Page 1

Page 2

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or registered

trademarks of their respective companies.

Page 3

Introduction

Thank you for selecting the Mitsubishi numerical control unit.

This instruction manual describes the handling and caution points for using this AC

servo/spindle.

Incorrect handling may lead to unforeseen accidents, so always read this instruction

manual thoroughly to ensure correct usage.

Make sure that this instruction manual is delivered to the end user.

Always store this manual in a safe place.

All specifications for the MDS-C1-SPA Series are described in this manual. However,

each CNC may not be provided with all specifications, so refer to the specifications for

the CNC on hand before starting use.

Notes on Reading This Manual

(1) Since the description of this specification manual deals with NC in general, for the

specifications of individual machine tools, refer to the manuals issued by the

respective machine manufacturers. The "restrictions" and "available functions"

described in the manuals issued by the machine manufacturers have precedence

to those in this manual.

(2) This manual describes as many special operations as possible, but it should be

kept in mind that items not mentioned in this manual cannot be performed.

Page 4

Precautions for safety

Please read this manual and auxiliary documents before starting installation, operation,

maintenance or inspection to ensure correct usage. Thoroughly understand the device, safety

information and precautions before starting operation.

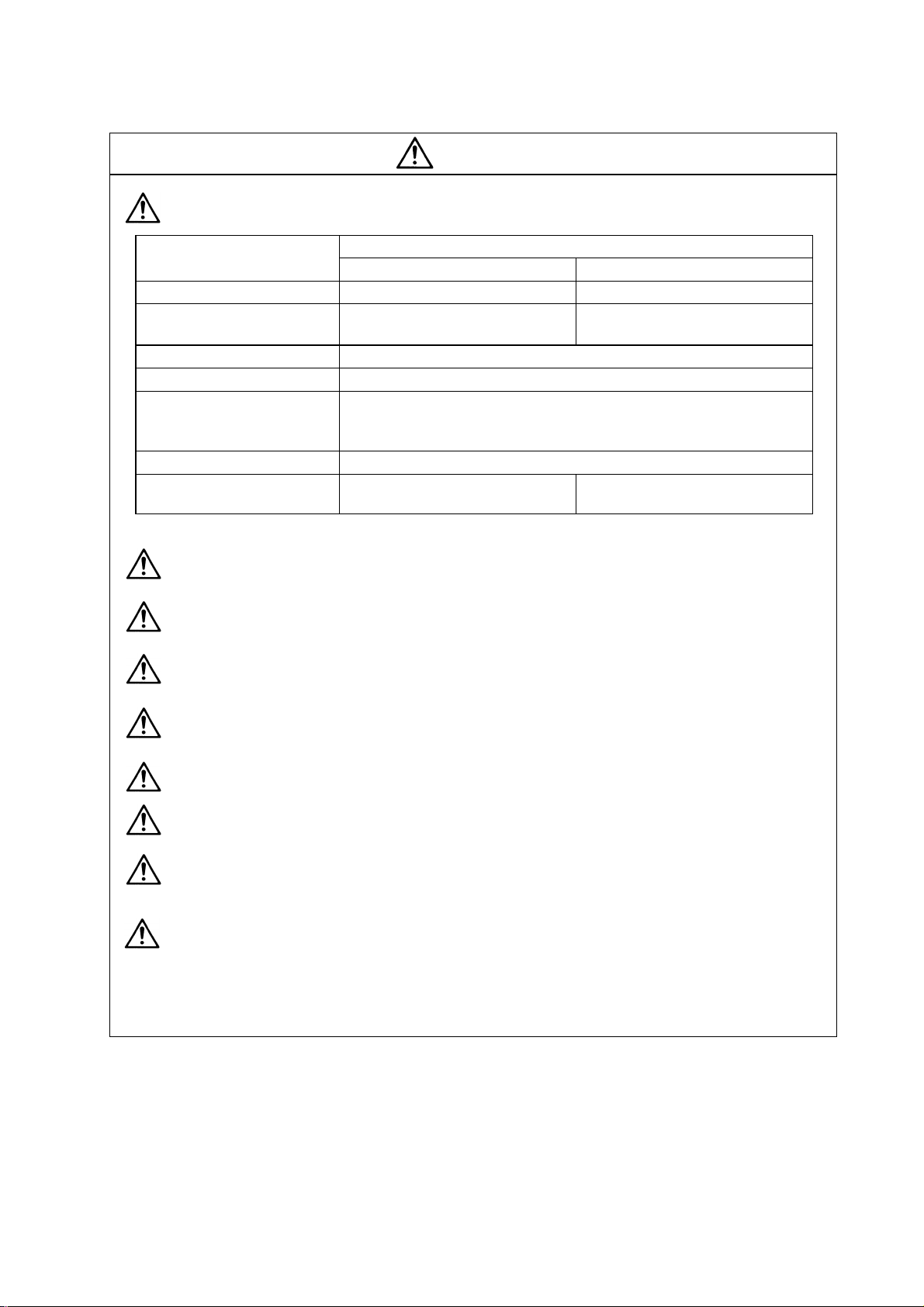

The safety precautions in this instruction manual are ranked as "WARNING" and "CAUTION".

Note that some items described as

the situation. In any case, important information that must be observed is described.

The numeric control unit is configured of the control unit, operation board, servo drive unit,

spindle drive unit, power supply unit, servomotor and spindle motor, etc.

In this section "Precautions for safety", the following items are generically called the

"servomotor".

• Servomotor

• Spindle motor

DANGER

WARNING

CAUTION

When there is a potential risk of fatal or serious injuries if

handling is mistaken.

When operator could be fatally or seriously injured if handling

is mistaken.

When a dangerous situation may occur if handling is mistaken

leading to medium or minor injuries, or physical damage.

CAUTION

may lead to major results depending on

In this section "Precautions for safety", the following items are generically called the "servo

drive unit".

• Servo drive unit

• Spindle drive unit

• Power supply unit

Page 5

1. Electric shock prevention

Do not open the front cover while the power is ON or during operation. Failure to observe this

could lead to electric shocks.

Do not operate the unit with the front cover removed. The high voltage terminals and charged

sections will be exposed, and can cause electric shocks.

Do not remove the front cover even when the power is OFF unless carrying out wiring work or

periodic inspections. The inside of the units is charged, and can cause electric shocks.

Wait at least 15 minutes after turning the power OFF before starting wiring, maintenance or

inspections. Failure to observe this could lead to electric shocks.

Ground the servo drive unit and servomotor with Class C (former class 3) grounding or higher.

Wiring, maintenance and inspection work must be done by a qualified technician.

Wire the servo drive unit and servomotor after installation. Failure to observe this could lead to

electric shocks.

Do not touch the switches with wet hands. Failure to observe this could lead to electric shocks.

Do not damage, apply forcible stress, place heavy items on the cables or get them caught.

Failure to observe this could lead to electric shocks.

WARNING

1. Fire prevention

Install the servo drive units, servomotors and regenerative resistor on noncombustible

material. Direct installation on combustible material or near combustible materials could le ad

to fires.

Shut off the power on the servo drive unit side if the servo drive unit fails. Fires could be

caused if a large current continues to flow.

When using a regenerative resistor, provide a sequence that shuts off the power with the

regenerative resistor's error signal. The regenerative resistor could abnormally o v erheat and

cause a fire due to a fault in the regenerative transistor, etc.

The battery unit could heat up, ignite or rupture if submerged in water, or if the poles are

incorrectly wired.

2. Injury prevention

Do not apply a voltage other than that specified in Instruction Manual on each terminal. Failure

to observe this item could lead to ruptures or damage, etc.

Do not mistake the terminal connections. Failure to observe this item could lead to ruptures or

damage, etc.

Do not mistake the polarity (

damage, etc.

The servo drive unit's fins, regenerative resistor and servomotor, etc., may reach high

temperatures while the power is ON, and may remain hot for some time after the power is

turned OFF. Touching these parts could result in burns.

CAUTION

+

,

). Failure to observe this item could lead to ruptures or

Page 6

CAUTION

3. Various precautions

Observe the following precautions. Incorrect handling of the unit could lead to faults, injuries and

electric shocks, etc.

(1) Transportation and installation

Correctly transport the product according to its weight.

Use the servomotor's hanging bolts only when transporting the servomotor. Do not transport

the servomotor when it is installed on the machine.

Do not stack the products above the tolerable number.

Do not hold the cables, axis or detector when transporting the servomotor.

Do not hold the connected wires or cables when transporting the servo drive units.

Do not hold the front cover when transporting the servo drive units. The unit could drop.

Follow this Instruction Manual and install in a place where the weight can be borne.

Do not get on top of or place heavy objects on the unit.

Always observe the installation directions.

Secure the specified distance between the servo drive unit and control panel's inne r wall, and

between other devices.

Do not install or run a servo drive unit or servomotor that is damaged or missing parts.

Do not block the intake or exhaust ports of the servomotor provided with a cooling fan.

Do not let foreign objects enter the servo drive units or servomotors. In particular, if

conductive objects such as screws or metal chips, etc., or combustible materials such as oil

enter, rupture or breakage could occur.

The servo drive units and servomotors are precision devices, so do not drop them or apply

strong impacts to them.

Page 7

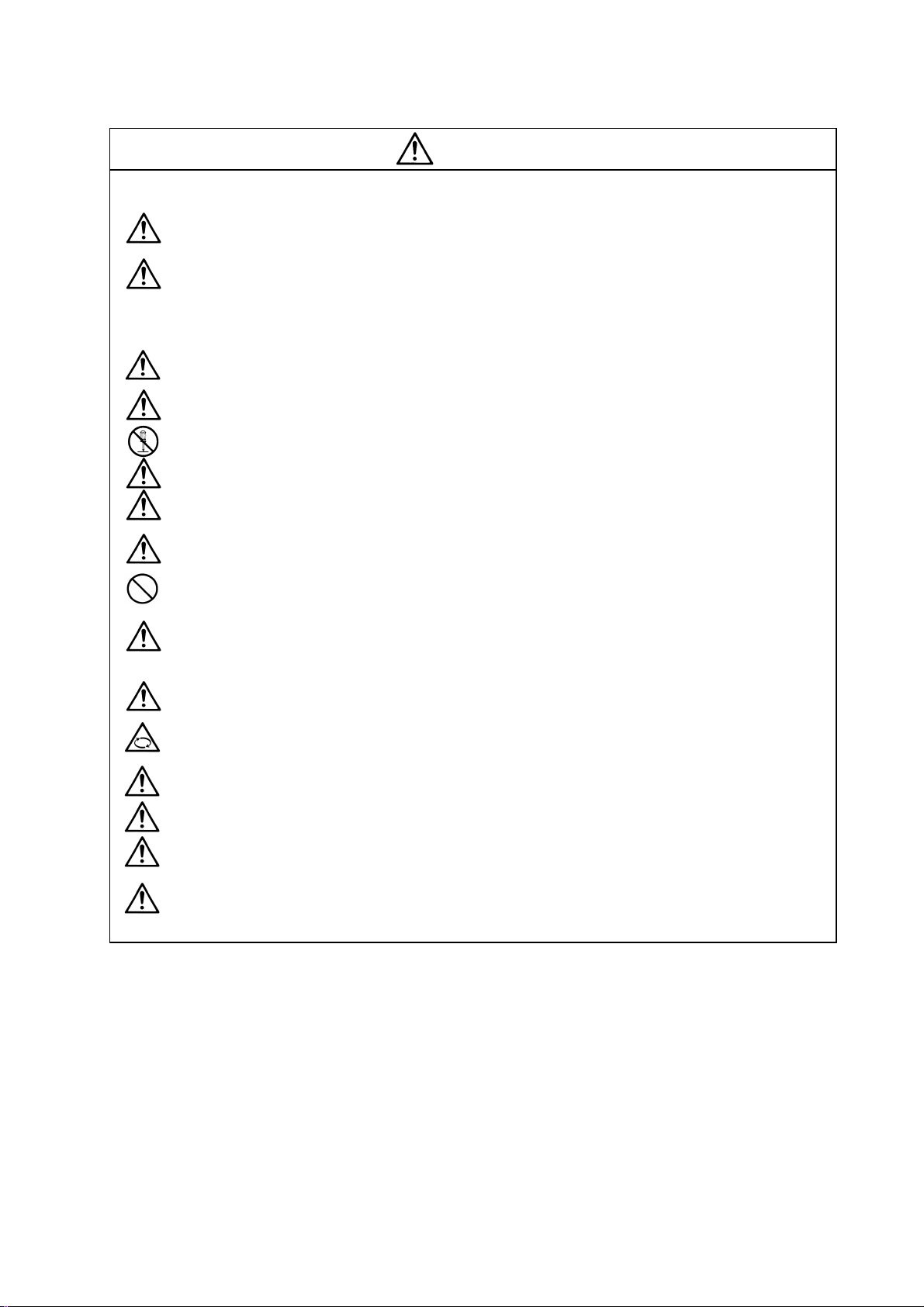

CAUTION

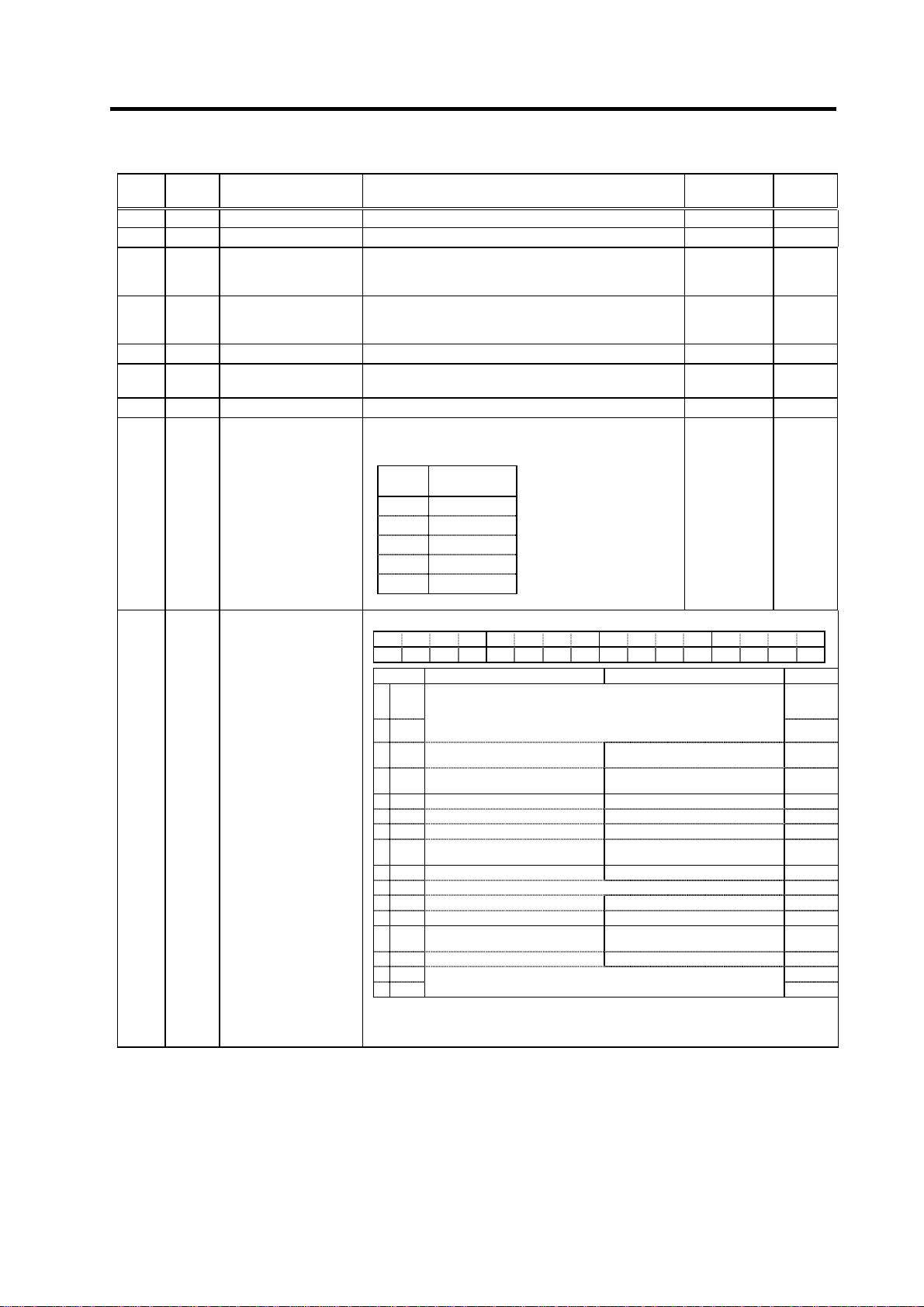

Store and use the units under the following environment conditions.

Ambient temperature 0°C to +55°C (with no freezing) 0°C to +40°C (with no freezing)

Ambient humidity

Storage temperature -15°C to +70°C

Storage humidity 90%RH or less (with no dew condensation)

Atmosphere

Altitude 1,000m or less above sea level

Environment

Vibration 4.9m/s

Securely fix the servomotor to the machine. Insufficient fixing could lead to the servomotor

slipping off during operation.

Always install the servomotor with reduction gear in the designated direction. Failure to do

so could lead to oil leaks.

Structure the rotary sections of the motor so that it can never be touched during operation.

Install a cover, etc., on the shaft.

When installing a coupling to a servomotor shaft end, do not apply an impact by

hammering, etc. The detector could be damaged.

Do not apply a load exceeding the tolerable load onto the servomotor shaft. The shaft

could break.

Store the motor in the package box.

When inserting the shaft into the built-in IPM motor, do not heat the rotor higher than

130°C. The magnet could be demagnetized, and the specifications characteristics will not

be ensured.

If the unit has been stored for a long time, always check the operation before starting

actual operation. Please contac t the Service Center or Service Station.

Servo drive unit Servomotor

90%RH or less

(with no dew condensation)

Indoors (where unit is not subject to direct sunlight),

with no corrosive gas, combustible gas, oil mist,

dust or conductive particles

2

(0.5G) or less

Conditions

80% RH or less

(with no dew condensation)

To follow each unit and motor

specifications

Page 8

(2) Wiring

CAUTION

Correctly and securely perform the wiring. Failure to do so could lead to runaway of the

servomotor.

Do not install a condensing capacitor, surge absorber or radio noise filter on the output side of

the servo drive unit.

Correctly connect the output side (terminals U, V, W). Failure to do so could lead to abnormal

operation of the servomotor.

Do not directly connect a commercial

power supply to the servomotor. Failure

to observe this could result in a fault.

Servodrive unit

COM

(24VDC)

Servodrive unit

COM

(24VDC)

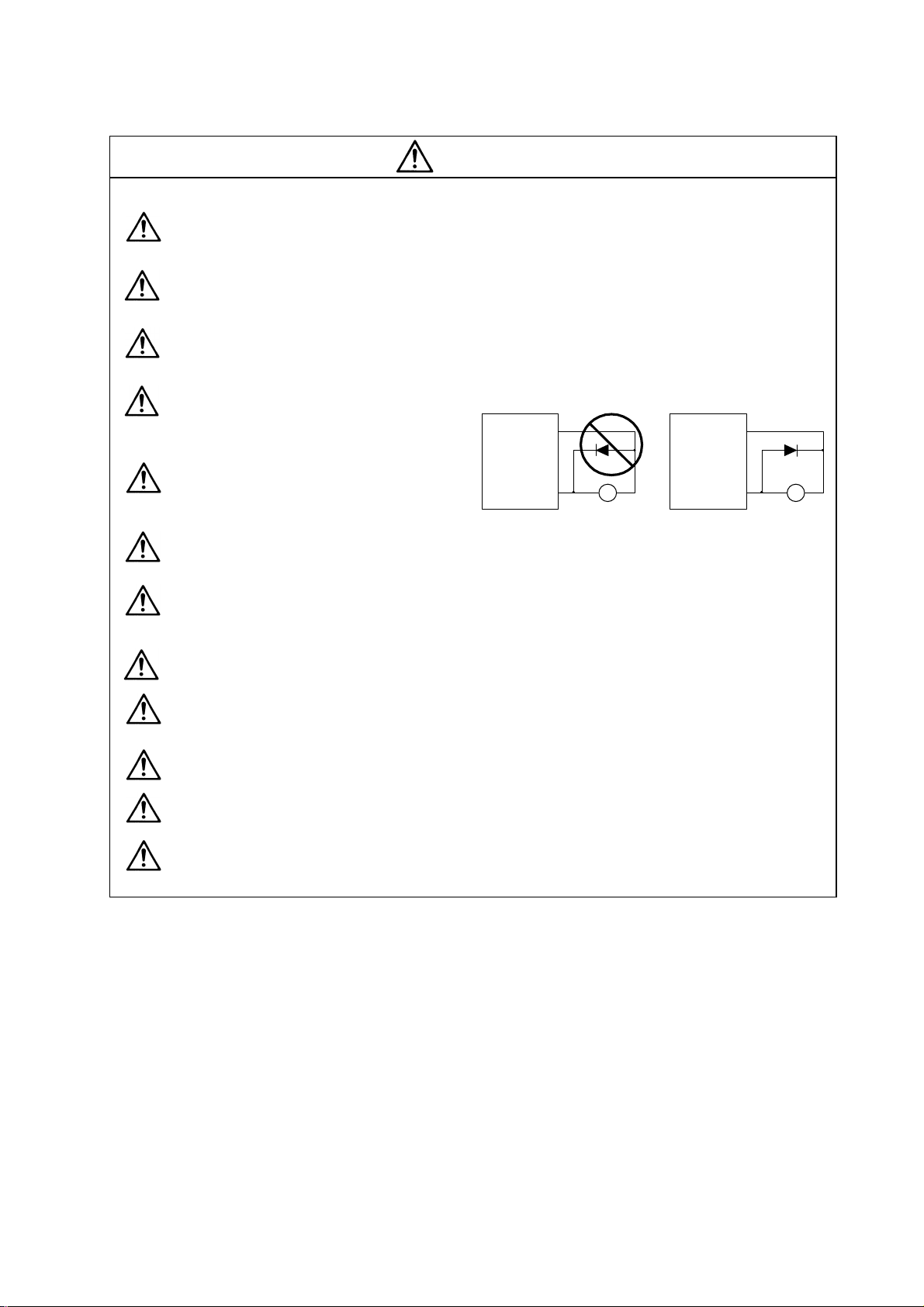

When using an inductive load such as a

relay, always connect a diode as a noise

measure parallel to the load.

Controloutput

signal

RA

Control output

signal

When using a capacitance load such as a lamp, always connect a protective resistor a s a

noise measure serial to the load.

Do not reverse the direction of a diode which connect to a DC relay for the control output

signals to suppress a surge. Connecting it backwards could cause the drive unit to malfunction

so that signals are not output, and emergency stop and other safety circuits are inoperable.

Do not connect/disconnect the cables connected between the units while the power is ON.

Securely tighten the cable connector fixing screw or fixing mechanism. An insecure fixing could

cause the cable to fall off while the power is ON.

When using a shielded cable instructed in the connection manual, always ground the cable with

a cable clamp, etc.

Always separate the signals wires from the drive wire and power line.

Use wires and cables that have a wire diameter, heat resistance and flexibility that conforms to

the system.

RA

Page 9

(3) Trial operation and adjustment

Check and adjust each program and parameter before starting operation. Failure to do so could

lead to unforeseen operation of the machine.

Do not make remarkable adjustments and changes as the operatio n could become unstable.

(4) Usage methods

Install an external emergency stop circuit so that the operation can be stopped and power

shut off immediately.

Turn the power OFF immediately if smoke, abnormal noise or odors are generated from the

servo drive unit or servomotor.

Unqualified persons must not disassemble or repair the unit.

Never make modifications.

Reduce magnetic damage by installing a noise filter. The electronic devices used near the

servo drive unit could be affected by magnetic noise.

Use the servo drive unit, servomotor and regenerative resistor with the designated combination.

Failure to do so could lead to fires or trouble.

The brake (magnetic brake) assembled into the servomotor is for holding, and must not be used

for normal braking.

There may be cases when holding is not possible due to the magnetic brake's life or the

machine construction (when ball screw and servomotor are coupled via a timing belt, etc.).

Install a stop device to ensure safety on the machine side.

After changing the programs/parameters or after maintenance and inspection, always test the

operation before starting actual operation.

Do not enter the movable range of the machine during automatic operation. Never place body

parts near or touch the spindle during rotation.

Follow the power supply specification conditions given in the separate specifications manual for

the power (input voltage, input frequency, tolerable sudden power failure time, etc.).

Set all bits to "0" if they are indicated as not used or empty in the explanation on the bits.

Do not use the dynamic brakes except during the emergency stop. Continued use of the

dynamic brakes could result in brake damage.

If a breaker is shared by several power supply units, the breaker may not activate when a

short-circuit fault occurs in a small capacity unit. This is dangerous, so never share the

breakers.

CAUTION

Page 10

(5) Troubleshooting

If a hazardous situation is predicted during power failure or product trouble, use a servomotor

with magnetic brakes or install an external brake mechanism.

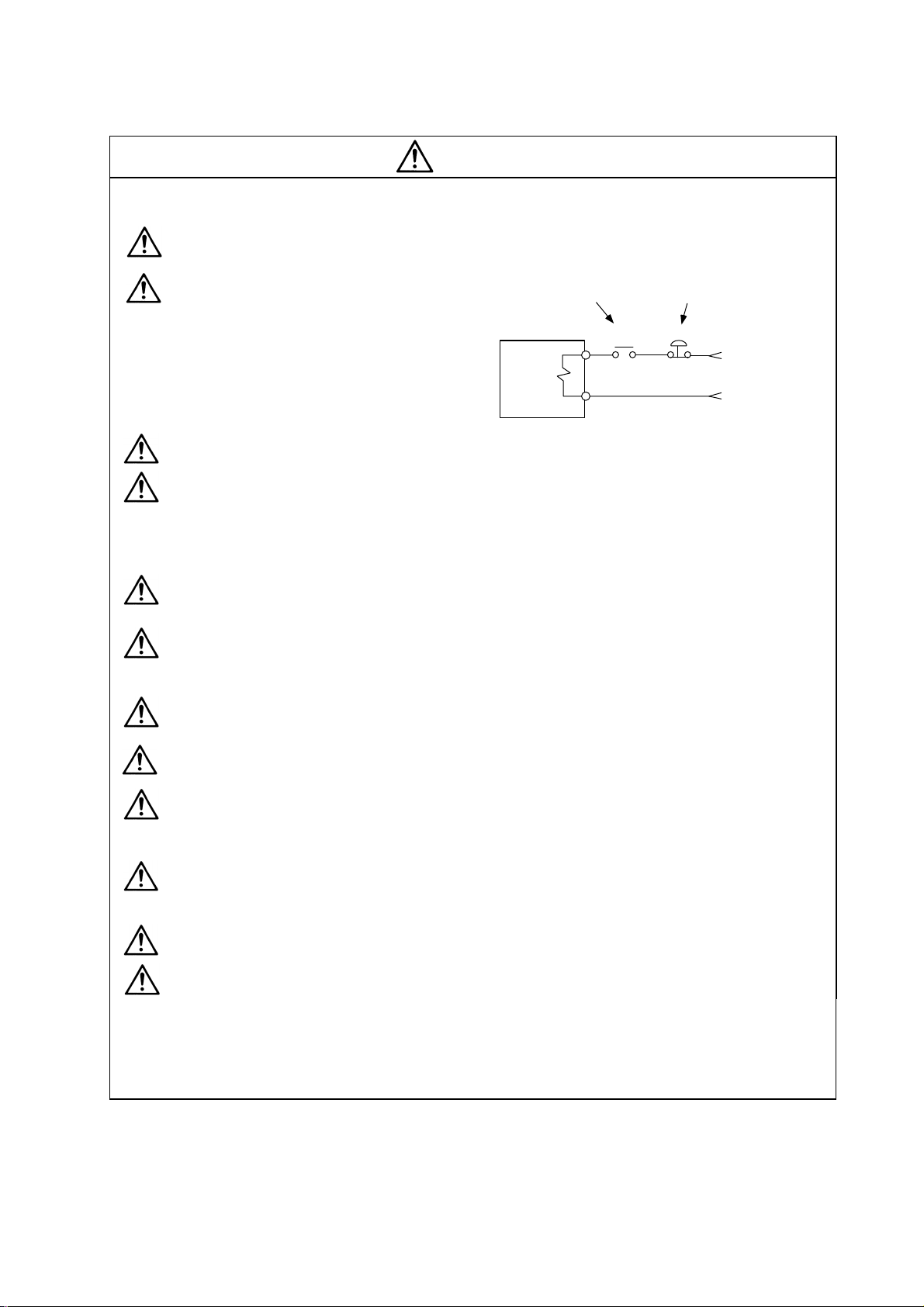

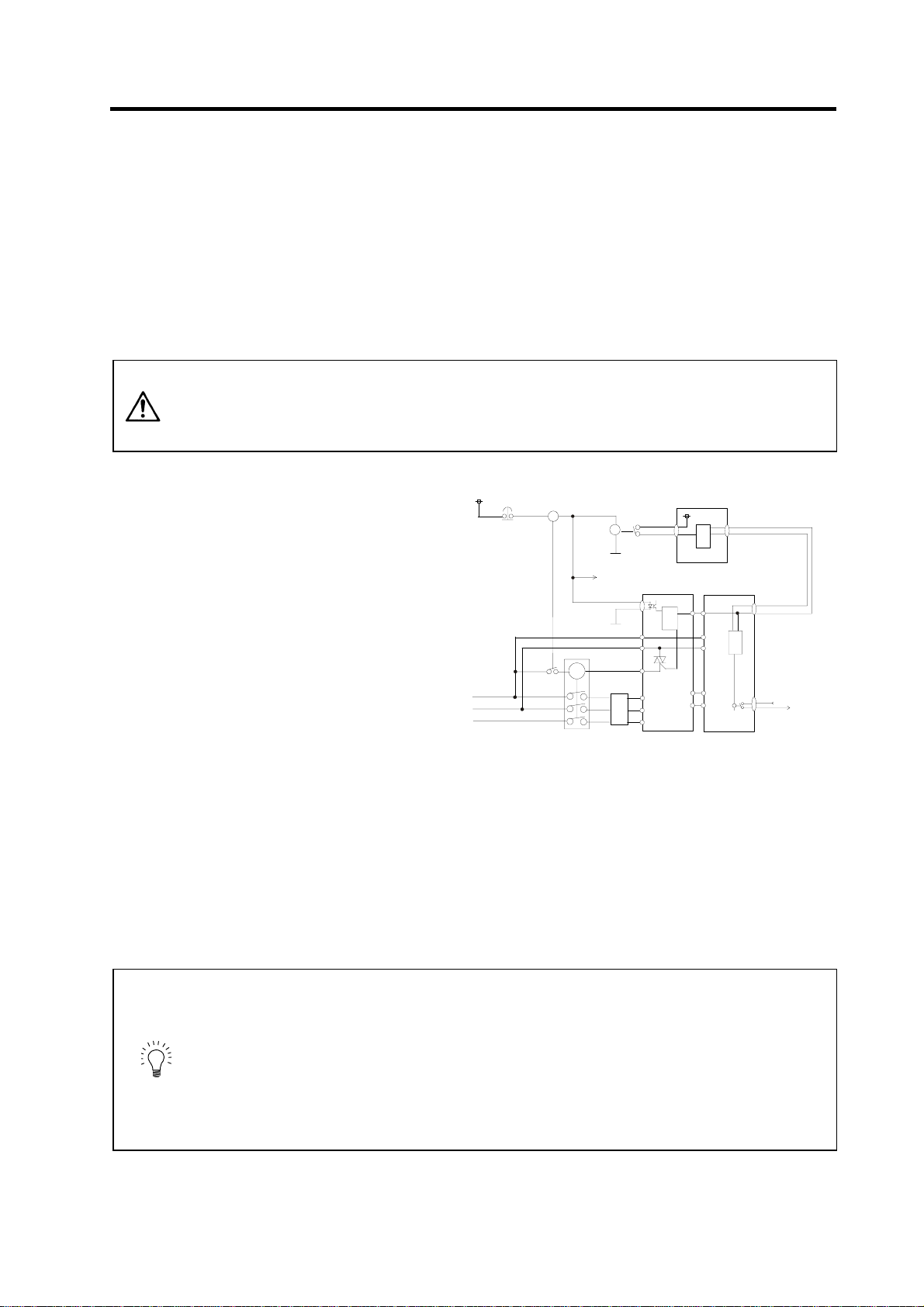

Use a double circuit configuration

that allows the operation circuit for

the magnetic brakes to be operated

even by the external emergency

stop signal.

CAUTION

Shut off with the servomotor

brake control output.

Servomotor

Magnetic

brake

Shut off with NC brake

control PLC output.

MBR

EMG

24VDC

Always turn the input power OFF when an alarm occurs.

Never go near the machine after restoring the power after a power failure, as the machine

could start suddenly. (Design the machine so that personal safety can be ensured even if the

machine starts suddenly.)

(6) Maintenance, inspection and part replacement

Always carry out maintenance and inspection after backing up the servo drive unit's programs

or parameters.

The capacity of the electrolytic capacitor will drop over time. To prevent secondary disasters

due to failures, replacing this part every five years when used under a normal environment is

recommended. Contact the Service Center or Service Station for replacement.

Do not perform a megger test (insulation resistance measurement) during inspections.

If the battery low warning is issued, save the machining programs, tool data and parameters

with an input/output unit, and then replace the battery.

Do not short circuit, charge, overheat, incinerate or disassemble the battery.

(7) Disposal

Treat this unit as general industrial waste. Note that MDS Series unit with a heat dissipating

fin protruding from the back of the unit contains substitute Freon. Do not dispose of this type

of unit as general industrial waste. Always return to the Service Center or Service Station.

Do not disassemble the servo drive unit or servomotor parts.

Dispose of the battery according to local laws.

(8) General precautions

The drawings given in this Specifications and Maintenance Instruction Manual show the covers and

safety partitions, etc., removed to provide a clearer explanation. Always return the covers or partitions to

their respective places before starting operation, and always follow the instructions given in this manual.

Page 11

CONTENTS

1. Installation

1-1 Installation of spindle motor.................................................................................................1-2

1-1-1 Environmental conditions .............................................................................................. 1-2

1-1-2 Shaft characteristics ...................................................................................................... 1-2

1-2 Installation of the control unit............................................................................................... 1-3

1-2-1 Environmental conditions .............................................................................................. 1-3

1-2-2 Installation direction and clearance ............................................................................... 1-4

1-2-3 Prevention of entering of foreign matter........................................................................ 1-4

1-2-4 Panel installation hole work drawings (Panel cut drawings)......................................... 1-5

1-2-5 Heating value................................................................................................................. 1-6

1-2-6 Heat radiation countermeasures................................................................................... 1-7

1-3 Installing the spindle detector.............................................................................................. 1-9

1-3-1 Magnetic sensor ............................................................................................................ 1-9

1-3-2 Spindle side detector................................................................................................... 1-11

1-4 Noise measures ................................................................................................................. 1-12

2. Wiring and Connection

2-1 Connection diagram............................................................................................................. 2-3

2-1-1 Part system connection diagram...................................................................................... 2-3

2-1-2 Detailed connection diagram ........................................................................................... 2-4

2-2 Main circuit terminal block/control circuit connector............................................................ 2-7

2-2-1 Names and applications of main circuit terminal block signals and control circuit

connectors..................................................................................................................... 2-7

2-2-2 Connector pin assignment............................................................................................. 2-8

2-3 Drive unit connection ......................................................................................................... 2-11

2-4 Motor and detector connection .......................................................................................... 2-14

2-4-1 Connection of the spindle motor.................................................................................. 2-14

2-5 Connection of power supply.............................................................................................. 2-17

2-5-1 Power supply input connection ...................................................................................... 2-17

2-5-2 Connecting the grounding cable.................................................................................. 2-20

2-5-3 Main circuit control ......................................................................................................... 2-21

2-6 Peripheral control wiring .................................................................................................... 2-23

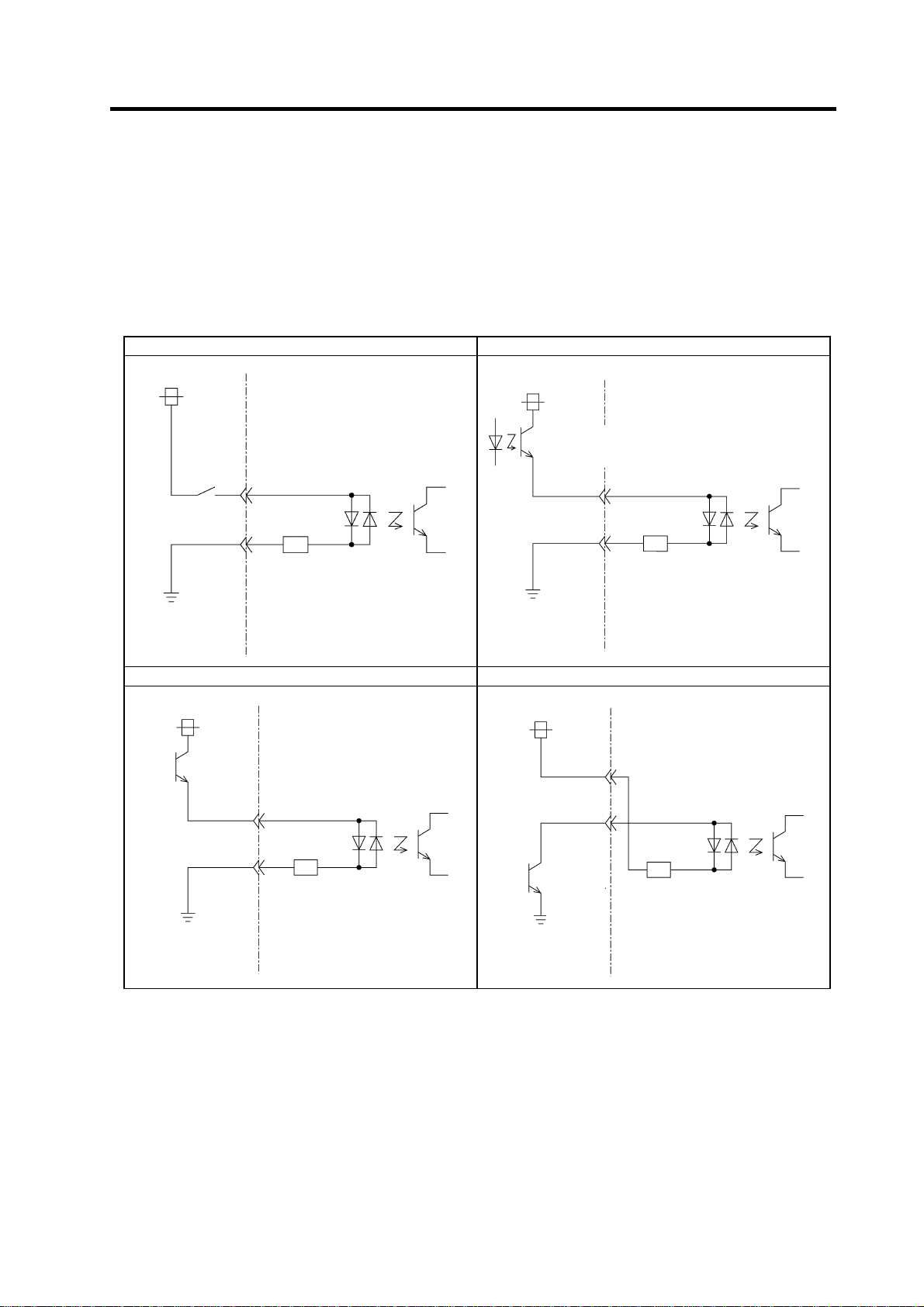

2-6-1 Input interface ..............................................................................................................2-23

2-6-2 Output interface ........................................................................................................... 2-25

2-6-3 Spindle coil changeover .............................................................................................. 2-27

2-6-4 Wiring of an external emergency stop......................................................................... 2-30

3. Setup

3-1 Initial setup ........................................................................................................................... 3-2

3-1-1 Setting the rotary switch ................................................................................................3-2

3-1-2 Transition of LED display after power is turned ON...................................................... 3-3

3-2 Setting the initial parameters for the spindle drive unit....................................................... 3-4

3-2-1 Parameter setting method ............................................................................................. 3-4

3-2-2 List of spindle parameters ............................................................................................. 3-6

3-3 Initial adjustment of the spindle PLG................................................................................. 3-26

3-3-1 Adjusting the PLG installation...................................................................................... 3-26

Page 12

4. Spindle Adjustment

4-1 D/A output specifications for spindle drive unit ................................................................... 4-2

4-1-1 D/A output specifications............................................................................................... 4-2

4-1-2 Setting the output data ..................................................................................................4-2

4-1-3 Setting the output magnification.................................................................................... 4-3

4-2 Spindle control signal........................................................................................................... 4-5

4-2-1 Spindle control input (NC to SP) ................................................................................... 4-5

4-2-2 Spindle control output (SP to NC)............................................................................... 4-15

4-3 Adjustment procedures for each control ........................................................................... 4-27

4-3-1 Basic adjustments........................................................................................................ 4-27

4-3-2 Adjusting the acceleration/deceleration operation...................................................... 4-30

4-3-3 Adjusting the orientation control.................................................................................. 4-39

4-3-4 Adjusting the multi-point indexing orientation control.................................................. 4-55

4-3-5 Adjusting S-analog high-speed tapping control .......................................................... 4-64

4-3-6 Adjusting coil changeover............................................................................................ 4-69

5. Troubleshooting

5-1 Points of caution and confirmation ...................................................................................... 5-2

5-1-1 LED display when alarm or warning occurs.................................................................. 5-3

5-2 Protective functions list of units ...........................................................................................5-4

5-2-1 List of alarms.................................................................................................................. 5-4

5-2-2 List of warnings .............................................................................................................. 5-6

5-3 Troubleshooting ................................................................................................................... 5-7

5-3-1 Troubleshooting at power ON ....................................................................................... 5-7

5-3-2 Troubleshooting for each alarm No............................................................................... 5-8

5-3-3 Troubleshooting for each warning No......................................................................... 5-21

5-3-4 Troubleshooting the spindle system when there is no alarm or warning ................... 5-22

6. Maintenance

6-1 Inspections........................................................................................................................... 6-2

6-2 Service parts ........................................................................................................................ 6-2

6-3 Adding and replacing units and parts.................................................................................. 6-3

6-3-1 Replacing the drive unit.................................................................................................6-3

6-3-2 Replacing the unit fan.................................................................................................... 6-4

Appendix 1. Cable and Connector Specifications

Appendix 1-1 Selection of cable ..............................................................................................A1-2

Appendix 1-1-1 Cable wire and assembly............................................................................A1-2

Appendix 1-2 Cable connection diagram.................................................................................A1-4

Appendix 1-3 Connector outline dimension drawings.............................................................A1-8

Appendix 2. Compliance to EC Directives

Appendix 2-1 Compliance to EC Directives ............................................................................A2-2

Appendix 2-1-1 European EC Directives..............................................................................A2-2

Appendix 2-1-2 Cautions for EC Directive compliance ........................................................A2-2

Page 13

Appendix 3. EMC Installation Guidelines

Appendix 3-1 Introduction ........................................................................................................A3-2

Appendix 3-2 EMC instructions ...............................................................................................A3-2

Appendix 3-3 EMC measures..................................................................................................A3-3

Appendix 3-4 Measures for panel structure.............................................................................A3-3

Appendix 3-4-1 Measures for control panel unit...................................................................A3-4

Appendix 3-4-2 Measures for door .......................................................................................A3-4

Appendix 3-4-3 Measures for operation board panel...........................................................A3-5

Appendix 3-4-4 Shielding of the power supply input section................................................A3-5

Appendix 3-5 Measures for various cables .............................................................................A3-6

Appendix 3-5-1 Measures for wiring in panel .......................................................................A3-6

Appendix 3-5-2 Measures for shield treatment.....................................................................A3-6

Appendix 3-5-3 Spindle motor power cable..........................................................................A3-7

Appendix 3-5-4 Servo motor feedback cable .......................................................................A3-7

Appendix 3-5-5 Spindle motor power cable..........................................................................A3-8

Appendix 3-5-6 Spindle motor feedback cable.....................................................................A3-8

Appendix 3-6 EMC countermeasure parts ..............................................................................A3-9

Appendix 3-6-1 Shield clamp fitting ......................................................................................A3-9

Appendix 3-6-2 Ferrite core ................................................................................................A3-10

Appendix 3-6-3 Power line filter..........................................................................................A3-11

Appendix 3-6-4 Surge protector..........................................................................................A3-16

Appendix 4. Servo/spindle drive unit categories based on higher harmonic suppression

countermeasure guidelines

Appendix 4-1 Servo/spindle drive unit circuit categories based on higher harmonic suppression

countermeasure guidelines...............................................................................A4-2

Page 14

Contents for MDS-C1-SPA Series SPECIFICATIONS MANUAL (IB-1500150)

1. Introduction

1-1 Spindle drive system configuration .....................1-2

1-1-1 System configuration.................................................1-2

1-1-2 Unit outline type.........................................................1-3

1-2 Explanation of type..............................................1-4

1-2-1 Spindle motor type.....................................................1-4

1-2-2 Spindle drive unit type ...............................................1-5

1-2-3 Power supply unit type...............................................1-6

1-2-4 AC reactor type..........................................................1-7

2. Specifications

2-1 Spindle motor ......................................................2-2

2-1-1 Specifications............................................................2-2

2-1-2 Output characteristics................................................2-7

2-2 Drive unit .............................................................2-12

2-2-1 Installation environment conditions............................2-12

2-2-2 Spindle drive unit.......................................................2-12

2-2-3 Power supply unit ......................................................2-17

2-2-4 AC reactor .................................................................2-18

2-2-5 D/A output specifications for spindle drive unit...........2-19

2-2-6 Explanation of each part............................................2-20

2-3 Restrictions and precautions ...............................2-22

2-3-1 Layout of unit.............................................................2-22

2-3-2 Precautions for installing multiple power supply units2-23

2-3-3 Precautions when installing multiple spindle drive

units to one power supply unit...................................2-24

3. Characteristics

3-1 Spindle motor ......................................................3-2

3-1-1 Environmental conditions...........................................3-2

3-1-2 Shaft characteristics ..................................................3-2

3-2 Drive unit characteristics .....................................3-3

3-2-1 Environmental conditions...........................................3-3

3-2-2 Heating value.............................................................3-4

4. Dedicated Options

4-1 Orientation option................................................4-2

4-1-1 Magnetic sensor........................................................4-3

4-1-2 Spindle side detector (OSE-1024-3-15-68,

OSE-1024-3-15-68-8)................................................4-6

4-2 Cables and connectors .......................................4-8

4-2-1 Cable connection diagram.........................................4-8

4-2-2 List of cables and connectors ....................................4-9

5. Peripheral Devices

5-1 Selection of wire ..................................................5-2

5-1-1 Example of wires by unit............................................5-2

5-2 Selection the AC reactor, contactor and no-fuse

breaker ...............................................................5-4

5-2-1 Standard selection.....................................................5-4

5-2-2 Selection of contactor for changing over spindle

motor drive wire.........................................................5-5

5-3 Earth leakage breaker .........................................5-6

5-4 Branch-circuit protection .....................................5-7

5-4-1 Circuit protector .........................................................5-7

5-4-2 Fuse protection..........................................................5-7

5-5 Noise filter ...........................................................5-8

5-6 Surge absorber ...................................................5-9

5-7 Speedometer and load meter..............................5-10

5-8 Cable for peripheral control.................................5-11

5-8-1 Cable for external emergency stop............................5-11

(Note) This is the content for SPECIFICATION MANUAL version A. The structure of section and page number may be different

other than version B.

Appendix 1. Outline Dimension Drawings

Appendix 1-1 Outline dimension drawings of spindle

motor ..................................................A1-2

Appendix 1-1-1 SJ Series...................................................A1-2

Appendix 1-1-2 SJ-V Series................................................ A1-5

Appendix 1-1-3 SJ-VS Series .............................................A1-15

Appendix 1-2 Unit outline dimension drawings.........A1-17

Appendix 1-2-1 Spindle drive unit.......................................A1-17

Appendix 1-2-2 Power supply unit ......................................A1-21

Appendix 1-2-3 AC rector ...................................................A1-25

Appendix 2. Cable and Connector Specifications

Appendix 2-1 Selection of cable ...............................A2-2

Appendix 2-1-1 Cable wire and assembly...........................A2-2

Appendix 2-2 Cable connection diagram.................. A2-4

Appendix 2-3 Connector outline dimension drawings

............................................................A2-8

Appendix 3. Selection

Appendix 3-1 Selecting the power supply................. A3-2

Appendix 3-1-1 Selecting according to the continuous

rated capacity............................................A3-2

Appendix 3-1-2 Selection example .....................................A3-3

Appendix 4. Explanation of Large Capacity Spindle Unit

Specifications

Appendix 4-1 Explanation of large capacity spindle unit

specifications......................................A4-2

Appendix 4-1-1 Outline.......................................................A4-2

Appendix 4-1-2 List of units ................................................A4-2

Appendix 4-1-3 Selection of AC reactor (B-AL), contactor

and NFB....................................................A4-2

Appendix 4-1-4 Outline dimension drawings.......................A4-3

Appendix 4-1-5 Panel cut dimension drawing.....................A4-8

Appendix 4-1-6 Heating value.............................................A4-9

Appendix 4-1-7 Selecting the power capacity.....................A4-9

Appendix 4-1-8 Selecting the wire size...............................A4-9

Appendix 4-1-9 Drive unit connection screw size................A4-10

Appendix 4-1-10 Connecting each unit...............................A4-10

Appendix 4-1-11 Restrictions..............................................A4-12

Appendix 4-1-12 Parameters..............................................A4-14

Appendix 4-1-13 Precautions..............................................A4-14

Appendix 5. Explanation of Small Capacity Spindle Drive Unit

Specifications

Appendix 5-1 Explanation of small capacity spindle

drive unit specifications....................... A5-2

Appendix 5-1-1 Outline.......................................................A5-2

Appendix 5-1-2 List of units ................................................A5-2

Appendix 5-1-3 Outline dimension drawings.......................A5-2

Appendix 5-1-4 Drive unit specifications list ........................A5-4

Appendix 5-1-5 Heating value.............................................A5-5

Appendix 5-1-6 Selecting the wire size...............................A5-5

Appendix 5-1-7 Drive unit connection screw size................A5-5

Appendix 5-1-8 Restrictions................................................A5-6

Appendix 6. Compliance to EU EC Directives

Appendix 6-1 Compliance to EC Directives..............A6-2

Appendix 6-1-1 European EC Directives ............................A6-2

Appendix 6-1-2 Cautions for EC Directive compliance........A6-2

Page 15

Contents for MDS-C1-SPA Series SPECIFICATIONS MANUAL (IB-1500150)

Appendix 7. EMC Installation Guidelines

Appendix 7-1 Introduction .........................................A7-2

Appendix 7-2 EMC instructions .................................A7-2

Appendix 7-3 EMC measures ...................................A7-3

Appendix 7-4 Measures for panel structure ..............A7-3

Appendix 7-4-1 Measures for control panel unit..................A7-3

Appendix 7-4-2 Measures for door......................................A7-4

Appendix 7-4-3 Measures for operation board panel..........A7-4

Appendix 7-4-4 Shielding of the power supply input section

..................................................................A7-4

Appendix 7-5 Measures for various cables...............A7-5

Appendix 7-5-1 Measures for wiring in panel......................A7-5

Appendix 7-5-2 Measures for shield treatment....................A7-5

Appendix 7-5-3 Servomotor power cable............................A7-6

Appendix 7-5-4 Servomotor feedback cable .......................A7-6

Appendix 7-5-5 Spindle motor power cable.........................A7-7

Appendix 7-5-6 Spindle motor feedback cable....................A7-7

Appendix 7-6 EMC countermeasure parts................A7-8

Appendix 7-6-1 Shield clamp fitting.....................................A7-8

Appendix 7-6-2 Ferrite core ................................................A7-9

Appendix 7-6-3 Power line filter..........................................A7-10

Appendix 7-6-4 Surge protector..........................................A7-15

Appendix 8. Instruction Manual for Compliance with UL/c-UL

Standard

Appendix 8 Instruction Manual for Compliance with UL/c-UL

Standard.................................................A8-2

Appendix 9. Compliance with China Compulsory Product

Certification (CCC Certification) System

Appendix 9-1 Outline of China Compulsory Product

Certification System............................A9-2

Appendix 9-2 First Catalogue of Products subject to

Compulsory Product Certification........A9-2

Appendix 9-3 Precautions for Shipping Products......A9-3

Appendix 9-4 Application for Exemption ...................A9-4

Appendix 9-5 Mitsubishi NC Product Subject to/Not Subject

to CCC Certification ............................A9-5

(Note) This is the content for SPECIFICATION MANUAL version A. The structure of section and page number may be different

other than version B.

Page 16

1. Installation

1-1 Installation of spindle motor ............................................................................................................... 1-2

1-1-1 Environmental conditions............................................................................................................1-2

1-1-2 Shaft characteristics.................................................................................................................... 1-2

1-2 Installation of the control unit ............................................................................................................. 1-3

1-2-1 Environmental conditions............................................................................................................1-3

1-2-2 Installation direction and clearance.............................................................................................1-4

1-2-3 Prevention of entering of foreign matter......................................................................................1-4

1-2-4 Panel installation hole work drawings (Panel cut drawings).......................................................1-5

1-2-5 Heating value ..............................................................................................................................1-6

1-2-6 Heat radiation countermeasures................................................................................................. 1-7

1-3 Installing the spindle detector.............................................................................................................1-9

1-3-1 Magnetic sensor.......................................................................................................................... 1-9

1-3-2 Spindle side detector.................................................................................................................1-11

1-4 Noise measures ...............................................................................................................................1-12

1 - 1

Page 17

1. Installation

1-1 Installation of spindle motor

1. Do not hold the cables, axis or detector when transporting the motor. Failure to

observe this could lead to faults or injuries.

2. Securely fix the motor to the machine. Insufficient fixing could lead to the

motor deviating during operation. Failure to observe this could lead to

injuries.

CAUTION

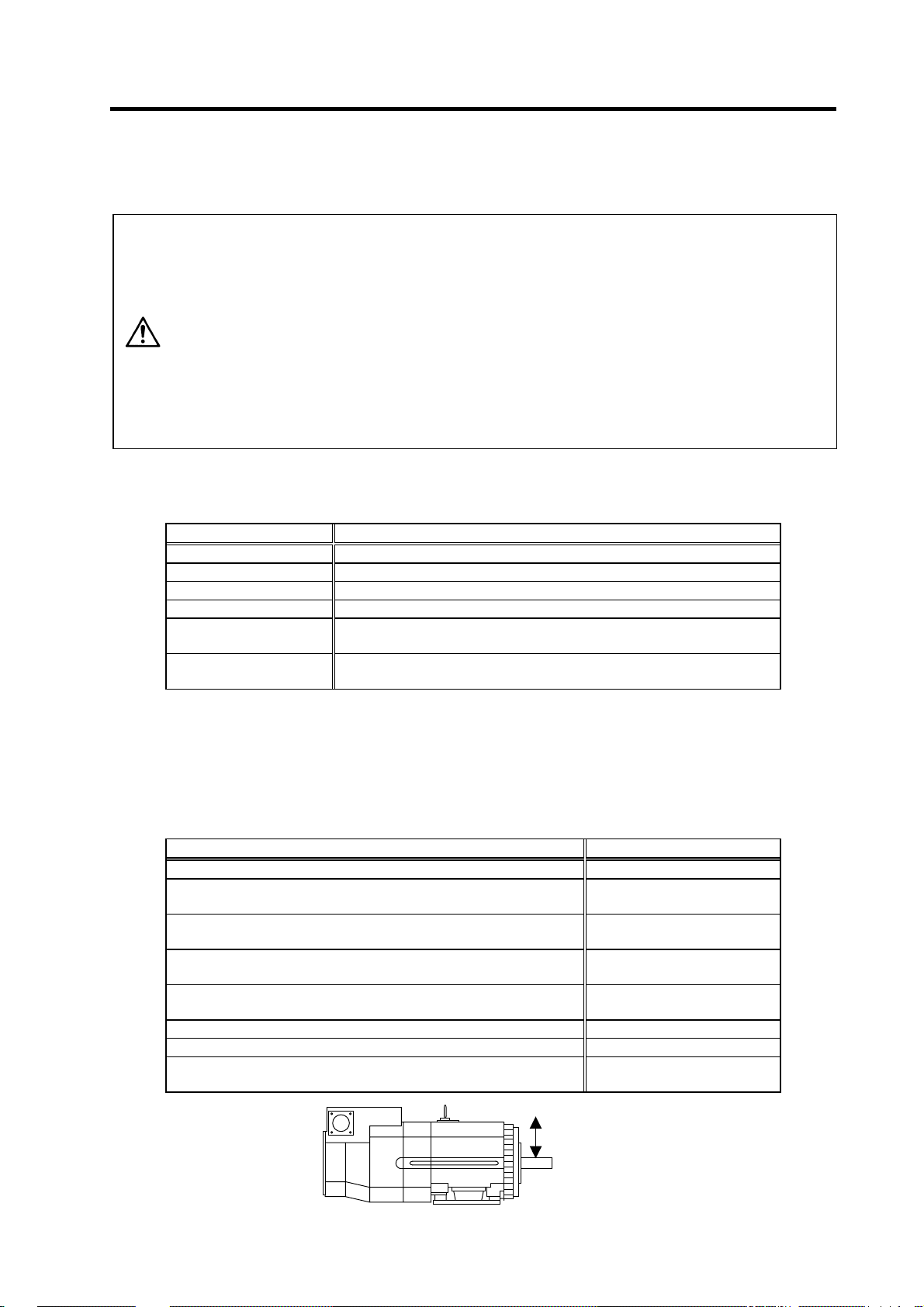

1-1-1 Environmental conditions

Environment Conditions

Ambient temperature 0°C to +40°C (with no freezing)

Ambient humidity 90%RH or less (with no dew condensation)

Storage temperature -20°C to +65°C (with no freezing)

Storage humidity 90%RH or less (with no dew condensation)

Atmosphere

Altitude

(Note) Refer to each spindle motor specifications for details on the spindle motor vibration conditions.

1-1-2 Shaft characteristics

There is a limit to the load that can be applied on the motor shaft. Make sure that the load applied on the

radial direction, when mounted on the machine, is below the tolerable values given below. These loads

also affect the motor output torque, so consider them when designing the machine.

SJ-V3.7-02ZM 490 N

SJ-V2.2-01, SJ-V3.7-01

SJ-V7.5-03ZM, SJ-V11-06ZM

SJ-V5.5-01, SJ-V11-08ZM

SJ-PMF01830-00

SJ-V7.5-01, SJ-V11-01

SJ-V22-06ZM, SJ-V30-02ZM, SJ-PMF03530-00

SJ-V11-09, SJ-V15-01, SJ-V15-03, SJ-V18.5-01, SJ-V18.5-03

SJ-V22-01, SJ-V22-05, SJ-V26-01, SJ-30A

SJ-22XW5 3920 N

SJ-37BP 4900 N

SJ-22XW8, SJ-45BP

SJ-V55-01

3. When coupling to a servomotor shaft end, do not apply an impact by

hammering, etc. The detector could be damaged.

4. Never touch the rotary sections of the motor during operations. Install a

cover, etc., on the shaft.

5. Do not apply a load exceeding the tolerable load onto the servomotor shaft.

The shaft could break. Failure to observe this could lead to injuries.

6. Do not connect or disconnect any of the connectors while the power is ON.

Indoors (Where unit is not subject to direct sunlight)

No corrosive gases, flammable gases, oil mist or dust

Operation/storage: 1000m or less above sea level

Transportation: 10000m or less above sea level

Spindle motor Tolerable radial load

980 N

1470 N

1960 N

2940 N

5880 N

Radial load

(Note) The load point is at the one-half of the shaft length.

1 - 2

Page 18

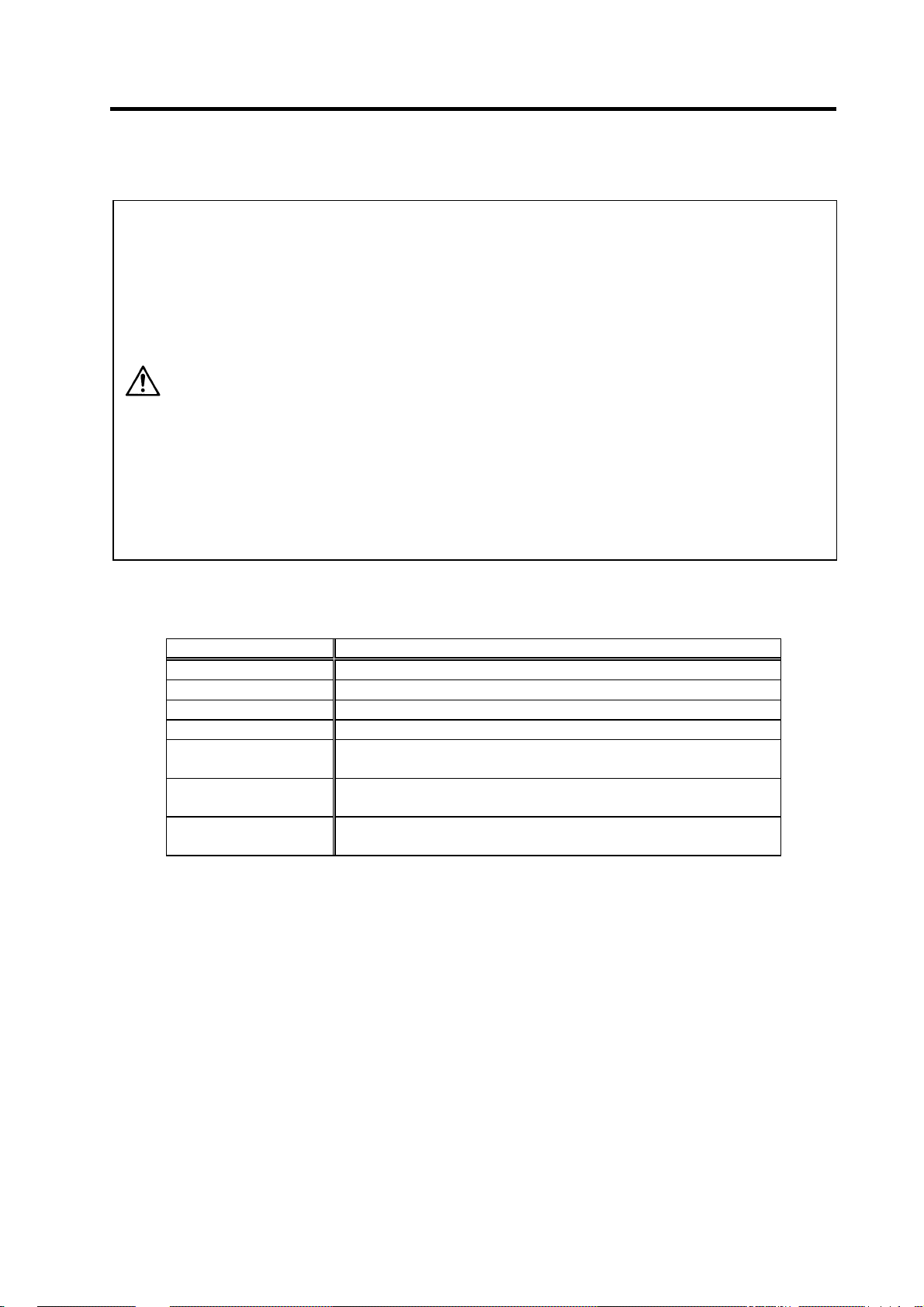

1-2 Installation of the control unit

1. Install the unit on noncombustible material. Direct installation on

combustible material or near combustible materials may lead to fires.

2. Follow the instructions in this manual and install the unit while allowing for

the unit weight.

3. Do not get on top of the units or motor, or place heavy objects on the unit.

Failure to observe this could lead to injuries.

4. Always use the unit within the designated environment conditions.

5. Do not let conductive objects such as screws or metal chips, etc., or

combustible materials such as oil enter the units.

CAUTION

6. Do not block the units intake and outtake ports. Doing so could lead to

failure.

7. The units and servomotor are precision devices, so do not drop them or apply

strong impacts to them.

8. Do not install or run units or servomotor that is damaged or missing parts.

9. When storing for a long time, please contact your dealer.

10. Always observe the installation directions. Failure to observe this could lead to

faults.

11. Secure the specified distance between the units and panel, or between the

units and other devices. Failure to observe this could lead to faults.

1. Installation

1-2-1 Environmental conditions

Environment Conditions

Ambient temperature 0°C to +55°C (with no freezing)

Ambient humidity 90%RH or less (with no dew condensation)

Storage temperature -15°C to +70°C (with no freezing)

Storage humidity 90%RH or less (with no dew condensation)

Atmosphere

Altitude

Vibration

(Note) When installing the machine at 1,000m or more above sea level, the heat dissipation characteristics will drop as the

altitude increases. The upper limit of the ambient temperature drops 1°C with every 100m increase in altitude. (The

ambient temperature at an altitude of 2,000m is between 0 and 45°C.)

no corrosive gases, inflammable gases, oil mist, dust or conductive particles

Indoors (no direct sunlight);

Operation/storage: 1000m or less above sea level

Transportation: 10000m or less above sea level

Operation/storage: 4.9m/s

Transportation: 49m/s

2

(0.5G) or less

2

(5G) or less

1 - 3

Page 19

1. Installation

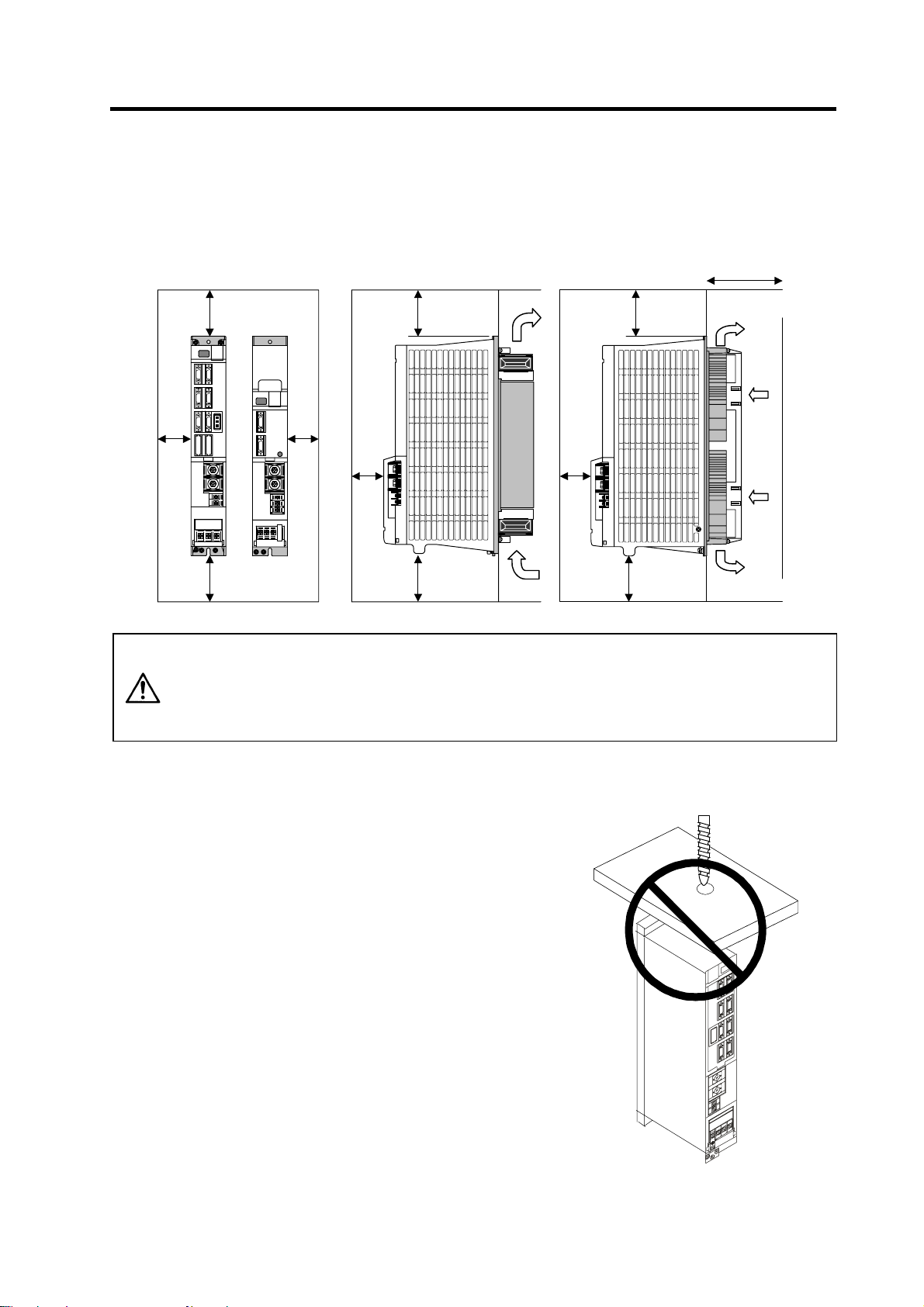

1-2-2 Installation direction and clearance

Wire each unit in consideration of the maintainability and the heat dissipation, as well as secure

sufficient space for ventilation.

75mm or more

10mm

or

more

100mm or

more

100mm or

more

10mm

or

more

50mm

or more

100mm or

more

100mm or

more

The ambient temperature condition for the power supply unit or the drive units is

55°C or less. Because heat can easily accumulate in the upper portion of the

CAUTION

units, give sufficient consideration to heat dissipation when designing the panel.

If required, install a fan in the panel to agitate the heat in the upper portion of the

units.

1-2-3 Prevention of entering of foreign matter

Treat the cabinet with the following items.

• Make sure that the cable inlet is dust and oil proof by using

packing, etc.

• Make sure that the external air does not enter inside by

using head radiating holes, etc.

• Close all clearances.

• Securely install door packing.

• If there is a rear cover, always apply packing.

• Oil will tend to accumulate on the top. Take special

measures such as oil-proofing to the top so that oil does

not enter the cabinet from the screw holds.

• After installing each unit, avoid machining in the periphery.

If cutting chips, etc., stick onto the electronic parts, trouble

may occur.

• When using the unit in an area with toxic gases or high

levels of dust, protect the unit with air purging (system to

blow clean air so that the panel's inner pressure is higher

than the outer pressure).

50mm

or more

100mm or

more

100mm or

more

1 - 4

Page 20

1. Installation

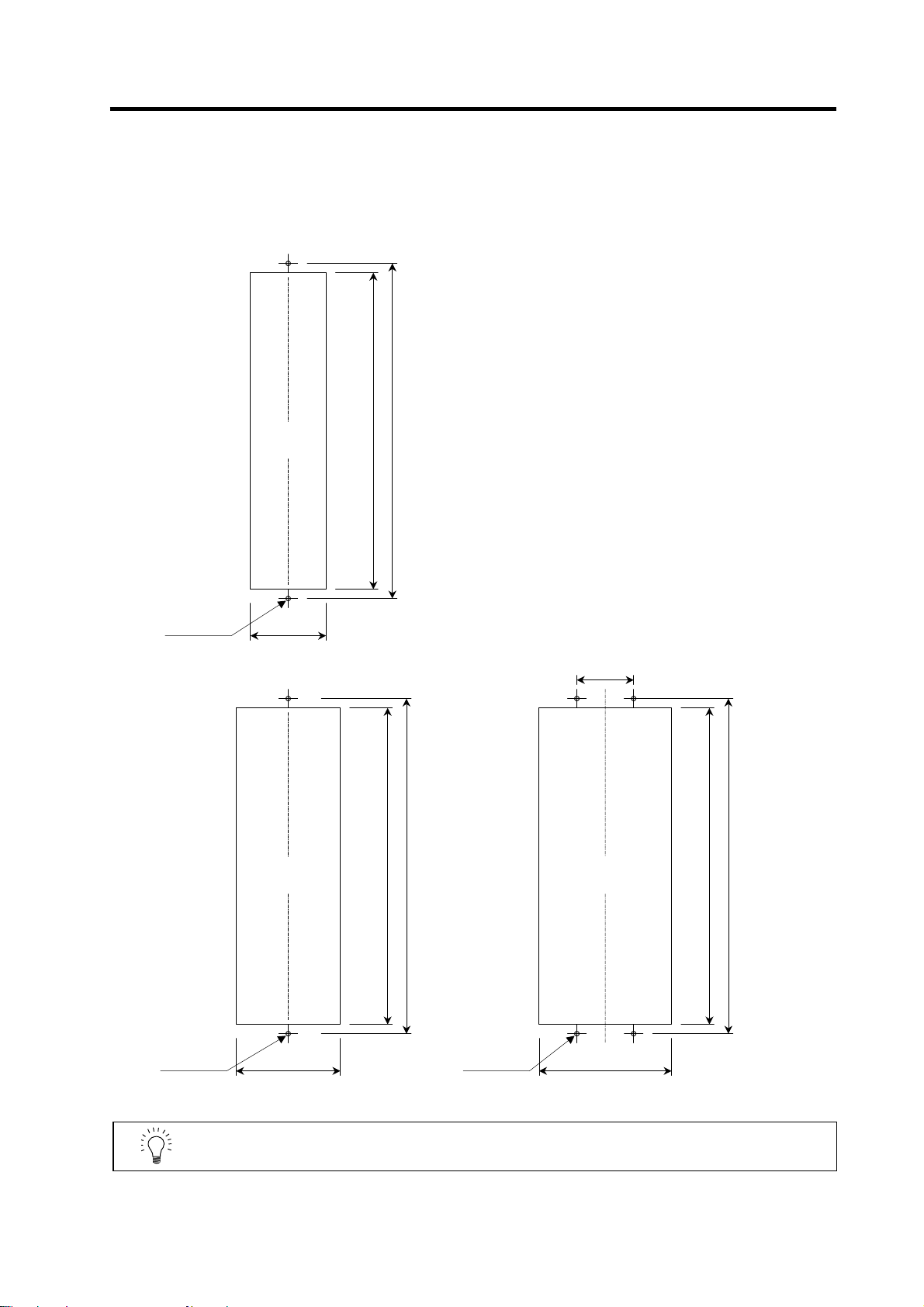

1-2-4 Panel installation hole work drawings (Panel cut drawings)

Prepare a square hole to match the unit width.

[Unit: mm]

2-M5 screw

Square hole

(Note 1)

82

Unit width: 90mm

Square hole

(Note 1)

342

360

342

360

60

Square hole

(Note 1)

342

360

2-M5 screw

112

Unit width: 120mm Unit width: 150mm

POINT

Attach packing around the square hole to provide a seal.

1 - 5

4-M5 screw

142

Page 21

1. Installation

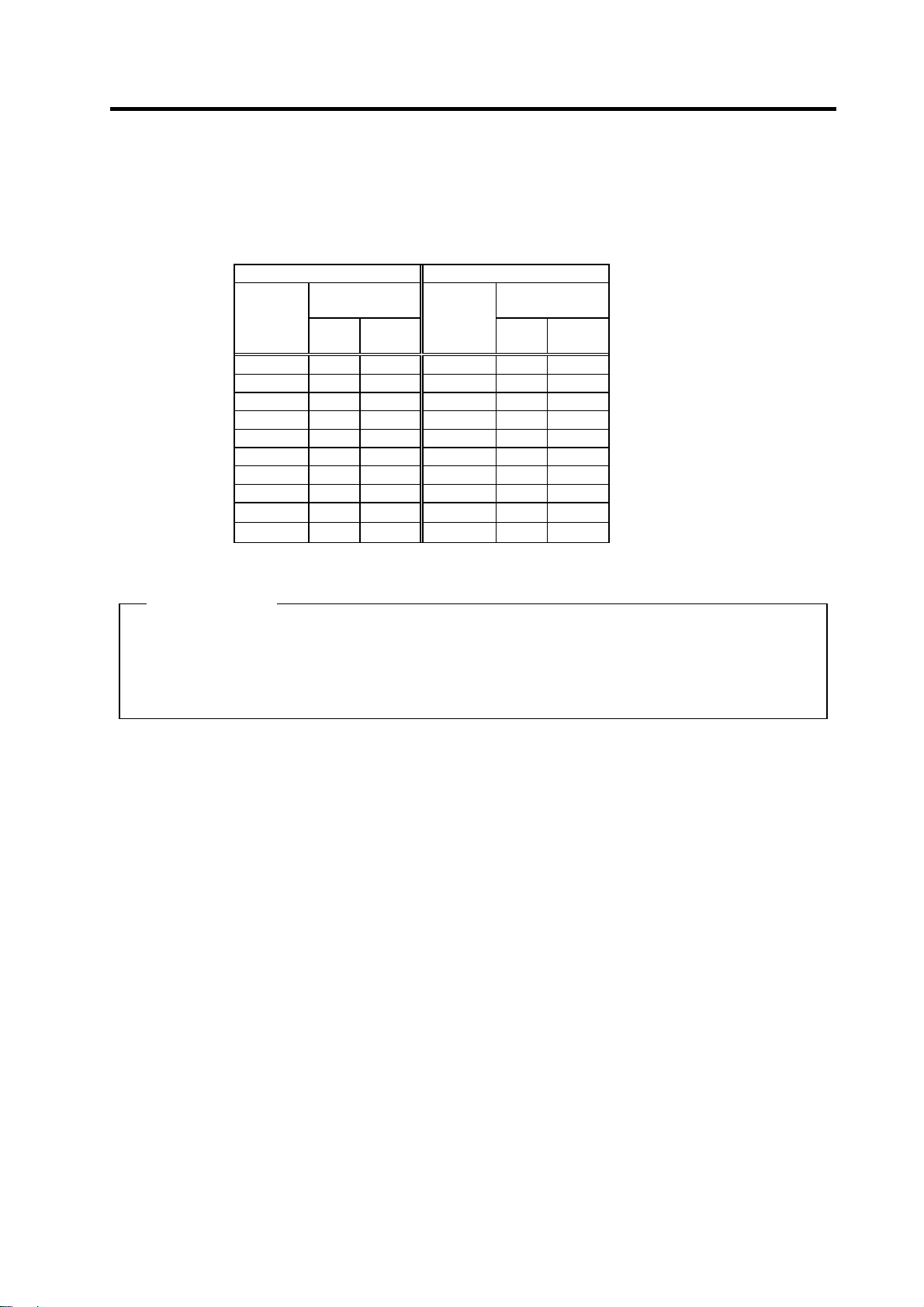

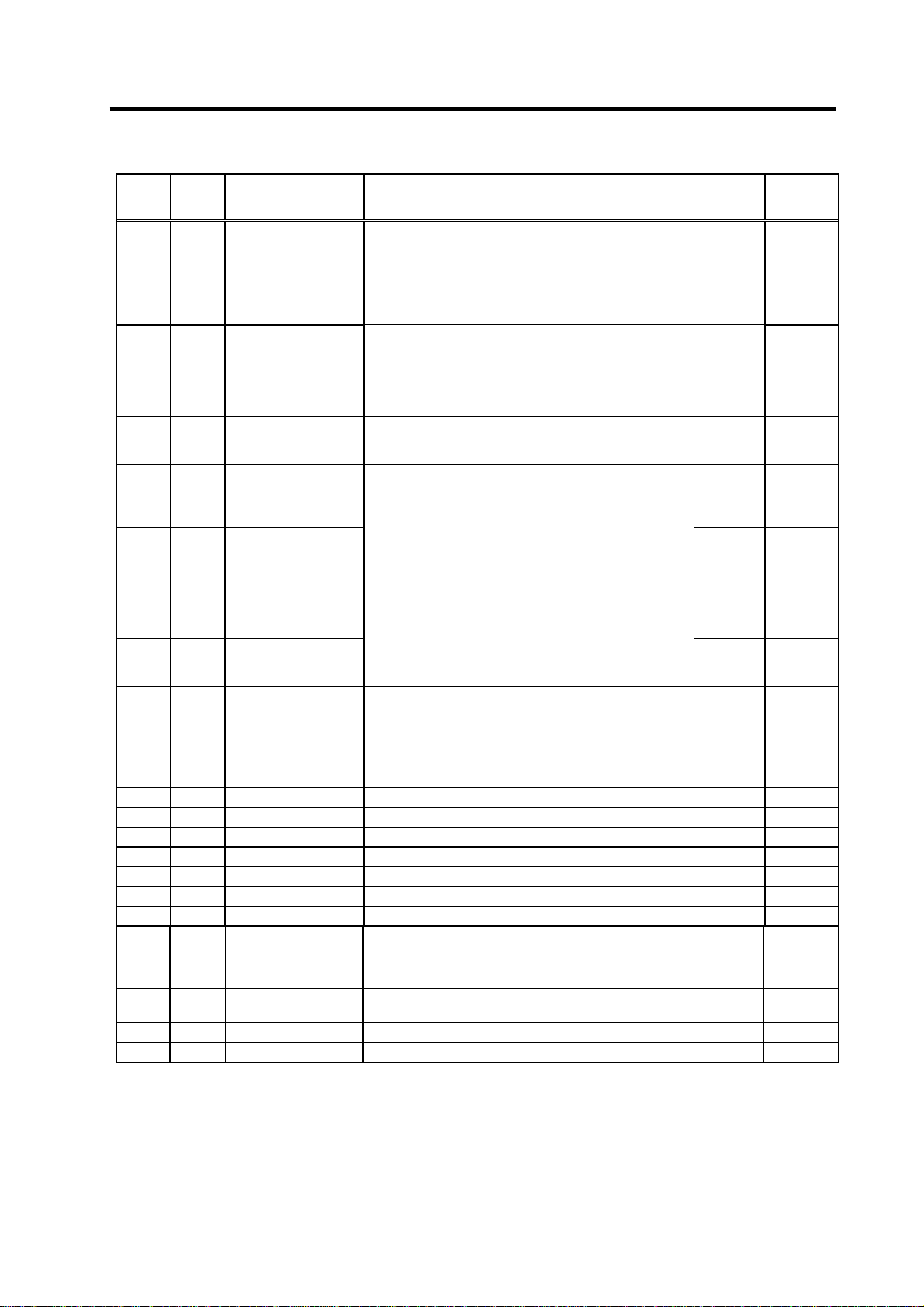

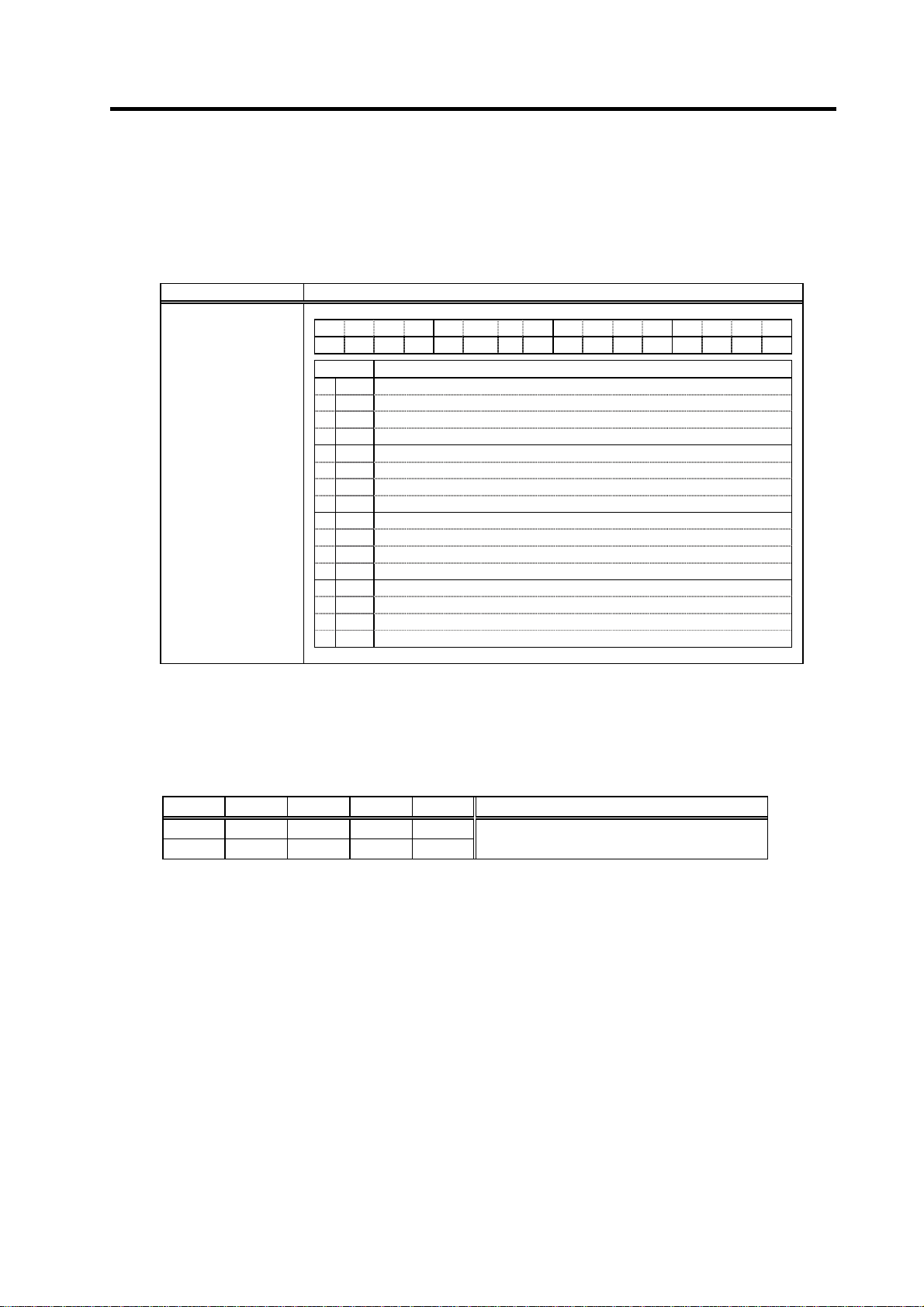

1-2-5 Heating value

Each heating value is calculated with the following values.

The values for the spindle drive unit are for a continuous rated output. The value for the power supply

unit includes the AC reactor's heating value.

Servo drive unit Power supply unit

Heating amount

Inside

panel

[W]

Outside

panel

Type

MDS-C1-

CV-300 46 274

CV-370 54 346

Type

MDS-C1-

SPA- 55 31 76 CV- 37 21 34

SPA- 75 35 102 CV- 55 23 42

SPA-110 41 140 CV- 75 25 55

SPA-150 48 187 CV-110 26 99

SPA-185 62 280 CV-150 29 126

SPA-220 65 301 CV-185 33 162

SPA-260 80 403 CV-220 35 175

SPA-300 98 522 CV-260 40 220

Heating amount

[W]

Inside

panel

Outside

panel

(Example 1)

When using MDS-C1-CV-185, MDS-C1-SPA[]-185[]

Total heating value = (33+162) + (62+280)

Heating value in panel = (33) + (62)

= 537 [W]

= 95 [W]

1 - 6

Page 22

1. Installation

1-2-6 Heat radiation countermeasures

In order to secure reliability and life, design the temperature in the panel so that the ambient

temperature of each unit is 55°C or less.

If heat accumulates at the top of the unit, etc., install a fan so that the temperature in the panel remains

constant.

(Note) Due to the structure, heat easily accumulates at the

top of the unit. Install a fan in the power distribution

panel to circulate the heat at the top of the unit.

(Inside panel)

Wind sp eed 2m/s or more

Fan

1 - 7

Page 23

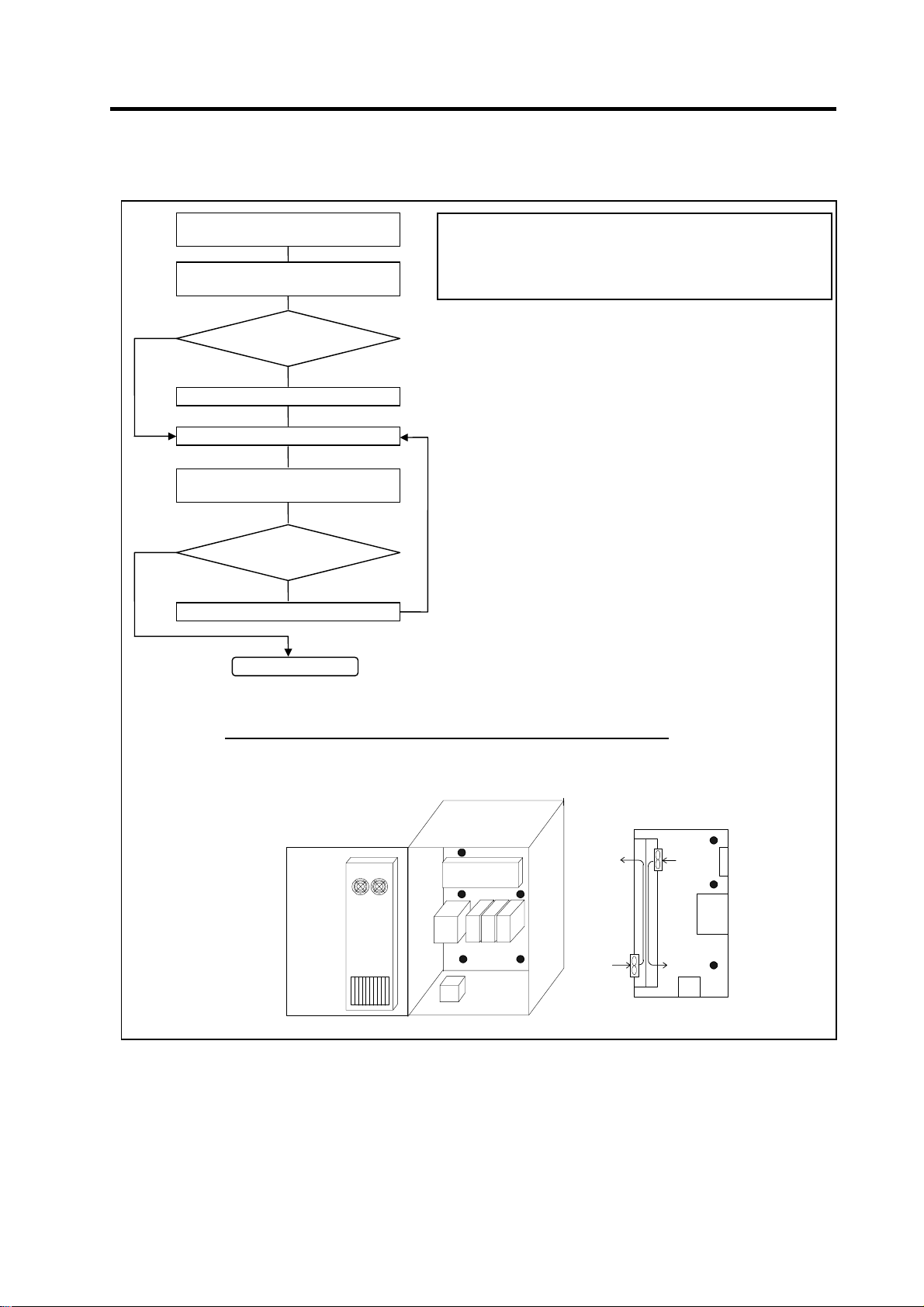

r

1. Installation

Please refer to following method for heat radiation countermeasures.

W ≤ W1

∆T

Calculate total heat radiation of each

mounted unit (W)

Calculate cabinet’s cooling capacity

Comparison of W and W1

Selection of heat exchanger

Collection of internal temperature rise

distribution data

≤10°C

(W1)

Mounting design

Evaluation

∆T>10°C

Improvements

Completion

W>W1

<Hypothetical conditions>

(1) Average temperature in cabinet : T ≤ 55°C

(2) Cabinet peripheral temperature : Ta ≤ 0°C to 45°C

(3) Internal temperature rise value : ∆T =T–Ta

<Supplement>

1) Refer to Specifications Manual, etc. for the heat

generated by each unit.

2) Enclosed cabinet (thin steel plate) cooling capacity

calculation equation

W1 = U × A × ∆T

U: 6W/m

4W/m

A: Effective heat radiation area (m

(Heat dissipation area in panel)

Sections contacting other objects are excluded.

∆T: Internal temperature rise value (10°C)

3) Points of caution for heat radiation countermeasures

when designing mounting state

• Layout of convection in panel

• Collect hot air at suction port in heat exchanger

cabinet.

4) Understanding the temperature rise distribution in the

panel

∆T (average value) ≤ 10°C

∆T

max (maximum value) ≤ 15°C

R (inconsistency) = (∆T

(Evaluate existence of heat spots)

2 ×

2

Examples of mounting and temperature measurement positions (reference)

z

Measurement position (example)

°C (with internal agitating fan)

× °C (without internal agitating fan)

max – ∆Tmin) ≤ 6°C

2

)

max= 10°C

Flow of air

Flow of air

Heat

exchange

Relay, etc

Unit

1 - 8

Page 24

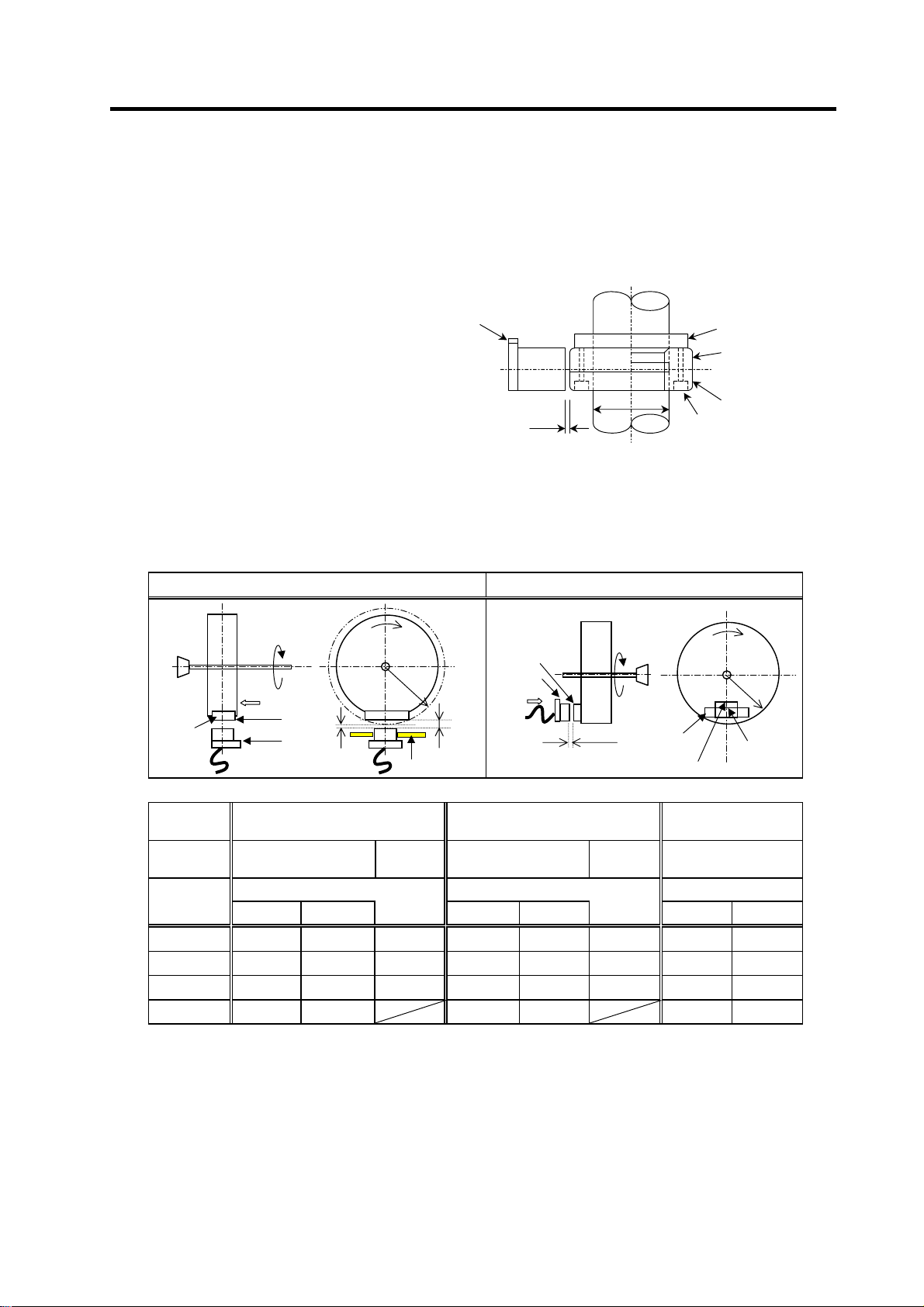

w

1-3 Installing the spindle detector

1-3-1 Magnetic sensor

(1) Installing the magnetic sensor

• Tolerance to shaft dimension should

be "h6" on the part for installing a

magnet.

• 2-øG hole can be used for positioning

of spindle and magnet.

• Magnet shall be installed as shown to

the right.

• Misalignment between sensor head

and magnetic center line shall be

within ±2mm.

• There is an NS indication on the side of

the cover. Install so that the reference

notch on the sensor head comes to the

case side.

(2) Gap between magnet and sensor

1. Installation

Reference notch

Spindle

G hole

h6

Gap

Reference drawing for magnet installation

Case

Cover

Spindle damping scre

Spindle

Magnet

Circumference installation

Direction of

rotation

Face A

Reference

hole

Reference

notch

Min. gap

Face A

R

NS

Max. gap

Mounting plate

Reference

hole

Reference

notch

Face B

Horizontal installation

Spindle

Face B

Gap

Magnet

Reference

notch

Direction of

rotation

N

S

R

Reference

hole

Magnet

model

Installation

direction

R (Radius)

mm

40 11.5±0.5 2.7±0.5 6.0±0.5 10.0±0.5 1.22±0.5 5.0±0.5 6.25±0.5 3.30±0.5

50 9.5±0.5 2.8±0.5 6.0±0.5 8.0±0.5 1.31±0.5 5.0±0.5 6.00±0.5 3.70±0.5

60 8.5±0.5 3.0±0.5 6.0±0.5 7.0±0.5 1.50±0.5 5.0±0.5 5.75±0.5 3.85±0.5

70 8.0±0.5 3.4±0.5 7.0±0.5 2.38±0.5 5.50±0.5 3.87±0.5

Max. value Min. value Max. value Min. value Max. value Min. value

BKO-C1810H03 BKO-C1730H06 BKO-C1730H09

Circumference

installation

Gap mm Gap mm Gap mm

Horizontal

installation

Circumference

installation

Horizontal

installation

Circumference

installation

1 - 9

Page 25

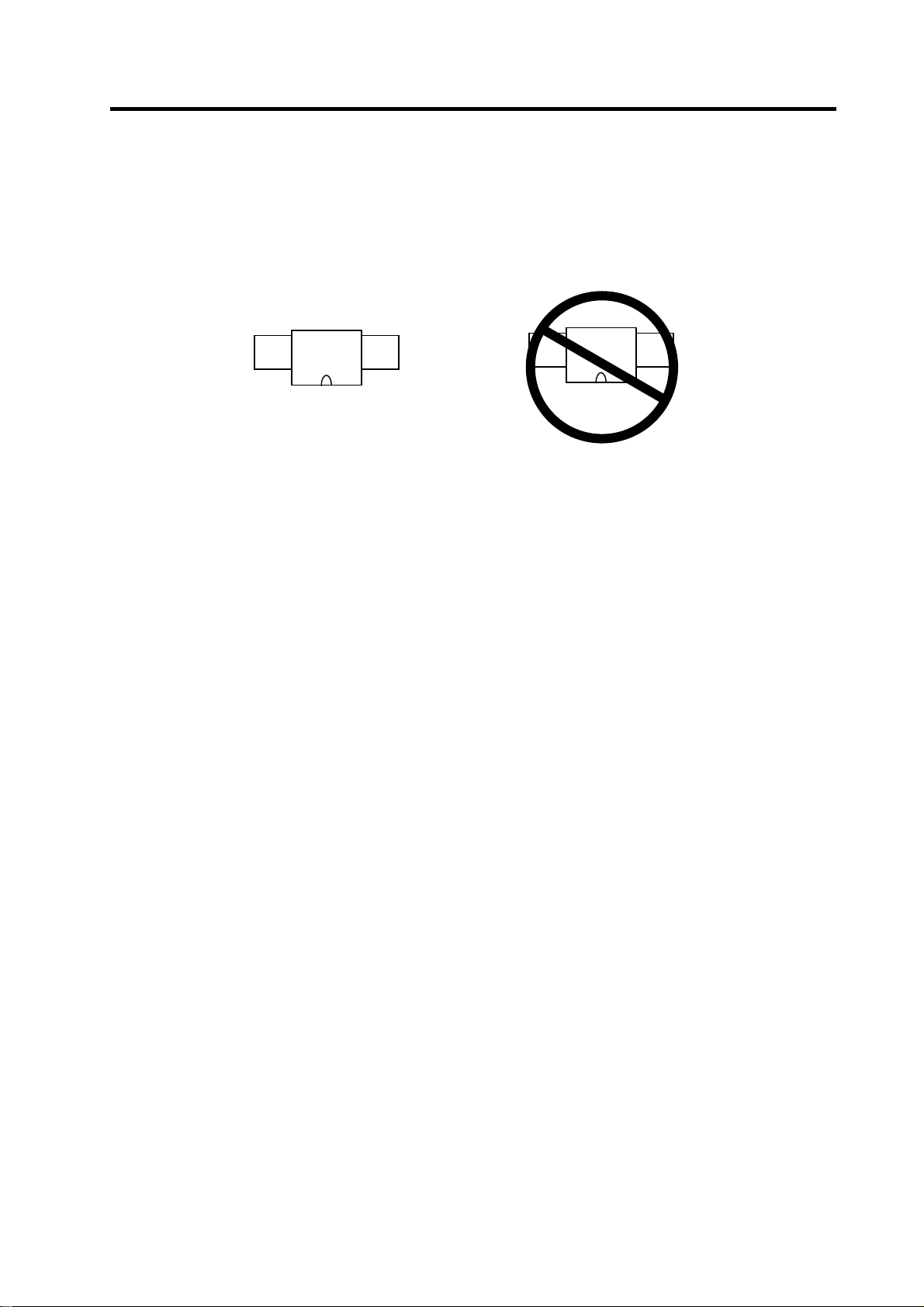

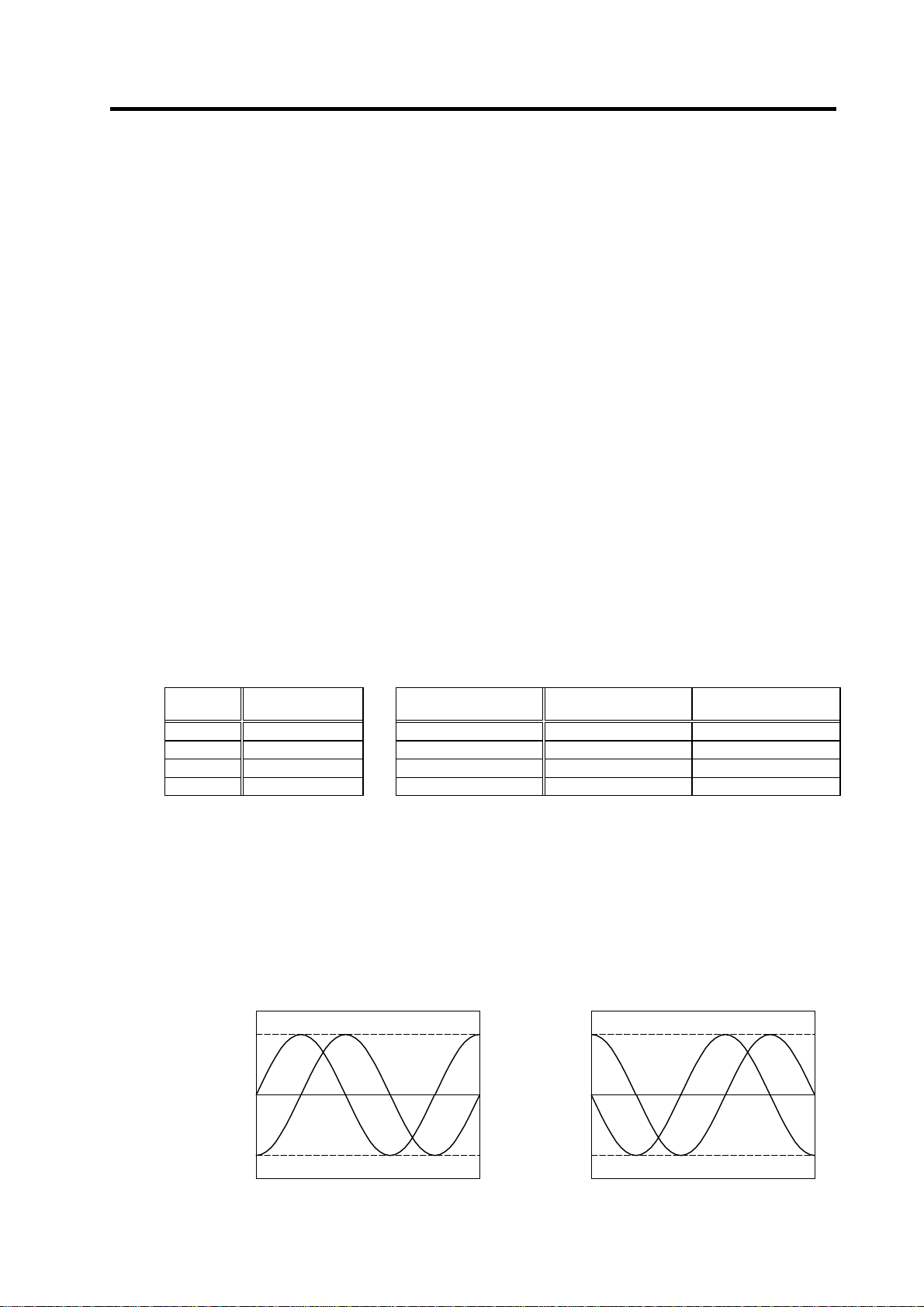

(3) Magnet and sensor installation directions

• Install so that the magnet's reference hole and sensor's reference notch are aligned.

(Standard/high-speed standards)

• Install so that the magnet's N pole comes to the left side when the sensor's reference notch is

faced downward. (High-speed compact/high-speed ring)

Sensor

N S

|

Reference notch

Magnet

(4) Cautions

[1] Do not apply impacts on the magnet. Do not install strong magnets near the magnet.

[2] Sufficiently clean the surrounding area so that iron chips and cutting chips do not adhere to the

magnet. Demagnetize the round disk before installing.

[3] Securely install the magnet onto the spindle with an M4 screw. Take measures to prevent

screw loosening as required.

[4] Balance the entire spindle rotation with the magnet installed.

[5] Install a magnet that matches the spindle's rotation speed.

[6] When installing the magnet onto a rotating body's plane, set the speed to 6,000r/min or less.

[7] Install so that the center line at the end of the head matches the center of the magnet.

[8] The BKO-C1730 is not an oil-proof product. Make sure that oil does not come in contact with

BNO-C1730 or BKO-C1810.

[9] When connecting to the spindle drive unit, wire so that the effect of noise is suppressed.

1. Installation

Sensor

S N

|

Reference notch

Magnet

1 - 10

Page 26

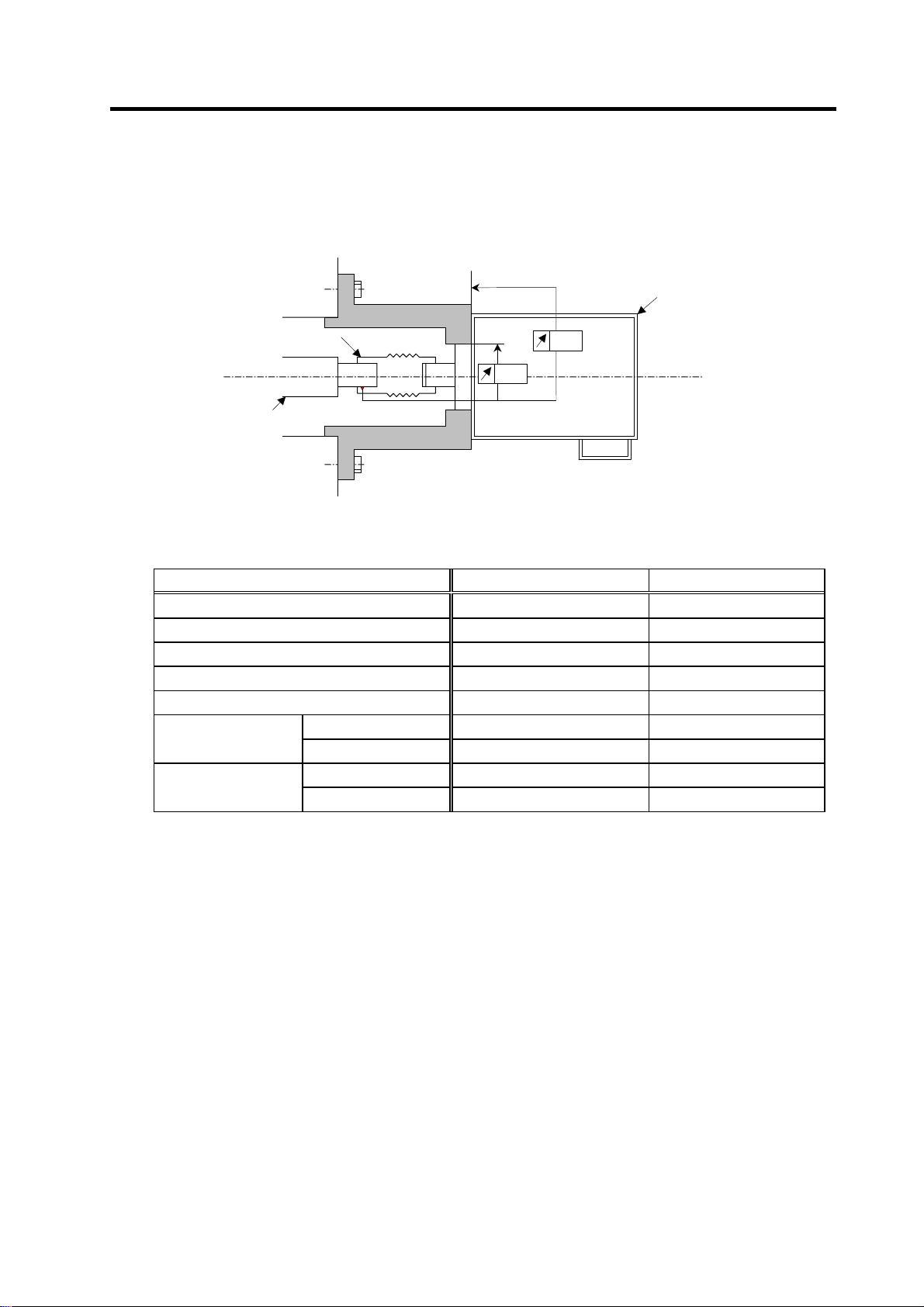

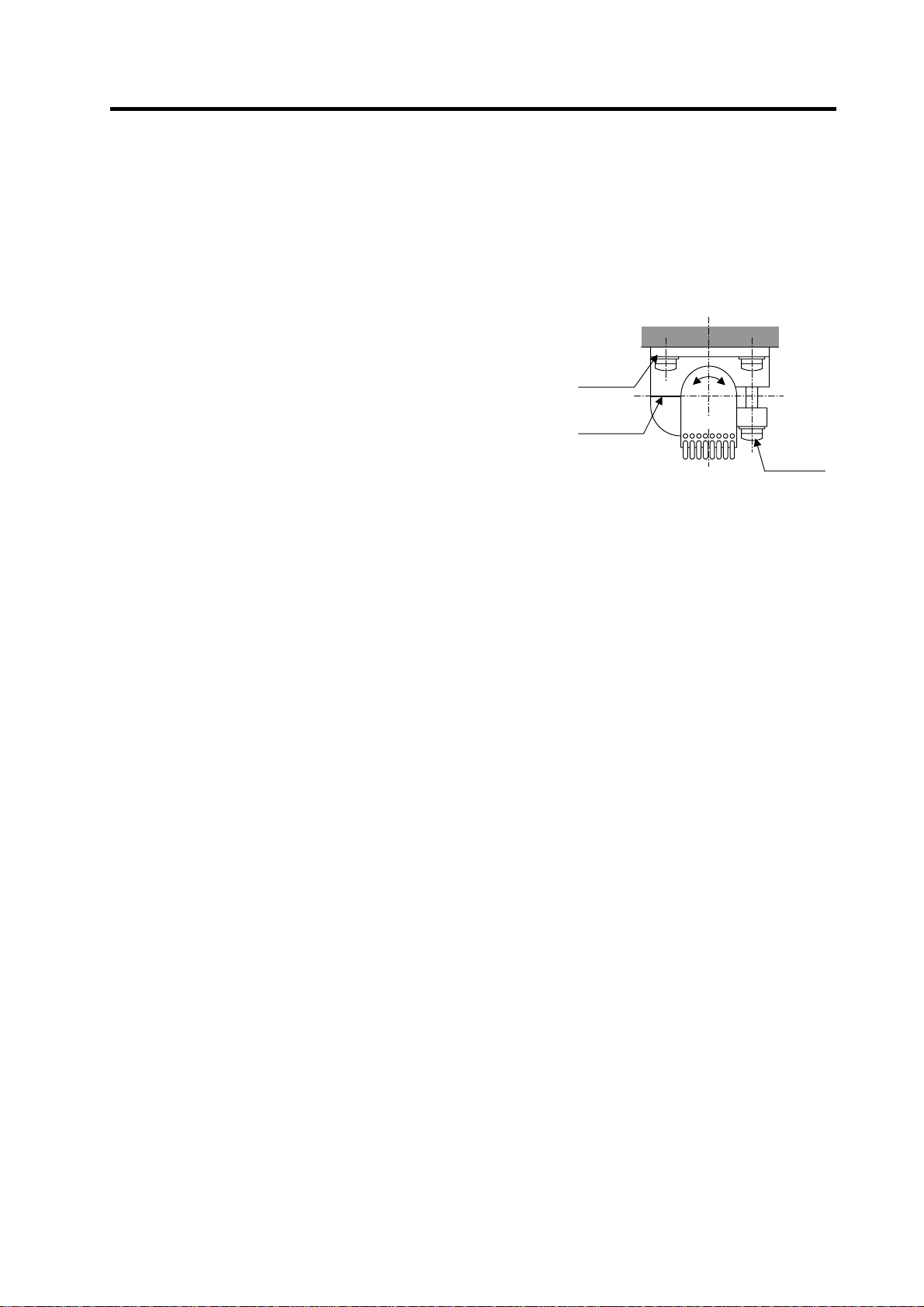

1. Installation

1-3-2 Spindle side detector

When coupling the spindle side detector with spindle, a flexible coupling should be used to couple the

spindle side detector with the spindle.

Detector

Flexible coupling

Opposite detector shaft

side

Detector and coupling installation accuracy

Recommended coupling

Recommendation 1 Recommendation 2

Manufacturer Tokushu Seiko Eagle

Model Model M1 FCS38A

Resonance frequency 1374Hz 3515Hz

Position detection error 0.8×10-3° 1.2×10-3°

Tolerable speed 20000r/min 10000r/min

Mis-alignment

Outline dimensions

Core deviation 0.7mm 0.16mm

Angle displacement

Max. length 74.5mm 33mm

Max. diameter

Refer to the coupling catalog, etc., for details on the coupling.

0.02

0.02

1.5° 1.5°

ø57mm ø38mm

1 - 11

Page 27

1. Installation

1-4 Noise measures

Noise includes "propagation noise" generated from the power supply or relay, etc., and propagated

along a cable causing the power supply unit or drive unit to malfunction, and "radiated noise"

propagated through air from a peripheral device, etc., and causing the power supply unit or drive unit to

malfunction.

Always implement these noise measures to prevent the peripheral devices and unit from malfunctioning.

The measures differ according to the noise propagation path, so refer to the following explanation and

take appropriate measures.

(1) General noise measures

• Avoid laying the drive unit's power line and signal wire in a parallel or bundled state. Always

separate these wires. Use a twisted pair shielded wire for the detector cable and signal wires

such as the communication cable connected with the NC, and accurately ground the devices.

• Use one-point grounding for the drive unit and motor.

• Accurately ground the AC reactor.

(2) Propagation noise measures

Take the following measures when noise generating devices are installed and the power supply

unit or drive unit could malfunction.

• Install a surge killer on devices (magnetic contacts, relays, etc.) which generate high levels of

noise.

• Install a power line filter in the stage before the power supply unit.

• Install a ferrite core on the signal wire.

• Ground the shield of the servo detector's cable with a cable clamp.

• Wire the spindle PLG detector cable away from other wires.

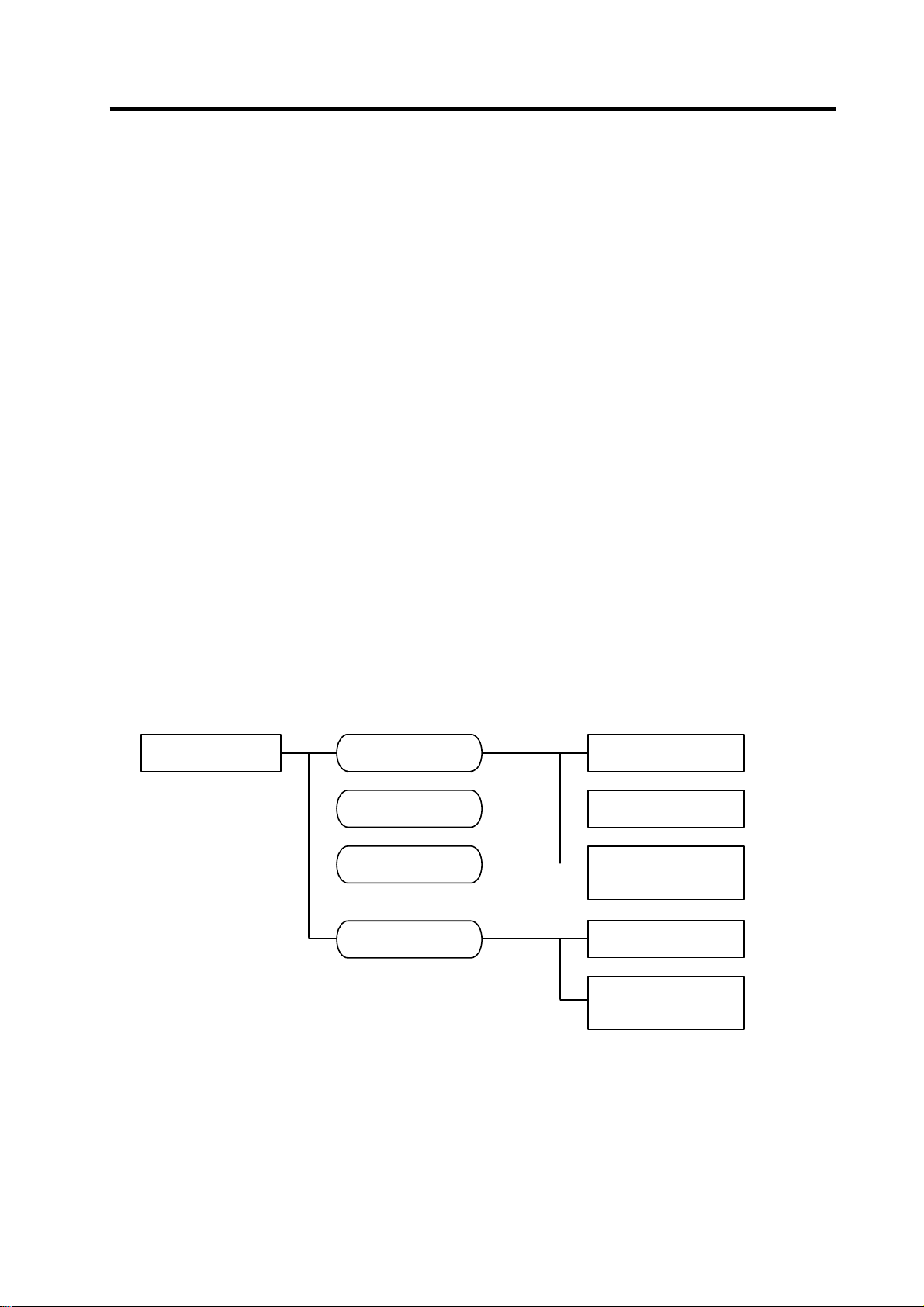

(3) Measures against radiated noise

The types of propagation paths of the noise and the noise measures for each propagation path are

shown below.

Noise generated from

drive unit

Airborne

propagation noise

Noise directly radiated

from drive unit

Path [1]

Magnetic ind uction

noise

Static ind uction

noise

Cable propagation

noise

Path [4]

and [5]

Noise radiated f rom

power line

Noise radiated f rom

spindle motor

Noise propagated over

power line

Noise lead in from

grounding wire by

leakage current

Path [2]

Path [3]Path [6]

Path [7]

Path [8]

1 - 12

Page 28

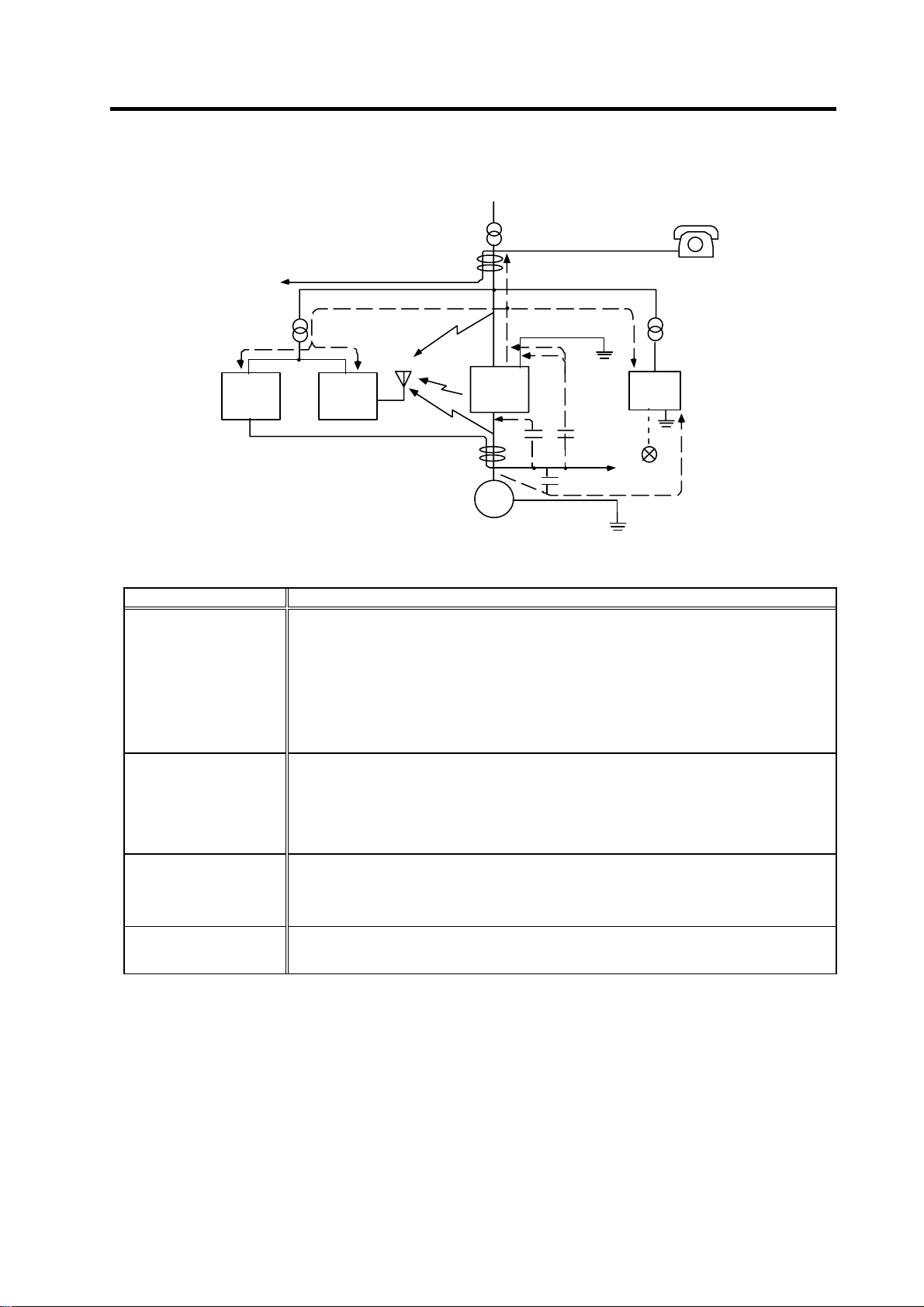

1. Installation

[5]

[7]

[2]

[1]

Drive

[3]

Spindle motor

Generated noise of drive system

unit

[4]

M

Instrument

[7]

Receiver

Noise propagation path Measures

When devices such as instrument, receiver or sensor, which handle minute signals and are easily

affected by noise, or the signal wire of these devices, are stored in the same panel as the drive

units and the wiring is close, the device could malfunction due to airborne propagation of the noise.

In this case, take the following measures.

[1] [2] [3]

[4] [5] [6]

[7]

[8]

(a) Install devices easily affected as far away from the drive units as possible.

(b) Lay devices easily affected as far away from the signal wire of the drive unit as possible.

(c) Avoid laying the signal wire and power line in a parallel or bundled state.

(d) Insert a line noise filter on the input/output wire or a radio filter on the input to suppress the

noise radiated from the wires.

(e) Use a shield wire for the signal wire and power line, or place in separate metal ducts.

If the signal wire is laid in parallel to the power line, or if it is bundled with the power line, the noise

could be propagated to the signal wire and cause malfunction because of the magnetic induction

noise or static induction noise. In this case, take the following measures.

(a) Install devices easily affected as far away from the drive unit as possible.

(b) Lay devices easily affected as far away from the signal wire of the drive unit as possible.

(c) Avoid laying the signal wire and power line in a parallel or bundled state.

(d) Use a shield wire for the signal wire and power line, or place in separate metal ducts.

If the power supply for the peripheral devices is connected to the power supply in the same system

as the drive units, the noise generated from the power supply unit could back flow over the power

line and cause the devices to malfunction. In this case, take the following measures.

(a) Install a radio filter on the power supply unit's power line.

(b) Install a power filter on the power supply unit's power line.

If a closed loop is created by the peripheral device and drive unit's grounding wire, a leakage

current could flow and cause the device to malfunction.

In this case, change the device grounding methods and the grounding place.

[6]

[2]

Sensor

power

supply

Sensor

[8]

1 - 13

Page 29

2. Wiring and Connection

2-1 Connection diagram........................................................................................................................... 2-3

2-1-1 Part system connection diagram..................................................................................................2-3

2-1-2 Detailed connection diagram........................................................................................................ 2-4

2-2 Main circuit terminal block/control circuit connector ..........................................................................2-7

2-2-1 Names and applications of main circuit terminal block signals and control circuit connectors ..2-7

2-2-2 Connector pin assignment ..........................................................................................................2-8

2-3 Drive unit connection........................................................................................................................ 2-11

2-4 Motor and detector connection ........................................................................................................2-14

2-4-1 Connection of the spindle motor ...............................................................................................2-14

2-5 Connection of power supply............................................................................................................. 2-17

2-5-1 Power supply input connection .................................................................................................2-17

2-5-2 Connecting the grounding cable ............................................................................................... 2-20

2-5-3 Main circuit control .................................................................................................................... 2-21

2-6 Peripheral control wiring...................................................................................................................2-23

2-6-1 Input interface............................................................................................................................ 2-23

2-6-2 Output interface.........................................................................................................................2-25

2-6-3 Spindle coil changeover............................................................................................................2-27

2-6-4 Wiring of an external emergency stop.......................................................................................2-30

2 - 1

Page 30

2. Wiring and Connection

1. Wiring work must be done by a qualified technician.

2. Wait at least 15 minutes after turning the power OFF and check the voltage

with a tester, etc., before starting wiring. Failure to observe this could lead to

electric shocks.

3. Securely ground the drive units and spindle motor.

DANGER

4. Wire the drive units and spindle motor after installation. Failure to observe this

could lead to electric shocks.

5. Do not damage, apply forcible stress, place heavy items on the cables or get

them caught. Failure to observe this could lead to electric shocks.

6. Always insulate the power terminal connection section. Failure to observe

this could lead to electric shocks.

1. Correctly and securely perform the wiring. Failure to do so could result in

runaway of the spindle motor or injury.

2. Do not mistake the terminal connections.

Failure to observe this item could lead to ruptures or damage, etc.

3. Do not mistake the polarity ( + ,

- ). Failure to observe this item could lead to

ruptures or damage, etc.

4. Do not mistake the direction of the diodes for the surge absorption installed

on the DC relay for the general-purpose output and contactor (magnetic

contactor) control. The signal might not be output when a failure occurs.

Servodrive unit

COM

(24VDC)

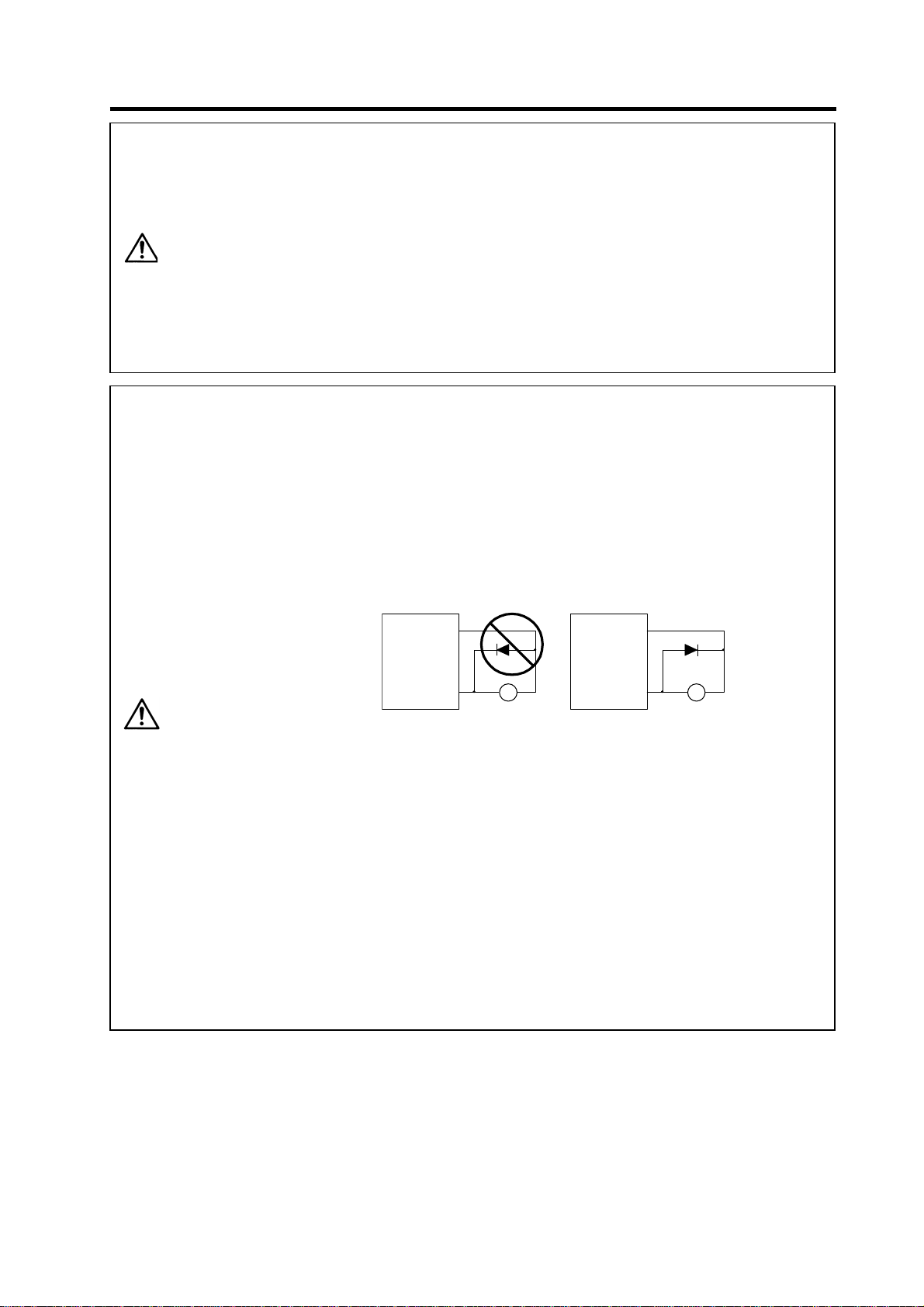

Servodrive unit

COM

(24VDC)

CAUTION

Controloutput

signal

RA

Control output

signal

RA

5. Electronic devices used near the drive units may receive magnetic

obstruction. Reduce the effect of magnetic obstacles by installing a noise

filter, etc.

6. Do not install a phase advancing capacitor, surge absorber or radio noise

filter on the power line (U, V, W) of the spindle motor.

7. Do not modify this unit.

8. The half-pitch connector (CN10, etc.) on the front of the drive units have the

same shape. If the connectors are connected incorrectly, faults could occur.

Make sure that the connection is correct.

9. When grounding the motor, connect to the protective grounding terminal on

the drive units, and ground from the other protective grounding terminal.

(Use one-point grounding) Do not separately ground the connected motor

and drive unit as noise could be generated.

2 - 2

Page 31

r

r

r

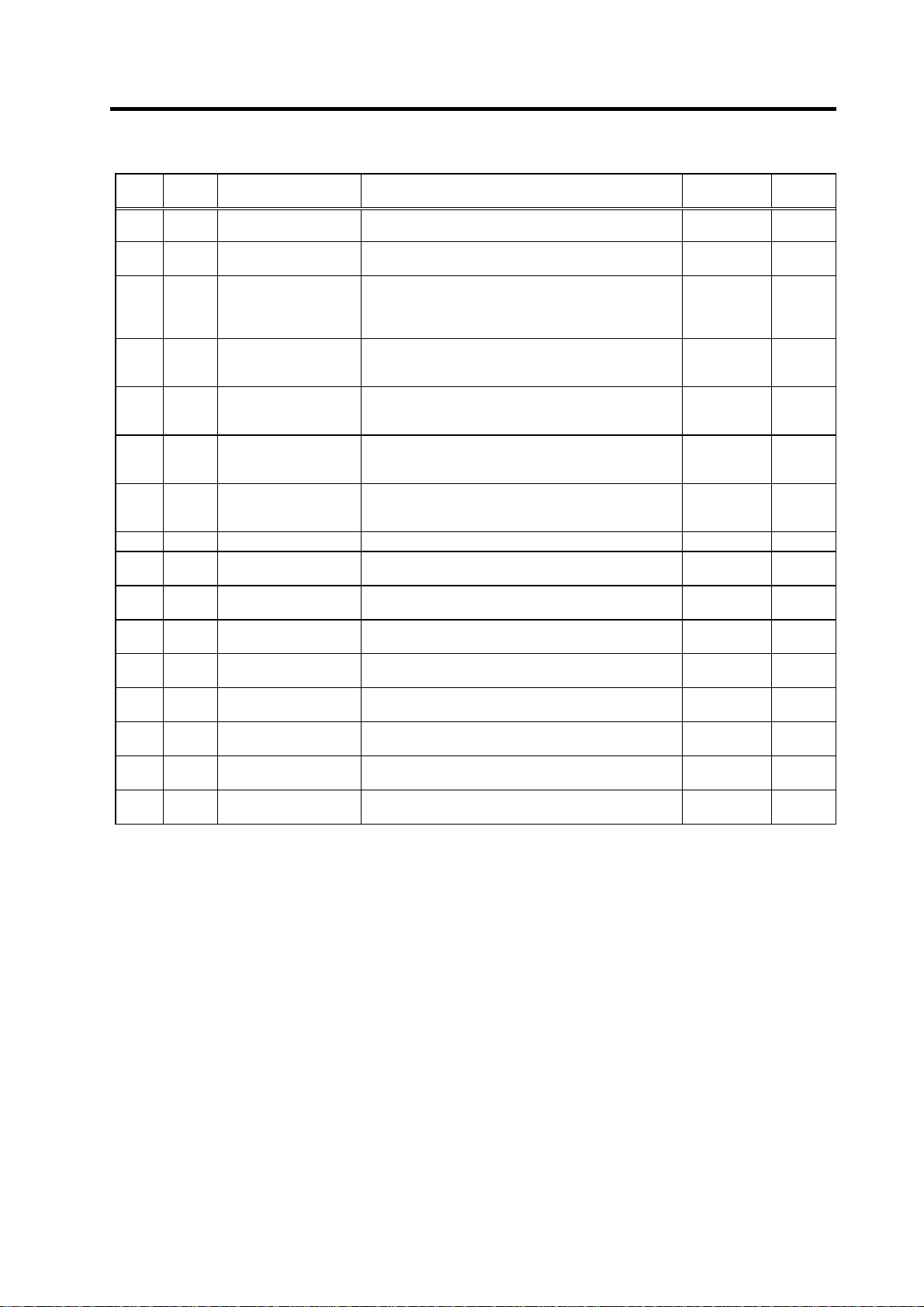

2. Wiring and Connection

2-1 Connection diagram

2-1-1 Part system connection diagram

No-fuse

breaker

R

S

T

: Main circuit

: Control circuit

External emergency stop input

AC

Contacto

reactor

Ground

Breake

MC

CN23

L1

L2

L3

MC1

L11

L21

TE1

TE3

TE2

CN4

CN9

L+

L-

Ground

L+

L-

L11

L21

Spindle drive unitPower supply unit

CN4

General purpose, general-purpose output

CN10

TE2

TE3

TE1

Orientation position command,

General-purpose output

CN11

Digital speed command,

general-purpose • error output

CN12

Speed • load meter, serial I/F

CN9A

S-analog speed command, pulse feedback

CN8A

Spindle side detector

CN6

CN5

U

V

W

Spindle

motor

Ground

PLG

ENC

NC

PC

DIO

Meter

Personal compute

(Note 1) The connection method will differ according to the used motor.

(Note 2) The main circuit (

) and control circuit ({) are safely separated.

2 - 3

Page 32

2. Wiring and Connection

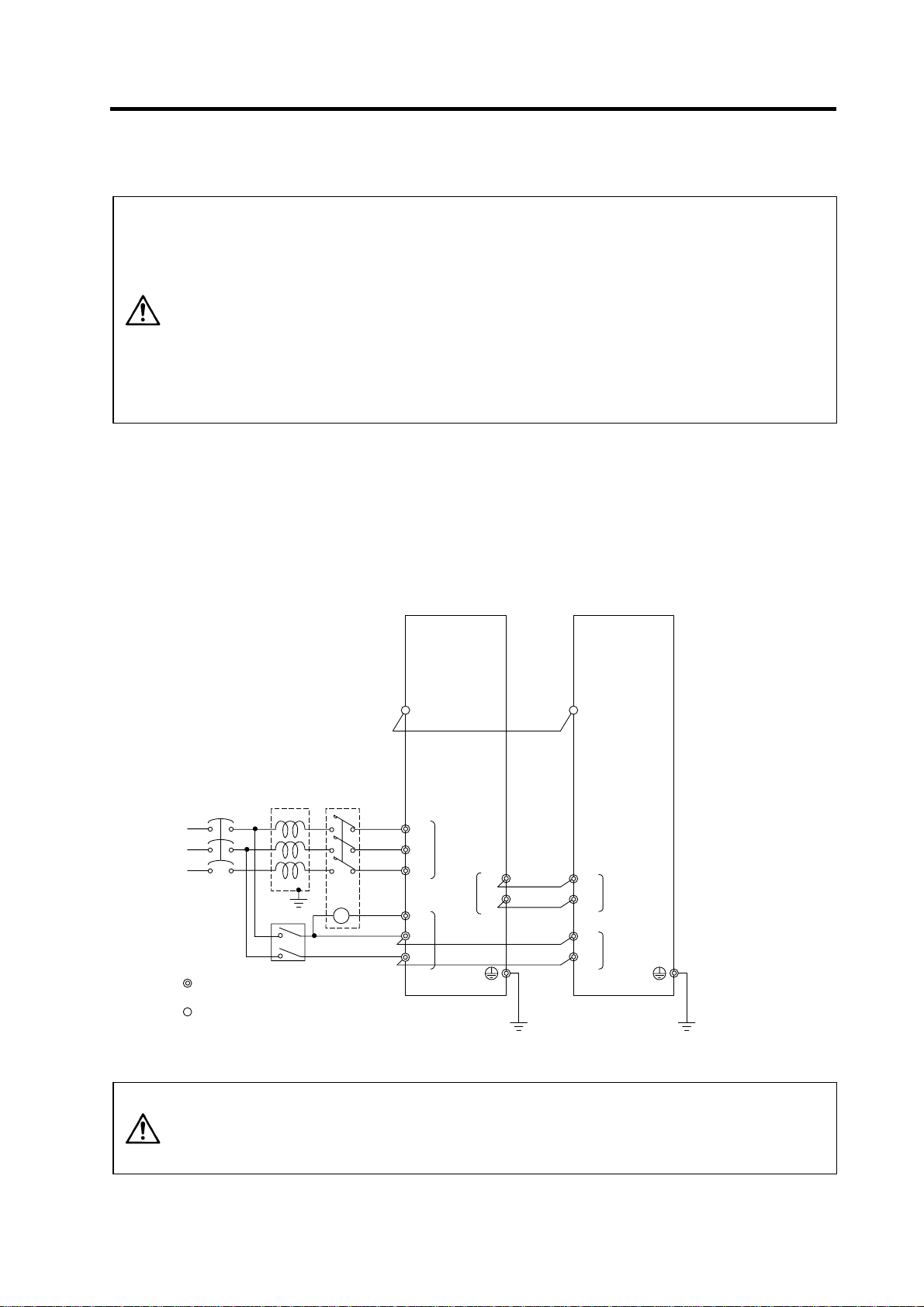

2-1-2 Detailed connection diagram

(1) With no orientation / When using motor built-in encoder orientation

B-AL

NFB3

Contactor

TYPE

MDS-C1-CV-□

TYPE

MDS-C1-SPA-

□

2 - 4

Page 33

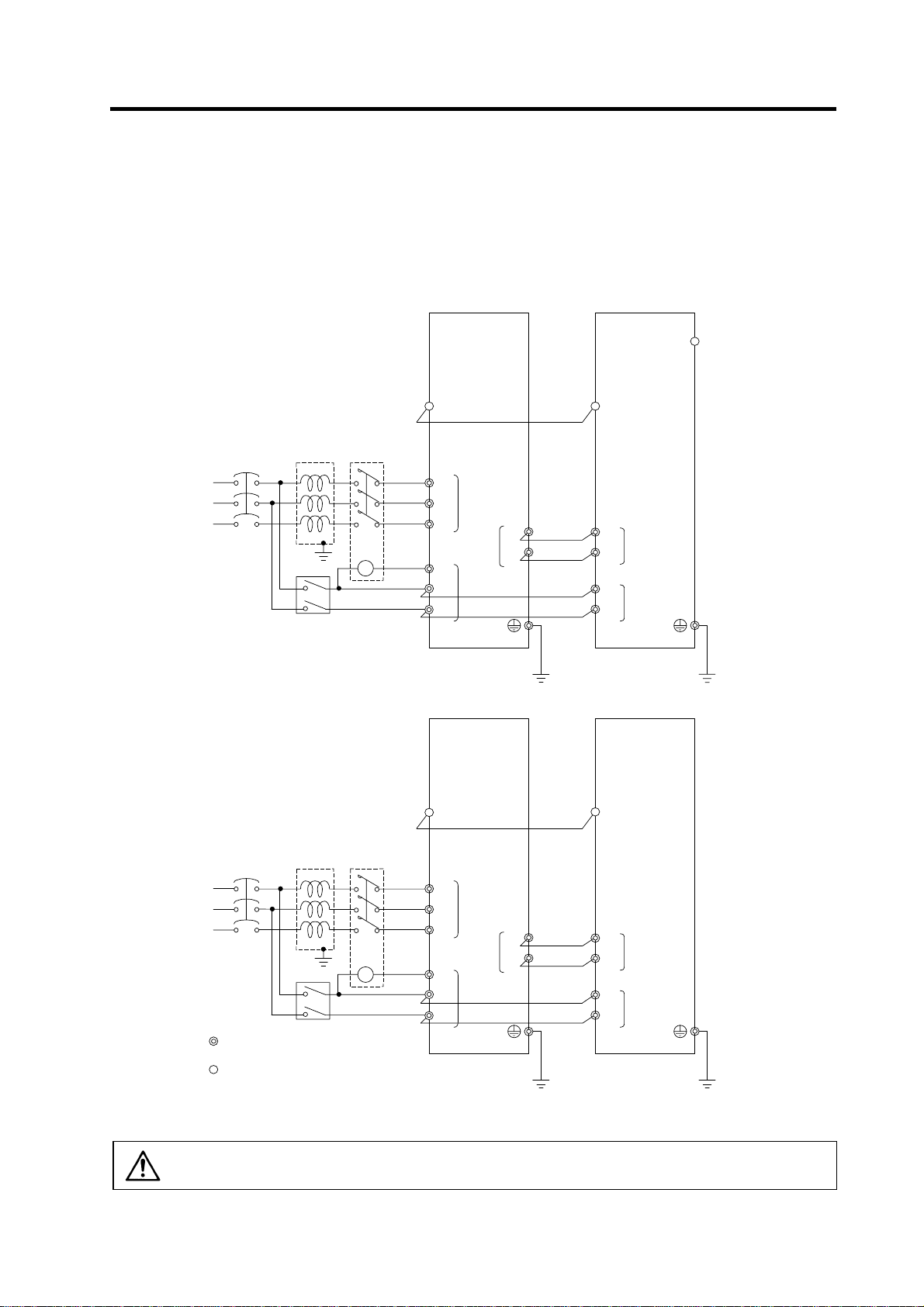

2. Wiring and Connection

(2) When using magnetic sensor orientation

B-AL Contactor

NFB3

TYPE

MDS-C1-CV-□

TYPE

MDS-C1-SPA-□

2 - 5

Page 34

(3) When using encoder orientation

2. Wiring and Connection

B-AL Contactor

NFB3

TYPE

MDS-C1-CV-□

TYPE

MDS-C1-SPA-□

2 - 6

Page 35

2. Wiring and Connection

2-2 Main circuit terminal block/control circuit connector

2-2-1 Names and applications of main circuit terminal block signals and control circuit

connectors

The following table shows the details for each terminal block signal.

Name Signal name Description

L1 . L2 . L3

L11 L21

MC1

U . V . W

LU . LV . LW

MU . MV . MW

Main circuit power

supply

Control circuit power

supply

Contactor control

Motor output

(Single-axis unit)

Motor output

(Dual-axis unit)

Protective grounding

(PE)

Main circuit power supply input terminal

Connect a 3-phase 200VAC/200 to 230VAC, 50/60Hz power supply.

Control circuit power supply input terminal

Connect a single-phase 200VAC/200 to 230VAC, 50/60Hz power supply.

Contactor control terminal

The MC1 terminal has the same phase as L21. Connect to a different phase than the

phase connected to L21.

Servo/spindle motor power output terminal

The servo/spindle motor power terminal (U, V, W) is connected.

Servo motor power output terminal (L-axis/M-axis)

The servo/spindle motor power terminal (U, V, W) is connected.

Grounding terminal

The servomotor/spindle motor grounding terminal is connected and grounded.

1. Always use one AC reactor per power supply unit. Failure to observe this

could lead to unit damage.

CAUTION

2. When sharing a breaker for several power supply units, of a short-circuit

fault occurs in a small capacity unit, the breaker could trip. This can be

hazardous, so do not share the breaker.

3. Be sure to use the breaker of proper capacity for each power supply unit.

2 - 7

Page 36

2-2-2 Connector pin assignment

2. Wiring and Connection

CAUTION

Do not apply a voltage other than that specified in Instruction Manual on each

terminal. Failure to observe this item could lead to rupture or damage, etc.

(1) Main circuit terminal block

Power supply unit

Terminal

Terminal

position

Unit

MDS-C1-CV-37 to 75 MDS-C1-CV-110 to 370

[2]

[3]

[1]

[2]

[3]

[1]

[4]

U V W

[1] TE1

Compatible unit CV-37 to 75

Screw size

Tightening torque

[2] TE2

[3] TE3

Terminal specification/Pin assignment

Compatible unit CV-37 to 75

[4]

Screw size M4

Tightening torque 2.0Nm

L+

L-

L11

L21

MC1

U V W

Compatible unit CV-110 to 185 CV-220 to 370

M4

1.6Nm

Compatible unit CV-37 to 370

Screw size

Tightening torque

Compatible unit CV-37 to 75 CV-110 to 370

Screw size M4 M4

Tightening torque 2.0Nm 1.6m

Screw size

Tightening torque

M6

5.0Nm

M5 M8

3.37Nm 13.2Nm

Compatible unit CV-110 to 185 CV-220 to 370

Screw size M5 M8

Tightening torque 3.37Nm 13.2Nm

[4]

2 - 8

Page 37

[2]

[3]

Spindle drive unit

Terminal

Terminal

position

[1] TE1

[2] TE2

Terminal specification/Pin assignment

[3] TE3

[4]

2. Wiring and Connection

Unit

MDS-C1-SPA- 55 to 185 220 to 300

Screw size M5 M8

Tightening torque 3.2Nm 13.2Nm

L+

L-

L11

L21

MDS-C1-SPA-55 to 300

[1]

[4]

U V W

Compatible unit All capacity

Screw size M6

Tightening torque 5.0Nm

Compatible unit All capacity

Screw size M4

Tightening torque 2.0Nm

The PE screw size is the same as TE1.

2 - 9

Page 38

Pin N

No.1

No.1

1

(2) Control circuit connector

Unit

Terminal

[5] CN5 [6] CN6 [9] CN8A [3] CN9A

Pin assignment

[7] CN10 [1] CN11 [2] CN12

Pin assignment

Connector

position

[1] CN11

[2] CN12

[3] CN9A

[4] CN4

[5] CN5

[6] CN6

[7] CN10

[8] CN8A

1 GND 11 GND

2 RD 12 RD*

3 MOH 13 RG

4 SD 14 SD*

5 P15 15 N15

6 PA 16 RA

7 PB 17 RB

8 PZ 18 9 P24 19 -

10 - 20 -

Connector specifications

1 REDY 11 SRN

2 SRI 12 IN1

3 IN2 13 IN3

4 IN4 14 IN5

5 IN6 15 IN7

6 IN8 16 IN9

7 - 17 +24V

8 IN10 18 IN11

9 IN12 19 CES1

10 RG 20 OUT6C

2. Wiring and Connection

[1]

[3]

[5]

[7]

Pin assignment

1 GND 11 GND

2 MA 12 MA*

3 MB 13 MB*

4 MZ 14 MZ*

5 P15B 15 GND

6 MSA 16 MSC

7 LSA 17 LSC

8 - 18 9 - 19 P5

10 P5 20 P5

Pin assignment

1 1H 11 2H

2 3H 12 4H

3 5H 13 6H

4 7H 14 8H

5 9H 15 10H

6 11H 16 12H

7 OUT1 17 OUT2

8 OUT3 18 OUT4

9 OUT5 19 CES3

10 OUT6 20 OUT7

MDS-C1-SPA-55 to 300

o.

No.10

No.20

Pin assignment

1 GND 11 GND

2 SYA 12 SYA*

3 SYB 13 SYB*

4SYZ 14SYZ*

5 SES 15 ORS

6RP 16OR3

7 SE1 17 OR2

8 SE2 18 OR1

9- 19-

10 - 20 -

Pin assignment

1 R1 11 R2

2 R3 12 R4

3 R5 13 R6

4 R7 14 R8

5 R9 15 R10

6 R11 16 R12

7 OUT1C 17 OUT2C

8 OUT3C 18 OUT4C

9 OUT5C 19 CES2

10 FA 20 FC

[2]

[4]

[6]

[9]

Pin assignment

1 GND 11 GND

2 DR 12 DX

3 CLK 13 FSX

4 P5 14 5 RX 15 TX

6 - 16 7 IU 17 IV

8 OUT8 18 P5

9 SM0 19 LM0

10 - 20 -

2 - 10

Page 39

2. Wiring and Connection

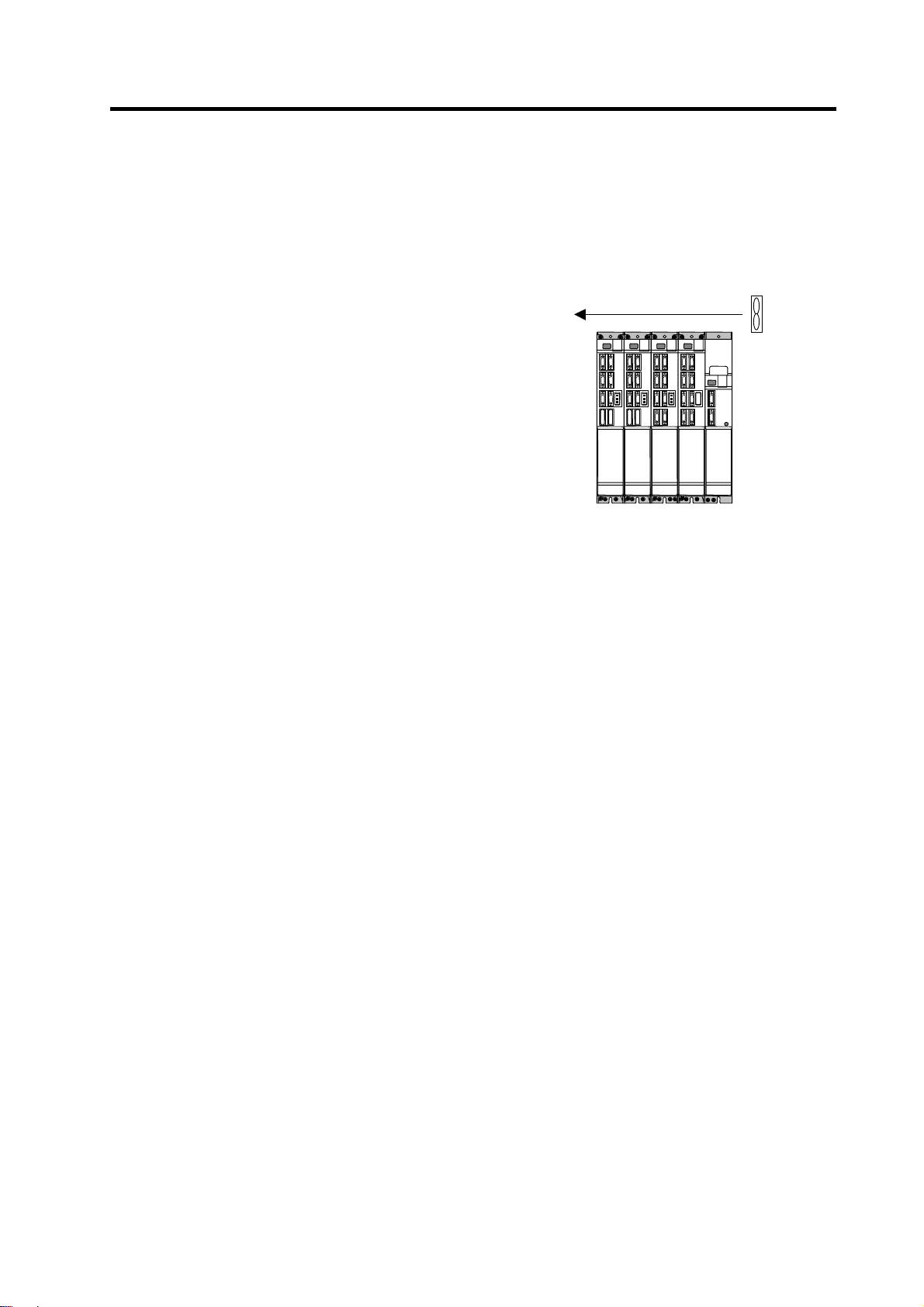

2-3 Drive unit connection

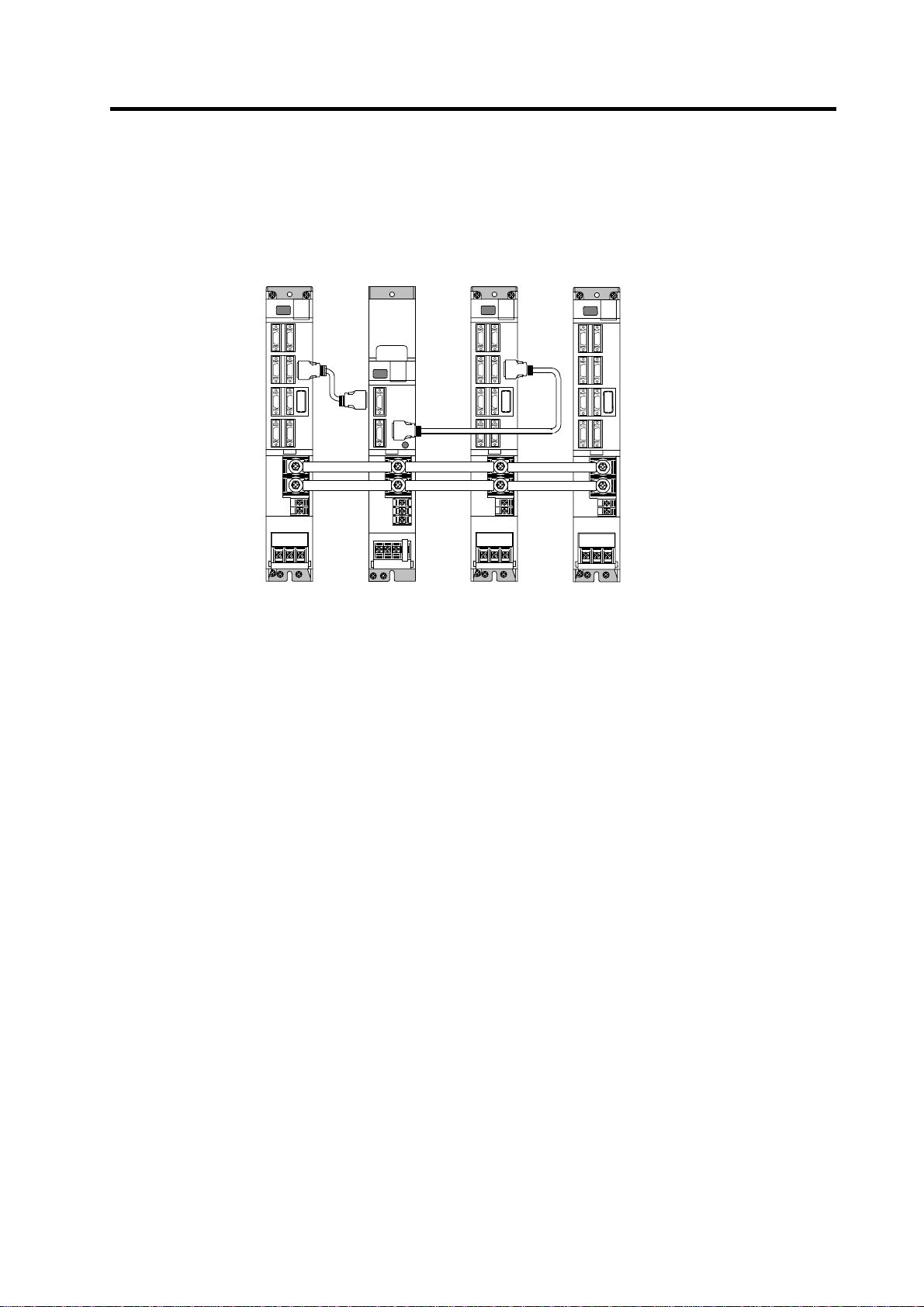

In this section, the connection between the spindle drive unit and power supply unit is shown. There is

space between units in the following diagram to make clearly understandable. However, actually, install

the drive units so that the space between the drive units is within 3cm.

POINT

(1) When using one power supply unit for one spindle drive unit

Even if two or more spindle drive units are used, keep the setting of the spindle

drive unit’s rotary switch to “0”. This switch has no relation to the axis No.

MDS-C1-SPA MDS-C1-CV

CN4

CN4

Connection when using one power supply unit

2 - 11

Page 40

2. Wiring and Connection

(2) When using two power supply units and connecting one spindle drive unit with each power

supply unit

Two or more power supply units may be required if the spindle drive unit capacity is large in a

machine applying two spindles specification. Make sure that the powers (L+, L-) of both power

supply units are supplied to only one spindle drive unit connected with each power supply, and do

not connect each other's powers.

MDS-C1-SPA

(No.1)

CN4

MDS-C1-CV

(No.1)

CN4

Power

cannot be

supplied

MDS-C1-SPA

(No.2)

CN4

MDS-C1-CV

(No.2)

CN4

Connections when using two power supply units

2 - 12

Page 41

2. Wiring and Connection

(3) When connecting two or more spindle drive units with one power supply unit

Connect units according to the following cautions.

MDS-C1-SPA

MDS-C1-CV

MDS-C1-SPA

MDS-C1-SPA

(No.1)

CN4

CN4

CN9

Connections when sharing one power supply

(

No.2

)

CN4

(

No.3

)

(Note 1) Connecting power supply unit and spindle drive unit.

Connect C1-CV CN4 and C1-SPA (No. 1) CN4 to C1-CV CN9 and C1-SPA (No.2) CN4. If

C1-SPA is connected with three or more axes, leave CN4 for C1-SPA (No. 3) and

following open.

Note that the C1-CV can be controlled (READY ON/OFF, alarm display, etc.) only by the

spindle drive unit connected to C1-CV CN4.

(Note 2) Make sure that the machine ready complete input turns ON and OFF simultaneously for all

the spindle drive units. Do not allow the signal to turn ON and OFF for only one spindle

drive unit.

(Note 3) When turning the machine ready complete input OFF during an emergency stop, always

have all the spindle drive units output the zero speed signal before turning the signal OFF.

(Note 4) If an alarm occurs in one of the spindle drive units, turn OFF the machine ready complete

input OFF for all the spindle drive units.

(Note 5) When connecting three or more spindle drive units, install the large-capacity spindle drive

units on both sides of the power supply unit.

2 - 13

Page 42