Page 1

761 Compact IC

METROHM Ltd.

CH-9101 Herisau

Switzerland

Phone ++41 71 353 85 85

Fax ++41 71 353 89 01

8.761.1063

Instructions for Use

Page 2

CH-9101 Herisau/Switzerland

Phone ++41 71 353 85 85

Fax ++41 71 353 89 01

Internet www.metrohm.ch

E-Mail info@metrohm.ch

761 Compact IC

Program «761 PC Software 1.1»

8.761.1063 Instructions for Use

07.07.2004 / chs

Page 3

Table of contents

761 Compact IC

I

Table of contents

1 Introduction............................................................................................................1

1.1 Instrument description .......................................................................................... 1

1.2 Parts and controls .................................................................................................. 3

1.3 Information on the Instructions for Use ...........................................................10

1.3.1 Organization ......................................................................................... 10

1.3.2 Notation and pictograms...................................................................... 11

1.4 Safety notes........................................................................................................... 12

1.4.1 Electrical safety..................................................................................... 12

1.4.2 General precautionary rules ................................................................. 12

2 Installation .......................................................................................................... 13

2.1 Overview ................................................................................................................13

2.1.1 Flow chart ............................................................................................. 13

2.1.2 Connections in the 761 Compact IC.................................................... 13

2.2 Setting up the instrument.................................................................................... 15

2.2.1 Packaging............................................................................................. 15

2.2.2 Check.................................................................................................... 15

2.2.3 Location ................................................................................................ 15

2.3 Attaching the accessories ..................................................................................15

2.3.1 Connection of detector block............................................................... 15

2.3.2 Connection of syringe and aspirating tubing ....................................... 16

2.3.3 Connection of the drain tube for the inner compartment..................... 16

2.3.4 Connection of the drain tube for bottle rack ........................................ 17

2.3.5 Connection of PEEK capillaries............................................................ 17

2.3.6 Filter unit PEEK ..................................................................................... 18

2.4 Mains connection ................................................................................................. 19

2.4.1 Setting the mains voltage..................................................................... 19

2.4.2 Fuses .................................................................................................... 20

2.4.3 Mains cable and mains connection ..................................................... 20

2.4.4 On/off switching of the instrument ....................................................... 20

2.5 Connection to the PC........................................................................................... 21

2.5.1 Connecting cable ................................................................................. 21

2.5.2 Software installation.............................................................................. 21

2.5.3 Basic settings ....................................................................................... 22

2.6 High-pressure pump ............................................................................................ 25

2.6.1 Removing the transport security screws .............................................. 25

2.6.2 Installing the pulsation dampener ........................................................ 25

2.6.3 Connecting the eluent bottle ................................................................ 27

2.6.4 Deaerating the pump and rinsing the pulsation dampener................. 29

2.7 Precolumns and separating columns ............................................................... 31

2.7.1 General information on precolumns..................................................... 31

2.7.2 Precolumns with cartridge head........................................................... 31

2.7.3 Precolumn glass cartridges with cartridge holder ............................... 33

2.7.4 IC anion precolumn SUPERSEP .......................................................... 34

2.7.5 General information on separating columns........................................ 35

2.7.6 Selection of the sample loop................................................................ 35

2.7.7 Installation of the separating column without suppressor ...................36

2.7.8 Installation of the separating column with suppressor ........................ 37

Page 4

Table of contents

761 Compact IC

II

2.8 Suppressor module ............................................................................................. 38

2.8.1 General information on suppressor module........................................ 38

2.8.2 Preparation of the peristaltic pump...................................................... 38

2.8.3 Connection of supply bottles ............................................................... 41

2.8.4 Connection of the suppressor module ................................................ 43

2.9 Putting into operation.......................................................................................... 45

2.9.1 Putting into operation without suppressor ........................................... 45

2.9.2 Putting into operation with suppressor ................................................ 46

2.10 Connection of external devices ......................................................................... 49

2.10.1 Connection of the 750 Autosampler .................................................... 49

2.10.2 Connection of the 766 IC Sample Processor ...................................... 50

2.10.3 Connection of other devices ................................................................ 52

3 Operating tutorial ....................................................................................... 53

3.1 Requirements........................................................................................................ 53

3.2 Preparations.......................................................................................................... 54

3.3 Calibration ............................................................................................................. 55

3.4 Sample determination ......................................................................................... 63

4 Operation............................................................................................................... 67

4.1 Fundamentals of the operation.......................................................................... 67

4.1.1 Starting/closing the program ............................................................... 67

4.1.2 Glossary................................................................................................ 68

4.1.3 Overview of program windows............................................................. 69

4.1.4 Main window elements......................................................................... 70

4.1.5 Icons of the main window..................................................................... 70

4.1.6 Overview of file types............................................................................ 71

4.1.7 Context sensitive menus ...................................................................... 72

4.1.8 Keyboard and mouse functions........................................................... 72

4.1.9 Help ...................................................................................................... 73

4.2 Instrument and software settings...................................................................... 74

4.2.1 Fonts..................................................................................................... 74

4.2.2 Security system .................................................................................... 74

4.2.3 Global settings ..................................................................................... 75

4.2.4 COM port.............................................................................................. 77

4.3 Systems ................................................................................................................. 78

4.3.1 System window .................................................................................... 78

4.3.2 System file handling ............................................................................. 78

4.3.3 System functions .................................................................................. 79

Connect and disconnect system ................................................. 79

Start/stop hardware and record baseline .................................... 79

Start/stop determinations............................................................. 80

Options for determinations........................................................... 80

4.3.4 System settings .................................................................................... 82

Modify system window ................................................................. 82

Watch window display.................................................................. 82

Set start mode .............................................................................. 82

Print system parameters .............................................................. 83

4.3.5 PC icon ................................................................................................. 83

Page 5

Table of contents

761 Compact IC

III

Menu options for PC icon............................................................. 83

Select processing method and data source................................ 83

4.3.6 Watch window....................................................................................... 84

Menu options for screen icon....................................................... 84

4.3.7 Instrument icon ..................................................................................... 85

Menu options for instrument icon................................................. 85

System parameters for disconnected system ............................. 85

Instrument control for connected system .................................... 86

Time program ...............................................................................88

Configuration ................................................................................90

Hardware settings ........................................................................ 91

4.3.8 Timer ..................................................................................................... 94

4.3.9 System state window............................................................................ 95

Status messages.......................................................................... 95

Error messages ............................................................................ 96

4.4 Methods .................................................................................................................97

4.4.1 Method file handling ............................................................................. 97

4.4.2 Passport................................................................................................ 97

General ......................................................................................... 98

Sample.......................................................................................... 99

Column ....................................................................................... 100

Eluent .......................................................................................... 101

Comment .................................................................................... 101

Method Log ................................................................................ 102

Data Log ..................................................................................... 103

4.4.3 Method setup...................................................................................... 104

General ....................................................................................... 104

Measure ...................................................................................... 104

Filters .......................................................................................... 105

Processing.................................................................................. 106

Math ............................................................................................ 107

4.4.4 Integration........................................................................................... 109

Setup........................................................................................... 110

Events .........................................................................................112

4.4.5 Calibration and quantification............................................................. 117

General information .................................................................... 117

Notations..................................................................................... 118

External standard calibration...................................................... 119

Component table........................................................................ 119

Peak identification ...................................................................... 121

Concentration table .................................................................... 123

Calibration curve......................................................................... 125

Update calibration ...................................................................... 127

Load and save calibration data.................................................. 128

Import and export calibration data ............................................. 128

Put out calibration curves ........................................................... 128

4.4.6 Report output...................................................................................... 129

Report options ............................................................................ 129

4.5 Chromatograms..................................................................................................141

4.5.1 Chromatogram window ...................................................................... 141

4.5.2 Chromatogram file handling............................................................... 142

Open chromatogram.................................................................. 142

Save chromatogram................................................................... 143

Close chromatogram.................................................................. 143

Delete chromatogram................................................................. 143

Export chromatogram................................................................. 143

Import chromatogram ................................................................ 144

4.5.3 Graphical representation.................................................................... 145

Page 6

Table of contents

761 Compact IC

IV

Appearance................................................................................ 145

Other graphical functions........................................................... 149

4.5.4 Peak editor.......................................................................................... 150

Switching on/off the peak editor ................................................ 150

Peak editor functions.................................................................. 150

Moving the cursor....................................................................... 151

4.5.5 Printing................................................................................................ 152

Page layout for printing .............................................................. 152

Printer settings............................................................................ 153

Print preview ............................................................................... 153

Printing........................................................................................ 153

4.5.6 Miscellaneous functions..................................................................... 153

Reintegration .............................................................................. 153

Recalibration............................................................................... 153

Subtraction of a chromatogram................................................. 154

Data compression ...................................................................... 154

Invert chromatogram.................................................................. 154

Autodatabase options................................................................ 155

Indicate active Autodatabase program ..................................... 155

4.6 Sample queue ..................................................................................................... 156

4.6.1 Sample queue file handling................................................................ 156

Open sample queue................................................................... 156

Save sample queue.................................................................... 156

Delete sample queue ................................................................. 156

4.6.2 Sample queue control ........................................................................ 157

Sample queue overview table .................................................... 157

Start sample queue .................................................................... 158

Pause sample queue ................................................................. 159

Cancel last run............................................................................ 159

Reset sample queue .................................................................. 159

4.6.3 Sample queue editor.......................................................................... 159

Open queue editor window........................................................ 159

Sample queue editor functions .................................................. 161

Print sample queue .................................................................... 161

Close sample queue editor ........................................................ 161

4.7 Batch reprocessing............................................................................................ 162

4.7.1 Batch reprocessing queue file handling ............................................ 162

Open batch reprocessing queue ............................................... 162

Create new batch reprocessing queue...................................... 162

Save batch reprocessing queue ................................................ 162

4.7.2 Perform batch reprocessing............................................................... 163

Reprocess options window........................................................ 163

Merge chromatograms .............................................................. 166

4.7.3 Batch reprocessing queue editor....................................................... 167

Open batch reprocessing queue editor window ....................... 167

Batch reprocessing queue editor functions............................... 168

Print batch reprocessing queue................................................. 168

Close batch reprocessing queue editor .................................... 168

Page 7

Table of contents

761 Compact IC

V

5 Notes – Maintenance – Faults.................................................... 169

5.1 Practical notes on ion chromatography .........................................................169

5.1.1 Separating columns............................................................................ 169

5.1.2 High-pressure pump .......................................................................... 170

5.1.3 Eluents ................................................................................................ 171

5.1.4 Peristaltic pump.................................................................................. 171

5.1.5 Suppressor module ............................................................................ 172

5.1.6 Connections........................................................................................ 172

5.2 Maintenance and servicing...............................................................................173

5.2.1 General information ............................................................................ 173

5.2.2 Passivation.......................................................................................... 173

5.2.3 Recycling ............................................................................................ 174

5.2.4 Shutdown............................................................................................ 174

5.2.5 Changing separating columns........................................................... 174

5.2.6 Maintenance work at the pump head ................................................176

5.2.7 Regeneration of the suppressor module ...........................................180

5.2.8 Cleaning the suppressor .................................................................... 181

5.2.9 Replacing the suppressor .................................................................. 183

5.2.10 Exchanging the pump tubing ............................................................. 185

5.3 Faults and malfunctions....................................................................................186

5.3.1 Error messages ..................................................................................186

5.3.2 Malfunctions and their rectification..................................................... 186

5.4 Diagnostic tests / Validation / GLP..................................................................188

6 Appendix.............................................................................................................. 189

6.1 Technical data.....................................................................................................189

6.1.1 Conductivity measurement................................................................. 189

6.1.2 Conductivity detector.......................................................................... 189

6.1.3 Injection valve .....................................................................................190

6.1.4 High-pressure pump .......................................................................... 190

6.1.5 Peristaltic pump.................................................................................. 191

6.1.6 Suppressor module ............................................................................ 191

6.1.7 Leak detector...................................................................................... 191

6.1.8 RS232 interface .................................................................................. 191

6.1.9 Remote interface................................................................................. 192

6.1.10 Analog output .....................................................................................192

6.1.11 Mains connection ............................................................................... 192

6.1.12 Safety specifications........................................................................... 192

6.1.13 Electromagnetic compatibility (EMC)................................................. 193

6.1.14 Ambient temperature.......................................................................... 193

6.1.15 Housing............................................................................................... 193

6.2 Standard equipment...........................................................................................194

6.3 Optional accessories .........................................................................................198

6.3.1 Accessories for capillary connections................................................ 198

6.3.2 High-pressure pump .......................................................................... 199

6.3.3 Separating columns and precolumns................................................ 200

6.3.4 Additional devices and cables ...........................................................205

6.4 Warranty and conformity...................................................................................206

6.4.1 Warranty.............................................................................................. 206

6.4.2 EU Declaration of conformity.............................................................. 207

6.4.3 Certificate of conformity and system validation .................................208

6.5 Index .....................................................................................................................209

Page 8

Table of contents

761 Compact IC

VI

List of figures

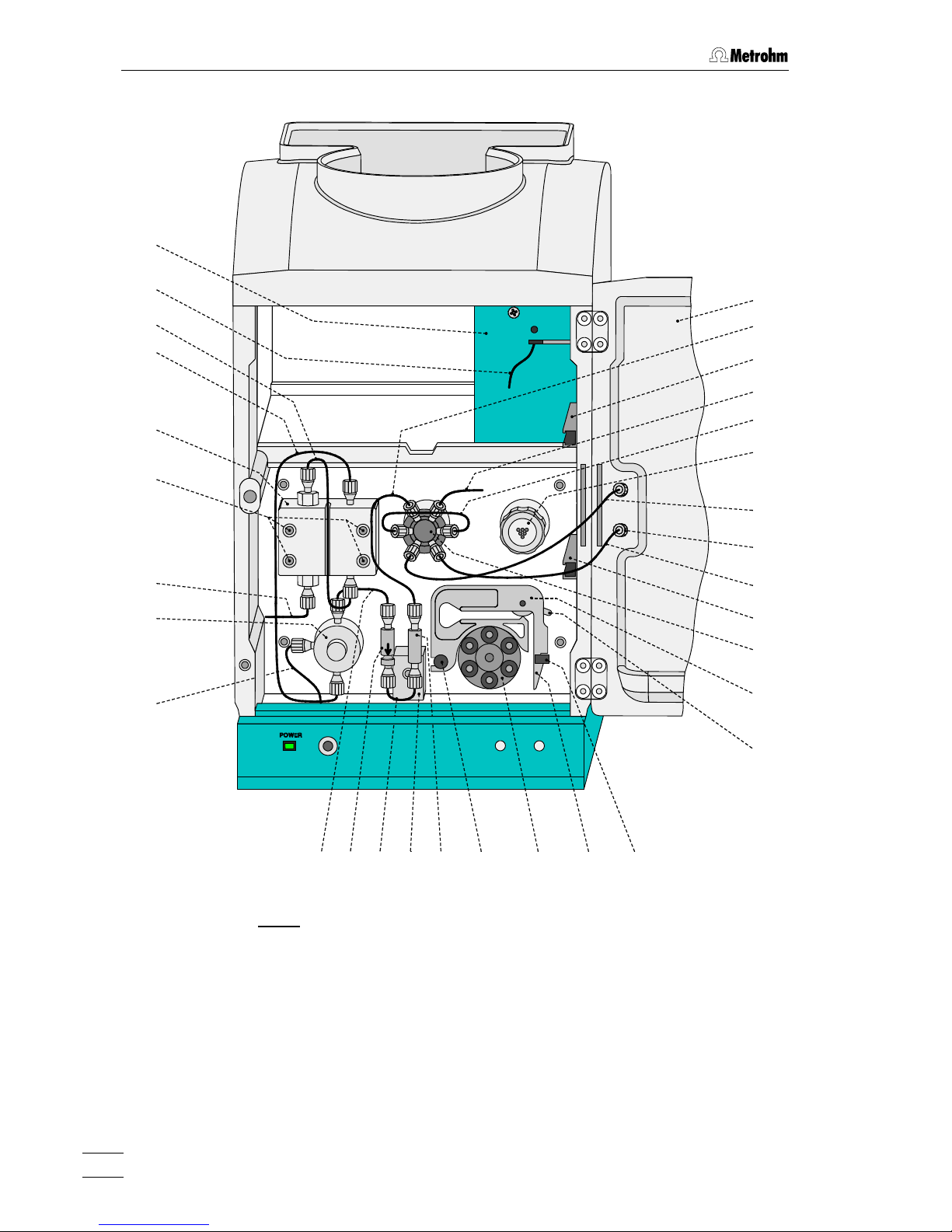

Fig. 1: Front of the 761 Compact IC .......................................................................... 3

Fig. 2

: Rear of the 761 Compact IC........................................................................... 4

Fig. 3

: Interior of the 2.761.0010 Compact IC ...........................................................6

Fig. 4

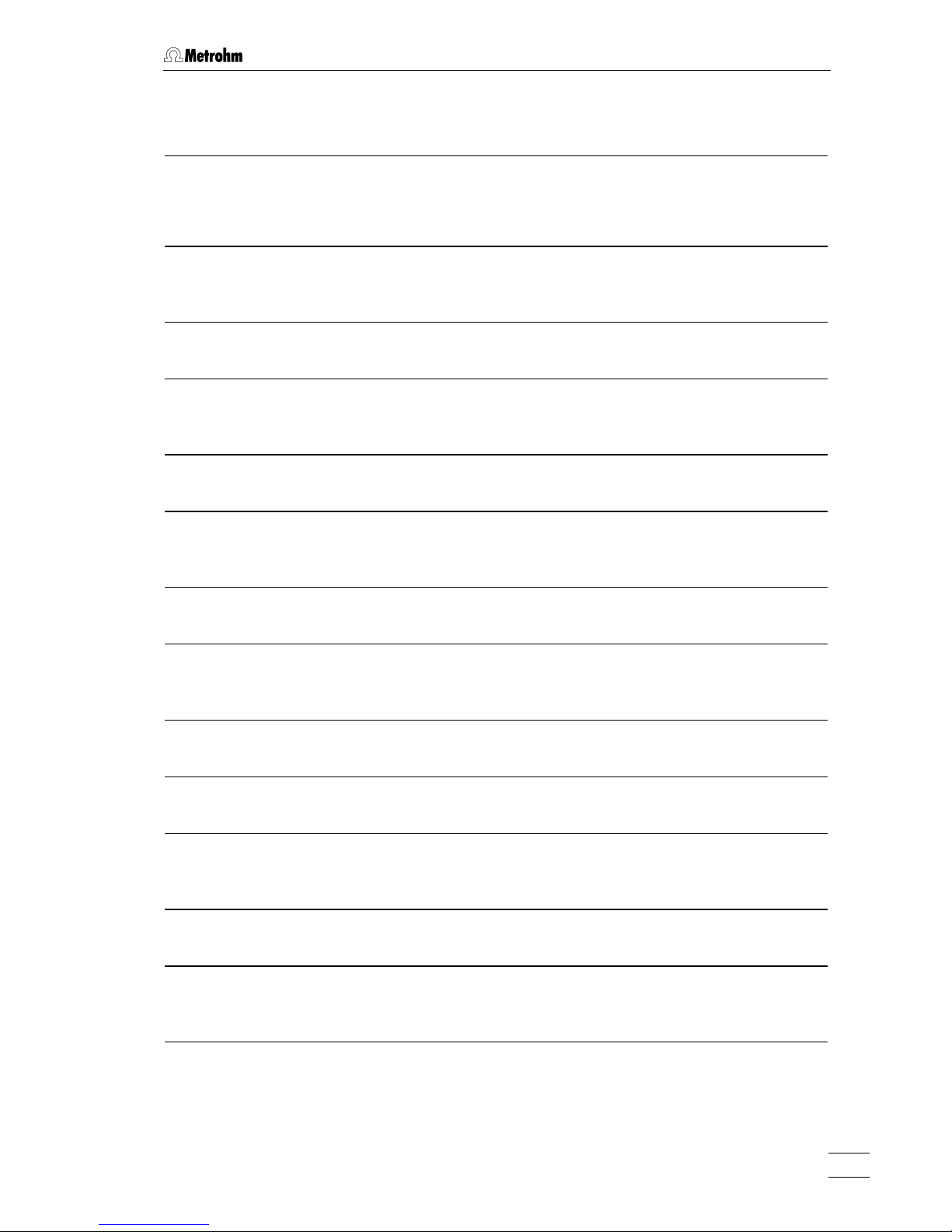

: Interior of the 2.761.0020 Compact IC ...........................................................8

Fig. 5

: Connecting diagram for 2.761.0010 Compact IC without suppressor........ 14

Fig. 6

: Connecting diagram for 2.761.0020 Compact IC with suppressor............. 14

Fig. 7

: Connectors for capillaries............................................................................. 17

Fig. 8

: 6.2821.000 Filter unit PEEK ..........................................................................18

Fig. 9

: Setting the mains voltage .............................................................................20

Fig. 10

: Connection of the pulsation dampener........................................................ 26

Fig. 11

: Connection of eluent bottle........................................................................... 28

Fig. 12

: Installation of precolumn cartridges with cartridge head............................. 32

Fig. 13

: Installation of precolumn glass cartridges with cartridge holder ................. 34

Fig. 14

: Installation of column without suppressor.................................................... 37

Fig. 15

: Installing pump tubings ................................................................................39

Fig. 16

: Connection of the separating column with suppressor ...............................40

Fig. 17

: Connection of supply bottles........................................................................ 42

Fig. 18

: Connections at suppressor module ............................................................. 43

Fig. 19

: Components of the pump head .................................................................177

Fig. 20

: Replacement of the piston seal 112 ..........................................................177

Fig. 21

: Components of inlet valve 113 and outlet valve 114................................. 179

Fig. 22

: Assembling the suppressor........................................................................ 183

Page 9

Table of contents

761 Compact IC

VII

List of numbered parts and controls

1 Door to interior .................................3,7,9

2 Connection for syringe...........................3

3 Feedthrough for aspirating tubing ......... 3

4 Aspirating tubing..............................3,7,9

5 Feedthrough for capillaries .................... 3

6 Connection for drain tube .....................3

7 Feedthrough for capillaries .................... 3

8 Connection to purge valve ....................3

9 Mains pilot lamp.....................................3

10 Bottle rack ........................................... 3,5

11 Opening for detector cable....................5

12 Opening for inlet capillaries ...................5

13 Opening for outlet capillaries.................5

14 Connection for drain tube ...................... 5

15 Knurled screw ........................................5

16 Rear panel opening ...............................5

17 Detachable rear panel ...........................5

18 Transport security screws ...................... 5

19 Mains switch .....................................5,20

20 Mains connection plug .....................5,20

21 Fuse holder ....................................... 5,20

22 RS232 interface...................................... 5

23 Connection for detector block ...............5

24 Remote interface.................................... 5

25 Serial number.........................................5

26 Inlet capillary for injector ................7,9,26

27 Mounting rail .............................7,9,37,40

28 Column connection

capillary ...........................7,9,32,34,37,40

29 Sample loop........................................7,9

30 Connection capillary to syringe ..........7,9

31 Rotary nipple for aspirating tube ........7,9

32 Injection valve.......................7,9,26,37,40

33 PEEK coupling ............................... 7,9,40

34 Leak detector ......................................7,9

35 Connection capillary .....................7,9,26

36 Filter unit PEEK ....................7,9,18,26,40

37 Connection capillary ......................7,9,26

38 Connection capillary ...........................7,9

39 Purge valve.....................................7,9,26

40 Aspirating capillary..............................7,9

41 Fastening screws ................................7,9

42 Pump head...................................7,9,177

43 Connection capillary............................7,9

44 Connection capillary............................7,9

45 Inlet capillary for

detector block .......................... 7,9,37,40

46 Detector block .......................... 7,9,37,40

47 Suppressor module...........................9,40

48 Tubing cartridge ...........................9,39,41

49 Contact pressure lever .................9,39,41

50 Holding clamp...................................9,41

51 Snap-action lever .........................9,39,41

52 Pump drive ........................................9,41

53 Mounting pin .....................................9,41

54 Compression fitting .... 17,18,32,34,39,42

55 Compression fitting ..............................17

56 Capillary..................................... 17,18,34

57 Filter-Screw of Filter Unit .................18,39

58 Filter.................................................18,39

59 Filter-Housing of Filter Unit ..................18

60 Pulsation dampener .............................26

61 Connection to injection valve ...............26

62 Connection to purge valve ...................26

63 Aspirating tubing ..................................28

64 Tubing nipple........................................28

65 Threaded stopper.................................28

66 Bottle attachment .................................28

67 Eluent bottle..........................................28

68 Aspirating filter......................................28

69 CO

2

absorber .......................................28

70 Cotton wool ..........................................28

71 SGJ clip ................................................28

72 Absorber tube.......................................28

73 Manufit housing....................................32

74 Steel connector ....................................32

75 PTFE gasket .........................................32

76 2 Steel meshes.....................................32

77 Precolumn cartridge.............................32

78 Steel spacer .........................................32

Page 10

Table of contents

761 Compact IC

VIII

79 4 Steel meshes ....................................32

80 Manufit pressure screw ....................... 32

81 Separating column .................... 32,37,40

82 End fitting............................................. 34

83 Screw cap for precolumn .................... 34

84 Sleeve for precolumn cartridge ...........34

85 Precolumn cartridge ............................34

86 Connection piece................................. 34

87 Screw cap for column.......................... 34

88 Column holder ................................37,40

89 Aspirating tubing for H

2

O........... 39,40,42

90 Aspirating tubing for H

2SO4

....... 39,40,42

91 Coupling ......................................... 39,40

92 Pump tubing for H

2SO4

................... 39,40

93 Pump tubing for H

2

O ......................39,40

94 Stopper ................................................ 39

95 PTFE tubing ....................................39,40

96 Suppressor inlet capillary

for eluent ......................................... 41,43

97 Suppressor outlet capillary

for eluent ......................................... 41,43

98 Suppressor inlet capillary

for H

2

O ............................................41,43

99 Suppressor inlet capillary

for H

2SO4

.................................... 39,41,43

100 Suppressor outlet capillary

for H

2

O ............................................41,43

101 Suppressor outlet capillary

for H

2SO4

......................................... 41,43

102 Bottle attachment.................................42

103 Supply bottle ........................................ 42

104 Screw..................................................177

105 Zircon piston ......................................177

106 Spring retainer.................................... 177

107 Spring.................................................177

108 Piston cartridge..................................177

109 Piston guide sleeve............................177

110 Sapphire supporting ring ................... 177

111 Piston guide sleeve............................177

112 Piston seal.......................................... 177

113 Inlet valve ....................................177,179

114 Outlet valve..................................177,179

115 Screw holder ......................................177

116 Special tool ........................................ 177

117 Special tool ........................................ 177

118 Valve housing..................................... 179

119 Sealing ring ........................................179

120 Sleeve................................................. 179

121 Sapphire sleeve .................................179

122 Sapphire sphere.................................179

123 Ceramic holder...................................179

124 Seal ....................................................179

125 Screw nut ...........................................183

126 Connection piece...............................183

127 Suppressor rotor ................................ 183

128 Suppressor holder .............................183

Page 11

1.1 Instrument description

761 Compact IC

1

1 Introduction

1.1 Instrument description

The 761 Compact IC is a PC-controlled system for ion chromatographic analyses. The two following versions are available:

• 2.761.0010 Compact IC without

suppressor module

• 2.761.0020 Compact IC with

suppressor module

The extremely compact housing of the 761 Compact IC contains everything needed to carry out ion chromatography at the highest quality

level:

• Injection valve – for individual injections or for use with a sample

changer such as the Metrohm 766 IC Sample Processor

• High-pressure pump – extremely low-pulsation double piston

pump with a flow range from 0.2 … 2.5 mL/min and a maximum

pressure of 25 MPa (250 bar)

• Pulsation dampener – even with low-level pressure variations the

pulsation dampener reliably protects the column against damage

• Column chamber – the perfect insulation of the housing provides

not only thermally stable conditions for the separation column but

also shields the system against electromagnetic interference

• Columns – whether anion columns with or without suppression,

separation columns for cations or organic acids – the 761 Compact

IC can accommodate them all

• Suppressor – the Metrohm Suppressor Module (MSM) is already

integrated in the 2.761.0020 Compact IC – pressure-resistant, with

fully automatic regeneration, highest performance and optimal reproducibility

• Peristaltic pump – integrated two-channel peristaltic pump with a

flow rate of 0.5 … 0.6 mL/min for regeneration and rinsing of the

suppressor module built into the 2.761.0020 Compact IC

• Detector – conductivity detector with outstanding temperature

stability. The detector temperature varies by less than 0.01°C and

can be optimally adapted to the ambient conditions.

All components which come into contact with eluent and sample are

metal-free.

Page 12

1 Introduction

761 Compact IC

2

The operation of the 761 Compact IC takes place via a PC connected

to the RS232 interface with the help of the control and evaluation program «761 Compact IC». This PC program can be used to create systems for recording and evaluating chromatograms. Time programs can

also be created in which a large number of instrument functions can be

triggered for each program step. It is also possible to use programmable signals to control external instruments such as the 750 Autosampler

or the 766 IC Sample Processor via the remote interface.

About 80 prepared system configurations for more than 300 applications are already permanently stored and additional new applications

can be downloaded at any time from the Internet under

«www.metrohm.ch».

The operating software for the 761 Compact IC meets all the requirements you could place today on a modern integration software: single

or multi-point calibration, internal or external standard, selectable algorithms for non-linear calibration, various integration modes with integration parameters and integration events, different methods for peak recognition, peak editor, free scaling, superimposing several

chromatograms, use of sample tables and batch reprocessing; a powerful and GLP-conform report generator with output interfaces for monitor, printer and external databases.

The independent «Autodatabase» PC programm supplied can be used

to save and handle results and chromatograms produced by the «761

Compact IC» program in a database. With «Autodatabase», data can

be sorted, filtered and searched with the help of different criteria. In addition, data and curves can be printed out according to user-defined

report templates.

Page 13

1.2 Parts and controls

761 Compact IC

3

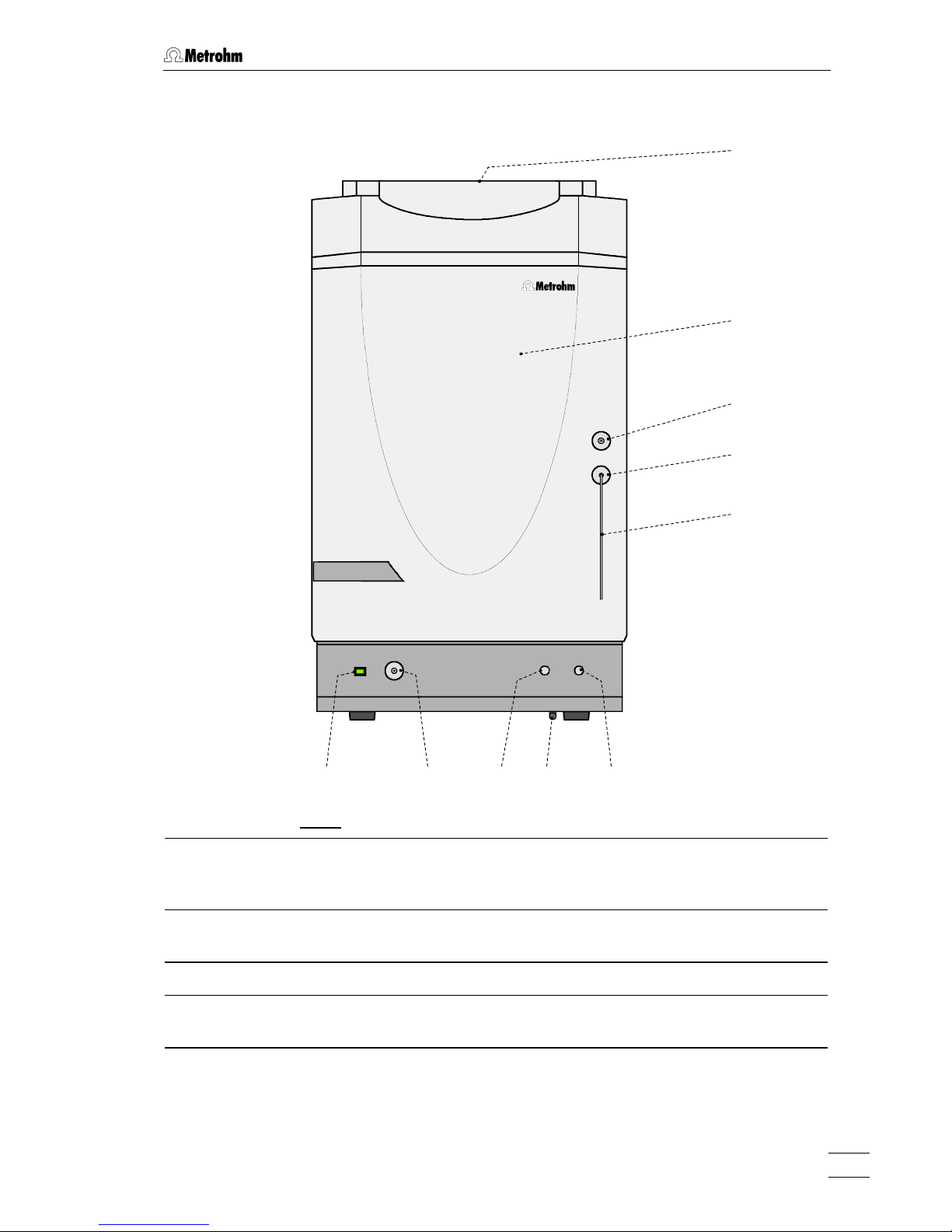

1.2 Parts and controls

POWER

761 Compact IC

89 76 5

2

3

4

1

10

Fig. 1

: Front of the 761 Compact IC

1

Door to interior 6 Connection for drain tube

for discharge of spilled liquid from the

interior

2 Connection for 6.2816.020 Syringe

for aspiration of the sample

7 Feedthrough for capillaries

3 Feedthrough for aspirating tubing 8 Connection to purge valve

4 Aspirating tubing

for sample

9 Mains pilot lamp

lit up when instrument switched on

5 Feedthrough for capillaries 10 Bottle rack

for holding supply bottles with eluent,

regeneration solution, and rinsing

solution

Page 14

1 Introduction

761 Compact IC

4

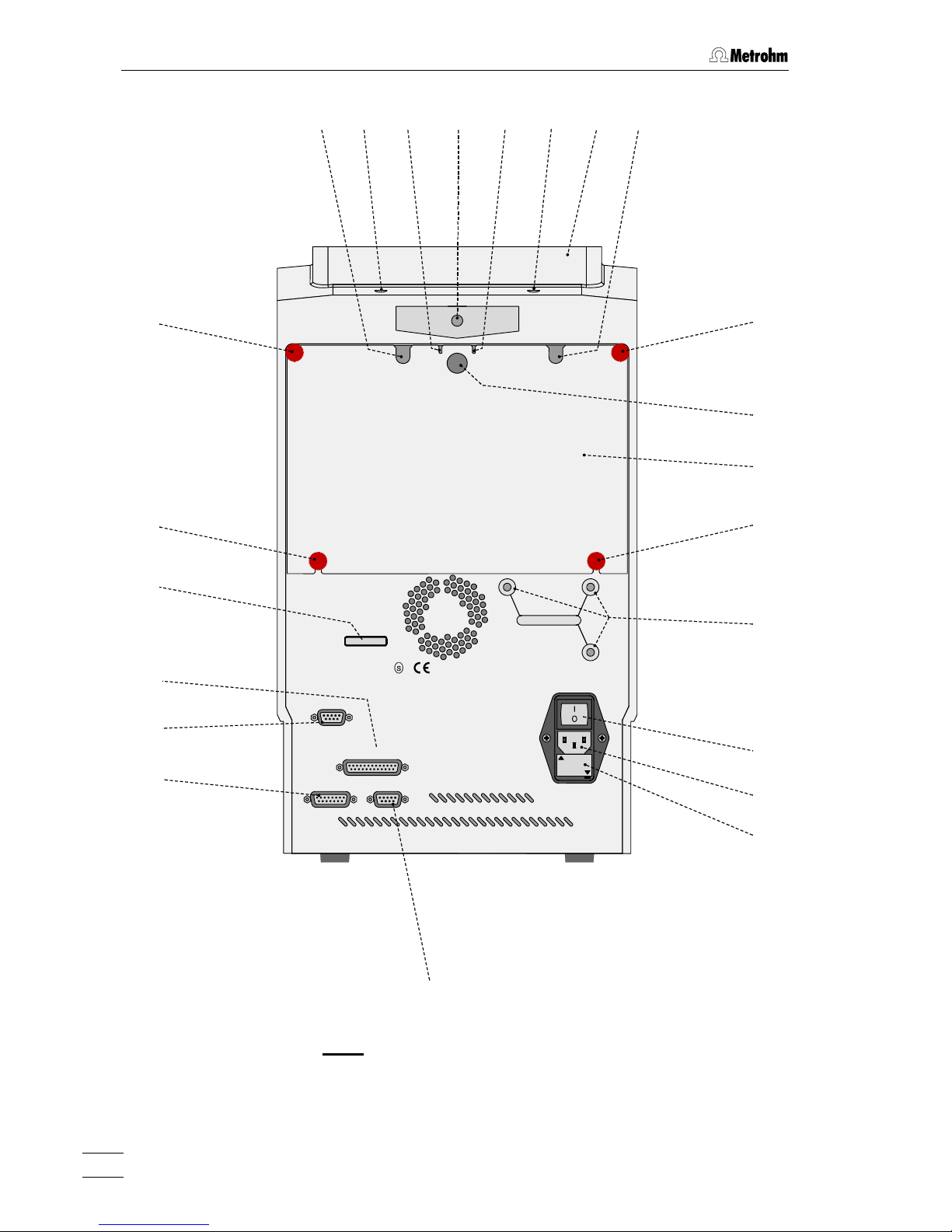

WARNING - Fire Hazard -

with the same type and rating of fuse

For continued protection replace only

Type 1.761.

Fuse

100-120V:

220-240V:

1,0A(T)

0,5A(T)

Made by Metrohm Herisau Switzerland

RS 232

Detector Block

Remote

Waste B

Waste A

Transport security scre ws

17

18

19

20

21

11

13 14 13 10

23a

22

15

25

24

12 12 11

15

16

15

15

f = 50-60 Hz

S = 100 VA

Analog Output

23

Fig. 2

: Rear of the 761 Compact IC

Page 15

1.2 Parts and controls

761 Compact IC

5

10 Bottle rack

for holding supply bottles with eluent,

regeneration solution, and rinsing

solution

18 Transport security screws

to secure the pump head when the

instrument is transported

11

Opening for detector cable 19 Mains switch

to switch instrument on and off:

I = ON 0 = OFF

12 Opening for inlet capillaries

for supply of eluent, regeneration

solution, and rinsing solution into the

inner compartment

20 Mains connection plug

mains connection, see section 2.4

13 Opening for outlet capillaries

for discharge of eluent, regeneration

solution, and rinsing solution from the

inner compartment

21 Fuse holder

changing the fuses, see section 2.4

14 Connection for drain tube

for discharge of spilled liquid from the

bottle rack

22 RS232 interface

connection of the PC

15 Knurled screw

for fastening the rear panel 17

23

23a

Connection for detector block

Analog output for measuring

signal

16 Rear panel opening

(closed with plastic stopper) for

additional supply and discharge lines to

and from the inner compartment

24 Remote interface

remote I/O lines for connection of

external devices

17 Detachable rear panel

access to upper part of inner

compartment

25 Serial number

Page 16

1 Introduction

761 Compact IC

6

37

44

1

26

27

27

28

29

30

31

32

43

42

41

40

39

38

36 35 34

4

33

45

46

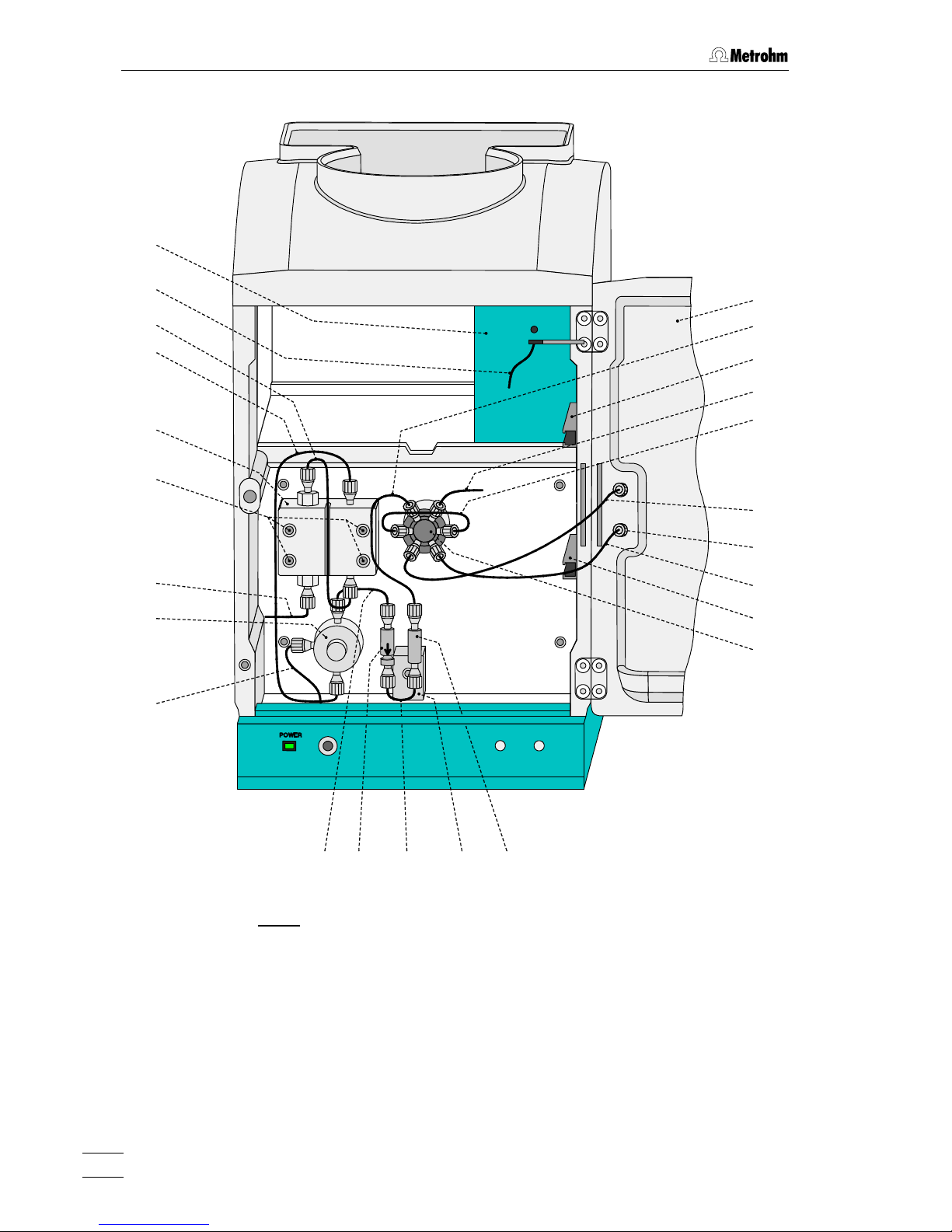

Fig. 3

: Interior of the 2.761.0010 Compact IC

(with permanently attached accessories and

1.733.0110 Detector block)

Page 17

1.2 Parts and controls

761 Compact IC

7

1 Door to interior 36 Filter unit PEEK (6.2821.120)

4

Aspirating tubing

for aspirating the sample;

6.1803.020 PTFE tubing,

length L = 52 cm

37 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

26 Inlet capillary for injector

6.1831.010 PEEK capillary,

length L = 24 cm

38 Connection capillary

6.1831.010 PEEK capillary,

length L = 15 cm

27 Mounting rail

for 6.2027.0X0 column holder

39 Purge valve

28 Column connection capillary

6.1831.010 PEEK capillary,

length L = 30 cm

40 Aspirating capillary

Connection for 6.1834.010 aspirating

tubing

29 Sample loop 10 µL

6.1825.230 PEEK sample loop

41 Fastening screws

for pump head 42

30 Connection capillary to syringe

6.1803.020 PTFE tubing,

length L = 30 cm

42 Pump head (6.2824.100)

31 Rotary nipple for aspirating tube

for fixing the aspirating tube

43 Connection capillary

Connection pump head – purge

valve, fixed mounting

32 Injection valve

44 Connection capillary

in pump head, fixed mounting

33 PEEK coupling (6.2744.040)

45 Inlet capillary for detector block

PEEK capillary, fixed mounting

34 Leak detector 46 Detector block (1.732.0110)

35 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

Page 18

1 Introduction

761 Compact IC

8

37

44

1

26

27

27

28

29

30

31

32

43

42

41

40

39

38

36 35 34

4

33

45

46

47

48

49

53 52

5051

Fig. 4

: Interior of the 2.761.0020 Compact IC

(with permanently attached accessories and

1.733.0110 Detector block)

Page 19

1.2 Parts and controls

761 Compact IC

9

1 Door to interior 39 Purge valve

4

Aspirating tubing

for aspirating the sample;

6.1803.020 PTFE tubing,

length L = 52 cm

40 Aspirating capillary

Connection for 6.1834.010 aspirating

tubing

26 Inlet capillary for injector

6.1831.010 PEEK capillary,

length L = 24 cm

41 Fastening screws

for pump head 42

27 Mounting rail

for 6.2027.0X0 column holder

42 Pump head (6.2824.100)

28 Column connection capillary

6.1831.010 PEEK capillary,

length L = 30 cm

43 Connection capillary

Connection pump head – purge

valve, fixed mounting

29 Sample loop 20 µL

6.1825.210 PEEK sample loop

44 Connection capillary

in pump head, fixed mounting

30 Connection capillary to syringe

6.1803.020 PTFE tubing,

length L = 30 cm

45 Inlet capillary for detector block

PEEK capillary, fixed mounting

31 Rotary nipple for aspirating tube

for fixing the aspirating tube

46 Detector block (1.732.0110)

32 Injection valve

47 Suppressor module

(inlet and outlet capillaries are not

shown)

33 PEEK coupling (6.2744.040)

48 Tubing cartridge (6.2755.000)

for 6.1826.060 pump tubing

34 Leak detector 49 Contact pressure lever

for adjusting the contact pressure

35 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

50 Holding clamp

for locking the tubing cartridge into

place

36 Filter unit PEEK (6.2821.120) 51 Snap-action lever

for releasing the tubing cartridge

37 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

52 Pump drive

roller head with contact rollers

38 Connection capillary

6.1831.030 PEEK capillary,

length L = 20 cm

53 Mounting pin

for attaching the tubing cartridges

Page 20

1 Introduction

761 Compact IC

10

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 761 Compact IC into operation. The Instructions for Use contain

information and warnings to which the user must pay attention in order

to assure safe operation of the instrument.

1.3.1 Organization

These 8.761.1063 Instructions for Use for the 761 Compact IC pro-

vide a comprehensive overview of the installation, startup procedure,

operation, fault rectification and technical specifications of this instrument. The Instructions for Use are organized as follows:

Section 1 Introduction

General description of instrument, parts and controls

and safety notes

Section 2 Installation

Installation of instrument, accessories,

and external devices

Section 3 Operating tutorial

Introduction to the operation using an example

Section 4 Operation

Detailed description of the operation

Section 5 Notes – Maintenance – Faults

Notes on ion chromatography, maintenance, fault rectification, diagnostic tests, validation

Section 6 Appendix

Technical data, standard equipment, options, warranty,

declarations of conformity, index

To find the required information on the instruments, you will find it an

advantage to use either the Table of contents or the Index at the

back.

As a supplement to the Instructions for Use, the Metrohm Monograph

8.732.2003 "Ion chromatography" is also supplied. This provides an

introduction to the theoretical fundamentals and general information on

separating columns and sample pretreatment.

The 8.732.2013 IC Applications Collection is also supplied; this contains all the Application Notes on the subject of ion chromatography.

Each of these applications can be carried out directly with the 761

Compact IC by loading the system file with the same name. The Applications Collection can be updated at any time by downloading the latest applications from the Internet under «www.metrohm.ch».

You will find detailed information on the separating columns available

from Metrohm and on special IC applications in the relevant "Applica-

tion Bulletins", which are available on request free of charge from your

Metrohm agency.

Page 21

1.3 Information on the Instructions for Use

761 Compact IC

11

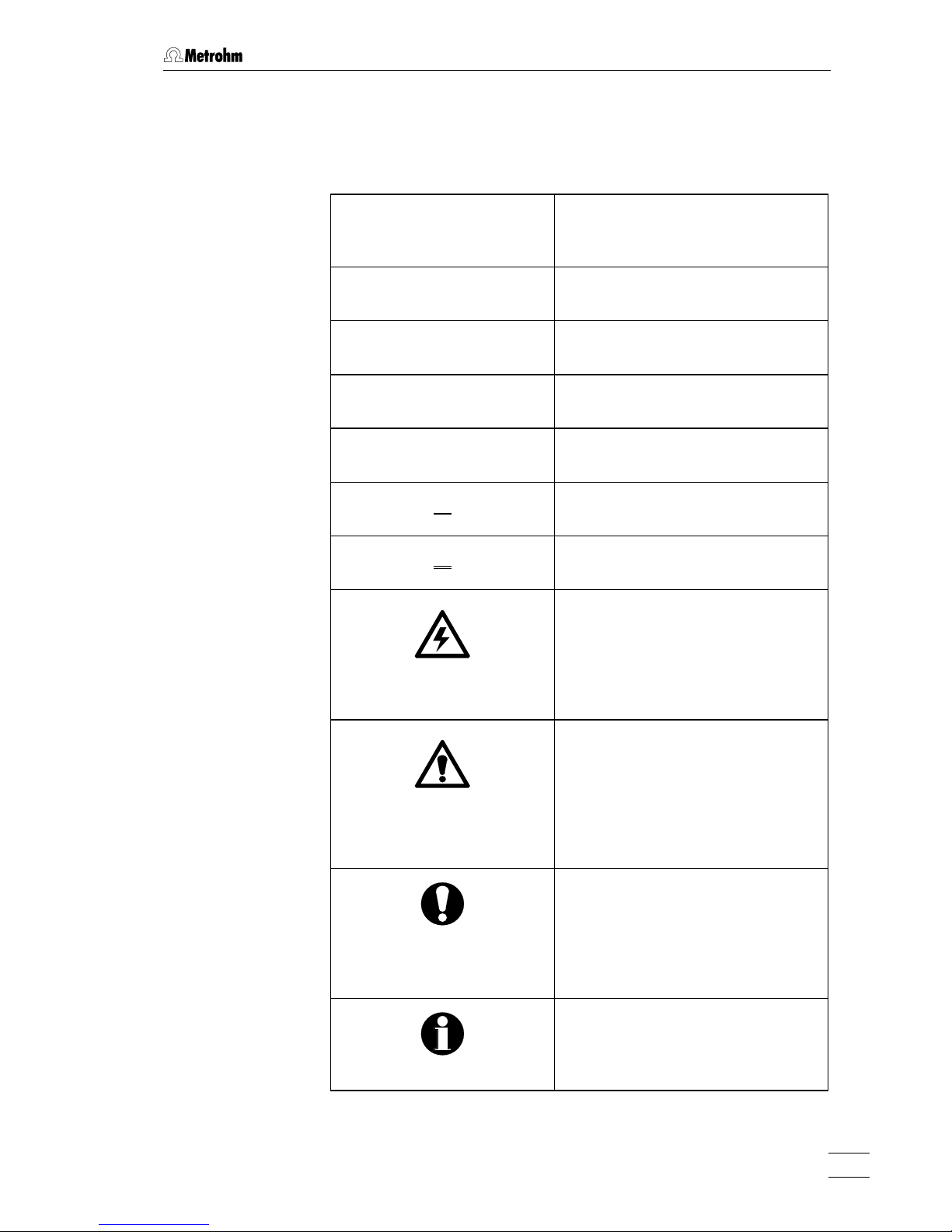

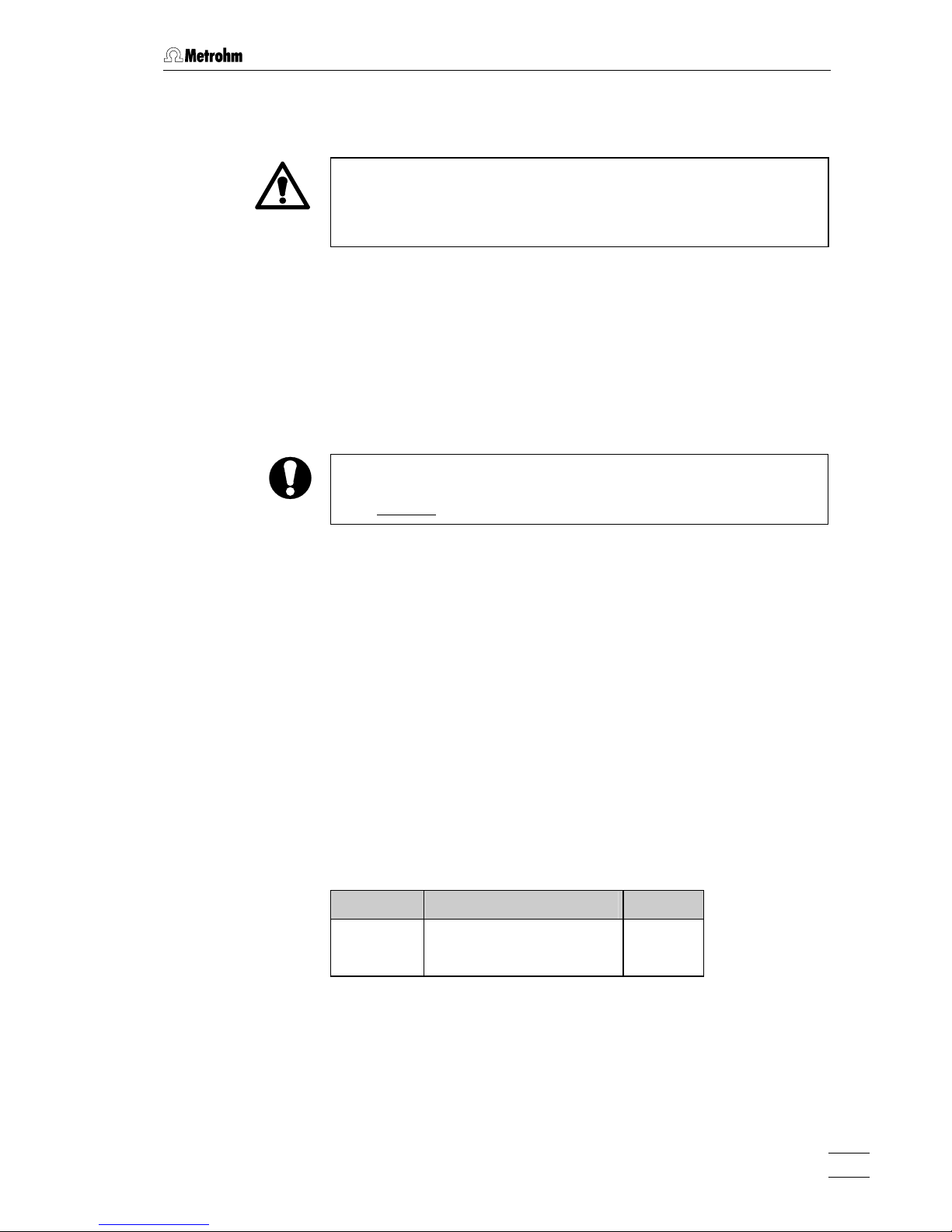

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

Range Menu item, parameter or entry

value

SYSTEM STATE Program window

<OK> Button

[ Ctrl ] Key

35 Part or control of 761

12 Part or control of 750

26 Part or control of 766

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important

information. First read the associated directions before you continue.

Comment

This symbol marks additional

information and tips.

Page 22

1 Introduction

761 Compact IC

12

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 761 Compact IC is assured

in the context of the specifications IEC 1010-1 (protection class 1, degree of protection IP20), the following points should be noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in section 2.4.

• Opening the 761 Compact IC

If the 761 Compact IC is connected to the power supply, the instrument must not be opened nor must parts be removed from it, otherwise there is a danger of coming into contact with components which

are live. Hence, always disconnect the instrument from all voltage

sources before you open it and ensure that the mains cable is

disconnected from mains connection 20 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 761 Compact IC, you should earth yourself and any tools

you are using by touching an earthed object (e.g. housing of the

instrument or a radiator) to eliminate any static charges which exist.

1.4.2 General precautionary rules

• Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

Page 23

2.1 Overview

761 Compact IC

13

2 Installation

2.1 Overview

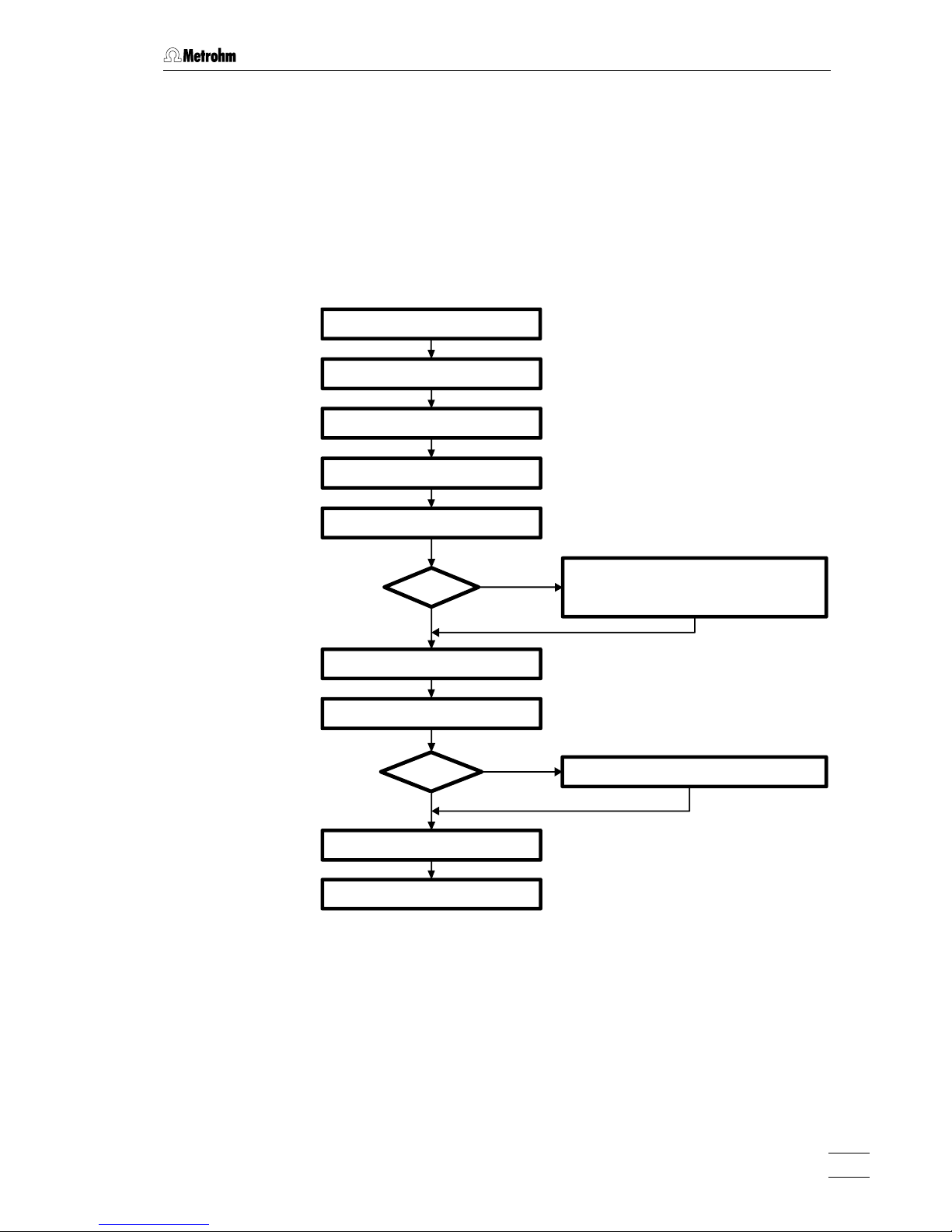

2.1.1 Flow chart

The following flow chart provides an overview of all installation work. You

will find more detailed information in the relevant sections.

Setting up sect. 2.2

Mains connection sect. 2.4

Connecting PC sect. 2.5

Installing accessories sect. 2.3

Suppressor Connect ing suppressor module sect. 2.8

Installing sample loop sect. 2.7.6

Conditioning sect. 2.9

Connecting external devices sect. 2.10

Precolumn

Precolumn with cartridge head sect. 2.7.2

Precolumn with cartridge holder sect. 2.7.3

IC anion precolumn SUPERSEP sect. 2.7.4

Yes

No

Connecting high pr. pump sect 2.6

Connecting column sect. 2.7.7/8

Yes

No

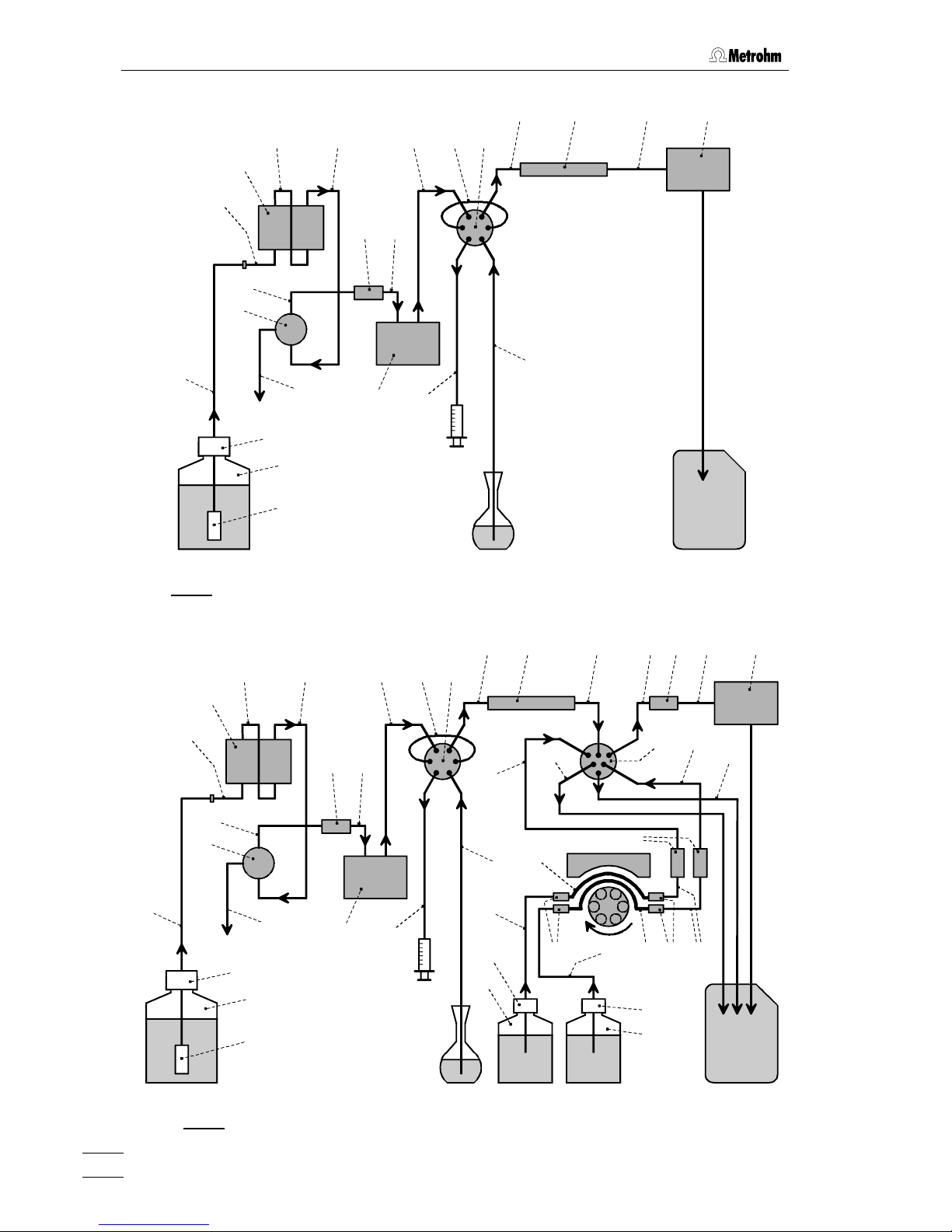

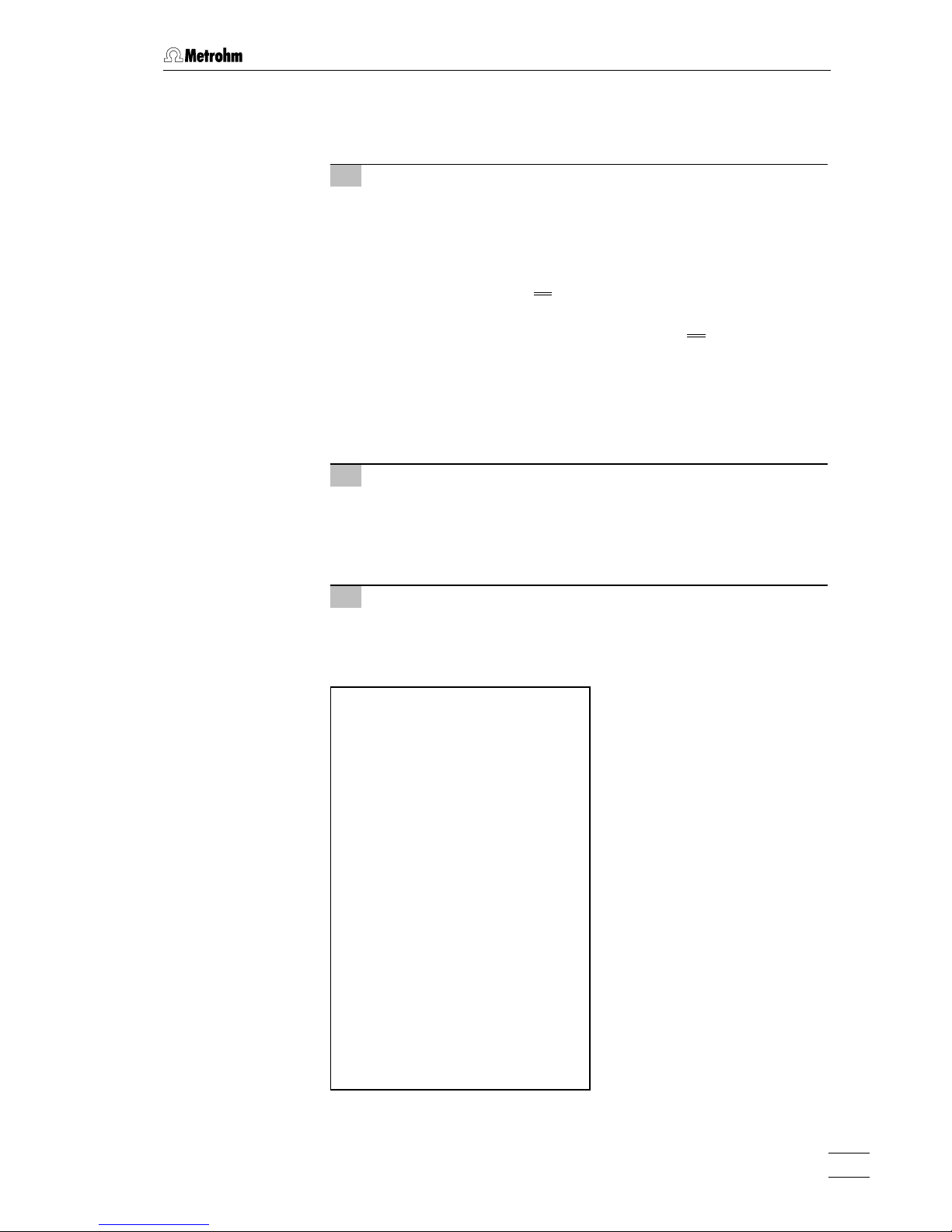

2.1.2 Connections in the 761 Compact IC

The two following illustrations show the internal connections in the 761

Compact IC in schematic form. The meanings of the various numbered

components are given in the detailed illustrations and descriptions in

sections 2.2 – 2.10.

Page 24

2 Installation

761 Compact IC

14

63

40

42

44 43

28 81 45 46

36 35

37

39

66

67

68

38

60

26 29 32

30

4

Fig. 5

: Connecting diagram for 2.761.0010 Compact IC without suppressor

63

40

42

44 43

28 81 96

47

97 33 45 46

36 35

37

39

66

67

68

38

60

26 29 32

99

100

98

4

30

36

92

103

102

89

90

103

102

9191 93 95

101

Fig. 6

: Connecting diagram for 2.761.0020 Compact IC with suppressor

Sample

Eluent

Injection valve

Column

Detector

Waste

Eluent

Column

Detector

Sample

H

2

OH2SO

4

Waste

Page 25

2.2 Setting up the instrument

761 Compact IC

15

2.2 Setting up the instrument

2.2.1 Packaging

The 761 Compact IC is supplied together with the separately packed

accessories in special packagings containing shock-absorbing foam

linings designed to provide excellent protection. The instrument itself is

packed in an evacuated polyethylene bag to prevent the ingress of

dust. Please store all these special packagings as only they assure

transport of the instrument free from damage.

2.2.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 6.2). In the case of transport damage, see

instructions in section 6.4.1 "Warranty".

2.2.3 Location

Position the instrument in the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

To avoid disturbing temperature influences on the insulated column

compartment, the instrument must be protected against direct

sunlight.

2.3 Attaching the accessories

2.3.1 Connection of detector block

The metal-free 1.732.0110 Detector block belongs to the scope of

supply of the 761 Compact IC; it must be inserted in the instrument and

connected up. Proceed as follows:

1 Note the cell constant

• The cell constant c = XX,X /cm is printed on the rear of the

detector block. Note this value; it must subsequently be entered in the software in order to ensure that an exact display

of the conductivity is obtained (see section 2.5.3).

2 Install detector block

• Unscrew the four knurled screws 15 from the top rear panel

17 of the 761 Compact IC and remove rear panel (see Fig. 2).

• Position detector block 46 from the back in the space pro-

vided in the 761 Compact IC and push fully to the front (see

Fig. 3 and Fig. 4).

Page 26

2 Installation

761 Compact IC

16

• Insert the cable permanently attached to the detector block

46 in one of the openings 11 and the outlet capillary in one of

the openings 13 of the rear panel 17.

• Replace rear panel 17 and screw to the 761 Compact IC

using the four knurled screws 15.

3 Connect detector block

• Plug the gray connecting cable permanently attached to the

detector block 46 into connection 23 "Detector Block" of the

761 Compact IC and fasten to the instrument by tightening

the screws in the cable connector (see Fig. 2).

4 Connect waste container

• Lead the outlet capillary of the detector block 46 to a suffi-

ciently large waste container and fix in place.

2.3.2 Connection of syringe and aspirating tubing

For manual filling of the sample loop 29 mounted on the injection valve,

the 6.2816.020 Syringe and the PTFE aspirating tubing 4 already

screwed to the valve are needed. These accessories are mounted or

adjusted as follows:

1 Connect syringe

• Push 6.2816.020 Syringe (without needle) as far as it will go

into connection socket 2 (see Fig. 1).

2 Adjust aspirating tubing

• Loosen the rotary nipple 31 screwed onto the interior side of

feedthrough 3 (see Fig. 3 and Fig. 4).

• Pull PTFE aspirating tubing 4 (see Fig. 3 and Fig. 4) by hand

out of feedthrough 3 as far as desired.

• Retighten rotary nipple 31 on the interior side of feedthrough

3 to fix the aspirating tubing 4 in place.

2.3.3 Connection of the drain tube for the inner compartment

The 761 Compact IC has a connection at the front to which a drain tube

for discharged liquids in the inner compartment can be attached. Proceed as follows:

1 Connect drain tube

• Mount 6.1816.020 Silicone tubing on connection nipple 6

(see Fig. 1).

2 Lead drain tube to collecting vessel

• Lead the other end of the drain tube to a suitable collecting

vessel and fix in place.

Page 27

2.3 Attaching the accessories

761 Compact IC

17

2.3.4 Connection of the drain tube for bottle rack

The 761 Compact IC has a connection at the rear to which a drain tube

for discharged liquids in the bottle rack can be attached. Proceed as

follows:

1 Connect drain tube

• Mount 6.1816.020 Silicone tubing on connection nipple 14

(see Fig. 2).

2 Lead drain tube to collecting vessel

• Lead the other end of the drain tube to a suitable collecting

vessel and fix in place.

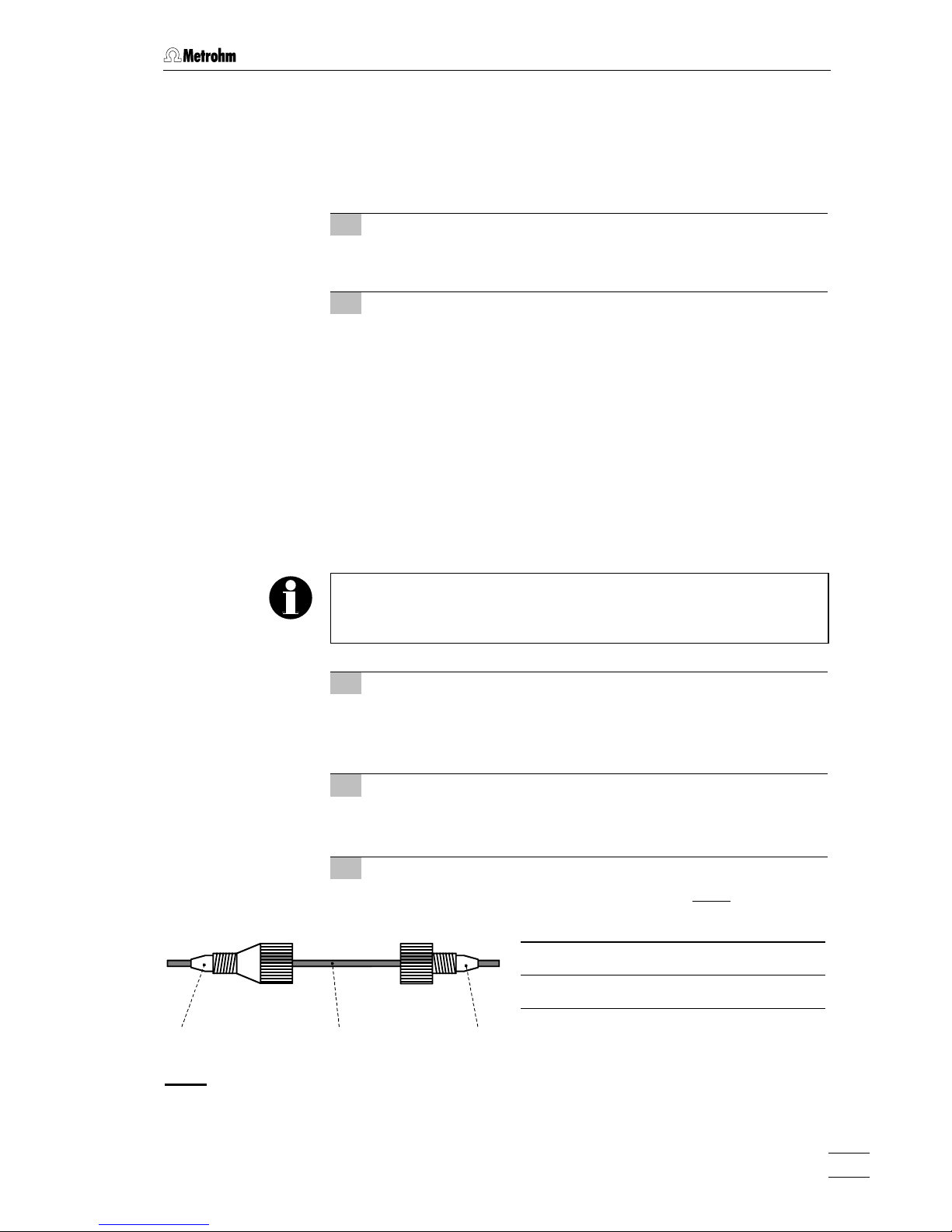

2.3.5 Connection of PEEK capillaries

For the connections between high-pressure pump and detector block

6.1831.010 PEEK capillaries (i.d. = 0.25 mm, e.d. =

1

/16") are used

which are connected using either 6.2744.010 PEEK compression fit-

tings (long) or 6.2744.070 PEEK compression fittings (short).

These PEEK connectors can also be used to connect 6.1822.010 PTFE

microcapillaries (i.d. = 0.3 mm). Proceed as follows:

Capillaries fitted with new connectors must have a perfectly flat cut

surface. To cut PEEK or PTFE capillaries it is best to use the

6.2621.080 Capillary tubing cutter.

1 Mount compression fitting

Slide a compression fitting 54 (6.2744.010) or a compression

fitting 55 (6.2744.070) over the end of the capillary 56 to be

fastened as shown in Fig. 7.

2 Insert capillary in connection

Push capillary end in the corresponding connection as far as it

will go (to avoid dead volume).

3 Tighten compression fitting

Tighten compression fitting 54 or 55 by hand (never use tools).

54 Compression fitting (6.2744.010)

55 Compression fitting (6.2744.070)

56 Capillary

6.1831.010 PEEK capillary or

6.1822.010 PTFE microcapillary

54 56 55

Fig. 7

: Connectors for capillaries

Page 28

2 Installation

761 Compact IC

18

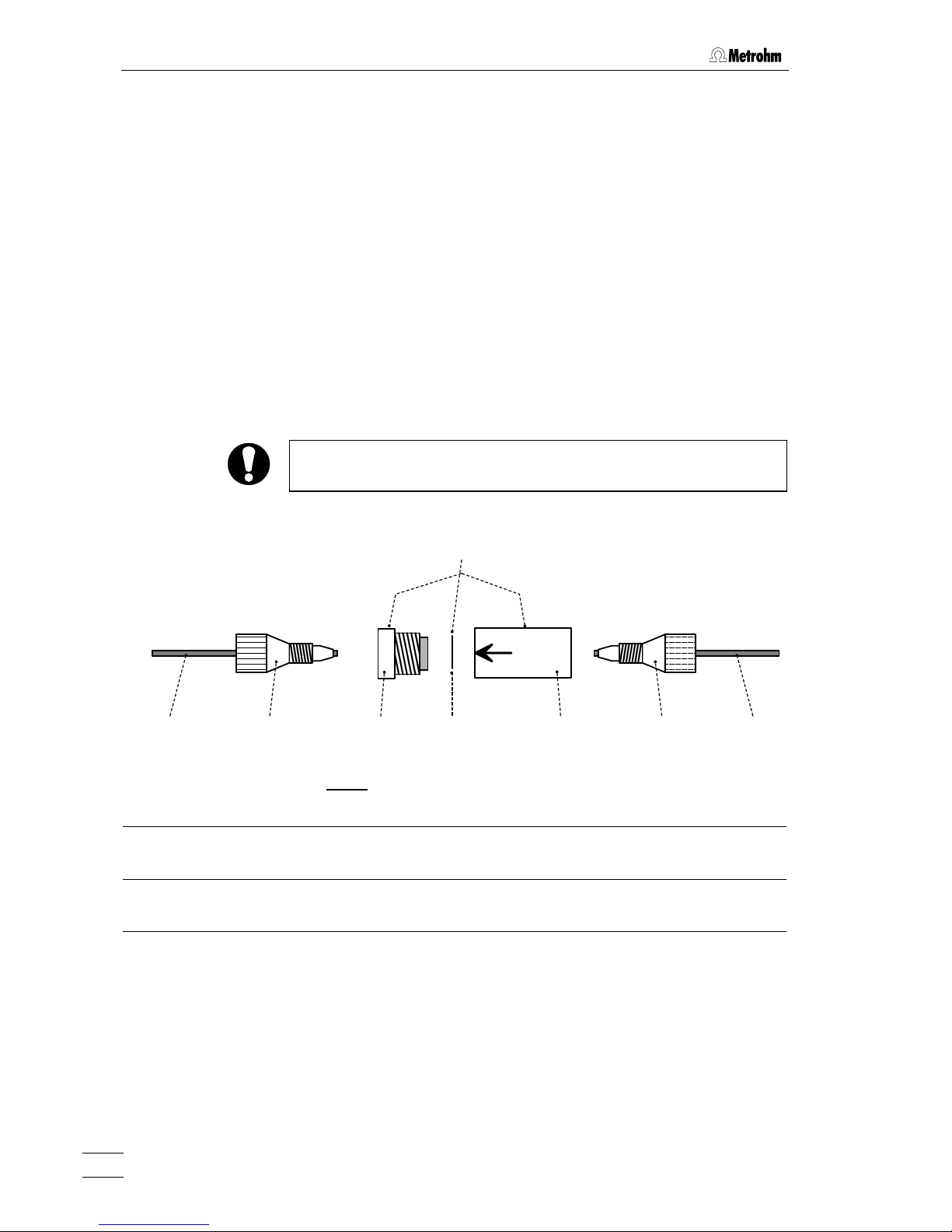

2.3.6 Filter unit PEEK

One 6.2821.120 Filter unit PEEK (see Fig. 8) is already installed be-

tween the high-pressure pump and the injection valve at the 761 Compact IC. This filter unit serves to avoid contamination by abrasive particles of the piston seals.

The two other filter units PEEK supplied with the 2.761.0020 Compact

IC (with suppressor) are installed between the pump tubings of the

peristaltic pump and the inlet capillaries for regeneration and rinsing solution (see section 2.8.2). These filter units serve to protect the suppressor module from foreign particles and bacterial growth.

The Filter unit PEEK 36 consists of the filter-housing 59, the filter-screw

57 and the 6.2821.130 filter 58. For the connection of capillaries 56

PEEK compression fittings 54 (6.2744.010 or 6.2744.070) must be

used. New filters 58 are available as an option with the ordering number

6.2821.130 (set of 10).

For the connection of the filter unit, please note the flow direction

arrow printed on the housing.

56 54

57

58

59 54 56

36

Fig. 8

: 6.2821.120 Filter unit PEEK

36 Filter unit PEEK (6.2821.120) 57 Filter-Screw of Filter Unit

Part of 6.2821.120 Filter unit

54 Compression fitting (6.2744.010) 58 Filter 6.2821.130

Part of 6.2821.120 Filter unit

56 Capillary

6.1831.010 PEEK capillary or

6.1822.010 PTFE microcapillary

59 Filter-Housing of Filter Unit

Part of 6.2821.120 Filter unit

Page 29

2.4 Mains connection

761 Compact IC

19

2.4 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

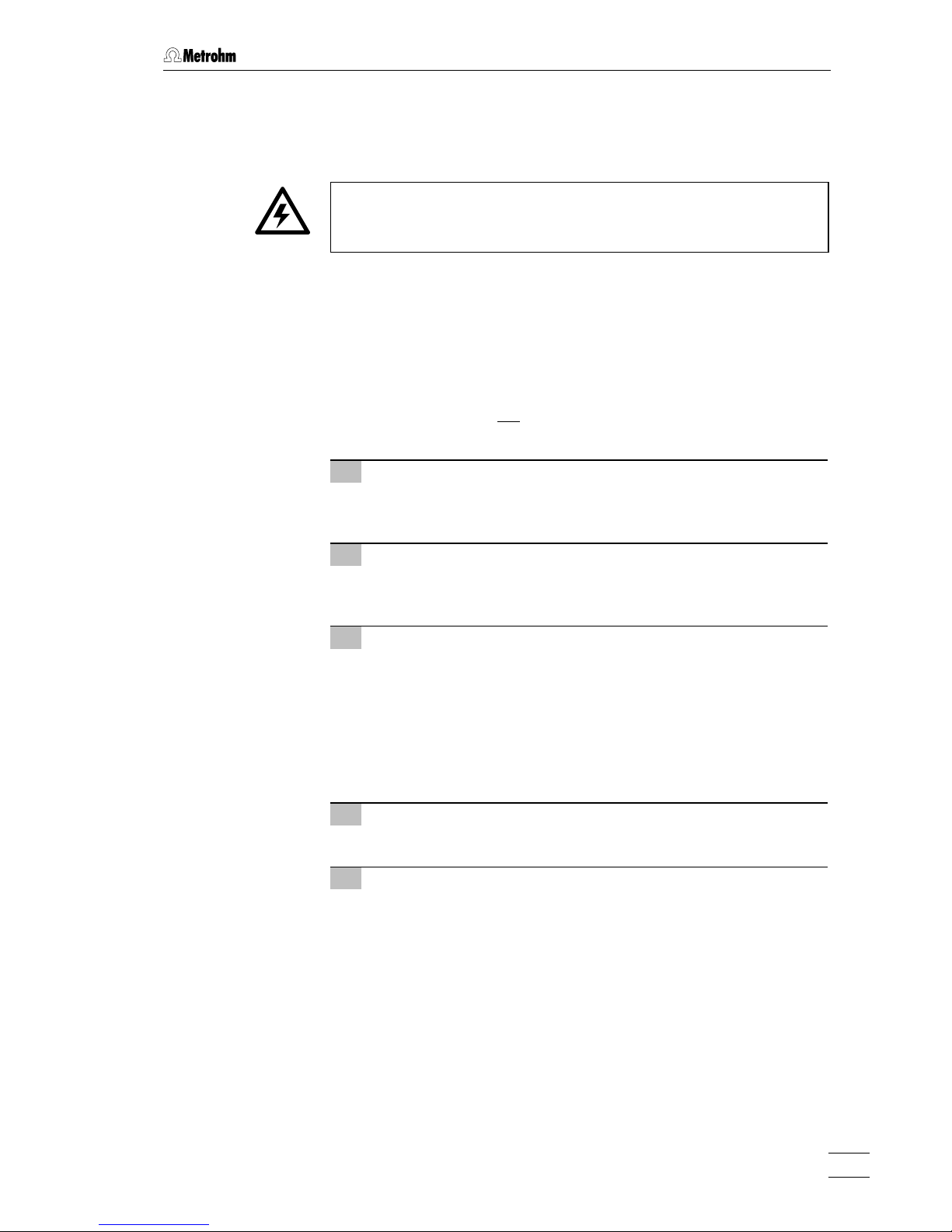

2.4.1 Setting the mains voltage

Before switching on the 761 Compact IC for the first time, check that

the mains voltage set on the instrument (see Fig. 9) matches the local

mains voltage. If this is not

the case, you must reset the mains voltage

on the instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 20 of the

761 Compact IC.

2 Remove fuse holder

Using a screwdriver, loosen fuse holder 21 below the mains

connection plug 20 and take out completely.

3 Check and change fuse if necessary

Carefully take the fuse installed for the desired mains voltage out

of fuse holder 21 and check its specifications (the position of the

fuse in the fuse holder is marked by the white arrow imprinted

next to the mains voltage range):

100…120 V 1.0 A (slow-blow) Metrohm No. U.600.0016

220…240 V 0.5 A (slow-blow) Metrohm No. U.600.0013

4 Insert fuse

Change fuse if necessary and reinsert in fuse holder 21.

5 Install fuse holder

Depending on the desired mains voltage, insert fuse holder 21

in the 761 Compact IC so that the corresponding mains voltage

range can be read normally and the adjacent white arrow points

to the white bar imprinted below the fuse holder (see Fig. 9).

Page 30

2 Installation

761 Compact IC

20

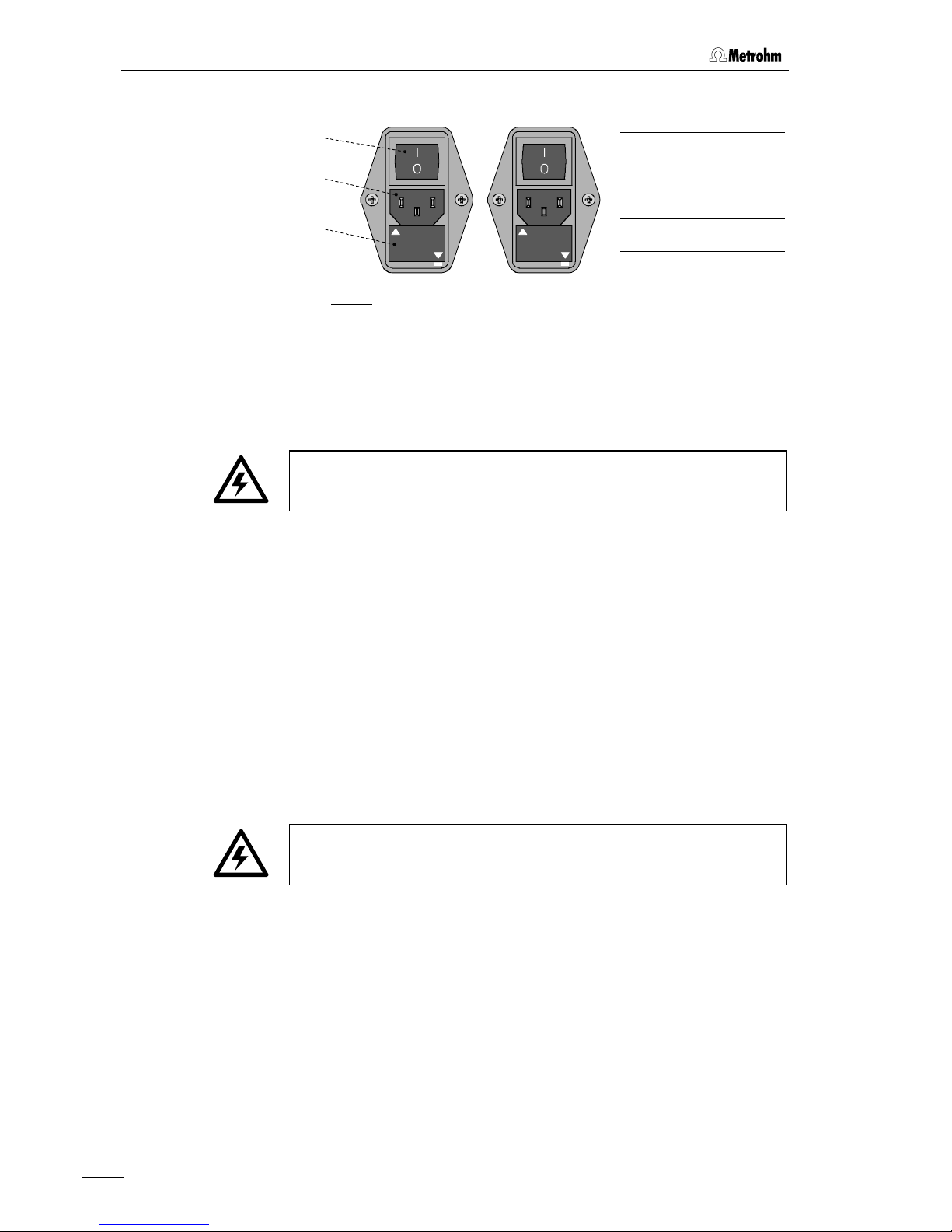

19

220 - 240 V

100 - 120 V

20

21

220 - 240 V

100 - 120 V

Fig. 9

: Setting the mains voltage

2.4.2 Fuses

One of the two fuses 1 A/slow-blow for 100…120 V or 0.5 A/slow-blow

for 220…240 V is installed in fuse holder 21 of the 761 Compact IC as

standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For checking or changing fuses, process as described in section 2.4.1.

2.4.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC standard) must

be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 20 of the 761 Compact IC (see Fig. 9).

2.4.4 On/off switching of the instrument

The 761 Compact IC is switched on and off using mains switch 19.

When the instrument is switched on, the mains pilot lamp 9 lights up.

100 – 120 V 220 – 240 V

19 Mains switch

20 Mains connec-

tion plug

21 Fuse holder

Page 31

2.5 Connection to the PC

761 Compact IC

21

2.5 Connection to the PC

2.5.1 Connecting cable

Always switch off 761 Compact IC and PC before you connect the two

instruments with the 6.2134.100 Cable.

Connect the RS232 interface 22 at the 761 Compact IC to one of the

serial COM ports at the PC using the 6.2134.100 Cable (9 pin/9 pin). If

only a 25-pin COM interface is available on the PC then the 6.2125.110

Adapter cable or a commercially available adapter must be used.

2.5.2 Software installation

These Instructions for Use describe the operation of a single 761

Compact IC connected to a PC. If several instruments should be

operated simultaneously with one PC, the «IC Net 2.0» PC program

must be installed for this purpose (details see Instructions for Use for

«IC Net»).

The PC program «761 Compact IC 1.1» is required for the operation of

the 761 Compact IC; this is contained on the 6.6030.013 CD included in

the accessories. This program runs under Windows 95, Windows 98

and Windows NT operating systems and is installed as follows:

1 Install program

• Insert 6.6030.013 Installation CD into CD drive.

• Select

<Start> and Run. Browse for the setup.exe file on the

installation CD and click on

<OK>. Follow the instructions

given in the setup program.

The software package will be installed in the desired direc-

tory. Icons are created in the program folder and in the

startup folder. In addition to the program files, the following

folders are installed:

Data Folder for storage of chromatogram files

(

*.chw) and batch reprocessing files (*.bar)

Devices Folder for storage of device files (*.dev)

Methods Folder for storage of method files (*.mtw)

Reports Folder for storage of report files (*.txt)

and graphic files (

*.wmf)

Systems Folder with subfolders with system files

(

*.smt) and sample queue files (*.que).

2 Registration

• Please send us your 8.761.8007 Registration card as soon as

possible. Only registered users will get updated program versions at a special price.

Page 32

2 Installation

761 Compact IC

22

The installed files (incl. system and method files) are generally not

write-protected. To prevent these files from being deleted by mistake,

switch on the write-protection or make a backup copy in another

directory.

2.5.3 Basic settings

When the program is started for the first time several basic settings

must be made for the 761 Compact IC. Proceed as follows:

1 Start program

• Double-click the software icon to start the program. The

program window with the opening picture is opened and the

Log In window appears on the screen:

• Do not

enter any password here, just click on <Log In>. The

following window appears:

• Enter company, division and name and click on

<OK>. This

window appears only one time after software installation.

2 COM port settings

This step must only be carried out if a different COM interface

from COM1 is used for connection to the 761 Compact IC.

Page 33

2.5 Connection to the PC

761 Compact IC

23

• Click on Options / 761 Compact IC:COM1 to open the Links

window:

• Click on

COM1 using the right mouse button and select the

Change menu item to open the following window listing all

available COM ports at the PC:

• Select the desired COM port to which the 761 Compact IC

has been connected and click on

<OK>. The window is

closed.

• Close the

Links window by clicking on <OK>.

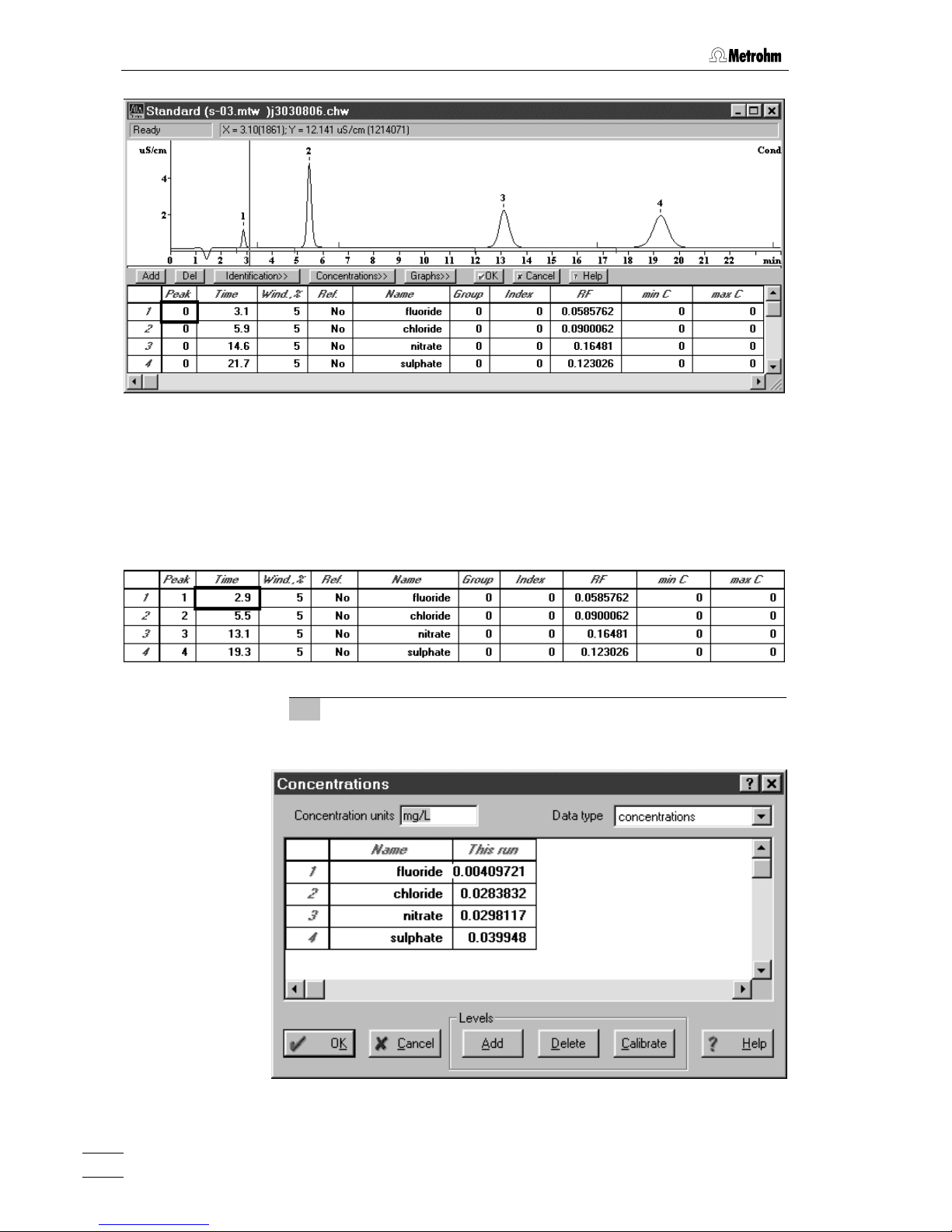

3 Open a system

• Click on File / Open / System in the main window. Open either

the subfolder

Non-suppressed (for 2.761.0010 Compact IC

without

suppressor) or the subfolder Suppressed (for

2.761.0020 Compact IC with

suppressor). Select the system

file

n-01.smt or s-01.smt and click on <Open>. The correspond-

ing system window is opened:

Page 34

2 Installation

761 Compact IC

24

• Select the Connect to workplace menu item of the Control menu

in this window.

• If the connection between PC and Compact IC is working the

message

Hardware settings file for 761 unit with serial number

'#####' not found! Create?

will appear. Click <Yes> in order to

create the configuration file

#####.761 for this instrument.

• If the connection between PC and Compact IC does not work

then the message

Detection of hardware failed[761 Compact IC

[ COM# ]]

appears in the SYSTEM STATE window. In this case

check whether the instrument has been switched on, whether

the connection cable is connected up properly and whether

the COM interface has been set correctly (see point 2). Then

repeat point 3.

4 Hardware settings

Of the general hardware settings only the input of the cell constant

is described. Standard settings can normally be used for all other

parameters.

• Click the 761 icon using the right mouse button and select

the

Hardware item. The Hardware settings window is opened:

• In the

Cell constant field enter the cell constant which is printed

on the 1.732.0110 Detector block (see section 2.3.1).

• Click on

<OK> to close the window and save the settings.

Page 35

2.6 High-pressure pump

761 Compact IC

25

2.6 High-pressure pump

In order to avoid damage to the pump it must never be operated dry.

Each time that the pump is switched on always first check that the

eluent supply has been connected up correctly and that sufficient

eluent is present in the eluent bottle.

2.6.1 Removing the transport security screws

In order to prevent the pump drive from being damaged during transport the pump head is fitted with three transport security screws 18 (see

Fig. 2). These transport security screws must be removed before the

high-pressure pump is started up. Also remove the red sticker attached

to the pump head.

In order to avoid damage to the pump head these three security

screws should be attached to the pump head each time that it is to be

transported.

2.6.2 Installing the pulsation dampener

To protect the column material against pressure drops caused by the

injector, the 6.2620.150 Pulsation dampener MF has to be installed

between the high-pressure pump and the injection valve of the 761

Compact IC. Proceed as follows (see Fig. 10):

1 Install pulsation dampener

• Position the pulsation dampener 60 in the interior of the 761

Compact IC on the base.

2 Connection to the pump

• Unscrew PEEK capillary 35 of coupling 33 and attach it to

connection 62 of the pulsation dampener 60.

3 Connection to injection valve

• Unscrew PEEK capillary 26 of coupling 33 and attach it to

connection 61 of the pulsation dampener 60.

The pulsation dampener is filled with isopropanol and must be rinsed

with eluent before connection to a separating column (see section

2.6.4).

The 6.2620.150 Pulsation dampener can be operated in both directions.

Page 36

2 Installation

761 Compact IC

26

37

39

36 35 62

32

26

6061

Fig. 10

: Connection of the pulsation dampener

26

Inlet capillary for injector

6.1831.010 PEEK capillary,

length L = 24 cm

39 Purge valve

32 Injection valve 60 Pulsation dampener (6.2620.150)

35 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

61 Connection to injection valve

36 Filter unit PEEK (6.2821.120) 62 Connection to purge valve

37 Connection capillary

6.1831.010 PEEK capillary,

length L = 13 cm

Page 37

2.6 High-pressure pump

761 Compact IC

27

2.6.3 Connecting the eluent bottle

The eluent supply line from the storage bottle to the high-pressure

pump is connected as follows (see Fig. 11):

Only degassed (with N

2

, He or vacuum) and microfiltered (0.45 µm

filter) eluents should be used!

The 6.1608.070 Eluent bottle (2 L) supplied is not suitable for

vacuum degassing. Use a pressure-resistant container for this.

Care must be taken that the eluent used is freely miscible with any

solvent remaining in the pump head (the pump head leaves the

factory filled with either isopropanol or methanol/water). If this is not

the case then the pump must first be rinsed with a solvent which is

miscible with both the previous eluent and the following eluent (e.g.

acetone).

1 Prepare eluent bottle

• Prepare, microfilter (0.45 µm microfilter) and degas (with N2,

He, or vacuum) the suitable eluent for the required application

and separating column.

• Fill eluent into eluent vessel 67 (clear glass, 2 L).

• Place eluent bottle 67 at the front in bottle holder 10 on the

761 Compact IC (see Fig. 1).

2 Install bottle attachment

• Firmly screw threaded stopper 65 (6.1446.040; part of

6.1602.160) into the smaller threaded opening (M6) of bottle

attachment 66 (6.1602.105; part of 6.1602.160).

• Firmly screw aspirating filter 68 onto aspirating tubing 63.

• Pull the other end of aspirating tubing 63 through the larger

threaded opening (M8) of bottle attachment 66 from below.

• Push O-ring (E.301.0021; part of 6.1602.160) over the free

end of aspirating tubing 63 and move it towards bottle attachment 66.

• Push tubing nipple 64 (4.420.4300; part of 6.1602.160) over

the free end of aspirating tubing 63, move it as far as required towards bottle attachment 66 and screw it loosely in

the larger opening of bottle attachment 66.

• Insert aspirating tubing 63 with screwed-on aspiration filter 68

into eluent bottle 67 and screw bottle attachment 66 onto

eluent bottle 67.

• Pull aspirating tubing 63 so far through the opening of tubing

nipple 64 that aspirating filter 68 is touching the bottom of

eluent bottle 67.

• Fix aspirating tubing 63 in place by screwing shut tubing

nipple 64.

Page 38

2 Installation

761 Compact IC

28

3 Mount CO2 absorber tube

• First place a piece of cotton wool 70 followed by CO2 ab-

sorber 69 (e.g. Merck soda-lime pellets with indicator, no.

6839.1000) in the large opening of absorber tube 72 and then