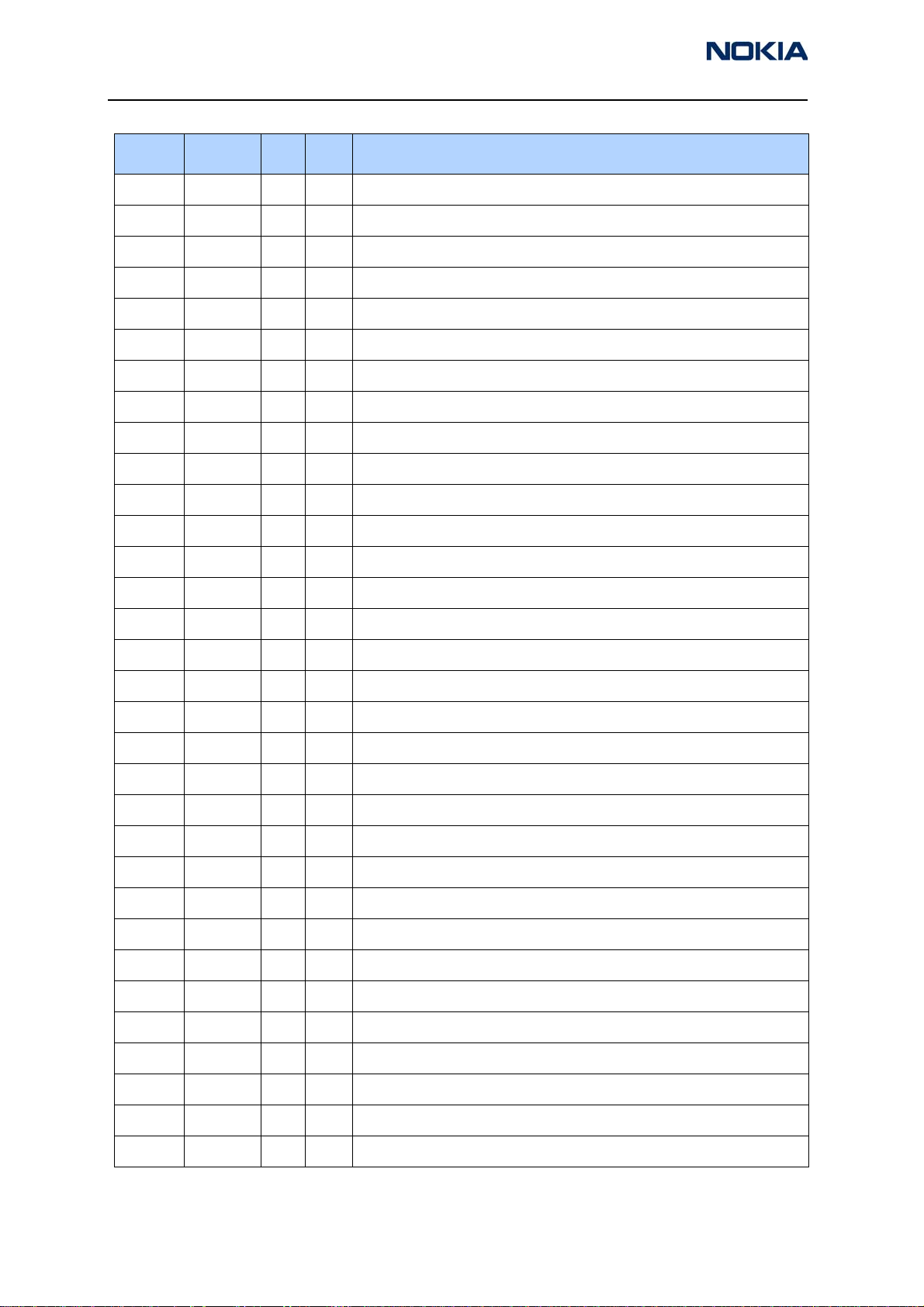

Item Side X Y Description

C2230 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2231 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2232 Bottom L 2 CHIPCAP X5R 1U K 6V3 0603

C2233 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2234 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2235 Bottom L 3 CHIPCAP X5R 1U K 6V3 0603

C2236 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2237 Bottom L 4 CHIPCAP X5R 1U K 6V3 0603

C2300 Bottom M 8 CHIPCAP X5R 10U M 6V3 0805

C2301 Bottom L 8 CHIPCAP X5R 100N M 16V 0402

C2302 Bottom L 8 CHIPCAP X5R 10U M 6V3 0805

C2400 Top C 6 CHIPCAP X5R 100N M 16V 0402

C2401 Top C 6 CHIPCAP X5R 100N M 16V 0402

C2403 Top A 6 CHIPCAP NP0 47P J 50V 0402

C2404 Bottom N 8 CHIPCAP X5R 1U0 M 25V 1206

C2405 Bottom L 7 CHIPCAP X5R 100N M 16V 0402

C2406 Bottom B 5 CHIPCAP NP0 22P J 50V 0402

C2407 Bottom M 8 CHIPCAP X5R 1U K 6V3 0603

C2700 Bottom R 8 CHIPCAP X5R 100N M 16V 0402

C2880 Bottom P 5 CHIPCAP X5R 100N M 16V 0402

C2881 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2882 Bottom M 7 CHIPCAP X5R 100N M 16V 0402

C2883 Bottom O 7 CHIPCAP X5R 100N M 16V 0402

C2884 Bottom M 5 CHIPCAP X5R 100N M 16V 0402

C2885 Bottom N 7 CHIPCAP X5R 100N M 16V 0402

C2900 Bottom O 7 CHIPCAP X7R 10N K 16V 0402

C2901 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C2902 Bottom O 7 CHIPCAP X7R 10N J 16V 0402

C2903 Bottom N 8 CHIPCAP X7R 1N0 K 50V 0402

C2904 Bottom O 8 CHIPCAP X7R 33N K 10V 0402

C2905 Bottom O 8 CHIPCAP X7R 10N J 16V 0402

C2906 Bottom O 8 CHIPCAP X7R 1N0 K 50V 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 21

Page 36

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

C2907 Bottom O 8 CHIPCAP X7R 33N K 10V 0402

C3000 Bottom L 5 CHIPCAP X7R 10N K 16V 0402

C3001 Bottom L 5 CHIPCAP X5R 100N M 16V 0402

C3002 Bottom M 5 CHIPCAP X7R 10N K 16V 0402

C6260 Bottom D 2 CHIPCAP NP0 2P2 C 50V 0402

C7000 Bottom I 8 CHIPCAP X7R 10N J 16V 0402

C7001 Bottom J 7 CHIPCAP X5R 100N M 16V 0402

C7002 Bottom I 8 CHIPCAP X7R 10N J 16V 0402

C7003 Bottom I 7 CHIPCAP NP0 10P J 50V 0402

C7004 Bottom I 7 CHIPCAP NP0 1P2 C 50V 0402

C7005 Bottom I 7 CHIPCAP NP0 1P2 C 50V 0402

C7006 Bottom J 8 CHIPCAP NP0 3P3 C 50V 0402

C7007 Bottom J 8 CHIPCAP NP0 220P J 25V 0402

C7008 Bottom I 7 CHIPCAP X7R 10N J 16V 0402

C7009 Bottom I 7 CHIPCAP NP0 47P J 50V 0402

C7010 Bottom I 8 CHIPCAP NP0 10P J 50V 0402

C7012 Bottom I 8 CHIPCAP NP0 0P5 C 50V 0402

C7013 Bottom I 7 CHIPCAP NP0 0P5 C 50V 0402

C7014 Bottom J 8 CHIPCAP NP0 100P J 50V 0402

C7015 Bottom K 8 CHIPCAP NP0 2N2 J 16V 0603

C7016 Bottom J 8 CHIPCAP NP0 100P J 50V 0402

C7018 Bottom I 8 CHIPCAP X7R 10N J 16V 0402

C7019 Bottom I 8 CHIPCAP NP0 18P J 50V 0402

C7020 Bottom J 8 CHIPCAP X5R 1U K 6V3 0402

C7021 Bottom J 8 CHIPCAP NP0 18P J 50V 0402

C7022 Bottom K 8 CHIPCAP X7R 10N J 16V 0402

C7023 Bottom J 7 CHIPCAP NP0 33P J 50V 0402

C7024 Bottom J 7 CHIPCAP NP0 18P J 50V 0402

C7025 Bottom J 7 CHIPCAP NP0 33P J 50V 0402

C7027 Bottom I 8 CHIPCAP NP0 3P3 C 50V 0402

C7028 Bottom I 8 CHIPCAP NP0 3P3 C 50V 0402

C7029 Bottom J 8 CHIPCAP NP0 8P2 C 50V 0402

Page 22 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 37

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

C7030 Bottom J 7 CHIPCAP NP0 8P2 C 50V 0402

C7100 Bottom H 6 CHIPCAP X7R 10N J 16V 0402

C7101 Bottom H 6 CHIPCAP X5R 330N K 10V 0603

C7102 Bottom H 6 CHIPCAP X7R 33N K 10V 0402

C7103 Bottom G 6 CHIPCAP NP0 33P J 50V 0402

C7104 Bottom G 6 CHIPCAP X7R 1N0 J 50V 0402

C7105 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7106 Bottom H 5 CHIPCAP X7R 10N K 16V 0402

C7107 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7108 Bottom G 5 CHIPCAP X7R 10N K 16V 0402

C7109 Bottom G 5 CHIPCAP X7R 10N K 16V 0402

C7110 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7111 Bottom H 4 CHIPCAP X7R 10N K 16V 0402

C7112 Bottom F 5 CHIPCAP X7R 10N K 16V 0402

C7113 Bottom G 5 CHIPCAP X7R 10N K 16V 0402

C7160 Bottom C 5 CHIPCAP NP0 56P J 50V 0402

C7161 Bottom C 6 CHIPCAP NP0 2P2 C 50V 0402

C7162 Bottom C 4 CHIPCAP X5R 100N M 16V 0402

C7163 Bottom C 4 CHIPCAP NP0 10P J 50V 0402

C7164 Bottom C 4 CHIPCAP NP0 0P5 C 50V 0402

C7165 Bottom C 4 CHIPCAP NP0 1P5 C 50V 0402

C7166 Bottom D 6 CHIPCAP NP0 100P J 50V 0402

C7168 Bottom D 5 CHIPCAP NP0 5P6 C 50V 0402

C7169 Bottom F 5 CHIPCAP NP0 6P8 C 50V 0402

C7170 Bottom D 5 CHIPCAP X7R 1N0 J 50V 0402

C7171 Bottom E 5 CHIPCAP NP0 10P J 50V 0402

C7172 Bottom D 6 CHIPCAP NP0 3P9 C 50V 0402

C7173 Bottom D 5 CHIPCAP NP0 4P7 C 50V 0402

C7174 Bottom F 5 CHIPCAP NP0 6P8 C 50V 0402

C7175 Bottom C 3 CHIPCAP NP0 100P J 50V 0402

C7176 Bottom D 4 CHIPCAP X7R 3N3 J 50V 0402

C7177 Bottom D 4 CHIPCAP X7R 3N3 J 50V 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 23

Page 38

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

C7178 Bottom E 5 CHIPCAP X5R 100N M 16V 0402

C7179 Bottom D 4 CHIPCAP NP0 22P J 50V 0402

C7180 Bottom E 4 CHIPCAP NP0 2P2 C 50V 0402

C7181 Bottom C 3 CHIPCAP NP0 100P J 50V 0402

C7182 Bottom G 4 CHIPCAP NP0 8P2 C 50V 0402

C7183 Bottom E 5 CHIPCAP NP0 100P J 50V 0402

C7184 Bottom C 5 CHIPCAP X7R 47N K 10V 0402

C7185 Bottom D 4 CHIPCAP NP0 12P J 50V 0402

C7186 Bottom C 4 CHIPCAP NP0 100P J 50V 0402

C7188 Bottom G 4 CHIPCAP NP0 8P2 C 50V 0402

C7200 Bottom L 4 CHIPCAP X5R 1U K 6V3 0402

C7203 Bottom L 4 CHIPCAP X7R 10N J 16V 0402

C7204 Bottom L 5 CHIPCAP X7R 1N0 J 50V 0402

C7207 Bottom L 4 CHIPCAP X7R 1N0 J 50V 0402

C7209 Bottom I 8 CHIPCAP NP0 470P J 6V3 0402

C7210 Bottom I 6 CHIPCAP NP0 470P J 6V3 0402

C7211 Bottom J 6 CHIPCAP X7R 470P J 50V 0402

C7212 Bottom I 5 CHIPCAP X7R 10N J 16V 0402

C7213 Bottom J 5 CHIPCAP X5R 100N M 16V 0402

C7214 Bottom J 6 CHIPCAP NP0 47P J 50V 0402

C7215 Bottom G 2 CHIPCAP X5R 1U K 6V3 0402

C7216 Bottom G 2 CHIPCAP X7R 10N J 16V 0402

C7218 Bottom J 6 CHIPCAP X7R 3N3 J 50V 0402

C7219 Bottom I 6 CHIPCAP X7R 1N0 J 50V 0402

C7220 Bottom I 5 CHIPCAP X7R 1N0 J 50V 0402

C7221 Bottom I 6 CHIPCAP X7R 33N K 10V 0402

C7222 Bottom I 6 CHIPCAP X7R 6N8 K 25V 0402

C7223 Bottom G 3 CHIPCAP NP0 1P8 C 50V 0402

C7224 Bottom H 4 CHIPCAP X5R 100N M 16V 0402

C7225 Bottom K 6 CHIPCAP X7R 10N J 16V 0402

C7226 Bottom K 5 CHIPCAP X5R 100N M 16V 0402

C7304 Bottom E 7 CHIPCAP X7R 1N0 J 50V 0402

Page 24 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 39

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

C7306 Bottom E 8 CHIPCAP X7R 10N J 16V 0402

C7307 Bottom D 7 CHIPCAP NP0 15P J 50V 0402

C7308 Bottom E 9 CHIPCAP NP0 2P7 C 50V 0402

C7309 Bottom E 9 CHIPCAP X7R 1N0 J 50V 0402

C7310 Bottom E 7 CHIPCAP X5R 10U M 6V3 0805

C7311 Bottom C 8 CHIPCAP X7R 10N J 16V 0402

C7312 Bottom C 8 CHIPCAP X7R 3N3 J 50V 0402

C7313 Bottom C 8 CHIPCAP X7R 3N3 J 50V 0402

C7314 Bottom D 7 CHIPCAP NP0 47P J 50V 0402

C7315 Bottom D 6 CHIPCAP NP0 2P7 C 50V 0402

C7316 Bottom K 8 CHIPCAP X7R 1N0 J 50V 0402

C7317 Bottom E 7 CHIPCAP X7R 1N0 J 50V 0402

C7318 Bottom E 6 CHIPCAP NP0 100P J 50V 0402

C7319 Bottom D 6 CHIPCAP X7R 1N0 J 50V 0402

C7320 Bottom D 7 CHIPCAP X7R 1N0 J 50V 0402

C7321 Bottom E 7 CHIPCAP NP0 3P3 C 50V 0402

C7322 Bottom D 8 CHIPCAP NP0 2P2 C 50V 0402

D2200 Bottom N 4 UEMC 4.4 LF W/DOG ENA VCORE1V5

D2400 Bottom P 4 DIX2 BAV70W CC 70V .5A 4NS SOT323

D2401 Top Q 4 LED LW L283 WHITE 0603

D2402 Top Q 6 LED LW L283 WHITE 0603

D2403 Top N 4 LED LW L283 WHITE 0603

D2404 Top N 6 LED LW L283 WHITE 0603

D2405 Top A 5 LED CL430S-WF WHITE >500MCDD?20MA

D2800 Bottom N 6 UPP8M v4.2/v4.3/4.31 C027 12x12 UBGA144

D3000 Bottom L 6 FLASH 4MX16 1V8/1V8 VFBGA44 PBFREE

F2000 Top T 4 SM FUSE F 1.5A 32V ROHS-FREE 0603

G7200 Bottom L 5 VCTCXO 19.2MHZ +-2PPM 2.78V 2.2MA

G7201 Bottom H 3 UHF VCO 986-1034MHz/2040-2140MHz

L2000 Top T 4 FERR.BEAD 0R03 42R/100MHZ 3A 0805

L2001 Top T 6 FERRITE BEAD 600R 300MA 0.6R 0402

L2002 Top T 6 FERRITE BEAD 600R 300MA 0.6R 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 25

Page 40

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

L2003 Top T 6 CHIP BEAD ARRAY 2X1000R 0405

L2004 Top T 7 CHIP BEAD ARRAY 2X1000R 0405

L2100 Bottom B 3 FERR.BEAD 240R/100M 0.4A 0R3 0402

L2101 Bottom B 3 FERR.BEAD 240R/100M 0.4A 0R3 0402

L2300 Bottom L 8 FERR.BEAD 0R03 42R/100MHZ 3A 0805

L2301 Bottom M 8 CHOKE 10UH M 0.49A 3.0X2.8X1.2MM

L2400 Bottom M 7 FERR.BEAD 0R03 42R/100MHZ 3A 0805

L2401 Bottom N 8 CHOKE 22U M 1R4 0.33A 3.3X3.3X1.5

L6253 Bottom D 2 CHIP COIL 15N J Q30/800MHZ 0402

L7000 Bottom I 7 CHIP COIL 27N J Q27/800MHZ 0402

L7001 Bottom I 7 CHIP COIL 33N J Q23/800MHZ 0402

L7002 Bottom I 7 CHIP COIL 27N J Q27/800MHZ 0402

L7003 Bottom I 8 CHIP COIL 6N8 J Q27/800MHZ 0402

L7004 Bottom I 7 CHIP COIL 12N J Q31/800MHZ 0402

L7005 Bottom I 8 CHIP COIL 6N8 J Q27/800MHZ 0402

L7101 Bottom G 6 CHIP COIL 33NH J Q12/100MHZ 0603

L7160 Bottom C 5 CHIP COIL 15N J Q30/800MHZ 0402

L7161 Bottom C 4 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7162 Bottom C 5 CHIP COIL 6N2 J Q20/250MHZ 0402

L7163 Bottom C 5 CHIP COIL 19N J Q25/250MHZ 0402

L7164 Bottom D 5 CHIP COIL 220N J Q8/50MHZ 0603

L7165 Bottom F 5 CHIP COIL 120N J Q16/100MHZ 0603

L7166 Bottom D 3 CHIP COIL 12N J Q31/800MHZ 0402

L7167 Bottom D 5 CHIP COIL 180N J Q13/100MHZ 0603

L7168 Bottom F 5 CHIP COIL 220N J Q8/50MHZ 0603

L7169 Bottom F 6 CHIP COIL 120N J Q16/100MHZ 0603

L7170 Bottom D 5 CHIP COIL 82N +-0N3 Q17/300M 0402

L7171 Bottom D 4 CHIP COIL 18N J Q29/800MHZ 0402

L7172 Bottom D 5 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7173 Bottom D 5 CHIP COIL 82N +-0N3 Q17/300M 0402

L7174 Bottom E 5 CHIP COIL 120N J Q16/100MHZ 0603

L7175 Bottom D 5 CHIP COIL 15N J Q30/800MHZ 0402

Page 26 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 41

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

L7176 Bottom G 4 CHIP COIL 120N J Q16/100MHZ 0603

L7177 Bottom G 4 CHIP COIL 120N J Q16/100MHZ 0603

L7178 Bottom F 6 CHIP COIL 220N J Q8/50MHZ 0603

L7179 Bottom G 4 CHIP COIL 100N J Q12/100MHZ 0603

L7200 Bottom G 3 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7302 Bottom C 7 DIR.COUPLER 1850-1910MHZ 1.6X0.8

L7304 Bottom C 6 CHIP COIL 10N J Q30/800MHZ 0402

L7305 Bottom E 7 CHIP COIL 3N3 +-0N3 Q28/800M 0402

L7306 Bottom C 7 DIR.COUPLER 824-849MHZ 1.6X0.8MM

L7308 Bottom D 8 CHIP COIL 3N9 +-0N3 Q28/800M 0402

L7310 Bottom K 8 CHIP COIL 27N J Q27/800MHZ 0402

N2000 Bottom L 8 VREG LP3985ITLX-2.8 NOPB USMD5

N2100 Bottom P 3 AF AMP 0.4W LM4890/NCP2890 PBFREE

N2300 Bottom M 8 DC/DC CONV LM2708H-1.35V/1.05V

N2400 Bottom N 8 DC/DC CONV TK65600 USMD8

N7000 Bottom J 8 JUPITER D4 PMB3365G VQFN-40

N7100 Bottom H 5 BATMAN RF RX ASIC STB7102FTR

N7160 Bottom D 5 LNA/MIXER/DOWNCNTR ALFRED VQFN-24

N7200 Bottom J 6 1XPLL/SYNTH 2.5GHZ(LMX2310U)MLF20

N7300 Bottom C 8 ASIP STPAC01F2 CDMA PWR DET BGA-8

N7301 Bottom E 7 PW AMP RF3449 CDMA800 LFM

N7302 Bottom E 8 PW AMP RF3448 CDMA1900

R2000 Bottom O 8 NTC RES 0W1 47K J B 4050+-3% 0402

R2001 Bottom L 8 CHIPRES 0W06 100K J 0402

R2002 Bottom Q 3 CHIPRES 0W06 100K J 0402

R2003 Bottom Q 3 RES NETWORK 0W06 2X47R J 0404

R2004 Bottom R 7 RES NETWORK 0W06 2X47R J 0404

R2006 Bottom R 7 RES NETWORK 0W06 2X47R J 0404

R2007 Bottom R 8 CHIPRES 0W06 220K J 0402

R2008 Top T 6 VARISTOR ARRAY 2XVWM16V VC50 0405

R2009 Top T 8 VARISTOR ARRAY 2XVWM16V VC50 0405

R2100 Bottom B 5 RES NETWORK 0W06 2X5R6 J 0404

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 27

Page 42

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

R2101 Bottom O 4 RES NETWORK 0W06 2X1K0 J 0404

R2102 Bottom P 4 CHIPRES 0W06 47K J 0402

R2103 Bottom Q 4 RES NETWORK 0W06 2X1K0 J 0404

R2104 Bottom R 3 RES NETWORK 0W06 2X1K0 J 0404

R2105 Bottom B 5 VARISTOR ARRAY 2XVWM16V VC50 0405

R2106 Bottom O 3 RES NETWORK 0W06 2X1K0 J 0404

R2107 Bottom P 3 CHIPRES 0W06 47K J 0402

R2108 Top T 7 RES NETWORK 0W06 2X1K0 J 0404

R2109 Top T 7 RES NETWORK 0W06 2X1K0 J 0404

R2110 Top T 8 RES NETWORK 0W06 2X5R6 J 0404

R2111 Bottom Q 3 CHIPRES 0W06 470R J 0402

R2112 Bottom Q 3 CHIPRES 0W06 5K6 J 0402

R2113 Bottom Q 3 CHIPRES 0W06 180K F 200PPM 0402

R2200 Bottom M 2 CHIPRES 0W25 0R22 J 0805

R2201 Bottom P 5 RES NETWORK 0W03 4X100K J 0804

R2202 Bottom P 4 RES NETWORK 0W06 2X4K7 J 0404

R2205 Bottom R 7 CHIPRES 0W06 10K J 0402

R2403 Bottom Q 4 CHIPRES 0W06 33R J 0402

R2404 Bottom Q 4 CHIPRES 0W06 68R J 0402

R2405 Bottom Q 4 CHIPRES 0W06 68R J 0402

R2407 Bottom Q 4 CHIPRES 0W06 150R J 0603

R2408 Bottom Q 4 CHIPRES 0W06 150R J 0603

R2409 Bottom A 5 CHIPRES 0W06 4K7 J 0402

R2410 Bottom Q 4 CHIPRES 0W06 3K3 J 0402

R2411 Bottom N 8 CHIPRES 0W06 22K F 200PPM 0402

R2412 Bottom N 8 CHIPRES 0W06 1K3 F 250PPM 0402

R2700 Bottom R 7 ASIP SIM INTERFACE ** PB-FREE **

R2900 Bottom O 7 CHIPRES 0W06 4K7 J 0402

R2901 Bottom O 7 CHIPRES 0W06 1K0 J 0402

R2902 Bottom O 7 CHIPRES 0W06 4K7 J 0402

R2903 Bottom O 8 CHIPRES 0W06 1K0 J 0402

R2904 Bottom O 8 CHIPRES 0W06 4K7 J 0402

Page 28 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 43

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

R3000 Bottom M 5 CHIPRES 0W06 4K7 J 0402

R7000 Bottom I 8 CHIPRES JUMPER 0R0 0402

R7001 Bottom J 8 CHIPRES 0W06 10K J 0402

R7002 Bottom J 8 CHIPRES 0W06 27K J 0402

R7003 Bottom I 7 CHIPRES 0W06 12K J 0402

R7004 Bottom K 7 CHIPRES JUMPER 0R0 0402

R7005 Bottom J 7 CHIPRES JUMPER 0R0 0402

R7006 Bottom K 7 CHIPRES JUMPER 0R0 0402

R7007 Bottom J 7 CHIPRES JUMPER 0R0 0402

R7008 Bottom H 8 CHIPRES JUMPER 0R0 0402

R7009 Bottom K 7 CHIPRES 0W06 150R J 0402

R7010 Bottom K 7 CHIPRES 0W06 100R J 0402

R7011 Bottom K 7 CHIPRES 0W06 33K J 0402

R7012 Bottom J 7 CHIPRES 0W06 2K2 J 0402

R7013 Bottom J 7 CHIPRES 0W06 39K J 0402

R7100 Bottom G 6 CHIPRES 0W06 1K0 J 0402

R7101 Bottom H 5 CHIPRES 0W06 470R J 0402

R7102 Bottom G 6 CHIPRES 0W06 4K7 J 0402

R7103 Bottom H 4 CHIPRES 0W06 8K2 J 0402

R7104 Bottom H 5 CHIPRES 0W06 27K J 0402

R7160 Bottom C 4 CHIPRES 0W06 4R3 J 0402

R7161 Bottom C 3 CHIPRES 0W06 47K J 0402

R7162 Bottom D 4 CHIPRES 0W06 82R J 0402

R7163 Bottom C 3 CHIPRES 0W06 47K J 0402

R7164 Bottom D 4 CHIPRES 0W06 4R3 J 0402

R7165 Bottom C 4 CHIPRES 0W06 47K J 0402

R7200 Bottom L 4 CHIPRES 0W06 10R J 0402

R7204 Bottom L 5 CHIPRES 0W06 1K0 J 0402

R7205 Bottom L 4 CHIPRES 0W06 10K J 0402

R7208 Bottom J 5 CHIPRES 0W06 10R J 0402

R7209 Bottom G 2 CHIPRES JUMPER 0R0 0402

R7210 Bottom G 3 CHIPRES 0W06 150R J 0402

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 29

Page 44

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View

Item Side X Y Description

R7211 Bottom I 6 CHIPRES 0W06 10K J 0402

R7212 Bottom I 5 CHIPRES 0W06 10K J 0402

R7213 Bottom J 6 CHIPRES 0W06 3K9 J 0402

R7215 Bottom H 4 CHIPRES 0W06 2K2 J 0402

R7216 Bottom K 6 CHIPRES 0W06 10R J 0402

R7300 Bottom E 8 CHIPRES JUMPER 0R0 0402

R7301 Bottom C 7 CHIPRES 0W06 56R J 0402

R7302 Bottom C 7 CHIPRES JUMPER 0R0 0402

R7304 Bottom H 8 CHIPRES 0W06 100R J 0402

R7305 Bottom I 8 CHIPRES 0W06 100R J 0402

R7307 Bottom C 6 CHIPRES 0W06 56R J 0402

R7308 Bottom E 7 CHIPRES JUMPER 0R0 0402

R7309 Bottom F 8 NTC RES 0W1 47K J B 4050+-3% 0402

R7330 Bottom E 4 CHIPRES JUMPER 0R0 0402

S2418 Bottom A 5 SM TACT SW SIDE TRAVEL 0.2 MM

V2000 Top T 5 TVS DI 1PMT16AT3 16V 175W PWRMITE

V2400 Bottom R 5 TRX2 UMT1/PUMT1 P40V100MA SOT363

V2401 Bottom Q 5 TRX2 UMT1/PUMT1 P40V100MA SOT363

V2402 Bottom Q 5 TRX2 UMT1/PUMT1 P40V100MA SOT363

V2403 Bottom P 4 TR DTC143ZE N RBE4K7/47K 0A1 SC75

V2404 Bottom R 4 TR DTC143ZE N RBE4K7/47K 0A1 SC75

V2900 Bottom O 8 TRX2+RX2 UMH3N N50V0.1A4K7 SOT363

V7100 Bottom G 5 CAP.DI BBY57-02W 1/4 16/4P SOD523

X2000 Bottom G 7 SM BATTERY CONN 3POL SPR 12V 2A

X2001 Bottom T 6 SM SYSTEM CONNECTOR 14POL

X2400 Top B 7 SM CONN 2X5F P0.5 PWB/PWB

X2700 Bottom Q 7 SM SIM CONNECTOR 6POL P2.54

X7300 Top B 4 SM COAX CONN+SW F 50R 250V 6GHZ

X8000 Top A 9 MODULE ID COMPONENT 2.8X1.8X0.3

Z2005 Top T 6 ASIP 4XESD *** PB-FREE *** BGA5

Z2400 Bottom R 6 ASIP KEYBOARD INTERFACE *PB-FREE*

Z7000 Bottom H 7 SAW FILT 836.5+-12.5MHZ 2X1.6

Page 30 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 45

2115i/2116/2116i (RH-66)

Nokia Customer Care Parts Lists and Exploded View

Item Side X Y Description

Z7001 Bottom H 7 SAW FILT 1880+-30MHZ/3.5DB 2X1.6

Z7160 Bottom C 6 SAW FILT 881.5+-12.5MHZ/2.5 2X1.6

Z7161 Bottom D 4 SAW FILT 1960+-30MHZ/3.2DB 2X1.6

Z7162 Bottom E 5 XTAL FILT 128.1MHZ/4DB 3X3X1

Z7163 Bottom F 4 SAW FILT 128.1MHZ 7X5X1.48

Z7300 Bottom B 6 DIPL 824-894/1850-1990MHZ 2X1.25

Z7301 Bottom D 8 DUPL 1850-1910MHz 5X5

Z7302 Bottom D 7 DUPL 824-849/869-894MHZ 3.8X3.8X1.5

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 31

Page 46

2115i/2116/2116i (RH-66)

Parts Lists and Exploded View Nokia Customer Care

This page intentionally left blank.

Page 32 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 47

Nokia Customer Care

2115i/2116/2116i (RH-66)

Mobile Terminals

Service Software Instructions

Issue 1 03/2005 Company Confidential ©2005 Nokia Corporation

Page 48

2115i/2116/2116i (RH-66)

Service Software Instructions

Contents Page

Introduction ..................................................................................................................................................... 3

Hardware and Operating System Requirements ................................................................................3

Phoenix Service Software............................................................................................................................. 4

Before You Begin .........................................................................................................................................4

Creating a Phoenix Connection ...............................................................................................................4

Scanning for a Product ..............................................................................................................................6

Using Components ......................................................................................................................................6

Using Profiles ................................................................................................................................................6

Diego Service Software................................................................................................................................. 7

Before You Begin .........................................................................................................................................7

Initial Session with Diego and FLS-4S Dongle ....................................................................................7

Scanning for a Product ..............................................................................................................................8

Using Components ......................................................................................................................................8

Uninstalling Service Software..................................................................................................................... 9

Page 2 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 49

2115i/2116/2116i (RH-66)

Nokia Customer Care Service Software Instructions

Introduction

You must obtain software support bundles (SSBs) to load software upgrade files to

customer-specific mobile terminal models. The SSBs are InstallShield executable

packages. Double-click on the package, and the software installs automatically. No

rebooting of the computer is required.

These bundles are created by Nokia Customer Care and made available by Nokia After

Market Services (AMS) on the Partners Web Page for your applicable region:

• Americas = https://americas.partners.nokia.com

•APAC = https://apac.partners.nokia.com

• China = https://china.partners.nokia.com

•EMEA = https://trade.online.nokia.com or https://europe.partners.nokia.com

The Web pages are password controlled. If you have not registered as a user, contact

Nokia Central Service.

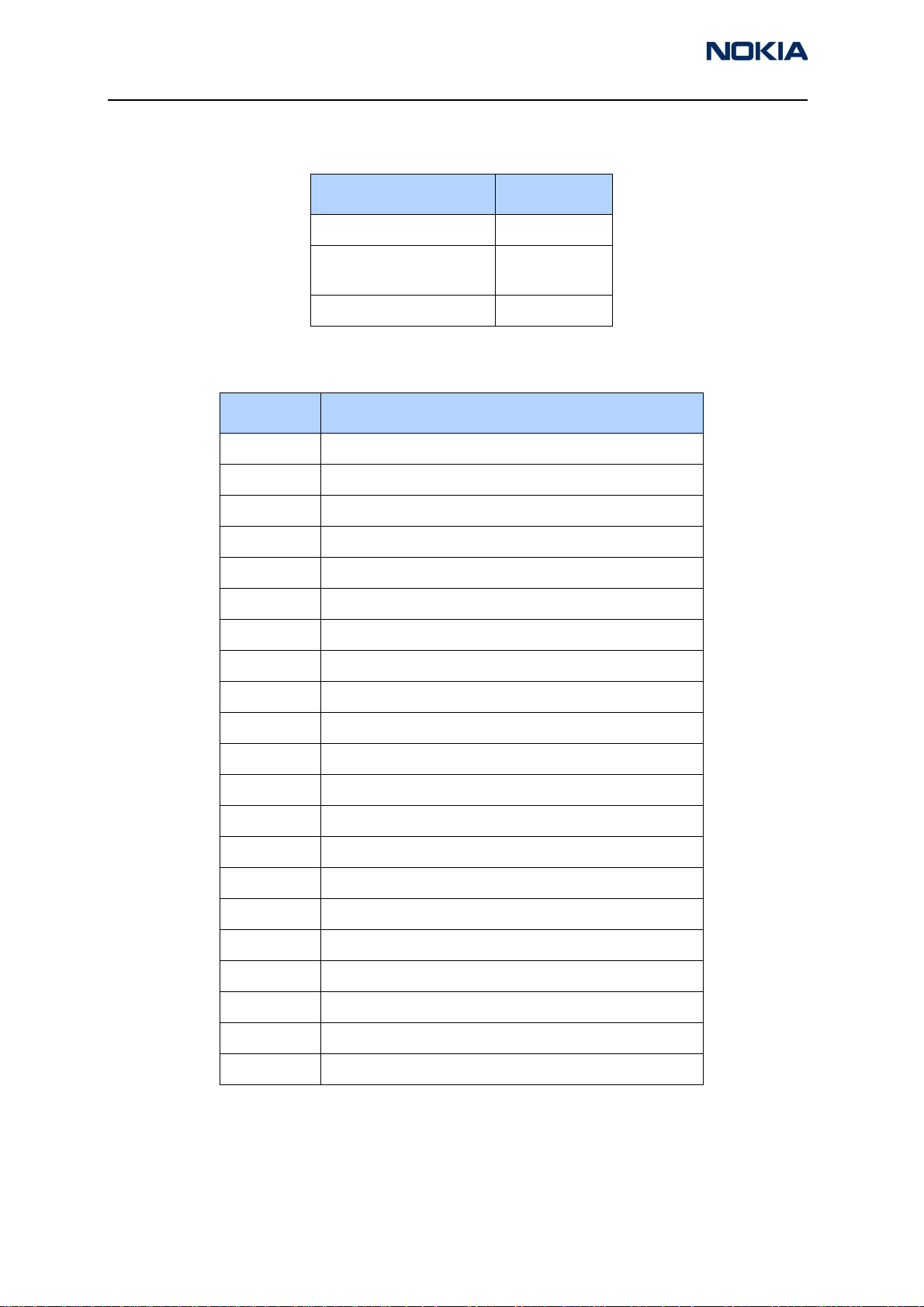

Hardware and Operating System Requirements

Table 1: Minimum Hardware Requirements

Hardware Minimum Value

Processor 700 MHz

RAM 256 MB

Disk space needed 100-200 MB

Interface ports Parallel or USB (dongle-

dependent)

Table 2: Supported Operating System Requirements

Operating System Notes

Windows 2000 Professional version

Windows XP

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 3

Page 50

2115i/2116/2116i (RH-66)

Service Software Instructions

Phoenix Service Software

Before You Begin

Before you installing Phoenix, ensure the following:

• Uninstall any previous versions of Phoenix that exist on the machine. See

"Uninstalling Service Software" on page 9.

• If the computer supports administrator rights, ensure that access is enabled for

the user performing the Phoenix installation.

• Phoenix requires the complete Phoenix installation package, which is around

30 MB.

• You MUST have a Nokia dongle installed on the computer prior to beginning the

software installation. The dongle is attached to the parallel port for PKD dongles,

or an FLS-4S dongle is attached to either the parallel port or the Universal Serial

Bus (USB) port (if the computer supports USB).

• Custom installation is only recommended for experienced users.

• After installation, reboot the computer prior to continuing.

Creating a Phoenix Connection

Use the following steps to create a connection the first time you use Phoenix.

1. Open the File menu, and select Manage Connections.

Figure 1: File Menu with the Manage Connections option

Page 4 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 51

2115i/2116/2116i (RH-66)

Nokia Customer Care Service Software Instructions

2. Click Add to create a new connection.

Figure 2: Manage Connection dialog box

3. Choose either Wizard or Manual on the Select mode dialog box.

• Wizard allows Phoenix to auto-detect your connection configuration.

• Manual allows you to manually select options to create the connection.

Figure 3: Select Mode dialog box

4. Click Next.

5. Once a connection is defined, make sure that the connection you want to use

appears at the top of the list.

If necessary, use the up and down arrows on the Manage Connection dialog box

to move the connection to the top, and click Apply.

6. Click Close when you are finished.

7. Proceed with the normal initiation of a session by scanning for or selecting a

product.

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 5

Page 52

2115i/2116/2116i (RH-66)

Service Software Instructions

Scanning for a Product

Many Phoenix features are product specific. At the beginning of a session, you must

configure Phoenix for the product on which you are working by opening the File menu

and clicking Scan Product. Phoenix automatically scans for the product and selects the

necessary configurations. The status bar at the bottom indicates the product type.

Using Components

Phoenix tasks are managed by specific software components. Use the main menu to

select the component you want to perform. When the new component window is

opened, Phoenix also opens an associated toolbar and adds component-specific menu

items to the window menu.

Using Profiles

Phoenix’s profile feature stores product, connection, and open components into

permanent storage by creating a file with an .nmp file extension. Saved profiles allow

you to configure Phoenix to open with specified components.

Opening and saving profiles is done via the Open Profile and Save Profile options in the

File menu. Phoenix stores profiles with user-defined names. As a result, there can be

multiple profiles for different repeated tasks or user preferences.

Page 6 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 53

2115i/2116/2116i (RH-66)

Nokia Customer Care Service Software Instructions

Diego Service Software

Before You Begin

Before installing Diego, ensure the following:

• Uninstall previous versions of Diego from the computer. See "Uninstalling Service

Software" on page 9.

• If the computer supports administrator rights, ensure that access is enabled for

the user performing the installation.

• Diego requires the complete Diego installation package, which is around 25 MB.

•You must install a Nokia dongle on the computer prior to beginning the software

installation. Attach an FLS-4S dongle to either the parallel port or the Universal

Serial Bus (USB) port (if the computer supports USB). You can use an FLS-2D, but

it does not support the new generation DCT-4 version mobile terminals.

• Custom installation is only recommended for experienced users.

• After installation, you must reboot the computer.

Initial Session with Diego and FLS-4S Dongle

You must configure a Virtual Port Connection the first time Diego is launched. During the

installation of the FLS-4S drivers (included in the Diego installation package), a virtual

Common Object Model (COM) port is set to the next available COM port number. Enter

this port selection into the Diego configuration.

Use the following steps to select a port:

1. Disable the port’s auto ping by double clicking on the status box.

Status box

Figure 4: Status box area

2. Open the Edit menu, and click Settings.

3. On the Settings dialog box, click the Serial Port tab.

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 7

Page 54

2115i/2116/2116i (RH-66)

Service Software Instructions

4. Select the FLS Virtual port setting.

Figure 5: Serial Port tab on the Settings dialog box

5. Click OK.

6. You can now proceed with the normal initiation of a session to scan for the

product.

Scanning for a Product

Many Diego features are product-specific, so at the beginning of a session you must

configure Diego for the product on which you are working. You can scan for a product

either automatically (default) or manually.

• In automatic scan mode, Diego scans for the product every 5 seconds (a rate

which you can customize in the setup menu) and selects the necessary

configurations.

• To manually scan, open the Settings dialog box, click the General tab, and click

Connect.

Using Components

Diego tasks are managed by specific software components. Use the main menu to select

the component you want to use. When the new component window is opened, Diego

also opens an associated toolbar and adds component-specific 1items to the menu.

Page 8 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 55

2115i/2116/2116i (RH-66)

Nokia Customer Care Service Software Instructions

Uninstalling Service Software

Failure to remove the program properly causes misconfiguration of the computer’s

registry. Use the following steps to uninstall Diego or Phoenix service software.

1. Navigate to the computer's Control Panel, which is accessible from the Start

button or by double-clicking the My Computer desktop icon.

2. Double-click the Add/Remove Programs icon.

3. Select the software version that you want to remove, and click Add/Remove.

4. Click OK to begin the removal process.

5. Follow the on-screen instructions.

6. When the removal is complete, reboot the computer.

Issue 1 03/2005 ©2005 Nokia Corporation Company Confidential Page 9

Page 56

2115i/2116/2116i (RH-66)

Service Software Instructions Nokia Customer Care

This page intentionally left blank.

Page 10 ©2005 Nokia Corporation Company Confidential Issue 1 03/2005

Page 57

Nokia Customer Care

2115i/2116/2116i (RH-66)

Mobile Terminals

Service Tools

Issue 1 03/2005 Company Confidential ©2005 Nokia Corporation

Page 58

2115i/2116/2116i (RH-66)

Service Tools

Contents Page

2115i/2116/2116i Service Tools................................................................................................................. 3

AAS-10A RF Probe ......................................................................................................................................3

CA-5S DC Service Cable ............................................................................................................................3

CA-10PS Service Power Cable .................................................................................................................3

CA-22DS Flash Cable ..................................................................................................................................4

CA-25RS RF Test Cable ..............................................................................................................................4

CA-41PS Service Power Cable .................................................................................................................4

CPL-8 GPS Antenna Coupler ....................................................................................................................5

DAU-9S FBUS/MBUS Cable ......................................................................................................................5

DAU-9T FBUS Cable ....................................................................................................................................5

DKU-5F Flash Cable ....................................................................................................................................6

FLA-30 Flash Adapter .................................................................................................................................6

FLS-4S Flashing Device ..............................................................................................................................6

FPS-8 Flash Prommer ................................................................................................................................. 7

FPS-10 Flash Prommer ...............................................................................................................................7

JBA-12 Audio Box ....................................................................................................................................... 7

JBV-1 Docking Station ...............................................................................................................................7

MJ-42 Module Test Jig ..............................................................................................................................8

MJF-17 Docking Station Adapter ...........................................................................................................8

PCS-1 Power Cable ..................................................................................................................................... 8

PKD-1 Software Security Dongle ............................................................................................................9

RJ-18 Power Amp LGA Rework Jig and ST-16 PA Stencil ...............................................................9