Page 1

Framework Manual

Page 2

The information in this document is subject to change without notice and does not represent a

commitment on the part of Native Instruments GmbH. The software described by this document is subject to a License Agreement and may not be copied to other media. No part of this

publication may be copied, reproduced or otherwise transmitted or recorded, for any purpose,

without prior written permission by Native Instruments GmbH, hereinafter referred to as Native

Instruments.

“Native Instruments”, “NI” and associated logos are (registered) trademarks of Native Instruments GmbH.

Mac, Mac OS, GarageBand, Logic, iTunes and iPod are registered trademarks of Apple Inc.,

registered in the U.S. and other countries.

Windows, Windows Vista and DirectSound are registered trademarks of Microsoft Corporation

in the United States and/or other countries.

All other trade marks are the property of their respective owners and use of them does not imply any affiliation with or endorsement by them.

Document authored by: David Forrester

Software version: 1.0 (09/2015)

Disclaimer

Page 3

NATIVE INSTRUMENTS GmbH

Schlesische Str. 29-30

D-10997 Berlin

Germany

www.native-instruments.de

NATIVE INSTRUMENTS North America, Inc.

6725 Sunset Boulevard

5th Floor

Los Angeles, CA 90028

USA

www.native-instruments.com

NATIVE INSTRUMENTS K.K.

YO Building 3F

Jingumae 6-7-15, Shibuya-ku,

Tokyo 150-0001

Japan

www.native-instruments.co.jp

Contact

NATIVE INSTRUMENTS UK Limited

18 Phipp Street

London EC2A 4NU

UK

www.native-instruments.com

© NATIVE INSTRUMENTS GmbH, 2015. All rights reserved.

Page 4

Table of Contents

Table of Contents

1 Anatomy of a Block ...................................................................................................

1.1 System Info Macro ...................................................................................................................... 9

1.2 Panel Macro ................................................................................................................................10

1.3 Process Core Cell ........................................................................................................................ 16

1.4 A Completed Block ...................................................................................................................... 19

1.2.1 Size Macro ................................................................................................................. 11

1.2.2 A/B Buttons Macro ..................................................................................................... 12

1.2.3 Panel Elements .......................................................................................................... 13

1.2.4 Mod Ring and Mod Return ......................................................................................... 14

1.3.1 Display Clk Distributor ............................................................................................... 16

1.3.2 A and B Distributors .................................................................................................. 17

1.3.3 Smoother Attributes ................................................................................................... 17

1.3.4 Smooth + A/B Mod .................................................................................................... 17

2 Connections and Signals ...........................................................................................

2.1 Audio Rate Connections .............................................................................................................. 21

2.2 Value Range ............................................................................................................................... 22

2.3 Pitch Scaling .............................................................................................................................. 23

2.4 Gate Signals ............................................................................................................................... 24

2.5 Gate Signals and Velocity ........................................................................................................... 25

3 Panel Widgets ...........................................................................................................

3.1 Color Schemes ............................................................................................................................ 29

3.2 Template Blocks ......................................................................................................................... 31

3.3 Process Macros ........................................................................................................................... 32

3.4 Knobs ......................................................................................................................................... 33

3.1.1 Additional Knob Colors .............................................................................................. 30

3.4.1 Basic Knobs ............................................................................................................... 33

7

20

27

REAKTOR Blocks - Framework Manual - 4

Page 5

Table of Contents

3.5 Customizing Knobs ..................................................................................................................... 38

3.6 Buttons .......................................................................................................................................41

3.7 Meters ........................................................................................................................................ 46

3.4.2 Basic Knobs (Bipolar) ................................................................................................ 34

3.4.3 Modulation Knobs ...................................................................................................... 34

3.4.4 Modulation Knobs (Bipolar) ....................................................................................... 35

3.4.5 OSC Tuning ................................................................................................................ 36

3.4.6 Multiplex Knobs ......................................................................................................... 37

3.5.1 Color .......................................................................................................................... 38

3.5.2 Labels ........................................................................................................................ 39

3.5.3 Values ....................................................................................................................... 39

3.6.1 Basic Button .............................................................................................................. 41

3.6.2 Basic Color Button ..................................................................................................... 41

3.6.3 Multistate Button ...................................................................................................... 42

3.6.4 Multistate Color Button ............................................................................................. 42

3.6.5 Radio Buttons ............................................................................................................ 43

3.6.6 Radio Color Buttons ................................................................................................... 43

3.6.7 Multiplex Buttons ...................................................................................................... 44

3.6.8 Multiplex Color Buttons ............................................................................................. 44

3.6.9 A/B Buttons ............................................................................................................... 45

3.7.1 Meter Mono ................................................................................................................ 46

3.7.2 Meter Stereo .............................................................................................................. 46

4 Process Macros ........................................................................................................

4.1 Inputs ......................................................................................................................................... 49

4.2 Smoothing and Modulation .........................................................................................................52

4.3 Select and Distribute .................................................................................................................. 55

4.4 Counting .....................................................................................................................................57

48

REAKTOR Blocks - Framework Manual - 5

Page 6

4.5 Demultiplex ................................................................................................................................ 58

4.6 Outputs ...................................................................................................................................... 61

Table of Contents

REAKTOR Blocks - Framework Manual - 6

Page 7

1 Anatomy of a Block

Anatomy of a Block

The Structure of a Block

Whatever the function, all REAKTOR Blocks are built in the same way. Three distinct Macros

each carry out a particular task. The Panel Macro contains all front end elements of the Block.

The System Info Macro houses all elements which provide the necessary system and project

information. Both the Panel and System Info Macros feed into the process Core Cell. This Core

Cell is where all of the actual processing happens, making use of the signals provided to it by

both system and user.

On either side of these three Macros are the Block’s inputs and outputs. In order to maintain a

degree of familiarity for the user, these ports should always be found in the same order.

Audio inputs are always in first position, followed by Pitch/Frequency inputs, Gate/Reset inputs, and finally modulation bus inputs. Outputs are also ordered in the same way.

REAKTOR Blocks - Framework Manual - 7

Page 8

The inputs and outputs in the Block Structure

Anatomy of a Block

REAKTOR Blocks - Framework Manual - 8

Page 9

Anatomy of a Block

System Info Macro

1.1 System Info Macro

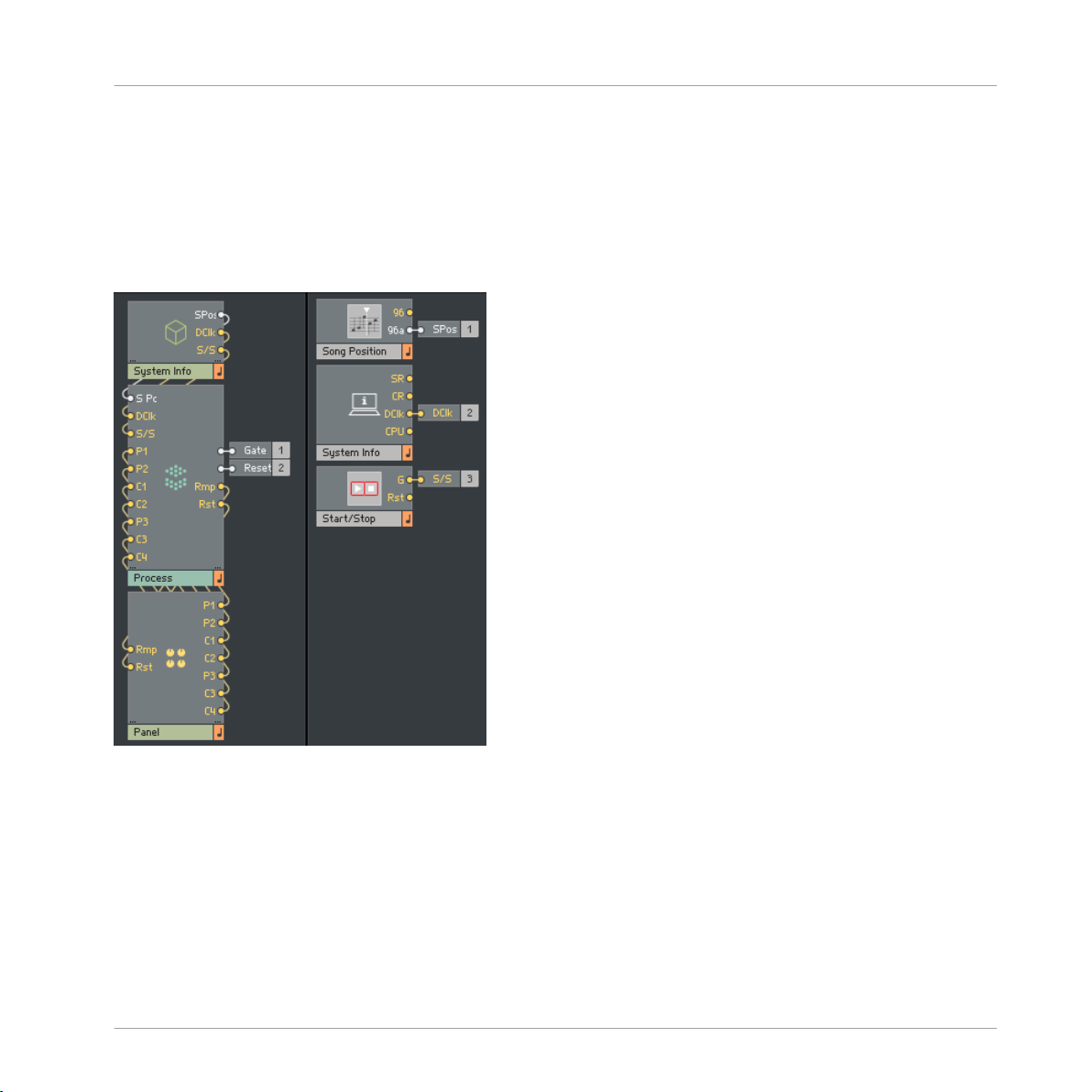

The System Info Macro serves to provide the Block with all necessary information from the system and project in which it resides. This might include system clocks, song position, tempo

information, random seeds, and so on.

The System Info Macro

In this example, the System Info Macro is providing the Process Core Cell with 3 signals. Audio

song position (SPos), display clock (DClk), and the master start/stop gate (S/S). These signals

are then connected directly to the Process Core Cell, where they are distributed as required.

REAKTOR Blocks - Framework Manual - 9

Page 10

Anatomy of a Block

1.2 Panel Macro

While the System Info Macro is providing the Process Core Cell with all system signals, the

Panel Macro deals with all user signals. This includes panel elements such as knobs, buttons,

text, displays, and anything else pertaining to how the Block looks and how the user can interact with it.

Panel Macro

The Panel Macro

REAKTOR Blocks - Framework Manual - 10

Page 11

Anatomy of a Block

In this example, the Panel Macro contains a number of different panel elements. The outputs

from all of these elements are connected directly to the Process Core Cell. The Panel Macro

also receives signals from the Process Core Cell. These signals are sent into the various panel

elements, where they are used to display any modulation that has been applied to that particular parameter.

In addition to all panel elements, the Panel Macro also contains 2 further Macros, A/B Buttons

and a size Macro.

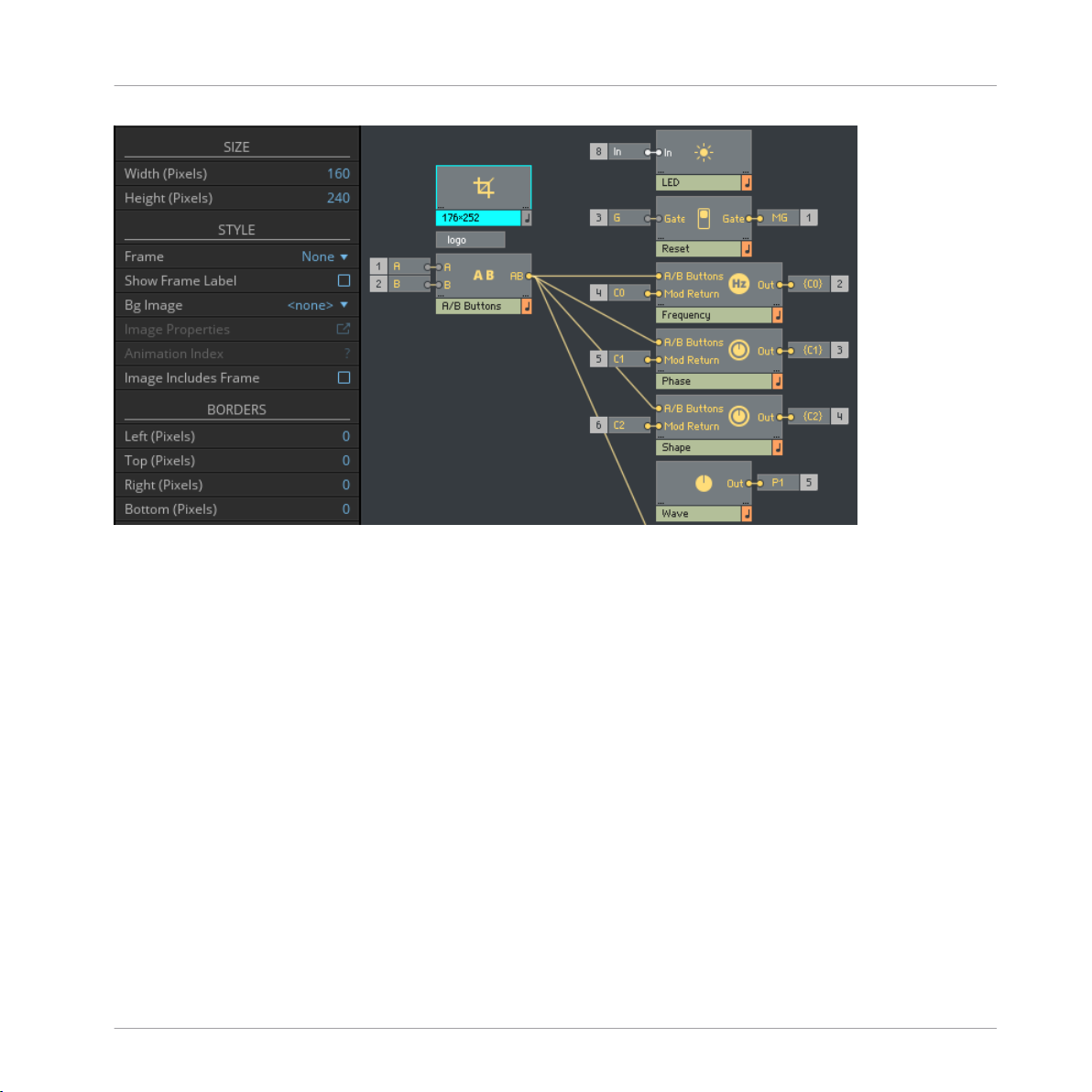

1.2.1 Size Macro

Inside every Panel Macro is a size Macro. The size Macro does not contain any modules, but

instead serves to determine that Block’s panel size.

In order for all Blocks to line up correctly in panel view, all panels are made to particular dimensions. Panels should always be 252 pixels in height, but width will vary depending on the

complexity of the panel. Never the less, width should still adhere to specific values for correct

alignment.

Block widths are calculated on a grid where 1 ‘unit’ is 60 pixels, and panel widths are multiples thereof. The 4 pixel gap between instruments should also be taken into account when calculating panel width.

Panel Macro

• Panel width in pixels = number of units * 60 - 4 pixel gap.

• The smallest available width is 2 units or 116 pixels: 2 * 60 - 4 = 116

The size Macro is in fact an empty stacked Macro, and setting its width and height in the view

properties menu will determine the size of the Block’s panel. REAKTOR always creates an additional border around any panel elements, which must be taken into consideration when setting the height and width. This border will always be 8 pixels on either side, and 6 pixels at

the top and bottom, and these values should be subtracted accordingly.

REAKTOR Blocks - Framework Manual - 11

Page 12

The Size Macro

Anatomy of a Block

Panel Macro

This example shows a 3 unit wide size Macro. The panel should be 176 pixels wide, and 252

pixels tall. To adjust for the border added by REAKTOR, the correct dimensions for the stacked

Macro should be Width (Pixels) = 160, and Height (Pixels) = 240.

1.2.2 A/B Buttons Macro

The A/B Buttons Macro serves two purposes. When a signal is connected to a modulation bus

input, the buttons on the panel will illuminate to display the signal’s strength and polarity. The

A/B Buttons Macro also determines when the modulation sliders are visible on the panel, and

so its output should be directly connected to the A/B Buttons input of all panel elements inside of that Block.

REAKTOR Blocks - Framework Manual - 12

Page 13

Anatomy of a Block

The A/B Buttons Macro, connected to Panel elements

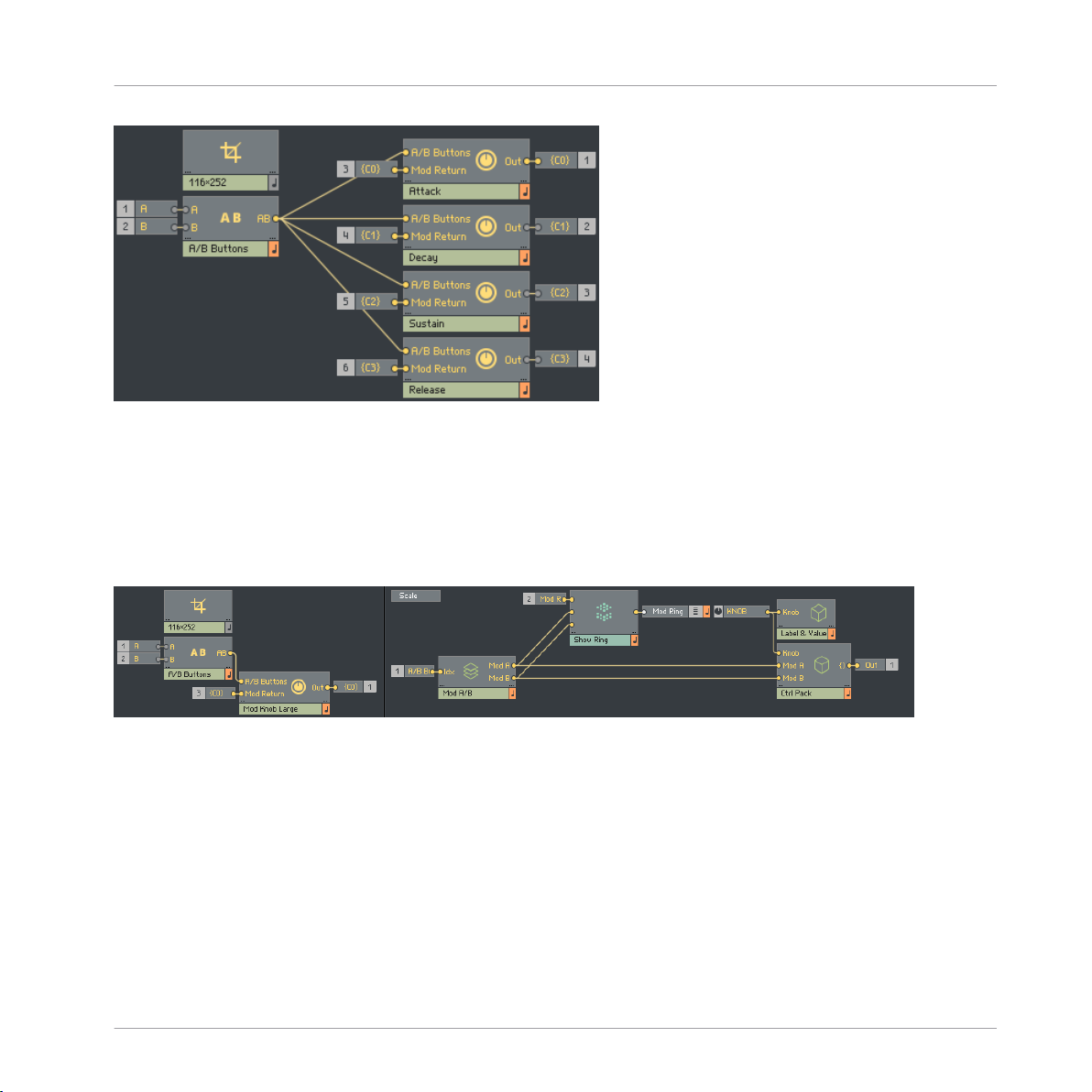

1.2.3 Panel Elements

There is a wide variety of panel elements provided with the template, all of which are covered

in more detail in the “Panel Widgets” section. However, the most commonly found element is

the modulatable knob.

Panel Macro

The modulatable knob in the Panel Macro

The left image shows how the modulatable knob should be placed inside of the Panel Macro,

while the right image shows the inside of the modulatable knob itself. The Mod Knob Macro is

comprised of a number of different elements. Most important are the main control, and the A

and B modulation sliders. The main control is found in the first level of the Mod Knob Macro,

while the modulation sliders are to be found in the Mod A/B stacked Macro, the panel index of

which is connected to the A/B Buttons Macro as discussed in the previous section.

Other elements found in the Mod Knob Macro are the Label & Value Macro, the Ctrl Pack Macro the Mod Ring display, and the Scale picture.

REAKTOR Blocks - Framework Manual - 13

Page 14

Anatomy of a Block

The Label & Value Macro contains a label for displaying the parameter name, a value display,

as well as some additional modules which determine what is currently visible on the panel.

Here you are able to change parameter names or use a different type of value display, depending on what the knob is controlling. A variety of different Label & Value Macros are already provided with the template which can be used to replace the default one, should a different value

display be required.

The Ctrl Pack Macro packages the signals from the main control, and both modulation faders

into a single signal which is then connected directly to the Process Core Cell. These signals are

then unpacked and used to control modulation depths and so on. Further information on this

can be found in the “Smooth + A/B Mod” section.

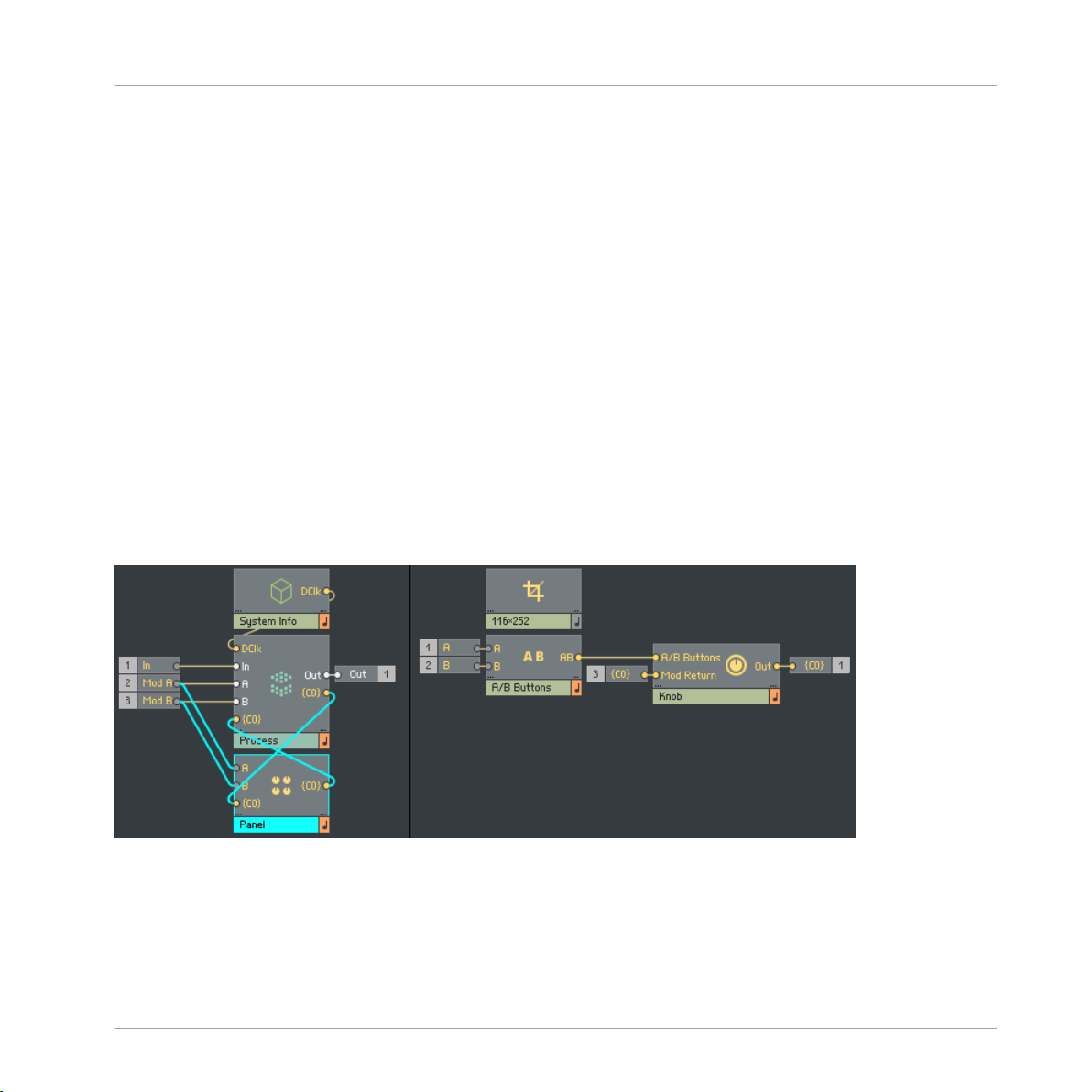

1.2.4 Mod Ring and Mod Return

The Mod Knob Macro sends all parameter values and modulation amounts into the process

Core Cell, where the actual modulation signals are scaled and summed accordingly. The result

of this summing will then be sent to wherever it is needed within the Process Core Cell. In addition, it is also routed back to the Panel Macro, and to the original panel element, where it is

displayed by the Mod Ring display.

Panel Macro

Connections between the Panel Macro and the Process Core Cell

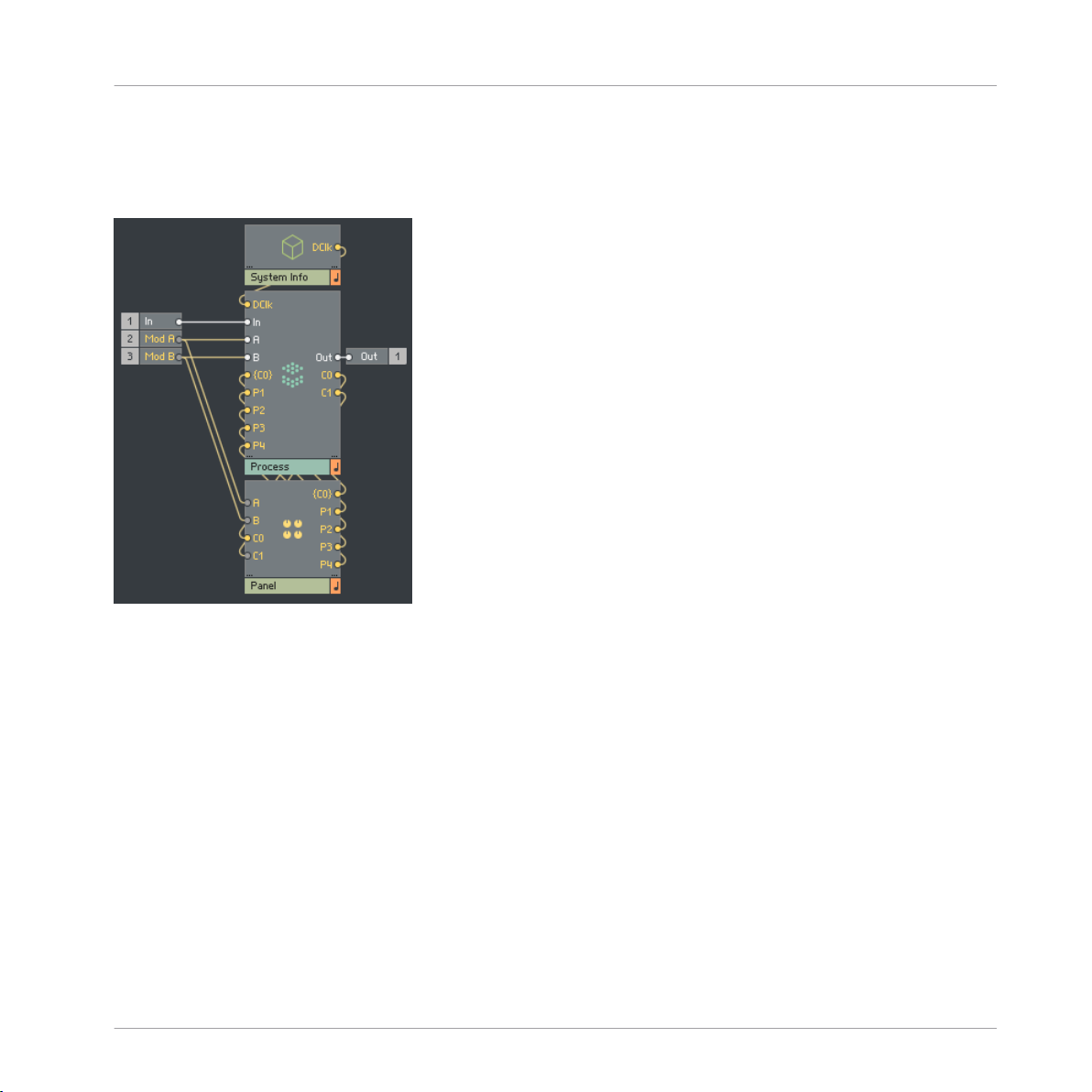

The left image shows the connections between the Panel Macro and the Process Core Cell. Parameter values are sent from the panel element via the {C0} output. All scaling of modulation

signals occur within the Core Cell, and the result is returned to the panel element via the {C0}

REAKTOR Blocks - Framework Manual - 14

Page 15

Anatomy of a Block

input. The right image shows how the Knob panel element is connected inside of the ‘Panel”

Macro. Again, parameter values are sent via the {C0} output, and the resulting modulation is

returned via the {C0} input.

Panel Macro

REAKTOR Blocks - Framework Manual - 15

Page 16

Anatomy of a Block

Process Core Cell

1.3 Process Core Cell

Both the System Info and Panel Macros are connected to the Process Core Cell, where all of

the actual signal processing occurs. The template includes several starter instruments, each of

which contains an empty Process Core Cell.

The Process Core Cell

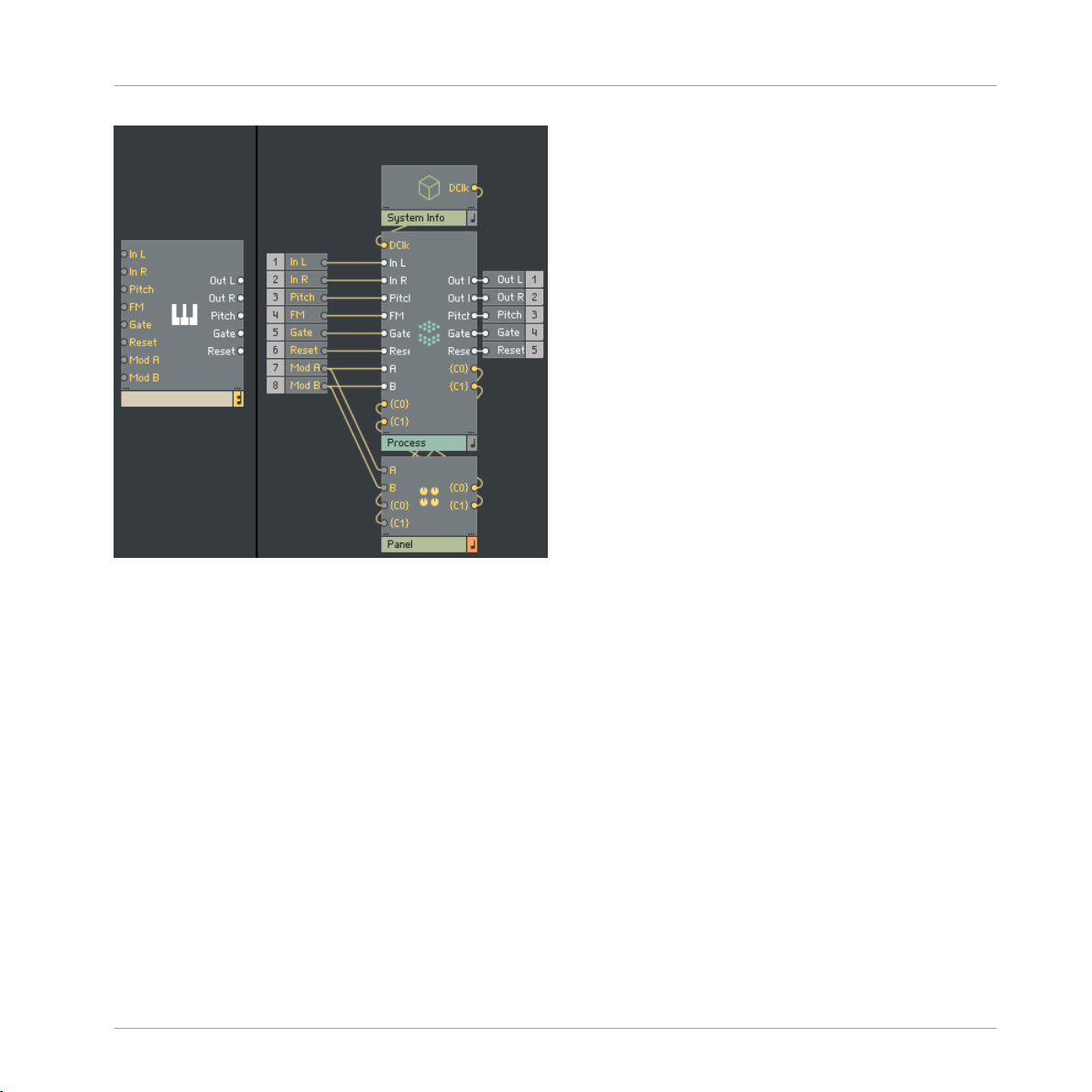

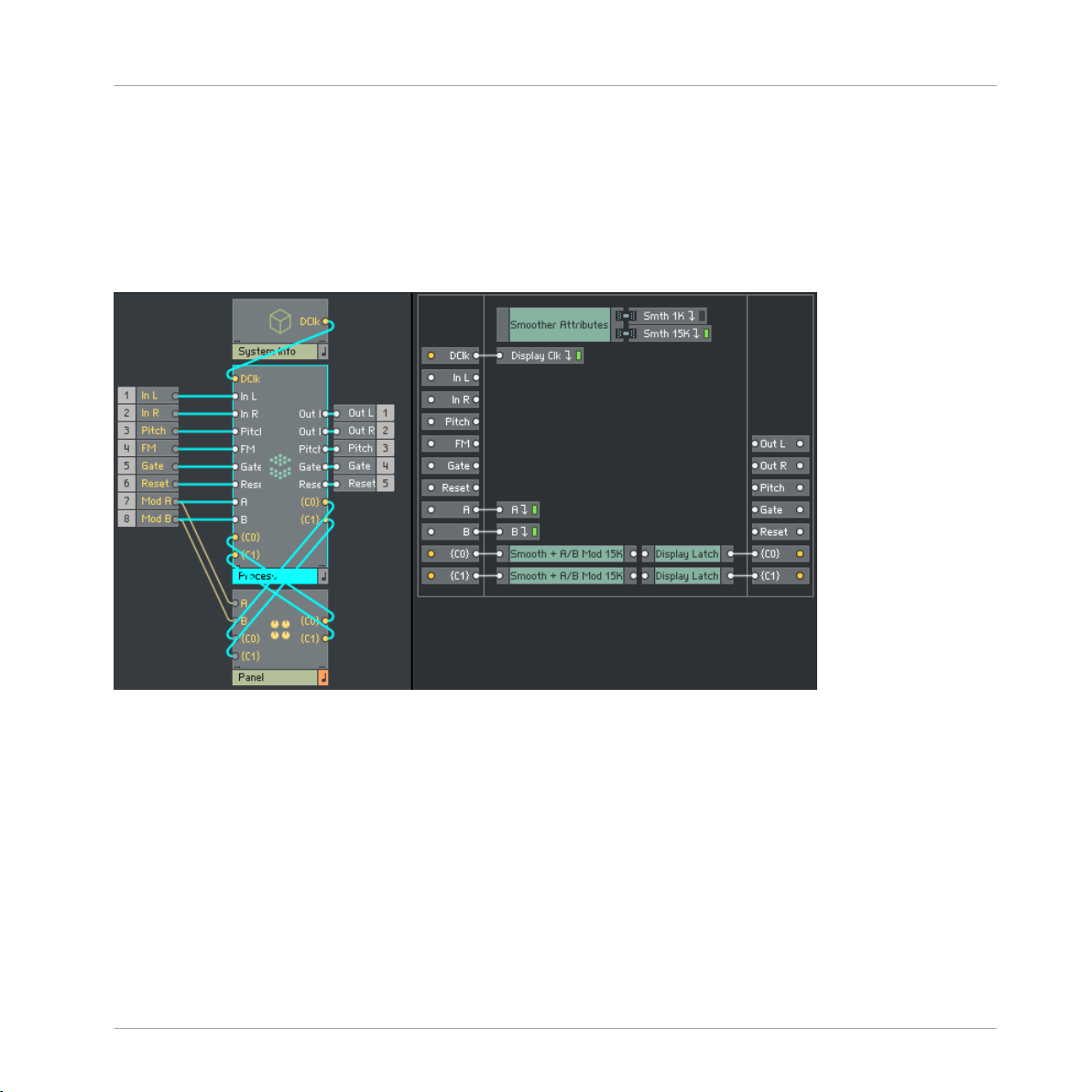

The left side of the image shows the connections between the System Info and Panel Macros,

and the Process Core Cell. The right side of the image shows the inside of the Core Cell itself.

By default, the template Core Cell will already contain many of the ports and elements required to receive signals from the System Info and Panel Macros.

1.3.1 Display Clk Distributor

The Display Clk distribution bus sends the display rate clock, as provided by the System Info

Macro, to the Display Latch Macros. This is where ‘modulation return’ signals are clocked before being routed back to their associated panel elements. Within Blocks, modulation signals

REAKTOR Blocks - Framework Manual - 16

Page 17

Anatomy of a Block

Process Core Cell

are audio rate, however this is a far higher rate than can be displayed on the panel. Attempting

to display audio rate signals would be inefficient. Instead, before leaving the Process Core Cell

‘modulation return’ signals are latched by the display rate clock, resulting in a noticeable increase in efficiency.

1.3.2 A and B Distributors

The A and B buses distribute all signals arriving at the A and B modulation buses throughout

the entire Core Cell, where they can be used as a modulation source. Typically, a completed

block will have a number of modulatable parameters. By distributing the signals arriving at the

A and B modulation buses in this way, it helps to keep structures cleaner and more organized.

1.3.3 Smoother Attributes

Any connection between two Blocks will be at audio rate, however the connection between a

panel element and the Process Core Cell within a Block will be control rate. Therefore, some

degree of smoothing is required in order to avoid potential discontinuity in signals, audible

‘pops’, and other such undesirable results. The Smoother Attributes Macro provides the various

signals required for smoothing parameters at 2 different clock rates; 1K and 15K. These attributes can be picked up anywhere within the Process Core Cell. In addition, the template also

provides a selection of different smoothers, which will automatically pick up all relevant information provided by the Smoother Attributes Macro.

1.3.4 Smooth + A/B Mod

The Smooth + A/B Mod Macro is one of the most important Macros within the Blocks framework. This Macro serves a variety of purposes. As mentioned in the “Panel elements” section,

before being sent to the Process Core Cell the 3 values inside of a modulatable parameter are

packaged together into a single connection. The first thing the Smooth + A/B Mod Macro does

is to unpack this connection into its individual components, the main control, and the 2 modulation sliders.

The second task of the Smooth + A/B Mod Macro is to apply smoothing to the 3 signals, before

receiving, scaling, and summing any modulation signals.

REAKTOR Blocks - Framework Manual - 17

Page 18

Anatomy of a Block

Process Core Cell

The Dmux and Prep Macros

The DMux Macro is responsible for unpacking the arriving signal, while the Prep Macro deals

with smoothing of parameters, and scaling/summing of modulation signals.

The DMux Macro

Having been unpacked by the DMux Macro, the 3 signals provided by the panel element are

routed to the Prep Macro and smoothed. In addition, signals connected to the A and B modulation buses are also received here before being scaled, summed with the main control value,

and clipped to ensure the result remains within the [0, 1] range.

REAKTOR Blocks - Framework Manual - 18

Page 19

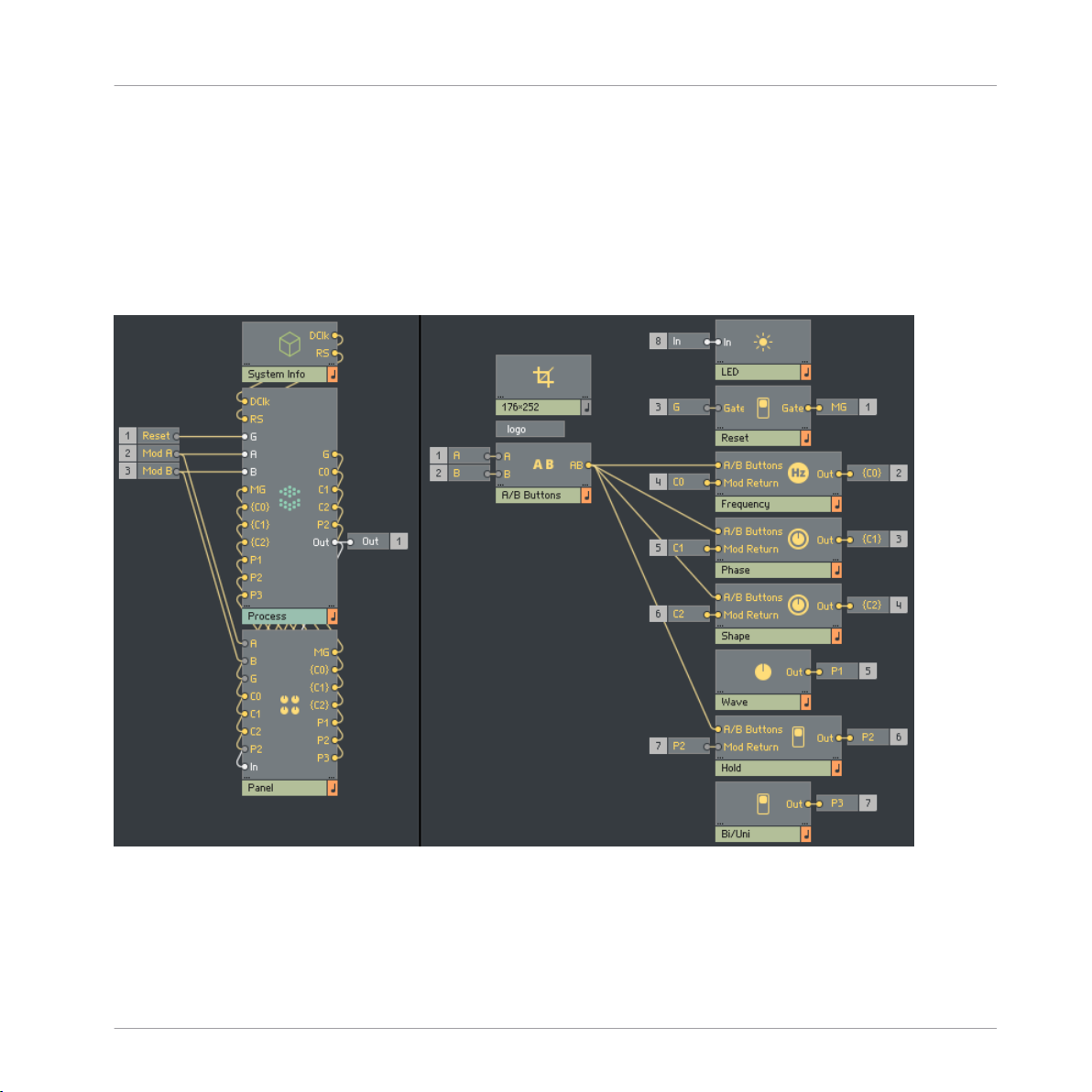

1.4 A Completed Block

Anatomy of a Block

A Completed Block

A completed Block

The left image shows the connections between the System Info Macro, Panel Macro, and the

Process Core Cell. The right image shows the inside of the Process Core Cell.

The packaged signals from the panel elements are routed into the Process Core Cell, where

they are unpacked, smoothed, and summed with any modulation received via the A and B distribution buses inside of the Smooth + A/B Mod Macros. The summed signals are then routed

to wherever they are needed within the Core Cell. They are also routed to Display Latch Macros, where they are latched at display rate by the clock received from the System Info Macro

via the Display Clk distribution bus. Finally, the signals are returned to the Panel Macro, where

they are used to display modulation.

REAKTOR Blocks - Framework Manual - 19

Page 20

2 Connections and Signals

A Blocks Patch

Connections and Signals

The most important aspect of the Blocks framework is the universal connectivity between each

Block. A user should be able to connect any output to any input and achieve predictable results, regardless of what modules they are connecting together.

In order to achieve this, all Blocks have been designed to interpret signals within a particular

range, in a particular way. It is important that any additional Blocks are built to the same criteria to ensure compatibility with already existing Blocks.

REAKTOR Blocks - Framework Manual - 20

Page 21

Connections and Signals

Audio Rate Connections

2.1 Audio Rate Connections

Ensuring that all connections between Blocks are audio rate signals serves 2 main purposes.

Primarily, using audio rate signals results in total interconnectivity across the entire framework,

meaning that the user is always able to make any connection they wish. Furthermore, using

audio rate signals ensures that any modulation within a patch is as smooth as possible and

very rapid modulations can be achieved with no detriment to audio quality.

LFO signal at control rate

LFO signal at audio rate

The first image shows the signal from an LFO at control rate. The second image shows the

same signal at audio rate. The higher clocking frequency results in a much smoother waveform.

All Blocks have been designed to function at a standard sample rate of 44.1kHz. Higher sample rates are also supported, but it is inadvisable to use a sample rate lower than 44.1kHz, as

this would have an adverse affect on audio quality.

REAKTOR Blocks - Framework Manual - 21

Page 22

Connections and Signals

2.2 Value Range

Just as all connections between Blocks should be audio rate signals, the value range of those

signals should always remain within a range of [-1, 1]. Again, this serves to ensure compatibility across the entire framework.

There remains still the possibility to exceed that range, either by mixing multiple signals together, or by simply applying excessive amounts of gain to a signal. Never the less, the [-1, 1]

range should be considered the standard operating range at all inputs and outputs.

Signal polarity or bias is less of a concern, and it is perfectly acceptable for signals between

Blocks to be offset or entirely unipolar. It is however inadvisable to connect a biased signal directly to the main output, as this could potentially cause damage to monitoring equipment in

the case where the audio interface used does not have an AC coupled output.

Value Range

REAKTOR Blocks - Framework Manual - 22

Page 23

Connections and Signals

2.3 Pitch Scaling

As all connections between Blocks are audio rate signals within the [-1, 1] range, on occasion

some scaling may be required to convert the signals patched between modules into standard

MIDI note values. To this end, Blocks adopts a scaling system similar to the volts per octave

scheme as found in Eurorack format modular systems.

In the Blocks framework, signals connected to a Pitch input are scaled up by a factor of 120,

so that a value of 0 results in a MIDI note of 0, a value of 0.5 results in a MIDI note of 60,

and a value of 1 results in a MIDI note of 120.

Pitch input scaling

Likewise, MIDI notes received from a host software or MIDI device are scaled down by the

same amount, so that they can be freely patched throughout the Framework.

Pitch Scaling

MIDI note scaling

This scaling scheme means that an increase of 0.1 in a signal connected to a Pitch input will

result in a 1 octave increase in pitch, and an increase of 0.00833333 results in a 1 semitone

increase in pitch.

REAKTOR Blocks - Framework Manual - 23

Page 24

Connections and Signals

2.4 Gate Signals

Various types of Blocks will have a Gate or Reset input, and while the result may be different

depending on the type of Block, a gate signal is always detected in the same way. Once again,

this is to ensure total interconnectivity across the entire framework.

Gate signal detection

The Gate input of any Block will be looking for a positive zero crossing in the signal connected

to it. This is the point at which a signal increases from a value of zero or less, to a value greater than zero. When this positive zero crossing occurs, it is considered a ‘Gate on’ event, and

when the signal returns to a value of zero or less, it is considered a ‘Gate off’ event.

Gate Signals

Gate detection for a sine wave

The actual result of the gate on and off messages will differ, depending on the type of module.

In a sequencer, the gate on event will cause the sequencer to advance 1 step. In an envelope

generator, the gate on event will trigger the envelope, while the gate off event will allow it to

continue into the release stage.

Whatever the type of module, detecting gate events in this way allows for any number of different sources to be used as a gate signal.

REAKTOR Blocks - Framework Manual - 24

Page 25

Connections and Signals

Gate Signals and Velocity

2.5 Gate Signals and Velocity

Blocks such as envelope generators can also be made to respond to gate velocity, rather than

just simple gate on/off messages. Velocity is determined in a manner similar to a typical gate

signal.

Velocity detection

Once again, the Gate input will be looking for a positive zero crossing in the signal connected

to it. When the positive zero crossing occurs it is again considered a ‘Gate on’ event, however

the amount by which the signal has exceeded zero is used to determine the velocity value.

Once the signal has returned to a value of 0 or less, it is considered a ‘Gate off’ message.

When using a triangle wave as a gate signal for a velocity sensitive Block, the resulting gate

signal has a very low velocity since the value at the initial positive zero crossing is very small:

Velocity detection for a triangle wave

When using a saw wave as a gate signal for a velocity sensitive Block, the value at the initial

positive zero crossing is very large, which results in a gate signal with a very high velocity:

REAKTOR Blocks - Framework Manual - 25

Page 26

Velocity detection for a saw wave

Connections and Signals

Gate Signals and Velocity

REAKTOR Blocks - Framework Manual - 26

Page 27

3 Panel Widgets

Panel Widgets

Blocks Panel template

The template contains a wide selection of panel widgets, which can be used when building a

new Block. Widgets are provided in both Light on Dark and Dark on Light color schemes so

that they are always visible, whatever the chosen panel color might be.

REAKTOR Blocks - Framework Manual - 27

Page 28

Panel Widgets

All widgets can be easily customized, making tasks such as renaming parameters, setting knob

color, or changing the type of value readout quick and simple to achieve.

REAKTOR Blocks - Framework Manual - 28

Page 29

3.1 Color Schemes

Panel Widgets

Color Schemes

Two color schemes

The template contains a wide selection of panel widgets, which can be used when building a

new Block. Widgets are provided in both Light on Dark and Dark on Light color schemes so

that they are always visible, whatever the chosen panel color might be.

All widgets can be easily customized, making tasks such as renaming parameters, setting knob

color, or changing the type of value readout quick and simple to achieve.

REAKTOR Blocks - Framework Manual - 29

Page 30

Panel Widgets

3.1.1 Additional Knob Colors

Knobs in different colors

The template contains a wide selection of panel widgets, which can be used when building a

new Block. Widgets are provided in both Light on Dark and Dark on Light color schemes so

that they are always visible, whatever the chosen panel color might be.

All widgets can be easily customized, making tasks such as renaming parameters, setting knob

color, or changing the type of value readout quick and simple to achieve.

Color Schemes

REAKTOR Blocks - Framework Manual - 30

Page 31

3.2 Template Blocks

Panel Widgets

Template Blocks

Empty Blocks

Also included with the template is a selection of empty Blocks. These have already been set to

the correct dimensions to ensure they fit with existing Blocks. In addition, each empty Block

also contains the most essential Macros needed to begin building. The most commonly used

sizes have been provided, however it is a very simple process to set different sizes too. More

information on this can be found in section ↑1.2.1, Size Macro.

REAKTOR Blocks - Framework Manual - 31

Page 32

Panel Widgets

Process Macros

3.3 Process Macros

Process Macros

As well as the various panel widgets, the template also includes a wide selection of Macros for

use inside of a Block’s Process Core Cell. Primarily, these are the Macros required to utilize

the various widgets most effectively, or to interpret any signals connected to a Block such as

Pitch and Gate.

REAKTOR Blocks - Framework Manual - 32

Page 33

Panel Widgets

3.4 Knobs

3.4.1 Basic Knobs

Basic knobs

Available in three different sizes, the signal provided by the basic knob requires no additional

Macros after entering a Core Cell, except for smoothing when necessary.

Knobs

Output value range is [0, 1].

Label & Value Macro

Inside of the basic knob Macro is another Macro named Label & Value. This contains the text

modules used for displaying parameter name and value, as well as additional modules used to

determine which is visible at any particular time. Here the parameter name can be changed,

and value display adjusted as needed. Alternatively, more complex Label & Value Macros have

been provided for more specific cases, and can be used as a replacement if desired.

REAKTOR Blocks - Framework Manual - 33

Page 34

Panel Widgets

3.4.2 Basic Knobs (Bipolar)

Bipolar knobs

Similar to the basic knob, with the only difference being that the bipolar knob includes a center point indicator, and a bipolar value display.

Output value range is [0, 1].

Customization of both label and value can be carried out in the exact same way as described

for the basic knob.

Knobs

3.4.3 Modulation Knobs

Modulation knobs

REAKTOR Blocks - Framework Manual - 34

Page 35

Panel Widgets

More complex than the basic knob, the modulation knob Macro also includes the two sliders

used for defining modulation depth, and an additional modulation ring which displays any

modulation currently assigned to that parameter. Connecting the output from the A/B Buttons

Macro to the A/B Buttons input gives control over when the modulation sliders are visible. Signals connected to the Mod Return input will be displayed by the modulation ring.

The signal sent from the modulation knob output is a multiplexed signal comprised of the

main knob as well as the two modulation depth sliders. Therefore, a Smooth + A/B Mod Macro

should be used inside of the Process Core Cell in order to correctly demultiplex the signal,

smooth, and apply modulation before routing the signal to its final destination.

Modulation knob parameter names and values can be customized inside of the Label & Value

Macro, or alternatively, the Label & Value Macro can be replaced with one of the others included with the template.

3.4.4 Modulation Knobs (Bipolar)

Knobs

Bipolar modulation knobs

Similar to the modulation knob, with the only difference being that the bipolar knob includes a

center point indicator, and a bipolar value display. Just like the modulation knob, the bipolar

modulation knob also outputs a multiplexed signal, and so a Smooth + A/B Mod Macro should

be used inside of the Process Core Cell.

Customization of both label and value can be carried out in the exact same way as described

for the modulation knob.

REAKTOR Blocks - Framework Manual - 35

Page 36

Panel Widgets

3.4.5 OSC Tuning

OSC Tuning Macro

The OSC tuning Macro contains all the parameters commonly used when building oscillator

Blocks. A switch to enable/disable key tracking, a modulatable coarse tuning control which

switches between note value or frequency value depending on whether key tracking is enabled,

and a fine tuning control.

The coarse tuning control output is a multiplexed signal as described in the Modulation Knob

section, the fine tuning control is a simple knob with an output value range of [0, 1], and the

key tracking switch is a simple on/off switch with an output value range of [0 .. 1].

Knobs

Since each parameter has its own output, these signals can all be treated separately if desired.

For ease of use however, the template also includes a Core Cell Macro specifically designed for

the purpose of receiving these values, along with any pitch signals patched into the Block.

OSC Tuning Macro in use

The left image shows the three signals sent from the OSC tuning Macro, as well as the modulation return needed to display modulation of the ‘Coarse’ parameter. The right image shows the

same three signals arriving in the Process Core Cell. Note that since the coarse parameter {C1}

is multiplexed, a Smooth + A/B Mod Macro is used to demultiplex and apply any modulation

REAKTOR Blocks - Framework Manual - 36

Page 37

Panel Widgets

before connection to the OSC Tuning Core Macro. In addition, the output from the Smooth +

A/B Mod Macro is also connected to a ‘Display latch’ Macro before being routed back to the

Panel Macro so that modulation can be displayed.

3.4.6 Multiplex Knobs

Multiplex knobs

The multiplex knobs Macro contains eight separate basic knobs, which are multiplexed into a

single output. While there are eight by default, additional knobs can be added, or removed as

required. Since the output from all knobs is multiplexed into a single connection, demultiplexing is required inside of the Process Core Cell. The template includes two suitable demultiplexing Core Macros. One will simply unpack the multiplexed input into its constituent signals,

while the other writes the signals into an array.

Knobs

The output value range of each knob is [0, 1], and the label and value displays of each knob

can be customized as needed.

REAKTOR Blocks - Framework Manual - 37

Page 38

Panel Widgets

Customizing Knobs

3.5 Customizing Knobs

3.5.1 Color

Changing the knob color

The multiplex knobs Macro contains eight separate basic knobs, which are multiplexed into a

single output. While there are eight by default, additional knobs can be added, or removed as

required. Since the output from all knobs is multiplexed into a single connection, demultiplexing is required inside of the Process Core Cell. The template includes two suitable demultiplexing Core Macros. One will simply unpack the multiplexed input into its constituent signals,

while the other writes the signals into an array.

The output value range of each knob is [0, 1], and the label and value displays of each knob

can be customised as needed.

REAKTOR Blocks - Framework Manual - 38

Page 39

Panel Widgets

Customizing Knobs

3.5.2 Labels

Changing the knob label

Changing the label displayed underneath a knob is a quick process. The text module used to

display the parameter name can always be found in the Label & Value Macro found in every

knob module.

Simply locate the Label Macro, and edit the text module inside.

3.5.3 Values

Changing the knob values

REAKTOR Blocks - Framework Manual - 39

Page 40

Panel Widgets

Customizing Knobs

By default, all panel widgets come with a basic [0, 100] value display, or [-100, 100] if the

parameter is bipolar. The value display is found in the same location as the label, and can be

edited in much the same way.

In cases where more complex value displays are required, such as frequency or envelope times,

the generic Label & Value Macro can be replaced in its entirety with one of the more specialized Macros included in the ‘Value Displays’ Macro.

REAKTOR Blocks - Framework Manual - 40

Page 41

Panel Widgets

3.6 Buttons

3.6.1 Basic Button

Basic Button

Available in three different sizes, the signal sent by the basic button requires no additional

Macros after entering a Core Cell, except for smoothing if necessary.

Output value range is [0 .. 1].

Buttons

By default, the basic button text display will switch between “OFF” and “ON”. This can be

changed by editing the multitext module found inside of the Macro.

3.6.2 Basic Color Button

Basic color button

Essentially the same as the basic button, with the only difference being that the color button

switches between grey when off, and a selectable color when on, allowing for easy panel customization. Integer values between 0 and 15 at the Color input select different colors.

REAKTOR Blocks - Framework Manual - 41

Page 42

Panel Widgets

Output value range is [0 .. 1].

By default, the basic color button will switch between “OFF” and “ON”. This can be changed

by editing the multitext module found inside of the Macro.

3.6.3 Multistate Button

Multistate button

While the basic button only provides two possible values, 0 and 1, the multistate button can

provide a definable number of values. The output value begins at 0, and increases by 1 every

time the button is clicked. Once the maximum value is reached, the output value returns to 0.

By default, the multistate button has 4 states and an output range of [0 .. 3]. The number of

states can be changed by editing the constant value found inside of the Macro. Similarly the

text displayed for each state can also be modified, by editing the multitext module inside of

the Macro.

Buttons

3.6.4 Multistate Color Button

Multistate color button

REAKTOR Blocks - Framework Manual - 42

Page 43

Panel Widgets

The multistate color button offers the same functionality as the multistate button, with the only difference being that the color button switches between grey when 0, and a selectable color

for all other values. Integer values between 0 and 15 at the Color input will select different

colors.

By default, the multistate color button has 4 states and an output range of [0 .. 3]. The number of states can be changed by editing the constant value found inside of the Macro. Similarly

the text displayed for each state can also be modified, by editing the multitext module inside

of the Macro.

3.6.5 Radio Buttons

Radio buttons

Similar to the multistate button Macro, the radio buttons Macro also provides a definable number of values. The difference being that rather than a using a single button, the different states

are selected via several on screen buttons.

Buttons

By default, the radio buttons Macro has six states with an output range of [0 .. 5] however,

states can be added or removed as required. In addition, the text display for each button can

also be modified by editing the text modules inside of the Macro.

3.6.6 Radio Color Buttons

Radio color buttons

REAKTOR Blocks - Framework Manual - 43

Page 44

Panel Widgets

With the same functionality as the radio buttons, the Radio Color Buttons switch between grey

when off, and a selectable color when on, allowing for easy panel customization. Integer values

between 0 and 15 at the Color input select different colors.

By default, the radio color buttons Macro has six states with an output range of [0 .. 5] however, states can be added or removed as required. In addition, the text display for each button

can also be modified by editing the text modules inside of the Macro.

3.6.7 Multiplex Buttons

Multiplex buttons

The multiplex buttons Macro contains eight separate basic buttons, which are multiplexed into

a single output. While there are eight by default, additional buttons can be added or removed

as required. Since the output from all buttons is multiplexed into a single connection, demultiplexing is required inside of the Process Core Cell. The template includes two suitable demultiplexing Core Macros. One will simply unpack the multiplexed input into its constituent signals,

while the other writes the signals into an array.

Buttons

The output value range of each button is [0 .. 1], and the text display of each button can be

customized as needed, by editing the text modules inside of the Macro.

3.6.8 Multiplex Color Buttons

Multiplex color buttons

Functionally the same as the Multiplex Buttons, but with the additional option to quickly select a different color for the on states. Integer values between 0 and 15 at the Color input select between the sixteen available colors.

REAKTOR Blocks - Framework Manual - 44

Page 45

Panel Widgets

The output value range of each button is [0 .. 1], and the text display of each button can be

customized as needed, by editing the text modules inside of the Macro.

3.6.9 A/B Buttons

A/B buttons

The A/B Buttons Macro does not connect to the Process Core Cell. Instead, its output should

be connected to the A/B Buttons input found on any modulatable panel widget, such as the

Modulation Knob. Clicking the A/B Buttons will then determine when that panel widget’s modulation sliders are visible.

The A/B Buttons Macro also has two inputs, A and B. These inputs should be connected to the

Block’s A and B modulation bus inputs in order to display the signal strength and polarity of

any incoming modulation.

Buttons

The A/B Buttons Macro output range is [0 .. 2]. When neither button is active, output value is

0 and no modulation faders are visible. When button A is active, output value is 1 and modulation bus A sliders are visible. When button B is active, output value is 2 and modulation bus B

sliders are visible.

REAKTOR Blocks - Framework Manual - 45

Page 46

Panel Widgets

3.7 Meters

3.7.1 Meter Mono

Meter Mono

The Meter Mono Macro is a simple level meter, useful for displaying mono signal levels in dB.

It is comprised of several different elements. As well as the main level meter, there is also a

peak level meter, and numeric readout which will change color when the input signal exceeds

0dB.

Meters

Integer values between 0 and 15 at the Color input will set the meter to one of the sixteen

available color options.

3.7.2 Meter Stereo

Meter Stereo

REAKTOR Blocks - Framework Manual - 46

Page 47

Panel Widgets

Stereo version of the Meter widget. As before, meter color can be selected at the color input.

An integer value between 0 and 15 will select one of the 16 available color options.

Meters

REAKTOR Blocks - Framework Manual - 47

Page 48

Process Macros

4 Process Macros

Process Macros

In addition to the wide selection of Panel Widgets, the template also includes several Macros

for use inside of a Block’s Process Core Cell. Primarily, these Core Macros are designed to work

in conjunction with the various panel elements available, or to interpret incoming signals such

as pitch, gate, and modulation.

REAKTOR Blocks - Framework Manual - 48

Page 49

Process Macros

4.1 Inputs

Display Clk

Display Clk

The DClk input and the attached Display Clk distributor receive a clocking signal sent from the

System Info Macro, and distribute it throughout the Process Core Cell. This clocking signal is

used to clock signals being returned to the Block’s panel, which are to be used for displaying

modulation. Modulation signals are audio rate, and it would be inefficient to connect them directly to any form of display. Clocking these signals at display rate results in a noticeable increase in efficiency.

Random Seed

Random Seed

Inputs

The RS input and the attached Random Seed distributor receive a value sent from the System

Info Macro, and distribute it throughout the Process Core Cell. A new random value is sent every time the patch is re-initialized. This value can be used as a seed wherever a degree of randomization is required, such as noise generators or random sequences.

Pitch / Pitch Mult

Pitch / Pitch Mult

Signals between Blocks should always remain within the [-1, +1] range. Typically a pitch signal will have a range of [0, 1], but on occasion it may be preferable to scale this up to typical

MIDI note values. The Pitch input will receive any signals connected to the Block’s Pitch input, while the Pitch Mult Macro scales this signal up to MIDI note values.

REAKTOR Blocks - Framework Manual - 49

Page 50

Process Macros

Gate / Int Gate / Vel Gate

Gate / Int Gate / Vel Gate

Signals connected to the Block’s Gate input are passed on to the Gate input of the Process

Core Cell. The Int Gate and Vel Gate Macros will convert the incoming audio rate signal into a

usable gate.

They both function in much the same way, by looking for a positive zero crossing in the input

signal. When the signal rises above 0 it is considered a gate on, and when the signal returns to

0 or less it is considered a gate off.

The Int Gate Macro effectively acts as an audio to logic converter, only outputting either 0 or

1. This can be used for any gated functions where velocity information is not required, such as

restarting an LFO or advancing a sequencer.

The Vel Gate also sends velocity information. Velocity is determined by the value of the input

signal, immediately after a positive zero crossing. This can be used for any gated function

where velocity information is required, such as an envelope generator.

Inputs

Reset

Reset

The Reset input and Macro function in much the same way as the Gate input. Signals connected to the Block’s reset input are passed on the Reset input of the Process Core Cell which is in

turn connected to the Reset Core Macro.

Like the Gate Macro, the Reset Macro is also looking for positive zero crossings in the input

signal. However, every time a positive zero crossing occurs the Reset Macro will output a value

of 0. This can be used to reset any counters within the Block, as might be found in a sequencer or clock divider.

REAKTOR Blocks - Framework Manual - 50

Page 51

Process Macros

A and B

A and B

The A and B inputs are where signals connected to the Mod A and Mod B inputs of the Block

are received inside of the Process Core Cell. Both inputs are connected directly to distributors,

so that incoming modulation can be picked up wherever needed within the Process Core Cell.

Macros such as the Smooth + A/B Mod are already designed to pick up signals distributed by

the A and B buses, so that no additional patching is required.

Inputs

REAKTOR Blocks - Framework Manual - 51

Page 52

Process Macros

Smoothing and Modulation

4.2 Smoothing and Modulation

Smoother Attributes

Smoother Attributes

The Smoother AttributesMacro is responsible for creating the various signals needed for the

smoothing of parameter inputs i.e. smoothing time and rate. These attributes are distributed

throughout the Process Core Cell by the two distributors. Two different smoothing rates are provided, 1 kHz and 15 kHz.

Macros such as the Smooth + A/B Mod are already designed to pick up signals distributed by

the Smoother AttributesMacro, so that no additional patching is required.

Smoother

Smoother

The smoother Macro serves to smooth the event rate signals arriving from the Panel Macro, in

order to avoid discontinuity in signals, audible ‘pops’ and other such undesirable artifacts. It

can be used after to smooth the signals received from knobs, buttons or any other non multiplexed input signal.

The smoother is available at either 1 kHz or 15kHz rate. Both Macros are already designed to

pick up the necessary signals, as distributed by the Smoother AttributesMacro.

For multiplexed signals, such as those sent by a Modulation Knob panel widget, the Smooth +

A/B Mod Macro should be used instead.

REAKTOR Blocks - Framework Manual - 52

Page 53

Process Macros

Smoothing and Modulation

Smooth + A/B Mod

Smooth + A/B Mod

As the signal sent from the Modulation knobs a multiplexed signal, comprised of the main

knob as well as the two modulation depth sliders, a Smooth + A/B Mod Macro should be used

inside of the Process Core Cell in order to correctly demultiplex the signal, smooth, and apply

modulation.

The Smooth + A/B Mod is available at either 1 kHz or 15kHz rate. Both versions are already

designed to pick up the signals distributed from the A and B modulation buses, as well as the

appropriate signals distributed by the Smoother AttributesMacro.

A/B Mod Q

A/B Mod Q

The A/B Mod Q Macro can also be used for demultiplexing signals arriving from Modulation

Knob panel elements, and applying modulation. The difference between this Macro and the

Smooth + A/B Mod Macro, is that the A/B Mod Q will quantize the resulting signal into a deter-

mined number of steps. This can be particularly useful when creating modulatable parameters

with only a small number of possible values, such as the length parameter of a sequencer.

The X input sets the number of steps. The *X output sends integer values ranging from 0 to X,

while the 1/X output scales the final value, so that it remains within the [0, 1] range. Typically

the *X output would be routed to wherever it is needed within the Core Cell, while the 1/X output should be routed back to the panel element to display modulation.

Uni 2 Bi

Uni 2 Bi

REAKTOR Blocks - Framework Manual - 53

Page 54

Process Macros

Smoothing and Modulation

All signals arriving in the Process Core Cell from the various panel widgets will be unipolar,

with a linear value range of [0, 1]. In some instances it may be preferable to convert these signals to a bipolar value range. These two simple Macros can be used to achieve just that.

A unipolar [0, 1] signal arriving at the input will be converted into a bipolar [-1, 1] signal at

the output. The Uni 2 Bi (lin) module output will have a linear control shape, while the Uni 2

Bi (Para) module output will have a parabolic (x^2) control shape.

Both modules should be placed after any modulation or smoothing Macros, such as the

Smooth + A/B Mod.

OSC Tuning

OSC Tuning

The OSC Tuning Macro is designed specifically to work in conjunction with the OSC Tuning

panel widget.

OSC Tuning in use

In the case of the Coarse parameter, the signal should be first connected to a Smooth + A/B

Mod Macro, in order to apply smoothing and modulation. The Fine parameter should be connected to a Smoother Macro, before being connected to the OSC Tuning Core Cell.

The KTrack parameter requires no additional processing, and the input signal can be connected directly to the Core Macro.

The Pitch input accepts values in the range of [0 ,1] meaning signal received from other

Blocks can be connected directly, without the need for any scaling.

The OSC Tuning Macro has two outputs. The Pitch output provides MIDI note values, while the

Freq output provides frequency values in Hertz.

REAKTOR Blocks - Framework Manual - 54

Page 55

Process Macros

Select and Distribute

4.3 Select and Distribute

Clk Select

Clk Select

The Clk Select Macro can be used to select between different input signals. By default it has

four inputs, but more can be added or removed if needed.

The input signals are connected to latches within the Macro. A Clock signal is then sent to the

latch of the desired input, allowing it to pass to the output. The sample rate clock (SR.C) is

connected by default, although a different clock can be connected to the Clk input if needed.

The Sel input accepts integer values for selecting which input is to be clocked.

Clk Distro

Clk Distro

The Clk Distro Macro can be used to distribute a clock signal between several different outputs. By default it has four outputs, but further outputs can be added or removed if needed.

In particularly complex structures, it is often preferential to distribute clocking signals only to

the sections of a structure which are currently in use. By distributing the clock exclusively to

where it is needed at that particular moment, structures can be made to be considerably more

efficient.

By default, the Clk Distro Macro will distribute the sample rate clock (SR.C) signal. A different

clock can be used by connecting it to the Clk input.

REAKTOR Blocks - Framework Manual - 55

Page 56

The Sel input accepts integer values, selecting which output to send the clock signal from.

Process Macros

Select and Distribute

Clk Distro in use

A typical application of the Clk Distro Macro. In this example, the clock signal is distributed

between the various different waveforms produced by an LFO. Only the shape currently selected receives a clock, while the remaining shapes are inactive, resulting in a significant increase

in efficiency.

REAKTOR Blocks - Framework Manual - 56

Page 57

Process Macros

4.4 Counting

Clk Count

Clk Count

The Clk Count Macro is a simple counter, ideal for counting gate events or button presses.

Clk Count in use

A typical application of the Clk Count Macro. Every positive zero crossing in the signal arriving

at the Gate input results in a value of 1 being sent from the Int Gate Macro output. This causes the value at the Clk Count output to increase by 1.

A positive zero crossing in the signal arriving at the Reset input results in a value of 0 being

sent from the Reset Macro output. This causes the Clk Count Macro to reset to zero, and begin

counting again.

Counting

Clk Count / Wrap

Clk Count / Wrap

The Clk count/Wrap Macro is similar to the Clk Count Macro, and both Clk and Rst inputs

function in exactly the same way. The Clk Count/Wrap Macro however also includes a Max input.

While the Clk Count Macro will advance indefinitely until it receives a reset signal, the Clk

Count/Wrap Macro will only count as far as the value provided at the Max input, after which it

will return to 0 and begin counting again.

REAKTOR Blocks - Framework Manual - 57

Page 58

Process Macros

4.5 Demultiplex

Button DMux

Button DMux

The Button DMux is a simple demultiplexer, designed to be used in conjunction with the Mul-

tiplex Buttons panel widget. The signal arriving from the panel widget should be connected directly to the Button DMux input. The values sent by the eight buttons will then available at the

eight outputs.

If additional buttons have been added to the Multiplex Buttons panel widget, then the Button

DMux Macro should also be suitably modified.

Demultiplex

Knob DMux

Knob DMux

Similar to the Button DMux Macro, the Knob DMux Macro is also a simple demultiplexer, however it is designed for use in conjunction with the Multiplex Knobs panel widget. The signal

arriving from the panel widget should be connected directly to the Knob DMux input. The values sent from the eight knobs will then be available at the eight outputs.

REAKTOR Blocks - Framework Manual - 58

Page 59

Process Macros

If additional buttons have been added to the Multiplex Knobs panel widget, then the Knob

DMux Macro should also be suitably modified.

Button DMux/Seq

Button DMux/Seq

The Button DMux/Seq Macro is another type of demultiplexer, designed to be used in conjunction with the Multiplex Buttons panel widget. How it differs from the basic Button DMux Macro

is that rather than simply routing each constituent button to a dedicated output, the state of

each button is written to an array within the Macro.

The Idx input accepts integer values, and specifies which index of the array is to be sent to the

Macro’s output. The Button DMux/Seq is especially suitable for making sequencers, by connecting the sequencer position to the Idx input.

If additional buttons have been added to the Multiplex Buttons panel widget, then the Button

DMux/Seq Macro should also be suitably modified.

Knob DMux/Seq

Demultiplex

Knob DMux/Seq

Similar in concept to the Button DMux/Seq Macro, the Knob DMux/SeqMacro is also a demultiplexer and array Macro, but designed for use with a multiplexed float signal, specifically that

provided by the Multiplex Knobs Macro.

As on the Button DMux/Seq Macro, the Idx input accepts integer values to determine which

index of the array is sent to the Macro’s output. Again, this is particularly useful when making

sequencers.

If additional buttons have been added to the Multiplex Knobs panel widget, then the Knob

DMux/Seq’Macro should also be suitably modified.

REAKTOR Blocks - Framework Manual - 59

Page 60

Process Macros

Knob DMux/Seq in use

Using the Knob DMux/Seq’Macro as part of a basic sequencer. The output from the Multiplex

Knobs panel widget is connected to the input of the Knob DMux/Seq’Macro. A positive zero

crossing in the signal arriving at the Gate input is converted to a value of 1 by the Int Gate

Macro. This will increase the output value of the Clk Count/Wrap Macro by 1, which in turn

selects the next index value from the Knob DMux/Seq’Macro.

Demultiplex

REAKTOR Blocks - Framework Manual - 60

Page 61

Process Macros

4.6 Outputs

Pitch Div

Pitch Div

Essentially the opposite of the Pitch Mult Macro. The function of the Pitch Div Macro is to

scale pitch signals back to the [0, 1] range, in the case where they had been previously scaled

up to standard MIDI note values.

Display Latch

Display Latch

The Display Latch Macro should be used before routing modulation signals back to the Panel

Macro for display. The Display Latch is designed to pick up the display clock signal distributed

within the Core Cell by the Display Clk distribution bus. Signals connected to the Display Latch

are then clocked at display rate, resulting in increased efficiency.

Outputs

Display iLatch

Display iLatch

The Display iLatch Macro is essentially the same as the Display Latch Macro, with the only difference being that while the Display Latch is designed for use with float signals, the Display

iLatch Macro should be used with integer signals.

REAKTOR Blocks - Framework Manual - 61

Loading...

Loading...