Forced Induction Racing

VQ35DE Install Kit Instructions

2002+ Nissan SE-R Spec-V (W/6spd)

Revised Date: 2/16/06

Thank you for purchasing our VQ35DE install kit. We have spent

numerous hours, designing, and perfecting this kit, over the past 8

months. The end result, is a user-friendly, easy to work with kit, that

will allow you to “bolt-in” a VQ35DE engine and 6 speed

transmission.

Recommended Tools:

Metric/Standard socket sets (3/8 and 1/2)

Torque wrench and Pry-Bar

Metric/Standard wrenches

Jack and jack stands

Eye/Ear and Respiratory protection

Disc Grinder and extension cord

Engine hoist and chain

**BEFORE YOUR BEGIN**

This kit was design with simplicity in mind. Installing the VQ drive-

train will be fairly straight-forward. However, it will require moderate

automotive knowledge, and the right tools to complete the job. If your

are unsure about the installation, PLEASE, bring your vehicle to a

qualified automotive shop to complete your installation. The hardest

aspect of this installation, is the wiring of the ECU (Engine Control

Unit) harness and sub-harness. Diagrams can be supplied upon

request, which will help you to complete this task. However, the

wiring aspect of this swap is fairly complicated, and should be left to a

very experienced automotive technician. Again, if you are unsure,

PLEASE, ask for help, or have someone who is qualified, do the work

for you. Forced Induction Racing and it’s associates will NOT be held

liable for any damages or injury from the use or misuse of this

product. You are responsible for making your vehicle emissioncompliant. This kit is sold as a off-road kit. It is up to you to bring

your vehicle up to compliance with state/federal laws. Now, on to the

fun part. ☺

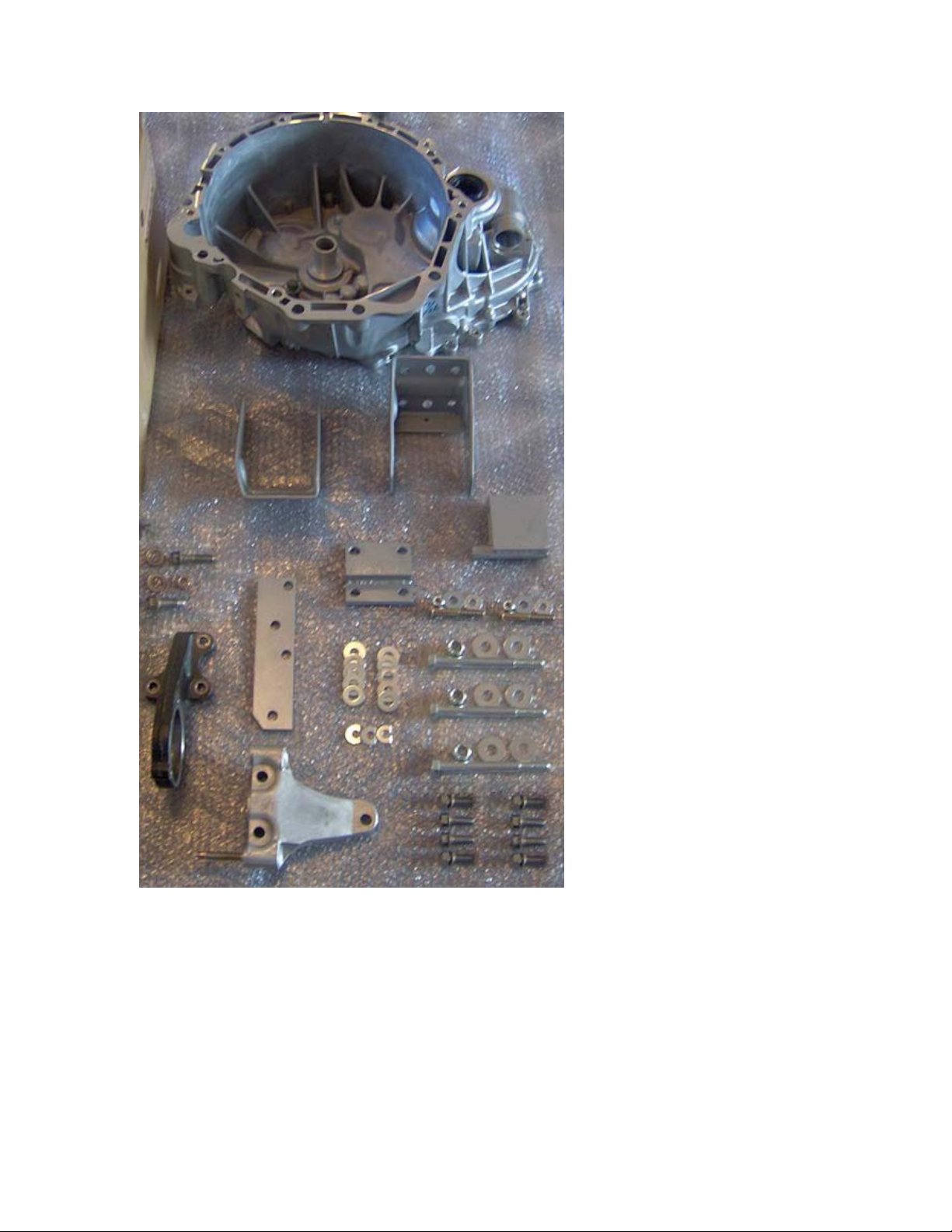

At this time, please take the time to go through your parts, and verify

that you have all of the following pieces:

(1) Rear VQ35DE steel mount bracket

(1) Front VQ35DE steel mount bracket

(1) Front QR to VQ stainless mount adaptor

(1) Aluminum VQ35DE passenger side mount bracket

(1) Passenger side QR to VQ stainless mount adaptor

(1) VQ35DE cast iron axle bracket (bearing carrier)

(1) Stainless VQ35DE axle bracket adaptor

(3) “C-shaped” washers (for axle spacing)

(1) Plastic bag of washers (for shimming passenger mount)

(10) M10 x 1.50 bolts (30mm long) and washers

(1) M10 x 1.50 bolt (45mm long) and washer

(1) 3/8” bolt (1.5” long) 2 washers/1 lock nut

(1) 3/8” bolt (2.5” long) 2 washers/1 lock nut

(1) 3/8” bolt (3” long) 1 washer/1 lock nut

(1) 1/2” bolt (6” long) 2 washers/1 lock nut

(2) 1/2” bolts (5” long) 4 washers/1 lock nut

(1) M10 x 1.75 lock nut and 1 washer

If you have purchased a full kit with the VQ35DE bell-housing, please

take the time to make sure the following is installed:

(1) Throw out bearing pivot ball

(1) Input shaft seal

(1) Passenger side axle seal

Once you have verified the contents of your kit, it’s time to move on to

the installation.

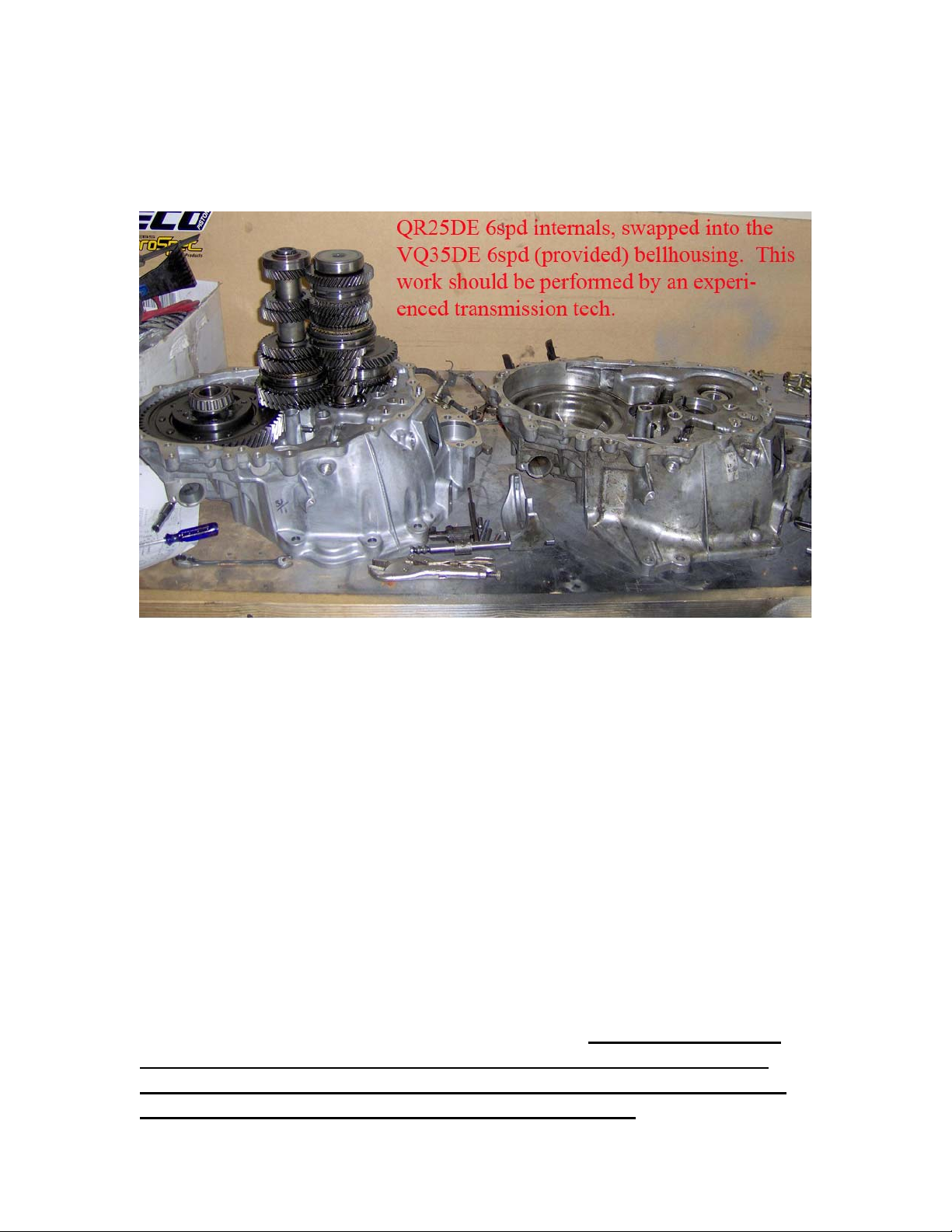

We will begin, with the assumption that you have removed your

QR25DE and transmission. We will also assume that you have

swapped over your bell-housing on your transmission, or, you have

purchased a 6 speed Maxima transmission. If you are attempting to

swap the bell-housing yourself, then you should be familiar with the

Factory Service Manual. If you need the manual for this particular

application, it will be saved in a separate folder on this installation

CD. Here is a picture, showing the difference between the QR and

VQ 6 speed bell-housings:

The VQ bell-housing is shown on the left side, with the QR internals

already installed. The old QR bell-housing is shown on the right. It is

important to check clearances and re-shim the main/input shaft and

gear stacks if necessary. As stated, please use the Factory Service

Manual, if you are have the knowledge/tools to perform this part of

the swap. If you do not, then please consult a local transmission

specialist to take care of this part of your swap.

Once you have your transmission squared away, it’s time to move on

to mounting the transmission to the engine. If your engine was mated

to an automatic transmission, you will need to source a VQ35DE

2002+ 6 speed flywheel and clutch. I recommend using a Jim Wolf

Technology aluminum flywheel, teamed with their 250mm/900Kg

clutch setup. This will yield a stock-like feel, as far as pedal pressure

and feedback are concerned. This combination is good for 450-500

wheel horsepower. Also, make sure to purchase new flywheel bolts

for a 6 speed flywheel. The automatic flex-plate bolts are too short to

be used with a manual transmission flywheel. You should torque

the flywheel bolts to 80ft lbs, and use a few dabs of Red LocTite. You should torque the pressure plate bolts to 20-22ft lbs,

and use a dab of Red Loc-Tite on those as well. I recommend the

use of a high quality clutch alignment tool. This will make the next

step a lot easier.

Grab a buddy, and have him/her help you lift the transmission up a

few inches. Slide the input shaft into the clutch disc splines. The

transmission should slide onto the two dowel pins that line it up

perfectly with the engine block. Thread in the 17mm and 14mm bolts.

If your engine did not come with the bolts, you will need to order them

from Nissan. Torque the 17mm bolts to 45ft lbs. Torque the

14mm bolts to 35ft lbs. You should go ahead and install your starter

at this time. Also, install your speedometer sensor and other misc.

sensors that you should have with your wiring.

Next, it’s time to move on to the engine mount brackets/adaptors.

Let’s start with the rear engine mount bracket:

A. Torque to 35-40ft lbs (back side of block)

B. Torque to 55ft lbs (goes through rear mount on cross-member

to be torqued down later)

Once you have the rear mount torqued down to the block, you can

install the passenger-side axle bracket and adaptor. The bracket and

adaptor will come loosely assembled as pictured:

A. Tighten this nut/bolt down LAST. Torque to 30-35ft lbs

B. Tighten these bolts into the block by hand, and just snug

them for now. We will torque them later. Don’t worry about the

C-shims right now, either.

C. This bolt hole is no longer used

Once you have completed the rear mount/brackets, it’s time to move

on to the front brackets. The front bracket/adaptor will be loosely

assembled. It should be as follows:

A. Torque to 35-40 ft lbs (mounts to front of engine block)

B. Torque to 50ft lbs (will be torqued later)

C. Torque to 50ft lbs (goes through QR front engine mount, will

be torqued later)

Once you have completed that task, you should install the passengerside engine mount bracket and adaptor. You should also take the

time to bolt your QR passenger side engine mount to the VQ

mount/adaptor bracket. Tighten it all up while the engine is still OUT

OF THE CAR. This will make your life MUCH easier. Trust me.. ☺ It

should look something like this:

C. Replace your VQ bracket with this modified version, using the

same 17mm bolts and bottom nut that should have come with

your engine. Torque these to 50-55ft lbs. DO THIS FIRST!

A. Torque these bolts to 40ft lbs

B. Bolt your QR passenger engine mount to these two mounting

holes. You will use your original nut/stud on the front hole, and

the supplied bolt/nut/washers on the back hole. You may wish

to use some of the supplied shims (washers to level off your

engine. I suggest using 2-3 shims. Unfortunately, there’s no

way to know if you need to shim the engine up or not until it’s in

the car. This makes things difficult on this end. All cars are a

little bit different, so we’ve provide a few shims if you need

them. Try 2-3 shims, and chances are, it will be close enough to

perfect to live with. If you are really picky about the engine

being perfectly level, then you will need to add/take out shims as

needed. Torque the stud/nut and bolt/lock washer on the holes

marked “B” to 45ft lbs.

Remember, it is VERY important that you tighten those bolts in

the sequence listed above. Otherwise, you will not be able to

tighten the 17mm VQ engine bracket that is behind the 3/8” bolt

for the QR mount!

Once you have finished that, you are ready to install the

engine/transmission.

Hoist the engine/transmission into the car on a angle, so that the

transmission side goes into the car first, and the engine is up, higher.

Once the transmission clears the frame rail, you can slide it over

towards the driver’s side as much as possible. Place a floor jack

under the transmission to hold it. Slowly, lower the hoist so that the

engine comes down into the engine bay. Have a friend jack up on

the transmission, so that eventually, the QR engine mount is sitting

back in it’s original place, and the transmission bracket slides into the

driver’s side mount. Slide the 14mm bolt into the transmission

mount/bracket on the driver’s side and tighten it down to 45ft

lbs. Using your hoist and a pry-bar, if necessary, line up your (3)

14mm bolt holes that hold the QR passenger side engine mount

in place. Thread the 3 bolts in, and tighten them to 40ft lbs.

Check to make sure that your engine is level from side to side. If it’s

close… great! If it’s way off, you will need to add/remove shims to

get it level. Here’s a few pictures of what this should look like:

A & B- Add/Remove shims from between the QR engine mount

and the adaptor plate, as needed to get your engine as level as

possible. Remember, start with 2-3. That should get you very

close. You may also have to use a few washers on the underside of the stud on the hole marked “B”, as the stud is a decent

length. There should be plenty of washers to accommodate you.

C- This hole is no longer used.

Listed above, is where you should insert your 14mm bolt to hold the

transmission bracket into the mount.

Once you’ve got your engine in place, it’s time to modify and install

the cross-member/front and rear mounts.

Using your grinder/dust mask/eye protection/ear plugs, grind the

posts on the rear QR engine mount, so that it fits into the rear VQ

engine mount bracket. You should have to grind roughly 3/8 of an

inch total to get it to fit inside the bracket. I have a picture shown

below, which points to the places that have to be ground.

Once you get the correct clearance, you will need to drill out the front

engine mount to fit the larger, 1/2” diameter bolt. Using the

corresponding drill bit, drill the front mount hole so that the 1/2” bolt

slides in and fits snug. The front mount is shown in the above picture

at the top.

After modifying the mounts, you can now install the cross-member

and front/rear mounts. Using your jack and a friend… have your

friend jack up on the transmission while you are under the car with

the cross-member. Install the rear mount first… Slide the mount into

the VQ bracket, and run the bolt through to hold the cross-member

up. Put your washer/lock nut on, and thread it until it gets snug. After

you get the rear mount in, pivot the front mount adaptor so that it lines

up with the QR engine mount isolator. You may have to use the jack

to pivot the engine/transmission in order to get the 1/2” bolt into the

mount. The fit will be very snug. Once you get the bolt in, place your

washer/lock-nut on the bolt to hold it in place. Using your jack, again,

jack up on wherever is needed to get your 17mm front and rear

cross-member-to-frame bolts in place. You may have to use a prybar to line this up. Once you get the bolts in, go ahead and

tighten everything down. The 1/2” bolts need to be at 55ft lbs.

The 17mm bolts should be at 45ft lbs.

This is what it should look like: (front mount)

A. QR to VQ mount adaptor

B. 1/2” bolt (Torque to 55ft lbs)

C. 1/2” bolt (Torque to 55ft lbs)

This one is pretty easy… There’s a second set of holes that are

closer towards the block. You will use those, instead of the original

holes. Torque the 1/2” bolt/nut to 55ft lbs.

The last step in the mechanical aspect of this install, is to install the

axles. The driver’s side axle, will bolt right in. No modification

required.

For the passenger side axle… You will need to remove the QR

bracket that bolts the axle to the QR block. It is held on by (3) 12mm

bolts. Once you take the bolts off, you will be able to slide the

adaptor off of the axle. Slide the axle through the new VQ axle

bracket (attached to the block already), and into the transmission.

You will slide the (3) 12mm bolts through the VQ bracket next and

thread them back into the QR axle. DO NOT forget to use the

provided “C-shims” between the axle and the bracket. This will space

the axle away from the bracket just a hair, and give you the right

install depth into the transmission. Torque the 12mm bolts to 25ft lbs,

and use Red Loc-Tite on the threads! After tightening the 12mm

bolts down, go back, and torque the engine mount adaptor bolts in

the block to 35-40ft lbs. I recommend using loctite on those as well.

Visually inspect the axle, and make sure that it’s sitting

flush/perpendicular in the transmission. It’s a good idea to push/hold

the axle into the transmission while tightening the mount adaptor

bolts. This will help to assure that the axle is in perfectly straight.

Here’s where the C-washers are placed:

That’s it for the install of the VQ/transmission! Now, you have lots of

wiring, and other “fun” things to tackle ☺.

Here’s a few recommendations/pointers that will help you along the

way…

The QR A/C compressor will bolt up, if you drill the two bottom holes

to accept the larger diameter 14mm bolts, which the VQ A/C bracket

uses. Here’s a picture:

You will only be able to use those 2 bolts, but it will hold up just fine.

Our test car has been running for almost 6 months with this setup. If

you drill the holes slightly larger, you can line the pulley up better, so

that you can use 6 rib belt, instead of 5 rib. Take your time, and line it

up, and you will be fine. Tighten those 14mm bolts down tight, and

use some Loc-Tite for added insurance.

The Power Steering pump from the VQ works fine. Your QR hoses

will clamp/bolt right up to it with no problems.

You will need to try some different radiator hoses. I used the QR

lower hose, and went to Autozone to eyeball a suitable hose to come

off of the engine and meet up with it. After some cutting, and using a

piece of aluminum tubing to join them together, I came up with a

combination that worked perfectly.

You will need slim fans… period.. Stockers will not fit. I recommend

getting (2) 12” PermaCool fans from Autozone, and wiring them up to

the QR’s factory fan relay. From there, you can put 12 volts switched

to the factory relay, and just run the fans constantly. This will help

keep things cool under the hood.

The wiring is a pain in the butt.. no way around it. You will end up

using sections of your QR harness along with the donor VQ harness.

Take your time, and if you need diagrams, let me know. I will do my

best to help you.

You MUST use the NATS (Nissan Anti Theft System) with the VQ

ECU. There is no way around this. If your car has the system

already, then it’s a simple task. You will need to wire up the Consult

plug to the VQ ECU (just a few wires), and have a Nissan Technician

re-flash your ECU/IMMU to allow the car to start. The only way

around this.. is if you were to get the ECU, IMMU unit (black box

around the key cylinder) and matching key, ALL from the same donor

car. If you get those parts, then, you can hook it up, and it will start

right up from the get-go. If your car came without NATS.. you will

need to source all of the components, and wire it up manually. Again,

wiring diagrams can be had for free… just let me know.

As for exhaust, you will need to have a Y-pipe made to come off of

the stock manifolds. I HIGHLY recommend purchasing aftermarket

headers/y-pipe from a VQ30 Maxima. This will bolt on, and the Ypipe can be modified to work in the Sentra without much fuss. I

recommend a 2.5”, mandrel bent exhaust system as well.

The VQ35 responds well to exhaust/headers, intake and a good tune

(AFC of Emanage). On slicks, expect mid-high 12 second ¼ mile

passes with full interior. With a gutted interior and bolt-on’s, expect

low-12 second ¼ mile times.

If you are going to install nitrous oxide, it’s a good idea to go with a

larger fuel pump. The Maxima pump should fit in without any

modification.

It’s a good idea to replace the belts/spark plugs with new units before

installing the engine..

Other than that.. good luck with your swap, and if you have any

questions, feel free to contact me at TravisFIR@gmail.com

713-1542 from 9am to 5pm Central Time. You can reach me afterhours on the forums (www.b15sentra.net

safe, and enjoy your newly found power! ☺

www.thevboard.com) Be

or 985-

Loading...

Loading...