Page 1

BE6027-12

Instruction Manual for

LumaSoft Gas Software

7810 and 7860

Page 2

Index

_________________________________________________________________________

Index

Index ................................................................................................................................. 2

Safety Consid era tions ............................................................................................................. 4

Safety Consid era tions. ......................................................................................................... 5

Warnings! ........................................................................................................................... 6

Chapter 1 Using this Manual .................................................................................................. 7

1.1 Introduction ............................................................................................................... 8

1.2 Screens ..................................................................................................................... 9

1.3 Stand-alone Use ......................................................................................................... 9

1.4 Tool-bar Icons in LumaSoft Gas Monitoring Software 7810 and 7860 ............................... 11

1.4.1 Toolbar: Manage Users ....................................................................................... 11

1.4.2 Toolbar: Main menu ........................................................................................... 11

1.4.3 Toolbar: Measurement ........................................................................................ 12

Chapter 2 Preliminary Tasks ................................................................................................ 13

2.1 Installing the LumaSoft Gas Single Point (7810) or Multi Point (7860) Monitoring Software 14

2.1.1 Computer requirements ...................................................................................... 14

2.1.2 Installing LumaSoft Gas ...................................................................................... 15

2.2 Connecting the Mo n itor and the Multiplexer to a PC ....................................................... 15

2.2.1 Fitting the USB Cable .............................................................................................. 15

2.2.1 Setting the USB Communication Parameters .............................................................. 16

2.2.3 Fitting the Ethernet (TCP/IP) Cable. .......................................................................... 16

2.2.4 Setting the TCP/IP Communication Parameters .......................................................... 16

2.2.5 Fitting the RS-232 Cable ......................................................................................... 19

2.2.6 Setting the RS232 Communication Parameters .......................................................... 19

2.2.7 Checking/Changing the RS-232 Communication Parameters in the Monitor .................... 20

2.2.8 Checking/Changing the Text line Terminator in the Monitor. ........................................ 21

2.2.9 Selecting the PC communication Port ........................................................................ 21

2.2.10 Setting up a Multipoint System with Multipoint Samplers - INNOVA 1309 .................... 21

2.2.11 Setting up a Multipoint System with Multi point Sampler and Doser - INNOVA 1303. ...... 22

2.3 Setting-up User Accounts ........................................................................................... 22

2.3.1 Add User Account .............................................................................................. 23

2.3.2 Edit User Account .............................................................................................. 25

2.3.3 Remove User Account ......................................................................................... 26

2.3.4 Change password of the administrator .................................................................. 26

2.4 Download of the latest version .................................................................................... 27

2.5 Back-up and Restoring of calibration data .................................................................... 27

Chapter 3 Set-up Measurement Task .................................................................................... 28

3.1 New task .................................................................................................................. 29

3.1.1 Configuration of the USB interface ....................................................................... 31

3.1.2 Configuration of the Ethernet (TCP /IP) interface .................................................... 32

3.1.3 Configuration of the RS-232 interface ................................................................... 35

3.2 Measurement set-up .................................................................................................. 37

3.2.1 Configuration .................................................................................................... 37

3.2.2 Monitor Setup .................................................................................................... 38

3.2.3 Multiplexer setup ............................................................................................... 42

3.2.4 Alarms.............................................................................................................. 44

3.2.5 Units ................................................................................................................ 49

Chapter 4 Perform Measurement .......................................................................................... 50

4.1 Measurement start and stop ....................................................................................... 51

4.1.1 Start Measurement ............................................................................................ 52

4.1.2 Stop Measurement ............................................................................................. 53

4.2 Presentation of Data in Graphical Window .................................................................... 53

4.2.1 Presentation of Data in G raphical Window Channel-View ............................................. 53

4.2.1.1 Configuration of the (Channel-View) graphical window ........................................ 54

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 2 of 194

Page 3

Index

_________________________________________________________________________

4.2.1.2 Select Gases (Channel view) ............................................................................ 55

4.2.1.3 Configuration of curves (Channel view) ............................................................. 56

4.2.1.4 Configuration of the Graph Window (Channel view) ............................................. 59

4.2.1.5 The Graphical Window ( Channel view) ............................................................... 62

4.2.1.6 Functions in the Gra phical Window (Channel view) .............................................. 63

4.2.1.7 User Events in the gr aphical window (Channel view) ........................................... 69

4.2.1.8 Printing the graphical window(Channel view ) ...................................................... 71

4.2.1.9 Displaying historical data (Channel view) ........................................................... 73

4.2.2 Presentation of Data in Graphical Window Gas-View ................................................... 75

4.2.2.1 Configuration of the (Gas-View) graphical window .............................................. 76

4.2.2.2 Select Channels (Gas view) .............................................................................. 77

4.2.2.3 Configuration of curves (Gas view).................................................................... 78

4.2.2.4 Configuration of filters (Gas view) ..................................................................... 80

4.2.2.5 Configuration of the Graph Window (Gas view) ................................................... 81

4.2.2.6 The Graphical Window (Gas view) ..................................................................... 84

4.2.2.7 Functions in the Graphical Window (Gas View) ................................................... 85

4.2.2.8 User Events in the graphical window (Gas view) ................................................. 91

4.2.2.9 Printing the graphical window(Gas view) ............................................................ 92

4.2.2.10 Displaying historical data (Gas vie w) ................................................................. 94

4.3 Presentation of Data in the Numeric Window ................................................................ 97

4.3.1 Configuration of the Numeric Window ................................................................... 97

4.3.2 The Numeric Window ......................................................................................... 101

4.3.3 User Events in the numeric window ..................................................................... 102

4.3.4 Printing the numeric w indow .............................................................................. 105

4.4 View Measurement alarms ......................................................................................... 107

4.5 Export Task ............................................................................................................. 108

4.5.1 Export Task (Channel view) .................................................................................... 108

4.5.2 Export Task (Gas view) .......................................................................................... 112

4.6 Errors/Warnings Window ........................................................................................... 115

4.7 Export log ............................................................................................................... 117

Chapter 5 Database Management ........................................................................................ 119

5.1 Export Task ............................................................................................................. 120

5.1.1 Export Task (Channel view) .................................................................................... 120

5.1.2 Export Task (Gas view) .......................................................................................... 124

5.2 Export/Import Task Configuration .............................................................................. 127

5.2.1 Export task configuration ................................................................................... 127

5.2.2 Import Task Configuration ................................................................................. 129

5.3 Backup/Rest ore/Delete Ta sk ...................................................................................... 131

5.3.1 Backup Task ..................................................................................................... 131

5.3.2 Restore Task .................................................................................................... 134

5.3.3 Delete Task ...................................................................................................... 136

5.4 Export Log .............................................................................................................. 137

Chapter 6 Warning and Error Messages ................................................................................ 141

6.1 Monitor Error/Warnings ............................................................................................. 142

6.2 Multiplexer (Multipoint sampler) Error/Warnings .......................................................... 142

Appendix A Installation Guide ............................................................................................. 143

Appendix B Remote SQL Server database installation ............................................................ 160

B.1 Remote installation of the LumaSoft Gas database .......................................................... 161

B.2 Finding the Computer name of the foreign PC ................................................................. 161

B.3 Restore(Store) the database onto a foreign PC’s SQL Server ............................................ 163

B.4 Configure LumaSoft Gas 7810/7860 to use a database on a foreign PC’s SQL Server .......... 166

Appendix C OPC Server Tags .............................................................................................. 169

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 3 of 194

Page 4

Safety Considerations

_________________________________________________________________________

Safety Considerations

October 2012

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 4 of 194

Page 5

Safety Considerations

_________________________________________________________________________

Safety Considerations.

Throughout this manual Monitor is used for:

Photoacoustic Gas Monitor – INNOVA 1412i

Photoacoustic Gas Monitor – INNOVA 1314i

LumaSense SF 6 L eak Detector - 3434i

The Monitor complies with:

• EN/IEC 61010-1, 2nd Edition: Safety requirements for electrical

equipment for measurement, control and laboratory use.

• Can/CSA-C22.2 No. 61010-1-04 - Safety Requirements fo r Electrical

Equipment for Measurement, Control, and Laboratory Use

• UL Std. No. 61010A-1 (2nd Edition) - Safety Requirements for

Electrical Equipment for Measureme nt, Control, and Laboratory Use.

To ensure safe operation and r etain the Monitor in safe condition, note

the following:

EXPLOSION HAZARD!

TO AVOID THE POSSIBILITY OF AN EXPLOSION; MONITORING

OF FLAMMABLE GASES IN EXPLOSIVE CONCENTRATIONS MUST

NEVER BE ATTEMPTED.

Never operate the Monitor in potentially explosive environments.

When monitoring potentially flammable or toxic gases it is essential

that:

• The instrument itself is placed in a well-ventilated area outside the

potentially hazard ou s zone.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 5 of 194

Page 6

Safety Considerations

_________________________________________________________________________

• A sufficiently long tube is connected to the air-outlet on the back

panel so that the sampled gas is carried away to the open air or to an

extraction and/or filtration unit.

Warnings!

• Avoid water condensation in the Monitor.

• Switch off all equipment before connecting or disconnecting their

digital interface. Failure to do so could damage the equipment.

• Whenever it is li kely that correct function or operating saf ety of the

apparatus has been impaired, the apparatus must be made inoperative and secured against unintended operation.

• Any adjustment, maintenance and repair of the open apparatus

under voltage must be a voided as far a s possible and , if unavo idable,

must be carried out only by trained personnel.

• If a fault is reporte d by the Monitor th at indicates corr ect function of

the instrument may be impaired, consult your local LumaSense

Technologies representative. Under no circumstances should repair

be attempted by persons not qualified in service of electronic

instrumentation.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 6 of 194

Page 7

Chapter 1

_________________________________________________________________________

Chapter 1

Using this Manual

October 2012

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 7 of 194

Page 8

Chapter 1

_________________________________________________________________________

1.1 Introduction

This manual can be used in several ways. The f irst time users can work

their way through the exa mples in order to get to know the monitoring

system. The more experienced users can jump directly to the relevant

chapters in order to gain assistance , an d expe rts ca n use t his manua l as

a reference book by using the index.

The LumaSoft Gas Single Point 7810 Software is used as a single

channel monitoring software for Photoacoustic Gas Monitor – INNOVA

1412i, Photoacoustic Gas Monitor – INNOVA 1314i and Lu maSense SF6

Leak Detector - 3434i.

The LumaSoft Gas Mult i Point 7860 Softwa re is used as a multi chan nel

monitoring Software for Photoacoustic Gas Monitor – INNOVA 1412i in

system, Photoacoustic Ga s Mo nito r – INNOVA 1314i and LumaSense SF6

Leak Detector - 3434i with up to two Multipoint Samplers – INNOVA

1309 or four Multipoint Sampler and Doser - INNOVA 1303.

NOTE: The LumaSoft Gas Multi Point 7860 Software requires a license

dongle connected to the USB port in order to run.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 8 of 194

Page 9

Chapter 1

SELECT SET-UP BRANCH

1. Menu bar option e.g. File

_________________________________________________________________________

1.2 Screens

The information displayed on screen is presented in this manual as

shown below:

2. Pull down menu option Export T a sk

3. Index card e.g. Gas

4. Group e.g. Gas Se t up

5. Select Field e.g. Select SIT

6. Check box used to select options

7. Soft-key e.g. Read Filter Info

1.3 Stand-alon e U se

Radio push-buttons : these are not illustrate d above, but are commonly

used in the softwar e. T hey act a s a tog gle func tion whe n s eve ral o ptions

are available, but only one can be selected at a time.

In some situations, it may be necessary to set up the Monitor without

connecting it to a P C. The way the se instruction s ar e prese nted is sho wn

below:

MEASUREMENT FORMAT CONFIGURATION

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 9 of 194

Page 10

Chapter 1

↵

_________________________________________________________________________

The display above is used through-out this manual. It assists you

displaying the text on screen and by indicating which of the pushbuttons can and should be pressed.

In general, the push-bu ttons shown ab ove are use d to navigate throug h

the various modes poss ible withi n the Monitor but are describe d in more

detail below:

These push-buttons are illustrated as S 1, S2 and S3. They correspond

to the key and their position on the instrument.

These select push-buttons enable you to select one of the options

displayed.

This gr oup of 5 push-buttons are referred to in this manu al collectively

as the direction keys. The symbols below are used to simplify the

instruction in this manua l .

▲ & ▼ enable you to increase & decrease numbers, respectively, or to

go to the Previous & Next Displays, respectively.

◄ & ► enable you to move across number fields o r go to the Previous &

Next gases, respectively.

, depending on the situations, acts as an “Enter” or “Go To Head” key.

Memory Function push-buttons are always represented with the name of

the push-button enclosed in a box which is shaded-in.

SYSTEM Text that appears on the display screen is shown in an open

shaded box, using UPPER case letters.

FORMAT System General Clock

When referring to any part of the Set-up “tr ee”, the text i s shown

in open shaded box es with the same type face as that used in t he

“tree”.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 10 of 194

Page 11

Chapter 1

_________________________________________________________________________

For further description refer to “BE6025 Instruction Manual, 1412i

Photoacoustic Gas Monitor“

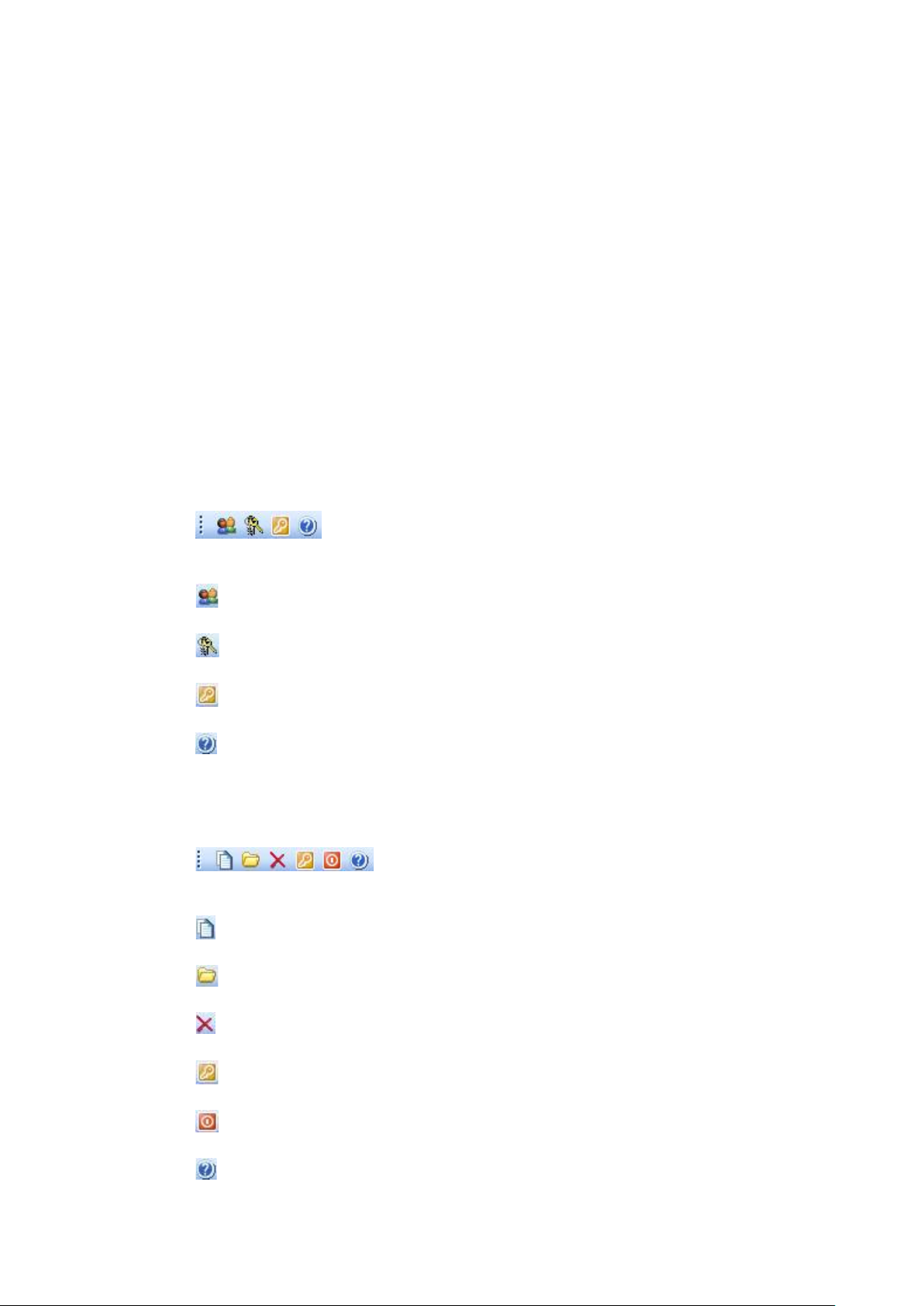

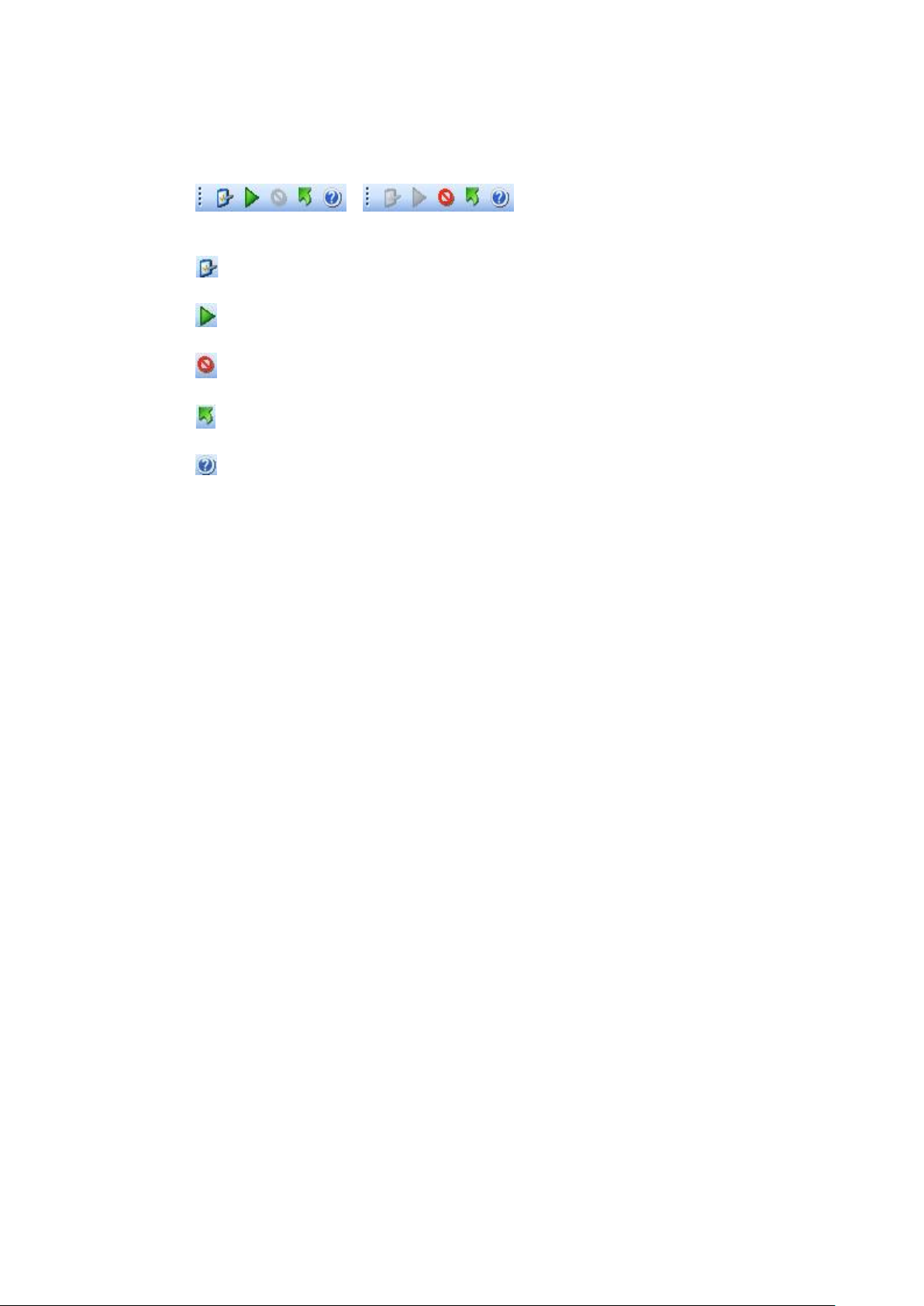

1.4 Tool-bar Icons in LumaSoft Gas Monitoring Softwar e 7810 and 7860

The instructions in this manual use the pull-down menu paths to

describe how operations are possible. However, in many cases, the icons

in the tool-bars can be used to speed things up. Top Level toolbars and

icons are presented in the following sections.

Other toolbars and icons will be presented in subsequent chapters.

1.4.1 Toolbar: Manage Users

Opens a window dialog to create new users

Change the password for the administrator

Log off administrator

Show information about software version

1.4.2 Toolbar: Main menu

Create new task

Open existing task

Delete task

Log off

Exit program

Show information about software v ersion

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 11 of 194

Page 12

Chapter 1

_________________________________________________________________________

1.4.3 Toolbar: Measurement

System configuration

Start measurement

Stop measurement

Close task

Show information about software v ersion

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 12 of 194

Page 13

Chapter 2

_________________________________________________________________________

Chapter 2

Preliminary Tasks

October 2012

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 13 of 194

Page 14

Chapter 2

Processor

Minimum: 1 gigahertz (GHz) Pentium processor

Operating

Windows XP SP2

Windows Vista

Windows 7

RAM

Minimum: 512 MB (XP) 1024 MB (Vista) 2048 MB (7)

Hard Disk

Up to 500 MB of available space may be required.

Display

Minimum: 1024 x 768 high color, 32-bit

Total port

2 USB ports

Or

1 USB port and 1 Ethernet (TCP/IP) port

Or

1 USB port and one RS232 port

Connection to

1 USB port

Or

1 Ethernet (TCP/IP) port

Or

1 RS-232 port

Connection to

dongle

1 USB port for LumaSoft Gas License Dongle Key (This

License Dongle key is delivered by Lu ma Sense)

_________________________________________________________________________

When taking delivery of the System three very important and

preliminary tasks must be completed before starting to operate it:

Install the LumaSoft Gas Software (7810 or 7860) see Section 2.1.

Connect the Monitor and the Multiplexer to a PC (Section 2.2).

Setting-up User Accounts (Section 2.3).

2.1 Installing the LumaSoft Gas Single Point (7810) or Multi Point (7860) Monitoring S oftware

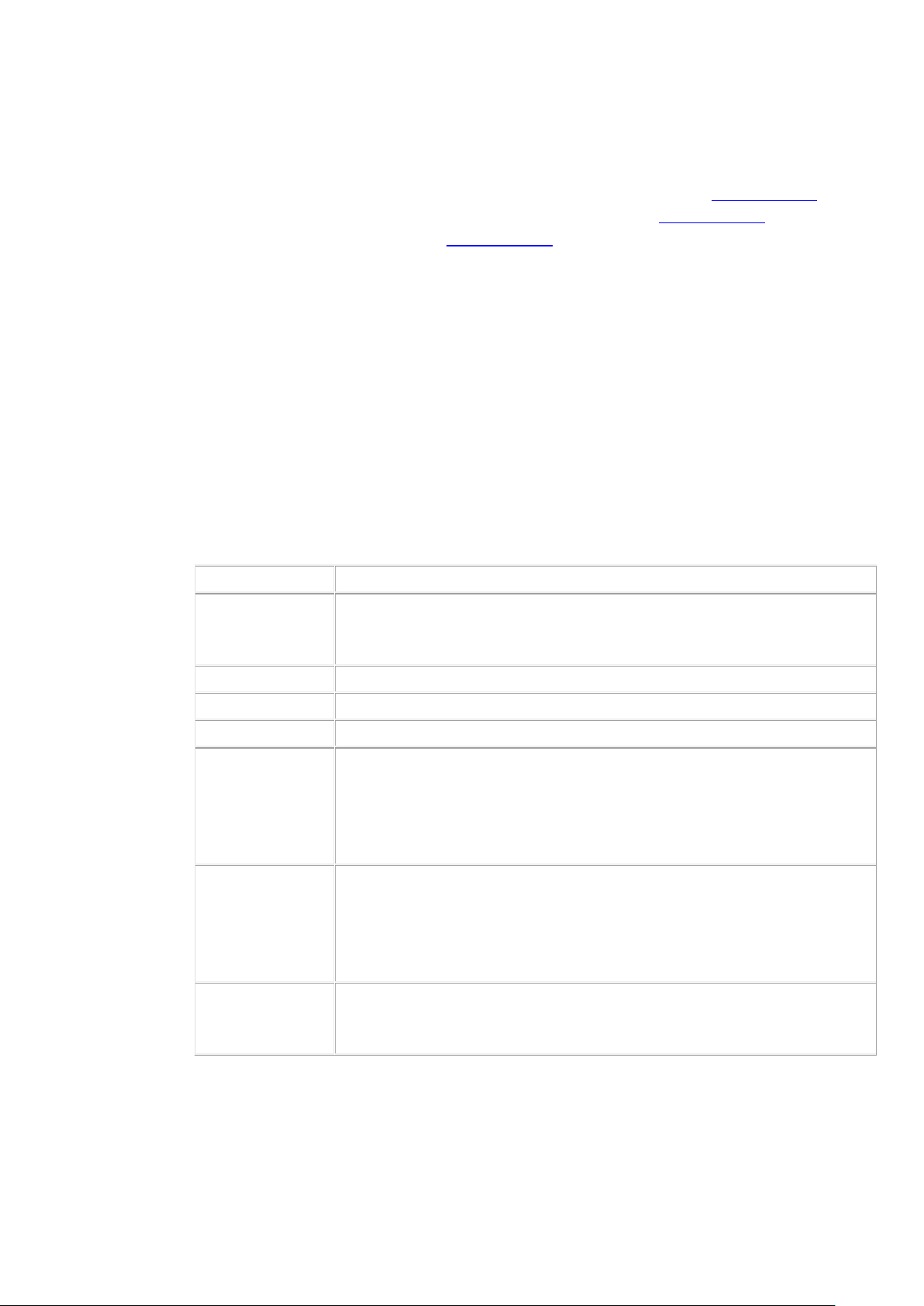

2.1.1 Computer requirements

The Software is targeted to w ork on a Desktop/Laptop PC environment

running a Microsoft Win do ws Oper a tin g Sys te m.

Before installing the Software the PC must mee t the following minimum

requirements:

System

connections

Gas Monitor

License

Microsoft Office is required if using the export to Excel file

format functionality in LumaSoft Gas.

Table 2.1 Computer requirements

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 14 of 194

Page 15

Chapter 2

_________________________________________________________________________

2.1.2 Installing LumaSoft Gas

The LumaSoft Gas software is delivered on a CD with an installation

program. Please refer to Appendix A how to perform the installation of

the LumaSoft Gas software. It is recommended that your system

administrator performs the task of installing the LumaSoft Gas program.

After the installation is successfully completed the LumaSense ->

LumaSoft Gas program menu is created.

The “LumaSoft Gas” program icon (Figure 2.1) is also placed on your

desktop for easy access to the program.

Figure 2.1 LumaSoft Gas desktop shortcut

2.2 Connecting the Monitor and the Multiplexer to a PC

The Monitor comes complete with an USB interface cable.

Optionally an Ethernet (TCP/IP) interface cable or a 9-pin to 9-pin null

modem RS-232 interface cable c an be delivered.

2.2.1 Fitting the USB Cable

The USB interface cable can be connected while the gas monitor is

switched on.

Locate an USB port at the back of the PC; refer to your PC manual if in

doubt. Pus h the connector on the USB cable on to the USB port socket

on the PC.

Locate the output labelled at the back of the Monitor. Push the

connector at the other end of the USB cable on to this socket.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 15 of 194

Page 16

Chapter 2

SELECT ADDRESSABLE SET-UP BRANCH

IS 1412i'S IP ADDRESS SET BY DHCP ?

_________________________________________________________________________

2.2.1 Setting the USB Communication Parameters

No setup on the 1412i/1314i/3434i gas monitor is necessary in order to

be able to communicate with the 1412i/1314i/3434i gas monitor

through an USB connection.

2.2.3 Fitting the Ethernet (TCP/IP) Cable.

The gas monitor can be connected to a local Ethernet network, which

communicates using the TCP/IP network interface protocol or to view

the homepage of the gas monitor in a standard PC internet browser.

The Ethernet network cable can be connected while the gas monitor is

switched on.

Locate the Ethernet socket connector labelled at the back of the

Monitor. Connect a standard Ethernet network cable to the Ethernet

socket connector on the back of the gas mo nitor. Connect t he other end

of the Ethernet network cable to your local network. The yellow LED on

the Ethernet socket connector will lit, if a local network connection is

detected.

2.2.4 Setting the TCP/IP Communication Parameters

It is recommended that your system administrator sets-up the TCP/IP

communication parameters.

The communication parameters for the TCP/IP interface can be set by

using the push-buttons on the front of the monitor.

1. Press SET-UP CONFIGURATION System Communication Addressable.

The screen display now shows the following text.

TCP/IP IEEE 4 8 8

2. Press TCP/IP to enter the TCP/IP setup. During this setup you can

also use the ▲ and ▼ keys to go back and forth between the

available TCP/IP settings. The screen display now shows the

following text.

NO YES

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 16 of 194

Page 17

Chapter 2

1412i'S IP ADDRESS 192.168.000.200

PRESS ENTER TO CHANGE VALUE

1412i'S IP ADDRESS 192.168.000.200

CANCEL DEFAULT

1412i'S IP PORT NUMBER: 23

PRESS ENTER TO CHANGE VALUE

_________________________________________________________________________

3. Here you can select whether the IP address of the 1412i/1314i/3434i

gas monitor is to be as signed by a DHCP se rver in the local network.

If you want the 1412i's, 1314i's or 3434i's IP address to be assigned

by the DHCP server pre ss the Yes key, where after you will proceed

to the below step 6 , as the IP a ddress is set by the DHCP se rver. If

you want yourself to set the IP address of the 1412i/1314i/3434i

press the No key. The screen display now shows the following text.

4. Here you can change the IP address of the 1412i/1314i/3434i gas

monitor in case the IP address is not set by a DHCP server in the

local network. If you want to change the IP address, press the ↵

key. If the IP address does no t need to be change d, press the ▼ key

and you will proceed to the below step 6.

If you selected to change the IP address, the screen display now

shows the following text.

5. Here you can change the 4 individual numbe rs in the IP address by

using the ▲ and ▼ keys. Each of the 4 individ ual nu mbe r s ca n be s e t

in the range from 000 to 255.

You can step between the 4 individual numbers in the IP address by

using the ◄ and ► keys.

In case you want to return to the start value of the IP addre ss press

the CANCEL key. In case you want to return to the default stored

value of the IP address press the DEFAULT key.

When you have set the IP address, press the ↵ key. The screen

display now shows the following text.

6. Here you can se t the IP port number for the TCP/IP co mmunication.

This normally does not need to be changed. If you want to change

the IP port number press the ↵ key. If the IP por t numbers does not

need to be changed, press the ▼ key and you will proceed to the

below step 8. If you selected to change the IP port number the

screen display now shows the following text.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 17 of 194

Page 18

Chapter 2

1412i'S IP PORT NUMBER: 23

CANCEL DEFAULT

PROTECTED IP ADDRESS 000.000.000.000

PRESS ENTER TO CHANGE VALUE

PROTECTED IP ADDRESS 000.000.000.000

_________________________________________________________________________

7. Now you can chang e the IP po r t n umber by using the ▲ and ▼ keys.

The port number can be set in the range from 0 to 32767.

In case you want to r eturn to the start value of the IP port numbe r

press the CANCEL key. In case you want to return to the default

stored value of the IP port number press the DEFAULT key.

When you have set the IP port number , press the ↵ key. The screen

display now shows the following text.

8. In case you want the 1412i/1314i/3434i gas monitor to be able to

communicate only with a certain PC on the local network, you can

set the IP address o f this PC a s t he pr otecte d IP addre ss. This ca n be

desired due to security reasons so no other PC is able to

communicate with the 1412i/1314i/3434i gas monitor.

If no protection is de sired the protected IP addre ss should be set to

a value of 000.000.000.000.

If you want to change the protected IP address, press the ↵ key. If

the protected IP ad dress does not need to be change d, press the ▼

key and you will proceed to the below step 10.

If you selected to change the pro te cte d IP a ddre s s t he scr e e n disp lay

now shows the following text.

CANCEL DEFAULT

9. Here you can change the 4 individual numbers in the protected IP

address by using the ▲ and ▼ keys. Each of the 4 individual

numbers can be set in the range from 000 to 255.

You can step between the 4 individual numbers in the protected IP

address by using the ◄ and ► keys.

In case you want to return to the start value of the protected IP

address press the CANCEL key. In case you want to return to the

default stored value of the protected IP address press the DEFAULT

key.

When you have set the protected IP address, press the ↵ key.

If you previously selecte d the IP address NO T to be set by the DHCP

server, you can proceed to t he below step 11.

If you instead selected that the IP address to be set by the DHCP

server, the screen display now shows the following text.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 18 of 194

Page 19

Chapter 2

CURRENT DHCP ADDRESS 192.168.000.062

ACCEPT

_________________________________________________________________________

10. Here the IP address of the 1412i/1314i/3434i, which has been

assigned by the DHCP server is displayed. This IP address can be

used to manually set TCP/IP communication in a PC application,

which accesses the 1412i/1314i/3434i gas monitor.

Press the ACCEPT key to accept.

11. This concludes the setup of the TCP/IP parameters of the

1412i/1314i/3434i gas monitor.

Press the SET-UP key to leave the setup.

2.2.5 Fitting the RS-232 Cable

Ensure that both th e Monitor and the PC ar e switched off at the mains .

Failure to do so may result in your equipment being damaged.

Locate the serial port at the back o f the PC ; refer to your PC manual if in

doubt.

Push the connector on the R S-232 cab le on to the s eria l po r t so cke t, a nd

secure it firmly using the securing screws.

Locate the output labelled “RS-232” at the back of the Monitor.

Push the connector at the other end of the RS-232 cable on to this

socket, and secure it firmly using the securing screws.

Turn on the PC. Wait for Windows to start up.

The Monitor can be turned on at the mains.

2.2.6 Setting the RS232 Communication Parameters

In order for the RS-232 communication to be successful, it is essential

that the communication para me ter s ar e se t cor re ctly. This is a two stage

process: the PC communication port is selected via the LumaSoft Gas

software while the baud rate, parity, data bits and stop bits are defined

via the Monitor.

The communication parameters necessary for the Monitor to

communicate with the LumaSoft Gas are shown below in Table 2.2.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 19 of 194

Page 20

Chapter 2

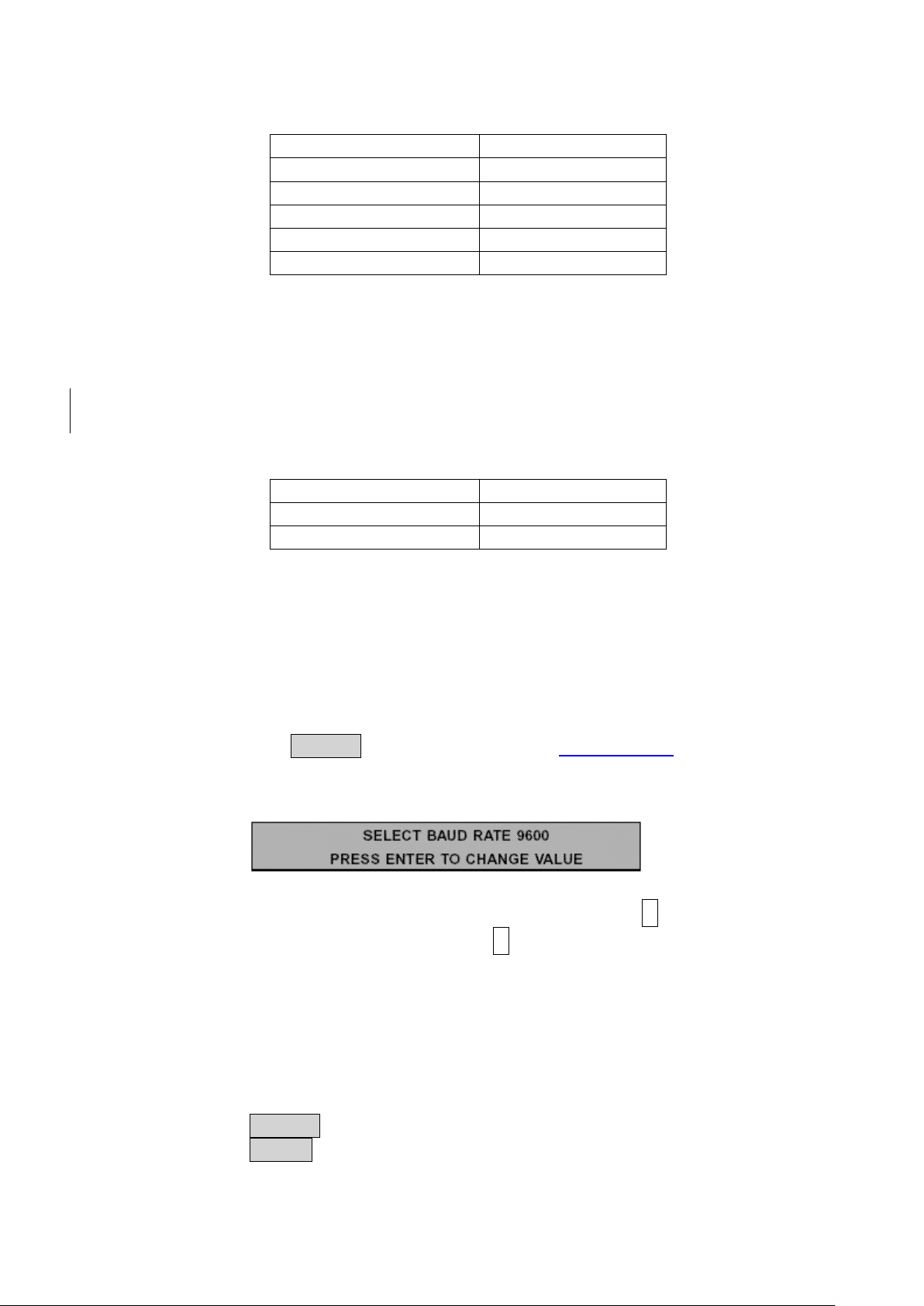

Baud rate

9600

Stop bits

1

Data bits

7

Parity

Even

Hardwire mode

Leased line

Handshake type

Hardwire

Text line Terminator

CR-LF

Print Data Log

NO

Print Error Log

NO

_________________________________________________________________________

Table 2.2 Monitor RS232 communication parameters

These are set as the default values in the Monitor.

To prevent commun icatio n errors, the te x t line te r minato r , p rin t data lo g

and print error log must be set as shown in Table 2.3.

Table 2.3 More Monitor parameters

2.2.7 Checking/Changing the RS-232 Communication Parameters in the Monitor

The communication parame ter s fo r the serial inte r face must be set using

the push-buttons on the front of the Monitor.

1. Press SET-UP S3 S1 S3 S1 (see Chapter 1.3) .The screen display

shows the following text.

If the baud rate displayed is incorrect press ↵ and use ▲ and ▼ to

display the correct value. Press ↵ again to store the selection.

If the baud rate displayed is correct, then press ▼ to continue to the

next parameter.

Press S1 to select 1 STOP BIT.

Press S1 to select 7 DATA BITS

Press S2 to select EVEN PARITY

Press S3 to select LEASED-LINE

Press S3 to select HARD-WIRED HANDSHAKE.

Press SET-UP to exit the set-up mode

Press RESET and S1 in order that the new settings are enabled.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 20 of 194

Page 21

Chapter 2

_________________________________________________________________________

The Monitor and the LumaSoft Ga s Monitoring Software are now able to

communicate together.

2.2.8 Checking/Changing the Text line Terminator in the Monitor.

The Text line Terminator must be set using the push-buttons on the

front of the Monitor.

Press SET-UP S2 ▼S3

Press SET-UP to exit the set-up mode

2.2.9 Selecting the PC communication Port

It is just a simple case of selecting the correct port on the PC. The

software shows the COM por ts that are pr esent in the sys tem to choos e

from: COM1, COM2, COM3…. If you are not sure which por t the cable is

connected on your computer refer to your PC manual.

2.2.10 Setting up a Multipoint System with Multipoint Sa mplers -

INNOVA 1309

The 1309(s) is connected to the Gas Monitor using IEEE-488 cable(s).

To avoid data errors, this cable must conform to the specifications laid

down in the IEEE-488 standard, particularly with regard to length,

connector type and “daisy -chaining”. LumaSense can supply the correct

cables, Cable order no. AO0265 (2m) or WL0845 (1m).

Caution: To avoid permanently damaging the delicate electronics in a

1309 or the Monitor , you must ensure t hat all IEEE-488 ins truments are

switched off before connecting or disconnecting the interface cables.

The IEEE–488 address of each 1309 in the system must be set before

communication with the PC can occur . T he addr ess is se t using t he e ight

DIP switches located on the back panel of the 1309. The decimal

address of the instrument is expressed as a binary number, the MSD

(Most significant DIP switch) being to the left looking onto the back

panel. Table 2.4 will guide you.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 21 of 194

Page 22

Chapter 2

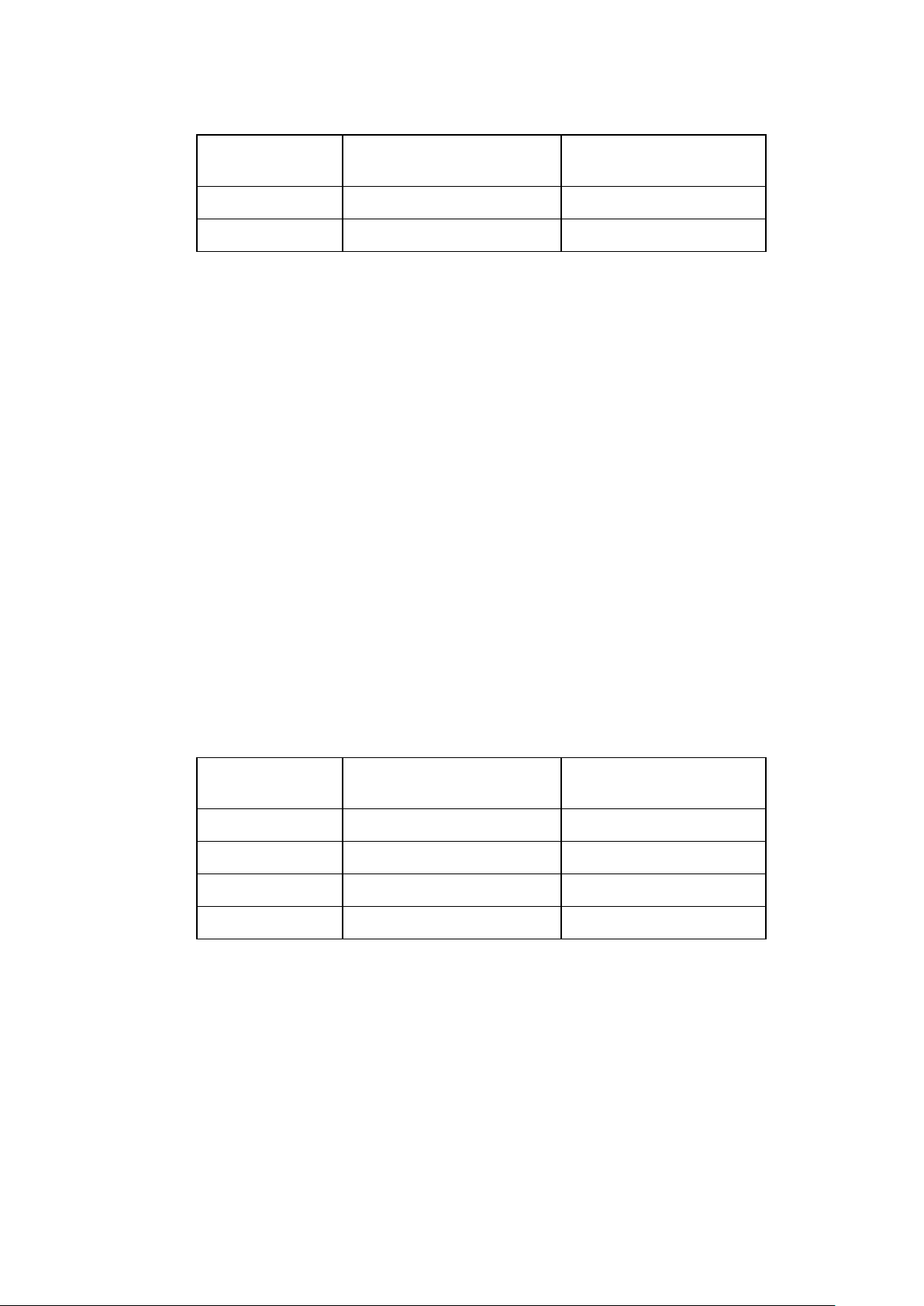

Decimal

(looking onto rear)

sampler

Decimal

_________________________________________________________________________

DIP switch setti ng

Address

15 0 0 0 0 1 1 1 1 1

13 0 0 0 0 1 1 0 1 2

Table 2.4 Setting the 1309 address

1309 multipoint

2.2.11 Setting up a Multipoint System with Multipoint Sampler

and Doser - INNOVA 1303.

The 1303(s) is connected to the Gas Monitor using IEEE-488 cable(s).

To avoid data errors, this cable must conform to the specifications laid

down in the IEEE-488 standard, particularly with regard to length,

connector type and “daisy -chaining”. LumaSense can supply the correct

cables, Cable order no. AO0265 (2m) or WL0845 (1m).

Caution: To avoid permanently damaging the delicate electronics in a

1303 or the Monitor, you must e nsure that all IE EE-488 instrume nts are

switched off before connecting or disconnecting the interface cables.

The IEEE–488 address of each 1303 in the system must be set before

communication with the PC can occur . T he addr ess is se t using t he e ight

DIP switches located on the back panel of the 1303. The decimal

address of the instrument is expressed as a binary number, the MSD

(Most significant DIP switch) being to the left looking onto the back

panel. Table 2.5 will guide you.

Address

DIP switch setti ng

(looking onto rear)

1303 multipoint

sampler

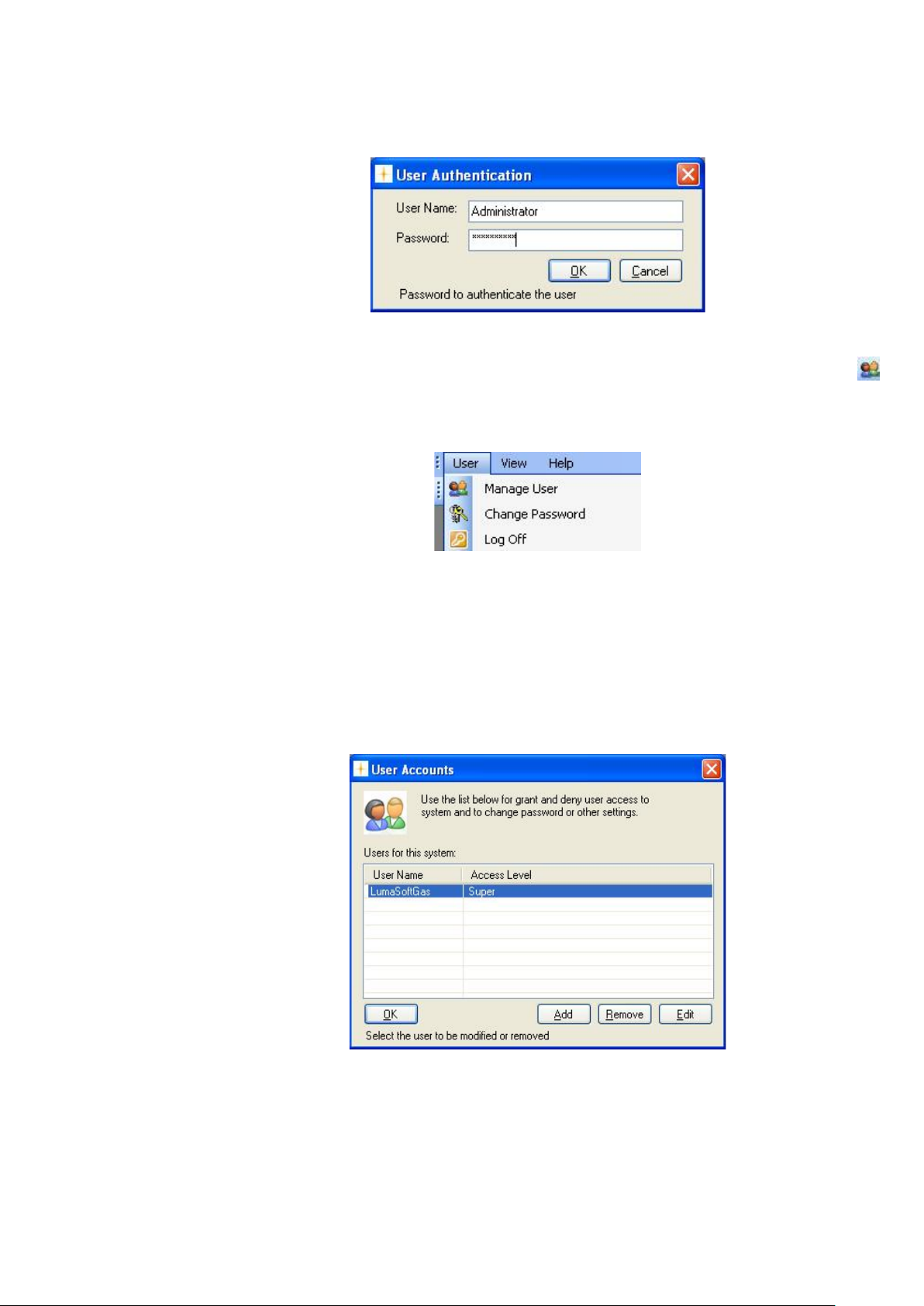

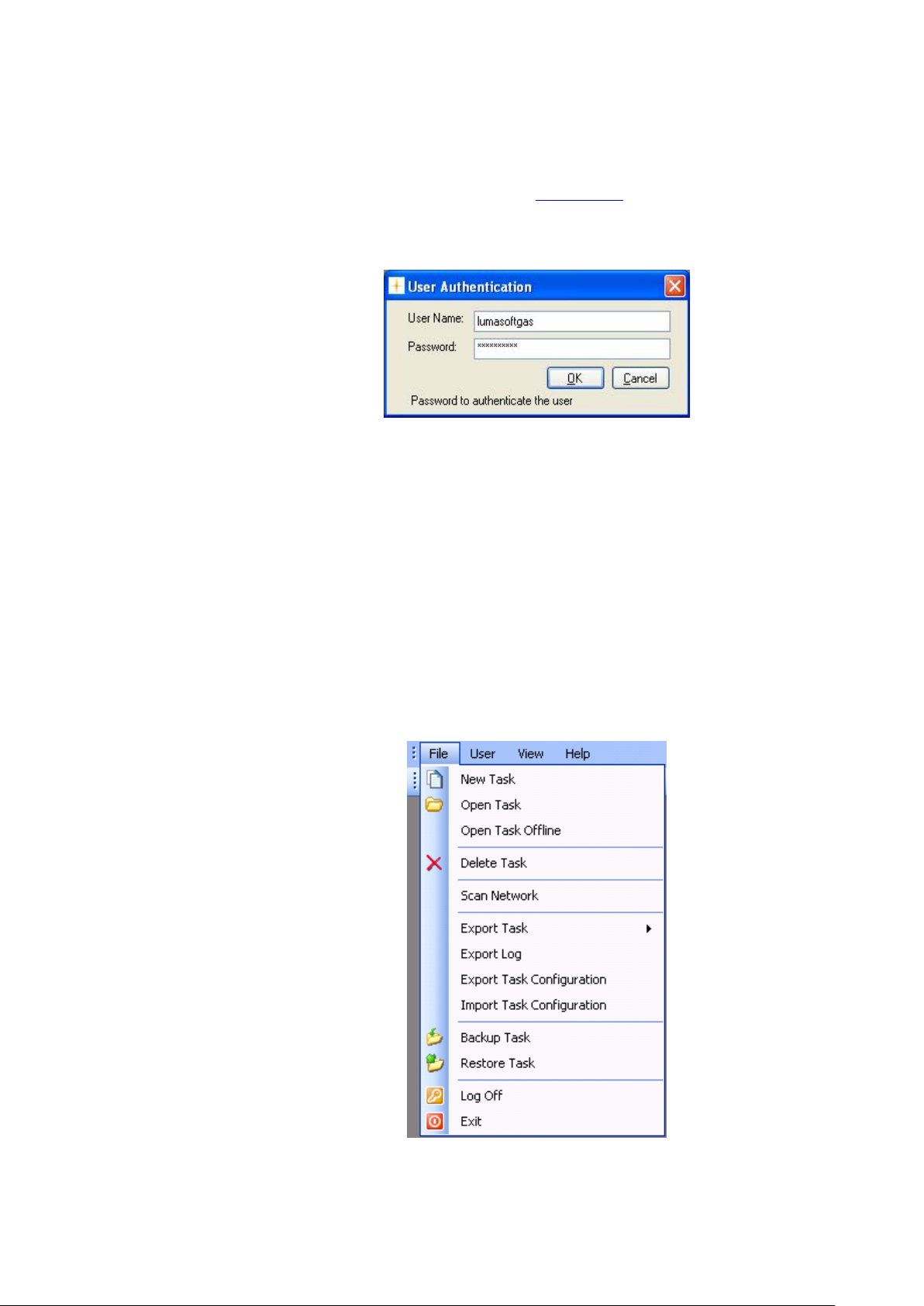

2.3 Setting-up User Accounts

Setting up user accounts can be performed by the administrator only.

After starting the LumaSoft Gas application the User Authentication

window opens, where yo u authenticate yourself as the admini strator by

specifying the administrator user name and password.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 22 of 194

15 0 0 0 0 1 1 1 1 1

13 0 0 0 0 1 1 0 1 2

12 0 0 0 0 1 1 0 0 3

11 0 0 0 0 1 0 1 1 4

Table 2.5 Setting the 1303 address

Page 23

Chapter 2

_________________________________________________________________________

The default administrator password is: Administra

Figure 2.2 Login dialogue window

To create new users you can either select the Manage User icon

from the toolbar or select Manage User from the User pull down

menu, see Figur e 2.3.

Figure 2.3 User pull-down: Manage User

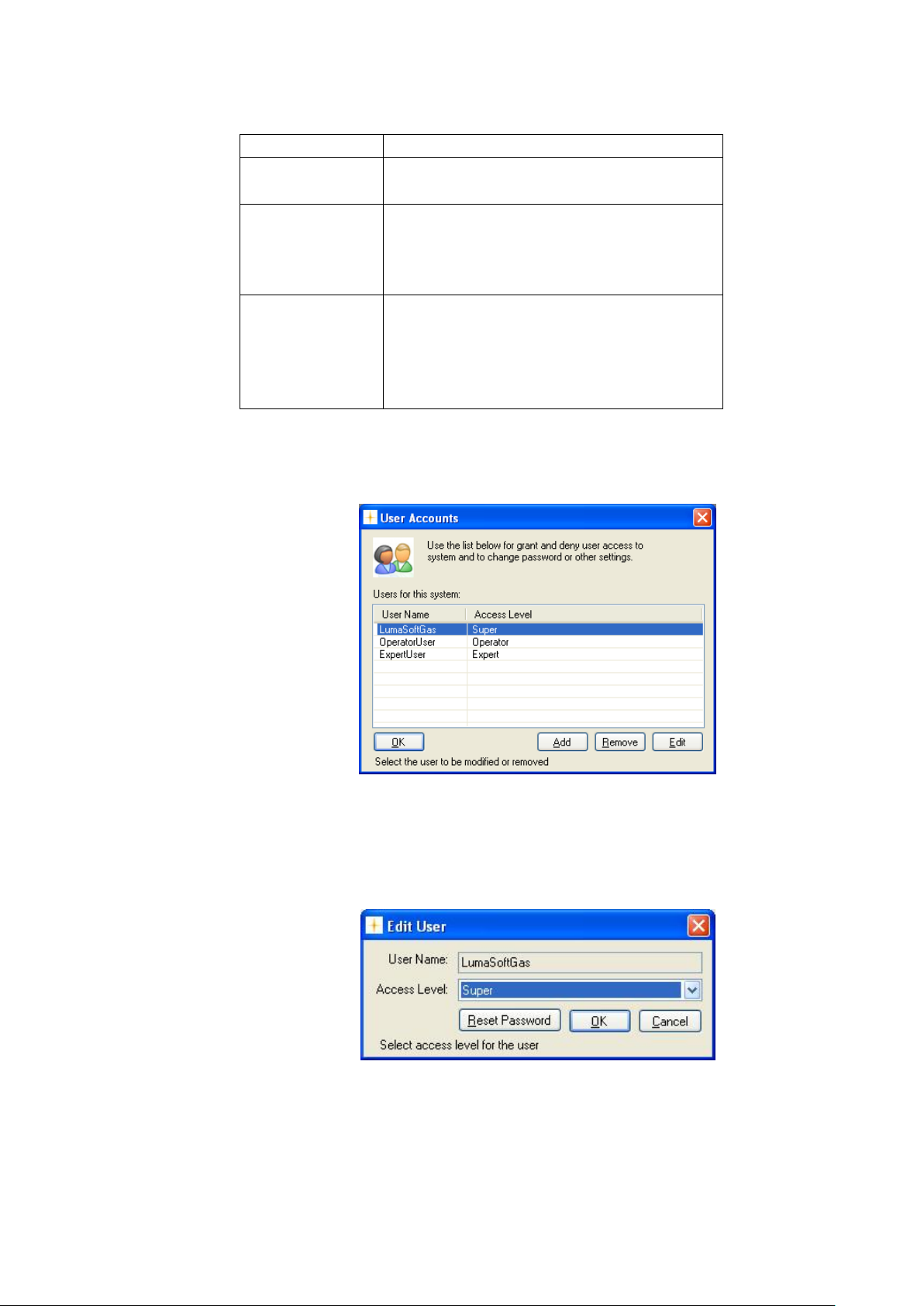

The User Accounts window appears showing a lis t of the current user

accounts, see Figure 2.4.

A predefined user a ccount named LumaSoftGas with the highest access

level appears the f irst time the User Accounts window is opened. The

predefined password for the LumaSoftGas user is: lumasoftgas

Figure 2.4 User Accounts

2.3.1 Add User Account

In order for the administrator to add a new user account the Add softkey can be selected.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 23 of 194

Page 24

Chapter 2

_________________________________________________________________________

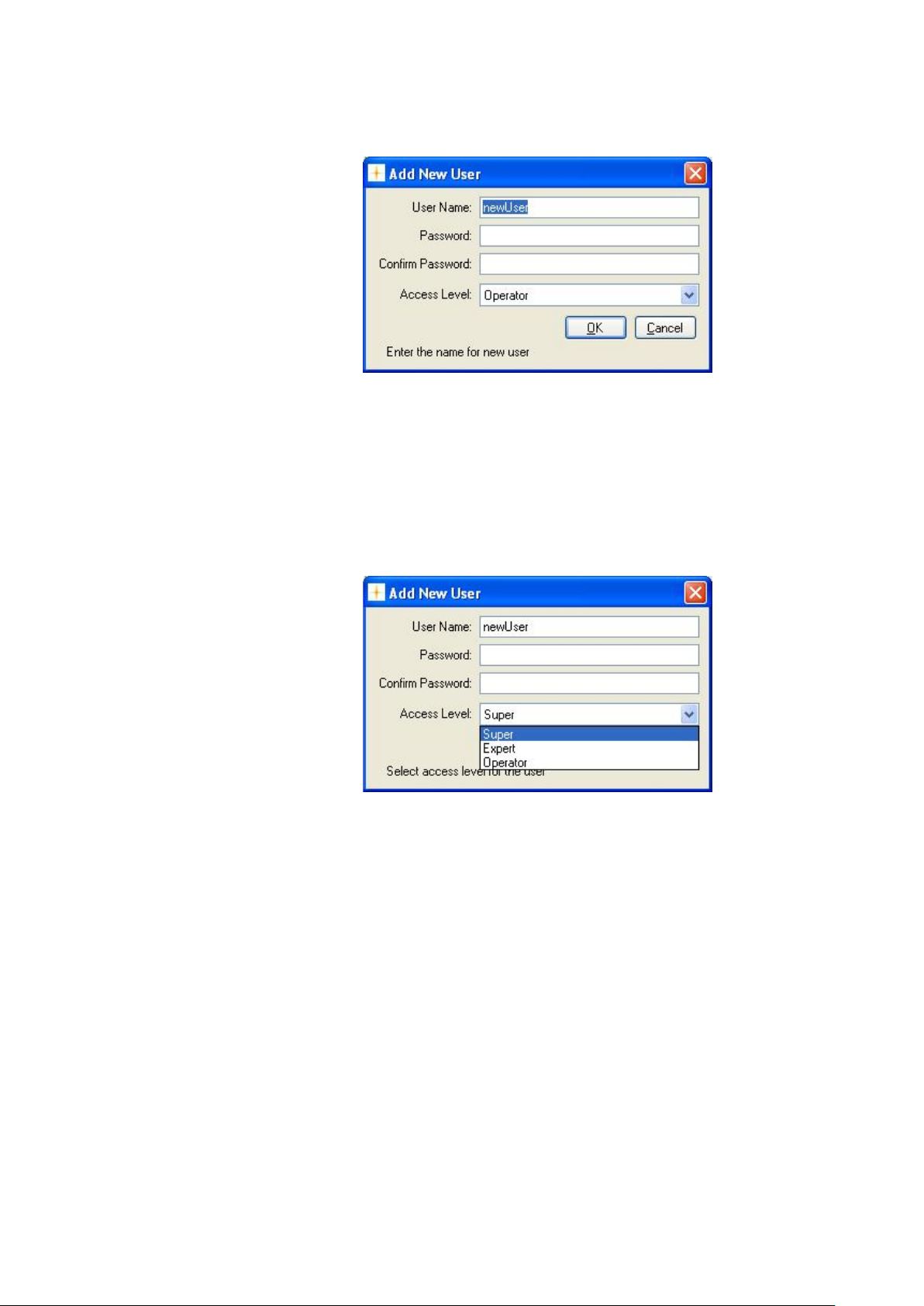

The Add New User window appears (see Figure 2.5).

Figure 2.5 Add User Account

The User Name, Password and Access Level for the new user

account can be specified.

Please note that the User Name and Password must contain at least 6

characters and must contain no special characters. Only alphabets and

numeric characters are allowed [(a-z), (A-Z), (0-9 )] fo r the User Name

and Password (see Figure 2.6).

Figure 2.6 User access Levels

Three different access levels can be specified. The rights for each of the

access levels are described below in table 2.6.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 24 of 194

Page 25

Chapter 2

Access level

Rights

Super

All expert rights

Delete task

Expert

All operator rights

Backup/restore a task

Operator

Open a task.

Export/import a task configuration

_________________________________________________________________________

Create a new task

Make setup of a task

Start a measurement

Export a task

Export log

Table 2.6 User access levels

2.3.2 Edit User Account

A user account can be edited by the administrator by selecting the Edit

soft-key in the User Acc ounts window. Before se lecting the Edit softkey a User Name must be selected in the Us e r Accounts window.

The access level can be changed by selecting the Access Level field.

Also the Password can be changed by selecting the Reset Password

soft-key. (See Figure 2.8).

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 25 of 194

Figure 2.7 User Accounts: Edit

Figure 2.8 Edit User Account

Page 26

Chapter 2

_________________________________________________________________________

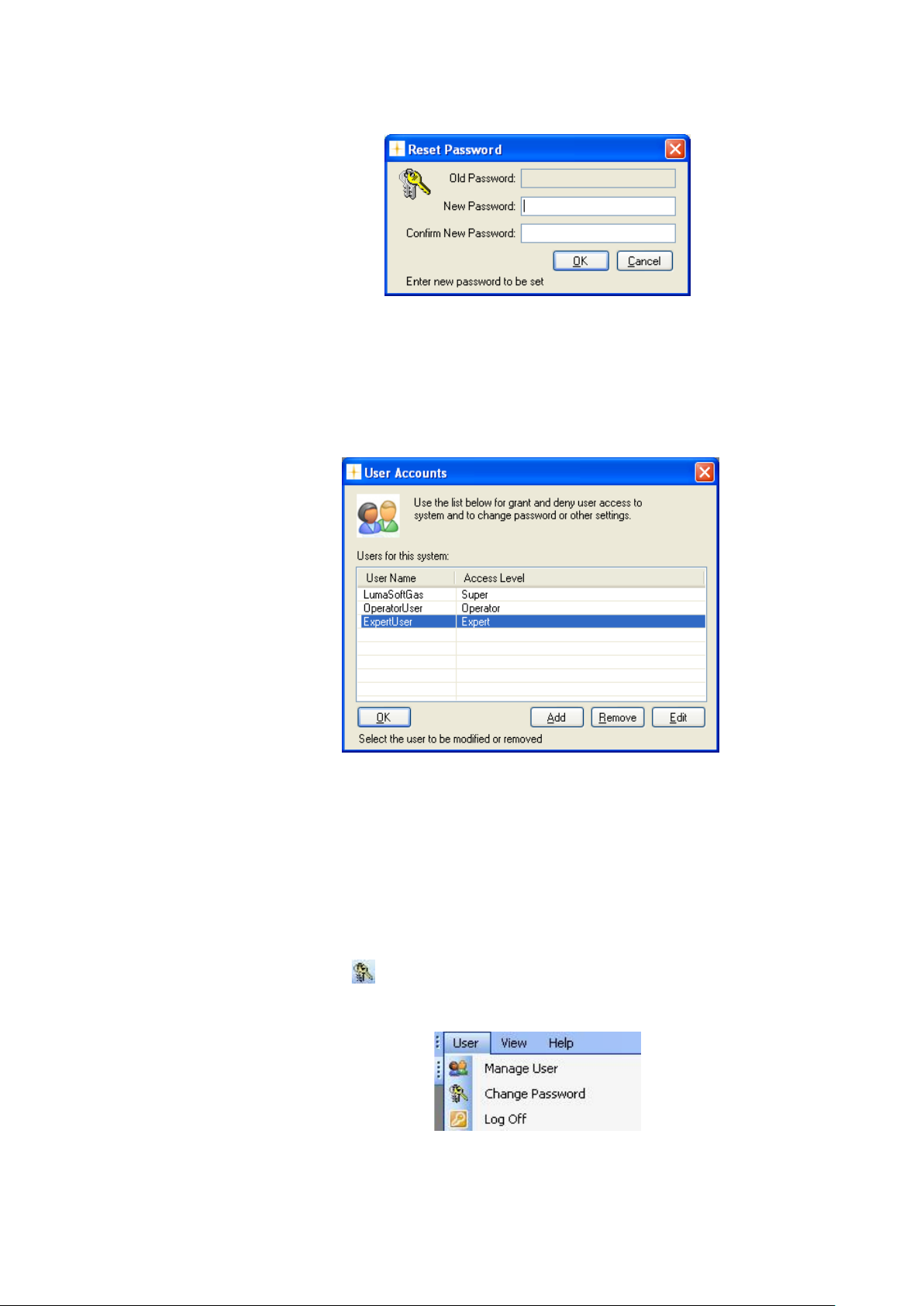

Figure 2.9 Reset password dialogue

The Reset Passwo rd dialogue window a ppears and the new password

for the user account can be entered. (See Figure 2.9).

2.3.3 Remove User Account

Figure 2.10 User Accounts: Remove

A user account can be removed by selecting the Remove soft-key i n the

User Accounts window, see Figure 2.10. Before selecting the Remove

soft-key a User Name must be selected in the User Accounts window.

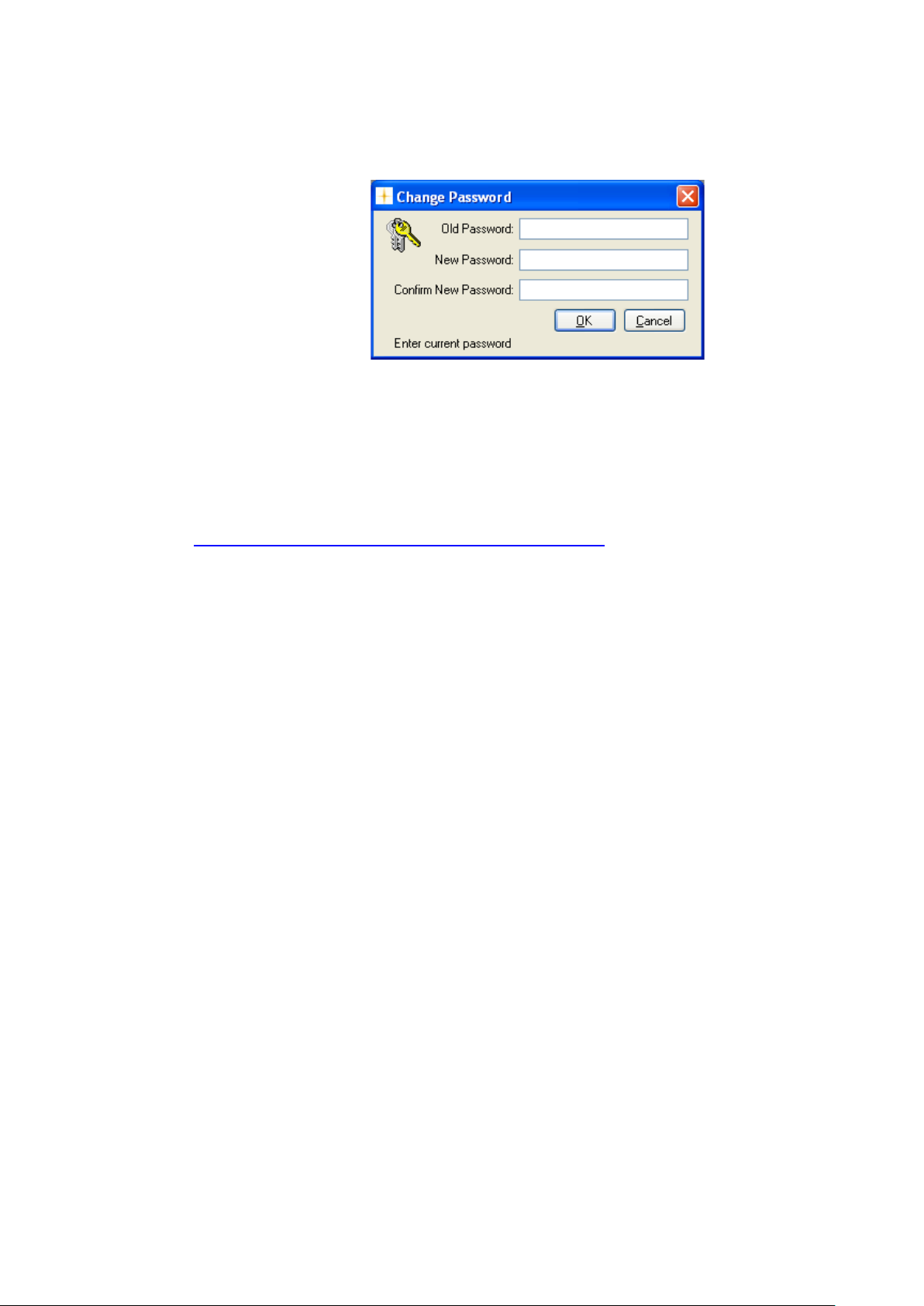

2.3.4 Change password of the administrator

To change the password of the administrator you select the Change

password icon from the toolbar or select Change Password from

the User pull down menu. (See Figure 2.11)

Figure 2.11 User pull-down: Change Password

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 26 of 194

Page 27

Chapter 2

_________________________________________________________________________

The Change Pass word dialogue wind ow (Figure 2.1 2) appears and the

old and new password for the administrator can be entered.

Figure 2.12 Change Password dialogue

2.4 Download of the latest version

You will find the latest version of the software on

http://innova.lumasenseinc.com/downloads

2.5 Back-up and Restoring of calibration data

If you have ordered a calibration from our calibration laboratory, you

will receive a CD with a backup of the calibration data. It is very

important that you store these data in your Gas Monitoring Software

7304, supplied with the Monitor. Please refer to the Instruction

Manual BE6025 fo r guidance in how to backup and r estore calibration

data.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 27 of 194

Page 28

Chapter 3

_________________________________________________________________________

Chapter 3

Set-up Measurement Task

October 2012

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 28 of 194

Page 29

Chapter 3

_________________________________________________________________________

This chapter will show the steps how to set-up a measurement task.

Please note that measurement set-up is only allowed for users with

Expert or Super access level. (See Table 2.6)

Log in to the software using your username and password.

Figure 3.1 User Authentication

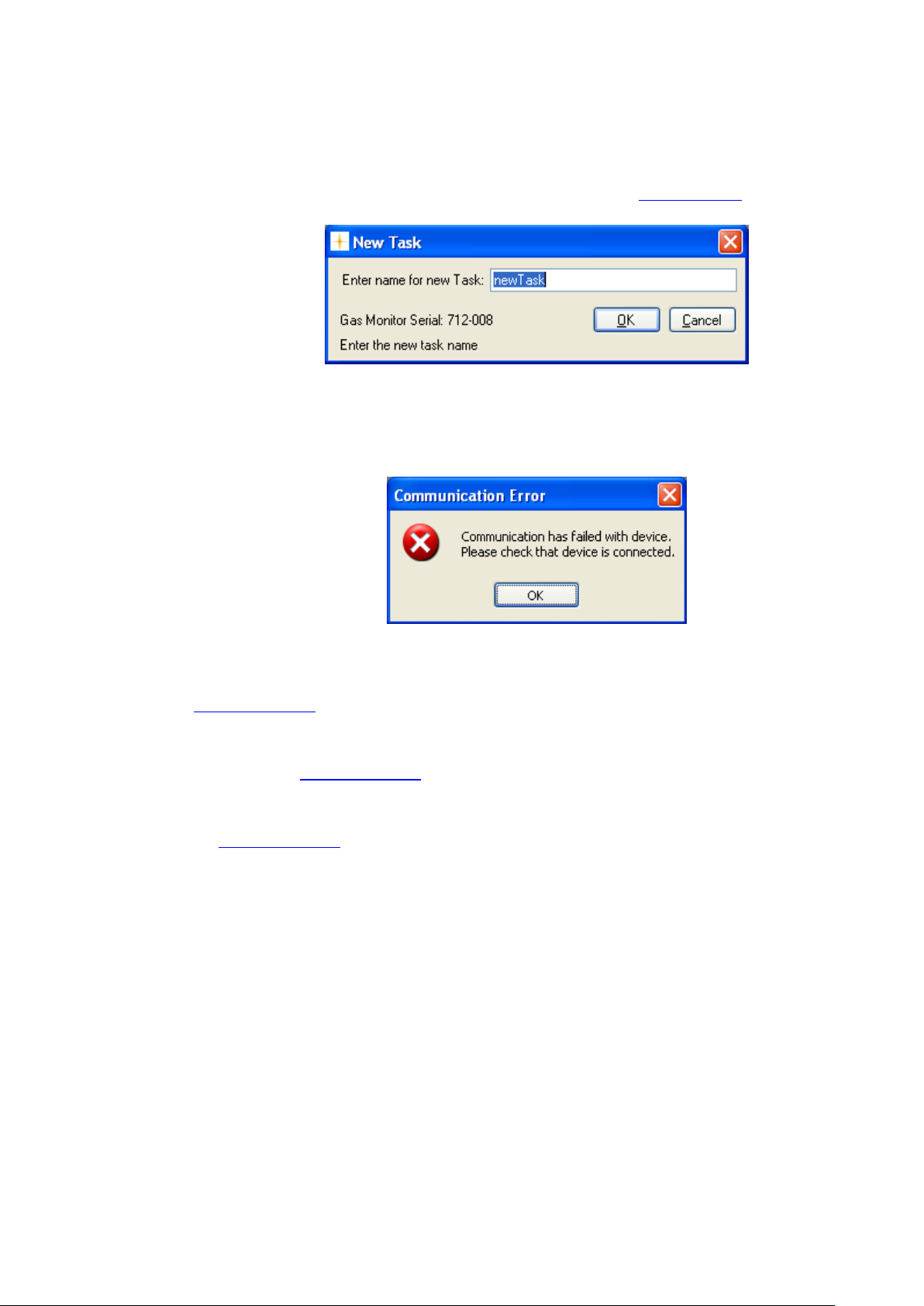

3.1 New task

Please make sure that you have an USB, Ether net (TCP/IP) or a RS-232

interface cab le connected to th e 1412i/1314i/3434i Gas Monitor device.

IMPORTANT! Please note that only one interface cable (either

USB, Ethernet (TCP/IP) or RS-232) should be connected at any

time.

In order to create a new task select the New Task pull-down menu

(Figure 3.2).

Figure 3.2 File pull-down: New Task

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 29 of 194

Page 30

Chapter 3

_________________________________________________________________________

If the 1412i/1314i/3434i device is recognized the New Task window

(Figure 3.3) opens, where you enter the name of the new task and press

the OK soft-key. After that you can proceed to section 3.2.

Figure 3.3 Type in the name of the new task.

If the 1412i/1314i/3434i device is NOT recognized the Communication

Error message box (Figure 3.4) will appear. Press the OK soft-key.

Figure 3.4 Communication Error message box.

If you are using the USB interface cable connection please proceed to

section 3.1.1.

If you are using the Ethernet (TCP/IP) interface cable connection please

proceed to section 3.1.2.

If you are using the RS-232 interface cable connection please proceed

to section 3.1.3.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 30 of 194

Page 31

Chapter 3

_________________________________________________________________________

3.1.1 Configuration of the USB interface

The System Configuration Setup window appears. Now you s elect the

USB radio button as shown in figure 3.5 in case it is not selected.

Figure 3.5 Select the USB communication interface.

To close the System Configuration Setup press the OK soft-key.

If the USB interface already was selected please make sure that the USB

interface cable between the PC and the 1412i/1314i/3434i Gas Monitor

is securely connected.

Finally please ask your Administrator to check for the presence of the

1412i USB driver in the Device Manager (Figure 3.6). Please note that

the 1412i USB driver also supports the 1314i and 3434i Gas Monitor.

Now proceed to section 3.2 in order to create a new task.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 31 of 194

Page 32

Chapter 3

_________________________________________________________________________

Figure 3.6 The 1412i USB driv er .

3.1.2 Configuration of the Ethernet (TCP/IP) interface

The System Configuration Setup window appears. Now you s elect the

TCP/IP: radio button as shown in figure 3.7 in case it is not selected.

Figure 3.7 Select the TCP/IP communication interface.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 32 of 194

Page 33

Chapter 3

_________________________________________________________________________

Enter the IP address of the Gas Monitor into the IP-address field as

shown in Figure 3.8.

Figure 3.8 Enter the IP Address of the Gas Monitor.

Refer to Section 2.2.4 to find the IP address of the 1412i/1314i/3434i

Gas Monitor.

Press the OK soft-key to close the System Configuration Setup

window. Proceed to Section 3.2 in order to create a new task.

If the creation of a new task failed the following message box will

appear. It is caused because LumaSoft Gas is unable to communicate

with the Gas Monitor through Ethernet (TCP/IP).

Figure 3.9 Communication failed with the Gas Monitor.

Please make sure that the Ethernet (TCP/IP) interface cable between

your network and the 1412i/1314i/3434i Gas Monitor is securely

connected.

Please ask your Administrator to check the TCP/IP settings of the

1412i/1314i/3434i Gas Monitor as described in Section 2.2.4.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 33 of 194

Page 34

Chapter 3

_________________________________________________________________________

Make sure that the PROTECTED IP ADDRESS either is set to the IP

Address of your PC or set to 000:000:000:000.

Make a note of the IP Address of the 1412i/1314i/3434i device as

displayed in the TCP/IP settings.

Your Administrator can now open a DOS Command Prompt to check for

a ping reply from the IP Address of the 1412i/1314i/3434i devic e.

Figure 3.10 Ping reply from the 1412i/1314i/3434i device.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 34 of 194

Page 35

Chapter 3

_________________________________________________________________________

3.1.3 Configuration of the RS-232 interface

The System Configuration Setup window appears. Now you select the

COM Port: radio button as shown in figure 3.11 in case it is not

selected. Press the OK soft-key.

Figure 3.11 Select the RS-232 communication interface.

Select the Scan Network pull-down menu (Figure 3.12).

Figure 3.12 File pull-down: Scan Network

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 35 of 194

Page 36

Chapter 3

_________________________________________________________________________

A search for a 1412i/1314i/3434i Gas Monitor connected to the RS-232

interface is now performed. When found the Scan Network window is

shown (Figure 3.13). Press the New Task soft-key.

Figure 3.13 Scan Network: COM2 port found

Now the New Task w indow o pens (Fi gu r e 3.1 4). Enter the desired name

for your task and press the OK soft-key. You can now proceed to

Section 3.2.

Figure 3.14 New Task: Enter task name

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 36 of 194

Page 37

Chapter 3

_________________________________________________________________________

3.2 Measurement set-up

The set up of a new measurement task is carried out in five steps.

3.2.1 Configuration

First step is System Configuration Setup, select Configuration in the

Set Up pull down menu (Fi gur e 3.1 5) or select the icon f r om the ta sk

bar.

Figure 3.15 Set-up pull-down: Configuration

The following System Configuration Set Up window will appear.

Figure 3.16 System Configuration SetUp

Then make check marks if any multiplexers (1303, 1309) are connected

to the Monitor. A maximum of four 1303 or two 1309 can be connected.

After finishing the set up, press OK.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 37 of 194

Page 38

Chapter 3

_________________________________________________________________________

3.2.2 Monitor Setup

Set up of the Monitor is done by selecting Monitor in the Set Up pull

down menu. (Figure 3.17)

Figure 3.17 Set up pull-down: Monitor

The Monitor Setup will appear. (Figure 3.18)

Figure 3.18 Monitor Setup, Sampling

Sampling Index Card

In the Flushing group box select if the flushing of the instrument should

be Auto or Fixed Time.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 38 of 194

Page 39

Chapter 3

Acceptable Values

Interval

Default

Value

Chamber: 2 to 60 s

Tube: 0 (=off), 3 to 120 s

1 s

1 s

8 s

3 s

_________________________________________________________________________

By selecting Auto the monitoring system controls the flushing by

selecting the optimum flushing time. This time can vary as the option

takes into account the cleanness of the e x te r nal air filters and the le ngth

of the sampling tube. Type in the length of the tubing. (See Figure

3.18).

Selecting Fixed Time allows the user to define a flushing time for

chamber and tubing. Table 3.1 shows the acce ptable values for f lushing

chamber and tubing.

Table 3.1 Acceptable values for flushing the system when selecting Fixed

Time flushing

In the Compensation group box, see Figure 3.18, compensation for

Water and Cross Interference can be checked on/off.

It is suggested that Water should be compensated for in all measuring

situations except where extremely dry gases are being measured.

If any interfe ring gas othe r than Water Vapour is present in the am bient

air sample, the Monitor can cross compensate for the interference

caused by its presenc e provided that a se lective optical fil ter is installed

in the Monitor to measure the concentration of the interfering gas

present.

In the Sample Information group box, see Figure 3.18, select whether

multiplexer sequences are continuous. Select Sample Continously if

you want the next multip lexer sequence immediately af ter finishing the

previous multiplexe r se quence . If Seq uen ce Int erva l is selecte d a time

interval (in minutes) can be set to define the start of one multiplexer

sequence to the beginn ing o f t he ne xt . If no multiplexe r is used the time

interval will be between the individual samples.

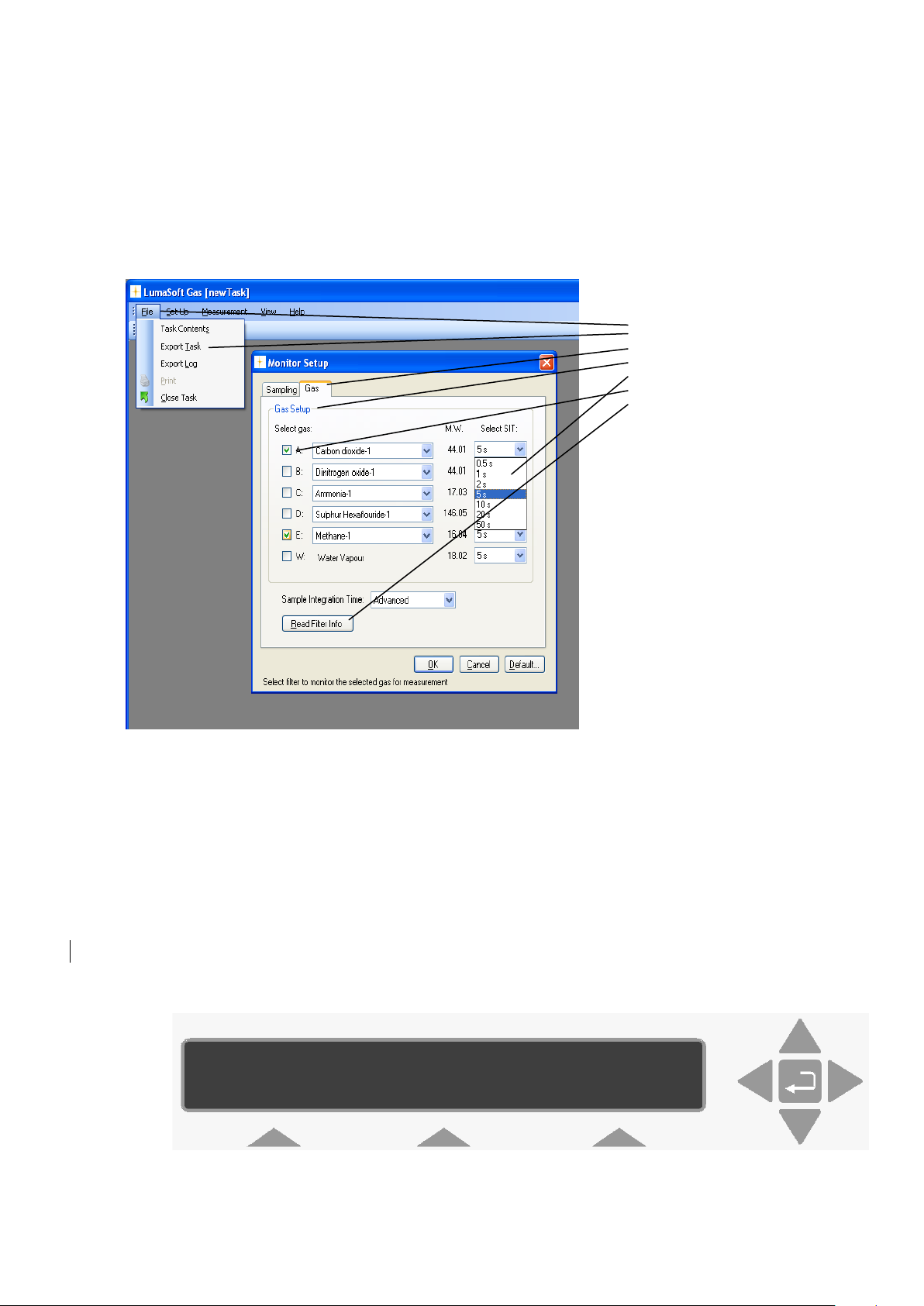

Gas Index Card

Select the Gas index card and press the Read Filter Info soft-key (See

Figure 3.19) to read the filter configuration from the Monitor.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 39 of 194

Page 40

Chapter 3

_________________________________________________________________________

Figure 3.19 Monitor Setup, Gasses to be measured

The calibrations in the Monitor wil l appear as Gas A, B, C , D and E, see

Figure 3.20. Select the gasses which should be measured by using the

checkboxes.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 40 of 194

Page 41

Chapter 3

_________________________________________________________________________

Figure 3.20 Monitor Setup

Also select the Sample Integration Time (SIT) to be used in the

measurements and press OK.

To select different SIT’s for diff erent gases use the Sam ple Integration

Time field selection and select Advanced.

A select field appears for each gas, see Figure 3 .21. Then it is possible

to define a SIT for individual gases.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 41 of 194

Page 42

Chapter 3

_________________________________________________________________________

Figure 3.21 By selecting Advanced the user can define SIT for the

3.2.3 Multiplexer setup

If a multiplexer is connected to the Monitor select Multiplexer in the

Set Up pull down menu. (See Figure 3.22)

Figure 3.22 Set Up pull-down: Multiplexer

different gases

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 42 of 194

Page 43

Chapter 3

_________________________________________________________________________

Figure 3.23 Multiplexer SetUp

Select the channels fr om wh ich the mu ltip le xer s hould dr aw air sa mples.

For each channel a specific location or name can be assigned.

Choose between a Normal sequence and a User se quenc e. By s electing

a normal sequence (see Figure 3.23), air samples will be drawn first

from channel 1 then 2, 3, 4 etc., that is in ascending order. Selecting

User Sequence allows you to define the sampling order arbitrarily, by

typing in the channel numbers in a specific order, see Figure 3.24.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 43 of 194

Page 44

Chapter 3

_________________________________________________________________________

3.2.4 Alarms

This function is used to define software alarms for each gas when the

concentration reaches either a minimum or a maximum level.

Select Alarm in the Set Up pull down menu, and the fo llowing window

will appear, Figur e 3 .2 6.

Figure 3.24 User defined sample sequence

Figure 3.25 Set Up pull-down: Alarm

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 44 of 194

Page 45

Chapter 3

_________________________________________________________________________

Figure 3.26 Alarm Setup for specific gases

First select the ch annel number in the field select ion box for which the

alarm should be configured, as shown in Figure 3.27.

Figure 3.27 Select a channel number in the left pull down box.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 45 of 194

Page 46

Chapter 3

_________________________________________________________________________

Then select the gas fo r which the alar m should be configur ed in the Gas

selection box , s ee Figure 3.28.

Figure 3.28 Select for which gas the alarm should be configured

There are four different alarms which can be configured: Low, Low Low,

High and High High. The Low alarm can be set to give a warning that

the concentration of the gas is dropping below the normal level. The

Low Low alarm can then be configur ed to give a warning whenever the

gas concentration drops below the lowest allowable concentration. The

High and the High High alarm levels are set to give a warning for a

concentration above a certain limit and that the maximum allowable

concentration is exceeded.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 46 of 194

Page 47

Chapter 3

_________________________________________________________________________

To set up an alarm first select between the four mentioned alarms,

select concentratio n unit, and then type in the c oncentration, se Figure

3.29.

Figure 3.29 Select a type of alarm and type in a value for the gas

concentration

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 47 of 194

Page 48

Chapter 3

_________________________________________________________________________

When the alarms have bee n configured choose whe ther there should be

a PC beep when th e alarm level is reached. Press Add soft-key to ad d

the configured alarms and then OK to proceed. (See Figure 3.30)

Figure 3.30 Press Add soft-key to add the configured alarms

To remove a gas from the alarm list highlight the gas using a mouse

click and press the Remove soft-key. (See Figure 3.30)

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 48 of 194

Page 49

Chapter 3

Display Text

Options

Default

NORMALIZATION TEMPERATURE

0°C, 20°C and 25°C

20°C

NORMALIZATION TEMPERATURE

32°F, 68°F and 77°F

68°F

NORMALIZATION TEMPERATURE

273K, 293K and 298K

293K

_________________________________________________________________________

3.2.5 Units

Select Unit in the Set Up drop down menu. (See Figure 3.31)

Figure 3.31 Set Up pull-down: Unit

Figure 3.32 Select in which units the data should be displayed

In this window the user can select in which units Humidity, Pressure,

Gas Concentration, Temperature and Length will be shown. The

Normalization Temperature can also be changed. The normalization

temperature is the r eference te mperature , for re porting data in absolute

unit mg/m3. A normalization temperature of 25°C means that the

measured gas concentrations will be calculated in mg/m3 at 25°C. The

user can choose between three different normalization temperatures,

see table 3.2.

Value

Table 3.2 The possible values and the default values of the

normalization temperature

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 49 of 194

Page 50

Chapter 4

_________________________________________________________________________

Chapter 4

Perform Measurement

October 2012

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 50 of 194

Page 51

Chapter 4

_________________________________________________________________________

This chapter shows how to

- perform a measurement task. (Section 4.1)

- present the measurement data in graphic display (Channel view).

(Section 4.2.1)

- present the measurement data in graphic di splay (Gas view). (Section

4.2.2)

- present the measurement data in numeric display. (Section 4.3)

- set user events. (Sections 4.2.1.7{Channel view}, 4.2.2.8{Gas view}

and 4.3.3)

- print graphic and numeric displays. (Sections 4.2.1.8{Channel view},

4.2.2.9{Gas view} and 4.3.4)

- display historical data. (Section 4.2.1.9{Channel view}, 4.2.2.10{Gas

view}

- view alarms. (Section 4.4)

- export measurement data. (Section 4.5)

- view error and warnings. (Section 4.6)

- export log (Section 4.7)

4.1 Measurement start and stop

If a measurement task is not open, select File and Open Task, see

Figure 4.1 or select from the task bar.

Figure 4.1 File pull-down: Open Task

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 51 of 194

Page 52

Chapter 4

_________________________________________________________________________

Select an existing task to open, see Figure 4.2.

Figure 4.2 Select which task to open

4.1.1 Start Measurement

To start the measu rement, select Measurement and Start, see Figure

4.3, or press the icon with the green arrow in the task bar.

Figure 4.3 Measurement pull-down: Start

The measurement can be started immediately (Now option) or at a

specific starting time by using the option: Start at, see Figure 4.4.

Figure 4.4 Start and stop measurement task

The measurement can be stopped manually (Manual option) or at a

fixed time using the Stop at option. (See Figure 4.4)

A measurement task can be stopped and then restarted at your

convenience.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 52 of 194

Page 53

Chapter 4

_________________________________________________________________________

4.1.2 Stop Measurement

To stop the measurement, select Measurement and Stop, see Figure

4.5, or press the icon in the task bar.

Figure 4.5 Measurement pull-down: Stop

4.2 Presentation of Data in Graphical Window

The measurement data can be presented graphically in two different

ways either channel-wise or gas-wise.

If measurement data is presented c hannel-wise the gas filters is shown

in a graphical view for each channel. Proceed to Section 4.2.1 for

presentation of graphical data channel-wise.

If measurement data is presented gas-wise the multip lexer channels is

shown in a graphical view for each gas filter. Proceed to Section 4.2.2

for presentation of graphical data Gas View.

4.2.1 Presentation of Data in Graphical Window Channel-View

To display measureme nt data graphical ly channel-wise select Graphical

Window>Single Channel with Selected Gases View in the View

pull-down menu. (See Figure 4.6)

Figure 4.6 View pull-down: Graphical Window>Single Channel with

Selected Gases V iew

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 53 of 194

Page 54

Chapter 4

_________________________________________________________________________

4.2.1.1 Configuration of the (Channel-View) graphical window

In the Configuration window select if the data shou ld be presented as

a Real Time Graph, while measurement is in progress, or Historical

Graph, see Figure 4.7.

Figure 4.7 Select if the data should be presented in real time or historic

Real Time Graph means that mea sureme nt data wi ll be plotted as they

arrive from the Moni tor.

Historical Graph means viewing of previously measured data

Select Real Time Graph and press Next to continue.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 54 of 194

Page 55

Chapter 4

_________________________________________________________________________

4.2.1.2 Select Gases (Channel view)

In the gas Configuration window, see Figure 4.8, select which of the

measured gases to be included in the Graph and press the right going

arrow.

Figure 4.8 Select which gasses to be presented

To select more gasses at one time press Ctrl while selecting. When the

gases have been chosen the y will appe ar in the right wi ndo w, see Figure

4.9. Press Next to proceed.

Figure 4.9 The gasses chosen for presentation

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 55 of 194

Page 56

Chapter 4

_________________________________________________________________________

4.2.1.3 Configuration of curves (Channel view)

CurveColor

Each of the filters has a default selected curve color, see Figure 4.10.

To change the color of the curves press the colored square in the

CurveColor column.

Figure 4.10 Change the color of the curves

Select a color for the curve in the Color window, see Figure 4.11.

Figure 4.11 Select a color for the curve

Repeat the procedure for all the gasses.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 56 of 194

Page 57

Chapter 4

_________________________________________________________________________

PointStyle

It is possible to change the style of the plotted measuring points to

Square or Circle using the field selection in the Point Style column.

Figure 4.12 Change the style of the measurement points

Scaling

The scaling on the Y-axis can be set to AutoScaleMinAndMax,

AutoScaleMax or AutoScaleOff in the field selection individually for

each filter in the Scaling column. The possible scaling types are

described in Table 4.1.

Figure 4.13 Setting the scaling of the axis

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 57 of 194

Page 58

Chapter 4

AutoScaleMinAndMax

The scale will cover from the

highest measured value, i.e. all

measurement points will be

visible on the graph.

AutoScaleMax

The Y-axis will begin at 0 and the

maximum value depends on the

highest measured value.

AutoScaleOff

The user defines both minimum

and maximum values for the Y

scale manually, by defining

. This

can be of use to view

measurement points in a

particular range.

_________________________________________________________________________

lowest measurement value to the

YScalemin and YScaleMax

Table 4.1 Shows the possible Scaling types of the Y-axis

Units

In the Unit column the unit in which each gas will be displayed in the

graphical window can be selected.

Figure 4.14 Select the unit in which the gas concentrations will be

Table 4.2 shows the possible parameter units and their default settings.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 58 of 194

displayed

Page 59

Chapter 4

_________________________________________________________________________

Parameters Units Default Unit

Humidity mg/m3, ppm, Tdew, kPa Tdew

Pressure mbar, mmHg, kPa kPa

Gas Concentrations mg/m3, ppm ppm

Table 4.2 The possible parameter u nits with defaults

Tension

By adjusting the Tension it is defined how so ft/hard the lines between

the measuring points sho uld be. If the tension is set to 0 the points are

connected by straight lines.

Figure 4.15 Define how hard/soft the lines between measurement points

should be

When all the settings has been adjusted press Next to proceed.

4.2.1.4 Configuration of the Graph Window (Channel view)

In this configuration window the trend properties are configured. The

trend can be given a title by entering a name in the Graph Title field.

(See Figure 4.16).

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 59 of 194

Page 60

Chapter 4

_________________________________________________________________________

Figure 4.16 Configuration of graph window properties

The number of decimals on the mea sured values can be selected in the

field selection: Y Axis Decimal places.

The time interval ( X Interval) on the X -axis can be set to days, hours,

minutes or seconds.

Back Color, Cursor Color, Text Color and Font etc. can be changed

by pressing the appropriate grey squares.

Gradient Mode gives a shading of a dark background color.

Grid Visible turns on/off the grid.

User Events turns on/off the display of user events (see Section

4.2.1.7).

Press Finish when the configuration is completed.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 60 of 194

Page 61

Chapter 4

_________________________________________________________________________

Figure 4.17 The graphical window(Channel View)

Changing the configuration

To change any of the above settings after the configuration is ended

press the right mouse button while the cursor is placed in the graph

area. Select Setup (see Figure 4.18) and the Configuration window

will appear, see Figure 4.10 and Figure 4.16.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 61 of 194

Page 62

Chapter 4

_________________________________________________________________________

Figure 4.18 To change the configuration in the graphical window press

the right button on the mouse

To add a curve for a measured gas, which has not been previously

added, press the right mouse button while the cursor is placed in the

graph area and select AddTag. (See Figure 4.18)

4.2.1.5 The Graphical Window (Channel view)

The graphic window sho ws the measur ement data in a grap h. Each filte r

in the Monitor has its own axis o n the graph, see Fi gure 4.1 8. Below the

graph a window containing a list of the measured gases, and statistics

performed from all obtained measurement data (Min, Max, Mean and

Std. Deviation) is shown. The bottom window is the Error and

Warnings and Alarm window. The number of curves displayed, their

color and style are de fined by the user as described in Section 4.2.1.1,

Section 4.2.1.2, Section 4.2.1.3 and Section 4.2.1.4.

________________________________________________________________________

BE6027-12 LumaSoft Gas Software LumaSense Technologies A/S

7810 and 7860 Page 62 of 194

Page 63

Chapter 4

_________________________________________________________________________

The user can toggle between the Errors/Warnings, Measurement

Errors/Warnings and Measurement Alarm windows. The

Errors/Warnings window will register if any errors have occurred while

running the measureme nt. The window can be hidden by pr essing Auto

Hide icon, or by selecting Errors/Warnings Window in the View