Page 1

Mobile crane

Product advantages

Max. load capacity: 220 t

Max. height under hook: 101 m

Max. radius: 88 m

LTM 1220-5.2

Page 2

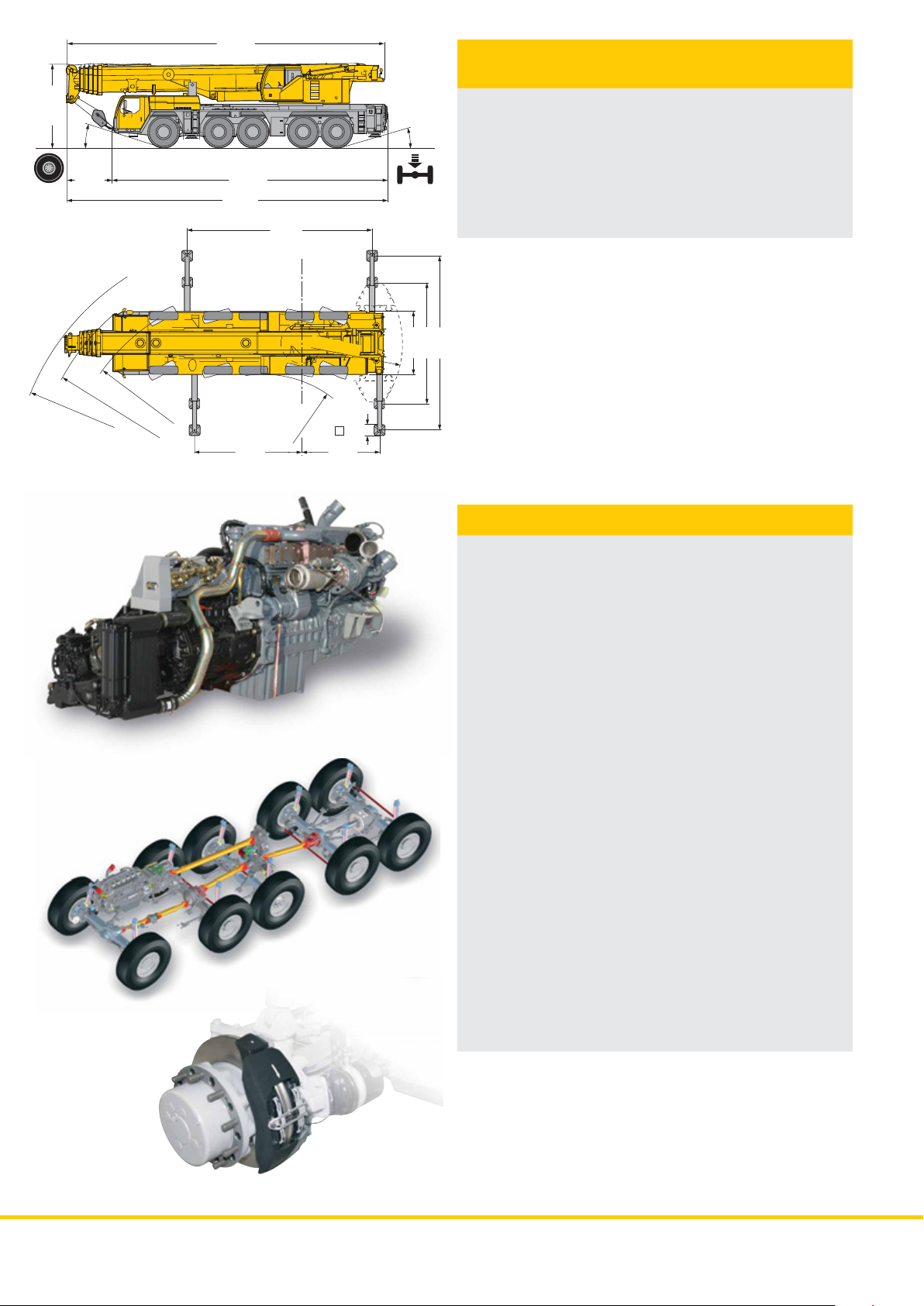

15323

Compact, maneuverable and

weight-optimized

40000

20°

16.00 R 25 12 t 12 t 12 t 12 t 12 t

2219

R = 12070

R

R

= 11010

= 9560

13298

15517

8899

5104

= 5450

R

R

=4850

600

3795

17°

3000

5500

• Overall length 15.52 m, carrier length 13.3 m

• Large overhang angles of up to 20°

• Smallest turning radius of 11.01 m with all-wheel steering

• Rear counterweight radius only 4.85 m

• 60 t total weight (axle load 5 x 12 t)

• Choice of 3 tyre sizes

14.00 R 25 carrier width 3 m

16.00 R 25 carrier width 3 m

20.5 R 25 carrier width 3.1 m

8300

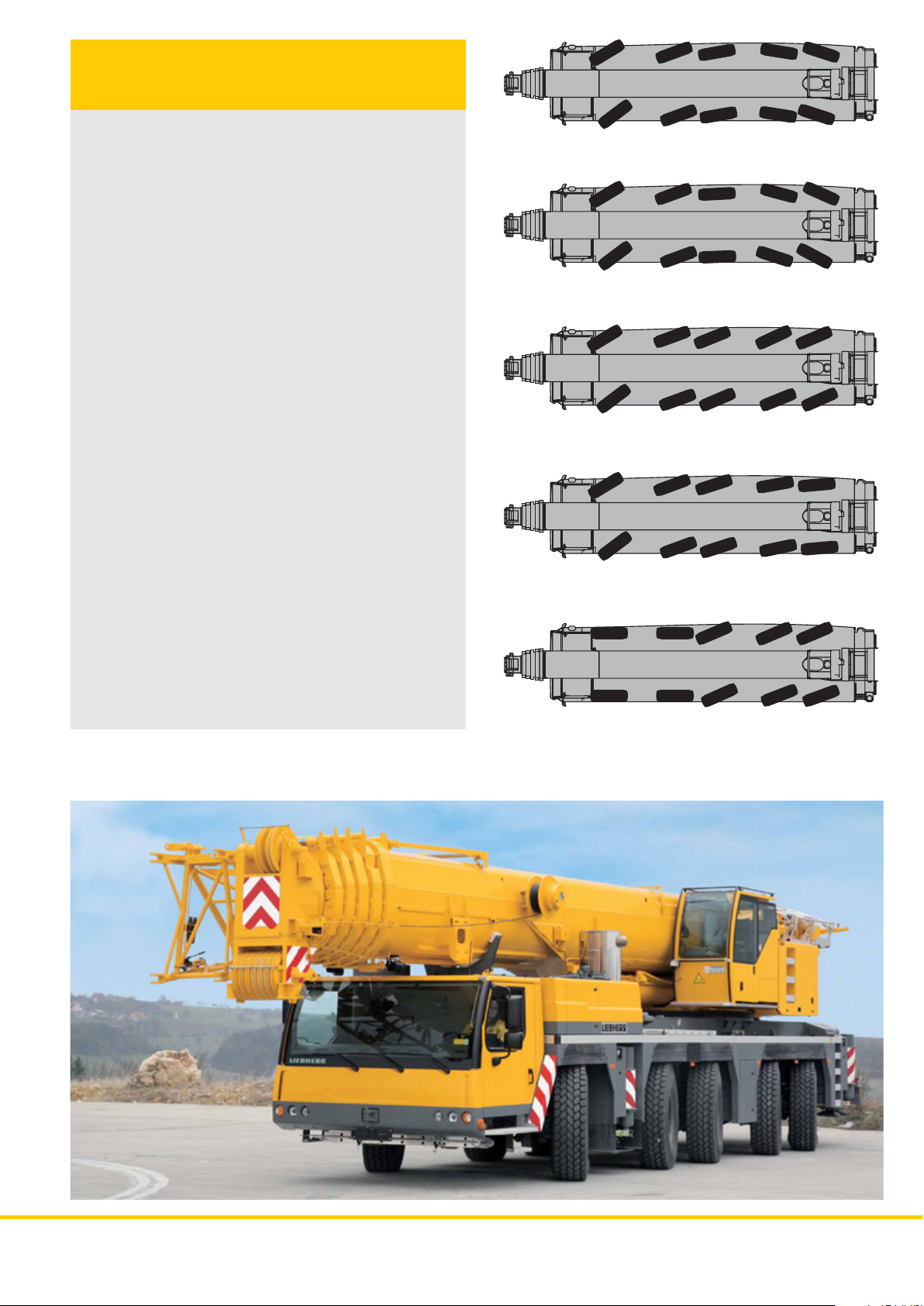

Modern drive concept

• Powerful, 6-cylinder Liebherr turbo-charged diesel engine

type D846 A7, 370 kW/503 hp, exhaust gas emissions

correspond to the directives 97/68/EC Stage 3 and

EPA/CARB Tier 3, robust and reliable, modern and

electronically-controlled engine management

• ZF power shift gear with automated AS-TRONIC control

system. ZF intarder fitted directly to the gear unit, 12 forward

and 2 reverse gears, automated control, reduced fuel

consumption due to a high number of gears

• 2-stage, robust transfer case with lockable transfer differential,

creeping speed 0.78 km/h

• Drive 10 x 6, axles 2, 4 and 5 driven

• Drive 10 x 8 (optional), axles 2, 4 and 5 driven, axle 1 can

be activated for off-road displacement

• Weight-optimized, robust, low-maintenance axles, perfect

track keeping and lateral stability due to special arrangement

of the steering knuckles; maintenance-free axle struts, steel

and rubber mounted

• Maintenance-free drive shafts; quick and easy fitting due to

70° diagonal toothing

• Hydropneumatic ”Niveaumatik” suspension, programcontrolled for ”setting crane on outriggers”, ”crane

displacement with equipment” and "crane displacement on

the road", suspension travel +150/-150 mm

• Lateral force released and maintenance-free suspension

rams, piston rods protected against damage

by synthetic pipes

• Sustained-action brakes:

Engine brake as exhaust retarder with Liebherr additional

brake system (ZBS), intarder on gear, optional Telma-type

eddy current brake

• Service brake:

All axles fitted with air disc brakes, high braking performance,

long maintenance intervals, rapid-change brake linings

LTM 1220-5.2 LTM 1220-5.2

Page 3

Variable steering

concept with

„active rear-axle steering“

Axles 3, 4 and 5 set up as „active rear-axle steering, 5 steering

methods are preselectable by fixed programs (P):

P1: On-road steering

Axles 1 and 2 are steered mechanically with hydraulic assistance

by the steering wheel. Axles 3, 4 and 5 are steered „actively“

speed-dependent, subject to the cramp of the front axles,

and over 30 km/h, axles 3 and 4 are set to straight displacement

and fixed, from 60 km/h, axle 5 is fixed equally to straight

displacement. The change of the steering angle in accordance

with the speed, results in a precise and stable driving quality

during higher speeds, tyre abrasion is reduced and the

maneuverability clearly improved.

P2: All-wheel steering

Axles 3, 4 and 5, dependent on the steering angle of axle 1

are cramped by means of the steering wheel so that the

smallest turning radii can be performed.

P3: Crab steering

Axles 3, 4 and 5 are cramped into the same direction as axles

1 and 2 by means of the steering wheel.

P4: Steering without swerving

Axles 3, 4 and 5 are cramped in accordance with axle 1 so

that no swerve out of the rear of the carrier takes place.

P5: Independent rear-axle steering

Axles 1 and 2 are cramped by the steering wheel, axles 3, 4

and 5 steered independent of the cramp of axles 1 and 2 by

momentary-contact buttons, whereby the cramp of axle 3 is

adapted to the required situation.

• A failure in the rear-axle steering makes it ineffective and

the rear axles are set to straight displacement by the centering

rams

• Two independent hydraulic circuits with wheel- and enginedriven hydraulic pump, thus maximum safety standard

• Two independent control processors (by existing E/A modules)

and diversified sensoriel system

• Entire know-how of the „active rear-axle steering“ by Liebherr

310

Page 4

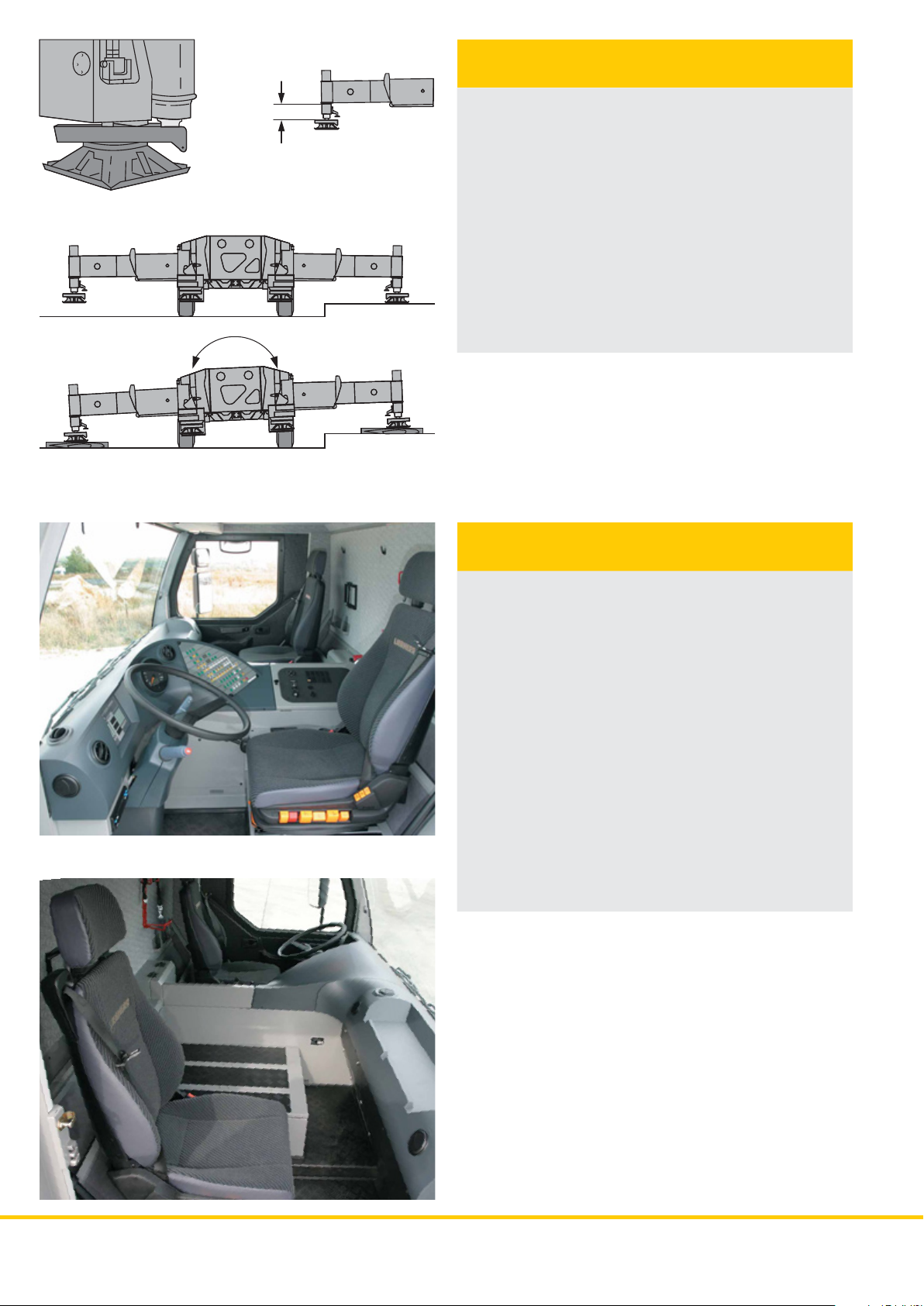

Setting crane on outriggers –

quick, convenient and safe

700

• Variable support basis

outriggers retracted

Support basis 5.5 m x 8.9 m

Support basis 8.3 m x 8.9 m

• Fix-mounted supporting pads with splash guard

• Supporting ram travel of up to 700 mm

• Level control of the outriggers, all-automatic push-button

crane levelling during the supporting procedure

• 2 x 9° lateral inclination of crane and crane superstructure

• Control panels at either side of the carrier with membrane

keyboard and electronic inclination indicator, push-buttons

for ENGINE/START/STOP and speed control are illuminated

and lockable

• Operation of the outrigger system in accordance with

accident-prevention legislation

• Illumination of the supporting area by 4 incorporated

projectors

Comfortable driver’s cab

of high functionality

• Modern, comfortable driver’s cab of high functionality and

convincing design, corrosion-resistant, sheet steel version,

cataphoretic dip-primed, front mounted on rubber shock

absorbers, rear cushioned hydraulically, internal sound and

heat absorbing panelling

• Safety glass all-round, greenish tinted front and side windows

for heat absorption, electric window lifters

• Arrangement of the control elements and displays according

to ergonomical aspects for safe and convenient handling

during continuous operation

• Digital display and keyboard units interconnected with the

functional blocks by data bus technology

• Driver’s seat cushioned pneumatically, with pneumatic lumber

support, headrest

• Steering wheel adjustable in height and inclination

• Heatable and electrically adjustable rear mirrors

• Safety belts for driver and co-driver

• 3 windscreen wipers with automatic wipe/wash system and

intermittent control

• Delayed switch-off of the interior lights

• Various racks and stackers

• Radio preparation

LTM 1220-5.2 LTM 1220-5.2

Page 5

Comfortable crane cab

of high functionality

• Crane cab in corrosion-resistant galvanized sheet steel

version, powder-coated, with sound and heat absorbing

internal panelling, interior of modern design, tinted windows

all-round, front knock-out window with large windscreen

wiper and wipe/wash device, skylight of bullet-proof glass

with large screen wiper and wipe/wash device, roller blind

on front window and skylight, space-saving sliding door

• Greenish tinted front and side windows for heat absorption

• Pneumatically lateral extendable footboard for safe access

to and from the carrier

• Crane cab tiltable to the rear by 20° to improve the sight

• 1 working projector of 70 Watt, at the front of the cab

• Spring-mounted and hydraulically cushioned crane operator’s

seat with pneumatic lumbar support and headrest

• Operator-friendly armrest-integrated controls, vertically and

horizontally adjustable master switch consoles and armrests,

ergonomically adjustable operating consoles

• Ergonomic control levers with integrated winch rotation and

slewing gear signalling device

• Modern instrument supporting base with incorporated

LICCON monitor, display of all essential operating data on

the LICCON screen

• Radio preparation

58

Page 6

Crane drive with

field-proven components

• Crane engine: 4-cylinder Liebherr turbo-charged diesel

engine type D934L A6 with 180 kW/245 hp, exhaust gas

emissions in accordance with the directives 97/68/EC Stage

3 and EPA/CARB Tier 3, robust and reliable, located opposite

the crane cab, thus lower noise emissions, electronic engine

management, optimized fuel consumption, stainless steel

exhaust gas system

• Hydraulic system with 5 axial-piston variable displacement

pumps with servo control and capacity regulation,

electronically-controlled oil cooler as standard

• Highly-efficient noise abatement of the diesel-hydraulic crane

drive as standard

Liebherr winch technology

• Liebherr-built winches (hoist gear 1 and 2) with special

grooving, with integrated planetary gears and spring-mounted

multi-disc brakes as static brakes

• Liebherr-built axial-piston constant-output engine, specially

designed for crane operation, exposed successfully to tough

fatigue tests

• Display of the winch rotation on the LICCON screen

• Non-rotating hoist rope

R = 4850

10 t

10 t

3600

5630

Ballasting –

in a matter of minutes

• Counterweight variants 12 t, 22 t, 34 t, 44 t, 54 t and 74 t

• Control of ballasting from the crane cab

• Quick ballasting by “key-hole” method

• Ballasting cylinder permanently mounted to superstructure

• Compact counterweight dimensions, e.g. 54-t counterweight

of only 3.6-m width

12 t

10 t

10 t

10 t

12 t

54 t

LTM 1220-5.2 LTM 1220-5.2

Page 7

Lifting of loads precise and safe

• 6-section, 60-m-long telescopic boom with rounded, oviform

bottom shell for high lateral stability

• Optimal utilisation of the telescopic boom due to a multitude

of telescoping variants

• 12.2-m – 22-m-long biparted swing-away jib extendable to

29 m and 36 m

• Swing-away jib mountable at 0°, 22.5° and 45°, hydraulic

fitting aid, hydraulic ram for continuous variation of the

swing-away jib from 0° – 45° (optional)

• Telescopic boom extension 7 m, resulting in a 7-m higher

attachment point for the swing-away jib

• Quick and easy re-reeving of the hoist rope by rope dead

end connection

• Load hook with rope dead end connection, cylindrical load

hook shape for easy displacement by rolling on the ground

110 m

100 m

90 m

80 m

70 m

K 36 m

K 29 m

22,5°

45°

7 m

60 m

60 m

50 m

40 m

30 m

20 m

10 m

56 m

52 m

47.7 m

43.4 m

39.1 m

34.8 m

30.5 m

26.2 m

21.9 m

17.6 m

13.3 m

oviform boom profile

76

Page 8

Outstanding

boom technology

The advantages of the

boom technology at a glance

The focal points of the successful boom technology for the

Liebherr mobile cranes are the oviform boom profile, the

internal interlocking system of the telescopes and the

telescoping system „Telematik“.

The oviform boom profile

It features a particular inherent stability against deflection and

torsion. In steep boom position as well as at large radii, the

oval boom profile offers optimal lifting capacities.

The patented internal interlocking system of

the telescopes

The interlocking process of the telescoping ram with a boom

section is performed successively by spring-loaded pins, and

followed by the mechanical release of the same section of the

telescopic boom. This method guarantees that a telescope

release can only take place if the telescopic section is

interlocked with the hydraulic ram.

The automatic telescoping system „Telematik“

An outstanding flexibility in controlling the various telescoping

lengths of the boom is achieved by the rapid-cycle telescoping

system. The most suitable boom configuration can be

preselected dependent on the job requirements. The

telescoping of the boom is practicable either by manual or

fully automatic control. The saving of time during the automatic

telescoping procedure and the combinatorial variety of the

telescoping paths determine the functionality of the telescopic

booms.

• Considerable increase in lifting height and reach due to

extraordinarily long telescopic booms

• Telescopic booms of inherent and lateral stability for maximum

lifting capacity requirements

• Outstanding functionality due to the automatic telescoping

system „Telematik“

• High working speeds due to the fully automatic telescoping

procedure

• Outstandingly easy operation - control of the telescoping

procedure by means of telescoping images on the LICCON

display screen

• Maintenance-free telescoping system

LTM 1220-5.2 LTM 1220-5.2

Page 9

Data bus technique

revolutionises the

crane electric system

The Liebherr mobile cranes are entirely equipped with data

bus transfer systems. The digital system is the basis for the

data bus. It permits the transfer of a multitude of information

almost parallel and faultless via one only cable. Liebherr has

developed its own system bus (LSB) which corresponds to

the manifold requirements in respect to all possible mobile

crane operations. All important electrical and electronical

components on the superstructure, such as length sensors,

angle sensors, load cells, proximity switches, master switches

and hoist limit switch are equipped with their own

microprocessors and communicate via various data bus

networks. The keyboard and display units, the outrigger control

as well as the engine and transmission control on the vehicle

are intelligent function blocks and equipped with bus interfaces.

A continuous self-test of the sensors during operation

guarantees a high functional reliability. The internetworking of

the LICCON computer system with the system bus establishes

entirely new and comprehensive diagnostic facilities in respect

to the crane.

The advantages of the

data bus technique at a glance

• Reduction of the operating costs due to a modern engine

and transmission management (CAN bus system); increased

economy due to improved endurance of the individual units

• Improved reliability due to a considerably reduced number

of electrical cables and contacts

• A continuous self-test of the „intelligent sensors“ guarantees

a maximum of reliability

• Comprehensive diagnostic facilities - quick error detection

• Self-manufactured bus systems, specially adapted to the

requirements of a mobile crane

• The data bus technique increases the comfort and safety

during driving and crane operation

94

Page 10

LICCON configuration and

operation program

• Standard application programs: Safe load indicator (LMB),

configuration program with configuration picture, operation

program with operating picture, telescoping program with

telescoping picture, test parameter program, test system;

supporting force indication and work area limitation as an

optional feature

• Setting of the configuration program by convenient

interactive functions

• Safe and reliable acknowledgement of the configuration set

• Representation of all essential data by graphic symbols on

the operation picture

• With integrated wind force test (optional)

• Reliable cut-off device when exceeding the admissible

load moments

• Load capacity values for any boom intermediate length

• Winch indications for precise lifting/lowering of the load

LICCON-assisted

telescoping system

• Telescoping by single-stage hydraulic ram with hydraulic

driving tenons (patented internal interlocking system)

• Telescoping procedure controllable by convenient operator’s

guide on the monitor, precise approach of the interlocking

positions

• Telescopable loads are displayed on the LICCON

operating picture

• Rapid-cycle telescoping system with „automatic mode“, i.e.

all-automatic telescoping to the required boom length

• Very compact and light-weight telescoping system, thus

increased load capacities, especially with long booms and

large radii

• Automatic cushioning in end positions during telescoping

and retracting for the preservation of the structural members

LTM 1220-5.2 LTM 1220-5.2

Page 11

The LICCON test system

• The test system assists the servicing personnel in quickly

localizing failures of the crane sensory system without the

need of measuring instruments

• The service starts on the display screen, troubleshooting

becomes a matter of seconds

• Occurring errors are indicated by error codes and error

descriptions on the display screen

• Convenient interactive functions permit the observation of

all inputs and outputs of the entire system by different

representations on the display screen even during crane

operation. It equally visualizes the allocation of the individual

sensors and actuators of the system and their functions.

The LICCON work area

limitation system

• It relieves the crane operator, especially in situations where

the handling of loads requires his full attention, by controlling

the work area limits. Work areas can be restricted by buildings,

bridges, roofs, high-tension power lines, pipelines or adjacent

cranes. The automatic work area limitation system (optional),

can easily be programmed. Four different limitation functions

are practicable:

• Height limitation of the pulley head

• Radius limitation

• Slewing angle limitation

• Limitation of edges

The LICCON work planner

• The LICCON work planner consists of a software program

on CD for planning, simulation and documentation of crane

applications on the display screen (optional)

• The 2D planner program enables the drawing of buildings,

to write texts and to represent a crane model true to scale

including the entire motions within a fictional construction

site

• The work planner permits the preparation of more transparent

offers, facilitates the briefing of crane operators and can be

run on a Laptop at the construction site

112

Page 12

Electronic SPS crane control with test system

• Control of the winches, slewing gear and the luffing and

telescoping motions by the LICCON computer system (PLC

control)

• Four working motions can be performed independently of one

another

• Speeds for lifting/lowering, luffing and slewing are pre-selectable

in 5 steps

• Very short response rates at the activation of crane motions

Single-stage

telescoping ram

LICCON

monitor

Joystick

selectors

Engine control

with hydraulic

interlocking

device

• Hoist gear and slewing gear operate within a "closed oil

circuit". This enables very sensitive lifting/lowering of loads,

or slewing. Moreover, during lowering of the load, the potential

energy generated is not converted into heat but can be reemployed for a second motion. This saves fuel and the oil

does not reach as high a temperature as during operation

within an open circuit.

• Functional test of all essential components by means of the

LICCON test system

Luffing ram

Control block

Liebherr

hoist winch I

Transmitters

Sensors

slewing gear

Liebherr

LICCON

control

Liebherr

slewing gear

1 double variable

displacement

pump

3 variable

displacement

pumps

Optional features contribute to an expension of the

application spectrum and increase comfort and safety

On the carrier

• Additional heater with engine preheating

• Eddy-current brake

• Supporting force indicator on the carrier and in the

operator’s cab

• Rope box

• Air-conditioning system

• Trailer coupling D12/D19

• Radio preparation

• Seat heating for driver’s and co-driver’s seat

• CD radio set

On the crane superstructure

• Additional heater with engine preheating

• 2nd hoist gear

• Air-conditioning system

• Seat heating

• Work area limitation

• Aircraft warning light

• XENON working projector on base section, electrically

adjustable

• Tele-diagnostic with installed GSM module

• CD radio set

• Emergency actuation

Liebherr

hoist winch II

Liebherr-Diesel engine

Further optional features by request.

Subject to modifications. PN 172.00.E08.2006

Liebherr-Werk Ehingen GmbH

Postfach 1361, 89582 Ehingen, Germany

콯 +49 7391 5 02- 0, Fax +49 73 91 5 02-33 99

www.liebherr.com, E-Mail: info.lwe@liebherr.com

Loading...

Loading...