Page 1

Page 2

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or registered

trademarks of their respective companies.

Page 3

Introduction

Thank you for selecting the Mitsubishi numerical control unit.

This instruction manual describes the handling and caution points for using this AC

servo/spindle.

Incorrect handling may lead to unforeseen accidents, so always read this instruction

manual thoroughly to ensure correct usage.

Make sure that this instruction manual is delivered to the end user.

Always store this manual in a safe place.

In order to confirm if all function specifications described in this manual are applicable,

refer to the specifications for each CNC.

Notes on Reading This Manual

(1) Since the description of this specification manual deals with NC in general, for the

specifications of individual machine tools, refer to the manuals issued by the

respective machine manufacturers. The "restrictions" and "available functions"

described in the manuals issued by the machine manufacturers have precedence

to those in this manual.

(2) This manual describes as many special operations as possible, but it should be

kept in mind that items not mentioned in this manual cannot be performed.

Page 4

Precautions for safety

Please read this manual and auxiliary documents before starting installation, operation,

maintenance or inspection to ensure correct usage. Thoroughly understand the device, safety

information and precautions before starting operation.

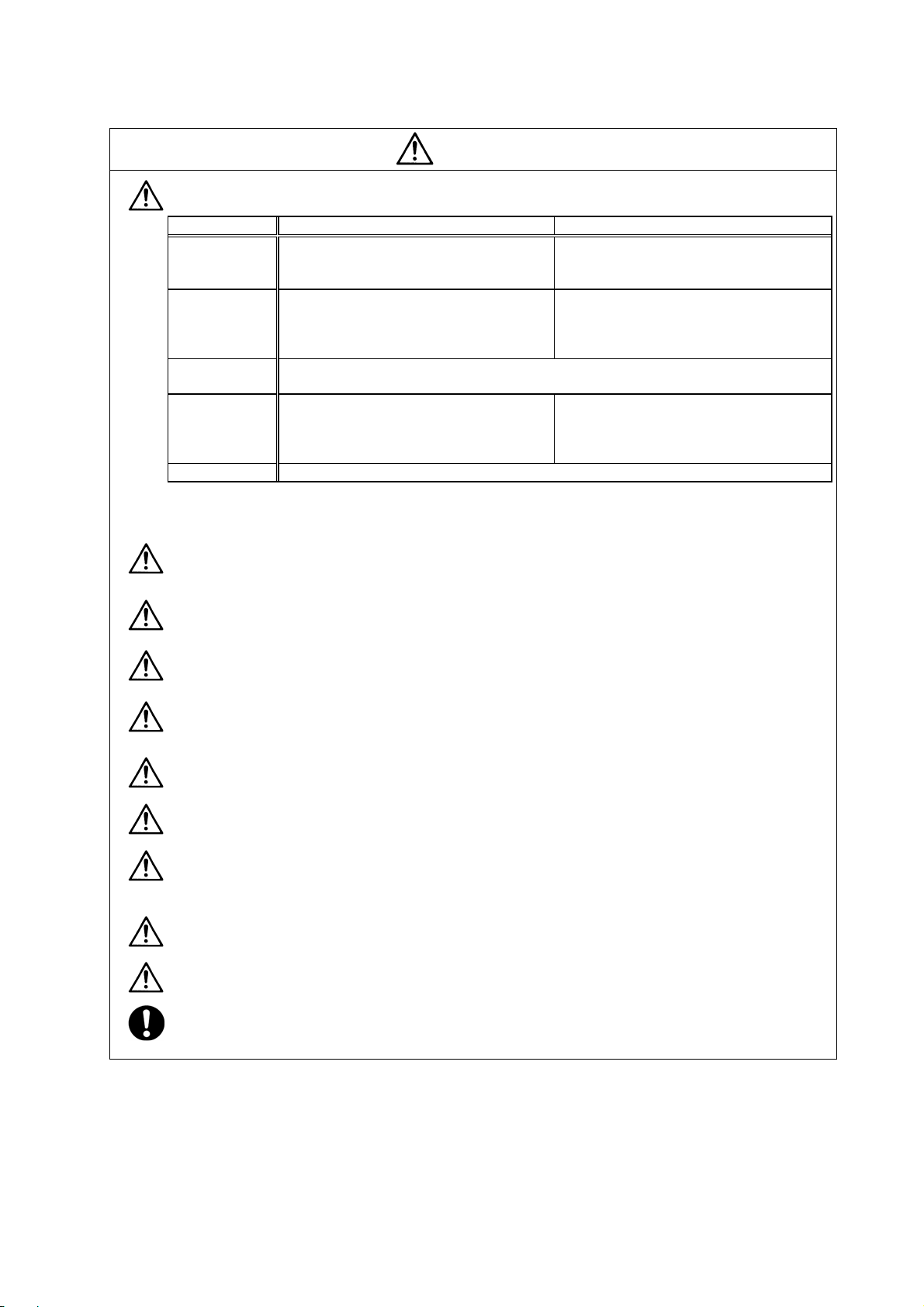

The safety precautions in this instruction manual are ranked as "WARNING" and "CAUTION".

Note that some items described as

the situation. In any case, important information that must be observed is described.

The signs indicating prohibited and mandatory matters are explained below.

DANGER

WARNING

CAUTION

When there is a potential risk of fatal or serious injuries if

handling is mistaken.

When a dangerous situation, or fatal or serious injuries may

occur if handling is mistaken.

When a dangerous situation may occur if handling is mistaken

leading to medium or minor injuries, or physical damage.

CAUTION

may lead to major results depending on

Indicates a prohibited matter. For example, "Fire Prohibited"

is indicated as .

Indicates a mandatory matter. For example, grounding is

indicated as

.

After reading this specifications and instructions manual, store it where the user can access it

easily for reference.

The numeric control unit is configured of the control unit, operation board, servo drive unit,

spindle drive unit, power supply, servomotor and spindle motor, etc.

In this section "Precautions for safety", the following items are generically called the "motor".

• Servomotor

• Linear servomotor

• Spindle motor

In this section "Precautions for safety", the following items are generically called the "unit".

• Servo drive unit

• Spindle drive unit

• Power supply unit

• Scale interface unit

• Magnetic pole detection unit

POINT

Important matters that should be understood for operation of this machine

are indicated as a POINT in this manual.

Page 5

1. Electric shock prevention

Do not open the front cover while the power is ON or during operation. Failure to observe this

could lead to electric shocks.

Do not operate the unit with the front cover removed. The high voltage terminals and charged

sections will be exposed, and can cause electric shocks.

Do not remove the front cover and connector even when the power is OFF unless carrying

out wiring work or periodic inspections. The inside of the units is charged, and can cause

electric shocks.

Since the high voltage is supplied to the main circuit connector while the power is ON or

during operation, do not touch the main circuit connector with an adjustment screwdriver o r

the pen tip. Failure to observe this could lead to electric shocks.

Wait at least 15 minutes after turning the power OFF, confirm that the CHARGE lamp has

gone out, and check the voltage between P and N terminals with a tester, etc., before starting

wiring, maintenance or inspections. Failure to observe this could lead to electric shocks.

Ground the unit and motor following the standards set forth by each country.

Wiring, maintenance and inspection work must be done by a qualified technician.

Wire the servo drive unit and servomotor after installation. Failure to observe this could lead to

electric shocks.

Do not touch the switches with wet hands. Failure to observe this could lead to electric shocks.

Do not damage, apply forcible stress, place heavy items on the cables or get them caught.

Failure to observe this could lead to electric shocks.

WARNING

2. Injury prevention

The linear servomotor uses a powerful magnet on the secondary side, and could adversely

affect pacemakers, etc.

During installation and operation of the machine, do not place portable items that could

malfunction or fail due to the influence of the linear servomotor's magnetic force.

Take special care not to pinch fingers, etc., when installing (and unpacking) the linear

servomotor.

In the system where the optical communication with CNC is executed, do not see directly the

light generated from CN1A/CN1B connector of drive unit or the end of cable. When the light

gets into eye, you may feel something is wrong for eye.

(The light source of optical communication corresponds to class1 defined in JIS C68 02 or

IEC60825-1.)

Page 6

1. Fire prevention

Install the units, motors and regenerative resistor on non-combustible material. Direct

installation on combustible material or near combustible materials could lead to fires.

Always install a circuit protector and contactor on the servo drive unit power input as explained

in this manual. Refer to this manual and select the correct circuit protector and contactor. An

incorrect selection could result in fire.

Shut off the power on the unit side if a fault occurs in the units. Fires could be caused if a large

current continues to flow.

When using a regenerative resistor, provide a sequence that shuts off the power with the

regenerative resistor's error signal. The regenerative resistor could abnormally overheat and

cause a fire due to a fault in the regenerative transistor, etc.

The battery unit could heat up, ignite or rupture if submerged in water, or if the poles are

incorrectly wired.

Cut off the main circuit power with the contactor when an alarm or emergency stop occurs.

2. Injury prevention

Do not apply a voltage other than that specified in this manual, on each terminal. Failure to

observe this item could lead to ruptures or damage, etc.

CAUTION

Do not mistake the terminal connections. Failure to observe this item could lead to ruptures or

damage, etc.

Do not mistake the polarity (

damage, etc.

Do not touch the radiation fin on unit back face, regenerative resistor or motor, etc., or place

parts (cables, etc.) while the power is turned ON or immediately after turning the power OFF.

These parts may reach high temperatures, and can cause burns or part damage.

Structure the cooling fan on the unit back face, etc., etc so that it cannot be touched after

installation. Touching the cooling fan during operation could lead to injuries.

+

,

). Failure to observe this item could lead to ruptures or

Page 7

CAUTION

3. Various precautions

Observe the following precautions. Incorrect handling of the unit could lead to faults, injuries and

electric shocks, etc.

(1) Transportation and installation

Correctly transport the product according to its weight.

Use the motor's hanging bolts only when transporting the motor. Do not transport the

machine when the motor is installed on the machine.

Do not stack the products above the tolerable number.

Follow this manual and install the unit or motor in a place where the weight can be borne.

Do not get on top of or place heavy objects on the unit.

Do not hold the cables, axis or detector when transporting the motor.

Do not hold the connected wires or cables when transporting the units.

Do not hold the front cover when transporting the unit. The unit could drop.

Always observe the installation directions of the units or motors.

Secure the specified distance between the units and control panel, or between the servo drive

unit and other devices.

Do not install or run a unit or motor that is damaged or missing parts.

Do not block the intake or exhaust ports of the motor provided with a cooling fan.

Do not let foreign objects enter the units or motors. In particular, if conductive objects such as

screws or metal chips, etc., or combustible materials such as oil enter, rupture or breakage

could occur.

The units and motors are precision devices, so do not drop them or apply strong impacts to

them.

Page 8

CAUTION

Store and use the units under the following environment conditions.

Environment

Ambient

temperature

Ambient

humidity

Atmosphere

Altitude

Vibration/impact

(Note 1) For details, confirm each unit or motor specifications in addition.

(Note 2) -15°C to 55°C for linear servomotor.

Operation: 0 to 55°C (with no freezing),

Storage / Transportation: -15°C to 70°C

Operation: 90%RH or less

(with no dew condensation)

Storage / Transportation: 90%RH or less

(with no dew condensation)

With no corrosive gas, inflammable gas, oil mist, dust or conductive fine particles

Operation/Storage: 1000 meters or less above

Transportation: 13000 meters or less above sea

Unit Motor

(with no freezing)

sea level,

level

According to each unit or motor specification

Operation: 0 to 40°C (with no freezing),

Storage: -15°C to 70°C

Operation: 80%RH or less

(with no dew condensation),

Storage: 90%RH or less

(with no dew condensation)

Indoors (no direct sunlight)

Operation: 1000 meters or less above sea level,

Storage: 10000 meters or less above sea level

(Note 2)

(with no freezing)

Securely fix the servomotor to the machine. Insufficient fixing could lead to the servomotor

slipping off during operation.

Always install the servomotor with reduction gear in the designated direction. Failure to do so

could lead to oil leaks.

Structure the rotary sections of the motor so that it can never be touched during operation.

Install a cover, etc., on the shaft.

When installing a coupling to a servomotor shaft end, do not apply an impact by hammering,

etc. The detector could be damaged.

Do not apply a load exceeding the tolerable load onto the servomotor shaft. The shaft could

break.

Store the motor in the package box.

When inserting the shaft into the built-in IPM motor, do not heat the rotor higher than 130°C.

The magnet could be demagnetized, and the specifications characteristics will not be

ensured.

Always use a nonmagnetic tool (explosion-proof beryllium copper alloy safety tool: NGK

Insulators, etc.) when installing the linear servomotor.

Always provide a mechanical stopper on the end of the linear servomotor's travel path.

If the unit has been stored for a long time, always check the operation before starting actual

operation. Please contact the Service Center, Service Station, Sales Office or delayer.

Page 9

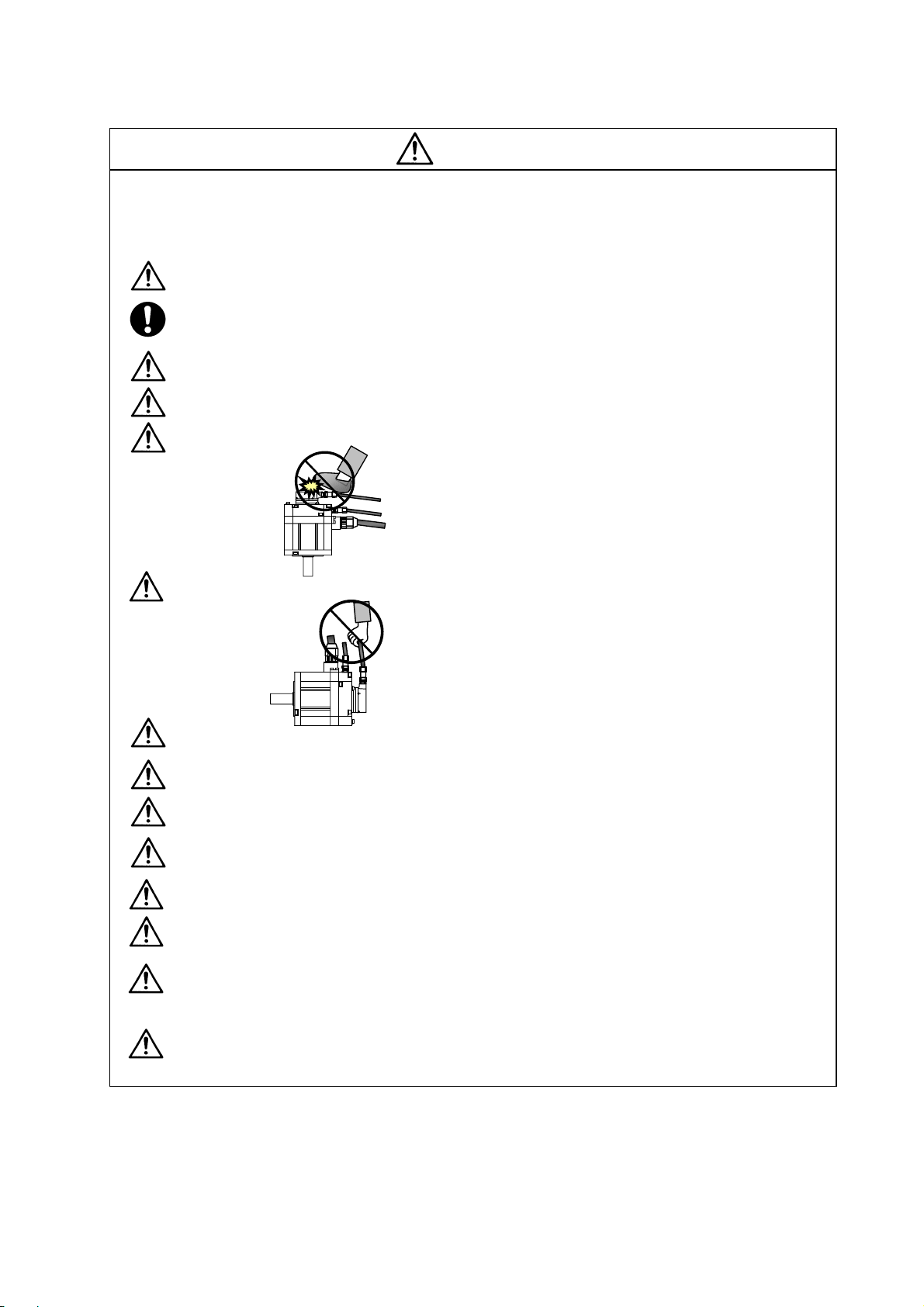

(2) Wiring

CAUTION

Correctly and securely perform the wiring. Failure to do so could lead to abnormal operation of

the motor.

Do not install a condensing capacitor, surge absorber or radio noise filter on the output side of

the drive unit.

Correctly connect the output side of the drive unit (terminals U, V, W). Failure to do so could

lead to abnormal operation of the motor.

When using a power regenerative power supply unit, always install an AC reactor for each

power supply unit.

In the main circuit power supply side of the unit, always install an appropriate circuit pro tector

or contactor for each unit. Circuit protector or contactor cannot be shared by several units.

Always connect the motor to the drive unit's output terminals (U, V, W).

Do not directly connect a commercial power supply to the servomotor. Failure to observe this

could result in a fault.

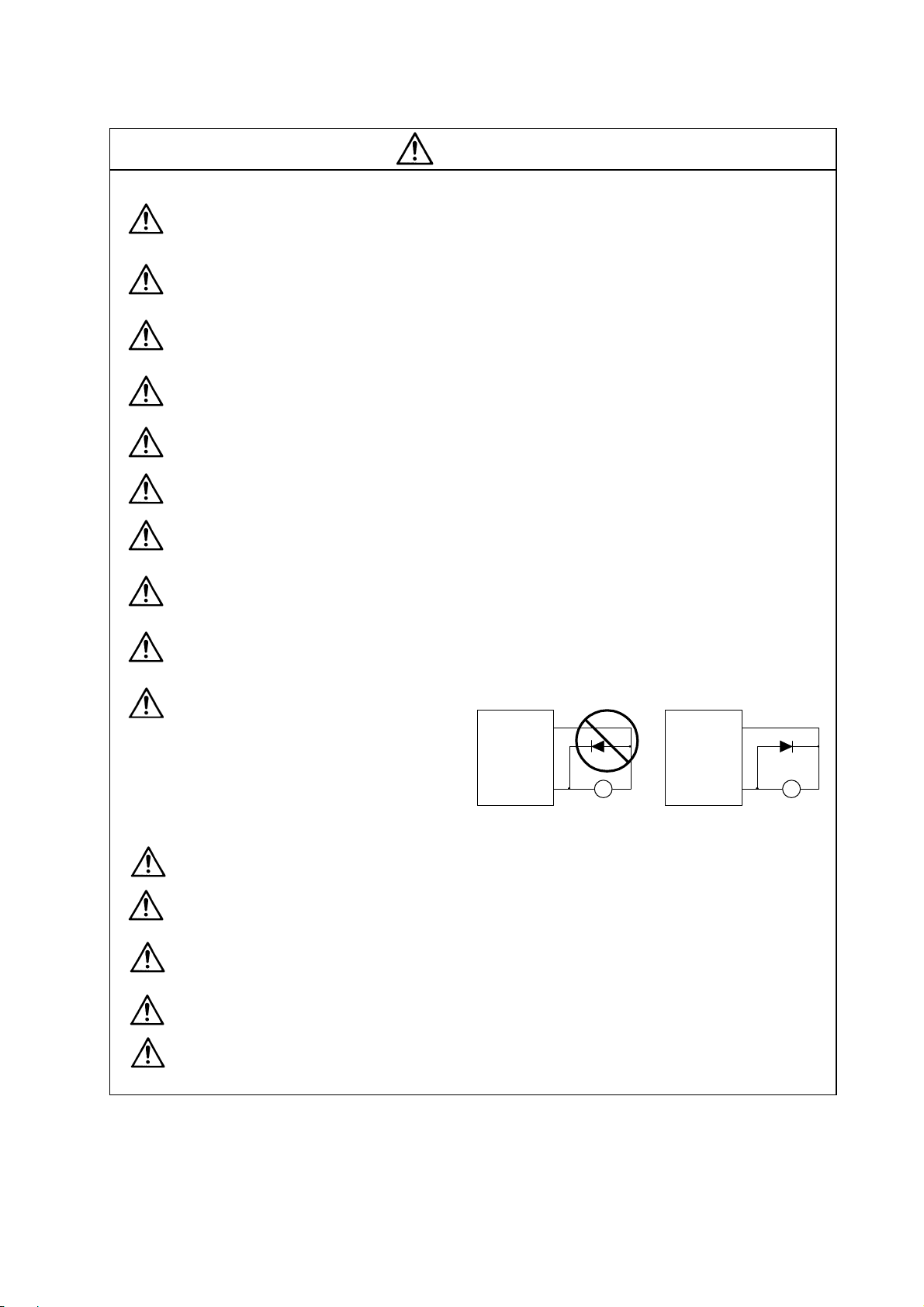

When using an inductive load such as a relay, always connect a diode as a noise measure

parallel to the load.

When using a capacitance load such as a lamp, always connect a protective resistor as a noise

measure serial to the load.

Do not reverse the direction of a diode

which connect to a DC relay for the

control output signals such as

Servodrive unit

COM

(24VDC)

Servodrive unit

COM

(24VDC)

contractor and motor brake output, etc.

to suppress a surge. Connecting it

backwards could cause the drive unit to

malfunction so that signals are not

Controloutput

signal

RA

Control output

signal

output, and emergency stop and other

safety circuits are inoperable.

RA

Do not connect/disconnect the cables connected between the units while the power is ON.

Securely tighten the cable connector fixing screw or fixing mechanism. An insecure fixing could

cause the cable to fall off while the power is ON.

When using a shielded cable instructed in the instruction manual, always ground the cable with

a cable clamp, etc.

Always separate the signals wires from the drive wire and power line.

Use wires and cables that have a wire diameter, heat resistance and flexibility that conforms to

the system.

Page 10

(3) Trial operation and adjustment

Check and adjust each program and parameter before starting operation. Failure to do so could

lead to unforeseen operation of the machine.

Do not make remarkable adjustments and changes of paramete r a s the ope ration could

become unstable.

The usable motor and unit combination is predetermined. Always check the models before

starting trial operation.

If the axis is unbalanced due to gravity, etc., balance the axis using a counterbalance, etc.

The linear servomotor does not have a stopping device such as magnetic brakes. Install a

stopping device on the machine side.

(4) Usage methods

In abnormal state, install an external emergency stop circuit so that the operation can be

stopped and power shut off immediately.

Turn the power OFF immediately if smoke, abnormal noise or odors are generated from the unit

or motor.

CAUTION

Do not disassemble or repair this product.

Never make modifications.

When an alarm occurs, the machine will start suddenly if an alarm reset (RST) is carried out

while an operation start signal (ST) is being input. Always confirm that the operation signal is

OFF before carrying out an alarm reset. Failure to do so could lead to accidents or injuries.

Reduce magnetic damage by installing a noise filter. The electronic devices used near the

unit could be affected by magnetic noise. Install a line noise filter, etc., if there is a risk of

magnetic noise.

Use the unit, motor and regenerative resistor with the designated combination. Failure to do so

could lead to fires or trouble.

The brake (magnetic brake) of the servomotor are for holding, and must not be used for normal

braking.

There may be cases when holding is not possible due to the magnetic brake's life, the machine

construction (when ball screw and servomotor are coupled via a timing belt, etc.) or the

magnetic brake’s failure. Install a stop device to ensure safety on the machine side.

After changing the programs/parameters or after maintenance and inspection, always test the

operation before starting actual operation.

Do not enter the movable range of the machine during automatic operation. Never place body

parts near or touch the spindle during rotation.

Follow the power supply specification conditions given in each specification for the power (input

voltage, input frequency, tolerable sudden power failure time, etc.).

Set all bits to "0" if they are indicated as not used or empty in the explanation on the bits.

Do not use the dynamic brakes except during the emergency stop. Continued use of the

dynamic brakes could result in brake damage.

If a circuit protector for the main circuit power supply is shared by several units, the circuit

protector may not activate when a short-circuit fault occurs in a small capacity unit. This is

dangerous, so never share the circuit protector.

Page 11

(5) Troubleshooting

If a hazardous situation is predicted during power failure or product trouble, use a servomotor

with magnetic brakes or install an external brake mechanism.

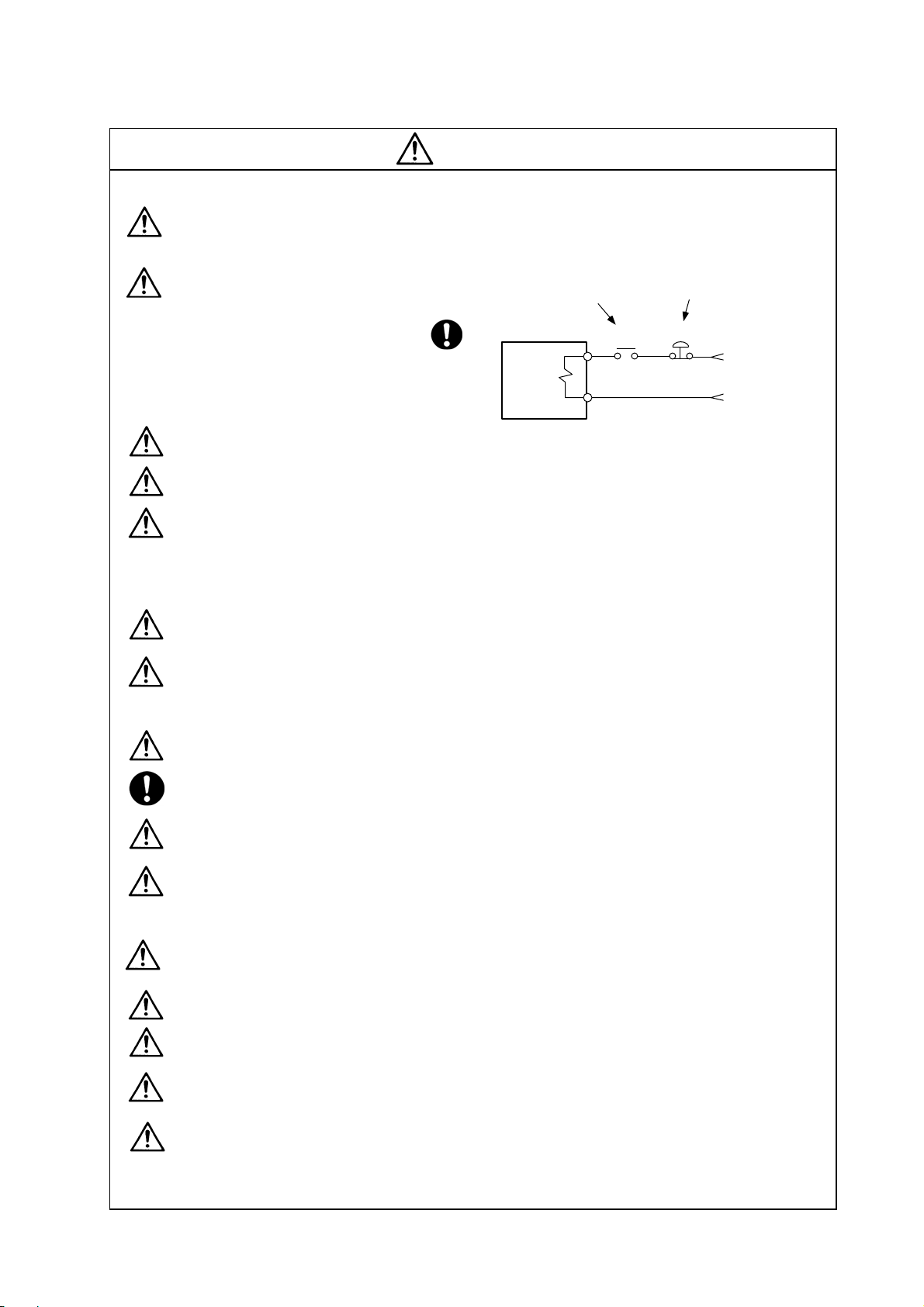

Use a double circuit configuration

that allows the operation circuit for

the magnetic brakes to be operated

even by the external emergency

stop signal.

CAUTION

Shut off with the servomotor

brake control output.

Servomotor

Magnetic

brake

Shut off with NC brake

control PLC output.

MBR

EMG

24VDC

Always turn the input power OFF when an alarm occurs.

If an alarm occurs, remove the cause, and secure the safety before resetting the alarm.

Never go near the machine after restoring the power after a power failure, as the machine

could start suddenly. (Design the machine so that personal safety can be ensured even if the

machine starts suddenly.)

(6) Maintenance, inspection and part replacement

Always backup the programs and parameters before starting maintenance or i nspections.

The capacity of the electrolytic capacitor will drop over time due to self-discharging, etc. To

prevent secondary disasters due to failures, replacing this part every five years when used

under a normal environment is recommended. Contact the Service Center, Service Station,

Sales Office or delayer for repairs or part replacement.

Do not perform a megger test (insulation resistance measurement) during inspections.

If the battery low warning is issued, back up the machining programs, tool data and

parameters with an input/output unit, and then replace the battery.

Do not short circuit, charge, overheat, incinerate or disassemble the battery.

The heat radiating fin used in some units contains substitute Freon as the refrigerant.Ta ke

care not to damage the heat radiating fin during maintenance and replacement work.

(7) Disposal

Do not dispose of this type of unit as general industrial waste. Always contact the Service

Center, Service Station, Sales Office or delayer for repairs or part replacement.

Do not disassemble the unit or motor.

Dispose of the battery according to local laws.

Always return the secondary side (magnet side) of the linear servomotor to the Service

Center or Service Station.

When incinerating optical communication cable, hydrogen fluoride gas or hydrogen chloride

gas which is corrosive and harmful may be generated. For disposal of optical communication

cable, request for specialized industrial waste disposal services that has incineration facility

for disposing hydrogen fluoride gas or hydrogen chloride gas.

Page 12

CAUTION

(8) Transportation

The unit and motor are precision parts and must be handled carefully.

According to a United Nations Advisory, the battery unit and battery must be transported

according to the rules set forth by the International Civil Aviation Organization (ICAO),

International Air Transportation Association (IATA), International Maritime Organization

(IMO), and United States Department of Transportation (DOT), etc.

(9) General precautions

The drawings given in this manual show the covers and safety partitions, etc., removed to provide a

clearer explanation. Always return the covers or partitions to their respective places before starting

operation, and always follow the instructions given in this manual.

Page 13

○ Treatment of waste ○

The following two laws will apply when disposing of this product. Considerations must be made to each

law. The following laws are in effect in Japan. Thus, when using this product overseas, the local laws will

have a priority. If necessary, indicate or notify these laws to the final user of the product.

1. Requirements for "Law for Promotion of Effective Utilization of Resources"

(1) Recycle as much of this product as possible when finished with use.

(2) When recycling, often parts are sorted into steel scraps and electric parts, etc., and sold to scrap

contractors. Mitsubishi recommends sorting the product and selling the members to appropriate

contractors.

2. Requirements for "Law for Treatment of Waste and Cleaning"

(1) Mitsubishi recommends recycling and selling the product when no longer needed according to

item (1) above. The user should make an effort to reduce waste in this manner.

(2) When disposing a product that cannot be resold, it shall be treat ed as a waste product.

(3) The treatment of industrial waste must be commissioned to a licensed industrial waste treatment

contractor, and appropriate measures, including a manifest control, must be taken.

(4) Batteries correspond to "primary batteries", and must be dispos ed of according to local disposal

laws.

Page 14

CONTENTS

1. Introduction

1-1 Servo/spindle drive system configuration............................................................................ 1-2

1-1-1 System configuration .....................................................................................................1-2

1-2 Explanation of type ..............................................................................................................1-3

1-2-1 Servomotor type ............................................................................................................ 1-3

1-2-2 Servo drive unit type...................................................................................................... 1-5

1-2-3 Spindle motor type......................................................................................................... 1-6

1-2-4 Spindle drive unit type ................................................................................................... 1-7

1-2-5 Power supply unit type .................................................................................................. 1-8

1-2-6 AC reactor type.............................................................................................................. 1-9

2. Specifications

2-1 Servomotor........................................................................................................................... 2-2

2-1-1 Specifications list ........................................................................................................... 2-2

2-1-2 Torque characteristics ...................................................................................................2-5

2-2 Spindle motor....................................................................................................................... 2-8

2-2-1 Specifications................................................................................................................. 2-8

2-2-2 Output characteristics.................................................................................................. 2-12

2-3 Drive unit ............................................................................................................................2-16

2-3-1 Installation environment conditions ............................................................................. 2-16

2-3-2 Servo drive unit............................................................................................................ 2-16

2-3-3 Spindle drive unit ...................................................................................................... ...2-17

2-3-4 Power supply unit ........................................................................................................ 2-17

2-3-5 AC reactor .................................................................................................................... 2-18

2-3-6 D/A output specifications for servo drive unit.............................................................. 2-19

2-3-7 D/A output specifications for spindle drive unit ...........................................................2-22

2-3-8 Explanation of each part.............................................................................................. 2-25

3. Characteristics

3-1 Servomotor........................................................................................................................... 3-2

3-1-1 Environmental conditions .............................................................................................. 3-2

3-1-2 Quakeproof level............................................................................................................ 3-2

3-1-3 Shaft characteristics ...................................................................................................... 3-3

3-1-4 Oil / water standards...................................................................................................... 3-4

3-1-5 Magnetic brake .............................................................................................................. 3-5

3-1-6 Dynamic brake characteristics ...................................................................................... 3-8

3-2 Spindle motor..................................................................................................................... 3-10

3-2-1 Environmental conditions ............................................................................................ 3-10

3-2-2 Shaft characteristics .................................................................................................... 3-10

3-3 Drive unit characteristics.................................................................................................... 3-11

3-3-1 Environmental conditions ............................................................................................ 3-11

3-3-2 Heating value............................................................................................................... 3-12

3-3-3 Overload protection characteristics............................................................................. 3-13

3-3-4 Drive unti arrangement ................................................................................................ 3-21

4. Dedicated options

4-1 Servo options ....................................................................................................................... 4-2

4-1-1 Dynamic brake unit (MDS-D-DBU) (mandatory selection for large capacity).............. 4-5

4-1-2 Battery option (MDS-A-BT, FCU6-BTBOX-36, ER6V-C119B, A6BAT)....................... 4-7

4-1-3 Ball screw side detector (OSA105-ET2, OSA166-ET2) ............................................. 4-15

4-1-4 Machine side detector ................................................................................................. 4-17

Page 15

4-2 Spindle options .................................................................................................................. 4-21

4-2-1 Spindle side detector (OSE-1024-3-15-68, OSE-1024-3-15-68-8)............................ 4-22

4-2-2 C axis detector (HEIDENHAIN ERM280) ................................................................... 4-24

4-3 Detector interface unit........................................................................................................ 4-26

4-3-1 MDS-B-HR................................................................................................................... 4-26

4-3-2 APE391M..................................................................................................................... 4-28

4-3-3 MJ831 .......................................................................................................................... 4-29

4-3-4 MDS-B-SD (Signal divided unit).................................................................................. 4-30

4-4 Drive unit option................................................................................................................. 4-32

4-4-1 DC connection bar....................................................................................................... 4-32

4-4-2 Side face protection cover........................................................................................... 4-33

4-5 Cables and connectors...................................................................................................... 4-34

4-5-1 Cable connection diagram........................................................................................... 4-34

4-5-2 List of cables and connectors...................................................................................... 4-35

4-5-3 Optical communication cable specifications ............................................................... 4-40

5. Selection of peripheral devices

5-1 Selection of wire................................................................................................................... 5-2

5-1-1 Example of wires by unit................................................................................................ 5-2

5-2 Selection of circuit protector and contactor ......................................................................... 5-5

5-2-1 Selection of circuit protector ..........................................................................................5-5

5-2-2 Selection of contactor.................................................................................................... 5-6

5-3 Selection of earth leakage breaker...................................................................................... 5-7

5-4 Branch-circuit protection (for control power supply)............................................................ 5-8

5-4-1 Circuit protection............................................................................................................ 5-8

5-4-2 Fuse protection ..............................................................................................................5-8

5-5 Noise filter ............................................................................................................................ 5-9

5-6 Surge absorber .................................................................................................................. 5-10

5-7 Relay .................................................................................................................................. 5-11

Appendix 1. Outline dimension drawings

Appendix 1-1 Outline dimension drawings of servomotor.......................................................A1-2

Appendix 1-1-1 HF-H motor..................................................................................................A1-2

Appendix 1-1-2 HP-H motor................................................................................................A1-11

Appendix 1-1-3 HC-H motor ...............................................................................................A1-16

Appendix 1-2 Outline dimension drawings of spindle motor.................................................A1-17

Appendix 1-3 Outline dimension drawings of unit.................................................................A1-29

Appendix 1-3-1 Servo drive unit..........................................................................................A1-29

Appendix 1-3-2 Spindle drive unit.......................................................................................A1-36

Appendix 1-3-3 Power supply unit ......................................................................................A1-42

Appendix 1-3-4 Installation position of drive unit cooling fan.............................................A1-45

Appendix 1-3-5 AC reactor .................................................................................................A1-47

Appendix 2. Cable and Connector Specifications

Appendix 2-1 Selection of cable ..............................................................................................A2-2

Appendix 2-1-1 Cable wire and assembly............................................................................A2-2

Appendix 2-2 Cable connection diagram.................................................................................A2-4

Appendix 2-3 Main circuit cable connection diagram............................................................A2-14

Appendix 2-4 Connector outline dimension drawings...........................................................A2-15

Appendix 2-5 Cable and connector assembly.......................................................................A2-27

Appendix 2-5-1 CM10-SP**S plug connector.....................................................................A2-27

Appendix 2-5-2 CM10-AP**S Angle Plug Connector.........................................................A2-34

Page 16

Appendix 3. Selection

Appendix 3-1 Selection of the servomotor series....................................................................A3-2

Appendix 3-1-1 Motor series characteristics ........................................................................ A3-2

Appendix 3-1-2 Servomotor precision ..................................................................................A3-2

Appendix 3-1-3 Selection of servomotor capacity................................................................A3-3

Appendix 3-1-4 Motor shaft conversion load torque.............................................................A3-6

Appendix 3-1-5 Expressions for load inertia calculation.......................................................A3-7

Appendix 3-2 Selection of the power supply unit ....................................................................A3-8

Appendix 3-2-1 Calculation of spindle output.......................................................................A3-8

Appendix 3-2-2 Calculation of servo motor output...............................................................A3-9

Appendix 3-2-3 Selection of the power supply unit............................................................A3-10

Appendix 3-2-4 Required capacity of power supply...........................................................A3-11

Appendix 3-2-5 Example for power supply unit and power supply facility capacity...........A3-12

Appendix 4. Transportation Restrictions for Lithium Batteries

Appendix 4-1 Restriction for packing.......................................................................................A4-2

Appendix 4-1-1 Target products ...........................................................................................A4-2

Appendix 4-1-2 Handling by user .........................................................................................A4-3

Appendix 4-1-3 Reference....................................................................................................A4-4

Appendix 4-2 Issuing domestic law of the United State for primary lithium battery

transportation ....................................................................................................A4-5

Appendix 4-2-1 Outline of regulation ....................................................................................A4-5

Appendix 4-2-2 Target products ...........................................................................................A4-5

Appendix 4-2-3 Handling by user .........................................................................................A4-5

Appendix 4-2-4 Reference....................................................................................................A4-5

Appendix 4-3 Example of hazardous goods declaration list...................................................A4-6

Appendix 5. Compliance to EC Directives

Appendix 5-1 Compliance to EC Directives ............................................................................A5-2

Appendix 5-1-1 European EC Directives..............................................................................A5-2

Appendix 5-1-2 Cautions for EC Directive compliance........................................................A5-2

Appendix 6. EMC Installation Guidelines

Appendix 6-1 Introduction ........................................................................................................A6-2

Appendix 6-2 EMC instructions ...............................................................................................A6-2

Appendix 6-3 EMC measures..................................................................................................A6-3

Appendix 6-4 Measures for panel structure.............................................................................A6-3

Appendix 6-4-1 Measures for control panel unit...................................................................A6-3

Appendix 6-4-2 Measures for door .......................................................................................A6-4

Appendix 6-4-3 Measures for operation board panel...........................................................A6-4

Appendix 6-4-4 Shielding of the power supply input section................................................A6-4

Appendix 6-5 Measures for various cables.............................................................................A6-5

Appendix 6-5-1 Measures for wiring in panel.......................................................................A6-5

Appendix 6-5-2 Measures for shield treatment.....................................................................A6-5

Appendix 6-5-3 Servo/spindle motor power cable................................................................A6-6

Appendix 6-5-4 Servo/spindle motor feedback cable...........................................................A6-7

Appendix 6-6 EMC countermeasure parts ..............................................................................A6-8

Appendix 6-6-1 Shield clamp fitting ......................................................................................A6-8

Appendix 6-6-2 Ferrite core ..................................................................................................A6-9

Appendix 6-6-3 Power line filter..........................................................................................A6-10

Appendix 6-6-4 Surge protector..........................................................................................A6-17

Page 17

Appendix 7. EC Declaration of conformity

Appendix 7-1 Compliance to EC Directives ............................................................................A7-2

Appendix 7-1-1 Low voltage equipment ...............................................................................A7-2

Appendix 7-1-2 EMC Directive (Electromagnetic compatibility).........................................A7-11

Appendix 8. Instruction Manual for Compliance with UL/c-UL Standard

Appendix 8.1 Operation surrounding air ambient temperature...............................................A8-2

Appendix 8.2 Notes for AC servo/spindle system...................................................................A8-2

Appendix 8.2.1 General Precaution......................................................................................A8-2

Appendix 8.2.2 Installation....................................................................................................A8-2

Appendix 8.2.3 Short-circuit ratings......................................................................................A8-2

Appendix 8.2.4 Capacitor discharge time.............................................................................A8-2

Appendix 8.2.5 Peripheral devices .......................................................................................A8-3

Appendix 8.2.6 Field Wiring Reference Table for Input and Output ....................................A8-3

Appendix 8.2.7 Motor Over Load Protection........................................................................A8-4

Appendix 8.2.8 Flange of servo motor..................................................................................A8-4

Appendix 8.2.9 Spindle Drive / Motor Combinations............................................................A8-5

Appendix 8.3 AC Servo/Spindle System Connection..............................................................A8-6

Appendix 8.3.1 MDS-D/DH-V/SP Series..............................................................................A8-6

Appendix 8.3.2 MDS-D-SVJ3/SPJ3 Series ..........................................................................A8-6

Appendix 9. Compliance with China Compulsory Product Certification (CCC Certification)

System

Appendix 9-1 Outline of China Compulsory Product Certification System.............................A9-2

Appendix 9-2 First Catalogue of Products subject to Compulsory Product Certification........A9-2

Appendix 9-3 Precautions for Shipping Products....................................................................A9-3

Appendix 9-4 Application for Exemption..................................................................................A9-4

Appendix 9-5 Mitsubishi NC Product Subject to/Not Subject to CCC Certification................A9-5

Page 18

1. Introduction

1-1 Servo/spindle drive system configuration ..........................................................................................1-2

1-1-1 System configuration...................................................................................................................1-2

1-2 Explanation of type............................................................................................................................. 1-3

1-2-1 Servomotor type..........................................................................................................................1-3

1-2-2 Servo drive unit type.................................................................................................................... 1-5

1-2-3 Spindle motor type ......................................................................................................................1-6

1-2-4 Spindle drive unit type................................................................................................................. 1-7

1-2-5 Power supply unit type................................................................................................................1-8

1-2-6 AC reactor type ...........................................................................................................................1-9

1 - 1

Page 19

t

t

r

A

1. Introduction

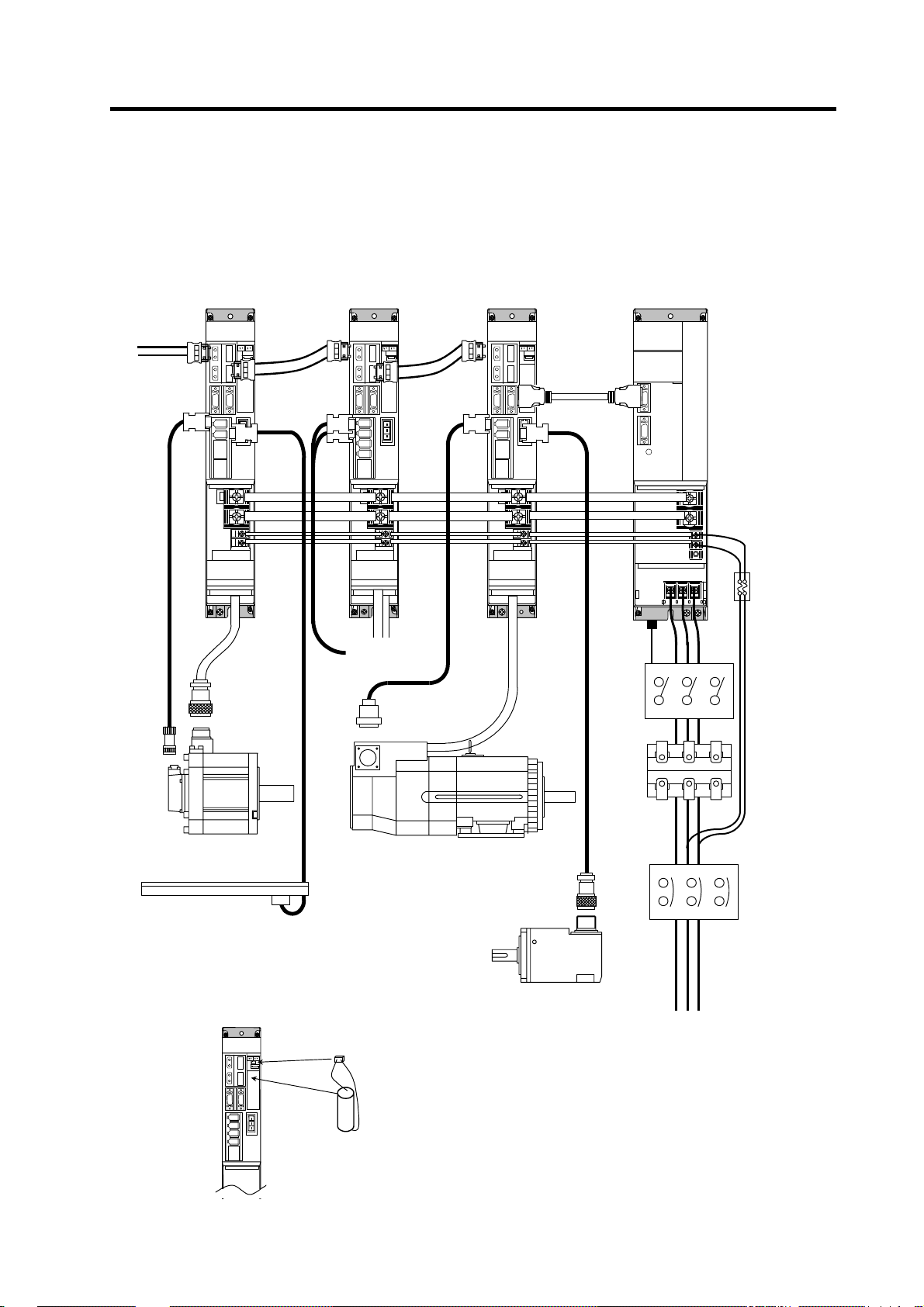

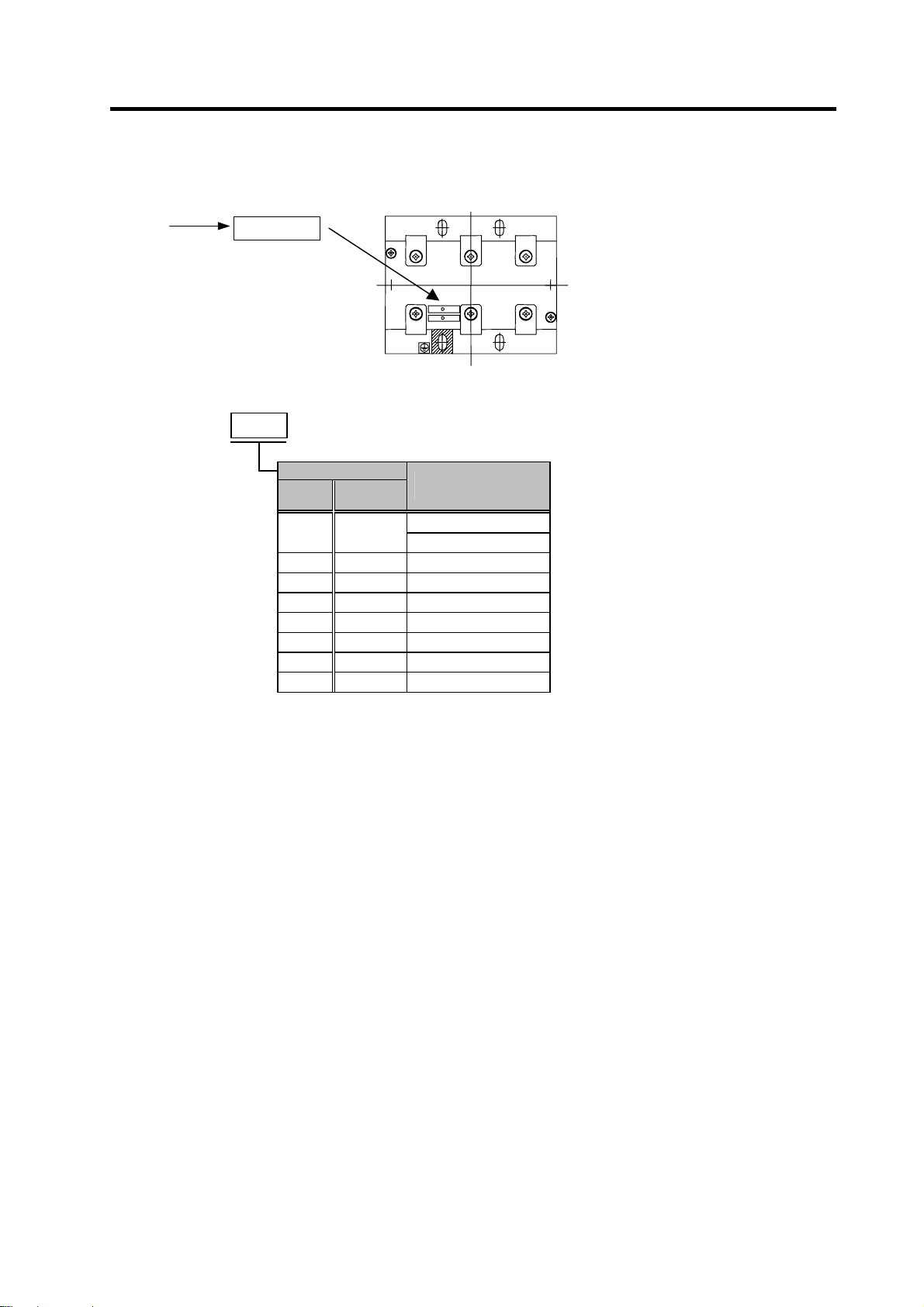

1-1 Servo/spindle drive system configuration

1-1-1 System configuration

1-axis servo drive uni

From NC

L+

L-

(MDS-DH-V1)

2-axis servo drive uni

(MDS-DH-V2)

Spindle drive unit

(MDS-DH-SP)

Power supply unit

(MDS-DH-CV)

To 2nd and 3rd

axis servo

Servomotor Spindle motor

Linear scale

(for full closed control)

(Note) Prepared by user

Cell battery

built in drive unit

(ER6V-C119B)

Spindle side detecto

Circuit protector

or

Protection fuse

(Note)

Prepared by

user

Contactor

(Note)

Prepared by

user

C reactor

(DH-AL)

Circuit protector

(Note)

Prepared by

user

3-phase 400VAC power supply

In addition to the cell bat tery in the above, the

external battery unit (MDS- A-BT) can be also

used.

1 - 2

Page 20

1. Introduction

1-2 Explanation of type

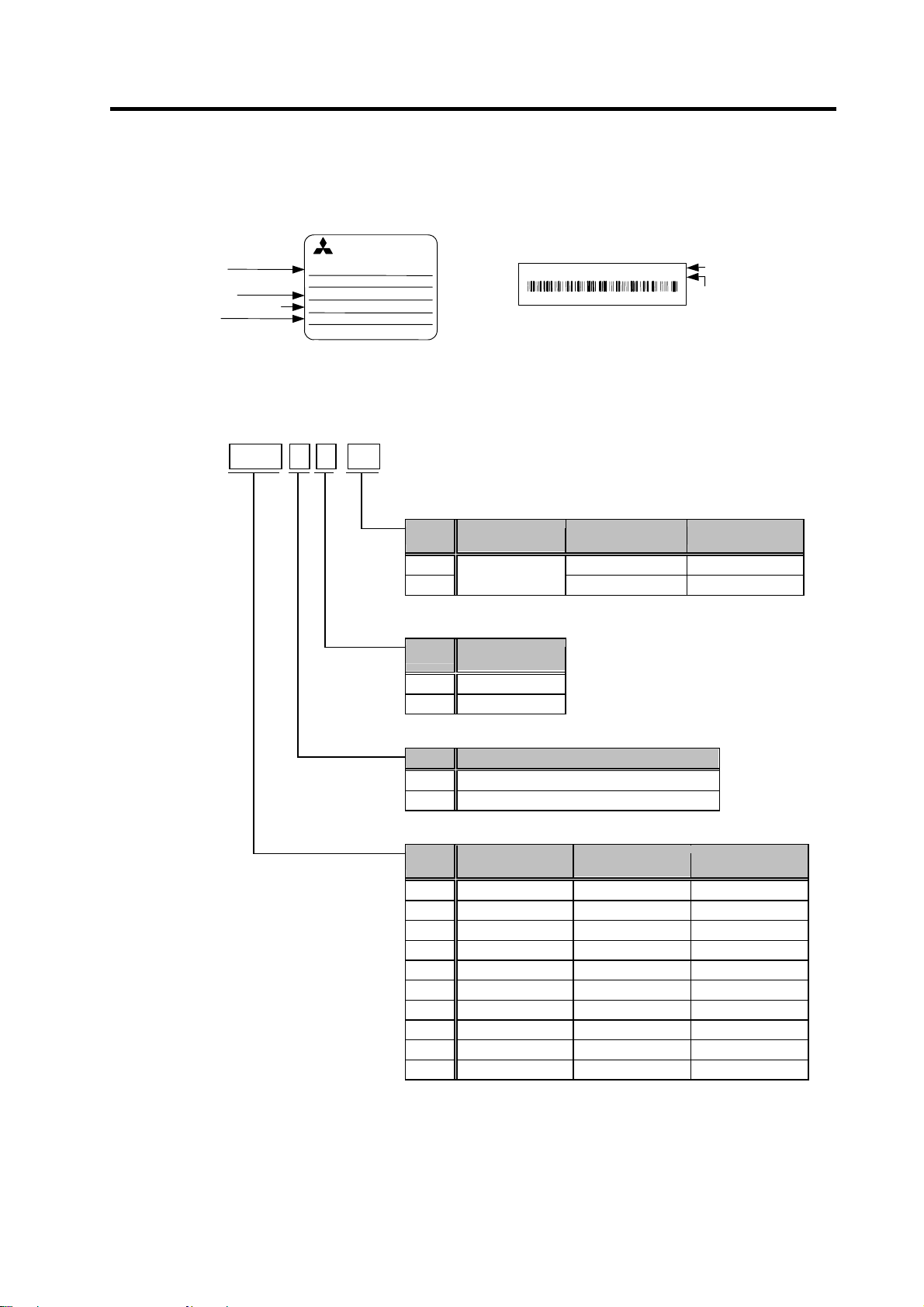

1-2-1 Servomotor type

Motor type

Rated output

Rated rotation speed

Serial No.

(1) HF-H Series

HF-H

(4) Detector

A51 1,000,000 p/rev OSA105S5

A74

(3) Shaft end structure

S Straight

T Taper

(2) Magnetic brakes

None None

B With magnetic brakes

(1) Rated output • Maximum rotation speed

75 0.75 kW 5000 r/min □90 mm

105 1.0 kW 5000 r/min □90 mm

54 0.5 kW 4000 r/min □130 mm

104 1.0 kW 4000 r/min □130 mm

154 1.5 kW 4000 r/min □130 mm

204 2.0 kW 4000 r/min □176 mm

354 3.5 kW 4000 r/min □176 mm

453 4.5 kW 3500 r/min □176 mm

703 7.0 kW 3000 r/min □176 mm

903 9.0 kW 3000 r/min □204 mm

(1) (2) (3) - (4)

MITSUBISHI

AC SERVO MOTOR

HF-HxxxBS

INPUT 3AC 456 V xxx A

x.x

OUTPUT

3000r/min

SER.No.

MITSUBISHI ELECTRIC

MADE IN JAPAN

kW

IP65 CI.F xx kg

xxxxxxxx*

IEC34-1 1994

DATE

04-1

00395298-01

Motor rating nameplate

Symbol

Symbol

Symbol

Symbol Rated output

ROTARY DETECTOR OSA166S5

SER. X X X X X X X X X X X DATE 0401

A2

Detector rating nameplate

Detection

method

Absolute position

Shaft end

structure

Magnetic brakes

Detector type

MITSUBISHI ELECTRIC CORP.

MADE IN JAPAN

Serial No.

D

Resolution Detector type

16,000,000 p/rev OSA166S5

(Note)

"Taper" is available for the motor whose

flange size is □90mm or □130mm.

Maximum rotation

speed

Flange size

1 - 3

Page 21

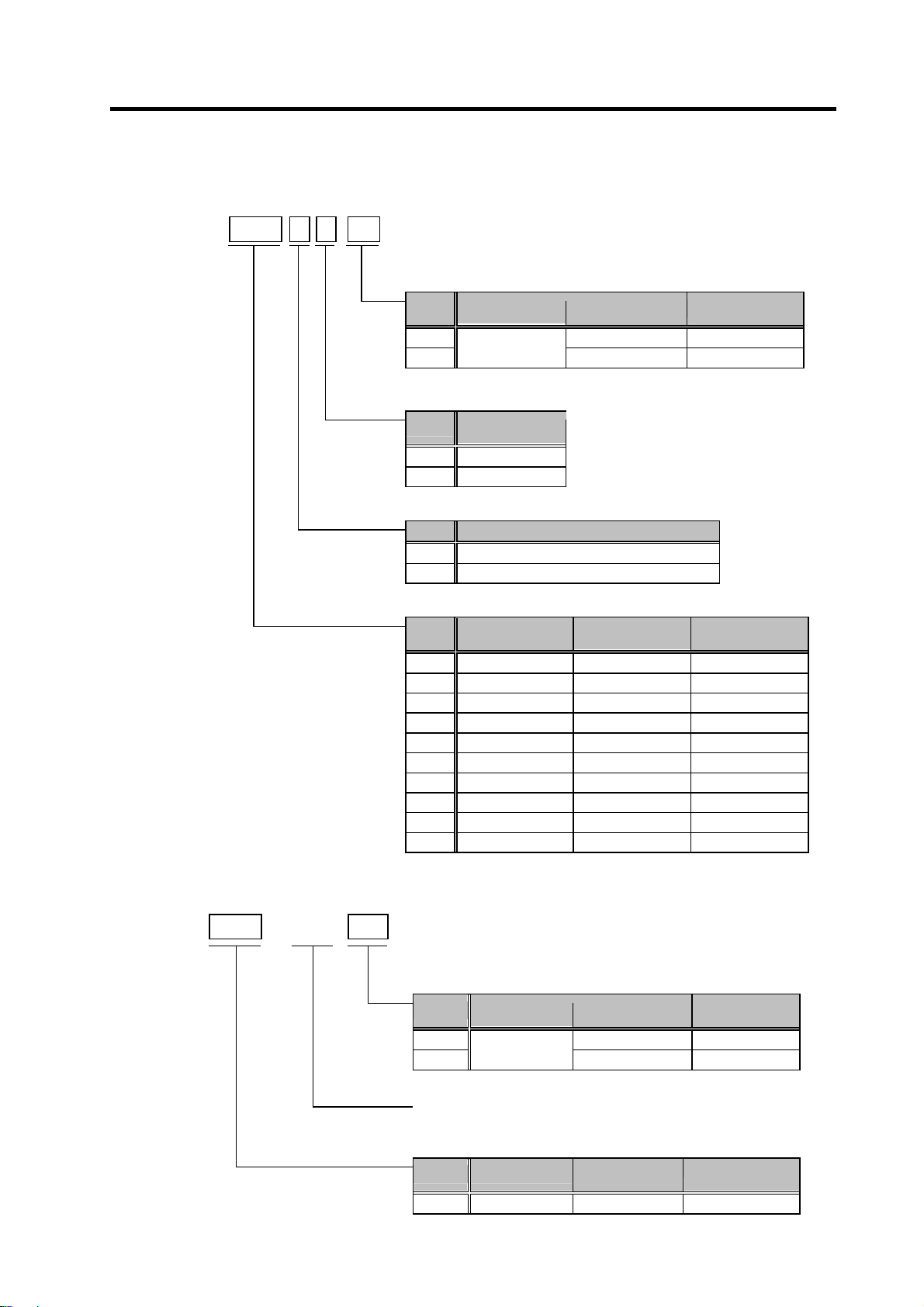

1. Introduction

(2) HP-H Series

HP-H

(4) Detector

A51 1,000,000 p/rev OSA105S5

A74

(3) Shaft end structure

S Straight

T Taper

(2) Magnetic brakes

None None

B With magnetic brakes

(1) Rated output • Maximum rotation speed

54 0.5 kW 4000 r/min □130 mm

104 1.0 kW 4000 r/min □130 mm

154 1.5 kW 4000 r/min □130 mm

224 2.2 kW 4000 r/min □130 mm

204 2.0 kW 4000 r/min □180 mm

354 3.5 kW 4000 r/min □180 mm

454 4.5 kW 4000 r/min □180 mm

704 7.0 kW 4000 r/min □180 mm

903 9.0 kW 3000 r/min □220 mm

1103 11.0 kW 3000 r/min □220 mm

(1) (2) (3) - (4)

Symbol

Symbol

Symbol

Symbol Rated output

Detection

method

Absolute position

Shaft end

structure

Magnetic brakes

Resolution Detector type

16,000,000 p/rev OSA166S5

(Note)

"Taper" is available for the motor whose

flange size is □130mm.

Maximum rotation

speed

Flange size

(3) HC-H Series

HC-H

(2) Detector

A51 1,000,000p/rev OSA105S5

A74

(1) Rated output • Maximum rotation speed

1502 15.0kW 2500r/min □280 mm

(1)

S- S10 -

(2)

Symbol

Compatible with DH series

Symbol Rated output

Detection

method

Absolute

position

1 - 4

Resolution Detector type

16,000,000p/rev OSA166S5

Maximum

rotation speed

Flange size

Page 22

1. Introduction

1-2-2 Servo drive unit type

Output

Applicable standard

Software No.

Serial No.

MDS-DH-

(1) Type

MDS-DH-

V1-10 10A

V1-20 20A

V1-40 40A

V1-80 80A

V1-80W 80A 90mm

V1-160 160A 120mm

V1-160W 160A 150mm

V1-200 200A 240mm

1-axis servo drive unit Compatible motor

Nominal

maximum

current

(Note) DC connection bar is required. Always install a large capacity drive unit in the left side of power supply unit, and connect with

DC connection bar.

§ Indicates the compatible motor for each servo drive unit.

2-axis servo drive unit Compatible motor

(1) Type

MDS-DH-

V2-1010 10+10A LM

V2-2010 20+10A

V2-2020 20+20A LM

V2-4020 40+20A

V2-4040 40+40A

V2-8040 80+40A

V2-8080 80+80A

Nominal

maximum

current

§ Indicates the compatible motor for each servo drive unit.

(1)

Unit

width

75 105 54 104 154 204 354 453 703 903 54 104 154 224 204 354 454 704 903 1103 1502S-S10

§ §

60mm

(Note)

Unit width Axis

60mm

90mm

MITSUBISHI

TYPE

POWER 9.0kW

INPUT 6A DC513-648V

0.1A 1PH380-440/380-480V 50/60Hz

OUTPUT 15A 3PH 456V 0-240Hz

EN50178 MANUAL #IB11500002

S/W BND5xxW000A0 H/W VER. *

SERIAL# HVACQFXJK50 DATE 04/01

MITSUBISHI ELECTRIC CORPORATION JAPAN

* H V A C Q F X J K 5 0 % *

Rating nameplate

HF-H HP-H

§ § § §

§ § § § §

75 105 54 104 154 204 354 453 703 903 54 104 154 224 204 354 454 704 903 1103

§ §

L

§ §

M

L

M

LM

L

M

LM

§ §

§ §

§ §

§ §

SERVO DRIVE UNIT

MDS-DH-V1-80

Type

Input/output conditions

Manual No.

§

§

HF-H HP-H

§ §

§ §

§ §

§ §

§ §

§

§

§ §

§ §

§ §

§ §

§ § §

§ § §

§ § §

§ §

§ §

§

HC-H

§

□

CAUTION

The dynamic brake unit (MDS-D-DBU) is required for the MDS-DH-V1-160W or

larger.

1 - 5

Page 23

1. Introduction

1-2-3 Spindle motor type

(1) Standard spindle motor series

MITSUBISHI AC SPINDLE MOTOR

TYPE

SJ-4-V5.5-01T

SI CONT 4 POLE

kW r/min

3.7 1500-6000 25 P OWE R FAC TOR 82 %

2.8 8000 17

S2 30 min S3 50 %

kW r/min

5.5 1500-6000 33

4.1 8000 23 INSULATION CLASS F

A MB TEMP. 0-40ºC

SERIAL

DATE

FRAME D90F WEIGHT 49 kg IP 44

IEC 34-1 1994 SPEC No.RSV00023*

MITSUBISHI ELECTRIC CORPORATION

A (~)

WIND CONNECT

max

MOTOR INPUT (

137 - 162 V

A (~)

AMP INPUT (

max

200-230V 50/60Hz

MADE IN JAPAN

A19103-01

Rating nameplate

3 PHASES

)

~

)

~

U

995291-01

SJ-4-

(1) (2)

(4) Special specifications

None

Z

(3) Specification code

(2) Short time rated output

2.2 2.2 kW

3.7 3.7 kW

5.5 5.5 kW

7.5 7.5 kW

11 11 kW

15 15 kW

18.5 18.5 kW

22 22 kW

26 26 kW

37 37 kW

45 45 kW

55 55 kW

(1) Motor series

VS

-

(3) (4)

T

For MDS-DH motor

Symbol

The SJ-4-V Series is indicated with a specification code (01 to 99).

Symbol

Symbol Motor series

V

Special

specifications

None

High-speed

Short time

rated output

(Note)

For the short time rated output of the wide range

constant output, high-speed and hollow shaft series,

refer to the specifications of each spindle motor.

Compact medium to

large capacity

Hollow shaft

(Note) The built-in spindle motor is available by special order.

1 - 6

Page 24

t

1. Introduction

1-2-4 Spindle drive unit type

Outpu

Applicable standard

Software No.

Serial No.

MDS-DH

(1) Capacity

SP-20 20A

SP-40 40A

SP-80 80A 90mm wide

SP-100 100A 120mm wide

SP-160 160A 150mm wide

SP-200 200A

SP-320 320A

SP-480 480A 300mm wide (Note)

(1)

-

MITSUBISHI

TYPE

POWER 37kW

INPUT 99A DC513-648V

0.1A 1PH380-440/380-480V 50/60Hz

OUTPUT 85A 3PH 340V 0-1167Hz

EN50178 MANUAL #IB1500003

S/W BND5xxW000A0 H/W VER. *

SERIAL# HV A79G06K 0R DATE 04/01

MITSUBISHI ELECTRIC CORPORATION JAPAN

* H V A 7 9 G 0 6 K 0 R G *

Rating nameplate

Symbol

(Note) DC connection bar is required. Always install a large capacity

Nominal maximum

current

drive unit in the left side of power supply unit, and connect with

DC connection bar.

SERVO DRIVE UNIT

MDS-DH-SP-200

Unit width

60mm wide

240mm wide (Note)

Type

Input/output conditions

Manual No.

1 - 7

Page 25

t

1-2-5 Power supply unit type

Outpu

Applicable standard

Software No.

Serial No.

MDS-DH-

CV-110 11.0 kW DH-AL-11K S-N21-AC400V NF63-CW3P-30A

CV-185 18.5 kW

CV-300 30.0 kW DH-AL-30K S-N50-AC400V NF125-CW3P-75A

CV-370 37.0 kW DH-AL-37K NF125-CW3P-100A

CV-450 45.0 kW

CV-550 55.0 kW DH-AL-55K S-N80-AC400V NF250-CW3P-150A

CV-750 75.0 kW

(1)

Power supply unit

(1) Type

MDS-DH-

CV-37

CV-75

(Note 1) This is an optional part, and must be prepared by the user.

(Note 2) When connecting with a large capacity drive unit, DC connection bar is required. Always install

a large capacity drive unit in the left side of power supply unit, and connect with DC connection

bar.

1. Introduction

MITSUBISHI

TYPE

POWER 37kW

INPUT 87A 3PH 380- 440/480V 50/60Hz

0.1A 1PH 380- 440/480V 50/60Hz

OUTPUT 99A DC513-648V

EN50178 MANUAL #IB1500003

S/W BND5xxW000A0 H/W VER. *

SERIAL# HVA3EG1796L DATE 04/01

MITSUBISHI ELECTRIC CORPORATION JAPAN

* H V A 3 E G 1 7 9 6 L M *

Rating nameplate

Rated

output

3.7 kW

7.5 kW

Unit width

Under

development

Under

development

90mm wide

150mm wide

(Note 2)

300mm wide

(Note 2)

SERVO DRIVE UNIT

MDS-DH-CV-450

Type

Input/output conditions

Manual No.

Compatible

AC reactor

DH-AL-7.5K S-N12-AC400V

DH-AL-18.5K S-N25-AC400V NF63-CW3P-50A

DH-AL-45K

DH-AL-75K S-N150-AC400V NF250-CW3P-200A

Compatible

contactor

(Mitsubishi)

(Note 1)

S-N65-AC400V

Compatible

circuit protector

(Mitsubishi)

(Note 1)

NF63-CW3P-10A

NF63-CW3P-20A

NF125-CW3P-125A

1 - 8

Page 26

1-2-6 AC reactor type

Type

DH-AL-

11K 11.0 kW MDS-DH-CV-110

18.5K 18.5 kW MDS-DH-CV-185

30K 30.0 kW MDS-DH-CV-300

37K 37.0 kW MDS-DH-CV-370

45K 45.0 kW MDS-DH-CV-450

55K 55.0 kW MDS-DH-CV-550

75K 75.0 kW MDS-DH-CV-750

DH-AL-18.5K

Nameplate

(1)

Top surf ace of AC reactor

AC reactor

(1) Type

DH-AL-

7.5K 7.5 kW

Capacity

1. Introduction

Compatible power

supply unit

MDS-DH-CV-37

MDS-DH-CV-75

1 - 9

Page 27

2. Specifications

2-1 Servomotor.........................................................................................................................................2-2

2-1-1 Specifications list.........................................................................................................................2-2

2-1-2 Torque characteristics.................................................................................................................2-5

2-2 Spindle motor.....................................................................................................................................2-8

2-2-1 Specifications .............................................................................................................................. 2-8

2-2-2 Output characteristics................................................................................................................2-12

2-3 Drive unit..........................................................................................................................................2-16

2-3-1 Installation environment conditions........................................................................................... 2-16

2-3-2 Servo drive unit .........................................................................................................................2-16

2-3-3 Spindle drive unit.......................................................................................................................2-17

2-3-4 Power supply unit...................................................................................................................... 2-17

2-3-5 AC reactor ................................................................................................................................. 2-18

2-3-6 D/A output specifications for servo drive unit............................................................................2-19

2-3-7 D/A output specifications for spindle drive unit .........................................................................2-22

2-3-8 Explanation of each part............................................................................................................2-25

2 - 1

Page 28

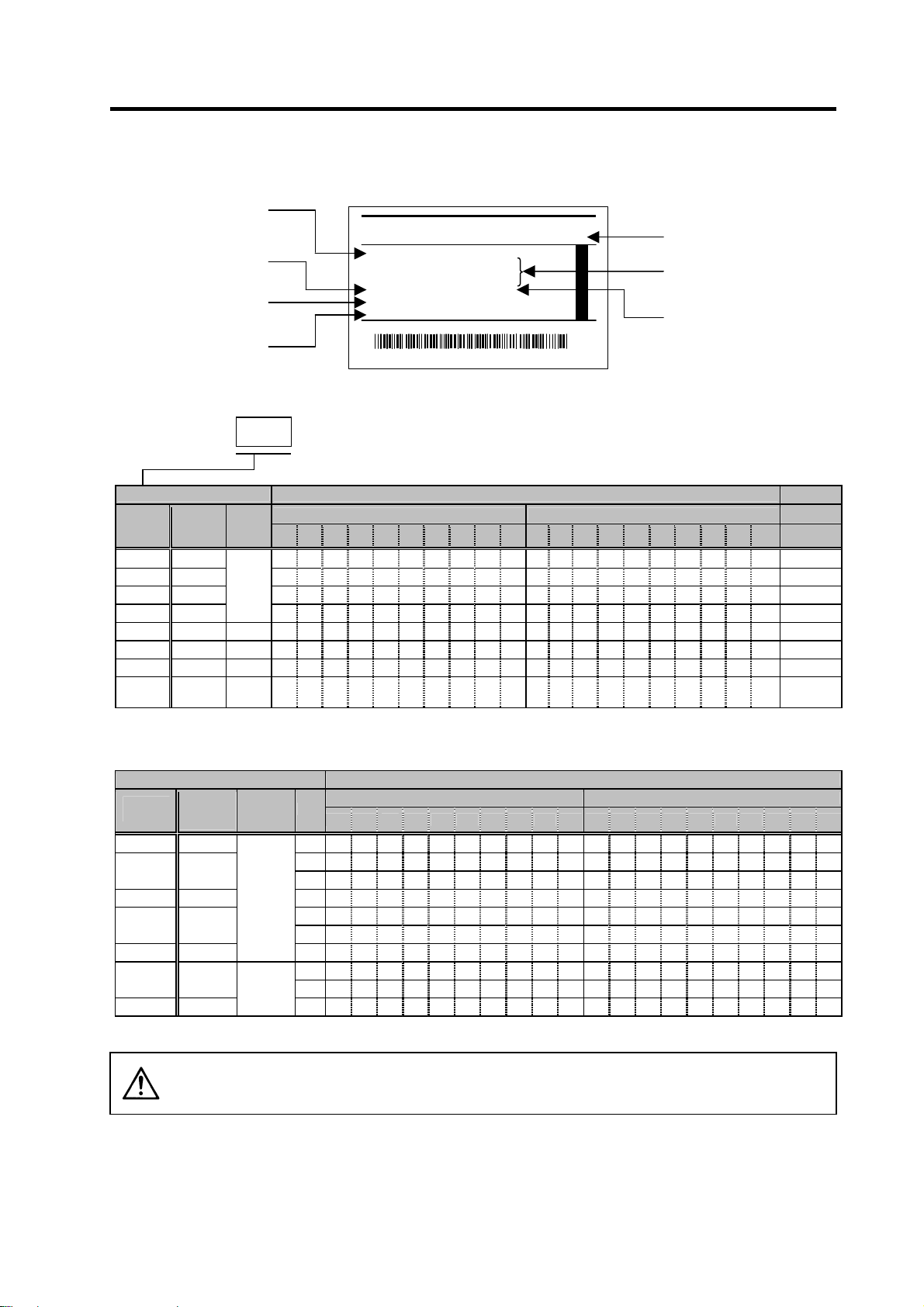

2. Specifications

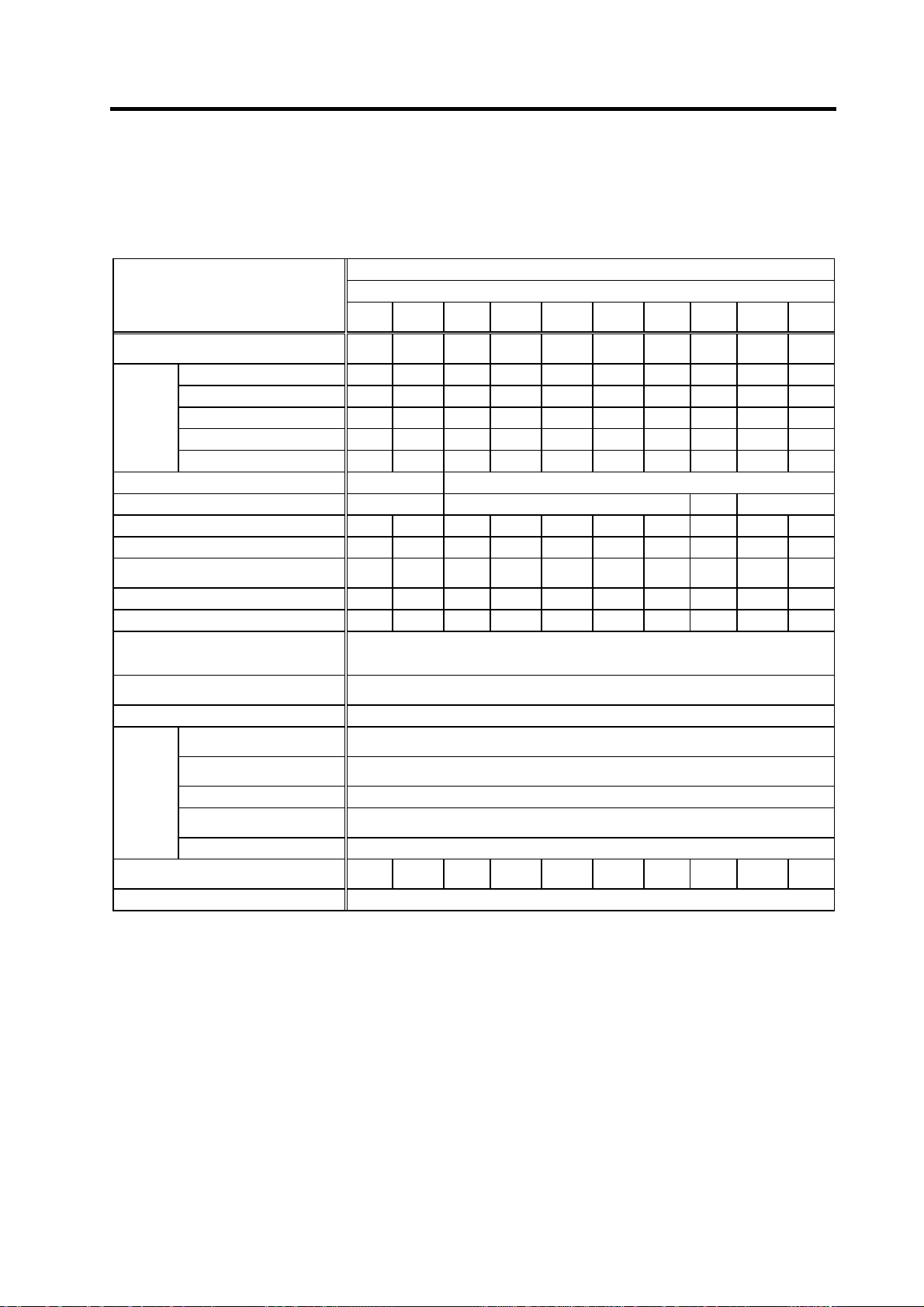

2-1 Servomotor

2-1-1 Specifications list

HF-H Series

HF-H Series

Servomotor type

Compatible servo drive

unit type

Rated output [kW] 0.75 1.0 0.5 1.0 1.5 2.0 3.5 4.5 7.0 9.0

Continuous

characteristics

Rated rotation speed [r/min] 4000 3000

Maximum rotation speed [r/min] 5000 4000 3500 3000

Maximum current [A] 7.0 7.75 8.4 14.5 26.0 28.5 58.0 52.1 54.2 102.0

Maximum torque [N·m] 8.0 11.0 13.0 23.3 42.0 47.0 90.0 122.0 152.0 208.0

Power rate at continuous

rated torque

Motor inertia [kg·cm2] 2.6 5.1 6.1 11.9 17.8 38.3 75.0 112.0 154.0 196.0

Motor inertia with brake [kg·cm2] 2.8 5.3 8.3 14.1 20.0 48.0 84.7 121.7 163.7 205.7

Maximum motor shaft conversion load

inertia ratio

Motor side detector

Structure Fully closed, self-cooling (Protection method: IP67) (Note3)

Environment

Weight

Without/with brake

Armature insulation class Class F

Rated current [A] 1.4 1.8 0.9 1.8 2.9 3.4 6.9 6.7 8.3 13.6

Rated torque [N·m] 1.8 2.4 1.6 3.2 4.8 6.4 11.1 14.3 22.3 28.7

Stall current [A] 1.6 2.3 1.6 3.3 5.5 7.3 14.0 17.0 18.2 28.0

Stall torque [N·m] 2.0 3.0 2.9 5.9 9.0 13.7 22.5 37.2 49.0 58.8

Ambient temperature

Ambient humidity

Atmosphere Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist, or dust

Altitude

Vibration X: 19.6m/s

MDS-DH-V1/2- 10 10 20 20 40 40 80 80 80W 160

[kW/s] 12.3 11.2 4.1 8.4 12.7 10.6 16.5 18.3 32.2 42.1

[kg]

HF-H

HF-H

75

105

High-speed, high-accuracy machine : 3 times or less of motor inertia

General machine tool (interpolation axis) : 5 times or less of motor inertia

General machine (non-interpolation axis) : 7 times or less of motor inertia

2.5/

3.9

4.3/

5.7

ABS specifications: HF-H-A74/-A51

HF-H

A74: 16,000,000 pulse/rev, A51: 1,000,000 pulse/rev

Operation: 80%RH or less (with no dew condensation),

Storage: 90%RH or less (with no dew condensation)

HF-H

54

104

Resolution per motor revolution

Operation: 0 to 40°C (with no freezing),

Storage: -15°C to 70°C (with no freezing)

Operation: 1000 meters or less above sea level,

Storage: 10000 meters or less above sea level

4.8/

6.5/

6.8

8.5

HF-H

154

2

8.3/

10.3

HF-H

(2G) Y: 19.6m/s2 (2G)

12.0/

18.0

204

HF-H

354

19.0/

25.0

HF-H

453

26.0/

32.0

HF-H

703

32.0/

38.0

HF-H

45.0/

903

51.0

(Note 1) The above characteristics values are representative values. The maximum current and maximum torque are the values

(Note 2) Use the HF-H motor in combination with the MDS-DH Series drive unit compatible with the 400VAC input.

(Note 3) The shaft-through portion is excluded.

when combined with the drive unit.

This motor is not compatible with the conventional MDS-B/C1/CH Series.

2 - 2

Page 29

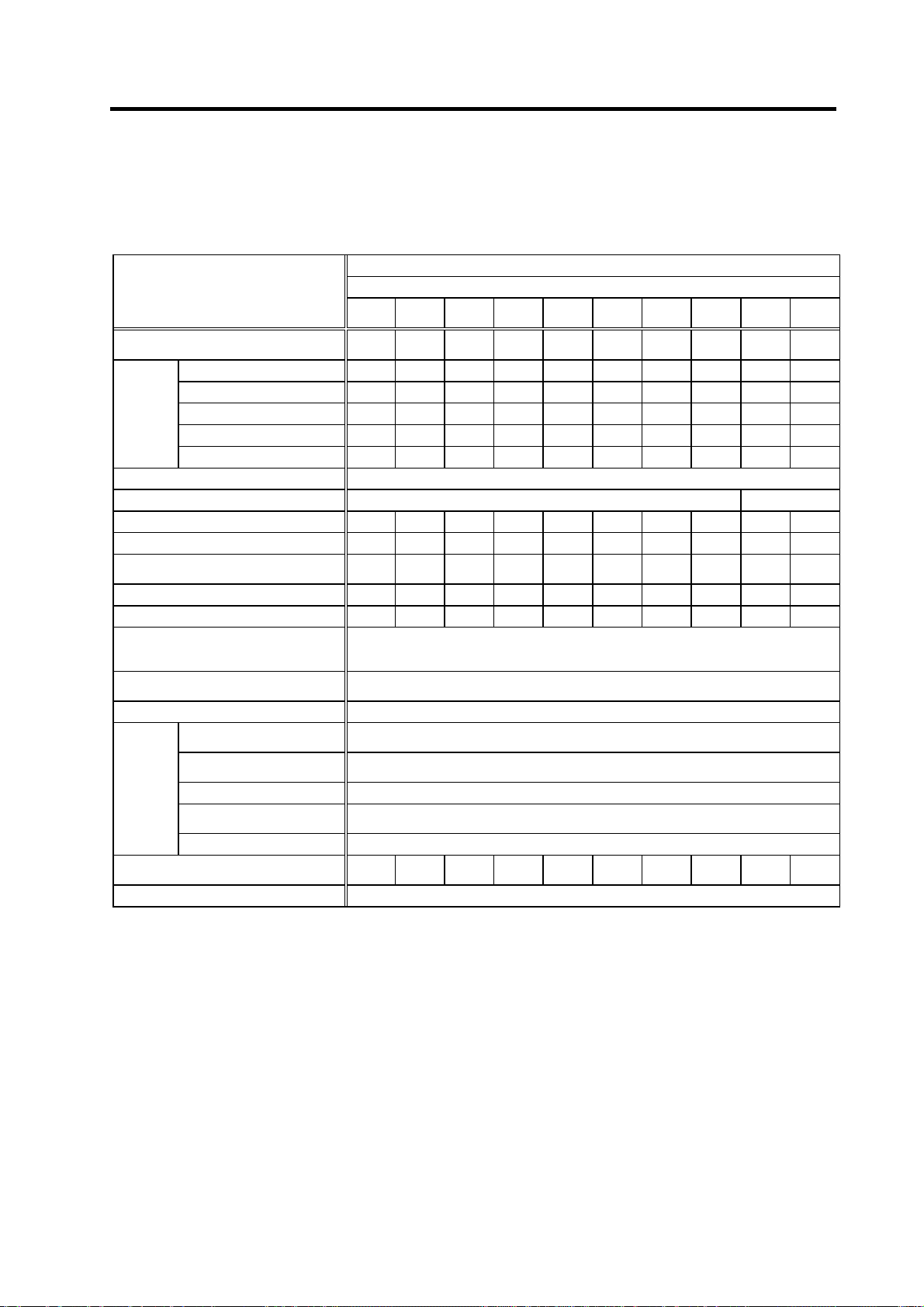

2. Specifications

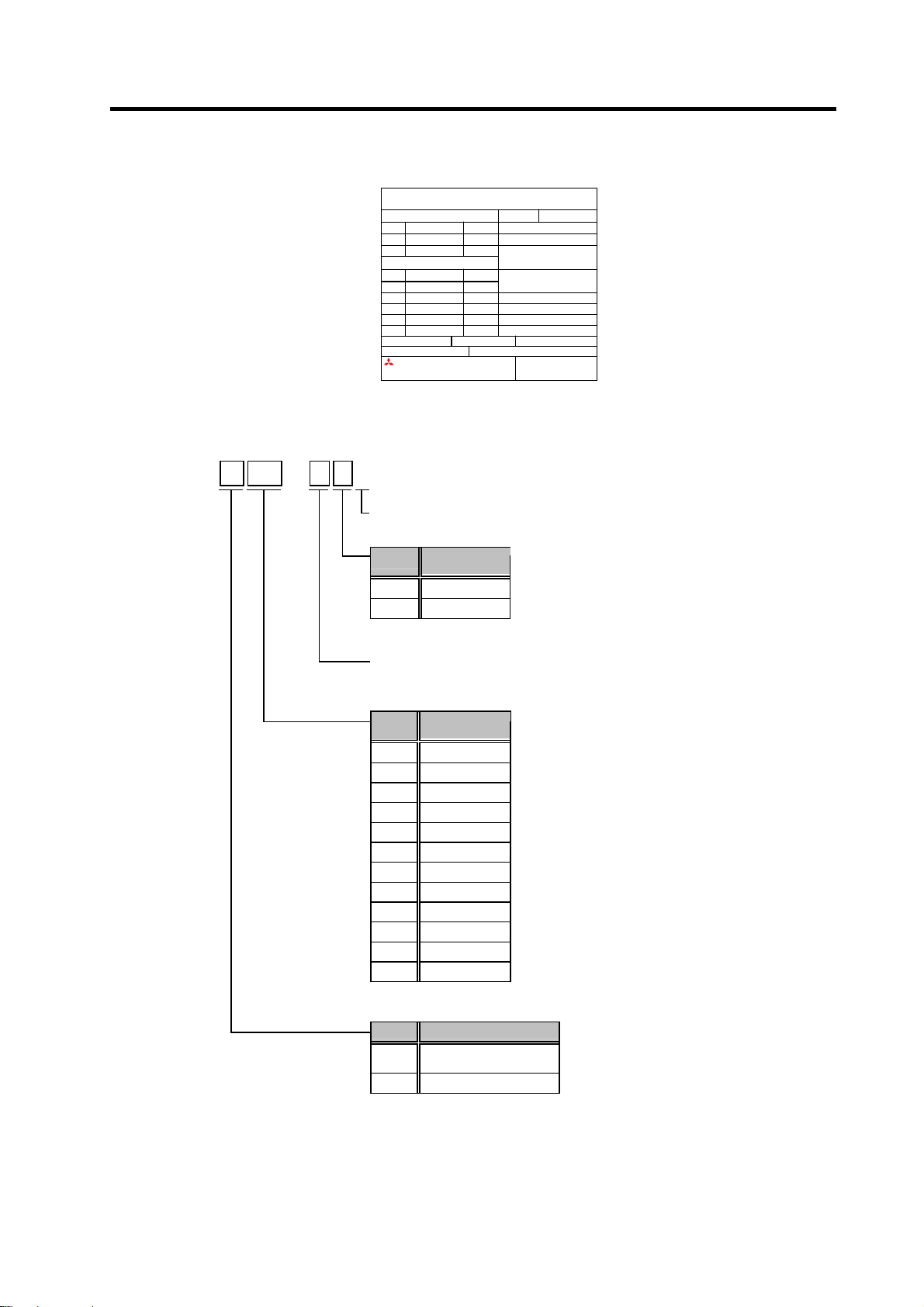

HP-H Series

HP-H Series

Servomotor type

Compatible servo drive

unit

Rated output [kW] 0.5 1.0 1.5 2.2 2.0 3.5 4.5 7.0 9.0 11.0

Continuous

characteristics

Rated rotation speed [r/min] 3000

Maximum rotation speed [r/min] 4000 3000

Maximum current [A] 8.4 12.8 26.0 28.5 28.5 58.0 58.0 58.0 86.0 106.0

Maximum torque [N·m] 11.0 19.2 36.5 46.0 43.0 66.0 95.0 120.0 170.0 260.0

Power rate at continuous

rated torque

Motor inertia [kg·cm2] 4.6 7.7 12.0 20.0 29.0 37.0 55.0 82.0 225.0 300.0

Motor inertia with brake [kg·cm2] 5.1 8.2 12.5 25.5 34.5 42.5 60.5 87.5 249.0 324.0

Maximum motor shaft conversion load

inertia ratio

Motor side detector

Structure Fully closed, self-cooling (Protection method: IP67) (Note3)

Environment

Weight

Without/with brake

Armature insulation class Class F

Rated current [A] 0.9 1.8 2.5 3.7 3.6 7.6 7.1 9.6 11.1 12.6

Rated torque [N·m] 1.6 3.2 4.8 6.4 6.4 11.1 14.3 22.3 28.7 35.0

Stall current [A] 1.8 3.4 4.7 7.0 7.7 15.5 16.0 21.0 27.0 39.5

Stall torque [N·m] 3.0 5.9 9.0 12.0 13.7 22.5 31.9 49.0 70.0 110.0

Ambient temperature

Ambient humidity

Atmosphere Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist, or dust

Altitude

Vibration X: 19.6m/s

MDS-DH-V1/2- 20 20 40 40 40 80 80 80W 160 160W

[kW/s] 5.5 13.0 19.0 20.0 14.0 33.0 36.0 59.0 52.0 48.0

[kg]

HP-H

HP-H

54

6.0/

7.3

104

High-speed, high-accuracy machine : 3 times or less of motor inertia

General machine tool (interpolation axis) : 5 times or less of motor inertia

General machine (non-interpolation axis) : 10 times or less of motor inertia

7.0/

8.5

ABS specifications: HP-H-A74/-A51

HP-H

A74: 16,000,000 pulse/rev, A51: 1,000,000 pulse/rev

Operation: 80%RH or less (with no dew condensation),

Storage: 90%RH or less (with no dew condensation)

HP-H

154

Operation: 0 to 40°C (with no freezing),

Storage: -15°C to 70°C (with no freezing)

Operation: 1000 meters or less above sea level,

storage: 10000 meters or less above sea level

8.0/

12.0/

9.5

HP-H

224

Resolution per motor revolution

13.9

14.0/

15.9

HP-H

204

2

(2G) Y: 19.6m/s2(2G)

17.0/

354

22.0

HP-H

454

21.0/

26.0

HP-H

704

37.0/

43.0

HP-H

903

51.0/

61.4

HP-H

1103

74.0/

84.4

(Note 1) The above characteristics values are representative values. The maximum current and maximum torque are the values

(Note 2) Use the HP-H motor in combination with the MDS-DH Series drive unit compatible with the 400VAC input.

(Note 3) The shaft-through portion is excluded.

when combined with the drive unit.

This motor is not compatible with the conventional MDS-B/C1/CH Series.

2 - 3

Page 30

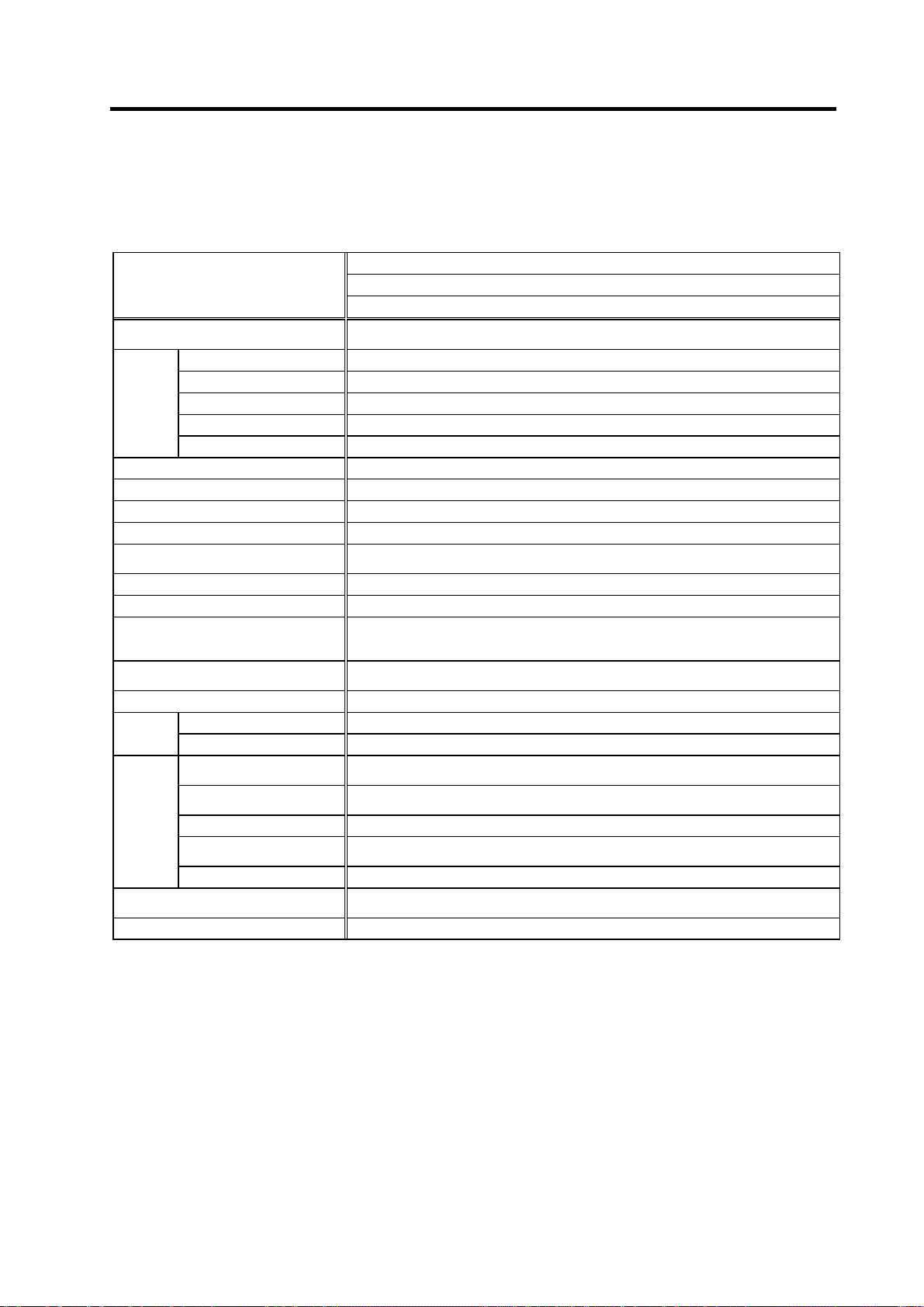

2. Specifications

HC-H Series

HC-H Series

Servomotor type

Compatible servo drive

unit

Rated output [kW] 15.0

Continuous

characteristics

Rated rotation speed [r/min] 2000

Maximum rotation speed [r/min] 2500

Maximum current [A] 160.0

Maximum torque [N·m] 280.0

Power rate at continuous

rated torque

Motor inertia [kg·cm2] 550

Motor inertia with brake [kg·cm2] ---

Maximum motor shaft conversion load

inertia ratio

Motor side detector

Structure Fully closed, self-cooling (Protection method: IP67) (Note3)

Cooling

fan

Environment

Weight

Without/with brake

Armature insulation class Class F

Rated current [A] 38.8

Rated torque [N·m] 71.6

Stall current [A] 76.8

Stall torque [N·m] 146.0

Input voltage

Maximum power consumption

Ambient temperature

Ambient humidity

Atmosphere Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist, or dust

Altitude

Vibration X: 9.8m/s

MDS-DH-V1- 200

[kW/s] 104.5

High-speed, high-accuracy machine : 3 times or less of motor inertia

General machine tool (interpolation axis) : 5 times or less of motor inertia

General machine (non-interpolation axis) : 10 times or less of motor inertia

[kg] 160/---

ABS specifications: HC-H-A74/-A51

HC-H1502S-S10

A74: 16,000,000 pulse/rev, A51: 1,000,000 pulse/rev

Operation: 80%RH or less (with no dew condensation),

Storage: 90%RH or less (with no dew condensation)

Operation: 1000 meters or less above sea level,

Resolution per motor revolution

3-phase 400V

85W

Operation: 0 to 40°C (with no freezing),

Storage: -15°C to 70°C (with no freezing)

storage: 10000 meters or less above sea level

2

(2G) Y: 9.8m/s2(2G)

(Note 1) The above characteristics values are representative values. The maximum current and maximum torque are the values

(Note 2) Use the HC-H motor in combination with the MDS-DH Series drive unit compatible with the 400VAC input.

(Note 3) The shaft-through portion is excluded.

when combined with the drive unit.

This motor is not compatible with the conventional MDS-B/C1/CH Series.

2 - 4

Page 31

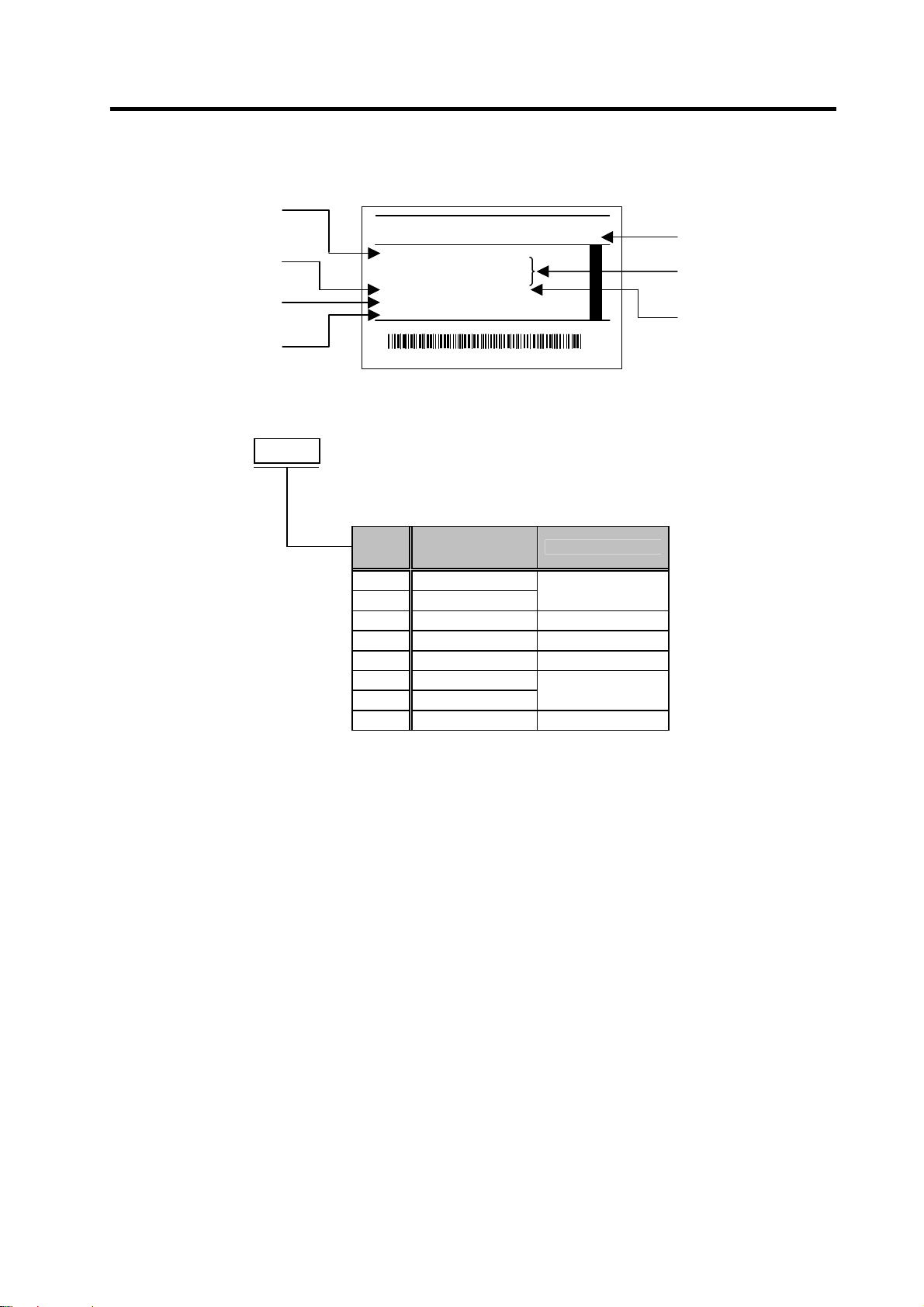

f

2-1-2 Torque characteristics

(1) HF-H Series

10

[ HF-H75 ]

2. Specifications

[ HF-H105 ]

12

7.5

m]

.

Short time operation range

5

Torque [N

2.5

Continuous operation range

0

0 2000 5000

Rotation speed [r/min]

4000 4000

[ HF-H54 ]

15

12

m]

.

9

6

Short time operation range

Torque [N

3

Continuous

operation range

0

0 2000 4000

Rotation speed [r/min]

[ HF-H204 ]

50

9

m]

.

Torque [N

Short time operation range

6

3

Continuous operation range

0

0 2000 5000

Rotation speed [r/min]

[ HF-H104 ]

25

20

m]

.

15

Short time operation range

10 20

Torque [N

5

Continuous

operation range

0

0 2000 4000

Rotation speed [r/min]

[ HF-H354 ]

100

50

40

m]

30

.

Short time operation range

Torque [N

10

Continuous

operation range

0

0 2000 4000

Rotation speed [r/min]

[ HF-H453 ]

125

[ HF-H154 ]

40

30

20

Short time operation range

10

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

[ HF-H703 ]

160

120

m]

.

80

Short time operation range

Torque [N

40

Continuous operation range

0

0 1000 3000

Rotation speed [r/min]

2000 2000

80

m]

60

.

Short time operation range

40

Torque [N

20

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

[ HF-H903 ]

240

180

m]

.

Torque [N

Short time operation range

120

60

Continuous operation range

0

0 1000 3000

Rotation speed [r/min]

100

m]

75

.

50

Torque [N

25

0

The abov e graphs show the data

(Note)

Short time operation range

Continuous operation range

0

1000

2000

Rotation speed [r/min]

when applied the input voltage o

380VAC. When the input voltage

is 380VAC or less, the short time

operation range is limited.

3000

3500

2 - 5

Page 32

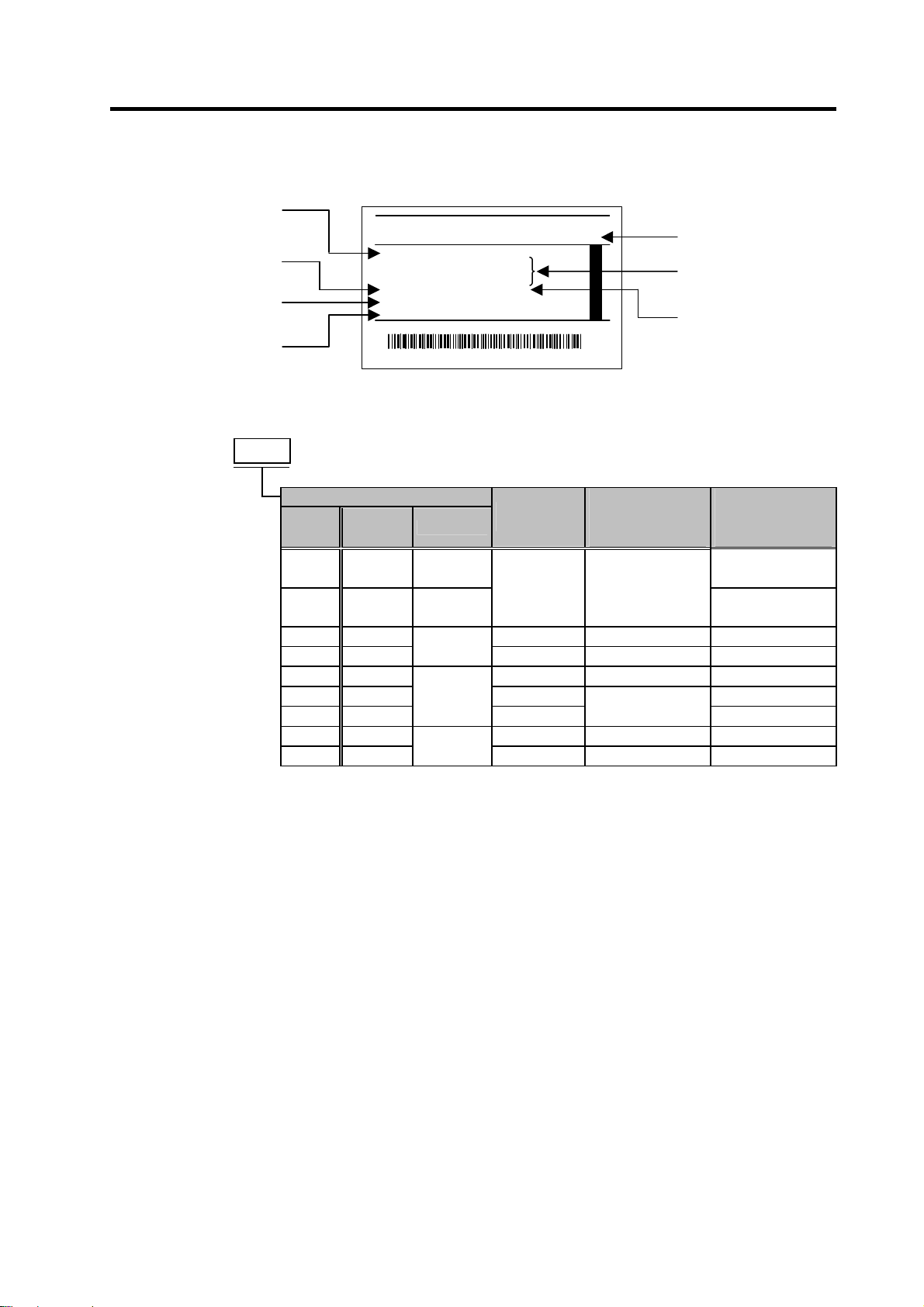

f

(2) HP-H Series

12

[ HP-H54 ]

2. Specifications

[ HP-H104 ]

20

40

[ HP-H154 ]

9

m]

.

6

Short time operation range

Torque [N

3

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

[ HP-H224 ]

50

40

m]

.

30

20

Torque [N

10

Short time operation ra nge

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

15

m]

.

10

Short time operation range

Torque [N

5

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

[ HP-H204 ]

50

40

m]

30

.

Torque [N

Short time operation range

20

10

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

30

m]

.

20

Short time operation range

Torque [N

10

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

[ HP-H354 ]

75

50

45

m]

.

Torque [N

Short time operation range

30

15

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

100

80

60

m]

.

Torque [N

Short time operation range

40

20

Continuous operation range

0

Rotation speed [r/min]

2000 4000

[ HP-H1103 ]

300

240

m]

180

[ HP-H454 ]

.

Torque [N

Short time operation range

120

60

Continuous operation range

0

0 1500 3000

Rotation speed [r/min]

[ HP-H704 ]

150

120

m]

90

.

Short time operation range

60

Torque [N

30

Continuous operation range

0

0 2000 4000

Rotation speed [r/min]

The above graphs show the data

(Note)

when applied the input voltage o

380VAC. When the input voltage

is 380VAC or less, the short time

operation range is limited.

180

[ HP-H903 ]

135

m]

.

Torque [N

Short time operation range

90

45

Continuous operation range

0

0 1500 3000

Rotation speed [r/min]

2 - 6

Page 33

(3) HC-H Series

[ HC-H1502S-S10 ]

400

300

m]

.

Torque [N

Short time operation range

200

100

Continuous operation rang e

0

0 1000 2500

2. Specifications

(Note) The above graphs show the data

when applied the input voltage of

380VAC. When the input voltage

is 380VAC or less, the short time

operation range is limited.

2000

Rotation speed [r/min]

2 - 7

Page 34

2. Specifications

2-2 Spindle motor

2-2-1 Specifications

Base rotation speed

1150r/min series , 1500r/min series

Spindle motor type

2.2

-03T

Compatible spindle drive unit type

MDS-DH-

Continuous rating

Output

capacity

Base rotation speed [r/min] 1500 1150 1500 1150

Maximum rotation speed [r/min] 10000 8000 6000 3450

Frame No. A90 B90 D90 A112 B112 A160 B160 C160 A180 B180 A225

Continuous rated torque [N·m] 9.5 14.0 23.5 35.0 47.7 70.0 95.5 118 140 249 236 374

GD2 [kg·m2]

Inertia [kg·m2]

Tolerable radial load [N] 980 1470 1960 2940 3920 5880

Cooling fan

Environment

Weight [kg] 25 30 49 60 70 110 135 155 280 390 450

Insulation Class F

[kW]

30-minute rating

50%ED rating [kW]

0.027 0.035 0.059 0.098 0.12 0.23 0.23 0.32 0.38 1.23 2.19 3.39

0.007 0.009 0.015 0.025 0.03 0.06 0.06 0.08 0.10 0.31 0.55 0.85

Input voltage Single-phase 400V 3-phase 400V

Maximum power

consumption

Ambient temperature Operation: 0 to 40°C (with no freezing), Storage: -20°C to 65°C (with no freezing)

Ambient humidity Operation: 90%RH or less (with no dew condensation), Storage: 90%RH or less (with no dew condensation)

Atmosphere Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist, or dust

Altitude

3.7

-03T

SP-20 SP-40 SP-80 SP-100 SP-160 SP-200 SP-320

1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45

2.2 3.7 5.5 7.5 11 15 18.5 22 26 37 45 55

30W 70W 72W (Note 5)

Operation: 1000 meters or less above sea level, Storage: 1000 meters or less above sea level,

5.5

-07T

7.5

-12T

Transportation: 13000 meters or less above sea level

11

-18T

SJ-4-V

15

-18T

18.5

-14T

22

-15T

26

-08T

37

-04T

45

-02T

55

-03T

(Note 1)

The rated output is guaranteed at the rated input voltage (380 to 440VAC 50Hz / 380 to 480VAC 60Hz) to the power supply

unit.

If the input voltage fluctuates and drops below 400VAC, the rated output may not be attained.

The 50%ED rating applies for a 10-minute cycle time consisting of ON for five minutes and OFF for five minutes.

(Note 2)

The tolerable radial load is the value calculated at the center of output shaft.

(Note 3)

The protection level is IP44.

(Note 4)

Confirm in each motor specifications.

(Note 5)

2 - 8

Page 35

2. Specifications

Wide range constant output series

Spindle motor type

11-18T 11-21T 15-20T 18.5-17T 22-16T

Compatible spindle drive unit type

MDS-DH-

Continuous rating

Output

capacity

Base rotation speed [r/min] 750

Maximum rotation speed [r/min] 6000

Frame No. B112 A160 B160

Continuous rated torque [N·m] 47.1 70.0 95.5 115 140

GD2 [kg·m2]

Inertia [kg·m2]

Tolerable radial load [N] 1960 2940

Cooling fan

Environment

Weight [kg] 70 110 135

Insulation Class F

[kW]

30-minute rating

50%ED rating [kW]

0.12 0.23 0.23 0.32 0.32

0.03 0.06 0.06 0.08 0.08

Input voltage 3-phase 400V

Maximum power

consumption

Ambient temperature Operation: 0 to 40°C (with no freezing), Storage: -20°C to 65°C (with no freezing)

Ambient humidity Operation: 90%RH or less (with no dew condensation), Storage: 90%RH or less (with no dew condensation)

Atmosphere Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist, or dust

Altitude

70W 72W

Operation: 1000 meters or less above sea level, Storage: 1000 meters or less above sea level,

SP-80 SP-100 SP-160

3.7 5.5 7.5 9 11

5.5 7.5 9 11 15

Transportation: 13000 meters or less above sea level

SJ-4-V

(Note 1)

The rated output is guaranteed at the rated input voltage (380 to 440VAC 50Hz / 380 to 480VAC 60Hz) to the power supply

unit.

If the input voltage fluctuates and drops below 400VAC, the rated output may not be attained.

(Note 2)

(Note 3)

(Note 4)

The 50%ED rating applies for a 10-minute cycle time consisting of ON for five minutes and OFF for five minutes.

The tolerable radial load is the value calculated at the center of output shaft.

The protection level is IP44.

2 - 9

Page 36

)

2. Specifications

High-speed series

Spindle motor type

3.7-05ZT 7.5-13ZT 11-22ZT 11-23ZT 22-18ZT 30-15ZT

Compatible spindle drive unit type

MDS-DH-

Continuous rating

Output

capacity

Base rotation speed [r/min] 3000 1500

Maximum rotation speed [r/min] 15000 12000 8000

Frame No. A90 A112 B112 A160 B160

Continuous rated torque [N·m] 7.0 35.0 35.0 47.7 70.0 118

GD2 [kg·m2]

Inertia [kg·m2]

Tolerable radial load [N] 490 980 1470 1960

Cooling fan

Environment

Weight [kg] 25 60 70 125 155

Insulation Class F

[kW]

30-minute rating

50%ED rating [kW]

Input voltage

Maximum power

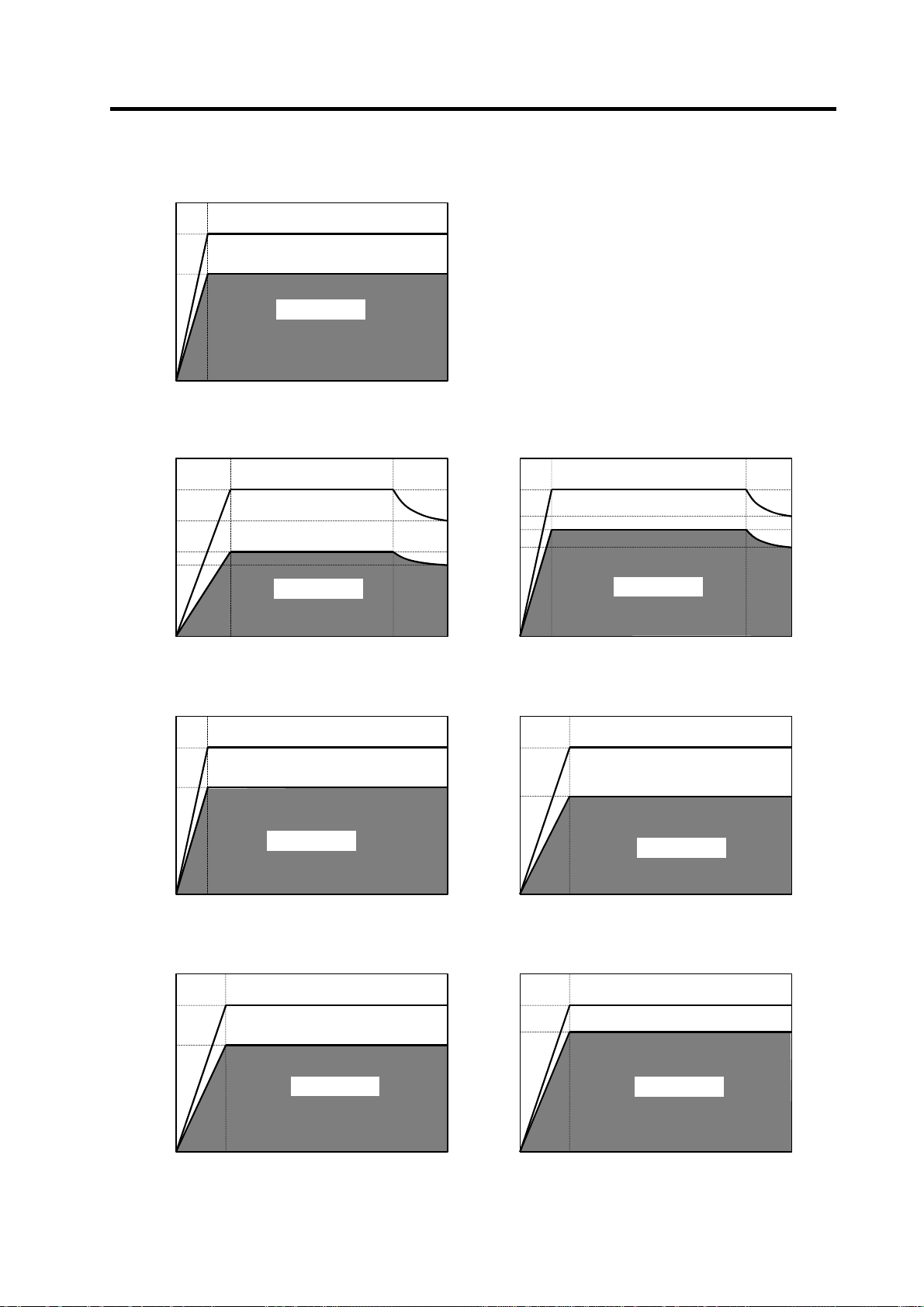

consumption