Nissan Xterra Clutch CL 2000 Owner's Manual

CLUTCH

GI

MA

CONTENTS

PRECAUTIONS ...............................................................2

Precautions..................................................................2

PREPARATION ...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools...........................................3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

CLUTCH

CLUTCH SYSTEM - HYDRAULIC TYPE........................5

Components.................................................................5

Inspection and Adjustment ..........................................6

ADJUSTING CLUTCH PEDAL

AIR BLEEDING PROCEDURE

CLUTCH MASTER CYLINDER.......................................8

Components.................................................................8

Disassembly and Assembly.........................................8

Inspection.....................................................................8

OPERATING CYLINDER.................................................9

Components.................................................................9

Inspection.....................................................................9

...................................................................4

....................................6

....................................7

SECTION

CLUTCH RELEASE MECHANISM...............................10

Components...............................................................10

Removal and Installation...........................................10

Inspection...................................................................11

Lubrication .................................................................11

Waterproof - for 4WD Model.....................................11

CLUTCH DISC, CLUTCH COVER AND

FLYWHEEL....................................................................12

Components...............................................................12

Inspection and Adjustment ........................................12

CLUTCH DISC

CLUTCH COVER AND FLYWHEEL

FLYWHEEL INSPECTION

Installation..................................................................13

SERVICE DATA AND SPECIFICATIONS (SDS).........14

Clutch Control System...............................................14

Clutch Master Cylinder (with clutch damper)............14

Clutch Operating Cylinder .........................................14

Clutch Disc.................................................................14

Clutch Cover..............................................................14

Clutch Pedal ..............................................................14

.........................................................12

CL

...........................13

........................................13

EM

LC

EC

FE

MT

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Precautions

PRECAUTIONS

SBR686C

Precautions

NGCL0001

I Recommended fluid is brake fluid “DOT 3”.

I Never reuse drained brake fluid.

I Be careful not to splash brake fluid on painted areas.

I When removing and installing clutch piping, use Tool.

I Use new brake fluid to clean or wash all parts of master

cylinder, operating cylinder, and clutch damper.

I Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning the clutch disc, wipe it with a dust collector. Do

not use compressed air.

CL-2

PREPARATION

Special Service Tools

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST20630000

(J26366)

Clutch aligning bar

ST20050240

(—)

Diaphragm spring adjusting wrench

Description

Installing clutch cover and clutch disc

a: 15.9 mm (0.626 in) dia.

b: 22.8 mm (0.898 in) dia.

c: 55 mm (2.17 in)

NT405

Adjusting unevenness of diaphragm spring of

clutch cover

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

NT404

Commercial Service Tools

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

Removing and installing clutch piping

a: 10 mm (0.39 in)

NGCL0002

GI

MA

EM

LC

EC

FE

NGCL0003

MT

AT

Bearing puller

Bearing drift

NT360

NT077

NT474

Removing release bearing

Installing release bearing

a: 52 mm (2.05 in) dia.

b: 45 mm (1.77 in) dia.

TF

PD

AX

SU

BR

ST

RS

BT

HA

CL-3

SC

EL

IDX

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

NGCL0027

NVH Troubleshooting Chart

NGCL0027S01

Use the chart below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, repair or replace these parts.

CLUTCH

Reference page

SUSPECTED PARTS

(Possible cause)

CL-6

CL-7

CL-8

CL-9

,

EM-41

EM-100

CL-10

CL-12

CL-12

CL-12

CL-12

CL-12

CL-12

CL-12

CL-12

CL-13

NGCL0027S0101

CL-13

CL-13

CL-13

Symptom

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

Clutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1234 55555 5667

FLYWHEEL (Distortion)

CL-4

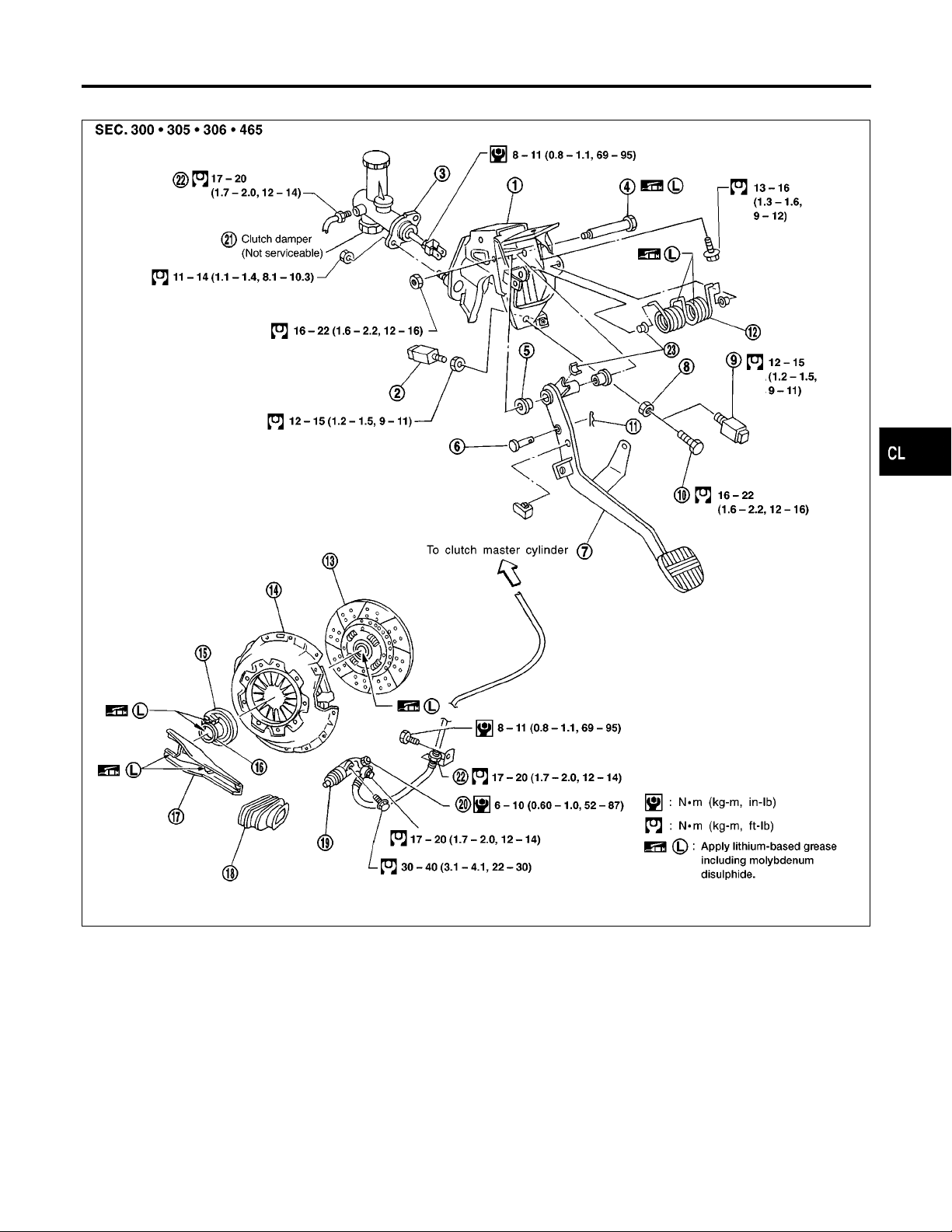

CLUTCH SYSTEM — HYDRAULIC TYPE

Components

Components

NGCL0004

GI

MA

EM

LC

EC

FE

MT

1. Clutch pedal bracket

2. Clutch interlock switch

3. Clutch master cylinder

4. Fulcrum pin

5. Bushing

6. Clevis pin

7. Clutch pedal

8. Lock nut

9. ASCD cancel switch

10. Pedal stopper

11. Snap pin

12. Assist spring

13. Clutch disc

14. Clutch cover

15. Release bearing

16. Release bearing sleeve

17. Withdrawal lever

18. Dust boot

19. Operating cylinder

20. Air bleeder

21. Clutch damper

22. Flare nut

23. Bushing

ACL106

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

CL-5

EL

IDX

Loading...

Loading...