Page 1

945 Professional Detector Vario

945 Professional Detector Vario – Conductivity & Amperometry

Manual

8.945.8003EN / 2014-06-23

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

945 Professional Detector Vario

945 Professional Detector Vario –

Conductivity & Amperometry

2.945.0030

8.945.8003EN / 2014-06-23

Manual

zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Intended use ......................................................................... 2

1.3 Safety instructions ................................................................ 2

1.3.1 General notes on safety ........................................................... 2

1.3.2 Electrical safety ........................................................................ 2

1.3.3 Tubing and capillary connections ............................................. 3

1.3.4 Flammable solvents and chemicals ........................................... 4

1.3.5 Recycling and disposal ............................................................. 4

1.4 About the documentation ................................................... 4

1.4.1 Content and scope .................................................................. 4

1.4.2 Symbols and conventions ........................................................ 5

2 Overview of the instrument 6

Table of contents

2.1 Front ...................................................................................... 6

2.2 Rear ........................................................................................ 8

3 Installation 9

3.1 Base tray and bottle holder ................................................. 9

3.1.1 Basic information on base tray and bottle holder ..................... 9

3.1.2 Mounting base tray and bottle holder (optional) ...................... 9

3.2 Connecting the instrument to a computer ....................... 14

3.3 Connecting the instrument to the power supply ............. 14

3.4 Conductivity detector ......................................................... 15

3.4.1 Connecting the detector capillaries ........................................ 15

3.5 Amperometric detector ...................................................... 18

4 Start-up 19

4.1 Instrument test with dummy cell ...................................... 19

4.2 Testing the leak sensor ...................................................... 21

4.3 Testing the preheating capillary ....................................... 22

4.4 Testing the detector outlet capillary ................................ 23

4.5 Testing the measuring cell ................................................. 24

4.6 Deaerating the measuring cell .......................................... 26

4.7 Connecting the electrode cables ....................................... 27

4.8 Attaching the front cover .................................................. 29

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

5 Operation and maintenance 30

5.1 General notes ...................................................................... 30

5.1.1 Care ...................................................................................... 30

5.1.2 Maintenance by Metrohm Service .......................................... 30

5.1.3 Operation .............................................................................. 30

5.1.4 Shutting down ...................................................................... 31

5.2 Conductivity detector ......................................................... 31

5.2.1 Maintenance ......................................................................... 31

5.2.2 Remedying blockage ............................................................. 31

5.3 Amperometric detector ...................................................... 32

5.3.1 Maintenance ......................................................................... 32

5.3.2 Preheating capillary maintenance ........................................... 32

5.4 Quality management and qualification with Metrohm .. 33

6 Troubleshooting 34

6.1 Problems with the hardware ............................................. 34

6.2 Problems with the baseline ............................................... 34

6.3 General remarks regarding sensitivity fluctuations ......... 37

6.4 Problems with sensitivity ................................................... 37

6.5 Problems with the pressure ............................................... 38

6.6 Problems with the measuring signal ................................ 38

6.7 Problems with the chromatogram .................................... 39

6.8 Other problems ................................................................... 40

6.9 Systematic error diagnostics ............................................. 41

7 Technical specifications 43

7.1 Reference conditions .......................................................... 43

7.2 Power connection ............................................................... 43

7.3 Conductivity detector ......................................................... 43

7.4 Amperometric detector ...................................................... 44

7.5 Leak sensor ......................................................................... 45

7.6 Ambient conditions ............................................................ 45

7.7 Housing ............................................................................... 46

■■■■■■■■

IV

7.8 Interfaces ............................................................................. 46

7.9 Safety specifications ........................................................... 46

7.10 Electromagnetic compatibility (EMC) ................................ 47

8 Warranty (guarantee) 48

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 7

■■■■■■■■■■■■■■■■■■■■■■

9 Accessories 50

Index 52

Table of contents

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

V

Page 8

Table of figures

Table of figures

Figure 1 Front – Front cover attached ............................................................. 6

Figure 2 Front – Front cover removed ............................................................. 7

Figure 3 Rear .................................................................................................. 8

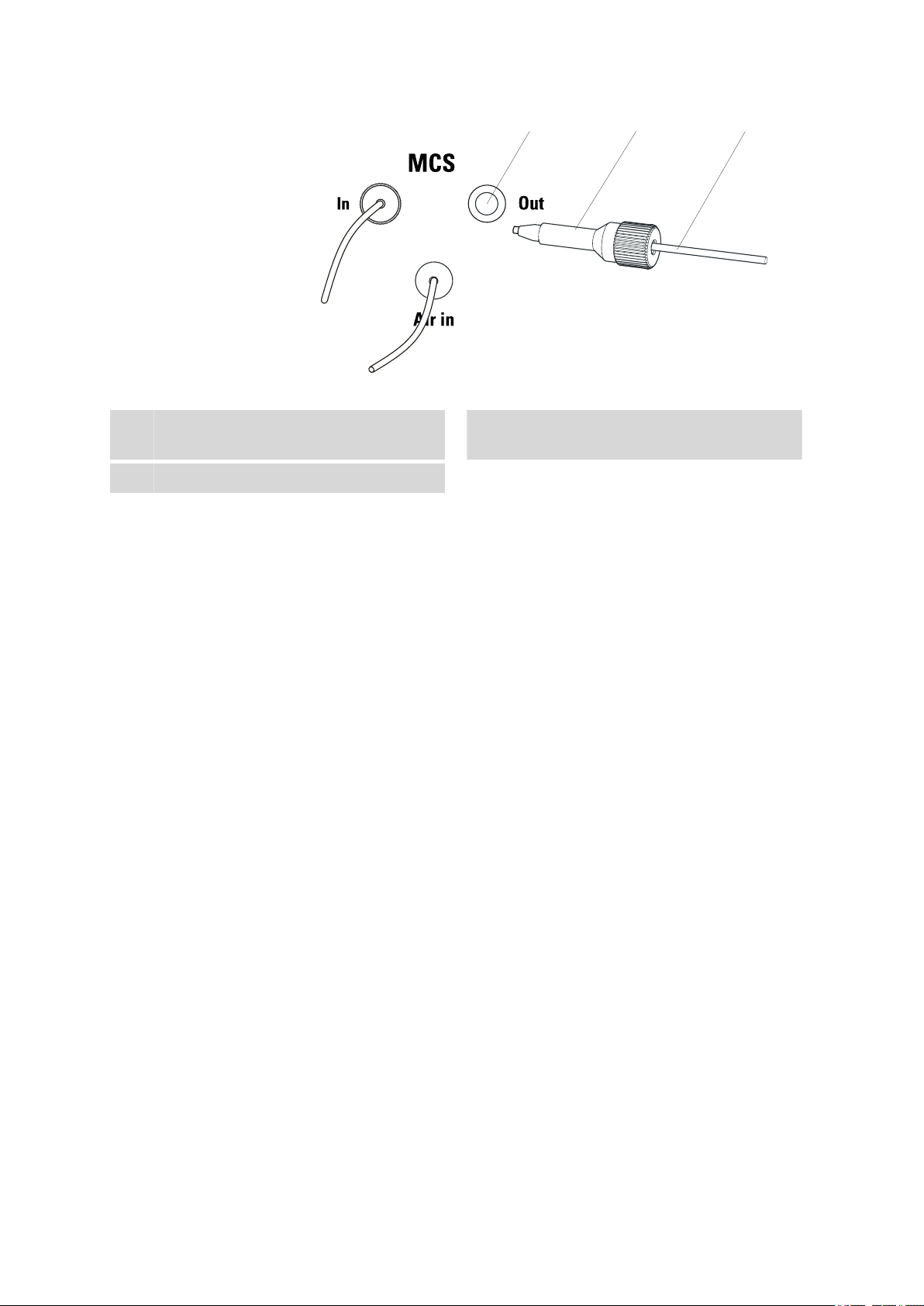

Figure 4 Connection detector–separation column ......................................... 17

Figure 5 Connection detector–suppressor ..................................................... 17

Figure 6 Connection detector–MCS .............................................................. 18

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

VI

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 945 Professional Detector Vario – Conductivity & Amperometry is an intelligent stand-alone detector equipped with a high-perfor-

mance conductivity detector and an amperometric detector.

As a stand-alone detector, it can be combined with instruments such as

those of the 940 Professional IC Vario family for which all available detector connectors have already been assigned to conductivity detectors

(AnCat systems or other multi-channel systems) and be used for the determination of electroactive substances in the mobile phase.

The 945 Professional Detector Vario – Conductivity & Amperometry enables multiple detector installations also with the instruments of the 930

Compact IC Flex family and with the 883 Basic IC plus, which are

equipped with only one detector connector, which is normally occupied

by a conductivity detector. This makes it possible to run applications that

require both conductivity detection and amperometric detection.

1 Introduction

The 945 Professional Detector Vario – Conductivity & Amperometry is a

stand-alone detector that combines the advantages of the IC Conductivity

Detector and the IC Amperometric Detector with the combination possibilities provided by 940 Professional IC Vario instruments. It is directly controlled by the MagIC Net software.

The 942 Extension Module Vario, 891 Professional Analog Out and 800

Dosinos, Remote Boxes, etc. can all be operated through the 945 Professional Detector Vario – Conductivity & Amperometry. This opens up the

flexibility of Metrohm IC systems considerably.

The instrument is comprised of the following modules:

Conductivity detector

The conductivity detector continuously measures the conductivity of the

liquid passing through and outputs the measured values in digital form

(DSP – Digital Signal Processing). The conductivity detector exhibits outstanding thermal stability and thus guarantees reproducible measuring

conditions.

Amperometric detector

With the 945 Professional Detector Vario – Conductivity & Amperometry,

electroactive substances can be determined in the mobile phase of an IC

system. Determination makes use of amperometric methods, which combine outstanding sensitivity with a high degree of selectivity. The installed

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

1

Page 10

1.2 Intended use

potentiostat generates the voltages for the direct current amperometry

(DC), for the pulse amperometry (PAD) and the flexible integrated pulse

amperometry (flexIPAD) as well as for the recording of cyclovoltammograms. The installed preheating capillary ensures a constant eluent temperature on the cell.

1.2 Intended use

The 945 Professional Detector Vario – Conductivity & Amperometry is

used as an independent detector in an IC system. With its two different

detector types, it is used on the one hand for the precise measurement of

conductivity during ion chromatography determination of anions and cations and on the other hand for the determination of electroactive substances in the mobile phase of an IC or general liquid chromatography system.

The present instrument is used for working with chemicals and flammable

samples. Usage of the 945 Professional Detector Vario – Conductivity &

Amperometry therefore requires the user to have basic knowledge and

experience in handling toxic and caustic substances. Knowledge with

respect to the application of the fire prevention measures prescribed for

laboratories is also mandatory.

■■■■■■■■■■■■■■■■■■■■■■

1.3 Safety instructions

1.3.1 General notes on safety

WARNING

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.3.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

WARNING

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

■■■■■■■■

2

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

WARNING

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

WARNING

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

WARNING

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

1.3.3 Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

3

Page 12

1.4 About the documentation

1.3.4 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.3.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

■■■■■■■■■■■■■■■■■■■■■■

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

1.4 About the documentation

CAUTION

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.4.1 Content and scope

This document describes the 945 Professional Detector Vario – Conductivity & Amperometry, its assembly and connection to the IC instru-

ment, as well as the installation, operation and maintenance of the individual components. Technical specifications, troubleshooting and information concerning scope of delivery and optional accessories make up the

rest of the manual.

■■■■■■■■

4

You will find additional information on the installation and maintenance

of the IC instrument and the Sample Processor in the respective manuals.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 13

■■■■■■■■■■■■■■■■■■■■■■

Additional information on the configuration and operation with

MagIC Net can be found in the "MagIC Net Tutorial" or in the MagIC Net

online help.

1.4.2 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

1 Introduction

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

WARNING

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

CAUTION

This symbol draws attention to possible damage to

instruments or instrument parts.

NOTE

This symbol highlights additional information and

tips.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

5

Page 14

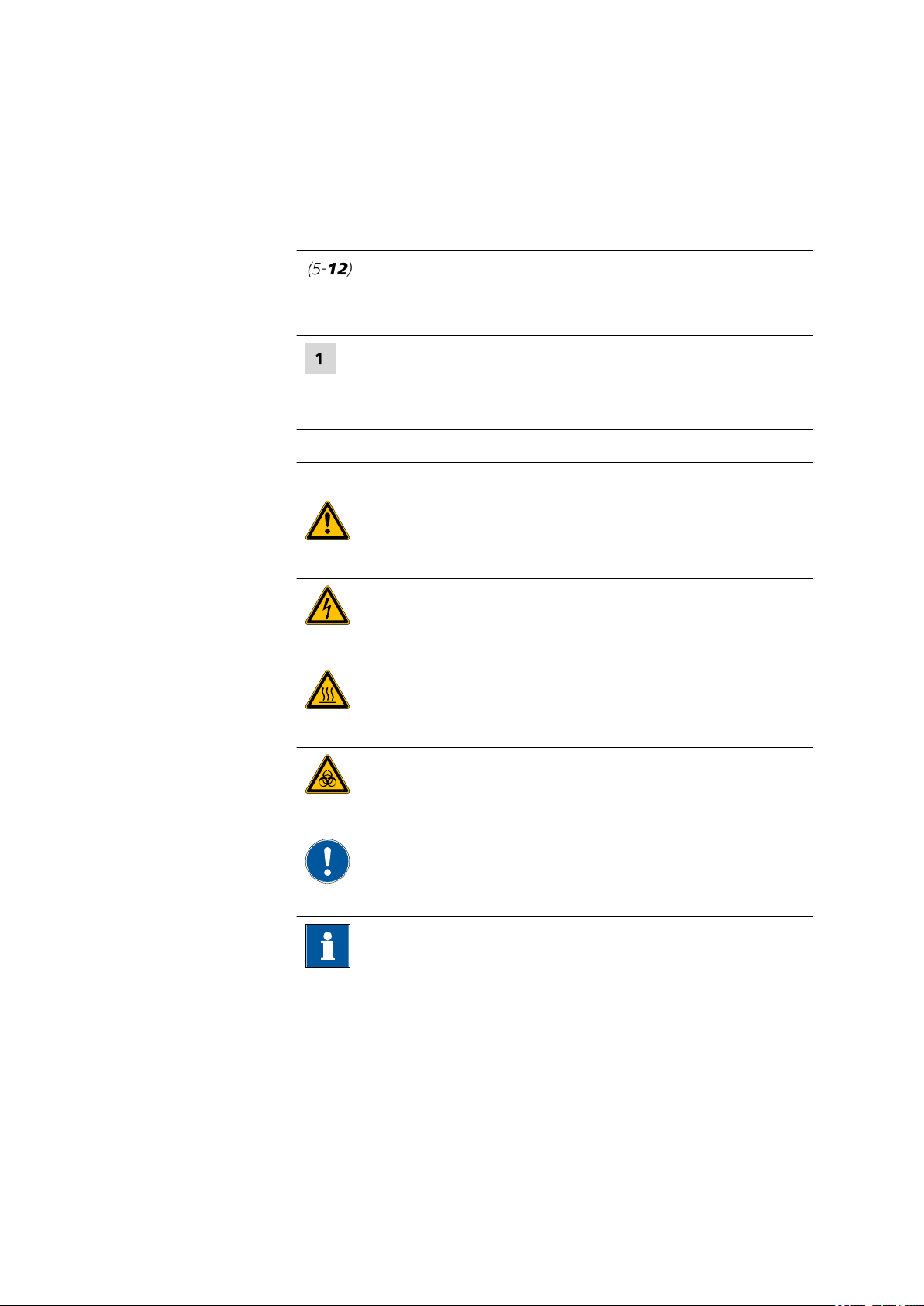

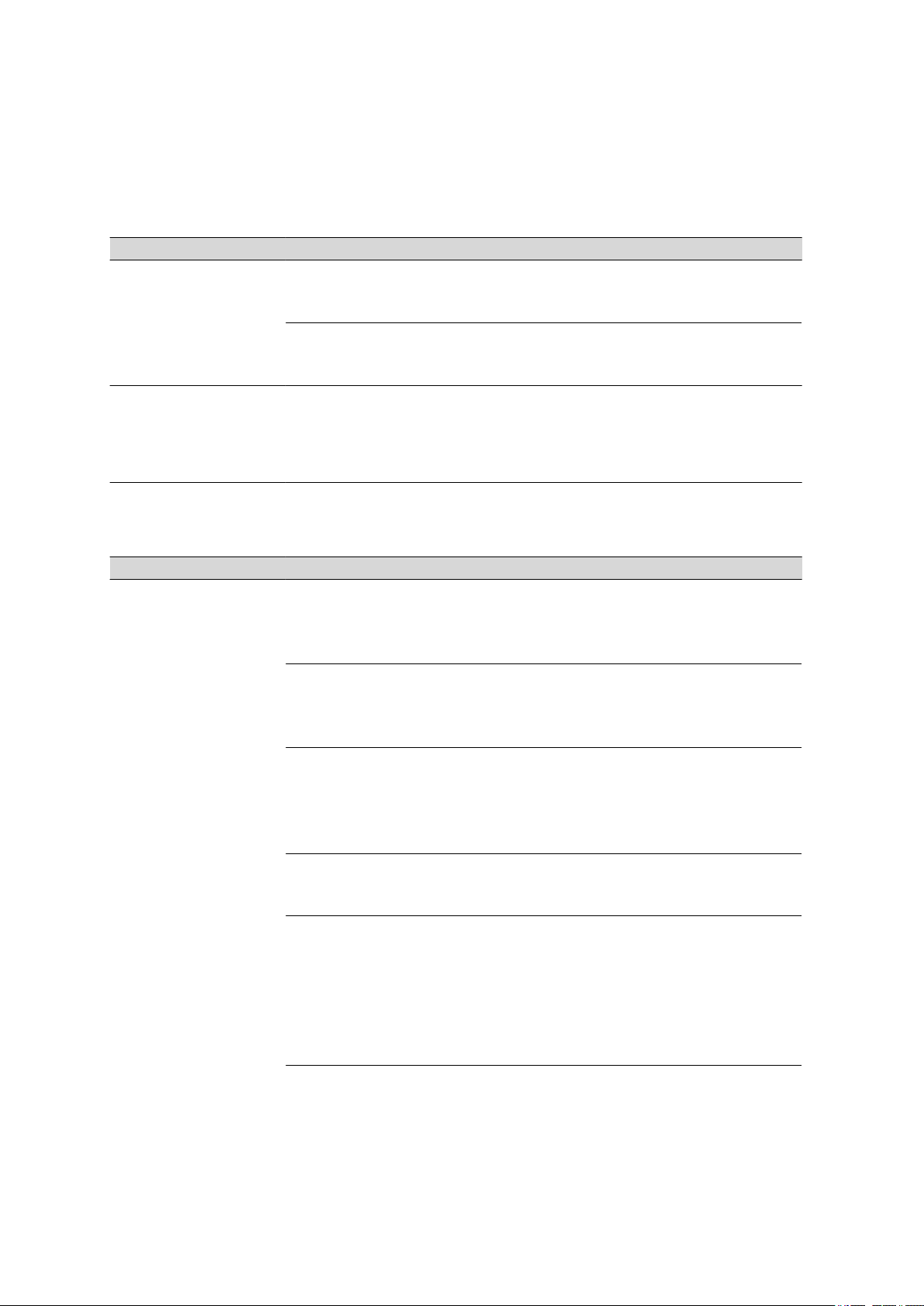

2.1 Front

2

3

1

4 5

6

7

8

2 Overview of the instrument

2.1 Front

■■■■■■■■■■■■■■■■■■■■■■

Figure 1 Front – Front cover attached

Power LED

1

Amperometric detector standby indicator.

Conductivity detector

3

Permanently installed.

Front cover

5

For the amperometric detector.

Coupling

7

For connecting the detector outlet capillary

of the conductivity detector. Labeled Cond.

Eluent out.

Amperometric detector

2

Permanently installed.

Power LED

4

Instrument standby indicator.

Knurled screw

6

For removing the front cover.

Detector inlet capillary

8

Of the conductivity detector. Permanently

mounted.

■■■■■■■■

6

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 15

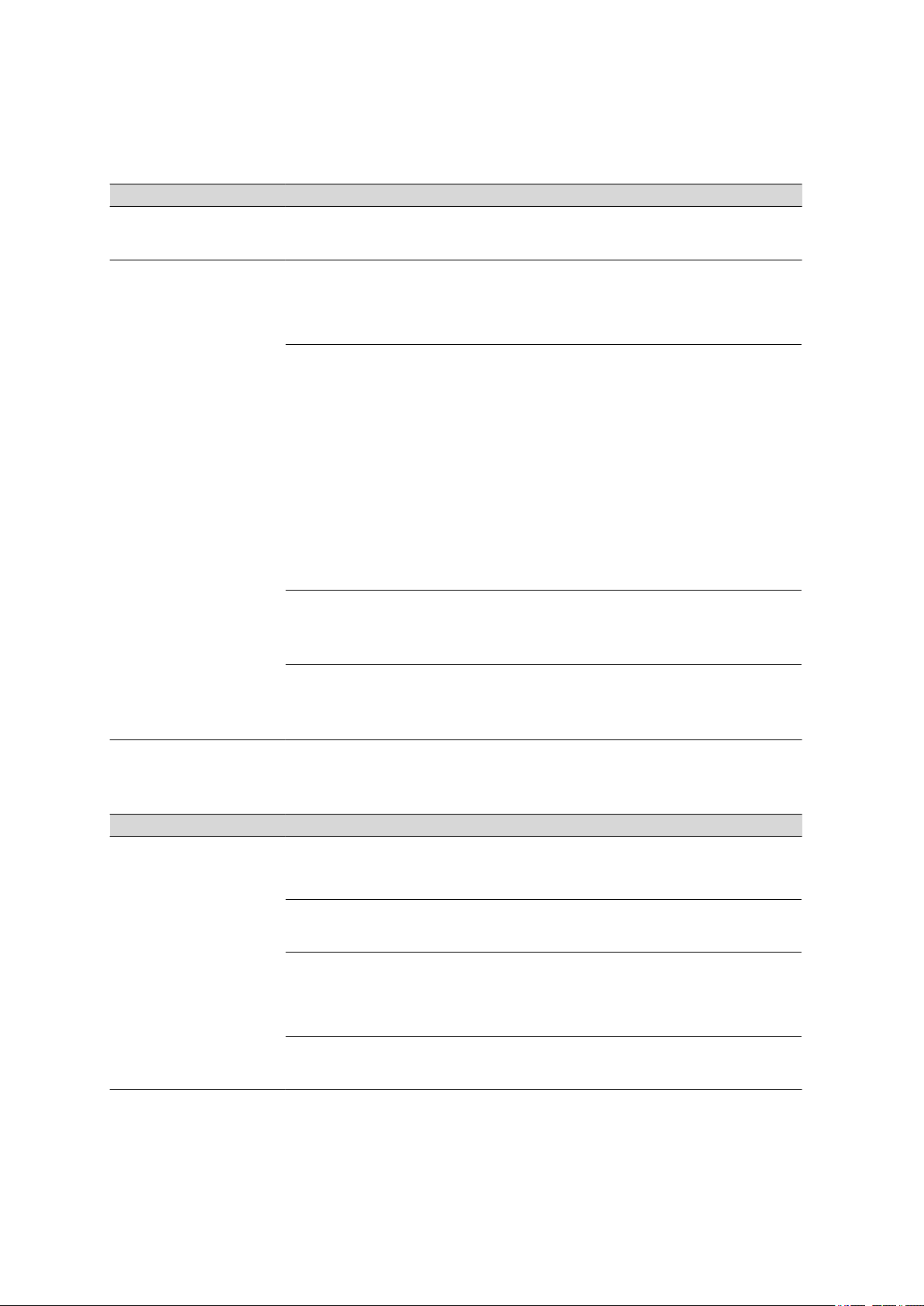

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

5

6

7

8 109

2 Overview of the instrument

Figure 2 Front – Front cover removed

AE connection socket

1

For connecting the auxiliary electrode.

Cell holder

3

With chip for the automatic detection of the

measuring cell.

RE connection socket

5

For connecting the reference electrode.

Tray

7

Thread

9

For the knurled screw used for fastening the

front cover.

Power LED

2

Amperometric detector standby indicator.

WE connection socket

4

For connecting the working electrode.

Coupling

6

For connecting a connection capillary to the

measuring cell. Labeled Eluent to cell.

Drain nozzle

8

For draining liquid from the tray. Plugged

with a stopper.

Coupling

10

For connecting the detector inlet capillary.

Labeled Eluent in.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

7

Page 16

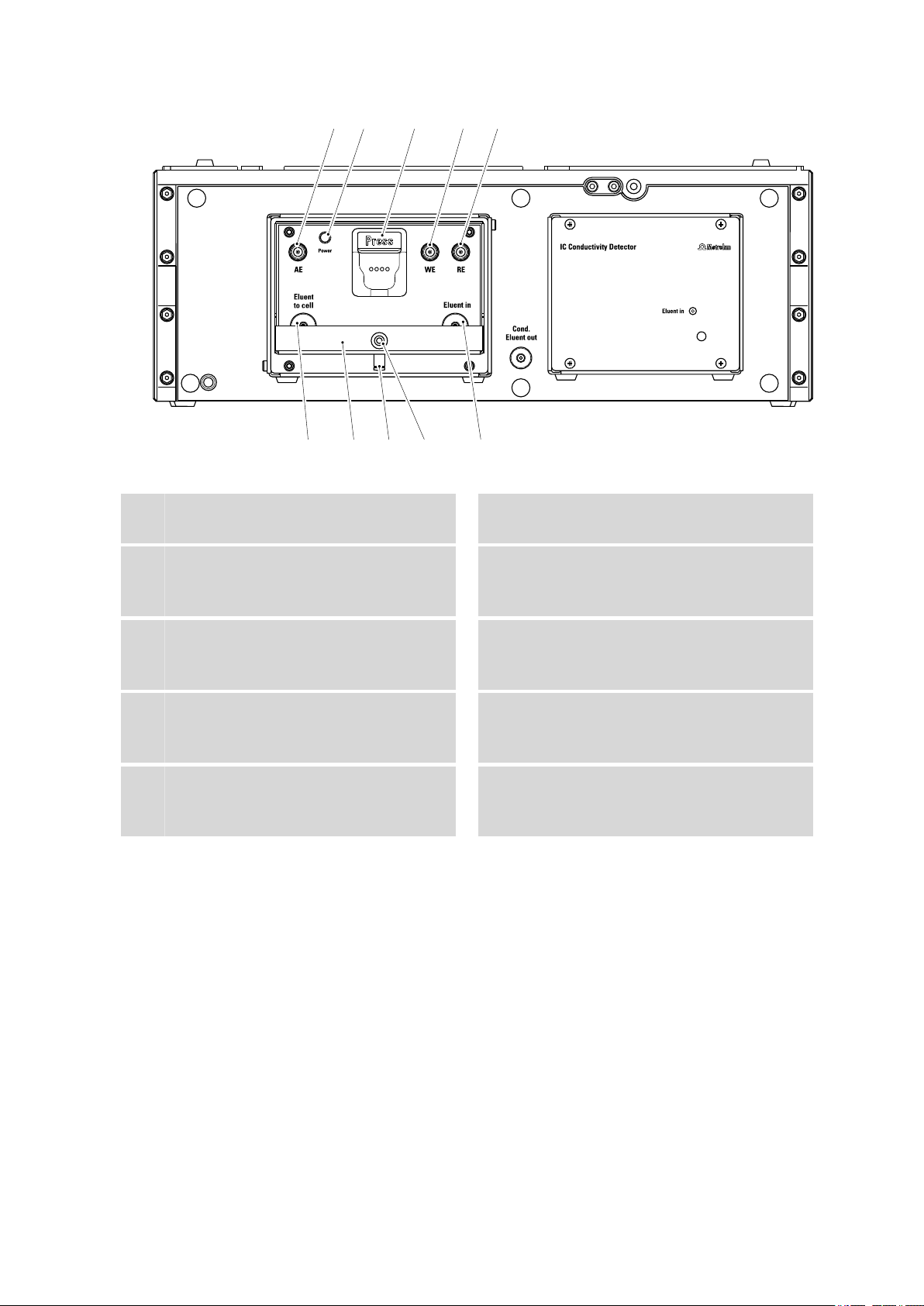

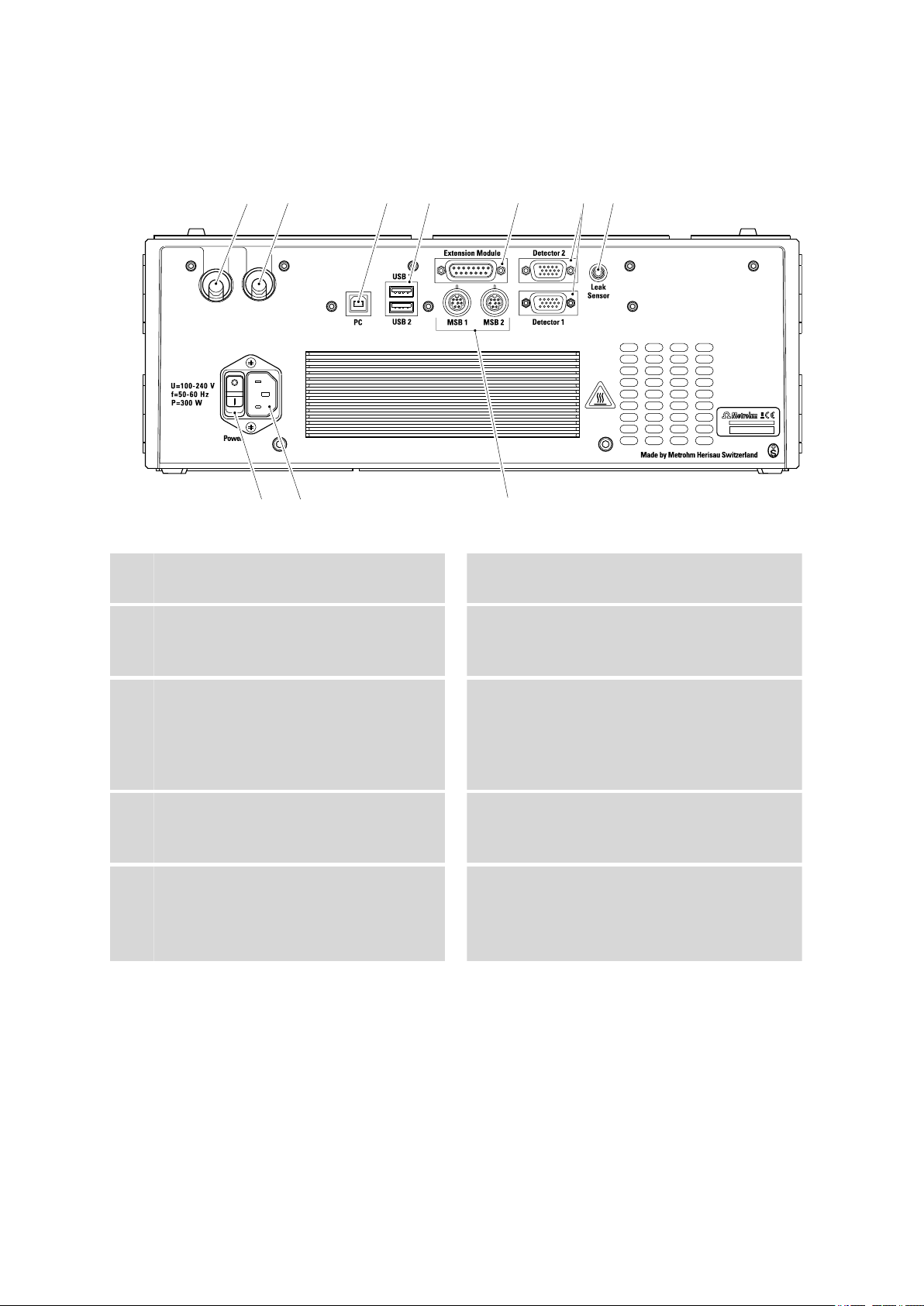

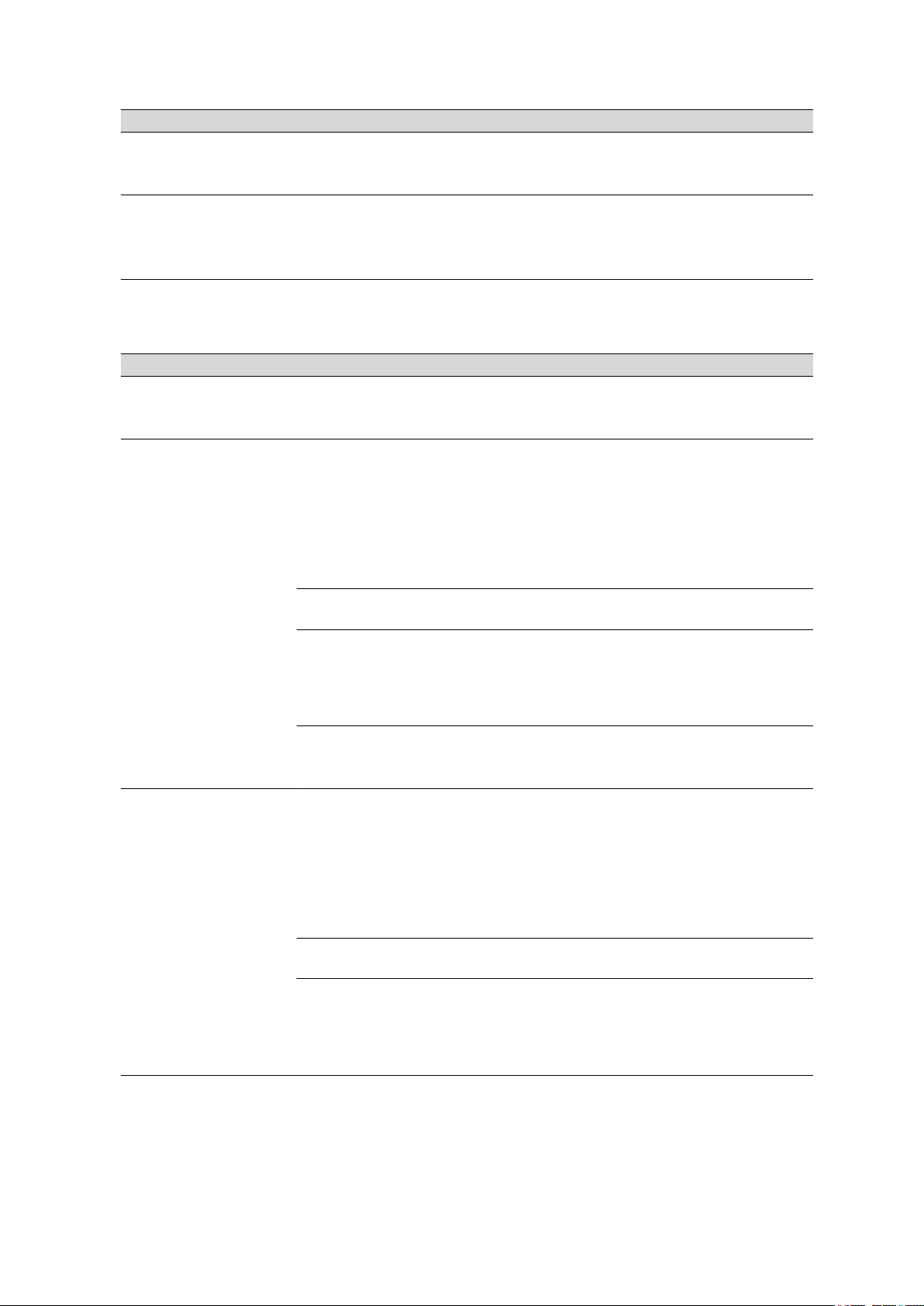

2.2 Rear

1

2

3

4

5

6

7

8 9

10

2.2 Rear

■■■■■■■■■■■■■■■■■■■■■■

Figure 3 Rear

Cable feed-through

1

Output for the detector cable.

PC connection socket

3

For connecting the instrument to the computer with the USB cable (6.2151.020).

Extension Module connection socket

5

For connecting a 942 Extension Module

Vario or an 891 Professional Analog Out.

Labeled Extension Module.

Leak sensor connection socket

7

For connecting the leak sensor connection

cable, labeled Leak Sensor.

Power socket

9

For connecting the power supply cable

(6.2122.0x0).

Cable feed-through

2

Output for the detector cable.

USB connection sockets

4

Two USB connection sockets, labeled USB 1

and USB 2.

Detector connection sockets

6

For the connection of the installed detector,

labeled Detector 1 and Detector 2. The

detector connection sockets which are not

used must be covered with a lid.

Power switch

8

For switching the instrument on and off.

MSB connection sockets

10

Two MSB connection sockets (labeled MSB 1

and MSB 2) for connecting MSB devices.

(MSB = Metrohm Serial Bus)

■■■■■■■■

8

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 17

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

3.1 Base tray and bottle holder

3.1.1 Basic information on base tray and bottle holder

The base tray (6.2061.110) and bottle holder (6.2061.100) protect IC

instruments from dust, dirt and leaking fluids. The supply bottles for eluent

and auxiliary solutions can be positioned neatly on the bottle holder.

In a complex IC system, several different instruments may be used, such as

an analyzer, an extension module and a detector. These instruments can

be set up in one or more stacks. We recommend that a base tray and bottle holder be mounted for each stack of IC instruments.

The bottle holder and base tray must be removed or set up every time one

of the following instruments is to be mounted on or under a 940 Professional IC Vario:

3 Installation

■ One or more 942 Extension Module Vario.

■ One 944 Professional UV/VIS Detector Vario.

■ One 945 Professional Detector Vario.

■ Or another instrument with the same-sized footprint.

3.1.2 Mounting base tray and bottle holder (optional)

The base tray and bottle holder come fully assembled on a new ion chromatograph. If you wished to install an extension module on the ion chromatograph, you would have to remove the bottle holder and put it back

on top of the topmost instrument. If you wished to install an extension

module below the ion chromatograph, you would have to remove the

base tray and set it under the lowest instrument.

3.1.2.1

Removing/mounting the base tray

The base tray must be removed if you want to install another instrument

under the IC instrument.

CAUTION

Do not allow capillaries or leak sensor cables to be pinched!

Pinches in the leak sensor cable or the capillaries fed through the guide

ducts between the base tray and the instrument may lead to malfunctions.

Unplug the leak sensor cable. Remove all of the capillaries from the

capillary ducts.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

9

Page 18

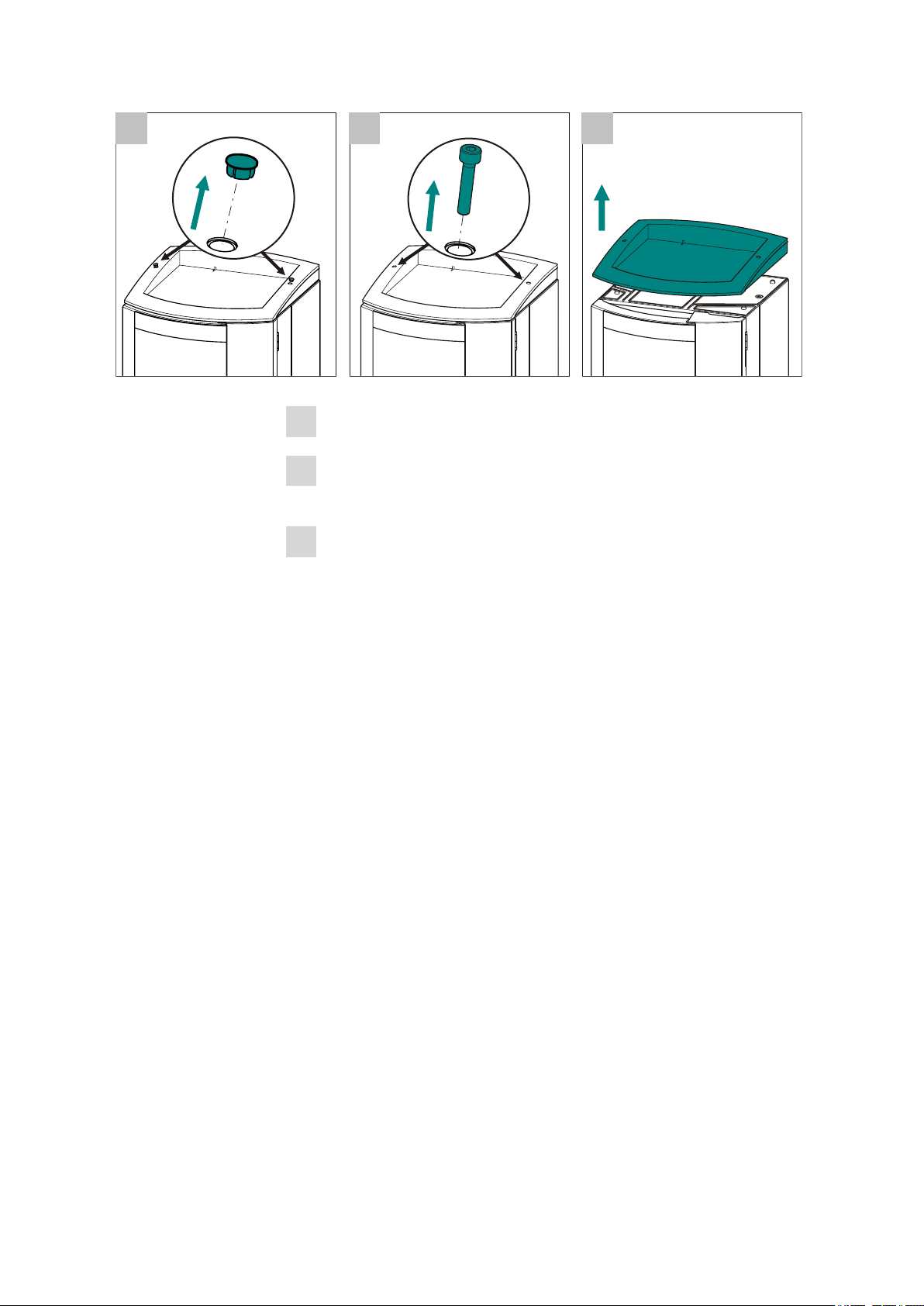

3.1 Base tray and bottle holder

1

2

3

■■■■■■■■■■■■■■■■■■■■■■

Removing the base tray

Before you can remove the base tray, the following preconditions must be

met:

■ The instrument is switched off.

■ The bottle holder is cleared.

■ All of the cable connections on the rear have been disconnected.

■ The capillaries are removed from the guide ducts between the instru-

ment and the base tray.

■ There are no loose parts in the instrument.

To remove the base tray, you need a 3 mm hex key (6.2621.100).

Tilt the instrument sideways and lay it down flat.

1

Loosen the four cylinder screws with the 3 mm hex key and remove

2

them and their washers.

Remove the base tray.

3

The base tray must always be mounted under the lowermost instrument

of the stack.

Mounting the base tray

Before you can mount the base tray, the following preconditions must be

met:

■ The instrument is switched off.

■ The bottle holder is cleared.

■ All of the cable connections on the rear have been disconnected.

■ There are no loose parts in the instrument.

■■■■■■■■

10

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 19

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

■ The instrument is lying on its side, and the bottom surface is visible.

To mount the base tray, you need a 3 mm hex key (6.2621.100).

Place the base tray in such a way that the openings in the base tray

1

match exactly the screw threads in the bottom of the instrument.

Slide the washers onto the cylinder screws, insert the screws and

2

tighten them with the 3 mm hex key.

Set the instrument back up on the base tray.

3

3.1.2.2

Stack other instruments in the required order. Mount the bottle holder

(6.2061.100) onto the topmost instrument on the stack (see "Mounting

the bottle holder", page 13).

Removing/mounting the bottle holder

The bottle holder must be removed if you want to install another instrument onto the IC instrument.

Removing the bottle holder

Before you can remove the bottle holder, the following preconditions

must be met:

■ The instrument is switched off.

■ The bottle holder is cleared.

■ Drainage tubing is disconnected from the drainage tubing connection

of the bottle holder.

■ The capillaries are removed from the guide ducts between the instru-

ment and the bottle holder.

To remove the bottle holder, you need a 3 mm hex key (6.2621.100).

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

11

Page 20

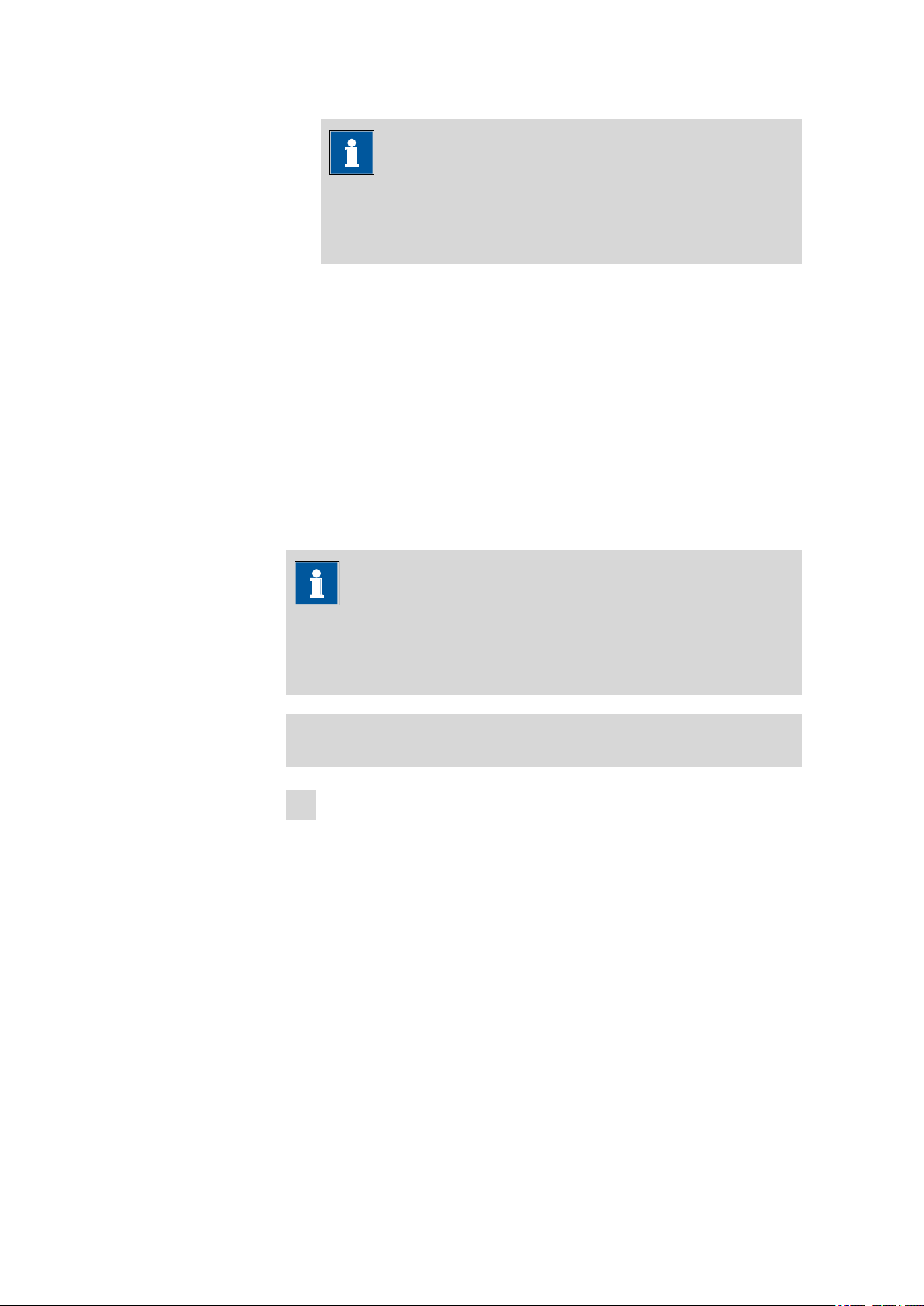

3.1 Base tray and bottle holder

1

2 3

■■■■■■■■■■■■■■■■■■■■■■

Remove the two covering stoppers.

1

Loosen the two cylinder screws with the 3 mm hex key and remove

2

them.

Remove the bottle holder.

3

Stack other instruments in the required order. Mount the bottle holder

(6.2061.100) onto the topmost instrument on the stack.

■■■■■■■■

12

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 21

■■■■■■■■■■■■■■■■■■■■■■

1

2 3

3 Installation

Mounting the bottle holder

Before you can mount the bottle holder, the following preconditions must

be met:

■ The instrument is switched off.

To mount the bottle holder, you need a 3 mm hex key (6.2621.100).

Place the bottle holder onto the topmost instrument in such a way

1

that the openings in the bottle holder exactly match the screw

threads on the top surface of the instrument.

Insert the two cylinder screws and tighten them with the 3 mm hex

2

key.

Insert both covering stoppers.

3

After attaching the bottle holder, all connections that were undone at the

beginning of the process must be reconnected.

Restoring the loosened connections

Plug in all necessary USB cables.

1

Plug in all necessary MSB cables.

2

Plug in the power supply cable.

3

Mount the drainage tubing again (see manual of the IC instrument).

4

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

13

Page 22

3.2 Connecting the instrument to a computer

■■■■■■■■■■■■■■■■■■■■■■

A longer section of silicone tubing (6.1816.020) may have to be cut

to size and mounted (see also the manual for the IC instrument).

If one of the instruments in the stack is equipped with a leak sensor

5

connection socket, connect the leak sensor (see manual of the IC

instrument).

Restore any capillary connections that may have been removed.

6

3.2 Connecting the instrument to a computer

NOTE

The instrument must be switched off when being connected to a computer.

Accessories

For this step you need the following accessories:

■ USB connecting cable (6.2151.020)

Connecting the USB cable

Insert the USB cable into the computer connection socket on the rear

1

of the instrument labeled PC.

Insert the other end into a USB port on the computer.

2

3.3 Connecting the instrument to the power supply

WARNING

The power supply unit must not get wet. Protect it from liquids.

The power supply cable is three-core and provided with a plug with

grounding. If another plug has to be mounted, the yellow/green conductor (IEC standard) must be connected to the protective ground (protection

class I).

Accessories

■■■■■■■■

14

For this step you need the following accessories:

■ For Switzerland, …: Power supply cable with IEC 60320 line socket,

type C13, with SEV 1011 plug, type 12 (6.2122.020), 1.5 m

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 23

■■■■■■■■■■■■■■■■■■■■■■

3 Installation

■ For Germany, …: Power supply cable with IEC 60320 line socket, type

C13, with CEE 7 plug, type VII (6.2122.040), 1.5 m

■ For the USA, …: Power supply cable with IEC 60320 line socket, type

C13, with NEMA 5-15 plug, type 498 (6.2122.070), 1.5 m

Connecting the power supply cable

1

Inserting the power supply cable

■ Insert the power supply cable into the instrument's power socket.

■ Connect the power supply cable to the power supply.

2

Switching on the instrument

Switch on the instrument using the power switch.

After being switched on, the LED on the front of the instrument

flashes. The instrument conducts a system test and establishes a connection to the software. Once the system test is complete and the

connection to the software has been established, the LED lights up

continuously.

3.4 Conductivity detector

3.4.1 Connecting the detector capillaries

Accessories

For this step you need the following accessories:

■ PEEK capillary (6.1831.030)

■ Pressure screw (6.2744.010)

Connecting the detector outlet capillary

■ Use a pressure screw (6.2744.010) to screw one end of the PEEK

1

capillary (6.1831.030) firmly to the coupling Cond. Eluent out.

■ Fasten the other end of the PEEK capillary (6.1381.030) to the

2

waste collector (6.5336.000) or guide it into a sufficiently large

waste container and fasten it there.

OR if the application requires a subsequent amperometric detection:

■ Connect the other end of the PEEK capillary (6.1381.030) to the

Eluent in connector on the amperometric detector.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

15

Page 24

3.4 Conductivity detector

■■■■■■■■■■■■■■■■■■■■■■

NOTE

The detector outlet capillary must be free of blockages in order to

generate sufficient backpressure (the measuring cell is tested to 5

MPa = 50 bar backpressure).

Connecting the detector inlet capillary

The detector inlet capillary is connected differently depending on the

equipment of the IC instruments:

■ For instruments without suppression, directly to the separation column

(see "Connecting the detector inlet capillary to the separation column", page 16).

■ For instruments with chemical suppression, to the suppressor (see

"Connecting the detector inlet capillary to the suppressor", page

17).

■ For instruments with sequential suppression, to the MCS (see "Con-

necting the detector inlet capillary to the MCS", page 17).

NOTE

In order to prevent unnecessary peak widening after separation, the

connection between the outlet of the separation column and the inlet

to the detector should be kept as short as possible.

Connecting the detector inlet capillary to the separation

column

1

Connecting the detector inlet

■ Fasten the detector inlet capillary (4-1) using a short PEEK pres-

sure screw (6.2744.070) (4-2) directly to the outlet of the column

(4-3).

■■■■■■■■

16

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 25

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

1 2

3

3 Installation

Figure 4 Connection detector–separation column

Detector inlet capillary

1

Separation column

3

PEEK pressure screw, short

2

(6.2744.070)

Connecting the detector inlet capillary to the suppressor

1

Connecting the detector inlet

■ Connect the detector inlet capillary (5-1) and the capillary of the

suppressor (5-2) labeled out to each other using a coupling

(6.2744.040) (5-3) and two short PEEK pressure screws

(6.2744.070) (5-4).

Figure 5 Connection detector–suppressor

Detector inlet capillary

1

Coupling (6.2744.040)

3

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Suppressor outlet capillary

2

Labeled out.

PEEK pressure screws, short

4

(6.2744.070)

Connecting the detector inlet capillary to the MCS

1

Connecting the detector inlet

■ Fasten the detector inlet capillary (6-1) with one long PEEK pres-

sure screw (6.2744.090) (6-2) to the outlet of the MCS (6-3).

■■■■■■■■

17

Page 26

3.5 Amperometric detector

3 2

1

■■■■■■■■■■■■■■■■■■■■■■

Figure 6 Connection detector–MCS

Detector inlet capillary

1

MCS outlet

3

3.5 Amperometric detector

The following tasks are part of the installation of the amperometric detector:

■ Inserting the working electrode and the reference electrode into the

measuring cell (see the measuring cell manual).

■ Connecting the capillaries to the preheating capillary or directly to the

measuring cell.

■ Inserting the measuring cell into the detector.

■ Deaerating the measuring cell.

■ Connecting the electrode cables.

■ Attaching the front cover.

Because not only the capillaries but also the electrode cables must be

tested prior to their first use, none of these installation tasks are carried

out until the time of the first start-up.

PEEK pressure screw, long

2

(6.2744.090)

■■■■■■■■

18

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 27

■■■■■■■■■■■■■■■■■■■■■■

4 Start-up

The 945 Professional Detector Vario – Conductivity & Amperometry is put

into operation together with the IC system. Additional information can be

found in the Start-up chapter in the manual for the IC instrument.

The following tests and installation tasks must be performed during the

first start-up of the IC instrument with the 945 Professional Detector Vario

– Conductivity & Amperometry.

4.1 Instrument test with dummy cell

When you are putting the 945 Professional Detector Vario – Conductivity

& Amperometry into operation for the first time, or when problems occur

which may be caused by signal recording or signal transfer, we recommend testing the electronics and the connection to the PC using the

dummy cell (6.2813.040).

4 Start-up

Proceed as follows:

Testing with the dummy cell

Prerequisites:

■ In order to achieve accurate results, we recommend that the front

cover be closed during the instrument test with the dummy cell. Since

the space under the front cover is rather limited, we further recommend removing the measuring cell from the cell holder for the instrument test with the dummy cell.

For the instrument test you require:

■ The dummy cell (6.2813.040)

■ The three electrode connection cables (6.2165.000)

1

Connecting the electrode connection cables to the dummy

cell

■ Plug the angled plug of the working electrode connection cable

(labeled WE) into the WE socket.

■ Plug the angled plug of the reference electrode connection cable

(labeled RE) into the RE socket.

■ Plug the angled plug of the auxiliary electrode connection cable

(labeled AE) into the AE socket.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

19

Page 28

4.1 Instrument test with dummy cell

■■■■■■■■■■■■■■■■■■■■■■

2

Connecting the electrode connection cables to the detector

(unless they are already connected)

■ Plug the straight plug of the working electrode connection cable

(red sleeve) into the WE socket of the detector.

■ Plug the straight plug of the reference electrode connection cable

(black sleeve) into the RE socket of the detector.

■ Plug the straight plug of the auxiliary electrode connection cable

(blue sleeve) into the AE socket of the detector.

3

Inserting the dummy cell

■ Place the dummy cell into the tray of the detector.

■ Attach the front cover.

NOTE

The metal parts of the cable plugs must not touch the front cover.

4

Adjusting settings in MagIC Net

In the Method program part, create a new method for the instrument test with the dummy cell.

■ Select the detector and add it as a new device.

■ Select the DC mode.

■ Set the following parameters for the DC mode:

– DC potential: 0.8 V

– Range: Auto

– Damping: off

■ Add an analysis for the detector channel Current.

■ Add the entry Current ▶ Start data acquisition in the Time

program subwindow.

■ Save the method.

In the Workplace program part:

■ Load the method.

■ In the Watch window, display the Current channel with at least

three decimal places.

5

Carrying out the test

In the Manual program part:

■■■■■■■■

20

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 29

■■■■■■■■■■■■■■■■■■■■■■

■ On the tab of the detector, switch on the dummy cell with

[Apply].

After no more than one minute, the detector signal should level

off at 2.667 nA ± 7%. Noise should not exceed 0.005 nA.

■ Switch the dummy cell off with [Cell Off].

With the dummy cell switched off and the detector hardware still

running, the signal should drop below an absolute value of 1 nA,

and noise should be limited to the third decimal place.

Exactly even signals may indicate that new detector data is not

correctly transmitted.

6

Removing the dummy cell

■ Pull out the electrode connection cables from the connectors AE,

WE and RE of the dummy cell.

■ Remove the dummy cell from the tray.

4 Start-up

The dummy cell incorporates a resistor (300 M

connected in parallel. If, in DC mode, a potential of 0.8 V is applied, then

a current of 2.667 nA (± 7%) is measured in the dummy cell. The capacitor simulates a well-working measuring cell.

4.2 Testing the leak sensor

The leak sensor should not respond during the start-up. If the leak sensor

nevertheless does respond during the start-up, you will find information

for eliminating the problem in Chapter (see Chapter 6.1, page 34).

To check whether the leak sensor is functioning, proceed as follows:

Testing the leak sensor

Hold a cloth moistened with eluent or tap water on the two contacts

1

of the leak sensor .

The leak sensor of the detector responds.

If the leak sensor does not respond, please request Metrohm Service.

Ω) and a capacitor (100 nF)

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

21

Page 30

4.3 Testing the preheating capillary

4.3 Testing the preheating capillary

The amperometric detector is equipped with a preheating capillary in its

interior to ensure that the eluent flows through the measuring cell at a

constant temperature. The preheating capillary need not, however, always

be connected. If the ambient conditions are optimal, then the measuring

results can be sufficiently accurate, even without the use of the preheating

capillary.

CAUTION

The preheating capillary may not be used when working with highly

flammable liquids.

The preheating capillary must be free of both leaks and blockages.

To check whether the preheating capillary is free of both leaks and blockages, proceed as follows:

■■■■■■■■■■■■■■■■■■■■■■

Testing the preheating capillary

1

Connecting the detector inlet capillary

Use a pressure screw (6.2744.014) to fasten the detector inlet capillary to the Eluent in connector on the detector.

2

Adjusting the settings in MagIC Net

■ In the program part Manual of MagIC Net, set the maximum

pressure of the high-pressure pump to 5 MPa.

■ Set the flow rate to 0.1 mL/min.

■ Start the high-pressure pump.

3

Observe the Eluent to cell connector

After a while, liquid must emerge from the Eluent to cell connector

(wipe up fluid with paper towel).

If no liquid emerges at the Eluent to cell connector, then the preheating capillary is likely to be blocked. To eliminate the problem, see

Chapter Preheating capillary maintenance, page 32.

4

Observe the pump pressure

Observe the pump pressure display in the program part Manual of

MagIC Net.

■■■■■■■■

22

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 31

■■■■■■■■■■■■■■■■■■■■■■

A constant pressure should establish itself after a while.

4.4 Testing the detector outlet capillary

The detector outlet capillary must be of a certain length in order to be

able to generate sufficient backpressure. The required length is dependent

on the flow that has been set. The table 1 shows the recommended

lengths, as determined by the set flow rate.

Table 1 Recommended lengths for the detector outlet capillary

Flow rate Capillary length (⌀0.25 mm)

2.0 mL/min 0.5 - 1.5 m

0.5 - 1.0 mL/min 1.0 - 2.5 m

0.25 mL/min 3 m

To check whether the detector outlet capillary is free of blockages, proceed as follows:

4 Start-up

Testing the detector outlet capillary

Prerequisites:

■ The detector inlet capillary is connected to the Eluent in connector.

■ The high-pressure pump runs with a flow rate of 0.1 mL/min.

1

Connecting the detector outlet capillary

Use a pressure screw (6.2744.014) to fasten the detector outlet

capillary to the Eluent to cell connector.

2

Adjusting the settings in MagIC Net

In the program part Manual of MagIC Net, increase the flow rate to

1.0 mL/min and wait until the pressure has stabilized.

3

Observe the end of the detector outlet capillary

After a while, liquid must emerge from the end of the detector outlet

capillary.

If no liquid emerges at the end of the detector outlet capillary, then

the detector outlet capillary is blocked and must either be cut back

once again or replaced.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

23

Page 32

4.5 Testing the measuring cell

■■■■■■■■■■■■■■■■■■■■■■

4

Loosening the detector outlet capillary

Loosen the detector outlet capillary from the Eluent to cell connector. Wipe up emerging liquid with a cloth.

5

Observe the pump pressure

Observe the pump pressure display in the program part Manual of

MagIC Net.

The drop in pressure should range from 0.1 MPa to a maximum of

0.3 MPa.

If the pressure differential is greater, then the detector outlet capillary

must be cut back once again or replaced.

6

Finish the test

■ In the program part Manual of MagIC Net, stop the high-pres-

sure pump.

■ Remove the detector outlet capillary from the Eluent to cell con-

nector.

4.5 Testing the measuring cell

To test the measuring cell, proceed as follows:

Testing the measuring cell

Prerequisites:

■ The measuring cell is completely assembled (see measuring cell man-

ual).

■ The working electrode and the reference electrode are inserted (see

measuring cell manual).

1

Connecting the measuring cell

■ Connecting the measuring cell inlet:

– When the preheating capillary is used: Use a pressure

screw (6.2744.014) to fasten a piece of the PEEK capillary

(6.1831.010) to the Eluent to cell connector on the

detector.

Use a pressure screw (6.2744.014) to fasten the other end

to the In connector of the measuring cell.

– If the preheating capillary is not used: Use a pressure screw

(6.2744.014) to fasten the detector inlet capillary directly to

the In connector on the measuring cell.

■■■■■■■■

24

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 33

■■■■■■■■■■■■■■■■■■■■■■

■ Connecting the measuring cell outlet:

Use a pressure screw (6.2744.014) to fasten the tested detector

outlet capillary to the Out connector on the measuring cell (see

"Testing the detector outlet capillary", page 23).

2

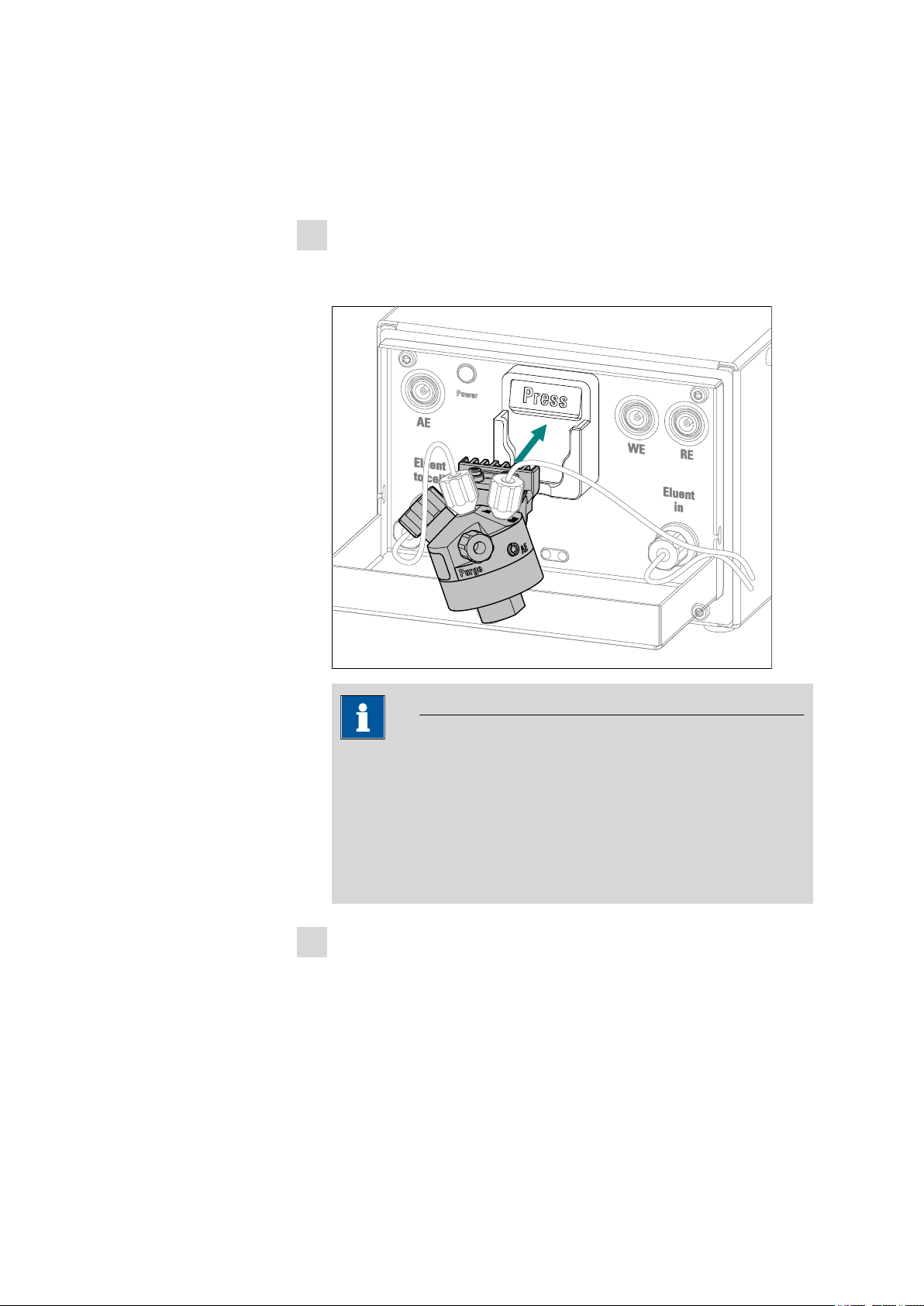

Inserting the measuring cell

Insert the chip of the measuring cell into the cell holder so that you

can hear it locking in.

4 Start-up

NOTE

Do not move the measuring cell for at least 5 seconds after having

inserted it.

During this time, data is read from the chip of the measuring cell

and written into the database. This process must not be interrupted, because otherwise the data may be transferred incorrectly or

incompletely.

3

Testing at low flow

■ In the program part Manual of MagIC Net, set the flow rate of

the high-pressure pump to 0.2 mL/min and start the high-pressure

pump.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

25

Page 34

4.6 Deaerating the measuring cell

■■■■■■■■■■■■■■■■■■■■■■

■ Watch the detector outlet capillary: Liquid must emerge from the

end of the detector outlet capillary.

If no liquid emerges from the end of the detector outlet capillary:

– Detach the capillary from the Out connection on the mea-

suring cell and check whether the end has been pinched by

the pressure screw.

– Shorten the capillary and fasten once again to the Out con-

nector on the measuring cell.

■ Observe the measuring cell: No liquid should emerge from the

body of the measuring cell.

If the measuring cell is leaking:

– Remove the measuring cell from the measuring cell holder.

– Remove all capillaries and cables.

– Check whether the pressure screw of the working electrode

is properly connected and retighten it.

– Restore the capillary connections.

– Reinsert the electrode cables.

– Reinsert the measuring cell.

– Repeat the test.

4

Testing at normal flow

■ In the program part Manual of MagIC Net, raise the flow rate of

the high-pressure pump to 1.0 mL/min.

■ Observe the measuring cell: No liquid should emerge from the

body of the measuring cell.

4.6 Deaerating the measuring cell

The cell must be deaerated in order to ensure that it contains no air bubbles.

The measuring cell must be deaerated after the installation and after each

subsequent opening of the cell.

Proceed as follows:

Deaerating the measuring cell

Prerequisites:

■ The high-pressure pump is switched on and pumps the eluent through

the IC system to the measuring cell.

■ The measuring cell is switched off.

1

Deaerating the reference electrode chamber

■ Unscrew the nut on the RE connector and remove it.

■■■■■■■■

26

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 35

■■■■■■■■■■■■■■■■■■■■■■

■ Lift out the reference electrode.

■ Wait until the reference electrode chamber has filled with eluent.

■ Reinsert the reference electrode. Wipe up any emerging eluent

with a cloth.

■ Screw the nut on the reference electrode connector back on

tightly.

2

Removing the purge stopper

Remove the stopper from the Purge connector.

4 Start-up

3

Deaerating the measuring cell

Observe the eluent that emerges through the deaeration opening.

Wipe up liquid with a cloth.

Once no more air bubbles are visible, screw the stopper back on the

Purge connector and tighten it by hand.

Switch off the high-pressure pump in MagIC Net.

4

4.7 Connecting the electrode cables

CAUTION

The electrode cables may not be plugged or unplugged unless the measuring cell is switched off in the software.

NOTE

The sockets and the plugs of the cables must be clean and dry.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

27

Page 36

4.7 Connecting the electrode cables

■■■■■■■■■■■■■■■■■■■■■■

Connecting the electrode cables to the detector

Prerequisites:

■ The measuring cell is switched off.

Plug the straight plug of the working electrode cable (red sleeve) into

1

the WE socket of the detector.

Plug the straight plug of the reference electrode cable (black sleeve)

2

into the RE socket of the detector.

Plug the straight plug of the auxiliary electrode cable (blue sleeve)

3

into the AE socket of the detector.

Connecting the electrode cables to the measuring cell

Prerequisites:

■ The working electrode and the reference electrode are inserted into

the measuring cell.

Plug the angled plug of the working electrode cable (labeled WE)

1

into the working electrode socket.

Plug the angled plug of the reference electrode cable (labeled RE)

2

into the reference electrode socket.

Plug the angled plug of the auxiliary electrode cable (labeled AE) into

3

the socket (labeled AE).

■■■■■■■■

28

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 37

■■■■■■■■■■■■■■■■■■■■■■

4.8 Attaching the front cover

In order to obtain good measuring results, we recommend that the front

cover be put back in place.

When you are attaching the front cover, observe the following:

■ Do not pinch any capillaries!

Guide the capillaries through the capillary feed-throughs .

■ Do not pinch any cables!

4 Start-up

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

29

Page 38

5.1 General notes

5 Operation and maintenance

5.1 General notes

5.1.1 Care

WARNING

Untrained personnel may not open the instrument's housing.

The instrument requires appropriate care. Excess contamination of the

instrument may result in malfunctions and a reduction in the service life of

the sturdy mechanical and electronic components.

CAUTION

■■■■■■■■■■■■■■■■■■■■■■

Even though design measures ensure that this will largely be prevented,

the detector should be switched off without delay in the event that

aggressive media have found their way into the interior of the detector.

This is the only way to prevent extreme damage to the instrument electronics. In such cases, Metrohm Service must be informed.

Spilled chemicals and solvents should be removed immediately. In particular, the plug connections (particularly the power plug) should be protected

from contamination.

Do not use scouring agents for cleaning the tray.

5.1.2 Maintenance by Metrohm Service

Maintenance of the instrument is best carried out as part of annual service, which is performed by specialist personnel from Metrohm. A shorter

maintenance interval is recommended if you frequently work with caustic

and corrosive chemicals. Metrohm Service provides professional technical

consultation at all times for the maintenance and servicing of all Metrohm

instruments.

5.1.3 Operation

■■■■■■■■

30

CAUTION

In order to avoid disruptive temperature influences, the entire system

must be protected from direct sunlight.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 39

■■■■■■■■■■■■■■■■■■■■■■

5.1.4 Shutting down

If the instrument is shut down for a longer period of time, the entire IC

system must be rinsed as follows to rid it of salts in order to prevent eluent salts from forming crystals which may cause subsequent damage.

■ Rinse all capillaries and the Dosino (if present) with methanol/ultrapure

water (1:4).

■ Rinse all pump tubings of the peristaltic pump with ultrapure water.

5.2 Conductivity detector

5.2.1 Maintenance

CAUTION

The conductivity detector must not be opened!

5 Operation and maintenance

WARNING

When rinsing the detector without column, the pressure must not

exceed 5 MPa.

In order to ensure this, set the maximum pressure of the high-pressure

pump to 5 MPa in MagIC Net.

5.2.2 Remedying blockage

The conductivity detector can become blocked if the ends of the detector

inlet capillary or the detector outlet capillary are pressed together too

tightly.

If this is the case, detach and shorten the detector inlet capillary or the

detector outlet capillary by a few millimeters.

If the conductivity detector is still blocked even if the capillary ends are

free then it can be rinsed in the direction opposite the normal flow direction. Proceed as follows:

Detach the detector inlet capillary or the detector outlet capillary

1

from the system.

Connect the detector outlet capillary directly to the outlet of the

2

high-pressure pump.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

31

Page 40

5.3 Amperometric detector

In MagIC Net, set the maximum pressure of the high-pressure pump

3

to 5 MPa.

Rinse the detector thoroughly with eluent.

4

5.3 Amperometric detector

5.3.1 Maintenance

WARNING

When rinsing the detector without column, the pressure must not

exceed 5 MPa.

In order to ensure this, set the maximum pressure of the high pressure

pump to 5 MPa in MagIC Net.

■■■■■■■■■■■■■■■■■■■■■■

5.3.2 Preheating capillary maintenance

The preheating capillary can become blocked, e.g. if the IC system has

inadvertently been run dry.

To dissolve this blockage, proceed as follows:

Rinsing the preheating capillary

1

Removing the separation column

Remove the separation column from the IC system and replace with

a coupling (6.2744.040).

2

Adjusting the settings in MagIC Net

In MagIC Net, adjust the following settings:

■ Maximum pressure of the high-pressure pump: 5 MPa

■ Flow rate: < 0.1 mL/min

Rinse the system with the same eluent as before the blockage or

3

with ultrapure water.

■■■■■■■■

32

The eluent requires sufficient time to trickle through and dissolve the

crystals.

Do not increase the flow rate until the pressure has stabilized.

4

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 41

■■■■■■■■■■■■■■■■■■■■■■

If the preheating capillary remains blocked, then you can attempt to rinse

the capillary in the opposite direction. To accomplish this, connect the

detector inlet capillary to the connector Eluent to cell and repeat the

procedure (see "Rinsing the preheating capillary", page 32).

If the blockage can also not be dissolved by rinsing in the opposite direction, then the preheating capillary must be replaced by a Metrohm Service

employee.

5 Operation and maintenance

5.4 Quality management and qualification with Metrohm

Quality management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software.

Qualification

Please contact your local Metrohm representative for support in qualification of instruments and software. The Installation Qualification (IQ)

and Operational Qualification (OQ) are offered by Metrohm representatives as a service. They are carried out by trained employees using standardized qualification documents and in accordance with the currently

applicable requirements of the regulated industry.

Maintenance

The electronic and mechanical functional groups of Metrohm instruments

can and should be checked by specialist personnel from Metrohm as part

of a regular preventive maintenance schedule. Please ask your local

Metrohm representative regarding the precise terms and conditions

involved in concluding a corresponding maintenance agreement.

For detailed information on this topic, please visit www.metrohm.com.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

33

Page 42

6.1 Problems with the hardware

6 Troubleshooting

6.1 Problems with the hardware

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Leak sensor

responds.

Leaking capillary connection.

Find any leaking capillary connections and seal

them.

Measuring cell leaking. Screw apart the measuring cell and then reas-

semble it.

The amperometric

detector is not rec-

IC system – No connection. ■ Check the cable connection.

■ Switch the IC instrument off and then on

ognized in the software.

6.2 Problems with the baseline

Problem

Pulsing baseline. High-pressure pump – Con-

Cause Remedy

Clean valves (see Chapter Operation and

taminated valves.

maintenance in the manual for the IC instru-

ment).

High-pressure pump –

Defective piston seal.

Replace the piston seals (see Chapter Operation and maintenance in the manual for the IC

instrument).

again after 15 seconds.

■■■■■■■■

34

High-pressure pump –

Quality of the pump is not

sufficient for the selected

sensitivity.

Measuring cell – Air bubble

in the measuring cell.

IC system – temperature

fluctuations.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■ Use a pulsation absorber.

■ Use a higher-performance high-pressure

pump.

■ Reduce the sensitivity.

■ Deaerate the measuring cell.

■ Degas the eluent continuously.

■ Switch on the column thermostat or the

column oven.

■ Amperometric detector – Connect the pre-

heating capillary .

■ Amperometric detector – Attach and close

the front cover (see Chapter 4.8, page 29).

Page 43

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

6 Troubleshooting

Smooth baseline (no

noise).

Measuring cell – Working

electrode contaminated.

Measuring cell – Measuring cell leaking.

IC system – Eluent contaminated.

Communications problem

between the amperometric

detector and MagIC Net.

All of the data lies outside

of the measuring range.

Short-circuit bridge

between the electrodes.

Clean the working electrode (see the leaflet for

the working electrode).

Check the capillary connections on the measuring cell.

Prepare a new eluent.

■ Check whether the electrode cables are

properly connected.

■ Check the electrode cable with dummy cell

(see Chapter 4.1, page 19).

■ Switch off the instrument, close and restart

MagIC Net, switch the instrument back on.

■ Adjust the measuring range.

■ Deaerate the measuring cell (see "Deaerat-

ing the measuring cell", page 26).

■ Examine the working electrode for promi-

nent deposits.

■ Polish the working electrode (see the leaflet

for the working electrode).

■ Replace the working electrode.

■ Clean the measuring cell.

■ Check the spacer.

The baseline has a

large amount of

noise.

The reference electrode is

Replace the reference electrode.

worn out.

The cause is not clear. Perform a systematic error diagnostics (see

Chapter 6.9, page 41).

Disruptive influences from

outside.

■ In the DC mode: Switch on the damping.

■ In the other measuring modes: Set a suit-

able smaller measuring range.

■ Attach the front cover.

The Ag/AgCl reference elec-

Replace the reference electrode.

trode is worn out.

The auxiliary electrode is

contaminated.

The working electrode is

contaminated.

Clean the auxiliary electrode of the measuring

cell.

■ Clean and polish the working electrode

(see the leaflet for the working electrode).

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

35

Page 44

6.2 Problems with the baseline

Problem Cause Remedy

■ Replace the GC working electrode if it has

been used with oxidative potentials at the

upper limit and polishing no longer helps.

■■■■■■■■■■■■■■■■■■■■■■

The baseline is drifting.

Unexpectedly high

or low baseline.

Air bubble in the measuring cell.

The background current is

too high, e.g. caused by

contaminated eluent.

IC system – Thermal equilibrium not yet attained.

IC system – Leak in the system.

IC system – Eluent is old

(too much CO2).

Pd reference electrode –

Working conditions not yet

achieved.

DC method – Working conditions not yet achieved.

Deaerate the measuring cell (see Chapter 4.6,

page 26).

Check the background current, e.g. use fresh

eluent.

Condition the system with the heater switched

on.

Check the capillary connections and seal them.

Prepare a new eluent.

Equilibrate until the electrode has adjusted to

the new elution conditions (over night).

An excessively high baseline is normal at the

start of the equilibration. Equilibrate until the

baseline corresponds to the one in the Application Works.

Detector parameters –

Potentials set incorrectly.

Set the potentials to correspond to the specifications in the leaflet and in the Application

Works.

Incorrect eluent in the reference chamber.

Remove the purge stopper on the measuring

cell, wait until approx. 1 mL of eluent has

emerged, screw the purge stopper back in

tightly.

Electrodes contaminated. ■ Clean and polish the working electrode.

■ Possibly clean the auxiliary electrode.

■ Replace the reference electrode with a

well-conditioned new reference electrode.

■■■■■■■■

36

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 45

■■■■■■■■■■■■■■■■■■■■■■

6 Troubleshooting

6.3 General remarks regarding sensitivity fluctuations

Sensitivity fluctuations of up to 20% per week are normal for an

unchanged system in constant operation.

The sensitivity can increase to approximately twice as much for a short

time when new working electrodes are inserted or when the conditions

change.

6.4 Problems with sensitivity

Problem

Declining sensitivity. Measuring cell – Auxiliary

Cause Remedy

electrode contaminated.

Incorrect eluent in the reference chamber.

Sample concentration is no

longer correct.

Temperature fluctuations. ■ Amperometric detector – Use preheating

Replace the measuring cell. ■ Use a measuring cell of the same type.

Software – Measurement

potential incorrect.

Clean the auxiliary electrode (see measuring

cell manual).

Remove the purge stopper on the measuring

cell, wait until approx. 1 mL of eluent has

emerged, screw the purge stopper back in

tightly.

Replace the sample and/or the standard solution.

capillary.

■ IC instruments – Use column oven.

■ Use the same spacer.

■ Use the same electrodes.

Optimize the measurement potential.

Measuring cell – Working

electrode contaminated.

IC system – Eluent contaminated.

IC system – pH of the eluent has changed.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Clean the working electrode (see the leaflet for

the working electrode).

Prepare a new eluent.

Check the pH value of the eluent and optimize

it if necessary.

■■■■■■■■

37

Page 46

6.5 Problems with the pressure

6.5 Problems with the pressure

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Marked drop in

pressure.

The pressure in the

system markedly

increases.

IC system – Leak in the system.

IC system – Inline filter

blocked.

IC system – Separation column contaminated.

Amperometric detector –

Preheating capillary

blocked.

Check the capillary connections and seal them.

Replace the filter pad (see Chapter Operation

and maintenance in the manual for the IC

instrument).

■ Regenerate the separation column (see

Chapter Operation and maintenance in

the manual for the IC instrument).

■ Replace the separation column (see Chap-

ter Operation and maintenance in the

manual for the IC instrument).

Note: Samples should always be micro-filtered

(see Chapter Operation and maintenance –

Inline sample preparation in the manual for

the IC instrument).

Perform a maintenance procedure for the preheating capillary (see Chapter 5.3.2, page 32).

Amperometric detector –

Detector outlet capillary

not free of blockage.

Test the detector outlet capillary (see Chapter

4.4, page 23).

6.6 Problems with the measuring signal

Problem

Measuring signal

"overload".

Cause Remedy

Air bubble in the measuring cell.

Measuring cell – Working

electrode damaged.

Measuring cell – Measuring cell not correctly connected.

Software – Measurement

potential incorrect.

Deaerate the measuring cell (see Chapter 4.6,

page 26).

Replace the working electrode.

Check the cable connections (see "Connecting

the electrode cables to the measuring cell",

page 28).

Optimize the measurement potential.

■■■■■■■■

38

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 47

■■■■■■■■■■■■■■■■■■■■■■

Problem Cause Remedy

6 Troubleshooting

No measuring signal.

Peaks cut off at the

top.

IC system – No power supply.

Measuring range too

small.

Check the power connection and the supply

voltage.

■ Set a less sensitive measuring range.

■ Reduce the peak height, e.g. by means of

sample dilution.

6.7 Problems with the chromatogram

Problem

Peak drift with

sugar analysis.

Peaks have poor resolution.

Cause Remedy

Carbonate absorption in

the eluent.

IC system – Diminished

separating efficiency of the

separation column.

Use the Metrosep CO3 Trap 1 (6.1015.300)

trap column.

■ Regenerate the separation column (see

Chapter Operation and maintenance in

the manual for the IC instrument).

■ Replace the separation column (see Chap-

ter Operation and maintenance in the

manual for the IC instrument).

The retention times

in the chromatogram have changed

unexpectedly.

IC system – Eluent is old. Prepare a new eluent.

The ionic strength of the

sample or the pH value of

Dilute the sample or optimize the pH value of

the sample.

the sample deviates greatly

from the eluent.

Absorption of analyte at

the electrodes.

IC system – Diminished

separating efficiency of the

separation column.

Use a suitable combination of electrodes and

eluent.

■ Regenerate the separation column (see

Chapter Operation and maintenance in

the manual for the IC instrument).

■ Replace the separation column (see Chap-

ter Operation and maintenance in the

manual for the IC instrument).

IC system – Eluent is old. Prepare a new eluent.

The ionic strength of the

sample or the pH value of

Dilute the sample or optimize the pH value of

the sample.

the sample deviates greatly

from the eluent.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

39

Page 48

6.8 Other problems

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

Extreme spread of

the peaks in the

chromatogram.

Splitting (dual

peaks)

IC system – Dead volume

at the ends of the separation column.

IC system – Dead volume

in the IC system.

Inhibition of the detection

mechanism by the analyte

(with PAD).

The column is overloaded. Dilute the sample.

6.8 Other problems

Problem

High background

current.

Cause Remedy

IC system – Eluent contaminated.

Software – Measurement

potential / pulse settings

incorrect.

Replace the separation column.

Check the capillary connections.

■ Dilute the sample.

■ Allow the waveform to run-in better.

■ Adjust the PAD waveform.

Prepare a new eluent.

Optimize the parameters.

Unstable temperature.

Current display/

charge display in the

software is frozen.

Very wide peaks through

substances with delayed

elution.

The set temperature is too

low.

Measuring cell – electrodes

are either not connected or

not correctly connected.

Measuring cell – Small air

bubbles in the measuring

cell.

Measuring cell – Electrode

connection cable defective.

Wait for the complete elution of these substances.

Set the temperature to at least 8 °C higher

than the highest ambient temperature to be

anticipated.

Connect the electrode connection cables correctly (see Chapter 4.7, page 27).

Deaerate the measuring cell (see Chapter 4.6,

page 26).

Perform an instrument test with the dummy

cell (see Chapter 4.1, page 19).

■■■■■■■■

40

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 49

■■■■■■■■■■■■■■■■■■■■■■

6.9 Systematic error diagnostics

If the causes of a malfunction cannot be found among the problem

descriptions in the above chapters, then proceed systematically as follows:

Systematic error diagnostics

1

Restarting the instrument and the software

■ Switch off the instrument.

■ Close and restart MagIC Net.

■ Switch the instrument back on again.

If the problem has not yet been localized, continue with Step 2.

2

Performing an instrument test with dummy cell

(see Chapter 4.1, page 19)

If the problem has not yet been localized, continue with Step 3.

3

Checking the software settings

■ Check the method parameters of the detector and reset them to

values that you know will function.

■ Check the measuring range and reset it to values that you know

will function or select a larger measuring range.

■ Check manual changes to the settings and reset them to values

that you know will function.

■ Check manual settings in the time program and reset them to val-

ues that you know will function.

6 Troubleshooting

If the problem has not yet been localized, continue with Step 4.

4

Cleaning the measuring cell

■ Switch off the measuring cell.

■ Remove the measuring cell.

■ Clean the measuring cell (see measuring cell manual).

■ Polish the working electrode (see the leaflet for the working elec-

trode).

■ Reinsert the measuring cell.

If the problem has not yet been localized, continue with Step 5.

5

Replacing the reference electrode

If the problem has not yet been localized, continue with Step 6.

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

41

Page 50

6.9 Systematic error diagnostics

■■■■■■■■■■■■■■■■■■■■■■

6

Replacing the working electrode

If the problem has not yet been localized, continue with Step 7.

7

Replacing the body of the measuring cell

Replace the body of the measuring cell with another one of the same

type.

If the problem has not yet been localized, continue with Step 8.

8

Requesting Metrohm Service

If none of these measures help, please request Metrohm Service.

NOTE

Please note that, when the electrodes are replaced, the system requires

a longer run-in time before the earlier values can be reproduced.

■■■■■■■■

42

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 51

■■■■■■■■■■■■■■■■■■■■■■

7 Technical specifications

7.1 Reference conditions

The technical specifications listed in this chapter refer to the following reference conditions:

7 Technical specifications

Ambient tempera-

+25 °C (± 3 °C)

ture

Instrument status Operating > 40 minutes (in equilibrium)

7.2 Power connection

Required voltage

Required frequency

Power consumption

Power supply unit ■ Up to 300 W maximum, electronically monitored

100 - 240 V ± 10% (autosensing)

50 - 60 Hz ± 3 Hz (autosensing)

■ 65 W for typical analysis application

■ 25 W standby (conductivity detector to 40 °C)

■ Internal fuse 3.15 A

7.3 Conductivity detector

Type

■ Microprocessor-controlled Digital Signal Processing (DSP technol-

ogy)

■ Intelligent detector with 6 reference chromatograms

Measuring range 0 - 15,000 µS/cm without range switching

Noise < 0.1 nS at 1 µS/cm

Linearity deviations

■ < 0.1% for conductivity values higher than 16 µS/cm

■ < 1% for conductivity values lower than 16 µS/cm

Drift < 0.2 nS/cm per hour

Measuring rate 10 measurements per second for optimum results without filtering

Resolution 0.0047 nS/cm

Baseline Noise < 0.2 nS/cm typical for sequential suppression

Conductivity

detector

Cell volume 0.8 µL

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

■■■■■■■■

43

Page 52

7.4 Amperometric detector

Cell constant ■ Individual calibration data saved in the detector

■ Adjustable in the range: 13.0 - 21.0 /cm

Electrodes Ring-shaped electrodes made from stainless steel

Materials in

Chemically inert PCTFE

contact with

eluent

Maximum oper-

5.0 MPa (50 bar)

ating pressure

Cell tempera-

20 - 50 °C in increments of 5 °C

ture

Temperature

< 0.001 °C

stability

Temperature

0 - 5%/K adjustable, default 2.3%/K

compensation

Heating time < 30 minutes (40 °C)

7.4 Amperometric detector

■■■■■■■■■■■■■■■■■■■■■■

Type

Microprocessor-controlled Digital Signal Processing (DSP technology)

Potentiostat

Potential range –5.0…+5.0 V in steps of 0.001 V

Potential step

< 1 ms

response time

Detection

modes

■ DC

■ PAD

■ flexIPAD (flexible IPAD)

■ CV

Measuring unit

AutoRange yes, (DC only)

Digital signal

range

DC mode 0.00012 pA…2 mA

PAD mode 0.012 pA…2 mA

flexIPAD mode 0.12 pC…200 µC

CV 0.12 pA…20 mA

Electronic noise

DC mode < 5 pA

PAD mode < 10 pA

flexIPAD mode < 30 pC

■■■■■■■■

44

945 Professional Detector Vario – Conductivity & Amperometry (2.945.0030)

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Filter

DC mode Hardware filter, can be selected by the user

All modes Software filter, can be set by the user

Temperature control

Temperature

better than 0.05 °C with ambient temperature +8 °C…80 °C

stability at the

heater

Operation

Direct Via Software MagIC Net

Remote Via Remote Box

Analog output With 891 Professional Analog Out

Output voltage 0…1000 mV

Full scale Can be adjusted within the digital signal range

Offset Can be adjusted within the digital signal range

7 Technical specifications

System standby ■ Automatic function test at start-up

■ Leak sensor

■ Temperature stability monitoring

Output channels ■ Current rating

■ Charge

GLP conformity Yes, optional

7.5 Leak sensor

Type