Nissan Versa 2007 Owner's Manual

C TRANSMISSION/TRANSAXLE

A

B

SECTION MT

CONTENTS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Special Service Tools ...............................................3

Commercial Service Tools ........................................ 4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ............................................................ 7

Cross-Secti o n al View ....... ........................................ 7

TRIPLE-CONE SYNCHRONIZER ........................ 8

REVERSE GEAR NOISE PREVENTION FUNC-

TION (SYNCHRONIZING METHOD) ................... 8

M/T OIL ....................................................................... 9

Changing M/T Oil ..................................................... 9

DRAINING ............................................................. 9

FILLING .................................................................9

Checking M/T Oil ...................................................... 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

SIDE OIL SEAL .... .................................................... 10

Removal and Installation ........................................ 10

REMOVA L ........................................................... 10

INSTALLATION ................................................... 10

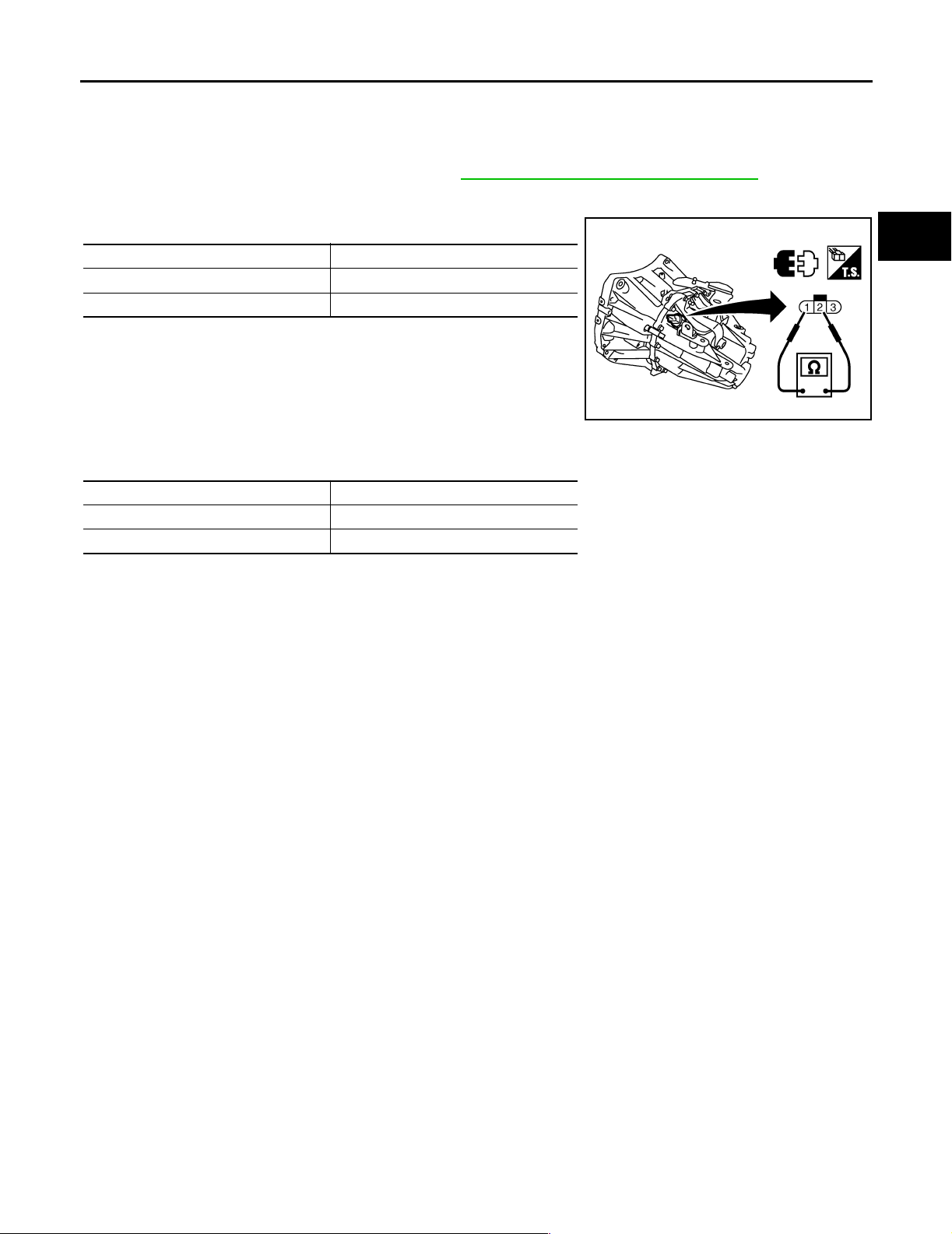

POSITION SWITCH ...................................................11

Checking .................................................................11

BACK-UP LAMP SWITCH ...................................11

PARK/NEUTRAL POSITION SWITCH ................11

CONTROL LINKAGE ............................................... 12

Components of Control Device and Cable ............. 12

Removal and Installation ........................................ 12

REMOVA L ........................................................... 12

INSTALLATION ................................................... 13

MANUAL TRANSAXLE

AIR BREA THER HOSE .... ............................... .........14

Removal and Insta llation ........................................14

COMPONENTS ...................................................14

REMOVAL ...........................................................14

INSTALLATION ...................................................14

TRANSAXLE ASSEMBLY ........................................15

Removal and Insta llation ........................................15

COMPONENTS ...................................................15

REMOVAL ...........................................................15

INSTALLATION ...................................................15

Disassembly and Assembly ....................................17

COMPONENTS ...................................................17

DISASSEMBLY ...................................................23

ASSEMBLY .........................................................28

INPUT SHAFT AND GEARS ....................................34

Disassembly and Assembly ....................................34

GENERAL PRECAUTIONS ........... .....................34

DISASSEMBLY ...................................................34

INSPECTION AFTER DISASSEMBLY ................3 6

ASSEMBLY .........................................................37

MAINSHAFT AND GEARS .......................................38

Disassembly and Assembly ....................................38

GENERAL PRECAUTIONS ........... .....................38

DISASSEMBLY ...................................................38

INSPECTION AFTER DISASSEMBLY ................3 9

ASSEMBLY .........................................................40

REVERSE IDLER SHAFT AND GEARS .................. 43

Disassembly and Assembly ....................................43

DISASSEMBLY ...................................................43

ASSEMBLY .........................................................44

FINAL DRIVE ............................................................ 4 5

Disassembly and Assembly ....................................45

DISASSEMBLY ...................................................45

INSPECTION AFTER DISASSEMBLY ................4 6

ASSEMBLY .........................................................46

SHIFT CONTROL ..................................................... 48

Inspection ...............................................................48

SERVICE DATA AND SPECIFICATIONS (SDS) ......49

General Specifications ............................................49

MT

D

E

F

G

H

I

J

K

L

M

Revision: June 2006 2007 Versa

MT-1

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions fo r Su ppl em ental Restraint System (SRS) “AIR BA G ” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front sea t belt, h el ps to red uce the ris k or sever ity of injur y to the driv er and f ron t passe nger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine th e front air bag deployment, and may only deploy one front

air bag, depending on the severity of a col lision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To av oid renderin g t he SRS inop erative , wh ich cou ld in creas e the risk of pers onal injury or deat h

in the event of a collision which w ould result in air bag inflation, all maintena nce must be performed by an authorized NISSAN/INFINITI dealer.

● Improper main tenance, including in correct removal and installation of the SRS, can lead to per-

sonal injury caused by un intenti onal act iva tion of t he syste m. Fo r removal o f Spiral Ca ble and Air

Bag Modu le, see the SRS section.

● Do not use electrical t est equipme nt on any circu it related to the SR S unless ins tructed to in this

Service Manual. SR S wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

ECS00GLL

Precautions UCS005LD

● If transaxle assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylinder).

Installed CSC returns to the origina l positio n when removing tr ansax le assem bly. Dust on clutch disc sliding parts may damage CSC seal, and may cause clutch fluid leakage.

● Do not reuse transaxle oil.

● Drain, fill and check transaxle oil with the vehicle on level surface.

● During removal or installation, keep inside of transaxle clear of dust or dirt.

● Check for the correct installation orientation prior to removal or disassembly. If matching marks are

required, be certain they do not interfere with the function of the parts they are applied to.

● In principle, tighte n bolts or nuts graduall y in several steps worki ng diagonally from ins ide to outside. If

tightening sequence is specified, follow it.

● Be careful not to damage the sliding surfaces and mating surfaces of parts.

Revision: June 2006 2007 Versa

MT-2

PREPARATION

PREPARATION PFP:00002

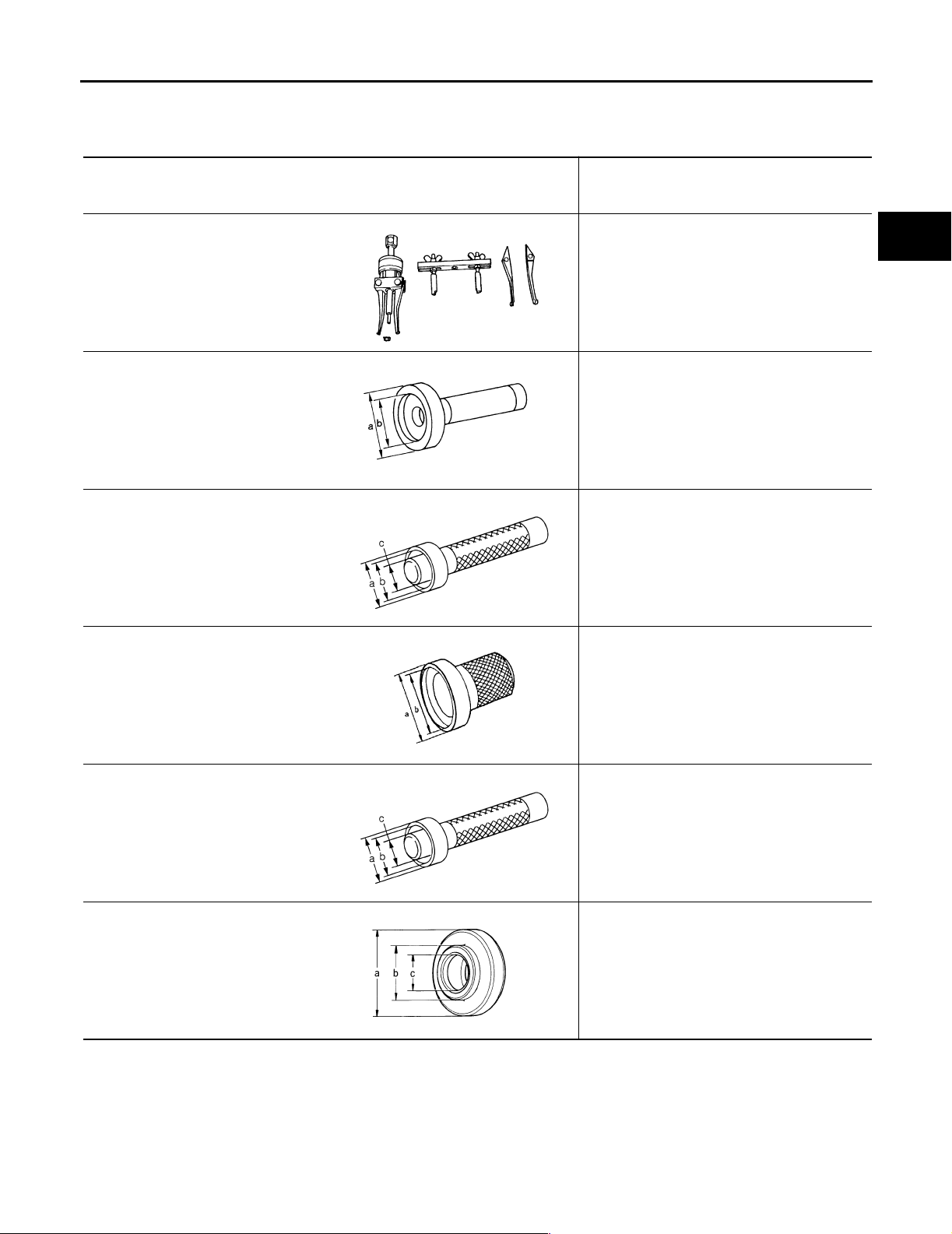

Special Service T ools UCS00655

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

KV381054S0

(J-34286)

Puller

ZZA0601D

KV38100200

(—)

Drift

ZZA1143D

ST33220000

(—)

Drift

Description

Removing mainshaft front bearing outer race

● Installing mainshaft front bearing outer race

● Installing mainshaft rear bearing outer race

● Installing differenti al side bearing outer race

(clutc h hou sing side)

a: 65 mm (2.56 in) dia.

b: 49 mm (1.93 in) dia.

Installing input shaft oil seal

a: 37 mm (1.46 in) dia.

b: 31 mm (1.22 in) dia.

c: 22 mm (0.87 in) dia.

A

B

MT

D

E

F

G

H

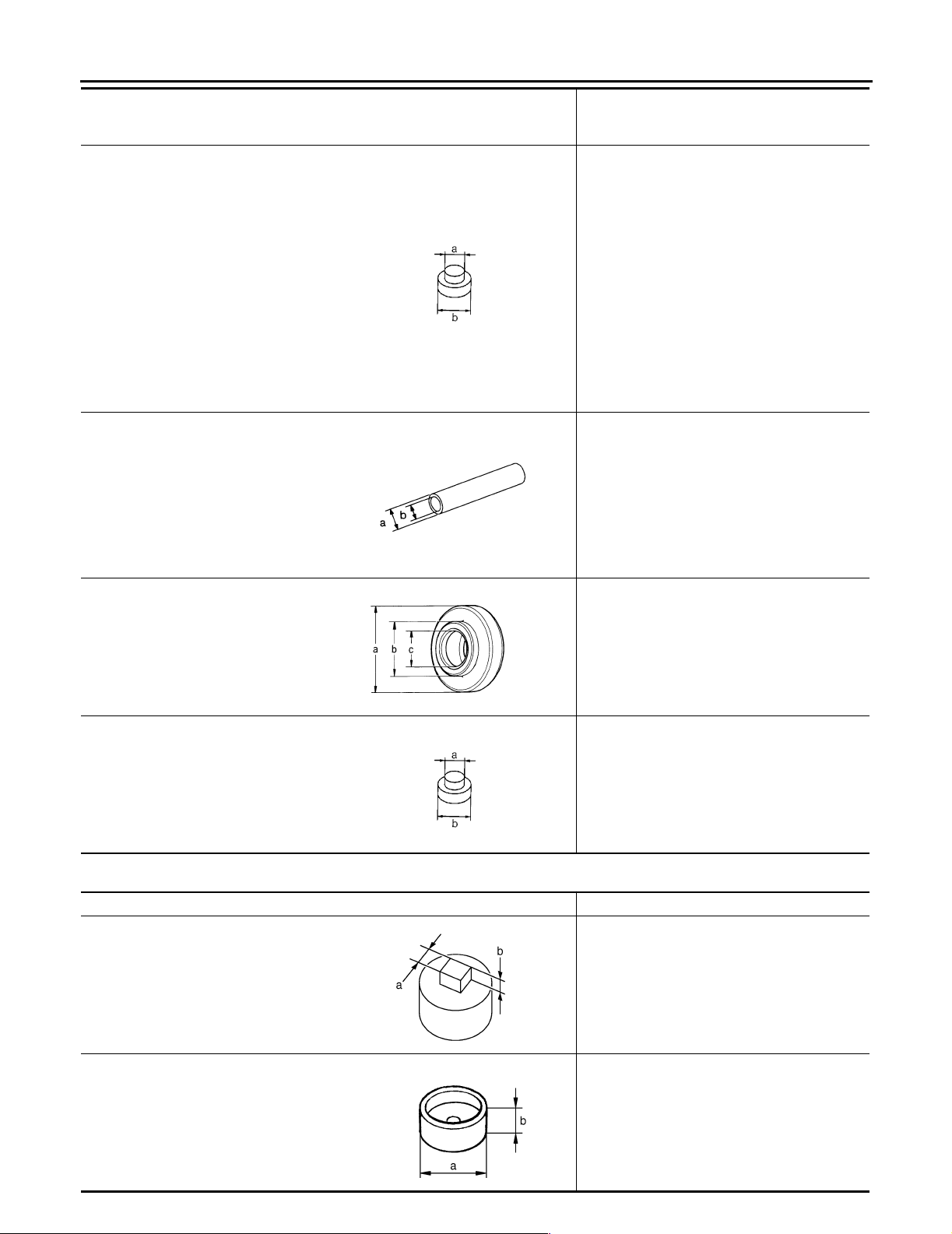

ST33400001

(J-26082)

Drift

KV38100300

(J-25523)

Drift

ST36720030

(—)

Drift

ZZA1046D

ZZA0814D

ZZA1046D

ZZA0978D

Installing differential side bearing outer race

(transaxle case side)

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing differential side oil seal

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia.

● Installing input sha ft rear bearing

● Installing mainshaft front bearing inner race

a: 70 mm (2.76 in) dia.

b: 40 mm (1.57 in) dia.

c: 29 mm (1.14 in) dia.

I

J

K

L

M

Revision: June 2006 2007 Versa

MT-3

PREPARATION

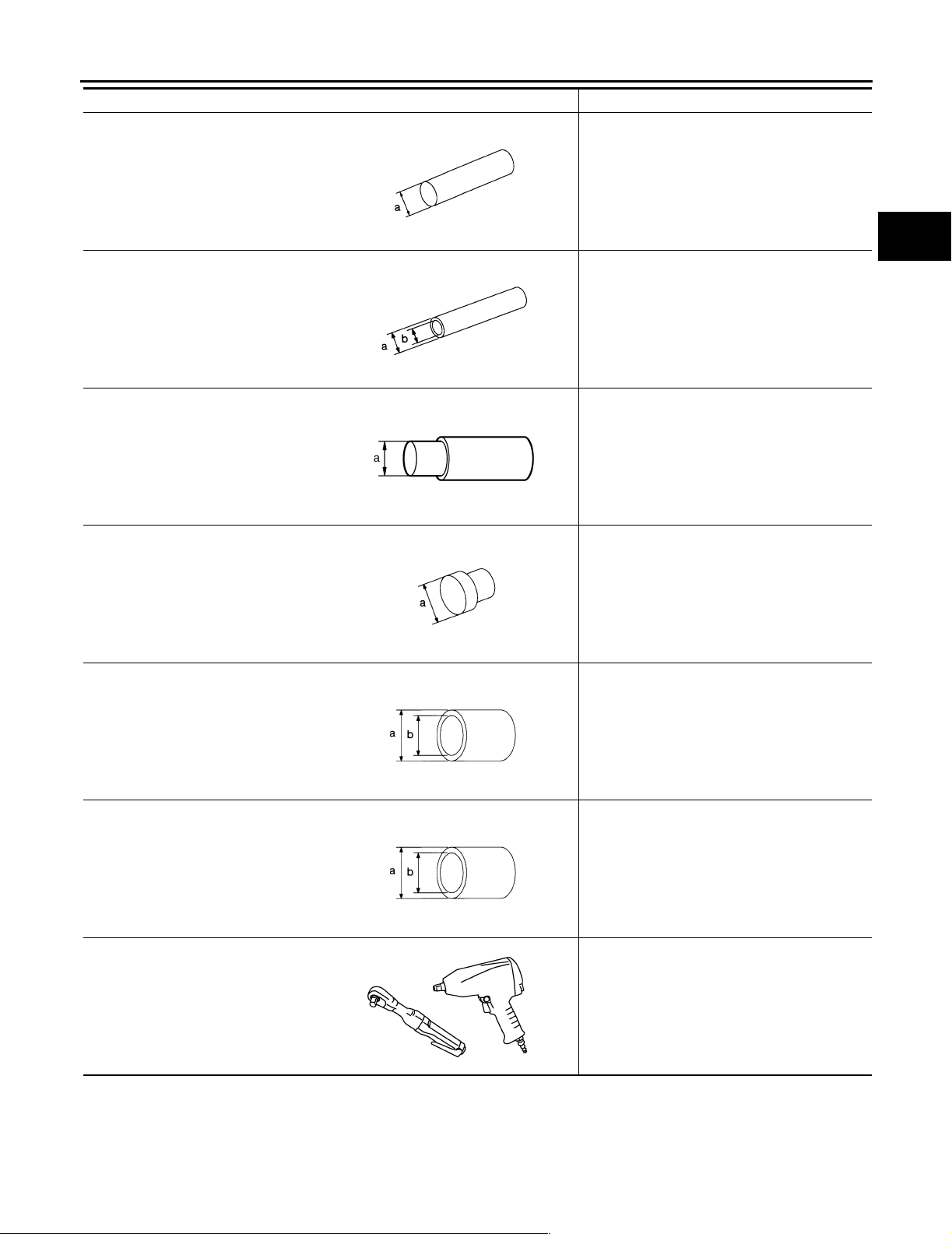

Tool num ber

(Kent-Moore No.)

Tool nam e

ST33052000

(—)

Drift

KV32102700

(—)

Drift

ST30901000

(J-26010-01)

Drift

ZZA0969D

S-NT065

Description

● Removing mainshaf t rear bea ring inne r race

● Removing 6th main gear

● Removing 5th main gear

● Removing 4th main gear

● Removing 1st main gear

● Removing 1st-2nd synchronizer assembly

● Removing 2nd main gear

● Removing bushing

● Removing 3rd main gear

● Removing mainshaft front bearing inner

race

a: 22 mm (0.87 in) dia.

b: 28 mm (1.10 in) dia.

● Installing bushi n g

● Installing 2nd main gear

● Installing 3rd main gear

● Installing 4th main gea r

● Installing 5th main gea r

● Installing 6th main gea r

a: 54 mm (2.13 in) dia.

b: 32 mm (1.26 in) dia.

Installing mainshaft rea r bearing inner race

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35.2 mm (1.386 in) dia.

ZZA0978D

ST33061000

(J-8107-2)

Drift

Removing differential side bearing inner race

(clutch housing side)

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

ZZA0969D

Commercial Service Tools UCS00656

Tool nam e Description

Socket Removing and installing drain plug

a: 8 mm (0.31 in)

b: 5 mm (0.20 in)

PCIB1776E

Spacer Removing mainshaft front bearing outer race

a: 25 mm (0.98 in) dia.

b: 25 mm (0.98 in)

PCIB1780E

Revision: June 2006 2007 Versa

MT-4

PREPARATION

Tool name Description

Drift ● Installing bushing

● Installing shift lever oil seal

● Installing control lever oil seal

a: 17 mm (0.67 in) dia.

S-NT063

Drift Installing input shaft front bearing

a: 35 mm (1.38 in) dia.

b: 25 mm (0.98 in) dia.

S-NT065

Drift Removing input shaft rear bearing

a: 24 mm (0.94 in) dia.

PCIB1779E

Drift

● Removing differential side bearing inner

race (transaxle case side)

● Installing input sha ft rear bearing

a: 43 mm (1.69 in) dia.

A

B

MT

D

E

F

G

H

I

NT109

Drift Installing differential side bearing inner race

(clutch housing side)

a: 45 mm (1.77 in) dia.

b: 39 mm (1.54 in) dia.

S-NT474

Drift Installing differential side bearing inner race

(transaxle case side)

a: 52 mm (2.05 in) dia.

b: 45 mm (1.77 in) dia.

S-NT474

Power tool

PBIC0190E

● Loose ning bolts and nuts

J

K

L

M

Revision: June 2006 2007 Versa

MT-5

NOISE , VIBRATION AND HARS HNESS (NVH) TROUBL ESHOOTING

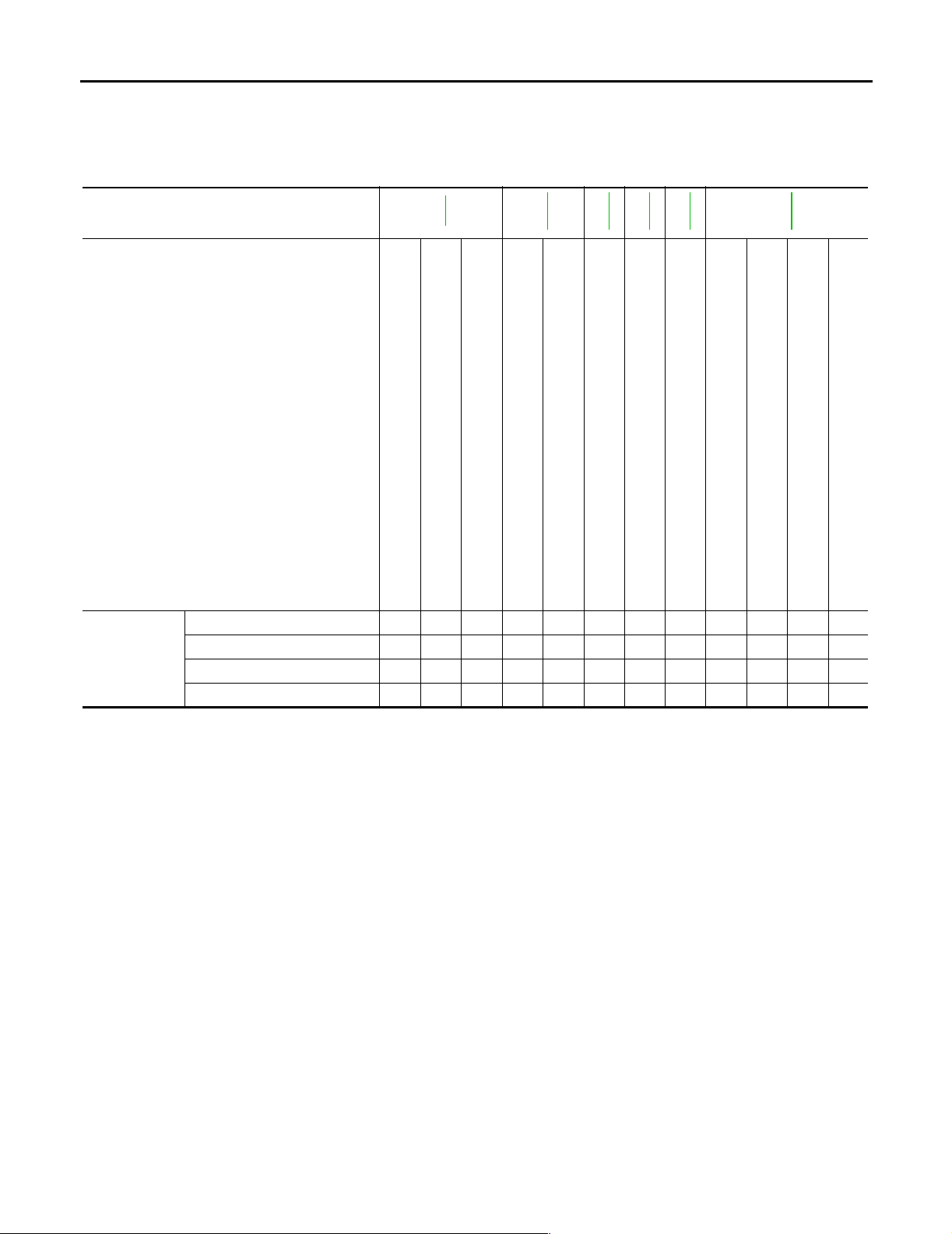

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003 NVH Troubleshooting Char t UCS005LG

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

Reference pa ge

SUSPECTED PARTS

(Possible cause)

Noise 1 2 3 3

Symptoms

Oil leakage 3 1 2 2 2

Hard to shift or will n o t shift 1 1 2 3 3

Jumps out of gear 1 3 3

MT-9

OIL (Oil level is low.)

OIL (Wrong oil.)

OIL (Oil level is high.)

MT-17

GASKET (Damag ed)

MT-21

MT-12

MT-21

OIL SEAL (Worn or dam aged )

O-RING (Worn or damaged)

SHIFT CONTROL LINKAGE (Worn)

SHIFT FO RK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

MT-18

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

Revision: June 2006 2007 Versa

MT-6

DESCRIPTION

DESCRIPTION PFP:00000

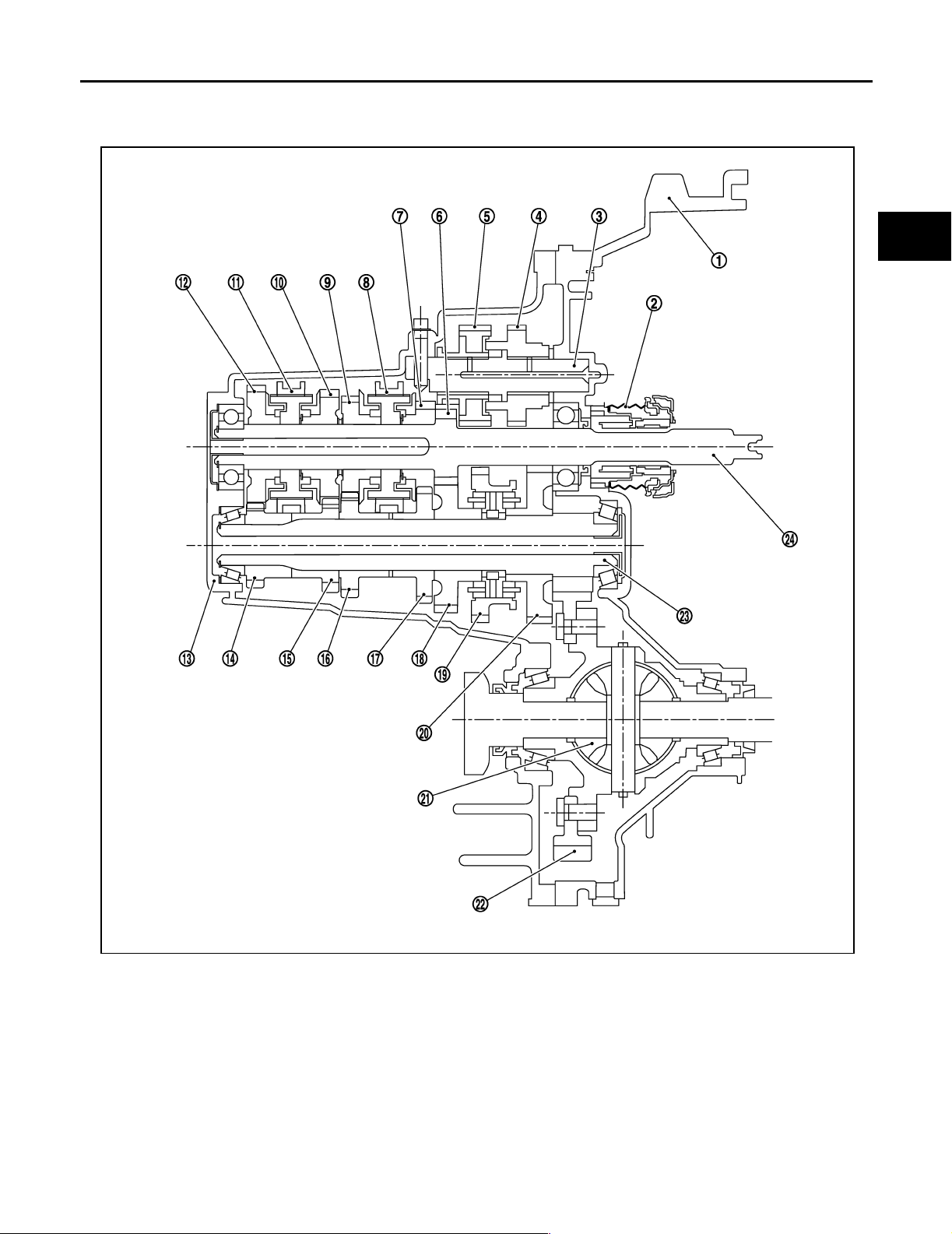

Cross-Secti onal View UCS0065I

A

B

MT

D

E

F

G

1. Clutch housing 2. CSC (Concentric Slave Cylinder) 3. Reverse idler shaft

4. Reverse input gear 5. Reverse output gear 6. 2nd input gear

7. 3rd input gear 8. 3rd-4th synchronizer assembly 9. 4th input gear

10. 5th input gear 11. 5th-6th synchronizer assem bly 12. 6th input gear

13. Transaxle case 14. 6th main gear 15. 5th main gear

16. 4th main gear 17. 3rd main gear 18. 2nd main gear

19. 1st-2nd synchronizer assembly 20. 1st main gear 21. Differential assembly

22. Final gear 23. Mainshaft 24. Input shaf t

H

I

J

K

L

M

SCIA7618E

Revision: June 2006 2007 Versa

MT-7

DESCRIPTION

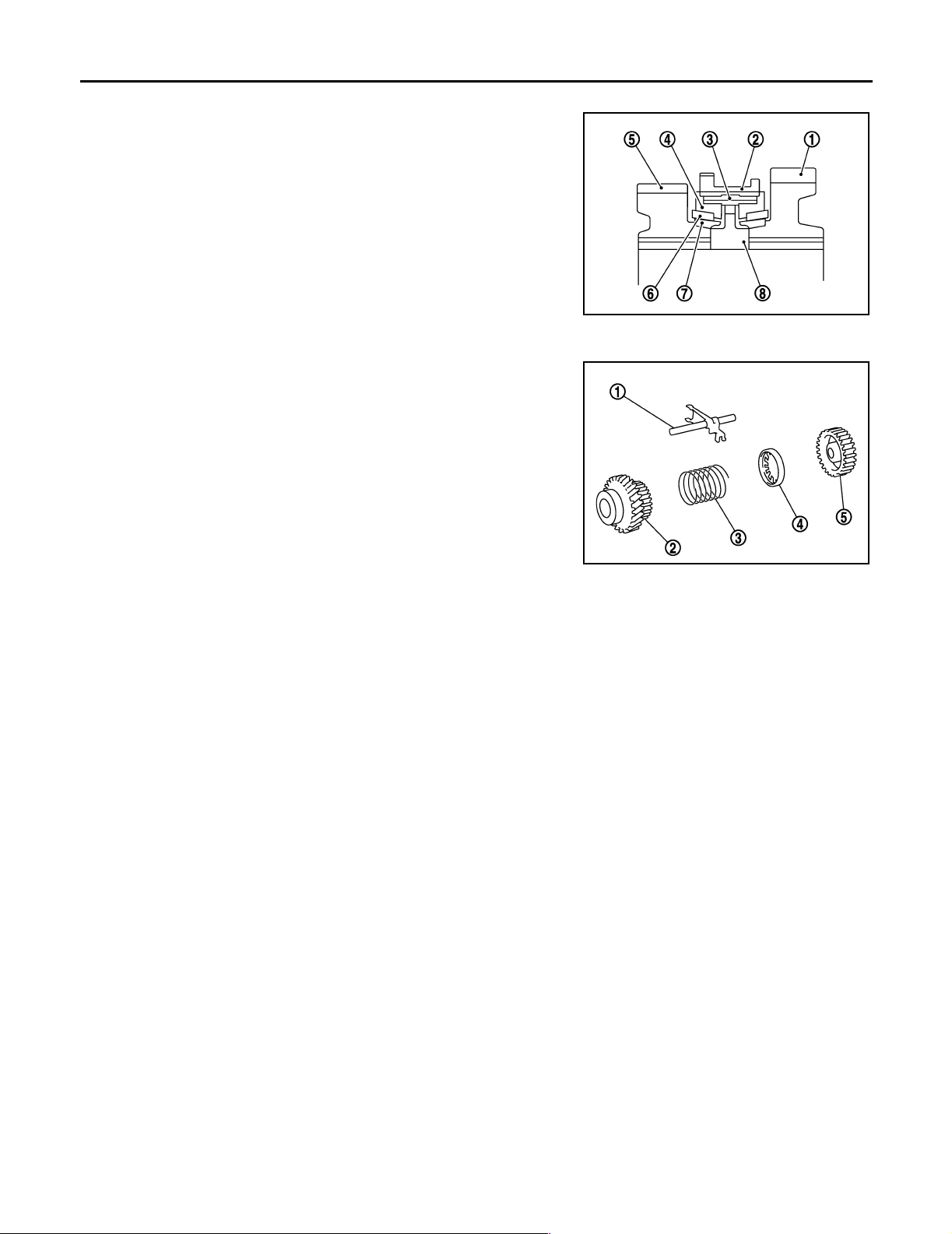

TRIPLE-CONE SYNCHRONIZER

Triple-cone synchronizer is used for the 1st and the 2nd gears to

reduce operating force of the shift lever.

● 1st main gear (1)

● 1st-2nd coupling sleeve (2)

● Insert key (3)

● Outer baulk ring (4)

● 2nd main gear (5)

● Synchronizer cone (6)

● Inner baulk ring (7)

● 1st-2nd synchronizer hub (8)

REVERSE GEAR NOISE PREVENTION FUNCTION (SYNCHRONIZING ME THOD)

Reverse gear assembly consists of reverse input gear, return spring,

reverse baulk ring and reverse output gear. When the shift lever is

shifted to the reverse position, the cons truction allows sm ooth shift

operation by stopping the reverse idler shaft rotation by frictional

force of synchronizer.

● Reverse fork rod (1)

● Reverse output gear (2)

● Return spring (3)

● Reverse baulk ring (4)

● Reverse input gear (5)

SCIA7636E

SCIA7621E

Revision: June 2006 2007 Versa

MT-8

M/T OIL

M/T OIL PFP:KLD20

Changing M/T Oil UCS005LI

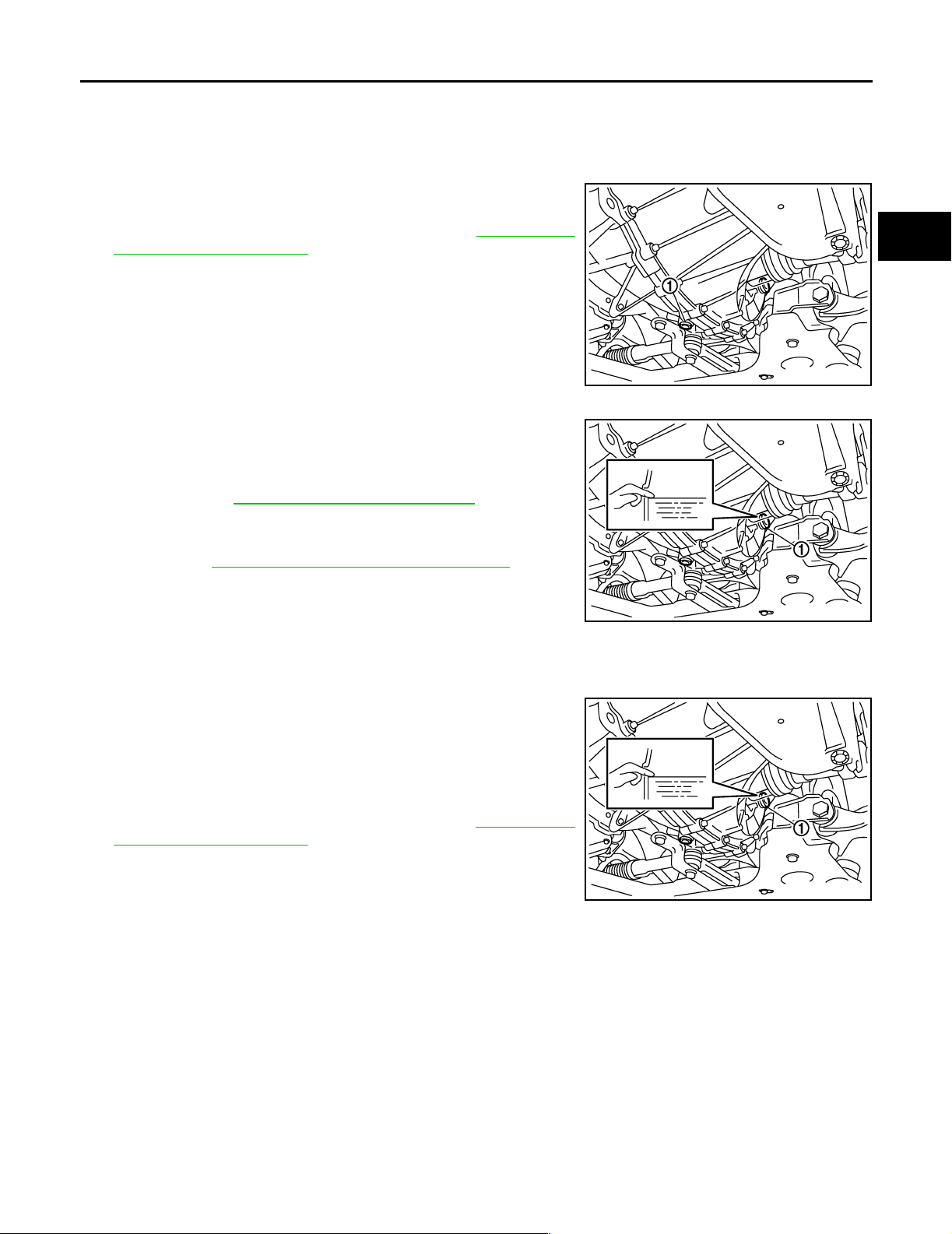

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new ga sket onto drain plug (1) and install it into transaxle. Tighten drain plug to specification. Refer to MT-17, "

and Housing Components" .

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug (1). F ill w ith new oil unt il oil lev el re aches th e

specified limit at filler plug hole as shown.

Case

SCIA7622E

A

B

MT

D

E

F

Oil grade and capacity

: Refer to MA-11, "

Fluids and Lubricants"

2. After refill in g oil, chec k oil l evel . Install a new gasket on filler pl ug

(1), then install it into transaxle. Tighten filler plug to sp ecification. Refer to MT-17, "

Case and Housing Components" .

CAUTION:

Do not reuse gasket.

SCIA7623E

Checking M/T Oil UCS005LJ

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil l evel at filler plug hole as

shown.

CAUTION:

Do not start engine while checking oil level.

3.

Install a new gasket onto filler plug (1) and install it into transaxle. Tighten filler plug to specifica tion. Refe r to MT-17, "

and Housing Components" .

CAUTION:

Do not reuse gasket.

Case

SCIA7623E

G

H

I

J

K

L

M

Revision: June 2006 2007 Versa

MT-9

SIDE OIL SEAL

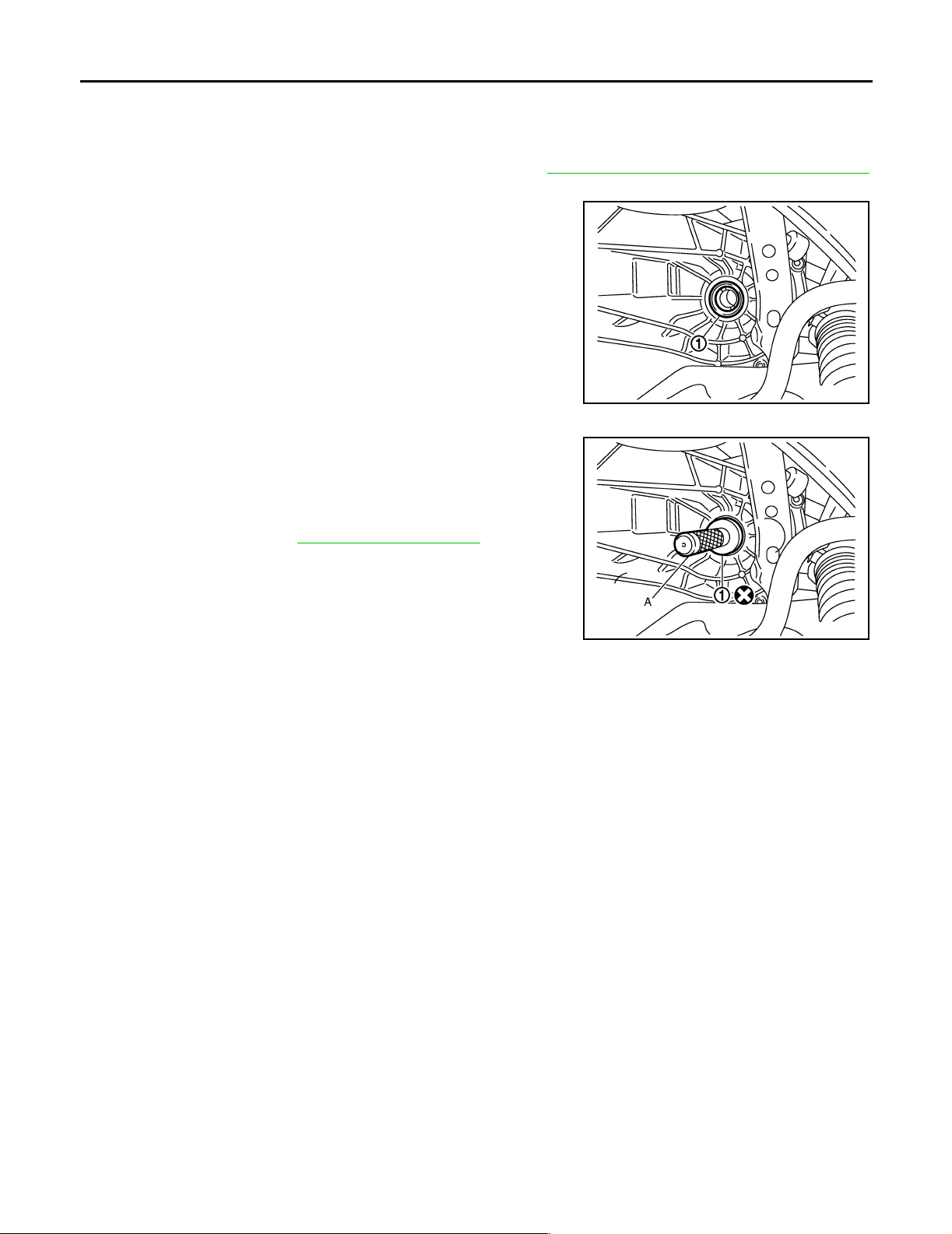

SIDE OIL SEAL PFP:32113 Removal and Installation UCS005LK

REMOVAL

1. Remove front drive shafts from transaxle assembly. Refer to F AX-8, "Removal and Installation (Left Side)"

.

2. Remove differential side oil seal (1) using a suitable tool.

CAUTION:

Be careful not to dama ge transaxle case and clutch housing.

SCIA7625E

INSTALLATION

1. Install differential side oil seal (1) to clutch housing and transaxle

case using Tool (A).

Tool number A: ST38100300 (J-25523)

2. Installation is in the reverse order of removal. Check oil level

after installation. Refer to MT-9, "

CAUTION:

Do not reuse oil seal.

Checking M/T Oil" .

SCIA7626E

Revision: June 2006 2007 Versa

MT-10

POSITION SWITCH

POSITION SWITCH PFP:32005

Checking UCS005LL

NOTE:

For removal and installation of the switches, refer to MT-17, "

BACK-UP LAMP SWITCH

● Check continuity between terminals 1 and 2 .

Gear position Continuity

Reverse Yes

Except reverse No

Case and Housing Components"

A

B

MT

D

E

PARK/NEUTRAL POSITION SWITCH

● Check continuity between terminals 2 and 3 .

Gear position Continuity

Neutral Yes

Except neutral No

PCIB1781E

F

G

H

I

J

K

L

M

Revision: June 2006 2007 Versa

MT-11

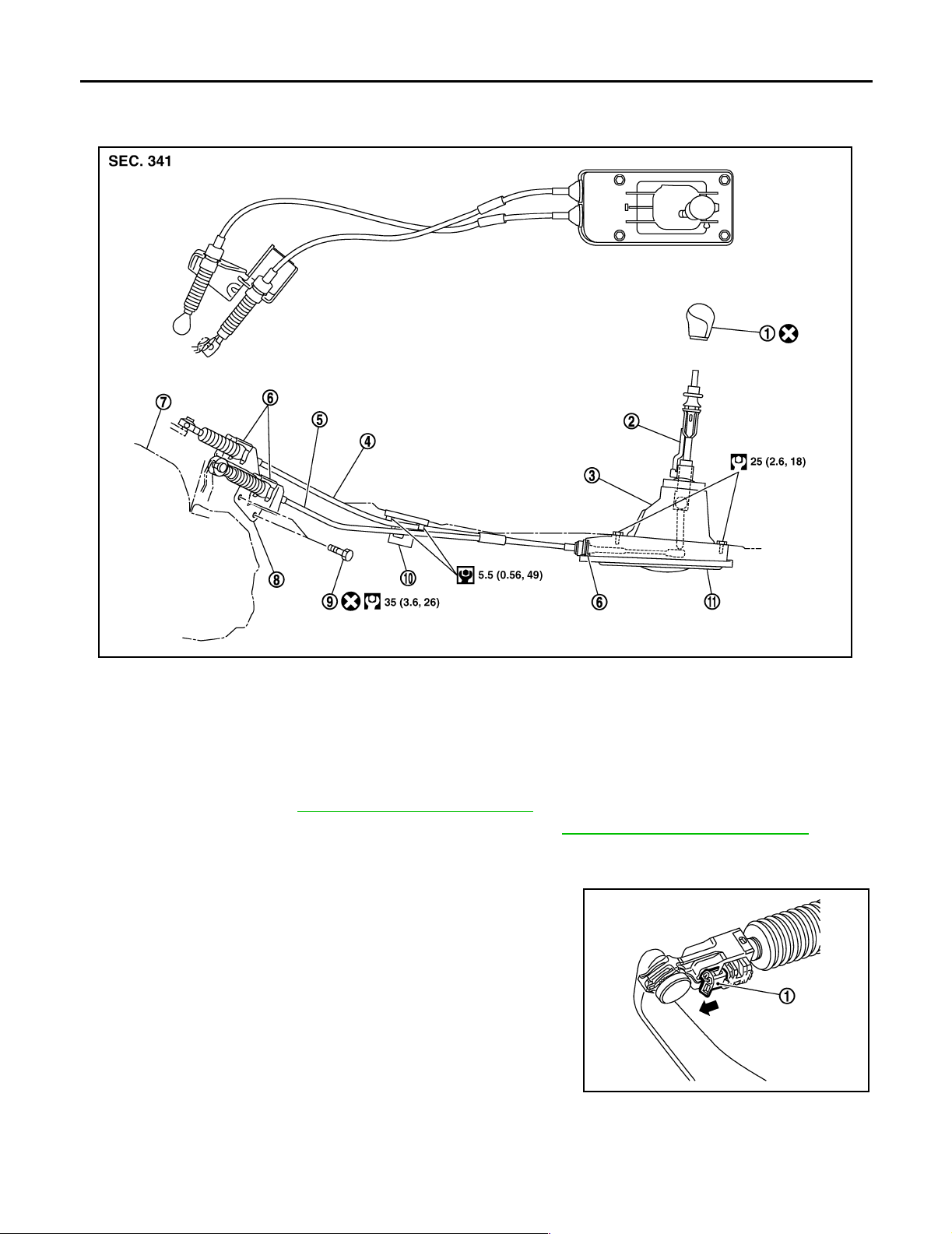

CONTROL LINKAGE

CONTROL LINKAGE PFP:34103 Components of Control Devi ce and Cable UCS005LM

WCIA0626E

1. Contro l lever knob 2. Contro l lever 3. Contr ol device assembly

4. Se lect cable 5. Shift cable 6. L ock plate

7. Cl utch housing 8. Cable bracket 9. Tapping bolt

10. Cable support bracket 11. Adapter plate

Removal and Installation UCS005LN

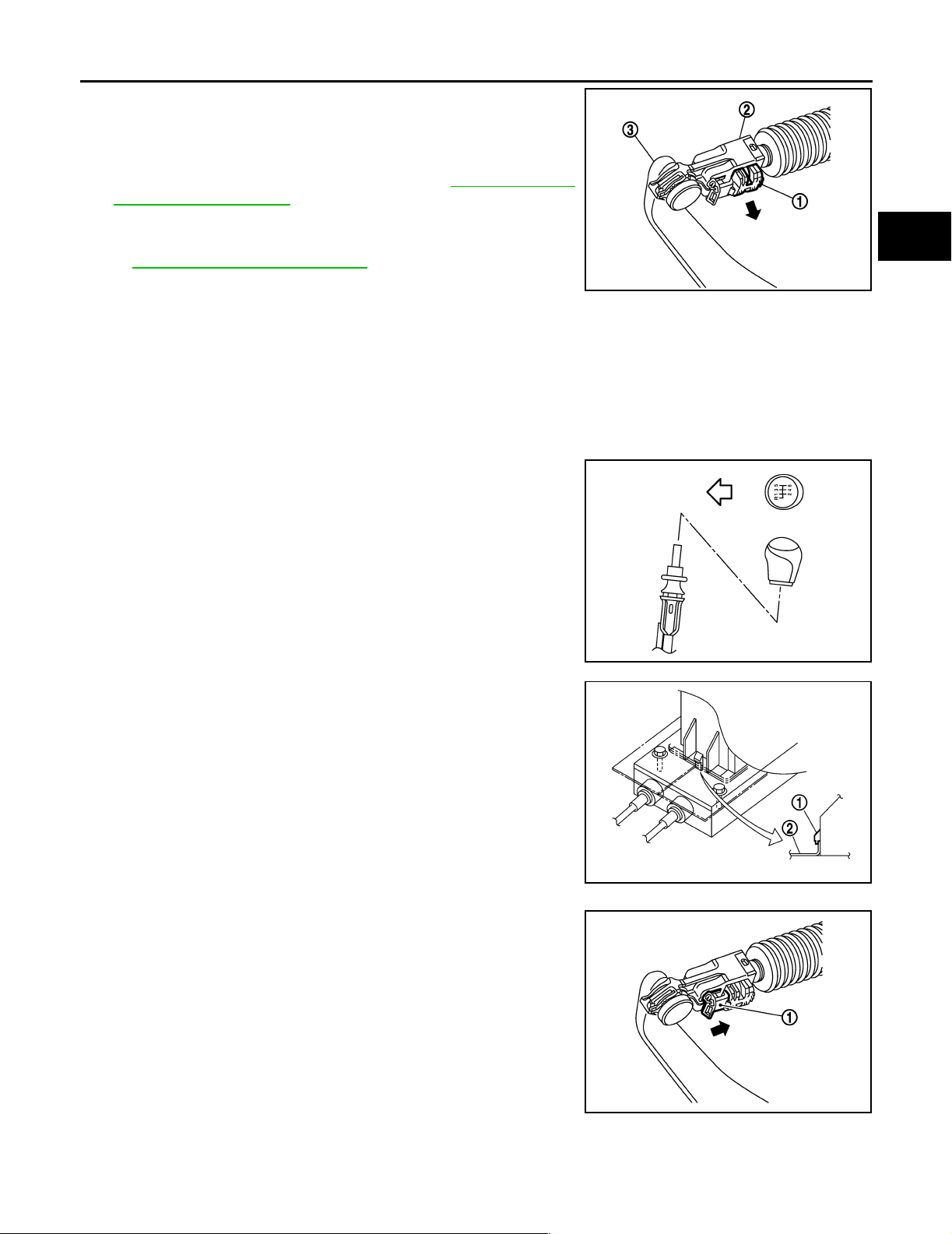

REMOVAL

1. Remove battery. Refer to SC-9, "Removal and Installation" .

2. Remove air duct (Inlet), air duct and air cleaner cas e . Refer to EM-16, "

3. Remove shift cable from shift lever.

4. Remove select cable according to the following.

a. Move sto pper (1) to the unlocked position.

Removal and Installation" .

SCIA7842E

Revision: June 2006 2007 Versa

MT-12

CONTROL LINKAGE

b. Pull the release button ( 1) of select ca ble (2) and then re move i t

from select lever (3).

5. Shift contro l lever to neut ral position.

6. Remove co ntrol lever knob.

7. Remove center console assembly. Refer to IP-22, "

CONSOLE ASSEMBLY" .

8. Remove control device assembly bolts.

9. Remove exhaust front tube, center muffler and heat plate. Refer

to EX-4, "

Removal and Installation" .

10. Remove cable support bracket .

11. Remove select cable and shift cable from cable bracket.

12. Remove control device ass embly from the vehicle.

CENTER

A

B

MT

WCIA0606E

D

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Self tapping bolts are used to attach cables to the clutch hous ing.

● Securely assemble each cable and lever of control shaft.

● Be careful about the installation direction, and push control lever

knob onto control lever.

CAUTION:

Do not reuse control lever knob.

● Make sure that the fro nt/rear cl aws (1) of contr ol d ev ice as sem-

bly are in contact with flange of the floor (2).

● When control lever is selected to 1st- 2nd side a nd 5th-6th side ,

confirm control lever returns to neutral position smoothly.

● When control lever is shifted to eac h position, make s ure there

is no binding or disconnection in each boot.

E

F

G

H

I

SCIA7630E

J

K

L

PCIB1510E

● Move stopper (1) to lock positi on when installing the shift ca ble

onto the shift lever.

SCIA7846E

Revision: June 2006 2007 Versa

MT-13

M

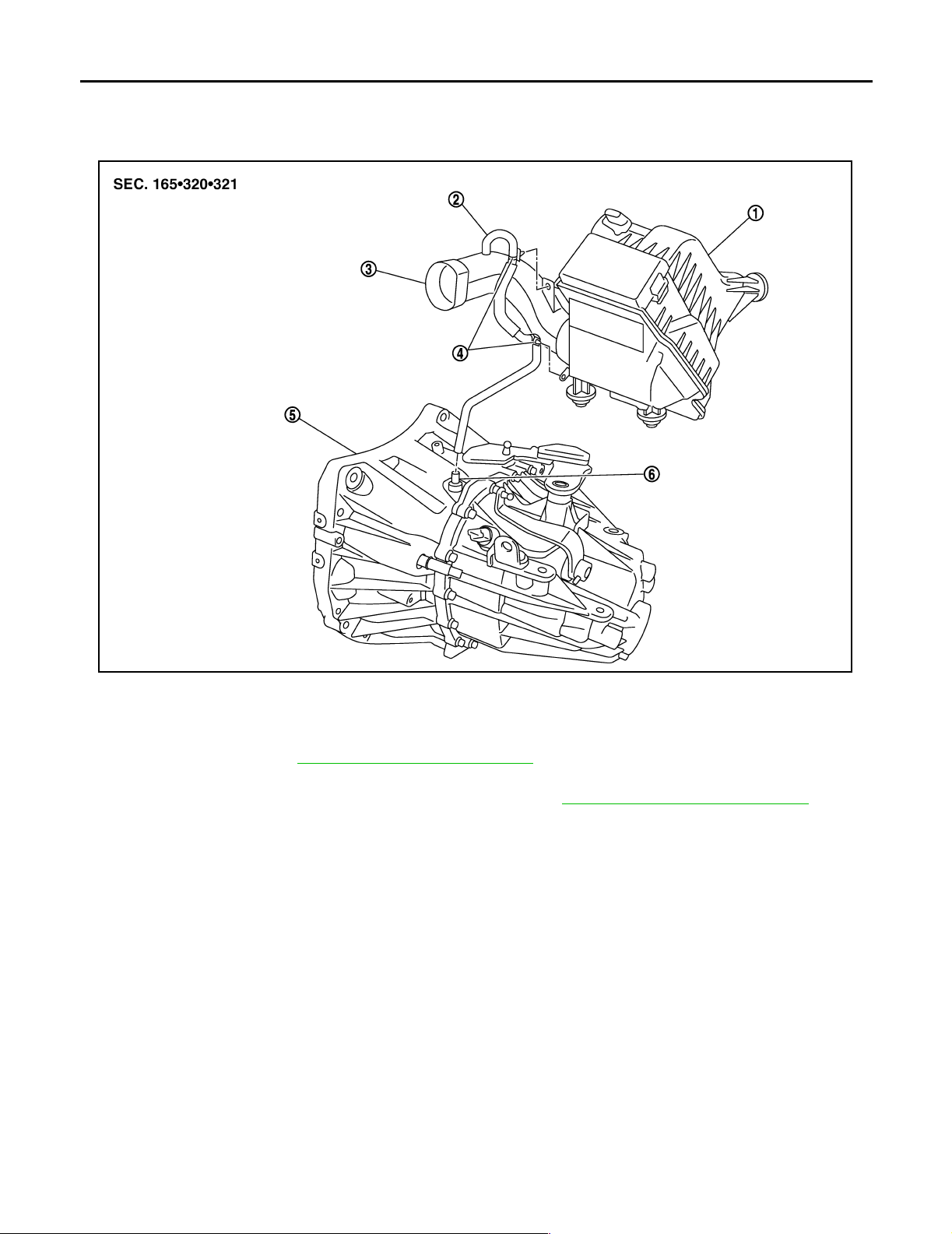

AIR BREATHER HOSE

AIR BREATHE R HOSE PFP:31098 Removal and Installation UCS005LO

COMPONENTS

SCIA7629E

1. Air cleaner case 2. Air breather hose 3. Air duct

4. Clip 5. Transaxle assembly 6. 2 way connector

REMOVAL

1. Remove battery. Refer to SC-9, "Removal and Installation"

2. Remove air duct (Inlet), air duct and air cleaner cas e . Refer to EM-16, "Removal and Installation" .

3. Remove air breather hose.

CAUTION:

When air breather hose is removed, be sure to hold two way connector securely.

INSTALLATION

Installation is in the reverse order of removal.

● When installing air breather hose on two way connector, aim paint mark face toward the v ehicle front.

● When installing air breather hose on two way connector, push it until it hits transaxle case.

● When installing air breather ho se to air duct and air cleaner case, make sure that clips are fully inserted.

CAUTION:

Make sure air breather hose is not collapsed or blocked due to folding or bending when installed.

Revision: June 2006 2007 Versa

MT-14

TRANSAXLE ASSEMBLY

TRANS AXLE ASSEMBLY PFP:32010

Removal and Installation UCS005LQ

CAUTION:

If transaxle assembly is removed from the vehicle, always replace CSC (Concen tric Slave Cylinder).

Inserted CSC returns to the orig inal positio n when removin g transaxle assembly. Dust on clutch disc

sliding parts may damage CSC seal, and may cause clutch fluid leakage.

A

B

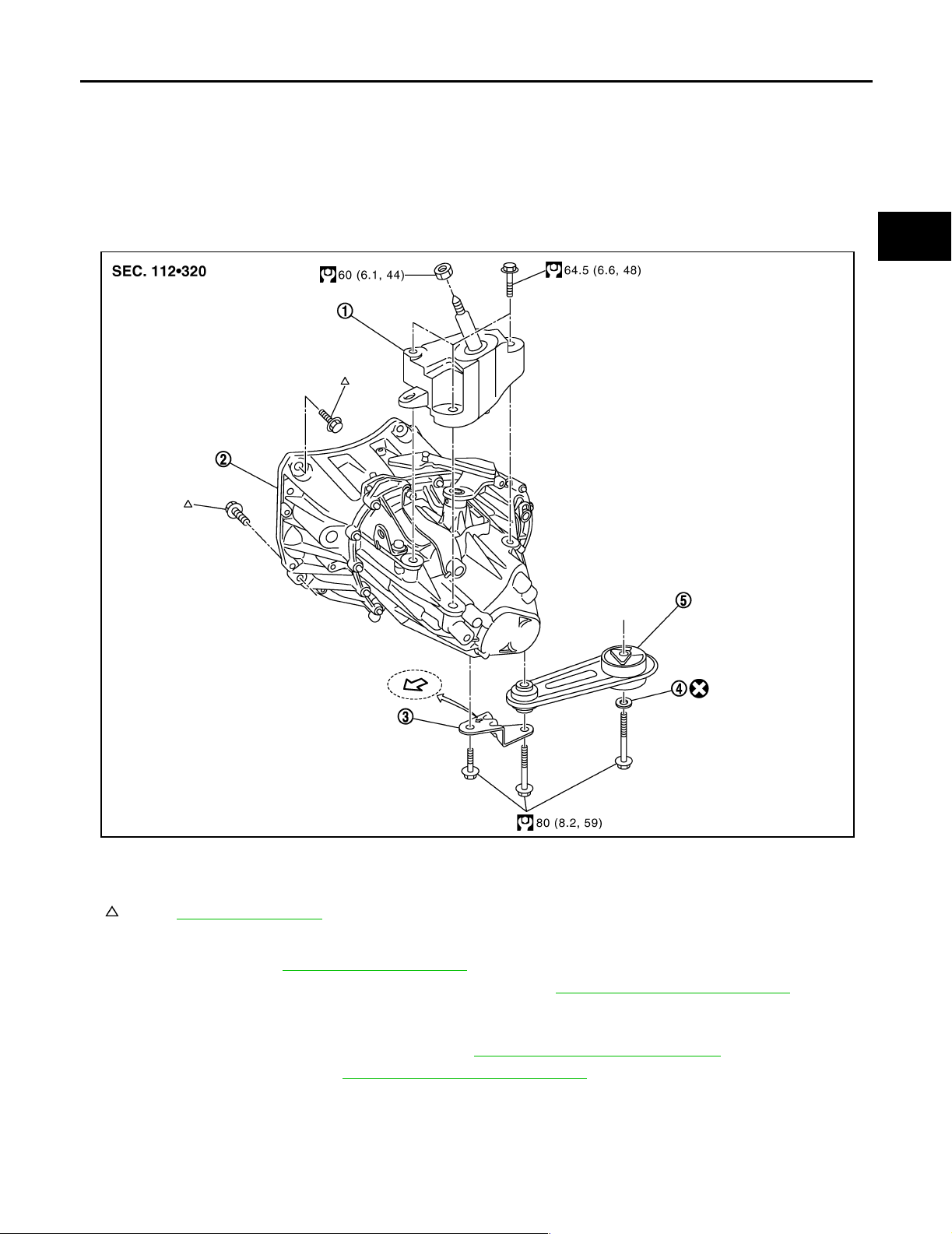

COMPONENTS

MT

D

E

F

G

H

I

J

1. LH engine mount bracket (transaxle

side)

4. Washer 5. Rear torque rod ⇐ Front

: Refer to MT-15, "

INSTALLATION" for specific ation.

2. Transaxle assembly 3. Rear engine mount bracket

REMOVAL

1. Drain gear oil. Refer to MT-9, "Changing M/T Oil" .

2. Drain clutch fluid and remove clutch tube from CSC. Refer to CL-9, "

Removal and Installation" .

CAUTION:

Do not depress clutch pedal during removal procedure.

3. Remove engine and transaxle assembly. Refer to EM-73, "

4. Remove starter motor. Refer to SC-23, "

Removal and Installation" .

Removal and Installation" .

5. Remove transaxle assembly to engine bolts.

6. Separate transaxle assembly from engine.

INSTALLATION

Installation is in the reverse order of removal.

K

L

SCIA7631E

M

Revision: June 2006 2007 Versa

MT-15

Loading...

Loading...