No. 99MBA038

A

SERIES No. 264

QM-Data 200

2D Data Processing Unit

(Operation Guide)

User’s Manual

Read this User’s Manual thoroughly

before operating the instrument. After reading,

retain it close at hand for future reference.

CONVENTIONS USED IN THIS MANUAL

Types of Notes

The following types of notes are used in this manual to help the operator obtain reliable

measurement data through correct instrument operation.

IMPORTANT

NOTE

TIP

• An important note provides information essential to the completion of a task. You cannot

disregard this note to complete the task.

• An important note is a type of precaution, which if neglected could result in a loss of

data, decreased accuracy or instrument malfunction/failure.

A note emphasizes or supplements important points of the main text. It also supplies

information about specific situations (e.g., memory limitations, equipment configurations,

or details that apply to specific versions of a program).

A tip is a type of note that helps the user apply the techniques and procedures described

in the text to his or her specific needs.

It also provides reference information associated with the topic being discussed.

Mitutoyo assumes no liability to any party for any loss or damage, direct or

indirect, caused by use of this instrument not conforming to this manual.

Information in this document is subject to change without notice.

No. 99MBA038A

© 2002 Mitutoyo Corporation. All rights reserved.

i

φ

Introduction

Thank you for using the “QM-Data 200” two-dimensional data processing unit.

This Operation Guide presents a collection of example applications that will help you

understand the basic operating procedures using the QM-Data 200.

Effective use of this Operation Guide will ensure that you use the QM-Data 200

correctly, and will help you in your measurement work.

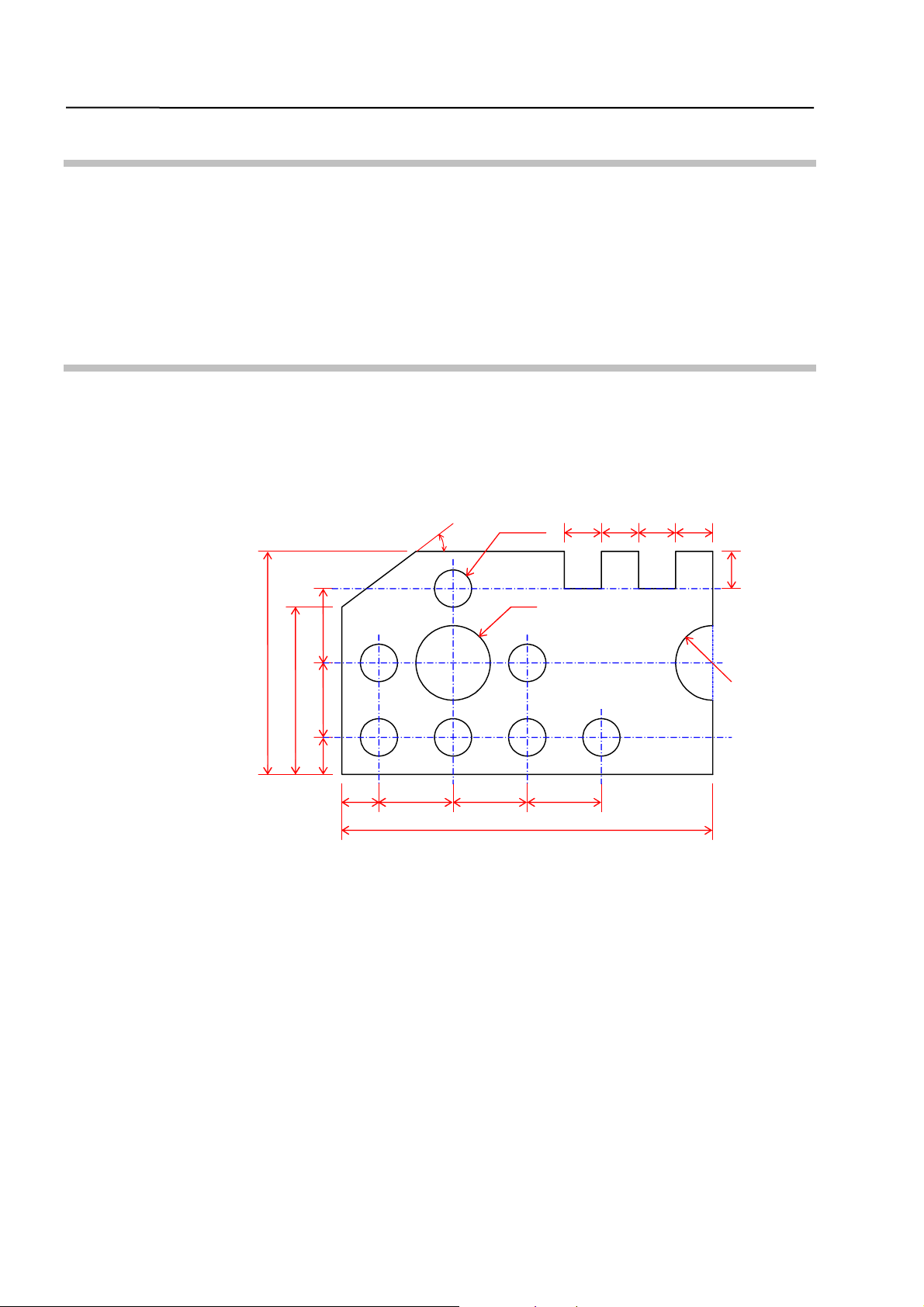

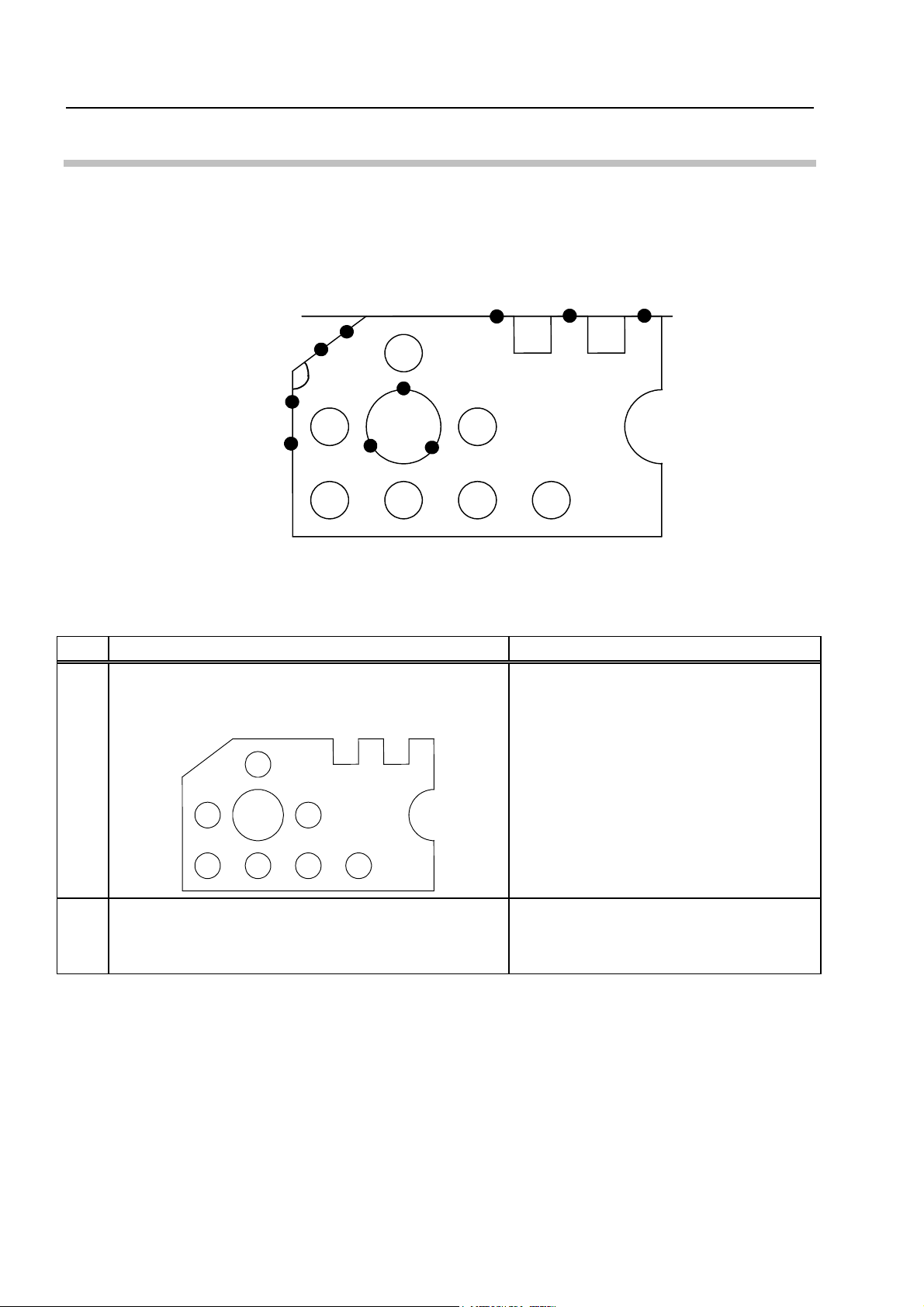

Model Workpiece

The model workpiece shown below is used in all the examples presented.

This model workpiece is designed for practice purposes; dimensional precision is not

guaranteed. Therefore, it should be noted that there may be some differences compared to

the data in the examples presented.

30°

7-φ2

2

2

2

2

2

4

4

12

9

4

2

2

4

4

4

20

R2

ii

No. 99MBA038A

Table of Contents

CONVENTIONS USED IN THIS MANUAL ......................................................................................................... i

Introduction.......................................................................................................................................................ii

Model Workpiece ..............................................................................................................................................ii

1 Before Starting Measurements.............................................................................................................1-1

1.1 Outline of Data Processing Unit .................................................................................................1-1

1.1.1 Appearance ........................................................................................................................1-1

1.1.2 Key Panel Layout...............................................................................................................1-2

1.1.3 Elements of LCD Screen ...................................................................................................1-3

1.1.4 Measurement Screen.........................................................................................................1-4

1.2 Preparing for Measurement ........................................................................................................1-5

1.2.1 Turning On the Power .......................................................................................................1-5

1.2.2 Setting Printer Output to ON (when printer is connected) ............................................1-6

2 Basic Measurements .............................................................................................................................2-1

2.1 Measuring a Circle .......................................................................................................................2-1

2.2 Measuring Angle Between Two Edges ......................................................................................2-3

2.3 Measuring a Width .......................................................................................................................2-5

2.4 Measuring Distance Between Two Circles................................................................................2-7

3 Aligning Part Coordinate System.........................................................................................................3-1

3.1 Aligning Part Coordinate System...............................................................................................3-1

3.2 Aligning Part Coordinate System Using Edges as Reference.................................................3-2

3.3 Aligning Part Coordinate System Using Circle Centers as Reference ...................................3-4

4 Applied Measurements..........................................................................................................................4-1

4.1 Multi-point Measurement ............................................................................................................4-1

4.2 Selecting and Outputting Required Measurement Items Only................................................4-4

4.3 Recalling Measured Features to Construct a New Feature .....................................................4-6

4.4 Performing Tolerance Judgment................................................................................................4-9

5 AI Measurement .....................................................................................................................................5-1

5.1 AI Measurement Function ...........................................................................................................5-1

5.2 Performing AI Measurement .......................................................................................................5-2

SERVICE NETWORK

No. 99MBA038A

iii

MEMO

iv

No. 99MBA038A

1 Before Starting

1

Measurements

This chapter presents practice on the preparations which precede

measurements using this data processing unit.

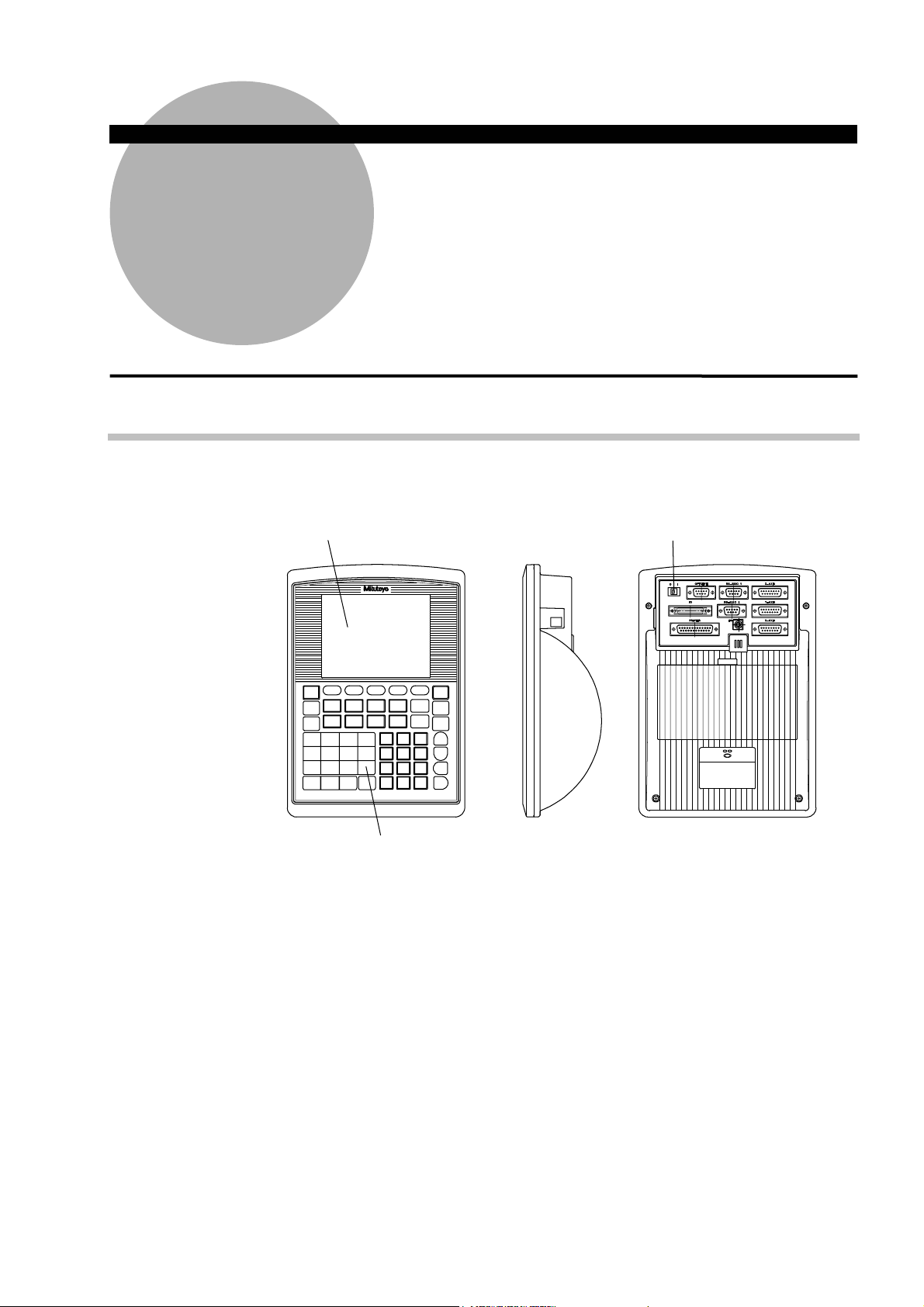

1.1 Outline of Data Processing Unit

1.1.1 Appearance

Display portion (LCD)

Power switch

No. 99MBA038A

Key panel

Fig. 1-1-1

1-1

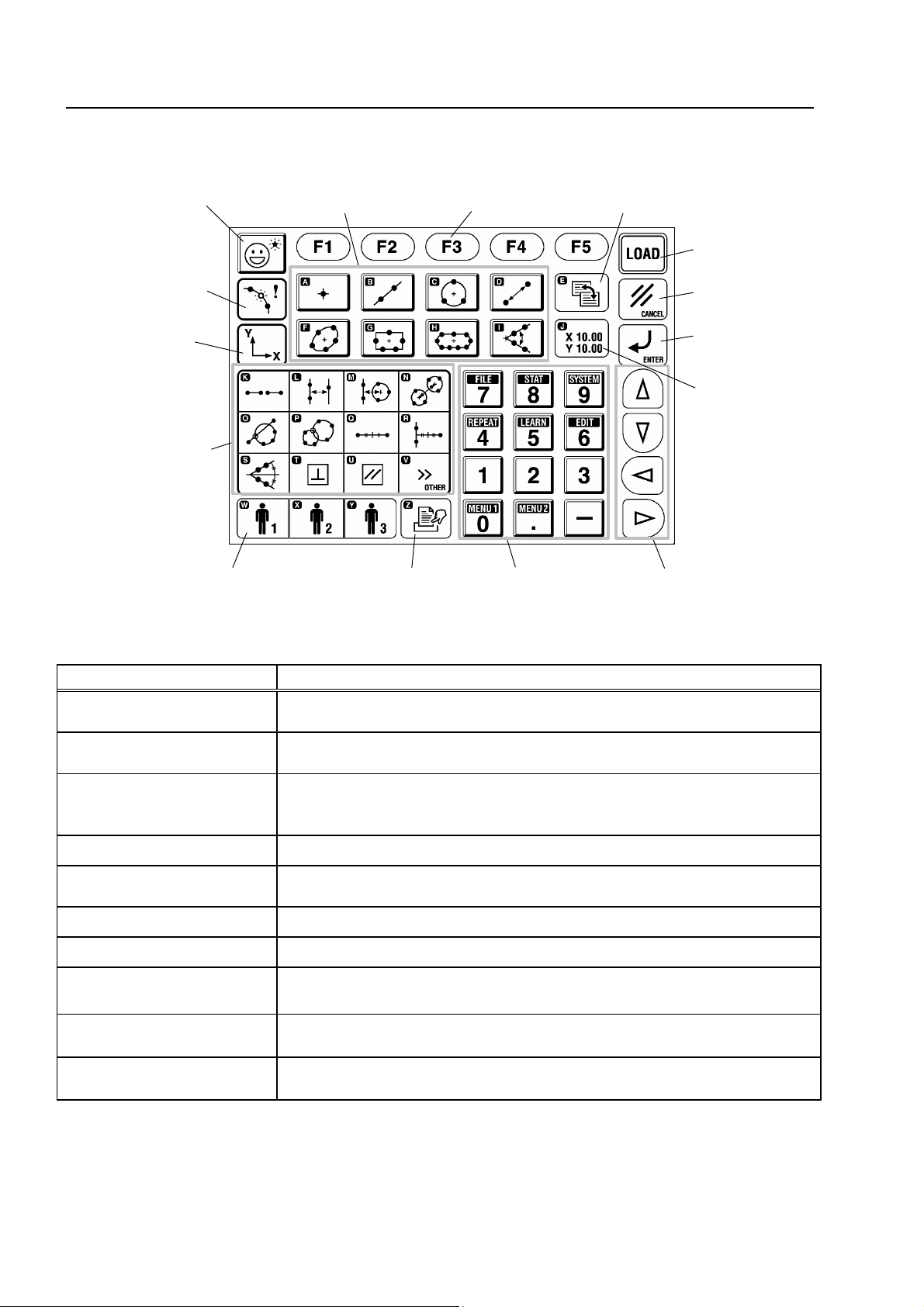

1.1.2 Key Panel Layout

AI measurement key

Basic feature measurement

command keys

Function keys

Screen switching key

[LOAD] key

Coordinate data

input style key

Coordinate

system

alignment menu

key

Measurement

macro command

keys

Key Function

Basic feature measurement

command keys

Measurement macro

command keys

Function keys

[CANCEL] key

[ENTER] key

Counter function

key

Manual print key

Numeric keys

Cursor keys User-defined menu keys

Fig. 1-1-2

Table 1-1-1 (No. 1)

Used to measure and calculate basic geometric shapes.

Used to measure and calculate width, pitch, perpendicularity, and other

values that are not basic features.

Used to select the icon for a function that can be used in a command which

is being executed.

The keys correspond to icons with function key numbers (F1, F2, ... F5).

[LOAD] key Used to input a measured point.

[CANCEL] key Cancels a measured point, or goes back to the immediately previous menu.

[ENTER] key Enters the selection or entry, and goes to the next step.

Cursor keys Used to move the cursor or select a parameter.

Numeric keys

Coordinate system alignment

menu key

Coordinate data input style

key

Used to input numerical values, such as when entering a nominal value.

These keys are also used to select menus shown on the LCD.

Used to set or change the coordinate system.

Used to change the coordinate data input style.

1-2

No. 99MBA038A

1. Before Starting Measurements

Table 1-1-1 (No. 2)

Key Function

AI measurement key

Screen switching key

Counter function key Uses the data processing unit as a simple counter.

Manual print key Prints the measurement results displayed on the screen.

Automatically recognizes the type of the measured basic feature and outputs

the results when measured points are input.

Switches the screen display mode (measurement screen, counter display

screen, etc.).

User-defined menu keys

TIP

Keys with a letter of the alphabet in their upper left corner, such as

to enter an alphabetic text, such as a file name and a comment.

Executes a previously registered part program or user-defined macro

command.

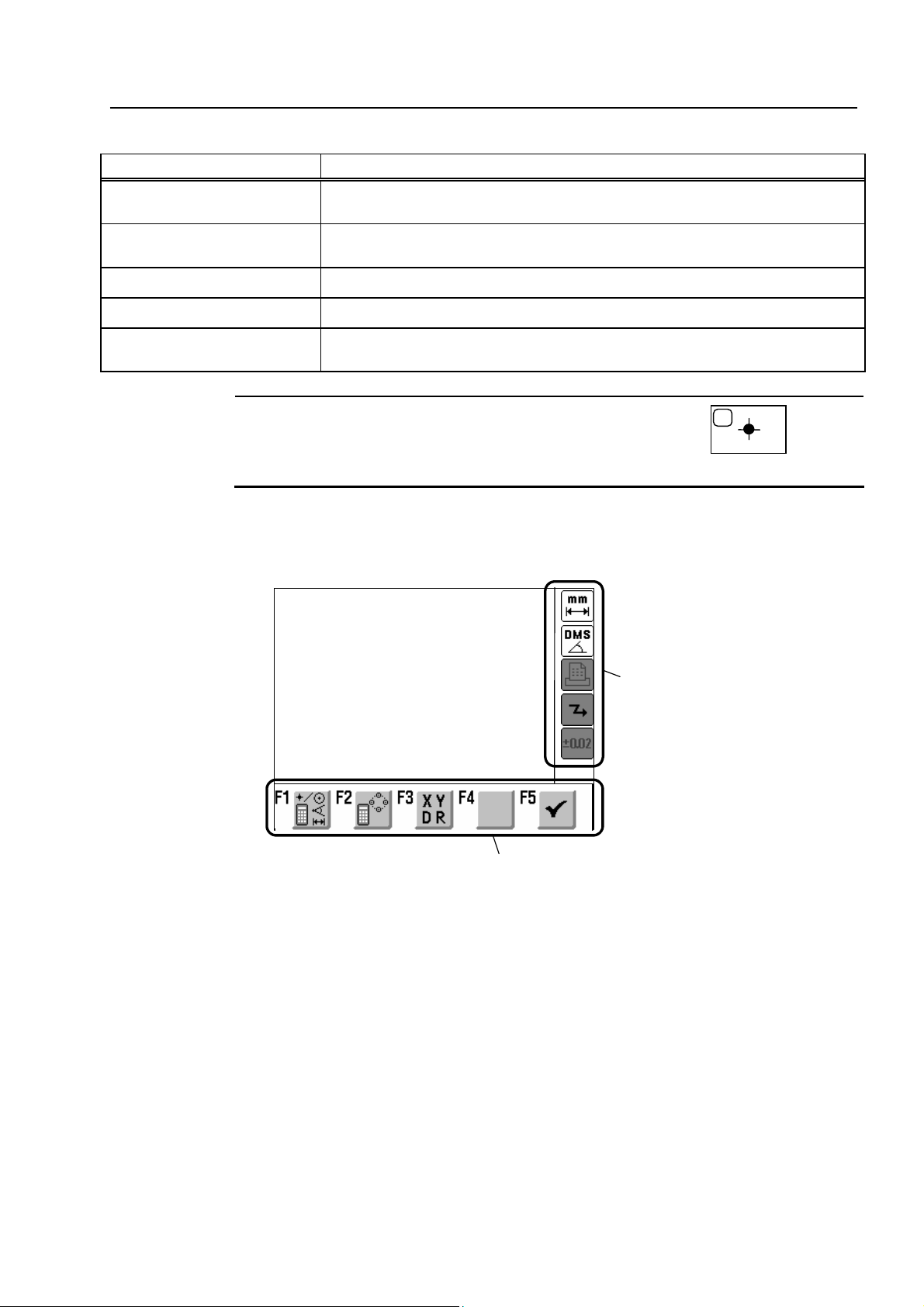

1.1.3 Elements of LCD Screen

Main display area

Status display area

A

, are used

[Main display area]

[Status display area]

[Function keys’ icon display area]

No. 99MBA038A

Function keys’ icon display area

Fig. 1-1-3

Displays counter values, measurement results, operation guidance, etc.

Displays information on the currently set functions.

Displays icons for the functions that can be used with a command which is being executed.

1-3

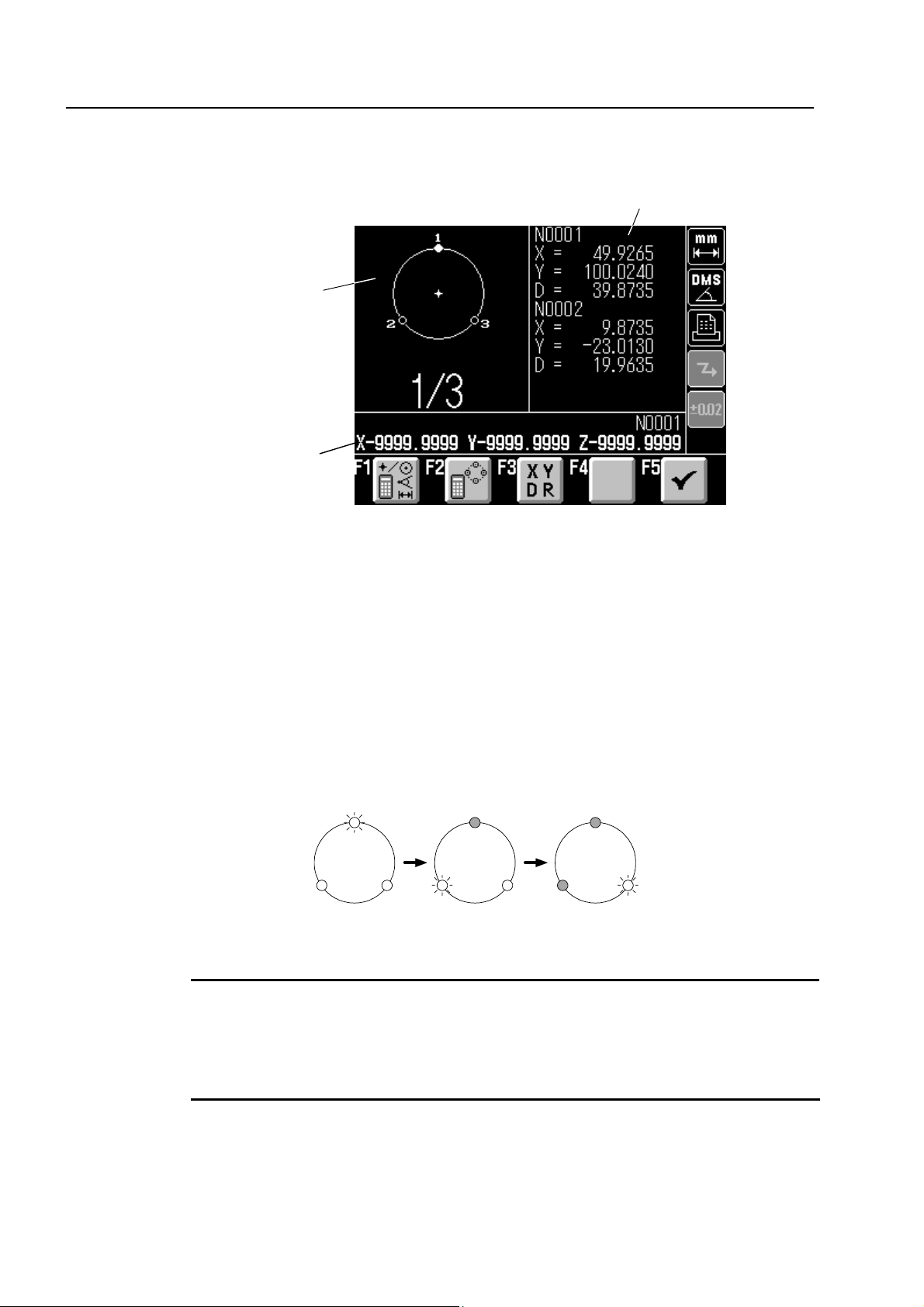

1.1.4 Measurement Screen

<Measurement standby screen (example of circle measurement)>

Navigation

window

Counter

F1: Recalls the measured features and performs calculations, etc.

F2: Recalls the measured features to adopt the representative point coordinates of those

features as measured points for the current measurement.

F3: Changes the measurement conditions ("Output Items", "Auto.MeasuringCompletion").

F4: (Enables/disables input of measured points based on edge detection if OPTOEYE is

mounted.)

F5: Completes the input operation of measurement points and outputs results at the multi-point

measurement.

In the navigation window, the next location to be measured flashes to navigate the next

measuring position. The flashing location moves as shown below, each time a point is entered.

1

Circle

Fig. 1-1-4

1

Measurement result window

1

1-4

3

2

2

1/3 2/3 3/3

3

23

Fig. 1-1-5

TIP

• When the results are displayed at the end of the measurement, the navigation window

returns to its initial input standby state (“1/3” in the above figure), and the same

measurement is repeated automatically.

• To perform a different measurement, press a different measurement command key.

No. 99MBA038A

1.2 Preparing for Measurement

[Purpose of Practice]

To learn the operating procedures from turning on the power to getting the state where

measurement commands can be executed.

[Operating Procedure]

1) Turn on the power for the data processing unit.

2) Set the printer output to ON.

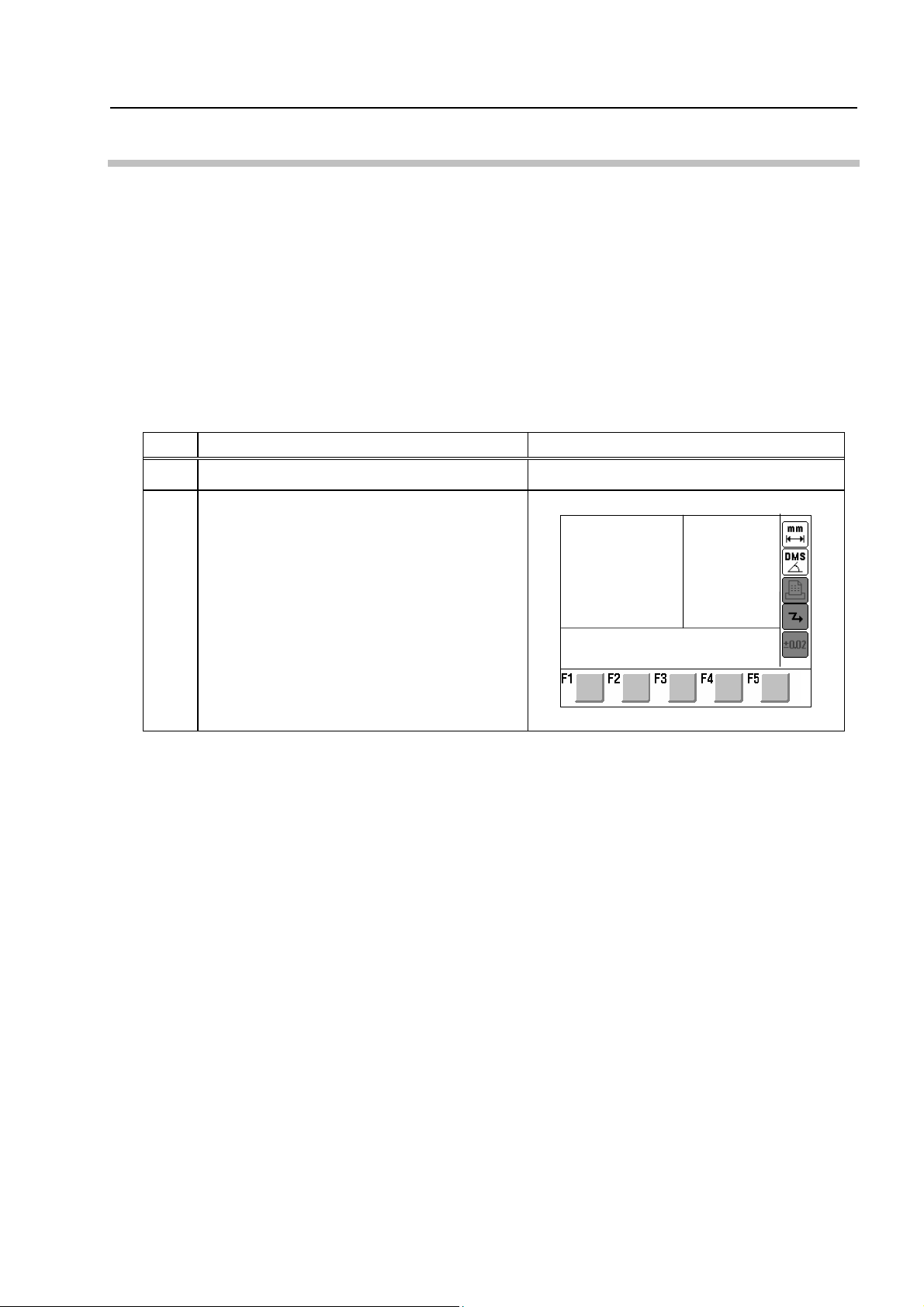

1.2.1 Turning On the Power

Table 1-2-1

No. Operation Screen display and remarks

1. Before Starting Measurements

1 Turn the power switch to ON.

The Startup Screen is displayed.

2

A little bit after the opening screen is

displayed, the startup screen shown at right is

displayed.

–

Press a measurement or menu key.

X 0.000 Y 0.000

No. 99MBA038A

1-5

1.2.2 Setting Printer Output to ON (when printer is connected)

NOTE

No. Operation Screen display and remarks

1

Be sure to turn on the printer power before setting the printer output to ON.

Table 1-2-2

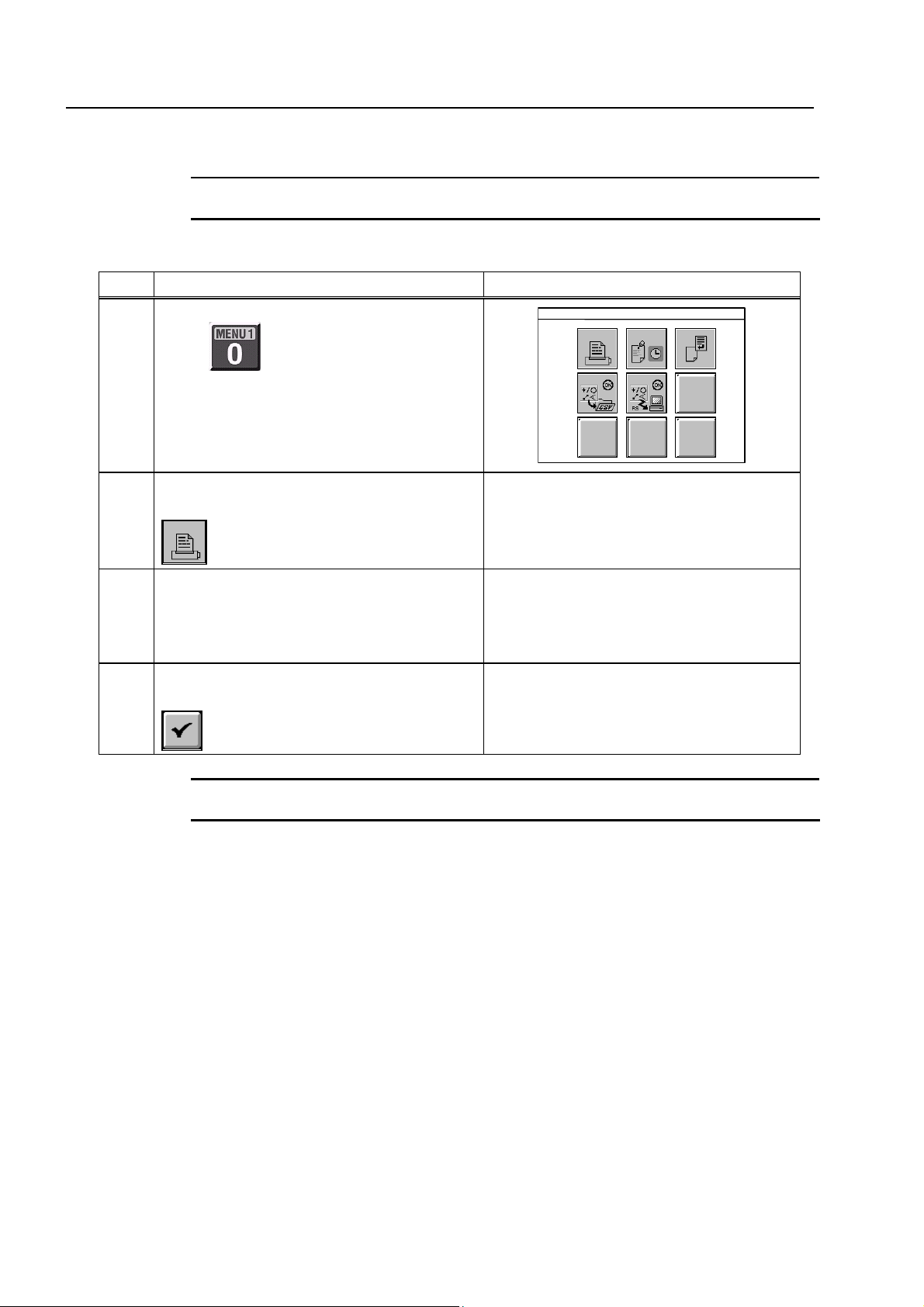

Selecting menu function

Press

.

MENU 1: Output Function Menu

7 8 9

4 5

Selecting printer setting

2

Press the numeric key corresponding to

.

Selecting ON for printer

3

Use the left and right cursor keys to select “All

Results w/o Command Names” for “Contents

to Be Printed”.

Finishing printer setting

4

Press the [F5] function key corresponding to

.

<Remarks>

Measurement results subsequent to this

setting are printed by the printer.

–

–

1-6

TIP

To cancel printer output, select “None” in step 3 above.

No. 99MBA038A

2 Basic Measurements

2

2.1 Measuring a Circle

[Purpose of Practice]

To measure a circle using the model workpiece.

This chapter presents practice for basic measurement procedures

using the model workpiece.

φ4

Fig. 2-1-1

[Operating Procedure]

Table 2-1-1

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown below,

and focus on it.

–

Measurement function selection

2

Press

.

–

No. 99MBA038A

2-1

No. Operation Screen display and remarks

Measuring circle (A)

3

At any three points on the circumference of circle (A),

center the projection screen crosshairs and then press the

[LOAD] key.

1

(A)

2

3

Results display

4

The circle (A) measurement results are displayed on the

screen.

D

NOTE

• The three points that are measured should be spaced as far apart from each other as

possible on the circumference in order to measure the circle precisely.

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

N0001

X =

Y =

D = 4.018

*.***

*.***

Diameter

• The X and Y coordinate results indicating the circle’s center position vary depending on

the position and orientation of the model workpiece on the XY table. In order to obtain

measurement results that match the dimensions shown in the section titled “Model

Workpiece”, before starting the measurement, perform the operation described in

Section 3.2 “Aligning Part Coordinate System Using Edges as Reference”.

TIP

• If an incorrect position was measured, it is possible to cancel the measured point data

by pressing the [CANCEL] key prior to entering the last measurement point. If the

[CANCEL] key is held down, the system returns to the standby state for the first

measurement point.

• The last measurement point cannot be canceled. If the last measurement point is not

correct, redo the measurement.

2-2

No. 99MBA038A

2. Basic Measurements

2.2 Measuring Angle Between Two Edges

[Purpose of Practice]

To measure the angle between two edges using the model workpiece.

(A)

150°

[Operating Procedure]

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown below,

and focus on it.

(B)

Fig. 2-2-1

Table 2-2-1

Measurement function selection

2

Press

Measuring edge (A)

3

Measure edge (A) at two points.

.

2

(A)

–

–

<Remarks>

Follow the information displayed on the

1

screen to perform the measurement.

No. 99MBA038A

2-3

No. Operation Screen display and remarks

Measuring edge (B)

4

Measure edge (B) at two points.

4

3

(B)

Results display

5

The measurement results (A1, A2) for the angle formed by

edge (A) and edge (B) are displayed on the screen.

A2

A1

NOTE

• Note that the obtained angle (A1) varies depending on the order in which the edges are

measured, as shown below.

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

N0001

X =

*.***

Y =

*.***

A1= 150.0142

A2= 209.5818

1

2

Measurement

method 1

4

3

4

1

2

Measurement

method 2

3

3

4

Measurement

method 3

2

1

3

4

Measurement

method 4

1 2

• The X and Y coordinate results of the intersection point vary depending on the position

and orientation of the model workpiece on the XY table. In order to obtain measurement

results that match the dimensions shown in the section titled “Model Workpiece”, before

starting the measurement, perform the operation described in Section 3.2 “Aligning Part

Coordinate System Using Edges as Reference”.

• Angle units can be switched between degrees (decimal notation) and degrees, minutes

and seconds (sexagesimal notation). See Chapter 6 of the “Software Guide” for the

switching procedure.

2-4

No. 99MBA038A

2.3 Measuring a Width

[Purpose of Practice]

To measure a width using the model workpiece.

2. Basic Measurements

(A)

2

(B)

Fig. 2-3-1

[Operating Procedure]

Table 2-3-1

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown below,

and focus on it.

Measurement function selection

2

Press

Measuring side (A)

3

Measure side (A) at two points.

.

(A)

–

–

<Remarks>

Follow the information displayed on the

1

2

screen to perform the measurement.

No. 99MBA038A

2-5

No. Operation Screen display and remarks

Measuring side (B)

4

Measure side (B) at one point.

(B)

1

5 The width measurement result (LC) is displayed on the

screen.

LC

NOTE

When measuring a width, be sure to enter two points for the edge being measured first,

and then enter one remaining point for the edge being measured second.

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

N0001

LC= 2.001

TIP

• If an incorrect position was measured, it is possible to cancel the measured point data

by pressing the [CANCEL] key prior to entering the last measurement point. If the

[CANCEL] key is held down, the system returns to the standby state for the first

measurement point.

• The last measurement point cannot be canceled. If the last measurement point is not

correct, redo the measurement.

2-6

No. 99MBA038A

2. Basic Measurements

2.4 Measuring Distance Between Two Circles

[Purpose of Practice]

To measure two circles to obtain the distance between them.

(A)

(B)

4

Fig. 2-4-1

[Operating Procedure]

Table 2-4-1

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown below,

and focus on it.

–

Measurement function selection

2

Press

Measuring circle (A)

3

Measure circle (A) at three points.

No. 99MBA038A

.

<Remarks>

Follow the information displayed on the

1

(A)

3

2

screen to perform the measurement.

–

2-7

No. Operation Screen display and remarks

Measuring circle (B)

4

Measure circle (B) at three points.

1

(B)

3

2

Results display

5

The measurement results (LC, LS, LL) for the distance

between circle (A) and circle (B) are displayed on the

screen.

(A)

(B)

LS

LC

LL

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

N0001

LC= 4.006

LL= 6.011

LS= 2.001

XD= *.***

YD= *.***

• The XD and YD measurement results indicating the distance between the two circles

TIP

along the X and Y axes vary depending on the position and orientation of the model

workpiece on the XY table. In order to obtain measurement results that match the

dimensions shown in the section titled “Model W orkpiece”, before starting the

measurement, perform the operation described in Section 3.2 “Aligning Part Coordinate

System Using Edges as Reference”.

2-8

No. 99MBA038A

3 Aligning Part Coordinate

3

System

This chapter presents practice on the procedures for aligning the

part coordinate system using the model workpiece.

3.1 Aligning Part Coordinate System

When the data processing unit is turned on, the coordinate values in the coordinate system

matching the moving directions of the XY table are output as measurement results. (See Fig.

3-1-1.)

Y

(x, y)

(0, 0)

Fig. 3-1-1

Therefore, in order to correctly evaluate information such as the center coordinates of a circle

on a workpiece as dimensions, the coordinate system must be aligned to match the workpiece’s

position and orientation.

The aligned coordinate system is called the part coordinate system (PCS). (See Fig. 3-1-2.)

X

No. 99MBA038A

Y

Once the part coordinate system is set, it is possible to obtain precise measurements and

calculations even if the workpiece’s orientation is not adjusted to be parallel with the moving

directions of the XY table.

(x, y)

(0, 0)

Fig. 3-1-2

X

3-1

3.2 Aligning Part Coordinate System Using Edges as Reference

[Purpose of Practice]

To align the part coordinate system based on two edges that are perpendicular to each

other, using the model workpiece.

[Description of Operation]

The part coordinate system is set using the coordinate system alignment macro command

(1).

Y

X

(0, 0)

Fig. 3-2-1

[Operating Procedure]

Table 3-2-1

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown below,

and focus on it.

–

Selecting the coordinate system alignment menu

2

Press

The coordinate system alignment function menu is

displayed.

Selecting the coordinate system alignment macro

3

command (1)

Press the numeric key corresponding to

.

–

–

.

3-2

No. 99MBA038A

3. Aligning Part Coordinate System

No. Operation Screen display and remarks

Measuring edge (A)

4

Measure edge (A) at two points.

(A)

(2)

Measuring edge (B)

5

(1)

Measure edge (B) at one point.

(3)

(B)

The part coordinate system is completed.

6

The part coordinate system is completed as shown below.

Y

Origin

X

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

<Remarks>

Once the part coordinate system is

completed, coordinate values are

defined from the origin, which serves as

a reference.

The part coordinate system established

in this example matches the coordinate

system shown in the section titled

“Model Workpiece”. Therefore, you can

refer to the drawing in that section while

practicing measurements.

NOTE

No. 99MBA038A

See Chapter 5 of the “Software Guide” for further details about the coordinate system

TIP

alignment functions.

When measuring edge (A), note the order in which the measurements are performed, as

the direction of the coordinate system’s reference axis varies depending on the

measurement order.

Y

X

Y

(2)

(A)

(1)

(1)

(A)

X

(2)

The X-axis direction orients from the first measured point to the second measured point.

3-3

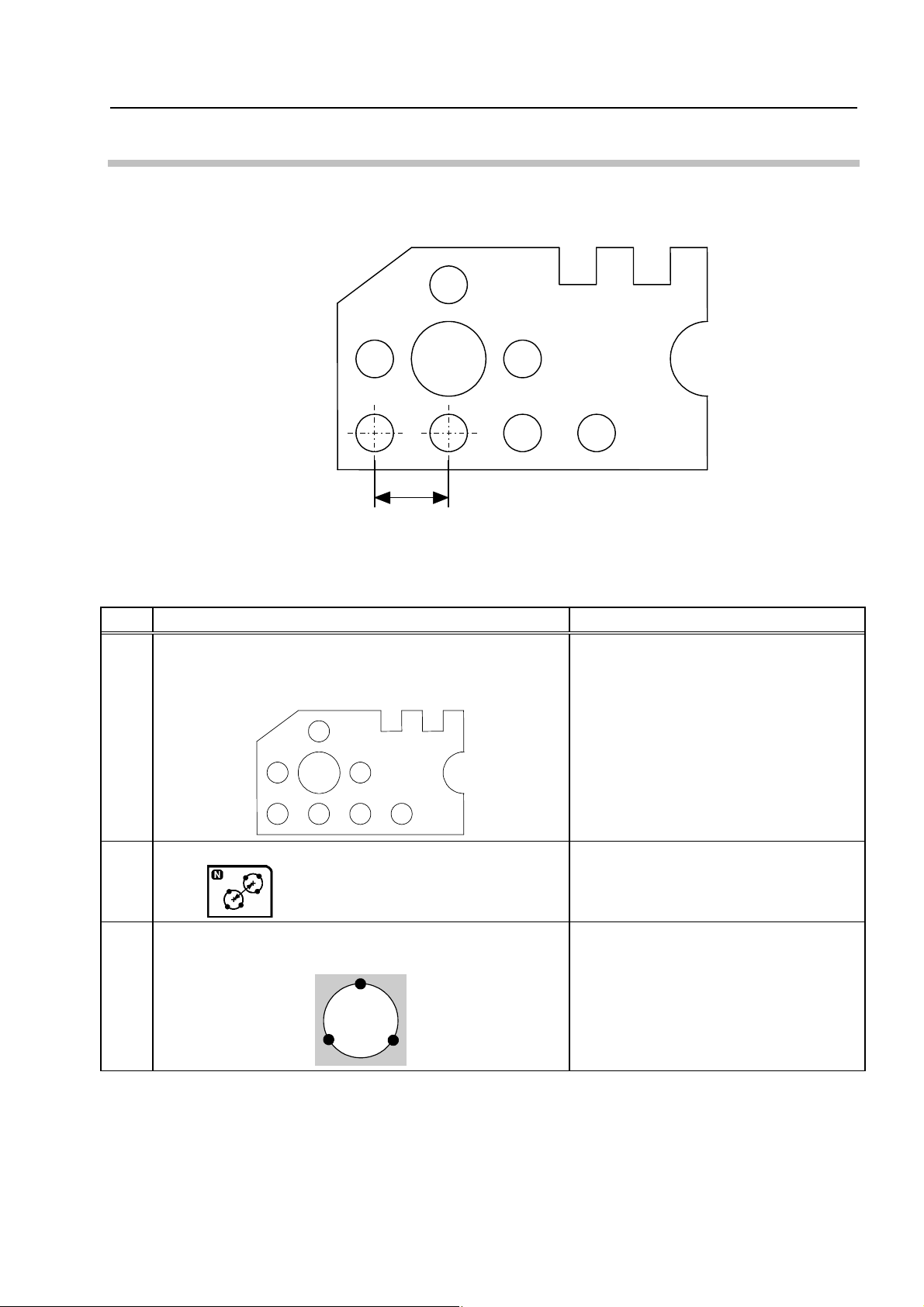

3.3 Aligning Part Coordinate System Using Circle Centers as Reference

[Purpose of Practice]

To align the part coordinate system based on two circle centers, using the model

workpiece.

[Description of Operation]

The part coordinate system is set using the coordinate system alignment macro command

(4).

Y

(A)

(B)

X

(0, 0)

Fig. 3-3-1

[Operating Procedure]

Table 3-3-1

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown below,

and focus on it.

–

3-4

Selecting the coordinate system alignment menu

2

Press

The coordinate system alignment function menu is

displayed.

Selecting the coordinate system alignment macro

3

command (4)

Press the numeric key corresponding to

.

–

–

.

No. 99MBA038A

3. Aligning Part Coordinate System

Y

No. Operation Screen display and remarks

Selecting the coordinate data input style

4

Press

.

Then, from the icon menu, press the numeric key

corresponding to

Measuring circle (A)

5

.

Measure circle (A) at three points.

(A)

Measuring circle (B)

6

Measure circle (B) at three points.

(B)

–

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

The part coordinate system is completed.

7

The part coordinate system is completed as shown below.

Origin

(A)

(B)

<Remarks>

Once the part coordinate system is

completed, coordinate values are

defined from the origin, which serves as

a reference.

X

No. 99MBA038A

3-5

NOTE

When measuring circle (A) and circle (B), note the order in which the measurements are

performed, as the direction of the coordinate system’s reference axis varies depending on

the measurement order.

Y

(A)

(1)

(B)

(2)

X

(A)

(2)

X

(B)

(1)

Y

The X-axis direction orients from the center of the first measured circle to the center of

the second measured circle.

TIP

After this measurement example, the coordinate data input style remains “Circle center

input”.

Use the following procedure to reset the coordinate data input style to “Actual point input”.

Table 3-3-2

No. Operation Screen display and remarks

Selecting the coordinate data input style

1

Press

.

Then, from the icon menu, press the numeric key

corresponding to

.

TIP

• See Chapter 5 of the “Software Guide” for further details about the coordinate system

alignment functions.

• See Chapter 4 of the “Software Guide” for further details about the coordinate data input

style.

–

3-6

No. 99MBA038A

4 Applied Measurements

4

4.1 Multi-point Measurement

[Purpose of Practice]

To practice taking measurements using multiple points. In this section, a line is measured

at three or more points to determine the angle formed by the line and the X-axis, and the

straightness of the line.

This chapter presents practice on applied measurement procedures

using the model workpiece.

(A)

Fig. 4-1-1

No. 99MBA038A

4-1

[Operating Procedures]

Table 4-1-1

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown

below, and focus on it.

–

Aligning the part coordinate system

2

For the aligning procedure, see Section 3.2 “Aligning

Part Coordinate System Using Edges as Reference”.

Measurement function selection

3

Press

.

The explanation for the operations from

step 3 onward assumes that the part

coordinate system has been aligned.

–

Changing measurement conditions

4

Press the [F3] function key corresponding to

Setting “Auto.MeasuringCompletion” to OFF

5

Press the [F3] key to set the

“Auto.MeasuringCompletion” to “OFF”.

Completion of changing measurement conditions

6

Press the [F5] function key corresponding to

Measuring edge (A)

7

Measure edge (A) at three or more points.

(A)

n

3

2

1

.

Auto.MeasuringCompletion: OFF

: Press [F3] to switch the status.

–

.

–

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

4-2

No. 99MBA038A

4. Applied Measurements

No. Operation Screen display and remarks

Completing the measurement

8

When two or more measured points required for

measuring a line are input,

Press the corresponding [F5] function key to complete

the measurement.

Results display

9

The measurement results for edge (A) are displayed on

the screen.

(A)

n

3

2

1

TIP

• To perform measurements in such a manner that a multi-point measurement is

automatically completed when the predetermined number of measuring points have

been input, reset “Auto.MeasuringCompletion” to “ON” (see steps 4 through 6).

is displayed.

CX

–

N0001

CX = 90.0215

F1 = 0.154

• The multi-point measurement can be performed using the same procedure on points,

circles, and ellipses in addition to lines.

No. 99MBA038A

4-3

4.2 Selecting and Outputting Required Measurement

Items Only

[Purpose of Practice]

To practice selecting and outputting just the required items as measurement results. In this

section, the point & angle feature formed by two adjacent edges is measured to output only

the intersection angle (A1).

(A)

150°

(A1)

[Operating Procedures]

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown

below, and focus on it.

(B)

Fig. 4-2-1

Table 4-2-1

4-4

Measurement function selection

2

Press

Starting output item selection

3

Press the [F3] function key corresponding to

.

–

–

.

–

No. 99MBA038A

4. Applied Measurements

No. Operation Screen display and remarks

Selecting output item

4

Use the up and down cursor keys

highlight the item to be selected.

Each time the [ENTER] key is pressed, an asterisk

(*) appears to the left of the highlighted item, or is

removed from the item.

In this example, place an asterisk (*) next to “Angle:

A1” only.

to

Coord: X

Coord: Y

RadDist: L

Angle: A

*

Angle: A1

Coord: Y

RadDist: L

Angle: A

*

Angle: A1

Angle: A2

<Remarks>

In some cases, it may not be possible to

display all of the output items at once. In such

cases, scroll through the screen to view the

hidden items using the up and down cursor

keys

.

Completing output item selection

5

Press the [F5] function key corresponding to

Measuring edges (A) and (B)

6

Measure edges (A) and (B).

(B)

3

1

4

Result display

7

(A)

2

Only the measurement result for the intersection

angle (A1) between edge (A) and edge (B) is

displayed on the screen.

A1

<Remarks>

Only the output items with an asterisk (*) next

.

to them will be output after the measurement.

<Remarks>

Follow the information displayed on the screen

to perform the measurement.

The procedure is the same as steps 3 to 4 in

Section 2.2 “Measuring Angle Between Two

Edges”.

N0001

A1 = 150.1826

No. 99MBA038A

TIP

The output item selection result made in the above example remains in effect until the

power is turned off.

4-5

4.3 Recalling Measured Features to Construct a New

Feature

[Purpose of Practice]

This section presents practice on recalling measured features to calculate a new feature.

In this section, the measurement results for two circles (A) and (B) are recalled to calculate

the midpoint between them.

(A)

[Operating Procedures]

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown

below, and focus on it.

(B)

Fig. 4-3-1

Table 4-3-1

–

Aligning the part coordinate system

2

For the aligning procedure, see Section 3.2 “Aligning

Part Coordinate System Using Edges as Reference”.

Selecting the circle feature measurement command

3

Press

.

The explanation for the operations from

step 3 onward assumes that the part

coordinate system has been aligned.

–

4-6

No. 99MBA038A

4. Applied Measurements

No. Operation Screen display and remarks

Measuring circles (A) and (B)

4

Measure circles (A) and (B) using the same procedure

as in step 3 of Section 2.1 “Measuring a Circle”.

1

2

3

Results display

5

The measurement results for circles (A) and (B) are

displayed on the screen.

D

D

Y

X

X

Selecting the point feature measurement command

6

Press

.

<Remarks>

Follow the information displayed on the

screen to perform the measurement.

N0001

X = 2.055

Y = 2.008

D =

N0002

X = 6.013

Y = 2.010

D =

• • • • •

• • • • •

–

Displaying the feature construction menu

7

Press the [F1] function key corresponding to

Selecting the midpoint construction

8

Press the numeric key corresponding to

Selecting the measured features

9

Use the up and down cursor keys

to highlight

the measurement result for circle (A) and then press the

[ENTER] key. Then perform the same operation for the

measured circle (B).

.

.

:

:

:

:

*10 {

*11 {

–

–

• • • •

X =

:

Y =

D =

• • • •

• • • •

:

:

:

No. 99MBA038A

4-7

No. Operation Screen display and remarks

Result display

10

The coordinates of the midpoint between circle (A) and

circle (B) are displayed on the screen.

Y

X

N0003

X = 4.034

Y = 2.009

4-8

No. 99MBA038A

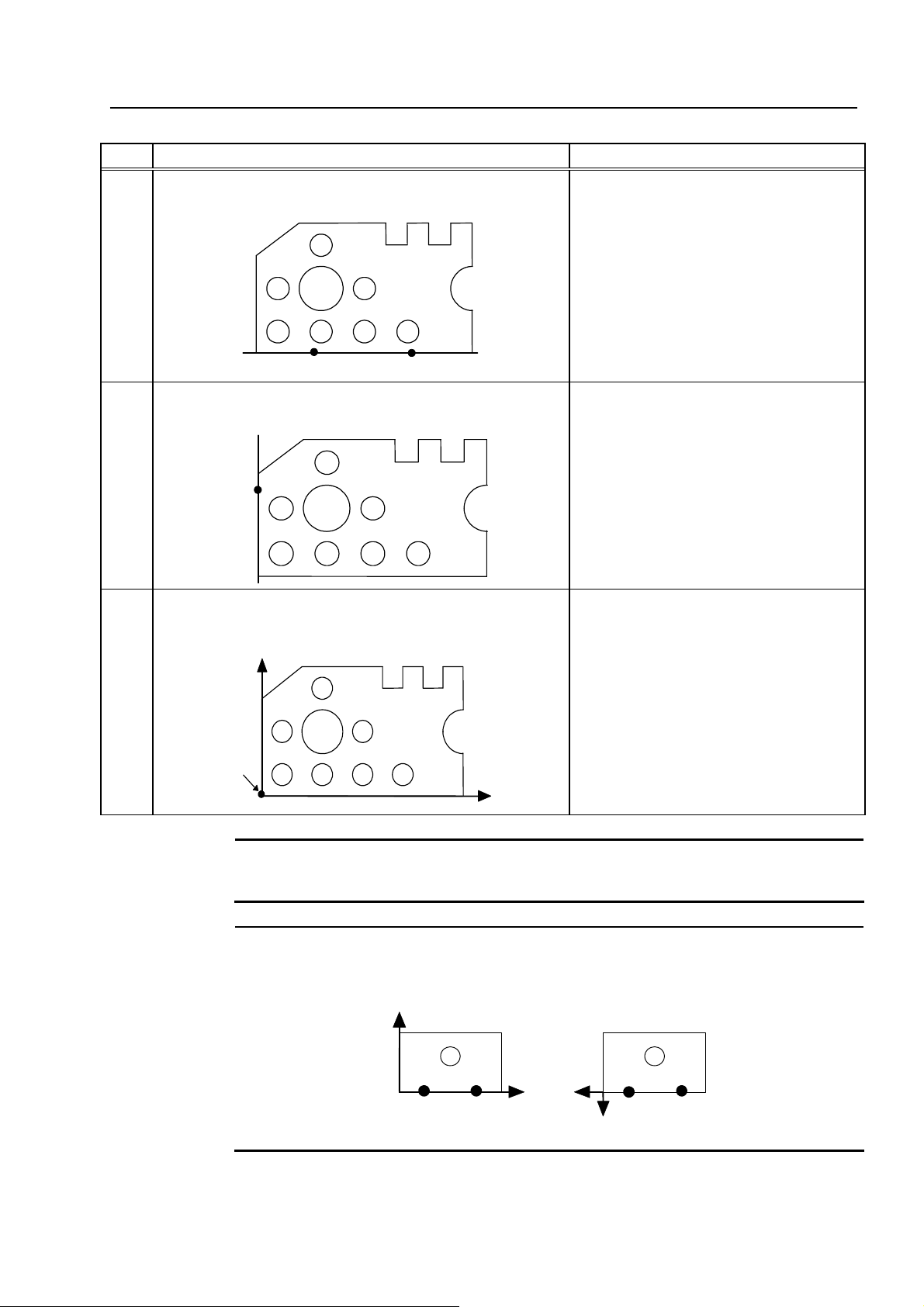

4.4 Performing Tolerance Judgment

[Purpose of Practice]

To compare measurement results with nominal values and tolerance zones, and to make a

GO/NG judgment.

In this section, circle (A) is measured and the tolerance judgment is performed.

(A)

Fig. 4-4-1

[Operating Procedures]

Table 4-4-1

4. Applied Measurements

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown

below, and focus on it.

–

Aligning the part coordinate system

2

For the aligning procedure, see Section 3.2 “Aligning

Part Coordinate System Using Edges as Reference”.

Selecting Menu 2

3

Press

.

The explanation for the operations from

step 3 onward assumes that the part

coordinate system has been aligned.

–

No. 99MBA038A

4-9

No. Operation Screen display and remarks

Selecting the command for setting the tolerance

4

judgment function to ON or OFF

Press the numeric key corresponding to

Setting the tolerance judgment function to ON

5

Confirm that “Tolerance Judgment” is set to “ON”,

and then press the [F5] function key corresponding

to

Measurement function selection

6

.

.

<Remarks>

The status display changes as follows.

(OFF) (ON)

–

Press

Measuring circle (A)

7

.

Measure circle (A) at three points.

2

(A)

3

<Remarks>

Follow the information displayed on the screen

to perform the measurement.

1

–

Inputting tolerance data

8

Move the cursor to the input columns and enter the

nominal values and tolerance values using the

numeric keys. Note that items with no input data are

not judged.

Completion of inputting the tolerance data

9

Press the [F5] function key corresponding to

Results display

10

The measurement results for circle (A) are

displayed on the screen.

(A)

D

Y

Output Item Nominal U. Tol. L. Tol.

Coord:

Coord: Y 6.000 0.010 -0.010

Dia: D 4.000 0.010 -0.010

.

6.000 0.010 -0.010

X

–

N0001

X = 6.001

Y = 6.005

D1 = 4.018 +NG

<Remarks>

If the deviation exceeds the tolerance zone,

“+NG” or “-NG” is displayed as GO/NG

X

judgment result.

4-10

No. 99MBA038A

5 AI Measurement

5

5.1 AI Measurement Function

The AI measurement (Artificial Intelligence measurement) is a function of automatically

recognizing the type of the measured basic feature, such as a circle, a straight line, etc. from

measured points data. The following types of basic feature can be automatically recognized by

the system using the AI function.

This chapter presents practice for measurements utilizing artificial

intelligence (AI), using the model workpiece.

Table 5-1-1

Type of feature

1 Point

2 Line

3 Circle

4 Distance

5 Ellipse

6 Rectangular hole

7 Slot

8 Point & angle

TIP

See Chapter 4 of the “Software Guide” for further details on the AI function.

Applicable number of

measurement points

1-100

2-100

3-100

2

5-100

5

9

2-50 each Measures two lines.

Remarks

No. 99MBA038A

5-1

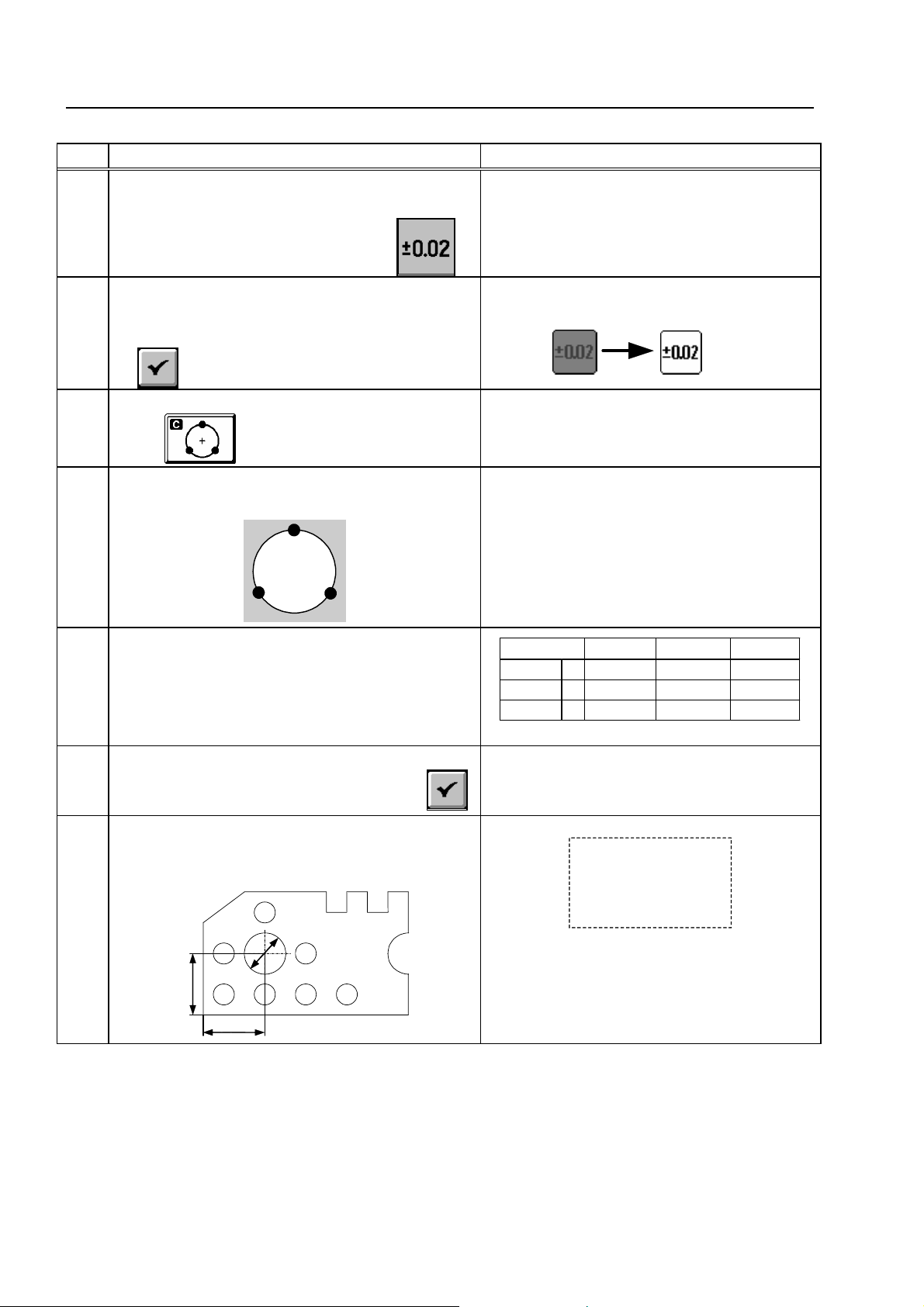

5.2 Performing AI Measurement

[Purpose of Practice]

To practice measurements utilizing the AI function using the model workpiece. In this

section, line (A), circle (B) and angle (C) are measured successively in the AI measurement

mode.

(A)

(C)

(B)

Fig. 5-2-1

[Operating Procedure]

Table 5-2-1

No. Operation Screen display and remarks

Preparing the workpiece

1

Set the model workpiece on the XY table as shown

below, and focus on it.

Aligning the part coordinate system

2

For the aligning procedure, see Section 3.2 “Aligning

Part Coordinate System Using Edges as Reference”.

–

The explanation for the operations from

step 3 onward assumes that the part

coordinate system has been aligned.

5-2

No. 99MBA038A

5. AI Measurement

No. Operation Screen display and remarks

Setting the AI measurement function to ON

3

Press

Measuring line (A)

4

.

Measure three points on line (A).

(1) (2)

Completion of line (A) measurement

5

(3)

(A)

After the desired measured points have been entered,

press the [F5] function key corresponding to

<Remarks>

The icon corresponding to the automatically

recognized basic feature type is highlighted.

.

–

–

Results display

6

The measurement results for line (A) are displayed.

Measuring circle (B)

7

Measure three points on circle (B).

(1)

(B)

(2)

(3)

N0001

CX = 0.0835

F1 = 0.012

<Remarks>

The icon corresponding to the automatically

recognized basic feature type is highlighted.

No. 99MBA038A

5-3

No. Operation Screen display and remarks

Completion of circle (B) measurement

8

After the desired measured points have been entered,

press the [F5] function key corresponding to

Results display

9

The measurement results for circle (B) are displayed.

Measuring angle (C)

10

Measure four points on the two lines forming angle

(C).

(4)

(3)

(C)

(1)

(2)

.

<Remarks>

The icon corresponding to the automatically

recognized basic feature type is highlighted.

–

N0002

X = 6.083

Y = 6.012

D = 4.000

Completion of angle (C) measurement

11

After the desired measured points have been entered,

press the [F5] function key corresponding to

Results display

12

The measurement results for angle (C) are displayed.

.

–

N0003

X = 0.083

Y = 0.012

A1 = 119.4837

A2 = 240.1123

TIP

If the automatically recognized feature type is not appropriate, the feature type can be

manually corrected. See Chapter 4 of the “Software Guide” for information on how to

correct feature type.

5-4

No. 99MBA038A

Loading...

Loading...