Page 1

760 Sample Changer760 Sample Changer

Instructions for Use

8.760.1013

Page 2

CH-9101 Herisau/Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

E-Mail info@metrohm.ch

Internet www.metrohm.ch

760 Sample Changer

Instructions for Use

8.760.1013

2000.07 up/dm

Page 3

Table of Contents

Page

1 OVERVIEW .................................................................1

1.1 Side View .................................................................... 1

1.2 Rear View ....................................................................2

1.3 Sensors ......................................................................3

2 INSTALLATION ............................................................4

2.1 Setting up the Instrument ...........................................4

2.2 Safety Considerations ................................................6

2.3 Arranging the Accessories .........................................7

2.3.1 Connecting the Keyboard ...................................7

2.3.2 Magnetic Stirrer ................................................. 7

2.3.3 Racks ............................................................... 7

2.3.4 Mounting and Setting up the Titration Heads ........ 8

2.3.5 Use of the sample beaker for Karl Fischer

Titration ........................................................... 10

2.4 Remote Connections ............................................... 11

2.4.1 Typical Combinations of Instruments ................ 12

2.5 Racks ........................................................................ 14

3 INTRODUCTION .........................................................15

3.1 Important Features ................................................... 15

3.2 Key Functions ........................................................... 16

3.3 Memory Initialization ................................................ 17

3.4 Configuration Procedure .......................................... 17

3.4 The Methods ............................................................. 20

4 APPENDIX ................................................................23

4.1 Error Messages ......................................................... 23

4.2 Method Listings ........................................................ 25

4.3 Technical Specifications ........................................... 29

4.4 Servicing and Maintenance ....................................... 30

4.4.1 Servicing ......................................................... 30

4.4.2 Maintenance / Attendance ................................ 30

4.5 Warranty and Conformity ......................................... 31

4.5.1 Warranty ......................................................... 31

4.5.2 Certificate of Conformity .................................. 32

4.6 Accessories .............................................................. 34

5 INDEX......................................................................37

Page 4

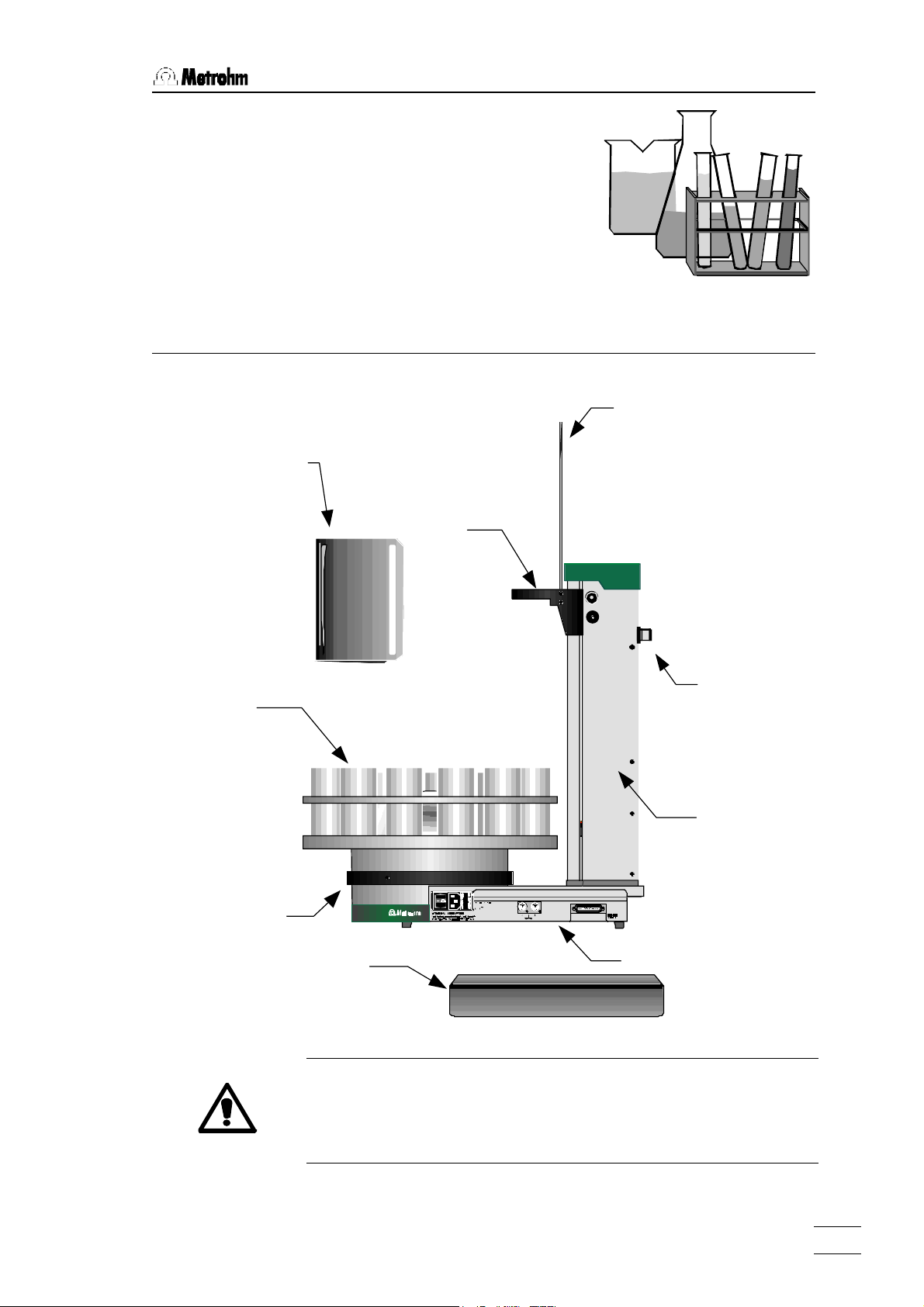

1.1 Side View

Plug cover

Rack

Line sleeve

Line frame

Tower

Connectors

Stirrer rail

1 Overview

1.1 Side View

Splash protection

Lift

760 Sample Changer, Overview

Safety note:

Never operate the 760 Sample Changer without splash protection

and plug cover being mounted. The plug cover prevents any contamination of the connectors, caused by spilled solvents or chemicals.

1

Page 5

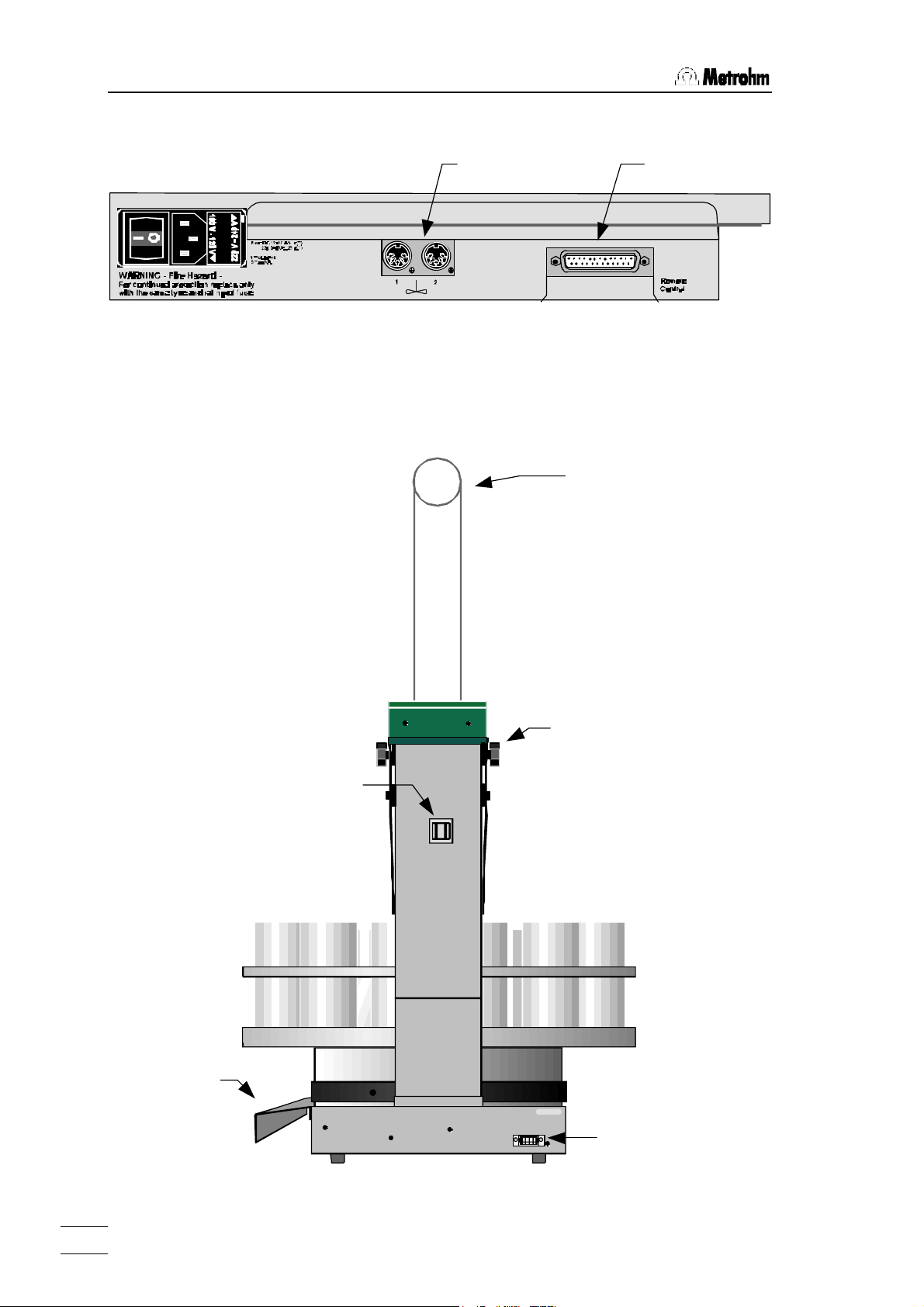

1.2 Rear View

Remote socket

Line sleeve

Plug cover

Keyboard connector

Line frame

The Connectors (side view):

Stirrer sockets

The remote socket serves the connection of Metrohm- or other

measuring instruments that communicate via a parallel cable

(see p. 11).

1.2 Rear View

Type 1.760.0010 Nr. 0010/01104

Keyboard

Made by Metrohm Herisau Switzerland

Mounting srew

for splash protection

760 Sample Changer, Overview

2

Page 6

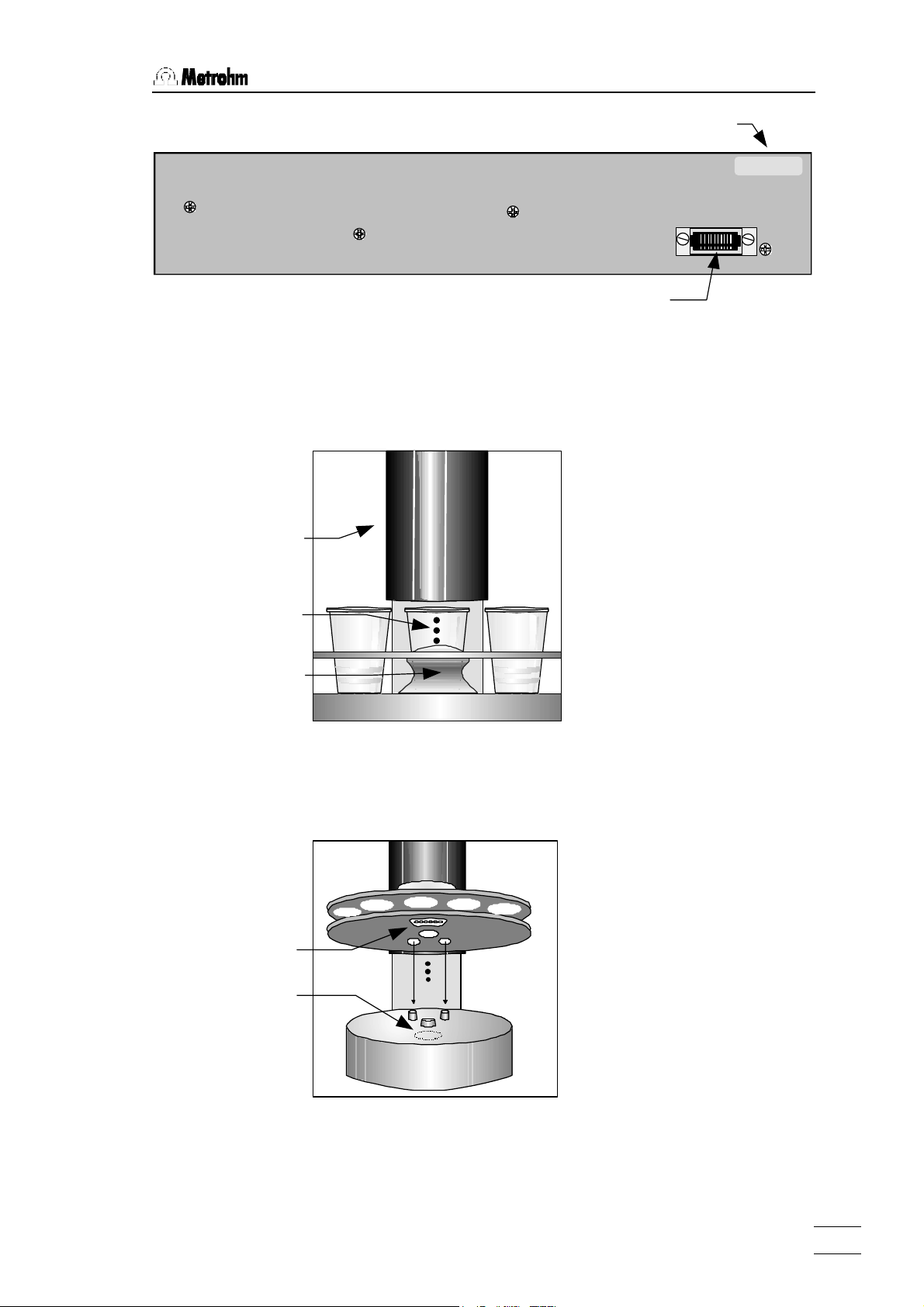

1.3 Sensors

Keyboard connector

Splash protection

Beaker indicator

Rack

Magnetic indicator

Manufacturing number

Magnet holder

Keyboard Connector (rear):

Type 1.760.0010 Nr. 0010/01104

Keyboard

1.3 Sensors

Beaker test

Made by Metrohm Herisau Switzerland

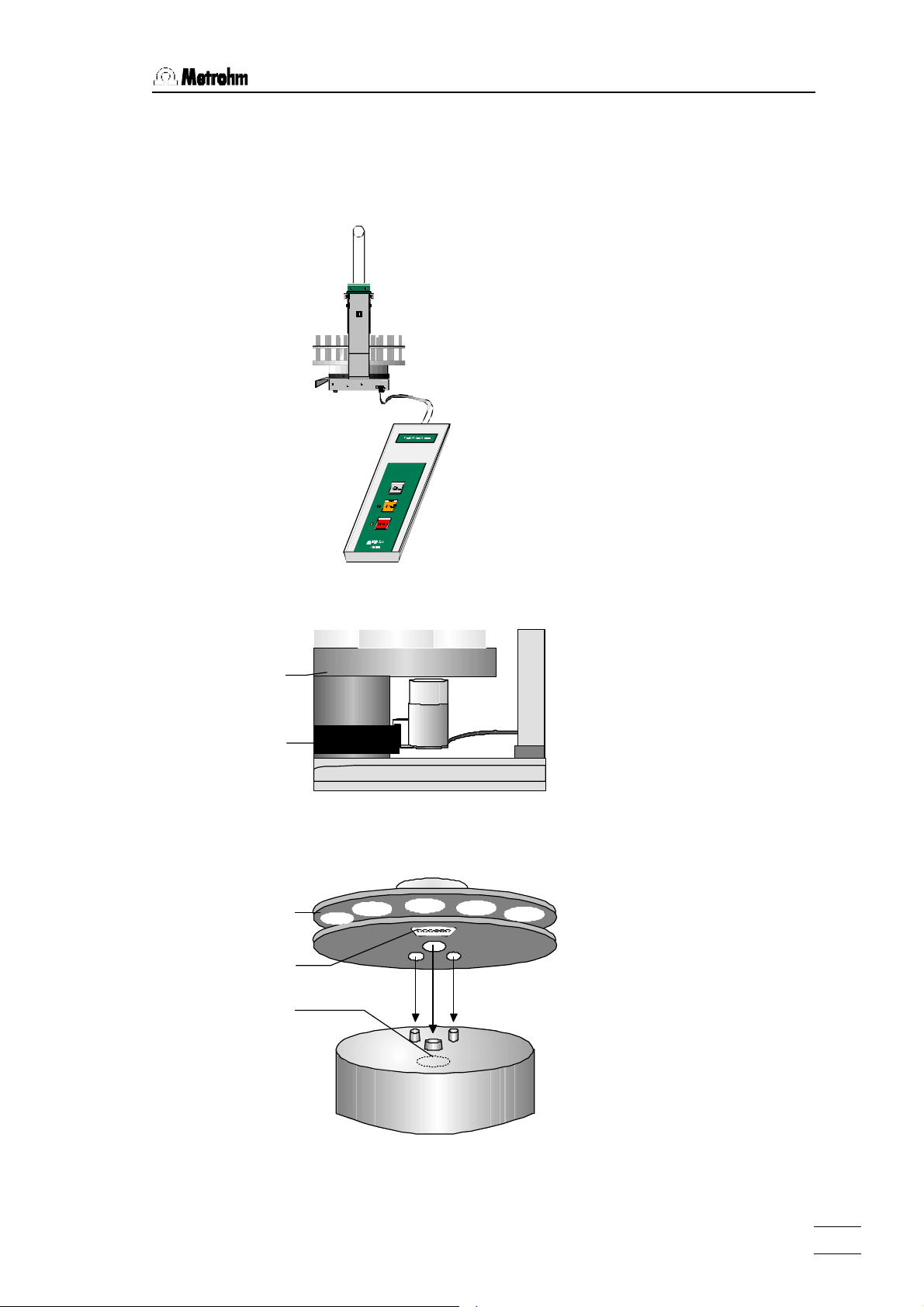

Each tower of the 760 Sample

Changer is equipped with a

beaker indicator to detect the

presence of a beaker in front

of the tower. This infrared

sensor detects many different

materials, if any object is

placed in correct position. This

beaker test is carried out after

each MOVE operation.

Front view

Magnetic rack code indicator

The magnetic sensor for the

detection of the individual rack

codes is mounted below the

sample changer's turntable.

The magnetic binary code of

the racks can only be read, if

the rack is in initial position

and therefore the magnet

holder is in accurate position

right above the rack code indicator. For this reason the

760 Sample Changer should

be initialized by <RESET> or

turned off and on right after

every rack change.

760 Sample Changer, Overview

3

Page 7

2.1 Setting up the Instrument

2 Installation

2.1 Setting up the Instrument

Packaging

The 760 Sample Changer is supplied with the accessories in separate special packages designed to ensure maximum protection.

These contain shock-absorbing foam linings. As only these special

packages guarantee damage-free transport of the instrument, it is

essential you store them in a safe place.

Control

Immediately following delivery, check that the consignment is

complete and undamaged (compare with delivery note and accessories list in the Instructions for Use, page 34). In case of damage

see "Warranty", page 31.

Setting up

The 760 Sample Changer is a rugged instrument and may be used

in rough environments such as laboratories and manufacturing

plants. It must not be exposed to a corrosive atmosphere. If the

sample changer is operated in a rough environment, regular maintenance is strongly recommended.

Power Supply

Follow these instructions to connect the 760 Sample Changer to

the power supply. Ensure that the instrument is never operated

with incorrect voltage ratings and/or with fuses of an incorrect rating, otherwise there is a fire hazard!

Setting the instrument supply voltage

Before switching on the 760 Sample Changer for the first time,

check that the line voltage set on the instrument (see next page)

matches the local power supply voltage. If this is not the case,

change the voltage setting as follows:

760 Sample Changer, Installation

4

Page 8

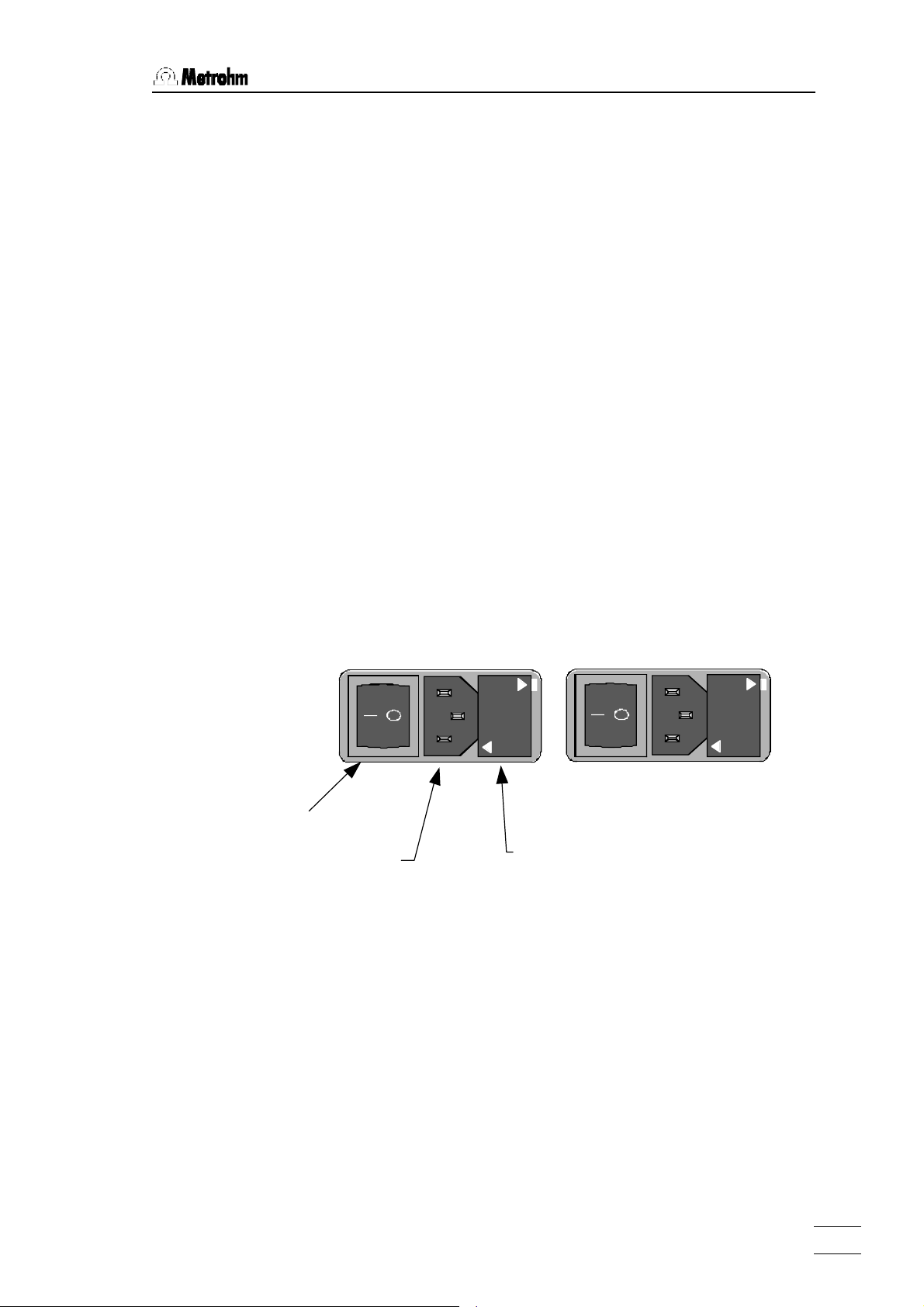

0 Power Supply

100 – 120 V

220 – 240 V

Fuse holder

• Disconnect line cable

Unplug the 760 Sample Changer.

• Remove fuse holder

Using a screw driver, loosen the fuse holder and pull it out.

• Checking and replacing fuse

Carefully remove the built-in fuse and check its specifications.

(The position of the fuse in the fuse holder is marked by the

white arrow printed next to the supply voltage):

100……120 V 0.5 A (slow) ord. no. U.600.0014

220……240 V 0.25 A (slow) ord. no. U.600.0011

• Replace fuse

Replace fuse if necessary and reinsert it in the fuse holder.

• Insert the fuse holder

Insert the fuse holder according to the appropriate supply voltage. The white arrow besides the desired voltage has to point

towards the white block mark printed on the fuse holder's panel

(see below).

100

-

-

120 V

240 V

-

-

220

220

-

-

240 V

120 V

-

-

100

Power switch

Power plug

760 Sample Changer, Installation

5

Page 9

2.2 Safety Considerations

2.2 Safety Considerations

Safety note:

Never operate the 760 Sample Changer without splash protection

and plug cover being mounted. The plug cover prevents any contamination of the connectors, caused by spilled solvents or chemicals.

If failure or malfunctioning occurs during operation of the 760 Sample Changer, the Metrohm Service Department should be

consulted.

If opening the instrument is unavoidable, the following safety precautions are to be strictly adhered to:

Before opening the instrument disconnect it from all electrical sources. Make sure that the power plug has been pulled

out.

Electronic components are sensitive to static electricity and can be

destroyed by discharge. Before touching any components inside

the instrument, both the person and his tools should be grounded

by grasping a grounded object (for example: a metallic part of the

casing of the instrument or a radiator) in order to eliminate any

static electricity.

Only in exceptional cases should the instrument be opened while it

is switched on. Because parts that conduct current are exposed in

this case, this should only be undertaken by an expert who is acquainted with the associated dangers.

When peripheral instruments are connected to the 760 Sample

Changer, the sample changer and the instruments to be connected

have to be switched off, otherwise all instruments could suffer

damage.

If it becomes apparent that the instrument can no longer be operated safely, it must be put out of operation.

760 Sample Changer, Installation

6

Page 10

2.3 Arranging the Accessories

Rack

Magnet holder

Magnetic sensor

Rack

2.3 Arranging the Accessories

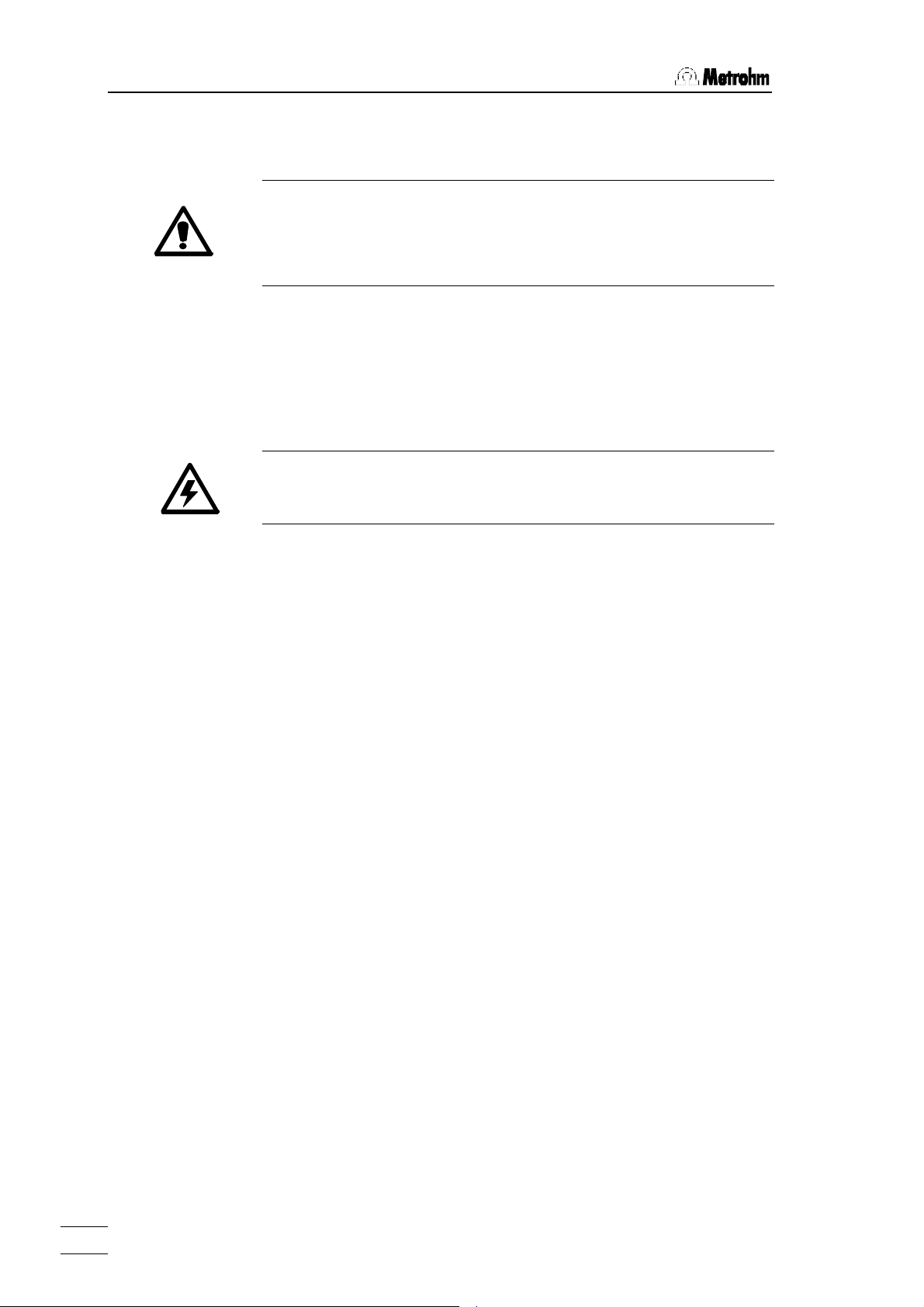

2.3.1 Connecting the Keyboard

Type 1.760.0010 Nr. 0010/01104

Keyboard

Made by Metrohm Herisau Switzerland

The keyboard is to be connected to the keyboard

socket on the rear side of the

sample changer.

To disconnect press the plug

together slightly on both

sides.

2.3.2 Magnetic Stirrer

Stirrer rail

2.3.3 Racks

Magnetic stirrers 2.741.0010

may be placed in any position

on the stirrer rail beneath the

rack.

After placing the rack on the

turntable, the sample

changer must be initialized by

pressing the <RESET> key

or turning the sampler

changer off and on. This

enables the safe reading of

the magnetic rack code and

can only be done if rack

position 1 is directed to

tower 1. Before a rack is

used for the first time, the lift

positions have to be set (s.

Chapter. 3.4).

760 Sample Changer, Installation

7

Page 11

2.3 Arranging the Accessories

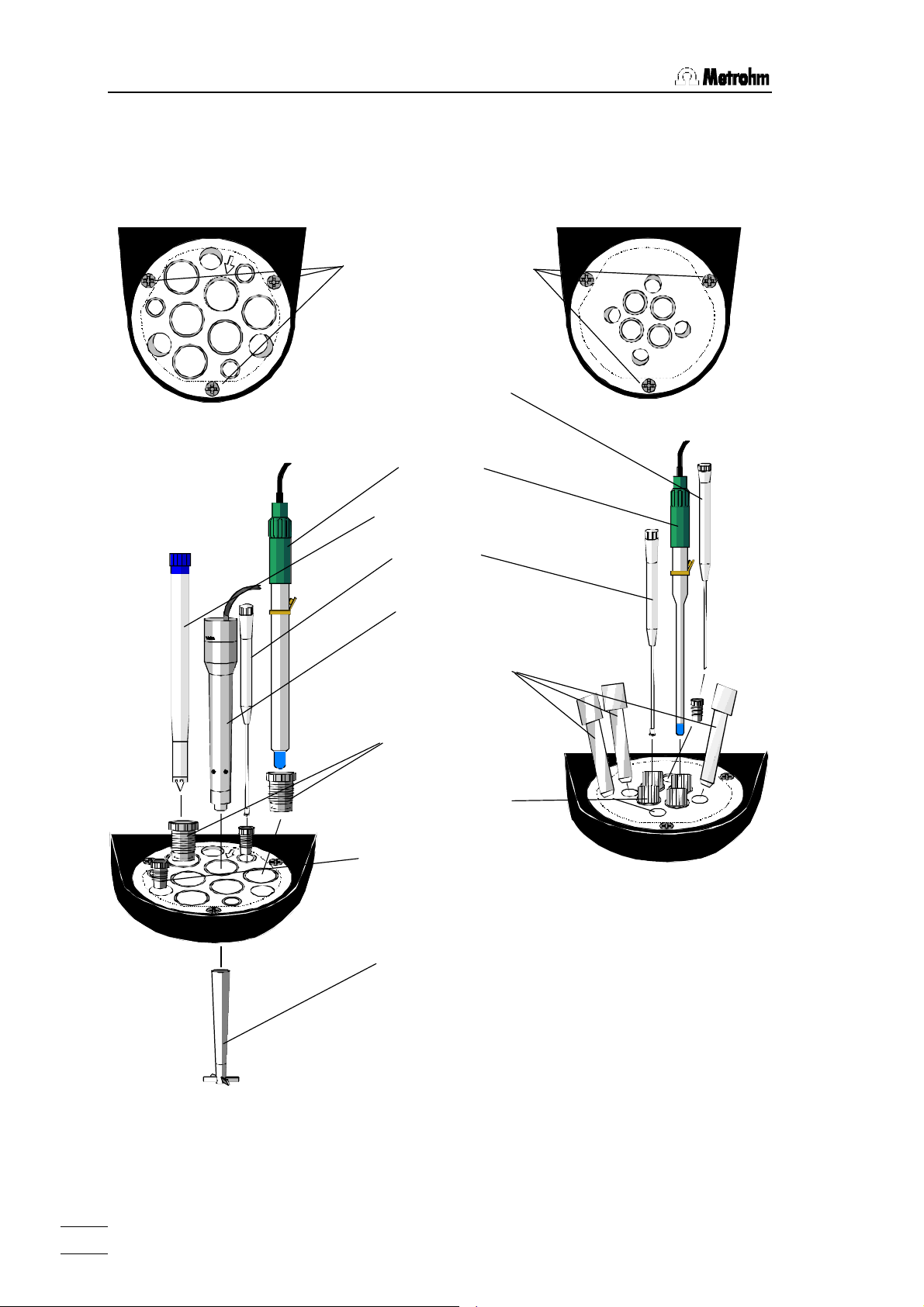

2.3.4 Mounting and Setting up the Titration Heads

Macro Titration head

6.1458.010

Micro Titration head

Mounting screws

M8 Aspiration tip

(also for Macro Titration head)

6.1543.170

Electrode

Rotating nozzle

6.2740.000

Burette tip

6.1543.200

Rod stirrer

2.722.0020

M6 Spray nozzles

(also for Macro-Titration head)

6.2740.020

SGJ14 sleeve

6.1236.020

M8 Thread stopper

4.658.0180

SGJ9 Guide sleeve

6.2709.070

Stirrer propeller

6.1909.020

6.1458.020

Use only the designated

Micro electrodes with the

Micro Titration head, see

accessory list, page 34.

Note on Macro Titration head

The arrow sign marks the slightly sloped SGJ14 boring, which enables to center a rod

stirrer or an electrode in a narrow titration vessel.

760 Sample Changer, Installation

8

Page 12

2.3 Arranging the Accessories

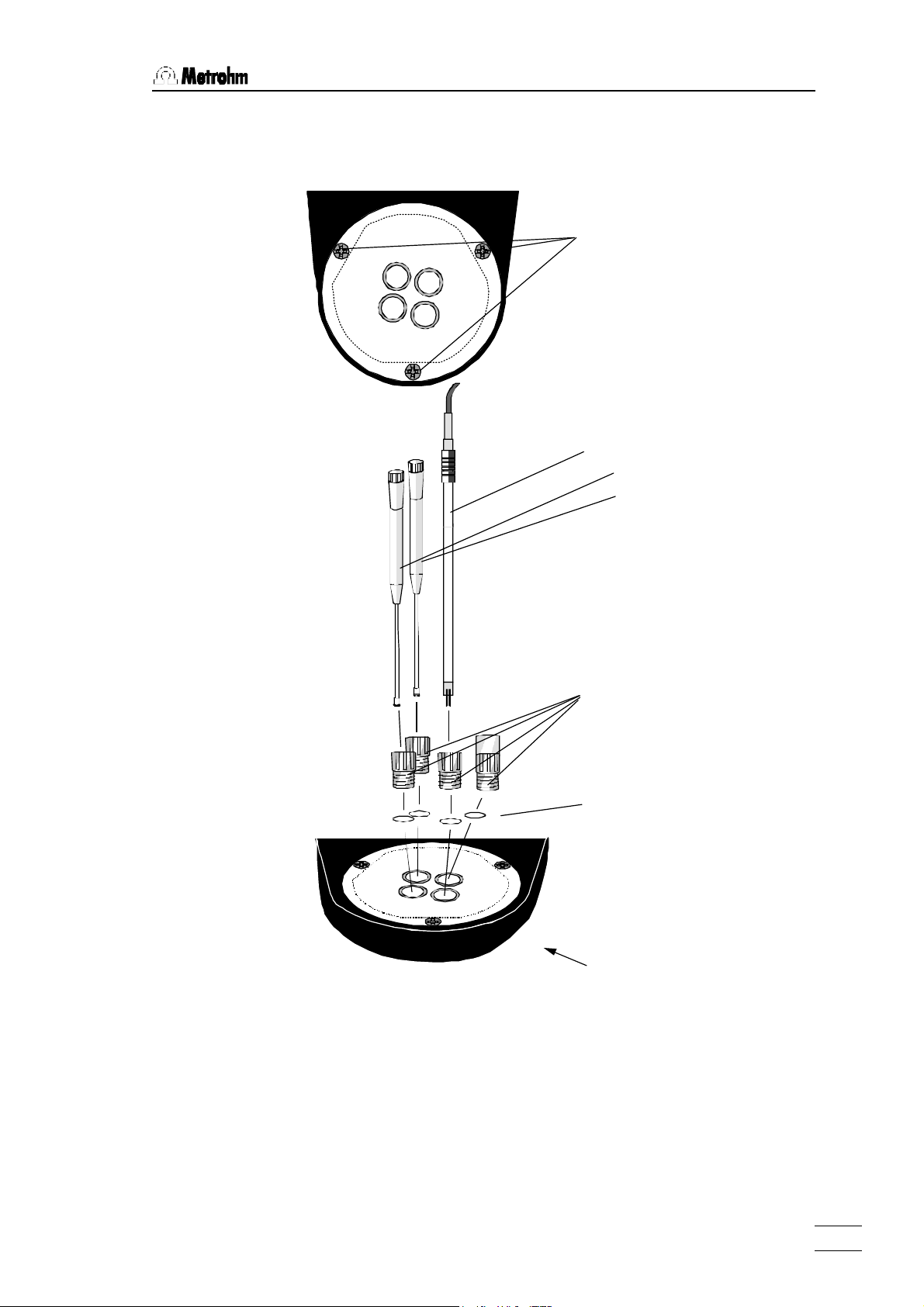

Mounting and Setting up the Titration head KFT

Titration head KFT

6.1458.030

Mounting screws

Double-Pt-Electrode

Burette tips

6.0340.000

6.1543.200

M10 Thread connectors

6.1543.200

O-Rings

E.301.0022

O-Ring (bottom side)

E.301.0080

Note:

For an optimal sealing of the titration vessel, the M10 thread con-

nectors should be mounted together with the O-rings.

All tubing and cables connected to the titration head should be

guided through the line frame to ensure full motility for the lift.

Note that there is enough line reserve for a complete down

movement of the lift.

760 Sample Changer, Installation

9

Page 13

2.3 Arranging the Accessories

Al foil

2.3.5 Use of the Sample Beaker for Karl Fischer Titration

For Karl Fischer titration the

Foil holder

6.2037.040

Sample beaker

During the method run the lift is moved down to the working

position. Thereby, the electrode and burette tips break through the

Al foil. Using Al foil 6.2820.000 this means no risk for the

instruments. This step can be facilitated by binding together all three

devices approx. 2 cm above the bottom of electrode and

burette tips using an O-ring E.301.0022. Thus, the impulse is

focused on a small area of the Al foil.

weighted sample is dosed into

the sample beaker together with

a stirring bar 6.1903.010.

The beaker is sealed with a

centered aluminium foil

6.2820.000 using the foil holder.

760 Sample Changer, Installation

10

Page 14

2.4 Remote Connections

2.4 Remote Connections

Remote

Dosimat

Titrino

Family

765

776

702

716

718

719

720

736

751

758

784

785

Valves

760 Sample Changer

Relay Box 731

Pumps,

e.g. 772

Connecting peripheral instruments to the 760 Sample Changer requires Metrohm cables. Otherwise a safe data transmission may

not be guaranteed.

The required cables are listed in the following table. Details about

the control commands are given in the Instructions for Use of the

corresponding instrument.

Connection of: Cable ordering no.

Titrino or 692/712/713 pH-Meter/Ionmeter/Conductometer 6.2141.020

Titrino and 765 or 776 Dosimat 6.2141.040

691 pH-Meter 6.2141.060

692 Ionmeter and 765 Dosimat 6.2141.070

678/682/686/672 Titroprocessors 3.980.3640

678/682/686/672 Titroprocessors and 671 Switch Box 3.980.3650

All instruments have to be switched off, before they are connected.

Otherwise the instruments could suffer from damage.

760 Sample Changer, Installation

11

Page 15

2.4 Remote Connections

Cable 6.2141.020

Inputs

Outputs

14 lines (Output 0–13) are available for the emission of signals.

For receiving signals 8 lines are provided (Input 0–7). The

assignment of these lines is fixed for the 760 Sample Changer.

Pin assignment of the Remote socket:

0 Volt

+5 Volt

Output 5

Output 3

Output 1

Output 12

Output 13

Input 0

Input 2

Input 4

Input 6

0 Volt

Output 6

Output 7

Output 4

Output 2

Output 0

Output 8

Output 9

Output 10

Input 1

Input 3

Input 5

Input 7

Output 11

The +5 V supply line may by charged with 20 mA maximally.

2.4.1 Typical Combinations of Instruments

760 Sample Changer — Titrino

with standard cable

+5V

active = low

inactive = high

active = low

inactive = high

760 Sample Changer, Installation

12

B

A

Titrino

C

D

Remote control commands:

Output 0: *************1 starts Titrino

Input 3: ****1*** awaits end of titration (EOD pulse)

Page 16

2.4 Remote Connections

760 Sample Changer — Titrino — Dosimat 765/776

B

A

Titrino

A

765

C

D

Cable 6.2141.040

D

B

C

Remote control commands:

Output 0: *************1 starts Titrino

Output 6: *******1****** starts Dosimat

Input 3: ****1*** awaits end of titration (EOD pulse)

Pump Control via Remote Lines

Using methods 3 and 4, external pumps can be controlled via the

remote interface. To start a pump, an inverted pulse of duration of

at least 200 ms is sent to pin 7 (Output 9) of the remote socket.

To continue with the method the pump must indicate its readiness

by setting the input line 1 (pin 9) to low level for at least 20 ms.

Ask your pump distributor or Metrohm for customized connecting

cables.

Pin 9 Input

t

p

t

>20 ms

p

+5V

active = low

inactive = high

Pin 7 Output

V

t

p

CEO

t

>200 ms

p

= 40 V

active = low

inactive = high

IC = 20 mA

760 Sample Changer, Installation

13

Page 17

2.5 Racks

2.5 Racks

A sample rack is a sort of turntable for the positioning of beakers

which are to be placed on the Sample Changer. Because for titration, various sizes of beakers are common or required, many kinds

of racks can be used and are easily interchangeable. The rack offers space for various numbers of samples depending on the

diameter of the beakers. Metrohm delivers the following predefined

types of standard racks:

Type Number of

beakers

M12-0 12 250 mL Metrohm glass beaker 000001 6.2041.310

M12-0 12 150 mL glass beaker or

M14-0 14 200 mL disposable beaker (Euro) 000011 6.2041.370

M14-0 14 8 oz disposable beaker (US) 000101 6.2041.380

M16-0 16 150 mL glass beaker 000010 6.2041.320

M16-0 16 120 mL disposable beaker (US) 100001 6.2041.390

M24-0 24 75 mL Metrohm glass beaker 001000 6.2041.340

Type of beaker Predefined

Code

100000 6.2041.360

200 mL disposable beaker (Euro)

Every single rack can be identified by a unique magnetic code.

Rod magnets which are attached to the bottom of the rack can be

combined to form a 6-place binary code. The sample changer can

then automatically recognize the mounted rack. This is possible

when the rack is positioned with the first rack position under lift 1.

After changing a rack, the sample changer should first be initialized by pressing the <RESET> key or turning the instrument off

and on. This way the save recognition of a rack and therefore the

correct beaker positioning is made possible.

Order Number

760 Sample Changer, Installation

14

Page 18

3.1 Important Features

3 Introduction

3.1 Important Features

Overview

The 760 Sample Changer provides most of the important features

of the 730 Sample Changer:

• Interchangeable Metrohm standard sample racks

• Working, rinsing and shift heights can be specifically defined

• Automatic rack recognition by means of standard rack codes

• Optical beaker test

• Two stirrers (magnetic or rod stirrer) can be connected

• Operation with most Metrohm instruments via Remote I/O lines

LimitationsLimitations

• 4 fixed procedures that cannot be edited

• No RS 232 interface, no built-in pumps

• Simple keyboard with 3 keys and 2 LEDs (green and red)

• The turning speed of the rack cannot be varied

• No special rack types can be defined

Basic Settings

• Working, rinsing and shift heights can be defined for each rack

type

• Stirrer speed can be defined for both stirrers together

• One of 4 methods can be selected as the standard method

760 Sample Changer, Introduction

15

Page 19

3.2 Key Functions

3.2 Key Functions

The 760 Sample Changer operates in two different modes where

the keys provide different functions:

The Basic Mode starts when the instrument is turned on. The

ready-to-operate status is indicated by the green LED.

Basic Mode:

(after Power on, green LED on)

START

RESET

STOP

Starts processing of a sample series.

Stops processing of a sample series or initializes the

760 Sample Changer.

Interrupts processing of a sample series, green LED

HOLD

blinks.

START

Continues processing of a sample series.

The Configuration Procedure starts when the instrument is

switched on with pressing <HOLD> simultaneously. The green

LED blinks once. Now, the method can be selected and working,

rinsing and shift heights as well as the stirrer speed can be defined.

Configuration Procedure:

(after Power on with <HOLD> pressed, green LED blinks once)

Accepts the setting of a value and moves on to the

START

next value.

Learning mode, manual execution of a changer func-

HOLD

tion for setting a configuration.

RESET

STOP

760 Sample Changer, Introduction

16

Cancels a configuration setting and initializes the 760

when <STOP> is pressed twice. Switches back to

basic condition.

Page 20

3.3 Memory Initialization

3.3 Memory Initialization

The system memory can be initialized to set default parameters

when required (e.g. in the case of mal-functions). For this purpose

press all keys while the sample changer is switched on.

It is recommended to execute an initialization before the first installation of the sample changer.

RESET

START HOLD STOP

3.4 Configuration Procedure

The Configuration Procedure starts when the instrument is

switched on with pressing <HOLD> simultaneously. The method is

being selected and working, rinsing and shift heights are defined

and assigned to the selected rack type. Additionally, the stirrer

speed can be defined.

If the 760 Sample Changer is used for the first time, the lift positions have to be adapted to the selected rack type. This applies

also if a new rack type is inserted for the first time.

Empty beakers with a stirrer bar if necessary should be used for

the definition of the lift positions. Additionally, the foil holder has to

be used without Al foil if the Sample Changer is being set up for

Karl Fischer titration.

The working position should be defined in such a way that the

connected electrode tip stands in the center of the sample. The

shift position should allow a free rotation of the sample rack. In the

rinsing position, the aspiration tip should touch the bottom of the

sample beaker. If no rinsing step is necessary (method 1 and 2),

no rinsing position has to be defined.

In order to proceed to the next point in the configuration procedure,

<START> must be pressed. This accepts the current setting.

<STOP> is pressed in order to cancel a setting. The configuration

procedure is terminated by pressing <STOP> again.

The LEDs show either the status of the sample changer or the current step in the configuration procedure.

and "Power on"

760 Sample Changer, Introduction

17

Page 21

3.4 Configuration Procedure

The Configuration Procedure

Key LEDs Explanation

HOLD

+

"Power ON"

HOLD

START

HOLD

START

green 1∗

red 1-4∗

green 1∗

green 2∗

red blinks

green 2∗

green 3∗

In order to start the configuration procedure the <HOLD> key

must be pressed while the sample changer is switched on.

The green LED lights up once to show that the configuration

procedure is active. The method can now be selected.

When the <HOLD> key is pressed the red LED blinks once

for the first method. Each time <HOLD> is pressed again the

next method is selected up to method 4, then method 1

again.

<START> accepts the setting. The green LED blinks twice.

The working position of the lift can now be set.

When the <HOLD> key is pressed the lift can be moved

manually. Each further time the <HOLD> key is pressed the

direction in which the lift moves is altered. In this way the

working position can be set accurately.

<START> accepts the setting. The working position is stored

specifically for the type of rack inserted. The green LED

blinks three times. The rinsing position of the lift can now

be set.

HOLD

START

HOLD

START

red blinks

When the <HOLD> key is pressed the lift can be moved manually. Each further time the <HOLD> key is pressed the

direction in which the lift moves is altered.

green 3∗

green 4∗

red blinks

<START> accepts the settings. The rinsing position is stored

specifically for the type of rack inserted. The green LED

blinks four times. The shift position of the lift can now be

set.

When the <HOLD> key is pressed the lift can be moved manually. Each further time the <HOLD> key is pressed the

direction in which the lift moves is altered.

green 4∗

<START> accepts the setting. The shift position is stored

specifically for the type of rack inserted. The green LED

blinks five times. The stirrer speed can now be set.

green 5∗

760 Sample Changer, Introduction

18

Page 22

3.4 Configuration Procedure

HOLD

START

RESET

STOP

red blinks

The <HOLD> key switches on the stirrer(s). If the <HOLD>

key is kept pressed down the speed increases continuously.

If the <HOLD> key is pressed again the stirrer speed is reduced in a similar manner. In this way the stirrer speed can

green 5∗

be set accurately.

<START> accepts the setting. The configuration procedure

is now complete. It can be restarted by pressing <HOLD> in

order to select the method.

blinks

lights up

The configuration procedure is terminated with <STOP>.

When the green LED is illuminated the sample changer is in

the basic condition and is ready to process a series of samples.

The individual steps of the configuration procedure:

1∗ Method selection

2∗ Setting the working position

3∗ Setting the rinsing position

4∗ Setting the shift position

5∗ Setting the stirrer speed

760 Sample Changer, Introduction

19

Page 23

3.5 The Methods

3.5 The Methods

All methods enable the dosing of auxiliary solutions before the titration if a 765 or a 776 Dosimat is used. The dosing volume is to

be defined in the Dosimat. The Sample Changer will start the distribution via a remote line.

The following titration instruments can be used with the 760 Sample Changer: all of the Titrino models (701, 702, 716, 718, 719,

720, 736, 751, 758, 784, and 785) and the Titroprocessors. Simple

measuring series may be performed as well instead of titrations.

The supported Metrohm meters are: 691 and 713 pH-Meter, 692

pH/Ion Meter, 712 Conductometer.

In each method all rack positions will be processed. After the

treatment of the last sample the special beaker (highest rack position) is moved to the tower and the lift will be lowered to work position immersing the electrode for rinsing or conditioning.

Method 1 (for exact sequence, see Appendix, p. 25)

Plain working procedure without rinsing

Procedure:

1. move the sample beaker to the tower

2. run lift to work position

3. switch on stirrer

4. start dosing device

5. wait 10 seconds

6. start titrator

7. await end of determination

8. switch off stirrer

9. run lift to shift position

760 Sample Changer, Introduction

20

Page 24

3.5 The Methods

Method 2 (for exact sequence, see Appendix, p. 26)

Working procedure with sensor conditioning by dipping. The special beaker (highest rack position) must be filled before with solvent or water.

Procedure:

1. move the sample beaker to the tower

2. run lift to work position

3. switch on stirrer

4. start dosing device

5. wait 10 seconds

6. start titrator

7. await end of determination

8. switch off stirrer

9. run lift to shift position

10. get special beaker

11. run lift to work position

12. switch on the stirrer for 5 seconds

13. run lift to shift position

Method 3 (for exact sequence, see Appendix, p. 27)

Working procedure with sensor rinsing in a special beaker using

an external pump.

Procedure:

1. move the sample beaker to the tower

2. run lift to work position

3. switch on stirrer

4. start dosing device

5. wait 10 seconds

6. start titrator

7. await end of determination

8. switch off stirrer

9. run lift to shift position

10. get special beaker

11. run lift to work position

12. switch on the external pump

13. await readiness of the pump

14. run lift to shift position

760 Sample Changer, Introduction

21

Page 25

3.5 The Methods

Method 4 (for exact sequence, see Appendix, p. 28)

Working procedure with sensor rinsing in the sample beaker using

an external pump.

Procedure:

1. move the sample beaker to the tower

2. run lift to work position

3. switch on stirrer

4. start dosing device

5. wait 10 seconds

6. start titrator

7. await end of determination

8. switch off stirrer

9. run lift to rinse position

10. switch on the external pump

11. await readiness of the pump

12. run lift to shift position

760 Sample Changer, Introduction

22

Page 26

4.1 Error Messages

4 Appendix

4.1 Error Messages

An error occurring during a sample series is displayed by a blinking red LED. The number of flashes indicates the error number.

This must be acknowledged with any key. If an error occurs during

processing of a sample series, the changer will then be switched

into the 'HOLD' state.

After the cause of the error has been rectified, the sample series

can be continued with the next command in the active sequence

by pressing the <START> key. If the error cannot be eliminated,

the method running can also be halted with <STOP>.

The list of possible error messages and their causes:

1* RAM defect Call Metrohm-Service.

3* battery low The battery for the permanent storage of user meth-

ods must be replaced.

4* manual stop The Sample Changer has been stopped manually.

No acknowledgement needed.

6* changer low power The power supply cannot deliver enough power for

the simultaneous operation of all components currently in use (stirrer, pumps, lifts).

7* rack data missing No sample rack is in position or no rack data can be

found for the sample rack that is in place.

8* invalid rack code The rack code read by the changer could not be

found in the internal position tables.

760 Sample Changer, Appendix

23

Page 27

4.1 Error Messages

9* missing beaker After a MOVE command no beaker could be found at

the selected position.

10* raise lift first Turning of a rack could not be carried out because a

lift was below the defined shift position.

12* changer overload Load or resistance too large to carry out the chosen

action.

14* changer not ready The changer cannot execute the command chosen

because it is busy carrying out another action.

760 Sample Changer, Appendix

24

Page 28

4.2 Method Listings

4.2 Method Listings

All four methods of the 760 Sample Changer are briefly described in chapter 3.5 on

pages 20 to 22. The present chapter contains the exact program listings of these methods together with more detailed explanations.

Method 1

760 Sample Changer 760.0012

parameters

method 760_1

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 MOVE 1 : sample

2 LIFT: 1 : work mm

3 STIR: * : ON s

4 CTL:Rm: START dos*

5 WAIT 10 s

6 CTL:Rm: START device1

7 SCN:Rm : End1

8 STIR: * : OFF s

9 LIFT: 1 : shift mm

10 WAIT 3 s

>final sequence

1 MOVE 1 : spec.1

2 LIFT: 1 : work mm

>changer settings

rack number 0

lift rate 25 mm/s

shift rate 20

shift direction: auto.

beaker test mode: single

on beaker error: MOVE

>stirring rates

stirrer 1 3

stirrer 2 3

>dosing unit def.

>manual stop

CTL Rmt: STOP device1

CTL RS232:

------------

¬ report header with program version

¬ method name

¬ number of samples (here full rack)

¬ initialize remote line

¬ initialize

sample position

¬ move next sample beaker to tower

¬ run lift with titration head to working position

¬ switch on stirrer

¬ start dosing device

¬ wait for 10 seconds

¬ start titrator

¬ wait for end of titration [EOD]

¬ switch off stirrer

¬ run lift with titration head to shift position

¬ wait for 3 seconds

¬ move special beaker to tower for conditioning

¬ run lift to work position to immerse sensor

------ settings of sampler functions --------------------

¬ on missing sample beaker, the next one is

selected automatically

------ stirring rates ----------------------------------------¬ cannot be selected independently

------ settings for dosing devices ------------------------

------ action after manual stop ------------------------¬ stop device 1

760 Sample Changer, Appendix

25

Page 29

4.2 Method Listings

Method 2

760 Sample Changer 760.0012

parameters

method 760_2

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 SHIFTRATE: + 20

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 STIR: * : ON s

5 CTL:Rm: START dos*

6 WAIT 10 s

7 CTL:Rm: START device1

8 SCN:Rm : End1

9 STIR: * : OFF s

10 LIFT: 1 : shift mm

11 WAIT 3 s

12 SHIFTRATE: - 20

13 MOVE 1 : spec.1

14 LIFT: 1 : work mm

15 STIR: * : ON s

16 WAIT 5 s

17 STIR: * : OFF s

18 LIFT: 1 : shift mm

19 WAIT 3 s

>final sequence

1 MOVE 1 : spec.1

2 LIFT: 1 : work mm

>changer settings

rack number 0

lift rate 25 mm/s

shift rate 20

shift direction: auto.

beaker test mode: single

on beaker error: MOVE

>stirring rates

stirrer 1 3

stirrer 2 3

>dosing unit def.

>manual stop

CTL Rmt: STOP device1

CTL RS232:

------------

¬ report header with program version

¬ method name

¬ number of samples (here full rack)

¬ initialize remote line

¬ initialize

sample position

¬ shift direction to increasing numbers

¬ move next sample beaker to tower

¬ run lift with titration head to working position

¬ switch on stirrer

¬ start dosing device

¬ wait for 10 seconds

¬ start titrator

¬ wait for end of titration [EOD]

¬ switch off stirrer

¬ run lift with titration head to shift position

¬ wait for 3 seconds

¬ shift direction to decreasing numbers

¬ move special beaker to tower

¬ run lift to work position to immerse sensor

¬ switch on stirrer

¬ wait for 5 seconds

¬ switch off stirrer

¬ run lift to shift position

¬ wait for 3 seconds

¬ move special beaker to tower for conditioning

¬ run lift to work position to immerse sensor

------ settings of sampler functions --------------------

¬ on missing sample beaker, the next one is

selected automatically

------ stirring rates ----------------------------------------¬ cannot be selected independently

------ settings for dosing devices ------------------------

------ action after manual stop ------------------------¬ stop device 1

760 Sample Changer, Appendix

26

Page 30

4.2 Method Listings

Methode 3

760 Sample Changer 760.0012

parameters

method 760_3

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 SHIFTRATE: + 20

2 MOVE 1 : sample

3 LIFT: 1 : work mm

4 STIR: * : ON s

5 CTL:Rm: START dos*

6 WAIT 10 s

7 CTL:Rm: START device1

8 SCN:Rm : End1

9 STIR: * : OFF s

10 LIFT: 1 : shift mm

11 WAIT 3 s

12 SHIFTRATE: - 20

13 MOVE 1 : spec.1

14 LIFT: 1 : work mm

15 CTL:Rm: ****1*********

16 CTL:Rm: ****0*********

17 SCN:Rm : ******1*

18 LIFT: 1 : shift mm

19 WAIT 3 s

>final sequence

1 MOVE 1 : spec.1

2 LIFT: 1 : work mm

>changer settings

rack number 0

lift rate 25 mm/s

shift rate 20

shift direction: auto.

Beaker test mode: single

on beaker error: MOVE

>stirring rates

stirrer 1 3

stirrer 2 3

>dosing unit def.

>manual stop

CTL Rmt: STOP device1

CTL RS232:

------------

report header with program version

¬ method name

¬ number of samples (here full rack)

¬ initialize remote line

¬ initialize

sample position

¬ shift direction to increasing numbers

¬ move next sample beaker to tower

¬ run lift with titration head to working position

¬ switch on stirrer

¬ start dosing device

¬ wait for 10 seconds

¬ start titrator

¬ wait for end of titration [EOD]

¬ switch off stirrer

¬ run lift with titration head to shift position

¬ wait for 3 seconds

¬ shift direction to decreasing numbers

¬ move special beaker to tower

¬ run lift to work position to immerse sensor

¬ switch on external pump

¬ reset remote line

¬ wait for ready signal of pump

¬ run lift to shift position

¬ wait for 3 seconds

¬ move special beaker to tower for conditioning

¬ run lift to work position to immerse sensor

------ settings of sampler functions --------------------

¬ on missing sample beaker, the next one is

selected automatically

------ stirring rates ----------------------------------------¬ cannot be selected independently

------ settings for dosing devices ------------------------

------ action after manual stop ------------------------¬ stop device 1

760 Sample Changer, Appendix

27

Page 31

4.2 Method Listings

Methode 4

760 Sample Changer 760.0012

parameters

method 760_4

number of samples: rack

>start sequence

1 CTL:Rm: INIT

2 SAMPLE: - 1

3 SAMPLE: + 1

>sample sequence

1 MOVE 1 : sample

2 LIFT: 1 : work mm

3 STIR: * : ON s

4 CTL:Rm: START dos*

5 WAIT 10 s

6 CTL:Rm: START device1

7 SCN:Rm : End1

8 STIR: * : OFF s

9 LIFT: 1 : rinse mm

10 CTL:Rm: ****1*********

11 CTL:Rm: ****0*********

12 SCN:Rm : ******1*

13 LIFT: 1 : shift mm

14 WAIT 3 s

>final sequence

1 MOVE 1 : spec.1

2 LIFT: 1 : work mm

>changer settings

rack number 0

lift rate 1 25 mm/s

shift rate 20

shift direction: auto.

beaker test mode: single

on beaker error: MOVE

>stirring rates

stirrer 1 3

stirrer 2 3

>dosing unit def.

>manual stop

CTL Rmt: STOP device1

CTL RS232:

------------

¬ report header with program version

¬ method name

¬ number of samples (here full rack)

¬ initialize remote line

¬ initialize

sample position

¬ move next sample beaker to tower

¬ run lift with titration head to working position

¬ switch on stirrer

¬ start dosing device

¬ wait for 10 seconds

¬ start titrator

¬ wait for end of titration [EOD]

¬ switch off stirrer

¬ run lift with titration head to shift position

¬ switch on external pump

¬ reset remote line

¬ wait for ready signal of pump

¬ run lift to shift position

¬ wait for 3 seconds

¬ move special beaker to tower for conditioning

¬ run lift to work position to immerse sensor

------ settings of sampler functions --------------------

¬ on missing sample beaker, the next one is

selected automatically

------ stirring rates ----------------------------------------¬ cannot be selected independently

------ settings for dosing devices ------------------------

------ action after manual stop ------------------------¬ stop device 1

760 Sample Changer, Appendix

28

Page 32

4.3 Technical Specifications

4.3 Technical Specifications

Dimensions Height: 0.79 m, Width: 0.28 m, Depth: 0.48 m

Weight 12.5 kg

Material Sample Changer case: metal case, multiple enamelling

Splash protection: Polymethylene methacrylate (PMMA)

Sample rack: Acrylnitrile butadiene styrene (ABS)

or Polypropylene (PP)

Lift path 235 mm

Lift Load: approx. 10 N

Stroke speed: adjustable, 3...25 mm/s

Turntable Turning speed: 20 angular degrees/s

Stirrer Stirring rate: adjustable to 15 levels

- magnet stirrer 180/min...2600/min

- rod stirrer 180/min...3000/min

Remote Interface Programmable parallel interface for controlling external

instruments

t

p

Input:

t

>20 ms

p

t

Output:

V

p

CEO

t

>200 ms

p

= 40 V

IC = 20 mA

+5 V: maximum load = 20 mA

Temperatures Nominal functional range 5...40 °C at 20…80% rel. humidity

Transport und storage –20...+60 °C

60 °C rel. humidity < 50%

50 °C rel. humidity < 85%

40 °C rel. humidity <95%

Power connection Voltage 100...120 V, 220...240 V

Frequency 50...60 Hz

Power input 40 VA

Fuses 0.5 AT (110 V), 0.25 AT (220 V)

+5V

active = low

inactive = high

active = low

inactive = high

All data are typical values with the exception of those specially marked.

Safety Specifications

Constructed and tested according to IEC 1010 / EN 61010 /

UL 3101-1, Safety Class III

Degree of protection IP 22

The instruction manual contains information and warnings which

the user should follow to guarantee the safe operation of the instrument.

760 Sample Changer, Appendix

29

Page 33

4.4 Servicing and Maintenance

Electromagnetic Compatibility (EMC)

Emitted Interference: The instrument complies with the basic specifications

EN 50081-1/2 1992, EN 55011 (class B), EN 55022 (class B).

Interference immunity: The basic specifications EN 50082-1 1997, and IEC 801-2 to

IEC 801-4 are adhered to.

4.4 Servicing and Maintenance

4.4.1 Servicing

The maintenance of the 760 Sample Changer should include a

yearly service check carried out by a specialist from Metrohm. If

caustic or corrosive chemicals are frequently used, shorter time intervals between service checks can be necessary.

The Metrohm Service Department can offer technical advice

regarding servicing and maintenance of all Metrohm instruments at

any time.

4.4.2 Maintenance / Attendance

Not only highly sensitive measuring instruments do require proper

care, a sample changer also requires this. Serious contaminations

can lead to functional disorders and a shortened life-span of the

rugged mechanics and electronics of the sample changer.

Heavy soiling of the titration heads can influence the results of

measurements. Regular cleaning of exposed parts can prevent

this for the most part.

Chemical or solvent spills should be cleaned up immediately. The

connectors (in particular the power supply) should be protected

from contamination. The sample changer should never be operated without the covering foreseen for this purpose.

If corrosive media has entered the inside of the instrument, the

power plug has to be disconnected immediately to avoid massive

damage to the instruments electronic components. In case of such

damage, the Metrohm service personnel should be notified.

The instrument should not be opened by untrained personnel.

760 Sample Changer, Appendix

30

Page 34

4.5 Warranty and Conformity

4.5 Warranty and ConformityWarranty and Conformity

4.5.1 Warranty

The warranty on our products is limited to defects that are traceable to material, construction or manufacturing error which occur

within 12 months from the day of delivery. In this case, the defects

will be rectified in our workshops free of charge. Transport costs

are to be paid by the customer.

For day and night operation, the warranty is limited to 6 months.

Glass breakage in the case of electrodes or other parts is not cov-

ered by the warranty. Checks which are not a result of material or

manufacturing faults are also charged during the warranty period.

For parts of outside manufacture insofar as these constitute an

appreciable part of our instrument, the warranty stipulations of the

manufacturer in question apply.

With the regard to the guarantee of accuracy, the technical specifications in the instruction manual are authoritative.

Concerning defects in material, construction or design as well as

the absence of guaranteed features, the orderer has no rights or

claims except those mentioned above.

If damage of the packaging is evident on receipt of a consignment

or if the goods show signs of transport damage after unpacking,

the carrier must be informed immediately and a written damage

report demanded. lack of an official damage report releases

Metrohm from any liability to pay compensation.

If any instruments and parts have to be returned, the original packaging should be used if at all possible. This applies above all to instruments, electrodes, burette cylinders and PTFE pistons. Before

embedment in wood shavings or similar material, the parts must

be packed in a dustproof package (for instruments, use of a plastic

bag is imperative). If open assemblies are enclosed in the scope of

delivery that are sensitive to electromagnetic voltages (e.g. data

interfaces etc.) these must be returned in the associated original

protective packaging (e.g. conductive protective bag). (Exception:

assemblies with built-in voltage source belong in a non-conductive

protective packaging).

For damage which arises as a result of non-compliance with these

instructions, no warranty responsibility whatsoever will be accepted by Metrohm.

760 Sample Changer, Appendix

31

Page 35

4.5 Warranty and Conformity

4.5.2 Certificate of Conformity and System Validation for the

760 Sample Changer

This is to certify the conformity to the standard specifications for electrical

appliances and accessories, as well as to the standard specifications for

security and to system validation issued by the manufacturing company.

Name of commodity: 760 Sample Changer

System software: Stored in ROMs

Name of manufacturer: Metrohm Ltd., Herisau, Switzerland

Principal technical information: Voltages: 100…120, 220…240 V

Frequency: 50…60 Hz

This Metrohm instrument has been built and has undergone final type testing

according to the standards:

Electromagnetic compatibility

IEC 801-2 (level 3), IEC 801-3 (level 2), IEC 801-4 (level 3),

EN 55011 / class B, EN 55022 / class B, EN 50081-1/2 1992,

EN 50082-1 1997

Security specifications

IEC 1010, EN 61010, UL 3101-1

It has also been certified by the Swiss Electronical Association (SEV), which is

member of the International Certification Body (CB / IEC).

The technical specifications are documented in the instruction manual.

The system software, stored in Read Only Memories (ROMs) has been validated in connection with standard operating procedures in respect to functionality and performance. The features of the system software are documented in

the instruction manual.

Metrohm Ltd. is holder of the SQS certificate of the quality system ISO 9001

for quality assurance in design/development, production, installation and servicing.

Herisau, March 5th, 1998

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

760 Sample Changer, Appendix

32

Page 36

4.5 Warranty and Conformity

Ionenanalytik • Analyse des ions • Ion analysis • Análisis iónico

760 Sample Changer

EU Declaration of Conformity

The Metrohm AG company, Herisau, Switzerland hereby certifies that the instrument:

760 Sample Changer

meets the requirements of EU Directives 89/336/EWG and 73/23/EWG.

Source of specifications:

EN 50081 Electromagnetic compatibility, basic specification Emitted Interference

EN 50082-1 Electromagnetic compatibility, basic specification Interference Immunity

EN 61010 Safety requirements for electrical laboratory measurement and control

equipment

Description of the instrument:

Sample changer for the automation of batch processing of larger sample series, applying titration, dosing and measuring methods in laboratory and industry.

Herisau, March 5th, 1998

Dr. J. Frank Ch. Buchmann

Development Manager Production and

Quality Assurance Manager

760 Sample Changer, Appendix

33

Page 37

4.6 Accessories

4.6 Accessories

760 Sample Changer 2.760.0010

includes the following accessories: Number

of pieces

SGJ14 sleeve 2 6.1236.020

FEP tubing connector M6 80cm 6.1805.110

Spiral band 7x0,75 0,5m 6.1815.010

Keyboard for 760 6.2142.100

Guiding sleeve 3 6.2709.070

Splash protection 6.2751.010

Plug cover 6.2752.010

Instructions for use 8.760.1013

760 Sample Changer KFT 2.760.0020

includes the following accessories: Number

of pieces

Magnetic stirrer 1.741.0010

Double Pt electrode 6.0340.000

Sample beaker 24 6.1432.210

Titration head for FKT 6.1458.030

FEP tubing connector M6 80cm 2 6.1805.110

Spiral band 7x0,75 0,5m 6.1815.010

Aspirating tube for 676 (Behr) 6.1821.000

Stirring bar 12mm 24 6.1903.010

Foil holder for beaker 6.1432.210 24 6.2037.040

Sample rack 24x75ml M24-0 6.2041.340

Cable 760-Titrino-765/776 6.2141.040

Keyboard for 760 6.2142.100

Splash protection 6.2751.010

Plug cover 6.2752.010

Al foil 0,010/80mm 1000 sheets 6.2820.000

O-ring 5,28/1,78 4 E.301.0022

O-ring 30/5 E.301.0080

Instructions for use 8.760.1013

760 Sample Changer, Appendix

34

Page 38

4.6 Accessories

Options

Accessories to separate order at additional charge:

722 Propeller Rod Stirrer for Sample Changer

Propeller rod stirrer 2.722.0020

Stirring propeller PP (104 mm) (incl.) 6.1909.020

741 Magnetic Stirrer

Magnetic stirrer 2.741.0010

Macro titration head (6 x SGJ 14, 3 x SGJ 9) 6.1458.010

Micro titration head (4 x M10) for rack 6.2041.340 6.1458.020

Sample Racks and Beakers

Sample Rack 12 x 250 mL M12-0 6.2041.310

Metrohm sample beaker glass 250 mL 6.1432.320

Metrohm sample beaker PP 200 mL 6.1453.220

Metrohm sample beaker PP 250 mL 6.1453.250

Sample Rack 12 x 150 mL M12-0 6.2041.360

for 150 mL standard beaker (high form) or

200 mL disposable beaker (Euro) PP 1000 pcs. 6.1459.310

Sample Rack 14 x 200 mL M14-0 6.2041.370

for 200 mL disposable beaker (Euro) PP 6.1459.310

Sample Rack 14 x 8 oz M14-0 6.2041.380

for disposable beaker (US) PP 8 oz

Sample Rack 16 x 150 mL M16-0 6.2041.320

for standard beaker (high form)

Sample Rack 16 x 120 mL M16-0 6.2041.390

for disposable beaker (US) 120 mL

Sample Rack 24 x 75 mL M24-0 6.2041.340

for Metrohm glass beaker 75 mL 6.1432.210

(Micro titration head necessary)

760 Sample Changer, Appendix

35

Page 39

4.6 Accessories

Electrodes for sample changer

For titrations with the macro titration head it is advisable to use

long life LL electrodes. Titrodes without standard ground joint

should be used with the SGJ sleeve 6.1236.040 made of silicone

rubber.

For direct titrations using the micro titration head, the following

special micro electrodes can be used:

LL Combined pH micro-electrode 16 cm 6.0234.110

Micro reference electrode Ag/AgCl 16 cm 6.0736.110

Micro pH glass electrode 16 cm 6.0134.110

Micro Ag-titrode 16 cm 6.0433.110

Micro-Pt-titrode 16 cm 6.0434.110

Micro Au-titrode 16 cm 6.0435.110

Pt 1000 Temperature sensor 16 cm 6.1110.110

Dosing Instruments

Dosimat 765 2.765.0010

Dosimat 776 2.776.0010

Exchange unit with ceramics stopcock 1 mL 6.3013.113

5 mL 6.3013.153

10 mL 6.3013.213

20 mL 6.3013.223

50 mL 6.3013.253

Exchange unit with PTFE stopcock 1 mL 6.3014.113

5 mL 6.3014.153

10 mL 6.3014.213

20 mL 6.3014.223

50 mL 6.3014.253

760 Sample Changer, Appendix

36

Page 40

5 Index

5 Index

A

Accessories...................... 34

Aluminium foil................... 10

Appendix.......................... 23

Aspiration tip......................8

B

Basic mode...................... 16

Basic settings................... 15

Battery............................. 23

Beaker test......................... 3

Burette tip..........................8

C

Certificate of Conformity.... 32

Configuration procedure.... 17

Connecting the keyboard.....7

Connectors.....................2, 3

D

Declaration of conformity... 33

Dimensions...................... 29

Dosimat ........................... 13

Dosing instruments........... 36

Double-Pt Electrode............9

E

Electrode.......................8, 36

Electrode rinsing............... 21

Electromagn. compatibility. 30

End of determ. (EOD) ....... 13

Environment.......................4

Error message.................. 23

External pump.............13, 22

F

Features .......................... 15

Foil holder........................ 10

Fuse..................................4

G

Guiding sleeve....................8

H

<HOLD> key .................... 16

I

Infrared sensor................... 3

Input ...........................11, 29

Installation..........................4

Instrument combinations ... 12

Instrument opening............. 6

Introduction...................... 15

K

Key functions.................... 16

Keyboard connector............ 3

KF sample beaker............. 10

KF titration head................. 9

L

LED................................. 16

Lift................................1, 29

Limitations........................ 15

Line frame...................... 1, 2

Line sleeve.....................1, 2

M

Macro titration head............ 8

Magnet holder ................ 3, 7

Magnetic sensor............. 3, 7

Magnetic stirrer...................7

Maintenance /Attendance.. 30

Manufacturing number ........3

Material............................ 29

Memory initialization ......... 17

Method listing................... 25

Methods........................... 20

Metrohm Service.............. 30

Micro electrode................... 8

Micro titration head .............8

Mounting screws.................8

O

Options............................ 35

O-Ring...............................9

Output.........................11, 29

Overview.......................1, 15

P

Packaging..........................4

parallel cable......................2

Pin assignment................. 11

Plug cover.......................... 1

Power connection............. 29

Power on.......................... 16

Power supply......................4

Procedure........................ 20

Pump control.................... 13

R

Rack.............................7, 14

Rack code.......................... 3

Rear view...........................2

Remote commands......12, 13

Remote connections .........11

Remote interface.........13, 29

Remote socket.............. 2, 11

Rinsing.............................21

Rinsing position................ 18

Rod stirrer..........................8

Rotating nozzle...................8

S

Safety considerations..........6

Safety measures.................6

Safety specification...........29

Sample beaker for KF

titration......................... 10

Sample rack................. 7, 14

Sensors..............................3

Servicing..........................30

Setting up....................... 4, 7

Shift position.....................18

Side view............................1

Signals............................. 11

Sleeves..............................8

Splash protection................1

Spray nozzle.......................8

Standard sample racks...... 14

<START> key................... 16

Stirrer...............................29

Stirrer propeller...................8

Stirrer rail....................... 1, 7

Stirrer sockets.....................2

Stirrer speed..................... 19

Stirring rate.......................29

<STOP> key.....................16

T

Technical specifications.....29

Temperatures................... 29

Thread stopper ...................8

Titration head .....................8

Titration head KFT..............9

Titrino..........................12, 13

Tower.................................1

Turntable.....................14, 29

W

Warranty and conformity....31

Weight ............................. 29

Working position...............18

760 Sample Changer, Index

37

Loading...

Loading...