Page 1

Page 2

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or registered

trademarks of their respective companies.

Page 3

Introduction

Thank you for selecting the Mitsubishi numerical control unit.

This instruction manual describes the handling and caution points for using this AC

servo/spindle.

Incorrect handling may lead to unforeseen accidents, so always read this instruction

manual thoroughly to ensure correct usage.

Make sure that this instruction manual is delivered to the end user.

Always store this manual in a safe place.

All specifications for the MDS-CH Series are described in this manual. However, each

CNC may not be provided with all specifications, so refer to the specifications for the

CNC on hand before starting use.

Notes on Reading This Manual

(1) Since the description of this specification manual deals with NC in general, for the

specifications of individual machine tools, refer to the manuals issued by the

respective machine manufacturers. The "restrictions" and "available functions"

described in the manuals issued by the machine manufacturers have precedence

to those in this manual.

(2) This manual describes as many special operations as possible, but it should be

kept in mind that items not mentioned in this manual cannot be performed.

Page 4

Precautions for safety

Please read this manual and auxiliary documents before starting installation, operation,

maintenance or inspection to ensure correct usage. Thoroughly understand the device, safety

information and precautions before starting operation.

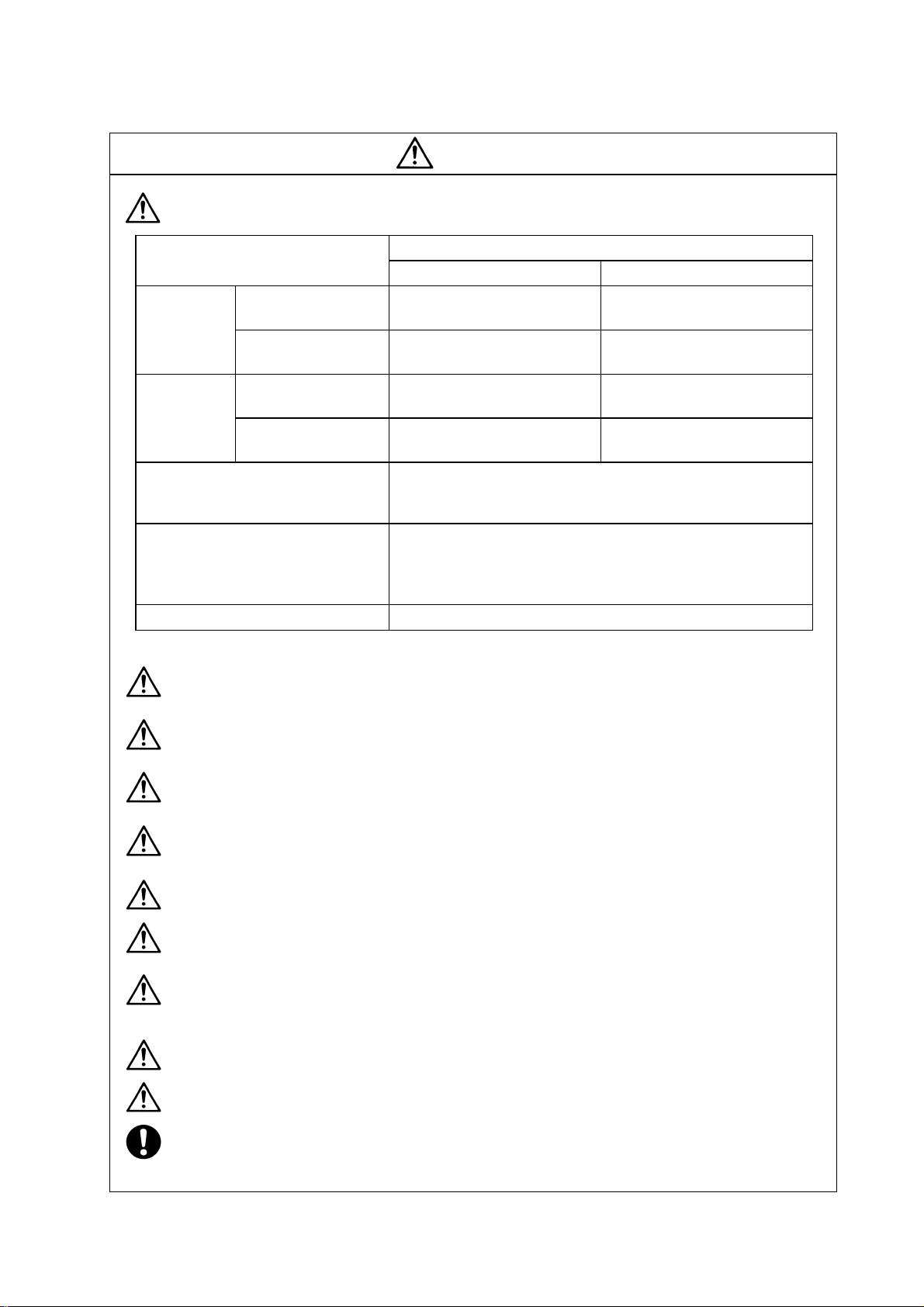

The safety precautions in this instruction manual are ranked as "WARNING" and "CAUTION".

Note that some items described as

the situation. In any case, important information that must be observed is described.

The numeric control unit is configured of the control unit, operation board, servo drive unit,

spindle drive unit, power supply, servomotor and spindle motor, etc.

In this manual, the following items are generically called the "motor".

• Servomotor

• Linear servomotor

• Spindle motor

DANGER

WARNING

CAUTION

When there is a potential risk of fatal or serious injuries if

handling is mistaken.

When a dangerous situation, or fatal or serious injuries may

occur if handling is mistaken.

When a dangerous situation may occur if handling is mistaken

leading to medium or minor injuries, or physical damage.

CAUTION

may lead to major results depending on

In this manual, the following items are generically called the "unit".

• Servo drive unit

• Spindle drive unit

• Power supply unit

• Scale I/F unit

• Magnetic pole detection unit

Page 5

There are no "DANGER" items in this manual.

1. Electric shock prevention

Do not open the front cover while the power is ON or during operation. Failure to observe this

could lead to electric shocks.

Do not operate the unit with the front cover removed. The high voltage terminals and charged

sections will be exposed, and can cause electric shocks.

Do not remove the front cover even when the power is OFF unless carrying out wiring work or

periodic inspections. The inside of the units is charged, and can cause electric shocks.

Wait at least 15 minutes after turning the power OFF before starting wiring or inspections.

Failure to observe this could lead to electric shocks.

Ground the unit and motor with Class C (former class 3) grounding or higher.

Wiring and inspection work must be done by a qualified technician.

Wire the servo drive unit and servomotor after installation. Failure to observe this could lead to

electric shocks.

Do not touch the switches with wet hands. Failure to observe this could lead to electric shocks.

Do not damage, apply forcible stress, place heavy items on the cables or get them caught.

Failure to observe this could lead to electric shocks.

DANGER

WARNING

2. Injury prevention

The linear servomotor uses a powerful magnet on the secondary side, and could adversely

affect pacemakers, etc.

During installation and operation of the machine, do not place portable items that could

malfunction or fail due to the influence of the linear servomotor's magnetic force.

Take special care not to pinch fingers, etc., when installing (and unpacking) the linear

servomotor.

1. Fire prevention

Install the units, motors and regenerative resistor on noncombustible material. Direct installation

on combustible material or near combustible materials could lead to fires.

Shut off the power on the power supply unit side if a fault occurs in the units. Fires could be

caused if a large current continues to flow.

Provide a sequence that shut off the power at the regenerative resistor error signal-ON when

using the regenerative resistor. The regenerative resistor could abnormally overheat and cause

a fire due to a fault in the regenerative transistor, etc.

The battery unit could heat up, ignite or rupture if submerged in water, or if the poles are

incorrectly wired.

CAUTION

Page 6

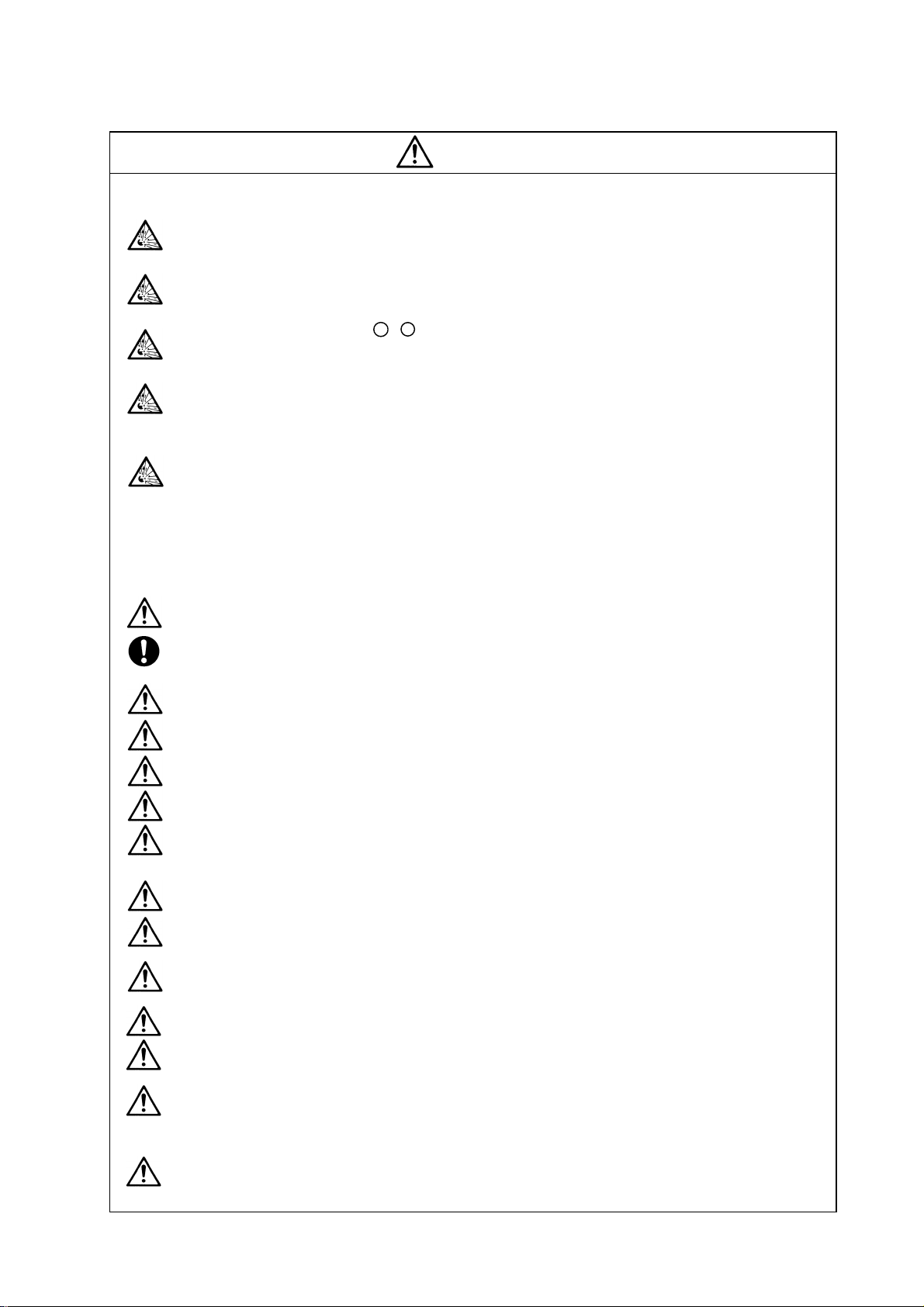

CAUTION

2. Injury prevention

Do not apply a voltage other than that specified in Instruction Manual on each terminal. Failure

to observe this item could lead to ruptures or damage, etc.

Do not mistake the terminal connections. Failure to observe this item could lead to ruptures or

damage, etc.

Do not mistake the polarity (

damage, etc.

Do not touch the radiation fin on unit back face, regenerative resistor or motor, etc., or place

parts (cables, etc.) while the power is turned ON or immediately after turning the power OFF.

These parts may reach high temperatures, and can cause burns.

Structure the cooling fan on the unit back face so that it cannot be touched after installation.

Touching the cooling fan during operation could lead to injuries.

+

,

). Failure to observe this item could lead to ruptures or

3. Various precautions

Observe the following precautions. Incorrect handling of the unit could lead to faults, injuries and

electric shocks, etc.

(1) Transportation and installation

Correctly transport the product according to its weight.

Use the motor's hanging bolts only when transporting the motor. Do not transport the motor

when it is installed on the machine.

Do not stack the products above the tolerable number.

Do not hold the cables, axis or detector when transporting the motor.

Do not hold the connected wires or cables when transporting the units.

Do not hold the front cover when transporting the unit. The unit could drop.

Follow this Instruction Manual and install the unit or motor in a place where the weight can be

borne.

Do not get on top of or place heavy objects on the unit.

Always observe the installation directions of the units or motors.

Secure the specified distance between the units and control panel, or between the servo drive

unit and other devices.

Do not install or run a unit or motor that is damaged or missing parts.

Do not block the intake or exhaust ports of the motor provided with a cooling fan.

Do not let foreign objects enter the units or motors. In particular, if conductive objects such as

screws or metal chips, etc., or combustible materials such as oil enter, rupture or breakage

could occur.

The units and motors are precision devices, so do not drop them or apply strong impacts to

them.

Page 7

CAUTION

Store and use the units under the following environment conditions.

During operation

Ambient

temperature

During operation

Ambient

humidity

Atmosphere

Altitude

Vibrat ion To follow each unit and motor specifications

Note 1) -15°C to 55°C for linear servomotor.

Environment

During storage/

transportation

(with no dew condensation)

During storage/

transportation

Securely fix the servomotor to the machine. Insufficient fixing could lead to the servomotor

slipping off during operation.

Always install the servomotor with reduction gear in the designated direction. Failure to do

so could lead to oil leaks.

Structure the rotary sections of the motor so that it can never be touched during operation.

Install a cover, etc., on the shaft.

When installing a coupling to a servomotor shaft end, do not apply an impact by

hammering, etc. The detector could be damaged.

Do not apply a load exceeding the tolerable load onto the servomotor shaft. The shaft

could break.

Store the motor in the package box.

When inserting the shaft into the built-in IPM motor, do not heat the rotor higher than

130°C. The magnet could be demagnetized, and the specifications characteristics will not

be ensured.

Always use a nonmagnetic tool (explosion-proof beryllium copper alloy safety tool: NGK

Insulators) when installing the linear servomotor.

Always provide a mechanical stopper on the end of the linear servomotor's travel path.

If the unit has been stored for a long time, always check the operation before starting

actual operation. Please contac t the Service Center or Service Station.

(with no dew condensation)

Indoors (where unit is not subject to direct sunlight),

Operation/storage: 1,000m or less above sea level

Unit Motor

0°C to 55°C

(with no freezing)

–15°C to 70°C

(with no freezing)

90%RH or less

90%RH or less

with no corrosive gas, combustible gas, oil mist,

dust or conductive particles

Transportation: 10,000m or less above sea level

Conditions

0°C to 40°C

(with no freezing)

–20°C to 65°C

(with no freezing)

20% to 90%RH

(with no dew condensation)

90% RH or less

(with no dew condensation)

(This specified value may be exceeded

only during air-transport)

Note 1)

Page 8

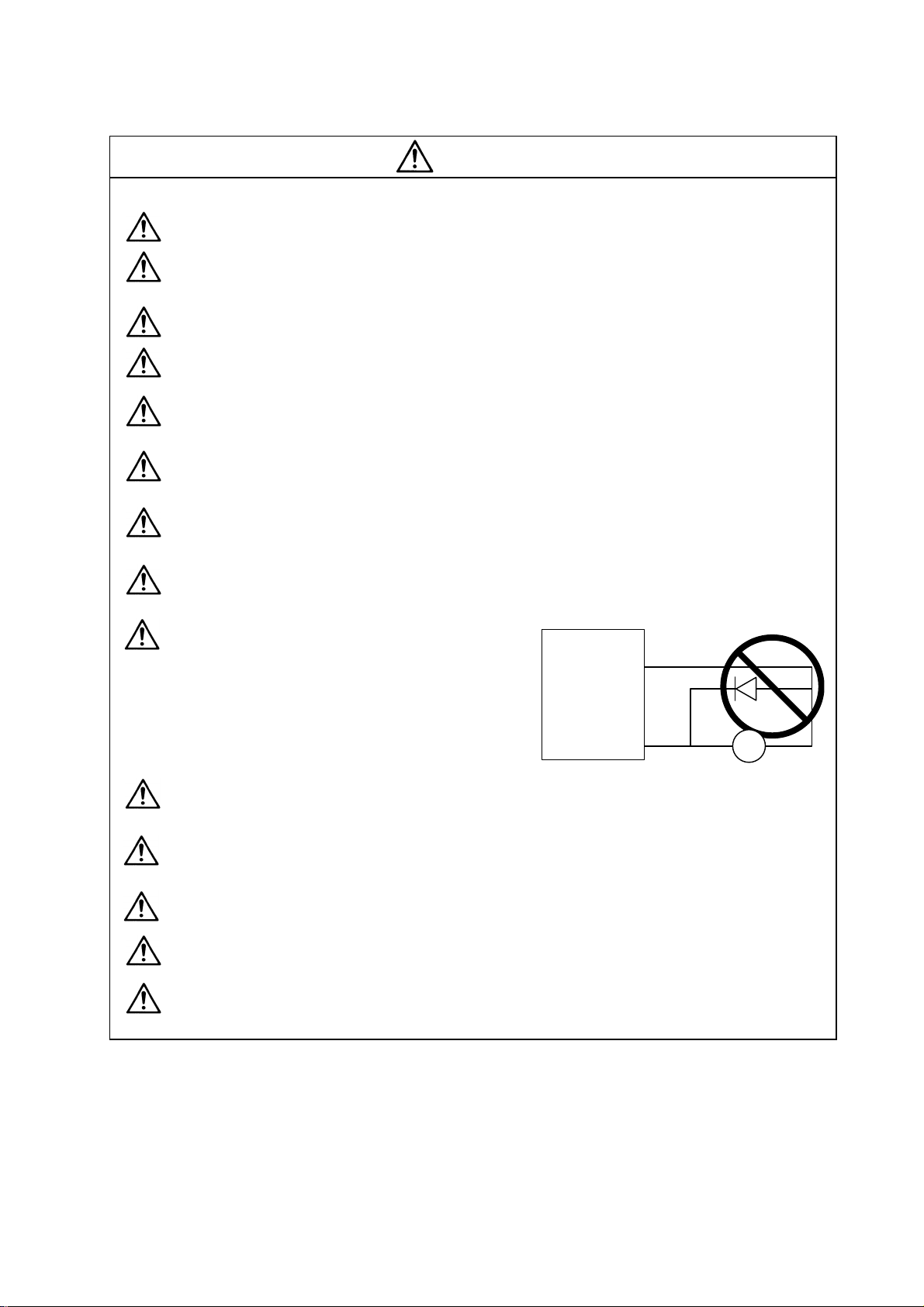

(2) Wiring

CAUTION

Correctly and securely perform the wiring. Failure to do so could lead to runaway of the motor.

Do not install a condensing capacitor, surge absorber or radio noise filter on the output side of

the drive unit.

Correctly connect the output side of the drive unit (terminals U, V, W). Failure to do so could

lead to abnormal operation of the motor.

Always install an AC reactor for each power supply unit.

Always install an appropriate breaker for each power supply unit. Breakers cannot be shared

by several units.

Direct application of a commercial power supply to the motor could cause burning. Always

connect the motor to the drive unit's output terminals (U, V, W).

When using an inductive load such as a relay, always connect a diode as a noise measure

parallel to the load.

When using a capacitance load such as a lamp, always connect a protective resistor as a noise

measure serial to the load.

Do not reverse the direction of a diode which

connect to a DC relay for the control output

signals to suppress a surge. Connecting it

backwards could cause the drive unit to

Drive unit

COM

(24VDC)

Diode reverse orientation

malfunction so that signals are not output, and

emergency stop and other safety circuits are

inoperable.

Control output

signal

Do not connect/disconnect the cables connected between the units while the power is ON.

Securely tighten the cable connector fixing screw or fixing mechanism. An insecure fixing could

cause the cable to fall off while the power is ON.

When using a shielded cable instructed in the connection manual, always ground the cable with

a cable clamp, etc.

Always separate the signals wires from the drive wire and power line.

Use wires and cables that have a wire diameter, heat resistance and flexibility that conforms to

the system.

RA

Page 9

(3) Trial operation and adjustment

Check and adjust each program and parameter before starting operation. Failure to do so could

lead to unforeseen operation of the machine.

Do not make remarkable adjustments and changes as the operatio n could become unstable.

The usable motor and unit combination is predetermined. Always check the models before

starting trial operation.

If the axis is unbalanced due to gravity, etc., balance the axis using a counterbalance, etc.

The linear servomotor does not have a stopping device such as magnetic brakes. Install a

stopping device on the machine side.

(4) Usage methods

Install an external emergency stop circuit so that the operation can be stopped and power

shut off immediately.

Turn the power OFF immediately if smoke, abnormal noise or odors are generated from the unit

or motor.

Unqualified persons must not disassemble or repair the unit.

CAUTION

Never make modifications.

Reduce magnetic damage by installing a noise filter. The electronic devices used near the unit

could be affected by magnetic noise.

Use the unit, motor and regenerative resistor with the designated combination. Failure to do so

could lead to fires or trouble.

The brake (magnetic brake) assembled into the servomotor are for holding, and must not be

used for normal braking. Do not apply the brakes in the servo ON state. Doing so will lead to a

drop in the brake life. Always turn the servo OFF before applying the brakes.

There may be cases when holding is not possible due to the magnetic brake's life or the

machine construction (when ball screw and servomotor are coupled via a timing belt, etc.).

Install a stop device to ensure safety on the machine side.

After changing the programs/parameters or after maintenance and inspection, always test the

operation before starting actual operation.

Do not enter the movable range of the machine during automatic operation. Never place body

parts near or touch the spindle during rotation.

Follow the power supply specification conditions given in the separate specifications manual for

the power (input voltage, input frequency, tolerable sudden power failure time, etc.).

Page 10

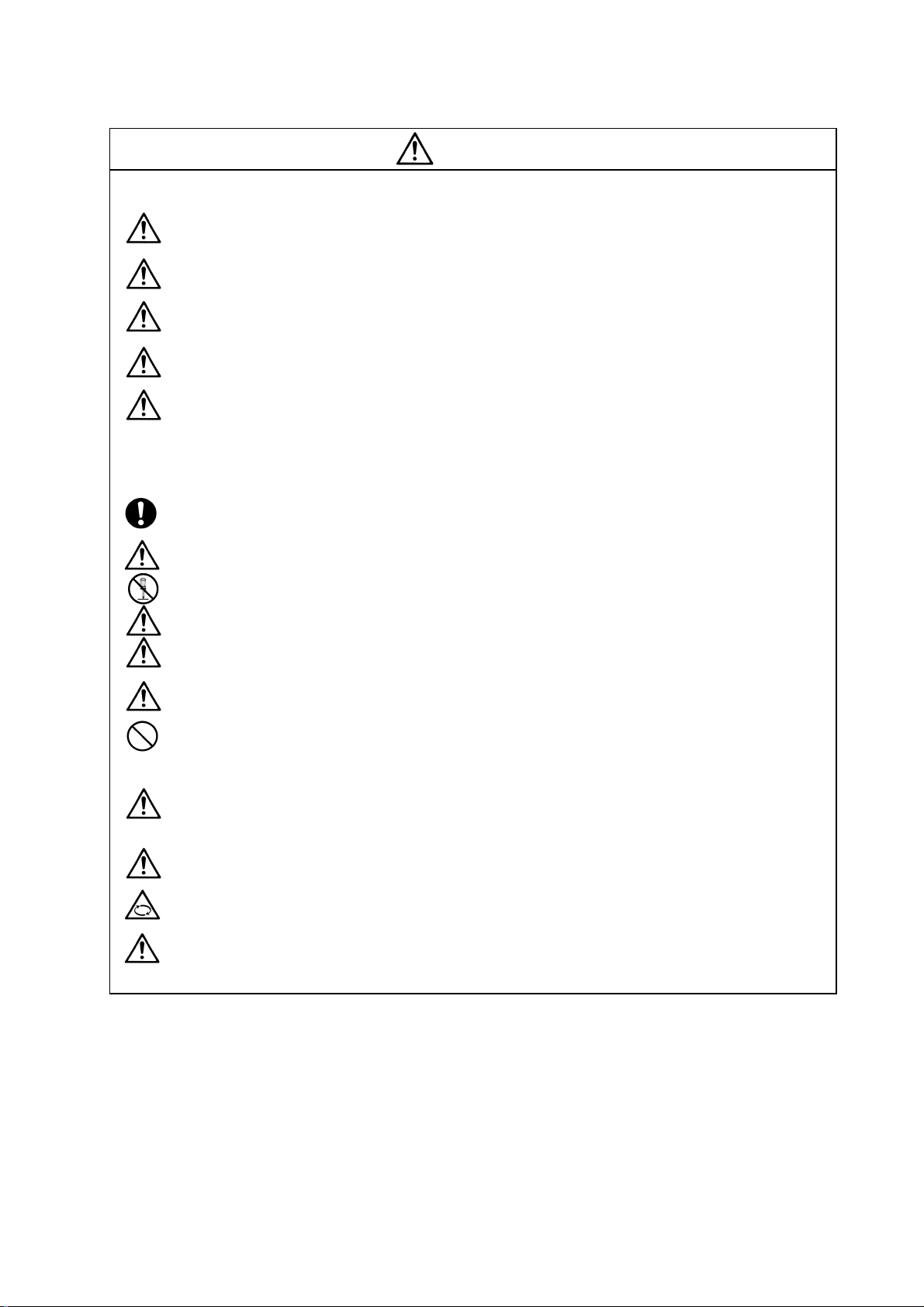

(5) Troubleshooting

If a hazardous situation is predicted during power failure or product trouble, use a servomotor

with magnetic brakes or install an external brake mechanism.

Use a double circuit configuration

that allows the operation circuit for

the magnetic brakes to be operated

even by the external emergency

stop signal.

CAUTION

Shut off with the servomotor

brake control output.

Servomotor

Magnetic

brake

Shut off with NC brake

control PLC output.

MBR

EMG

24VDC

Always turn the input power OFF when an alarm occurs.

Never go near the machine after restoring the power after a power failure, as the machine

could start suddenly. (Design the machine so that personal safety can be ensured even if the

machine starts suddenly.)

(6) Maintenance, inspection and part replacement

Always backup the programs and parameters in the CNC device before starting maintenance

or inspections.

The capacity of the electrolytic capacitor will drop over time due to self-discharging, etc. To

prevent secondary disasters due to failures, replacing this part every five years when used

under a normal environment is recommended. Contact the Service Center or Service Station

for replacement.

Do not perform a megger test (insulation resistance measurement) during inspections.

If the battery low warning is issued, back up the machining programs, tool data and

parameters with an input/output unit, and then replace the battery.

Do not short circuit, charge, overheat, incinerate or disassemble the battery.

The heat radiating fin used in the 37kW and smaller unit contains substitute Freon as the

refrigerant.

Take care not to damage the heat radiating fin during maintenance and replacement work.

(7) Disposal

Do not dispose of this unit as general industrial waste. The

37kW and smaller unit with heat radiating fin protruding from

the back of the unit contains substitute Freon. Do not dispose

of this type of unit as general industrial waste. Always return

to the Service Center or Service Station.

Heat

radiating

fin

Do not disassemble the unit or motor.

Dispose of the battery according to local laws.

Always return the secondary side (magnet side) of the linear servomotor to the Service

Center or Service Station.

Page 11

CAUTION

(8) Transportation

(9) General precautions

The drawings given in this Specifications and Maintenance Instruction Manual show the covers and

safety partitions, etc., removed to provide a clearer explanation. Always return the covers or partitions to

their respective places before starting operation, and always follow the instructions given in this manual.

The unit and motor are precision parts and must be handled carefully.

According to a United Nations Advisory, the battery unit and battery must be transported

according to the rules set forth by the International Civil Aviation Organization (ICAO),

International Air Transportation Association (IATA), International Maritime Organization

(IMO), and United States Department of Transportation (DOT), etc.

Page 12

CONTENTS

1. Preface

1-1 Inspection at purchase.................................................................................................................. 1-2

1-1-1 Package contents ................................................................................................................. 1-2

1-1-2 Rating nameplate.................................................................................................................. 1-2

1-1-3 Power supply unit model....................................................................................................... 1-2

1-1-4 Servo drive unit model.......................................................................................................... 1-3

1-1-5 Spindle drive unit model........................................................................................................ 1-3

1-2 Explanation of each part............................................................................................................... 1-4

1-2-1 Explanation of each power supply unit part.......................................................................... 1-4

1-2-2 Explanation of each servo drive unit part.............................................................................. 1-5

1-2-3 Explanation of each spindle drive unit part........................................................................... 1-5

2. Wiring and Connection

2-1 Part system connection diagram.................................................................................................. 2-3

2-2 Main circuit terminal block/control circuit connector..................................................................... 2-5

2-2-1 Connector pin assignment.................................................................................................... 2-5

2-2-2 Names and applications of main circuit termi nal block signals and control circuit connectors 2-7

2-2-3 How to use the control circuit terminal block (MDS-CH-SP-750)......................................... 2-8

2-3 NC and drive unit connection ....................................................................................................... 2-10

2-4 Motor and detector connection..................................................................................................... 2-11

2-4-1 Connection of HC-H Series .................................................................................................. 2-11

2-4-2 Connection of the spindle motor........................................................................................... 2-14

2-4-3 Connection of the linear servomotor LM-NP Series............................................................. 2-15

2-5 Connection of power supply......................................................................................................... 2-16

2-5-1 Standard connection............................................................................................................. 2-16

2-5-2 DC connection bar................................................................................................................ 2-18

2-5-3 Two-part system control of power supply unit....................................................................... 2-19

2-5-4 Using multiple power supply units ........................................................................................ 2-20

2-6 Connection of AC reactor............................................................................................................. 2-21

2-6-1 Features of the AC reactor.................................................................................................... 2-21

2-6-2 Wiring of AC reactor.............................................................................................................. 2-21

2-7 Wiring of contactors...................................................................................................................... 2-22

2-7-1 Contactor power ON sequences........................................................................................... 2-23

2-7-2 Contactor shutoff sequences................................................................................................ 2-23

2-7-3 Contactor control signal (MC1) output circuit........................................................................ 2-24

2-8 Wiring of the motor brake............................................................................................................. 2-25

2-8-1 Motor brake release sequence............................................................................................. 2-25

2-8-2 Control during the servo OFF command .............................................................................. 2-25

2-8-3 Operation sequences when an emergency stop occurs....................................................... 2-25

2-8-4 Motor brake control connector (CN20) output circuit............................................................ 2-26

2-9 Wiring of an external emergency stop.......................................................................................... 2-27

2-9-1 External emergency stop setting ......................................................................................... . 2-27

2-9-2 Operation sequences of CN23 external emergency stop function....................................... 2-28

2-9-3 Example of emergency stop circuit.......................................................................................

2-10 Connecting the Grounding Cable............................................................................................... 2-30

2-10-1 Connecting the Frame Ground (FG)................................................................................... 2-30

2-10-2 Grounding cable size.......................................................................................................... 2-30

3. Installation

3-1 Installation of the units.................................................................................................................. 3-2

3-1-1 Environmental conditions...................................................................................................... 3-2

3-1-2 Installation direction and clearance ...................................................................................... 3-3

3-1-3 Prevention of entering of foreign matter............................................................................... 3-3

3-1-4 Panel installation hole work drawings (Panel cut drawings)................................................. 3-4

3-1-5 Heating value........................................................................................................................ 3-5

3-1-6 Heat radiation countermeasures........................................................................................... 3-6

2-29

Page 13

3-2 Installation of servomotor/spindle motor....................................................................................... 3-7

3-2-1 Environmental conditions...................................................................................................... 3-7

3-2-2 Cautions for mounting load (prevention of impact on shaf t)................................................. 3-8

3-2-3 Installation direction.............................................................................................................. 3-8

3-2-4 Tolerable load of axis............................................................................................................ 3-9

3-2-5 Oil and waterproofing measures........................................................................................... 3-10

3-2-6 Cable stress.......................................................................................................................... 3-12

3-3 Installing the linear servomotor..................................................................................................... 3-13

3-3-1 Installation environment........................................................................................................ 3-13

3-3-2 Installing the linear servomotor............................................................................................. 3-13

3-3-3 Cooling the linear servomotor............................................................................................... 3-15

3-4 Noise measures............................................................................................................................ 3-16

4. Setup

4-1 Initial setup.................................................................................................................................... 4-2

4-1-1 Setting the rotary switch........................................................................................................ 4-2

4-1-2 Transition of LED display after power is turned ON.............................................................. 4-3

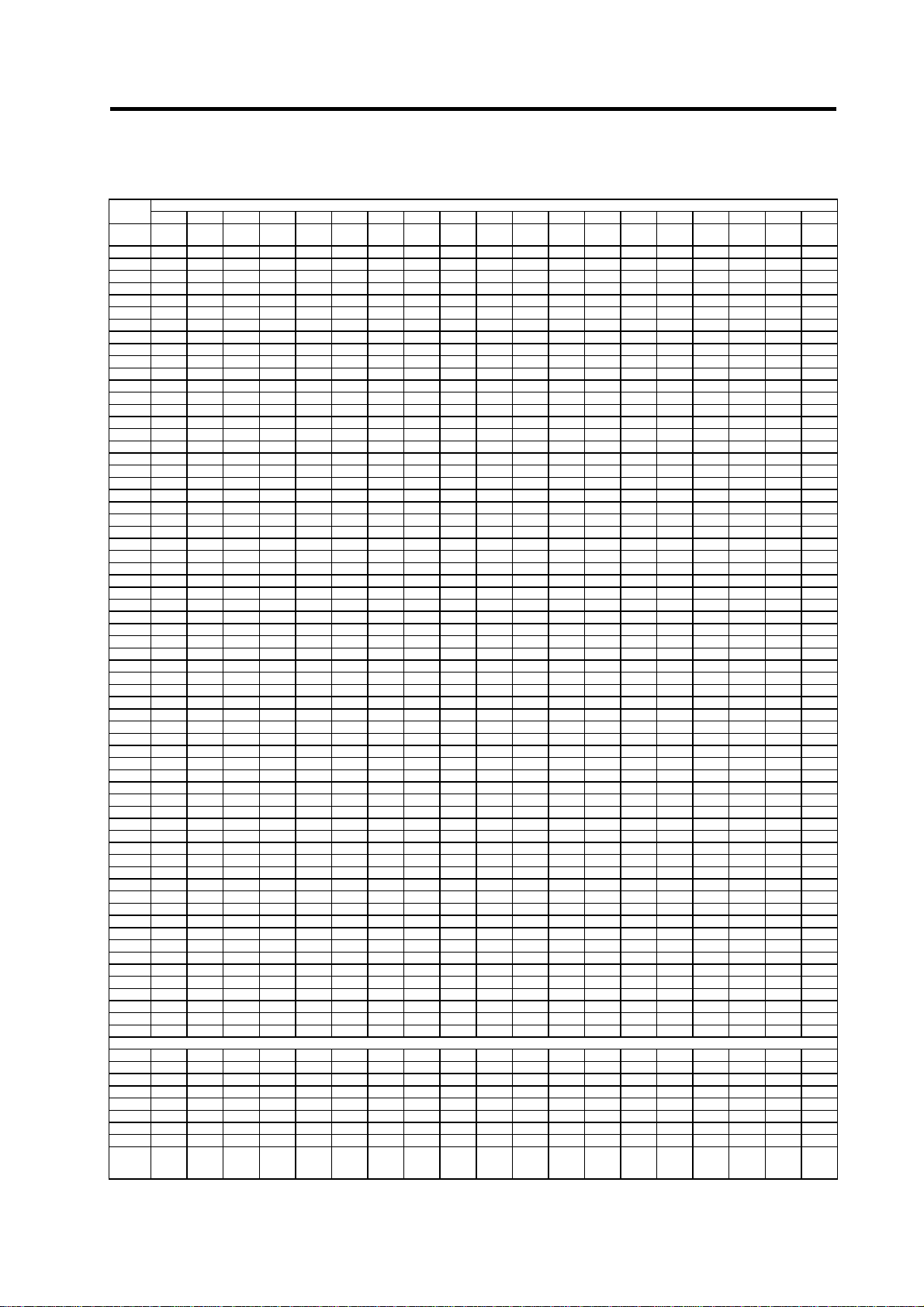

4-2 Servo drive unit initial parameter settings..................................................................................... 4-4

4-2-1 List of servo parameters....................................................................................................... 4-4

4-2-2 Limitations to electronic gear setting value........................................................................... 4-19

4-2-3 Setting excessive detection error width................................................................................ 4-19

4-2-4 Setting motor and detector model......................................................................................... 4-20

4-2-5 Setting servo specifications.................................................................................................. 4-21

4-2-6 Initial setup of the linear servo system.................................................................................. 4-22

4-2-7 Standard parameter list according to motor.......................................................................... 4-31

4-3 Spindle drive unit initial parameter settings.................................................................................. 4-33

4-3-1 List of spindle parameters..................................................................................................... 4-33

4-3-2 Details of bit-corresponding parameters............................................................................... 4-50

4-3-3 Setting spindle drive unit and motor model .......................................................................... 4-54

4-3-4 Spindle specification parameters screen.............................................................................. 4-55

4-3-5 Spindle control signals.......................................................................................................... 4-58

5. Adjustment

5-1 Servo adjustment data output function (D/A output) .................................................................... 5-2

5-1-1 D/A output specifications ...................................................................................................... 5-2

5-1-2 Setting the output data.......................................................................................................... 5-2

5-1-3 Setting the output magnification ........................................................................................... 5-2

5-2 Gain adjustment............................................................................................................................ 5-3

5-2-1 Current loop gain .................................................................................................................. 5-3

5-2-2 Speed loop gain.................................................................................................................... 5-3

5-2-3 Position loop gain.................................................................................................................. 5-5

5-3 Characteristics improvement........................................................................................................ 5-8

5-3-1 Optimal adjustment of cycle time.......................................................................................... 5-8

5-3-2 Vibration suppression measures .......................................................................................... 5-11

5-3-3 Improving the cutting surface precision................................................................................ 5-15

5-3-4 Improvement of protrusion at quadrant changeover............................................................. 5-23

5-3-6 Improvement of characteristics during acceleration/deceleration ........................................ 5-26

5-4 Settings for emergency stop......................................................................................................... 5-29

5-4-1 Vertical axis drop prevention control..................................................................................... 5-29

5-4-2 Deceleration control.............................................................................................................. 5-31

5-4-3 Dynamic braking stop ........................................................................................................... 5-32

5-5 Collision detection function........................................................................................................... 5-33

5-6 Spindle adjustment data output function (D/A output).................................................................. 5-36

5-6-1 D/A output specifications ...................................................................................................... 5-36

5-6-2 Parameter settings................................................................................................................ 5-36

5-6-3 Output data settings.............................................................................................................. 5-36

5-6-4 Setting the output magnification ........................................................................................... 5-37

Page 14

5-7 Spindle adjustment....................................................................................................................... 5-40

5-7-1 Items to check during trial operation..................................................................................... 5-40

5-7-2 Adjusting the spindle rotation speed..................................................................................... 5-40

5-7-3 Adjusting the acceleration/deceleration................................................................................ 5-40

5-7-4 Adjusting the orientation....................................................................................................... 5-42

5-7-5 Synchronous tap adjustment................................................................................................ 5-49

5-7-6 Z-phase (magnetic) automatic adjustment (Only when using IPM spindle motor)............... 5-51

5-7-7 PLG automatic adjustment ................................................................................................... 5-51

5-7-8 Calculating the theoretical acceleration/deceleration........................................................... 5-52

5-8 Spindle specifications ................................................................................................................... 5-54

5-8-1 Spindle coil changeover........................................................................................................ 5-54

6. Dedicated Options

6-1 Dynamic brake unit .................................................................................................................. 6-2

6-1-2 Outline dimension drawings of dynamic brake unit.............................................................. 6-3

6-2 Battery option................................................................................................................................ 6-4

6-2-1 Battery unit............................................................................................................................ 6-4

6-2-2 Connection............................................................................................................................ 6-8

6-2-3 Dedicated battery cable drawing .......................................................................................... 6-8

6-3 Cables and connectors................................................................................................................. 6-9

6-3-1 Cable option list .................................................................................................................... 6-10

6-3-2 Connector outline dimension drawings................................................................................. 6-14

6-3-3 Flexible conduits................................................................................................................... 6-21

6-3-4 Cable wire and assembly...................................................................................................... 6-23

6-3-5 Option cable connection diagram......................................................................................... 6-25

6-3-6 Main circuit cable connection drawing.................................................................................. 6-28

6-4 Scale I/F unit................................................................................................................................. 6-29

6-4-1 Outline................................................................................................................................... 6-29

6-4-2 Model configuration............................................................................................................... 6-29

6-4-3 List of specifications.............................................................................................................. 6-29

6-4-4 Unit outline dimension drawing............................................................................................. 6-30

6-4-5 Description of connector ....................................................................................................... 6-30

6-4-6 Example of detector conversion unit connection.................................................................. 6-31

6-4-7 Cables................................................................................................................................... 6-32

6-5 Magnetic pole detection unit......................................................................................................... 6-36

6-5-1 Outline................................................................................................................................... 6-36

6-5-2 Model configuration............................................................................................................... 6-36

6-5-3 List of specifications.............................................................................................................. 6-36

6-5-4 Outline dimensions ............................................................................................................... 6-36

6-5-5 Assignment of connector pins............................................................................................... 6-37

6-5-6 Installing onto the linear servomotor..................................................................................... 6-37

6-6 Detectors ...................................................................................................................................... 6-38

6-6-1 List of detector specifications................................................................................................ 6-38

6-6-2 Outline dimension drawings.................................................................................................. 6-39

6-6-3 Cable connection diagram.................................................................................................... 6-41

6-6-4 Maintenance .............................................................................................................

6-7 Spindle option specification parts................................................................................................. 6-43

6-7-1 Magnetic sensor orientation (one-point orientation)............................................................. 6-44

6-7-2 Multi-point orientation using encoder (4096-point orientation)............................................. 6-48

6-7-3 Multi-point orientation using motor built-in encoder (4096-point orientation) ....................... 6-51

6-7-4 Contour control (C axis control) encoder.............................................................................. 6-53

6-7-5 Integrated rotary encoder (Special order part)...................................................................... 6-56

6-8 AC reactor..................................................................................................................................... 6-57

6-8-1 Combination with power supply unit..................................................................................... 6-57

6-8-2 Outline dimension drawings.................................................................................................. 6-57

............ 6-42

Page 15

7. Peripheral Devices

7-1 Selection of wire ........................................................................................................................... 7-2

7-1-1 Example of wires by unit....................................................................................................... 7-2

7-2 Selection of main circuit breaker and contactor ........................................................................... 7-5

7-2-1 Selection of earth leakage breaker....................................................................................... 7-5

7-2-2 Selection of no-fuse breaker................................................................................................. 7-6

7-2-3 Selection of contactor ........................................................................................................... 7-7

7-3 Control circuit related.................................................................................................................... 7-8

7-3-1 Circuit protector..................................................................................................................... 7-8

7-3-2 Fuse protection..................................................................................................................... 7-9

7-3-3 Relays................................................................................................................................... 7-10

7-3-4 Surge absorber..................................................................................................................... 7-11

8. Troubleshooting

8-1 Points of caution and confirmation ............................................................................................... 8-2

8-2 Troubleshooting at start up........................................................................................................... 8-3

8-3 Protective functions list of units .................................................................................................... 8-4

8-3-1 List of alarms......................................................................................................................... 8-4

8-3-2 List of warnings..................................................................................................................... 8-16

8-3-3 Protection functions and resetting methods ......................................................................... 8-17

8-3-4 Parameter numbers during initial parameter error................................................................ 8-19

8-3-5 Troubleshooting.................................................................................................................... 8-20

8-4 Spindle system troubleshooting.................................................................................................... 8-39

8-4-1 Introduction........................................................................................................................... 8-39

8-4-2 First step............................................................................................................................... 8-39

8-4-3 Second step.......................................................................................................................... 8-40

8-4-4 When there is no alarm or warning....................................................................................... 8-41

9. Characteristics

9-1 Overload protection characteristics.............................................................................................. 9-2

9-1-1 Servomotor (HC-H series) .................................................................................................... 9-2

9-1-2 Linear servomotor (LM-NP Series)....................................................................................... 9-9

9-2 Duty characteristics ...................................................................................................................... 9-10

9-3 Magnetic brake characteristics..................................................................................................... 9-14

9-4 Dynamic brake characteristics...................................................................................................... 9-17

9-4-1 Deceleration torque............................................................................................................... 9-17

9-4-2 Determining the coasting amount with emergency stop....................................................... 9-18

9-5 Vibration class .............................................................................................................................. 9-20

10. Specifications

10-1 Power supply unit/drive unit........................................................................................................ 10-2

10-1-1 Installation environment conditions..................................................................................... 10-2

10-1-2 Servo drive unit................................................................................................................... 10-2

10-1-3 Spindle drive unit................................................................................................................. 10-3

10-1-4 Power supply unit................................................................................................................ 10-3

10-1-5 Outline dimension drawings................................................................................................ 10-4

10-1-6 Terminal layout.................................................................................................................... 10-8

10-1-7 The combination of servo drive unit and a motor ............................................................... 10-9

10-2 Servomotor................................................................................................................................. 10-10

10-2-1 Specifications list................................................................................................................. 10-10

10-2-2 Torque characteristics......................................................................................................... 10-12

10-2-3 Model configuration............................................................................................................. 10-14

10-2-4 Outline dimension drawings................................................................................................ 10-15

Page 16

10-3 Linear servomotor....................................................................................................................... 10-21

10-3-1 List of specifications............................................................................................................ 10-21

10-3-2 Outline dimension drawings................................................................................................ 10-22

11. Selection

11-1 Selection of servomotor.............................................................................................................. 11-2

11-1-1 Servomotor.......................................................................................................................... 11-2

11-1-2 Regeneration methods........................................................................................................ 11-3

11-1-3 Motor series characteristics ................................................................................................ 11-4

11-1-4 Servomotor precision.......................................................................................................... 11-4

11-1-5 Selection of servomotor capacity........................................................................................ 11-6

11-1-6 Example of servo selection................................................................................................. 11-10

11-1-7 Motor shaft conversion load torque..................................................................................... 11-13

11-1-8 Expressions for load inertia calculation............................................................................... 11-14

11-1-9 Other precautions................................................................................................................ 11-15

11-2 Selection of linear servomotor.................................................................................................... 11-16

11-2-1 Maximum feedrate .............................................................................................................. 11-16

11-2-2 Maximum thrust................................................................................................................... 11-16

11-2-3 Continuous thrust................................................................................................................ 11-18

11-3 Selection of the power supply unit.............................................................................................. 11-20

11-3-1 Selection of the power supply unit capacity ........................................................................ 11-20

11-3-2 Selection with continuous rated capacity............................................................................ 11-20

11-3-3 Selection with maximum momentary rated capacity ........................................................... 11-22

12. Inspection

12-1 Inspections.................................................................................................................................. 12-2

12-2 Service parts............................................................................................................................... 12-2

12-3 Daily inspections......................................................................................................................... 12-3

12-3-1 Maintenance tools............................................................................................................... 12-3

12-3-2 Inspection positions ............................................................................................................ 12-3

12-4. Replacement methods of units and parts..................................................................................... 12-4

12-4-1 Drive unit and power supply unit replacements..................................................................... 12-4

12-4-2 Battery unit replacements...................................................................................................... 12-4

12-4-3 Cooling fan replacements...................................................................................................... 12-4

Appendix 1. Compliance to EC Directives

1. European EC Directives.................................................................................................................... A1-2

2. Cautions for EC Directive compliance............................................................................................... A1-2

Appendix 2. EMC Installation Guidelines

1. Introduction........................................................................................................................................ A2-2

2. EMC Instructions............................................................................................................................... A2-2

3. EMC Measures.................................................................................................................................. A2-3

4. Measures for panel structure............................................................................................................. A2-3

4.1 Measures for control box unit................................................................................................... A2-3

4.2 Measures for door.................................................................................................................... A2-4

4.3 Measures for operation board panel........................................................................................ A2-4

4.4 Shielding of the power supply input section............................................................................. A2-4

5. Measures for various cables ............................................................................................................. A2-5

5.1 Measures for wiring in box ....................................................................................................... A2-5

5.2 Measures for shield treatment.................................................................................................. A2-5

5.3 Servomotor power cable .......................................................................................................... A2-6

5.4 Servomotor feedback cable ..................................................................................................... A2-6

5.5 Spindle motor power cable....................................................................................................... A2-7

5.6 Cable between control box and operation board panel........................................................... A2-7

Page 17

6. EMC Countermeasure Parts ............................................................................................................. A2-8

6.1 Shield clamp fitting................................................................................................................... A2-8

6.2 Ferrite core............................................................................................................................... A2-9

6.3 Power line filter......................................................................................................................... A2-10

6.4 Surge protector......................................................................................................................... A2-12

Appendix 3. EC Declaration of conformity

1. Low voltage equipment...................................................................................................................... A3-2

2. Electromagnetic compatibility............................................................................................................ A3-12

Appendix 4. Instruction Manual for Compliance with UL/c-UL Standard

1. UL/c-UL listed products..................................................................................................................... A4-2

2. Operation surrounding air ambient temperature ............................................................................... A4-3

3. Notes for AC servo/spindle system................................................................................................... A4-3

3.1 General Precaution .................................................................................................................. A4-3

3.2 Installation................................................................................................................................ A4-3

3.3 Short-circuit ratings .................................................................................................................. A4-3

3.5 Field Wiring Reference Table for Input and Output.................................................................. A4-4

3.6 Motor Over Load Protection..................................................................................................... A4-6

3.7 Flange of servomotor ............................................................................................................... A4-7

3.8 Spindle Drive / Motor Combinations......................................................................................... A4-7

4. AC Servo/Spindle System Connection.............................................................................................. A4-8

Appendix 5. Higher Harmonic Suppression Measure Guidelines

1. Calculating the equivalent capacity of the higher harmonic generator ............................................. A5-3

1.1 Calculating the total equivalent capacity (Step 1).................................................................... A5-3

1.2 Calculating the higher harmonic current flow (Step 2)............................................................. A5-4

Appendix 6. Transportation Restrictions for Lithium Batteries

Appendix 6-1 Transportation restrictions for lithium batteries ............................................................ A6-2

Appendix 6-1-1 Restriction for packing.......................................................................................... A6-2

Appendix 6-1-2 Issuing domestic law of the United State for primary lithium battery transportation A6-5

Appendix 7. Compliance with China Compulsory Product Certification (CCC Certification) System

Appendix 7-1 Outline of China Compulsory Product Certification System......................................... A7-2

Appendix 7-2 First Catalogue of Products subject to Compulsory Product Certification ................... A7-2

Appendix 7-3 Precautions for Shipping Products...............................................................................

Appendix 7-4 Application for Exemption............................................................................................. A7-4

Appendix 7-5 Mitsubishi NC Product Subject to/Not Subject to CCC Certification............................ A7-5

A7-3

Page 18

1. Preface

1-1 Inspection at purchase....................................................................................................................... 1-2

1-1-1 Package contents........................................................................................................................1-2

1-1-2 Rating nameplate........................................................................................................................ 1-2

1-1-3 Power supply unit model.............................................................................................................1-2

1-1-4 Servo drive unit model................................................................................................................. 1-3

1-1-5 Spindle drive unit model.............................................................................................................. 1-3

1-2 Explanation of each part ....................................................................................................................1-4

1-2-1 Explanation of each power supply unit part ................................................................................ 1-4

1-2-2 Explanation of each servo drive unit part.................................................................................... 1-5

1-2-3 Explanation of each spindle drive unit part ................................................................................. 1-5

1 - 1

Page 19

1. Preface

1-1 Inspection at purchase

Open the package, and read the rating nameplates to confirm that the drive units, power supply unit and

servomotor are as ordered.

1-1-1 Package contents

Packaged parts Qty. Packaged parts Qty.

Power supply unit 1 Servo drive unit 1

Servo/spindle motor 1 Spindle drive unit 1

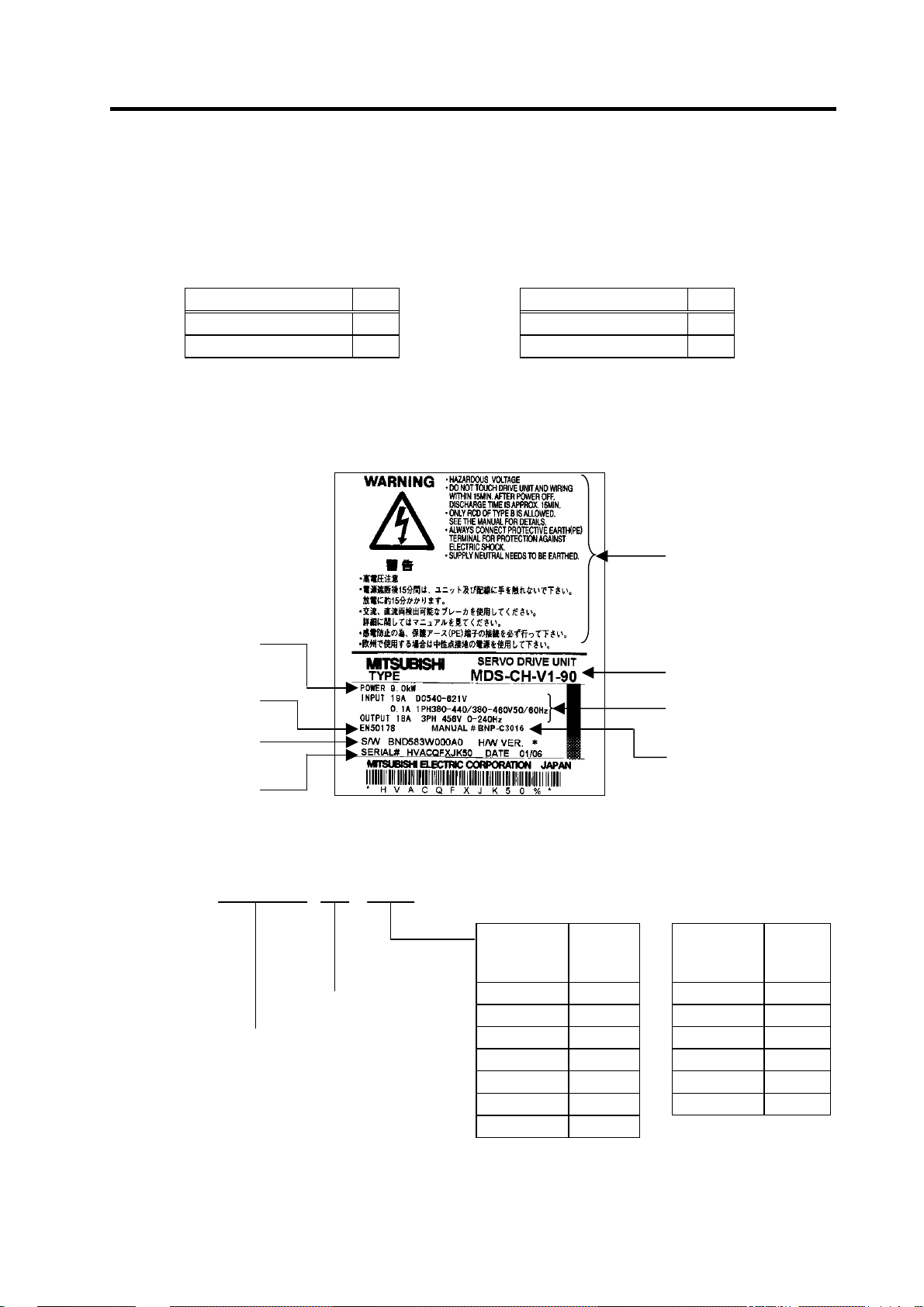

1-1-2 Rating nameplate

The rating nameplate is attached to the front of the unit.

The following rating nameplate is for the servo drive unit. The same matters are indicated on the power

supply unit and spindle drive unit.

Unit Capacity

Global industrial

standards

Software version

Serial No., Date of

manufacture

1-1-3 Power supply unit model

MDS - CH - CV - [ ]

Power supply unit

Series

(Note) DC connection bar is required. Always install a large capacity drive unit in the left

side of power supply unit, and connect with DC connection bar.

Rated

Symbol

37 2.2 260 22.0

55 3.7 300 26.0

75 5.5 370 30.0

110 7.5 450(Note) 37.0

150 11.0 550(Note) 45.0

185 15.0 750(Note) 55.0

220 18.5

Output

[kW]

Caution statement

Model

Input/output condition

Instruction manual No.

Rated

Symbol

Output

[kW]

1 - 2

Page 20

1-1-4 Servo drive unit model

MDS - CH - V1 - [ ]

1-axis servo drive unit

Series

(Note) DC connection bar is required. Always install a large capacity drive unit in the left side of

power supply unit, and connect with DC connection bar.

MDS - CH - V2 - [ ]

2-axis servo drive unit

Series

1-1-5 Spindle drive unit model

MDS - CH - SP[ ] - [ ]

Series

Spindle drive unit

(Note) DC connection bar is required. Always install a large capacity drive unit in the left side of

power supply unit, and connect with DC connection bar.

1. Preface

Symbol

Rated

Output

[kW]

Symbol

Rated

Output

[kW]

05 0.5 70 7.0

10 1.0 90 9.0

20 2.0 110 11.0

35 3.5 150 15.0

45 4.5 185(Note) 18.5

Symbol

Rated

Output

[kW]

Symbol

Rated

Output

[kW]

0505 0.5 / 0.5 3510 3.5 / 1.0

1005 1.0 / 0.5 3520 3.5 / 2.0

1010 1.0 / 1.0 3535 3.5 / 3.5

2010 2.0 / 1.0 4520 4.5 / 2.0

2020 2.0 / 2.0

4535 4.5 / 3.5

Symbol

Cont.

Rating

[kW]

Symbol

Cont.

Rating

[kW]

15 0.75 185 15.0

22 1.5 220 18.5

37 2.2 260 22.0

55 3.7 300 26.0

75 5.5 370(Note) 30.0

110 7.5 450(Note) 37.0

150 11.0 550(Note) 45.0

750(Note) 55.0

Symbol

Corresponding spindle motor

None Standard specifications part

H • High-speed part: 10000r/min or more

• C axis detector (1/10000

o

)

correspondence:

ERM280 (HEIDENHAIN)

• IPM spindle motor compatible

(Conventional SPM class has been

eliminated.)

1 - 3

Page 21

1

1. Preface

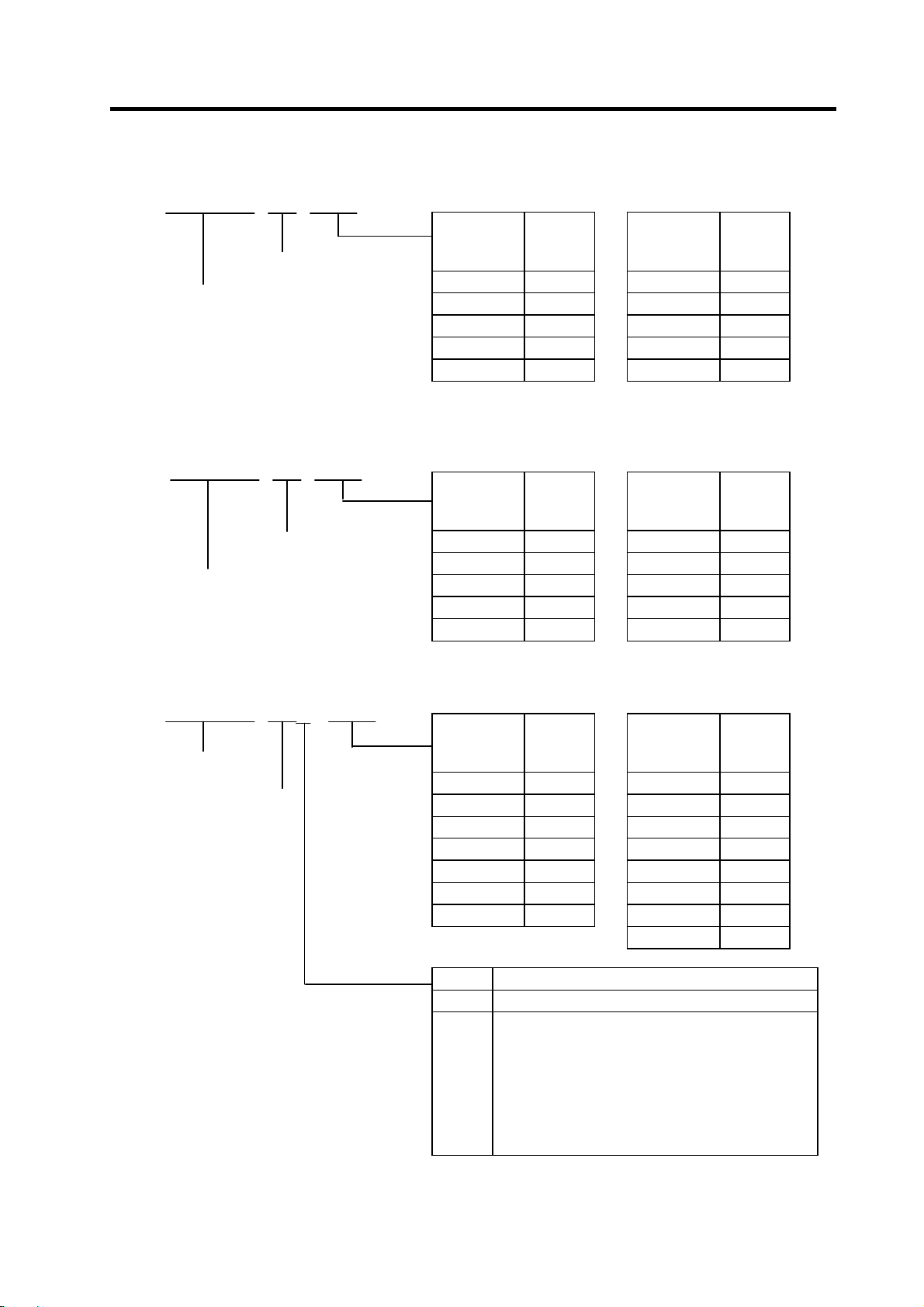

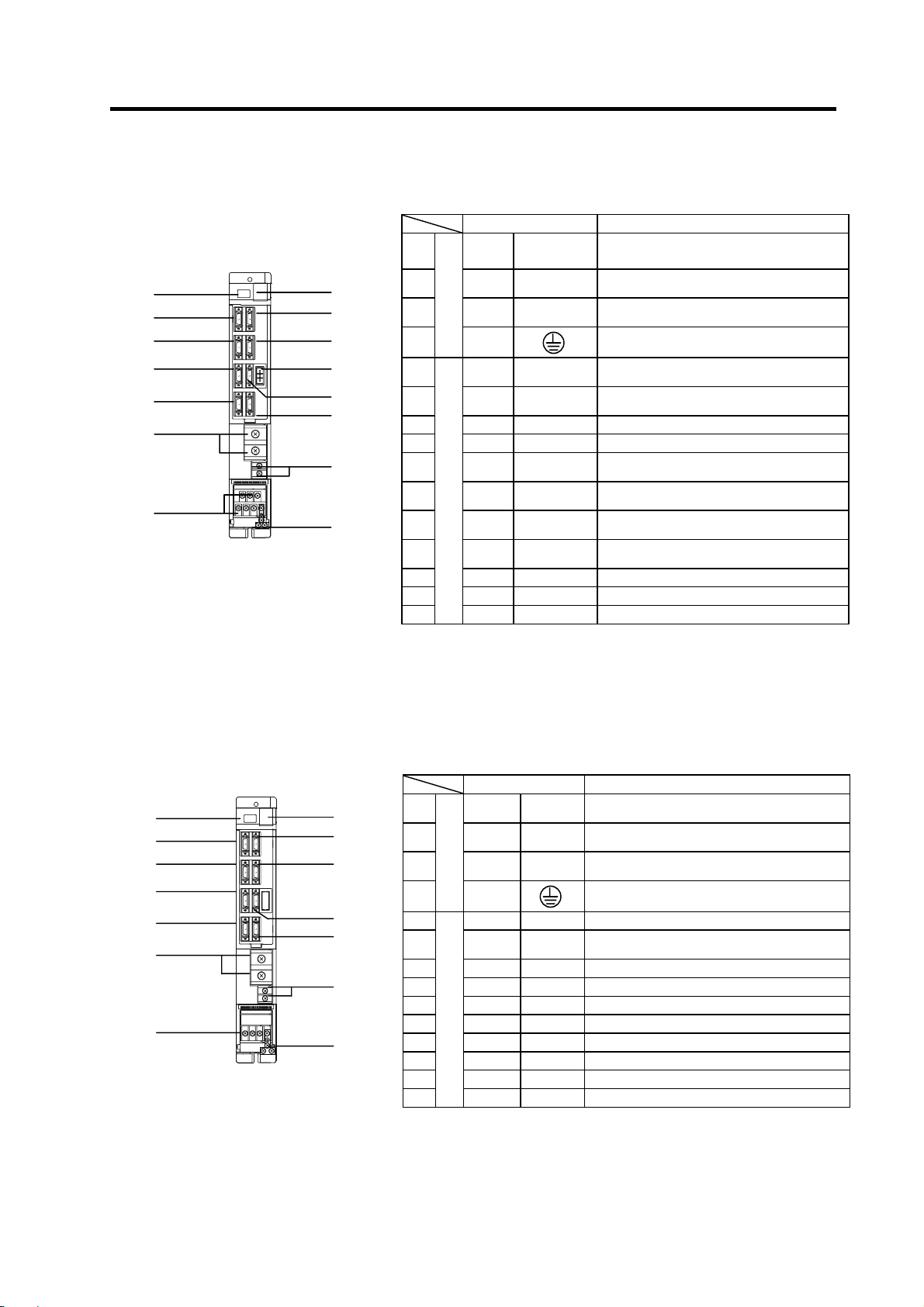

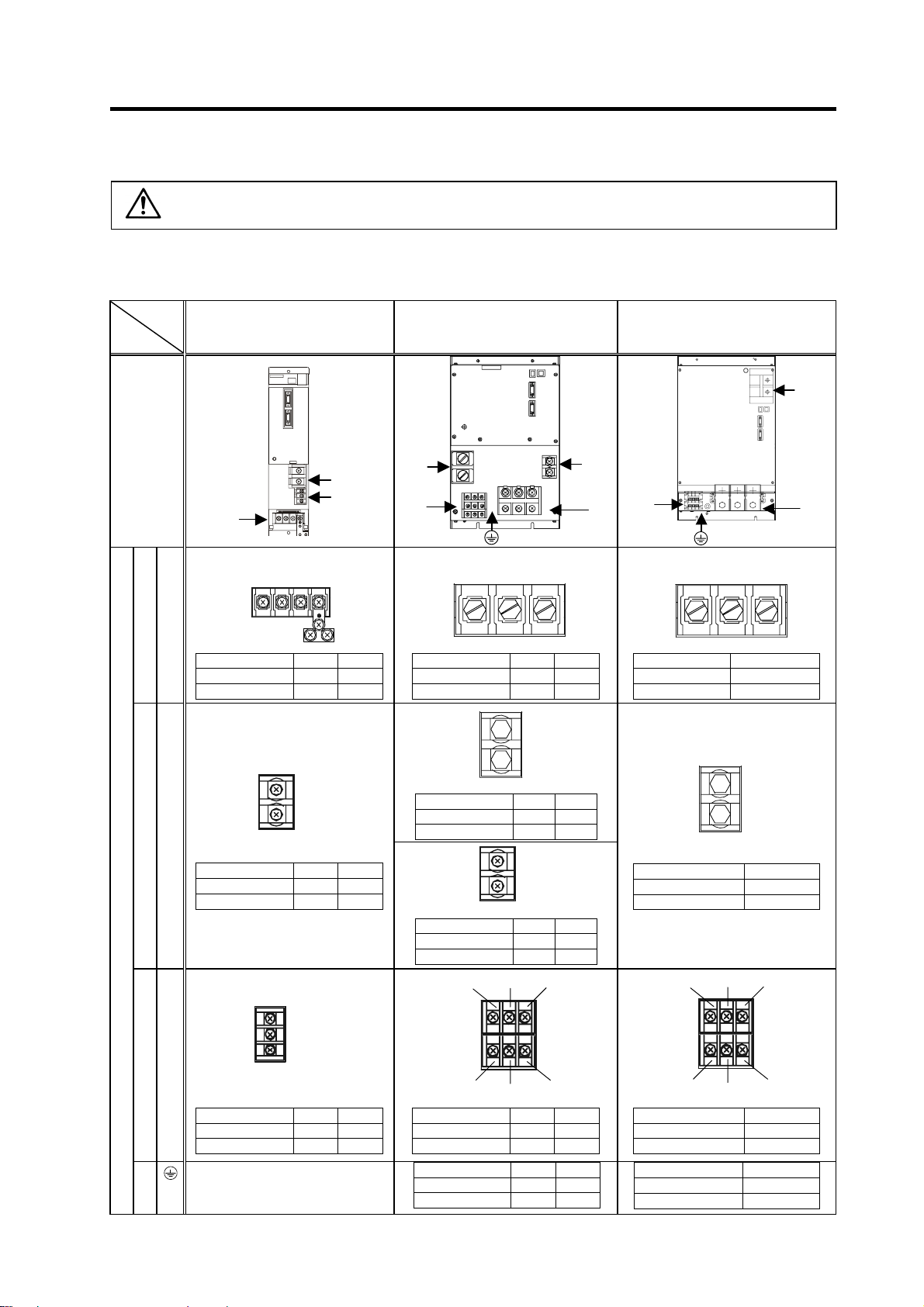

1-2 Explanation of each part

1-2-1 Explanation of each power supply unit part

<9>

<5>

<6>

<2>

<1>

<9>

<10>

<2>

<8>

<10>

<3>

<4>

<7>

-

<3>

<1>

<4>

Each part name

<1> TE1 L1, L2, L3

<2> TE2 L+, L–

<3> TE3

Main circuit

<4> PE

<10>

<5> CN4 ---

<6> CN9 --<7> CN23 --- External emergency stop input connector

<8> SW1 --- Power supply setting switch

Control circuit

<9>

Precautions

CN23 is located at the bottom of the power supply unit.

Each part name

<8>

<5>

<6>

<1> TE1 L1, L2, L3

-1

<2>

-2

<2>

<3> TE3

<4> PE

-2

<2>

<10>

<5> CN4 ---

<6> CN9 --<7> CN23 --- External emergency stop input connector

<8> SW1 --- Power supply setting switch

<7>

<9>

Precautions

CN23 is located at the bottom of the power supply unit.

TE2-2 is used to connect a 30kW or smaller drive unit.

Main circuit

Control circuit

The connector layout will differ according to the units being used.

Check each unit outline drawing for details.

Name Description

Power supply input terminal

(3-phase AC input)

Converter voltage output terminal

(DC output)

L11, L21

MC1 External contactor control terminal

CHARGE

---

LED --- Power supply status indication LED

TE2-1 L+, L–

TE2-2 L+, L–

LAMP

Name Description

L11, L21

MC1, MC2 External contactor control terminal

CHARGE

---

LED --- Power supply status indication LED

Control power input terminal (single-phase

AC input)

Grounding terminal

TE2 output charging/discharging circuit

indication LED

Servo/spindle communication connector

(master)

Servo/spindle communication connector

(slave)

Power supply input terminal

(3-phase AC input)

Voltage output terminal (DC output)

CV-450/550/750

Voltage output terminal (DC output)

CV-450/550

Control power input terminal

(single-phase AC input)

LAMP

Grounding terminal

TE2 output charging circuit indication

LED

Servo/spindle communication connector

(master)

Servo/spindle communication connector

(slave)

1 - 4

Page 22

r

r

r

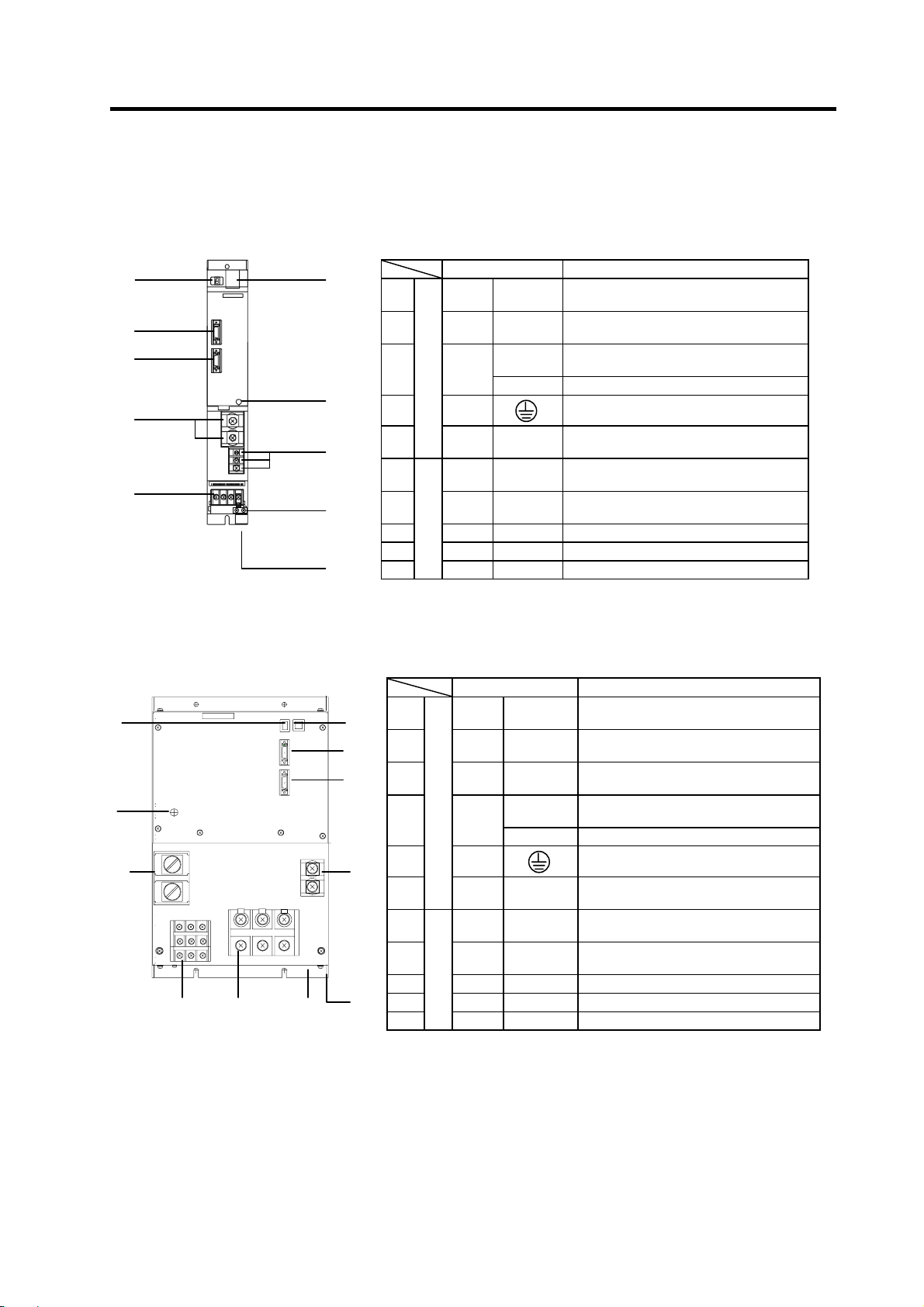

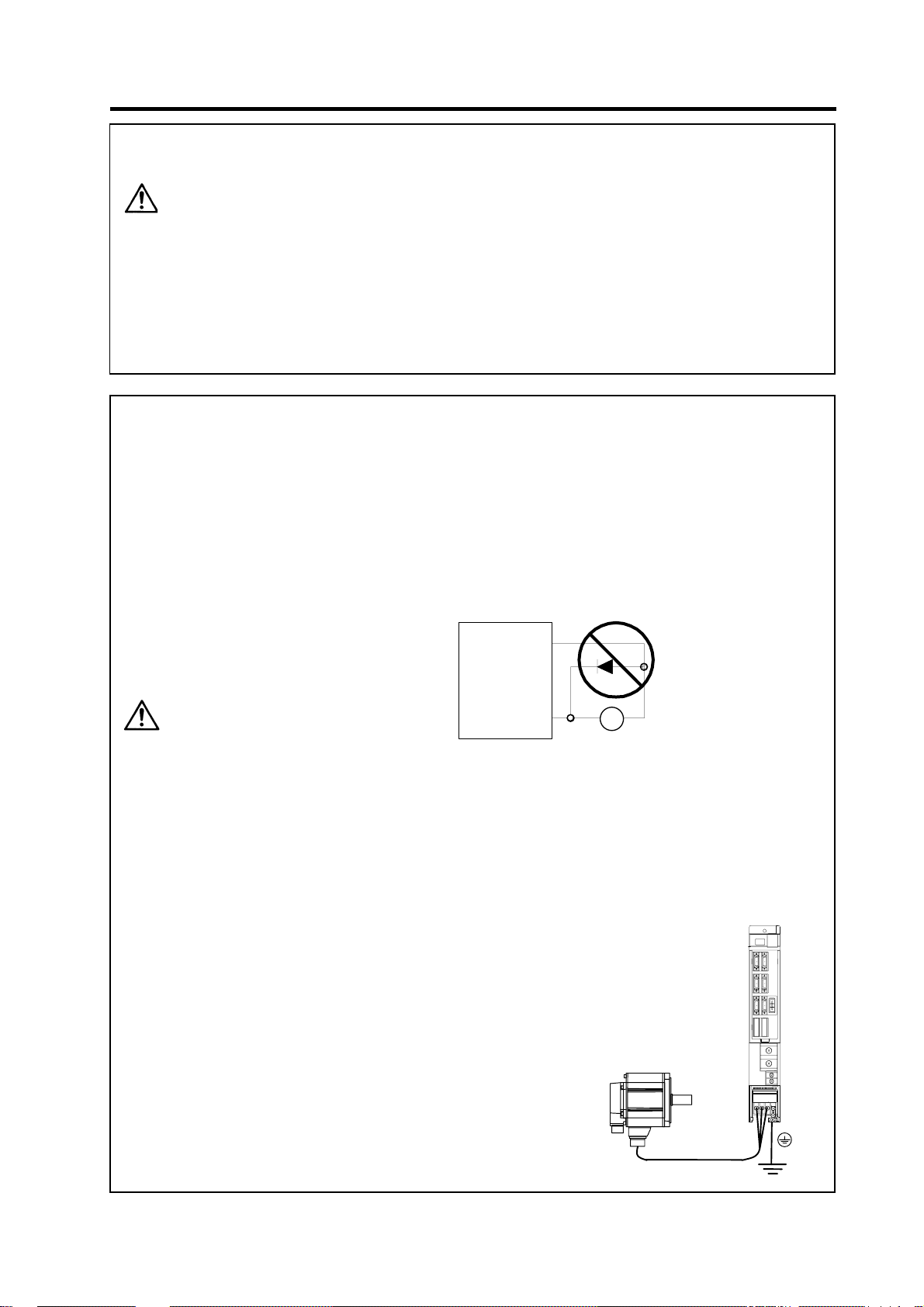

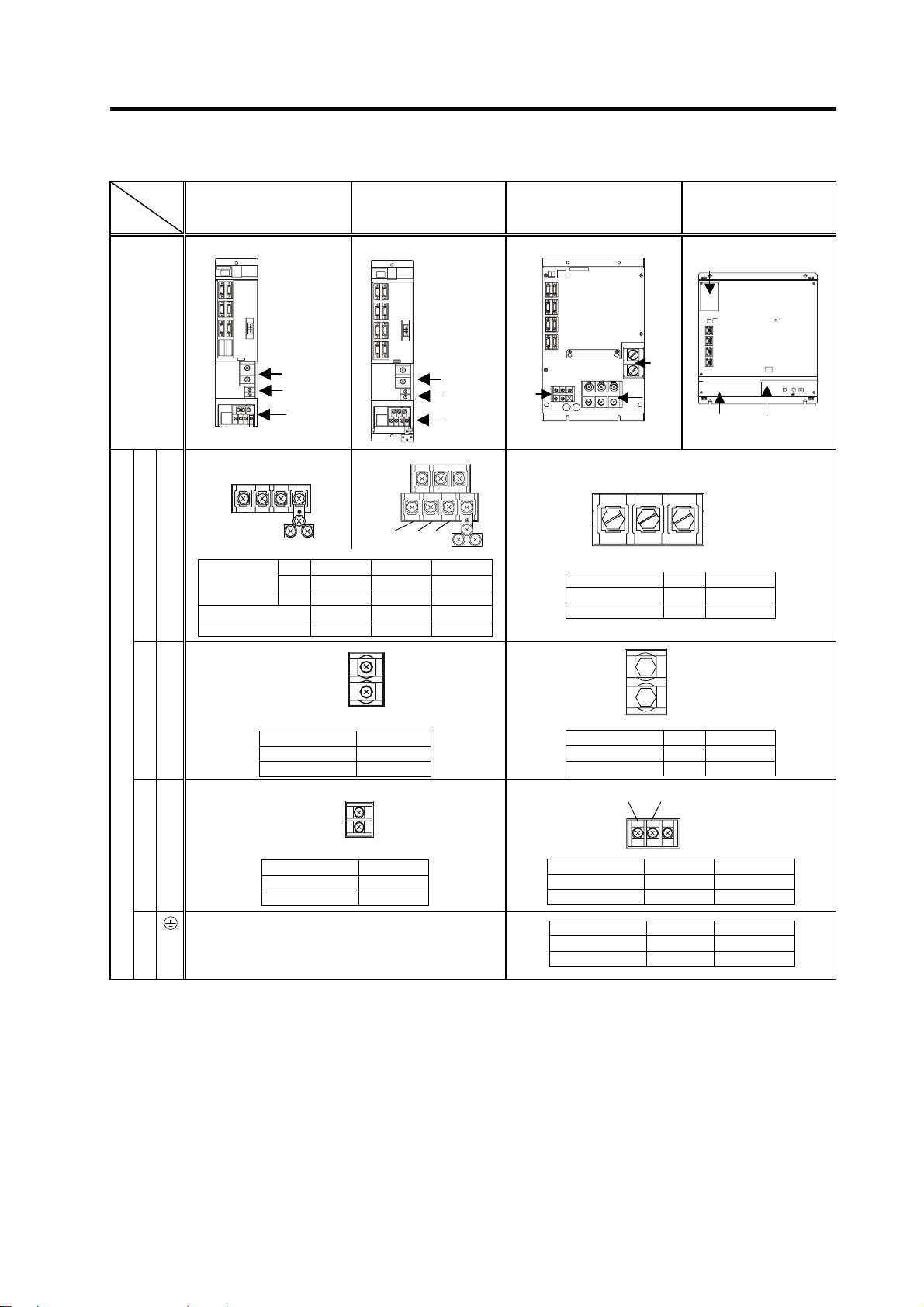

1. Preface

1-2-2 Explanation of each servo drive unit part

Each part name

<1> TE1

<15>

<5>

<8>

<9>

<10>

<2>

<1>

<14>

<6>

<7>

<13>

<11>

<12>

<3>

<4>

<2> TE2 L+, L–

<3> TE3 L11, L21

Main circuit

<4>

<5> CN1A --<6> CN1B ---

<7> CN4 --<8> CN9 ---

<9> CN2L --<10> CN2M --<11> CN3L --<12> CN3M ---

<13> CN20 --- Electromagnetic/dynamic brake connector

<14> SW1 --- Axis No. setting switch

<15>

Precautions

1. The connector names differ for the V1 drive unit.

(CN2L/CN3L → CN2/CN3, CN2M/CN3M → Not mounted)

The MU, MV and MW terminals are not provided. The LU, LV and LW terminals

are named U, V and W.

PE

Control circuit

LED --- Unit status indication LED

1-2-3 Explanation of each spindle drive unit part

<15>

<5>

<10>

<8>

<9>

<2>

<1>

<14>

<6>

<7>

<11>

<12>

<3>

<4>

Each part name

<1> TE1 U, V, W

<2> TE2 L+, L–

<3> TE3 L11, L21

<4>

<5> CN1A --<6> CN1B --<7> CN4 ---

<8> CN9 ---

<9> CN5 --<10> CN7 --<11> CN6 --<12> CN8 --<14> SW1 --- Axis No. setting switch

<15>

Precautions

Main circuit

PE

Control circuit

LED --- Unit status indication LED

The connector and terminal block layout will differ according to the

units being used.

Check each unit outline drawing for details.

Name Description

MU, MV, MW

LU, LV, LW

Name Description

Motor drive output terminal

(3-phase AC output)

Converter voltage input terminal

(DC input)

Control power input terminal

(single-phase AC input)

Grounding terminal

NC or upward axis communication

connecto

Battery unit/terminator

Lower axis communication connecto

Power supply communication connector

Maintenance connector (normally not used)

Motor side detector connection connector

(L axis)

Motor side detector connection connector

(M axis)

Machine side detector connection

connector (L axis)

Machine side detector connection

connector (M axis)

Motor drive output terminal

(3-phase AC output)

Converter voltage input terminal

(DC input)

Control power input terminal

(single-phase AC input)

Grounding terminal

NC or upward axis communication connector

Battery unit/terminator lower axis

communication connecto

Power supply communication connector

Maintenance connector (normally not used)

Internal PLG encoder connection connector

C axis control encoder connection connector

Magnetic sensor connection connector

CNC connection connector

1 - 5

Page 23

2. Wiring and Connection

2-1 Part system connection diagram........................................................................................................ 2-3

2-2 Main circuit terminal block/control circuit connector ..........................................................................2-5

2-2-1 Connector pin assignment ..........................................................................................................2-5

2-2-2 Names and applications of main circuit terminal block signals and control circuit connectors ..2-7

2-2-3 How to use the control circuit terminal block (MDS-CH-SP-750) ...............................................2-8

2-3 NC and drive unit connection...........................................................................................................2-10

2-4 Motor and detector connection ........................................................................................................2-11

2-4-1 Connection of HC-H Series.......................................................................................................2-11

2-4-2 Connection of the spindle motor ...............................................................................................2-14

2-4-3 Connection of the linear servomotor LM-NP Series.................................................................. 2-15

2-5 Connection of power supply............................................................................................................. 2-16

2-5-1 Standard connection .................................................................................................................2-16

2-5-2 DC connection bar.....................................................................................................................2-18

2-5-3 Two-part system control of power supply unit........................................................................... 2-19

2-5-4 Using multiple power supply units.............................................................................................2-20

2-6 Connection of AC reactor.................................................................................................................2-21

2-6-1 Features of the AC reactor........................................................................................................2-21

2-6-2 Wiring of AC reactor.................................................................................................................. 2-21

2-7 Wiring of contactors .........................................................................................................................2-22

2-7-1 Contactor power ON sequences............................................................................................... 2-23

2-7-2 Contactor shutoff sequences ....................................................................................................2-23

2-7-3 Contactor control signal (MC1) output circuit............................................................................2-24

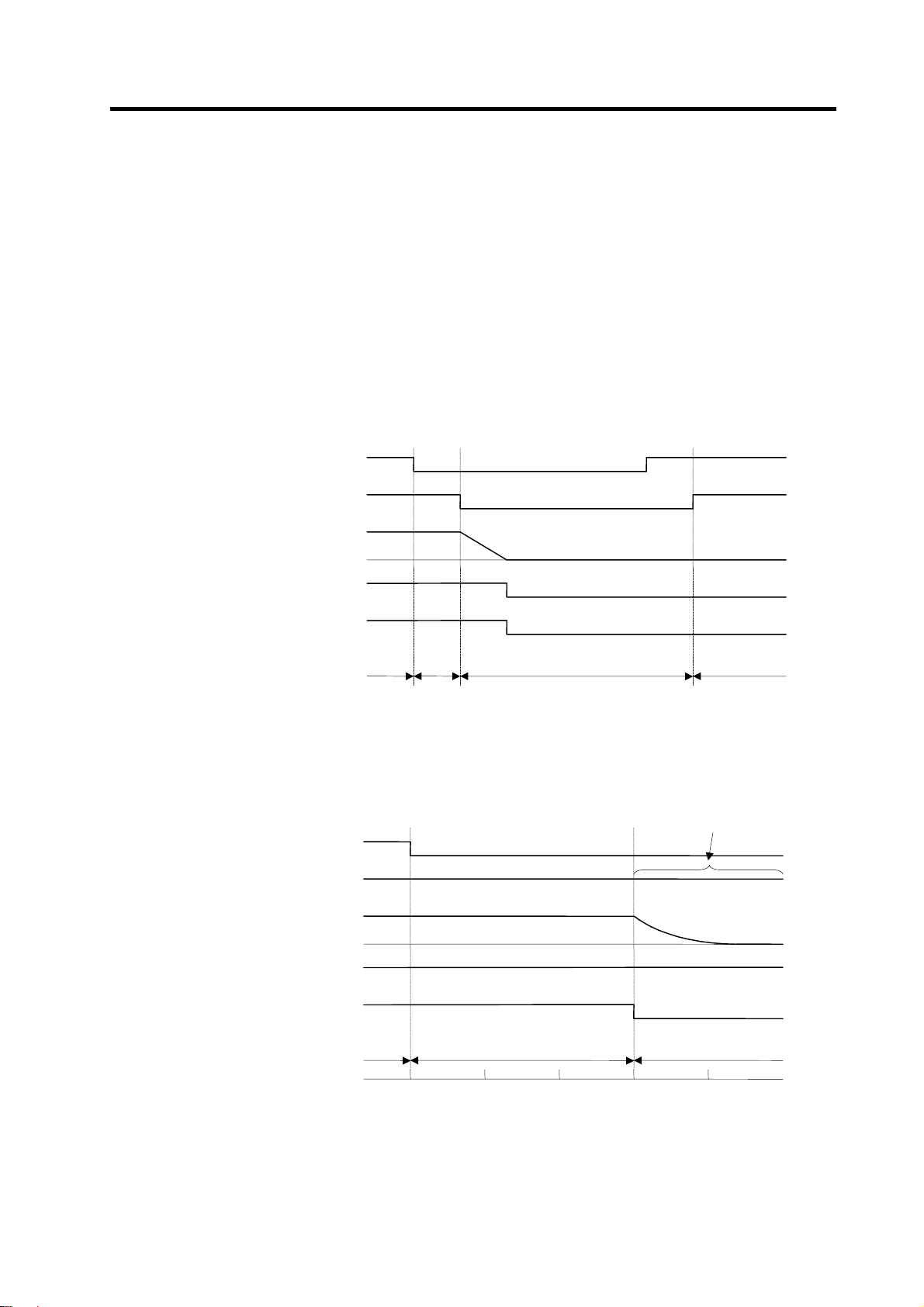

2-8 Wiring of the motor brake.................................................................................................................2-25

2-8-1 Motor brake release sequence..................................................................................................2-25

2-8-2 Control during the servo OFF command...................................................................................2-25

2-8-3 Operation sequences when an emergency stop occurs...........................................................2-25

2-8-4 Motor brake control connector (CN20) output circuit................................................................2-26

2-9 Wiring of an external emergency stop .............................................................................................2-27

2-9-1 External emergency stop setting...............................................................................................2-27

2-9-2 Operation sequences of CN23 external emergency stop function ........................................... 2-28

2-9-3 Example of emergency stop circuit...........................................................................................2-29

2-10 Connecting the Grounding Cable................................................................................................... 2-30

2-10-1 Connecting the Frame Ground (FG).......................................................................................2-30

2-10-2 Grounding cable size...............................................................................................................2-30

2 - 1

Page 24

2. Wiring and Connection

DANGER

1. Wiring work must be done by a qualified technician.

2. Wait at least 15 minutes after turning the power OFF and check the voltage

with a tester, etc., before starting wiring. Failure to observe this could lead to

electric shocks.

3. Securely ground the drive units and servo/spindle motor with Class 3

grounding or higher.

4. Wire the drive units and servo/spindle motor after installation. Failure to

observe this could lead to electric shocks.

5. Do not damage, apply forcible stress, place heavy items on the cables or get

them caught. Failure to observe this could lead to electric shocks.

6. Always insulate the power terminal connection section. Failure to observe

this could lead to electric shocks.

1. Correctly and securely perform the wiring. Failure to do so could lead to

runaway of the servo/spindle motor.

2. Do not mistake the terminal connections.

Failure to observe this item could lead to ruptures or damage, etc.

3. Do not mistake the polarity ( + ,

– ). Failure to observe this item could lead to

ruptures or damage, etc.

4. Do not mistake the direction of the diodes for the surge absorption installed

on the DC relay for the motor brake and contactor (magnetic contactor)

control. The signal might not be output when a failure occurs.

Drive uni t

COM

(24VDC)

CAUTION

Control output signal

RA

5. Electronic devices used near the drive units may receive magnetic

obstruction. Reduce the effect of magnetic obstacles by installing a noise

filter, etc.

6. Do not install a phase advancing capacitor, surge absorber or radio noise

filter on the power line (U, V, W) of the servo/spindle motor.

7. Do not modify this unit.

8. The half-pitch connector (CN1A, etc.) on the front of the drive units have the

same shape. If the connectors are connected incorrectly, faults could occur.

Make sure that the connection is correct.

9. When grounding the motor, connect to

the protective grounding terminal on the

drive units, and ground from the other

protective grounding terminal.

(Use one-point grounding)

Do not separately ground the connected

motor and drive unit as noise could be

generated.

2 - 2

Page 25

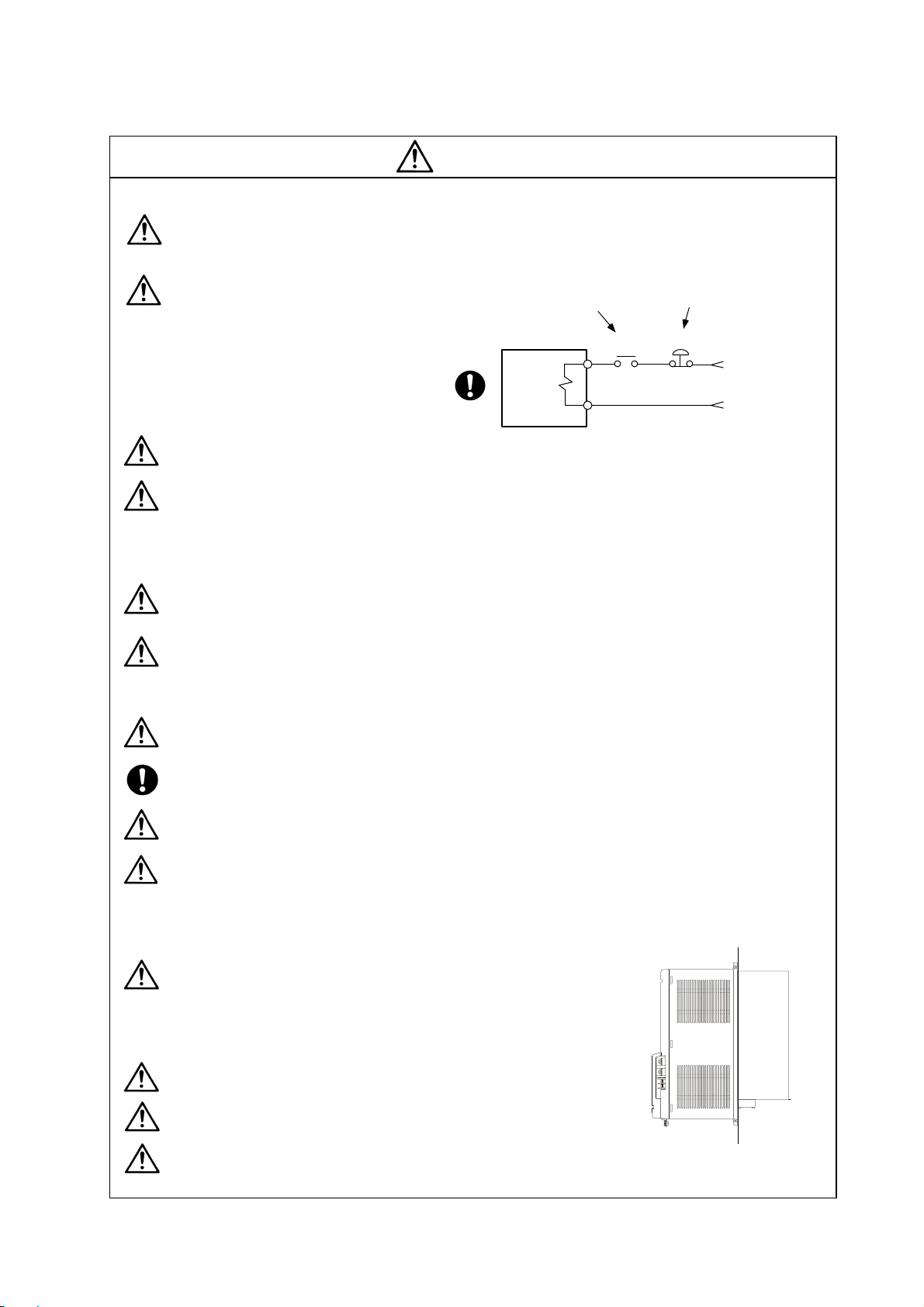

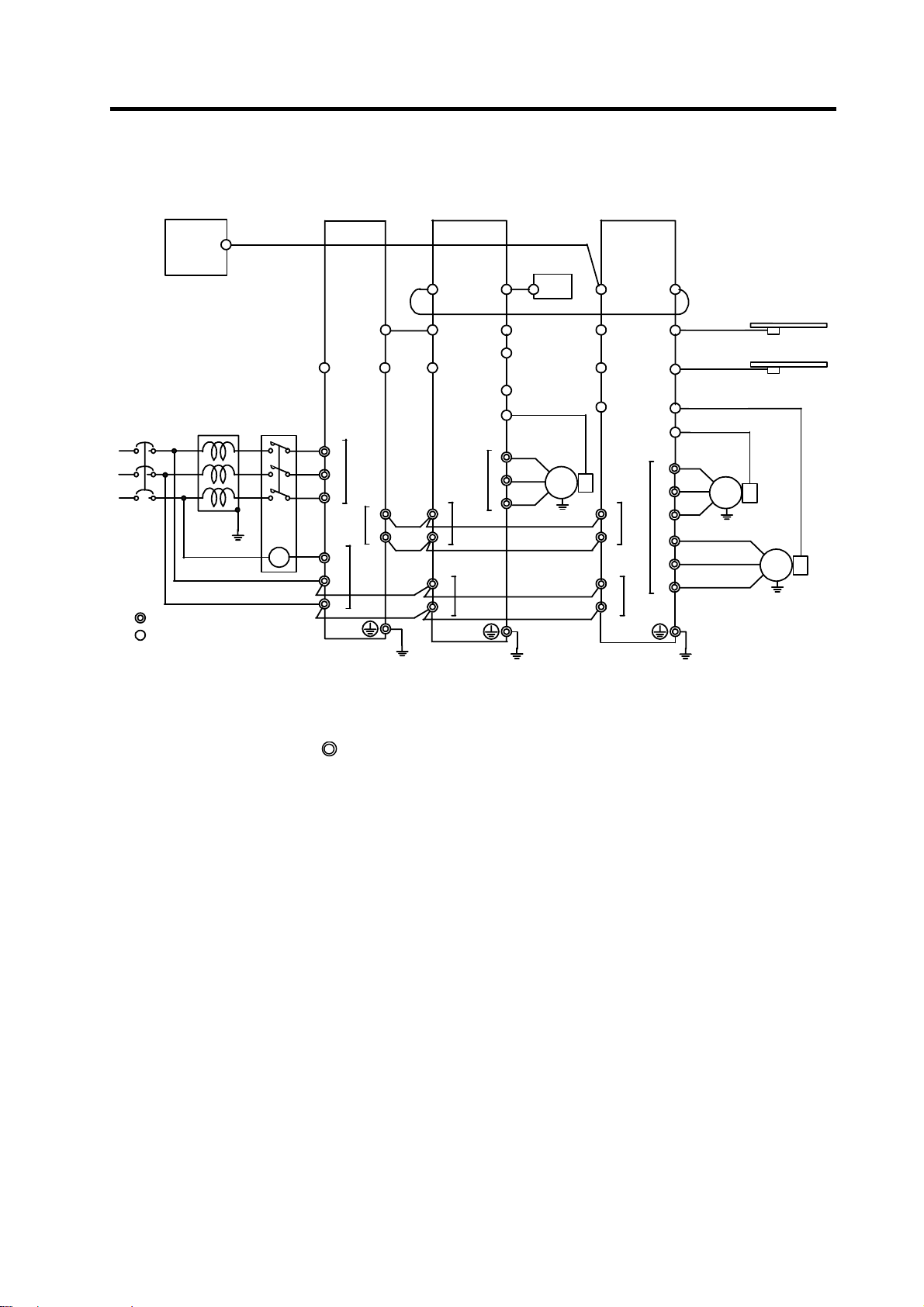

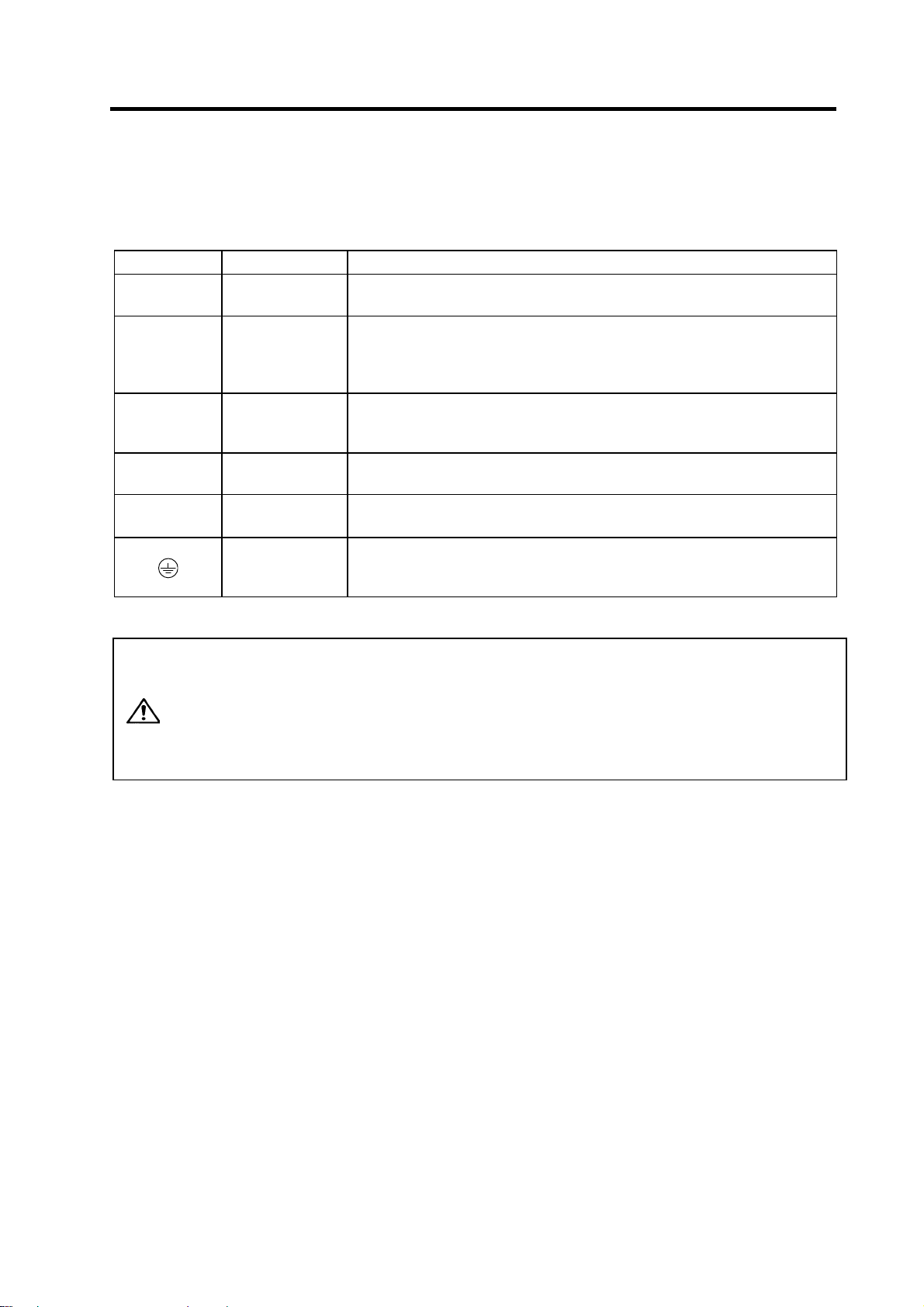

A

2. Wiring and Connection

2-1 Part system connection diagram

Mitsubishi CNC

Ground

SH21 cable

External emergency

stop

Magnetic

contactor

Circuit breaker

R

S

T

Main circuit

Control circuit

SV1,2

(CSH21)

C reactor

CH-AL[ ] K

CH-AL[ ]K

(Note 1) The total length of the SH21 cable must be within 30m.

(Note 2) The connection method will differ according to the used motor.

(Note 3) When not using an absolute position detector, connect the terminal connector (R-TM).

(Note 4) The main circuit (

MC

MDS-CH-CV-[ ]

CN4

CN23

CN9

TE1

L1

L2

L3

TE2

L+

L-

TE3

MC1

L11

L21

Ground

MDS-CH-SP-[ ]

CN1B

CN1A

CN8

CN4

CN7

CN9

CN6

CN5

TE1

U

V

TE2

L+

L-

L11

L21

W

TE3

Ground

Battery unit

BT-[ ]

BT-[ ]

CN1A

SH21 cable

CNP5S cable

M

3~

MDS-CH-V2-[ ]

PLG

) and control circuit ({) are safely separated.

CN1A

CN4

CN9

CN20

TE2

L+

L-

TE3

L11

L21

CN1B

CN3M

CN3L

CN2L

CN2M

TE1

Ground

MU

MV

MW

LU

LV

LW

CNV13 cable

CNV13 cable

CNV12 cable

CNV12 cable

M

3~

Machine side

detector

Machine side

detector

Motor side

detector

M

3~

Motor side

detector

2 - 3

Page 26

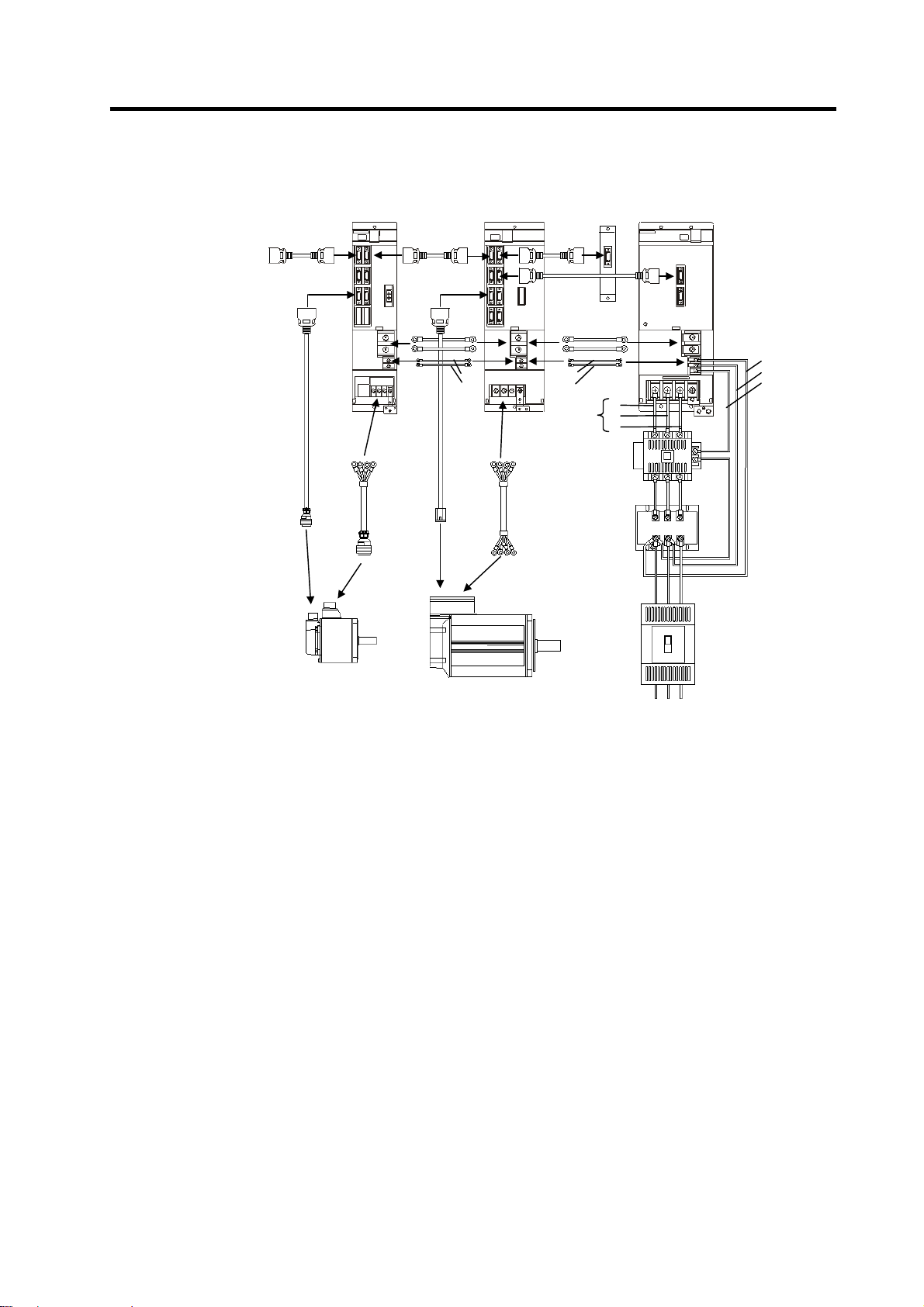

S

S

2. Wiring and Connection

Example of actual wiring

Battery

unit

Power supply unit Spindle drive unitServo drive unit

NC controller

H21

H21

L11

L21

DRTE1

cable

L+

L-

L1

L2

L3

L+

L-

L11

L21

CNV12 cable

CNP5S cable

(Drive line)

DRSV cable

(Drive line)

DRSP cable

AC reactor

Servo motor

Spindle motor

L1 L2 L3

Note)

The main circuit cable wiring must be prepared by the user.

The wiring to the grounding cable is not shown. Refer to section "2-10 Wiring the Grounding Cable".

L11

L21

MC1

2 - 4

Page 27

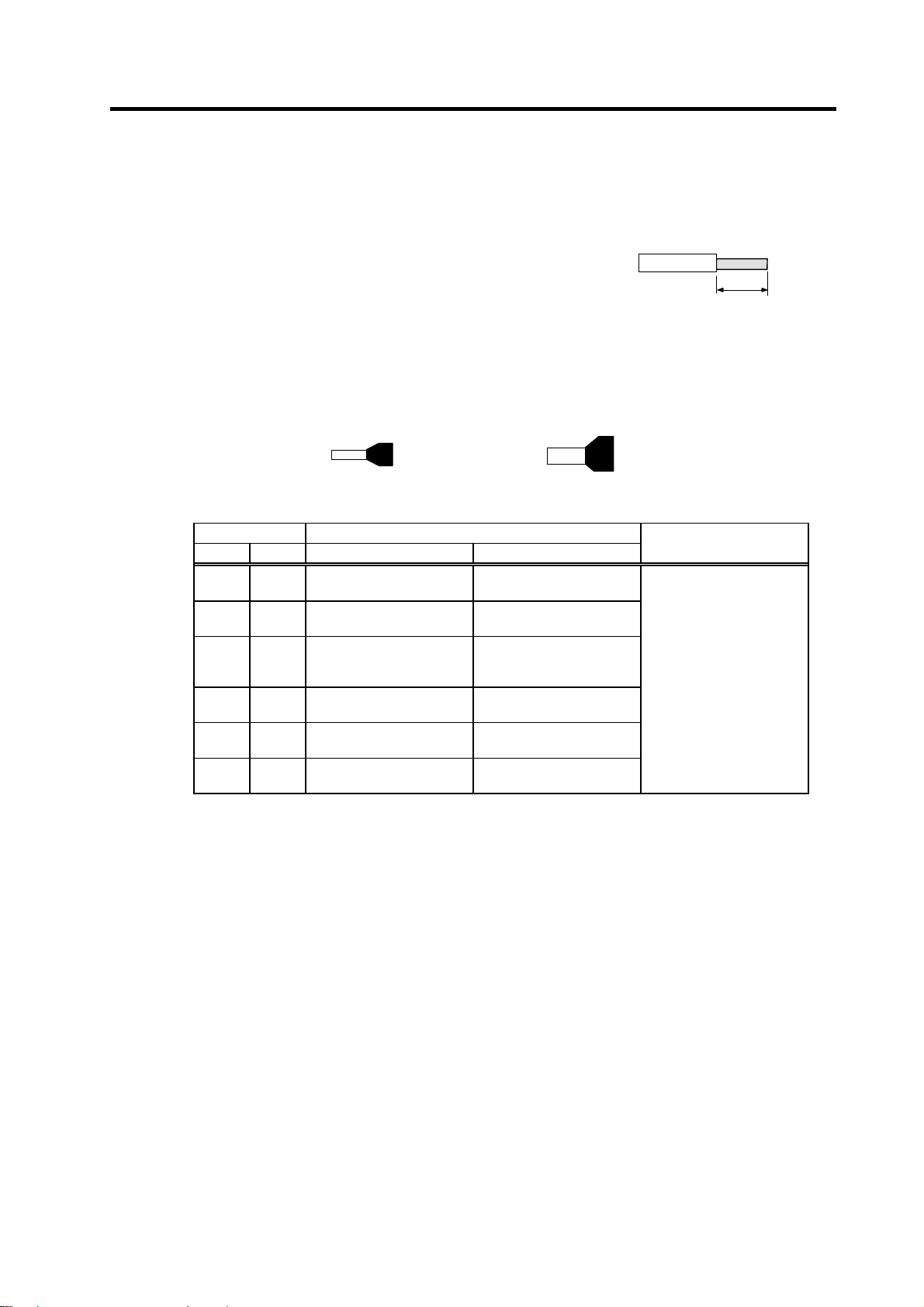

2. Wiring and Connection

2-2 Main circuit terminal block/control circuit connector

CAUTION

2-2-1 Connector pin assignment

Power supply unit

Unit

Terminal

Terminal

position

MDS-CH-CV-37 to

<1>

Do not apply a voltage other than that specified in Instruction Manual on each

terminal. Failure to observe this item could lead to rupture or damage, etc.

MDS-CH-CV-370

<2>

<3>

<2>

<3>

MDS-CH-CV-450

MDS-CH-CV-550

1

<2>

<1>

MDS-CH-CV-750

<2>

2

<3>

<1>

<1> TE1

<1>

L1 L2 L3