Page 1

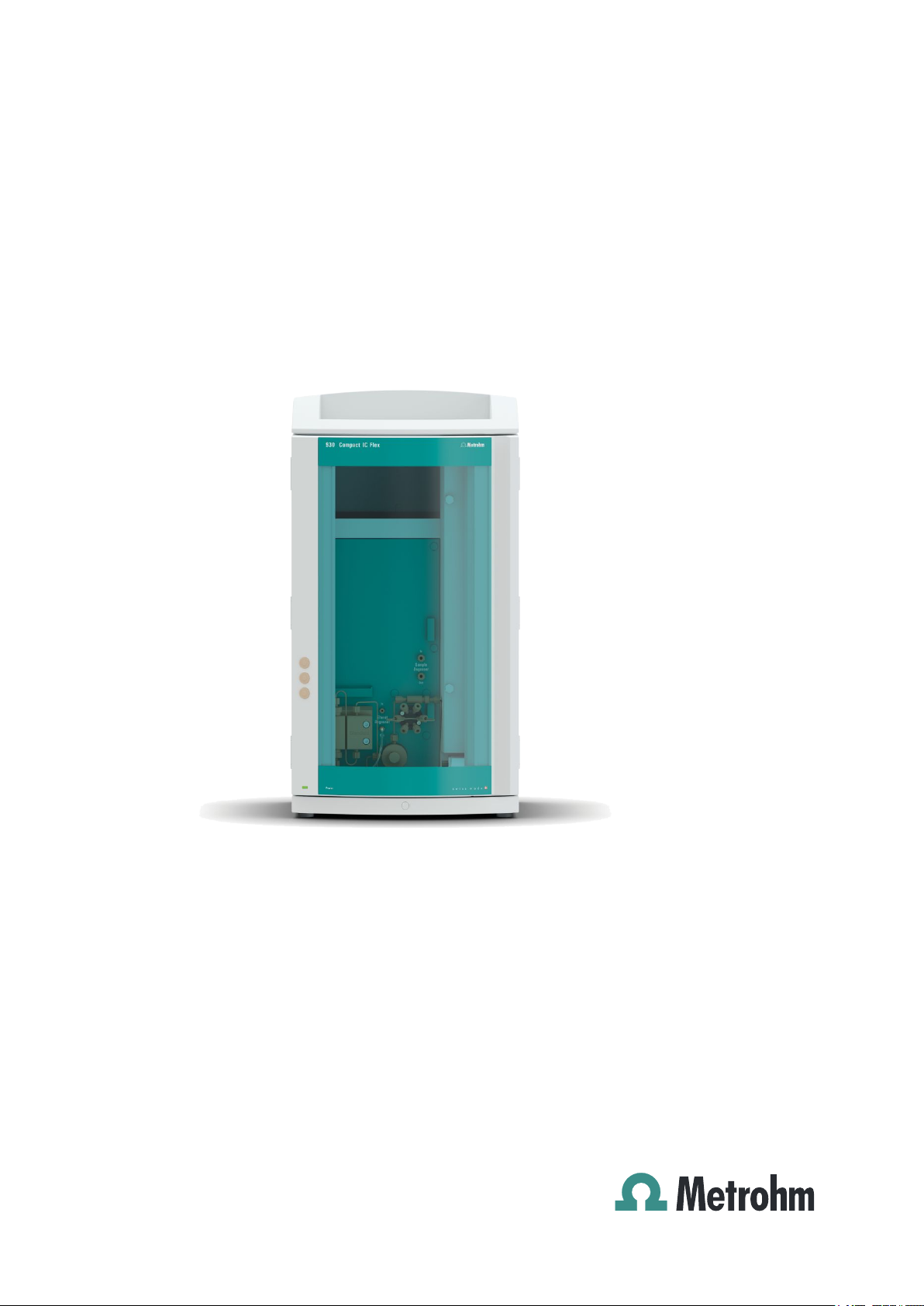

930 Compact IC Flex

930 Compact IC Flex Oven/Deg

Manual – Short Instructions

8.930.8112EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

930 Compact IC Flex

930 Compact IC Flex Oven/Deg

2.930.2160

8.930.8112EN

Manual – Short Instructions

11.2013 zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 About these Short Instructions 1

2 Introduction 2

2.1 Instrument description ......................................................... 2

2.2 Intended use ......................................................................... 4

2.3 Safety instructions ................................................................ 4

2.3.1 General notes on safety ........................................................... 4

2.3.2 Electrical safety ........................................................................ 4

2.3.3 Tubing and capillary connections ............................................. 5

2.3.4 Flammable solvents and chemicals ........................................... 5

2.3.5 Recycling and disposal ............................................................. 6

2.4 Symbols and conventions .................................................... 6

3 Overview of the instrument 8

Table of contents

3.1 Front ...................................................................................... 8

3.2 Rear ........................................................................................ 9

4 Installation 11

4.1 Setting up the instrument .................................................. 11

4.1.1 Packaging .............................................................................. 11

4.1.2 Checks .................................................................................. 11

4.1.3 Location ................................................................................ 11

4.2 Removing transport locking screws ................................. 11

4.3 Connecting the drainage tubing and leak sensor ............ 13

4.3.1 Installing the drainage tubing ................................................ 13

4.3.2 Connecting the leak sensor .................................................... 14

4.4 Column oven ....................................................................... 15

4.5 Connecting the eluent bottle ............................................. 15

4.6 Connecting the eluent degasser ........................................ 17

4.7 Installing the high-pressure pump .................................... 17

4.8 Installing an inline filter ..................................................... 17

4.9 Installing the pulsation absorber ...................................... 17

4.10 Injection valve ..................................................................... 17

4.11 Installing the detector ........................................................ 17

4.12 Connecting the sample degasser (optional) ..................... 18

4.13 Connecting the instrument to a computer ....................... 19

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.14 Connecting the instrument to the power supply ............. 20

4.15 Initial start-up ..................................................................... 21

4.16 Connecting and rinsing the guard column ....................... 23

4.17 Connecting the separation column ................................... 25

4.18 Conditioning ........................................................................ 27

5 Operation 29

6 Warranty (guarantee) 30

7 Accessories 32

Index 34

■■■■■■■■

IV

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 7

■■■■■■■■■■■■■■■■■■■■■■

Table of figures

Figure 1 Front ................................................................................................. 8

Figure 2 Rear .................................................................................................. 9

Figure 3 Removing the transport locking screws ............................................ 12

Table of figures

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

V

Page 8

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 About these Short Instructions

This short instruction manual contains important chapters from the comprehensive manual. In addition to an introduction, safety instructions and

an overview of the instrument, you will also find information about installing and operating the 930 Compact IC Flex Oven/Deg as well as information regarding the warranty. You can download the detailed manual as a

PDF file from the Internet.

Downloading the manual

You can find the detailed manual on the Internet under http://docu-

ments.metrohm.com.

1. Click on Instruments ▶ Ion Chromatography.

2. Select the line of instruments, e.g. 930 Compact IC Flex.

3. Select the instrument.

All available manuals for the instrument will be displayed.

1 About these Short Instructions

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

1

Page 10

2.1 Instrument description

2 Introduction

2.1 Instrument description

The 930 Compact IC Flex is a professional ion chromatograph. It is distinguished by:

■ Its intelligence: All of the functions are monitored, optimized and

documented in an FDA-compatible manner. Intelligent components,

such as iColumns, save important data onto a chip.

■ Its compact design: It has a small footprint.

■ Its transparency: All components are easily accessible and located for

simple visibility and can be monitored during operation through a large

window.

■ Its safety: The wet end and electronics are physically separated, thereby

preventing fluids from coming into contact with the electronics to a

large extent. A leak sensor is integrated into the wet end.

■ Its environmental compatibility.

■ Its low noise emissions.

■ The intelligent MagIC Net™ software

■■■■■■■■■■■■■■■■■■■■■■

The 930 Compact IC Flex is operated solely using the MagIC Net software.

A USB cable is used to connect the instrument to a computer with

MagIC Net installed. The intelligent software detects the instrument automatically and checks its functionality. The software controls and monitors

the instrument, evaluates the measured data and manages it in a database.

The 930 Compact IC Flex Oven/Deg consists of the following modules:

Leak sensor

The leak sensor detects leaking liquid that collects in the instrument's base

tray. Liquid that leaks in the instrument is routed to the base tray using

drainage tubing and detected there.

Column oven

The column oven tempers the separation column and the eluent and

thereby provides stable measuring conditions. A column holder with a

chip reader is located in the column oven.

Eluent degasser

The eluent degasser removes gas bubbles and dissolved gases from the

eluent.

■■■■■■■■

2

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 11

■■■■■■■■■■■■■■■■■■■■■■

2 Introduction

High-pressure pump

The intelligent and low-pulsation high-pressure pump pumps the eluent

through the system. It is equipped with a chip where its technical specifications and "life history" (operating hours, service data, etc.) are saved.

Inline filter

Inline filters protect the separation column reliably from potential contamination from the eluent. The small filter pads with 2 µm pore size can be

replaced quickly and easily. They remove particles from the solutions, such

as bacteria and algae.

Pulsation absorber

The pulsation absorber protects the separation column from damage

caused by pressure fluctuations when switching the injection valve, and

reduces interfering pulsations during highly sensitive measurements.

Injection valve

The injection valve connects the eluent path to the sample path. By a

quick and precise switching of the valve a quantity of sample solution

defined by the size of the sample loop is injected and flushed to the separation column with the eluent.

Detector

Metrohm offers a series of different detectors for various analysis tasks. A

suitable detector type must be ordered as a separate accessory.

Sample degasser

The sample degasser removes gas bubbles and dissolved gases from the

sample.

Separation column

The intelligent separation column separates different components according to their interactions with the column. Metrohm separation columns

are equipped with a chip where their technical specifications and history

(start-up, operating hours, etc) are stored.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

3

Page 12

2.2 Intended use

2.2 Intended use

The 930 Compact IC Flex Oven/Deg is used for the determination of cations and anions without suppression using ion chromatography.

The present instrument is suitable for processing chemicals and flammable

samples. Usage of the 930 Compact IC Flex therefore requires the user to

have basic knowledge and experience in handling toxic and caustic substances. Knowledge with respect to the application of the fire prevention

measures prescribed for laboratories is also mandatory.

2.3 Safety instructions

2.3.1 General notes on safety

WARNING

■■■■■■■■■■■■■■■■■■■■■■

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

2.3.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

WARNING

WARNING

■■■■■■■■

4

There are no parts inside the housing which can be serviced or replaced

by the user.

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 13

■■■■■■■■■■■■■■■■■■■■■■

2 Introduction

Mains voltage

WARNING

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

Protection against electrostatic charges

WARNING

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

2.3.3 Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

2.3.4 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

5

Page 14

2.4 Symbols and conventions

2.3.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

2.4 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

■■■■■■■■■■■■■■■■■■■■■■

Instruction step

Carry out these steps in the sequence shown.

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

WARNING

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

■■■■■■■■

6

CAUTION

This symbol draws attention to possible damage to

instruments or instrument parts.

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2 Introduction

NOTE

This symbol highlights additional information and

tips.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

7

Page 16

3.1 Front

3 Overview of the instrument

3.1 Front

■■■■■■■■■■■■■■■■■■■■■■

1

3

5

7

■■■■■■■■

8

Figure 1 Front

Bottle holder

Offers space for the eluent bottle and additional accessories.

Column oven

Inline filter

Pulsation absorber

Column holder

2

For hanging the separation column (iColumn). With column recognition.

Sample degasser

4

Injection valve

6

Base tray

8

With leak sensor.

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 17

■■■■■■■■■■■■■■■■■■■■■■

3 Overview of the instrument

Purge valve

9

For deaerating the high-pressure pump.

With rotary knob in the center and pressure

sensor.

Eluent degasser

11

3.2 Rear

High-pressure pump

10

Pumps the eluent through the IC system.

Detector chamber

12

Offers space for an embedded detector and

additional accessories.

Figure 2

Bottle holder

1

930 Compact IC Flex Oven/Deg (2.930.2160)

Rear

Drainage tubing connection

2

For connecting the drainage tubing, which

guides escaped fluids away from the bottle

holder.

■■■■■■■■

9

Page 18

3.2 Rear

■■■■■■■■■■■■■■■■■■■■■■

Knurled screws

3

For fastening the removable back panel.

Drainage tubing connection

5

For connecting the drainage tubing, which

guides escaped fluids away from the detector chamber.

Exhaust opening

7

Labeled Exhaust. For extracting the air from

the vacuum chamber.

Service connection socket

9

For Metrohm service only.

Drainage tubing connections

11

For connecting two drainage tubings that

guide the escaped fluid to the leak sensor

and from there to the waste container.

Type plate

13

Leak sensor connection socket

15

Labeled Leak Sensor. For connecting the

leak sensor connection cable.

Back panel

4

Removable. Enables access to the detector

chamber.

Transport locking screws

6

For securing the vacuum pump when transporting the instrument.

Auxiliary connection socket

8

For connecting an 891 Professional Analog

Out (2.891.0010).

Transport locking screws

10

For securing the high-pressure pump when

transporting the instrument.

Base tray

12

With leak sensor.

Serial number

14

Detector connection socket

16

Labeled Detector. For connecting Metrohm

detectors.

MSB connection sockets

17

Labeled MSB 1 and MSB 2. For connecting

MSB devices.

PC connection socket

19

For connecting the instrument to the computer with the USB cable (6.2151.020).

Power socket

21

Power socket for connecting the power

cable and power switch for switching the

instrument on and off.

USB connection sockets

18

Labeled USB 1 and USB 2. For connecting

USB devices.

Vacuum connection

20

Plugged with a stopper.

■■■■■■■■

10

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 19

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

4.1 Setting up the instrument

4.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

4.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

4.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

4 Installation

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

4.2 Removing transport locking screws

To avoid damage to the drives for the high-pressure pump and the vacuum pump during transport, the pumps are secured with transport locking screws. These are located at the rear of the instrument and labeled

with Transport security screws.

Remove these transport locking screws before the initial start-up.

Accessories

For this step you need:

■ Hex key 4 mm (6.2621.030)

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

11

Page 20

4.2 Removing transport locking screws

Remove the transport locking screws

■■■■■■■■■■■■■■■■■■■■■■

Figure 3 Removing the transport locking screws

Transport locking screws

1

For the vacuum pump. Only present if the

instrument has a degasser.

Store the transport locking screws in a safe place. Reinsert the transport

locking screws each time you transport the instrument a significant distance.

The pumps may be damaged if you transport the instrument without

inserting the transport locking screws.

CAUTION

Transport locking screws

2

For the high-pressure pump.

■■■■■■■■

12

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 21

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

4.3 Connecting the drainage tubing and leak sensor

The leak sensor detects leaking liquid that collects in the instrument's base

tray. Liquid that leaks in the bottle holder or in the detector chamber is

routed to the base tray using drainage tubing and is detected there.

If the leak sensor detects a leak in the IC system, the IC instrument is

switched off and a warning is output in the software.

The leak sensor functions properly only if the following preconditions are

met:

■ The drainage tubing is connected.

■ The leak sensor connection cable is inserted into the leak sensor con-

nection socket.

■ The 930 Compact IC Flex is switched on.

■ The leak sensor is switched to active in the software.

4.3.1 Installing the drainage tubing

Liquid that leaks in the bottle holder or detector chamber flows to the rear

of the instrument and is drained through openings on the bottle holder

and in the detector chamber. The drainage tubing has to be mounted at

these openings. This drainage tubing guides the leaking liquid to the base

tray where the leak sensor is located.

Accessories

For this step you need the following parts from the accessory kit: Vario/

Flex Basic (6.5000.000):

■ 2 × silicone tubing (6.1816.020)

■ Y connector (6.1807.010)

You also need scissors.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

13

Page 22

4.3 Connecting the drainage tubing and leak sensor

Connecting the drainage tubing

■■■■■■■■■■■■■■■■■■■■■■

4.3.2 Connecting the leak sensor

Plugging in the leak sensor connection cable

The leak sensor connection cable is coiled up in the base tray.

■■■■■■■■

14

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 23

■■■■■■■■■■■■■■■■■■■■■■

4.4 Column oven

The column oven is completely connected. No installation work is

required.

4.5 Connecting the eluent bottle

The eluent is aspirated out of the eluent bottle via the eluent aspiration

tubing . The eluent aspiration tubing is installed on the input for the eluent degasser.

4 Installation

Accessories

For this step you need the following accessories:

These parts are part of the accessory kit Vario/Flex ONE (6.5000.010).

■ Eluent bottle (6.1608.070)

■ The eluent bottle cap GL 45 accessory set (6.1602.160)

This accessory set contains the bottle cap, an M6 tubing nipple, an M8

tubing nipple, two O-rings and an M6 and M8 threaded stopper.

■ The tubing adapter for aspiration filter accessory set (6.2744.210)

This accessory set contains a filter holder, a clamping screw and tubing

weighting.

■ An aspiration filter (6.2821.090)

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

15

Page 24

4.5 Connecting the eluent bottle

■■■■■■■■■■■■■■■■■■■■■■

Connecting the eluent aspiration tubing

■■■■■■■■

16

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 25

■■■■■■■■■■■■■■■■■■■■■■

4.6 Connecting the eluent degasser

The eluent degasser is completely connected. No installation work is

required.

4.7 Installing the high-pressure pump

The high-pressure pump is completely connected. No installation work is

required.

4.8 Installing an inline filter

The inline filter is completely connected. No installation work is required.

4.9 Installing the pulsation absorber

4 Installation

The pulsation absorber is installed between the high-pressure pump and

the injection valve. It protects the separation column from damage caused

by pressure fluctuations such as those when switching the injection valve,

and reduces interfering pulsations during highly sensitive measurements.

The pulsation absorber is completely connected. No installation work is

required.

4.10 Injection valve

The injection valve is completely connected. No installation work is

required.

4.11 Installing the detector

The 930 Compact IC Flex provides enough space for two detectors and

additional accessories in the detector chamber. The detectors are available

as accessories and are supplied with separate manuals.

Placing the detector in the instrument

Follow the instructions in the chapter Inserting the detector in the manual

for the detector.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

17

Page 26

4.12 Connecting the sample degasser (optional)

Connecting the detector to the eluent path

NOTE

The separation column is not inserted into the instrument until it is

being started up for the first time. Until then, the detector input capillary has to be connected directly to the column input capillary using a

coupling (6.2744.040).

Accessories For this step you need the following accessories:

■ Coupling (6.2744.040)

■ 2 × pressure screw (6.2744.010)

■■■■■■■■■■■■■■■■■■■■■■

4.12 Connecting the sample degasser (optional)

Gas bubbles in the sample lead to poor reproducibility, as the quantity of

sample in the sample loop is not always the same. Therefore, we recommend degassing samples that contain gas before injection.

NOTE

The sample degasser does not have to be connected. We recommend

only using the sample degasser if the application requires it.

The rinsing time increases by at least 2 minutes when the sample

degasser is connected.

Accessories

For this step you need the following accessories:

■ 2 × pressure screw, long (6.2744.090)

■ PTFE capillary (6.1803.040)

■■■■■■■■

18

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 27

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

Connecting the sample degasser

CAUTION

If the sample degasser is not used, the input and output must be

sealed with threaded stoppers (6.2744.220).

4.13 Connecting the instrument to a computer

NOTE

The instrument must be switched off when being connected to a computer.

Accessories

For this step you need the following accessories:

■ USB connecting cable (6.2151.020)

■ USB connection cable (6.2151.020) from the accessory kit: Vario/Flex

Basic (6.5000.000)

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

19

Page 28

4.14 Connecting the instrument to the power supply

Connecting the USB cable

Insert the USB cable into the computer connection socket on the rear

1

of the instrument.

Insert the other end into a USB port on the computer.

2

■■■■■■■■■■■■■■■■■■■■■■

4.14 Connecting the instrument to the power supply

WARNING

The power supply unit must not get wet. Protect it from liquids.

The power supply cable is three-core and provided with a plug with

grounding. If another plug has to be mounted, the yellow/green conductor (IEC standard) must be connected to the protective ground (protection

class I).

Accessories

For this step you need the following accessories:

■ For Switzerland, …: Power supply cable with IEC 60320 line socket,

type C13, with SEV 1011 plug, type 12 (6.2122.020), 1.5 m

■ For Germany, …: Power supply cable with IEC 60320 line socket, type

C13, with CEE 7 plug, type VII (6.2122.040), 1.5 m

■ For the USA, …: Power supply cable with IEC 60320 line socket, type

C13, with NEMA 5-15 plug, type 498 (6.2122.070), 1.5 m

■■■■■■■■

20

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 29

■■■■■■■■■■■■■■■■■■■■■■

Connecting the power supply cable

1

Inserting the power supply cable

■ Insert the power supply cable into the instrument's power socket.

■ Connect the power supply cable to the power supply.

2

Switching on the instrument

Switch on the instrument using the power switch.

4 Installation

After being switched on, the LED on the front of the instrument

flashes. The instrument conducts a system test and establishes a connection to the software. Once the system test is complete and the

connection to the software has been established, the LED lights up

continuously.

4.15 Initial start-up

Even before the guard column and separation column are installed, the

entire system has to be completely rinsed with eluent for the first time.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

21

Page 30

4.15 Initial start-up

■■■■■■■■■■■■■■■■■■■■■■

Rinsing the IC system

CAUTION

The guard column and separation column must not be installed for the

initial start-up.

Make sure that a coupling (6.2744.040) is being used instead of the

columns.

1

Preparing the software

■ Start the MagIC Net computer program.

■ Open the Equilibration tab in MagIC Net: Work-

place ▶ Run ▶ Equilibration.

■ Select (or create) a suitable method.

Also see: MagIC Net tutorial and online help.

2

Preparing the instrument

■ Ensure that the eluent aspiration tubing is immersed in the eluent

and there is enough eluent in the eluent bottle.

■ Switch on the instrument.

MagIC Net detects the instrument and all of its modules.

3

Starting equilibration

■ Start the equilibration in MagIC Net: Workplace ▶ Run ▶ Equi-

libration ▶ Start HW.

■■■■■■■■

22

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 31

■■■■■■■■■■■■■■■■■■■■■■

4

Deaerating the high-pressure pump

4 Installation

Use the syringe to aspirate eluent until there are no more air

bubbles in the eluent.

5

Rinsing the instrument without columns

■ Rinse the instrument (without columns) with eluent for 5 minutes.

4.16 Connecting and rinsing the guard column

CAUTION

New guard columns are filled with solution and sealed with stoppers or

caps on both sides.

Before inserting the guard column, ensure that this solution can be

mixed with the eluent being used (follow information from the manufacturer).

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

23

Page 32

4.16 Connecting and rinsing the guard column

NOTE

The guard column may not be connected until after the instrument has

already been put into operation once (see Chapter 4.15, page 21). The

guard column and separation column have to be replaced by a coupling

(6.2744.040) until then.

Accessories For this step you need the following accessories:

■ Guard column (suitable for the separation column)

Connecting the guard column

■■■■■■■■■■■■■■■■■■■■■■

Rinsing the guard column

1

Rinsing the guard column

■ Place a beaker under the guard column's output.

■ Start manual control in MagIC Net and select the high-pressure

pump: Manual ▶ Manual control ▶ Pump

– Flow: in accordance with column leaflet

– On

■ Rinse the guard column with eluent for approx. 5 minutes.

■ Use manual control in MagIC Net to stop the high-pressure pump

again: Off.

■■■■■■■■

24

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 33

■■■■■■■■■■■■■■■■■■■■■■

4.17 Connecting the separation column

CAUTION

New separation columns are filled with solution and sealed with stoppers on both sides. Before inserting the column, ensure that this solution can be mixed with the eluent being used (follow information from

the manufacturer).

NOTE

The separation column may not be connected until after the instrument

has already been put into operation once (see Chapter 4.15, page 21).

The guard column and separation column have to be replaced by a

coupling (6.2744.040) until then.

4 Installation

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

25

Page 34

4.17 Connecting the separation column

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

26

Rinse the separation column as follows.

Connecting the separation column

1

Rinsing the separation column

■ Place a beaker under the separation column's outlet.

■ Start manual control in MagIC Net and select the high-pressure

pump: Manual ▶ Manual control ▶ Pump

– Flow: in accordance with column leaflet

– On

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 35

■■■■■■■■■■■■■■■■■■■■■■

■ Rinse the separation column with eluent for approximately 10

■ Use manual control in MagIC Net to stop the high-pressure pump

4.18 Conditioning

After installation, after each time the instrument is switched on and after

each time the eluent is changed, the system has to be conditioned with

eluent long enough that a stable baseline is attained.

The conditioning time can lengthen considerably after changing the

eluent.

Conditioning the system

4 Installation

minutes.

again: Off.

NOTE

1

Preparing the software

CAUTION

Ensure that the configured flow is not higher than the flow permitted for the corresponding column (refer to the column leaflet and

the chip data record).

■ Start the MagIC Net computer program.

■ Open the Equilibration tab in MagIC Net: Work-

place ▶ Run ▶ Equilibration.

■ Select (or create) a suitable method.

Also see: MagIC Net tutorial and online help.

2

Preparing the instrument

■ Ensure that the column is inserted correctly in relation to the flow

direction marked on the sticker (arrow has to point in the direction of flow).

■ Ensure that the eluent aspiration tubing is immersed in the eluent

and there is enough eluent in the eluent bottle.

3

Starting equilibration

■ Start the equilibration in MagIC Net: Workplace ▶ Run ▶ Equi-

libration ▶ Start HW.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

27

Page 36

4.18 Conditioning

■■■■■■■■■■■■■■■■■■■■■■

■ Visually inspect whether all capillaries and their connections from

the high-pressure pump to the detector are leak-tight. If eluent is

leaking out anywhere, tighten the corresponding pressure screw

further, or loosen the pressure screw, check the end of the capillary and shorten it using the capillary cutter if necessary and

retighten the pressure screw.

4

Conditioning the system

Rinse the system with eluent until the required stability of the baseline is attained (normally 30 minutes).

The instrument is now ready for measuring samples.

■■■■■■■■

28

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 37

■■■■■■■■■■■■■■■■■■■■■■

5 Operation

5 Operation

The 930 Compact IC Flex Oven/Deg is operated solely using the

MagIC Net software. You can find information on operating the software

in the tutorial for MagIC Net or in the online help.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

29

Page 38

6 Warranty (guarantee)

Metrohm guarantees that the deliveries and services it provides are free of

defects in materials, design or manufacturing.

The general warranty period is 36 months (exclusions below) from the

date of delivery, or 18 months in the event of continuous operation. The

warranty remains valid on the condition that the servicing is provided by a

service organization authorized by Metrohm at defined intervals and with

a defined scope.

The warranty period for anion suppressors of the type "MSM" is 120

months from the date of delivery or 60 months in the case of continuous

operation.

The warranty period for IC separation columns is 90 days after start-up.

For third-party components that are recognizable as such, the manufacturer's warranty regulations apply.

■■■■■■■■■■■■■■■■■■■■■■

For instruments sold under the Metrohm NIRSystems brand, a full 16month warranty is applicable. In the event of continuous operation, the

warranty period is reduced by half.

Consumables and materials with limited storage life and glass breakage in

the case of electrodes or other glass parts are excluded from the warranty.

Warranty claims cannot be asserted if the ordering party has failed to

meet its payment obligations according to schedule.

During the warranty period, Metrohm undertakes either to replace free of

charge or to credit the purchaser for any modules or components that can

be shown to be faulty. Any transport or customs fees that may apply are

the responsibility of the ordering party.

The precondition for this is that the ordering party has to specify the article number, the article designation, an adequate error description, the

delivery date and (if applicable) the serial number or chip data in the Support Tracker. Metrohm then decides whether a replacement or a credit

note is to be issued or whether the faulty part has to be returned using

the Return Material Authorization (RMA). If a replacement or credit note is

issued, the ordering party undertakes to store the faulty part for at least

24 months in accordance with the current storage directives (in compliance with ESD guidelines) and to hold it in readiness for onsite inspection

or for return shipment to Metrohm. Metrohm reserves the right to invoice

the ordering party for these articles, including retroactively, in the event of

noncompliance with these preconditions.

■■■■■■■■

30

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 39

■■■■■■■■■■■■■■■■■■■■■■

6 Warranty (guarantee)

The same warranty periods that are specified for a corresponding new

part apply to parts that are replaced or repaired within the above-mentioned warranty periods. However, replacement or repair of a part does

not extend the warranty period of the entire system.

Deficiencies arising from circumstances that are not the responsibility of

Metrohm, such as improper storage or improper use, etc., are expressly

excluded from the warranty.

Metrohm also offers a 120-month spare parts availability guarantee and a

60-month PC software support warranty, calculated from the date on

which the product is withdrawn from the market. The content of this warranty is the ability of the customer to obtain functioning spare parts or

appropriate software support at market prices during the time of the warranty period. This does not apply for software products sold under the

Metrohm NIRSystems brand.

If Metrohm AG is unable to meet this obligation due to circumstances

beyond the control of Metrohm AG, then the ordering party shall be

offered alternative solutions at preferential conditions.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

31

Page 40

7 Accessories

Up-to-date information on the scope of delivery and optional accessories

for your instrument can be found on the Internet.

When you receive your new instrument, we recommend downloading

the accessories list from the Internet, printing it out and keeping it

together with the manual for reference purposes.

Instruments currently sold

If you do not know the article number of your instrument, proceed as follows:

Downloading the accessories list

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Go to the Metrohm website http://www.metrohm.com/com.

1

2

Click on .

The Search webpage will be displayed.

Enter a search term relating to the instrument into the search field

3

and click on Find.

The search results will be displayed.

In the search results, select the Devices tab (if it is not already

4

selected) and then click on the Metrohm article number of the

required instrument (e.g. 2.852.0050).

The page with information pertaining to the searched article is displayed.

Select the Parts tab.

5

The complete list of accessories with the scope of delivery and the

optional accessories will be displayed.

6

Click on .

■■■■■■■■

32

930 Compact IC Flex Oven/Deg (2.930.2160)

Page 41

■■■■■■■■■■■■■■■■■■■■■■

7 Accessories

The Partslists webpage will be displayed.

Select the desired output language.

7

With the article number entered, click on the command Generate

8

PDF.

The PDF file with the accessories data will be created in the language

selected.

Direct access for all instruments

If you are unable to find your instrument using the search as described

above, this may be due to the instrument not being sold anymore. Using

the article number, you can download accessories lists for all instruments

as follows:

Downloading the accessories list

Type http://partslists.metrohm.com into your Internet browser.

1

The Partslists webpage will be displayed.

Select the desired output language.

2

Enter the article number and click on the Generate PDF command.

3

The PDF file with the accessories data will be created in the language

selected.

930 Compact IC Flex Oven/Deg (2.930.2160)

■■■■■■■■

33

Page 42

Index

Index

■■■■■■■■■■■■■■■■■■■■■■

A

Aspiration tubing for eluent ...... 16

B

Baseline

Conditioning ...................... 28

C

Column

See also "Separation column"

........................................... 25

Computer connection ............... 19

Conditioning ............................ 28

Connect

To computer ...................... 19

To power supply ................. 20

D

Degasser

Sample degasser ................. 18

Drainage tubing

Installation ......................... 13

E

Electrostatic charge .................... 5

Eluent

Aspirate .............................. 16

Eluent bottle

Installation ......................... 15

Equilibration ....................... 22, 27

F

Filter

See also "Inline filter" .......... 17

G

Guarantee ................................ 30

Guard column

Installation ......................... 23

Rinse .................................. 24

H

High-pressure pump

Protection .......................... 12

I

IC column

See also "Separation column"

........................................... 25

Injection valve ............................ 3

Installation ......................... 17

Inline filter ................................ 17

Installation

Drainage tubing ................. 13

Eluent bottle ....................... 15

Guard column .................... 23

Injection valve .................... 17

Leak sensor ........................ 14

Pulsation absorber .............. 17

Sample degasser ................. 18

Separation column ............. 25

L

Leak sensor

Installation ......................... 14

Leak-tightness .......................... 23

M

Mains voltage ............................. 5

P

Power connection .............. 20, 21

Power supply cable ................... 20

Pulsation absorber

Installation ......................... 17

R

Rinse

Guard column .................... 24

Separation column ............. 26

S

Safety instructions ...................... 4

Sample degasser

Installation ......................... 18

Separation column

Installation ......................... 25

Protection ...................... 3, 17

Rinse .................................. 26

Service ....................................... 4

Switch on ................................. 21

T

Transport locking screws .......... 11

V

Vacuum pump

Protection .......................... 12

Valve

See also "Injection valve" .... 17

W

Warranty .................................. 30

■■■■■■■■

34

930 Compact IC Flex Oven/Deg (2.930.2160)

Loading...

Loading...