Page 1

GB

TB5 TB15

TB5 TB15

bb

TB5 TB15

c

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB7 TB3

TB5 TB15

TB5 TB15

TB7 TB3

(1)

(1)

(3)

(3)

(1)

(3)

(3)

(2)

(2)

(2)

(4)

(1)

(1)

a

a

dde d

ed

bb

g

f

(1)

(3)

TB5

TB4

TB1

TB4

(3)

(3)

(1)

TB4

TB4

TB5

TB1

TB4

TB5

TB1

TB1

TB4

TB5

(1)

(1)

(3)

(3)

(3)

a

bb

d

a

bb

de

a

bb

dde

TB4

TB4

TB4

TB4TB4

TB4

TB4TB4

TB1 TB1 TB1

TB1TB1

TB5

TB5

TB5

TB5

TB5

(2)

(1)

(3)

(3)

(1)

(2) (2)

(2)

aa a a

b bbbbb bb

de

PAC-YT51CRA

TEMP.

ON/OFF

B

C

A

D

h

16(5/8) 16(5/8)

25(1)

25(1)

102(4)

54(2-1/8)

20

(13/16)

10

(3/8)

44(1-3/4)

83.5±0.4(3-3/8±1/32)

ø6(1/4OD)

20(13/16) 20(13/16)

6

(1/4)

ø6(1/4OD)

d

d

TB4

TB4

TB4

TB4

TB4

TB4

TB1

TB1 TB1

TB1

TB5

TB5

TB5

TB5 TB5 TB5

a

bbb bbb

de

aa a

11

(7/16)

10

(13/32)

80mm

(3-3/16 in)

WT03594X02

CITY MULTI Control System

and Mr. SLIM Air Conditioners

Simple MA Controller PAC-YT51CRA

Installation Manual

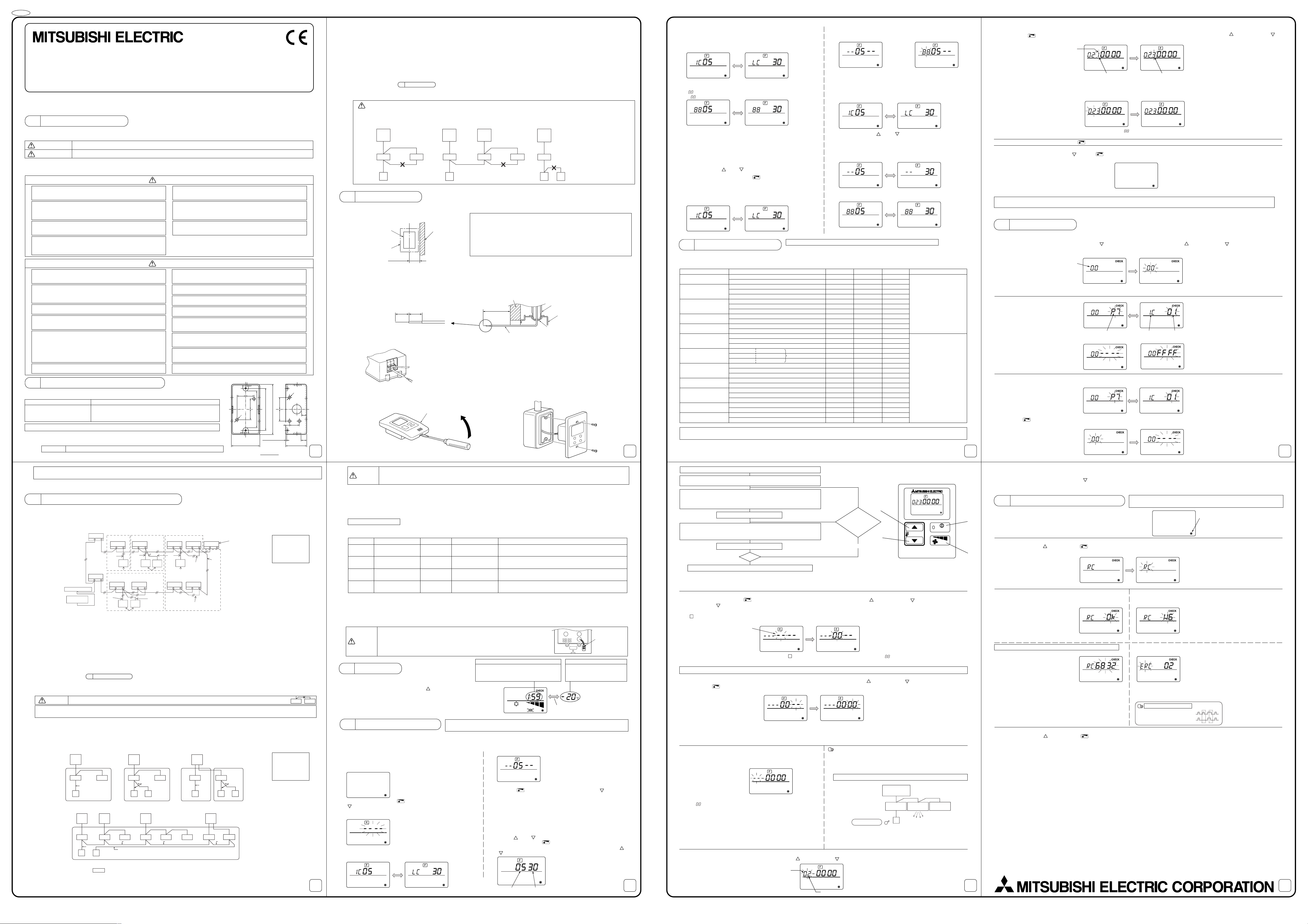

This instruction manual describes how to install the Simple MA Controller for Mitsubishi Building Air Conditioning Systems, direct expansion type CITY

MULTI air conditioner indoor units (“-A” type and later), and Mr. SLIM air conditioners. Please read this manual thoroughly and install the remote

controller accordingly. For information on how to wire and install the air conditioning units, refer to the installation manual for them.

1 Safety Precautions

● Read these Safety Precautions and perform installation work accordingly.

● The following two symbols are used to dangers that may be caused by incorrect use and their degree:

WARNING

CAUTION

● After reading this installation manual, give it and the indoor unit installation manual to the end user.

● The end user should keep this manual and the indoor unit installation manual in a place where he or she can see it at anytime. When someone moves

or repairs the PAC-YT51CRA, make sure that this manual is forwarded to the end user.

Ask your dealer or technical representative to install the unit.

Any deficiency caused by your own installation may result in an electric shock

or fire.

Install in a place that is strong enough to withstand the weight of the

PAC-YT51CRA.

Any lack of strength may cause the PAC-YT51CRA to fall down, resulting in

personal injury.

Firmly connect the wiring using the specified cables. Carefully check

that the cables do not exert any force on the terminals.

Improper wiring connections may produce heat and possibly a fire.

Never modify or repair the PAC-YT51CRA by yourself.

Any deficiency caused by your modification or repair may result in an electric

shock or fire.

Consult with your dealer about repairs.

Do not install in any place exposed to flammable gas leakage.

Flammable gases accumulated around the body of PAC-YT51CRA may cause

an explosion.

Do not use in any special environment.

Using in any place exposed to oil (including machine oil), steam and sulfuric

gas may deteriorate the performance significantly or give damage to the component parts.

Wire so that it does not receive any tension.

Tension may cause wire breakage, heating or fire.

Completely seal the wire lead-in port with putty etc.

Any dew, moisture, insects entering the unit may cause an electric shock or a

malfunction.

When installing the remote controller in a hospital or communication

facility, take ample countermeasures against noise.

Inverters, emergency power supply generators, high-frequency medical equipment, and wireless communication equipment can cause the remote controller to malfunction or to fail. Radiation from the remote controller may effect

communication equipment and prevent medial operations on the human body

or interfere with image transmission and cause noise.

Never contact the power supply with the control wiring terminals.

Doing so will certainly cause the controller to catch fire.

2 Cheking the Supplied Parts

Check that the box includes the following parts in addition to this installation manual:

Remote Controller Model Name

PAC-YT51CRA

NOTE: The parts listed below must be purchased separately.

(1) Cable connecting the remote controller to the indoor unit:

Use the cable specified below.

Cable type VCTF or CVV (2-core): 0.75 – 1.25 mm2 (stranded 16 to 20 AWG) or equivalent

* CVV is a control cable which is sheathed in polyvinyl chloride with polyvinyl insulated wires inside.

This symbol denotes what could lead to serious injury or death if you misuse the PAC-YT51CRA

This symbol denotes what could lead to a personal injury or damage to your property if you misuse the PAC-YT51CRA

WARNING

Ensure that installation work is done correctly following this installation manual.

Any deficiency caused by installation may result in an electric shock or fire.

All electrical work must be performed by a licensed technician, according to local regulations and the instructions given in this manual.

Any lack of electric circuit or any deficiency caused by installation may result

in an electric shock or fire.

Do not move and re-install the PAC-YT51CRA yourself.

Any deficiency caused by installation may result in an electric shock or fire.

Ask your distributor or special vendor for moving and installation.

CAUTION

Do not install in any place at a temperature of more than 40°C (104°F) or

less than 0

The PAC-YT51CRA may be deformed or may malfunction.

Do not touch any control button with your wet hands.

Doing so may cause an electric shock or a malfunction.

Do not wash with water.

Doing so may cause an electric shock or a malfunction.

Do not press any control button using a sharp object.

Doing so may cause an electric shock or a malfunction.

Do not touch any PCB (Printed Circuit Board) with your hands or with

tools. Do not allow dust to collect on the PCB.

Doing so may cause fire or an electric shock.

Do not install in any place where acidic or alkaline solution or special

spray are often used.

Doing so may cause an electric shock or malfunction.

Do not install in any steamy place such a bathroom or kitchen.

Avoid any place where moisture is condensed into dew. Doing so may cause

an electric shock or a malfunction.

Use standard wires in compliance with the current capacity.

A failure to this may result in an electric leakage, heating or fire.

Enclosed Parts

(1) Simple MA Controller ..........................................................1

(2) Cross-recessed pan-head screws ...................................... 2

(3) Operation manual ............................................................... 3

°C (32°F) or exposed to direct sunlight.

Switch box

1.5 (1/16) or less

Unit: mm (in)

(2) When grouping with difference refrigerant systems

•

Group using the remote controller wiring. Connect the remote controller to an arbitrary indoor unit of each refrigerant system you want to group.

• When mixing different types of indoor units in the same group, always make the outdoor unit connecting the indoor unit with the most

functions (wind velocity, vane, louver, etc.) the master unit (refrigerant address = 00). Also, when the master unit is the simultaneous

multi type, always satisfy the conditions of (1) above.

• The MA compact remote controller can control up to 16 refrigerant systems as one group.

(3) Up to two remote controllers can be connected to one group

• When two remote controllers are connected to one group, always set the master remote controller and subordinate remote controller.

• When only one remote controller is connected to one group, set it as the master controller. When two remote controllers are connected to one

group, set the master remote controller and subordinate remote controller. (For a description of how to set the master/subordinate switch, see

step 5 in section 4 How To Install .)

(4) Total length of remote controller wiring

• The remote controller can be wired up to 200 m (656-1/8 ft). Procure 0.75 ~ 1.25 mm2 (16 ~ 28 AWG), 2-core cable at the installation site.

CAUTION - The wiring cannot be connected to TB5 of the indoor unit of the same refrigerant system. If so connected, the system will not

operate normally.

- Remote controllers cannot be wired together. Only one wire can be connected to the remote controller terminal block.

Simultaneous twin

- When connecting to TB5, connect up to two wires of the same size to one terminal block.

Refrigerant

address=00

Standard 1:1

Simultaneous twin

Refrigerant

address=00

Refrigerant

address=01

Standard 1:1

Refrigerant

address=00

a Outdoor unit

b Indoor unit

d Main Remote Controller

e Sub remote controller

4 How To Install

1. Mount the switch box

(1) Install the switch box (purchased separately) as ex-

plained below.

Switch box

Outline of remote

controller

40 mm (1-19/32 in) or more

Projecting

object such as

a stud

NOTE: - Be sure to install the switch box with the clearance shown in the illustra-

tion at the left. (Check the space between the unit and any projection

such as a stud.)

- Leave a space of 120 mm (4-3/4 in) or more below the remote controller

so that the screwdriver can be used.

- Since the remote controller is equipped with a temperature sensor, install the remote controller in a location where the average room temperature can be detected and which is not directly affected by some heat

source, direct sunlight or air blown from an air conditioner.

(2) Purchase the thin-copper wiring pipe and locknuts and bushings separately.

2. Install the remote controller

(1) Pull out about 80 mm of cable from the wall and remove the insulation from its end.

(2) Use putty to seal the cable lead-in hole in order to prevent insects from damaging the wiring and to prevent air from condensing on the remote

controller circuit board. If the hole is not sealed well, the remote controller circuit board may be damaged.

Wall

Wiring pipe

One switch box (with cover)

Leading

wire

lation

SheathInsu-

Cable

Seal with putty.

(3) Connect the cable to the terminal board in the bottom rear of the simple MA controller unit.

• The cable does not have polarity.

• When connecting stranded cable, hold down the button on the terminal board while inserting

the cable.

Button:

Press here.

• The cable connects to the main terminal board when it is inserted into the bottom terminal.

• When disconnecting the cable, hold down the button while pulling out the cable.

• After inserting the cable, slightly tug on it to check that it does not easily disconnect. If the

Insert the cable.

cable is not securely connected, a short-circuit or malfunction may occur.

(4) Remove the controller cover using a standard screwdriver, then attach the simple MA controller unit to the switch box using the two enclosed

cross-recessed pan-head screws. Use a standard screwdriver with a blade that is 4 mm (5/32 in) or wider to remove the cover.

Remove controller cover

1 3

7 Press the [ON/OFF] button, and register the set indoor unit address

and LOSSNAY address.

- Registration end display

- Confirmation end display (When

LOSSNAY or OA processing unit

is not connected.)

- Registered indoor unit address does not exist.

The indoor unit address and “IC” and LOSSNAY address and “LC”

are alternately displayed.

LC: LOSSNAY

FU: OA Process-

ing unit

< 3. Deletion procedure >

- Registration error display

If the address is not registered correctly, the indoor unit address and [

] and the registered LOSSNAY or OA processing unit address and

[ ] are alternately displayed.

Use this procedure when you want to delete registration of indoor units

connected by the remote controller and LOSSNAY or OA processing unit.

; Confirm (see 2. Confirmation procedure) the LOSSNAY or OA pro-

cessing unit you want to delete and display the indoor units and

LOSSNAY or OA processing unit confirmation results.

LC: LOSSNAY

FU: OA Process-

ing unit

Cannot be registered because the registered indoor unit or LOSSNAY

or OA processing unit does not exist.

Cannot be registered because another LOSSNAY or OA processing

unit was registered at the registered indoor unit.

< 2. Confirmation procedure >

8 Set the address of the indoor unit connected by the remote con-

A Press the [TEMP. (

onds, and delete registration of the LOSSNAY or OA processing unit

address registered at the set indoor unit.

- Deletion end display

Indoor unit address and “– –” and registered LOSSNAY or OA processing unit address and “– –” are alternately displayed.

) and ( )] button simultaneously for 2 sec-

troller whose LOSSNAY or OA processing unit you want to confirm

using the [TEMP. ( ) and ( )] buttons. (01 to 50)

9 Press the [ON/OFF] button and [ (Fan Speed Adjustment)]

button simultaneously for 2 seconds, and check the Lossnay address registered at the set indoor unit address.

- Confirmation end display (When LOSSNAY is connected.)

The indoor unit address and “IC” and registered LOSSNAY address and “LC” are alternately displayed.

LC: LOSSNAY

FU: OA Process-

ing unit

7 Function Selection

Please set the following functions connected with Mr.SLIM if it is neccessary.

(Cannot be performed with CITY MULTI Control system.)

- Deletion error display

When deletion was not performed properly.

Set the functions of each indoor unit from the remote controller, as required. The functions of each indoor unit can be selected only from the remote controller.

Set the functions by selecting the necessary items from Table 1.

Table 1. Function selection contents (For a detailed description of the factory settings and mode of each indoor unit, refer to the indoor unit installation manual.)

Function

Power failure automatic

recovery

Indoor temperature

detecting

OA processing unit

connectivity

Power voltage

AUTO mode

Filter sign

Fan speed

No. of air outlets

Installed options (high-

performance filter)

Up/down vane setting

Energy saving air flow

(Heating mode)

Humidifier

(Direct Add-on type)

Not available

Available (Approximate 4 minutes wait-period after power is restored.)

Indoor unit operating average

Set by indoor unit’s remote controller

Remote controller’s internal sensor

Not Supported

Supported (indoor unit is not equipped with outdoor-air intake)

Supported (indoor unit is equipped with outdoor-air intake)

240 V

220 V, 230 V

Energy saving cycle automatically enabled

Energy saving cycle automatically disabled

100 Hr

2500 Hr

No filter sign indicator

Quiet

Standard

High ceiling

4 directions

3 directions

2 directions

Not supported

Supported

No vanes

Equipped with vanes (No. 1 set)

Equipped with vanes (No. 2 set)

Disabled

Enabled

Not supported

Supported

Settings

Standard

High ceiling 1 PL(H)(A)-P·AA type

High ceiling 2

Mode No.

01

01

02

02

02

03

03

03

04

04

05

05

07

07

07

08

08

08

09

09

09

10

10

11

11

11

12

12

13

13

Setting No.

1

2

1

2

3

1

2

3

1

2

1

2

1

2

3

1

2

3

1

2

3

1

2

1

2

3

1

2

1

2

Check Object unit address No.

Unit address No. 00

These items are set for all indoor units.

Unit address No. 01 to 04 or

AL

These items are set for each

indoor unit.

NOTE: When the indoor unit functions were changed using the function selection after installation is complete, always indicate the set contents by

entering 嘷 or other mark in the appropriate check field of Table 1.

[Function selection flow]

First grasp the function selection flow. The following describes setting of “Room temperature detection position” of Table 1 as an example.

(For the actual setting procedure, see [Setting procedure] 1 to ?.)

7 Select the setting contents of the selected mode.

When the D [

(Fan Speed Adjustment)] button is pressed, the

current setting No. flashes. Use this to check the currently set contents.

Setting No. display

Setting No. 1 = Simultaneous operation indoor units balance

Select the setting No. using the B [TEMP. ( )] and C [TEMP. ( )]

buttons.

Setting No. 3 = Remote controller built-in sensor

8 The contents set at steps 3 to 7 are registered.

When the A [ON/OFF] button is pressed, the mode No. and setting No. flash and registration begins. The flashing mode No. and

setting No. change to a steady light and setting ends.

* When “– –” appears at the mode No. and setting No. displays and “

” flashes at the room temperature display, communication is probably abnormal.

Make sure there are no noise sources near the transmission line.

9 To select more functions, press the D [

(Fan Speed Adjustment)] and repeat steps 3 to 8.

? End function selection.

Press and hold down the C [TEMP. ( )] and D [ (Fan Speed Adjustment)] buttons at the same time for two seconds or longer.

After a while, the function selection display disappears and the remote controller returns to the air conditioner off display.

* Do not operate the air conditioner from the remote controller for 30 seconds after the end of function selection.

NOTE: When the functions of an indoor unit were changed by function selection after the end of installation, always indicate the set contents

by entering a 嘷 or other mark in the appropriate check field of Table 1.

8 Self diagnosis

Retrieve the error history of each unit using the simple MA controller.

1 Switch to the self-diagnosis mode.

When the A [ON/OFF] button and the C [TEMP. (

)] button

are pressed for 5 seconds or longer, the figure shown below is

displayed.

Self-diagnosis address or selfdiagnosis refrigerant address

3 Self-diagnosis result display <Error history> (For the contents of the error code, refer to the indoor unit installation manual or service handbook.)

Error code 4 digits or error code 2 digits Error detection attribute Address 4 digits or unit address No. 2 digits

<When there is no error history>

4 Error history reset

The error history is displayed in 3 self-diagnosis results display.

When the D [ (Fan Speed Adjustment)] button is pressed two

times successively within three seconds, the self-diagnosis object address and refrigerant address flash.

2 Set the address or refrigerant address No. you want to self-diagnosis.

When the B [TEMP. (

)] and C [TEMP. ( )] are pressed, the address

decreases and increases between 01 and 50 or 00 and 15. Set it to the

address No. or refrigerant address No. you want to self-diagnosis.

Approximately three seconds after the change operation, the self-diagnosis refrigerant address changes from flashing to a steady light and self-diagnosis begins.

(Alternate

display)

<When opposite side does not exist>

(Alternate

display)

When the error history was reset, the display shown below appears.

When error history reset failed, the error contents are displayed again.

5 7

NOTE: If you need to use a cable extension longer than 10 m (32 ft), select an electric wire that meets the following specifications:

Wire specification VCTF or CVV (2-core): 1.25 mm2 (stranded 16 AWG) or equivalent

(2) The switch box is necessary for mounting. Use the switch box specified in the right.

3 How To Wire Transmission Line

The wiring is different when the remote controller is connected to a CITY MULTI control system (“-A” type and later) and when it is connected to a Mr.

SLIM air conditioner (A control type). The wiring also differs with the system configuration. Check the system used.

1. Connecting to CITY MULTI control system

The numbers (1) to (4) in the figure correspond to items (1) to (4) in the following description.

(1) Wiring from the remote controller

• Connect to the MA remote controller terminal block (TB15) on the indoor unit.

• The terminal block has no polarity. Continue to the terminal block at the rear bottom of the remote controller.

(2) Operating in a group (Groups 03, and 04 above)

• Interconnect the MA remote controller terminal block (TB5) of the indoor units you want to operate as a group, and connect the MA remote

controller to that point.

• When also it in combination with a CITY MULTI control system as shown in the figure above, group setting at the system controller (central

controller in the figure above) is necessary.

(3) Number of connectable remote controllers (groups 02 and 04)

• A main remote controller and one sub remote controller, a total of two, can be connected to a group made up of indoor units.

(4) To interlock to a LOSSNAY or OA processing unit, make the following settings using the remote controller. (For a description of how to set an

interlock, see section 6 Ventilation Setting .)

Set the LOSSNAY or OA processing unit address and the address of all the indoor units you want to interlock.

(5) Total length of remote controller wiring

• The simple MA controller can be wired up to 200 m (656 ft). Procure 0.75 - 1.25 mm2 (stranded 16 - 28 AWG), 2-core cable at the installation site.

CAUTION

NOTE: When interlocking the MA remote controller with a LOSSNAY or OA processing unit, always set the address of all the indoor units in the

group and the address of the LOSSNAY or OA processing unit.

Remote controllers cannot be wired together. Only one wire can be connected to the remote controller terminal block.

2. Connecting to Mr. SLIM air conditioner

The remote controller wiring depends on the system configuration. Check the system configuration. Wire the remote controller as shown in the

example below.

The numbers (1) to (3) in the figure correspond to items (1) to (3) in the following description.

[1] Connecting the remote controller for each refrigerant system (Standard 1:1, simultaneous twin, simultaneous triple, simultaneous four, indi-

vidual twin)

Simultaneous twin

[2] When grouping by different refrigerant systems

Standard 1:1

* Set the refrigerant address using the outdoor unit dip switches. (For more information, refer to the outdoor unit installation manual.)

* All the indoor units enclosed in are controlled as one group.

(1) Wiring from remote controller

• Connect to indoor unit TB5 (remote controller terminal block). (The terminal block has no polarity.)

• For simultaneous multi type, when mixing various types of indoor units, always connect the remote controller to the indoor unit with the

most functions (wind velocity, vane, louver, etc.).

Address=51

Address=55

Refrigerant

address=00

Refrigerant

address=00

(Master)

Group01

Address=01 Address=03

Address=08 Address=07 Address=06 Address=05

Group04

Simultaneous twin

Simultaneous twin

Refrigerant address=01

(Subordinate)

Group02 Group03

Address=02 Address=04

Refrigerant

address=00

Simultaneous triple

Refrigerant address=02

(Subordinate)

Refrigerant

address=00

Address=09

Individual twin

Refrigerant

address=00

Individual twin

Refrigerant

address=03

(Subordinate)

a Outdoor unit

b Indoor unit

c LOSSNAY or OA processing unit

d Main Remote Controller

e Sub Remote Controller

f Central controller

g Power supply unit for transmission line

Refrigerant

address=04

(Subordinate)

a Outdoor unit

b Indoor unit

d Main Remote Controller

(Simple MA Controller)

e Sub remote controller

(Simple MA Controller)

Connect to

TB15 on the

indoor unit.

de

Connect to

TB5 on the

indoor unit.

CAUTION

- Attach the remote controller to a level surface. Do not over tighten the screws, otherwise the case may become deformed or

break.

(5) When using two remote controllers in one group, set the dip switches.

When using two remote controllers in one group, specify the main and sub remote controllers using dip switch No. 1 shown below.

• When connecting only one remote controller to one group, it is always the main remote controller. When connecting two remote controllers to

one group, set one remote controller as the main remote controller and the other as the sub remote controller.

• The factory setting is “Main”.

Setting the dip switches

There are switches on the front of the remote controller. Remote controller Main/Sub and other function settings are performed using these

switches. Ordinarily, only change the Main/Sub setting of SW1. (The factory settings are all “ON”.)

- Forcing off the cover using a screwdriver that is less than 4 mm (5/32 in) wide may result in damage to the equipment.

SW No

1

2

3

4

SW contents Main

Remote controller

Main/Sub setting

Temperature display

units setting

Cooling/heating display in AUTO mode

Indoor temperature

display

ON

Main

Celsius

Ye s

Ye s

OFF

Sub

Fahrenheit

No

No

Set one of the two remote controllers at one group to “Main”

When the temperature is displayed in [Fahrenheit], set to “No”.

When you do not want to display “Cooling” and “Heating” in the

Auto mode, set to “No”.

When you do not want to display the indoor temperature, set to

“No”.

Comment

(6) After setting the remote controller address, attach the remote controller cover.

When attaching the remote controller cover, set the top of the cover onto the two top hooks, then push in on the bottom of the cover until it snaps

into place.

If the bottom of the cover is attached first, the top of the cover cannot be attached. Forcefully pushing in the top of the cover to attach it may

break the hooks.

- Press in on the bottom of the cover until it snaps into place.

- When attaching the remote controller cover, be careful not to move the room tem-

CAUTION

perature sensor out of place. Moving the sensor out of place or pinching it while

attaching the cover may result in the sensor malfunctioning or being damaged.

5 Test Run

1. Before making a test run, refer to the “Test Run” section of the

The amount of time: remaining for the test run is

Display range: 2:00 to 0:01

After two hours, the test run stops automatically.

test run time

displayed.

indoor unit piping temperature

Display range: –20°C (–4°F) to

“–20°C” or “70°C” flashes on the

display

Room temperature sensor

70°C (158°F)

indoor unit installation manual.

2. When the [ON/OFF] button and [TEMP.] ( ) button are pressed

simultaneously for 2 seconds or longer, test run is performed.

3. Stop the test run by pressing the [ON/OFF] button.

4. If trouble occurred during the test run, refer to the “Test Run” section of the indoor unit installation manual.

6 Ventilation Setting

Make this setting only when interlocked operation with LOSSNAY or OA processing unit is

necessary with CITY MULTI models.)

Alternately displays the test run time

and indoor unit piping temperature.

(–4°F)

(This setting cannot be made with Mr. SLIM air conditioners.)

Perform this operation when you want to register the LOSSNAY or OA processing unit, confirm the registered units, or delete the registered units controlled by the remote controller.

The following uses indoor unit address 05 and LOSSNAY or OA processing unit address 30 as an example to describe the setting procedure.

[Setting Procedure]

- When LOSSNAY or OA processing unit are not registered

1 Stop the air conditioner using the remote controller [ON/OFF] button.

If the OFF display shown below does not appear at this time, step 2

cannot be performed.

4 If registration is unnecessary, end registration by pressing and holding

down the [ (Fan Speed Adjustment)] and [TEMP. ( )] buttons at the

same time for two seconds.

2 Press and hold down the [ (Fan Speed Adjustment)] and [TEMP.

( )] buttons at the same time for two seconds. The display shown below appears. The remote controller confirms the registered LOSSNAY

or OA processing unit addresses of the currently connected indoor units.

If a new LOSSNAY or OA processing unit must be registered, go to step 1.

Registration procedure . If you want to confirm another LOSSNAY or OA

processing unit, go to step 2. Confirmation procedure. To delete a registered LOSSNAY or OA processing unit, go to step 3. Deletion procedure.

< 1. Registration procedure >

5 Set the address of the LOSSNAY or OA processing unit and the indoor

unit connected by the remote controller you want to register using the

[TEMP. ( ) and ( )] buttons. (01 to 50)

6 After setting, press the [ (Fan Speed Adjustment)] button and set the

3 Registration confirmation result

- The indoor unit address and registered LOSSNAY or OA processing

Lossnay address you want to register by operating the [TEMP. ( ) and

(

)] buttons. (01~50)

unit address are displayed alternately.

LC: LOSSNAY

FU: OA Process-

ing unit

2 4

<Indoor unit address and indoor unit display> <LOSSNAY address display and LOSSNAY display>

Indoor unit address LOSSNAY or OA processing unit address

1 Check the function selection set contents.

2 Switch to the FUNCTION SELECTION mode.

(Press D and C simultaneously in the remote controller OFF state.)

3 Refrigerant address specification → 00 (Outdoor unit specification)

4 Unit address No. specification → 00 (Indoor unit specification)

(Buttons B, C and D operation)

5 Registration (Press button A.)

6 Mode No. Selection → 02 (Room temperature detection position)

7 Setting No. selection → 3 (remote controller fixed)

(Buttons B, C and D operation)

8 Register (Press button A.)

(Unnecessary for single refrigerant system.)

(Specified indoor unit →

Fan operation)

End?

NO

NO

YES

Change

refrigerant

address and unit

address No.?

9

YES

? Ending function display (Press buttons D and C simultaneously.)

[Procedure] (Set only when change is necessary.)

1

Check the set contents of each mode. When the set contents of a mode were changed by function selection, the functions of that mode also change.

Check the set contents as described in steps 2 to 7 and change the setting based on the entries in the Table 1 check field. For the factory settings, refer to the indoor unit installation manual.

2 Set the remote controller to Off.

Press and hold down the D [ (Fan Speed Adjustment)] and

the C [TEMP. ( )] buttons at the same time for two seconds or

longer.

“ F (FUNCTION)” blinks for a while, then the remote controller

3 Set the outdoor unit refrigerant address No.

When the B [TEMP. ( )] and C [TEMP. ( )] buttons are pressed, the

refrigerant address No. decreases and increases between 00 and 15.

Set it to the refrigerant address No. whose function you want to select.

(This step is unnecessary for single refrigerant system.)

display changes to the display shown below.

Refrigerant address

display

* If the remote controller enters the OFF state after the “ F (FUNCTION)” and room temperature displays “ ” have flashes for two seconds, commu-

nication is probably abnormal. Make sure there are no noise sources near the transmission line.

NOTE: If you make a mistake during operation, end function selection by step ? and repeat selection from step 2.

4 Set the indoor unit address No.

Press the D [ (Fan Speed Adjustment)] button. The unit address No. display “– –” flashes.

Unit address No. display

When the B [TEMP. ( )] and C [TEMP. ( )] buttons are pressed, the unit

address No. changes in 00 ↔ 01 ↔ 02 ↔ 03 ↔ 04 ↔ AL order. Set it to the

unit address No. of the indoor unit whose functions you want to set.

* When setting mode 1 to 3, set the unit address No. to “00”.

* When setting modes 7 to 11:

- When setting for each indoor unit, set the unit address No. to “01-04”.

- When batch setting for all indoor units, set the unit address No. to “AL”.

5 Refrigerant address and unit address No. registration

Press the A [ON/OFF] button. The refrigerant address and unit address No. are registered.

After a while, the mode No. display “– –” flashes.

Mode No. display

* When “ ” flashes at the room temperature display, the selected refrig-

erant address is not in the system.

When registered using the A

[ON/OFF]

, the registered indoor unit begins fan operation. When you want to know the location of the indoor

units of the unit address No. whose functions were selected, check here.

When the unit address No. is 00 or AL, all the indoor units of the selected

refrigerant address perform the fan operation.

Ex) When refrigerant address 00, unit address No. = 02 registered

Refrigerant address 00

Outdoor unit

Indoor unit

Unit address

No. 01

Unit address

No. 02

Unit address

No. 03

When “F” is displayed at the unit address No. display, and when it flashes

together with the refrigerant address display, the selected unit address

No. does not exist. Correctly set the refrigerant address and unit address No. by repeating steps 2 and 3.

Registration

* When grouping by different refrigerant systems and an indoor unit other

Simple MA Controller

than the specified refrigerant address performs the fan operation, the

Fan operation

refrigerant address set here is probably duplicated.

Recheck the refrigerant address at the outdoor unit dip switches.

6 Mode No. selection

Select the mode No. you want to set with the B [TEMP. ( )] and C [TEMP. ( )] buttons. (Only the settable mode numbers can be selected.)

Mode No. display

Mode No. 02 = Room temperature detection position

5 Self-diagnosis reset

There are the following two ways of resetting self-diagnosis.

Press the A [ON/OFF] button and the C [TEMP. ( )] button simultaneously for 5 seconds or longer. → Resets self-diagnosis and returns to the state before self-diagnosis.

Press the A [ON/OFF] button.→ Self-diagnosis resets and indoor units stop.

(When operation is prohibited, this operation is ineffective.)

9 Remote Controller Check

1 First check the power mark.

When the air conditioner cannot be controlled from the simple MA controller,

use this function to check the remote controller.

Power mark

When normal voltage (DC12V) is not applied to the remote controller,

the power mark goes off.

When the power mark is off, check the remote controller wiring and

the indoor unit.

2 Switch to the remote controller check mode.

When the B [TEMP. ( )] button and D [ (Fan Speed Adjustment)] button are pressed simultaneously for 5 seconds or longer,

When the A [ON/OFF] button is pressed,

remote controller check begins.

the figure shown below is displayed.

3 Remote controller check result

<When remote controller is normal>

<When remote controller is faulty>

(Error display 1) “NG” flashes → Remote controller send/receive circuit abnormal

Since there is no problem at the remote controller, check for other causes.

Remote controller switching is necessary.

When the problem is other than the checked remote controller

(Error code 2) “E3” “6833” “6832” flash → Cannot send

There is noise on the transmission line, or the indoor unit or another

remote controller is faulty. Check the transmission line and the other

remote controllers.

(Error display 3) “ERC” and data error count are displayed → Data error generation

“Data error count” is the difference between the number of bits of remote controller

send data and the number of bits actually sent to the transmission line. In this

case, the send data was disturbed by the noise, etc. Check the transmission line.

When data error count is 02

Remote controller send data

Send data on transmission line

4 Remote controller check reset

When the B [TEMP. ( )] button and D [ (Fan Speed Adjustment)] button are pressed simultaneously for 5 seconds or longer, remote

controller diagnosis is reset and the [HO] and run lamp flash and 30 seconds later the remote controller returns to its state before diagnosis.

6 8

Loading...

Loading...