Page 1

General ........................

00

WORKSHOP

MANUAL

SUPPLEMENT

FOREWORD

This manual outlines changes in servicing

procedures related to the chassis including

vehicle inspections and adjustments in the

newly added models. Use the following

manuals in combination with this manual as

required.

TECHNICAL INFORMATION MANUAL

PYJE9002

WORKSHOP MANUAL

ENGINE GROUP PWEE____

(Looseleaf edition)

CHASSIS GROUP PWJE9086(Basic)

PWJE9086-G(Supplement)

PWJE9086-H(Supplement)

PWJE9086-I(Supplement)

ELECTRICAL WIRING PHJE9026(Basic)

PHJE9026-D(Supplement)

PHJE9026-E(Supplement)

PHJE9026-F(Supplement)

PHJE9026-G(Supplement)

PHJE9026-H(Supplement)

PHJE9026-I(Supplement)

PARTS CATALOGUE B60356A2Aj

Engine .........................

Engine Lubrication .............

Fuel ...........................

Engine Cooling ................

Intake and Exhaust .............

Engine Electrical ...............

Engine and Emission Control . . .

Interior and Supplemental

Restraint System (SRS) ........

Chassis Electrical ..............

11

12

13

14

15

16

17

52

54

All information, illustrations and product

descriptions contained in this manual are

current as at the time of publication. We,

however, reserve the right to make changes

at any time without prior notice or obligation.

E Mitsubishi Motors Corporation May 2001

Page 2

GENERAL - How to Use This Manual/Vehicle Identification

ith

turboch

ith

turboch

00-1

GROUP 00

GENERAL

HOW TO USE THIS MANUAL

INDICATION OF TIGHTENING TORQUE

Tightening torques (units: N·m) are set to take into account the central value and the allowable tolerance.

The central value is the target value, and the allowable tolerance provides the checking range for tightening

torques. If bolts and nuts are not provided with tightening torques, refer to P.00-5.

VEHICLE IDENTIFICATION

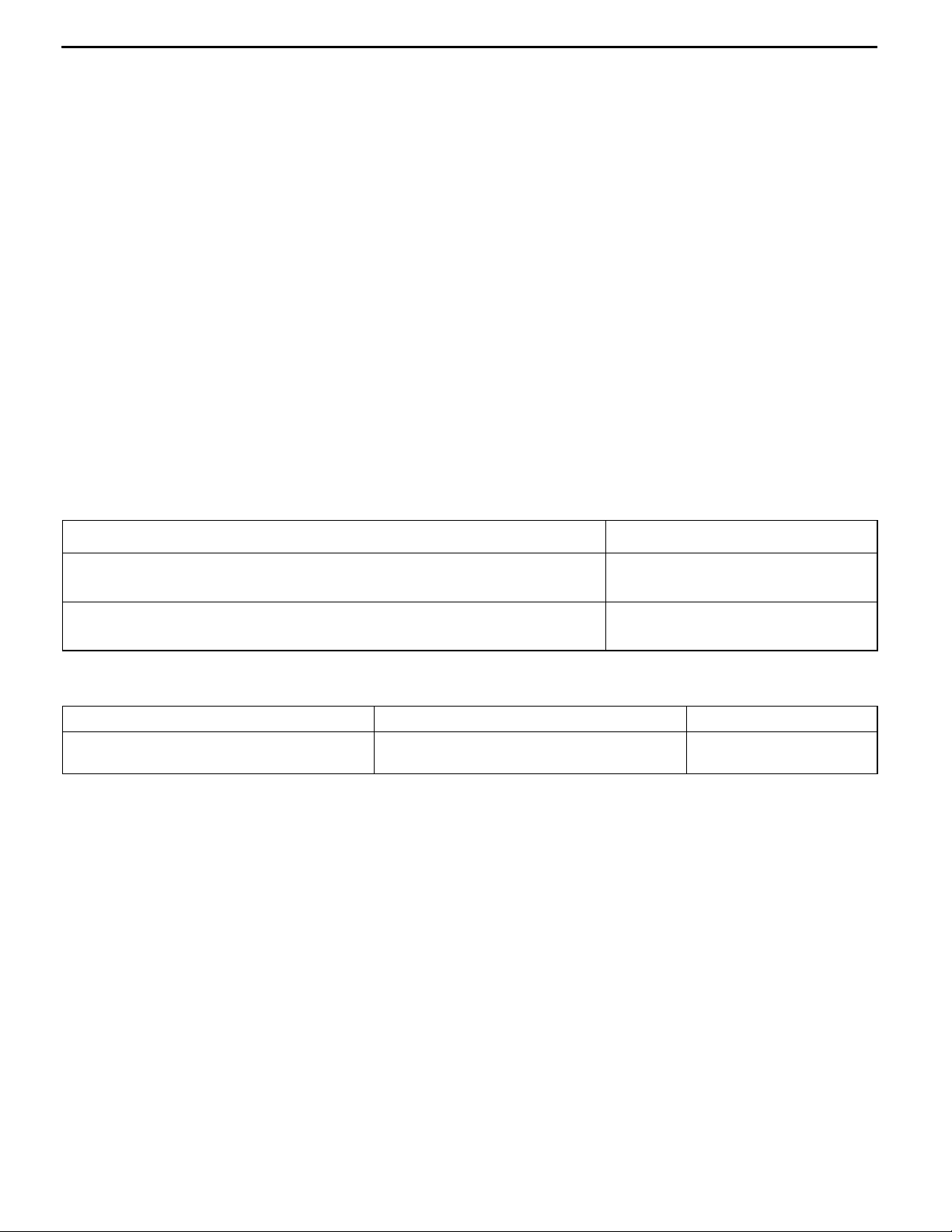

MODELS

<2-DOOR MODELS>

Model code Engine model Transmission model Fuel supply system

V24W NDGL6Y 4D56 (2,477 mL)

w

GNDGL6Y

<4-DOOR MODELS>

Model code Engine model Transmission model Fuel supply system

V44W NDGL6Y 4D56 (2,477 mL)

GNDGL6Y

and inter-cooler

w

and inter-cooler

arger

arger

V5MT1 <5M/T> Injection

V5MT1 <5M/T> Injection

Page 3

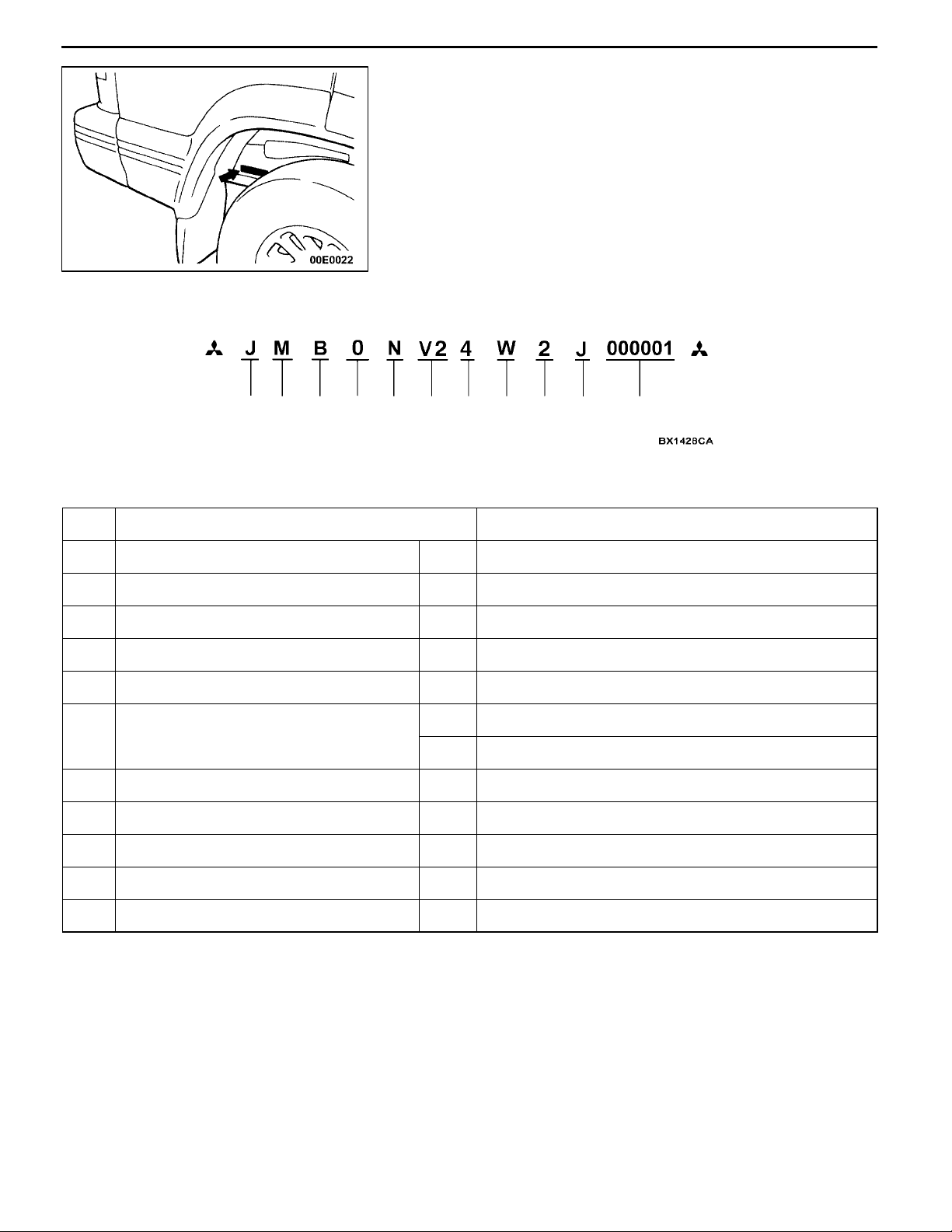

00-2

GENERAL - Vehicle Identification

CHASSIS NUMBER

The chassis number is stamped on the side wall of the frame

near the right rear wheel.

12 3 4

No. Items Contents

1 Fixed figure J Asia

2 Distribution channel M Japan channel

3 Destination B For Europe, left hand drive

4 Body style 0 4 or 2-door with tailgate(back door)

5 Transmission type N 5-speed manual transmission

6 Development order V2 PAJERO 2-door models

7 Engine 4 4D56: 2,477 mL diesel engine

8 Sort W Station wagon

9 Model year 2* 2002

5

6

V4 PAJERO 4-door models

7

89

10

11

10 Plant J Pajero Manufacturing Co., Ltd. *

11 Serial number - -

NOTE

*: Indicates changes.

Page 4

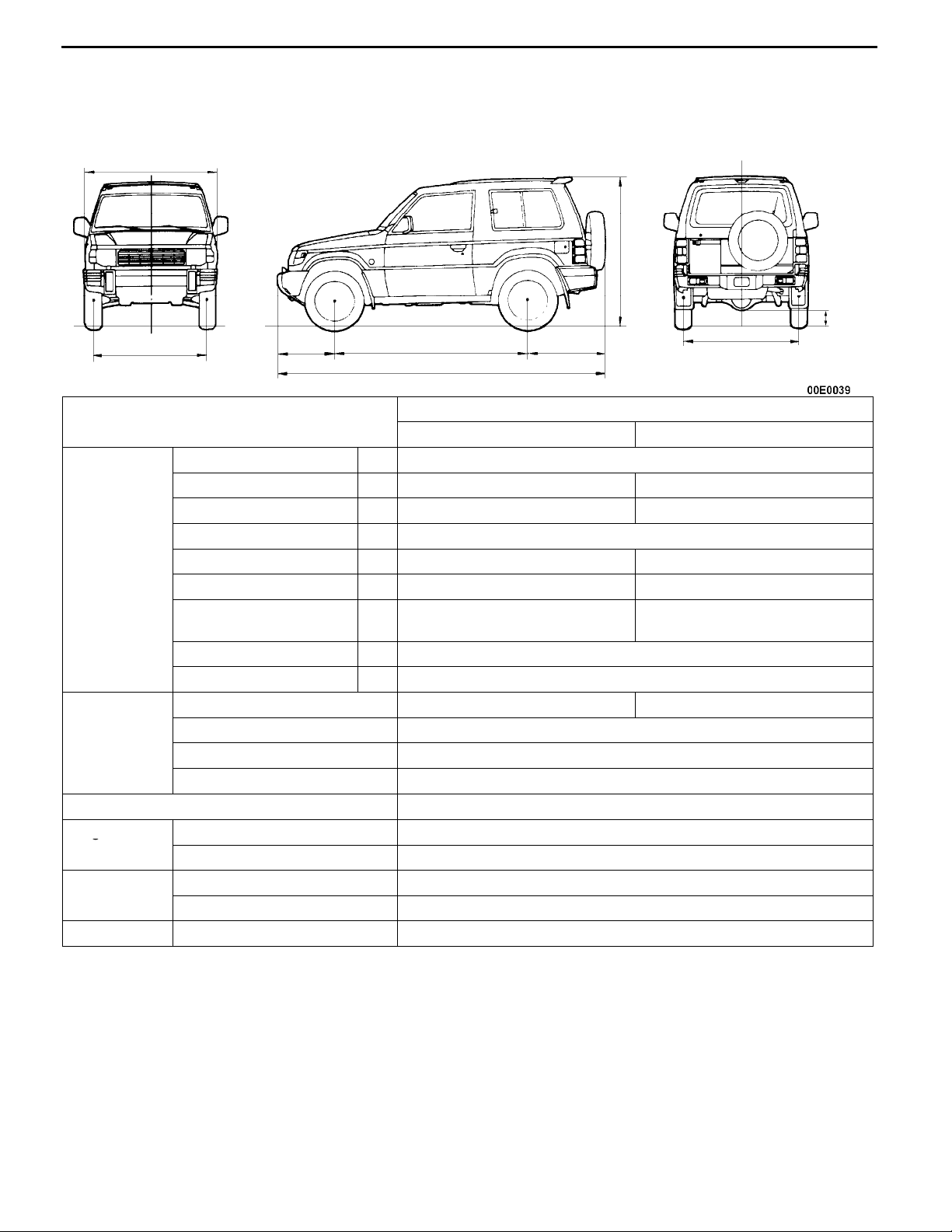

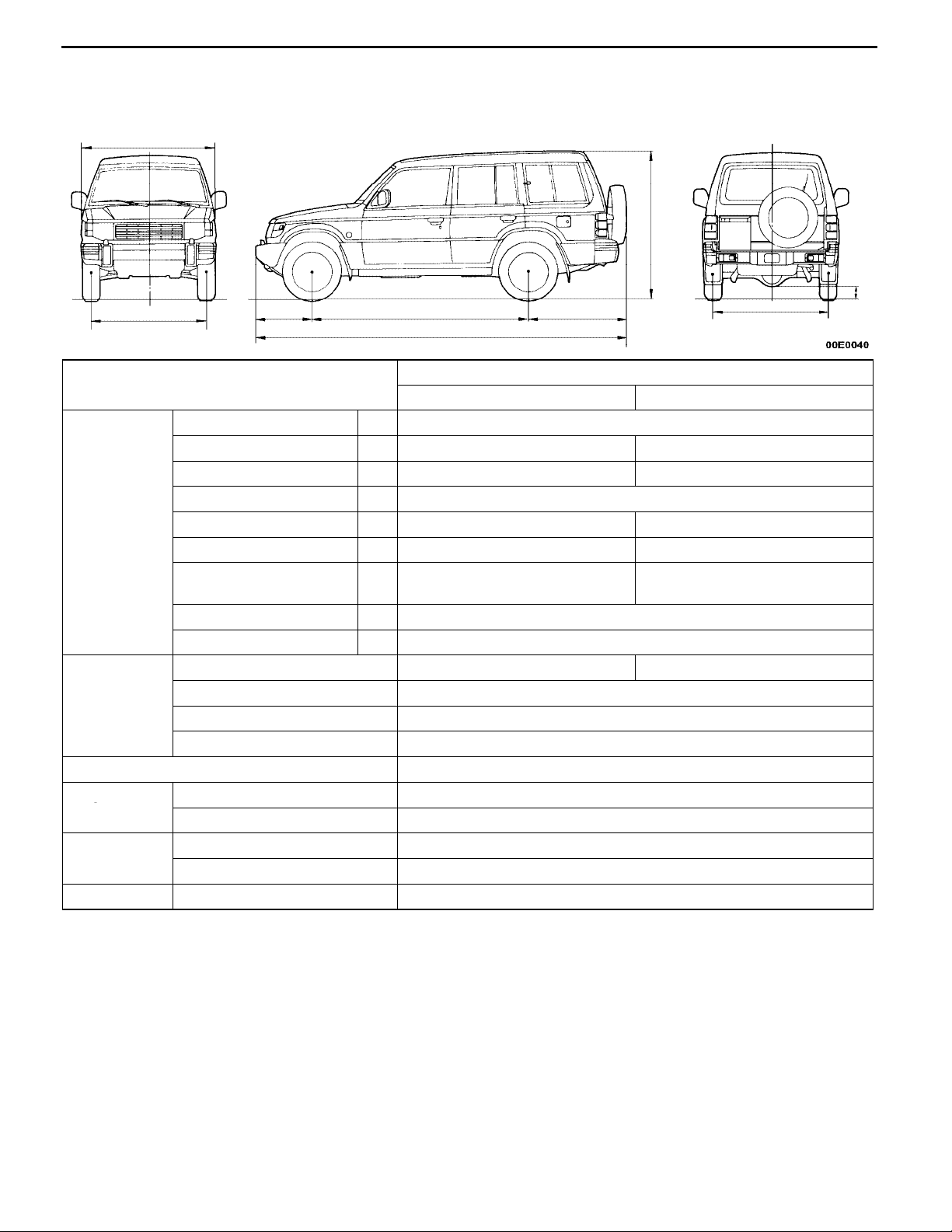

GENERAL - Major SpecificationsGENERAL - Major Specifications

mm

g

MAJOR SPECIFICATIONS

2-DOOR MODELS

2

5

84 9

00-3

3

7

6

1

Items

Vehicle

dimensions

Vehicle

weight kg

Seating capacity 5

Engine Model No. 4D56 Intercooler Turbocharger

Transmission

Fuel system Fuel supply system Injection

Overall length 1 4,075

Overall width 2 1,695 1,785

Overall height (unladen) 3 1,835 1,845

Wheelbase 4 2,420

Track-front 5 1,420 1,465

Track-rear 6 1,435 1,480

Ground clearance

(unladen)

Overhang-front 8 675

Overhang-rear 9 980

Kerb weight 1,700 1,755

Max. gross vehicle weight 2,510

Max. axle weight rating-front 1,070

Max. axle weight rating-rear 1,750

Total displacement mL 2,477

Model No. V5MT1

Type 5-speed manual

V24W

NDGL6Y GNDGL6Y

7 205 215

Page 5

00-4

mm

g

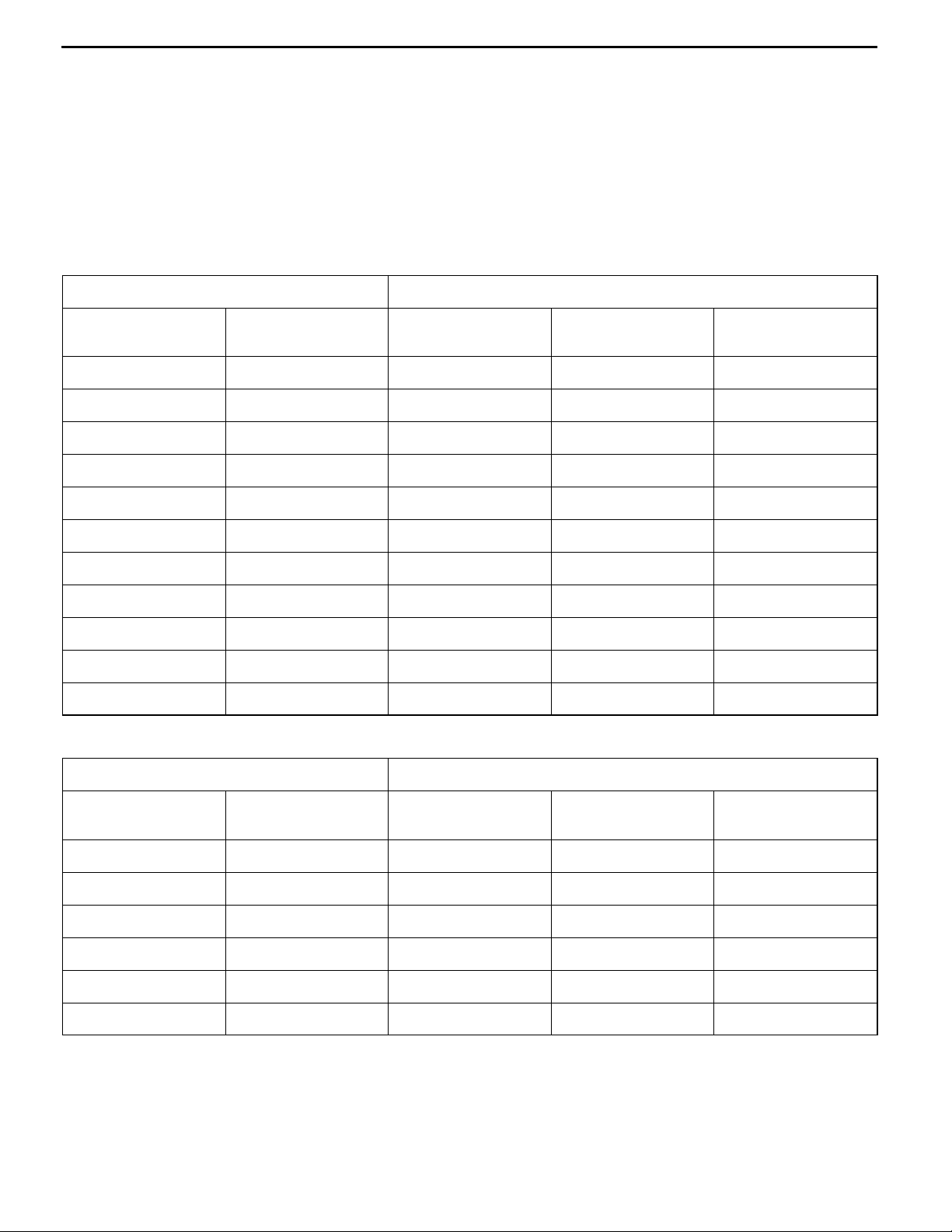

4-DOOR MODELS

2

5

GENERAL - Major Specifications

84

1

3

7

9

6

Items

Vehicle

dimensions

Vehicle

weight kg

Seating capacity 7

Engine Model No. 4D56 Intercooler Turbocharger

Transmission

Fuel system Fuel supply system Injection

Overall length 1 4,655

Overall width 2 1,695 1,775

Overall height (unladen) 3 1,890 1,900

Wheelbase 4 2,725

Track-front 5 1,420 1,465

Track-rear 6 1,435 1,480

Ground clearance

(unladen)

Overhang-front 8 650

Overhang-rear 9 1,280

Kerb weight 1,875 1,930

Max. gross vehicle weight 2,750

Max. axle weight rating-front 1,090

Max. axle weight rating-rear 1,780

Total displacement mL 2,477

Model No. V5MT1

Type 5-speed manual

V44W

NDGL6Y GNDGL6Y

7 205 215

Page 6

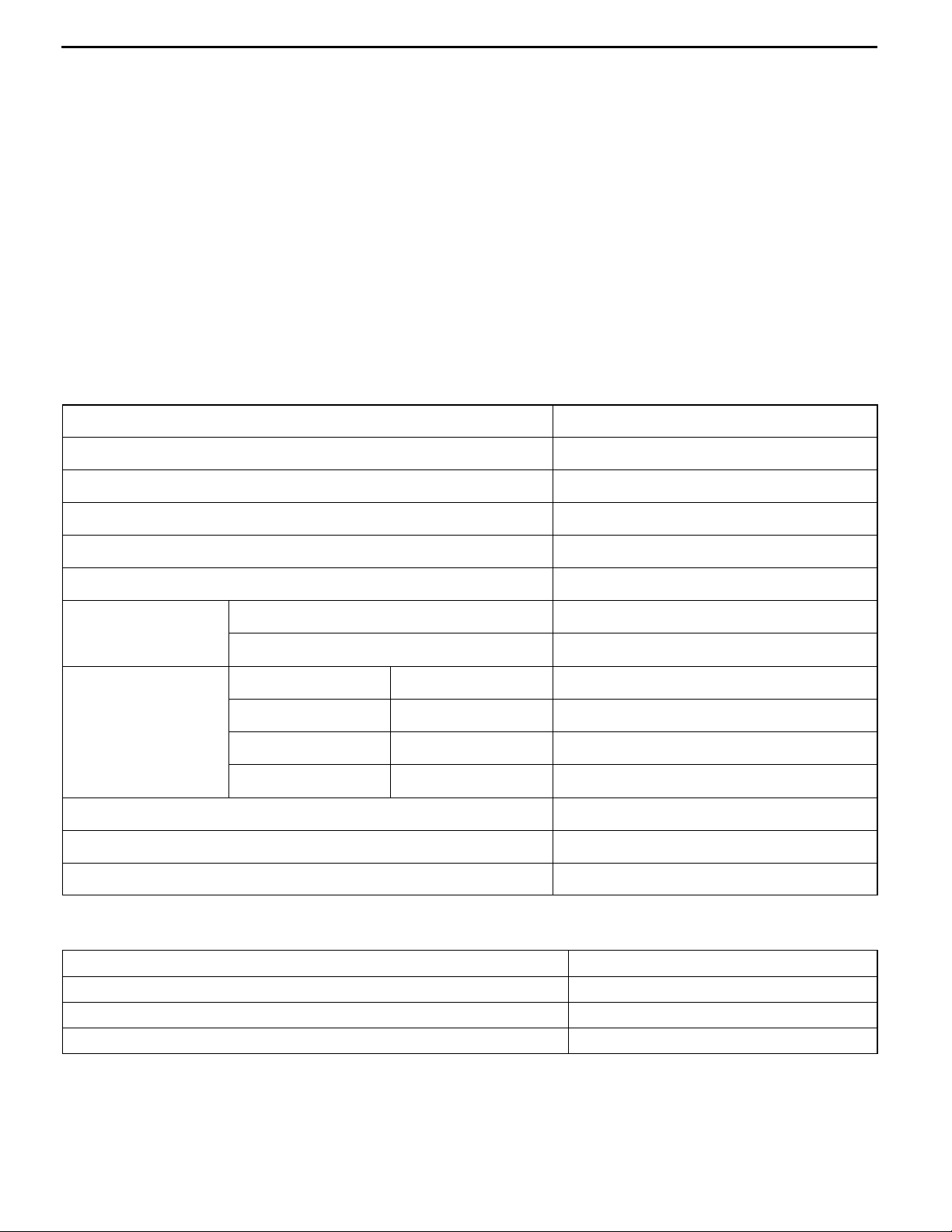

GENERAL - Standard Part/Tightening-Torque Table

STANDARD PART/TIGHTENING-TORQUE TABLE

00-5

Each torque value in the table is a standard value

for tightening under the following conditions.

(1) Bolts, nuts and washers are all made of steel

and plated with zinc.

(2) The threads and bearing surface of bolts and

nuts are all in dry condition.

The values in the table are not applicable:

(1) If toothed washers are inserted.

(2) If plastic parts are fastened.

(3) If bolts are tightened to plastic or die-cast

inserted nuts.

(4) If self-tapping screws or self-locking nuts are

used.

Standard bolt and nut tightening torque

Thread size Torque N·m

Bolt nominal

diameter (mm)

M5 0.8 2.50.5 5.01.0 6.01.0

M6 1.0 5.01.0 9.02.0 102

M8 1.25 122 224 254

M10 1.25 244 4410 537

M12 1.25 418 8312 9812

M14 1.5 7312 14020 15525

Pitch (mm) Head mark “4” Head mark “7” Head mark “8”

M16 1.5 11020 21030 23535

M18 1.5 16525 30040 34050

M20 1.5 22535 41060 48070

M22 1.5 30040 55585 64595

M24 1.5 39555 735105 855125

Flange bolt and nut tightening torque

Thread size Torque N·m

Bolt nominal

diameter (mm)

M6 1.0 5.01.0 102 122

M8 1.25 132 244 275

M10 1.25 264 499 587

M10 1.5 244 458 5510

M12 1.25 468 9515 10515

M12 1.75 438 8312 9812

Pitch (mm) Head mark “4” Head mark “7” Head mark “8”

NOTE

1. Be sure to use only the specified bolts and nuts, and always tighten them to the specified torques.

2. Bolts marked with indications such as 4T or 7T are reinforced bolts. The larger the number, the

greater the bolt strength.

Page 7

NOTES

Page 8

ENGINE

CONTENTS

11-1

ENGINE <4D5-Step III>2.............

GENERAL 2.................................

Outline of Changes 2...........................

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

SEALANT 3..................................

SPECIAL TOOLS 3...........................

ON-VEHICLE SERVICE 4.....................

Injection Timing Check and Adjustment 4.........

Idle Speed Check 4............................

OIL PAN AND OIL SCREEN 5................

TIMING BELT AND TIMING BELT B 7........

CYLINDER HEAD GASKET 11................

Page 9

G

l/G

l

Inf

11-2

ENGINE <4D5-Step III>-

enera

Specifications

enera

ormation/Service

ENGINE <4D5-Step

III

>

GENERAL

OUTLINE OF CHANGES

Some service procedures have been revised as the following changes have been made to comply to

the Emission Regulation Step III.

D The injection timing check and adjustment procedure and the idle speed check procedure have been

changed.

D The oil pan has a cover in order to reduce noise due to an enhanced engine output.

D A crank angle sensor and crankshaft sensing blade have been added due to the introduction of

an electronic-controlled fuel injection pump. Due to this change, the timing belt front lower cover

has been reshaped.

D The tightening torque of the cylinder head bolts and the cylinder head gasket have been changed.

GENERAL INFORMATION

Items 4D56

Total displacement mL 2,477

Bore x Stroke mm 91.1 x 95.0

Compression ratio 21

Combustion chamber Vortex chamber type

Camshaft arrangement SOHC

Number of valve Intake 4

Exhaust 4

Valve timing Intake Opening BTDC 20_

Exhaust Closing ABDC 49_

Intake Opening BBDC 55_

Exhaust Closing ATDC 22_

Fuel system Electronically controlled type injection pump

Rocker arm Roller type

Adjusting screw Elephant foot type

SERVICE SPECIFICATIONS

Items Standard value

Timing belt tension mm 4-5

Timing belt B tension mm 4-5

Idle speed r/min 750 ± 30

Page 10

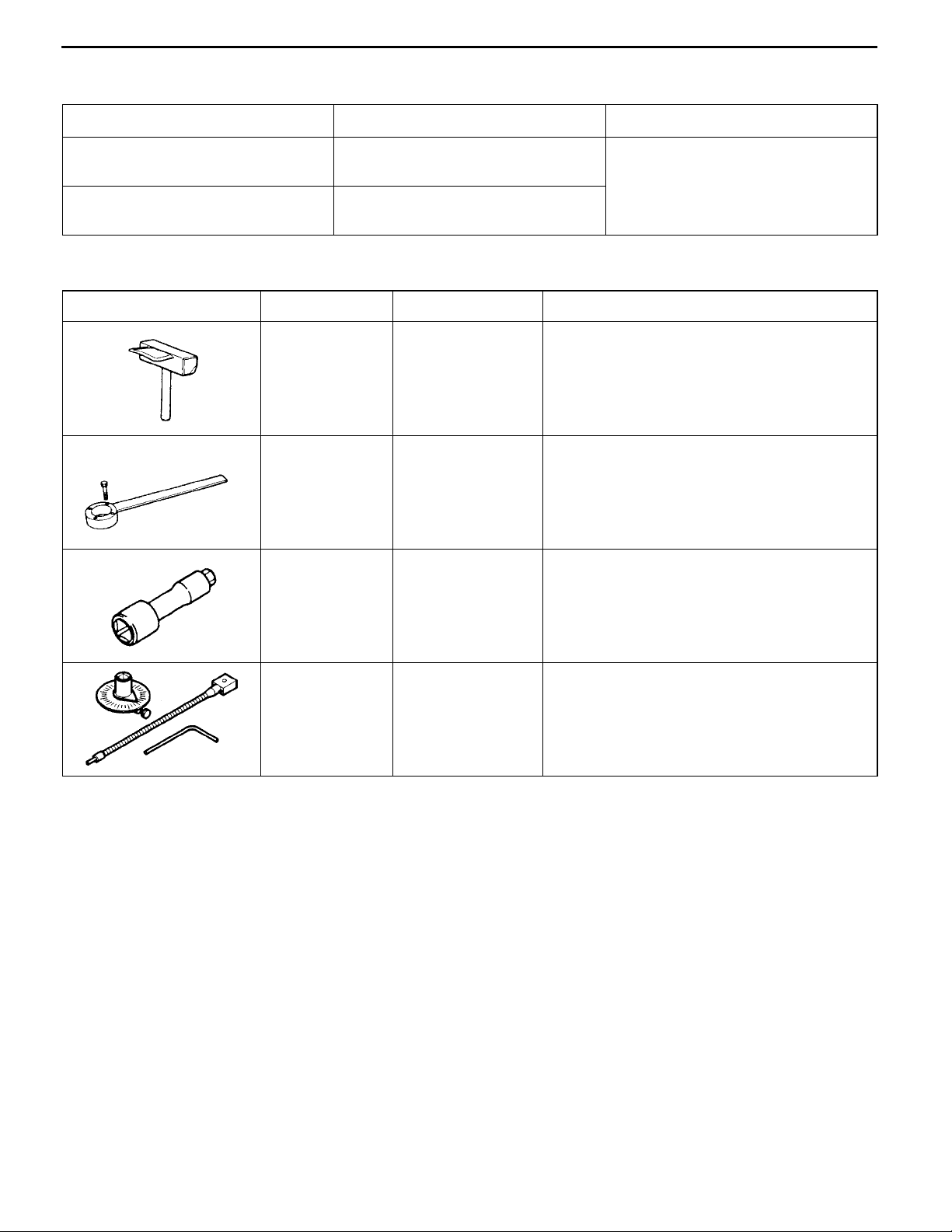

ENGINE <4D5-Step III>-Sealant/Special Tools

SEALANT

Items Specified sealant Remarks

11-3

Oil pan MITSUBISHI GENUINE PART

MD970389 or equivalent

Semi-circular packing and rocker

cover seal, and cylinder head seal

3M ATD Part No. 8660 or equivalent

SPECIAL TOOLS

Tools Number Name Use

MD998727 Oil pan remover Removal of oil pan

MD998721 Crankshaft pulley

holder

MD998051 Cylinder head bolt

wrench

Semi-drying sealant

Holding the crankshaft pulley

Removal and installation of the cylinder head

bolt

MB991614 Angle gauge Tightening of the cylinder head bolts

Page 11

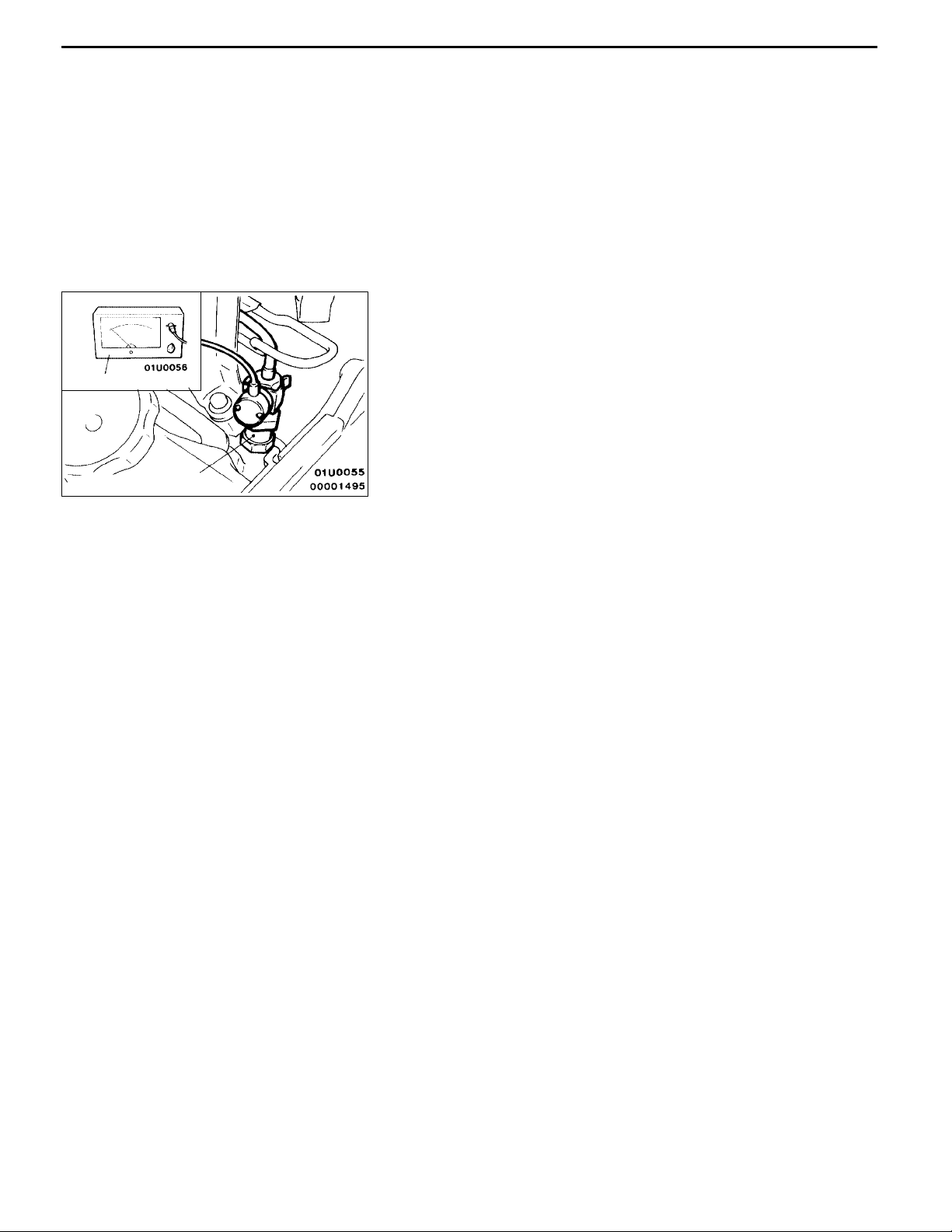

11-4

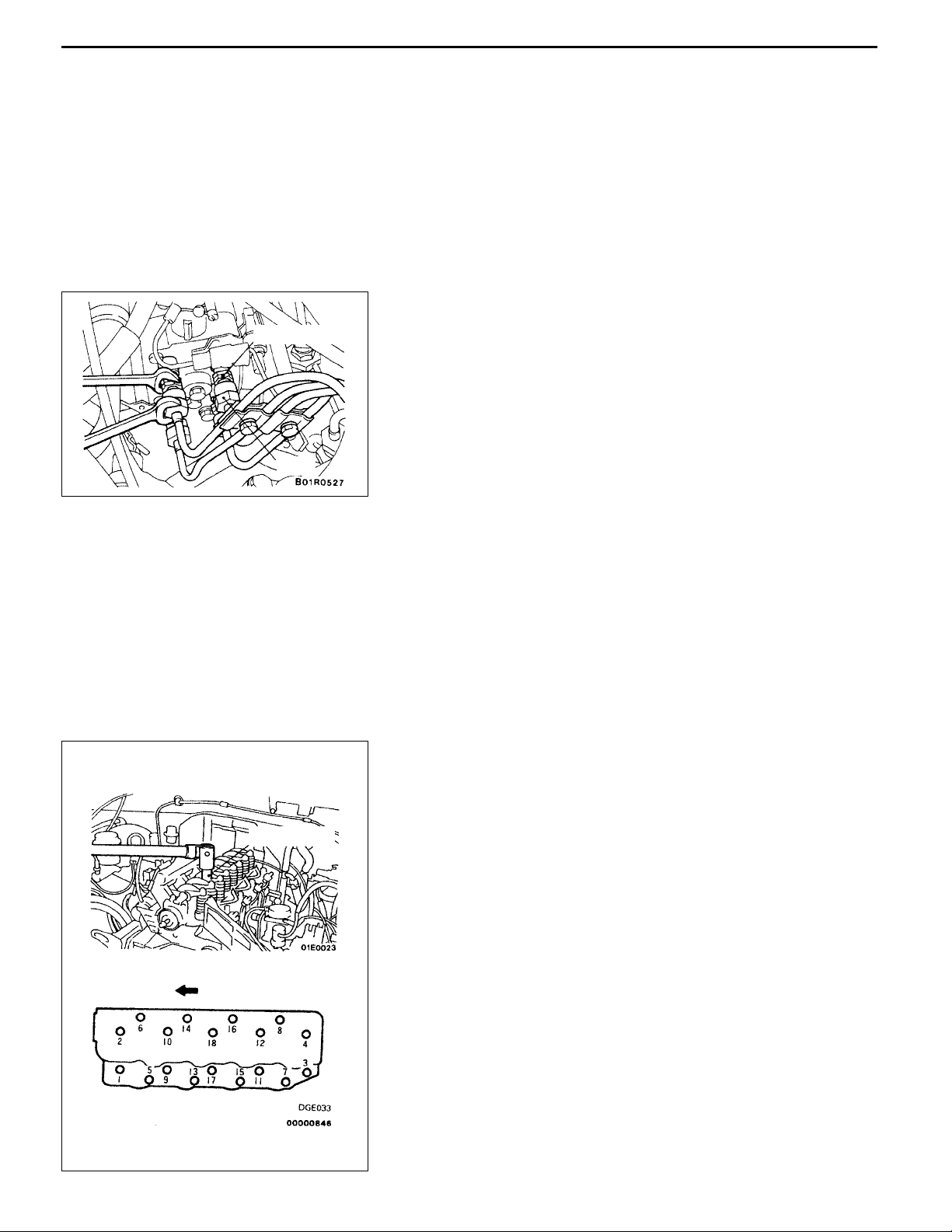

Tachometer

ENGINE <4D5-Step III>-On-vehicle Service

ON-VEHICLE SERVICE

INJECTION TIMING CHECK AND

ADJUSTMENT

The cold start device (wax type) has been discontinued as

an electronically controlled injection pump has been used.

The other inspection and adjustment procedures are the same

as before.

IDLE SPEED CHECK

1. Set the vehicle to the pre-inspection condition.

2. Turn the ignition switch to “LOCK” (OFF) position, and

connect the diagnosis connector to the MUT-II.

If the MUT-II is not used, connect a tachometer to the

injection nozzle or the pipe.

3. Start the engine, and let it run at idle.

4. Check the idle speed.

Injection nozzle

Standard value: 750 ± 30 r/min

5. If the idle speed is not within the standard value, refer

to 13C - Troubleshooting to check the electronic controlled

fuel injection system.

NOTE

The idle speed is controlled by the engine-ECU.

Page 12

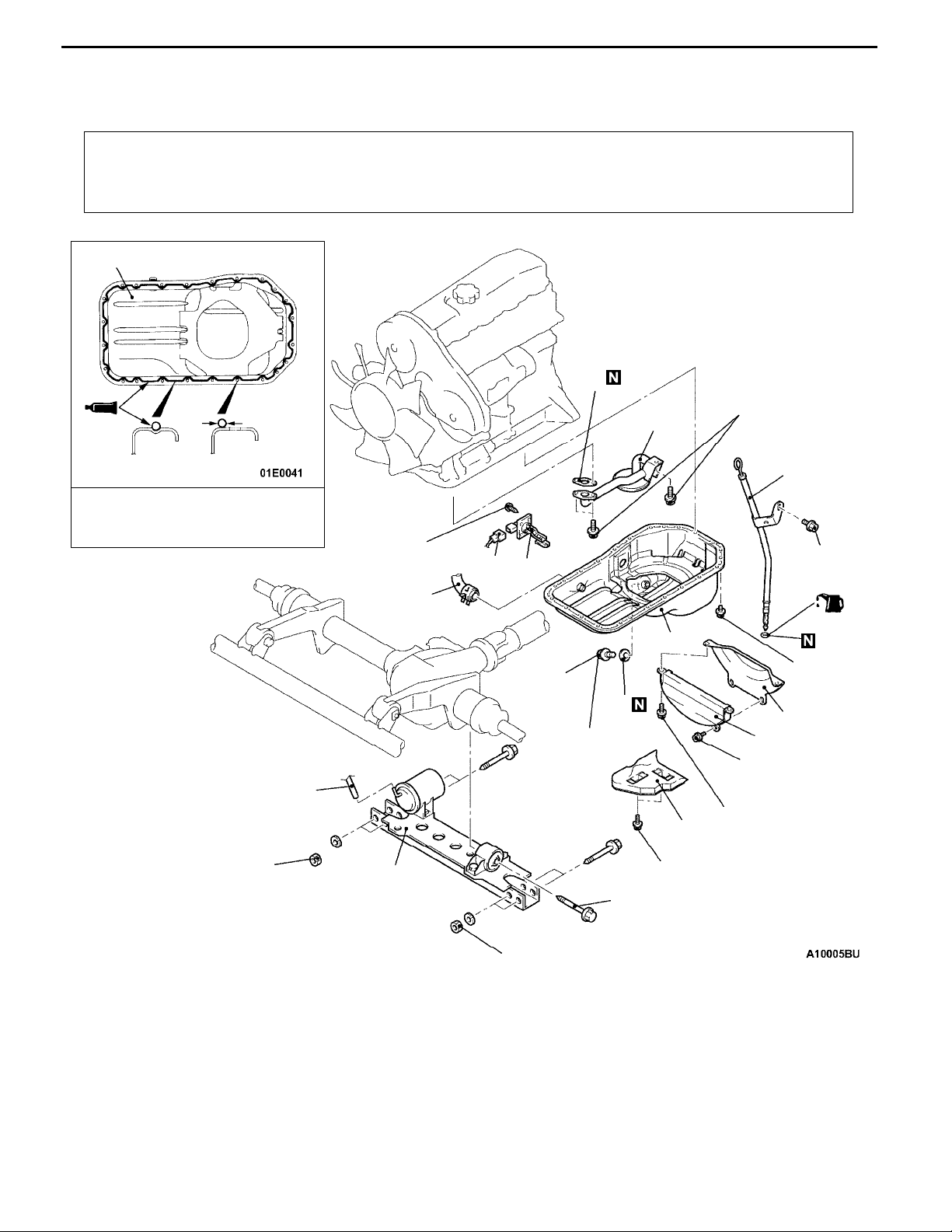

ENGINE <4D5-Step III>-Oil Pan and Oil Screen

OIL PAN AND OIL SCREEN

REMOVAL AND INSTALLATION

11-5

Pre-removal and Post-installation Operation

D Skid Plate and Under Cover Removal and Installation.

D Front Exhaust Pipe Removal and Installation (Refer

to GROUP 15 - Exhaust Pipe and Muffler.)

12

4mm

(0.16 in.)

diameter

Hole of boltGroove

Sealant:

MITSUBISHI GENUINE Part No.

MD997110 or equivalent

9.0 ± 1.0 N·m

D Engine Oil Draining and Supplying.

15

19 ± 3 N·m

14

4

8

9

12 ± 1 N·m

7

(Engine oil)

12

1

110 ± 10 N·m

Removal steps

1. Vacuum hose connection

2. Bolt

3. Front suspension crossmember

4. Engine oil level gauge and guide

assembly

5. Drain plug

"BA 6. Drain plug gasket

7. Alternator vacuum pump oil return

hose connection

5

7.0 ± 1.0

N·m

6

11

39 ± 5 N·m

10

35 ± 6 N·m

9.0 ± 1.0 N·m

13

3

9.0 ± 1.0 N·m

2

110 ± 10 N·m

8. Oil level sensor connector

9. Oil level sensor

10. Space rubber

11. Bell housing cover

AA""AA. 12. Oil pan

13. Oil pan cover

14. Oil screen

15. Oil screen gasket

Page 13

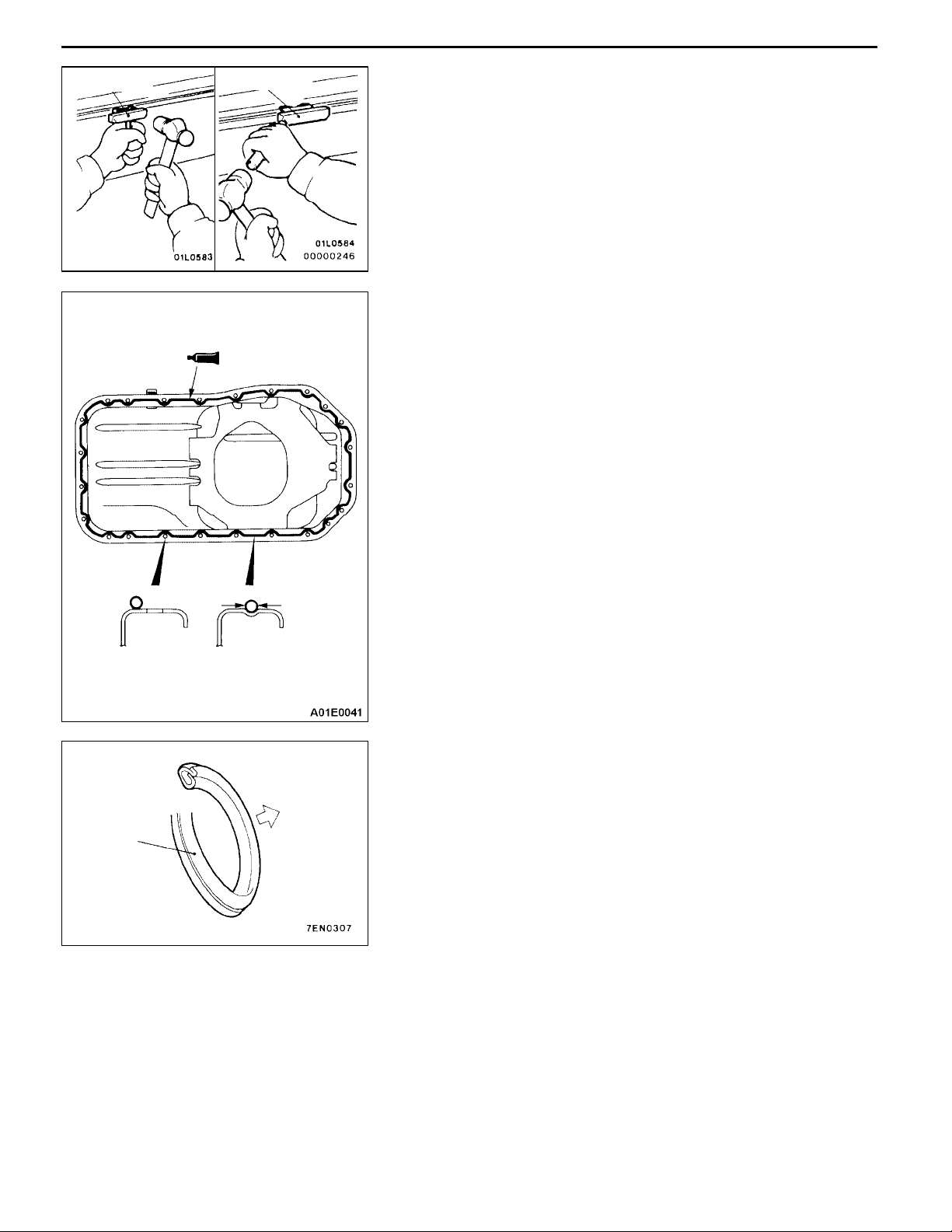

11-6

ENGINE <4D5-Step III>-Oil Pan and Oil Screen

MD998727

MD998727

φ 4mm

GrooveBolt hole

REMOVAL SERVICE POINT

AA" OIL PAN REMOVAL

INSTALLATION SERVICE POINTS

"AA OIL PAN INSTALLATION

1. Remove sealant from oil pan and cylinder block mating

surfaces.

2. Degrease the sealant-coated surface and the engine

mating surface.

3. Apply a continuous bead of the specified sealant to the

oil pan mating surface as shown.

Specified sealant:

MITSUBISHI GENUINE PART No. MD970389 or

equivalent

NOTE

The sealant should be applied in a continuous bead

approximately 4 mm in diameter.

4. Assemble oil pan to cylinder block within 15 minutes after

applying the sealant.

Caution

After installing the oil pan, wait at least 1 hour before

starting the engine.

Drain plug

gasket

"BA DRAIN PLUG GASKET INSTALLATION

Install a new gasket in the direction so that it faces as shown

in the illustration.

Oil pan

side

Page 14

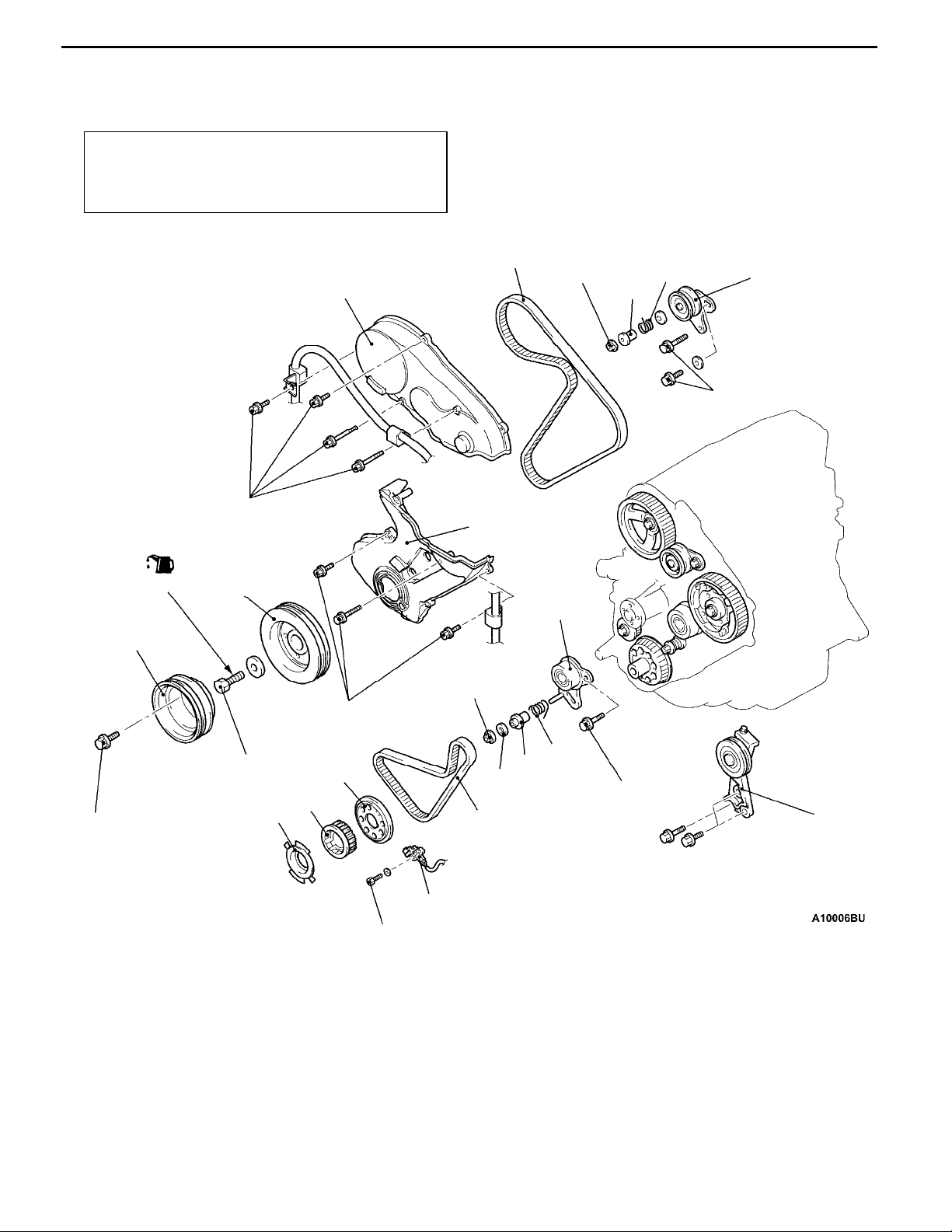

ENGINE <4D5-Step III>-Timing Belt and Timing B

TIMING BELT AND TIMING BELT B

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Intercooler Removal and Installation

(Refer to GROUP 15.)

D Cooling Fan Removal and Installation.

11-7

(Engine oil)

3

11 ± 1 N·m

4

1

11 ± 1 N·m

5

26 ± 3 N·m

6

26 ± 3 N·m

18

8

9

7

26 ± 3 N·m

177 ± 9 N·m

26 ± 3 N·m

Removal steps

"CA 1. Timing belt front upper cover

2. Tension pulley and tension pulley

bracket assembly

3. Crankshaft pulley (for power steering and A/C)

AA""DA 4. Crankshaft pulley

"CA 5. Timing belt front lower cover

AB""BA 6. Timing belt

7. Tensioner spacer

8. Tensioner spring

11

13

12

9.0 ± 1.0 N·m

10

17

16

15

26 ± 3 N·m

14

9. Timing belt tensioner

10. Crank angle sensor

11. Crankshaft sensing blade

12. Crankshaft sprocket

13. Flange

AC""AA 14. Timing belt B

15. Gasket

16. Tensioner spacer B

17. Tensioner spring B

18. Timing belt tensioner B

2

Page 15

11-8

ENGINE <4D5-Step III>-Timing Belt and Timing B

REMOVAL SERVICE POINTS

Timing marks

MD998721

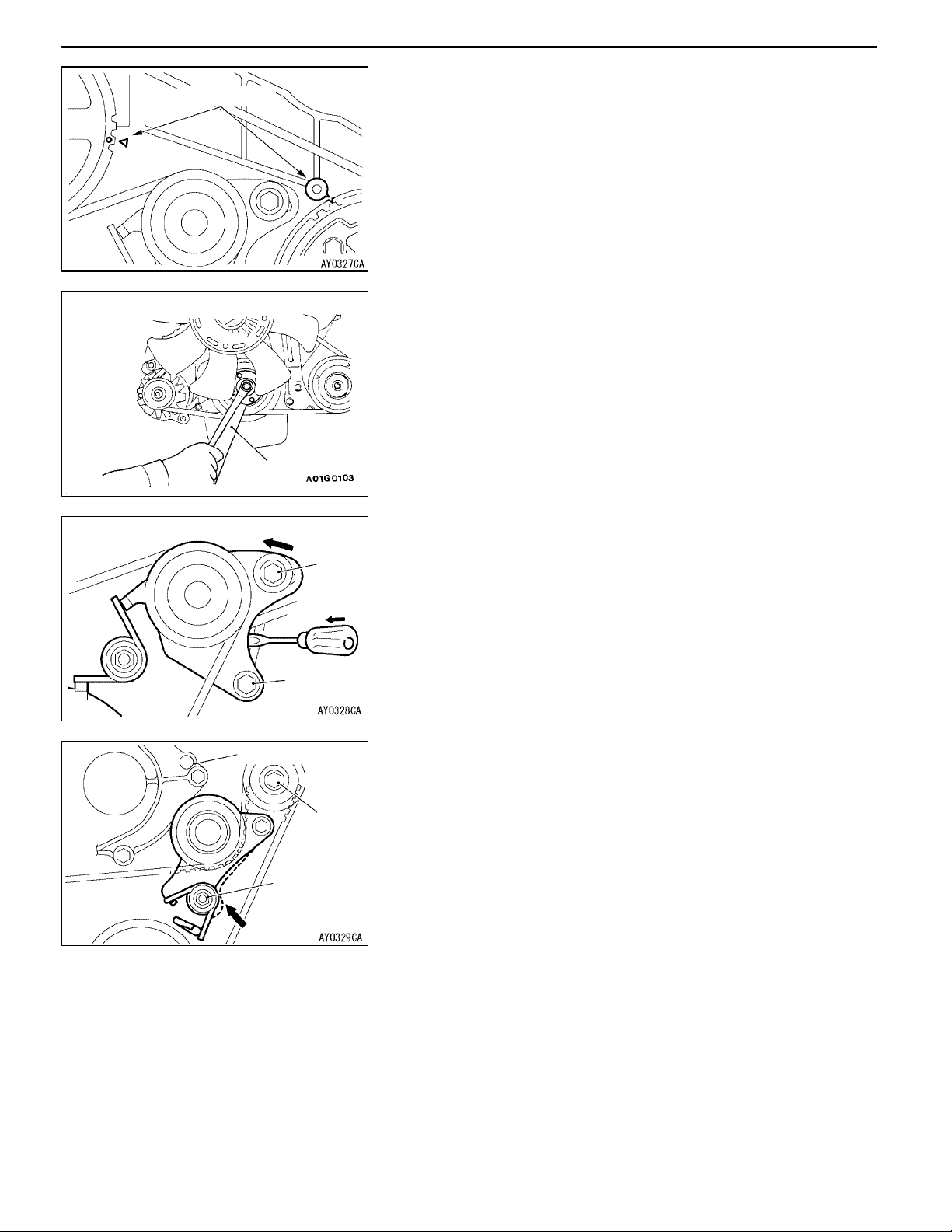

AA" CRANKSHAFT PULLEY REMOVAL

1. Turn the crankshaft clockwise, align the timing marks

to set No.1 cylinder to TDC of its compression stroke.

Caution

Never turn the crankshaft anticlockwise.

2. Use the special tool to keep crankshaft from turning and

remove the bolts.

Tilt to water pump side

Water pump

D

AB" TIMING BELT REMOVAL

1. When reinstalling timing belt, mark an arrow at the belt

A

to show rotation direction.

2. Loosen the tensioner mounting bolt A and B.

3. Push timing belt tensioner to water pump side and tighten

the tensioner mounting bolt A and B. Secure so that

tensioner will not move back.

B

AC" TIMING BELT B REMOVAL

1. When reinstalling timing belt B, mark an arrow at the

belt to show rotation direction.

C

2. Loosen the tensioner mounting bolt C and nut D.

3. Push timing belt tensioner to water pump side and tighten

the tensioner mounting bolt C and nut D. Secure so that

tensioner will not move back.

Page 16

Timing

marks

ENGINE <4D5-Step III>-Timing Belt and Timing Belt BENGINE <4D5-Step III>-Timing Belt and Timing Belt B

INSTALLATION SERVICE POINTS

Timing mark

C

Deflection

side

D

Tension

side

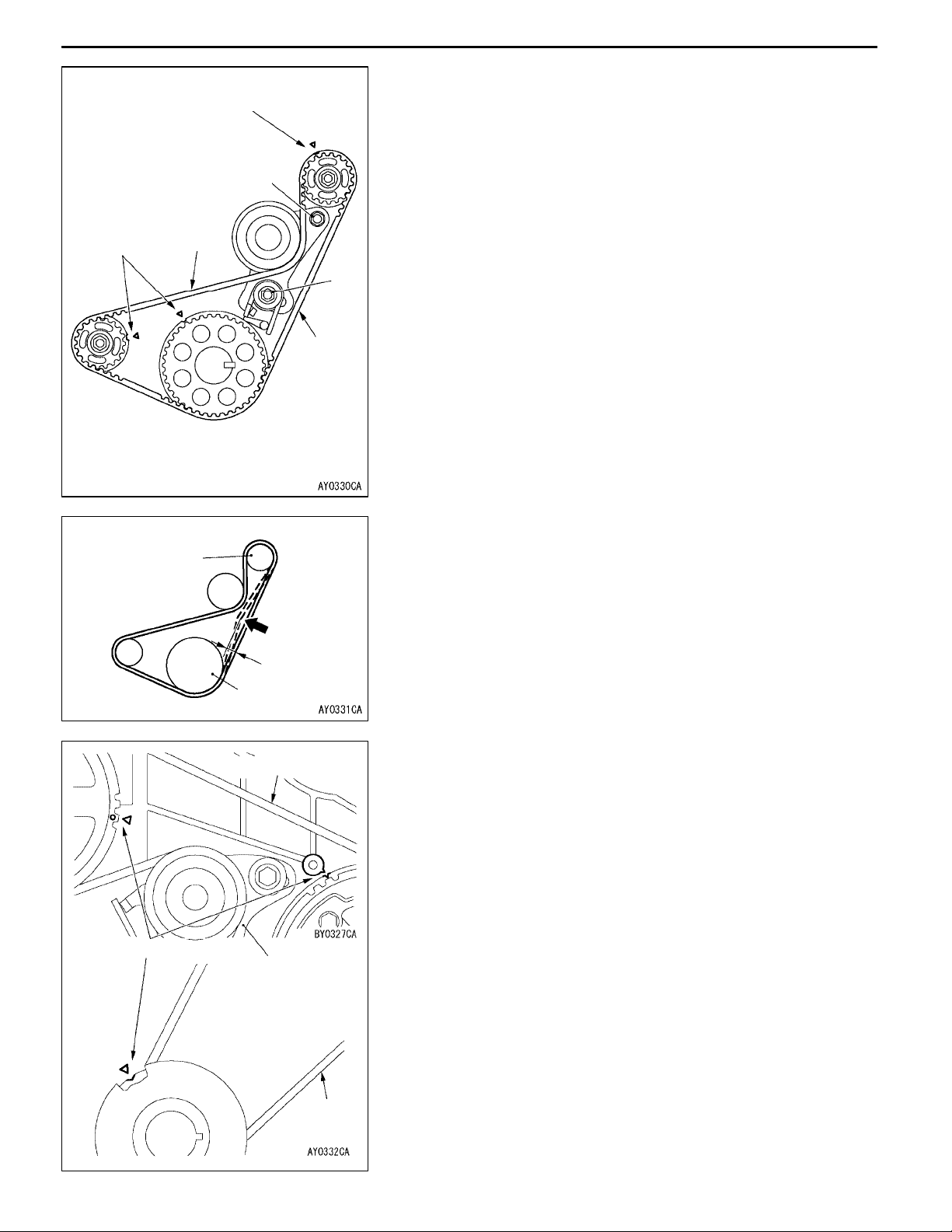

"AA TIMING BELT B INSTALLATION

1. Align the timing marks of the 3 sprockets.

2. When reusing timing belt B, make sure the arrow mark

is pointing in the same direction as when the belt was

removed.

3. Install timing belt B and make sure there is no deflection

on the tension side.

4. Press the deflection side of timing belt B with the hand

and fully stretch the tensioner side.

5. Make sure that the timing marks are aligned.

6. Loosen the tensioner mounting bolt and nut so that only

the pressure of the spring is applied to timing belt B.

7. Tighten the tensioner mounting bolt C and nut D, tightening

the nut first. If the bolt is tightened first, the tensioner

will move and tension the belt.

Tightening torque: 26 ± 3 N·m

11-9

Counterbalance

shaft sprocket

Timing marks

Belt deflection

Crankshaft

sprocket B

Tension side

Water pump

8. Press in the direction of the arrow in the figure with the

index finger to check the amount of deflection.

Standard value: 4 - 5 mm

"BA TIMING BELT INSTALLATION

1. Align the timing marks of the 3 sprockets.

2. When reusing timing belt, make sure the arrow mark is

pointing in the same direction as when the belt was

removed.

3. Install the timing belt to the crankshaft sprocket, to injection

pump sprocket, to tensioner and to camshaft sprocket

in that order. Being careful not to allow deflection on

the tension side of the timing belt.

Caution

(1) Engage the belt on the various sprockets while

maintaining tension on the belt of tension side.

(2) Align the injection pump sprocket with the timing

mark, hold the sprocket so that is does not turn

and engage the belt.

4. Loosen the tensioner mounting bolts and apply tension

with the spring.

Tension

side

Page 17

11-10

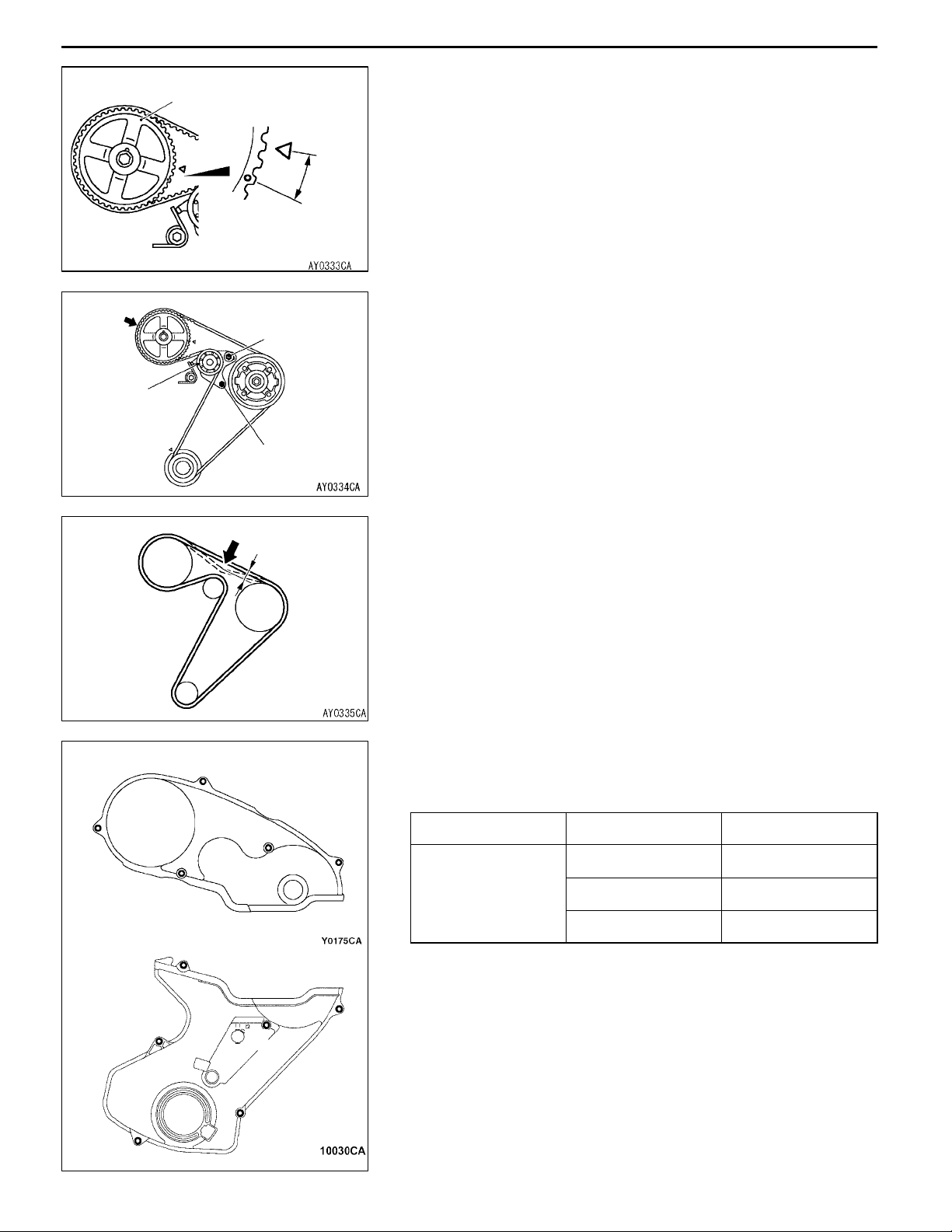

A

Tensioner

ENGINE <4D5-Step III>-Timing Belt and Timing Belt BENGINE <4D5-Step III>-Timing Belt and Timing Belt B

5. Turn the crankshaft clockwise and stop at the second

Camshaft sprocket

2 teeth

Tensioner

mounting bolt

Tensioner

mounting bolt

lobe of the camshaft sprocket.

Caution

(1) When turning the crankshaft in item (5), strictly

observe the specified amount of rotation (2 teeth

on the camshaft sprocket) in order to apply a

constant force to the tension side of the belt.

(2) Do not turn the crankshaft counterclockwise.

(3) Do not touch the belt during adjustment.

6. Make sure that the part indicated by arrow A does not

float upward.

7. Tighten the tensioner mounting bolts, starting with the

bolt in the elongated hole. If the lower bolt is tightened

first, belt tension will become too tight.

8. Turn the crankshaft anticlockwise and align the timing

mark. Next, make sure that the timing marks of all

sprockets are aligned.

Amount of belt

deflection

9. Press on the center of the bolt with an index finger to check

the amount of deflection.

Standard value: 4 - 5 mm

"CA TIMING BELT FRONT LOWER COVER/TIMING

A

BELT FRONT UPPER COVER INSTALLATION

Install the bolts to the timing belt cover at the shown positions.

A

C

B

A

Name Symbols Size mm (d×l)

Flange bolt A 6×22

B 6×50

C 6×60

d=Nominal diameter

l=Nominal length

A

B

A

"DA CRANKSHAFT PULLEY INSTALLATION

Using the special tool to install the crankshaft pulley as same

as removal procedure.

A

A

Page 18

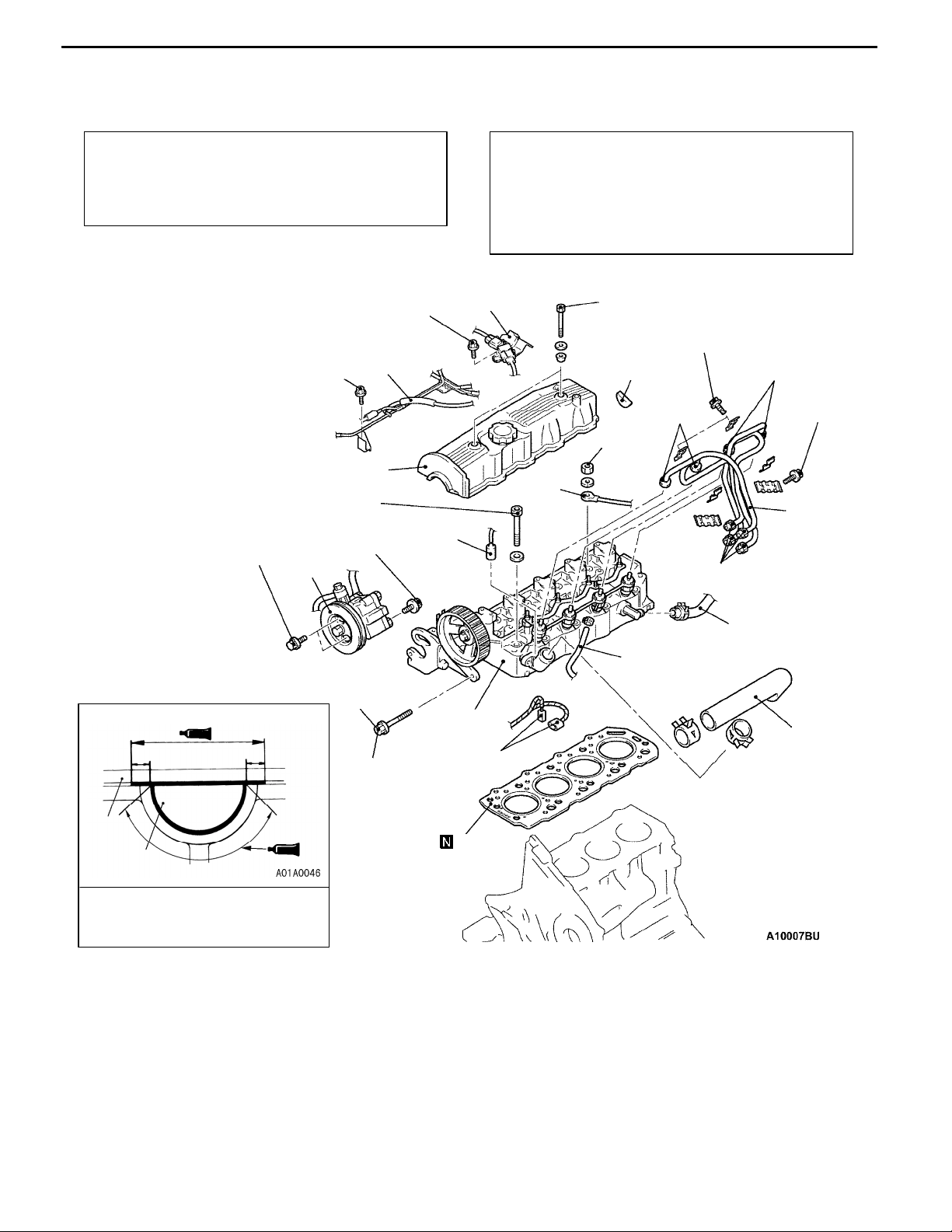

ENGINE <4D5-Step III>-Cylinder Head Gasket

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

11-11

Pre-removal Operation

D Intake and Exhaust Manifold Removal

(Refer to GROUP 15.)

D Timing Belt Removal (Refer to P.11-4.)

D Engine Coolant Draining.

13 ± 2 N·m

10 ± 2 N·m

29 ± 2 N·m → +120°

(During cold engine)

22 ± 4 N·m

22 ± 4 N·m

12

10

Post-installation Operation

D Timing Belt Installation (Refer to P.11-4.)

D Intake and Exhaust Manifold Installation

(Refer to GROUP 15.)

D Fuel Line Air Bleeding

(Refer to GROUP 13 - On-vehicle Service.)

D Engine Coolant Filling

8

9

5.9 ± 1.0 N·m

4.9 ± 1.0 N·m

11

30 ± 6

N·m

4.9 ± 1.0

N·m

30 ± 6 N·m

4.9 ± 1.0 N·m

3

5

2

30 ± 6 N·m

10 mm

10 mm

10

11

Sealant:

3M ATD Part No. 8660 or

equivalent

Removal steps

1. Engine coolant temperature switch

connector (for A/C)

2. Engine coolant temperature gauge

unit and sensor connector

3. Glow plug terminal

AA""DA 4. Radiator upper hose

AB""CA 5. Fuel injection pipe

6. Heater hose or water by-pass hose

connection

7. Fuel hose connection

6

7

13

14

4

1

24 ± 4 N·m

15

8. Boost sensor and bracket assembly

9. Vacuum hose and pipe assembly

10. Rocker cover

11. Semi-circular packing

AC" 12. Power steering oil pump assembly

13. Power steering oil pump bracket

bolt

AD""BA 14. Cylinder head assembly

"AA 15. Cylinder head gasket

Page 19

11-12

ENGINE <4D5-Step III>-Cylinder Head Gasket

REMOVAL SERVICE POINTS

AA" RADIATOR UPPER HOSE DISCONNECTION

After making mating marks on the radiator upper hose and

the hose clamp, disconnect the radiator upper hose.

AB" FUEL INJECTION PIPE REMOVAL

Delivery holder

Nut

When loosening nuts at both ends of injection pipe, hold

the delivery holder (for pump side) and the injection nozzle

assembly (for nozzle side) with wrench and loosen nut.

Caution

After disconnecting the injection pipe, plug the opening

so that no foreign particles get inside the pump or into

the injection nozzle.

MD998051

AC" POWER STEERING OIL PUMP REMOVAL

Remove the power steering oil pump from the bracket with

the hose attached.

NOTE

Place the removed power steering oil pump in a place where

it will not be a hindrance when removing and installing the

engine assembly, and tie it with a cord.

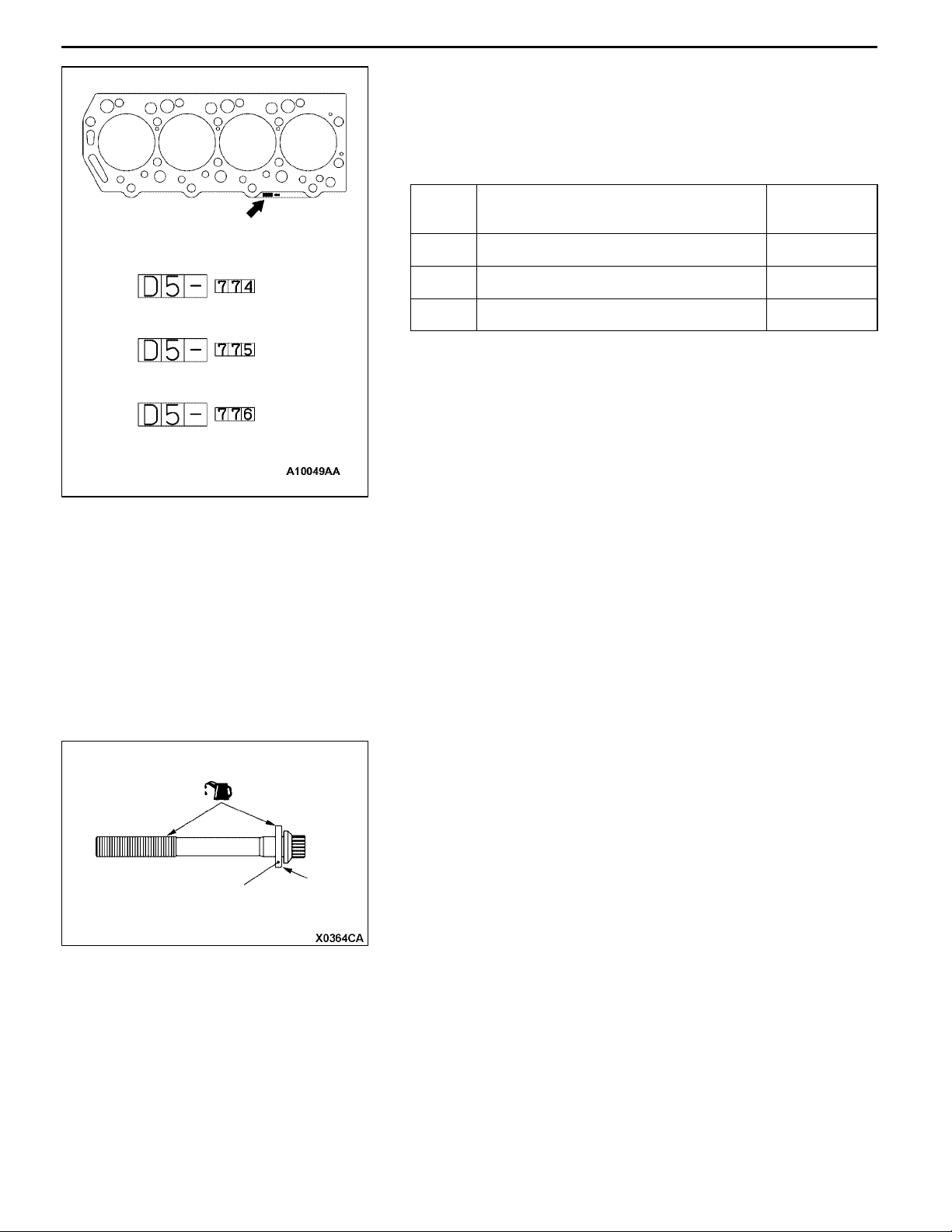

AD" CYLINDER HEAD ASSEMBLY REMOVAL

Use the special tool to tighten each bolt 2 - 3 times in the

order shown in the illustration.

Front

Page 20

Identification mark

ENGINE <4D5-Step III>-Cylinder Head Gasket

INSTALLATION SERVICE POINTS

"AA CYLINDER HEAD GASKET INSTALLATION

When replacing the cylinder head gasket only, confirm the

gasket identification mark, and then select a replacement

part according to the table below:

Spec Identification mark (size) Parts num-

A D5 -774 (fitted thickness 1.45 ± 0.04) MD377774

11-13

ber

A

B

B D5 -775 (fitted thickness 1.50 ± 0.04) MD377775

C D5- 776 (fitted thickness 1.55 ± 0.04) MD377776

Caution

The thickness of the original cylinder head gasket is

selected according to the protrusion amount of the piston.

C

Therefore, if the piston or the connecting rod is replaced,

the protrusion amount may be changed. Always select

a correct gasket by measuring the protrusion amount.

(For details, refer to the Engine Workshop Manual.)

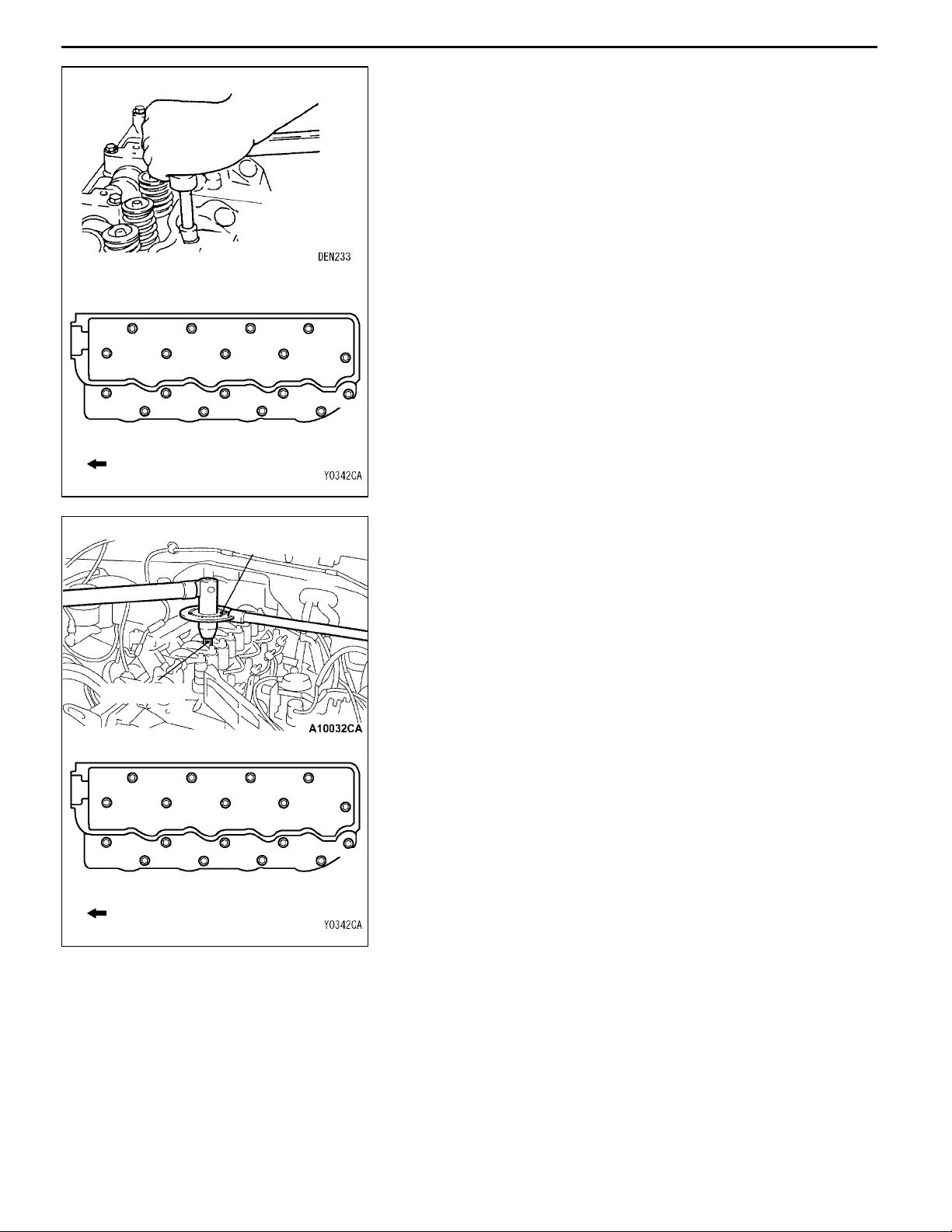

"BA CYLINDER HEAD INSTALLATION

1. Select a cylinder head gasket of correct specification.

2. Clean the cylinder head assembly and the cylinder block

mating surfaces with a scraper or a wire brush.

Caution

Do not allow foreign material to enter the engine

coolant or oil passages and the cylinder.

Cylinder head

bolt washer

3. Install the cylinder head bolt washer to the cylinder head

bolt so that the washer chamfered side faces as shown.

4. Apply a small amount of engine oil to the cylinder head

bolt thread and the washer.

Chamfered

side

Page 21

11-14

ENGINE <4D5-Step III>-Cylinder Head Gasket

5. Tighten the cylinder head bolts according to the following

procedure (angle-tightening procedure.)

(1) Use the special tool to tighten the cylinder head bolts

in the order of the illustrated numbers to 29 ± 2 N·m.

MD998051

13

13

14

14

9

10

9

10

17

18

Front of engine

MD998051

17

18

5

6

3

1

2

11

7

4

8

12

15

16

(2) Place the special tool in a wrench to tighten the

MB991614

cylinder head bolt in the order of the illustrated

numbers to 120_.

"CA FUEL INJECTION PIPE INSTALLATION

When tightening the nuts at both ends of the fuel injection

pipe, hold the delivery holder (for pump side) and the injection

nozzle assembly (for nozzle side) with a wrench, and tighten

the nuts to the specified torque.

Tightening torque: 30 ± 6 N·m

"DA RADIATOR UPPER HOSE CONNECTION

5

3

1

11

7

15

To reuse the radiator upper hose, align the mating marks

that were made during removal, and then install the hose

clamp.

6

4

2

12

8

16

Front of engine

Page 22

LUBRICATION - General/Lubricant

It

4D5-St

III

12-1

GROUP 12

LUBRICATION

GENERAL

OUTLINE OF CHANGE

D The engine oil quantity has been changed as variable geometry (VG) turbocharger has been used.

LUBRICANT

ems

Engine oil quantity L Oil filter 0.8

Oil cooler 0.4

Total 7.5

ep

Page 23

NOTES

Page 24

FUEL

CONTENTS

13-1

FUEL SYSTEM <4D5-step III>2.......

GENERAL 2.................................

Outline of Changes 2...........................

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 5.................

SEALANT 5..................................

SPECIAL TOOLS 5...........................

TROUBLESHOOTING 7.......................

ON-VEHICLE SERVICE 57....................

Injection Timing Check and Adjustment 57.........

Idle Speed Check and Adjustment 57.............

Injection Nozzle Check and Adjustment 57.........

Accelerator Pedal Position Sensor (APS)

Adjustment 58.................................

Control Relay Continuity Check 59................

Accelerator Pedal Position Sensor (APS)

Check 59......................................

Idle Switch Check 60............................

Boost Air Temperature Sensor (Intake Air

Temperature Sensor) Check 60..................

Engine Coolant Temperature Sensor Check 61.....

EGR Valve Position Sensor Check 61.............

Fuel Injection Pump Check 62....................

Throttle Solenoid Valve Check 63.................

Throttle Actuator Check 64......................

Variable Geometry Solenoid Valve Check 64.......

EGR Control Solenoid Valve Check 64............

FUEL INJECTION PUMP 65..................

CRANKSHAFT POSITION SENSOR 66........

ACCELERATOR PEDAL 67...................

Page 25

13-2

FUEL SYSTEM <4D5-step III> - General/General Information

FUEL SYSTEM <4D5-step III>

GENERAL

OUTLINE OF CHANGES

Some service procedures have been established as the following changes have been made due to the

compliance with the Emission Regulation Step III.

D An electronic-controlled fuel injection pump has been used.

D A crankshaft position sensor has been used as the electronic-controlled fuel injection pump has been

used.

D An engine-ECU has been used as the electronic-controlled fuel injection pump has been used.

Removal and installation procedure of the engine-ECU is the same as for vehicles with 4G6 engine

or 6G7 engine.

D Due to the introduction of the electronic-controlled injection pump, the accelerator cable has been

abolished, and the accelerator pedal position sensor has been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

Page 26

FUEL SYSTEM <4D5-step III> - General Information

SELF-DIAGNOSIS FUNCTION

D When an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

D When an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

D The RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Intercooler Fan Motor Relay Control

Controls the intercooler fan motor relay based on the boost air temperature and vehicle speed input

signals.

6. Glow Control

Refer to GROUP 16.

7. EGR Control

Refer to GROUP 17.

13-3

Page 27

13-4

FUEL SYSTEM <4D5-step III> - General Information

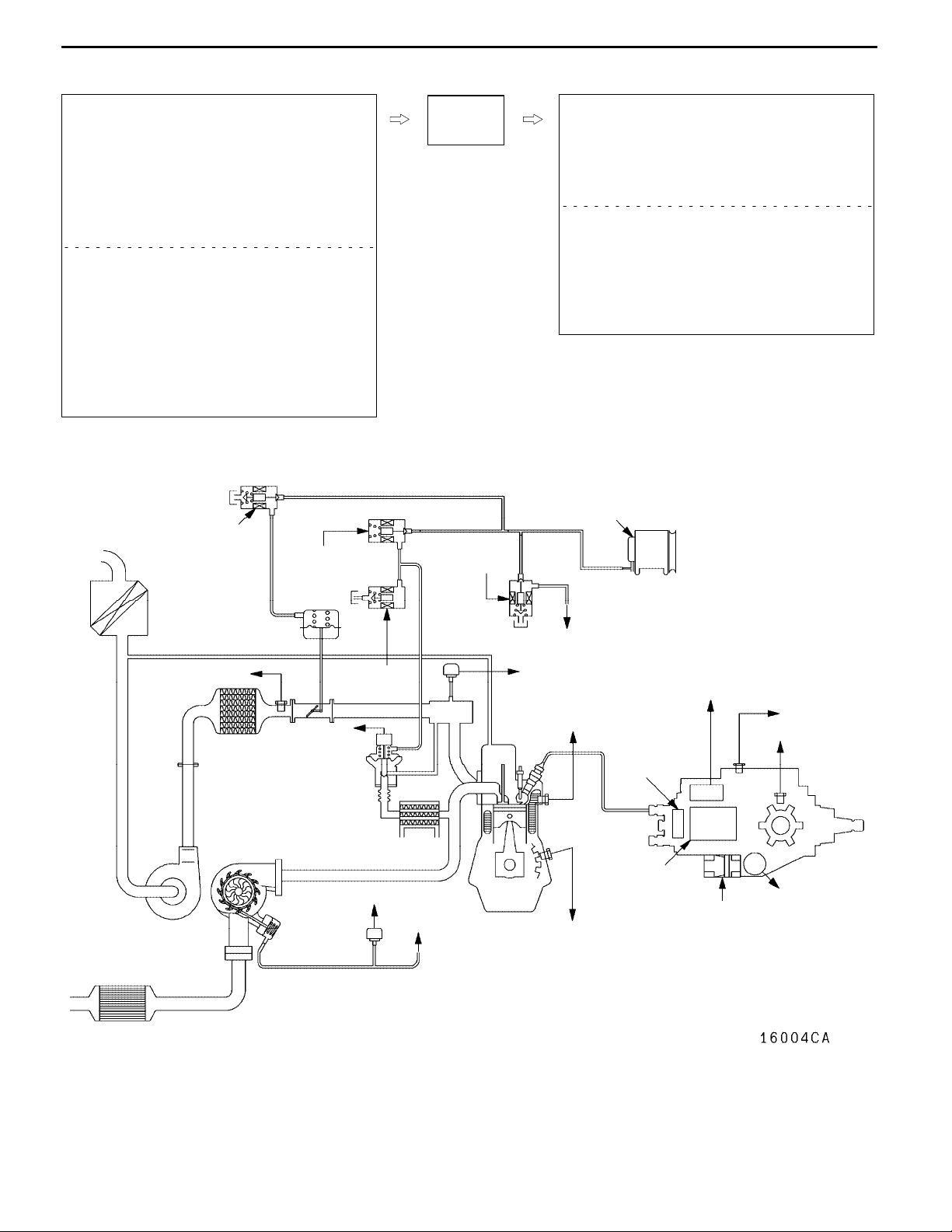

CONTROL SYSTEM DIAGRAM

L1. Pump speed sensor

L2. Crank angle sensor

L3. Engine coolant temperature sensor

L4. Boost pressure sensor

L5. Fuel temperature sensor

L6. Boost air temperature sensor

L7. Control sleeve position sensor

L8. Timer piston position sensor

L9. EGR valve position sensor

L10. Variable geometry control pressure sensor

D Accelerator pedal position sensor (main)

D Accelerator pedal position sensor (sub)

D Idle switch

D Power supply

D Ignition switch-IG

D Ignition switch-ST

D Vehicle speed sensor

D A/C switch

D A/C relay switch

D Injection volume adjusting ROM

D Barometric pressure sensor (ECU built-in)

l5 Throttle solenoid valve

3

l

EGR control

solenoid valve No. 1

Throttle

actuator

EngineECU

7

l

Variable geometry

solenoid valve

l1. GE actuator (electronic governor)

l2. Timing control valve

l3. EGR control solenoid valve No. 1

l4. EGR control solenoid valve No. 2

l5. Throttle solenoid valve

l6. Fuel cut solenoid valve

l7. Variable geometry solenoid valve

D Control relay

D A/C relay

D Condenser fan relay

D Intercooler fan relay

D Glow indicator lamp

D Glow plug relay

D Engine warning lamp

D Diagnosis output

Vacuum pump

Alternator

6 Boost air

L

temperature sensor

Catalytic converter

L9 EGR

valve position

sensor

EGR valve

Variable geometry

turbocharger

Variable

geometry

actuator

4 EGR control

l

solenoid

valve No. 2

L10 Variable geometry control

pressure sensor

To variable geometry solenoid valve

To variable

geometry actuator

L4 Boost pressure

sensor

L3 Engine coolant

temperature sensor

l6 Fuel cut

l1 GE actuator

L2 Crank angle

sensor

L7 Control

sleeve

position

sensor

solenoid

valve

l2 Timing control

valve

L5 Fuel

temperature

sensor

L1 Pump speed

sensor

L8 Timerpiston

position

sensor

Page 28

FUEL SYSTEM <4D5-step III>-Service Specifications/Sealant/Special Tools

p(p

g

p

p

p

p

SERVICE SPECIFICATIONS

Item Standard value

Fuel injection initial pressure kPa 14,710 - 15,490

Accelerator pedal position sensor reference voltage V 0.985 - 1.085

Accelerator pedal position sensor resistance kΩ 3.5 - 6.5

Boost air temperature sensor (Intake air temperature

sensor) resistance kΩ

Engine coolant temperature sensor resistance kΩ

Fuel cut solenoid valve resistance Ω 6.8 - 9.2

Timing control valve resistance Ω 10.8 - 11.2

Timer piston position sensor resistance Ω

Control sleeve position sensor resistance Ω

GE actuator (electronic governor) resistance Ω Connector terminals No. 6 - No. 10 0.64 - 0.72

Fuel temperature sensor resistance kΩ Connector terminals No. 7 - No. 11 1.4 - 2.6

Pump speed sensor resistance kΩ 1.36 - 1.84

Throttle solenoid valve resistance Ω 36 - 44

When the temperature is 20_C 2.3 - 3.0

When the temperature is 80_C 0.30 - 0.42

When the temperature is 20_C 2.1 - 2.7

When the temperature is 80_C 0.26 - 0.36

Connector terminals No. 1 - No. 2 160 - 168

Connector terminals No. 1 - No. 3 80 - 84

Connector terminals No. 2 - No. 3 80 - 84

Connector terminals No. 4 - No. 12 11.2 - 12.4

Connector terminals No. 4 - No. 8 5.6 - 6.2

Connector terminals No. 8 - No. 12 5.6 - 6.2

13-5

SEALANT

Item Specified sealant

Engine coolant temperature sensor 3M Nut Locking Part No. 4177 or equivalent

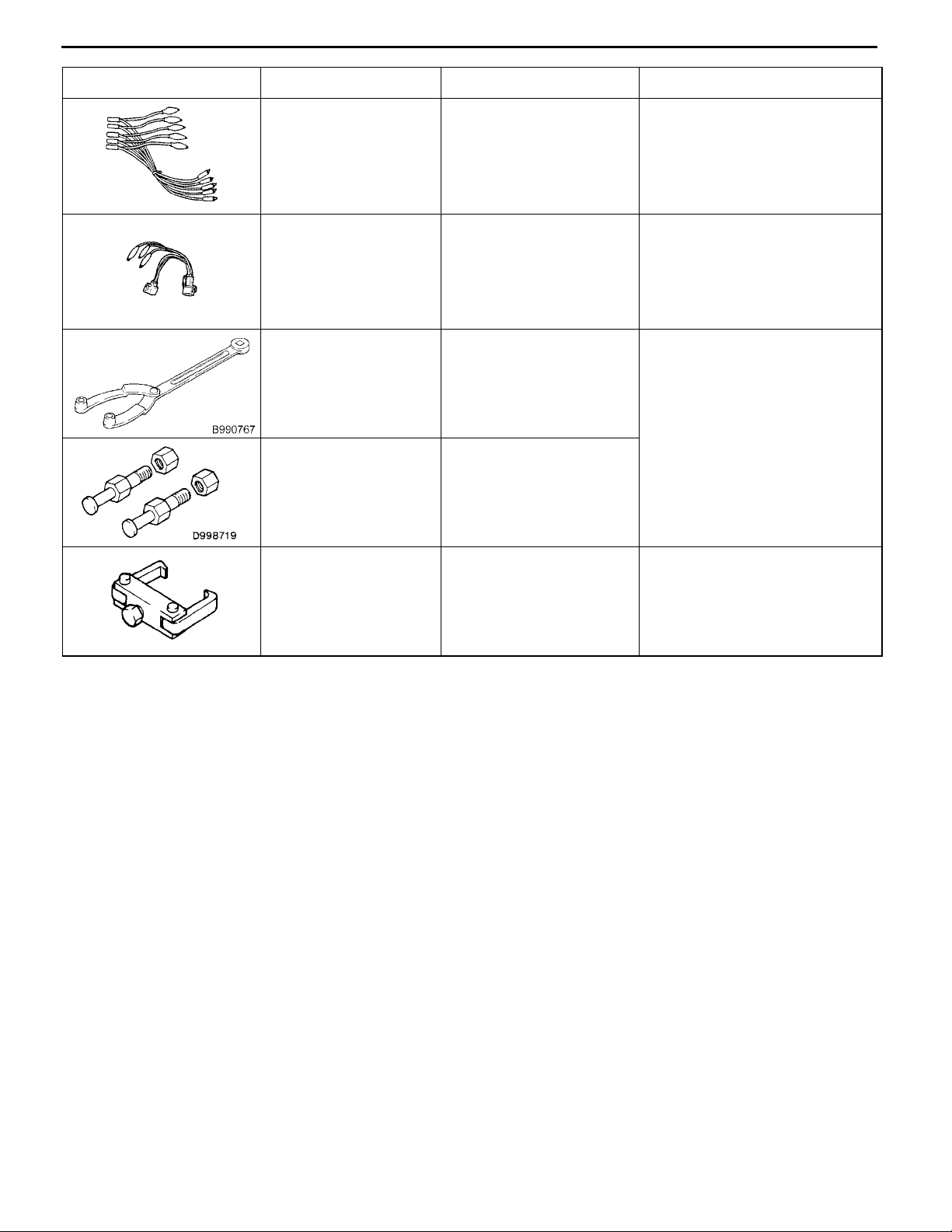

SPECIAL TOOL

Tool Number Name Use

MB991502 MUT-II sub

assembly

MB991529 Diagnosis code

check harness

MB991348 Test harness set D Boost pressure sensor check

Electronically controlled fuel injection system check

Diagnosis code reading

D Variable geometry control

pressure sensor check

Page 29

13-6

Tool UseNameNumber

FUEL SYSTEM <4D5-step III> - Special Tools

MB991658 Test harness set D APS adjustment

D Inspection using an analyzer

MD998478 Test harness

(3-pin, square)

MB990767 End yoke holder Holding the fuel injection pump

MD998719 Crankshaft pulley holder

pin

MD998388 Injection pump sprocket

puller

D Crank angle sensor check

D Inspection using an analyzer

sprocket

Fuel injection pump sprocket

removal

Page 30

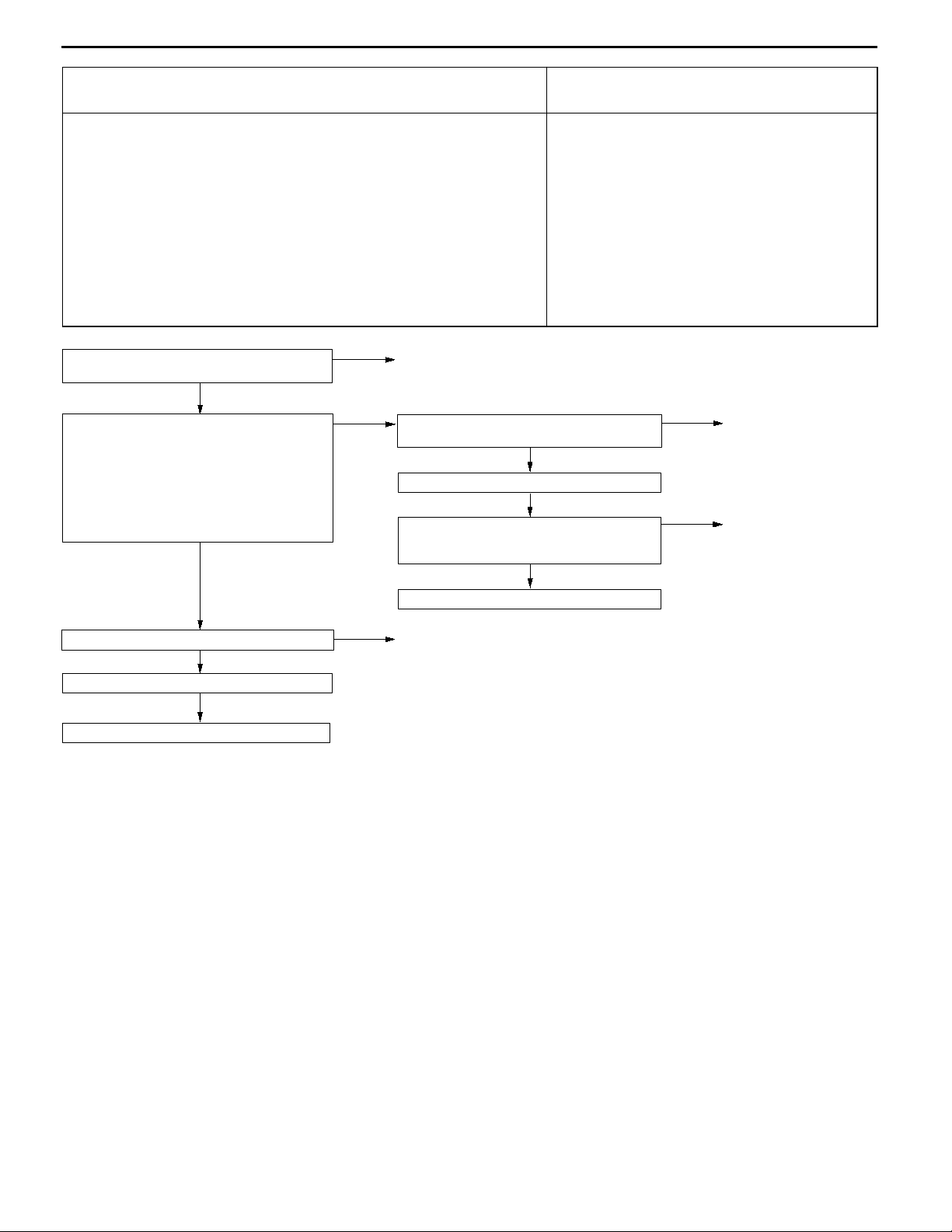

FUEL SYSTEM <4D5-step III> - Troubleshooting

Engine warning lamp

(check engine lamp)

13-7

TROUBLESHOOTING

STANDARD FLOW OF DIAGNOSTIC

TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

NOTE

When replacing the engine-ECU, replace immobilizer-ECU

and ignition key as well at the same time.

DIAGNOSIS FUNCTION

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

Engine warning lamp is lit when any abnormality takes place

in the item related to electronically controlled fuel injection

system shown in the following table.

If the malfunction indicator lamp has been on and/or is lit

when the engine is in operation, check the diagnosis output.

Engine warning lamp check items

Accelerator pedal position sensor (main)

Accelerator pedal position sensor (sub)

Boost pressure sensor (Boost sensor)

Crank angle sensor

Control sleeve position sensor

Timer piston position sensor

Throttle solenoid valve

GE actuator

Variable geometry control pressure sensor

Barometric pressure sensor

Timing control valve

Idle switch

Engine-ECU

METHOD OF ERASING AND ERASING DIAGNOSIS

CODES

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

INSPECTION USING MUT-II DATA LIST AND

ACTUATOR TESTING

1. Carry out inspection by means of the data list and the

actuator test function.

If there is an abnormality, check and repair the chassis

harnesses and components.

2. After repairing, re-check using MUT-II and check that

the abnormal input and output have returned to normal

as a result of the repairs.

3. Erase the diagnosis code memory.

4. Remove the MUT-II.

5. Start the engine again and carry out a road test to confirm

that the problem has disappeared.

Page 31

13-8

FUEL SYSTEM <4D5-step III> - Troubleshooting

FAIL-SAFE, BACKUP FUNCTIONS

When abnormalities in the major sensors are detected by diagnosis functions, pre-set control logic operates

to maintain a safe driving condition for the vehicle.

Diagnosis item Control features in malfunction

Accelerator pedal position sensor D Accelerator pedal released (idle switch ON)

Acceleration opening degree = 0 %

D Accelerator pedal applied (idle switch OFF)

Engine controlled at low speed

Acceleration opening degree = 30 % fixed

D Void EGR control

Idle switch Void idling speed control.

Engine speed sensor D Engine controlled at low speed

D Void EGR control

D Void variable geometry turbocharger control

Boost air temperature sensor D Maintain the intake air temperature at 50_C.

D Void EGR control

Vehicle speed sensor D Void idling speed control.

D Void EGR control

Engine coolant temperature sensor D Maintain the engine coolant temperature at 80_C (However, the system

assumes the coolant temperature as 0_C when engine is started.).

D Void EGR control

Control sleeve position sensor D Engine controlled at low speed

D Void EGR control

D Void variable geometry turbocharger control

Timer piston position sensor D Injection timing stabilizing control

D Void EGR control

Barometric pressure sensor (ECU

built-in)

Fuel temperature sensor Maintain the fuel temperature at 40_C.

Boost pressure sensor D Keep the boost pressure as barometric pressure (101 kPa).

Injection volume adjusting ROM Void correction.

GE actuator D Engine controlled at low speed

Over boost D Void variable geometry turbocharger control

Timing control valve D Injection timing stabilizing control

EGR valve position sensor Void EGR control

Variable geometry control pressure

sensor

D Keep the barometric pressure at 101 kPa.

D Void EGR control

D Void variable geometry turbocharger control

D Void EGR control

D Void variable geometry turbocharger control

D Void EGR control

D Void variable geometry turbocharger control

D Engine controlled at low fuel injection

D Void EGR control

D Void EGR control

D Void variable geometry turbocharger control

Page 32

FUEL SYSTEM <4D5-step III> - Troubleshooting

INSPECTION CHART FOR DIAGNOSIS CODES

Code No. Diagnosis item Reference

page

11 Accelerator pedal position sensor (main) system 13-10

12* Boost pressure sensor system 13-11

13 Barometric pressure sensor (ECU built-in) system 13-12

14 Fuel temperature sensor system 13-12

15 Engine coolant temperature sensor system 13-13

16 Boost air temperature sensor system 13-13

17 Vehicle speed sensor system 13-14

18 Pump speed sensor system 13-15

21 Crank angle sensor system 13-16

23 Idle switch (accelerator pedal position sensor built-in) system 13-17

25* Timer piston position sensor system 13-18

26* Control sleeve position sensor system 13-19

27 Accelerator pedal position sensor (sub) system 13-20

41* Throttle solenoid valve system 13-21

43 Timing control valve system 13-22

46 Injection volume adjusting ROM system 13-23

48* GE actuator (in the middle of control sleeve position sensor inoperative) system 13-24

49* Over boost (variable geometry control pressure sensor system malfunction) 13-25

51 EGR valve position sensor system 13-26

52 Variable geometry control pressure sensor system 13-27

54 Immobilizer system 13-28

13-9

Caution

If the above-mentioned diagnosis code number with the asterisks can be displayed along with another

code number in parentheses simultaneously, check the other code number before replacing the

engine-ECU.

12 (41, 49), 26 (48), 25 (43), 41 (12, 49), 48 (26), 49 (12, 41)

Page 33

13-10

FUEL SYSTEM <4D5-step III> - Troubleshooting

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No. 11 Accelerator pedal position sensor (main)

system

Range of Check

D Ignition switch: ON, accelerator pedal position sensor (sub) operative, except

for during engine cranking

Set Conditions

D Accelerator pedal position sensor output voltage is as below for 1 second:

Sub side: 0.2 V or more, less than 2.5 V

Main side: 4.5 V or more

or

Sub or main side: less than 0.2 V

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D The output voltage of accelerator pedal position sensor (main and sub) for

0.2 second is 0.2 V or higher, or lower than 4.5 V and the difference in

sensor output voltage between the main and sub is 1 V or higher, or idle

switch: ON, and sensor main output voltage is 1.875 V or higher.

Accelerator pedal position sensor check

(Refer to P.13-59.)

OK

Measure at C-134 accelerator pedal position

sensor connector

D Disconnect the connector and measure

at the harness side.

D Voltage between 2 and earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 1 and earth

OK: Continuity

OK

NG

NG

Replace

Check the following connector: C-43

Check the trouble symptoms.

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

Replace the engine-ECU.

Probable cause

D Accelerator pedal position sensor inoperative

D Accelerator pedal position sensor open circuit,

short circuit, or connector contact inoperative

D Engine-ECU inoperative

NG

OK

NG

NG

OK

Repair

Repair

Measure at C-43 engine-ECU connector

D Connect the connector.

D Voltage between 84 and the earth

(Ignition switch: ON)

OK: 0.9 - 1.1 V

(Throttle lever idling position)

4.1 V or higher

(Throttle lever fully opened position)

OK

Check the following connector: C-43

OK

Check the trouble symptoms.

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

OK

Replace the engine-ECU.

NG

NG

NG

NGNGNGNGNG

NG

Check the following connectors:

C-43, C-134

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Repair

Repair

NG

Repair

Page 34

FUEL SYSTEM <4D5-step III> - Troubleshooting

13-11

Code No. 12 Boost pressure sensor (boost sensor)

system

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D Sensor output voltage for 1 second is 4.5 V or higher

(boost pressure is approximately 267 kPa).

or

D Sensor output voltage for 1 second is 0.2 V or lower

(boost pressure is approximately 51.7 kPa or lower)

Range of Check

D Engine speed is 2,000 r/min or higher, barometric pressure is 69.7 kPa or

less (equivalent to an altitude of 300 m) and under high load.

Set Conditions

D Boost pressure is lower than the barometric pressure + 13 kPa for 3

seconds.

Measure at A-129 boost pressure

sensor connector

D Connect the connector.

(Test harness: MB991348 used)

D Voltage between 1 and the earth

(Engine: Idling)

OK: 1.3 - 1.7 V

D Voltage between 1 and the earth

OK: When the accelerator pedal

is suddenly pressed from

the idling condition, the

voltage temporarily increases from 1.3 V to 1.7

V.

OK

NG

Measure at A-129 boost pressure

sensor connector

D Disconnect the connector and

measure at the harness side.

D Voltage between 3 and the earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 2 and the

earth

OK: Continuity

OK

Check the following connector:

A-129

OK

Probable cause

D Boost pressure sensor inoperative

D Boost pressure sensor open circuit, short circuit,

or connector contact inoperative

D Boost pressure sensor hose disconnected

D Engine-ECU inoperative

NG

NG

Checkthefollowing connector:C-130

OK

NG

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the boost pressure

sensor connector.

NG

Repair

Replace the engine-ECU.

OK

Repair

Repair

Measure at C-43 engine-ECU

connector

D Connect the connector.

D Voltage between 85 and the

earth (Engine: Idling)

OK: 1.3 - 1.7 V

OK

Check the following connector:

C-43

NG

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

NG

Repair

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the boost pressure

sensor connector.

OK

Check the vacuum hose between the

boost pressure sensor and the intake

manifold.

OK

Replace the boost pressure sensor.

Check the following connector:

A-129

OK

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the boost pressure

sensor connector, and repair if

necessary.

NG

NG

NG

Repair

Repair

Repair

Page 35

13-12

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 13 Barometric pressure sensor system Probable cause

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D The sensor output voltage is for 3 seconds is 4.5 V or higher (the

barometric pressure is approximately 114 kPa or over).

or

D The sensor output voltage is for 3 seconds is 1.5 V or lower (the barometric

pressure is approximately 40 kPa or under).

Range of Check

D Ignition switch: ON

D The coolant temperature is 40_C or lower

Set conditions

D Difference between the barometric pressure and boost pressure sensors is

13.3 kPa or more

Engine-ECU inoperative

Check the trouble symptoms.

NG

Replace the engine-ECU.

Code No. 14 Fuel temperature sensor system Probable cause

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D The sensor output voltage for 3 seconds is 0.2 V or lower (the fuel

temperature is approximately 125°C or higher).

or

D The sensor output voltage for 3 seconds is 4.6 V or higher (the fuel

temperature is approximately - 47°C or lower).

Fuel temperature sensor check (Refer to

P.13-62.)

OK

Measure at A-131 fuel temperature sensor

connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 11 and the earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 7 and the earth

OK: Continuity

OK

Check the following connector: A-131

OK

Check the trouble symptoms.

NG

Repair

NG

NG

NG

Replace the injection pump.

Check the following connectors:

C-43, C-130

Check the trouble symptoms.

Check the harness between the

engine-ECU and the fuel temperature

sensor connector.

Replace the engine-ECU.

Replace the engine-ECU.

D Fuel temperature sensor inoperative

D Fuel temperature sensor open circuit, short circuit,

or connector contact inoperative

D Engine-ECU inoperative

NG

OK

NG

NG

OK

Repair

Repair

Page 36

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 15 Engine coolant temperature sensor system Probable cause

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D The sensor output voltage for 3 seconds is 4.9 V or higher (the coolant

temperature is approximately - 45_C or lower).

or

D The sensor output voltage for 3 seconds is 0.2 V or lower (the coolant

temperature is approximately 140_C or higher).

D Engine coolant temperature sensor inoperative

D Engine coolant temperature sensor open circuit,

short circuit, or connector contact inoperative

D Engine-ECU inoperative

13-13

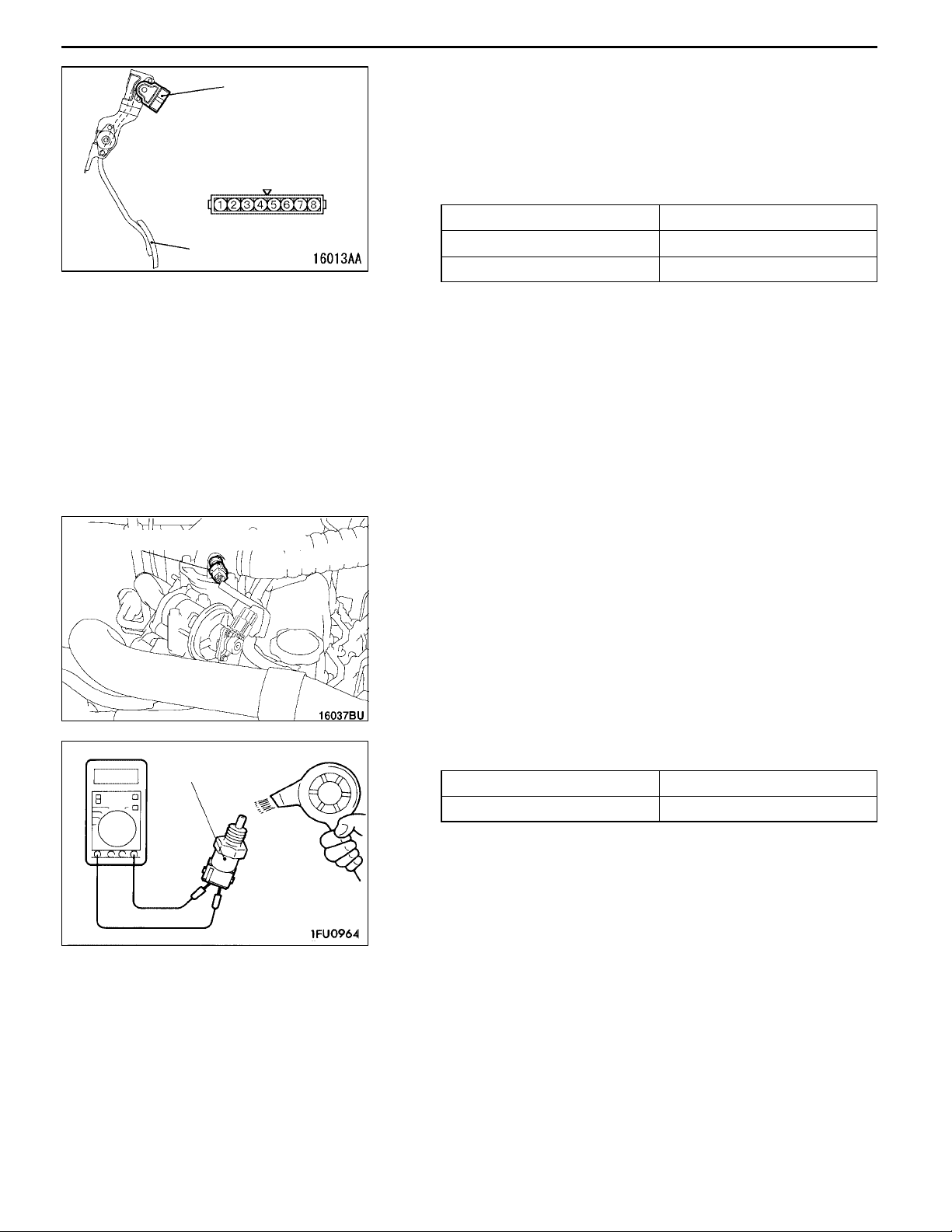

Engine coolant temperature sensor check

(Refer to P.13-60.)

OK

Measure at A-113 engine coolant temperature

sensor connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 1 and the earth

(Ignition switch: ON)

OK: 4.1 - 4.9 V

D Continuity between 2 and the earth

OK: Continuity

OK

Check the following connector: A-113

OK

Check the trouble symptoms.

NG

Repair

NG

NG

NG

Replace

Check the following connectors:

C-43, C-130

Check the trouble symptoms.

Check the harness between the

engine-ECU and the engine coolant

temperature sensor connector.

Replace the engine-ECU.

Replace the engine-ECU.

Code No. 16 Boost air temperature sensor (intake air

sensor) system

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D The sensor output voltage for 3 seconds is 4.6 V or higher (the intake air

temperature is approximately - 45_C or lower).

or

D The sensor output voltage for 3 seconds is 0.3 V or lower (the intake air

temperature is approximately 110_C or higher).

NG

OK

NG

NG

OK

Repair

Repair

Probable cause

D Boost air temperature sensor inoperative

D Boost air temperature sensor open circuit, short

circuit, or connector contact inoperative

D Engine-ECU inoperative

Boost air temperature sensor check

(Refer to P.13-60.)

OK

Measure at C-136 boost air temperature

connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 1 and the earth

(Ignition switch: ON)

OK: 4.0 - 5.3 V

D Continuity between 2 and the earth

OK: Continuity

OK

Check the following connector: C-136

OK

Check the trouble symptoms.

NG

Repair

NG

NG

NG

Replace

Check the following connectors:

C-43, C-130

OK

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the boost air temperature

sensor connector.

OK

Replace the engine-ECU.

Replace the engine-ECU.

NG

NG

Repair

Repair

Page 37

13-14

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 17 Vehicle speed sensor system Probable cause

Range of Check

D Ignition switch: ON

D Engine speed: 2,800 r/min or higher

D Driving with heavy load

Set Conditions

D Slower than vehicle speed of 3 km/h

D Vehicle speed sensor inoperative

D Vehicle speed sensor open circuit, short circuit, or

connector contact inoperative

D Engine-ECU inoperative

Check the vehicle speed sensor.(Refer toGROUP54-Combination

Meters.)

OK

Measure at combination meter connector C-05, C-06.

D Disconnect the connector and measure at the harness side.

1. Voltage between 1 and earth (Ignition switch: ON)

OK: 4.8 - 5.2 V

2. Continuity between 43 and earth

OK: Continuity

OK

Check the following

connectors:

C-05, C-06

OK

Check trouble symptom.

NG

Check the harness wire

between the engine-ECU

and the combinationmeter

connector.

OK

Replace the engine-ECU.

NG

NG

Repair

Repair

NG

1. NG

2. NG

Replace

Check the following

connector:

C- 75, C-24, C-43

OK

Check trouble symptoms.

NG

Check the harness wire

betweentheengine-ECU

and the combination meter connector.

OK

Replace the engine-ECU.

Check the harness wire between the combination meter and the

earth, and repair if necessary.

NG

NG

Repair

Repair

Page 38

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 18 Pump speed sensor system Probable cause

Range of Check

D Ignition switch: ON

D Not during the engine cranking

Set Conditions

D The difference between the pump speed sensor and the crank angle sensor

output value is 500 r/min or higher for 4 seconds

D Malfunction of pump speed sensor

D Open circuit or short-circuit in pump speed sensor

circuit, or poor sensor contact

D Engine-ECU inoperative

13-15

Pump speed sensor check (Refer to

P.13-63.)

OK

Measure at engine-ECU connector C-130.

D Connect the connector.

D Voltage between 51 - 61.

(Engine: idling and then raced)

OK: Voltage increases from the voltage

when engine is idling

OK

Check the following connector: C-130

OK

Check trouble symptoms.

NG

Replace the engine-ECU.

NG

NG

NG

Repair

Replace the injection pump.

Check the following connector:

A-133, C-130

OK

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the pump speed sensor

connector, and repair if necessary.

NG

Repair

Page 39

13-16

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 21 Crank angle sensor system Probable cause

Range of Check

D Engine cranking

Set Conditions

D Sensor output voltage does not change for 2 seconds (no pulse signal input)

Range of Check

D Ignition switch: ON

D Not during the engine cranking

D Pump speed sensor circuit: Normal

Set Conditions

D When crank angle sensor signal is being input normally, suddenly no sensor

signal is input for 0.3 seconds or more

D Malfunction of crank angle sensor

D Open circuit or short-circuit in crank angle sensor

circuit, or poor connector contact

D Engine-ECU inoperative

Measure at crank angle sensor

connector A-112

D Connect the connector.

(Test harness: MB998478 used)

D Voltage between 2 (black clip)

and the earth

OK: 0.4 - 4.0 V

(Engine: cranking)

1.5 - 2.5 V

(Engine: idling)

OK

Replace the engine-ECU.

NG

Measure at crank angle sensor

connector A-112.

D Disconnect the connector and

measure at the harness side.

(1) Voltage between 3 and the earth

(Ignition switch: ON)

OK: System voltage

(2) Continuity between 2 and the

earth (Ignition switch: ON)

OK: 4.6 - 5.4 V

(3) Continuity between 1 and the

earth

OK: Continuity

OK

Check the following connector:

A-112

NG

OK

Check the trouble symptoms.

NG

Replace the crank angle sensor.

Repair

(1) NG

(2) NG

(3) NG

Check the following connector:

C-126

OK

Check the trouble symptoms.

NG

Check the harness between the

crank angle sensor and the engine

control relay, and repair if necessary.

Check the following connector:

C-43

OK

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the crank angle

sensor.

Replace the engine-ECU.

Check the harness between the

crank angle sensor and the earth,

and repair if necessary.

OK

NG

Repair

NG

Repair

NG

Repair

Page 40

FUEL SYSTEM <4D5-step III> - Troubleshooting

13-17

Code No. 23 Idle switch (accelerator pedal position

sensor built-in) system

Range of Check

Ignition switch: ON, accelerator pedal position sensor (main, sub) operative,

except for during engine cranking

Set Conditions

D Idle switch (built-in): ON for 0.8 second, accelerator pedal position sensor

(main, sub) output voltage 1.875 V or higher

D Idle switch (built-in): OFF for 10 minutes, accelerator pedal position sensor

(main, sub) opening degrees less than 1.17 %

Idle switch check (Refer to P.13-59.)

OK

Measure at C-134 accelerator pedal position

sensor connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 4 and the earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 5 and the earth

OK: Continuity

OK

Check the following connector: C-134

OK

Check the trouble symptoms.

NG

NG

NG

NG

Repair

Replace

Check the following connectors:

C-24, C-42

Check the trouble symptoms.

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

Replace the engine-ECU.

Probable cause

D Accelerator pedal position sensor inoperative

D Accelerator pedal position sensor open circuit,

short circuit, or connector contact inoperative

D Idle switch “ON” inoperative

D Idle switch signal line short circuit

D Engine-ECU inoperative

NG

OK

NG

NG

OK

Repair

Repair

Replace the engine-ECU.

Page 41

13-18

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 25 Timer piston position sensor system Probable cause

Range of Check

D Ignition switch: OK

D Not during the engine cranking

Set Conditions

D The sensor output voltage for 1 second is 4.9 V* or more

or

D The sensor output voltage for 1 second is 0.25 V* or less

D Timer piston position sensor inoperative

D Timer piston position sensor open circuit, short

circuit, or connector contact inoperative

D Engine-ECU inoperative

NOTE:

*: This voltage is derived from the input pulse signal converted in the engine-ECU and cannot be measured.

Timer piston position sensor check

(Refer to P.13-63.)

OK

Check the following connector: A-132

OK

Check the trouble symptoms.

NG

MUT-II Data list

19 Injection timing (command value)

(Refer to P.13-43.)

OK

MUT-II Data list

18 Actual injection timing (Refer to P.13-43.)

NG

Replace injection pump assembly (timer

piston fully closed/opened position

inoperative, etc.)

NG

NG

NG

OK

Replace injection pump assembly.

Check the following connector: C-43

OK

Check the trouble symptoms.

OK

Check the harness between the

engine-ECU and the timer piston sensor

connector.

Replace the engine-ECU.

Replace the engine-ECU.

Check the trouble symptoms.

NG

NG

NG

NG

Repair

Repair

Page 42

FUEL SYSTEM <4D5-step III> - Troubleshooting

13-19

Code No. 26 Control sleeve position sensor system Probable cause

Range of Check

D Ignition switch: ON

Set Conditions

D The sensor output voltage for 0.3 second is 4.5 V* or more

or

D The sensor output voltage for 0.3 second is 0.25 V* or less

D Control sleeve position sensor inoperative

D Control sleeve position sensor open circuit, short

circuit, or connector contact inoperative

D Engine-ECU inoperative

NOTE:

*: This voltage is derived from the input pulse signal converted in the engine-ECU and cannot be measured.

Control sleeve position sensor check (Refer

to P.13-62.)

OK

Check the following connector: A-131

OK

Check the trouble symptoms.

NG

MUT-II Data list

17 Control sleeve position sensor (target

value) (Refer to P.13-43.)

OK

MUT-II Data list

23 Control sleeve position sensor (actual

value) (Refer to P.13-43.)

NG

Replace injection pump assembly.

NG

NG

NG

OK

Replace injection pump assembly.

Check the following connector: C-43

OK

Check the trouble symptoms.

OK

Check the harness between the

engine-ECU and the injection pump

assembly connector.

Replace the engine-ECU.

Replace the engine-ECU.

Check the trouble symptoms.

NG

NG

NG

NG

Repair

Repair

Page 43

13-20

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 27 Accelerator pedal position sensor (sub)

system

Range of Check

D Ignition switch: ON, accelerator pedal position sensor (main) operative, except

for during engine cranking

Set Conditions

D Accelerator pedal position sensor output voltage for 1 second

Sub side: 0.2 V or higher, lower than 2.5 V

Main side: 4.5 V or higher

or

Sub or main: Lower than 0.2 V

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D The difference in the output sensor voltage between the main and the sub

sensor is 1 V or higher, or the idle switch ON, and sensor main output

voltage is 1.875 V or higher.

Accelerator pedal position sensor check

(Refer to P.13-59.)

OK

Measure at C-134 accelerator pedal position

sensor connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 8 and the earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 7 and the earth

OK: Continuity

OK

NG

NG

Replace

Check the following connector:

C-24

Check the trouble symptoms.

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

Replace the engine-ECU.

Probable cause

D Accelerator pedal position sensor inoperative

D Accelerator pedal position sensor open circuit,

short circuit, or connector contact inoperative

D Engine-ECU inoperative

NG

OK

NG

NG

OK

Repair

Repair

Check the following connector: C-134

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

NG

Repair

Page 44

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 41 Throttle solenoid valve system Probable cause

Range of Check

D Ignition switch: OFF

D Barometric pressure is 95.4 kPa or over (equivalent to an altitude of 500 m).

Set Conditions

D Boost pressure sensor output does not change.

D Throttle solenoid valve inoperative

D Throttle solenoid valve open circuit, short circuit, or

connector contact inoperative

D Engine-ECU inoperative

D Malfunction of throttle actuator

13-21

Throttle solenoid valve check

(Refer to P.13-63.)

OK

Throttle actuator check

(Refer to P.13-64)

OK

Measure at A-128 throttle solenoid valve

connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 2 and the earth

(Ignition switch: ON)

OK: System voltage

OK

Measure at C-41 engine-ECU connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 14 and the earth

(Ignition switch: ON)

OK: System voltage

OK

Check the following connector: C-41

OK

Check the trouble symptoms.

NG

NG

NG

NG

NG

NG

Replace

Replace

Check the following connector: C-126

OK

Check the trouble symptoms.

NG

Check and repair the harness between the

control relay and the solenoid valve

connector.

Check the following connectors:

A-128, C-126

OK

Check the trouble symptoms.

NG

Check and repair the harness between the

engine-ECU and the solenoid valve

connector.

Repair

Replace the engine-ECU.

NG

NG

Repair

Repair

Page 45

13-22

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 43 Timing control valve system Probable cause

Range of Check

D Engine coolant temperature 80_C or higher and the engine running

Set Conditions

D Target value minus actual value is 0.64 V or more for 5 seconds

D Timing control valve inoperative

D Timing control valve open circuit, short circuit, or

connector contact inoperative

D Engine-ECU inoperative

D Blockage in fuel system

Timing control valve check

(Refer to P.13-62.)

OK

Measure at A-131 injection pump assembly

connector.

D Disconnect the connector and measure at

the harness side.

D Voltage between 5 and the earth

(Ignition switch: ON)

OK: System voltage

OK

Measure at C-41 engine-ECU connector.

D Disconnect the connector and measure at

the harness side.

D Voltage between 3 and the earth

(Ignition switch: ON)

OK: 11 V or higher

OK

Check the following connector: C-41

OK

Fuel system blockage check

D Fuel filter blocked

D Fuel hose blocked or bent

D Fuel tank filter blocked

OK

Check the trouble symptoms.

NG

NG

NG

NG

NG

NG

Replace injection pump assembly.

Check the following connector: C-126

OK

Check the trouble symptoms.

NG

Check and repair the harness between the

control relay and the injection pump

assembly connector.

Check the following connector: A-131

OK

Check the trouble symptoms.

NG

Check and repair the harness between the

engine-ECU and the injection pump

assembly connector.

Repair

Replace

Replace the engine-ECU.

NG

Repair

NG

Repair

Page 46

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 46 Injection volume adjusting ROM system Probable cause

Range of Check

D Ignition switch: ON

Set Conditions

D When communication fails

D Injection volume adjusting ROM inoperative

D Engine-ECU inoperative

13-23

Measure at A-134 injection volume adjusting

ROM connector.

D Disconnect the connector and measure at

the harness side.

D Voltage between 3 and the earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 4 and the earth

OK: Continuity

OK

Check the following connector: A-134

OK

Check the trouble symptoms.

NG

NG

Check the following connector: C-130

OK

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the injection volume

adjusting ROM connector.

OK

Replace the engine-ECU.

Repair

Check the harness between the

engine-ECU and the injection volume

adjusting ROM connector.

OK

Replace the engine-ECU.

Check the trouble symptoms.

NG

Replace injection pump assembly.

NG

NG

NG

Repair

Repair

Repair

Page 47

13-24

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 48 GE actuator (in the middle of control sleeve

position sensor inoperative) system

Range of Check

D Ignition switch: ON

Set Conditions

D Target value minus actual value is 1 V or more for 1 second

GE actuator check (Refer to P.13-62.)

OK

Measure at A-131 injection pump assembly

connector.

D Disconnect the connector and measure at

the harness side.

D Voltage between 6 and the earth

(Ignition switch: ON)

OK: System voltage

OK

Measure at C-41 engine-ECU connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 1 and the earth

(Ignition switch: ON)

OK: 9 V or higher

OK

Check the following connector: C-41

OK

Check the trouble symptoms.

NG

NG

NG

NG

NG

Replace injection pump assembly.

Check the following connector: C-126

Check the trouble symptoms.

Check and repair the harness between the

control relay and the injection pump

assembly connector.

Check the following connector: A-131

Check the trouble symptoms.

Check and repair the harness between the

control relay and the injection pump

assembly connector.

Repair

Replace the engine-ECU.

Probable cause

D Control sleeve position sensor inoperative

D GE actuator inoperative

D Control sleeve position sensor open circuit, short

circuit, or connector contact inoperative

D Engine-ECU inoperative

NG

Repair

OK

NG

NG

Repair

OK

NG

Page 48

FUEL SYSTEM <4D5-step III> - Troubleshooting

Code No. 49 Over boost Probable cause

Range of Check

D Ignition switch: ON

Set Conditions

D Boost pressure is higher than the barometric pressure + 133 kPa

D Malfunction of the variable geometry actuator

D Malfunction of variable geometry solenoid valve

D Variable geometry solenoid valve open circuit, short

circuit, or connector contact inoperative

D Engine-ECU inoperative

13-25

Variable geometry actuator check (Refer to

GROUP 15 - On-vehicle Service.)

OK

Variable geometry solenoid valve check

(Refer to GROUP 15 - On-vehicle Service.)

OK

Measure at A-127 variable geometry solenoid

valve connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 2 and earth

(Ignition switch: ON)

OK: System voltage

OK

Measure at C-41 engine-ECU connector

D Disconnect the connector and measure at

the harness side.

D Voltage between 17 and earth

(Ignition switch: ON)

OK: System voltage

OK

Check the following connector: C-41

OK

Connect a boost gauge to the boost

pressure sensor hose. When the vehicle is

driven at 1st gear with full throttle, does

boost pressure exceed 133 kPa

momentarily?

NO

NG

NG

NG

NG

NG

YES

Replace

Replace

Check and repair the harness between the

control relay and the solenoid valve

connector.

Check the following connector: A-127

OK

Check the trouble symptoms.

NG

Check and repair the harness between the

engine-ECU and the solenoid valve

connector.

Repair

Replace the turbocharger assembly.

NG

Repair

Check the trouble symptoms.

NG

Replace the engine-ECU.

Page 49

13-26

FUEL SYSTEM <4D5-step III>-Troubleshooting

Code No. 51 EGR valve position sensor system Probable cause

Range of Check

D Ignition switch: ON, except during engine cranking

Set Condition

D Output voltage of EGR valve position sensor for 3 seconds is 4.85 V or

higher, or lower than 0.15 V

D EGR valve position sensor inoperative

D EGR valve position sensor open circuit, short

circuit or connector circuit inoperative

D Engine-ECU inoperative

EGR valve position sensor check

(Refer to P.13-61.)

OK

Measure at A-135 EGR valve position sensor

connector.

D Disconnect the connector and measure at

the harness side.

D Voltage between 2 and earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 3 and earth

OK: Continuity

OK

Measure at C-43 engine-ECU connector

D Connect the connector.

D Voltage between 90 and earth.

OK: 0.4 - 0.6 V

(Ignition switch: ON)

4.1 - 4.8 V

(When 60 kPa of negative pressure is

applied to the EGR valve nipple and the

valve is fully open)

OK

Check the following connector: C-43

OK

NG

NG

NG

NG

Replace

Check the following connector: C-130

OK

Check the trouble symptoms.

NG

Check the harness between the

engine-ECU and the EGR valve position

sensor connector.

OK

Replace the engine-ECU.

Check the following connector: A-135

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Repair

NG

Repair

NG

Repair

NG

Repair

Check the trouble symptoms.

NG

Check the harness between the engine-ECU

and the EGR valve position sensor

connector.

OK

Replace the engine-ECU.

NG

Repair

Page 50

FUEL SYSTEM <4D5-step III>-Troubleshooting

13-27

Code No. 52 Variable geometry control pressure sensor

system

Range of Check

D Ignition switch: ON, except during engine cranking

Set Condition

D 4.5 V or higher, or 0.2 V or lower

Range of Check

D Engine idling

Set Conditions

D The difference between target and actual negative pressures remains 10.6

kPa or more for 10 seconds.

Measure at A-130 variable geometry

control pressure sensor connector.

D Connect the connector.

(Use the test harness:

MB991348)

D Voltage between 1 and earth

(Ignition switch: ON)

OK: Altitude 0 m: 3.7 - 4.3 V

Altitude 1,200 m: 3.2 - 3.8

V

OK: 0.5 - 1.2 V when 80 kPa

of negative pressure is applied to the sensor

OK

Measure at C-42 engine-ECU

connector

D Connect the connector.

D Voltage between 45 and earth.

(Ignition switch: ON)