Mitsubishi PLA-RP_AA(1), PLA-RP_AA(1).UK, PEA-RP_EA, PEAD-RP_EA, PEAD-RP_EA.UK TECHNICAL MANUAL

...

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

No. OCT04

SERVICE TECHNICAL GUIDE R410A

<Indoor unit> |

[Service Ref] |

[Model names] |

PLA-RP·AA

PEA-RP·EA

PEAD-RP·EA

PLA-RP·AA

PLA-RP·AA1 PLA-RP·AA.UK PLA-RP·AA1.UK PEA-RP·EA.TH-A PEAD-RP·EA.UK PEAD-RP·EA1.UK

<Outdoor unit> |

[Service Ref] |

[Model names] |

PUHZ-RP·VHA

PUHZ-RP·VHA PUHZ-RP·VHA-A

CONTENTS

1.PAIRING TABLE OF THE INDOOR AND OUTDOOR UNIT ·····2

2.SPECIFICATIONS FOR ELECTRICAL WORK ···········

3.WIRING DIAGRAM·······················

4.REFRIGERANT SYSTEM DIAGRAM ···············

5.HOW TO CHECK THE PARTS ··················

6.MICROPROCESSOR CONTROL·················

7.INDOOR UNIT CONTROL····················

8.OUTDOOR UNIT CONTROL···················

9.DIP SWITCH FUNCTION ·····················

10.FUNCTION SETTING ······················

11.TEST RUN • REPLACEMENT OPERATION

&EMERGENCY OPERATION···················

12.SELF-DIAGNOSIS ························

13.TEST POINT DIAGRAM ·····················

14.TROUBLESHOOTING ······················

15.SYSTEM CONTROL·······················

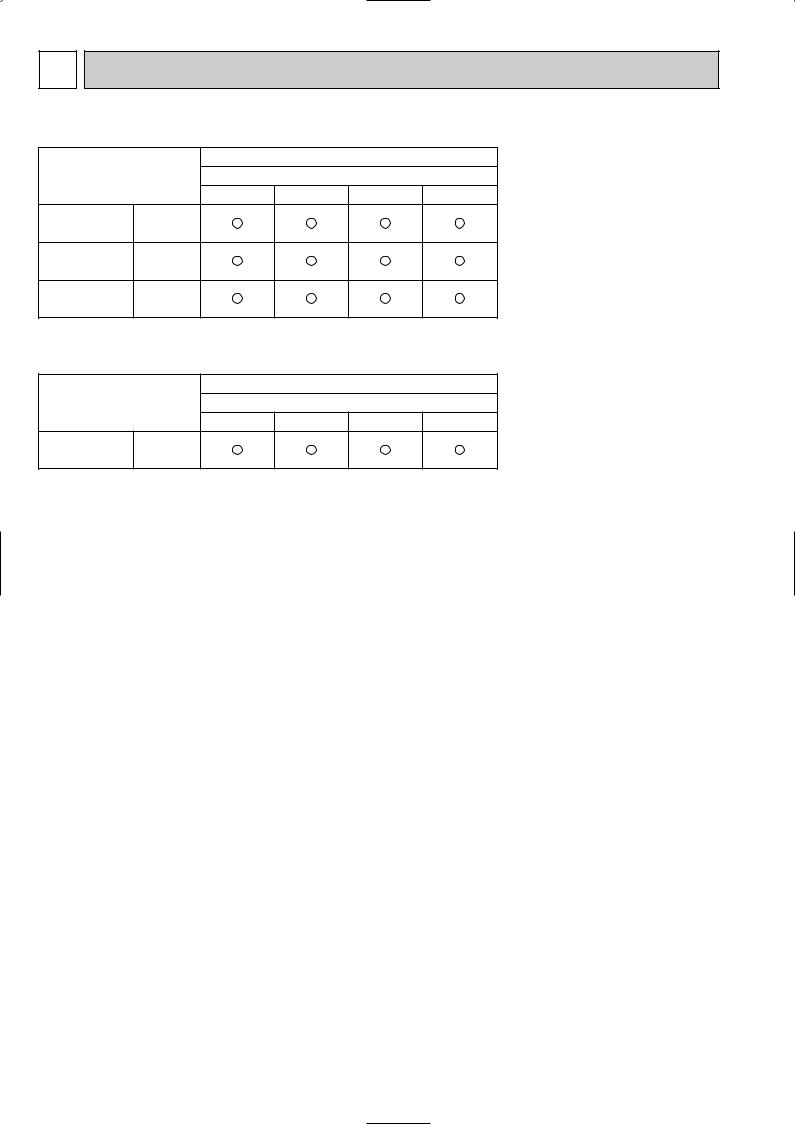

1 PAIRING TABLE OF THE INDOOR AND OUTDOOR UNITS

Outdoor unit [PUHZ]

Indoor unit |

OC294 |

RP3VHA RP4VHA RP5VHA RP6VHA

PLA-RP·AA |

OC293 |

PLA-RP·AA1 |

REVISED EDITION-A |

PLA-RP·AA.UK OC297

PLA-RP·AA1.UK REVISED EDITION-A

PEAD-RP·EA.UK

—

PEAD-RP·EA1.UK

|

|

Outdoor unit [PUHZ] |

Indoor unit |

OC300 REVISED EDITION-A |

|

|

|

RP3VHA-A RP4VHA-A RP5VHA-A RP6VHA-A |

PEA–RP·EA.TH-A |

OC299 |

|

REVISED EDITION-A |

|

|

2

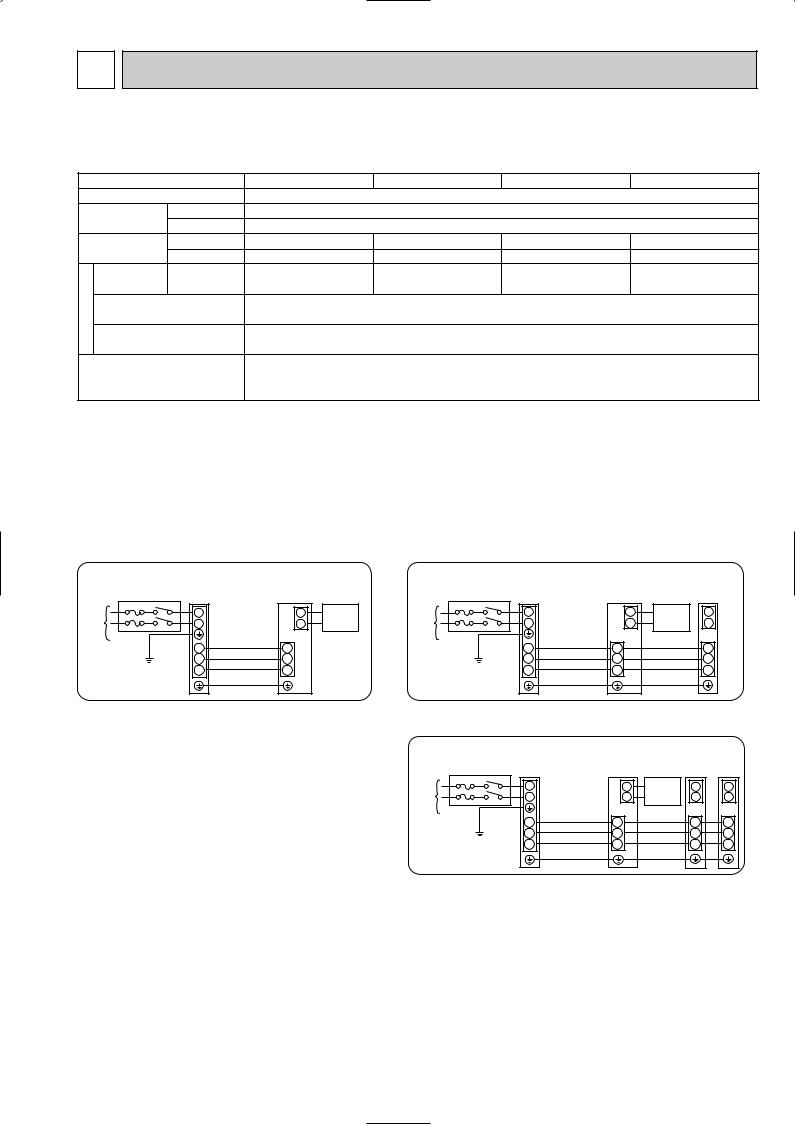

2 SPECIFICATIONS FOR ELECTRICAL WORK

2-1. Field electrical wiring(power wiring specifications) PUHZ-RP•VHA

PUHZ-RP•VHA-A

Models (Outdoor unit) Indoor unit power supply

Outdoor unit |

Phase |

|

Power supply |

Frequency & Voltage |

|

Input capacity |

Indoor unit(A) |

|

Main switch/Fuse |

Outdoor unit(A) |

|

Outdoor unit |

Wire No. |

|

Power supply |

||

|

||

Wiring Wire No. o size (e) |

||

Indoor unit/Outdoor unit connecting

Remote controller-indoor unit connecting Wire No. o size (e)

Control circuit rating

RP3V |

RP4V |

RP5V |

RP6V |

|

~ / N (Single), 50Hz, 220-230-240V |

|

|

|

|

~ / N (Single) |

|

|

|

50Hz, 220-230-240V |

|

— |

— |

— |

— |

25/25 |

32/32 |

32/32 |

40/40 |

3 |

3 |

3 |

3 |

3 o 2.5 cable (Polar)

Cable 2C o 0.69

This wire is accessory of remote controller (Wire length: 10m, Non-polar) Indoor unit-Outdoor unit: S1-S2 AC220V-230V-240V

S2-S3 DC24V

Remote controller-Indoor unit: DC14V

Check items

1.Wiring size must comply with the applicable local and national code.

2.Be careful about choosing the installation location for the earth leakage breaker and how it is installed as the initial electric current may cause it to malfunction.

3.Power supply cords and indoor unit / Outdoor unit connecting cords shall not be lighter than polychloroprene sheathed flexible cord. (design 254 IEC 57)

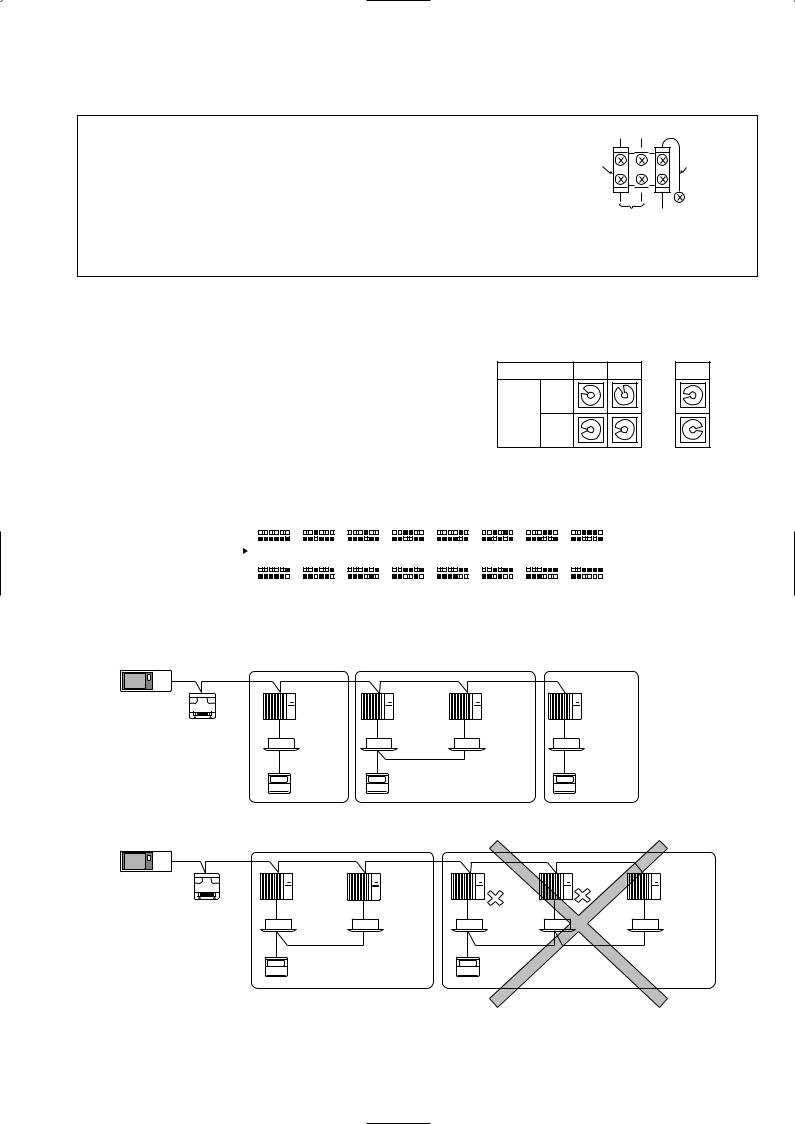

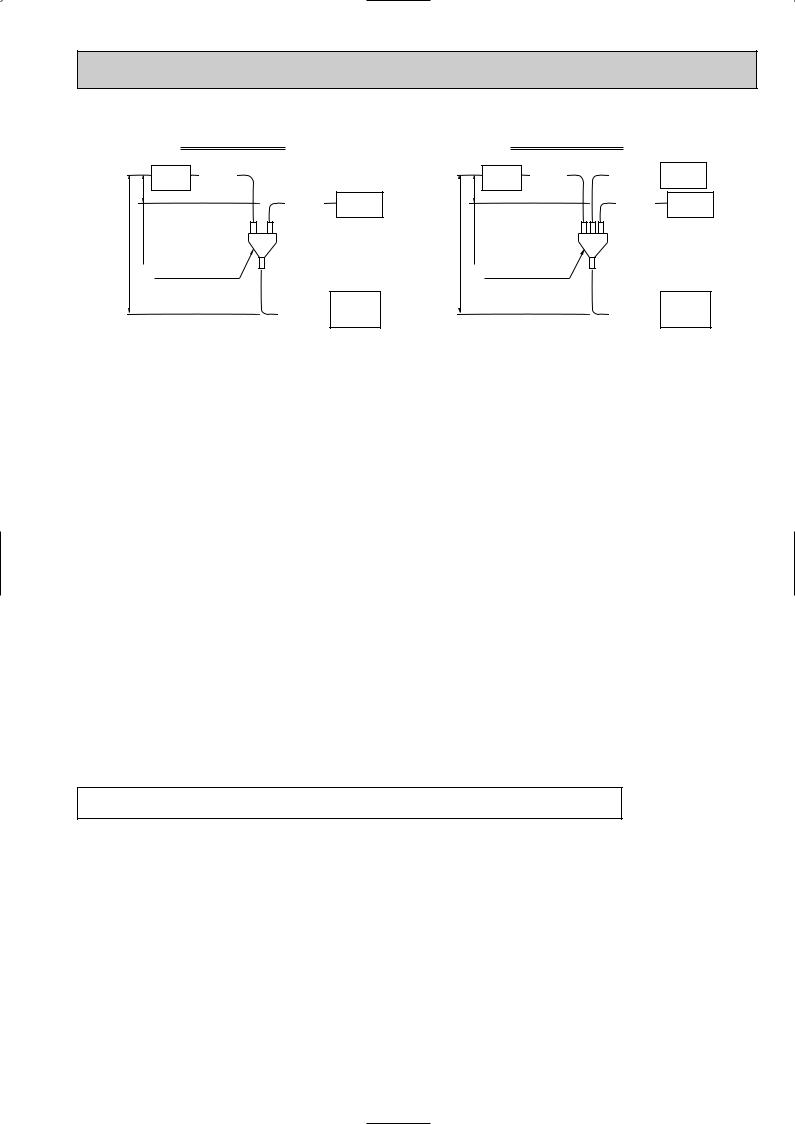

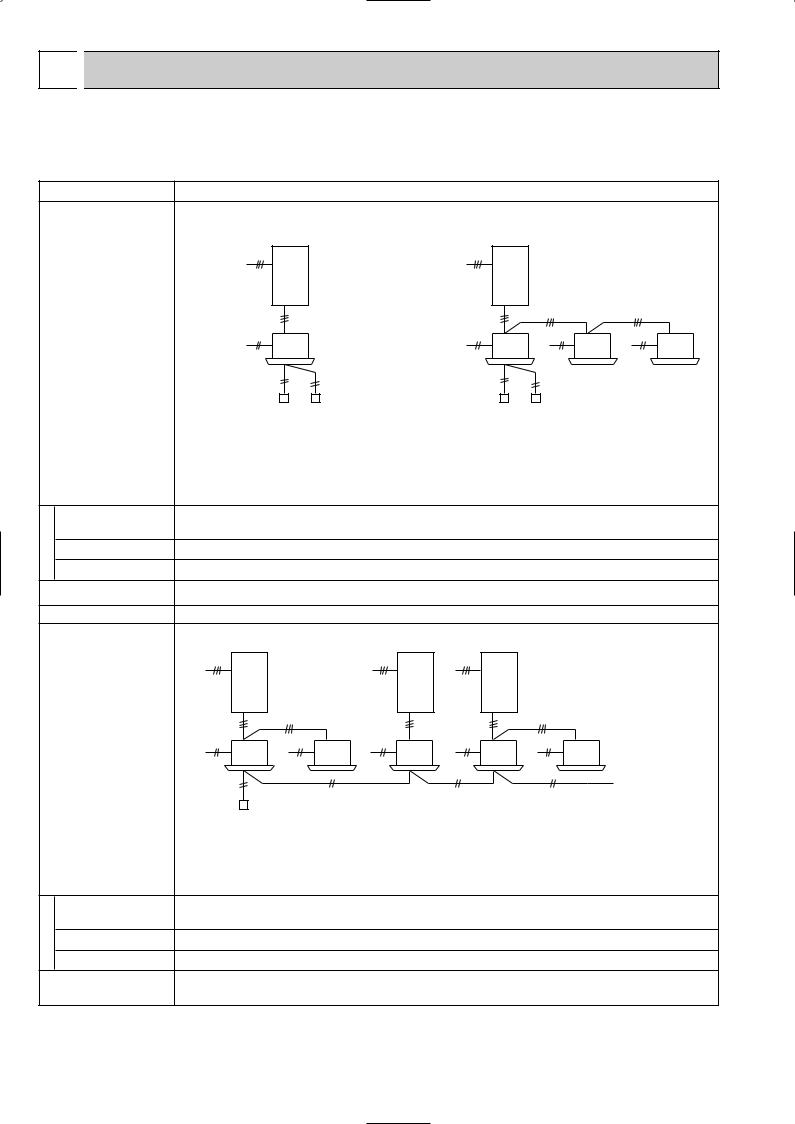

1:1 system |

|

|

|

|

Synchronized twin and triple system |

Electrical wiring |

|||||

|

|

|

|

|

• Synchronized twin |

|

|

|

|

|

|

|

Outdoor |

Indoor |

|

|

Outdoor |

Indoor |

|

Indoor |

|||

|

unit |

|

unit |

|

|

unit |

|

unit |

|

unit |

|

Unit |

L |

|

1 |

Remote |

Unit |

L |

|

1 |

Remote |

|

1 |

power |

N |

|

2 |

controller |

power |

N |

|

2 |

controller |

2 |

|

supply |

|

Indoor/outdoor |

|

|

supply |

|

Indoor/outdoor |

|

|

|

|

|

|

unit connection |

|

|

|

|

unit connection |

|

|

|

|

|

S1 |

cable |

S1 |

|

|

S1 |

cable |

S1 |

|

|

S1 |

|

|

|

|

|

|

|

|||||

|

S2 |

|

S2 |

|

|

S2 |

|

S2 |

|

|

S2 |

Grounding |

S3 |

|

S3 |

|

Grounding |

S3 |

|

S3 |

|

|

S3 |

|

|

|

|

|

• Synchronized triple |

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor |

Indoor |

|

Indoor Indoor |

||

|

|

|

|

|

|

unit |

|

unit |

|

unit |

unit |

|

|

|

|

|

Unit |

L |

|

1 |

Remote |

1 |

1 |

|

|

|

|

|

power |

N |

|

2 |

controller |

2 |

2 |

|

|

|

|

|

supply |

|

Indoor/outdoor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1 |

connection cable |

S1 |

|

S1 |

S1 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

S2 |

|

S2 |

|

S2 |

S2 |

|

|

|

|

|

Grounding |

S3 |

|

S3 |

|

S3 |

S3 |

3

2-2. M-NET wiring method

(Points to notice)

(1)Outside the unit, transmission wires should stay away from electric wires in order to prevent electromagnetic noise from making an influence on the signal communication. Place them at intervals of more than 5cm. Do not put them in the same conduit tube.

(2)Terminal block (TB7) for transmission wires should never be connected to 220~240V power supply. If it is connected, electronic parts on M-NET p.c. board may be burn out.

(3)Use 2-core x 1.25mm2 shield wire (CVVS, CPEVS) for the transmission wire. Transmission signals may not be sent or received normally if different types of transmission wires are put together in the same multi-conductor cable. Never do this because this may cause a malfunction.

Group |

|

Refrigerant |

Refrigerant |

Refrigerant |

|

address 00 |

address 00 |

address 00 |

|

remote |

|

|||

controller |

|

M-NET |

M-NET |

M-NET |

|

Power |

address 01 |

address 02 |

address 03 |

|

supply |

|

|

|

|

unit for |

|

|

|

|

transmission |

|

|

|

|

wire |

|

|

|

A-control |

A-control |

A-control |

remote |

remote |

remote |

controller |

controller |

controller |

It would be ok if M-NET wire (non-polar, 2-cores) is arranged in addition to the wiring for A-control.

(4)Ground only one of any appliances through M-NET transmission wire (shield wire). Communication error may occur due to the influence of electromagnetic noise.

“Ed” error will appear on the LED display of outdoor unit. “0403” error will appear on the central-control remote controller.

Bad example (Multi spot grounding of shield wire)

Central |

|

Power |

|

M-NET type |

|

M-NET type |

|

M-NET type |

remote |

|

supply |

|

|

|

|||

|

|

outdoor unit |

|

outdoor unit |

|

outdoor unit |

||

controller |

|

appliance |

|

|

|

|||

|

|

|

|

|

|

|

M-NET transmission wire

Good example 1 (Single spot grounding of shield wire) |

|

||||

Central |

Power |

M-NET type |

M-NET type |

M-NET type |

|

remote |

supply |

||||

outdoor unit |

outdoor unit |

outdoor unit |

|||

controller |

appliance |

||||

|

|

|

|||

M-NET transmission wire |

|

|

|

||

Good example 2 (Single spot grounding of shield wire) |

|

||||

Central |

Power |

M-NET type |

M-NET type |

M-NET type |

|

remote |

supply |

||||

outdoor unit |

outdoor unit |

outdoor unit |

|||

controller |

appliance |

||||

|

|

|

|||

M-NET transmission wire |

|

|

|

||

If there are more than two grounding spots on the shield wire, noise may enter into the shield wire because the ground wire and shield wire form one circuit and the electric potential difference occurs due to the impedance difference among grounding spots. In case of single spot grounding, noise does not enter into the shield wire because the ground wire and shield wire do not form one circuit.

To avoid communication errors caused by noise, make sure to observe the single spot grounding method described in the installation manual.

4

|

|

|

|

|

|

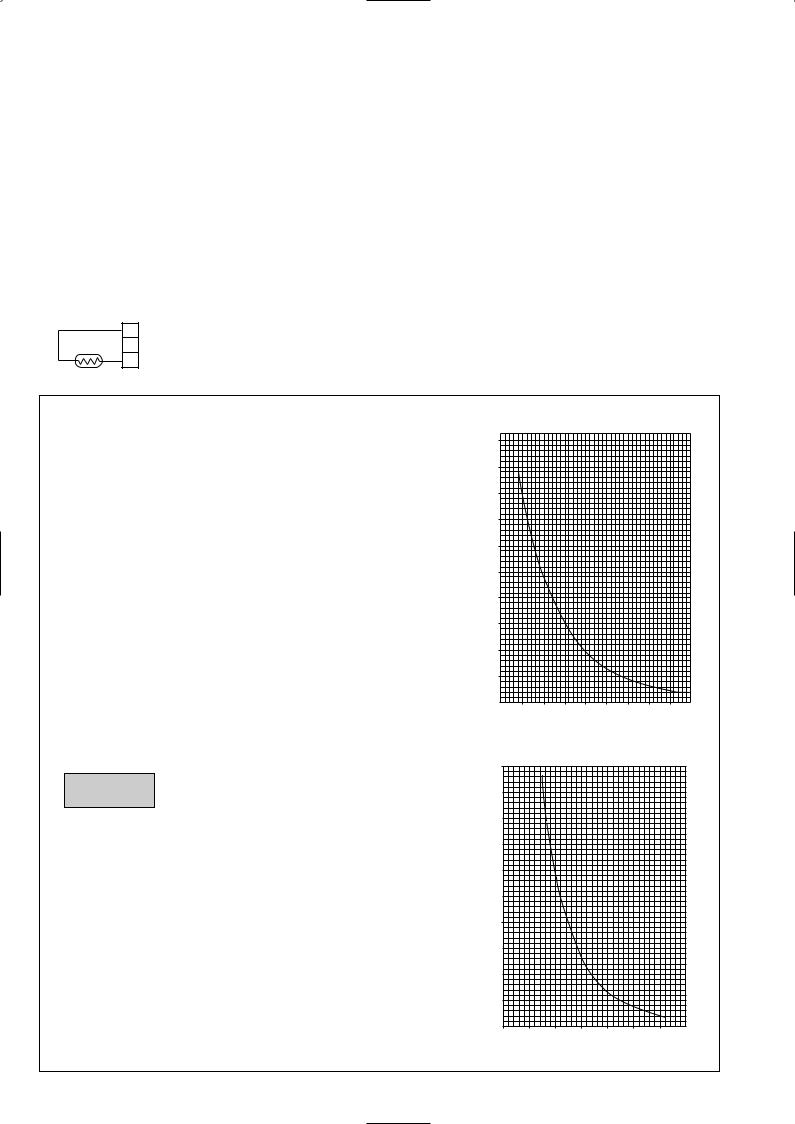

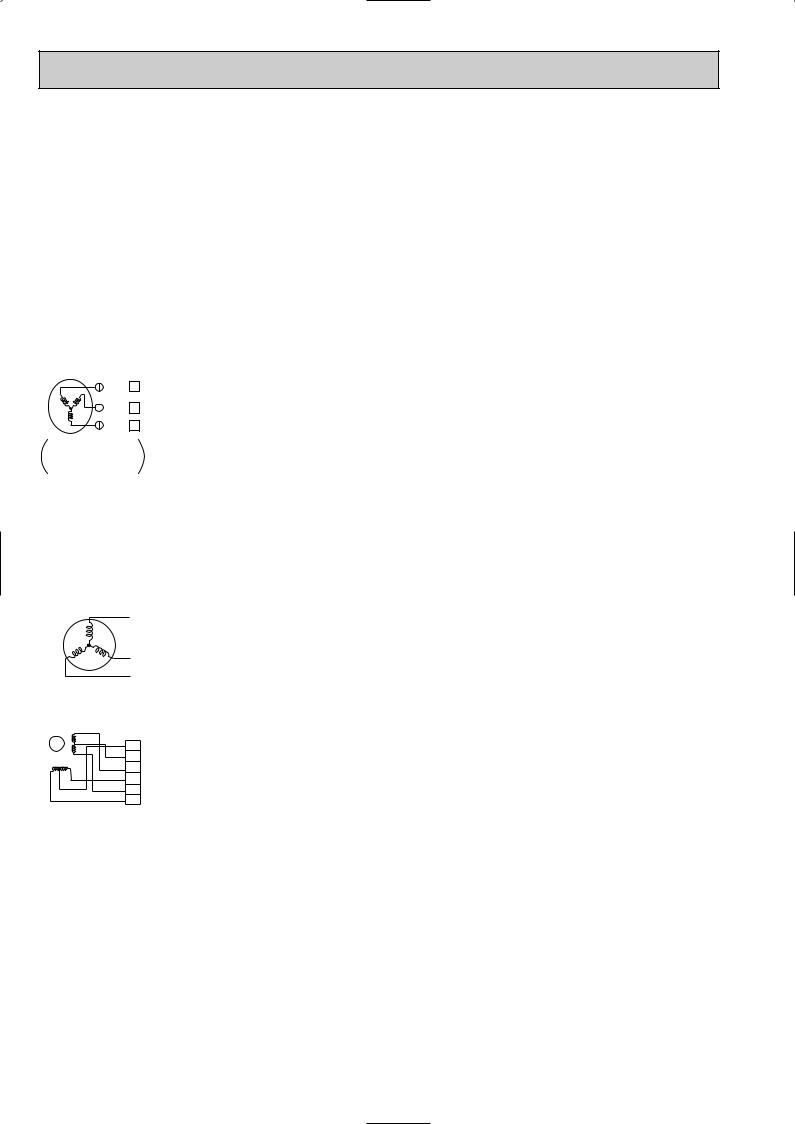

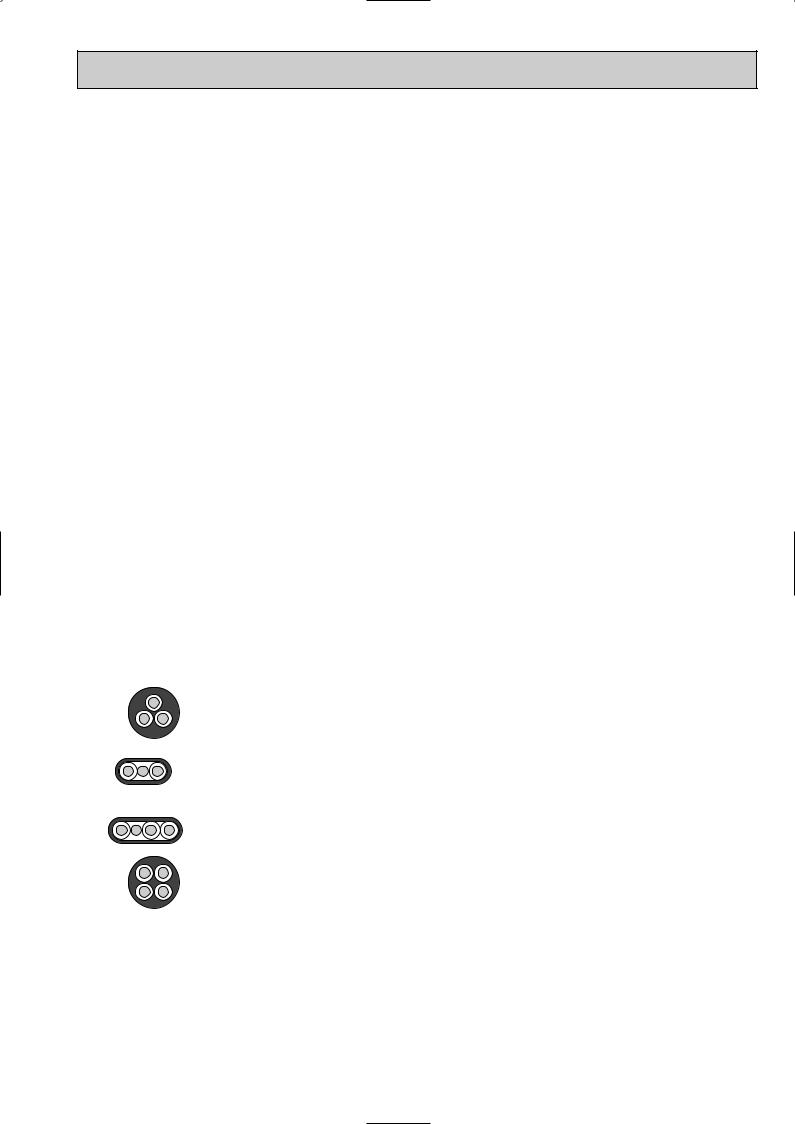

● M-NET wiring |

|

|

|

||

(1) |

Use 2-core x 1.25mm2 shield wire for electric wires. |

M-NET |

|

|

|

|

|

||||

|

(Excluding the case connecting to system controller.) |

terminal |

|

Ground |

|

|

block |

|

|||

(2) |

Connect the wire to the M-NET terminal block.Connect one core of the |

|

wire |

||

|

|

||||

|

|

|

|||

|

transmission wire (non-polar) to A terminal and the other to B. Peel the |

|

|

|

|

|

A B |

S |

|||

|

shield wire, twist the shield part to a string and connect it to S terminal. |

||||

|

Transmission |

Shield |

|||

(3) |

In the system which several outdoor units are being connected, the terminal |

||||

wire |

part |

||||

|

|

||||

(A, B, S) on M-NET terminal block should be individually wired to the other

outdoor unit’s terminal, i.e. A to A, B to B and S to S.In this case, choose one of those outdoor units and drive a screw to fix an ground wire on the plate as shown on the right figure.

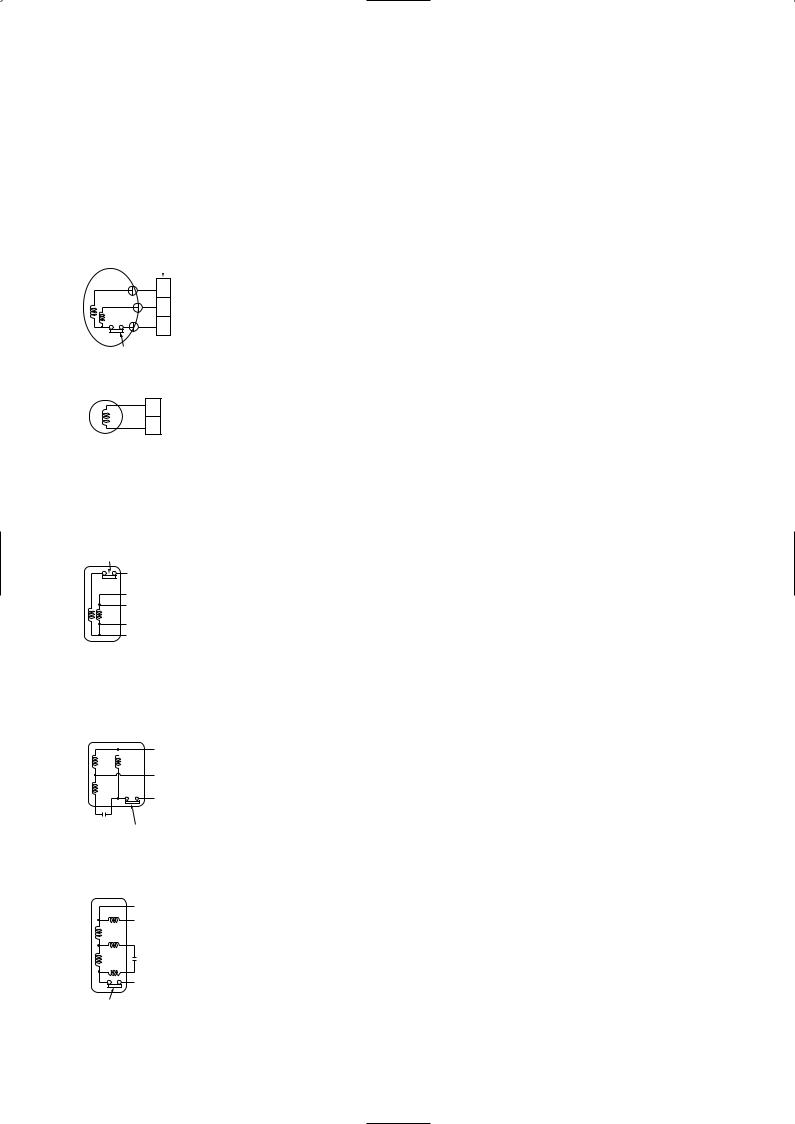

2-2-1. M-NET address setting

In A-control models, M-NET address and refrigerant address should be set only for the outdoor unit. Similar to Free Combo system, there is no need to set the address of outdoor unit and remote controller. To construct a central control system, the setting of M-NET address should be conducted only upon the outdoor unit. The setting range should be 1 to 50 (the same as that of the indoor unit in Free Combo system), and the address number should be consecutively set in a same group.

Address number can be set by using rotary switches (SW11 for ones digit and SW12 for tens digit), which is located on the M-NET p.c. board of outdoor unit.

(Factory setting: all addresses are set to “0”.)

2-2-2. Refrigerant address setting

<Setting example> M-NET Address No.

SW11

ones

Switng digit setting SW12

tens digit

1

2 |

34 |

|

01 |

5 |

|

9 |

7 |

6 |

8 |

|

|

2 |

34 |

|

01 |

5 |

|

9 |

7 |

6 |

8 |

|

|

2 |

|

50 |

|||

2 |

34 |

2 |

34 |

||

01 |

5 |

01 |

5 |

||

9 |

7 |

6 |

9 |

7 |

6 |

8 |

|

8 |

|

||

2 |

34 |

~ |

34 |

||

2 |

|||||

01 |

5 |

01 |

5 |

||

9 |

7 |

6 |

9 |

7 |

6 |

8 |

|

8 |

|

||

In case of multiple grouping system (multiple refrigerant circuits in one group), indoor units should be connected by remote controller wiring (TB5) and the refrigerant address needs to be set. Leave the refrigerant addresses to “00” if the group setting is not conducted. Set the refrigerant address by using DIP SW1-3 to -6 on the outdoor controller board. [Factory setting: all switches are OFF. (All refrigerant addresses are “00”.)]

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Refuigrant |

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

4 |

5 |

6 |

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

4 |

5 |

6 |

|||||||||

|

|

|

|

|

0 |

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

address |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

11 |

|

|

|

|

|

|

12 |

|

|

|

|

|

|

13 |

|

|

|

|

|

|

14 |

|

|

|

|

|

|

15 |

|

|

|

||||||

2-2-3. Regulations in address settings

In case of multiple grouping system, M-NET and refrigerant address settings should be done as explained in the above section. Set the lowest number in the group for the outdoor unit whose refrigerant address is “00” as its M-NET address.

|

|

Group A |

Group B |

|

Group C |

System |

|

Refrigerant |

Refrigerant |

Refrigerant |

Refrigerant |

|

address 00 |

address 00 |

address 01 |

address 00 |

|

controller |

|

||||

|

M-NET |

M-NET |

M-NET |

M-NET |

|

|

|

||||

|

Power |

address 01 |

address 02 |

address 03 |

address 04 |

|

|

|

|

|

|

|

supply |

|

|

|

|

|

unit for |

|

|

|

|

|

transmission |

|

|

TB5 |

|

|

wire |

|

|

|

|

|

|

A-control |

A-control |

|

A-control |

|

|

remote |

remote |

|

remote |

|

|

controller |

controller |

|

controller |

w Refrigerant addresses can be overlapped if they are in the different group.

|

Group A |

|

|

Group B |

|

|

System |

Refrigerant |

Refrigerant |

Refrigerant |

Refrigerant |

Refrigerant |

|

address 00 |

address 01 |

address 00 |

address 01 |

address 02 |

||

controller |

||||||

M-NET |

M-NET |

M-NET |

M-NET |

M-NET |

||

|

||||||

Power |

address 01 |

address 02 |

address 04 |

address 03 |

address 05 |

|

supply |

|

|

|

|

|

|

unit for |

|

|

|

|

|

|

transmission |

|

|

TB5 |

|

|

|

wire |

|

|

|

|

||

|

A-control |

|

A-control |

|

|

|

|

remote |

|

remote |

|

|

|

|

controller |

|

controller |

|

|

wIn group B, M-NET address of the outdoor unit whose refrigerant address is “00” is not set to the minimum in the group. As “3” is right for this situation, the setting is wrong. Taking group A as a good sample, set the minimum M-NET address in the group for the outdoor unit whose refrigerant address is “00”.

5

3

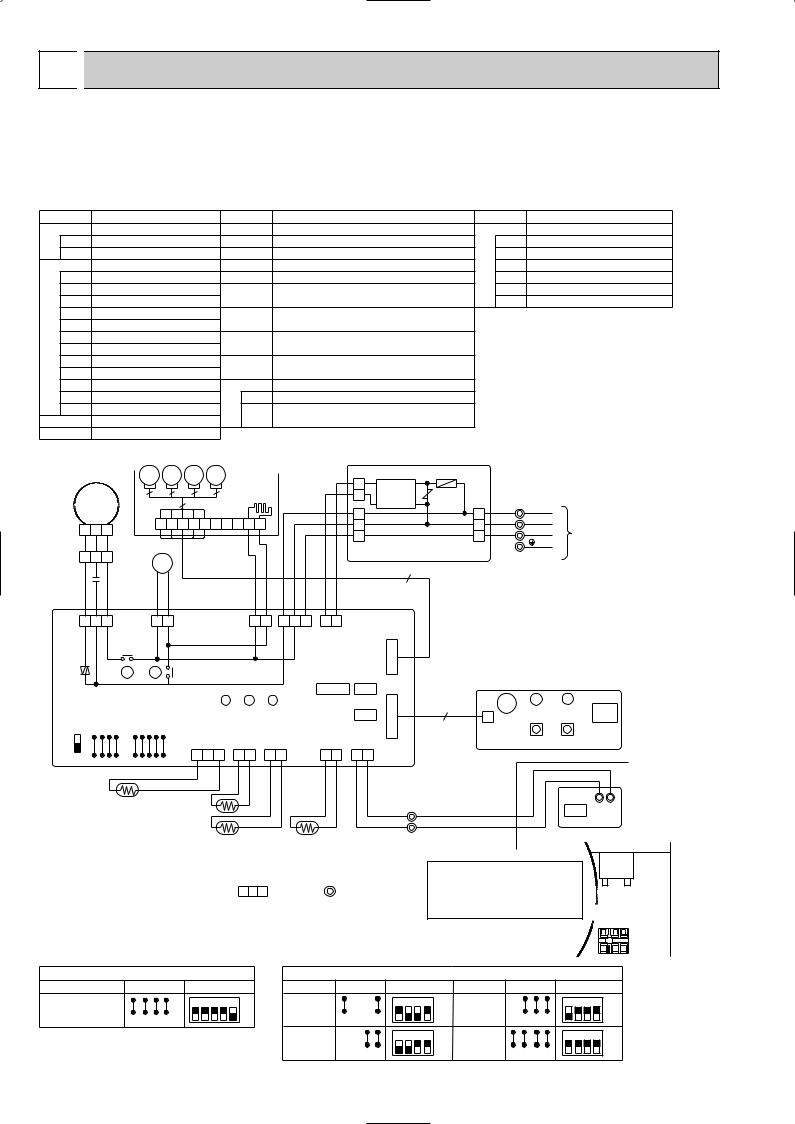

WIRING DIAGRAM

WIRING DIAGRAM

PLA-RP3AA

PLA-RP3AA1 PLA-RP3AA.UK PLA-RP3AA1.UK

[LEGEND]

PLA-RP4AA

PLA-RP4AA1 PLA-RP4AA.UK PLA-RP4AA1.UK

PLA-RP5AA

PLA-RP5AA1 PLA-RP5AA.UK PLA-RP5AA1.UK

PLA-RP6AA

PLA-RP6AA1 PLA-RP6AA.UK PLA-RP6AA1.UK

SYMBOL |

|

NAME |

|

|

SYMBOL |

NAME |

|

SYMBOL |

|

NAME |

||

P.B |

INDOOR POWER BOARD |

MV |

|

VANE MOTOR |

|

W.B |

WIRELESS REMOTE CONTROLLER BOARD |

|||||

F1 |

FUSE (4A) |

|

|

|

DP |

|

DRAIN-UP MACHINE |

|

|

RU |

RECEIVING UNIT |

|

ZNR |

VARISTOR |

|

|

DS |

|

DRAIN SENSOR |

|

|

BZ |

BUZZER |

|

|

I.B |

INDOOR CONTROLLER BOARD |

H2 |

|

DEW PREVENTION HEATER |

|

|

LED1 |

LED (RUN INDICATOR) |

||||

CN2L |

CONNECTOR (LOSSNAY) |

TB4 |

|

TERMINAL BLOCK (INDOOR/OUTDOOR CONNECTING LINE) |

|

LED2 |

LED (HOT ADJUST) |

|||||

CN32 |

CONNECTOR (REMOTE SWITCH) TB5 |

|

TERMINAL BLOCK (REMOTE CONTROLLER |

|

SW1 |

SWITCH (HEATING ON/OFF) |

||||||

CN41 |

CONNECTOR (HA TERMINAL-A) |

|

|

TRANSMISSION LINE) |

|

|

SW2 |

SWITCH (COOLING ON/OFF) |

||||

SW1 |

JUMPER WIRE (MODEL SELECTION) TH1 |

|

ROOM TEMPERATURE THERMISTOR |

|

|

|

|

|||||

SW2 |

JUMPER WIRE (CAPACITY CORD) |

|

|

(0:/15kΩ , 25:/5.4kΩ DETECT) |

|

|

|

|

|

|||

SWE |

SWITCH (EMERGENCY OPERATION) TH2 |

|

PIPE TEMPERATURE THERMISTOR/LIQUID |

|

|

|

|

|||||

X1 |

RELAY (DRAIN PUMP) |

|

|

|

(0:/15kΩ , 25:/5.4kΩ DETECT) |

|

|

|

|

|

||

X4 |

RELAY (FAN MOTOR) |

|

TH5 |

|

COND./EVA. TEMPERATURE THERMISTOR |

|

|

|

|

|||

FC |

FAN PHASE CONTROL |

|

|

(0:/15kΩ , 25:/5.4kΩ DETECT) |

|

|

|

|

|

|||

LED1 |

POWER SUPPLY (I.B) |

|

R.B |

|

REMOTE CONTROLLER BOARD |

|

|

|

|

|

||

LED2 |

POWER SUPPLY (I.B) |

|

|

CN2 |

CONNECTOR (PROGRAM TIMER) |

|

|

|

|

|

||

LED3 |

TRANSMISSION (INDOOR-OUTDOOR) |

|

TB6 |

TERMINAL BLOCK (REMOTE CONTROLLER |

|

|

|

|

||||

C |

CAPACITOR (FAN MOTOR) |

|

|

TRANSMISSION LINE) |

|

|

|

|

|

|||

MF |

FAN MOTOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GRILLE |

|

|

|

|

|

P.B |

|

|

|

|

|

MV MV MV MV |

|

CN2S(WHT) |

F1 |

|

|

|

||||

|

|

|

|

|

|

|

||||||

|

|

|

2 |

|

|

|

|

|||||

|

|

5 |

5 |

5 |

|

|

|

|

|

|

|

|

MF |

5 |

H2 |

1 DC14V |

ZNR |

|

TB4 |

|

|||||

|

5 |

|

|

|

|

|||||||

|

|

|

|

3 |

|

1 |

YLW |

S1 |

|

|||

|

|

1 2 3 6 |

7 4 |

8 9 5 10 |

|

ORN |

S2 |

|

||||

1 2 3 |

2 |

|

2 |

|

||||||||

|

BRN |

S3 |

TO OUTDOOR UNIT |

|||||||||

|

|

|

|

|

1 |

|

3 |

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

1 |

2 |

3 |

|

C |

|

|

I.B |

RED |

WHT |

BLK |

FAN 1 3 5 (WHT)

FC

SWE |

SW2 |

ON |

J24 J23 J22 J21 |

OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTROLLER BOARD OUTDOOR UNIT |

|

|

|||

|

|

|

|

|

DP |

|

|

|

|

|

|

|

|

|

|

CN02 (WHT) |

CN01 (BLU) |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YLW |

YLW |

|

|

|

|

YLW YLW |

|

YLW ORN |

BRN |

BLK |

WHT |

POWER VANE |

|

|

|

|||

D.U.M |

1 3 |

D.HEATER |

1 3 |

1 3 5 |

1 2 |

|

|

|

|||||||||||||

CNP |

|

CNC (RED) |

CN2D |

CN6V |

|

|

|

||||||||||||||

(BLU) |

|

|

|

|

|

|

|

|

|

|

POWER |

(WHT) |

(WHT) |

|

|

|

|||||

X4 |

|

|

|

|

|

|

|

|

|

|

|

|

CN03 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(RED) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

X4 |

|

|

|

X1 |

X1 |

|

|

|

|

|

|

|

CN41 CN2L |

W.B |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LED3 LED2 LED1 |

|

|

|

CN32 |

9 |

BZ |

LED1 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LED2 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

SW1 |

D.SENSOR INTAKE LIQUID |

|

PIPE |

REMOCON |

CNB |

|

RU |

|||||||||||||

|

|

|

|

|

|

CN31 |

|

CN20 |

CN21 |

|

CN29 |

CN22 |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

SW1 |

SW2 |

||||||||||

J11 |

J12 |

J13 |

|

J14 |

J15 |

(WHT) |

(RED) |

(WHT) |

|

(BLK) |

(BLU) |

WIRELESS |

|

||||||||

|

1 |

2 |

3 |

1 |

2 |

1 |

2 |

|

1 |

2 |

1 |

2 |

CN90 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(WHT) |

|

|

|

|

BLK |

BLK |

BLK |

BLK |

BLK |

BLK |

BLU BLU |

|

|

DS |

TH1 |

|

|

TH5 |

|

|

2TB5 |

CN2 |

|

|

TH2 |

|

|

|

|

|

|||

NOTES: |

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

TRANSMISSION |

||

1.Since the outdoor side electric wiring may change be sure to |

|

|

|

WIRES DC12V |

|||||

check the outdoor unit electric wiring for servicing. |

|

|

|

|

|

|

|||

2.Indoor and outdoor connecting wires are made with polarities, make |

|

|

Please set the voltage using |

||||||

wiring matching terminal numbers (S1,S2,S3). |

|

|

|

|

|

|

the remote controller. |

||

3.Symbols used in wiring diagram above are, |

|

:Connector, |

:Terminal (block). |

|

For the setting method, please |

||||

|

|

|

|

|

|

|

|

|

refer to the indoor unit Installation |

[Servicing] |

|

|

|

|

|

|

|

|

Manual. |

Fasten terminal of the terminal board "TB4" equips lock system.

To remove the fastened terminal, pull it while pressing the protruding portion (locking lever) of the terminal. The fastened terminal protruding portion should face upward.

R.B

1 2 TB6

C

TB4

TB4

|

SW1 |

|

MODELS |

Manufacture Service board |

|

PLA-RP3,4,5,6AA |

|

1 2 3 4 5 |

PLA-RP3,4,5,6AA1 |

|

ON |

J11J12J13J14J15 |

OFF |

|

|

|

|

MODELS

PLA-RP3AA PLA-RP3AA1

PLA-RP4AA PLA-RP4AA1

|

|

|

SW2 |

|

|

|

|

|

|

Manufacture Service board |

MODELS |

Manufacture |

Service board |

||||||

1 |

2 |

3 |

4 |

PLA-RP5AA |

|

1 |

2 |

3 |

4 |

|

|

|

ON |

|

|

|

|

ON |

|

J21J22J23J24 |

|

|

OFF |

|

J21J22J23J24 |

|

|

|

OFF |

1 |

2 |

3 |

4 |

PLA-RP5AA1 |

|

1 |

2 |

3 |

4 |

|

|

|

ON |

PLA-RP6AA |

|

|

|

|

ON |

J21J22J23 J24 |

|

|

OFF |

PLA-RP6AA1 |

J21J22J23 J24 |

|

|

|

OFF |

6

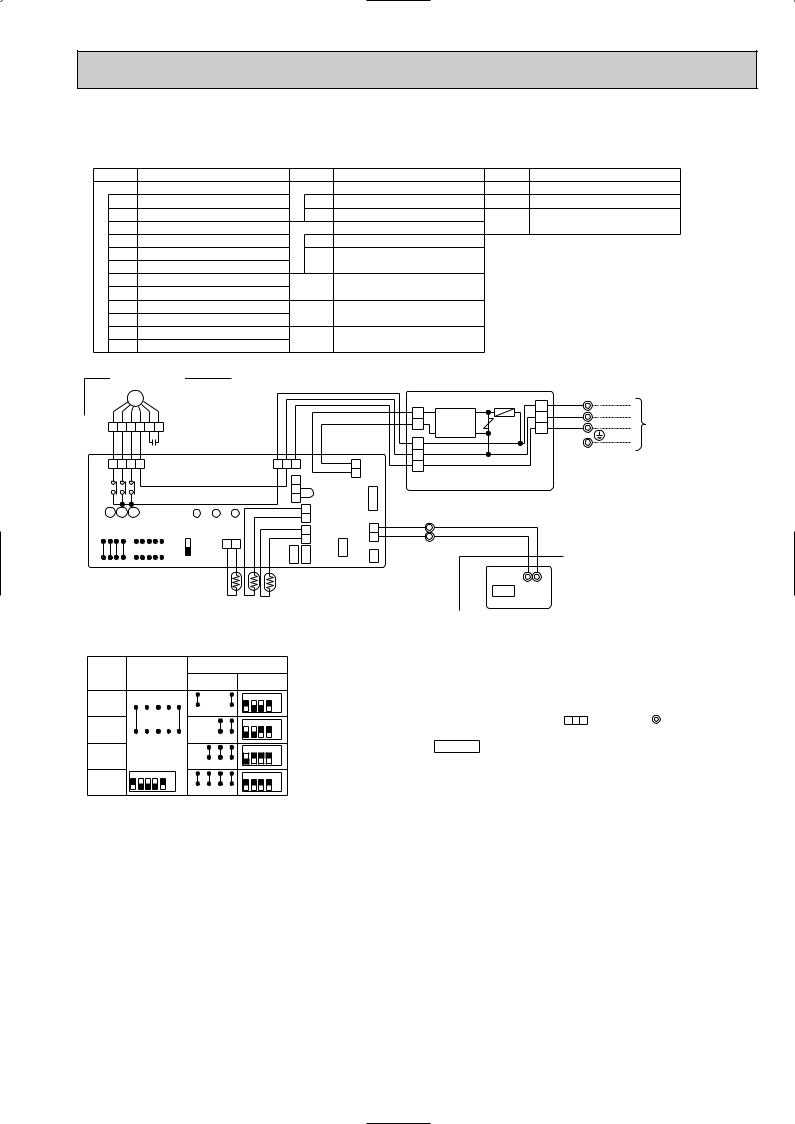

PEA-RP3EA.TH-A PEA-RP5EA.TH-A

PEA-RP4EA.TH-A PEA-RP6EA.TH-A

SYMBOL |

NAME |

SYMBOL |

NAME |

SYMBOL |

NAME |

I.B |

INDOOR CONTROLLER BOARD |

P.B |

INDOOR POWER BOARD |

C |

CAPACITOR(FAN MOTOR) |

CN2L |

CONNECTOR(LOSSNAY) |

F1 |

FUSE(4A) |

MF |

FAN MOTOR |

CN32 |

CONNECTOR(REMOTE SWITCH)) |

ZNR |

VARISTOR |

TB4 |

TERMINAL BLOCK |

CN41 |

CONNECTOR(HA TERMINAL-A) |

R.B |

REMOTE CONTROLLER BOARD |

|

(INDOOR/OUTDOOR CONNECTING LINE) |

LED1 |

POWER SUPPLY(I.B) |

CN2 |

CONNECTOR(PROGRAM TIMER) |

|

|

LED2 |

POWER SUPPLY(R.B) |

TB6 |

TERMINAL BLOCK(REMOTE |

|

|

LED3 |

TRANSMISSOION(INDOOR • OUTDOOR) |

|

CONTROLLER TRANSMISSON LINE) |

|

|

SW1 |

JUMPER WIRE(MODEL SELECTION) |

TH1 |

ROOM TEMPERATURE THERMISTOR |

|

|

SW2 |

JUMPER WIRE(CAPACITY CORD) |

|

(0˚C/15kΩ , 25˚C/5.4kΩ DETECT) |

|

|

SWE |

SWITCH(EMERGENCY OPERATION) |

TH2 |

PIPE TEMPERATURE THERMISTOR/LIQUID |

|

|

X4 |

RELAY(FAN MOTOR) |

|

(0˚C/15kΩ , 25˚C/5.4kΩ DETECT) |

|

|

X5 |

RELAY(FAN MOTOR) |

TH5 |

COND./EVA. TEMPERATURE THERMISTOR |

|

|

X6 |

RELAY(FAN MOTOR) |

|

(0˚C/15kΩ , 25˚C/5.4kΩ DETECT) |

|

|

INDOOR UNIT

|

|

MF |

|

|

|

|

|

|

|

|

|

|

|

2 |

3 |

4 |

1 |

|

5 |

6 |

|

|

|

|

|

|

|

BLK |

BLU |

BRN |

WHT |

RED |

C |

ORN |

|

YLW |

ORN |

BRN |

WHT |

BLK |

|

I.B |

|

|

|

|

|

|

|

|

|

|

|

|

|

FAN 1 |

3 |

5 |

7 |

|

|

|

|

POWER |

1 3 |

5 |

|

|

1 POWER |

(WHT) |

|

|

|

|

|

|

|

CN03 |

|

|

|

|

2 CN2D |

|

|

|

|

|

|

|

|

(RED) |

|

3 |

CN31 |

(WHT) |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

2 |

|

WIRELESS |

|

X6 X5 X4 |

|

|

|

|

|

|

1 |

|

|

CN90 |

|||

|

|

|

|

|

|

|

|

|

|

|

2 |

LIQUID |

(WHT) |

X6 X5 X4 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

1 |

CN21 |

REMOCON |

||||

|

|

|

|

|

|

|

LED3 LED2 LED1 |

|

|

(WHT) |

|||

|

|

|

|

|

|

|

|

|

2 INTAKE |

CN22 |

|||

SW2 |

|

|

SW1 |

|

SWE |

PIPE |

|

|

(BLU) 2 |

||||

|

|

|

|

|

1 |

CN20 |

1 |

||||||

J24 J23 J22 J21 |

J15 J14 J13 J12 J11 |

ON |

CN29 2 1 |

|

|

|

(RED) |

|

|||||

OFF |

(BLK) |

|

|

|

CN41 |

CN2L |

|||||||

|

|

|

|

|

|

|

|

CN24 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

CN32 |

|

TH5 TH2 TH1

CN2S(WHT) |

|

|

|

TB4 |

|

||

F1 |

1 |

YLW |

S1 |

|

|||

|

|

|

|||||

2 |

|

|

ORN |

S2 |

|

||

DC14V |

|

2 |

TO OUTDOOR UNIT |

||||

1 |

ZNR |

BRN |

S3 |

||||

3 |

|||||||

|

|

|

|

|

|

||

3

2

1

CONT.BOARD OUTDOOR CN02(WHT) CN01(BLU)

P.B

TB5

BLU

BLU 2

1TRANSMISSION WIRE DC12V

R.B

CN2

1 2

TB6

MODELS |

SW1 |

SW2 |

|

|

Manufacture Service board |

||||

|

|

|||

<For manufacture> |

1 2 3 4 |

|||

3EA |

|

|

ON |

|

|

J21J22J23J24 |

OFF |

||

|

|

|

||

4EA |

|

1 2 |

3 4 |

|

|

|

ON |

||

|

J21J22J23J24 |

OFF |

||

J11J12J13J14J15 |

||||

|

||||

5EA |

|

1 2 |

3 4 |

|

|

|

ON |

||

|

|

OFF |

||

<For service board> |

J21J22J23J24 |

|||

|

||||

1 2 |

3 4 5 |

1 2 |

3 4 |

|

6EA |

ON |

|

ON |

|

OFF |

J21J22J23J24 |

OFF |

||

|

|

|

||

[NOTES]

1.Since the outdoor side electric wiring may change be sure to check the outdoor unit electric wiring for servicing.

2.Indoor and outdoor connecting wires are made with polarities,make wiring

matching terminal numbers(S1,S2,S3). |

|

3.Symbols used in wiring diagram above are, |

:Connector, :Terminal (block). |

[Self diagnosis]

1.When pressing the CHECK switch twice on the remote controller,the unit changes to the self-diagnosis mode and will display the check code by LED(light Emitting Diode)

Refer to the right table for the check codes and abnormarities.

7

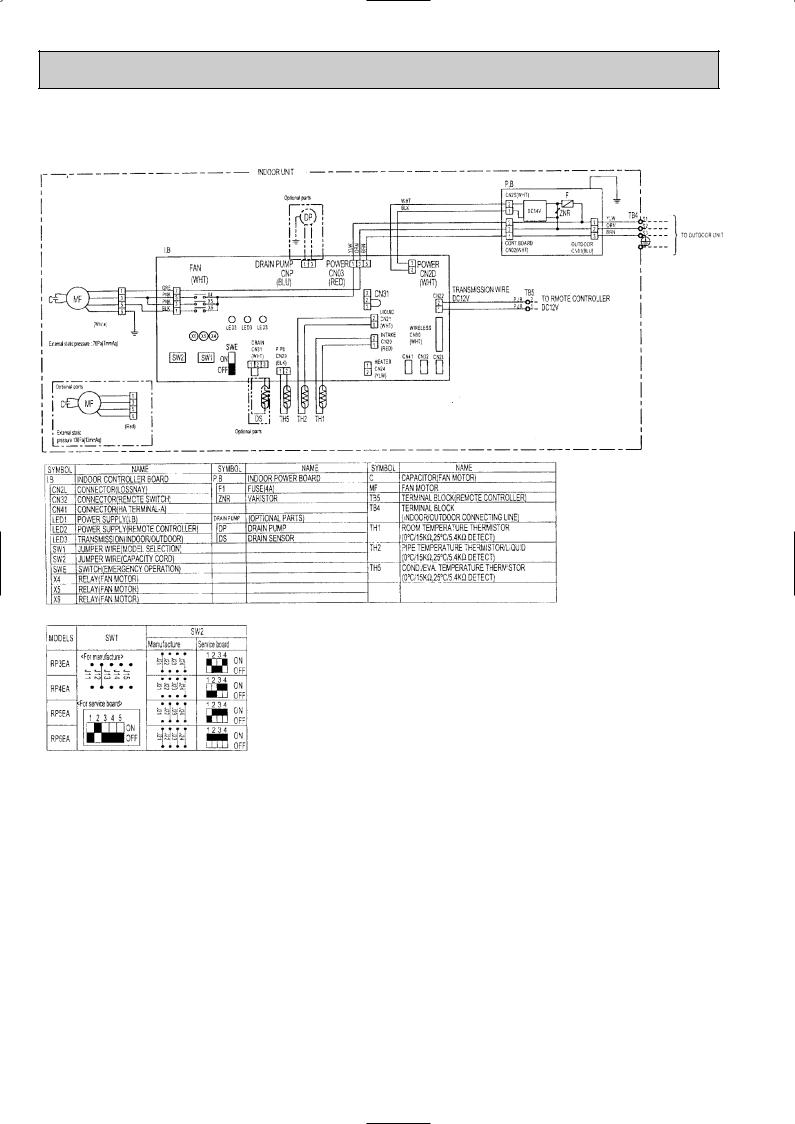

PEAD-RP3EA.UK PEAD-RP4EA.UK PEAD-RP5EA.UK PEAD-RP6EA.UK PEAD-RP3EA1.UK PEAD-RP4EA1.UK PEAD-RP5EA1.UK PEAD-RP6EA1.UK

8

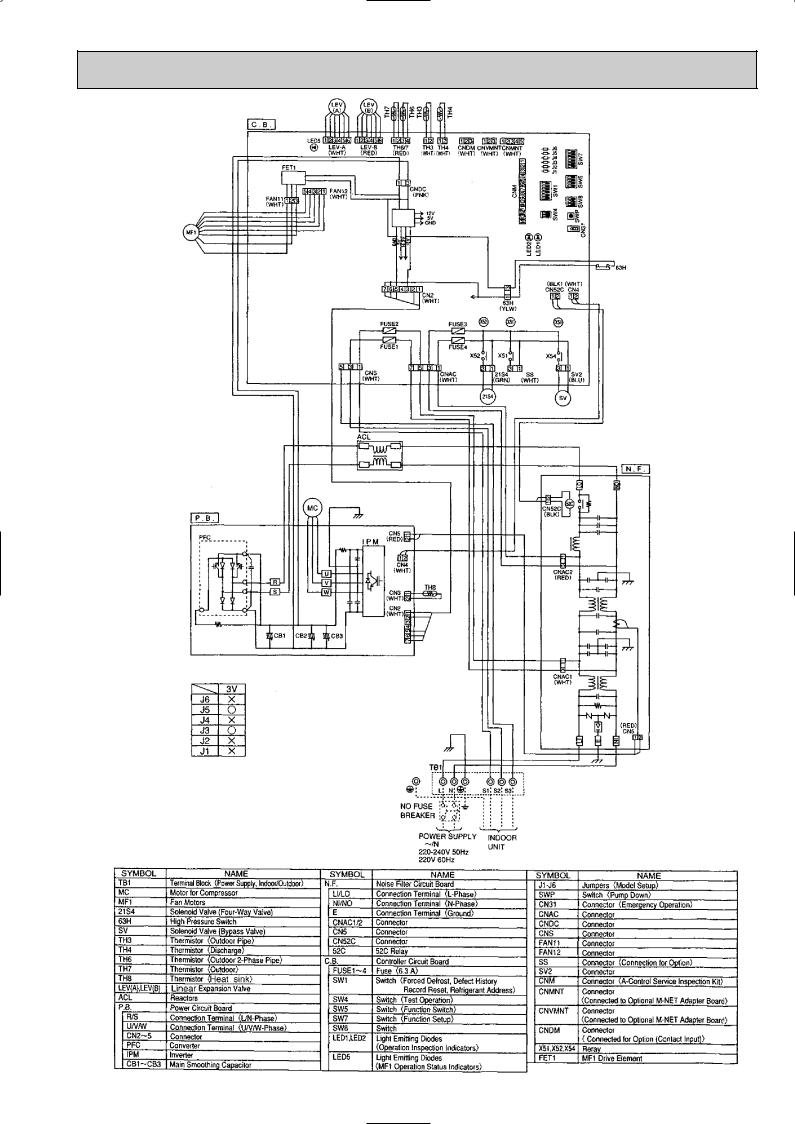

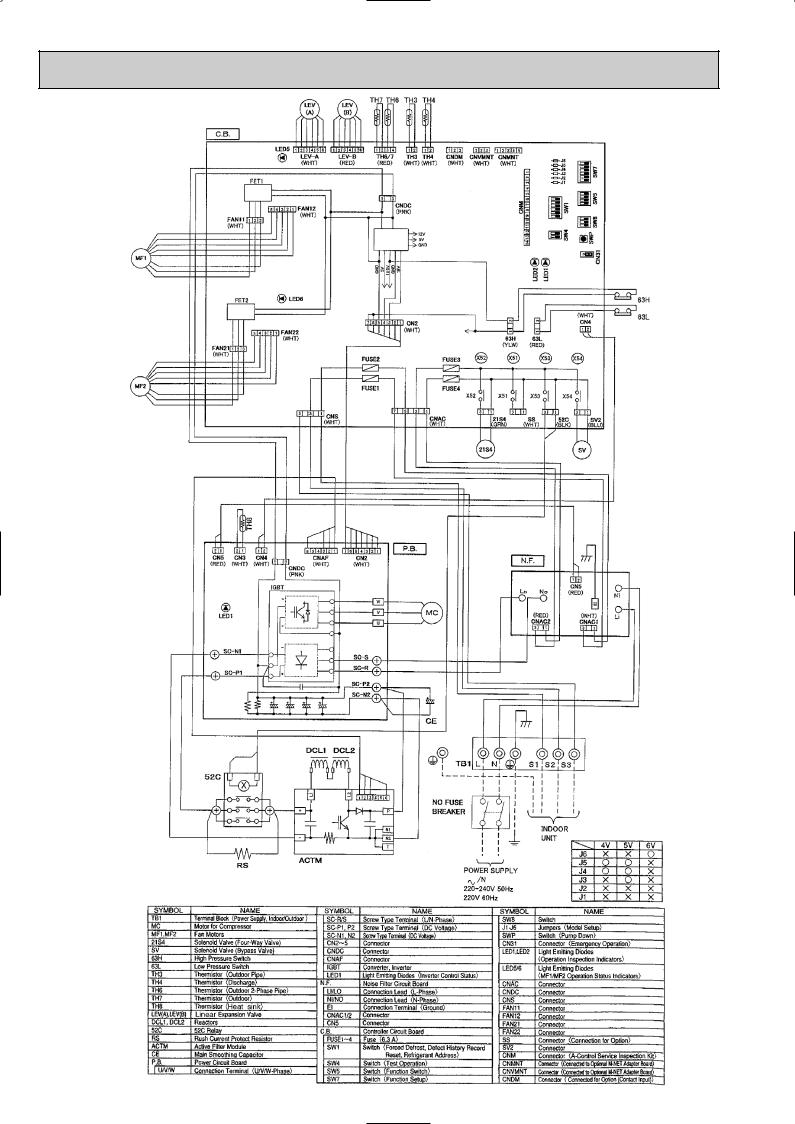

PUHZ-RP3VHA PUHZ-RP3VHA-A

9

PUHZ-RP4VHA PUHZ-RP5VHA PUHZ-RP6VHA PUHZ-RP4VHA-A PUHZ-RP5VHA-A PUHZ-RP6VHA-A

10

4

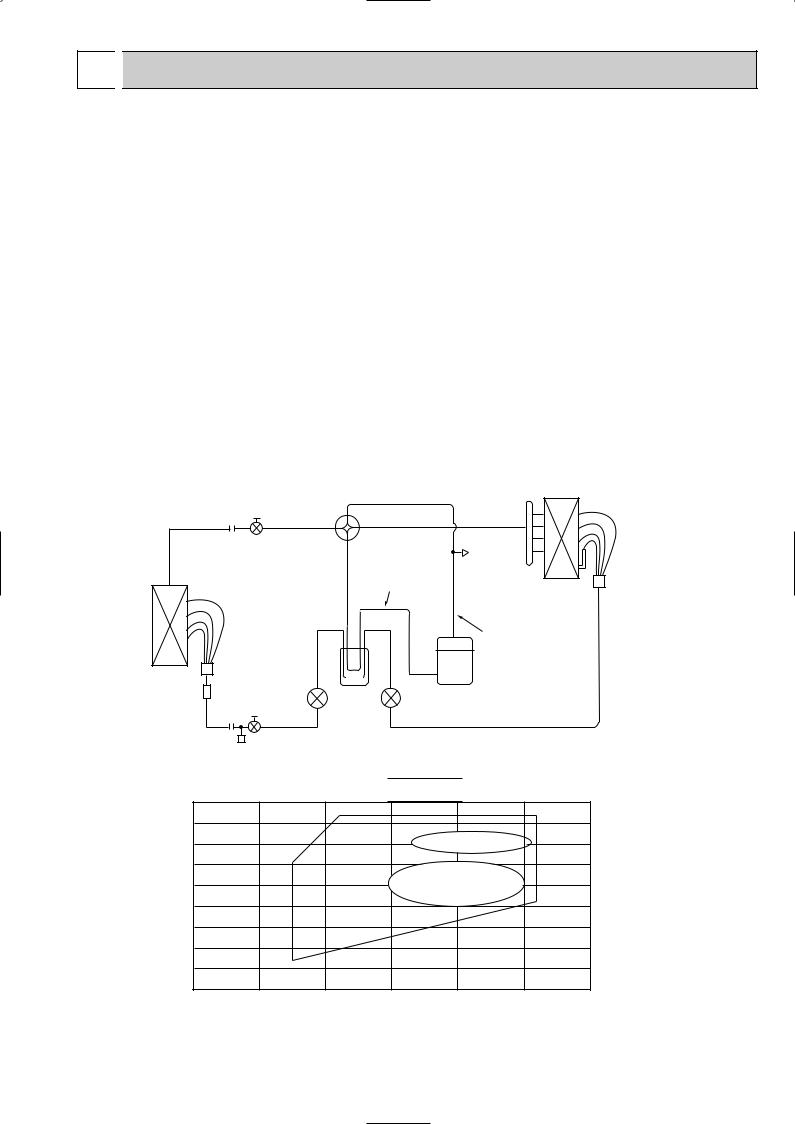

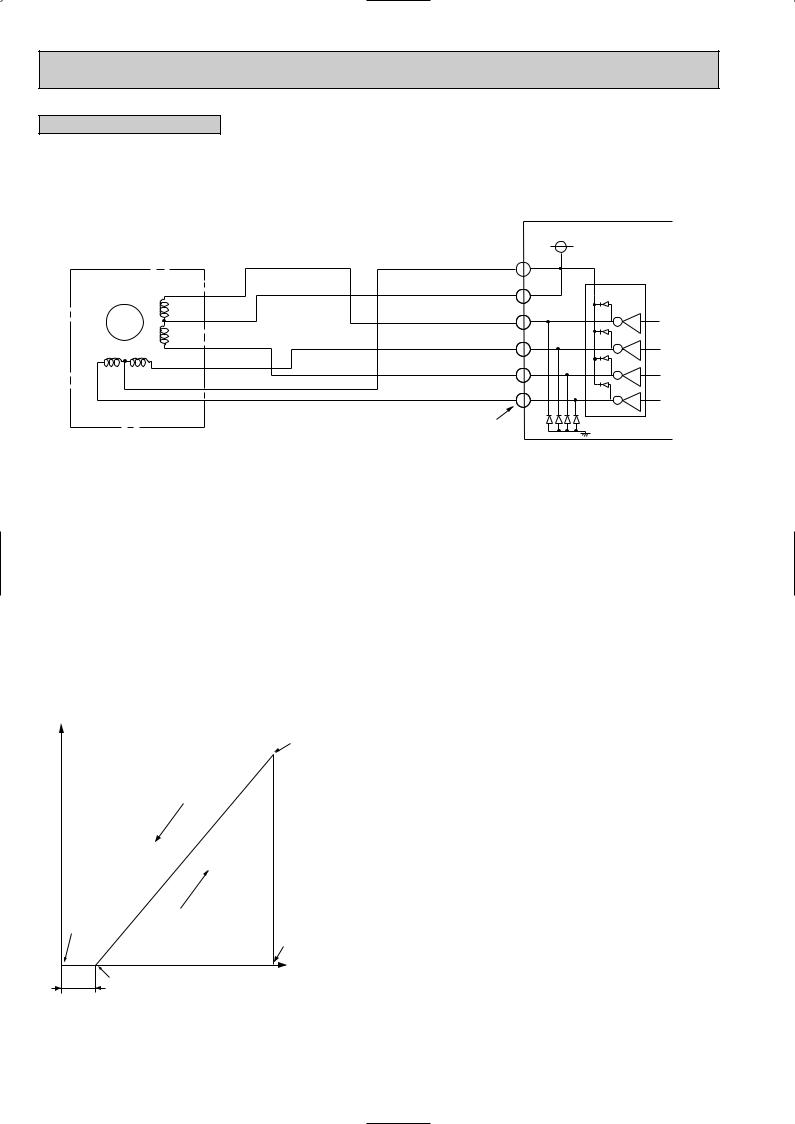

REFRIGERANT SYSTEM DIAGRAM

REFRIGERANT SYSTEM DIAGRAM

4-1. Checking operation statuses PUHZ-RP • HA

4-1-1. Measurement points and items

•The table and diagrams below show the measurement item for each measurement point, and the pressure and temperature near the ISO T1 standard operating conditions.

•Measure the temperature and pressure of each part by following the descriptions in the table.

•Measurement time: Be sure to wait until the refrigerant circuit has stabilized (30 minutes to 1 hour) before taking measurements.

|

Measurement item |

Pressure/temperature near JIS |

Measurement method, remarks |

|

|

standard operating conditions |

|||

|

|

|

||

A |

High pressure (MPa) |

COOL: 2.3 ~ 3.0 |

HEAT: 2.0 ~ 3.2 |

Connect the pressure gauge to the high-pressure check valve. |

|

|

|

|

|

B |

Low pressure (MPa) |

0.55 ~ 1.0 |

Connect the pressure gauge to the low-pressure check valve. |

|

|

|

|

|

|

C |

Discharge pipe temperature (:) |

50 ~ 100 |

Measured with piping surface thermometer. |

|

|

|

|

|

|

D |

Suction pipe temperature (:) |

-2 ~ +18 |

Measured with piping surface thermometer. |

|

|

|

|

|

|

E |

Indoor intake temperature (:) |

COOL: 27: HEAT: 20: |

Can be displayed on remote controller. |

|

|

|

|

|

|

F |

Indoor outlet temperature (:) |

COOL: 8 ~ 20 |

|

|

|

|

HEAT: 30 ~ 50 |

|

|

|

|

|

|

|

G |

Outdoor intake temperature (:) |

COOL: 35 |

HEAT: 7 |

Measured with piping surface thermometer. |

|

|

|

|

|

H |

Outdoor outlet temperature (:) |

COOL: 40 ~ 50 |

HEAT: 0 ~ 5 |

Measured with piping surface thermometer. |

|

|

|

|

|

Notes : The operation statuses vary depending on the compressor's operating frequency because units are inverter-type.

Outdoor

heat exchanger

Ball valve |

4-way valve |

A

B

D

C

Indoor heat |

|

|

|

exchanger |

Linear |

Power |

Compressor |

|

expansion |

||

|

valve B |

receiver |

Linear |

|

Stop valve |

|

expansion |

|

(with service port) |

|

valve A |

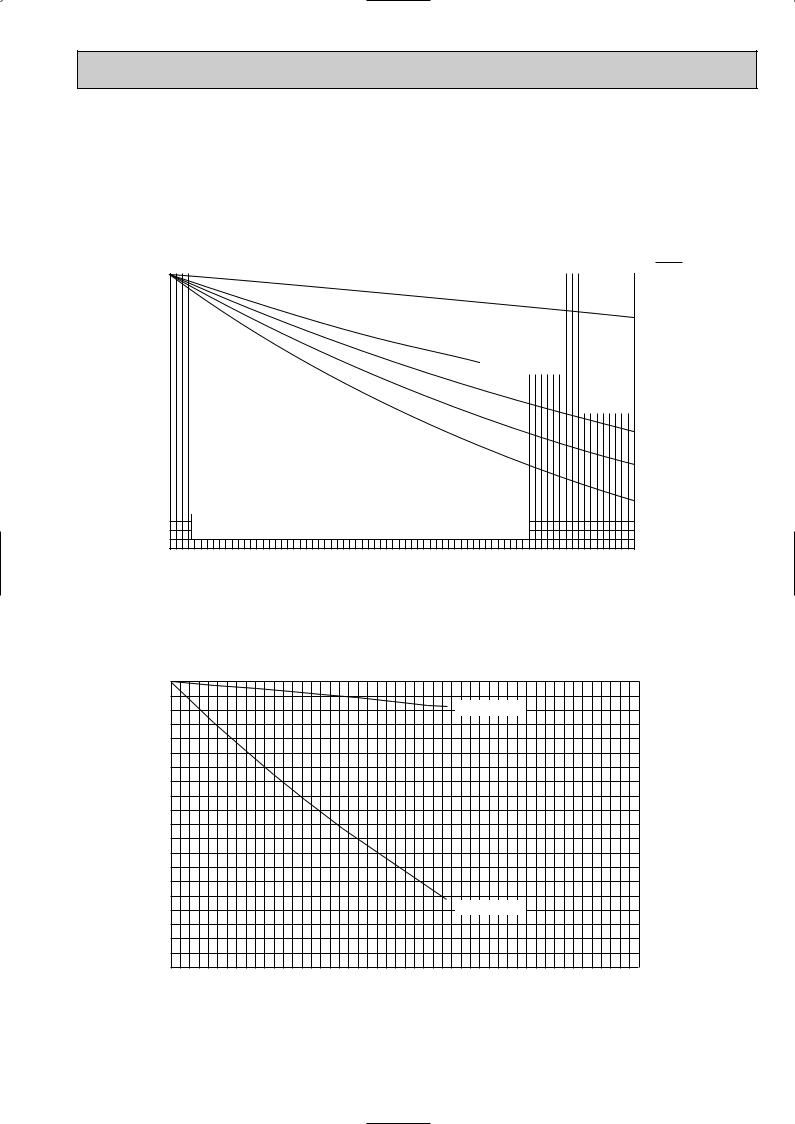

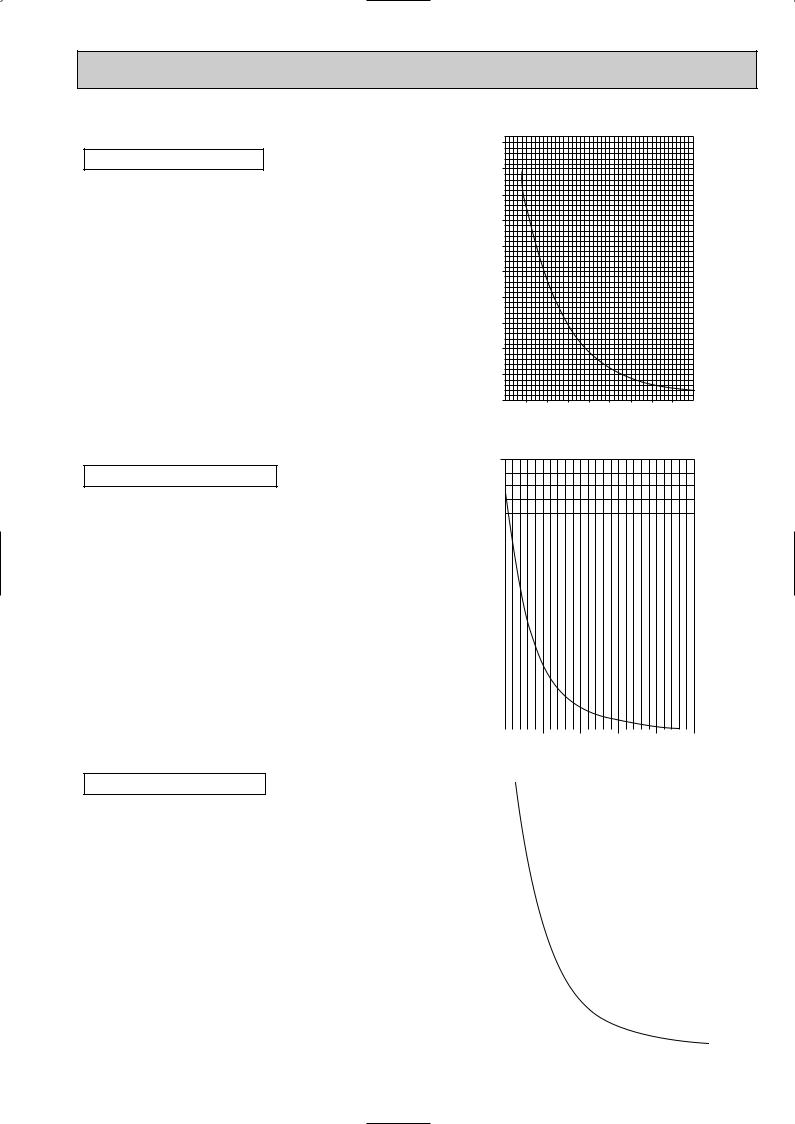

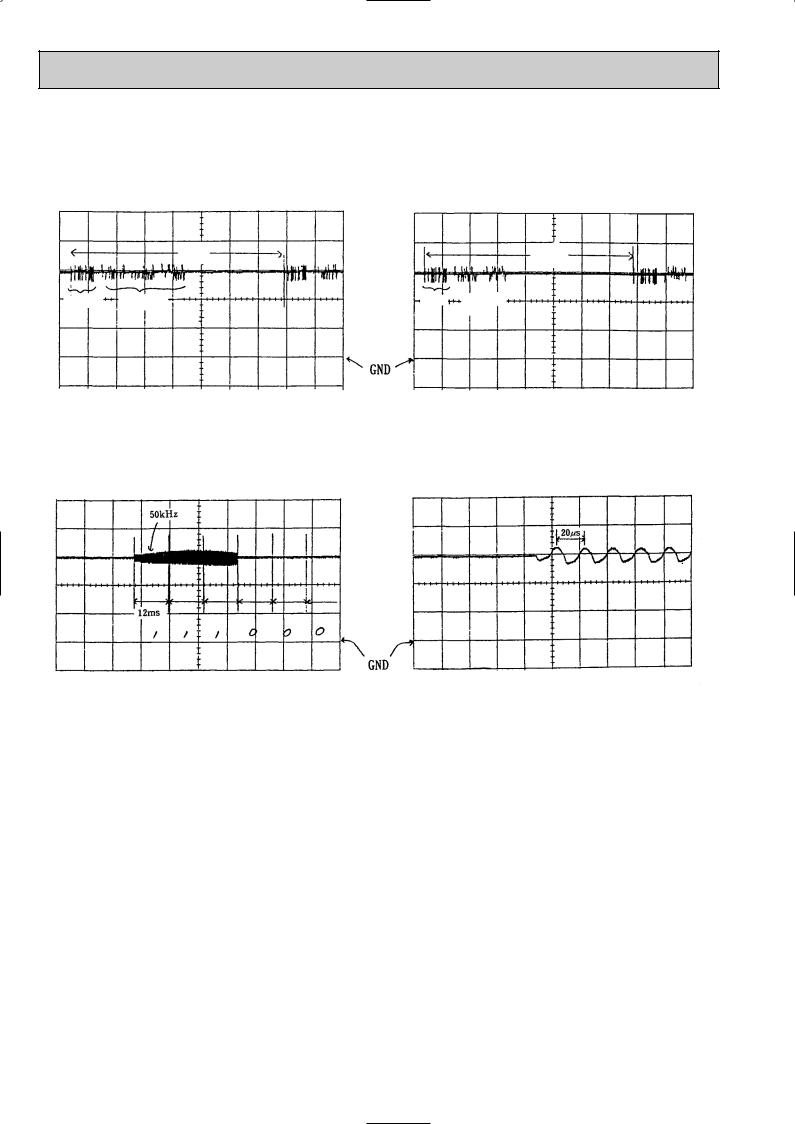

4-1-2. Operation pressure ranges

Discharge pressure (MPa)

Permissible operation range Normal operation range

4.5

4 |

|

3.5 |

Overload operation |

|

|

3 |

|

2.5 |

Standard operation |

2

1.5

1

0.5

0

0 |

0.2 |

0.4 |

0.6 |

0.8 |

1 |

1.2 |

Suction pressure (MPa)

11

4-2. Refrigerant System Diagram

PLA-RP3AA

PLA-RP3AA1 PLA-RP3AA.UK PLA-RP3AA1.UK PEA-RP3EA.TH-A PEAD-RP3EA.UK PEAD-RP3EA1.UK

PLA-RP4AA

PLA-RP4AA1 PLA-RP4AA.UK PLA-RP4AA1.UK PEA-RP4EA.TH-A PEAD-RP4EA.UK PEAD-RP4EA1.UK

Heat exchanger

PLA-RP5AA

PLA-RP5AA1 PLA-RP5AA.UK PLA-RP5AA1.UK PEA-RP5EA.TH-A PEAD-RP5EA.UK PEAD-RP5EA1.UK

Strainer #50

PLA-RP6AA

PLA-RP6AA1 PLA-RP6AA.UK PLA-RP6AA1.UK PEA-RP6EA.TH-A PEAD-RP6EA.UK PEAD-RP6EA1.UK

|

Refrigerant GAS pipe connection |

|

(Flare) |

|

Condenser/evaporator |

|

temperature thermistor |

|

(TH5) |

|

Refrigerant flow in cooling |

|

Refrigerant flow in heating |

|

Refrigerant LIQUID pipe connection |

|

(Flare) |

|

Pipe temperature |

Room temperature |

thermistor/liquid |

thermistor (TH1) |

(TH2) |

Distributor |

Strainer |

|

#50 |

||

with strainer |

||

|

||

#50 |

|

12

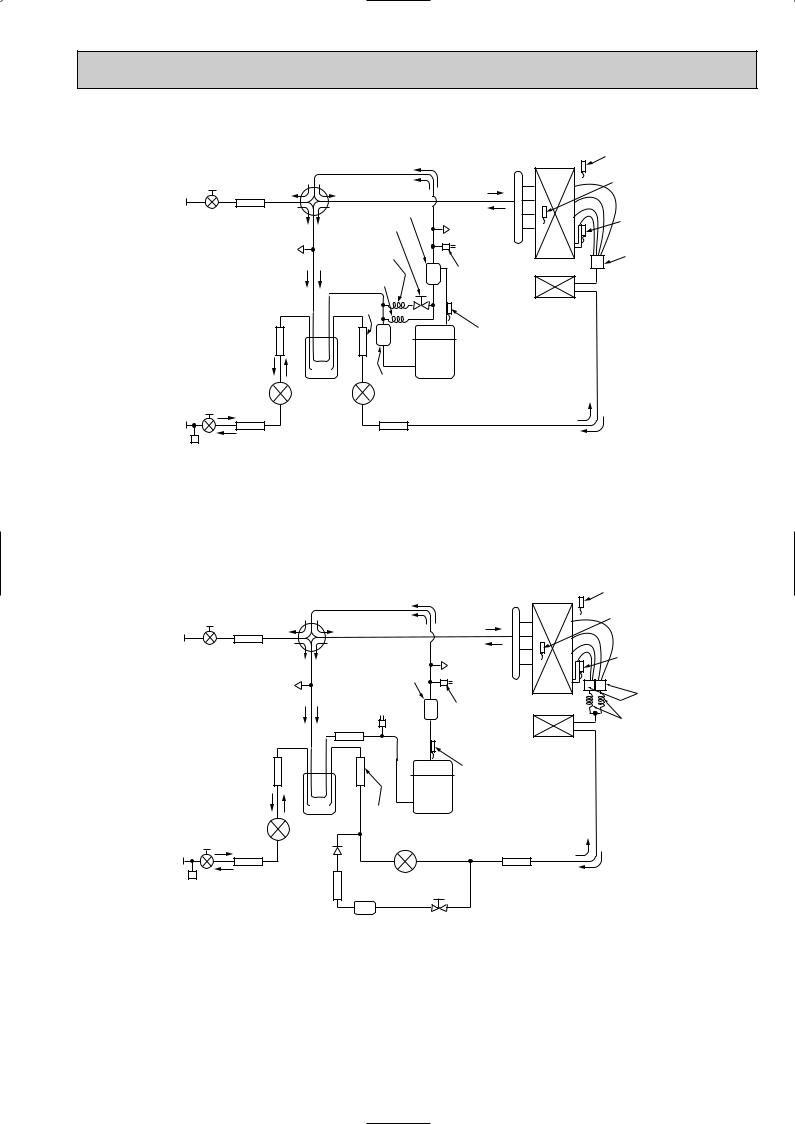

PUHZ-RP3VHA |

|

|

|

Heat exchanger |

Thermistor TH7 |

PUHZ-RP3VHA-A |

|

|

|

||

|

|

|

(Outdoor) |

||

|

|

|

|

||

|

|

|

|

|

|

Ball valve Strainer |

4-way valve |

|

Thermistor TH6 |

||

Refrigerant GAS pipe |

#50 |

|

|

|

(Outdoor 2-phase pipe) |

|

|

|

|

||

|

|

|

|

|

|

connection(5/8F) |

|

|

Oil separator |

|

|

|

|

|

Service port |

Thermistor TH3 |

|

|

|

|

Bypass valve |

||

|

|

|

(High pressure) |

(Outdoor pipe) |

|

|

|

|

|

||

|

Service port |

|

Capillary tube |

|

|

|

(Low pressure) |

O.D.4.0OI.D.2.4OL500 |

|

Distributor |

|

|

|

Capillary tube |

High pressure |

|

|

|

|

switch 63H |

|

||

|

|

O.D.2.5OI.D.0.6OL1000 |

|

||

|

|

|

|

||

|

|

|

Strainer |

|

|

|

|

|

#100 |

|

|

|

|

|

|

Thermistor TH4 |

|

|

Strainer |

|

|

(Discharge) |

|

|

#100 |

|

|

|

|

|

|

Power |

Muffler Compressor |

|

|

Stop valve |

|

receiver |

|

|

|

|

|

Linear expansion valve A |

|

||

(with service port) |

Linear |

|

|||

|

|

|

|||

Refrigerant LIQUID pipe |

|

expansion |

|

|

|

|

valve B |

|

|

|

|

connection(3/8F) |

|

|

|

|

|

Strainer |

|

Strainer |

|

|

|

|

|

|

|

||

|

#100 |

|

#100 |

|

|

PUHZ-RP4VHA PUHZ-RP5VHA PUHZ-RP6VHA PUHZ-RP4VHA-A PUHZ-RP5VHA-A PUHZ-RP6VHA-A

|

Thermistor TH7 |

Heat exchanger |

(Outdoor) |

|

|

Ball valve Strainer |

4-way valve |

|

Thermistor TH6 |

|

|

|

|

(Outdoor 2-phase pipe) |

|||

Refrigerant GAS pipe |

#50 |

|

|

|

|

|

|

|

|

|

|

||

connection(5/8F) |

|

|

|

|

|

Thermistor TH3 |

|

|

|

|

|

Service port |

|

|

|

|

|

|

(Outdoor pipe) |

|

|

|

|

|

|

(High pressure) |

|

|

|

Service port |

|

Muffler |

|

|

|

|

|

|

|

|

|

|

|

(Low pressure) |

|

Low pressure |

|

Distributor |

|

|

|

|

|

|

|

|

|

|

|

switch 63L |

High pressure |

|

|

|

|

|

Strainer |

|

|

|

|

|

|

switch 63H |

Capillary tube |

|

|

|

|

|

#100 |

|

(O.D.4.0OI.D.3.0OL200)O2pcs |

|

|

Strainer |

|

|

Thermistor TH4 |

|

|

|

|

|

(Discharge) |

|

|

|

|

#100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power |

Strainer |

Compressor |

|

|

Linear expansion valve B |

#100 |

|

|||

|

Stop valve |

receiver |

|

|

||

|

|

Linear expansion valve A |

|

|||

|

(with service port) |

Restrictor |

|

|||

Refrigerant LIQUID pipe |

|

|

|

|

||

|

valve |

|

|

|

||

connection(3/8F) |

|

Strainer |

|

|

Strainer |

|

|

|

|

|

|

||

|

|

#100 |

Strainer |

|

#100 |

|

|

|

|

#100 |

|

|

|

|

|

|

|

Replace filter |

Bypass valve |

|

|

|

|

|

|

|

|

13

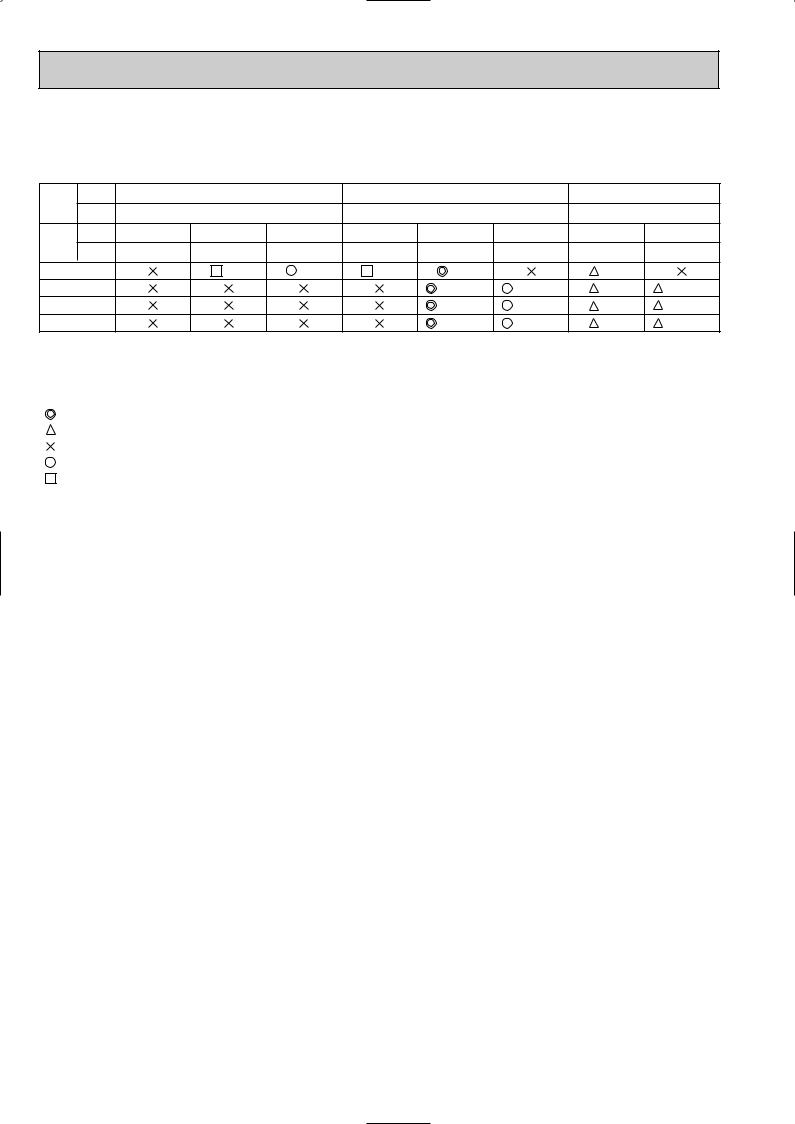

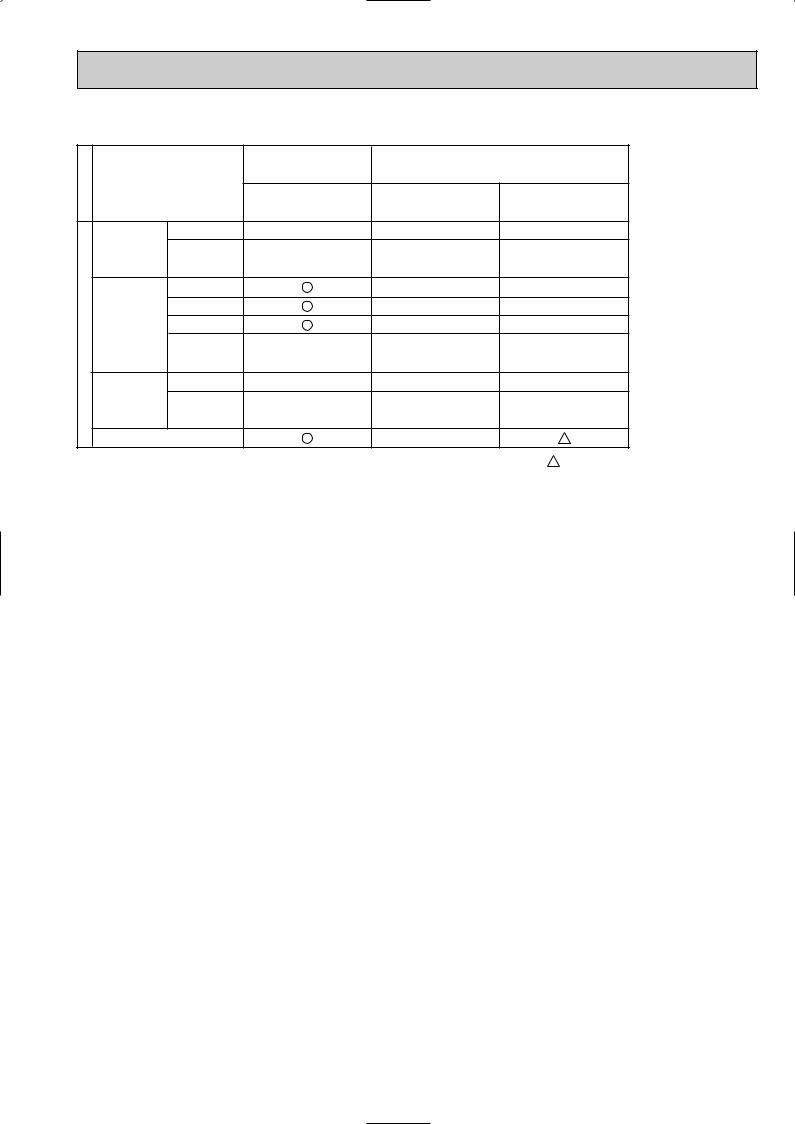

4-3. Applicable extension pipe for each model

4-3-1. 1:1 system

(a) Pipe length

<Table 1> Pipe length for 1:1 system

Liquid |

OD |

|

[6.35 |

|

|

[9.52 |

|

|

[12.7 |

|

pipe |

Thick- |

|

t0.8 |

|

|

t0.8 |

|

|

t0.8 |

|

(mm) |

|

|

|

|

|

|||||

ness |

|

|

|

|

|

|||||

Gas |

OD |

[9.52 |

[12.7 |

[15.88 |

[12.7 |

[15.88 |

[19.05 |

[15.88 |

[19.05 |

|

pipe |

Thick- |

t0.8 |

t0.8 |

t1.0 |

t0.8 |

t1.0 |

t1.0 |

t1.0 |

t1.0 |

|

(mm) |

||||||||||

ness |

||||||||||

RP3 |

|

10m |

10m |

30m |

50m |

|

30m |

|

||

RP4 |

|

|

|

|

75m (*2) |

50m (*1) |

50m |

50m (*1) |

||

RP5 |

|

|

|

|

75m (*2) |

50m (*1) |

50m |

50m (*1) |

||

RP6 |

|

|

|

|

75m (*2) |

50m (*1) |

50m |

50m (*1) |

||

*1: Set DIP SW8-1 on outdoor unit controller board to ON.

*2: The maximum length is 50 m in case of using existing pipes.

*3: The height difference between indoor and outdoor unit should be kept within 30 m for all models.

[Marks in the table above]

:Normal piping

:It can be used, however, additional refrigerant charge is required when the pipe length exceeds 20m.  Refer to table 4.

Refer to table 4.

:It cannot be used.

:It can be used.

:It can be used, however, the capacity is lowered.  Refer to (C) Capacity correction.

Refer to (C) Capacity correction.

(b)Adjusting the amount of refrigerant

•Additional refrigerant charge is not necessary for the pipe length up to 30 m. When the pipe length exceeds 30 m or service (refrigerant replacement) is performed, charge proper amount of refrigerant for each pipe length referring to table below. Use refrigerant R410A. Use charge hose exclusive for R410A.

•When charging additional refrigerant, charge the refrigerant from low-pressure side of the port valve using a safety charger.

•Make sure that air purge for this unit at refrigerant replacement is performed from both high-pressure check valve and service port. (If air purge is performed only from one of them, air in not purged enough.)

•When replacing refrigerant, charge the refrigerant from service port. When charged refrigerant is less than specified amount, charge the refrigerant again from low pressure side of the port valve using a safety charger.

•Tighten the service port cap (nut) of stop valve firmly. The tightening torque is 12 to 16 N·m. (For the prevention of slow-leak)

•Check additional refrigerant charging amount referring to table 4 when liquid pipe is one size larger than standard diameter, and table 2 when the pipe is standard diameter.

<Table 2> Additional refrigerant charging amount for pipe of standard diameter |

|

|

|

|

|

|||||||||||

|

|

|

|

|

Permitted |

|

Additional refrigerant charging amount for pipe |

Number of |

Height |

|

||||||

Outdoor unit |

|

|

|

length exceeding 30 m (kg) |

|

|||||||||||

|

pipe length |

|

|

|

|

|

|

|

bends |

difference |

|

|||||

|

|

|

|

|

|

31 — 40m |

41 — 50m |

51 — 60m |

61 — 75m |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||

PUHZ-RP3 |

|

50m or below |

|

0.6Kg |

1.2Kg |

— |

— |

15 |

30m or |

|

||||||

PUHZ-RP4 — |

RP6 |

|

75m or below |

|

0.6kg |

1.2kg |

1.8kg |

2.4kg |

above |

|

||||||

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<Table 3> |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor unit |

|

Permitted |

Additional refrigerant charging amount for recharging (above) and pipe length exceeding 30m (below) (kg) |

|||||||||||||

|

pipe length |

10m or below |

11 — 20m |

21 — 30m |

31 — 40m |

41 — 50m |

51 — 60m |

61 — 75m |

||||||||

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PUHZ-RP3 |

|

50m or below |

|

3.1 |

3.3 |

3.5 |

4.1 |

4.7 |

— |

— |

||||||

|

|

0.6 |

1.2 |

— |

— |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PUHZ-RP4 — |

RP6 |

|

75m or below |

|

5.1 |

5.3 |

5.5 |

6.1 |

6.7 |

7.3 |

7.9 |

|||||

|

|

0.6 |

1.2 |

1.8 |

2.4 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||||||

<Table 4> Additional refrigerant charging amount for liquid pipe which is one size larger than |

|

|

|

|||||||||||||

standard diameter |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Liquid pipe dia |

Chargeless |

Max. pipe length |

Additional refrigerant charging amount |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RP3 |

[12.7 |

|

20m |

|

30m |

|

100 g addition per 1 m when pipe length exceeds 20 m |

|

|

|

|

|||||

RP4 — RP6 |

[12.7 |

|

20m |

|

50m |

|

100 g addition per 1 m when pipe length exceeds 20 m |

|

|

|

|

|||||

14

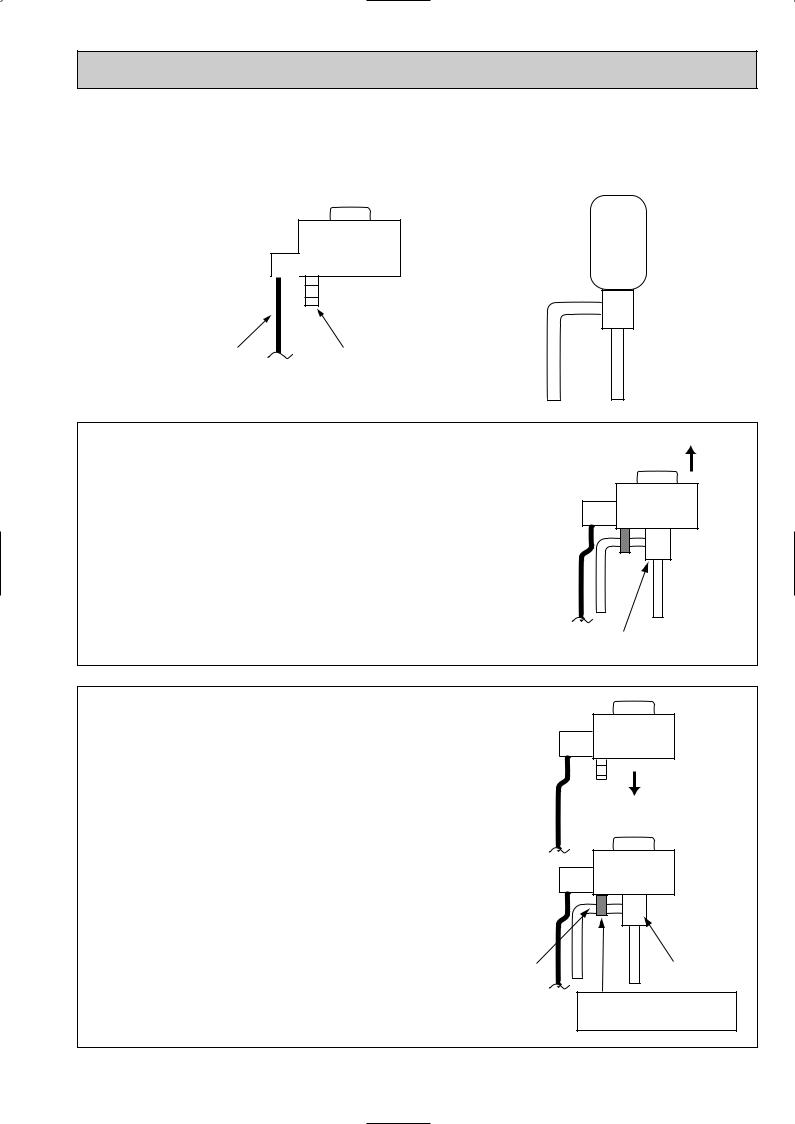

(c) Capacity correction

Cooling and heating capacity is lowered according to pipe length. Capacity can be obtained by referring to the capacity curves below. When the diameter of gas pipe is one size smaller than standard diameter, cooling capacity is lowered comparing to the standard diameter. The lowered capacity can be obtained by referring to capacity curves for gas pipe which is one size smaller than standard size.

Corrected pipe length (m) = actual pipe length (m) + number of bends x 0.3 (m)

1 Capacity curves for PUHZ-RP • HA model <Standard size> |

|

|

|

|

|

|

|

|

|

|

|

|

Cooling |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heating |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heating RP3, 4, 5 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

95 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and 6 models |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(Up to 55m for |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

ratio [%] |

90 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RP3 model |

|

|

|

|

|

|

|

|

|

|

RP3 model) |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

Capacity |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RP4 model |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

80 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

75 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RP5 model |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|