Page 1

BE6028-14

Instruction

Manual

3434i

SF6 Leak Detector

Page 2

Index

________________________________________________________________________

Index

Index ................................................................................................................................... 2

3434i SF6 Leak Detector ........................................................................................................ 4

Safety Considerations. ...................................................................................................... 5

Applying Power ................................................................................................................ 7

Chapter 1 Using this Manual ................................................................................................. 8

1.1 Introduction ............................................................................................................ 9

1.2 Online Monitoring .................................................................................................... 9

1.3 PC Use BZ7002 Calibration Software .......................................................................... 9

1.4 PC Use BZ7003 Offline Software ................................................................................ 9

1.5 Stand-alone Use ...................................................................................................... 9

Chapter 2 Preliminary Tasks ............................................................................................... 12

2.1 Connecting the Monitor to the PC ............................................................................ 13

2.2 Checking /changing the Fuses in the Monitor. ........................................................... 14

2.3 Setting the USB Communication Parameters ............................................................. 17

2.4 Setting the RS-232 Communication Parameters ........................................................... 18

2.5 Setting the Ethernet Communication Parameters ....................................................... 19

2.6 Setting-up user Levels ........................................................................................... 23

2.7 Restoring of calibration data ................................................................................... 25

Chapter 3 Philosophy of Operation ....................................................................................... 26

3.1 PC Use – Online .................................................................................................... 27

3.2 Stand-alone Use .................................................................................................... 28

Chapter 4 Introduction to and Familiarization with the Monitor ............................................... 30

4.1 Special Terminology ............................................................................................... 31

4.2 Attaching the Sampling Tube and External Filter ........................................................ 34

4.3 Familiarization with the Monitor using the Front Panel ................................................ 35

Chapter 5 The Monitor ....................................................................................................... 56

5.1 Introduction .......................................................................................................... 57

5.2 Front Panel ........................................................................................................... 57

5.3 Starting-up or Restarting the Monitor ....................................................................... 61

5.4 Configuring the Monitor .......................................................................................... 64

5.5 Alarm Relay .......................................................................................................... 67

5.6 Continuous Warm System ...................................................................................... 69

Chapter 6 Keying-in Parameters .......................................................................................... 70

6.1 Types of Parameters .............................................................................................. 71

Chapter 7 Setting-up and Starting a Monitoring Task ............................................................ 74

7.1 The Parameters’ Units ............................................................................................ 75

7.2 The Measurement Parameters ................................................................................. 77

7.3 Setting-up the Monitor’s Alarm Levels ...................................................................... 85

7.4 Starting a Monitoring Task ...................................................................................... 86

Chapter 8 Viewing Measurement Data – Using the Monitor .................................................... 90

8.1 Displayed Monitoring Task Data............................................................................... 91

8.2 Printed Monitoring Task Data .................................................................................. 96

8.3 Storage Space in the Display Memory ...................................................................... 99

Chapter 9 Storage of Data in the Monitor’s Memory .............................................................. 100

9.1 Types of Memory in the Monitor ............................................................................. 101

9.2 Storage of Measurement Results ............................................................................ 109

9.3 Management of Data in Background Memory ........................................................... 112

Chapter 10 Using a Printer with the Monitor ......................................................................... 116

10.1 Introduction ......................................................................................................... 117

10.2 Printer Cables ...................................................................................................... 117

10.3 Setting-up Communication Parameters ................................................................... 118

10.4 Additional Parameters Required .............................................................................. 123

10.5 Data Logging Function .......................................................................................... 124

10.6 Error Logging Function .......................................................................................... 124

10.7 Printing-out Data from the Monitor ......................................................................... 125

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 2 of 191

Page 3

Index

________________________________________________________________________

Chapter 11 Maintenance of the 3434i .................................................................................. 126

11.1 Changing the Fine Air-filters .................................................................................. 127

11.2 Cleaning the Filter in the Ventilation Unit ................................................................. 132

11.3 Cleaning the Instrument ........................................................................................ 133

Chapter 12 Calibration of the Optical Filters ......................................................................... 134

12.1 About the Installed Optical Filters ........................................................................... 135

12.2 What is Calibration and Why is it Necessary? ........................................................... 136

12.3 Tasks Before Starting Any Calibration ..................................................................... 138

12.4 The Basic Calibration Set-up .................................................................................. 144

12.5 General Settings – Stand-alone Use ........................................................................ 147

12.6 Zero-point Calibration ........................................................................................... 151

12.7 Humidity-interference Calibrations – Stand-alone Use ............................................... 155

12.8 Span Calibration ................................................................................................... 159

12.9 Calibration of the Water-vapour Filter – Stand-alone Use ........................................... 167

12.10 Setting-up a Combined Zero-point and Humidity-interference Calibration – Stand-

alone Use ................................................................................................................ 173

12.11 Setting-up any Combined Calibration – Stand-alone Use ...................................... 175

Chapter 13 Messages Related to Calibration ......................................................................... 177

13.1 “Successful” Calibration Messages .......................................................................... 178

13.2 “Successful *” Calibration Messages ........................................................................ 178

13.3 “Invalid” Calibration Messages ............................................................................... 179

13.4 Error Messages Displayed when the INFO button is used ........................................... 179

Chapter 14 Warning and Error Messages ............................................................................. 185

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 3 of 191

Page 4

Safety Considerations

________________________________________________________________________

3434i SF6 Leak Detector

July 2014

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 4 of 191

Page 5

Safety Considerations

______________________________________________________________________

Safety Considerations.

Throughout this manual Monitor is used for:

The 3434i SF6 Leak Detector

The Monitor complies with:

• EN/IEC 61010-1, 2

equipment for measurement, control and laboratory use.

• Can/CSA-C22.2 No. 61010-1-04 - Safety Requirements for

Electrical Equipment for Measurement, Control, and Laboratory

Use.

• UL Std. No. 61010A-1 (2

Electrical Equipment for Measurement, Control, and Laboratory

Use.

To ensure safe operation and retain the Monitor in safe condition,

note the following:

TO AVOID THE POSSIBILITY OF AN EXPLOSION; MONITORING

OF FLAMMABLE GASES IN EXPLOSIVE CONCENTRATIONS

nd

Edition: Safety requirements for electrical

nd

Edition) - Safety Requirements for

EXPLOSION HAZARD!

MUST NEVER BE ATTEMPTED.

Never operate the 3434i SF6 Leak Detector in potentially

explosive environments.

When monitoring potentially flammable or toxic gases it is essential

that:

• The instrument itself is placed in a well-ventilated area outside the

potentially hazardous zone.

• A sufficiently long tube is connected to the air-outlet on the back

panel so that the sampled gas is carried away to the open air or to

an extraction and/or filtration unit.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 5 of 191

Page 6

Safety Considerations

______________________________________________________________________

Environmental Conditions for transport and storage:

Temperature: -25 to +55ºC

Relative Humidity: 0 to 80% RH

Atmospheric Pressure: 800 to 1060 hPa

Warnings!

• Avoid water condensation in the instrument.

• Switch off all equipment before connecting or disconnecting their

digital interface. Failure to do so could damage the equipment.

• Whenever it is likely that correct function or operating safety of

the apparatus has been impaired, the apparatus must be made

inoperative and secured against unintended operation.

• Any adjustment, maintenance and repair of the open apparatus

under voltage must be avoided as far as possible and, if

unavoidable, must be carried out only by trained personnel.

• If a fault is reported by the monitor that indicates correct function

of the instrument may be impaired, consult your local LumaSense

Technologies representative. Under no circumstances should repair

be attempted by persons not qualified in service of electronic

instrumentation.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 6 of 191

Page 7

Safety Considerations

______________________________________________________________________

Applying Power

Before using the 3434i check that the available mains voltage match

the specified voltage and frequency for the instrument.

SAFETY SYMBOLS

The apparatus will be marked with this symbol when it is important

that the user refers to the associated warning statement given in the

User Guide.

Frame or Chassis Dangerous voltage Protective earth

Copyright © 2014 LumaSense Technologies A/S

All rights reserved. No part of this publication may be reproduced or

distributed in any form or by any means without prior consent in

writing from LumaSense Technologies A/S, Denmark

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 7 of 191

Page 8

Chapter 1

______________________________________________________________________

Chapter 1

Using this Manual

July 2014

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 8 of 191

Page 9

Chapter 1

______________________________________________________________________

1.1 Introduction

This manual can be used in several ways. The first time users can

work their way through the examples in order to get to know this

monitoring system. The more experienced users can jump directly to

the relevant chapters in order to gain assistance, and experts can

use this manual as a reference book by using the index.

The monitor can be operated in different ways; Online Monitoring

using LumaSoft Gas Single point 7810, Online Calibration and backup using the Calibration Software BZ7002, Offline using the Offline

Software BZ7003 , and as a Stand-alone instrument. This manual

focuses on the Stand-alone use. For instruction in the use of BZ7002

and BZ7003 please refer to the User Manuals BE6034 and BE6035

respectively.

1.2 Online Monitoring

LumaSoft Gas Single Point 7810 is supplied with the instrument. This

is to be used for Online monitoring (PC use) please follow the

instructions in the BE6027 User Manual for online monitoring and

set-up.

1.3 PC Use BZ7002 Calibration Software

The BZ7002 Calibration Software is used for calibration of the gas

monitor from a PC. Please refer to the BZ7002 User Manual BE6034

and Chapter 12 of this Manual.

1.4 PC Use BZ7003 Offline Software

Data from the display memory can be copied to the background memory

after a measurement task is performed. The BZ7003 Offline Software is

used for upload of these measurement data from the monitor to the PC in

either excel format or text format files. Please refer to the User Manual

BE6035 and Chapter 9 of this manual for further instructions.

1.5 Stand-alone Use

In some situations, it may be necessary to set up without connecting

it to a PC. The procedure to do this are covered in this manual under

the Stand-alone use headings. The way these instructions are

presented is shown below:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 9 of 191

Page 10

Chapter 1

↵

SELECT SET-UP BRANCH

S1 S2 S3

______________________________________________________________________

MEASUREMENT FORMAT CONFIGURATION

The display above is used continuously through-out this manual. It

assists you displaying the text on screen and by indicating which of

the push-buttons can and should be pressed.

In general, the push-buttons shown above are used to navigate

through the various modes possible within the 3434i but are

described in more detail below:

These push-buttons are illustrated as S1, S2 and S3. On the 3434i

they correspond to the key and their position on the instrument.

These select push-buttons enable you to select one of the options

displayed.

This group of 5 push-buttons are referred to in this manual

collectively as the direction keys. The symbols below are used to

simplify the instruction in this manual.

▲ & ▼ enable you to increase & decrease numbers, respectively, or

to go to the Previous & Next Displays, respectively.

◄ & ► enable you to move across number fields or go to the

Previous & Next gases, respectively.

, depending on the situations, acts as an “Enter” or “Go To Head”

key.

Memory Function push-buttons are always represented with the name

of the push-button enclosed in a box which is shaded-in.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 10 of 191

Page 11

Chapter 1

______________________________________________________________________

SYSTEM Text that appears on the display screen is shown in an open

shaded box, using UPPER case letters.

FORMAT System General Clock

When referring to any part of the Set-up “tree”, the text is

shown in open shaded boxes with the same typeface as that

used in the “tree”.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 11 of 191

Page 12

Chapter 2

______________________________________________________________________

Chapter 2

Preliminary Tasks

July 2014

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 12 of 191

Page 13

Chapter 2

______________________________________________________________________

When taking delivery of the 3434i SF6 Leak Detector, five very

important and preliminary tasks must be completed before starting

to operate it:

Install the BZ7002 Calibration Software to enable operation Back-up

of the calibration file supplied with the instrument if calibrations are

performed by LumaSense Technologies A/S.

Connect the Monitor to a PC (see section 2.1).

Check/Change the fuses in the monitor (see section 2.2).

Set the Communication parameters. USB (see section 2.3), RS232

(see section 2.4), Ethernet (see section 2.5).

Set-up the password protected user levels (see section 2.6).

2.1 Connecting the Monitor to the PC

The monitor comes complete with a USB interface cable. The

maximum length of an USB cable is 5 meters. USB extension kits can

be used to extend the USB connection to 30 meters.

The gas monitor can also be connected to a PC using a 9-pin to 9-pin

null modem RS-232 interface cable (optional accessory WL950-003).

Finally the monitor can be connected to a PC using the Ethernet

network connection.

2.1.1 Fitting the RS-232 Cable.

Ensure that both the monitor and the PC are switched off at the

mains. Failure to do so may result in your equipment being

damaged.

Locate the serial port at the back of the PC; refer to your PC manual

if in doubt.

Push the connector on the RS-232 cable on to the serial port socket,

and secure it firmly using the securing screws.

Locate the output labelled “RS-232” at the back of the Monitor.

Push the connector at the other end of the RS-232 cable on to this

socket, and secure it firmly using the securing screws.

Turn on the PC. Wait for Windows to start up.

The instruments can be turned on at the mains now.

2.1.2 Fitting the USB Cable.

The gas monitor can be connected to an USB port on the PC in order

to make measurements using the LumaSoft Gas Single Point 7810 PC

application, which communicates using the USB interface

communication protocol.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 13 of 191

Page 14

Chapter 2

______________________________________________________________________

The USB interface cable can be connected while the gas monitor is

switched on.

2.2.3 Fitting the Ethernet Cable.

The gas monitor can be connected to a local Ethernet network in

order to make measurements using the LumaSoft Gas Single Point

7810 PC application, which communicates using the TCP/IP network

interface protocol or to view the homepage of the gas monitor in a

standard PC internet browser.

The Ethernet network cable can be connected while the gas monitor

is switched on.

Connect a standard Ethernet network cable to the Ethernet socket

connector on the back of the gas monitor. Connect the other end of

the Ethernet network cable to your local network. The yellow LED on

the Ethernet socket connector will lit, if a local network connection is

detected.

2.2 Checking /changing the Fuses in the Monitor.

Unplug the Monitor from the mains power supply and pull out the

plug in the AC Mains socket of the Monitor

If the fuses in the Monitor are blown it can indicate a serious fault in

the instrument, therefore it is advisable to contact your LumaSense

service representative before changing the fuse!

2.2.1 Checking/changing the Fuses in the 3434i

1. Turn the 3434i so that it stands on its back panel and remove

the rubber “shoes” mounted on the four “feet” of its baseplate.

2. Using Pozidrive screwdriver No. 1, undo and completely

remove the screws located under the rubber “shoes” which

have just been removed.

Note: these screws hold the upper and lower covers of the

3434i together. If the screws are not completely undone you

will not be able to remove the upper cover as explained in step

5.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 14 of 191

Page 15

Chapter 2

______________________________________________________________________

3. Undo the upper four screws holding the frame over the back-

panel of the 3434i using Pozidrive screwdriver No. 0.

4. Using the Pozidrive screwdriver No.0 undo the upper four

screws which hold the frame over the front panel of the 3434i.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 15 of 191

Page 16

Chapter 2

______________________________________________________________________

5. Gently lift off the upper cover of the 3434i by pulling it firmly

upward.

6. Use a screwdriver to remove the fuse-holder:

7. Remove the old fuse from the holder and replace it with a new.

Check that the fuse has the correct rating.

The fuse must be:

Slow-blow (T) fuse with a rating of 2.5 A, 250 VAC, 5x20 mm, UL

approved.

LumaSense order number: VF0102A

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 16 of 191

Page 17

Chapter 2

______________________________________________________________________

8. Install the fuse-holder and re-assemble the 3434i again.

The figure below shows the inside of the top cover of the 3434i. Note

that the front side of the cover has square flanges. Place the top

cover back in its correct position on top of the 3434i and screw in the

all screws.

2.3 Setting the USB Communication Parameters

The LumaSoft Gas 7810 application with USB communication is able

to communicate with the 3434i gas monitor through a USB cable.

BZ7002 and BZ7003 applications with USB communication are able

to communicate with the 3434i gas monitor through a USB cable .

No setup on the 3434i gas monitor is necessary in order to be able to

communicate with the 3434i gas monitor through an USB connection.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 17 of 191

Page 18

Chapter 2

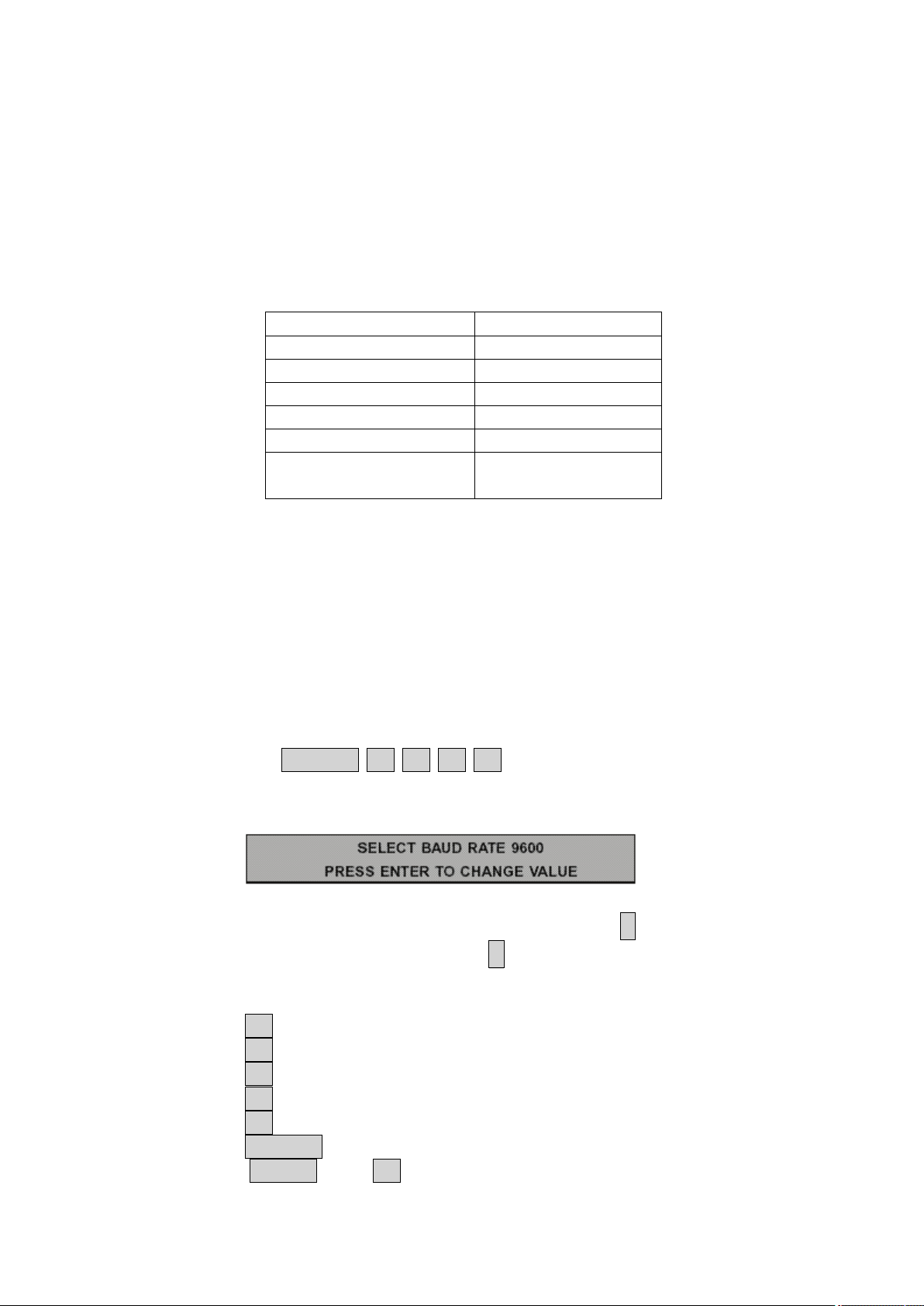

Baud rate

9600

Stop bits

1

Data bits

7

Parity

Even

Hardwire mode

Leased line

Handshake type

Hardwire

Text Line

Terminator

CR-LF

______________________________________________________________________

2.4 Setting the RS-232 Communication Parameters

2.4.1 Default RS-232 Communication Parameters.

The Default RS-232 Communication parameters are shown in the

table below.

Performing a full reset will set all parameters to the default settings.

2.4.2 Checking/Changing the RS-232 Communication Parameters

The communication parameters for the serial interface must be set

using the push-buttons on the front of the monitor.

1. Press SET-UP S3 S1 S3 S1 .The screen display now shows the

following text.

If the baud rate displayed is incorrect press ↵ and use ▲ and ▼ to

display the correct value. Press ↵ again to store the selection.

If the baud rate displayed is correct, then press ▼ to continue to the

next parameter.

Press S1 to select 1 STOP BIT.

Press S1 to select 7 DATA BITS

Press S2 to select EVEN PARITY

Press S3 to select LEASED-LINE

Press S3 to select HARD-WIRED HANDSHAKE.

Press SET-UP to exit the set-up mode

Press RESET and S1 in order that the new settings are enabled.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 18 of 191

Page 19

Chapter 2

SELECT ADDRESSABLE SET-UP BRANCH

______________________________________________________________________

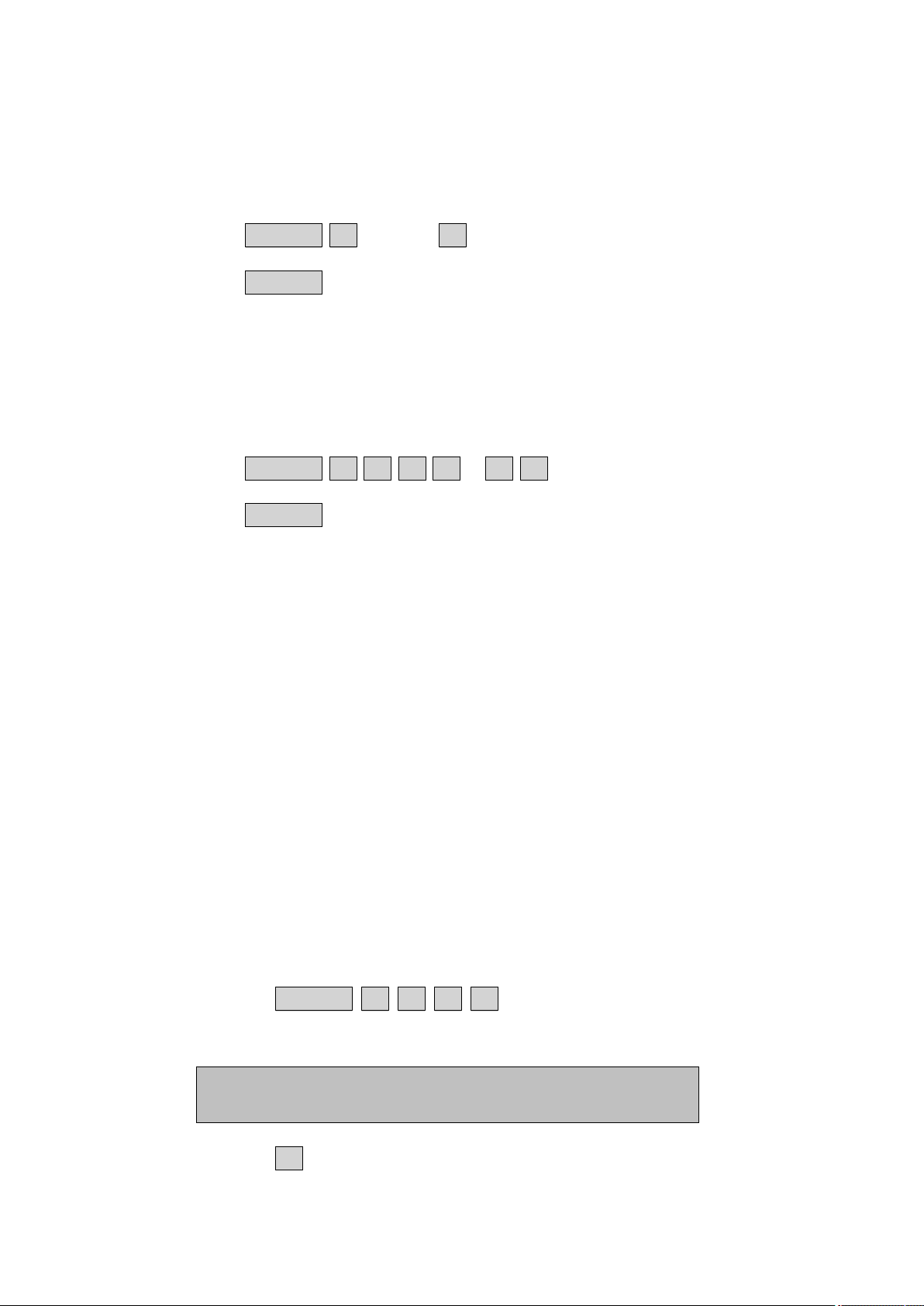

2.4.3 Checking/Changing the Text line Terminator.

The Text line Terminator must be set using the push-buttons on the

front of the monitor.

Press SET-UP S2 ▼ ▼ ▼ S3

Press SET-UP to exit the set-up mode

2.4.4 Checking/Changing the Data Log and Error Log Options.

The Data Log and Error Log must be set using the push-buttons on

the front of the monitor.

Press SET-UP S3 S1 S1 S3 ▼S1 S1

Press SET-UP to exit the set-up mode

2.5 Setting the Ethernet Communication Parameters

The LumaSoft Gas 7810 application with Ethernet communication is

able to communicate with the 3434i gas monitor through a local

Ethernet network.

The homepage of the 3434i gas monitor can also be displayed in a

web browser, when the 3434i gas monitor is connected to a local

Ethernet network.

2.5.1 Checking/Changing the Ethernet Communication Parameters

The communication parameters for the Ethernet interface can be set

by using the push-buttons on the front of the monitor.

1. Press SET-UP S3 S1 S3 S2. The screen display now shows the

following text.

Ethernet IEEE 488

2. Press S1 to enter the Ethernet setup. During this setup you can

also use the ▲ and ▼ keys to go back and forth between the

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 19 of 191

Page 20

Chapter 2

IS 3434i'S IP ADDRESS SET BY DHCP ?

3434i 'S IP ADDRESS 192.168.000.200

PRESS ENTER TO CHANGE VALUE

3434i'S IP ADDRESS 192.168.000.200

CANCEL DEFAULT

3434i'S IP PORT NUMBER: 23

______________________________________________________________________

available Ethernet settings. The screen display now shows the

following text.

NO YES

3. Here you can select whether the IP address of the 3434i gas

monitor is to be assigned by a DHCP server in the local network.

If you want the 3434i's IP address to be assigned by the DHCP

server press the S3 (Yes) key, where after you will proceed to the

below step 6 as the IP address is set by the DHCP server. If you

want yourself to set the IP address of the 3434i press the S1 (No)

key. The screen display now shows the following text.

4. Here you can change the IP address of the 3434i gas monitor in

case the IP address is not set by a DHCP server in the local

network. If you want to change the IP address, press the ↵ key. If

the IP address does not need to be changed, press the ▼ key and

you will proceed to the below step 6.

If you selected to change the IP address, the screen display now

shows the following text.

5. Here you can change the 4 individual numbers in the IP address

by using the ▲ and ▼ keys. Each of the 4 individual numbers can

be set in the range from 000 to 255.

You can step between the 4 individual numbers in the IP address

by using the ◄ and ► keys.

In case you want to return to the start value of the IP address

press the S1 (CANCEL) key. In case you want to return to the

default stored value of the IP address press the S3 (DEFAULT)

key.

When you have set the IP address, press the ↵ key. The screen

display now shows the following text.

PRESS ENTER TO CHANGE VALUE

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 20 of 191

Page 21

Chapter 2

PROTECTED IP ADDRESS 000.000.000.000

3434i'S IP PORT NUMBER: 23

PROTECTED IP ADDRESS 000.000.000.000

CANCEL DEFAULT

______________________________________________________________________

6. Here you can set the IP port number for the Ethernet

communication. This normally does not need to be changed. If

you want to change the IP port number press the ↵ key. If the IP

port numbers does not need to be changed, press the ▼ key and

you will proceed to the below step 8. If you selected to change the

IP port number the screen display now shows the following text.

CANCEL DEFAULT

7. Here you can change the IP port number by using the ▲ and ▼

keys. The port number can be set in the range from 0 to 32767.

In case you want to return to the start value of the IP port

number press the S1 (CANCEL) key. In case you want to return to

the default stored value of the IP port number press the S3

(DEFAULT) key.

When you have set the IP port number, press the ↵ key. The

screen display now shows the following text.

PRESS ENTER TO CHANGE VALUE

8. In case you want the 3434i gas monitor to be able to

communicate only with a certain PC on the local network, you can

set the IP address of this PC as the protected IP address. This can

be desired due to security reasons so no other PC is able to

communicate with the 3434i gas monitor.

If no protection is desired the protected IP address should be set

to a value of 000.000.000.000.

If you want to change the protected IP address, press the ↵ key.

If the protected IP address does not need to be changed, press

the ▼ key and you will proceed to the below step 10.

If you selected to change the protected IP address the screen

display now shows the following text.

9. Here you can change the 4 individual numbers in the protected IP

address by using the ▲ and ▼ keys. Each of the 4 individual

numbers can be set in the range from 000 to 255.

You can step between the 4 individual numbers in the protected IP

address by using the ◄ and ► keys.

In case you want to return to the start values of the protected IP

address press the S1 (CANCEL) key. In case you want to return to

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 21 of 191

Page 22

Chapter 2

CURRENT DHCP ADDRESS 192.168.000.062

______________________________________________________________________

the default stored value of the protected IP address press the S3

(DEFAULT) key.

When you have set the protected IP address, press the ↵ key.

If you previously selected that the IP address was NOT to be set

by the DHCP server you will proceed to the below step 11.

If you instead selected that the IP address to be set by the DHCP

server, the screen display now shows the following text.

ACCEPT

10. Here the IP address of the 3434i, which has been assigned by the

DHCP server, is displayed. This IP address can be used to

manually set Ethernet communication in a PC application, which

accesses the 3434i gas monitor.

Press the S2 (ACCEPT) key to accept.

11. This concludes the setup of the Ethernet parameters of the 3434i

gas monitor.

Press the SET-UP key to leave the setup.

2.5.2 Display the Homepage of the Monitor

The homepage of the 3434i gas monitor can be displayed if the gas

monitor is connected to a Ethernet network.

In section 2.5.1 it is explained how to set-up the Ethernet

parameters in the 3434i gas monitor.

Any web browser can be used to display the homepage of the gas

monitor. The IP address obtained from the Ethernet set-up of the

3434i gas monitor, can be entered in the address field of the web

browser in order to display the homepage.

The last measured gas values are displayed together with

information about the gas monitor, like the device serial number, if

water- and cross-compensation is performed.

Error and warning messages (see Chapter 14 for further details) will

also be displayed on the homepage.

The grey "Update Measurements" link can be used to update the

homepage with the last measurement results.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 22 of 191

Page 23

Chapter 2

______________________________________________________________________

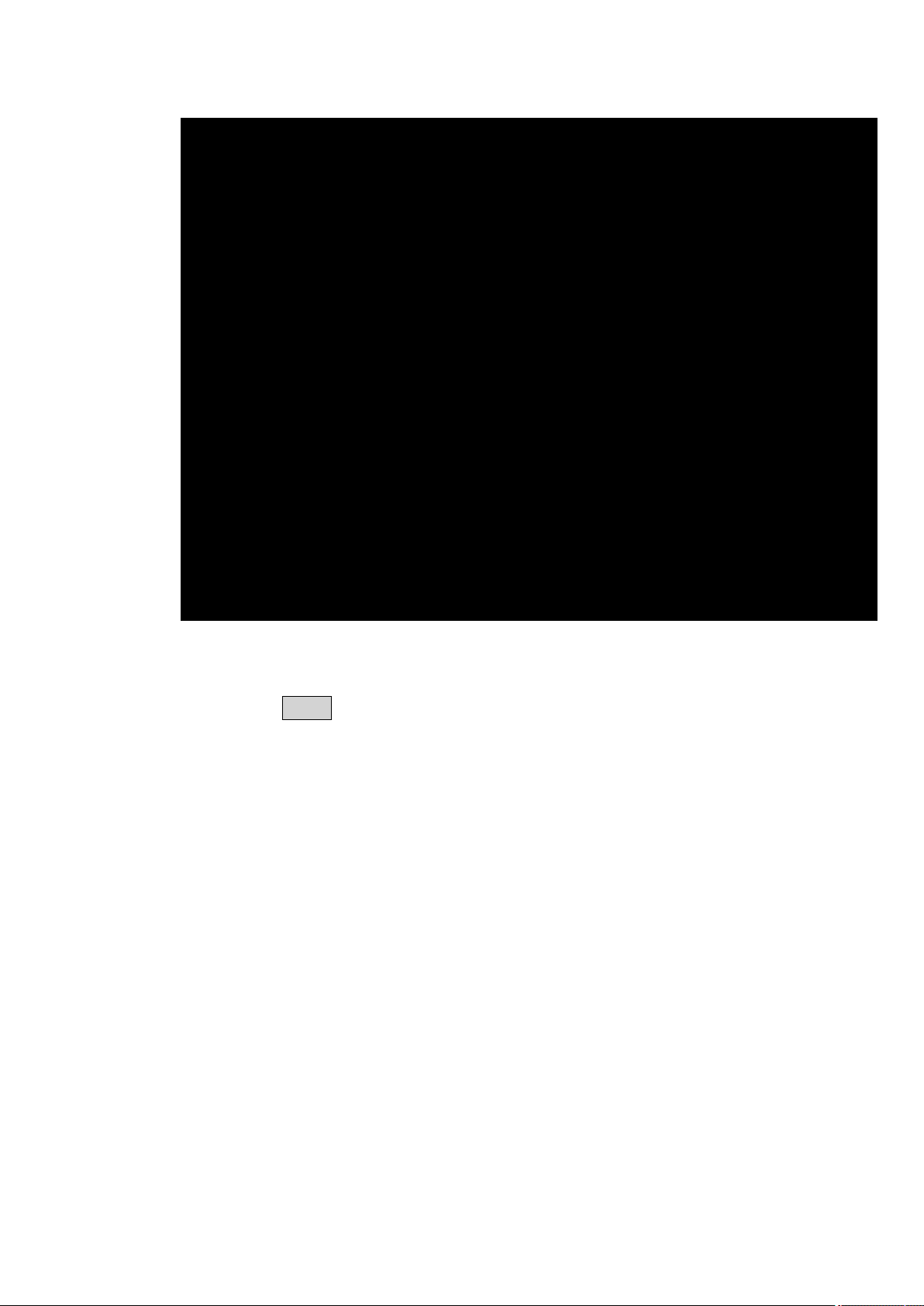

Fig.2.1 The 3434i gas monitor homepage

2.6 Setting-up user Levels

Press the Lock function push button on the front of the Monitor.

This enables setting up 3 different user levels, Level 1, Level 2 and

Level 3.

These user levels are password protected.

Level 1 is the Operator level, which enables start/stop and reading of

measurement results. Partial Reset is possible.

Level 2 is the Expert level, which in addition to Level 1 access

enables set up of parameters. Full Reset is possible.

Level 3 is the Super-User level, which allows all possible operations

including calibration.

2.6.1 Default settings for User Level and Password.

Before dispatch from the factory the User Level and the Password are

set to the following default setting.

User Level 3

And the default setting for the Password is:

Password: ***** (5 times *)

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 23 of 191

Page 24

Chapter 2

CURRENT USER LEVEL IS X

CHANGE USER LEVEL CHANGE PASSWORD

ENTER PASSWORD "*****"

PASSWORD IS "*****"

PRESS ENTER TO CHANGE VALUE

ENTER PASSWORD "*****"

______________________________________________________________________

These settings are to be used to change user level or password the

first time.

2.6.2 Changing the Password

In order to change the Password Press the Lock function push

button on the front of the Monitor.

The following text is displayed.

Press S3 “CHANGE PASSWORD”

The following text appears.

PRESS ENTER TO CHANGE VALUE

1. Press ↵ to change value.

The following text appears.

CANCEL DEFAULT

2. Enter the old Password using the ▲ and ▼ keys.

3. Press ↵.

The following text appears.

4. Type in the new Password using the ▲ and ▼ keys.

5. Press ↵.

2.6.3 Changing the User Level

In order to change the User Level Press the Lock function push

button on the front of the Monitor

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 24 of 191

Page 25

Chapter 2

ENTER PASSWORD "*****"

CURRENT USER LEVEL IS X

CHANGE USER LEVEL CHANGE PASSWORD

CURRENT USER LEVEL IS X

______________________________________________________________________

The following text is displayed.

1. Press S1 “CHANGE USER LEVEL”

The following text appears.

PRESS ENTER TO CHANGE VALUE

2. Press ↵.

3. Enter the current Password using the ▲ and ▼ keys.

4. Press ↵.

The following text appears.

PRESS ENTER TO CHANGE VALUE

5. Press ↵.

6. Use the ▲ and ▼ keys to change the User level.

7. Press ↵.

8. Press the Lock function push button to exit.

2.7 Restoring of calibration data

If you have ordered a calibration from our calibration laboratory, you

will receive a CD with a backup of the calibration data. It is very

important that you store these data in your Calibration Software

BZ7002. Please store the data before using the Gas Monitor. Please

refer to the User Manual BE6034 regarding this procedure.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 25 of 191

Page 26

Chapter 3

______________________________________________________________________

Chapter 3

Philosophy of Operation

July 2014

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 26 of 191

Page 27

Chapter 3

______________________________________________________________________

The monitor has several essential operational features, which enable

you to operate it without undue reference to this Instruction Manual.

The main features of the monitor which ensure its simple and easy

operation, are listed below:

• The fully, comprehensive Software BZ7002 and BZ7003.

• The LumaSoft Gas Single Point 7810 application software.

• The short, self-explanatory texts, which appear in the monitor

display when the monitor is being used, give operational guidance

to the user.

• The small light-emitting diodes at some of the push-buttons allow

the user to identify how the monitor is operating at any particular

time.

• Audible warnings “beep” if any push-buttons are used in the

wrong way.

3.1 PC Use – Online

A monitoring system, where you use the PC environment to set-up

the monitor prior to measuring, display measurement data on the PC

screen while monitoring and store the measurement results directly

on the PC’s hard disc. The LumaSoft Gas Single Point 7810

application software is used for making online measurements. The

measurement results can be used by other programs that fetch data

from the SQL Server Express database server featured by the 7810

application. A manual BE6027 for the 7810 application is available

for reference.

Using the online mode (7810 Application Software) provides you with

a variety of Software Alarm options. Not only are the alarm trigger

levels definable, but the action resulting from an alarm being

triggered can also be defined here. This enables you to connect

external warning systems to the monitoring system.

The philosophy behind the 7810 Application Software is common to

almost all Windows programs. Access to the various levels of the

program is gained by use of the MENU BAR, PULL-DOWN MENUS,

NEW WINDOW options and INDEX-CARD separators. These familiar

procedures, together with the simple software structure, make the

instructions in the On-line sections of this manual understandable

and easy to implement.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 27 of 191

Page 28

Chapter 3

CURRENT TIME IS 2011-06-13 17:12

SELECT SET-UP BRANCH

SELECT SET-UP BRANCH

______________________________________________________________________

3.2 Stand-alone Use

This method of operation is available to those of you who wish to use

the monitor without connection it to a PC. The monitor is set-up and

the results are displayed via the monitor’s front panel.

The structure of the monitor set-up can be viewed like an inverted

tree. The main branches divide and separate into minor branches.

These in turn divide again and again.

To move through the tree, the branches are selected using the

“select” push-buttons (see section 1.5). Use the Set-up Tree,

supplied with the monitor and the example steps below to see how

the instructions progress. Starting from the initial screen display.

MONITOR IS READY FOR USE

1. Press SET-UP, and the text changes to that displayed below.

MEASUREMENT FORMAT CONFIGURATION

2. To select the MEASUREMENT branch, press S1. (Pressing either

of the other “select” push-buttons will take you along another

branch of the set-up tree. The following text is displayed.

MONITORING TASK ENVIRONMENT

To select the ENVIRONMENT branch, press S3. The text is

displayed.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 28 of 191

Page 29

Chapter 3

SELECT FLUSHING MODE

LENGTH OF SAMPLING TUBE 00.00 m

______________________________________________________________________

AUTO FIXED TIME

3. To select the AUTO flushing mode, press S1. The following text is

displayed.

PRESS ENTER TO CHANGE VALUE

This branch does not divide again. At this stage you are able to

define the parameters in this branch of the tree using the direction

push-buttons.

If the branch had divided again, it is a simply process of using the

correct “select” push-button to continue down the desired branch.

Parameters that are already selected are displayed either with a

cursor under the current selection or the value is displayed on the

top line.

When the correct value or parameter is already selected, you can

continue on through the tree using the ▼direction push-button.

To exit SET-UP mode press SET-UP

Defining parameters is covered in section 6.1.

The procedures in the example above are common to all the

situations where the “select” push-buttons can be used to access the

different levels in the monitor.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 29 of 191

Page 30

Chapter 4

______________________________________________________________________

Chapter 4

Introduction to and Familiarization

with the Monitor

July 2014

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 30 of 191

Page 31

Chapter 4

______________________________________________________________________

The Monitor is an extremely versatile measuring instrument, which

can be used to perform almost any kind of monitoring task. Its

versatility may appear overwhelming at first, but to avoid such a

reaction, we suggest that you read this chapter thoroughly, and

follow the practical exercises, which are included. These exercises

give you a “guided tour” through a number of different practical

procedures – monitoring task; performance of a monitoring task;

scrolling through data after completion of a monitoring task. By

following these different procedures the Monitor operating philosophy

will become apparent and you will be able to quickly familiarise

yourself with its operation and control.

4.1 Special Terminology

Certain terms are used to describe the operation of the Monitor and

it is necessary to fully understand what these terms mean before you

start any practical exercise with the Monitor.

4.1.1 Measurement Cycle

A description of a measurement cycle is given on page 2 of the

Product Data Sheet (see boxed-in text and schematic diagram of the

measurement system of the Monitor). “Measurement Cycle” is the

term used to describe everything that takes place in the Monitor from

the time the pump starts to flush out the “old” gas sample in its

analysis cell, until the signal in the measurement chamber has been

measured using the last relevant optical filter.

The time taken to complete a measurement cycle is dependent upon

the following factors:

The sample integration time selected – longer measurement times

provide greater accuracy.

The flushing times selected for the measurement chamber and the

tube as well as the length of the sampling tube attached to the

Monitor’s air-inlet – the longer the tube, the more time is needed to

flush it out between measurement cycles.

The cleanliness of air-filters which filter the air drawn into the cell

(this affects the pumping time required to draw a fresh air sample

into the analysis cell).

The degree of fluctuation in the concentration of the gas measured in

consecutive measurement cycles (this affects the time required to

adjust the gain of the amplifier attached to the microphones).

Table 4.1 gives some indication to the measurement times depending

on the number of gases measured and the measurement times

selected. However, these times may vary from one measurement

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 31 of 191

Page 32

Chapter 4

Monitor Setup

Volume of Air

Response Times

S.I.T.: “Normal” (5s)

One gas: ~27s

S.I.T.: “Fast” (1s)

“OFF”

One gas: ~13s

~22s

______________________________________________________________________

cycle to another due to the cleanliness of the filters and the degree

of fluctuation in the concentration of the various gases.

Table 4.1 Approx imate measurement times

SIT : “Low Noise”

(20s)

Flushing:

Auto, (tube 1m)

Flushing:

Chamber 4s, Tube

4.1.2 Monitoring Task

A monitoring task consists of a series of similar measurement cycles.

These cycles can either be repeated at regular intervals or be

continuous:

4.1.3 Sampling Interval

The sampling interval is a measure of the time between the start of

one measurement cycle and the start of the following measurement

cycle.

When the Monitor is not sampling continuously the sampling interval

has to be defined by the user and is a fixed period of time (see

Fig.4.1).

140 cm3/sample

20cm3/sample

One gas +water

~40s

One gas +water

~70s

One gas + water

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 32 of 191

Page 33

Chapter 4

______________________________________________________________________

Fig.4.1 An illustration of the fixed sampling intervals of the monitor

when it is not sampling continuously.

4.1.4 Continuous Sampling

The Monitor is said to be sampling continuously when each

measurement cycle is followed immediately by another similar

measurement cycle (see Fig.4.2).

Fig.4.2 An illustration of continuous sampling

4.1.5 Monitoring Period

The monitoring period is the time between the start of the first

measurement cycle in a monitoring task and the finish of the final

measurement cycle in a monitoring task.

The monitoring period can either be pre-set by the user – in which

case the Monitor automatically stops monitoring after the monitoring

period is over – or, not pre-set – in which case the Monitor will

continue to monitor until the user stops the monitoring task manually

(see section 4.3.8).

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 33 of 191

Page 34

Chapter 4

______________________________________________________________________

The maximum time you can set a pre-set monitoring period to be is

7 days. If you try to enter a greater number of days, the Monitor will

automatically change the period to 7 days. However, if you do not

set a pre-defined monitoring period, the Monitor will just store as

much data as possible before starting to overwrite the “oldest” stored

measurement results.

4.2 Attaching the Sampling Tube and External Filter

1 Cut a short section of sampling tube of Poly-Tetra-Fluoro-

Ethylene (Teflon) tubing, (optional accessory).

2 Using Fig.4.3 and the instructions below, attach one end of this

tube to the air-inlet stub on the back-panel of the Monitor.

Push one end of the Teflon tubing through the non-threaded end

of the nut.

Hold the end of the tubing between the fingers and gently push

the tubing over the end of the Monitor’s air-inlet stub as far as it

will go.

Note: if the tubing is bent/broken during this procedure, remove

the tubing from the stub and repeat this step using an

undamaged length of tubing.

Screw the threaded-nut firmly onto the end of the air-inlet stub.

Fig.4.3 Attaching tubing to the air-inlet stub and the external filter

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 34 of 191

Page 35

Chapter 4

______________________________________________________________________

3. Attach the other end of the sampling tube to the external air-filter

which is provided as an optional accessory.

4.3 Familiarization with the Monitor using the Front Panel

4.3.1 Setting the Internal Clock

Before dispatch from the factory, the internal clock of the Monitor is

set to the correct local (Danish) time. If the monitor is to be used as

a stand-alone instrument, then the clock can be adjusted to your

local time using the following instructions.

1. Switch on the AC Mains power switch on the back-panel of the

Monitor.

2. Press SET-UP.

Refer to the Set-Up Tree, supplied with the Monitor, so that you can

follow your movement through the various branches of this “tree” in

the following sequence of button presses.

3. Press S3 S1 S1 S1.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 35 of 191

Page 36

Chapter 4

↵

↵

↵

↵

CURRENT DATE 2014-04-19

CURRENT TIME 12:00

______________________________________________________________________

The following screen picture appears:

PRESS ENTER TO CHANGE VALUE

Dates are entered as the Year-Month-Day, for example the 19th April,

2014 has to be entered as 2014-04-19.

4. To change the date, press

5. Use the direction keys to enter the correct date.

Note: press S1 to revert back to the original date.

6. Press

This causes the text on the display screen to change to the

following:

to accept date.

PRESS ENTER TO CHANGE VALUE

.

7. To change the time, press

.

8. Use the direction keys to enter the correct time. If you make a

mistake in entering the correct date just press S1 and start again.

The current time is entered as the time read on a 24-hour digital

clock. For example, 13:45 is 15 minutes to 2 o’clock in the afternoon.

9. Press

When this step is completed, the display then moves to the previous

head of the Set-Up Tree.

10. Press ▲ three times and follow the path you take en route

through the Set-Up Tree.

The screen display shows the following text:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 36 of 191

to accept time.

Page 37

Chapter 4

SELECT SET-UP BRANCH

SELECT CONCENTRATION UNIT

______________________________________________________________________

MEASUREMENT FORMAT CONFIGURATION

11. Press SET-UP to exit.

4.3.2 Setting Units

All data in the Monitor is stored as raw data. The different units,

which you can select here, enable you to enter gas concentrations

and to display temperatures, lengths and pressures in units, which

you are comfortable with. These units are also used to present

measurement data in a form that is most convenient for you.

The Monitor can display gas concentrations either in absolute units of

mg/m3 unit that is dependent on a particular temperature, termed

the normalization temperature, or in units of parts per million (by

volume) – which is independent of the temperature of the gas. You

can inform the monitor about the units you intend to use – for

example: the length of the sampling tube attached to the Monitor’s

inlet (in meters or feet) atmospheric pressure (kPa or mBar or

mmHg) and unit for humidity (ppm or Tdew or kPa or mg/m3).

The measurement units can be changed using the push-buttons on

the front of the monitor:

1. Press SET-UP.

2. Press S3 and then S2.

The following text appears on the screen display:

mg/m3 ppm

The cursor appears under the unit which is presently in the active

set-up.

3. Press S1 to select mg/m

3

.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 37 of 191

Page 38

Chapter 4

↵

↵

SELECT HUMIDITY UNIT mg/m3

SELECT FLUSHING MODE

______________________________________________________________________

4. Select metres as the unit of length, °C as the temperature unit,

and kPa as the pressure unit by using a procedure similar to that

described in the previous steps.

After the pressure unit has been selected the following text appears

on the display:

PRESS ENTER TO CHANGE VALUE

There are more than three humidity units to choose from therefore

the means by which a unit is selected differs:

5. Press

.

6. Use ▲ & ▼ to scroll through the options.

7. When Tdew is displayed, press

.

The display automatically returns to the head of the

CONFIGURATION setup branch.

8. Press SET-UP to exit.

4.3.3 Setting the Environment Parameters

Environmental parameters describe the factors which influence the

measurement situation – the length of the sampling tube attached to

the Monitor and the normalization temperature. These parameters

are discussed more fully later on in this section.

1. Press SET-UP, S1 and then S3.

This brings you into the Environment branch of the Set-Up Tree

where the following text is displayed:

AUTO FIXED TIME

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 38 of 191

Page 39

Chapter 4

↵

↵

↵

LENGTH OF SAMPLING TUBE 0.00 m

NORMALIZATION TEMPERATURE 20.0 º C

______________________________________________________________________

The Auto option regulates the flushing time depending on the

sampling tube length and the cleanliness of the air-filter (as the filter

become dirtier, the flushing time will increase). The Fixed Time

option is divided in to two parts; chamber flushing time and sample

tube flushing time. Once defined, these times are constant regardless

of the sampling tube length and cleanliness of the filters.

Auto Option

a. Press S1, and the following display appears.

PRESS ENTER TO CHANGE VALUE

b. Press

.

c. Use the direction keys to define the tube length: ▲ and ▼ to

increase and decrease the numbers, respectively; t and u to

move the cursor across the fields.

Change the length of the sampling tube shown on the screen to

the length of the tube you attached to the Monitor in section 4.2.

Note: the range of acceptable values for the sampling tube

ranges from 00.00m to 99.00m.

d. Press

to select displayed length.

The following display appears:

PRESS ENTER TO CHANGE VALUE

The Monitor measures gas concentrations in the absolute unit of

mg/m3 – a unit which is dependent on temperature. Alternatively,

the Monitor can calculate gas concentrations in parts per million

(ppm) by volume – this unit is independent of the temperature of

the gas. If mg/m3 is chosen as the gas concentration unit it is

therefore necessary to define the temperature at which you wish the

Monitor to calculate gas concentrations. This pre-defined

temperature is termed the NORMALIZATION TEMPERATURE.

e. Press

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 39 of 191

to change value.

Page 40

Chapter 4

↵

↵

↵

SELECT MEASUREMENT SET-UP BRANCH

CHAMBER FLUSHING TIME 8 s

TUBE FLUSHING ?

______________________________________________________________________

f. Use the direction keys to define the normalization temperature: ▲

and ▼ to increase and decrease the numbers, respectively; t and

u to move the cursor across the fields.

g. Press

to select displayed temperature.

The display screen then jumps to the “head” of the MEASUREMENT

branch of the Set-Up Tree and the following text is shown:

MONITORING TASK ENVIRONMENT

Fixed Time Option

a. Press S3, and the screen displays the following text.

PRESS ENTER TO CHANGE VALUE

b. Press

.

c. Use the direction keys to define the chamber flushing time.

Note: the range of acceptable values for chamber flushing ranges

from 2s to 60s, increasing in 1s intervals.

d. Press

to select displayed flushing time, and the following text is

displayed.

NO YES

e. Press S3 to enable sample tube flushing. The screen displays the

following text.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 40 of 191

Page 41

Chapter 4

↵

↵

TUBE FLUSHING TIME 3 s

NORMALIZATION TEMPERATURE 20.0°C

______________________________________________________________________

PRESS ENTER TO CHANGE VALUE

f. Press

.

g. Use the direction keys to define the tube flushing time.

Note: the range of acceptable values for tube flushing ranges

from 3s to 120s, increasing in 1s steps.

h. Press

to select displayed flushing time.

The following text is displayed.

PRESS ENTER TO CHANGE VALUE

i. Press SET-UP

4.3.4 Setting up a Monitoring Task

The optical filter in the monitor has to be calibrated before it can be

used to measure gas concentrations. The user can only set-up a

monitoring task using the optical filters which has been installed. In

the 3434i gas A (that is, to measure gas A’s concentration using the

UA0988 optical filter installed in position “A” of the filter carousel)

and water vapour.

The parameters which describe the monitoring task we shall set-up,

are listed below:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 41 of 191

Page 42

Chapter 4

Stand-alone Settings

section 12.3.3

↵

↵

MONITORING TASK SET-UP NUMBER 1

______________________________________________________________________

Monitoring Task Set-up Number = 1

Sampling = Continuous

Monitor for pre-set period = No

Compensate for Water Vapour

Interference = Yes

Compensate for cross-interference =

No

Measure Gas A: XXXXXX = Yes

Measure Water Vapour = Yes

Note: flushing is set in Environmental

Parameters, section 4.3.3

S.I.T’s are set up in the Filters setup,

, and the

1. Press SET-UP, S1 and then S1.

This brings you into the Monitoring Task branch of the Set-Up Tree

where the following text is displayed:

Up to 10 different monitoring tasks can be set-up while operating the

Monitor in Set-up mode. The parameters describing these tasks are

automatically stored in the memory of the Monitor.

2. If the number on the display is already “1” then press q to

“accept” the value.

If the number is not “1”:

PRESS ENTER TO CHANGE VALUE

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 42 of 191

a. Press

and use the direction keys to change its value to “1”.

b. Press

to accept the value.

The text which appears on the display during the next step is really

self-explanatory and it is therefore possible for you to follow why the

Page 43

Chapter 4

STORE MEASUREMENT HISTORY

______________________________________________________________________

button-pushes listed in the next step will set-up the monitoring task

which is described at the beginning of section 4.3.4.

3. Press S3 S1 S3 S1 S3, then press S1 until the text

MEASURE WATER VAPOUR appears on the display.

4. Press the S3 button to answer “YES” to measure water vapour.

4.3.5 Store Measurement History.

The following screen is displayed.

NO YES

a. If you select to answer No, then only the last measured

values are stored in the display memory.

b. If you select to answer Yes all measured values are

stored in display memory.

5. Press the S3 button to answer “YES” to store the measurement

history.

Once this step is complete, monitoring task number 1 has been setup and the display moves to the previous head of the Set-Up Tree.

6. Press SET-UP to exit the Set-Up mode.

4.3.6 Starting a Monitoring Task

Note: before a monitoring task can be started, the Measurement

Units, Environment Parameters and Monitoring Task Settings must

be defined, see sections 4.3.2, 4.3.3 and 4.3.4.

This section will explain how to perform a monitoring task – for

example, monitoring task number 1 which was set-up in section

4.3.4.

1. Press MEASURE.

The following text appears on the screen:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 43 of 191

Page 44

Chapter 4

↵

ACTIVE TASK: MONITORING TASK NUMBER 1

SELECT TASK

MONITORING TASK SET-UP NUMBER 1

______________________________________________________________________

START TASK DELAYED TASK CHANGE TASK

Please note: if you do not use one of the “select” keys within a

short time after the above text appears, the Monitor will

automatically stop operating in Measure mode (the light-emitting

diode in the MEASURE key switches off).

If this happens just press MEASURE again.

The active monitoring task number is the number of the monitoring

task you wish the Monitor to perform.

2. If the number on the display is number 1 then go to step 5.

If the number on the display is not number 1 then press S3 to

change the task number to number 1.

This changes the display text to the following:

MONITORING TASK CALIBRATION TASK

3. Press S1.

This causes the following text to appear on the display:

PRESS ENTER TO CHANGE VALUE

The number appearing on the screen will be a number from 1 to 10.

4. Press

and use the direction keys to change the monitoring task

number to 1.

Then press ↵ again to accept the task number.

The following text appears on the display screen:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 44 of 191

Page 45

Chapter 4

MEASUREMENT IN PROGRESS

RESULTS NOT YET AVAILABLE

ACTIVE TASK: MONITORING TASK NUMBER 1

WARNING: DISPLAY MEMORY WILL BE DELETED

A: 14.5 E+00 B:________ C: ________

______________________________________________________________________

START TASK DELAYED TASK CHANGE TASK

5. Press S1 to start the monitoring task.

The following warning then appears on the display:

PROCEED STOP

Display Memory is where the Monitor stores the results of all

measurements while it is performing a monitoring task. If the

monitoring task is stopped and then started again all the data

already collected will be deleted from Display Memory. However, the

data in Display Memory can be copied into and stored in the

Monitor’s Bac kground Memory. This operation is described in section

9.2.

6. Press S1.

The following text then appears on the screen:

7. When the first measurement cycle is complete the Monitor will

automatically display the results and update them every time a

new measurement cycle is completed. An example is shown

below:

D:________ E:________ W: 8.25 E+00

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 45 of 191

Page 46

Chapter 4

DATA IN DISPLAY MEMORY RECORDED

2014-01-16 09:50 TO 2014-01-16 10:04

FILTER A USED TO MEASURE

(the name of the gas will appear here)

GAS A: MAX 14.5E+00 µ 8.03+00

______________________________________________________________________

This display gives the overview of the gas/vapour concentrations last

measured – in this case the concentration of gas A and humidity of

the water vapour are in the units that were selected – that is mg/m3

for gas A and Tdew for water vapour (see section 4.3.2).

4.3.7 Displaying Measurement Results while a Monitoring Task is in Progress

If store measurement history is selected in the MEASUREMENT setup branch (see section 4.3.5) all measurement data collected during

a monitoring task is stored in Display Memory together with the

parameters which describe the task (see section 4.3.4).

Using the direction keys, you can scroll through this data.

1. After the monitoring task has been running for 10-15 minutes,

press q.

An example of the text which appears on the screen is shown below:

FROM

This screen text allows you to find out how long the monitoring task

has been running here from 9:50 to 10:04 on the same day. The

date on the right-hand side of the display indicates the time at which

the last measurement cycle was completed while a monitoring task is

in progress this date is, of course, constantly updated.

2. Press q and then use t & u until the following text appears on

the display:

The displays which follow indicate the type of text which appears

each time q is pressed:

ALARM 1_____ MIN 7.42E+00 s 2.36E+00

While a monitoring task is being performed a running statistical

analysis of the monitored gases/vapours is made and the results are

displayed as shown above, where:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 46 of 191

Page 47

Chapter 4

µ

σ

A

2014-01-16 09:50:32 ___________ 7.42 mg/m3

A

2014-01-16 09:51:33 ___________ 7.42 mg/m3

SAMPLING IS CONTINUOUS

MONITORING PERIOD IS NOT PRE-SET

______________________________________________________________________

MAX = maximum concentration of gas A measured during the

period of time the monitoring task has been performed.

MIN = minimum concentration of gas A measured during the

period of time the monitoring task has been performed.

ALARM 1= the user-defined concentration of gas A which, if

measured by the Monitor, will trigger a switch in the

Monitor and activate an external alarm relay connected to

it.

= linear average, or mean value, of all the gas A

concentrations measured during the period of time the

monitoring task has been performed

= standard deviation of gas A’s concentrations from the

mean value (m) described above (see section 8.1 for

further details).

All numbers are written in the exponential form, for example:

14.5E+00 = 14.5 x 10+0 = 14.5

The concentration unit in this case is mg/m3 as this was chosen in

the active set-up (see section 4.3.2).

3. Press q.

: Sulphur Hexafluoride 972.06 mBar

: Sulphur Hexafluoride 972.06 mBar

As you can see, the display provides the date and time at which the

measurement was made, and the concentration of gas A is given in

the units mg/m3 because this was the unit chosen for gas

concentration in the active set-up. The dashed lines, which appear

after the time will be replaced by a number as soon as the

monitoring task has been stopped (see section 4.3.8).

After scrolling through the list of individual measurement results for

gas A, the following text is displayed:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 47 of 191

Page 48

Chapter 4

COMPENSATION FOR WATER VAP. INTERFERENCE

MONITORING TASK STARTED 2011-01-16 09:50

MEASUREMENT CHAMBER TEMPERATURE 29.6°C

SAMPLE INTEGRATION TIME W: 5s

A: 5s B:___s C:___s D:___s E:___s

A:Sulphur hexaflouride B:________ C:___________

D: ___________ E:__________ W: WATER VAP

A: 7.42E+00 B: ________ C:___________

DATA IN DISPLAY MEMORY RECORDED FROM

2014-01-16 09:50 TO 2011-01-16 10:04

WATER VAPOUR MEASURED

MONITORING PERIOD IS NOT PRE-SET

______________________________________________________________________

D: ____________ E: ________ W: 8.13+00

The last display above shows the up-dated overview of the gas

concentrations measured during the most recent measurement cycle.

This display does not appear, after the monitoring task has been

stopped.

Data collected during a monitoring task is stored in the Display

Memory of the Monitor and therefore, before a new monitoring task

is started, all data stored in this memory is deleted. D isplay Memory

has finite size, and therefore there is a limit to how much data can

be stored in it. Once this memory has been filled-up all subsequent

data collected during the task will start to overwrite the data already

collected during the start of the monitoring task. Only in this event

will the date displayed after the text MONITORING TASK STARTED

on the above screen be different from the earliest date on the

display (shown below) which give the most up-to-date overview of

the monitoring task:

4. Press u.

This causes the following text to appear on the screen:

Use q to scroll through the following screen displays:

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 48 of 191

Page 49

Chapter 4

WATER: MAX 8.55E+00 µ 8.15+00

MIN 7.01E+00 σ 816E-03

W: WATER VAPOUR: 971.88mBar

2014-01-16 09:50:32 _________ 7.39Tdew

W: WATER VAPOUR: 971.88mBar

2014-01-16 09:51:33 ________ 7.49Tdew

A:

972.06 mBar

2014-01-16 09:51:33 ___________ 7.43 mg/m3

A: 7.42E+00 B:__________ C:___________

D: _________ E:__________ W: 8.13+00

STOP MONITORING TASK ?

______________________________________________________________________

5. Press u.

This causes the display to jump over to the list of measurement

results for gas A. The following text appears:

Sulphur hexafluoride

By using p and q you can now scroll through the list of

measurement results for gas A.

If you do not wish to view the results anymore, press ↵, this acts as

a “go to head” function. The following text appears:

4.3.8 Stopping a Monitoring Task

1. Let the Monitor, monitor for a total period of about 30 minutes

and then press MEASURE.

The following text will appear on the screen:

NO YES

If you pressed MEASURE accidentally, this screen enables you to

cancel the request to stop the monitoring task in progress – by

pressing S1.

2. Press S3 to stop the task.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 49 of 191

Page 50

Chapter 4

DATA IN DISPLAY MEMORY RECORDED FROM

2014-01-16 09:50 TO 2014-01-16 10:04

______________________________________________________________________

The text, which appears briefly on the screen, indicates that the

Monitor is aborting the monitoring task and a summary of the

monitoring task will appear on the display as soon as the Monitor has

aborted the task. For example:

4.3.9 Scrolling through Measurement Results after Completion of a Monitoring Task

All measurement data collected during a monitoring task, is stored in

Display Memory together with the parameters which describe the

task (a description of the task is given in section 4.3.4).

Using the direction push-buttons, you can scroll through the set-up

parameters as well as the individual gas concentration

measurements results as explained in section 4.3.7. The organisation

of data collected during a monitoring task is illustrated in Fig. 4.4.

This illustration also shows the function of the various direction keys.

For example, u enables you to move from the measurement results

of one gas to the measurement results of another.

_____________________________________________________________________________

BE6028-14 3434i SF6 Leak Detector LumaSense Technologies A/S

Page 50 of 191

Page 51

Chapter 4

______________________________________________________________________