Nissan Primera User Manual

LIGHTING SYSTEM

K ELECTRICAL

A

B

SECTION

CONTENTS

PRECAUTION ............................................................ 4

Precautions for Supplemental Restraint Sy stem

(SRS) “AIR BAG” and “SEATBELT PRE-TEN-

SIONER” .................................................................. 4

Precaution ................................................................ 4

Wiring Diagrams and Trouble Diagnosis .................. 4

HEADLAMP -CONVENTIONAL TYPE- ..................... 5

System Description .................................................. 5

DESCRIPTION ...................................................... 5

LOW BEAM OPERATION ..................................... 5

HIGH BEAM OPERATION/FLASH-TO-PASS

OPERATION ......................................................... 5

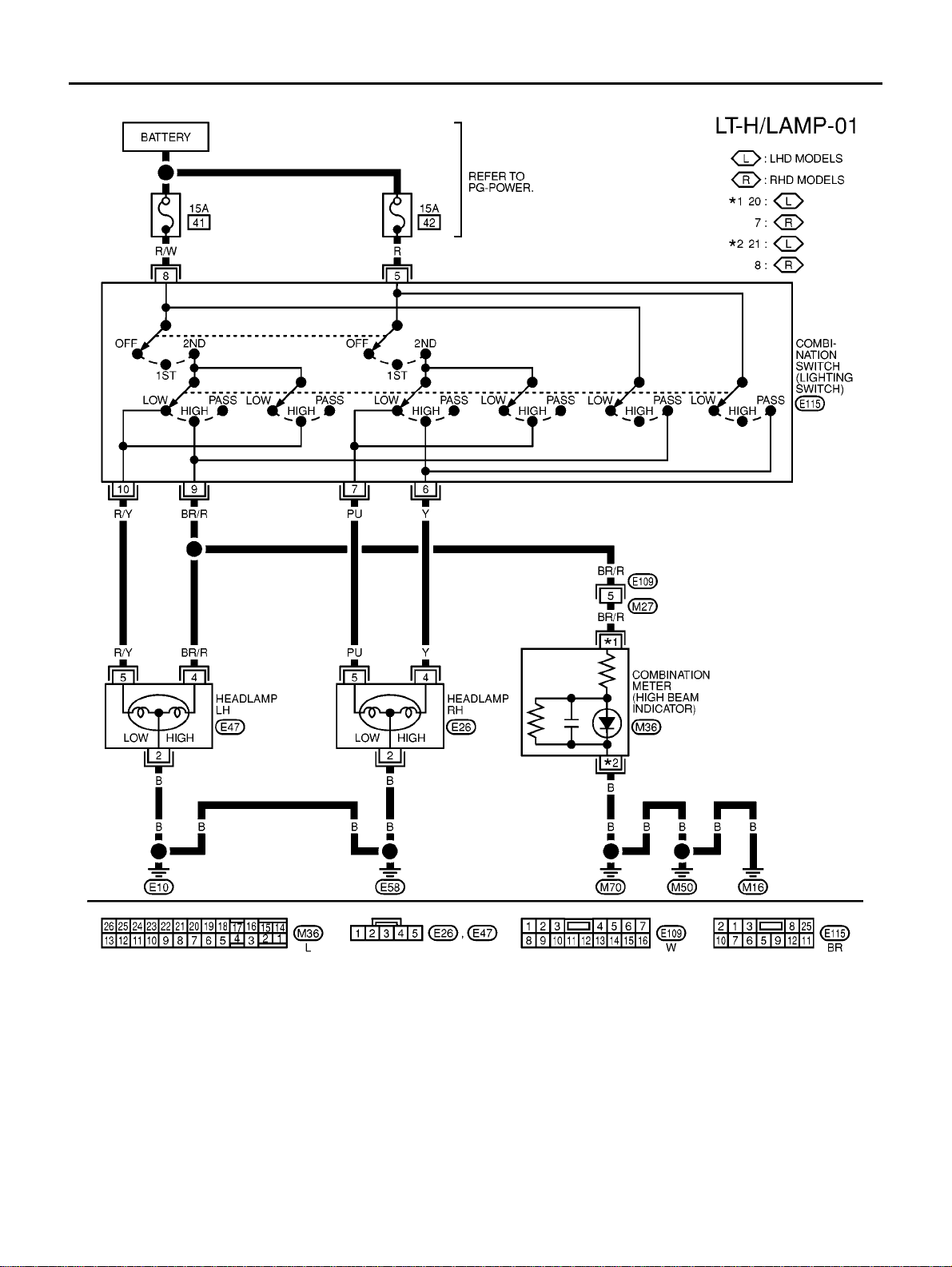

Wiring Diagram — H/LAMP — ................................. 6

Trouble Diagnoses . .................................................. 7

Aiming Adjustment ................................................... 7

LOW BEAM ........................................................... 8

Bulb Replacement .................................................... 9

HEADLAMP ..........................................................9

CLEARANCE LAMP, FRONT TURN SIGNAL

LAMP .................................................................... 9

Removal and Installation ..........................................9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

HEADLAMP - XENON TYPE - ................................. 10

System Description ................................................ 10

LOW BEAM OPERATION ................................... 10

HIGH BEAM OPERATION/FLASH-TO-PASS

OPERATION ....................................................... 10

Wiring Diagram - H/LAMP - .................................... 12

Trouble Diagnosis .................................................. 14

Aiming Adjustment ................................................. 15

LOW BEAM ......................................................... 15

Bulb Replacement .................................................. 16

XENON BULB (LOW BEAM) .............................. 16

HIGH BEAM ........................................................ 16

CLEARANCE LAMP, FRONT TURN SIGNAL

LAMP .................................................................. 17

Removal and Installation ........................................ 17

REMOVAL ........................................................... 17

INSTALLATION ................................................... 17

LIGHTING SYSTEM

HEADLAMP (WITHDAYTIME)- CONVENTIONAL

TYPE - ....................................................................... 18

System Description .................................................18

DESCRIPTION ....................................................18

HEADLAMP OPERATION ..................................18

DAYTIME LIGHT OPERATION ...........................18

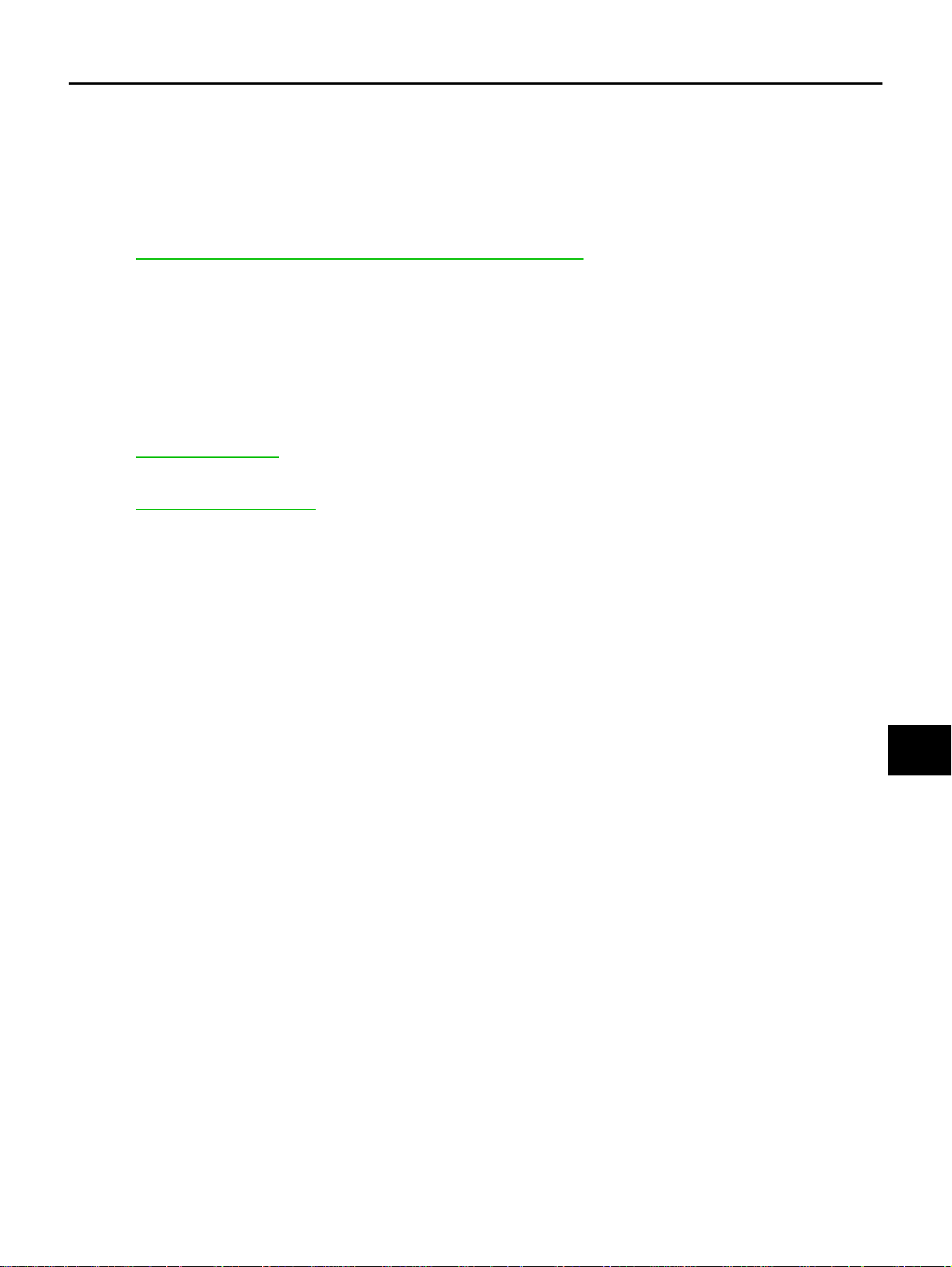

Schematic ...............................................................19

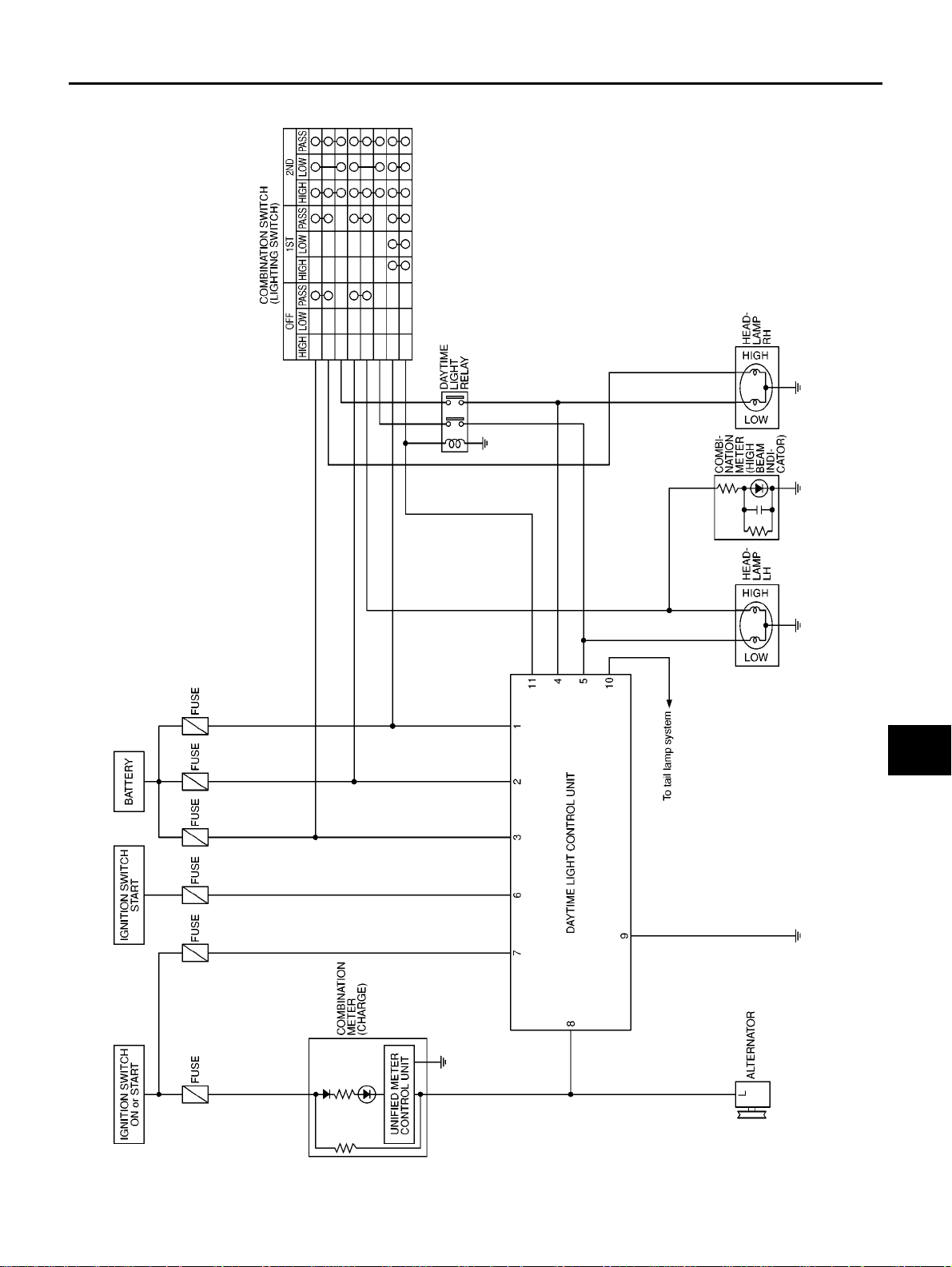

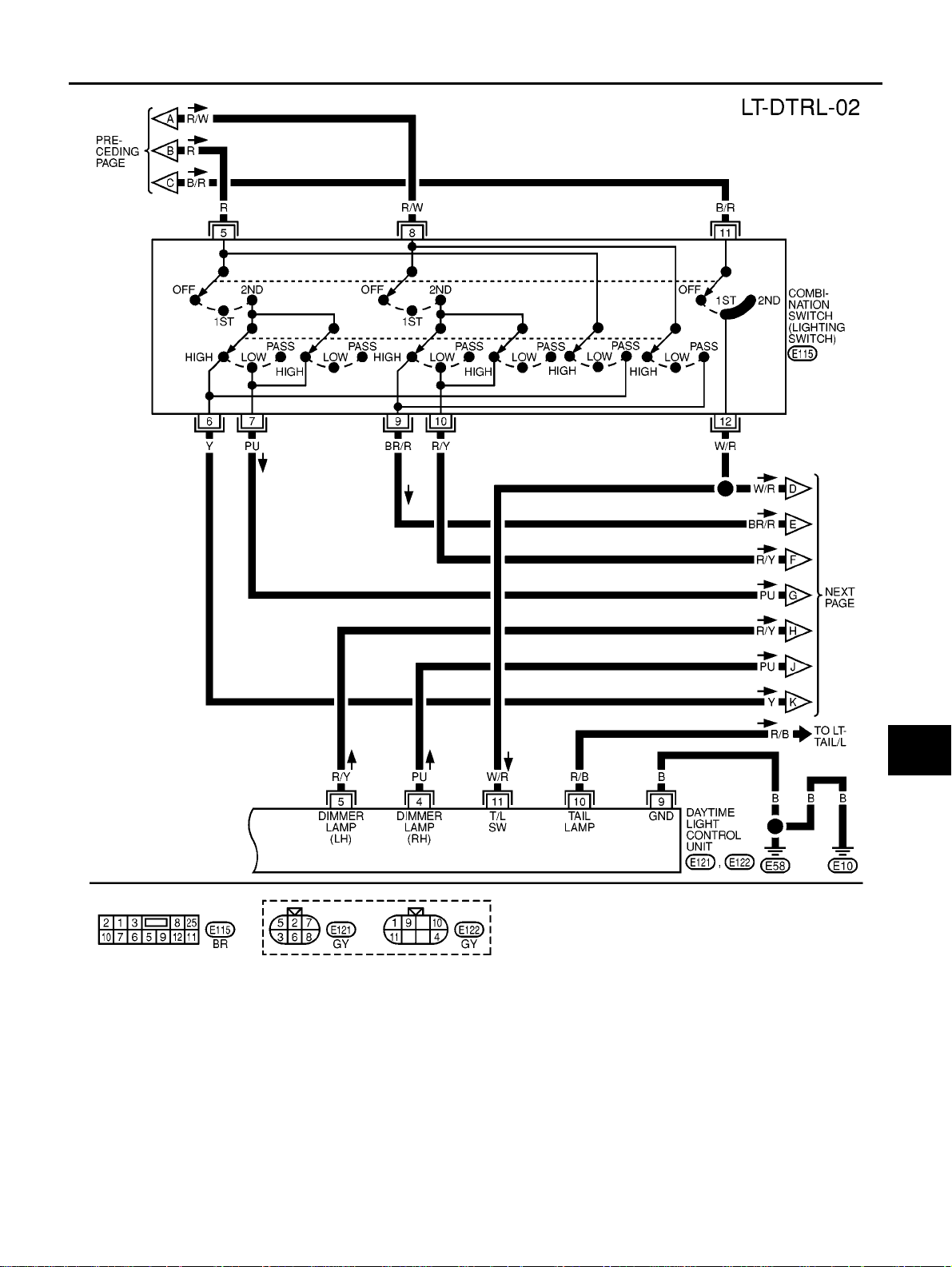

Wiring Diagram — H/LAMP — ...............................20

Trouble Diagnoses .................................................23

Aiming Adjustment ..................................................2 4

Bulb Replacement ..................................................24

HEADLAMP .........................................................24

CLEARANCE LAMP, FRONT TURN SI GNAL

LAMP ...................................................................24

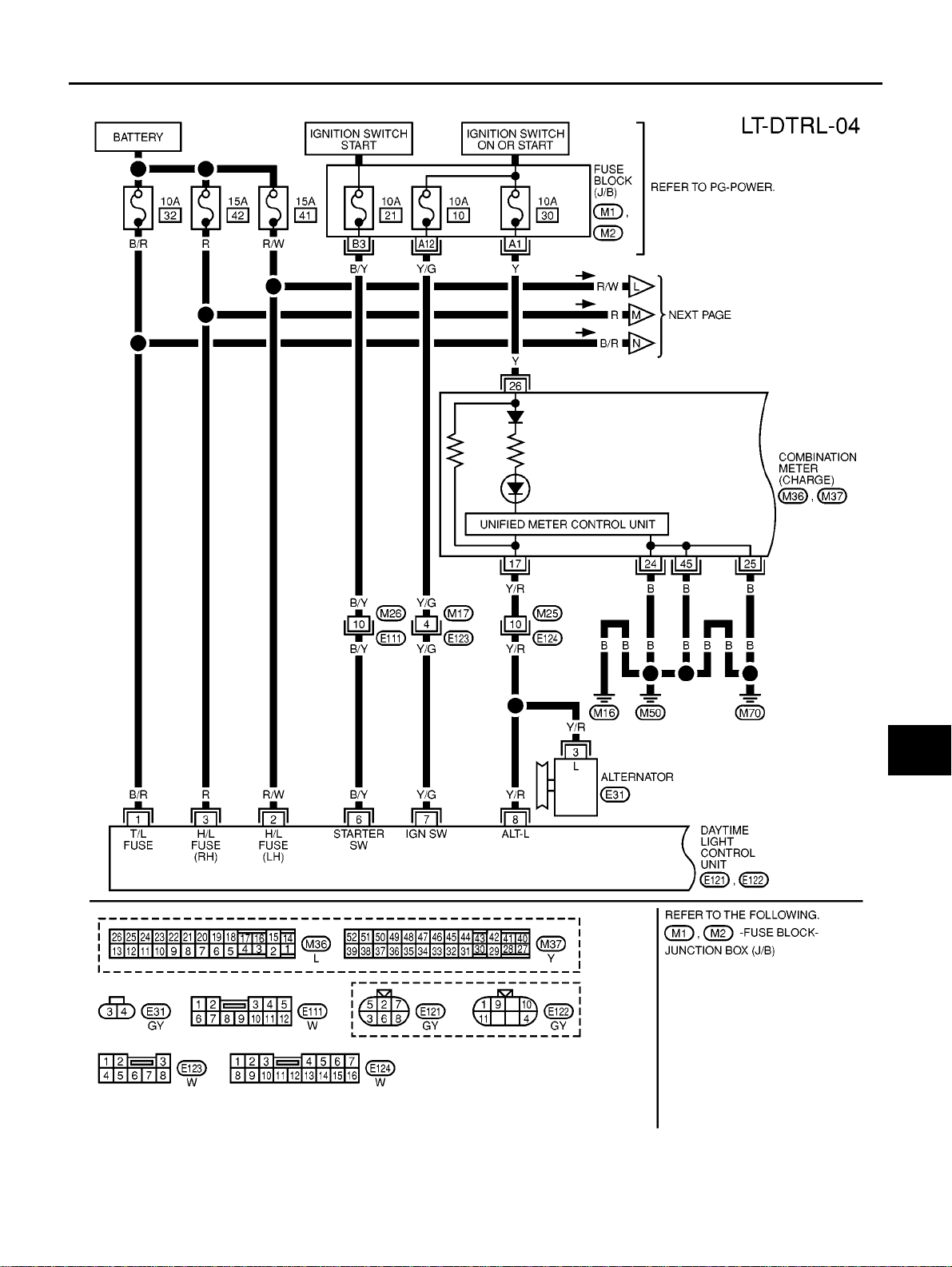

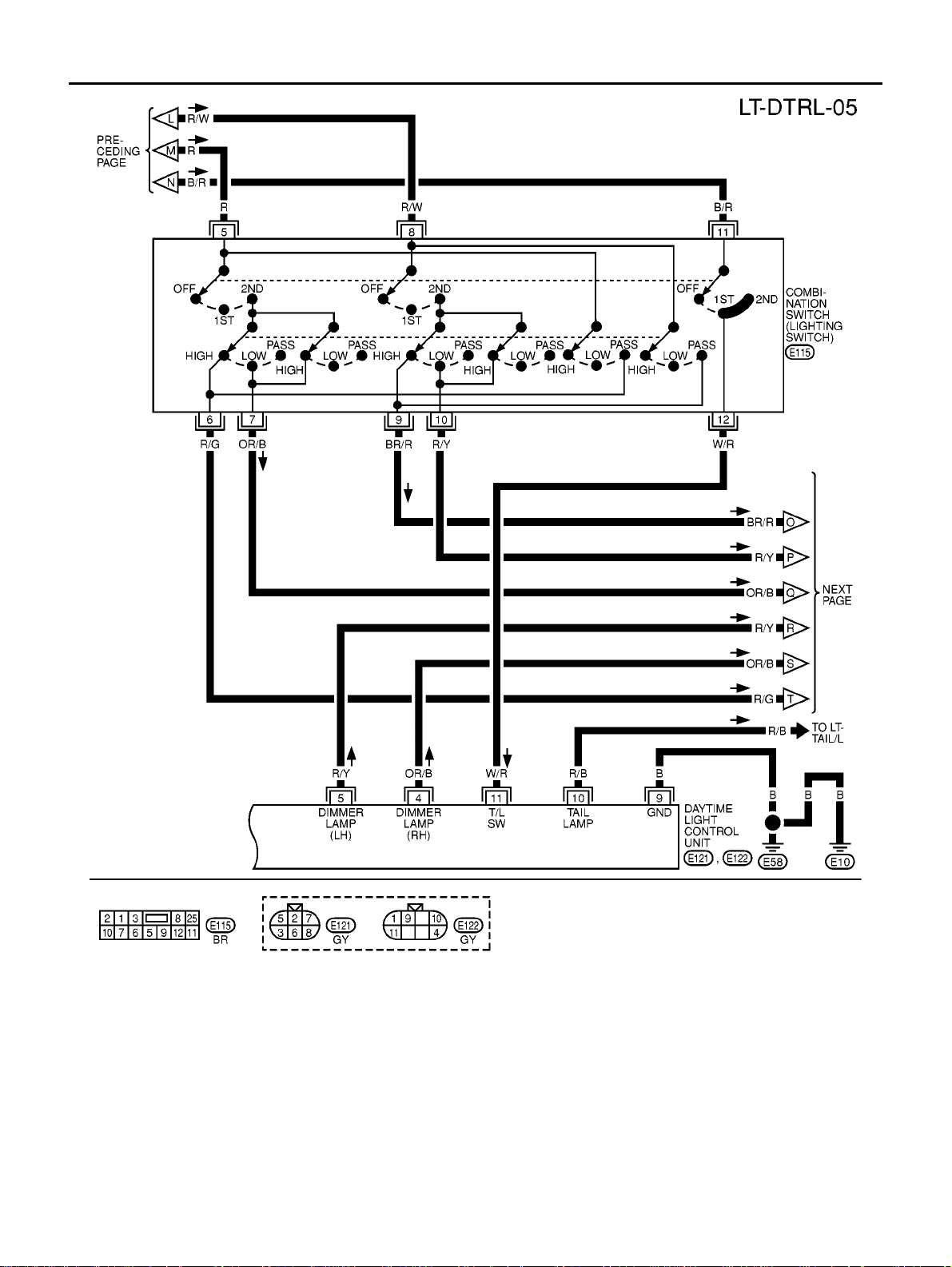

HEADLAMP (WITH DAYTIME) - XENON TYPE - .... 25

System Description .................................................25

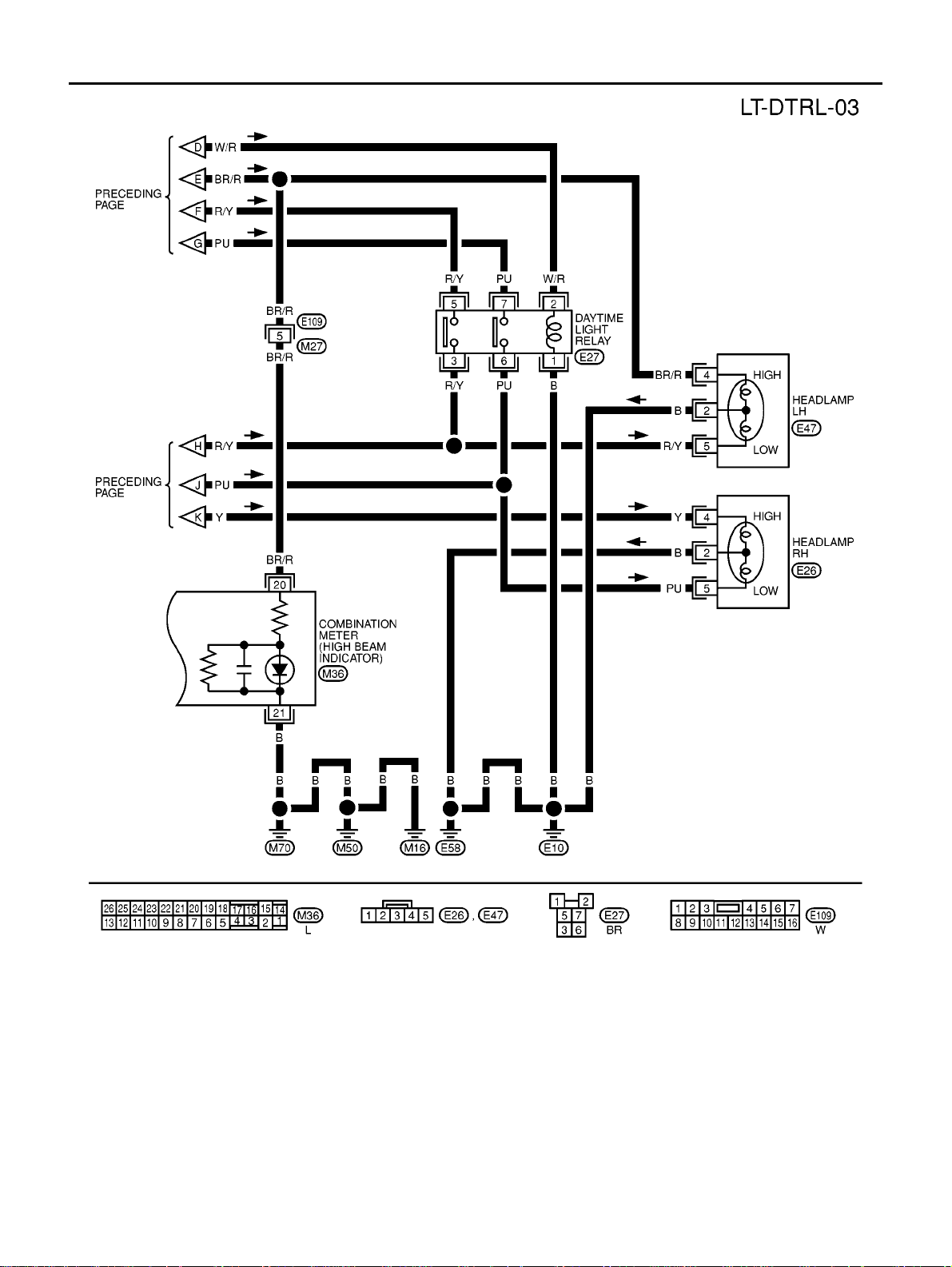

Schematic ...............................................................26

Wiring Diagram - DTRL - ........................................27

Trouble Diagnoses .................................................30

DAYTIME LIGHT UNIT INSPECTION TABLE .....3 0

Bulb Replacement ..................................................30

Aiming Adjustment ..................................................3 0

HEADLAMP AIMING CONTROL (M ANUAL) ..........31

Wiring Diagram — H/AIM — ...................................31

Removal an d Installation ........................................32

Switch Circuit Inspection ........................................32

HEADLAMP AIMING CONTROL (AUTO) ................ 33

System Description .................................................33

Component Parts and Harness ..............................33

CONNECTOR LOCATION ..................................33

Wiring Diagram - H/AIM - .......................................34

CONSULT-II ............................................................36

CONSULT-II INSPECTION PROCEDURE ..........36

CONSULT-IIDIAGNOSTICTESTMODEFUNC-

TION ....................................................................37

INITIALIZATION ..................................................37

SELF-DIAGNOSTIC RESULTS ITEM CHART ....38

Check Power and Ground for Height Sens or .........38

Check LightingSwitch Circuit .................................39

Check Speed Signal Circuit Chec k .........................39

C

D

E

F

G

H

I

J

LT

L

M

LT-1

Check Headlamp Aiming Motor ..............................40

Removal and installation .........................................41

TURN SIGNAL AND HAZARD WARNING LAMPS... 42

System Description .................................................42

TURN SIGNAL OPERATION ...............................42

HAZARD LAMP OPERATION .............................43

MULTI-REMOTE CONTROL SYSTEM OPERA-

TION ....................................................................43

Wiring Diagram — TURN — ...................................45

Terminaland Reference Valvefor Smart Entrance

Control Unit .............................................................47

Turn Signal And Hazard Warning Lamp Do Not

Operate ...................................................................47

Turn S ignal Lamps Do Not Operate Bu t Hazard

Warning Lamp Do Operate .....................................48

Hazard WarningLamps Do Not Operate But Turn

Signal Lamp Do Operate ........................................49

Turn Signal Lamps LH Do Not Operate ..................51

Turn Signal Lamps R H Do Not Operate .................52

LH and RH Turn Indicators Do Not Operate ...........53

Bulb Re placement ..................................................54

FRONT TURN SIGNAL LAMP ............................54

SIDE TURN SIGNAL LAMP ................................54

REAR TURN SIGNAL LAMP ...............................54

RemovalandInstallationforS ideTurnSignalLamp...54

RemovalandInstallationforRearTurnSignalLamp...54

LIGHTING AND TURN SIGNAL SWITCH ................ 55

Removal and Installation ........................................55

Switch Circuit Inspection ........................................55

HAZARD SWITCH ....................................................56

Removal and Installation ........................................56

REMOVAL ...........................................................56

INSTALLATION ....................................................56

STOP L AMP ..............................................................57

Wiring Diagram — STOP/L — ................................57

Bulb Re placement ..................................................59

STOP LAMP ........................................................59

Removal and Installation ........................................59

STOP LAMP ........................................................59

BACK-UP LAMP .......................................................60

Wiring Diagram — BACK/L — ................................60

Bulb Replacement (Sedan) ....................................62

Bulb Replacement (Wagon) ....................................62

Removal a nd Installation (Sedan) ...........................62

Removal a nd Installation (Wagon) ..........................62

PARKING, LICENSE PLATE AND TAIL LAMPS ......63

Wiring Diagram - TAIL/L -/LHD MODELS ...............63

Wiring Diagram - TAIL/L -/RHD MODELS ..............66

Bulb Re placement ..................................................69

PARKING AND TAIL LAMPS ...............................69

LICENSE PLATE LAMP ......................................69

Removal and Installation ........................................69

PARKING AND TAIL LAMPS ...............................69

LICENSE PLATE LAMP ......................................69

FRONT FOG LAMP ..................................................71

System Description .................................................71

DESCRIPTION ....................................................71

FOG LAMP OPERATION ....................................71

Wiring Diagram — F/FOG — ..................................72

Aiming Adjustment ..................................................73

Bulb Replacement ...................................................73

Removal and Installation .........................................73

REMOVAL ............................................................73

INSTALLATION ....................................................74

REAR FOG LAMP .....................................................75

Wiring Diagram — R/FOG — /Without Front Fog

Lamp ....................................................................... 75

WiringDiagram—R/FOG—/WithFrontFogLamp...76

Bulb Replacement (Sedan) .....................................79

Bulb Replacement (Wagon) ....................................79

Removal and Installation .........................................79

REMOVAL (SEDAN) ............................................79

INSTALLATION (SEDAN) ....................................79

CLEARANCE LAMP/TAIL LAMP .............................80

Bulb Replacement (Clearance Lamp) .....................80

Bulb Replacement(Tail Lamp) ................................ 80

Removal and Installation of Clearance Lamp .........80

Removal and Installation of Tail Lamp ....................80

HIGH-MOUNTED STOP LAMP .................................81

Bulb Replacement ...................................................81

HIGH-MOUNTED STOP LAMP (SEDAN) ...........81

HIGH-MOUNTED STOP LAMP (WAGON) ..........81

Removal and Installation .........................................81

HIGH-MOUNTED STOP LAMP (SEDAN) ...........81

HIGH-MOUNTED STOP LAMP (WAGON) ..........81

REAR COMBINATION LAMP ...................................82

Wiring Diagram —STOP/L— ..................................82

Bulb Replacement (Sedan) .....................................84

Bulb Replacement (Wagon) ....................................84

Removal and Installation .........................................84

REMOVAL (SEDAN) ............................................84

INSTALLATION .................................................... 84

COMBINATION SWITCH ..........................................86

Removal and Installation .........................................86

Switch Circuit Inspection .........................................87

ILLUMINATION ..........................................................89

System Description .................................................89

Schematic ...............................................................90

Wiring Diagram ....................................................... 91

INTERIOR ROOM L AMP ..........................................96

System Description .................................................96

POWER SUPPLY AND GROUND .......................96

SWITCH O PERATION ......................................... 97

INTERIOR ROOM LAMP TIMER OP ERATION...97

ON-OFF CONTROL .............................................97

Schematic ...............................................................98

Wiring Diagram - ROOM/L -/LH D MODELS ...........99

Wiring Diagram - ROOM/L -/RHD MODELS .........103

Terminal and Reference Valve for Smart Entrance

Control Unit ...........................................................107

CONSULT-II Inspection Procedure .......................107

“ROOM LAMP” ...................................................107

CONSULT-II Application Items ..............................108

ROOM LAMP .....................................................108

Interior Room Lamp Timer Does Not Operate ......109

Interior Room Lamp Timer Does Not C ancel ........114

LT-2

Bulb Replacement .................................................118

INTERIOR ROOM LAMP ...................................1 18

STEP LAMP .......................................................119

ASHTRAY ..........................................................1 19

Removal and Installation .......................................119

INTERIOR ROOM LAMP ...................................1 19

STEP LAMP .......................................................119

ASHTRAY ..........................................................1 19

SPOT,VANITYMIRRORAND TRUNK(LUGGAGE)

ROOM LAMPS ....................................................... 120

Wiring Diagram — INT/L — ................................. 120

Bulb Replacement ................................................ 123

SPOT LAMP ...................................................... 123

TRUNK ROOM LAMP ....................................... 123

LUGGAGE ROOM LAMP ................................. 123

Removal and Installation ...................................... 123

SPOT LAMP ...................................................... 123

TRUNK ROOM LAMP ....................................... 123

LUGGAGE ROOM LAMP ................................. 124

CAN COMMUNICATION ........................................ 125

System De scription .............................................. 125

CANCommunicationUnitForLHDModel swithTyre

Pressure Monitoring System ................................ 125

TYPE 1 .............................................................. 126

TYPE 2 .............................................................. 127

TYPE 3 .............................................................. 128

TYPE 4 .............................................................. 129

TYPE 5 .............................................................. 130

TYPE 6 .............................................................. 131

CANCommunicationUnitForLHDModelswithout

Tyre Pressure Monitoring System ........................132

TYPE 7 ..............................................................133

TYPE 8 ..............................................................134

TYPE 9 ..............................................................135

TYPE 10 ............................................................136

TYPE 11 ............................................................137

TYPE 12 ............................................................138

CAN Communication Unit For RHD Models with

Tyre Pressure Monitoring System ........................139

TYPE 13 ............................................................140

TYPE 14 ............................................................141

TYPE 15 ............................................................142

TYPE 16 ............................................................143

TYPE 17 ............................................................144

TYPE 18 ............................................................145

CANCommunicationUnitForRHDModelswithout

Tyre Pressure Monitoring System ........................146

TYPE 19 ............................................................147

TYPE 20 ............................................................148

TYPE 21 ............................................................149

TYPE 22 ............................................................150

TYPE 23 ............................................................151

TYPE 24 ............................................................152

BULB SPECIFICATIONS ........................................153

Headlamp .............................................................153

Exterior Lamp .......................................................153

Interior Lamp/Illumination .....................................153

A

B

C

D

E

F

G

H

I

LT

J

L

M

LT-3

PRECAUTION

PRECAUTION

PFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BEL T PRE-TENSIONER”

The Supplemental Restraint System s uch as "AIR BAG" and "SEAT BELT PRE- TENSIONER", used along

with a front seat belt, helps to reduce the ris k or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINIT I dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activatio n of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SR S unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harness connectors.

Precaution

● Do not touch the glass of bulb d irectly by hand. Keep grease and other oily matters away from it. Do not

touch bulb by hand w hile it is lit or right after being turned off. Burning may result.

● Do not leave bulb out of headlamp reflector for a long time because dust, moisture smoke, etc. ma y affect

the per formance of the headlamp. When replacing the bulb, be sure to replace i t with a new one.

● Adjust aiming by tightening aiming screw. (To adjust it toward loosening side, first loosen adjusting screw,

and then make adjustment by tightening.)

● To remove soil or sealant of bulbs, do not use organic solvent (thinner, gasoline, etc.)

● When replacing bulb, be sure to hold bulb socket and pull it out straight. If wiring harness of the bulb is

pulled at an angle, the bulb may be caught in the lamp, making it difficult to take out.

EKS003T7

EKS003T8

Wiring Diagrams and Trouble Diagnosis

When you rea d wiring diagrams, refer to the following:

● Refer to GI-14, "How to Read Wiring Diagrams" in GI section

● Refer to PG- 3, "POWER SUPPLY ROUTING" for power distribution circuit in PG section

When you per form trouble diagnosis, refer to the following:

● Refer to GI-11,"HOW TO FOLLOW TEST GR OUPS IN TROUBLE DIAGNOSES" in GI section

● Refer toGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident" in GI section

EKS003T9

LT-4

HEADLAMP -CONVENTIONAL TYPE-

HEADLAMP -CONVENTIONAL TYPE- PFP:26010

System Description

DESCRIPTION

The headlamps are controlled by the lighting switch which is built into the combination switch.

Power is supplied at all times

● to lighting switch terminal 8

● through 15A fuse (No. 41, located in the fuse and fusible link box), and

● to lighting switch terminal 5

● through 15A fuse (No. 42, located in the fuse and fusible link box).

LOW B EAM OPERATION

When the lighting swi tch is turned to the 2ND posi tion and placed in LOW (“B”) position, power is supplied

● from lighting switch terminal 10

● to terminal 5 of the headlamp LH, and

● from lighting switch terminal 7

● to terminal 5 of the headlamp RH.

Terminal 2 of ea ch headlamp supplies ground through body grounds E10 and E58.

With power and ground supplied, the low beams will illuminate.

EKS004P6

A

B

C

D

E

F

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

When the lighting switch is turned to the 2ND position and placed in HIGH (“A”) position or PASS (“C”) position, power is supplied

● from lighting switch terminal 9

● to terminal 4 of headlamp LH, and

● to combination meter terminal 20 (LHD models) or 7 (RHD models) for the HIGH BEAM in dicator.

● from lighting switch terminal 6

● to terminal 4 of headlamp RH.

Ground is supplied to terminal 21 (LHD models) or 8 (RHD models) of the c ombination meter through body

grounds M16, M50 and M70.

Ground is supplied to terminal 2 of each headlamp thr ough body grounds E10 and E58.

With power and ground supplied, the high beams and the HIGH BEAM indicator illuminate.

G

H

I

J

LT

L

M

LT-5

HEADLAMP -CONVENTIONAL TYPE-

Wiring Diagram — H/LAMP —

EKS004P7

LT-6

MKWA0001E

HEADLAMP -CONVENTIONAL TYPE-

T rouble Diagnoses

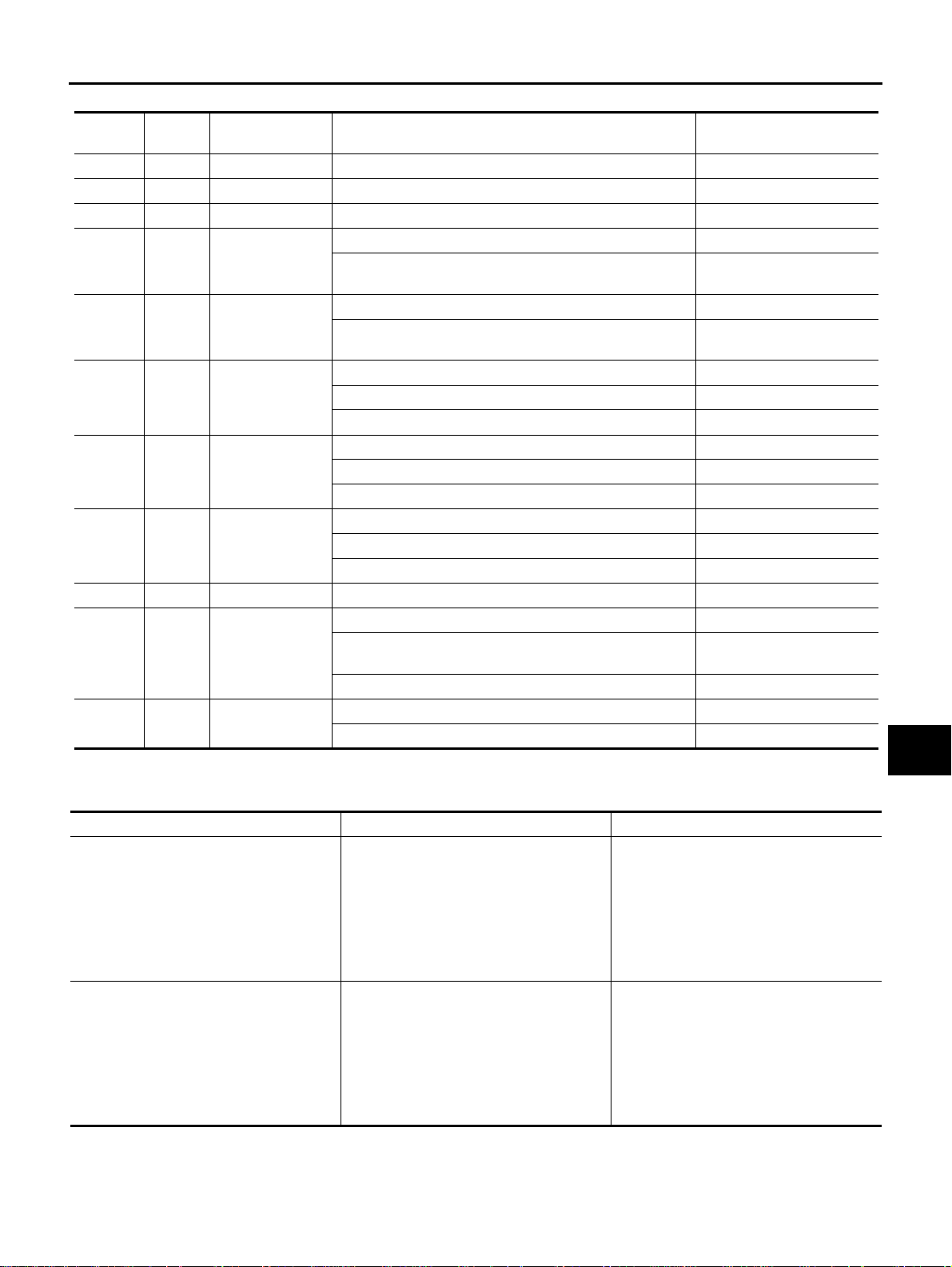

Symptom Possible cause Repairorder

LH headlamps do not operate.

RH headlamps do not operate.

LH high beam does not operate, but LH

low beam operates.

LH low beam does not operate, but LH

high beam operates.

RH high beam does not operate, but RH

low beam operates.

RH low beam does not operate, but RH

high beam operates.

High beam indicator does not work.

1. Bulb

2.G rounds E10 and E58

3.15A fuse

4. Lighting switch

1. Bulb

2.G rounds E10 and E58

3.15A fuse

4. Lighting switch

1. Bulb

2.O pen in LH high beams circuit

3. Lighting switch

1. Bulb

2.Open in LH lo w beam circuit

3. Lighting switch

1. Bulb

2.O pen in RH high beams circuit

3. Lighting switch

1. Bulb

2.Open in RH low beam circuit

3. Lighting switch

1. Bulb

2.G rounds M16, M50 and M70

3.O pen in high beam circuit

EKS004P8

1.Check bulb.

2.Check grounds E10 and E58.

3.Check 15A fuse (No. 41, located in fuse

and fusible link box).

Verify battery positive voltage is present

at terminal 8 of lighting switch.

4.Check lighting switch.

1.Check bulb.

2.Check grounds E10 and E58.

3.Check 15A fuse (No. 42, located in fuse

and fusible link box).

Verify battery positive voltage is present

at terminal 5 of lighting switch.

4.Check lighting switch.

1.Check bulb.

2. Check continuity between lighting switch

terminal 9 (BR/R) and LH headlamp terminal 4 (BR/R) for an open circuit.

3.Check lighting switch.

1.Check bulb.

2. Check continuity between lighting switch

terminal10 (R/Y) and LH headlamp terminal 5 (R/Y) for an open circuit.

3.Check lighting switch.

1.Check bulb.

2. Check continuity between lighting switch

terminal 6 (Y) and RH headlamp terminal 4 (Y) for an open circuit.

3.Check lighting switch.

1.Check bulb.

2. Check continuity between lighting switch

terminal 7 (PV) and RH headlamp terminal5(PV)foranopencircuit.

3.Check lighting switch.

1.Check bulb in combination meter.

2.Check grounds M16, M50 andM70.

3. Check continuity between lighting switch

terminal 9 (BR/R) and combination

meter terminal 20 (BR/R) LHD or 7 (BR/

R) RHD for an open circuit.

A

B

C

D

E

F

G

H

I

J

LT

L

M

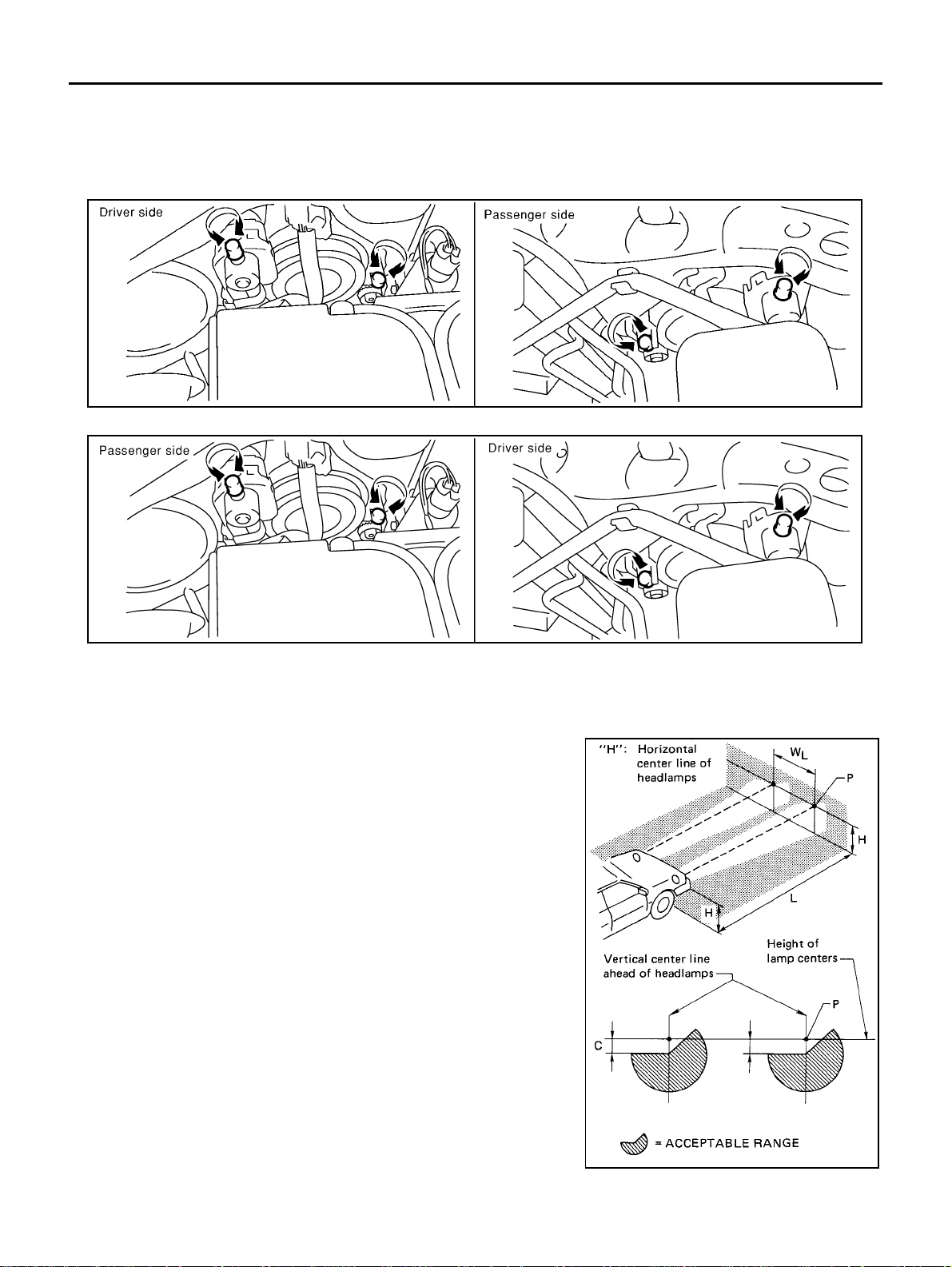

Aiming Adjustment

EKS004P9

When performing headlamp aiming adjustment, use an aiming machine, aiming wall screen or headlamp

tester. Aimers should be in good repair, calibrated and operated in accordance with respective operation manuals.

If any aimer is not available, aiming adjustment can be done as follows:

For details, refer to the regulations in your own country.

● Keep all tires inflated to correct pressures.

● Place vehicle and tester on one and same flat surface.

● See that there is no-load in vehicle (coolant, engine oil filled up to correct level and full fuel tank) other

than the driver (or equivalent weight pla ced in driver′s position).

LT-7

HEADLAMP -CONVENTIONAL TYPE-

CAUTION:

Be sure aiming switch is set to “0” when performing aiming adjustment.

LOW BEAM

1. Turn headlamp low beam on.

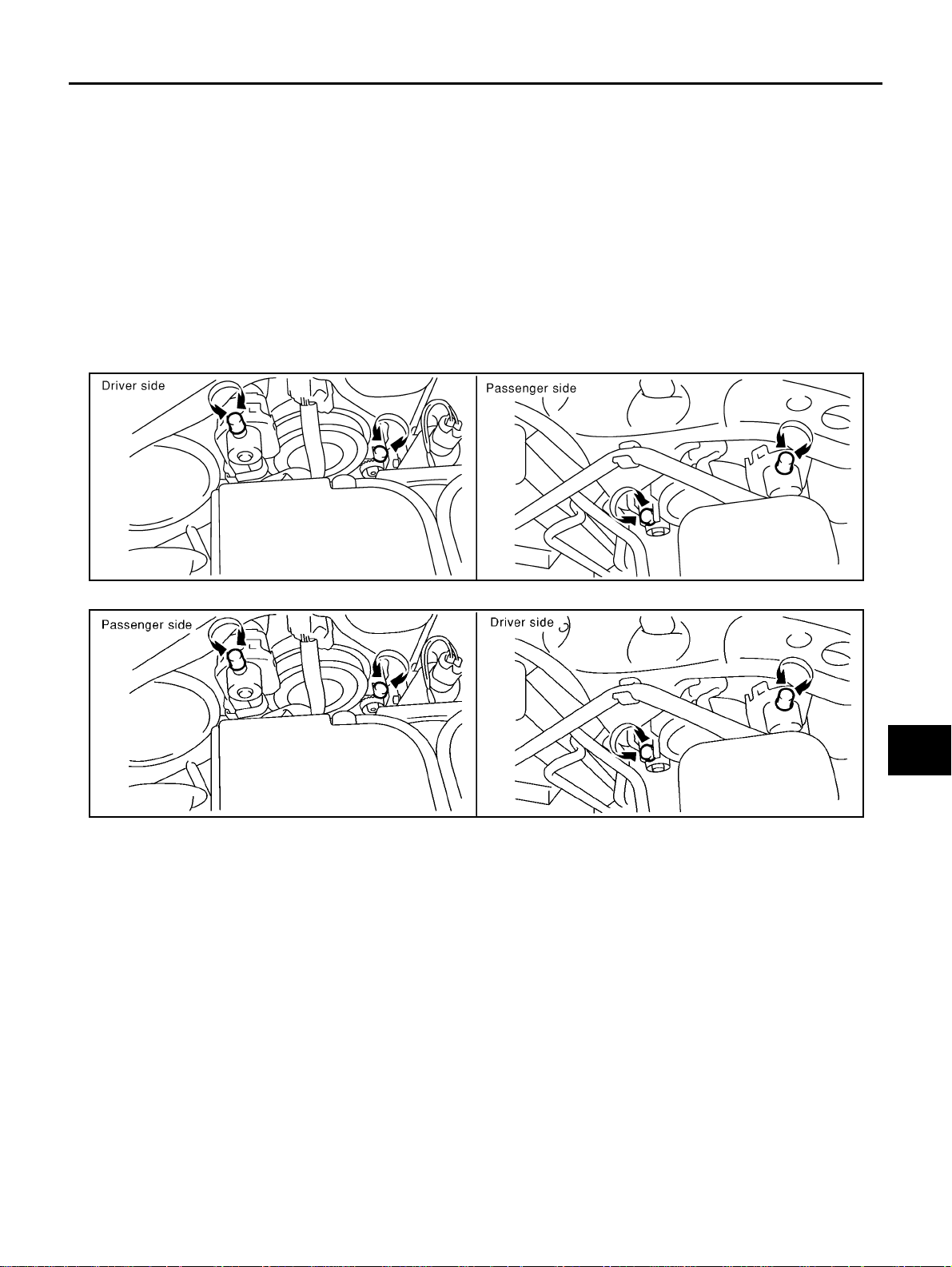

LHD models

RHD models

MKIA0048E

MKIA0049E

2. Use adjusting pots to perform aiming adjustment.

● First tighten the adjusting pot all the way and then make adjustment by loosening the pot.

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check aiming. Use the aiming chart shown in the figure.

● Adjust headlamps so that main axis of light is parallel to cen-

ter line of body and is aligned with point P shown in illustration.

● Figure to the left shows headlamp aiming pattern for driving

on right side of road; for driving on left side of road, aiming

pattern is reversed.

● Dotted lines to point P in illustrati on show center of headlamp.

“H” : Horizontal center line of headlamps

“W

L

: Distance between each headlamp center

”

“L” : 25 m (98.43 in)

“C” : 250 mm (9.84 in)

● Basic illum inating area for adjustment should be within the

range shown in the figure. Adjust headlamps accordingly.

CAUTION:

Be sure aiming switch is set to “0” when preforming aiming

adjustment .

LT-8

SEL254L

HEADLAMP -CONVENTIONAL TYPE-

Bulb Replacement

EKS004PA

HEADLAMP

1. Disconnect connector of headlamp.

2. Unlock retaining spring, then remove bulb.

Headlamp (Low) : 12V - 55W (H7)

Headlamp (High) : 12V - 55W (H7)

MKIB0116E

CLEARANCE LAMP, FRONT TURN SI GNAL LAMP

1. Turn the bulbsocket counterclockwise and unlock it.

2. Remove the bulb from its socket.

Clearance lamp : 12V - 5W

Front turn signal lamp : 12V - 21W

CAUTION:

● Do not touch the glass of bulb directly by hand. Keep grease and other oily matters away from it.

Do not touch bulb by hand while it is lit or right after being turned off. Burning may result.

● Do not leave bulb out of headlamp reflector for a long time because dust, moisture smoke, etc.

may affect the performance of headlamp. When replacing bulb, be sure to replace it with new one.

● When bulb is installed, be sure to lock rubber cap to ensure watertightness.

A

B

C

D

E

F

G

H

Removal and Installation

REMOVAL

1. Disconnect connector of headlamp and clearance lamp.

2. Remove the front gr ille. Refer to EI-12, "

3. Remove the headlamp mounting bolts.

4. Pull the headlamp toward the front of the vehicle.

INSTALLATION

● Install in the reverse order of removal, taking ca re of the following points.

Headlamp mounting screws and nu t

Tightening torque : 4.4 - 5.8 N·m (0.45 - 0.59 kg-m, 39 - 51 in-lb)

FRONT GRILL" .

EKS004PB

MKIB0117E

I

J

LT

L

M

LT-9

HEADLAMP - XENON TYPE -

HEADLAMP - XENON TYPE System Description

PFP:26010

EKS004PC

The headlamps are controlled by lighting swi tch which is built into the combination switch.

Power is supplied at all times

● to lighting switch terminal 8

● through 15A fuse (No. 41, located in the fuse and fusible link box) and

● to lighting switch terminal 5

● through 15A fuse (No. 42, located in the fuse and fusible link box) and

● to headlamp LH relay terminal 3

● through 20A fuse (No. 37, located in the fuse and fusible link box) and

● to headlamp RH relay terminal 3

● through 20A fuse (No. 36, located in the fuse and fusible link box).

LOW BEAM OPERATION

When the lighting switch is turned to the 2ND position and placed in LOW (“B”) position, power is supplied

● from terminal 5 of each headl amp relay

● to terminal 5 of each headlamps

Terminal 3 of each headlamp supplies ground through body grounds E 10 and E58.

With power and ground supplied, the low beams will illuminates.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

When the lighting switch is turned to 2ND position and placed in HIGH (“A”) position or PASS (“C”) position,

power is suppli ed.

● from lighting switch terminal 6

● to terminal 4 of headlamp RH, and

● from lighting switch terminal 9

● to terminal 4 of headlamp LH, and

● to combination meter termina l 20 (LHD models) or 7 (RH D models) for the HIGH BEAM indicator.

Ground is supplied to terminal 21 (LHD models) or 8 (RHD models) of the combination meter through body

grounds M16, M50 and M70.

Ground is supplied to terminal 2 of each headlamp through body grounds E10 and E58.

With power and ground supp lied, the high beams and HIGH BEAM indicator illuminate.

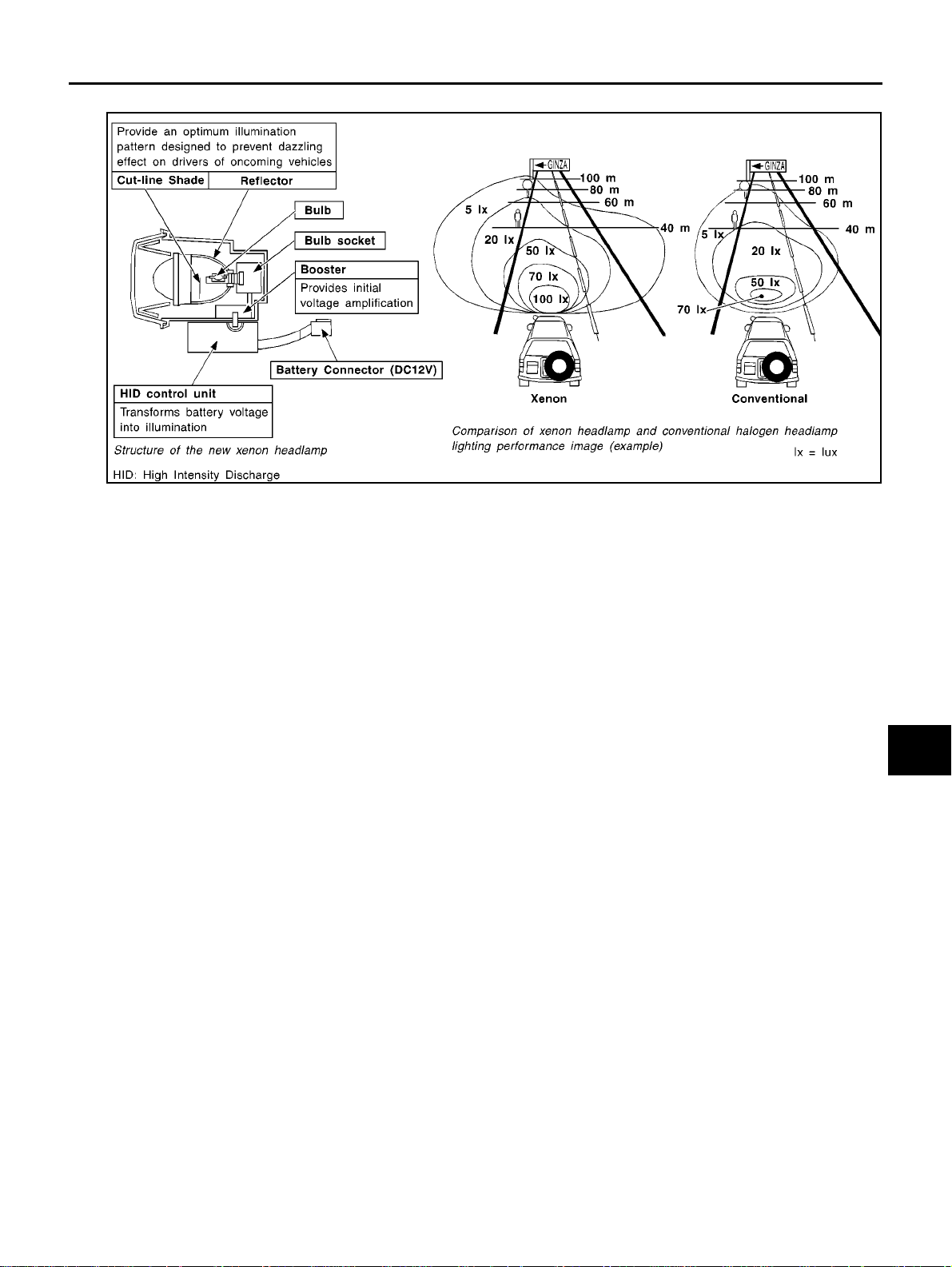

Xenon type headlamp is adopted to the low beam headlamps. Xenon bulbs do not use a filament. Instead,

they produce light when a high v oltage current is passed between two tungsten electrodes through a mixture

of xenon (an insert gas) and certain other metal hal ides. In addition to added lighting power, electronic control

of the power supply gives the headlamps stable quality and tone color.

Following are so me of the many advantage of the xenon type headlamp.

● The light produced by the headlamps is white color approximating sunlight that is easy on the eyes.

● Light output is nearly double that of halogen headlamps, affor ding increased area of illumination.

● The light features a high relative spectral distribution at wav elengths to the human eye is most sensitive,

which means that even in the rain, more light is reflected back from the road surface toward the vehicle,

for add ed visibility.

LT-10

HEADLAMP - XENON TYPE -

● Power consumption is approximately 25 percent less than halogen headlamps, reducing battery loa d.

SEL440V

A

B

C

D

E

F

G

LT

H

I

J

L

M

LT-11

HEADLAMP - XENON TYPE -

Wiring Diagram - H/LAMP -

EKS004PD

LT-12

MKWA0002E

HEADLAMP - XENON TYPE -

A

B

C

D

E

F

G

LT

H

I

J

L

M

LT-13

MKWA0003E

HEADLAMP - XENON TYPE -

WARNING:

● The xenon headlamp has a high-tension current generating area. Be extremely careful when

removing and installing. Be certain to disconnect the battery negative cable prior to removing or

installing.

● When the xenon headlamp is lit, do not touch the harness (covered with red or amber insulation),

bulb itself or the bulb socket with your bare hands.

● Never service a xenon headlamp with wet hands.

● When checking body side harness with a circuit tester, be certain to disconnect the harness con-

nector from the xenon headlamp.

● When the xenon headlamp is lit, the xenon bulb must be installed in the headlamp housing. (Never

turn on xenon headlamp, if the bulb is out of the headlamp housing.)

CAUTION:

Make sure to install the bulb securely; if the xenon bulb is improperly installed in its socket, high-tension current leaks occur. This may lead to a melted bulb and/or bulb socket.

T rouble Diagnosis

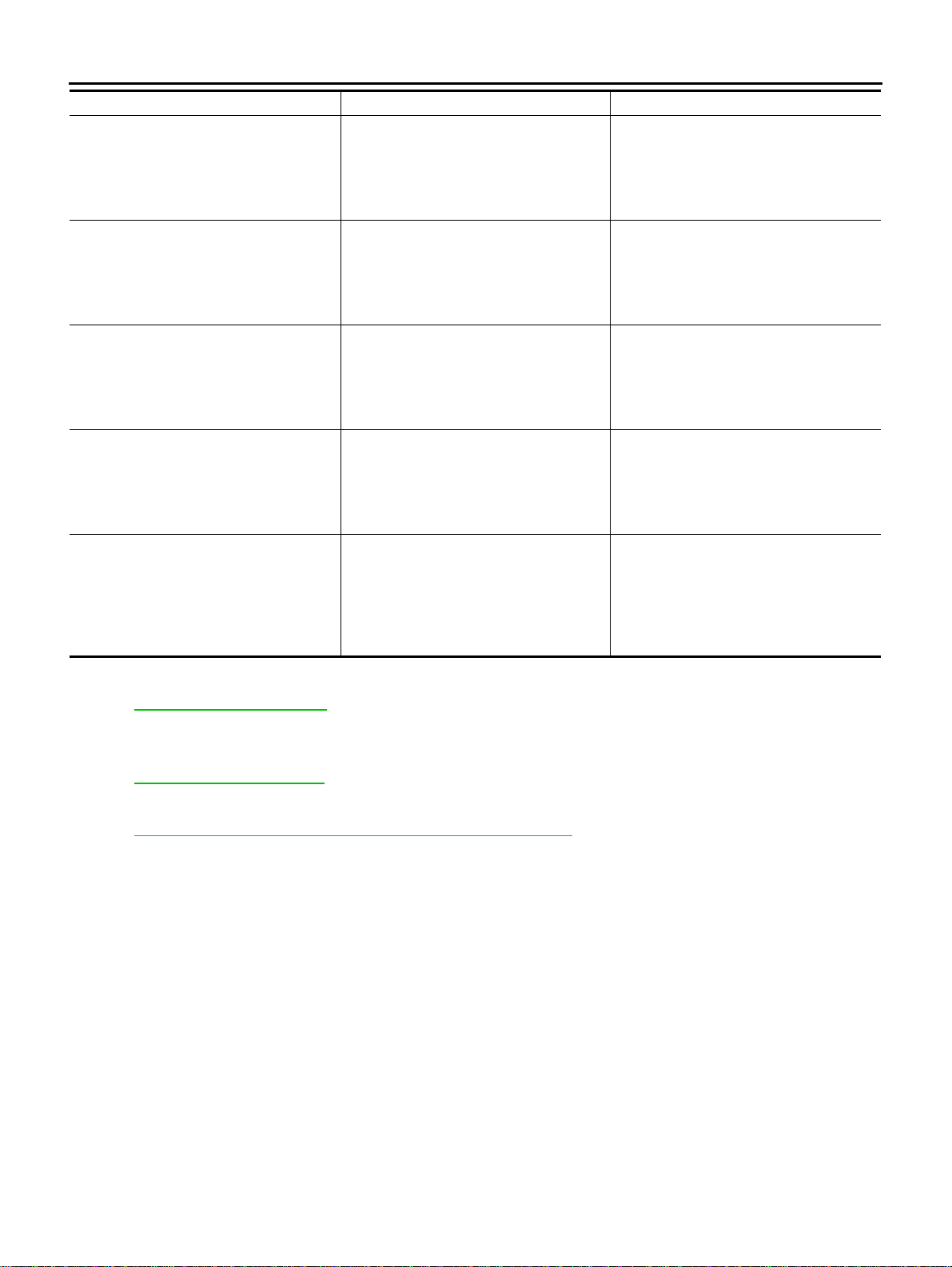

Symptom Possible cause Repair order

LH or RH xenon headlamp (low beam)

blinks, lacks brightness or does not illuminate.

LH or RH [both headlamp high and xenon

(low) beam] do not illuminate.

LH or RH headlamp high beam does not

illuminate.

High beam indicator does not work.

HID:High Intensity Discharge

1.20A fuse

2.Relay

3.Power supply circuitto headlamp low

beam

4.Xenon bulb

5.HID controlunit and booster

1.Bulb

2.15A fuse

3.Relay

4.Ground circuit

1.Bulb

2.Power supply circuitto headlamp high

beam

1.Bulb

2.Grounds M16, M50 and M70

3.Open in high beam circuit

EKS004PE

1.Check 20Afuse[No.37: LH, No. 36: RH,

locatedinfuseandfusiblelinkbox].

2.Check Headlamp relay.

3.Verify battery positive voltage is present

at terminal 5 of headlamp harness with

lighting switch in “2nd” and “Low” positions.(Beforeinspectingheadlamp terminal, disconnect headlamp connector

with lighting switch in “OFF” position.)

4.Replace the xenon bulb with the other

side bulb or new one. (If headlamps illuminatecorrectly, replace the bulb.)

5.ReplacetheHIDcontrolunitandbooster

as a headlamp assembly.

1.Check bulb.

2.Check 15A fuse [No. 41: LH, No. 42

locatedinfuseandfusiblelinkbox].

3.Check headlamp relay.

4.Check continuity between headlamp terminal 2 and body ground. (Before

inspecting headlamp terminal, disconnect headlamp connectorwith lighting

switch in “OFF” position.)

1.Check bulb.

2.Verify battery positive voltage is present

at terminal 2, 3 of headlamp harness

with lighting switch in “2nd” and “HIGH”

position. (Before inspecting headlamp

terminal, disconnect headlamp connector with lighting switch in “OFF” po sition.)

1.Check bulb in combinationmeter.

2.Check grounds M16, M50 and M70.

3.Check continuity betweenlighting switch

terminal 9 (BR/R) and combination

meter terminal20 (BR/R) LHD or 7 (BR/

R) RHD for an open circuit.

LT-14

HEADLAMP - XENON TYPE -

Aiming Adjustment

EKS004PF

When performing headlamp aiming adjustment, use an aiming machine, aiming wall screen or headlamp

tester. Aimers should be in good repair, calibrated and operated in accordance with respective operation manuals.

If any aimer is not available, aiming adjustment can be done as follows:

For details, refer to the regulations in your own country.

● Keep all tires inflated to correct pressures.

● Place vehicle and tester on one and same flat surface.

● See that there is no-load in vehicle (coolant, engine oil filled up to correct level and full fuel tank) other

than the driver (or equivalent weight pla ced in driver′s position).

LOW BEAM

1. Turn headl amp low beam on.

LHD models

MKIA0048E

RHD models

A

B

C

D

E

F

G

H

MKIA0049E

2. Use adjusting pots to perform aiming adjustment.

● First tighten the adjusting pot all the way and then make adjustment by loosening the pot.

If the vehicle front body has been repai red and/or the headlamp assembly has been replaced, check aiming. Use the aiming chart shown in the figure.

I

J

LT

L

M

LT-15

HEADLAMP - XENON TYPE -

● Adjust headlamps so that main axis of light is parallel to cen-

ter line of body and is aligned with point P shown in illustration.

● Figure to the left shows headlamp aiming pattern for driving

on right side of road; for driving on left side of road, aiming

pattern is reversed.

● Dotted lines to point P in illustrati on show center of headlamp.

“H” : Horiz ontal center line of headlamps

“W

L

: Distance between each h eadlamp center

”

“L” : 25 m (98.43 in)

“C” : 250 mm (9.84 in)

● Basic illum inating area for adjustment should be within the

range shown at left. Adjust headlamps accordingly.

SEL254L

Bulb Replacement

EKS004PG

CAUTION:

● After r eplacing a new xenon bulb, be sure to make aiming adjustmen ts.

● Hold only the plastic base when handling the bulb. Never touch the glass envelope.

● Do not leave headlamp reflector without bulb for a long period of time. Dust, moist ure, smoke, etc.

entering headlamp body may affect the performance of the headlamp. Remove headlamp bulb

from the headlamp reflector just before a replacement bulb is installed.

1. Disconnect negative battery cable.

2. Disconnect headlamp connector.

WARNING:

Never service a xenon headlamp with wet hands.

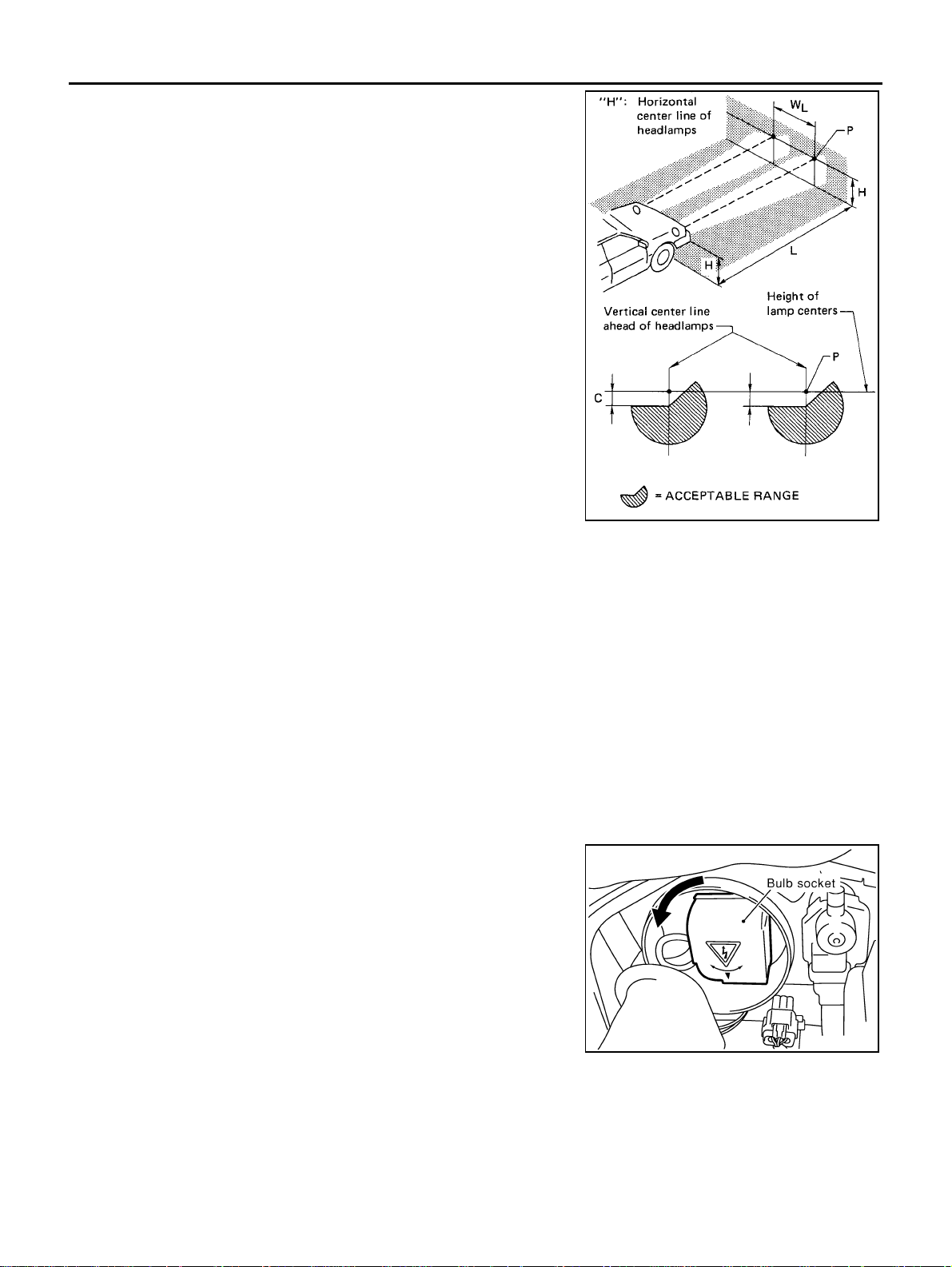

XENON BULB (LOW BEAM)

1. Remove washer inlet. (RH bulb)

2. Remove headlamp seal cover.

Turn bulb socket counterclockwise and unlock it.

3. Release retaining pin.

4. Remove the xenon bulb.

5. Install in the reverse orderof removal.

Headlamp (LOW) : 12V - 35W (D2R)

CAUTION:

● When disposing of the xenon bulb, do not break it;

always dispose of it as is.

● Make sure to install the bulb securely; if the xenon bulb is

improperly installed in its socket, high-ten sion cu rrent

leaks o ccur. This may lead to a melted bulb and/or bulb socket.

MKIB0118E

HIGH BEAM

1. Pull off headlamp seal cover.

LT-16

HEADLAMP - XENON TYPE -

2. Disconnect bulb connecto r.

3. Release retaining pin.

4. Remove the bulb.

5. Install in the reverse order of removal.

Headlamp (HIGH) : 12V - 55W (H7)

A

B

CLEARANCE LAMP, FRONT TURN SI GNAL LAMP

Refer to LT-17, "CLEARANCE LAMP, FRONT TURN SIGNAL LAMP" .

CAUTION:

● Do not touch the glass of bulb directly by hand. Keep grease and other oily matters away from it.

Do not touch bulb by hand while it is lit or right after being turned off. Burning may result.

● Do not leave bulb out of headlamp reflector for a long time because dust, moisture smoke, etc.

may affect the performance of headlamp. When replacing bulb, be sure to replace it with new one.

● When bulb is installed, be sure to lock rubber cap to ensure watertightness.

Removal and Installation

EKS004PH

REMOVAL

Refer to LT-17, "REMOVAL" .

INSTALLATION

Refer to LT-17, "INSTALLAT IO N" .

C

D

E

F

G

H

I

J

LT

L

M

LT-17

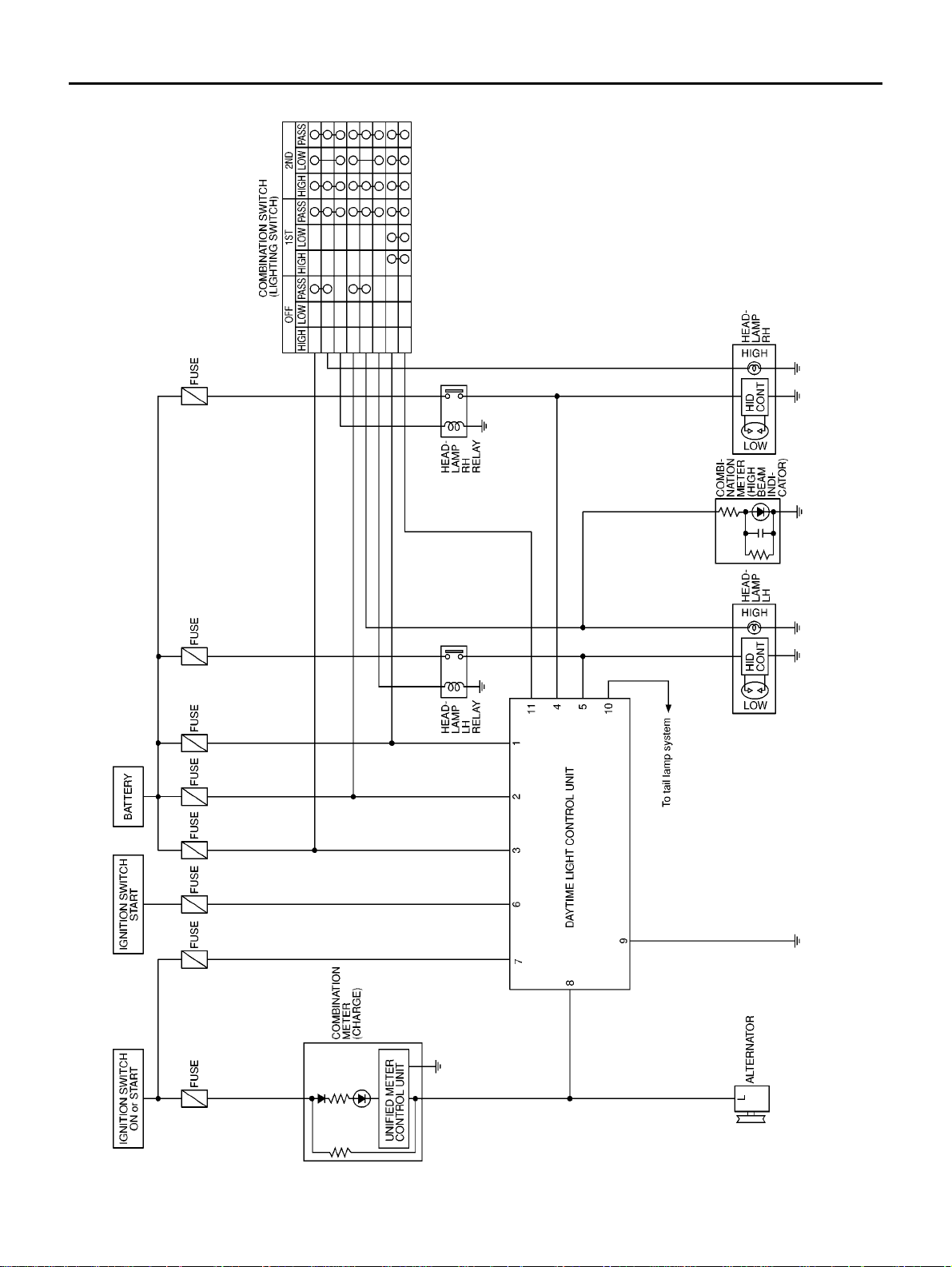

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE -

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE System Description

PFP:26010

EKS004PI

DESCRIPTION

The headlamp system for Northern Europe vehicles c ontains a daytime light control unit that activates the low

beam headlamps whenever the engine is running.

Power is supplied at all times

● to daytime light control unit terminal 1

● to lighting switch terminal 11

● through 10A (No. 32, located in the fuse and fusible link box), and

● to daytime light control unit terminal 3

● to lighting switch terminal 5

● through 15A (No. 42, located in the fuse and fusible link box), and

● to daytime light control unit terminal 2

● to lighting switch terminal 8

● through 15A (No. 41, located in the fuse and fusible link box)

Ground is supplied to daytime light control unit terminal 9 through body grounds E10, E58 and E122.

When the ignition switch is in the ON or START position, power is supplied

● to daytime light control unit terminal 7

● through 10A (No. 10, located in the fuse and fusible link box)

When the ignition switch is in the START position, power is also supplied

● to daytime light control unit terminal 6

● through 10A (No. 21, located in the fuse and fusible link box)

HEADLAMP OPERATION

For description, refer to LT-5, "System D escription"

DAYTIME LIGHT OPERATION

When the engine running, the lighting switch in the OFF positi on, power is supplied

● from alternator terminal 3

● to daytime light control unit terminal 8, and

● from daytime light control unit terminal 2

● through daytime light control unit terminal 5

● to terminal of LH headlamp

● from daytime light control unit terminal 3,

● through daytime light control unit terminal 4

● to terminal of RH headlamp, and

● from daytime light control unit terminal 1

● through daytime light control unit terminal 1 0

Ground is supplied to terminal 2 of each headlamp through body grounds E10 and E58.

LT-18

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE -

Schematic

EKS004PJ

A

B

C

D

E

F

G

H

LT

I

J

L

M

LT-19

MKWA0004E

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE -

Wiring Diagram — H/LAMP —

EKS004PK

LT-20

MKWA0005E

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE -

A

B

C

D

E

F

G

LT

H

I

J

L

M

LT-21

MKWA0006E

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE -

LT-22

MKWA0007E

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE -

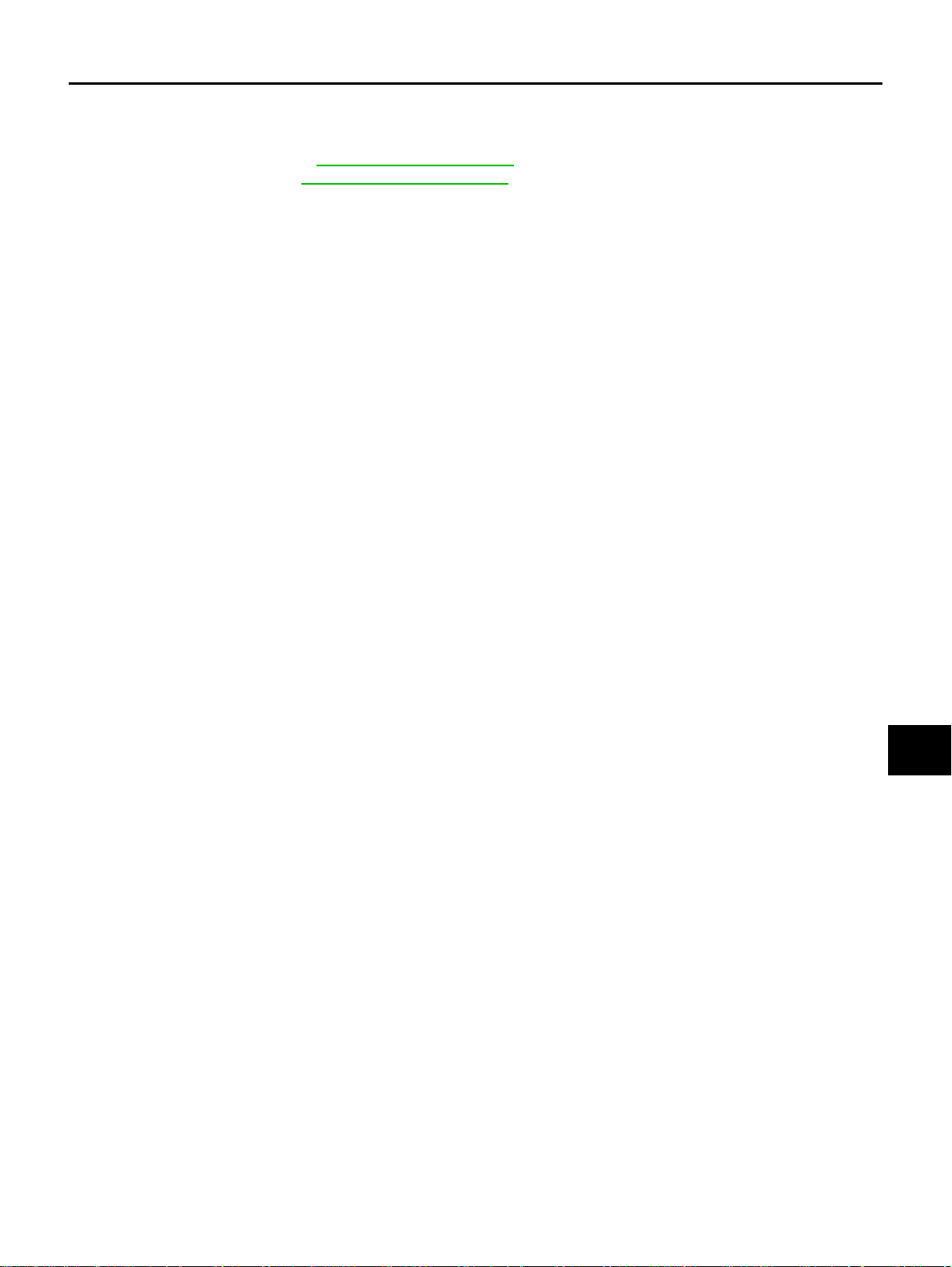

Terminal and Reference Value for Daytime Light Control Unit

Terminal

No.

1 B/R Power source Ignition switch “OFF” Battery voltage

2 R Power source Ignitionswitch “OFF” Battery voltage

3 R/W Power source Ignition switch “OFF” Battery voltage

4 PU RH low beam

5 R/Y LH low beam

6 B/Y Start signal

7 Y/G Power source

8 Y/R Alternator

9 B Ground — —

10 R/B Tail lamp

11 W/R Lightingswitch

*: Daytime light operating: Lighting switch in “OFF” position with enginerunning.

Wire

color

Item Condition

When lighting switch is turned to the 2ND position Battery voltage

When engine is running and turning lighting switch to

“OFF” (daytime light operation)

When lighting switch is turned to the 2ND position Battery voltage

When engine is running and turning lighting switch to

“OFF” (daytime light operation)

When turning ignition switch to “START” Battery voltage

When turning ignition switch to “ON” from “START” Less than 1V

When turning ignition switch to “OFF” Less than 1V

When turning ignition switch to “ON” Battery voltage

When turning ignition switch to “START” Battery voltage

When turning ignition switch to “OFF” Less than 1V

When turning ignition switch to “ON” Less than 1V

When engine is running Battery voltage

When turning ignition switch to “OFF” Less than 1V

When turning ignition switch to “ON” 0V

When engine is running and turning lighting switch to

“OFF” (daytime light operation*)

When turning ignition switch to “OFF” 0V

When turning lighting switch to 1ST or 2ND Battery voltage

When turning ignition switch to “OFF” 0V

Battery voltage

Battery voltage

Battery voltage

Voltage

(Approximate values)

A

B

C

D

E

F

G

H

I

J

LT

T rouble Diagnoses

Symptom Possible cause Repairorder

LH headlamps do not operate.

RH headlamps do not operate.

1. Bulb

2.G rounds E10 and E58

3.15A fuse

4. Lighting switch

1. Bulb

2.G rounds E10 and E58

3.15A fuse

4. Lighting switch

LT-23

EKS004PL

1.Check bulb.

2.Check grounds E10 and E58.

3.Check 15A fuse (No. 41, located in fuse

and fusible link box).

Verify battery positive voltage is present

at terminal 8 of lighting switch.

4.Check lighting switch.

1.Check bulb.

2.Check grounds E10 and E58.

3.Check 15A fuse (No. 42, located in fuse

and fusible link box).

Verify battery positive voltage is present

at terminal 5 of lighting switch.

4.Check lighting switch.

L

M

HEADLAMP (WITH DAYTIME) - CONVENTIONAL TYPE -

Symptom Possible cause Repair order

LH high beam does not operate, but LH

low beam operates.

LH low beam does not operate, but LH

high beam operates.

RH high beam does not operate, butRH

low beam operates.

RH low beam does not operate, but RH

high beam operates.

High beam indicator does not work.

1.Bulb

2.Open in LH high beams circuit

3.Lighting switch

1.Bulb

2.Open in LH low beam circuit

3.Lighting switch

1.Bulb

2.Open in RH high beams circuit

3.Lighting switch

1.Bulb

2.Open in RH low beam circuit

3.Lighting switch

1.Bulb

2.Grounds M16, M50 and M70

3.Open in high beam circuit

1.Check bulb.

2.Check continuity betweenlighting switch

terminal 9 (BR/R) and LH headlamp terminal 4 (BR/R) for an open circuit.

3.Check lighting switch.

1.Check bulb.

2.Check continuity betweenlighting switch

terminal 10 (R/Y) and LH headlamp terminal 5 (R/Y) for an open circuit.

3.Check lighting switch.

1.Check bulb.

2.Check continuity betweenlighting switch

terminal 6 (Y) and RH headlamp terminal 4 (Y) for an open circuit.

3.Check lighting switch.

1.Check bulb.

2.Check continuity betweenlighting switch

terminal 7 (PU) and RH headlamp terminal 5 (PU) for an open circuit.

3.Check lighting switch.

1.Check bulb in combinationmeter.

2.Check grounds M16, M50 and M70.

3.Check continuity betweenlighting switch

terminal 9 (BR/R) and combination

meter terminal20 (BR/R) LHD or 7 (BR/

R) RHD for an open circuit.

Aiming Adjustment

Refer to LT-7, "Aiming Adjustment"

Bulb Replacement

HEADLAMP

Refer to LT-9, "Bulb Replacement"

CLEARANCE LAMP, FRONT TURN SIGNAL LAMP

Refer to LT-9, "CLEARANCE LAMP, FRONT TURN SIGNA L LAMP"

EKS004PN

EKS004PM

LT-24

HEADLAMP (WITH DAYTIME) - XENON TYPE -

HEADLAMP (WITH DAYTIME) - XENON TYPE - PFP:26010

System Description

For headlamp operation, refer to LT-5, "System Description" .

For daytime operation, refer to LT-18, "

System Description" .

EKS0054P

A

B

C

D

E

F

G

LT

H

I

J

L

M

LT-25

HEADLAMP (WITH DAYTIME) - XENON TYPE -

Schematic

EKS004PP

LT-26

MKWA0008E

HEADLAMP (WITH DAYTIME) - XENON TYPE -

Wiring Diagram - DTRL -

EKS004PQ

A

B

C

D

E

F

G

H

LT

I

J

L

M

LT-27

MKWA0009E

HEADLAMP (WITH DAYTIME) - XENON TYPE -

LT-28

MKWA0010E

HEADLAMP (WITH DAYTIME) - XENON TYPE -

A

B

C

D

E

F

G

LT

H

I

J

L

M

LT-29

MKWA0011E

HEADLAMP (WITH DAYTIME) - XENON TYPE -

T rouble Diagnoses

DAYTIME LIGHT UNIT INSPECTION TABLE

Refer to LT-23, "Trouble Diagnoses" .

Bulb Replacement

Refer to LT-16, "Bulb Replacement" .

Aiming Adjustment

Refer to LT-15, "Aiming Adjustme nt" .

EKS004PR

EKS004PS

EKS004PT

LT-30

Loading...

Loading...