Page 1

Bolt Grips andNut Grips

http://support.mts.com

MTS Fundamental™

Accessories

100-230-712A

Page 2

Copyright information 2010 MTS Systems Corporation. All rights reserved.

Declaration This manual describes all the available MTS fastener fixtures. The actual fixtures

supplied to the customer depend on the specs and types of specimen and relevant

standards stated in the purchase contract. Refer to Appendix A in fixture

purchasing and usage.

Trademark information MTS is a registered trademark and MTS Fundamental is a trademark of MTS

Systems Corporation within the United States. These trademarks may be

protected in other countries.

Publication

information

MANUAL PART NUMBER PUBLICATION DATE

100-230-712A January 2011

2

Page 3

Contents

Introduction 5

Component Identification 6

Safety 11

Installation 17

Operation 21

Bolt Tests 21

Proof Load Test for Nuts 26

Tests for Other Types of Specimens 29

Appendix A 31

MTS Fundamental™ Bolt Grips and Nut Grips

3

Page 4

4

MTS Fundamental™ Bolt Grips and Nut Grips

Page 5

Introduction

The MTS Fundamental fixtures are designed for tension, proof load ,and wedge

load tests of bolts and nuts.

Thread Specifications Table

P

ART NUMBER THREAD SPECIFICATIONS

F-JLL305A1

F-JLL305A2

F-JLL605A1

F-JLL605A2

F-JLL106A1

F-JLL106A2

The bolt length (l) should be no less than 3 times of the nominal diameter of bolts

(d), l≥3d.

The fixtures can perform tension, proof load and wedge load tests specified by

the following standards:

• GB/T 1231-2006 Specification of hexagon bolts, hexagon nuts, and plain

washers for high strength structural bolting with large width across flats.

• GB/T 3098.1-2000 (idt ISO 898-1 :1999) Mechanical properties of fasteners

– Bolts, screws and studs.

• GB/T 3098.2-2000 (idt ISO 898-2 :1992) Mechanical properties of fasteners

– Nuts – Coarse thread.

M5 to M20

M5 to M24

M5 to M30

• GB/T 3098.4-2000 (idt ISO 898-6 :1994) Mechanical properties of fasteners

– Nuts – Fine pitch thread.

• ASTM F606-07 Internally Threaded Fasteners, Washers, Direct Tension

Indicators, and Rivets.

MTS Fundamental™ Bolt Grips and Nut Grips Introduction

5

Page 6

Component Identification

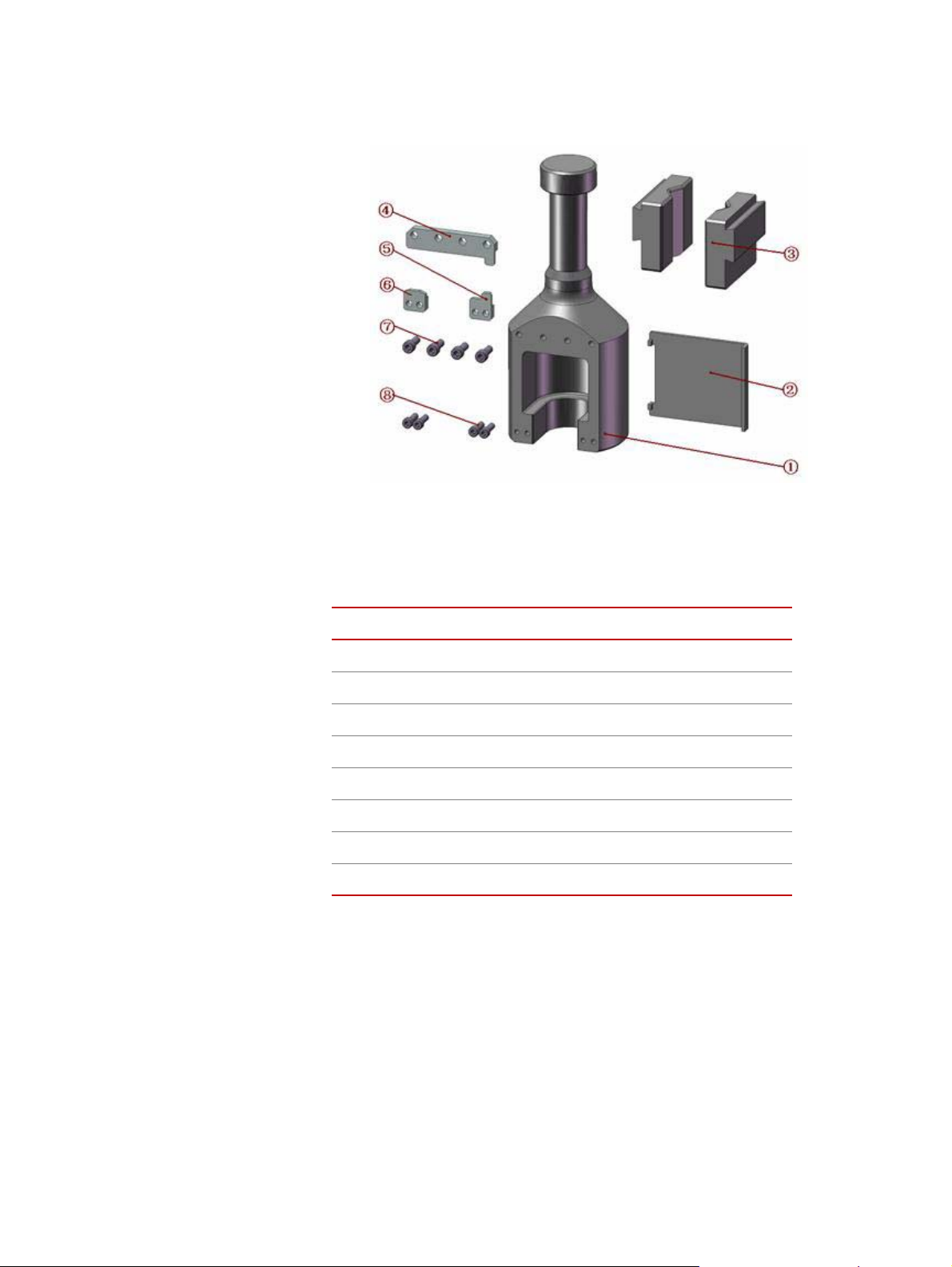

The fixture consists of two assemblies: upper assembly indicated by Figure 1 and

Figure 2; Lower assembly indicated by Figure 3 and Figure 4. The wedge faces

(Part 3) have markers for pairs, use wedge faces which have same markers

together.

Figure 1 Parts of Upper Assembly

(F-JLL605A1/ F-JLL605A2/ F-JLL106A1/ F-JLL106A2)

Parts of Upper Assembly

C

ALLOUT DESCRIPTION

1

2

3

4

5

6

7

8

9

Upper Joint

Upper Protection Plate

Wedge Faces

Square Nut

Leading Block 1

Leading Block 2

Leading Block 3

Allen Screw M6×16

Hexagon Spanner (5mm)

6

Introduction

MTS Fundamental™ Bolt Grips and Nut Grips

Page 7

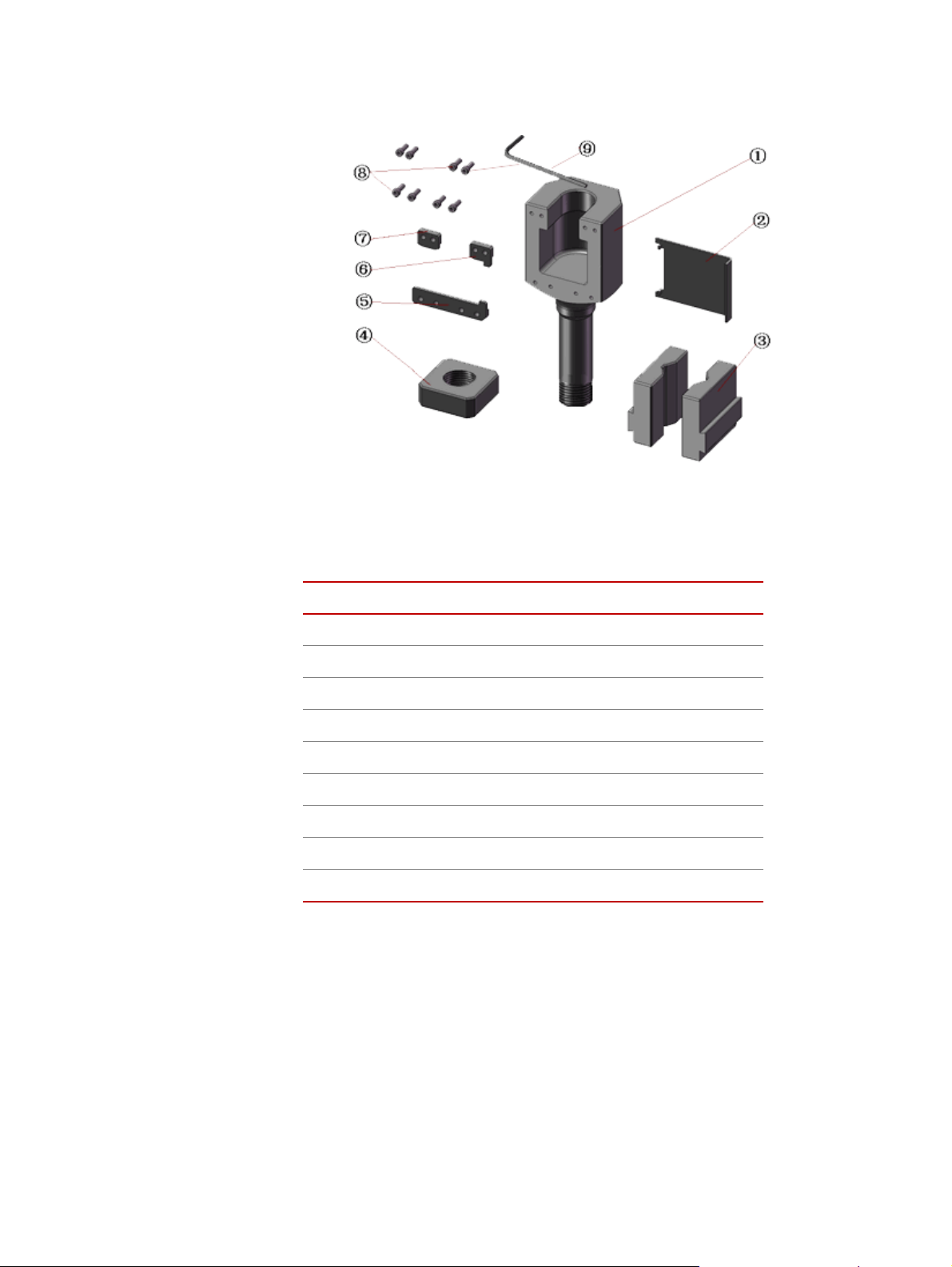

Figure 2 Parts of Upper Assembly

(F-JLL305A1/ F-JLL305A2)

Parts of Upper Assembly

C

ALLOUT DESCRIPTION

1

2

3

4

5

6

7

8

Upper Joint

Upper Protection Plate

Wedge Face

Leading Block 1

Leading Block 2

Leading Block 3

Allen Screw M6×16

Allen Screw M5×16

MTS Fundamental™ Bolt Grips and Nut Grips Introduction

7

Page 8

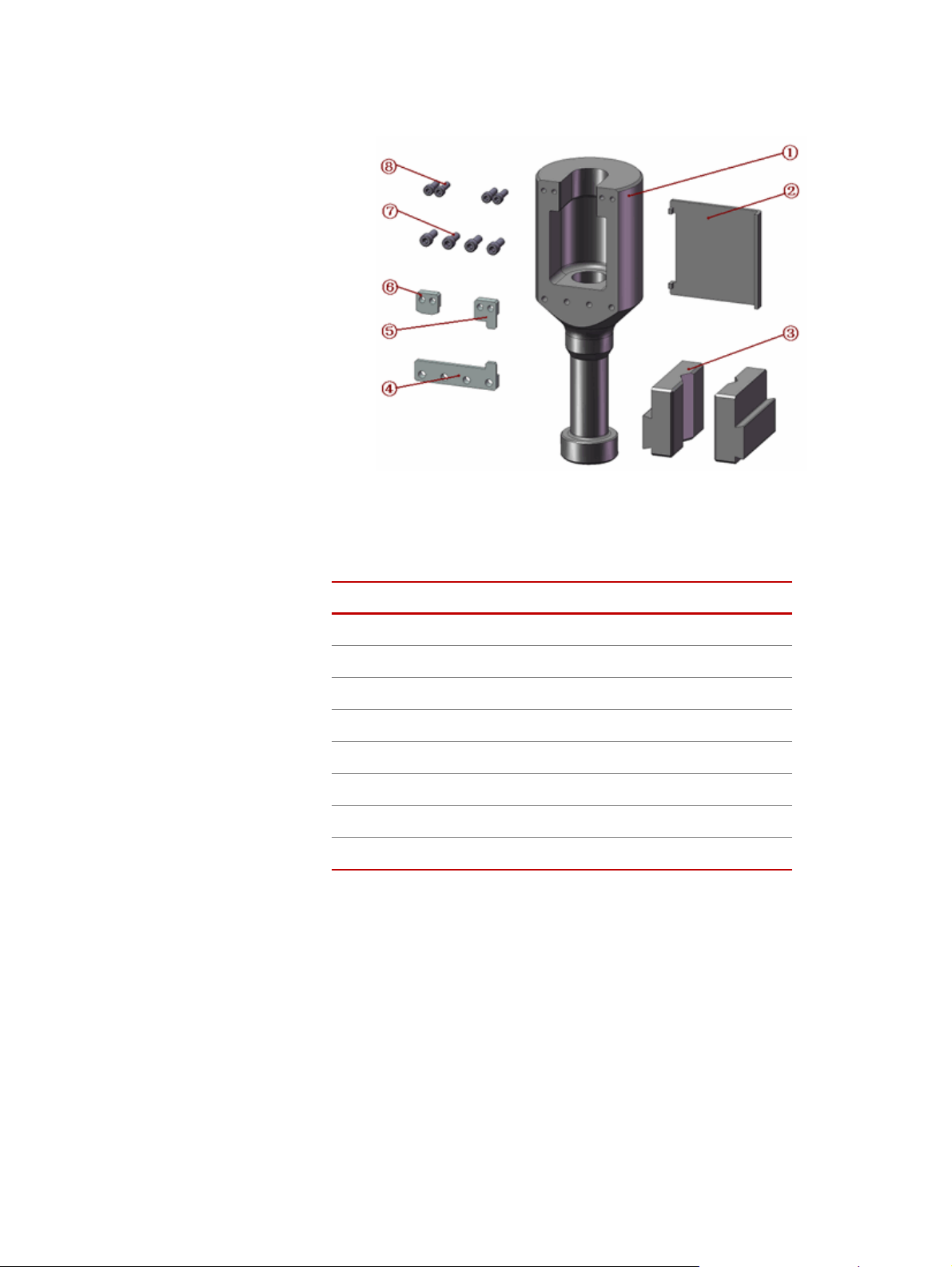

Figure 3 Parts of Lower Assembly

(F-JLL605A1/ F-JLL605A2/ F-JLL106A1/ F-JLL106A2)

Parts of Lower Assembly

C

ALLOUT DESCRIPTION

1

2

3

4

5

6

7

8

9

Lower Joint

Lower Protection Plate

Wedge Face

Square Nut

Leading Block 4

Leading Block 5

Leading Block 6

Allen Screw M6×16

Hexagon Spanner (5mm)

8

Introduction

MTS Fundamental™ Bolt Grips and Nut Grips

Page 9

Figure 4 Parts of Lower Assembly

(F-JLL305A1/ F-JLL305A2)

Parts of Lower Assembly

ALLOUT DESCRIPTION

C

1

2

3

4

5

6

7

8

Lower Joint

Lower Protection Plate

Wedge Face

Leading Block 4

Leading Block 5

Leading Block 6

Allen Screw M6×16

Allen Screw M5×16

MTS Fundamental™ Bolt Grips and Nut Grips Introduction

9

Page 10

10

Introduction

MTS Fundamental™ Bolt Grips and Nut Grips

Page 11

Safety

General Safety

Practices: Grips and

Fixtures

This section provides general information about safety issues that pertain to MTS

systems that use grips and fixtures. These issues include statements to the

intended use and foreseeable misuse of the system, definitions for the graphical

hazard labeling that is affixed to your product, and other (more general) safety

information that relates to the high-pressure and high-performance characteristics

of MTS static hydraulic and electromechanical systems.

When you prepare to operate a system that includes grips or fixtures, ensure the

following:

• Do not allow personnel to operate the system who are not experienced,

trained, or educated in the inherent dangers associated with highperformance static hydraulics and who are not experienced, trained, or

educated with regard to the intended operation as it applies to this test

system.

• Do not disable safety components or features (including limit detectors,

light curtains, or proximity switches/detectors).

• Do not attempt to operate the system without appropriate personal safety

gear (for example, hearing, hand, and eye protection).

• Do not modify the system or replace system components using parts that are

not MTS component parts or effect repairs using parts or components that

are not manufactured to MTS specifications.

• Do not operate the grips or fixtures in an explosive atmosphere.

• Do not use the system in a test area where uncontrolled access to the test

system is allowed when the system is in operation.

• For servohydraulic systems, do not operate the system unless an interlock is

installed to monitor supply pressure into the HSM and initiate a system

interlock if a low or no pressure event occurs.

If you have system-related responsibilities (that is, if you are an operator, service

engineer, or maintenance person), you should study safety information carefully

before you attempt to perform any test system procedure.

You should receive training on this system or a similar system to ensure a

thorough knowledge of your equipment and the safety issues that are associated

with its use. In addition, you should gain an understanding of system functions

by studying the other manuals supplied with your test system. Contact MTS for

information about the content and dates of training classes that are offered.

MTS Fundamental™ Bolt Grips and Nut Grips Safety

11

Page 12

It is very important that you study the following safety information to ensure that

WARNING

your facility procedures and the system’s operating environment do not

contribute to or result in a hazardous situation. Remember, you cannot eliminate

all the hazards associated with this system, so you must learn and remain aware

of the hazards that apply to your system at all times. Use these safety guidelines

to help learn and identify hazards so that you can establish appropriate training

and operating procedures and acquire appropriate safety equipment (such as

gloves, goggles, and hearing protection).

Each test system operates within a unique environment which includes the

following known variables:

• Facility variables (facility variables include the structure, atmosphere, and

utilities)

• Unauthorized customer modifications to the equipment

• Operator experience and specialization

• Test specimens

Because of these variables (and the possibility of others), your system can

operate under unforeseen circumstances that can result in an operating

environment with unknown hazards.

Improper installation, operation, or maintenance of your system can result in

hazardous conditions that can cause death, personal injury, or damage to the

equipment or to the specimen. Common sense and a thorough knowledge of the

system’s operating capabilities can help to determine an appropriate and safe

approach to its operation.

The larger capacity grips are heavy.

Dropped grips can cause injury to personnel and damage to equipment.

Be sure to have help or a proper lifting device to position the grips for installation.

Read all manuals Study the contents of this manual and the other manuals provided with your

system before attempting to perform any system function for the first time.

Procedures that seem relatively simple or intuitively obvious may require a

complete understanding of system operation to avoid unsafe or dangerous

situations.

Avoid pinch/crush

Safety

12

points

Pinch points exist between the parts of the grip or fixture that contact the

specimen. Be aware of these pinch points when installing a specimen or working

around the grip or fixture during test setup. High forces generated when grip

pressure is activated can pinch, cut, or crush anything in the path of the grip/

fixture specimen contact area and cause serious injury. Stay clear of any potential

pinch points.

MTS Fundamental™ Bolt Grips and Nut Grips

Page 13

A crush point exists between the grips. Whenever possible, use tongs or a similar

tool when handling the specimen during specimen installation. Never allow any

part of your body to enter the path of machine movement or to touch moving

machinery, linkages, hoses, cables, specimens, and so forth. These present

serious crush points or pinch points.

Locate and read

hazard placards/labels

Know facility safe

procedures

Find, read, and follow the hazard placard instructions located on the equipment.

These placards are placed strategically on the equipment to call attention to areas

such as known crush points, electrical voltage, and high pressure hazards.

Most facilities have internal procedures and rules regarding safe practices within

the facility. Be aware of these safe practices and incorporate them into your daily

operation of the system.

Know controls Before you operate the system for the first time, make a trial run through the

operating procedures with the power off. Locate all hardware and software

controls and know what their functions are and what adjustments they require. If

any control function or operating adjustment is not clear, review the applicable

information until you understand it thoroughly.

Know specimen

properties

The user is responsible for understanding the characteristics of the test specimen.

Be sure to use appropriate personal protective equipment (clothing, hand gloves,

eye protection, and so forth).

Use protective guards such as cages, enclosures, and special laboratory layouts

when you work with hazardous test specimens (for example, brittle or

fragmenting materials or materials that are internally pressurized).

Have first aid available Accidents can happen even when you are careful. Arrange your operator

schedules so that a properly trained person is always close by to render first aid.

In addition, ensure that local emergency contact information is posted clearly and

in sight of the system operator.

Be aware of

component movement

with hydraulics off

Keep bystanders

safely away

MTS Fundamental™ Bolt Grips and Nut Grips Safety

The actuator rod can also drift down when hydraulics are turned off, hitting

anything in its path. This uncommanded movement is because of oil movement

between the pressure/return ports and oil blow by across the piston hub. Be aware

that this can happen and clear the area around the actuator rod when hydraulics

are turned off.

Keep bystanders at a safe distance from all equipment. Never allow bystanders to

touch specimens or equipment while the test is running.

13

Page 14

Wear proper clothing Do not wear neckties, shop aprons, loose clothing or jewelry, or long hair that

could get caught in equipment and result in an injury. Remove loose clothing or

jewelry and restrain long hair.

Remove flammable

fluids

Check bolt ratings and

torques

Practice good

housekeeping

Do not exceed the

Maximum Supply

Pressure

Remove flammable fluids from their containers or from components before you

install the container or component. If desired, you can replace the flammable

fluid with a non-flammable fluid to maintain the proper proportion of weight and

balance.

To ensure a reliable product, fasteners (such as bolts and tie rods) used in MTSmanufactured systems are torqued to specific requirements. If a fastener is

loosened or the configuration of a component within the system is modified, refer

to information in this product manual to determine the correct fastener, fastener

rating, and torque. Overtorquing or undertorquing a fastener can create a

hazardous situation due to the high forces and pressures present in MTS test

systems.

On rare occasions, a fastener can fail even when it is correctly installed. Failure

usually occurs during torquing, but it can occur several days later. Failure of a

fastener can result in a high velocity projectile. Therefore, it is a good practice to

avoid stationing personnel in line with or below assemblies that contain large or

long fasteners.

Keep the floors in the work area clean. Hydraulic fluid that is spilled on any type

of floor can result in a dangerous, slippery surface. Do not leave tools, fixtures,

or other items not specific to the test, lying about on the floor, system, or decking.

For hydraulic grips and fixtures, make sure that the hydraulic supply pressure is

limited to the maximum pressure defined by the grip or fixture identification (ID)

tag.

Do not disable safety

devices

Provide adequate

lighting

Provide means to

access out-of-reach

components

Wear appropriate

personal protection

Your system may have active or passive safety devices installed to prevent

system operation if the device indicates an unsafe condition. Do not disable such

devices as it may result in unexpected system motion.

Ensure adequate lighting to minimize the chance of operation errors, equipment

damage, and personal injury. You need to see what you are doing.

Make sure you can access system components that might be out of reach while

standing on the floor. For example, ladders or scaffolding might be required to

reach load cell connectors on tall load units.

Wear eye protection when you work with high-pressure hydraulic fluid,

breakable specimens, or when anything characteristic to the specimen could

break apart.

Wear ear protection when you work near electric motors, pumps, or other devices

that generate high noise levels. Some systems can create sound pressure levels

that exceed 70 dbA during operation.

Wear appropriate personal protection equipment (gloves, boots, suits, respirators)

whenever you work with fluids, chemicals, or powders that can irritate or harm

the skin, respiratory system, or eyes.

14

Safety

MTS Fundamental™ Bolt Grips and Nut Grips

Page 15

Handle chemicals

safely

Whenever you use or handle chemicals (for example, cleaning fluids, hydraulic

fluid, batteries, contaminated parts, electrical fluids, and maintenance waste),

refer to the appropriate MSDS documentation for that material and determine the

appropriate measures and equipment required to handle and use the chemical

safely. Ensure that the chemical is disposed of appropriately.

Know system

interlocks

Interlock devices should always be used and properly adjusted. Interlock devices

are designed to minimize the chance of accidental damage to the test specimen or

the equipment. Test all interlock devices for proper operation immediately before

a test. Do not disable or bypass any interlock devices, as doing so could allow

hydraulic pressure to be applied regardless of the true interlock condition. The

Reset/Override button is a software function that can be used to temporarily

override an interlock while attempting to gain control of the system.

Know system limits Never rely on system limits such as mechanical limits or software limits to

protect you or any personnel. System limits are designed to minimize the chance

of accidental damage to test specimens or to equipment. Test all limits for proper

operation immediately before a test. Always use these limits and adjust them

properly.

Do not disturb sensors Do not bump, wiggle, adjust, disconnect, or otherwise disturb a sensor (such as

an accelerometer or extensometer) or its connecting cable when hydraulic

pressure is applied.

Ensure secure cables Do not change any cable connections when electrical power or hydraulic pressure

is applied. If you attempt to change a cable connection while the system is in

operation, an open control loop condition can result. An open control loop

condition can cause a rapid, unexpected system response which can result in

severe personal injury, death, or damage to equipment. Also, ensure that all

cables are connected after you make any changes in the system configuration.

Stay alert Avoid long periods of work without adequate rest. In addition, avoid long periods

of repetitious, unvarying, or monotonous work because these conditions can

contribute to accidents and hazardous situations. If you are too familiar with the

work environment, it is easy to overlook potential hazards that exist in that

environment.

Contain small leaks Do not use your fingers or hands to stop small leaks in hydraulic or pneumatic

hoses. Substantial pressures can build up, especially if the hole is small. These

high pressures can cause the oil or gas to penetrate your skin, causing painful and

dangerously infected wounds. Turn off the hydraulic supply and allow the

hydraulic pressure to dissipate before you remove and replace the hose or any

pressurized component.

Stay clear of moving

equipment/avoid crush

points

Stay clear of mechanical linkages, connecting cables, and hoses that move

because you can get pinched, crushed, tangled, or dragged along with the

equipment. High forces generated by the system can pinch, cut, or crush anything

in the path of the equipment and cause serious injury. Stay clear of any potential

crush points. Most test systems can produce sudden, high-force motion. Never

assume that your reactions are fast enough to allow you to escape injury when a

system fails.

MTS Fundamental™ Bolt Grips and Nut Grips Safety

15

Page 16

Know the causes of

unexpected actuator

motions

The high force and velocity capabilities of MTS actuators can be destructive and

dangerous (especially if actuator motion is unexpected). The most likely causes

of unexpected actuator response are operator error and equipment failure due to

damage or abuse (such as broken, cut, or crushed cables and hoses; shorted wires;

overstressed feedback devices; and damaged components within the servocontrol

loop). Eliminate any condition that could cause unexpected actuator motion.

16

Safety

MTS Fundamental™ Bolt Grips and Nut Grips

Page 17

Installation

The grips are usually assembled before shipment.

Inspect and clean the

parts

Assembly Refer to the component identification illustrations in the Introduction section for

F-JLL305A1

F-JLL305A2

F-JLL605A1

F-JLL605A2

F-JLL106A1

F-JLL106A2

Installation

Make sure you have all the parts. Check to see if the parts are correct. All parts

should be free of deformities or surface damages, and the screw holes should be

free of iron filings. Clean all parts before assembling.

the location of parts in the following paragraphs.

1. Mount the Leading Block 1 on the Upper Joint with an Allen Screw. The

uneven side of the Leading Block 1 should face the upper joint to form a

slot.

2. Insert the Upper Protection Plate into the slot and mount the Leading Block

2 and Leading Block 3 on the upper joint with an Allen Screw, so as to

mount the upper protection plate to the upper joint.

3. Repeat Steps 1 and 2 for the lower assembly.

Note When tightening the Allen screws, adjust the clearance of the leading

blocks and check that they are parallel. Make the protection plate slip

smoothly in the slots which are formed by the leading blocks and the

upper/lower joint.The fixtures must be stored with anti-rust oil applied.

Installing fixtures requires you to operate the equipment, which can cause

expected grip or crosshead movements.

Unexpected grip or crosshead movements can cause personal injury and

damage to the equipment.

Take every precaution to avoid unexpected grip and crosshead movements while

installing the fixtures.

MTS Fundamental™ Bolt Grips and Nut Grips Installation

17

Page 18

Open the grips of the testing machine. Make sure all of the small pistons of grips

Baffle Board

Cushion Plate

Upper Crosshead

Hexgon Spanner (6mm)

for M8

×16 Allen Screws

withdraw totally. Dismount the existing wedge faces from the grips and clean the

grooves.

F-JLL605A1

F-JLL605A2

F-JLL106A1

F-JLL106A2

Install the upper assembly according to actions shown in Figure 5.

Figure 5 Installation Procedure of Upper Assembly

1. Pick out two wedge faces which have the same marks, and mount one

wedge face into the upper grip as per ① and lock it with the baffle-board

(the baffle-board is used to prevent the wedge from moving during the test).

2. Mount another wedge face into the upper grip as per ② and lock it with the

baffle-board.

3. Insert the square nut between the wedge faces and the grip as per ③ .

4. Mount the upper assembly on the square nut as per ④, ⑤. Make the column

of the upper joint touch the surface of the V-shape groove of the wedge

faces.

5. Close the upper grip.

6. Use similar steps to install the lower assembly to the lower grip.

18

Installation

MTS Fundamental™ Bolt Grips and Nut Grips

Page 19

F-JLL305A1

Upper Crosshead

Baffle-Board

Cushion Plate

F-JLL305A2

Install the upper assembly according to actions shown in Figure 6.

Figure 6 Installation Procedure of Upper Assembly

1. Pick out two wedge faces which have the same marks, and mount one

wedge face into the upper grip as per ① and lock it with the baffle-board.

2. Mount another wedge face into the upper grip as per ② and lock it with the

baffle-board.

3. Mount the upper assembly on the square nut as per ③, ④. Make the column

of the upper joint touch the surface of the V-shape groove of the wedge

faces.

4. Close the upper grip.

5. Use similar steps to install the lower assembly to the lower grip.

MTS Fundamental™ Bolt Grips and Nut Grips Installation

19

Page 20

20

Installation

MTS Fundamental™ Bolt Grips and Nut Grips

Page 21

Operation

Contents Bolt Tests 21

Bolt Tests

Specimen Refer to Thread Specs Table in the Introduction section of this manual.

Proof Load Test for Nuts 26

Tests for Other Types of Specimens 29

Testing is dangerous because the broken specimen may be projected

violently from the testing zone.

The projected specimen can cause personal injury.

Close the protection plates of the fixtures and clear the personnel in front of the

fixtures before testing.

Check the diameter and length of the specimen; make sure they can meet the

requirement of the fixtures.

To ensure a valid test, the specimen should be free of any thread damages or

other deformities.

Proof load test Choose appropriate loading plates and threaded adapters for the specimen.

There are two types of loading plates and threaded adapters for different

specimens.

• Figure 7 shows the structure and installation manner for specimens of M5 to

M10.

• Figure 8 shows the structure and installation manner for specimen of M12 to

M30.

MTS Fundamental™ Bolt Grips and Nut Grips Operation

21

Page 22

The test can not be performed with the wrong loading plates and threaded

1

2

3

4

5

6

adapter.

Be sure to choose the appropriate loading plates and threaded adapters for the

specimen.

Figure 7 Proof Load Test (M5–M10)

ALLOUT DESCRIPTION

C

22

Operation

1

2

3

4

5

6

Flat Loading Plate(M5–M10)

Specimen

Threaded Adapter (M5-M10)

Spec Mark

Lower Protection Plate

Upper Protection Plate

MTS Fundamental™ Bolt Grips and Nut Grips

Page 23

Figure 8 Proof Load Test (M12–M30)

1

2

3

WARNING

C

ALLOUT DESCRIPTION

1

2

3

Debris can be discharged as a result of testing.

Debris can cause injury to personnel and damage to equi pment.

Be sure to close the protection plates of the fixture and clear the personnel in front

of the fixture before testing.

Loading Plate (M12–M30)

Specimen

Threaded Adapter (M12-M30)

Tensile test You can install the fixture and specimen the same as with the proof load test.

Wedge load test Choose appropriate wedge loading plates and threaded adapters for the specimen.

There are two types of wedge loading plates and threaded adapters for different

specimens.

• Figure 9 shows the structure and installation manner for specimens of M5 to

M10.

• Figure 10 shows the structure and installation manner for specimens of M12

to M30.

MTS Fundamental™ Bolt Grips and Nut Grips Operation

23

Page 24

Figure 9 Loading Plate (M5-M10)

Figure 10 Wedge Loading Plate (M12-M30)

The test can not be done if mounting the specimen on the opponent

position.

Be sure to make the loading plate surface engraved with "UP" on top and touching

the head of the bolt during the test.

24

Operation

There are spec marks on the wedge loading plates and threaded adapters, choose

appropriate loading plates and threaded adapters for the specimen (See Figure

11).

There are three kinds of wedge angles 4°, 6° and 10°, choose the appropriate

wedge loading plate to do the test.

You can do the test after completing the installation of fixture and specimen.

MTS Fundamental™ Bolt Grips and Nut Grips

Page 25

Debris can be discharged as a result of testing.

WARNING

Upper Protection Plate

Lower Protection Plate

Spec Mark

Debris can cause injury to personnel and damage to equi pment.

Be sure to close the protection plates of the fixture and clear the personnel in front

of the fixture before testing.

Figure 11 Wedge Load Test

CALLOUT DESCRIPTION

1

2

3

4

5

MTS Fundamental™ Bolt Grips and Nut Grips Operation

Wedge Loading Plate (M5–M10)

Specimen (M5–M10)

Threaded Adapter (M5–M10)

Wedge Loading Plate (M12–M30)

Threaded Adapter (M12–M30)

25

Page 26

Proof Load Test for Nuts

WARNING

Choose appropriate fixtures for the specimen. There are two kinds of fixtures for

different specimens (See Figure 12 and Figure 13).

All of the loading plates, threaded rods, high strength bolts and threaded adapters

have spec marks. Choose those parts according to the marks. For same thread

specs, the hole of the nuts’ loading plate is smaller than that of the bolts’ loading

plate. Do not misuse these loading plates.

Debris can be discharged as a result of testing.

Debris can cause injury to personnel and damage to equi pment.

Be sure to close the protection plates of the fixture and clear the personnel in front

of the fixture before testing.

Proof load test for nuts

(M5 to M10)

Choose appropriate loading plates and threaded rods for the specimen. A

threaded adapter of M12 should also be used. Screw the M12 thread of the thread

rod into the threaded adapter, Screw the other end of the thread rod into the

specimen (see Figure 12).

26

Operation

MTS Fundamental™ Bolt Grips and Nut Grips

Page 27

Proof load test for nuts

Upper Protection Plate

Lower Protection Plate

(M12 to M30)

Choose appropriate loading plates, nut loading plate and high strength bolt. See

Figure 13 for installation.

Figure 12 Proof Load Test for Nuts (M5-M10)

ALLOUT DESCRIPTION

C

1

2

3

4

Specimen (M5–M10)

Nut Loading Plate (M5–M10)

Threaded Rod (M5–M10)

Threaded Adapter (M12)

MTS Fundamental™ Bolt Grips and Nut Grips Operation

27

Page 28

Figure 13 Proof Load Test for Nuts (M12-M30)

Spec Mark

ex. N M12

Lower Protection

Plate

Upper Protection

Plate

ALLOUT DESCRIPTION

C

1

2

3

4

Loading Plate (M12–M30)

High-Strength Bolt (M12–M30)

Nut loading Plate (M12–M30)

Specimen (M12–M30)

28

Operation

MTS Fundamental™ Bolt Grips and Nut Grips

Page 29

Tests for Other Types of Specimens

By using appropriate loading plates, thread rods, thread adapters, and high

strength bolts, the fixtures can perform tests for specimens of fine pitch threads

and inch threads. Double-headed studs can also be tested. If you want to test

these kinds of specimens, you must state it clearly in your order.

T ests for specimens of

fine pitch threads

Tests for specimen of

inch threads

If you want to run tests for bolts, nuts, and studs which have fine pitch thread,

you need to change threaded adapters and high strength bolts (or threaded rods).

If you want to run the tests for bolts, nuts, and studs which have inch threads, you

need to change loading plates, wedge loading plates, threaded adapters, and high

strength bolts (or threaded rods).

MTS Fundamental™ Bolt Grips and Nut Grips Operation

29

Page 30

Tests for studs If you want to run tests for studs, you should use high strength nuts (no less than

Lower

Protection Plate

Upper

Protection Plate

class 12). One end of the stud should be connected to the high strength nut; the

other end be connected to the threaded adapter. Figure 14 illustrates the

installation manner. Refer to bolt proof load test for details.

Figure 14 Tests for Studs (M5–M30)

Tests for Studs

C

ALLOUT DESCRIPTION

1

2

3

4

High Strength Nut (No Less Than Class 12)

Loading Plate (M5–M30

Specimen (M5–M30)

Threaded Adapter (M5–M30)

30

Operation

MTS Fundamental™ Bolt Grips and Nut Grips

Page 31

Appendix A

Optional Fixture References

M5,M6,

M7,M8,M10

M12,M14,M16,M18,

M20,M22,M24,M27,M30

E

XAMPLES OF

MARK

REMARK

Bolts Threaded adapter Determined by

Loading plate M6,M20 aperture

4° wedge loading plate 4°×M20

6° wedge loading plate 6°×M20

10° wedge loading

plate

Nuts M4 -

M10

M12M30

Loading plate

for nuts

Threaded rod Determined by

Threaded

adapter

(M12)

Loading plate -- Determined by the

High strength

bolt

the specimen and

test method, one

for each

Determined by

the specimen,

one each

the specimen,

one each

One for all M12 see note

Determined by the

specimen and test

method, one for each

-- N-M6

specimen, one

Determined by the

specimen, one

M6,M20

10°×M20

M6

M20 see note

designed by

medium

clearance as

per GB/T

5227

Nut loading

plate

Note:

The loading plates and threaded adapter (M12) used in the proof load test of nuts are the same as the

loading plates and threaded adapter (M12) used in tensile test of bolts. Therefore, only one set is

necessary for both tests.

MTS Fundamental™ Bolt Grips and Nut Grips Appendix A

Determined by the

specimen, one

N-M20

31

Page 32

m

MTS Systems Corporation

Http://www.mts.com/en/global/index.asp

Loading...

Loading...