Page 1

30’, 36’ & 39’

Model 972/973/974

HARVEST HEADER

SLOW SPEED

TRANSPORT OPTION

OPERATOR’S MANUAL

Form 46581 Issue 11/04

Sugg. Retail: $10.00

Page 2

TRANSPORT OPTION

1

Some 30’, 36’ & 39 ’ foot h eaders are equipped with the tra nsport optio n which a llows piv oting the gaug e

wheels 90° to allow towing the head er sid e wa ys.

This supplement pro vides instructions for Set-U p, Converting to and from T ransport Position, Transport

Safety and recommended Maintenance.

TABLE OF CONTENTS

Set-up Instructions ................................................................................................................................2 - 9

Electrical Schematic.................................................................................................................................10

Converting from Field Position to Transport .....................................................................................11 - 14

Transport Safety.......................................................................................................................................15

Converting from Transport to Field Position .....................................................................................16 - 20

Raising Wheels to Storage Position.........................................................................................................21

Poly Wearplate Modification for 973 & 974 Headers...............................................................................21

Maintenance / Service........................................................................................................................22, 23

Form # 46581 Issue 11/04

Page 3

2

SET-UP INSTRUCTIONS

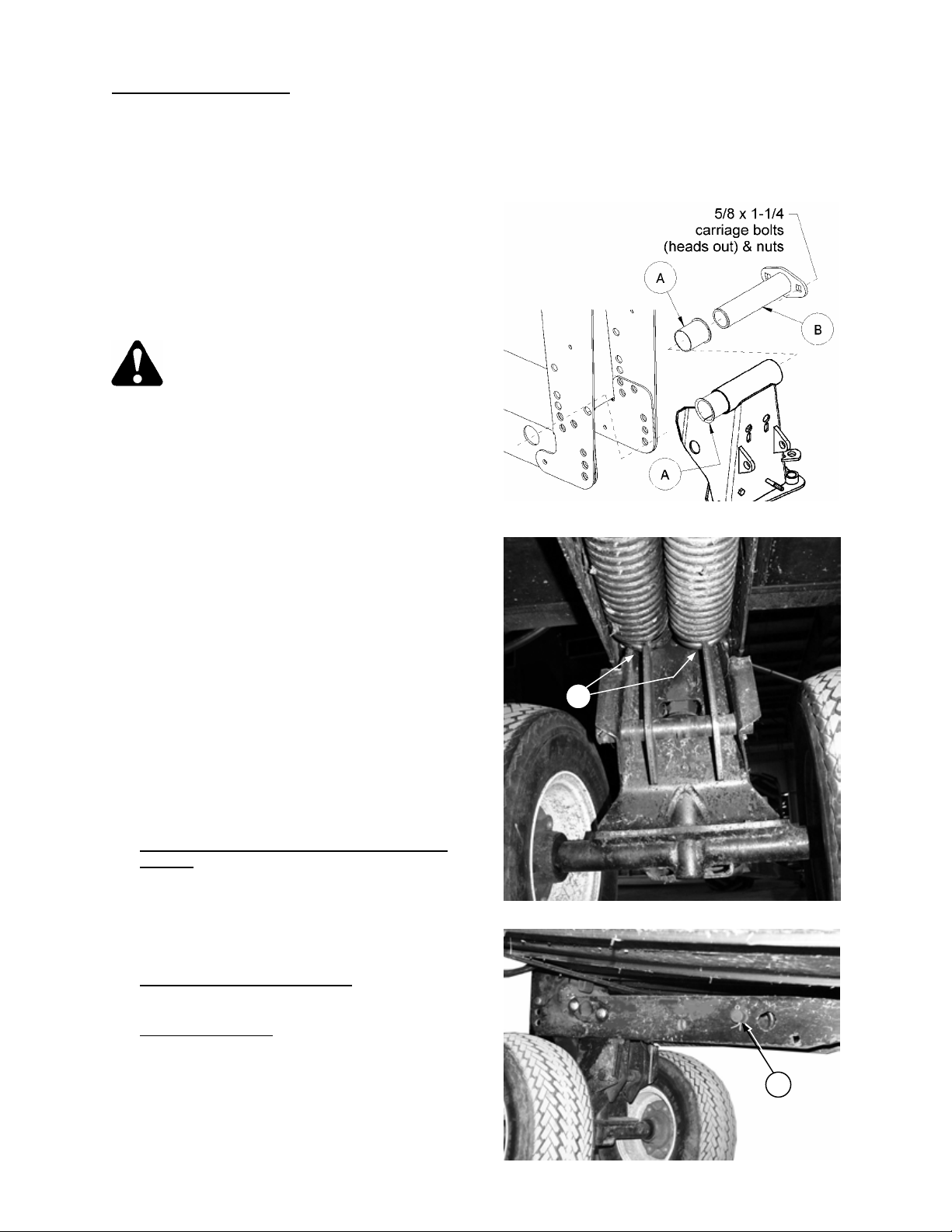

NOTE: For ease of assembly, if header is still in

shipping position insta ll wh eel suppor ts and

springs before lowering header to field position.

Take care not to damage components when

header is lowered. These instructions assume

the header is already lowered to field position.

1. Use a lifting vehicle to raise rear of header,

or attach header to windrower or combine

and raise header fully.

DANGER: To avoid bodily injury or

death from unexpected start-up or

fall of raised header, stop engine,

remove key and engage header lift

cylinder stops before going under

header for any reason. If using a

lifting vehicle, be sure header is

secure before proceeding.

2. Identify right and left wheel supports. Left

wheel support has dual spindle.

3. Ensure plastic bush ings (A) are installed (2

per support). Position wheel assembly in

header leg and install tube (B) from right

side of header leg through wheel support.

Secure with two 5/8 x 1-1/4” carriage bolts

(heads outboard) and flange nuts.

IMPORTANT: If wheels are required for

transport only and will not be us ed in field mode

to assist header floatation or to stabilize sway,

installation of springs is not required. Leaving

the springs off makes putting the wheels into

and out of transport position easier, however

springs are required if used for floatation in f ield

mode. See “Raising Wheels to Storage

Position”, page 21.

4. Attach springs:

With 872 Combine Adapter or W indrower

Tractor: For 30’ single sickle header

install two springs at left side of header,

one spring at right side. For 30’ double

sickle or 36’ headers, install two at both

sides (an extra spri ng is prov ided with thes e

headers).

With 873 Combine Adapter

spring at each side.

L/H Wheel Support

anchor (C) at wheel support, then attach

front end of springs to header leg with pin

(D). Secure with cotter pins.

: Engage spring hook s in

: Install one

TRANSPORT OPTION

NOTE: Tube (B) is designed to be a press-fit

into leg. Use a hamm er or the hardware to fully

engage tube into leg (with flange on tube flush to

leg).

ATTACH SPRINGS – L/H SHOWN

INSTALL WHEEL SUPPORTS

C

D

Form # 46581 Issue 11/04

Page 4

3

OUTBOARD SIDE

–

INBOARD INSTALLATI

ON –

972

ONLY

TRANSPORT OPTION

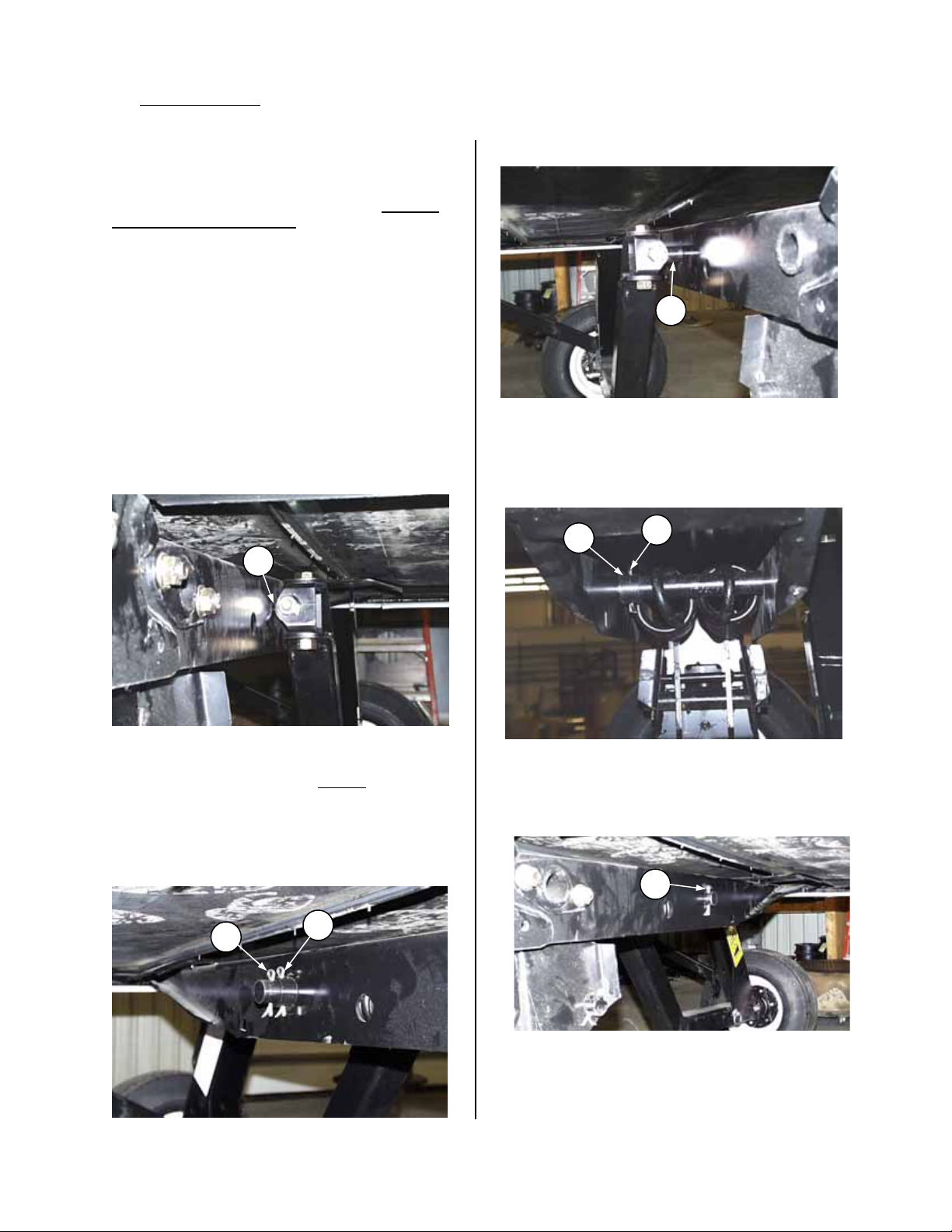

5. R/H Wheel Support:

a. Engage spring hook(s) in anchor at wheel

support same as L/H side shown in Step 4.

Attach front end of spring(s) and trans-axle

assembly to header R/H leg as follows:

NOTE: The trans-axle can be installed on inboard or

outboard side of leg for 972 or 973 headers, but must

be outboard on 974 Headers. This determines the

side of the leg where the trans-axle wheel will be

placed in storage. For headers with R/H decks that can

be split for end delivery, choose the side that places the

working wheel away from the windrow delivery

opening.

IMPORTANT: For 973/974 headers, spacer (E) for

transaxle is not used. Install 33mm ID x 57mm OD

flat washer provided in kit instead. For both

inboard (973) and outboard (973/974) installations,

position washer on outside of leg with one cotter

pin inside leg and one outside.

For installation outboard of header leg - 972:

b. Knuckle (A) must be tight against face of header

leg when trans-axle is mounted on outboard

side of header leg.

For installation inboard of header leg – 972:

d. Space knuckle away from leg as at (D) when

installing on inboard side of header leg.

D

VIEW FROM REAR OF HEADER – INBOARD SIDE

- INBOARD INSTALLATION – 972 ONLY

e. Install spacer (E) against inside face of header

leg to maintain knuckle spacing away from other

face of header leg. Install cotter pin (G).

A

VIEW FROM REAR OF HEADER –

OUTBOARD SIDE – OUTBOARD INSTALLATION

c. Install cotter pin (B) through second hole from

end of pivot shaft and through spacer to hold

knuckle against other face of header leg. Store

second cotter pin (C) in outer hole of pivot shaft.

NOTE: Assembly of knuckle away from face of

leg will result in excessive “toe-in” of R/H wheel

located underneath cutterbar.

C

B

E

G

VIEW FROM FRONT OF HEADER – INSIDE LEG

- INBOARD INSTALLATION – 972 ONLY

f. Install cotter pin (F) through last hole in pivot

shaft on outboard side of leg.

F

VIEW FROM REAR OF HEADER – INBOARD SIDE

Form # 46581 Issue 11/04

VIEW FROM REAR OF HEADER –

OUTBOARD INSTALLATION – 972 ONLY

Page 5

TRANSPORT OPTION

4

H G

H

G

BOLT POSITION 14

ABOVE CUTTERBAR.

BOLT POSITION 10

DIRECTION OF TRAVEL

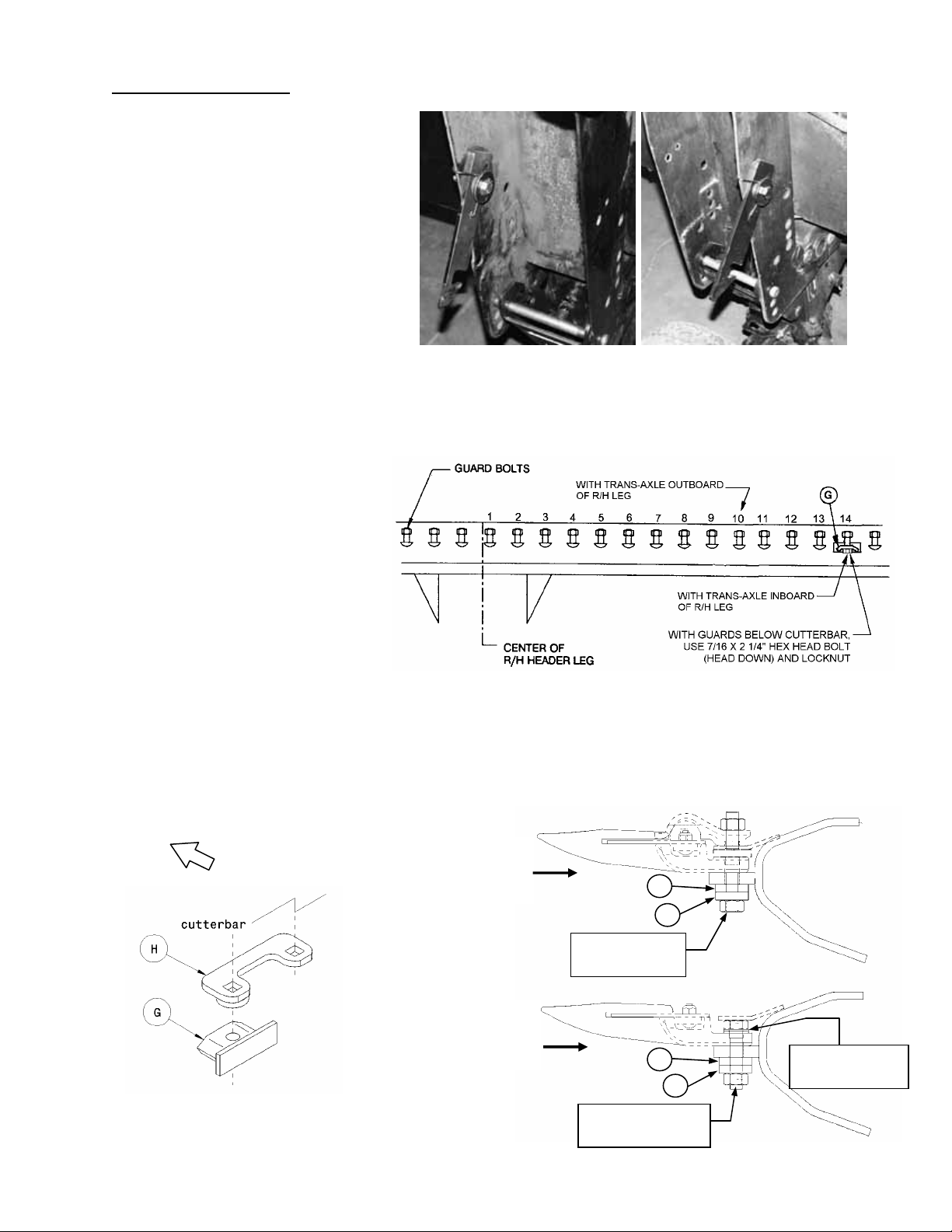

SET-UP INSTRUCTIONS

6. Install trans-axle storage latch at

right header leg. Install on same

side of leg as trans-axle. See Step

5. Engage top leg of torsion spring

on edge of header leg as shown.

NOTE: Step 7 is for 972 and 973

Headers only – Not required for 974 Header.

7. Install anchor (G) for diagonal brace under

cutter bar.

For trans-axle positioned

inboard of R/H leg: Install

anchor at 14

th

guard bolt inboard

of center of R/H header leg.

For trans-axle positioned

outboard of R/H leg: Install

anchor at 10

th

guard bolt inboard

of center of R/H header leg.

NOTE: For applications where

the sickle guards are in stalled

above the cutterbar, install

anchor spacer (H) and special

hardware as shown. For

applications where guards are

below cutterbar, use 7/16 x 2 ¼ hex head

bolt (head down) and locknut. Spacer (H)

and special hardware are not used with

guards below cutterbar.

TRANS-AXLE INBOARD OF

HEADER LEG. GUARDS

TRANS-AXLE OUTBOARD

OF HEADER LEG. GUARDS

ABOVE CUTTERBAR.

TRANS-AXLE INBOARD TRANS-AXLE OUTBOARD

STEP 6: INSTALL STORAGE LATCH

INSTALL BRACE ANCHOR AT CUTTERBAR

7/16 x 3” BOLT,

HEAD DOWN

TWO 7/16” I.D.

FLATWASHERS

Form # 46581 Issue 11/04

7/16 x 2 ¼” BOLT,

HEAD UP

Page 6

TRANSPORT OPTION

5

STEP 8:

SET-UP INSTRUCTIONS

8. Attach the four gauge wheels to hubs.

Torque wheel bolts to 80 to 90 ft. lbs. (110 to

120 N·m). Use the two longer wheel bolts

(9/16 NF x 1 ½”) t o bolt handle to trans-axle

wheel.

HANDLE BOLTS TO TRANS- AX LE W H EEL

9. At L/H support, install upper pin (A) in

desired stubble height position and secure

with split ring. When header is lowered,

spring-loaded brack et will engage upper pin

as shown below.

Push down on handle (B) and lock under

welded bolt head to raise pin (C) to allow

wheel to pivot. Pivot whee l to field position.

Release handle (B) fr om under bolt head to

lower pin (C) and lock in field position.

A

C

B

L/H WHEEL SUPPORT: FIELD POSITION

10. At R/H support, install upper pin (D) in

desired stubble height position and secure

with split ring. When header is lowered,

spring-loaded brack et will engag e upper pin .

Push down on handle (F) and lock under

welded bolt head to raise pin (G) to allow

wheel to pivot. Pivot wheel to desired field

position. Releas e handle (F) from under bolt

head to lower pin (G) and lock in field

position.

NOTE: Wheel can be positioned on either

side of support, depending on delivery

opening position. (See Step 5.)

D

F

G

R/H WHEEL SUPPORT: FIELD POSITION

NOTE: Install the two decals provided on the

inboard face of left and right frame legs as

shown below. The decals indicate proper pin

position for storage, different levels of stubble

height, and transport.

DECAL PLACEMENT

LEFT FRAME LEG

DECAL PLACEMENT

RIGHT FRAME LEG

Form # 46581 Issue 11/04

Page 7

TRANSPORT OPTION

6

STEP 11:

PLACE R/H WHEEL IN ST OR AG E

SET-UP INSTRUCTIONS

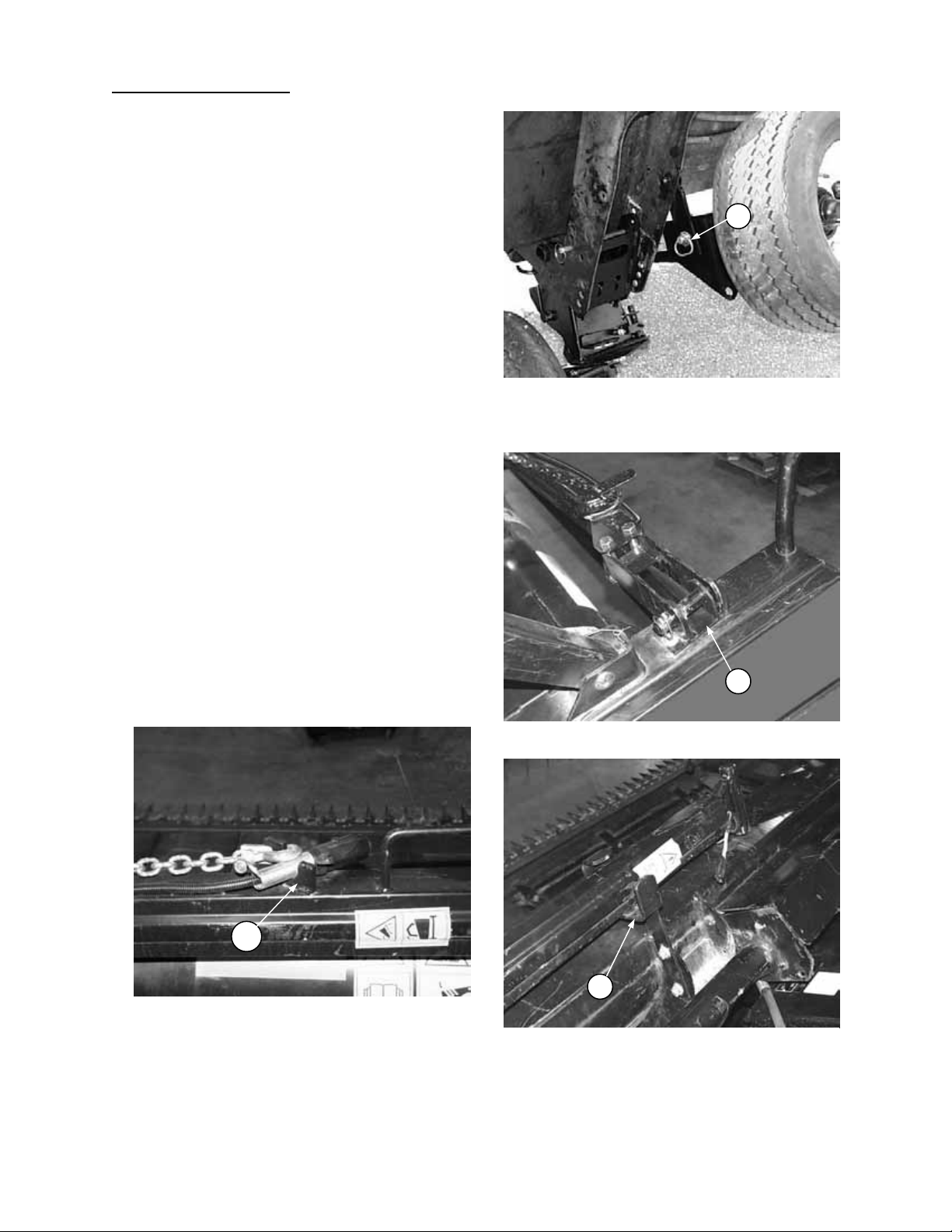

11. Roll the trans-ax le to the rear of the header.

Lift and engage head of hitch pin ( C) in notch

of storage latch.

12. Lower header onto gauge wheels.

13. Check tire pressure. Inflate to 100 psi (690

kPa).

14. Place hitch in storage on back tube: At left

endsheet, install stor age s upport ( D) with ½ x

1 short neck carriage bolt and flange lock

nut.

NOTE: Orient support (D) for best clearance

of tow pole to header hoses, etc. in storage.

Lay hitch clevis over s torage support (D ) and

secure with hitch pin and lynch pin. At

inboard end, attach s upport (E) to header lef t

leg with two ½ x 1 carr iage bolts and flange

nuts. Rest hitch in support (E). Secure hitch

chain and electrical har ness at brack et (F) as

shown. Use the lock ing device on hitch cha in

to secure the hook.

C

D

STEP 14: HITCH STORAGE AT ENDSHEET

F

E

STEP 14: CHAIN & HARNESS STORAGE

STEP 14: HITCH STORAGE AT LEG

Form # 46581 Issue 11/04

Page 8

TRANSPORT OPTION

7

STEP 15:

END VIEW

STEP 15:

SET-UP INSTRUCTIONS

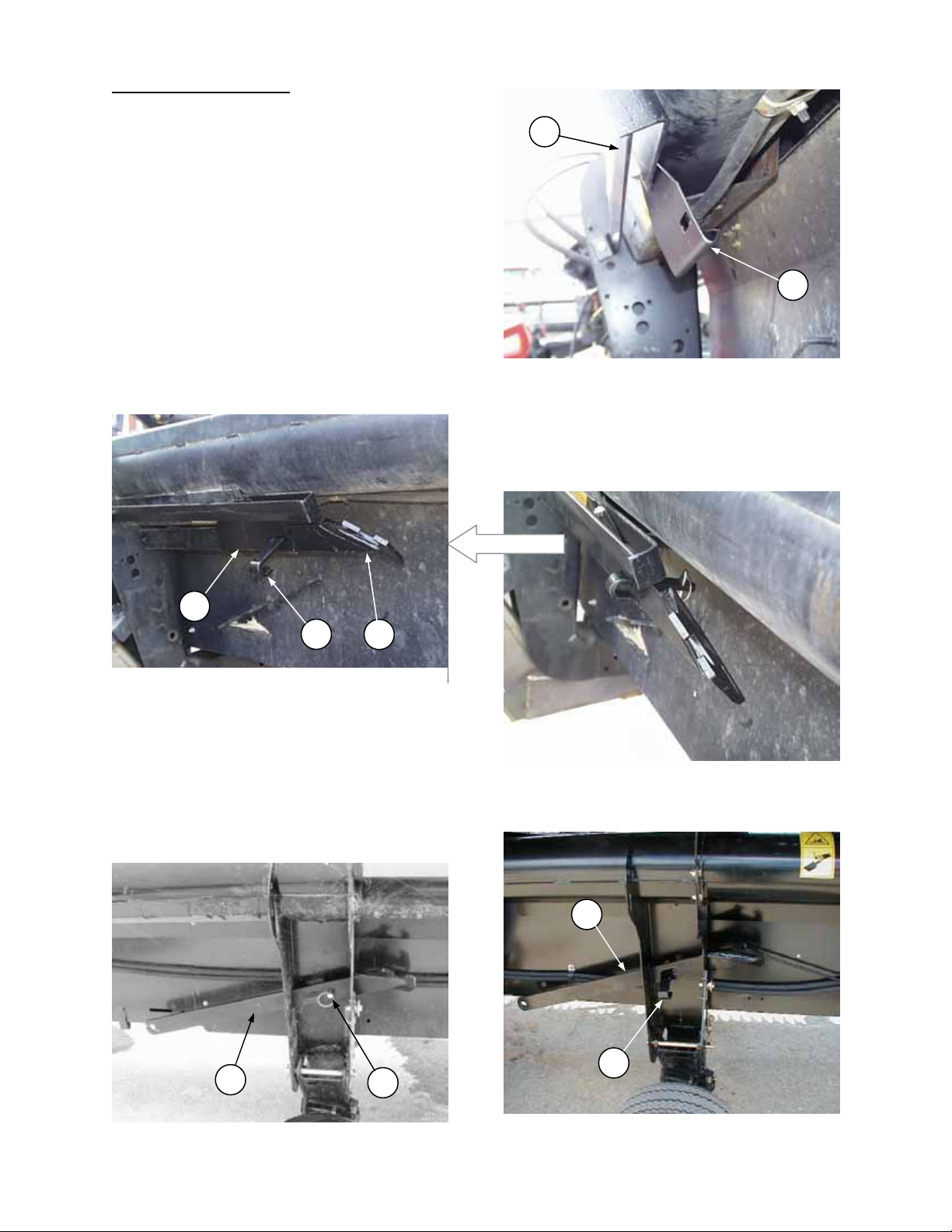

15. 972 Headers: Store diago nal brace on back

tube: Install diagonal brace storage bracket

(G) at right end of channel under header back

tube using one 3/8 x 1 carriage bolt and

flange lock nut.

NOTE: Use lower hole in bracket (G) to

mount on 36’ 972 Headers. For 30’ 972

Headers, use top hole to lower bracket

sufficiently to allow installation of diagonal

brace. (Crop lifter storage bracket (H) is not

present on all headers.)

Place diagonal brace ( K) in brack et as sho wn

below and insert J-bar (J) through slots in

bracket (G) and diagona l brace. Sec ure J-bar

with lynch pin as shown. For 972 headers

with 973 style cutterbar po l y s k ids, us e lon ger

J-bar provided in poly kit.

DIAGONAL BRACE & J-BAR STORAGE - 972

973 Headers: Store diago nal brace (K) in slo ts

provided in right frame leg. Insert J-bar (J) in

slot in diagonal brace and secure with lynch

pin. For 973 Headers with cutterbar poly skids,

use the longer J-bar provided in poly kit.

974 Headers: Store diago nal brace (K) in slo ts

provided in right frame leg. Install clevis pin

and split ring at (L).

G

J

K

H

G

STEP 15:

STORAGE BRACKET FOR BRACE - 972

DIAGONAL BRACE & J-BAR STORAGE - 972

K

J

K

STEP 15: DIAGONAL BRACE STORAGE – 974

Form # 46581 Issue 11/04

L

STEP 15: DIAGONAL BRACE STORAGE – 973

Page 9

TRANSPORT OPTION

8

STEP 16: ROUTE HEADER HARNESS

SET-UP INSTRUCTIONS

16. Route header wiring harness as follows:

• Route the harness from the outboard L/H

header leg up and through space between the

back sheet and the he ader back tube. Route t he

harness with the lines along front of tube and

back into the inboard L/H header leg at (Z).

Attach ground wire (M) with 1/4 x 1/2 inch hex

head bolt and flange nut. Continue routing

harness through back tube to R/H end.

NOTE: Cable tie harness to existing hydraulic

lines running along the front of back tube.

Z

P

T

M

• Secure harness at the outboard L/H header

leg with harness clip at (P). Pl ace other clip s

for best appearance. S ecur e with cab le tie at

(T), leaving 24” (610 mm) of harness from

bottom of header leg to connector. After

installing hitch for the first time, swing wheel

W

assembly to simulate 90º turns left and right.

Ensure adequate harness slack and install

cable ties at (W).

17. At the R/H end sheet, install lamp module and support as follows: For Single Sickle Headers

(N) with the hardware that secures the sickle storage tube. For Double Sickle Headers

clamp (V).

V

N

STEP 17: INSTALL LAMP MODULE – Double Sickle STEP 17: INSTALL LAMP MODULE – Single Sickle

18. Connect header harness and end sheet harness to

lamp module. Route end s heet harness to top of end

sheet through hole at reel support arm anchor (S).

19. Instal l lights at R/H end sh eet using the hard ware that

secures the pivoting amber lights. Secure harness

R

with plastic tie at (R).

, install at

, install at

S

Form # 46581 Issue 11/04

STEP 19: INSTALL LIGHTS AT END SHEET

Page 10

TRANSPORT OPTION

9

SET-UP INSTRUCTIONS

20. Install lights at R/H reel support arm using

1/2 x 1 inch carriage bolts and flange nuts

as shown.

NOTE: For headers with floating divider

option, a different light mounting bracket is

required. See instructions packaged with

dividers.

21. Install harness guard as shown at (A).

22. For 972 Headers:

Install harness guard

holder (G) on reel arm as shown. Secure

holder with 5/8 x 1 inch hex head bolt and

lock nut.

23. Route harness up inside reel support arm

and over bolt (D). Pass harness through

guard to lights and make the connections.

Secure harness with plastic tie at (C) (see

inset, top photo).

NOTE: Wire colors do not match up when

connecting harness to lights. Refer to wiring

schematic on page 10.

24. For 972 single sickle drive headers:

Attach

Slow Moving Vehicle sign to R/H endsheet

with spacer (between sign and endsheet), 3/8

x 1 ¾ carriage bolt an d flange nut as shown

below left.

For 972 double sickle drive headers

: If not

present, drill a 0.406” hole in R/H reel

support arm located 7 ½” (190 mm)

rearward of reel lif t cylinder pin (F), and 3/8”

(10 mm) above center -li ne of r eel lif t cylinder

pin (F). Attach sign to reel arm with spacer

(between sign and arm ), 3/8 x 1 ¾ carriage

bolt and flange nut as shown below center at

(E).

For 973 & 974 headers:

Attach Slow Moving Vehicle sign to R/H reel support arm with spacer

(between sign and arm), 3/8 x 1 ¾ carriage bolt and flange nut as shown below right. For these

headers, harness guard holder (G) is not used. Position harness guard above SMV hardware to

secure back end.

A

INSTALL LIGHTS & HARNESS GUARD AT

R/H REEL ARM

D

INSTALL GUARD HOLDER - 972

C

G

E

F

972 SINGLE SICKLE DRIVE 972 DOUBLE SICKLE DRIVE 973 / 974 HEADERS

INSTALL SMV SIGN

Form # 46581 Issue 11/04

Page 11

10

ELECTRICAL SCHEMATIC

TRANSPORT OPTION

Form # 46581 Issue 11/04

Page 12

TRANSPORT OPTION

11

CONVERTING FROM FIELD POSITION

TO TRANS P O R T

WARNING: To avoid injury or

caused by machine tip-o ver, move

reel fore-aft position to stabilize

the load on the tw o rear wheels in

transport. Do not move reel while

machine is in transport.

1. Move reel ful ly back on support arm s unless

combine adapter is ins talle d in h eader *. Se e

"Reel Position - Fore & Aft" in Header

Operator’s Manual for adjustment details.

For manual for e-aft: To avoid bind ing, m ove

reel two positions at a time, alternating sides

so reel moves back evenly.

Lower reel. NOTE: To prevent damage to

reel support arms, do not trans port with reel

props engaged.

* IMPORTANT: If header is being

transported with combine adapt er insta l led:

• With pick up reel – Mo ve reel to a midrange fore-aft position.

• With bat reel – Move reel further

forward.

Always check stability of load before

transporting. The rear wheels should be

carrying approximately the same weight.

2. Fully retract center link between header and

adapter.

3. Raise header fully.

DANGER: To avoid bodily injury or

death from unexpected start-up or

fall of raised header, stop engine,

remove key and engage header lift

cylinder stops before going under

header for any reason.

4. Engage float lockout on combine adapter.

See Adapter Operator’s Manual.

NOTE: Steps 5 to 9 are for 974 Flex Header

only.

5. Move all four wing float lockout pins to

“lockout” position (E). To move pins from

“float engaged” position (F) to position (E),

see “974 Flex Header: Wing Float Set-Up

and Pre-Delivery Check” in Unloading and

Assembly section of Header Operator’s

Manual.

NOTE: Steps 6 to 9 are intended to increase

ground clearance in transp ort. If you desire more

than 300 mm (12”) clearanc e under the com bine

adapter when transporting , proceed with s teps 6

to 9. Otherwise, go to step 10.

6. Place two 250 mm (10”) blocks (A) under

center section of cutterbar as shown below.

7. Lower header onto blocks.

8. At left and r ight bel lcrank , inst all clev is pin (B)

into the transport position (through the bell

crank top link) as shown and secure with

hairpin. This locks the header in the “frown”

position.

9. Raise header full y, engage lift cylinder stops

and proceed to step 10.

E

B

F

• LOCK OUT WING FLOAT – 974 HEADER

• LOCK HEADER INTO FROWN POSITION

FOR INCREASED GROUND CLEARANCE

IN TRANSPORT

A

974 HEADER - BLOCK CENTER SECTION

OF CUTTERBAR

Form # 46581 Issue 11/04

Page 13

TRANSPORT OPTION

12

STEP 13

:

ENGAGE STRUT HOOK ON CUTTERBAR

STEP 13

: INSTALL PIN IN STRUT

STEP 12

:

RELEASE R/H WHEEL FROM STORAGE

At R/H end:

10. Disengage header lift cylinder stops and

slowly lower header until wheels are on the

ground. Continue lowering header until

upper pins are loose. Remove upper pins

(C) at left and right wheels . Pins (C) will be

installed in transport position in step 17.

11. Raise header fully.

DANGER: To avoid bodily injury or

death from unexpected start-up or fall

of raised header, stop engine, remove

key and engage header lift cylinder

stops before going under header for

any reason.

12. Lift the R/H cutterbar-side wheel to release

storage latch at (A). Roll the wheel and tr ans axle under cutterbar to transport position.

13. Remove hitch pin from strut channel. Pivot

strut channel upwards an d enga ge s tr ut ho ok

into slot on back edge of cutterbar. Install

hitch pin in transport position (B). Secure

with split ring.

NOTE: For 973 and 974 Headers with poly

wearplates on cutterbar, it will be necessary to

notch poly in two places. See page 21.

14. Remove diagonal brace from storage

position on header.

For 972 and 973 Headers: Engag e head of

brace on cutterbar anchor and rotate brace

clockwise to engage head behind the guard

trash bar.

For 974 Header: Install brace onto lug

welded to rear of cutterb ar and secur e wit h ¾

x 1-3/16 clevis pin and split ring.

C

A

B

STEP 14: ENGAGE BRACE ON LUG –

974 HEADER

Form # 46581 Issue 11/04

STEP 14: ENGAGE BRACE ON ANCHOR –

972 & 973 HEADERS

Page 14

TRANSPORT OPTION

13

STEPS 17

-

19:

POSITION R/H REAR WHEEL

CONVERTING FROM FIELD POSITION

TO TRANS P O R T

15. Engage other end of di ago nal br ac e on pin at

strut. Secure with lynch pin.

16. 972 & 9 73 Headers onl y: Hook the J-bar on

back edge of cutterbar an d through head of

diagonal brace. Secure with lynch pin. For

972 & 973 Headers with 9 73 style cutterbar

poly skids, use the longer J-bar provided in

poly kit.

17. Install pins removed in step 10 in transport

position (A), engaging the hole in spring

loaded bracket as shown in lower right photo.

Secure with split ring.

18. Raise header fully and engage lift cylinder

stops.

19. At R/H rear wheel, push down on ha ndle (F)

and lock under welded bolt head to raise p in

(G) to allow wheel to pivot. Pivot wheel to

transport position. Release handle (F) from

under bolt head t o lower pin (G) and lock in

transport position.

(continued)

A

STEP 15: SECURE BRACE TO STRUT

STEP 16: INSTALL J-BAR –

972 & 973 HEADERS

A

F

G

Form # 46581 Issue 11/04

Page 15

TRANSPORT OPTION

14

STEP 20

:

INSTALL HITCH IN SPINDLE SOCKET

STEP 23

:

STEPS 21

-

22:

CONVERTING FROM FIELD POSITION

TO TRANS P O R T

At L/H end:

20. Install hitch in socket of dual whee l spindle,

engaging hitch end-pin in channel slots.

21. Lower the top chan nel and secure with lynch

pin (A). Push do wn on handle (B) and lock

under welded bolt head to raise pin (C) to

allow wheel to piv ot. Leave han dle in lock ed

position, as the dual wheel assembly must

be free to pivot in transport.

22. Connect header wiring harness to hitch

harness at (D).

23. Swing the hitch pole around to the left end.

24. If combine adapter is to remain with the

header, ensure float lock-outs are engaged.

25. Disengage header lift cylinder stops and

slowly lower header until wheels are on the

ground. Block the tires to prevent header

rolling.

26. Detach header from power unit. See

Windrower Tractor or Combine Adapter

Operator's Manual. Be sure reel is fully

down and all hydraulic lines are properly

disconnected and stored.

WARNING: For headers with

hydraulic reel fore-aft, never

connect the fore-aft couplers to

each other. This would complete

the circuit and allow th e reel to creep f orward

in transport, resulting in instability.

(continued)

C

B

A

D

L/H DUAL WHEELS – TRANSPORT POSITION

SWING HI TC H TO TR ANSPORT POSITI O N

Form # 46581 Issue 11/04

Page 16

TRANSPORT OPTION

15

ATTACHING TO TOWING VEHICLE

CAUTION: To avoid bodily injury and/or machine damage caused by loss of control:

1. To ensure adequate braking performance and control, do not tow with a vehicle weighing less

than 5000 lbs. (2300 kg).

2. To increase header stability in transport, ensure th at reel is down and fully back on support

arms. For headers with hydraulic reel fore-aft, never connect the fore-aft couplers to each

other. This would complete the circuit and allow the reel to creep forward in transport,

resulting in instability.

3. Check that all pins are properly secured in transport position at wheel supports, hitch and

cutterbar support.

4. Check tire condition and pressure prior to transporting.

5. Connect hitch to towing vehicle with a proper hitch pin with a spring locking pin or other

suitable fastener.

6. At tach hitch chain to tow ing vehicle. Adjust chain length to r emove all slack except what is

needed for turns.

7. Connect header wiring harness 7-pole plug to mating receptacle on towing vehicle. (The 7-pole

receptacle is available from your dealer parts department.)

8. Ensure lights are functioning properly, and clean the slow moving vehicle emblem and other

reflectors.

TOWING THE HEADER

CAUTION: THIS IS INTENDED AS A LOW SPEED TRANSPORT. To avoid bodil y injury

and or machine damage caused by loss of control:

1. Do not exceed 20 mph (30 km/h). Reduce transport speed for slippery or rough conditions.

2. Turn corners only at very low speeds [5 mph (8 km/h) or less]. While cornering, header

stability is reduced as front wheel moves to the left.

3. Obey all highway traffic regulations in your area when transporting on public roads. Use

flashing amber lights unless prohibited by law.

Form # 46581 Issue 11/04

Page 17

TRANSPORT OPTION

16

J STEP 6:

L/H DUAL WHEELS

–

FIELD POSITION

CONVERTING FROM TRANSPORT TO

FIELD POSITION

1. Block the tires to prevent header rolling.

2. Attach header to power unit.

See Windrower Tr actor or Combine Adap ter

Operator Manual.

3. Raise header fully.

4. Swing the hitch pole around to the back of

the header. Detach header wiring harness

from hitch harness at 4-way connector (A).

Wrap header harness around lynch pin

locking bracket (C) once hitch is removed.

5. Remove lynch pin (B), raise the top channe l

and remove hitch f rom socket of dual wheel

spindle.

6. At L/H support, install upper pin (D) in

desired stubble height position and secure

with split ring. When header is lowered,

spring-loaded brack et will engage upper pin

as shown.

Release handle (E) fr om under bolt head to

lower pin (F) and lock in field position.

NOTE: If cutting low to the groun d an d no g au ge

wheel contact is desired , wheels can be raised

to storage position. See page 21.

At R/H end

:

7. 972 & 973 Headers: Det ach J-bar (J ) which

locks diagonal brace to cutterbar.

974 Header: Remove split ring and clevis pin

(K) securing diagonal brace to lug at rear of

cutterbar.

DANGER: To avoid bodily injury or

death from unexpected start-up or

fall of raised header, stop engine,

remove key and engage header lift

cylinder stops before going under

header for any reason.

K

B

A

STEP 5: DETACH HITCH

D

F

E

C

STEP 7: REMOVE CLEVIS PIN FROM LUG –

Form # 46581 Issue 11/04

STEP 7: DETACH J-BAR – 972 & 973 HEADER

974 HEADER

Page 18

TRANSPORT OPTION

17

STEP 8: DETACH BRACE FR OM STR UT

& REMOVE PIN

CONVERTING FROM TRANSPORT TO

FIELD POSITION

8. Detach diagonal brace from s trut channel at

(A) and remove brace head from cutterbar.

Remove pin (B) from transport position.

9. Disengage strut hook from cutterbar and

pivot strut channel down to collapsed

position on the trans-axle. Install pin (B) in

storage position (through hole D in above

photo) and secure with split ring.

NOTE: Install pin so head is on correct side

for storage of trans-axle wheel. See Step 11.

10. At R/H support, install upper pin (D) in

desired stubble height position and secure

with split ring. When header is lowered,

spring-loaded brack et will engag e upper pin .

Push down on handle (F) and lock under

welded bolt head to raise pin (G) to allow

wheel to pivot. Pivot wheel to desired field

position. Release handle (F) f rom under bolt

head to lower pin (G) and lock in field

position.

NOTE: Wheel can be positioned on either

side of support, depending on delivery

opening position.

(continued)

D

B

STEP 9: DETACH STRUT HOOK

F

A

D

G

Form # 46581 Issue 11/04

STEP 10: R/H FIELD WHEEL

Page 19

TRANSPORT OPTION

18

STEP 11:

TRANS

-

AXLE WHEEL STORAGE

CONVERTING FROM TRANSPORT TO

FIELD POSITION

11. Roll the trans-axle to the r ear of the header.

Lift and engage head of hitch pin (C) in

notch of storage latch.

NOTE: Trans-axle can be positioned on

either side of leg, depending on delivery

opening position.

12. Lower header to cutting height and move

reel to desired operating position. For

manual fore-af t: To avoid b inding, m ove reel

two positions at a time, alt ernating sides so

reel moves back evenly.

13. Place hitch in storage on back tube: At left

endsheet, lay hitch clevis over storage

support (D) and secure with hitch pin and

lynch pin. At inboard end, rest hitch in

support (E). Secure hitch chain and

electrical harness at bracket (F) as shown.

Use the locking device on hitch chain to

secure the hook.

STEP 13: CHAIN & HARNESS STORAGE

(continued)

F

C

D

STEP 13: HITCH STORAGE AT ENDSHEET

Form # 46581 Issue 11/04

E

STEP 13: HITCH STORAGE AT LEG

Page 20

TRANSPORT OPTION

19

STEP 14:

END VIEW

CONVERTING FROM TRANSPORT TO

FIELD POSITION

14. 972 Headers: Place diagonal brace (K) in

bracket (G) at right end of channel under

header back tube as s ho wn bel o w a nd inser t

J-bar (J) through slots in bracket (G) and

diagonal brace. Secure J -bar with lynch pin

as shown.

(continued)

G

J

K

973 Headers: Stor e diagonal brace (K) in slots

provided in right fr am e leg. Ins er t J- bar (J ) in s lot

in diagonal brace and secure with lynch pin.

974 Headers: Stor e diagonal brace (K) in slots

provided in right fram e leg. Install clevis pin and

split ring at (L).

DIAGONAL BRACE & J-BAR STORAGE - 972

K

J

STEP 14: DIAGONAL BRACE STORAGE – 973

K

L

STEP 14: DIAGONAL BRACE STORAGE – 974

Form # 46581 Issue 11/04

Page 21

TRANSPORT OPTION

20

CONVERTING FROM TRANSPORT TO

FIELD POSITION

15. Raise header fully.

16. Disengage flo at lockout on com bine adapter

and extend center link to desired operating

position. See Adapter Operator’s Manual.

NOTE: Remaining steps are for 974 Flex

Header only.

NOTE: If pins (B) were installed through

bellcrank top link to increase ground clearance

in transport, complete steps 17 to 20 to move

pins to storage position as follows:

17. Place two 250 mm (10”) blocks (A) under

center section of cutterbar as shown.

18. Lower header onto blocks.

19. At left and right bellcrank, retract clevis pin

(B) to the storage position as shown and

secure with hairpin.

20. Raise header and engage lift cylinder stops.

21. Move all four wing float lock out pins to “float

engaged“ position (F).

22. Disengage lift cylinder stops and lower

header.

(continued)

DANGER: To avoid bodily injury or

death from unexpected start-up or

fall of raised header, stop engine,

remove key and engage header lift

cylinder stops before going under

header for any reason.

A

974 HEADER - BLOCK CENTER SECTION

OF CUTTERBAR

B

974 HEADER – MOVE “FROWN LOCK” PINS

TO STORAGE POSITION

F

974 HEADER –

DISENGAGE WING FLOAT LOCKOUT

Form # 46581 Issue 11/04

Page 22

TRANSPORT OPTION

21

POLY

WEARPLATE MODIFICATION

FOR 973 & 974 HEADERS

as a guide to notch poly

RAISING WHEELS TO STORAGE POSITION

If cutting low to the ground and no gauge wheel

contact is desired, wheels can be raised to

storage position, as follows:

• Raise header fully.

DANGER: To avoid bodily injury or

death from unexpected s tart-up or

fall of raised header, stop engine,

remove key and engage header lift

cylinder stops before going under

header for any reason.

• If springs were removed f rom wheels, simply

raise wheel support b y hand and install pin

in storage position, b oth sides. If springs are

installed, proceed as follows:

• Place 10” (250 mm) blocks under L/H and

R/H gauge wheels as shown.

• Lower header until cutterbar touches

ground.

• Place pins (D) into storage location to lock

wheels in raised position.

• Raise header and remove blocks.

NOTE: When converting to transport position

when wheels are in s torage as above, it will be

necessary to block wheels as shown to allow

removal of pin (D) (if springs are installed).

POLY WEARPLATE MODIFICATION FOR

973 & 974 HEADERS

For 973 and 974 Headers with poly wearplates

on cutterbar, it will be nece ssar y to notch poly in

two places.

At R/H outer leg, notch poly wearplate assembly

(K) and poly skid shoe (L) as shown below.

NOTE: Notches are required for clearance for

trans-axle strut hook where it engages the

cutterbar in transport.

Trim poly skid

shoe as shown

D

BLOCK WHEELS TO MOVE PIN TO

STORAGE POSITION

L

Use notch in steel wearplate

Form # 46581 Issue 11/04

77 mm (3”)

77 mm (3”)

40 mm (1-9/16”)

K

Page 23

TRANSPORT OPTION

22

MAINTENANCE / SERVICE

100 Hour or Annual Greasing

Wheel Support Pivots (A) – four fittings

(2 per wheel support)

500 Hour or Annual Greasing

Wheel Hub Bearings (B) – one fitting per wheel

WHEEL SUPPORT PIVOTS

A

B

WHEEL HUB BEARINGS

Form # 46581 Issue 11/04

Page 24

TRANSPORT OPTION

23

MAINTENANCE / SERVICE

Wheel Bolts

Check and tighten wheel bolts after the first 10

hours of operation and every 100 hours

thereafter.

Whenever a wheel is rem oved and re-installed,

check torque after one hour of operation.

Maintain torque of 80 to 90 ft.lbs. (110 to 120

N⋅m)

Follow the proper bolt tightening sequence

shown.

NOTE: When installing wheel, be sure valve

stem (C) points away from wheel support.

Tire Inflation

Check tire pressure dai ly

kPa).

beyond 35 psi (241 kPa) to seat the bead on

the rim. Replace the tire if it has a defect.

Replace a wheel rim, which has cracks, w ear

or severe rust. Never w eld a wheel rim. M ake

sure all the air is remo ved from a tire befor e

removing the tire from a rim. Nev er use force

on an inflated or partially inflated tire. Make

sure the tire is correctly seated before

inflating to operating pressure.

Do not remove, install or make repairs to a

tire on a rim unless you have the proper

equipment and experience to perform the

job. Take the tire and rim to a qualified tire

repair shop. If the tire is not in correct

position on the rim, or is too full of air, the

tire bead can loosen on one side, causing air

to leak at high speed and wit h great f orce. An

air leak of this nature can thrust the tire in

any direction, endangering anyone in the

area.

(A) - Use a safety cage if available.

(B) - Do not stand over tire. Use a clip-on chuck

and extension hose.

. Maintain 100 psi (6 90

WARNING: Service tires safely. A

tire can explode during inflation

and cause serious injur y or death.

Never increase air pressure

1

C

3

6

5

4

2

BOLT TIGHTENING SEQUENCE

SERVICE TIRE S SAFELY

Form # 46581 Issue 11/04

Loading...

Loading...