Page 1

944 Professional UV/VIS Detector Vario

2.944.0010

Manual

8.944.8001EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

944 Professional UV/VIS Detector

Vario

2.944.0010

8.944.8001EN

Manual

11.2013 zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Intended use ......................................................................... 1

1.3 About the documentation ................................................... 1

1.3.1 Symbols and conventions ........................................................ 2

1.4 Safety instructions ................................................................ 3

1.4.1 General notes on safety ........................................................... 3

1.4.2 Electrical safety ........................................................................ 3

1.4.3 Tubing and capillary connections ............................................. 4

1.4.4 Flammable solvents and chemicals ........................................... 4

1.4.5 Recycling and disposal ............................................................. 4

2 Overview of the instrument 6

2.1 Front ...................................................................................... 6

Table of contents

2.2 Rear ........................................................................................ 7

3 Installation 8

3.1 Setting up the instrument .................................................... 8

3.1.1 Packaging ................................................................................ 8

3.1.2 Checks .................................................................................... 8

3.1.3 Location .................................................................................. 8

3.2 Setup configurations ............................................................ 8

3.3 Base tray and bottle holder ............................................... 10

3.3.1 Basic information on base tray and bottle holder ................... 10

3.3.2 Mounting base tray and bottle holder (optional) .................... 10

3.4 Installing the flow-through cell ......................................... 15

3.5 Connecting the flow-through cell ..................................... 17

3.6 Connecting the instrument ................................................ 19

3.6.1 Connecting the instrument to a computer ............................. 19

3.6.2 Connecting the instrument to the power supply .................... 19

4 Start-up 21

5 Operation 23

6 Operation and maintenance 24

6.1 Care ...................................................................................... 24

6.2 Maintenance by Metrohm Service .................................... 24

6.3 Door ..................................................................................... 25

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

6.4 Replacing the UV lamp ....................................................... 25

6.5 Replacing the VIS lamp ...................................................... 28

6.6 Adjusting the lamp settings .............................................. 28

6.7 Cleaning the flow-through cell .......................................... 29

6.8 Quality Management and qualification with

Metrohm ............................................................................. 33

7 Troubleshooting 34

7.1 Problems and their solutions ............................................. 34

8 Technical specifications 35

8.1 Reference conditions .......................................................... 35

8.2 UV/VIS detector .................................................................. 35

8.3 Lamps .................................................................................. 37

8.4 Ambient conditions ............................................................ 37

8.5 Housing ............................................................................... 37

8.6 Power connection ............................................................... 38

8.7 Interfaces ............................................................................. 38

8.8 Safety specifications ........................................................... 38

8.9 Electromagnetic compatibility (EMC) ................................ 39

8.10 Weight ................................................................................. 39

9 Warranty (guarantee) 40

10 Accessories 42

Index 44

■■■■■■■■

IV

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 Front ................................................................................................. 6

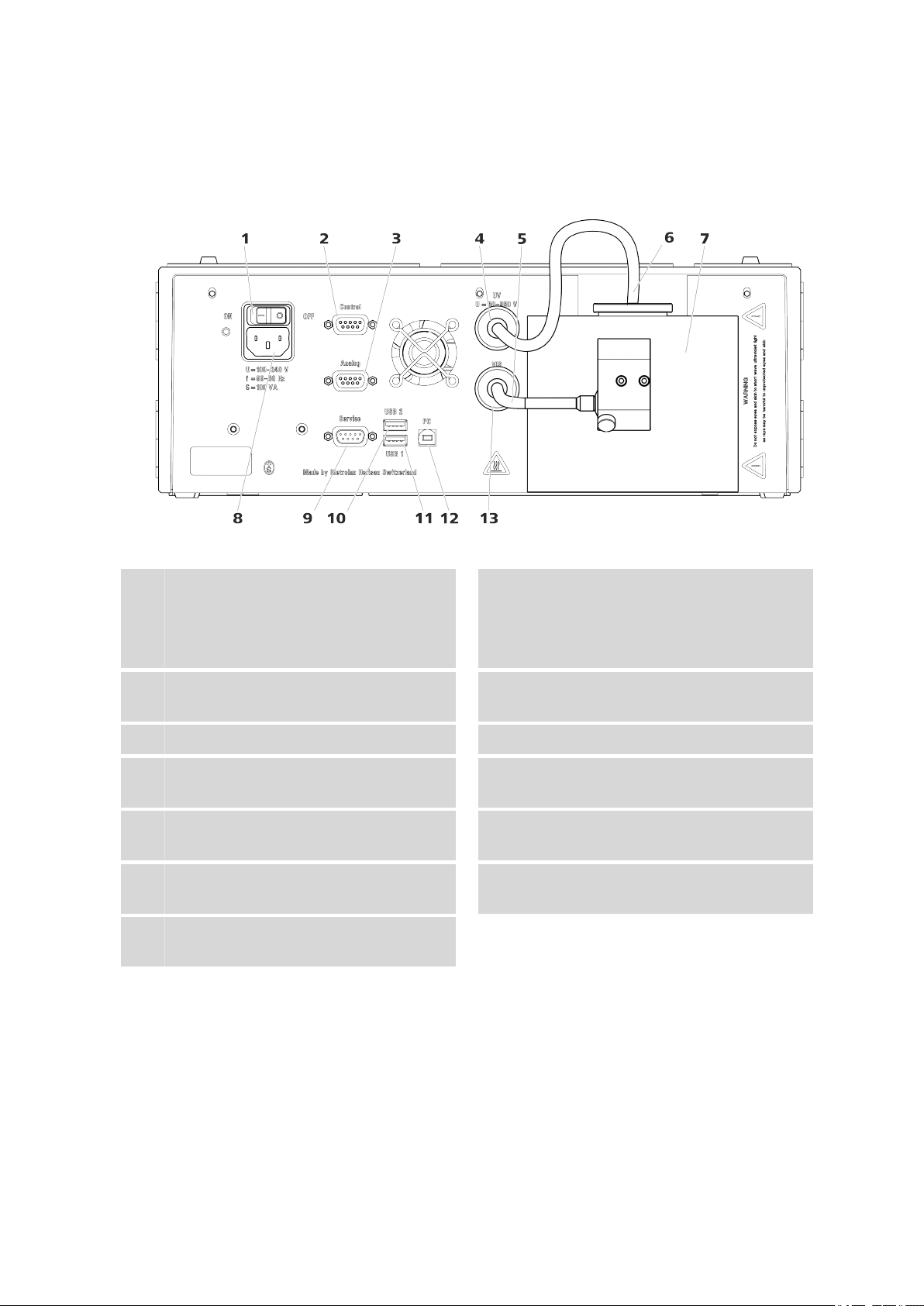

Figure 2 Rear .................................................................................................. 7

Figure 3 Setup configurations ......................................................................... 9

Figure 4 Cell block ........................................................................................ 15

Figure 5 Connecting the detector input ......................................................... 17

Figure 6 Connecting the detector outlet ........................................................ 18

Figure 7 Intensity spectrum OK ..................................................................... 22

Figure 8 Lamp intensity too high ................................................................... 22

Figure 9 Operating hours counter ................................................................. 25

Figure 10 Lamp module .................................................................................. 25

Figure 11 Lamp module – without UV lamp .................................................... 27

Figure 12 Flow-through cell – parts ................................................................. 31

Table of figures

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 944 Professional UV/VIS Detector Vario is an independent instrument for the photometric determination of light-absorbing substances in

the UV/VIS range. It serves as UV/VIS detector within an ion chromatography system.

The 944 Professional UV/VIS Detector Vario is operated with the

MagIC Net software. It is connected to a PC on which MagIC Net is

installed with a USB cable. The software detects the instrument automatically and checks its functionality. MagIC Net controls and monitors the

instrument, evaluates the measured data and manages it in a database.

Additional information on operating MagIC Net can be found in the document "MagIC Net Tutorial" or in the software's online help.

1 Introduction

1.2 Intended use

The 944 Professional UV/VIS Detector Vario is used as an independent

detector with various analysis instruments of the Metrohm line of instruments.

The present instrument is suitable for processing chemicals and flammable

samples. Usage of the 944 Professional UV/VIS Detector Vario therefore

requires the user to have basic knowledge and experience in handling

toxic and caustic substances. Knowledge with respect to the application

of the fire prevention measures prescribed for laboratories is also mandatory.

1.3 About the documentation

CAUTION

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

1

Page 10

1.3 About the documentation

1.3.1 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

■■■■■■■■■■■■■■■■■■■■■■

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

WARNING

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

CAUTION

This symbol draws attention to possible damage to

instruments or instrument parts.

NOTE

This symbol highlights additional information and

tips.

■■■■■■■■

2

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.4 Safety instructions

1.4.1 General notes on safety

WARNING

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.4.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

WARNING

1 Introduction

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

WARNING

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

WARNING

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

3

Page 12

1.4 Safety instructions

Protection against electrostatic charges

WARNING

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

1.4.3 Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

■■■■■■■■■■■■■■■■■■■■■■

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1.4.4 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.4.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

■■■■■■■■

4

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 13

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

5

Page 14

2.1 Front

1

2

2 Overview of the instrument

2.1 Front

■■■■■■■■■■■■■■■■■■■■■■

Figure 1 Front

Flow-through cell

1

Standby indicator

2

■■■■■■■■

6

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2.2 Rear

2 Overview of the instrument

Figure 2 Rear

Power switch

1

For switching the instrument on and off.

I = On

O = Off

Analog connection socket

3

Output for analog signals.

VIS lamp connection cable

5

Lamp cooling element

7

Service connection socket

9

Connector for service.

USB 1 connection socket

11

For connecting additional USB devices.

VIS connection socket

13

For connecting the cable of the VIS lamp.

Control connection socket

2

Not Used.

UV connection socket

4

For connecting the cable of the UV lamp.

UV lamp connection cable

6

Power socket

8

For connecting the power supply cable.

USB 2 connection socket

10

For connecting additional USB devices.

PC connection socket

12

For connecting the USB cable to the PC.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

7

Page 16

3.1 Setting up the instrument

3 Installation

3.1 Setting up the instrument

3.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

3.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

3.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

■■■■■■■■■■■■■■■■■■■■■■

Place the instrument in a location of the laboratory which is suitable for

operation and free of vibrations and which provides protection against

corrosive atmosphere and contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

The distance between the rear of the instrument and the wall must be

large enough to ensure air circulation on the cooling plate.

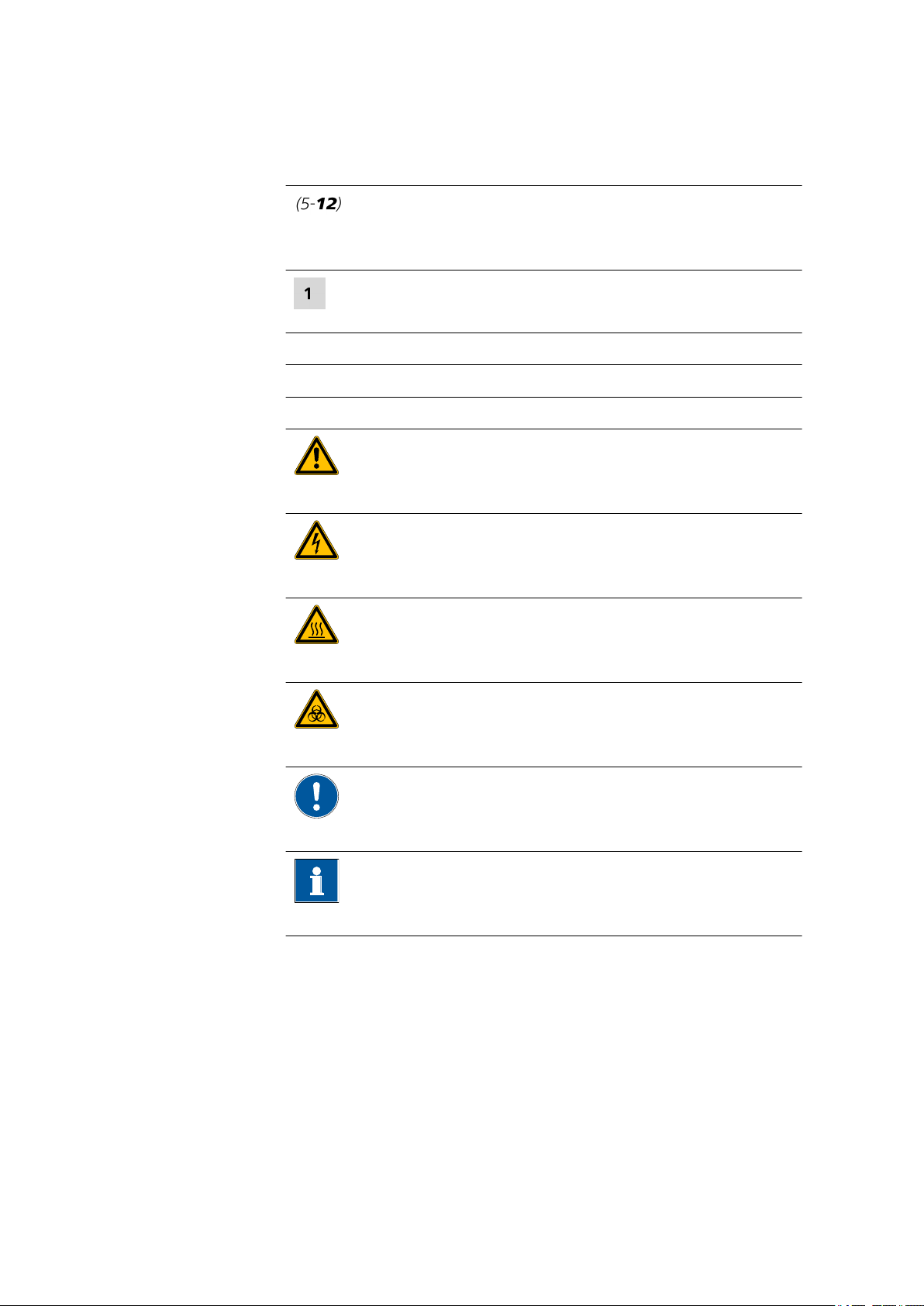

3.2 Setup configurations

The 944 Professional UV/VIS Detector Vario can be used as a detector

with the instruments of the 940 Professional IC Vario and 930 Compact IC

Flex family. For many applications with photometric detection, a post-column derivatization with the 943 Professional Thermostat / Reactor Vario

(2.943.0110) is required. To build such a system, you will need a 944 Professional UV/VIS Detector Vario and the following instruments:

■ any 940 Professional IC Vario, or

any 930 Compact IC Flex

■ a 943 Professional Thermostat / Reactor Vario

■ optionally: a 942 Extension Module Vario for sample preparation

■ optionally, if the reagent is pumped with a high-pressure pump: a Met-

rosep BP 1 Guard/2.0 backpressure column (6.1015.100)

■■■■■■■■

8

An IC system with photometric detection and post-column derivatization

can be set up in in various configurations.

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 17

■■■■■■■■■■■■■■■■■■■■■■

2.944.0010

2.943.0110

2.940.xxxx

2.942.xxxx

2.940.xxxx

2.942.xxxx

2.944.0010

2.943.0110

6.2061.100

6.2061.110

2.940.xxxx

2.930.xxxx

2.944.0010

2.943.0110

2.942.xxxx

6.2061.110

6.2061.100

2.930.xxxx

6.2061.120

2.942.xxxx

6.2061.100

2.944.0010

2.943.0110

6.2061.110

3 Installation

Figure 3 Setup configurations

Notes on the setup configurations

If you want to set up the instruments in two stacks, we recommend you

order the following accessories to protect the instruments of the second

stack:

■ Bottle holder (ProfIC) (6.2061.100)

■ Base tray with sensor for Professional IC instruments (6.2061.110)

If you would like to stack a 930 Compact IC Flex on a 944 Professional

UV/VIS Detector Vario, a 943 Professional Thermostat / Reactor Vario and/

or a 942 Extension Module Vario, then you will need the System Connector (6.2061.120) to accommodate the different base sizes.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

9

Page 18

3.3 Base tray and bottle holder

■■■■■■■■■■■■■■■■■■■■■■

3.3 Base tray and bottle holder

3.3.1 Basic information on base tray and bottle holder

The base tray (6.2061.110) and bottle holder (6.2061.100) protect IC

instruments from dust, dirt and leaking fluids. The supply bottles for eluent

and auxiliary solutions can be positioned neatly on the bottle holder.

In a complex IC system, several different instruments may be used, such as

an analyzer, an extension module and a detector. These instruments can

be set up in one or more stacks. We recommend that a base tray and bottle holder be mounted for each stack of IC instruments.

The bottle holder and base tray must be removed or set up every time one

of the following instruments is to be mounted on or under a 940 Professional IC Vario:

■ One or more 942 Extension Module Vario.

■ Or another instrument with the same-sized footprint.

3.3.2 Mounting base tray and bottle holder (optional)

The base tray and bottle holder come fully assembled on a new ion chromatograph. If you wished to install an extension module on the ion chromatograph, you would have to remove the bottle holder and put it back

on top of the topmost instrument. If you wished to install an extension

module below the ion chromatograph, you would have to remove the

base tray and set it under the lowest instrument.

3.3.2.1

Removing/mounting the base tray

The base tray must be removed if you want to install another instrument

under the IC instrument.

CAUTION

Do not allow capillaries or leak sensor cables to be pinched!

Pinches in the leak sensor cable or the capillaries fed through the guide

ducts between the base tray and the instrument may lead to malfunctions.

Unplug the leak sensor cable. Remove all of the capillaries from the

capillary ducts.

■■■■■■■■

10

Removing the base tray

Before you can remove the base tray, the following preconditions must be

met:

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 19

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

3 Installation

■ The instrument is switched off.

■ The bottle holder is cleared.

■ All of the cable connections on the rear have been disconnected.

■ The capillaries are removed from the guide ducts between the instru-

ment and the base tray.

■ There are no loose parts in the instrument.

To remove the base tray, you need a 3 mm hex key (6.2621.100).

Tilt the instrument sideways and lay it down flat.

1

Loosen the four cylinder screws with the 3 mm hex key and remove

2

them and their washers.

Remove the base tray.

3

The base tray must always be mounted under the lowermost instrument

of the stack.

Mounting the base tray

Before you can mount the base tray, the following preconditions must be

met:

■ The instrument is switched off.

■ The bottle holder is cleared.

■ All of the cable connections on the rear have been disconnected.

■ There are no loose parts in the instrument.

■ The instrument is lying on its side, and the bottom surface is visible.

To mount the base tray, you need a 3 mm hex key (6.2621.100).

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

11

Page 20

3.3 Base tray and bottle holder

1

3

2

■■■■■■■■■■■■■■■■■■■■■■

Place the base tray in such a way that the openings in the base tray

1

match exactly the screw threads in the bottom of the instrument.

Slide the washers onto the cylinder screws, insert the screws and

2

tighten them with the 3 mm hex key.

Set the instrument back up on the base tray.

3

3.3.2.2

Stack other instruments in the required order. Mount the bottle holder

(6.2061.100) onto the topmost instrument on the stack (see "Mounting

the bottle holder", page 14).

Removing/mounting the bottle holder

The bottle holder must be removed if you want to install another instrument onto the IC instrument.

Removing the bottle holder

Before you can remove the bottle holder, the following preconditions

must be met:

■ The instrument is switched off.

■ The bottle holder is cleared.

■ Drainage tubing is disconnected from the drainage tubing connection

of the bottle holder.

■ The capillaries are removed from the guide ducts between the instru-

ment and the bottle holder.

To remove the bottle holder, you need a 3 mm hex key (6.2621.100).

■■■■■■■■

12

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 21

■■■■■■■■■■■■■■■■■■■■■■

1

2 3

Remove the two covering stoppers.

1

Loosen the two cylinder screws with the 3 mm hex key and remove

2

them.

Remove the bottle holder.

3

3 Installation

Stack other instruments in the required order. Mount the bottle holder

(6.2061.100) onto the topmost instrument on the stack.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

13

Page 22

3.3 Base tray and bottle holder

1

2 3

■■■■■■■■■■■■■■■■■■■■■■

Mounting the bottle holder

Before you can mount the bottle holder, the following preconditions must

be met:

■ The instrument is switched off.

To mount the bottle holder, you need a 3 mm hex key (6.2621.100).

Place the bottle holder onto the topmost instrument in such a way

1

that the openings in the bottle holder exactly match the screw

threads on the top surface of the instrument.

Insert the two cylinder screws and tighten them with the 3 mm hex

2

key.

Insert both covering stoppers.

3

After attaching the bottle holder, all connections that were undone at the

beginning of the process must be reconnected.

Restoring the loosened connections

Plug in all necessary USB cables.

1

Plug in all necessary MSB cables.

2

Plug in the power supply cable.

3

Mount the drainage tubing again (see manual of the IC instrument).

4

■■■■■■■■

14

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 23

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

3

4

A longer section of silicone tubing (6.1816.020) may have to be cut

to size and mounted (see also the manual for the IC instrument).

If one of the instruments in the stack is equipped with a leak sensor

5

connection socket, connect the leak sensor (see manual of the IC

instrument).

Restore any capillary connections that may have been removed.

6

3.4 Installing the flow-through cell

3 Installation

Cell holder

1

Holder for the flow-through cell.

Knurled screws

3

Figure 4

Cell block

Cover plate

2

Protects the cell holder form contamination

if no cell is installed.

Cylinder screw

4

For the correct alignment of the flowthrough cell.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

15

Page 24

3.4 Installing the flow-through cell

1

2

3

4

■■■■■■■■■■■■■■■■■■■■■■

Installing the flow-through cell

Loosen and remove the knurled screws (4-3).

1

Remove the cover plate (4-2).

2

Insert the flow-through cell (6.2839.130) such that the opening in

3

top right corner is aligned with the cylinder screw (4-4) on the cell

block.

Screw in the knurled screws again.

4

NOTE

In order to fix the flow-through cell in the correct position, the

two knurled screws must be tightened symmetrically and with

constant force.

Any tilting, twisting or canting of the flow-through cell influences

the light incidence and thus the measuring results.

■■■■■■■■

16

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 25

■■■■■■■■■■■■■■■■■■■■■■

2

1

3

3.5 Connecting the flow-through cell

To connect the capillaries to the flow-through cell, proceed as follows:

Connecting the capillaries

1

Connecting the detector input

3 Installation

Detector input capillary

1

PEEK capillary (6.1831.100).

Pressure screw

3

Figure 5 Connecting the detector input

Detector inlet

2

Labeled IN.

■ Unscrew the pressure screw from the IN detector inlet.

■ Slide the presssure screw over the detector input capillary such

that a small part of the capillary is visible at the top.

■ Tighten the detector input capillary in the detector inlet using the

pressure screw.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

17

Page 26

3.5 Connecting the flow-through cell

3

4

1

2

2

Connecting the detector outlet

Figure 6 Connecting the detector outlet

■■■■■■■■■■■■■■■■■■■■■■

Detector input capillary

1

Detector outlet

3

Labeled OUT.

Detector output capillary

2

PEEK capillary (6.1831.100).

Pressure screw

4

■ Unscrew the pressure screw form the OUT detector outlet.

■ Slide the presssure screw over the detector output capillary such

that a small part of the capillary is visible at the top.

■ Screw the detector output capillary to the detector outlet with the

pressure screw.

NOTE

The detector output capillary (6.1831.100) is 1 m long and may

not be shortened.

■■■■■■■■

18

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 27

■■■■■■■■■■■■■■■■■■■■■■

3.6 Connecting the instrument

3.6.1 Connecting the instrument to a computer

NOTE

The instrument must be switched off when being connected to a computer.

Accessories For this step you need the following accessories:

■ USB connecting cable (6.2151.020)

Insert the USB cable into the computer connection socket on the rear

1

of the instrument labeled PC.

Insert the other end into a USB port on the computer.

2

3 Installation

3.6.2 Connecting the instrument to the power supply

WARNING

The power supply unit must not get wet. Protect it from liquids.

The power supply cable is three-core and provided with a plug with

grounding. If another plug has to be mounted, the yellow/green conductor (IEC standard) must be connected to the protective ground (protection

class I).

Accessories

For this step you need the following accessories:

■ For Switzerland, …: Power supply cable with IEC 60320 line socket,

type C13, with SEV 1011 plug, type 12 (6.2122.020), 1.5 m

■ For Germany, …: Power supply cable with IEC 60320 line socket, type

C13, with CEE 7 plug, type VII (6.2122.040), 1.5 m

■ For the USA, …: Power supply cable with IEC 60320 line socket, type

C13, with NEMA 5-15 plug, type 498 (6.2122.070), 1.5 m

Connecting the power supply cable

1

Plugging in the power supply cable

■ Plug the power supply cable into the instrument's power socket.

■ Connect the power supply cable to the power supply.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

19

Page 28

3.6 Connecting the instrument

■■■■■■■■■■■■■■■■■■■■■■

2

Switching on the instrument

Switch on the instrument using the power switch.

After being switched on, the LED on the front of the instrument

flashes. The instrument conducts a system test and establishes a connection to the software. Once the system test is complete and the

connection to the software has been established, the LED lights up

continuously.

■■■■■■■■

20

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 29

■■■■■■■■■■■■■■■■■■■■■■

4 Start-up

4 Start-up

The 944 Professional UV/VIS Detector Vario is put into operation together

with the IC instrument.

The following preconditions must be met before initial start-up:

■ The 944 Professional UV/VIS Detector Vario is installed as outlined in

this manual and connected to the ion chromatograph.

You can find additional information on carrying out initial start-up in the

Start-up chapter in the manual for the IC instrument and the MagIC Net

online help.

We recommend checking the intensity spectrum of the lamps in addition

to performing the initial start-up with the IC system.

Checking the intensity spectrum

Before you can check the intensity of the lamps, the following preconditions must be met:

■ The lenses and the flow path of the flow-through cell must be clean.

1

Rinsing the flow-through cell with ultrapure water

Rinse the flow-through cell with ultrapure water at a flow rate of

0.5 mL/min.

Ensure that no air bubbles remain in the flow-through cell.

2

Checking the intensity of the lamps

In MagIC Net, adjust the following settings:

■ Go to the Manual program part.

■ Click on the icon for the 944 UV/VIS Detector.

■ On the UV lamp tab, switch on the UV Lamp.

■ On the VIS lamp tab, switch on the VIS lamp.

■ On the Detector tab, select the Intensity spectrum.

First click on [Reset baseline] and then click on [View].

The lamp's intensity range is monitored and the spectrum is

recorded.

If the intensity spectrum looks similar to the spectrum in Figure 7, then the

lamp is correctly adjusted.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

21

Page 30

■■■■■■■■■■■■■■■■■■■■■■

Figure 7 Intensity spectrum OK

If the intensity spectrum is cut off like the one in Figure 8, then the lamp

settings must be adjusted (see Chapter 6.6, page 28).

Figure 8

Lamp intensity too high

■■■■■■■■

22

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 31

■■■■■■■■■■■■■■■■■■■■■■

5 Operation

5 Operation

The instrument is operated via MagIC Net software only. Additional information on operating MagIC Net can be found in the document

"MagIC Net Tutorial" or in the software's online help.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

23

Page 32

6.1 Care

6 Operation and maintenance

6.1 Care

The instrument requires appropriate care. Excess contamination of the

instrument may result in malfunctions and a reduction in the lifetime of

the sturdy mechanical and electronic components.

The instrument must be cleaned immediately if chemicals or solvents are

spilled on it. In particular, the plug connections (particularly the power

plug) have to be protected from contamination.

CAUTION

The instrument has been designed so that liquid is largely prevented

from being able to get inside the instrument. However, unplug the

power plug immediately if you suspect that corrosive media have gotten inside the instrument. This is the only way to prevent extreme damage to the instrument electronics. Notify Metrohm Service.

■■■■■■■■■■■■■■■■■■■■■■

WARNING

Untrained personnel may not open the instrument's housing.

6.2 Maintenance by Metrohm Service

Maintenance of the instrument is best carried out as part of annual service, which is performed by specialist personnel from Metrohm. A shorter

maintenance interval is recommended if you frequently work with caustic

and corrosive chemicals. Metrohm Service offers every form of technical

advice for maintenance and service of all Metrohm instruments.

■■■■■■■■

24

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 33

■■■■■■■■■■■■■■■■■■■■■■

0

2000

HOURS

1

2

3

4

5

6.3 Door

CAUTION

The door is made of PMMA (poly(methyl methacrylate)). It must never

be cleaned with abrasive media or solvents.

CAUTION

Never hold the instrument by the door when lifting or moving it.

6.4 Replacing the UV lamp

After a a prolonged burning time, the radiation of the UV lamp starts to

decrease, which can be noticed by an increased noise on the baseline.

Check the effective burning time on the operating hours counter fixed to

the cable of the lamp. This counter measures the effective hours of operation and displays them on a scale.

6 Operation and maintenance

Figure 9

Operating hours counter

The UV lamp must be replaced if the noise on the baseline becomes too

strong or when the lamp does not ignite.

Figure 10

Lamp cooling element

1

Lamp module

VIS lamp holder

2

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

25

Page 34

6.4 Replacing the UV lamp

1

2

3

■■■■■■■■■■■■■■■■■■■■■■

VIS lamp

3

Halogen lamp (6.2804.050).

Fastening ring

5

For UV lamp.

UV lamp

4

Deuterium lamp (6.2804.060) with operating hours counter.

Removing the old UV lamp

WARNING

After longer operation, the UV lamp becomes hot!

Risk of burns!

Switch off the instrument and allow the lamp to cool before you start

working.

1

Disconnecting the UV lamp

Loosen the retaining ring of the UV lamp plug and pull the plug out

of the UV connection socket.

2

Loosening the fastening ring

Loosen and remove the fastening ring of the UV lamp.

3

Removing the UV lamp

Carefully remove the old UV lamp from the housing.

■■■■■■■■

26

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 35

■■■■■■■■■■■■■■■■■■■■■■

1

2

3

4

3

2

1

6 Operation and maintenance

Figure 11 Lamp module – without UV lamp

Lamp cooling element

1

VIS lamp

3

VIS lamp holder

2

Opening

4

For UV lamp.

Inserting the new UV lamp

CAUTION

Do not touch the glass of the UV lamp!

Residues on the glass diminish light transmission. In addition, they can

burn into the glass and permanently damage the lamp.

If the glass is dirty, clean it with alcohol before inserting the lamp again.

1

Inserting the UV lamp

Insert the new UV lamp (6.2804.060) into the opening for the UV

lamp on the lamp cooling element.

When doing so, make sure that the groove on the lamp socket and

the screw in the lamp cooling element are aligned with each other.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

27

Page 36

6.5 Replacing the VIS lamp

2

Fastening the UV lamp

Slide the fastening ring over the cable of the UV lamp and screw it to

the lamp cooling element.

3

Connecting the UV lamp

Plug the plug of the UV Lamp into the connection socket UV of the

instrument and secure it with the fastening ring.

6.5 Replacing the VIS lamp

NOTE

A description on how to replace the VIS lamp (6.2804.050) is described

in the leaflet supplied with the VIS lamp.

■■■■■■■■■■■■■■■■■■■■■■

6.6 Adjusting the lamp settings

The lamp settings are set correctly at delivery.

CAUTION

The lamp settings may be adjusted only in the following cases:

■ After initial start-up, if the the check of the intensity spectrum shows

a cut-off (see Figure 8, page 22).

■ After having replaced the UV lamp (see Chapter 6.4, page 25) or the

VIS lamp (see Chapter 6.5, page 28), if the check of the intensity

spectrum shows a cut-off (see Figure 8, page 22).

Before each adjustment of the lamp values, it is mandatory to check the

intensity spectrum. The lamp settings may only be adjusted if the intensity

spectrum is cut off at the top.

Adjusting the lamp settings

Before you can adjust the lamp settings, all the following preconditions

must be unconditionally met:

■■■■■■■■

28

■ The UV lamp has been burning for at least 30 minutes.

■ The flow-through cell is clean.

■ The flow-through cell is rinsed with ultrapure water.

■ The flow-through cell is free of air bubbles.

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 37

■■■■■■■■■■■■■■■■■■■■■■

6 Operation and maintenance

■ The intensity spectrum has been checked and shows a cut-off (see Fig-

ure 8, page 22).

1

Starting the automatic lamp setting

■ In MagIC Net, select the 944 UV/VIS Detector from the device

table in the Configuration program part.

■ Click on Edit ▶ Properties... to open the properties window.

■ On the Detector tab, click on [Settings] to open the detector

settings.

■ In the detector settings, click on [Adjust automatically] to start

the automatic lamp adjustment.

The lamp settings are made based on a built-in algorithm. This algorithm calculates and sets the optimized values for Integration dura-

tion and VIS intensity level. After the automatic adjustment, a

new intensity spectrum is displayed.

2

Saving the lamp settings

■ Check the new intensity spectrum that is displayed and click on

[OK] to complete the lamp optimization.

The adjusted lamp values are transferred to the instrument. The dialog window is closed.

6.7 Cleaning the flow-through cell

Depending on the application, hardly visible deposits may form on the lenses, which leads to higher absorption and thus increasing noise on the

baseline.

If the baseline is very noisy and the problem is not caused by other parts

of the system, the flow-through cell must be cleaned.

For the cleaning of the flow-through cell, we recommend a three-step

process:

1. Rinse the flow-through cell with methanol.

2. Rinse the flow-through cell with a different solvent.

3. Dismantle the flow-through cell and clean it manually.

Always start the cleaning process with step 1. If this does not solve the

problem, perform step 2. Perform step 3 only if the deposits are persistent.

Rinsing the flow-through cell with methanol

Disconnect the input capillary from the IC system.

1

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

29

Page 38

6.7 Cleaning the flow-through cell

■■■■■■■■■■■■■■■■■■■■■■

Connect the input capillary to a high-pressure pump or a peristaltic

2

pump and rinse the flow-through cell as described below; make sure

that the permissible maximum pressure of 5 MPa is not exceeded:

■ first rinse with ultrapure water to avoid precipitates,

■ then rinse several minutes with methanol, to dissolve the deposits,

and

■ finally, rinse with ultrapure water for at least another 15 minutes

to wash away the dissolved deposits.

Observe the baseline during the last rinsing with ultrapure water.

3

If the baseline is only slightly noisy, then the flow-through cell is

clean.

If the noise on the baseline persists, rinse the flow-through cell once

again with another solvent (see "Rinsing the flow-through cell with

another solvent", page 30).

Rinsing the flow-through cell with another solvent

A solvent made up of a 1:2 mixture of acetic acid and isopropanol has

shown good results. Depending on the application, other solvents may

also prove efficient.

Prerequisites:

■ Rinsing with methanol was ineffective.

■ The input capillary is connected to a high-pressure pump or a peristaltic

pump.

Rinse the flow-through cell as described below; make sure that the

1

maximum permissible pressure of 5 MPa is not exceeded:

■ first rinse with ultrapure water to avoid precipitates,

■ then rinse several minutes with the selected solvent to dissolve

the deposits, and

■ finally, rinse with ultrapure water for at least another 15 minutes

to wash away the dissolved deposits.

Observe the baseline during the last rinsing.

2

■■■■■■■■

30

If the baseline is only slightly noisy, then the flow-through cell is

clean.

If the noise on the baseline persists, the flow-through cell must be

dismantled and cleaned manually (see "Dismantling and cleaning the

flow-through cell", page 31).

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 39

■■■■■■■■■■■■■■■■■■■■■■

5

4

3

1

4

3

1

2

6

6 Operation and maintenance

Dismantling and cleaning the flow-through cell

NOTE

Ex works, the retaining screws are tightened with a torque wrench. This

guarantees a pressure stability up to 5 MPa (50 bar).

Once the flow-through cell has been opened and closed again, this

maximum pressure stability can no longer be guaranteed.

Prerequisites:

■ Rinsing the flow-through cell with solvent was ineffective.

Required tools:

■ To open the measuring cell, you need a slotted screwdriver, size 5.

■ Seals (6.2764.000).

1

Removing the flow-through cell

■ Unscrew the input capillary and the output capillary.

■ Loosen and remove the knurled screws.

■ Remove the flow-through cell from the optical block.

Figure 12 Flow-through cell – parts

Retaining screw

1

Lens

3

Measuring cell – opening

5

944 Professional UV/VIS Detector Vario (2.944.0010)

2

4

6

Outer seal

Inner seal

Cell holder

■■■■■■■■

31

Page 40

6.7 Cleaning the flow-through cell

■■■■■■■■■■■■■■■■■■■■■■

2

Removing the lens

■ Loosen the retaining screw (12-1) with a slotted screwdriver, size

5, and remove it.

Remove the seal from the inside of the retaining screw (12-2).

■ Carefully remove the lens (12-3) and the inner seal (12-4) from

the measuring cell.

■ Put the lens onto a white paper, this allows you to see possible

deposits.

3

Cleaning the lens

■ Clean the lens with ultrapure water, methanol or another suitable

solvent (depending on the application) and wipe with a lint-free

cloth.

■ Rinse again with ultrapure water and dry with a lint-free cloth.

4

Reinserting the lens

■ Insert a new inner seal (12-4) into the measuring cell; make sure

that it lies flat and centered in the recess of the measuring cell.

■ Reinsert the lens (12-3) with its flat side facing inwards; make

sure that it lies flat and centered in the recess of the measuring

cell.

■ Insert a new outer seal into the retaining screw (12-2).

■ Reinsert the retaining screw (12-1) and tighten it with a slotted

screwdriver, size 5.

5

Cleaning the second lens

Repeat steps 2 to 4 on the opposite side of the cell holder.

6

Reinserting the flow-through cell

Follow steps 3 and 4 of "Installing the flow-through cell", page 16.

■■■■■■■■

32

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 41

■■■■■■■■■■■■■■■■■■■■■■

6 Operation and maintenance

6.8 Quality Management and qualification with Metrohm

Quality management

Metrohm offers you comprehensive support in implementing quality management measures for instruments and software. Further information on

this can be found in the brochure "Metrohm Quality Management"

available from your local Metrohm representative.

Qualification

Please contact your local Metrohm representative for support in qualification of instruments and software. The Installation Qualification (IQ)

and Operational Qualification (OQ) are offered by Metrohm representatives as a service. They are carried out by trained employees using standardized qualification documents and in accordance with the currently

applicable requirements of the regulated industry. Further information on

this can be found in the brochure "Analytical Instrument Qualifica-

tion – Confidence in quality with IQ/OQ".

Maintenance

The electronic and mechanical functional groups of Metrohm instruments

can and should be checked by specialist personnel from Metrohm as part

of a regular preventive maintenance schedule. Please ask your local

Metrohm representative regarding the precise terms and conditions

involved in concluding a corresponding maintenance agreement. Further

information on this can be found in the brochure "Metrohm Care Con-

tracts – Protect your investment the smart way" available from your

local Metrohm representative.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

33

Page 42

7.1 Problems and their solutions

7 Troubleshooting

7.1 Problems and their solutions

Problem Cause Remedy

■■■■■■■■■■■■■■■■■■■■■■

No measuring signal.

The baseline has a

large amount of

noise.

The lamp is not lit. Replace the UV lamp (see Chapter 6.4, page

25) or the VIS lamp (see Chapter 6.5, page

28).

Air bubbles are trapped in

the flow-through cell.

Flow-through cell – The

lenses are dirty.

UV lamp – The radiation is

too weak.

The eluent's absorption is

too strong.

The wavelength is unsuitable.

■ Clean the flow-through cell (see Chapter

6.7, page 29).

■ Ensure that the PEEK capillary (6.1831.100)

is connected to the cell outlet.

■ Use the eluent degasser.

Clean the flow-through cell (see Chapter 6.7,

page 29).

Check the intensity spectrum (see Chapter 4,

page 21). If the intensity is too low, replace

the UV lamp (see Chapter 6.4, page 25).

Change the eluent.

Set a different wavelength in MagIC Net.

The baseline is drifting.

Lamp does not

ignite.

■■■■■■■■

34

The flow-through cell is

leaky.

Thermal equilibrium is not

attained.

The lamp is defective. Replace the UV lamp (see Chapter 6.4, page

Check all connections and fix the leak.

Ensure a constant temperature.

25) or the VIS lamp (see Chapter 6.5, page

28).

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 43

■■■■■■■■■■■■■■■■■■■■■■

8 Technical specifications

8.1 Reference conditions

The technical specifications listed in this chapter refer to the following reference conditions:

8 Technical specifications

Ambient temperature

Instrument status > 30 min in operation with both lamps switched on.

+25 °C (± 3 °C)

8.2 UV/VIS detector

Detector type

Diode array

detector

Measuring range

Absorption –2.0 - +2.0 AU

Number of

channels

Resolution 2.5 x 10–7 AU

Noise 2.5 x 10–5 AU (at a 1/s data rate)

Drift

at reference

conditions

512 diodes

8 measuring channels, 4 of them readable in analog mode

5 x 10–4 AU/h

Wavelength range

Wavelength

range

λ

Bandwidth ±1 - 50 nm

Accuracy, absolute

Stability ±1 nm (across temperature range)

Optical resolution

Measuring interval

Data rate for

each channel

944 Professional UV/VIS Detector Vario (2.944.0010)

190 - 900 nm

±3 nm

5 nm (at 254 nm)

0.5 - 50 samples/sec

■■■■■■■■

35

Page 44

8.2 UV/VIS detector

1

2

3

4

5

67

89

0V

0V

0V

0V

0V

■■■■■■■■■■■■■■■■■■■■■■

Integration

10 - 247 ms

duration

Duration of

50 - 2,000 ms

measurement

Analog output

Voltage range –1.0 - +1.0 V

Resolution 30 µV

Noise < 30 µV

Output impe-

50 Ω (sustained short circuit-proof)

dance

Offset error ±1.5 mV

Plug 9-pin DSUB plug (female)

Control input

Input voltage

0 - 5 V (5 V logic or switching contact control possible)

range

Impedance 22 kΩ (permanent resistance up to 50 V. Secured against ESD.)

Function Start, zero, 2x reserve

Caution: If "reserve 2" input is active when the instrument is switched

on, the instrument enters long-term test mode, which switches

through all elements following a time schedule and cannot be terminated, not even by power failure. Can only be terminated by service software or RS-232 commands.

36

■■■■■■■■

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 45

■■■■■■■■■■■■■■■■■■■■■■

8.3 Lamps

UV lamp

Type D2 (Deuterium)

Power consumption

Lifetime approx. 1,000 h

VIS lamp

Type Halogen

Power consumption

Lifetime approx. 10,000 h

approx. 20 - 30 W

approx. 5 W

8.4 Ambient conditions

8 Technical specifications

Operation

Ambient temperature

Humidity 20 - 80% relative humidity

Storage

Ambient temperature

Transport

Ambient temperature

+5 - +45 °C

–20 - +70 °C

–40 - +70 °C

8.5 Housing

Dimensions

Width 370 mm

Height 131 mm

Depth 495 mm

Material of base

tray, housing and

bottle holder

944 Professional UV/VIS Detector Vario (2.944.0010)

Polyurethane hard foam (PUR) with flame retardation for fire class

UL94V0, CFC-free, coated

■■■■■■■■

37

Page 46

8.6 Power connection

Operating elements

Indicators LED standby indicator

On/off switch On the rear of the instrument

8.6 Power connection

■■■■■■■■■■■■■■■■■■■■■■

Required supply

100 - 240 V ± 10%

voltage

Required fre-

50 - 60 Hz

quency

Power consump-

100 VA

tion

8.7 Interfaces

USB

Input 1 plug type B (for connection to PC)

Output 2 plugs type A

Further connections

Control 1 15-pin D-sub plug (female)

Analog Output 1 15-pin D-sub plug (female)

Service 1 15-pin D-sub plug (male)

8.8 Safety specifications

This instrument fulfills the following electrical safety requirements:

CE marking in accordance with the EU directives:

■ 2006/95/EC (Low Voltage Directive, LVD)

■ 2004/108/EC (EMC Directive, EMC)

Federal Inspectorate for Heavy Current Installations ESTI (Accreditation

Number SCESp 033)

■ Safety mark for certification type 2 in accordance with NEV (type

testing with market monitoring, EMC conformity)

Design and testing According to EN/IEC/UL 61010-1, CSA-C22.2 No. 61010-1, protection

class I, EN/IEC 60529, degree of protection IP40.

Safety instructions This document contains safety instructions which have to be followed

by the user in order to ensure safe operation of the instrument.

■■■■■■■■

38

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 47

■■■■■■■■■■■■■■■■■■■■■■

8.9 Electromagnetic compatibility (EMC)

Requirements ■ EN/IEC 61326-1

Emission ■ EN/IEC 61000-6-3

■ EN 55011 / CISPR 11

■ EN/IEC 61000-3-2

■ EN/IEC 61000-3-3

Immunity ■ EN/IEC 61000-6-2

■ EN/IEC 61000-4-2

■ EN/IEC 61000-4-3

■ EN/IEC 61000-4-4

■ EN/IEC 61000-4-5

■ EN/IEC 61000-4-6

■ EN/IEC 61000-4-8

■ EN/IEC 61000-4-11

■ EN/IEC 61000-4-14

■ EN/IEC 61000-4-28

8 Technical specifications

8.10 Weight

1.944.0010

10.7 kg (without accessories)

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

39

Page 48

9 Warranty (guarantee)

Metrohm guarantees that the deliveries and services it provides are free of

defects in materials, design or manufacturing.

The general warranty period is 36 months (exclusions below) from the

date of delivery, or 18 months in the event of continuous operation. The

warranty remains valid on the condition that the servicing is provided by a

service organization authorized by Metrohm at defined intervals and with

a defined scope.

The warranty period for anion suppressors of the type "MSM" is 120

months from the date of delivery or 60 months in the case of continuous

operation.

The warranty period for IC separation columns is 90 days after start-up.

For third-party components that are recognizable as such, the manufacturer's warranty regulations apply.

■■■■■■■■■■■■■■■■■■■■■■

For instruments sold under the Metrohm NIRSystems brand, a full 16month warranty is applicable. In the event of continuous operation, the

warranty period is reduced by half.

Consumables and materials with limited storage life and glass breakage in

the case of electrodes or other glass parts are excluded from the warranty.

Warranty claims cannot be asserted if the ordering party has failed to

meet its payment obligations according to schedule.

During the warranty period, Metrohm undertakes either to replace free of

charge or to credit the purchaser for any modules or components that can

be shown to be faulty. Any transport or customs fees that may apply are

the responsibility of the ordering party.

The precondition for this is that the ordering party has to specify the article number, the article designation, an adequate error description, the

delivery date and (if applicable) the serial number or chip data in the Support Tracker. Metrohm then decides whether a replacement or a credit

note is to be issued or whether the faulty part has to be returned using

the Return Material Authorization (RMA). If a replacement or credit note is

issued, the ordering party undertakes to store the faulty part for at least

24 months in accordance with the current storage directives (in compliance with ESD guidelines) and to hold it in readiness for onsite inspection

or for return shipment to Metrohm. Metrohm reserves the right to invoice

the ordering party for these articles, including retroactively, in the event of

noncompliance with these preconditions.

■■■■■■■■

40

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 49

■■■■■■■■■■■■■■■■■■■■■■

9 Warranty (guarantee)

The same warranty periods that are specified for a corresponding new

part apply to parts that are replaced or repaired within the above-mentioned warranty periods. However, replacement or repair of a part does

not extend the warranty period of the entire system.

Deficiencies arising from circumstances that are not the responsibility of

Metrohm, such as improper storage or improper use, etc., are expressly

excluded from the warranty.

Metrohm also offers a 120-month spare parts availability guarantee and a

60-month PC software support warranty, calculated from the date on

which the product is withdrawn from the market. The content of this warranty is the ability of the customer to obtain functioning spare parts or

appropriate software support at market prices during the time of the warranty period. This does not apply for software products sold under the

Metrohm NIRSystems brand.

If Metrohm AG is unable to meet this obligation due to circumstances

beyond the control of Metrohm AG, then the ordering party shall be

offered alternative solutions at preferential conditions.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

41

Page 50

10 Accessories

Up-to-date information on the scope of delivery and optional accessories

for your instrument can be found on the Internet.

When you receive your new instrument, we recommend downloading

the accessories list from the Internet, printing it out and keeping it

together with the manual for reference purposes.

Instruments currently sold

If you do not know the article number of your instrument, proceed as follows:

Downloading the accessories list

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Go to the Metrohm website http://www.metrohm.com/com.

1

2

Click on .

The Search webpage will be displayed.

Enter a search term relating to the instrument into the search field

3

and click on Find.

The search results will be displayed.

In the search results, select the Devices tab (if it is not already

4

selected) and then click on the Metrohm article number of the

required instrument (e.g. 2.852.0050).

The page with information pertaining to the searched article is displayed.

Select the Parts tab.

5

The complete list of accessories with the scope of delivery and the

optional accessories will be displayed.

6

Click on .

■■■■■■■■

42

944 Professional UV/VIS Detector Vario (2.944.0010)

Page 51

■■■■■■■■■■■■■■■■■■■■■■

10 Accessories

The Partslists webpage will be displayed.

Select the desired output language.

7

With the article number entered, click on the command Generate

8

PDF.

The PDF file with the accessories data will be created in the language

selected.

Direct access for all instruments

If you are unable to find your instrument using the search as described

above, this may be due to the instrument not being sold anymore. Using

the article number, you can download accessories lists for all instruments

as follows:

Downloading the accessories list

Type http://partslists.metrohm.com into your Internet browser.

1

The Partslists webpage will be displayed.

Select the desired output language.

2

Enter the article number and click on the Generate PDF command.

3

The PDF file with the accessories data will be created in the language

selected.

944 Professional UV/VIS Detector Vario (2.944.0010)

■■■■■■■■

43

Page 52

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

A

Ambient conditions .................. 37

B

Base tray

Mount ................................ 11

Remove .............................. 10

Bottle holder

Mount ................................ 14

Remove .............................. 12

C

Care ......................................... 24

Clean

Flow-through cell ............... 29

Computer connection ............... 19

Connect

To computer ...................... 19

To power supply ................. 19

Connection

Power ................................ 38

D

Dimensions .............................. 37

Door ........................................ 25

E

Electromagnetic compatibility ... 39

Electrostatic charge .................... 4

EMC ......................................... 39

Emission ................................... 39

F

Flow-through cell ..................... 15

Clean .................................. 29

Connecting ........................ 17

Install ................................. 16

Frequency ................................ 38

G

GLP .......................................... 33

Guarantee ................................ 40

H

Housing ................................... 37

Humidity .................................. 37

I

Immunity .................................. 39

Instrument

Connect ............................. 19

Interface

USB .................................... 38

Interfaces

Further connections ............ 38

L

Lamp

Adjust settings .................... 28

Lamp settings

Adjust ................................ 28

M

Mains voltage ............................. 3

Maintenance Agreement .......... 33

Material .................................... 37

P

Power connection .............. 19, 38

Power consumption ................. 38

Power supply cable ................... 19

Q

Quality Management ................ 33

R

Reference conditions ................ 35

S

Safety instructions ...................... 3

Seal .......................................... 32

Service ................................. 3, 24

Standards ................................. 39

Storage .................................... 37

Supply voltage .......................... 38

Switch on ................................. 20

T

Technical specifications

Reference conditions .......... 35

Temperature ............................. 37

Transport ................................. 37

U

USB .......................................... 38

UV lamp

Replace .............................. 25

V

Validation ................................. 33

VIS lamp

Replacing ........................... 28

W

Warranty .................................. 40

■■■■■■■■

44

944 Professional UV/VIS Detector Vario (2.944.0010)

Loading...

Loading...