Page 1

PW8

Pick-Up Header

Operator ’s Manual

169489 Revision A

Original Instruction

The harvesting specialists worldwide.

Page 2

This manual contains instructions for safety, operation, and maintenance/service for the MacDon®PW8 Pick-Up

Header.

Published in March, 2014

Page 3

Declaration of Conformity

Figure 1: EC Declaration of Conformity

169489

i

Revision A

Page 4

Serial Number

RECORD THE SER

____________

The Serial Nu

Introduc

This manual describes operating and m aintenance procedures for the MacDon Swathmaster™ Combine Pick-Up

Headers for the following combines:

IAL NUMBER OF THE PW8 COMBINE PICK-UP HEADER HERE:

________________________________

mber plate is located on the left endsheet (A).

Figure 2

tion

Combine Model

Case IH

John Deere

New Holland

CAREFULLY READ ALL THE MATERIAL PROVIDED BEFORE ATTEMPTING TO UNLOAD , ASSEMBLE, OR USE

THE MACHINE. Store this operator’s manual and the parts catalog in the manual case (B) attached to the back of

the header.

Use this manual as your first source of information about the machine. If you follow the instructions given in this

manual, the pick-up header will work well for many years. Use the Table of Contents and the Index to guide you to

specific areas. Study the Table of Contents to familiarize yourself with how the material is orga niz ed.

The PW8 Pick-Up Header Parts Catalog (MD #169497) is also supplied with your new header.

Keep this manual handy for frequent reference, and to pass on to new Operators or Owners. Call your MacDon

Dealer if you need assistance, information, or additional copies of this manual.

5088, 6088, 7088, 7010, 8010, 7120, 8120, 9120, 5130, 6130, 7130, 7230, 8230, 9230,

5140, 6140, 7140

60, 70, and S Series

All CR/CX Series

169489

i

i

Revision A

Page 5

TABLE OF CONTENTS

Declaration of Conformity.................................................................................................................. i

Serial Number ..................................................................................................................................ii

Introduction ......................................................................................................................................ii

1 Safety.................................................................................................................................................... 1

1.1 Safety Alert Symbols........................................................................................................................ 1

1.2 Signal Words................................................................................................................................... 2

1.3 General Safety ................................................................................................................................ 3

1.4 Maintenance Safety ......................................................................................................................... 5

1.5 Hydraulic Safety .............................................................................................................................. 6

1.6 Tire Safety....................................................................................................................................... 7

1.7 Safety Signs .................................................................................................................................... 8

1.7.1 Installing Safety D e ca ls ............................................................................................................ 8

1.8 Safety Sign Locations ...................................................................................................................... 9

1.9 Interpreting Safety Signs ................................................................................................................. 11

2 Description .......................................................................................................................................... 17

2.1 D efinitions ..................................................................................................................................... 17

2.2 PW8 Header Specifications............................................................................................................ 19

2.3 PW8 Header Dimensions ............................................................................................................... 20

2.4 PW8 Component Identification........................................................................................................ 21

3 Operation............................................................................................................................................ 23

3.1 Owner/Operator Responsibilities..................................................................................................... 23

3.2 Operational Safety ......................................................................................................................... 24

3.3 Endshields .................................................................................................................................... 25

3.3.1 Opening LH Endshield............................................................................................................ 25

3.3.2 Closing LH Endshield ............................................................................................................. 26

3.4 Header Lift Cylinder Safety Props ................................................................................................... 28

3.5 Hold-Down Lift Cylinder Safety Props.............................................................................................. 29

3.6 Daily Start-up Check ...................................................................................................................... 30

3.7 Shutdown Procedure ..................................................................................................................... 31

3.8 Break-In Period ............................................................................................................................. 32

3.9 Changing Header Opening............................................................................................................. 33

3.10 Header Attachment and Detachment .............................................................................................. 34

3.10.1 Case IH................................................................................................................................. 34

Attaching to Case IH Combine......................................................................................... 34

Detaching from Case IH Combine.................................................................................... 37

3.10.2 John Deere 60, 70, and S Series ............................................................................................. 41

Attaching to John Deere 60, 70 and S Series Combine ..................................................... 41

Detaching from John Deere 60, 70, and S Series Combine ............................................... 45

3.10.3 New Holland CR/CX Series Combine ...................................................................................... 47

Attaching to New Holland CR/CX Series Combine ............................................................ 47

Detaching from New Holland CR/CX Combine.................................................................. 51

3.11 Header Transport........................................................................................................................... 54

3.11.1 Transport Lights ..................................................................................................................... 54

3.12 Header Operation .......................................................................................................................... 55

3.12.1 Operating Speed .................................................................................................................... 55

Adjusting Draper Speed .................................................................................................. 56

3.12.2 Auger .................................................................................................................................... 56

Auger Speed .................................................................................................................. 56

Auger Position ................................................................................................................ 56

Auger Float .................................................................................................................... 58

Stripper Plate Clearance ................................................................................................. 61

3.12.3 Operating Height.................................................................................................................... 62

Header Height ................................................................................................................ 62

169489

ii

i

Revision A

Page 6

TABLE OF CONTENTS

Pick-Up Height ............................................................................................................... 63

3.12.4 Hold-Down............................................................................................................................. 65

Hold-Down Position ........................................................................................................ 65

Hold-Down Rod Angle..................................................................................................... 66

3.12.5 Crop Deflectors ...................................................................................................................... 66

Installing Crop De flectors ................................................................................................ 66

Removing Crop Deflectors............................................................................................... 67

3.12.6 Draper Belt Tension................................................................................................................ 68

Checking Draper Belt Tension.......................................................................................... 68

Adjusting Draper Belt Tension on Front Deck .................................................................... 69

Adjusting Draper Belt Tension on Rear Deck .................................................................... 69

3.12.7 Driveline ................................................................................................................................ 71

Clutch ............................................................................................................................ 71

Guard ............................................................................................................................ 71

3.13 Unplugging the Header .................................................................................................................. 72

3.14 Storing the Header......................................................................................................................... 73

4 Maintenance and Servicing................................................................................................................. 75

4.1 Prepare Header for Servicing ......................................................................................................... 75

4.2 Maintenance Specifications ............................................................................................................ 76

4.2.1 Torque Specifications ............................................................................................................. 76

Metric Bolt Spe cifications ................................................................................................ 76

Metric Bolt Spe cifications Bolting into Cast Aluminum ....................................................... 79

Flare-Type Hydraulic Fittings ........................................................................................... 79

O-Ring Boss (ORB) Hydraulic Fittings (Adjustable) ........................................................... 81

O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable) .................................................... 83

O-Ring Face Seal (ORFS) Hydraulic Fittings .................................................................... 84

4.2.2 Recommended Fluids and Lubricants...................................................................................... 85

4.2.3 Conversion Chart ................................................................................................................... 86

4.3 Maintenance Requirements............................................................................................................ 87

4.3.1 Maintenance Schedule ........................................................................................................... 87

Maintenance Schedule/Record ........................................................................................ 88

4.3.2 Pre-Season/Annual Service .................................................................................................... 89

4.3.3 End of Season Service ........................................................................................................... 89

4.4 Lubrication .................................................................................................................................... 90

4.4.1 Greasing Procedure ............................................................................................................... 90

4.4.2 Greasing Points ..................................................................................................................... 91

4.4.3 Sealed Bearing ...................................................................................................................... 92

4.5 Endshields .................................................................................................................................... 93

4.5.1 Removing LH Endshield ......................................................................................................... 93

4.5.2 Installing LH Endshield ........................................................................................................... 94

4.5.3 Replacing Endshield Brackets .................................................................................................95

4.6 Drives ........................................................................................................................................... 97

4.6.1 Header Driveshaft .................................................................................................................. 97

4.6.2 Header Driveline .................................................................................................................... 97

Removing Header Driveline............................................................................................. 97

Installing Header Driveline............................................................................................... 99

Replacing Driveline Clutch..............................................................................................100

Driveline Guard .............................................................................................................101

Driveline Splined Shaft................................................................................................... 105

4.6.3 Draper Drives........................................................................................................................105

Removing Front Hydraulic Motor.....................................................................................105

Installing Front Hydraulic Motor....................................................................................... 106

Removing Rear Hydraulic Motor .....................................................................................107

Installing Rear Hydraulic Motor .......................................................................................108

169489

v

i

Revision A

Page 7

TABLE OF CONTENTS

Removing Hydraulic Motor Hoses ................................................................................... 109

Installing Hydraulic Motor Hoses ..................................................................................... 111

4.6.4 Auger Drive ..........................................................................................................................113

Auger Drive Chain ......................................................................................................... 113

Auger Drive Sprockets ................................................................................................... 117

4.7 Auger...........................................................................................................................................123

4.7.1 Replacing Auger Fingers .......................................................................................................123

4.7.2 Replacing Auger Finger Guides..............................................................................................124

4.7.3 Replacing Stripper Plates ......................................................................................................126

4.7.4 Replacing Flighting Extensions...............................................................................................127

4.8 Decks ..........................................................................................................................................128

4.8.1 Draper Belts..........................................................................................................................128

Removing Front Draper Belt ...........................................................................................128

Installing Front Drape r Belt .............................................................................................129

Removing Rear Draper Belt............................................................................................131

Installing Rear Draper Belt..............................................................................................132

4.8.2 Draper Fingers/Draper Guides ...............................................................................................133

Replacing Draper Fingers...............................................................................................134

Replacing Draper Guide.................................................................................................134

4.8.3 Draper Roll Bearings .............................................................................................................136

Rear Deck - Drive Roller Bearings ..................................................................................136

Rear Deck - Idler Roller Bearings.................................................................................... 144

Front Deck - Drive Roller ................................................................................................146

Front Deck - Idler Roller .................................................................................................149

4.9 Hold-Down...................................................................................................................................151

4.9.1 Replacing Fiberglass Rods ....................................................................................................151

4.9.2 Replacing Hold-Down Hydraulic Cylinders ..............................................................................152

Master Cylinder ............................................................................................................. 153

Slave Cylinder ...............................................................................................................155

Bleeding Cylinders and Lines ......................................................................................... 159

4.9.3 Hydraulic Hoses and Lines ....................................................................................................160

Removing Master Cylinder Hose..................................................................................... 160

Installing Master Cylinder Hose.......................................................................................163

4.10 Height Controllers ......................................................................................................................... 165

4.11 Draper Speed Sensor ...................................................................................................................166

4.11.1 Checking Draper Speed Sensor Position ................................................................................166

4.11.2 Adjusting Draper Speed Sensor .............................................................................................166

4.11.3 Replacing Draper Speed Sensor............................................................................................167

4.12 Wheels and Tires..........................................................................................................................169

4.13 Lights...........................................................................................................................................171

4.13.1 Adjusting Transport Lights .....................................................................................................171

4.13.2 Replacing Transport Light Bulb ..............................................................................................172

4.13.3 Replacing Lens .....................................................................................................................172

4.13.4 Replacing Lamp Housing .......................................................................................................173

5 Troubleshooting.................................................................................................................................175

6Opt

7 Unloading and Assembly ...................................................................................................................181

ions and Attachments ..................................................................................................................179

6.1 H ol

Index ..................................................................................................................................................183

d-Down Performance Kit .......................................................................................................... 179

169489

v

Revision A

Page 8

Page 9

1Safety

1.1 Safety Alert Symbols

This safety alert symbol indicates important safety

messages in this manual and on safety signs on

the header.

This symbol means:

• ATTENTION!

• BECOME ALERT!

• YOUR SAFETY IS INVOLVED!

Carefully read and follow the safety message

accompanying this symbol.

Why is safety important to you?

• Accidents disable and kill.

• Accidents cost.

• Accidents can be avoided.

Figure 1.

Operatin

1: Read Operator’s Manual Before

g

169489

1

Revision A

Page 10

SAFETY

1.2 Signal Words

Three signal words, DANGER, WARNING, and CAUTION, are used to alert you to hazardous situations. The

appropriate signal word for each situation has been selected using the following guidelines:

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death, or serious injury.

WARNING

Indicates a pote

mayalsobeused

ntially hazardous situation that, if not avoided, could result in death, or serious injury. It

to alert against unsafe practices.

CAUTION

Indicates a potentially hazardous situation that, if not avoided, may result in minor, or moderate injury. It

may be used to alert against unsafe practices.

169489

2

Revision A

Page 11

SAFETY

1.3 General Safety

CAUTION

The following are general farm safety precautions

that should be part of your operating procedure for

all types of machinery.

Protect yourself

• When assembling, operating, and servicing machinery,

wear all the protective clothing and personal safety

devices that COULD be necessary for the job at hand.

Don’t take chances.

• You may need:

– A hard hat

– Protective footwear with slip resistant soles

Figure 1.2

– Protective glasses or goggles

– Heavy gloves

– Wet weather gear

– A respirator or filter mask

– Hearing protection

Be aware that exposure to loud noise can c ause

impairment or loss of hearing. Wearing suitable

hearing protection devices such as ear muffs or ear

plugs. These will help protect against objectionable

or loud noises.

•Provideafirs

•Keepafire ext

extinguishe

proper use.

•Keepyoungc

all times.

•Beawaretha

is tired or i

consider th

of fatigue

t aid kit for use in case of emergencies.

inguisher on the machine. Be sure the fire

r is properly maintained. Be familiar with its

hildren away from the machinery at

t accidents often happen when the Operator

nahurrytogetfinished. Takethetimeto

e safest way. Never ignore warning signs

.

Figure 1.3

Figure 1.4

169489 3 Revision A

Page 12

SAFETY

•Wearclosefitting clothing and cover lo n g hair. Never

wear dangling items such as scarves or bracelets.

• Keep all shields in place. Never alter or remove safety

equipment. Make sure driveline guards can rotate

independently of the shaft and can telescope freely.

• Use only service and repair parts, made, or approved by

the equipment manufacturer. Substituted parts may not

meet strength, design, or safety requirements.

• Keep hands, feet, clothing, and hair away from moving

parts. Never attempt to clear obstructions or objects,

from a machine while the engine is running.

•Do NOT modify the machine. Non-authorized

modifications may impair machine function and/or safety.

It may also shorten the machine’s life.

Figure 1.5

• Stop engine and remove key from ignition before leaving

operator’s seat for any reason. A child or even a pet

could engage an idling machine.

• Keep the area used for servicing machinery clean

and dry. Wet or oily floors are slippery. Wet spots

can be dangerous when working with e lectrical

equipment. Be sure all electrical outlets and tools are

properly grounded.

• Keep work area well lit.

• Keep machinery clean. Straw and chaff, on a hot

engine, are a fire hazard. Do NOT allow oil or grease to

accumulate on service platforms, ladders, o r controls.

Clean machines before storage.

• Never use gasoline, naphtha, or any volatile material

for cleaning purposes. These materials may be toxic

and/or flammable.

• When storing machinery, cover sharp or extending

components to prevent injury from accidental contact.

Figure 1.6

Figure 1.7

169489

4

Revision A

Page 13

SAFETY

1.4 Maintenance Safety

To ensure your safety while maintaining the machine:

• Review the operator’s manual and all safety items before

operation and/or maintenance of the machine.

• Place all controls in Neutral, stop the engine, set the park

brake, remove the ignition key, and wait for all moving

parts to stop before servicing, adjusting, and/or repairing.

• Follow good shop practices:

– Keep service area clean and dry.

–Besureelectricaloutletsandtoolsareproperly

grounded.

– Use adequate light for the job at hand.

• Relieve pressure from hydraulic circuits before servicing

and/or disconnecting the machine.

• Before applying pressure to a hydraulic system, make

sure all components are tight and that steel lines, hoses,

and couplings are in good condition.

Figure 1.8: Slip on Puddle

• Keep hands, feet, clothing, and hair away from all moving

and/or rotating parts.

• Clear the area of bystanders espec ia lly children when

carrying out any maintenance and repairs or when

making any adjustments.

• Install transport lock or place safety stands under the

frame before working under the header.

• If more than one person is servicing the machine at the

sametime,beawarethatrotatingadrivelineorother

mechanically driven component by hand (for example,

accessing a lube fitting) will cause drive components in

other areas (belts, pulleys, and knife) to move. Stay clear

of driven components at all times.

• Wear protective gear when working on the machine.

• Wear heavy gloves when working on knife components.

Figure 1.9: Keep Away

Figure 1.10: Safety Gear

169489 5 Revision A

Page 14

SAFETY

1.5 Hydraulic Safety

• Always place all hydraulic controls in Neutral before

dismounting.

• Make sure that all components in the hydraulic system

are kept in good condition and clean.

• Replace any worn, cut, abraded, flattened, or crimped

hoses and steel lines.

• Do not attempt any makeshift repairs to the hydraulic

lines, fittings, or hoses by using tapes, clamps, cements,

or welding. The hydraulic system operates under

extremely high pressure. Such makeshift repairs will fail

suddenly and create a hazardous and unsafe condition.

• Wear proper hand and eye protection when searching for

a high-pressure hydraulic leak. Use a piece of cardboard

as a backstop instead of hands to isolate and identify

aleak.

Figure 1.11: Checking Hydraulic Leaks

• If injured by a concentrated high-pressure stream of

hydraulic fluid, seek medical attention immediately.

Serious infection or toxic reaction can develop from

hydraulic fluid piercing the skin.

• Before applying pressure to a hydraulic system, make

sure all components are tight and that steel lines, hoses,

and couplings are in good condition.

Figure 1.12: Hydraulic Pressure Hazard

Figure 1.13: Wear Safety Glasses

169489 6 Revision A

Page 15

SAFETY

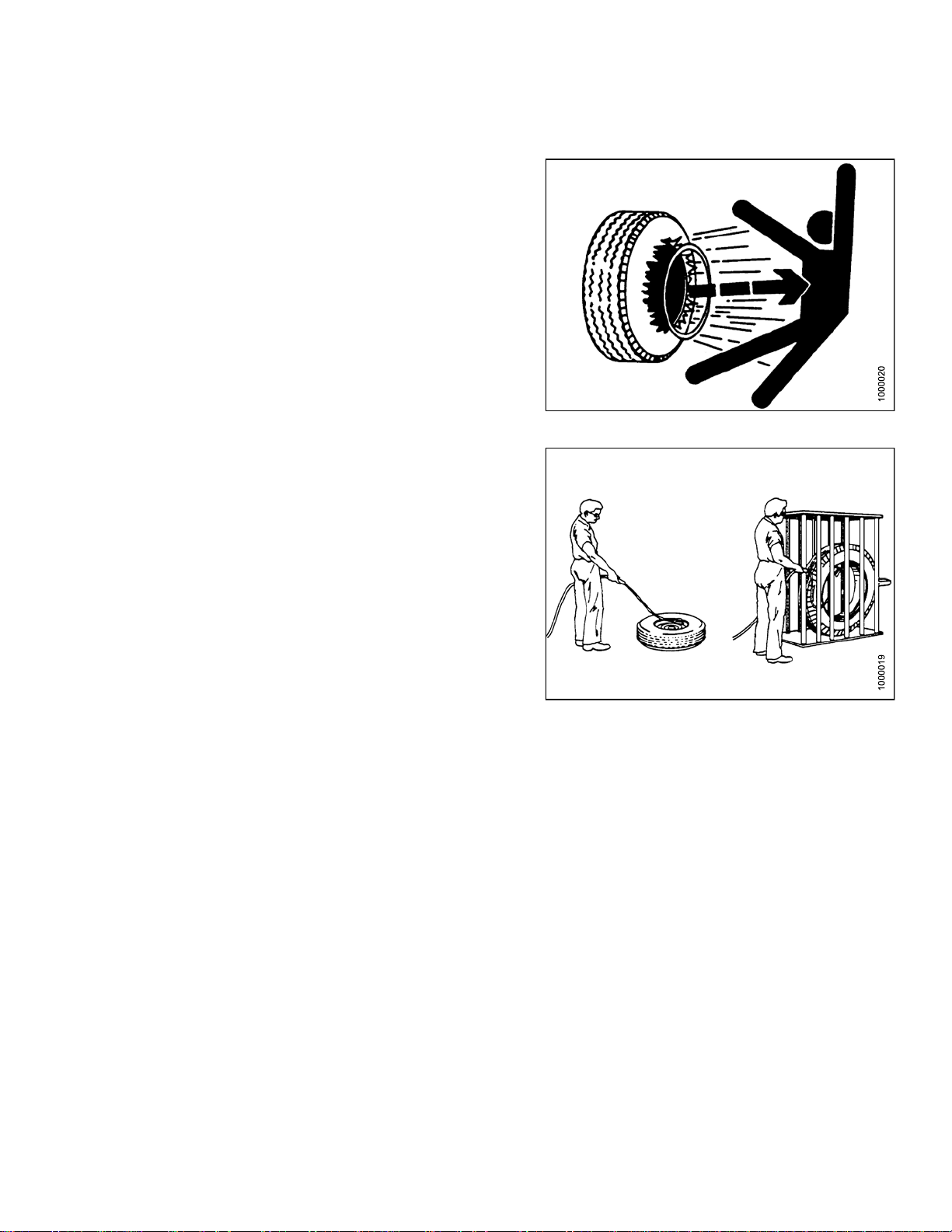

1.6 Tire Safety

• Failure to follow proper procedures when mounting a tire

on a wheel or rim can produce an explosion that may

result in serious injury or dea th .

•DoNOT attempt to m ount a tire unless you have the

proper training and equipment.

Figure 1.14: Over-Inflating a Tire

• Have a qualified tire dealer or repair service perform

required tire maintenance.

Figure 1.15: Saf ely Filling a Tire with Air

169489

7

Revision A

Page 16

SAFETY

1.7 Safety Signs

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or

become illegible.

• If original parts on which a safety sign was installed are

replaced, be sure the repair part also bears the current

safety sign.

• Safety signs are available from your Dealer

Parts Department.

1.7.1 Installing Safety Decals

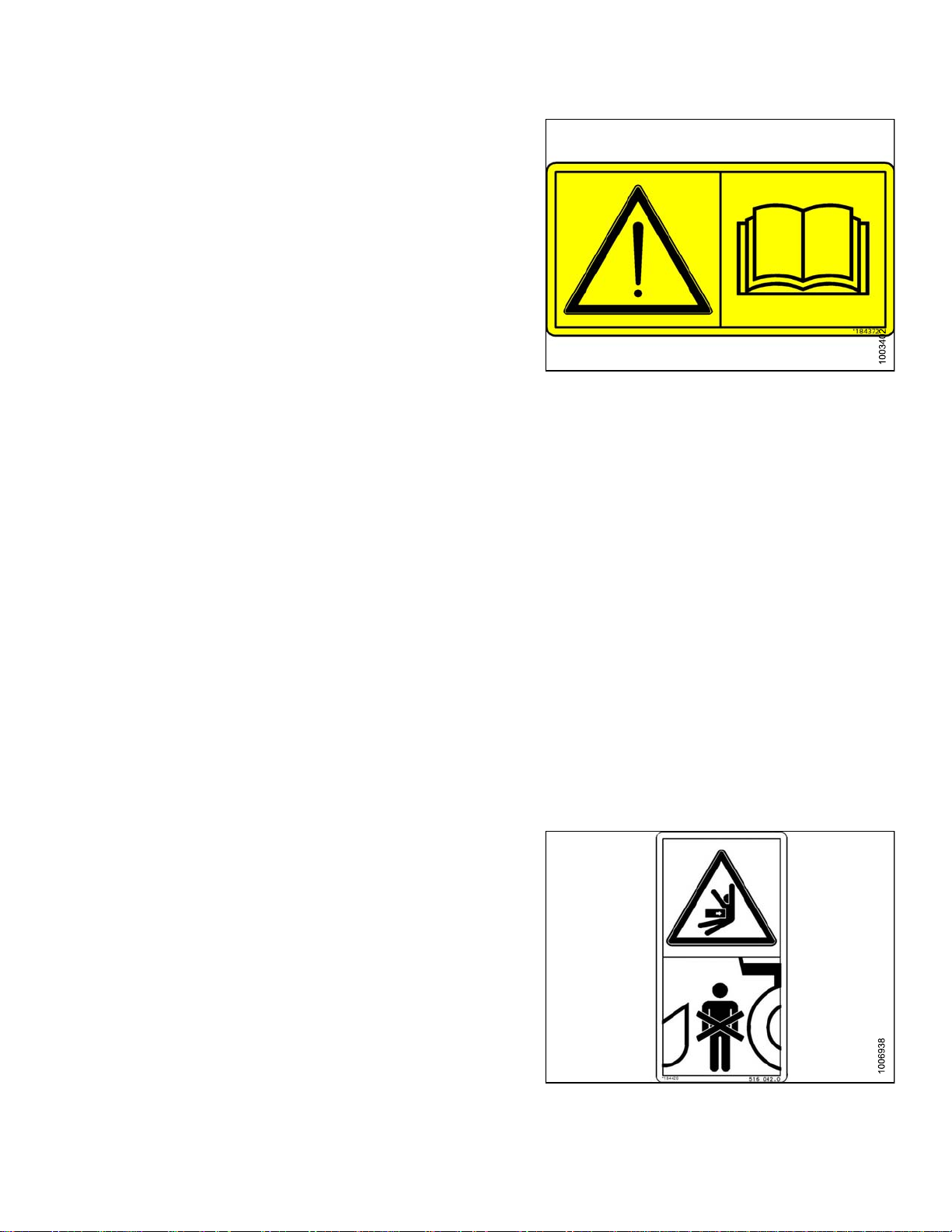

Figure 1.16: Read Operator’s Manual before

Operating

To i n s t a l

1. Be sure th

2. Decide on

3. Remove t

4. Place th

5. Small ai

l a safe ty dec al, follow these steps:

e sign in position an d slowly peel back the remaining pap er, smoothin g the sign as it is applied.

r pockets can be smoothed out or pricked with a pin.

e installation area is c l ea n and dry.

the exact location before you remove the decal backing paper.

he smaller portion of the split backing paper.

169489 8 Revision A

Page 17

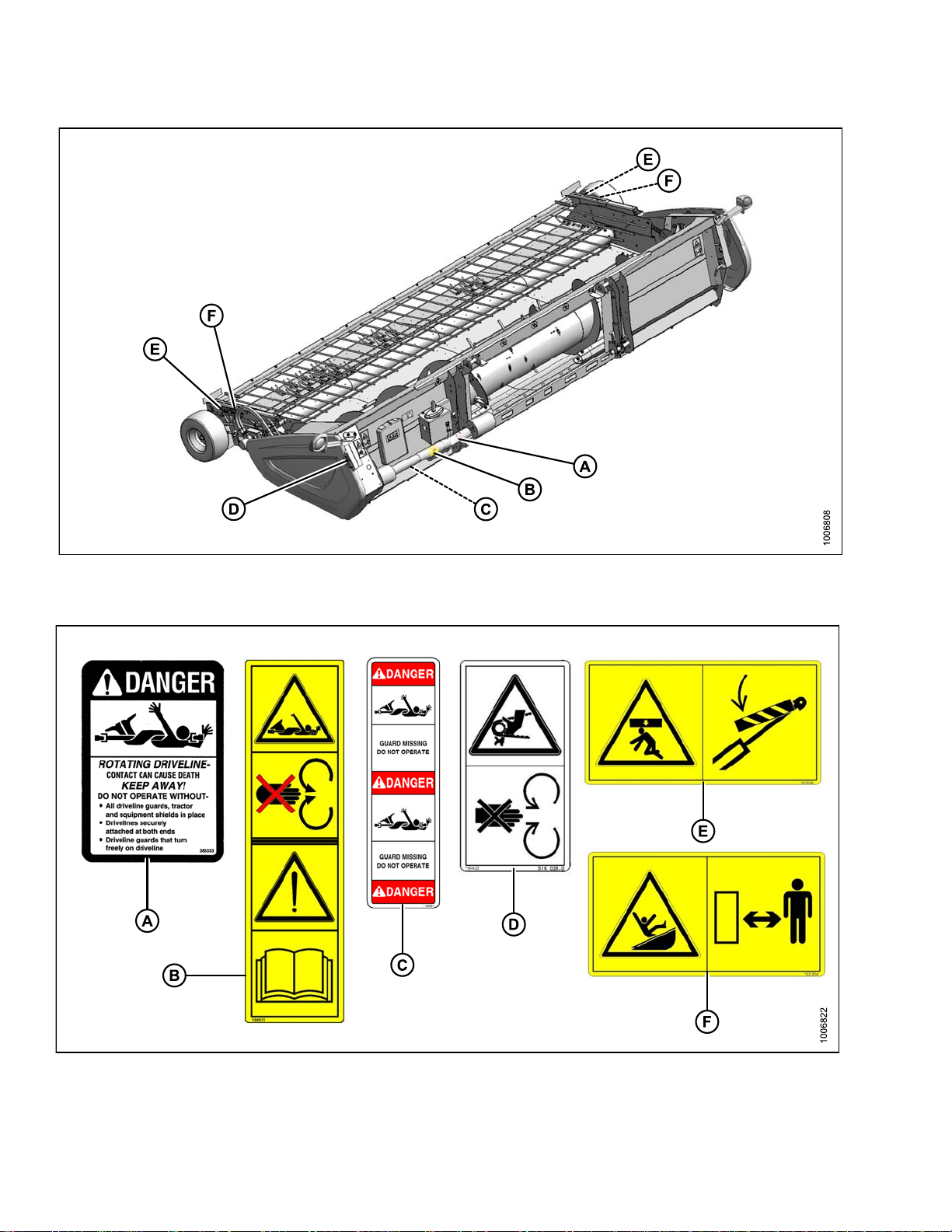

1.8 Safety S ign Locations

SAFETY

Figure 1

A - MD #184370 B - MD #166466 C - MD #184372 D - MD #184371

E - MD #184420 F - MD #237298

.17: Header Decals

169489 9 Revision A

Page 18

SAFETY

Figure 1.18: Driveline and Hold-Down Decals

A - MD #30316 B - MD #191099 C - MD #36651

D - MD #184422 (Behind Endshield) E - MD #237229 F - MD #237254

169489 1

0

Revision A

Page 19

SAFETY

1.9 Interpreting Safety Signs

In the safety sign explanations below, (a) refers to the top or

left position panel, (b) refers to the bottom or right position

of the safety decal depending on decal orientation.

NOTE: If there are more than two panels in a decal, the

lettering will continue downward or to the right,

depending on decal orientation.

1. MD #30316

a. Rotating driveline

b. DA NGER

Rotating Driveline contact can cause death - KEEP

AWAY! Do not operate without:

• All driveline guards, tractor and equipment

shields in place.

• Drivelines securely attached at both ends.

• Driveline guards that turn freely on driveline.

2. MD #36651

a. Rotating driveline

b. DA NGER

• Stop engine and remove key before opening

shield.

• Do not operate if guard is missing or shields not

in place.

• Failure to comply will result in death or serious

injury.

Figure 1.19: MD #30316

Figure 1.20: MD #36651

169489

1

1

Revision A

Page 20

3. MD #166466

a. High pressure oil hazard.

b. WARNING

Do no t go near leaks.

• High pressure oil easily punctures skin causing

serious injury, gangrene, or death.

• If injured, seek emergency medical help.

Immediate surgery is required to remove oil.

•Donotusefinger or skin to check for leaks.

• Lower load or relieve hydraulic pressure before

loosening fittings.

4. MD #184370

a. Crushing hazard.

b. CAUTION

• Rest header on ground or engage cylinder safety

props before going under unit.

SAFETY

Figure 1.21: MD #166466

• Failure to comply could result in death or serious

injury.

5. MD #184371

a. Open drive hazard.

b. WARNING

• Guard missing. Do not operate.

• Keep all shields in place.

Figure 1.22: MD #184370

Figure 1.23: MD #184371

169489

2

1

Revision A

Page 21

6. MD #184372

a. General hazard pertaining to machine operation

and servicing.

b. CA UTION

To avoid injury or death from improper or unsafe

machine operation:

• Read the operator’s manual and follow all safety

instructions. If y ou do not have a manual, obtain

one from your Dealer.

• Do not allow untrained persons to operate

the machine.

SAFETY

• Review safety instructions with all

Operators annually.

• Ensure that all safety sign s are installed

and legible.

• Make certain everyone is clear of machine

before starting engine and during operation.

• Keep riders off the machine.

• Keep all shields in place and stay clear of

moving parts.

• Disengage header drive, put transmission in

Neutral, and wait for all movement to stop before

leaving operator’s position.

• Shut off the engine and remove the key from

ignition before servicing, adjusting, lubricating,

cleaning, or unplugging machine.

• Engage safety props to prevent lowering of

raised unit before servicing in the raised position.

• Use slow moving vehicle emblem and flashing

warning lights when operating on roadways

unless prohibited by law.

Figure 1.24: MD #184372

7. MD #184420

a. Crushing hazard

WARNING

• To avoid injury from being pinned or crushed,

stay clear of header while machine is operating

or in motion. Failure to comply could result in

death or serious injury.

169489 1

3

Figure 1.

25: MD #184420

Revision A

Page 22

8. MD #184422

a. Keep shields in place hazard.

b. WARNING

• To avoid injury, stop engine before opening

power drive system shield.

• Keep all shields in place.

SAFETY

Figure 1.26: MD #184422

169489

4

1

Revision A

Page 23

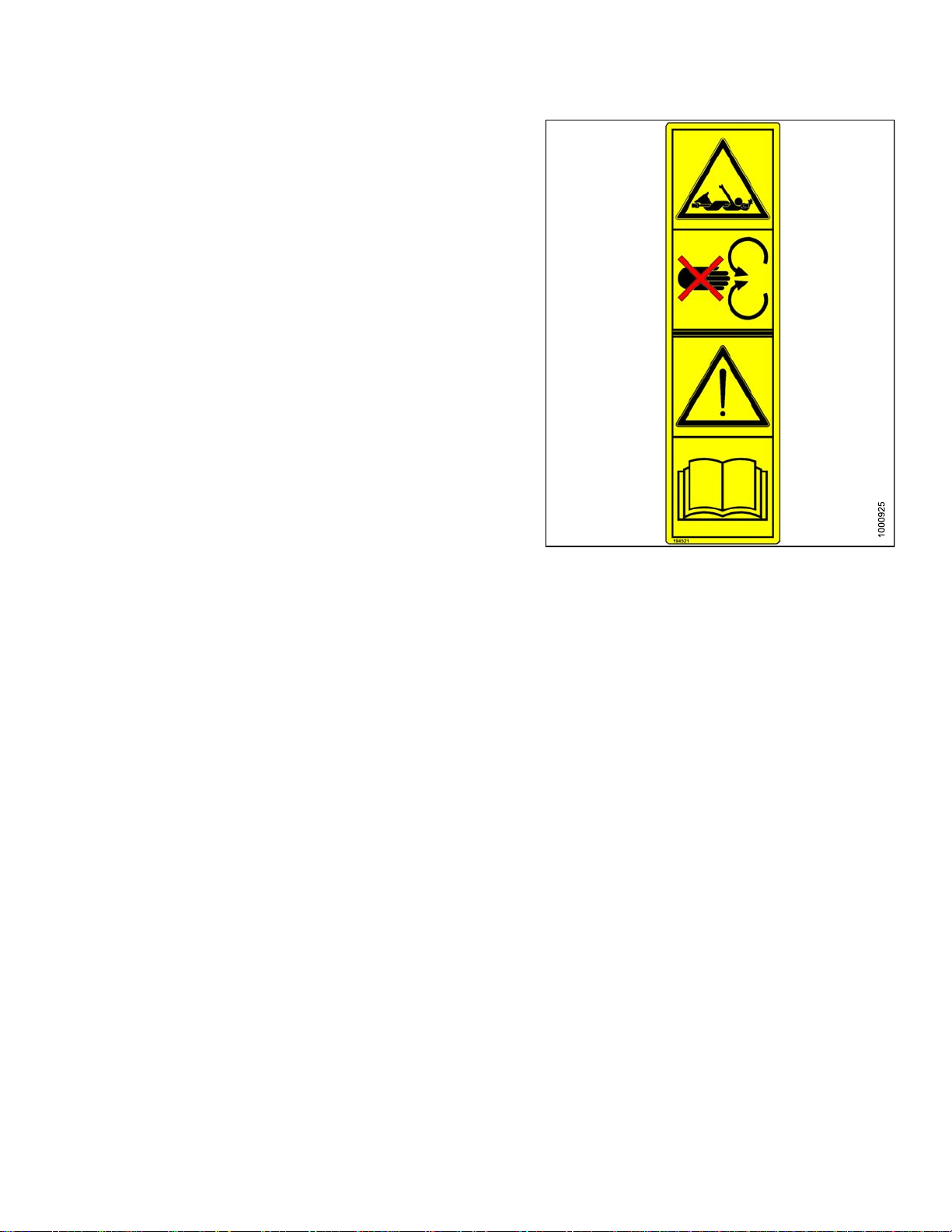

9. MD #191099

a. Auger entanglement hazard.

b. CA UTION

• To avoid injury from entanglement with rotating

auger, stand clear of header while machine

is running.

c. General hazard pertaining to machine operation

and servicing.

d. CA UTION

• Read the operator’s m anual and follow safety

instructions. If y ou do not have a manual, obtain

one from your Dealer.

• Do not allow untrained persons to operate

the machine.

• Review safety instructions with all

Operators annually.

• Ensure that all safety sign s are installed

and legible.

SAFETY

• Make certain everyone is clear of machine

before starting engine and during operation.

• Keep riders off the machine.

• Keep all shields in place and stay clear of

moving parts.

• Disengage header drive, put transmission in

Neutral, and wait for all movement to stop before

leaving operator’s position.

• Stop the engine and remove the key from ignition

before servicing, adjusting, lubricating, cleaning,

or unplugging machine.

• Engage safety props to prevent lowering of unit

before serv icing in the raised position.

• Use slow moving vehicle emblem and flashing

warning lights when operating on roadways

unless prohibited by law.

Figure 1.

27: MD #191099

169489 1

5

Revision A

Page 24

10. MD #237229

a. Header crushing hazard

b. WARNING

• Rest header on ground or engage cylinder safety

props before going under unit.

11. MD #237254

a. Header entanglement hazard

b. CAUTION

• To avoid injury from entanglement with crop

gathering elements, stand clear of header while

machine is running.

SAFETY

Figure 1.28: MD #237229

12. MD #237298

a. Auger entanglement hazard

b. CAUTION

• To avoid injury from rotating auger, stand clear

of auger while machine is running.

Figure 1.29: MD #237254

Figure 1.30: MD #237298

169489 1

6

Revision A

Page 25

2 Description

2.1 Definitions

The following definitions and acronyms may be used in this manual:

Term Definition

API American Petroleum Institute.

ASTM American Society of Testing and Materials.

Bolt

CGVW Combined Vehicle Gross Weight.

Finger t

F.F. F. T

GVW Gross Vehicle Weight.

hp Horsepower

JIC

n/a Not a

Nut

NPT

ORB

ORFS

Pick-Up Header

ight

A headed and externally threaded fastener that is designed to be paired with a nut.

Finger tight is a reference position where sealing surfaces or components are

making contact with each other and the fitting has been tightened to a point where

the fitting is no longer loose.

Flats from finger tight.

Joint Industrial Council: a standards body that developed the standard sizing and

shape for original 37° flared fitting.

pplicable

An internally threaded fastener that is designed to be paired with a bolt.

National Pipe Thread: a style of fitting used for low pressure port openings. Threads

on NPT fittings are uniquely tapered for an interference fit.

O-ring Boss: a style of fitting commonly used in port opening on manifolds, pumps

and m otors.

O-ring Face Seal: a style of fitting commonly used for connecting hoses and tubes.

This style of fitting is also commonly called ORS, which stands for O-ring Seal.

A machine that picks up grain that has been cut and laid in windrows, and is

attached to a combine.

PTO Power Take-Off.

RoHS (Reduction of

Hazardous Substances)

SAE Society Of Automotive Engineers.

Screw

Soft joint

spm

Ten si o n

T.F. F. T.

169489

A directive by the European Union to restrict the use of certain hazardous

substances (such as hexavalent chromium used in some yellow zinc platings).

A headed and externally threaded fastener that threads into preformed threads or

forms its own thread in one of the mating parts.

A joint made with the use of a fastener where the joining materials are compressible

or experience relaxation over a period of time.

Strokes per minute

Axial load placed on a bolt or screw, usually measured in pounds (lb) or Newtons (N).

Turns from finger tight.

7

1

Revision A

Page 26

Term Definition

DESCRIPTION

Tor qu e

Torque angle

Torque-ten

Tractor Agricultural-type tractor.

Truck A four-wheel highway/road vehicle weighing no less than 7500 lb (3400 kg).

Washer

sion

The product of a force X lever arm length, usually measured in foot-pounds (ft·lbf)

or Newton-meters (N·m).

A tightening procedure where the fitting is assembled to a p recondition (finger

tight) and then the nut is turned further a number of degrees or a number of flats to

achieve its final position.

The relationship between the assembly torque applied to a piece of hardware and

the axial load it induces in the bolt or screw.

A thin cylinder with a hole or slot located in the center and is to be used as a spacer,

load distribution element or a locking mechanism.

169489 1

8

Revision A

Page 27

DESCRIPTION

2.2 PW8 Header Specifications

PW8 Header Model SWATHMASTER™

Frame and Structure

WidthToEdgeofTires

PICK-UP

AUGER

Width (Transport Lights Extended)

Depth

Height (Transport Lights Extended)

Weight (Not Including Completion Packages) 3006 lb (1366 kg)

Carrier

Lighting Two Amber Transport

Manual Storage Header Mounted Manual Storage Case

rBatWidth

Finge

Actual Picking Width

Draper Width

Quantity of Pick-Up Fingers

per Drives

Dra

Diameter (including Flighting) 24 in. (615 mm)

ube Diameter

T

Quantity of Fingers

Refer to Section 2.3 PW8 Header

Dimensions, page 20

AGCO, CLAAS, Case IH, New Holland,

John Deere, Lexion

N/A

Refer to Section 2.3 PW8 Header

Dimensions, page 20

392

Two5.9cu. in. (97cc)HydraulicMotors

16 in. (410 mm)

13–22

Finger Diameter

Speed (Combine Dependent)

DRIVELINE

Type

Connections Locking Collar

TIRES

Size 18.5 / 8.5 x 8

Pressure

NOTE: Specifications and design are subject to change without notice or obligation to revise previously

sold units.

5/8 in. (16 mm) Diameter. Induction Hardened

141–204 rpm

Heavy Duty PTO Type, Fully Shielded

With Built-In Clutch.

35–45 psi (240–310 kPa)

169489 1

9

Revision A

Page 28

DESCRIPTION

2.3 PW8 Header Dimensions

Figure 2.1: Header Dimensions

A - 222-3/4 in. (5658 mm) B - 203-1/2 in. (5170 mm) C - 178-1/8 in. (4523 mm)

D - 187-5/8 in. (4766 mm) E - 209-3/8 in. (5318 mm)

Figure 2.2: Header Dimensions

A - 96-7/8 in. (2460 mm) B - 98-7/8 in. (2513 mm) C - 60-3/4 in. (1544 mm) D - 54-3/8 in. (1380 mm)

169489 2

0

Revision A

Page 29

DESCRIPTION

2.4 PW8 Component Identification

Figure 2

A - Transport Light B - Endshield - Fixed

D - Stripper Plate

G - Auger Pan H - Multi-Coupler Receptacle

J - Driveline

M-Hold

P - Gauge Wheel Q - Reflector

S - Draper Finger

V - Forward Draper Deck W - Rear Draper Deck X - Auger Flighting

.3: PW8 Header

-Down Cylinder Safety Prop

E - Auger F - Auger Finger

K-ManualCase

N - Draper Drive Motor

T - Hold-Down U - Hold-Down Fiberglass Rod

C - Window Frame

I-NotUsed

L - Endshield - Latched

-Down Lift Cylinder

O-Hold

R-Handle

169489

1

2

Revision A

Page 30

Page 31

3 Operation

3.1 Owner/Operator Responsibilities

CAUTION

• It is your responsibility to read and understand this manual completely before operating the header.

Contact your MacDon Dealer if an instruction is not clear to you.

• Follow all safety messages in the manual and on safety decals on the machine.

• Remember that YOU arethe key to safety. Good safety practices protectyou and the people aroundyou.

• Before allowing anyone to operate the header, for however short a time or distance, make sure they

have been instructed in its safe and proper use.

• Review the manual and all safety related items with all Operators annually.

• Be alert for other Operators not using recommended procedures or not following safety precautions.

Correct these mistakes immediately, before an accident occurs.

• Do NOT modify the machine. Unauthorized modifications may impair the function and/or safety and

affect machine life.

• The safety information given in this manual does not replace safety codes, insurance needs, or laws

governing your area. Be sure your machine meets the standards set by these regulations.

169489 2

3

Revision A

Page 32

OPERATION

3.2 Operational Safety

Follow these safety precautions:

CAUTION

• Follow all safety and operational instructions given in your combine Operator's Manual. If you do not

have a combine manual, get one from your Dealer and read it thoroughly.

• Never start or move the machine until you are sure all bystanders have cleared the area.

• Stop combine engine and remove key before adjusting or removing plugged material from the machine.

A child or even a pet could engage the drive.

• Check for excessive vibration and unusual noises. If there is any indication of trouble, shut down and

inspect the machine.

CAUTION

Follow proper shutdown procedure:

• Engage combine brake.

• Turn off engine and remove key.

• Wait for all movement to stop.

• Dismount and engage safety props before inspecting raised machine.

• Operate only in daylight or good artificial light.

169489

4

2

Revision A

Page 33

OPERATION

3.3 Endshields

The endshields are molded polyethylene covers that are attached to the ends of the header. They mainly provide

shielding for the header drive components and also display the make of the combine. The left endshield is hinged

to the endsheet, and can be opened for routine maintenance or easily removed for major servicing. The right

endshield is bolted directly to the header.

3.3.1 O pening LH Endshield

DANGER

Stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even

a pet could engage an idling machine.

1. Lower header to ground, shut down engine, and

remove key from ignition.

2. Unlock endshield (B) by turning latch (A)

counterclockwise until it stops (slightly more than

one-half turn) using a standard end screwdriver.

3. Grasp forward end of endshield (A) and pull open

until support (B) engages and holds endshield in open

position.

NOTE: If additional access to the drive area is

required, remove the endshield. Refer to

Section: 4.5.1 Removing LH Endshield,

page 93.

Figure 3.1: Endshield Closed

Figure 3.2: Endshield O pen

169489 2

5

Revision A

Page 34

OPERATION

3.3.2 Closing

1. Move the endshield (A) slightly so that support (B) can

be moved out of lock position.

2. Close shield (A), ensuring that magnet (B) and stop (C)

in header frame are aligned. This will ensure that the

latch (D) will line up with the receptacle (E).

NOTE: Latch (D) and magnet (B) positions are properly

adjusted at the fac tory.

LH Endshield

Figure 3.3: Disengaging Support

3. If required, loosen nuts (B) on clips (C) at the back of

the shield (A) and reposition the shield. Tighten the

nuts (B) but do not overtighten to prevent damage to

the shield.

Figure 3.4: Closing Endshield

Figure 3.5: Adjusting Endshield

169489 2

6

Revision A

Page 35

OPERATION

4. Close the shield and turn latch (A) clockwise until

it stops (slightly more than one-half turn ) using a

standard end screwdriver.

5. Check that magnet (B) on endshield is against the stop

on endsheet and that latch is engaged.

Figure 3.6: Endshield Closed

169489

7

2

Revision A

Page 36

OPERATION

3.4 Header Lift Cylinder Safety Props

Refer to your Combine Operator’s Manual.

169489 2

8

Revision A

Page 37

OPERATION

3.5 Hold-Down Lift Cylinder Safety Props

WARNING

To avoid bodily injury from fall of raised hold-down, always engage cylinder safety props before going

under raised hold-down for any reason.

IMPORTANT:

To prevent damage to hold-down support arms, do not transport header with cylinder safety props engaged.

Lift cylinder safety props are located at each hold-down support arm.

To engage lift cylinder safety props:

1. Raise hold-down to maximum height.

2. Move safety props to engaged position.

3. Lower hold-down onto safety props.

To disengage lift cylinder safety props:

4. Raise hold-down to maximum height.

5. Move safety props to disengaged position.

Figure 3.7: Engaged

Figure 3.8: Disengaged

169489 2

9

Revision A

Page 38

OPERATION

3.6 Daily Start-up Check

CAUTION

• Besure combineand header areproperlyattached,

all controls are in Neutral and combine brake is

engaged.

• Clear the area of other persons, pets, etc. Keep

children away from machinery. Walk around the

machine to be sure no one is under, on, or close to

it.

• Wear close-fitting clothing and protective shoes

with slip-resistant soles.

• Remove foreign objects from the machine and

surrounding area.

• As well, carry with you any protective clothing and

personal safety devices that COULD be necessary

through the day. Don’t take chances. You may

need a hard hat, protective glasses or goggles,

heavy gloves, a respirator or filter mask, or wet

weather gear.

• Protect against noise. Wear a suitable hearing

protective device such as ear muffs or ear plugs

to protect against objectionable or uncomfortable

loud noises.

Complete the following tasks each day before start-up:

1. Check the machine for leaks or any parts that are

missing, broken, or not working correctly.

NOTE: Use proper procedure when searching for

pressurized fluid leaks. Refer to 4.9.3 Hydraulic

Hoses and Lines, page 160.

2. Clean all lights and reflective surfaces on the machine.

3. Perform all daily maintenance. Refer to Section

Maintenance Schedule/Record, page 88.

Figure 3.9

personal s

: Use protective clothing and

afety devices

169489 3

0

Revision A

Page 39

OPERATION

3.7 Shutdown Procedure

CAUTION

Before leaving the combine seat for any reason:

• Park on level ground if possible.

• Lower the header fully.

• Place all controls in Neutral, and engage combine brake.

• Stop engine and remove key from ignition.

• Wait for all movement to stop.

169489 3

1

Revision A

Page 40

OPERATION

3.8 Break-In Period

CAUTION

Before investigating an unusual sound orattempting tocorrect a problem, shut offengine, engage parking

brake and remove key.

1. After attaching header to combine for the first time, operate the machine slowly for 5 minutes, watching and

listening care fully FROM THE COMBINE SEAT for bin d ing or interfering parts.

2. Perform the items specified in Maintenance Schedule/Record, page 88, under AFTER FIRST 10 HOURS.

NOTE: Until you become familiar with the sound and feel of your new header, be extra alert and attentive.

169489 3

2

Revision A

Page 41

OPERATION

3.9 Changing Header Opening

To minimize the set up at the dealer, PW8 combine pick-up headers are shipped from the factory in a configuration

to suit a particlular combine make, model and feeder house size. Each header includes the necessary parts and

hardware to modify it, if required, to accommodate another model of combine with a different size feeder house.

The conversion procedure is included in the Unloading and Assembly Instruction that is provided with the header.

Factory Header Configuration Modified Header Configuration

Combine Make Combine Model(s) Feeder House Size Combine Model(s) Feeder House Size

John Deere

New Holland

9550, 9650, 9750,

9660, 9760, 9860

CR970, CR

980

55 in. (1397 mm)

50 in. (12

70 mm)

9610

CX 60 in. (1524 mm)

CR920, CR940,

CR960

65 in. (1651 mm)

40 in. (1016 mm)

169489 3

3

Revision A

Page 42

OPERATION

3.10 Header Attachment and Detachment

This section includes instructions on attaching and detaching PW8 Pick-Up Headers to the combines listed below.

PW8 headers are configured for each particular combine model.

Combine Refer to Section

Case IH 3.10.1 Case IH, page 34

John Deere 60, 70 and S Series 3.10.2 John Deere 60, 70, and S Series, page 41

New Holland C R, CX 3.10.3 New Holland CR/CX Series Combine, page 47

3.10.1 Case IH

This section provides instruction for attaching the MacDon

PW8 pick-up to and detaching from Case IH combines,

including 5088, 6088, 7088, 7010, 8010, 7120, 8120, 9120,

5130, 6130, 7130, 7230, 8230, 9230, 5140, 6140, 7140.

AttachingtoCaseIHCombine

1. Pull handle (A) on combine to raise hooks (B) on both

sides of the feeder house.

Figure 3.10: Case IH Combine

Figure 3.11: Feederhouse Locks

169489 3

4

Revision A

Page 43

OPERATION

2. Slowly drive combine up to header until feeder house

saddle (A) is directly under the header top cross

member.

3. Raise feeder house slightly to lift header, ensuring

feeder saddle is properly engaged in header frame.

WARNING

Stop combine engine and remove key before making

adjustments to machine. A child or even a pet could

engage the drive.

4. Stop engine, and remove key from ignition.

5. Lift lever (A) on header at left side of feeder house,

and push handle (B) on combine to engage locks (C)

on both sides of the feeder house.

6. Push down on lever (A) so that slot in lever engages

handle (B) to lock handle in place.

Figure 3.12: Header on Combine

7. If locks (C) do not fully engage pins (D) on header,

loosen nut (E), and adjust position of pin (D) as

necessary (both sides). Tighten nut.

8. To obtain full lock on pin (D) when (A) and (B) are

engaged, loosen bolts (F), and adjust lock as required.

Retighten bolts.

e 3.13: Engaging Locks

Figur

169489 3

5

Revision A

Page 44

OPERATION

9. Rotate disc (B) on header driveline storage hook (A),

and remove driveline from hook.

10. Pull back collar ( A) on end of driveline, and push onto

combine output shaft (B) until collar locks.

Figure 3.14: Driveline

11. Open cover (A) on header receptacle.

12. Push in lock button (B), and pull handle (C) upward to

full open position.

13. Remove coupler (D) from combine, and clean mating

surfaces.

Figure 3.15: Attaching Driveline

Figure 3.16: Coupler Lock

169489 3

6

Revision A

Page 45

OPERATION

14. Position coupler (A) onto header receptacle, and push

handle (B) downward to engage coupler pins into

receptacle.

15. Push handle to closed position until lock button (C)

snaps out.

16. Open cover on header electrical receptacle (D).

17. Remove electrical connector (E) from storage cup on

combine, and route to header receptacle (D).

18. Align lugs on electrical connector (E) with slots in

receptacle, push connector onto receptacle (D), and

turn collar on connector to lock it in place.

Figure 3.17: Attaching Coupler

Detaching from Case IH Comb ine

DANGER

Stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even

a pet could engage an idling machine.

1. Choose a level area. Position header slightly above

ground. Stop engine and remove key.

2. Push in lock button (C), and pull handle (B) upward to

release coupler (A).

Figure 3.18

169489 3

7

Revision A

Page 46

OPERATION

3. Position coupler (A) onto storage plate (B) on combine.

4. Disconnect electrical connector (A) from header.

Figure 3.19

5. Place electrical connector (A) into storage cup (B) on

combine.

Figure 3.20

Figure 3.21

169489 3

8

Revision A

Page 47

OPERATION

6. Ensure cover on header electrical receptacle (A)

closes.

7. Push handle (B) on header down into storage position

until lock button (C) snaps out.

8. Close cover (D).

9. Open driveshield (A) on combine.

10. Pull back collar (B) on driveline (C), and pull driveline

(C) from combine.

Figure 3.22

169489 3

e3.23

Figur

9

Revision A

Page 48

OPERATION

11. Slide driveline into storage hook (A) on header so that

disc (B) drops to secure driveline.

12. Close driveshield (A) on combine.

Figure 3.24

13. Lift lever (A), pull and lower handle (B) to disengage

feeder house/header lock (C).

14. Lower feeder house until it disengages header support.

15. Slowly back combine away from header.

Figure 3.25

Figure 3.26

169489 4

0

Revision A

Page 49

OPERATION

3.10.2 John De

This section p

PW8 Pick-Up He

combines incl

and S Series -

rovides instruction for attaching the MacDon

ader to and detaching from John Deere

uding: 9660, 9760, 9860, 9670, 9770, 9870

Contour Master and Level Land.

ere 60, 70, and S Series

Figure 3.27: John Deere Combine

AttachingtoJohnDeere60,70andSSeriesCombine

1. Push handle (A) on combine coupler toward feeder

house to retract pins (B) at bottom corners of feeder

house.

2. Slowly drive combine up to header until feeder house

saddles (A) are directly under the header top beam (B).

3. Raise feeder house to lift header, ensuring feeder

saddles are properly engaged in header frame.

4. Position header until slightly off the ground, stop engine

and remove key from ignition.

WARN

Stop combine engine and remove key before making

adjustments to machine. A child or even a pet could

engage the drive.

169489

ING

4

e 3.28: Feederhouse Locks

Figur

ure 3.29: Header on Combine

Fig

1

Revision A

Page 50

OPERATION

5. Open driveshield on combine feeder house.

6. Rotate disc (B) on header driveline storage hook (A),

and remove driveline from hook.

Figure 3.30: Combine Driveshield

7. Pull back collar (A) on e n d of d r ive line and slide

driveline on feeder house driveshaft until the

collar locks.

8. Close feeder house driveshield.

Figure 3.31: Driveline

Figure 3.32: Attaching Driveline

169489

2

4

Revision A

Page 51

OPERATION

9. Remove cover (A) from combine multi-coupler

receptacle.

10. Pull handle (A) on header to release multi-coupler

(B) from storage position. Remove coupler, and push

handle back into header to store.

Figure 3.33: Combine Receptacle

11. Place coupler (A) onto combine receptacle.

12. Pull out knob (B) to release handle, and pull handle (C)

to engage pins in coupler.

Figure 3.34: Releasing Coupler

Figure 3.35: Engaging Coupler

169489 4

3

Revision A

Page 52

OPERATION

13. Pull handle (A) to full horizontal position as shown to

fully engage coupler, and to extend pins (B) at base of

feeder house into the locking plates (C). Knob (D) will

engage handle to lock handle.

NOTE: If handle does not move to full horizontal position,

check alignment of locking plates (A) on the

header with locking pins (B) on both sides of the

feeder house. If necessary, loosen nuts (C), and

adjust plates (A) to line up with pins (B). Retighten

nuts.

Figure 3.

Figure 3.37: Aligning Locking Plates

36: Locking Feederhouse

169489

4

4

Revision A

Page 53

OPERATION

Detaching from John Deere 60, 70, and S Series Combine

1. Choose a level area. Position header slightly above

ground. Stop engine and remove key.

WARNING

Stop combine engine and remove key before making

adjustments to machine. A child or even a pet could

engage the drive.

2. Pull out knob (A) on combine coupler, and move

handle (B) toward feeder house to release coupler (C)

from combine, and to retract locking pins at base of

feeder house.

3. Lower handle (A) on header, and position coupler (B)

in header as shown.

Figure 3.38

Figure 3.39

169489 4

5

Revision A

Page 54

OPERATION

4. Raise handle (A) to lock coupler.

5. Open feeder house driveshield (B).

6. Pull back colla r (A) on driveline, and pull driveline off

combine output shaft.

Figure 3.40

7. Slide driveline in storage hook (A) on header so that

disc (B) drops to secure driveshaft.

Figure 3.41

Figure 3.42

169489 4

6

Revision A

Page 55

OPERATION

8. Close combine driveshield (A).

9. Start engine, and lower feeder house until saddle (B)

disengages and clears header support (C).

10. Slowly back combine away from header.

Figure 3.43

3.10.3 New Holland CR/CX Series Combine

This section provides instructions for attaching the MacDon

PW8 Pick-Up Header to and detaching from all New

Holland CR/CX Series combines.

Attach

ing to New Holland CR/CX Series Combine

WARNING

Stop combine engine and remove key before making

adjustments to machine. A child or even a pet could

engage the drive.

1. Pull handle (A) on combine to raise hooks (B) on both

sides of the feeder house.

169489

4

Figure

Figure 3.45: Feeder House Locks

3.44: New Holland Combine

7

Revision A

Page 56

OPERATION

2. Slowly drive combine up to header until feeder house

saddle (A) is directly under the header top beam (B).

3. Raise feeder house to lift header, ensuring feeder

saddle (A) is properly engaged in header frame.

4. Lift lever (A) on header at left side of feeder house and

push handle (B) on combine so that hooks (C) engage

pins (D) on both sides of the feeder house.

5. Push down on lever (A) so that slot in lever engages

handle to lock handle in place.

Figure 3.46: Header on Combine

6. If locks (C) do not fully engage pins (D) on header,

loosen nut (E) and adjust position of pin (D) as

necessary (both sides). Tighten nut.

7. To obtain full lock on pin (D) when (B) and (A) are

engaged, loosen bolts (F), and adjust lock as required.

Retighten bolts.

e 3.47: Engaging Locks

Figur

169489 4

8

Revision A

Page 57

OPERATION

8. Rotate disc (B) on header driveline storage hook (A),

and remove driveline from hook.

9. Pull back collar (B) on end of driveline, and push onto

combine output shaft (A) until collar locks.

Figure 3.48: Driveline

10. Open cover (A).

11. Push in lock button (B), and pull handle (C) halfway up

to open position.

Figure 3.49: Attaching Driveline

Figure 3.50: Header Receptacle

169489 4

9

Revision A

Page 58

OPERATION

12. Remove coupler (A) from storage location on combine,

and clean mating surface of coupler.

13. Position coupler onto header receptacle (A), and push

handle (B) downward to engage pins into receptacle.

14. Push handle (B) to closed position until lock button (C)

snaps out.

15. Open cover (D) on header electrical receptacle.

Figure 3.51: Combine Coupler/Connector

16. Remove electrical connector (E) from combine.

17. Align lugs on electrical connector (E) with slots

in header receptacle, and push connector onto

receptacle. Turn collar on connector to lock it in place.

Figure 3.52: Attaching Coupler

169489 5

0

Revision A

Page 59

OPERATION

Detaching from New Holland CR/CX Combine

1. Choose a level area. Position header slightly off the

ground. Stop engine and remove key.

WARNING

Stop combine engine and remove key before making

adjustments to machine. A child or even a pet could

engage the drive.

2. Push in lock button (C), and pull handle (B) upward to

release coupler (A).

3. Remove coupler (A) from header receptacle.

4. Position coupler (A) onto storage plate (B) on combine.

5. Disconnect electrical connector from header, and place

in storage cup (C) on combine.

Figure 3.53

Figure 3.54

169489 5

1

Revision A

Page 60

OPERATION

6. Close cover (A) on header hydraulic receptacle, and

cover (B) on electrical receptacle.

7. Push handle (C) on header down into storage position,

and the lock button (D) snaps out.

8. Pull back collar (A) on driveline (B), and pull driveline

from combine.

Figure 3.55

9. Slide driveline into storage hook (A) on header so that

disc (B) drops to secure driveline.

Figure 3.56

Figure 3.57

169489 5

2

Revision A

Page 61

OPERATION

10. Lift lever (A), pull and lower handle (B) to disengage

feeder house/header lock (C).

11. Lower feeder house until it disengages header support.

12. Slowly back combine away from header.

Figure 3.58

169489 5

3

Revision A

Page 62

OPERATION

3.11 Header Transport

Refer to your combine operator’s manual for transporting headers when attached to the combine.

3.11.1 Transport Lights

The transport lights, which are mounted on both ends of

the header, are activated by switches in the combine cab.

They function as flashing hazard lights and turn signals,

and should be positioned perpendicular to the endsheet.

See your combine operator’s manual for operating

instructions.

Figure 3.5

9: Transport Lights

169489 5

4

Revision A

Page 63

OPERATION

3.12 Header Operation

Satisfactory operation of the header in all situations requires making proper adjustments to suit various crops and

conditions.

Correct operation reduces crop loss and increases productivity. As well, proper adjustments and timely maintenance

will increase the length of service you rece ive from the machine.

The variables listed below and detailed on the following pages, will affect the performance of the header.

You will quickly become adept at adjusting the machine to give you the desired results. Most of the adjustments

have been set at the factory but if desired, the settings can be changed to suit crop conditions.

Variable Section

Pick-Up Speed 3.12.1 Operating Speed, page 55

Auger Speed Auger Speed, page 56

Header Height Header Height, page 62

Pick-Up Height Pick-Up Height, page 63

Hold-Down Position Hold-Down Position, page 65

Hold-Down Rod Angle Hold-Down Rod Angle, page 66

Auger Position Auger Position, page 56

Stripper Plates Stripper Plate Clearance, page 61

Draper Belt Tension

Checking Draper Belt Tension, page 68

3.12.1 Operating Speed

Performance of the pick-up in va rious crop an d field conditions largely depends upon the speed at w hich the drapers

are turning, and the forward speed of the combine.

• If the swath is pushed ahead, the draper speed is too low, and some of the crop may remain unpicked.

• If the swath is torn apart and is pulled toward the combine header, the draper speed is too high, and uneven

combine feeding will occur.

Generally, optimum pick-up speed for most conditions shall be selected so that the swath is always pushed slightly

ahead.

Draper speed is adjusted from the combine cab by regulating oil flow to the pick-up hydraulic motors, typically usin g

the reel speed controls for the combine. The ratio of pick-up speed to combine ground speed can be set using the

combine header controls. See your combine operator’s manual.

IMPORTANT:

Do NOT over-speed pick-up. Over-speeding the pick-up causes premature wear of drive

components and adversely affects pick-up performance.

The following operating speeds are suggested:

Front and Rear Deck Aft Roller: 51 rpm per 1 mph (1.6 km/h) of combine ground speed.

Example: For combining at 5 mph (8 km/h), the rear roller shaft should run at 51 x 5 mph = 255 rpm

(51 x 8/1.6 = 255 rpm).

169489 5

5

Revision A

Page 64

OPERATION

Adjusting Draper Speed

Draper speed is determined by measuring the rpm of the

aft roller on the rear pick-up deck.

1. Check the roller rpm (A) with a handheld tachometer,

and adjust with the reel speed control in the combine.

NOTE: Some combines are equipped with a speed

sensor (B) that indicates the roller rpm in the

combine cab.

3.12.2 Auger

Figure 3.60

Auger Speed

The header is sup

connection to th

or slower auger

Refer to Sectio

plied with an auger drive sprocket to match your combine. The auger is driven by a direct

e feeder house, and auger speed depends on the feeder house speed. In certain crops, a higher

speed may be desired. Contact your Dealer for available sprocket options.

n: Auger Drive Sprockets, page 117 for instructions on changing the sprocket.

Auger Position

The auger position is c ritical for a smooth, high capacity flow of crop into the feeder house. It is factory set for normal

crop conditions but may require adjustment for different crops and conditions.

The auger must rotate freely without touching the auger pan or stripper bars, and the position should be checked

prior to operating the pick-up.

The clearance (A) between the auger flighting (B) and

pan (C) should be 3/16–7/16 in. (5–11 mm).

169489 5

Figure 3.61: Auger to Pan Clearance

6

Revision A

Page 65

OPERATION

The clearance (A) between the auger fingers (B) and pan

(C) should be 13/16–1 in. (20–25 mm).

Figure 3.62: Finger to Pan Clearance

Adjusting Auger Position

If adjustments are required, proceed as follows:

NOTE: Both ends of the auger are adjustable to maintain a uniform clearance across the width of the

header.

NOTE: Access the auger/pan area from top of header.

DANGER

Stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even

a pet could engage an idling machine.

1. Lower header to the ground, shut down combine and

remove key from ignition.

2. Open endshield (A) on left end of header. Refer to

Section: 3.3.1 Opening LH Endshield, page 25.

Figure 3.63

169489 5

7

Revision A

Page 66

OPERATION

3. Loosen the two bolts (A) on auger stops on both ends

of header.

4. Loosen jam nuts (B) on adjuster bolts (C).

5. Turn adjuster bolt (C) to lower or raise the auger.

6. Manually rotate the auger to check for interference, and

to check clearances between the auger flighting and

auger pan, and adjust as necessary.

7. Tighten jam nuts (B), and downstop nuts (A).

8. Check clearances between auger flighting and stripper

plates, and adjust as required. Refer to Section:

Stripper Plate Clearance, page 61.

Figure 3.64: Left End

Figure 3.65: Right End

Auger Float

The auger has an upward float range of 1-5/16 in. (34 mm), but can be locked so that it does not float, which may

be desirable in certain crop conditions.

169489 5

8

Revision A

Page 67

OPERATION

Locking Auger Float

Lock auger as follows:

DANGER

Stop engine and remove key from ignition before

leaving operator’s seat for any reason. A child or

even a pet could engage an idling machine.

1. Lower header to the ground, shut down combine and

remove key from ignition.

2. Open left endshield (A). Refer to Section: 3.3.1

Opening LH Endshield, page 25.

3. Loosen the two bolts (A) on auger upstops (B) on both

ends of header.

4. Slide the stops (B) downward until they contact the

rubber blocks (C) on the auger arm.

Figure 3.66

5. Tighten bolt s (A).

Figure 3.67: Left End

169489 5

Figure 3.68: Right End

9

Revision A

Page 68

OPERATION

6. Close endshield (A). Refer to Section: 3.3.2 Closing

LH Endshield, page 26.

Unlocking Auger Float

Unlock auger float as follows:

DANGER

Figure 3.69

Stop engine and remove key from ignition before

leaving operator’s seat for any reason. A child or

even a pet could engage an idling machine.

1. Lower header to the ground, shut down combine and

remove key from ignition.

2. Open left endshield (A). Refer to Section: 3.3.1

Opening LH Endshie ld, page 25.

3. Loosen the two bolts (A) on auger upstops (B) on both

ends of header.

4. Slide stops (C) upward to desired float range.

5. Tighten bolts (A).

6. Close left endshield. Refer to section: 3.3.2 Closing

LH Endshield, page 26.

Figure

3.70

169489 6

re 3.71: Left End

Figu

0

Revision A

Page 69

OPERATION

Stripper Plate Clearance

The header is equipped with a pair of stripper plates (A)

located on either side of the center opening, and are

designed to minimize crop carryover behind the auger

when properly adjusted.

Figure 3.72: Right End

• If the clearance between the flighting and stripper plate

is too large, crop will tend to wrap around the auger and

disrupt crop flow into the combine.

• If the clearance is too little, the auger flighting may

contact the stripper plates, and cause excessive wear

to the flighting and stripper plates.

Stripper plate clearance has been set to 1/8–1/4 in. (3–6

mm) at the factory.

Figure 3.73: Stripper Plates

Checking Stripper Plate Clearance

Check and adjust the clearance if necessary whenever the auger position is changed:

To check stripper plate clearance:

DANGE

Stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even

a pet could engage an idling machine.

1. Lower header to the ground, shut down combine and remove key from ignition.