Lexmark 4227-200, 4227-100 Service Manual

Lexmark Forms Printer 4227

4227-X00

•Table of Contents

•Start Diagnostics

•Safety and Notices

•Trademarks

• Index

Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries.

4227-X00

Edition: October 2000

The following paragraph does not apply to any country where such provisions are inconsistent with local law: LEXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied warranties in certain transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the information herein; these changes will be incorporated in later editions. Improvements or changes in the products or the programs described may be made at any time.

A form for reader’s comments is provided at the back of this publication. If the form has been removed, comments may be addressed to Lexmark International, Inc., Department D22/035-3, 740 New Circle Road N.W., Lexington, Kentucky 40550, U.S.A. Lexmark may use or distribute any of the information you supply in any way it believes appropriate without incurring any obligation to you. You can purchase additional copies of publications related to this product by calling 1-800-553-9727. In other countries, contact your point of purchase.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries.

Color Jetprinter is a trademark of Lexmark International, Inc.

Other trademarks are the property of their respective owners.

© Copyright Lexmark International, Inc. 1996, 2000. All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use, duplication or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc., Lexington, KY 40550.

4227-X00

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

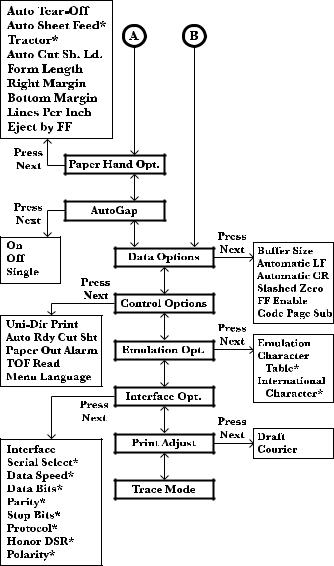

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Voltage, Ground, and Continuity Readings . . . . . . . . . . . . . . 1-3 Maintenance Approach. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 Using the Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6 Using the Function Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Setting Printer Functions . . . . . . . . . . . . . . . . . . . . . . . . . 1-8 Overview of Function Menus . . . . . . . . . . . . . . . . . . . . . . 1-9 Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11 Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 Error Indication Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 Symptom Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4 Service Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10 Auto Gap Service Check . . . . . . . . . . . . . . . . . . . . . . . . 2-10 Auto Sheet Feeder (ASF) Service Check. . . . . . . . . . . . 2-12 Carrier Drive Service Check. . . . . . . . . . . . . . . . . . . . . . 2-14 Intermittent Problem Service Check . . . . . . . . . . . . . . . 2-15 No Print or Abnormal Print Service Check . . . . . . . . . . . 2-18 Operator Panel Service Check. . . . . . . . . . . . . . . . . . . . 2-19 Paper Feed Service Check . . . . . . . . . . . . . . . . . . . . . . 2-20 POST Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24 Power Failure Service Check . . . . . . . . . . . . . . . . . . . . . 2-25 Print Quality Service Check . . . . . . . . . . . . . . . . . . . . . . 2-27 Print Wire Drive Failure Service Check . . . . . . . . . . . . . 2-28 Ribbon Drive Service Check . . . . . . . . . . . . . . . . . . . . . 2-30 Tractor 2 Service Check. . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Diagnostic Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Power-On Self Test (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 Hex Trace Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Hex Trace Mode Sample . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Interface Selection (4227-100) . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Operation with the Top Cover Removed . . . . . . . . . . . . . . . . 3-3

vii

4227-X00

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Factory Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Printhead Bank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Jam / PSet Sensor Test. . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Impact Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Log Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Print Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Other Print Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Handling ESD-Sensitive Parts . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Printhead Installation Adjustment . . . . . . . . . . . . . . . . . . 4-2

Printhead-to-Platen Gap Adjustment. . . . . . . . . . . . . . . . 4-2

Bidirectional Print Adjustment . . . . . . . . . . . . . . . . . . . . . 4-4

Removal Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Top Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Auto Gap Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Auto Sheet Feeder Gears Removal . . . . . . . . . . . . . . . . 4-9

Auto Sheet Feeder Pick-up Roller Removal . . . . . . . . . 4-10

Belt Tension Pulley Plate Assembly Removal. . . . . . . . 4-11

Base Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . 4-11

Carrier Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Carrier Motor Assembly Removal . . . . . . . . . . . . . . . . . 4-15

Carrier Plate Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Label Jam Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Lower Feed Roller Removal . . . . . . . . . . . . . . . . . . . . . 4-17

Lower Pinch Roller Removal . . . . . . . . . . . . . . . . . . . . . 4-21

Main Logic Board Removal . . . . . . . . . . . . . . . . . . . . . . 4-22

Memory Module Removal . . . . . . . . . . . . . . . . . . . . . . . 4-22

Operator Panel Assembly Removal . . . . . . . . . . . . . . . 4-23

Paper Empty Sensor /TOF Sensor Removal. . . . . . . . . 4-23

Paper Feed Motor Removal . . . . . . . . . . . . . . . . . . . . . 4-26

Paper Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Paper Guide / Platen Assembly Removal . . . . . . . . . . . 4-26

Paper Select Lever Removal. . . . . . . . . . . . . . . . . . . . . 4-27

Paper Select Sensor Removal . . . . . . . . . . . . . . . . . . . 4-27

Paper Separator Removal . . . . . . . . . . . . . . . . . . . . . . . 4-28

Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Power Supply Fan Removal . . . . . . . . . . . . . . . . . . . . . 4-30

Print Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Printhead Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

viii

4227-X00

Printhead Cables Removal. . . . . . . . . . . . . . . . . . . . . . . 4-34 Ribbon Drive Motor Assembly Removal. . . . . . . . . . . . . 4-35 Right Side Frame Removal . . . . . . . . . . . . . . . . . . . . . . 4-36 Sub Logic Board Removal . . . . . . . . . . . . . . . . . . . . . . . 4-38 Upper Feed Roller Removal. . . . . . . . . . . . . . . . . . . . . . 4-39

Connector Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

4227-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Main Logic Board Connectors . . . . . . . . . . . . . . . . . . . . . 5-3 4227-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 Sub Logic Board Connectors . . . . . . . . . . . . . . . . . . . . . . 5-4 4227-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 Operator Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . 5-5

Component Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 Component Location Illustrations . . . . . . . . . . . . . . . . . . 5-7 Signal Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9 Connector Block Diagram . . . . . . . . . . . . . . . . . . . . . . . 5-20 Tractor 2 Cable Connectors . . . . . . . . . . . . . . . . . . . . . . 5-21

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 Specified Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 Lubrication Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

How to Use This Parts Catalog. . . . . . . . . . . . . . . . . . . . . . . . 7-1 Assembly 1: Covers and Operator Panel . . . . . . . . . . . . . . . . 7-2 Assembly 2: Paper Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4 Assembly 3: Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6 Assembly 4: Base and Electronics . . . . . . . . . . . . . . . . . . . . . 7-8 Assembly 5: ASF Side Frame / Covers . . . . . . . . . . . . . . . . 7-10 Assembly 6: ASF Roller / Support . . . . . . . . . . . . . . . . . . . . 7-12 Assembly 7: Tractor 2 Option . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

ix

4227-X00

Preface

This manual describes the Lexmark Forms Printer 4227-100 and 4227-200. It contains maintenance procedures for service personnel and is divided into the following chapters:

•General Information contains a general description of the printer and the maintenance approach used to repair it. Special tools and test equipment are listed in this chapter, as well as general environmental and safety instructions.

•Diagnostic Information contains error code table, symptom table, and service checks used to isolate failing field replaceable units (FRUs).

•Diagnostic Aids contains tests and checks used to locate or repeat symptoms of printer problems.

•Repair Information provides instructions for making printer adjustments and removing and installing FRUs.

•Connector Locations uses illustrations to identify the major components and test points on the printer.

•Preventive Maintenance contains lubrication specifications, and maintenance information to prevent problems and maintain optimum performance.

•Parts Catalog contains illustrations and part numbers for individual FRUs.

x Service Manual

4227-X00

Preface xi

4227-X00

Notices

Safety Information

•This product is designed, tested and approved to meet strict global safety standards with the use of specific Lexmark components. The safety features of some parts may not always be obvious. Lexmark is not responsible for the use of other replacement parts.

•The maintenance information for this product has been prepared for use by a professional service person and is not intended to be used by others.

•There may be an increased risk of electric shock and personal injury during disassembly and servicing of this product. Professional service personnel should understand this and take necessary precautions.

Consignes de Sécurité

•Ce produit a été conçu, testé et approuvé pour respecter les normes strictes de sécurité globale lors de l'utilisation de composants Lexmark spécifiques. Les caractéristiques de sécurité de certains éléments ne sont pas toujours évidentes. Lexmark ne peut être tenu responsable de l'utilisation d'autres pièces de rechange.

•Les consignes d'entretien et de réparation de ce produit s'adressent uniquement à un personnel de maintenance qualifié.

•Le démontage et l'entretien de ce produit pouvant présenter certains risques électriques, le personnel d'entretien qualifié devra prendre toutes les précautions nécessaires.

xii Service Manual

4227-X00

Norme di sicurezza

•Il prodotto è stato progettato, testato e approvato in conformità a severi standard di sicurezza e per l’utilizzo con componenti Lexmark specifici. Le caratteristiche di sicurezza di alcune parti non sempre sono di immediata comprensione. Lexmark non è responsabile per l’utilizzo di parti di ricambio di altri produttori.

•Le informazioni riguardanti la manutenzione di questo prodotto sono indirizzate soltanto al personale di assistenza autorizzato.

•Durante lo smontaggio e la manutenzione di questo prodotto, il rischio di subire scosse elettriche e danni alla persona è più elevato. Il personale di assistenza autorizzato, deve, quindi, adottare le precauzioni necessarie.

Sicherheitshinweise

•Dieses Produkt und die zugehörigen Komponenten wurden entworfen und getestet, um beim Einsatz die weltweit gültigen Sicherheitsanforderungen zu erfüllen. Die sicherheitsrelevanten Funktionen der Bauteile und Optionen sind nicht immer offensichtlich. Sofern Teile eingesetzt werden, die nicht von Lexmark sind, wird von Lexmark keinerlei Verantwortung oder Haftung für dieses Produkt übernommen.

•Die Wartungsinformationen für dieses Produkt sind ausschließlich für die Verwendung durch einen Wartungsfachmann bestimmt.

•Während des Auseinandernehmens und der Wartung des Geräts besteht ein zusätzliches Risiko eines elektrischen Schlags und körperlicher Verletzung. Das zuständige Fachpersonal sollte entsprechende Vorsichtsmaßnahmen treffen.

Notices xiii

4227-X00

Pautas de Seguridad

•Este producto se ha diseñado, verificado y aprobado para cumplir los más estrictos estándares de seguridad global usando los componentes específicos de Lexmark. Puede que las características de seguridad de algunas piezas no sean siempre evidentes. Lexmark no se hace responsable del uso de otras piezas de recambio.

•La información sobre el mantenimiento de este producto está dirigida exclusivamente al personal cualificado de mantenimiento.

•Existe mayor riesgo de descarga eléctrica y de daños personales durante el desmontaje y la reparación de la máquina. El personal cualificado debe ser consciente de este peligro y tomar las precauciones necesarias.

Informações de Segurança

•Este produto foi concebido, testado e aprovado para satisfazer os padrões globais de segurança na utilização de componentes específicos da Lexmark. As funções de segurança de alguns dos componentes podem não ser sempre óbvias. A Lexmark não é responsável pela utilização de outros componentes de substituição.

•As informações de segurança relativas a este produto destinam-se a profissionais destes serviços e não devem ser utilizadas por outras pessoas.

•Risco de choques eléctricos e ferimentos graves durante a desmontagem e manutenção deste produto. Os profissionais destes serviços devem estar avisados deste facto e tomar os cuidados necessários.

xiv Service Manual

4227-X00

Informació de Seguretat

•Aquest producte està dissenyat, comprovat i aprovat per tal d'acomplir les estrictes normes de seguretat globals amb la utililització de components específics de Lexmark. Les característiques de seguretat d'algunes peces pot ser que no sempre siguin òbvies. Lexmark no es responsabilitza de l'us d'altres peces de recanvi.

•La informació pel manteniment d’aquest producte està orientada exclusivament a professionals i no està destinada a ningú que no ho sigui.

•El risc de xoc elèctric i de danys personals pot augmentar durant el procés de desmuntatge i de servei d’aquest producte. El personal professional ha d’estar-ne assabentat i prendre les mesures convenients.

Notices xv

4227-X00

xvi Service Manual

4227-X00

1. General Information

Description

The Lexmark Form Printer 4227-100 and 4227-200 are dot matrix, electro-mechanical printers that form characters on print media using a printhead and fabric ribbon. The printhead is composed of 18 miniature solenoids containing print wires and operates on electromagnetic principles. When a solenoid is energized, the small print wire pin is “fired” toward the ribbon to make a dot on the paper. The printer receives commands in the form of an electronic data stream from the PC through the parallel or serial port connector. The printer logic receives and translates the electronic data stream into carrier returns, line spacing, characters, or graphics as instructed.

General Information 1-1

4227-X00

This is a versatile printer that combines excellent print quality along with the ability to print several print styles and graphics. Some of the features and functions included with this printer are:

Feature |

Function |

|

|

Multi-speed Printing |

FastDraft - 533 cps (4227-100) |

|

Draft - 400 cps (4227-100) |

|

Courier and Gothic (NLQ) - 100 cps (4227-100) |

|

FastDraft -720 cps (4227-200) |

|

Draft - 600 cps (4227-200)) |

|

Courier and Gothic (NLQ) - 150 cps (4227-200) |

|

|

Resident Fonts |

FastDraft, Draft, Courier and Gothic |

|

|

Forms Handling |

Forms (straight paper path) |

|

Automatic tear-off |

|

Automatic paper loading/unloading |

|

|

Cut Sheets |

Manual |

|

Optional Auto Sheet Feeder |

|

|

Multiple Part Forms |

6-Part Forms (carbon and carbonless) |

|

(4227-200 - up to 8-Part Forms) |

|

|

Interface Connection |

Parallel, Serial RS-422, Serial RS-232 |

|

|

Auto Gap |

When Auto Gap is set to On, the printer |

|

automatically adjusts to the thickness of paper |

|

you are using. |

|

|

1-2 Service Manual

4227-X00

Voltage, Ground, and Continuity Readings

Voltage Readings

All DC voltages must be within +5% through -10% of the values to be considered correct. Unless stated otherwise, all connectors should be connected normally when a voltage measurement is done.

When a “Line Voltage” measurement is to be done, the voltage on United States and Canada machines should be between 100 V ac and 127 V ac. On World Trade machines, the voltage is according to each country’s specification.

Ground Checks

To check for a correct ground, measure the voltage between the ground and a known good voltage source. The voltage measurement must be the same as the source voltage to consider the ground is correct. Continuity measurements may be used to check grounds, however, be sure to measure to a known good ground using the lowest ohms scale and check for zero ohms.

Note: Always unplug the power cord before doing any continuity measurement.

Continuity Readings

When measuring continuity, be sure no back circuits affect the measurement. If necessary, unplug connectors to remove any back circuits. Zero the ohm range on the lowest scale (X1). An open circuit will read infinity. A circuit with correct continuity will read zero ohms.

General Information 1-3

4227-X00

Maintenance Approach

The diagnostic information in this manual leads you to the correct field replaceable unit (FRU) or part. Use the error indication table, symptom/check table, service checks and diagnostic aids to determine the symptom and repair the failure. Begin with ““Start” on page 2-1”

Options

The following options may be installed:

•Auto Sheet Feeder (ASF)

•Tractor 2

•Extended Cut-sheet Paper Guides

•32kb Memory Module

•Extended National Language Support modules (Non-U.S. only)

Tools

The basic tools needed are:

•Basic CE tool kit

•#1 magnetic Phillips screwdriver

•#2 magnetic Phillips screwdriver

•Feeler gauges 0.35 mm (0.014 in.) 0.4 mm (0.016 in.)

•Analog or digital volt-ohmmeter

1-4 Service Manual

4227-X00

Abbreviations

ASF |

Automatic Sheet Feeder |

ASIC |

Application-Specific Integrated Circuit |

CSU |

Customer Setup |

DRAM |

Dynamic Random Access Memory |

EPROM |

Erasable Programmable Read-Only Memory |

ESD |

Electrostatic Discharge |

FRU |

Field Replaceable Unit |

HVPS |

High Voltage Power Supply |

LAN |

Local Area Network |

LCD |

Liquid Crystal Display |

LED |

Light-Emitting Diode |

LVPS |

Low Voltage Power Supply |

NVRAM |

Nonvolatile Random Access Memory |

OEM |

Original Equipment Manufacturer |

POR |

Power-On Reset |

POST |

Power-On Self Test |

PQET |

Print Quality Enhancement Technology |

ROS |

Read-Only Storage |

SRAM |

Static Random Access Memory |

UPR |

Used Parts Replacement |

V ac |

Volts alternating current |

V dc |

Volts direct current |

General Information 1-5

4227-X00

Using the Operator Panel

This section provides a brief description of the operator panel buttons, lights and settings. Refer to the User’s Guide for additional information.

Note: Application software may allow the user to operate the printer from a computer. Changes made to the printer settings from a software application override settings made from the operator panel, with the exception of the Font and Pitch Lock features.

Changeable printer functions include:

•

•

•

•

•

•

•

•

•

Set Top of Form Tractor selection Character options Paper handling options Interface options Emulation options

Macro definition and selection Print tests

Auto Gap functions

1-6 Service Manual

4227-X00

Using the Function Menus

Use the Item and Item buttons to move through the menu and option directories. Press Next to move away from the Main Menu to the subordinate directories and choices. Press Prev. if you want to go back in a menu or return to the Main Menu.

General Information 1-7

4227-X00

Setting Printer Functions

1.Press Start/Stop.

2.Press Menu to enter the function menu.

3.Press Item or Item until the function menu you want appears on the display.

Note: The selectable function menu is different depending on the selected data stream mode (IBM PPDS or Epson emulation) and the Interface mode (Parallel, RS-232 or RS-422).

4.Press Next to enter that menu item.

5.Press Item or Item until the value you want appears on the display.

6.Press Store to save the selected value.

Note: The currently selected default value is displayed with an asterisk (*).

If you have to change the optional value in another function menu, repeat steps 3 through 5. Otherwise, go to the next step.

7.To print the function setting, press Item or Item until the Print Settings message appears on the display.

8.Press Start/Stop to print the current setting values.

9.Press Quit to exit the function menus.

Note: If you have changed any settings, the printer performs a Power-On Self Test, see “Power-On Self Test (POST)” on page 3-1 . If you did not change any settings, the printer enters the not-ready state.

1-8 Service Manual

4227-X00

Overview of Function Menus

Use the Item and Item buttons to move through the menu and option directories. Press Next to move away from the Main Menu to the subordinate directories and choices. Press Prev. if you want to go back in a menu or return to the Main Menu.

Menu items marked with an asterisk (*) may not appear on the operator panel, depending on the printer settings or what printer options are installed

General Information 1-9

4227-X00

1-10 Service Manual

4227-X00

Buttons

When using the function menus, press Item or Item to scroll through the menu items. Press Next or Prev. to move to the next, or previous menu level.

Press this button: |

To: |

|

|

Menu |

• Enter the function menu. The printer goes |

|

offline. |

|

|

Quit |

• Exit the function menus. |

|

• Run a Power-On Self Test (POST). |

|

|

Tear Off |

• Advance the forms to the tear-off position. |

|

• Retract the forms to the Top-of-Form (TOF) |

|

position when the forms are at the tear-off |

|

position. |

|

|

Store |

• Save the values selected in the menus. |

|

|

Font |

• Select a font. |

|

|

Item |

• Scroll down. |

|

|

Pitch |

• Select a pitch. |

|

|

Item |

• Scroll up. |

|

|

Micro |

• Advance the forms down 0.35 mm (1/72 in.). |

|

|

Next |

• Scroll forward. |

|

|

Micro |

• Advance the forms up 0.35 mm (1/72 in.). |

|

|

Prev. |

• Return to the previous function menu. |

|

|

Start/Stop |

• Used to return to Ready and to Start/Stop. |

|

• Load the forms to TOF position with the |

|

ready light on. |

|

|

Load/Unload |

• Load paper (cut or continuous forms) to the |

|

TOF position. |

|

• Retract the forms to the tractor position. |

|

|

LineFeed |

• Advance the paper to the next line. |

|

|

FormFeed |

• Advance the paper to the TOF position on |

|

the next page. |

|

• Load the forms to the TOF position. |

|

|

General Information 1-11

4227-X00

Lights

Light |

When you see this light |

|

|

Power (Green) |

The printer power is on. |

|

|

Ready (Green) |

The printer is online and ready to print. |

|

The following conditions cause the Ready light |

|

to turn off: |

|

• Pressing Start/Stop |

|

• An end-of-form (EOF) |

|

• A paper jam |

|

• A cover open |

|

• A hardware error |

|

• A Power-On Self Test failure. |

|

• The printer is offline. |

|

|

Check (Yellow) |

Any of the following conditions may have |

|

occurred: |

|

• An end-of-form (EOF) |

|

• A paper jam |

|

• A cover open |

|

• A hardware error |

|

• A data transmission error |

|

• An interface mode error |

|

• A Power-On Self Test (POST) |

|

failure. |

|

|

Auto Gap (Green) |

Auto Gap is on. Auto Gap automatically adjusts |

|

the printer according to the thickness of the |

|

paper you are using. |

|

|

Tractor2 (Green) |

The Tractor 2 Feeder is selected. (The Tractor 2 |

|

Feeder option must be installed.) |

|

|

1-12 Service Manual

4227-X00

2. Diagnostic Information

Start

Make a quick visual check for defects (loose or broken parts, unplugged connectors, or paper jams).

If there is no power after turning the printer on, go to the “Power Failure Service Check” on page 2-25.

If an error indicator appears, go to the “Error Indication Table” on page 2-2 and take the indicated action.

Run the “Print Test” on page 3-5 and refer to the “Error Log” on page 3-6 for details of error indication information. If no error indication appears, refer to the “Symptom Table” on page 2-4.

Diagnostic Information 2-1

4227-X00

Error Indication Table

The following table describes the service check entries for the printer error indication codes.

When an error indication changes after you have entered a service check, you have an intermittent problem. If this occurs, leave the service check and go to “Symptom Table” on page 2-4 .

Display Indication |

Description / Action |

|

|

631 Machine Check |

Display RAM Read/Write Error. This error |

Display RAM Error |

is detected only during POST. Replace the |

|

operator panel. |

|

|

632 Machine Check |

System RAM Read/Write Error. |

System RAM Error |

Replace the main logic board and |

|

adjust the “Bidirectional Print |

|

Adjustment” on page 4-4. Check the |

|

“Printhead-to-Platen Gap Adjustment” |

|

on page 4-2. |

|

|

633 Machine Check |

Timer Interrupt Controller Error. Replace |

Timer Interrupt Error |

the main logic board and adjust the |

|

“Bidirectional Print Adjustment” on |

|

page 4-4. Check the “Printhead-to- |

|

Platen Gap Adjustment” on page 4-2. |

|

|

636 Machine Check |

Non-Volatile Memory Read/Write Error. |

NOVRAM Error |

Replace the main logic board and adjust |

|

the “Bidirectional Print Adjustment” on |

|

page 4-4. Check the “Printhead-to- |

|

Platen Gap Adjustment” on page 4-2. |

|

|

637 Machine Check |

Home Timeout Error. Go to the “Carrier |

CA Drive Error |

Drive Service Check” on page 2-14. |

|

|

638 Machine Check |

Carrier Drive Error. |

CA Drive Error |

No emitter pulse detected. Go to the |

|

“Carrier Drive Service Check” on page |

|

2-14. |

|

|

639 Machine Check |

Carrier Drive Error. |

CA Drive Error |

Carrier positioning error. Go to the “Carrier |

|

Drive Service Check” on page 2-14. |

|

|

63B Machine Check |

Button Scanning Error. |

Key Scan Error |

Go to the “Operator Panel Service |

|

Check” on page 2-19. |

|

|

2-2 Service Manual

4227-X00

Display Indication |

Description / Action |

|

|

63C Machine Check |

Auto Gap Error. |

Auto Gap Error |

Go to the “Auto Gap Service Check” on |

|

page 2-10. |

|

|

63D Machine Check |

Tractor 2 Home Position Error. |

Tractor2 HP Error |

Go to the “Tractor 2 Service Check” on |

|

page 2-31. |

|

|

63E Machine Check |

Head Thermal Sensor Error. |

Head Thermal Error |

Go to the “Print Wire Drive Failure |

|

Service Check” on page 2-28. |

|

|

63F Machine Check |

Option RAM Read/Write Error. |

Option RAM Error |

Replace the 32Kb Memory Module. |

|

|

640 Machine Check |

Carrier Thermal Sensor Error. |

CA Thermal Error |

Go to the “Carrier Drive Service Check” |

|

on page 2-14. |

|

|

Diagnostic Information 2-3

4227-X00

Symptom Table

1.Select the symptom that best describes the problem.

2.Perform the appropriate action before you go to the indicated service check.

Abnormal Indications

Symptom |

Action |

|

|

All LEDs turn on but |

Disconnect the interface cable from the printer and |

do not turn off. |

turn the printer off and then on. If POST now runs |

The Power LED is |

correctly, the problem is in the computer or |

interface cable. |

|

on, but POST will |

Go to the “POST Service Check” on page |

not run. |

|

|

2-24. |

|

|

Abnormal Print Operation Problems |

|

|

|

Symptom |

Action |

|

|

Printer will not print, |

Be sure the interface cable is connected properly. |

or become Ready. |

Go to the “No Print or Abnormal Print Service |

|

|

Abnormal operation, |

Check” on page 2-18. |

incorrect characters, |

|

or incorrect line |

|

width. |

|

Printer is ready but |

|

will not print from the |

|

computer correctly. |

|

Undefined or |

|

incorrect characters. |

|

|

|

2-4 Service Manual

4227-X00

Auto Sheet Feeder Problems

Symptom |

|

Action |

|

|

|

Auto sheet feeder |

|

Be sure Auto Sheet Feed is set to On in the Paper |

will not feed paper. |

|

Handling Option Menu. |

Auto sheet feeder |

|

Be sure the paper select lever is in the cut sheet |

double feeds. |

|

position. |

Auto sheet feeder |

|

Go to the “Auto Gap Service Check” on page |

has intermittent feed |

|

2-10. |

problems. |

|

|

Paper Skews |

|

Isolate the problem by removing the auto sheet |

|

|

|

|

|

feeder and feeding paper, using the manual feed |

|

|

tray. Go to the “Auto Sheet Feeder (ASF) |

|

|

Service Check” on page 2-12. |

|

|

|

6XX Error Indications |

|

|

|

|

|

Symptom |

|

Action |

|

|

|

6XX Machine Check |

|

Turn the printer off and then on. |

is displayed. |

|

Go to “Error Indication Table” on page 2-2. |

|

|

|

|

|

|

Paper Feed Problems |

|

|

|

|

|

Symptom |

|

Action |

|

|

|

Paper Empty |

|

Be sure the paper empty sensor is not blocked. |

Add Paper |

|

|

is displayed with |

|

There may be a problem with the paper select |

paper in the printer. |

|

sensor. Go to the “Paper Feed Service Check” |

Print operation starts |

|

on page 2-20. |

|

|

|

without paper. |

|

|

|

|

|

Diagnostic Information 2-5

4227-X00

Symptom |

Action |

|

|

Load/Unload |

Be sure the paper select lever is in the correct |

does not function. |

position. |

Form feed length is |

There may be a problem with the paper select |

not correct. |

sensor. Go to the “Paper Feed Service Check” |

Load/Unload |

on page 2-20. |

|

|

functions with cut |

|

sheets in use. |

|

|

|

Paper feeds, but |

Be sure the paper select lever is in the cut sheet |

Auto Loading does |

position. |

not work. |

Be sure Auto Cut Sheet is enabled in the Paper |

|

|

|

Handling Option Menu. |

|

Go to the “Paper Feed Service Check” on |

|

page 2-20. |

|

|

Lower feed roll shaft |

Be sure the paper select lever is in the correct |

rotates, but paper |

position. |

does not feed. |

Go to the “Paper Feed Service Check” on |

|

|

Pressing Form Feed |

page 2-20. |

does not feed paper. |

|

Abnormal noise |

|

while feeding. |

|

Paper jams, skews |

|

or creases. |

|

Incorrect or no line |

|

spacing: wider, |

|

narrower, or |

|

overlapping lines. |

|

Incorrect Top of |

|

Form positioning. |

|

|

|

2-6 Service Manual

Loading...

Loading...