Page 1

Operating instructions Page 14

Refrigerator

Read the operating instructions before switching on for the rst time

GB

7084 677-00

MKv

Page 2

Content

Features .................................................................................16

Climate rating .........................................................................16

Energy consumption ..............................................................16

Temperature increase after a power failure ............................ 16

Range of appliance use .......................................................... 16

Setting up ...............................................................................16

Appliance dimensions ............................................................ 16

Electrical connection .............................................................. 17

Operating and control elements ............................................. 17

Interior temperature ................................................................ 17

Switching the appliance on and o ........................................ 18

Audible warning signal .......................................................... 18

Power failure alarm ................................................................. 18

Door open alarm ..................................................................... 18

Setting the delay time for the door open alarm ....................... 18

Audible warning signal settings .............................................. 19

Alarm messages .................................................................... 19

Alarm test ............................................................................... 19

Calling up stored alarm events and reading the

temperature progression ........................................................ 20

Resetting the recorded temperature progression

Example of an alarm query ....................................................20

Changing the network address ............................................. 21

Resetting the parameters to factory settings ......................... 21

Setting the real time clock ......................................................21

Interior light MKv 3913 ............................................................ 22

Safety lock ..............................................................................22

Defrosting ...............................................................................22

Setting the display indication for the defrost phase ...............22

Cleaning and disinfection ....................................................... 23

Malfunctions ...........................................................................23

Shutting your appliance down ................................................23

External alarm ........................................................................24

Changing over door hinges .................................................... 25

..........20

Disposal notes

The appliance contains reusable materials and should

be disposed of properly - not simply with unsorted

household refuse. Appliances which are no longer

needed must be disposed of in a professional and

appropriate way, in accordance with the current local

regulations and laws.

When disposing of the appliance, ensure that the refrigerant circuit

is not damaged to prevent uncontrolled escape of the refrigerant

it contains (data on type plate) and oil.

• Disable the appliance.

• Pull out the mains plug.

• Cut through the connection cable.

WARNING

Danger of suocation due to packing material

and plastic lm!

Do not allow children to play with packaging

material.

Take the packaging material to an ocial collection point.

A rechargeable battery is installed in the appliance.

Disposal instructions for batteries

The battery must be removed when you wish to dispose of the

appliance and sent for separate waste treatment for batteries.

Do not damage or short circuit the battery.

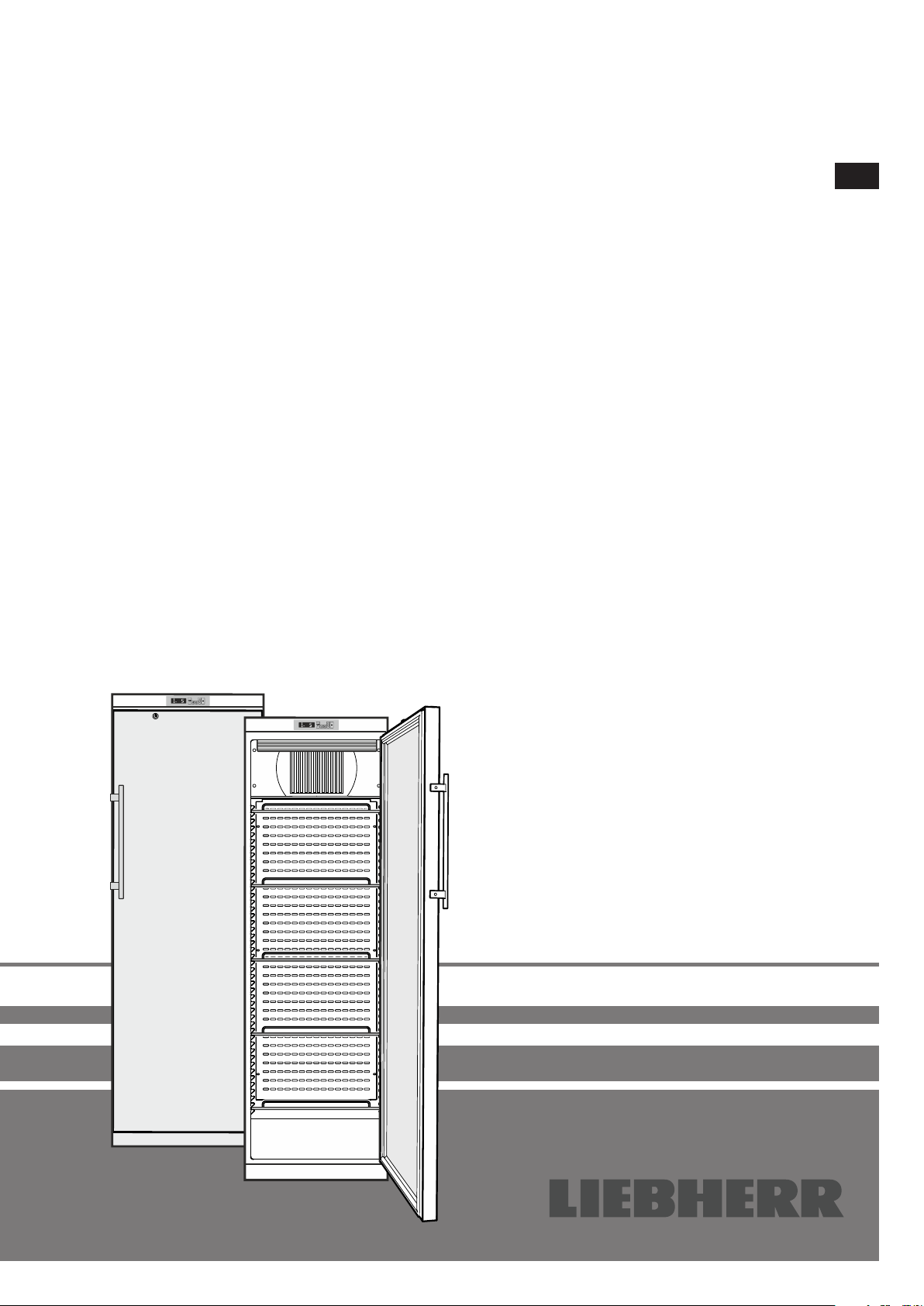

Description of the appliance

Operating and control elements

Type plate

Grid shelves

The grid shelves can be moved to accommo-

date dierent height bottles or packages.

Interior light (MKv 3913)

(LED light strip)

The ventilation slots of the recirculating

fan on the inside must not be covered!

14

Reference sensor for monitoring the

temperature

Adjustable-height feet

Page 3

Safety instructions and warnings

GB

• To prevent injury or damage to the unit, the appliance should be unpacked and set up by two

people.

• In the event that the appliance is damaged on

delivery, contact the supplier immediately before

connecting to the mains.

• To guarantee safe operation, ensure that the ap-

pliance is set up and connected as described in

these operating instructions.

• Disconnect the appliance from the mains if any

fault occurs. Pull out the plug, switch off or remove

the fuse.

• When disconnecting the appliance, pull on the

plug, not on the cable.

• Any repairs and work on the appliance should

only be carried out by the customer service

department, as unauthorised work could prove

highly dangerous for the user. The same applies

to changing the mains power cable.

• Do not use electrical appliances inside the appliance.

• If you have a lockable appliance, do not keep the

key near the appliance or within reach of children.

• The appliance is designed for use in enclosed

areas. Do not operate the appliance outdoors or

in areas where it is exposed to splash water or

damp conditions.

• The LED light strip illuminates the interior of the

appliance. It is not suitable for lighting a room.

• Do not install the appliance in the immediate

vicinity of an air-conditioning unit. The appli-

ance should also not be operated under a wall-

mounted air-conditioning unit.

• The appliance is not suitable for storing blood

bottles pursuant to DIN 58371.

• In special elds of application which are subject

to their own standard, the user is responsible for

complying with this standard.

• Do not allow naked flames or ignition sources

to enter the appliance. When transporting and

cleaning the appliance, ensure that the refrigerant

circuit is not damaged. In the event of damage,

make sure that there are no ignition sources

nearby and keep the room well ventilated.

• Do not stand on the plinth, drawers or doors or

use them to support anything else.

• This appliance can be used by children of 8 years

old and over, and also by persons with restricted

physical, sensory or mental capacity or lack of

experience and knowledge, if they are supervised

or have been instructed on safe use of the appli-

ance and understand the resulting risks. Children

must not be allowed to play with the appliance.

Cleaning and user maintenance must not be

carried out by children without supervision.

• Avoid prolonged skin contact with cold surfaces or

chilled/frozen food. This could cause pain, numbness and frostbite. In the case of prolonged skin

contact, protective measures should be taken,

e.g. gloves should be worn.

• Do not store explosives or sprays using com-

bustible propellants such as butane, propane,

pentane, etc. in the appliance. Electrical components might cause leaking gas to ignite. You

may identify such sprays by the printed contents

or a flame symbol.

15

Page 4

Features

- Audible and visual temperature alarm.

- Audible and visual door open alarm.

- Floating contact for connection to a remote monitoring system.

- Serial interface (RS485) for external temperature and alarm

documentation.

- Maximum/minimum interior temperatures are stored.

- Last 3 temperature alarms are saved with time, date and duration

of alarm.

- Last 3 power cuts are saved with time, date and duration of power

cut.

- Safety thermostat to avoid temperatures below +2°C.

It is essential to use these safety facilities to avoid damage

to stored items. These facilities must not be deactivated or

decommissioned!

Range of appliance use

The appliance is designed for storing and cooling pharmaceuticals to DIN 58345 as long as the

following conditions are satised:

• The appliance only complies with DIN 58345 if

the battery of the power failure alarm integrated

in the appliance is fully charged (see section

entitled "Electrical connection").

• The appliances only satisfies the requirements

of DIN 58345 with its factory temperature set-

ting. If the temperature setting is adjusted (which

can only be done by the service technician), its

compliance with DIN 58345 will be void.

Climate rating

The climate rating indicates the room

temperature at which the appliance may

be operated in order to achieve full refrig-

eration performance.

The climate rating is indicated on the

type plate.The position of the type plate

is shown in the section entitled Description of the appliance.

Climate rating Room temperature

SN +10°C to +32°C

N +16°C to +32°C

ST +16°C to +38°C

T +16°C to +43°C

SN-ST +10°C to +38°C

SN-T +10°C to +43°C

Do not operate the appliance outside the

specied room temperature range.

Energy consumption

Temperature increase after a power failure

The appliance is not suitable for use in explosion-

hazard areas.

Setting up

• Avoid positioning the appliance in direct sunlight or near cookers,

radiators and similar sources of heat.

• The floor on which the appliance stands should be horizontal

and level. Compensate for uneven floors with the adjustable feet.

•

Do not cover ventilation openings

or grille.

• Standard EN 378 specifies that the room in

which you install your appliance must have

a volume of 1 m

ant used in the appliance, so as to avoid the

formation of inflammable gas/air mixtures in

the room where the appliance is located in

the event of a leak in the refrigerant circuit.

The quantity of refrigerant used in your appliance is indicated on the type plate on the

inside of the appliance.

3

per 8 g of R 600a refriger-

Model MKv 3910 MKv 3913

Energy consumption to

DIN 58345

Temperature increase after

a power failure from +5°C to

+10°C

16

0.8 kWh/24h 1.5 kWh/24h

50 minutes 30 minutes

Appliance dimensions

Page 5

Electrical connection

Only operate the appliance with alternating current (AC).

The permissible voltage and frequency are indicated on the type

plate. The position of the type plate is shown in the section entitled

Description of the appliance.

The socket must be properly earthed and protected by a fuse.

The tripping current of the fuse must be between 10 A and 16 A.

The socket must not be situated behind the appliance and must be easily accessible.

Do not connect the appliance using an exten-

sion cable or extension socket.

Do not use stand-alone inverters (conversion

of direct current to alternating/three-phase

current) or energy-saving plugs. Risk of damage to the electronic control system!

• Connect the appliance to the

mains - the display reads OFF.

GB

Operating and control elements

1ON/OFF button (to switch the appliance on and o)

2Selection buttons

3Set button (Enter)

4Audible warning on/o button

5Button for calling up stored alarm events

6Temperature display

7Interior light on/o button (MKv 3913)

Symbols in the display

Compressor is running

Note

It will take 24 hours for the batteries in the power failure

alarm to become fully charged.

Instructions for decommissioning the appliance

When decommissioning the appliance, it is essential

to follow the instructions in the section entitled "Shut-

ting your appliance down".

Otherwise, the power failure alarm will be activated

when the mains plug is disconnected.

LED ashing - refrigeration unit switches on after a delay. The

compressor will start automatically after the pressure in the

refrigerant circuit has equalised.

Fan is running

Appliance is defrosting

AUX Temperature display using reference sensor

Interior light is switched on (MKv 3913)

Alarm function

If appears in the display, the appliance has a fault. Consult

your nearest customer service point.

HACCP (Hazard Analysis Critical Control Point)

The HACCP display means that the power supply and

interior temperature of the appliance are recorded.

If HACCP ashes in the display, there has either been a

power failure or the temperature in the appliance exceeded

the permissible range.

Interior temperature

The temperature inside the appliance is set to +5°C (+/-3K) as

required by DIN 58345 and cannot be changed.

Important note

Items must not be stored in the appliance until

the temperature has reached 5°C.

17

Page 6

Switching the appliance on and o

Switching the appliance on

Keep the ON/OFF button pressed for approx. 5 seconds - the

display reads ON.

No alarm is displayed or sounded when the appliance is switched

on for the rst time.

Door open alarm

When the door is opened, the LED lights up and the tempera-

ture display begin to ash.

When the door has been left open for more than 60 seconds, the

LED

ash alternately in the display.

begin s to ash, and and the temperature indication

If the appli ance is discon nected from the m ains for a long time af ter

it has been switched on for the rst time and if the temperature

inside the appliance rises above the upper alarm limit, this will

be detected as a fault by the electronic control system (HACCP

appears in the display).

When the appliance is switched on again, this display must be

reset as shown below.

Press button

Press

The HACCP LED will now light up permanently.

Press for 5 seconds.

The electronic control system will switch back to normal operating mode.

.

+ for 5 seconds. The display will read .

Switching the appliance o

Keep the ON/OFF button pressed for approx. 5 seconds - the

display reads OFF.

The audible warning signal sounds.

If the door has to stay open for longer in order to insert items to be

cooled, cancel the audible warning signal by pressing button

Setting the delay time for the door open alarm

The time before the audible warning signal sounds after the door

has been opened can be adjusted.

Press

Setting range = 1 - 5 minutes

Use buttons and to select the desired setting.

Press for 5 seconds.

for 5 seconds. Display =

Display =

Display = (minute)

Display =

.

Audible warning signal

The audible warning signal will sound in certain alarm events.

It can be cancelled by pressing button

.

Power failure alarm

In the case of a power failure, the

audible warning signal will sound

and

display.

If HACCP appears in the refrigerator’s display, the

temperature has risen above the upper alarm limit

of + 8°C.

Check the temperature progression as described in the section

entitled

Calling up stored alarm events

and then make a decision on what you wish to do with the items

stored in the refrigerator.

will be shown in the

The electronic control system will switch back to normal operating mode.

18

Page 7

Audible warning signal settings

GB

Alarm messages

The audible warning signal will be muted for the current alarm

after the button

Complete the following steps if you want the audible warning

signal to reactivate automatically.

Press

Display =

Display =

Display =

Display =

Display =

Display =

Display =

Display =

has been pressed.

for 5 seconds. Display =

1. LED flashes

appears in the display, the appliance has a fault.

If

Consult your nearest customer service point.

2. LED

The power failure alarm battery is supplying too low a voltage

or is defective.

Consult your nearest customer service point.

3. LED

The interior is too warm (HI) or too cold (LO).

The audible warning signal sounds.

4. HACCP flashes - the current interior temperature,

and

There has been a power cut of some length or the interior was

too warm or too cold during a certain period of time.

Up to three alarm events can be stored and called up.

flashes and appears in the display

flashes, the display reads HI or LO

are displayed alternately

Automatic reactivation of the audible warning signal is now active.

The time before the audible warning signal sounds again must be set.

Display =

Display = Time in minutes after which the audible

warning signal will sound again after the

button

range = 1 - 120 minutes.

Use buttons

Display =

Press for 5 seconds.

The electronic control system will switch back to normal operating mode.

and to select the desired setting.

has been pressed. Setting

Alarm test

This test checks the function of the internal and any external

connected alarm device.

The appliance does not stop its refrigerating function during

this test.

Activating the test

Press

• The display will change to a temperature value of 0.2°C below

the set upper alarm limit.

• The temperature value will now rise by 0.1°C every 2 seconds.

• When the upper alarm limit is reached,

display. An external alarm unit connected to the floating alarm

output will now be activated.

• The temperature value will continue to rise up to 0.2°C above

the upper alarm limit.

• The same process will take place automatically for the lower

alarm limit.

The LED

+ for 5 seconds.

will appear in the

will appear in the display.

will be lit during the test.

The electronic control system will automatically switch back to

normal operating mode.

Cancelling the test prematurely

Press

for 5 seconds.

19

Page 8

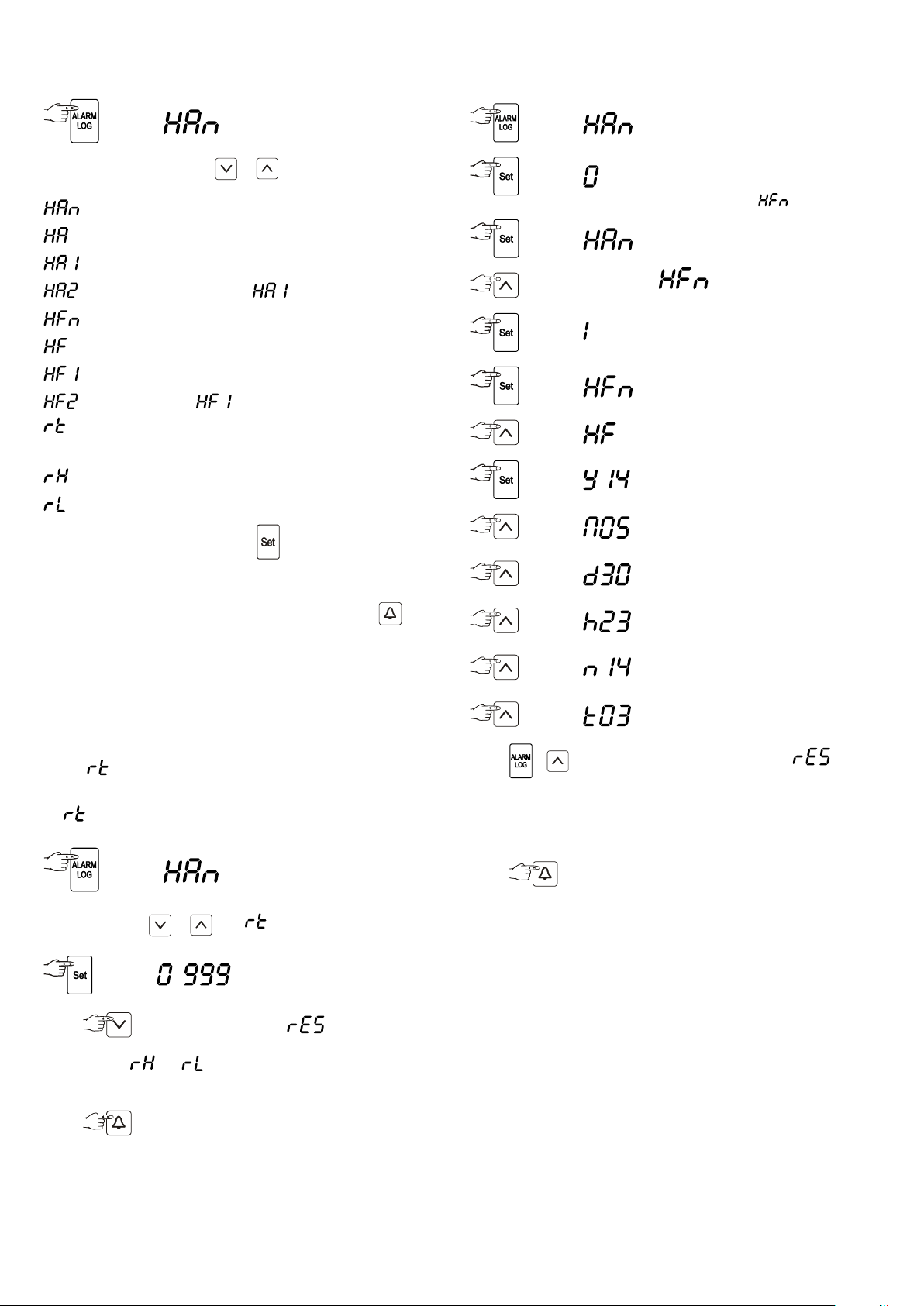

Calling up stored alarm events and reading

the temperature progression

Example of an alarm query

Situation: HACCP ashes in the display.

Display =

Scroll through the list using or .

Number of temperature alarms

Last temperature alarm

Last temperature alarm but one

Temperature alarm before

Number of power cuts

Last power cut

Last power cut but one

Power cut before

Period in hours in which the maximum and minimum interior

temperatures were measured

Maximum (highest) measured temperature

Lowest measured temperature

Select the required item using the

again to return to the list.

button. Press this button

Display =

Display =

Display =

Press this button until appears in the display.

Display = 1 power failure has occurred.

Display =

Display =

Display = Year 2014

Display = Month 05 (May)

Display = Day 30

There has not been an alarm status with

a too high or too low temperature. You

must switch to display

Last power failure.

.

Note: You can exit the menu at any time by pressing

seconds.

If no button is pressed within 60 seconds, the electronic control

system switches back automatically.

for 5

Resetting the recorded temperature progression

Complete the following steps if you wish to reset the value saved

for

in the previous section to 0.

Display =

Press the button or until appears in the display.

Display = -

Press for 5 seconds. Display = .

Display = Hour 23

Display = Minute 14

Display = The power failure lasted 3 hours.

Press

The HACCP LED will now light up permanently.

The electronic control system is now ready for the next alarm.

Press

The electronic control system will switch back to normal operating mode.

+ for 5 seconds. The display will read .

for 5 seconds.

The values for

temperature) are then reset to the current interior temperature.

Press

The electronic control system will switch back to normal operating mode.

20

and (highest and lowest measured interior

for 5 seconds.

Page 9

Changing the network address

When connecting several appliances via the RS485 interface,

each appliance must have its own network address.

GB

Setting the real time clock

The real time clock is preset (CET). Other time zones or summer/

winter time must be adjusted manually.

Press

Use buttons or to change the network address ( - ).

Press for 5 seconds.

The electronic control system will switch back to normal operating mode.

for 5 seconds. Display =

Display =

Display =

Display =

Display =

Resetting the parameters to factory settings

The alarm limits and sensor calibration values can be reset

to the factory settings using this function.

Press

for 5 seconds. Display =

Display =

Display = Year 2014

Display = Set the year by pressing the buttons.

= save new setting

Display = Mo n th (1-12)

Display = Set the month by pressing the

buttons.

= save new setting

Display = Day (1- 31)

Display = Set the day by pre ssing the buttons.

Pull out the mains plug.

Keep

Display =

The electronic control system will switch back to normal operating mode.

pressed and connect the mains plug.

Display =

= save new setting

Display = Days of the week (1 = Monday, 7 =

Sunday)

Display = Set the day of the week by pressing the

buttons.

= save new setting

Display = Hour (0-23)

Display = Set the hour by pressing the

buttons.

= save new setting

Display = Minute (0-59)

Display = Set the minutes by pressing the

buttons.

= save new setting

Press

The electronic control system will switch back to normal operating mode.

for 5 seconds.

Note

When appears in the display, the real time clock must

be reset.

21

Page 10

Interior light MKv 3913

The interior light is tted on the inside at the top.

The interio r light can be switch ed

on and o using the

The light intensity of the LED

light corresponds to laser

class 1/1M.

button.

Defrosting

The appliance defrosts automatically. The water that forms on the

rear wall drains into a reservoir at the back of the appliance and

evaporates automatically through the compressor heat.

Setting the display indication for the defrost

phase

The following indications can be set for the defrost phase.

Important

The light cover may only be

removed by customer service

sta.

If the cover is removed, do not look directly at the light

through optical lenses from close distance.

This can damage your eyes.

Safety lock

The lock in the appliance door is equipped with a safety mechanism.

Locking the appliance

• Insert the key as shown by arrow 1.

• Turn the key 90°.

To unlock the appliance, the same

procedur e must be repeated in the

same order.

• Symbol

perature in the interior of the appliance.

• Symbol

(factory setting).

• Symbol

+ alternating display of and the current tem-

+ temperature before the start of the defrost phase

+ .

Change the display during the defrost phase

Press for 5 seconds. Display =

Display =

Use buttons and to select the desired setting.

= alternating display of and the current temperature in

the interior of the appliance.

= temperature before the start of the defrost phase.

= display of only.

Display =

Press for 5 seconds.

The electronic control system will switch back to normal operating mode.

22

Page 11

Cleaning and disinfection

Always switch o the appliance before cleaning and disinfecting it.

GB

Malfunctions

You may be able to rectify the following faults by checking

the possible causes yourself:

Disconnect the appliance from the mains.

• Only disinfect the appliance with ethyl alcohol-based products.

• First clean the soiled areas and grid shelves with a damp cotton

cloth.

• Clean the interior container, grid shelves and outer walls with

lukewarm water, ethyl alcohol-based cleaning products or waterbased household cleaning products.

Do not use chemical solvents or any cleaning agents containing

sand or acid.

Do not use steam cleaners because of the

risk of injury and damage.

• Ensure that no cleaning water penetrates

into the elec trical components or ventilation

grille.

• The dust should be removed from the re-

frigeration unit and heat exchanger - metal

grid at the back of the appliance - once a

year.

• Appliance does not function:

– Is the appliance switched on?

– Is the plug correctly fitted in the mains socket?

– Is the fuse intact?

• Loud running noise:

– Is the appliance set up firmly on the floor?

– Does the appliance cause nearby items of furniture or objects to

vibrate? Please note that noises caused by the refrigerant circuit

cannot be avoided.

• The temperature is not low enough:

– Is the temperature setting correct (see "Setting the temperature")?

– Does the separately installed thermometer show the correct

reading?

– Is the ventilation system working properly?

– Is the appliance set up too close to a heat source?

•

– Reset the real time clock (see "Setting the real time clock").

If none of the above causes

apply and you cannot rectify

the fault yourself, contact the

nearest customer service

department stating the type

designation

ber

ber

type plate.

appears in the display:

1, service num-

2and appliance num-

3 as indicated on the

• Do not damage or remove the type plate on the inside of the

appliance. It is very important for servicing purposes.

• The appliance’s materials are only resistant to the cleaning

products listed above.

• Regular cleaning and disinfection prevents severe soiling.

The position of the type plate is shown in the section entitled

Description of the appliance.

Shutting your appliance down

If the appliance is to be left switched o for any length of time,

complete the following steps to disconnect the power failure

alarm battery from the electronic control system.

• Keep the ON/OFF button

the display reads OFF.

• Press

> The display will read

• Remove the plug.

• Clean the appliance and leave the door open in order to prevent

unpleasant smells.

+ for 5 seconds.

pressed for approx. 5 seconds -

.

The appliance complies with the relevant safety regulations and

EC Directives 2004/108/EC and 2006/95/EC.

23

Page 12

External alarm

We recommend connecting the appliance

to an external alarm device.

There are various connection options at

the back of the appliance.

The appliance may only be connected

to an external alarm device by trained

personnel.

Floating alarm output

These three contacts can be used to connect the appliance to

an optical or acoustic alarm device.

The connection is designed for a maximum of 42 V/8 A DC from

a safety extra-low voltage (SELV) source (minimum current:

150 mA).

Important

W h en su p pl y in g m a in s v ol t ag e t o t he o a ti n g a la r m c o n t a c t,

the technical safety requirements of standard EN 60335

will not be satised.

Connection to

RS485 interface

Terminating resistor

When connecting several appliances

via the RS485 interface, the terminating resistor must remain on the last

appliance.

Remove the terminating resistors

from the appliances in between.

Note

The connectors are secured with

screws. To remove the connectors,

undo the left and right screws.

Floating alarm

output

N.O

Alarm output

Connection for a visual warning light or

an acoustic alarm signal.

N.C

Operating light

Connection for a control lamp to indicate

that the appliance is in normal mode.

COM

External power supply unit

42 V/8 A DC maximum

Minimum current: 150 mA

RS485 interface

Rx- / Tx-

Send/Receive data cable (negative

pole)

Rx+ / Tx+

Send/Receive data cable (positive

pole)

24

GND

Earth cable

Page 13

Changing over door hinges

1. Unscrew the hinge bracket.

Important: The doo r mounting has

a spring mechanism enabling the

door to close by itself. The hinge

bracket turns to the left when the

screws are undone.

2. Pull the door out at the bottom

and lift o.

3. Transfer handle and plugs to the

opposite side of the door.

GB

4. Transfer pin on hinge bracket to the

opposite side.

5. Transfer upper hinge components to

the opposite side.

6. Transfer cover plate to the opposite

side.

7. Mount door on hinge pin and close.

8. Insert hinge bracket in lower door

mounting.

9. Turn hinge bracket by 90° - spring

is compressed. Screw on hinge

bracket.

25

Loading...

Loading...