Page 1

R113/R116

Pull-Type Disc Mower

Unloading and Assembly Instruction: North America

214713 Revision A

Original Instruction

The harvesting specialists.

Page 2

R113/R116 Pull-Type Disc Mower

1010571

Published: June, 2018

Page 3

Introduction

This instruction manual describes the unloading, setup, and predelivery requirements for the MacDon R113 and

R116 Pull-Type Disc Mower.

To ensure your customers receive the best performance and safety from this product, carefully follow the unload

and assembly procedure from the beginning through to completion.

Retain this instruction for future reference.

Carefully read all the material provided before attempting to unload, assemble, or use the machine.

NOTE:

Keep your MacDon publications up-to-date. The most current version can be downloaded from our website

(www.macdon.com) or from our Dealer-only site (https://portal.macdon.com) (login required).

This instruction is available in English and French and can be ordered from MacDon, downloaded from our Dealer

Portal, or from our International website (http://www.macdon.com/world).

214713 i Revision A

Page 4

List of Revisions

At MacDon, we’re continuously making improvements; occasionally these improvements affect product

documentation. The following list provides an account of major changes from the previous version of this

document.

Summary of Change

Updated images with slow moving vehicle signs Various

Updated images to remove old jack stand and mount Various

Added new jack stand information

Added image for transport pin installation

Updated topic with new slow moving vehicle sign

Location

• 3.3.1 Installing Drawbar Hitch, page 16

• 5.3.1 Attaching with Drawbar Hitch, page 93

• 4.3.1 Installing Drawbar Hitch, page 65

Installing Transport Assembly, page 34

Installing Slow Moving Vehicle (SMV) Sign, page 55

214713 ii Revision A

Page 5

TABLE OF CONTENTS

Introduction................................................................................................................................................i

Chapter 1: Safety ....................... ............................................................................................................. 1

1.1 Signal Words .......................................................................................................................................1

1.2 General Safety.....................................................................................................................................2

1.3 Tire Safety...........................................................................................................................................4

1.4 Safety Signs ........................................................................................................................................5

Chapter 2: Unloading Truck Shipment .............................................................................................. 7

Chapter 3: Assembling the Disc Mower (With or Without the Dealer-Installed

Transport) ................................................................................................................. ................ 9

3.1 Repositioning Center-Link Top Anchor ...................................................................................................9

3.2 Attaching Hitch to Carrier....................................................................................................................12

3.3 Installing Tractor Mating Hitch to Carrier Hitch......................................................................................16

3.3.1 Installing Drawbar Hitch .............................................................................................................16

3.3.2 Installing Two-Point Hitch (Cat. II) Adapter ..................................................................................20

3.4 Installing Hitch Swing Cylinder ............................................................................................................24

3.5 Attaching Clutch Driveline... ................................................................................................................26

3.6 Attaching Steering Arm. ......................................................................................................................28

3.7 Connecting Transport Lighting Module.................................................................................................30

3.8 Installing Options ...............................................................................................................................31

™

3.8.1 Installing Road Friendly Transport

Installing Components ..............................................................................................................31

Installing Hydraulics..................................................................................................................44

Installing Electrical Components ................................................................................................50

Installing Cover ........................................................................................................................56

3.8.2 Installing Hydraulic Center-Link (Optional) ..................................................................................56

3.8.3 Installing Tall Crop Divider (Optional) ..........................................................................................56

System ................................................................................31

Chapter 4: Assembling the Disc Mower (Factory-Installed Transport) .................................. 57

4.1 Repositioning Center-Link Top Anchor .................................................................................................57

4.2 Attaching Hitch to Carrier....................................................................................................................61

4.3 Installing Tractor Mating Hitch to Carrier Hitch......................................................................................65

4.3.1 Installing Drawbar Hitch .............................................................................................................65

4.3.2 Installing Two-Point Hitch (Cat. II) Adapter ..................................................................................69

4.4 Installing Hitch Swing Cylinder ............................................................................................................73

4.5 Attaching Clutch Driveline... ................................................................................................................74

4.6 Attaching Steering Arm. ......................................................................................................................76

4.7 Removing Slow Moving Vehicle Sign (SMV) Covering...........................................................................78

™

4.8 Completing Road Friendly Transport

4.8.1 Removing Cover .......................................................................................................................79

4.8.2 Installing Transport Alignment Control.........................................................................................79

214713 iii Revision A

System Installation ....................................................................79

Page 6

TABLE OF CONTENTS

4.8.3 Installing Hydraulic Lines and Hoses...........................................................................................81

4.8.4 Installing Electrical Components.................................................................................................84

Connecting Selector Valve and Transport Lighting Module...........................................................84

Installing Light Assembly...........................................................................................................85

Connecting Transport Lighting Module .......................................................................................85

Installing Remote Control ..........................................................................................................85

4.8.5 Installing Cover .........................................................................................................................87

4.9 Installing Options ...............................................................................................................................88

4.9.1 Installing Hydraulic Center-Link (Optional) ..................................................................................88

4.9.2 Installing Tall Crop Divider (Optional) ..........................................................................................88

4.10 Installing Road Friendly Transport

™

Wheels .......................................................................................89

Chapter 5: Setting up the Tractor ..................................................................................................... 91

5.1 Adjusting the Drawbar ........................................................................................................................91

5.2 Installing Drawbar Hitch Adapter .........................................................................................................92

5.3 Attaching Disc Mower to the Tractor .................................................................................................... 93

5.3.1 Attaching with Drawbar Hitch .....................................................................................................93

5.3.2 Attaching with Two-Point Hitch ...................................................................................................95

5.3.3 Connecting Hydraulics...............................................................................................................98

5.3.4 Connecting Electrical Wiring Harness .........................................................................................99

5.4 Installing Field Wheels.. ....................................................................................................................100

5.5 Priming the Hitch Swing Cylinder.......................................................................................................102

5.6 Setting up Forming Shields ...............................................................................................................104

5.6.1 Setting up Forming Shields for Finger Conditioner .....................................................................104

5.6.2 Setting up Forming Shields for Roll Conditioner .........................................................................109

5.7 Unpacking Curtains.......................................................................................................................... 110

5.8 Discharge Shield (No Conditioner) .................................................................................................... 112

5.8.1 Removing Discharge Shield (No Conditioner)............................................................................ 112

5.8.2 Installing Discharge Shield (No Conditioner).............................................................................. 114

5.9 Removing Disc Mower from Shipping Pallet (No Transport Installed).................................................... 116

5.10 Removing Disc Mower from Shipping Pallet (Transport Installed)....................................................... 117

Chapter 6: Lubricating the Disc Mower ........................................................................................119

6.1 Opening Driveshields ....................................................................................................................... 119

6.2 Lubrication Points ............................................................................................................................121

6.3 Closing Driveshields.........................................................................................................................126

Chapter 7: Performing Predelivery Checks ............................................ .....................................127

7.1 Checking Wheel Bolts ...................................................................................................................... 127

7.2 Checking Tire Pressure .................................................................................................................... 128

7.3 Checking Conditioner Drive Belt........................................................................................................129

7.3.1 Adjusting Conditioner Drive Belt ............................................................................................... 129

7.4 Checking Cutting Angle .................................................................................................................... 130

214713 iv Revision A

Page 7

TABLE OF CONTENTS

7.5 Checking Skid Shoes ....................................................................................................................... 131

7.6 Checking Disc Mower Float ..............................................................................................................132

7.6.1 Adjusting Disc Mower Float..... .................................................................................................132

7.7 Checking and Adding Conditioner Roll Timing Gearbox Lubricant........................................................134

7.8 Checking and Adding Disc Mower Drive Gearbox Lubricant ................................................................ 135

7.9 Checking and Lubricating Forward and Rear Swivel Gearboxes ..........................................................136

7.10 Checking and Adding Cutterbar Lubricant ........................................................................................ 138

7.11 Checking Roll Gap .........................................................................................................................140

7.11.1 Adjusting Roll Gap (Steel Rolls) .............................................................................................. 140

7.11.2 Adjusting Roll Gap (Polyurethane Rolls) .................................................................................. 141

7.12 Checking Roll Timing......................................................................................................................142

7.13 Checking Roll Tension .................................................................................................................... 143

7.13.1 Adjusting Roll Tension ........................................................................................................... 143

7.14 Adjusting Conditioner Baffle Position ............................................................................................... 144

7.15 Checking Lights .............................................................................................................................145

7.16 Checking Manuals..........................................................................................................................146

7.17 Checking Clutch Operation .............................................................................................................147

7.17.1 Adjusting Clutch .................................................................................................................... 148

7.18 Running up the Header................................................................................................................... 151

7.19 Checking and Adjusting the Cam on the Transport Deploy/Swing Mechanism..................................... 152

Chapter 8: Transporting the Disc Mower......................................................................................153

8.1 Preparing Disc Mower for Transport .................................................................................................. 153

8.2 Transporting with a Tractor ............................................................................................................... 156

8.3 Transport Lighting ............................................................................................................................157

™

8.3.1 Lighting (With Road Friendly Transport

8.3.2 Lighting (Without Road Friendly Transport

8.4 Converting from Transport to Field Mode (Without Road Friendly Transport

8.5 Converting from Field Mode to Transport (Without Road Friendly Transport

™

8.6 Road Friendly Transport

Option ......................................................................................................160

8.6.1 Converting from Field to Transport Mode (With Road Friendly Transport

8.6.2 Converting from Transport to Field Mode (With Road Friendly Transport

Option) .......................................................................157

™

Option) .................................................................. 157

™

) ......................................158

™

) ......................................159

™

).................................. 160

™

).................................. 166

Chapter 9: Changing the Conditioner ...........................................................................................171

9.1 Separating Header from Carrier ........................................................................................................171

9.2 Removing the Conditioner ................................................................................................................174

9.2.1 Removing Cutterbar Deflectors ................................................................................................177

9.3 Installing the Conditioner ..................................................................................................................178

9.3.1 Installing Cutterbar Deflectors ..................................................................................................180

9.3.2 Installing Conditioner Drive ...................................................................................................... 181

9.4 Assembling Header and Carrier ........................................................................................................183

214713 v Revision A

Page 8

TABLE OF CONTENTS

Chapter 10: Hydraulic Schematics.................................................................................................187

Chapter 11: Reference ....................................................................................................................... 203

11.1 Opening Cutterbar Doors ................................................................................................................203

11.2 Engaging Locks .............................................................................................................................204

11.3 Disengaging Locks .........................................................................................................................205

11.4 Closing Cutterbar Doors .................................................................................................................206

11.5 Recommended Lubricants ..............................................................................................................207

11.6 Torque Specifications .....................................................................................................................208

11.6.1 SAE Bolt Torque Specifications...............................................................................................208

11.6.2 Metric Bolt Specifications ....................................................................................................... 210

11.6.3 Metric Bolt Specifications Bolting into Cast Aluminum............................................................... 212

11.6.4 Flare-Type Hydraulic Fittings ..................................................................................................213

11.6.5 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable) ..................................................................214

11.6.6 O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable) ...........................................................216

11.6.7 O-Ring Face Seal (ORFS) Hydraulic Fittings ...........................................................................217

11.6.8 Tapered Pipe Thread Fittings ..................................................................................................218

11.7 Conversion Chart ...........................................................................................................................219

11.8 Definitions .....................................................................................................................................220

™

11.9 Converting Road Friendly Transport

Decal.....................................................................................222

Predelivery Checklist.........................................................................................................................223

214713 vi Revision A

Page 9

Chapter 1: Safety

1.1 Signal Words

Three signal words, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. Signal

words are selected using the following guidelines:

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury. It

may also be used to alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It

may be used to alert against unsafe practices.

214713 1 Revision A

Page 10

SAFETY

1.2 General Safety

CAUTION

The following are general farm safety precautions that

should be part of your operating procedure for all types

of machinery.

Protect yourself.

• When assembling, operating, and servicing machinery,

wear all protective clothing and personal safety devices

that could be necessary for job at hand. Do NOT take

chances. You may need the following:

• Hard hat

• Protective footwear with slip-resistant soles

• Protective glasses or goggles

• Heavy gloves

• Wet weather gear

• Respirator or filter mask

• Be aware that exposure to loud noises can cause hearing

impairment or loss. Wear suitable hearing protection

devices such as earmuffs or earplugs to help protect

against loud noises.

• Provide a first aid kit for use in case of emergencies.

1000004

Figure 1.1: Safety Equipment

1000005

Figure 1.2: Safety Equipment

• Keep a fire extinguisher on the machine. Be sure fire

extinguisher is properly maintained. Be familiar with its

proper use.

• Keep young children away from machinery at all times.

• Be aware that accidents often happen when Operator is

tired or in a hurry. Take time to consider safest way.

Never ignore warning signs of fatigue.

Figure 1.3: Safety Equipment

214713 2 Revision A

1010391

Page 11

1000007

1000008

1000009

SAFETY

• Wear close-fitting clothing and cover long hair. Never

wear dangling items such as scarves or bracelets.

• Keep all shields in place. NEVER alter or remove safety

equipment. Make sure driveline guards can rotate

independently of shaft and can telescope freely.

• Use only service and repair parts made or approved by

equipment manufacturer. Substituted parts may not meet

strength, design, or safety requirements.

• Keep hands, feet, clothing, and hair away from moving

parts. NEVER attempt to clear obstructions or objects

from a machine while engine is running.

• Do NOT modify machine. Unauthorized modifications

may impair machine function and/or safety. It may also

shorten machine’s life.

Figure 1.4: Safety around Equipment

• To avoid bodily injury or death from unexpected startup of

machine, ALWAYS stop the engine and remove the key

from the ignition before leaving the operator’s seat for

any reason.

• Keep service area clean and dry. Wet or oily floors are

slippery. Wet spots can be dangerous when working with

electrical equipment. Be sure all electrical outlets and

tools are properly grounded.

• Keep work area well lit.

• Keep machinery clean. Straw and chaff on a hot engine is

a fire hazard. Do NOT allow oil or grease to accumulate

on service platforms, ladders, or controls. Clean

machines before storage.

• NEVER use gasoline, naphtha, or any volatile material for

cleaning purposes. These materials may be toxic and/or

flammable.

• When storing machinery, cover sharp or extending

components to prevent injury from accidental contact.

Figure 1.5: Safety around Equipment

Figure 1.6: Safety around Equipment

214713 3 Revision A

Page 12

SAFETY

1.3 Tire Safety

WARNING

• Service tires safely.

• A tire can explode during inflation which could cause

serious injury or death.

• Follow proper procedures when mounting a tire on a

wheel or rim. Failure to do so can produce an

explosion that may result in serious injury or death.

WARNING

• Do NOT stand over tire. Use a clip-on chuck and

extension hose.

1000020

Figure 1.7: Overinflated Tire

• Do NOT exceed maximum inflation pressure indicated

on tire label.

• Replace tires that have defects.

• Replace wheel rims that are cracked, worn, or

severely rusted.

• Never weld a wheel rim.

• Never use force on an inflated or partially inflated tire.

• Make sure tire is correctly seated before inflating to

operating pressure.

• If tire is not correctly positioned on rim or is overinflated, tire bead can loosen on one side causing air

to escape at high speed and with great force. An air leak of this nature can thrust tire in any direction

endangering anyone in area.

• Make sure all air is removed from tire before removing tire from rim.

• Do NOT remove, install, or repair a tire on a rim unless you have proper equipment and experience to

perform job.

• Take tire and rim to a qualified tire repair shop.

Figure 1.8: Safely Inflating Tire

1000019

214713 4 Revision A

Page 13

1000694

SAFETY

1.4 Safety Signs

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or illegible.

• If original part on which a safety sign was installed is

replaced, be sure repair part also bears current

safety sign.

• Safety signs are available from your MacDon Dealer.

Figure 1.9: Operator’s Manual Decal

214713 5 Revision A

Page 14

Page 15

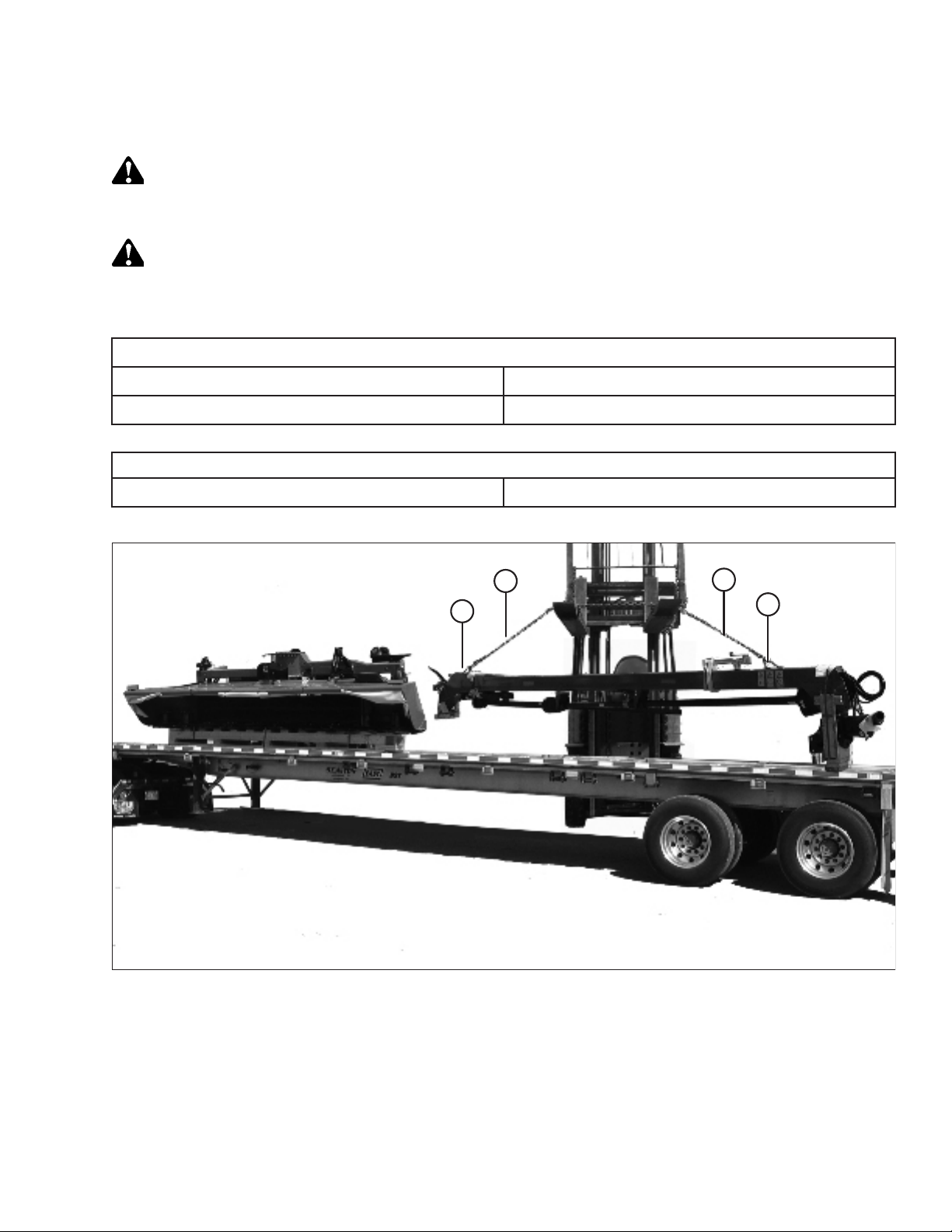

Chapter 2: Unloading Truck Shipment

CAUTION

To avoid injury to bystanders from being struck by machinery, do NOT allow persons to stand in

unloading area.

CAUTION

Equipment used for unloading must meet or exceed the requirements specified below. Using inadequate

equipment may result in chain breakage, vehicle tipping or machine damage.

Lifting Vehicle

Minimum capacity

Minimum height

Overhead lifting quality 12.7 mm (1/2 inch) 2270 kg (5000 lb.) minimum working load

Figure 2.1: Unloading Hitch

B

Chain

A

3630 kg (8000 lb.)

4.5 m (15 ft.)

A

B

1. Remove hauler's tie-down straps and chains.

2. Attach chain (A) to two brackets (B) on top of hitch as shown.

3. Adjust chain lengths so hitch is lifted evenly.

4. Raise hitch off deck, back up until unit clears trailer, and slowly lower to 150 mm (6 in.) from ground.

IMPORTANT:

Take care not to contact the other machine if load is two headers wide.

214713 7 Revision A

1010549

Page 16

UNLOADING TRUCK SHIPMENT

5. Take to storage or assembly area, and set hitch down securely on level ground.

6. Repeat for second hitch (if required).

7. Check for shipping damage and missing parts.

8. Approach disc mower (A) from back with forklift (B) as

shown, and slide forks as far as possible into pallet.

NOTE:

Pallet is designed to be lifted from the backside only.

9. Raise disc mower off deck.

IMPORTANT:

Take care not to contact the other machine if load is

two-wide.

10. Back up until unit clears trailer, and slowly lower to

150 mm (6 in.) from ground.

11. Take to storage or set-up area, and set machine down

securely on level ground.

Figure 2.2: Unloading Disc Mower

NOTE:

When possible, approach from the backside to

minimize potential for contacting the unit.

12. Repeat for second disc mower (if required).

13. Check for shipping damage and missing parts.

IMPORTANT:

Do NOT remove disc mower from pallet until instructed.

14. Unload remaining pallets and boxes, and take to assembly area.

B

A

1015097

214713 8 Revision A

Page 17

Chapter 3: Assembling the Disc Mower (With or Without

1011354

A

B

C

1011500

A

B

the Dealer-Installed Transport)

Perform the following procedures in the order provided to assemble the disc mower without the transport system, or

when the Road Friendly Transport

To assemble a disc mower with the factory-installed transport, refer to 4 Assembling the Disc Mower (Factory-

Installed Transport), page 57.

™

will be installed by the Dealer.

3.1 Repositioning Center-Link Top Anchor

Perform this procedure to reposition the center-link top anchor into working position.

1. Place forklift forks (B) under top beam and lift carrier

frame (A) slightly until pin at base of center-link anchor

is loose. Use a piece of wood (C) to protect paint

on frame.

Figure 3.1: Carrier

2. Loosen jam nut (A) and fully loosen float spring bolt (B).

Repeat on the opposite side.

Figure 3.2: Float Spring

214713 9 Revision A

Page 18

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3. Remove four M10 hex head bolts (A) and flat washers,

and remove top shield (B).

CAUTION

To avoid injury, keep fingers clear of opening at base of

anchor.

4. Remove cotter pin (B), washer (C), and shipping

tag (D).

5. Remove pin (A) from center location and lower forks on

forklift.

NOTE:

Pin should slide out freely. Adjust forklift or move carrier

until pin is loose. Do NOT use hammer to remove pin.

B

A

Figure 3.3: Top Shield (Left of Center-Link)

D

A

C

B

1013184

1018340

6. Install pin (A) and secure with washer (B) and cotter

pin (C). Move the carrier and anchor so the pin can be

installed in working location.

Figure 3.4: Center-Link Anchor (Right of

Center-Link)

B

A

C

1018340

Figure 3.5: Center-Link Anchor (Right of

Center-Link)

214713 10 Revision A

Page 19

1013184

A

B

1014709

B

A

C

D

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

7. Install top shield (B) and secure with four M10 hex head

bolts (A) and flat washers. Torque to 27–30 Nm

(20–22 lbf·ft).

NOTE:

If transport is also being installed, leave bolts (A) loose.

These bolts will be tightened when installing the lighting

harness.

Figure 3.6: Top Shield (Left of Center-Link)

8. Close the disc mower’s lift cylinder lock-out valve (A) on

each lift cylinder by turning the handle to the horizontal

position.

9. Loosen jam nut (B).

10. Turn the adjuster bolt (C) and set dimension (D) to

130 mm (5-1/8 in.).

• Turn bolt clockwise (towards spring) to increase float

• Turn bolt counterclockwise (away from spring) to

decrease float

11. Tighten jam nut (B) against spring.

Figure 3.7: Lift Cylinder Lock-Out Valve, Jam

Nut, and Adjuster Bolt

214713 11 Revision A

Page 20

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3.2 Attaching Hitch to Carrier

1. Remove M20 bolts (A), washers, and nuts from carrier

at the hitch attachment location. Retain bolts, washers,

and nuts.

2. Cut banding (A) securing wood supports, then

remove supports (B).

3. Remove the two bolts securing wood support to hitch

pin (C). Discard bolts.

A

1011361

Figure 3.8: Carrier

C

A

4. Place sling (A) around the hitch frame. Adjust sling

position until hitch is balanced when lifting.

• R113: Approximately 2.7 m (106 in.) from the edge

of the tractor end of the hitch (B)

• R116: Approximately 3.5 m (138 in.) from the edge

of the tractor end of the hitch (B)

5. Raise the hitch approximately 610 mm (24 in.) off

the ground.

B

1013890

Figure 3.9: Hitch Packing

B

A

1012287

Figure 3.10: Lifting Hitch

214713 12 Revision A

Page 21

1013891

A

B

C

1011365

A

1015168

A

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

NOTE:

Hitch pin (C) is heavy. Support it appropriately before

removing bolt (A).

6. Support hitch pin (C), remove bolt (A) and wood

block (B) from top of pin, and remove hitch pin (C).

Figure 3.11: Hitch Packing

7. Install hitch pin (A) fully into hitch.

Figure 3.12: Hitch Pin

8. Pivot the gearbox (A) towards the right side of the

header. This will increase the clearance to the driveline

clutch when installing hitch onto carrier frame.

Figure 3.13: Gearbox

214713 13 Revision A

Page 22

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

9. Move hitch pivot (A) into attachment location (B) on

carrier, and line up hitch pin with hole in carrier.

A

Figure 3.14: Hitch to Carrier

10. Slowly lower hitch (A) while maintaining pin alignment

until hitch pin (B) is fully inserted. Use a large soft

hammer if necessary to seat hitch pin.

B

B

1011501

11. Line up holes in hitch pin (A) with holes in the carrier

frame. Install six M20 x 65 bolts (B) with hardened

washers under the bolt head and lock nuts (C).

A

1011372

Figure 3.15: Hitch Pin

A

B

C

1011373

Figure 3.16: Hitch Pin

214713 14 Revision A

Page 23

1018594

A

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

12. Tighten the outer bolts (A) first to draw the plate against

the frame. Then tighten the inner bolts.

13. Torque bolts to 461 Nm (340 lbf·ft).

Figure 3.17: Hitch Pin

214713 15 Revision A

Page 24

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3.3 Installing Tractor Mating Hitch to Carrier Hitch

Depending on disc mower configuration, refer to the applicable installation procedure:

• 3.3.1 Installing Drawbar Hitch, page 16

• 3.3.2 Installing Two-Point Hitch (Cat. II) Adapter, page 20

3.3.1 Installing Drawbar Hitch

If attaching the disc mower to a tractor with a drawbar hitch, proceed as follows. If attaching the disc mower to a

tractor with a two-point hitch, refer to 3.3.2 Installing Two-Point Hitch (Cat. II) Adapter, page 20.

1. Remove shipping wire or banding (A) securing shipping

blocks (B) at front of hitch, and remove blocks.

2. Swivel lower gearbox until the input shaft is

facing forward.

3. Remove shipping wire (A) from the jack stand

support (D) and jack (B). Remove the jack stand

support and jack from the pallet. Leave the drawbar

hitch attached to the pallet.

4. Remove the hardware bag from the jack stand support.

A

B

Figure 3.18: Hitch End Packing

D

A

C

Figure 3.19: Jack and Drawbar Hitch Packing

1011296

B

1026323

214713 16 Revision A

Page 25

1026356

A

B

1026352

A

B

1011298

A

B

C

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

5. Install jack support stand (A) as shown. Secure with two

M12 X 1.75 X 40 bolts (B), M12 washers and M12

center lock nuts per side. Torque hardware to 68.5 Nm

(51 lbf ft)

Figure 3.20: Jack Stand Support

6. Install jack (A) at front of hitch, and secure with pin (B).

7. Lower forklift until hitch is resting on hitch jack (A).

Figure 3.21: Jack Stand

8. Remove shipping wire (A) that secures pin (B) in

casting. Do NOT remove other strapping.

9. Remove pin (B) from casting and remove bolt (C) and

nut from pin.

Figure 3.22: Hitch Casting

214713 17 Revision A

Page 26

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

10. Using a floor jack or equivalent under pallet (A), raise

drawbar hitch (B) into position under the gearbox.

11. Move drawbar hitch (B) so pin (C) can be installed.

12. Secure pin with bolt (D) and nut.

13. Remove floor jack, and if necessary, remove remaining

strapping and pallet (A) from hitch adapter.

C

D

14. Remove cone shield (A).

15. Retrieve the primary driveline (D) from the shipping

location.

16. Remove nut (C), washer (B) and pin (A) from the disc

mower end of the primary driveline (D).

B

Figure 3.23: Drawbar Hitch

A

Figure 3.24: Cone Shield

A

1026357

1026358

D

A

B

C

Figure 3.25: Primary Driveline

214713 18 Revision A

1023655

Page 27

1026360

A

B

1014852

A

B

C

D

1026361

A

B

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

17. Slide the primary driveline (A) onto the gearbox input

shaft. Align the pinhole (B) in the yoke with the groove

on the input shaft.

Figure 3.26: Primary Driveline

18. Insert tapered pin (A) by hand. Ensure the pin lines up

with groove in yoke and is fully inserted. The notch in

the pin should be facing toward the shaft.

19. Clean the threads on pin (A) after it has been inserted.

20. Install washer (B) and nut (C) on tapered pin and torque

to 149 Nm (110 lbf·ft). The end of the pin must be

recessed approximately 9–11 mm (0.35–0.43 in.) (D).

NOTE:

Do NOT use an impact wrench to install or torque

the nut.

Figure 3.27: Primary Driveline

21. Install the cone shield (A) over the primary driveline (B).

Use the latches to secure it to the gearbox.

22. Place the primary driveline (B) on the driveline support.

23. Install hitch swing cylinder. Refer to 3.4 Installing Hitch

Swing Cylinder, page 24.

Figure 3.28: Cone Shield

214713 19 Revision A

Page 28

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3.3.2 Installing Two-Point Hitch (Cat. II) Adapter

1. Remove shipping wire or banding (A) securing shipping

blocks (B) at front of hitch, and remove blocks.

2. Swivel lower gearbox until the input shaft is

facing forward.

3. Retrieve two-point hitch adapter shipment.

4. Remove shipping wire (A) and material from stand (B),

and remove stand from hitch adapter (C).

5. Remove strapping that secures pin (A) to adapter (B).

Do NOT remove other strapping.

6. Remove pin (A) from adapter, and remove bolt (C) and

nut from pin (A).

A

B

1011296

Figure 3.29: Hitch Packing

B

A

C

1011306

Figure 3.30: Two-Point Hitch Packing

A

B

C

Figure 3.31: Two-Point Hitch Adapter

214713 20 Revision A

1011311

Page 29

1023634

A

B

C

D

1023633

A

B

C

1023642

A

B

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

7. Using a floor jack or equivalent, raise two-point hitch

adapter (A) into position under the gearbox.

8. Maneuver adapter (A) so that pin (B) can be installed to

secure adapter to hitch.

9. Secure pin with bolt (C) and nut (D).

10. Remove floor jack, and remove remaining strapping

and pallet from hitch adapter.

Figure 3.32: Two-Point Hitch Adapter

11. Retrieve stand (A).

12. Position stand (A) under gearbox as shown, and install

hitch pin (B) to secure the stand.

13. Install hairpins (C) to secure hitch pin (B).

14. Lower hitch and stand to the ground.

15. Install springs (A) into hooks (B). Repeat on

opposite side.

Figure 3.33: Stand

Figure 3.34: Springs

214713 21 Revision A

Page 30

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

16. Remove cone shield (A).

A

Figure 3.35: Cone Shield

17. Retrieve the primary driveline (D) from the shipping

location.

D

18. Remove nut (C), washer (B), and pin (A) from the disc

mower end of primary driveline (D).

1026370

A

19. Slide driveline (A) onto gearbox input shaft (B). Align

the pinhole in the yoke with the groove on the

input shaft.

B

C

1023655

Figure 3.36: Primary Driveline

B

A

1026375

Figure 3.37: Primary Driveline

214713 22 Revision A

Page 31

1014852

A

B

C

D

1026376

A

B

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

20. Insert tapered pin (A) by hand. Ensure the pin lines up

with groove in the yoke and is fully inserted. The notch

in the pin should be facing toward the shaft.

21. Clean the threads on pin (A) after it has been inserted.

22. Install washer (B) and nut (C) on the tapered pin and

torque to 149 Nm (110 lbf·ft). The end of the pin must

be recessed 9–11 mm (0.35–0.43 in.) (D).

NOTE:

Do NOT use an impact wrench to install or torque

the nut.

Figure 3.38: Primary Driveline

23. Install cone shield (A) over the primary driveline. Place

driveline (B) on the driveline support.

Figure 3.39: Cone Shield

214713 23 Revision A

Page 32

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3.4 Installing Hitch Swing Cylinder

The hitch swing cylinder can be installed on either side of the hitch, depending on whether or not the Road Friendly

Transport

™

system will be installed. Be sure to follow the instructions carefully.

1. Remove the banding (A) securing the hitch swing

cylinder (B) to the hitch.

2. Remove pin (C) securing cylinder (B) to hitch.

A

C

B

Figure 3.40: Steering Cylinder

To install cylinder on unit WITHOUT the Road Friendly Transport

™™

system, proceed as follows:

1. Reposition cylinder (A) at left side of hitch and attach

rod end to carrier frame lug with pin at location (B).

Secure with cotter pin (C).

2. Place a container or rag under the cylinder to catch oil.

3. Remove pin from location (D) at the clevis end of the

cylinder.

D

A

1011322

4. Swing the hitch until clevis lines up with lug on hitch.

5. Install clevis pin at location (D) and secure with cotter

pin (E).

NOTE:

Loosen the hydraulic fittings, if assistance is required to align

the clevis and lug.

6. If loosened, tighten the fittings on cylinder.

E

C

Figure 3.41: Hitch Swing Cylinder

B

1013472

214713 24 Revision A

Page 33

1011502

A

B

C

D

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

To install cylinder on unit WITH the Road Friendly Transport™™system, proceed as follows:

1. Disconnect the hoses from the cylinder and cap off

openings on cylinder and hoses.

2. Reposition cylinder (A) at right side of hitch. Use pin (C)

to attach barrel end to lug (B). Secure with cotter

pin (D).

NOTE:

The clevis end of cylinder will be attached to the Road

Friendly Transport

™

system casting after the system is

primed. Refer to 5.5 Priming the Hitch Swing Cylinder,

page 102.

3. Turn the valve on the hitch swing cylinder 180 degrees,

so that fittings are pointing up.

Figure 3.42: Hitch Swing Cylinder

214713 25 Revision A

Page 34

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

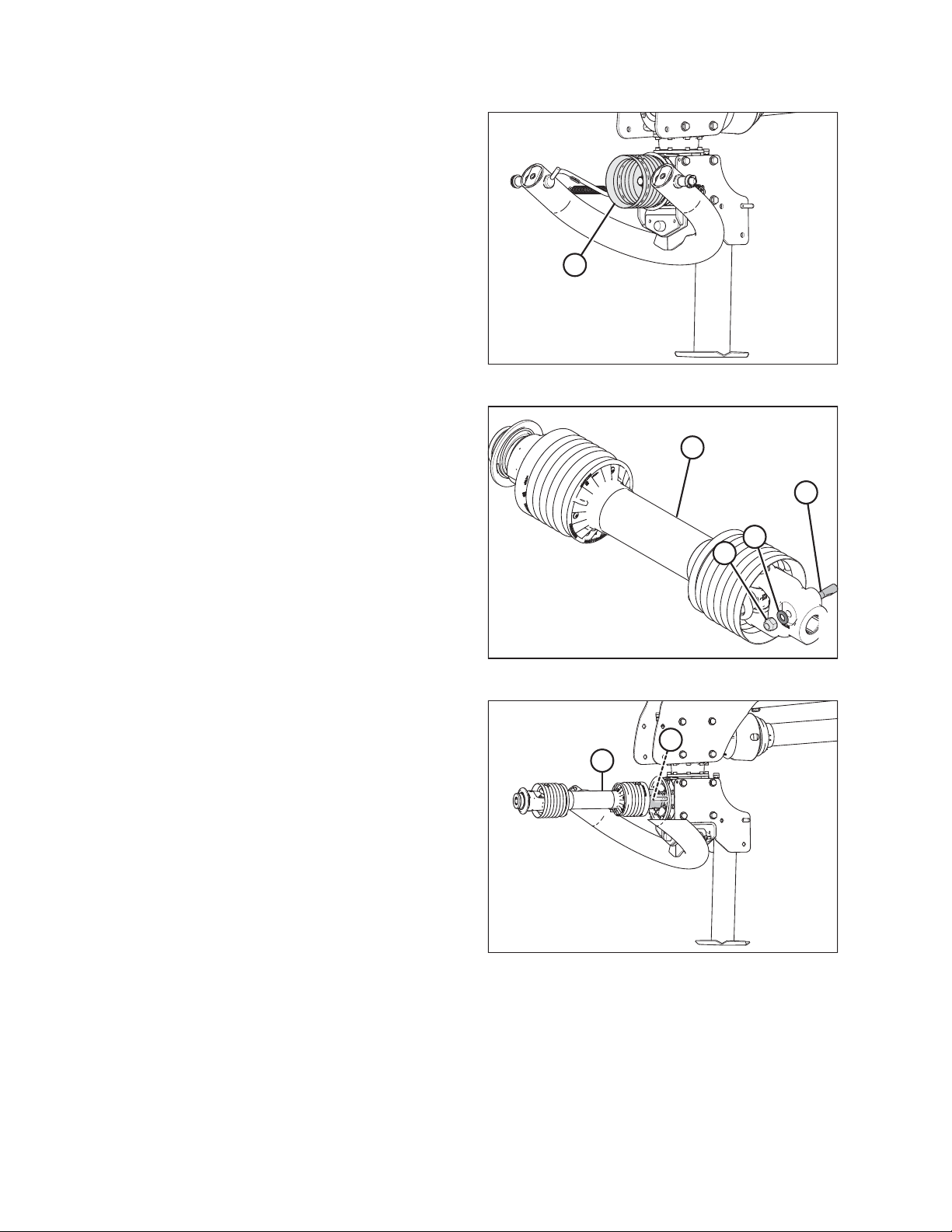

3.5 Attaching Clutch Driveline

This procedure describes how to attach the clutch driveline to the header drive gearbox.

IMPORTANT:

If a conditioner swap is required before delivery to the customer, do NOT perform this step at this time. Skip to 5.4

Installing Field Wheels, page 100 and then return to this topic to complete the setup.

1. Support driveline (B) and remove strapping (A) securing

it to hitch. Remove all packing material.

A

B

Figure 3.43: Driveline Strapping

1011377

2. Remove strapping (A) and packing material securing

steering arm (B) to hitch. Pivot steering arm to the side

for now.

NOTE:

Strapped contents may be under pressure.

3. At the top of the upper rear swivel gearbox, remove two

bolts (A) with spacers (B). Retain hardware.

4. Undo latches (C) securing driveline shield (D) to the

upper rear swivel gearbox and remove the shield. If

necessary, use a screwdriver or equivalent to undo

latches (C).

5. Rotate the upper rear swivel gearbox until the input

shaft is facing towards the driveline.

A

B

Figure 3.44: Steering Arm Strapping

B

D

1011397

A

C

Figure 3.45: Driveline Shield

214713 26 Revision A

1015161

Page 35

1011385

A

B

C

D

E

1015164

A

1014852

A

B

C

D

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

6. Slide cone (A) onto driveline with latches (B) towards

the gearbox.

7. Remove nut (C) and washer (E) from tapered pin (D),

and tap out pin from yoke using a hammer.

Figure 3.46: Clutch Driveline

8. Attach driveline (A) to the upper rear swivel

gearbox shaft.

Figure 3.47: Clutch Driveline

9. Insert tapered pin (A) by hand. Ensure the pin lines up

with groove in the yoke and is fully inserted. The notch

in the pin should be facing toward the shaft.

10. Clean the threads on pin (A) after it has been inserted.

11. Install washer (B) and nut (C) on the tapered pin, and

then torque to 149 Nm (110 lbf·ft). The end of the pin

must be recessed 0–2mm(0–0.08 in.) (D).

NOTE:

Do NOT use an impact wrench to install or torque

the nut.

12. Install the shield onto the upper rear swivel gearbox.

Use the latches to secure it.

Figure 3.48: Clutch Driveline

214713 27 Revision A

Page 36

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3.6 Attaching Steering Arm

This procedure describes how to attach the steering arm to the header drive gearbox.

IMPORTANT:

If a conditioner swap is required before delivery to the customer, do NOT perform this step at this time. Skip to 5.4

Installing Field Wheels, page 100 and then return to this topic to complete the setup.

1. Lower arm (A) from under the hitch and slide the

steering arm (B) off the support tube.

2. Apply grease to arm (A).

3. Slide steering arm (C) onto the support tube (A) in the

opposite direction.

4. Position steering arm (C) onto gearbox (D).

A

B

5. Line up the two mounting holes in arm weldment with

the forward threaded holes in the upper rear swivel

gearbox.

6. Install spacers (A) into steering arm (B).

7. Install washer (D), onto the M16 x 80 hex head

bolts (C). Install high-strength threadlocker (Loctite

®

262 or equivalent) onto the bolt threads.

8. Torque bolts to 203 Nm (150 lbf·ft).

C

D

Figure 3.49: Steering Arm

A

C

D

Figure 3.50: Steering Arm

A

1011400

B

1011402

214713 28 Revision A

Page 37

1014331

A

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

9. Attach safety chain (A) from driveline shield to slotted

hole in the steering arm.

NOTE:

Ensure chain is shortened to prevent any driveline

wrapping.

Figure 3.51: Driveline Shield

214713 29 Revision A

Page 38

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3.7 Connecting Transport Lighting Module

1. Locate plugs P102 on trailer harness (A) at the header

end of the hitch. Route plug P102 towards the transport

lighting module.

2. Connect plug P102 (B) to the upper input receptacle on

the transport lighting module (C).

Figure 3.52: Trailer Harness

A

C

B

1025979

214713 30 Revision A

Page 39

1014333

A

B

C

1022720

A

B

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3.8 Installing Options

Install the following optional kits if they were supplied with your disc mower.

3.8.1 Installing Road Friendly Transport™™System

This section explains how to install the Road Friendly Transport™system (C2002). The basic components are

installed first, then the hydraulic systems, and then lighting and signage.

Installing Components

This section explains how to install the basic parts of the Road Friendly Transport™System.

Installing Latch Assembly

1. Disconnect right light electrical connection (A).

2. Remove the two bolts (B) that secure right light

assembly (C) to the carrier frame.

3. Remove light assembly (C). Retain the light assembly

and hardware for installation later.

4. On the transport pallet, remove the shipping banding

and packing material from latch assembly (A). Remove

the latch assembly.

5. Remove the two M20 mounting bolts, washers, and

nuts (B) from the latch assembly, and retain for

use later.

Figure 3.53: Light Bracket

Figure 3.54: Latch Packing

214713 31 Revision A

Page 40

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

6. Install latch assembly (A) onto the carrier frame as

shown, and secure with the M20 bolts, washers, and

nuts (B) retained in Step 5, page 31.DoNOT fully

A

tighten bolts; adjustment of the latch assembly may be

necessary.

B

Figure 3.55: Latch Assembly

7. Loosen fitting (A) on the cylinder lockout valve.

8. Remove elbow fitting (B) from the cylinder.

1011183

9. Install tee fitting (A) in place of the elbow fitting.

10. Install cylinder lockout valve (B) on tee fitting (A)

as shown.

11. Attach hydraulic hose (C) from the latch assembly to

tee fitting (A) as shown.

A

B

1023770

Figure 3.56: Latch Plumbing

B

C

A

1023769

Figure 3.57: Latch Plumbing

214713 32 Revision A

Page 41

A

B

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

12. Retrieve clevis pin (A) and cotter pin (B) from the

shipping bag and install onto the hitch bracket at the

side of the hitch.

Figure 3.58: Latch Pin

214713 33 Revision A

Page 42

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

Installing Transport Assembly

1. Remove two bolts (A), hardened washer, and nut

securing slow moving vehicle (SMV) sign (B) to the

carrier frame, and remove sign. Retain sign and

hardware for reinstallation.

B

Figure 3.59: SMV Sign Attached to

Carrier Frame

2. Remove transport wheels (A) from the pallet.

A

1025984

3. Remove the five M20 hex head bolts (B), washers, and

nuts in transport assembly pin (C). Do NOT remove pin.

4. Using a forklift, pick up the pallet holding the transport

assembly (A) and align it with the rear of the

disc mower.

5. Position the assembly close behind the frame and align

pin (B) in transport assembly with hole (C) in the carrier.

Use a soft hammer or equivalent to fully insert pin (B).

B

A

C

1022722

Figure 3.60: Transport Packing

B

C

A

Figure 3.61: Road Friendly Transport

214713 34 Revision A

™™

1011186

Page 43

1022604

A

B

1026195

A

B

C

D

1022611

A

B

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

6. Install two M20 x 65 bolts (A), hardened washers,

and nuts.

7. Temporarily install bolts (B) to help align the assembly.

Figure 3.62: Pin Support

8. Rotate pin (A), until hole in pin aligns with holes in

welded collar (B). Insert pin (C) (MD #19958) through

the collar and pin.

9. Insert cotter pin (D) (MD #18608) and bend over the

legs to secure it.

Figure 3.63: Pin Installation

10. Retrieve cover assembly (B) from the shipping location.

11. Remove two bolts (A) from the cover assembly (B).

Retain bolts and cover for installation later.

Figure 3.64: Cover Assembly

214713 35 Revision A

Page 44

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

12. Install cover support (B).

13. Secure cover support (B) in place with one M20 x 65

bolt (A), hardened washer, and nut.

14. Torque bolts (A) to 461 Nm (340 lbf·ft).

15. Remove and retain bolts (B).

B

A

Figure 3.65: Cover Support

Figure 3.66: Cover Support

1022605

A

B

1022606

Installing Transport Valve

NOTE:

Cover support bracket removed from illustrations for clarity.

1. Retrieve valve assembly (A) from the pallet.

2. Position valve assembly (A) on the carrier hitch pin

plate as shown.

3. Install two M20 x 65 bolts (B), hardened washers,

and nuts.

4. Retrieve two M10 x 20 bolts from the shipping bag and

install bolts at location (C) with threads facing up. Install

nuts, but do not tighten.

5. Torque bolts (B) to 461 Nm (340 lbf·ft).

B

C

A

1016394

Figure 3.67: Selector Valve

214713 36 Revision A

Page 45

1022693

A

B

D

C

1014868

A

C

B

1014950

A

B

C

D

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

6. Disconnect plugs P102 (A) and P301 (B) from the

transport lighting module.

7. Remove bolts (C) and remove the transport lighting

module, complete with support bracket (D).

Figure 3.68: Lightening Module Harness

8. Install support plate (A) and secure it with bolts (B).

9. Install bolts (C), but do NOT tighten.

Figure 3.69: Support Plate

10. Remove nut (A) from support (D).

11. Install bolt (B) through support (D) and support (C), and

then reinstall nut (A).

Figure 3.70: Support Plate

214713 37 Revision A

Page 46

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

Installing Transport Swing Cylinder

1. Remove the shipping bag from the pallet.

2. Retrieve the clevis pin from the shipping bag.

3. Support transport swing cylinder (A). Cut straps

securing the cylinder to the pallet.

A

Figure 3.71: Transport Swing Cylinder

IMPORTANT:

Transport swing cylinder (A) must be primed before

installing it on the carrier frame.

B

4. To prime the cylinder, use a hydraulic power pack or

tractor hydraulics. Extend and retract transport swing

cylinder (A) until all the air has been removed. Extend

transport cylinder (A) to 142 cm (56 in.) between center

of pins.

A

1014867

C

NOTE:

If you need to adjust the cylinder length, remove bolt (C)

that secures the clevis end. Rotate the clevis to

lengthen or shorten the distance between pins (B).

When the cylinder length is correct, reinstall bolt (C) to

secure the clevis end.

5. Install barrel end of the transport swing cylinder (A) onto

the carrier frame with clevis pin (B). Secure clevis pin

with cotter pin (C).

Figure 3.72: Transport Swing Cylinder

B

C

A

Figure 3.73: Transport Swing Cylinder

1016379

1014869

214713 38 Revision A

Page 47

1014871

A

B

C

D

1011190

A

B

1015155

A

B

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

6. Connect clevis end (B) of the transport swing

cylinder (A) to transport casting. Align holes and install

clevis pin (C). Secure with cotter pin (D).

Figure 3.74: Swing Cylinder (Rear Left View)

Installing Transport Wheels

1. Cut the straps securing the transport assembly to the

pallet.

2. Slowly lower forklift until transport assembly wheel

spindles (A) are approximately 305 mm (12 in.) off

the ground.

3. Remove wheel bolts (B) from spindle hub (A) on the

left side.

4. Remove bolt (B) holding axle assembly (A) in place.

5. Slide axle assembly (A) out of the support.

Figure 3.75: Transport Wheel

Figure 3.76: Axle Assembly Relocation

214713 39 Revision A

Page 48

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

6. Install axle assembly (A) into the support.

7. Install bolt (B) with nut, and torque to 68 Nm (50 lbf·ft).

8. Remove the wheel bolts from hub (A).

CAUTION

When installing wheel, be sure to match countersunk

holes with bolt head profiles. Holes that are not

countersunk do NOT correctly seat the bolts.

B

Figure 3.77: Axle Assembly Relocation

9. Retrieve the transport wheels and install with the wheel

bolts. Ensure the valve stem faces outboard. Do NOT

fully tighten bolts.

10. Lower wheels to the ground and back forklift away.

1

11. Torque wheel bolts to 160 Nm (120 lbf·ft) following the

tightening sequence shown.

3

A

1015156

5

NOTE:

Whenever a wheel is installed, check torque after one

hour of operation.

12. Check tire pressure and adjust as required. Refer to 7.2

Checking Tire Pressure, page 128.

Installing Transport Alignment Control

1. Remove cam assembly (A) from shipping support (B).

2. Remove nuts (C) from the cam assembly.

6

4

Figure 3.78: Tightening Sequence

A

2

1015147

C

B

1014884

Figure 3.79: Alignment Controls (Front

Right View)

214713 40 Revision A

Page 49

1014876

A

C

B

1014886

A

B

1014334

A

B

C

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

3. Secure cam assembly (A) onto hitch swing cylinder

plate (B) with bolts and nuts (C). Torque nuts (C) to

55–60 Nm (40–45 lbf·ft).

NOTE:

When installing cam assembly (A), check for hose

twisting. If required, loosen hose fitting to allow hose to

untwist. Torque fitting when complete.

Figure 3.80: Alignment Control (Rear

Right View)

4. Remove two bolts (B), then remove shipping

support (A) and discard.

Figure 3.81: Shipping Support (Front

Right View)

5. Check the travel of cam arm (A) by sliding it in and out

of cam assembly (B).

NOTE:

If the cam arm does not slide easily, loosen valve

mounting bolts (C) and position valve (B) at the top of

the mounting holes. Retighten valve mounting bolts (C).

Figure 3.82: Alignment Control (Rear

Right View)

214713 41 Revision A

Page 50

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

6. Align the hole in cam arm (A) with the hole in cylinder

clevis (B).

Figure 3.83: Alignment Control (Rear

Right View)

7. Ensure the end of cam arm (A) is parallel with the clevis

end (B) of the cylinder. If adjustment is required, use a

bar to turn the clevis until the clevis is parallel with

cam arm (A).

NOTE:

The clevis end of the cylinder will be attached to the

™

Road Friendly Transport

casting when the system

is primed. Refer to 5.5 Priming the Hitch Swing

Cylinder, page 102.

A

B

1014337

A

B

Figure 3.84: Cam Arm Alignment

214713 42 Revision A

1014336

Page 51

1014877

A

B

C

1014882

A

B

C

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

8. Retrieve completion valve assembly (A) and one

M12 x 25 flanged hex head bolt from the shipping bag.

9. Remove bolts (B) from the standoffs on rear of carrier.

Install valve assembly (A) behind support plate (C).

Secure it to the standoffs using the three M12 x 25

flanged hex head bolts (B).

Figure 3.85: Control Valve

10. Retrieve paddle assembly (B) from the shipping bag.

11. Install washers (A) onto the bolts welded to the

completion valve assembly.

12. Install paddle assembly (B) onto the welded bolts and

secure with nuts (C).

NOTE:

Make sure that paddle (B) is centered on the valve and

moves freely.

Figure 3.86: Control Valve

214713 43 Revision A

Page 52

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

Installing Hydraulics

This section explains how to install the transport hydraulic control system.

Installing Hydraulic Lines and Hoses

NOTE:

Cover support bracket removed from illustrations for clarity.

NOTE:

Refer to 11.6 Torque Specifications, page 208 for hydraulic fitting installation details.

1. Retrieve steel lines and hoses from shipping bag.

2. Place a container or rag under the fitting on the hitch

swing cylinder.

3. Remove existing fitting (A) from the block.

4. Remove the cap from tee fitting (C).

5. Retrieve ORFS-6 x ORB-6 connector (B) from shipping

bag and install at location (A).

NOTE:

Ensure that the direction arrow on check valve (D)

points away from tee fitting (C).

6. Remove the cap from fitting (A).

7. Remove the plug from hose (B). Install hose to

fitting (A) as shown.

D

C

B

A

1018408

Figure 3.87: Alignment Valve Fitting

B

A

Figure 3.88: Alignment Valve Fitting

214713 44 Revision A

1014896

Page 53

1023782

A

B

C

D

1024973

A

B

C

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

8. Install steel line (A) from port A on the completion

assembly to tee fitting (D).

9. Install steel line (B) from port B on the completion

assembly to tee fitting (C).

Figure 3.89: Completion Assembly Plumbing

10. Attach hose (A) to steel line connecting to port C of

transport swing control.

11. Attach hose (B) to steel line connecting to port D of

transport swing control.

12. Secure hoses (A) and (B) together with cable tie.

NOTE:

Ensure that direction arrow on check valve (C) points

toward tee fitting.

Figure 3.90: Transport Swing Cylinder

214713 45 Revision A

Page 54

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

13. Install hose (A) from outer port (rod end) on transport

cylinder block to tee fitting (D) in port D of transport

swing control.

14. Install hose (B) from inner port (base end) on transport

cylinder block to tee fitting (C) in port C of transport

swing control.

A

B

D

C

Figure 3.91: Transport Swing Control

1014929

15. Connect hose (B) with red collar #2, from the rear of the

hitch, to fitting in port A1 on selector valve (C).

16. Connect hose (A) with blue collar #2, from the rear of

the hitch, to fitting in port A2 of the selector valve (C).

17. Secure hoses (A) and (B) together with cable tie.

B

A

C

1022691

Figure 3.92: Selector Valve Supply

214713 46 Revision A

Page 55

1014903

A

B

C

1014913

A

B

C

D

E

A

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

Installing secondary lift hose for field wheels

NOTE:

The secondary lift hose is required to lift the field wheels fully into storage position when the disc mower is in

transport mode.

Retrieve the following secondary lift hose from the shipping bag according to your disc mower size:

• 4.0 m (13 ft.) headers: Use hose MD #224160.

• 4.9 m (16 ft.) headers: Use hose MD #224162.

18. Retrieve the blue collars with the number one (blue

collar #1) on them from the shipping bag. Place one

collar on each end of the secondary lift hose (B).

19. Undo adjustable strap (A) around hoses at aft end

of hitch.

20. Locate the green wire preinstalled in the hitch for pulling

hoses through the hitch.

NOTE:

If you are installing a hydraulic center-link, pull the

hydraulic hoses through the hitch at the same time as

the lift hose.

21. At rear of hitch, feed male ORB end of hose (B) into

access hole (C). Route hose through the hitch to the

opening at front.

22. Position long hose (A) so that the exposed length at the

front of hitch matches existing hose (B). Route hose

through guide (C).

23. At front of hitch, loosen nut (D) on hose clamp (E) until

hose (A) can be positioned in clamp.

24. Tighten nut (D).

Figure 3.93: Lift Hoses

Figure 3.94: Lift Hoses

214713 47 Revision A

Page 56

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

25. Retrieve ORB-8 coupler (A) and plastic cap (B) from the

hardware bag.

26. At forward end of hitch, install coupling (A) and plastic

A

cap (B) onto secondary lift hose (C). Do NOT attach

hoses to tractor at this time.

B

Figure 3.95: Lift Hose Fittings

27. At rear of hitch, secure the hoses with adjustable

strap (A).

A

C

1016548

Figure 3.96: Lift Hoses

1022602

214713 48 Revision A

Page 57

1022603

A

B

C

D

E

1011227

A

B

C

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

28. Route hose (A) through opening (E) at the rear of

the frame.

29. Feed shortest hose (A) through opening (B) in carrier

frame as shown with male end (C) at the hitch pivot.

30. Connect hose (A) (MD #247106) and hose (D)

(MD #224160 or MD #224162) at the hitch pivot.

31. Retrieve ORFS-6 x ORB-8 elbow from the

hardware bag.

32. Remove plug at base of lift cylinder and install elbow (A)

as shown.

33. Connect hose (B) to elbow and tighten.

34. Tighten remaining connections.

35. Secure hose to cylinder with cable tie (C).

Figure 3.97: Lift Hose

Figure 3.98: Lift Cylinder

214713 49 Revision A

Page 58

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

Installing Electrical Components

Installing Light Assemblies

1. Disconnect the wiring harnesses at the left light

assembly; there are two connectors per assembly.

2. Remove the left light assembly (A).

NOTE:

Right side was removed earlier.

3. Remove red lamp (C) from the right light assembly

(removed in an earlier procedure). Align red lamp (C)

with the predrilled holes, in the left lamp bracket, next to

amber lamp. Secure the red lamp with

existing hardware, as shown.

4. Install right light assembly (A) on the left float spring

mount using bolts (B) removed in Step 2, page 50. Red

lamp (C) should be towards rear of machine when in

transport mode.

A

1015032

Figure 3.99: Transport Lighting

C

B

A

5. Retrieve new light bracket (C) from shipment.

6. Install amber lamp (A) and red lamp (B) onto new

bracket (C), previously removed from the right lamp

bracket, with hardware provided.

1015039

Figure 3.100: Left Side of Carrier

B

A

C

1011253

Figure 3.101: Light Assembly

214713 50 Revision A

Page 59

1011254

A

B

1022674

A

B

C

D

1022676

A

B

C

D

E

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

7. Install light assembly (A) onto header left end with two

M10 x 20 carriage bolts (B) and lock nuts from the

shipping bag. Ensure the amber lamp faces the front of

header and reflector faces outboard.

Figure 3.102: Header Left Side Lighting

Installing Left Side Transport Harness

1. Retrieve transport harness (A) (MD #281614) from the

shipping bag.

2. Route connectors P201 and P202 on the end of

harness (A) to cover support (D).

3. Using a draw tape or equivalent, route connectors P401

and P404 on the other end of the harness (A) through

opening (B) at front of carrier to opening (C) adjacent to

center-link.

4. Route the harness until the plugs reach the left light

assembly on the header.

5. Locate plug P301 (D) on harness (E) (MD #281613). It

was disconnected from the old lighting module.

6. Connect plug P201 (B) on harness (A) (MD #281614)

into the lower output receptacle on the lighting module.

7. Connect plug P301 (D) to receptacle P202 (C).

Figure 3.103: Harness Routing

Figure 3.104: Harness Connection

214713 51 Revision A

Page 60

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

8. Route harness (A) to light (B) on header as shown.

9. Retrieve p-clips, plastic clamps, and cable ties from

shipping bag.

10. Remove bolts (C) on header at locations shown.

11. Secure harness (A) with p-clips, existing bolts (C), and

plastic clamp (D) into existing holes.

NOTE:

4.0 m (13 ft.) header: Harness for disc mower is

secured with one plastic clamp (D).

NOTE:

4.9 m (16 ft.) header: Harness for disc mower is

secured with two plastic clamps (D).

12. Secure harness (A) to light bracket with two

cable ties (E).

13. Push excess harness into carrier frame.

14. Connect plug P401 and P404 into the light (B).

Connecting Right Side Transport Harness

1. Route transport harness (A) from opening into light

bracket (B) and plug into light connectors.

2. Secure harness (A) to light bracket with two cable

ties (C).

A

C

D

B

E

Figure 3.105: Harness Routing – R113 Shown

(R116 Similar)

1014366

3. Push excess harness into carrier frame.

B

C

A

Figure 3.106: Transport Light

1011292

214713 52 Revision A

Page 61

1022681

A

B

C

D

1015230

A

1015231

A

B

C

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

Connecting Selector Valve and Transport Lighting Module

1. Locate plugs P102 (A) and P502 (B) on the transport

harness at the header end of the hitch. Route plugs

P102 (A) and P502 (B) towards selector valve (C).

2. Connect plug P502 (B) to the receptacle on selector

valve (C).

3. Connect plug P102 (A) to the upper input receptacle on

transport lighting module (D).

Figure 3.107: Selector Valve Supply

Installing Remote Control

1. Retrieve remote control (A) with wiring harness.

2. Place remote control (A) on hitch temporarily.

3. Locate connector (C) that branches off the seven-pole

transport plug (A) and attach it to the remote wiring

harness (B).

Figure 3.108: Remote Control on Top of Hitch

Figure 3.109: Transport Harness

214713 53 Revision A

Page 62

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

4. If your tractor has a three-pin auxiliary power

connection:

NOTE:

The remote control has internal protection which

prevents damage caused by incorrect wiring, short

circuits, or overload conditions.

A

Connect two wires (B) from the three-pin auxiliary

connector (A) to the remote control wires (C) on the

remote control, wrap connections with electrical tape,

and proceed to Step 6, page 54.

C

• The wire with no tag connects to the tractor ground.

• The wire with the red tag connects to the

tractor power.

Figure 3.110: Three-Pin Auxiliary Connector

NOTE:

If connections are reversed, the lamp will not illuminate when the toggle switch is in field mode. Try the

following to correct the issue:

• Check internal fuse may have blown.

B

10236931023693

• Check for short in wires to solenoid valve on header.

• Check for incorrect wire connections (reversed) at the power supply or solenoid valve.

If your tractor does NOT have a three-pin auxiliary

power connection:

NOTE:

The remote control has internal protection which

prevents damage caused by incorrect wiring, short

circuits, or overload conditions.

5. Connect remote control wires (A) to the tractor’s power

supply:

• Connect wire (B) with no tag to tractor ground.

• Connect wire (C) with the red tag to tractor power.

NOTE:

If the red tag is missing, identify the power by locating

the wire with the number 1 printed on it. The ground

B

wire has a number 2 printed on it.

NOTE:

If connections are reversed, the lamp will not illuminate

C

when the toggle switch is in field mode. Try the

following to correct the issue:

A

1023703

• Check internal fuse may have blown.

Figure 3.111: Remote Control

• Check for short in wires to solenoid valve on header.

• Check for incorrect wire connections (reversed) at

the power supply or solenoid valve.

6. Place the remote control inside the tractor cab.

214713 54 Revision A

Page 63

1025989

B

A

1025993

A

C

B

D

1026208

A

B

C

D

ASSEMBLING THE DISC MOWER (WITH OR WITHOUT THE DEALER-INSTALLED TRANSPORT)

Installing Slow Moving Vehicle (SMV) Sign

1. Retrieve SMV sign that was previously removed.

2. Remove bolts (A), and discard existing bracket (B).

Retain the bolts and nuts.

Figure 3.112: SMV Sign

3. Retrieve bracket (A).

4. Attach bracket (A) to left end float spring member with

M12 bolts (B) and nuts retained from earlier step.