Page 1

ECG-9620L

ECG-9620M

ECG-9620N

ECG-9620P

ECG-9620S

ECG-9620T

ECG-9620U

SERVICE MANUAL

cardiofax

ELECTROCARDIOGRAPH

ECG-9620

08CK2.782.00516E

Page 2

CONTENTS

Contents

GENERAL HANDLING PRECAUTIONS .................................................................................i

WARRANTY POLICY .............................................................................................................ii

EMC RELATED CA UTION..................................................................................................... iii

Conventions Used in this Manual and Instrument..................................................................iv

Dangers, Warnings, Cautions and Notes.....................................................................iv

Explanations of the Symbols in this Manual and Instrument ........................................v

Section 1 General ...................................................................................1C.1

Introduction ......................................................................................................................... 1.1

General Information on Servicing ....................................................................................... 1.2

Service Policy, Service Parts and Patient Safety Checks ................................................... 1.4

Service Policy ........................................................................................................... 1.4

Service Parts ............................................................................................................ 1.4

Patient Saf ety Checks............................................................................................... 1.5

Maintenance Equipments and Tools ......................................................................... 1.5

General Safety Inf ormation ................................................................................................. 1.6

Specifications.................................................................................................................... 1.11

Panel Descriptions............................................................................................................ 1.14

Front Panel ............................................................................................................. 1.14

Left Side Panel........................................................................................................ 1.14

Operation Panel...................................................................................................... 1.15

Right Side Panel ..................................................................................................... 1.15

Rear Panel.............................................................................................................. 1.16

Composition...................................................................................................................... 1.17

Standard Components............................................................................................ 1.17

Options ................................................................................................................... 1.17

Location ............................................................................................................................ 1.18

Section 2 Maintenance ...........................................................................2C.1

Replacement....................................................................................................................... 2.1

Periodic Replacement Schedule............................................................................... 2.1

Cleaning and Lubrication .................................................................................................... 2.2

Cleaning and Greasing Schedules ........................................................................... 2.2

Cleaning the Paper Mark Sensor and P aper Empty Sensor..................................... 2.2

Cleaning the Motor Rotation Sensor and Lubricating the Motor Gear and Gear

Meshed with Motor Gear .......................................................................................... 2.3

Maintenance Check Sheet.................................................................................................. 2.5

Section 3 Troubleshooting and System Error Message ......................3C.1

Troubleshooting Flowchart .................................................................................................. 3.1

T roub leshooting T able ......................................................................................................... 3.4

Troubleshooting General Operation Problem ............................................................ 3.4

Service Manual ECG-9620 C.1

Page 3

CONTENTS

Troubleshooting Recording Problem......................................................................... 3.6

System Error Message ....................................................................................................... 3.7

Section 4 System Test, Adjustment and Setting ..................................4C.1

System Test ........................................................................................................................ 4.1

Overall ...................................................................................................................... 4.1

Calling up the System Test Level 1 ........................................................................... 4.2

Calling up the System Test Level 2 ........................................................................... 4.3

Entering the System Test Number ............................................................................ 4.4

Executing the System Test........................................................................................ 4.5

Quitting the System Test ........................................................................................... 4.6

Exiting the System Test Mode................................................................................... 4.6

Demonstration .................................................................................................................... 4.7

Recorder ............................................................................................................................. 4.8

Thermal Head ................................................................................................................... 4.10

Key.................................................................................................................................... 4.11

Memory............................................................................................................................. 4.12

Single Memory Test Mode ...................................................................................... 4.13

Continuous Memory Test Mode .............................................................................. 4.13

LCD/LED........................................................................................................................... 4.14

Input Unit .......................................................................................................................... 4.16

Calibration......................................................................................................................... 4.17

Communication................................................................................................................. 4.18

CRO/EXT1........................................................................................................................ 4.20

System Setup Initialization................................................................................................ 4.22

ECG Findings List Recording............................................................................................ 4.23

Recording Resolution Setting ........................................................................................... 4.24

Date and Time Setting ...................................................................................................... 4.25

Setting the Date and Time ...................................................................................... 4.25

Section 5 Board/Unit Description..........................................................5C.1

Block Diagram..................................................................................................................... 5.1

Pow er Unit .......................................................................................................................... 5.2

ECG Control Board ............................................................................................................. 5.2

Section 6 Disassembly...........................................................................6C.1

Before You Begin................................................................................................................. 6.1

Warnings and Cautions ............................................................................................ 6.1

Required T ools.......................................................................................................... 6.1

Cable Connection ............................................................................................................... 6.2

Removing the Upper Casing............................................................................................... 6.4

Removing the Magazine and Recording Paper ........................................................ 6.4

Removing the Battery Pack ...................................................................................... 6.4

Removing the Upper Casing..................................................................................... 6.4

Removing the Thermal Head and Motor Assy .................................................................... 6.5

Removing the Thermal Head.................................................................................... 6.5

C.2 Service Manual ECG-9620

Page 4

CONTENTS

Removing the Motor Assy......................................................................................... 6.6

Removing the ECG Control Board...................................................................................... 6.6

Removing the Power Board ................................................................................................ 6.8

Removing the Power Board ...................................................................................... 6.8

Replacing the Po wer Fuse and Battery Fuse ........................................................... 6.9

Removing the Key Board and LCD Unit............................................................................ 6.10

Section 7 Replaceable Parts List...........................................................7C.1

Instrument........................................................................................................................... 7.2

Section 8 Connector Pin Assignment ..................................................... 8.1

Attaching the Ferrite Core......................................................................................... 8.1

EXT-IN Connector..................................................................................................... 8.2

CRO-OUT Connector ............................................................................................... 8.2

SIO Connector.......................................................................................................... 8.2

Service Manual ECG-9620 C.3

Page 5

GENERAL HANDLING PRECAUTIONS

This device is intended for use only by qualified medical personnel.

Use only Nihon Kohden approved products with this device. Use of non-approved products or in

a non-approved manner may affect the performance specifications of the device. This includes,

but is not limited to, batteries, recording paper, pens, extension cables, electrode leads, input

boxes and AC power.

Please read these precautions thoroughly before attempting to operate the instrument.

1. To safely and effectively use the instrument, its operation must be fully understood.

2. When installing or storing the instrument, take the following precautions:

(1) Avoid moisture or contact with water, dust, extreme atmospheric pressure, excessive humidity and temperatures,

poorly ventilated areas, and saline or sulphuric air.

(2) Place the instrument on an even, level floor. Avoid vibration and mechanical shock, even during transport.

(3) Avoid placing in an area where chemicals are stored or where there is danger of gas leakage.

(4) The power line source to be applied to the instrument must correspond in frequency and voltage to product

specifications, and have sufficient current capacity.

(5) Choose a room where a proper grounding facility is available.

3. Before Operation

(1) Check that the instrument is in perfect operating order.

(2) Check that the instrument is grounded properly.

(3) Check that all cords are connected properly.

(4) Pay extra attention when the instrument is in combination with other instruments to avoid misdiagnosis or other

problems.

(5) All circuitry used for direct patient connection must be doubly checked.

(6) Check that battery level is acceptable and battery condition is good when using battery-operated models.

4. During Operation

(1) Both the instrument and the patient must receive continual, careful attention.

(2) Turn power off or remove electrodes and/or transducers when necessary to assure the patient’s safety.

(3) Avoid direct contact between the instrument housing and the patient.

5. To Shutdown After Use

(1) Turn power off with all controls returned to their original positions.

(2) Remove the cords gently; do not use force to remove them.

(3) Clean the instrument together with all accessories for their next use.

6. The instrument must receive expert, professional attention for maintenance and repairs. When the instrument is

not functioning properly, it should be clearly marked to avoid operation while it is out of order.

7. The instrument must not be altered or modified in any way.

8. Maintenance and Inspection:

(1) The instrument and parts must undergo regular maintenance inspection at least every 6 months.

(2) If stored for extended periods without being used, make sure prior to operation that the instrument is in perfect

operating condition.

Service Manual ECG-9620 i

Page 6

(3) Technical information such as parts list, descriptions, calibration instructions or other information is available for

qualified user technical personnel upon request from your Nihon Kohden distributor.

9. When the instrument is used with an electrosurgical instrument, pay careful attention to the application and/or

location of electrodes and/or transducers to avoid possible burn to the patient.

10. When the instrument is used with a defibrillator, make sure that the instrument is protected against defibrillator

discharge. If not, remove patient cables and/or transducers from the instrument to avoid possible damage.

WARRANTY POLICY

Nihon Kohden Corporation (NKC) shall warrant its products against all defects in materials and workmanship for one year

from the date of delivery. However, consumable materials such as recording paper, ink, stylus and battery are excluded from

the warranty.

NKC or its authorized agents will repair or replace any products which prove to be defective during the warranty period,

provided these products are used as prescribed by the operating instructions given in the operator’s and service manuals.

No other party is authorized to make any warranty or assume liability for NKC’s products. NKC will not recognize any other

warranty, either implied or in writing. In addition, service, technical modification or any other product change performed by

someone other than NKC or its authorized agents without prior consent of NKC may be cause for voiding this warranty.

Defective products or parts must be returned to NKC or its authorized agents, along with an explanation of the failure.

Shipping costs must be pre-paid.

This warranty does not apply to products that have been modified, disassembled, reinstalled or repaired without Nihon

Kohden approval or which have been subjected to neglect or accident, damage due to accident, fire, lightning, vandalism,

water or other casualty, improper installation or application, or on which the original identification marks have been

removed.

ii Service Manual ECG-9620

Page 7

EMC RELATED CAUTION

This equipment and/or system complies with the International Standard IEC60601-1-2 for electromagnetic

compatibility for medical electrical equipment and/or system. However, an electromagnetic environment

that exceeds the limits or levels stipulated in the IEC60601-1-2, can cause harmful interference to the

equipment and/or system or cause the equipment and/or system to fail to perform its intended function or

degrade its intended performance. Therefore, during the operation of the equipment and/or system, if

there is any undesired deviation from its intended operational performance, you must avoid, identify and

resolve the adverse electromagnetic effect before continuing to use the equipment and/or system.

The following describes some common interference sources and remedial actions:

1. Strong electromagnetic interference from a nearby emitter source such as an authorized radio station

or cellular phone:

Install the equipment and/or system at another location if it is interfered with by an emitter source such

as an authorized radio station. Keep the emitter source such as cellular phone away from the

equipment and/or system.

2. Radio-frequency interference from other equipment through the AC power supply of the equipment

and/or system:

Identify the cause of this interference and if possible remove this interference source. If this is not

possible, use a different power supply.

3. Effect of direct or indirect electrostatic discharge:

Make sure all users and patients in contact with the equipment and/or system are free from direct or

indirect electrostatic energy before using it.

4. Electromagnetic interference with any radio wave receiver such as radio or television:

If the equipment and/or system interferes with any radio wave receiver, locate the equipment and/or

system as far as possible from the radio wave receiver.

If the above suggested remedial actions do not solve the problem, consult your Nihon Kohden Corporation

subsidiary or distributor for additional suggestions.

The CE mark is a protected conformity mark of the European Community. The products herewith comply

with the requirements of the Medical Device Directive 93/42/EEC.

The CE mark is applied only to the ECG-9620L/M/N Electrocardiograph.

This equipment complies with EUROPEAN STANDARD EN-60601-1-2 (1993) which requires EN-55011, class

B.

Service Manual ECG-9620 iii

Page 8

Conventions Used in this Manual and Instrument

Dangers, Warnings, Cautions and Notes

Warnings, cautions and notes are used in this manual to alert or signal the reader to specific information.

DANGER

A danger is used to alert the user to a hazardous situation which will cause death or serious injury.

WARNING

A warning alerts the user to possible injury or death associated with the use or misuse of the instrument.

CAUTION

A caution alerts the user to possible injury or problems with the instrument associated with its use or

misuse such as instrument malfunction, instrument failure, damage to the instrument, or damage to other

property.

NOTE

A note provides specific information, in the form of recommendations, prerequirements, alternative

methods or supplemental information.

iv Service Manual ECG-9620

Page 9

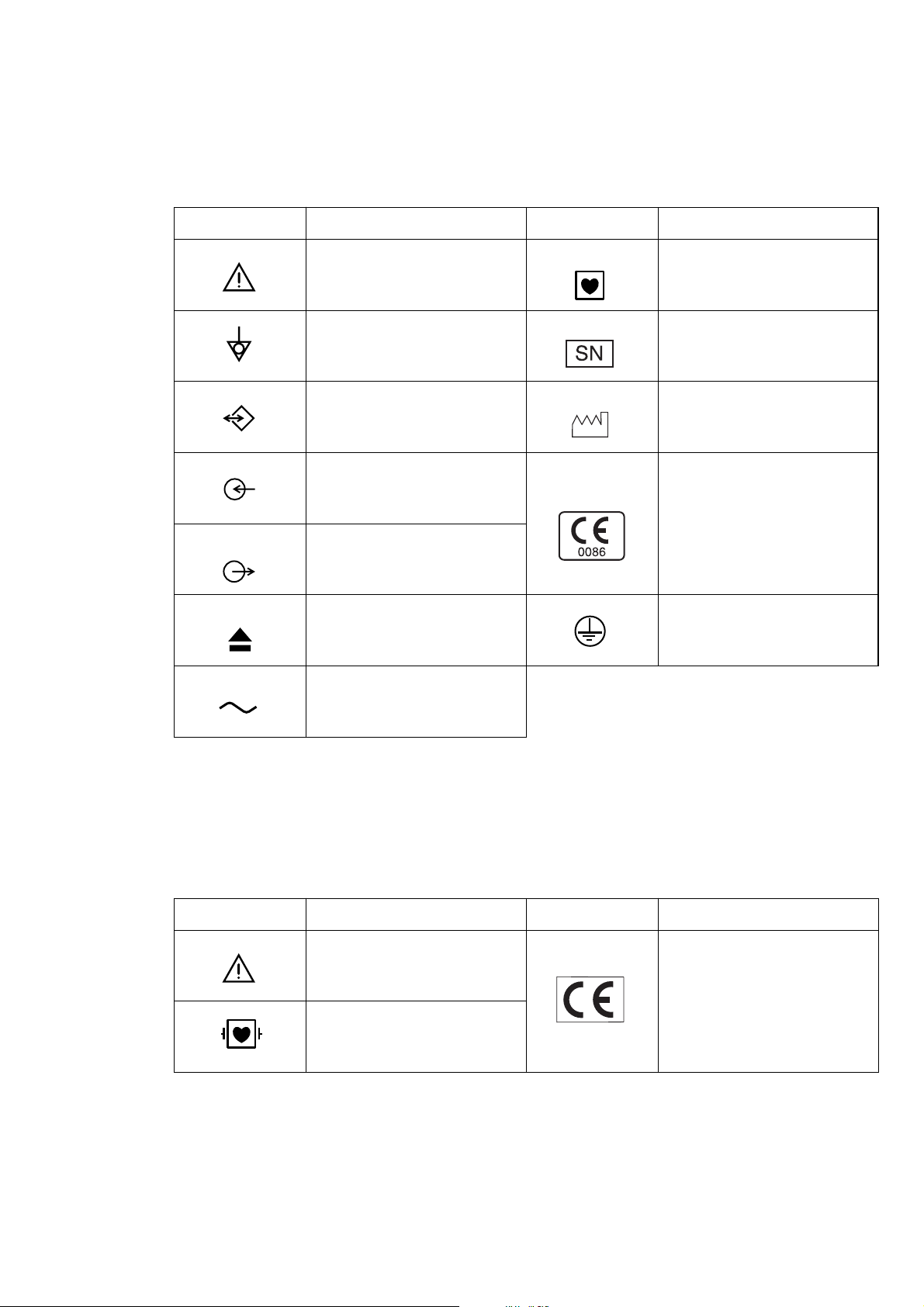

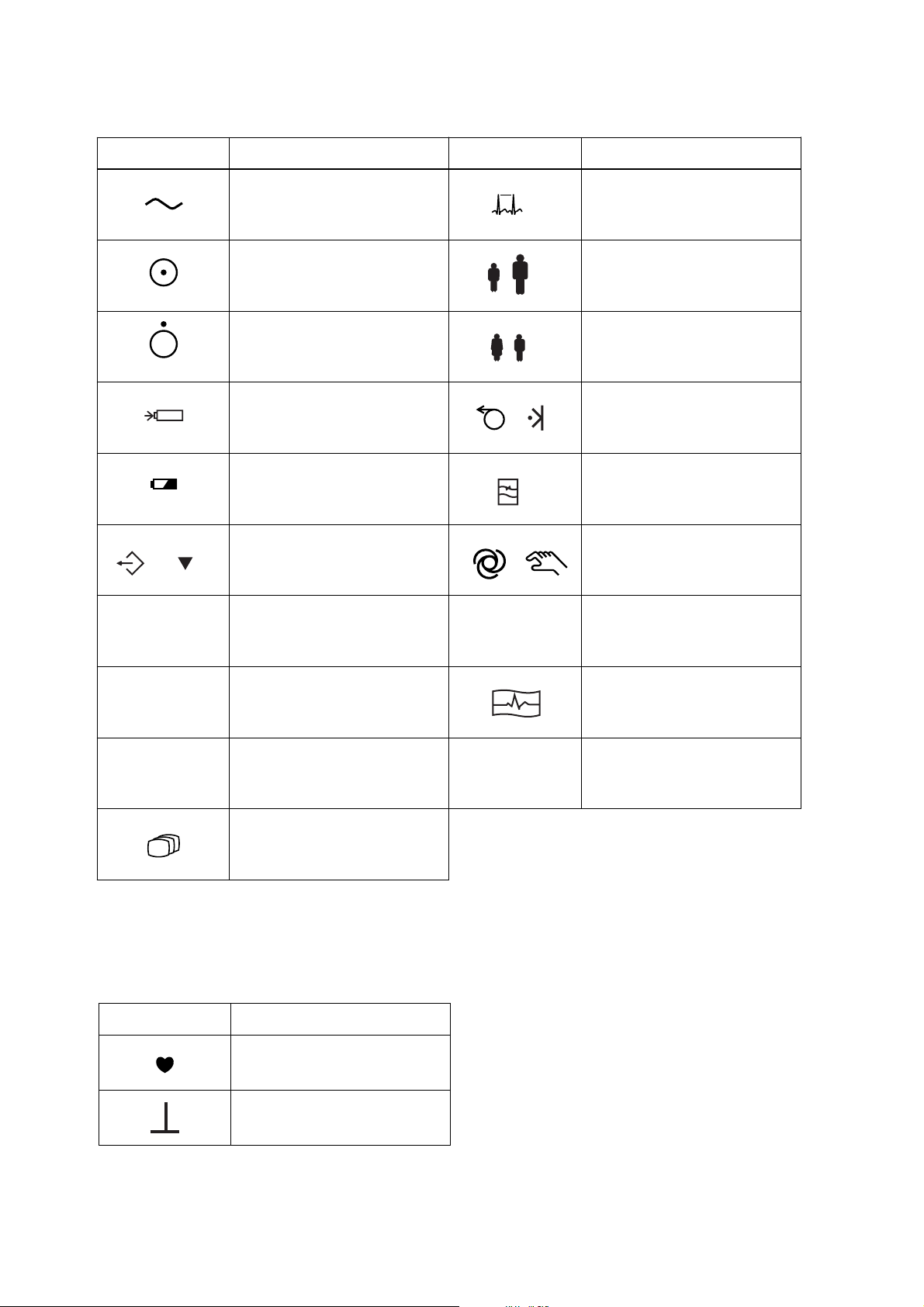

Explanations of the Symbols in this Manual and Instrument

The following symbols found in this manual/instrument bear the respective descriptions as given.

Cardiograph

Symbol Description Symbol Description

Attention, consult operator’s

manual

Equipotential terminal Serial number

Serial input/output terminal

Input terminal for analog signal

Output terminal for analog

signal

Eject (magazine release button)

Alternative current

Type CF applied part

Date of manufacture

The CE mark is a protected

conformity mark of European

Community. The products

herewith comply with the

requirements of the Medical

Device Directive 93/42/EEC.

Protective earth

Patient cable

The CE mark is applied only to the

ECG-9620L/M/N Electrocardiograph.

Symbol Description Symbol Description

Attention, consult operator’s

manual

Defibrillation-proof

Type CF applied par

The CE mark is a protected

conformity mark of European

Community. The products

herewith comply with the

requirements of the Medical

Device Directive 93/42/EEC.

Service Manual ECG-9620 v

Page 10

Operation panel

Symbol Description Symbol Description

F1

Alternating current

“On” only for a part of

equipment

“Off” only for a part of

equipment

Battery charging

Battery check

/

Copy / Calibration / Automatic / Manual control

0

F1 function key

1

/

CLR

Rhythm

5

Age

6

Sex

7

Paper feed / Mark

8

Filter

9

Clear

On screen

F2

F3

Symbol Description

F2 function key Start/Stop recording

2

F3 function key

3

Mode

4

QRS sync mark

CAL mark

ENT

Enter

A key with a numeric number is used to enter

numbers in the System Setup screen and paient

information.

vi Service Manual ECG-9620

Page 11

Section 1 General

Introduction ........................................................................................................................ 1.1

General Information on Servicing ...................................................................................... 1.2

Service Policy, Service Parts and Patient Safety Chec ks .................................................. 1.4

Service Policy .......................................................................................................... 1.4

Service Parts ........................................................................................................... 1.4

Patient Safety Checks.............................................................................................. 1.5

Maintenance Equipments and Tools ........................................................................ 1.5

General Safety Inf ormation ................................................................................................ 1.6

Specifications................................................................................................................... 1.11

Panel Descriptions........................................................................................................... 1.14

Front Panel ............................................................................................................ 1.14

Left Side Panel....................................................................................................... 1.14

Operation Panel..................................................................................................... 1.15

Right Side Panel .................................................................................................... 1.15

Rear Panel............................................................................................................. 1.16

Composition..................................................................................................................... 1.17

Standard Components........................................................................................... 1.17

Options .................................................................................................................. 1.17

Location ........................................................................................................................... 1.18

Service Manual ECG-9620 1C.1

Page 12

Introduction

1. GENERAL

This service manual provides useful information to qualified service personnel to

understand, troubleshoot, service, maintain and repair the ECG-9620L/M/N/P/S/T/

U Electrocardiograph (referred to as “the instrument” in this service manual).

The System test, Adjustment and Setting section in this service manual describes

the maintenance that should be performed by qualified service personnel. The

Maintenance section in the operator’s manual describes the maintenance that can

be performed by the user.

The information in the operator’s manual is primarily for the user. However, it is

important for service personnel to thoroughly read the operator’s manual and

service manual before starting to troubleshoot, service, maintain or repair this

instrument. This is because service personnel need to understand the operation of

the instrument in order to effectively use the information in the service manual.

Service Manual ECG-9620 1.1

Page 13

1. GENERAL

General Information on Servicing

Note the following information when servicing the instrument.

Safety

• There is the possibility that the outside surface of the instrument,

such as the operation keys, could be contaminated by contagious

germs, so disinfect and c lean the instrument before servicing it.

When servicing the instrument, wear rubber gloves to protect

yourself from infection.

• There is the possibility that when the lithium battery is broken, a

solvent inside the lithium battery could flow out or a toxic substance

inside it could come out. If the solvent or toxic substance touches

your skin or gets into your eye or mouth, immediately wash it with a

lot of water and see a physician.

CAUTIONS

Liquid ingress

The instrument is not waterproof, so do not install the instrument

where water or liquid can get into or fall on the instrument. If liquid

accidentally gets into the instrument or the instrument accidentally

drops into liquid, disassemble the instrument, clean it with clean

water and dry it completely. After reassembling, verify that there is

nothing wrong with the patient safety checks and function/

performance checks. If there is something wrong with the

instrument, contact your Nihon Kohden representative for repair.

Environmental Safeguards

Depending on the local laws in your community, it may be illegal to

dispose of the lithium battery in the regular waste collection. Check

with your local officials for proper disposal procedures.

Disinfection and cleaning

To disinfect the outside surface of the instrument, wipe it with a nonabrasive cloth moistened with alcohol. Do not use any other

disinfectants or ultraviolet rays to disinfect the instrument.

1.2 Service Manual ECG-9620

Page 14

1. GENERAL

Caution - continued

Transport

• Use the specified shipment container and packing material to

transport the instrument. If necessary, double pack the instrument.

Also, put the instrument into the shipment container after pac king so

that the buffer material does not get inside the instrument.

• When transporting a board or unit of the instrument, be sure to put it

in a conductive bag. Ne ver use an aluminum bag to transport a

board or unit. Also, never use a styrene foam or plastic bag which

generates static electricity to wrap the board or unit of the

instrument.

Handling the instrument

• Because the outside surface of the instrument is made of resin, the

outside surface of the instrument is easily damaged. So when

handling the instrument, remo ve clutter from around the instrument

and be careful to not damage the instrument or get it dirty.

• Because most of the boards in the instrument are multilayer boards

with surface mount electrical devices (SMD), a special tool is

required to remove and solder the electrical devices on it. To avoid

damaging other electrical components, do not remo ve and solder

SMD components yourself.

Measuring and Test Equipment

Maintain the accuracy of the measuring and test equipment by

checking and calibrating it according to the chec k and calibration

procedures.

Service Manual ECG-9620 1.3

Page 15

1. GENERAL

Service Policy, Service Pa rts and P atient Safety Checks

Service Policy Our technical service policy for this instrument is to replace the faulty unit, board

or part or damaged mechanical part with a new one. Do not perform electrical

device or component level repair of the multilayer board or unit. We do not support

component level repair outside the factory for the following reasons:

• Most of the boards are multilayer boards with surface mount electrical

devices, so the mounting density of the board is too high.

• A special tool or high degree of repair skill is required to repair the multilayer

boards with surface mount electrical devices.

Only disassemble the instrument or replace a board or unit in an environment

where the instrument is protected against static electricity.

Service Parts

Refer to “Replaceable Parts List” of this manual for the service parts for technical

service that we provide.

NOTE

When ordering parts or accessories from your Nihon Kohden

representative, please quote the NK code number and part name

which is listed in this service manual, and the name or model of the

unit in which the required part is located. This will help us to

promptly attend to your needs. Always use parts and accessories

recommended or supplied by Nihon Kohden Corporation to assure

maximum performance from your instrument.

1.4 Service Manual ECG-9620

Page 16

1. GENERAL

Patient Safety Checks

Maintenance Equipments

and T ools

Periodic maintenance procedures and diagnostic check procedures are provided in

this manual to ensure that the instrument is operating in accordance with its design

and production specifications. To verify that the instrument is working in a safe

manner with regard to patient safety, patient safety checks should be performed on

the instrument before it is first installed, periodically after installation, and after any

repair is made on the instrument.

For patient safety checks, perform the following checks as described in the

IEC60601-1 “Medical electrical equipment - Part 1: General requirements for

safety”:

• Protective earth resistance check

• Earth leakage current check

• Enclosure leakage current check

• Patient leakage current check

• Withstanding voltage check

Test equipment

When repairing or calibrating the instrument, the following test equipment is

required.

• Oscilloscope: 2 channels or more for input signal, 50 mV to 5 V input range, 1/

10 attenuating probe and 100 MHz or more frequency response characteristic

must be provided.

• Digital voltmeter: standard type (An oscilloscope can be used instead of the

digital voltmeter.)

Service Manual ECG-9620 1.5

Page 17

1. GENERAL

General Safety Information

• Never use this cardiograph in the presence of any flammab le

• Never use this cardiograph in a high-pressure oxygen medical tank.

Using with an electrical surgical unit (ESU)

• Never use this cardiograph near an ESU. The cardiograph may

• When using this cardiograph with an ESU, refer to the instruction

DANGER

anesthetic gas or high-concentration oxygen atmosphere. Failure to

follow this warning may cause e xplosion or fire.

Failure to follow this warning may cause explosion or fire.

WARNING

malfunction due to high-frequency noise from the ESU.

manual for the ESU. Before measurement, check that the return

plate is correctly attached to the patient and check that the

cardiograph operates correctly when using with the ESU. If the

return plate is not attached correctly, it may burn the patient’s skin

where the electrodes are attached.

MRI examination

• Do not install this cardiograph in an MRI examination room. The

cardiograph may not operate properly due to high-frequency

magnetic noise from the MRI.

• When performing MRI tests, remo ve from the patient all electrodes

which are connected to this cardiograph. Failure to follow this

warning may cause serious electrical burn on the patient due to local

heating caused by dielectric electromotive force. For details, refer to

the instruction manual for the MRI.

When performing defibrillation

• Before defibrillation, remo ve all electrodes and gel from the chest of

the patient. If the defibrillator paddle touches electrodes or gel, the

discharged energy may burn the patient’s skin.

• Before defibrillation, all persons must keep clear of the bed and must

not touch the patient or any equipment connected to the patient.

Failure to follow this warning may cause serious electrical burn,

shock or other injury.

1.6 Service Manual ECG-9620

Page 18

1. GENERAL

Warning - continued

Use only the following specified patient cables when using with a

defibrillator or ESU. When the specified patient cable is connected,

the cardiograph is type CF defibrillation-proof compliance. Failure to

follow this warning will cause serious electrical burn where the

electrode is attached and damage the cardiograph due to discharge

energy when defibrillation is performed.

Patient cable: BJ-901D – IEC standard, 3 mm diameter tip

BJ-902D – IEC/DIN standard, 4 mm diameter tip

BJ-903D – IEC/DIN standard, c lip

BA-901D – AHA requirement, 3 mm diameter tip

BA-903D – AHA requirement, color clip

When using an ESU and defibrillator with the cardiograph, use silver

chloride disposable electrodes.

Installation

WARNING

• Only use the 3-prong power cord provided with the cardiograph.

Failure to follow this caution may cause electrical shock to the

patient and operator.

• Only use the specified patient cable and connect the external

instruments with the specified installation procedure. Failure to

follow this warning may cause a serious electrical shoc k to the

patient and operator by leakage current.

CAUTION

• When the provided 3-prong power cord cannot be used, operate the

cardiograph on battery power. When another type of power cord

(especially 2-prong power cord) is used, this may cause electrical

shock to the patient and operator.

• When several medical instruments are used together, ground all

instruments at the same one-point ground to protect the patient and

operator from electrical shock. Any potential difference between

instruments may cause electrical shock to the patient and operator.

• When connecting an external instrument to connectors marked with

, the external instrument and this cardiograph must be connected

according to the IEC60601-1-1 “Medical electrical equipment - Part 11: General requirements for safety - Collateral standard: Safety

requirements for medical electrical systems”. Failure to follow this

warning may cause electrical shock to the patient and operator.

• When inserting or removing the battery from the cardiograph, make

sure that the cardiograph is turned off. Otherwise, the patient and

operator may get an electrical shock.

Service Manual ECG-9620 1.7

Page 19

1. GENERAL

Battery Pack

DANGER

• Keep the battery pack awa y from fire. Do not heat the battery pack.

Otherwise, the substance liquid leaks out and the battery pack

explodes.

• Never short-circuit the + and – terminals on the battery pack with a

wire. Never store or carry the battery pack with metal such as

necklace or hair pins. The battery pack short-circuits and a large

current flows, causing leakage of the substance liquid inside the

battery and battery explosion.

• Never disassemble or modify the battery pack. Never damage or

directly solder the sheath tube. The battery pack short-circuits, the

substance liquid comes out and the battery pack explodes.

• Do not use a battery pack which is damaged, such as from falling.

There is a gas discharge valve inside the battery and if this valve is

damaged, the gas cannot be dischar ged, causing the battery pack to

explode.

• Do not subject the battery pack to a strong mechanical shock. The

susbstance liquid inside the battery leaks and explodes.

• If the battery pack is damaged and substance liquid inside the

battery contacts the eyes or skin, wash immediately and thoroughly

with water and see your physician. Never rub your eyes, otherwise

you may lose your eyesight.

• Only charge the battery pack with the ECG-9620 cardiograph. If any

other battery charger is used, abnormal current flows and the

substance liquid inside the battery leaks and the battery explodes.

• Do not connect the battery pack to an AC outlet or lighter socket in a

car. The substance liquid inside the battery leaks out and the battery

pack explodes.

• The battery has + and – polarity. Make sure that the battery is

installed with the correct polarity direction. Otherwise, the

substance inside the battery leaks out and the battery pack explodes.

• Use only the SB-901D battery pack.

WARNING

• Do not immerse the battery pack in water or seawater. The battery

heats up and rusts and the substance liquid inside the battery leaks.

• Never use a battery pack which is damaged, discolored or has

leakage. A damaged battery pack explodes if used.

• Do not leave the battery pack unused for more than one year. The

battery may leak.

1.8 Service Manual ECG-9620

Page 20

1. GENERAL

CAUTION

• Do not charge the deteriorated battery pack. Otherwise, the

cardiograph cannot operate on battery power.

• Do not expose the battery pack to direct sunlight or leave in a high

temperature place. The life time of the battery pack may be

shortened, the performance of the battery pack may be degraded and

the substance liquid inside the battery may leak.

• Do not leave the battery pack where patients can reach it.

• Before disposing of the battery pack, c heck with your local solid

waste officials for details in your area for rec ycling options or proper

disposal. The battery is recyc lable. At the end of its useful life, under

various state and local laws, it may be illegal to dispose of this

battery into the municipal waste stream.

Operation

CAUTION

• Enter the patient information correctly. Otherwise, the ECG data may

be lost or mixed up with another patient’s ECG data.

ECG recording judgement

• The cardiograph provides automatic ECG analysis function. The

automatic ECG analysis is performed for acquired ECG waveforms

only and does not reflect all conditions of the patient. The results of

the analysis may not correspond to the judgment of a physician.

• Overall judgement must be performed by the ph ysician, referring to

the analysis result, c linical findings, and other examination results.

After the physician’ s overall judgement, the analysis results should

be signed or initialed by the physician.

• Take care when judging the ECG recording because the 25 Hz EMG

filter may cause greater distortion of P-waves and QRS-waves

depending on the waveform shape. The characteristics of the EMG

filter are similar to a conventional analog filter.

• Do not use the output signal from the output connector for a

synchronization signal such as the synchr onized cardioversion

signal. There is a time delay between the input ECG signal and

output signal.

• When the cardiograph operates on battery power and large leakage

current is input from the connected external instrument, ground the

cardiograph or use an isolation transformer for the external

instrument. Failure to follow this caution may cause electrical shock

to patient and operator.

• Use only the KD-103E cart for the cardiograph. When another cart is

used, the cardiograph may fall off or the cart may tip over.

Service Manual ECG-9620 1.9

Page 21

1. GENERAL

Maintenance

Caution - continued

• Never use the cardiograph with its side panel downward. Failure to

follow this caution may cause the cardiograph to fall over or cause

battery liquid leakage.

NOTE

• When using the battery pack and the battery operation lamp is

blinking in orange, measurement results may not be saved.

CAUTION

• Before maintenance (cleaning, disinfection), make sure that the

cardiograph is turned off and the power cord is removed from the AC

outlet and cardiograph. Otherwise, the operator may get an electrical

shock and the cardiograph may malfunction.

• Before battery replacement, make sure that the cardiograph is turned

off and the power cord is removed from the AC outlet and

cardiograph. Otherwise, the operator may get an electrical shock.

• Do not disassemble or repair the cardiograph. Disassembly and

repair must be performed b y qualified service personnel.

1.10 Service Manual ECG-9620

Page 22

Specifications

ECG input

Input impedance 10 MΩ or more

Electrode offset tolerance ±500 mV or more

Input unit protection Isolated and defibrillator protected only when the following specified patient

Standard sensitivity 10 mm /mV ±2%

Common mode rejection ratio 100 dB or more

Frequency response 0.05 to 150 Hz – 3 dB or more

Waveform data processor

Sample rate 500 samples/s (input unit: 8,000 samples/s)

AC line filter 50/60 Hz

High-cut filter 75, 100, 150 Hz

EMG filter 25/35 Hz

Time constant 3.2 s or more

Waveform status detection Electrode detachment (polarization voltage),

Sensitivity selection 5, 10 , 20 mm/mV

1. GENERAL

cable is connected

Patient cable: BJ-901D, BJ-902D, BJ-903D, BA-901D, BA-903D

Noise (high frequency)

LCD

Size 3.8 inch

Number of dots 320 × 240

ECG waveform 6 channel: 2.8 s

Displayed data Waveform, patient information, recording settings, operation mode, heart rate,

QRS sync mark, error message, electrode detachment, noise

Recorder

Printing method High resolution thermal printer head

Printing density 200 dpi (8 dots/mm)

Scanning line density 1 ms

Recording width 56 mm

Number of recording channels 1, 2, 3

Paper speed 25, 50 mm/s

Number of recording lines Up to 14

Printed data Program type, version, date and time, paper speed, sensitivity, lead name, filter,

Patient information (ID number, sex, age zone), timing mark, event mark,

electrode detachment, noise

Mechanical noise 48 dB or less at paper speed 25 mm/s

External input/output

External input 10 mm/0.5 V ±5%, input impedance 100 kΩ or more

Signal output 0.5 V/1 mV ±5%, output impedance 100 Ω or less

Serial I/O Communication method: RS-232C

Baud rate: 2400, 4800, 9600, 19200, 38400,

57600, 115200

Service Manual ECG-9620 1.11

Page 23

1. GENERAL

Power requirement

Line voltage ECG-9620L: 220 V AC ±10%

Line frequency 50 or 60 Hz

Power input 45 VA

Power consumption 45 W or less

Built-in battery (SB-901D) Voltage: 12 V

ECG-9620M: 230 V AC ±10%

ECG-9620N: 240 V AC ±10%

ECG-9620P: 220 V AC ±10%

ECG-9620S: 110 V AC ±10%

ECG-9620T: 120 V AC ±10%

ECG-9620U: 127 V AC ±10%

Current consumption: 6 A or less

Battery operation time: 2 hours or more (when using a new fully charged

battery in manual mode, at 25 mm/s of recording

speed, 3 ch, and in continuous recording.)

Remaining battery power can change depending on

the surrounding temperature and quality of

recording waveform.

Environment

Operating temperature 5 to 40°C (41 to 104°F)

Operating humidity

25 to 85% RH (with battery pack and recording paper)

20 to 85% RH (with battery pack and without recording paper)

25 to 90% RH (with recording paper and without battery pack)

25 to 95% RH (without battery pack and recording paper)

Operating atmospheric pressure 70 to 106 kPa

Storage temperature

Cardiograph: -20 to 65°C (−4 to 149°F)

Battery pack: -20 to 50°C (−4 to 122°F) (within 30 days)

Recording paper: -20 to 50°C (−4 to 122°F)

Storage humidity

Cardiograph: 10 to 95% RH (non-condensing)

Battery pack: 10 to 85% RH (non-condensing) (within 60 days)

Recording paper: 10 to 90% RH (non-condensing)

Storage atmospheric pressure 70 to 106 kPa

-20 to 40°C (−4 to 104°F) (within 90 days)

-20 to 30°C (−4 to 86°F) (within one year)

45 to 85% RH (non-condensing) (more than 60 days)

Electromagnetic compatibility

IEC60601-1-2 (1993), CISPR11 (1990) Group 1 Class B

IEC60601-2-25 Amendment 1 (1999), protection against electrosurgery interference

Other

Indoor portable

1.12 Service Manual ECG-9620

Page 24

Dimensions and weight

Dimensions 280 W × 70 H × 216 D mm (excluding protrusions)

Weight Approx. 3.1 kg (with battery)

Approx. 2.7 kg (without battery)

Safety

Safety standard:

IEC60601-1 (1998)

IEC60601-1 Amendment 1 (1991)

IEC60601-1 Amendment 2 (1995)

IEC60601-2-25 (1993)

IEC60601-2-25 Amendment 1 (1999)

Type of protection against electric shock:

AC power: Class I

Battery power: Internally powered equipment

Degree of protection against electric shock:

Defibrillator proof type CF applied part when patient cable BJ-901D, BJ-902D, BJ-903D, BA-901D or

BA-903D is used

Degree of protection against harmful ingress of water:

Ordinary equipment

Degree of safety of application in the presence of a flammable anaesthetic mixture with air, oxygen or nitrous

oxide:

Not suitable for use in the presence of a flammable anaesthetic mixture with air, oxygen or

nitrous oxide

Mode of operation:

Continuous

1. GENERAL

Service Manual ECG-9620 1.13

Page 25

1. GENERAL

Panel Descriptions

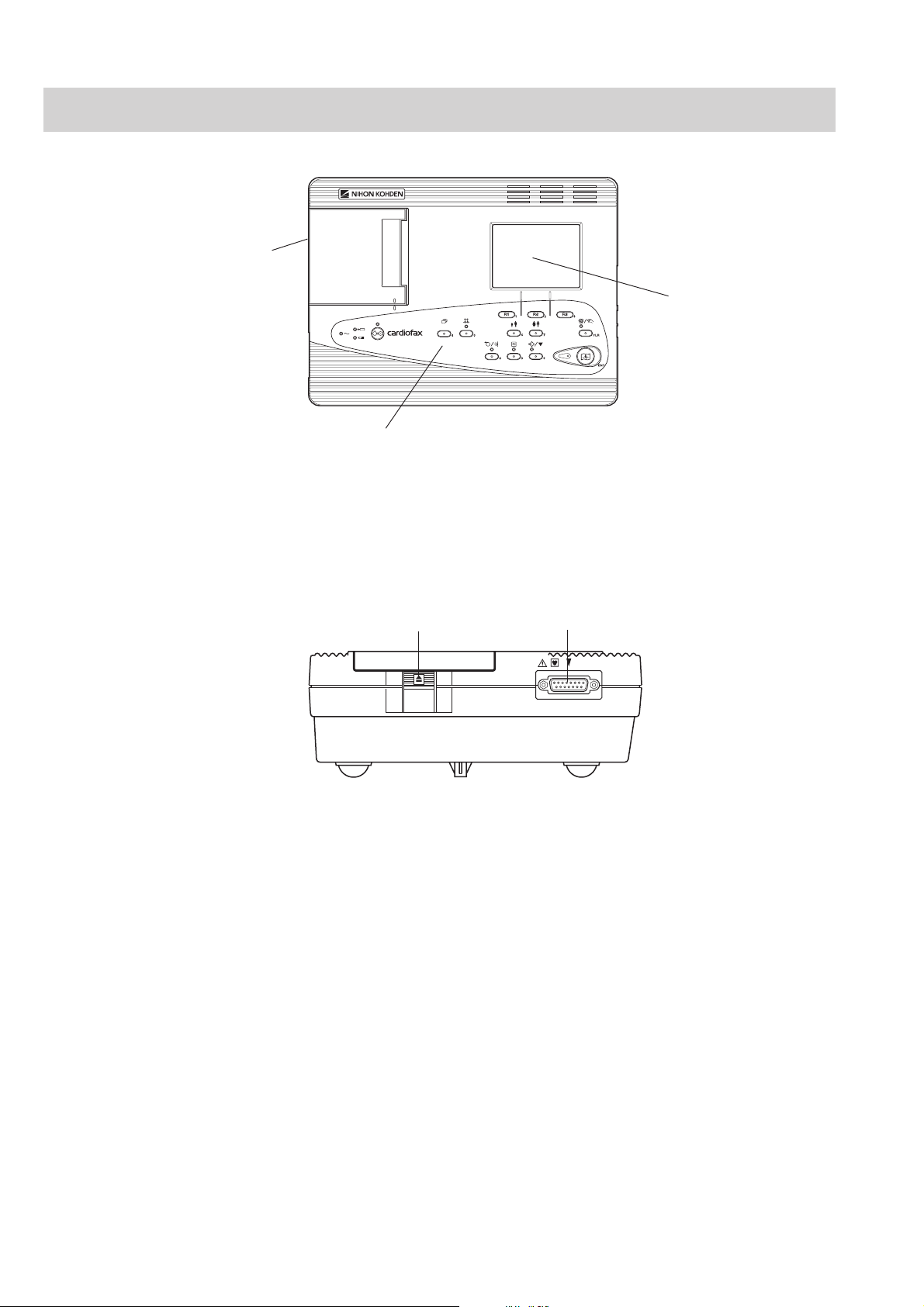

Front Panel

2

3

1

Name

1. Operation panel

2. Magazine (paper container)

3. LCD screen

Left Side Panel

1

Name

1. Magazine release button

2. Patient cable connector

2

1.14 Service Manual ECG-9620

Page 26

Operation Panel

1. GENERAL

7

8

3

1

2

4

5

6

11

12

13

9

10

14

Name

1. AC power lamp

2. Battery operation lamp

3. Battery charge lamp

4. Power key/lamp

5. Mode key

6 Rhythm key/lamp

7. F1, F2, F3 function keys

Name

8. Age key

9. Sex key

10. Auto/Manual key/lamp

11. Feed/Mark key

12. Filter key/lamp

13. Copy/CAL key lamp

14. Start/Stop key/lamp

Right Side Panel

CAUTION

• When connecting an external instrument to connectors marked with , the external instrument and this

cardiograph must be connected according to the IEC60601-1-1 “Medical electrical equipment - Part 1-1:

General requirements for safety - Collateral standard: Safety requirements for medical electrical

systems”. Failure to follow this warning may cause electrical shock to the patient and operator.

• Do not use the output signal from the output connector for a synchronization signal such as the

synchronized cardioversion signal. There is a time delay between the input ECG signal and output

signal.

2

1

Name

1. EXT-IN connector

2. CRO-OUT

3. SIO connector

4. AC power cord socket

5. Equipotential ground terminal

Service Manual ECG-9620 1.15

3

4

5

Page 27

1. GENERAL

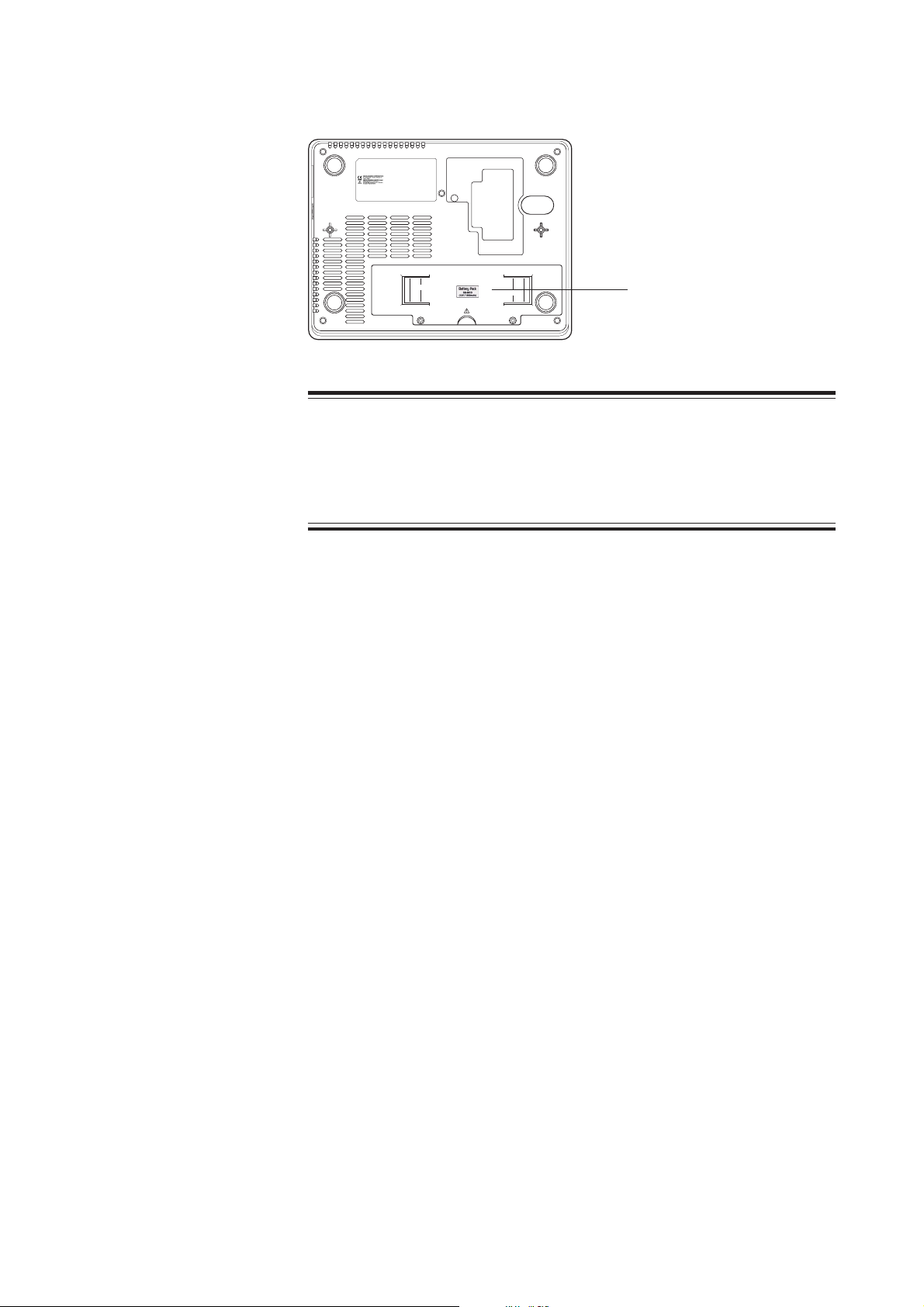

Rear Panel

The CE mark is applied only to the

ECG-9620L/M/N Electrocardiograph.

Battery

CAUTION

Always install the battery even when the cardiograph operates on AC

power. Otherwise sudden power down occurs when any electrode is

detached during recording.

1.16 Service Manual ECG-9620

Page 28

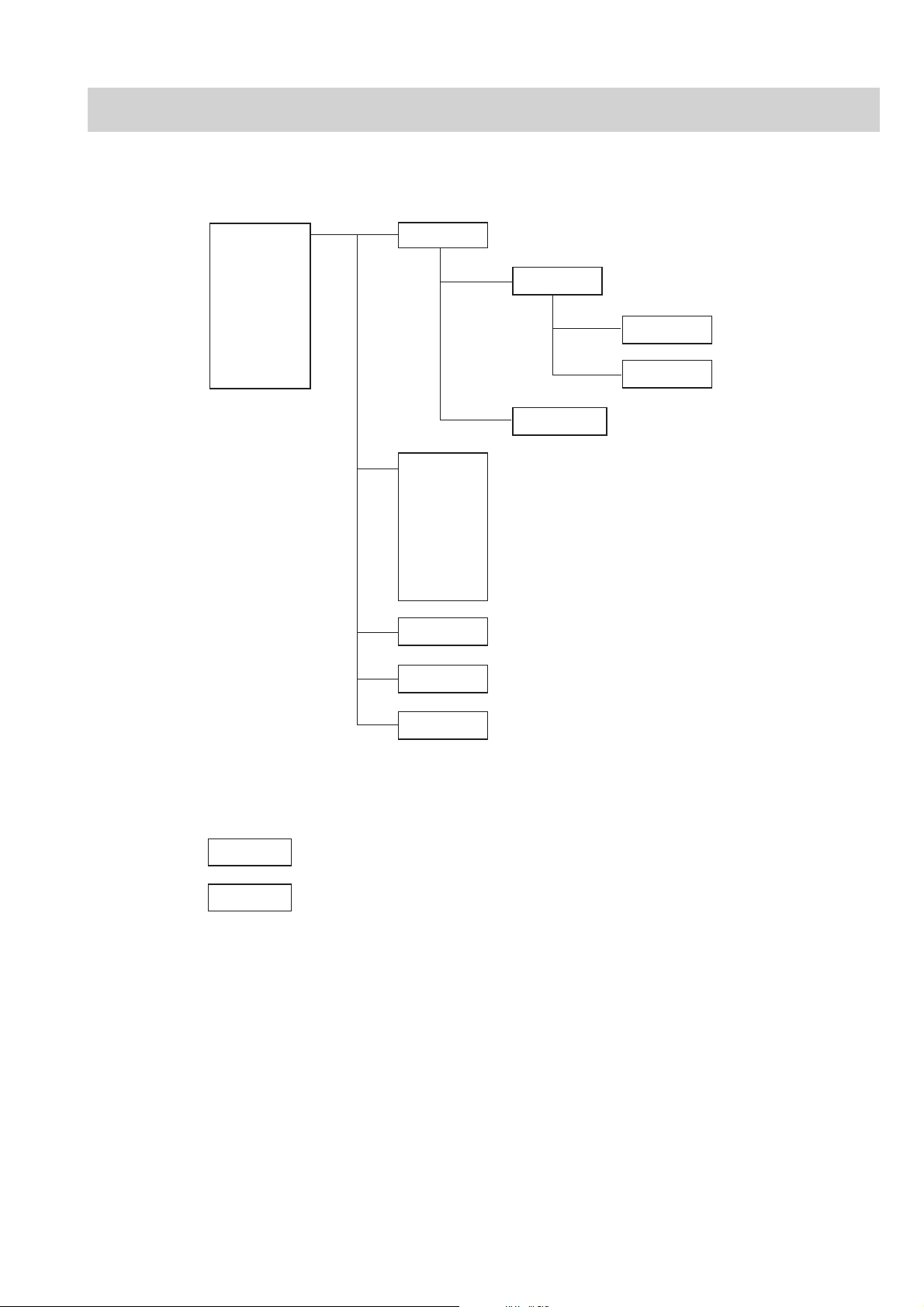

Composition

Standard Components

1. GENERAL

ECG-9620L

ECG-9620M

ECG-9620N

ECG-9620P

ECG-9620S

ECG-9620T

ECG-9620U

RHC-0004 Record Assy

RHC-00041 Motor Assy

UTC-0009 Paper senser board

UTC-0010 Motor sensor board

RHC-00042 Magazine Assy

RKC-0001 Transfer Assy (220 V) for L and P version

RKC-0002 Transfer Assy (230 V) for M version

RKC-0003 Transfer Assy (240 V) for N version

RKC-0004 Transfer Assy (110 V) for S version

RKC-0005 Transfer Assy (120 V) for T version

RKC-0006 Transfer Assy (127 V) for U version

UTC-0006 Key board

UTC-0007 ECG control board

Options

UTC-0008 Power board

KD-103E Cart

KH-801E Patient Cable Hanger

· To order a replacement assembly above, use the Code No.

· To order a replacement component inside an assembly, refer to “Section 7

Replaceablet Parts List”.

Service Manual ECG-9620 1.17

Page 29

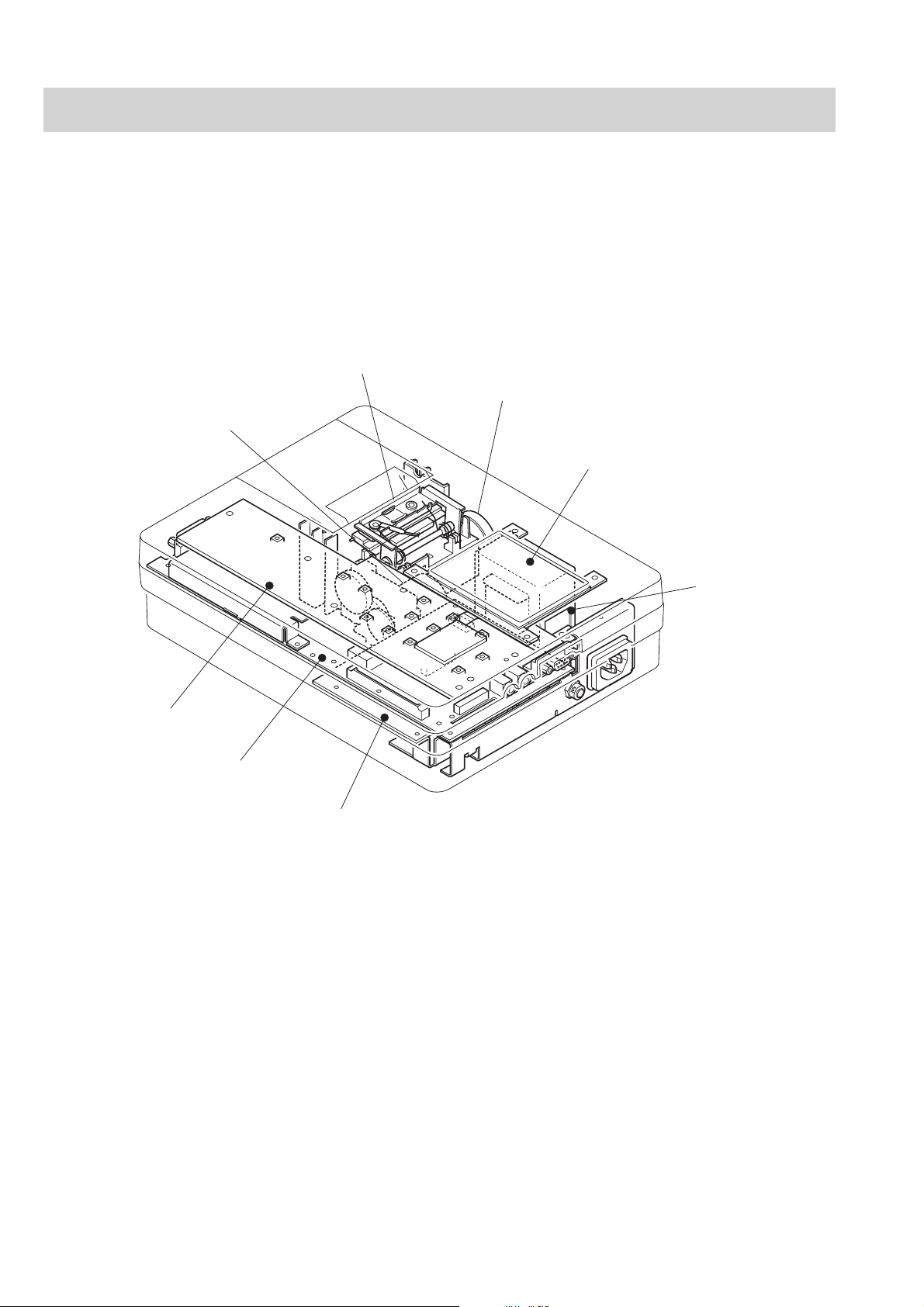

1. GENERAL

Location

Thermal Head Assy

Buzzer

Motor Assy

LCD

Ke y board

ECG control board

Transfer Assy

Power board

1.18 Service Manual ECG-9620

Page 30

Section 2 Maintenance

Replacement...................................................................................................................... 2.1

Periodic Replacement Schedule.............................................................................. 2.1

Cleaning and Lubrication ................................................................................................... 2.2

Cleaning and Greasing Schedules .......................................................................... 2.2

Cleaning the Paper Mark Sensor and P aper Empty Sensor.................................... 2.2

Cleaning the Motor Rotation Sensor and Lubricating the Motor Gear and Gear

Meshed with Motor Gear ......................................................................................... 2.3

Maintenance Check Sheet................................................................................................. 2.5

Service Manual ECG-9620 2C.1

Page 31

Replacement

2. MAINTENANCE

This section describes the periodic replacement and cleaning of parts which are

required to maintain the instrument in good working condition.

This subsection only describes replacement schedule for parts that need to be

periodically replaced. The actual replacement procedures are described in the section

for Disassembly and Assembly. Read the whole “Disassembly and Assembly” section,

especially its Warnings and Cautions, before replacing any of the parts described here.

Periodic Replacement

Schedule

To maintain the performance of the instrument, the parts listed in the table below must

be periodically replaced by qualified service personnel.

Code No. Description Recommendation

SB-901D Battery pack * See below.

08SK3.878.00046 Thermal head, KYT-56-8MPP1-SKH After 50 km recording

RHC-00041 Motor Assy After 1000 hours operation

* Replace the battery pack when it cannot last for 30 minutes during battery operation

at the temperatures between 20 and30°C.

Service Manual ECG-9620 2.1

Page 32

2. MAINTENANCE

Cleaning and Lubrication

This subsection describes the cleaning and lubrication procedures for parts that

must be cleaned and lubricated by qualified service personnel. The cleaning

procedures for parts that can be cleaned by the user are described in the Operator’s

Manual.

Cleaning and Lubricating

Schedules

Cleaning the Paper Mark

Sensor and Paper Empty

Sensor

To maintain the performance of the instrument, the parts listed in the table below

must be regularly cleaned or lubricated.

Part Frequency Performed by

Instrument (external) After each use User

Thermal Head Once a month User

Platen Roller assy Once a year User

Paper Sensor Once a month Qualified service personnel

Motor Sensor Once a year Qualified service personnel

Motor Gear and Gear Once a year Qualified service personnel

Meshed with Motor Gear

1. Remove the magazine. The illustration below shows the location of the paper

sensor.

2. Use a piece of cotton moistened with alcohol to clean both sensors.

Paper sensor

2.2 Service Manual ECG-9620

Page 33

2. MAINTENANCE

Cleaning the Motor

Rotation Sensor and

Lubricating the Motor Gear

and Gear Meshed with

Motor Gear

M3 binding head screw

Thermal head unit

1. Remove the upper casing from the lower casing. Refer to “Removing the

Upper Casing” in Section 6.

2. Remove the two M3 pan screws with washers and spring washers which fasten

the ground leads to the power transformer unit.

Ground lead

M3 pan screw with washer

and spring washer

CNA012 cable

CNA011 cable

Motor assy

3. Disconnect the CNA011 and CNA012 cables from the ECG control board.

4. Remove the three M3 binding head screws which fasten the thermal head unit

to the lower casing and remove the thermal head unit.

5. Remove the two M3 binding head screws which fasten the motor assy to the

thermal head unit and remove the motor assy.

6. Remove the two M3 pan screws with spring washers which fasten the motor

sensor board to the motor assy and remove the motor sensor board.

7. Use a piece of cotton moistened with alcohol to clean the motor rotation

sensor.

8. Use a brush to clean the holes in the gear.

Motor sensor board

Service Manual ECG-9620 2.3

Page 34

2. MAINTENANCE

9. Use grease to lubricate the motor gear and the gear which directly meshes with

the motor gear as shown below.

Top view

Motor

Motor gear

Gear meshed with motor gear

2.4 Service Manual ECG-9620

Page 35

2. MAINTENANCE

Maintenance Check Sheet 1/2

Date:

Customer:

Customer Address:

Service Personnel: Service Company:

Instrument Name: Instrument Model:

Instrument Serial Number: Hardware Revision:

Software Revision:

Overview Outside of instrument is clean. Yes No

No loose screws. Yes No

No physical damage, no bent parts and no contact with liquid. Yes No

Operation panel is not torn or broken. Yes No

All keys, buttons and controls are undamaged. Yes No

Power cord, patient cable are not frayed

and are correctly connected to the instrument. Yes No

Paper magazine opens and closes correctly. Yes No

Thermal head is clean. Yes No

The paper feeding roller is clean. Yes No

Motor rotation sensor is clean. Yes No

Paper detection sensor is clean. Yes No

Motor gear is lubricated properly. Yes No

Accessories Enough electrolyte cream (CardioCream) Yes No

Enough recording paper. Yes No

Installation Instrument is installed in the proper location. Yes No

Specified 3-prong power cord and ground lead are used. Yes No

Battery pack is in the instrument. Yes No

Recording paper is loaded. Yes No

Power on There is no fire, smoke or smell. Yes No

There is no electrical shock when touching the instrument. Yes No

Instrument is not abnormally hot. Yes No

Instrument does not affect surrounding equipment. Yes No

AC lamp lights when the AC power is supplied. Yes No

Battery charge lamp lights when the AC power is supplied. Yes No

Basic operation The screen display is correct. (brightness, no distortion) Yes No

Key lamp indication is correct. Yes No

All keys operate properly. Yes No

All settings are correct. Yes No

The battery is fully charged. Yes No

Electrode detachment functions properly. Yes No

There is no error message or abnormal operation. Yes No

Service Manual ECG-9620 2.5

Page 36

2. MAINTENANCE

Maintenance Check Sheet

Monitoring ECG waveform display is correct. Yes No

The continuity of the ECG connection cable is correct. Yes No

Heart rate display is correct. Yes No

QRS sync mark is displayed and heart rate sync sound generates. Yes No

ECG lead and sensitivity can be changed properly. Yes No

Alarms setting and alarm function is correct. Yes No

Sound volume can be changed properly. Yes No

Recording Paper is fed correctly (no skewing or jam). Yes No

Waveforms and letters are clearly recorded. Yes No

Time printed on the recording paper is correct. Yes No

System T est Recorder Pass Fail

Key Pass Fail

Memory Pass Fail

LCD/LED Pass Fail

Input unit Pass Fail

Calibration Pass Fail

Communication Pass Fail

CRO/EXT1 Pass Fail

2/2

Safety Protective earth resistance Pass Fail

Earth leakage current Pass Fail

Enclosure leakage current Pass Fail

Withstanding voltage Pass Fail

2.6 Service Manual ECG-9620

Page 37

Section 3 T roubleshooting and

System Error Message

Troubleshooting Flowchart................................................................................................. 3.1

T roub leshooting T a ble ........................................................................................................ 3.4

Troubleshooting General Operation Problem ........................................................... 3.4

Troubleshooting Recording Problem........................................................................ 3.6

System Error Message ...................................................................................................... 3.7

Service Manual ECG-9620 3C.1

Page 38

This section describes how to troubleshoot the instrument, using the following:

Is there any response when

any key is pressed?

Check that the LCD cable is

connected to the CNJ201

connector on the key board.

The LCD unit is faulty.

The key board is faulty.

The ECG control board is faulty.

The power LED is on but

there is no LCD display.

No

Yes

Normal

The key board is faulty.

The ECG control board is faulty.

Normal

Check that the CNA013 cable is connected to the

CNJ033 connector on the ECG control board and

CNJ101 connector on the key board.

- flowchart

- troubleshooting table

- system error messages at power-up

If the power is not turned off by pressing the Power key, press and

hold the Power ke y 5 seconds or more.

Troubleshooting Flo wc hart

Use the troubleshooting flowchart to find the possible sources of a problem.

3. TROUBLESHOOTING AND SYSTEM ERR OR MESSAGE

NOTE

Service Manual ECG-9620 3.1

Page 39

3. TROUBLESHOOTING AND SYSTEM ERROR MESSAGE

The power of the

instrument does not turn

on.

Does the instrument

operate during AC

power operation?

No

Does the LED of the AC power

light?

The key board is faulty.

The ECG control board is faulty.

The power board is faulty.

The instrument does not

operate during battery

power operation.

Is the battery charged?

Yes

Yes

No

Yes

No

Charge the battery.

Check the following cable connections

Between transformer unit and power board

CNA014 (between the power board and

ECG control board

CNA013 (between the ECG control board

and key board)

Normal

Check the power fuse in the

fuse holder.

Normal

The power board is faulty.

The power transformer is faulty.

Check the following cable connections

Between transformer unit and power board

CNA014 (between the power board and

ECG control board

CNA013 (between the ECG control board

and key board)

Normal

Is the battery F101 or F102

Yes

fuse on the power board blown?

No

The power unit is faulty.

The power transformer is faulty.

Replace the battery fuse

on the power board.

3.2 Service Manual ECG-9620

Page 40

The recorder does not

feed the recording paper

when the Start key is

pressed.

3. TROUBLESHOOTING AND SYSTEM ERR OR MESSAGE

Does the LED for the Start

Brinks

key light?

Lights

Does the recorder print

when the recording paper

is manually pulled out

from under the thermal

head?

Yes

Check that CNA011 cable is

connected to the CNJ036 connector

on the ECG control board.

Normal

The motor is faulty.

The ECG control board

is faulty.

Is the recording paper set?

No

No

Check that the CNA013 cable is

connected to the CNJ033 connector

on the ECG control board and

CNJ101 connector on the key board.

Normal

The ECG control board

is faulty.

The key board is faulty.

Set the recording paper.

Service Manual ECG-9620 3.3

Page 41

3. TROUBLESHOOTING AND SYSTEM ERROR MESSAGE

T roubleshooting Table

Use the troubleshooting table to locate, identify and solve a problem in the

instrument. The problems are divided into general operation and recording. Each

category has its own troubleshooting table for fast and easy troubleshooting.

How to use the troubleshooting table

1. Determine which troubleshooting table to use.

2. In the “Problem” column find the trouble item that matches the problem.

3. Do the action recommended in the “Corrective Action” column.

4. If the problem is not solved, do the action for the next possible cause or criteria.

5. If none of the actions solve the problem, contact your nearest Nihon Kohden

dealer.

Troubleshooting General

Operation Problem

Problem Possible Cause Action

The power LED lights but nothing is

displayed on the LCD screen.

The instrument does not operate on AC

power.

Faulty cable connection. Check the following cable connection.

CNA013: between the ECG control

board and key board

LCD cable: CNJ201 connector on the

key board.

CNA014: between the power board

and ECG control board

Faulty LCD unit. Replace the LCD unit.

Faulty key board. Replace the key board.

Faulty ECG control board. Replace ECG the control board.

Faulty power fuse. Replace the power fuse.

Faulty cable connection Check the following cable connection.

CNA013: between the ECG control

board and key board

CNA014: between the power board

and ECG control board.

Power cable:between the power board

and power transformer

unit

Faulty power cord Replace the power cord.

Faulty power board. Replace the power board.

Faulty key board. Replace the key board.

Faulty ECG control board. Replace ECG the control board.

Faulty power transformer unit, Replace the power transformer unit.

3.4 Service Manual ECG-9620

Page 42

3. TROUBLESHOOTING AND SYSTEM ERR OR MESSAGE

Problem Possible Cause Action

The instrument does not operate on

The battery is not charged. Charge the battery.

battery power.

Faulty battery fuse. Replace the battery fuse.

Faulty battery. Replace the battery.

Check the following cable connection.

CNA013: between the ECG control

board and key board

CNA014: bet ween the power board

and ECG control board.

Battery cable:CNJ102 connector on the

power board

Faulty power board. Replace the power board.

No key operation Faulty cable connection Check the following cable connection.

CNA013: between the ECG control

board and key board

CNA014: bet ween the power board

and ECG control board.

Faulty key board. Replace the key board.

Faulty ECG control board. Replace ECG the control board.

No ECG waveform appears in a

specific lead or artifact appears on the

waveform.

Faulty electrode attachment. Check that the electrodes are properly

attached to the patient.

Faulty patient cable connection. Check that the patient cable is firmly

connected to the electrodes and

instrument.

Faulty ECG control board. Replace the ECG control board.

No ECG waveform appears in all

channels or artifact appears on the

waveform.

No electrode is attached to the patient

or the RF (RL) electrode is not attached

to the patient.

Check that the electrodes are properly

attached to the patient.

Faulty ECG control board. Replace the ECG control board.

Vertical and horizontal stripes appear

on the LCD screen at constant interval.

Faulty cable connection. Check the following cable connection.

CNA013: between the ECG control

board and key board

LCD cable: CNJ201 connector on the

key board.

Faulty ECG control board. Replace the ECG control board.

Faulty LCD unit. Replace the LCD unit.

No sound Faulty cable connection. Check that the speaker cable is firmly

connected to the CNJ032 connector on

the ECG control board.

Faulty speaker. Replace the speaker.

The date and time is reset to January 1,

1980 and the “Error 09” error message

appears.

The lithium battery is completely

discharged.

Replace the ECG control board. The

lithium battery is in the real time clock

IC on the ECG control board.

Service Manual ECG-9620 3.5

Page 43

3. TROUBLESHOOTING AND SYSTEM ERROR MESSAGE

Troubleshooting Recording

Problem

Problem Possible Cause Action

The recorder does not feed the

recording paper when the Start key is

pressed.

No printing. The thermal head is incorrectly

Sometimes the recorder does not pr int. The thermal head protection circuit

The paper skews. Dirty thermal head. Clean the thermal head.

Dirty paper sensor. Clean the paper sensor.

Faulty cable connection. Check the following cable connection.

CNA013: between the ECG control

board and key board

CNA011: between the ECG control

board and feeding motor,

motor sensor and paper

sensor

Faulty key board. Replace the key board.

Faulty ECG control board. Replace the ECG control board.

Faulty feeding motor. Replace the feeding motor.

Readjust the position of the thermal

positioned.

Faulty cable connection. Check the following cable connection.

Faulty thermal head. Replace the thermal head.

Faulty power board. Replace the power board.

Faulty ECG control board. Replace the ECG control board.

which protects the thermal head from

large artifact, such as AC interference is

rejecting noisy waveforms.

The recording paper is not properly set

in the instrument.

The thermal head is incorrectly

positioned.

Faulty feeding roller. Replace the paper magazine.

head.

CNA013: between the ECG control

board and key board

CNA011: between the ECG control

board and feeding motor,

motor sensor and paper

sensor

Check the electrode attachment. If

necessary, adjust the electrode position

so that clear ECG waveforms are

displayed.

Make sure that the recording paper is

aligned with the lower recording paper

guide.

Readjust the position of the thermal

head.

3.6 Service Manual ECG-9620

Page 44

System Error Message

During power-up and operation the instrument continuously checks itself for

system failure. If a failure is detected, system information and error history are

printed on the recording paper and all operations are stopped. System information

and error history are also displayed or printed due to transient noise. After printing

the system information and error history, the power of the instrument is

automatically turned off.

3. TROUBLESHOOTING AND SYSTEM ERR OR MESSAGE

NOTE

If the same system information appears again after restarting the

instrument, do not use the instrument until service personnel has

corrected the cause of the problem. Sending a copy of the system

information to your nearest Nihon Kohden distributor helps us to

troubleshoot your problem quickly.

System Information

Indicates an error number to identify the problem. To solve the problem, do the

corrective action described below.

Error No. Meaning Corrective Action

00 Input unit error: An interrupt signal of 2 ms

is generated.

01 Input unit error: There is no response to the

host.

02 Input unit error: Communication protocol

error.

03 4 bit CPU error: Initialization error. Replace the ECG control board.

04 4 bit CPU error: “No response” error. Replace the ECG control board.

05 A key on the key board is short-circuited. Replace the key board.

06 RTC error: No interrupt signal of 125 ms. Replace the ECG control board.

07 RTC error: Incorrect data in SRAM. Replace the ECG control board.

09 The lithium battery to back up the date and

time and all system settings is completely

discharged. The system settings other than

the items described in the following note

are returned to the factory initial settings.

10 Bus error. Replace the ECG control board.

11 Address error. Replace the ECG control board.

Replace the ECG control board.

Replace the ECG control board.

Replace the ECG control board.

Replace the ECG control board. The

lithium battery is in the real time clock IC

on the ECG control board. The date and

time is reset to January 1, 1980.

Service Manual ECG-9620 3.7

Page 45

3. TROUBLESHOOTING AND SYSTEM ERROR MESSAGE

Error No. Meaning Corrective Action

12 Illegal command. Replace the ECG control board.

13 Zero division error. Replace the ECG control board.

14 Power off time out. Replace the ECG control board.

15 EEPROM error: This occurs due to the

EEPROM check error, installed language

error or communication error between the

host and EEPROM.

16 Local language flash memory error. Replace the ECG control board.

17 ECG model error. Replace the ECG control board.

18 Local lang uage is not installed. I nstall the local language.

19 Local lang uage is not installed. I nstall the local language.

Error in memory area for local language. Re-install the local language.

20 Local language text file version does not

match the ECG software version.

21 ECG inte r pretation error (Time over). Check the input waveforms. I f any noi se

22 The entered information does not match

the data in the flash memory.

27 Program version error. T he program is

updated.

Replace the ECG control board.

Install the local language text file which is

the same version as the ECG software.

is superimposed on the waveforms, find

and eliminate the cause. If no noise is

superimposed on the waveform, replace the

ECG control board.

Replace the ECG control board.

Turn the power off, then on and check that

the ECG waveforms are displayed

correctly.

NOTE

••

• “Error 05” also appears when any key on the operation panel is

••

pressed and held down.

••

• When “Error 08” appears, the following settings are not reset to

••

the factory initial settings even if the instrument is initialized.

- display language - hum filter

- hospital name - direct/modem connection

- recording resolution setting - elapsed time

- local language font - saved ECG data

3.8 Service Manual ECG-9620

Page 46

3. TROUBLESHOOTING AND SYSTEM ERR OR MESSAGE

Error History

Indicates the latest three errors and the date of the latest error, as in the example

below.

Service Manual ECG-9620 3.9

Page 47

Section 4 System Test, Adjustment,

And Setting

System T est ....................................................................................................................... 4.1

Overall ..................................................................................................................... 4.1

Calling up the System Test Level 1 .......................................................................... 4.2

Calling up the System Test Level 2 .......................................................................... 4.3

Entering the System Test Number ........................................................................... 4.4

Executing the System Test....................................................................................... 4.5

Quitting the System Test .......................................................................................... 4.6

Exiting the System Test Mode.................................................................................. 4.6

Demonstration ................................................................................................................... 4.7

Recorder ............................................................................................................................ 4.8

Thermal Head .................................................................................................................. 4.10

Key................................................................................................................................... 4.11

Memory............................................................................................................................ 4.12

Single Memory Test Mode ..................................................................................... 4.13

Continuous Memory Test Mode ............................................................................. 4.13

LCD/LED.......................................................................................................................... 4.14

Input Unit ......................................................................................................................... 4.16

Calibration........................................................................................................................ 4.17

Communication................................................................................................................ 4.18

CRO/EXT1....................................................................................................................... 4.20

System Setup Initialization............................................................................................... 4.22

ECG Findings List Recording........................................................................................... 4.23

Recording Resolution Setting .......................................................................................... 4.24

Date and Time Setting ..................................................................................................... 4.25