Page 1

r

PW7

Pick-Up Heade

OPERATOR’S MANUAL

Part #169149 Rev. E

$15

Page 2

Page 3

INTRODUCTION

In order to ensure that the header/pickup will operate smoothly and efficiently for years to come, it is

important that it be correctly set up and properly maintained. Windrow headers with pickup

attachments are designed to pick up windrows of agricultural products such as wheat, soybeans,

canola, barley, etc. and small seed pick ups, and are only intended for such use.

Contained in this manual are safety precautions, operating instructions, and service and maintenance

procedures for the PW7 Pickup Header, and Series IV Rake-Up and SwathMaster pickups. The units

covered in this manual are compatible with John Deere 50 Series and 60 Series combines, Case IH

Combines, New Holland Combines, Gleaner/Massey/Challenger Combines and Claas/Lexion

combines.

The following header sizes are covered in this manual:

13 foot

15 foot

The following pickup models are covered in this manual:

PICKUP SERIES IV ATTACHMENTS

Rake-Up

12’ Small Seed

14’

16’

SwathMaster

12’ Small Seed

14’

16’

Note: Left and right hand are referenced from the operator’s seat looking forward. The illustrations

in this manual may not match your exact machine.

We welcome your suggestions, questions or comments regarding the installation, operation or

maintenance of the header /pickup.

All printed publications are classified as uncontrolled documents and are subject to change without notice at the discretion of MacDon Industries Ltd.

Published: February 2013

Form 169149 Revision E

I

Page 4

TABLE OF CONTENTS

INTRODUCTION............................................................................................................... I

SECTION 1 – PRODUCT IDENTIFICATION

1.1 Serial Numbers ...............................................................................................1

SECTION 2 – SAFETY

2.1 General Safety Practices ................................................................................3

2.2 Safety During Attachment to Combine..........................................................3

2.3 Safety During Operation ................................................................................4

2.4 Safety During Servicing .................................................................................5

2.5 Safety Information/Sign Location..................................................................7

SECTION 3 – SETUP COMPLETION

3.1 Connecting Header/Pickup to Combine – John Deere / Lexion / Agco ........13

3.2 Connecting Header/Pickup to Combine – Case IH / New Holland ...............19

3.3 Feeder house Width Conversion ....................................................................21

3.4 Disengaging Storage Braces / Removing Cylinder Braces ............................22

3.5 Testing Hydraulic Hold down ........................................................................23

SECTION 4 – ADJUSTMENTS

4.1 Tire Pressure and Wheel Nut Torque .............................................................24

4.2 Teeth Height (Wheel) Adjustment .................................................................24

4.3 Suspension Adjustment ..................................................................................25

4.4 Spring wire / Fiberglass Rod Adjustment ......................................................25

4.5 Draper Belt Tensioning ..................................................................................26

4.6 Pickup Drive Belt Tension .............................................................................29

4.7 Speed Control and Height Control Adjustment .............................................29

4.8 Auger Finger Adjustment ..............................................................................30

4.9 Auger Adjustment ..........................................................................................31

4.10 Stripper Bar Adjustment ................................................................................32

4.11 Header Drive Chain Adjustment ....................................................................33

SECTION 5 - OPERATING INSTRUCTIONS

5.1 Operating Speed .............................................................................................35

5.2 Operating Height ............................................................................................36

5.3 Hold down Positioning ..................................................................................37

5.4 Radial Pin Clutch (on driveshaft) ..................................................................38

5.5 Disconnection Header/Pickup From Combine ..............................................38

5.6 Unplugging the Auger....................................................................................39

Form 169149 Revision E

II

Page 5

TABLE OF CONTENTS

SECTION 6 – MAINTENANCE/LUBRICATION

6.1 First Time Use – Maintenance .......................................................................40

6.2 Daily Maintenance/Lubrication (10 hours) ....................................................40

6.3 Weekly Maintenance/Lubrication (50 hours) ................................................40

6.4 Yearly Maintenance/Lubrication (100 hours) ................................................41

6.5 Lubrication Points ..........................................................................................43

6.6 Maintenance/Lubrication Chart/Grease Spec ................................................45

SECTION 7 – SERVICE

7.1 Attaching Pickup to Header ...........................................................................46

7.2 Opening Header Side Panels ..........................................................................48

7.3 Removing Pick Up Shields ............................................................................49

7.4 Hydraulic System ...........................................................................................49

7.5 Drive Shaft Installation ..................................................................................58

7.6 Replacing Header Drive Chain Sprockets .....................................................59

7.7 Replacing Auger Fingers ...............................................................................61

7.8 Replacing Teeth .............................................................................................62

7.9 Replacing Draper Belts ..................................................................................62

7.10 Replacing Drive Belt ......................................................................................63

7.11 Replacing Small Gear Box (RakeUp) ............................................................64

7.12 Crown and/or Pinion Removal/Installation (RakeUp) ...................................68

7.13 Finger Bar Idler Arm Removal/Installation (RakeUp) ..................................71

7.14 Extremity Light Bulb Replacement ...............................................................72

7.15 Wiring Schematics ........................................................................................73

7.16 Belt Guide (SwathMaster Small Seed) ..........................................................73

SECTION 8 – TROUBLE SHOOTING ............................................................................74

SECTION 9 – SPECIFICATIONS

9.1 Torque Chart ..................................................................................................78

9.2 General Specifications ...................................................................................79

SECTION 10 – STORAGE

10.1 Storage of Header/Pickup ..............................................................................80

10.2 Removing From Storage ................................................................................80

INDEX ...................................................................................................................................81

NOTES ..................................................................................................................................82

Form 169149 Revision E

III

Page 6

Form 169149 Revision E

IV

Page 7

SECTION 1

PRODUCT IDENTIFICATION

When ordering parts or when requesting information or assistance always give the following

information:

1. Model

2. Serial Number and Year of Production

Pickup Serial Plate Location

Record model and serial number of your header/pickup below:

PICK-UP

Model _____________________________

Serial Number _____________________________

Form 169149 Revision E

1

Page 8

SECTION 2 - SAFETY

The Safety Alert Symbol is used to alert the reader to important safety messages in this manual.

When you see this symbol, be alert to the possibility of injury. Carefully read and observe all safety

messages and symbols in this manual and on your machine to avoid serious injury or death.

SAFETY ALERT SYMBOL

THIS SYMBOL MEANS

DANGER: Indicates an imminently hazardous situation that,

if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation that,

if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation that,

if not avoided, may result in minor or moderate injury.

ATTENTION: Indicates a potentially hazardous situation that,

if not avoided, could result in machine damage.

-ATTENTION!

-BECOME ALERT!

-YOUR SAFETY IS INVOLVED!

***IMPORTANT***

Before any person uses this product he/she should take sufficient time learning all necessary

precautions and procedures. Each operator should:

Ensure all people, pets and tools are clear.

Read and fully understand all procedures/precautions in the Operators Manual.

Be instructed and experienced in safe and proper use of the unit.

If information not covered in this manual is required, contact your local dealer.

Form 169149 Revision E

2

Page 9

SECTION 2 SAFETY

2.1 GENERAL SAFETY PRACTICES

All operators must:

Be instructed in the safe and proper use

of this machine and understand all safety

signs and instructions in this manual.

Carefully read all safety messages in this

manual and on your machine.

Keep all safety signs in good condition.

Replace when necessary.

Use and maintain all safety lights and

devices.

Wear necessary protective clothing when

operating or servicing machinery.

Be prepared for emergencies by keeping

a first aid kit and emergency numbers

easily accessible.

Have authorized personnel repair/replace

any damaged or deteriorated parts

immediately to reduce the risk of

personal injury.

Find a spacious, clear, and level surface

to perform any maintenance or

adjustments.

Always shut-off machinery before

performing any adjustments or service.

Never remove obstructions from running

machinery.

Never operate machinery without all

shields in place.

Never engage pickup drive with people

near machine.

Review safety instructions annually.

Modifications to the machine not

approved by MacDon Industries Ltd.

are not allowed. Unapproved

modifications may affect the safety,

reliability, and durability of the

machine and void warranty.

2.2 SAFETY DURING COMBINE

ATTACHMENT

Find a spacious, clear, and flat work area.

Read and understand all installation

procedures. Refer to applicable section

in this manual for reference.

Check for obstructions on combine,

header, and in work area before starting.

Lower header and pickup to ground or

engage feeder safety locks, shut off

combine, remove key and wait until all

moving parts have stopped before

working around header/combine.

Take extreme care when working around

hydraulic lines. Hydraulic fluid under

high pressure can penetrate the skin and

cause serious tissue damage. Seek

immediate medical attention if skin

penetration occurs.

At all times keep body parts away from

the pickup & header when moving.

Form 169149 Revision E

3

Page 10

SECTION 2 SAFETY

2.3 SAFETY DURING OPERATION

A) Extremity Lights

P00541

Extremity Light

P00542

Extremity Lights

The header comes with a left and right hand

extremity light that works in conjunction with

the flashing/signal combine lights. For bulb

replacement, see appropriate section in this

manual.

ATTENTION: Reflectors that are damaged

or worn are to be replaced immediately.

NOTE: Red and Orange Reflectors are visible

from the rear; amber is visible from the front.

New reflectors are available from your dealer.

B) Drive Shaft Safety

Shields are in place for your

protection. Replace any worn or

missing shields.

Drive shaft shields are to rotate

freely at all times (free from binding

while chained). Replace worn shield

bearings promptly.

Never operate header without

shields in place.

Never make modifications to the

drive shaft and shields.

ALWAYS store the drive shaft in

its storage holder. Never use safety

chains to support drive shaft.

DO NOT step on the drive shaft.

Any servicing to the drive shaft

must only be done when the header

is lowered to the ground or the

combine feeder house locks are

engaged, the machine is shut off,

the ignition key is removed and all

moving parts have stopped. Never

make adjustments to, or clean a

running combine.

Make sure drive shaft is attached

properly before operation.

Keep any loose fitting clothing,

jewelry, or long hair away from

moving parts, components, or

retainer chains.

Form 169149 Revision E

4

Page 11

SECTION 2 SAFETY

2.4 SAFETY DURING SERVICING

Any servicing to machinery must only be

done after the header is lowered to the

ground or combine, feeder house is

locked, is shut off, the ignition key is

removed and all moving parts have

stopped.

Take extreme caution around hydraulic

lines. Release all pressure in the system

before servicing or inspecting for leaks.

Hydraulic fluid under high pressure can

penetrate the skin and cause serious

injury. Never use your hands to inspect

lines. Seek immediate medical attention

if fluid is injected into the skin.

Familiarize yourself with proper

servicing procedures in this manual.

Wear protective clothing and use

personal safety devices when required.

A) Tire Safety

A tire that explodes could cause serious

injury. Have a qualified service

technician service the tires.

When inflating tires take extreme care.

An over inflated tire can explode.

Recommended tire pressure is 8-10 psi.

Replace rim if overly rusted or cracks are

noticed.

Stand clear from tire when inflating. Use

a clip-on air chuck, and extension hose.

B) Pickup Hold down Safety Locks

WARNING: OVERHEAD

OBJECT HAZARD Always

activate safety locks before

working under raised hold down.

a) Raise hold down all the way up with

hydraulic cylinder.

b) Engage hold down safety locks as shown.

P00669

Safety Lock Engaged

c) Complete work underneath hold down.

d) Disengage safety locks as shown.

P00670

Safety Lock Disengaged

Form 169149 Revision E

5

Page 12

SECTION 2 SAFETY

C) Combine Feeder House Safety Locks

(Safety Locks Will Vary According to Combine)

WARNING: At no time is any

service procedure to be performed

without the header lowered to the

ground or the feeder house safety locks

engaged.

a) Raise feeder house up completely.

b) Engage feeder house lock.

P00030

Feeder House Lock Engaged

(May not be exactly as shown)

c) Complete work underneath header/pickup.

d) Disengage feeder house lock

P00009

Feeder house Lock Disengaged

(May not be exactly as shown)

Form 169149 Revision E

6

Page 13

SECTION 2 SAFETY

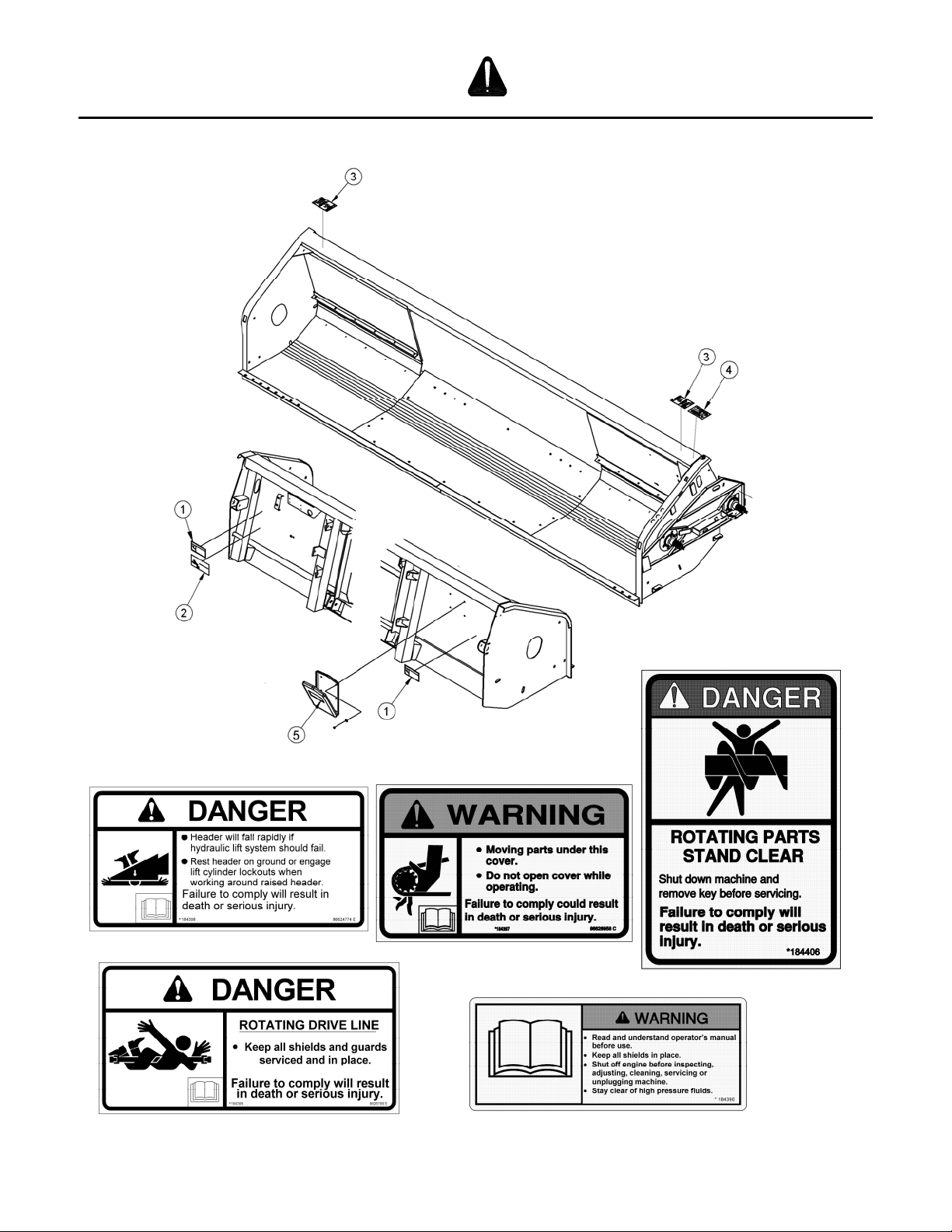

2.5 SAFETY INFORMATION/SIGN LOCATION

Operators must read and follow all safety information in this manual and on safety signs located

on the machine.

Missing, damaged, or illegible safety signs must be replaced immediately.

All new shields or components must include the latest safety signs.

All safety signs and their locations are shown in the illustrations below. Both three-panel (with

text) and two-panel (graphics only) versions are shown.

Safety signs displaying the “Read Operators Manual” symbol are intending to

direct the operator to the Operators Manual for further information regarding

safety, adjustments, maintenance and/or procedure for specific areas of the unit.

RAKE-UP SPECIFIC SAFETY SIGNS

Rotating Drive Hazard, Pinch Point

Located on Belt Guard

184371 2-PANEL 184386

184397 3-PANEL 184393

Form 169149 Revision E

7

Page 14

SECTION 2 SAFETY

Rotating Drive Hazard

Located on Frame under Belt Guard

SWATHMASTER SPECIFIC SIGNS

Rotating Drive Hazard

Located Frame under Belt Guard

Rotating Drive Hazard

Located on Belt Guard

2-PANEL - 184371

2-PANEL - 184401

3-PANEL - 184404

3-PANEL - 184397

Form 169149 Revision E

8

Page 15

SECTION 2 SAFETY

PICKUP SAFETY SIGNS (Rake-Up & SwathMaster)

P00012

Warning, Safety Lock

Located on Lower Hold down Arms

Storage Brace Rotation

RH & LH Wind guard

Pinch Point Located on LH Idler Rotor

Shield (Rake-Up shown, SwathMaster similar)

2-PANEL - 184386

2-PANEL - 191496

3-PANEL - 184365

2-PANEL - 184384

3-PANEL - 184392

3-PANEL - 184393

Form 169149 Revision E

9

Page 16

SECTION 2 SAFETY

HEADER SAFETY SIGNS

P00205

Danger, Rotating Driveline, European

Located on Drive Shaft

P00017

Danger, Missing Shield

Located on Driveshaft (under shield)

Decal, Chain Entanglement

Located Above Chain (behind header LH shield)

3-PANEL - 30316

2-PANEL - 191104

3-PANEL - 36651

2-PANEL - 184401

3-PANEL - 184404

Form 169149 Revision E

10

Page 17

SECTION 2 SAFETY

HEADER FRAME 2-PANEL DECALS

1. Header Crushing Hazard

184370

4. Rotating Drive Hazard

184371

3. Auger Wrapping Hazard

191494

5. Read Operators Manual

2. Keep Shields in Place

184385

Form 169149 Revision E

11

184372

Page 18

SECTION 2 SAFETY

HEADER FRAME 3-PANEL DECALS

1. Header Crushing Hazard - 184398

4. Rotating Drive Hazard

184397

3. Rotating Parts Hazard - 184406

2. Rotating Drive Line Hazard - 184395

Form 169149 Revision E

5. Read Operator’s Manual - 184390

12

Page 19

SECTION 3

SETUP COMPLETION

3.1 CONNECTING HEADER/PICKUP TO

COMBINE: JOHN DEERE / LEXION/

AGCO

NOTE: For Case IH and New Holland

Combines, see Section 3.2

NOTE: The operator of the combine should

be well trained in the use of combine controls.

Improper use of the combine could result in

damage to property or serious injury or

death.

a) Check to see that all header and feeder house

locking devices are open and ready for

engagement.

b) On combines equipped with feeder house

lateral tilt, position the feeder house front

face to be square with feeder house floor.

c) Lower the combine feeder house so that the

feeder house saddle will just pass under the

upper beam of the header.

d) Enter the header opening and lift the header

off the ground. The feeder house saddle and

header beam should now be firmly engaged.

e) Raise the feeder house completely.

f) TURN OFF COMBINE ENGINE,

REMOVE THE KEY FROM THE

IGNITION, AND ENGAGE THE

FEEDER HOUSE SAFETY LOCK.

HEADER UPPER BEAM

FEEDER SADDLE

P00029

Positioning on Combine

(May not be exactly as shown)

P00030

Engaged Feeder House Lock

(May not be exactly as shown)

g) Engage the header locking mechanisms,

wiring and hydraulics. Refer to the

“Completing Hook Up to Your Combine”

section for combine specific instructions.

h) Attach auger drive shaft. See “Drive Shaft

Installation”-section 7.5 in this manual.

i) Disengage the feeder house locks and secure

in the storage position.

Form 169149 Revision E

13

Page 20

SECTION 3 – SETUP COMPLETION

P00009

Disengaged Feeder House Lock

(May not be exactly as shown)

Completing Hook Up To Your Combine

Each combine manufacturer has a different

design for lower locking mechanism on the

header. The locking mechanism is an important

step in protecting your header/pickup from

damage.

On all models the feeder house must be properly

installed onto the header before the locks could

be activated.

ATTENTION: Do not operate or move

header without engaging the lower locking

mechanism. Failure to do so may cause

damage to your equipment.

3.1.1 JOHN DEERE

50 Series:

a) Take the John Deere locking pin out of its

storage position and slide it into the slot of

the header.

b) Loosen the nuts of the header locking plates.

c) Position the plate so that the lower corner of

the plate rests against the pin.

d) Check that pin moves freely in and out.

e) Tighten the header adjustment plate nuts.

f) Modification to hydraulic lines and wiring

harnesses may be required if adapter kit is

not available from local dealer.

P00032

HEADER

ADJUSTMENT

PLATE

John Deere Locked Position

P00033

50 Series Open Position

60 Series:

60 Series combines come equipped with a multi

function system, which connects the hydraulics,

electrical and mechanical locks.

a) Remove the hydraulic multi coupler from the

storage bracket.

b) Install the multi coupler onto the feeder

house coupler.

Form 169149 Revision E

14

Page 21

SECTION 3 – SETUP COMPLETION

c) Lower the lever into the engaged or locking

position. This will automatically engage the

header / feeder house locks, wiring and

hydraulics.

P00493R

Hydraulic Coupler in Storage Bracket

P00547

Hydraulic Coupler in Field/Locked Position

To Adjust Plates:

a) Loosen the nuts of the header locking plates.

b) Position the plate so that the lower corner of

the plate rests against the pin.

c) Check that pin moves freely in and out.

d) Tighten the header adjustment plate nuts.

P00546

Lower Locking Pin

3.1.2 CLAAS / LEXION

a) Check that locking pins are in outward

position and secured with clevis pin in hole

#2.

Install Guide Plates Standard Feeder

Only

Hole #2

b) Guide plates are stored in the document

holder on the back side of the header.

Install guide plates at lower slots on

standard feeder house only. Guide plates

are not required with HP (Header Pitch)

feeder house.

Form 169149 Revision E

15

Page 22

SECTION 3 – SETUP COMPLETION

c) Disengage the feeder house locks and

secure in the storage position.

Lower feeder house so hooks are below

mounting bracket.

d) Move combine into header opening and align

cylinders or feeder hooks with mounting

brackets on header.

Header Mounting Brackets

Standard Feeder HP Feeder

Feeder Hooks

e) Raise feeder house completely and engage

feeder house lock.

f) Insert lock pins in place using hole #1. Pin

must be at the top of the slot as shown.

Note: On combines equipped with feeder house

fore-aft tilt, the feeder house face must be

positioned so that the header floor is parallel to

the ground when header is in operating position.

Hole #1

Hole #1

Combines with auto-contour:

Extend cylinder to approximately the middle

position. Install guide plates as above to lock

the auto contour. Guide plates are stored in

the document holder on the back side of the

header.

ATTENTION: Not installing locking guide

plates on combines with auto-contour may

lead to pickup disconnecting from

combine, especially when auto-contour is

tilted to one side. Severe machine damage

can result.

g) Disengage pickup storage braces. See

Storage Brace Disengagement in this

manual.

ATTENTION: Never lower header to the

ground while the locking pins are in place

and storage braces are engaged. This will

cause severe damage to your machine

ATTENTION: Locking pins must be

correctly engaged into feeder slots.

Operating the unit with locking pins

disengaged or improperly engaged can

severely damage the unit.

Standard Feeder with Guide Plates

Form 169149 Revision E

HP Feeder

16

Page 23

SECTION 3 – SETUP COMPLETION

h) Remove the hydraulic/electrical multi

coupler cover from the storage bracket.

i) Install the multi coupler from the feeder

house onto the header multi coupler.

j) This will automatically engage the wiring

and hydraulics.

Header Multi Coupler

Feeder house Multi Coupler in Storage

3.1.3 AGCO

a) Engage lower locking mechanism as follows:

Insert concave door tool (E) in latch socket

(F) and rotate latch clockwise to lock hooks

(G) into the adapter frame (both sides).

MAKE CERTAIN that the latch is rotated

over-center to securely lock the hooks. If it

does not latch, check to determine if the

lower pins (H) are seated in the adapter back.

If not, place a block under the left end of the

adapter and lower the adapter to reseat the

pins. Re-latch the hooks.

H

F

G

E

LOCK HOOKS INTO ADAPTER FRAME

BOTH SIDES - Agco

Form 169149 Revision E

17

Page 24

SECTION 3 – SETUP COMPLETION

b) Attach hydraulics and electrical - Single

Point Connection (if equipped):

Clean all hydraulic hoses and couplings

before connecting to prevent contamination of

hydraulic system.

Align the single point header connector (A)

with the single point connector on the

combine (B) and lock by moving latch (C)

over-center.

NOTE: To install a header with single point

connector on a combine without a single point

connector, an adapter is required. See your

combine dealer.

A

Agco Single Point Connector – Header Side

C

B

Agco Single Point Connector – Combine Side

d) Connect hydraulic hoses to combine –

Without Single Point Connection:

Attach the ½ inch hydraulic hose from

the combine to the female coupler on the

header.

Attach the ½ inch hydraulic hose from

the header to the female coupler on the

combine.

Attach the 3/8 hydraulic hose (hold-down

line) from the header to the combine.

Agco Hydraulic Connections

(Non Single Point Connector)

e) Connect wiring harness – Without Single

Point Connection:

Attach extremity lighting wiring harness

to the combine receptacle, located on the

left side of the feeder house. Ensure

harness connector is pushed in far enough

to lock into receptacle.

Agco Electrical Connections

(Non Single Point Connector)

Form 169149 Revision E

18

Page 25

SECTION 3 – SETUP COMPLETION

3.2 CONNECTING HEADER/PICKUP TO

COMBINE – CASE IH &

NEW HOLLAND

NOTE: The operator of the combine should

be well trained in the use of combine controls.

Improper use of the combine could result in

damage to property or serious injury or

death.

NOTE: For New Holland combines built prior

to Model Year 2009, order B5614 – NH Auto

Header Height Sensor Kit from your MacDon

Dealer. Installation instructions are provided

with the kit.

a) Check to see that all header and feeder house

locking devices are open and ready for

engagement. Ensure handle (A) is positioned

so that hooks (B) can engage header lower

mounts.

B

A

b) On combines equipped with feeder house

lateral tilt, position the feeder house front

face to be square with feeder house floor.

c) Lower the combine feeder house so that the

feeder house saddle will just pass under the

upper beam of the header

d) Enter the header opening and lift the header

off the ground. The feeder house saddle and

header beam should now be firmly engaged.

HEADER UPPER BEAM

FEEDER SADDLE

Positioning on Combine

(May not be exactly as shown)

e) Raise the feeder house completely.

f) TURN OFF COMBINE ENGINE,

REMOVE THE KEY FROM THE

IGNITION, AND ENGAGE THE

FEEDER HOUSE SAFETY LOCK.

P00030

Engaged Feeder House Lock

(May not be exactly as shown)

P00029

Form 169149 Revision E

19

Page 26

SECTION 3 – SETUP COMPLETION

g) Push up on handle (A) on combine so that

hooks (B) from photo on page 2 engage

header lower mounting pins (K) on both

sides of the feeder house.

h) Be sure slot in lever (E) engages welded rod

on handle (A) to lock handle in place.

i) If hook (B) does not fully engage header

lower mounting pin (K) on both sides of the

feeder house when (A) and (E) are engaged,

adjust position of mounting pin (K) in slot as

required.

If force to engage handle (A) and lever (E) is

too loose or excessive, loosen bolts (G), and

adjust lock force as required. Re-tighten

bolts.

K

j) Connect Hydraulic Multi-coupler at (H) and

electrical harness at (J).

H

H

E

A

B

G

k) Disengage the feeder house locks and secure

in the storage position.

Disengaged Feeder House Lock

(May not be exactly as shown)

J

Form 169149 Revision E

20

Page 27

SECTION 3 – SETUP COMPLETION

3.3 FEEDERHOUSE WIDTH

CONVERSION

For John Deere, Case IH, New Holland and

Agco Combines, see the instructions supplied

with the mechanical completion package to

initially configure the header to suit your

combine. For Lexion combines, machines are

factory configured for narrow combine feeder.

Before use with a Lexion combine with wide

feeder house, the header must be reconfigured

using the supplied parts as follows:

Lexion – Narrow to Wide:

NOTE: These instructions can also be used to

convert a header configured for a John Deere

narrow feeder combine to a wide feeder house.

For Agco combines, see your dealer for

conversion instructions for the three available

feeder house widths.

a) Remove the two outer auger hand hole

covers to gain access to inside of auger.

Flight extension

c) Remove finger hole covers and add two

additional auger fingers and finger guides at

the next two open locations at both sides of

the auger (total of 4). These are shipped in

the document case at back of header.

d) Reinstall hand hole covers.

e) Remove lower stripper bar and stripper bar

extensions.

f) Move lower stripper bars outward one hole

so they are flush with combine feeder house

opening and bolt to the header floor.

Hand hole Covers

b) Remove the auger flight extensions. These

Extension bracket/bars

are the innermost pieces of flighting on each

side of auger center.

Form 169149 Revision E

21

Page 28

SECTION 3 – SETUP COMPLETION

g) Attach removed stripper bar extensions to the

outside of the back wall of header for

storage.

Stripper Bar Storage

h) Adjust stripper bars. See section 4.10 in this

manual.

i) Save all removed components for conversion

back to narrow opening at a later date if

necessary. In this case, the process described

above must be reversed.

3.4 DISENGAGING STORAGE BRACES /

REMOVING CYLINDER BRACES

NOTE: Before disengaging storage braces,

raise the header so wheels are just off the

ground.

Pickups are delivered with the storage and

cylinder braces engaged. Storage and cylinder

braces are located on each side of the pickup.

Before the pickup can be used, storage braces

must

be disengaged or machine will be

damaged.

P00659

Storage Brace Disengagement

a) Remove clevis pin.

b) Rotate storage brace upward into the

stiff-arm clevis.

Stiff Arm Clevis

Clevis Pin

P00677

c) Place clevis pin in stiff-arm clevis and

replace clip pin to secure brace upwards.

P00678

Storage Brace Disengaged

Form 169149 Revision E

22

Page 29

SECTION 3 – SETUP COMPLETION

Remove Cylinder Shipping Braces

NOTE: Do not remove yellow shipping braces

(D) until unit is laid down and arms are moved to

working position.

a) Support front of hold down assembly (E) and

remove the top lynch pins, washers and

cylinder pins securing braces (D), both sides.

b) Rotate braces down. Raise cylinders until

aligned with top pin position and reinstall top

cylinder pins, washers and lynch pins.

c) Remove bottom lynch pins and washers.

Remove braces and reinstall the washers and

lynch pins, both sides.

E

D

Remove Cylinder Shipping Braces

3.5 TESTING HYDRAULIC HOLD DOWN

NOTE: All testing should be performed

with the header/pickup in operating

position so that the wheels are on the

ground and the distance from the ground

to the center of the rear roller is about 14”

(356mm).

a) The hold down is controlled by the reel lift

control located in the combine cab. Activate

the control to lift the hold down. The

cylinders should begin lifting

simultaneously.

b) Lift the hold down completely to the top.

Continue to force the cylinders up for one to

two seconds to ensure the cylinders re-phase.

Both cylinders should be fully extended.

c) Lower the hold down. The cylinders should

lower at the same time and at the same rate.

It should take from 12 to 18 seconds for the

hold down to lower from the highest point.

d) Completely lower the hold down. The

cylinders should stop at the same time. It is

acceptable for the slave cylinder to remain

extended from 0 to 1/2” (13mm) when the

master cylinder is fully retracted.

Should the hydraulics not perform as above refer

to the procedures in the service section of this

manual.

Form 169149 Revision E

23

Page 30

SECTION 4 – ADJUSTMENTS

Pickup adjustments to be performed only

when:

Feeder house locks are engaged or

pickup is lowered to the ground.

Combine is shut off.

The key is removed.

All moving parts have stopped.

4.1 TIRE PRESSURE AND WHEEL

TORQUE

WARNING: An over inflated

tire could explode and cause

serious injury or death. Read tire

safety section before continuing.

a) Tire inflation: 8 to 10 PSI (55-69kPa)

b) Wheel bolt torque: 60 lb-ft

4.2 TEETH HEIGHT (WHEEL)

ADJUSTMENT

The proper height adjustment should be checked

to ensure the set-up of the pickup is correct. A

clearance of 1/2 inch (12mm) between the teeth

and the ground is recommended as an initial

setting. Line up the 6th cog from the bottom on

the pick up frame wheel plate with the

adjustment cog on the wheel spindle plate. See

following.

P00699

Recommended Initial Setting

1. Make sure tire pressure is in desired

range. (8-10 psi.)

2. Position the pickup rear roller height to

14“ above the ground (350mm). Check

tooth height at this time and proceed

with further adjustment if required.

3. Raise pickup until center of rear roller is

approximately 20” off of the ground.

4. Using a 3/4” wrench, loosen the

clamping bolt on one side of the pickup.

5. Using two 3/4” wrenches, move the

adjustment nut to the desired clearance.

P00686

Wheel Adjustment

P00686

Form 169149 Revision E

24

Page 31

SECTION 4 - ADJUSTMENTS

6. Tighten the clamping bolt to lock into

place

7. Repeat steps 4 to 6 for the other side.

Match the LH and RH wheel height using

the cogs on the wheel plates.

8. Adjust suspension.

NOTE: When wheel height is changed,

suspension should be adjusted as well.

4.3 SUSPENSION ADJUSTMENT

Wheels start

to lift off

ground

2

3

5

4

1

6

Suspension System Assembly and Parts List

(Illustration May Differ)

1. Lifter Adjustment Bolt (w/rubber stoppers)

2. Spring Bolt

3. Spring Bolt Locking Nut

4. Lifter Adjustment Bolt Locking Nut

5. Spring

6. Lifter Bracket

7. Mounting Bracket Plate

8. Channel Upright

a) Adjust tooth/wheel height. See previous

page.

b) Lower header until wheels just touch the

ground. [Rear roller approximately 20

inches (508 mm) above the ground.]

c) Tighten the spring bolt (2) evenly on both

sides until the wheels begin to lift off the

ground. Turn the spring bolt clockwise to

lift the wheels and counter clockwise to

lower the wheels.

NOTE: The friction in the gas shock

absorbers must be compensated for by lifting

the wheels during tightening and allowing

them to fall to their normal resting position.

The height of the wheels should be checked in

this manner after every 1/2 inch (12mm) of

spring adjustment.

d) Tighten the spring bolt-locking nut (3)

against the spring casting to prevent

loosening.

e) Raise header so wheels are approximately 6

inches (150 mm) off the ground.

8

f) Lower storage brace into engaged (float

lockout) position and insert clevis pin (see

7

Section 3.4). If pin does not go in, adjust

lifter adjustment bolt (1) so clevis pin can be

easily installed and removed.

g) Jam the lifter adjustment bolt-locking nut (4)

against the lifter bracket (6).

Note: If ground speed is above 7 mph

(11 km/h) it may be necessary to back off the

float to prevent the header from bouncing

excessively.

Note: During field operation, the rear roller

shaft should be at 14 inches (350 mm) above

the ground.

4.4 SPRINGWIRE/FIBREGLASS ROD

ADJUSTMENT

The spring wires and the fiberglass rods must be

set properly for different crop and conditions.

a) Remove the clevis and hitch pins and adjust

the spring wire tube so that the spring wires

protrude up through the fiberglass rods as

illustrated. This will protect the fiberglass

rods from becoming damaged by the spring

wire edges.

Form 169149 Revision E

25

Page 32

SECTION 4 - ADJUSTMENTS

NOTE: The purpose of the fiberglass rods is

to provide a smooth, even flow of material

under the auger and to the combine.

ADJUSTMENT POINT

D00046

Spring Wire and Fiberglass Rod Adjustment

P00701

Hold down Clevis and Hitch Pins

NOTE: To reduce shelling in heavy swaths, it

may be necessary to rotate the spring wires

completely out of the way.

P00171

Hold down Adjusted for Short Crops

P00172

Hold down Adjusted for Average Crops

P00173

Hold down Adjusted for Heavy Crops

NOTE: In some cases, if the hold down

assembly is moved substantially the

suspension should be retuned. Rotate the

spring wires clear before continuing to

operate.

4.5 DRAPER BELT TENSIONING

The pickup draper belts are installed and set

at the factory, however the draper belt

tension should be checked before operating.

A) Adjustment:

D00042A

Draper Belt Adjustment

Form 169149 Revision E

26

Page 33

SECTION 4 - ADJUSTMENTS

a) Loosen 1/2-inch carrier bracket bolts

shown in Pickup Belt Tensioner and

Carrier Bracket Bolts.

b) The belts are tensioned using 1/2 inch set

screw.

Carrier Bracket Bolts

Pickup Belt Tension Set Screws

c) Tension the belts until there is

approximately 1 1/2 inches of belt sag on

conventional Rake-Up and Swathmaster

pickups and SwathMaster Small Seed

pickups, and 2 inches of belt sag on

Rake-Up Small Seed pickups when

lifting midway between rollers. This

adjustment is shown in the Draper Belt

Adjustment For Conventional/Small Seed

Pickups.

d) Tighten 1/2-inch carrier bracket bolts.

P00685

P00679

NOTE:

1. When the pickup is mounted on the

combine, there should be visible sag in the

bottom side of the draper belt(s).

2. Some draper belts when new are very

tacky. Talcum or baby powder rubbed

into the belts may help to reduce the

tackiness. In addition, for the first few

hours of break-in, the belts may need to be

run looser than normal.

P00664

DO NOT OVER-TIGHTEN THE BELTS!

This can cause a number of problems:

1. Joining bolts can pull out of draper belts.

2. The center belts will slip on conventional

pickups.

3. The belts will crawl over the dividers.

4. The rollers or bearings could be damaged.

Any belts that fail from being over

tightened will not be covered under

warranty!

B) Belt Alignment–SwathMaster Small

Seed Pickups

If you are having trouble with the belts moving

sideways out of the pulleys and wearing the belt

edges, the following procedure should be

followed:

(a) First, check draper belt tension. An over

tensioned draper belt will tend to crawl

sideways more. If you are not sure, try

loosening the belt very slightly and then reevaluating.

Form 169149 Revision E

27

Page 34

SECTION 4 - ADJUSTMENTS

(b) Check that each side of the draper is

tightened evenly. If the drapers are not

tightened evenly, sometimes diagonal

ripples will appear running across the belt.

Generally, loosen the side that the ripples

are moving away from at the rear roller.

(c) If draper is tracking off to one side, loosen

the opposite side slightly. Make small

adjustments and watch tracking for a

minute before re-adjusting.

ADJUSTMENT TUBE

Form 169149 Revision E

28

Page 35

SECTION 4 - ADJUSTMENTS

4.6 PICKUP DRIVE BELT TENSION

Both Rake-Up and SwathMaster models come

equipped with self-tightening v-belts.

SwathMaster units have an additional method

to increase tension if required.

SwathMaster adjustment is as follows:

1. Remove drive shields. (See Service-Section

7)

2. Eliminate v-belt tension. (See Service-

Section 7)

3. Remove tension spring and reposition so

the extension is outside the mount bracket.

P00687

Factory

Setting

Extension Spring

Position for

Increased Tension

4. Tighten the tension spring hardware and

put v-belt back on sheaves.

4.7 SPEED CONTROL & HEIGHT

CONTROL

Depending of availability of these features on

various combine makes, the units may be

factory equipped with the speed control and

height control features. Refer to the following

for information to adjust and operate these

features.

Speed Control

In order for the speed control to operate properly

the sensor must be adjusted to read the target or

sprocket teeth.

The sensor height can be adjusted up or down by

loosening the 3/4” jam nuts with a wrench.

Adjust to a horizontal clearance of 3/16”(5mm).

Loosen the target sensor and slide it on the roller

shaft until the desired clearance is achieved

between the sensor and a sprocket tooth. When

proper alignment is achieved, tighten the lower

nut to lock the sensor into place and tighten the

setscrew to maintain target adjustment. Refer to

Section 5.1 for optimum pick up speeds and your

combine operator’s manual for the combine

portion of Dial-a-Speed operation.

ATTENTION: Loosen the lower nut first

when removing or adjusting the sensor.

Sensor Details

(Target May Not Be As Shown)

Height Control

NOTE: Never make any adjustments to the

AHC while the AHC unit is active in the

combine. Adjusting the AHC unit will cause

the feeder house to raise and lower.

Under normal conditions, the optimum pick up

height is achieved when the rear draper roller is

14” off of the ground. For normal conditions, set

the AHC so that it is in the neutral position when

D00126

Form 169149 Revision E

29

Page 36

SECTION 4 - ADJUSTMENTS

the pickup rear roller is at the 14” mark. See

following illustration.

Potentiometer Arm

Rotate Around

This Bolt

Mount Bracket

P00665

Components in Neutral Position

To set the AHC to this position:

1. The AHC switch in the combine should be

turned off and the draper belts properly

tensioned. (See Section 4.5) Each

subsequent time the belts are adjusted, the

AHC should be adjusted as well

2. Lift the header until the rear draper roller is

14” from the ground.

3. Loosen slightly, both nuts that hold the

potentiometer to the mount bracket. Rotate

the assembly around the left side bolt. The

right bolt will move along the slot. When

the arm on the potentiometer is

perpendicular to the potentiometer bracket

it is in the neutral position.

4. Retighten the nuts so that the potentiometer

is secure.

5. Refer to your combine operator’s manual

for the in-cab calibration procedure.

6. Test the function of the AHC. If the front

end of the pick-up goes up (as if going up a

hill) the header height should move up to

compensate. If the pick-up front goes

down (as if dropping into a hole) the

header should drop to compensate.

4.8 AUGER FINGER ADJUSTMENT

ATTENTION: Do not adjust fingers to

less than the minimum 1/4-inch clearance

to the header bottom.

Finger Adjustment Procedure

a) Loosen the clamping nut.

CLAMPING NUT

P00503

Finger Adjustment

b) Move the handle in the desired direction.

Counterclockwise = Fingers retract

Clockwise = Fingers extend

c) When the desired position is found,

tighten the clamping nut.

Form 169149 Revision E

30

Page 37

SECTION 4 - ADJUSTMENTS

4.9 AUGER ADJUSTMENT

The auger is a very important component in

getting a smooth, high capacity flow of crop

into the feeder house. Factory auger setting is

not intended to be field ready for all types of

crops. The auger must be adjusted for

different crop conditions.

The auger must also rotate freely without

touching the header floor or stripper bars.

Check the minimum factory clearance prior to

operation.

D00302

Factory Settings

(Illustration May Not Be Exactly as Shown)

A) Auger Clearance to Header Bottom

For heavy or bulky crops, a clearance of

25mm (1 inch) can increase header capacity.

For a lighter crop, a minimum clearance of

6mm (1/4 inch) will prove to be more

effective.

ATTENTION: If the auger contacts the

header bottom, excessive wear will occur to

auger and header bottom.

The clearance between auger and header

bottom can be adjusted as follows:

Adjust both ends of the auger to maintain a

uniform clearance across the width of the header.

a) Shields can remain in place.

b) Loosen clamp bolts protruding through

rubber stopper and sidewall.

c) Back off the lower auger height adjustment

nuts.

CLAMP BOLTS

ADJUSTMENT NUTS

P00491

Auger Height Adjustment Nuts

a) Turn the top nuts to raise or lower the auger

on both ends.

b) Turn the auger by hand and check for

clearance along the entire length of the auger.

c) Tighten the lower adjustor nuts.

Clearance between auger and strippers is to be

rechecked after the auger height setting has been

changed. See Auger Clearance to Stripper Bar.

B) Auger Forward/Rearward Adjustment

The auger can be moved forward or rearward to

adjust stripper clearance or improve augerfeeding performance. The factory settings will

prove very effective in most crop conditions. In

some cases of small grain crops, the auger may

Form 169149 Revision E

31

Page 38

SECTION 4 - ADJUSTMENTS

be moved further ahead or back in the auger

trough to improve performance.

Ensure that that the auger is adjusted evenly on

both sides.

a) Loosen the auger forward/rearward

adjustment nut on both sides. See

Forward/Rearward Adjustments.

b) Turn the rearward nut to pull the auger back

to reduce clearance.

c) Turn the forward nut to push the auger ahead

to increase the clearance.

d) Tighten the adjusting nuts to lock the auger

in the desired position.

`

REARWARD NUT

(HIDDEN)

FORWARD NUT

P00347

PIVOT BOLT

Forward/Rearward Adjustments

4.10 STRIPPER BAR ADJUSTMENT

The header is equipped with a pair of upper and

lower stripper bars.

DANGER: Lower header to the

ground or engage feeder house

locks, shut-off combine, remove

ignition key, and wait for parts to stop moving

before performing this adjustment

P00544

Upper and Lower Stripper Bars

The clearance between the auger and

stripper bars is set at the factory to a

minimum of 2mm (3/32 inch). Minimizing

the clearance of the auger and stripper bar

can reduce crop carry over.

The upper stripper bar bolts are accessible

from the top of the header.

A maximum reach of 16mm (5/8inch) can

be accomplished by using the slotted holes

in the upper stripper bar bracket and bar. If

more clearance is desired, see Auger

Forward/ Rearward Adjustment.

ATTENTION: If the auger comes in

contact with the stripper bar excessive

wear will occur. Disconnect the driveshaft

from combine and rotate auger by hand

to find the minimum clearance, than

complete all adjustments from that point.

Form 169149 Revision E

32

Page 39

SECTION 4 - ADJUSTMENTS

4.11 HEADER DRIVE CHAIN

ADJUSTMENT

DANGER: Lower header to the

ground or engage feeder house

locks, shut off combine, remove

ignition key, and wait for parts to stop

moving before performing this adjustment

NOTE: Check and adjust chain tension

after the first 3 hours of operation, and at

regular intervals thereafter.

Check header drive chain tension with a flat

screwdriver using the access hole on the left

side shield. See picture following.

P00480

Checking Chain Tension

The drive chain must be adjusted to give 1/2

inch to 3/4-inch deflection at the bottom with

approximately 10 lb (5kg) of force applied.

D00523

Drive Chain Deflection

Adjustment Procedure:

NOTE: It is not necessary to remove the side

panel for chain tension adjustment.

a) Loosen the 4 drive shaft bracket bolts only

enough to allow the bracket to slide in slots.

ATTENTION: Attempting to adjust chain

tension without loosening all 4 drive shaft

bracket nuts will damage the chain tension

bolt bracket.

P00525

Drive Shaft Bracket Bolts

b) Loosen the locknut on the chain tension bolt.

CHAIN

TENSION

BOLT

LOCK NUT

P00525

c) To relieve the chain tension, turn the chain

tension bolt counterclockwise.

d) To tighten the chain, turn the chain tension

bolt clockwise.

Form 169149 Revision E

33

Page 40

SECTION 4 - ADJUSTMENTS

e) Retighten the 4 drive shaft bracket bolts to

57 - 60 ft lb.

f) Tighten the lock nut to secure the chain

tension bolt.

g) Re-check chain tension as above.

Form 169149 Revision E

34

Page 41

SECTION 5

OPERATING INSTRUCTIONS

5.1 OPERATING SPEED

Performance of the pickup in various crop

and field conditions largely depends upon its

operating speed. If the swath is pushed

ahead, the pickup speed is too low and some

of the crop may remain unpicked. If the

swath is torn apart and is pulled toward the

combine header, the pickup speed is too high

and uneven combine feeding will occur.

Pickup operating speed is adjusted from the

combine cab by regulating oil flow to the

pickup hydraulic motor.

RAKE-UP: As a guide for initial settings of

pickup operating speed, a ratio of 11 RPM of

idler or drive rotor per 1 MPH of combine

ground speed can be used. For example:

when a combining speed of 5 MPH (8 km/h)

is selected, the rotors shall run at 11 x 5 = 55

RPM: at 3.5 MPH (5.6 km/h), the rotors shall

turn at 11 x 3.5 = 38.5 RPM.

If a shaft tachometer is available, set the rear

roller shaft speed at 73 RPM per 1 MPH of

combine speed. For example: when a

combining speed of 5 MPH (8km/h) is

selected the rear roller shaft shall run at 73 x

5 = 365 RPM.

SWATHMASTER: As a reference for

initial settings of pickup operating speed, a

ratio of 13 RPM of the front draper belt per 1

MPH of combine ground speed can be used.

For example: when a combining speed of 5

MPH (8km/h) is selected, the front draper

belt shall run at 13 x 5 = 65 RPM; at 3.5

MPH (5.6km/h) the draper belt shall run at

13 x 3.5 = 45.5 RPM.

If a shaft tachometer is available, set the rear

draper - rear roller shaft speed at 73 RPM per

1 MPH of combine speed. For example:

when a combining speed of 5 MPH (8km/h)

is selected the rear draper - rear roller shaft

shall run at 73 x 5 = 365 RPM.

In general, maximum pick up speed for picking

conditions shall be selected so that the swath is

always pushed slightly ahead.

IMPORTANT: The maximum front draper belt

speed on a SwathMaster pickup should not

exceed 104 RPM equivalent to a combine speed

of 8 MPH. The maximum idler or drive rotor

speed on a Rake-Up pickup should not exceed

88 RPM equivalent to a combine speed of 8

MPH. Over speeding the pick up may cause

premature wear of drive components and

minimize performance

ATTENTION: Do not over-speed pickup.

Over-speeding pickup will cause premature

wear of drive components and adversely

affect pickup performance.

HEADER: The header is supplied with an auger

drive sprocket to match your combine. In certain

crops, a higher or slower auger speed may be

desired. Contact your dealer for available

sprocket options.

Form 169149 Revision E

35

Page 42

SECTION 5 – OPERATING INSTRUCTIONS

5.2 OPERATING HEIGHT

A) Header Operating Height

Lift the header until the center of the rear draper

roller is 14" (356mm) above the ground. This is

an appropriate header operating height.

D00049

Proper Header Height

(Rake-Up Shown)

B) Pickup Operating Height

Depending on field conditions, it may be

necessary to either increase or decrease the

amount of clearance between the teeth and the

ground. Two general symptoms will indicate

that this adjustment is necessary:

a) The pickup leaves material unpicked in the

field. This is an indication that the teeth are

too high.

b) The pickup teeth are wearing quickly or are

picking up dirt and stones. This indicates

that the teeth are set too low.

NOTE: After adjusting tooth height, the

suspension system must be retuned for

optimal performance. See Suspension

Adjustment.

5.3 HOLDDOWN POSITIONING

Hold down position is important to the

performance of the pickup and must be

adjusted according to crop conditions. The

spring wires on the front of the pick up are

designed to keep the swath from forming a

ball or rolling sideways in front of the teeth.

Fiberglass rods hold the swath in contact

with belts and guide the crop under the

auger. Ideally, the spring wires should

touch the top of the swath to keep it in

contact with the pickup teeth. Constant

down pressure on the crop will assist in

pickup performance.

A) Hold down Height Adjustment

The hydraulic hold-down option allows you

to fine tune the hold-down position using the

combines reel height adjust.

NOTE: In the case of plugging the feeder

house, raise the hold-down out of the way

before using the reverser.

DANGER: Lower header to

the ground or engage feeder

house locks, shut-off combine,

remove ignition key, and wait for parts to

stop moving before performing this

adjustment

D00002

Hydraulic Lift

Form 169149 Revision E

36

Page 43

SECTION 5 – OPERATING INSTRUCTIONS

B) Hold-down Orientation

The spring wires and the fiberglass rods must

be set properly for different crop and

conditions.

b) Remove the clevis and hitch pins and

adjust the spring wire tube so that the

spring wires protrude up through the

fiberglass rods as illustrated. This will

protect the fiberglass rods from becoming

damaged by the spring wire edges.

NOTE: The purpose of the fiberglass rods

is to provide a smooth, even flow of

material under the auger and to the

combine.

ADJUSTMENT POINT

D00046

Spring Wire and Fiberglass Rod Adjustment

P00701

Hold-down Clevis and Hitch Pins

NOTE: To reduce shelling in heavy swaths, it

may be necessary to rotate the spring wires

completely out of the way.

P00171

Hold-down Adjusted for Short Crops

P00172

Hold-down Adjusted for Average Crops

P00173

Hold-down Adjusted for Heavy Crops

NOTE: In some cases, if the hold-down

assembly is moved substantially the

suspension should be retuned. Rotate the

spring wires clear before continuing to operate.

Form 169149 Revision E

37

Page 44

SECTION 5 – OPERATING INSTRUCTIONS

5.4 RADIAL PIN CLUTCH

(On all header drive shafts)

Every header is equipped with a driveshaft,

which contains a radial pin clutch. This clutch

emits a rattling sound and pulsating motion when

slippage occurs.

P00174

Radial Pin Clutch

The purpose of this clutch is to provide

protection against overload. When an obstruction

encounters the auger and creates an overload, the

clutch will slip notifying the operator of a

problem. Frequent slippage for more than two or

three seconds may result in clutch damage.

ATTENTION: Prolonged operation of the

header with the clutch slipping will cause

damage to the header and/or clutch.

5.5 DISCONNECTING FROM

COMBINE

ATTENTION: Always lock the storage

brace prior to disconnection. Failure to

lock storage braces will result in difficulty

reconnecting the header to the combine.

TIP: Engaged braces for long trips from

field to field on rough terrain will prevent

the pickup from bouncing.

a) Remove the clevis pins from storage

clevis.

b) Pull storage braces downward out of

storage brace holders and place in locking

position.

Clevis Pin

P00677

Storage Brace - Engaged

c) Reinstall the clevis pins in storage braces.

To ease pin installation it may be

necessary to slightly raise or push down

on pickup wheel.

d) Move unit to storage location.

e) Disconnect all hydraulics and wiring

between the header and combine. Some

combine models use a multi function

coupler that disconnects the hydraulics,

Form 169149 Revision E

38

Page 45

SECTION 5 – OPERATING INSTRUCTIONS

electrical wiring and feeder house locks

simultaneously. The coupler is to be

unlocked and stored in the storage

bracket. Other models have a coupler

system for the hydraulics and separate

electrical harness connections.

f) Remove the drive shaft from the feeder

house and place it on the storage bracket.

g) Engage the feeder house lock.

h) Unlock the lower hookup points on

header.

i) Disengage the feeder house lock.

j) Lower the feeder and slowly drive out of

the feeder house opening of the header.

5.6 UNPLUGGING THE AUGER

Occasionally the auger may become plugged

and will require unplugging.

To unplug feeder house or auger with

combine reverser:

a) Refer to your combine manual for

operating instructions.

b) Stop combine forward travel.

c) Shut off pickup unit.

d) Raise hold down all the way up.

e) Engage reverse mode.

NOTE: To prevent damage to the pickup

motor, DO NOT engage the feeder reverser

for more than 5 seconds if the feeder and

auger will not turn.

ATTENTION: Pickups cannot run in

reverse. Any attempt to run pick up in

reverse will seriously damage pick up

and/or pick up motor.

Form 169149 Revision E

39

Page 46

SECTION 6 –

MAINTENANCE/LUBRICATION

Read and follow all safety procedures in the

beginning of the Operators manual.

WARNING: Take Extreme

caution around escaping hydraulic

fluid. Release all pressure in the

system before servicing or inspecting

leaking lines. Hydraulic fluid under high

pressure can penetrate the skin and cause

serious injury. Never use your hands to

inspect lines. Seek immediate medical

attention if fluid penetrates your skin.

DANGER: Lower header to the

ground or engage feeder house

locks, shut-off combine, remove

ignition key, and wait for parts to stop moving

before performing this procedure.

6.1 FIRST TIME USE – MAINTENANCE

Inspect the wheel bolts for looseness. Torque

after first 10 hours of use. (60 lb-ft)

6.2 DAILY MAINTENANCE /

LUBRICATION (10 hours)

Check tire pressure. The pressure should be 8

– 10 PSI. (55-69 kPa)

Check for loose fasteners.

Grease header drive shaft daily as per

lubrication chart.

Inspect teeth for straightness.

Check SwathMaster Small Seed belt

guides for wear.

6.3 WEEKLY MAINTENANCE /

LUBRICATION (50 hours)

Oil chain and sprockets with chain lube.

Check header drive chain tension.

Check wheel bolt tightness.

Check draper belt tension.

Inspect bearings and seals.

RAKE-UP

Check that the pickup drive belt

tensioner oscillates freely. Apply a spray

lubricant to the idler arm pivot point.

Check that the 1/2 inch x 1 1/2 inch

UNC bolt that secures the drive rotor to

the large gearbox is tight. Also, check

that the 1/2-inch x 1 1/2 inch UNC bolt

that secures the idler rotor to the frame is

tight. These bolts may work loose even

though they have been drilled and

secured with wire.

NOTE: Neglecting to keep the idler and

drive rotor retaining bolts tight can result

in catastrophic failure of the pickup drive

system. Failures of this nature are easily

prevented with proper maintenance and

as such are not covered by warranty.

Form 169149 Revision E

40

Page 47

SECTION 6 – MAINTENANCE/LUBRICATION

D00047 D00048

Drive Rotor Idler Rotor

Rake-Up Attachment Bolts

Check the setscrews for tightness on the

main gearbox pulley.

P00053

Rake-Up Main Gear Box Pulley Set Screws

6.4 YEARLY MAINTENANCE /

LUBRICATION (100 hours)

Perform all daily and weekly procedures.

RAKE-UP & SWATHMASTER

If pickup is equipped with the height

control (AHC or AHHC), lubricate all

height sensor pivot points seasonally.

Check v-belt condition.

RAKE-UP

The six small gearboxes at the drive end of the

pickup require seasonal lubrication. Remove

the pipe plugs and fill with NLGI Grade 000

extreme pressure, semi-fluid lithium grease,

such as Mobilux EP 023, Petro-Can Precision

XL EP000, or Chevron Dura-Lith EP000. With

the header raised and secured, add grease until

level with plug. Do one gearbox at a time then

rotate the next one to the front.

Inspect all gearboxes for signs of wear.

P00072

Small Gear Box Lubrication

P00259

P00259r

Main gearbox Plug

The main gearbox is filled at the factory with

14.4 Fluid Oz (425 ml or 0.112 US gal) of

NLGI Grade 000 extreme pressure, semifluid lithium grease, such as Mobilux EP

023, Petro-Can Precision XL EP000, or

Chevron Dura-Lith EP000. Lower viscosity

oils may leak out of the gearbox.

Continued next page…

Form 169149 Revision E

41

Page 48

SECTION 6 – MAINTENANCE/LUBRICATION

NOTE: To ensure that the proper amount of

grease has been added, remove the plug and

insert a wire into the hole. With the pickup in

the field position the grease level should be

1 1/2” (38mm) below the lid of the gearbox.

HEADER

Clean and grease the header drive shaft

splines once a year. This will prevent

excessive corrosion from forming.

P00338

Header Drive Shaft

Form 169149 Revision E

42

Page 49

SECTION 6 – MAINTENANCE/LUBRICATION

6.5 LUBRICATION POINTS

E

B

D

C

A – Drive Shaft

B – Six Small Gear Boxes (Mirror Model shown)

C – Main Gearbox (Mirror Model Shown)

P00667

B

A – Drive Shaft

B – Height Control Sensor

A

Rake-Up Lubrication Points

D– Belt Tension Idler Arm

E – Height Control Sensor (If equipped)

F – Header Drive Chain and Sprocket

A

SwathMaster Lubrication Points

C – Header Drive Chain & Sprocket

(If equipped)

P00079

F

C

Form 169149 Revision E

43

Page 50

SECTION 6 – MAINTENANCE/LUBRICATION

H A1

NOTES:

A2

A3 A4

Drive Shaft Lubrication Points

A5

A1 U-Joint

P00078

A2 Shield Bearing

A3 Telescoping Tube

A4 Shield Bearing

A5 U-Joint

P00178

H Clutch

Form 169149 Revision E

44

Page 51

SECTION 6 – MAINTENANCE/LUBRICATION

6.6 MAINTENANCE / LUBRICATION CHART / GREASE SPEC

Read Maintenance/Lubrication Section for proper procedures. Use this chart as a quick reference only.

GREASE SPEC: Use SAE Multi-Purpose Grease per the following:

All locations except Driveline slip joints

Driveline slip joints – High Temp. Extreme Pressure (EP) Performance With 10% Max Molybdenum

GEAR LUBE (Rake-Up): NLGI Grade 000 extreme pressure, semi-fluid lithium grease, such as

1 Drive Shaft Splines 100 100

2 Drive Shaft (Points A1, A3, A5) 50

3 Drive Shaft Clutch 50

4 Header Drive Chain & Sprocket 50

5 Six Small Gear Boxes (Rake Up Only) 100

6 Main Gear Box (Rake Up Only) 100

7 Belt Tension Idler Arm (Rake Up Only) 50

8 Tire Pressure * 100

9 Loose Fasteners 10

10 Hose Leaks 10

11 Wheel Bolts 100

12 Drive Chain Tension * 50

13 Draper Belt Tension * 50

14 Idler Rotor Bolt 50

15 Drive Rotor B olt 50

16 Bearing Damage 100

17 Teeth Wear 100

18 Gear Box Wear 100

19 Worn Paint Spots 100

20 Cleaning of Units 100

21 Wear Inspection 100

22 Drive Shaft (Points A2, A4) 10

23 Belt Guide (SwathMaster Grass Seed) 50

24 Height Control Sensor Pivot Points 100

* Check first 10 hours of operation, and then at regular chart intervals.

Disulphide (NLGI Grade 2). Lithium Base

Mobilux EP 023, Petro-Can Precision XL EP000, or Chevron Dura-Lith EP000.

Service to Perform

– High Temp. Extreme Pressure (EP2) Performance With 1%

Max Molybdenum Disulphide (NLGI Grade 2). Lithium Base

Frequency In Hours

Grease

Lubricate

Check

Clean

Change

Form 169149 Revision E

45

Page 52

SECTION 7

SERVICE

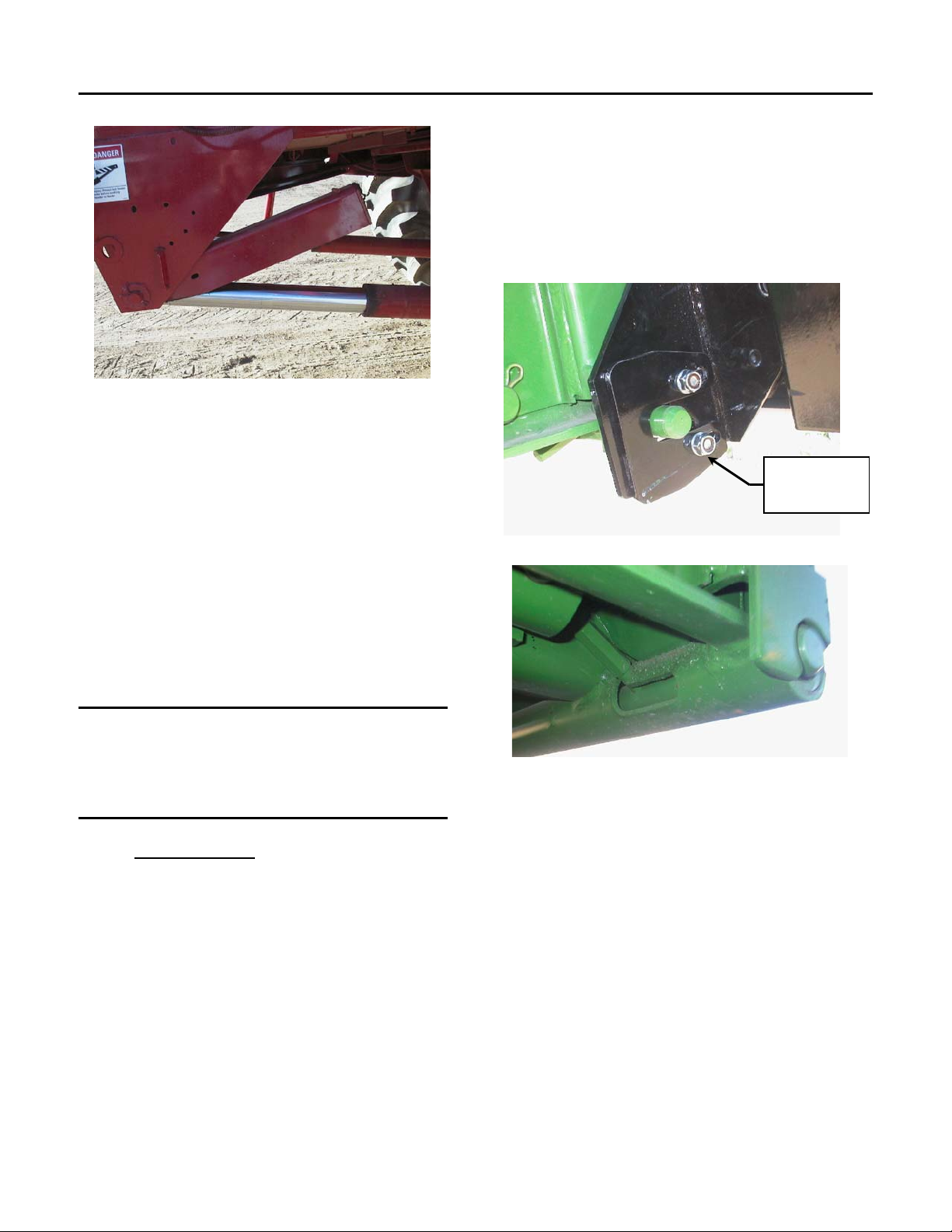

7.1 ATTACHING PICKUP TO HEADER

DANGER: Lower header to the

ground or engage feeder house

locks, shut-off combine, remove

ignition key, and wait for parts to stop moving

before servicing.

ATTENTION: Do not lift the header

without the header braces properly installed.

Attempting to lift the header without header

braces will damage the pick up or header.

Parts damaged due to improper handling are

not covered by warranty.

Positioning on Header

a) Support the pickup with the rear roller at

approximately 14 inches (356mm) above the

ground with wooden blocks located under the

shock tubes. See following drawings.

Installing Rake-Up onto the Header

D00332

Installing SwathMaster onto the Header

13 FT. HEADER: With the header mounted

on the combine, position the header cutter bar

under the pick up mounting bracket for 12ft

pickups and above the mounting bracket for

14ft pick ups.

Position the header such that the left and right

hand channel uprights on the pickup frame are

equal distances from the sides of the header.

On 14ft pick ups, the channel uprights are

outside the header.

See illustrations next page.

D00333A

Form 169149 Revision E

46

Page 53

SECTION 7 – SERVICE

D00268A

Mount Bracket Orientation

15 FT. HEADER: With the header mounted

on the combine, position the header cutter bar

above mounting brackets for 16ft pick ups.

Position the header such that the left and right

hand channel uprights on the pickup frame are

equal distances from the sides of the header.

On 16ft pick ups, the channel uprights are

outside the header.

D00062

Centering the Rake-Up on the Header

(Rake-Up Frame not exactly as shown)

d) Loosely bolt the header braces to the channel

uprights and the header sidewall.

P00386

Mounted Header Brace

e) Bolt the mounting brackets to the cutter bar

using the 7/16-inch carriage bolts, spring lock

washers, and nuts provided. There are three

bolts for each side of the pickup. The

clearance between the cutter bar and rear

roller can be increased, if desired, by

positioning the shim between the cutter bar

and mount bracket. (True only for 14ft pick

up on 13 ft. headers and 16ft pick up on 15 ft.

headers.)

NOTE: It may be necessary to shift the

pickup slightly off center to align the

mounting bracket and the cutterbar with the

holes.

f) Make sure mounting bracket is secure and

flush to cutter bar. Tighten all header brace

bolts. Lift the header and remove the wooden

blocks.

Form 169149 Revision E

47

Page 54

SECTION 7 – SERVICE

7.2 OPENING HEADER SIDE PANELS

John Deere / Lexion / Agco:

To remove left panel, unscrew bolts and lift up

on panel.

P00551

Left Hand Shield: John Deere / Lexion / Agco

To remove right panel unscrew bolts and pull

away from header.

P00552

Right Hand Shield: John Deere/Lexion/Agco

NOTE: It is not necessary to remove panels

to perform adjustments on units. See 4.11

Header Drive Chain Adjustment.

Case IH / New Holland:

D

a) To open shield, push release tab (D) towards

rear of machine. Latch will release top of

shield.

b) Swing shield down and away from machine

to allow enough room to lift it. Lift shield

enough to disengage lower hooks and

remove the shield.

c) To close shield, engage shield hooks (E) in

slots at bottom of frame.

d) Swing shield up to engage upper tab latch

mechanism (F).

e) Close side panel until it is securely latched.

F

Form 169149 Revision E

48

E

Page 55

SECTION 7 – SERVICE

7.3 REMOVING PICKUP SHIELDS

SWATHMASTER

Upper Ridge

Thumbscrews

Removal:

P00689

a) Unscrew the upper and side

thumbscrews.

b) Grabbing hold of the upper ridge,

pull off the Shield.

Installation:

a) Position the shield onto the brackets

and slide back and forth until circular

indentation falls into the rear guide.

Rear Guide

P00700

b) Tighten the thumbscrews.

RAKE-UP

Remove four 5/16” bolts and pertaining

hardware.

P00688

Rake-Up Drive Shield Removal

7.4 HYDRAULIC SYSTEM

CAUTION: High-pressure

hydraulic oil can cause serious

injuries such as burns, cuts, and

tissue damage! Always take

precautions when working with hydraulic oil.

Wear safety goggles, gloves and thick

clothing. Seek immediate medical attention if

cut or burnt.

ATTENTION: On some combine models,

hydraulically driven after-market chaff

spreaders are connected to the pickup drive

hydraulic pump. When the pickup is sharing

the drive with a chaff spreader, the pickup

performance can be adversely affected or

damage may occur to the hydraulic system. If

the hydraulic motor on the pickup is mounted

in series in front of the chaff spreader,

backpressure from the chaff spreader may

cause damage to the pickup motor. The

pickup motor warranty is voided under these

conditions.

Form 169149 Revision E

49

Page 56

SECTION 7 – SERVICE

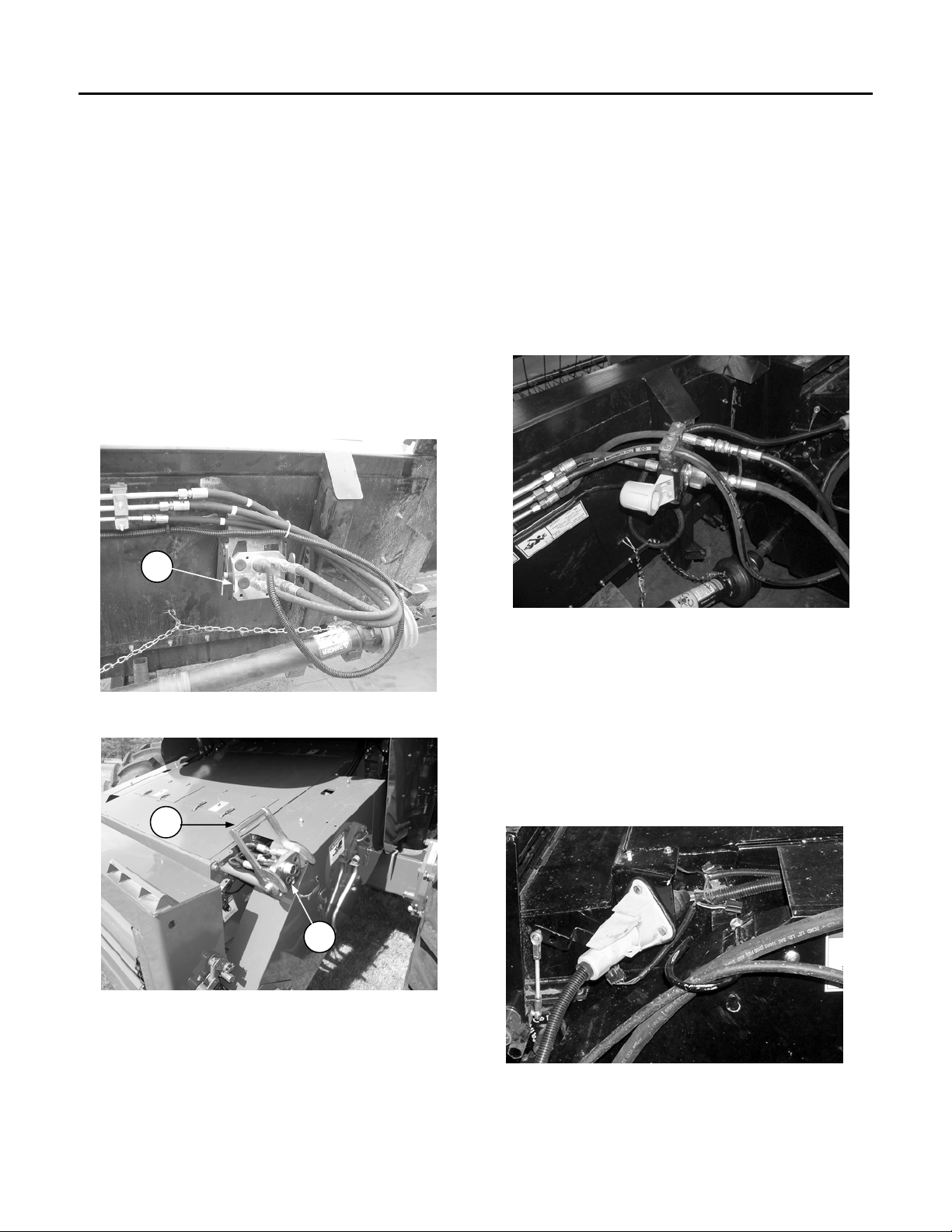

NOTE: Swath Master units use the 101-1011

(MacDon #184266) orbit motor (ORB ports).

Rake-Up units use 101-1010 (MacDon

#184265) orbit motor (ORB ports). These

motors perform well on most combines. On

combines with less flow capacity the 101-1009

(MacDon #184264) orbit motor (ORB ports)

may be required to increase pickup speed.

A) Hydraulic Motor Installation/Removal

RAKE-UP

Removal:

a) Lower the pickup to the ground shut off

combine and remove key.

b) Remove the two hydraulic lines from the

motor if the motor is being replaced or

repaired. Be sure to have some rags and a

bucket to catch the oil in the hoses.

c) Remove all shields that will interfere with

this procedure.

d) Loosen the setscrew on the motor coupler.

e) Extract the two flange head bolts until they

contact the motor.

f) Proceed to extract the bolts one revolution at

a time until the motor is removed.