Page 1

21’ & 25’ Model 972

HARVEST HEADER

SLOW SPEED

TRANSPORT

MANUAL SUPPLEMENT

Form 131126 Issue 11/07

Sugg. Retail: $10.00

Page 2

Inside Front Cover

(blank)

Page 3

Model 972 Header

21’ & 25’ TRANSPORT OPTION

The transport option can be installed on 21 and 25 foot headers to allow towing the header behind the

windrower tractor.

This supplement provides instructions for Set-Up, Transport Safety and Converting to and from Transport

Position, recommended Maintenance and Repair Parts Listing.

TABLE OF CONTENTS

Set-up Instructions ..............................................................................................................................2 - 22

Transport Safety.......................................................................................................................................23

Converting from Field Position to Transport .....................................................................................24 - 29

Converting from Transport to Field Position .....................................................................................30 - 34

Maintenance / Service........................................................................................................................35, 36

Repair Parts ......................................................................................................................................37 - 53

Form # 131126 Issue 11/07

1

Page 4

SET-UP INSTRUCTIONS

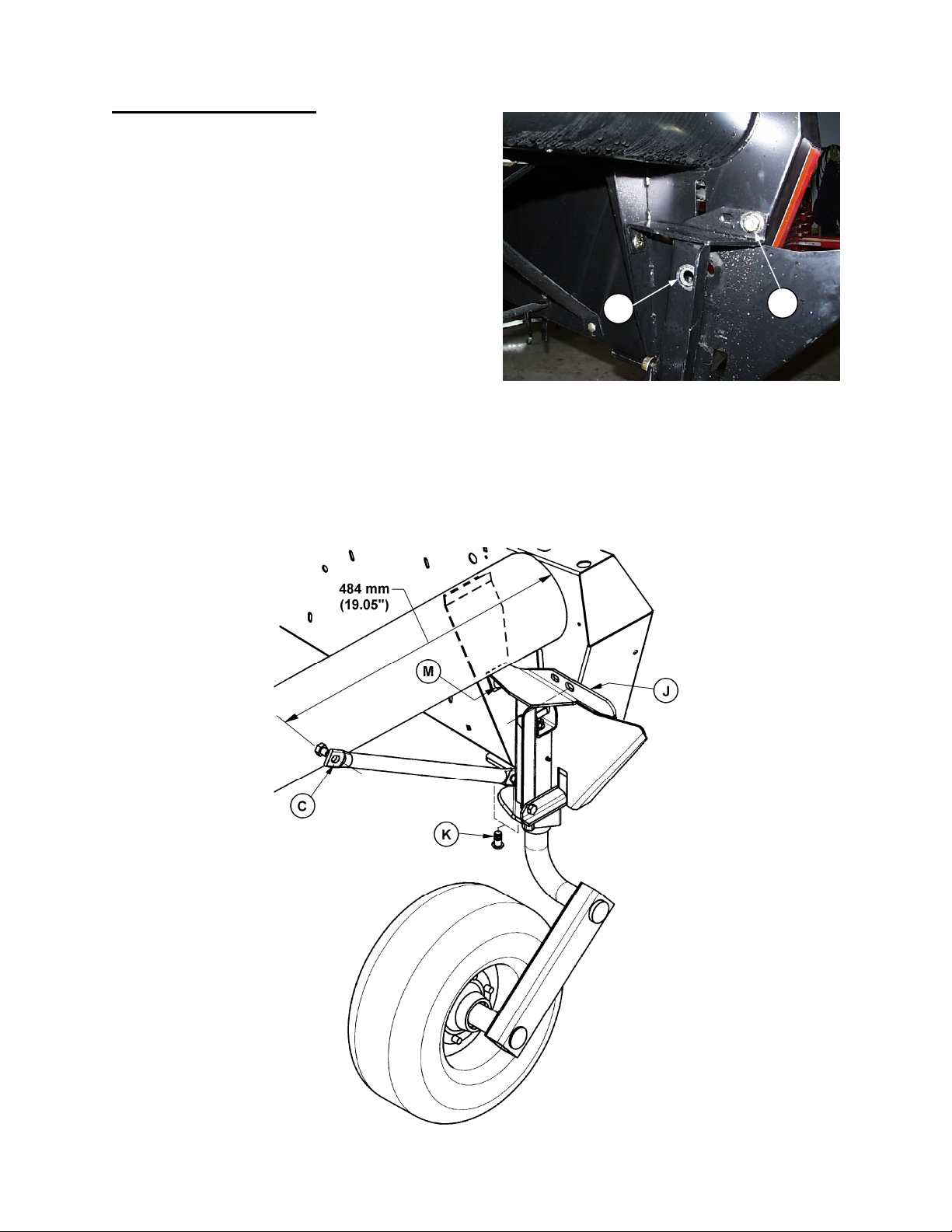

LEFT END (FORWARD) WHEEL

1. On bottom flange of left endsheet, drill

two 0.656” holes* (B) as shown.

NOTE: Holes in bottom flange may be

round or square.

* These holes will be present on headers

built in Model Year 2001 and later.

2. Attach left wheel assembly at the two

holes drilled in step 1, using 5/8 x 1-1/4

carriage bolts at (H) (heads down) and

5/8 flange nuts.

3. Mark the position for hole (A) on the

endsheet, using the wheel assembly as

a guide. Drill a 0.656” diameter hole*.

* This hole will be present on headers

built in Model Year 2001 and later.

4. Position brace tube so that hole (C) is

484 mm (19.05”) from left endsheet as

shown. Mark this position and tack weld

a 5/8 x 1 inch black bolt from kit to main

tube. Position brace onto bolt and

confirm proper bolt position, then

remove brace from bolt and place a 5

mm (3/16”) weld completely around bolt

head.

NOTE: Ends of brace will bend slightly when initially tightened.

26 mm = 1.02”

170 mm = 6.69”

193 mm = 7.60”

LEFT ENDSHEET HOLES

LEFT ENDSHEET HOLE & WELDED BOLT

Form # 131126 Issue 11/07

2

Page 5

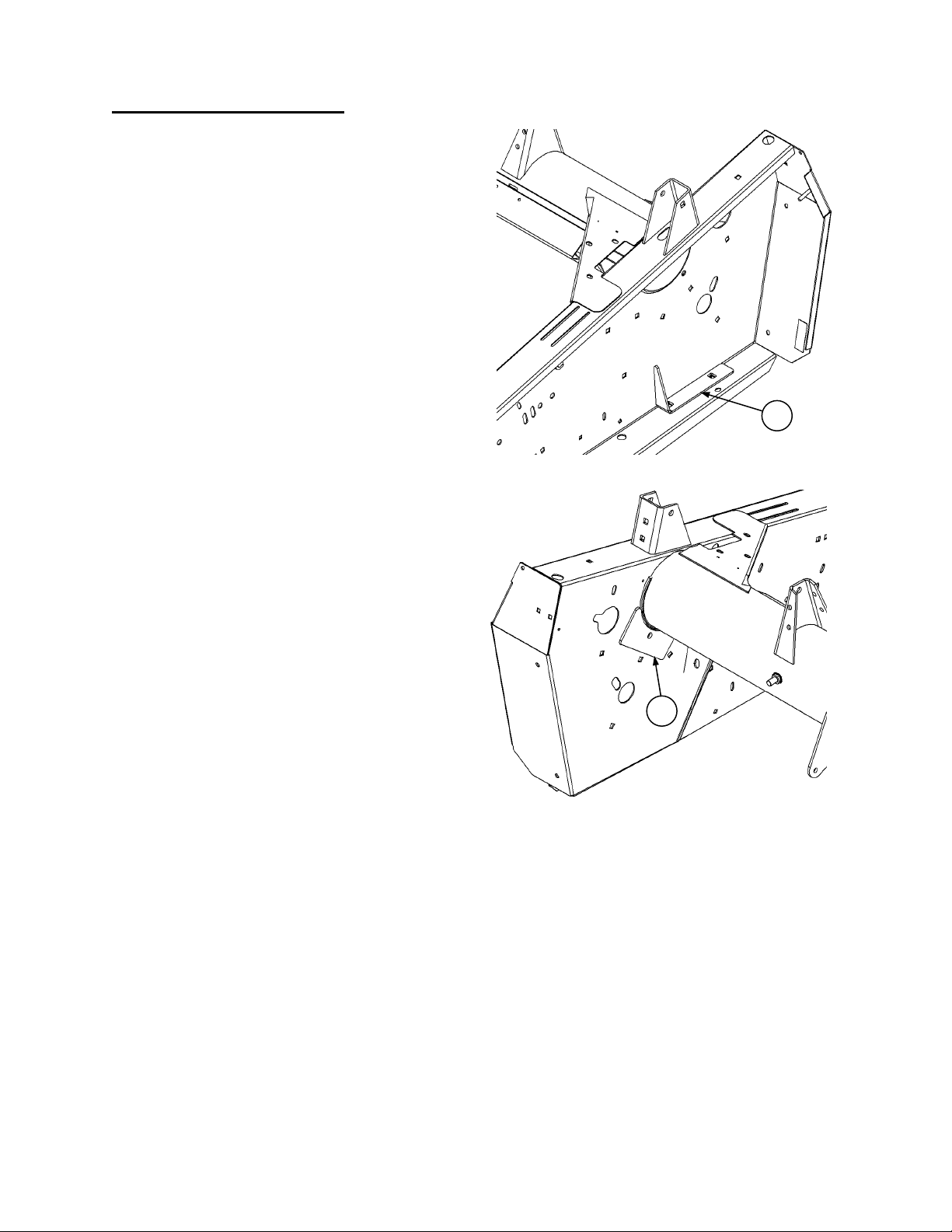

SET-UP INSTRUCTIONS

LEFT END (FORWARD) WHEEL (continued)

5. Remove left wheel assembly installed in

step 2.

6. Align holes in plate (C) (from kit) with

endsheet holes and place a 3mm (1/8”)

fillet weld all around the outside edges of

plate (C).

NOTE: Two bolts can be used in holes to

hold plate (C) during welding.

7. Align hole in plate (D) (from kit) with

endsheet hole and mate the radius of plate

with backtube. Place a 3mm (1/8”) fillet

weld around the outsides edges of plate

(D).

NOTE: A bolt can be used to hold plate (D)

in position during welding.

C

WELD OUTER SUPPORT PLATE – L/H ENDSHEET

D

WELD INNER SUPPORT PLATE – L/H ENDS SHEET

Form # 131126 Issue 11/07

3

Page 6

SET-UP INSTRUCTIONS

LEFT END (FORWARD) WHEEL (continued)

IMPORTANT: Steps 8-11 are for single sickle headers, for double sickle headers proceed to step 12.

8. Bolt left hand caster mount (E) into position

against inside surface of plate (D) welded in step 7

(refer to page 6 for instruction).

9. Position triangular gusset (F) (from kit) 6mm (1/4”)

above left hand caster mount and flush against

plate (D) and backtube. Tack gusset (F) in

position.

10. Remove left hand caster mount and weld gusset

(F). Place a 5mm (3/16“) fillet weld on top and

bottom edges against header backtube and plate

(D).

11. Proceed to step 15.

MOUNT LEFT HAND CASTER SUPPORT

D

E

F

POSITION & WELD GUSSET (F)

Form # 131126 Issue 11/07

4

Page 7

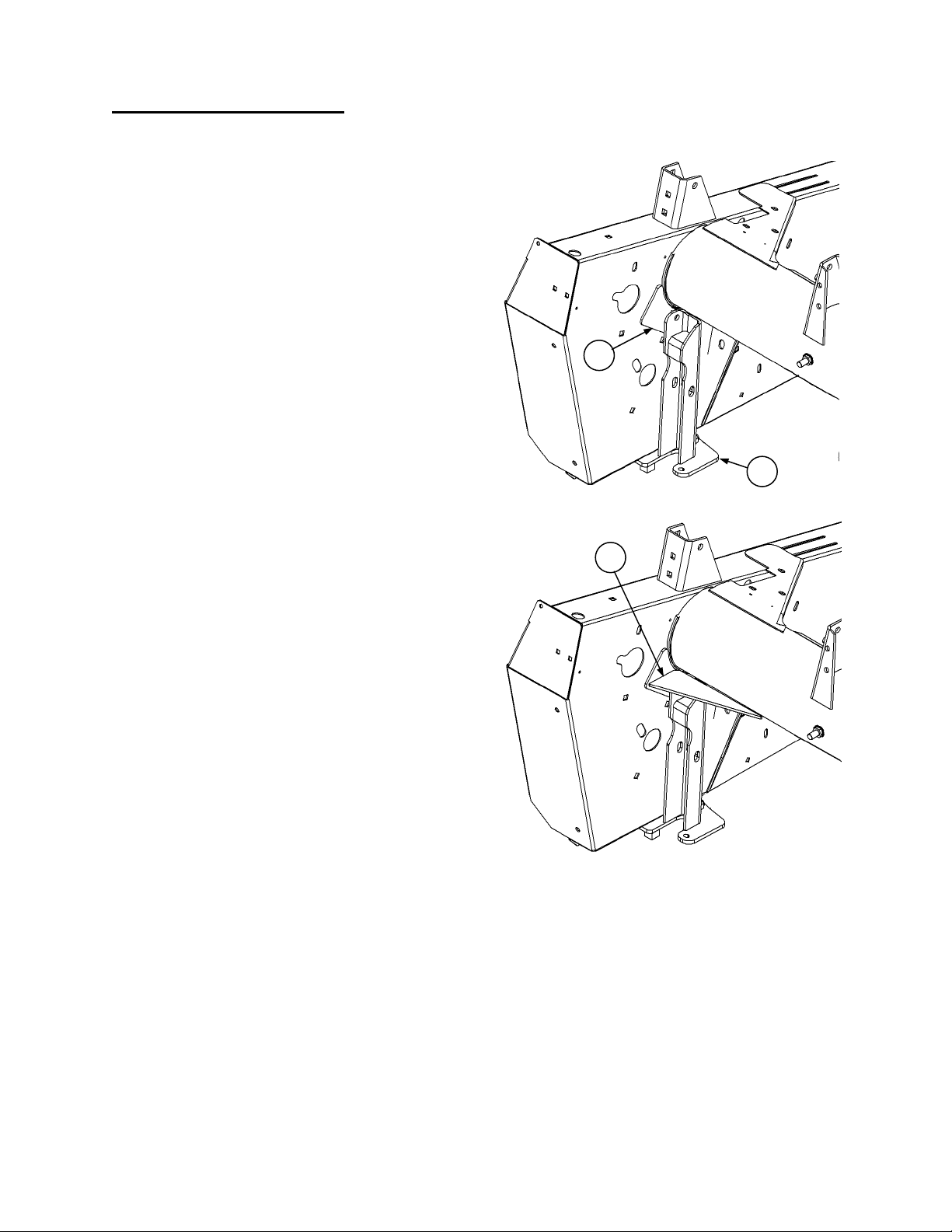

SET-UP INSTRUCTIONS

LEFT END (FORWARD) WHEEL

IMPORTANT: Steps 12-15 are for double sickle headers, for single sickle headers see page 4.

12. Bolt left hand caster mount (E) into position

against inside surface plate (D) welded in step 7

(refer to next page for instruction).

13. Position rectangular (100 x 68mm) gusset (G)

(from kit) 6mm (1/4”) above left hand caster mount

and flush against plate (D) and backtube. Position

the 100mm (4”) side of gusset against plate (D).

Tack gusset (G) in position.

14. Remove left hand caster mount and weld gusset

(G). Place a 3mm (1/8”) fillet weld on top and

bottom edges against header backtube, end panel

gusset and plate (D).

(continued)

D

MOUNT LEFT HAND CASTER SUPPORT

E

G

POSITION & WELD GUSSET (G)

(

END PANEL GUSSET REMOVED FOR CLARITY)

Form # 131126 Issue 11/07

5

Page 8

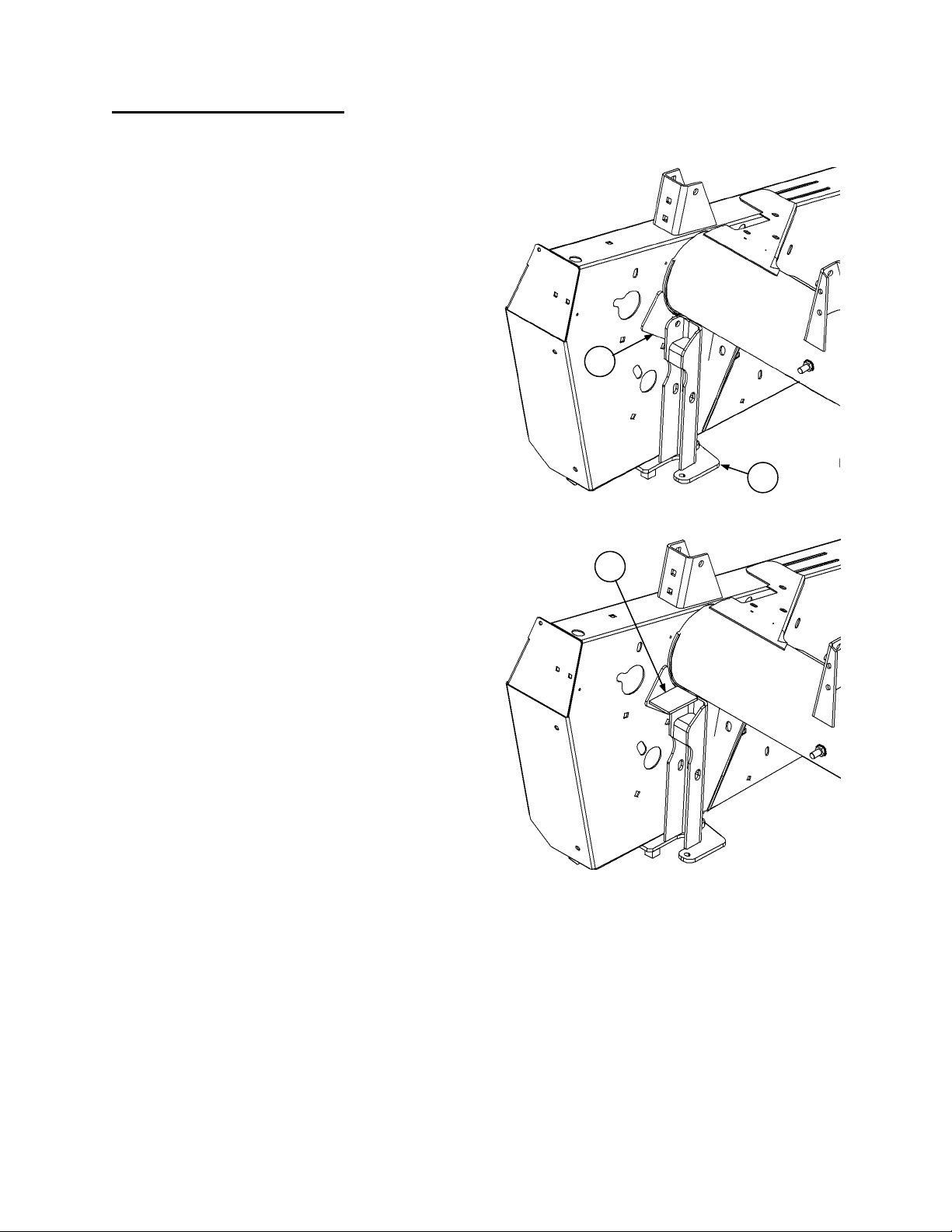

SET-UP INSTRUCTIONS

LEFT END (FORWARD) WHEEL

15. Install left wheel assembly as shown below:

• At the two holes in bottom flange of endsheet, use two 5/8 x 1-1/4 carriage bolts at (H) (heads

down) and 5/8 flange nuts.

• At hole in side of left endsheet, use one 5/8 x 2” hex head bolt (D), 5/8 flat washers (F) (three for

single sickle & four for double sickle headers), and 5/8 flange nut (G).

• At bolt welded to frame tube, use one 5/8 flange nut (J) to secure brace tube.

• Attach storage bracket to rear of left endsheet with two 1/2 x 1 inch short neck carriage bolts and

1/2 flange nuts at (K).

NOTE: For single sickle headers

double sickle drive headers, at top bolt, use the existing belt tension adjusting bolt to secure

bracket.

(continued)

, If not present, drill 0.531” hole (L) at dimensions shown. For

Three required for Single Sickle

Four required for Double Sickle.

LEFT WHEEL ASSEMBLY

Form # 131126 Issue 11/07

6

Page 9

SET-UP INSTRUCTIONS

RIGHT END (REAR) WHEEL

1. On bottom flange of right endsheet, drill two 0.656” holes* (C) as shown.

NOTE: Holes in bottom flange may be round or square.

* These holes will be present on headers built in Model Year 2001 and later.

38 mm = 1.50”

100 mm = 3.94”

80 mm = 3.15”

RIGHT ENDSHEET HOLES

Form # 131126 Issue 11/07

7

Page 10

SET-UP INSTRUCTIONS

RIGHT END (REAR) WHEEL

2. Attach right wheel assembly at the two holes

drilled in Step 1, using 5/8 x 1-1/4 carriage head

bolts at (K) (heads down) and 5/8 flange nuts.

Secure at gusset under frame tube with 5/8 x 11/4 carriage head bolt (M) and flange nut.

3. Drill a 0.812” diameter hole in the endsheet,

using the hole (A) in wheel assembly as a

guide. (Disassemble as required for fit-up.) This

hole will be present on headers built in Model

Year 2001 and later.

4. Mark the position for hole (B) as follows:

For double sickle drive headers: Use the rear

hole in support (J) as shown.

For single sickle drive headers: Use the forward

hole in support (J).

Drill a 0.750” diameter hole. This hole will be present on headers built in Model Year 2001 and later.

5. Position brace tube so that hole (C) is 484 mm (19.05”) from right endsheet as shown. Mark this

position and tack weld a 5/8 x 1 inch black bolt from kit to main tube. Position brace onto bolt and

confirm proper bolt position, then remove brace from bolt and place a 5 mm (3/16”) weld completely

around bolt head.

(continued)

A

B

RIGHT ENDSHEET HOLES – DOUBLE SICKLE

HEADER SHOWN

RIGHT ENDSHEET HOLES & WELDED BOLT

Form # 131126 Issue 11/07

8

Page 11

SET-UP INSTRUCTIONS

RIGHT END (REAR) WHEEL

6. Install right wheel assembly as shown below:

• Install 3/4 x 4-1/2” hex head bolt through wheel assembly and new 0.812” hole in endsheet.

Position plate (G) on outside face of endsheet and secure with 3/4 nut (E).

NOTE: If necessary, elongate hole in endsheet horizontally as required to fit.

• At new 0.75” hole in endsheet, install 5/8 x 1-1/4 hex head bolt (F) and secure with nut (H).

NOTE: For double sickle drive headers

shown. For single sickle drive headers

• At bolt welded to frame tube, use one 5/8 flange nut (L) to secure brace tube.

(continued)

use top hole in plate (G) and rear hole in support (J) as

, use lower hole in plate (G) and forward hole in support (J).

RIGHT WHEEL ASSEMBLY

Form # 131126 Issue 11/07

9

Page 12

SET-UP INSTRUCTIONS

FRONT (CUTTERBAR) WHEEL

1. At right hand header leg

2. Weld rectangular bar (A) across bottom of leg, using a 5 mm (3/16”) weld on top surface (B) both

sides as shown below. Ensure there is no weld at edges.

3. Weld two cropped bars* (C) to sides of leg, with crop towards cutterbar as shown below. Use a 5 mm

(3/16”) weld at edges (D), both sides.

* These welded bars (C) will be present on headers built in Model Year 2001 and later.

, remove skid shoe, if installed.

10 mm = 0.39”

227 mm = 8.94”

259 mm = 10.20”

R/H LEG MODIFICATIONS

Form # 131126 Issue 11/07

10

Page 13

SET-UP INSTRUCTIONS

FRONT (CUTTERBAR) WHEEL

4. Install front wheel assembly as shown below.

• Install wheel assembly over guard tips (E) at right header leg.

• Ensure clamp is seated up inside leg.

• Operate lever (F) to engage clamp on leg plate.

• If leg mounted skid shoes are required, install new shoe (G) (with higher front lip) from kit at right

header leg.

NOTE: Leg mounted skid shoes can not be installed when combine adapter is installed.

(continued)

FRONT WHEEL ASSEMBLY

Form # 131126 Issue 11/07

11

Page 14

SET-UP INSTRUCTIONS

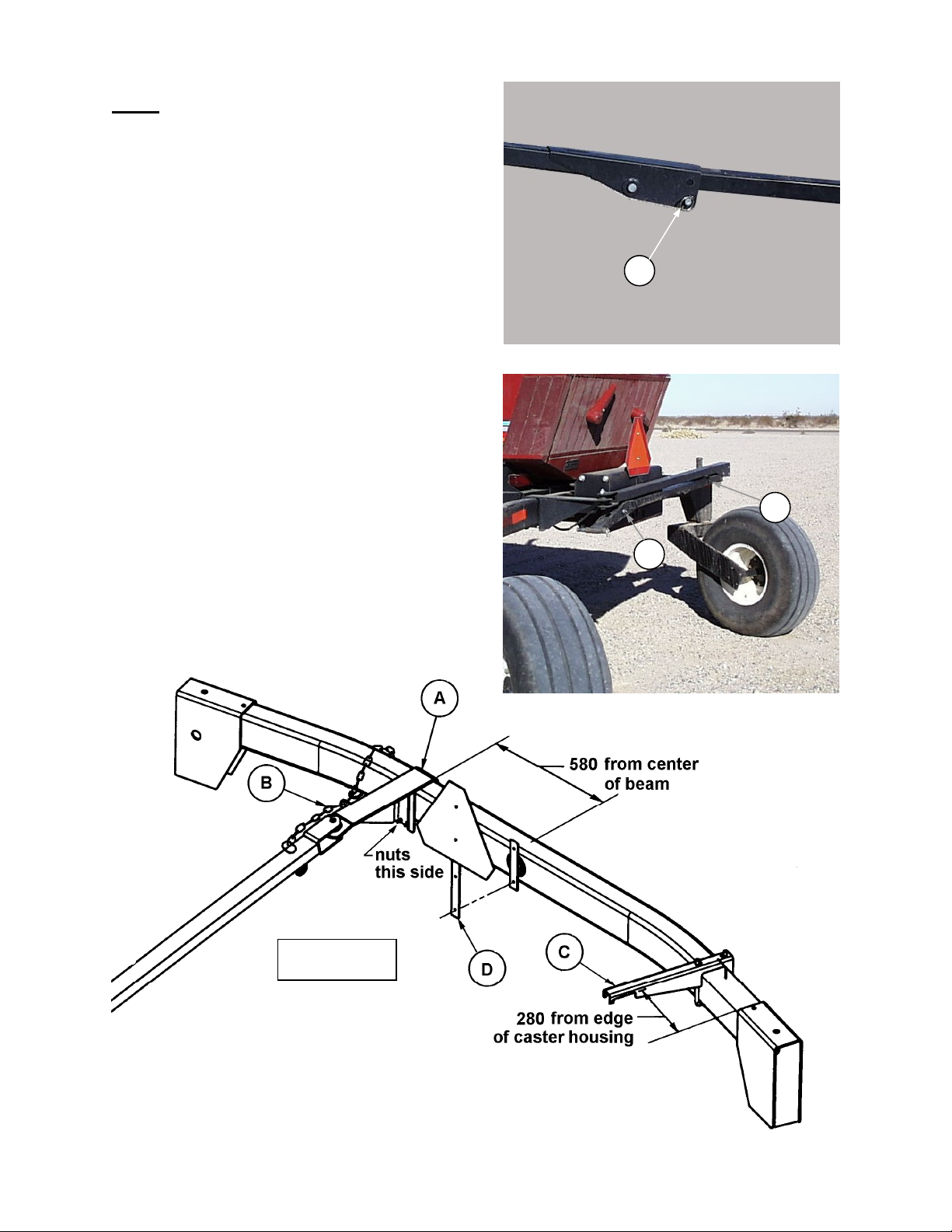

HITCH

1. Slide bracket (A) over walking beam and

position as shown below. Secure with two 5/8 x

5-1/2” hex head bolts and flange nuts.

2. Route hitch chain (B) through chain support on

bracket (A), then wrap around walking beam

and lock hook on chain.

3. Position storage bracket (C) as shown below

and secure with U-bolt and 1/2 NC flange nuts.

4. Remove SMV sign from welded mount. Attach

extension bar (D) to welded mount using new

self-tapping screws.

NOTE: Use the larger holes in bar (D) to attach

to welded mount. It may be necessary to bend

the welded mount out slightly.

5. Attach SMV sign to smaller holes in bar (D)

using the existing self-tapping bolts removed

form welded mount.

6. Remove split ring and remove lock pin from

hitch knee joint at (E).

7. Store hitch as follows: Place front section of

hitch on top of storage bracket (C) at right side

of walking beam. Fold hitch and place rear

section into notch in bottom of bracket (C).

Install pin from knee joint to lock the two

sections at (G) and secure with split ring.

E

REMOVE LOCK PIN FROM HITCH JOINT

C

G

HITCH STORAGE

580 mm = 22.84”

280 mm = 11.02”

ATTACH HITCH TO TRACTOR

Form # 131126 Issue 11/07

12

Page 15

SET-UP INSTRUCTIONS

TRANSPORT LIGHTS ON HEADER

1. Open left hand drive shield and route header section of transport wiring harness through inside of

frame tube to right endsheet.

NOTE: The end of the harness with the 6-way connector goes to the right endsheet.

NOTE: For European applications, the lamp module

referred to in steps 2 and 3 is not used. Header

harness connects directly to end sheet harness.

2. At the R/H end sheet, install lamp module and

support as follows: For Single Sickle Headers

Install at (N) with the hardware that secures the

sickle storage tube as shown at right. For Double

Sickle Headers, install at clamp (V) as shown

below.

,

N

INSTALL LAMP MODULE – Single Sickle

(EXCEPT EUROPEAN APPLICATIONS)

V

INSTALL LAMP MODULE – Double Sickle

(EXCEPT EUROPEAN APPLICATIONS)

3. Connect header harness and end sheet

harness to lamp module. Route end sheet

harness to top of end sheet through hole at reel

support arm anchor (S).

4. Install lights at R/H endsheet as shown at right,

using the hardware that secures the pivoting

amber lights. Secure harness with plastic tie at

(R). NOTE: For European applications, pivoting

amber lights are not installed. Install transport

lights using hardware provided.

NOTE: Wire colors do not match up when

connecting harness to lights. Refer to wiring

schematic on Page 15.

R

S

INSTALL LIGHTS AT END SHEET

R

S

INSTALL LIGHTS AT ENDSHEET

Form # 131126 Issue 11/07

13

Page 16

SET-UP INSTRUCTIONS

(

)

TRANSPORT LIGHTS ON HEADER

5. Install lights at R/H reel support arm using ½ x

1 inch carriage bolts and flange nuts as shown.

Mounting for 2001 and newer headers shown

in top photo. For pre-2001 headers, light mount

is attached as shown in second photo.

NOTE: For headers with floating divider option, a

different light mounting bracket is required. See

instructions packaged with dividers.

6. For 2001 and newer headers, install harness

guard as shown at (A). For pre-2001 header

install harness guard as shown at (B).

7. Install harness guard holder (G) on reel arm as

shown. Secure holder with 5/8 x 1 inch hex

head bolt and lock nut. Route harness up

inside reel support arm and over bolt (D). Pass

harness through guard to lights and make the

connections. Secure harness with plastic tie at

(C) (see inset, top photo).

NOTE: Wire colors do not match up when

connecting harness to lights. Refer to wiring

schematic on page 15.

D

INSTALL GUARD HOLDER

8. For single sickle drive headers

and flange nut as shown below left.

For double sickle drive headers

from bottom of sign as shown at (E). Also drill a 0.406” hole in RH reel arm located 7 ½” (190 mm)

rearward of reel lift cylinder pin (F), and 3/8” (10 mm) above centerline of reel lift cylinder pin (F).

Attach sign with spacer, 3/8 x 1 ¾ carriage bolt and flange nut as shown below right.

(continued)

A

INSTALL LIGHTS & HARNESS GUARD AT

R/H REEL ARM

B

G

INSTALL LIGHTS & HARNESS GUARD AT

R/H REEL ARM - Pre-2001 Header

, attach Slow Moving Vehicle sign with spacer, 3/8 x 1 ¾ carriage bolt

, drill a 0.406” hole in SMV sign, centered on base and 2.16” (55 mm)

C

E

F

INSTALL SMV SIGN

SINGLE SICKLE DRIVE HEADERS

Form # 131126 Issue 11/07

14

(DOUBLE SICKLE DRIVE HEADERS)

INSTALL SMV SIGN

Page 17

SET-UP INSTRUCTIONS

TRANSPORT LIGHTS ON HEADER

9. At left end, route harness (G) as shown and

engage tab of 4-way connector in hole in

endsheet at (H) for storage. Ensure harness

will reach to hitch section before securing.

10. Secure harness at clamp (J) and cable tie at

(K) as shown. Attach harness ground wire at

bolt for clamp (J) with 3/8 nut provided.

(continued)

K

J

G

H

G

HEADER HARNESS – LEFT END

DOUBLE SICKLE

K

H

HEADER HARNESS – LEFT END

SINGLE SICKLE

CONNECTIONS TO LIGHTS

Form # 131126 Issue 11/07

15

Page 18

SET-UP INSTRUCTIONS

AROU

REFLECTORS ON HEADER

1. Add eight amber reflectors to header as shown below:

FRAME TUBE AT CENTER OPENING

LEFT END – TWO REFLECTORS

WRAP THREE REFLECTORS

ND CENTER OF REEL TUBE

RIGHT END – TWO REFLECTORS

DOUBLE SICKLE HEADER

RIGHT END – TWO REFLECTORS

SINGLE SICKLE HEADER

Form # 131126 Issue 11/07

16

Page 19

SET-UP INSTRUCTIONS

RE-ROUTE HEADER HOSES AND HARNESS

1. At left header leg, remove reel lift hose and

header wiring harness from their clamped

position at (A). Remove female 1/4” quick

coupler from reel lift hose.

2. Re-route reel lift hose and header wiring

harness into v-channel under main tube and out

rectangular hole at (B). Reinstall quick coupler

on reel lift hose.

3. Remove clamp from draper drive hoses at (B).

B

A

4. Install new support (C) as shown, using existing

hardware. Remove female quick coupler from

draper drive hose and install on support (C)

with dished washer (D) positioned as shown

below. Install insulated clip (E) with 3/8 x 3/4”

carriage bolt and flange nut to attach reel lift

hose and header wiring harness.

5. Connect harness extension (F) from kit [1200

mm, (48”) long] to header harness and tie to

draper drive hose and reel lift hose as shown.

F

HOSE / HARNESS ROUTING

C

F

HOSE / HARNESS ROUTING

E

D

HOSE / HARNESS ROUTING

Form # 131126 Issue 11/07

17

Page 20

SET-UP INSTRUCTIONS

RE-ROUTE HEADER HOSES AND HARNESS

6. At right header leg, remove reel drive hoses

from the existing mounting bracket. Remove

bracket from header.

7. Install hoses on new support (G) and mount

support to header leg as shown with two 3/8 x

3/4 carriage bolts and flange nuts (nuts inside

leg).

(continued)

G

REEL DRIVE HOSE MOUNT

REEL DRIVE HOSE MOUNT

Form # 131126 Issue 11/07

18

Page 21

SET-UP INSTRUCTIONS

REPOSITION TRACTOR HOSES & HARNESS

1. Remove female coupler from draper drive hose

at tractor left side.

2. Install 900 mm (35”) long hose (A) where

coupler was removed. Use existing dished

washer between hose (A) and bracket.

3. Attach 1/2 NPT 45° elbow (G) to hose (A).

4. Position new bracket (B) on tractor as shown at

right and tighten bolts to clamp in place.

5. Attach female coupler (C), removed above, to

hose (A) at new bracket, using dished washer

between bracket and coupler as shown.

6. Move reel lift coupler (D) from existing bracket

to new bracket. Install 1/4 NPT 45° elbow (H)

as shown. Use dished washer between bracket

and coupler as shown.

7. Insert two-prong connector

(E) from existing

tractor wiring harness through smaller hole in

bracket. NOTE: Three-prong connector (F) is

from the tractor section of the transport

harness, which will be installed on the next

page. When installed, clamp both harnesses to

bracket.

NOTE: If tractor has optional hydraulic reel fore-aft

kit installed, move fore-aft coupler mount to inboard

set of holes as shown below.

B

C

F

A

D

E

REPOSITION TRACTOR COUPLERS &

HARNESS

FORE-AFT

COUPLERS

TRANSPORT

COUPLERS

TRANSPORT LIGHTS ON TRACTOR

1. Bolt lights to left tractor spring anchor as shown.

2. Repeat at right side.

INSTALL TRANSPORT LIGHTS ON

TRACTOR

Form # 131126 Issue 11/07

19

Page 22

SET-UP INSTRUCTIONS

TRANSPORT HARNESS – TRACTOR SECTION

1. Route tractor section of transport wiring harness as shown below. Route over frame cross members

along left side of tractor and secure with cable ties for best protection and appearance.

2. Connect harness to hitch harness at rear of tractor

TRANSPORT HARNESS

(TRACTOR SECTION)

Form # 131126 Issue 11/07

20

Page 23

SET-UP INSTRUCTIONS

CENTER LINK CLIP

1. For tractors with mechanical center link, install

spring clip (A) as shown at right to retain link in

raised position during hook-up.

• Remove pin from center link at tractor.

• Install spring (A) as shown (spring outlined

for photo clarity).

• Replace pin through frame bracket, spring

coil and center link ball end. Secure with hair

pin.

• Looped end of spring engages under frame

plate at (B).

HAY CONDITIONER STORAGE COMPONENTS

If header has a hay conditioner, install components

for support of conditioner during transport and

conversion to and from transport.

1. Attach bracket (C) and transfer chain (D) to right

hand tractor floorboard as at right. This chain is

only used during conversion to and from

transport.

NOTE: For high clearance tractors (XX52

models) add the short extension chain provided

to achieve proper length (see Parts Catalog page

50/51 for hardware used).

2. Attach bracket (E) for transfer chain (D) to right

side of conditioner top sheet using longer bolts

provided as shown below right.

3. Attach bracket (F) to inside of header right leg as

shown below. This bracket is used to support

conditioner in transport by engaging conditioner

support chain (G).

A

CENTER LINK SPRING CLIP

ATTACH TRANSFER CHAIN

E

B

C

D

F

G

ATTACH TRANSFER CHAIN BRACKET

TO CONDITIONER

SUPPORT CHAIN BRACKET

Form # 131126 Issue 11/07

21

Page 24

SET-UP INSTRUCTIONS

WEIGHT BOX WHEELS & HITCH

For units with the optional wheels and hitch package for the front end weight box:

1. Slide strap (A) into V-channel inside box (accessible from the bottom) and bolt hitch to weight box as

shown, using two 5/8 x 1-1/4 hex head bolts (A) and lockwashers (C). NOTE: Welded nuts on strap

(A) go to the inside.

2. Install two 5/8 x 1-1-4 carriage head bolts (B) and secure with 5/8 flange lock nuts (D) as shown.

(OPTION)

3. Slide wheel axles into tubes in weight box and tighten 1/2 x 2 hex head bolts (E) through welded nuts

and into axles to secure the assemblies.

Form # 131126 Issue 11/07

22

Page 25

TRANSPORT SAFETY

ATTACHING TO TOWING VEHICLE

CAUTION: To avoid bodily injury and/or machine damage caused by loss of control:

1. To ensure adequate braking performance and control, do not tow with a vehicle weighing less

than 5000 lbs. (2300 kg).

2. When towing with windrower tractor, weight box MUST be installed on front linkage to provide

adequate stability and control.

3. To increase header stability in transport, ensure that reel is down and moved back on support

arms to the 10

th

hole from the rear or further. For headers with hydraulic reel fore-aft, never

connect the fore-aft couplers to each other. This would complete the circuit and allow the reel

to creep forward in transport, resulting in instability.

4. Check that all latches and pins are properly secured in transport position at wheel supports,

hitch and cutterbar support.

5. Check tire condition and pressure prior to transporting.

6. If towing with vehicle other than windrower tractor, connect hitch to towing vehicle with a

proper hitch pin with a spring locking pin or other suitable fastener.

7. Attach hitch chain to towing vehicle. Adjust chain length to remove all slack except what is

needed for turns.

8. Ensure lights are functioning properly, and clean the slow moving vehicle emblem and other

reflectors.

TOWING THE HEADER

CAUTION: THIS IS INTENDED AS A LOW SPEED TRANSPORT. To avoid bodily injury

and or machine damage caused by loss of control:

1. Do not exceed 19 mph (30 km/h). Reduce transport speed for slippery or rough conditions.

2. Turn corners only at very low speeds [5 mph (8 km/h) or less].

3. Obey all highway traffic regulations in your area when transporting on public roads. Use

flashing amber lights unless prohibited by law.

Form # 131126 Issue 11/07

23

Page 26

CONVERTING TO TRANSPORT

CONVERTING FROM FIELD POSITION

TO TRANSPORT

1. On a level area, stop tractor and engage park brake.

WARNING: To avoid injury or caused by machine tip-over, move reel back on support

arms before converting to transport. Do not move reel forward while machine is in

transport.

2. Move reel back on support arms to the 10

Aft" in Header Operator’s Manual for adjustment details.

3. Lower reel fully. NOTE: To prevent damage to reel support arms, do not transport with reel props

engaged.

4. Raise header fully.

DANGER: To avoid bodily injury or death from unexpected start-up or fall of raised

header, stop engine, remove key and engage header lift cylinder stops before going

under header for any reason.

NOTE: Steps 5 through 10 are for headers with hay

conditioner. For headers without hay conditioner, go

to Step 11.

5. Install transfer chain (A) between conditioner

and tractor R/H floorboard.

6. Remove header lift cylinder stops and lower

header until cutterbar is approximately 4 inches

(100 mm) from ground.

7. Move conditioner support chain (B) (the chain

attached to conditioner R/H shoe) from pin (C)

located on inside of tractor leg to support (D) on

header leg.

th

hole from the rear or further. See "Reel Position - Fore &

A

ATTACH TRANSFER CHAIN

C

B

DISCONNECT SUPPORT CHAIN

Form # 131126 Issue 11/07

24

SUPPORT CHAIN BRACKET ON HEADER

D

B

Page 27

CONVERTING TO TRANSPORT

8. Raise header fully.

DANGER: To avoid bodily injury or

death from unexpected start-up or fall of

raised header, stop engine, remove key

and engage header lift cylinder stops

before going under header for any reason.

9. Remove transfer chain (A) from top of conditioner

and store at (E).

10. Disconnect conditioner float spring chain (F) on

left side of conditioner.

11. Remove pins (G) from lower header legs.

E

A

DETACH AND STORE TRANSFER CHAIN

F

DISCONNECT FLOAT SPRING

G

REMOVE LOWER LEG PINS

Form # 131126 Issue 11/07

25

Page 28

CONVERTING TO TRANSPORT

12. Lower left wheel into transport position and secure latch (A) as shown.

A

LEFT WHEEL – TRANSPORT POSITION

13. Lower right wheel into transport position and secure latch (B) in notch in plate as shown.

B

RIGHT WHEEL – TRANSPORT POSITION

Form # 131126 Issue 11/07

26

Page 29

CONVERTING TO TRANSPORT

14. Install front transport wheel at cutterbar, aligned with R/H header leg as follows:

• Install wheel assembly over guard tips (E) at right header leg.

• Ensure clamp is seated up inside leg.

• Operate lever (F) to engage clamp on leg plate.

INSTALL FRONT WHEEL AT CUTTERBAR

15. Remove “L” pin (B), both sides and detach float

springs.

16. Disengage header lift cylinder stops.

17. Be sure area is clear of bystanders, then start

engine. Retract lift cylinders to lower header

onto transport wheels.

B

DETACH FLOAT SPRINGS

Form # 131126 Issue 11/07

27

Page 30

CONVERTING TO TRANSPORT

18. Disconnect driveline from header shaft and

store at (A).

19. Disconnect draper drive hoses at left side and

couple together at (B) and at header.

20. Disconnect reel lift hose and cap at (C) and at

header.

21. For headers with hydraulic reel fore-aft,

disconnect hoses and cap lines.

WARNING: For headers with hydraulic

reel fore-aft, never connect the header

fore-aft couplers to each other. This

would complete the circuit and allow

the reel to creep forward in transport, resulting

in instability.

22. Detach electrical harnesses at (D).

23. Disconnect reel drive hoses at right side.

Couple together at (E) and cap at header.

24. Detach center link at header (F). If necessary,

adjust length of center link to release load on

front pin.

D

B

C

A

DETACH DRIVELINE, HOSES & HARNESS

E

25. Slowly back tractor away from header. If hay

conditioner is attached, watch clearances at left

and right sides.

26. Remove pins from linkage mounts on weight

box. Pick up weight box on tractor lift linkage

and raise fully

. Install pins (G), ensuring that

DETACH & STORE REEL DRIVE HOSES

they engage U-bracket in lift linkage, both

sides. Install lynch pin through welded nut and

secure with ring of lynch pin over flange on pin

(G) as shown.

27. Engage header lift cylinder stops (H).

H

G

ATTACH WEIGHT BOX TO TRACTOR

ENGAGE LIFT CYLINDER STOPS

Form # 131126 Issue 11/07

28

Page 31

CONVERTING TO TRANSPORT

28. Back the tractor close to the left end of the

header.

29. Remove lock pin on tow hitch and swing hitch

out from storage position toward header. Attach

hitch to left transport wheel support at (A) and

secure with split ring.

30. Connect electrical harness from hitch to header

at (B).

31. Drive tractor ahead until hitch falls straight.

32. Install lock pin under hitch knee joint at (C) and

secure with split ring.

33. Do a walk-around check on the following items:

Front wheel lock engaged.

Warning lights on tractor and header are

clean and working.

Outer wheels latched correctly.

SMV sign, and reflectors on reel, header

tube and endsheets are clean and visible.

Hitch pin installed and locked with split ring.

Hitch knee joint pin installed and locked with

split ring.

Weight box pins installed and locked with

lynch pins.

Header lift cylinder stops engaged.

A

B

ATTACH HITCH & CONNECT HARNESS

C

LOCK HITCH JOINT WITH PIN

Form # 131126 Issue 11/07

29

Page 32

CONVERTING TO FIELD

CONVERTING FROM TRANSPORT POSITION TO FIELD

1. On a level area, stop tractor and engage park

brake.

2. Remove pins (G) at weight box links, both

sides.

3. Move header lift cylinder stops to storage

position (H).

4. Remove split ring and detach hitch pin at (A).

5. Disconnect wiring harness at (B) and store

header harness by engaging clip on 4-way

connector in hole on back panel of left

endsheet.

G

REMOVE WEIGHT BOX PINS

H

STORE HEADER LIFT CYLINDER STOPS

A

B

DETACH HITCH & HARNESS

STORE HEADER HARNESS

Form # 131126 Issue 11/07

30

Page 33

CONVERTING TO FIELD

6. Remove split ring and remove lock pin from

hitch knee joint at (C).

7. Store hitch as follows: Place front section of

hitch on top of storage bracket (D) at right side

of walking beam. Fold hitch and place rear

section into notch in bottom of bracket (D).

Install pin from knee joint to lock the two

sections at (E) and secure with split ring.

8. Drop weight box off tractor linkage in a suitable,

level location. Fully retract header lift cylinders.

9. Slowly drive tractor forward so that lift linkage

enters header legs. Continue to drive slowly

forward until linkage contact support plate in the

lower header leg, and header nudges forward.

Stop engine, set park brake and remove key.

10. Connect center link to header at (F).

C

REMOVE LOCK PIN FROM HITCH JOINT

D

E

HITCH STORAGE

11. Connect driveline to header drive shaft.

12. Connect reel lift hose, draper drive hoses and

electrical harnesses from tractor to header at

left side.

13. Connect reel drive hoses from tractor to header

at right side.

14. Raise header fully.

NOTE: Steps 15 through 20 are for headers with

hay conditioner. For headers without hay

A

conditioner, go to Step 21.

15. Connect conditioner transfer chain (A) to right

side of conditioner.

Form # 131126 Issue 11/07

31

ATTACH TRANSFER CHAIN

Page 34

CONVERTING TO FIELD

16. Lower header until cutterbar is approximately 4

inches (100 mm) from ground.

17. Move conditioner support chain (B) (the chain

attached to conditioner R/H shoe) from support

(D) on header leg to pin (C) inside of tractor leg.

C

B

CONNECT SUPPORT CHAIN TO TRACTOR

18. Raise header fully.

DANGER: To avoid bodily injury or

death from unexpected start-up or fall

of raised header, stop engine, remove

key and engage header lift cylinder

stops before going under header for any

reason.

19. Remove transfer chain (A) from top of

conditioner and store at (E).

20. Connect conditioner float spring chain (F) on

left side of conditioner.

D

B

REMOVE SUPPORT CHAIN FROM BRACKET

E

A

DETACH AND STORE TRANSFER CHAIN

F

CONNECT FLOAT SPRING

Form # 131126 Issue 11/07

32

Page 35

CONVERTING TO FIELD

21. Install pins (G) in lower header legs, engaging U-

bracket in tractor lift linkage.

22. Install “L” pin (B), both sides to engage float

springs.

23. Raise left transport wheel to field storage

position. Install hitch pin, removed in Step 4, at

(A) to lock the wheel in storage.

G

REMOVE LOWER LEG PINS

B

ATTACH FLOAT SPRINGS

A

LEFT WHEEL – FIELD STORAGE

Form # 131126 Issue 11/07

33

Page 36

CONVERTING TO FIELD

24. Raise right transport wheel to field storage position, engaging caster tube bracket on thickness of

support plate at (C).

C

RIGHT WHEEL – FIELD STORAGE

25. Operate lever (F) to release clamp on front wheel and lift off guards (E). For units with optional hitch

on weight box, cutterbar wheel may be stored on weight box, engaging cutterbar clamp in slot of hitch

handle as shown.

REMOVE FRONT WHEEL FROM CUTTERBAR

FRONT WHEEL STORAGE

26. Move reel forward to desired position.

Form # 131126 Issue 11/07

34

Page 37

MAINTENANCE / SERVICE

GREASING: 500 Hours or Annually

Outer Wheel Casters (A) & (B) – two fittings.

A

Wheel Hub Bearings (C) – three fittings

Optional Weight Box Wheel Hubs (D) – two fittings

B

C

D

Form # 131126 Issue 11/07

35

Page 38

MAINTENANCE / SERVICE

Wheel Bolts

Check and tighten wheel bolts after the first 10

hours of operation and every 100 hours thereafter.

Whenever a wheel is removed and re-installed,

check torque after one hour of operation.

Maintain torque of 80 to 90 ft.lbs. (110 to 120 N⋅m)

Follow the proper bolt tightening sequence shown.

NOTE: When installing wheel, be sure valve stem

(C) points away from wheel support.

Tire Inflation

Check tire pressure daily

on cutterbar tire and 70 psi (480kPa) on L/H and R/H

tires.

seat the bead on the rim. Replace the tire if it has

a defect. Replace a wheel rim, which has cracks,

wear or severe rust. Never weld a wheel rim. Make

sure all the air is removed from a tire before

removing the tire from a rim. Never use force on

an inflated or partially inflated tire. Make sure the

tire is correctly seated before inflating to

operating pressure.

Do not remove, install or make repairs to a tire on

a rim unless you have the proper equipment and

experience to perform the job. Take the tire and

rim to a qualified tire repair shop. If the tire is not

in correct position on the rim, or is too full of air,

the tire bead can loosen on one side, causing air

to leak at high speed and with great force. An air

leak of this nature can thrust the tire in any

direction, endangering anyone in the area.

(A) - Use a safety cage if available.

(B) - Do not stand over tire. Use a clip-on chuck and

extension hose.

. Maintain 100 psi (690 kPa)

WARNING: Service tires safely. A tire

can explode during inflation and cause

serious injury or death. Never increase

air pressure beyond 35 psi (241 kPa) to

C

6

1

3

5

4

2

BOLT TIGHTENING SEQUENCE

SERVICE TIRES SAFELY

Form # 131126 Issue 11/07

36

Page 39

Model 972 Harvest Header

21’ & 25’ TRANSPORT OPTION

REPAIR PARTS

CONTENTS

Hitch & Header Transport Lights................................................................................................................ 38, 39

Left Hand Transport Wheel........................................................................................................................40, 41

Cutterbar Transport Wheel.........................................................................................................................42, 43

Right Hand Transport Wheel......................................................................................................................44, 45

Transport Weight Box ................................................................................................................................46, 47

Tractor Mounted Transport Parts & Header Hose Supports...................................................................... 48, 49

Hay Conditioner Supports..........................................................................................................................50, 51

Decals ..............................................................................................................................................................52

Numerical List ..................................................................................................................................................53

ABBREVIATIONS

L/H – left hand (Determined from Operator’s

position, facing forward.)

R/H – right hand

I.D. – inside diameter

O.D. – outside diameter

A/R – as required (quantity varies with

header size)

NOTE: Common hardware is not illustrated. Alphabetic references are used to designate position and

description of these items. When ordering, be sure the complete and proper serial number is given.

SERIAL NUMBER BREAKS

The side of the serial number on which the dash (-) appears determines whether the part is used “up to”

or “after” the serial number given.

Example: -74924 Used on machines up to and including serial number 74924.

74925- Used on machines including and after serial number 74925.

REF – reference, part number called up

elsewhere in catalog

SUB – Substitute (Revised design may be

used to repair previous design when

stock is depleted.)

NC – national coarse thread

NF – national fine thread

Form # 131126 Issue 11/07

37

Page 40

HITCH & HEADER TRANSPORT LIGHTS

Form # 131126 Issue 11/07

38

Page 41

REF PART DESCRIPTION QTY SERIAL

1 131117 HITCH – front................................................................................................1

2 131001 HITCH – rear.................................................................................................1

3 REF MOUNT – walking beam to hitch, see Tractor Mounted Transport Parts.....1

4 113532 CLAMP – hose..............................................................................................1

5 131128 HARNESS – wiring, hitch section .................................................................1

6 18629 PIN – clevis, 3/4” x 95 mm ............................................................................2

7 118137 RING – split...................................................................................................2

8 131043 PIN – hitch, 3/4 x 7 inch................................................................................1

9 REF CASTER – see Left Hand Transport Wheel .................................................1

10 113519 SUPPORT – rear lamp .................................................................................1

11 113518 LAMP – amber/red, ECE/SAE ......................................................................2

12 113579 MODULE – lamp, except European .............................................................1

13 113520 SUPPORT – lamp module, except European...............................................1

14 113524 HARNESS – wiring, module to lamps...........................................................1

15 131080 HARNESS – wiring, header section (hitch to module) .................................1

16 39272 CLIP – insulated............................................................................................3

17 113569 GUARD – harness ........................................................................................1

18 113572 HOLDER – harness guard............................................................................1

19 117056 SUPPORT – front lamp, with amber reflector...............................................1

20 43843 SIGN – slow moving vehicle .........................................................................1

21 31061 CONNECTOR KIT – 4-way, includes male and female connectors.........A/R

22 18608 PIN – cotter, 3/16” x 1-1/2 inch .....................................................................1

23 13710 SPACER – tube ............................................................................................1

A 30896 BOLT – hex head, 3/4 NC x 3-1/2 inch

B 102636 NUT – side lock, 3/4 NC

C 50186 NUT – lock, 1/2 NC, distorted thread

D 30228 NUT – lock, smooth flange, 3/8 NC distorted thread

E 21868 BOLT – round head, square neck, 1/2 NC x 1 inch

F 135020 SCREW – truss head, #8 NC x 3/4 inch

G 135021 NUT – keps lock, #8 NC

H 50163 BOLT – hex head, 5/8 NC x 5-1/2 inch

J 21580 BOLT – hex head, 1/4 NC x 1/2 inch

K 21455 NUT – serrated flange lock, 1/4 NC

L 113611 BOLT – hex head, 5/8 NC x 1 inch

M 18666 NUT – lock, 5/8 NC distorted thread

N 50076 BOLT – hex head, flange, 3/8 NC x 5/8 inch

P 50225 NUT – flange, lock, 5/8 NC

R 50197 BOLT – round head, square neck, 3/8 NC x 1-3/4 inch

NUMBER NUMBER

NOTE: For Tractor-mounted lights, see Tractor Mounted Transport Parts, page 48

HITCH & HEADER TRANSPORT LIGHTS

Form # 131126 Issue 11/07

39

Page 42

LEFT HAND TRANSPORT WHEEL

Form # 131126 Issue 11/07

40

Page 43

LEFT HAND TRANSPORT WHEEL

REF PART DESCRIPTION QTY SERIAL

NUMBER NUMBER

1 131012 CASTER – left hand ..................................................................................... 1

2 131021 SHAFT – caster, left hand ............................................................................ 1

3 131015 MOUNT – left hand caster............................................................................ 1

4 131022 TUBE – diagonal ..........................................................................................1

5 131023 LATCH – left hand wheel .............................................................................1

6 19739 SPRING – latch ............................................................................................1

7 18624 PIN – clevis, 5/8” x 70 mm ........................................................................... 1

8 13125 PIN – hair......................................................................................................1

9 18671 FITTING – grease, 1/4 –28 .......................................................................... 1

10 30517 CONE – bearing, with seal, inner .................................................................1

11 41982 HUB – with bearing cups & grease fitting..................................................... 1

12 21376 CONE – bearing, with seal, outer................................................................. 1

13 21540 WASHER – hardened ..................................................................................1

14 18648 PIN – cotter, 3/16 x 1-1/4 inch...................................................................... 1

15 5512 NUT – hex, slotted, 3/4 NF........................................................................... 1

16 30520 CAP – dust ................................................................................................... 1

17 103697 RIM – 10 x 6 x 6 ...........................................................................................1

113020 VALVE STEM............................................................................................... 1

18 103696 TIRE – 20.5 x 8 x 10, 12 ply ......................................................................... 1

19 18916 BOLT – wheel, 9/16-18 NF x 1-1/4 inch....................................................... 6

20 131024 SUPPORT – storage, left hand wheel.......................................................... 1

21 100200 WASHER – flat ............................................................................................ 4

22 129819 PLATE – welded, L/H endsheet (inboard surface) ..................................1

23 129820 GUSSET – welded, L/H endsheet (outboard surface)............................. 1

24 129822 GUSSET – welded, single knife headers (triangular).............................. 1

25 128824 GUSSET – welded, double knife headers (square)................................. 1

A 50186 NUT – lock, flange, 1/2 NC

B 21578 BOLT – hex head, 1/2 NC x 2-1/4 inch

C 50225 NUT – lock, flange, 5/8 NC

E 20077 BOLT – hex head, 3/8 NC x 1 inch

F 18637 WASHER – lock, 3/8 ID

G 21868 BOLT – round head, square neck, 1/2 NC x 1 inch

H 21587 BOLT – hex head, 5/8 NC x 2 inch

K 103562 BOLT – round head, square neck, 5/8 NC x 1-1/4 inch

Form # 131126 Issue 11/07

41

Page 44

CUTTERBAR TRANSPORT WHEEL

Form # 131126 Issue 11/07

42

Page 45

REF PART DESCRIPTION QTY SERIAL

1 131054 SUPPORT – front wheel .............................................................................. 1

2 131063 SUPPORT – cutterbar..................................................................................1

3 131062 LATCH – front wheel .................................................................................... 1

4 45157 WASHER – dished .......................................................................................1

5 9415 SPRING – latch............................................................................................ 1

6 30517 CONE – bearing, with seal, inner................................................................. 1

7 41982 HUB – with bearing cups & grease fitting..................................................... 1

8 21376 CONE – bearing, with seal, outer.................................................................1

9 21540 WASHER – hardened .................................................................................. 1

10 5512 NUT – hex, slotted, 3/4 NF........................................................................... 1

11 18648 PIN – cotter, 3/16 x 1-1/4 inch...................................................................... 1

12 30520 CAP – dust ................................................................................................... 1

13 103696 TIRE – 20.5 x 8 x 10, 12 ply ......................................................................... 1

14 103697 RIM – 10 x 6 x 6 ...........................................................................................1

113020 VALVE STEM............................................................................................... 1

15 18916 BOLT – wheel, 9/16-18 NF x 1-1/4 inch....................................................... 4

16 113278 HANDLE – wheel.......................................................................................... 1

17 113576 BOLT – wheel handle, 9/16-18 NF x 1-1/2 inch........................................... 2

18 131031 SHOE – skid................................................................................................. 1

A 50225 NUT – lock, flange, 5/8 NC

B 21565 BOLT – hex head, 1/2 NC x 1-3/4 inch

C 50186 NUT – lock, flange, 1/2 NC

NUMBER NUMBER

CUTTERBAR TRANSPORT WHEEL

Form # 131126 Issue 11/07

43

Page 46

RIGHT HAND TRANSPORT WHEEL

Form # 131126 Issue 11/07

44

Page 47

REF PART DESCRIPTION QTY SERIAL

1 131092 CASTER – right hand wheel ........................................................................1

2 131081 TUBE – pivot, right hand wheel....................................................................1

3 131086 MOUNT – right hand wheel..........................................................................1

4 131022 TUBE – diagonal ..........................................................................................1

5 131090 PLATE – right hand wheel............................................................................ 1

6 131091 LATCH – right hand wheel ........................................................................... 1

7 18671 FITTING – grease, 1/4 –28 .......................................................................... 1

8 30441 WASHER – hardened, 5/8 ID.......................................................................1

9 30517 CONE – bearing, with seal, inner................................................................. 1

10 41982 HUB – with bearing cups & grease fitting..................................................... 1

11 21376 CONE – bearing, with seal, outer................................................................. 1

12 21540 WASHER – hardened ..................................................................................1

13 5512 NUT – hex, slotted, 3/4 NF........................................................................... 1

14 18648 PIN – cotter, 3/16 x 1-1/4 inch...................................................................... 1

15 30520 CAP – dust ................................................................................................... 1

16 103696 TIRE – 20.5 x 8 x 10, 12 ply ......................................................................... 1

17 103697 RIM – 10 x 6 x 6 ...........................................................................................1

113020 VALVE STEM............................................................................................... 1

18 18916 BOLT – wheel, 9/16-18 NF x 1-1/4 inch....................................................... 1

A 50225 NUT – lock, flange, 5/8 NC

B 21733 BOLT – hex head, 3/4 NC x 4-1/2 inch

C 18689 NUT – lock, 3/4 NC

D 21585 BOLT – hex head, 5/8 NC x 1-1/4 inch

E 21575 BOLT – hex head, 1/2 NC x 1 inch

F 50186 NUT – lock, flange, 1/2 NC

G 103562 BOLT – round head, square neck, 5/8 NC x 1-1/4 inch

NUMBER 15’/18’/21’/25’ NUMBER

RIGHT HAND TRANSPORT WHEEL

Form # 131126 Issue 11/07

45

Page 48

TRANSPORT WEIGHT BOX

Form # 131126 Issue 11/07

46

Page 49

TRANSPORT WEIGHT BOX

REF PART DESCRIPTION QTY SERIAL

NUMBER NUMBER

1 131034 FRAME – weight box.................................................................................... 1

2 131043 PIN – hitch, 3/4 x 7 inch ...............................................................................2

3 50193 PIN – lynch ...................................................................................................2

4 B3089 WHEELS & HITCH KIT – for weight box.................................................OPT

Kit available through WholeGoods only

5 131073 HITCH – weight box ..................................................................................... 1

6 131078 STRAP – hitch.............................................................................................. 1

7 30517 CONE – bearing, with seal, inner................................................................. 2

8 41982 HUB – with bearing cups & grease fitting..................................................... 2

9 21376 CONE – bearing, with seal, outer.................................................................2

10 21540 WASHER – hardened ..................................................................................2

11 5512 NUT – hex, slotted, 3/4 NF........................................................................... 2

12 18648 PIN – cotter, 3/16 x 1-1/4 inch...................................................................... 2

13 30520 CAP – dust ................................................................................................... 2

14 103696 TIRE – 20.5 x 8 x 10, 12 ply ......................................................................... 2

15 103697 RIM – 10 x 6 x 6 ...........................................................................................2

113020 VALVE STEM............................................................................................... 2

16 18916 BOLT – wheel, 9/16-18 NF x 1-1/4 inch..................................................... 12

17 41155 SPINDLE – weight box.................................................................................2

A 103562 BOLT – round head, square neck, 5/8 NC x 1-1/4 inch

B 21585 BOLT – hex head, 5/8 NC x 1-1/4 inch

C 18639 WASHER – lock, 5/8 ID

D 50225 NUT – lock, flange, 5/8 NC

E 21813 BOLT – hex head, 1/2 NC x 2 inch TFL

Form # 131126 Issue 11/07

47

Page 50

TRACTOR MOUNTED TRANSPORT PARTS

& HEADER HOSE SUPPORTS

Form # 131126 Issue 11/07

48

Page 51

TRACTOR MOUNTED TRANSPORT PARTS

& HEADER HOSE SUPPORTS

REF PART DESCRIPTION QTY SERIAL

NUMBER NUMBER

1 131113 HITCH – walking beam to tow pole.............................................................. 1

2 131112 SUPPORT – hitch storage ...........................................................................1

3 131111 BOLT – u-bolt ...............................................................................................1

4 131027 BAR – extension, SMV mounting................................................................. 1

5 131048 LAMP – amber.............................................................................................. 2

6 131051 MOUNT – R/H tractor lamp.......................................................................... 2

7 131053 HARNESS – R/H lamp ................................................................................. 1

8 131045 MOUNT – L/H tractor lamp........................................................................... 2

9 131049 HARNESS – L/H lamp.................................................................................. 1

10 131104 MOUNT – hose............................................................................................. 1

11 45153 WASHER – dished, 1/2” coupler..................................................................2

12 45157 WASHER – dished, 1/4” coupler..................................................................1

13 131107 SPRING – center link ...................................................................................1

14 131109 BRACKET – draper drive & reel lift hoses (header).....................................1

15 103738 CLIP – insulated ........................................................................................... 1

16 131108 MOUNT – reel drive hoses (header) ............................................................ 1

17 131118 HARNESS – wiring, transport – tractor section............................................ 1

18 47009 HOSE – draper drive, extension...................................................................1

19 131127 TERMINAL – splice, to red tail light.............................................................. 1

20 131106 CLAMP – electrical connectors .................................................................... 1

21 21763 FASTENER – plastic tie ............................................................................... 6

22 131135 FITTING – hydraulic, 45° street elbow, 8-8.................................................. 1

23 131134 FITTING – hydraulic, 45° street elbow, 4-4.................................................. 1

24 47325 HARNESS – wiring, extension, header to tractor.........................................1

31062 CONNECTOR KIT – 3 way, includes male and female plugs

112443 CONNECTOR KIT – 2 way, includes male and female plugs

A 50186 NUT – lock, flange, 1/2 NC

B 21055 SCREW – self tapping, hex washer head, ¼ NC x 1/2 inch

C 50163 BOLT – hex head, 5/8 NC x 5-1/2 inch

D 50225 NUT – lock, flange, 5/8 NC

E 30228 NUT – flange, 3/8 NC, distorted thread

F 21483 BOLT – round head, square neck, 1/4 NC x 1-1/2 inch

G 18724 NUT – lock, 1/4 NC

H 21863 BOLT – round head, square neck, 3/8 NC x 3/4 inch

Form # 131126 Issue 11/07

49

Page 52

HAY CONDITIONER SUPPORTS

Form # 131126 Issue 11/07

50

Page 53

HAY CONDITIONER SUPPORTS

REF PART DESCRIPTION QTY SERIAL

NUMBER NUMBER

1 125135 SUPPORT – attached to hay conditioner..................................................... 1

2 125002 SUPPORT – attached to tractor................................................................... 1

3 125003 CHAIN – transfer, from tractor to hay conditioner........................................ 1

4 131121 SUPPORT – chain, attached to RH header leg ...........................................1

5 118343 CHAIN – extension, for XX52 tractors (130 mm) .........................................1

A 21471 BOLT – round head, square neck, 1/2 NC x 1-1/4 inch

B 18697 NUT – lock, 1/2 NC

C 30515 BOLT – round head, square neck, 1/2 NC x 1-3/4 inch

D 18591 NUT – hex, 1/2 NC

E 21575 BOLT – hex head, 1/2 NC x 1 inch

F 30228 NUT – flange, 3/8 NC, distorted thread

G 19965 BOLT – round head, square neck, 3/8 NC x 1 inch

H 18695 NUT – lock, 1/2 NC

J 18723 BOLT – hex head, 1/2 x 1-1/2 inch

K 18599 WASHER – flat, 17/32 inch I.D.

Form # 131126 Issue 11/07

51

Page 54

DECALS

1

1A

3

2

4

REF PART DESCRIPTION QTY SERIAL

NUMBER NUMBER

1 113565 DECAL – Tire Pressure – 100PSI – cutterbar tire

1A 131140 DECAL – Tire Pressure - 70 PSI – L/H and R/H tires

2 129261 DECAL – General Hazard, Transport Hitch

3 43843 DECAL – Slow Moving Vehicle, Transport

4 115146 REFLECTOR – Amber

115147 REFLECTOR – Red

Form # 131126 Issue 11/07

52

Page 55

NUMERICAL LIST

PART NO. PAGE PART NO. PAGE PART NO. PAGE PART NO. PAGE

5512 41

5512 43

5512 45

5512 47

9415 43

13125 41

13710 39

18608 39

18624 41

18629 39

18648 41

18648 43

18648 45

18648 47

18671 41

18671 45

18916 41

18916 43

18916 45

18916 47

19739 41

21376 41

21376 43

21376 45

21376 47

21540 41

21540 43

21540 45

21540 47

21763 49

30441 45

30517 41

30517 43

30517 45

30517 47

30520 41

30520 43

30520 45

30520 47

31061 39

31062 49

39272 39

41155 47

41982 41

41982 43

41982 45

41982 47

43843 39

43843 52

45153 49

45157 43

45157 49

47009 49

47325 49

50193 47

100200 41

103696 41

103696 43

103696 45

103696 47

103697 41

103697 43

103697 45

103697 47

103738 49

112443 49

113020 41

113020 43

113020 45

113020 47

113278 43

113518 39

113519 39

113520 39

113524 39

113532 39

113565 52

113569 39

113572 39

113576 43

113579 39

115146 52

115147 52

117056 39

118137 39

118343 51

125001 51

125002 51

125003 51

129261 52

129819 41

129820 41

129822 41

129824 41

131001 39

131012 41

131015 41

131021 41

131022 41

131022 45

131023 41

131024 41

131027 49

131031 43

131034 47

131043 39

131043 47

131045 49

131048 49

131049 49

131051 49

131053 49

131054 43

131062 43

131063 43

131073 47

131078 47

131080 39

131081 45

131086 45

131090 45

131091 45

131092 45

131104 49

131106 49

131107 49

131108 49

131109 49

131111 49

131112 49

131113 49

131117 39

131118 49

131121 51

131127 49

131128 39

131134 49

131135 49

131140 52

B3089 47

Form # 131126 Issue 11/07

53

Loading...

Loading...