Page 1

INTRODUCTION

Your new MacDon Model 4000 Mower Conditioner is designed to cut, condition and lay in windrows, a wide

variety of grasses and hay crops.

Use this manual as your first source of information about the machine. If you follow the instructions given in

this manual, your Mower Conditioner will work well for many years.

The manual contains instructions for "Safety", "Operation", and "Maintenance/Service". In addition, "Unloading

and Assembly" information is given towards the back of this book.

CAREFULLY READ ALL THE MATERIAL PROVIDED BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE,

OR USE THE MACHINE.

Use the Table of Contents and the Index to guide you to specific areas. Study the Table of Contents to

familiarize yourself with how the material is organised.

Keep this manual handy for frequent re ference and to pass on to new ope ra tors or ow ners. Call y o ur Deal er

if you need assistance, information, or additional copies of this manual.

NOTE: Right hand (R/H) and left hand (L/H) designations are determined from the operator’s position, facing

forward.

1

Page 2

TABLE OF CONTENTS

PAGE

INTRODUCTION .....................................................................................................................................1

SERIAL NUMBER LOCATION ................................................................................................................4

SAFETY

Safety Alert Symbol.......................................................................................................................5

Signal Words .................................................................................................................................5

Safety Signs...................................................................................................................................6

General Farm Safety .................................................................................................................. 7,8

SPECIFICATIONS

Mower Conditioner....................................................................................................................9,10

Tractor Requirements.................................................................................................................. 10

Torque Specifications............................................................................................................. 11,12

Bearing Installation......................................................................................................................12

OPERATION

Your Responsibilities as an Owner/Operator............................................................................... 13

To the New Operator...................................................................................................................13

Preparing the Tractor...................................................................................................................14

Preparing the Mower Conditioner................................................................................................15

Attaching Mower Conditioner to Tractor......................................................................................16

Detaching Mower Conditioner from Tractor.................................................................................17

Break-In Period............................................................................................................................18

Pre-Starting Checks: Annual .......................................................................................................19

Pre-Starting Checks: Daily........................................................................................................... 20

Operate Correctly ........................................................................................................................21

Lift Cylinder Stop - Raising and Lowering the Machine...............................................................22

Positioning the Hitch....................................................................................................................23

Engaging the PTO.......................................................................................................................24

Opening the Field ........................................................................................................................24

Cutting Width...............................................................................................................................24

Cornering..................................................................................................................................... 24

Operating Variables:

Ground Speed................................................................................................................... 25

Reel Speed........................................................................................................................26

Reel Position................................................................................................................27,28

Cutting Height - Skid Plates ..............................................................................................28

Cutterbar Angle.................................................................................................................29

Header Flotation................................................................................................................30

Roll Gap ............................................................................................................................ 31

Forming Shields ................................................................................................................ 32

Light Crop Deflectors .....................................................................................................32

Feed Pan Extensions.....................................................................................................33

Haying Tips:

Topsoil Moisture................................................................................................................33

Climate and Topography................................................................................................... 34

Swath / Windrow Characteristics ......................................................................................34

Running Tractor Tire on Previously Cut Swath................................................................. 34

Raking and Tedding..........................................................................................................34

Chemical Drying Agents....................................................................................................34

Unplugging the Mower Conditioner: Knife................................................................................... 35

Unplugging the Mower Conditioner: Rolls ...................................................................................35

Shut-Down Procedure .................................................................................................................36

Transporting the Mower Conditioner ...........................................................................................36

Storage Procedure....................................................................................................................... 37

2

Page 3

TABLE OF CONTENTS

MAINTENANCE/SERVICE

Service Procedures .....................................................................................................................38

Recommended Lubricants...........................................................................................................39

Capacities of Enclosed Drives.....................................................................................................39

Greasing the Mower Conditioner..........................................................................................40 - 43

Linkage Ball Joints.......................................................................................................................44

Hydraulics....................................................................................................................................45

Electrical......................................................................................................................................45

Main Drive:

Main Gearbox Lubricant.................................................................................................... 46

Main Gearbox Removal ....................................................................................................46

Over-Running Clutch.........................................................................................................47

Knife and Knife Drive:

Knife Lubrication................................................................................................................ 48

Knife Sections ...................................................................................................................48

Knife Removal and Installation..........................................................................................49

Knife Storage - ToolBox....................................................................................................49

Guards ..............................................................................................................................50

Knife Clips.........................................................................................................................50

Knife Drive Belt Tension....................................................................................................51

Knife Drive Belt Replacement ...........................................................................................51

Wobble Box Mounting Bolts..............................................................................................52

Wobble Box Lubricant....................................................................................................... 52

Reel and Reel Drive:

Reel Drive Belt Tension.....................................................................................................53

Reel Drive Belt Replacement............................................................................................53

Reel Drive Chain Lubricant ...............................................................................................54

Reel Drive Chain Tension ................................................................................................. 54

Reel Tines.........................................................................................................................54

Reel Shaft R/H Bearing Access ........................................................................................ 54

Roll Timing...................................................................................................................................55

Wheels and Tires:

Wheel Bolts.......................................................................................................................56

Tire Inflation ......................................................................................................................57

Maintenance Schedule...........................................................................................................58,59

Maintenance Record....................................................................................................................60

PAGE

TROUBLE SHOOTING...................................................................................................................61 - 64

ATTACHMENTS:

Four or Six Bat Reel ....................................................................................................................65

Stub Guard Conversion Kit..........................................................................................................65

UNLOADING AND ASSEMBLY......................................................................................................66 - 70

INDEX .....................................................................................................................................71,72

3

Page 4

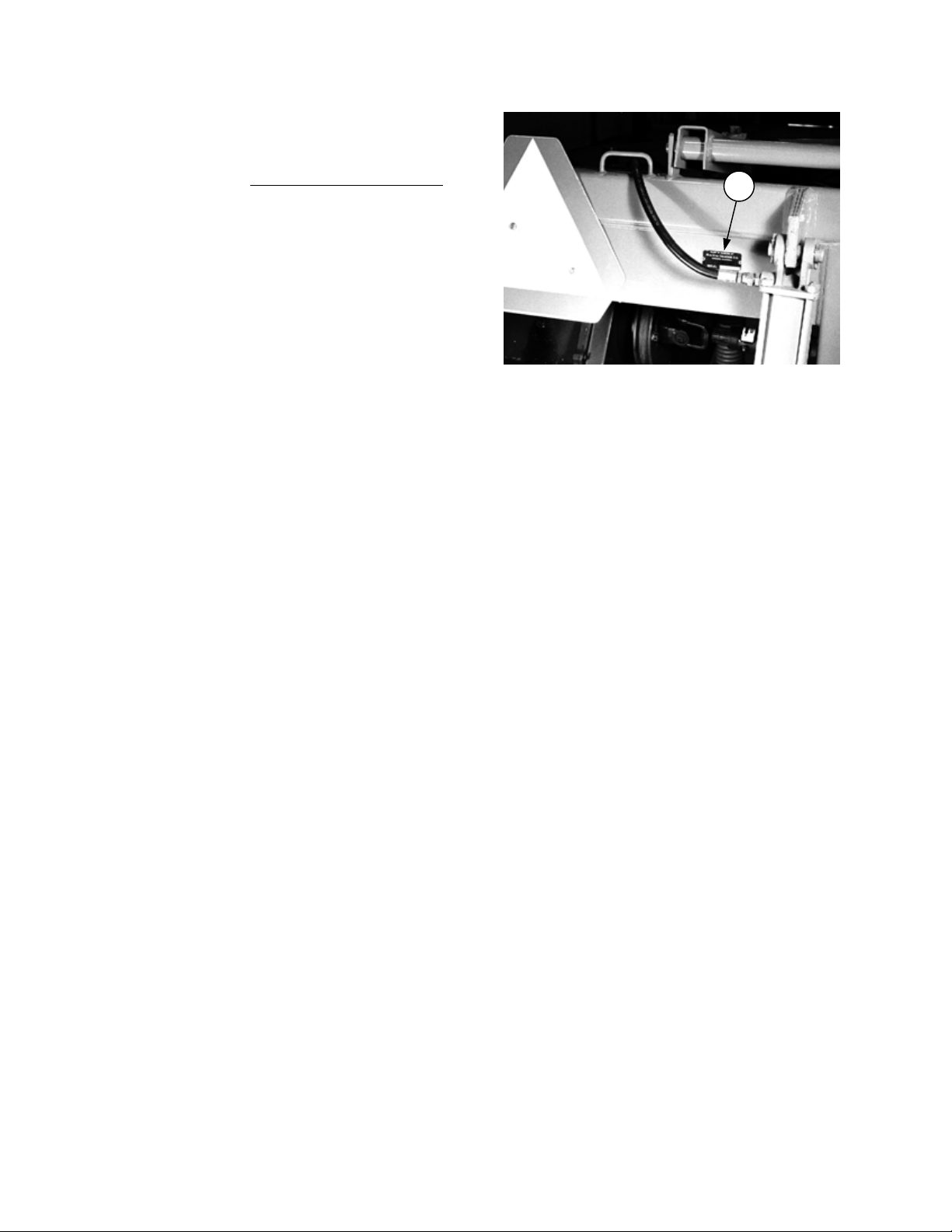

SERIAL NUMBER LOCATION

Record the serial number in the space provided.

Mower Conditioner:

Serial number plate (A) is located on the bac k of

the drives frame.

NOTE: When ordering parts and service, be sure

to give your dealer the complete and proper serial

number.

A

SERIAL PLATE LOCATION

4

Page 5

SAFETY ALERT SYMBOL

This safety alert symbol indicates important safety messages in this manual and

on safety signs on the mower conditioner.

This symbol means:

ATTENTION !

BECOME ALERT !

YOUR SAFETY IS INVOLVED !

Carefully read and follow the safety message accompanying this symbol.

Why is SAFETY important to you?

3 BIG REASONS

• ACCIDENTS DISABLE AND KILL

• ACCIDENTS COST

• ACCIDENTS CAN BE AVOIDED

SIGNAL WORDS

SAFETY

Note the use of the signal words DANGER, WARNING, and CAUTION with safety messages. The appropriate

signal word for each message has been selected using the following guidelines:

DANGER – Indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury.

WARNING – Indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury. It is also used to alert against unsafe practices.

CAUTION – Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It is also used as a reminder of good safety practices.

5

Page 6

SAFETY

SAFETY SIGNS

• The safety signs reproduced below appear on the windrower at the locations listed.

• Keep safety signs clean and legible at all times

• Replace safety signs that are missing or become illegible.

• If original parts on which a safety sign was installed are replace d, be su re the re pair part al so bears

the current safety sign.

• Safety signs are available from your Dealer Parts Department.

To install safety signs:

1. Be sure the installation area is clean and dry.

2. Decide on the exact location before you remove the decal backing paper.

3. Remove the smaller portion of the split backing paper.

4. Place the sign in position an d slo w ly peel back t he remainin g p aper, smo ot hing th e sign as it is

applied.

5. Small air pockets can be smoothed out or pricked with a pin.

6

Page 7

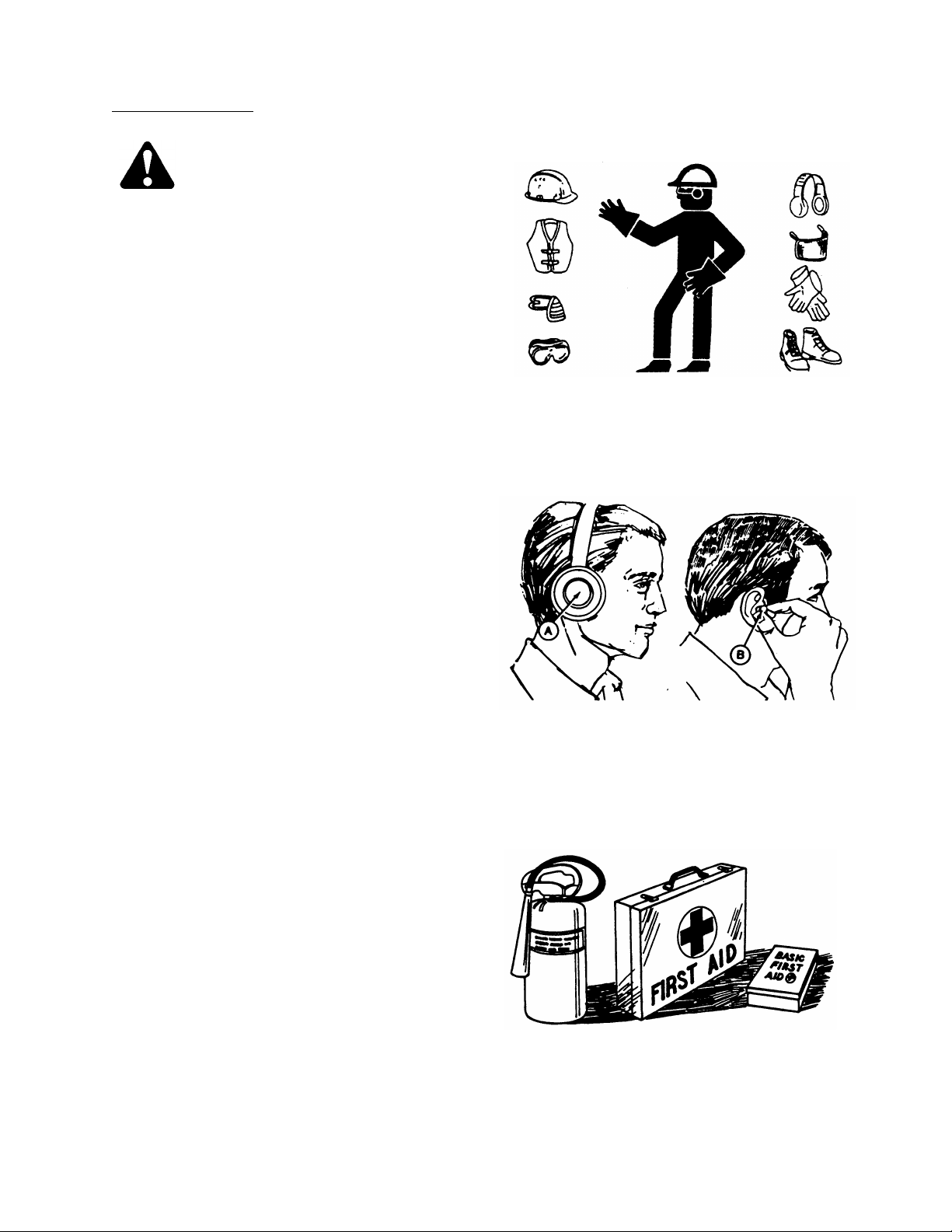

GENERAL SAFETY

PROTECT YOURSELF

BE PREPARED FOR EMERGENCIES

The following are general farm

safety precautions that should be

part of your operating pr oce dur e for

all types of machinery.

1. Protect yourself.

When assembling, operating and servicing

machinery wear all the protective clothing

and personal safety devices that COULD be

necessary for the job at hand. Don’t take

chances.

You may need:

· a hard hat.

· protective shoes with slip resistant soles.

· protective glasses or goggles.

· heavy gloves.

· wet weather gear.

· respirator or filter mask.

· hearing protec ti on. Be awar e tha t pr olon ged

exposure to loud noise can cause

impairment or loss of hearing. Wearing a

suitable hearing protective device such as

earmuffs (A) or earplugs (B) protects

against objectionable or loud noises.

SAFETY

2. Provide a first-aid kit for use in case of

emergencies.

3. Keep a fire extinguisher on the machine. Be

sure the extinguisher is properly

maintained and be familiar with its proper

use.

4. Keep young children away from machinery

at all times.

5. Be aware that accidents often happen when

the operator is tired or in a hurry to get

finished. Take the time to consider the

safest way. Never ignore warning signs of

fatigue.

PROTECT AGAINST NOISE

7

Page 8

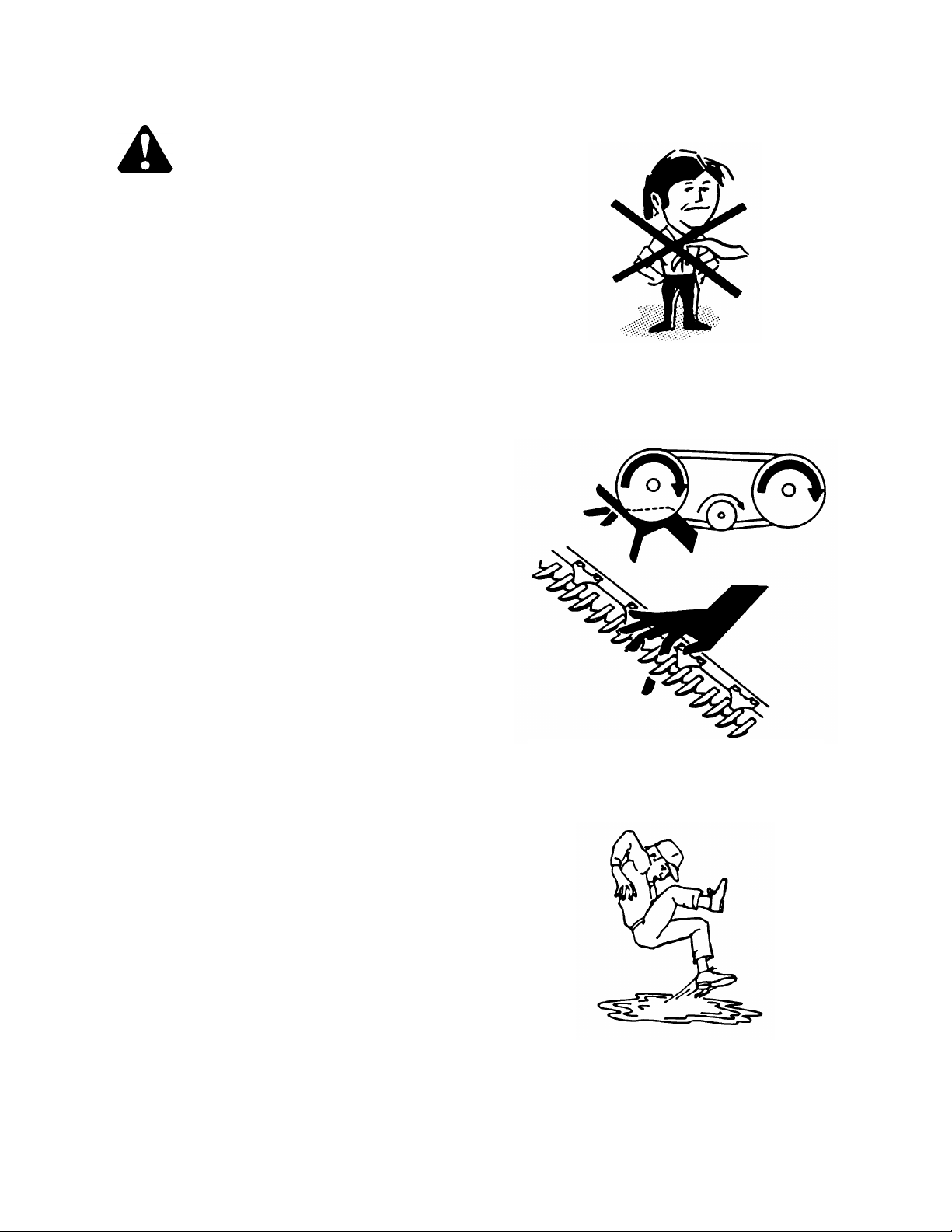

GENERAL SAFETY (continued)

NEVER WEAR LOOSE

KEEP SERVICE AREA CLEAN AND DRY

6. Wear close-fitting clot hing and co ver long

hair. Never wear dangling items such as

scarves or bracelets.

7. Keep hands, feet, clothing and hair away

from moving parts. Never attempt t o clear

obstructions or objects from a machine

while the engine is running.

8. Keep all shields in place. Never alter or

remove safety equipment.

driveline guards can rotate independently

of the shaft and can telescope freely.

9. Use only service and repair parts made or

approved by the equipment manufacturer.

Substituted parts may not meet strength,

design, or safety requirements.

Make sure

SAFETY

OR DANGLING CLOTHES

10. Do not modify the machine. Unauth orized

modifications may impair the function

and/or safety and affect machine life.

11. Stop engine and remove key from ignition

before leaving operator’s seat for any

reason. A child or even a pet could engage

an idling machine.

12. Keep the area used for servicing machinery

clean and dry. Wet or oily floors are

slippery. Wet spo ts c a n b e da nge r ous whe n

working with electrical equipment. Be sure

all electrical outlets and too ls are properly

grounded.

13. Use adequate light for the job at hand.

14. Keep machinery clean. Straw and chaf f o n

a hot engine are a fire hazard. Do not allow

oil or grease to accumulate on service

platforms, ladders or controls. Clean

machines before storage.

15. Never use gasoline, naphtha or any volatile

material for cleaning purposes. These

materials may be toxic and/or flammable.

KEEP AWAY FROM MOVING PARTS

16. When storing machinery, cover sharp or

extending components to prevent injury

from accidental contact.

8

Page 9

SPECIFICATIONS

DIMENSIONS 9 FT. MOWER CONDITIONER

Overall Width:

Transport Position 147.5 in. (3750 mm)

Field Position 167.0 in. (4243 mm)

Overall Length:

Transport Position 159.8 in. (4059 mm)

Field Position 166.8 in. (4238 mm)

Overall Height:

Transport Position 59.5 in. (1510 mm)

Field Position 42.6 in. (1083 mm)

Weight 3318 lbs. (1505 kg)

CUTTERBAR

Cutterbar Width 111 in. (2819 mm)

Cutting Height (on skids) 1 to 4 in. (25 to 100 mm)

at 9° guard angle

Guard Angle (adjustable) 6° to 12° below horizontal

HEADER

Header Flotation -2.5 to +6.7 in. (-64 to +170 mm)

Maximum Header Lift 21.5 in. (545 mm) to guard tip

KNIFE

Drive Type Belt driven wobble box (enclosed oil bath)

Speed 1620 strokes or 810 cycles per minute

Stroke 3 in. (76 mm)

Sections Over-serrated, low shoulder

REEL

Drive Type Belt primary to chain final

Reel Type 5 bats (4 or 6 bats optional), replaceable steel pick-up tines,

cam action, polymer tine tube bearings

Diameter 42.5 in. (1080 mm)

Tine Tip (Peripheral) Speed 6.6, 7.0, 7.5 or 7.9 mph (10.6, 11.3, 12.0 or 12.7 km/h)

Rotational Speed 53, 56, 60 or 63 rpm

Length 104.3 in. (2650 mm)

9

Page 10

SPECIFICATIONS

CONDITIONER ROLLS 9 FT. MOWER CONDITIONER

Drive Type Gear driven through telescoping u-joints

Roll Type Helical intermeshing fabric reinforced rubber

Or

Helical intermeshing steel

Roll Diameter Rubber: 9.5 in (242 mm) Steel: 10.0 in (254 mm)

Roll Length 105.8 in (2687 mm)

Roll Speed 729 rpm

WHEELS

Tread Width 100 in (2540 mm)

Tires 9.5L – 14 I1 Rib Implement

Tire Pressure 20 psi (138 kPa)

MATERIAL DISCHARGE

Minimum Width 33.3 in (845 mm)

Maximum Width 84.9 in (2156 mm) (wider in heavy crop)

Number of Width Settings 7

OPERATING SPEED

Range up to 8 mph (13 Km/h)

Recommended Speed for Most Conditions 5 mph (8 Km/h)

TRACTOR REQUIREMENTS

Minimum Power 35 hp (26 kW)

Minimum Weight 5000 lbs. (2268 kg)

PTO 540 rpm with ASAE Standard location

Drawbar Clevis or straight, ASAE Standard hitch location

Hydraulics:

Type Two double acting remote circuits

Minimum Pressure 1350 psi (9300 kPa)

(SPECIFICATIONS AND DESIGN ARE SUBJECT TO CHANGE WITHOUT

NOTICE OR OBLIGATION TO REVISE UNITS PREVIOUSLY SOLD.)

10

Page 11

TORQUE SPECIFICATIONS

8.8

10.9

N·m

[lb-ft]

N·m

[lb-ft]

M3

0.5

[.4]

1.8

[1.3]M43

[2.2]

4.5

[3.3]M56

[4]9[7]M610

[7]15[11]M825

[18]35[26]

M1050[37]70[52]

M1290[66]

125

[92]

M14

140

[103]

200

[148]

M16

225

[166]

310

[229]

M20

435

[321]

610

[450]

M24

750

[553]

1050

[774]

M30

1495

[1103]

2100

[1550]

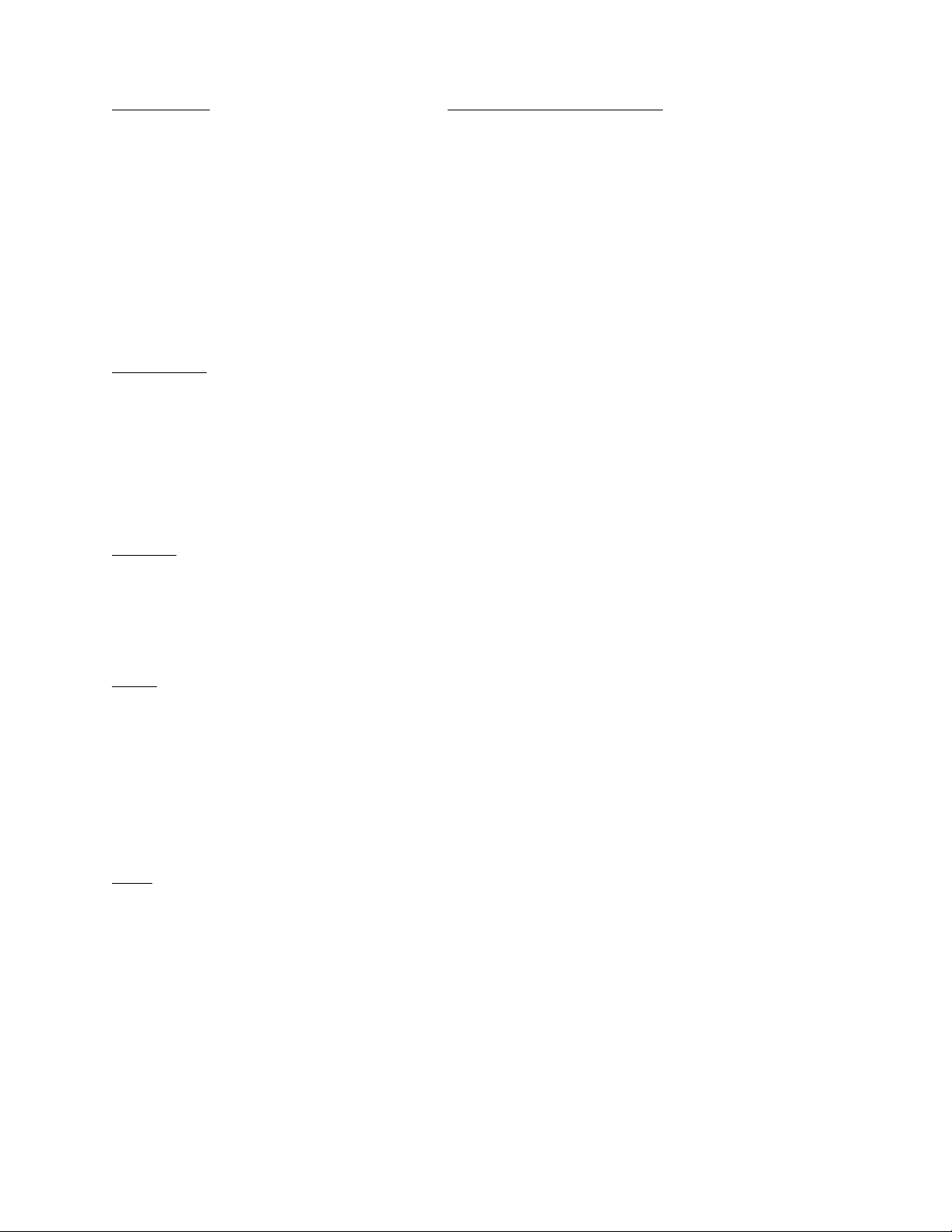

CHECKING BOLT TORQUE

The tables shown below give correct torque values for various bolts and capscrews. Tighten all bolts to the

torques specified in chart unless otherwise not ed thr ough out th is manual. Check tightn ess of bolts periodi cal ly,

using bolt torque chart as a guide. Replace hardware with the same strength bolt.

ENGLISH TORQUE SPECIFICATION

NC Bolt Torque*

Bolt

Dia.

"A" N·m [lb-ft] N·m [lb-ft]

1/4" 12 [9] 15 [11]

5/16" 24 [18] 34 [25]

3/8" 43 [32] 56 [41]

7/16" 68 [50] 95 [70]

1/2" 102 [75] 142 [105]

9/16" 149 [110] 202 [149]

5/8" 203 [150] 271 [200]

3/4"

7/8" 569 [420] 813 [600]

1" 867 [640] 1205 [890]

SAE 5 SAE 8

359 [265]

495 [365]

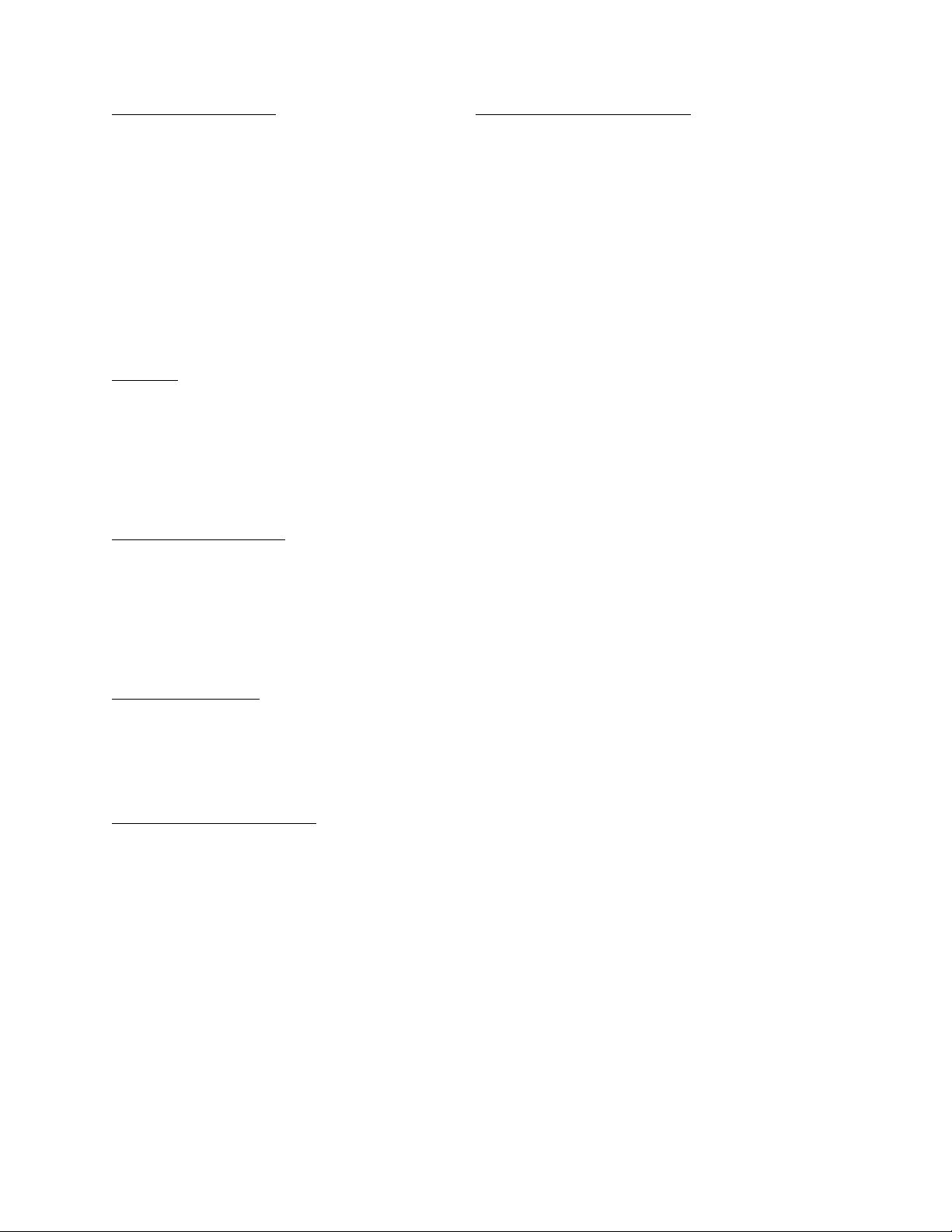

METRIC TORQUE SPECIFICATIONS

Bolt

Dia.

"A"

M36 2600 [1917] 3675 [2710]

Torque figures indicated above are valid for non-greased or non-oiled threads and heads unless otherwise

specified. Do not grease or oil bolts or capscrews unles s specified in this manual. W hen using locking

elements, increase torque values by 5%.

Bolt Torque*

* Torque value for bolts and capscrews are identified by their head markings.

11

Page 12

TORQUE SPECIFICATIONS

N·m

[lb-ft]

Flats

Turns

TIGHTEN COLLAR IN DIRECTION

SHAFT ROTATES

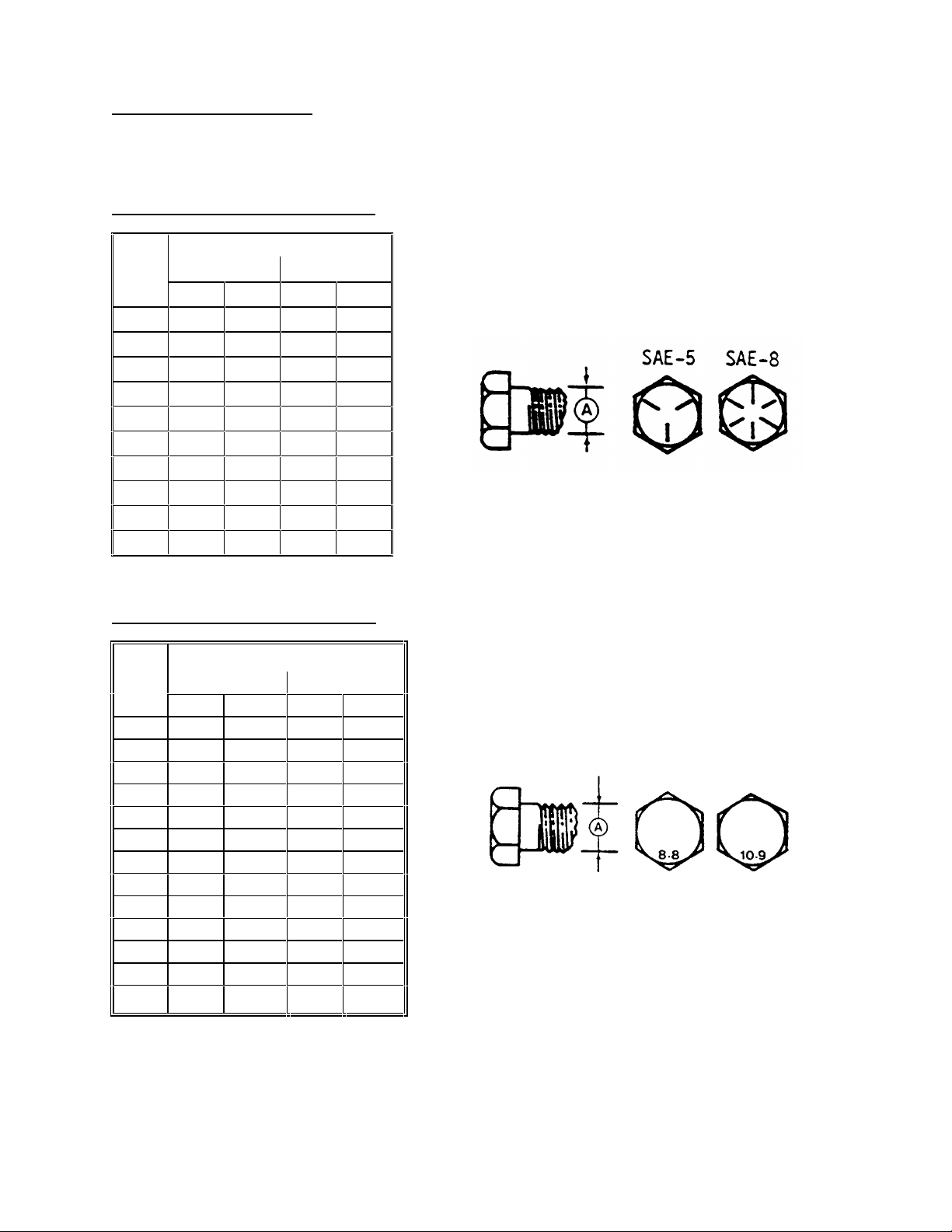

TIGHTENING HYDRAULIC O-RING FITTINGS*

1. Inspect O-ring and seat for dirt or obvious

defects.

2. O n angle fittings, back the lock nut off until

washer bottoms out at top of groove.

3. Hand tighten f itting until back up washer or

washer face (if straight fitting) bottoms on face

and O-ring is seated.

4. Position angle fittings by unscrewing no more

than one turn.

5. Tighten straight fittings to torque shown.

6. T ighten angle fittings to torque shown while

holding body of fitting with a wrench.

* The torque values shown are based on

lubricated connections as in reassembly

.

Recommended

Turns to Tighten

(after finger

tightening)

Thread

Size

(in.)

Nut Size

Across

Flats

(in.)

Torque Value*

3/8 1/2 8 [6] 2 1/3

7/16 9/16 12 [9] 2 1/3

1/2 5/8 16 [12] 2 1/3

9/16 11/16 24 [18] 2 1/3

3/4 7/8 46 [34] 2 1/3

7/8 1 62 [46] 1-1/2 1/4

1-1/16 1-1/4 102 [75] 1 1/6

1-3/16 1-3/8 122 [90] 1 1/6

1-5/16 1-1/2 142 [105] 3/4 1/8

1-5/8 1-7/8 190 [140] 3/4 1/8

1-7/8 2-1/8 217 [160] 1/2 1/12

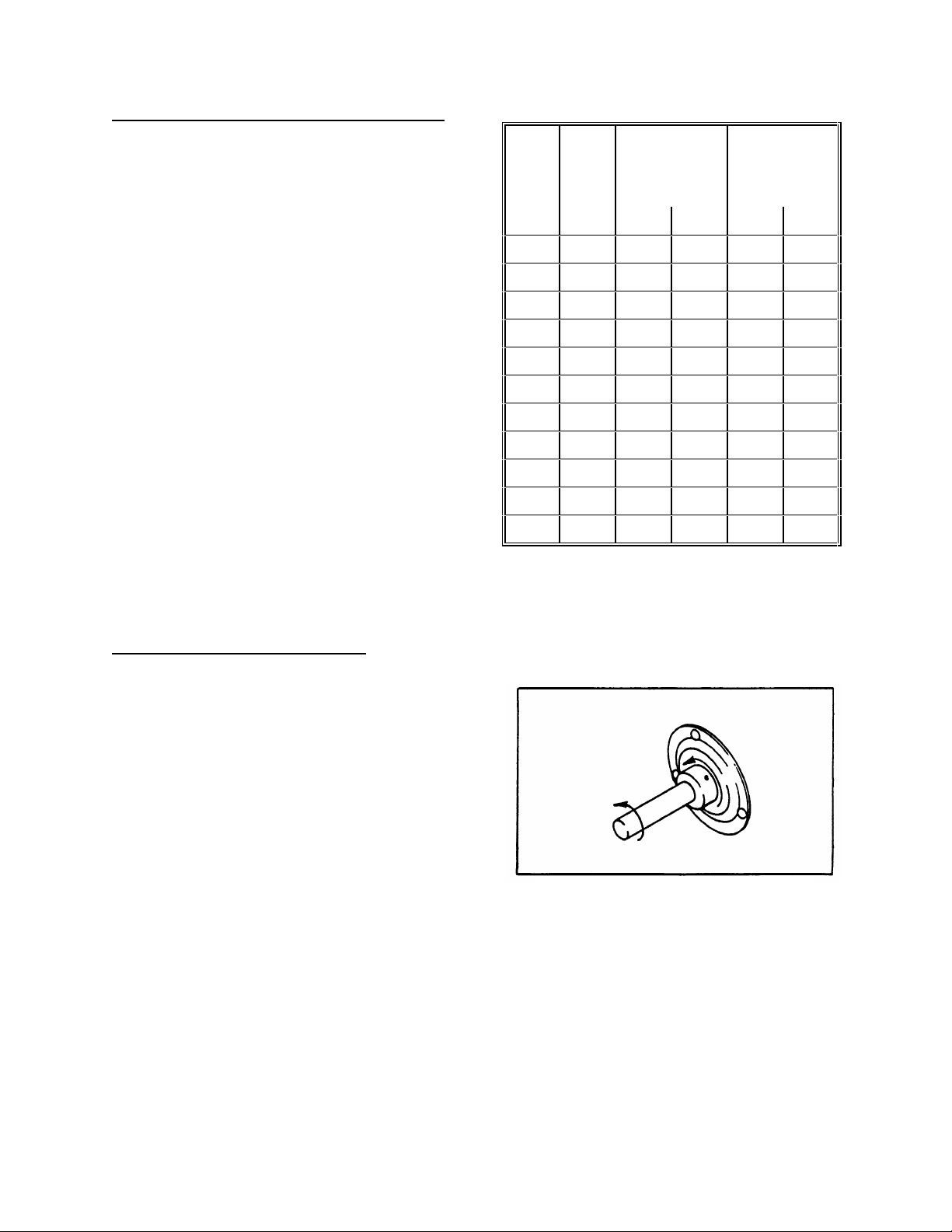

SEALED BEARING INSTALLATION

1. Clean shaft and coat with rust preventative.

2. Install flangette, bearing, flangette and lock

collar. The locking cam is only on on e side of

the bearing.

3. Install (but do not tighten) the flangette bolts.

4. W hen the shaft is located correctly, lock the

lock collar with a punch. The collar should be

locked in the same direction the shaft rotates.

Tighten the setscrew in the collar.

5. Tighten the flangette bolts.

6. Loosen the flangette bolts on the mating

bearing one turn and re-tighten. This will a llow

the bearing to line up.

12

Page 13

OPERATION

YOUR RESPONSIBILITIES AS AN OWNER/OPERATOR

CAUTION:

1. It is your responsibility to read and

understand this manual completely before

operating the windrower. Contact your

dealer if an instruction is not clear to you.

2. Follow all safety messages in th e manual

and on safety signs on the machine.

3. Remember that YOU

Good safety practices protect you and the

people around you.

4. Before allowing anyone to operate the

windrower, for however short a time or

distance, make sure they have been

instructed in its safe and proper use.

5. Review the manual and all safety related

items with all operators annually.

6. Be alert for other operators not using

recommended procedures or not following

safety precautions. Correct these mistakes

immediately, before an accident occurs.

7. Do not modify the machine. Un authorized

modifications may impair the function

and/or safety and affect machine life.

8. The safety information given in this manual

does not replace safety codes, insurance

needs, or laws governing your area. Be sure

your machine meets the standards set by

these regulations.

are the key to safety.

TO THE NEW OPERATOR

It’s natural for an operator to be anxious to get

started with a new machine. Please take the time

to familiarize yourself with the windrower by

reading the Operator’s Manual and safety signs

before attempting operation.

13

Page 14

OPERATION

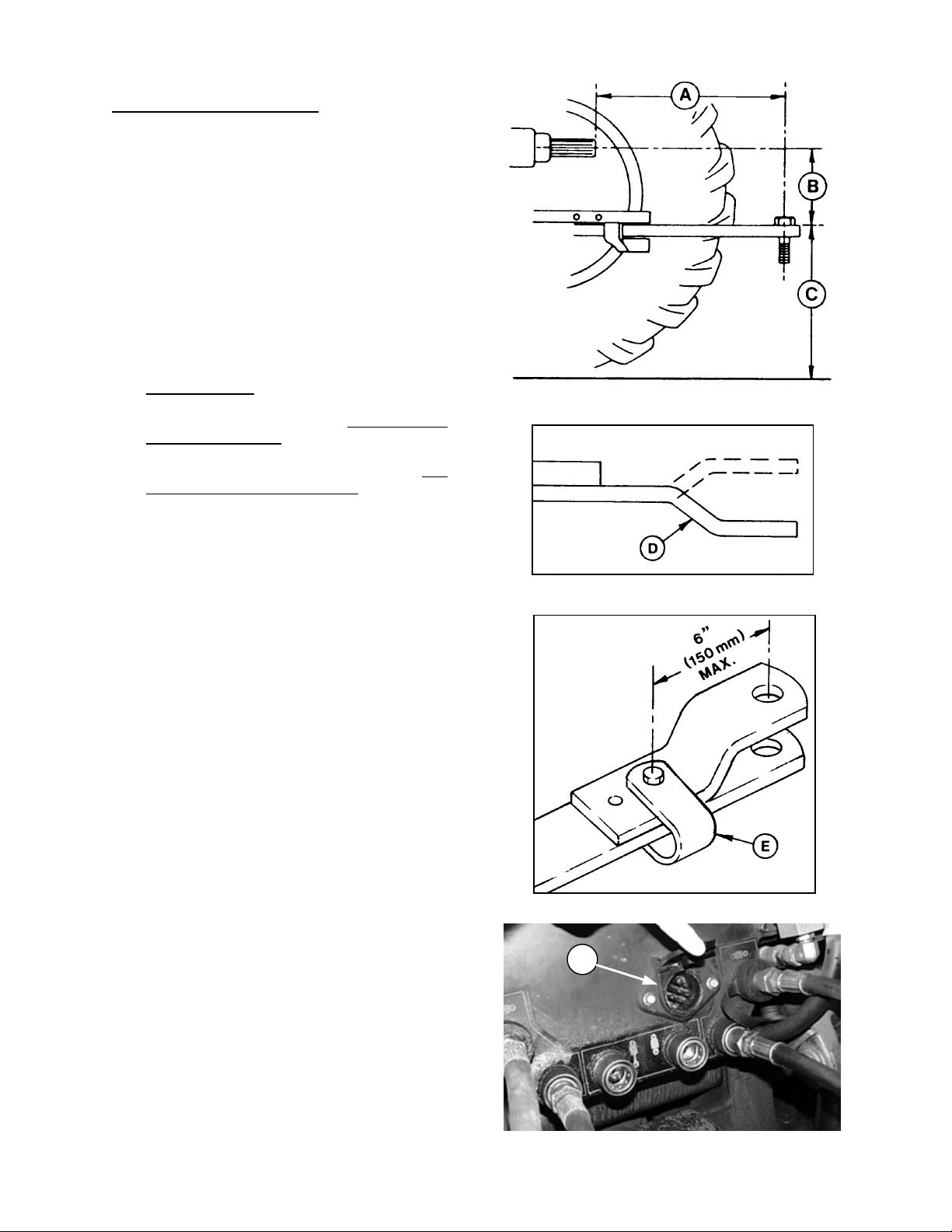

PREPARING THE TRACTOR

1. Select proper tractor size. The minimum

power required is 35 hp (26 kw). Also,

minimum tractor weight is 5000 lbs. (2268 kg)

and minimum hydraulic press ure r equired is

1350 psi (9300 kPa).

2. Adjust tractor drawbar to meet ASAE

Standard specifications as lis ted below. An

improperly located drawbar may damage the

universal joints of the implement driveline,

and/or affect header flotation and guard

angle.

Be sure the following specifications are met:

(A) 14 in. (356 mm) for 540 rpm

(B) 6 to 12 in. (152 to 305 mm) with 8 in. (203

mm) recommended.

(C) 13 to 17 in. (330 to 432 mm) from ground with

16 in. (406 mm) recommended.

NOTE: An offset drawbar (D) can be turned over

if required to meet specifications (B) and (C).

3. Secur e the drawbar so the hitch pinhole is

directly below the driveline.

NOTE: If the tractor has a 3-point hitch, r aise the

lower links as high as possible, to prevent

damage.

4. Use 540 rpm PTO speed only.

5. Attach support (E) for hitch chain to s uitable

location on tractor drawbar, maxim um 6 in.

(150 mm) from hitch pinhole.

STANDARD DRAWBAR SPECIFICATIONS

OFFSET TRACTOR DRAWBAR

6. Tractor must be equipped with a seven

terminal electrical outlet (F ) to supply power

to the mower conditioner warning lights.

ATTACH SUPPORT FOR HITCH CHAIN

F

SEVEN TERMINAL ELECTRICAL OUTLET

14

Page 15

PREPARING THE MOWER CONDITIONER

1. Use correct hitch type:

For tractors with clevis type drawbar, use hitch as

shown at (A).

For tractors with straight drawbar, re-position bar

(B) to give clevis type hitch.

OPERATION

A

HITCH CONFIGURATION FOR TRACTORS

WITH CLEVIS TYPE DRAWBAR

B

HITCH CONFIGURATION FOR TRACTORS

2. With the tractor drawbar adjusted to the

WITH STRAIGHT DRAWBAR

recommendations listed under “Preparing the

Tractor”, use the hanger beari n g ad justment (C)

so that the implement drive line (D) is as near

level as possible going to the tractor.

IMPORTANT: The telescoping implement driveline

(D) should slide under hand pressure. Grease if

required.

3. Check the tires and inflate if necessary.

D

Recommended pressure is 20 psi (138 kPa).

CAUTION: When inflating tires, use a

clip-on chuck and extension hose long

enough to allow you stand to one side

ADJUST DRIVELINE HANGER BEARING

and not facing the tire.

4. Check for proper assembly and adjustment and make sure that all bolts are tightened securely.

C

5. Check the tension of both belts and adjust if required. Check the over-running clutch for proper

spring lengths. See Maintenance/Service section.

6. Lubricate the machine completely and check the oil levels of the main gearbox (two places) and the

wobble box. Check that breathers have been installed in boxes. See Maintenance/Service section.

7. Install quick coupler tips, matching the tractor to be used, on the hose ends.

15

Page 16

OPERATION

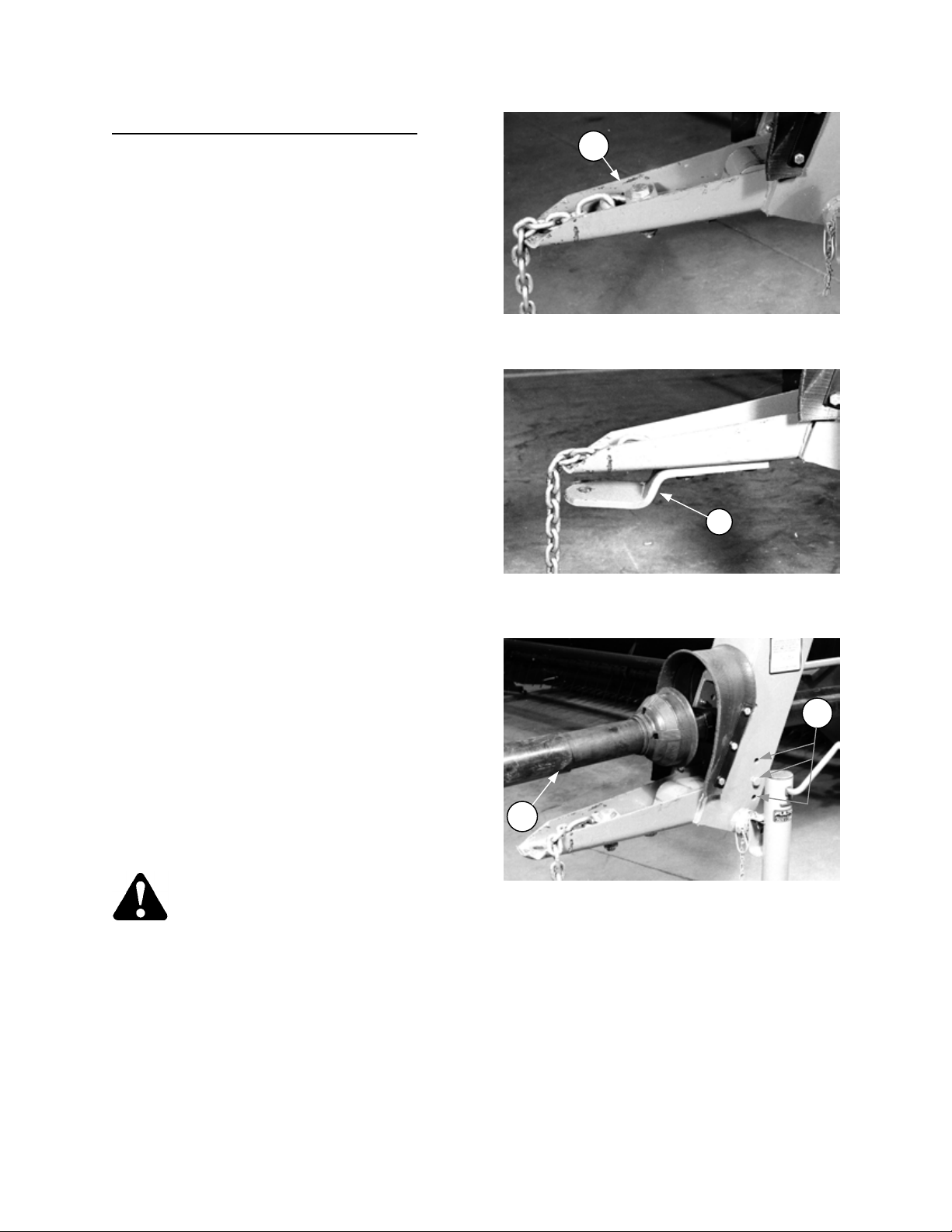

ATTACHING MOWER CONDITIONER TO TRACTOR

CAUTION: Shut off tractor, engage

parking brake and remove key

before working around hitch.

CAUTION: N eve r a tta ch mo wer hi tc h

to tractor rear axle or three-point

hitch arms.

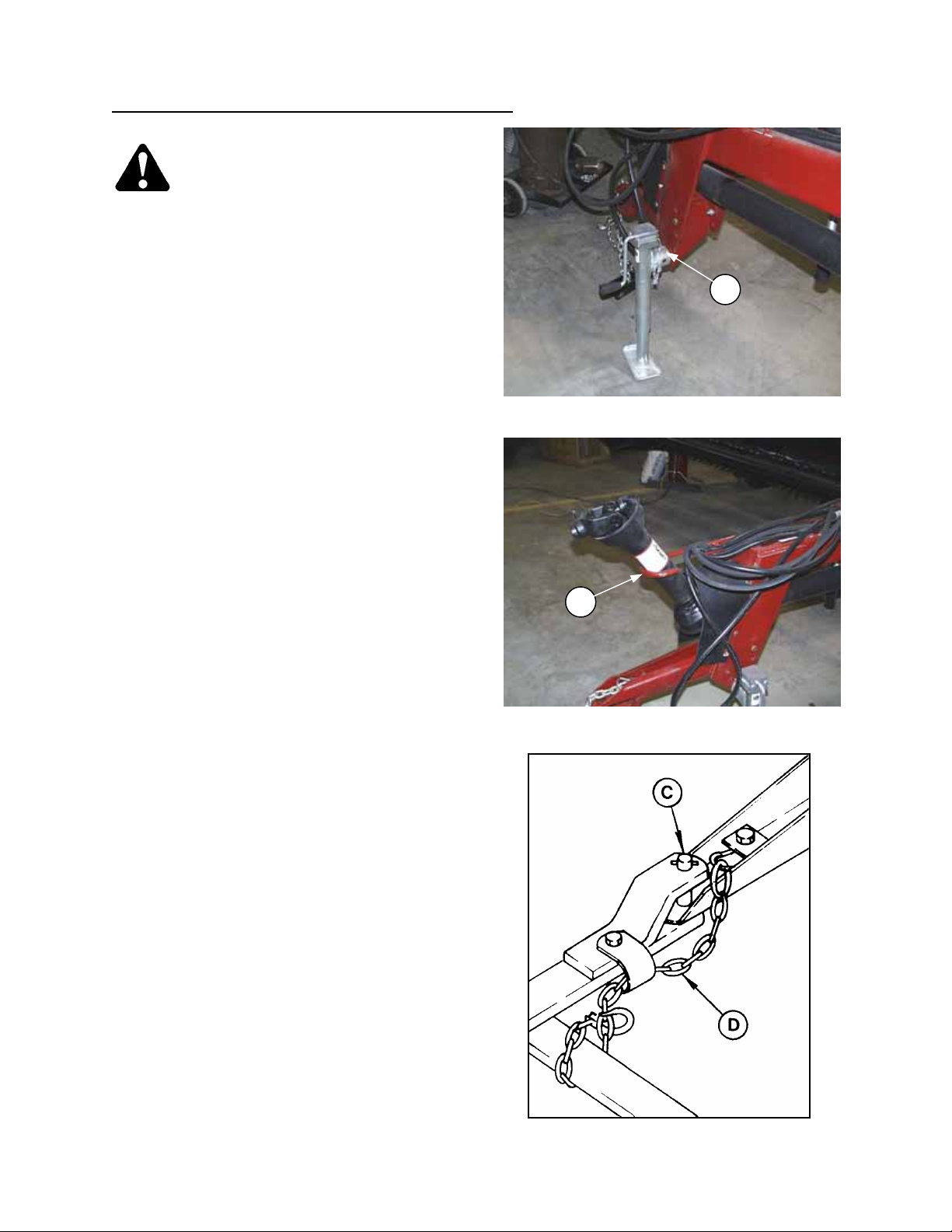

1. Attach mower conditioner to tractor drawbar

with a 3/4 to 1 inch diameter hitch pin and

secure with a spring locking pin or other

suitable fastener.

CAUTION: To prevent damage to

driveline guards, use a drawbar

hitch pin with a low head.

2. Route hitch chain from mower conditioner

through chain support (A), around drawbar

support and lock hook (B) on chain.

INSTALL HITCH PIN AND CHAIN

IMPORTANT: Adjust chain length to remove all

slack except what is needed for turns.

3. Remove weight from jack. Pull pin securing jack

and move to storage position (C) on drives

frame.

4. Push button (D) on telescoping driveline yoke

and slide yoke onto tractor PTO shaft. Be sure

yoke locks in position on shaft.

5. Connect hydraulic hoses to the remote cylinder

control valves on tractor.

6. Connect mower conditioner wiring harness plug

to outlet on tractor.

C

JACK STORAGE

D

16

ATTACH DRIVELINE TO PTO

Page 17

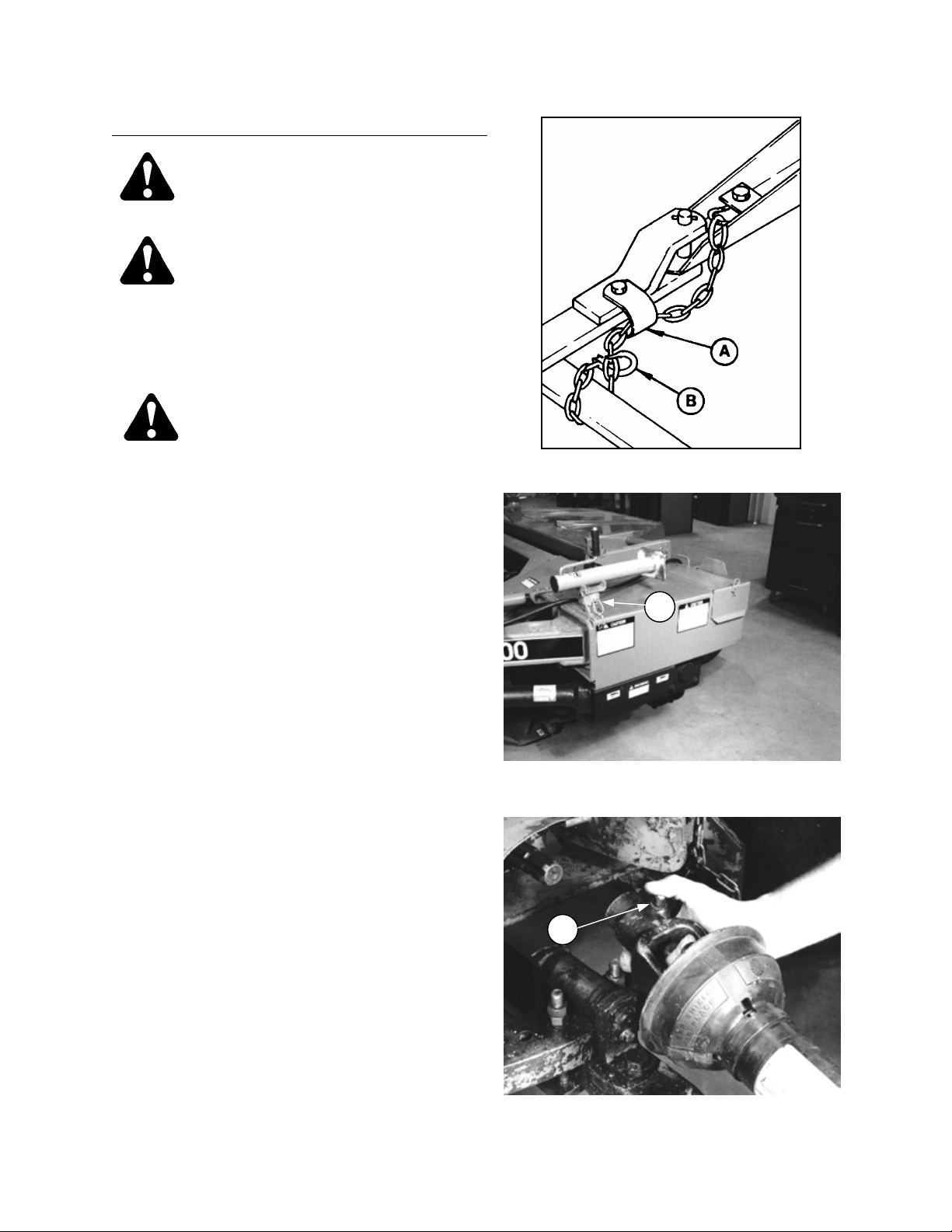

OPERATION

STORE DRIVELINE

DETACHING MOWER CONDITIONER FROM TRACTOR

CAUTION: To prevent accidental

movement of tractor, shut off

engine, engage parking brake, and

remove key.

To maintain stability, always lower

the machine completely. Block

mower conditioner wheels before

detaching from tractor.

Park machine on flat level surface.

Move remote cylinder control valve

lever back and forth to rel ie ve stor ed

hydraulic pressure.

A

1. Pull pin securing jack and move to working

position (A).

2. Lower jack to take weight off tractor drawbar.

3. Push button on telescoping driveline yoke to

unlock grip on PTO shaft. Remove driveline

from PTO and store in support (B).

4. Disconnect hydraulic hoses and electrical

harness. Store so ends are off ground.

5. Remove hitch pin (C) and unhook chain (D)

from tractor. Wrap chain around mower

conditioner hitch for storage.

MOVE JACK TO WORKING POSITION

B

6. Slowly drive tractor away from mower

conditioner.

REMOVE HITCH PIN AND CHAIN

17

Page 18

OPERATION

CHECK WOBBLE BOX MOUNTING BOLTS

BREAK-IN PERIOD

1. After attaching mower conditioner to tractor for

the first time, operate the machine slowly for 5

minutes, watching and listening FROM THE

TRACTOR SEAT for binding or interfering

parts.

CAUTION: Before investigating an

unusual sound or attempting to

correct a problem, shut off tract or,

engage parking brake and remove

key.

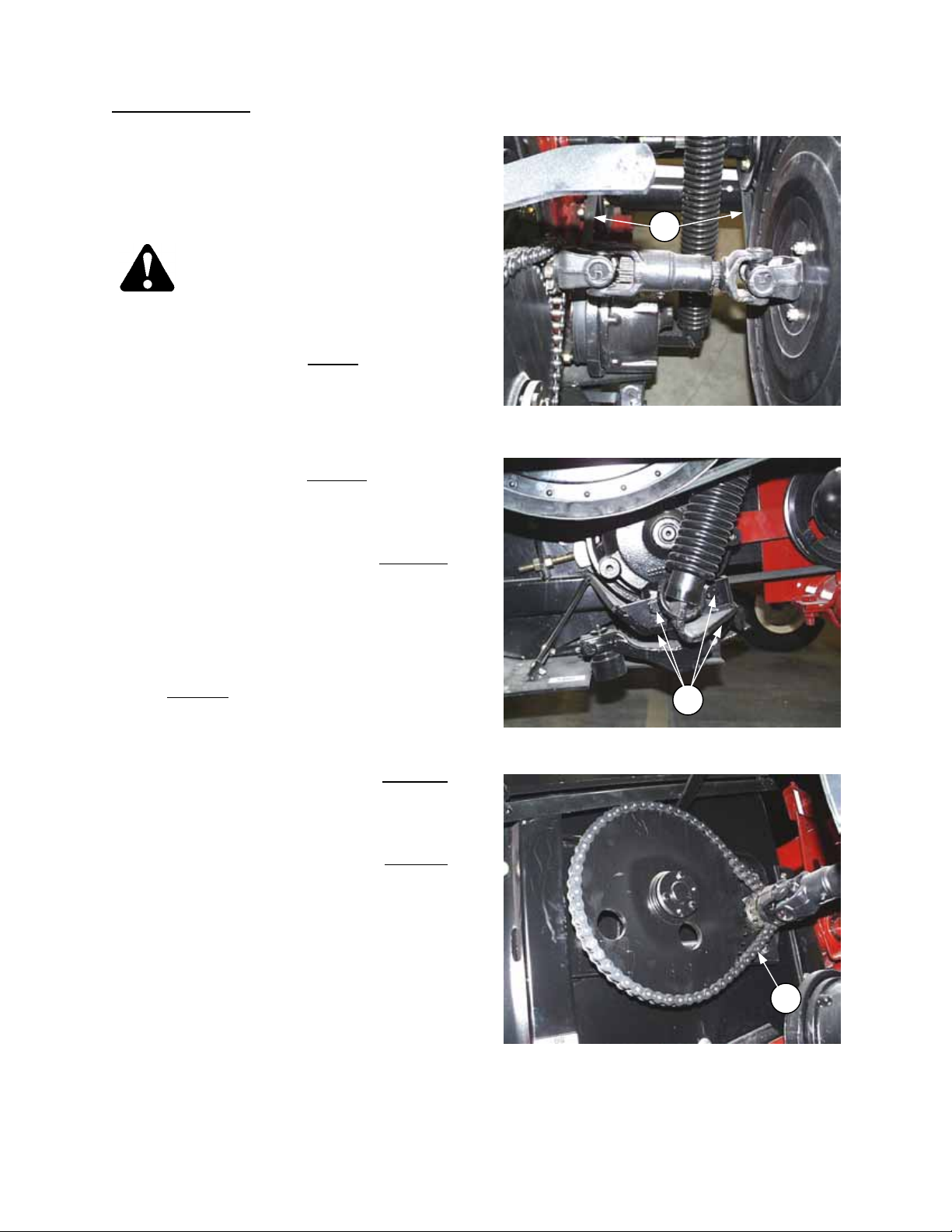

2. Check both belts (A) after 5 hours operation for

initial stretch. Tighten as necessary. (See

Maintenance/Service section). Continue to

check the belts periodically for the first 50

hours.

3. Check hardware after 5 hours operation.

Tighten as necessary. See Specifications

section for recommended torques.

A

CHECK BELT TENSION

4. Check wheel bolt torque after 10 hours

operation and periodically thereafter (at least

every 100 hours).

Torque: 50 to 60 ft. lbs. (68 to 81 N⋅m)

5. Tighten the four wobble box mounting bolts (B)

after 10 hours operation and every 100 hours

thereafter. Torque to 200 ft. lbs. (270 N⋅m),

starting with the side mounting bolts.

6. Check reel drive chain (C) after 10 hours

operation for proper tension. See

Maintenance/Service section.

7. Change wobble box lubricant after 50 hours

operation and every 1000 hours (or 3 years)

thereafter. See Maintenance/Service section.

8. Until you become familiar with the s ound and

feel of your new mower conditioner, be extra

alert and attentive.

B

C

CHECK REEL DRIVE CHAIN TENSION

18

Page 19

OPERATION

PRE-STARTING CHECKS

Do the following at the start of each operating

season:

CAUTION:

1. Review the Operator’s Manual to refresh

your memory on safety and operating

recommendations.

2. Review all safety signs and other deca ls on

the mower conditioner and note hazard

areas.

3. Be sure all shields and guards are properly

installed and secured. Never alter or remove

safety equipment.

4. Be sur e you under st a n d an d ha v e p r a ct i c e d

safe use of all controls. Know t he capacity

and operating characteristics of the

machine.

5. Check the first aid kit and fire extinguisher.

Know where they are and how to use them.

Also:

6. Adjust tension on drive belts. See

Maintenance/Service section.

7. Perform all Annual maintenance. See

Maintenance/Service section.

19

Page 20

OPERATION

PRE-STARTING CHECKS

Do the following each day before start-up:

CAUTION:

1. Clear the area of other perso ns, pets etc.

Keep children away from machinery. Walk

around the windrower to be sure no one is

under, on or close to it.

2. Remove foreign objects f rom the machine

and surrounding area.

3. Wear close fitting clothing and protective

shoes with slip resistant soles.

As well, carry with you any protective

clothing and personal safety dev ices that

COULD be necessary through the day.

Don’t take chances.

You may need:

- a hard hat

- protective glasses or goggles

- heavy gloves

- respirator or filter mask

- wet weather gear.

PROTECT YOURSELF

4. Protect against noise. Wear a suitable

hearing protective device such as earmuffs

or earplugs to pr otect aga in st obj e ctio nable

or uncomfortable loud noises.

5. Check the machine for leaks or any parts

that are missing, broken, or not working

correctly.

NOTE: Use proper procedure when

searching for pressurized fluid leaks. See

"Hydraulics" in Maintenance/Service

section.

6. Be sure tractor and windrower are properly

attached, all controls are in neutral and

tractor brake is engaged.

7. Clean all lights and reflective surfaces on

the machine. Check lights for proper

operation.

8. Perform all Daily maintenance. See

Maintenance/Service section.

PROTECT AGAINST NOISE

20

Page 21

OPERATION

OPERATE CORRECTLY

CAUTION:

1. Follow all safety and operational instructions given in your tractor Operator’s Manual. If you do

not have a tractor manual, get one from your dealer and read it thoroughly.

2. Never attempt to start the tractor engine or operate the mower conditioner except from the tractor

seat.

3. Check the operation of all controls in a safe clear area before starting work.

4. Do not allow riders on tractor or mower conditioner.

5. Never start or move the machine until you are sure all bystanders have cleared the area.

6. Avoid travelling over loose fill, rocks, ditches or holes.

7. Drive slowly through gates and doorways.

8. If mowing ditch banks, us e extr eme caut ion. If the mo wer condi tione r hits an obst ructi on, the front

of the tractor will usually swerve towards the ditch.

9. When working on inclines, travel uphill or downhill when possible. Be sure to keep tractor

transmission in gear when travelling downhill.

10. Never attempt to get on or off a moving tractor.

11. Do not get off the tractor while the mower conditioner is in operation.

12. Stop tractor engine and remove key before adjusting or removing plugged material from the

machine. A child or even a pet could engage the drive.

13. Check for excessive vibration and unusual noises. If there is any indication of trouble, shut down

and inspect the machine. Follow proper shutdown procedure:

- engage tractor brake

- disengage PTO

- turn off engine and remove key

- wait for all movement to stop

- dismount and engage cylinder stop before inspecting rais ed machine.

14. Operate only in daylight or good artificial light.

IMPORTANT: Correct operation reduces crop loss and allows cutting of more acres. The length of service

you receive from your mower conditioner depends upon timely maintenance and proper adjustments.

Satisfactory function of this machine in all crop conditions requires making proper adjustments to suit various

conditions.

21

Page 22

OPERATION

LIFT CYLINDER STOP

LIFT CYLINDER STOP

(RAISING AND LOWERING MOWER CONDITIONER)

WARNING: To avoid bodily injury or

death from fall of raised machine,

always engage lift cylinder stop

before going under mower

conditioner for any reason.

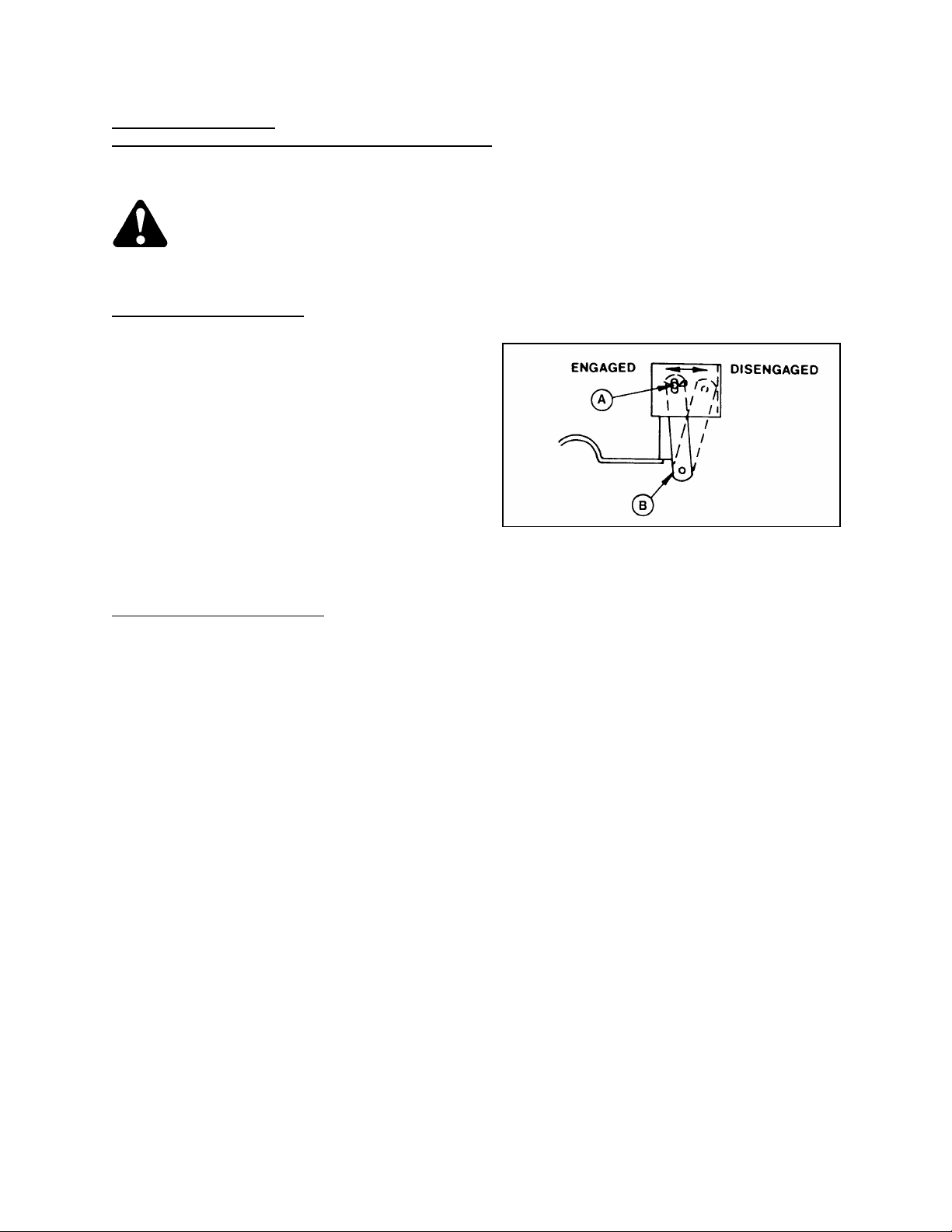

To engage cylinder stops:

1. Raise machine to maximum height by

activating remote cylinder control valve in

tractor.

2. Remove pin (A) and move support (B)

forward, aligning hole in support with slot in

frame lug.

3. Replace pin (A) to secure the s upport in the

engaged position.

4. Lower machine slightly so support takes some

weight.

To lower mower conditioner:

1. Raise machine to maximum height to take

weight off support (B).

2. Remove pin (A) and move support back to

disengaged position.

3. Replace pin (A) to secure the support in

disengaged position.

4. Lower machine by activating remote cylinder

control valve in tractor.

22

Page 23

OPERATION

HITCH CYLINDER HYDRAULIC VALVE

POSITIONING THE HITCH

The mower conditioner hitch can be moved

between transport position (A) and f ield position

(B) with the hitch shift cylinder without moving the

tractor.

In the field, use a position that allows cutting a full

machine width while maintaining clearance

between the right tractor tire and the standing

material.

IMPORTANT: To avoid machine damage with

machine in field position and tractor turned sharply

right, do not activate hitch shift cylinder. Trac tor

tire can contact lean bar.

WARNING: Before transporting

mower conditioner, close hydraulic

valve (C) to prevent inadvertent

cylinder ext ens io n tha t would cau se

machine to swing out unexpectedly.

Closed position is with handle at 90º

to oil flow direction as shown. Open

position is with handle in line with

oil flow direction.

C

23

Page 24

OPERATION

ENGAGING THE P TO

DANGER: Be sure all bystanders are

clear of the machine before

engaging the PTO. Never leave

tractor seat with the PTO engaged.

Entanglement with rotating driveline

will cause serious injury or death.

The PTO should be engaged slowly, just before

the mower conditioner is moved up to the standing

crop.

Be sure tractor PTO is running at 540 rpm before

starting to cut.

Disengage the PTO when not operating the mower

conditioner.

OPENING THE FIELD

CAUTION: Check the work area

before starting operation. Look for

ditches, potholes, drop-offs, steep

slopes, stumps, standing water etc.

Remove any debris or f oreign objec t

that may be picked up and thro wn

out by the mower conditioner.

CLEAR THE AREA BEFORE ENGAGING PTO

If the operato r i s in famil i ar te rri t ory, the first swath

may be cut counter-clockwise (A) around the

outside. This allows a full cut for the back swath.

However, if there may be hidden obstacles or

holes along the field border it is better to cut the

first few swaths clockwise ( B), then cut the back

swath counter-clockwise after any obstacles have

been exposed.

CUTTING WIDTH

The left side of the machine should be run close to

the edge of the standing crop, taking a full cut.

CORNERING

Reduce speed, turn tractor sharply right as the

cutterbar comes to the edge of the standing crop.

Use the right wheel brake on the tractor to push

the machine back, then straighten out the tractor

along the new edge of crop. Do not raise mower to

make square corners.

OPENING THE FIELD - A

24

OPENING THE FIELD - B

Page 25

OPERATION

OPERATING VARIABLES

The eight variables covered here will affect the operation of your mower conditioner. You will quickly become

adept at adjusting the machine to give you the desired results.

1. GROUND SPEED

CAUTION: Reduce speed when turning, crossing slopes, or when travelling over rough

ground.

Tractor ground speed should not exceed 8 mph (13 km/h). For most crop conditions a ground speed of 5 mph

(8 km/h) has been found satisfactory.

Choose a ground speed that allows the knife to cut the crop smoothly and evenly.

The chart below indicates the relationship between ground speed and area cut for the 9 ft. mower conditioner.

Example: At ground speed of 5 mph (8 km/h) with a 9 ft. mower conditioner, the area cut would be

approximately 5 1/2 acres (2.3 hectares) per hour.

25

Page 26

OPERATING VARIABLES (continued)

OPERATION

2. REEL SPEED

For best feeding of the crop into the

conditioning rolls, reel speed should be jus t

faster than ground speed. This gently sweeps

material across knife into the rolls.

The reel speed is factor y set at 63 rpm . See

chart below for reel speed options.

position of:

rpm tine tip speed

mph (km/h)

53 6.6 (10.6) inside inside

56 7.0 (11.3) inside outside

60 7.5 (12.0) outside inside

63 7.9 (12.7) outside outside

In down and tangled crops, a faster reel speed

will result in a more even stubble height.

yoke

plate (B)

shim (F)

A

REEL DRIVE PULLEY ASSEMBLY

To change reel speed:

a. Loosen reel drive belt enough that it can be

removed from drive pulley (A) at main

gearbox. See "Reel Drive Belt" in

"Maintenance/Service" section for tension

adjustment procedure. Do not pry belt over

pulley.

b. Scratch an alignment m ark on pulley half ( A)

and yoke plate (B) to maintain roll timing on

re-assembly. Do not use pulley half (E) for

alignment.

c. Remove three bolts (C).

d. Collapse the driveline at the telescoping shaft

(D) and remove pulley half (E).

NOTE: Shim (F) is open one side and can be

removed once bolts are removed.

e. Re-assemble for desired reel speed,

positioning yoke plate (B) and shim (F) inside

or outside pulley halves as indicated in chart

above. Remember to align marks before

tightening bolts.

f. Replace belt and adjust belt tension.

53 RPM REEL SPEED

26

63 RPM REEL SPEED

Page 27

OPERATION

Wet or dead material collects on cutterbar,

OPERATING VARIABLES (continued)

3. REEL POSITION

Reel position has been found to be a cri tical factor in achieving good results in adverse conditions. The reel

position is factory set for average straight standing crop. It can be adjusted both ver tically and horizontally

(fore-aft) for different crop conditions.

See the chart below for recommended reel position in unusual crop conditions.

REEL POSITION CHART

Unusual Crop Condition Reel Position

Crop down or lodged.

plugging knife.

Short crop.

Thick stemmed or heavy standing crop.

To adjust reel horizontal (fore-aft) position:

a. Loosen nuts (A), four on L/H side, thr ee on

R/H side.

b. Move reel to desired position.

NOTE: T he reel slides in angled slots which

lower the reel as it i s moved forw ard, a nd rai se

the reel as it is moved back.

c. Tighten nuts (A).

Forward and down (also increase reel speed).

Back and down (close to guards).

Back.

Up and forward.

REEL POSITION ADJUSTMENTS - LEFT SIDE

To adjust reel vertical position:

a. Loosen nuts (A), four on L/H side, thr ee on

R/H side.

b. Adjust reel up or down using lock nuts ( B) on

eyebolts, both sides.

c. Tighten nuts (A), total 7.

NOTE: Chain tension is not affected by reel

position adjustments.

REEL POSITION ADJUSTMENTS - RIGHT SIDE

27

Page 28

OPERATION

CUTTING HEIGHT ADJUSTMENT

OPERATING VARIABLES (continued)

3. REEL POSITION (continued)

After adjusting reel position:

a. Check that the reel rotates freely. Tines must not contact feed pan, header beam, guards or ground.

b. Check that the reel is adjus ted to the same position on both sides. Reel tube should appear par allel to

header beam from both side and front.

c. Check header float and adjust if required. See "Header Flotation" in this section.

4. CUTTING HEIGHT

Control cutting height with skid plates, not with the

hydraulic cylinder. Having the header "ride" on the

skid plates allows the three-point float linkage to

float header over obstacles and follow ground

contours, rather than supporting the header with

the cylinder.

NOTE: Lowering the skid plates raises the cutting

height. This may be desirable in stony conditions,

to reduce damage to cutting components. Also, a

longer stubble length helps material dry faster.

To adjust cutting height:

WARNING: To avoid bodily injury or

death from unexpected start-up or

fall of raised machine, stop engine,

remove key and engage lift cylinder

stop before going under machine to

adjust skid plates or for any reason.

a. Remove pin (A) at each skid plate.

b. Raise or lower skid plate (B) to desired

position.

c. Replace pin (A).

After adjusting cutting height:

a. Check that skid plates are adjusted to the

same position.

b. Check header float and adjust if required. See

"Header Flotation" in this section.

A

B

WARNING: Stones or other foreign objects carried into the conditioner rolls can be ejected

with force in ANY direction. Keep everyone several hundred feet away from your operation

and be sure you are adequately protected. See "General Safety" in Safety section for

recommended protective wear.

28

Page 29

OPERATION

OPERATING VARIABLES (continued)

5. CUTTERBAR ANGLE

Cutterbar angle can be varied from 6° to 12° below horizontal. Choose an angle that maximizes performance

for your crop and field conditions. A flatter guard angle provides better clearance in stony condi tions while a

steeper guard angle is required in down crops for better lifting action.

To adjust cutterbar angle:

a. Loosen nut (A).

b. To decrease (flatten) cutterbar angle, turn nut (B) clockwise.

c. To increase (steepen) cutterbar angle, tun nut (B) counter-clockwise.

d. Tighten nut (A) to 160 ft.lbs. (210 N.m)

After adjusting cutterbar angle:

a. Check cutting height and adjust if required. See "Cutting Height" in this section.

b. Check header float and adjust if required. See "Header Flotation" in this section.

A

B

CUTTERBAR ANGLE ADJUSTMENT

29

Page 30

OPERATION

HEADER FLOTATION ADJUSTMENT

OPERATING VARIABLES (continued)

6. HEADER FLOTATION

Header flotation springs are normally set so 70 l bs.

force (311 N) is required to lif t each end of the

header just off the ground.

In rough or stony conditions, it may be desirable to

change setting to 35-50 lbs. (156-222 N) to protect

cutting components.

NOTE: When float setting is light, it may be

necessary to use a slower ground speed to avoid

excessive bouncing and leaving a ragged cut.

To increase header flotation, which decreases the

force required to lift header:

a. Back jam nut (A) away from spring.

b. Turn adjuster bolt (B) further into spring to

increase flotation.

c. Tighten jam nut (A) against spring insert (C) to

secure the setting.

IMPORTANT: Float setting (or lifting f orce) mus t

be equal on both springs. Weight difference

between left and right ends requires different

spring lengths to achieve equal floa t at both end s.

Note that other operating variable adjustments

may affect float setting. Check the float and

readjust if necessary after adjusting reel position,

cutting height, or cutterbar angle. Also, if using a

tractor with drawbar height different than 16 i nches

(406 mm), flotation will be affected. Adjust as

required.

B

A

C

30

Page 31

OPERATION

OPERATING VARIABLES (continued)

7. ROLL GAP

WARNING: To avoid bodily injury or

death from unexpected start-up or

fall of raised machine; stop engin e,

remove key and engage lift cylinder

stop before going under machine to

examine roll gap or for any other

reason.

Rubber rolls "condition" the crop by crack ing the

stems, while steel rolls crim p the stem in sever al

places. Both methods allow mo isture release f or

quicker drying. The degree to which the crop is

conditioned as it passes through the rolls is

controlled by roll gap (A), measured from lug to

groove (or bar to roll tube). The gap is factory set

for normal operation at 1/16 inch (1.5 mm) for

rubber rolls and 3/8 inch (10 mm) for steel rolls.

Correct conditioning of alfalfa, clover and other

legumes is usually indicated when 90% of the

stems show cracking, but no more than 5% of the

leaves are damaged. Use only enough roll gap to

achieve this result.

ROLL GAP (RUBBER ROLLS SHOWN)

A slightly larger gap may be desirable in thick

stemmed cane- type crops; however, too large a

gap will cause feeding problems.

Grass type crops may require less gap for proper

feeding.

To adjust roll gap:

a. Loosen nut (B) at both roll support arms.

NOTE: Use roll gap decal (D) to gauge your

adjustment. The decal marks roll gap in 1/8 inch (3

mm) increments. The bottom edge of inner

channel (E) is the gauge indicator.

b. To increase roll gap, turn nut (C) clockwise.

c. To decrease roll gap, turn nut (C) counter-

clockwise.

d. Tighten nut (B) to 160 ft.lbs. (210 N.m) at both

arms.

IMPORTANT: Gap settings must be equal at both

ends of roll. To avoid excessive crushing, do not

operate rubber rolls at less than 1/32 inch (1 mm)

gap.

NOTE: Roll tension (the force holding the rolls

together) is factory set and non-adjustable.

C

B

E

D

ROLL GAP ADJUSTMENT

31

Page 32

OPERATION

MATERIAL DISCHARGE WIDTH

BAFFLE (C) CONTROLS DISCHARGE WIDTH /

OPERATING VARIABLES (continued)

8. FORMING SHIELDS

WARNING: Keep hands and feet away from discharge opening. Keep everyone several

hundred feet away from your oper ation. Never direct the discharge toward anyone. Stones

or other foreign objects can be ejected with force.

A baffle inside the forming shields controls the degree to which they narrow the discharge of cut material. The

decision to lay a full width swath or narrow windrow (or one of the five intermediate widths) should be based

on the following factors:

- weather conditions (rain, sun, humidity, wind)

- type and yield of crop

- drying time available

- method of processing (bales, silage, "green-feed")

A wide swath will generally dry faster and more evenly, resulting in less protein loss. Fast drying is especially

important in areas where the weather allows only a few days to cut and bale. See "Haying Tips" in this section

for more information.

Where weather conditions permit or when drying is not critical, for example, when cutting for silage or "greenfeed", a narrower windrow may be preferred for ease of pick-up.

To adjust material discharge width:

a. Pull spring-loaded pin (A) out of adjustm ent

hole.

b. Raise or lower handle (B). Handle fully up (as

shown) raises baffle (C) completely, producing

the narrowest windrow. Handle fully down

lowers baffle completely, producing the widest

swath. There are five intermediate positions.

c. Release pin (A) into desired adjustment hole.

Light crop deflectors

Deflectors (D) are only required when windrowing

light crop to aid in proper windrow formation. In

relatively heavy crops, the deflectors may cause

bunching at the sides of the windrow.

A

B

ADJUSTMENT

C

D

DEFLECTORS (D) FOR LIGHT CROP

32

Page 33

OPERATION

OPERATING VARIABLES

8. FORMING SHIELDS (continued)

Feed Pan Extensions

Extensions should be installed in working position

(E) when light crop conditions cause m aterial to

fall between feed pan and rolls. Extensions should

remain in storage position (F), under feed pan (G)

in normal to heavy conditions.

FEED PAN EXTENSIONS FOR LIGHT CROP

HAYING TIPS

There is one certainty when making hay - a quick cure will maintain top quality. It is critical to have the cured

hay baled as quickly as possible, for two reasons:

1. Every day that hay lies on the ground, 5% of the protein is lost.

2. The sooner the cut hay is off, the earlier the start for next growth.

Generally, leaving the swath as wide and thin as possible makes for the quickest curing, however there are

other factors which affect curing time:

1. TOPSOIL MOISTURE

When the ground is wetter than the hay, moisture from the soil is absorbed by the hay above it. Determine

topsoil moisture level before cutting. Use a moisture tester or estimate level:

Over 45% - WET - Soil will be muddy

25 - 45% - DAMP - Walking on soil leaves tracks

Under 25% - DRY - Soil will be dusty on top

When ground is wet due to irrigation, wait until soil moisture drops below 45%. When ground is wet due to

frequent rains, cut when weather allows and let the forage lie on wet ground until it dries to the moisture level

of the ground. At this point, the cut hay will dry no more until the ground under it dries, so consider moving the

windrow to drier ground.

On wet soil, the general rule of "wide and thin" does not apply. A narrower windrow will dry faster than hay left

flat on wet ground.

33

Page 34

OPERATION

HAYING TIPS (continued)

2. CLIMATE AND TOPOGRAPHY

a. Try to have as much hay cut as possible by midday, when drying conditions are best.

b. Fields sloping south get up to 100% more exposure to the sun’s heat than do north sloping fields. If you

bale and chop, consider baling the south facing fields and chopping those facing north.

c. W hen relative humidity is high, the evaporation rate is low and hay dries slower. If there is no wind,

saturated air becomes trapped around the swath, further hindering the drying process. Raking or tedding

will expose the hay to fresher, less saturated air. Cutting hay perpendicular to the direction of the

prevailing winds may also help.

3. SWATH/WINDROW CHARACTERISTICS

See "Operating Variables" in this section. Control the f ac tor s lis ted to pr oduc e a windrow or s wath with the

following characteristics:

a. High and fluffy for good air flow.

b. Consistent formation, not bunchy.

c. Even distribution, not piled in the middle.

d. Properly conditioned without excessive leaf damage.

4. RUNNING TRACTOR ON PREVIOUSLY CUT SWATH:

This can lengthen drying time by a full day in hay that will not be raked. If practical, set forming shields for a

narrower windrow that can be straddled. However, in high-yielding alfalfa, driving on the hay may be

unavoidable if a full width swath is necessary.

5. RAKING AND TEDDING

Raking or tedding will speed up drying, however the benefits must be weighed against the additional leaf

losses, which will result. When the ground beneath the down hay is dry, raking or tedding is probably not

worthwhile.

Big windrows or swat hs on damp or we t g round shou ld be turned ove r w hen the y reach 40-50% moisture. Hay

should not be raked or tedded at less than 25% moisture, or excessive yield losses will result.

6. CHEMICAL DRYING AGENTS

Hay drying agents work by removing wax from legume surf aces, enabling water to escape and evaporate

faster. However, treated hay lying on wet ground will also absorb ground moisture faster.

Before deciding to use a drying agent, costs and benefits relative to your area should be carefully compared.

34

Page 35

OPERATION

CLEARING PLUGGED ROLLS

UNPLUGGING THE MOWER CONDITIONER

WARNING: Stop tractor engine and

remove key before removing

plugged material from mower

conditioner. A child or even a pet

could engage the drive.

If the knife plugs:

1. Stop forward movement of the tractor and stop

the PTO.

2. Lift the cutterbar about 12 inches (300 mm).

3. Back up about 3 feet (1 m etre) while slowly

engaging the PTO.

4. If the plug does not clear; raise machin e, shut

off engine, remove key and lock tractor

brakes.

5. Engage lift cylinder stop.

WARNING: Wear heavy gloves when

working around knife.

6. Clean off cutterbar by hand.

If knife plugging persists, see Trouble Shooting

section.

If the rolls plug:

1. Stop forward movement of the tractor and stop

the PTO.

2. Raise the machine and slowly engage the

PTO.

NOTE: Raising the mower conditioner automati-

cally reduces roll tension, to ease plug removal.

3. If plug does not clear: with machine still raised,

shut off engine, remove key and lock tractor

brakes.

4. Engage lift cylinder stop.

WARNING: Wear heavy gloves when

working around knife.

5. Clean off cutterbar and area under reel by

hand.

6. Use rocking wrench (A) on r ight hand end of

lower roll to turn rolls forward until plug clears.

A

NOTE: W rench is stored in toolbox at lef t end of

main frame.

If roll plugging persists, see Trouble Shooting

section.

35

Page 36

OPERATION

SHUT-DOWN PROCEDURE

CAUTION: Before leaving the tractor seat for any reason:

1. Park on level ground if possible.

2. Lower the mower conditioner fully.

3. Place all controls in NEUTRAL or PARK.

4. Disengage PTO.

5. Engage the park brake.

6. Stop engine and remove key from ignition.

7. Wait for all movement to stop.

8. Lock tractor anti-vandalism covers and closures when leaving the machine unattended.

TRANSPORTING THE MOWER CONDITIONER

CAUTION: Use correct transport procedure as detailed:

1. Shift hitch into transport position and close hydraulic valve at shift cylinder. See "Positioning the

Hitch" in this section.

2. Raise the mower conditioner fully and engage lift cylinder stop. See "Lift Cylinder Stop" in this

section.

3. Do not tow with a vehicle weighing less than 5000 lbs. (2300 kg).

4. Be sure hitch chain is properly attached to towing vehicle. Provide only enough slack in chain to

permit turning. See "Attaching Mower Conditioner to Tractor" in this section.

5. Be sure driveline is properly attached to tractor PTO. See "Attaching Mower Conditioner to

Tractor" in this section. If tra nsporting with a truc k, re move the front hal f of the dr ivelin e a nd store

the rear half in the driveline support.

6. Check local laws for width regulations and lighting or marking requirements before transporting

on roads.

7. Keep Slow Moving Vehicle emblem, reflectors and lights clean and visible.

8. Be aware of roadside obstructions, oncoming traffic and bridges.

9. Travel speed should be such that complete control and machine stability are maintained at all

times. Do not exceed 20 mph (30 km/h). Reduce speed for corners and slippery conditions.

10. When transporting on roads, use tractor lights and Mower Conditioner’s flashing amb er and red

tail lights to provide adequate warning to operators of other vehicles.

11. Do not transport the mower conditioner on a road or highway at night, or in conditions which

reduce visibility, such as fog or rain.

36

Page 37

OPERATION

STORAGE PROCEDURE:

Do the following at the end of each operating

season:

CAUTION:

1. Clean the mower conditioner thoroughly.

Never use gasoline, naphtha or a ny volatile

material for cleaning purposes. These

materials may be toxic and/or flammable.

2. Cover cutterbar and knife guards to

prevent injury from accidental contact.

Also:

3. Store in a dry, protected place if possible. If

stored outside, always cover mower

conditioner with a waterproof canvas or other

protective material.

4. If possible, block up the mower conditioner to

take weight off tires.

5. Repaint all worn or chipped painted s urfac es

to prevent rust.

6. Loosen both drive belts.

7. Lubricate the mower conditioner thor oughly,

leaving excess grease on fittings to keep

moisture out of bearings. Apply grease to

exposed threads and sliding surfaces of

components. Oil knife components to prevent

rust.

8. Check for worn components and repair.

9. Check for broken components and order

replacements from your dealer. Attention to

these items right away w il l save time and effort

at beginning of next season.

10. Replace or tighten any missing or loose

hardware. See Specifications section for

torque charts.

37

Page 38

MAINTENANCE/SERVICE

SERVICE PROCEDURES

CAUTION: To avoid personal injury,

before servicing mower conditioner

or opening drive covers:

1. Fully lower the mower conditioner. If

necessary to service in the raised position,

always engage lift cylinder stop.

2. Disengage PTO.

3. Stop engine and remove key.

4. Engage park brake.

5. Wait for all moving parts to stop.

Park on level surface when possible. Block

wheels securely i f mower co ndi tion er is pa rk ed

on an incline. Follow all recommendations in

your Tractor Operator’s Manual.

Wear close-fitt ing c lothing and cover long h air .

Never wear dangling items such as scarves or

bracelets.

Wear protective shoes with slip-resistant

soles, a hard hat, protective glasses or

goggles and heavy gloves.

Be prepared if an accident should occur. K now

where the firs t a id kit and fire e x ti ngui s he r s ar e

located and how to use them.

Keep the service area clean and dry. Wet or

oily floors are slippery. Wet spots can be

dangerous when working with electrical

equipment. Be sure all electrical outlets and

tools are properly grounded.

Use adequate light for the job at hand.

Replace all shields removed or opened for

service.

Use only service and repair parts made or

approved by the equipment manufacturer.

Substituted parts may not meet strength,

design, or safety requirements.

Keep the machine clean. Never use gasoline,

naphtha or any volatile material for cleaning

purposes. These materials may be toxic and/or

flammable.

38

Page 39

MAINTENANCE/SERVICE

RECOMMENDED LUBRICANTS

GREASE

Use SAE Multi-Purpose Hig h Temperature Grease

with Extreme Pressure (EP) Performance and

containing at least 1.5% molybdenum disulphide.

Also acceptable is an SAE Multi-Purpose Lithium

Base Grease.

WOBBLE BOX & GEAR BOX LUBRICANT

In knife drive wobble box and main drive gearbox

use SAE 85W140 gear lubricant (API Service

Classification GL-5)

CAPACITIES

Wobble Box (Knife Drive) - 900 ml (1.0 U.S. quart)

Main Drives Gearbox - Upper Case: 2900 ml (3.1 U.S. quart)

- Lower Case: 700 ml (0.7 U.S. quart)

STORING LUBRICANTS

Your machine can operate at top efficiency only if

clean lubricants are used. Use clean containers to

handle all lubricants. Store them in an area

protected from dust, moisture, and other

contaminants.

39

Page 40

MAINTENANCE/SERVICE

STAY CLEAR OF ROTATING DRIVELINES

GREASING THE MOWER CONDITIONER

See "Recommended Lubricants" in this section for

recommended greases.

The following greasing points are m arked on the

machine by decals showing a grease gun (A), and

grease interval (B) in hours of operation. Log your

hours of operation and use the "Maintenance

Checklist" provided to keep a record of scheduled

maintenance.

Procedure:

1. Wipe gr ease fitting with a clean cloth before

greasing, to avoid injecting dirt and grit.

2. Inject grease through fitting with grease gun

until grease overflows fitting.

3. Leave excess grease on fitting to keep out dirt.

4. Replace any loose or broken fittings

immediately.

SAMPLE GREASE DECAL

5. If fitting will not take grease, remove and clean

thoroughly. Also clean lubricant passageway.

Replace fitting if necessary.

10 Hours or Daily

DANGER: Stay clear of drivelines

until all movement has stopped.

Entanglement with rotating driveline

will cause serious personal injury or

death. Avoid loose fitting or

dangling clothing.

1. Telescoping Driveline (C) - three fittings.

C

2. Fixed Driveline (D) - one fitting

TELESCOPING DRIVELINE

D

FIXED DRIVELINE

40

Page 41

MAINTENANCE/SERVICE

GREASING THE MOWER CONDITIONER

10 Hours or Daily (continued)

3. Upper & Lower Roll Universal Shafts

(E) & (F) - three fittings each

E

F

ROLL UNIVERSALS

25 Hours

4. Reel Drive Universal Shaft (G) - three fittings

G

REEL DRIVE UNIVERSAL

1. Knife Head (H) - one fitting

IMPORTANT: To prevent binding and/or

excessive wear caused by knife pressing on

guards, do not over grease.

H

KNIFE HEAD

41

Page 42

MAINTENANCE/SERVICE

LEFT

SIDE RIGHT SIDE

ROLL BEARINGS

GREASING THE MOWER CONDITIONER (continued)

50 Hours:

1. Roll Shaft Bearings (A) & (B) - four fittings

B

A

2. Left and Right Saddle Bearings (F) - two

fittings

F

F

SADDLE BEARINGS

42

Page 43

MAINTENANCE/SERVICE

GREASING THE MOWER CONDITIONER (continued)

100 Hours or Annually

1. Reel Shaft Bearing (A) - one fitting

A

REEL SHAFT BEARING

2. Wheel Hub Bearings (D) - two fittings

D

WHEEL HUB BEARINGS

43

Page 44

MAINTENANCE/SERVICE

OIL CENTER LINK

LINKAGE BALL JOINTS

Apply SAE 30 or equivalent lightweight oil to the

ball joints every 50 hours.

NOTE: Do not oil ball joints if operating in s andy

conditions. Oil will cause sand to adhere to joints,

causing excessive wear.

(A) Top center float link (2 joints)

(B) Right hand float link (2 joints)

(C) Left hand float link (2 joints)

(D) Spring pivot (2 joints)

B

OIL R/H LINK

A

C

OIL L/H LINK

D

OIL SPRING PIVOTS

44

Page 45

MAINTENANCE/SERVICE

SEARCH PROPERLY FOR LEAKS

REPLACING AMBER OR RED LIGHTS

HYDRAULICS

Check hydraulic hoses daily for signs of leaks.

WARNING: Avoid high-pressure

fluids. Escaping fluid can penetrate

the skin causing serious injury.

Relieve pressure before

disconnecting hydraulic lines. Tighten all

connections before applying pressure. Keep

hands and body away from pinholes and

nozzles, which eject fluids under high

pressure. Use a piece of cardboard or paper to

search for leaks. If ANY fluid is injected into

the skin, it must be surgically removed within

a few hours by a doctor familiar with this type

of injury or gangrene may result.

IMPORTANT: Keep hydraulic coupler tips and

connectors clean. Dust, dirt, water and foreign

material are the major causes of hydr aulic system

damage.

AVOID HIGH-PRESSURE FLUIDS

ELECTRICAL

Use electrical tape and wire clips as required to

prevent wires from dragging or rubbing.

Keep lights clean and replace burnt bulbs.

To replace amber or red light bulbs:

1. Using a screwdriver, pry plastic lens (B) from

fixture.

2. Replace bulb and plastic lens.

NOTE: Bulb trade #1156.

Wiring Harness:

WHITE - ground

BROWN - red tail light

YELLOW - L/H amber

GREEN - R/H amber

B

45

Page 46

MAINTENANCE/SERVICE

CHECK MAIN GEARBOX OIL

MAIN DRIVE

Main Gearbox Lubricant

The main gearbox consists of two separate cases.

Check both lubricant levels befor e first operation

and every 100 hours thereafter.

To check:

1. Lower mower conditioner to ground. T op of

gearbox will be approximately level in this

position.

2. Remove plug (A) from upper case and plug

(B) from lower case.

3. Add lubricant until it overflows at plug ports.

See "Recommended Lubricants" for specified

gear lube and capacity of box.

4. Replace plugs.

Main Gearbox Removal

To remove main gearbox:

1. Disconnect driveline input and output yokes.

2. Loosen four mounting bolts (C), lowering box

until rod (D) engages hooks (E).

3. Remove mounting bolts completely, allowing

box to swing on hooks.

A

D

B

E

4.

CAUTION: Use proper lifting

methods and apparatus when

removing box from hooks. Box

weighs approximately 170 lbs. (77

kg).

C

E

REMOVING MAIN GEARBOX

46

Page 47

MAINTENANCE/SERVICE

SECURE BOLT TO YOKE WITH WIRE

OVER-RUNNING/SLIP CLUTCH

MAIN DRIVE (continued)

Over-running/Slip Clutch

The clutch is designed to protect the machine

against damage from overloading.

It is factory set, and with the exception of replacing

friction discs, should require no further service.

IMPORTANT: Should the clutch slip during

operation, determine the cause and r emove the

obstruction. See "Unplugging the Mower

Conditioner" in Operation section.

Telescoping Driveline

If telescoping driveline is rem oved, ensure when

replacing that bolt (B) is wired to yoke to prevent

bolt from backing out.

B

47

Page 48

MAINTENANCE/SERVICE

KEEP HANDS AWAY FROM KNIFE

OIL KNIFE DAILY EXCEPT IN SANDY SOIL

KNIFE AND KNIFE DRIVE

WARNING: Keep hands clear of the

area between gu ar ds an d knife at all

times.

CAUTION: Wear heavy gloves when

working around or handling knives.

Knife Lubrication

Apply SAE 10 or equivalent light weight oil daily

(one or two drops per section) along entire length

of knife.

NOTE: Do not oil knife if operating in sandy

conditions. Oil will cause sand to adhere to knif e

components, resulting in excessive wear.

Knife Sections

Check daily that sections are firm ly bolted to the

knife back and are not worn or broken. Replace as

required.

To replace knife section:

1. A worn or broken knife section (A) can be

replaced without removing knife from

cutterbar.

2. Remove locknuts and lift section off of bolts.

IMPORTANT: Do not mix heavy and light

knife sections on same knife.

3. Clean any dirt off of knife back and position

new knife section on bolts. Secure with

locknuts.

A

BOLT-ON SECTIONS

48

Page 49

MAINTENANCE/SERVICE

INSTALLING KNIFE

KNIFE AND KNIFE DRIVE (continued)

To Remove Knife

WARNING: Always stand to rear of

knife during removal to reduce risk

of injury from cutting edges. Wear

heavy gloves when handling knife.

1. Clean area around knife head. Stroke knife to

its outer limit and remove bolt (A).

2. Insert screwdriver in slot (B) and pry up on

knife head pin to free knife.

3. Pull knife out.

4. Cover knife head to shield bearing from dirt.

To Install Knife

WARNING: Always stand to rear of

knife during installation to reduce

risk of injury from cutting edges.

Wear heavy gloves when handling

knife.

A

B

REMOVING KNIFE

IMPORTANT: Always align guards and re-set

knife clips while replacing knife. See "Guards" and

"Knife Clips" in this section.

1. Slide knife into place and replace bolt (A).

NOTE: Notch in knife head pin must align with

bolt.

2. Tighten bolt (A) to 160 ft.lbs. (217 N.m).

IMPORTANT: To avoid prem ature knife head or

wobble box failure, be sure there is no looseness

in:

a) Fit of knife head pin and needle bearing.

b) Fit of knife head pin and pitman arm.

Knife Storage - Tool Box

A spare knife can be stored in the main frame tube

with access at toolbox (A) at left end of frame.

Hook last section (B) into s lot in toolbox so k nife

slides in and out with box.

Latch box with hairpin (C).

NOTE: Box is also used for storage of tool (D) for

guard straightening or rocking wrench.

A

C

D

B

A

KNIFE STORAGE - TOOL BOX

49

Page 50

MAINTENANCE/SERVICE

SETTING KNIFE CLIPS

KNIFE AND KNIFE DRIVE (continued)

Guards

Check daily that guards are aligned to obtain

proper shear cut between knife section and guard.

Knife sections should contact shear surface of

each guard.

Align guards with the guard-straightening tool

provided as shown:

To bend guard tips up, position tool as shown at

(B) and pull up.

To bend tips down, positi on to ol as at (C ) and pu sh

down.

B

NOTE: Tool is stored in toolbox at left end of main

frame.

TIP: If trouble is encountered cutting tangled, but

easy to cut material (canola, peas, grain) r eplace

guards with stub guards and install a sick le holddown on every guard. If material is tough to cut,

install stub guards with top guard and adjuster

plate from the MacDon 930 Series "Grass Seed

Special" Headers. A stub guard kit f or the 4000

Mower Conditioner is available from your dealer.

Excessive Breakage

Excessive breakage of knife sections and guards

can be controlled by several factors. See "Cutting

Height", "Cutterbar Angle" and "Header Flotation"

in Operation section for recommendations.

Knife Clips