MANUAL No. 99MBE021A

SERIES No. 264

DP-1VR

Digimatic Mini-Processor

User's Manual

In order to obtain the best possible performance from the Mitutoyo

Digimatic Mini-Processor DP-1VR,

read this user’s manual thoroughly before operation.

After reading, retain it close at hand for future reference.

THE MARKS USED IN USER'S MANUAL

The meaning of symbol mark and contents describe with each symbol mark used

in users manual is as follow.

Notice on Safety

In user's manual, to use exactly this unit, and to protect from yours and other

peoples damage and property, several chart expression. The expression and

meaning are as follows.

● Following expressions shown general notices, cautions and dangers, but not

limited.

Neglecting this expression, if you deal with this unit by incorrect way, it

will be imminent occurrence of human death or heavy injury.

Neglecting this expression, if you deal this unit by incorrect way, it will be

supposed to occur possibility of human death or heavy injury.

Neglecting this expression, if you deal with this unit by incorrect way, it

will be supposed to occur possibility of human damage and physical

damage.

i

THE MARKS USED IN USER'S MANUAL

● The following marks show notice, exhibit of action/compulsion

This marks show that there is contents urge the notice (include danger,

warning. In the chart, concrete notice meaning is shown (left chart mean

electrical shock)

This mark express exhibited action. Concrete exhibited actions are drawn

in the charts or near the charts. (left chart means exhibit of disassemble)

This mark express the action under compulsion or direction. Concrete

directed actions are drawn in the charts or near the charts. (left chart

shows necessity of earth)

ii

THE MARKS USED IN USER'S MANUAL

About several kinds of notice.

Several kinds of "notice" which assist to obtain high reliable measured data

show in following words.

Important

Notice

Reference

◆ Notice indicates necessary information to achieve the purpose.

Do not neglect this direction.

◆ If you do not follow this direction, there are the possibilities to loss

or difficult to maintain the performance and accuracy of this unit.

This word indicates especially emphasize or supplementary information.

It shows that there are attentions for specified operation (limit of

memory, construction of equipment, information concerned with

special version of program. etc.)

This word indicates reference information concerned with operating

method and procedure described in this manual to apply for particular problem or details explanation of operation and function.

And if there are other reference informations, they may be shown the

reference portion

When any damages happen by the method not to depend on this

manual, our company does not have any responsibilities.

Contents of this manual may be changed without advance notice.

(c) Copyright Mitutoyo Corporation. All rights reserved.

iii

NOTICE ON SAFETY (PLEASE READ SURELY)

To use safely, you should observe following.

◆ This unit is intended to be used for a general equipment (measuring

equipment, or machine tool etc.) Do not use this unit for medical

machine, aerospace vehicle, train or atomic power etc. which miss

operation of this unit have possibility to injure the human body or

treated human life. When you intend to use for such purpose, please

inform to our company in advance.

◆ If accidents happen such as smoke, curious smell or abnormal

operation, cut power and pullout AC adapter from consent, then

inform to service network. If you continue operation, it causes fire or

electric shock.

◆ When you drop this unit and it is damaged, cut power and pullout AC

adapter from consent, then inform to service network. If you continue

operation, it causes fire or electric shock.

◆ Do not repair or modify this unit by user. As it causes fire or electric

shock, do not implement absolutely.

◆ When foreign object puts into this unit, cut power and pullout AC

adapter from consent, then inform to service network.

iv

NOTICE ON SAFETY (PLEASE READ SURELY)

◆ Please keep specified power source voltage. When this unit is used

with not specified power source voltage. it causes damage of inside,

fire or electric shock.

◆ Please do not put this unit at the place opened to direct sunshine or

hot temperature. Inner temperature of this unit increases and causes

fire.

◆ Do not put this unit close to wall. Inner temperature increases and

causes malfunction. And also please put this unit apart about 10 cm

from wall as you can pullout the cord of power source without moving

this unit.

REGARDING TO EC COMMAND CONFORMITY

◆ This unit is conformed to following EC Command.

EMC Command EN61326-1997+A1:1998

v

CONTENTS

The marks used in this user's manual........................................................................... i

Notice on Safety (Please read thoroughly) ................................................................ iv

WARRANTY .............................................................................................................vi

1. OUTLINE........................................................................................................ 1

1. Introduction ........................................................................................................... 1

2. Features ..................................................................................................................1

2. SET UP .......................................................................................................... 3

1. Power supply ......................................................................................................... 3

1.1 Setting the battery ......................................................................................... 3

1.2 Connection of the AC adapter....................................................................... 5

2. Set of recording paper............................................................................................ 6

3. Connection of the measuring tool .......................................................................... 7

4. Other connection.................................................................................................... 8

4.1 Attachment of strap....................................................................................... 8

4.2 Footswitch..................................................................................................... 9

4.3 RS-232C Cable • GO±NG judgement cable................................................. 9

4. PARAMETER ............................................................................................... 10

1. Parameter ............................................................................................................. 10

2. In the case of connecting caliper micrometer ...................................................... 10

3. In the case of printout of RS232C linearscale output .......................................... 12

4. Example of parameters setting ............................................................................ 15

4.1 DP-1 parameter setting procedure .............................................................. 15

5. SUMMARY OF FUNCTIONS....................................................................... 19

1. Key functions....................................................................................................... 19

2. Function of each mode ........................................................................................ 20

3. Timer input function ............................................................................................ 21

6. OPERATION ................................................................................................ 22

1. Power ON/OFF .................................................................................................... 22

2. Basic Operation 1 ................................................................................................ 23

2.1 Data input, cancel, clear.............................................................................. 23

vi

CONTENTS

3. Basic operation 2 .................................................................................................25

3.1 Input of tolerance limit data........................................................................ 25

3.2 Confirmation/renew of limit data ...............................................................27

3.3 Release of limit data ...................................................................................28

3.4 Data input, cancel, clear.............................................................................. 29

4. Mode 3 ................................................................................................................. 32

5. Print RS232C of counter...................................................................................... 34

6. OTHER NOTICES........................................................................................ 36

7. MAINTENANCE........................................................................................... 37

1. Clean printer head ................................................................................................ 37

2. Clean paper sensor ............................................................................................... 37

8. ERROR MESSAGE...................................................................................... 39

1. Alarms concerning electric power ....................................................................... 39

2. Other alarms ........................................................................................................ 40

9. CALCULATION METHOD ........................................................................... 42

1. Significant figure .................................................................................................42

2. Overflow and calculation tolerance ..................................................................... 43

3. Calculation tolerance detail .................................................................................44

4. Calculation formula .............................................................................................45

4.1 Calculation of Mode1, Mode2 .................................................................... 45

4.2 Calculation Mode3...................................................................................... 46

10. OUTPUT....................................................................................................... 47

1. Output of GO/±NG Judgment Result .................................................................. 47

2. Output in Accordance with RS-232C Format...................................................... 47

2.1 Communication Specifications ................................................................... 48

2.2 Data Format ................................................................................................ 48

2.3 Error Code .................................................................................................. 49

2.4 Data request command................................................................................ 49

11. TROUBLESHOOTING................................................................................. 50

12. SPECIFICATIONS ....................................................................................... 52

SERVICE NETWORK .................................................................................. 54

vii

1

OUTLINE

1. Introduction

DV-1VR is an exclusive piece of data processing equipment that records data from a

Mitutoyo digimatic tool so it can be statistically processed operation is easy and

statistical results can be obtained quickly.

2. Features

(1) Abundant statistical parameters:

Number of samples (N) • Maximum value (MAX) • Minimum value (MIN) •

Range (R) • Mean value (X) • Standard deviation (σ-n, σn-1) • Process capability

index (C

Limit data 5 types

(2) Preparation of histogram

(3) Preparation of a chart of displacement that expresses the time history of mea-

sured data D (Displacement).

(4) Several calculation functions necessary to prepare the X-R control chart.

(5) Timer input function.

(6) Data output function.

Output of measured data (RS-232C, TTL Level)

Output result of success or failure (+NG, GO, −NG)

It can be connected to Mitutoyo Instrument Network System (µNET System)

(7) Output of success or failure by LED.

(8) Power source system of AC adapter or four AA type Nickel Hydrogen batteries

(Ni-MH)/Alkali batteries (LR6)

(9) Standard equipment of 48 m recording paper.

P, CPK) • Number of defects (±NG) • Percent detective (P)

- 1 -

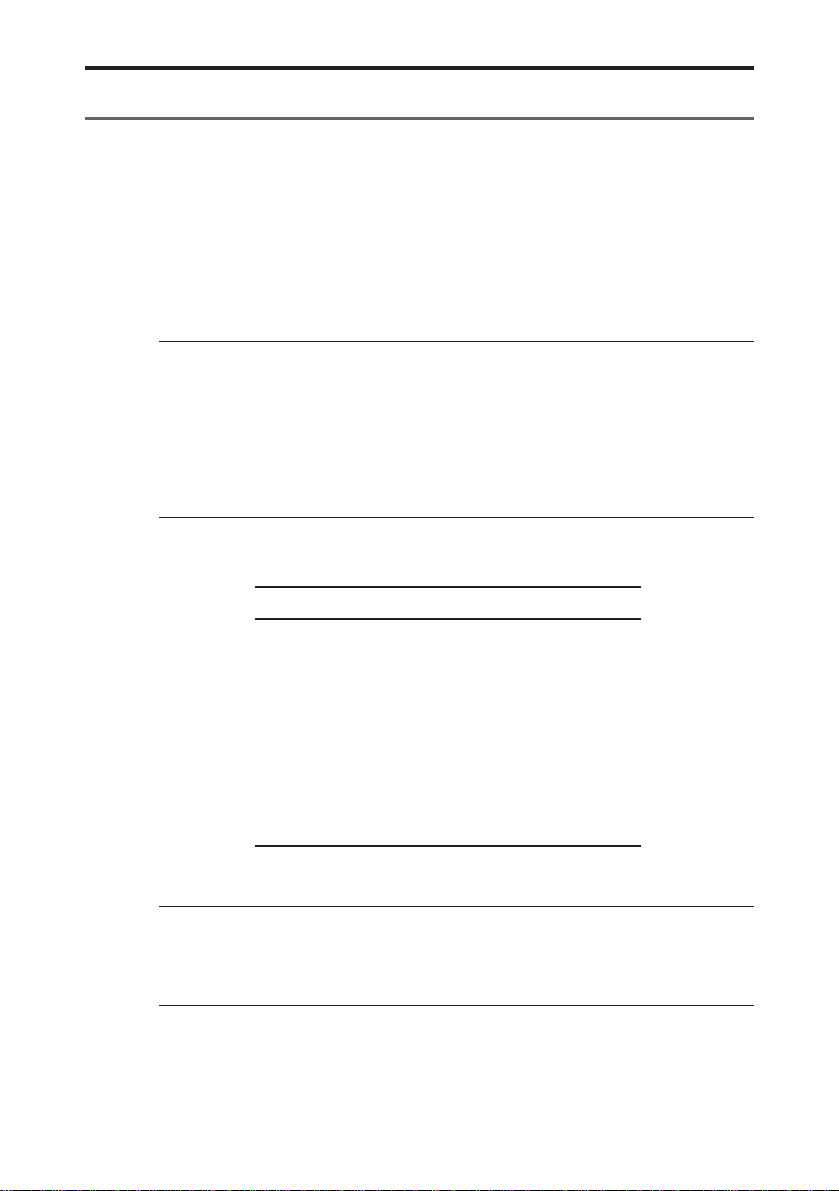

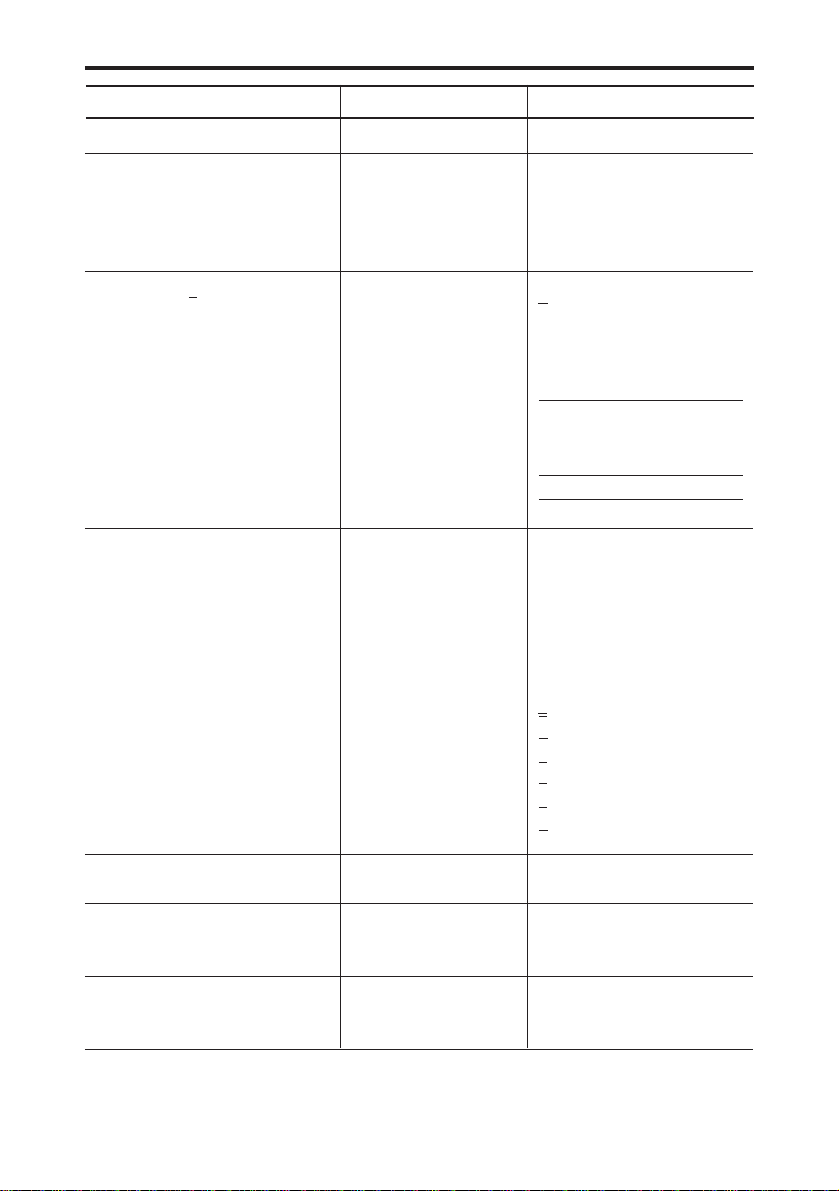

OUTLINE

75.2

Recording paper cover/

Recording paper

94

+ −

Mitutoyo Corporation

Code No.

Model

Serial No.

Power

OPEN

MADE IN JAPAN

Release lever

Adapter jack

GO/±NG LED

NG

+

GO

DIGIMATIC MINI-PROCESSOR

NG

−

Battery box

Alkaline battery LR6

AA Ni-MH battery

Must use the following types of battery

for battery operation.

INPUT OUTPUT ADAPTER

Input connector

Output connector

CESTAT

PRINTER CL

Strap attachment

43.9

Foot switch connector

EXT.P

FEED DATA

TOL.

POWER

POWER

LIMIT

Power source LED

201.1

External view

Parts List

Parts name Quantity

DP-1VR (Main unit) 1

AC adapter 1

Recording paper 1

Strap 1

Quick reference 1

User’s manual 1

- 2 -

2

SET UP

1. Power supply

● Power is supplied to this unit by the AC adapter or four AA type Nickel Hydrogen

batteries (Ni-Mh)/Alkali batteries (LR6)

● When the AC adapter is used while batteries installed, the power will be supplied

from the AC adapter (batteries are not included). The AC adapter cannot charge the

batteries, charge them with a dedicated battery charger, if necessary.

● When a voltage drop occurs when using the battery or AC adapter, the power

source LED will blink and show an abnormal condition.

1.1 Setting the battery

Set the batteries. If using the AC adapter, refer to section 1.2

qq

q Open the battery box.

qq

Code No.

Model

Serial No.

Power

+ −

Mitutoyo Corporation

MADE IN JAPAN

Must use the following types of battery

for battery operation.

Alkaline battery LR6

AA Ni-MH battery

Push down the stopper of the battery box and pull forward.

- 3 -

SET UP

ww

w Set the batteries.

ww

Be sure to set correctly the poles of the size AA Alkali batteries (LR6) or Nickel

Hydrogen batteries (Ni -MH AA)

e Close the battery box by the inverse process of q firmly until you hear the

clicking sound.

IMPORTANT

◆ Set the poles of batteries correctly.

◆ Do not use different kinds of batteries.

◆ Use either size AA Alkali batteries (LR6) or AA Nickel Hydrogen batteries

(Ni-MH AA)

◆ Manganese batteries R6 cannot be used.

◆ When Alkali batteries are used, printed letters may fade accordingly.

◆ When Alkali batteries or Nickel Hydrogen batteries are used, print speed is

slower compared with the AC adapter.

◆ In the case of using batteries, if the surface shows peeling or breaks on the pole

of the battery, it may cause poor contact and start-up. Please use batteries only

after you check there is no peeling or surface breaks on the poles of batteries.

◆ If DP-1VR is not used for a long period, please remove the batteries from DP-

1VR. If the batteries remain connected to the DP-1VR for long time, fluid

leakage may damage the DP-1VR.

◆ The operational temperature of the batteries must remain over 10°C. If the

temperature is less than 10°C, undesirable things, such as printed letters

become thin, etc., may occur.

- 4 -

NOTE

◆ DP-1VR has no charger function. If you need to charge the batteries, a

dedicated battery charger is needed.

◆ Battery life is about 10,000 lines, (using 1,600 m Ah Ni-MH, and print large,

letter one time per 5 sec.)

◆ Battery life varies drastically in accordance with environmental conditions.

1.2 Connection of the AC adapter

Connect the AC adapter to the DP-1VR.

Skip this page when using batteries.

DIGIMATIC MINI-PROCESSOR

POWER

−

NG

GO+NG

POWER

PRINTER CL

TOL.

CESTAT

LIMIT

FEED DATA

Insert firmly all the way.

SET UP

◆ The AC adapter specified by our company should be used.

100/115V 09EAA088

230V 09EAA088D

230V UK 09EAA088E

◆ If the specified AC adapters are not used, print quality and life expectancy will

be reduced.

- 5 -

SET UP

2. Set of recording paper

q

● Push the release lever downward

● Move the cover of recording paper upward, then open it.

w

OPEN

● Peel tape fixing the edge of record paper, then set the recording paper with a little

bit of the paper pulled out.

● Set the core of the recording paper firmly in the holder. If the recording paper is

wrinkled, it can cause the paper to jam while printing, so be sure it is straight.

● Close the cover of the recording paper, pulling out the edge the recording paper a

little bit.

● Press the ‘power’ key to power ON and press the ‘FEED’ key, to send out the

recording paper about 100 mm.

- 6 -

● When paper is set, be careful not to injure your hand by the paper cutter.

IMPORTANT

◆ After setting the recording paper, be sure to press the ‘FEED’ key. This will

perform a self-alignment thereby reducing paper jamming.

◆ When you open the recording paper cover, the printer head is exposed.

Immediately after printing, the printer head is hot. Do not touch to avoid being

burned.

◆ DP-1VR recording paper has superior characteristic of conservation, tolerance

to chemicals and weather-proof. Please use the recording paper specified by

our company. (Part No. 09EAA082 10 roll pack)

◆ Print quality is not guaranteed if the specified recording paper is not used.

◆ Recording paper should be stored in a cool and dark place.

3. Connection of the measuring tool

Before connection, confirm that electric power to the digimatic measuring tool is OFF.

(1) Connection to the digimatic measuring tool.

Connect one connector of the connecting cable to DP-1VR input connector and the

other connector to the output connector of the digimatic measuring tool. Some con-

necting cables are different, depending on the type of measuring tool, please refer

to each user's manual.

SET UP

OUTPUTINPUT

• Be careful to connect the connector correctly.

• Pull and put the connector in straight.

Connection of the input connector

- 7 -

SET UP

4. Other connection

4.1 Attachment of the strap

Attach the strap to the DP-1VR as necessary

q Take the sling off the hook.

w Press the sling through the attachment point of the DP-1 as shown in the figure.

Must use the following types of battery

for battery operation.

Alkaline battery LR6

AA Ni-MH battery

Insert strap here

Sling

Hook

e Hang the hook on the ring and pull out.

- 8 -

4.2 Footswitch

Data can be input by a foot switch.

Connect to a foot switch connector, part No. 937179T (optional accessory)

DIGIMATIC MINI-PROCESSOR

POWER

−

NG

GO+NG

POWER

PRINTER CL

TOL.

CESTAT

LIMIT

FEED DATA

4.3 RS-232C Cable • GO±NG judgement cable

SET UP

q RS-232C cable (part No. 09EAA084)

RS-232C output can be obtained from DP-1VR and used for printing RS-232C,

output of a linear scale counter. Connect the RS-232C cable to the DP-1VR output

connector.

w GO±NG judgment cable (part No. 965516)

The results of a judgment can be obtained from the DP-1VR. Connect it to output

connector of the DP-1VR.

NOTICE

The RS-232C cable and GO±NG judgment cable can not be used simultaneously.

Be sure to connect / disconnect the cables only when the power is OFF.

- 9 -

3

PARAMETER

1. Parameter

Parameter functions can customize the actions of the DP-IVR. Set up in accordance

with the purpose.

There are two kinds of parameter settings in accordance with connecting measuring

equipment to DP-1VR.

Select parameters in accordance with the measuring equipment used.

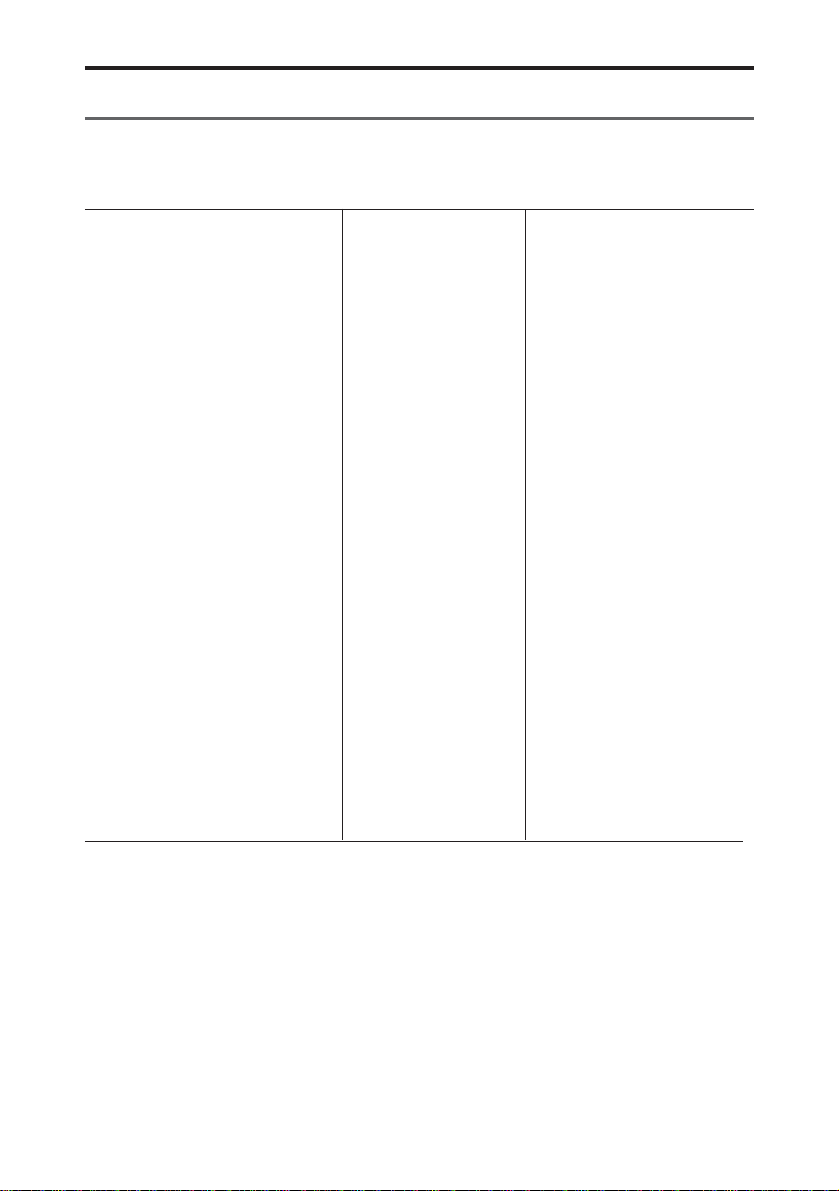

2. In the case of connecting calipers or micrometers

Parameters are established for digimatic interfaces such as calipers or micrometers

when connected to DP-1VR.

Start parameter setting mode by pushing the 'DATA' key and 'POWER' key simulta-

neously.

After parameter mode is started, parameters are printed in order. When you want to

change a setting, push the 'STAT' key and when you don't want to change a setting,

push the 'DATA' key; then the parameter will be set.

Next, a table of parameters is shown.

- 10 -

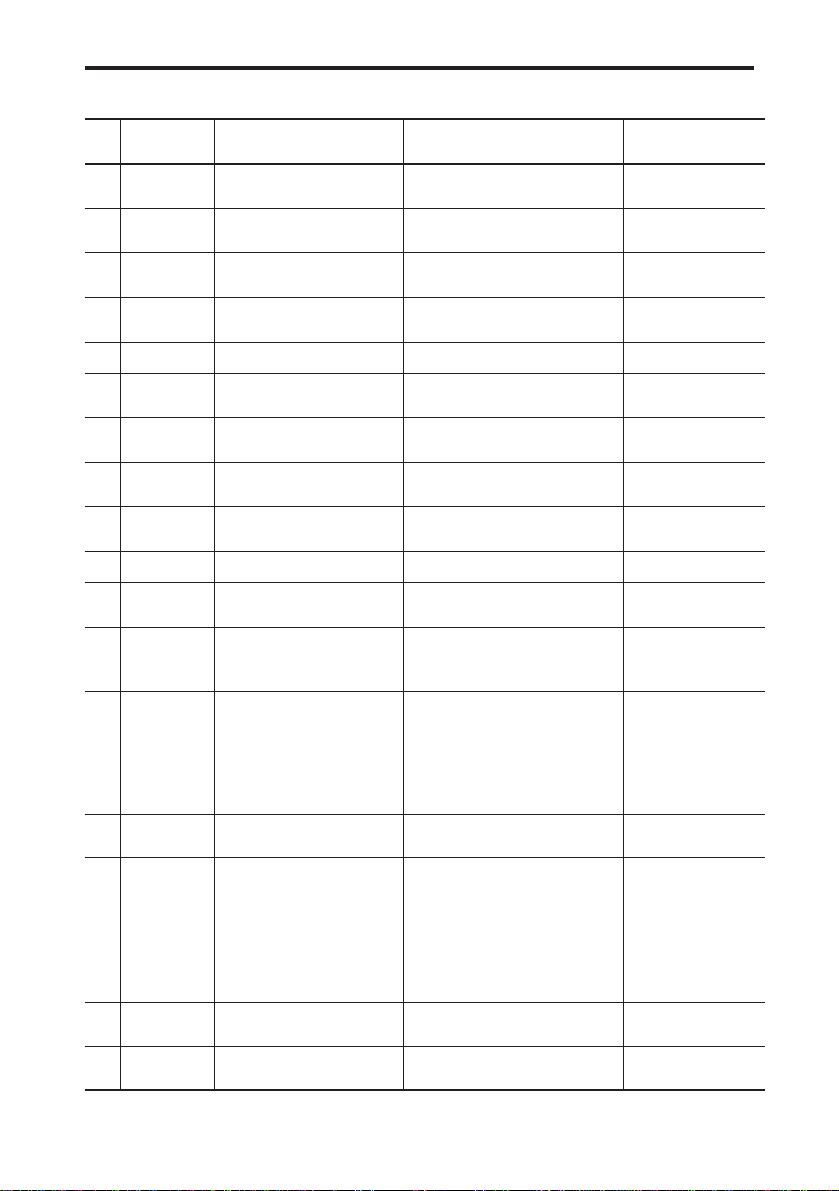

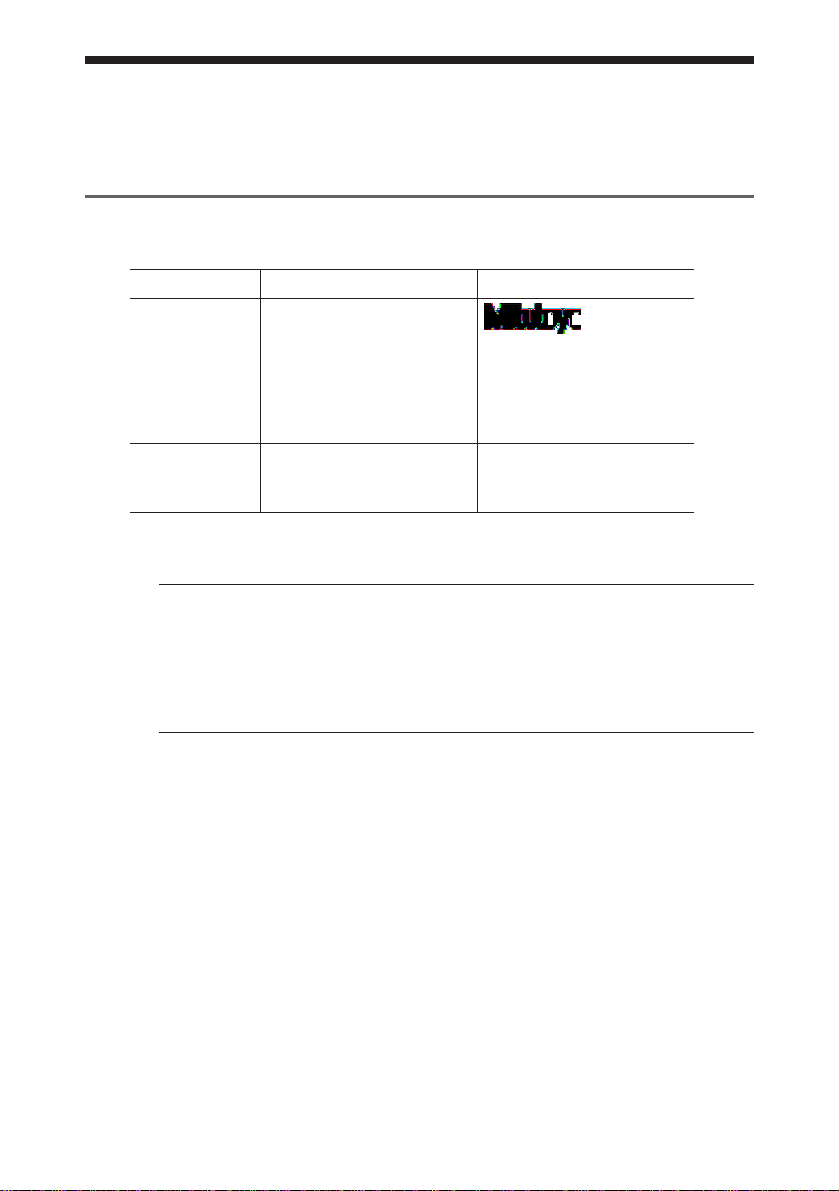

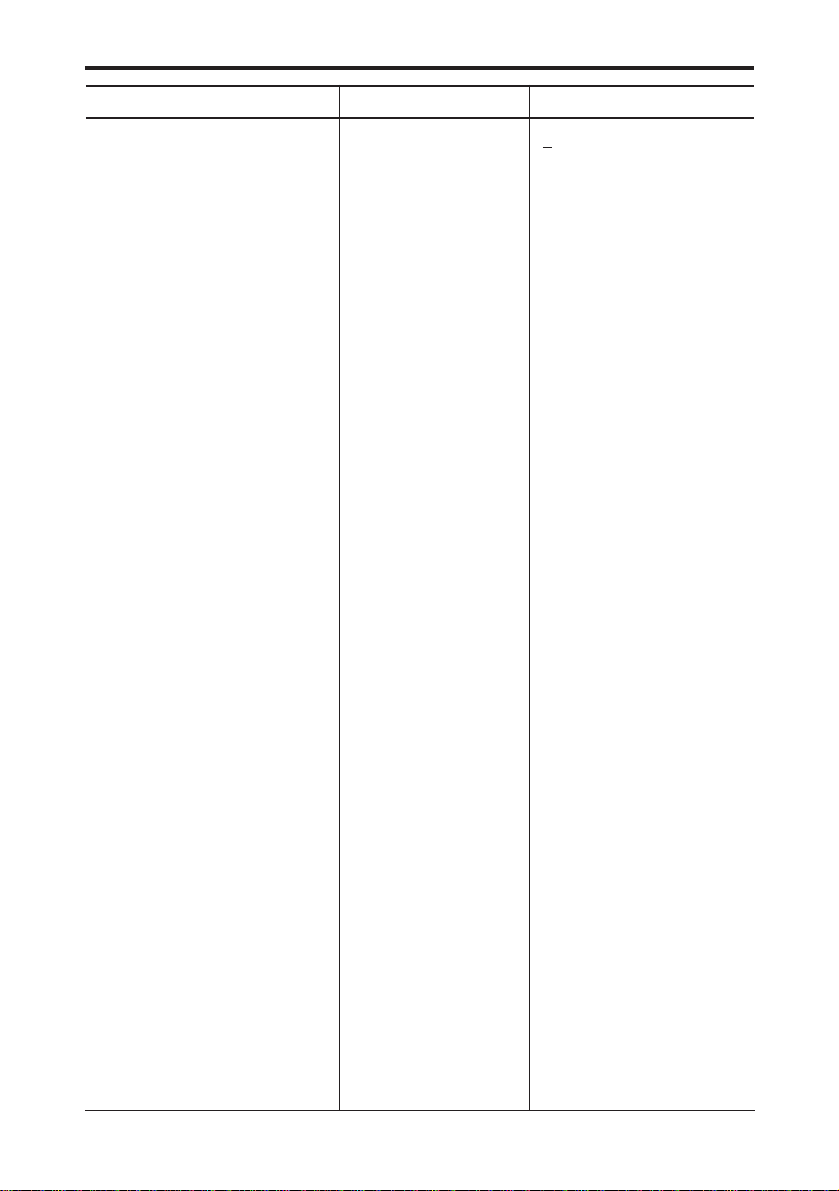

Table 1 Parameter in DP-1 MODE

PARAMETER

-rO

red

1

2

3

4

5

6

7

8

9

01

11

21

31

41

51

metIgnitteSnoitareporetnirPtluafeD

-TEMARAP

RAELCRE

METSYS

EDOM

KROW

EDOM

DUAB

ETAR

YTIRAP

ATAD

TNIRP

EZIS

EVAS

TNIRP

EMIT

TNIRP

ATAD

ATAD

EMIT

TINU

8/7

HTGNEL

REWOP

YTISNED

EDOMZB

TAMROF

hcnI

enoN

marG

noT

ecnuO

raelcretemaraP

itluM/edom1-PDteS 1-PD edom 1-PD

/1EDOM/0EDOM

3EDOM/2EDOM

/0084/0042/0021

00291/0069

ddO/nevE/enoN

8/7

lamroN/egraL

lamroN/evasrewoP

kraD/lamroN

FFO/NOedomZB

FFO/NOTNIRPEMIT

TAMROFETAD

GNITTESETADgnitnirpnehW.g.e ,2.naJ

GNITTESEMITdradnatSnapaJ

)hcni/mm(citamotuA

retemilliM

edargitneC

FFO/NO

FFO/NO

0002 tamrofatadgnisu

hcni/mm

mm

hcni

g

C°

t

.bL

1EDOM/0EDOM

3EDOM/2EDOM

0084/0042/0021

00291/0069

DDO/NEVE/NON

LAMRON/EVAS

KRAD/LAMRON

DD/MM/YYYY

YYY/DD/MMM

YYY/MMM/DD

2/1/0002

0002/2/NAJ

0002/NAJ/2

RAELCRETEMARAP

RAELCONRETEMARAP

LAMRON/EGRAL

.21nidenifedgnittes

raelctonoD

sretemarap

1edoM

0084

NEVE

7

EGRAL

si2edomnehW

lamronylnotes

siezisgnitnirp

elbaliava

lamroN

lamroN

NO

DD/MM/YYYY

dradnatSnapaJ

emiT

emiT

citamotuA

- 11 -

PARAMETER

IMPORTANT

◆ Set DP-1 for action mode.

NOTE

◆ When entered into parameter input mode, limit data is cleared.

◆ When parameters are cleared, they are set to default, except the date and time.

Date and time are reset to 2001/1/1, 0:0.

◆ If a unit setting is selected, the unit set by this parameter is printed, regardless

of the unit of the input data. In this case the unit information of input data is

neglected.

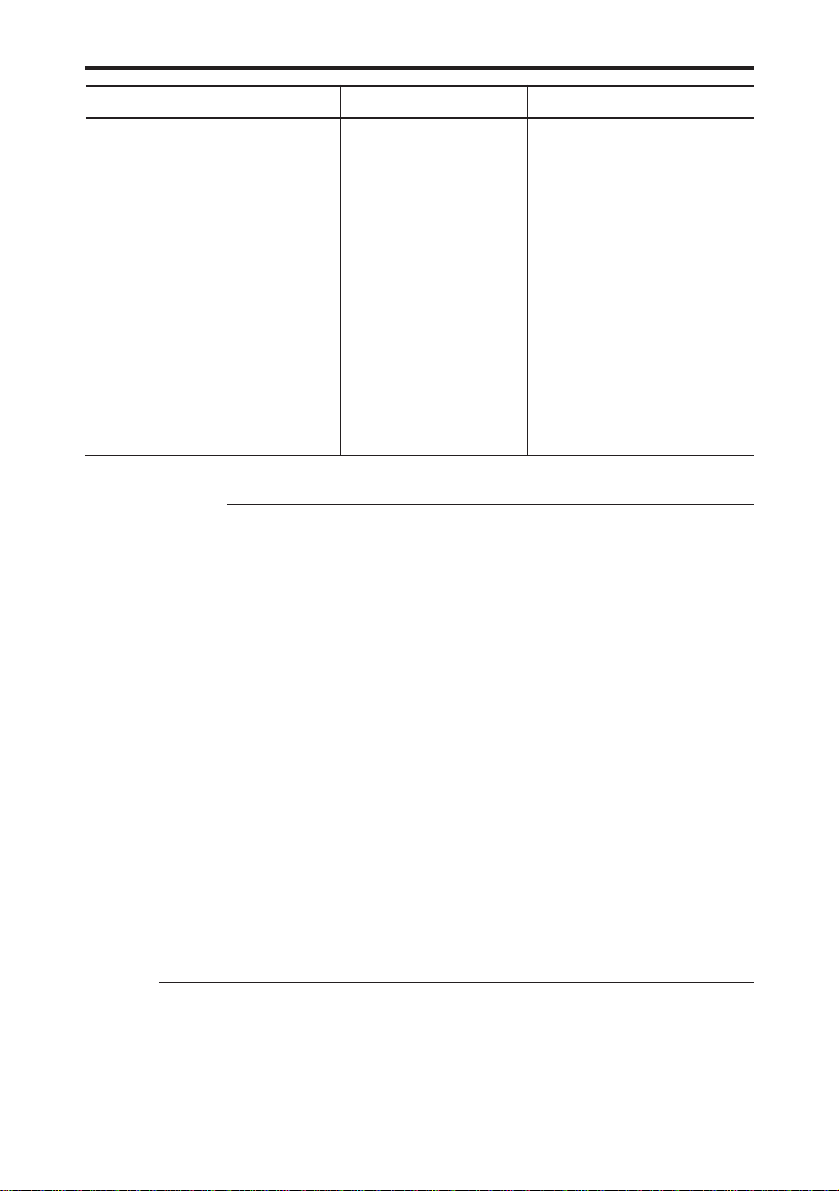

3. Printout of a RS232C linearscale output

The following explains the parameter setting when the RS232C interface is attached

to the linear scale and printed by the DP-1VR.

To start parameter setting mode: Simultaneously press 'DATA' key and 'POWER' key.

After parameter mode is started, setting parameters are printed in order. When you

want to change a setting, press 'STAT' key and when you don't want to change the

setting, push 'DATA' key, then the parameter will be set.

Next, a table of parameters is shown.

- 12 -

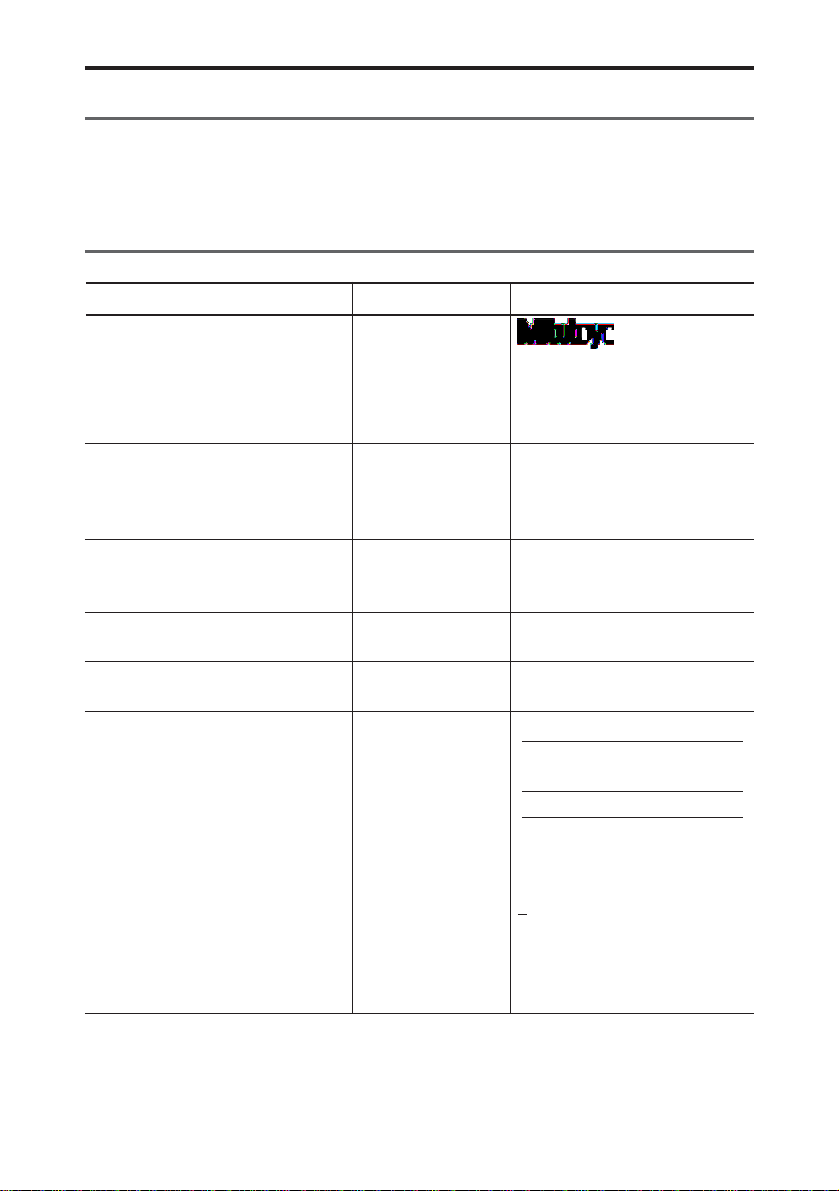

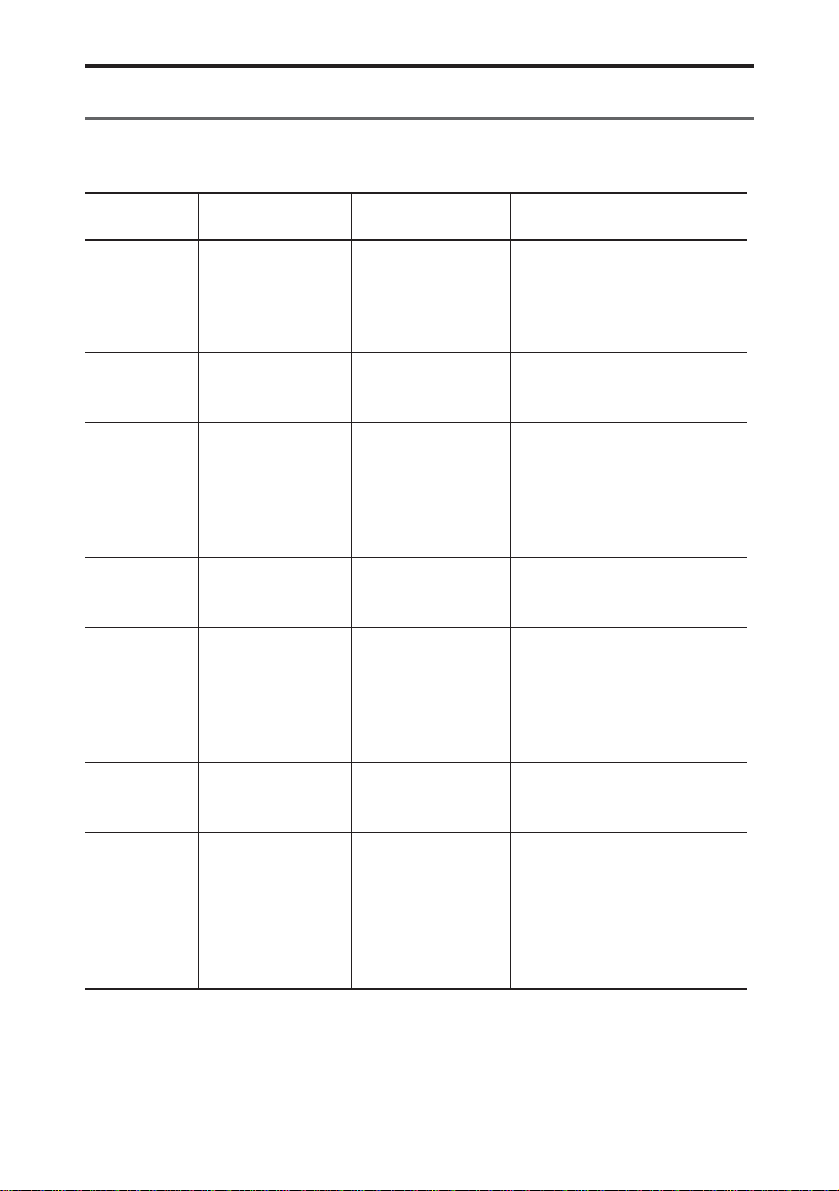

PARAMETER

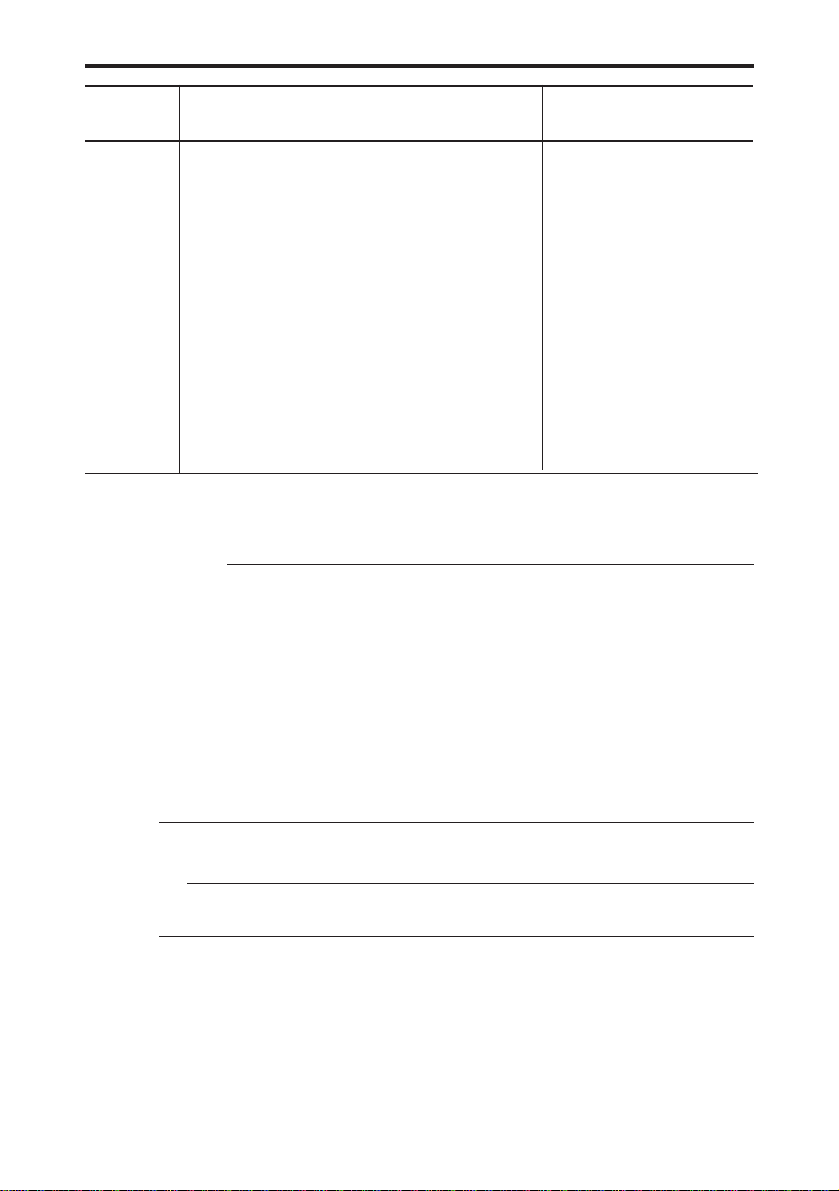

Table 2 Parameter in printing RS232CS output of counter

-rO

red

1

2

3

4

5

6

7

8

9

01

11

21

31

41

51

61

71

metIgnitteSnoitareporetnirPtluafeD

-TEMARAP

RAELCRE

METSYS

EDOM

KROW

EDOM

DUAB

ETAR

YTIRAP

ATAD

EZIS

EVAS

EMIT

ATAD

ATAD

EMIT

TINU

SIXA

7

THGNEL

TNIRP

REWOP

TNIRP

YTISNED

EDOMZB

TNIRP

TAMROF

hcnI

enoN

marG

noT

ecnuO

TUPNI

SIXALUC

raelcretemaraP

itluM/edom1-PDniteS PM edom1-PD

1EDOM/0EDOM

/0084/0042/0021

00291/0069

ddO/nevE/enoN

8/7

lamroN/egraL

lamroN/evasrewoP

kraD/lamroN

FFO/NOedomZB

FFO/NOTNIRPEMIT

TAMROFETAD

GNITTESETADgnitnirpnehW.g.e ,2.naJ

gnitteSEMITdradnatSesenapaJ

retemilliM

edargitneC

atadfosixateS

gnissecorp

mm

hcni

g

C°

t

.bL

tupniatadotsixateS

00291/0069

FFO/NO

FFO/NO

0002 tamrofatadgnisu

2/1/0002

0002/2/NAJ

0002/NAJ/2

ZYX

ZYX

RAELCRETEMARAP

1EDOM/0EDOM

0084/0042/0021

DDO/NEVE/NON

LAMRON/EGRAL

LAMRON/EVAS

KRAD/LAMRON

DD/MM/YYYY

YYYY/DD/MM

YYYY/MM/DD

.21nidenifedgnittes

RAELCONRETEMARAP

raelctonoD

sretemarap

1edoM

0084

NEVE

7

egraL

lamroN

lamroN

NO

DD/MM/YYYY

dradnatSesenapaJ

emiT

emiT

A/N

/sixaY/sixaX

sixaZ

sixaX

- 13 -

PARAMETER

IMPORTANT

◆ Set MP in action mode.

◆ Even if you do not perform statistical calculations, data processing axis should

still be set.

NOTE

◆ If the parameter is cleared, it is set to the default, except date and time.

◆ If the parameter is cleared, date and time is reset to 2001/1/1, 0:0

◆ Unit information is not sent out from the linear scale counter. So, if the unit is

not set, the unit is not printed in the data.

◆ It’s possible to connect with K series counter only.

- 14 -

PARAMETER

4. Example of parameter settings

Procedure to correctly set parameters is shown.

4.1 DP-1 parameter setting procedure

By entering the parameter mode, parameters can be set. To enter the parameter setting

mode when the electrical power is OFF, simultaneously press 'DATA' key and

'POWER' key. Then, the unit will enter the parameter mode.

In the parameter input mode, the following key operations can change setting details.

Parameter setting key Time setting

STAT

Setting change

PRINTER

Increase time

DATA

Set

CL

STAT

DATA

Date setting

PRINTER

STAT

DATA

Additional settings

● Parameter clear

● Letter size

● Date

● Time

Examples of settings are shown on the following pages.

CL

CE

Year increase

Month increase

Day increase

Prints date

Sets Date

Minutes increase

Prints time

Sets time

- 15 -

PARAMETER

Table 3 Example of parameter setting procedure

Key

operation

‘DATA’

+

‘POWER’

starting

STAT

DATA

Print Comments

PARAMETER SETUP MODE

SYSTEM MODE : DP-1

WORK MODE : MODE1

BAUDRATE : 4800

PARITY : EVEN

DATA LENGTH : 7

PRINT SIZE : LARGE

POWER SAVE : NORMAL

PRINT DENSITY : NORMAL

BUZZER MODE : ON

TIME PRINT : ON

DATE FORMAT : YYYY/MM/DD

DATE : 2000/ 1/ 1

TIME : 10:10

UNIT : AUTO

PUSH DATA : DATA FIX & GO

PUSH STAT : DATA CHANGE

PARAMETER NO CLEAR

PARAMETER CLEAR

PARAMETER CLEAR

SYSTEM MODE : DP-1

Print the current setup in

parameter setting mode.

Print all parameters.

If selecting clear, a buzzer

sounds 4 times.

DATA

DATA

DATA

DATA

DATA

STAT

DATA

DATA

DATA

DATA

MODE : MODE1

BAUDRATE : 4800

PARITY : EVEN

DATA LENGTH : 7

PRINT SIZE : LARGE

PRINT SIZE : NORMAL

POWER SAVE : NORMAL

PRINT DENSITY : NORMAL

BUZZER : ON

TIME PRINT : ON

- 16 -

If mode 2 is chosen,

'NORMAL' is selected and

this item can not be input.

Letter size can be changed

by the 'STAT' key.

Set by the 'DATA' key

PARAMETER

Key

operation

DATA

CE

CL

PRINTER

STAT

DATA

CL

PRINTER

STAT

DATA

Print Comments

CE : DAY

CL : MONTH

PRINTER : YEAR

PUSH EACH KEY TO INCREMENT

DATE 2001/1/1

'CE' key increments date

Rotate 1~31

'CL' key increments month

Rotate 1~12

'PRINTER' key

increment change by rotating 00~20

'STAT' key print date setting is not printed by

'CE' 'CL' 'PRINTER' key operations

Finish setting by the 'DATA' key

YYYY/MM/DD : 2001/2/2

CL : MIN

PRINTER : HOUR

PUSH EACH KEY TO INCREMENT

TIME 11:11

'CL' key increments minute

Rotate 0~59

'PRINTER' key increments time

Rotate 0~23

'STAT' key print time setting is not printed by

'CL' 'PRINTER' keys

HH:MM:SS 11:11: 0

Finish setting by the 'DATA' key

HH:MM:SS 11:11: 0

UNIT : AUTO

Change last 2 digits.

Seconds are fixed at 0.

Date and time is set and

written by the 'DATA' key.

In this case, second setting

is 0.

- 17 -

PARAMETER

Key

operation

DATA SYSTEM MODE : DP-1

WORK MODE : MODE1

BAUDRATE : 4800

PARITY : EVEN

DATA LENGTH : 7

PRINT SIZE : NORMAL

POWER SAVE : NORMAL

PRINT DENSITY : NORMAL

BUZZER : ON

TIME PRINT : ON

DATA FORMAT : YYY/MM/DD

DATE 2001/2/2

TIME 11:11

UNIT : AUTO

Print Comments

IMPORTANT

◆ Parameter input is memorized through the last operation. Do not stop the

operation if not completed.

◆ Setting the date and time is written when the time input is set.

◆ Appropriateness of data and time is not checked. Input normal value. Ex:

February 30th is incorrect.

◆ Leap years and length of months are calculated automatically.

◆ Clock is stopped during the parameter setting. When you set other parameters,

you should set the time too.

◆ Set time in the 24-hour system.

Printed summary of set

parameters

NOTICE

◆ After input is finished, it is transferred to the data input mode.

- 18 -

4

C

C

T

S

F

D

P

P

SUMMAR Y OF FUNCTIONS

1. Key functions

noitcnuF

yeK

L

)yekraelc(

E

yeklecnac(

TIMIL.LO

)yektimil(

TAT

)yektats(

DEE

)yekdeef(

ATA

)yekatad(

REWO

)yekrewop(

●

●

●

●

●

●

●

FFO/NORETNIR

)yekffo/noretnirp(

●

0edoM2,1edoM

tupnierofeb

.stimilrewoldna

noitcaoN

●

.atadderusaemylnosraelC

●

ylmrifhsup)niamersgnittes(

1.oN

stimiltesotecnavdani

tsujatadderusaemseteleD

●

tupni

uoynehwyeksihtsserP

●

ehtmorftixerootniretne

reppufonoitarepognittes

lacitsitatS

●

llahtiwedom

tuotnirpatad

detaluclac

dnatluser

ekam

margotsih

rewopcirtceleehtfoFFO/NO

gniruD

tluser

ehtsetelpmoc

ehtsretnedna

tuodefsirapapgnidrocer,desserpnehW

tnempiuqegnirusaemmorftupnisiataD

hctiwssihtybFFO/NOdenrutsiretnirP

3edoM

puorgbuS

gnirusaem

morftupni-eR

●

derusaemslecnaC

●

erofebtsujatad

foerusaemhsiniF

-uclacdnapuorgbus

tnirpdnaR,Xetal

dnasetaluclaC

●

rab-Xehttuostnirp

nehtseulavRdna

edomtnemerusaem

edomnoitaluclac

.detnirp

puorgbusretfA

signirusaem

etelpmoc

ylnosraelC

atadderusaem

)niamersgnittes(

-busseteleD

erofebtsujpuorg

tupnidehsinif

-buSehtroF

esohwspuorg

sahtupniatad

,detelpmocneeb

ehtfonoitaluclac

sistimillortnoc

dnatuodeirrac

erastlusereht

NOTICE

◆ Sample size is determined by ‘STAT’ of subgroup 1

‘STAT’ of subgroup 2 and following are effective when data of sample 2 option

is input.

- 19 -

SUMMARY OF FUNCTION

2. Function of each mode

0edoM1edoM2edoM3edoM

●

egduj

)a

G

hsup 'TIMIL.LOT' .erusaemotog,tonoduoyfI.yek

M

A

H

J

ehtyB 'ATAD' atupniremit,yek

/OG ±,

▲

LL

▼

LL

ton

●

noitcnuF

tnirpoT

derusaem

dna,atad

.ecnarelot

gnittestimiL

tnemerusaeM)b

lacitsitatS)c

noitaluclac

.detcudnoc

noitcnuF

egduj,atad

.margotsih

hsup,tnempiuqe 'ATAD' .yek

ehtgnihsupybteS 'TIMIL.LOT' .yek

dna,tnempiuqegnirusaem

.dedrocereraatadderusaem

timilreppurevo

timilrewolrednu

.margotsih

derusaemtnirpoT

mrofrep,ecnarelot

-aluclaclacitsitats

etarenegdna,snoit

ehtgnihsupybdegnahcebnac 'TATS' yek

ehthsup,tnempiuqegnirusaem 'ATAD' .yek

sdnammoctseuqerehtatad,ro

toof,tupniC232-SRehtmorf

fohctiwstuptuoataddnahctiws

●

왘

왗

noitaluclaclacitsitatS)c

ehtyB 'ATAD' remit,yek

.dedrocer

.tuptuo

LL

LL

noitcnuF

dna,snoitaluclac

ehtnoylsuoenatlumiseulavtimilrehtonatcelesoT

tnemerusaeM)b

tseuqeratad,tupni

ehtsesserpxedna

timil

rofdetcudnocsinoitaluclaclacitsitatS

ehtybemittahtotpuatadderusaem 'TATS'

dnastluserdetaluclacsdrocerdna,yek

●

hparg(trahc-DtnirpoT

ehtswohsylbisivtaht

derusaemfonoitairav

lacitsitatsmrofrep,)atad

.margotsihetareneg

,margotsihaeraperpdnastimiltnemgdujdroceruoyfI

.oNatadtimiL.5fospuorgniderotsebnacatadtimiL

yek

gnirusaemehtnoehttimilrewolroreppusserpxeoT

-SRehtmorfsdnammoc

derusaem,tupniC232

eratrahcDdnaatad

segduj,emitemasehttA

noitcejerroecnatpecca

tnemgdujgniwollof

timilreppurevo

rewolrednu

)c

G

M

noitcnuF

lliwti,atadgniretneyB

-Rawarddnaetaluclac

.trahclortnoc

S)atnemerusaempuorgbu

ybdetcudnocebnac

ehtgnihsup 'TIMIL.LOT'

tupniebnac9999foXAM

.puorgbusa

puorgbusafoeziselpmaS

.01~2si

tnemerusaeM)b

ehtyB 'ATAD' remit,yek

tseuqeratad,tupni

-SRehtmorfsdnammoc

dnahctiwstoof,tupniC232

fohctiwstuptuoatad

,tnempiuqetnemerusaem

eraatadderusaemdna

.dedrocer

tnemeganamnoitaluclaC

hsuP 'TATS' enoyek

,R,Xehtneht,emit

puorgtahtfonoitaluclac

.detnirpsi

dnaemiteromenohsuP

eulavtimillortnochcae

puatadhtiwdetaluclacsi

.detnirpdnaemittahtot

- 20 -

SUMMARY OF FUNCTION

3. Timer input function

This function is used when you intend to take in data automatically from measuring

equipment in the same interval.

Press the PRINTER ON/OFF key, and at this state pushing the PRINTER ON/OFF

key enters the unit to this function, and the following pressed key can set the interval

time. When you finish this function, press the PRINTER ON/OFF key, while pressing

the ‘CL’ key.

NOTE

1. ‘CL’ ‘CE’ ‘ STAT’ keys fulfill their functions even if taking in data by the

interval timer.

2. When the interval timer is finished, if data is stored in the buffer, that data may

be printed.

3. During data input by the interval timer, if you intend to change the interval

time, finish this mode once, clear data and reset.

● Each key and interval times are as follows.

Key Interval time

STAT 0.25 sec

TOL.LIMIT 1 sec

CE 5 sec

CL 30 sec

DATA 1 sec

FEED 30 minute

PRINTER ON/OFF 60 minute

NOTE

◆ Setting 0.25 sec, 1 sec, only statistical calculation results can be printed.

Measured data can not be printed. Also, when using 0.25 sec., the data buzzer

will not sound.

- 21 -

5

OPERATION

1. Power ON/OFF

Operation of power ON/OFF.

noitarepOyeKtnirP

NOrewoP

FFOrewoP

NOTE

◆ To prevent mis-operation, power can be cut only when the 'POWER' key is

pressed more than 2 sec. Note that the power can not be cut if the pushing time

is short.

◆ Contents of printout are a little different in the case of using extended letter

size from that of the standard letter size.

REWOP

*RV1-PD*

*1-EDOM*

2/2/0002ETAD

63:31EMIT

REWOP

dna.ces2nahteromsserP

.esaeler

- 22 -

2. Basic Operation 1

Basic operations that do not have set limits are shown.

Similar operations are conducted in Mode0, Mode1, Mode2 also.

2.1 Data input, cancel, clear

Function Operation Print

OPERATION

● Power ON

● Data input

Data can be input with the foot

switch interval timer or the

'DATA' key

● Data cancel

Cancel previous input data.

● Data all clear

Clear all input data

● Time printing

Print date and time

● Statistical calculation

Statistically calculates input data.

(This function is not available in

mode 0)

POWER

DATA

DATA

CE

CL

PRINTER ON/OFF

+ DATA

STAT

* DP-1VR *

* MODE 1 *

DATE 2000/ 2/ 2

TIME 13: 35

Take data from the measuring

tool and print.

1 12.23 mm

2 26.25 mm

* CANCEL *

* CLEAR *

DATE 2000/ 2/ 2

TIME 13:36

PART NO.

DATE 2000/ 2/ 2

TIME 13: 35

NAME:

*RESULT*

N56

MAX 81.26 mm

MIN 25.66 mm

R 55.60 mm

X 54.23 mm

σn 12.5635 mm

σn-1 13.5897 mm

- 23 -

OPERATION

IMPORTANT

◆ Recording paper of DP-1 is superior to characteristics of conservation and

tolerance to chemicals, but it shares limits with other thermal papers. In the

case of long storage (more than 5 years), or if used for public documents, you

should make a photocopy.

◆ If cutting fluid comes in contact with the recording paper, and those documents

will be stored for a long time, it is recommended to photocopy.

◆ In the case of mode 0

Statistical calculation can not be conducted.

Maximum data that can be handled: 100000

◆ In the case of mode 1

Maximum data that can be handled: 9999.

When 9999 data is input, statistical calculations are conducted automatically.

◆ In the case of mode 2

Maximum data that can be handled: 9999.

When 9999

Print type is same to mode1.

◆ If the time print parameter is OFF, date and time will not be printed.

data is input, statistical calculations are conducted automatically.

- 24 -

OPERATION

3. Basic operation 2

Operation procedures when tolerance limits are set is shown. Similar operations are

conducted in mode 0, mode 1 and mode 2.

3.1 Input of tolerance limit data

Operation to input limit data. Data is input through the connection of the measuring

equipment to the DP-1VR.

● Power ON

● Tolerance limit input mode

Tolerance limit input mode can

be entered the 'TOL.LIMIT' key.

Limit number can be changed

from 5 by the 'STAT' key.

● Input of limit data

After setting the upper and lower

limit for calipers, etc., press the

'DATA' key

Input order of the upper or lower

limit are performed in either order.

Data is recorded by the

'TOL.LIMIT' key.

POWER

TOL.LIMIT

STAT

DATA

DATA

TOL.LIMIT

Finish setting limits

* DP-1VR *

* MODE 1*

DATE 2000/ 2/ 2

TIME 13: 35

*LIMIT DATA 1*

LSL 12.56 mm

USL 25.89 mm

TOL 13.33 mm

*LIMIT MODE*

*LIMIT DATA 1*

*NO LIMIT DATA*

*LIMIT DATA 2*

LSL 12.56 mm

USL 25.89 mm

TOL 13.33 mm

LMT1 15.12 mm

LMT2 16.36 mm

*NEW LIMIT DATA*

*LIMIT DATA 2*

DATE 2000/ 2/ 2

TIME 13: 35

LSL 5.12 mm

USL 16.36 mm

TOL 1.19 mm

- 25 -

OPERATION

NOTE

◆ To enter the tolerance limit input mode, q it is necessary that data is not input

just after power on, or w all data is cleared by operation of the 'CL' key.

◆ In limit mode, limit data can changed by operation of the 'STAT' key. Maxi-

mum limit data of 5 is recorded. Reset limit data as necessary.

◆ When limit data is input by selecting the number of limit data already set, new

data is saved and old data removed.

◆ Limit data remains in memory even if the power is cut.

◆ Just after power ON, limit data used at the time of power cut are selected.

◆ When tolerance limit data is not necessary (when limit judgment is not

needed), select the limit number without limit data (refer to 3.2), or delete the

set limit data (refer to 3.3).

- 26 -

3.2 Confirmation/reset of the limit data

The operation of confirming contents of 5 of tolerance limit data and resetting

tolerance limit data to use.

OPERATION

● Confirmation and reset of limit

data. If limit data is not input or it

is cleared by the 'CL' key, the

operation is possible.

Tolerance limit data is renewed by

'STAT'.

Press the 'TOL.LIMIT' key, for the

required tolerance limit data.

Renewed limit data is obtained.

TOL.LIMIT

STAT

STAT

STAT

TOL.LIMIT

LIMIT MODE*

*LIMIT DATA 2*

LSL 12.36 mm

USL 25.67 mm

TOL 13.31 mm

*LIMIT DATA 3*

LSL 12.56 mm

USL 25.89 mm

TOL 13.33 mm

*LIMIT DATA 4*

* NO LIMIT DATA *

*LIMIT DATA 5*

LSL 12.36 mm

USL 25.67 mm

TOL 13.31 mm

*NEW LIMIT DATA*

*LIMIT DATA 5*

DATE 2000/ 2/ 2

TIME 13: 35

LSL 12.36 mm

USL 25.67 mm

TOL 13.31 mm

- 27 -

OPERATION

3.3 Release of the limit data

Operation to release the tolerance limit data. It is conducted when the limit data is not

necessary.

● Limit release

Press the 'CL' key to release

tolerance limit data. Limit data is

released.

TOL.LIMIT

CL

*LIMIT DATA 1*

LSL 12.36 mm

USL 25.67 mm

TOL 13.31 mm

*LIMIT CLEARD*

DATE 2000/ 2/ 2

TIME 13: 35

*LIMIT DATA 1*

*NO LIMIT DATA*

- 28 -

3.4 Data input, cancel, clear

Table 2 DP1 mode1, operation example 2

Function Operation Print

OPERATION

● Power ON

● Time print

● Data cancel

Prior input is canceled.

● Data input

All input data is cleared.

● Data input

Limit judgment is conducted for

the input data, displayed (LED)

and printed.

POWER

PRINTER ON/OFF +

DATA

CE

CL

DATA

DATA

DATA

* DP-1VR *

* MODE 1*

DATE 2000/ 2/ 2

TIME 13: 35

*LIMIT DATA 1*

LSL 12.36 mm

USL 25.67 mm

TOL 13.31 mm

DATE 2000/ 2/ 2

TIME 13: 35

* CANCEL *

* CLEAR *

H 1 12.00 mm

2 26.25 mm

G 3 32.56 mm

Input data, and relationship of display (LED) and print.

Input

Display

(LED)

Print

Input

data

−NG GO +NG −NG GO +NG −NG GO +NG

Lower

쏝

limit

value

Lower

limit

value

Input

data

Upper

limit

value

- 29 -

Upper

limit

value

Input

쏝

data

왖왔

OPERATION

Input data

Function Operation Print

Statistical calculation

● Statistical calculations are

conducted, when 9999 or more

data is input.

STAT

PART NO.

DATE 2000/ 2/ 2

TIME 13: 35

NAME

*RESULT*

N56

MAX 81.26 mm

MIN 25.66 mm

R 55.60 mm

X 54.23 mm

σn 12.5635 mm

σn-1 13.5897 mm

−NG 2

+NG 4

P 18.56%

Cp 0.45670

Cpk 0.30000

*HISTOGRAM*

LSL 12.36 mm

USL 25.67 mm

TOL 13.31 mm

DIV 10

- 30 -

−NG 2| □

LSL |NNNNNN

NNN

A2|□

B4|□□

C5|□□

D8|□□□□

E9|□□□□

F 11| □□□□□□

G4|□□

H9|□□□□

I5|□□

J4|□□

USL |NNNNNN

Function Operation Print

IMPORTANT

◆ DP-1 recording paper has superior characteristics of conservation and tolerance

to chemicals, but it shares limits with other thermal papers. In the case of long

storage (more than 5 years), or if used for public documents, you should make

photocopy.

◆ If cutting fluid comes in contact with the recording paper, and those papers are

necessary to be stored a long time, it is recommended to store after photocopying.

◆ In the case of mode 0

Statistical calculation cannot be performed.

Maximum data that can be handled: 100000

◆ In the case of mode 1

Maximum data that can be handled: 9999.

When 9999 data is input, statistical calculations are performed automatically.

◆ In the case of mode 2

Maximum data that can be handled: 9999.

When 9999 is input, statistical calculations are performed automatically.

Printing format of the data will be a D chart (analogical, volume changing

print)

◆ If the time printing parameter is OFF, date and time will not be printed.

OPERATION

NNN

+NG 4| □□

□ = 2

A 12.3600p

B 13.6910p

C 15.0220p

D 16.3530p

E 17.6840p

F 19.0150p

G 20.3460p

H 21.6770p

I 23.0080p

J 24.3390p

25.6700p

- 31 -

OPERATION

4. Mode 3

Function Operation Print

Example mode3 operation

Power ON

Initiate measurement of a subgroup

Transfer a subgroup to measuring

mode.

Data receiving

(Subgroup measure mode)

Data cancel

Cancels prior input data.

('CL' key pressed during

measurement of a subgroup)

Subgroup data is all cleared.

Data in subgroup is all cleared,

and are measured again from No.1

data.

('CL' key pressed during

measurement of subgroups)

Time printing

Finish measurement of subgroup

and calculate X-R of subgroup.

(Normal sub-group measure mode

is finished)

POWER

TOL.LIMIT

DATA

DATA

DATA

CE

CL

PRINTER ON/OFF+

DATA

STAT

* DP-1VR *

* MODE 3*

DATE 2000/ 2/ 2

TIME 13: 35

SUB GR. NO.1

Print data received in from

measuring equipment.

1 12.00 mm

2 26.25 mm

3 32.56 mm

* CANCEL *

* CLEAR SUB DATA*

DATE 2000/ 2/ 2

TIME 13: 35

X 0.92335 mm

R 2.77568 mm

PART NO.

DATE 2000/ 2/ 2

TIME 13: 35

NAME

Stop measurement of subgroup, and

release subgroup measure mode.

(Subgroup measure mode forced

finish)

TOL.LIMIT

- 32 -

* EXIT SUB GR. *

OPERATION

Function Operation Print

Measure next subgroup

Data input

Finish measurement of subgroup

and calculate X-R of subgroup

Calculation of control limits is

carried out from all the sub-group

data which has been input, and the

result is printed.

Time stamp

Cancels prior subgroup data. 'CE'

key is pressed after finishing

measurement of subgroup.

Clears measured data

'CL' key is pressed after finishing

measurement of subgroup.

TOL.LIMIT

DATA

DATA

DATA

STAT

STAT

PRINTER ON/OFF+

DATA

CE

CL

SUB GR. 2

Input data from measuring

equipment.

1 12.00 mm

2 26.25 mm

3 32.56 mm

X 0.92335 mm

R 2.77568 mm

PART NO.

DATE 2000/ 2/ 2

TIME 13: 35

NAME

*CONTROL LIMIT*

DATE 2000/ 2/ 2

TIME 13: 35

NO.OF SUB GR.

5

SAMPLE SIZE

8

X 4.1999 mm

X-UCL 6.9057 mm

X-LCL 1.4970 mm

R 2.6458 mm

R-UCL 6.8082 mm

R-LCL 6.8082 mm

DATE 2000/ 2/ 2

TIME 13: 35

*CLEAR SUB GR.*

*CLEAR ALL DATA*

- 33 -

OPERATION

5. Print RS232C of counter

Function Operation Print

● Power ON

If parameter time stamp is 'OFF',

data and time are not printed.

● Time stamp

● Data cancel

Prior data input is canceled.

● Data all clear

All input data is cleared.

● Data input

Limit judgment is conducted for

input data and displayed (LED) and

printed.

Meanings of the symbols are as

follows.

H : DATA lLower limit

: Lower limit mDATA m Upper

limit

G :Upper limit l DATA

DATA : Input data

Statistical calculation

● Statistical calculations are

started automatically where the

th

data is input.

9999

POWER

PRINTER ON/OFF +

DATA

CE

CL

DATA

DATA

DATA

STAT

* DP-1VR *

* MODE 1*

DATE 2000/ 2/ 2

TIME 13: 35

*LIMIT DATA 1*

LSL 12.365

USL 25.675

TOL 13.310

DATE 2000/ 2/ 2

TIME 13: 35

* CANCEL *

* CLEAR *

H1 X 12.000

Y 23.565

2 X 24.254

Y 23.896

G3 X 32.566

Y 23.896

*RESULT*

PART NO.

DATE 2000/ 2/ 2

TIME 13: 35

- 34 -

NAME

N56

MAX 81.26

MIN 25.66

OPERATION

Function Operation Print

R 55.60

X 54.23

σn 12.5635

σn-1 13.5897

−NG 2

+NG 4

P 18.56%

Cp 0.45670

Cpk 0.30000

*HISTOGRAM*

LSL 12.36

USL 25.67

TOL 13.31

DIV 10

−NG 2| □

LSL |NNNNNN

NNN

A2|□

B4|□□

C5|□□

D8|□□□□

E9|□□□□

F 11| □□□□□□

G4|□□

H9|□□□□

I5|□□

J4|□□

USL |NNNNNN

NNN

+NG 4| □□

□ = 2

- 35 -

A 12.3600p

B 13.6910p

C 15.0220p

D 16.3530p

E 17.6840p

F 19.0150p

G 20.3460p

H 21.6770p

I 23.0080p

J 24.3390p

25.6700p

6

In order to ensure data reliability of the SDP interface, DP-1VR reads the data twice.

Some models (KC counter with code out unit No. 09CAA462 etc.) are incapable of

performing the above data checking routine.

For those models, you must perform the following procedures by changing the

interface mode.

Interface mode is interchangeable with the former products (DP-1HS) by setting it for

COMPATIBLE.

STAT: To change modes

DATA: To set the mode and to end the operation

OTHER NO TES

Operation Printout

CE + POWER * DP-1VR *

SELECT SDPINTERFACE

PUSH STAT: MODE CHANGE

PUSH DATA: MODE FIX

INTERFACE: ADVANCED

STAT INTERFACE: COMPATIBLE

DATA Changing to data input mode

- 36 -

7

Daily maintenance of DP-1VR

MAINTENANCE

1. Clean printer head

When dust collects on the printer head, print quality is adversely affected, and

sometimes printing is impossible due to damage to the printer head. It is recommended cleaning the printer head periodically.

Cleaning method:

After opening the printer cover the printer head can be seen. Rub the printer head

with a cotton swab soaked in a little alcohol. After that, wipe off the remaining

alcohol lightly with a dry cotton swab until dry.

2. Clean paper sensor

If the paper sensor becomes dirty, detection of the record paper is impossible and

normal operation can not be conducted. It is recommended to clean the paper sensor

portion periodically.

Cleaning method:

After opening the printer cover the printer sensor can be seen. Rub the printer sensor

with a cotton swab soaked in a little alcohol. After that, wipe off the remaining

alcohol lightly with a dry cotton swab until completely dry.

◆ Just after finishing printing, do not clean. Printer head is hot; you may burn

your hand. Also, that heat may set the alcohol on fire.

◆ Alcohol left on the head should be dried completely, since there is a possibility

it could ignite.

◆ Handle the alcohol carefully.

◆ Do not use thinners, benzene etc., only use alcohol.

- 37 -

MAINTENANCE

Paper sensor

Printer head

Paper cutter

- 38 -

8

ERROR MESSAGE

1. Alarms concerning electric power

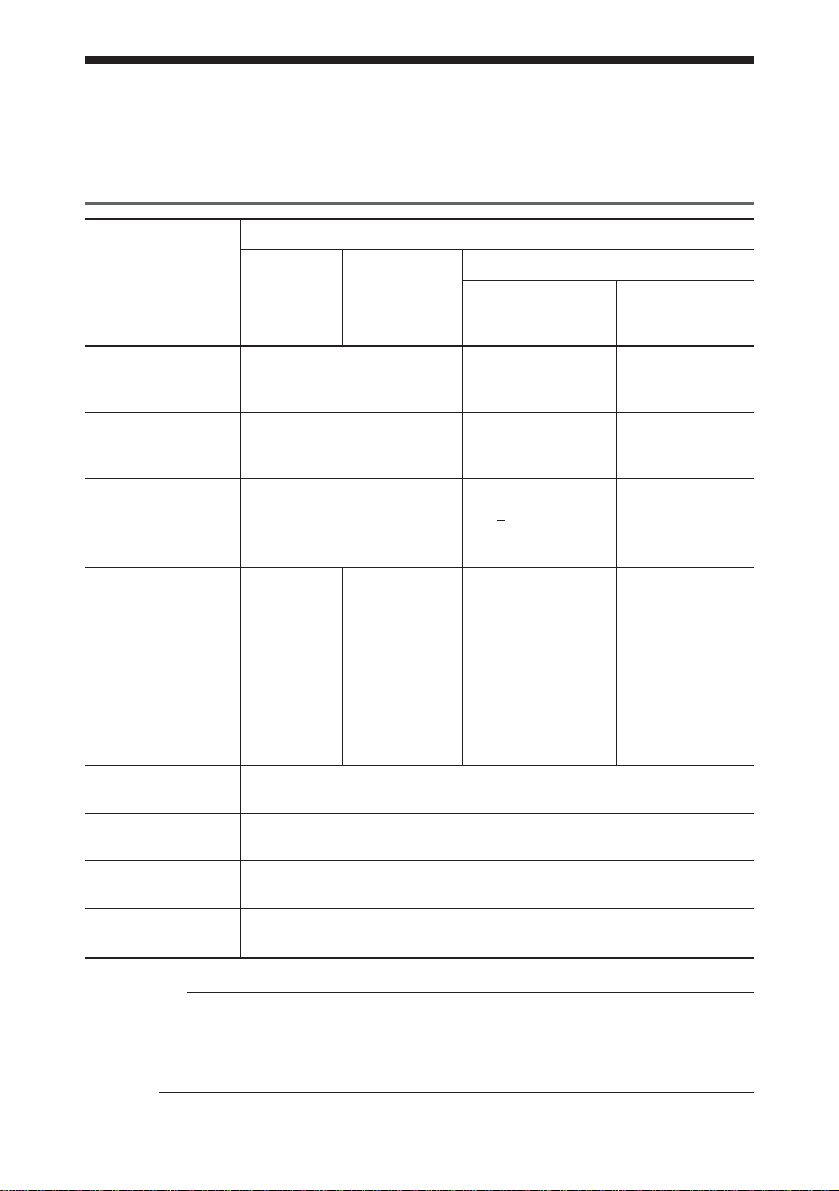

Table 1 Power related alarms

noitidnoC

hgihyllamronbA

egatlov

lamroNV5.4~0.01nosyawlAelbissoP

;egatlovwolylthgilS

noituac

egatlovtahtesacehtnI

yrettabehtspord

.decudersiyticapac

egatlovwolyllamronbA

egatlovtahtesacehtnI

semocebdnawolsi

.elbissopmi

egatloV

noitceted

nahterom

V0.01

V2.4~V5.4ces3.0,FFOces5.1

NO

V2.4nahtsseLces6.0,NOces6.0

NOTICE

◆ If the power goes off, data that was not saved is lost. Be sure to save all data

before removing the AC adapter from the DP-1VR during operation, even if

the DP-1VR is not being operated by the AC adapter.

◆ Using batteries under 10°C may shorten battery life expectancy. If the

operating temperature is under 10°C, use the AC adapter.

hsalfDELrewoP

FFOdnaNO

nretap

ces6.0,noces6.0

taeperffo

ces3.0,FFOces3.0

taeperNO

taeperFFO

ataD

tupni

elbissopmIniaganorewoP

elbissoPfirevoceR

elbissopmIniaganorewoP

esaeleR

noitidnoc

snruteregatlov

lamronot

.noiger

- 39 -

ERROR MESSAGE

2. Other alarms

Table Error alarm of DP-1VR

fodniK

mrala

●

metsyS

●

rorre

●

* WOLFREVO *

wolfrevO

●

motpmySesuacelbissoPseidemeR

rewopretfatsuJ

lla,no sDEL hsalf

●

●

dnaffodnano

fororrelataF

.derrucco1-PD

gnitarepO

.sdnuosrezzub

.wolootrohgih

●

dnoyebsitI

.detnirpsi

●

fI.niagapurewopotyrT

ruomrofni,sruccoerelbuort

ecivresroeciffotseraen

ootsierutarepmet

gnitaluclacelbissop

.krowten

●

●

'ybatadraelC LC yek'

C°54~C°0neewtebesU

.noitarepo

.aera

●

repapoN

●

DEL fo − GN ,

+ GN dnanosehsalf

●

gnidroceroN

●

repapgnidrocerecalpeR

.repap

.ffo

●

enilderA

ehtnosraeppa

.repapdrocer

●

●

neporevoC

)pudaeH(

sitnempiuqe

.detcennocton

●

DEL fo − GN ,

+ GN dnanosehsalf

.ffo

* EGAGON *

tnemerusaeM

●

●

forevoC

●

revocesolC

sirepapgnidrocer

.nepo

.detnirpsi

●

●

silootgnirusaeM

●

.detcennocton

elbacgnitcennoC

●

tnempiuqe

lootgnirusaemtcennoC

elbacgnitcennocegnahC

.nekorbsi

●

●

tamrof

* TAMROF

tcerroctoN

●

RORRE *

tcatnoclamronbA

●

elbacgnitcennocni

tupnifotamroF

●

●

.tnereffidsiatad

gnitcennocehtmrifnoC

.elbacgnitcennocfonoitrop

.elbacgnitcennocegnahC

gnitcennocehtmrifnoC

.elbacfonoitrop

●

tinu

* RORRETINU *

tnereffiD

●

atadtupnifotinU

●

.tnereffidsi

fotinunehwdetnirpsitI

laitinimorftnereffidsiatad

emasfoatadtupnI.atadtupni

.atadtupnilaitinisatinu

●

-elottesmorftinutnereffiD

tupnI.tupnisiatadtimilecnar

.atadtimilsatinuemasfoatad

- 40 -

ERROR MESSA GE

fodniK

mrala

nirorrE

* RORRETNIOP *tnioplamiceD

tnioplamiced

motpmySesuacelbissoPseidemeR

●

tupnifonoitisop

.tnereffidsiatad

lamicedehtnehwdetnirpsitI

morftnereffidsinoitisoptniop

lamicedehT.atadtupnilaitini

emasehtebdluohsnoitisoptniop

.atadlaitiniehtsa

●

tnioplamicedtnereffiD

siatadtimiltesmorfnoitisop

emasehtfoatadtupnI.tupni

timilsanoitisoptnioplamiced

.atad

●

fonoituaC

●

wolfrevo

rofspeebowT

●

tupniatadhcae

wolfrevootraeN

●

dna,tnemerusaemhsiniF

.noitaluclaclacitsitatstcudnoc

ehtgnisuatadraelc,tahtretfA

' LC .yek'

- 41 -

9

CALCULATION METHOD

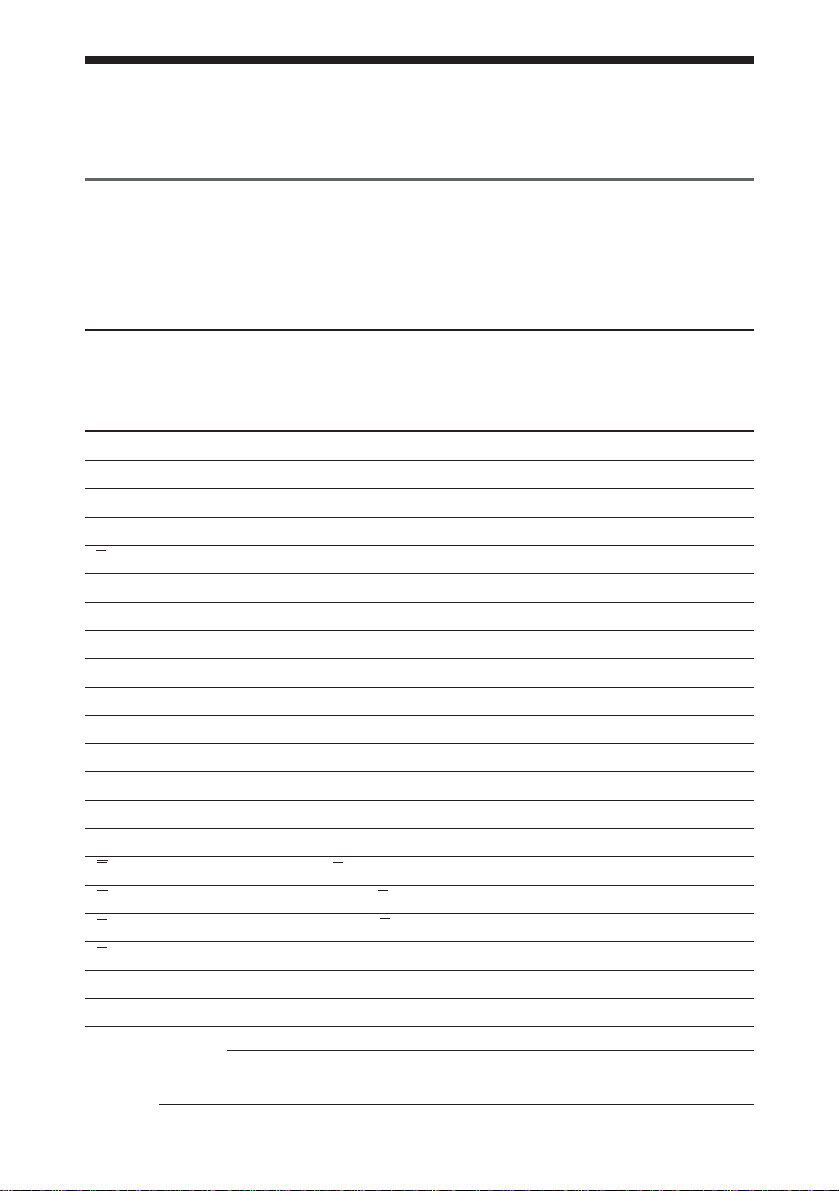

1. Significant figure

Significant figures of calculation are as follows.

When significant figures (figures after the decimal point) of input data are A, signifi-

cant figures are displayed.

Significant Figure

Displayed

Sign Meaning

DATA Input data A —

N Data count 0 —

MAX Maximum value A —

MIN Minimum value A —

R Range A —

X Mean A+2 Last figure±1

σn Standard deviation A+2 Last figure±1

σn-1 Standard deviation A+2 Last figure±1

P Percent defective 3 (**.***%) Last figure±1

CP Process capability index 3 Last figure±1

CPK Process capability parameter 3 Last figure±1

LSL Lower limit value A Last figure±1

USL Upper limit value A Last figure±1

DIV Histogram division number 10 division fix —

Histogram region express A+2 Last figure±1

X Center (X control) A+2 Last figure±1

X-UCL Upper control limit (X control) A+2 Last figure±1

X-LCL Lower control limit (X control) A+2 Last figure±1

R Center (R control) A+2 Last figure±1

R-UCL Upper control limit (R control) A+2 Last figure±1

R-LCL Lower control limit (R control) A+2 Last figure±1

significant figure

(figure after the

decimal point)

Error

IMPORTANT

Range to apply calculation error is revealed in the calculation error detail.

- 42 -

CALCULATION METHOD

2. Overflow and calculation error

● Overflow and calculation error

Overflow conditions of DP-1VR and calculation error are shown below:

Overflow of DP-1VR is different due to mean value and amount of data.

This is shown in the graph overflow condition.

● Viewpoint of graph

If mean value 10 m is measured with 2 figures after the decimal point (by caliper

etc.), how much of data can be measured, is checked.

q Data 10000.00 is changed to 1000000 as no decimal point.

w Vertical axis 1000000 on graph is extended to the horizontal direction and

compared to the horizontal axis.

e 2000 is obtained as the number of the data.

r When the data of the mean value 10 m is measured about 2000, it is recog-

nized that the overflow happens.

Condition of overflow

10000000

8000000

6000000

4000000

2000000

-2000000

Data mean value

-4000000

-6000000

-8000000

-10000000

0

0

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Overflow region

Overflow region

IMPORTANT

◆ Overflow seldom happens in usual measurement by calipers or micrometers

etc.

◆ When this unit is used for printing of a linear scale counter, overflow may

happen. Be careful when referring to a graph of this condition that overflow

may happen.

Data Count

- 43 -

CALCULATION METHOD

NOTE

◆ Mean value of the data shows the state when the decimal point of the data is

neglected.

Ex 10.00 is changed to read 1000

3. Calculation error detail

Calculation error of DP-1VR is shown below:

Calculation error of DP-1VR is defined as follows.

q Last figure ±1 count. Graph expresses the inside of the overflow limit of the

calculation preciseness.

Dispersion of data is set at ±5% of the mean value.

w When the dispersion of the mean value is far beyond the mentioned value,

calculation error is over ±5.

e For A region (±1000000, data count less than 2000), in all cases, calculation error

is less than ±1.

Preciseness of calculation

10000000

8000000

6000000

4000000

2000000

-2000000

Data mean value

-4000000

-6000000

-8000000

-10000000

0

0

A

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Overflow region

Overflow region

NOTICE

Data Count

◆ Mean value of data shows the state when the decimal point is neglected.

Ex 10.00 is changed to read 1000

- 44 -

CALCULATION METHOD

4. Calculation formula

4.1 Calculation of Mode1, Mode2

Table 2 Calculation formula 1

PRINT MEANING FORMULA

N

MAX

MIN

R

X

σn

σn-1

−

NG

+NG

P

CP

CPK

Data count

Maximum value of data

Minimum value of data

Range of data

Mean value of data

Standard deviation

Sample standard derivation

Amount of data smaller

than lower limit

Amount of data larger than

upper limit

Fraction defective

Process capability index

Process capability index

which considers deviation.

MAX-MIN

ΣXi/N

σn = n

((N NΣXi

2

− (ΣXi )

2

) / N2 )

1/2

σn - 1 =

((N NΣXi

2

− (ΣXi )

2

) / N N(N−1))

1/2

Number of data to become LSL LXi

Number of data to become LSL lXi

P =

((−NG) + (+NG))/N

P =

C

TOL/(6σN+1)

(TOL:USL+LSL)

PK=

C

Zmin/3

Zmin: ZUSL, ZLSL Smaller value of ZLZL

-

ZUSL = (USL

ZLSL = (X

X) /σn-1

-

LSL) /σn-1

- 45 -

CALCULATION METHOD

4.2 Calculation Mode3

N : Data count

MAX: Maximum value of data

MIN: Minimum value of data

n : Number of subgroup

A2 : Refer to table

D3 : Refer to table

D4 : Refer to table

Maximum number of data in each subgroup is 10

Table 3 Mode3 table of variables

SAMPLE SIZE n A2 D3 D4

2 1.880 3.267

3 1.023 2.574

4 0.729 2.282

5 0.577 2.114

6 0.483 2.004

7 0.419 0.076 1.924

8 0.373 0.136 1.864

9 0.337 0.184 1.816

10 0.308 0.223 1.777

Sign Meaning Formula

X

R

X

X-UCL

R

R-UCL

R-LCL

Mean value of subgroup

Range of subgroup

Center value

Upper control limit

Center (R control)

Upper control limit

(R control)

Lower control limit

(R control)

X = ΣXi/ N

R = Xmax - Xmin

X = ΣXi/ n

X - UCL = X - A2 N R

R = ΣRi/ n

R - UCL = D4 N R

R - UCL = D3 N R *1

ADDITION

*1 R-LCL is not printed, when the number of samples is less than 6

- 46 -

10

By connecting the optional cable (NO. 965465) to the OUTPUT connector located at

the side of this unit, either GO/±NG judgment for the input data or measured data in

RS-232C format can be output through the OUTPUT connector.

OUTPUT

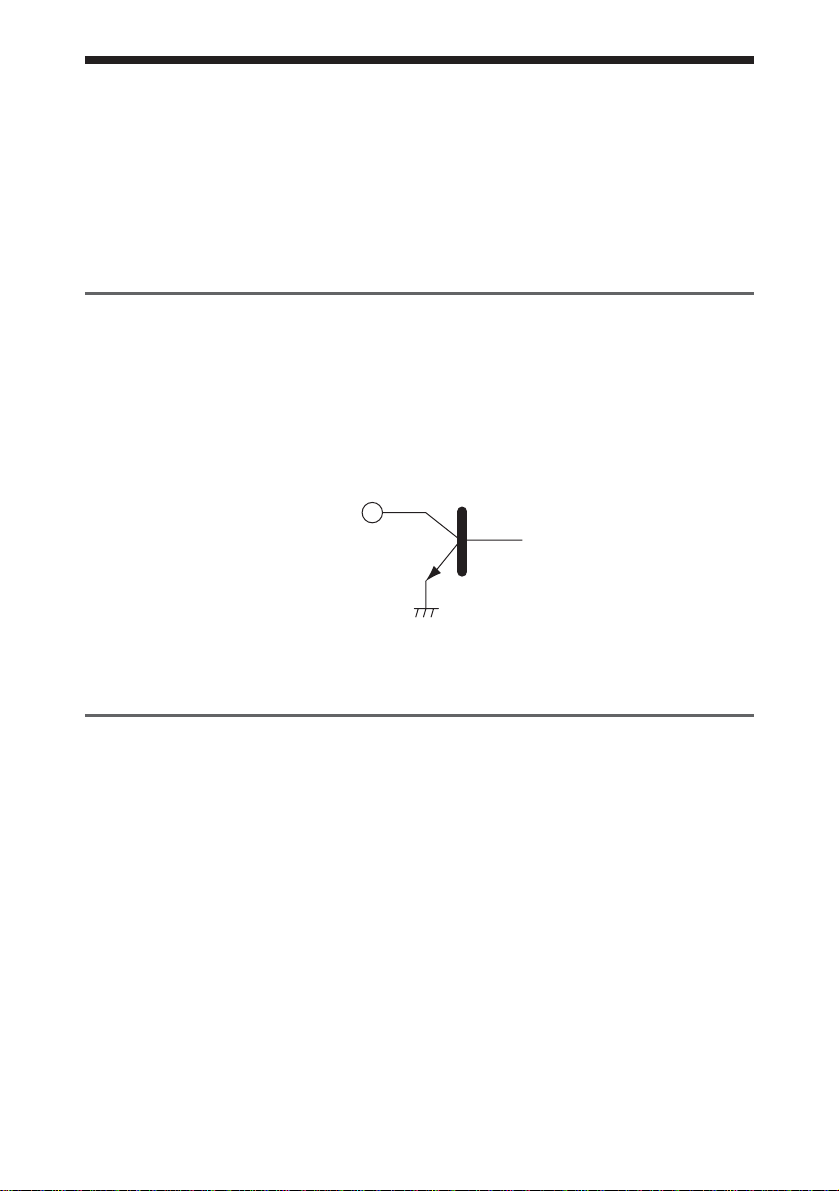

1. Output of GO/±NG Judgment

When the optional GO/±NG judgment result output cable (NO. 965516) is connected

to this unit, and it is in MODE0, MODE1, or MODE2 with the upper and lower

tolerance limits set. These judgment results will be output though an open collector.

2SC4047 or equivalent

Vceo (max) = 50V

IC (max) = 100mA

2. Output in Accordance with RS-232C Format

The data entered in the DP-1VR will be output to an external device in RS-232C

format when: the 'DATA' key of this unit is pressed, timer signals are input, this unit

receives a data request command via the RS-232C, or when the foot switch or data

output key is pressed on the measuring unit. However, the results of the calculations

performed in this unit are not output to an external device. Use the RS-232C conversion cable (Part No. 09EAA084) to output from this unit. Also use this cable to

receive output signals in RS-323C format from the Liner Scale Counter.

- 47 -

OUTPUT

2.1 Communication Specifications

Output Signal Level: TTL Level

Communication Method: Half-Duplex

Transmission Speed: 1200, 2400, 4800, 9600, 19200

Bit Construction: Start bit 1 bit

Data bit 7/8 bits

Parity Check EVEN/ODD/NONE

2.2 Data Format

D13D4D3D2D1 D5-D12

CR

DATA (Floating decimal point) D12LSD

Sign: positive (+) and negative (-)

Measuring item: A

Channel No.: 1

Code No.: 0

- 48 -

2.3 Error Code

D4D3D2D1

CR

Error Code: 1 Data entry error

2 Entry does not satisfy the specified format

9 System error

Head temperature error

Power voltage error

Over flow

Channel No.: 1

Error Format: 9

2.4 Data request command

OUTPUT

Paper error

D2D1

CR

Code No.: 1 or A

- 49 -

11

Checks and Remedies-Before diagnosing a problem as a defect, check the following

information.

When the DP-1VR malfunctions, diagnose the problem and remedy of the situation

with the aid of the following table.

If the problem still persists, please contact your dealer or the nearest Mitutoyo sales

office. (For the addresses, refer to the end of this manual.)

The warranty period of the DP-1VR is one year from the date of purchase for use.

Repair of this unit may be subjected to charge, depending on the case within and after

this period.

TROUBLESHOO TING

- 50 -

TROUBLESHOOTING

Symptom Possible cause Remedies

When printing, the

DP-1VR unexpectedly returns to the

initial state seen

after the power is

turned ON.

Printing is too

light

Printer does not

print

Miscounting often

occurs on the

measuring

instrument side

● Manganese dry cells are used by

mistake

● Peeling or poor fitting of the seal

is present on the battery pole

● The specified AC adapter is not

used.

● The DP-1VR supply power is

connected to the measuring

instrument.

● Input voltage to the AC adapter

(i.e. AC line voltage) is too low;

falls 5% or more than the rated

voltage

● The AC adapter is sharing the

same power line with a highvoltage or large-current device

● The printing head is not clean

● [PRINTER ON/OFF] switch is

turned to OFF

● The printer is jammed with

paper, etc

● The DP-1VR is in the timer

input mode and the input interval is

set to 0.25 or 1 sec.

● The AC adapter is sharing the

same power line with a highvoltage of large-current device.

● Use properly charged size AA

Nickel Hydrogen battery (Ni-Mh)

or Alkali battery (LR6)

● Correct the peeling or poor

fitting of the seal

● Use the dedicated AC adapter

09EAA088 (100/115V)

09EAA088D (230V)

09EAA088E (230V UK)

supplied with the DP-1VR

● The DP-1VR power supply

should not be connected to the

measuring device. Use a separate

power supply for each of them

● Adjust the voltage supply of the

power line correctly, and confirm

the result

● Connect the AC adapter to a

separate power line

● Clean the printing head with a

cotton swab, etc

● Press the [PRINTER ON/OFF]

switch again to turn on.

● Remove it by tweezers, etc

● When the input interval is set to

0.25 or 1 sec, the printer will be

automatically turned off.

● Connect the AC adapter to a

separate power line

- 51 -

12

Item Description Remarks

Code No.

Printing Method

Character format

Printing Speed

Printing line

numbers per

printing roll

Power supply

Operating

Temperature

Storage Temperature

Accuracy

Clock battery life

expectancy

Battery life

Dimensions

Weight

Printouts

SPECIFICATIONS

264-504

Line thermal 384 dot

36 × 24 (Large) 24 × 14 (Normal)

0.5 sec. per line

7000 lines / 1 roll (normal)/

1000 lines / 1 roll (large)

AC adapter (6V, 500 mA)

Alkali battery size AA (LR6)

Or 4 size AA Ni-MH batteries

0 ~ 45°C (AC Adapter)

10 ~ 45°C (batteries)

−10 ~ 50°C

±2 min. max / month

Approx. 10 years

10000 lines 1600 mAh Ni-MH

Printing every 5 sec.

201.1 × 94 × 75.2

(D × W × H)

390 g

Measurements, GO/±NG judgment results

Measurements, GO/±NG judgment

results, Number of measurements, MAX.,

MIN., Range, Standard deviation (σ–n,

σn-1), Number of defects, Percentage of

defects, Process capability index (C

CPK), Histogram

Same as above plus D-Chart

Function of calculating the center value

between the control limits required for

generating various control charts

100V

When using AC adapter

Dual power supply

*AC adapter input voltage

within a range of 100VAC

±5%

In a package as specified by

Mitutoyo

Average life expectancy

Average life expectancy but

valies with usage

Without accessories

Mode 0

Mode 1

P,

Mode 2

Mode 3

- 52 -

SPECIFICATIONS

Item Description Remarks

Processing

capability

Output function

Timer-controlled

data input

Standard accessories

Optional accessories:

100000

9999

10 × 9999 = 99990

(Sample size × Number of sub-groups =

total number of measurements)

5 sets of limit data

Measured data (RS-232C, TTL level)

GO/±NG

Judgment results (+NG, GO, −NG)

0.25 sec, 1 sec, 5 sec, 30 sec, 1 min, 30

min, 60 min.

AC Adapter

Recording paper: 1 pc.

(58 mm (W) × 48 m (L))

Strap

Quick Reference

User’s manual

Mode 0

Both Mode 1 and 2

Mode3

110V/115V 09EAA088

230V 09EAA088D

230V (UK) 09EAA088E

When ordering

Part No. 09EAA082

(10 pcs.)

09EAA079

09EAA090

99MBE021

Item Name Parts No.

RS-232C conversion cable No. 09EAA084

9 pins for AT connector

GO/±NG judgment result output cable No. 965516

Foot Switch No. 937179T

Consumables:

Item Name Parts No.

Printing Paper (10 packs) No. 09EAA082

- 53 -

SPECIFICATIONS

SERVICE NETWORK

MTI Corporation

New Jersey Office

18 Essex Road, Paramus, N.J. 07652, U.S.A.

TEL: (201)368-0525 TELEX: 134317 FAX: (201)343-4969

Detroit Office

45001 Five Mile Road, Plymouth, M? 48170, U.S.A.

TEL: (313)459-2810 FAX: (313)459-0455

Chicago Office

965 Corporate Blvd., Aurora, IL 60504, U.S.A.

TEL: (708)820-9666 FAX: (708)820-7403

Dallas Office

2410 Gateway Drive, Irving TX 75062, U.S.A.

TEL: (214)550-8645 FAX: (214)550-8861

Los Angeles Office

16925 East Gale Ave., city of Industry, CA91745, U.S.A.

TEL: (818)961-9661 FAX: (818)333-8019

MTI Canada Ltd.

2121 Meadowvale Blvd., Missiassauga, Ont, L5N 5N1,

CANADA

TEL: (905)821-1261~3 FAX:(905)821-4968

Mitutoyo do Brasil Industria e Comercio Ltda.

AV. Joao Carlos da Silva Borges, 1240, CEP 04726

Santo Amaro P.O. Box 4255 Sao Paulo, BRASIL

TEL: (011)522-7755 TELEX: 1123768 MTOY BR

FAX: (011)523-3661

Mitutoyo Mexicana S.A. de C.V.

Ave. Primero de Mayo No. 236-A San Andres, Atoto 53500

Naucalpan, Edo. de MEXICO

TEL: 576-8799 TELEX: 1772007 FAX: (915)576-8039

Mitutoyo Mebgerate GmbH

Borsigstr. 8-10, 41469 Neuss F.R. GERMANY

TEL: (02137)102-0 TELEX: 8517702 FAX: (02137)8685

Mitutoyo Nederland B.V.

Postbus 550, Landjuweel 35, 3905 PE Veenendaal,

NETHERLANDS

TEL: 08385-34911 FAX: 08385-16568

Mitutoyo Scandinavia A.B.

Box 712, Stockholmsvagen 26, 194 27 Upplands-Vasby,

SWEDEN

TEL: (08)590 921 35 TELEX: 15353 FAX: (08)590 924 10

Mitutoyo Belgium N.V.

Hogenakkerhoek straat 8, 9150 Kruibeke, BELGIUM

TEL: (03)8303063 FAX: (03)8278360

Mitutoyo France S.A.R.L.

123, rue de la Belle Etoile, B.P. 50267-Z.I. Paris Nord II

95957 Roissy CDG Cedex, FRANCE

TEL: (01)49 38 35 00 TELEX: 233913 FAX: (01)49 38 35 35

Mitutoyo France S.A.R.L., Agence de Lyon

Bat L133, avenue du Dr. Georges Levy 69200

VENISSIEUX

TEL: (16)78752010

Mitutoyo Italiana S.R.L.

Corso Europa No.7, 20020 Lainate, Milano, ITALY

TEL: (02)935781 FAX: (02)9373290

Mitutoyo Schweiz AG

Steinackerstrasse 35, 8902 Urdorf-Zurich, SWITZERLAND

TEL: (01)7361150 FAX: (01)7361151

Mitutoyo (U.K.) Ltd.

Joule Road, West Point Business Park, Andover,

Hampshire

SP10 3UT UNITED KINGDOM

TEL: (01264)353123 TELEX: 477694 FAX: (01264)354883

Mitutoyo Asia Pacific Pte. Ltd.

Reginal Headquarters

24 kallang Avenue, Mitutoyo Building, SINGAPORE 339415

TEL: 294-2211 TELEX: RS 25875 MTYSIN FAX: 299-6666

Malaysia

Head office

Mitutoyo (Malaysia) Sdn. Bhd.

Lots 1-8 Ground Floor, Asia Jaya Commercial Complex,

Section 52, 46200 Peteling Jaya, Selangor, MALAYSIA

TEL: (60)3-757-2524 FAX: (60)3-757-2540

Panan Branch Office

No.9 Jalan Selat, Taman Selat 12000, Butterworth, Penang,

MAYALYSIA

TEL: (60)4-310915/8 FAX: (60)4-310907

Johor Office

20A, Jalan Abiad, Taman Tebrau Jaya 80400, Johor Bahru,

Johor, MAYALYSIA

TEL: (60)4-310915/8 FAX: (60)7-336861

Thailand:

Representative Office

9th Floor, Unit D2-3, MBK Tower, 444 Phayathai Road,

Bangkok, THAILAND 10330

TEL: (66)2-217-9651/3 FAX: (66)2-217-9654

India:

Representative Office

702, Arunachal Building, 19, Barakhamba Road,

New Delhi-110001, INDIA

TEL: (91)11-332-4419 TELEX: 031-62939 MAP IN

Mitutoyo Taiwan Co., Ltd.

5th FL. No. 123, Wu Kung First Road, Wu Ku Industrial

Park, Taipei Hsien, TAIWAN, R.O.C

TEL: (02)299-5266 FAX (02)299-2358

Please contact your nearest technical service center, for problems or questions about this

product.

- 54 -

Mitutoyo Corporation

20-1, Sakado, 1-chome, Takatsu-ku, Kawasaki, Kanagawa 213-0012, Japan Printed in Japan

Loading...

Loading...